Laser-ultrasmall current GMA compound heat power supply welding method

A composite heat source and welding method technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of large deformation of welded joints, and achieve the advantages of improving welding efficiency, refining weld grains, and reducing deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The test conditions are as follows: the laser is the HL2006D Nd:YAG solid-state laser produced by the German HAAS company, the maximum output power is 2.0kW, the wavelength is 1.06μm, the welding torch with the focal length of 200mm is used, and the laser focus is located at 0.5mm below the surface of the workpiece; the arc welding machine is Austrian TPS5000 digital GMA welding machine produced by Fonius;

[0020] Examples of aluminum alloy welding:

[0021] The specific implementation scheme will be described below by taking the 5A06 aluminum alloy plate as an example. Use 5356 welding wire with a diameter of 1.2mm; the test plate is 5A06 aluminum alloy with a thickness of 2.0mm, and the size of the test plate is 50mm×400mm;

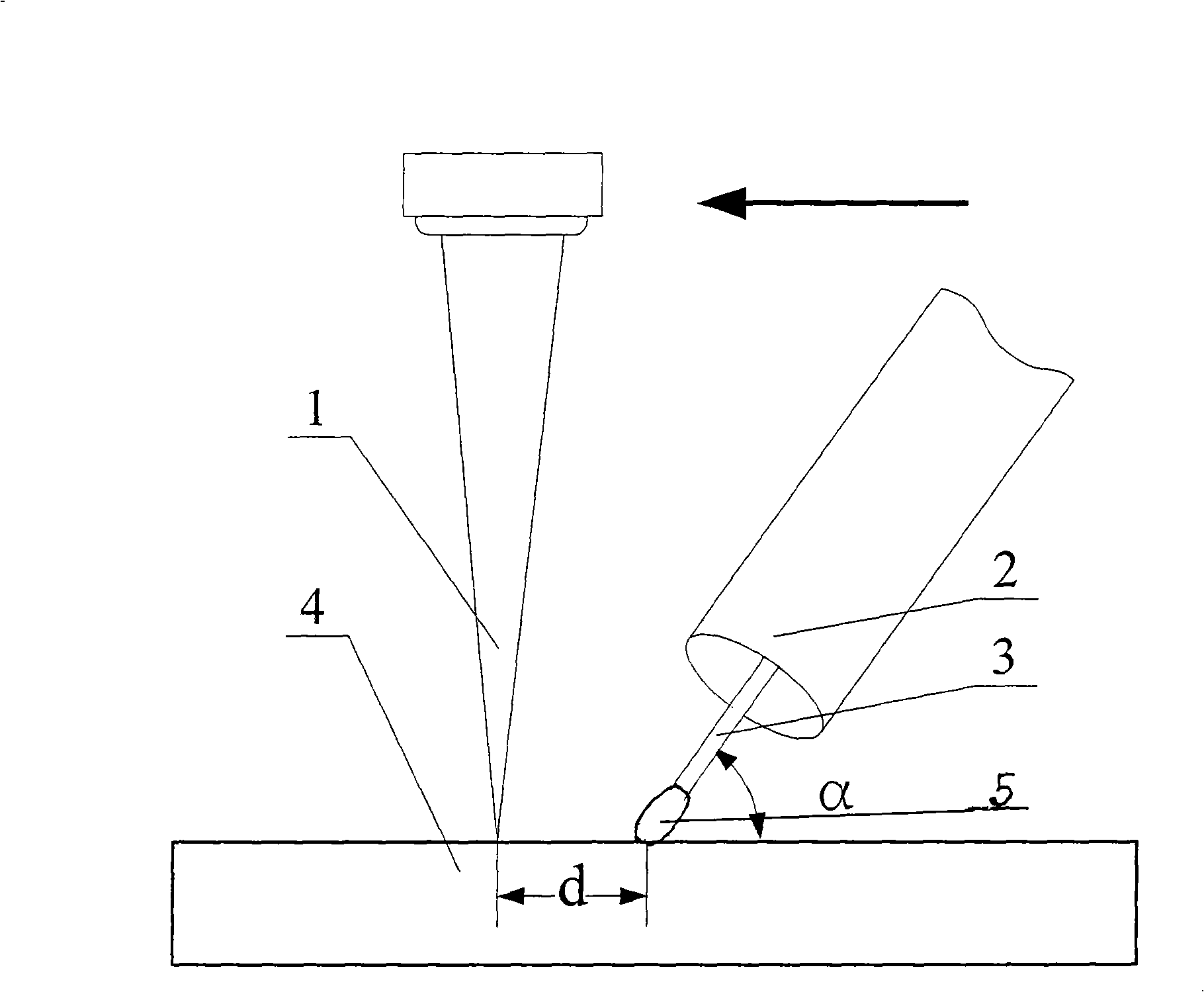

[0022] Laser-ultra-small current GMA composite heat source welding parameters: the spacing d of the light wire on the surface of the workpiece is 1mm, the welding speed is 1m / min, the laser power is 1850W, the wire feeding speed is 1.0m / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com