Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1374results about How to "Fast welding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

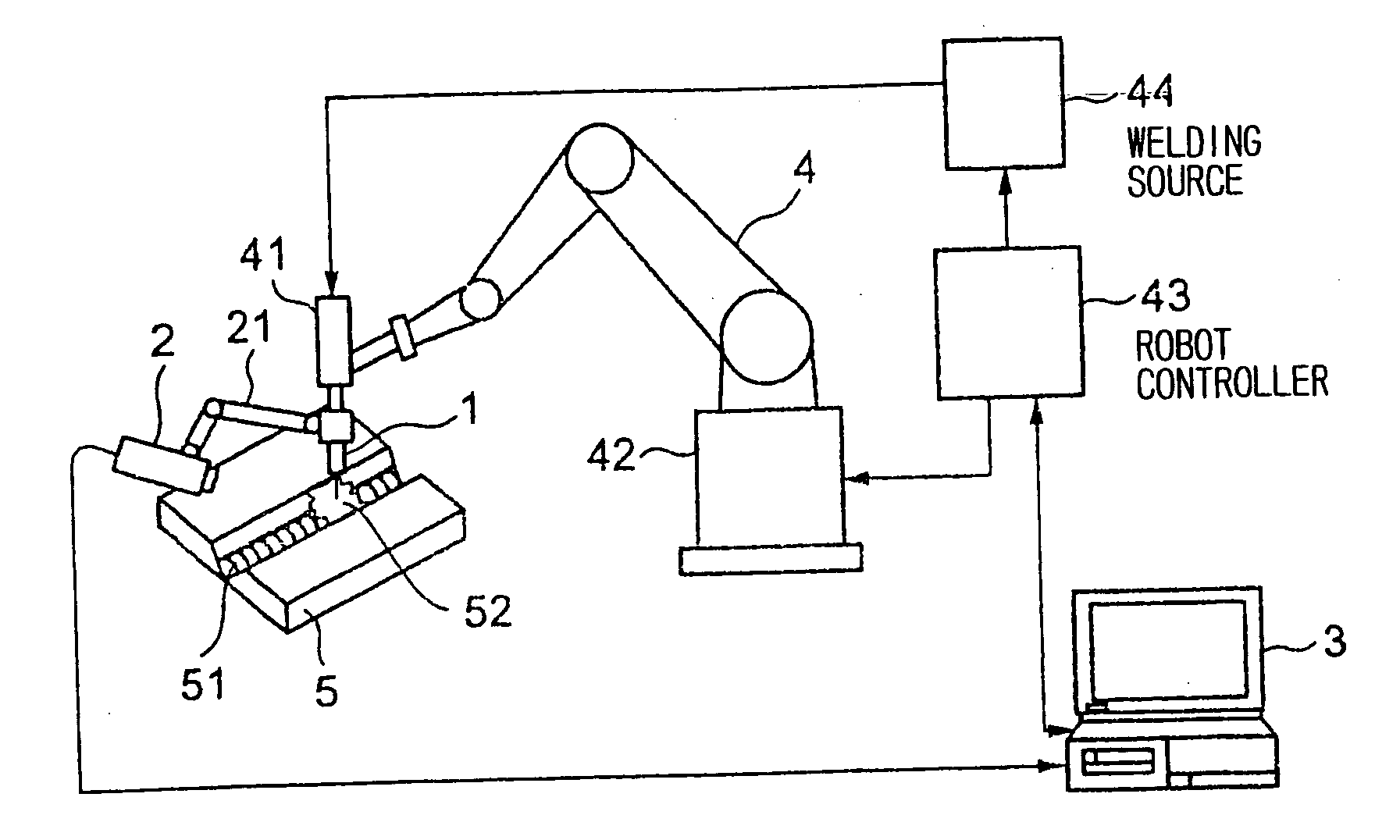

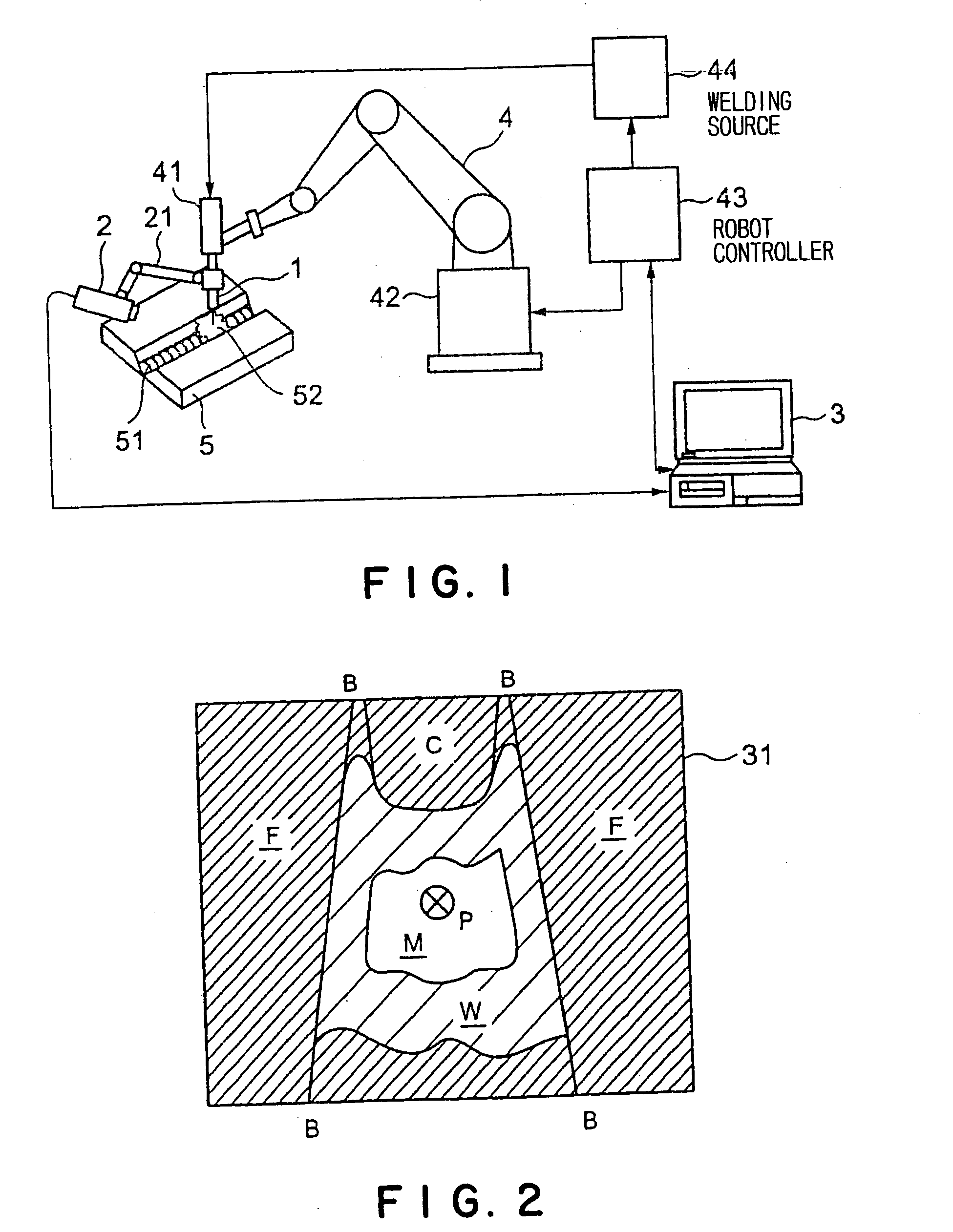

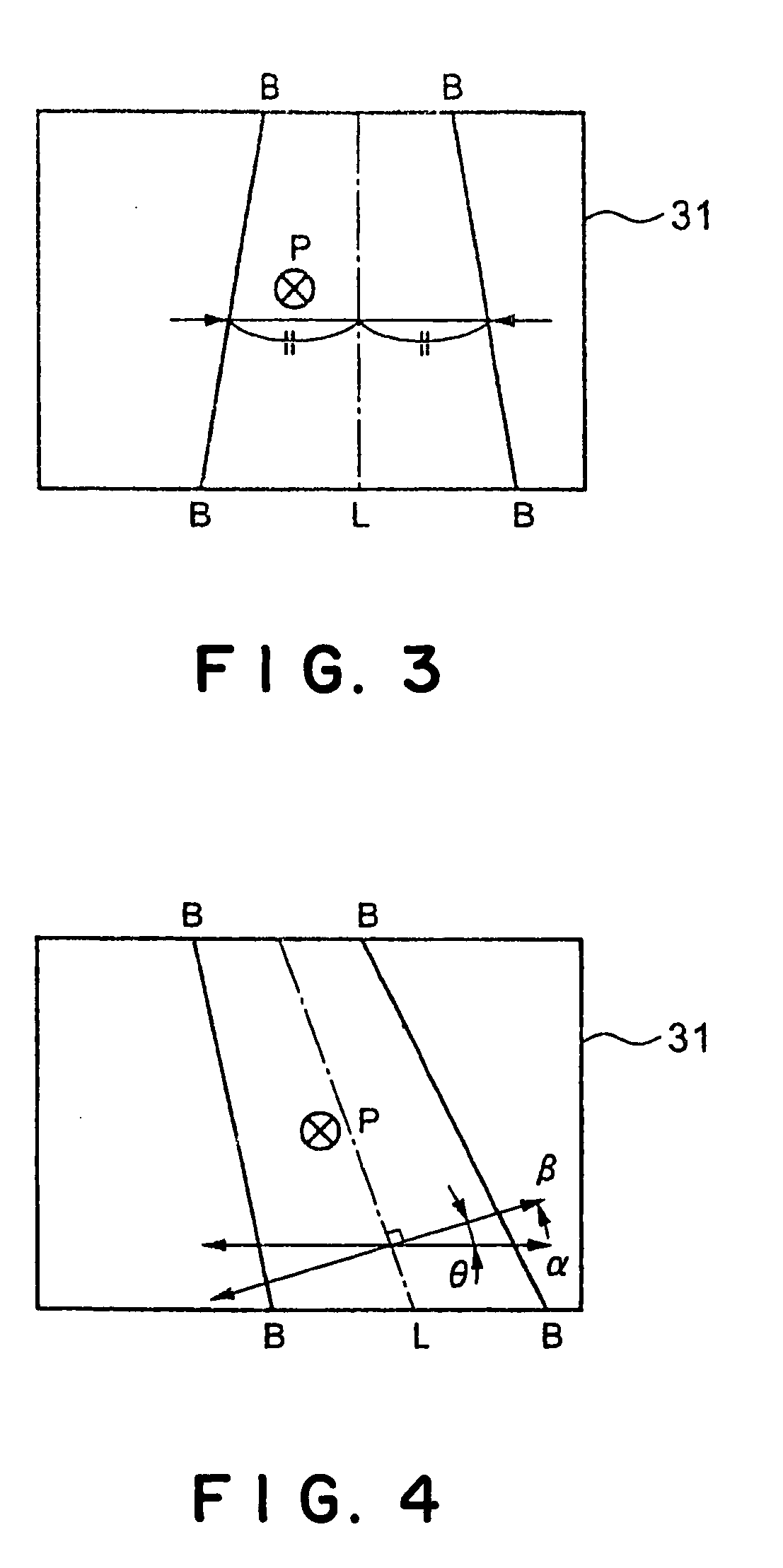

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

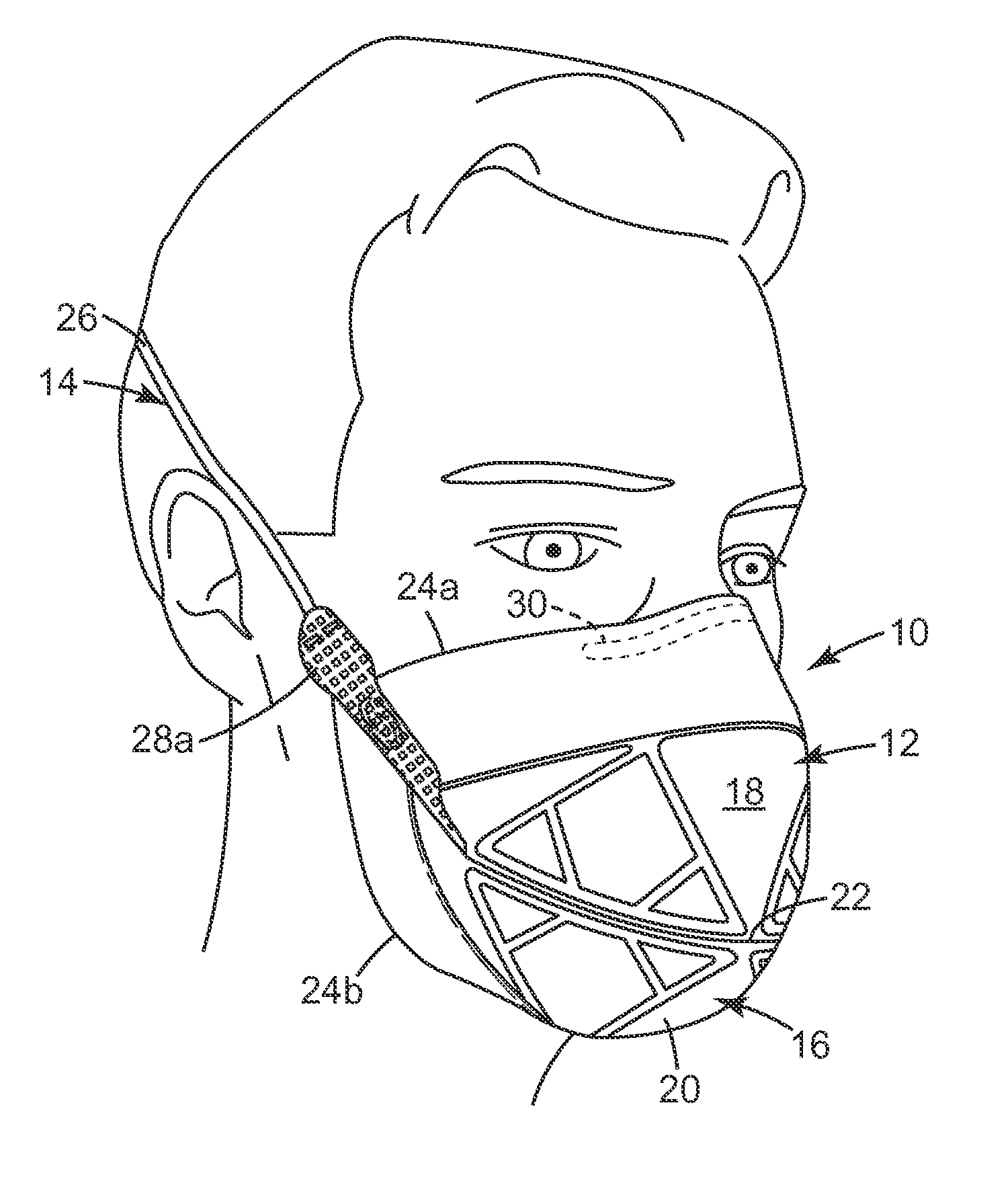

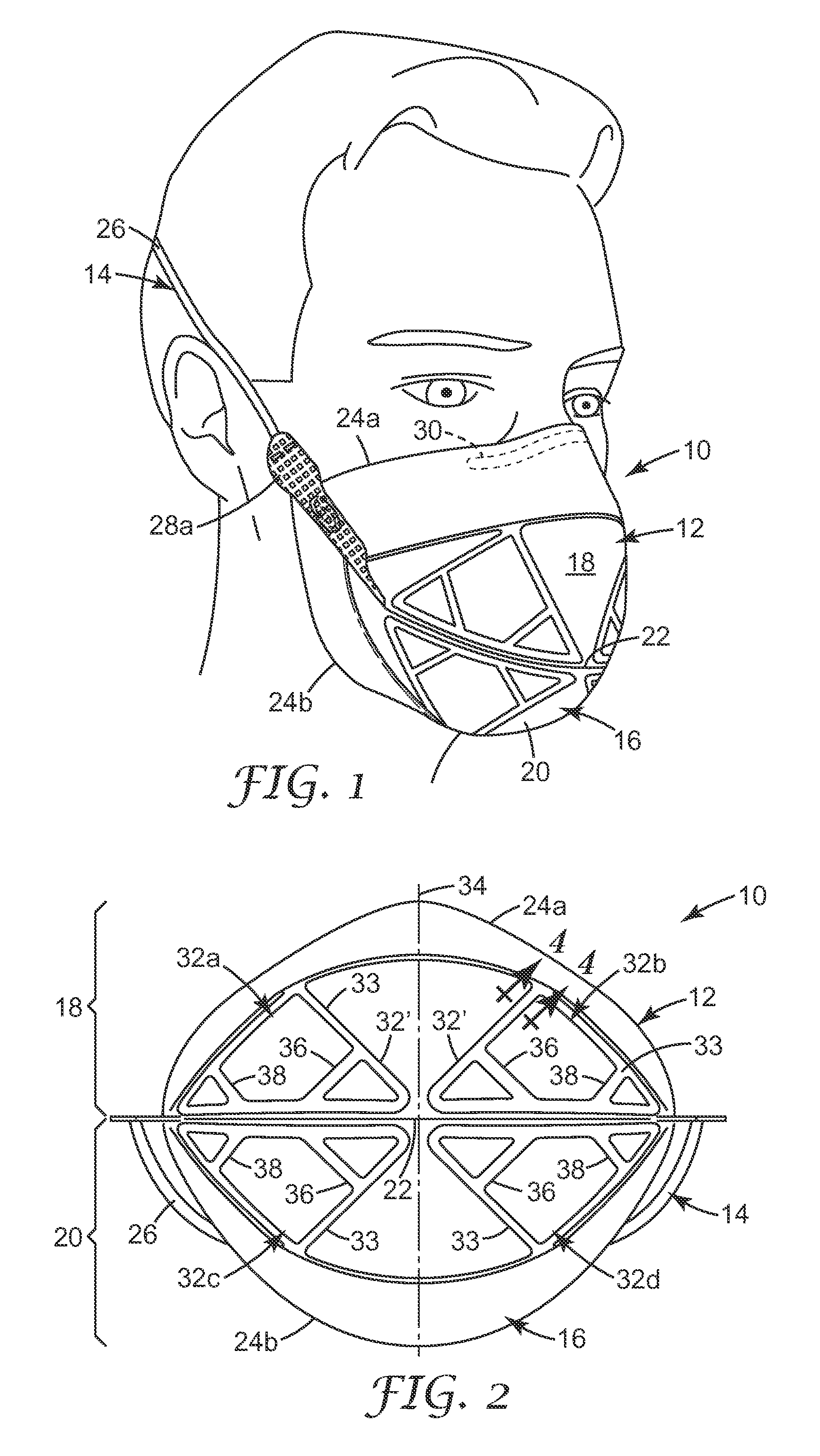

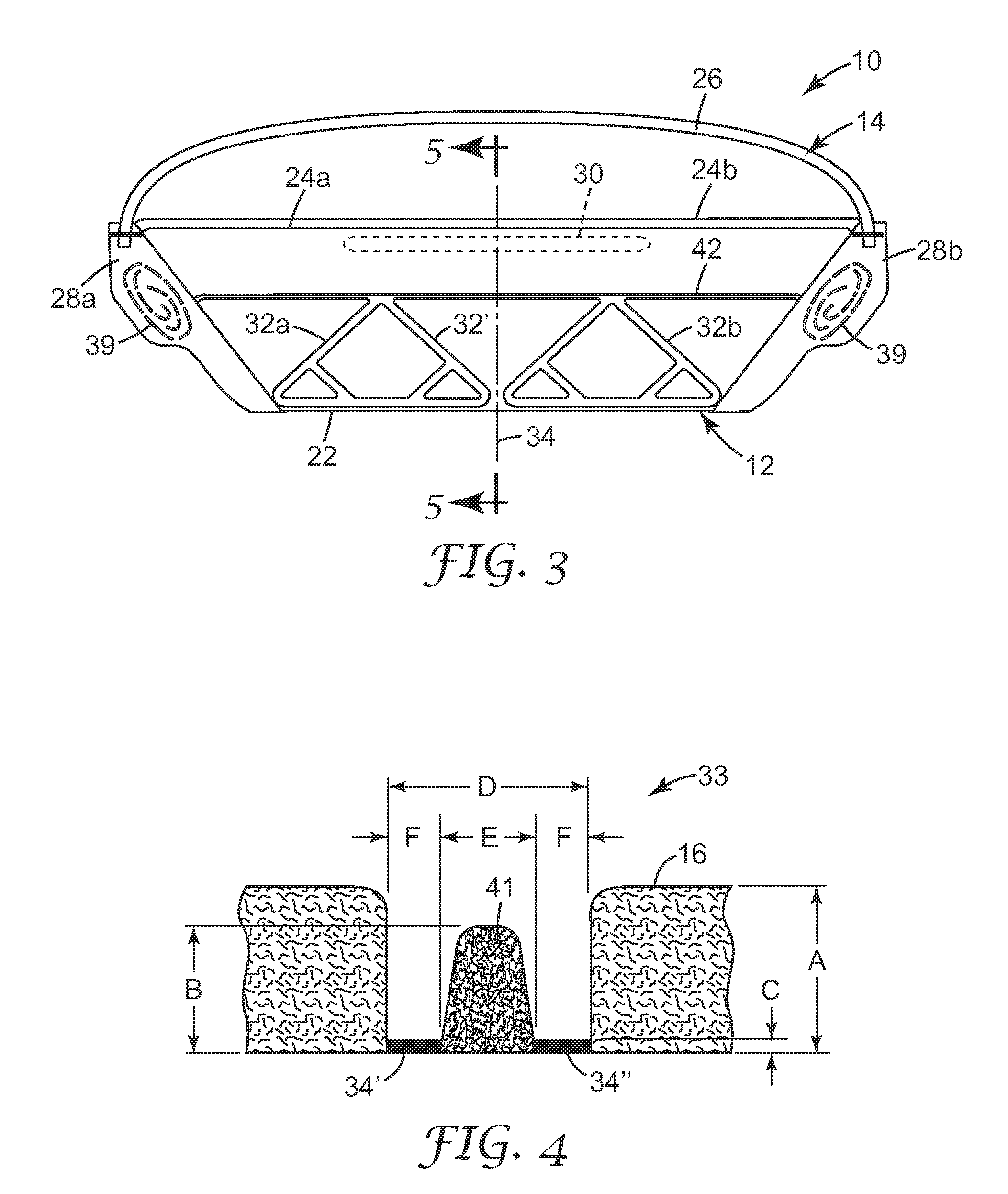

Filtering face-piece respirator having parallel line weld pattern in mask body

ActiveUS20110094515A1Reduce usageDeformation MinimizationBreathing filtersBreathing masksRespiratorEngineering

A respirator 10 that has a harness 14 and a mask body 12 that is joined to the harness 14. The mask body 12 includes a filtering structure 16 that may contain a plurality of layers of nonwoven fibrous material 58, 60, 62. The layers of nonwoven fibrous material 58, 60, 62 have a thickness A and are welded together by at least two parallel weld lines 34′, 34″ that are spaced at 0.5 to 6 times A. A mask body that uses parallel weld lines may exhibit better resistance to collapse and may be manufactured at faster speeds than similar structures which use single weld lines of comparable width.

Owner:3M INNOVATIVE PROPERTIES CO

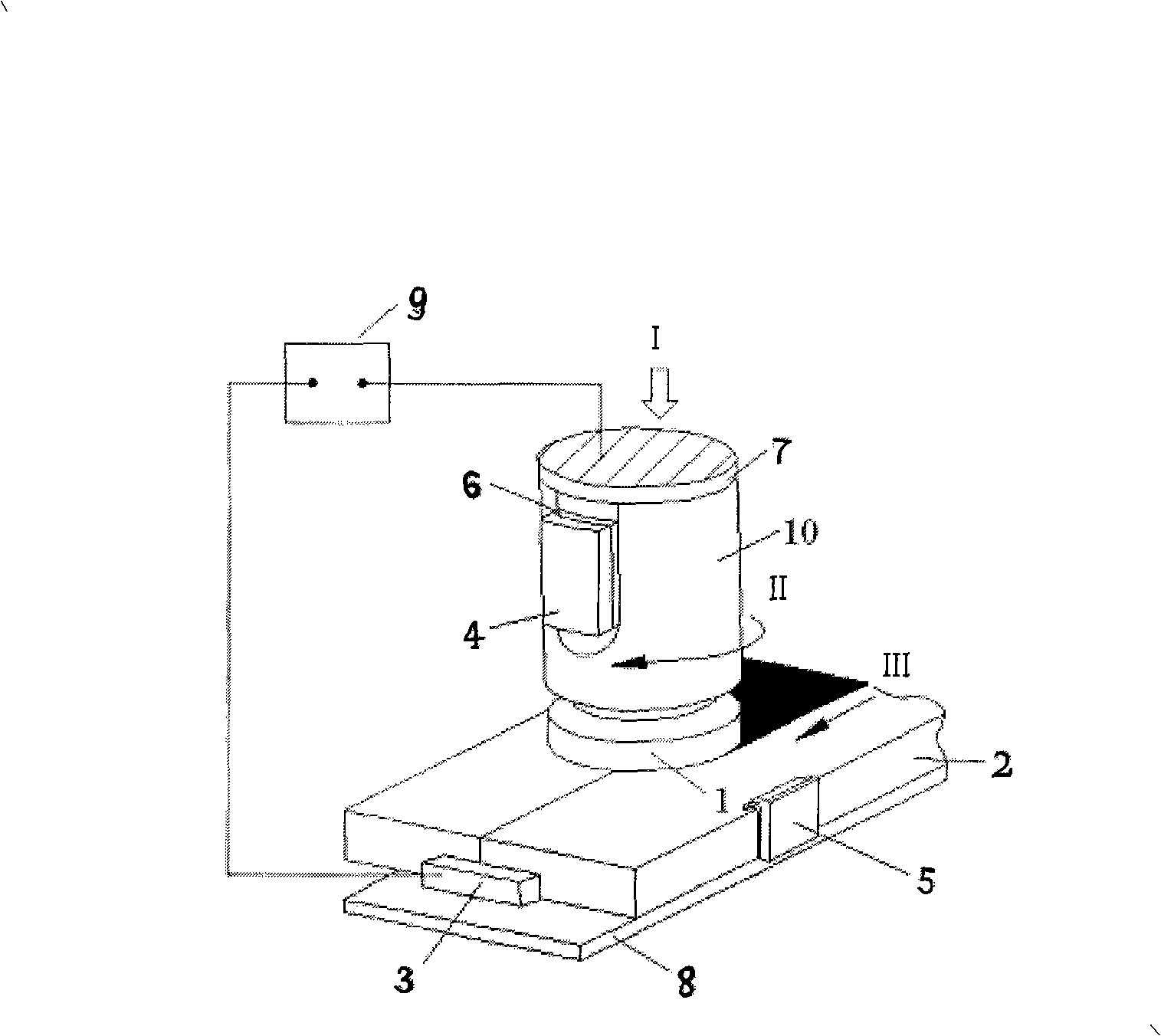

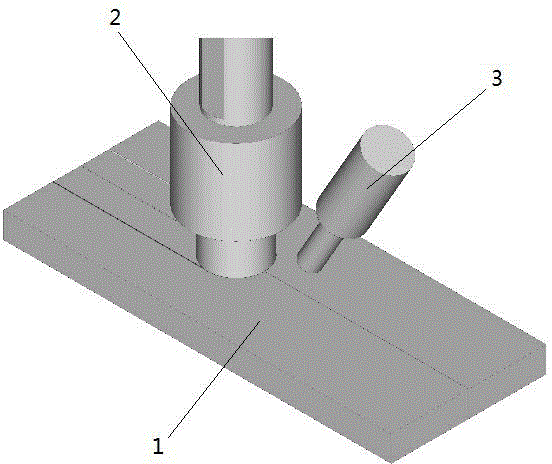

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

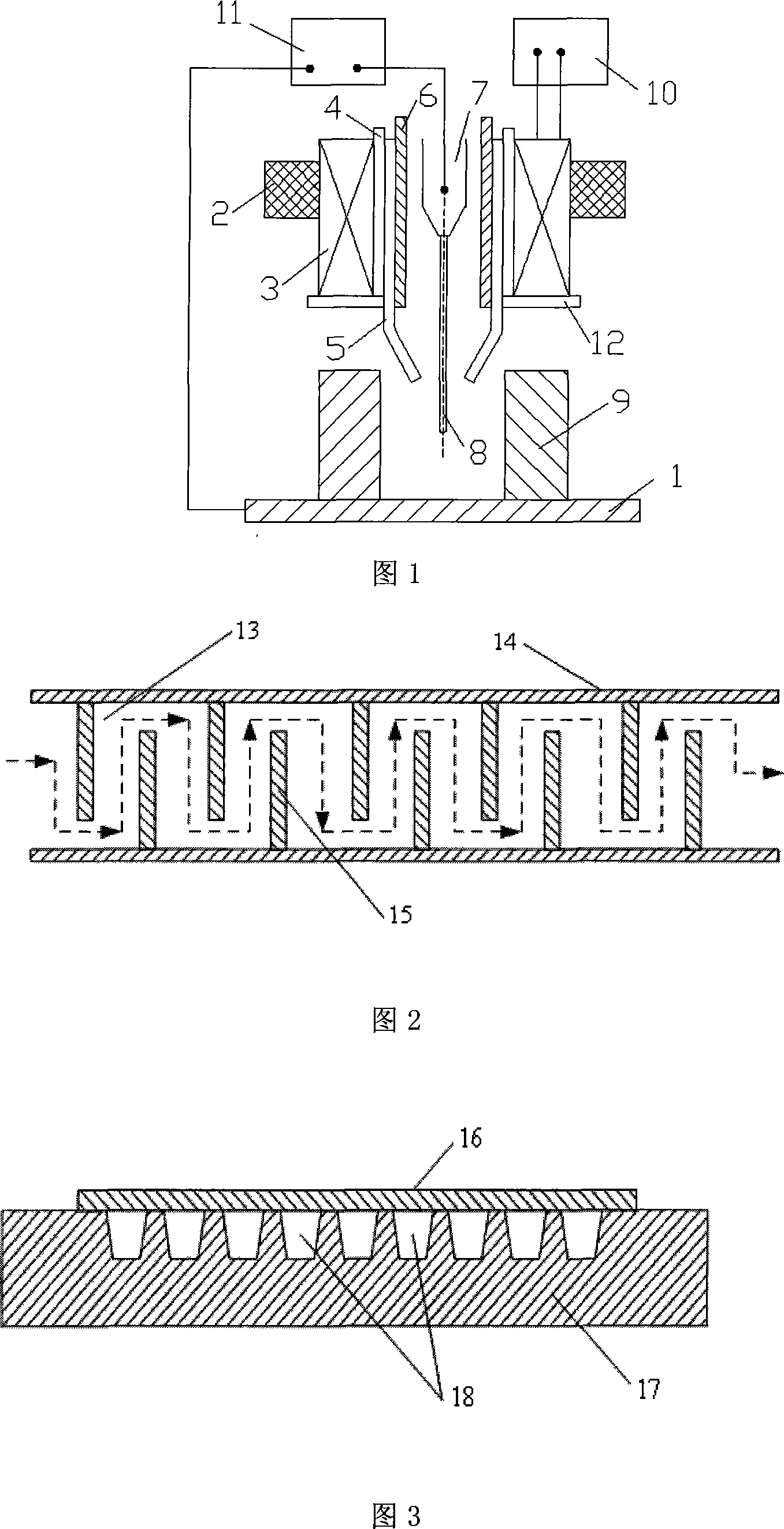

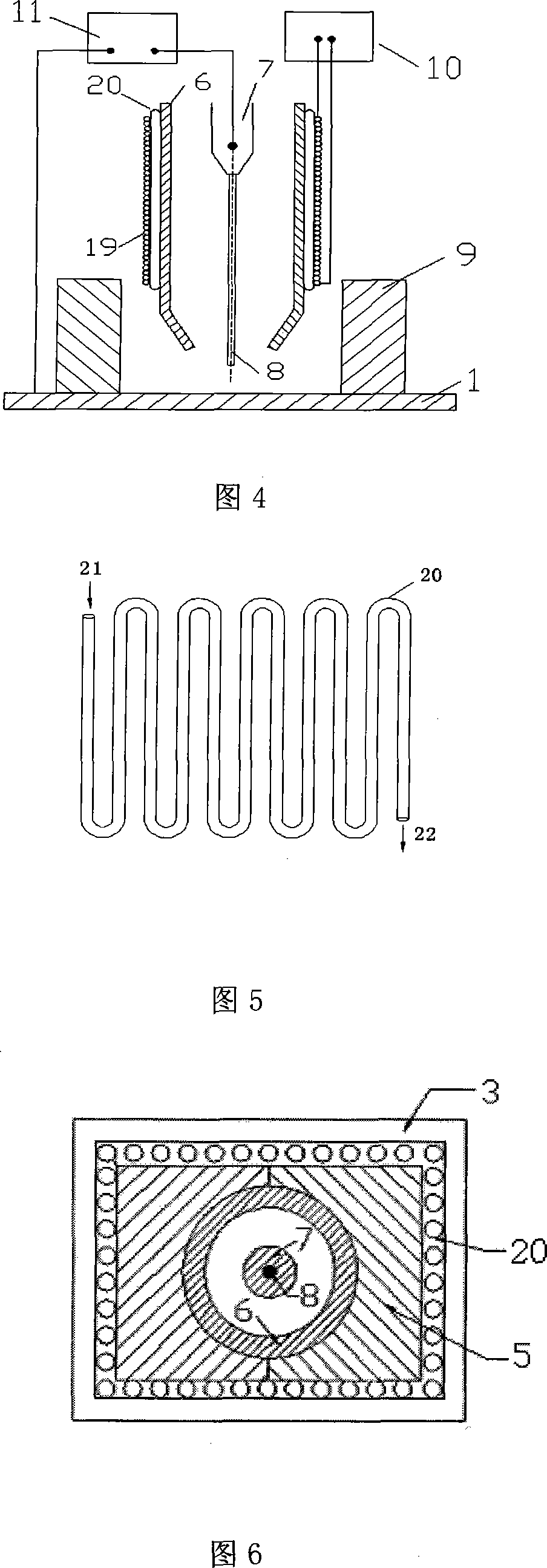

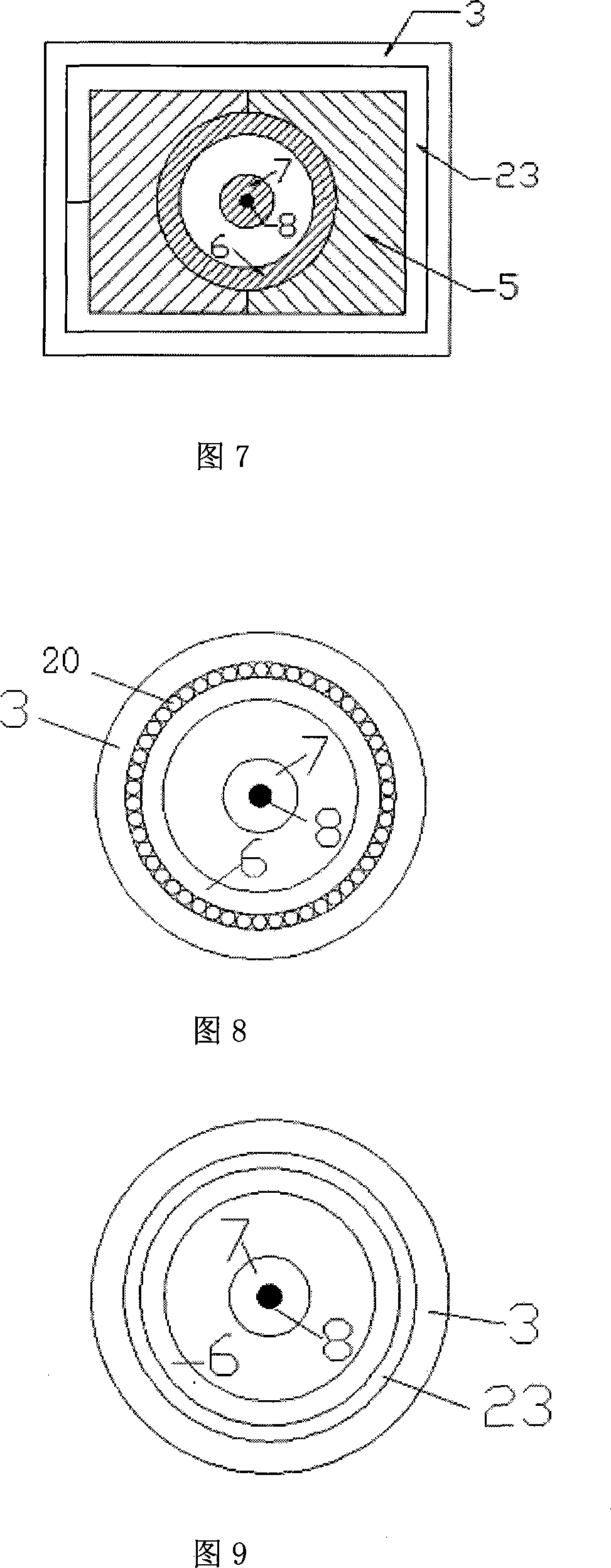

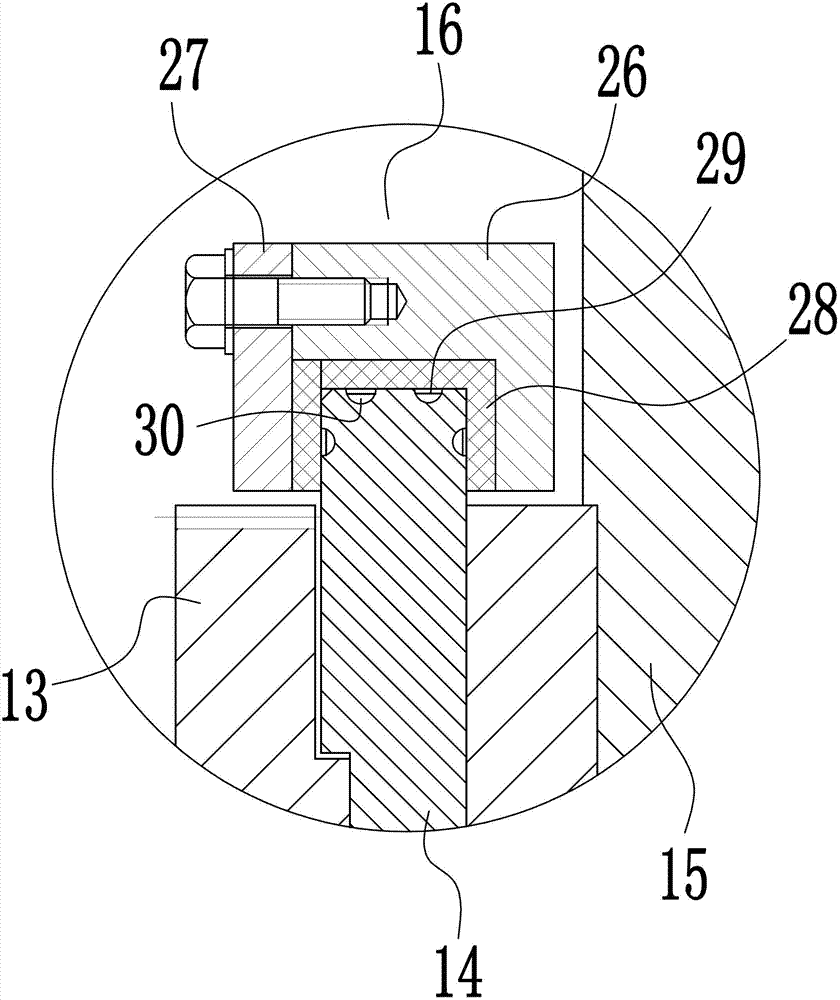

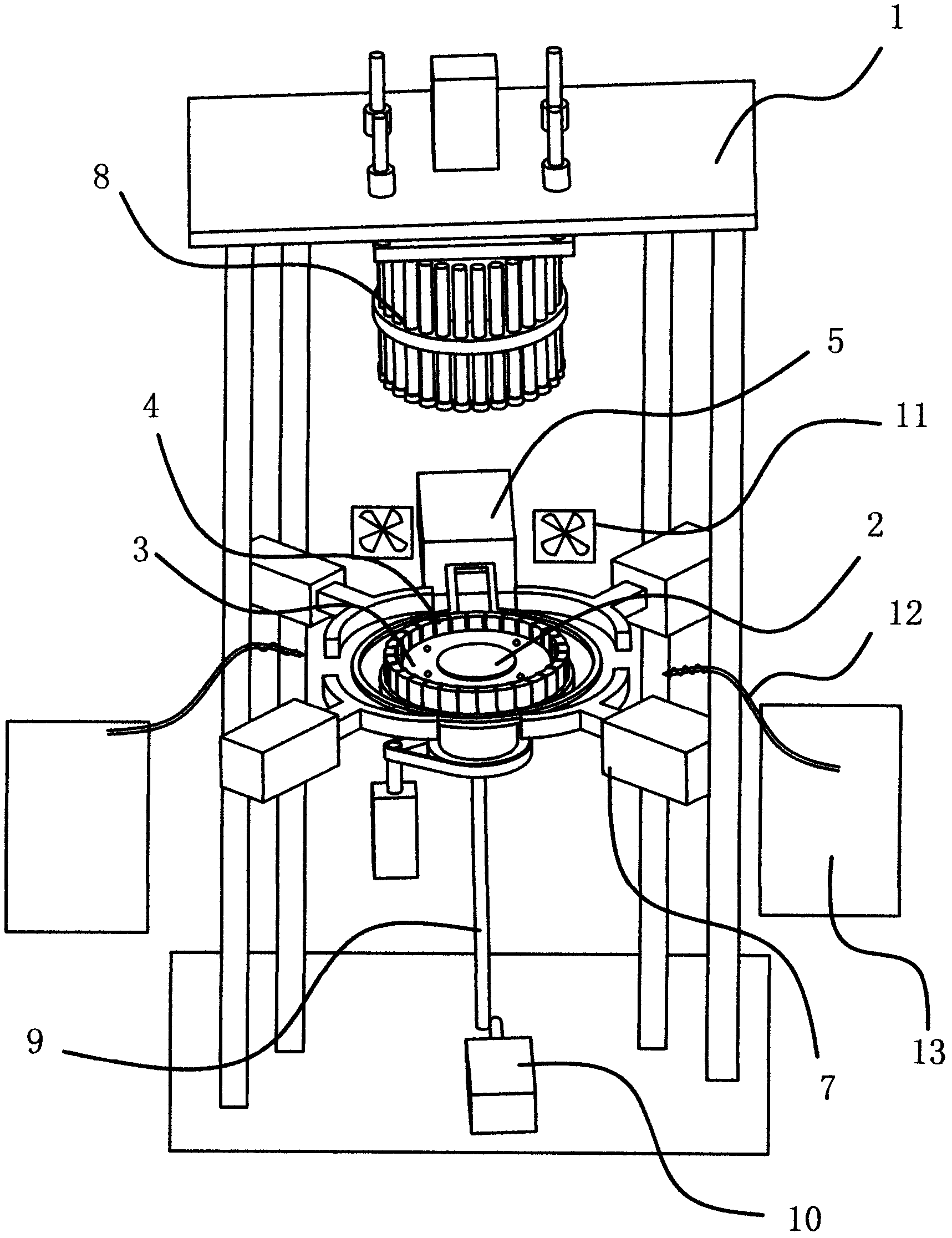

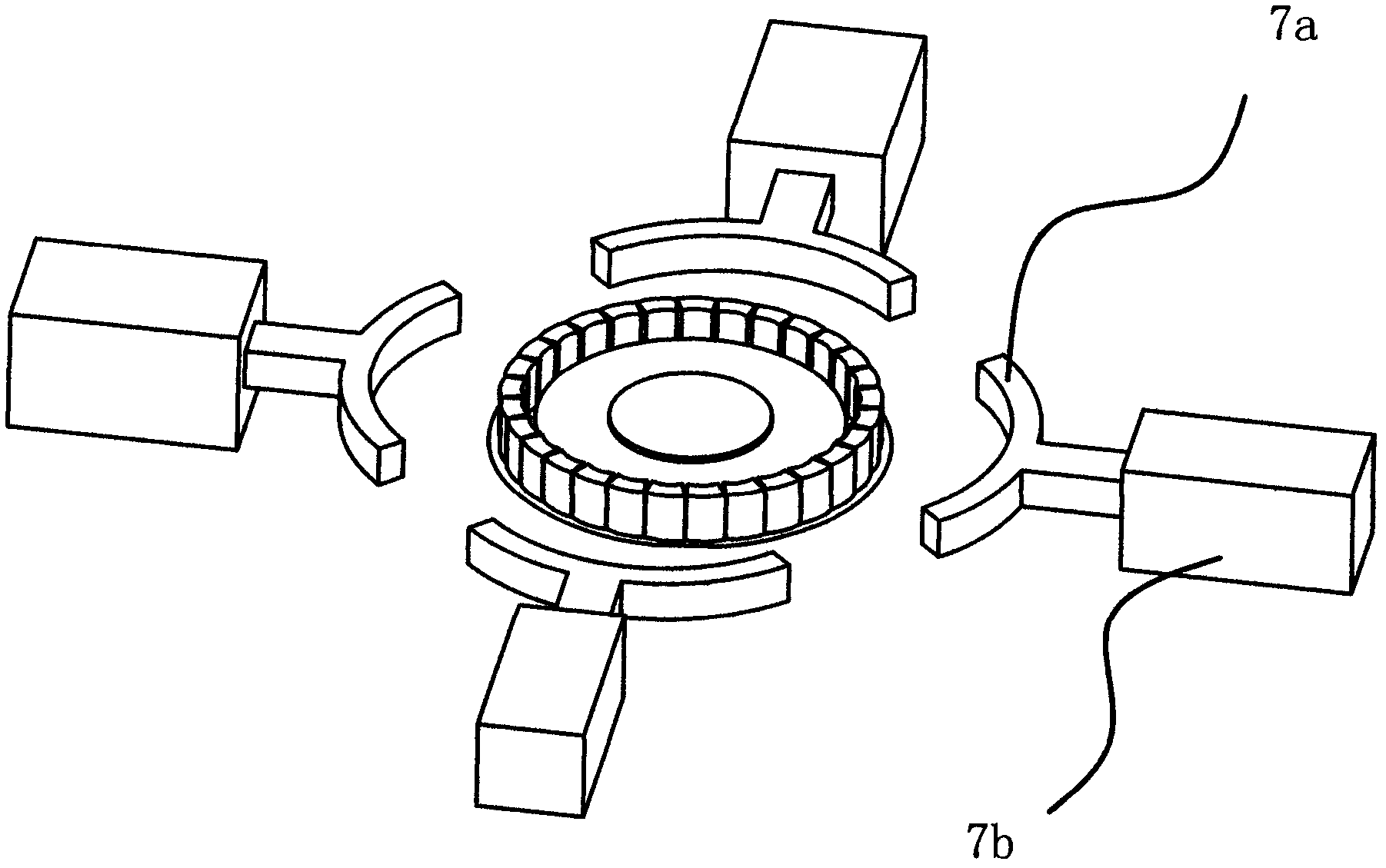

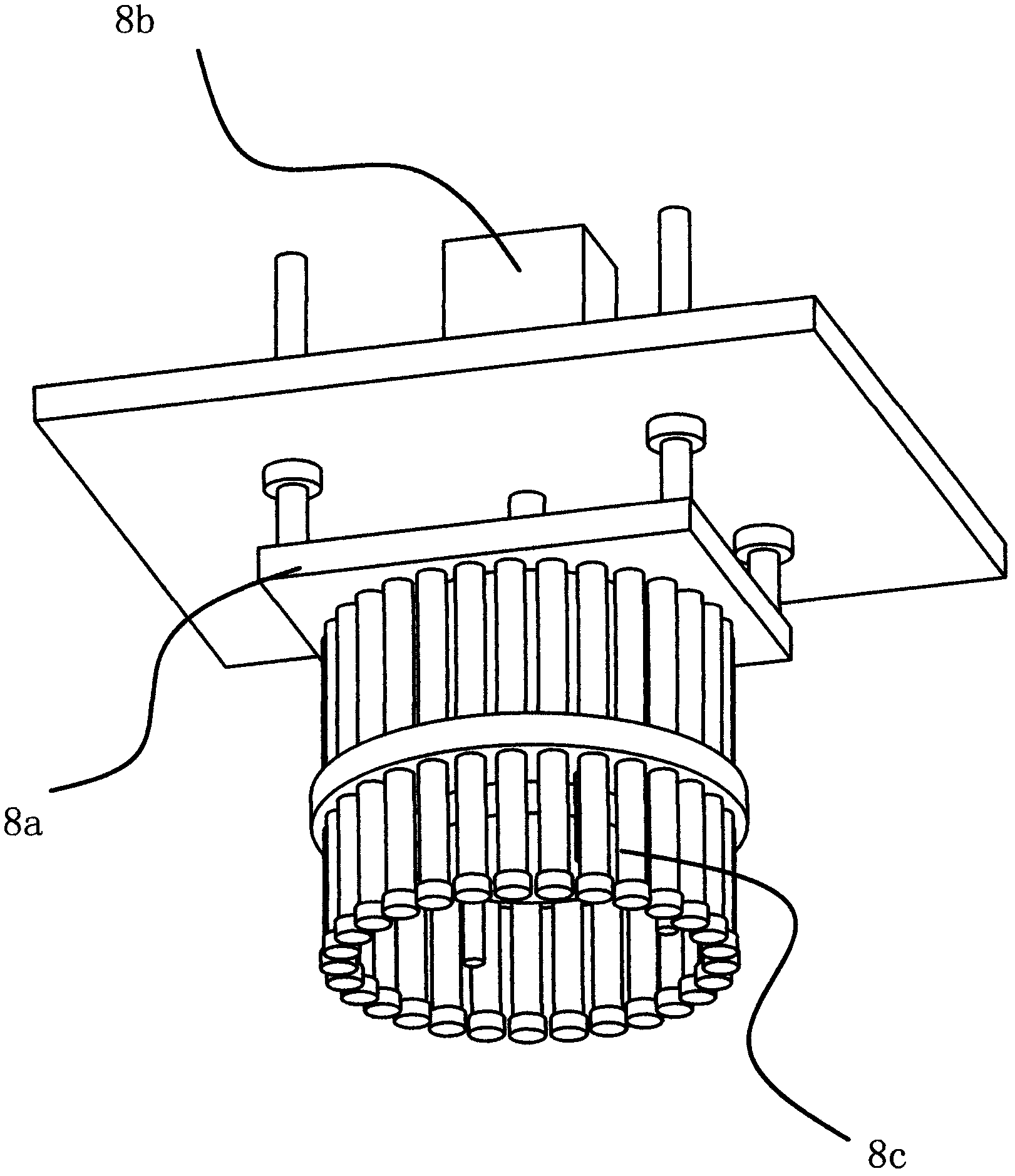

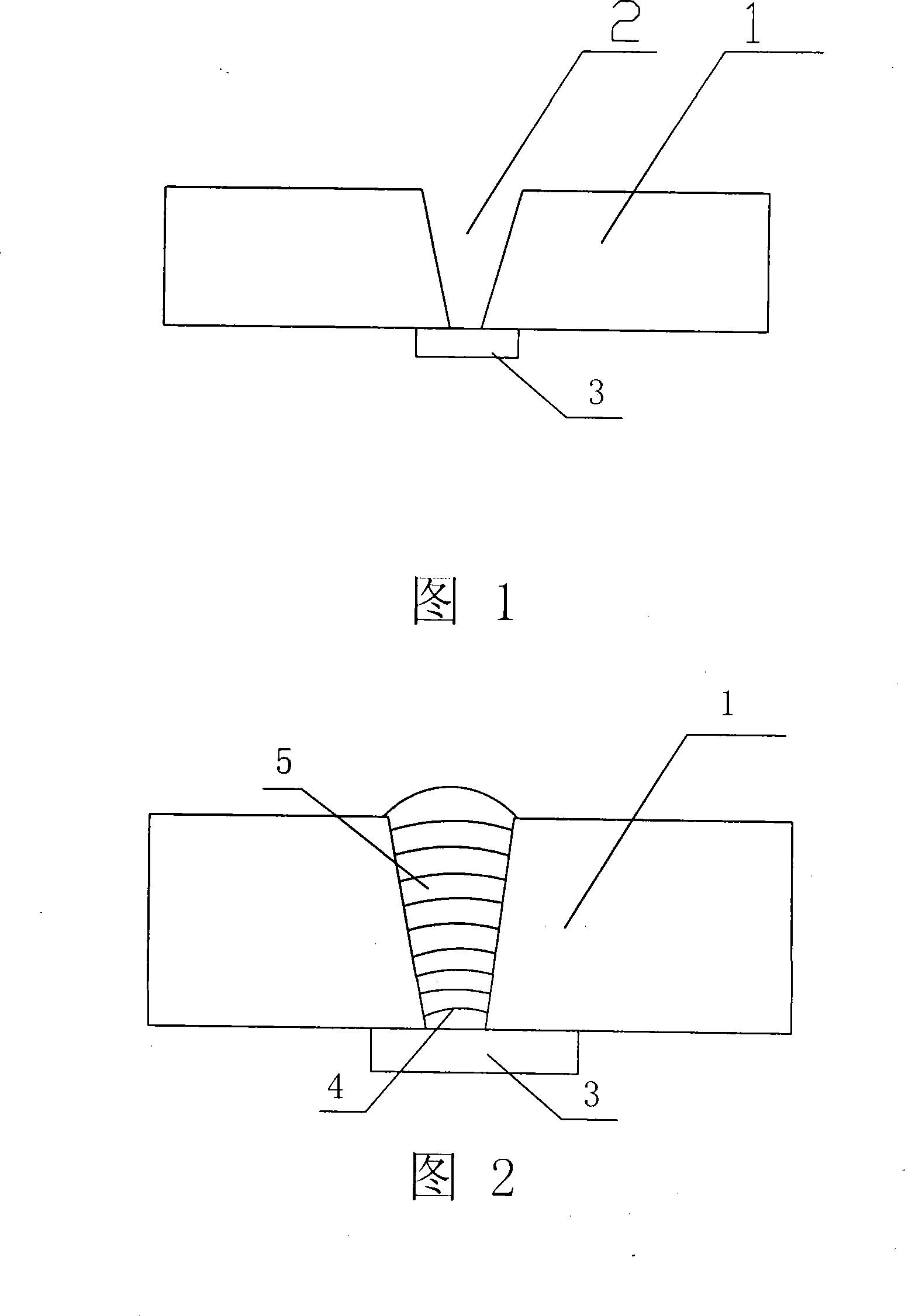

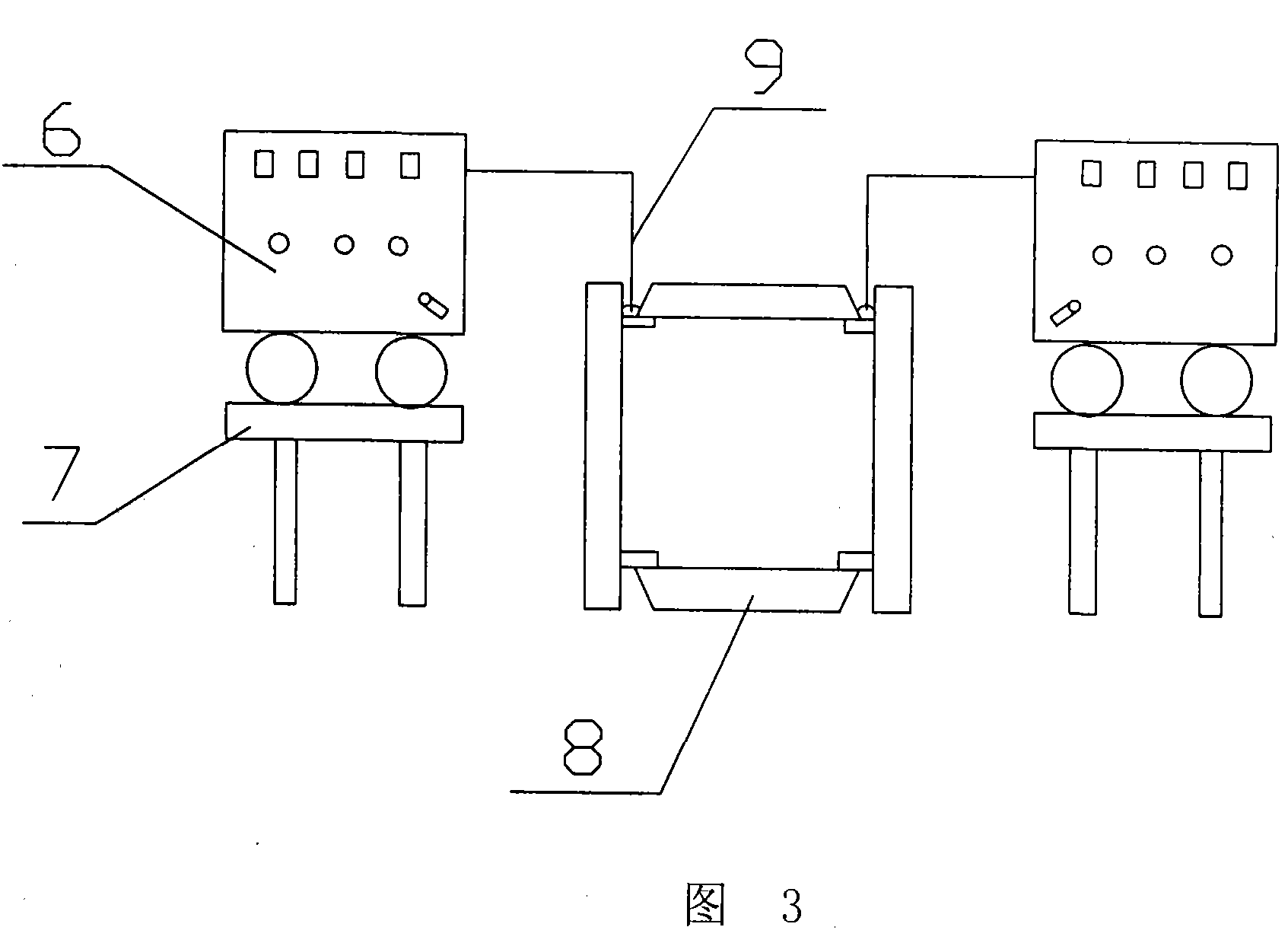

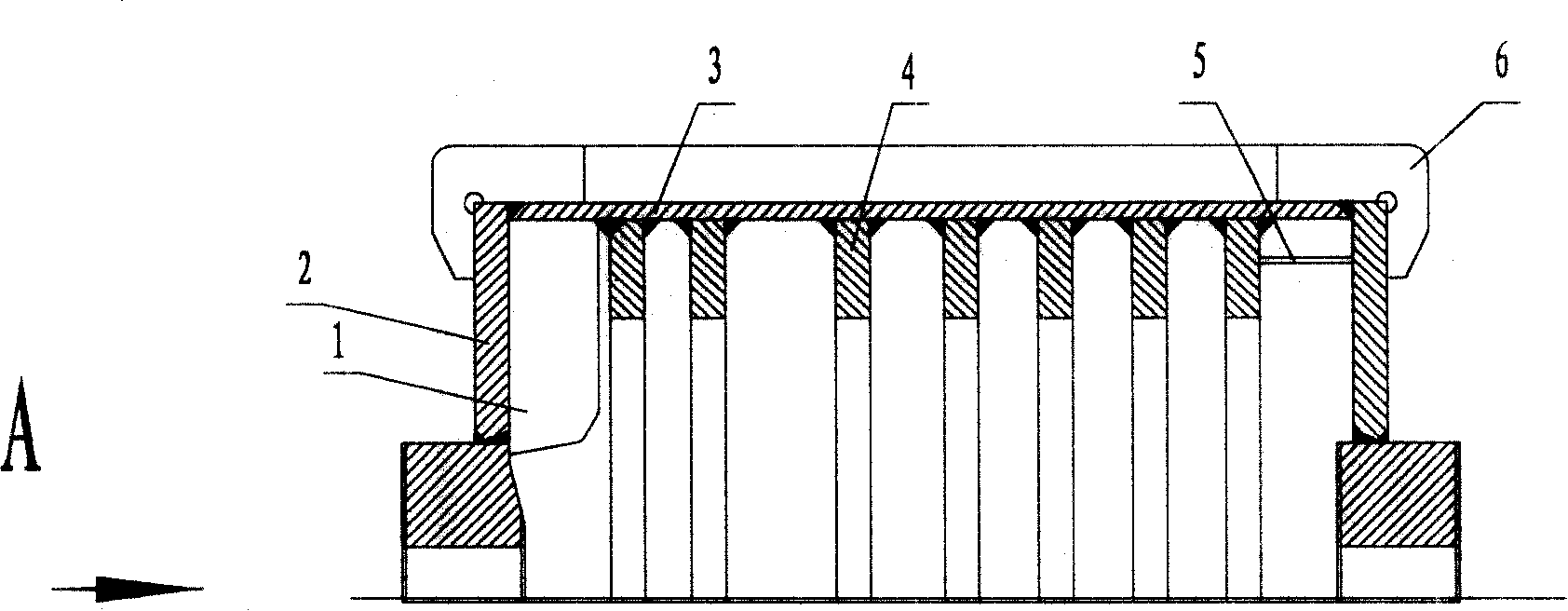

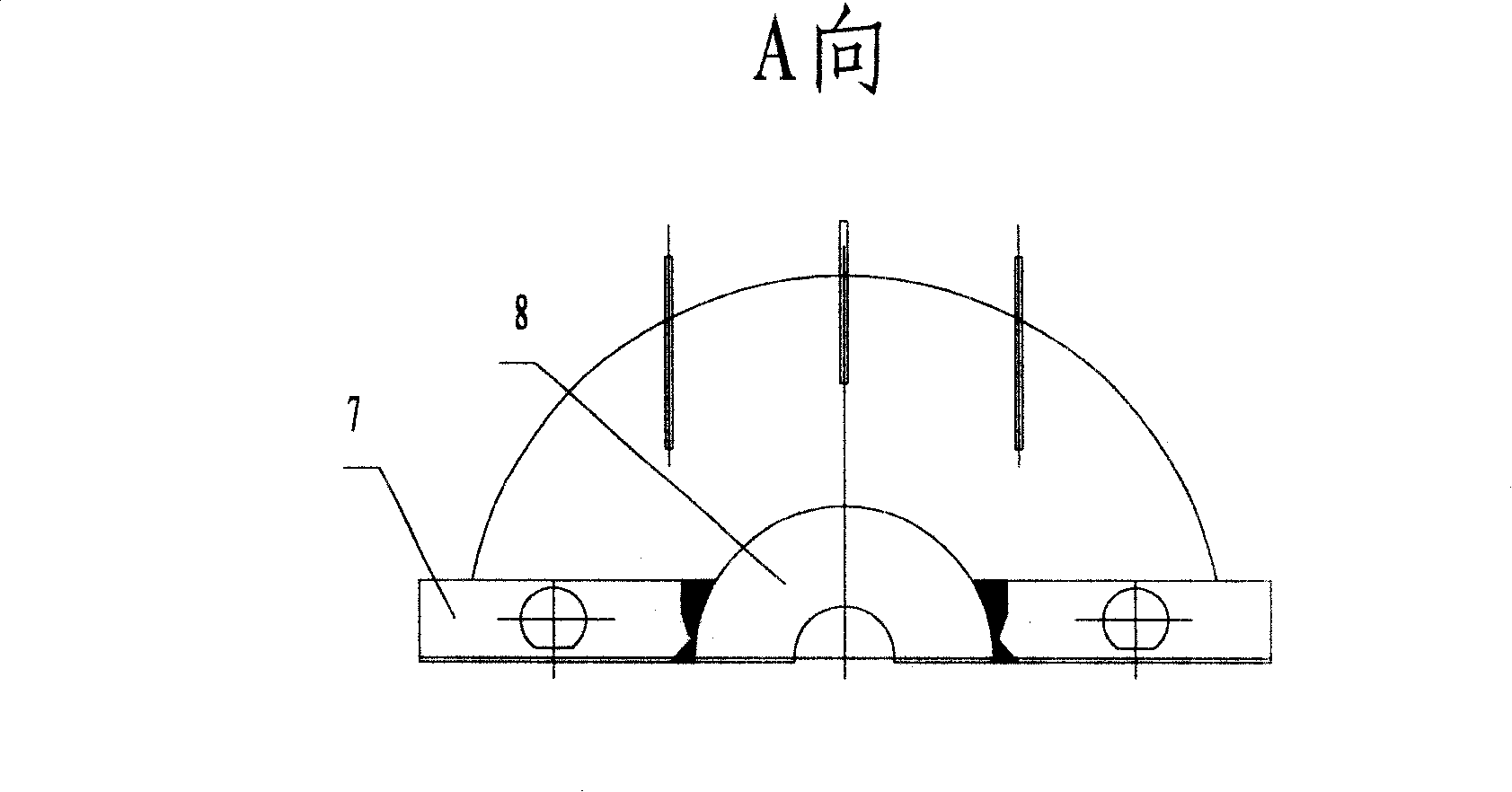

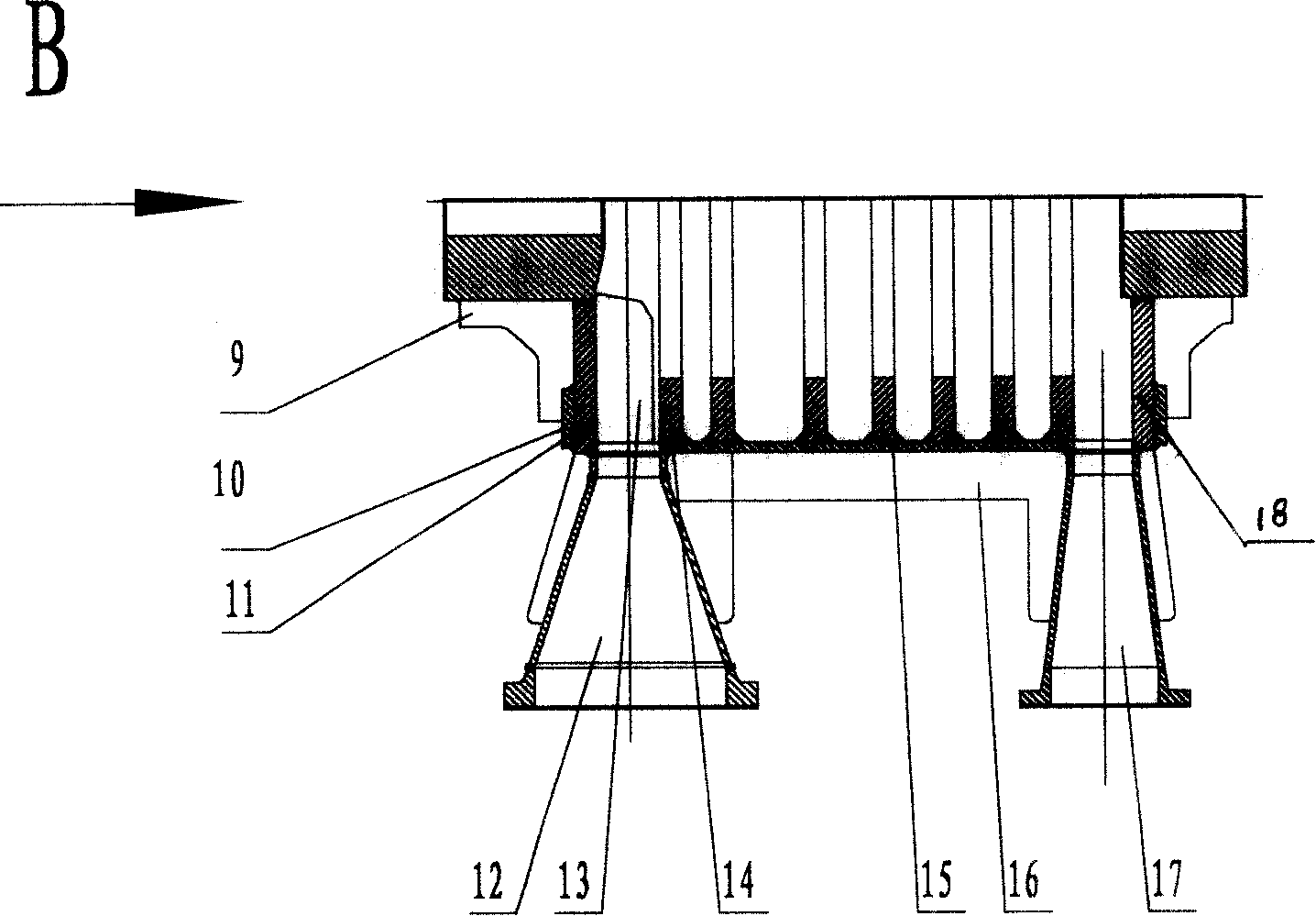

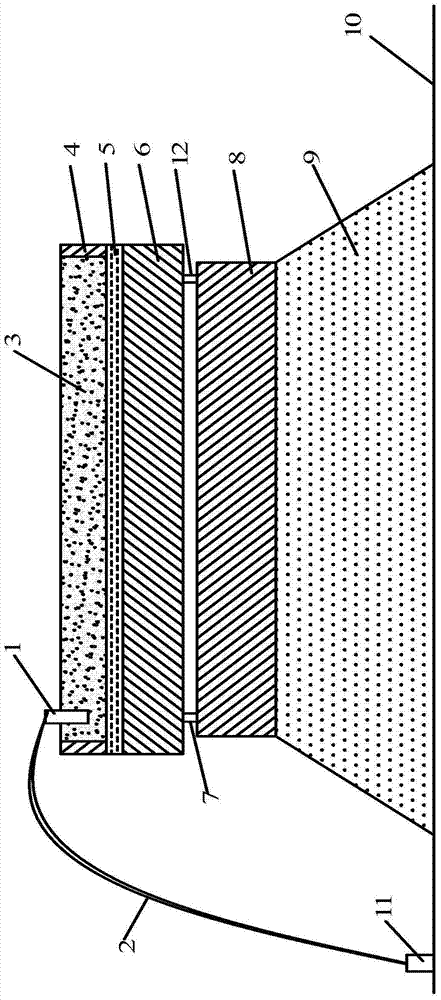

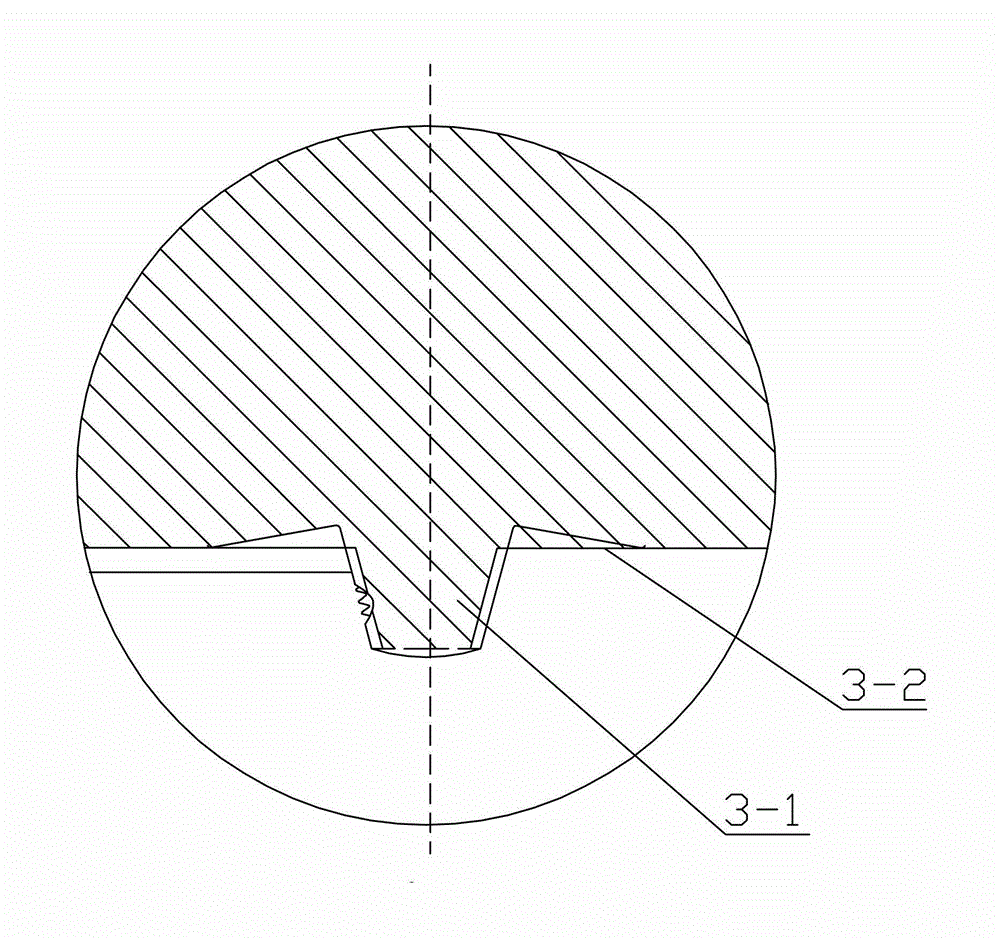

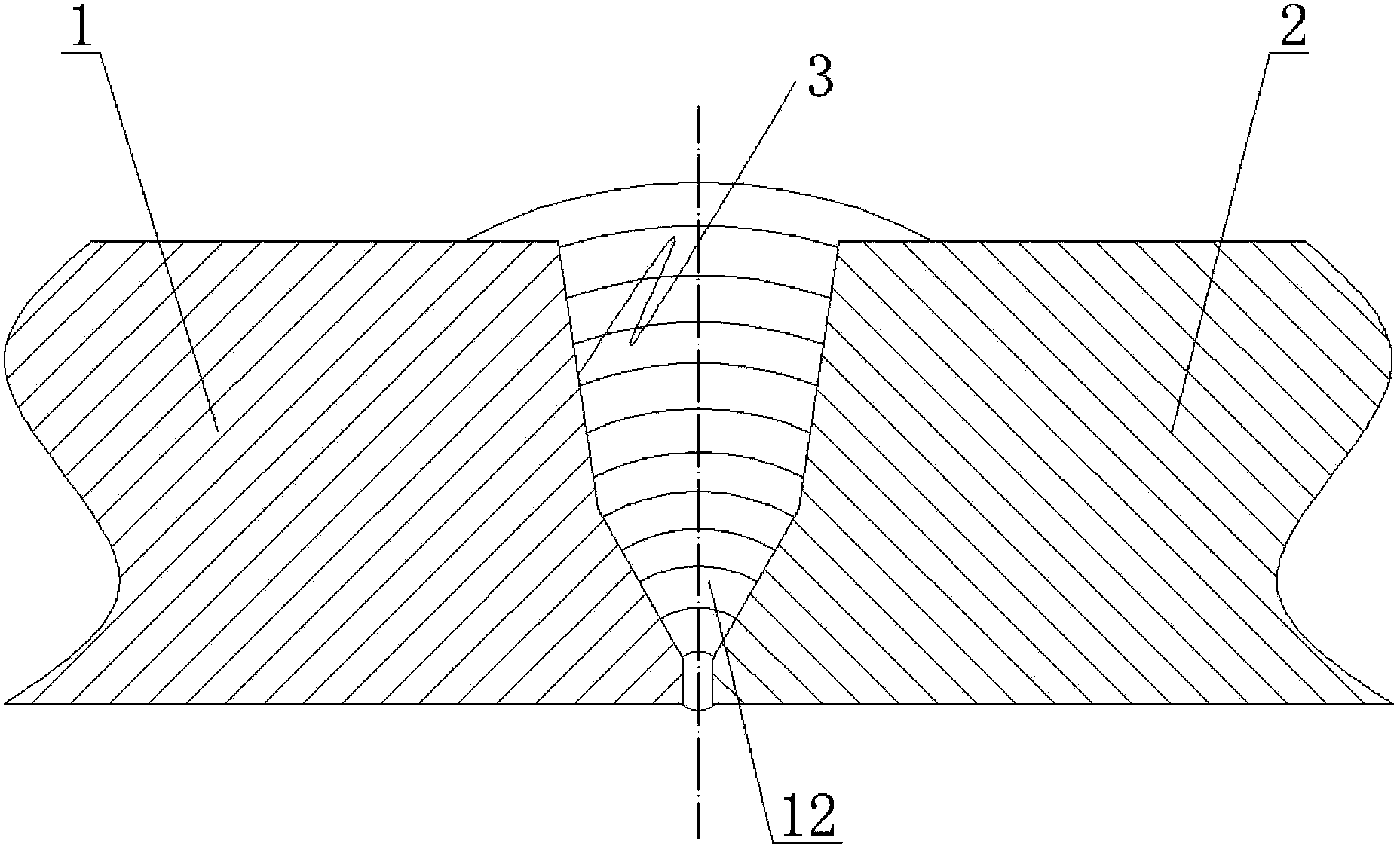

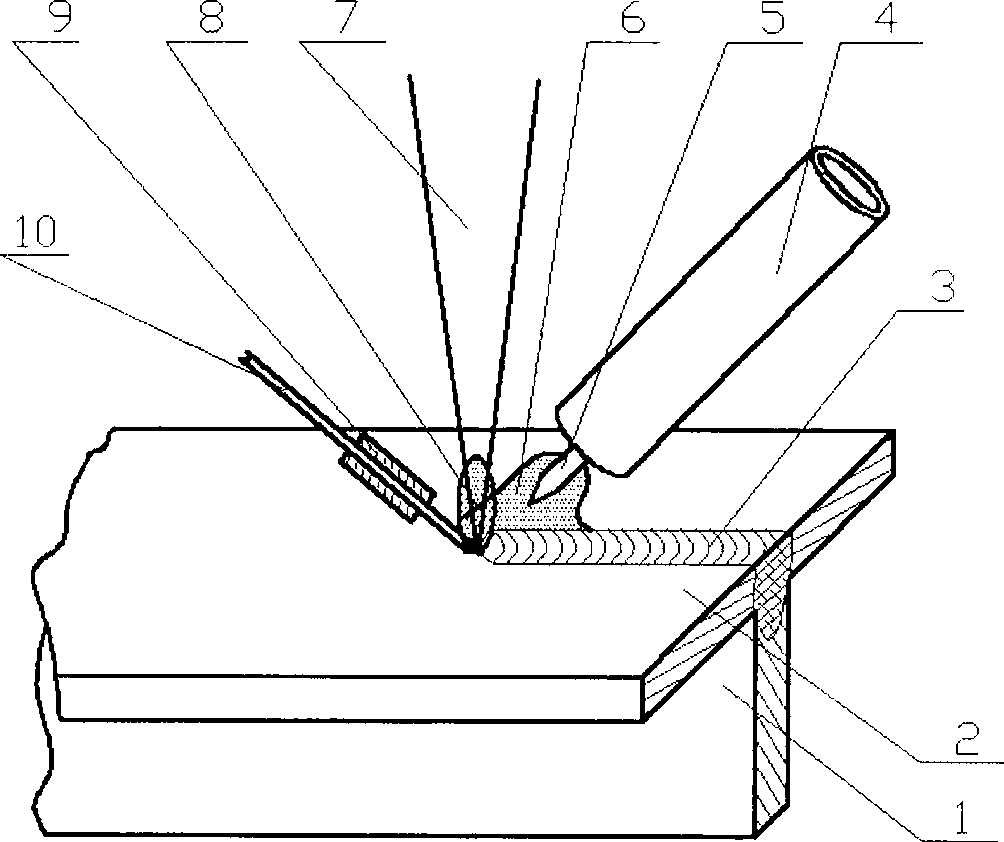

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

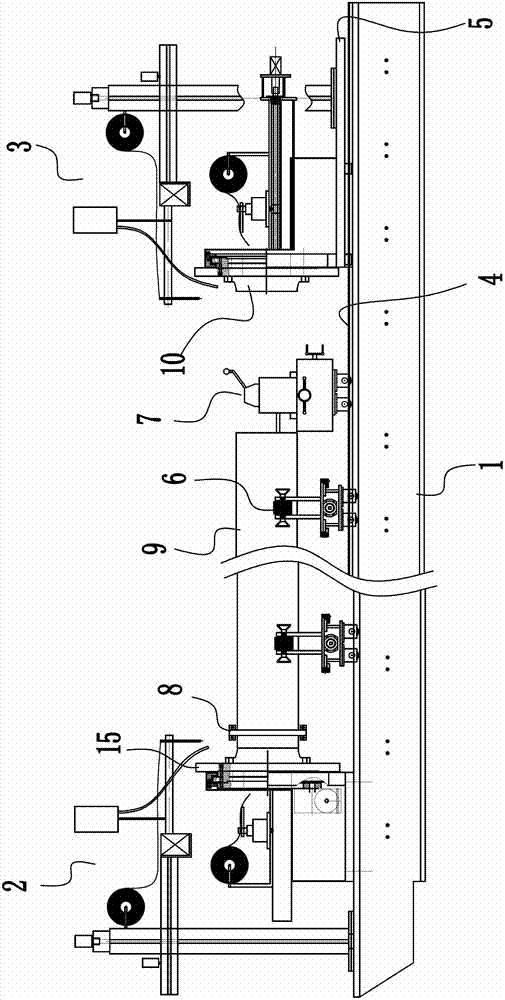

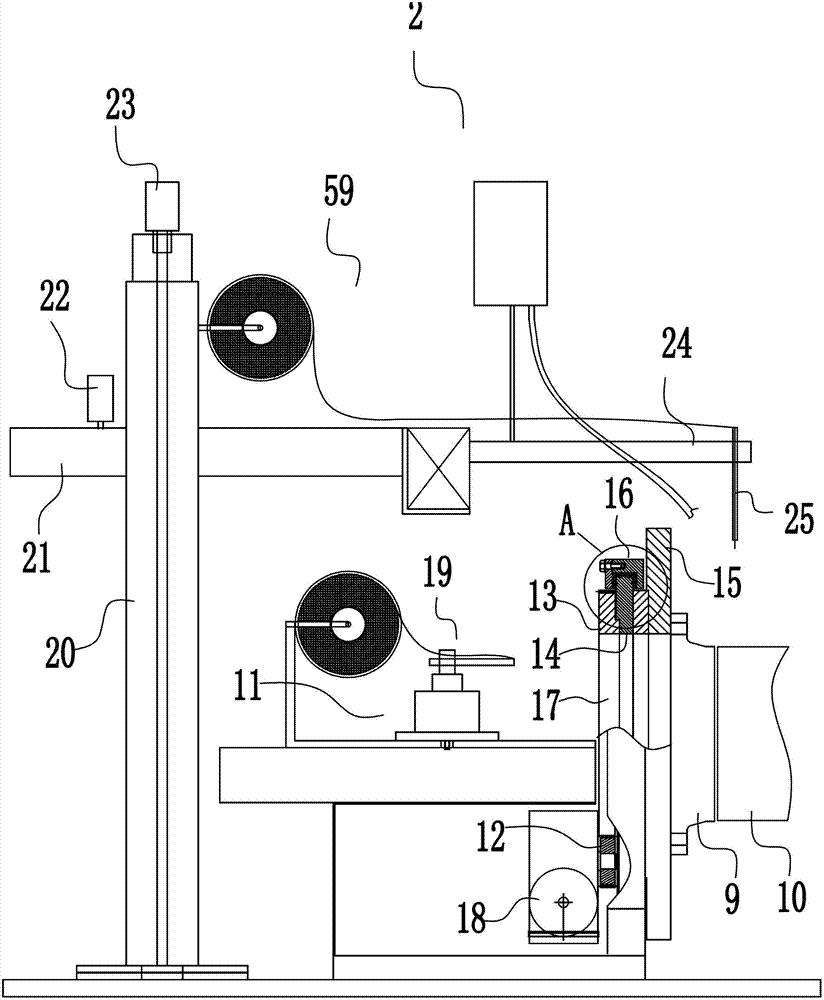

Integrated steel pipe and flange splicing and machining machine and machining process thereof

InactiveCN102729045ALarge amount of welding depositionImprove welding speed and qualityArc welding apparatusOther manufacturing equipments/toolsSteel tubeMachining process

The invention discloses an integrated steel pipe and flange splicing and machining machine and a machining process thereof and aims to provide an integrated steel pipe and flange splicing and machining machine which can improve the manufacturing precision and the production efficiency and reduce the labor intensity and is high in steel pipe and flange welding quality and a machining process of the machine. The integrated steel pipe and flange splicing and machining machine comprises a working platform, and a supporting bracket which is arranged on the working platform and is used for supporting a steel pipe, wherein one end of the working platform is provided with a first welding device; a first guide rail which extends to the other end of the working platform is arranged on the top of the working platform; a first mounting plate is arranged on the first guide rail in a sliding mode; a second welding device is arranged on the first mounting plate; and flange fixing templates are arranged on the first welding device and the second welding device. The machining process comprises the following steps of: lifting the steel pipe to the supporting bracket, and fixing the flange to a flange fixing template; and welding annular gaps of the inner and outer side faces of the steel pipe and the flange through the first welding device and the second welding device.

Owner:戴刚平

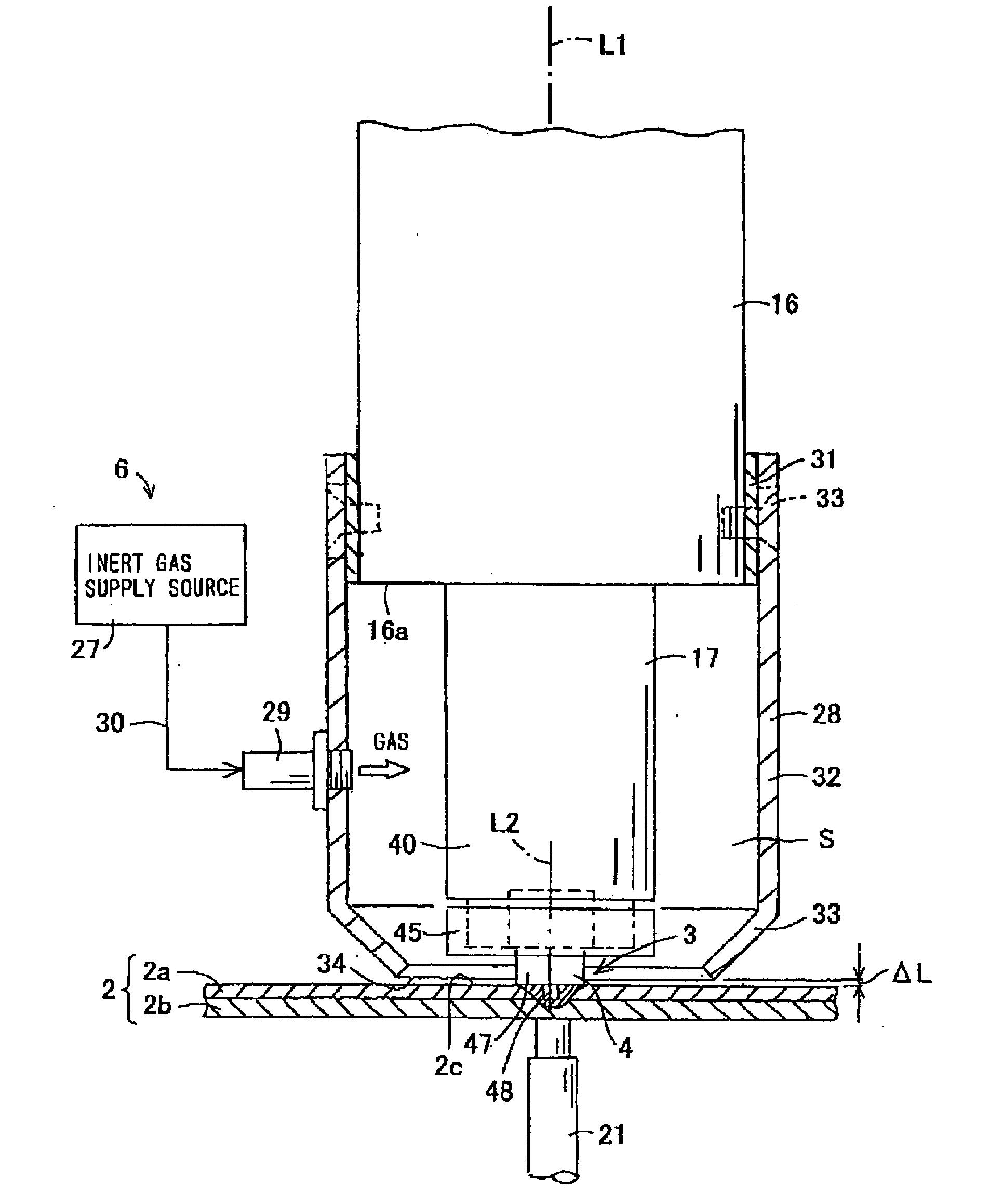

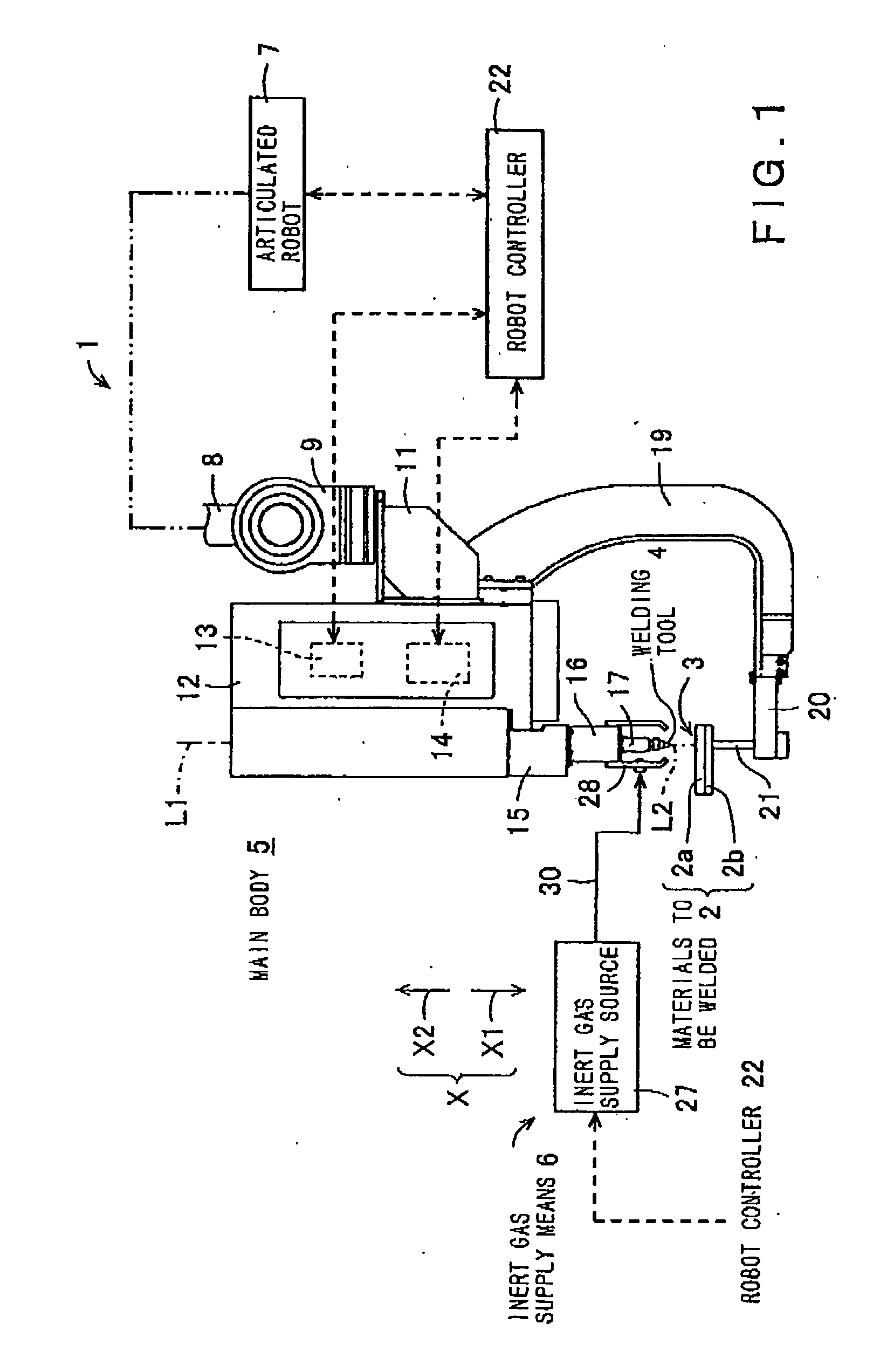

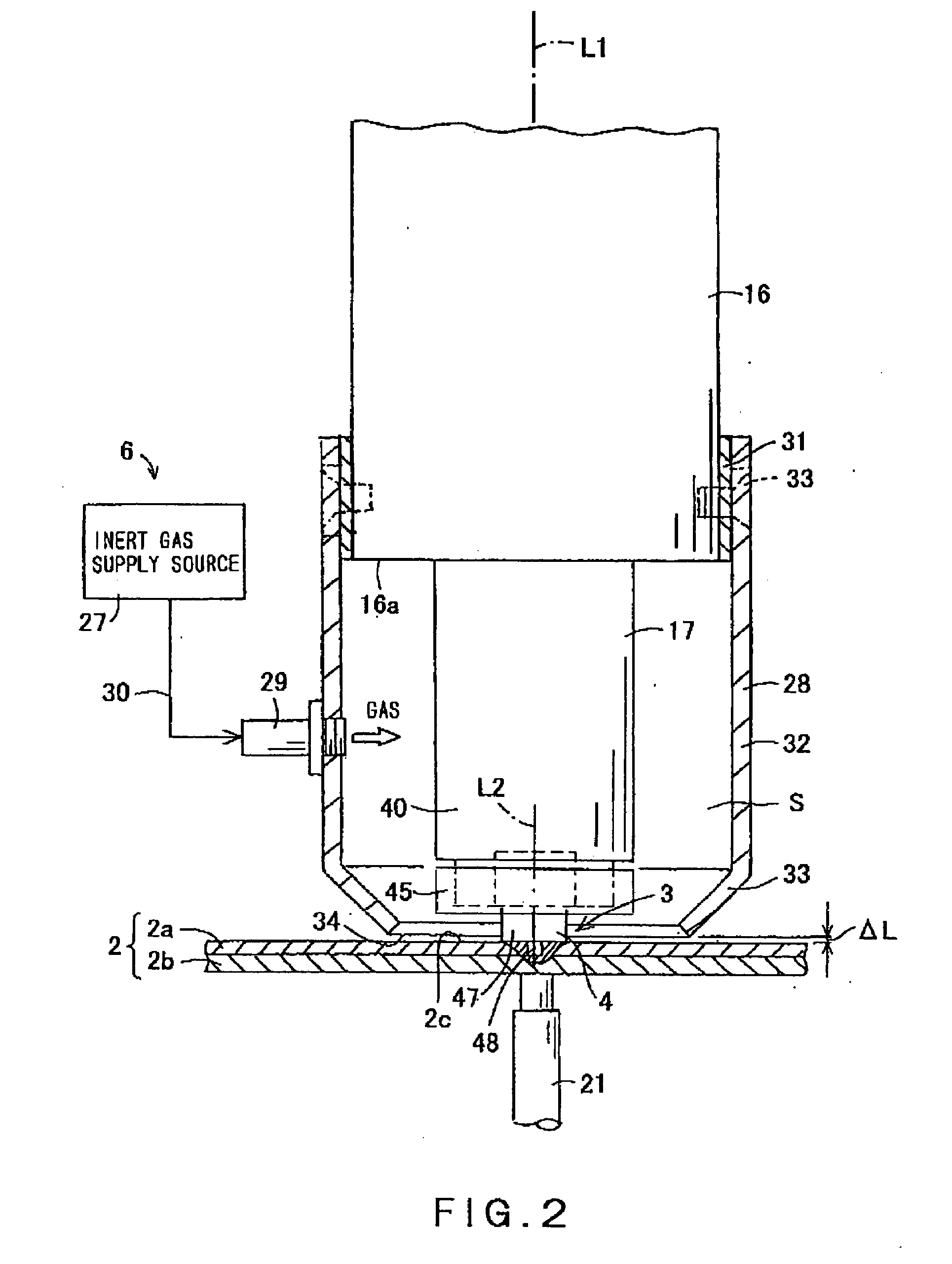

Friction stir welding machine and friction stir welding tool

ActiveUS20080023524A1Prolong lifeInhibit wearWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNitride

The present invention is a friction stir welding machine adapted to perform solid phase welding on a welding portion of materials to be welded, by pressing a welding tool against the welding portion of the materials to be welded while rotating the welding tool, and forcing the welding tool to be advanced into a softened portion which is softened by a frictional heat while stirring the softened portion, wherein a coating made of aluminum nitride is formed on at least a region of the welding tool to be in contact with the materials to be welded.

Owner:KAWASAKI HEAVY IND LTD

Automatic millstone welder

ActiveCN102615414APrecise positioningQuality improvementHigh frequency current welding apparatusElectric machineryEngineering

The invention provides an automatic millstone welder, which belongs to the technical field of machinery. The welder solves the problems that welding quality is poor and welding efficiency is low in existing welding process of diamond millstones. The automatic millstone welder comprises a frame and a working platform. A millstone can be fixed on the working platform. A high-frequency induction coil device is disposed on the periphery of the working platform and the high-frequency induction coil device can perform high-temperature heating and welding to the millstone and bit tools. The working platform is driven to rotate by a motor. A correction device which enables the bit tools to be positioned to the millstone accurately is disposed on the periphery of the working platform. A pressing device which can press the bit tools and fix the bit tools on steps of the millstone is disposed right above the working platform. The automatic millstone welder is fine in welding effect, high in welding efficiency, and the welded millstone has high quality.

Owner:浙江振兴阿祥集团有限公司

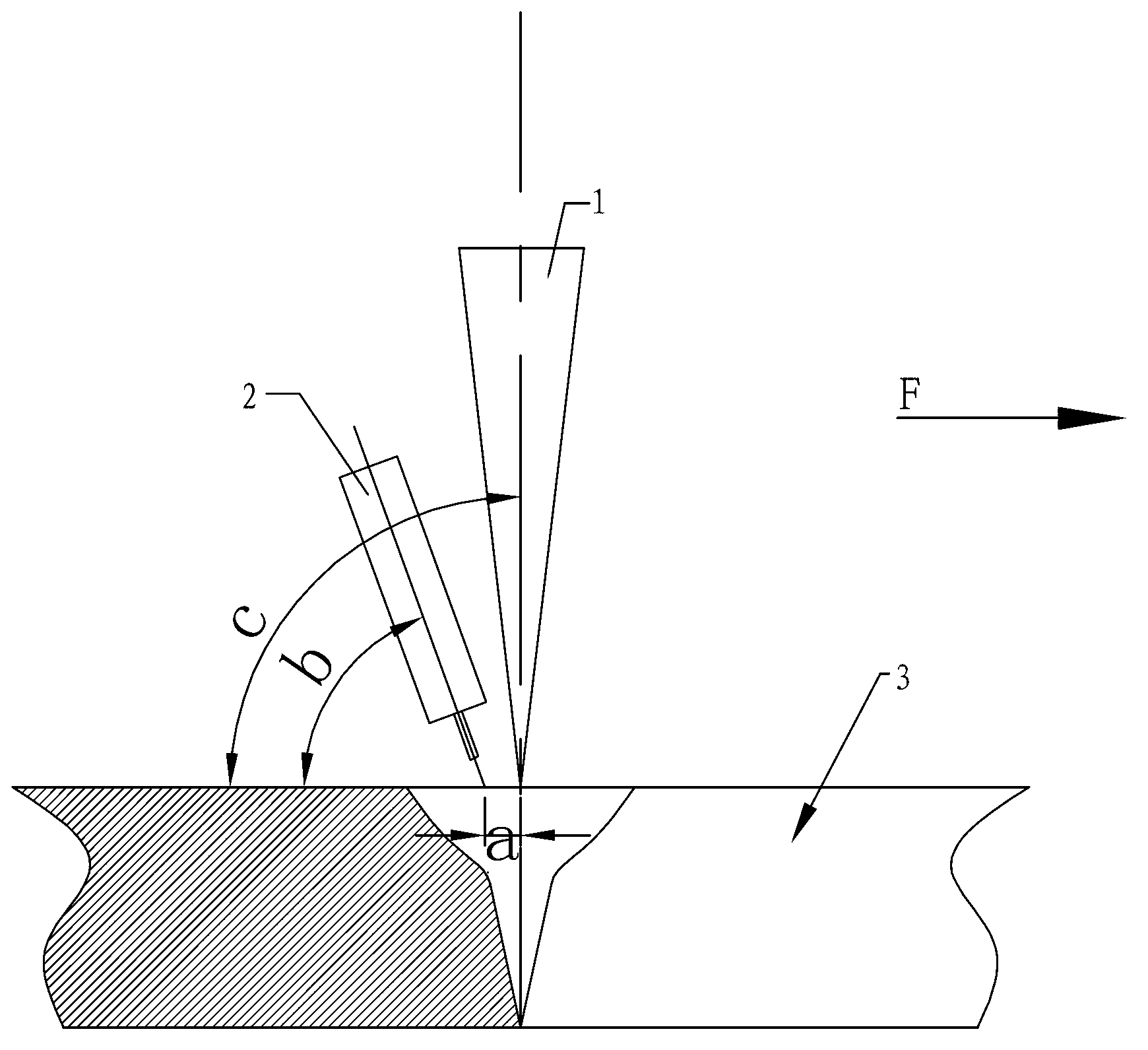

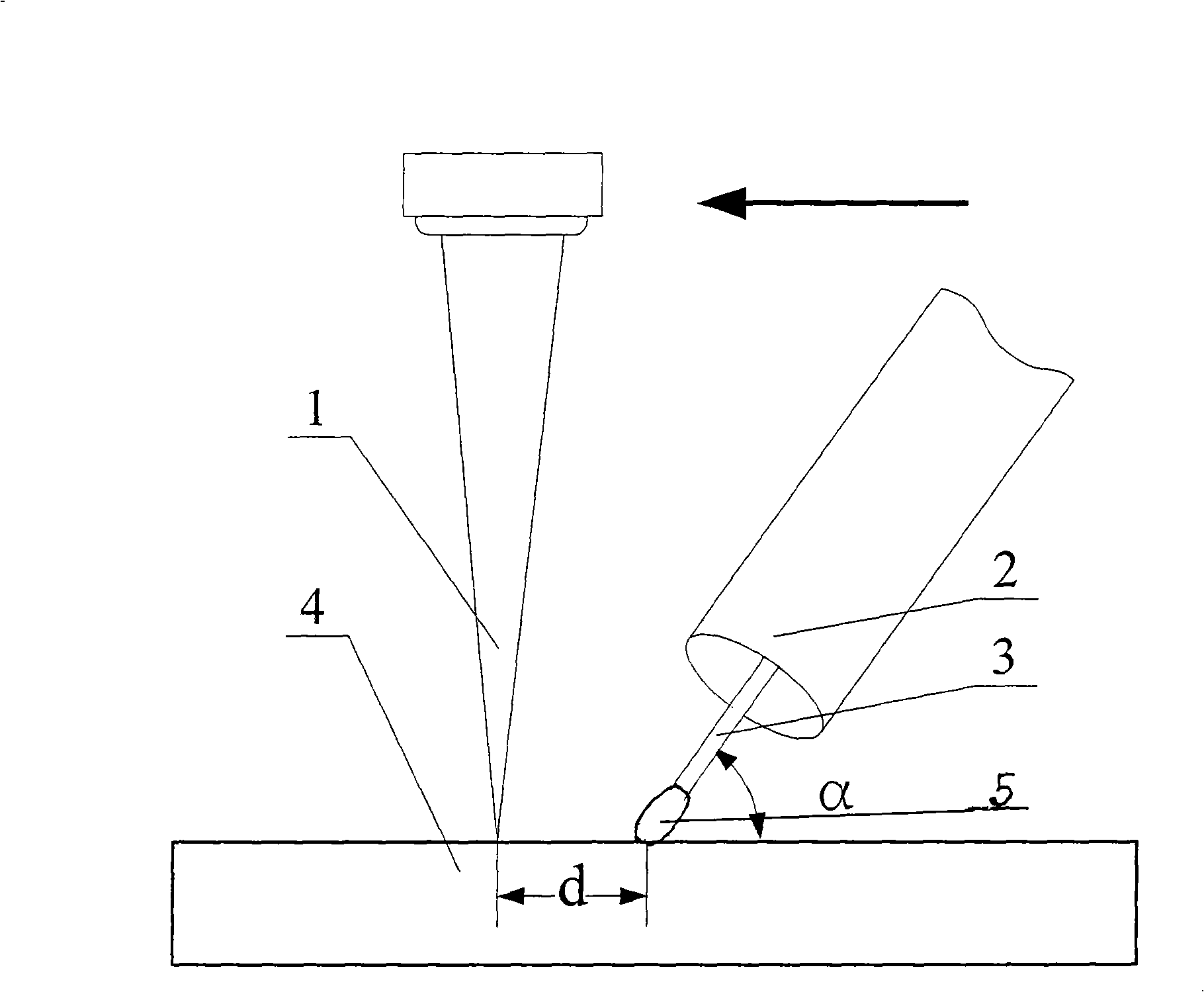

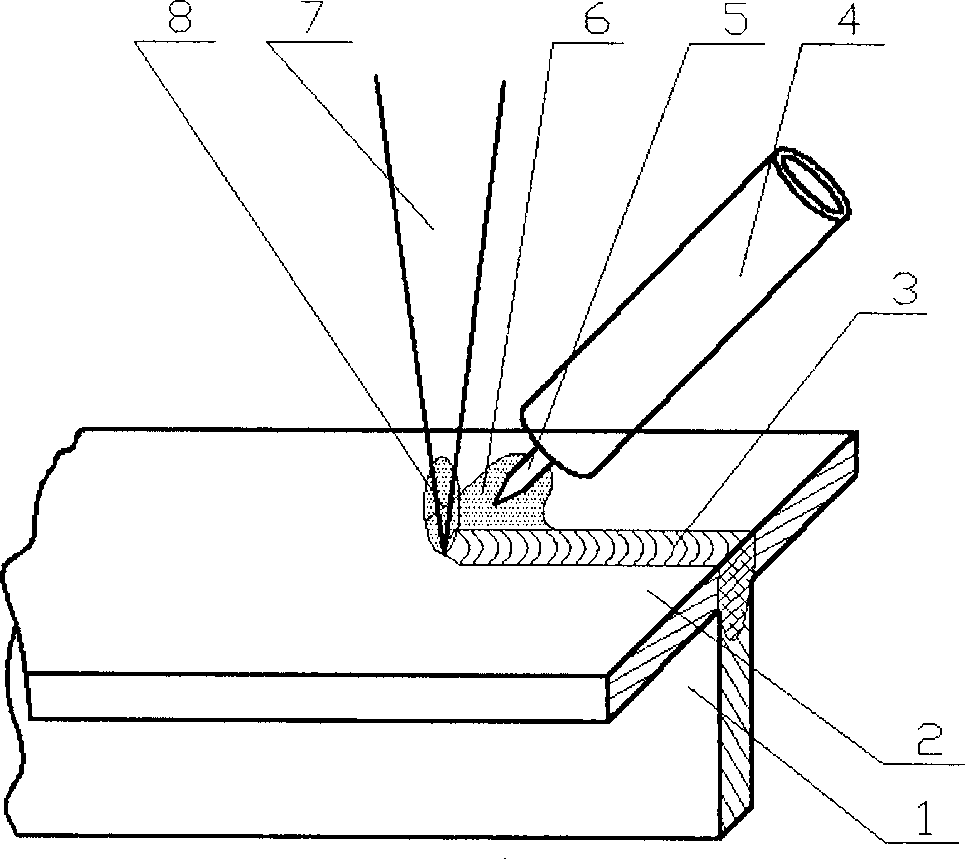

Laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel

The invention discloses a laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel. The laser and MIG arc composited welding method is characterized by comprising the following steps of: design of a welding joint; design of a welding mode; setting of a composite way and heat source spaces; selection of protective gas for the composite welding; setting of welding technology parameters according to the composite way; and synchronous implementation of the composite welding. Compared with the prior art, the laser and MIG arc composited welding method has the advantages of being capable of implementing the welding of the high-nitrogen steel with middle thickness and achieving weld joints which have clean and smooth surfaces and are good in forming and free from sunken parts; and meanwhile, the welding method has the characteristics of low loss and uniform distribution of nitrogen elements at connectors, high welding penetration, high welding speed, small deformation of workpieces, low assembly requirements and the like.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

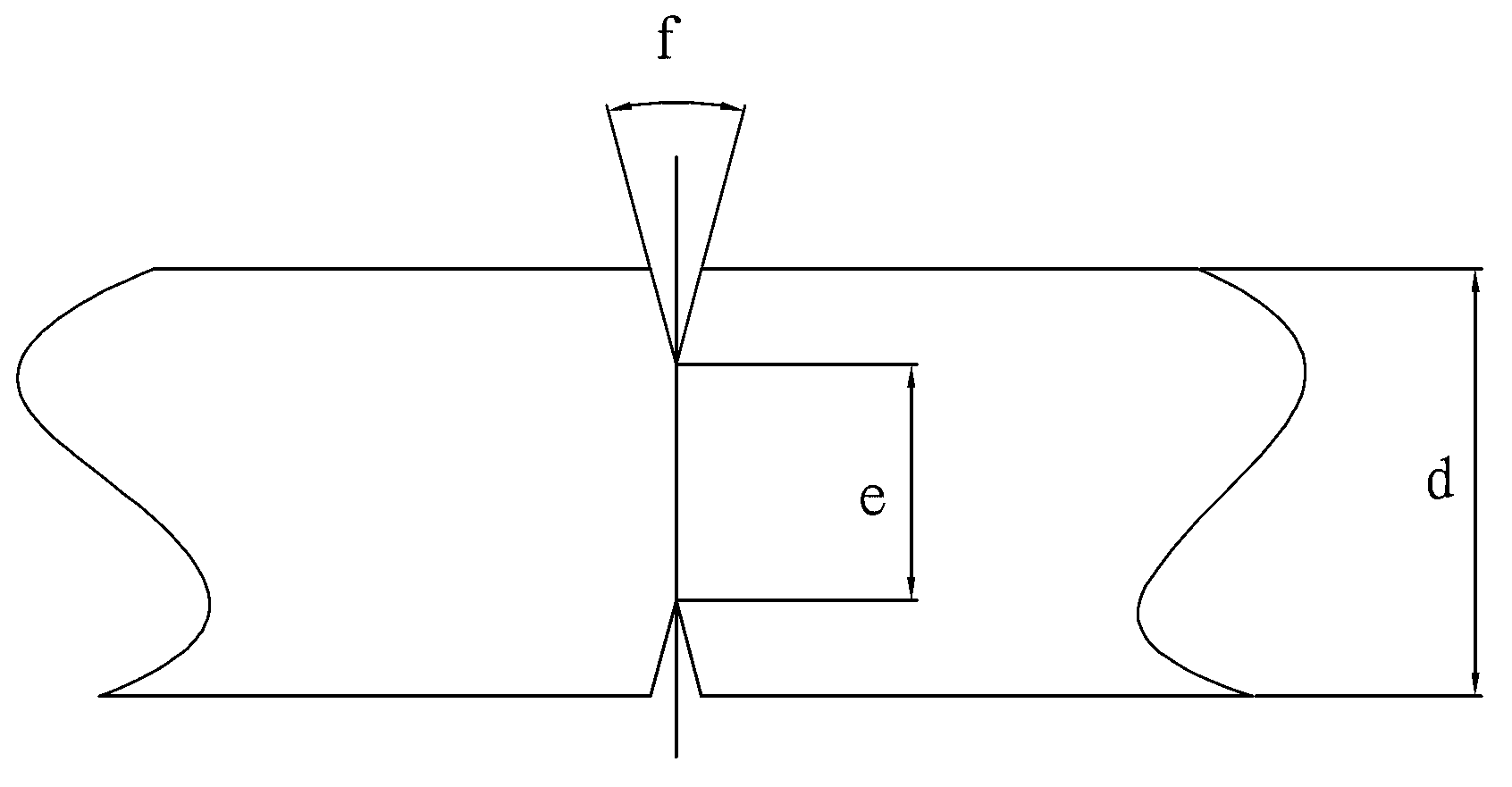

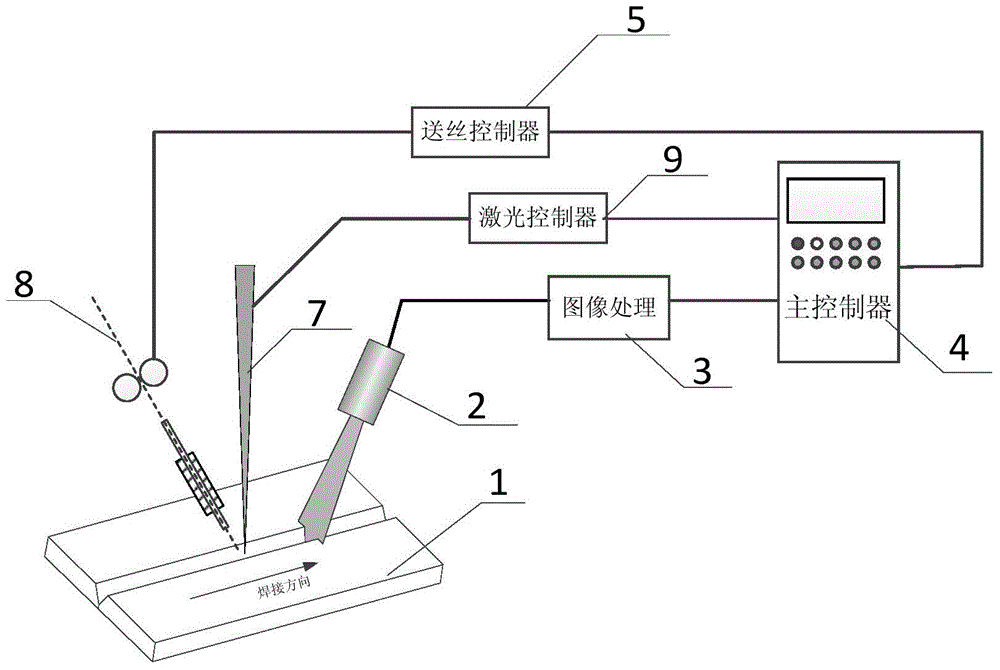

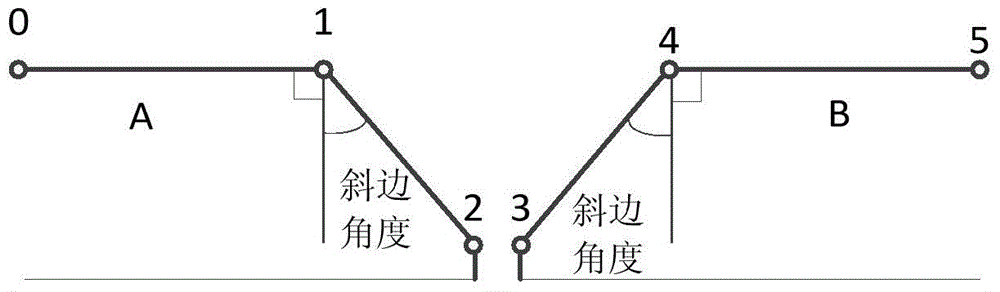

Adaptive welding method for laser filler wire welding of high-strength steel sheet

ActiveCN104057204ARealize adaptive adjustmentGuaranteed stabilityMetal working apparatusLaser beam welding apparatusNuclear powerMathematical model

The invention provides an adaptive welding method for laser filler wire welding of a high-strength steel sheet. The method comprises: step 1, performing process experiment on the high-strength steel sheet, and building a process parameter model of welding wire filling area and upper-groove width; step 2, during welding, acquiring the welding wire filling area and the groove width of a current groove in real time based on a laser vision sensor; step 3, according to the filling area and the groove width of the current groove and the process parameter model, adjusting process parameters in real time, so as to realize adaptive control during welding. Through an expert database or a process mathematical model built in specific materials and groove forms, and the groove filling area acquired in real time based on the laser vision sensor, adaptive adjustment on the process parameters during welding is realized, the stability and uniformity of the welding quality are ensured, the welding efficiency is improved, welding defects are reduced, and the method has very high practical values during welding large sheet elements in the fields such as aviation, spaceflight and nuclear power.

Owner:SHANGHAI JIAO TONG UNIV +1

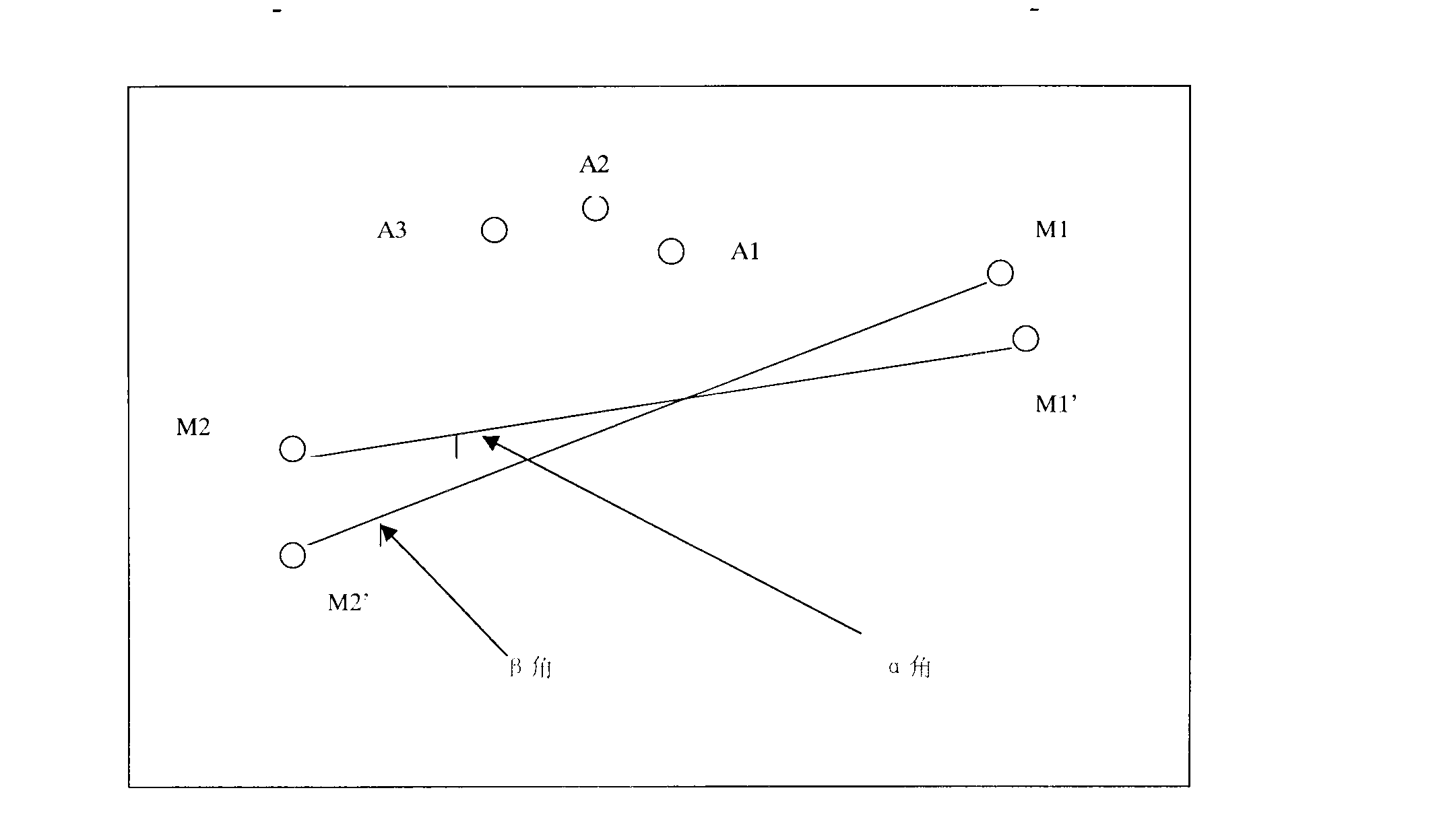

Method for fixing printed circuit board (PCB) with mark point location function

ActiveCN102974964ADoes not affect welding accuracyShorten welding timePrinted circuit assemblingWelding/cutting auxillary devicesProgramming processPrinted circuit board

Disclosed is a method for fixing a printed circuit board (PCB) with a mark point location function. The method is characterized by including the following steps: (1) firstly obtaining two mark point images on a reference PCB with a camera when programs are made, (2) obtaining two mark point images which are matched with two chosen mark point positions in the programming process and are on the detected PCB with the camera in the process of welding, and (3) comparing two groups of mark points which are captured in the step (1) and the step (2). If the two groups of the mark points are not out of position, the board position is normal, and if skewing exists, the PCB can be compensated. By the means of the method for fixing the PCB with the mark point location function, welding precision can not be influenced by the factors such as the size, the height and the skewing of the PCB, and simultaneously, welding time is deceased and welding speed is increased.

Owner:廖怀宝

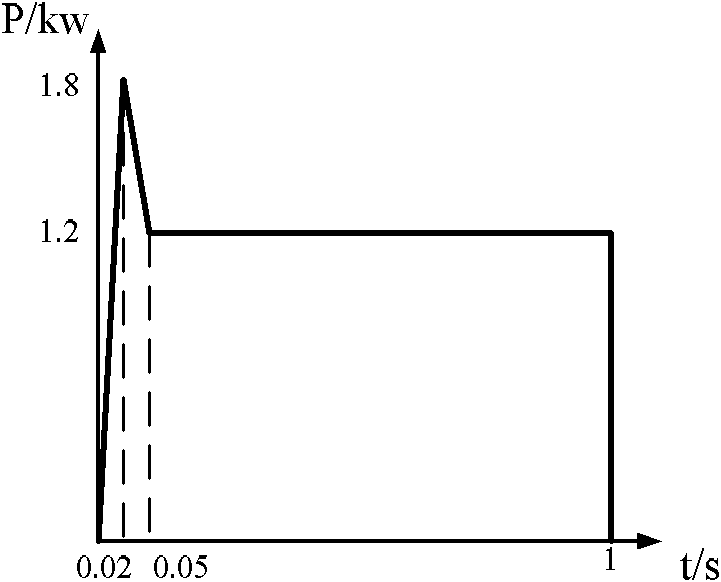

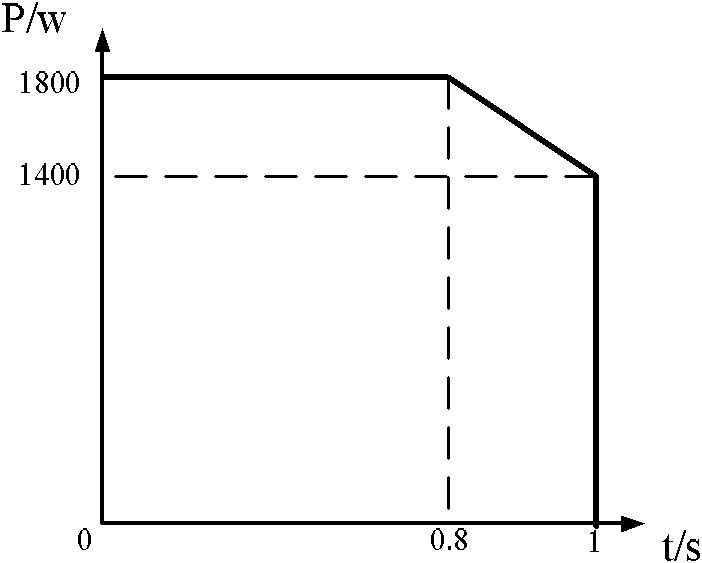

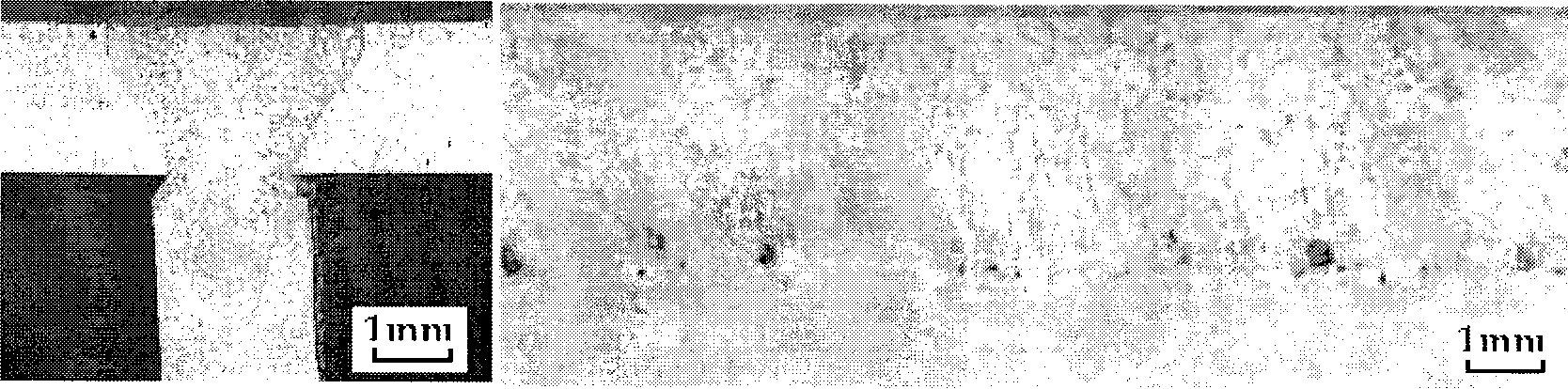

Laser pulse spot welding method for metal sheet

InactiveCN102091871AReduce crackingReduce slumpWelding/soldering/cutting articlesMetal working apparatusMetallic materialsMetal sheet

The invention relates to a novel laser spot welding method, in particular relates to a laser pulse spot welding method for a metal sheet, aiming at solving the problems that in the prior art, the burning loss of the material is high, air holes, cracks and collapse are easy to generate in the laser spot welding process, and particularly the reflectivity of the aluminum alloy material to laser is high so that the stability in the spot welding process is poor. The laser pulse spot welding method for a metal sheet comprises the following specific steps: (1) preprocessing a workpiece to be welded, (2) fixing the workpiece to be welded, and (3) welding by adopting the laser pulse spot welding method. The laser pulse spot welding method for a metal sheet has the advantages of enhancing the welding efficiency, improving the welding spot quality, ensuring good uniformity of the sizes of the welding spots and realizing the spot welding of a plate of moderate thickness by a small-power laser. The laser pulse spot welding method for a metal sheet is mainly used for welding metal materials and particularly used for welding the metal sheet.

Owner:HARBIN INST OF TECH

FSW (Friction-stir Welding) method assisted by heat source

InactiveCN104551379AFast welding speedSolve the longevity problemNon-electric welding apparatusFriction weldingButt welding

The invention discloses an FSW (Friction-stir Welding) method assisted by a heat source. The method comprises the following steps of: A, splicing and fixing to-be-welded materials, preheating to-be-welded regions by an auxiliary heat source until the welded materials are in a plasticized or alloyed state; and B, enabling the auxiliary heat source and a friction-stir head to be positioned on same pair of butt welding wires, and after the welded materials are heated to be in the plasticized state, enabling the friction-stir head to advance along the heating path of the auxiliary heat source so as to perform friction welding. The invention provides a composite welding method which is reasonable in cost, long in service life of stir head, capable of realizing high high-melting-point metal and dissimilar metal welding speed, and high in welding quality. According to the welding method, the service life problem of the stir head of high-melting-point metal FSW and the problem of dissimilar metal FSW welded seam alloying are successfully solved, the welding cost of the high-melting-point metal and the welding cost of the dissimilar metal are greatly lowered and the welding quality is improved.

Owner:董春林

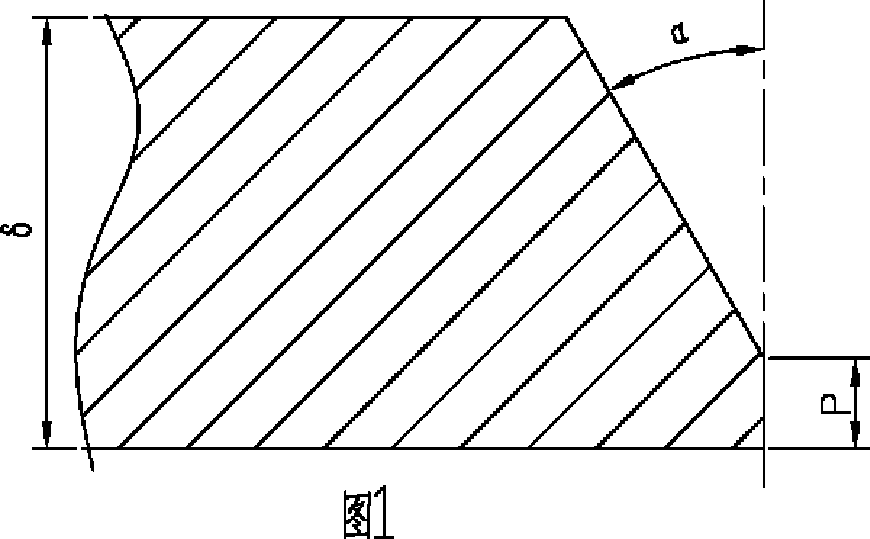

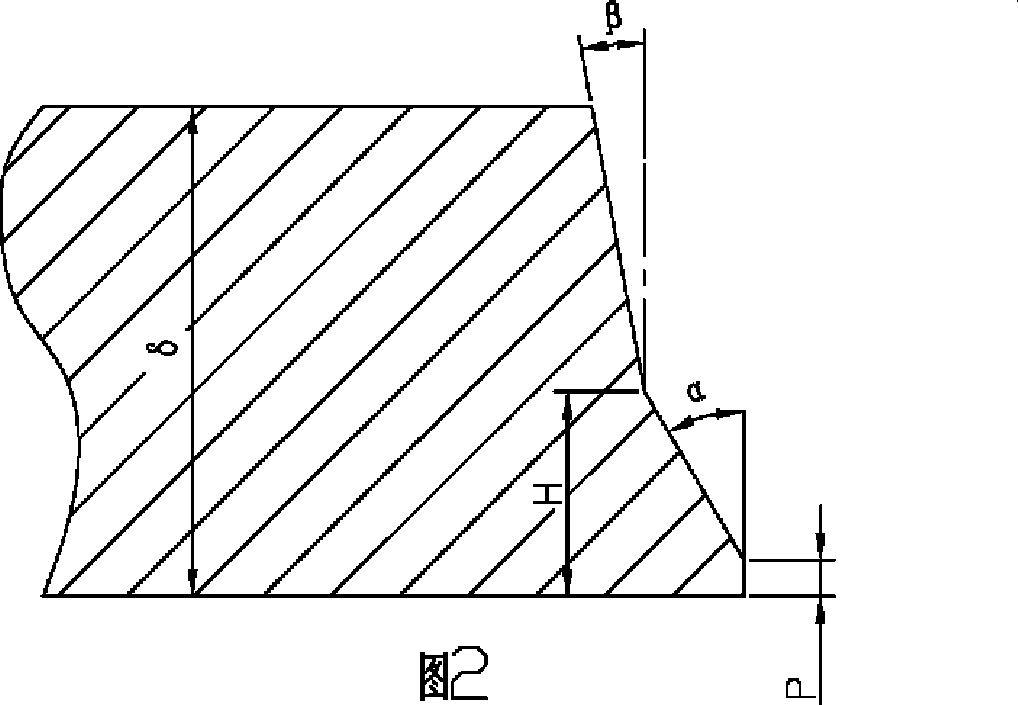

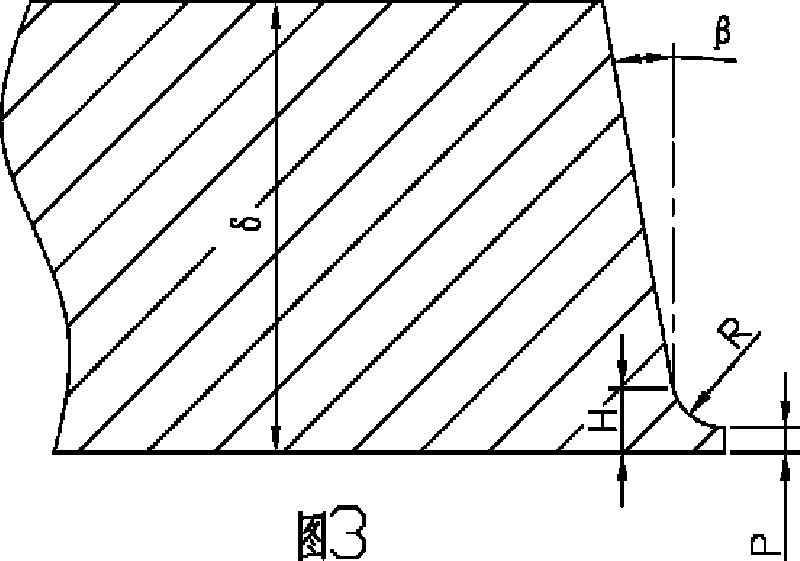

Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

The invention relates to a welding technique, especially a combined welding process combining small bevel angle full-automatic CO2 gas shielded protection welding with unionmelt welding, comprising following steps: (1) opening a corresponding small angle bevel on the weldment with a bevel angle of 25+50DEG; (2) paring, ensuring welding space of 8+20mm; (3) grounding welding by using full-automatic CO2 gas shielded protection welding; (4) performing filling in and capping welding by using unionmelt welding. The advantages of the invention are: (1) small bevel angle welding, saving material and improving productivity; (2) grounding welding by using unionmelt welding, the electrical arc heat quantity is centralized, the heated area is small, the welding speed is quick, head affection range is contracted, and welding deformation is small; (3) crackle generation tendency is decreased; (4) bottom slag cleaning is avoided to prepare for narrow gap welding and welding efficiency is increased; (5) filling in and capping are performed by using unionmelt welding, so that welding speed and external appearance forming quality are assured.

Owner:MCC JINGTANG CONSTR

Process for transmission laser welding of plastic parts

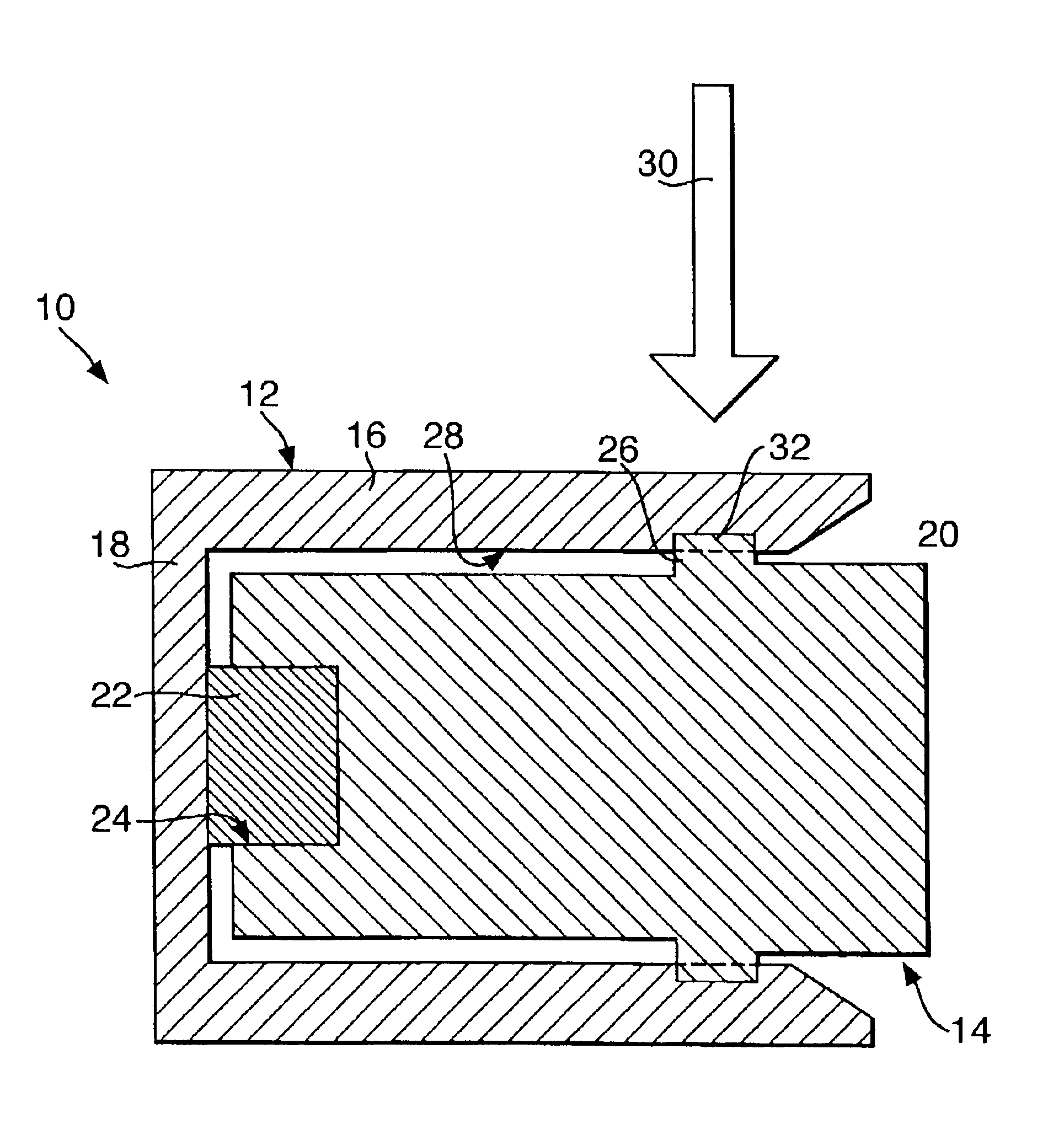

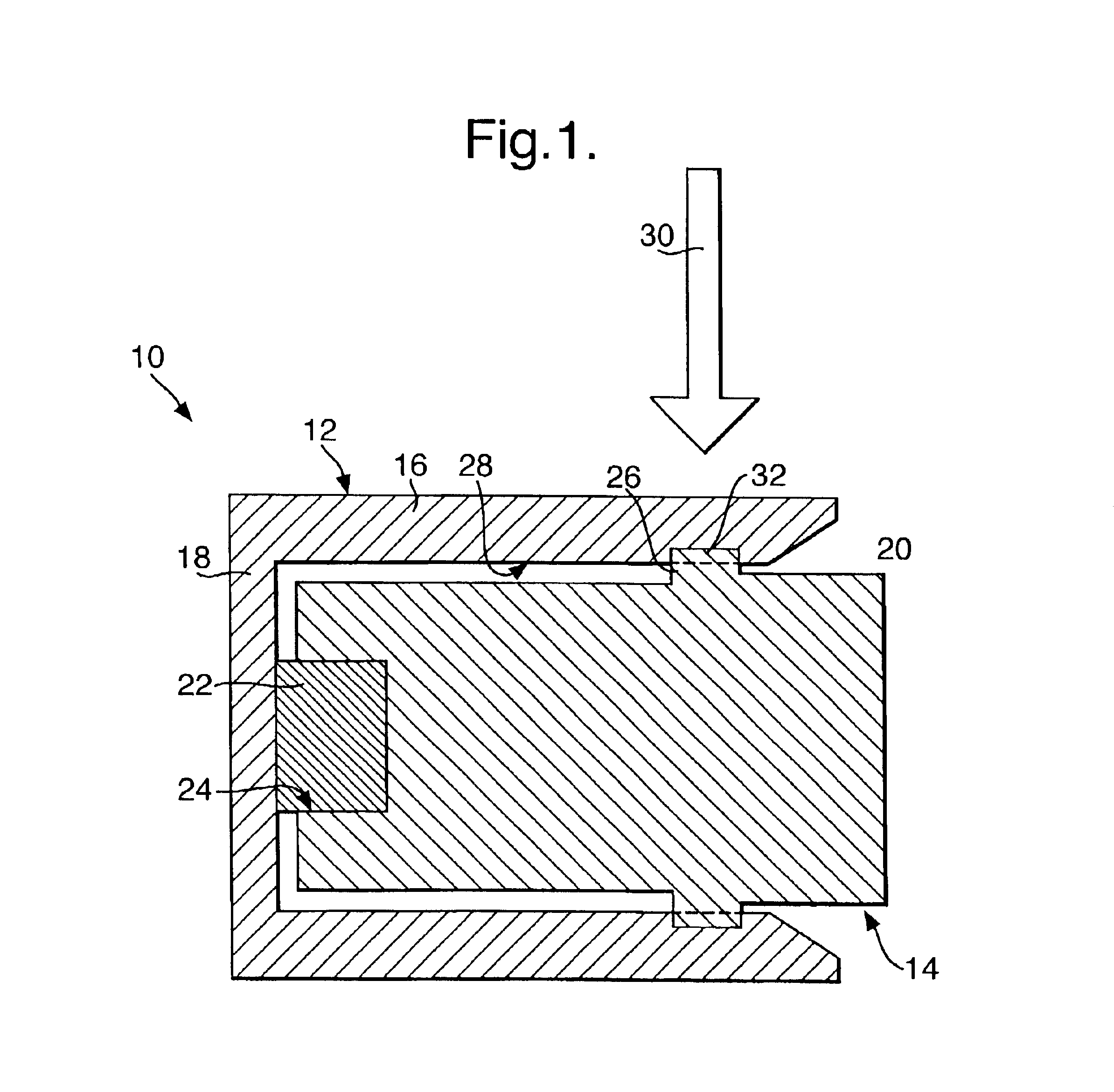

InactiveUS6802929B2Quality improvementSimple welding processLamination ancillary operationsLaminationInterference fitLight beam

A process for transmission laser welding of a first plastic part and a second plastic part that can be at least partially received in the first plastic part is proposed. The second plastic part is introduced into the first plastic part, to which it is connected by means of an interference fit connection, whereby at least one contact zone between the second plastic part and the first plastic part is formed as a result of this interference fit. A laser beam is directed to impinge on the second plastic part, through the first plastic part, along the at least one contact zone to form a weld.

Owner:DELPHI TECH INC

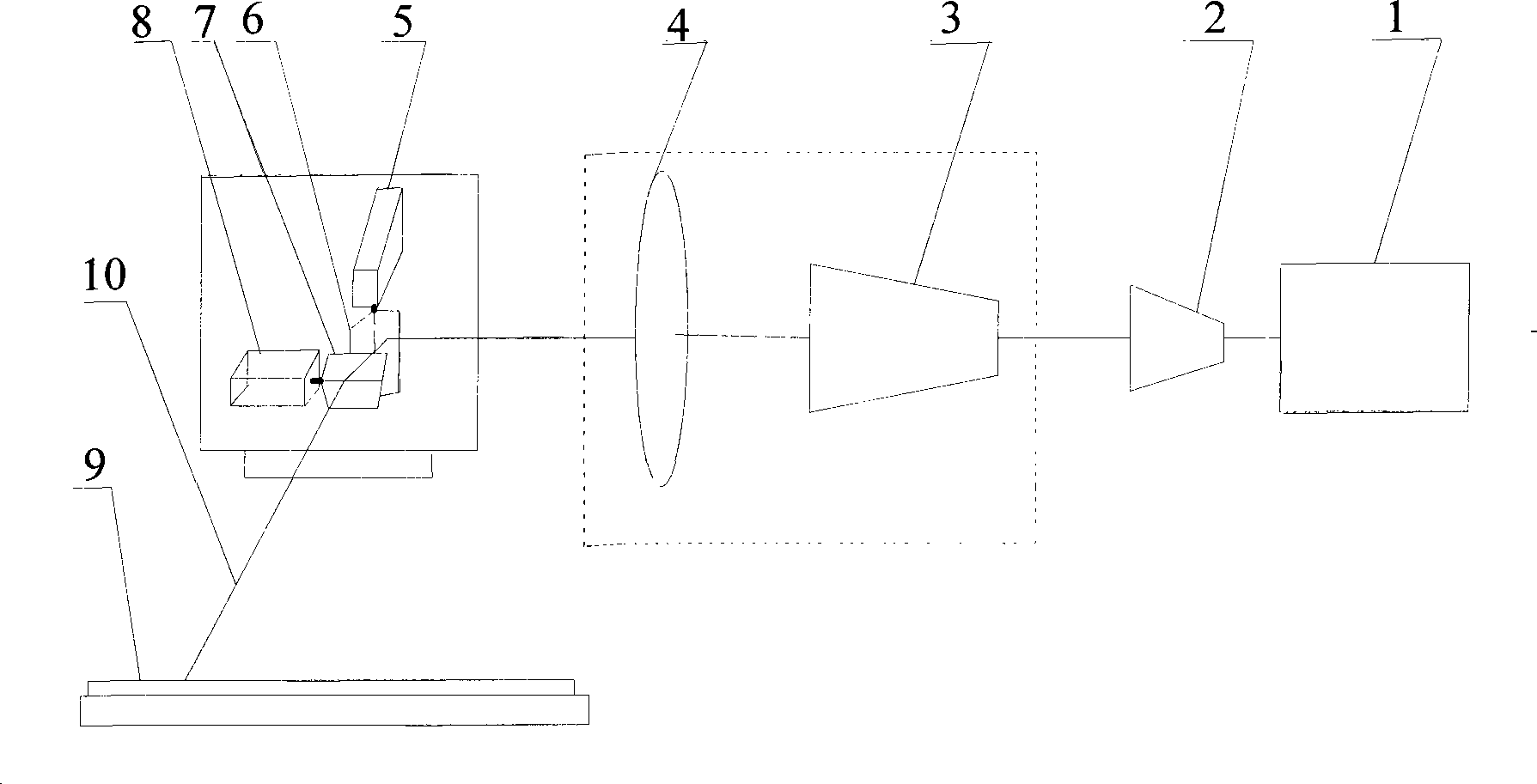

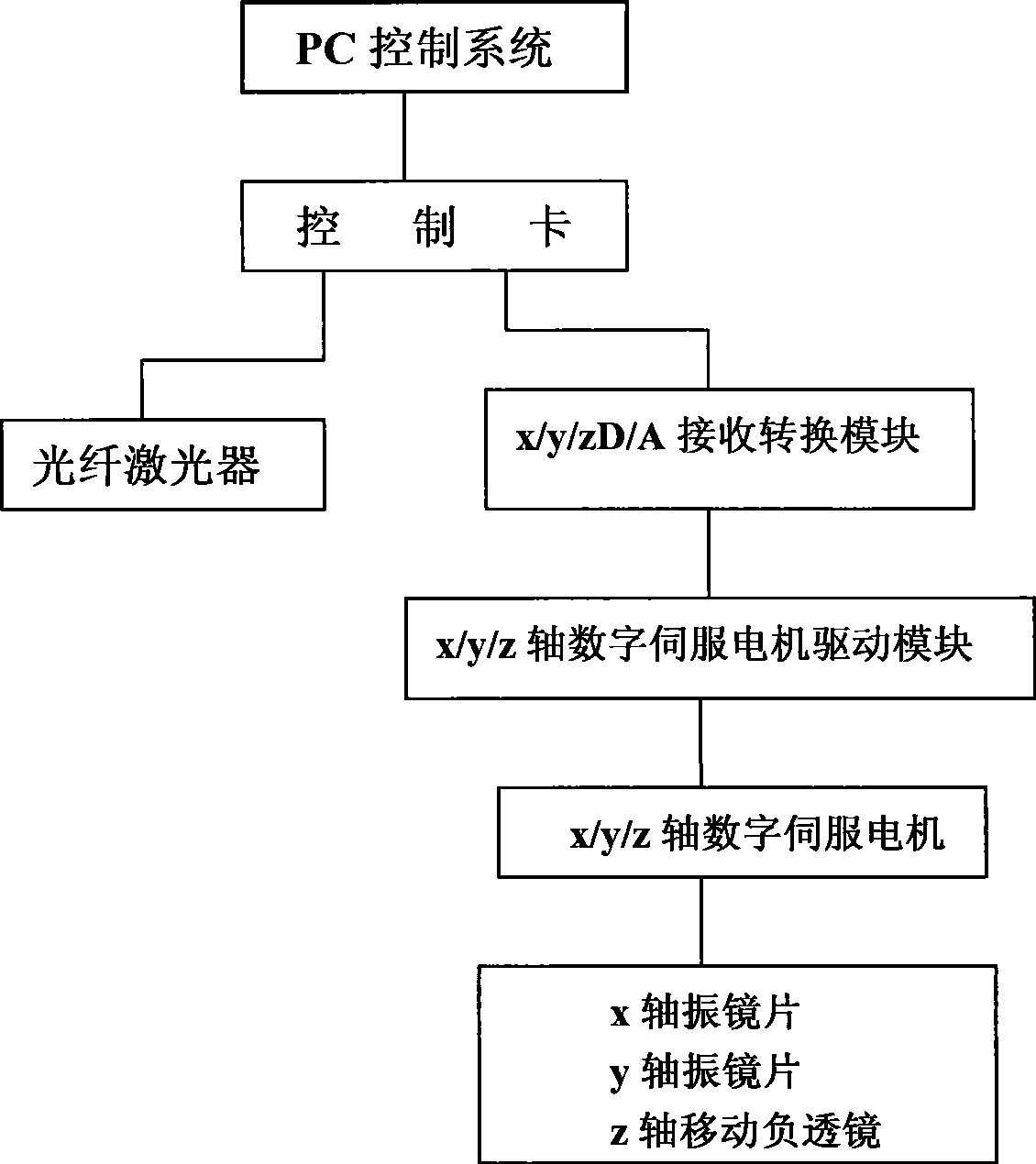

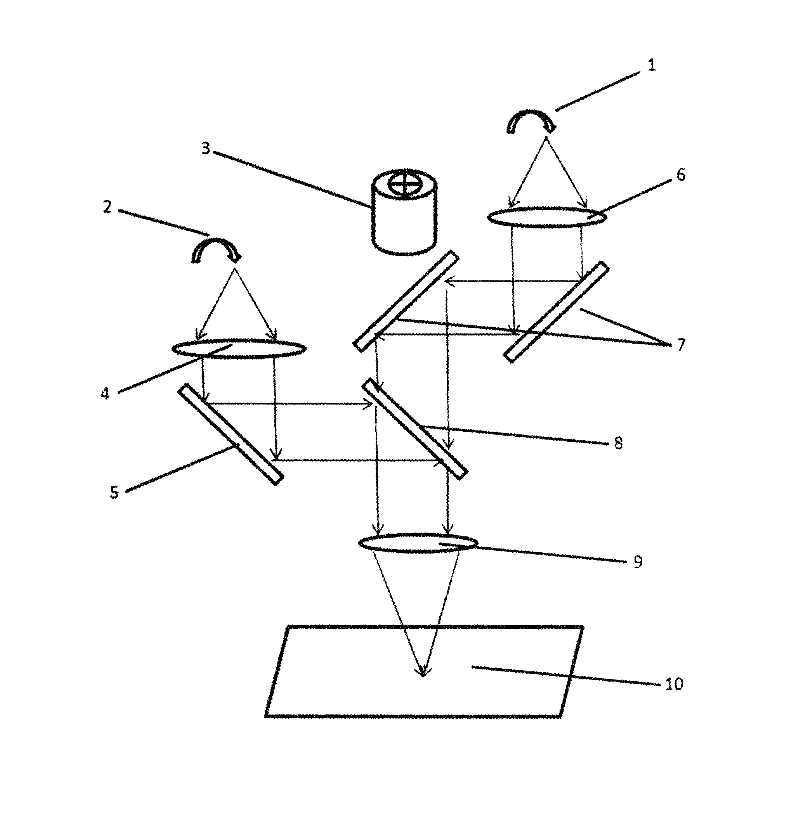

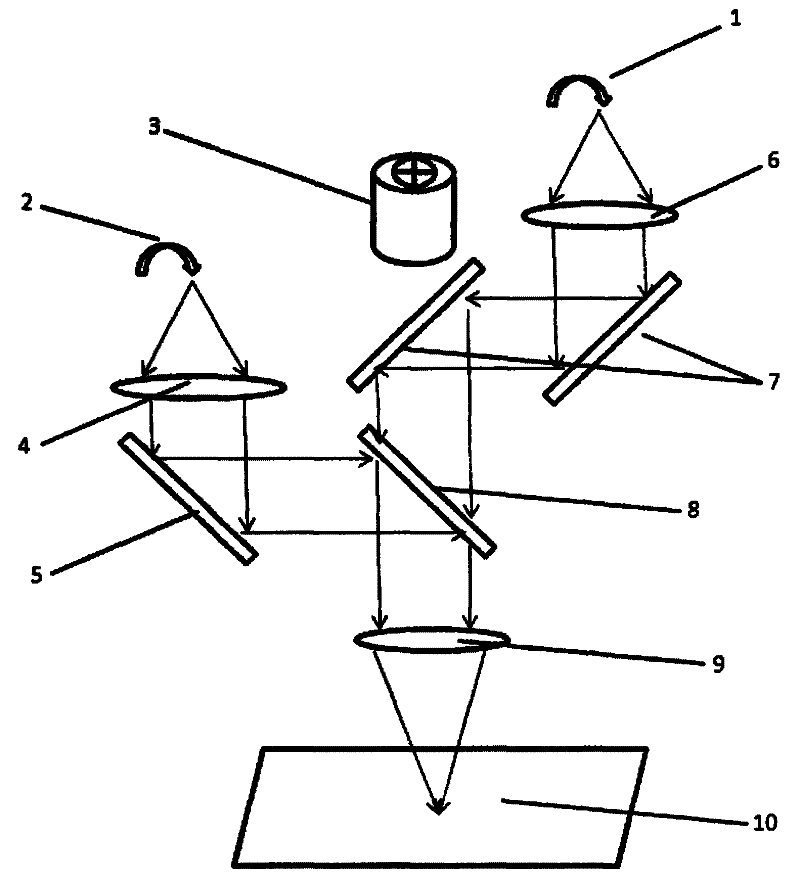

Optical fiber laser dynamic focusing vibration mirror scanning type spot welding system and welding method thereof

InactiveCN101439441AFast welding speedInfluence intensityLaser beam welding apparatusOptical elementsControl systemLight beam

The invention discloses an oscillating-mirror scanning spot welding system which focuses optical-fibre laser dynamically. The system comprises a PC control system and a fibre laser, a beam expanding lens, a dynamic focusing unit, an X-axis vibration lens and a Y-axis vibration lens which are connected in sequence along a light path. The X-axis vibration lens is arranged on a rotating shaft of an X-axis servo motor; the Y-axis vibration lens is arranged on a rotating shaft of a Y-axis servo motor; the dynamic focusing unit consists of a moving negative lens and a focusing lens; the moving negative lens is arranged on a rotating shaft of a Z-axis servo motor; and a stepping motor is controlled by a PC or hand control, so as to realize long-distance travel of the moving negative lens and the Z-axis servo motor along the transferring direction of the light beam, thereby obtaining different working distances (focuses); therefore, the corresponding scanning range changes between 200 millimetres and 1450 millimetres and the spot diameter is between 30 microns and 200 microns.

Owner:广州瑞通千里激光设备有限公司

Welding process of low temperature steel welding body case

InactiveCN101209508AShorten welding cycleStable deliveryArc welding apparatusFurnace typesPower flowCurrent range

The invention relates to a welding technique in equipment manufacture industry, which is a welding speciality technique of a welding casing of an MCL-typed horizontal cutting centrifugal compressor, in particular to a welding process of the welding casing of the centrifugal compressor with low-temperature steel 09MnNiDR material at -70 DEG C. The gas protection welding is adopted; the welding wire grade is HS09MnNiDR and the diameter of the welding wire is Phi1.2mm; the polarity of the power supply is reversed DC power. The invention comprises a processing before welding, a welding process and a processing after welding; wherein, the process parameters in the welding process are that the welding current ranges from 150A to 200A, the welding voltage ranges from 24V to 28V, the protection gas is the mixed gas with 80% of Ar and 20% of CO2 according to the volume percentage, the welding speed ranges from 250mm / min to 280mm / min, the dry elongation ranges from 10mm to 15mm, and the gas flux ranges from 20L / min to 25L / min. The welding wire of the gas protection welding of the invention is not required to be dried, the welding wire is automatically fed in the welding process, and a welding rod is not required to be replaced; as the heat of the MAG melting polar gas protection welding is concentrated, the invention has the advantages of narrow thermal effect area, little deformation, beautiful forming, good quality, low cost, fast welding speed, high welding efficiency, etc.

Owner:SHENYANG BLOWER WORKS GROUP CORP

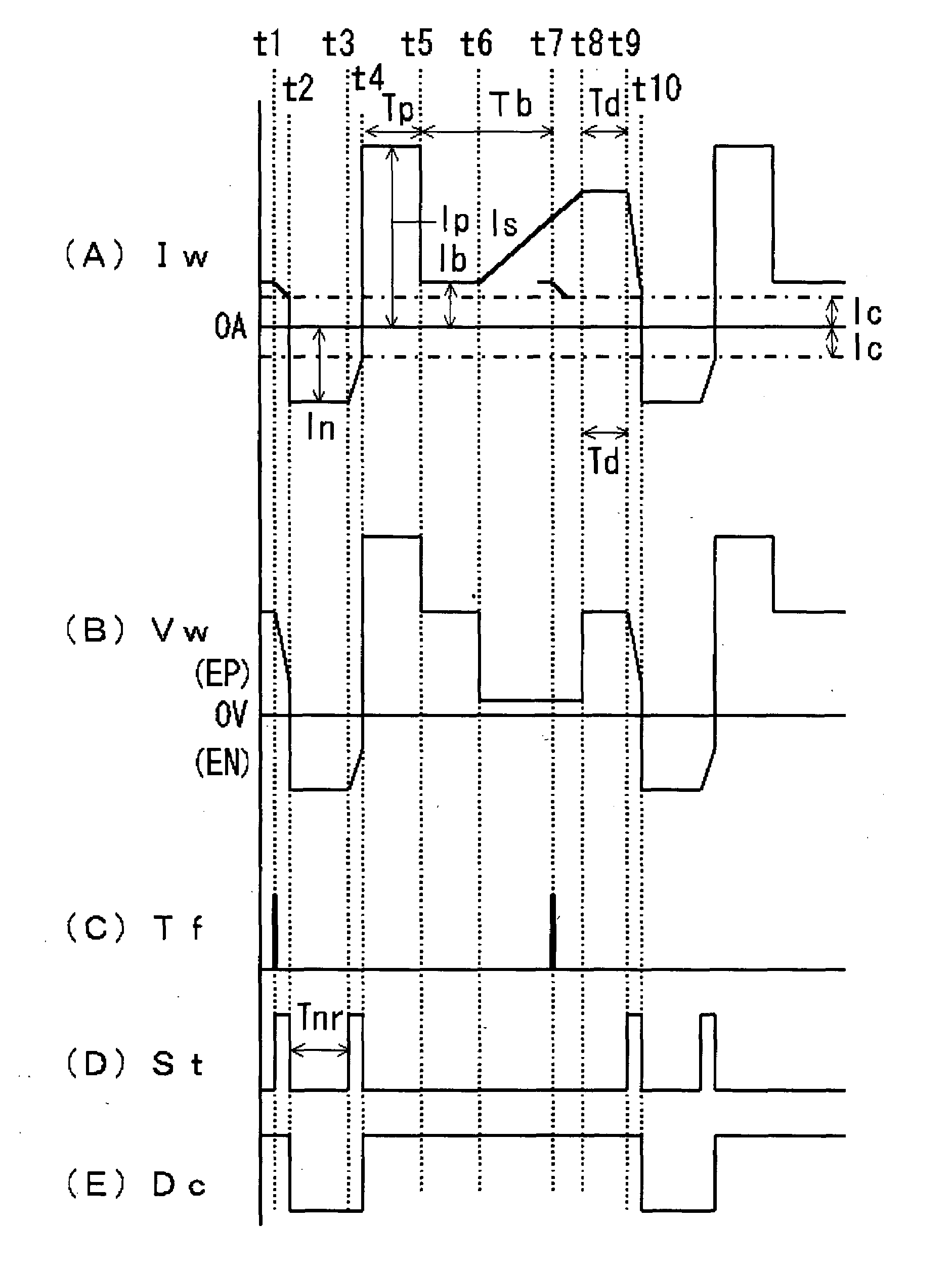

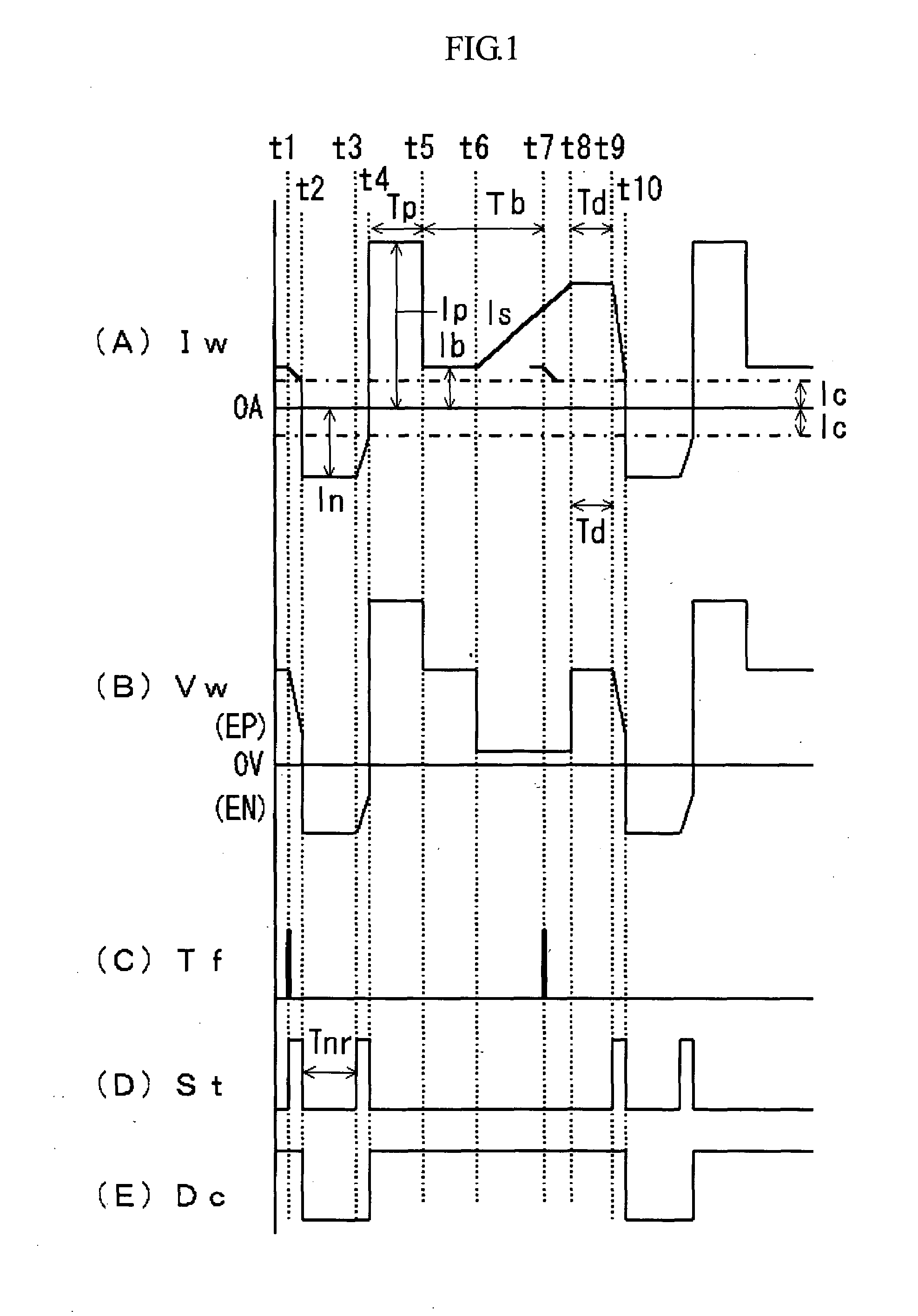

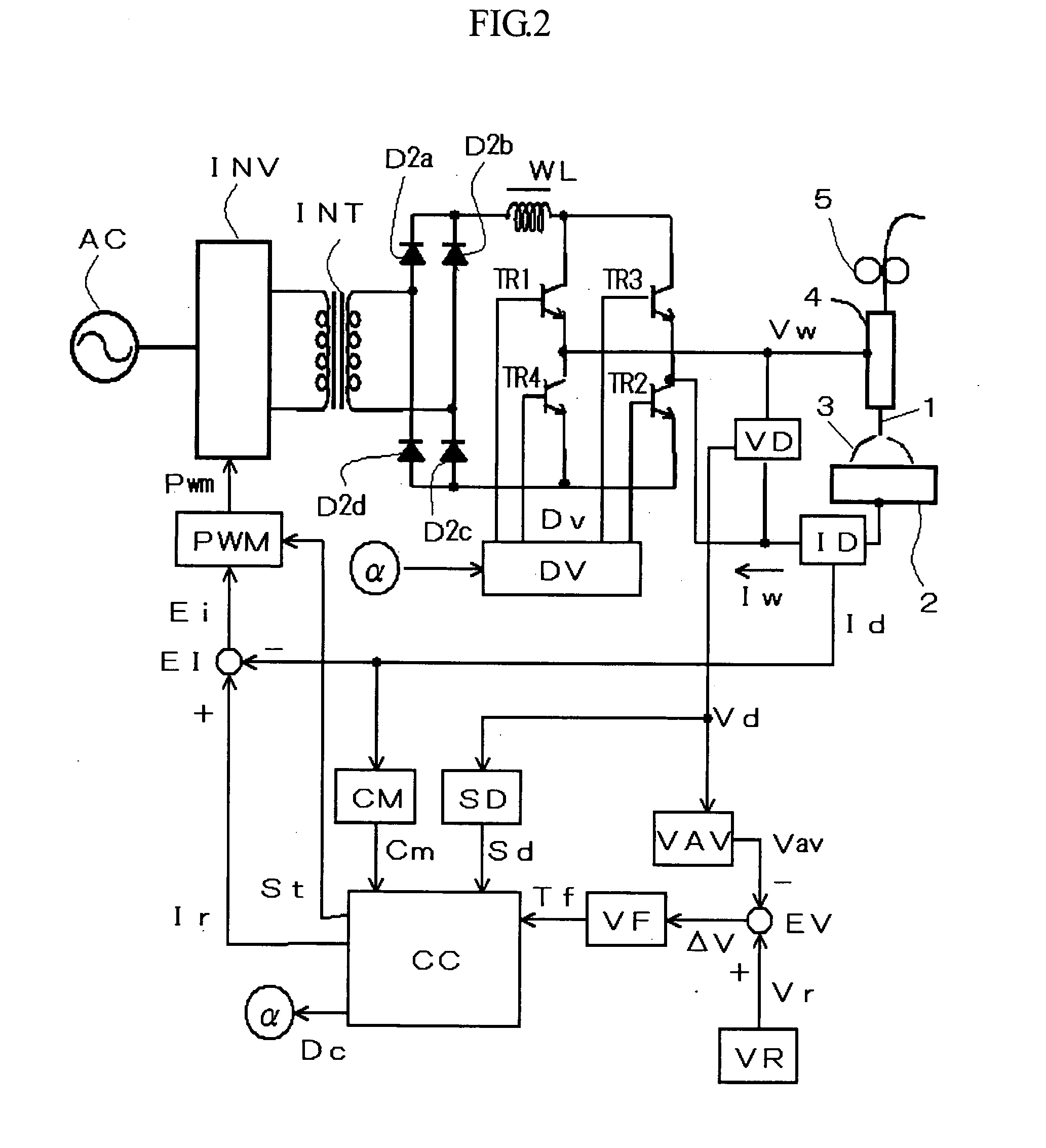

Polarity switching method in consumable electrode AC pulse arc welding

ActiveUS20070246448A1Stable switchingReduce heat conductionArc welding apparatusElectric arcPeak current

A polarity switching control method is provided for consumable electrode AC pulse arc welding. By the method, a peak current and a base current are applied during an electrode-positive polarity period, while an electrode-negative current is applied during an electrode-negative polarity period. For performing the welding, polarity switching is performed to alternate the electrode-positive polarity period and the electrode-negative polarity period. When a consumable electrode and a base metal are in short circuit with each other, the polarity switching is performed after the short circuit is broken and an arc is generated.

Owner:DAIHEN CORP

Semi-automatic welding method of metal flux cored filler rod conduit root

ActiveCN101417364AQuality improvementReduce cleanup costsArc welding apparatusWorkpiece edge portionsShielding gasMetal powder

The invention relates to the technical field of welding of a long distance pipeline and is a semi-automatic welding method of root welding of a pipeline with metal powder core welding wire; the root welding layer welding is carried out as follows: the metal powder core welding wire and short arc control technology are adopted, protective gases are added to carry out welding of root welding bead of full position; the welding parameters are as follows: welding current is 140A to 200A; the welding voltage is 15V to 18V; the welding speed is 16cm / min to 26cm / min; the wire feed speed is 350cm / min to 500cm / min; the wire extension is 8mm to 12mm; and the pendulum deflection is based on that weld metal is deposited to the edge of a welding pipeline. The method solves the bottleneck problem of restraining the flow construction operation of the semi-automatic welding, effectively solves the problems of undercut, depression and the like of the back surface of welding seams of circular welding joints, reduces the cost of cleaning of the surface of welding pipelines, reduces the labor intensity of workers, increases the thickness of deposited metal, reduces the welding layers, greatly improves welding production efficiency, obtains high-quality welding seams and improves the welding speed, can reduce one third time of welding compared with manual welding and reduces the operation cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

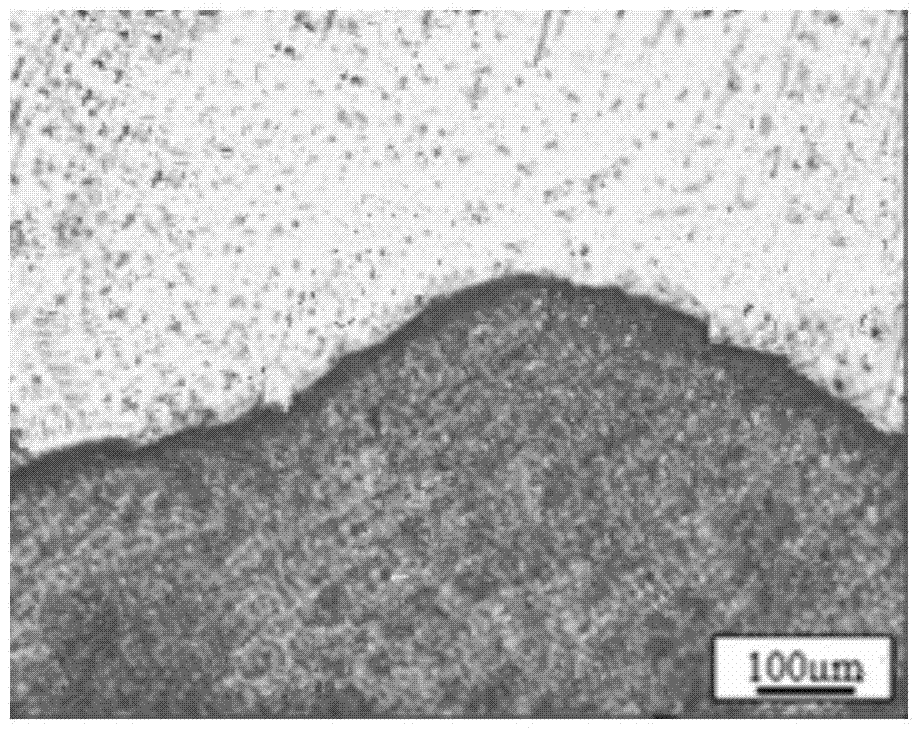

Explosive welding forming method of magnesium and aluminum alloy composite plates

InactiveCN103586574AImprove compactnessAdvancedMetal working apparatusNon-electric welding apparatusAlloy compositeFuel oil

The invention relates to an explosive welding forming method of magnesium and aluminum alloy composite plates. The explosive welding is performed according to the performance requirements of the magnesium and aluminum alloy composite plates, ammonium nitrate fuel oil mixture is adopted, and long-distance instantaneous explosive form is performed on a ground sand base. The welding method is high in forming speed, welding line is firm and is good in metallographic structure compactness, the combined rate is up to 99.5%, the interfacial shear strength is 120MPa, on the premise of strict operation, the welding process is safe and reliable, and the method is reliable and effective in magnesium and aluminum alloy composite plate production.

Owner:TAIYUAN UNIV OF TECH

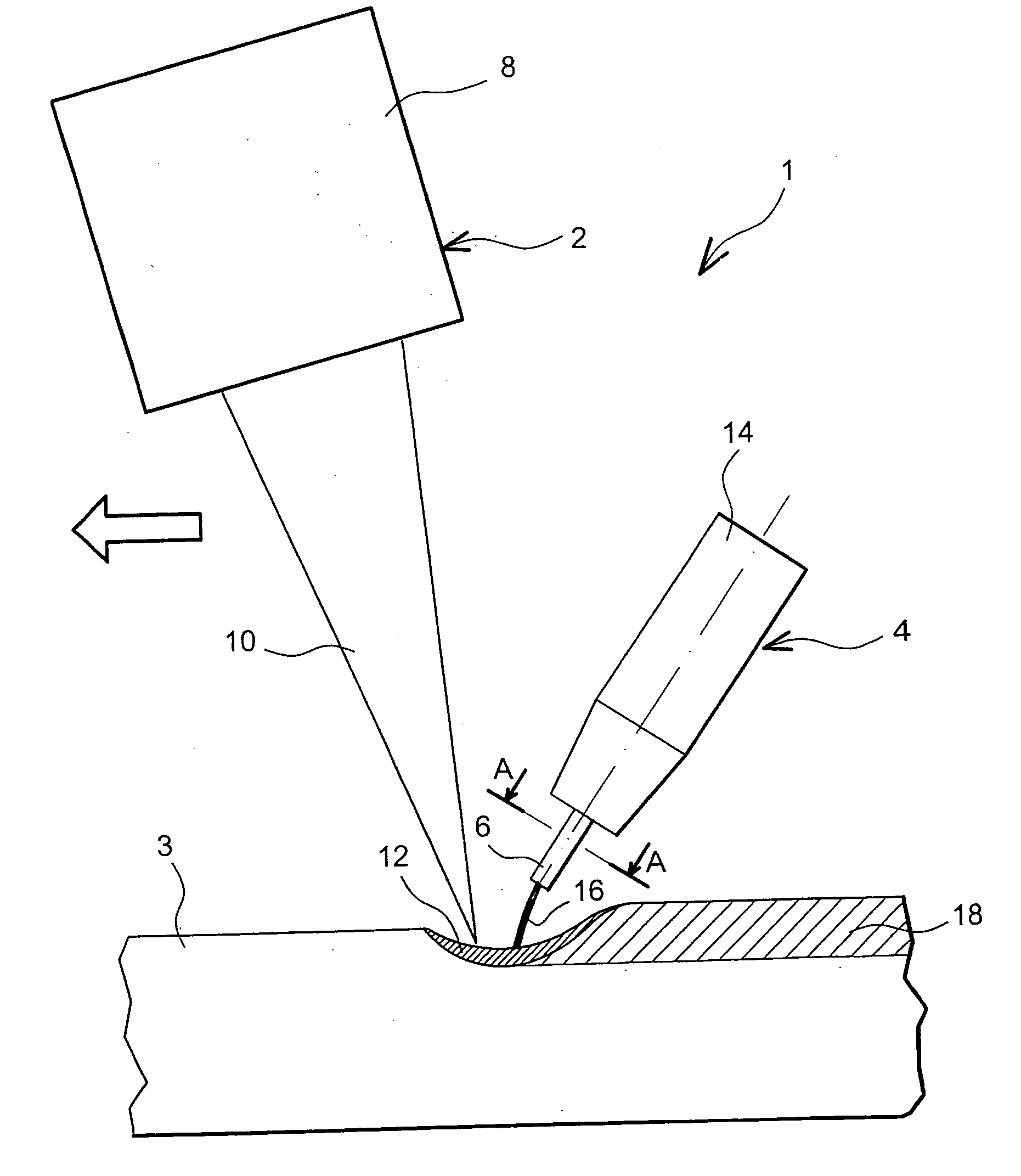

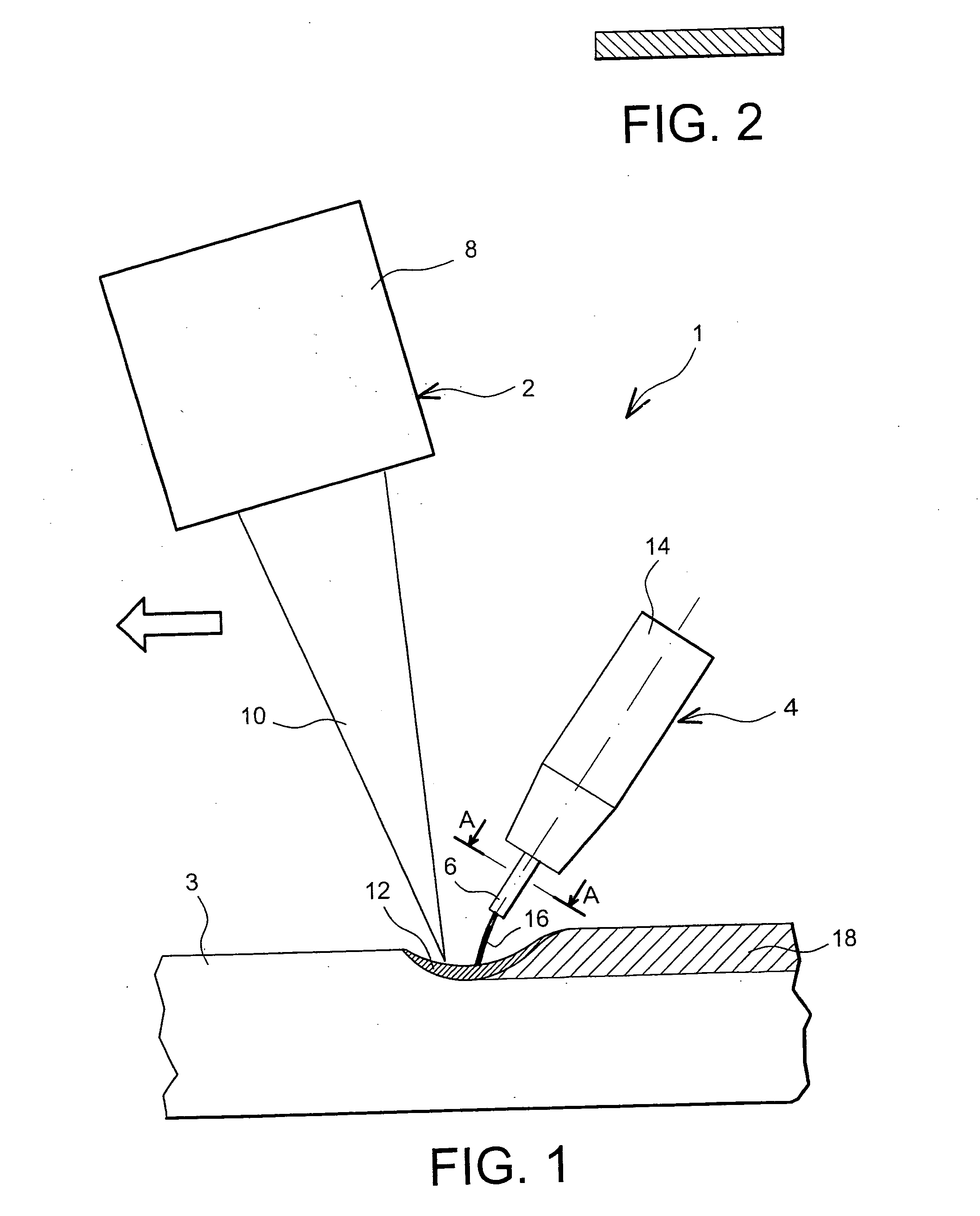

Device and method for hybrid welding

InactiveUS20050006355A1Small sizeLow costArc welding apparatusWelding/cutting media/materialsEngineeringMechanical engineering

This invention relates to a hybrid welding device (1) comprising laser welding means. (2) and electric arc welding means (4) with meltable electrode (6). The device (1) according to the invention is made such that the meltable electrode (6) has an approximately rectangular cross-section. This invention also relates to a hybrid welding method that can be used by such a device. Application to the automobile field.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

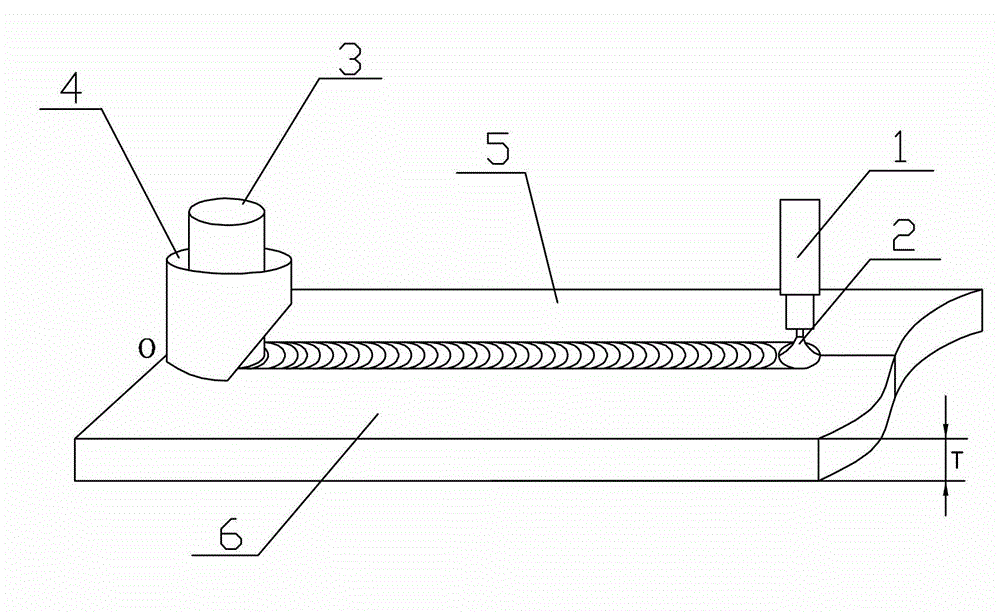

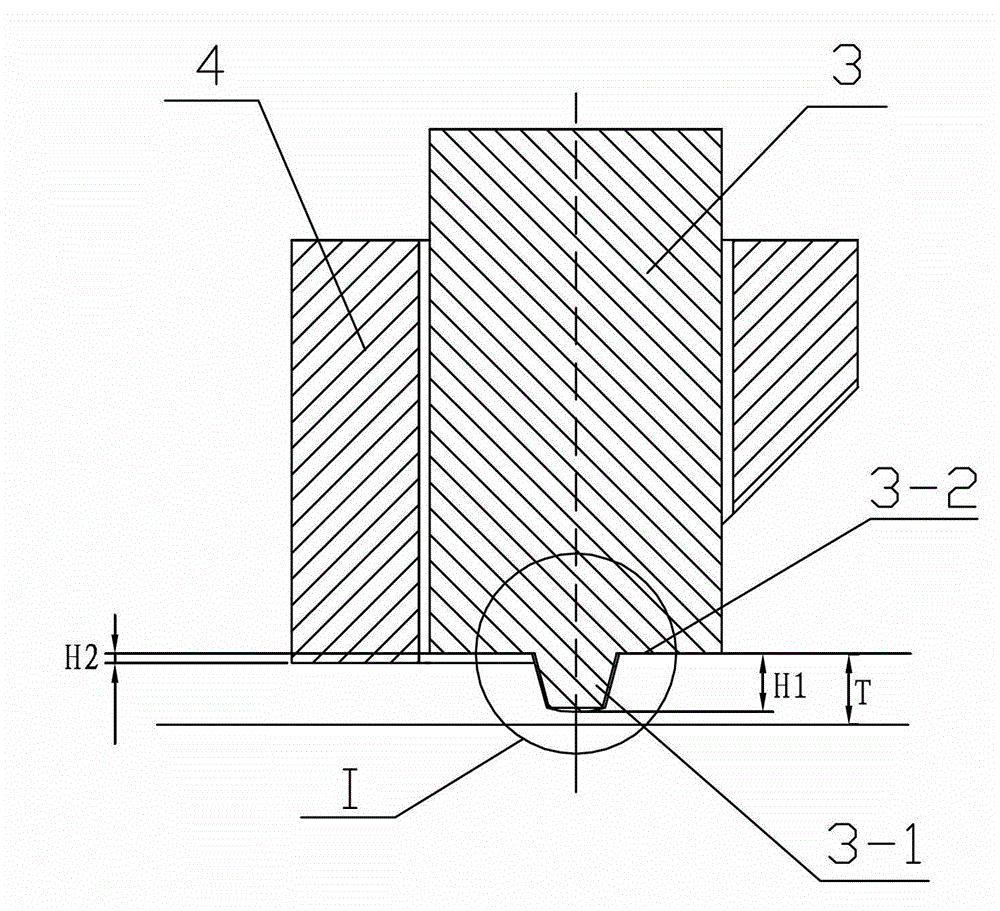

Pre-filled wire stirring friction welding method

InactiveCN102941414AFast welding speedSolve problems such as thinning of the effective thickness of the weldNon-electric welding apparatusFriction weldingEngineering

The invention discloses a pre-filled wire stirring friction welding method and relates to a stirring friction welding method. By the method, the problem that the effective thickness of a weld joint is reduced in the conventional stirring friction welding process. The method comprises the following steps of: 1, clamping a welded workpiece; 2, welding a start section of a pre-filled wire, wherein the welding length is 100mm, and a stirring head stands still at a start position of the pre-filled wire; 3, determining the pressing depth of the stirring head, namely pressing the stirring head into the welded workpeice at the start position of the pre-filled wire, wherein the depth of a shoulder pressed into the workpiece is 0.1mm, and the depth of a semicylindrical static shoulder sleeve pressed into the workpiece is 0.05mm; and 4, performing stirring friction welding on the pre-filled wire, namely performing pre-filled wire welding by a welding gun along the welding direction by using a TIG (tungsten-inert gas) or MIG (metal-inert gas) welding method, wherein the welding current is 100A, the traveling speed of the welding gun is 1.0 m / min, and the stirring head and the welding gun synchronously perform stirring friction welding. The method is applied to stirring friction welding of aluminum alloy, magnesium alloy, copper alloy and special materials.

Owner:HARBIN INST OF TECH

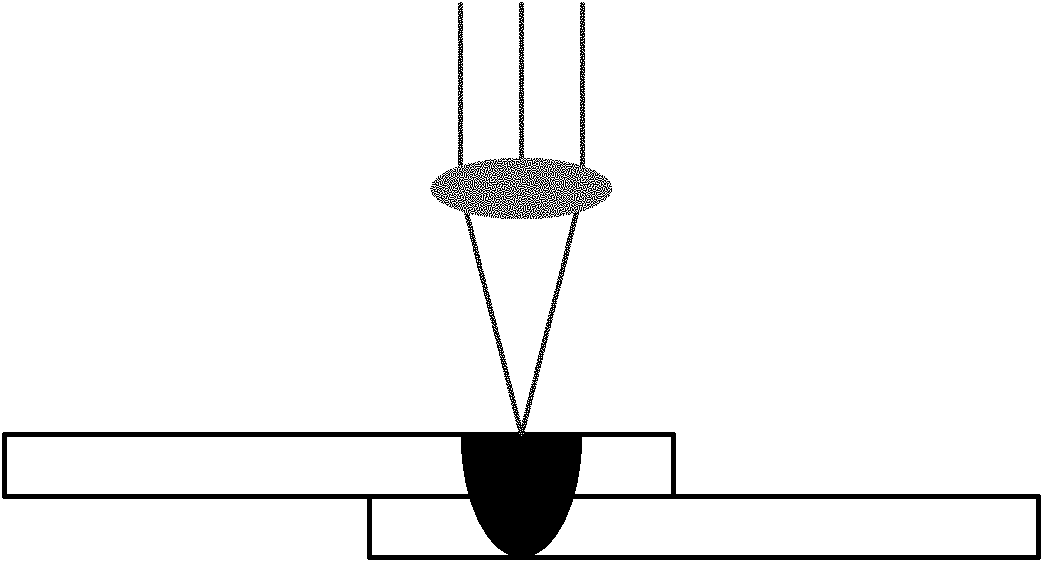

Laser-ultrasmall current GMA compound heat power supply welding method

InactiveCN101347870ASmall amount of deformationImprove mechanical propertiesLaser beam welding apparatusAverage currentLaser beams

The invention discloses a welding method of a laser-ultra-small current GMA composite heat source; the welding method can solve the technical problem of large deformation when a metal thin plate is welded; the invention mainly comprises the following steps; in composite heat source welding, the adopted average current of a GMA arc (5) is 15A to 30A; when the steel material is welded, the power of the laser (1) is more than 800W, and when the aluminium alloy is welded, the power of the laser (1) is more than 1,600W; a laser beam (1) is at the front and the GMA arc is at the back; and the distance of chevilled silk is 0mm to 3mm and the two molten pools are connected together. The welding method is applicable to the welding of thin metal plates with the thickness to be 0.5mm to 4mm such as aluminium alloy, carbon steel, low alloy and more than two dissimilar metals.

Owner:HARBIN WELDING INST LTD

Field welding method of domestic A335 P91 high-pressure thick-wall pipe

InactiveCN105728908AImprove toughnessAvoid crackingArc welding apparatusMetal working apparatusEngineeringThick wall

The invention provides a field welding method of a domestic A335 P91 high-pressure thick-wall pipe, and belongs to the technical field of welding. A welded part of a welded pipe is processed as a double-V-shaped groove; a process of welding 3 layers for bottoming by using manual argon arc welding GTAW and filling a cover surface by using automatic submerged arc welding SAW is adopted; multi-layer and multi-pass welding is adopted; each layer of welding line sections is decreased; and the welding line crystallization conditions are changed, so that the toughness of a welding joint is improved, an overthick welding bead is prevented from narrowing a heat affected zone, and a softening belt of the welding joint is prevented from generating cracks in long-time operation at high temperature; a small-diameter welding wire with a diameter of not more than 2.5 mm and a low-hydrogen welding agent are adopted to weld to reduce the linear energy in the welding process, so that grains of base metal are refined, and the possibility of generating such defects as air holes and cracks in welding lines is reduced; and compared with a traditional manual welding method, the field welding method effectively shortens the heat treatment and welding period, improves the welding line quality and the welding efficiency, relieves the labor intensity of welders, and saves the construction cost.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

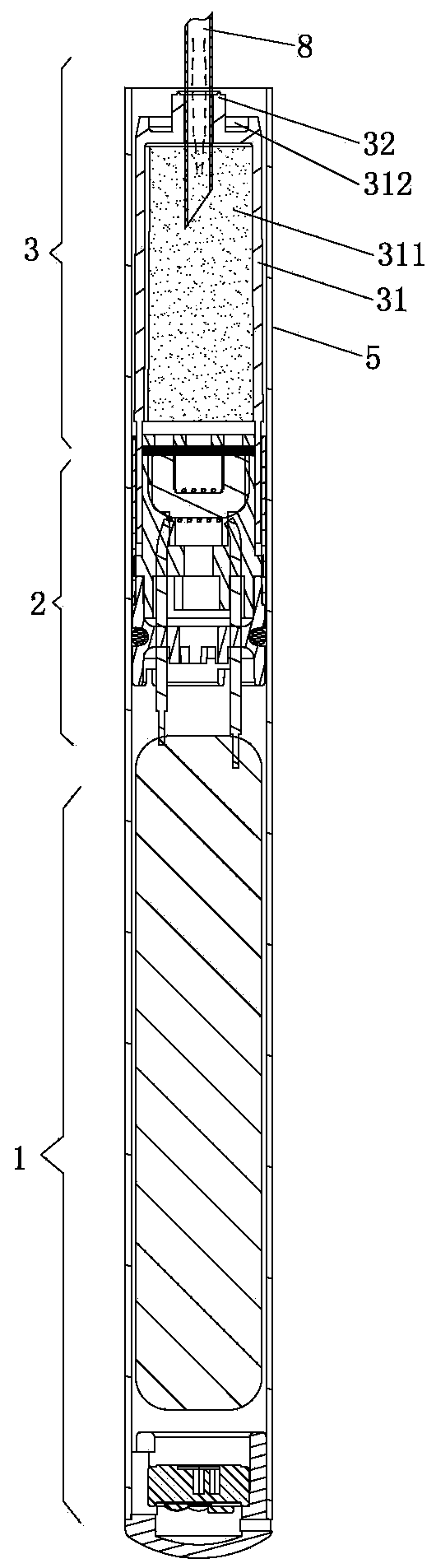

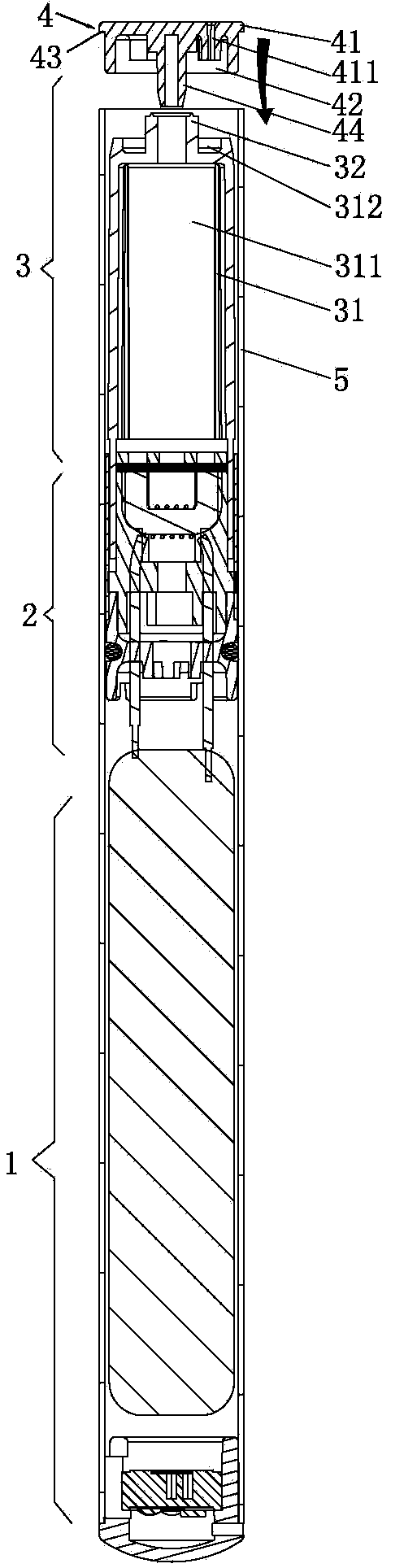

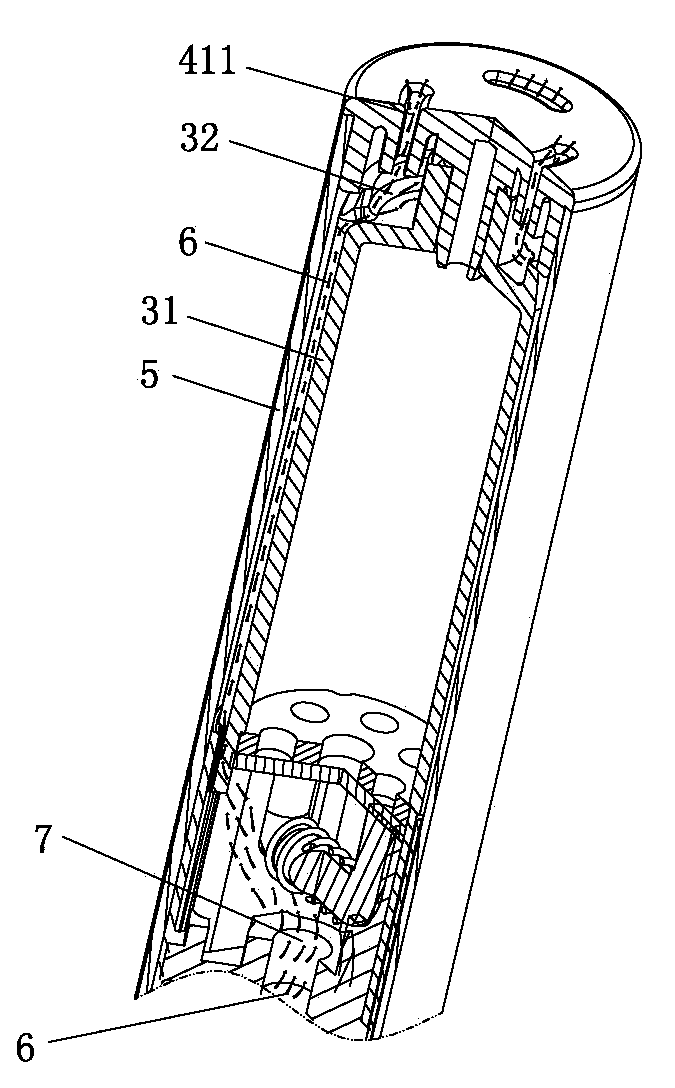

Electronic cigarette, manufacture method of electronic cigarette, and injection method of electronic cigarette

ActiveCN103750571AImprove sealingSimple and fast operationTobacco devicesElectronic cigaretteEngineering

The invention relates to an electronic cigarette, a manufacture method of the electronic cigarette, and an injection method of the electronic cigarette. The electronic cigarette comprises a power unit, an atomizer unit, and a nozzle and liquid bottle unit; the units are assembled in sequence; the bottom end of a liquid bottle of the nozzle and liquid bottle unit is provided with an injection through hole hermetically connected through a plug. A gas passage forms among the liquid bottle, an outer tube and a nozzle. A nozzle liquid storage unit is assembled by: unplugging the plug, injecting tobacco juice into the liquid bottle, pressing the plug into the injection through of the liquid bottle with the injected tobacco juice, and mounting the liquid bottle with the mounted plug into the nozzle and liquid bottle unit. The injection method includes: making the protruding liquid injection through hole in the bottom end of the liquid bottle and manufacturing the plug used for plugging the injection through hole; sealing the gas passage of the electronic cigarette; inserting an injection head into the injection through hole of the liquid bottle for injection; unplugging the injection head and hermetically connecting the plug into the injection through hole in the bottom end of the liquid bottle. The method of assembling the liquid bottle prior to injection is provided to adapt to automatic high-efficiency production of electronic cigarettes and the injection method of electronic cigarettes.

Owner:林光榕

Dual-laser beam hybrid welding device and hybrid welding method

InactiveCN102500919AImprove absorption efficiencyCompact structureLaser beam welding apparatusNd:YAG laserErbium lasers

The invention provides a dual-laser beam hybrid welding device and a hybrid welding method. The dual-laser beam hybrid welding device comprises an ND: YAG (Neodymium-Doped Yttrium Aluminum Garnet) laser beam light path, and a dual-laser beam light path which is provided with a semiconductor laser beam light path and is arranged on a vertical dual-laser beam lens cone body. The dual-laser beam light path is provided with an ND: YAG total reflection lens, a semiconductor total reflection and ND: YAG total transmission combined lens, and a semiconductor and ND: YAG total transmission gathering lens in sequence from top to bottom. According to the invention, the high-freedom degree welding machining can be realized; the structure of the dual-laser beam hybrid welding device is simple and small; the alignment position is more accurate; and the automation is easy to realize. The dual-laser beam hybrid welding device can be used for welding positions which cannot be welded in a conventional manner, and a high-reflection and high-thermal conductivity material which cannot be welded by single laser, so that the application field of laser welding is enlarged, particularly a working piece is pre-heated by using a continuous semiconductor laser. The absorption efficiency of a material of the working piece to ND: YAG laser is improved, the welding fusion depth is increased, the welding speed and the welding efficiency are improved, and the occurrence of air vents and cracks in the welding process of working pieces is avoided.

Owner:UNITED WINNERS LASER CO LTD

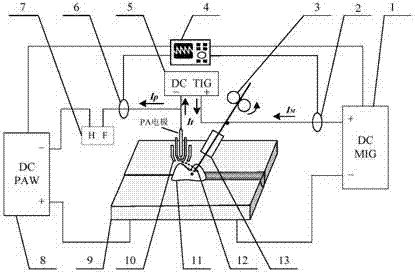

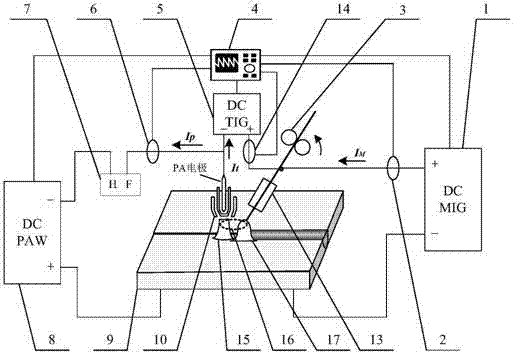

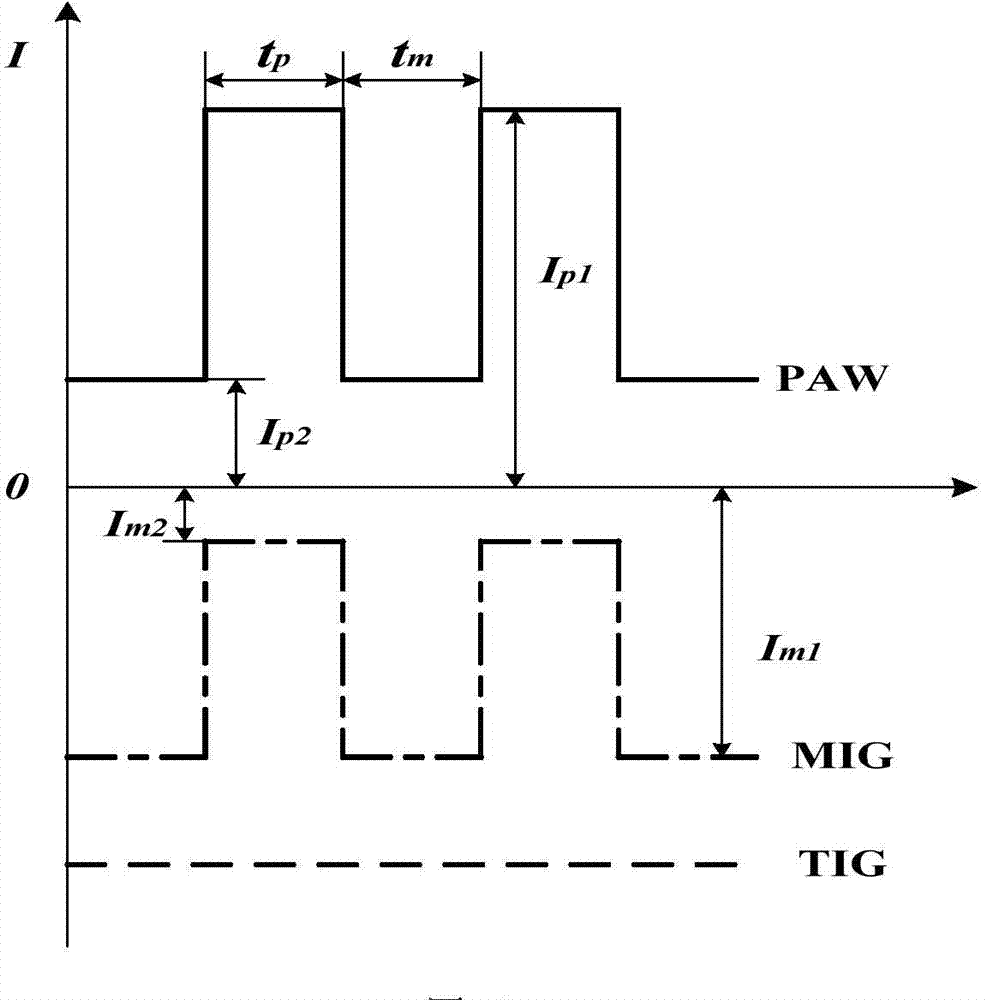

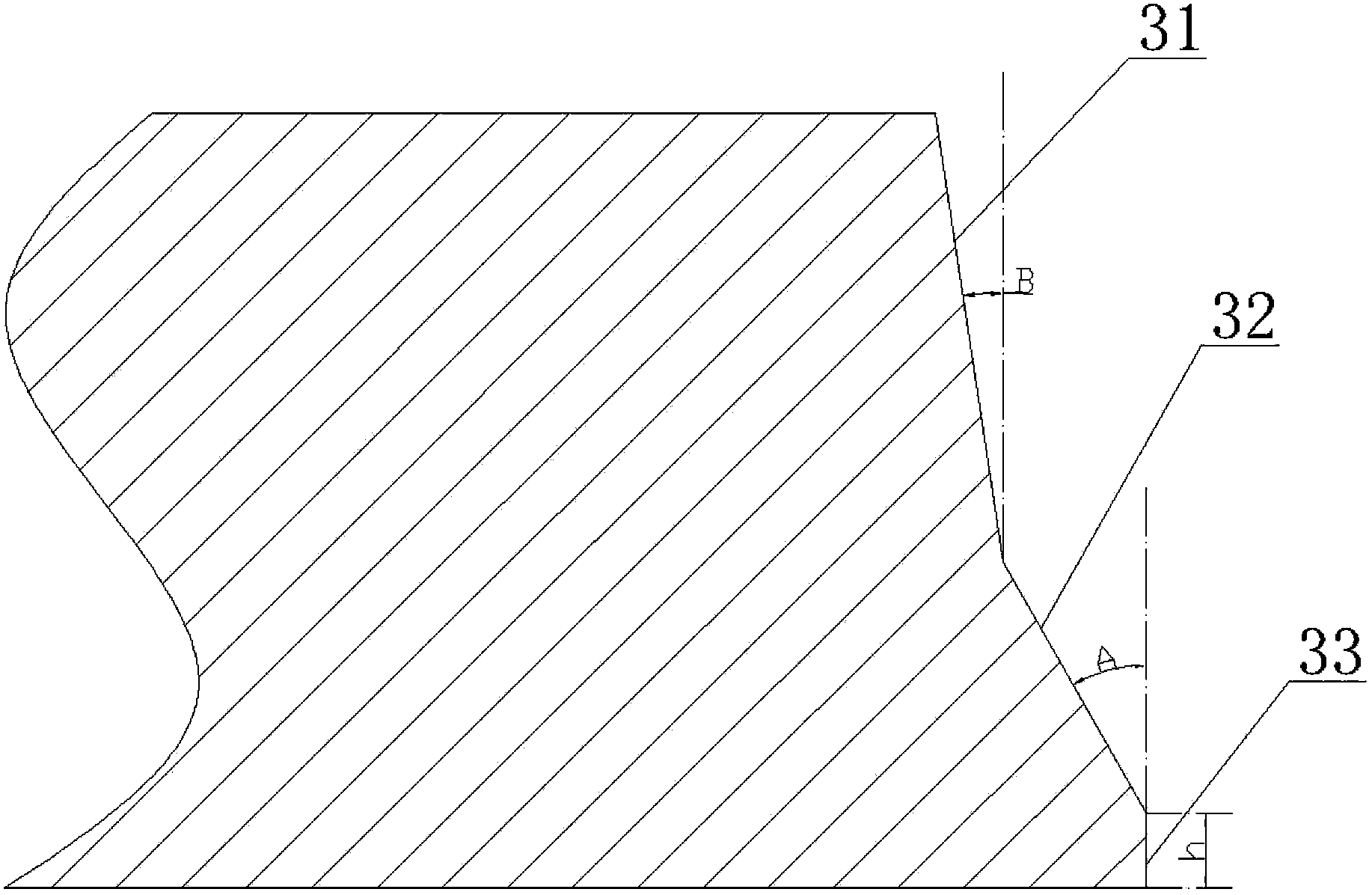

Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

ActiveCN104493368AHigh tensile strengthHigh elongationWelding apparatusPower flowWelding power supply

The invention provides a plasma-melting electrode electric arc dynamic composite welding device and a welding method thereof. A plasma arc welding gun is combined with a melting electrode electric arc welding gun to obtain a composite welding gun; the two electric arc welding guns are respectively connected with a negative pole of a direct-current pulsed plasma arc welding power supply and a positive pole of a direct-current pulsed melting electrode arc welding power supply and are also connected with a negative pole and a positive pole of an argon arc welding power supply (a TIG power supply); and a negative pole of the plasma arc welding power supply and a positive pole of the melting electrode arc welding power supply are connected with a workpiece. In order to prevent electromagnetic interference between a plasma arc and a melting electrode electric arc during welding, a pulsed coordination control method is used, namely, when melting electrode electric arc current waveform is a pulsed basic value pilot arc, the plasma arc is a pulse peak value, and welding is carried out; and when plasma arc current waveform is a pulse basic value, the melting electrode arc is pulse peak value welding current, and so forth. By the plasma-melting electrode electric arc dynamic composite welding device and the welding method thereof, the problems that electromagnetic interference between electric arcs is large, parameters are adjusted complexly, and electrodes are burnt down severely are solved.

Owner:HARBIN ENG UNIV

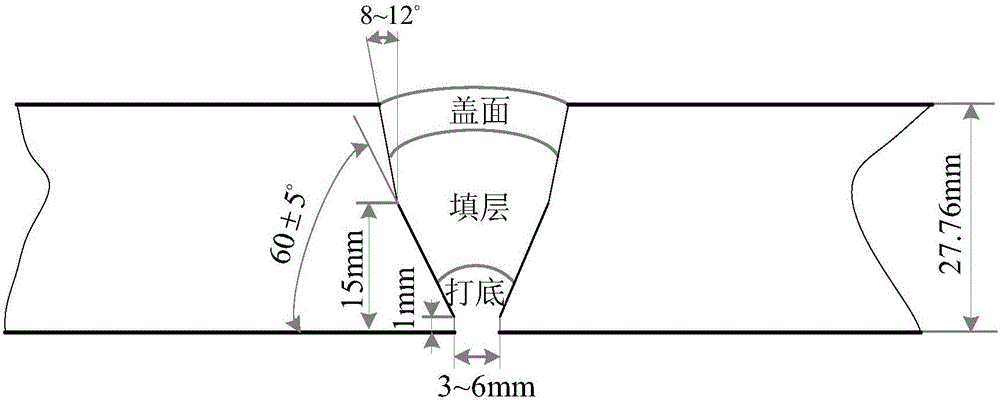

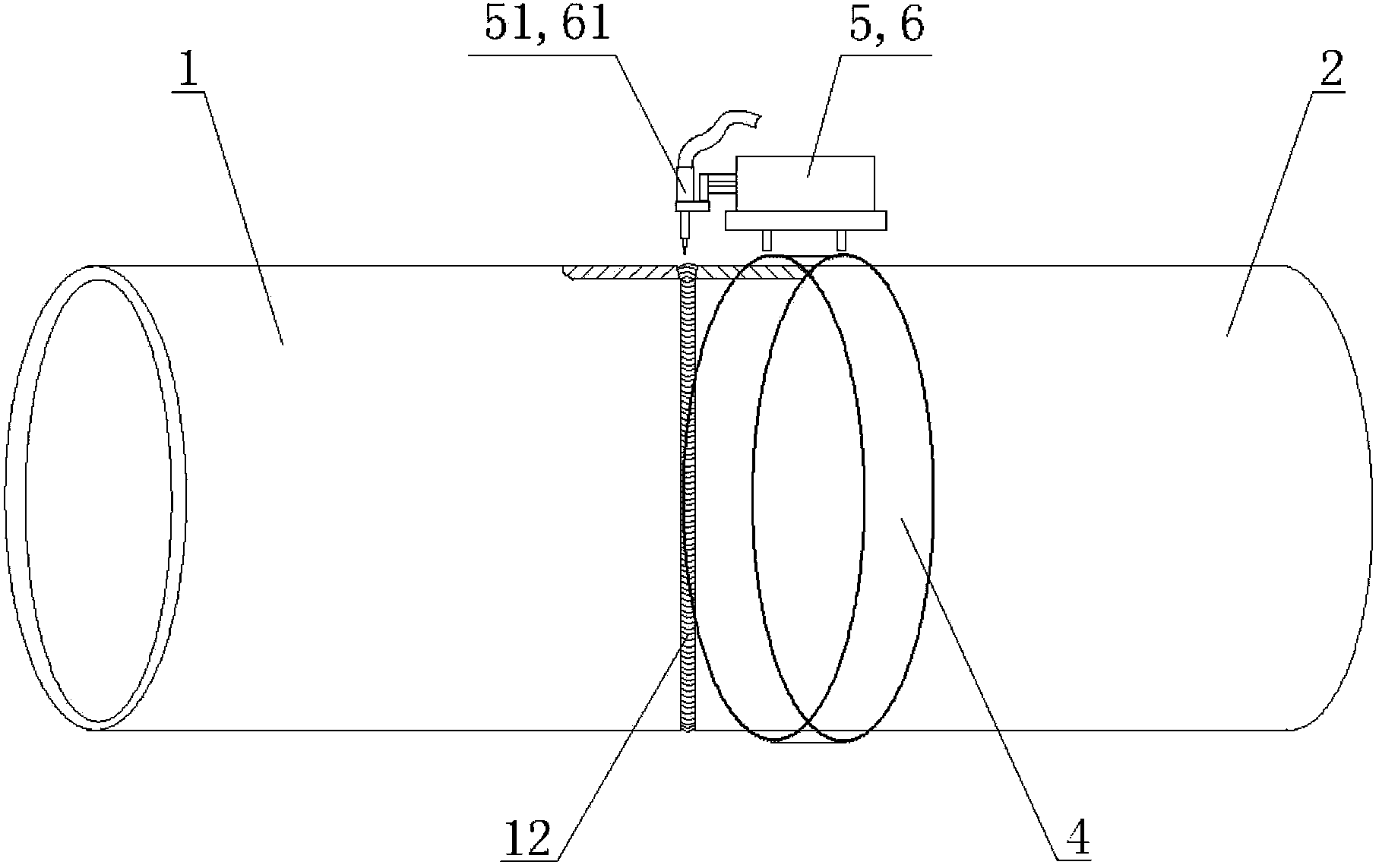

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Laser-arc hybrid welding method of light sheet T type joint

InactiveCN101474727AEasy to shapeImproved weld toe transitionLaser beam welding apparatusLight beamEngineering

The invention relates to a laser-arc composite welding method for a T-shaped joint of a thin plate, belonging to the technical field of laser materials processing. The method adopts a laser-arc composite thermal source to complete the welding of the T-shaped joint on the lateral face of a bottom plate, a laser bean enters from the top face of the bottom plate, an electric arc is in paraxial arrangement at the front part or the rear of the laser bean, and the composite thermal source accomplishes the penetration fusion welding from the lateral face of the bottom plate of the T-shaped joint. The welding seam of the joint welded by the method is favorably shaped, a weld toe of the connection part of a rib plate and the bottom plate is uniformly and smoothly transited, and air holes, cracks and other defects are not presented after the welding seam is anatomized. The method fully utilizes the characteristics of the composite thermal source; and under the mutual actions of laser and arc, the stability of a welding process is obviously improved, the welding efficiency is increased, and the welding deformation can be lessened.

Owner:BEIJING UNIV OF TECH

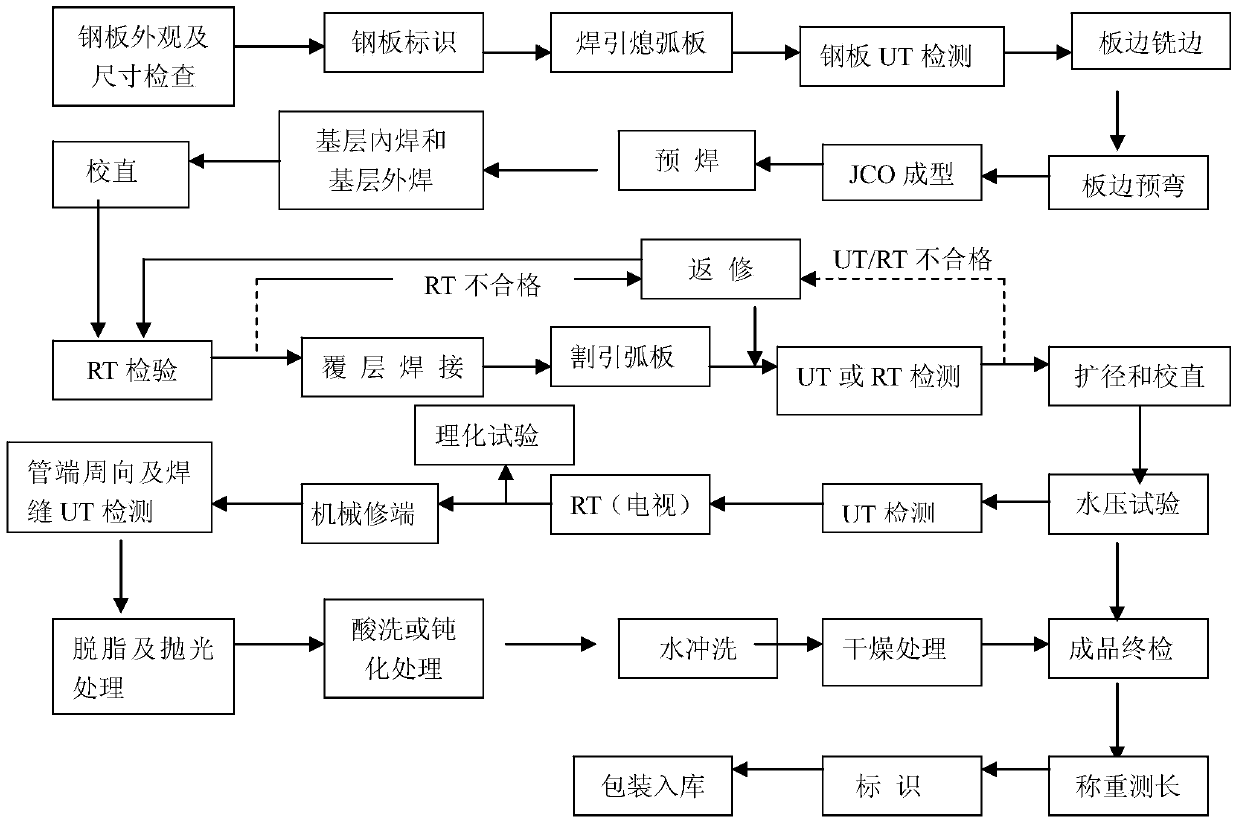

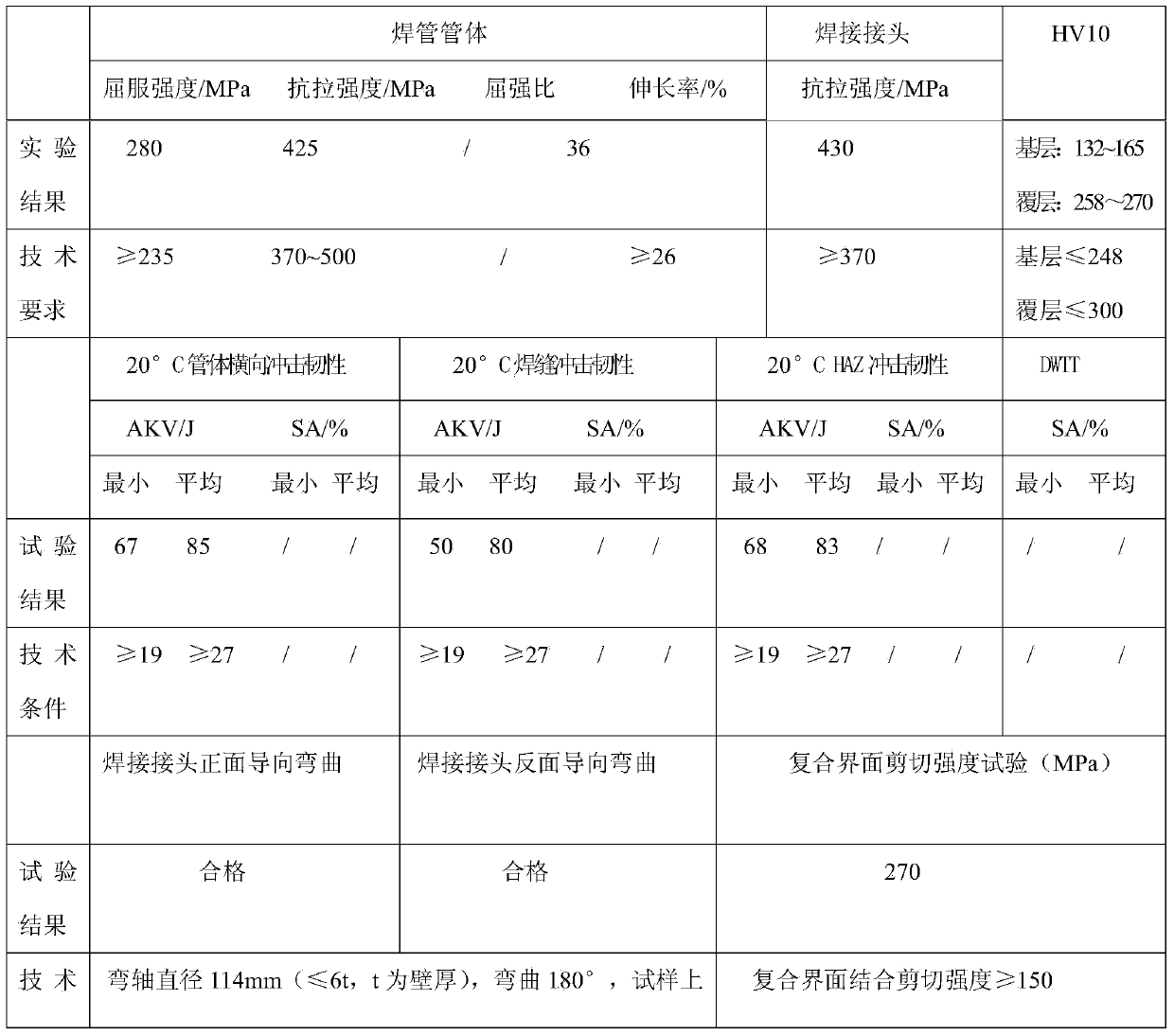

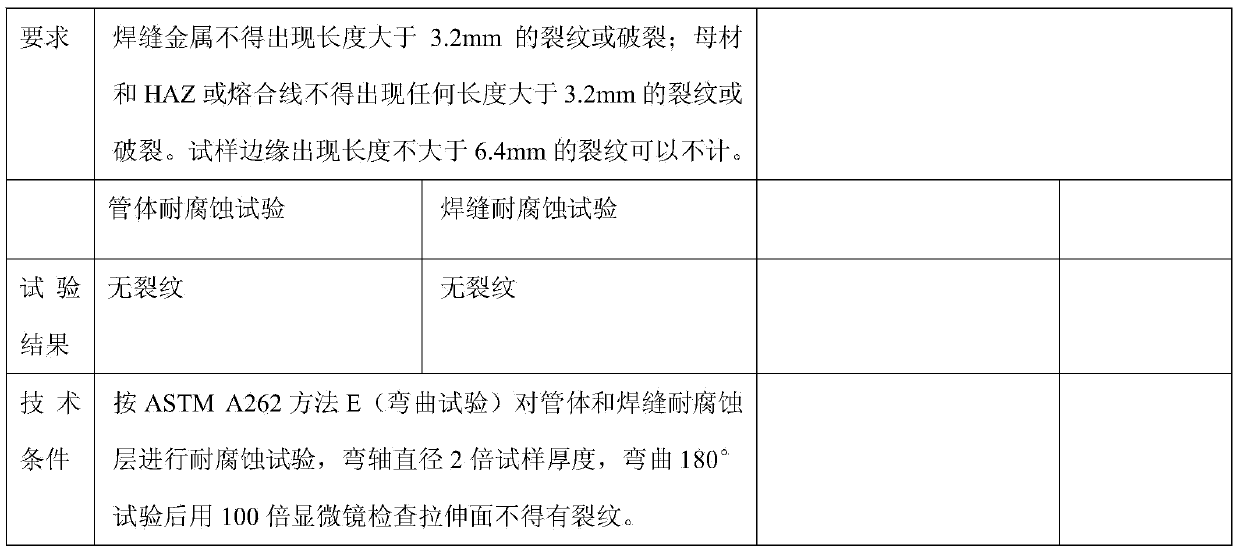

Corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe and method for manufacturing same

ActiveCN103722346AHigh strengthStrong integrityArc welding apparatusMetal rolling arrangementsSteel tubeSteel plates

The invention provides a corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and a method for manufacturing the same. The method includes steps of (1), manufacturing bimetal composite steel plates by a hot rolling process; (2), carrying out edge milling, pre-bending, JCO forming and pre-welding on the bimetal composite steel plates manufactured in the step (1); (3), welding weld joints of a steel pipe by a submerged-arc welding process, particularly, welding a carbon steel layer of a base layer at first when the weld joints are welded, and then welding metal of a clad layer of a corrosion-resistant layer. The steel pipe is obtained after JCO forming and pre-welding are carried out on the bimetal composite steel plates. The corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and the method have the advantages that the corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe is manufactured by a hot rolling metallurgical composite bimetal steel plate and JCOE pipe manufacturing process and the efficient automatic submerged-arc welding process, double layers of metal of the steel pipe can be metallurgically combined with each other, and accordingly the steel pipe is high in strength, integrity and corrosion resistance; the JCOE pipe manufacturing process is adopted, so that the steel pipe is high in mechanical degree, production efficiency and overall dimensional accuracy, and steel pipes with the lengths of 12 meters can be produced by the method.

Owner:江苏玉龙钢管科技有限公司

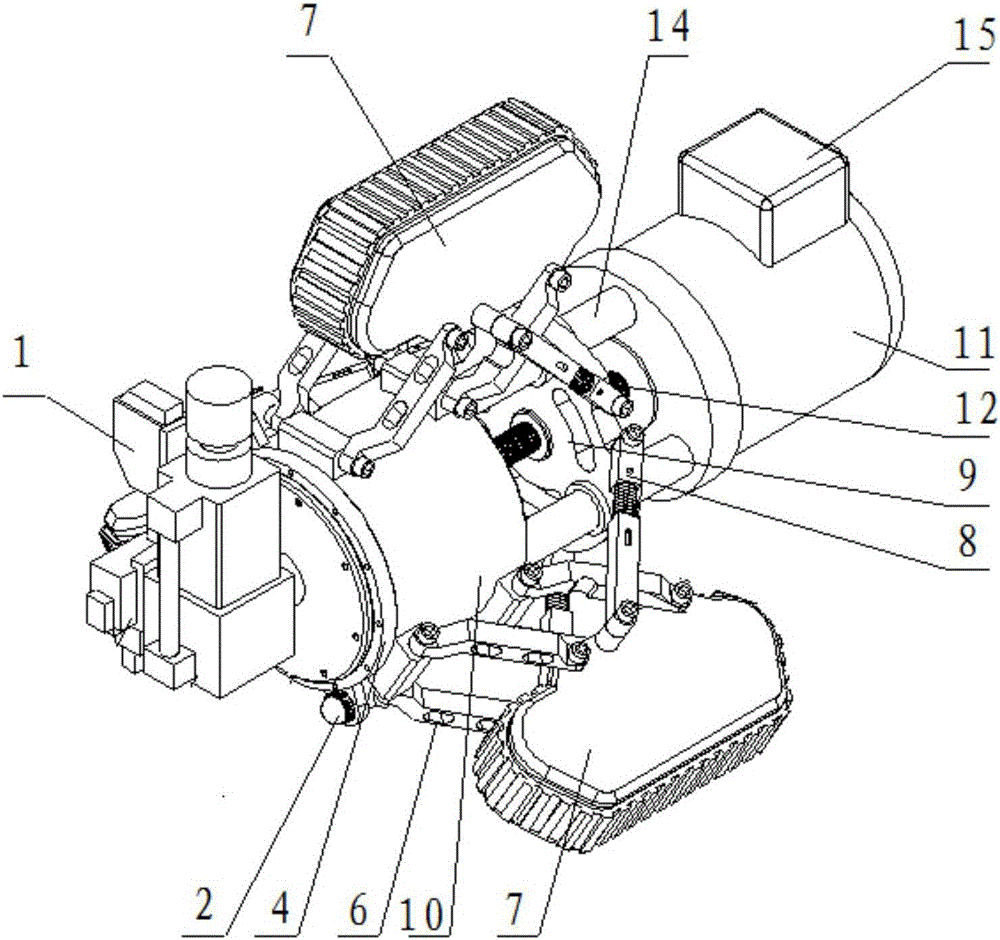

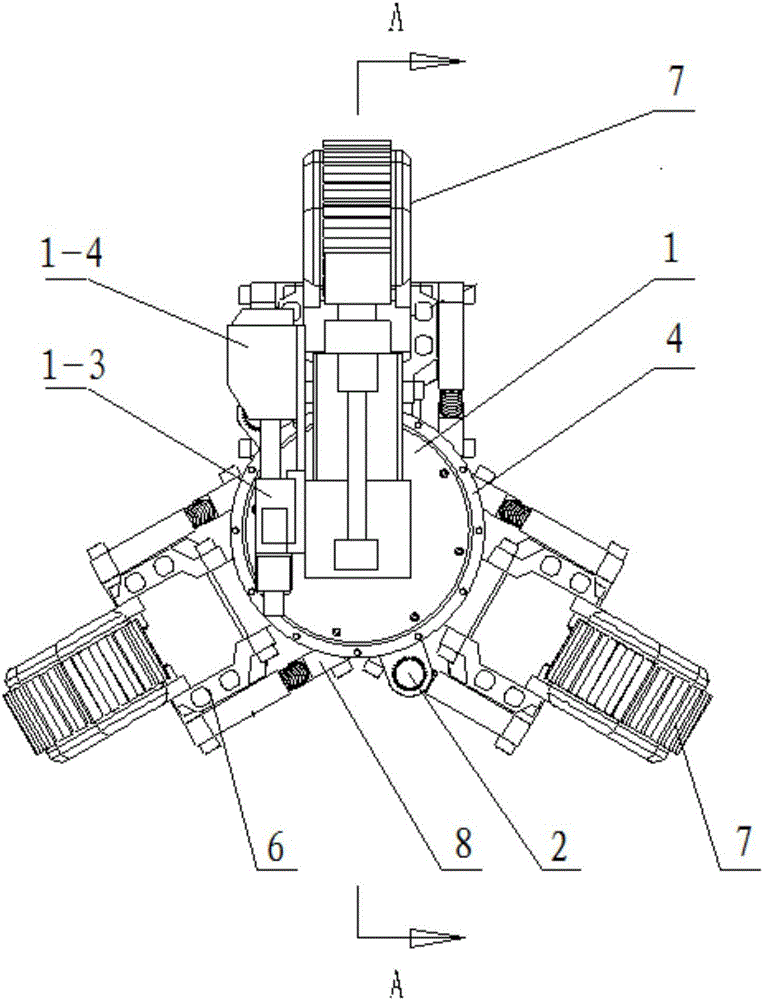

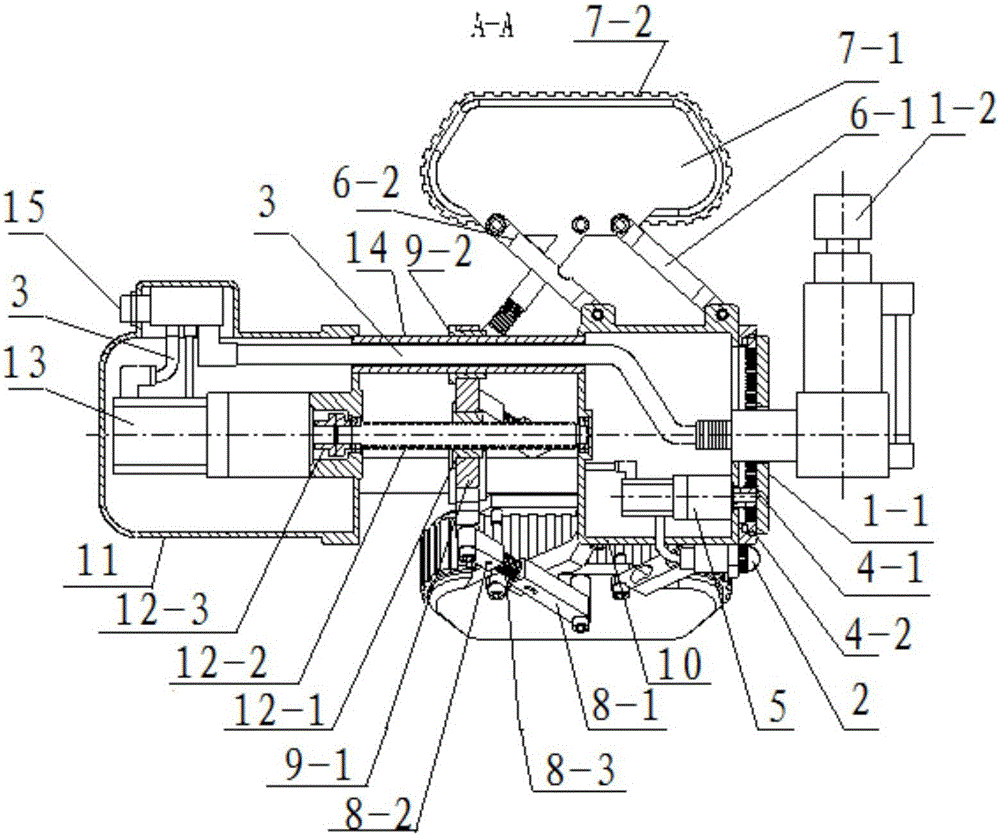

Laser root welding robot inside pipeline

ActiveCN105834586AAccurate guidanceQuality assurancePipeline systemsEndless track vehiclesEngineeringPipe welding

The invention discloses a laser root welding robot inside a pipeline and belongs to the technical field of pipeline welding. The laser root welding robot inside the pipeline comprises a weld joint welding device. A first transmission device is connected with the weld joint welding device. A front end machine base is connected with the first transmission device. A first gear motor is arranged in the front end machine base. One end of a connecting device is movably connected with the front end machine base. A crawler type traveling device is movably connected with the other end of the connecting device. One end of a pushing device is movably connected with the crawler type traveling device. A driving device is movably connected with the other end of the pushing device. A second transmission device is connected with the driving device. One end of the second transmission device is movably connected with the front end machine base. According to the laser root welding robot inside the pipeline, the welding fusion depth is large, the welding speed is high, accurate welding track guidance is provided for a laser welding head, and the quality of laser root welding is guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com