Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5000results about "Resistance welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

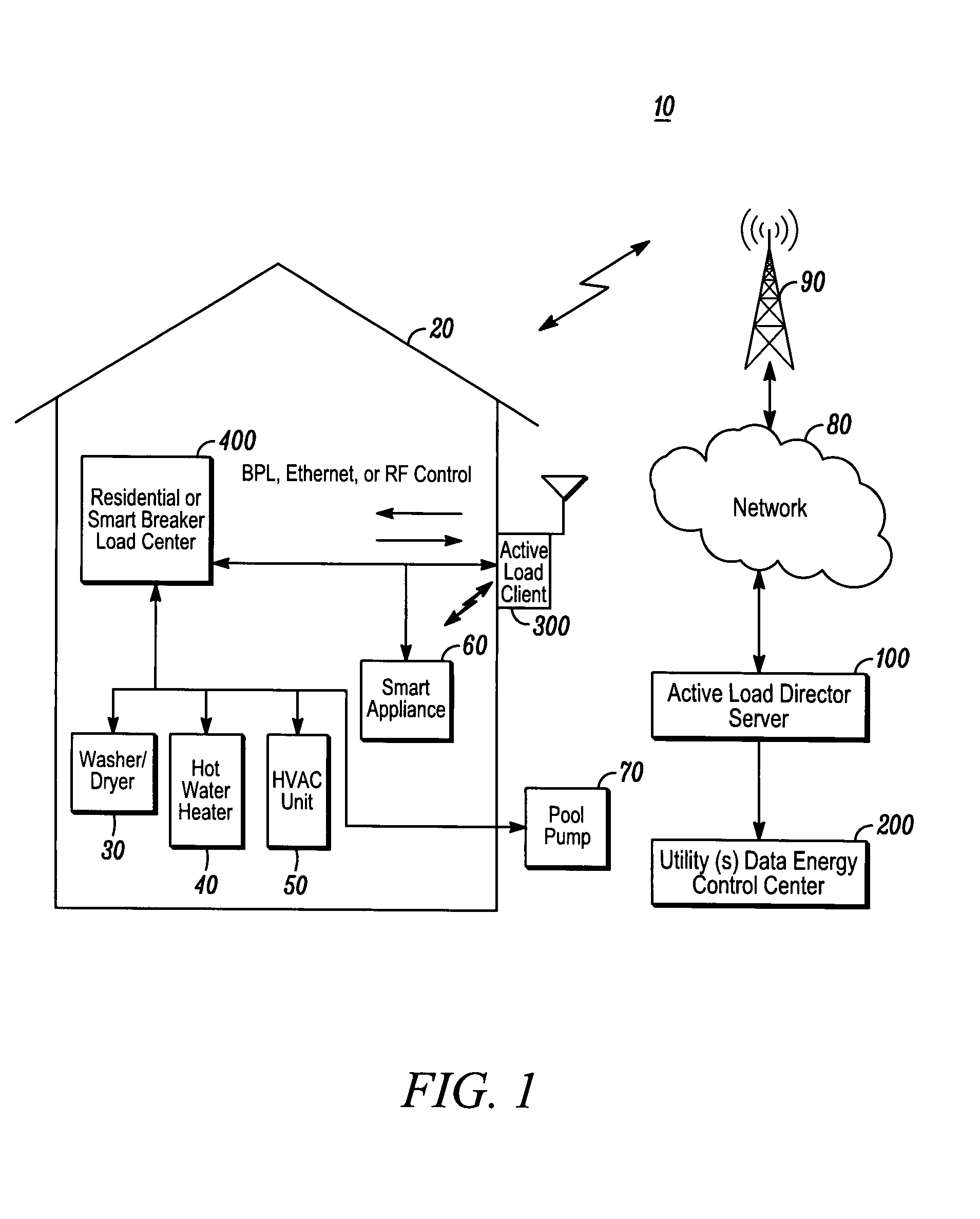

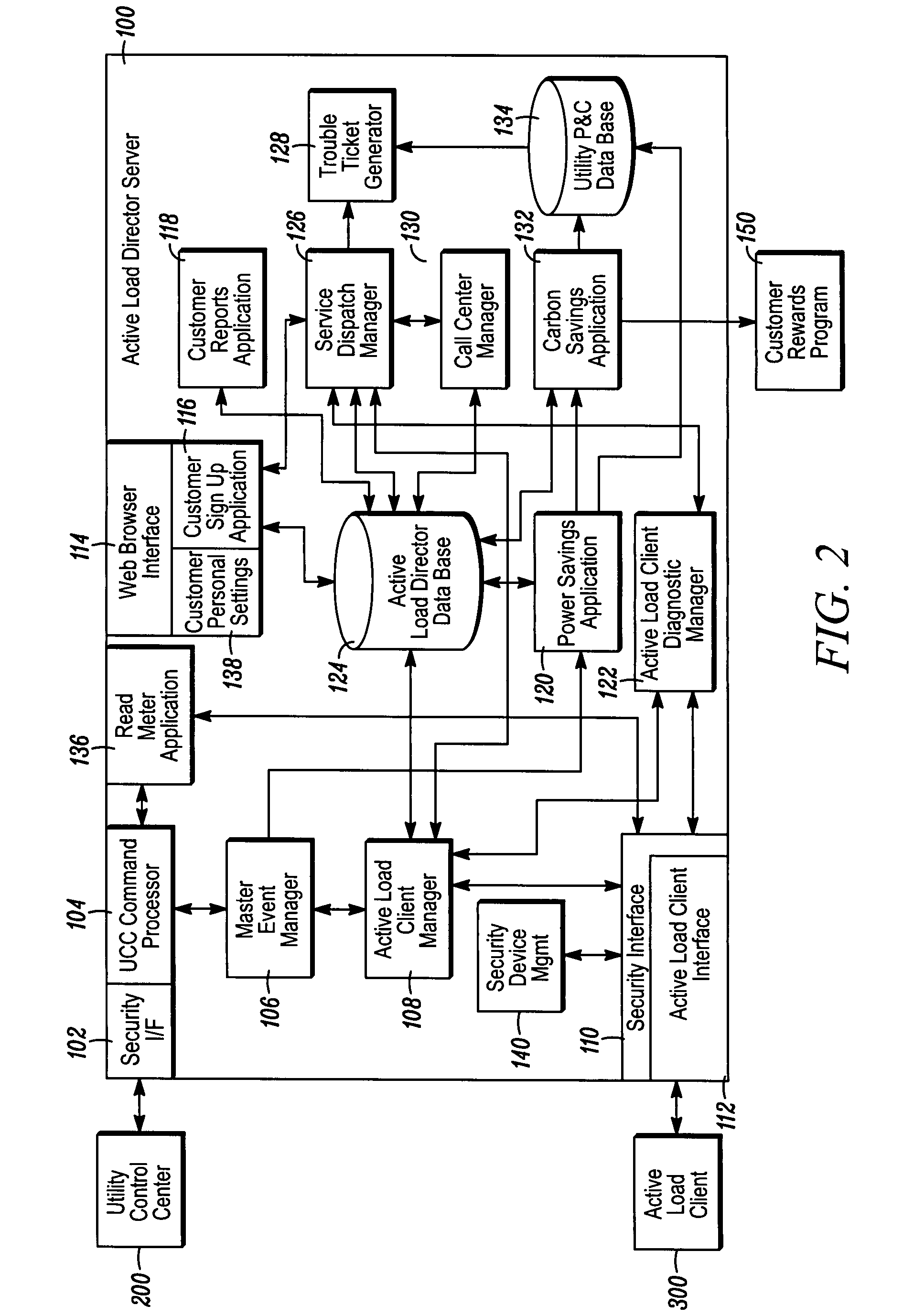

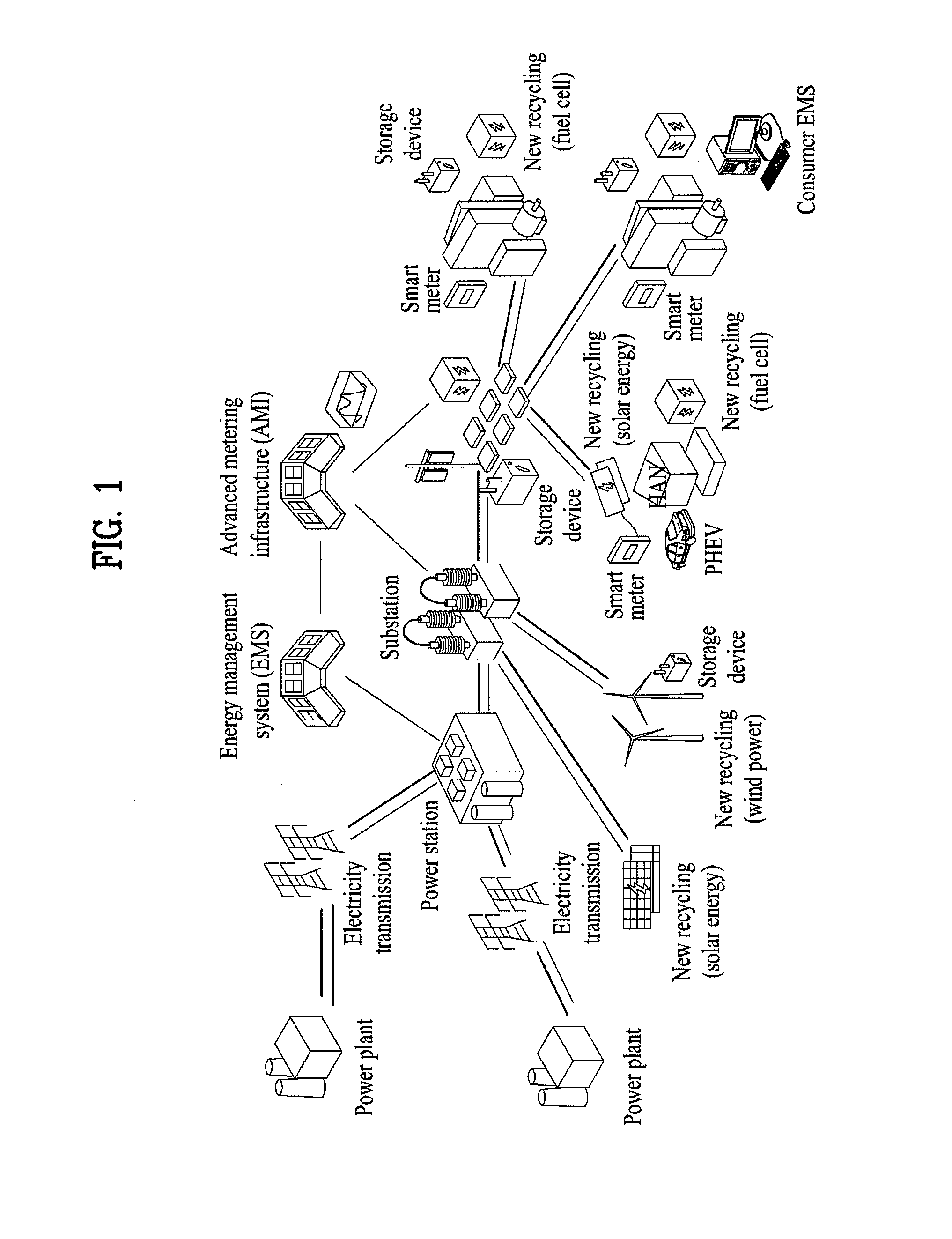

System and method for energy usage curtailment

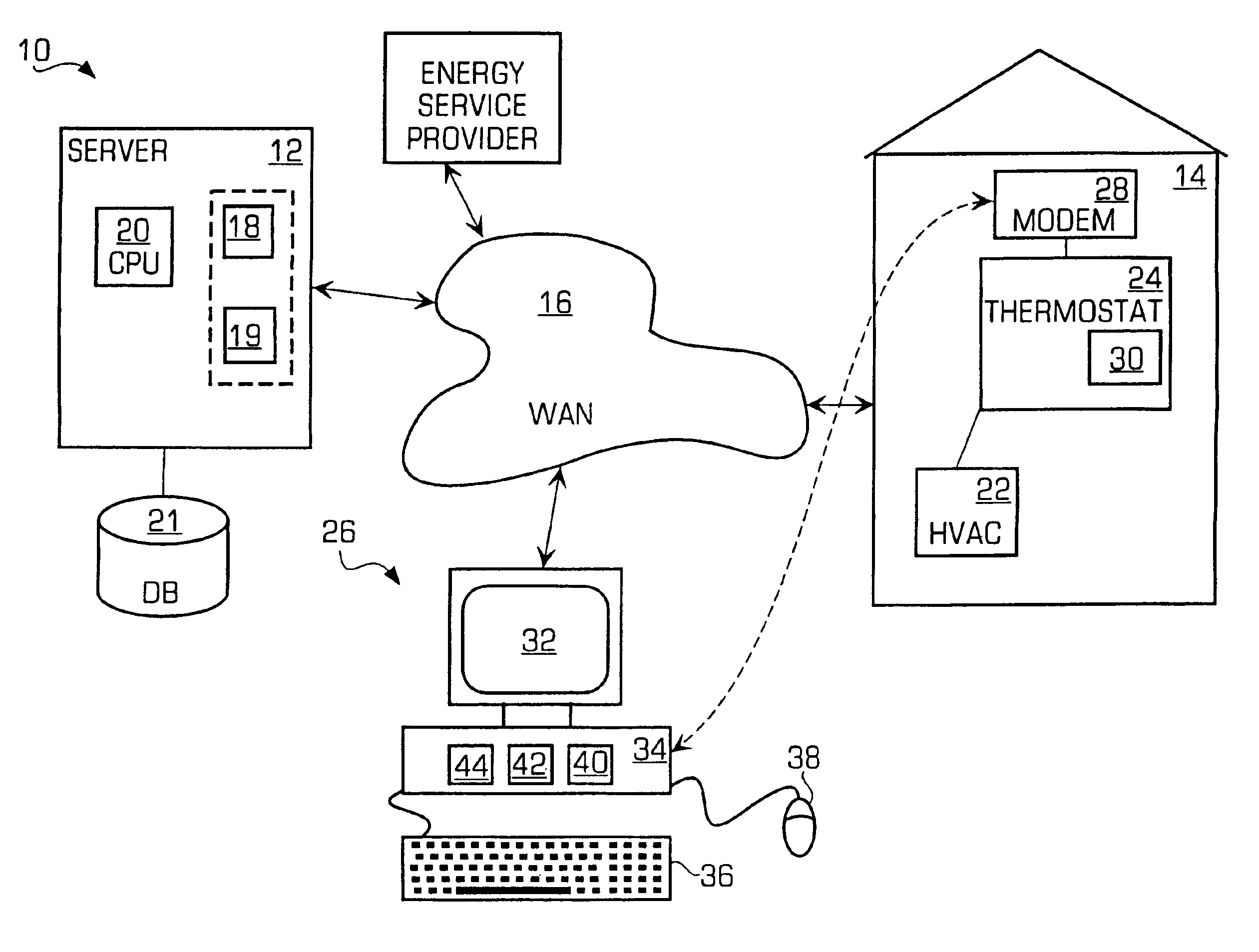

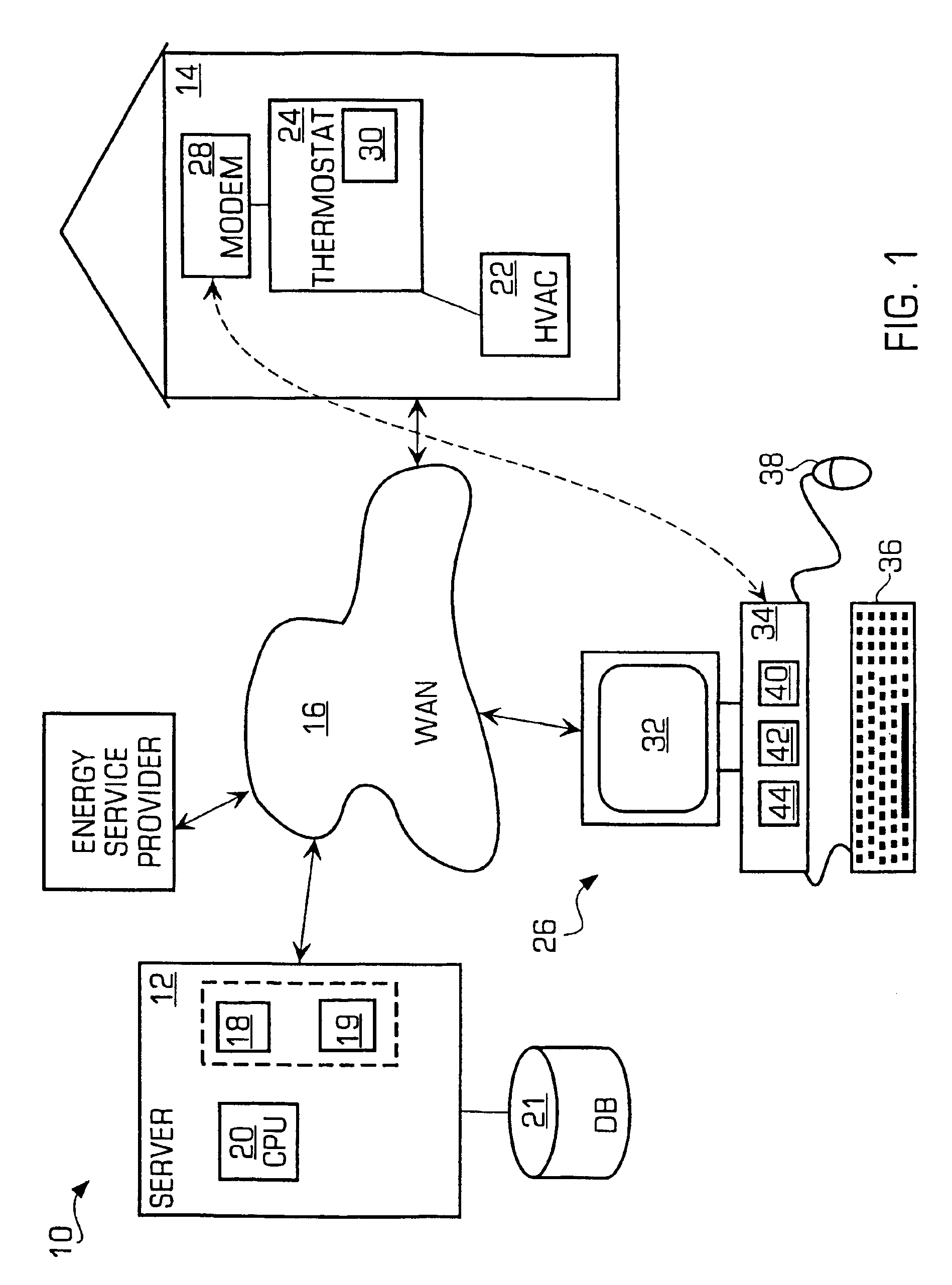

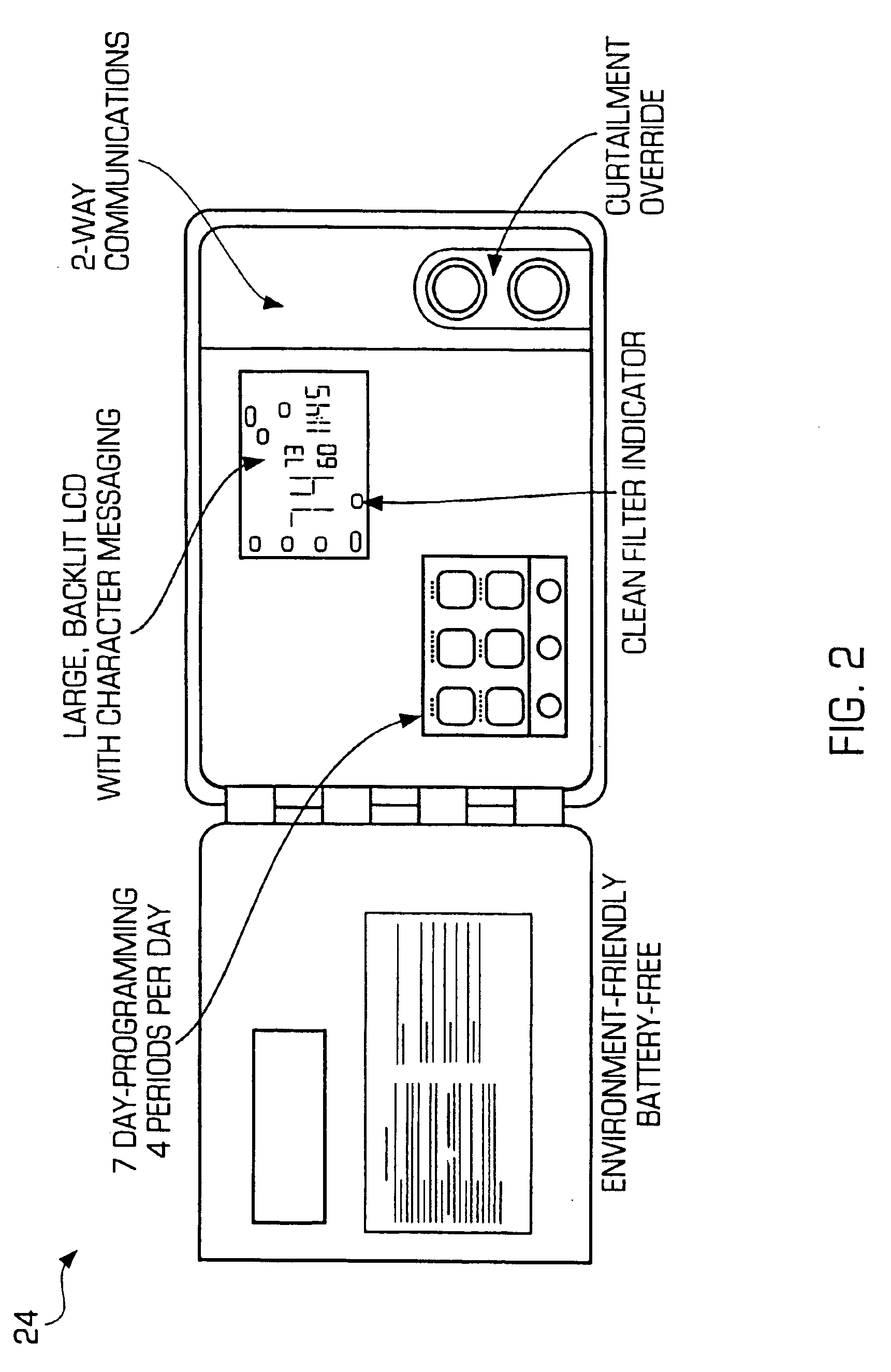

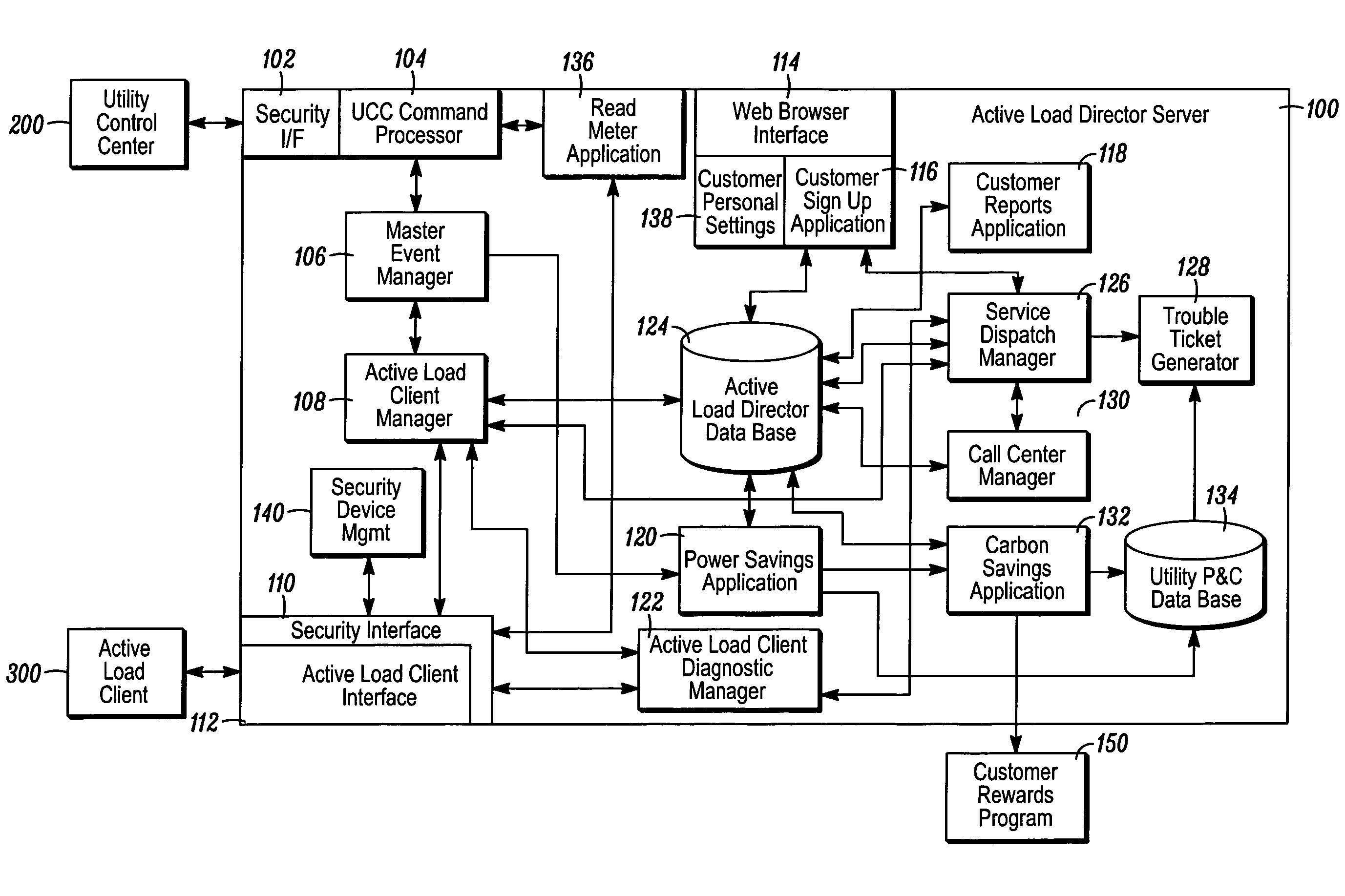

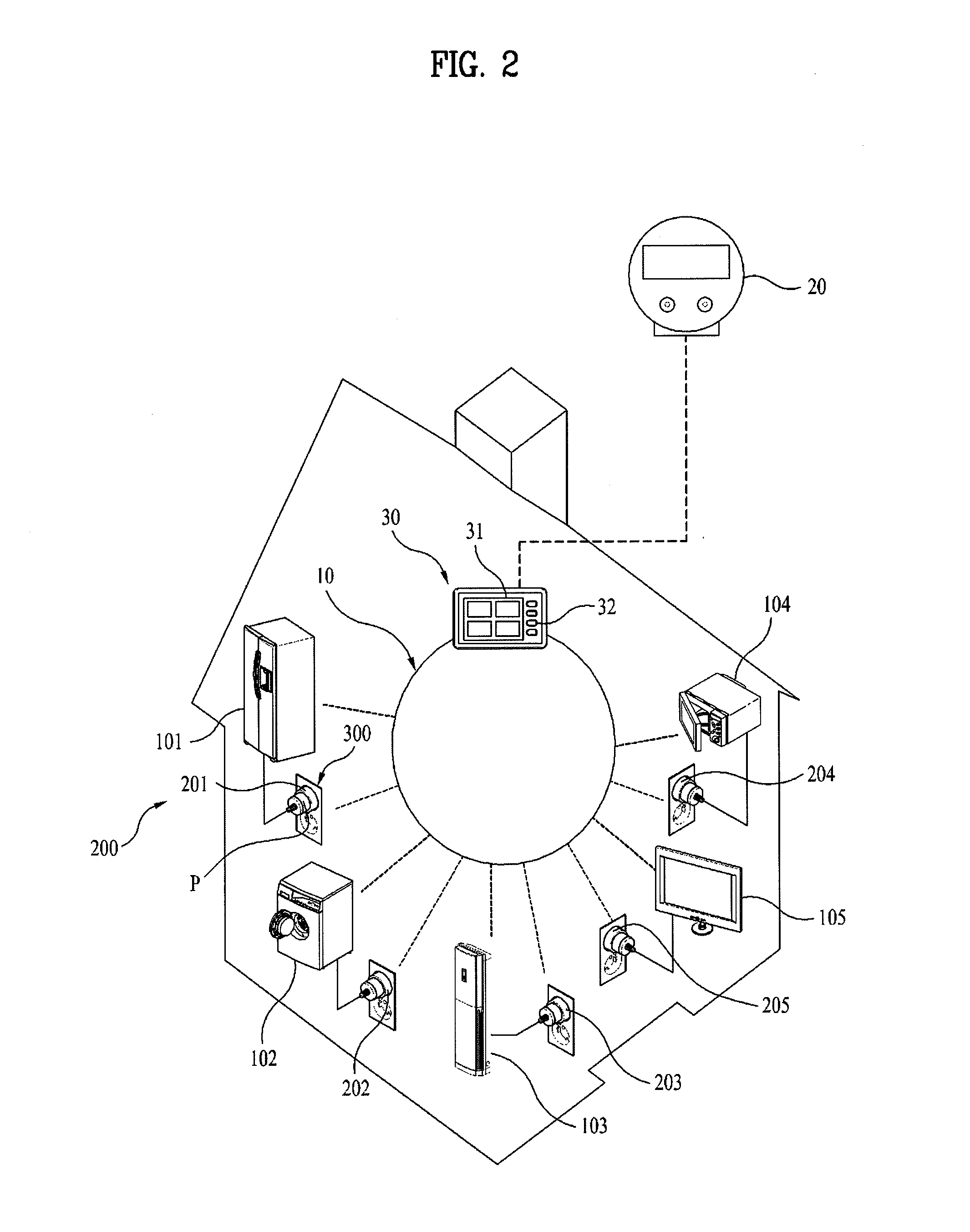

A system and method are disclosed for performing energy usage management within a network. The system may include an energy management system, such as a thermostat device, that may be associated with an energy consuming entity, such as a residence. A server may be remotely located from the energy consuming entity and may perform one or more energy curtailment management operations within the network. The server may be in communication with the energy management system over the network. One or more software applications may be stored thereon for remotely controlling the energy management system in accordance with a particular energy curtailment management operation. Additionally, a database may be associated with the server for storing curtailment event information relating to the network. A signal may be transmitted by the server to the thermostat device to alter an offset temperature setting of the thermostat device thereby remotely controlling the operation of the thermostat device. The thermostat device may also include a networking software application for enabling the remote monitoring and controlling of the thermostat device.

Owner:ITRON

System and method for managing consumption of power supplied by an electric utility

ActiveUS7715951B2Accurately reportAccurate calculationLevel controlResourcesComputer scienceElectric power

Owner:LANDISGYR TECH INC

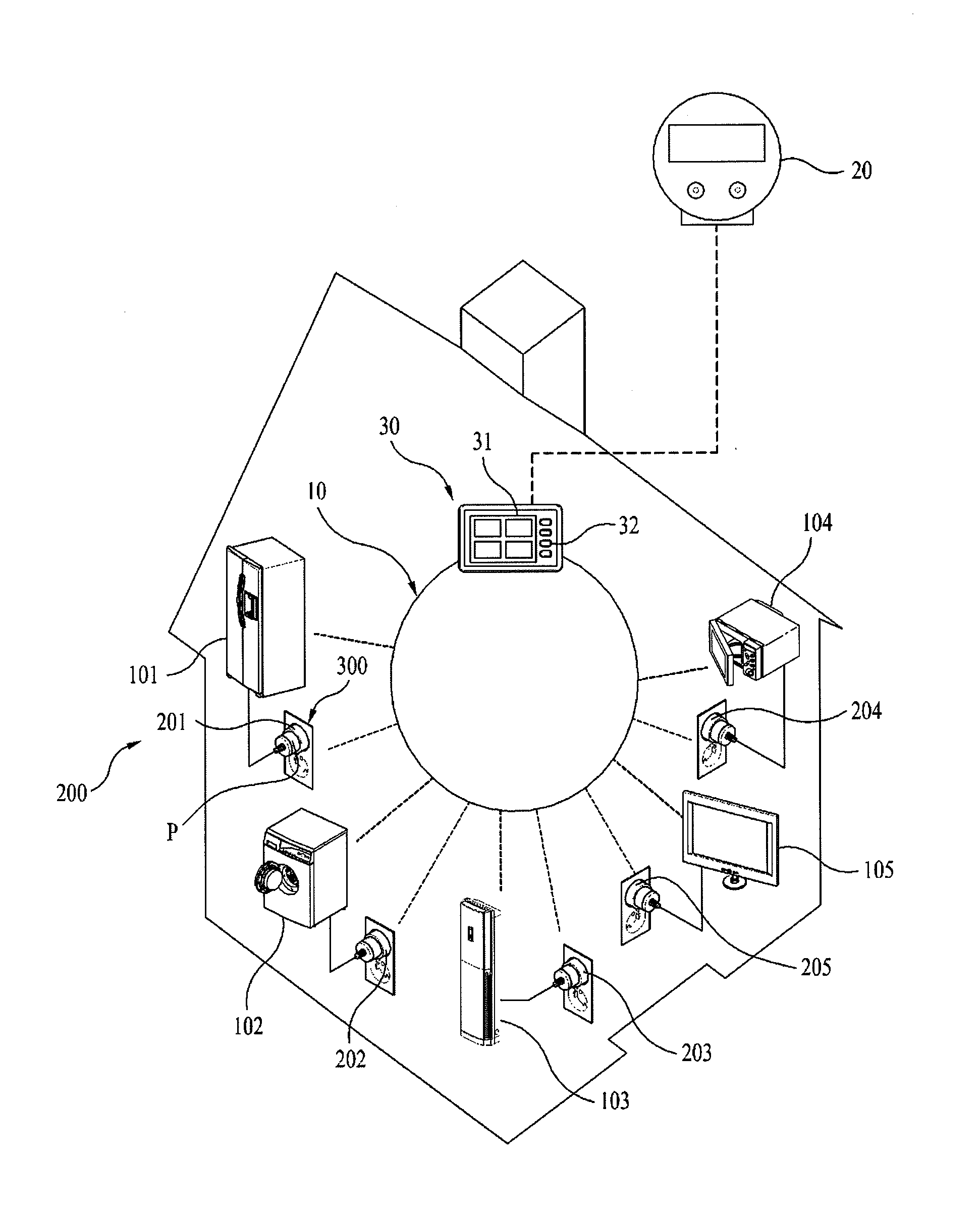

Apparatus for controlling a power using a smart device and method thereof

ActiveUS20110196547A1Reduce power consumptionUnnecessary controlLevel controlDigital data processing detailsSmart gridEngineering

A smart device is discussed, which is connected to a smart grid to perform a power saving function. According to an embodiment, the smart device includes a power information receiving unit configured to receive power information through the smart grid network; a power saving control unit configured to perform the power saving function for at least one apparatus based on the power information in a power saving mode; at least one mode switching unit configured to switch from the power saving mode to a manual mode according to a user command; and a manual mode operational time determining unit configured to determine a manual mode operational time for operating the at least one apparatus in the manual mode, the at least one mode switching unit further configured to switch from the manual mode back to the power saving mode, automatically, when the manual mode operational time expires.

Owner:LG ELECTRONICS INC

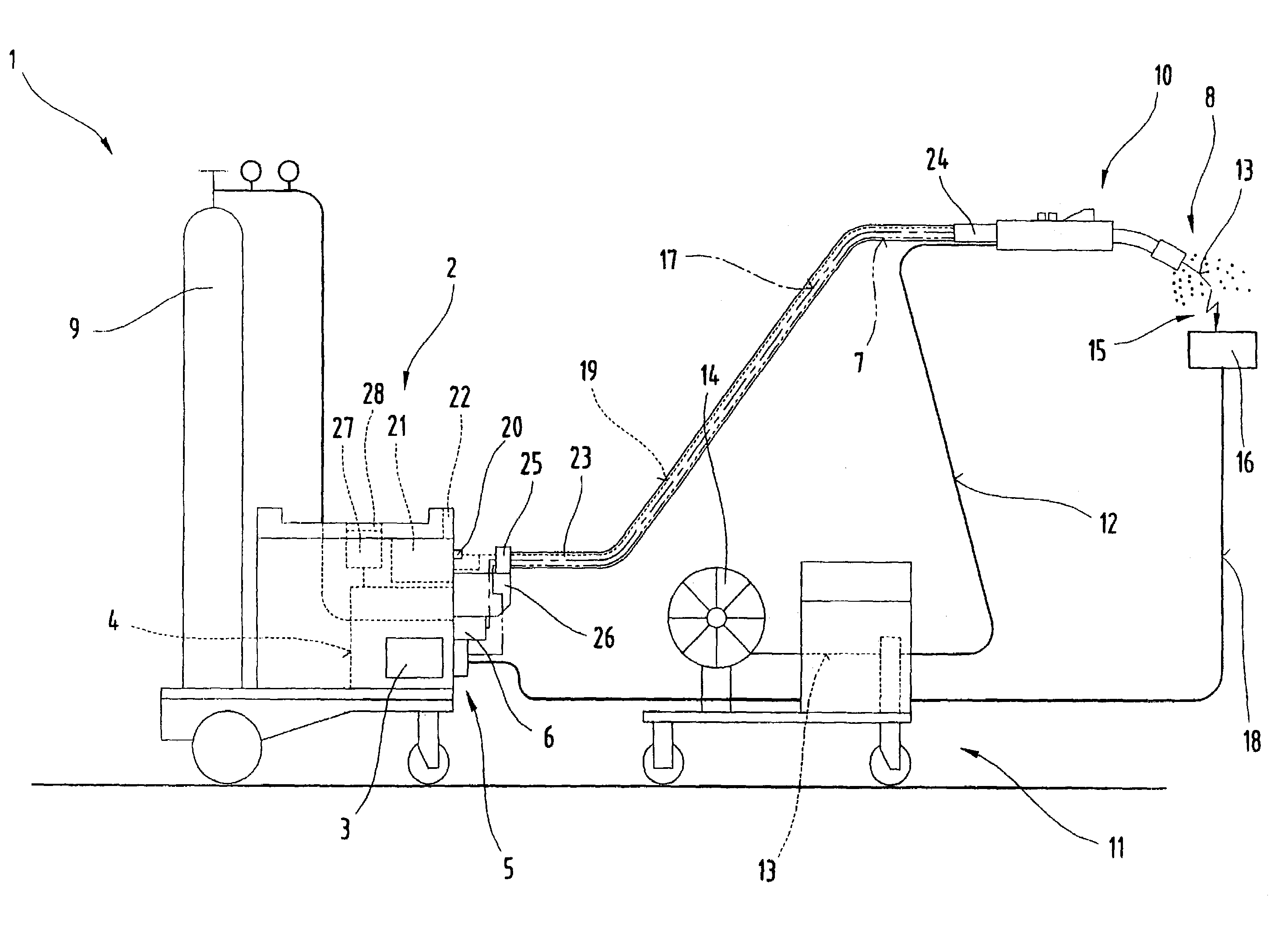

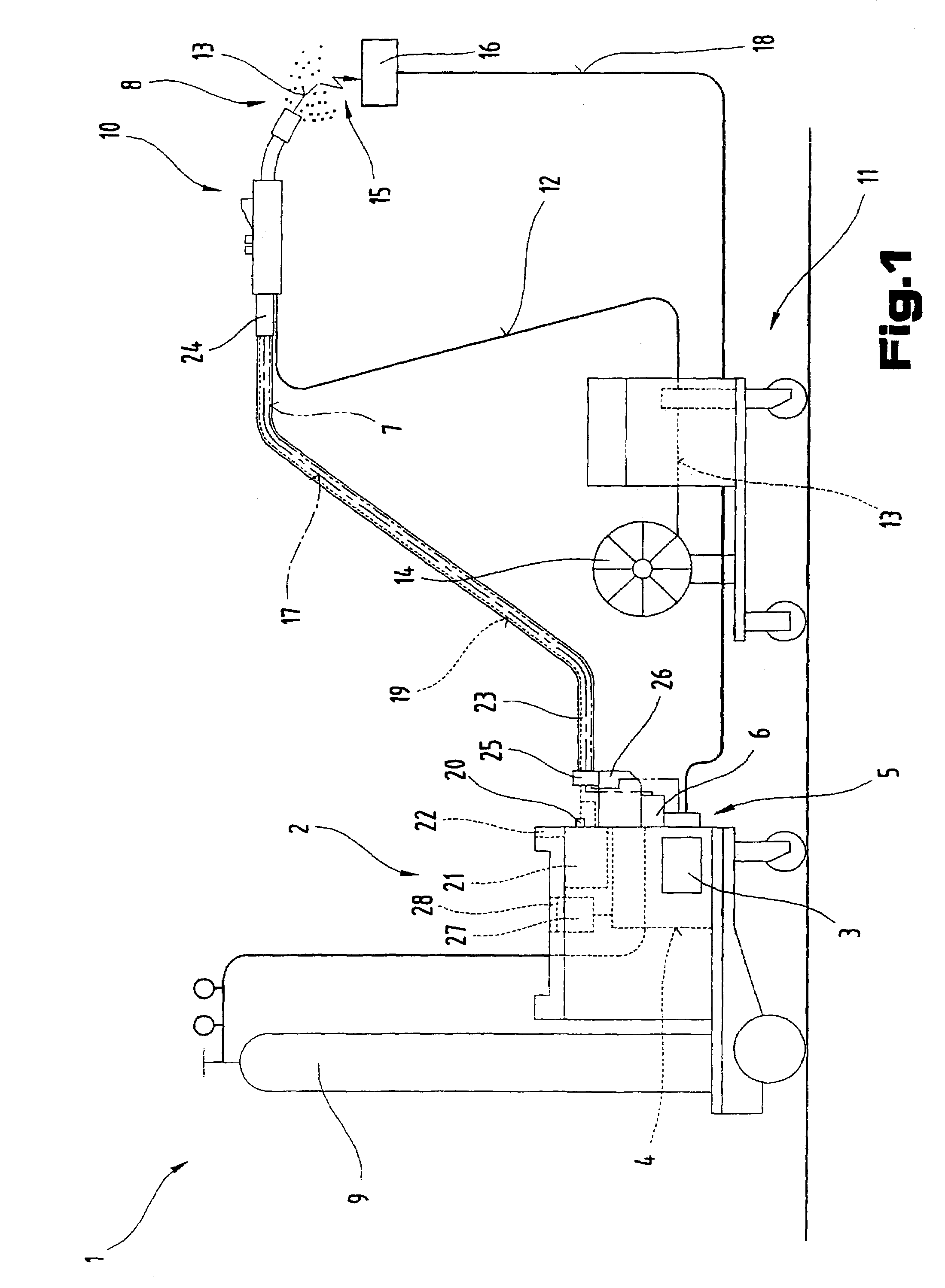

Assessing and/or determining of user authorizations using a transponder, a finger print recognition routine or the like

InactiveUS7523069B1Easy to carryUser identity/authority verificationUnauthorized memory use protectionControl systemEngineering

The invention describes a welding device (1) or a current source (2), with a control system (4), preferably comprising a microprocessor controller with a memory unit, a power component (3), in particular a current-inverting source, and additional components such as a welding torch (10), a wire feed device (11), etc., which are connected to the welding device (1) or the current source (2) via appropriate interfaces. An add-on module (27) is connected to the control system (4) or to the current source (2) for identifying a person by means of biometric physical characteristics such as an electronic fingerprint, voice recognition, iris recognition, recognition of a facial shape, recognition of writing, etc. or alternatively a transponder code via a transponder system.

Owner:FRONIUS INTERNATIONAL GMBH

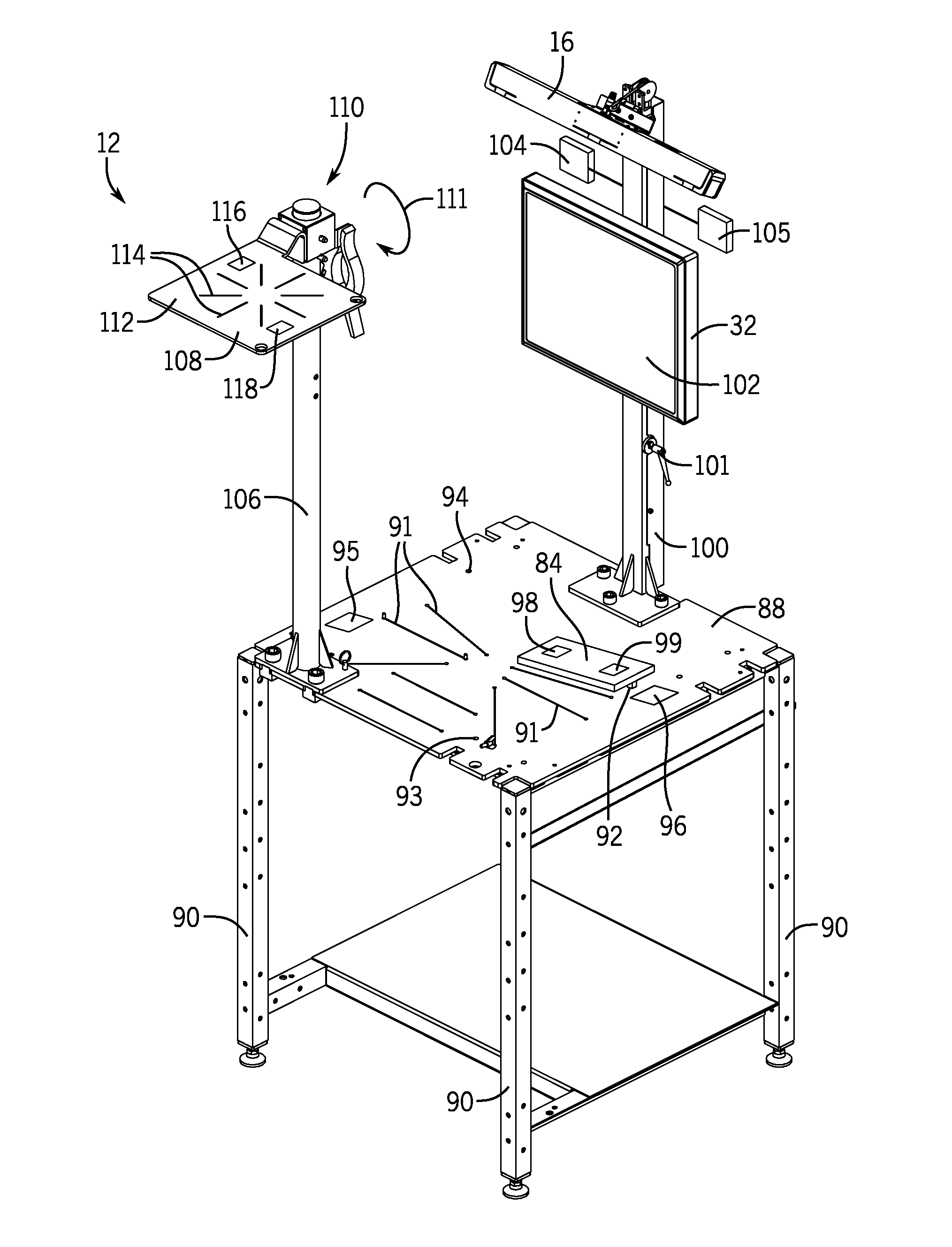

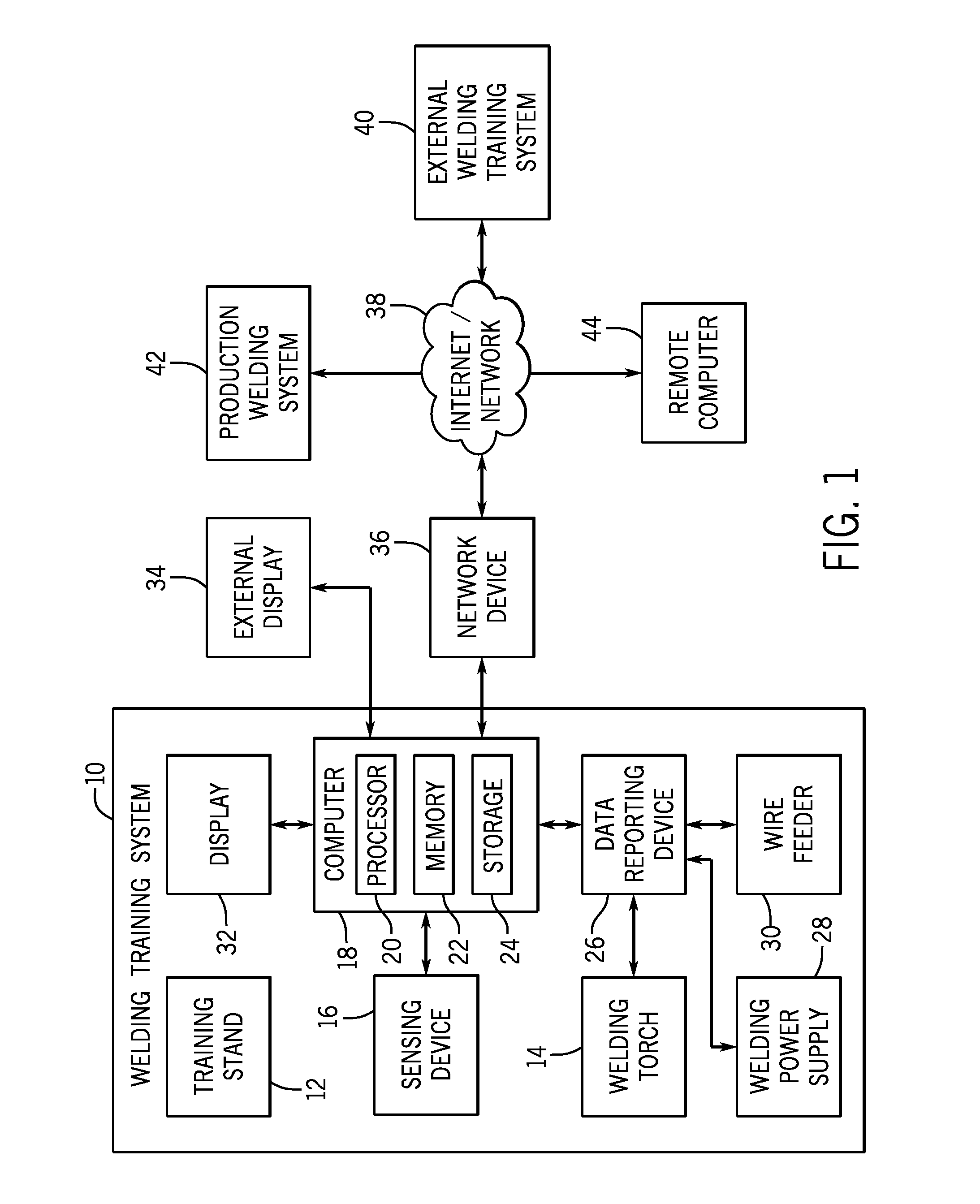

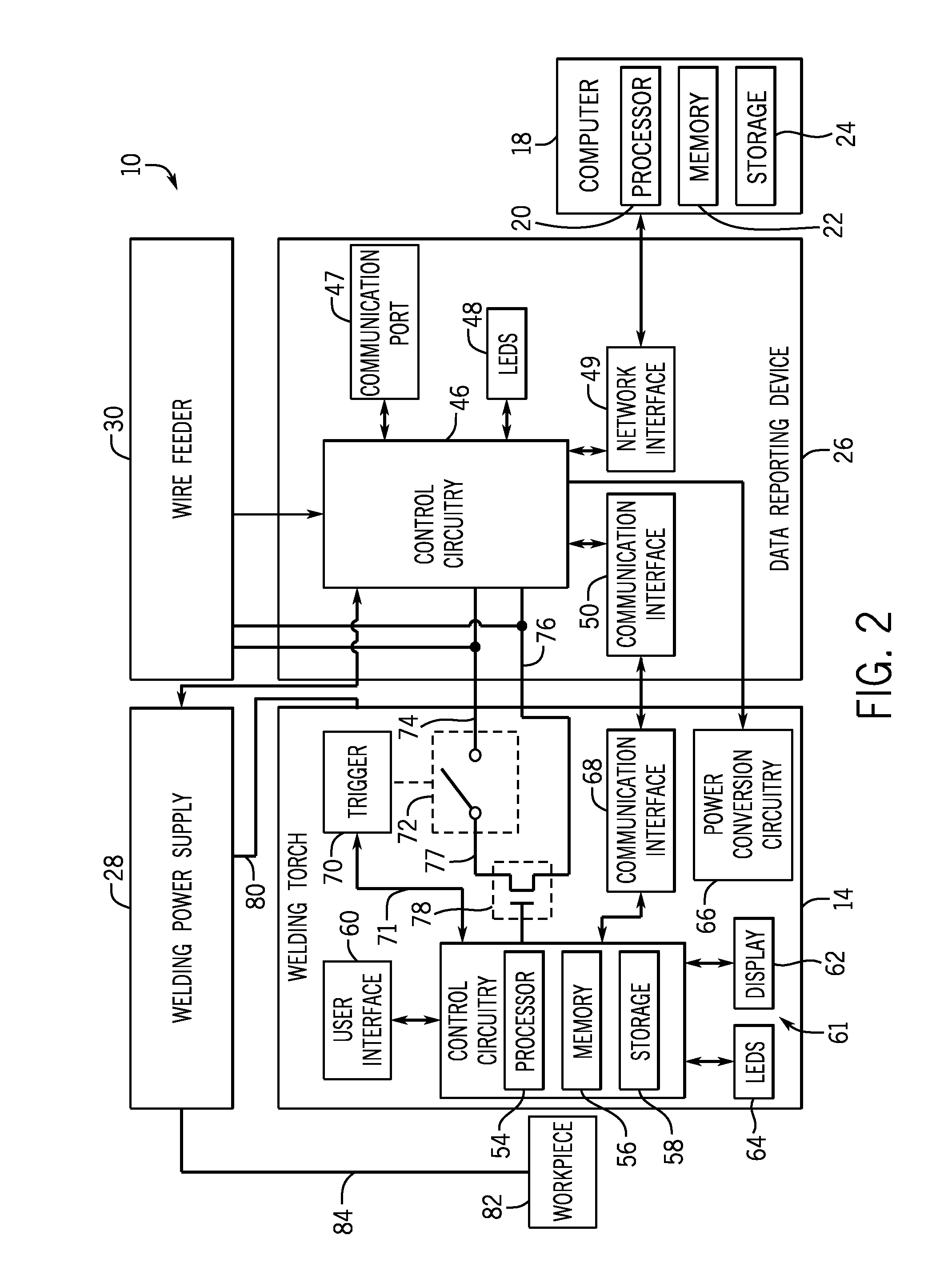

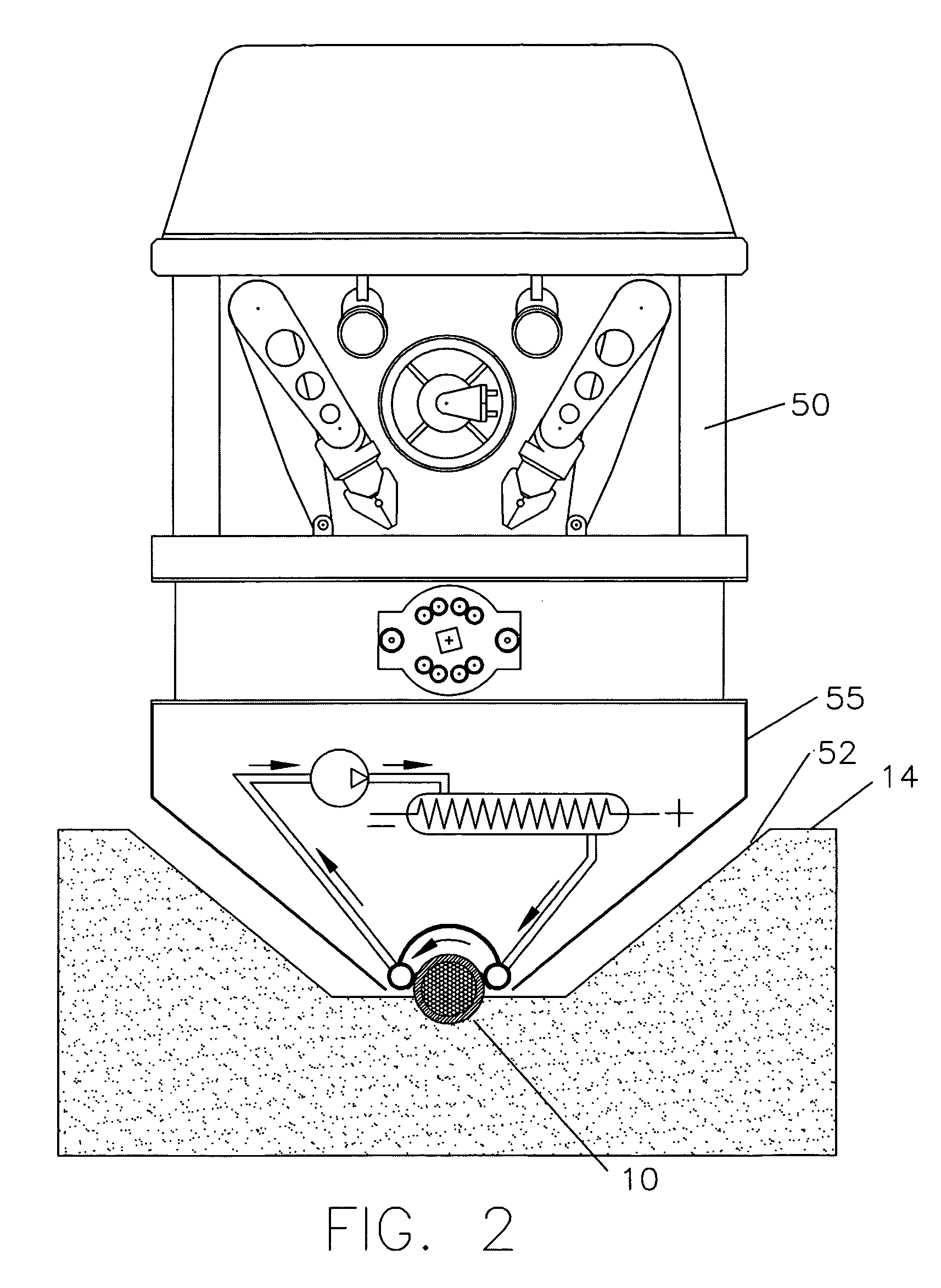

Calibration devices for a welding training system

A welding training system includes a welding surface, a computer configured to execute a welding training software, and a calibration device. The welding training system also includes a sensor communicatively coupled to the computer and configured to sense a position of the calibration device, an orientation of the calibration device, or some combination thereof. The sensor is also configured to provide calibration data to the welding training software to calibrate a location of the welding surface relative to the sensor. The calibration data includes the position of the calibration device, the orientation of the calibration device, or some combination thereof.

Owner:ILLINOIS TOOL WORKS INC

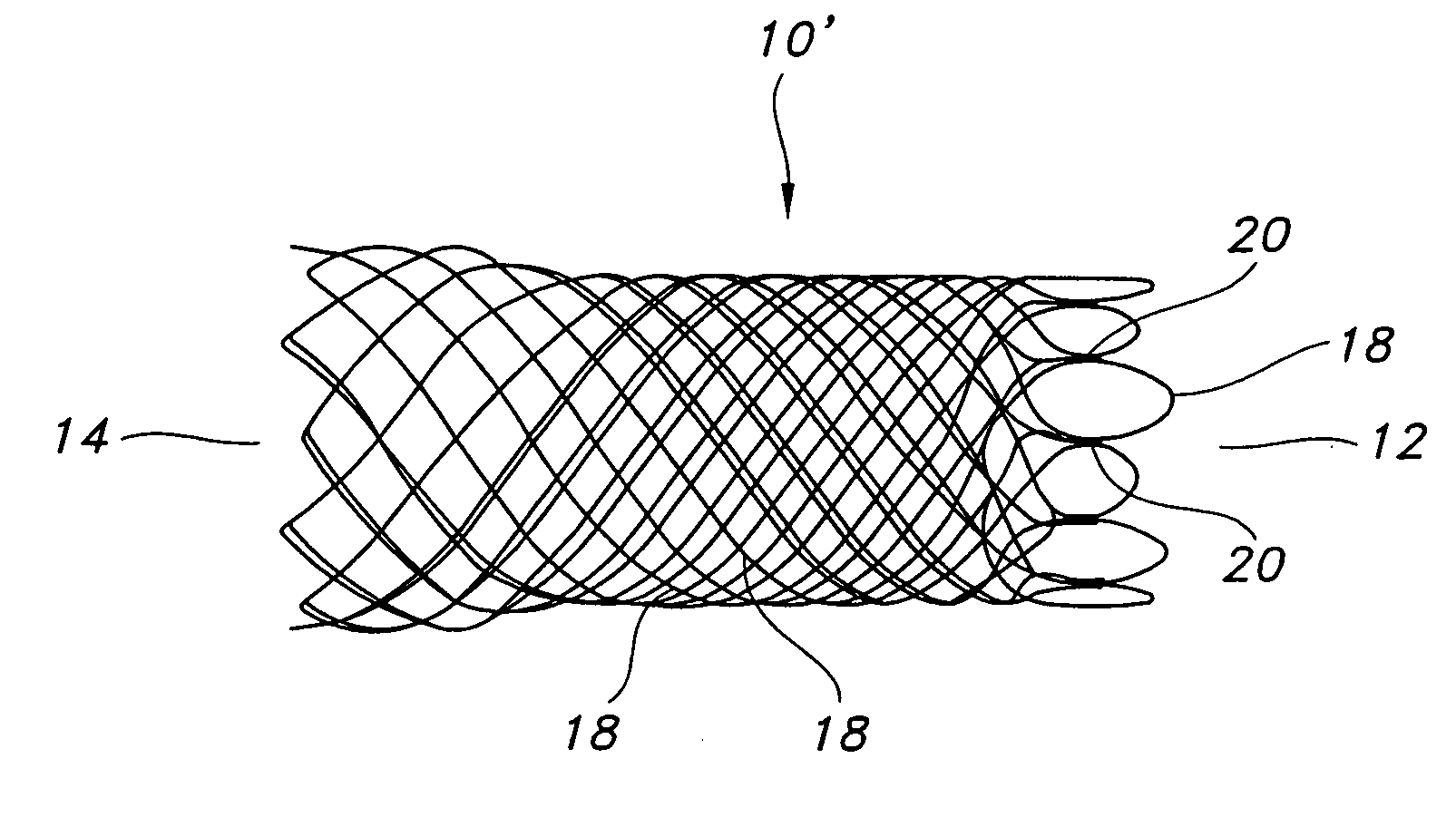

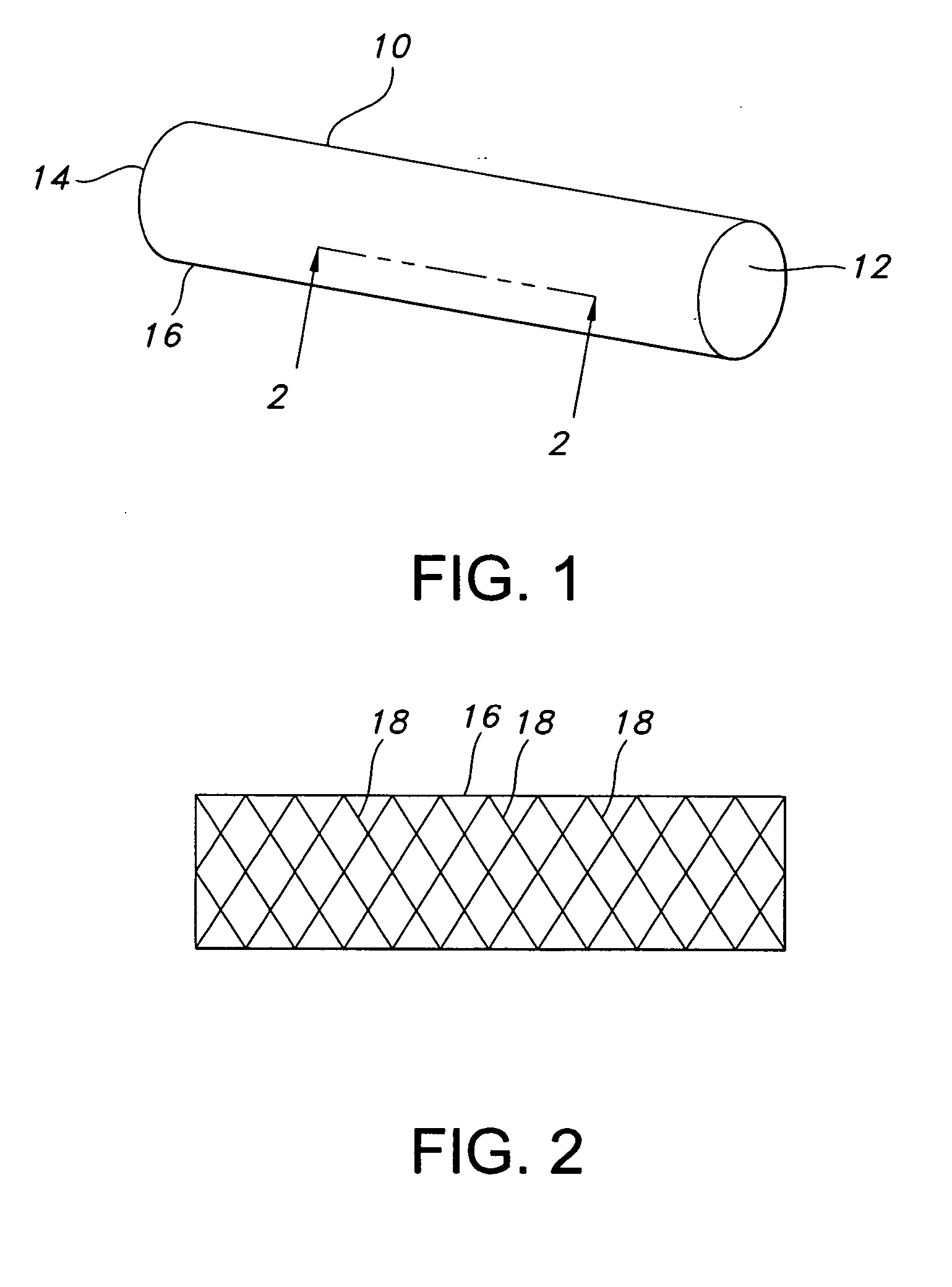

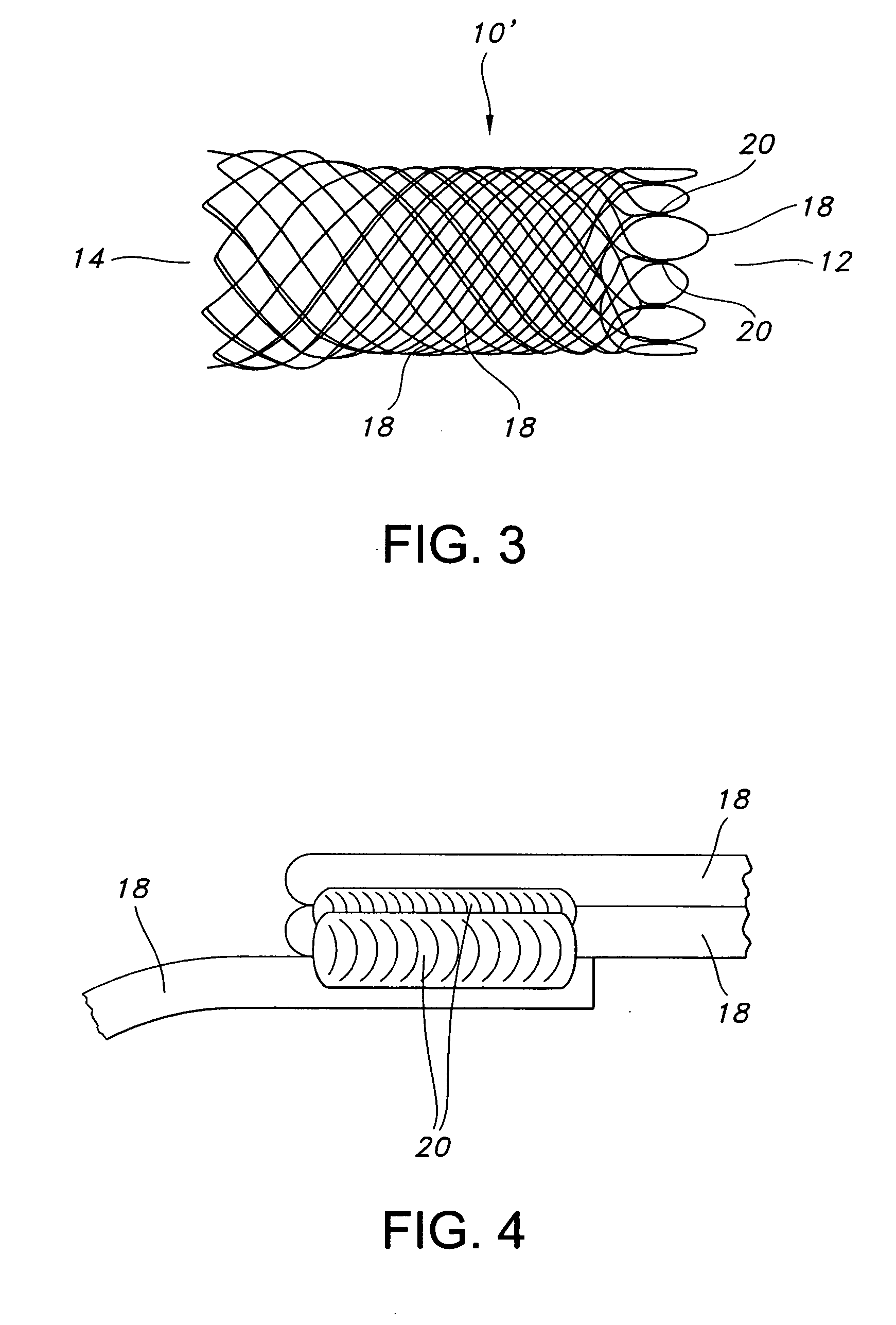

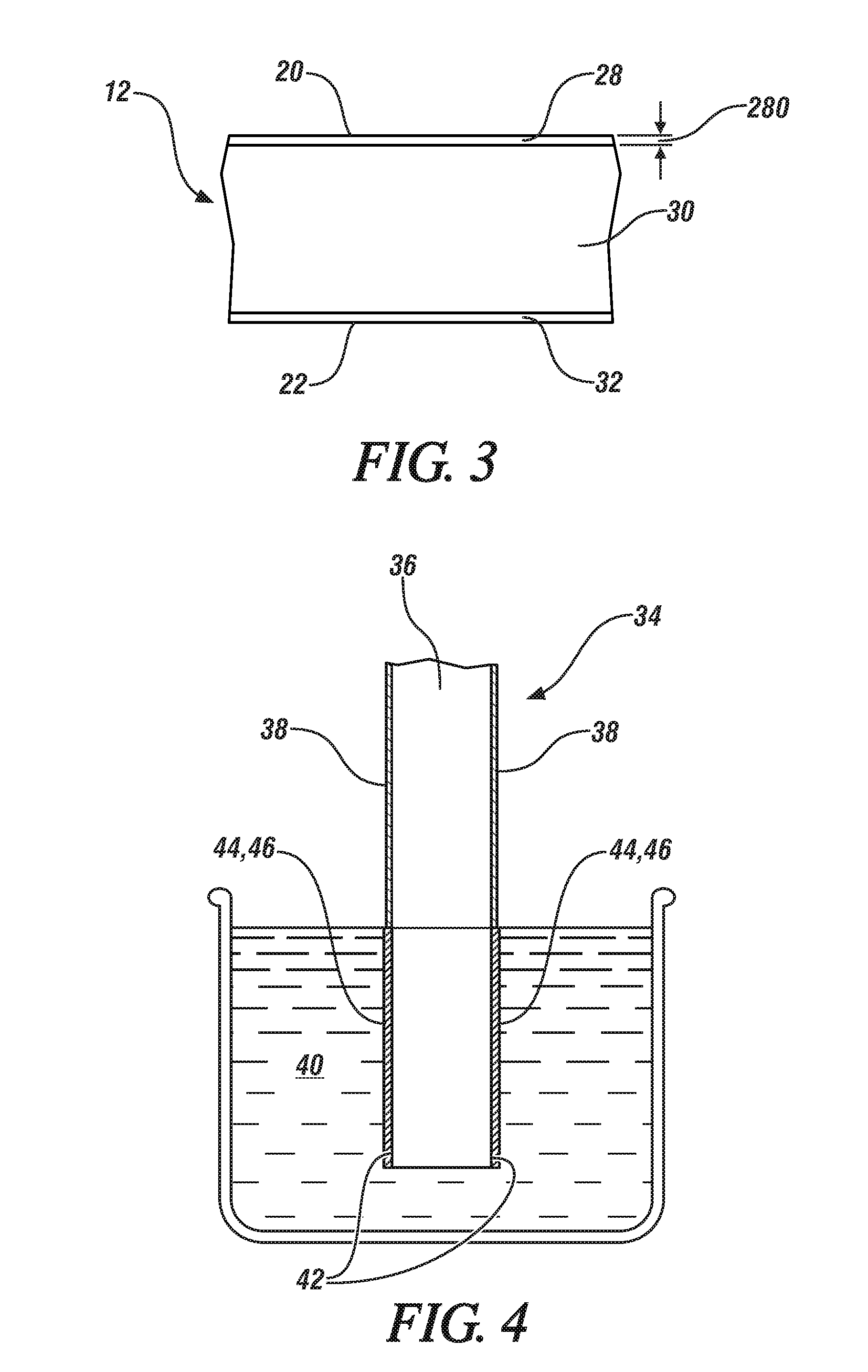

Method for reducing stent weld profiles and a stent having reduced weld

InactiveUS20050256563A1Easy to captureEasy to grabOrnamental textile articlesWelding/cutting auxillary devicesWire rodInsertion stent

A method for making an implantable stent includes the steps of (i) providing a plurality of elongate stent wires; (ii) forming said wires into a hollow tubular structure having opposed first and second open ends; (iii) terminating said wires at the second end; (iv) aligning the wires at the second end into a plurality of mated adjacent wires to define a plurality of abutting regions; (v) welding the mated adjacent wires to one and the other at the abutting regions to define a plurality of welds; and optionally (vi) chemically or electro-chemically removing a portion of the welds. The method may further include the steps of (a) extending at least one of the mated stent wires to provide an extended stent wire; (b) looping the extended stent wire so the extended end abuts a proximal pair of stent wires; and (c) welding the extended and looped wire to the proximal pair of wires. The step of looping may include the forming of the wire into a equilaterally arched loop having an apex, but not having other sharp bends.

Owner:BOSTON SCI SCIMED INC

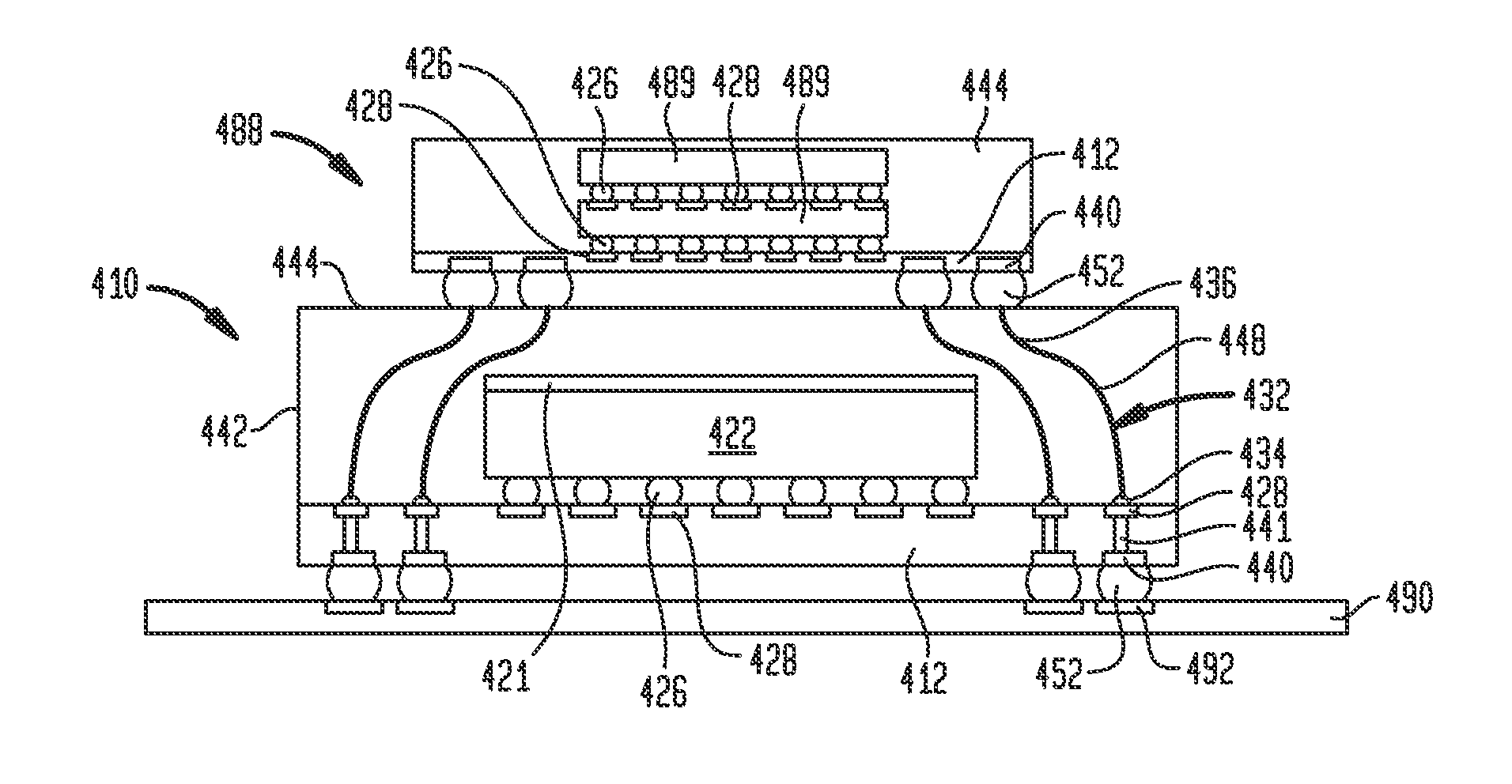

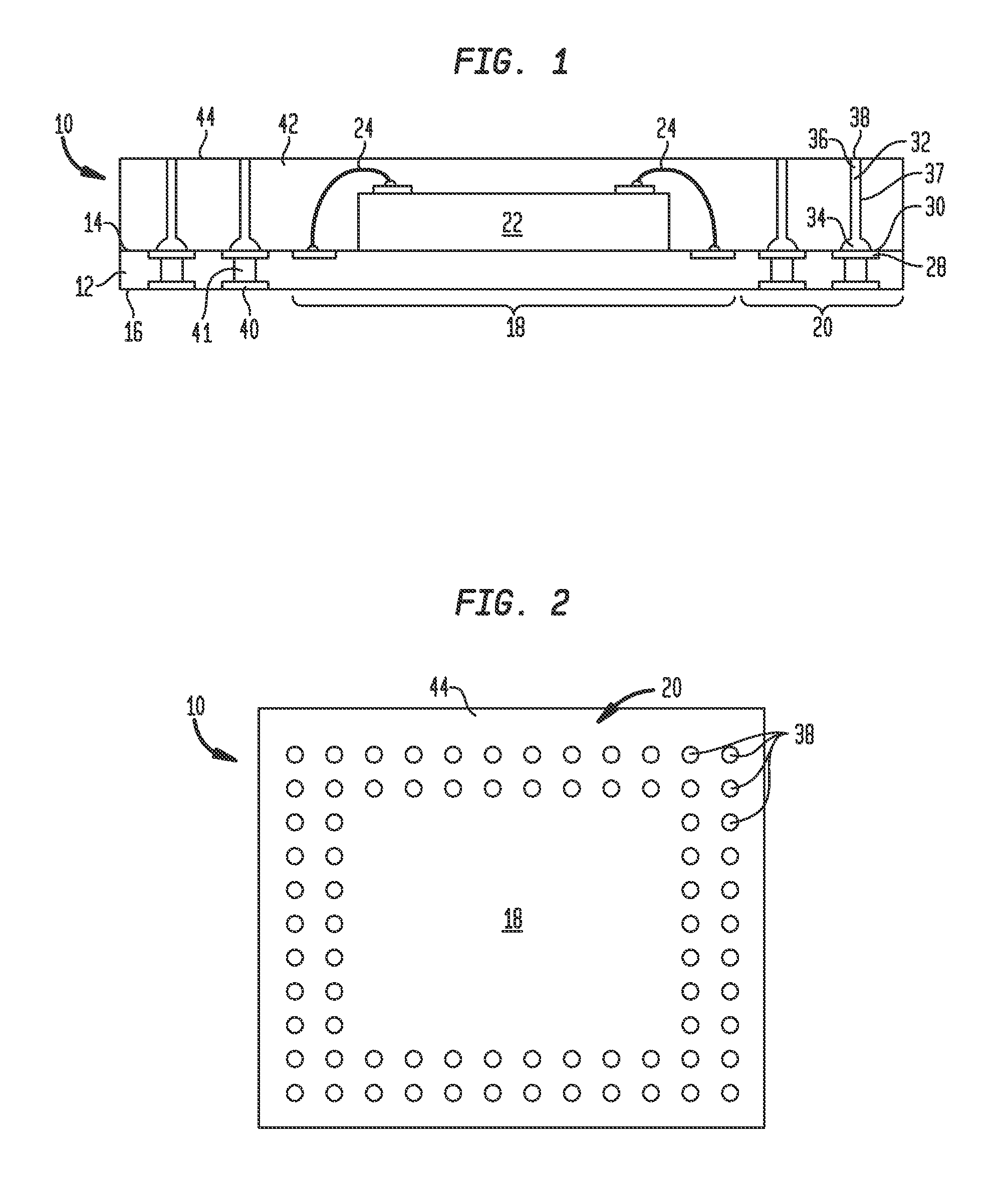

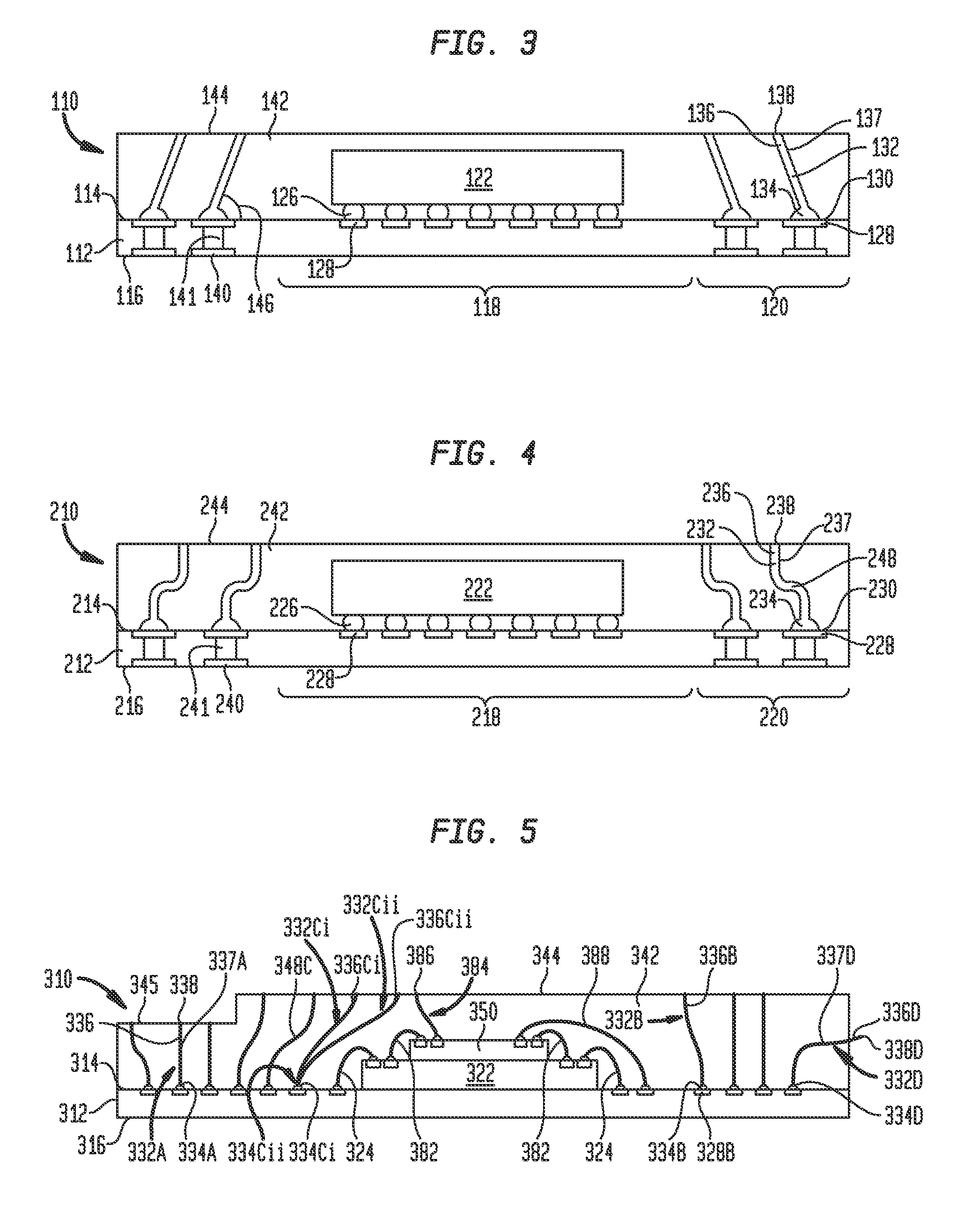

Method for package-on-package assembly with wire bonds to encapsulation surface

ActiveUS8372741B1Less thicknessSemiconductor/solid-state device detailsSolid-state devicesEdge surfaceEngineering

A microelectronic assembly includes a substrate having a first and second opposed surfaces. A microelectronic element overlies the first surface and first electrically conductive elements can be exposed at at least one of the first surface or second surfaces. Some of the first conductive elements are electrically connected to the microelectronic element. Wire bonds have bases joined to the conductive elements and end surfaces remote from the substrate and the bases, each wire bond defining an edge surface extending between the base and the end surface. An encapsulation layer can extend from the first surface and fill spaces between the wire bonds, such that the wire bonds can be separated by the encapsulation layer. Unencapsulated portions of the wire bonds are defined by at least portions of the end surfaces of the wire bonds that are uncovered by the encapsulation layer.

Owner:INVENSAS CORP

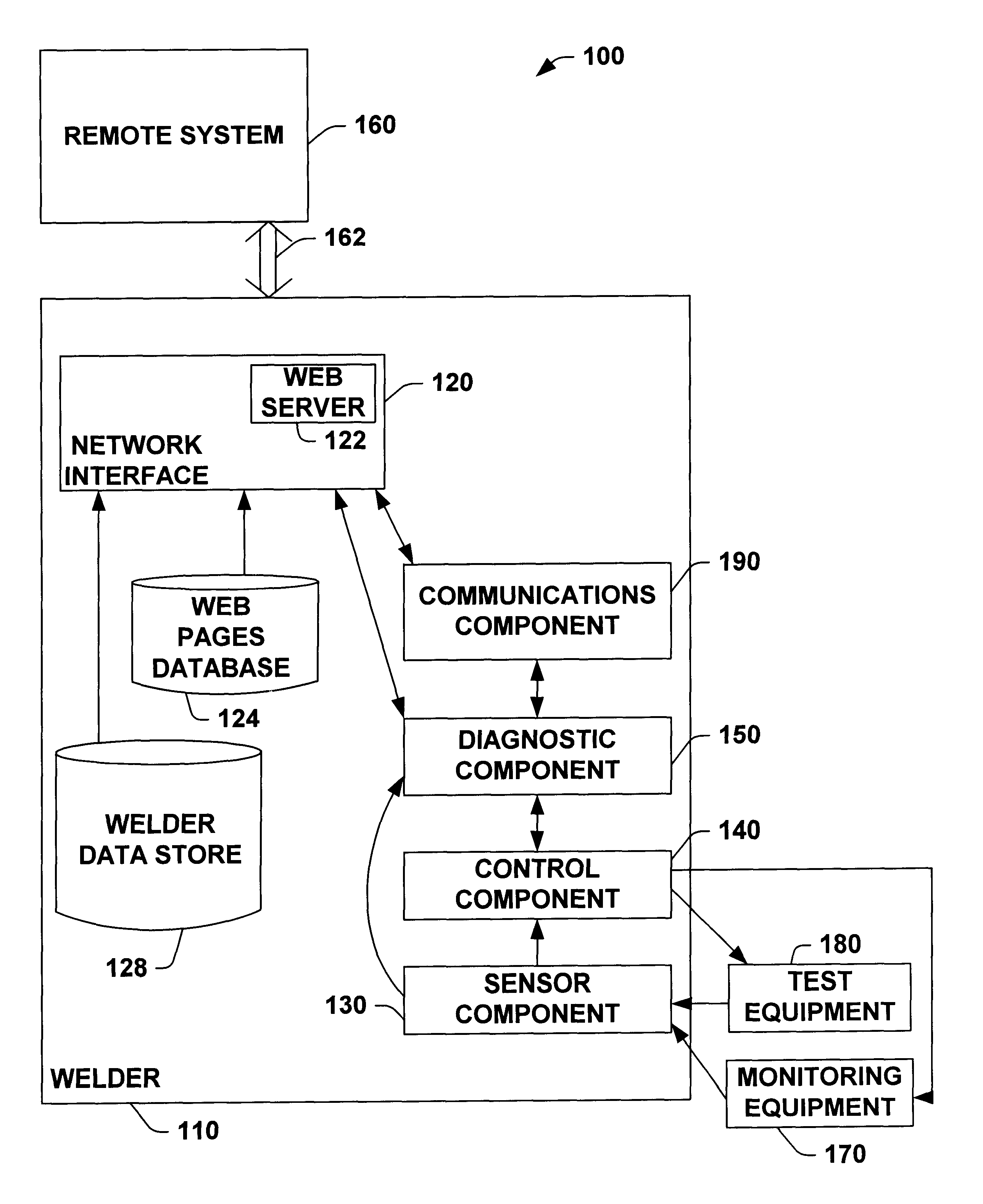

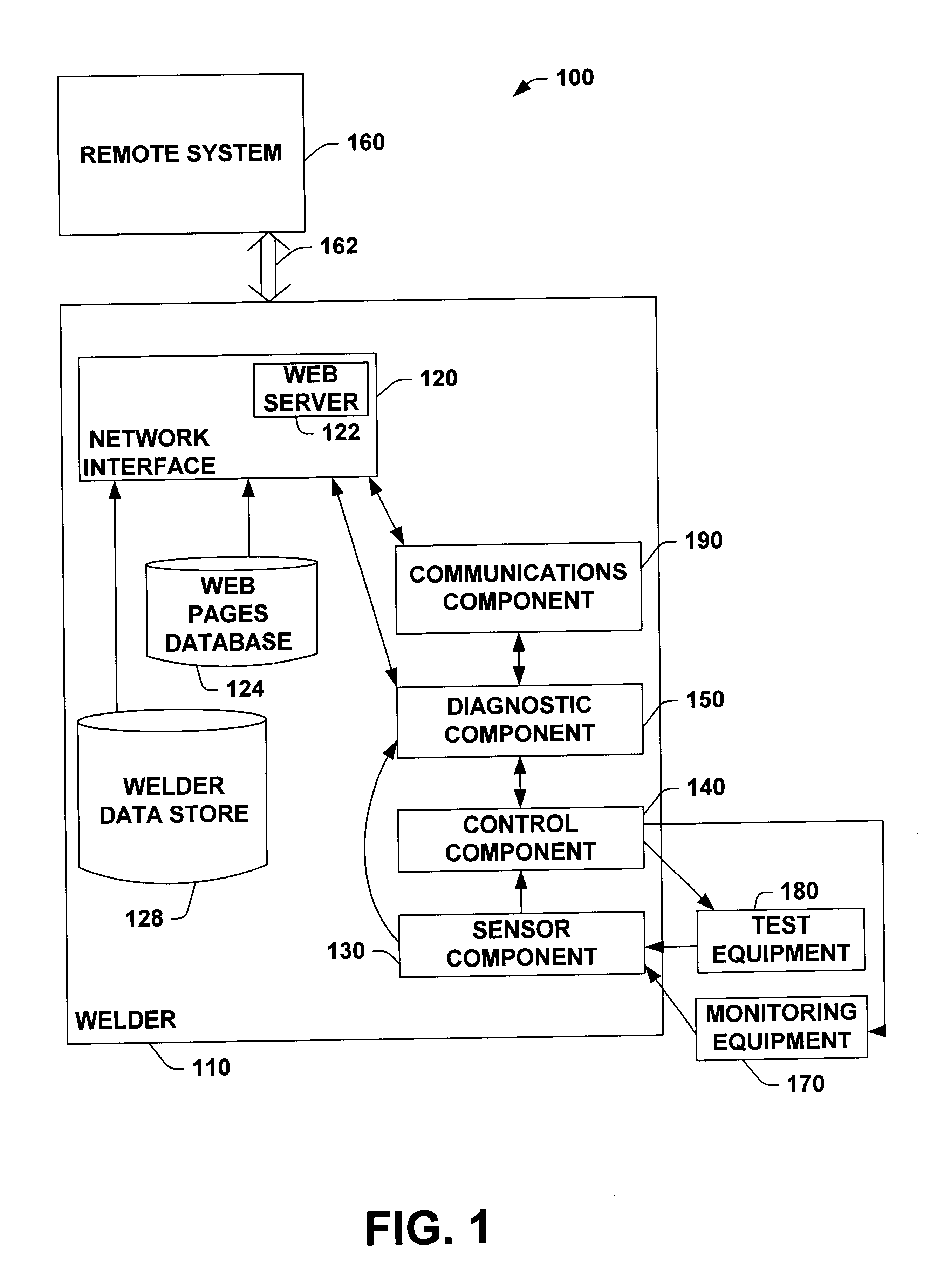

System and method for facilitating welding system diagnostics

InactiveUS6795778B2Facilitate welding diagnosticsBatteries circuit arrangementsArc welding apparatusRemote systemSmart technology

A system and method for facilitating welding system diagnostics is provided. The invention includes a welder, a local system, a remote system, and / or an alarm component. The invention further provides for receiving sensor input(s), performing test sequence(s) based, at least in part, upon the sensor input(s) and / or performing internal diagnostics. The invention further provides for determining a health status of the welder and communicating the health status of the welder to the local system, the remote system and / or the alarm component. The health status of the welder can include welder alarm(s) and / or fault(s). Information regarding the health status of the welder can be sent by telephone, voicemail, e-mail and / or beeper. The welder can communicate with the local system and / or remote system to schedule maintenance. The invention further provides for a expert component to facilitate welding diagnostics based, at least in part, upon the health status of the welder, welder data, an expert data store, a local service support data store, a remote expert data store and / or a remote service support data store. The expert component can employ various artificial intelligence technique(s) (e.g., Bayesian model, probability tree network, fuzzy logic and / or neural network) to facilitate welding diagnostics based, at least in part, upon the health status received from the welder. The expert component can adaptively modify its modeling technique(s) based upon historical success (e.g., learn from success of previous welding diagnostics). The invention further provides for the welder, local system and / or remote system to initiate corrective action, at least temporarily, based, at least in part, upon the health status of the welder.

Owner:LINCOLN GLOBAL INC

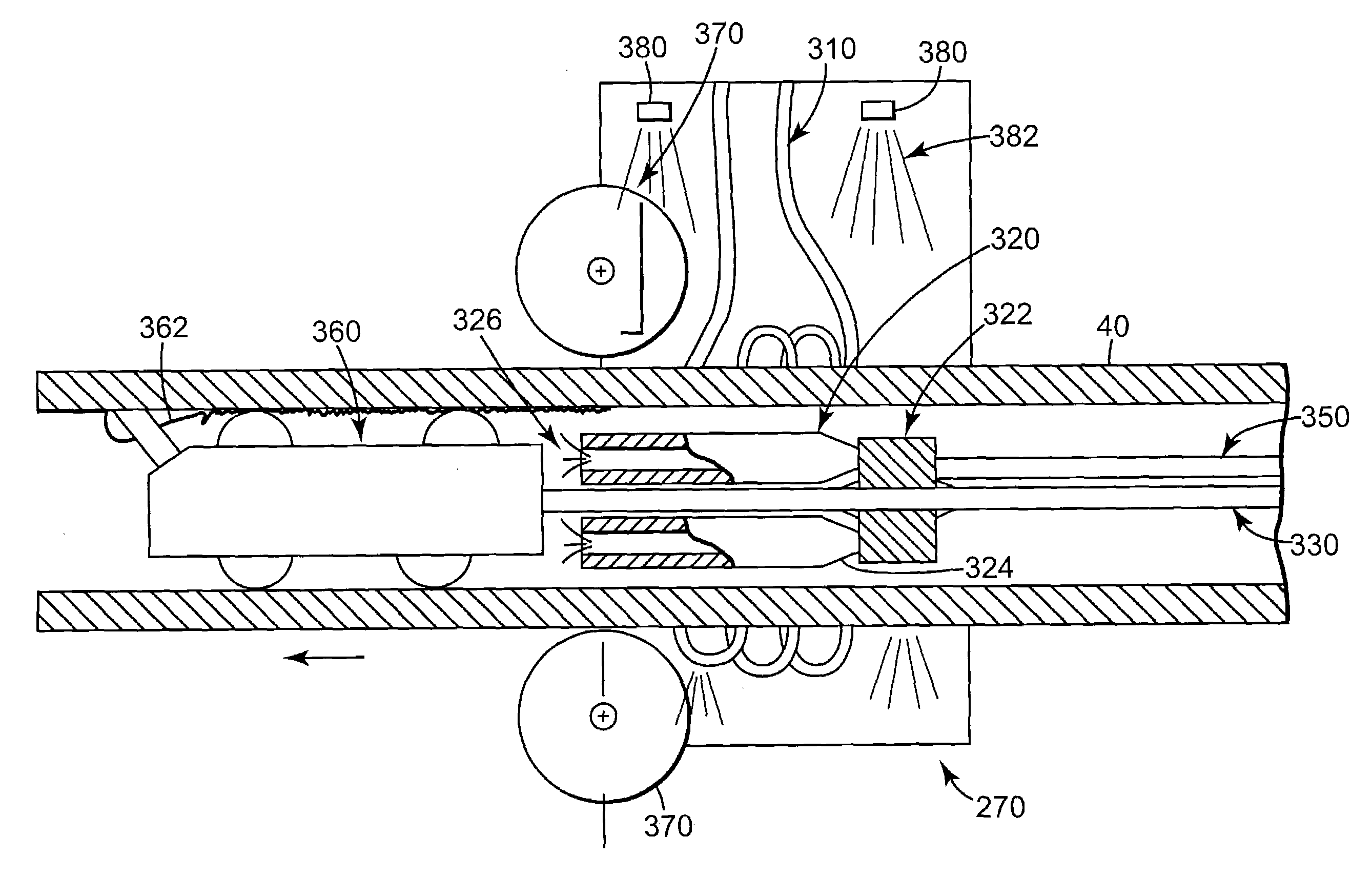

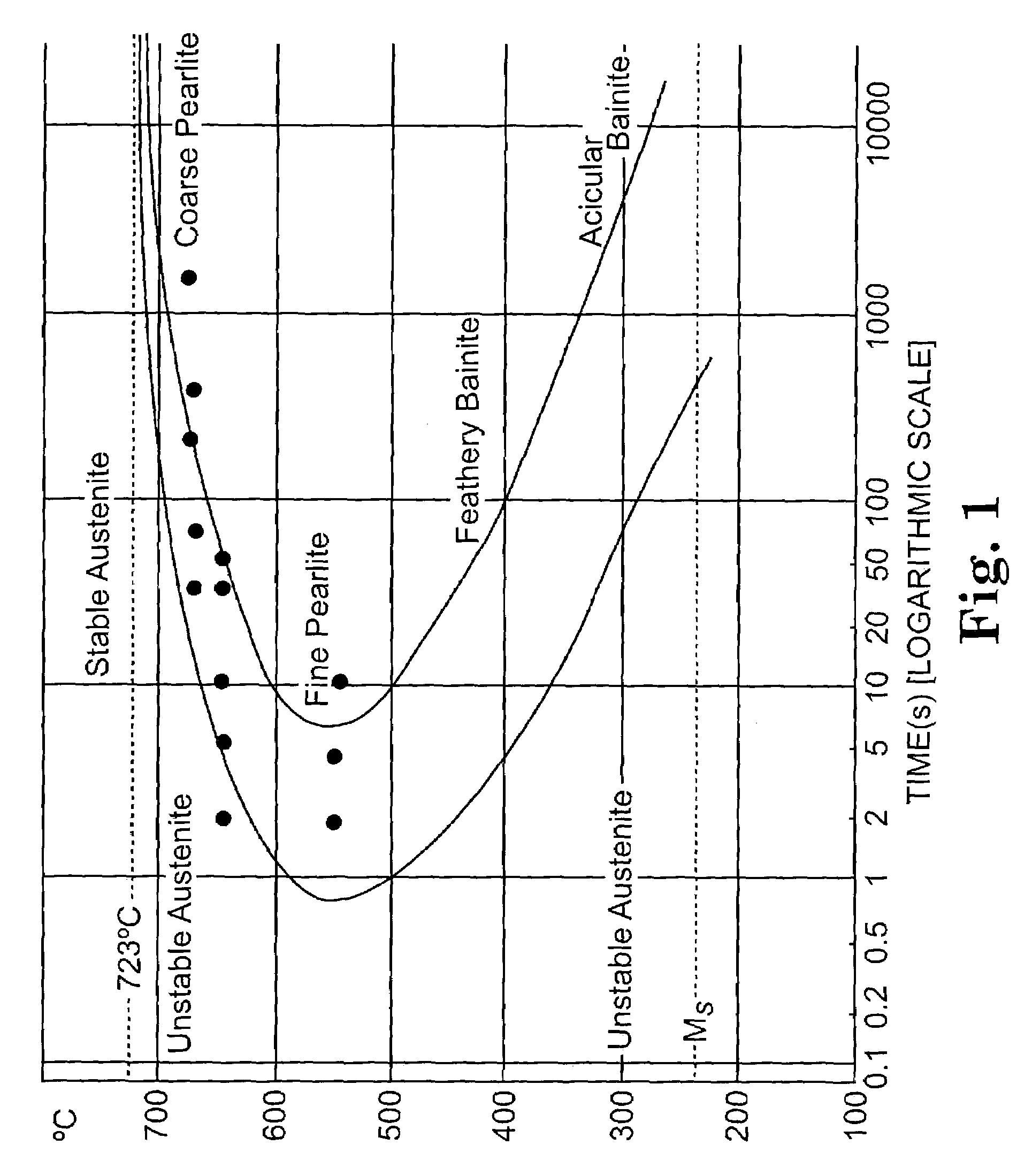

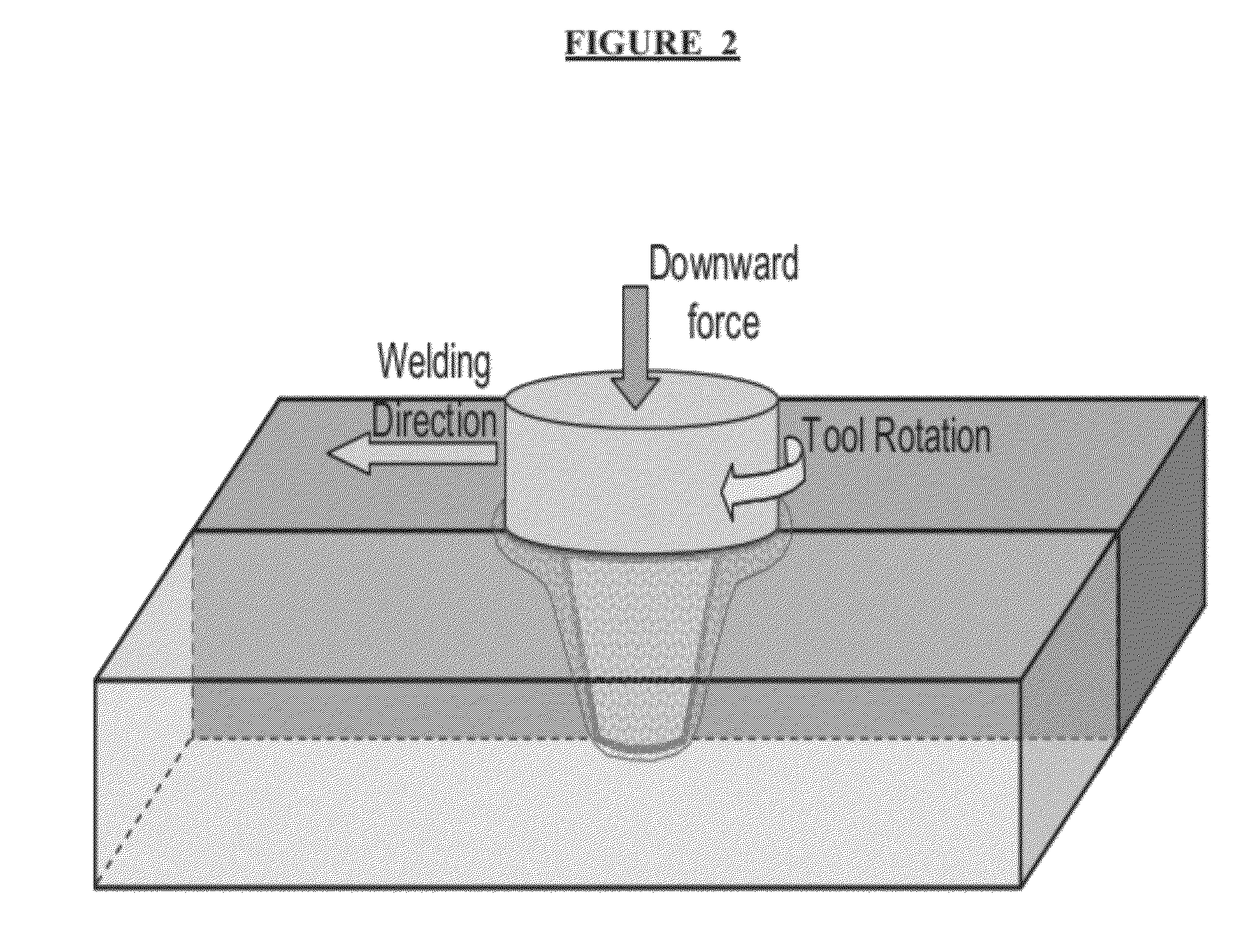

Seam-welded metal pipe and method of making the same without seam anneal

InactiveUS7032809B1Efficient processingEliminates annealing stepArc welding apparatusFurnace typesSufficient timeWeld seam

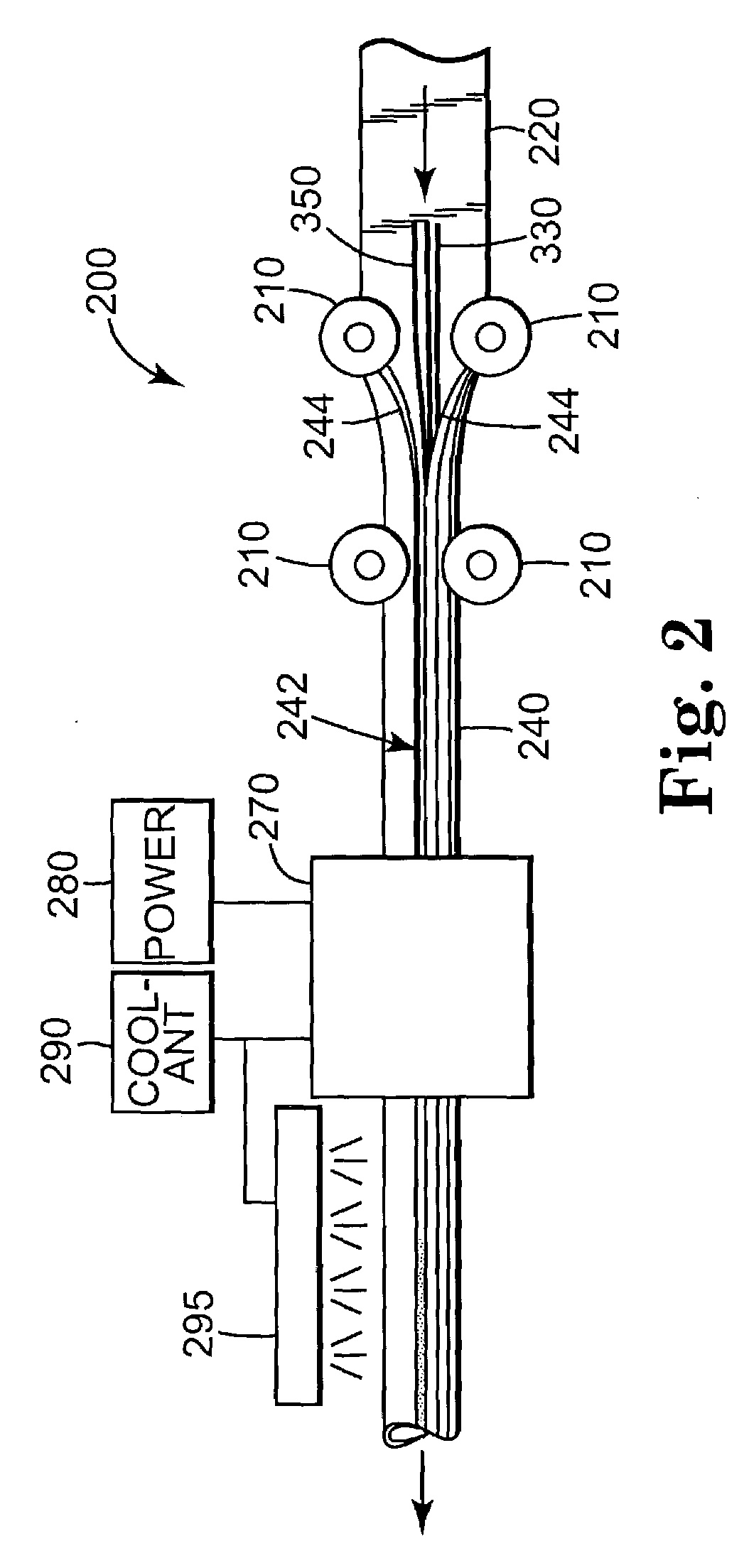

An apparatus and method for making a seam-welded steel pipe free of untempered martensite without seam anneal. The method includes selecting a steel containing a carbon concentration below a predetermined level, for example, 0.14% or 0.12% by weight. The method also includes flooding both outside and inside of the strip with a coolant while the weld seam is being formed, and continuing to immerse the welded strip for a sufficient time after the weld seam is formed to prevent the formation of untempered martensite. The apparatus includes a heater capable of heating the strip to a temperature sufficient to form a welded seam, a cooling module configured to supply a coolant to the welded seam both inside and outside of the strip as the weld seam is being formed, and another cooling module configured to immerse the welded strip in a coolant after the weld seam is formed for a sufficient length of time to prevent the formation of untempered martensite.

Owner:STEEL VENTURES

Automatic and semi-automatic welding systems and methods

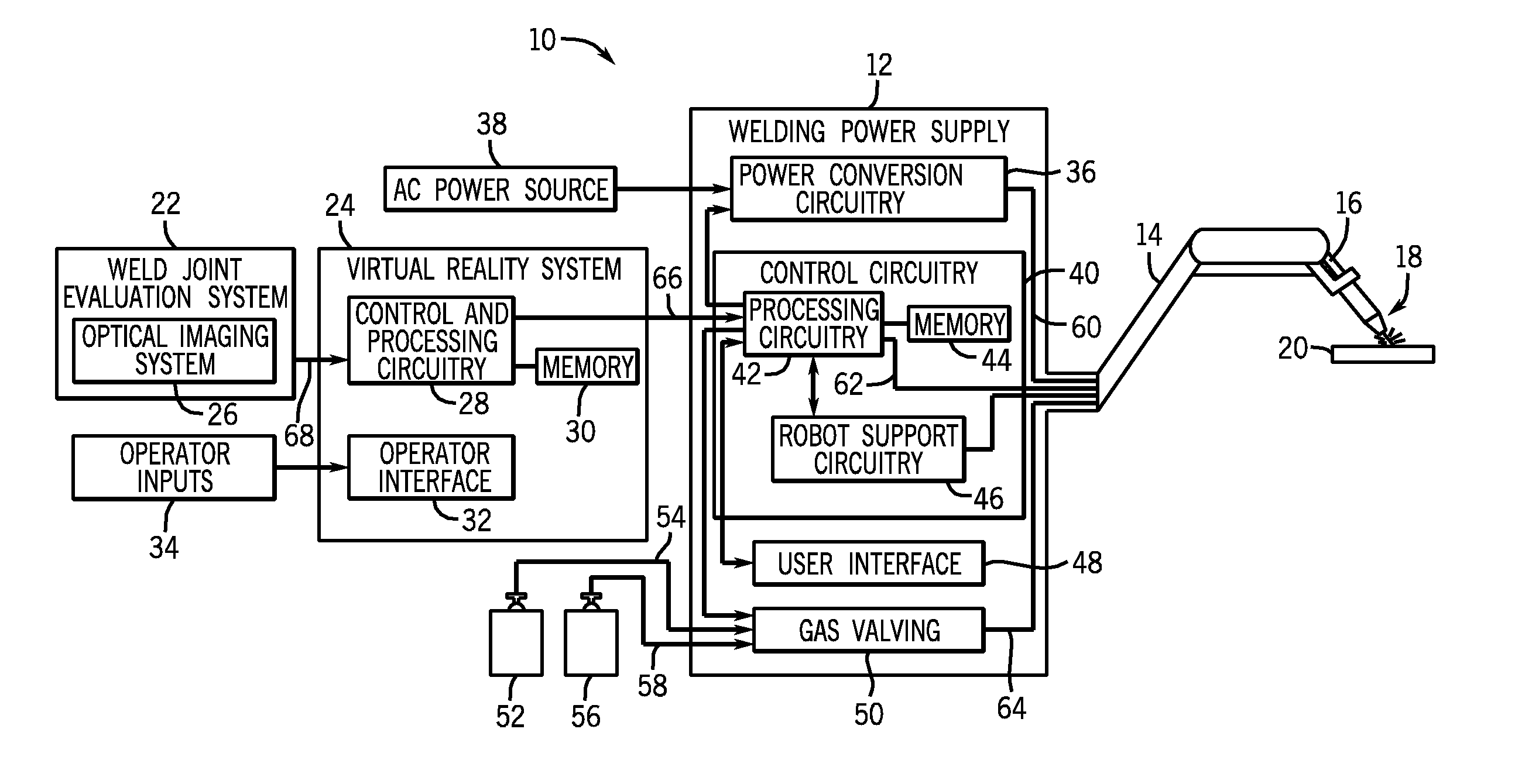

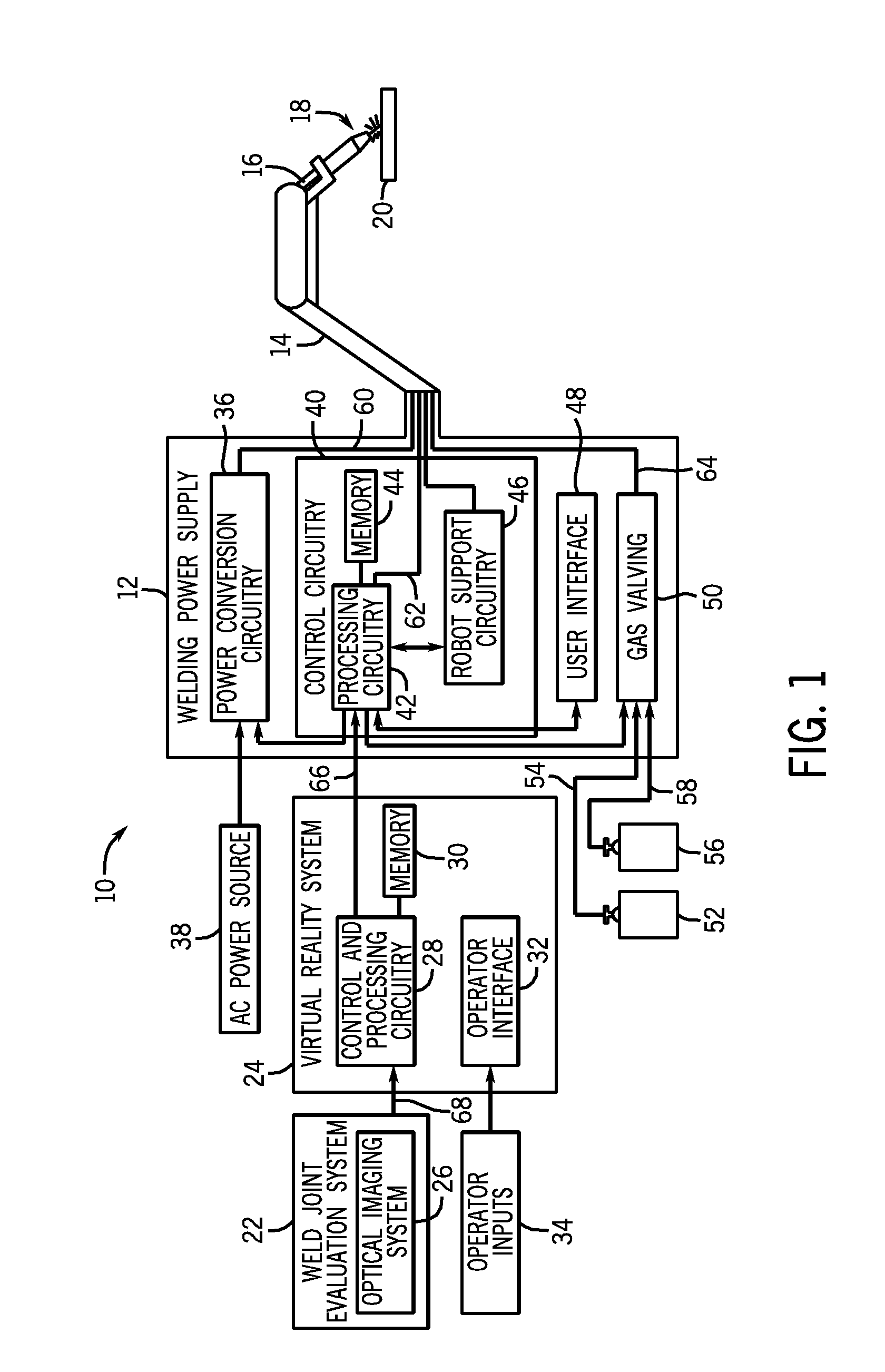

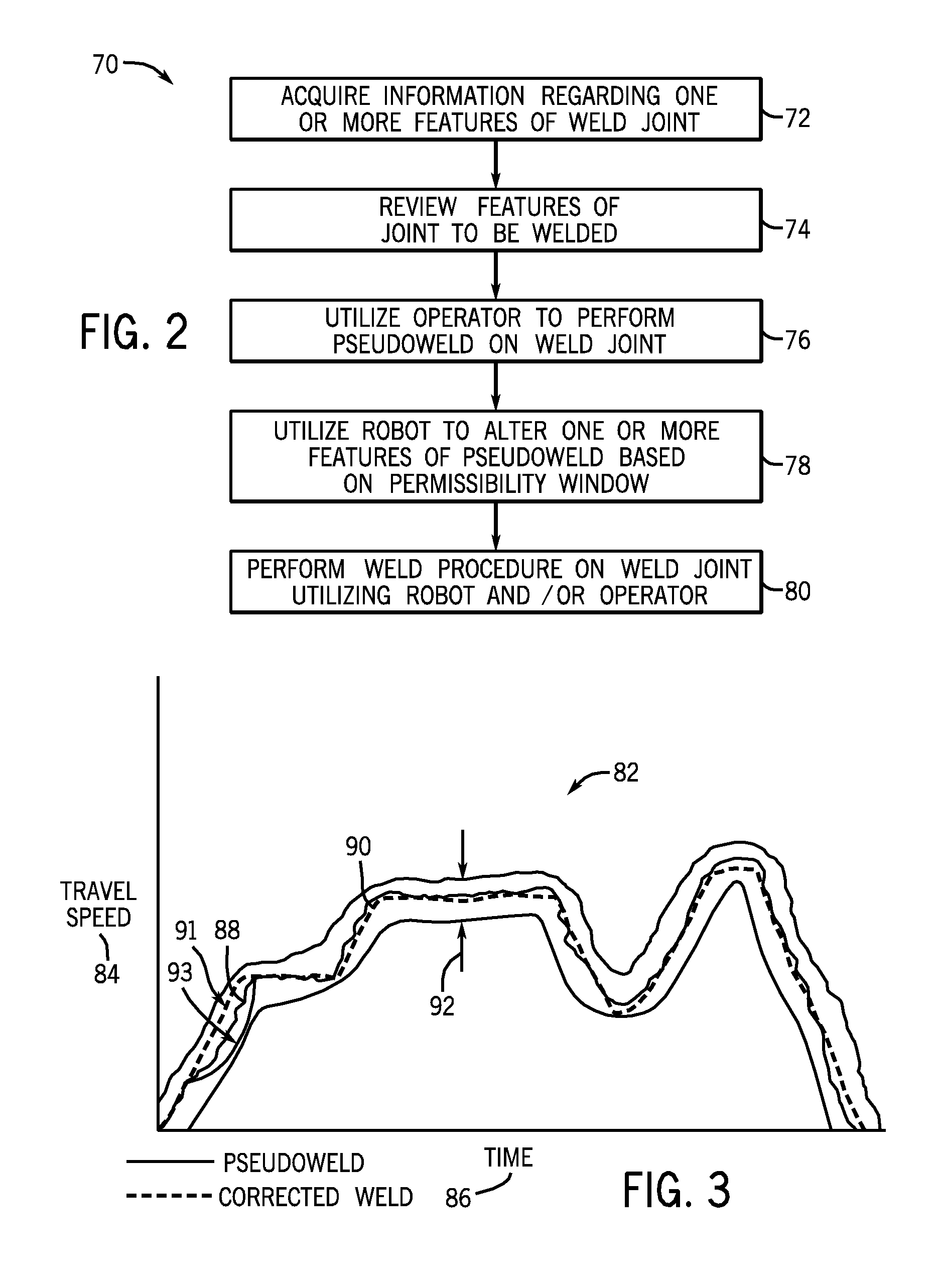

Methods and devices for control for an automated welding system are provided. Disclosed control methods may include receiving a data set including one or more features of a joint to be welded and receiving a weld procedure for the joint to be welded. The weld procedure for the joint is determined based on a sample virtual weld performed by an operator, a stored procedure developed for a substantially similar weld joint, or a combination thereof. The method may further include determining one or more desired changes to the weld procedure based on the received features of the joint to be welded and generating an updated weld procedure by altering one or more parameters of the received weld procedure in accordance with the one or more desired changes, wherein the one or more parameters are included within a predetermined allowable data set.

Owner:ILLINOIS TOOL WORKS INC

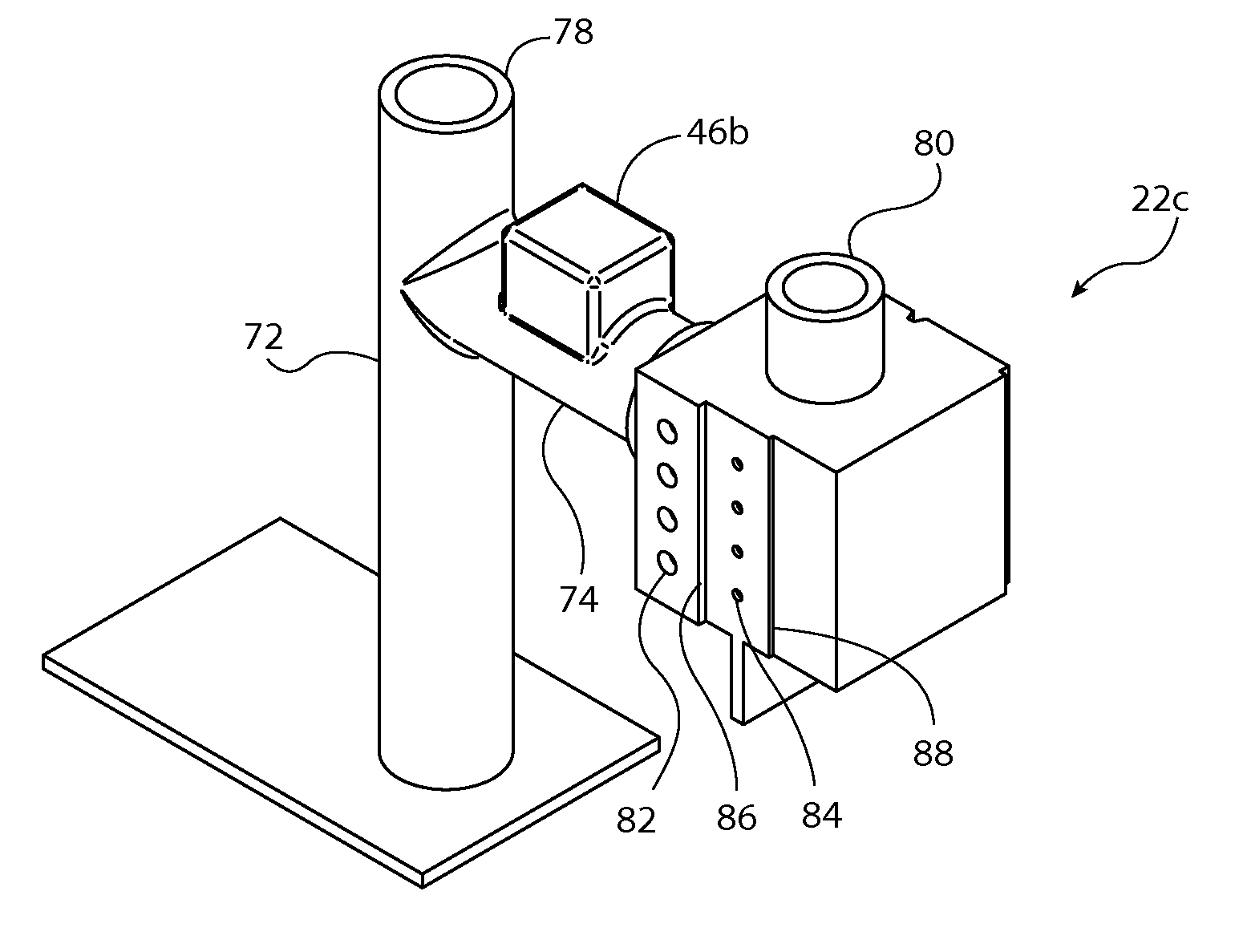

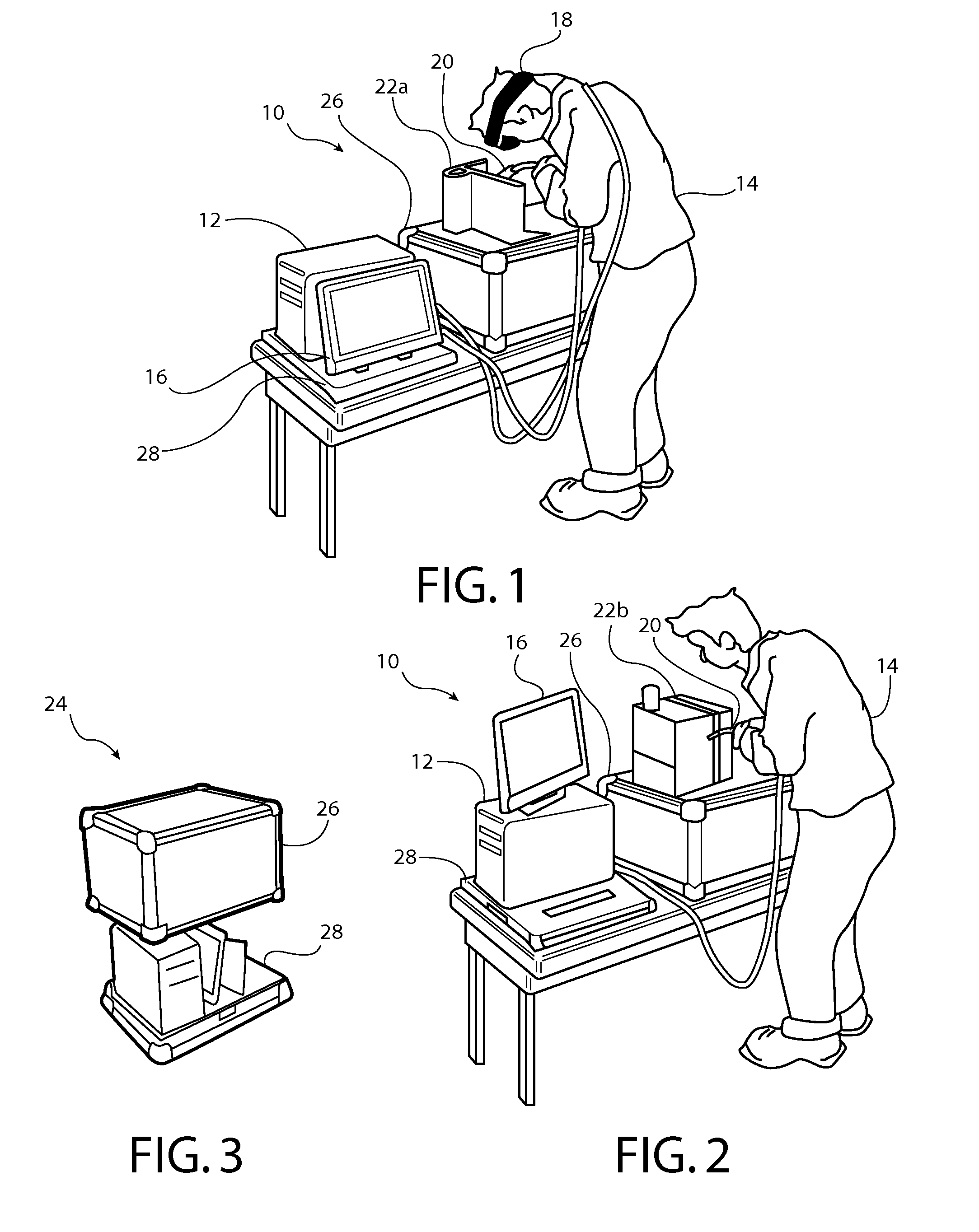

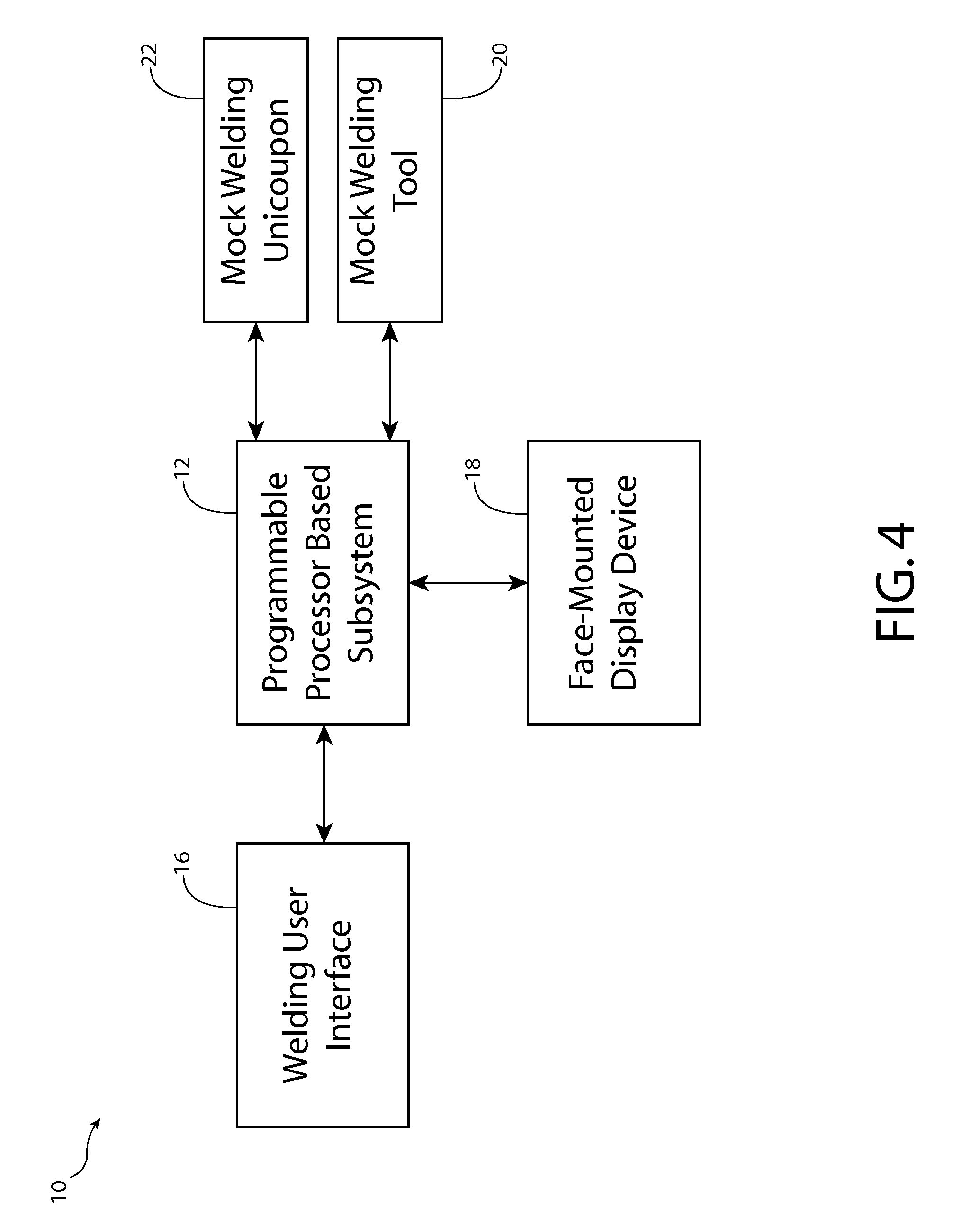

Unicoupon for virtual reality welding simulator

A mock welding unicoupon for a virtual welding system includes a first exterior surface and a second exterior surface perpendicular to the first exterior surface. The first exterior surface and the second exterior surface together provide a plurality of grooves configured for simulation of a plurality of different types groove welds on the mock welding unicoupon. A curved exterior surface is configured for simulation of a pipe fillet weld on the mock welding unicoupon. A magnet source is configured to generate a magnetic field around the mock welding unicoupon for tracking movements of a mock welding tool with respect to the mock welding unicoupon.

Owner:LINCOLN GLOBAL INC

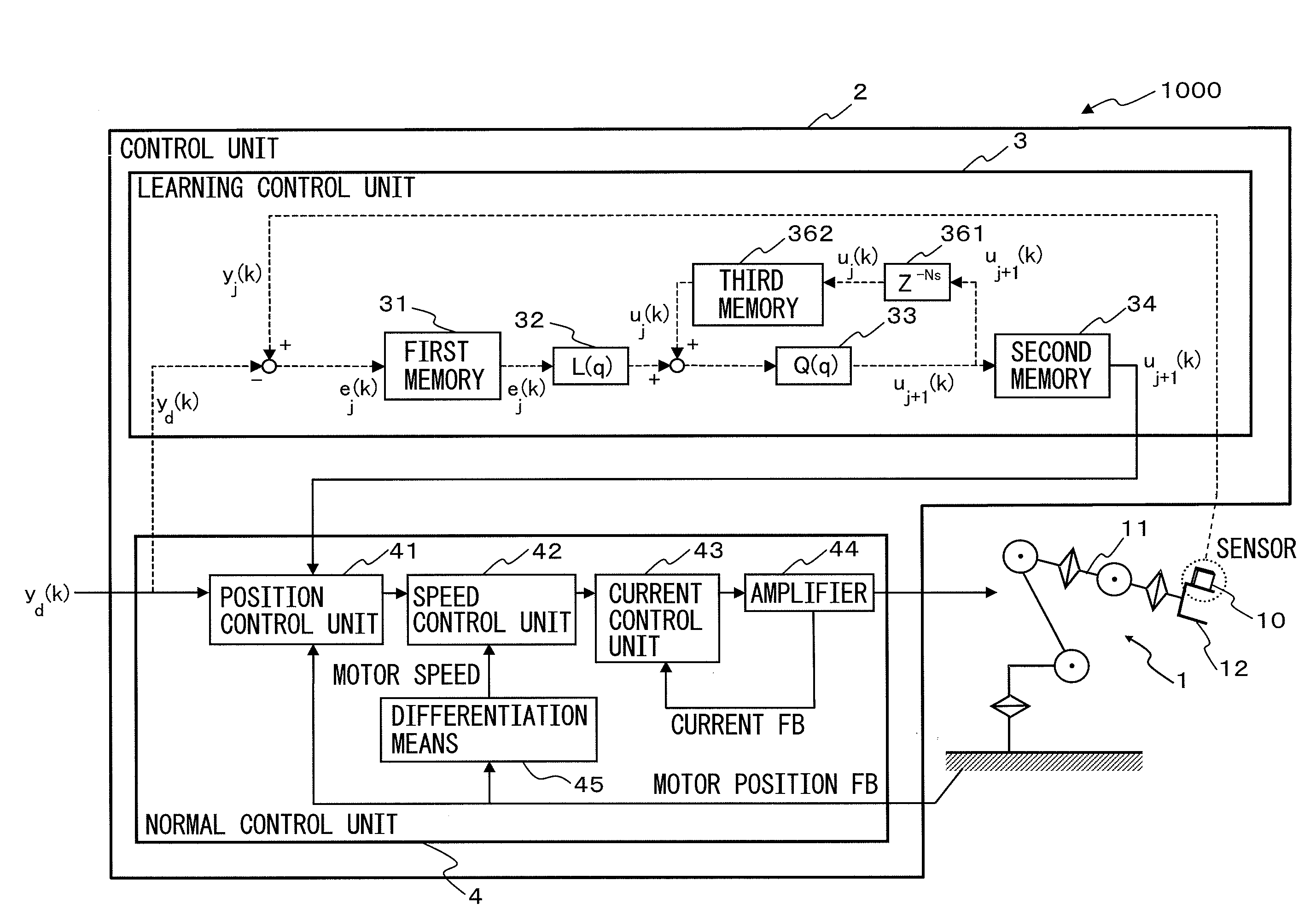

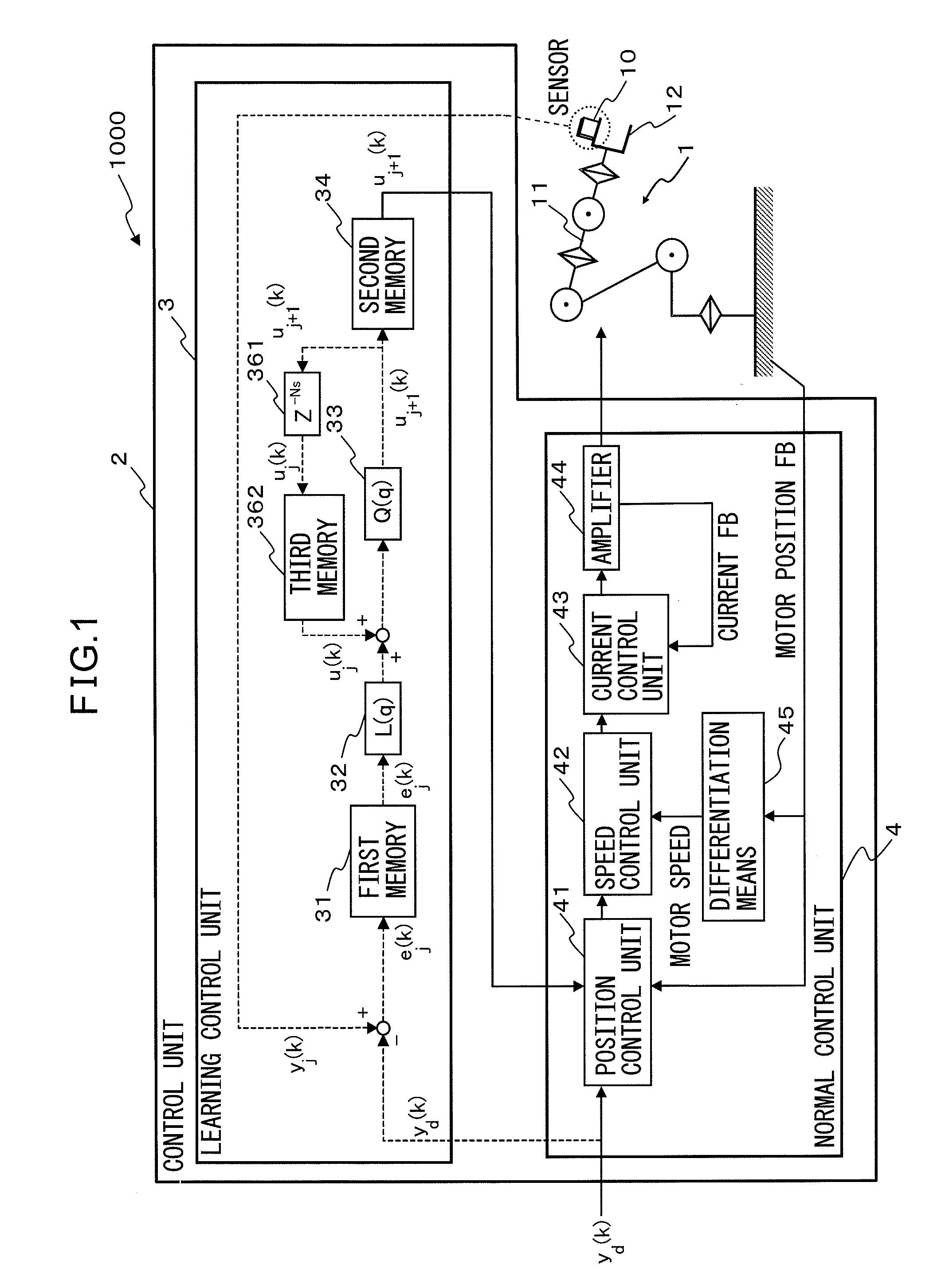

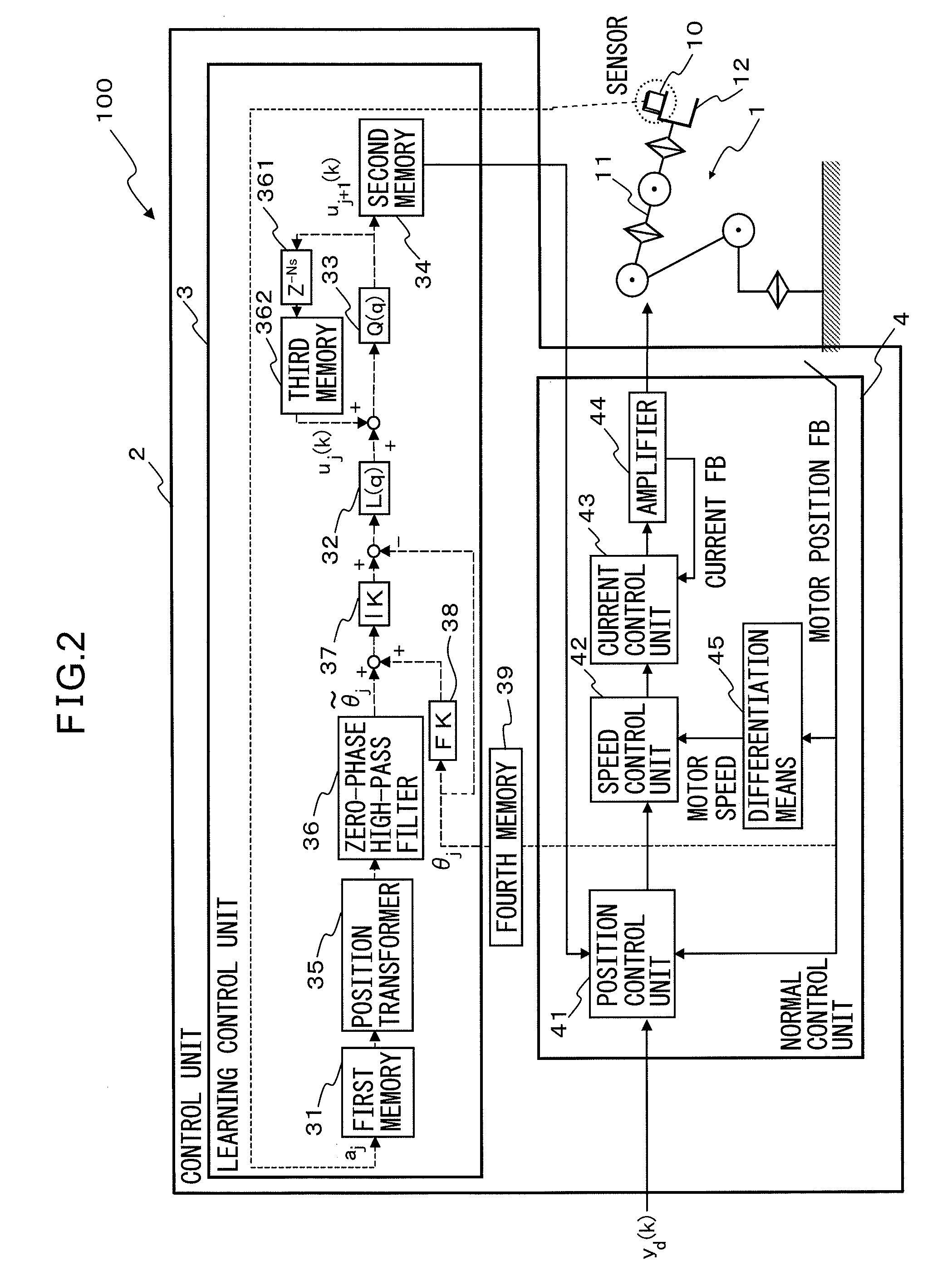

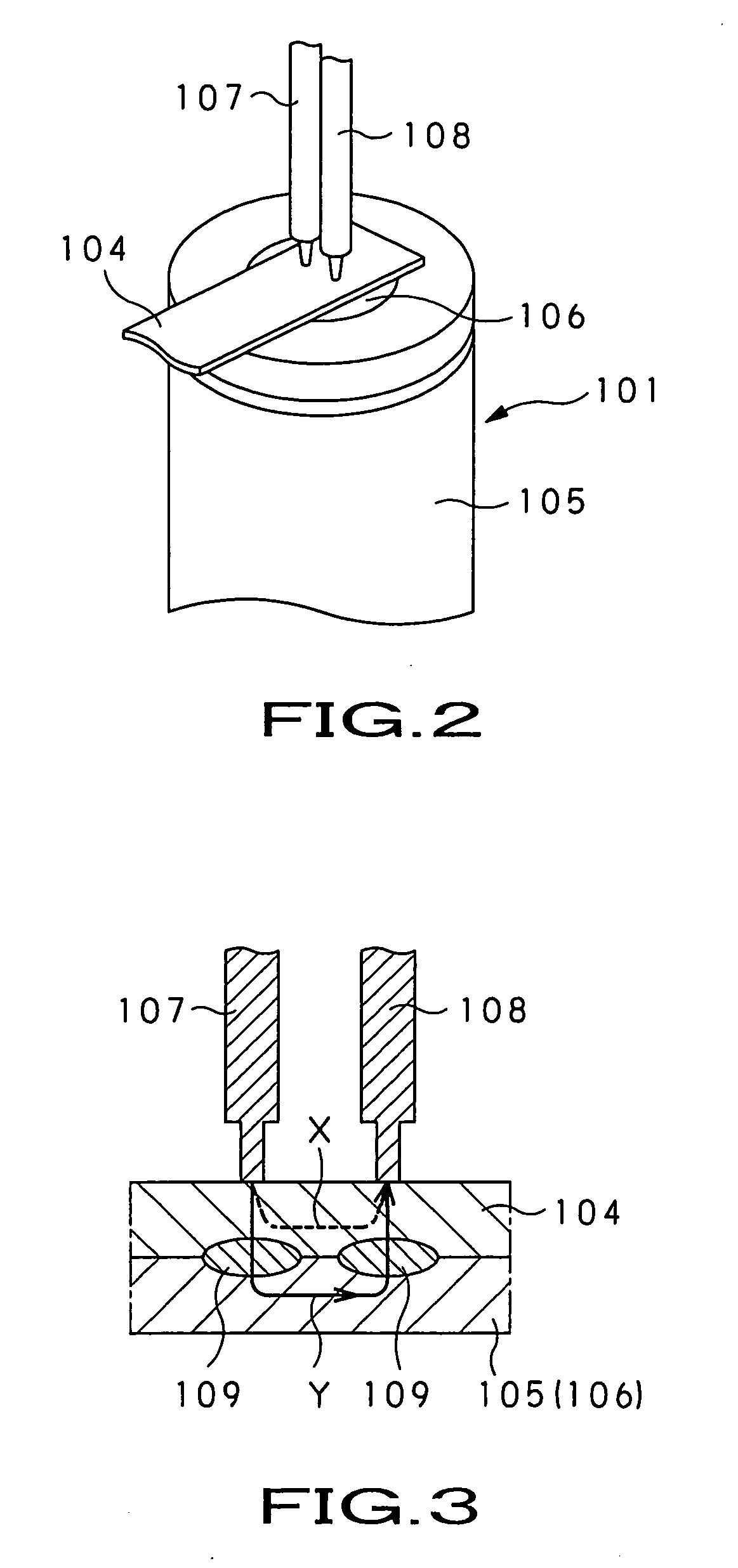

Robot and spot welding robot with learning control function

ActiveUS20120296471A1Improve accuracyImprove securityProgramme-controlled manipulatorComputer controlControl objectiveNormal control

A robot (100) has a robot mechanism unit (1) having a sensor (10) and a control unit (2), and the control unit (2) includes a normal control unit (4) that controls the operation of the robot mechanism unit, and a learning control unit (3) that, when the robot mechanism unit (1) is operated by a speed command that is given by multiplying a teaching speed designated in a task program by a speed change ratio, performs learning to calculate, from a detection result by the sensor (10), a learning correction amount for making the trajectory or position of the control target in the robot mechanism unit (1) approach the target trajectory or target position, or for reducing the vibration of the control target, and performs processes so that the control target position of the robot mechanism unit (1) moves along a fixed trajectory regardless of the speed change ratio.

Owner:FANUC LTD

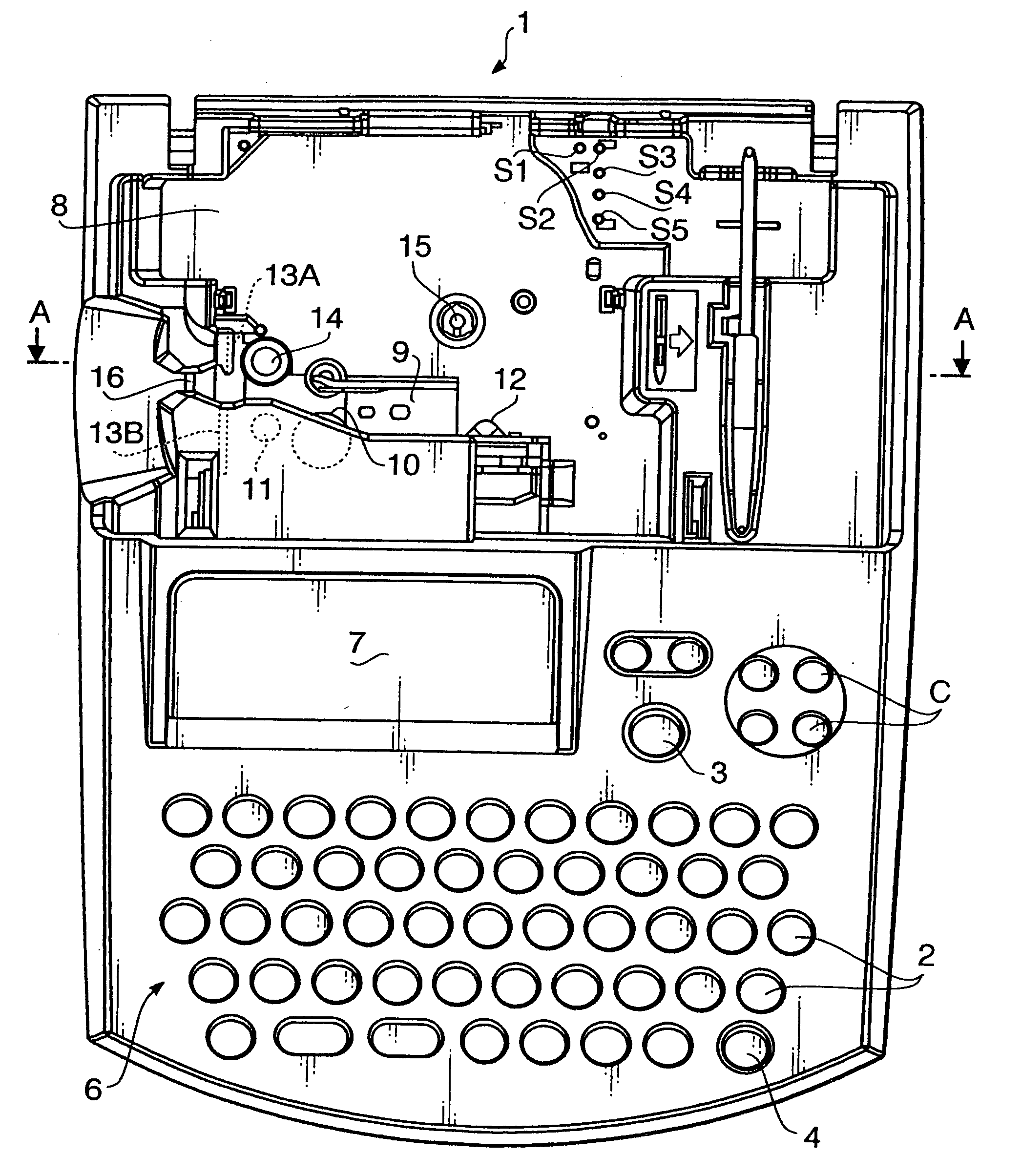

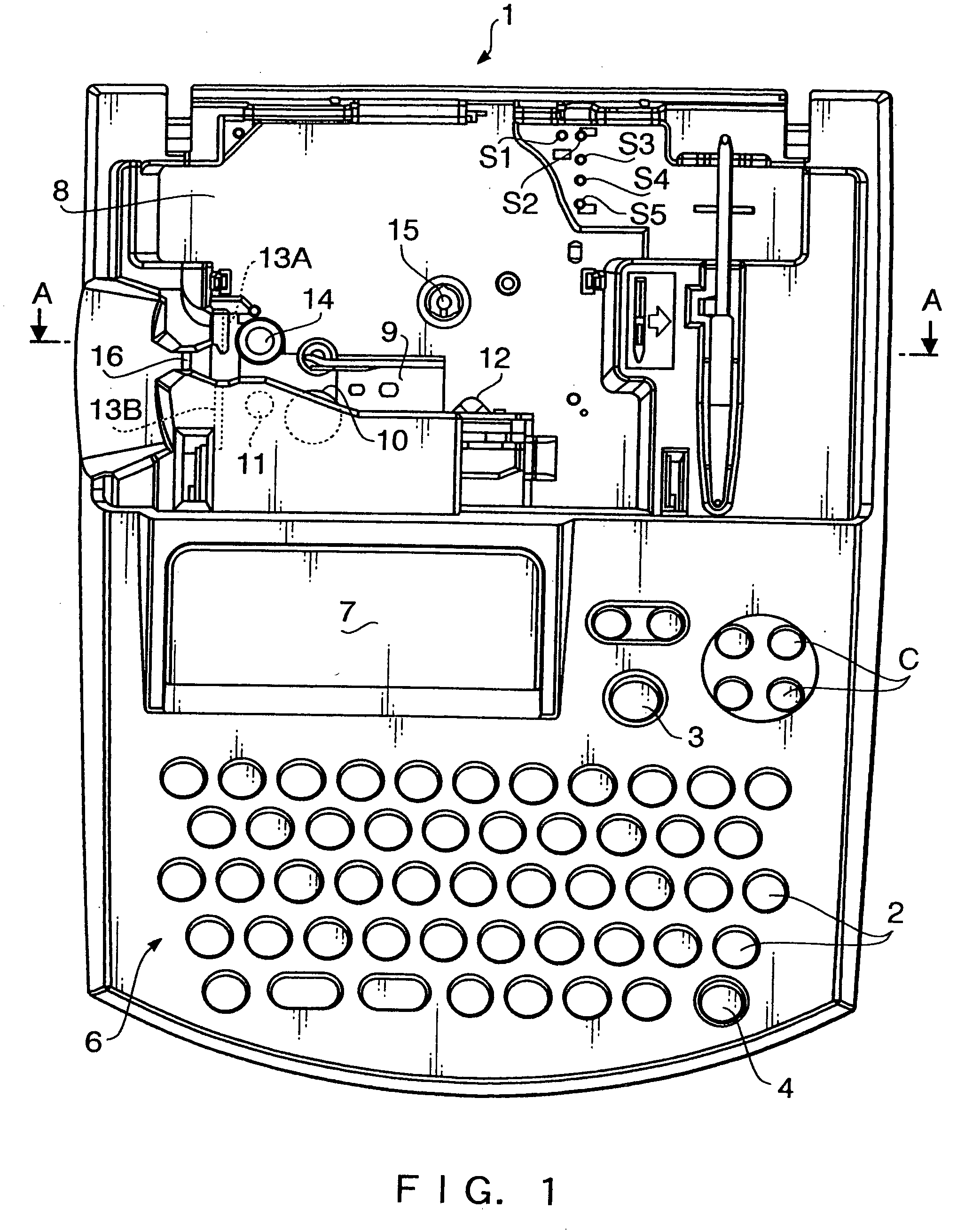

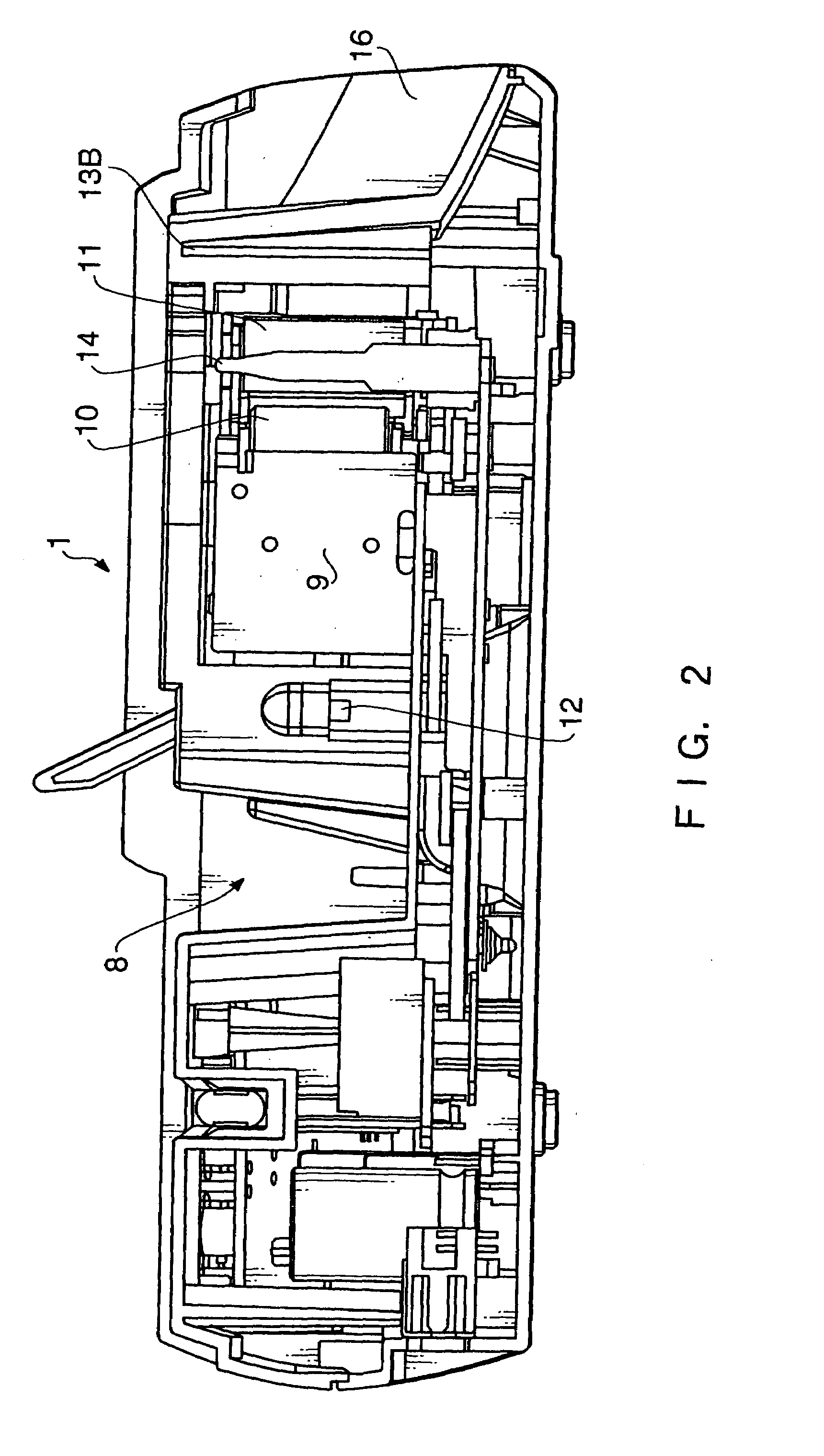

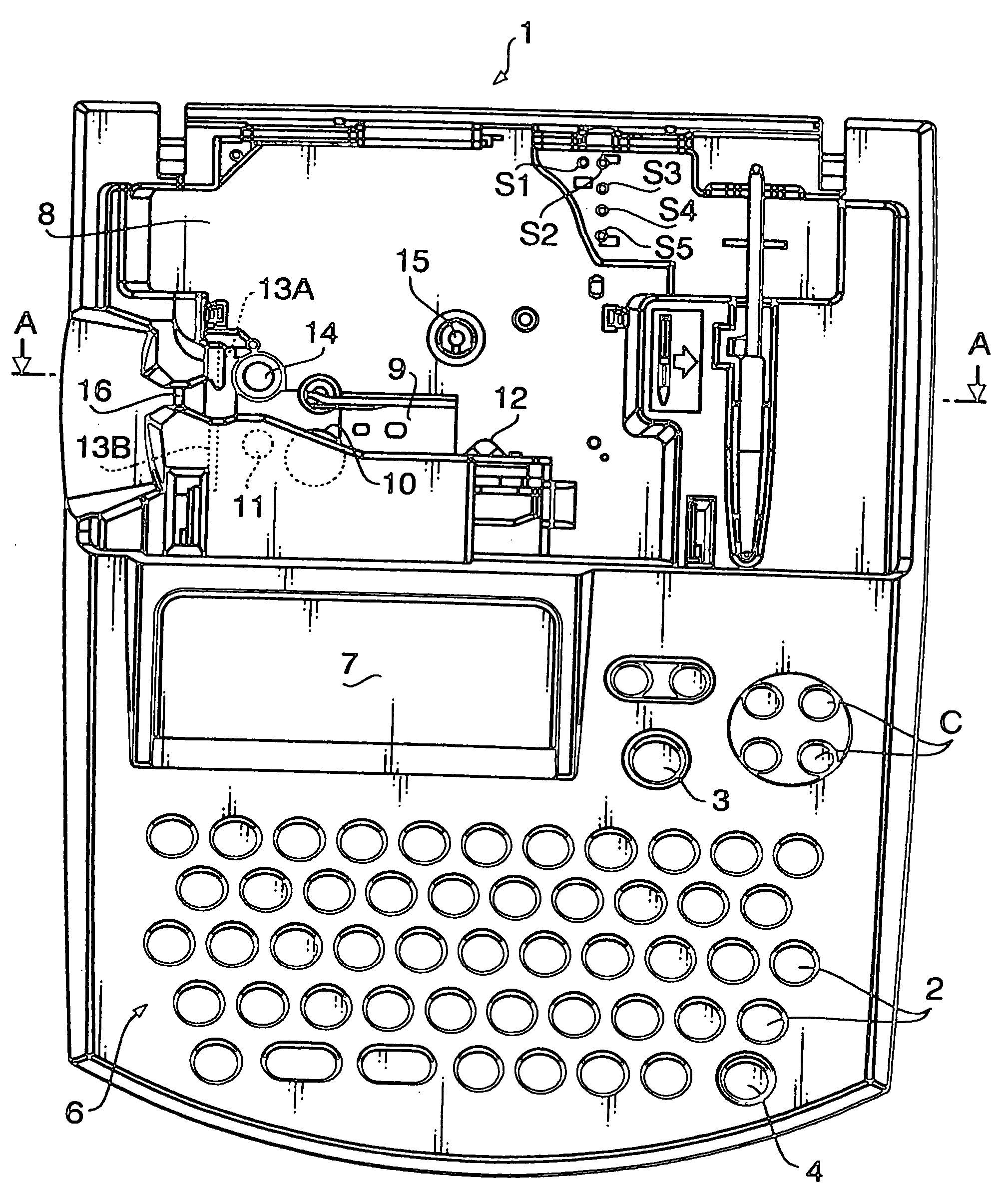

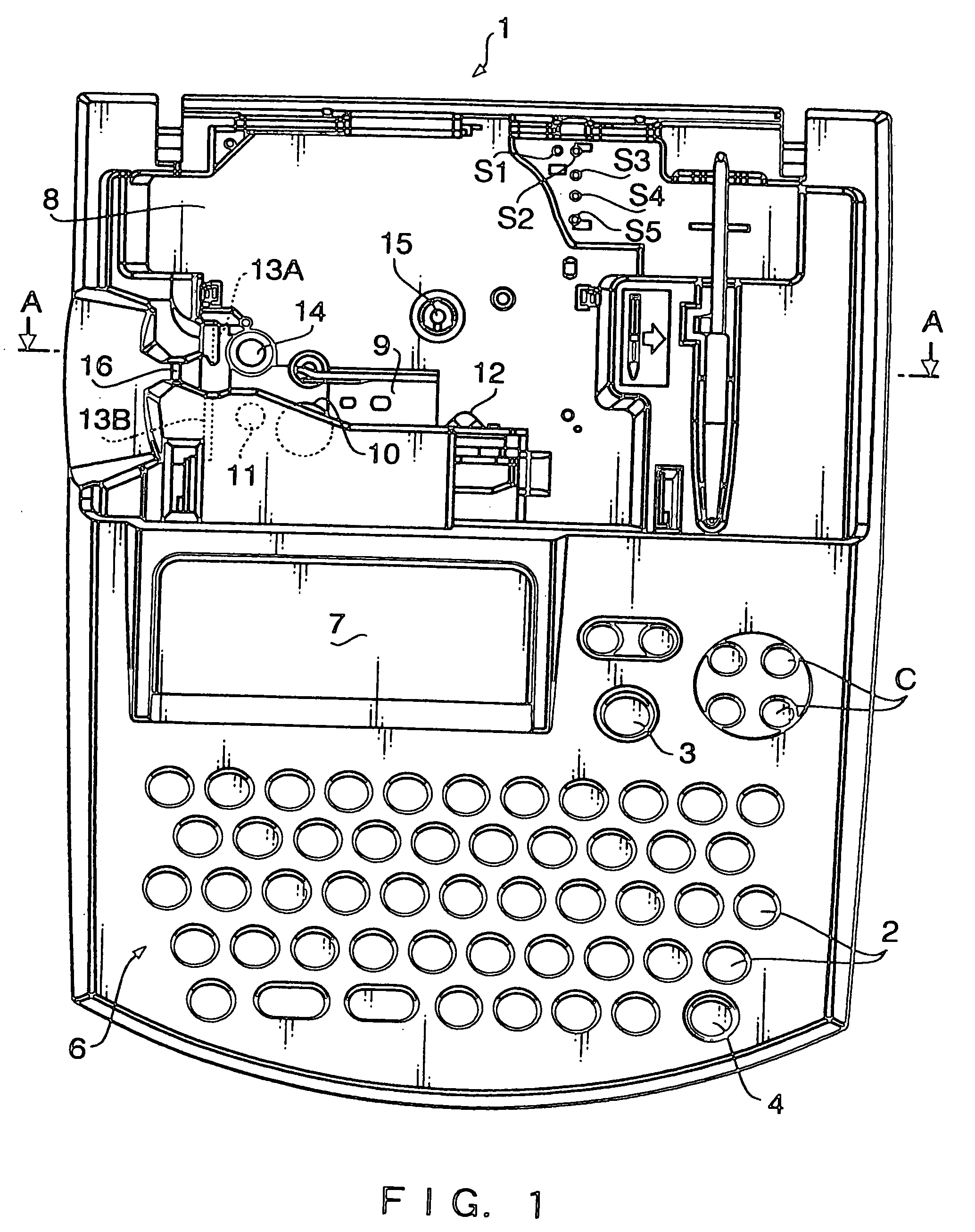

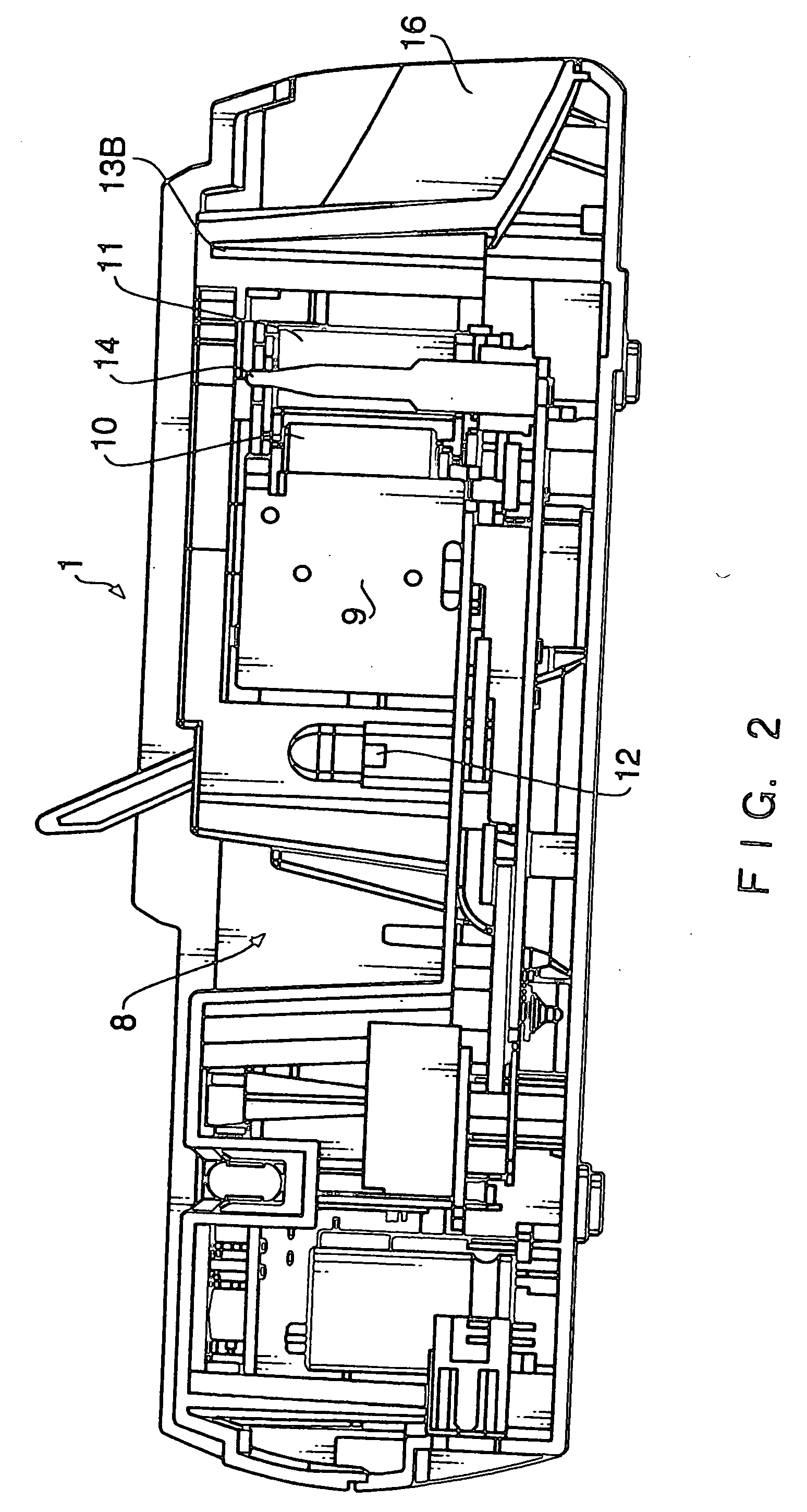

Placing printing elements and mark sensor at proper positions with respect to the cutter member

A tape printer, wherein when a label tape (36) is fed to a tape cutting position after the label (39) of the label tape (36) is printed out, the heating elements (R1 to Rn) of a thermal head (9) are disposed so as to be opposed to the position of a next printed label (39) slightly on the upstream side of a label head position on the downstream side of thereof in the feeding direction and to be opposed to the position of the next printed label (39) on the downstream side of the printing start position thereof (so that a<b can be established in FIG. 7), and a mark detection sensor (12)is disposed on the upstream side of the heating elements (R1 to Rn) so as to be opposed to the position slightly on the downstream side of the position opposed to a position detection mark (39B) (so that c<e can be established in FIG. 7).

Owner:BROTHER KOGYO KK

Tape printing device and tape cassette

InactiveUS20070009306A1Enabling detectionTypewritersOther printing apparatusMagnetic tapeThermal Head

When a label tape 36 after the printing on a label 39 has been fed to a tape cutting position, heating elements R1-Rn of a thermal head 9 is situated to face a position slightly on the upstream side of a label front end position (at the downstream end in the feeding direction) of the next label 39 which will be printed on next and to face a position on the downstream side of a print start position of the next label 39 (a<b in FIG. 7), and a mark sensor 12 is situated on the upstream side of the heating elements R1-Rn and to face a position slightly on the downstream side of a position indication mark 39B (c<e in FIG. 7).

Owner:BROTHER KOGYO KK

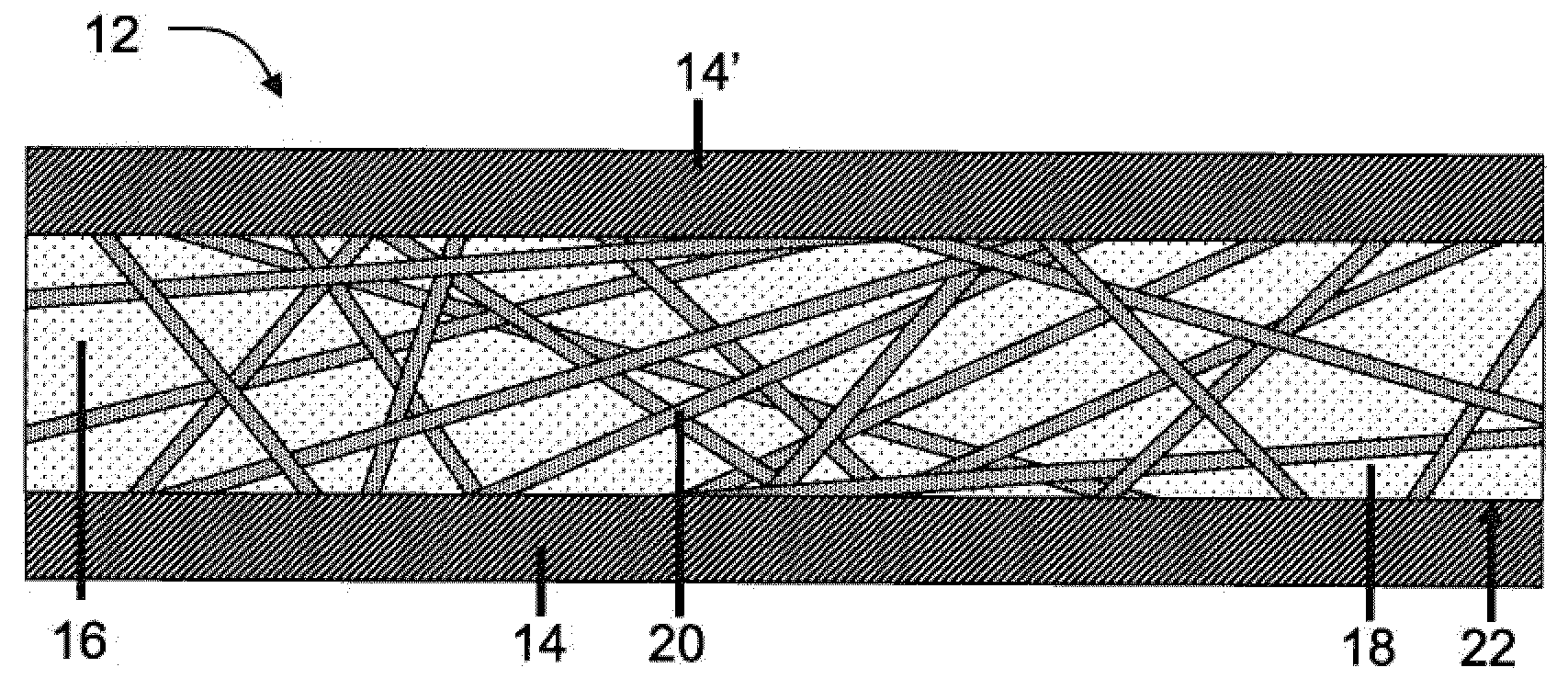

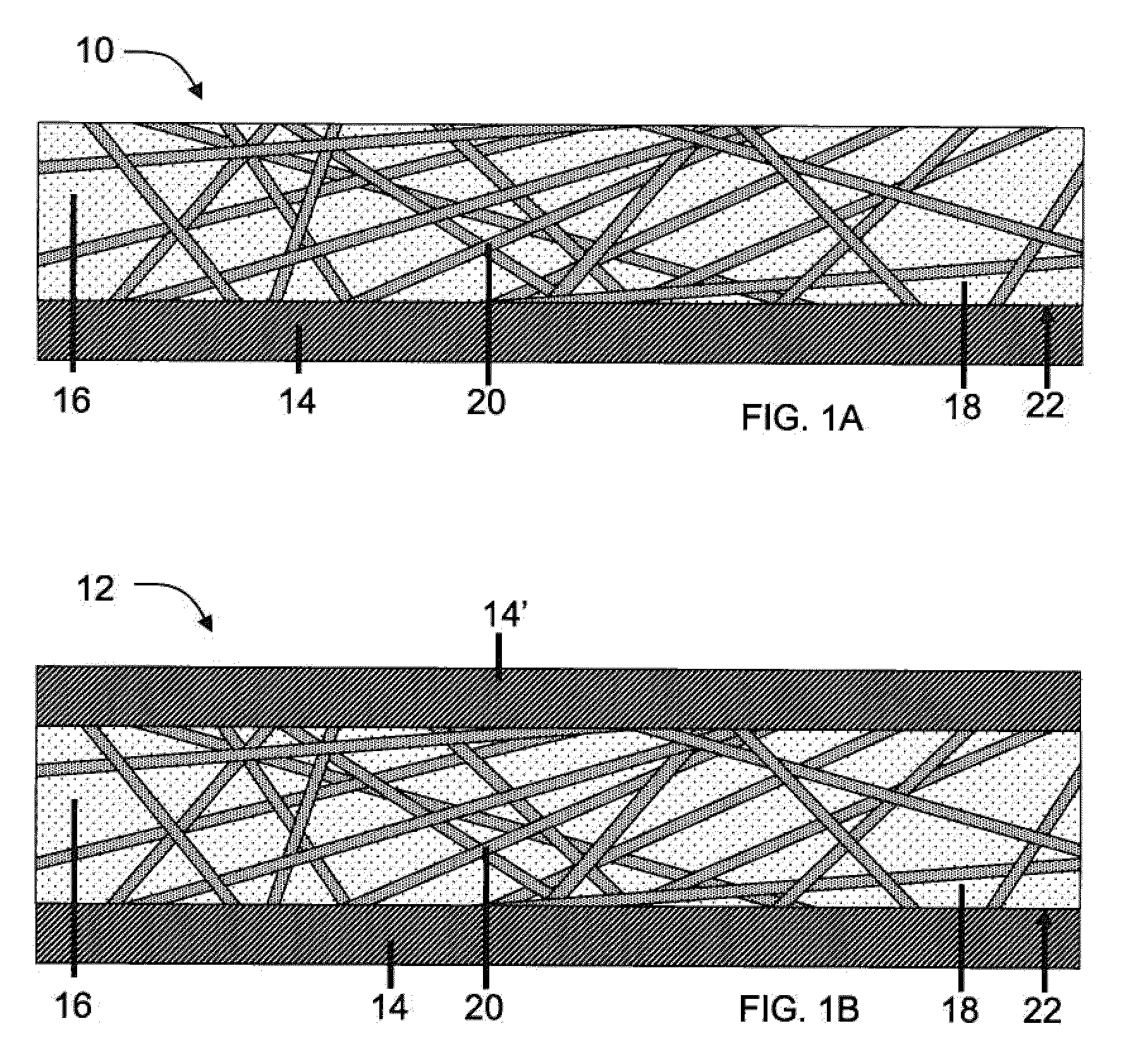

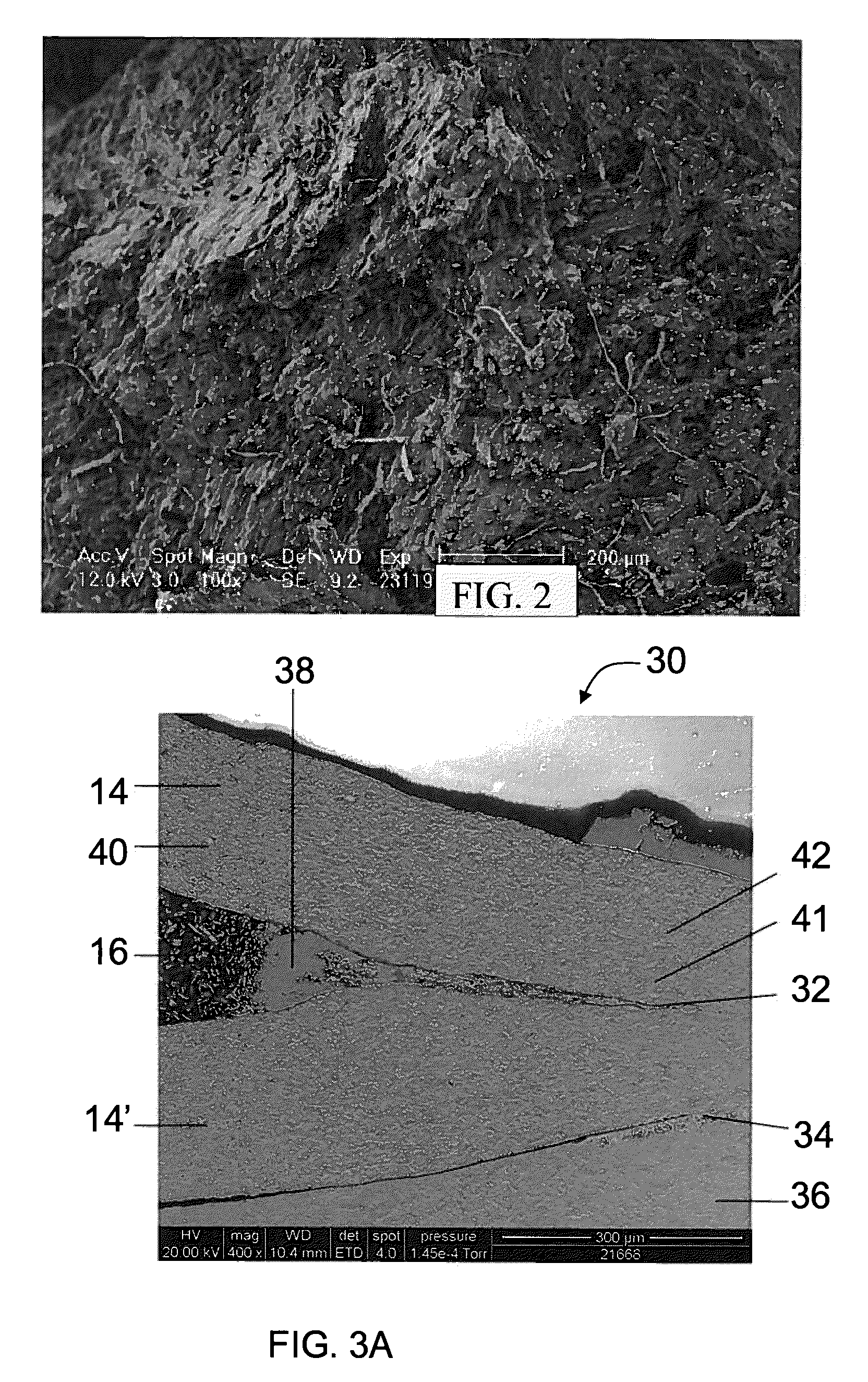

Formable light weight composites

ActiveUS20100040902A1Synthetic resin layered productsLaminationElectrical resistance and conductanceMetal fibers

The present invention relates to light weight composite materials which comprise a metallic layer and a polymeric layer, the polymeric layer containing a filled thermoplastic polymer which includes a thermoplastic polymer and a metallic fiber. The composite materials of the present invention may be formed using conventional stamping equipment at ambient temperatures. Composite materials of the present invention may also be capable of being welded to other metal materials using a resistance welding process such as resistance spot welding.

Owner:PRODIVE RES

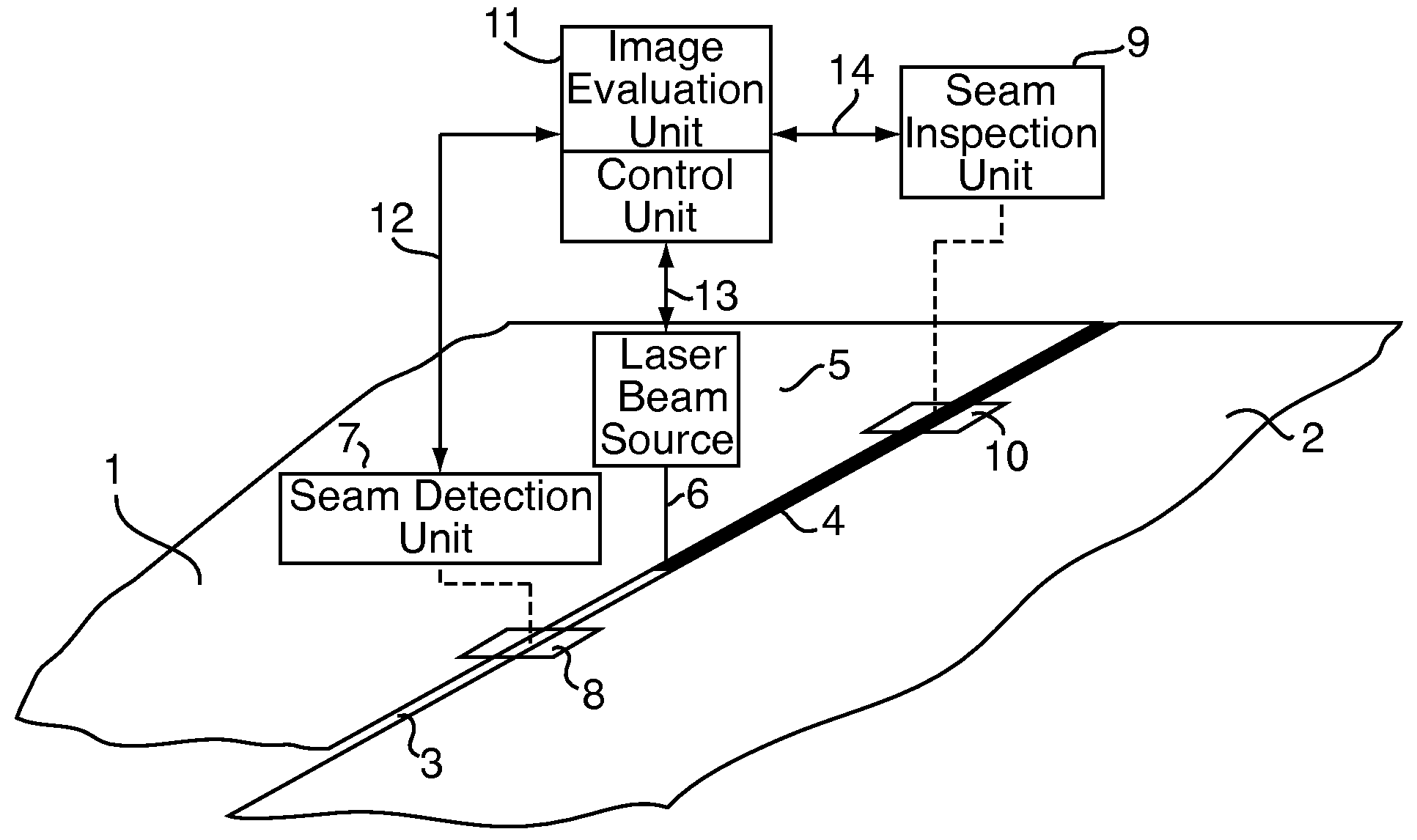

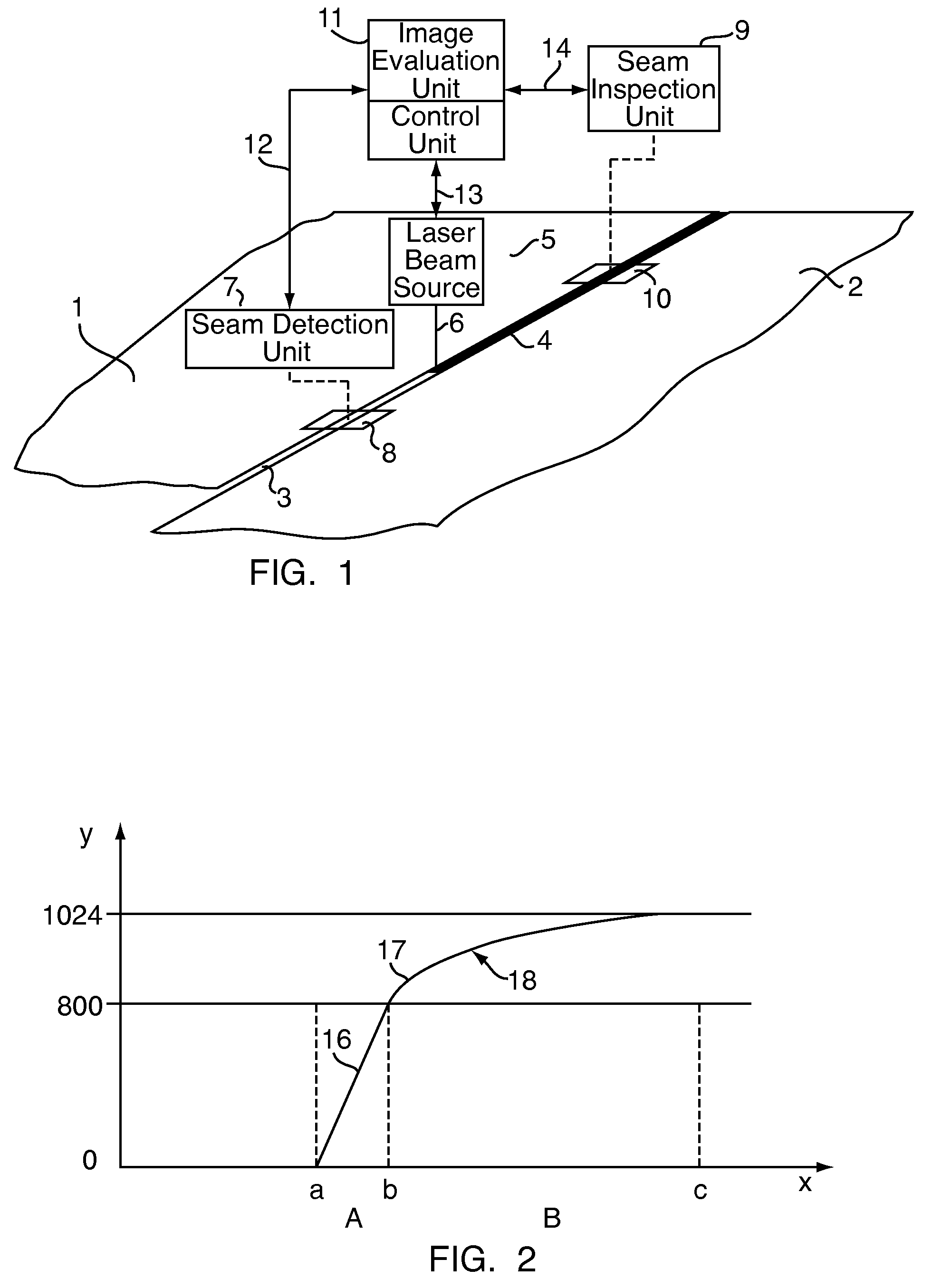

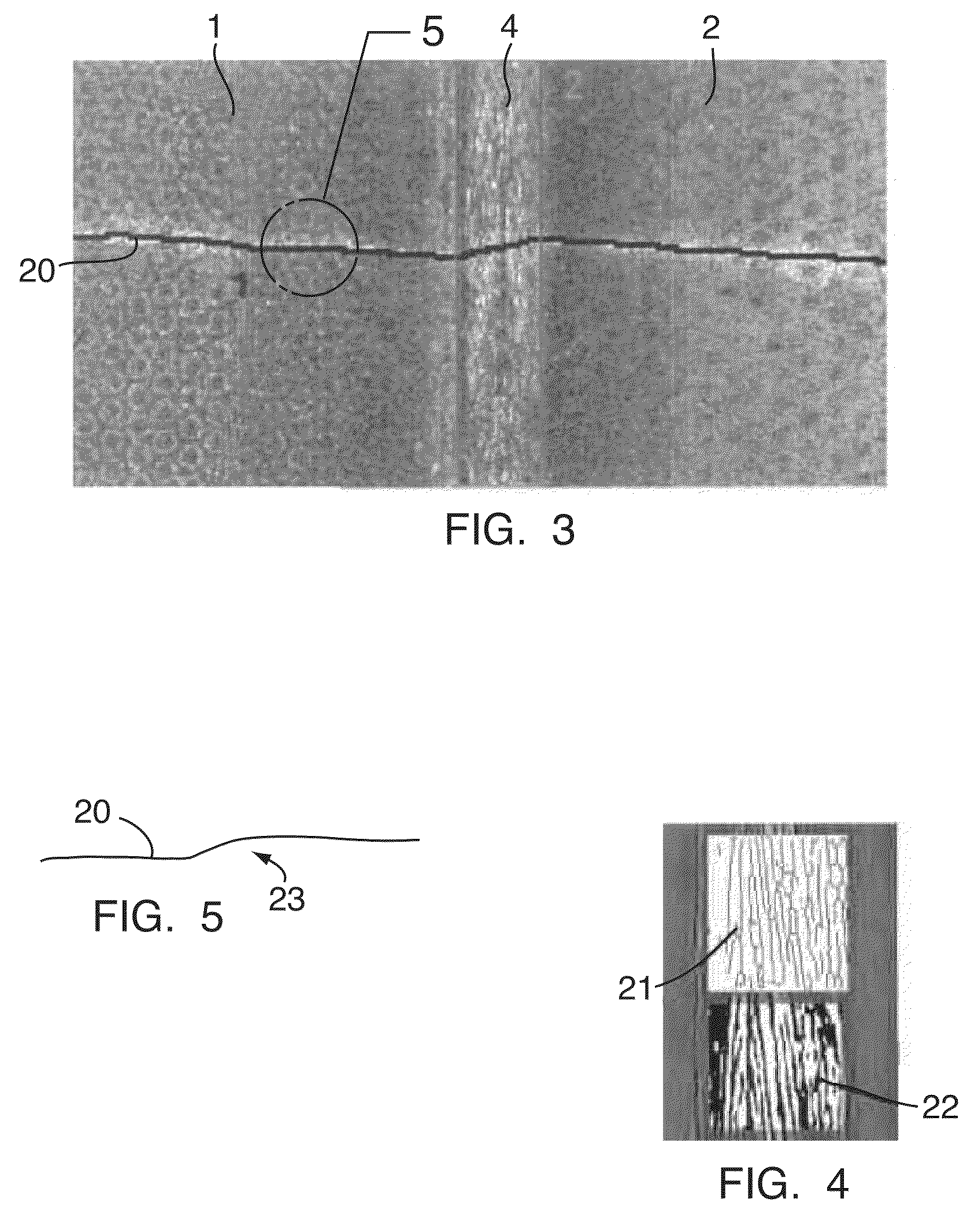

Method and device for evaluation of jointing regions on workpieces

ActiveUS7577285B2Easy to checkEasy to recordElectrode supporting devicesCharacter and pattern recognitionEngineeringGrayscale

Owner:PRECITEC VISION +1

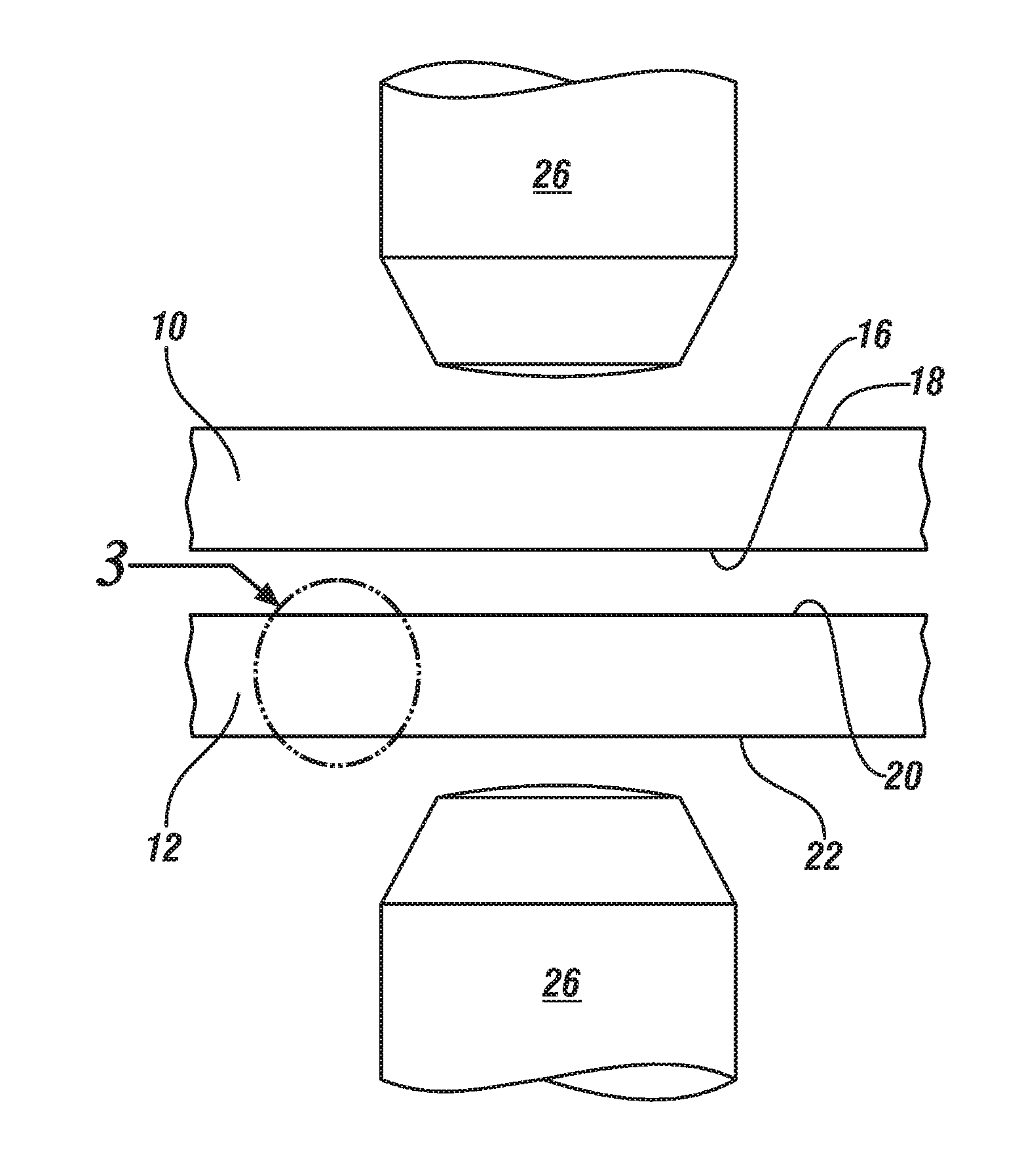

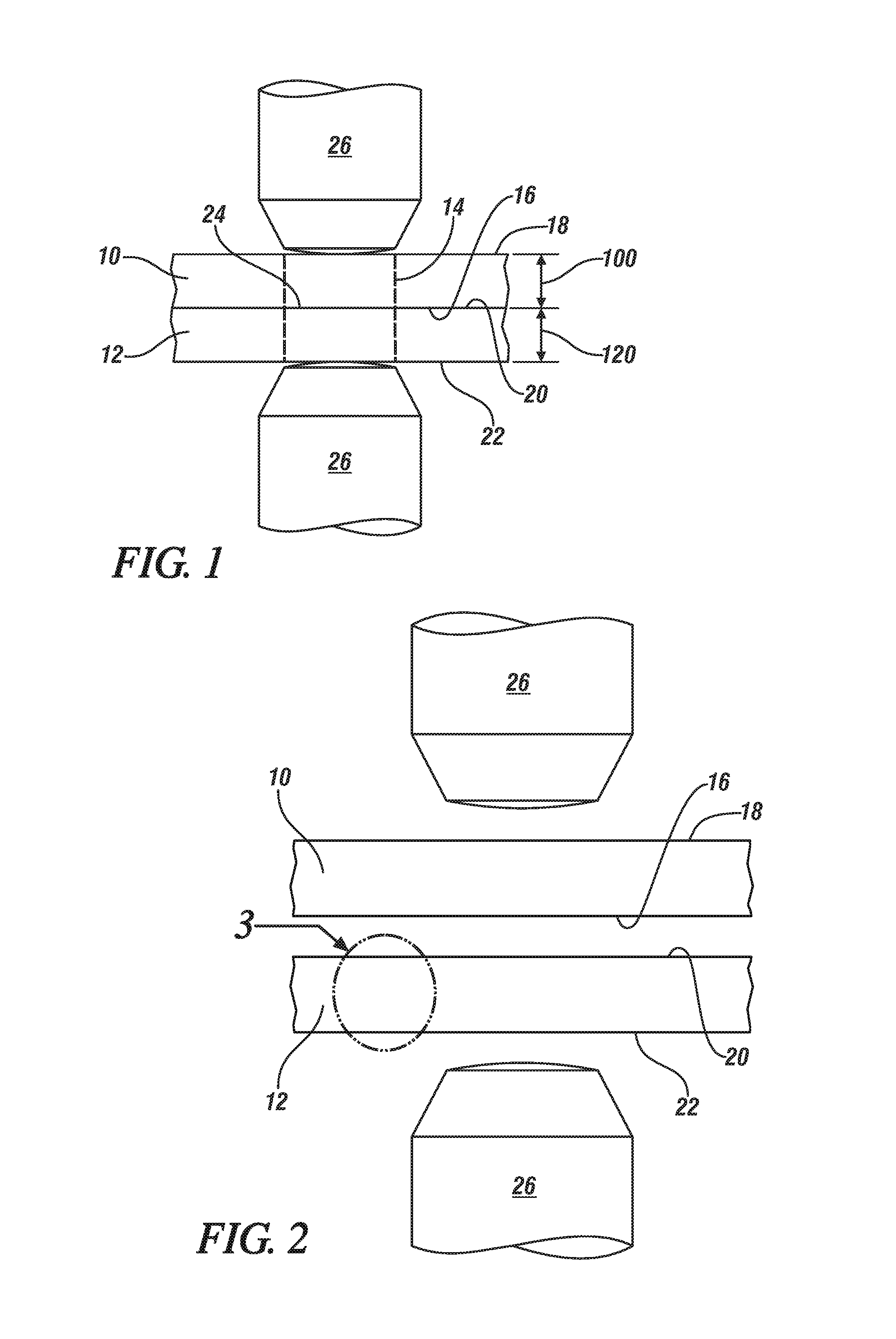

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

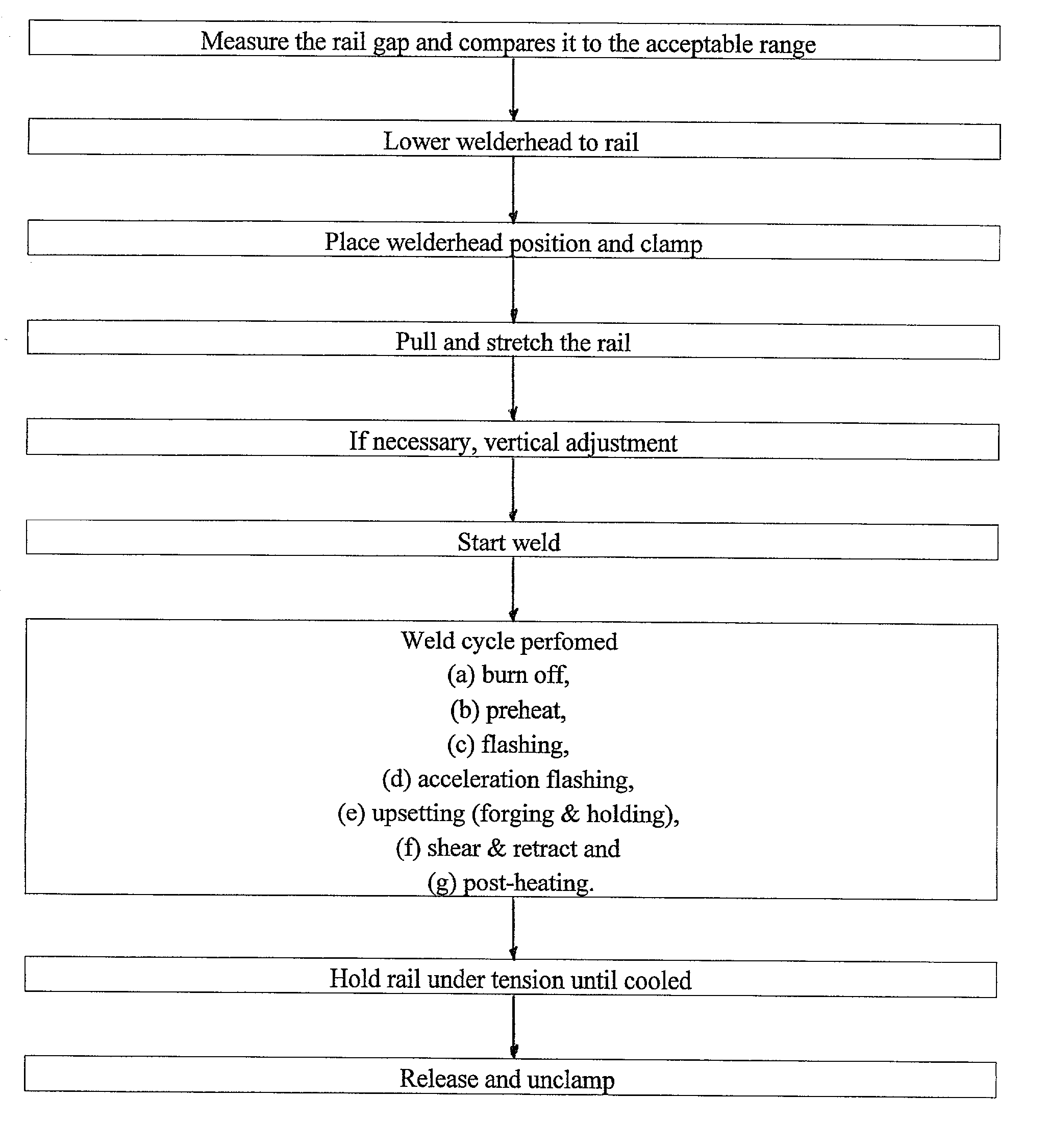

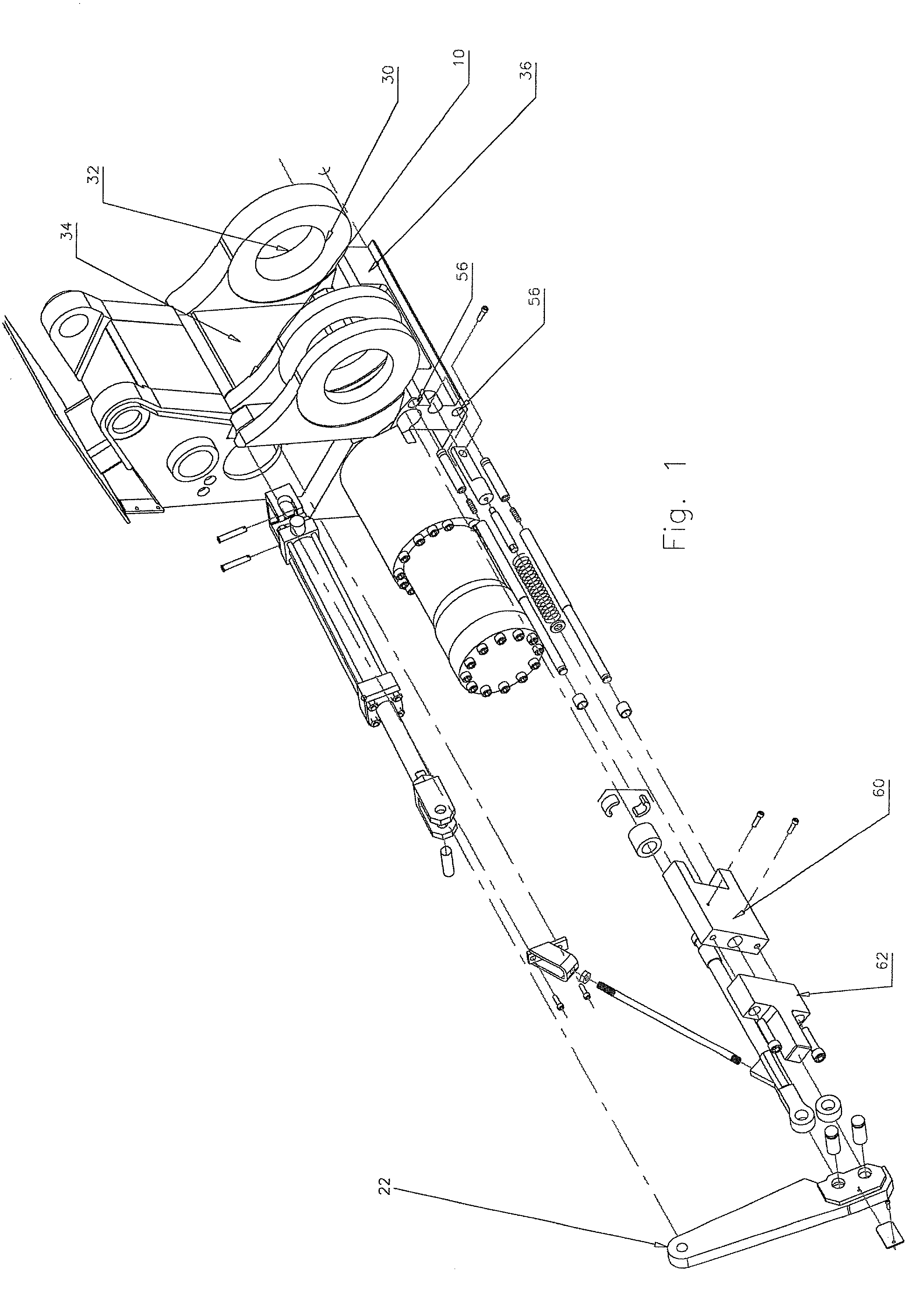

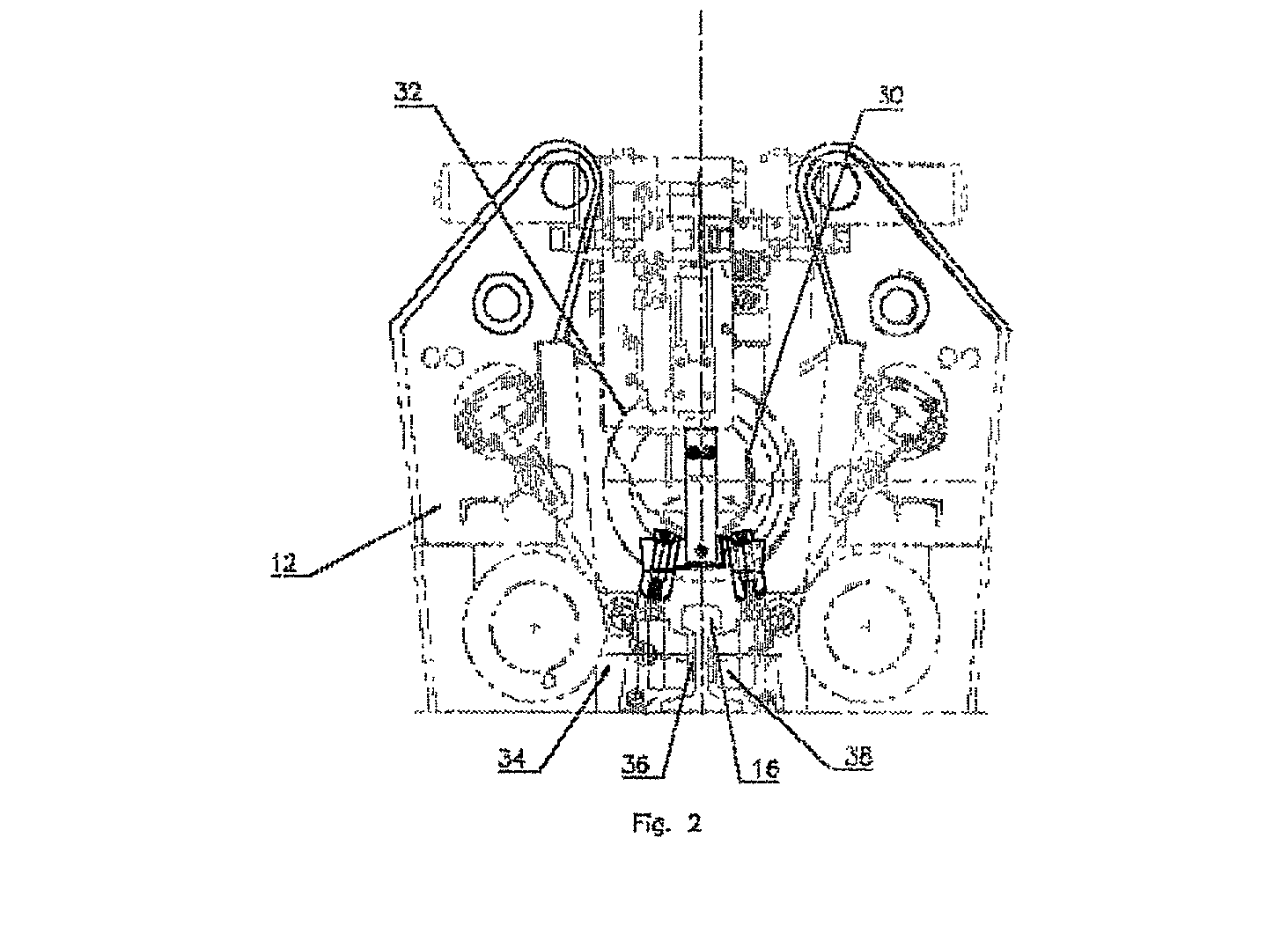

Rail welderhead shear apparatus

A flash butt rail welding welderhead combines in a single unit, the ability for the three functions of rail pulling, flash butt forging and maintaining the "after forged" displacement without any change in platen position such that shearing may be accomplished in three stages, a single stage, multiple stages or a progressive stage, all while maintaining clamping and stretching force on the rails.

Owner:HOLLAND CO

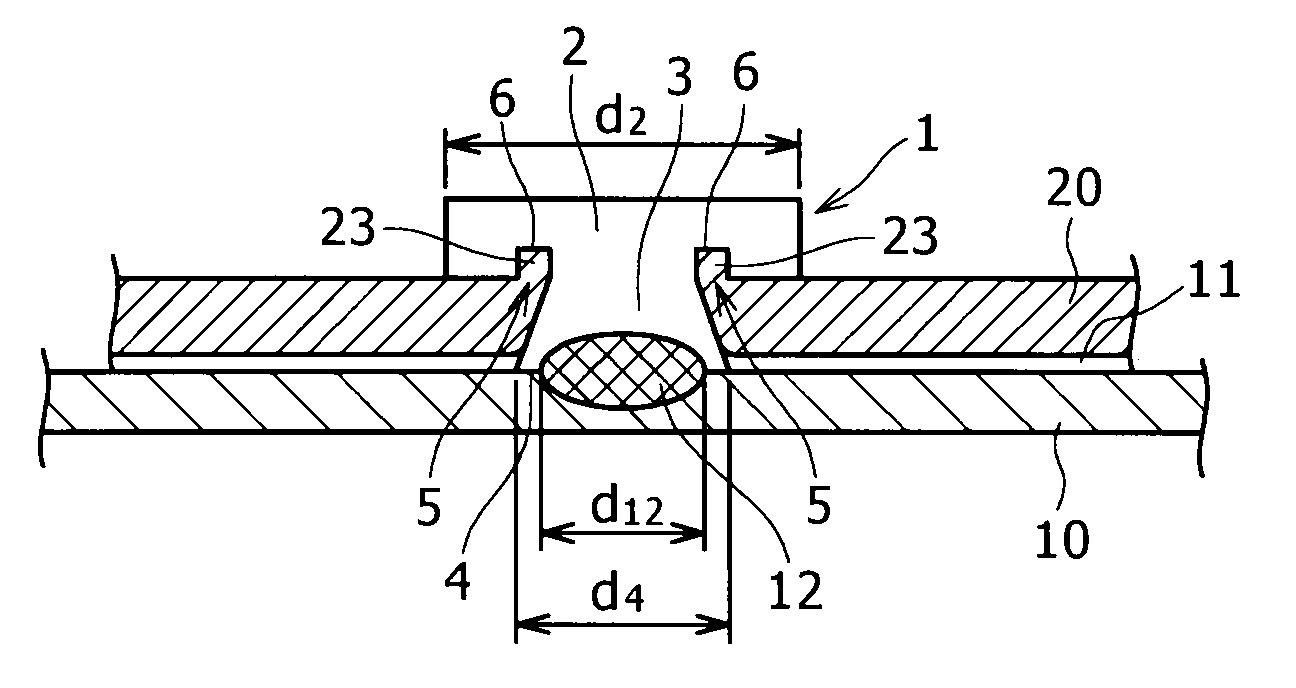

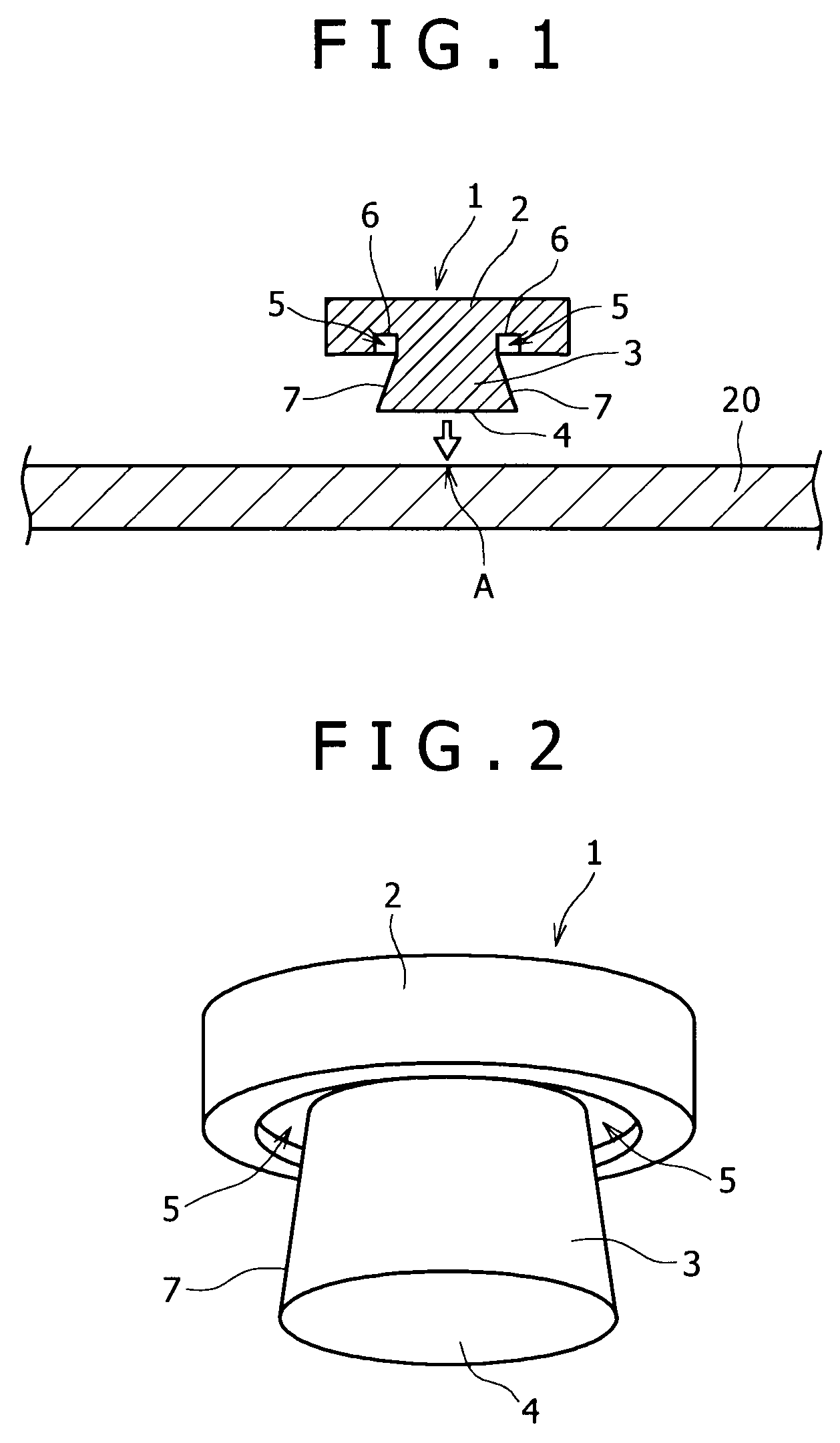

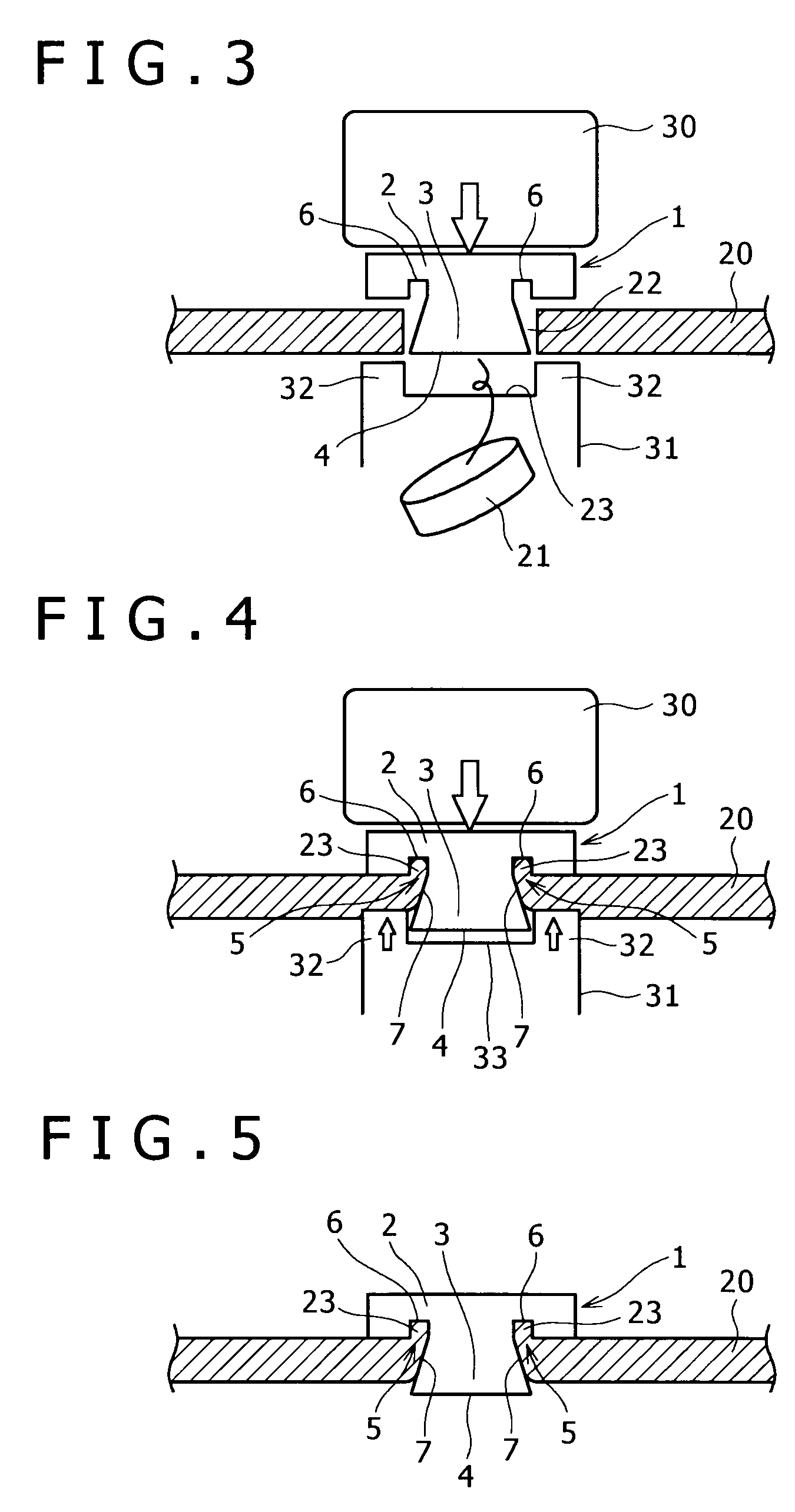

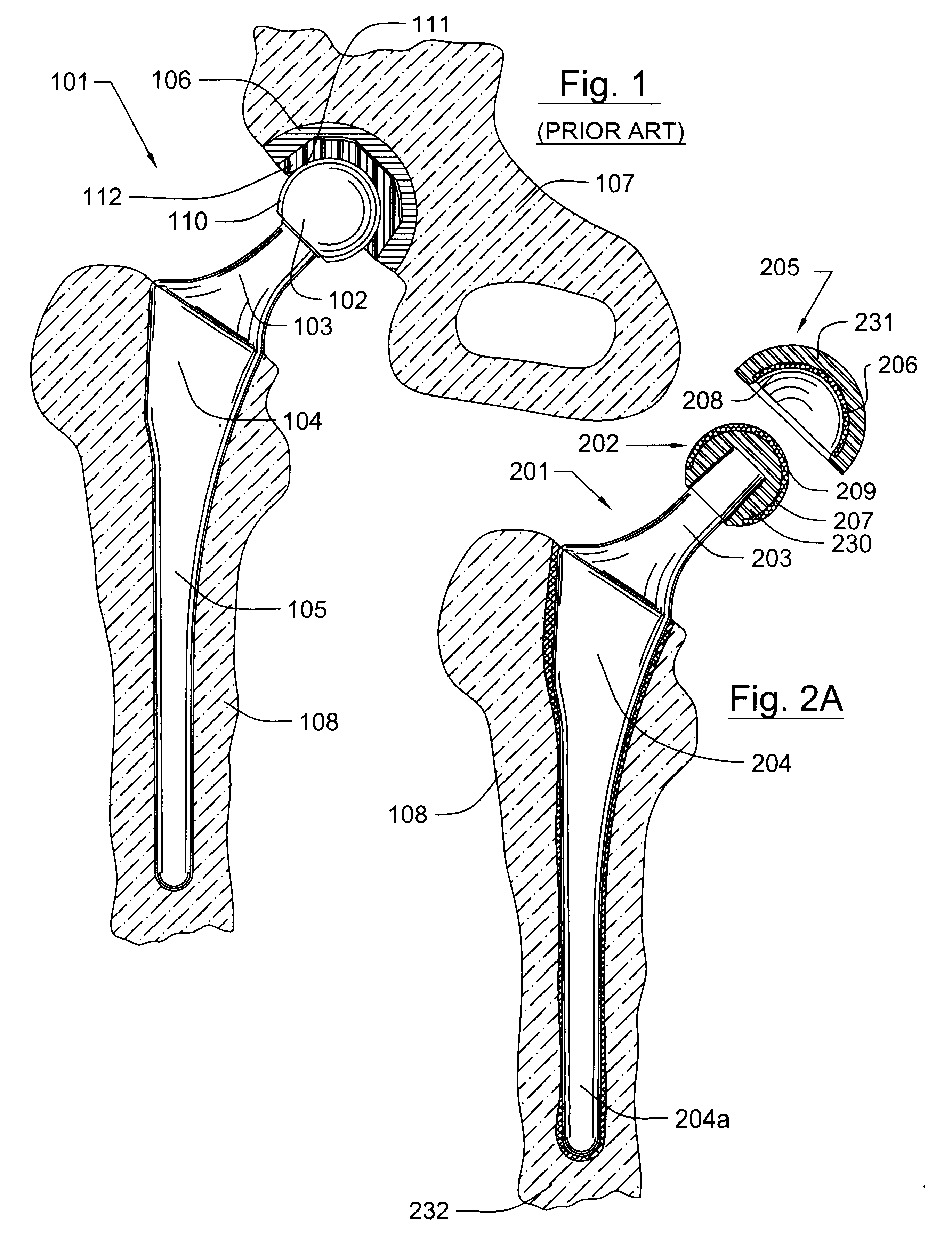

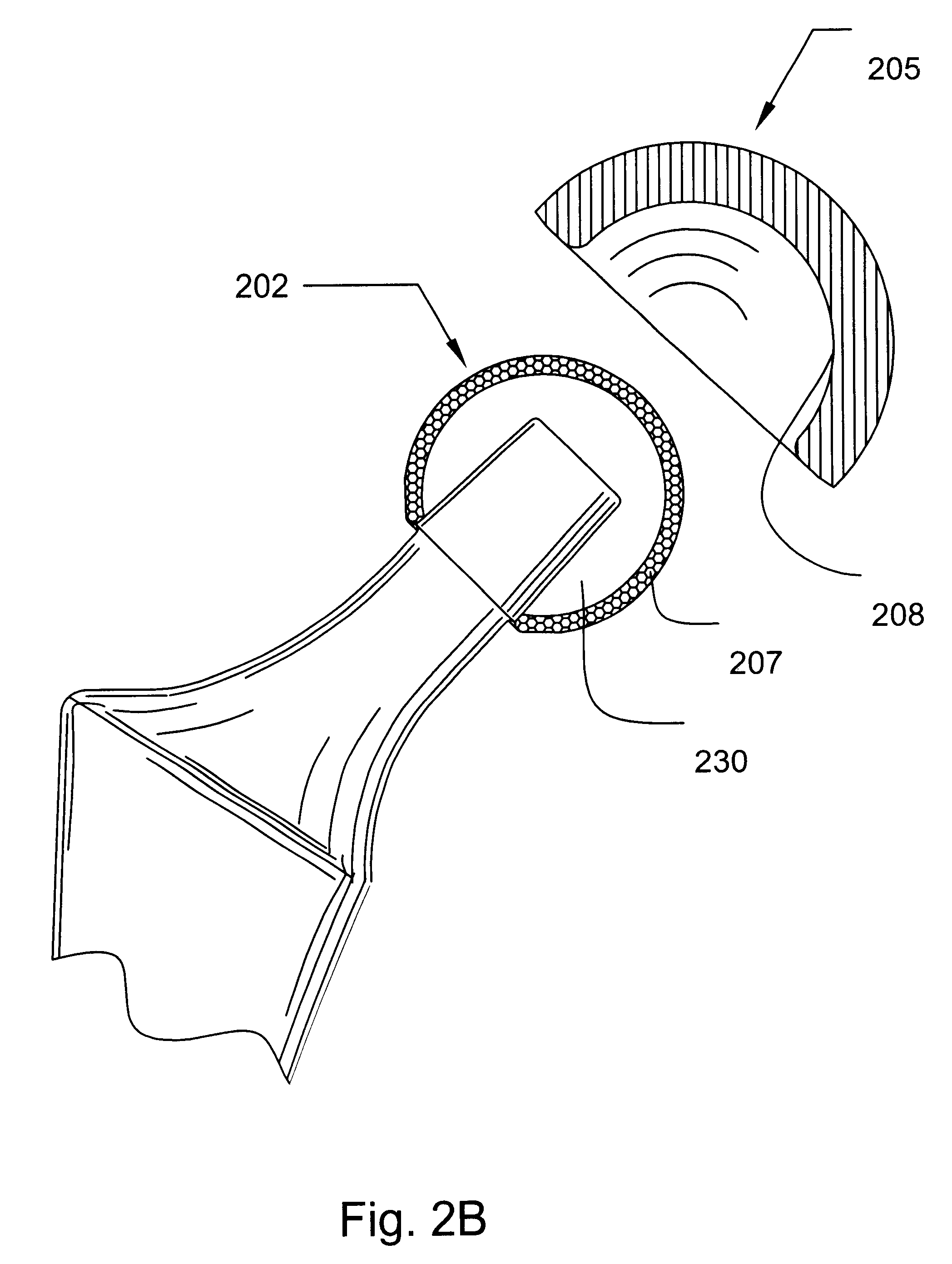

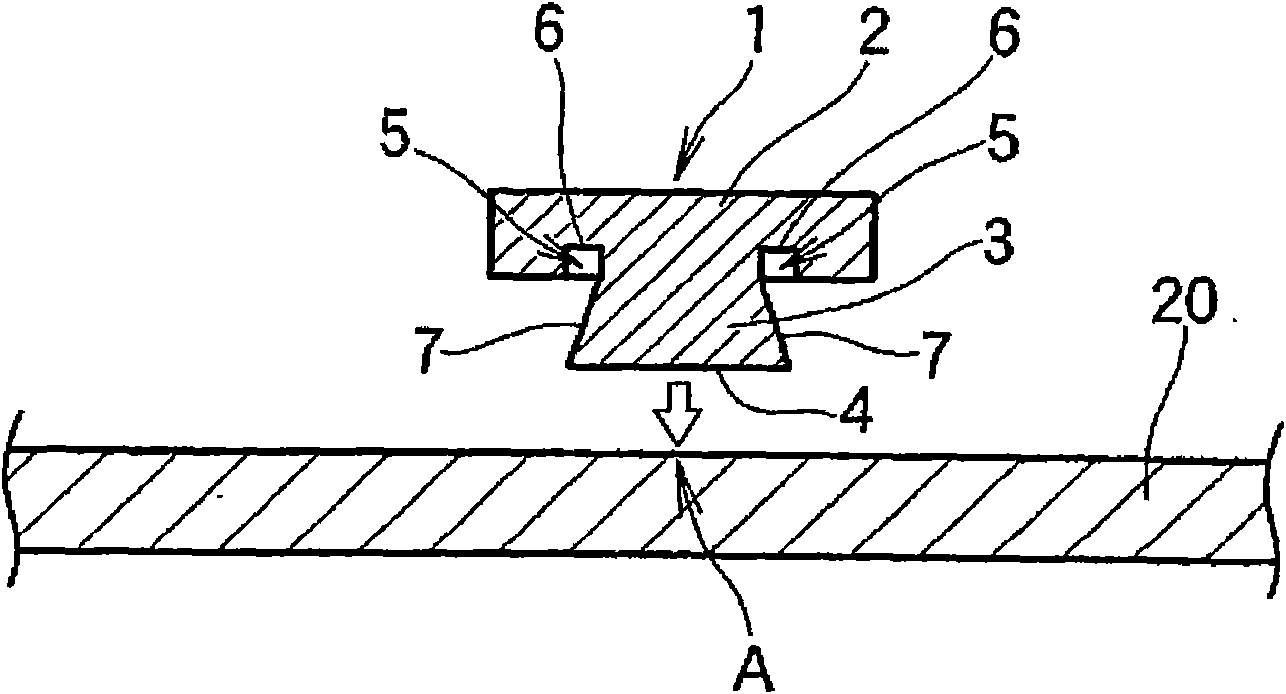

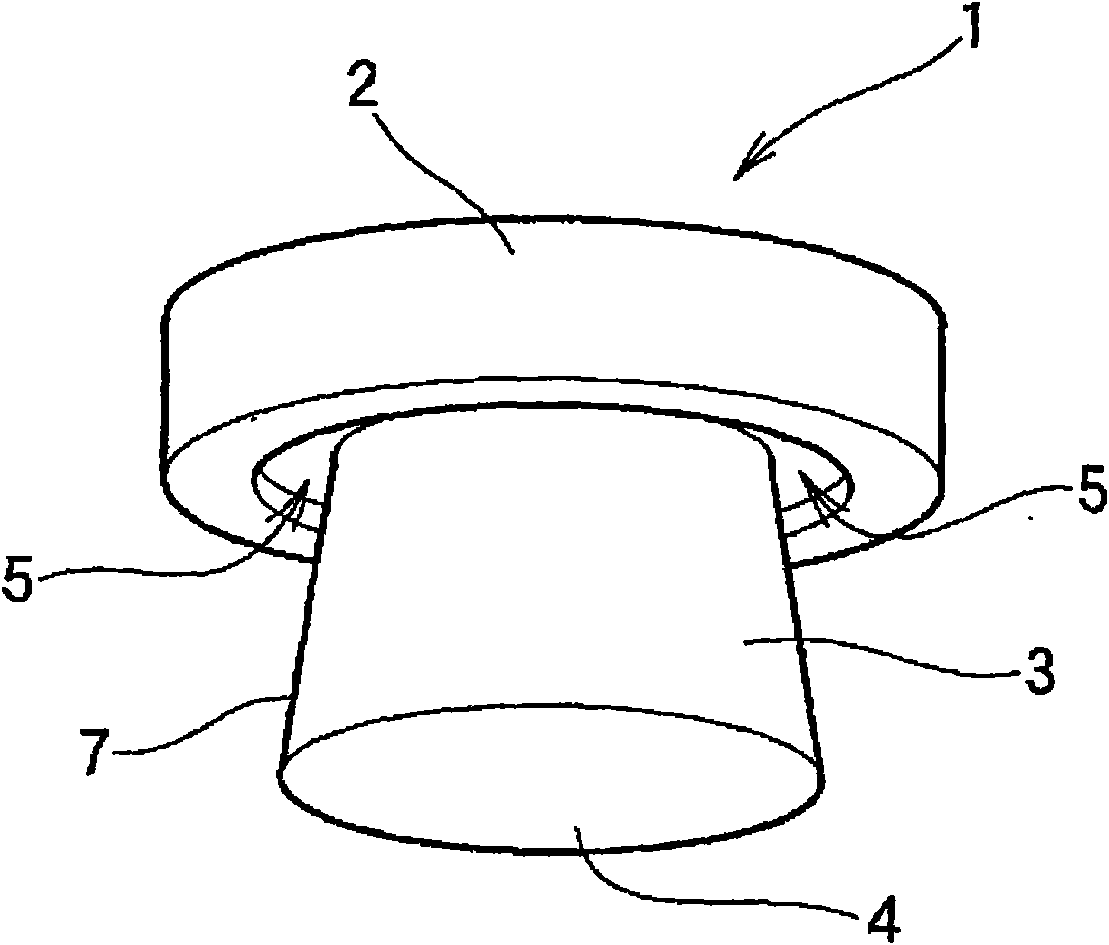

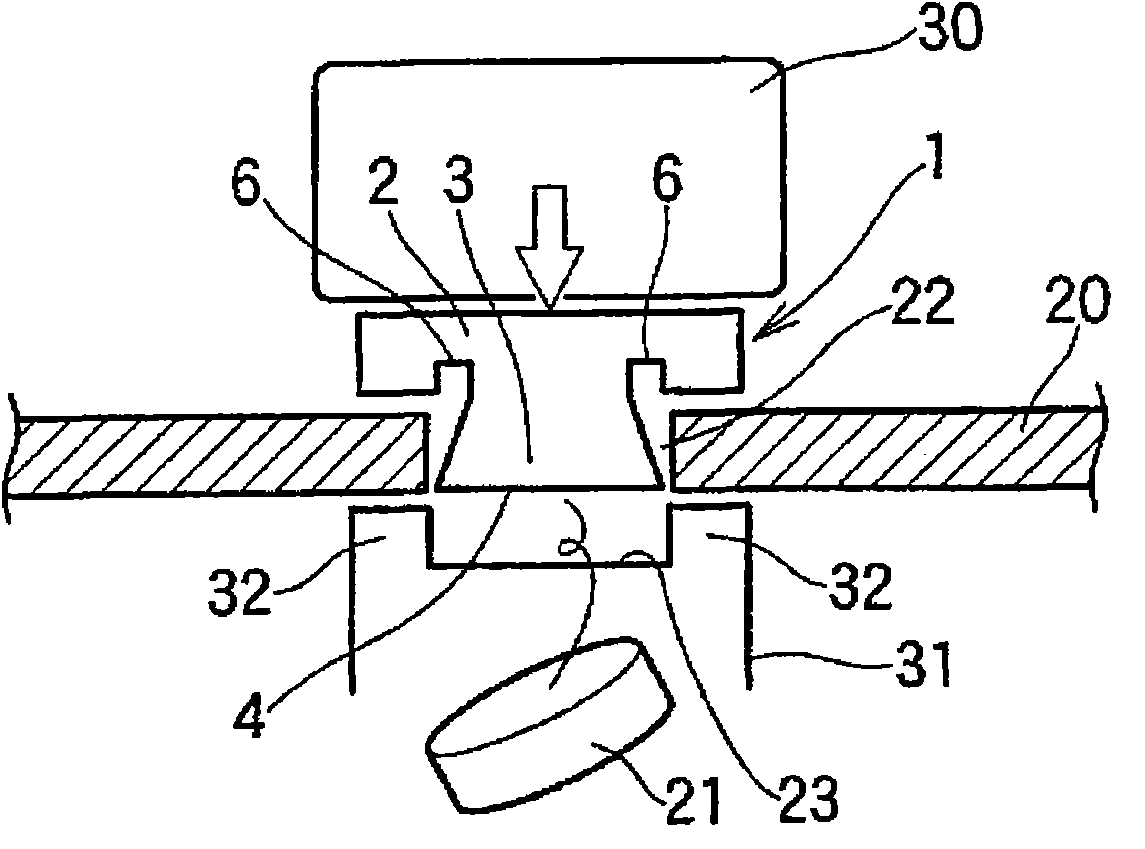

Method for joining dissimilar metals of steel product and light metal product with each other

InactiveUS20090294410A1Overcome limitationsImprove joint strengthShrinkage connectionsSheet joiningSpot weldingUltimate tensile strength

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron—iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

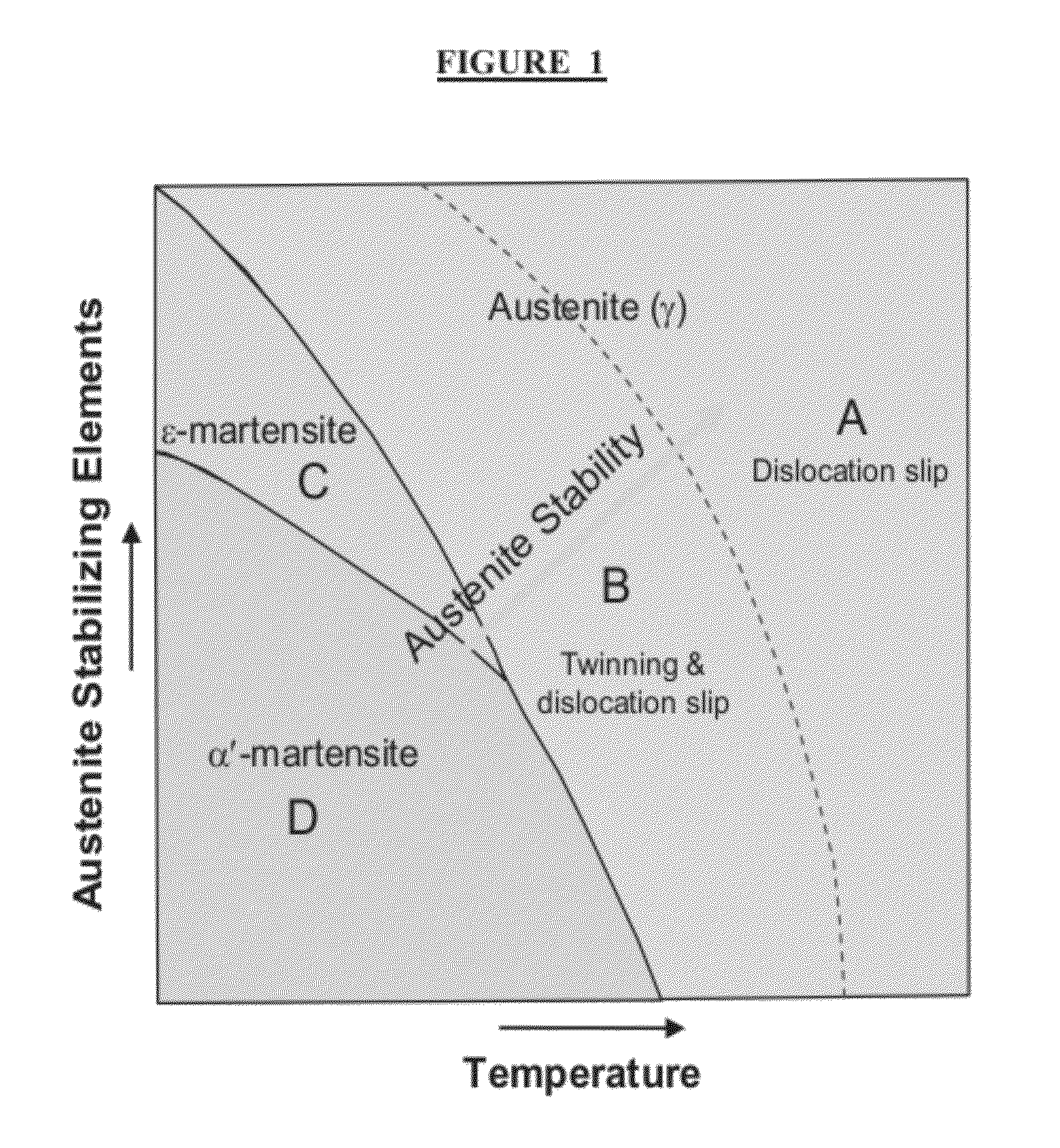

High manganese containing steels for oil, gas and petrochemical applications

Provided are high manganese containing ferrous based components and their use in oil, gas and / or petrochemical applications. In one form, the components include 5 to 40 wt % manganese, 0.01 to 3.0 wt % carbon and the balance iron. The components may optionally include one or more alloying elements chosen from chromium, nickel, cobalt, molybdenum, niobium, copper, titanium, vanadium, nitrogen, boron and combinations thereof.

Owner:EXXON RES & ENG CO

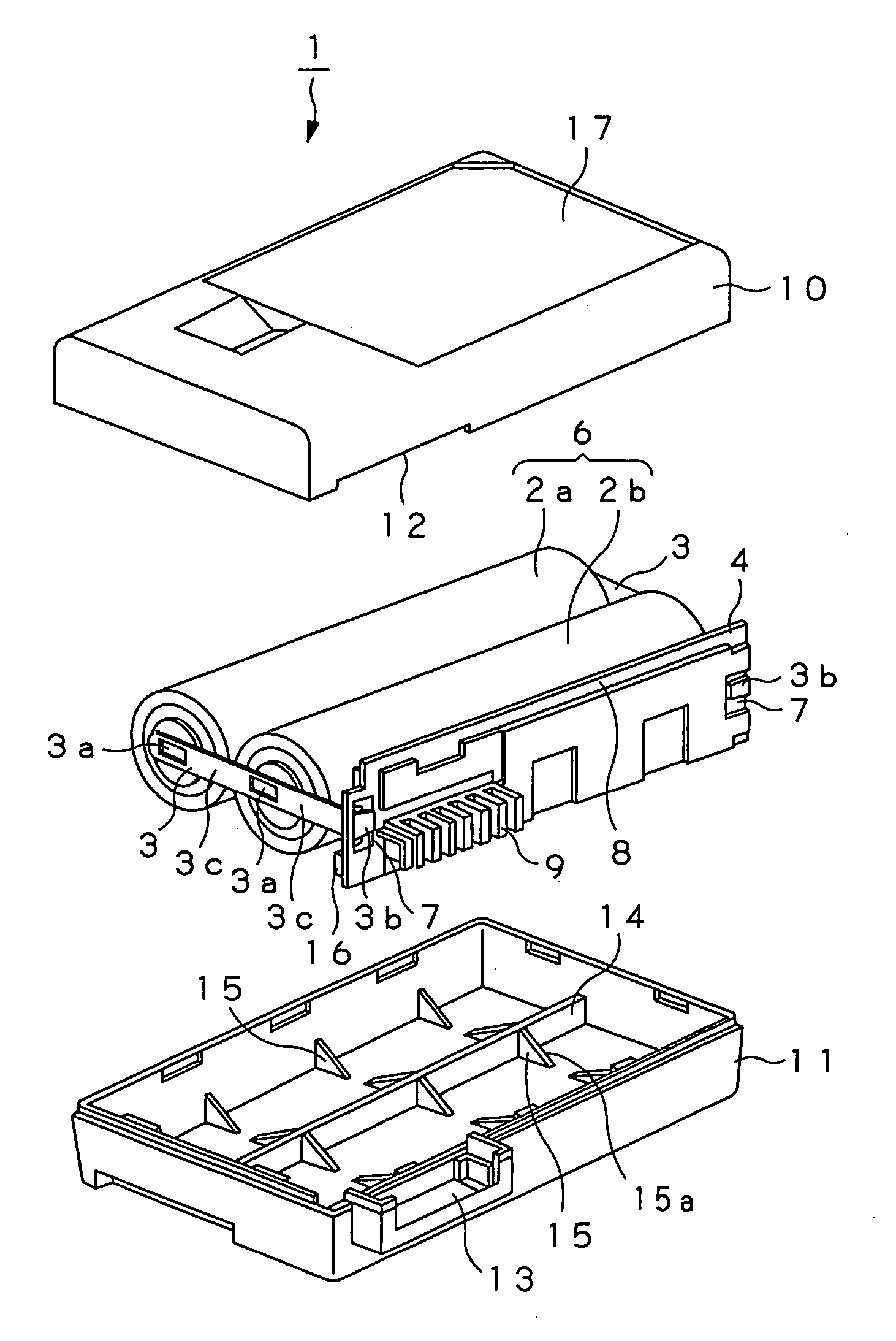

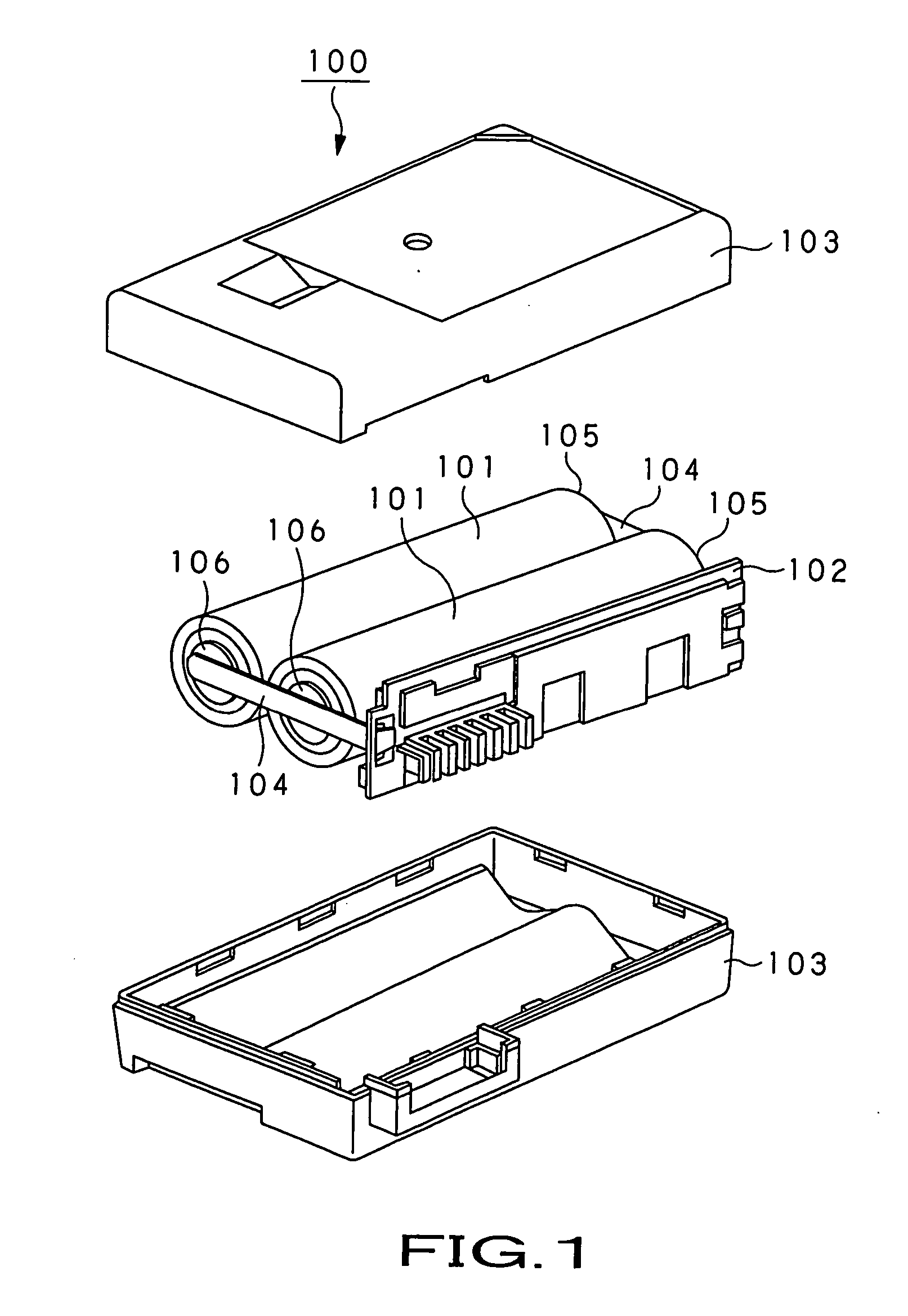

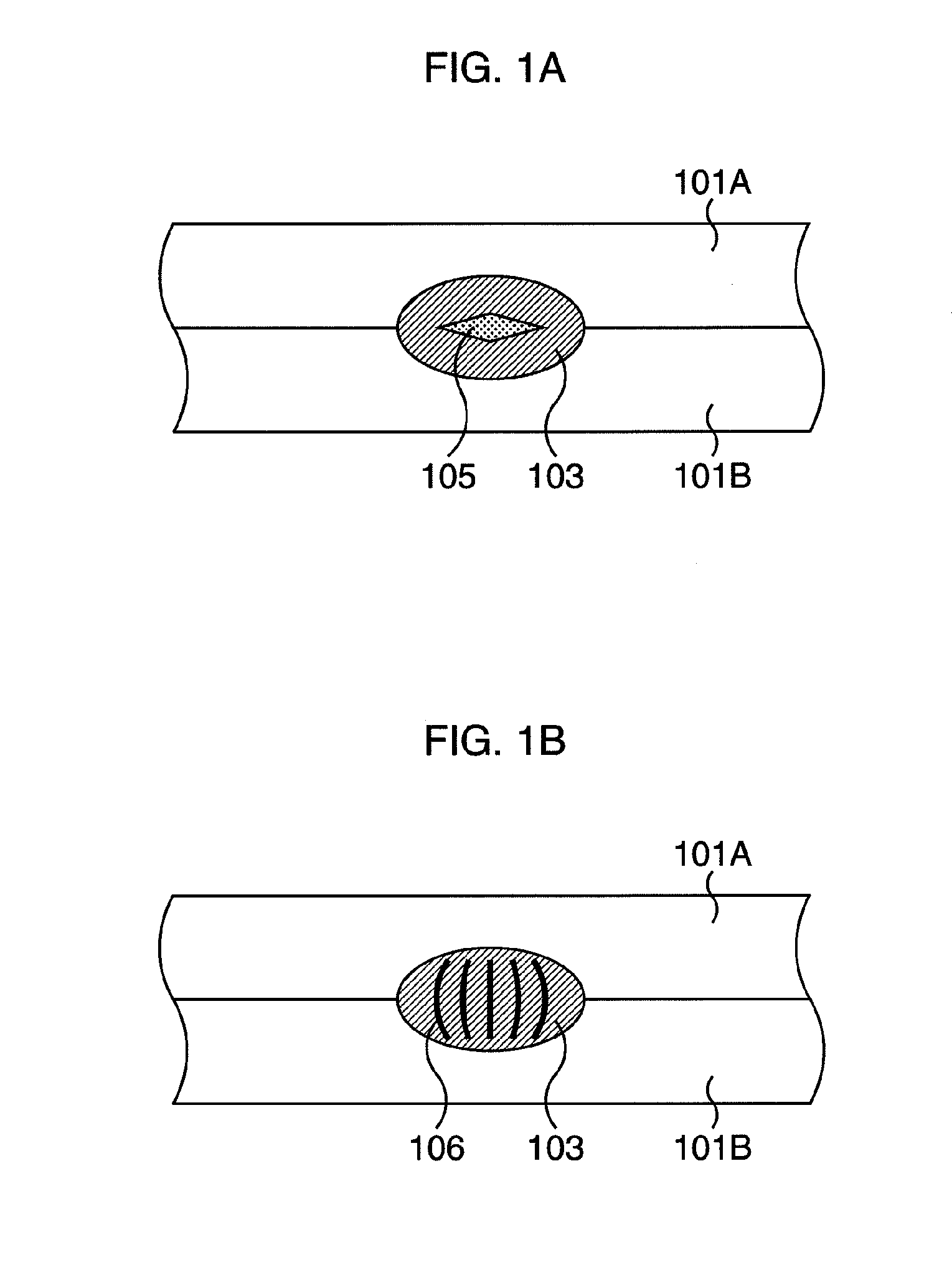

Lead terminal and power supply device

InactiveUS20060032667A1Improve welding strengthImprove electrical resistancePrinted electric component incorporationSoldered/welded conductive connectionsElectricityElectrical resistance and conductance

The present invention is directed to a power supply apparatus in which a battery and a circuit wiring board or boards are electrically connected by using lead terminals. The lead terminal (3) is adapted so that thickness of a welding portion (3a) is caused to be thinner than the thickness of a conductive portion (3b). Thus, current for welding flows to much degree in a thickness direction so that electric resistance of the welding portion becomes large, and heat based on the electric resistance also becomes large. From this fact, welding nugget (63) can be enlarged. As the result of the fact that large welding nugget is formed, the lead terminals are welded to terminal portions (37a) of the battery (2) with high reliability.

Owner:SONY CORP

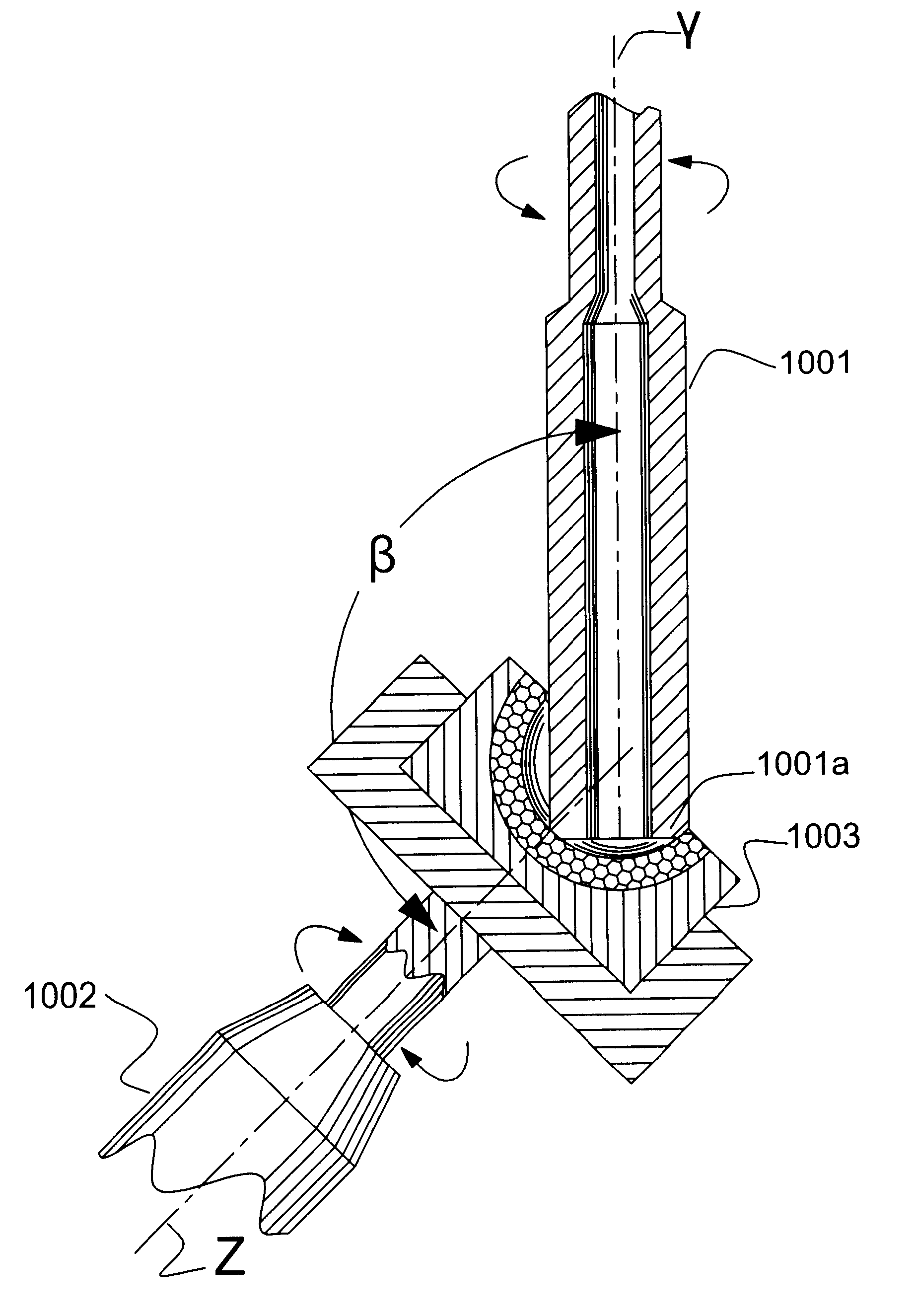

Methods for shaping and finishing prosthetic joint components including polycrystalline diamond compacts

InactiveUS6410877B1Less disruptiveImprove overall utilizationElectrode vibration holdersElectrical-based machining electrodesHeat-affected zoneElectric discharge

A method of rough shaping a prosthetic joint component that includes a generally spherical polycrystalline diamond compact by electric discharge machining is disclosed. The discharge machining electrode roughens a polycrystalline diamond compact sphere while the electrode and the sphere are rotating about different axes. By controlling the amount of discharge current, the depth and amount of the heat affected zone can be minimized. In the case of a polycrystalline diamond compact, the heat affected zone can be kept to about 3 to 5 microns in depth and is easily removable by grinding and polishing.

Owner:DIAMICRON

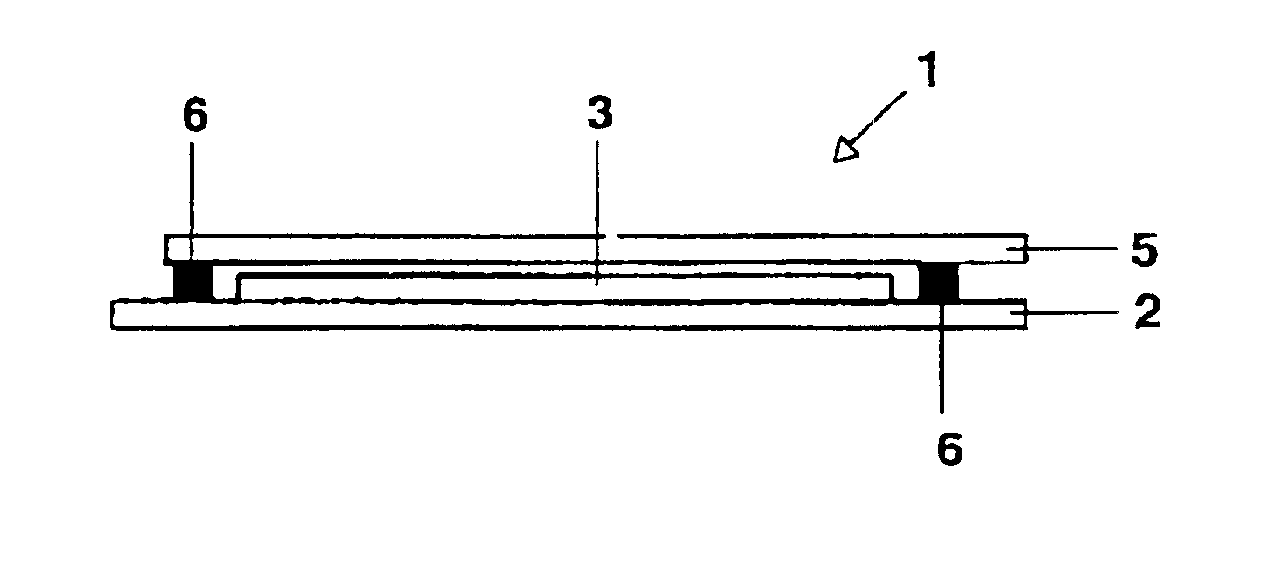

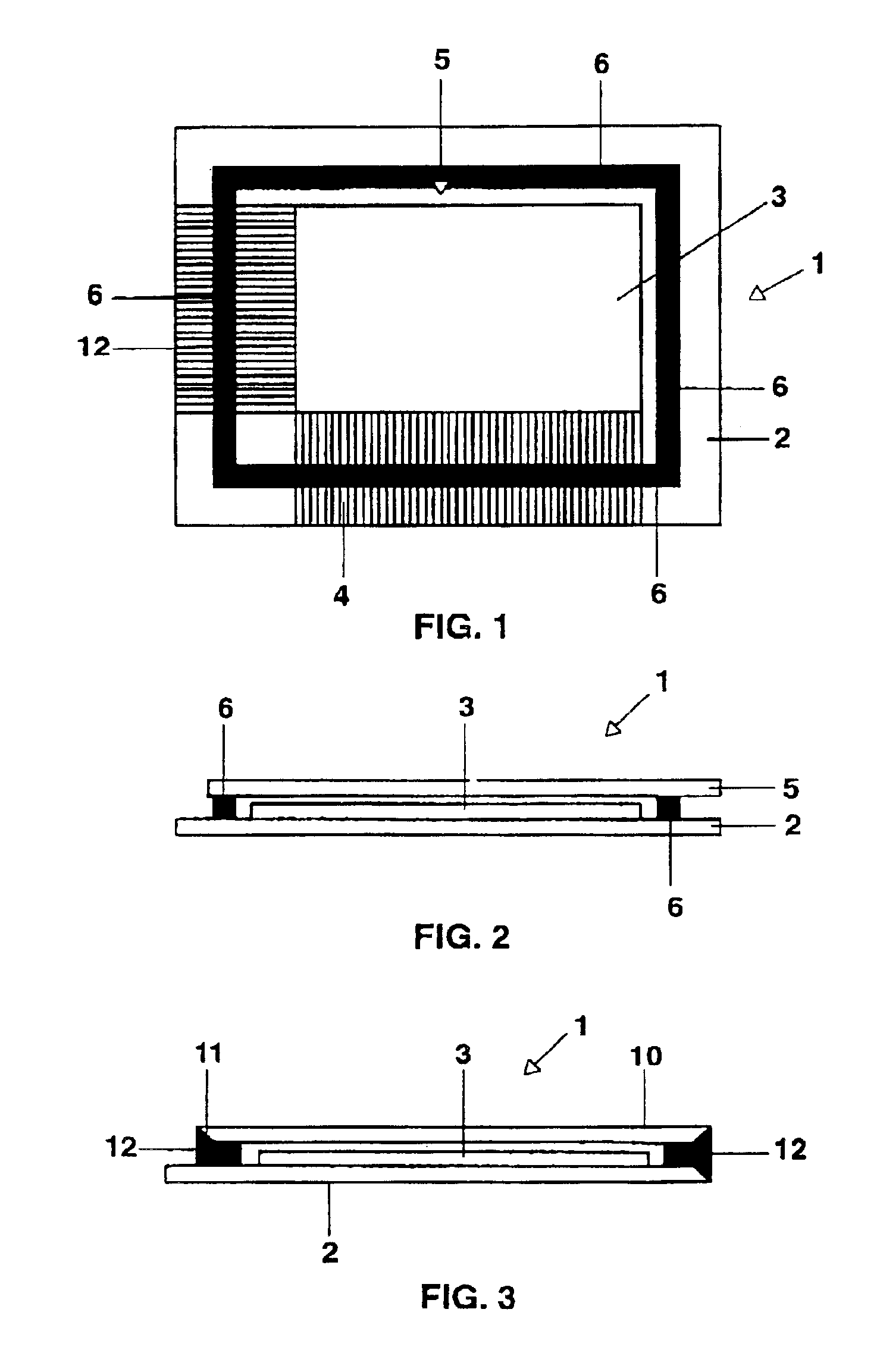

Process for encapsulating a component made of organic semiconductors

InactiveUS6936963B2Improve sealingLong life-timeDischarge tube luminescnet screensElectroluminescent light sourcesElectrical connectionThermal expansion

A process for encapsulating a component made of organic semiconductors is provided which includes steps of: a) providing a housing including a substrate with electrical connections and a cover; b) mixing a soldering glass with at least one of a binder and a solvent; c) applying the soldering glass at least to the cover, in the form of an encircling bank; d) expelling the binder or solvent; e) sintering-on of the solder; f) covering the substrate with layers which represent the semiconductor component together with electrodes; g) placing the cover onto the substrate; and h) locally heating the soldering glass by means of a light source with a predetermined peak wavelength, wherein the housing parts and soldering glass are matched to one another such that their coefficients of thermal expansion differ from one another by less than 1.0×10−6K−1.

Owner:PATENT TREUHAND GES GMBH

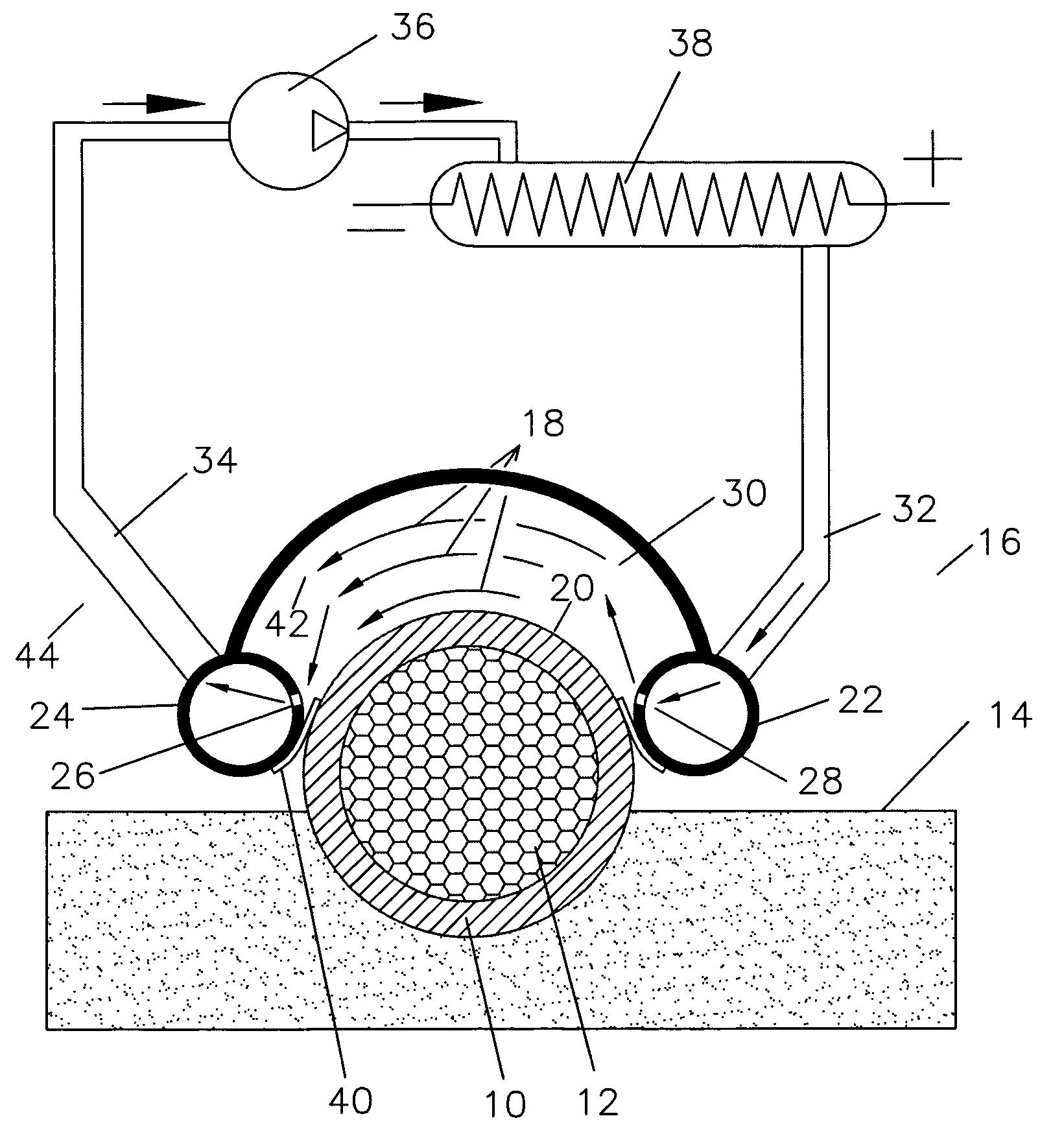

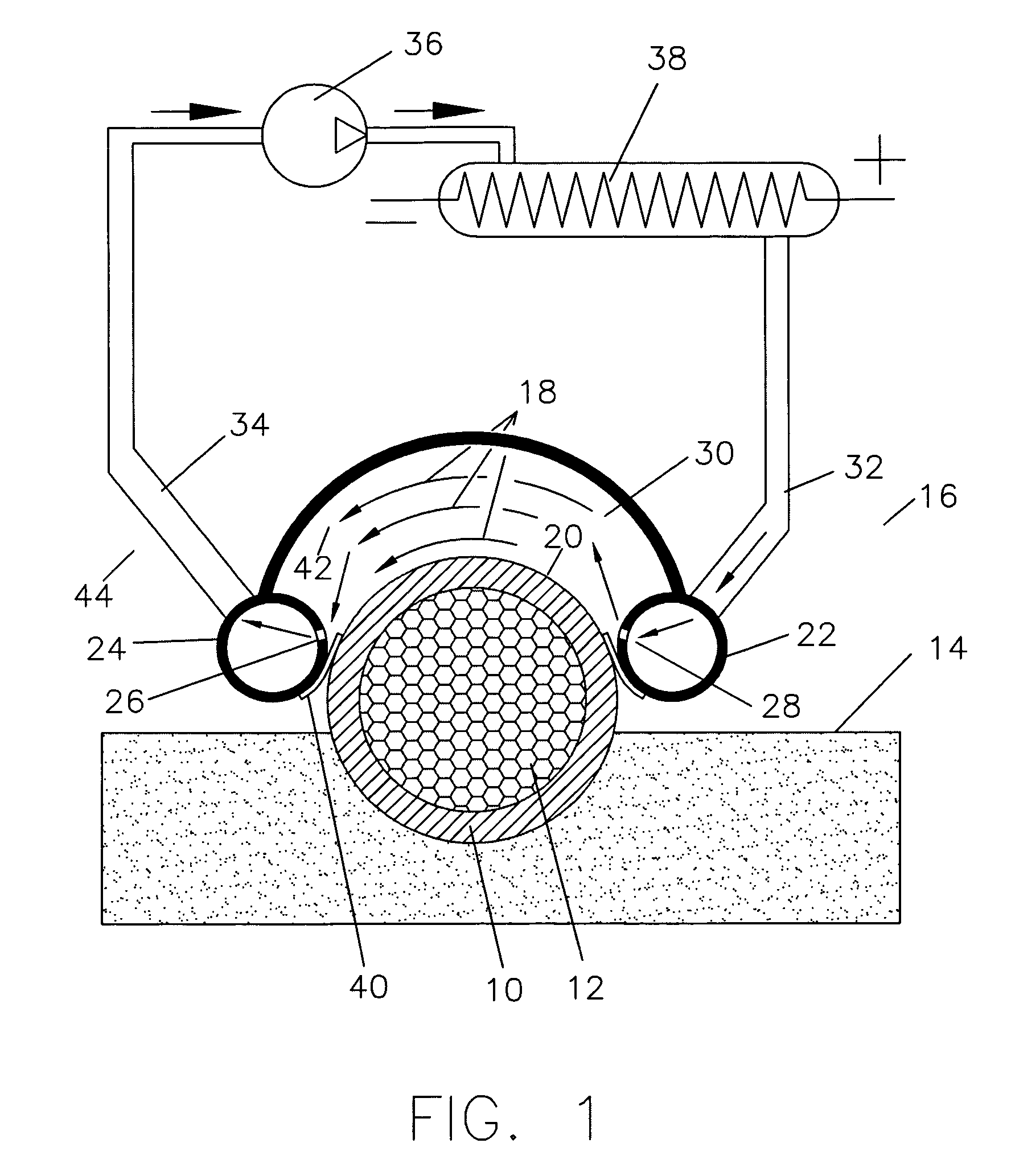

Subea pipeline blockage remediation method

InactiveUS6939082B1Raise the outlet temperatureMinimize disturbanceUnderground chambersPipe heating/coolingOcean bottomMarine engineering

The method of taking a remotely operated vehicle to the ocean floor to land on and move along a subsea pipeline above or below the seafloor and repeatedly circulate seawater which has been heated electrically, mechanically, or chemically across the outer surface of the pipeline to melt hydrates or paraffins which have formed on the inside of the pipeline.

Owner:BAUGH BENTON F

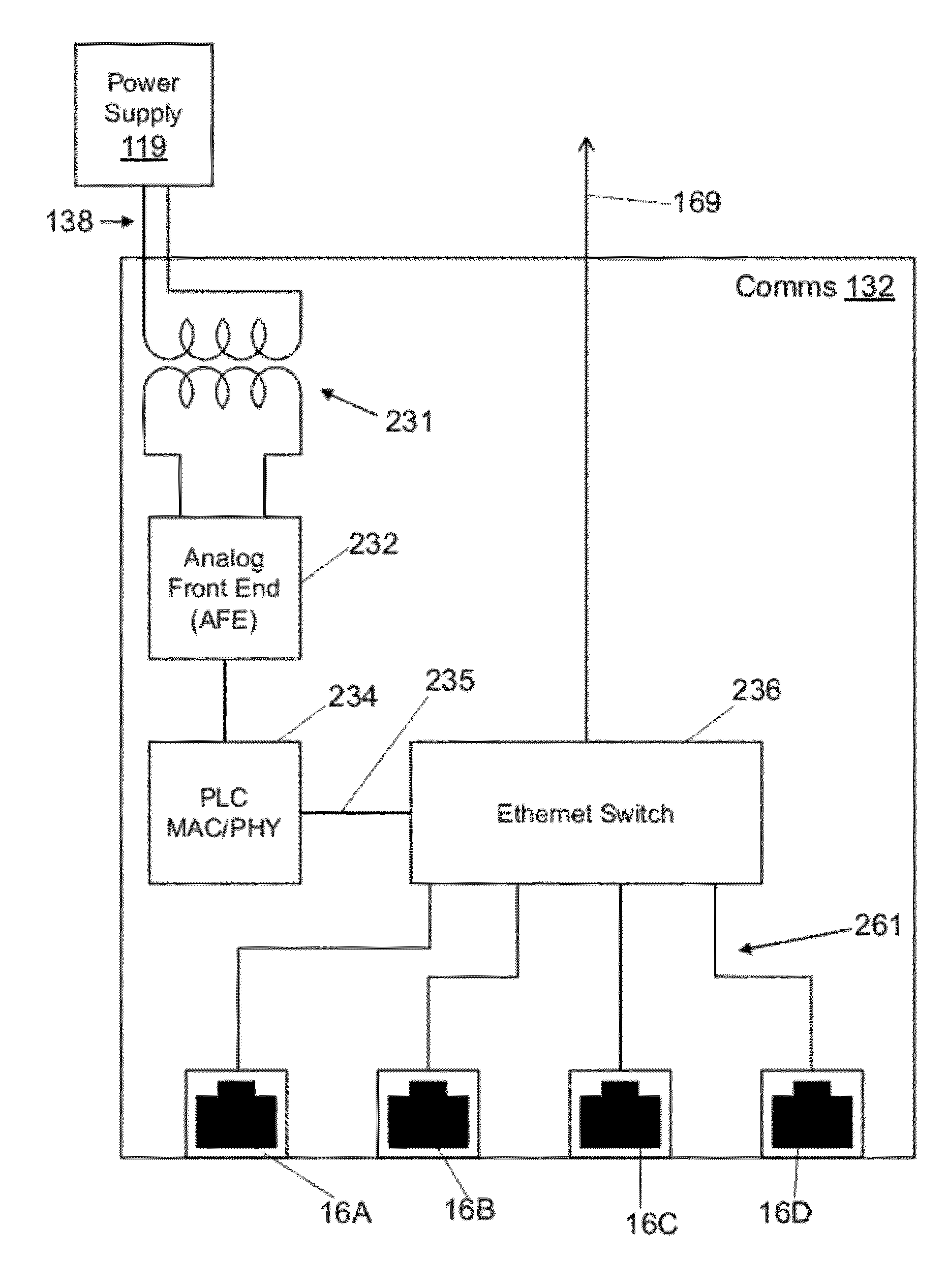

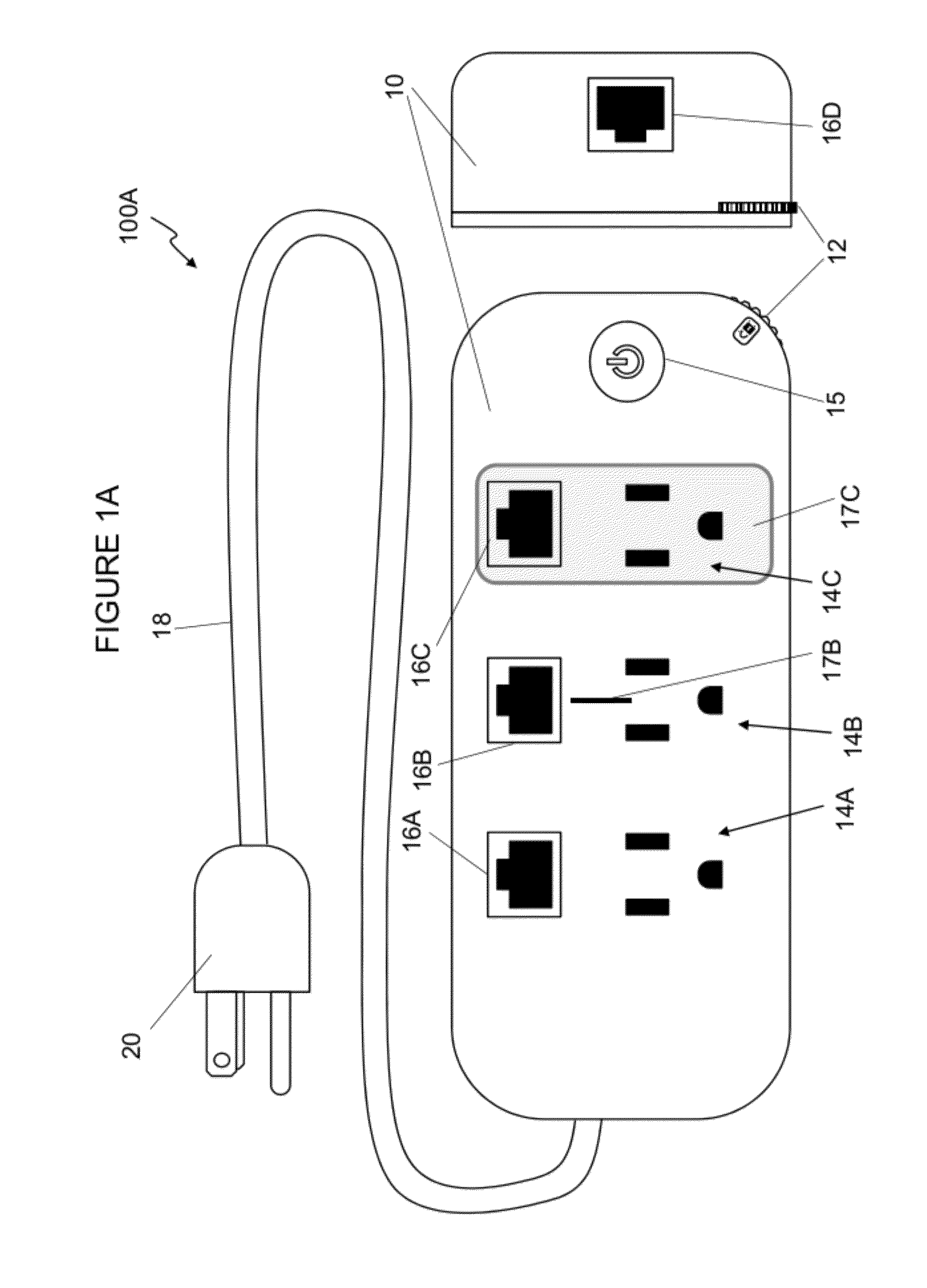

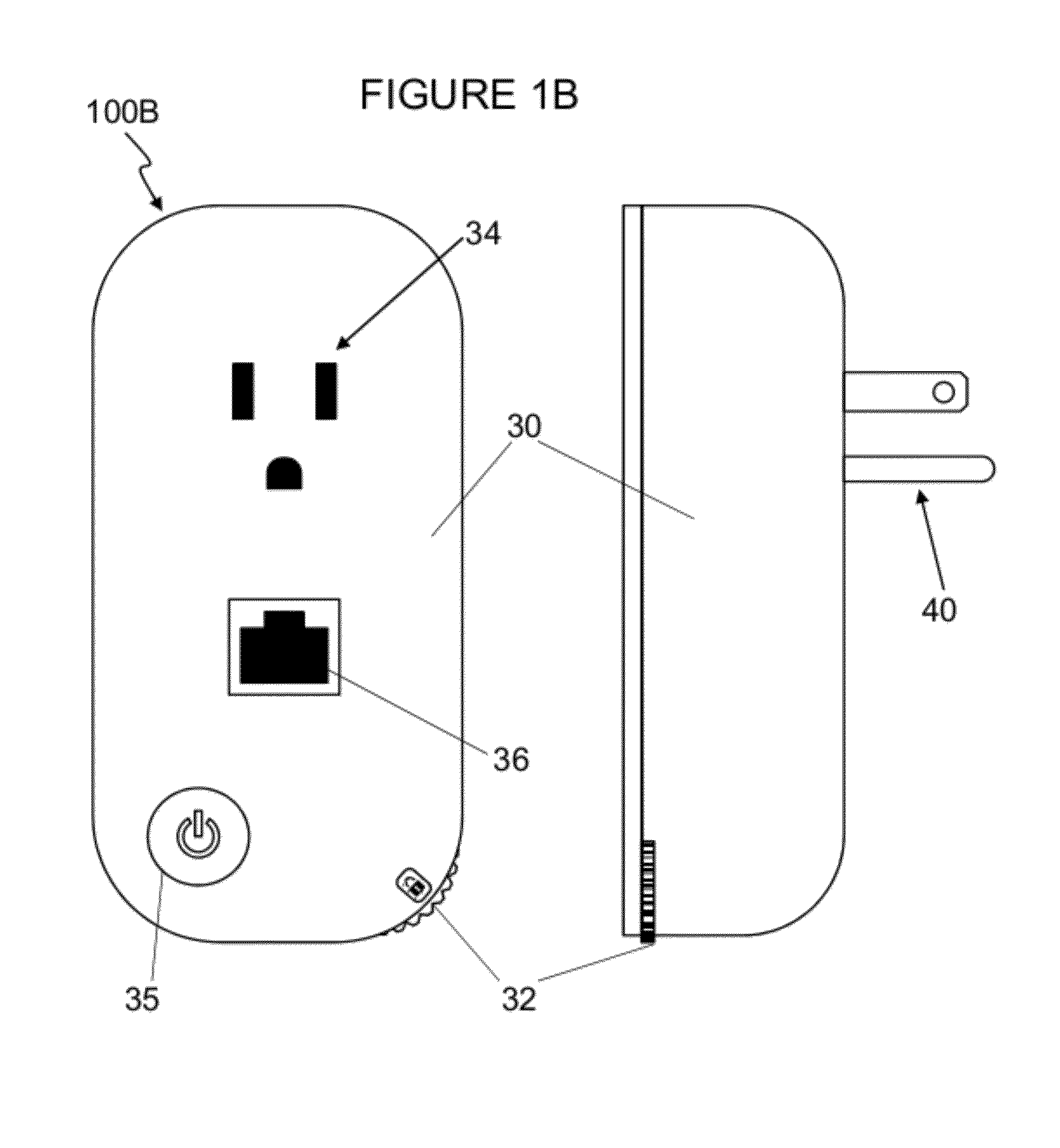

Power node with network switch

ActiveUS20120060044A1Coupling device connectionsDigital data processing detailsPower line networkNetwork integration

A power node provides energy management and network expansion features in a networked data communications and control environment that may be utilized in an energy management system implementing a method of managing energy. Network expansion may be provided by integrating a networking bridge from a power line network to one or more wired network ports or a wireless network. The power outlet on the power node providing power to a device may be identified and associated with information about the device.

Owner:SIGNIFY HLDG BV

Method for joining dissimilar metals of steel product and light metal product

InactiveCN101590598AOvercome limitationsRemove constraintsShrinkage connectionsSheet joiningMetallic materialsSpot welding

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron-iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

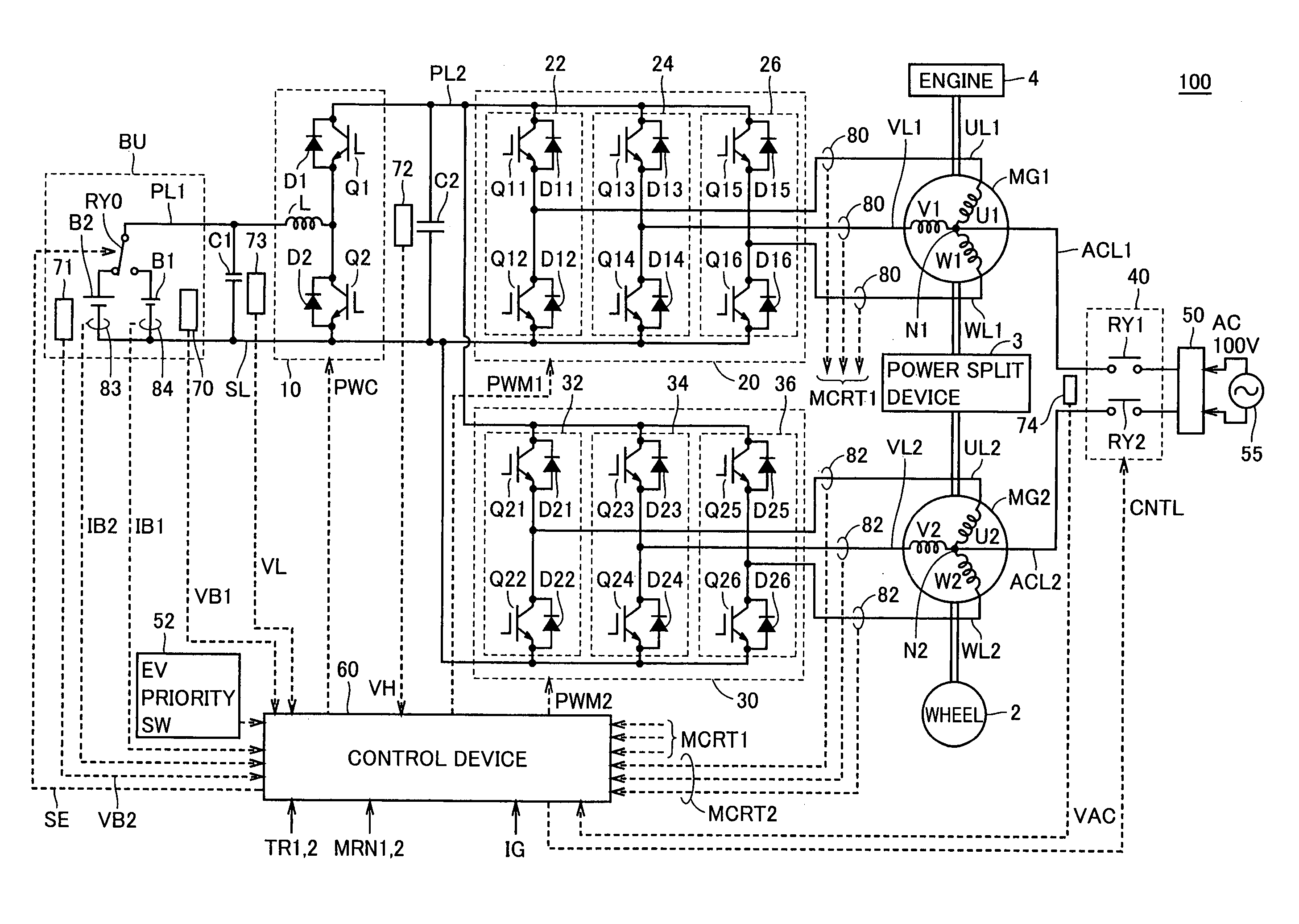

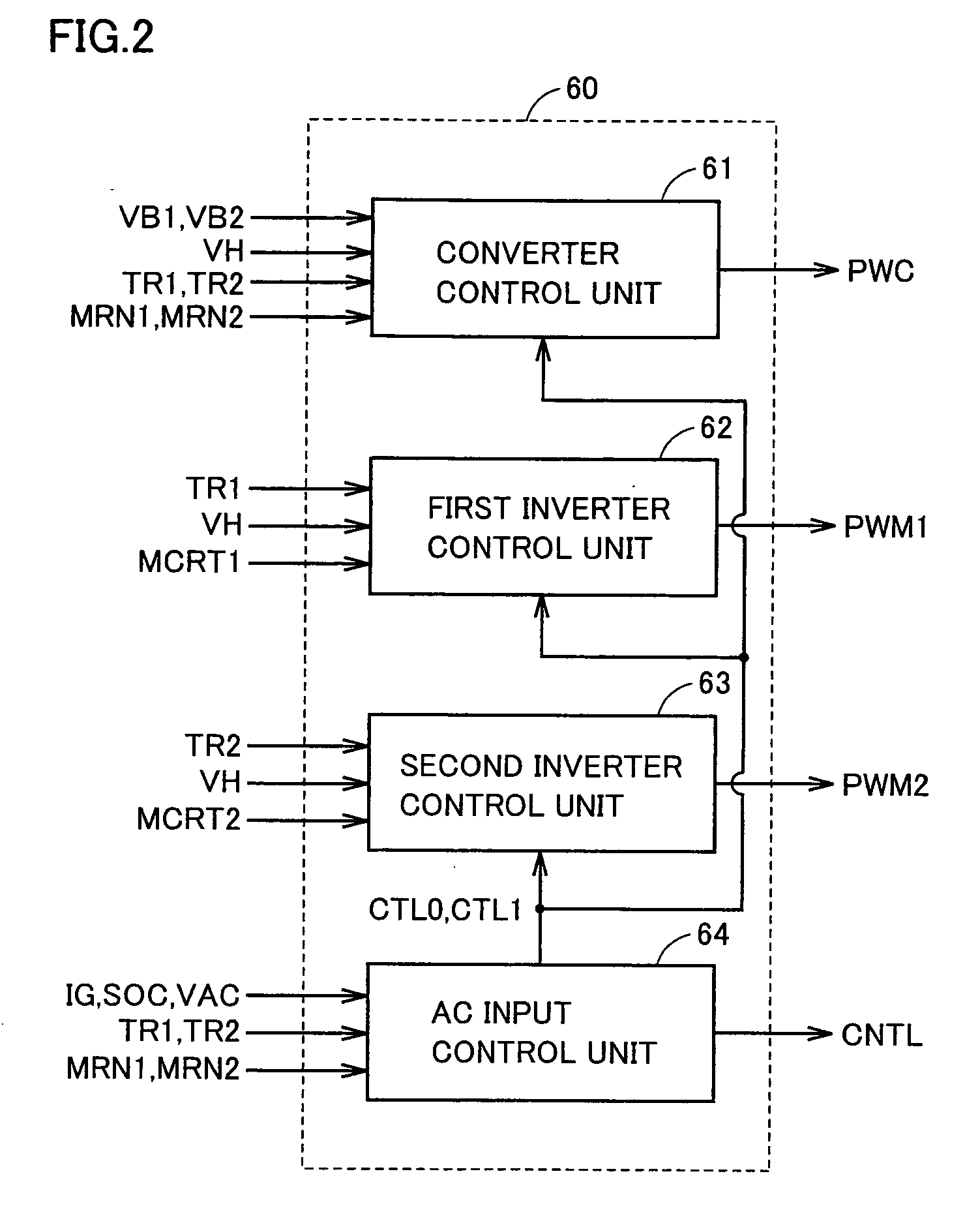

Power supply device for vehicle and method of controlling the same

InactiveUS20070029986A1Improve energy efficiencyLong-time drivingMultiple ac dynamo-electric motors controlPlural diverse prime-mover propulsion mountingElectricityElectrical battery

A power supply device for a vehicle includes a battery serving as a first electric storage device, a battery serving as a second electric storage device, a motor generator driving a wheel, a selection switch selecting one of the first and second electric storage devices and connecting the selected electric storage device to the motor generator, and a control device controlling switching of the selection switch in accordance with a state of charge of each of the first and second electric storage devices. In the case where the selection switch selects the first electric storage device, when charging is performed and the state of charge of the first electric storage device becomes higher than a first prescribed level, the control device instructs the selection switch to select the second electric storage device.

Owner:TOYOTA JIDOSHA KK

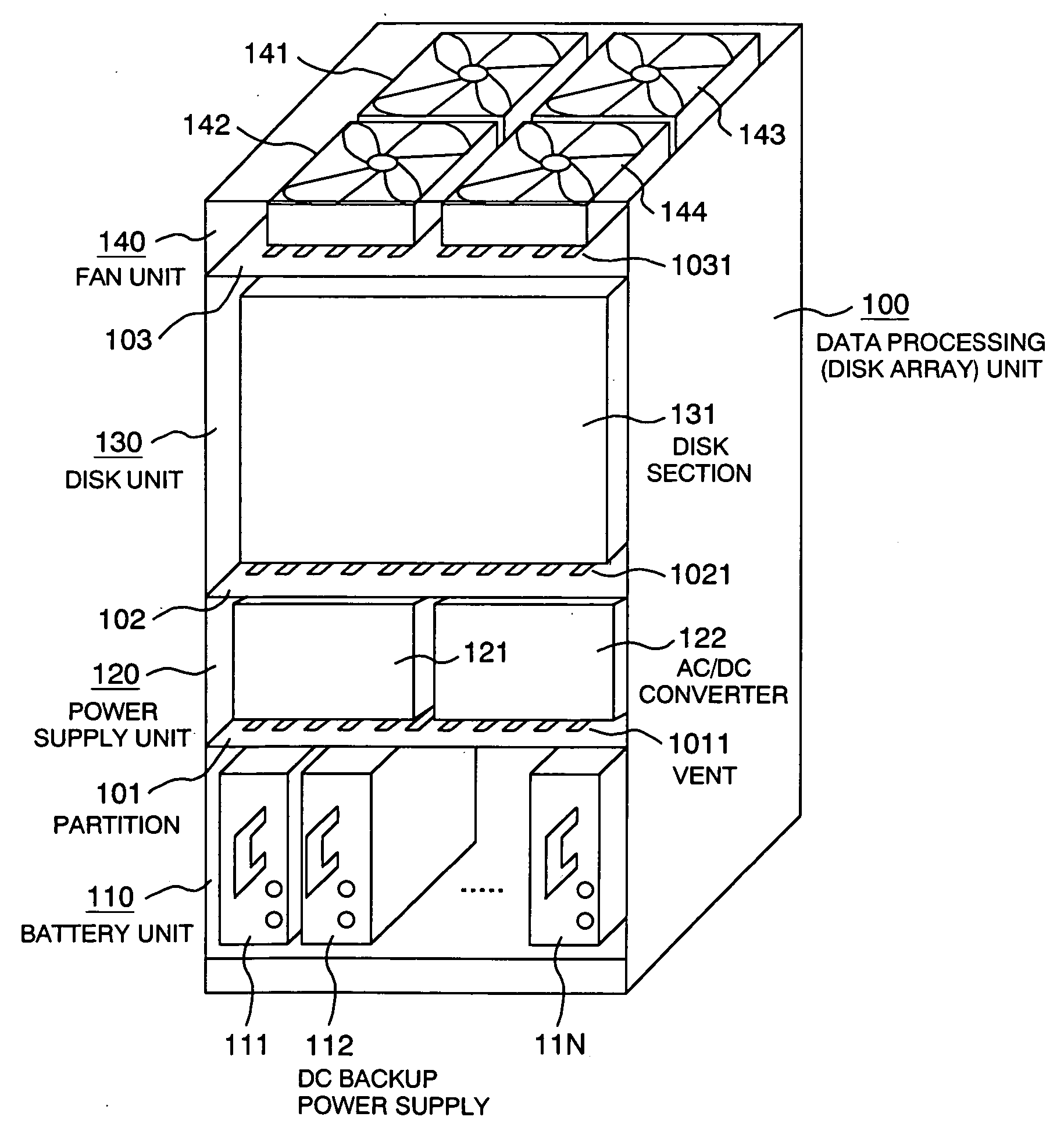

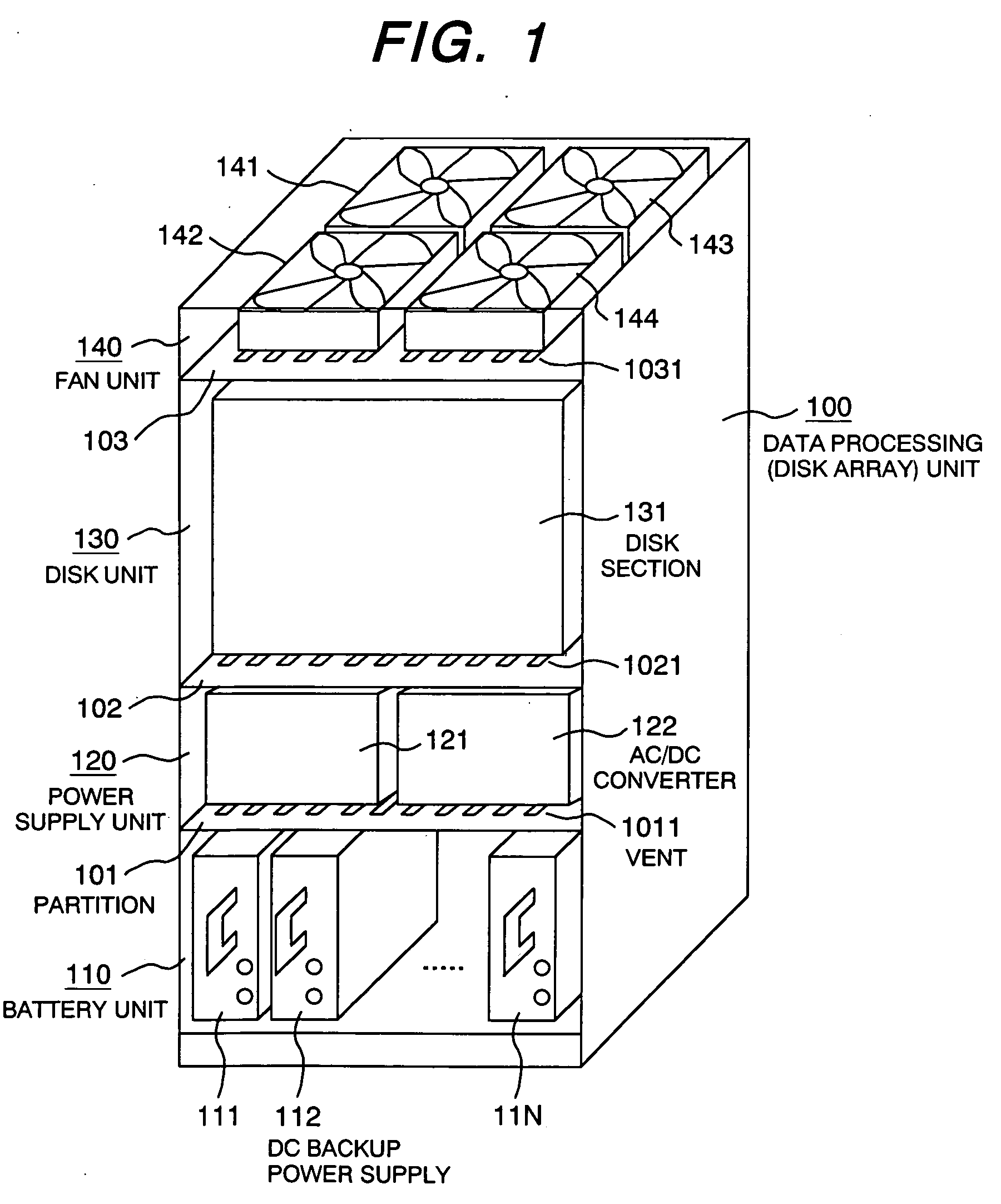

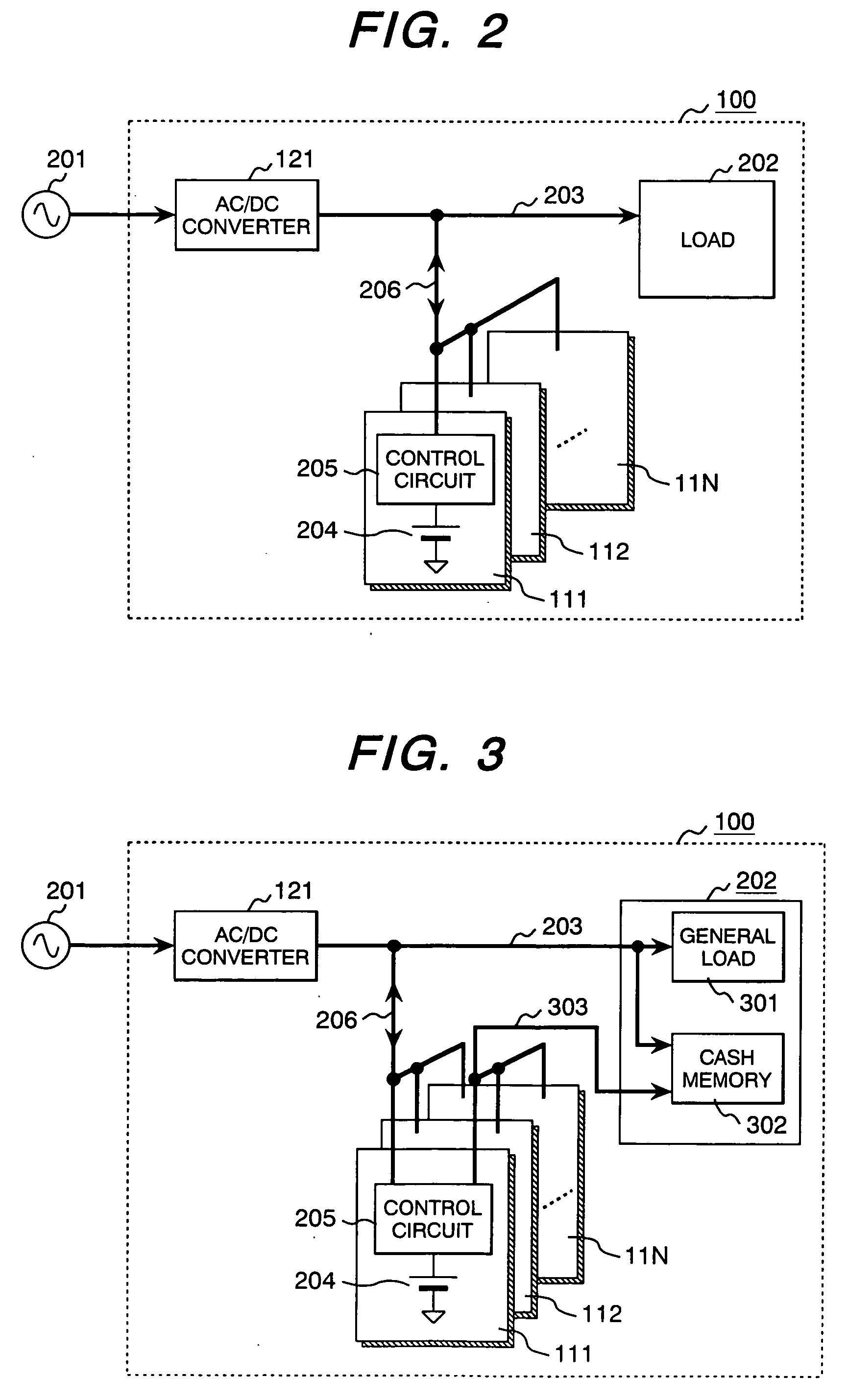

Data processing unit and DC backup power supply

InactiveUS20060056142A1Compact and economicImprove discharge capacityDigital data processing detailsVolume/mass flow measurementElectrical batteryStandby power

A backup power supply is so constructed that it is provided with multiple DC backup power supplies 111 to 11N, each containing nickel-metal hydride battery, stored upright on the bottom of the disk array unit 100; cooled by cooling air through the vents 1011 for ventilation from the bottom to the top; and connected with the output of the AC / DC converters 121, 122 with the backboard 151. Very compact disk array unit with an uninterruptible power supplying function can be realized.

Owner:HITACHI INFORMATION & TELECOMM ENG LTD

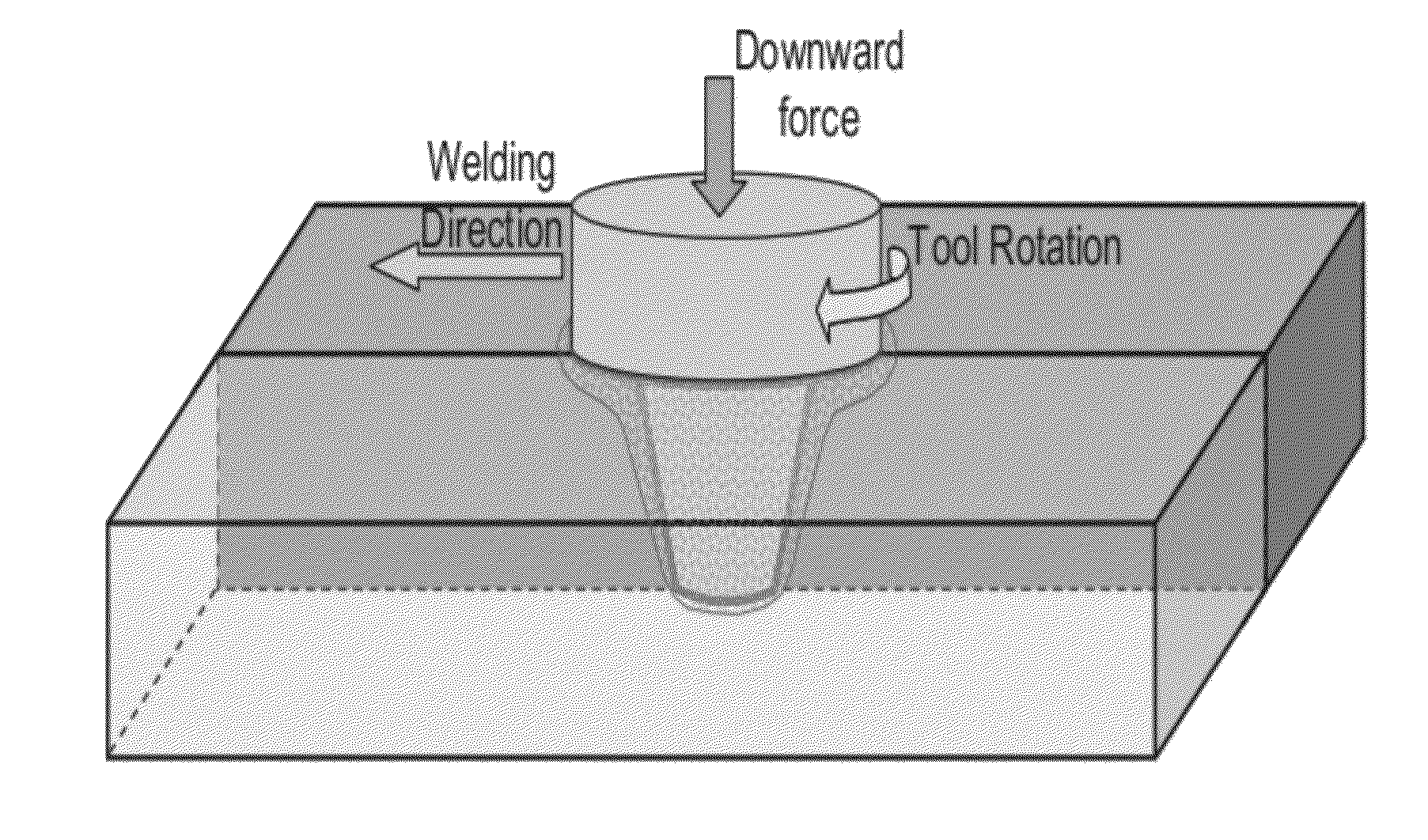

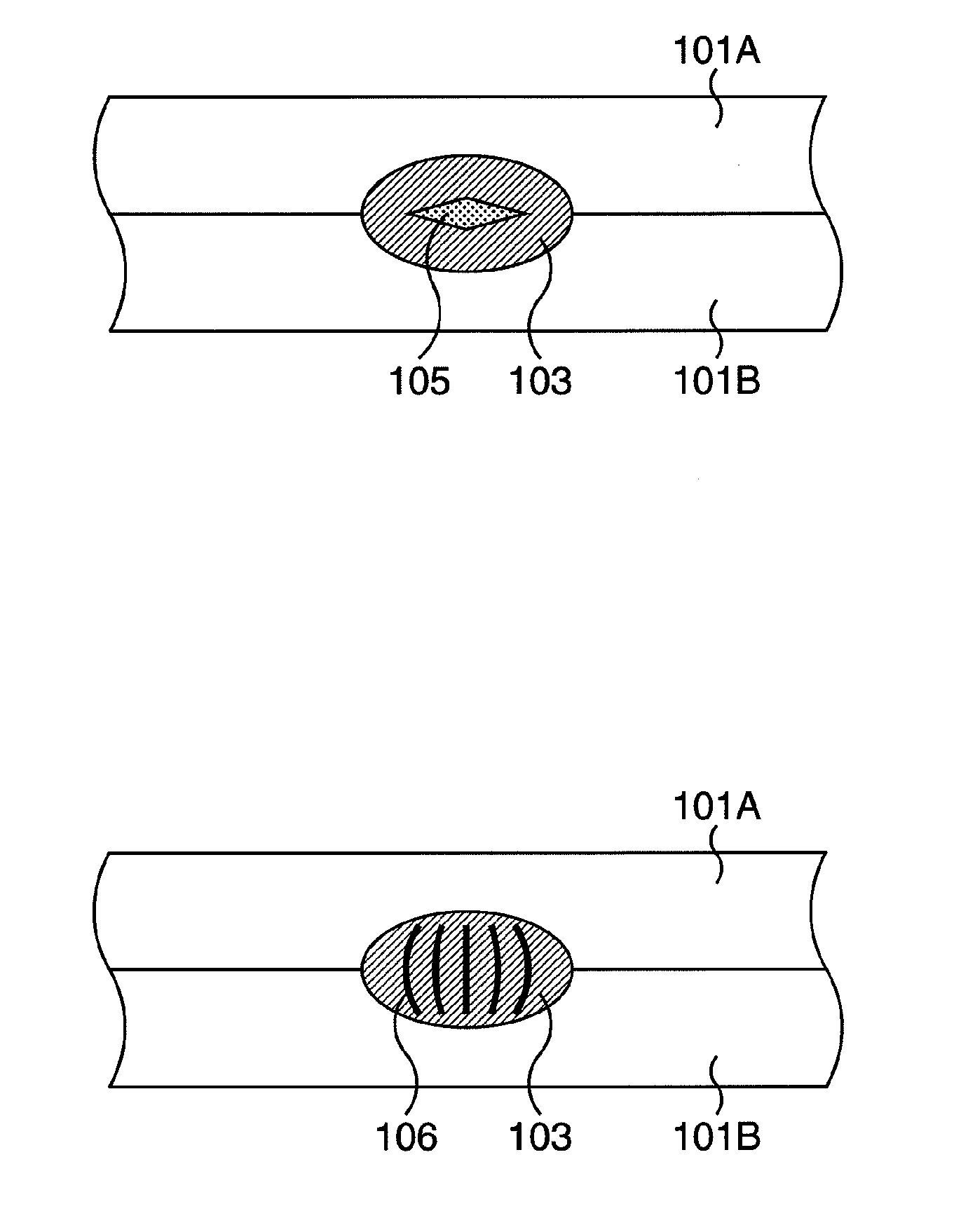

Spot welded joint and spot welding method

ActiveUS20120141829A1Improve machinabilityImprove reliabilityArc welding apparatusWelding/soldering/cutting articlesNumber densityCarbide

Provided is a spot welded joint (10) which includes at least one thin steel plate with a tensile strength of 750 MPa to 1850 MPa and a carbon equivalent Ceq of equal to or more than 0.22 mass % to 0.55 mass % and in which a nugget (3) is formed in an interface of the thin steel plates (1A, 1B). In a nugget outer layer zone, a microstructure consists of a dendrite structure in which an average value of arm intervals is equal to or less than 12 μm, an average grain diameter of carbides contained in the microstructure is 5 nm to 100 nm, and a number density of carbides is equal to or more than 2×106 / mm2.

Owner:NIPPON STEEL CORP

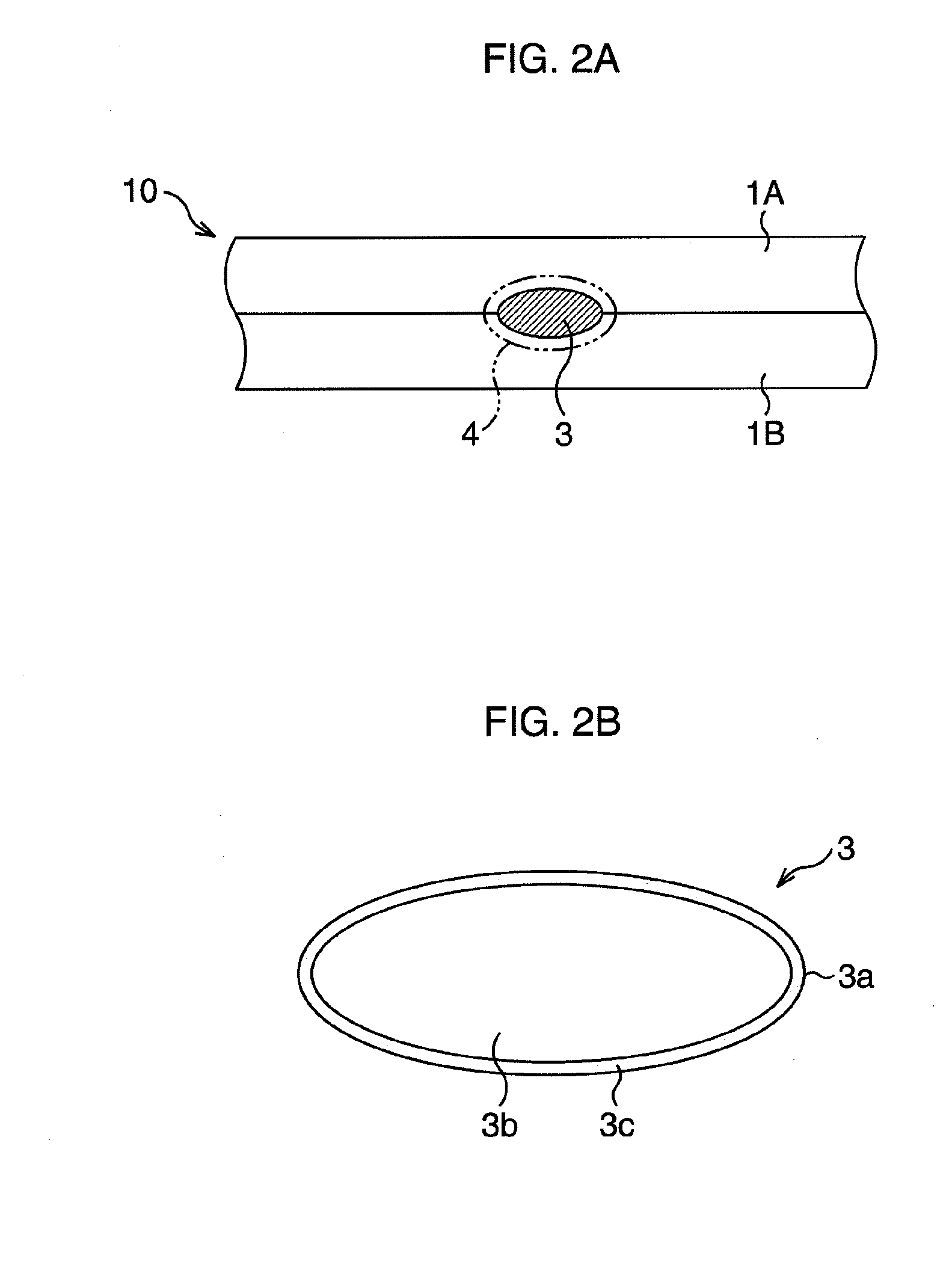

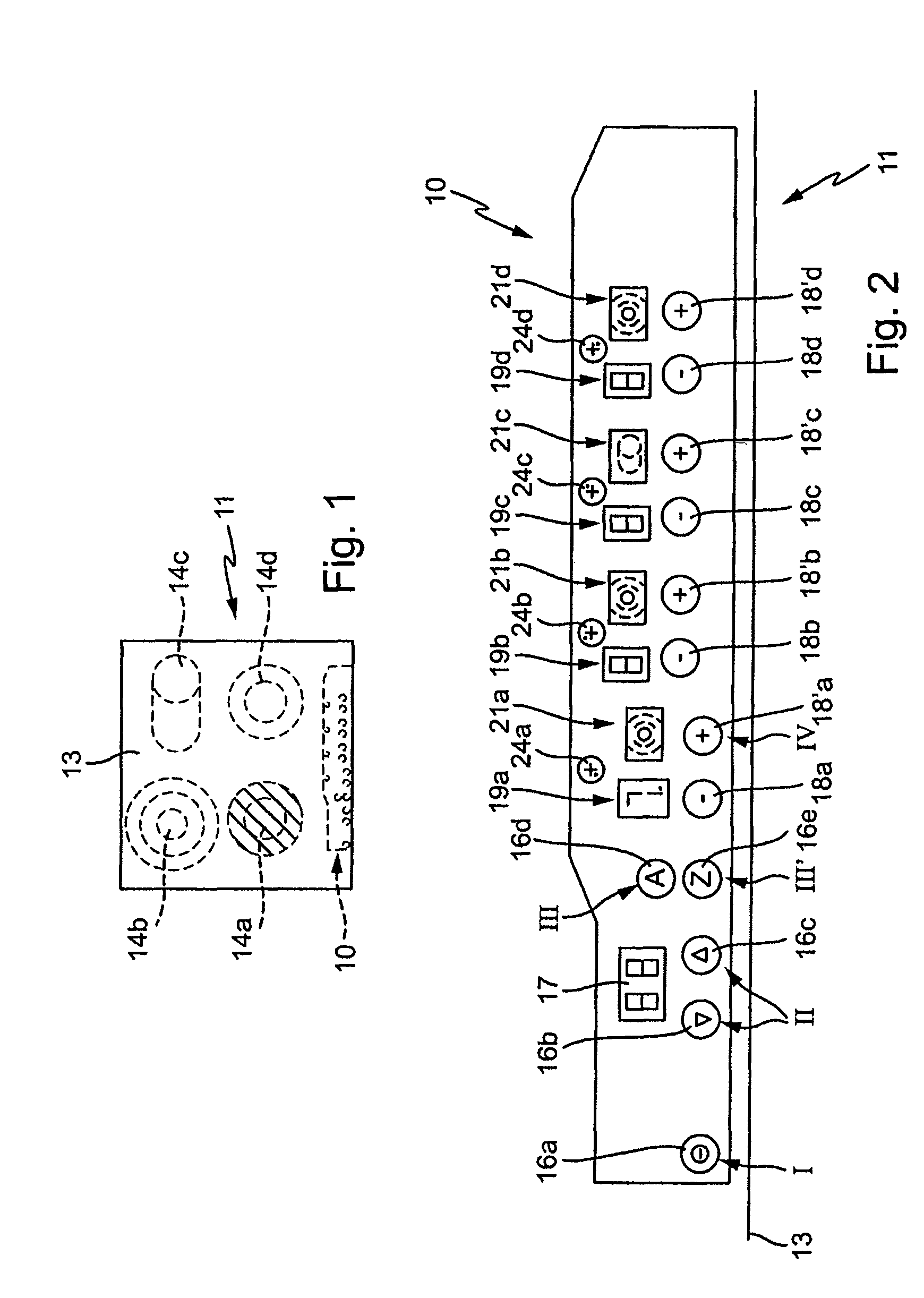

Method for operating a heating device of an electric heating appliance having a plurality of heating devices

InactiveUS8581137B2Accurate operationEasy to implementDomestic stoves or rangesLighting and heating apparatusMultiple useProcess engineering

In an operating method for a hob having a plurality of heating elements, an operating action for a heating element, such as heating with an additional region on the cooktop or invoking a parboiling step, is selected in an initial step by providing input to a general input sensor element that is not associated with any specific heating element. In a subsequent step, the selected operating action is allocated or associated with a specific heating element by operating a cooking element specific sensor element, for example when setting the power level for that heating element. Therefore, sensor elements can be provided with an advantageous multiple-use effect for general operating actions. Furthermore, the operating sequence permits simple and convenient operation.

Owner:E G O ELEKTRO GERAETEBAU GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com