Method for joining dissimilar metals of steel product and light metal product

A technology of dissimilar materials and joining methods, applied in the direction of thin plate connection, shrinkage connection, connection members, etc., can solve the problem of large reduction in the strength of the heat-generating fusion part and HAZ, impossibility, and inability to easily make assumptions, etc., to achieve flatness Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, specific modes for implementing the present invention will be described with reference to the drawings. In addition, the following description will also focus on aluminum alloy materials among light alloy materials, but the case of magnesium alloy materials is basically the same as that of aluminum alloy materials.

[0049] (The joining of iron rivets to aluminum alloy materials)

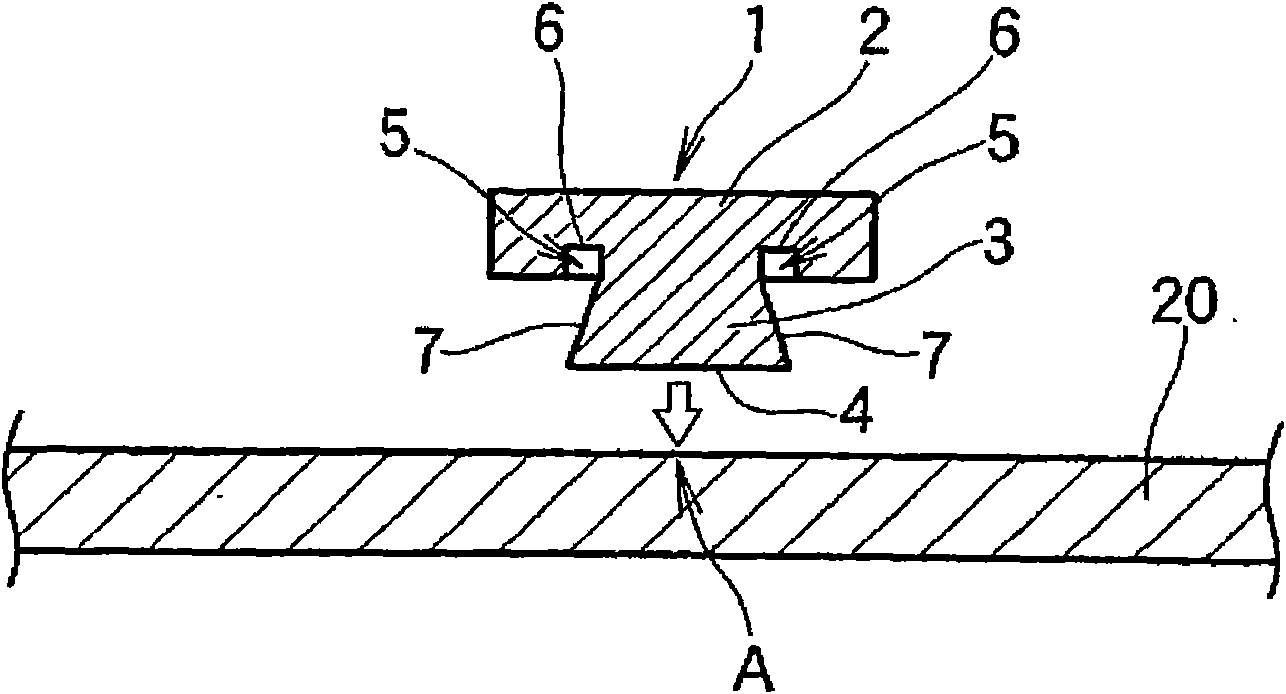

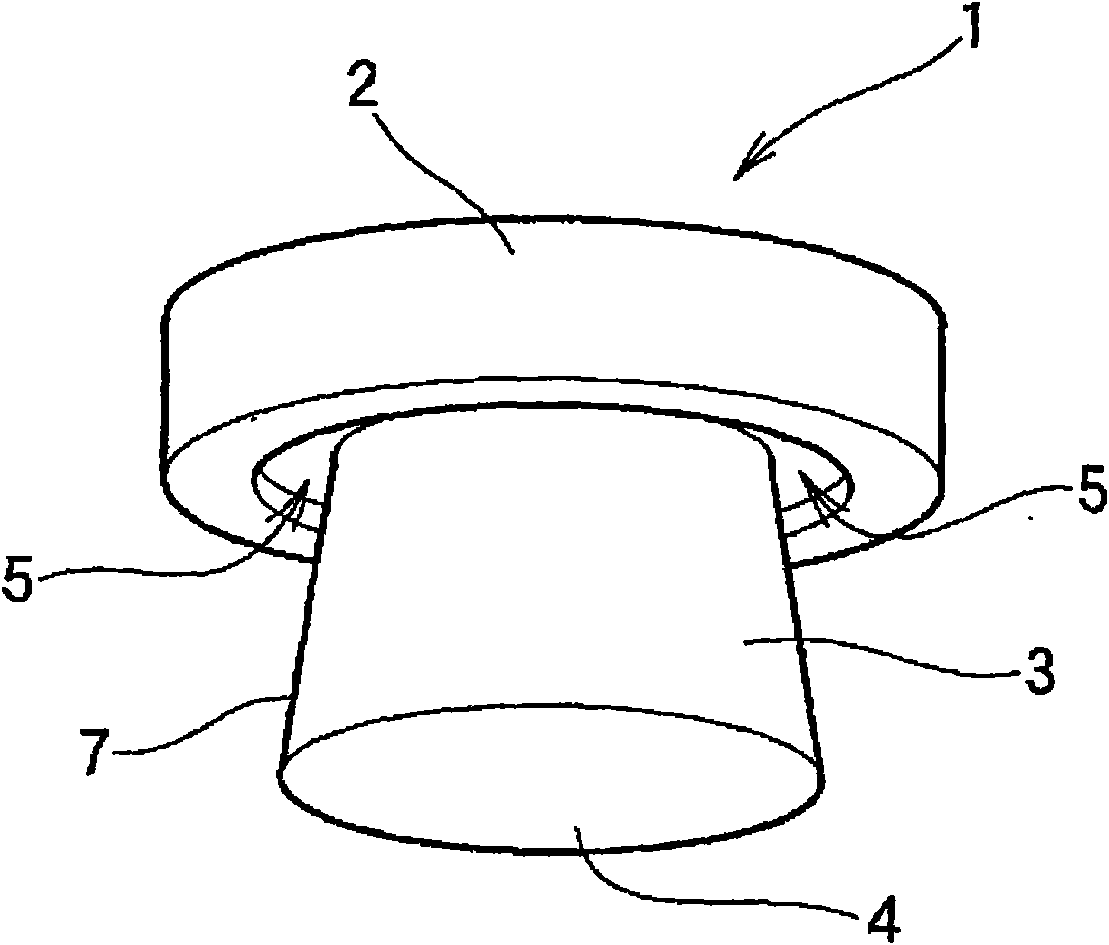

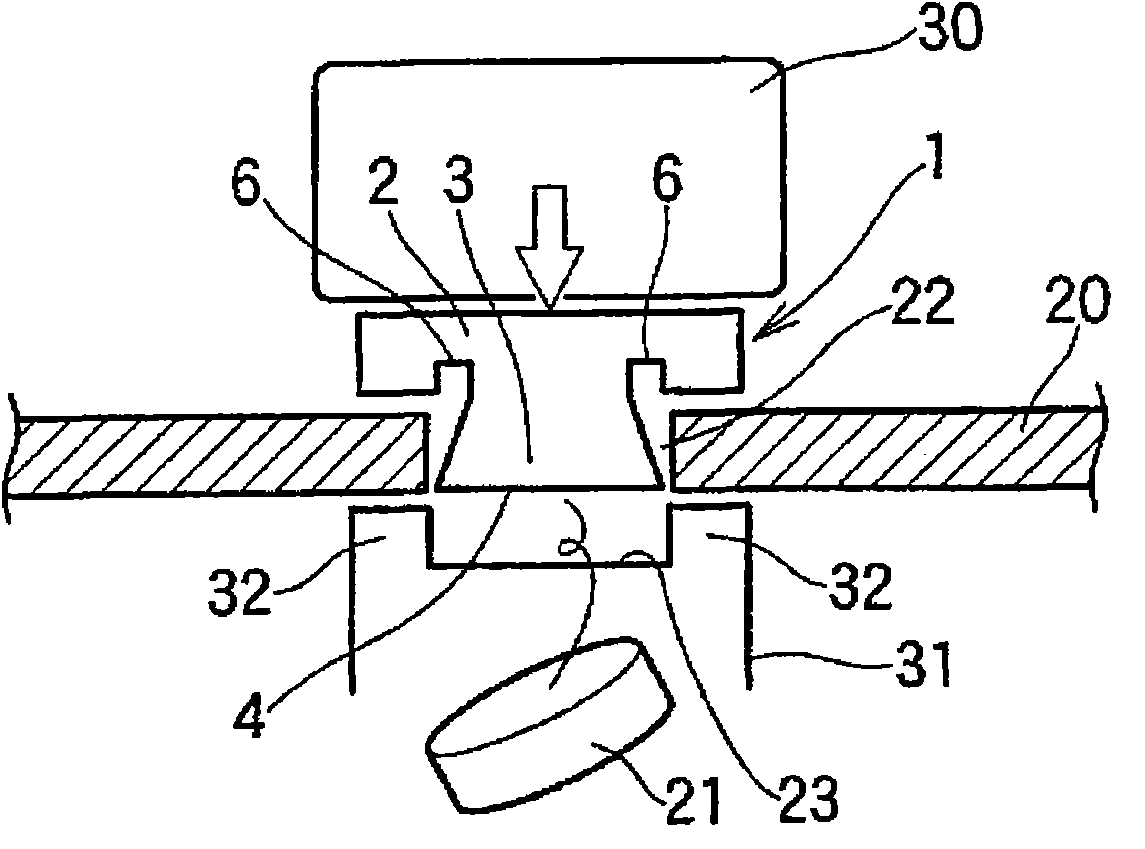

[0050] As a prerequisite, in the present invention, rivet joining and spot welding are used in combination to join dissimilar materials between steel materials and aluminum alloy materials. In this case, as the requirement a., it is the pre-process (other process) of the process of spot welding steel and aluminum alloy material, for example, in the press forming process of aluminum alloy material, the aluminum alloy material and the Iron-based rivets are mechanically joined in advance between aluminum-iron dissimilar materials. Then spot welding the rivet and steel.

[0051] (Joint o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com