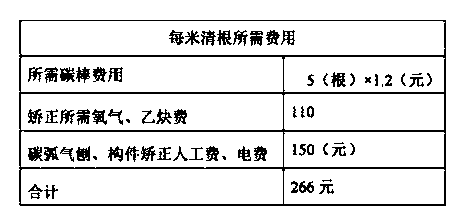

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

926 results about "Fillet weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

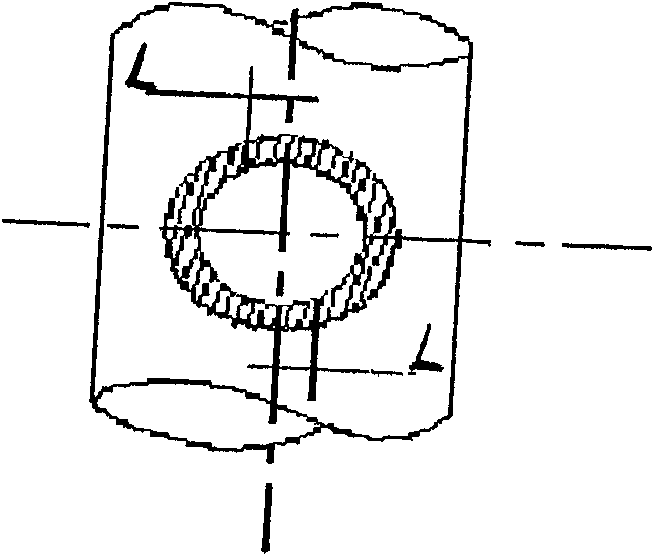

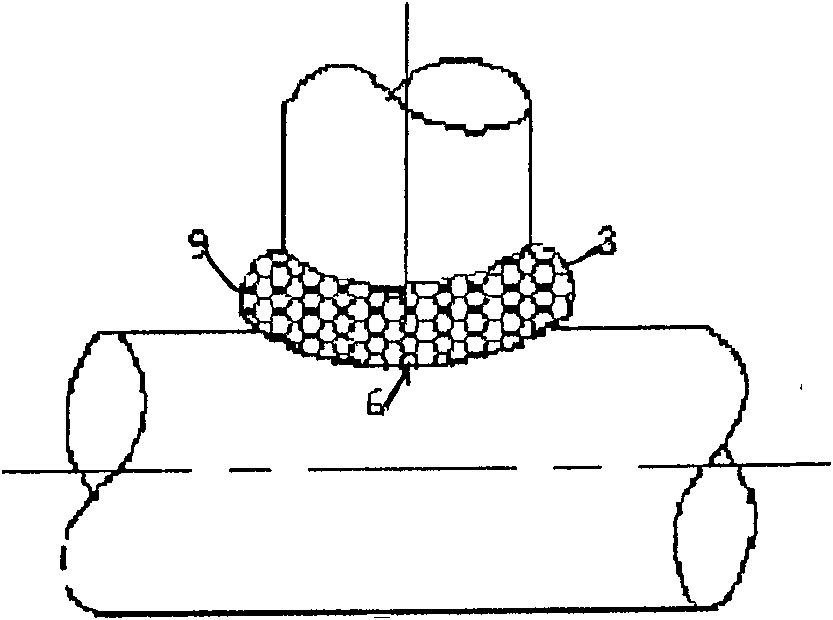

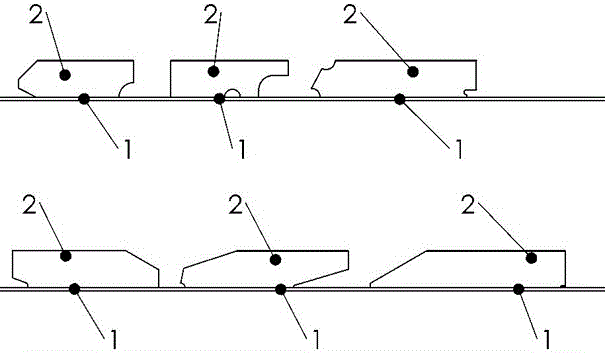

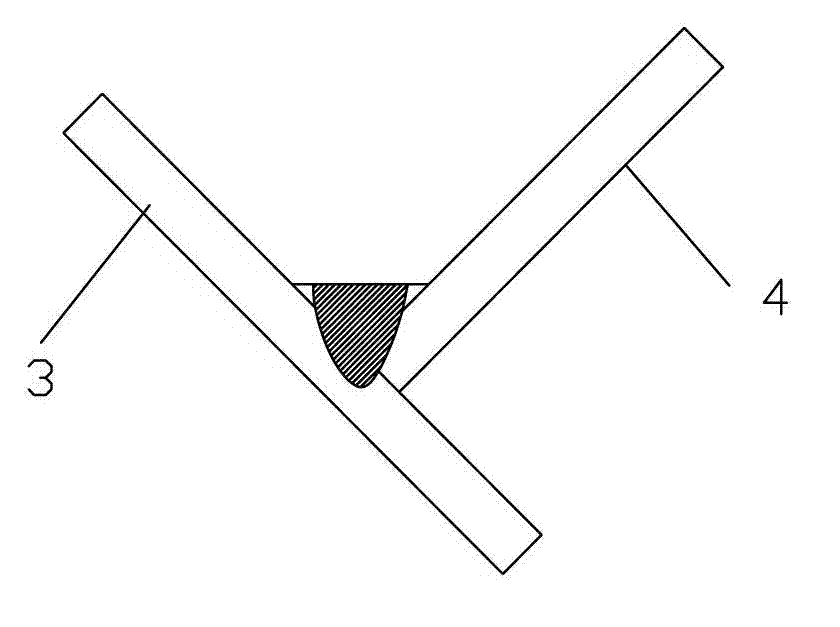

Fillet welding refers to the process of joining two pieces of metal together whether they be perpendicular or at an angle. These welds are commonly referred to as Tee joints which are two pieces of metal perpendicular to each other or Lap joints which are two pieces of metal that overlap and are welded at the edges. The weld is aesthetically triangular in shape and may have a concave, flat or convex surface depending on the welder’s technique. Welders use fillet welds when connecting flanges to pipes, welding cross sections of infrastructure, and when fastening metal by bolts isn't strong enough and wear off easily.

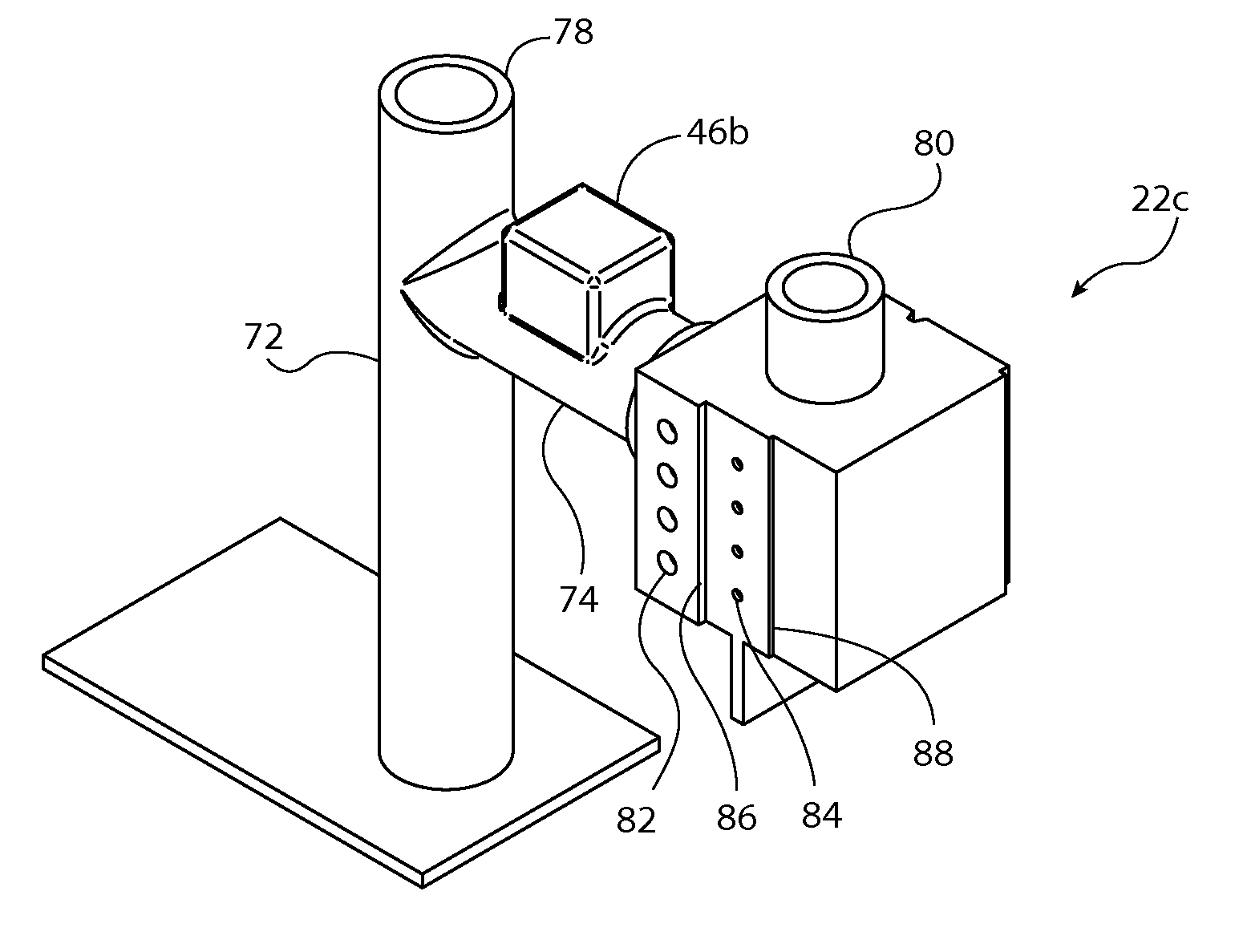

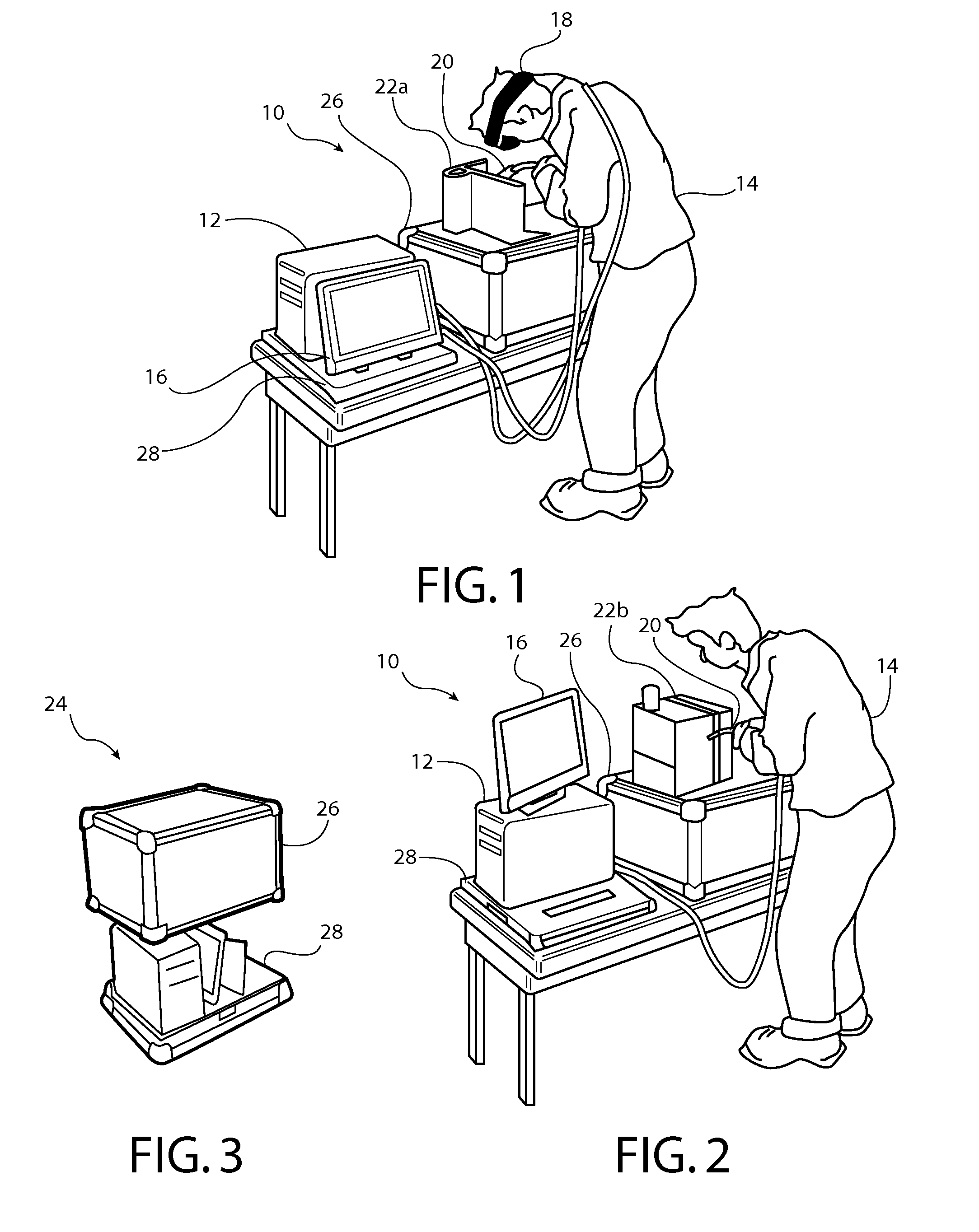

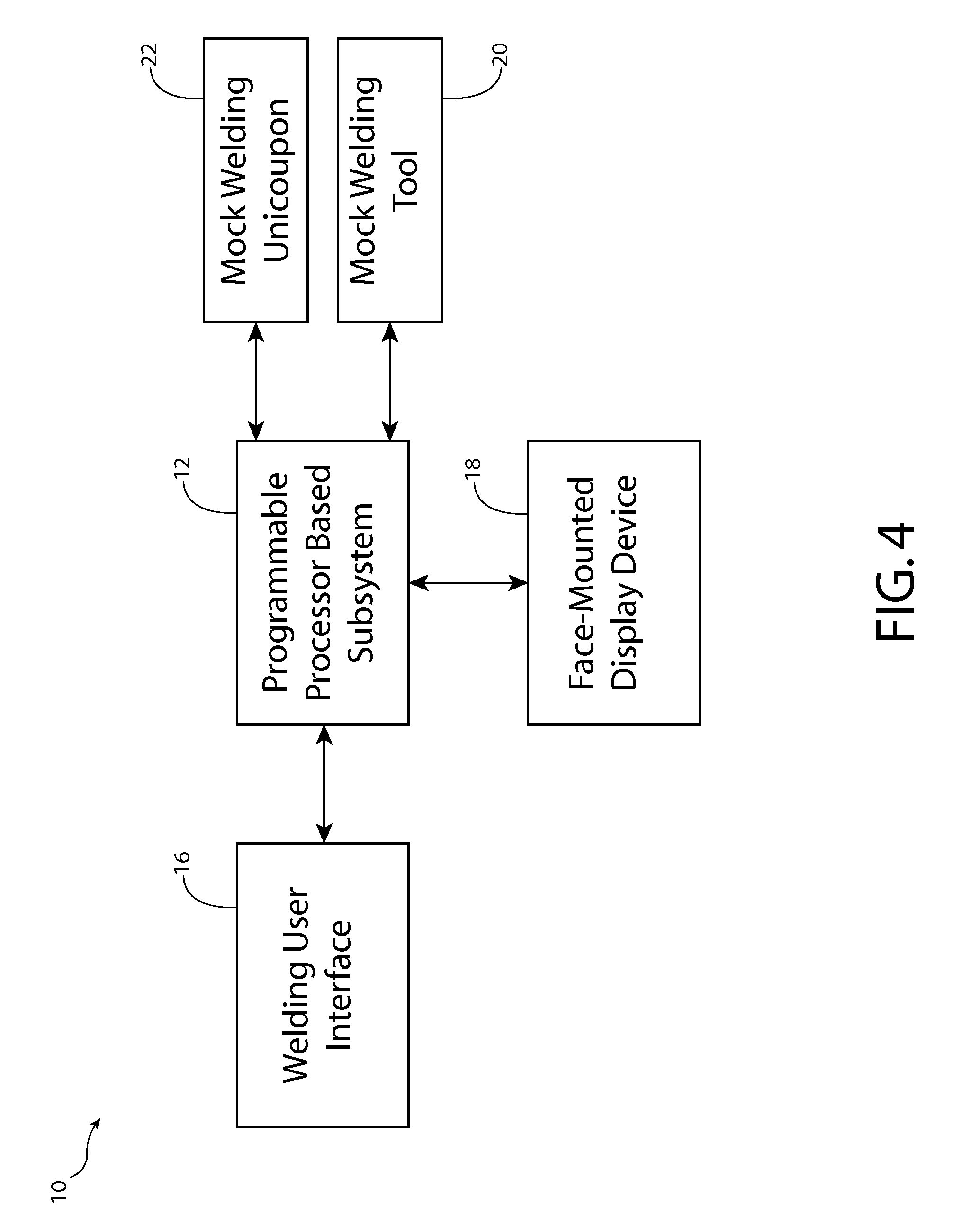

Unicoupon for virtual reality welding simulator

A mock welding unicoupon for a virtual welding system includes a first exterior surface and a second exterior surface perpendicular to the first exterior surface. The first exterior surface and the second exterior surface together provide a plurality of grooves configured for simulation of a plurality of different types groove welds on the mock welding unicoupon. A curved exterior surface is configured for simulation of a pipe fillet weld on the mock welding unicoupon. A magnet source is configured to generate a magnetic field around the mock welding unicoupon for tracking movements of a mock welding tool with respect to the mock welding unicoupon.

Owner:LINCOLN GLOBAL INC

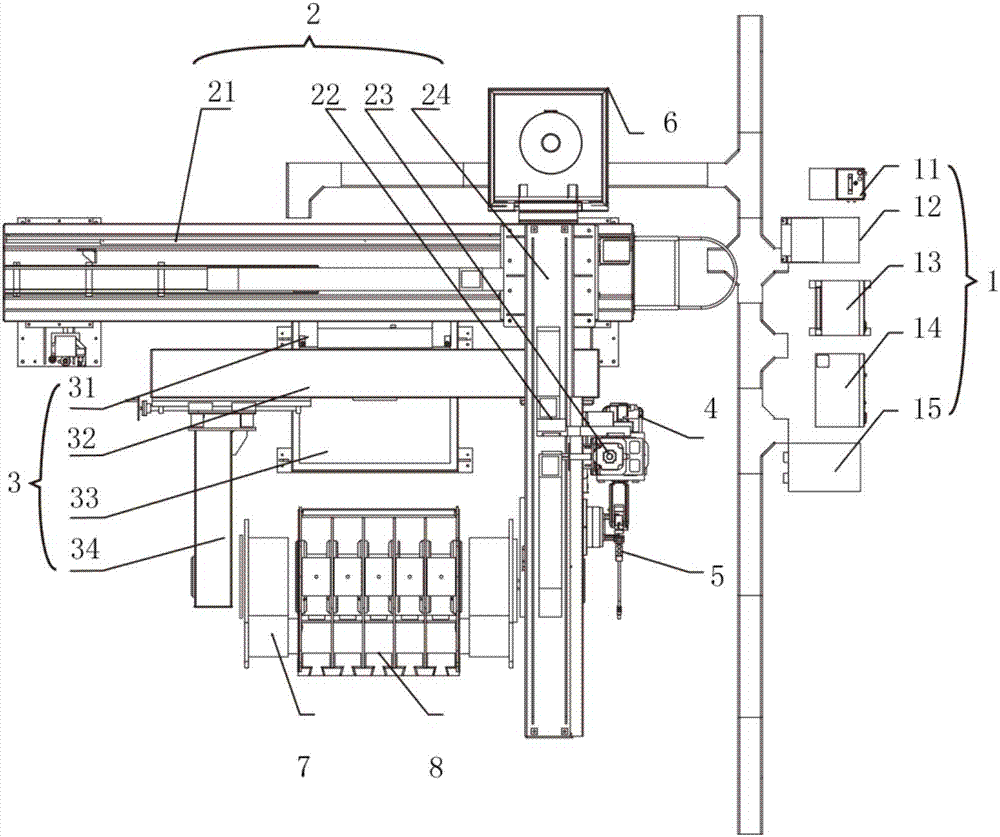

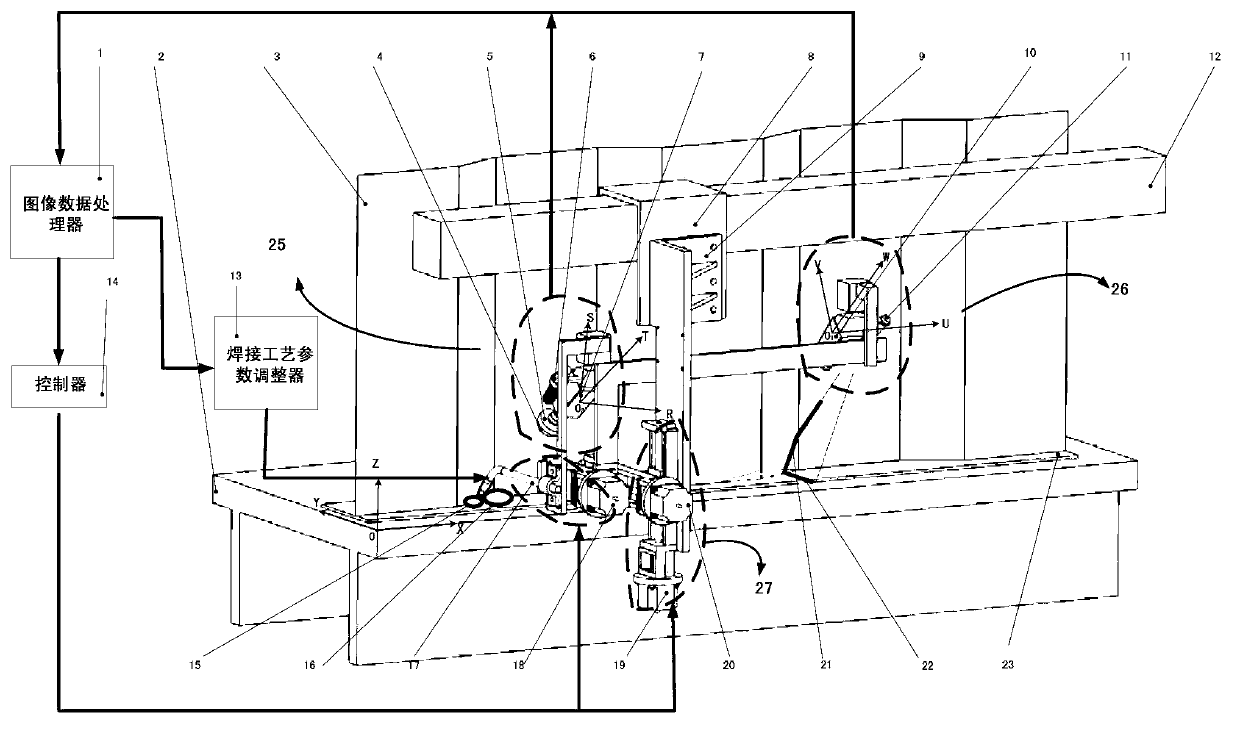

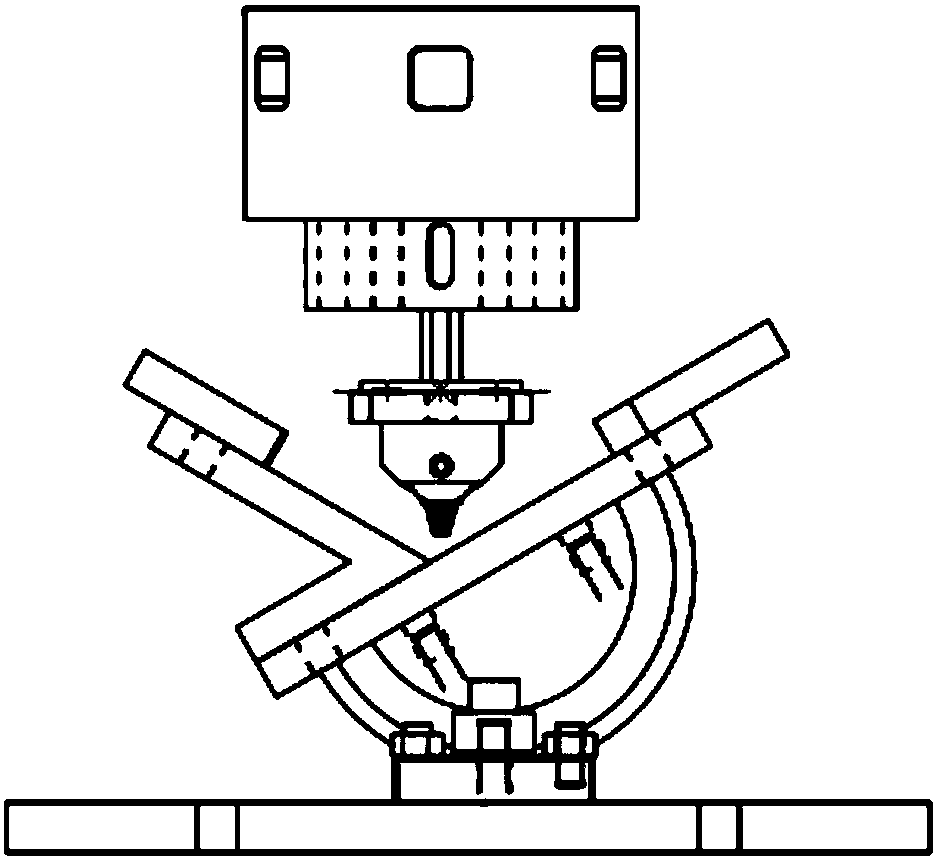

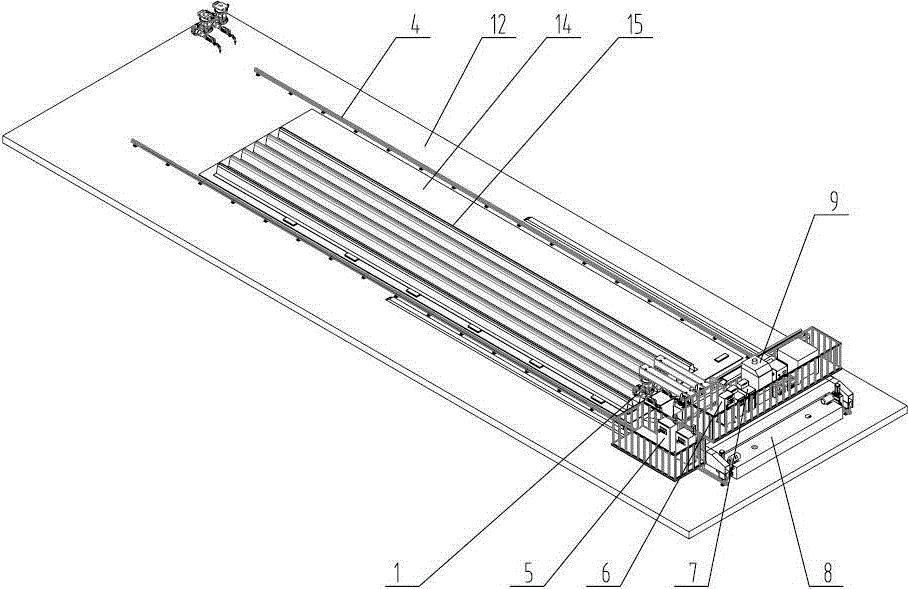

Welding robot device for welding of plunger pump power end shell

PendingCN107234358AGuarantee quality and efficiencyGuaranteed welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFillet weldControl system

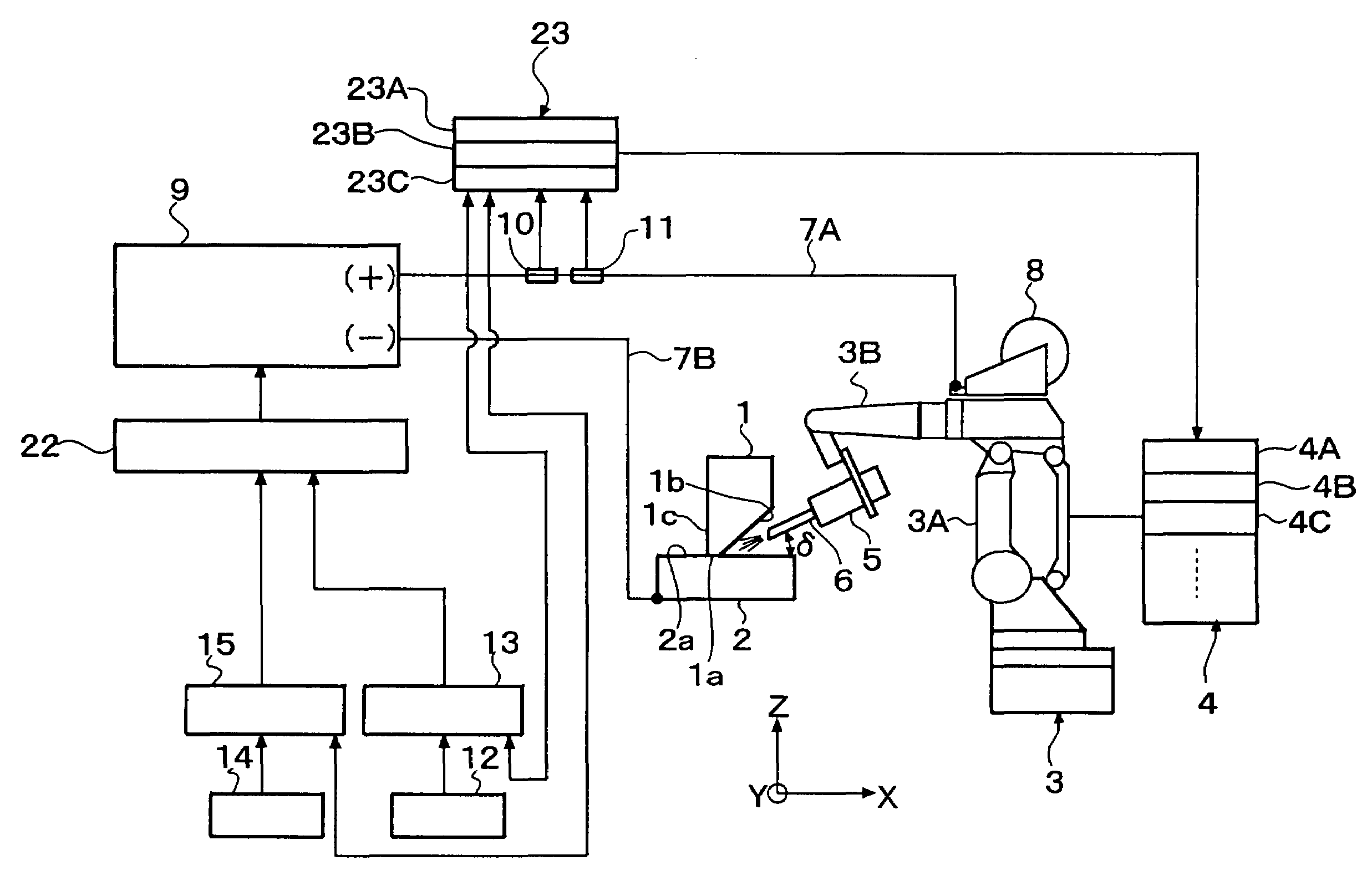

The invention provides a welding robot device for welding of a plunger pump power end shell. The welding robot device for welding of the plunger pump power end shell comprises a controlling system, a portal frame X-Y-Z coordinate system, a welding system, a space positioner and a tool clamp. The tool clamp is used for clamping the plunger pump power end shell, and a plunger pump shell can be one-time clamped; all welding joints of the plunger pump shell can be positionally changed to a flat welding position or a flat fillet welding position through the space positioner; a welding mechanical arm is connected with a coordinate Z-axis in the portal frame X-Y-Z coordinate system, and welding of welding joints in the different positions can be finished; and synchronized driving of the welding mechanical arm, a coordinate X-axis, a coordinate Y-axis, the coordinate Z-axis and the space positioner can be realized, so that continuity during the welding process is guaranteed, and welding quality and welding efficiency are ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

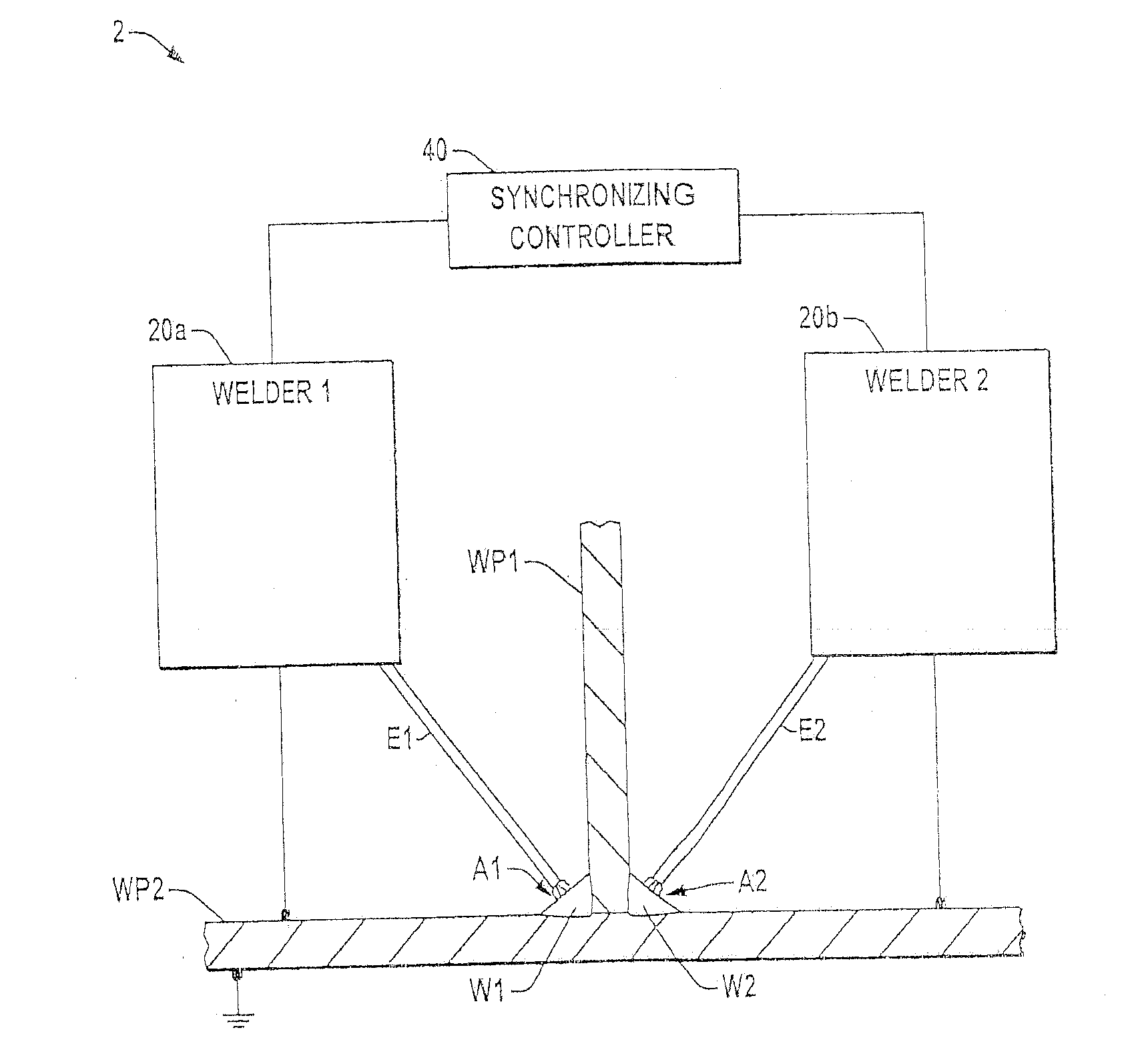

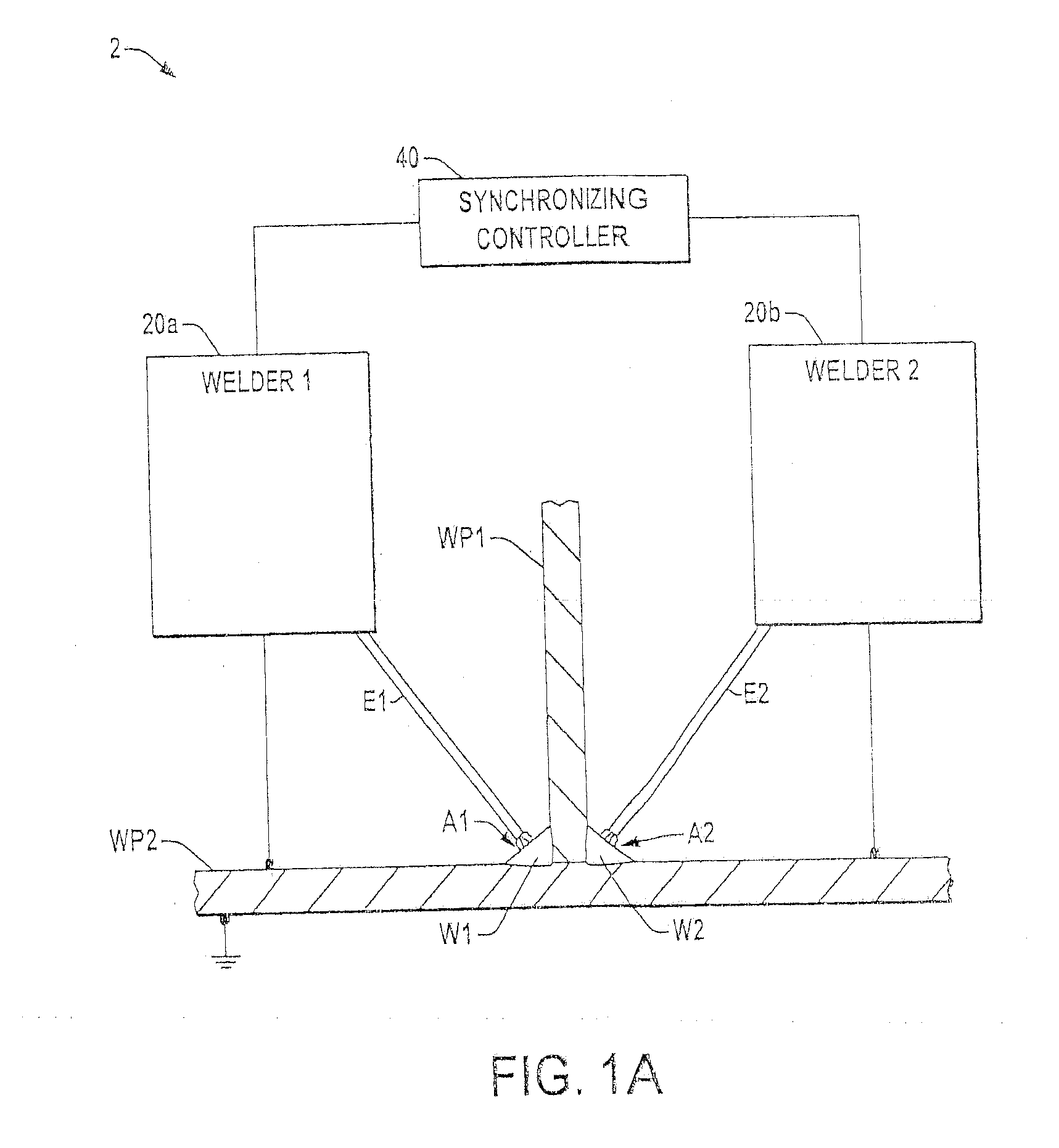

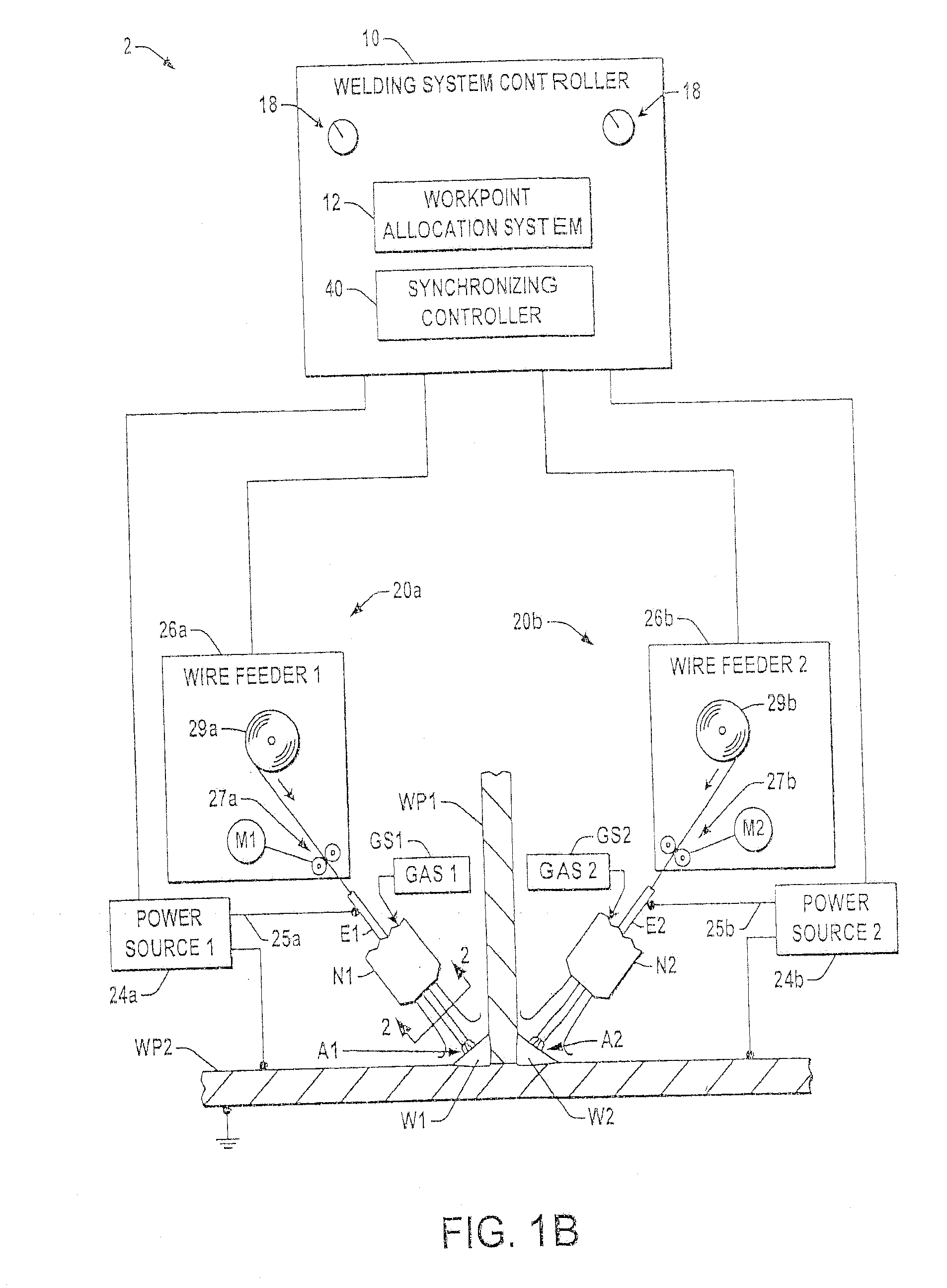

Welding methods and systems

A welding system is provided, in which two electrodes are directed at a joint between two work pieces and the electrodes are energized with DC pulse or AC welding waveforms at a controlled waveform phase angle. The systems include a synchronizing controller to synchronize the welding waveforms, and a work point allocation system provides one or more work point values to the welding machines to provide synergic control of the welding according to a user selected system work point value or parameter. The systems and methods further provide for synchronized work point value modulation for the opposite sides of a dual fillet weld. The system and method further provide a high energy heat source that directs intense heat at a portion of the weld joint to improve weld penetration.

Owner:LINCOLN GLOBAL INC

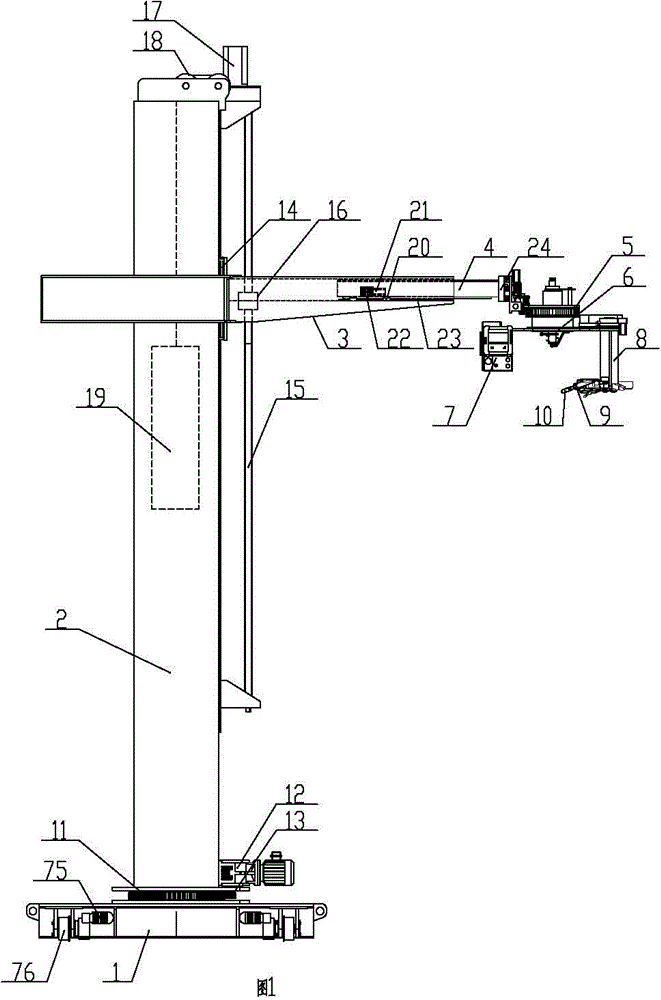

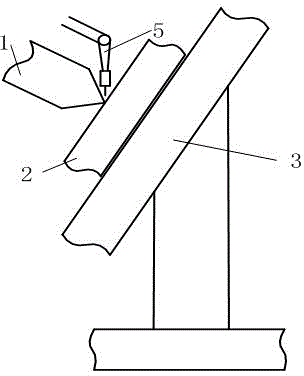

Multifunctional single-cantilever cutting and welding integrated machine

InactiveCN104308333AAvoid frequent movementReduce the number of card positioningWelding/cutting auxillary devicesAuxillary welding devicesFillet weldEngineering

The invention relates to the technical field of automated cutting and welding, and discloses a multifunctional single-cantilever cutting and welding integrated machine. The integrated machine comprises a machine frame base, a machine frame stand column, a stand column rotary device, a vertical lifting device, a machine frame transverse arm, a left-right translation device, a telescopic arm, a front-rear transverse moving device and a multi-joint machine head, wherein the machine frame stand column is mounted on the machine frame base through the stand column rotary device, and the machine frame transverse arm is mounted at the upper part of the machine frame stand column through the vertical lifting device. The integrated machine is reasonable and compact in structure and convenient to use; the welding of longitudinal, circumferential and fillet weld seams, cutting of an intersecting line hole and automatic welding of a saddle-shaped weld seam between a barrel body and a connecting pipe can be finished in a relatively fixed station through the stand column rotary device, the vertical lifting device, the left-right translation device, the front-rear transverse moving device and the multi-joint machine head, the frequent motion of a workpiece can be avoided, the clamping and positioning frequency of the workpiece is greatly reduced, the welding efficiency and quality are remarkably improved, and the labor intensity of welding workers is reduced.

Owner:新疆威奥科技股份有限公司

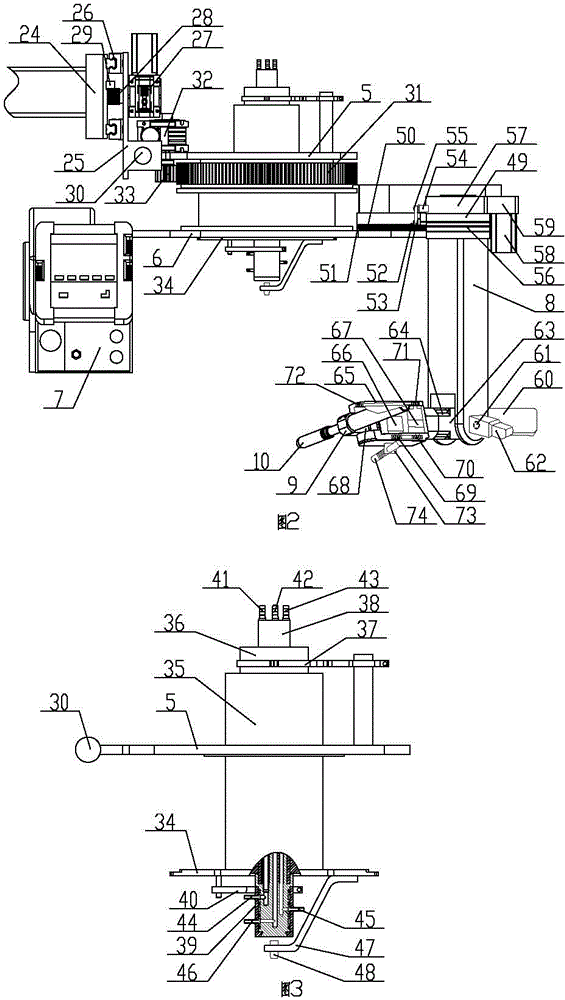

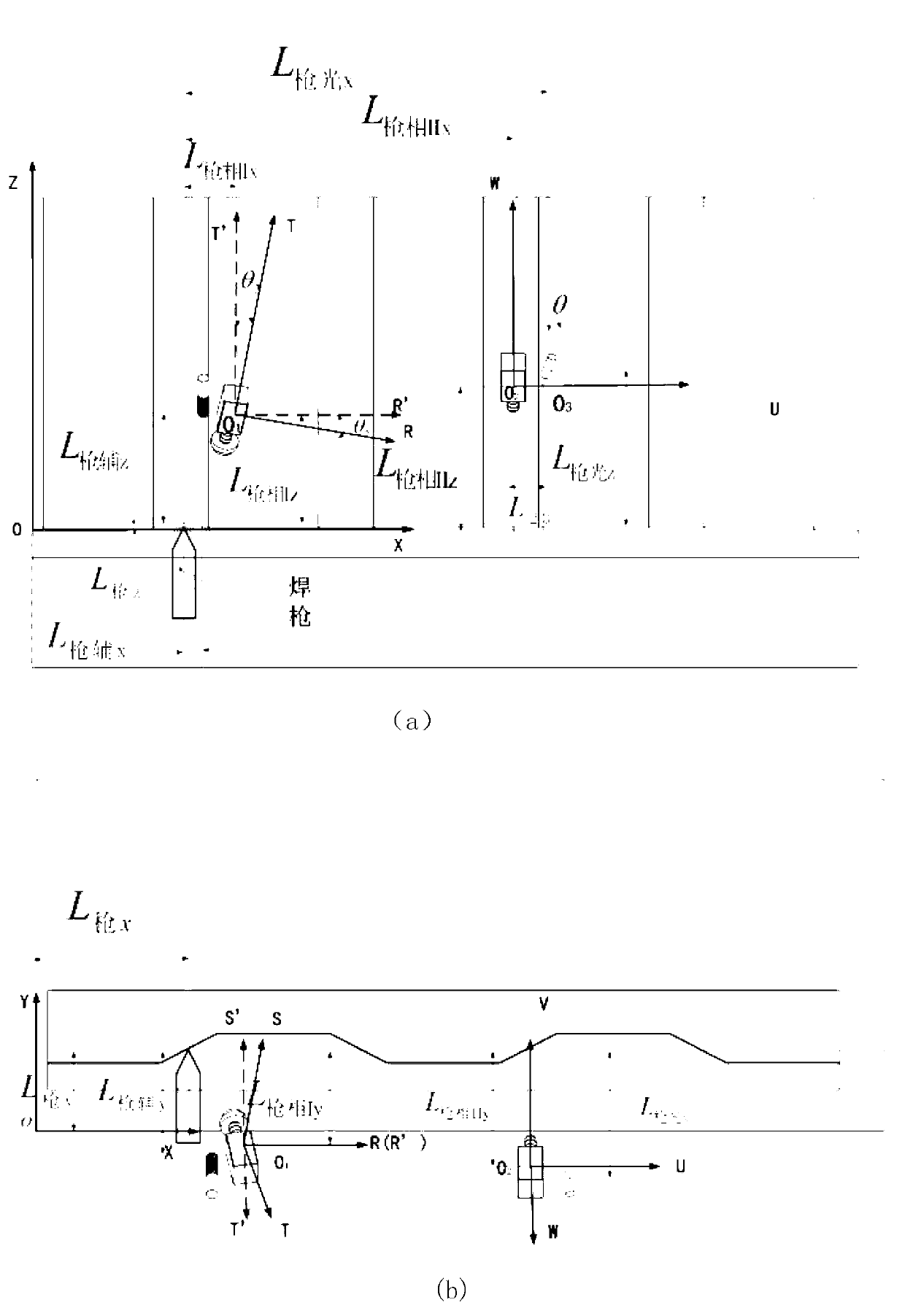

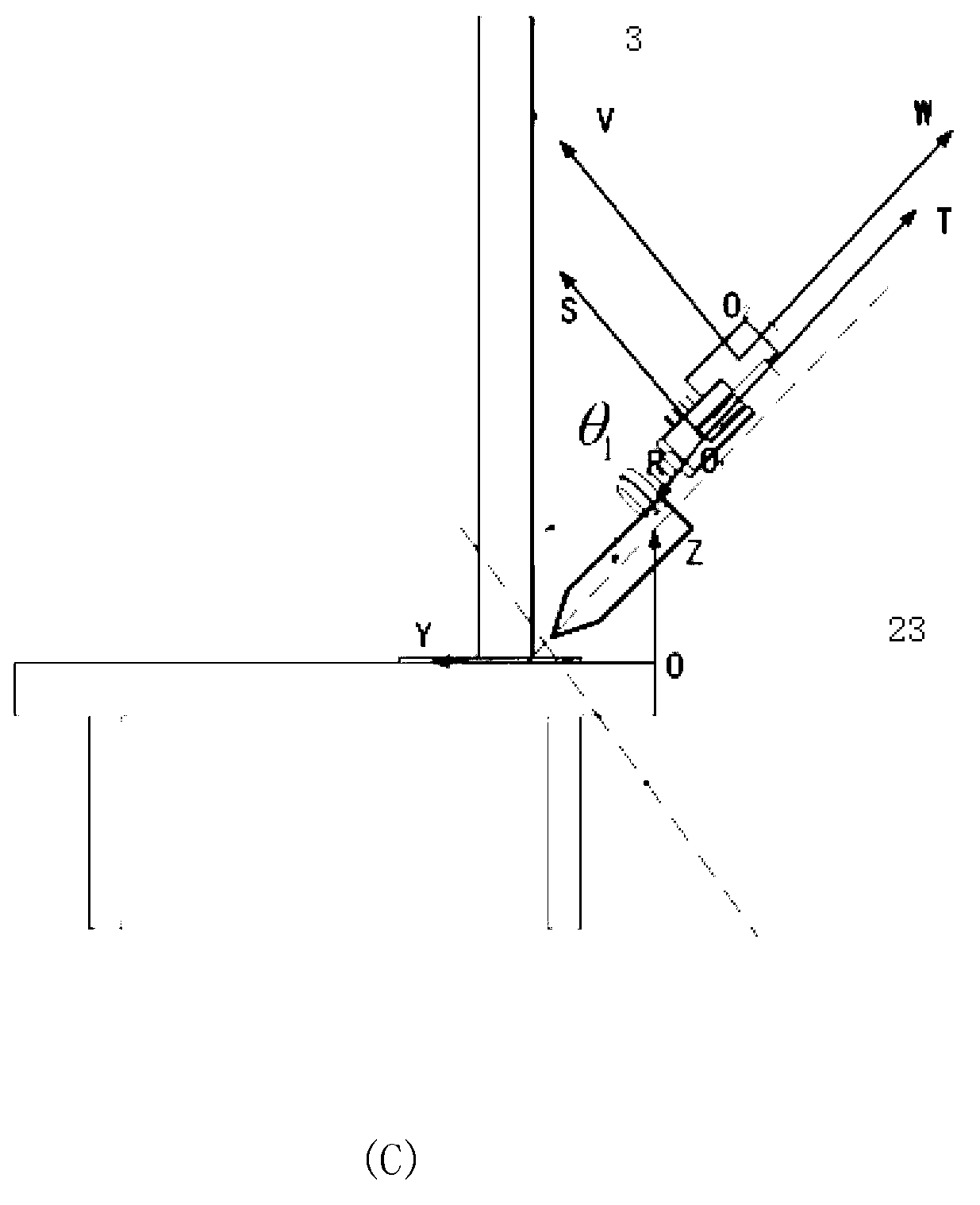

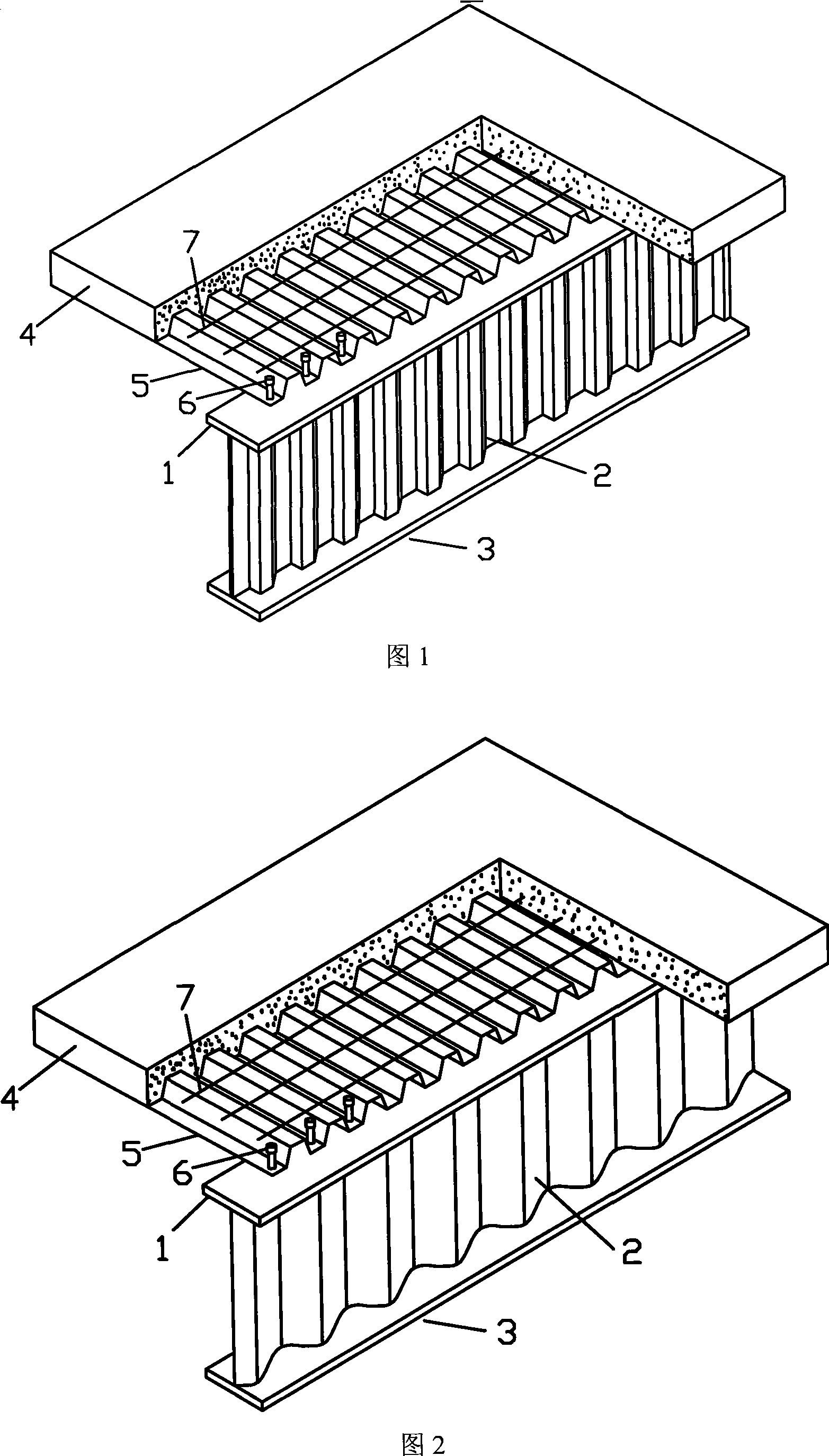

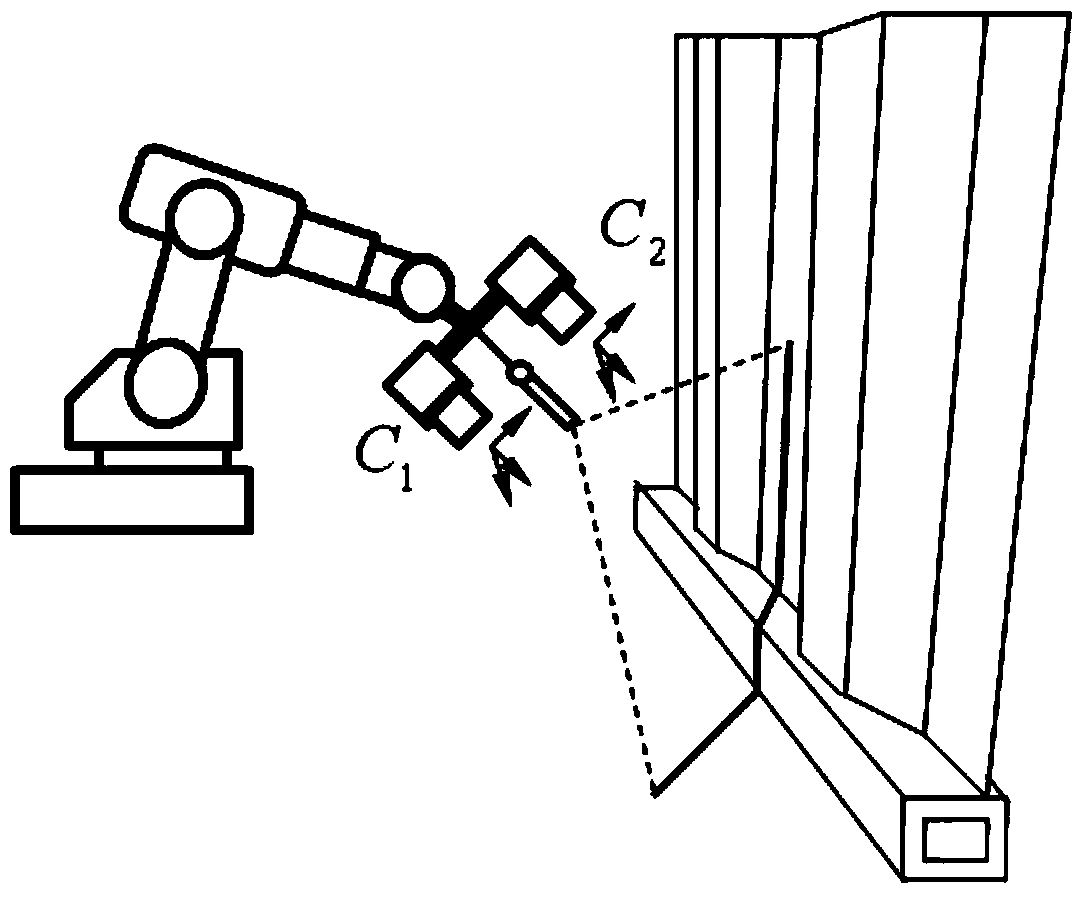

Visual tracking monitoring system and method in automatic corrugated thin plate fillet weld welding

ActiveCN103273171ARealize intelligent tracking and monitoringImprove adaptabilityArc welding apparatusFillet weldMonitoring system

The invention discloses a visual tracking monitoring system and method in automatic corrugated thin plate fillet weld welding. The visual tracking monitoring system and method in the automatic corrugated thin plate fillet weld welding comprises a welding gun, a system installing frame, a welding technological parameter adjuster, a vision device I, a vision device II, an image data processor, a welding gun drive device, a tracking drive device and a controller. The vision device I and the vision device II are respectively connected with the image data processor; the image data processor is respectively connected with the controller and the welding technological parameter adjuster; the controller is respectively connected with the welding gun drive device and the tracking drive device. According to the visual tracking monitoring system and method in the automatic corrugated thin plate fillet weld welding, binocular vision devices are adopted, the front vision device II is used for leading the movement of the welding gun, the direct-sight vision device I monitors a weld pool and welding joints before the weld pool and conducts adjustment on welding gun track deviation caused by factors such as thermal welding deformation and welding wire bending.

Owner:SOUTH CHINA UNIV OF TECH

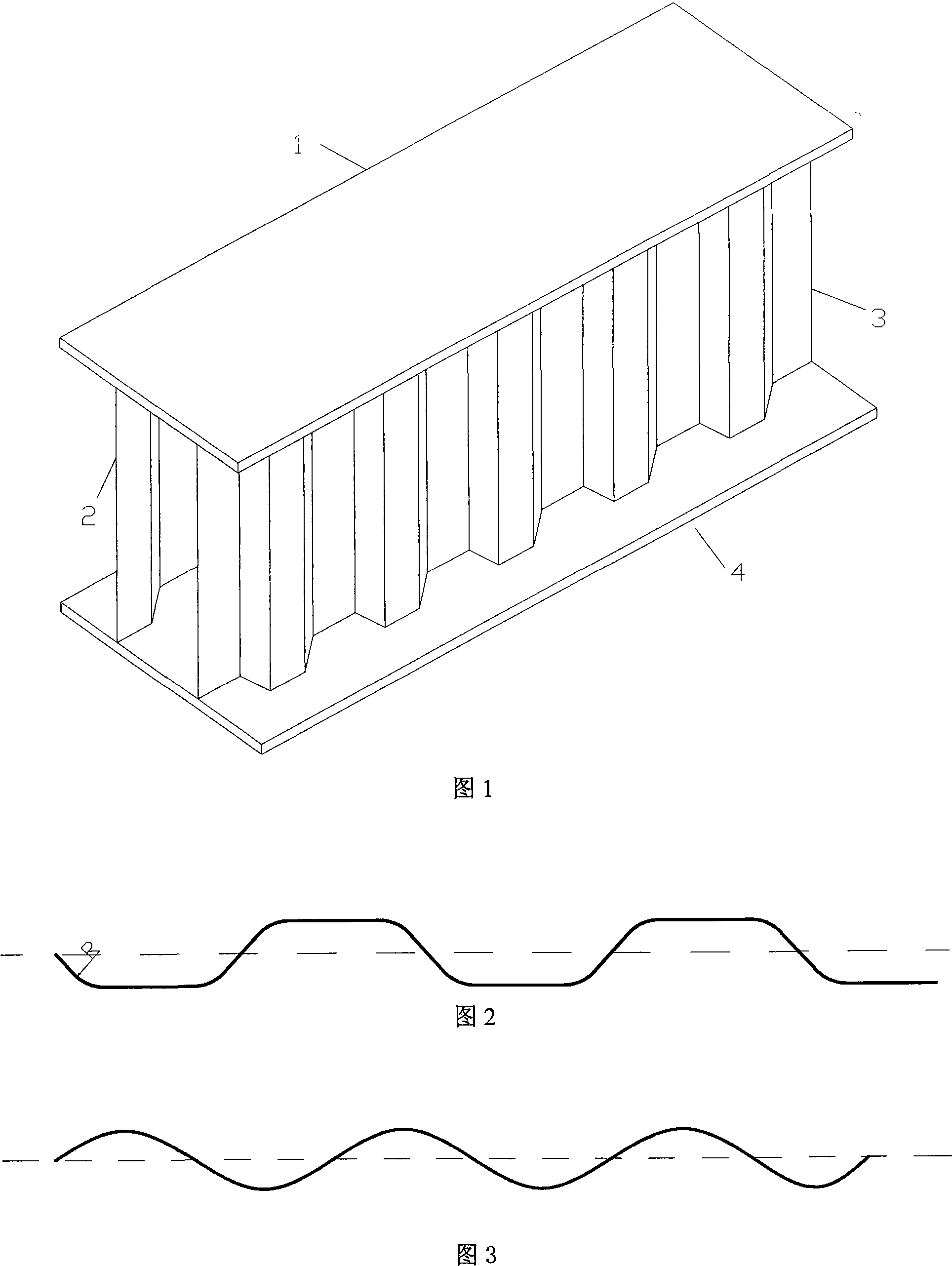

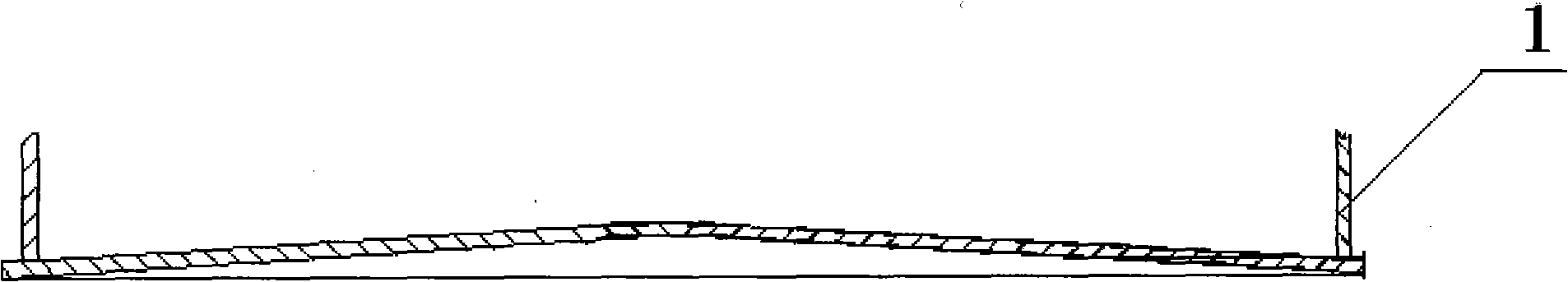

Double corrugated web plate steel box girder

The invention belongs to the technical field of building materials and in particular relates to a double undulated web slab steel box girder. The cross-section fracture shape is composed of a middle web slab, an upper flange and a lower flange which are integrated, wherein the upper flange is parallel to the lower flange, a double web slab is vertically located between the upper flange and the lower flange, the double web slab is arranged symmetrically and takes a honeycomb structure, the web slab and the flange slabs adopt one side fillet weld to connect, the web slab is an undulated web slab whose length direction are periodically repeated evenly or unevenly, and the undulated cross section takes circular arc angle trapezoid and sinusoidal curve. The product can replace products such as normal welded box steel girders, hot rolled H-shaped steel, I-shaped steel and the like, has wider usage compared with the products, and can realize maximization and can be used in the special fields and special places including the building of bridges with large spans, the manufacture of ships and the like.

Owner:TONGJI UNIV +1

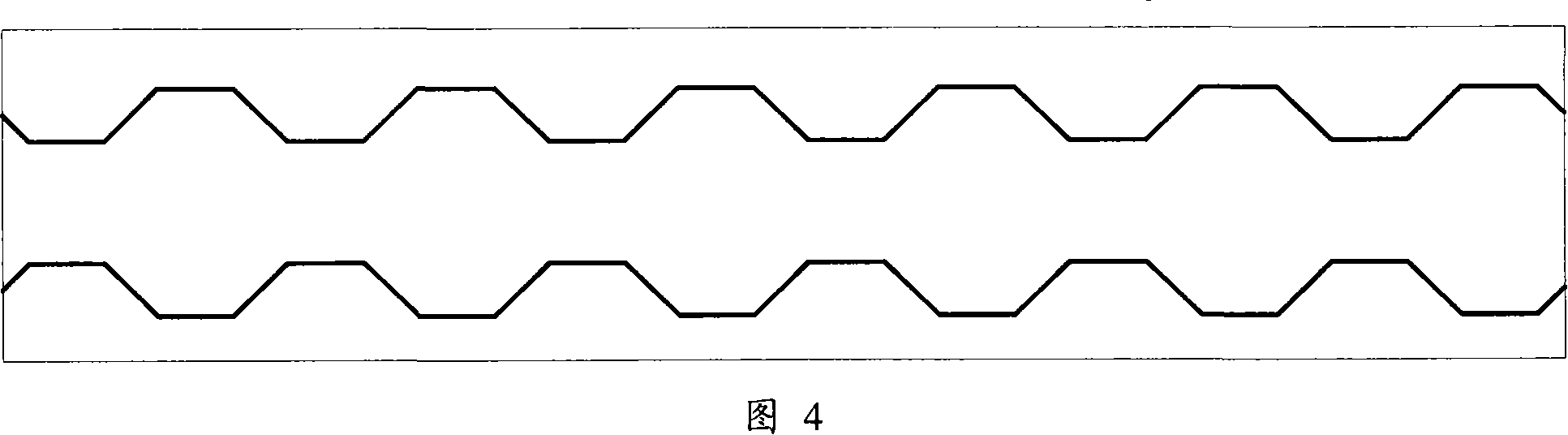

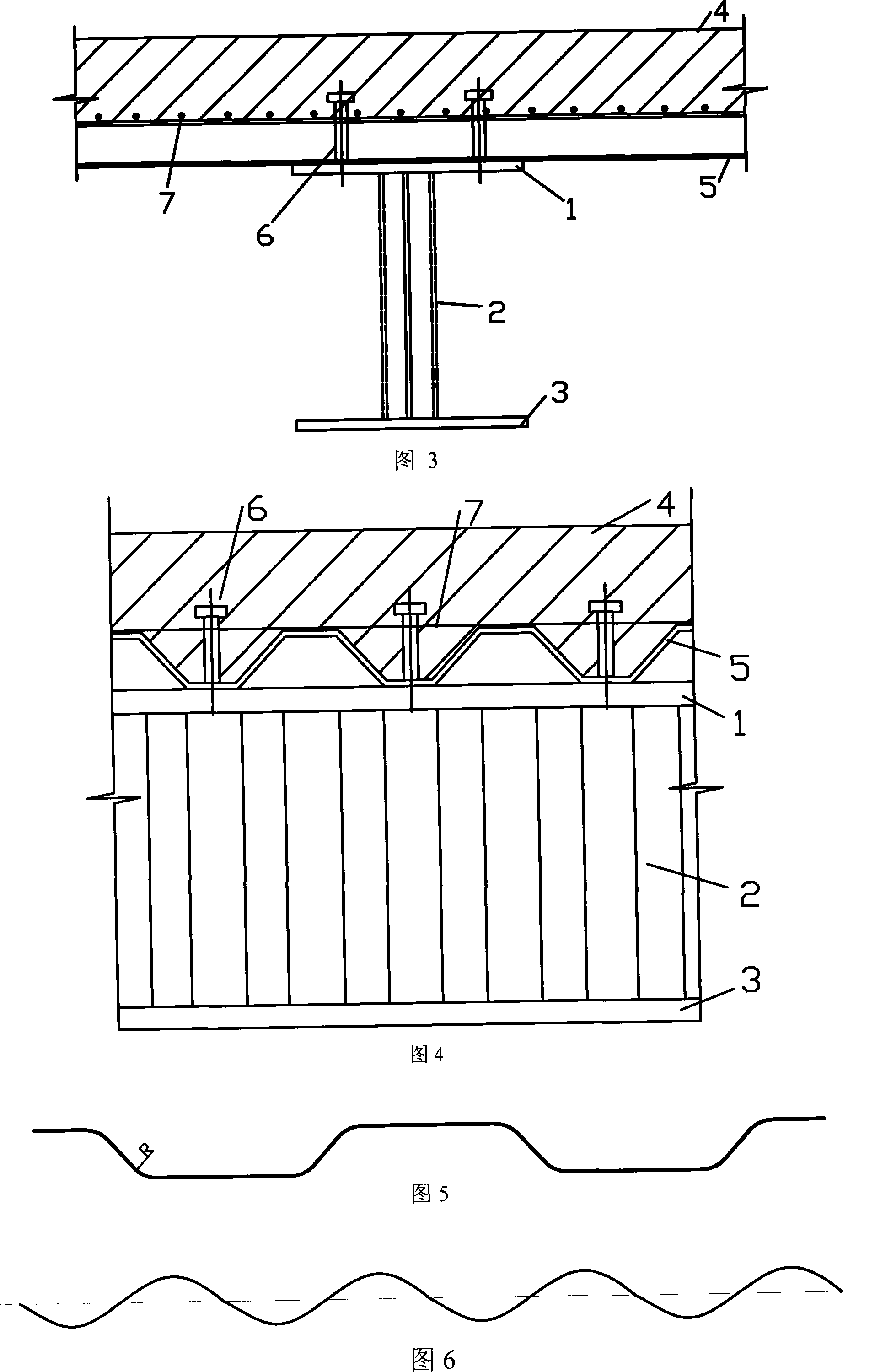

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

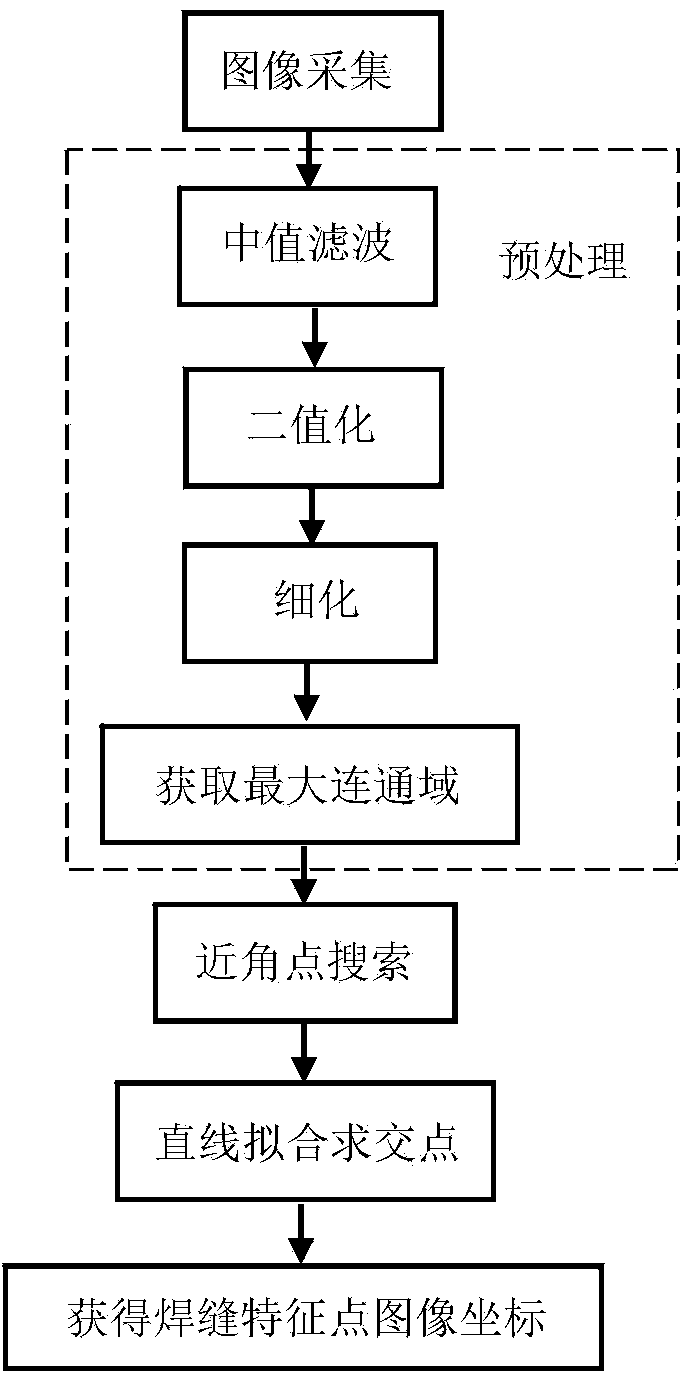

Complex fillet weld joint position detecting method based on laser binocular vision

ActiveCN103759648ARapid positioningPrecise tracking fitUsing optical meansPretreatment methodSoftware system

The invention discloses a complex fillet weld joint position detecting method based on laser binocular vision. The complex fillet weld joint position detecting method based on the laser binocular vision overcomes the defect that a traditional image detecting algorithm is poor in extracting precision and extracting stability of fillet weld joint feature points. According to the technical scheme, the complex fillet weld joint position detecting method based on the laser binocular vision includes the following steps that a laser scanning workpiece is used, a binocular CCD camera is used for collecting an image, and the collected grey level image is transmitted to a software system of a computer to be processed; the processing procedures are sequentially median filtering, binarization, refining, obtaining the maximum connected domain, close angular point searching, straight line fitting and intersection point obtaining; finally, image coordinates of the weld joint feature points are obtained. The pre-processing method (median filtering, binarization, refining, obtaining the maximum connected domain) is used for removing interference of the background of the image and narrowing the retrieval range of sequential processing. A close angular point searching strategy is provided, the speed of angular point detection is improved and finally, the detection precision reaches the sub-pixel class by means of the straight line fitting and intersection point obtaining method.

Owner:SOUTH CHINA UNIV OF TECH

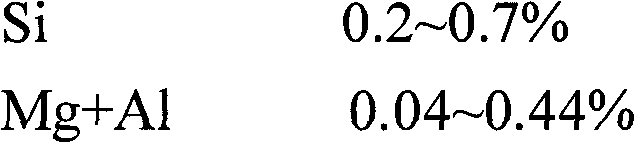

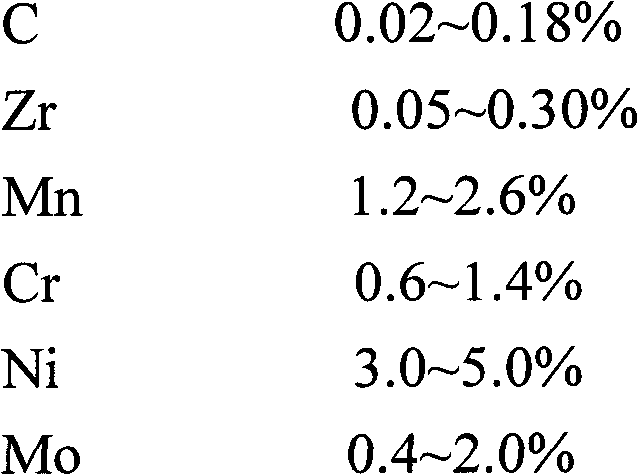

High-strength and high-toughness metal powder flux-cored wire

InactiveCN102179640AGood welding process adaptabilityStable mechanical propertiesArc welding apparatusWelding/cutting media/materialsFillet weldHydrogen

The invention relates to a high-strength and high-toughness metal powder flux-cored wire which comprises a carbon steel sheath (weight percentage: 78-84%) and a flux core (weight percentage: 16-22%), wherein the flux core comprises the following components in percentage by weight: 0.10-1.5% of TiO2, 0.10-0.5% of SiO2, 0.02-0.20% of Na2O+K2O, 0.2-0.7% of Si, 0.04-0.44% of Mg+Al, 0.02-0.18% of C, 0.05-0.30% of Zr, 1.2-2.6% of Mn, 0.6-1.4% of Cr, 3.0-5.0% of Ni, 0.4-2.0% of Mo, 0.2-1.0% of one or two of NaF or CaF2 and the balance of Fe and inevitable impurities. Through adopting a metal powder cored slag system and cooperating with the protection of argon-rich mixed gas (consisting of 80% of Ar and 20% of CO2), the high-strength and high-toughness metal powder flux-cored wire provided by the invention is mainly applicable to downward welding and horizontal fillet welding. In addition, the high-strength and high-toughness metal powder flux-cored wire is good in welding process adaptability, stable in mechanical performance, good in cold cracking resistance, fine in seawater corrosion resistance and excellent in anti-explosion performance; and meanwhile, the yield ratio of weld metalsis below 0.87, and the diffusible hydrogen in deposited metals reaches an ultra-low hydrogen level.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

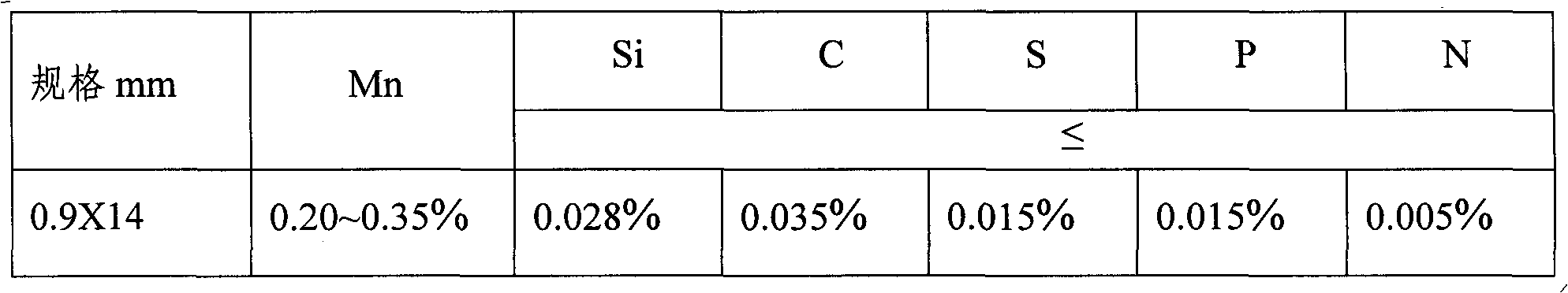

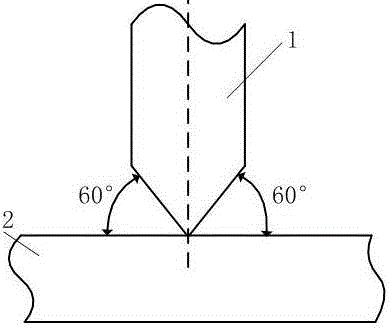

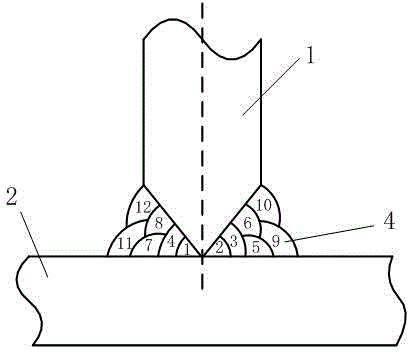

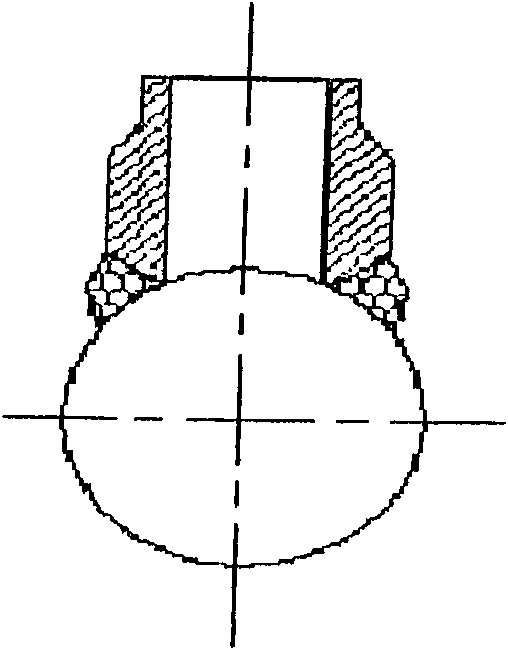

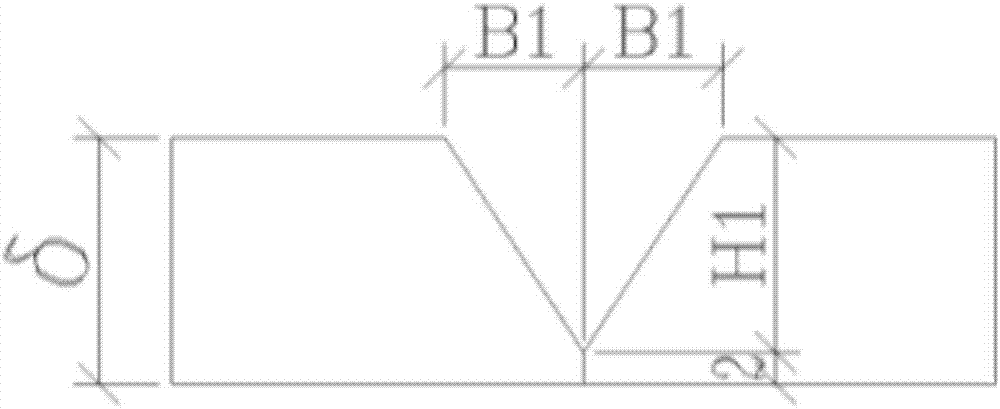

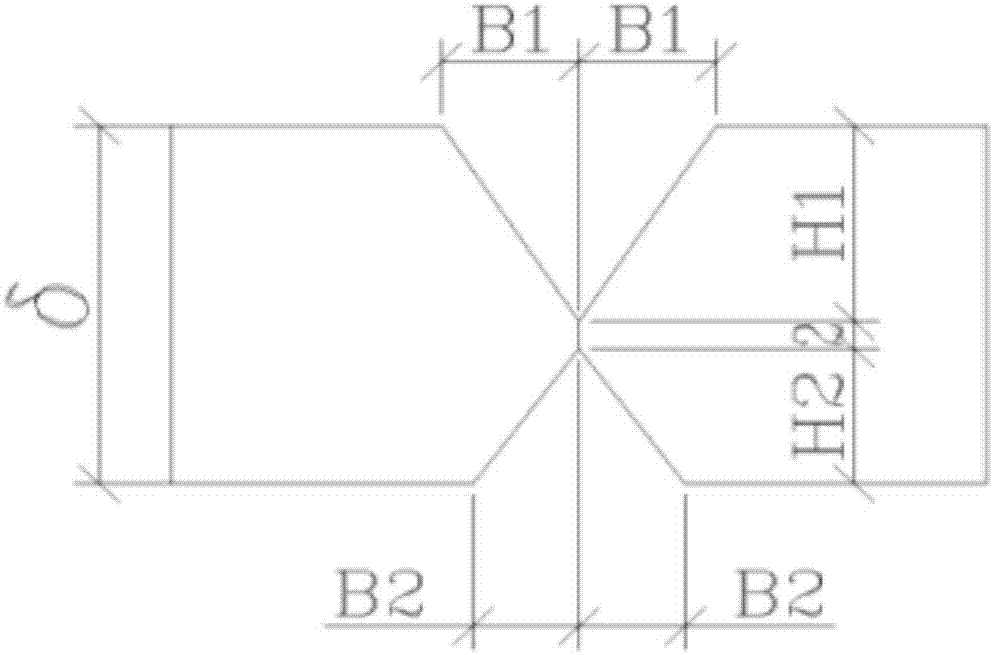

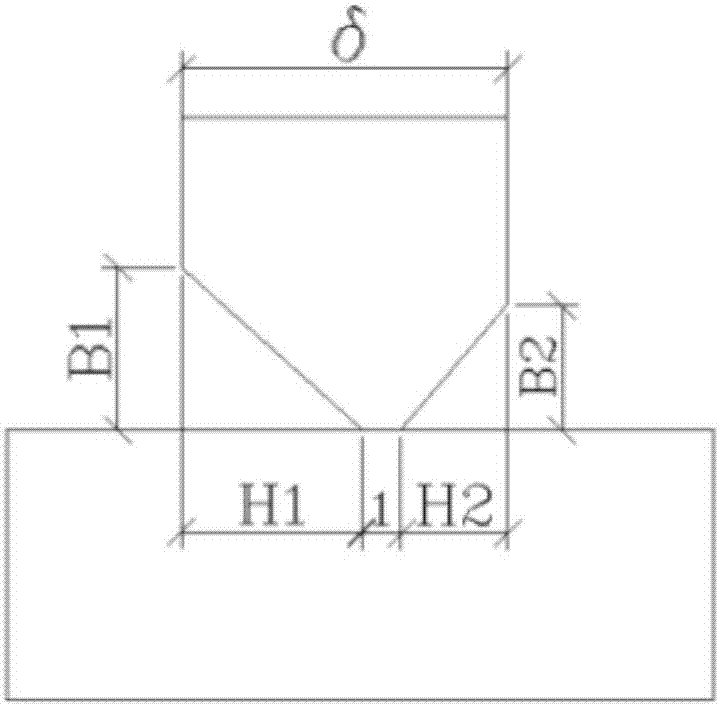

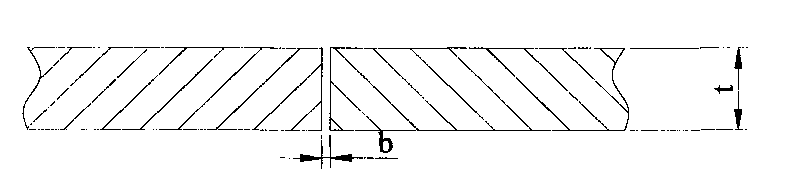

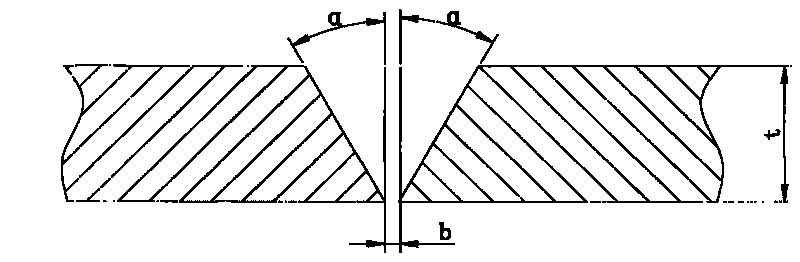

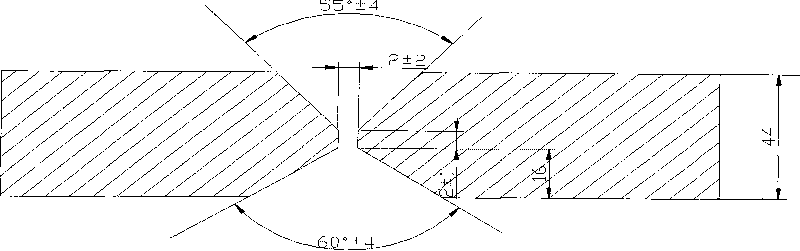

Fillet weld welding structure for K-type grooves of moderately-thick plate without back chipping and welding technology of fillet weld welding structure

InactiveCN105081595AFull penetration ensuresImprove the construction environmentArc welding apparatusWelding/soldering/cutting articlesFillet weldThick plate

The invention relates to a fillet weld welding structure for K-type grooves of a moderately-thick plate without back chipping and a welding technology of the fillet weld welding structure. The fillet weld welding structure is characterized in that symmetric grooves are formed in the two sides of a web plate, the web plate and a bottom plate are tightly attached when assembled in welding, and no gap is reserved when the web plate and the bottom plate are assembled; the grooves of the web plate are machined through a milling machine, no truncated edge is reserved, and the length parts between the two ends in the grooves are fixed at equal diversion points and polished; a welding robot is used for stably welding a welding bead at the position of ship-type welding, welding is carried out alternatively on the two sides in a multi-layer and multi-run manner, back chipping is not carried out on the back face, and slag is not removed in the bead; and the backward deformation theory is utilized in the assembling process, and double-face alternating welding is adopted in the welding process to restrain deformation. By means of the technology, full penetration of the fillet weld below the K-type grooves of the moderately-thick plate is ensured, and the welding quality is improved; and meanwhile, the welding automation degree and the production efficiency are obviously improved, and the welding construction environment is improved.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

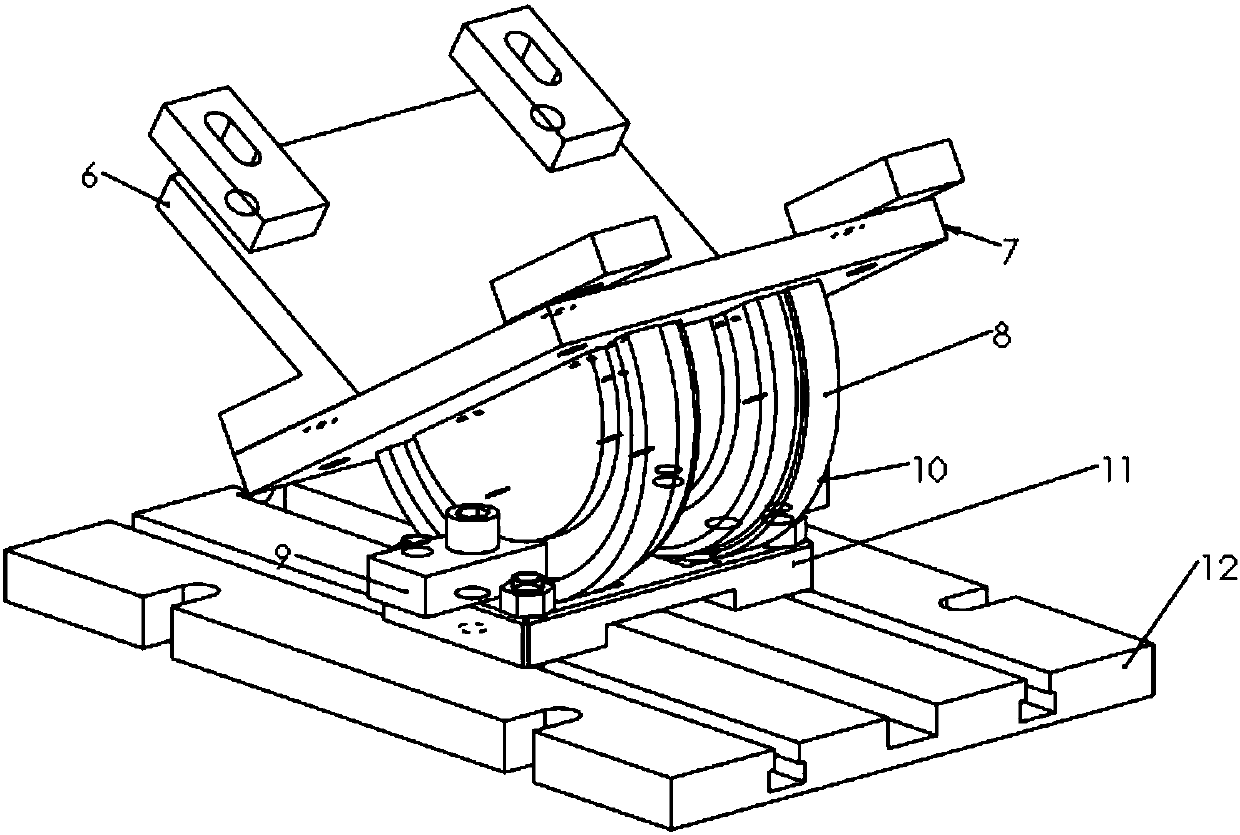

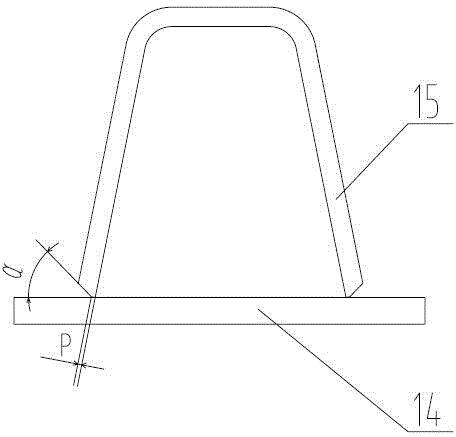

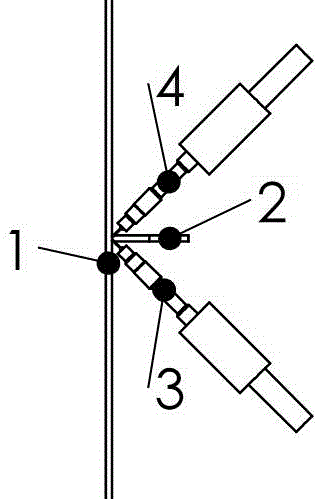

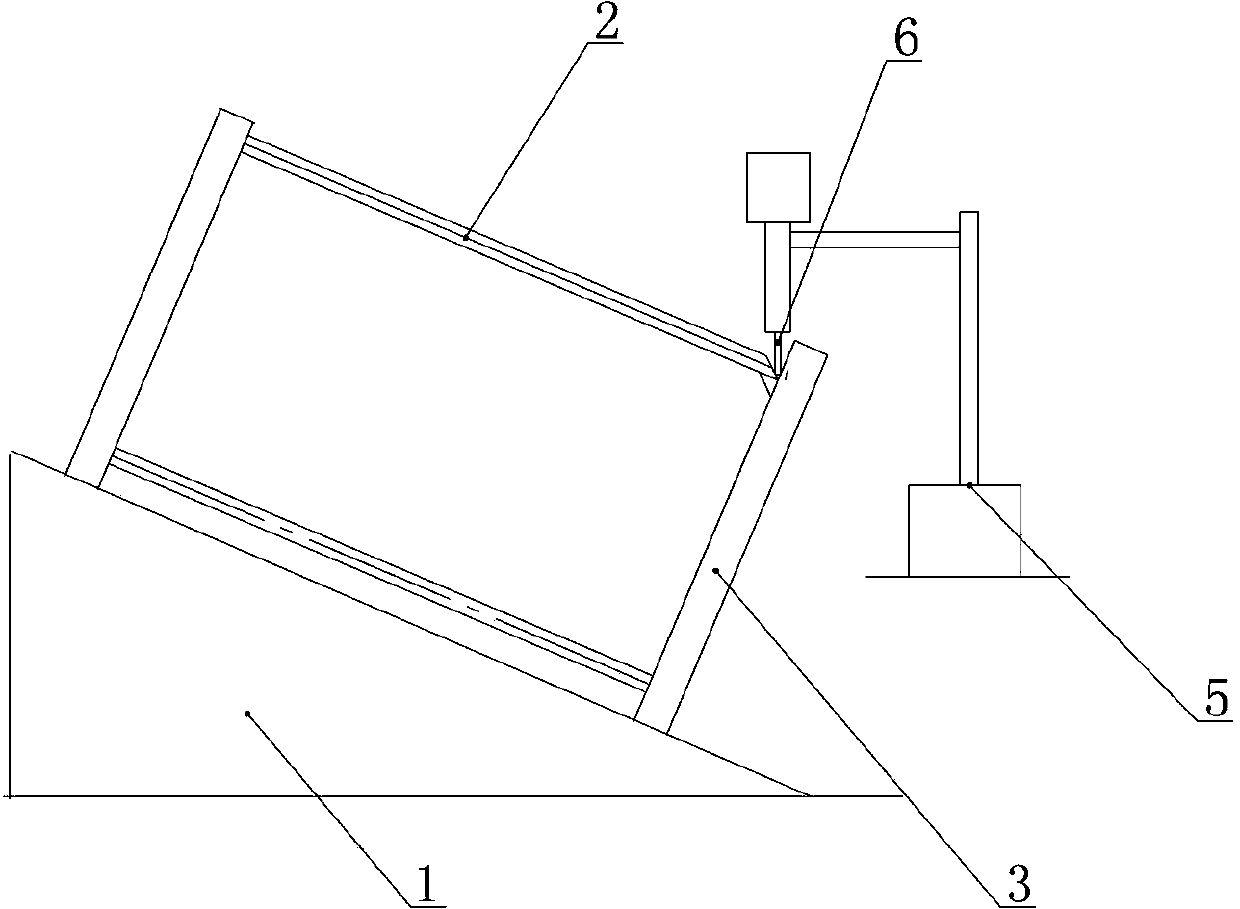

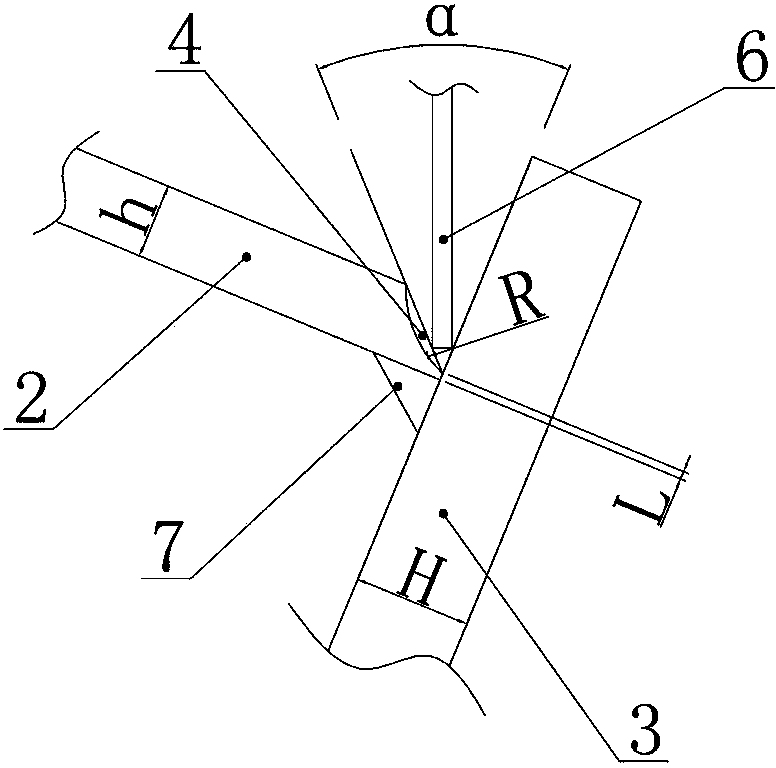

Stationary shoulder friction stir welding device and method for variable-angle fillet joints

ActiveCN107931822AImprove performanceEasy to installNon-electric welding apparatusFillet weldStructural engineering

The invention provides a stationary shoulder friction stir welding device for variable-angle fillet joints. The stationary shoulder friction stir welding device comprises a stationary shoulder stirring head and a matched platform capable of changing the fillet weld angle and fixing a to-be-welded workpiece. The stationary shoulder stirring head comprises a stirring pin, a stationary shoulder, a rigid connecting device and a sealing stacking ring, wherein the stationary shoulder is connected with a spindle of a friction stir welding machine through rigid fixation, and the stainless steel sealing stacking ring is arranged between the stirring pin and the stationary shoulder and used for preventing aluminum alloy from being squeezed into a gap between the stationary shoulder and the stirringpin in the welding process. The platform capable of fixing the to-be-welded workpiece comprises a base plate for supporting an aluminum alloy plate, a semicircular sliding block capable of changing the inclination angle, pressing plates for fixing the sliding block, a base for supporting the sliding block, and a workbench with T-shaped grooves. According to fillet welds with different thicknessesand different angles, welding can be carried out only by adjusting the angles of the stationary shoulder and the base plate, and thus the time and cost for replacing the platform capable of fixing theto-be-welded workpiece when fillet welds with different angles are welded are avoided.

Owner:NANJING UNIV OF SCI & TECH

Operating method for welding fillet weld of tube seat on header

InactiveCN102151954AImprove performanceAvoid Weld CrackingArc welding apparatusFillet weldEngineering

The invention provides an operating method for welding a fillet weld of a tube seat on an HRSG P91 header, which solves the problems in the traditional welding method of SA-335P91 material adopted on a boiler header. The operating method featured by bottom layer welding for the fillet weld of the tube seat on the header, intermediate layer welding for the fillet weld of the tube seat, facing layer welding for the fillet weld of the tube seat and multilayer and multichannel welding with no oscillation as much as possible is adopted, and an annealing weld bead is formed during facing. Heat input can be reduced appropriately so that the primary qualified rate of supersonic flaw detecting reaches over 99%, inward recessing, crack and other defects of a bottom layer are effectively prevented, and the flat and eye-pleasing metal surface of a weld seam is maintained.

Owner:格菱动力设备(中国)有限公司

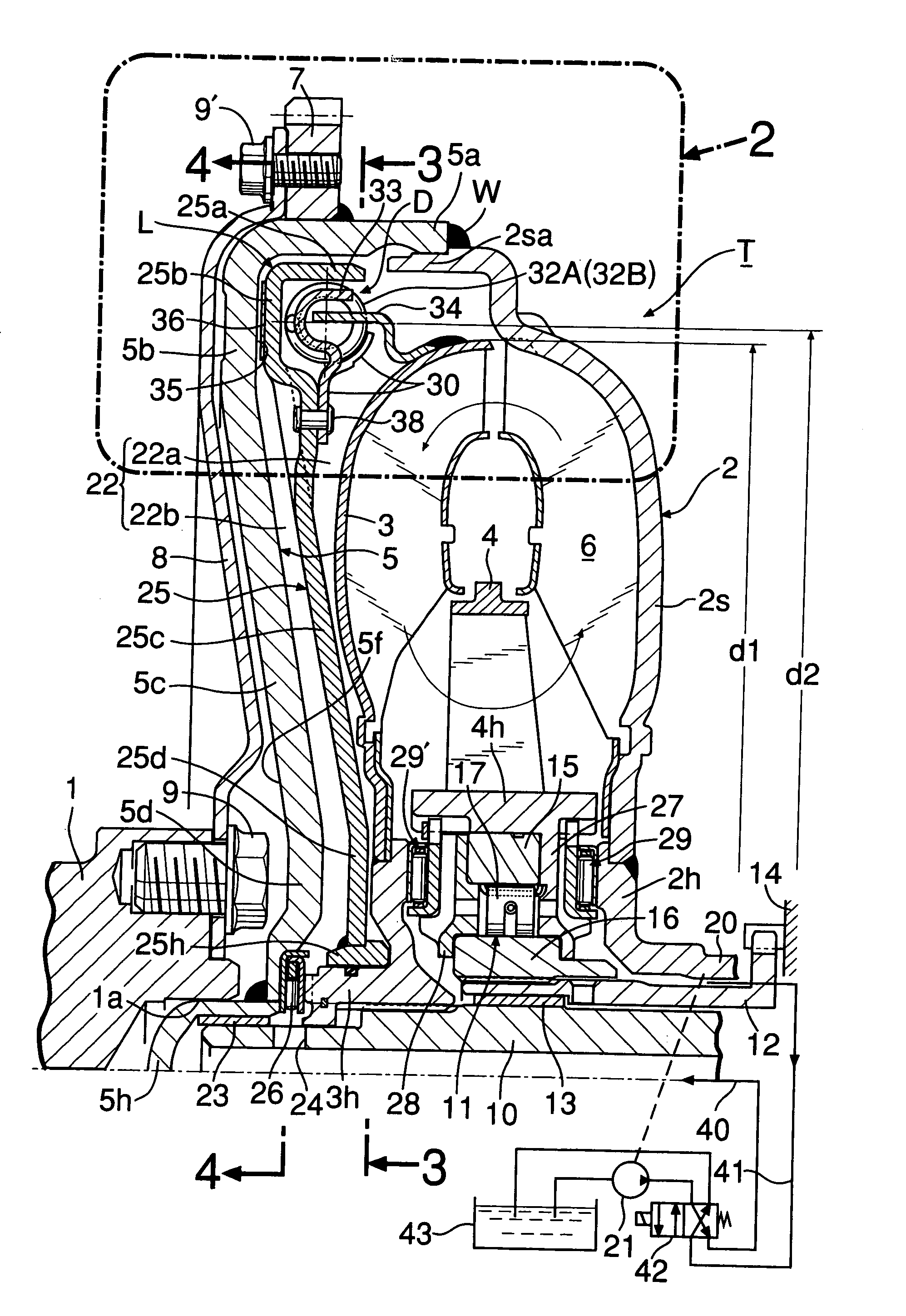

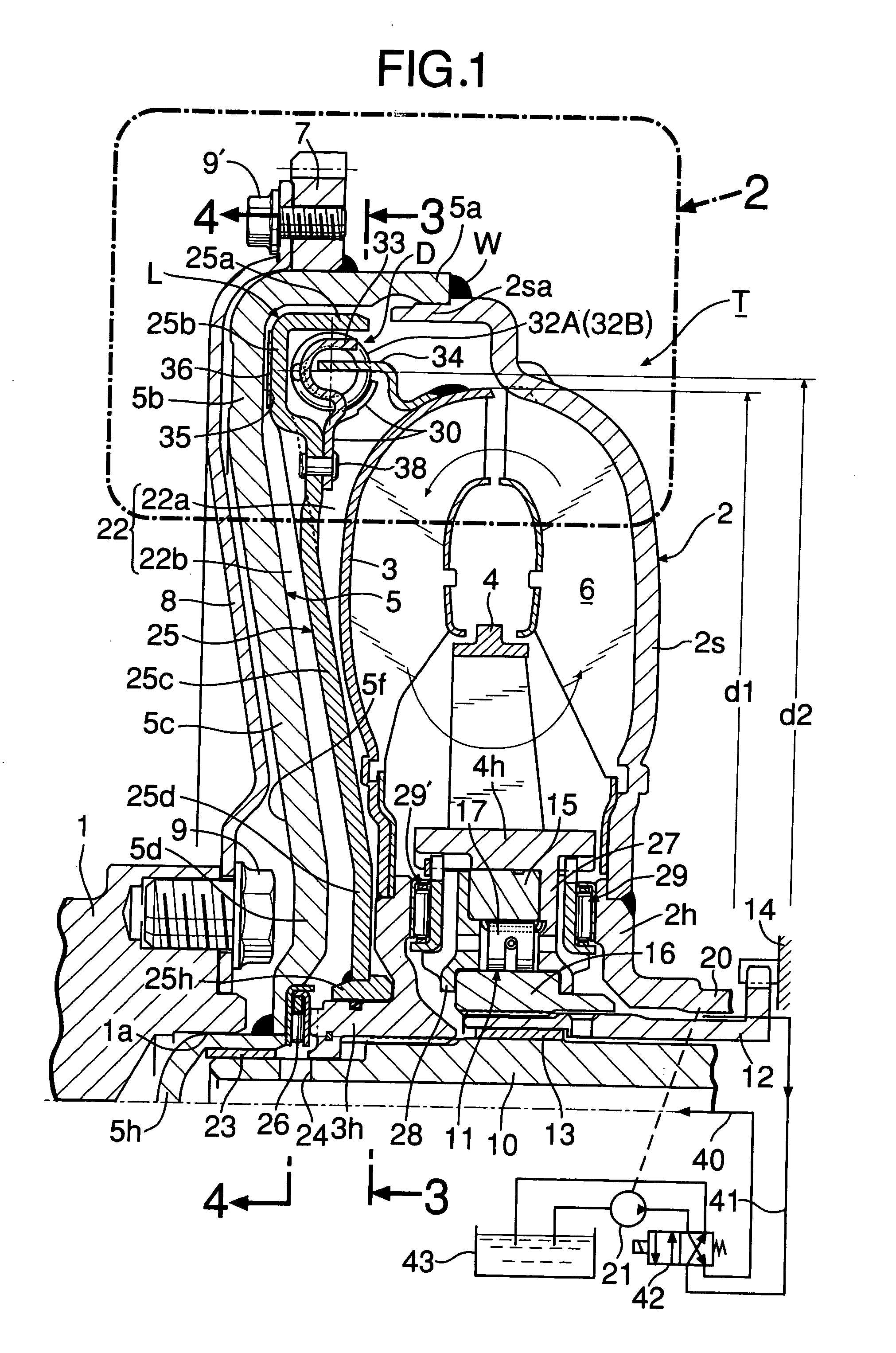

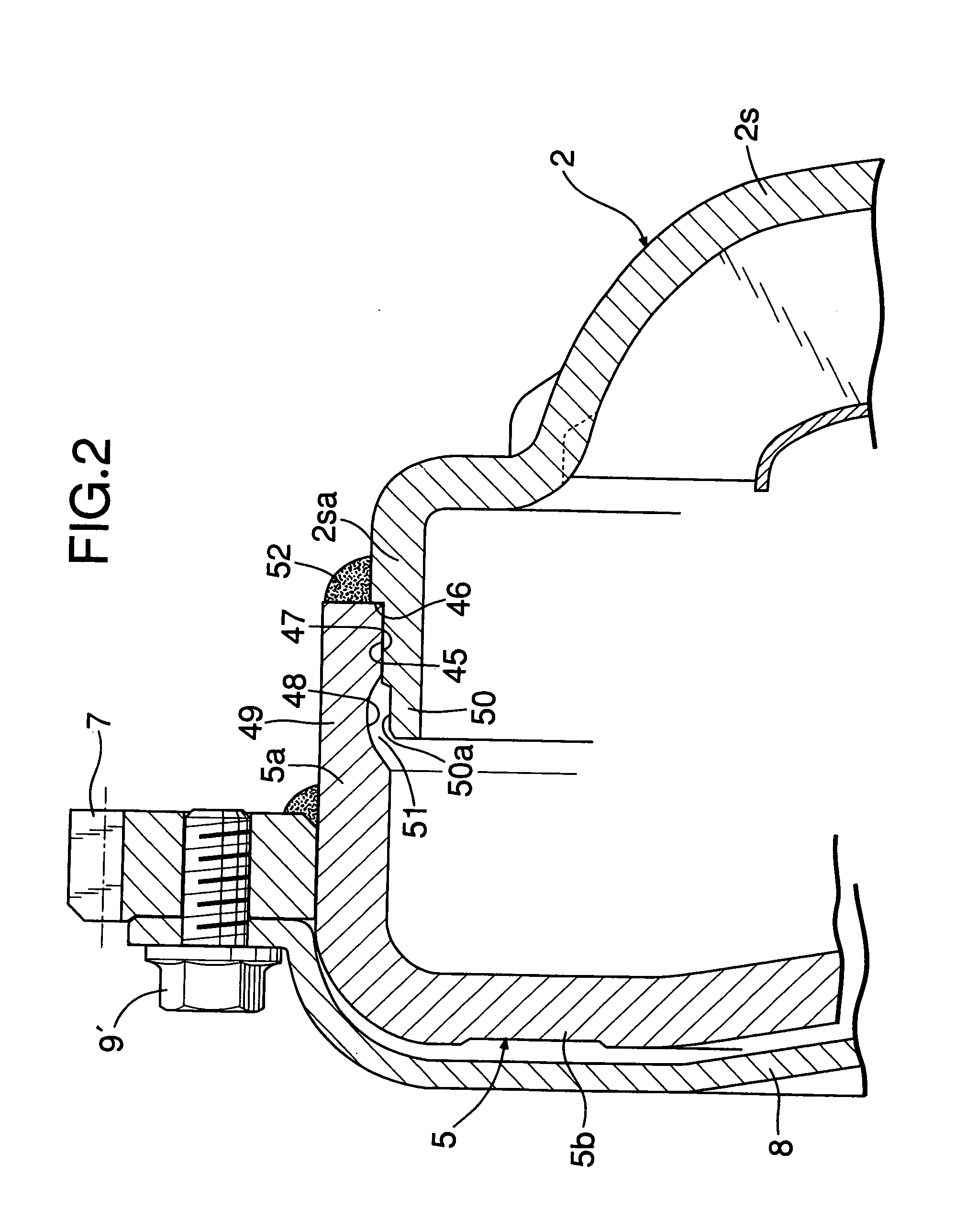

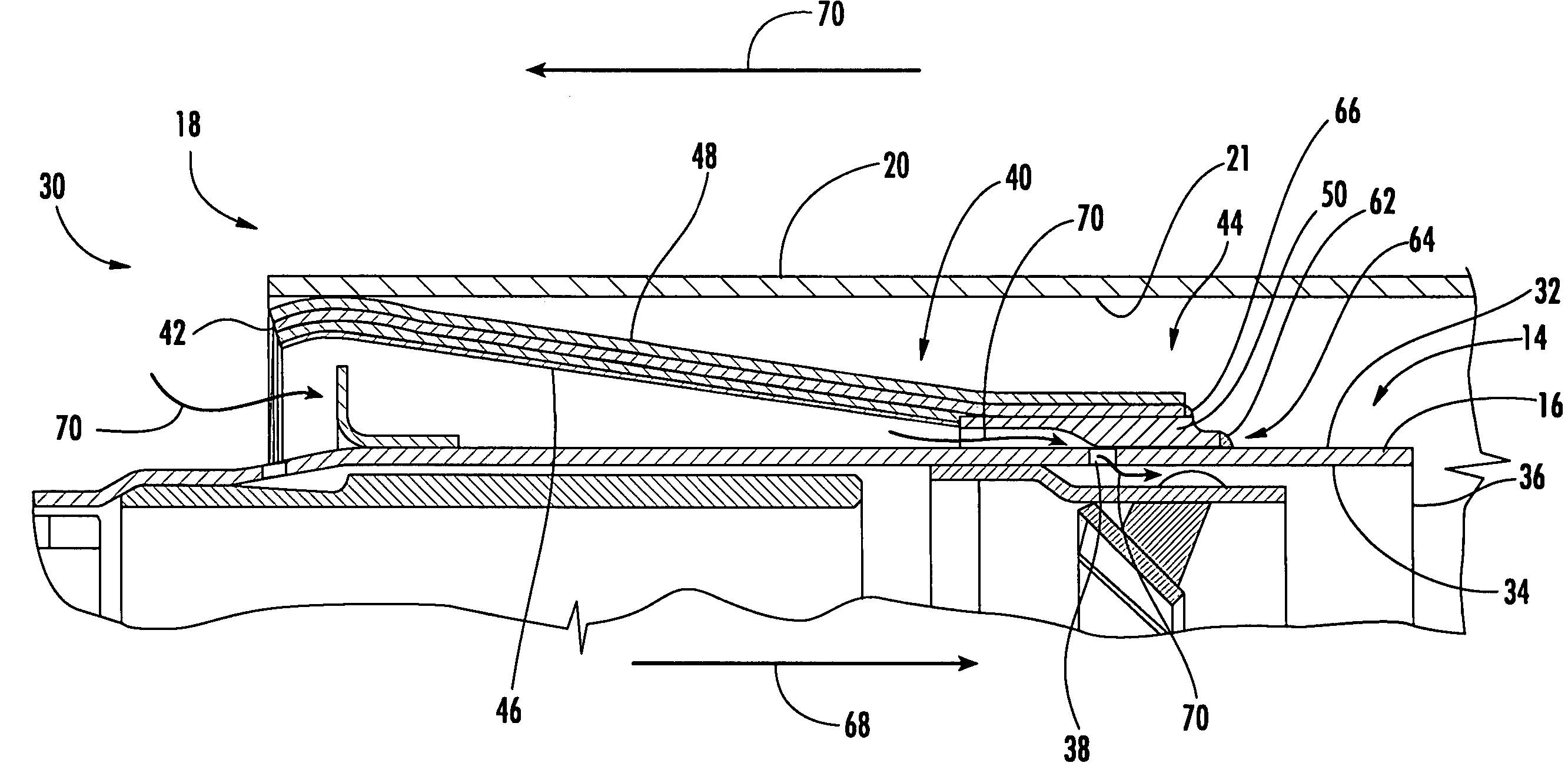

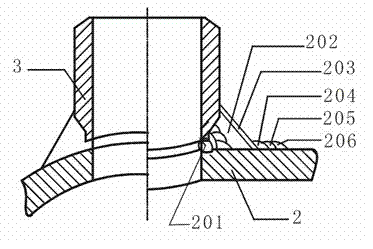

Fluid transmission device

InactiveUS20060000682A1Increased durabilityFacilitate transmissionRotary clutchesFriction clutchesFillet weldStress concentration

In a fluid transmission device, a male fitting surface of a periphery of a diameter-expanded portion of a pump shell is fitted to a female fitting surface of an inner circumference of a peripheral wall portion of a cylindrical transmission cover, and a fillet weld being is formed between an end surface of the peripheral wall portion and a peripheral surface of the diameter-expanded portion along an entire circumference, thereby connecting together the pump shell and the transmission cover. An annular recess is formed in an inner circumferential surface of the peripheral wall portion to adjoin the female fitting surface on the side opposite from the fillet weld. A portion of the transmission cover corresponding to the recess constitutes an annular thin-walled portion which has a thickness smaller than the portions of the transmission cover along the opposite sides of the annular thin wall portion. Therefore, even if the diameters of the pump shell and the transmission cover are increased, the durability of the pump shell and the transmission cover can be improved by alleviating excessive stress concentration on the fillet weld between the pump shell and the transmission cover.

Owner:YUTAKA GIKEN CO LTD

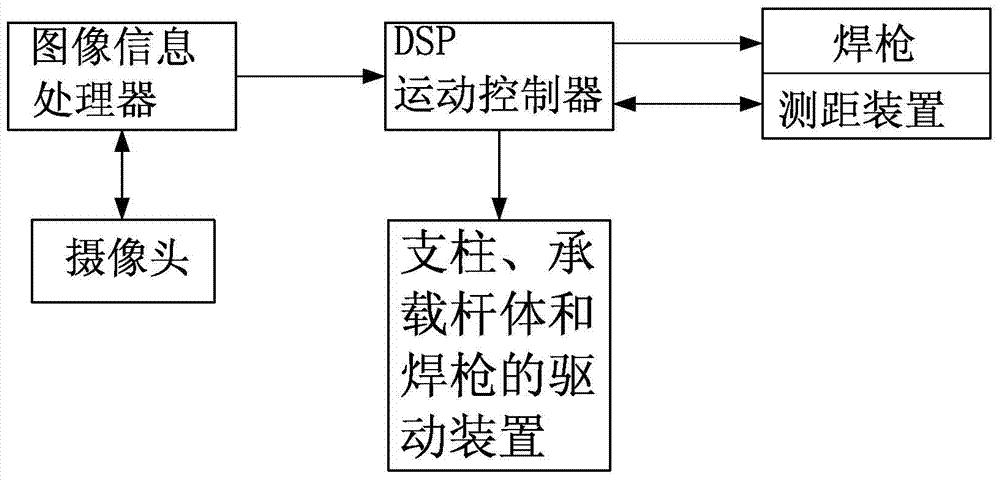

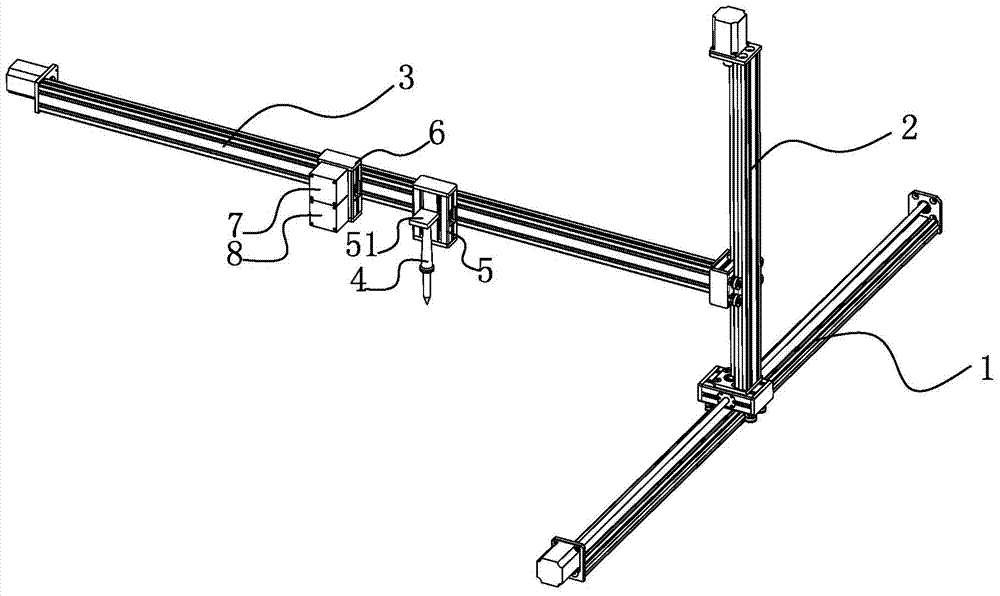

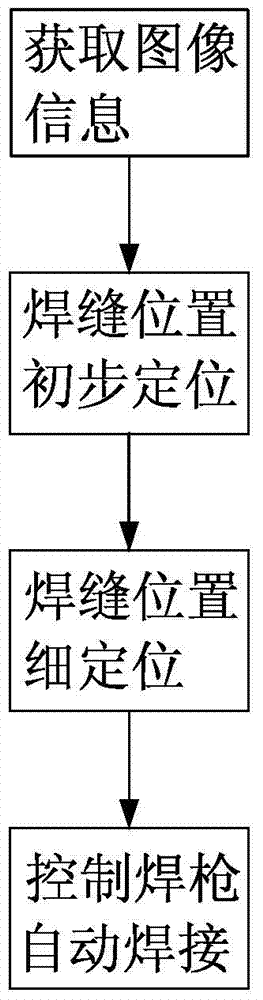

Fillet weld recognition device and welding control method thereof

ActiveCN103752992AAccurately determineEasy to control and calculateWelding/cutting auxillary devicesArc welding apparatusFillet weldDigital signal processing

The invention discloses a fillet weld recognition device and a welding control method thereof and belongs to the technical field of automatic welding. The fillet weld recognition device comprises an image frame, an image information processor, a camera and a DSP (digital signal processor) motion controller. The camera collects weld image information and transmits the same to the image information processor; the image information processor transmits weld coordinate signals to the DSP motion controller which controls motion of a welding gun; the welding gun and a distance measuring device are arranged on the image frame, and the distance measuring device transmits distance signals to the DSP motion controller. The welding control method thereof includes that the image information is collected through the camera, coarse positioning of welding positions is completed through the image information processor, the distance signals of the weld coordinate signals and an infrared distance measuring device are inputted to the DSP motion controller for accurate positioning, and the welding gun performs welding according to guidance and calibration of the DSP motion controller.

Owner:浙江菲达科技发展有限公司

Method for assembling corrugated bulkhead block

The invention relates to the shipbuilding field, and particularly discloses a method for assembling a corrugated bulkhead block. The method comprises the following steps: hoisting a deck subsection to an overturning area, and making the reverse side thereof face upward; hoisting the corrugated bulkhead subsection to the deck subsection, and fixedly connecting the corrugated bulkhead subsection on the reverse side of the deck subsection to form the corrugated bulkhead block; and overturning the corrugated bulkhead block and hoisting the corrugated bulkhead block to a dock / shipbuilding platform. According to the method, the assembly of the corrugated bulkhead block is completed at the overturning area, and then the corrugated bulkhead block is hoisted to the dock / shipbuilding platform. The method has the advantages that a large quantity of hoisting and welding work is completed at the overturning area, so that the operation in a closed compartment is avoided, and the safety factor of the operation is improved; horizontal overhead position welding is transformed into flat fillet welding in the assembling process, so that the welding quality is improved; and the times of repeatedly hoisting the corrugated bulkhead subsection and the deck subsection to the dock / shipbuilding platform are reduced, thereby being favorable for assembling the corrugated bulkhead block quickly, and shortening the manufacturing cycle of the dock / shipbuilding platform.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

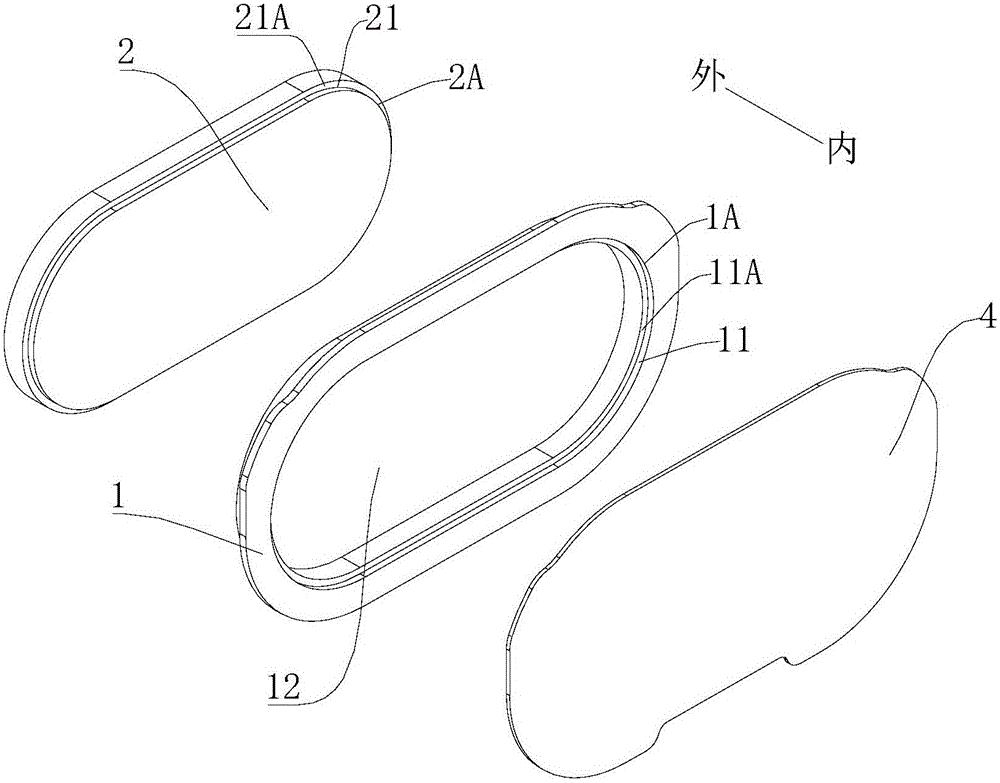

Fingerprint sensor component used in terminal and terminal provided with the same

ActiveCN105844237ACompact structureExquisite structureCharacter and pattern recognitionTelephone set constructionsFillet weldEngineering

The invention discloses a fingerprint sensor component used in a terminal and a terminal provided with the same. The fingerprint sensor component comprises a decorative ring, a fingerprint chip, and sealant. A mounting hole is defined by the inner ring of the decorative ring; the decorative ring is provided with a first annular recess; the fingerprint chip is assembled inside the mounting hole; the fingerprint chip is provided with a second annular recess; the second annular recess is communicated with the first annular recess for jointly defining an annular sealant groove; the sealant is filled in the annular sealant groove for sealing the annular space between the mounting hole and the fingerprint chip. According to the fingerprint sensor component used in a terminal, liquid is prevented from entering in the inner side of the fingerprint chip through the annular space between the mounting hole and the fingerprint chip, and therefore, fillet weld legs of the fingerprint chip are prevented from being corroded by liquids and short circuit failure is prevented; the annular sealant groove is set to dispense sealant for waterproofing; therefore, the processing and assembling difficulty of the decorative ring and the fingerprint chip can be reduced to make the structure of the fingerprint sensor component more compact and exquisite.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

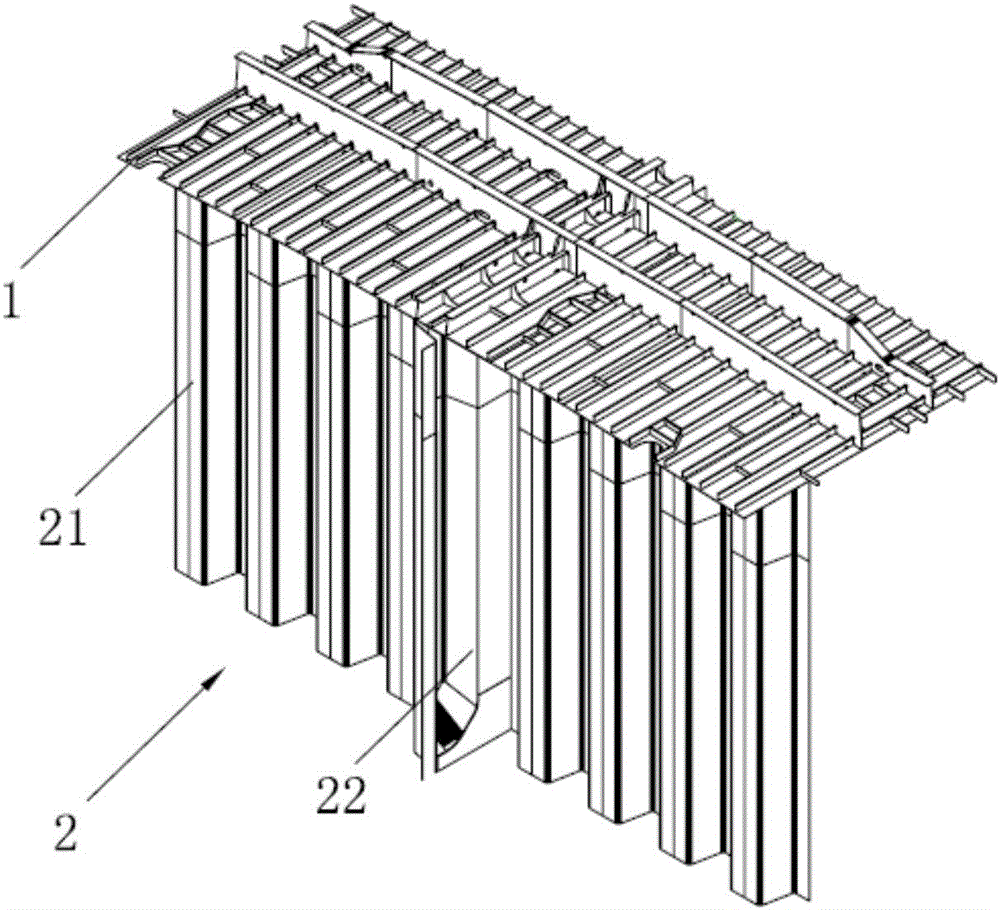

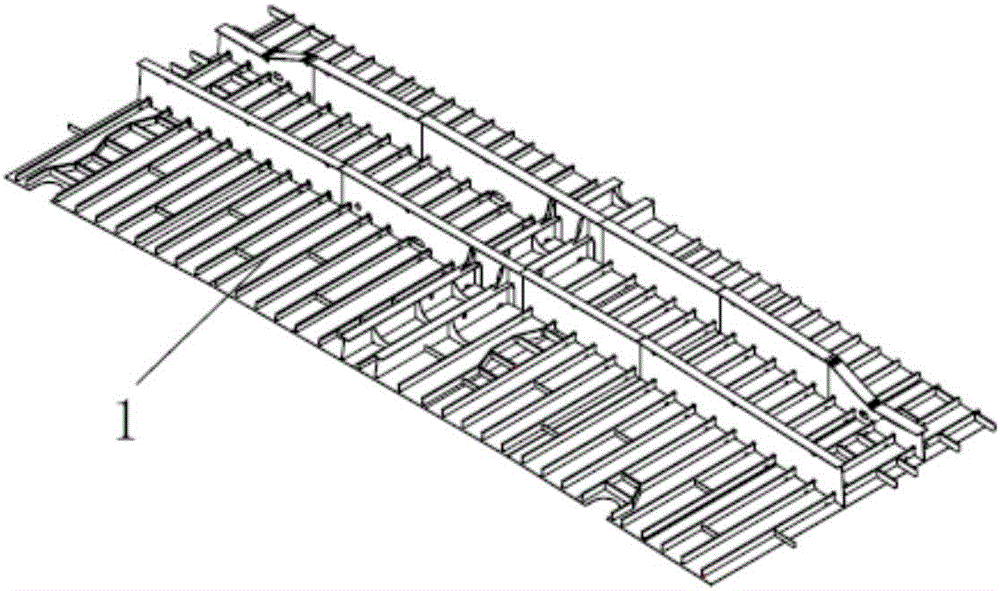

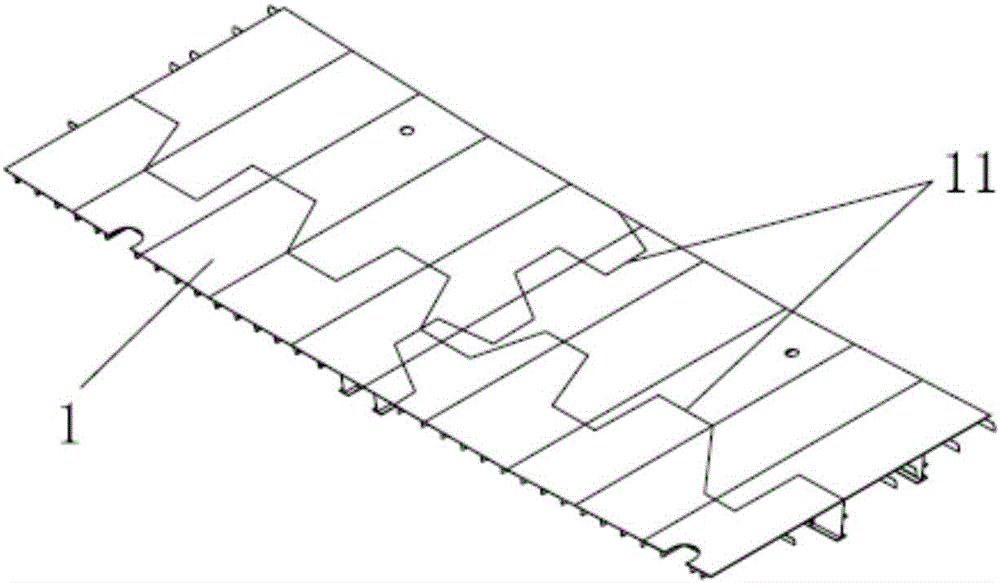

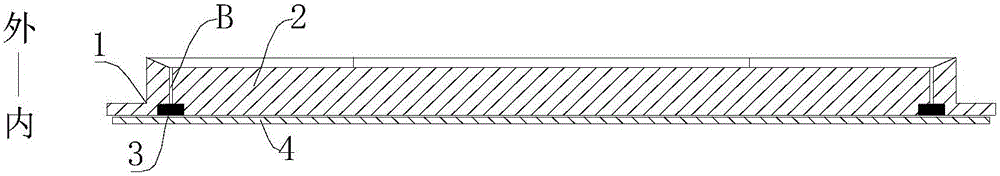

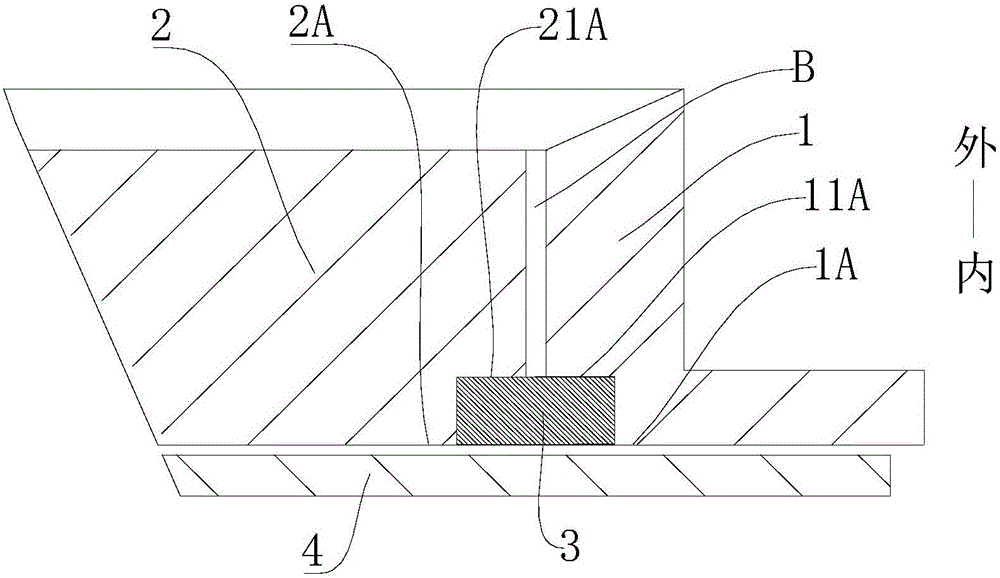

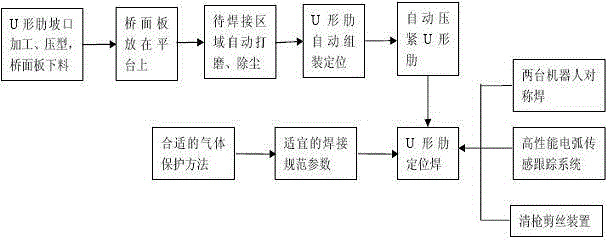

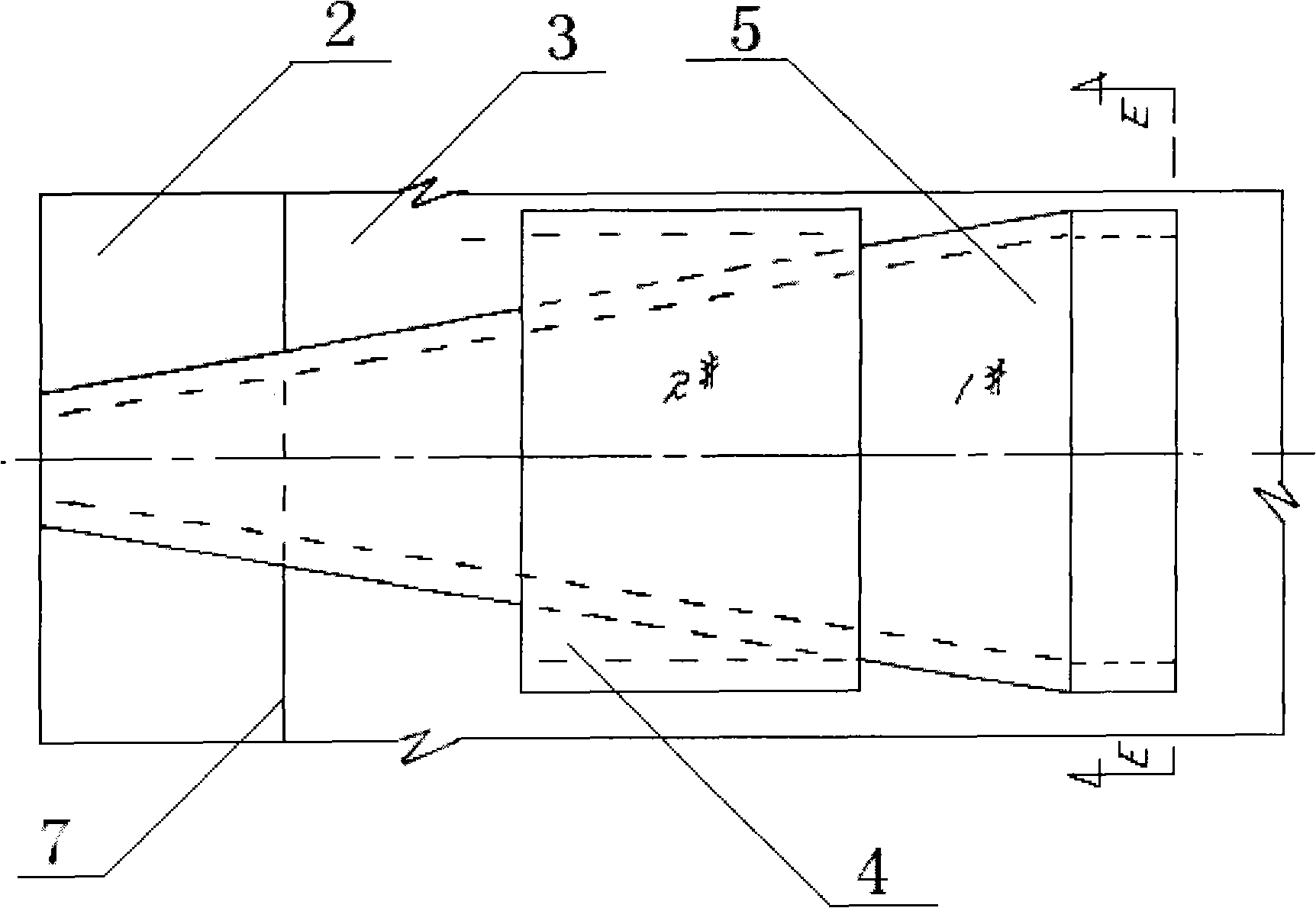

Automatic assembly method for orthotropic plate unit U-shaped ribs

ActiveCN103056491AWith dust removal functionCreate pollutionArc welding apparatusWorkpiece edge portionsFillet weldBridge deck

The invention discloses an automatic assembly method for orthotropic plate unit U-shaped ribs. The method comprises: S1, molding U-shaped ribs; S2, blanking a bridge deck slab and forming a U-shaped rib assembly locating line; S3, locating the U-shaped ribs on an area to be welded on the bridge deck slab through a U-shaped rib assembly locating device; S4, clamping the U-shaped ribs through the U-shaped rib assembly locating device; S5, using a welding robot for U-shaped rib fillet welding positioned welding; and S6, repeating the steps till U-shaped ribs on the whole plate unit are assembled and subjected to positioned welding. The method has the advantages of being high in assembly accuracy and assembly production efficiency, stable in welding quality and the like of orthotropic plate unit U-shaped ribs and is high in applicability, capable of being popularized and applied in manufacture fields of steel structures such as ship steel structures, mechanical steel structures and building steel structures and wide in the application range.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD +1

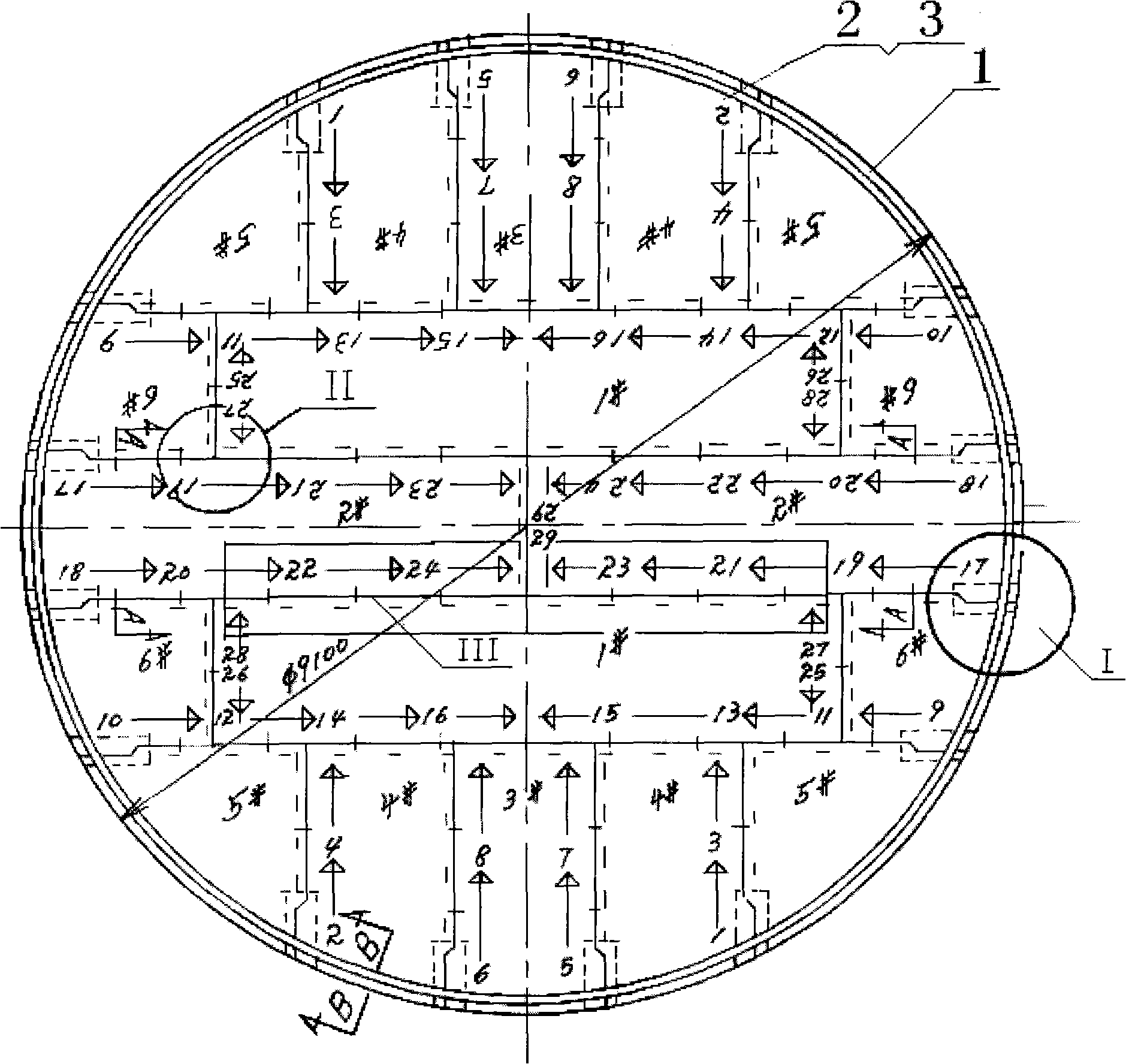

Metal oil tank production method

InactiveCN101491863AGuaranteed flatnessSolving for slip variablesDomestic vesselsWelding apparatusFillet weldStress concentration

The invention relates to the field of mechanical processing, in particular to a welding production method for a metallic oil tank and a tank bottom. The method for producing the metallic oil tank comprises adopting a tank wall, an upper bottom plate of the tank bottom, a lower bottom plate of the tank bottom, an angle steel head, a tapered iron, and a liner plate. The method comprises the following steps: 1) performing the plate arrangement and numbering; 2) welding tank bottom plates and a tank wall plate, wherein firstly outside fillet welds between the tank bottom plates and the tank wall plate are welded, and then inside fillet welds between the tank bottom plates and the tank wall plate are welded; and 3) welding the tank bottom plates according to a numbering sequence. The method for producing the metallic oil tank is to draw a plate arrangement drawing according to the circular area of the tank bottom before the construction, weld longitudinal and transverse welds according to the sequence, calculate the shrinkage factor, and reserve adequate lapping allowance so as to avoid the hazard of sliding variable and stress concentration produced among the plates due to an action force of thermal expansion and cold shrinkage during the welding, and can effectively eliminate accumulated stress. The method for producing the metallic oil tank is applicable to the manufacturing and processing of metallic oil tanks with a volume of between 500 and 10,000 m.

Owner:傅凤义

Horizontal fillet welding seam angle-wrapping process suitable for automatic welding

ActiveCN106312259AWelding looseWelding, the weld is full, and the size of the weld meets the loose requirementsArc welding apparatusFillet weldEngineering

The invention provides a horizontal fillet welding seam angle-wrapping process suitable for automatic welding, and the horizontal fillet welding seam angle-wrapping process is suitable for unit vertical welding in a ship building process, adopts gas-shielded welding to carry out automatic welding to complete horizontal fillet welding seam angle-wrapping welding for a bottom plate and reinforcing ribs, and belongs to the technical field of gas-shielded welding automatic welding. According to the technical scheme adopted by the invention, two robots drive two welding guns; arcs are initiated from the two sides to drive the welding guns to move to the middle of the reinforcing ribs, so that angle-wrapped welding is completed, welding seams are full, and dimensions of the welding seams meet requirements. The horizontal fillet welding seam angle-wrapping process provided by the invention has the positive effects of reducing times of overlap welding, arc initiating and arc extinguishing, avoiding defects, reducing interferences of the welding guns and workpieces, especially reinforcing ribs with circular-arc holes in end parts, expanding automatic welding cover range and greatly simplifying trial teaching workload. The horizontal fillet welding seam angle-wrapping process is wide in scope of application, easily realizes automatic welding, has relatively low requirements on workpiece pairing, and improves welding quality and working efficiency.

Owner:TANGSHAN KAIYUAN AUTOWELDING SYST

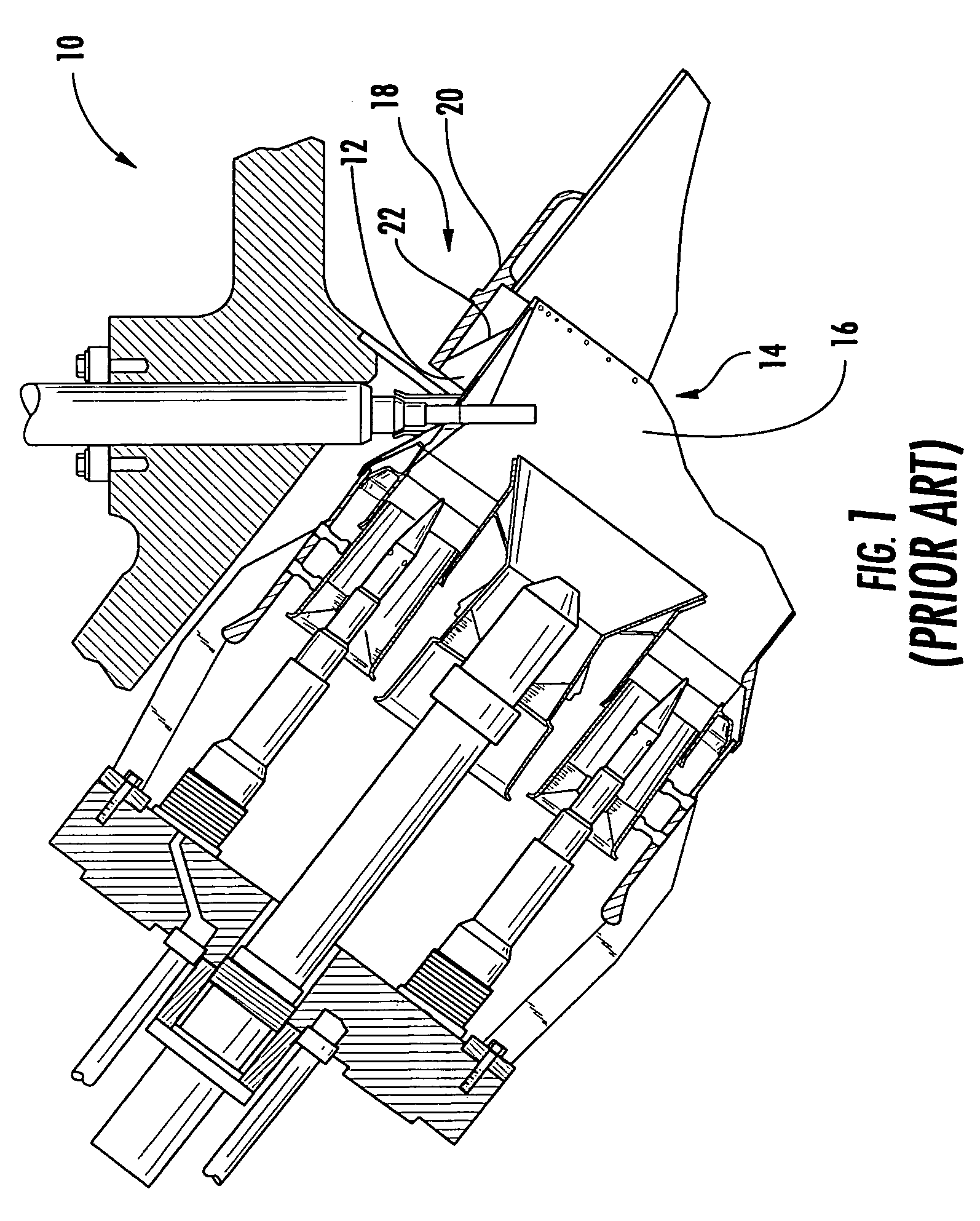

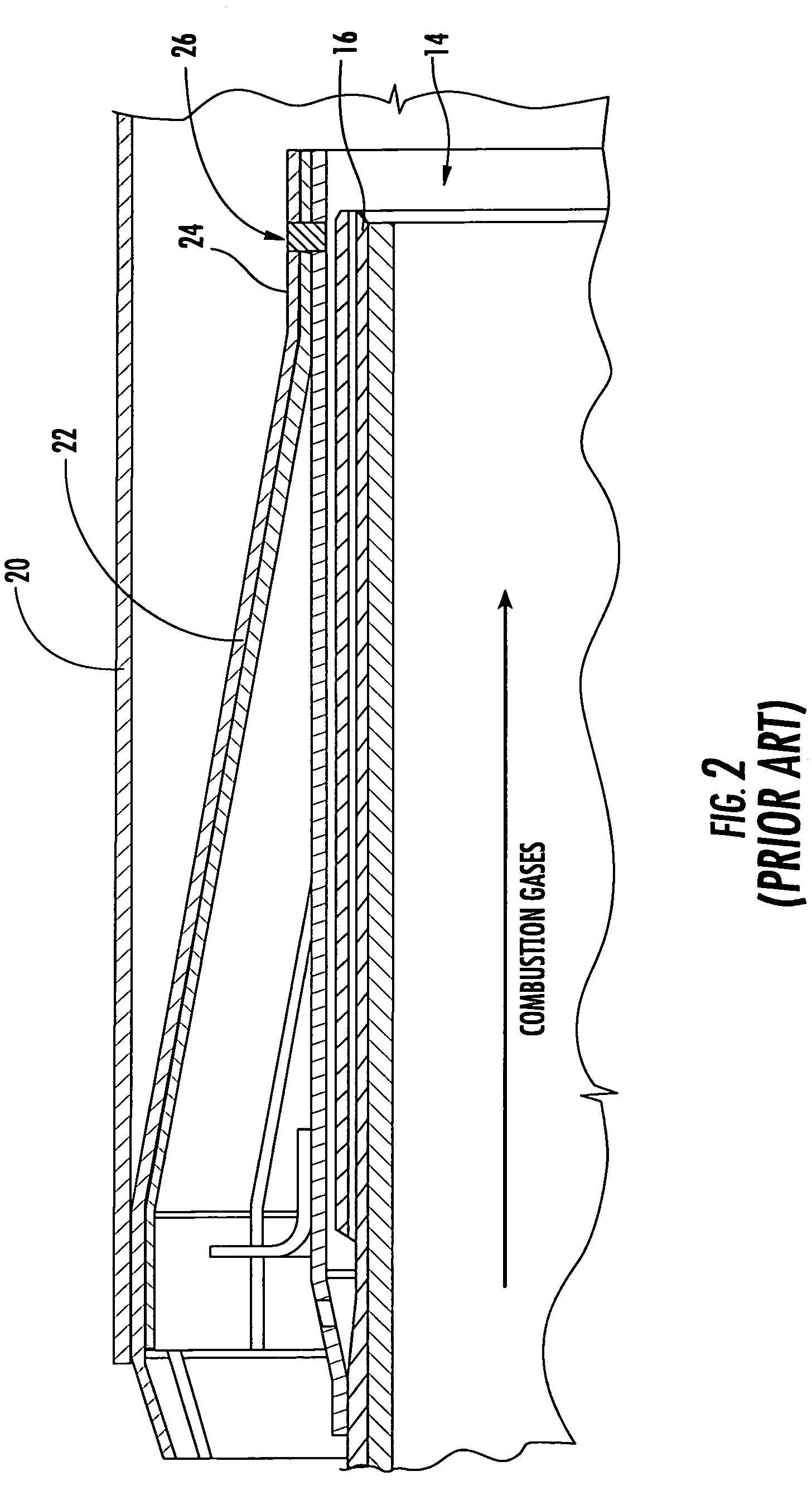

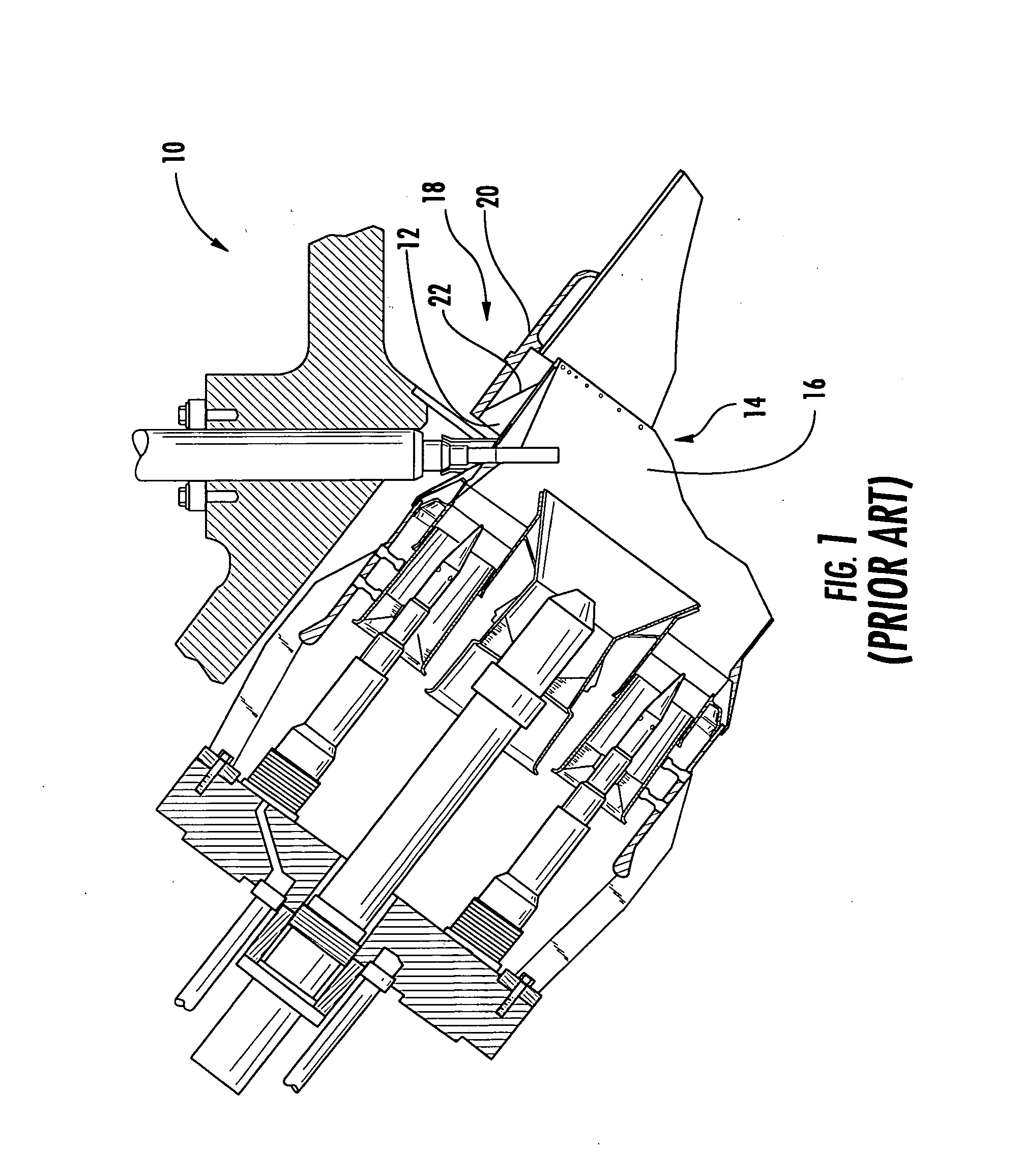

Combustor spring clip seal system

Aspects of the invention are directed to a sealing system for the interface between a combustor liner and transition duct. The system includes a spring clip seal. A first end of the spring clip seal operatively engages the inner peripheral surface of the transition duct. A second end of the spring clip seal is indirectly attached to the liner by an insert disposed therebetween. The spring clip seal can be attached to the insert by any kind of welding process that does not involve melting of the spring clip seal and the insert, such as fillet welding. The insert and the liner can be attached in a similar manner. Because fillet welds are relatively easy to cut, the spring clip, insert and liner can be separated without the need for cutting any of these individual components. Thus, the system can facilitate the repair, disassembly and reassembly of the interface.

Owner:SIEMENS ENERGY INC

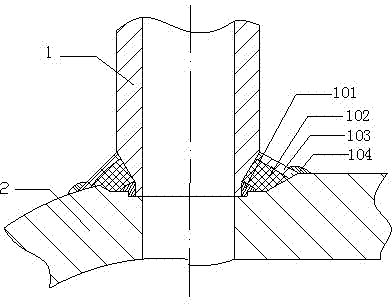

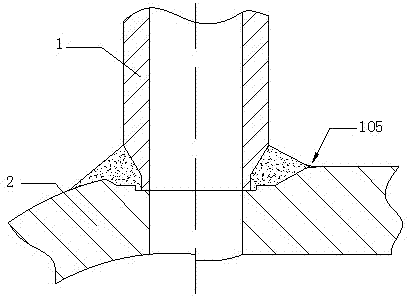

Tube socket fillet weld reheat crack prevention method

ActiveCN103170712ASolve the problem of reheat crackingSimple processArc welding apparatusFillet weldStructural engineering

The invention discloses a tube socket fillet weld reheat crack prevention method which comprises the following steps: first step, installing and welding a tube socket fillet weld; second step, grinding and cleaning the tube socket fillet weld and figuring weld toe; third step, welding a pressure weld pass of the weld toe of the tube socket fillet weld, wherein the welding method of the pressure weld pass is manual tungsten electrode argon-arc welding or welding rod electric-arc welding; fourth step, grinding or machining to eliminate the pressure weld pass of the weld toe, and enabling weld metal and a tube body to smoothly transit; fifth step, grinding and cleaning the test surface of the tube socket fillet weld, and carrying out a 100% nondestructive test; sixth step, after the100% nondestructive test is qualified, carrying out a post-weld heat treatment; seventh step, grinding or polishing the tube socket fillet weld and carrying out a 100% nondestructive review. The tube socket fillet weld reheat crack prevention method is simple in whole technical process, convenient to produce and carry out and good in application effect. The socket fillet weld reheat crack prevention method effectively solves the problem of thick-wall 12 Cr1MoV header tube socket fillet weld reheat crack, ensures production cycles and quality of products and reduces economic losses.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

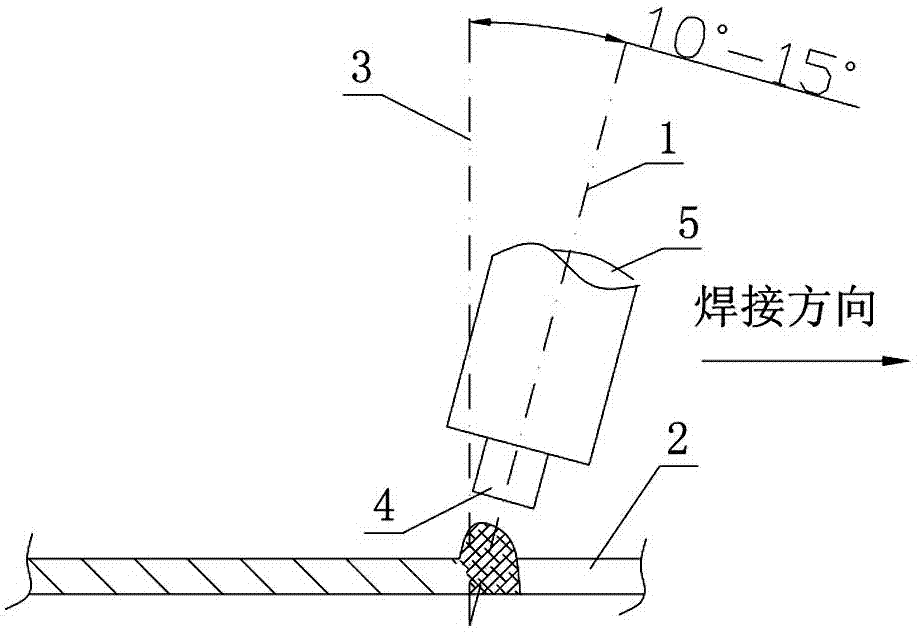

Welding method for Q420qENH coating-free weathering steel for steel bridge

InactiveCN106956064AGuaranteed compatibility of ingredientsSolve weather resistanceArc welding apparatusWelding/cutting media/materialsFillet weldWeather resistance

A welding method of Q420qENH coating-free weather-resistant steel for steel bridges, the Q420qENH coating-free weather-resistant steel has an atmospheric corrosion resistance index I≥6.5, a welding sensitivity index Pcm≤0.23, and when the welded joint form is a butt weld, The combined welding process of solid wire gas-shielded welding for backing and submerged arc automatic welding for filling and covering is adopted; when the welding joint form is T-shaped penetration fillet weld, the gas-shielded welding process of flux-cored welding wire is adopted; the welding joint form is single-sided bridge deck When welding double-sided formed joint welds, a combined welding process of solid wire gas shielded welding for bottoming and submerged arc automatic welding for filling and covering is used. The atmospheric corrosion resistance index I of the welding wire in the present invention is ≥ 6.5, and the relative corrosion rate of the deposited metal is ≤ 8%, which ensures that the welding seam matches the composition of the steel plate, and solves the weather resistance of the welding seam of the coating-free weather-resistant steel. Coating the weather-resistant steel bridge solved the technical bottleneck.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

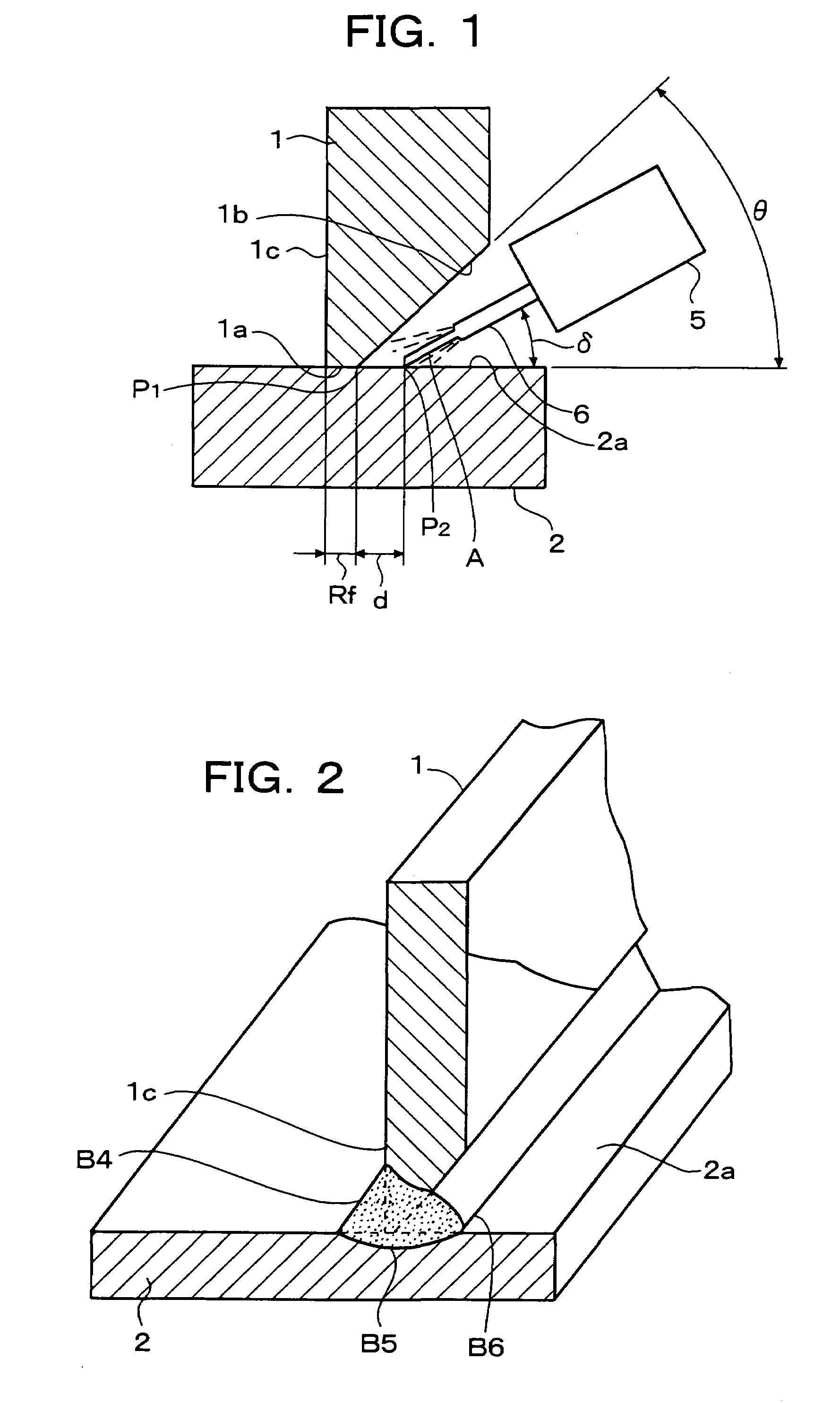

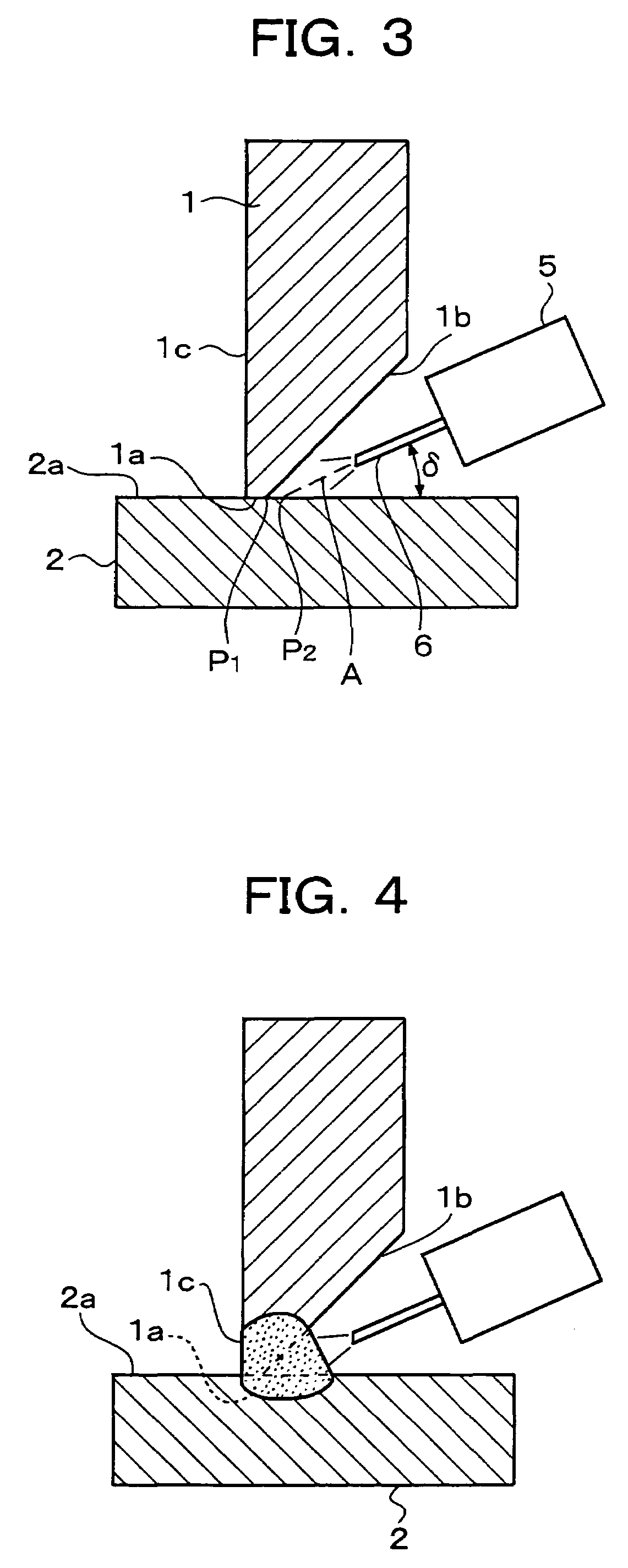

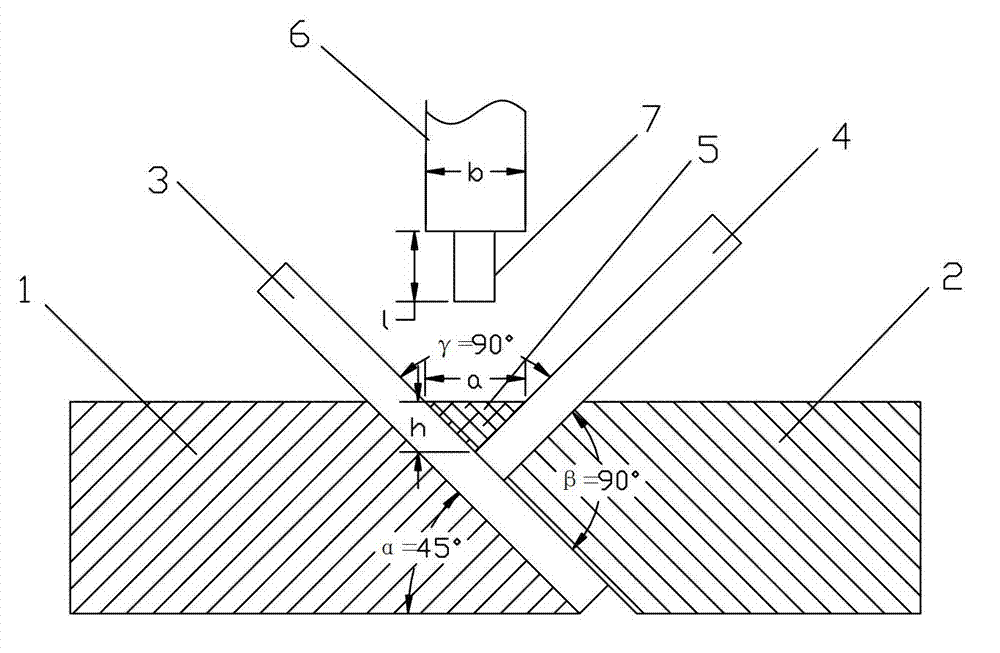

Welding method, welding device, welded joint, and welded structure

InactiveUS7005607B2Accurately force outExcellent welding workabilityArc welding apparatusWelding/cutting media/materialsFillet weldButt welding

A welding method is disclosed for butt welding a first base material 1 and a second base material 2 with each other. To also permit stable and efficient formation of a bead in the form of a fillet weld on a back side of a groove by conducting arc welding from the side of the groove without arranging a bead beforehand on the back side of the groove, the first member 1, on which a root face 1a and a single groove face 1b have been formed, is brought at its root face 1a into contact with a flat surface 2a of the second base material 2. A welding wire 6 is arranged facing on the groove formed by the contact between the first base material 1 and the second base material 2. The first base material 1 and the second material 2 are caused to fuse at an area of contact between them by an arc from the welding wire 6. A melt, which has been formed by the fusion at the area of contact and the like, is forced out to the back side of the groove to form a bead B4 in the form of a fillet weld on the back side of the groove.

Owner:NIHON KENKI CO LTD

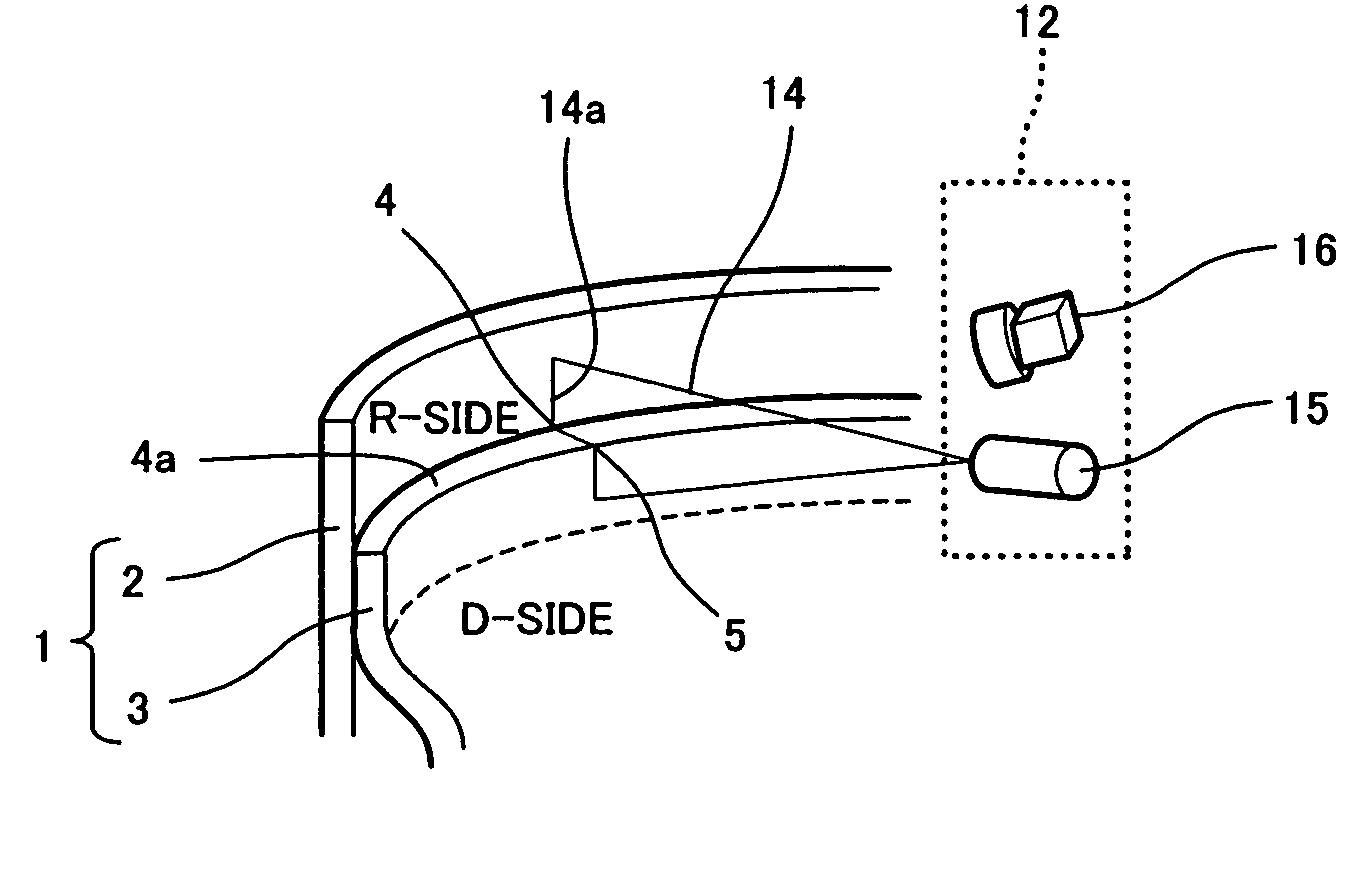

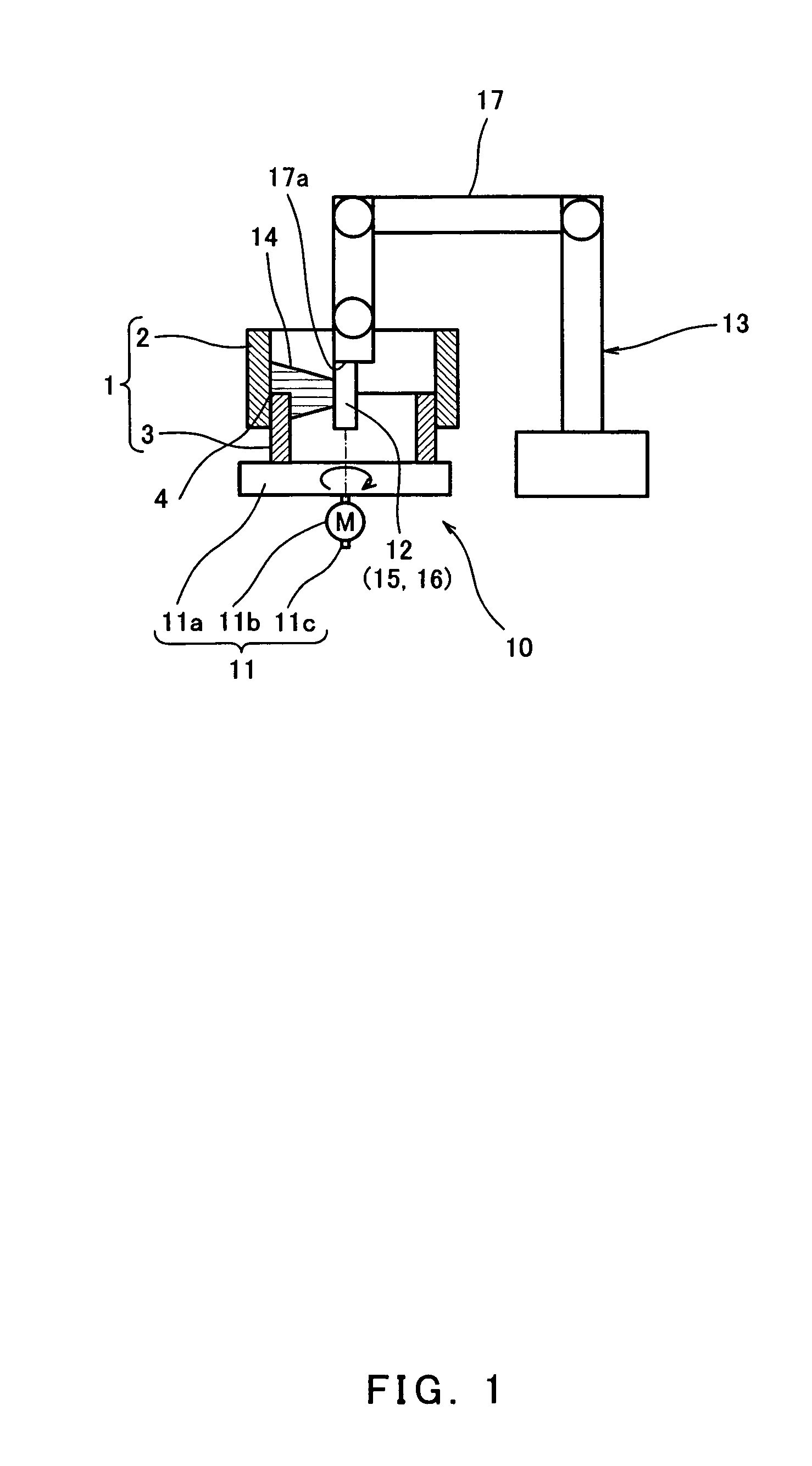

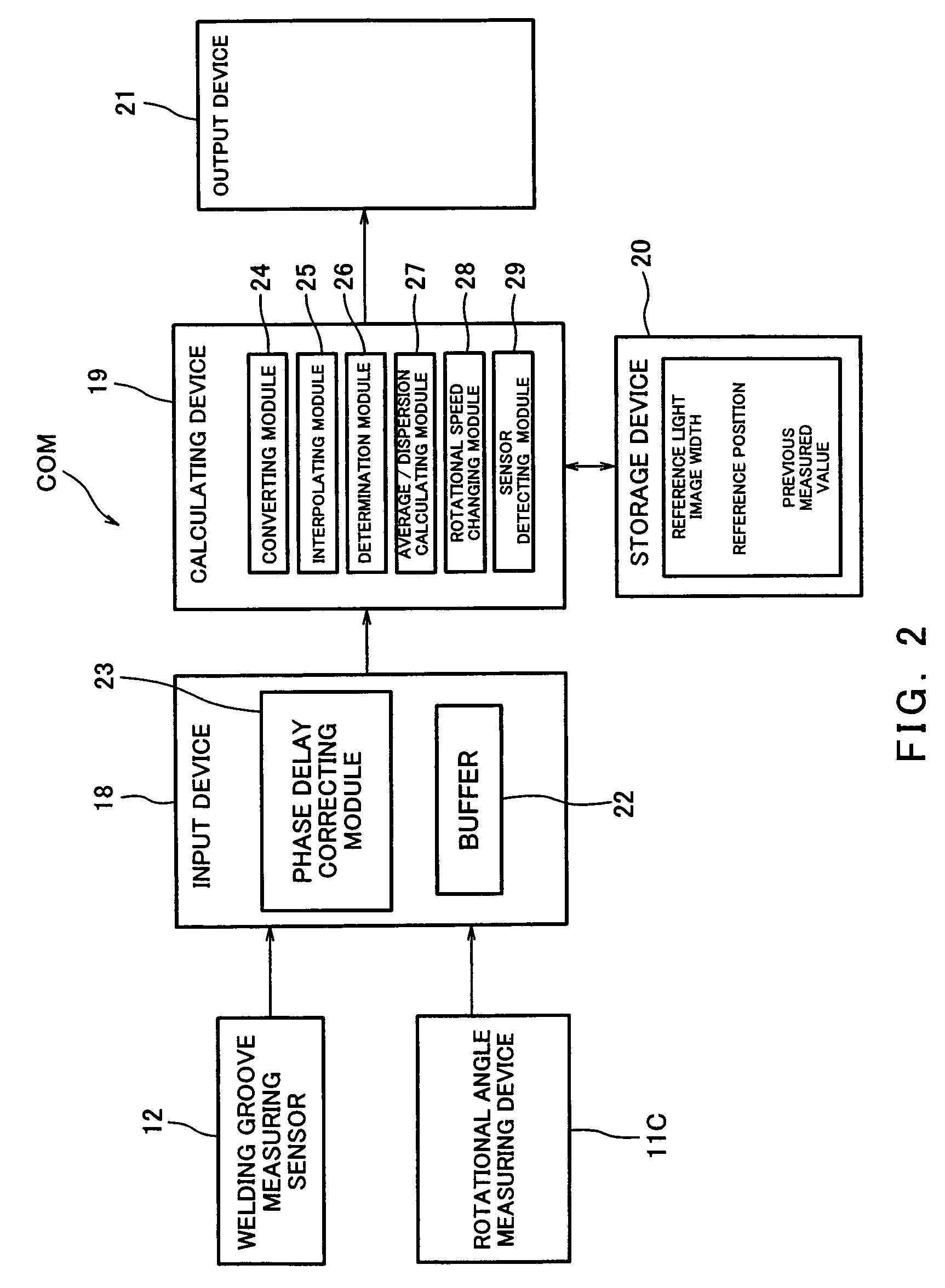

Method, apparatus and system for measuring a welding-groove position

InactiveUS7657082B2Reduce impactEasy to moveCooking-vessel materialsOptical rangefindersFillet weldImage acquisition

A method of measuring a welding-groove position for an over-lapped fillet welding of thin members, comprising a projection step of projecting a slit light so that the slit light is projected on both the thin members crossing a welding-groove face, a two-dimensional image acquisition step of capturing the slit-light image projected on each of the thin members as two-dimensional images; a three-dimensional conversion step of converting the two-dimensional images into three-dimensional images using a predetermined three-dimensional conversion parameter, and a calculation step of calculating the welding-groove position based on the three-dimensional data of the projected slit-light images, and relative positions between the projected slit-light images in the three-dimensional data defined by shapes and arrangement of the thin members.

Owner:KAWASAKI HEAVY IND LTD +1

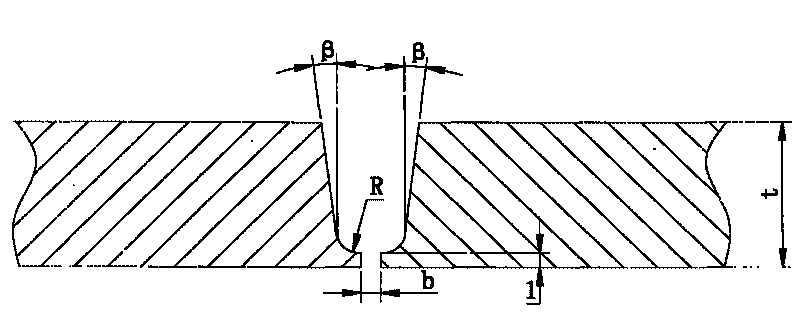

Full penetration fillet weld back-gouging-free welding technology

InactiveCN104259634AImprove rigidityImprove deformation resistanceArc welding apparatusWorkpiece edge portionsFillet weldEngineering

The invention belongs to the technical field of steel structure welding and provides a full penetration fillet weld back-gouging-free welding technology. The welding technology comprises the following steps of: 1) processing a groove of a web plate and decreasing the welding groove as much as possible, 2) fabricating a welding body, ensuring an inclination angle of the welding body to allow a center line of a welding wire to be located on a bisector of an included angle between the groove of the web plate and a wing plate during welding, 3) assembling and placing the web plate and the wing plate on the welding body in a push-against manner, ensuring the straightness and planeness of the web plate and the wing plate and accurately controlling focuses of the web plate and the wing plate, 4) selecting an appropriate welding wire material according to performance of a base material, and carrying out carbon dioxide gas shielded welding on a weld on the reverse side of the groove of the web plate to form a welding backing plate for later groove welding, 5) carrying out union melt welding as the first U-shaped groove welding, and 6) carrying out layered filling welding via the union melt welding, and finally carrying out cosmetic welding, wherein the groove of the web plate is a unilateral U-shaped or V-shaped groove.

Owner:CHINA SIXTH METALLURGICAL CONSTR

Method for cold arc welding of titanium and titanium alloy

ActiveCN101695784AFlawlessQualified performanceWorkpiece edge portionsWelding accessoriesButt weldingEngineering

The invention provides a method for cold arc welding of titanium and titanium alloy, which comprises the five steps of welding groove setting, a welding mode, selection of protective gas, splashing control in the welding process and establishment of welding process parameters, wherein the welding groove setting is divided into an I type welding groove, a V type welding groove and a U type welding groove; the welding mode comprises cold arc welding CMT butt welding, cold arc impulse welding CMT plus P butt welding or cold arc impulse welding CMT plus P fillet welding; the protective gas is He plus Ar mixed gas; besides the protective gas, the splashing in the welding process is mainly affected by arc length correction, impulse correction or dynamic correction, the arc length correction is controlled to be between 0 and 20 percent, and the impulse correction or the dynamic correction is controlled to be between 0 and 2.0; and the establishment of the welding process parameters differs because of the fillet welding and the butt welding. The method has the advantages of having a stable welding process, obtaining indefectible and performance-qualified welding lines, effectively reducing welding deformation of complex structure parts of titanium and titanium alloy, lowering the residual stress of the welding lines and improving product quality and production efficiency.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

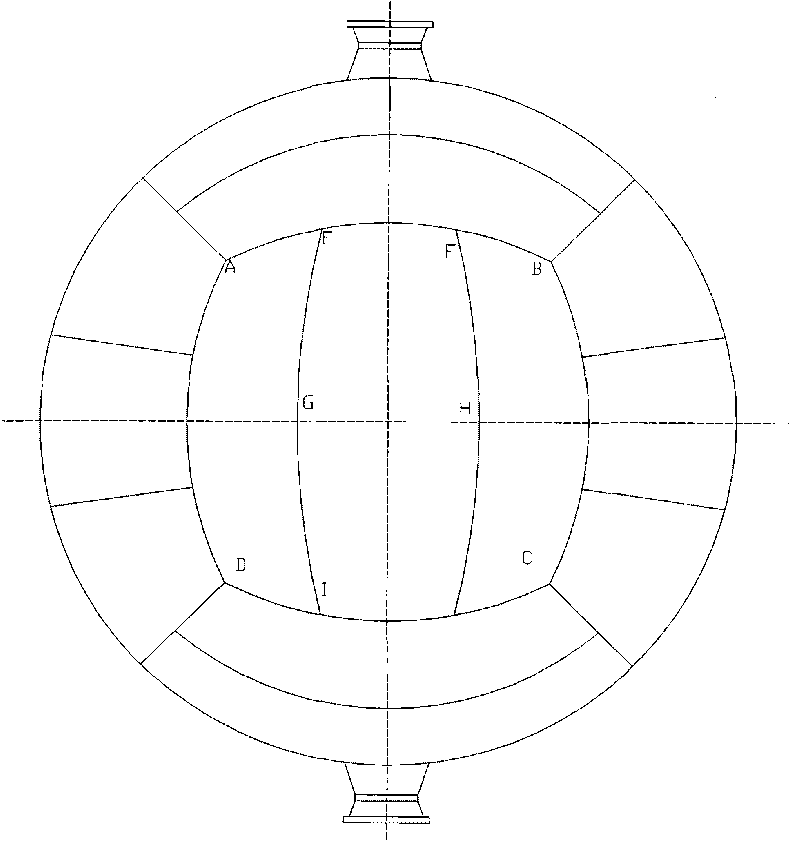

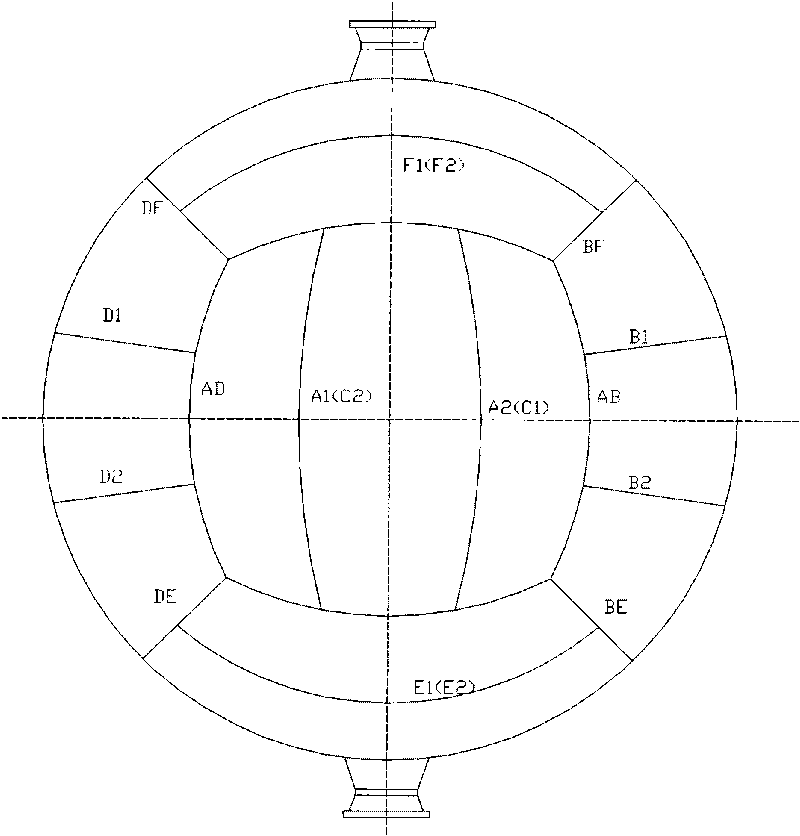

Assembly method of shirt support and spherical shell plate of 1000m<3> nitrogen spherical tank

InactiveCN101737614AIncrease the bearing areaReduce stress concentrationArc welding apparatusPressure vesselsFillet weldStress concentration

The invention relates to an assembly method of a shirt support and a spherical shell plate of a 1000m<3> nitrogen spherical tank, which comprises the steps of: assembling bulk spherical tanks; setting up an inner scaffold and an outer scaffold; installing and welding a positioning block; manufacturing and installing a ladder and a platform; preheating before the welding; welding lifting points; assembling the spherical tanks; dismantling the scaffolds and the positioning block; and thermally treating the whole spherical tank. The invention increases the stress area of supporting the spherical tank, also reduces the stress concentration of fillet welds in contact with uprights, and has uniform stress, good stability and reliable connection. The quantity of the spherical shell plates is reduced to 18, which reduces the workload for the manufacture of the spherical tank. The invention increases the quality of the whole spherical tank, improves the safety factor of the operation of the spherical tank, greatly lowers the total installation cost, remarkably enhances the safety of the spherical tank, prolongs the service life of the spherical tank, and decreases the operation and maintenance cost of the spherical tank.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES +1

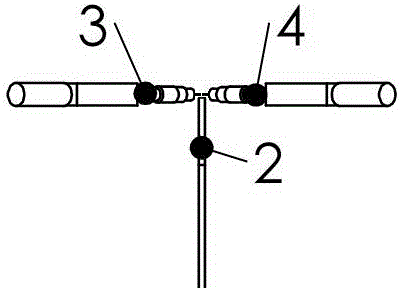

Method and device for welding inside fillet welds of T-shaped joints through infilling-type friction-stir welding

InactiveCN102922125AHigh strengthUnique structureNon-electric welding apparatusFillet weldEngineering

The invention discloses a method and a device for welding inside fillet welds of T-shaped joints through infilling-type friction-stir welding. The method is implemented through the steps that an inside fillet weld of a T-shaped joint is located at a flat-welding position by using a special fixture, and a process auxiliary cushion block made of a material same as that of a parent metal is embedded in the position of the inside fillet weld; a plane required by the friction of a shaft shoulder of a stir-welding head is formed at the inside fillet weld of the T-shaped joint; a weld of the T-shaped joint is heated by using the frictional heat generated by the cushion block and the shaft shoulder of the stir-welding head; and a weld of friction-stir welding is formed under the heat-engine joint action of a stirring pin. The device for implementing the method disclosed by the invention is unique in structure, low in cost and strong in universality. According to the method and the device disclosed by the invention, an effect of welding inside fillet welds of T-shaped joints through friction-stir welding can be achieved; and because the cushion block and the parent metal which are same in material are fused together, the weld reinforcement of welds can be increased, and the strength of joints is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Combustor spring clip seal system

Aspects of the invention are directed to a sealing system for the interface between a combustor liner and transition duct. The system includes a spring clip seal. A first end of the spring clip seal operatively engages the inner peripheral surface of the transition duct. A second end of the spring clip seal is indirectly attached to the liner by an insert disposed therebetween. The spring clip seal can be attached to the insert by any kind of welding process that does not involve melting of the spring clip seal and the insert, such as fillet welding. The insert and the liner can be attached in a similar manner. Because fillet welds are relatively easy to cut, the spring clip, insert and liner can be separated without the need for cutting any of these individual components. Thus, the system can facilitate the repair, disassembly and reassembly of the interface.

Owner:SIEMENS ENERGY INC

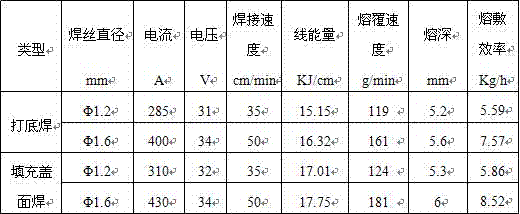

Method for automatically welding hydraulic support structural component through welding wires with diameter being 1.6 mm

ActiveCN106914686AMeet the requirements of the weldSolve serious burn damageArc welding apparatusFillet weldButt welding

The invention discloses a method for automatically welding a hydraulic support structural component through welding wires with the diameter being 1.6 mm. The method includes the steps that firstly, the part tolerance and the splicing precision of the hydraulic support structural component are checked before welding, and the depth tolerance of a welding groove and the angle tolerance of the welding groove are controlled; secondly, the two sides of a weld bead are ground before welding till metallic luster appears; thirdly, all to-be-welded weld joints of the hydraulic support structural component are located at flat welding or flat fillet welding positions; fourthly, off-line programming or on-site programming teaching is conducted on a welding robot; and fifthly, multi-layer and multi-channel welding is conducted on the to-be-welded weld joints through the welding robot by means of the welding wires with the diameter being 1.6 mm in a gas shielded welding manner. According to the method, robot welding is conducted through the welding wires with the diameter being 1.6 mm, and compared with traditional welding conducted through welding wires with the diameter being 1.2 mm, under the condition that the ton cost of the welding wires is not changed and all mechanical properties of the weld joints can meet requirements, the weld penetration of the weld joints is increased, efficiency is improved by 40% or above, and the comprehensive cost of welding conducted through each ton of welding wires is saved by RMB 1500 yuan or above.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com