Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

503results about How to "Flawless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition and preparation method of silicon solar battery electrode slurry

InactiveCN101651155AEnhanced ohmic contactReduced series resistanceRenewable energy productsSemiconductor devicesBack surface fieldOhm

The invention relates to composition and a preparation method of silicon solar battery electrode slurry. The silicon solar battery electrode slurry comprises silicon solar battery sunny slope grid electrode silver slurry, back surface field silver-aluminium slurry and back surface field aluminium slurry which are used for preparing an ohm contact layer containing silicon alloy powder. In the invention, silver powder, aluminium powder, a simple substance element and the silicon alloy powder are used as raw materials, and an organic bond and an inorganic bond are used as accessories, and after the raw materials and the accessories are evenly mixed, a three-roller rolling mill is utilized to roll the mixture into the silicon solar battery electrode slurry of which the fineness is 20.0-25.0mum and the viscosity is 20000-40000mpa.s.

Owner:谭富彬

Ceramic glaze and preparation method thereof

The invention discloses ceramic glaze prepared from the following components in weight percentages: 40 to 80% of SiO2, 8 to 20% of Al2O3, 0 to 5% of B2O3, 3 to 13% of CaO, 1 to 6% of MgO, 1 to 10% of BaO, 0 to 5% of ZnO, 1 to 4% of K2O, 1 to 4% of Na2O, 5 to 13% of ZrO2, 0 to 0.5% of Fe2O3, and 0 to 0.5% of TiO2. The invention also discloses a preparation method of the ceramic glaze. In the preparation method of the invention, some raw materials in the glaze formula are calcined at high temperature in advance, which helps to reduce defects such as bubbles and pinholes on the glaze and improves the quality of a product, meanwhile, the melting temperature of the glaze is properly reduced, the fluidity of a glaze melt at the high temperature is increased, and a flat, fine and smooth surface can be easily obtained. By adoption of the preparation method of the invention, the matte glaze with good hand feel and low glossiness can be obtained, and the high gloss glaze with a smooth surface and without pinholes or bubbles can also be obtained, so as to obtain the ceramic product with more excellent performance.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

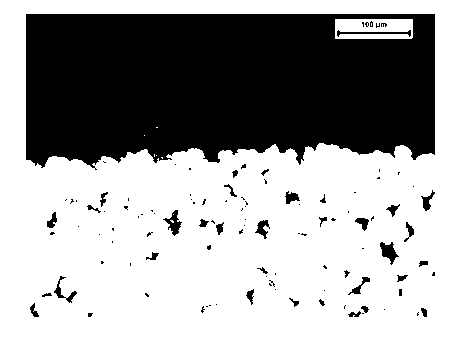

Preparation method of porous ceramic-metal composite film material

ActiveCN102836642AHigh specific surface areaIncrease contact areaSemi-permeable membranesCeramic coatingPorous metal

The invention provides a preparation method of a porous ceramic-metal composite film material. The method comprises steps of: using ceramic as a rigid outer mold; preparing a ceramic coating in the inner surface of the rigid outer mold; adding a metal powder into a hollow cavity between the rigid outer mold and an elastic inner mold; sealing; forming by cold isostatic pressure; sintering a formed porous ceramic-metal composite film blank together with the rigid outer mold; and separating a sintering body from the rigid outer mold. Through improvement on the preparation process, the ceramic coating and the metal powder subjected to isostatic pressure forming are sintered under high temperature condition, so that a porous metal substrate and the ceramic film layer expand synchronously under effect of compressive stress of the rigid outer mold during the sintering. The prepared porous ceramic composite film material has strong adhesion, high strength, smooth, flat and flawless film layer, and improved practicability.

Owner:南京髙谦功能材料科技有限公司

High-strength high-conductivity copper alloy contact wire for rapid transit railway

ActiveCN1811998AExcellent thermal stability and corrosion and wear resistanceFine grain structureSingle bars/rods/wires/strips conductorsCable/conductor manufactureCrystalliteChromium

Owner:郑茂盛 +1

Manufacturing method of large size thin-walled titanium alloy cylindrical part and cylindrical mould

The invention provides a manufacturing method of a large size thin-walled titanium alloy cylindrical part, comprising the steps of: (1) raw material powder selection; (2) powder loading and encapsulation; (3) hot isostatic pressing; and (4) cylindrical part blank processing. The invention also provides a cylindrical mould used for manufacturing the large size thin-walled titanium alloy cylindrical part, comprising a cylindrical outer sheath and a cylindrical inner sheath. A cavity for loading titanium alloy powder is formed by the outer sheath and the inner sheath, and the inner sheath is internally provided with a cylindrical shaped mould; an upper sheath cover and a lower sheath cover for encapsulating the cavity are respectively fixed at the top end and the bottom end of the cavity for loading titanium alloy powder; and the upper sheath cover is also provided with a gas removing pipe. Different from a plurality of traditional manufacturing methods, the invention can simultaneously meet the requirements of high performance, no defect, large size thin-wall, large length-diameter ratio, high precision, low cost, and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

SMC sheets and its prepn. method

InactiveCN1903563AShorten the curing timeLow molding temperatureSynthetic resin layered productsGlass/slag layered productsGlass fiberHigh surface

A SMC sheet with high surface quality and luster is composed of both surficial PE films and a core material prepared from glass fibers through immersing them in the resin paste which is proportionally from unsaturated polyester resin, low-shrinkage additive, internal demoulding agent, calcium carbonate, styrene, trigger and magnesium oxide.

Owner:北京玻钢院复合材料有限公司

Polishing solution containing ceric oxide powder/colloid silicon dioxide mixed abrasive and preparing process thereof

ActiveCN103992743AImprove removal rateImprove surface qualityPolishing compositions with abrasivesSilica particleCerium(IV) oxide

The invention relates to a chemically mechanical polishing solution and a preparation process thereof, and particularly to a polishing solution containing a ceric oxide powder / colloid silicon dioxide mixed abrasive and a preparing process thereof. The polishing solution containing the mixed abrasive is simple in preparing process, practical and prone to production. Raw materials of the polishing solution comprise 3-10% of ceric oxide powder having a particle size of 100-2000 nm, 5-50% of colloid silicon dioxide having a particle size of 10-200 nm, and 0.001-0.5% of a dispersing agent, with the balance being water. The polishing solution is prepared by selecting a container, adding the colloid silicon dioxide solution, adding the ceric oxide powder, stirring uniformly, adding the dispersing agent and the water to the required volume, and stirring uniformly. The ceric oxide powder and the colloid silicon dioxide of different particle sizes are adopted as the abrasive. In the polishing solution, the smaller silicon dioxide particles decrease scratches, pits, and other defects so as to improve the surface quality, and the larger ceric oxide particles obtain a high removing rate.

Owner:杰明纳微电子股份有限公司 +1

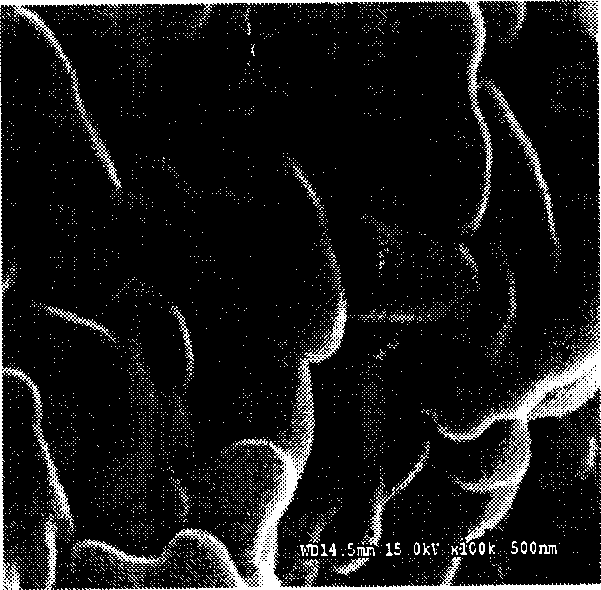

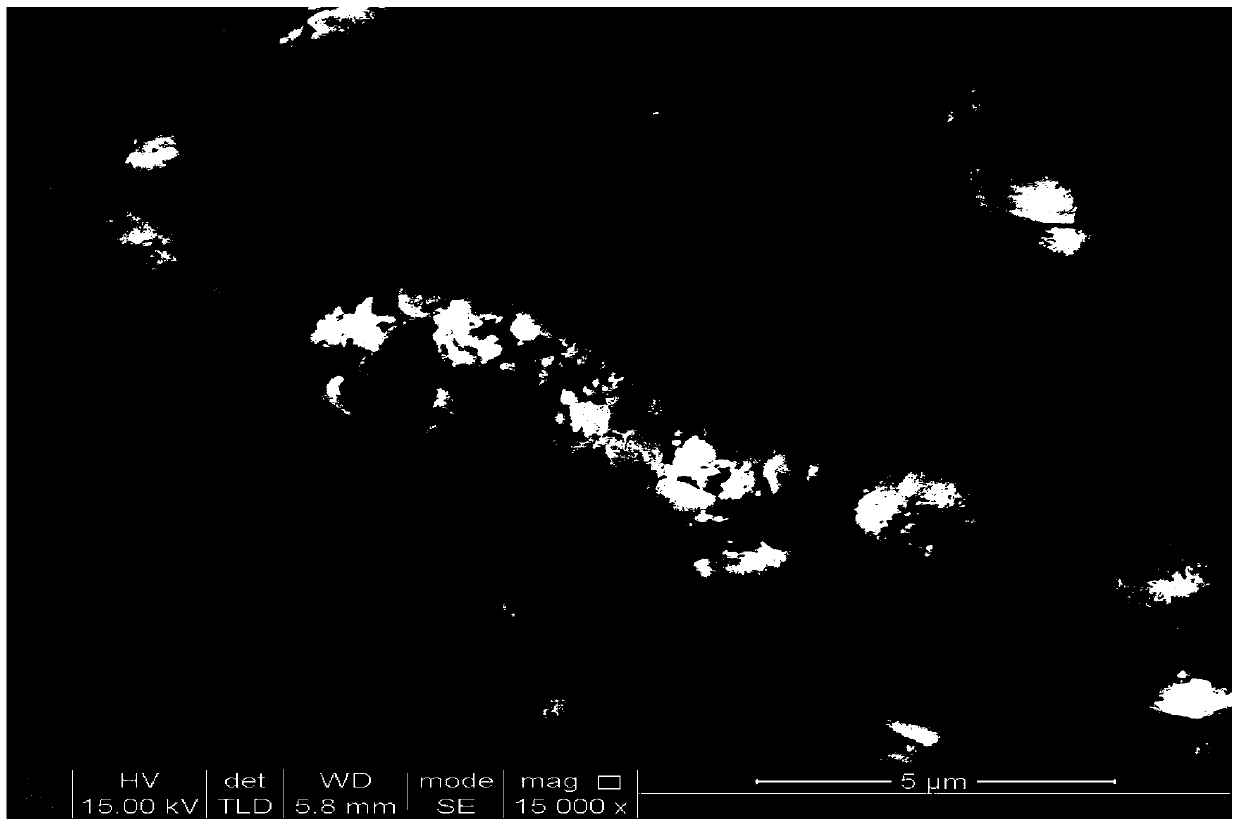

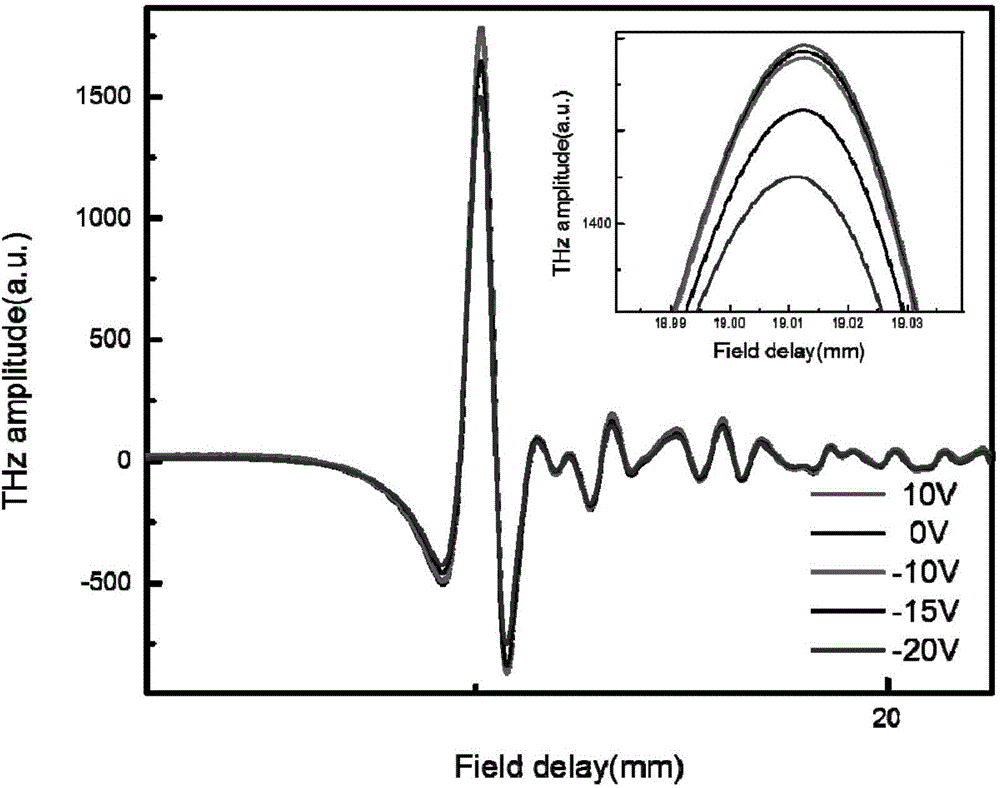

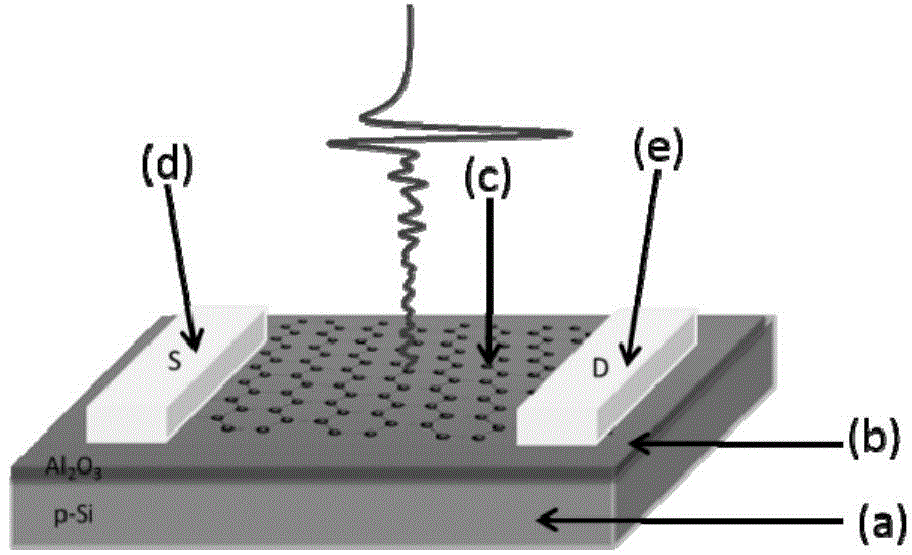

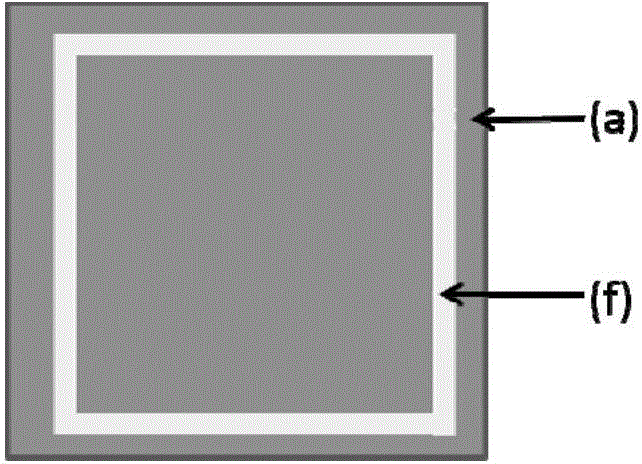

Graphene field effect transistor terahertz wave modulator and manufacture method thereof

InactiveCN104678597AReduce thicknessReduce leakage currentNon-linear opticsCommunications systemGrating

The invention provides a graphene field effect transistor terahertz wave modulator and a manufacture method thereof and aims to increase the modulating speed and depth of the graphene field effect transistor terahertz wave modulator. The graphene field effect transistor terahertz wave modulator comprises a semiconductor substrate, and a medium layer, a graphene film and source and drain electrodes which are arranged on the substrate, and an annular grating electrode which is arranged on the back of the substrate. The terahertz wave modulator is characterized in that the medium layer is an Al2O3 layer, and the thickness ranges from 5 to 100nm; the Al2O3 is deposited by the ALD (atomic layer deposition) method, and the Al2O3 is high in evenness, is free of defects and pores and has better voltage resistance; the leakage current is reduced greatly. The modulating speed of the terahertz wave modulator can be 178 KHz, the corresponded modulating depth is larger than 22%, and the modulating speed and depth are increased significantly; the terahertz wave modulator can be widely applied to the fields of terahertz wave communication systems, terahertz wave detection and terahertz wave imaging.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Environmental-protection type multifunctional efficient acid washing mist inhibition corrosion inhibitor

The invention belongs to the technical field of metal surface cleaning treatment, and more particularly relates to an environmental-protection type multifunctional efficient acid washing acid inhibition corrosion inhibitor, which is formed by mainly compounding 2-6 parts of a surfactant, 8-15 parts of a corrosion inhibitor, 0.5-1 part of a penetrating agent, 2-4 parts of an acid washing accelerating agent, 74-87.5 parts of water, and other components, wherein the product achieves the optimal mist inhibition corrosion inhibition effect in the acid washing through the synergy effect of various components. The corrosion inhibitor of the present invention has the following beneficial effects that: (1) the rust removing is fast, the rust removing speed is significantly increased with the additions of the penetrating agent and the accelerating agent, and the rust can be completely removed within 5-30 min when the addition amount is 2%; (2) the mist inhibition property is good, and the good mist inhibition effects are provided for hydrofluoric acid, nitric acid, and the like; and (3) the corrosion inhibition is good .

Owner:浏阳市三鹰新材料有限责任公司

Injection-molded reactive sintered SiC ceramic material and preparation method thereof

The invention relates to an injection-molded reactive sintered SiC ceramic material and a preparation method thereof. The ceramic material is prepared from the following raw materials in percentage by mass: 55-80% of silicon carbide, 3-10% of carbon powder, 1-3% of a surfactant, 6-20% of a lubricant and 6-20% of a binder through the steps of mixing, molding, degreasing and sintering, wherein the sum of the amount of components is 100%. The reactive sintered SiC ceramic molded by using the method provided by the invention has the advantages of uniform density of a billet and high dimensional precision, and can be used for manufacturing high-quality ceramic parts with complex structures and no defects. As for the prepared reactive sintered SiC ceramic material, the bulk density is more than 2.7g / cm<3>, and the three-point bending strength can be above 260MPa.

Owner:SHANDONG UNIV

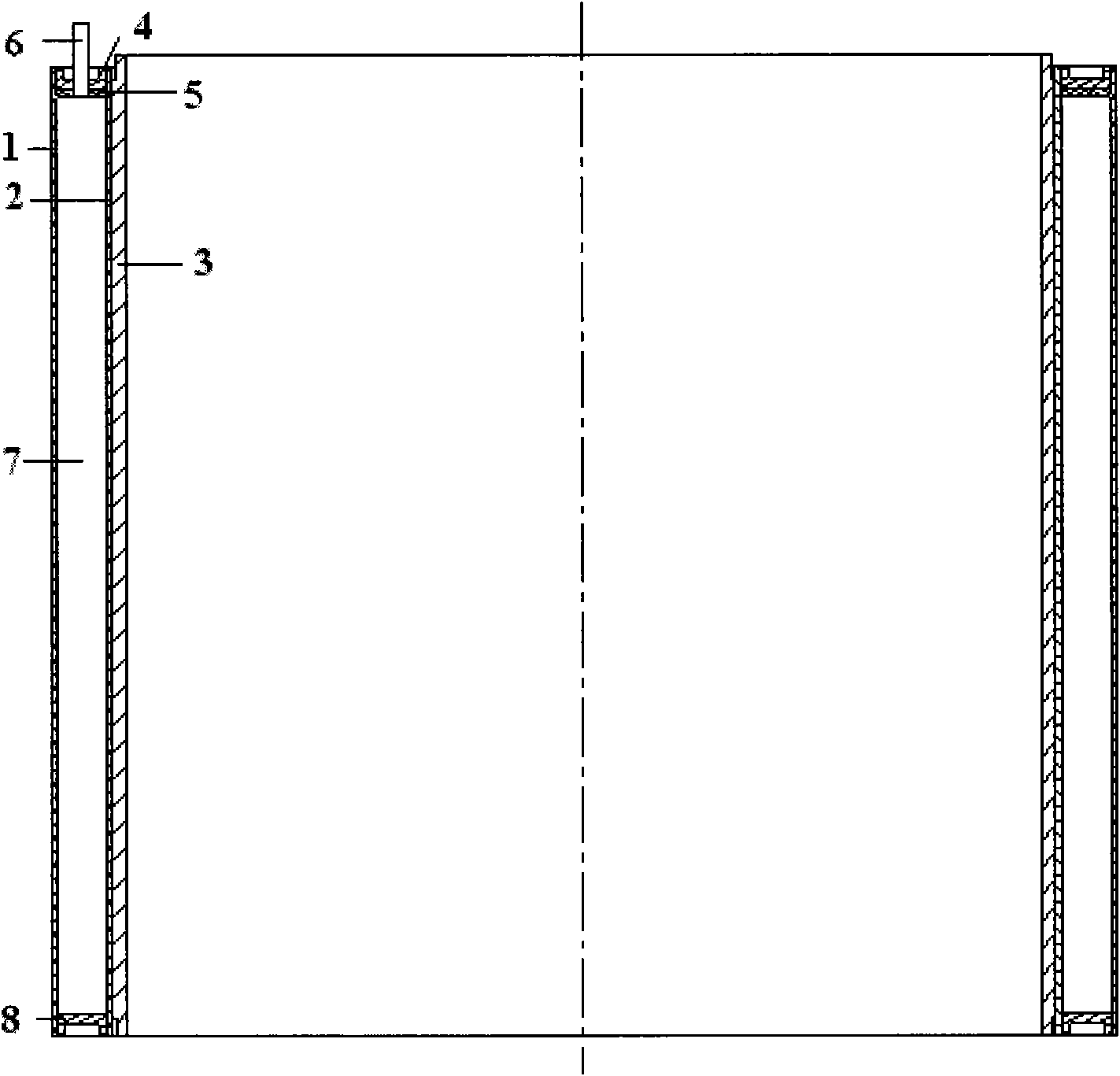

Composite reverse osmosis membrane and preparation method thereof

ActiveCN103071404AUniform pore size distributionUniform performanceSemi-permeable membranesUltrafiltrationReverse osmosis

The invention discloses a composite reverse osmosis membrane and a preparation method thereof. The method comprises the following steps of (1) dissolving polysulfone and polyethylene sulfone in a solvent to obtain a casting membrane liquid, (2) pouring the casting membrane liquid onto non-woven fabric, placing in a coagulating bath for gel membrane forming to obtain a support membrane, and obtaining a support body formed by the non-woven fabric and the support membrane, and (3) steeping the support body in a solution a and a solution b respectively, obtaining a polyamide layer on the support body and obtaining the composite reverse osmosis membrane. Compared with the prior art, a little PPSU (polyphenylsulphone) having better compatibility with a main body material is added to the main body material polysulfone (or polyethersulfone) of the support layer, the original membrane forming condition is changed, a microporous structure and surface pore size distribution of the support body can be regulated, and a macromolecular alloy ultrafiltration membrane with uniform pore size distribution and a complete spongy pore structure can be obtained. The prepared alloying support body can further conduct interfacial polymerization reaction to form the composite reverse osmosis membrane with uniform and stable properties and no defect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

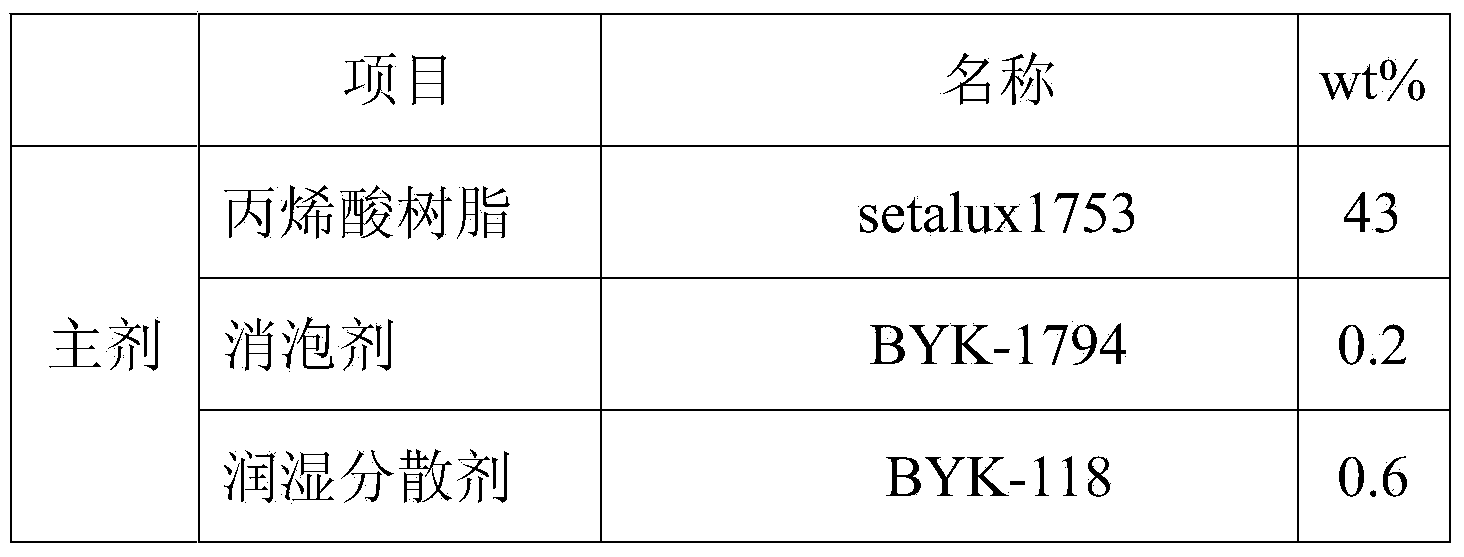

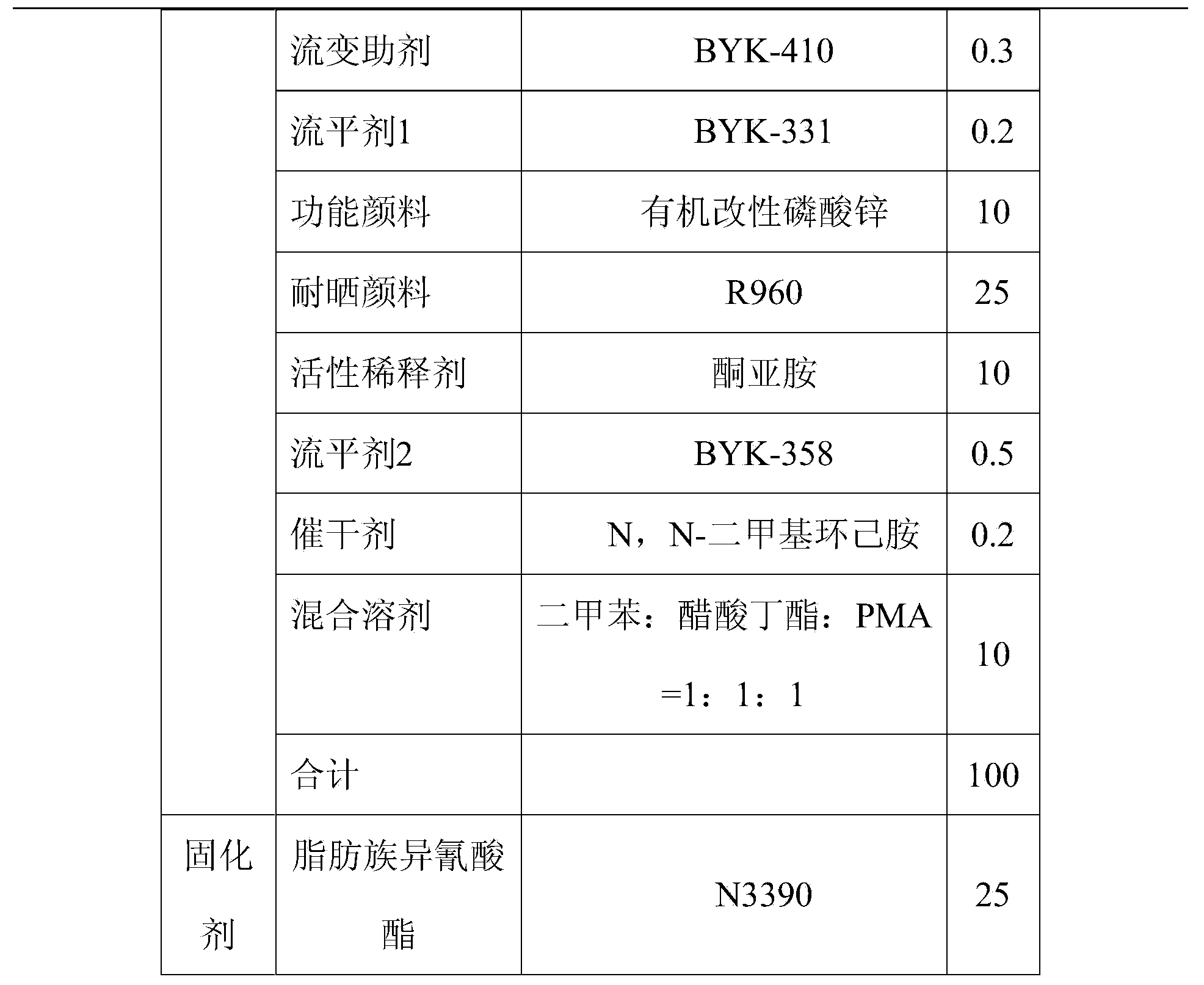

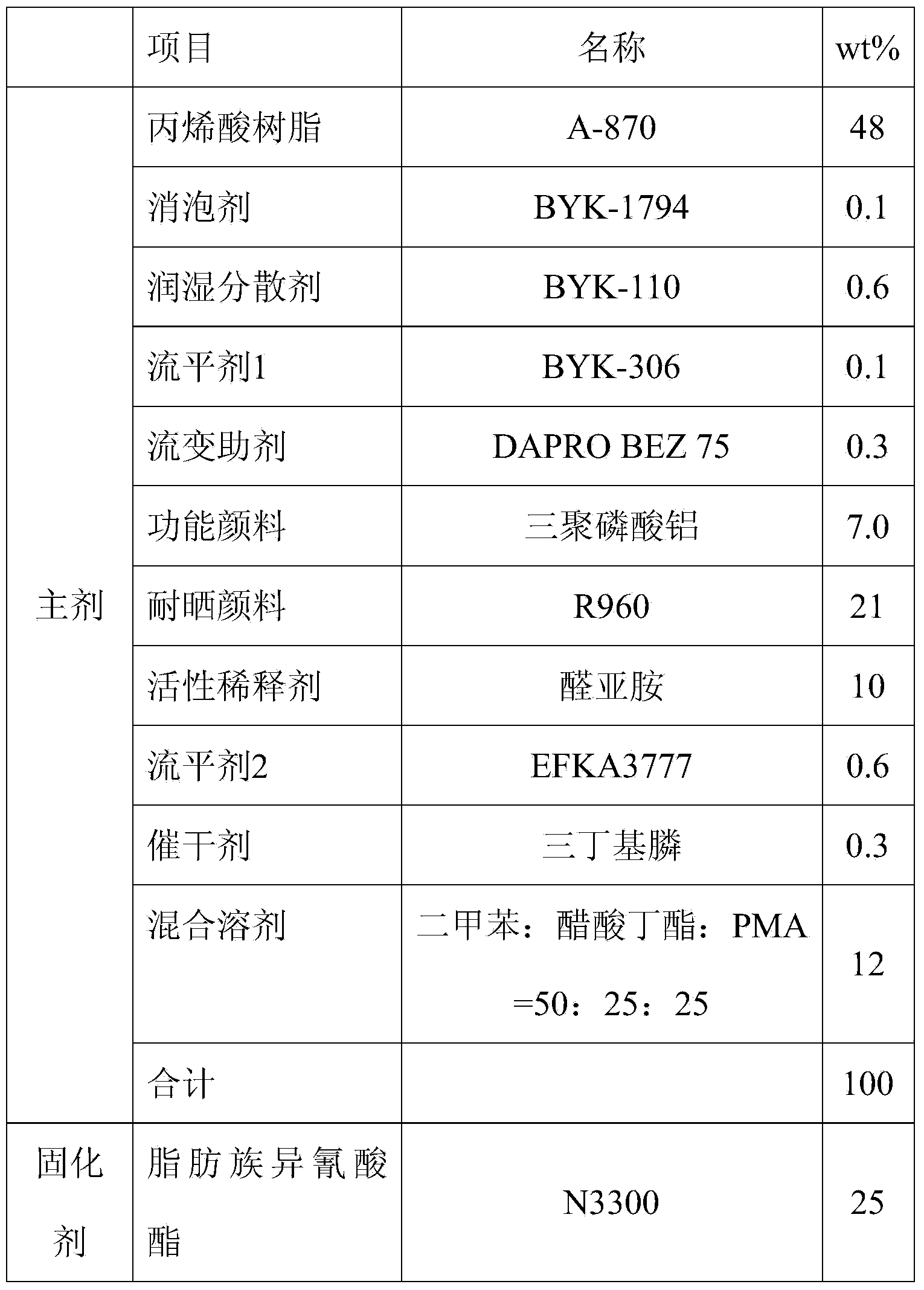

High solid coating for container and preparation method of high solid coating

ActiveCN103666229APromote environmental protectionImprove efficiencyAnti-corrosive paintsPolyurea/polyurethane coatingsChemical industryAcrylic resin

The invention discloses a high solid coating for a container and a preparation method of the high solid coating, and relates to the field of the coating chemical industry. The high solid coating comprises a host and a curing agent; the mass ratio of the host to the curing agent is 4:1; the host comprises the following components by mass: 40-60 percent of high solid low viscosity hydroxy acrylic resin, 1-5 percent of a rheological agent, 1-10 percent of a functional pigment, 20-25 percent of a sunproof pigment, 0-1 percent of an antifoaming agent, 1-3 percent of a wetting dispersant, 0.1-0.5 percent of a flatting agent I, 0.1-0.5 percent of a flatting agent II, 1-10 percent of a reactive diluent, 0.1-5 percent of a drier, and 1-5 percent of a mixed solvent. The coating has the advantages that the content of volatile organic compounds is low, the one-step film formation thickness is 150 microns, the surface dry purpose is achieved within 15 min, the film abrasion resistance is low to 40 mg, the coating is saved, the emission and coating time of volatile organic compounds are reduced, and the corrosion resistance, the abrasion resistance and the weathering resistance meet the requirement for anticorrosion outside the container, and adapt to the rapid production requirement of the container production line.

Owner:洛阳双瑞防腐工程技术有限公司

Multilayer composite protective coating on surface of sintered NdFeB magnet by multi-arc ion plating and process thereof

ActiveCN104018133AAvoid failureDeterioration of corrosion resistanceVacuum evaporation coatingSputtering coatingCoating systemAlloy

The invention belongs to the technical field of surface protective coating, and particularly relates to a multilayer composite protective coating on the surface of a sintered NdFeB magnet by multi-arc ion plating and a process thereof. By adopting the multi-arc ion plating deposition technology, a transition layer, a corrosion-proofing layer and a surface barrier and wearing layer composite protective coating are prepared on the surface of the sintered NdFeB magnet, the corrosion resistance of the sintered NdFeB magnet is obviously improved, and the service life is prolonged. The process comprises the following steps: (1) removing oil and rust on the surface of a magnet, cleaning the surface; (2) cleaning the surface by glow discharge backwashing in a vacuum coating chamber; (3) preparing a Ti or Cr transition layer by multi-arc ion plating; (4) preparing Al or Al alloy by multi-arc ion plating; (5) preparing an AlN layer by multi-arc ion plating. By adopting the arc ion coating technology and combining the design of a multifunctional layered composite structure coating system, the process has the characteristics of high deposition efficiency, high coating binding force and compactness, simple process, environmental friendliness, no pollution and low cost, and batch large-scale production is easy to realize.

Owner:北京钐元新材料股份有限公司

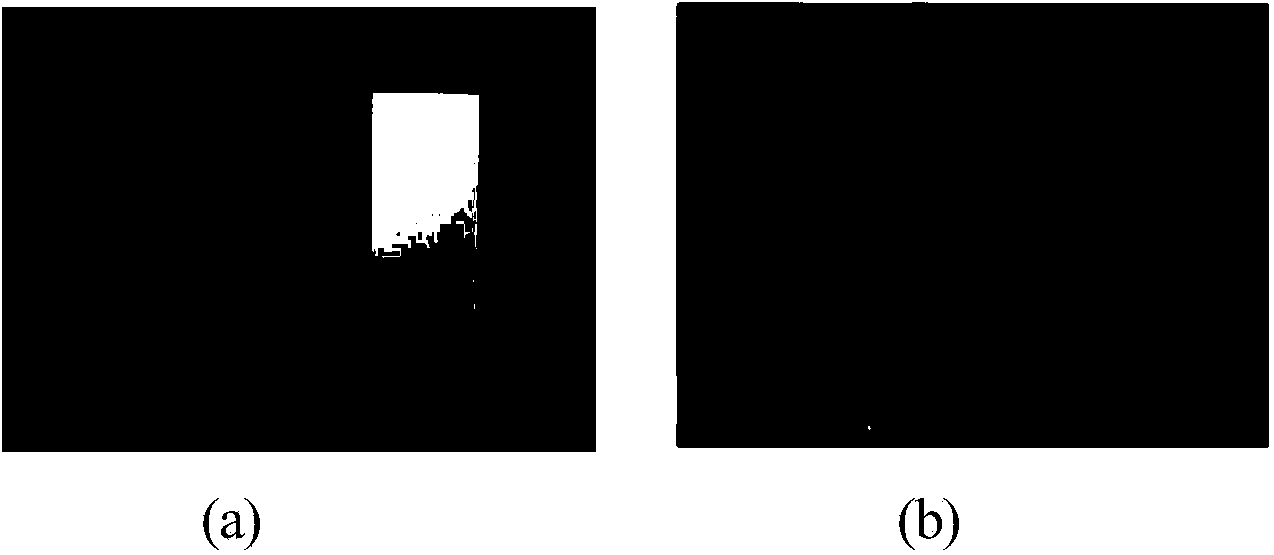

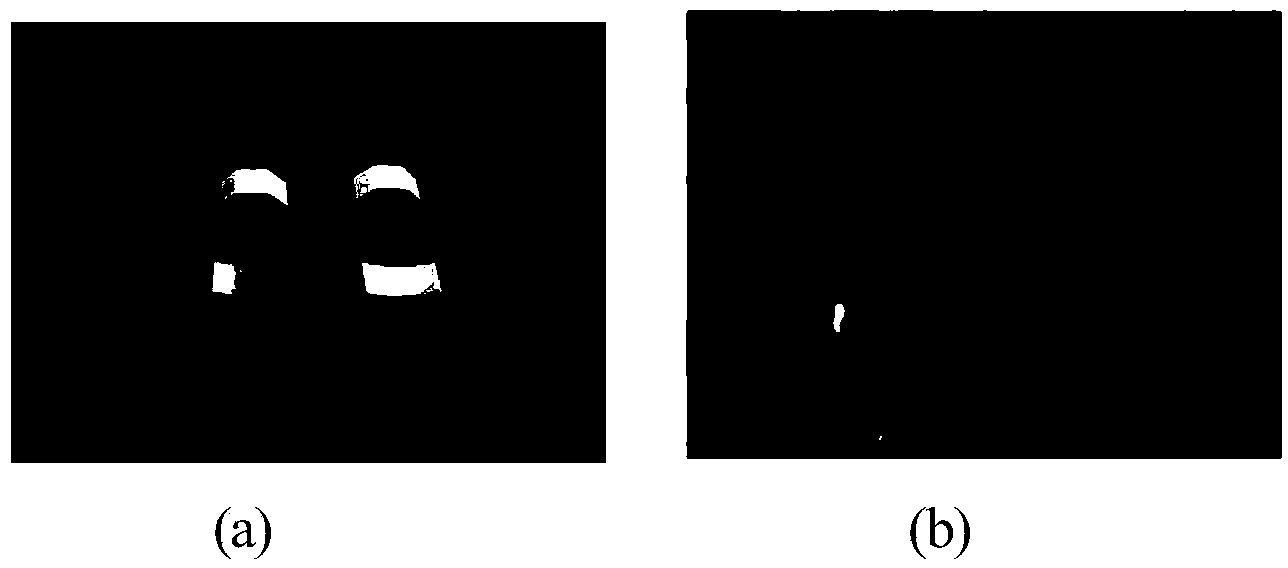

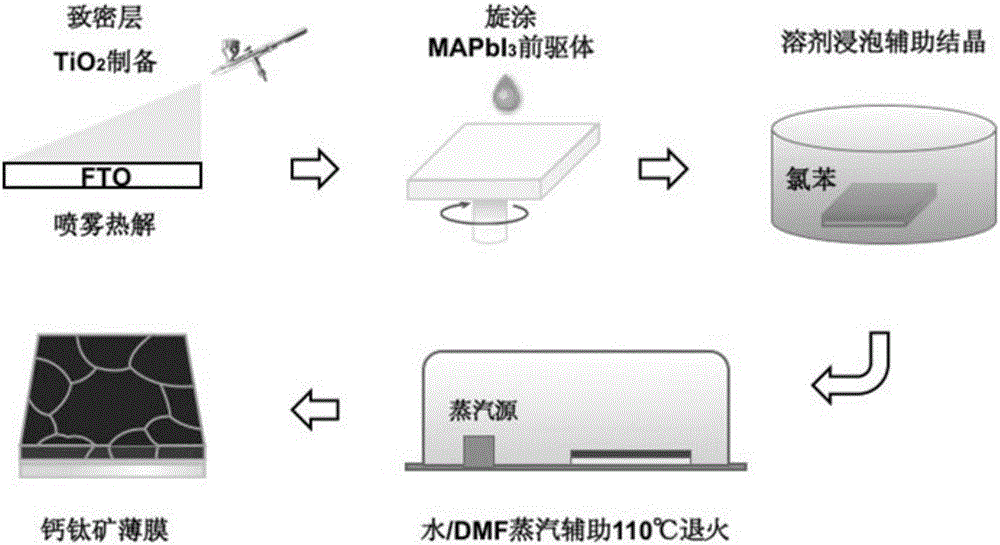

High quality perovskite thin film, solar cell and preparation method thereof

ActiveCN105702864AHigh crystallinityFlawlessSolid-state devicesSemiconductor/solid-state device manufacturingSolventChemistry

The invention discloses a high quality perovskite thin film, a solar cell and a preparation method thereof. The method uses solvent soaking to assist crystallization, and uses a mixed steam of water and organic solvents to assist baking so as to prepare the high quality organic and inorganic composite perovskite thin film. The high quality perovskite thin film prepared by the method is good in crystallinity, and uniform, smooth and with no defects and holes in a wide range. The preparation method provided by the invention is simple in operation, strong in operability and controllability, and very suitable for preparation of large area perovskite thin film solar cell, therefore, the preparation method has a great potential application value in the field of solar cell or other scientific fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Infrared isolation pulp and infrared isolation coating for toughened glass thereof

The invention relates to a coating, in particular to an infrared separating slurry which is prepared from the following raw materials by weight percentages: 20 to 25 weight percentages of nanometer ATO powder or nanometer ITO powder, 20 to 30 weight percentages of alcohol, 15 to 25 weight percentages of glycol, 20 to 30 weight percentages of isopropanol, 15 to 25 weight percentages of water and 2 to 5 weight percentages of a dispersing agent SDBS. The nanometer silicon dioxide sol prepared by the sol-gel method of the infrared separating coating prepared from the slurry and used for tempered glass is different from the traditional organic resin, the coated film layer has high hardness, and after being processed at a high temperature with the glass, the coated film layer has the hardness of 5 H to 6H, aging resistance and twenty-year durability. The coating has very thin film layer, guarantees the transparency and high penetration rate of visual light of the glass, is convenient for transportation and the construction are convenient, greatly reducesthe cost.

Owner:江苏柏鹤涂料有限公司 +1

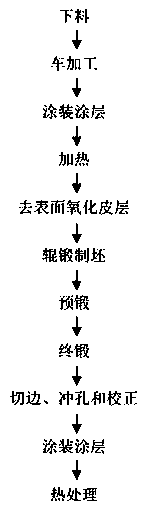

Large-scale locomotive connecting rod forging technology

ActiveCN104057263AReduce depthGuarantee the quality of raw materialsShaping toolsRailway componentsPunchingSurface oxidation

The invention discloses a large-scale locomotive connecting rod forging technology which comprises the steps of blanking, lathing, anti-decarburization coating application, blank heating, surface oxidation layer removal, roll forging of blanks, pre-forging, finish forging, trimming, punching and calibration, anti-decarburization coating application and heat treatment. According to the large-scale locomotive connecting rod forging technology, forming can be achieved through one time of heating only. Compared with the traditional technology that heating needs to be conducted twice or more, the technology has the advantages that surface oxidation and decarburization of a connecting rod are effectively reduced, the mechanical performance of the connecting rod is guaranteed, and time and energy resources are saved. Due to the adoption of roll forging of blanks, speed is high, labor is saved, the consistency of manufactured blanks is high, and time and labor are saved during forging in later periods. Due to the fact that high-temperature-resistant and oxidation-resistant anti-decarburization coating application is conducted twice during the whole technology, the decarburized layer on the surface of a final forged piece is thinner than 0.3 mm, and product quality is improved effectively. Due to the fact that the connecting rod forged piece is vertically hoisted for heat treatment, bending deformation of the forged piece is effectively prevented during heat treatment.

Owner:SICHUAN HAOTE JINGGONG EQUIP CO LTD

Molding method and molding apparatus of composite material toughened thin rod

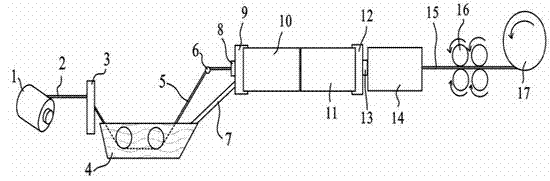

ActiveCN102729493AReduced precision requirementsReduced pull-out frictionFiber bundleReaction temperature

The invention discloses a molding method and a molding apparatus of a composite material toughened thin rod. The molding method comprises the steps that: first, a resin-impregnated fiber bundle penetrates a primary molding mold, such that fiber bundle primary molding body with a shape same as that of an axial primary molding mold through hole mold cavity cross-section is produced; second, the primary molding body fiber bundle is heated for a first time, wherein the temperature is an initial reaction temperature of the resin; third, the fiber bundle is delivered into a second heating process, wherein the heating temperature is the resin gelatinization temperature; then, the fiber bundle is delivered into a molding mold, wherein the middle part of the molding mold is an equal-cross-section axial molding through hole mold cavity; and finally, the fiber bundle discharged from the molding mold is delivered into a third heating process, wherein the heating temperature is controlled at a value between the exothermic peak temperature of the resin and the reaction stopping temperature of the resin. Therefore, the thin rod reaches a curing degree above 70%, such that the resin-containing fiber bundle is solidified into the thin rod product. The heating durations in the three heating processes are determined according to the dimension of the thin rod and the thermal performance of the resin.

Owner:TIANJIN POLYTECHNIC UNIV

Technique for packaging long stator iron core assembly

The invention is a long stator iron core component packaging process, belonging to electric machine manufacturing technical field, comprising the steps of: a. putting solidified long stator iron core component together with connecting piece into an epoxy resin or unsaturated polyester resin injection mould and heating to 60-200 deg.C, preserving heat for 2-60 min; b. pressurizing the injection mould while vacuumizing and pouring epoxy resin or unsaturated polyester resin and keeping 2-60 min at a pressure of 1-5MPa; c. opening the injection mould and putting injected piece into an oven or baking channel for post-solification and making the long station iron core packaged piece. And the invention has advantages of convenient operating, saving labor and time, simplifying injection device, etc. and the surface of the packaged long stator iron core component is compact, and smooth and birght and clean, and has no air holes and defects, and the invention is especially applied to packaging long stator iron core components for high speed magnetic suspension train and driving motor iron core components for city railway traffic.

Owner:WOLONG ELECTRIC GRP CO LTD

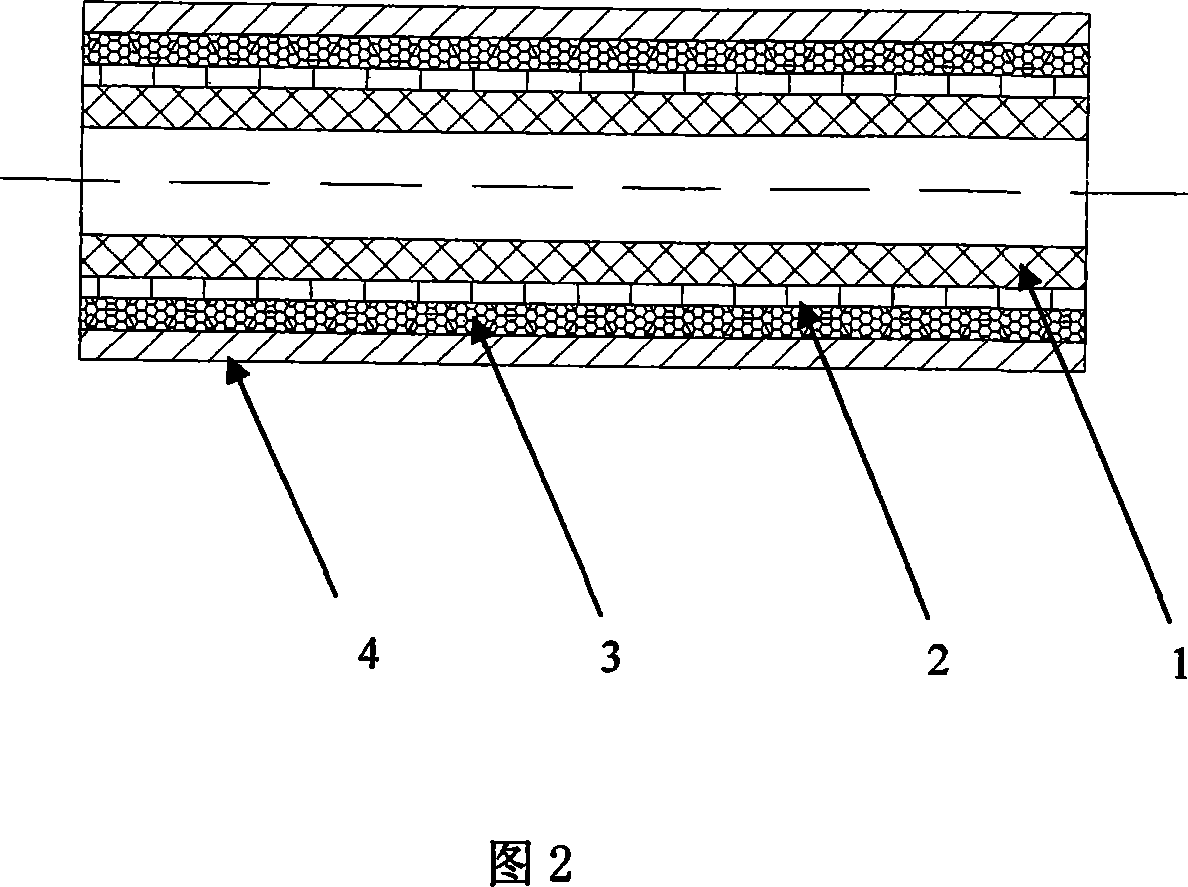

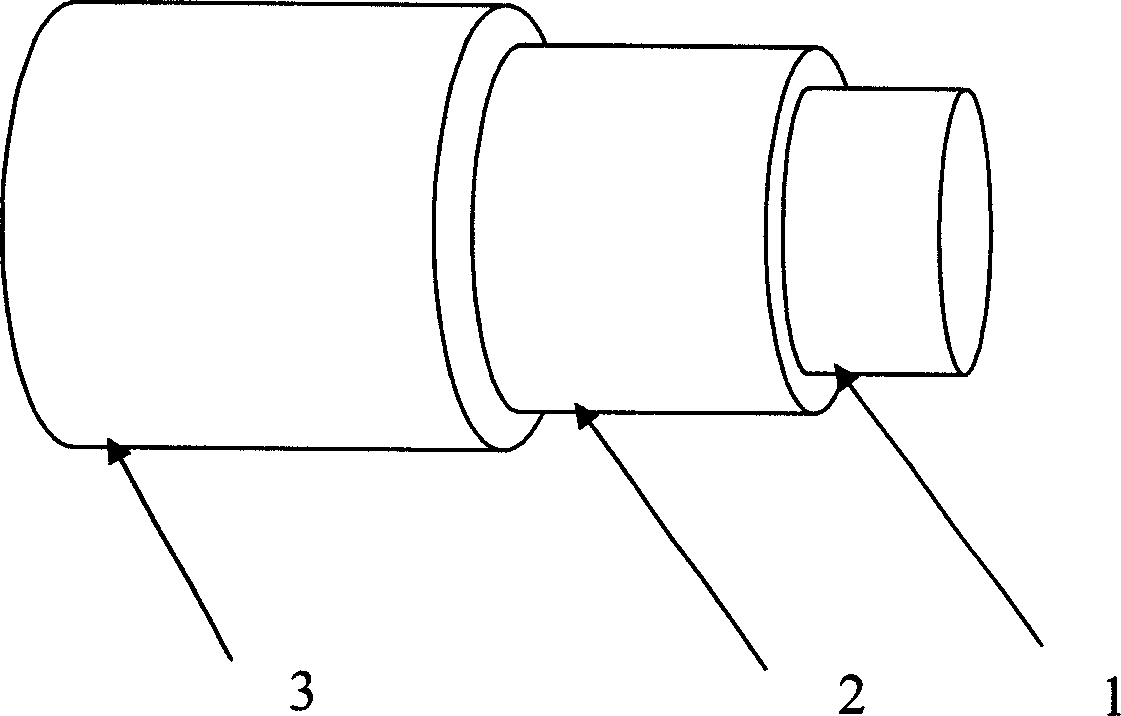

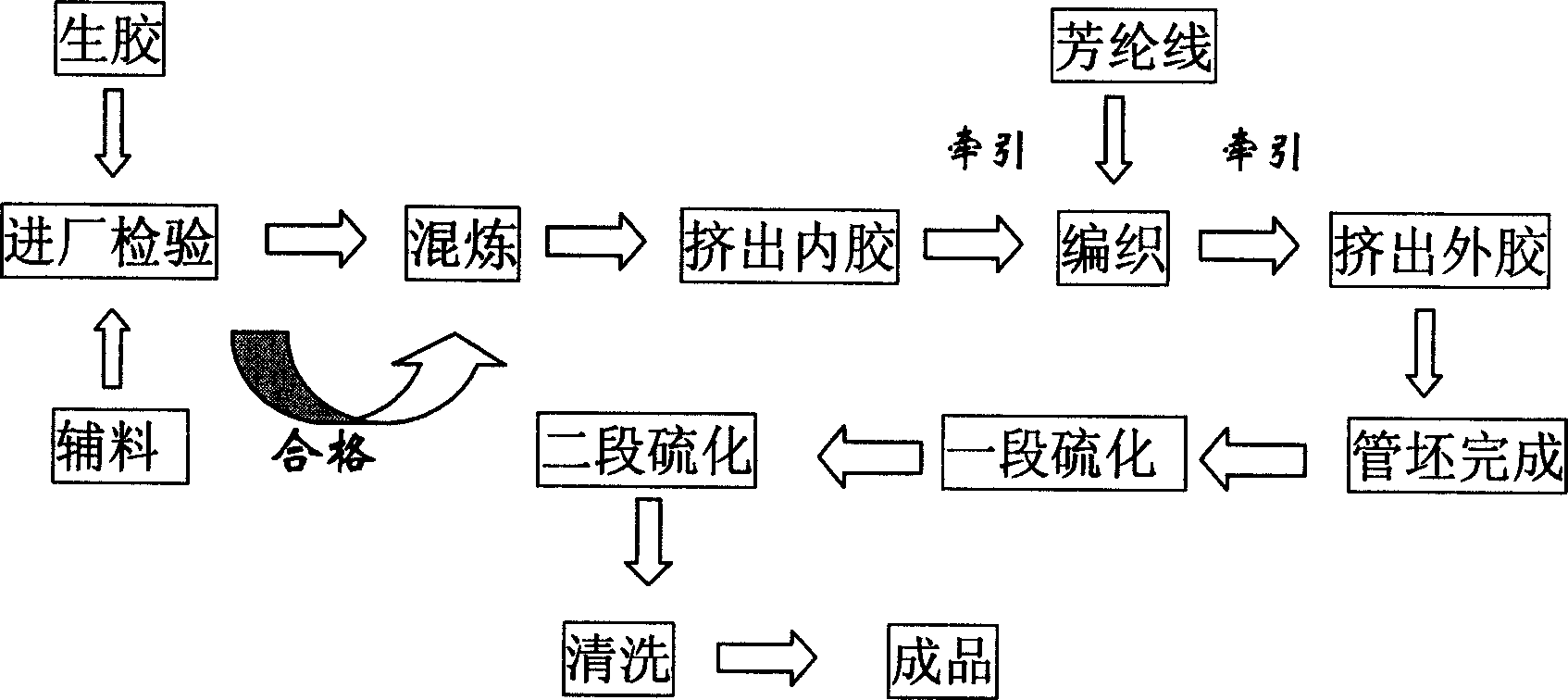

Turbine booster hose of fluorine rubber, oil-resisting silicon rubber and silicon rubber and its production

The invention discloses an extrusion production, the fluorine rubber inner layer (1), resistance oil silicone rubber middle (2), kevlar line (3) and the outer layer of silicone rubber (4) composed of automobile turbocharged hose, broke the previous three-layer structure of the turbocharged, four- layer structure used, and uses advanced extrusion technology, braided hose to a molding process, the turbocharged hose reached appearance no impurities, without defects, flat and smooth. Not only increase production efficiency, but also through our compound formula, the structure of several aspects of research and development, so that the hose can meet the performance requirements of use, the hose improve the oil resistance, high temperature resistant, resistant infiltration, and improve the bursting pressure, the hose of the service life is extension.

Owner:TIANJIN PENGYI GRP CO LTD

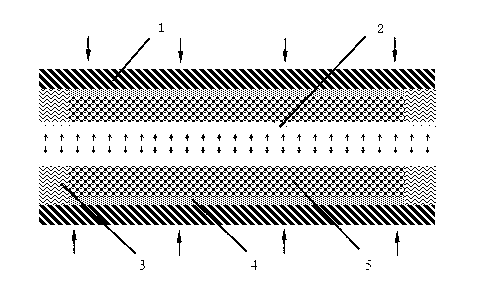

Composite porous electrode for sulfuric acid system and preparation method thereof

InactiveCN101949031AImprove structural strengthImprove bindingElectrode melt handlingElectrode carriers/collectorsChemical platingPorous layer

The invention discloses a composite porous electrode for a sulfuric acid system and a preparation method thereof. From inside to outside, the electrode is sequentially provided with an enhanced metal substrate, a Pb or Pb-based alloy (Pb-Me') transition layer and a Pb or Pb-based alloy (Pb-Me'') porous layer. The preparation method for the electrode comprises the following steps of: preparing the transition layer by performing chemical plating and metal melt immersion plating in the molten salts of chlorides or directly by performing the metal melt immersion plating, and preparing the porous layer by adopting an infiltration method or an antigravity infiltration method. Due to the adoption of the transition layer, the enhanced metal substrate and the porous layer in the composite porous electrode are combined more firmly, even electrolyte cannot permeate into and corrode the substrate through the porous layer, and the electrode has longer service life. The method of the invention has the advantages of preparing the composite porous electrode with firm combination among composite layers, strong strength, high corrosion resistance and long service life, and solving the long-term problems of short service life and weak strength of the electrode in the sulfuric acid system, along with simplicity and rational structure.

Owner:CENT SOUTH UNIV

Quasi-TC4 titanium alloy for laser additive manufacturing application

ActiveCN111455216APromote nucleationPromote decompositionAdditive manufacturing apparatusTransportation and packagingManufacturing technologyCrucible

The invention discloses quasi-TC4 titanium alloy for laser additive manufacturing application. The quasi-TC4 titanium alloy for laser additive manufacturing application comprises, by mass percentage,1%-2% of Mo, 5.5%-6.8% of Al, 3.5%-4.5% of V and the balance Ti and inevitable impurities. The quasi-TC4 titanium alloy is obtained in the mode that dried pre-alloyed powder or dried element mixed powder of the quasi-TC4 titanium alloy are manufactured according to a laser additive manufacturing method. The Mo is added to the quasi-TC4 titanium alloy, the synergistic effects that intracrystallinealpha battens are thinned, and the alpha-phase volume fraction is increased are effectively achieved under the action of the heat cycle of laser additive manufacturing, and the strength and the plasticity of the quasi-TC4 titanium alloy are improved. According to the quasi-TC4 titanium alloy for laser additive manufacturing application, the manufacturing technology is simple, the operation response is fast, machining is easy, crucibles or other electrode materials are not required in the manufacturing process, and alloy elements are prevented from being contaminated.

Owner:CHANGAN UNIV

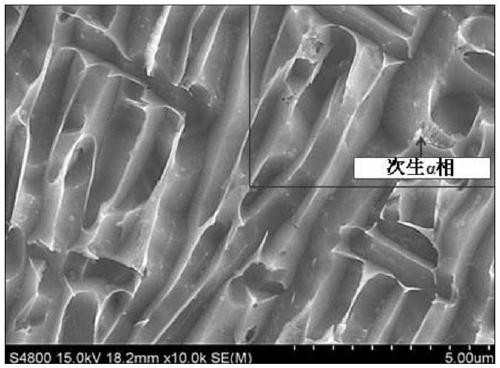

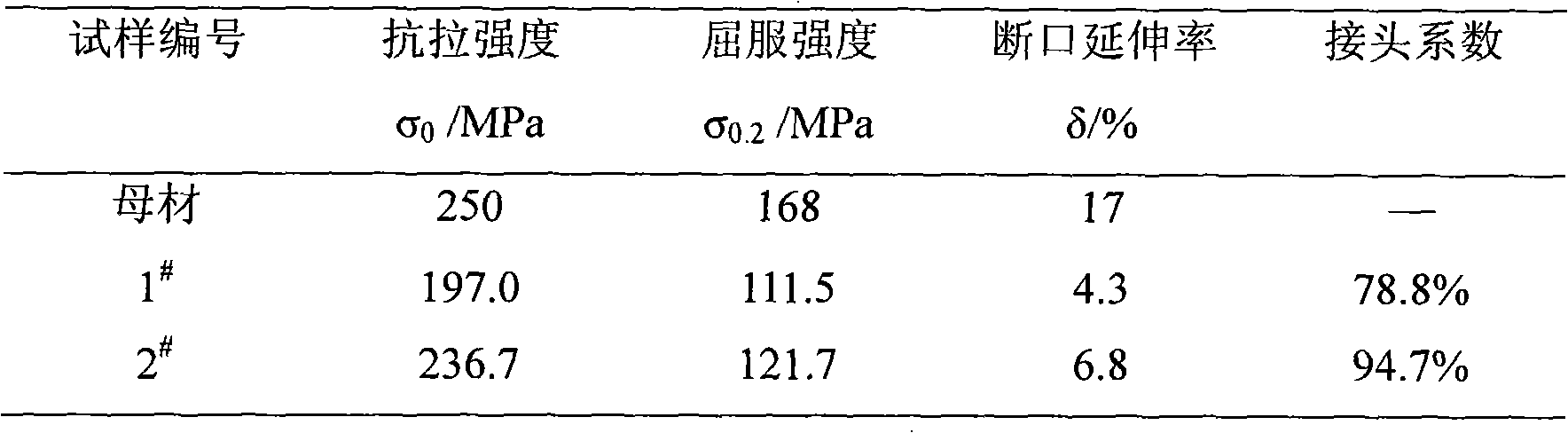

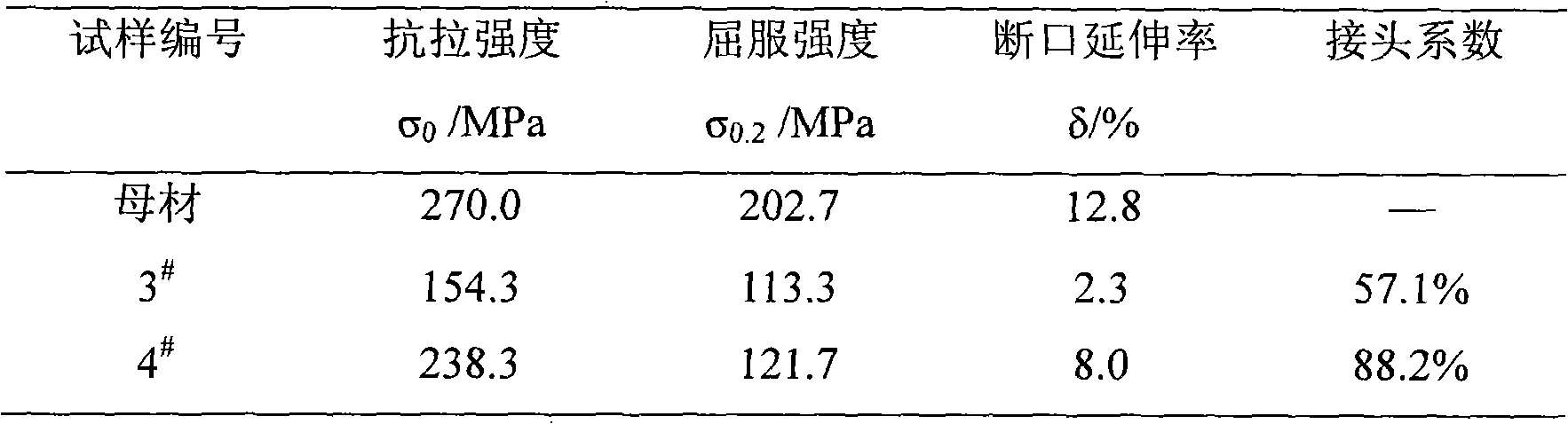

Friction stir welding method of medium plate AZ AZ1 magnesium alloy

InactiveCN101885109ABeautiful shapeNo surface cracksNon-electric welding apparatusMaterials processingFrustum

The invention relates to a friction stir welding method of a medium plate AZ AZ1 magnesium alloy, belongs to the technical field of welding process used in material processing projects, and particularly provides a friction stir welding method of a 10 to 20-millimeter-thick AZ31 magnesium alloy. The welding inclined angle of a stirring head is 2.5 to 3 DEG, the pressing depth is 0.1 to 0.2 millimeter, the rotation speed is 600 to 1,400r / min, and the welding speed is 100 to 200 mm / min; the shaft shoulder of the stirring head is concave and a stirring pin is frustum-shaped and spiral; the diameter of the shaft shoulder of the stirring head is 28 to 35 millimeters; the diameter of the root part of the stirring pin is 10.3 to 15.1 millimeters, and the diameter of the end part of the stirring pin is 7.8 to 9.3 millimeters; and the length of the stirring pin is 9.6 to 19.5 millimeter. By selecting reasonable welding parameters, the obtained joint is formed elegantly, the maximum tensile strength is up to 94.7 percent of that of a parent metal, and the well welding of the medium plate AZ AZ1 magnesium alloy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Stripping liquid composition of photoresist

InactiveCN102163011AExcellent peeling effectImplementation temperature is lowPhotosensitive material processingPhotoresistLiquid composition

The invention provides a stripping liquid composition of a photoresist, comprising inorganic alkali, organic alkali, water-soluble organic solvent, anti-corrosion agent and water. The mass proportion rate between the inorganic alkali and the organic alkali is 1: 30 to 30: 1. The stripping liquid of the invention is specifically suitable for stripping a dry film of which the thickness is more than 100 mum; and the thick dry film is totally stripped under the low temperature (45-55 DEG C) and the short time (less than 30 min).

Owner:西安东旺精细化学有限公司

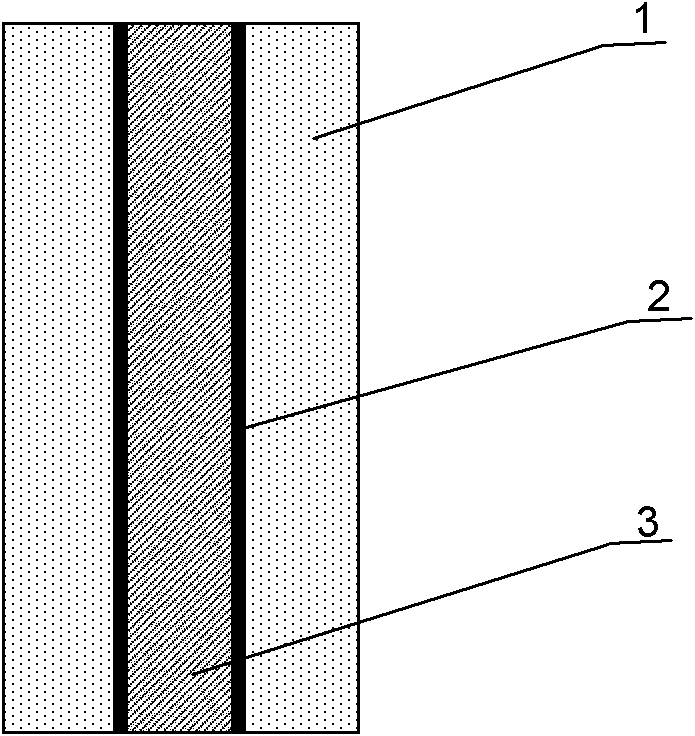

Silicone tube with large inside diameter in lock pin and preparation method

A silicone rubber pipe with great internal diameter and locking needle structure is composed of internal silicone rubber layer, reinforcing layer with locking needle structure and external silicone rubber layer. Its preparing process includes such steps as preparing pipe blank through extruding out and weaving, and sulfurizing. Its advantages are high adhesion between layers and high pressure tolerance (more than 0.4 MPa).

Owner:TIANJIN PENGYI GRP CO LTD

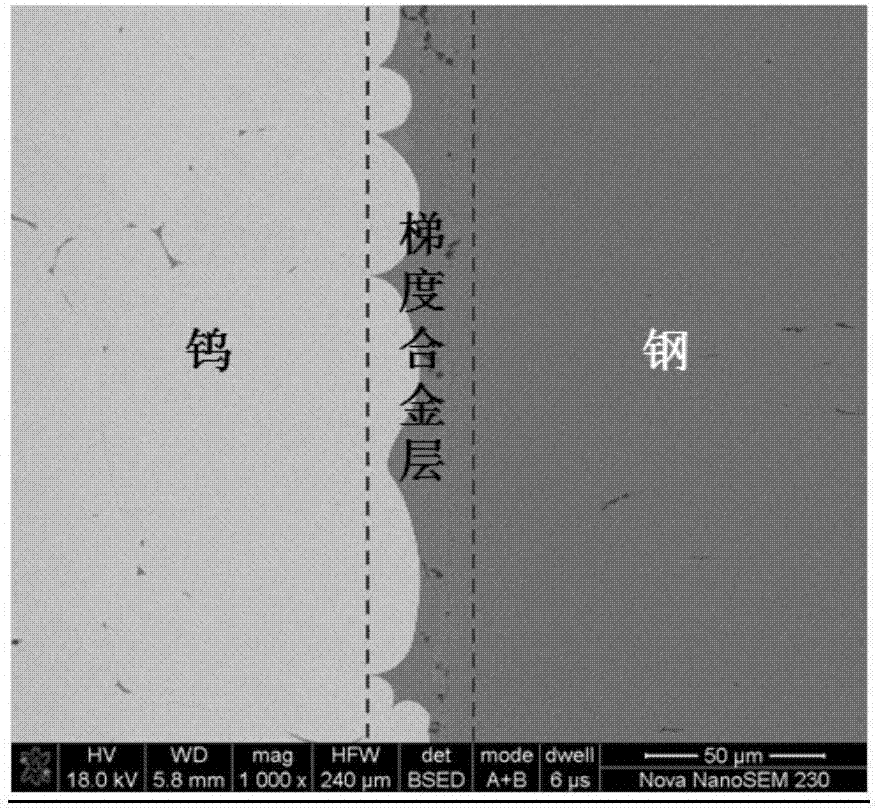

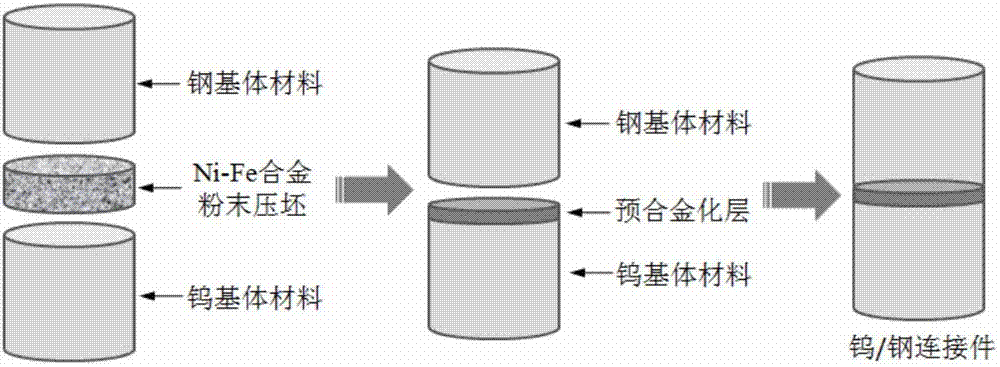

Tungsten/steel dispersion connecting method based on tungsten surface gradient alloying

InactiveCN107225249AImprove thermal fatigue performanceHigh strengthSoldering apparatusWelding/soldering/cutting articlesPowder mixtureDivertor

The invention relates to a tungsten / steel diffusion connection method based on tungsten surface gradient alloying, belonging to the technical field of composite material preparation. In the present invention, the nano-scale pre-alloyed mixed powder with a mass ratio of Ni and Fe of 7:3 is used as a raw material, and the surface of the tungsten substrate is subjected to gradient alloying treatment by high-temperature cladding and vacuum hot-pressing composite technology, and then the vacuum of tungsten and steel is carried out. Diffuse connection. The present invention forms a gradient alloy layer on the surface of the tungsten substrate through the configuration of nickel and iron components, vacuum hot pressing, high temperature cladding and vacuum diffusion and other process or parameter optimization, and obtains no defects at the interface and thermal fatigue performance Good, high interface stability of tungsten / steel composite structural parts. It can be used in the preparation of helium-cooled divertor components in magnetic confinement nuclear fusion experimental devices.

Owner:CENT SOUTH UNIV

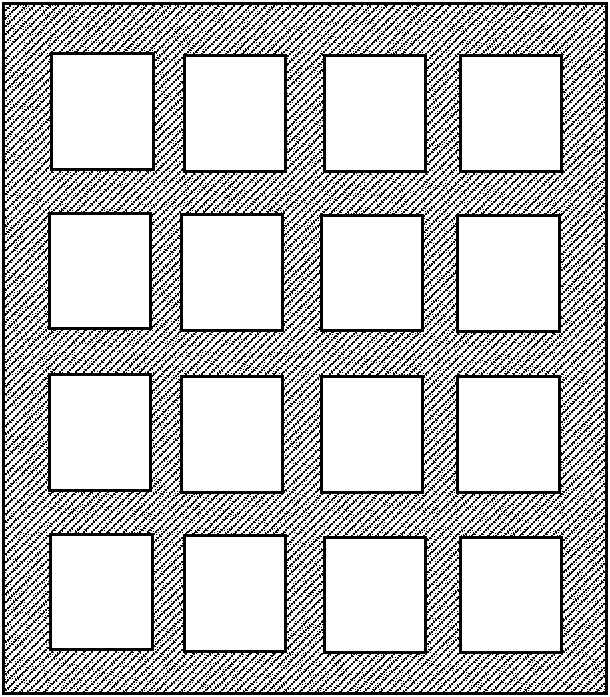

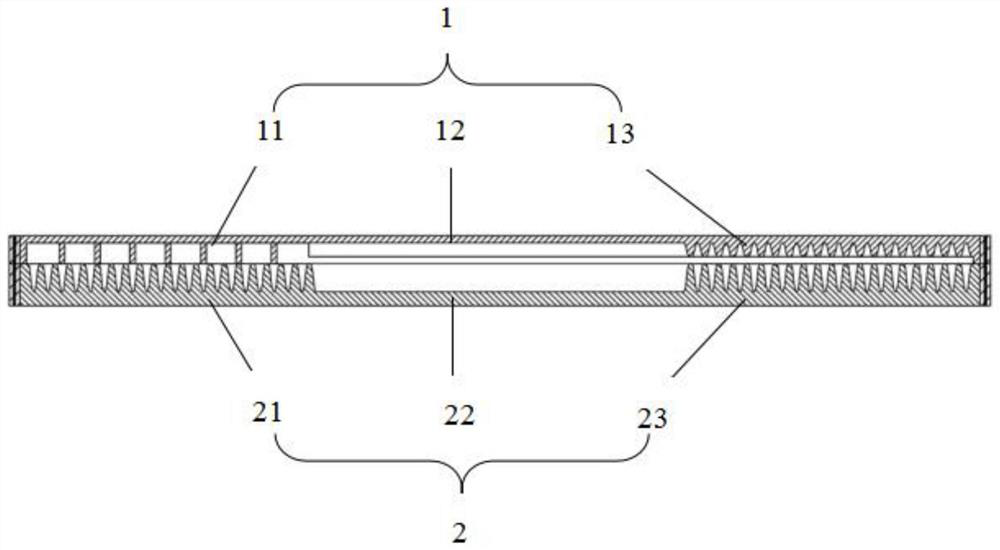

Partition-optimized ultrathin VC with thickness of 0.1-0.4 mm and preparation method

PendingCN111879158AEmission reductionSpeed up distributionIndirect heat exchangersMicro nanoNano structuring

The invention discloses a partition-optimized ultrathin VC with the thickness of 0.1-0.4 mm and a preparation method. The ultrathin VC comprises an upper cover plate and a lower cover plate, and the upper cover plate and the lower cover plate are welded. Each of the upper cover plate and the lower cover plate comprises an evaporation section, a heat insulation section and a condensation section; the surface of the evaporation section of the upper cover plate is of a super-hydrophilic cavity-shaped micro-nano structure, the surface of the heat insulation section of the upper cover plate is of asuper-hydrophilic equal-width groove micro-nano structure, and the surface of the condensation section of the upper cover plate is of a super-hydrophobic conical micro-nano structure; and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the evaporation section of the lower cover plate, a super-hydrophilic cactus-like wedge-shaped groove micro-nano structure is arranged on the surface of the area of the heat insulation section, and a super-hydrophilic conical micro-nano structure is arranged on the surface of the area of the condensation section. The invention further discloses a preparation method of the ultrathin VC. A steam cavity structure, a liquid cavity structure and volume distribution in a heat pipe can be optimized, and good capillary water absorption performance and low water resistance and heat resistance of the heat pipe can be guaranteed.

Owner:绍兴镭纳激光科技有限公司

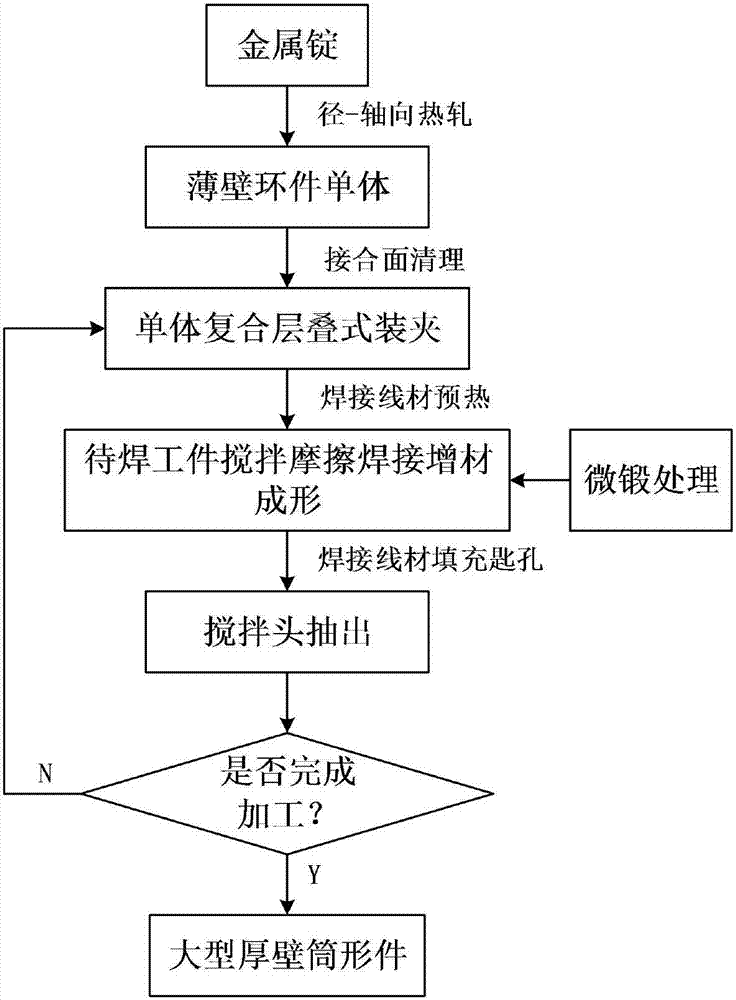

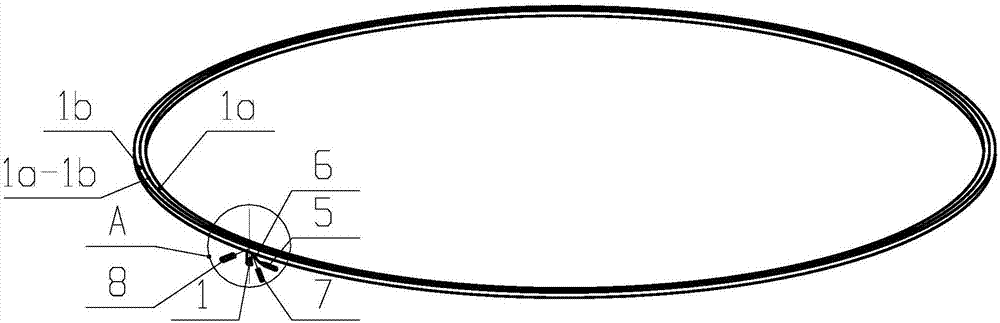

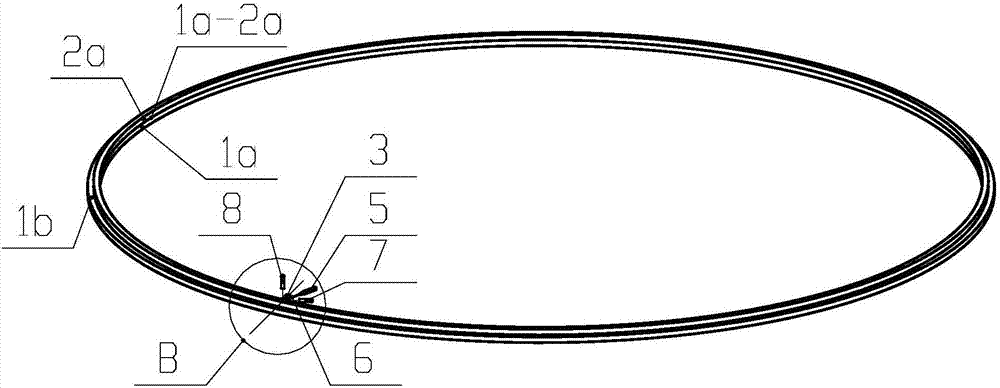

Composite stack-up type stirring friction welding additional material forming technology of large-scale thick-wall cylindrical piece

InactiveCN107020447AImprove mechanical propertiesIncrease profitNon-electric welding apparatusFriction weldingRoll forming

The invention discloses a composite stack-up type stirring friction welding additional material forming technology of a large-scale thick-wall cylindrical piece. The forming technology comprises the following steps: first, carrying out roll forming on a thin-wall annular piece monomer; then, carrying out radial stack-up type stirring friction welding additional material forming on the thin-wall annular piece monomer to finish the forming process of a first thin-wall annular piece monomer radial stack-up type stirring friction welding additional material of a first layer; then, carrying out axial stack-up type stirring friction welding additional material forming technology on the thin-wall annular piece monomer, and carrying out axial superposition welding on a third thin-wall annular piece monomer of a second layer and the first thin-wall annular piece monomer; then, carrying out radial and axial stack-up type stirring friction welding additional material forming technology on the thin-wall annular piece monomers, and carrying out radial and axial welding on a fourth thin-wall annular piece monomer, the second and third thin-wall annular piece monomers of the second layer; and finally, carrying out radial, axial and radial and axial composite stack-up type stirring friction welding additional material forming on the thick-wall cylindrical piece. With adoption of the forming technology, the material utilization ratio is remarkably increased, the energy consumption is reduced, and the overall performance of the product is improved.

Owner:XI AN JIAOTONG UNIV +1

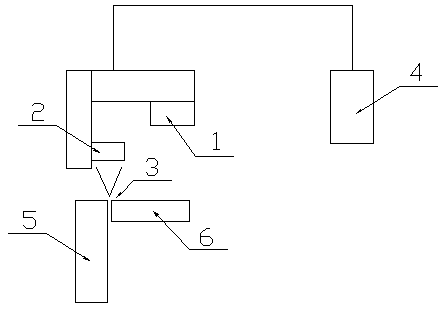

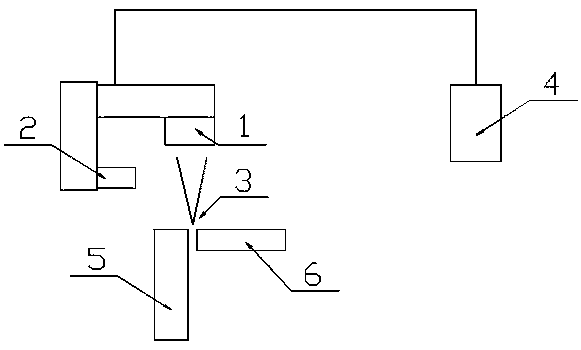

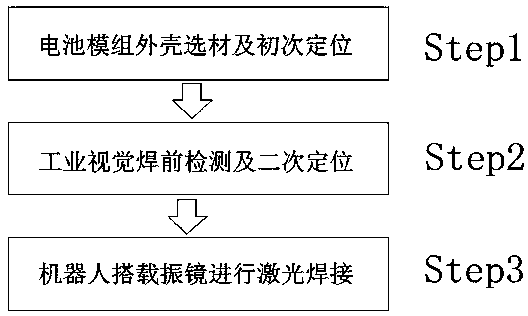

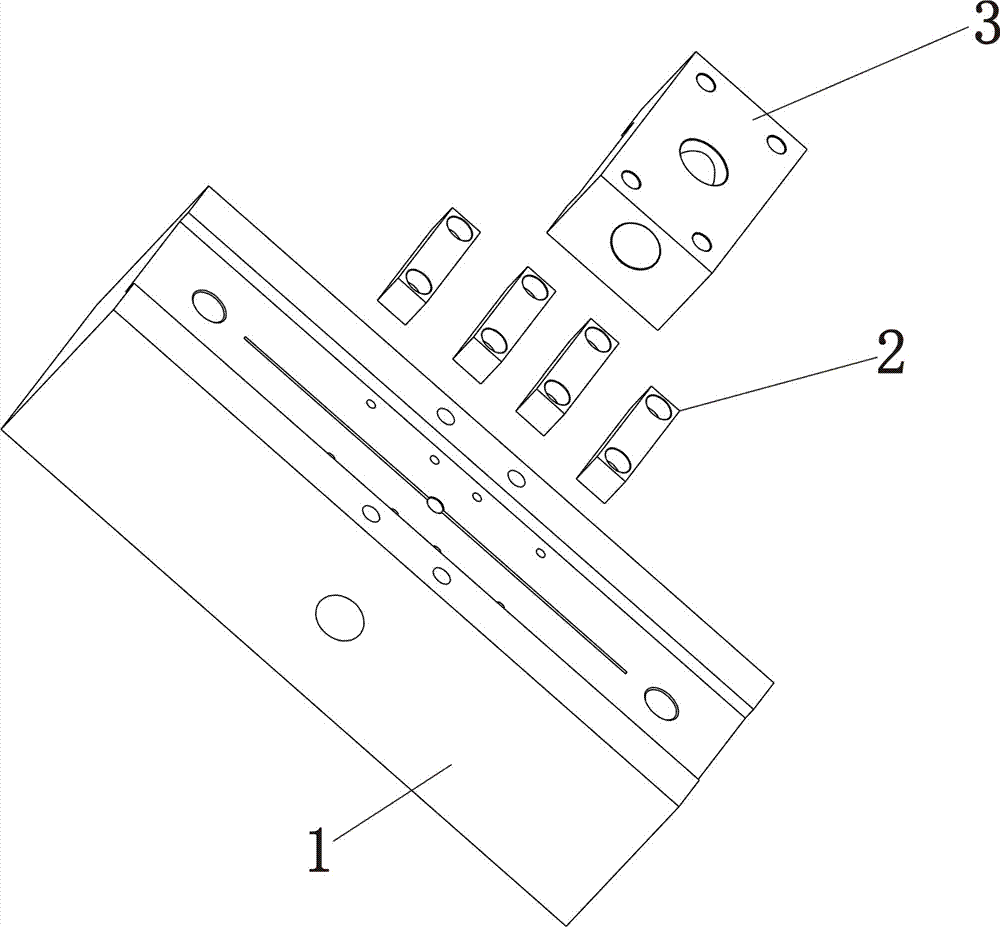

Laser welding method for aluminum alloy shell of automobile power battery

InactiveCN108098140AMeet needsEasy to operateLaser beam welding apparatusPower batteryElectrical battery

The invention discloses a laser welding method for an aluminum alloy shell of an automobile power battery. According to the technical scheme, a galvanometer, an intelligent camera, a joint, a controller, a module end plate, a module side plate are involved, and the method comprises the steps that 1, battery module shell material selecting and primary positioning are carried out; 2, industrial visual pre-welding detecting and secondary positioning are carried out; and 3, laser welding is carried out by a robot carrying the galvanometer. According to the laser welding method for the aluminum alloy shell of the automobile power battery, the operation steps are simple, the practicability is high, the positioning precision is high, the parameters of the laser welding process are optimized, theperformance of the weld joint is guaranteed to be good, a formed shell is attractive, no defect exists, the requirements of customers are met, and great help is provided for people.

Owner:SHANGHAI SKEQI AUTOMATION ENG CO LTD

Method and system for splicing and growing single-crystal diamond

InactiveCN108103570ASolve the bottleneckSolve bottlenecksPolycrystalline material growthFrom chemically reactive gasesBottle neckChemistry

The invention belongs to the technical field of diamond preparation and discloses a method and a system for splicing and growing single-crystal diamonds. The method comprises the following steps: putting a seed crystal into a plasma CVD equipment cavity, sucking off ultimate pressure, introducing hydrogen, inputting energy, generating power discharge, and adjusting the temperature of the seed crystal; introducing a methane (or carbon-containing gases such as acetone and carbon dioxide) gas, growing the seed crystal for 1-100 hours at 800-1000 DEG C, and the like. According to the method, single-crystal diamonds are grown by using a CVD method through spicing growth, the purpose that the single-crystal diamonds is grown in a large scale is achieved, synthesis sizes directly depend on sizesof the seed crystals since conventional growth of single-crystal diamonds can be only longitudinally amplified on original seed crystals, two single-crystal diamond flakes of a same size and approximate thicknesses are fixed and spliced and grown simultaneously, then a large-size single-crystal diamond is grown, and bottle neck problems are solved.

Owner:湖北碳六科技有限公司

Dissimilar material connecting method of nickel titanium shape memory alloy and copper alloy and clamp thereof

InactiveCN104259663AActive connectionHigh strengthWelding/cutting auxillary devicesFurnace typesNd:YAG laserTitanium alloy

The invention relates to a laser welding method of nickel titanium shape memory alloy and copper alloy in the technical field of materials, machines, electrical engineering and the like, belongs to the technical field of dissimilar material connecting. According to the method, the functions of a sensor, an executor and the like are achieved through the high conductivity of copper and the superelasticity or shape memory character of nickel titanium alloy. The method comprises the process steps that after the to-be-welded face of a nickel titanium shape memory alloy and copper alloy wire or belt or plate is polished and washed, the lap-joint or butt-joint mode is adopted, a designed clamp is utilized, the nickel titanium shape memory alloy part or the connecting position is heated through a Nd:YAG laser device, and a high-strength, defect-free and low-impedance dissimilar material welding connector can be obtained by adjusting laser and heat treatment process parameters.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com