Manufacturing method of large size thin-walled titanium alloy cylindrical part and cylindrical mould

A manufacturing method and technology of titanium alloy, which is applied in the field of manufacturing titanium alloy cylindrical parts, can solve the problems of poor dimensional accuracy, non-integral products, and many product defects of large-scale thin-walled titanium alloy cylindrical parts, and achieve product quality. Good dimensional stability, good defect control, good dimensional control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

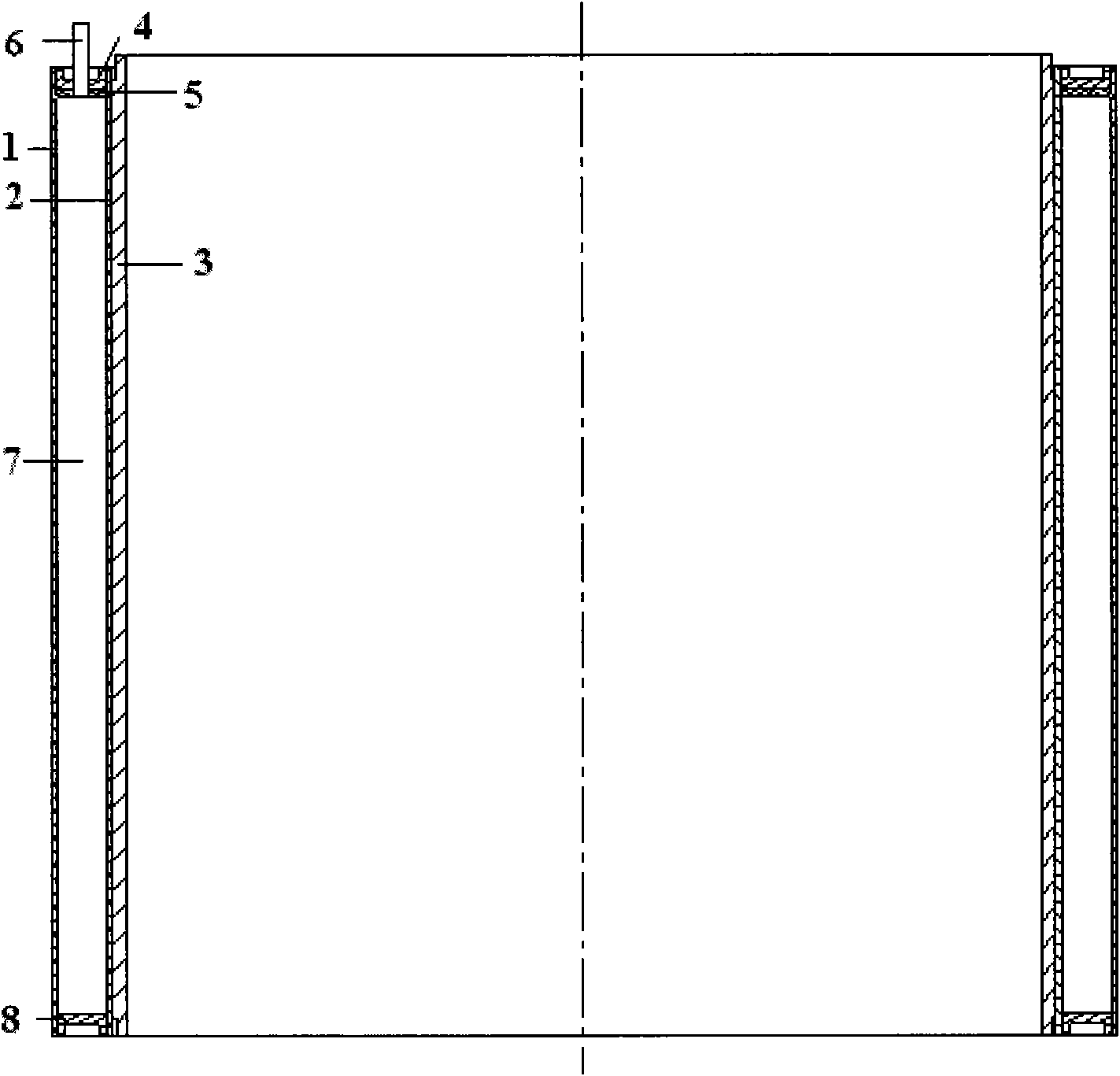

[0030] Such as figure 1 As shown, manufacture a kind of size is Φ600 * 2 * 800mm (outer diameter * wall thickness * height) TC4 titanium alloy cylindrical piece, adopt the manufacturing method of a kind of large-scale thin-walled titanium alloy cylindrical piece of the present invention and cylindrical moulds.

[0031] Such as figure 2 As shown, the mold used includes a cylindrical outer sheath 1 and a cylindrical inner sheath 2, the outer sheath 1 and the inner sheath 2 form a cavity 7 filled with titanium alloy powder, and the inner sheath 2 is provided with a cylindrical Shaping die 3; the top and bottom ends of the cavity 7 filled with titanium alloy powder are respectively fixed with an upper wrapping cover 4 and a lower wrapping cover 8 for encapsulating the cavity; the upper wrapping cover 4 is provided with a degassing pipe 6 , a gasket 5 is provided under the upper cover cover 4 . Above-mentioned outer sheath 1, inner sheath 2 and setting die 3 are all made of car...

Embodiment 2

[0044] Manufacture a TA7 large-size thin-walled cylindrical part with a size of Φ200×1.5×300mm (outer diameter×wall thickness×height), using such as figure 2 For the cylindrical mold shown, the specific manufacturing steps are as follows:

[0045] (1) Selection of raw material powder:

[0046]Select TA7 titanium alloy spherical powder with mixed particle size within the particle size range of 45μm~250μm, of which the particle size is 181μm~250μm accounting for 50% of the total, the particle size is 151μm~180μm accounting for 20% of the total, and the particle size is 45μm~150μm 30% of the total.

[0047] (2) Powder loading and packaging:

[0048] Put the titanium alloy powder into the cavity 7 formed by the outer sheath 1 and the inner sheath 2 to fill the titanium alloy powder under the condition of vibration. The cover 4, the vacuum degree in the cavity 7 is higher than 4×10 -2 Pa.

[0049] (3) hot isostatic pressing

[0050] The cylindrical mold of the above-mentione...

Embodiment 3

[0054] To manufacture a TC4 large-size thin-walled cylindrical part with a size of Φ800×10×1000mm (outer diameter×wall thickness×height), the specific manufacturing steps are as follows:

[0055] (1) Selection of raw material powder:

[0056] Select TC4 titanium alloy spherical powder with a mixed particle size within the particle size range of 45μm-250μm, of which the particle size is 181μm-250μm accounting for 30% of the total, the particle size is 151μm-180μm accounting for 50% of the total, and the particle size is 45μm-150μm 20% of the total.

[0057] (2) Powder loading and packaging:

[0058] Put the titanium alloy powder into the cylindrical mold under the condition of vibration, after filling, degas, and use argon arc welding to seal the mold under the vacuum condition, the vacuum degree in the mold is higher than 4×10 -2 Pa.

[0059] (3) hot isostatic pressing

[0060] The cylindrical mold of the above-mentioned encapsulated titanium alloy powder is subjected to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com