Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1134 results about "Roughcast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roughcast or pebbledash is a coarse plaster surface used on outside walls that consists of lime and sometimes cement mixed with sand, small gravel, and often pebbles or shells. The materials are mixed into a slurry and are then thrown at the working surface with a trowel or scoop. The idea is to maintain an even spread, free from lumps, ridges or runs and without missing any background.

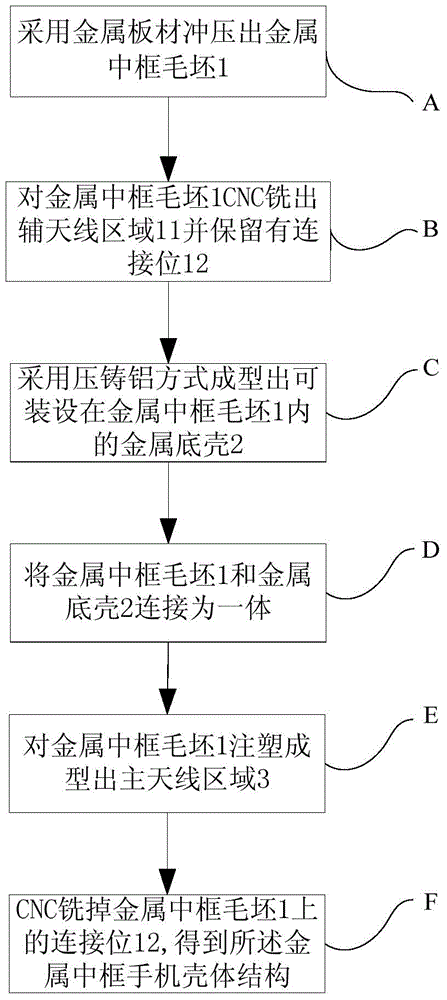

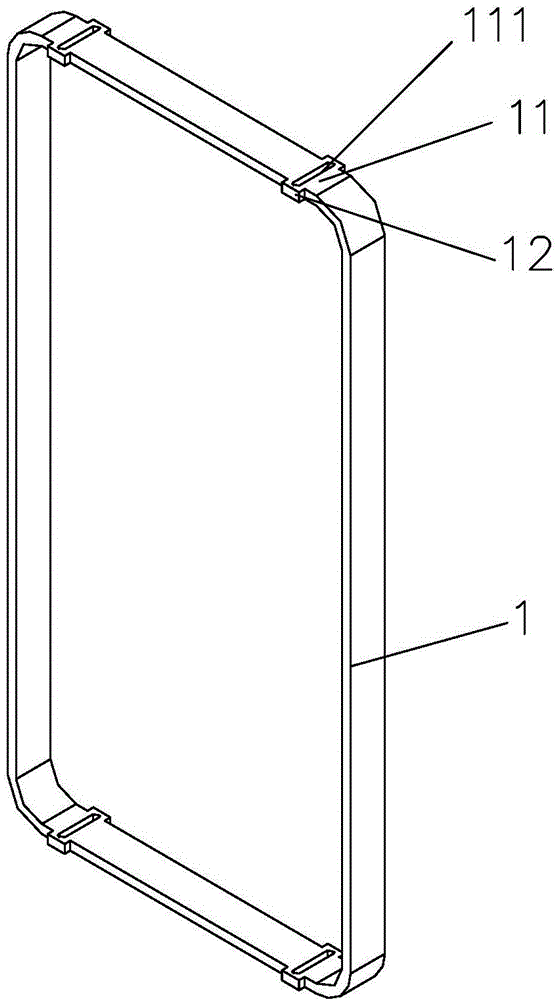

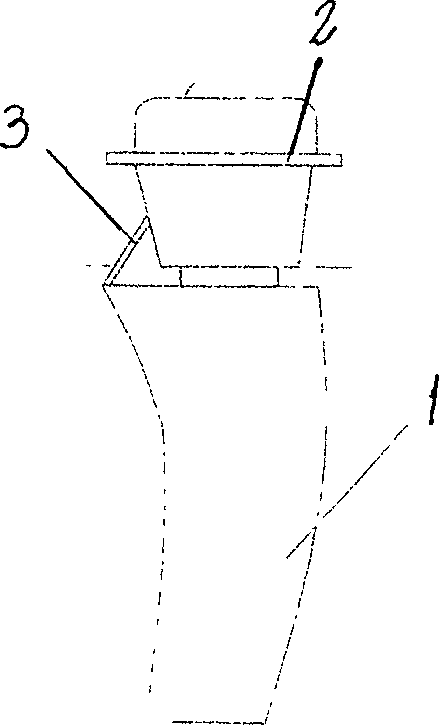

Processing method of metal middle frame mobile phone shell structure

ActiveCN104551562ASolve processabilitySolve the costTelephone set constructionsWhole bodyDie casting

The invention discloses a processing method of a metal middle frame mobile phone shell structure and relates to the technical field of processing of mobile phones. The processing method comprises the following steps: A, stamping a blank of the metal middle frame by using a metal plate; B, milling an auxiliary antenna area on the blank of the metal middle frame in a CNC manner and retaining a connection position; C, forming a metal bottom shell by using an aluminum die casting manner; D, connecting the blank of the metal middle frame with the metal bottom shell to be a whole body; E, forming a main antenna area on the blank of the metal middle frame by using an injection molding manner; and F, milling off the connection position on the blank of the metal middle frame in the CNC manner to obtain the metal middle frame mobile phone shell structure. By combining processes of stamping molding, injection molding and CNC processing, the metal middle frame mobile phone shell structure is processed; the metal middle frame mobile phone shell structure is stable in process, high in production efficiency, short in processing time and low in production cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Fine casting method for super long lower pressure partition guide blade of turbine in stainless steel investment mold

The present invention discloses precise investing process of super long low pressure partition guide blade of stainless steel for turbine. Crankled stainless steel guide blade with length up to 960 mm and weight up to 42 kg may be manufactured through investing process. The present invention adopts pre-deforming profiling design and improved investing process and the produced guide blade for 600 KW steam turbo generator has high performance. The investing process includes making wax mold, making shell, smelting and casting, and heat treatment.

Owner:HARBIN XINRUN IND

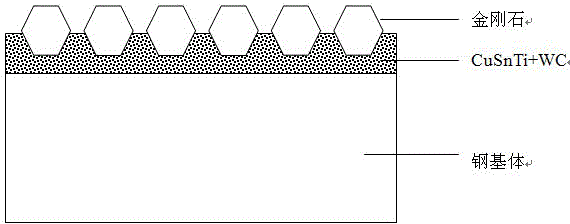

Manufacturing method of single-layer brazing diamond grinding wheel

InactiveCN103817610ALow costImprove wear resistanceAbrasion apparatusGrinding devicesChemical reactionFiller metal

The invention discloses a manufacturing method of a single-layer brazing diamond grinding wheel. The manufacturing method includes steps of preparing a base body of the diamond grinding wheel by a machining method, deoiling and descaling; utilizing mixture of Cu powder, Sn powder, TiH2 powder and WC (wolfram carbide) powder as brazing filler metal of the diamond grinding wheel, and mechanically blending uniformly; sequentially arranging the base body, the brazing filler metal and diamond grains of the diamond grinding wheel to manufacture a tool forming blank; placing the tool forming blank into a vacuum furnace, subjecting the brazing filler metal and the diamond grains to chemical reaction by means of brazing process, cooling to the room temperature along with the furnace, and discharging. Cost for raw materials can be reduced to some extent and oxidation pollution can be avoided by utilizing TiH2 as a Ti source, wear resistance and heat resistance of the brazing filler metal can be improved by adding the superfine WC powder into the Cu powder, the Sn powder and the TiH2 powder, graphitization of diamond can be reduced, thereby heat damage of the diamond can be reduced, and the diamond grinding tool can sufficiently give into play.

Owner:ZHONGYUAN ENGINEERING COLLEGE

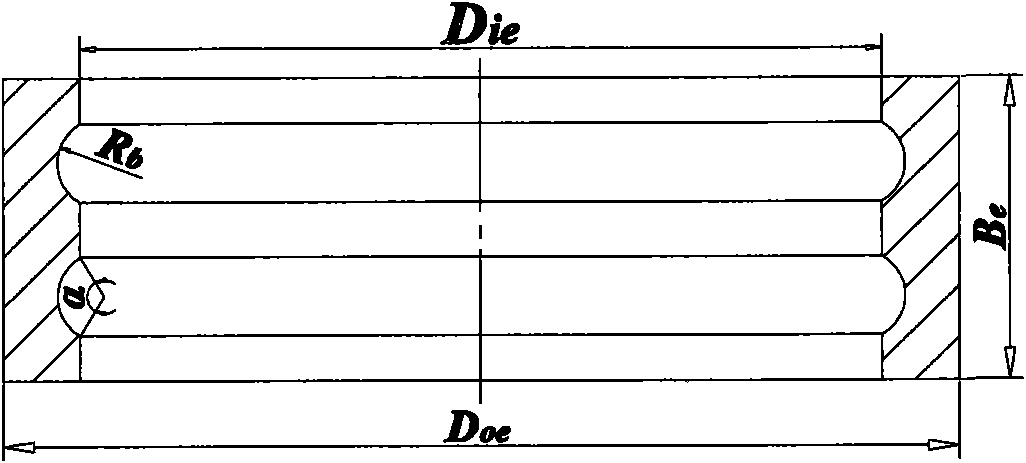

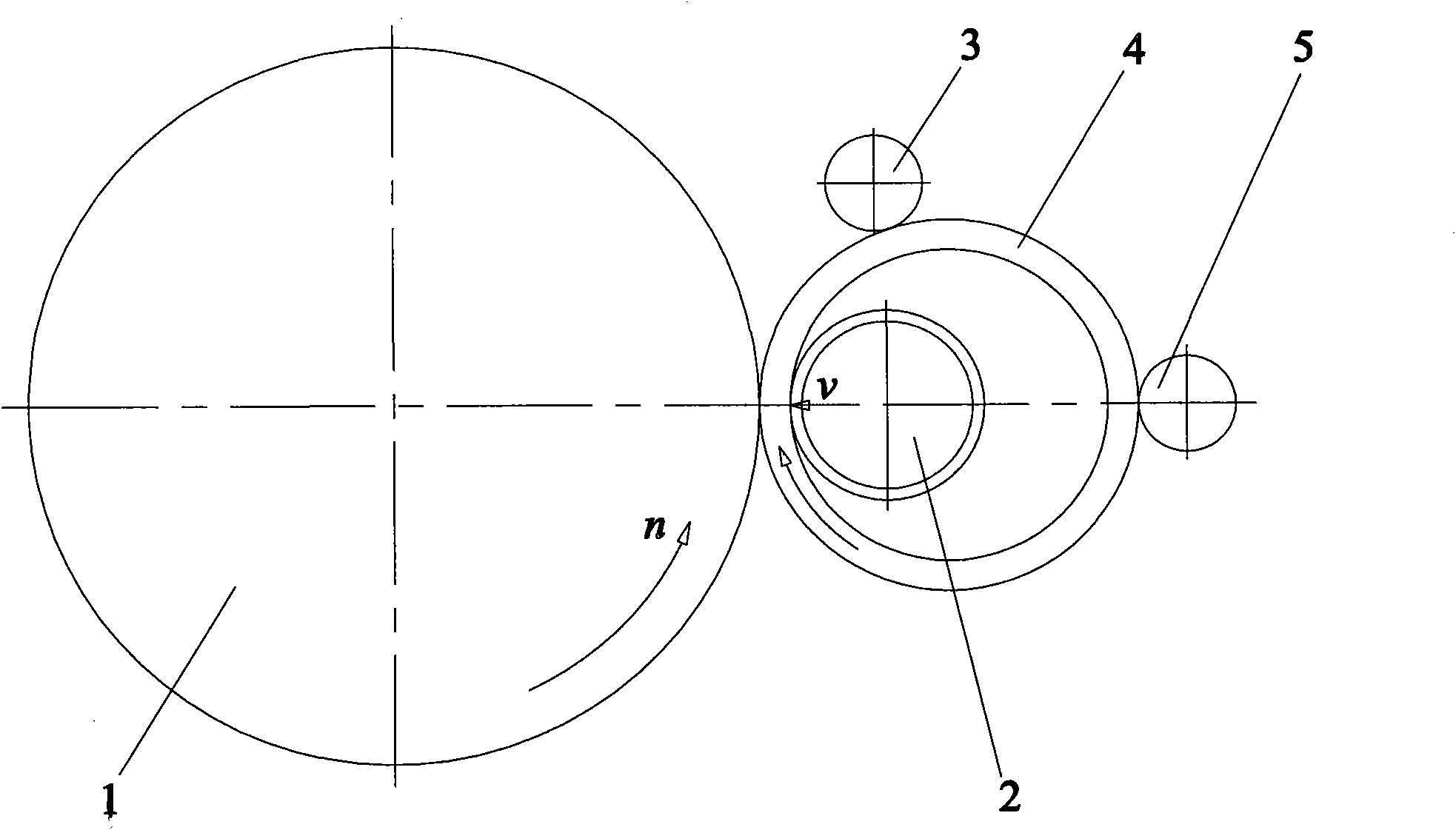

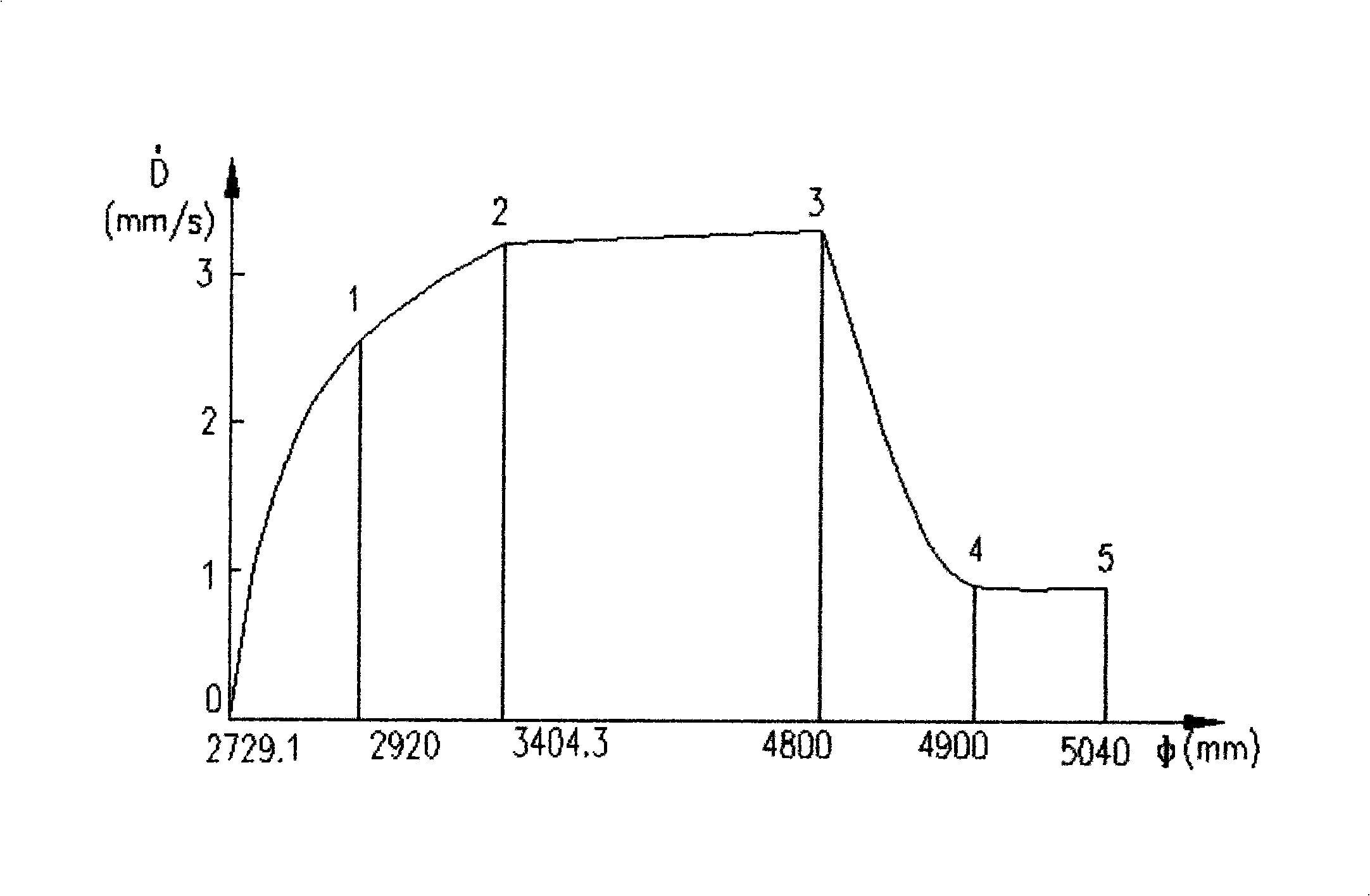

Cold ring rolling forming method for double-flute section ring

ActiveCN101829745AImprove distributionImprove tissue performanceRollsMetal rolling arrangementsFlutePunching

The invention relates to a cold ring rolling forming method for a double-flute section ring. The method comprises the following implementation steps of: (1) preforming, namely uniformly heating a bar section to the forging temperature from room temperature; upsetting, punching and punching wad to form a ring roughcast used for ring rolling; and designing the size of the ring roughcast; (2) roll pass design; and (3) ring rolling forming by using a ring rolling machine, wherein a core roll stops feeding and a ring rolling process is finished when the outside diameter of an obtained double-flute section ring is measured to reach a predetermined value; and the ring roughcast finally forms the double-flute section ring in a predetermined size. In the method, the double-flute section ring is produced by adopting a cold ring rolling process; the double-flute section ring is formed through continuous local plastic deformation of a rectangular section ring by reasonably designing the ring roughcast, ring rolling pass and forming parameters; and therefore, the consumption of raw materials and processing time are reduced, metal streamline distribution and organization properties of the ring are improved, work efficiency and product quality are improved, and production cost is reduced.

Owner:WUHAN UNIV OF TECH +1

Swaging manufacturing method of light aluminum alloy rim

InactiveCN101653901ASimple structureEasy to manufactureShaping toolsRimsPerformance indexNational standard

The invention relates to a swaging manufacturing method of a light aluminum alloy rim. The method comprises the following processing steps: (1) baiting; (2) heating; (3) carrying out ring rolling; (4)manufacturing a spinning blank; (5) carrying out hot spinning; (6) carrying out head back hot spinning; (7) carrying out heat treatment; and (8) fine machining the blank into a rim product. The performance indexes of the rim all reach national standards. The method only needs a pair of spinning moulds, i.e. an upper spinning mould and a lower spinning mould for processing, wherein the moulds havesimple structure, easy manufacture and low manufacturing cost. High temperature and high speed hot spinning processing is adopted so as to ensure that the metallographic structure of the rim has uniformity, refined crystalline grain, light weight, thin thickness, mechanical property improvement of the rim, high precision and good quality, and compared with a rim processed by cold spinning, the rim of the invention cannot crack and generate pinholes and has long service life. The blank processed by the method is annular and has high material utilization rate, less waste and processing amount reduction. Meanwhile, the invention provides a new variety for the rims in the car accessory market. Consumers can conveniently replace and adjust the rims of different shapes and types as required atany time without dismantling a tire so as to quickly change the type of the whole tire.

Owner:丁松伟

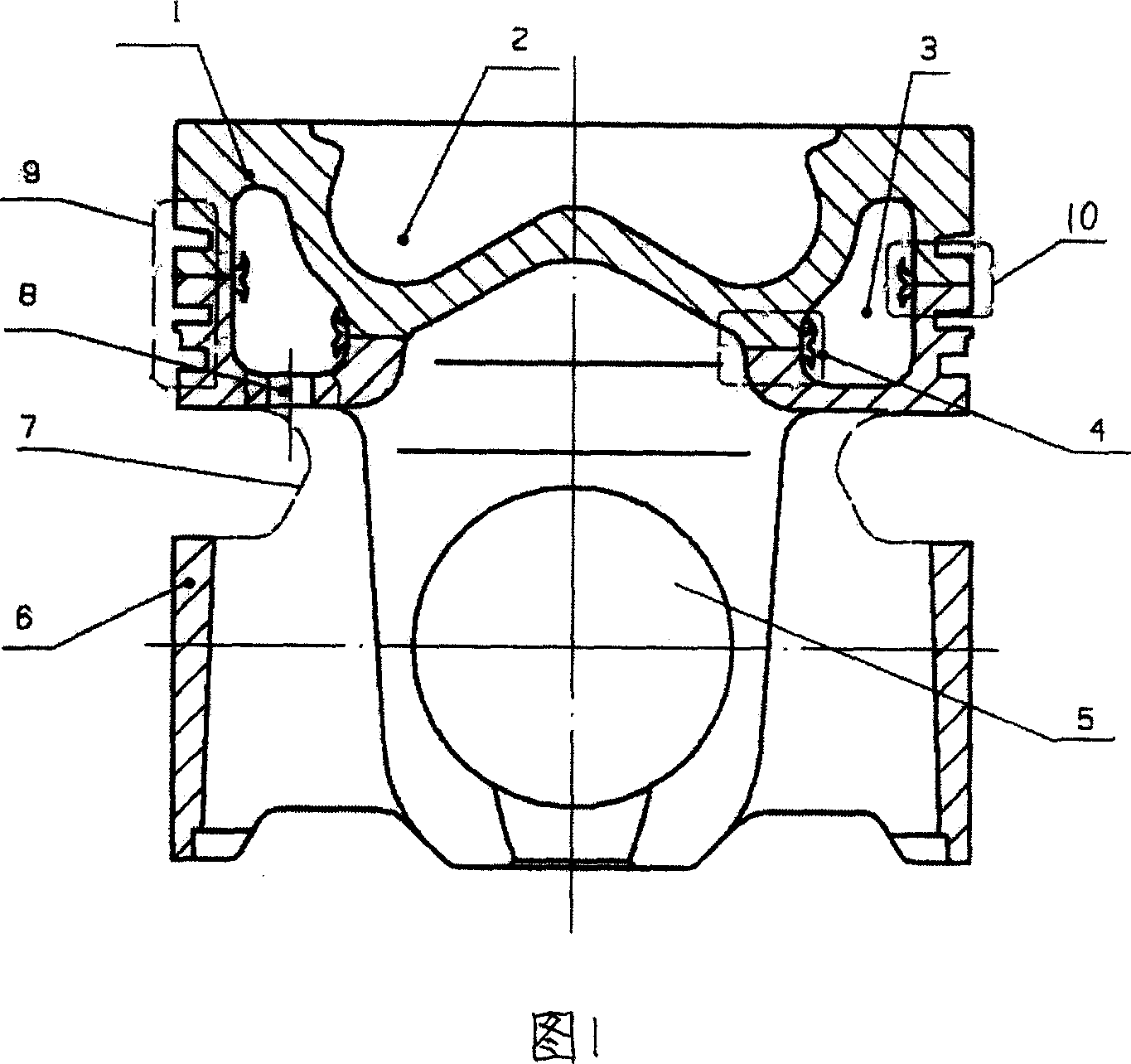

Welded forged steel integrated piston and its producing method

InactiveCN1944994AImprove structural rigidityReduce weightMachines/enginesPistonsFriction weldingCombustor

The present invention is welded integral forged steel piston and its manufacturing process. The manufacturing process includes the following steps: forging the head blank and the skirt blank; separate heat treatment of the head blank and the skirt blank; coarse machining the head blank and the skirt blank; friction welding the head and the skirt together; machining the ring slot, combustor, pin hole, excircle and oil outlet in the piston; and final surface phosphorizing or graphitizing treatment of the piston. The present invention has raised manufacturability, high integral structural rigidity, lowered weight and low machine oil consumption compared with available integrally cast piston.

Owner:SHANDONG BINZHOU BOHAI PISTON

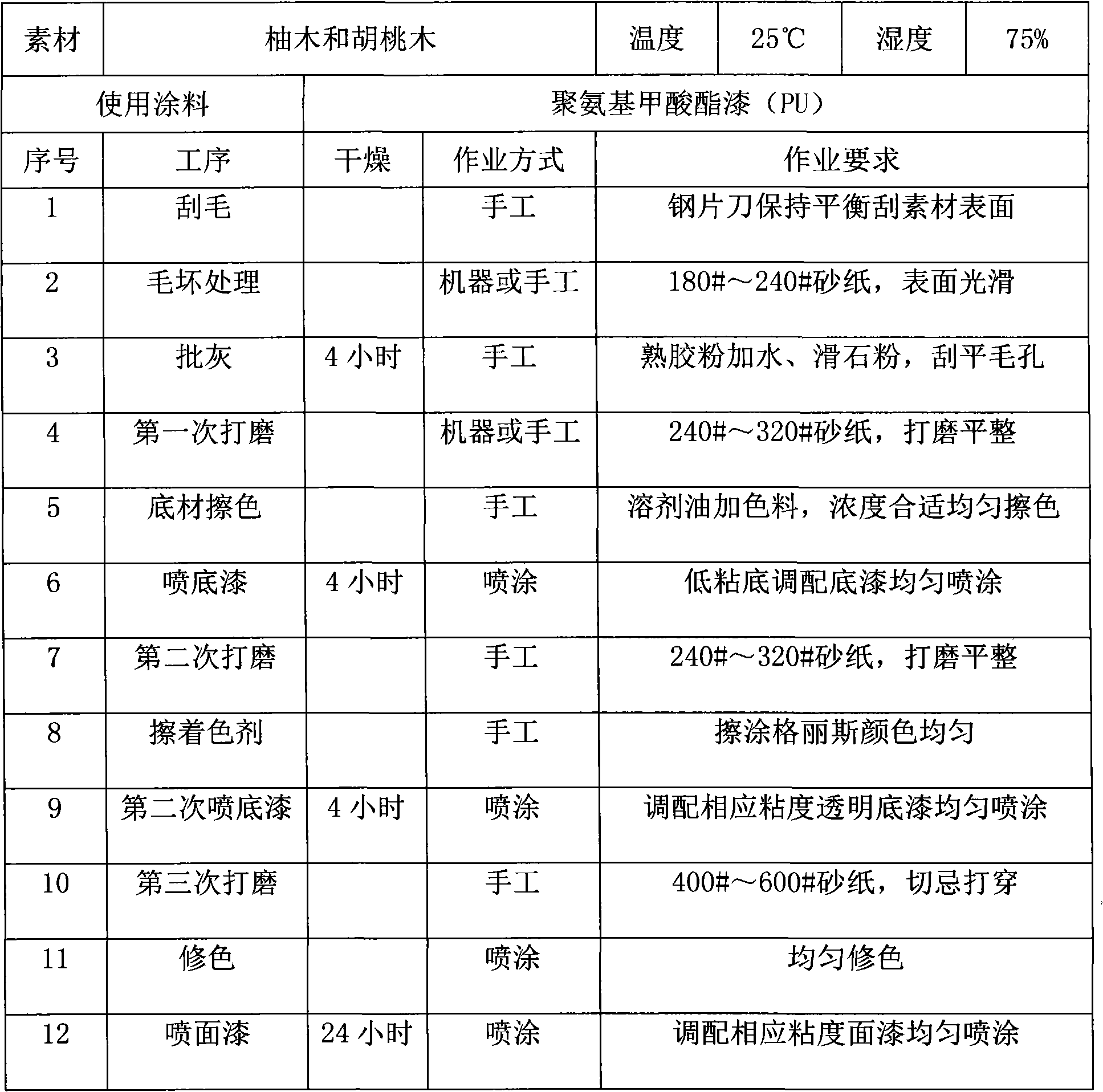

Paint coating process for wooden furniture

InactiveCN101670335AShorten the timeConsistent colorPretreated surfacesCoatingsRoughcastMaterials science

The invention relates to the field of paint coating processes, in particular to a paint coating process for wooden furniture. The paint coating process for the wooden furniture comprises the followingworking procedures: (1) scraping, (2) blank treatment, (3) plastering, (4) primary polishing, (5) base material coloring, (6) base paint spraying, (7) secondary polishing, (8) colorant coating, (9) secondary base paint spraying, (10) third polishing, (11) tinting, and (12) finish paint spraying. The paint coating process for the wooden furniture provided by the invention overcomes the defects that the blank treating and polishing time is long and the plane is not easy to be smoothened, improves the color definition of the furniture, and improves the visual effect and appreciation of the furniture.

Owner:莫有根

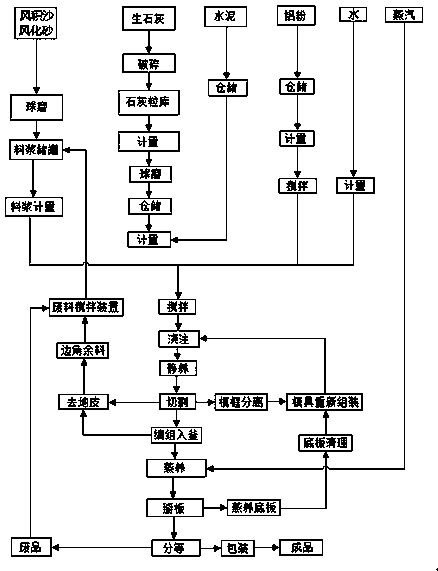

Autoclaved aeolian sand aerated concrete building block and wallboard

The invention provides an autoclaved aeolian sand aerated concrete building block and wallboard which are prepared by the following method: performing ball milling on aeolian sand or weathered sand to obtain slurry with the mass percentage concentration of 50 to 70%; crushing quick lime, grinding into quick lime powder; mixing aluminum powder; according to mass percentage, respectively taking cement, the slurry and the quick lime powder for mixing into a base material, proportionally adding the aluminum powder and gypsum, and stirring evenly to obtain finished product slurry; according to an autoclaved aerated concrete building block production process in the prior art, pouring, curing and cutting to form a green body or a workblank, removing wastes on the green body or the workblank, grouping into a reactor; performing autoclaving and maintaining and other processes, and packaging qualified products to obtain the autoclaved aeolian sand aerated concrete building block or wallboard; collecting produced waste to prepare waste slurry; and adding the waste slurry into the finished product slurry for using again. The concrete building block and wallboard can be prepared into building and environmental protection materials with good performances by comprehensive utilization of the aeolian sand and the weathered sand, and the river sand and ore sand collection and waste of resources can be reduced.

Owner:JINGTAI FUHAI SUNSHINE BUILDING MATERIAL

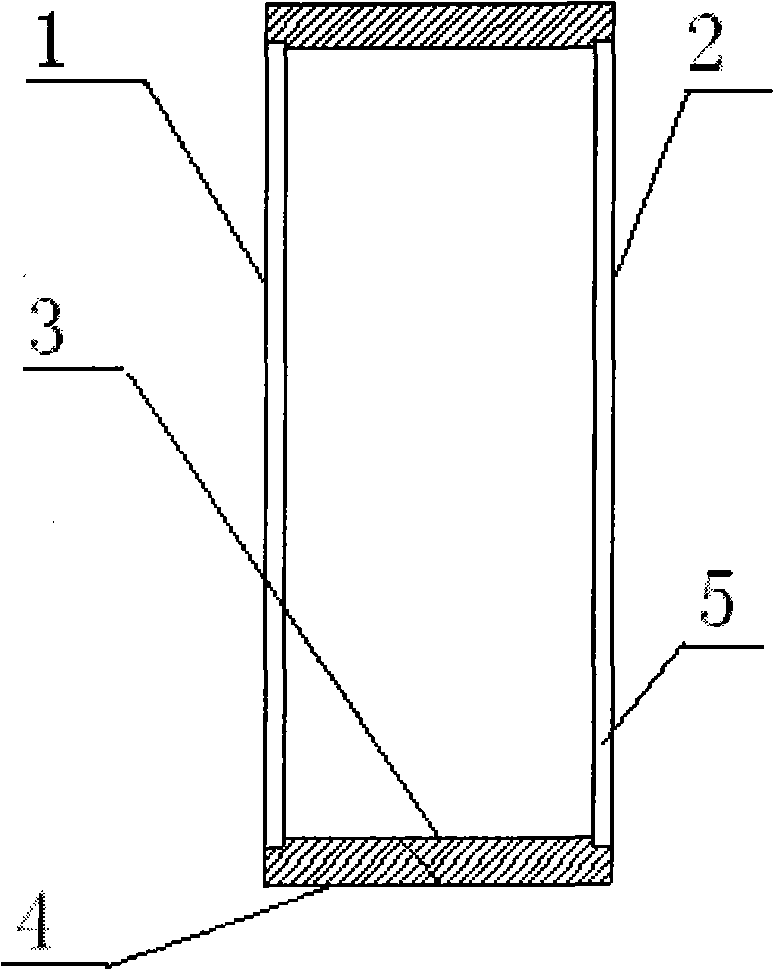

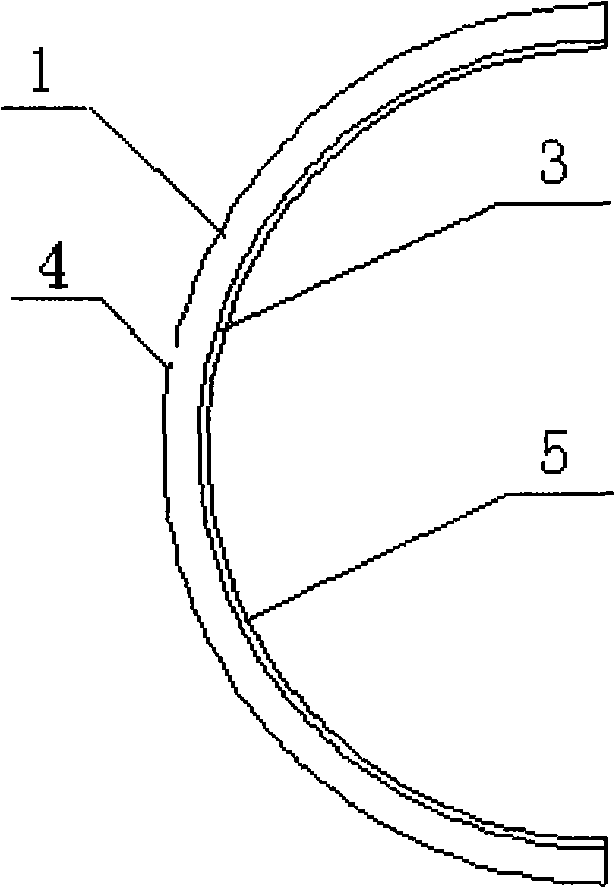

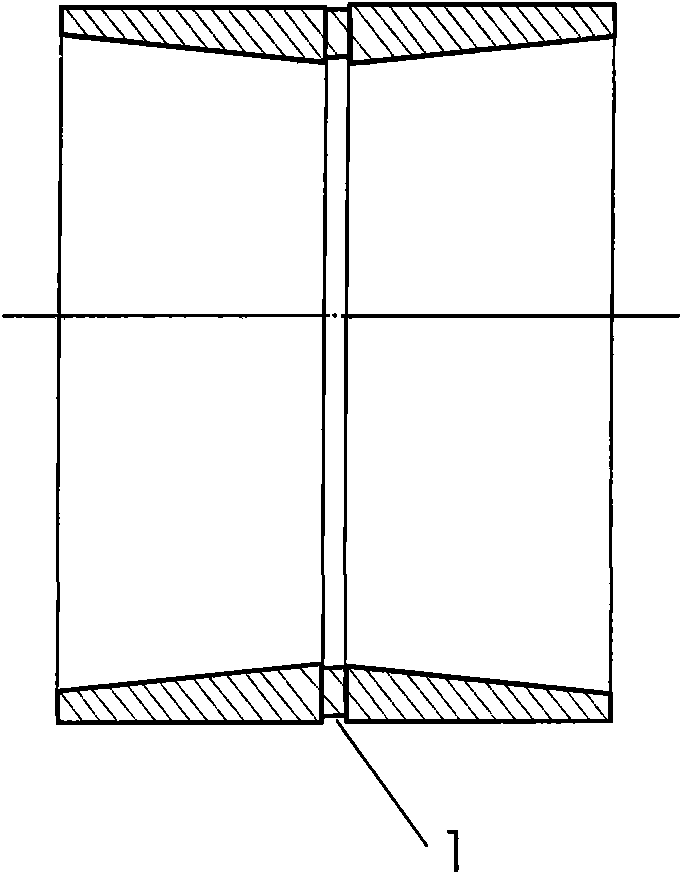

Manufacturing method of large size thin-walled titanium alloy cylindrical part and cylindrical mould

The invention provides a manufacturing method of a large size thin-walled titanium alloy cylindrical part, comprising the steps of: (1) raw material powder selection; (2) powder loading and encapsulation; (3) hot isostatic pressing; and (4) cylindrical part blank processing. The invention also provides a cylindrical mould used for manufacturing the large size thin-walled titanium alloy cylindrical part, comprising a cylindrical outer sheath and a cylindrical inner sheath. A cavity for loading titanium alloy powder is formed by the outer sheath and the inner sheath, and the inner sheath is internally provided with a cylindrical shaped mould; an upper sheath cover and a lower sheath cover for encapsulating the cavity are respectively fixed at the top end and the bottom end of the cavity for loading titanium alloy powder; and the upper sheath cover is also provided with a gas removing pipe. Different from a plurality of traditional manufacturing methods, the invention can simultaneously meet the requirements of high performance, no defect, large size thin-wall, large length-diameter ratio, high precision, low cost, and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

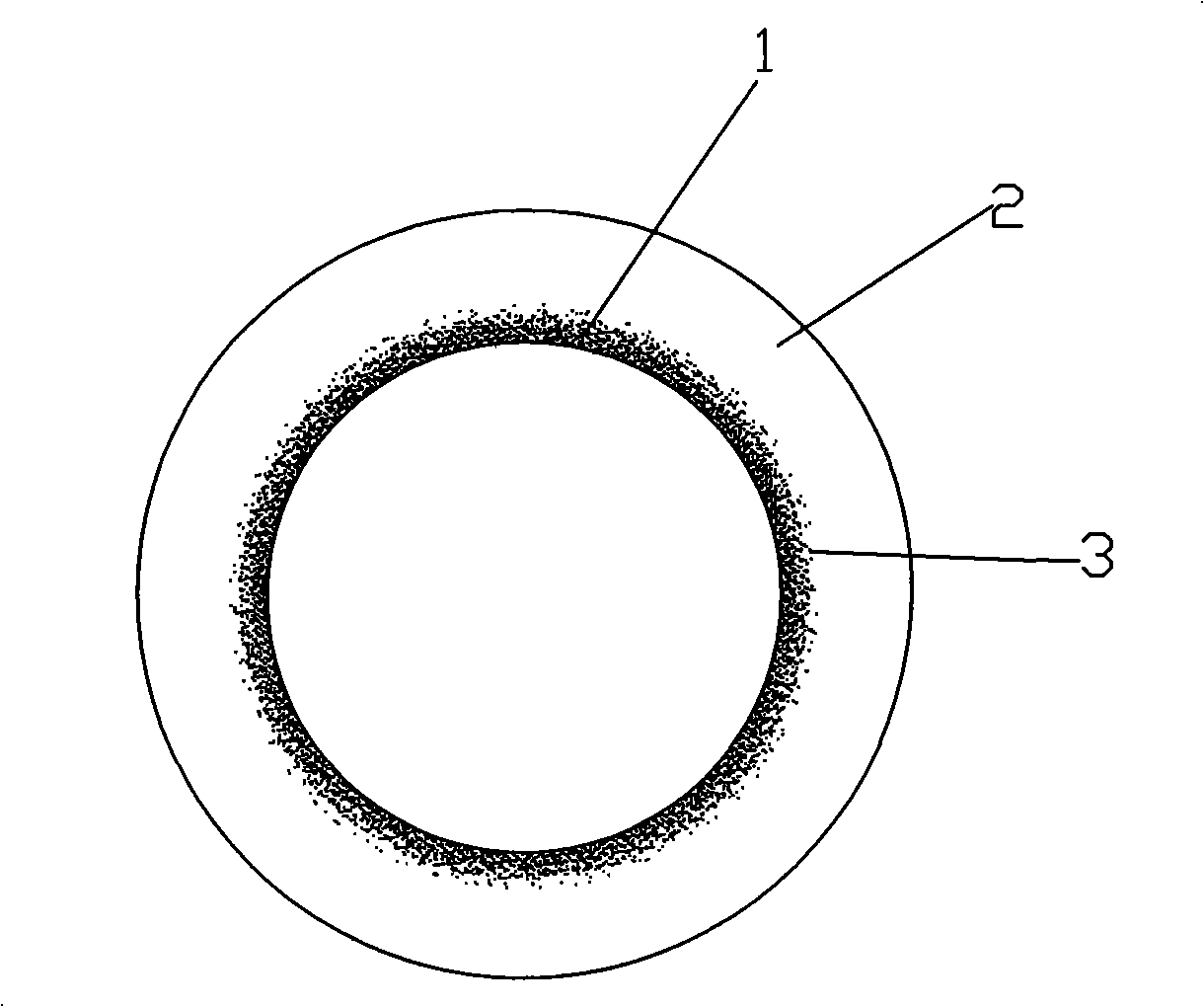

Inner layer granule reinforced cylinder sleeve and method of manufacture

The present invention discloses a reinforced internal layer particle cylinder sleeve and a manufacturing method thereof. The reinforced internal layer particle cylinder sleeve comprises a cylinder sleeve substrate which comprises a radial inner reinforced layer and an outer non-reinforced layer. The reinforced layer consists of reinforced particles distributed in the cylinder body substrate. The reinforced layer and the non-reinforced layer are combined by an alloy combined transition layer. The transition of the reinforced layer and the non-reinforced layer of the present invention is uniform, slow, stable and firm, thereby prolonging the service life of the cylinder sleeve; the cylinder sleeve has light weight, low porosity factor and good mechanical performance and thermal performance and improves the working efficiency of an engine; the manufacturing method has simple technical process and high production efficiency; the content of the reinforced particles in the non-reinforced layer is zero, thereby increasing the wearability of the inner layer and also causing no influence on the integral mechanical performance of the cylinder sleeve, such as the intensity of tension, and the like; the cylinder sleeve uses a centrifugal casting method to form an inner layer particles segregated roughcast and then is made by the heat treatment and mechanical cutting, processing and manufacturing of the roughcast.

Owner:CHONGQING UNIV

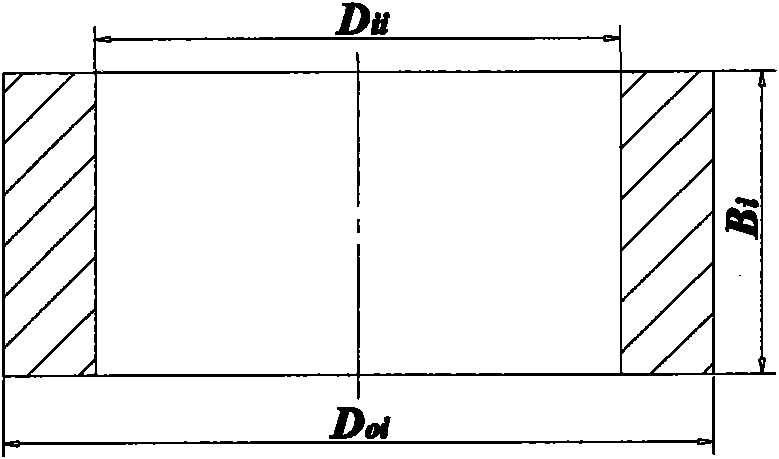

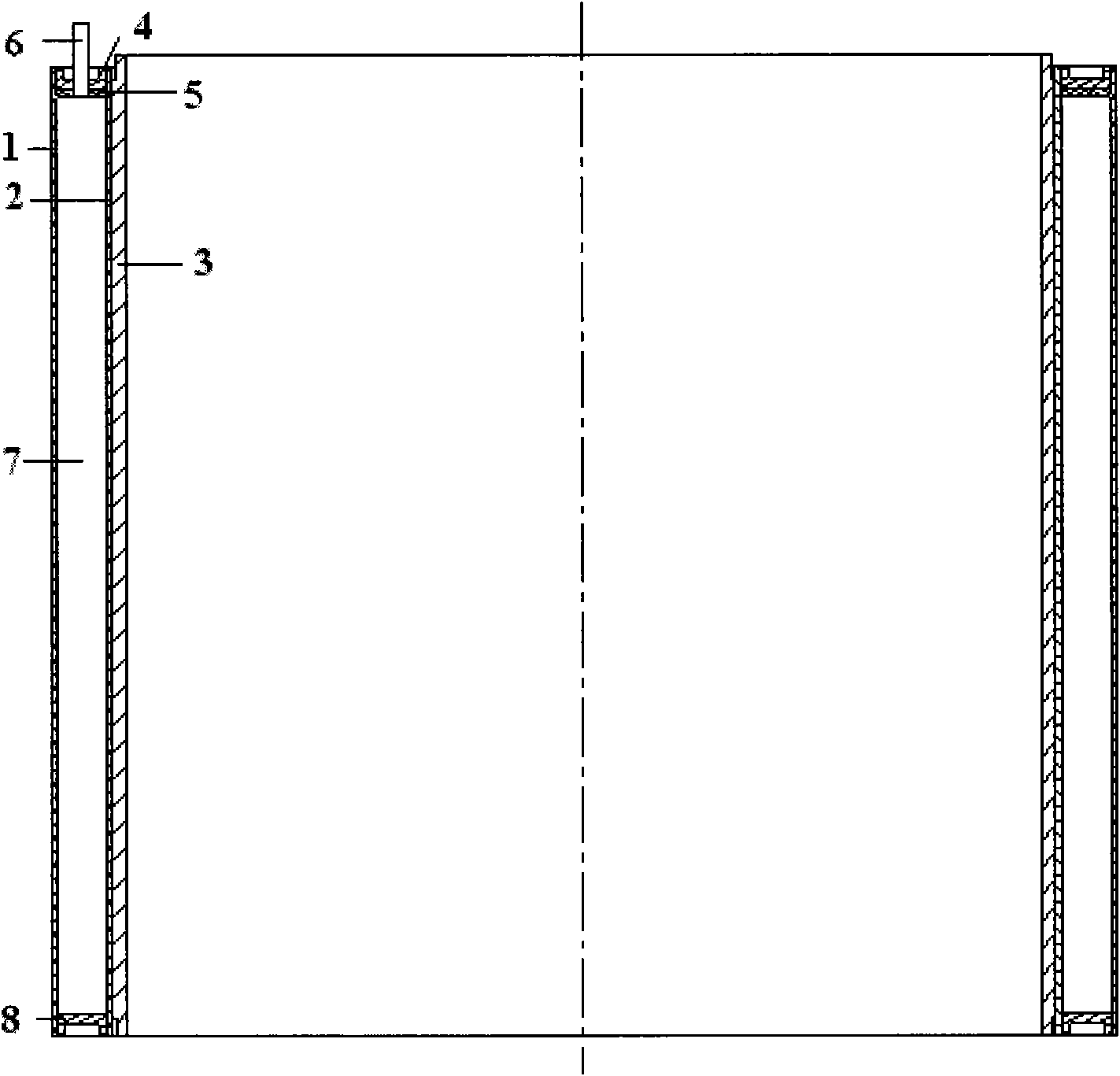

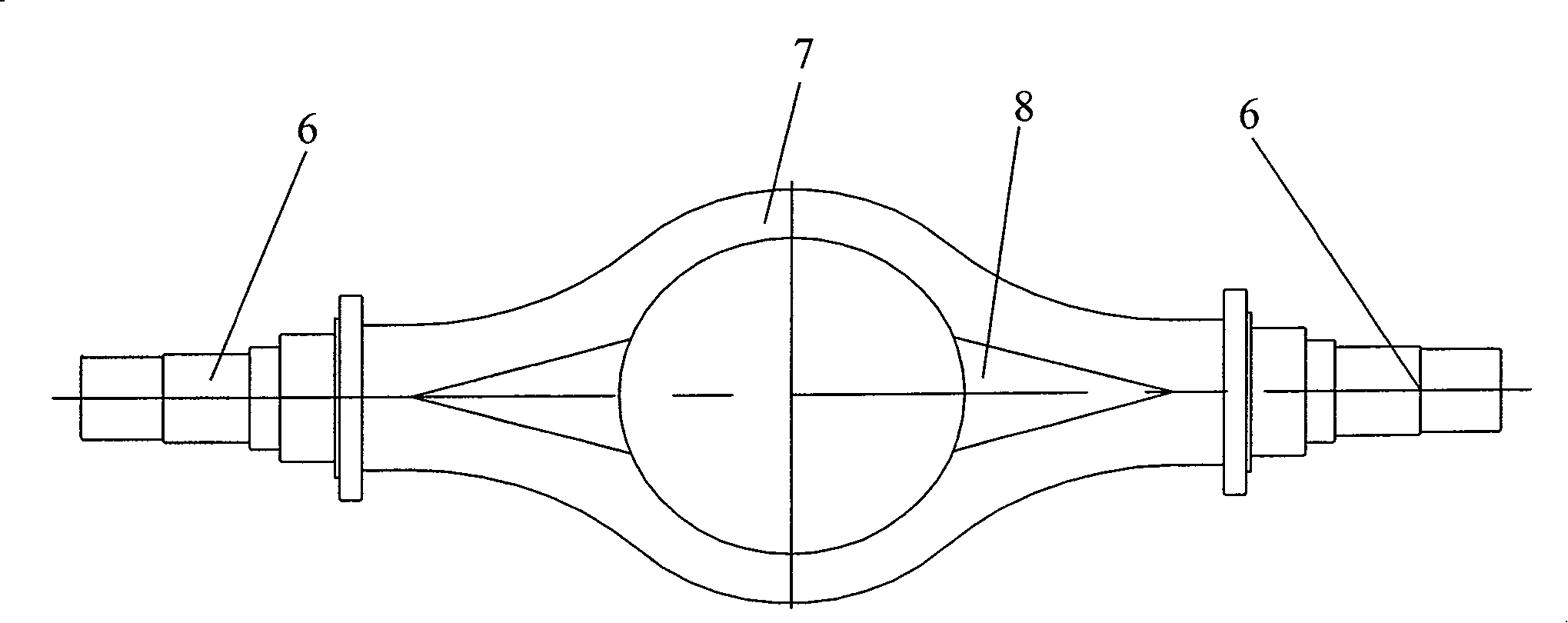

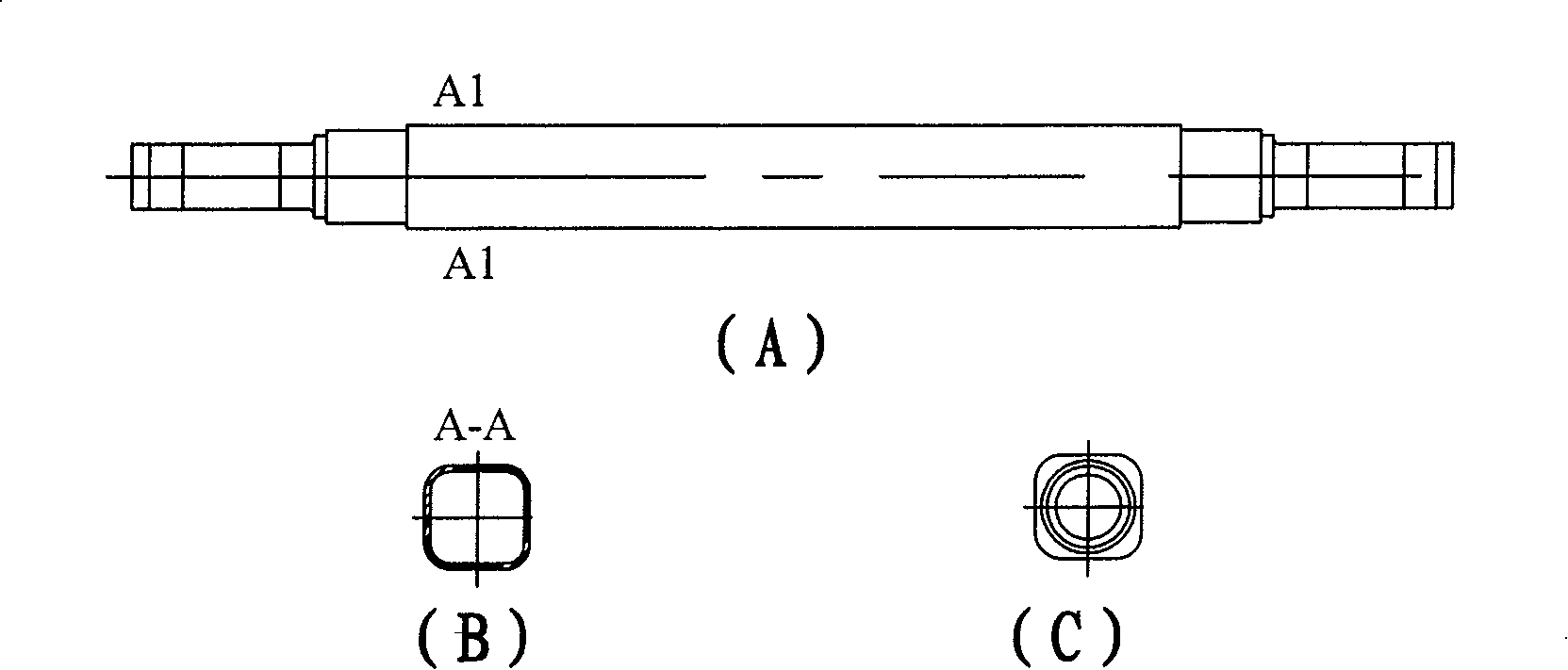

Aluminum alloy ring piece rolling technique and device

InactiveCN101337256AStepless adjustable speedMeet speed requirementsRoll mill control devicesRolling mill drivesNumerical controlMaterials processing

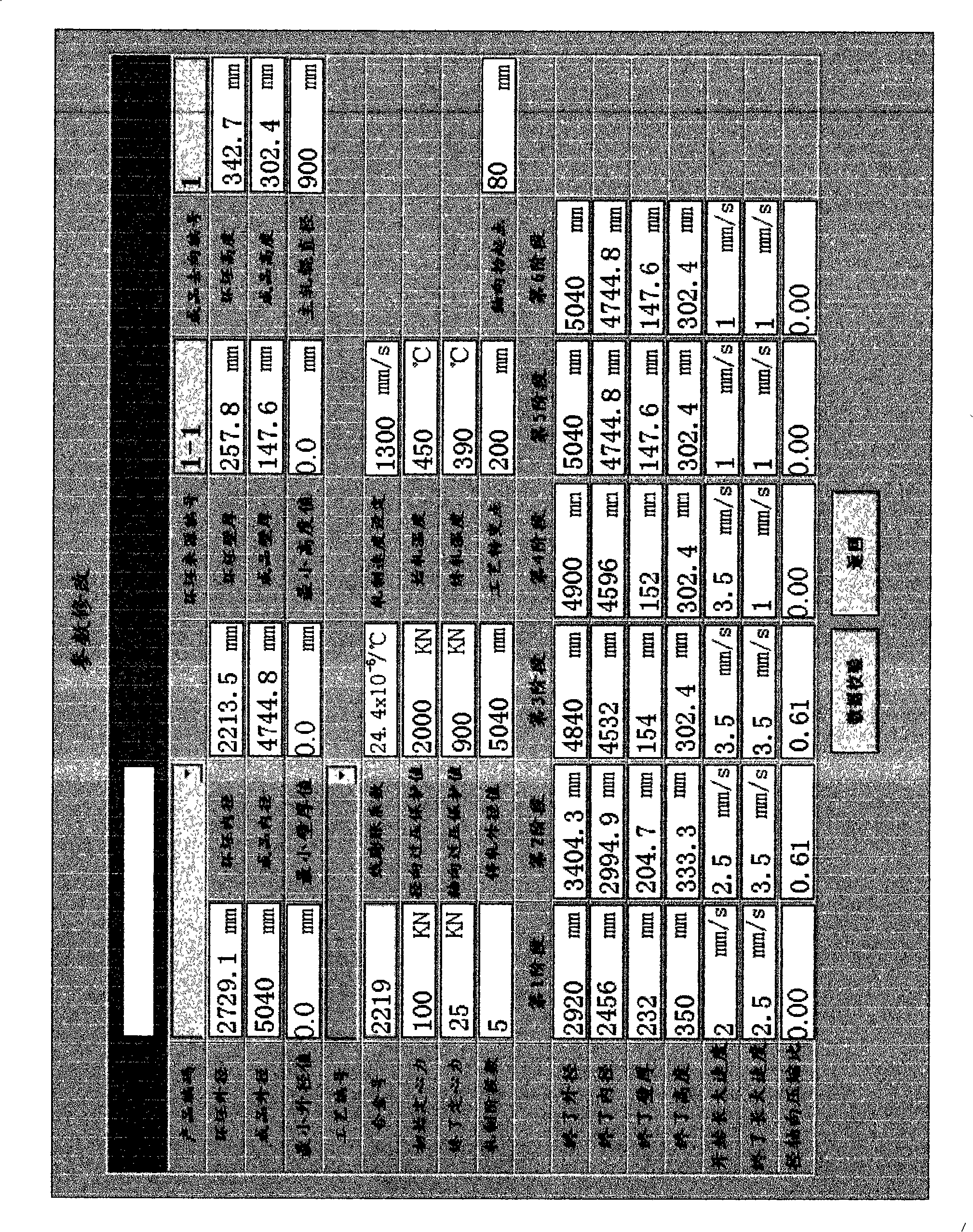

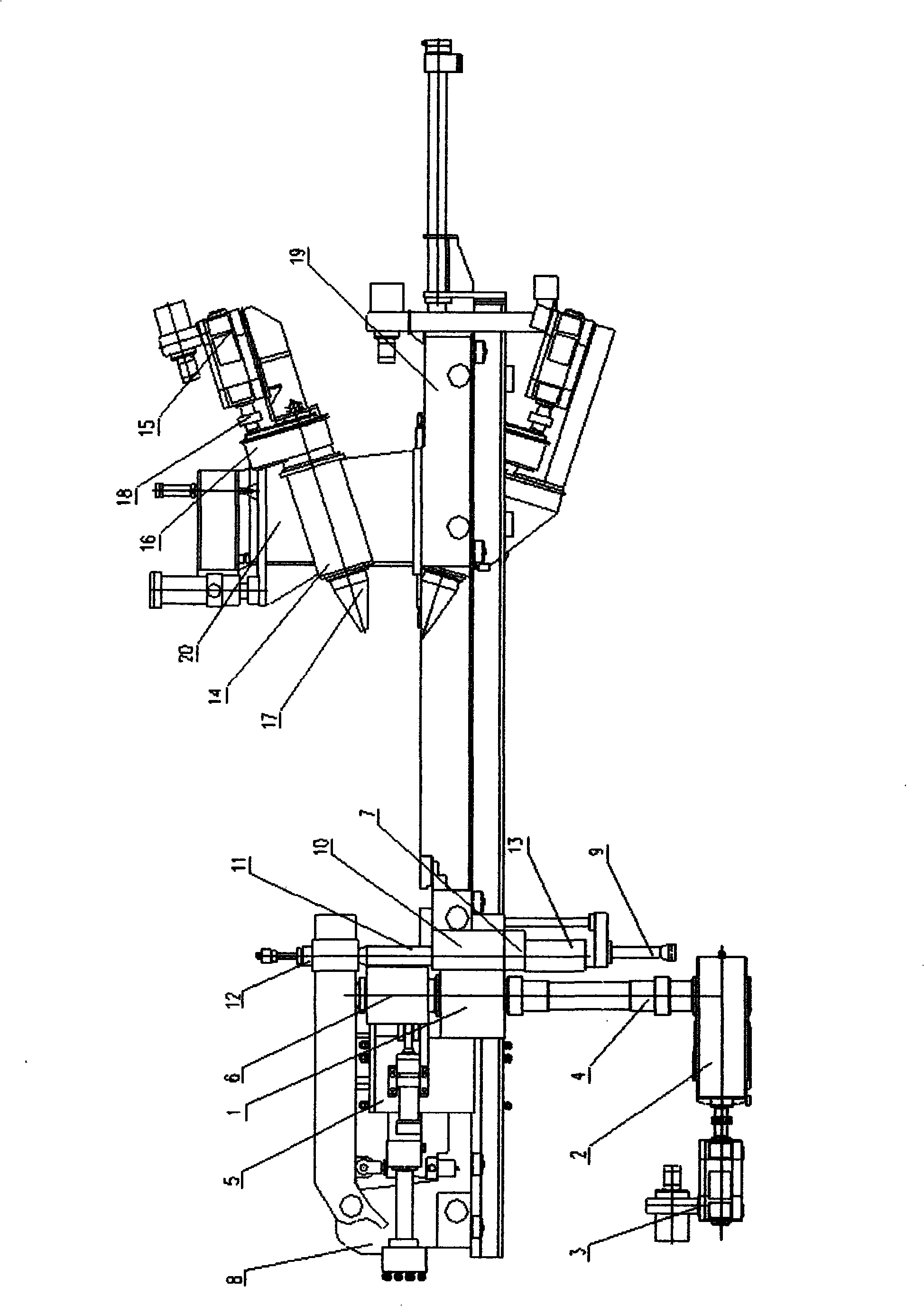

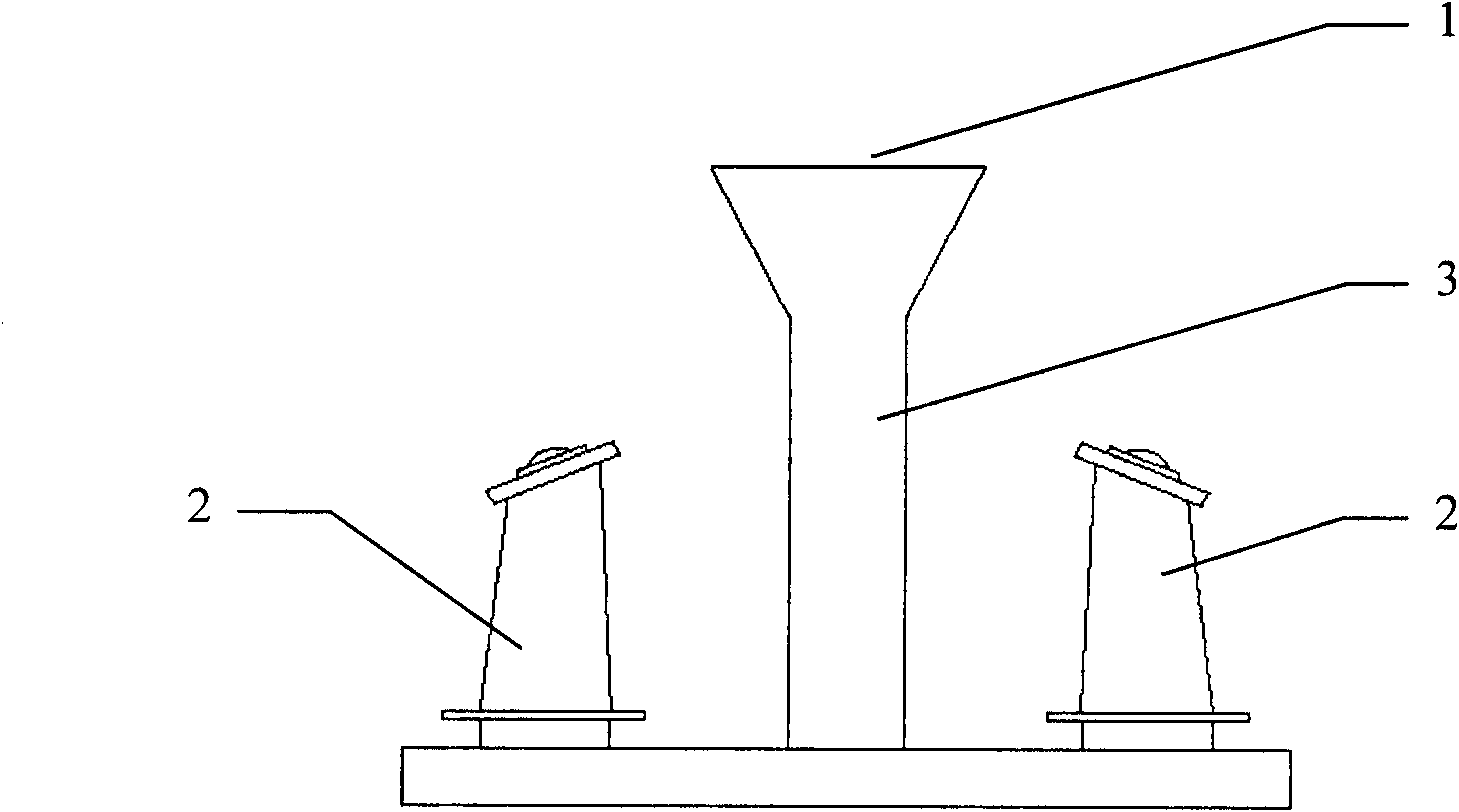

The invention relates to a method and equipment for processing metal material, particularly to a technology and equipment for rolling superlarge-diameter aluminium alloy ring pieces. The method and the equipment are characterized in that the rolling technology comprises the following steps: A. calculating parameters: calculating technical control parameters including the dimensions of a roughcast, the rolling linear speed, the radial-axial rolling force during various stages, the enlargement rate of the ring pieces, the radial-axial feed speed, the external diameter of the ring pieces, the height of the ring pieces and the wall thickness of the ring pieces according to the dimensions of a product ring; B. inputting parameters: inputting the various technical control parameters into a numerical control ring rolling mill computer according to the calculation results; C. numerically controlled rolling: fully automatic control is adopted during the rolling process. A radial rolling mechanism and an axial rolling mechanism are connected on the chassis of the equipment; and the radial rolling mechanism is connected with a king roller drive mechanism (1) and a core roller mechanism (7). The axial rolling mechanism is connected with an axial roller drive mechanism (14). The technology and the equipment for rolling superlarge-diameter aluminium alloy ring pieces lead to smooth rolling process and high-precision of the dimensions of product rings.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Precision-investment casting method of titanium aluminum base alloy aircraft engine blade

A precision-investment casting method of a titanium aluminum base alloy aircraft engine blade relates to a preparation method of an aircraft engine blade and solves the problems of easy deformation, complicated processing procedures and low processing efficiency caused by the thin aircraft engine blades with diverse shapes when the existing blank processing mode is adopted. The invention adopts a water jacketed copper crucible vacuum induction melting centrifugal casting method to realize the preparation of the titanium aluminum base alloy aircraft engine blade. The aluminum content of the titanium aluminum base alloy is 46-48at%. Under vacuum argon shield, the melting is implemented and the melting power is 330-350kW in the melting process. With the centrifugal casting technology adopted, the casting is carried out by adopting a bottom casting type casting system and a casting system composed of blade type shells. The preheating temperature of a casting type shell is 400-600 DEG C and the shell cools with a furnace after casting, and the oxygen content of the alloy is 0.04-0.08% after casting. The method is simple in technology, low in processing cost and is applicable to processing various aircraft engine blades.

Owner:HARBIN INST OF TECH

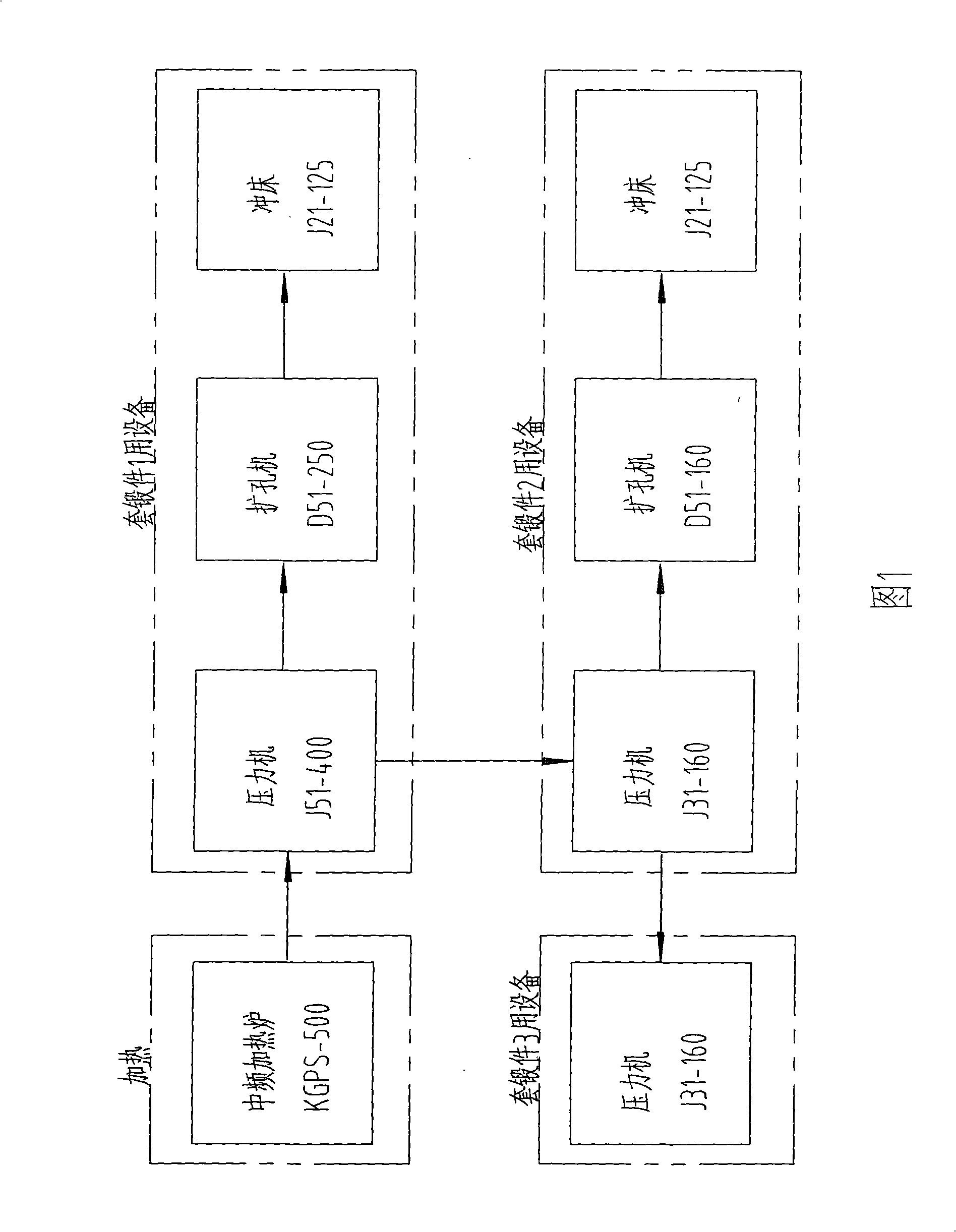

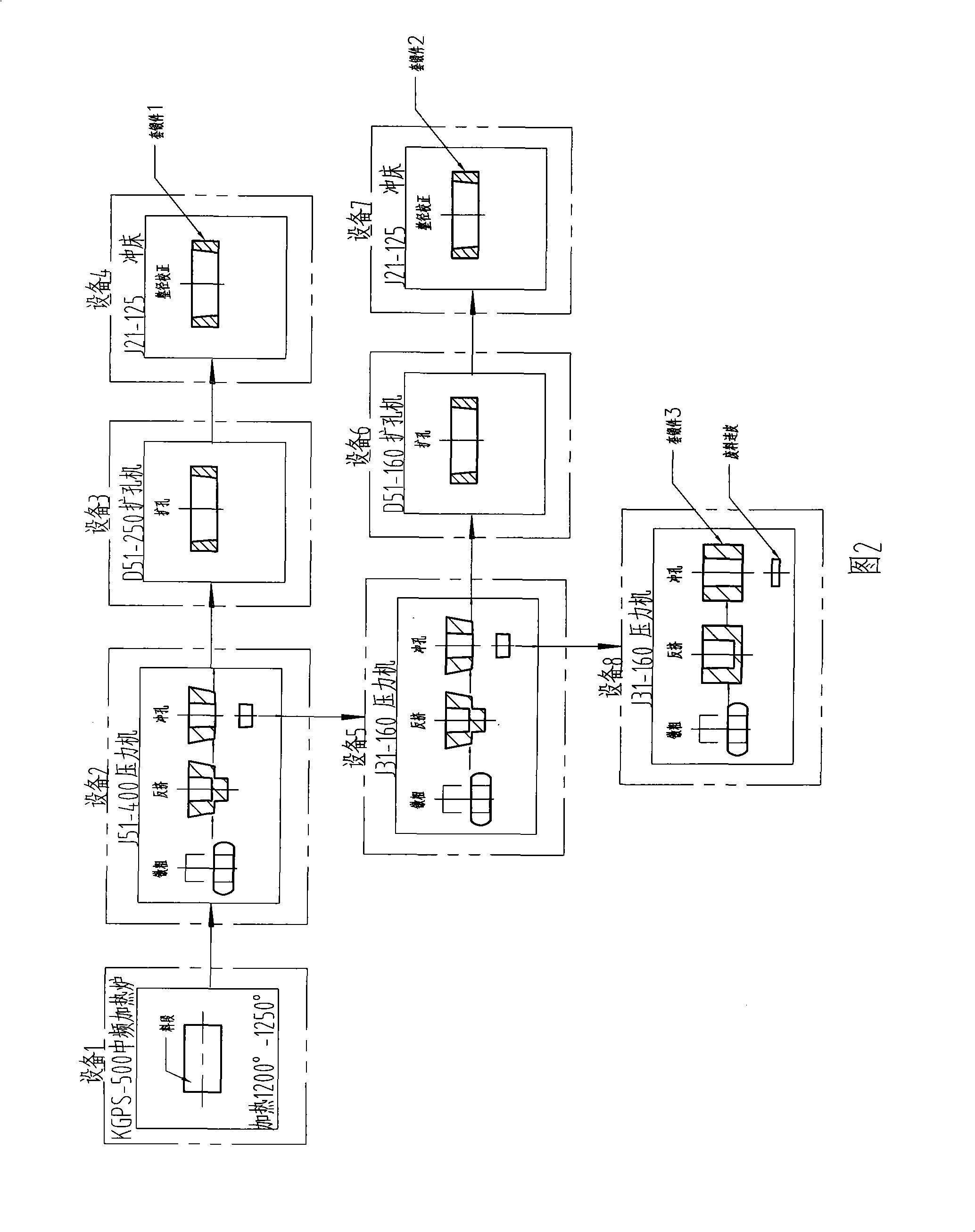

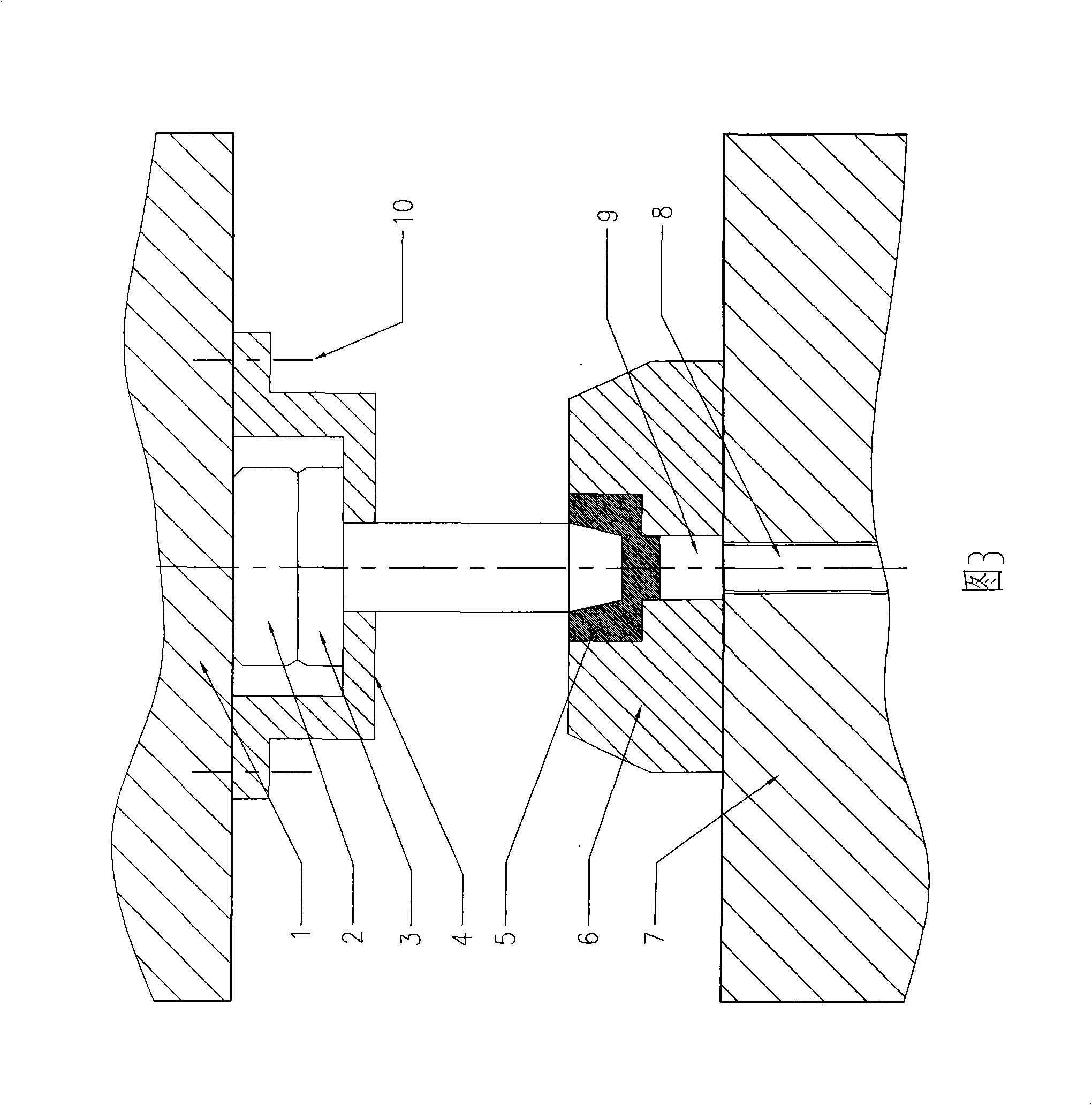

Bearing ferrule workblank triple external member smithing and molding process

InactiveCN101402163ASimple production processImprove productivityExtrusion control devicesMetal rollingIntermediate frequencyRoughcast

The invention discloses a process for forging and molding three connecting kits of a bearing ring roughcast. On equipment which is put in an I-shaped arrangement, a metal material section is sent to an intermediate frequency heating furnace of equipment 1; after the heating temperature of the metal material section reaches between 1,200 and 1,250 DEG C, the metal material section is sent to the equipment, is subjected to continuous upsetting, back extrusion, punching and ring rolling; and the bearing ring roughcast after chambering is subjected to finishing and correction to complete the processing of the first kit, the second kit and the third kit (the ring roughcasts). The process for forging and molding three connecting kits of the bearing ring roughcast can fully utilize residual materials, achieve effective conservation of the materials, simplify the production process, improve production efficiency and complete the production of a plurality of forging pieces of the bearing ring roughcast on one production line under the condition of not increasing the consumption of the raw materials.

Owner:XIANGYANG YUQING FORGING CO LTD

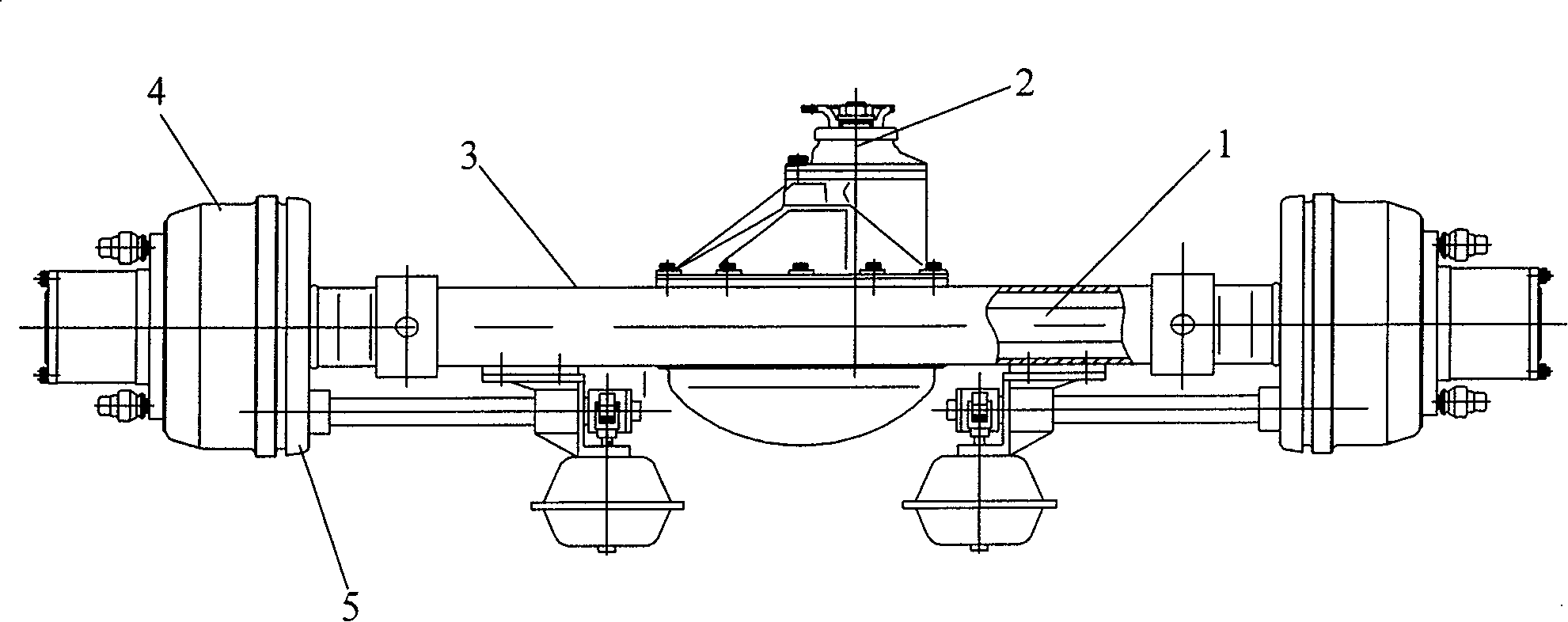

Roll type cold pressing processing method and device for vehicle driving axle housing

InactiveCN101185946ASimple structureHigh mechanical strengthExtrusion control devicesRams/plungersAxial pressureEngineering

Owner:梅利红

Manufacturing process of high-power low-speed diesel shaft bushing

InactiveCN101275606AReduced edge defectsHigh bonding strengthBearing componentsManufacturing technologyLow speed

Owner:CHONGQING YUEJIN MACHINERY

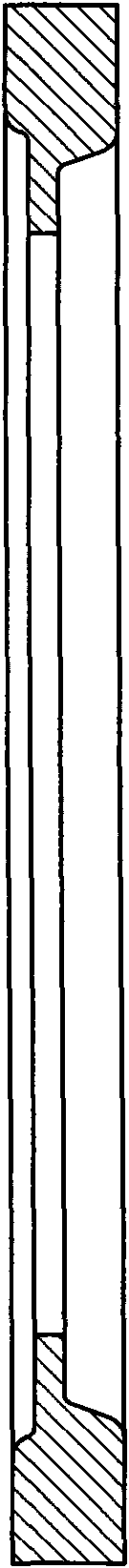

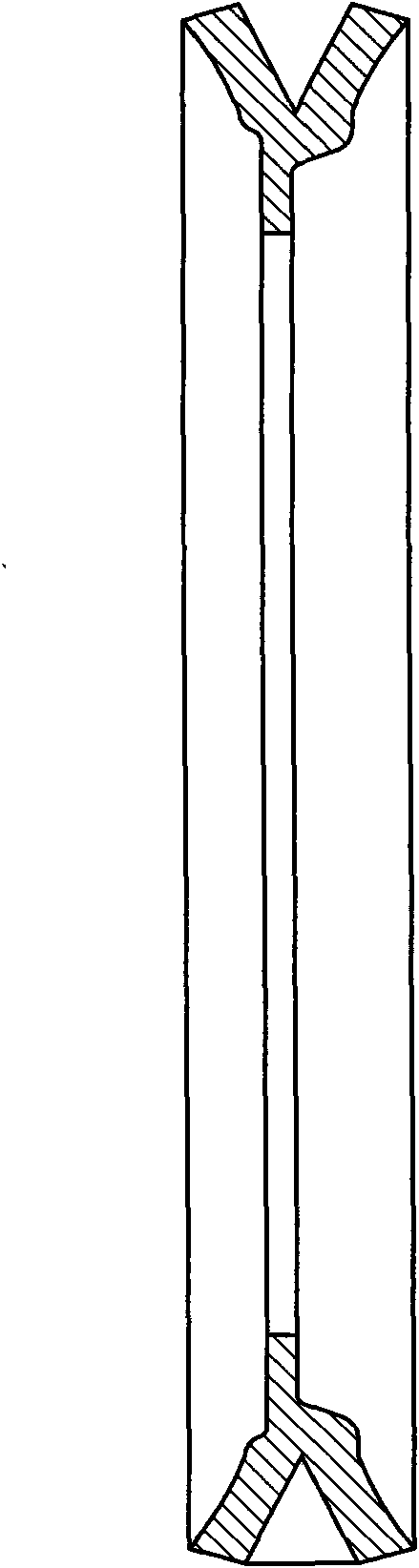

Two-in-one method for processing narrow series thin-wall bearing ferrule

A 2-in-1 machining way for a narrow thin-wall bearing ring. Wherein, a blank of two narrow thin-wall bearing ring is clamped integrally on a chuck of a lathe, the I.D., O.D., ends of the blank are turned, chamfered, then heat treatment is carried; after heat treatment, grinding is carried out; after that, the two bearing rings are cut apart. The specific machining procedures are: clamping and positioning one end of a forged and preliminarily formed blank, turning and chamfering the end face, ID, OD of another end; then changing another end for positioning and clamping, turning and chamfering the end face, ID, OD; carrying out heat treatment, grinding after heat treatment; cutting along the cutting interface, finishing the cut at the cutting interface; carrying out aging treatment. The invention solves the problem of warpage and deformation at hardening of narrow thin-wall bearing rings, improves the production efficiency and improves the utilization rate of raw materials.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Asbestos-free clutch facing used in vehicle and manufacture method therefor

InactiveCN101033786AImprove performanceHigh strengthFriction liningHeat treatedTemperature and pressure

The invention discloses a kind of none asbestos clutch facing used in cars and its production technology. The recipe of the component is that: E-glass fiber 30~50%, fragrance fiber 1~4%, polyacrylonitrile fiber 0.6~1.2%, the oil of cashew shell friction-type mix 3~6%, oil coke blacking 3~5%, particle graphite 5~8%, zinc oxide 0.2~1%, calcium sulfate 5~15%, heavy calcium carbonate 10~20%, flour acrylonitrile butadiene rubber 15~25%, anti-aging protective TMQ 0.2~0.5%, curing accelerator MBTS 0.2~0.5%, the oil of cashew shell resin modified 6~12%. Banburying mix the component told above in proportions at the proper temperature then make up pellicle by smelting and at last rolls in with the E-glass fiber then forms different ordinance blanks by winding. The blanks confect by heat pressing at the proper temperature and pressure then make into production by grinding and drilling holes. It has the merits like that: high strength, good ductility and stabilize coefficient of friction and so on.

Owner:福建冠良汽车配件工业有限公司

Method for manufacturing outer ring of tapered roller bearing

The invention discloses a method for manufacturing an outer ring of a tapered roller bearing, comprising the following steps of: a: taking a material: setting the quality of the finished product outer ring as M, setting the outer diameter as D, taking a bearing steel pipe with the outer diameter of D1 as the raw material, taking the bearing steel pipe with the quality of M1 and meeting the condition that one half of D is less than or equal to D1 which is less than D, and M1 is equal to 2M plus M2 plus 2M3, wherein M2 is the margin of quality by cutting, and M3 is the margin of quality of single outer ring by grinding process; b: cold rolling: rolling on the bearing steel pipe taken in the step a for obtaining a combined blank of the outer ring; c. cutting: cutting the combined blank at the connecting ring for obtaining a single blank of the two outer rings; d: thermal processing; and e: finish machining: grinding the single blank of the outer ring. The proposal leads the outer ring of the tapered roller bearing to realize the cold rolling for shaping, has the advantages of small material loss, saved energy consumption, simple process, high production efficiency and the like, and simultaneously ensures the product quality.

Owner:NINGXIA QINCHANG ROLLING BEARING MFG

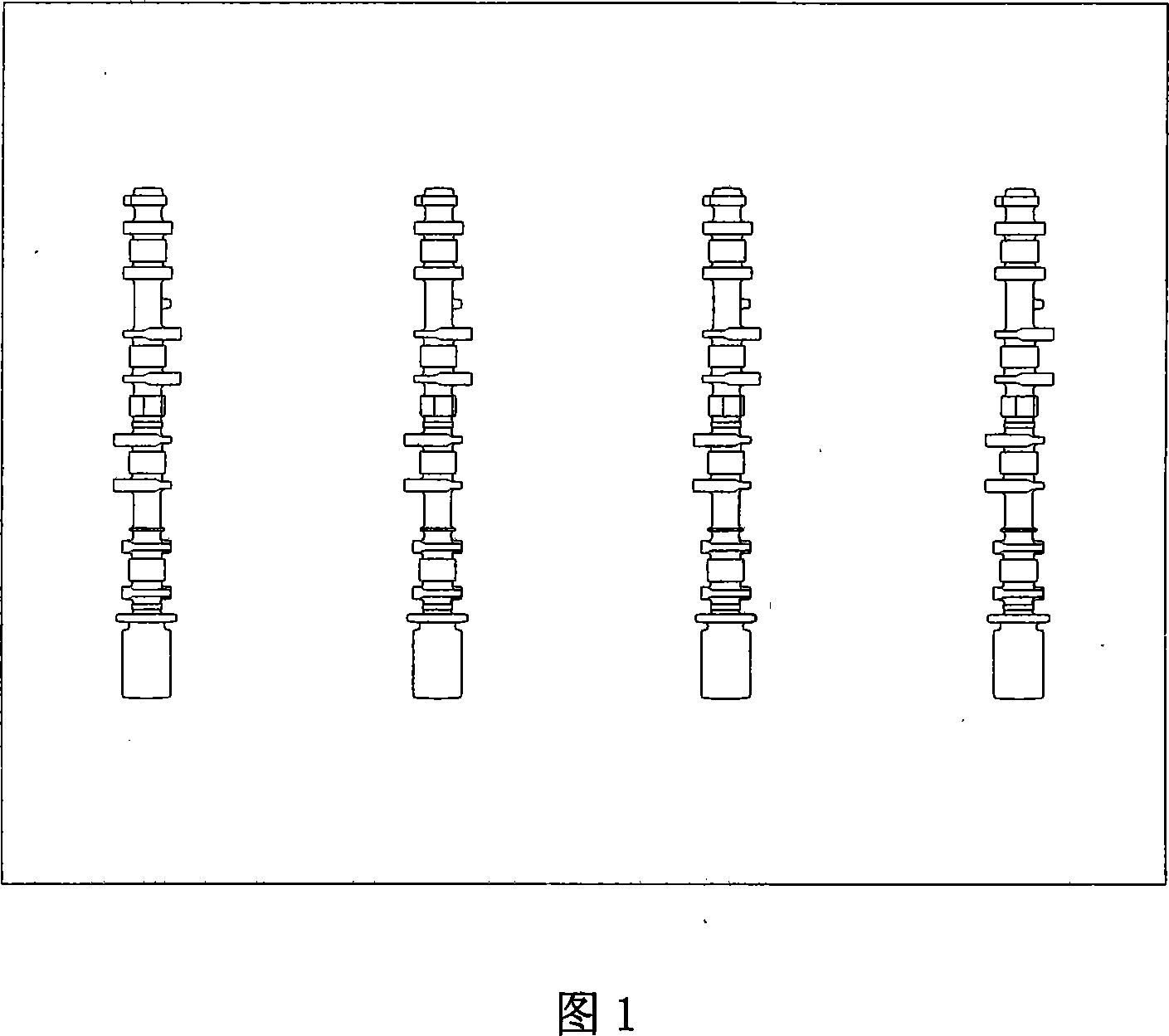

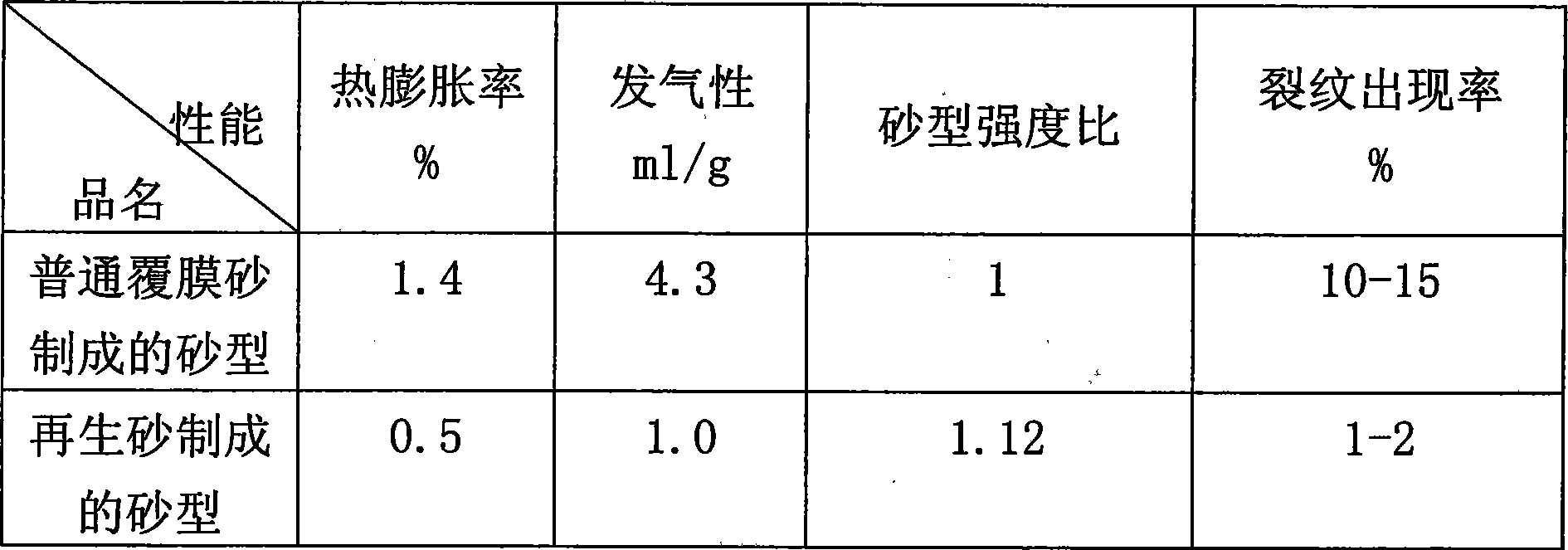

Camshaft sand mold manufactured with tectorial membrane sand with reclaimed sand as roughing sand and manufacturing method thereof

InactiveCN101195148AAvoid deformationAvoid breakingFoundry mouldsFoundry coresTectorial membraneThermal expansion

The invention discloses a camshaft sand mould for manufacturing coated sands, which takes regenerated sands as base sands. The invention is characterized in that the invention is a passing shaft which is composed of an upper sand mould of the coated sands and a lower sand mould of the coated and, and provided with a boss in the middle portion. A manufacturing method comprises firstly, enabling waste sands to regenerate under high temperature, secondly, producing the regenerated sand, thirdly, taking the regenerated sands as the base sands and producing the coated sands, fourthly, heating the mould to 290-310 DEG C, fifthly, inbreathing the coated sands into the camshaft sand mould through compressed air, heating for 110-130 seconds, and curing into the mold, sixthly, obtaining an intact camshaft sand mould after adhering the upper sand mould and the lower sand mould. The superiorities of the invention lie in that blank dimensions of camshaft casts can be more accurate and process redundancy can be minimized due to the low thermal expansion rate of the sands, and cost can be saved. Defects of casts as air holes can be lowered due to low air forming property, and simultaneously effects to environment can be minimized, deformation and cracks of sand moulds can be avoided due to high strength, which is beneficial to arrange and transport, and the quality of cast surfaces can be increased. Flow ability can be improved, and defective indexes of the casts can be lowered. The invention has high strength, smooth surface and good breathing property.

Owner:TIANJIN YABU NEW TECH

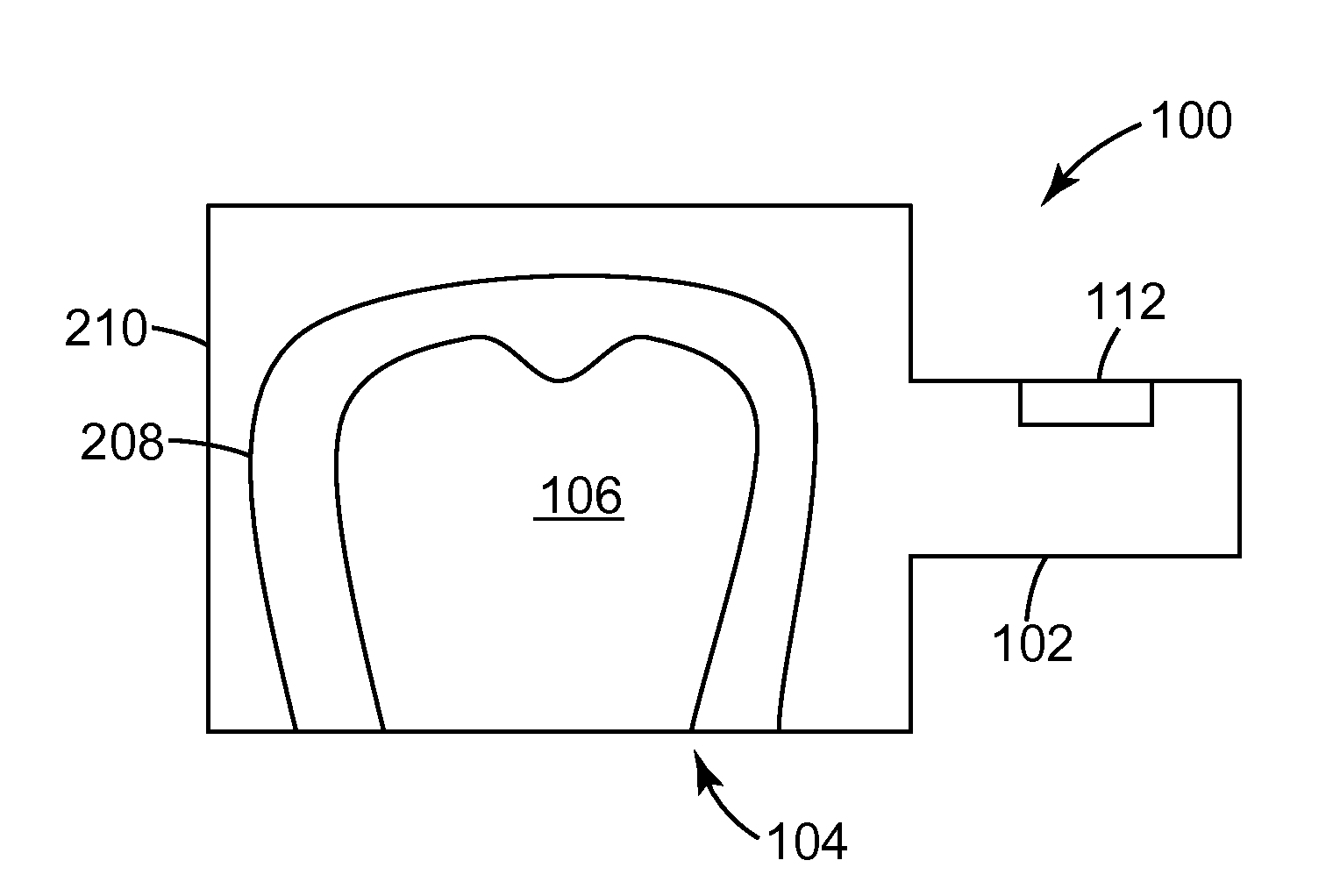

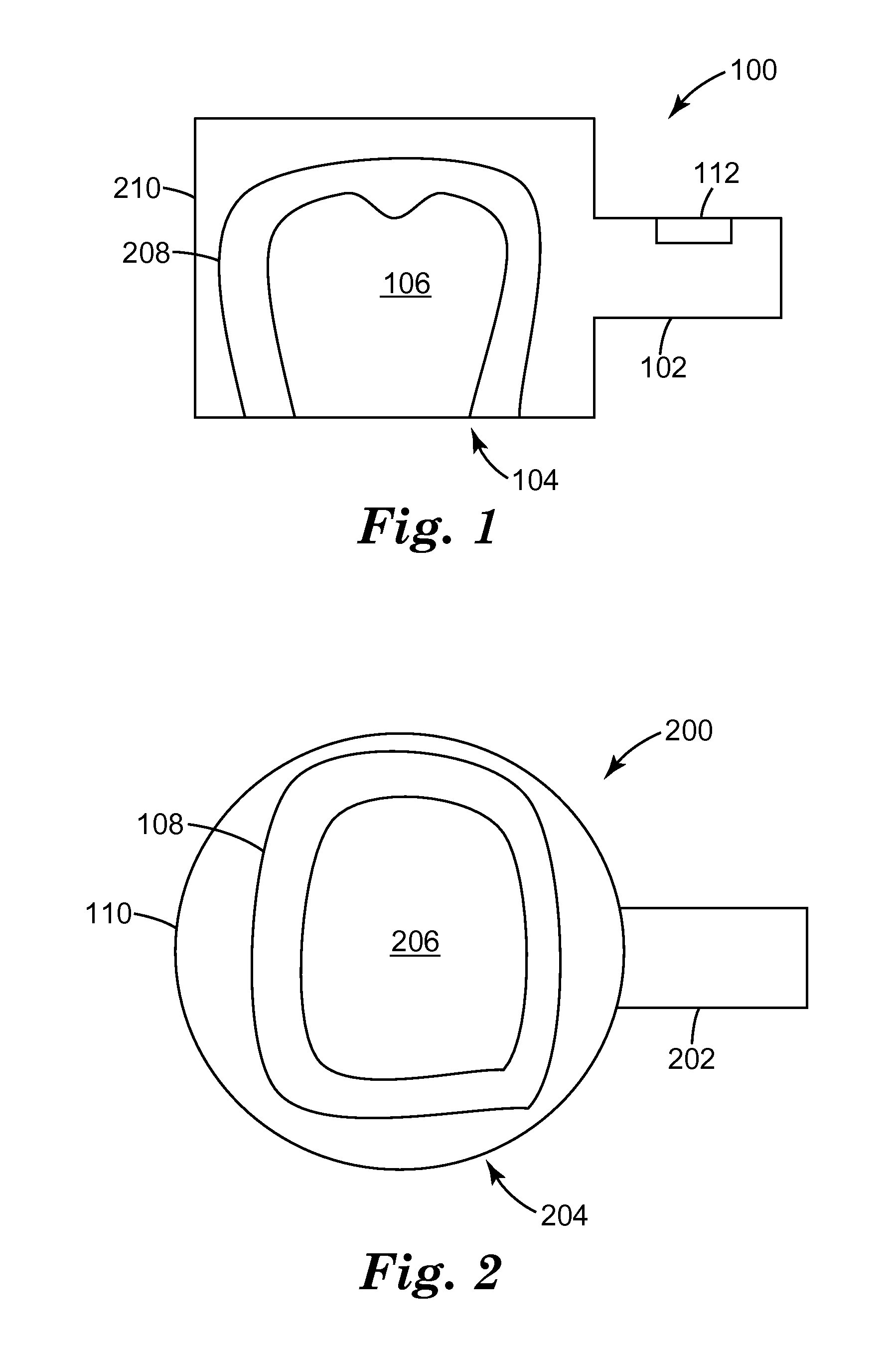

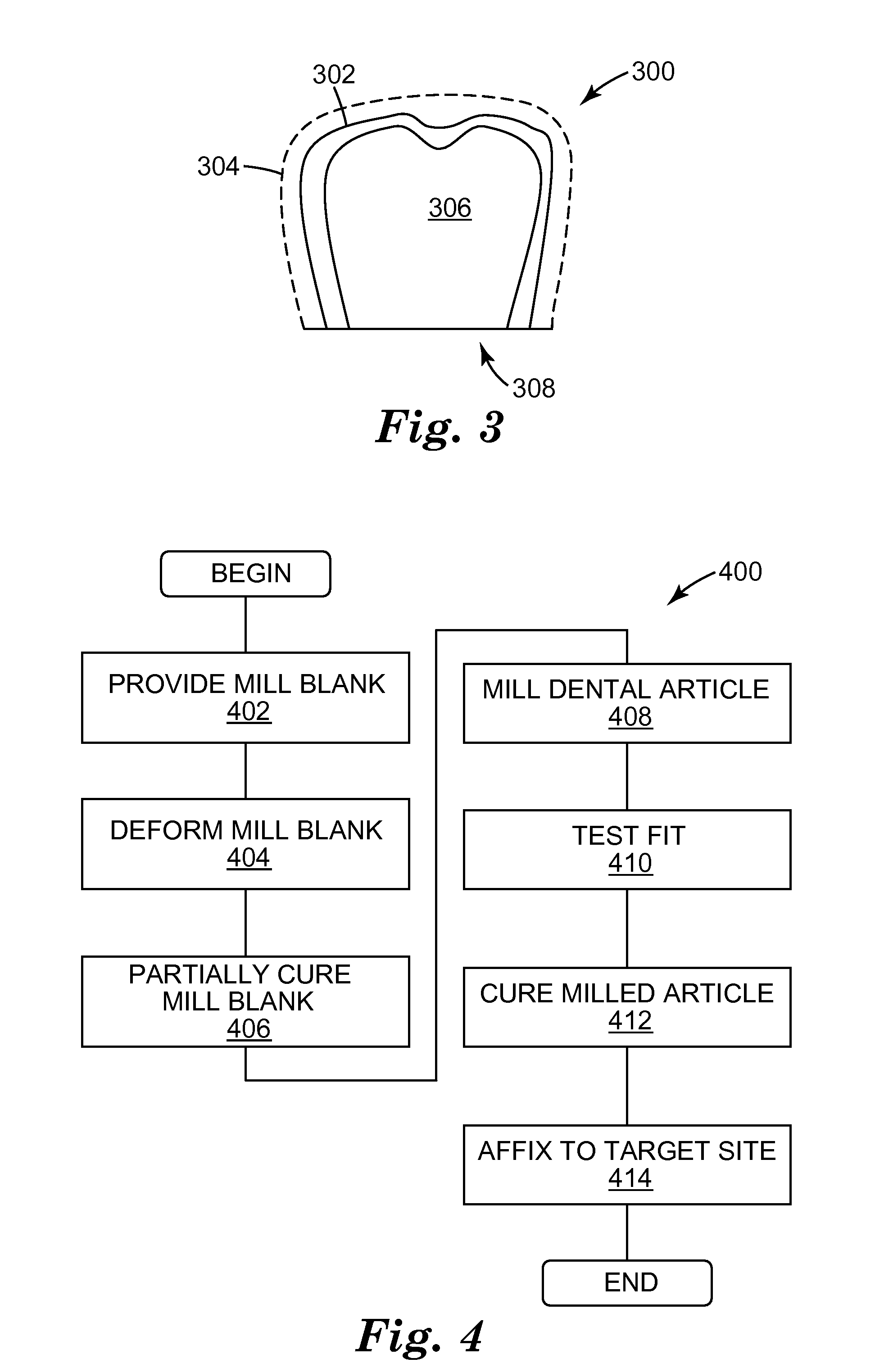

Compound smc dental mill blanks

A dental mill blank is formed from a number of different self-supporting, malleable, curable (SMC) materials distributed within the blank so that a dental article machined from the blank closely resembles natural dentition in appearance or function. When in an uncured state, a single mill blank can be adapted to fit a variety of different tooth sizes and shapes, thus reducing the inventory of mill blank types required for fabrication of the range of possible tooth shapes and sizes.

Owner:3M INNOVATIVE PROPERTIES CO

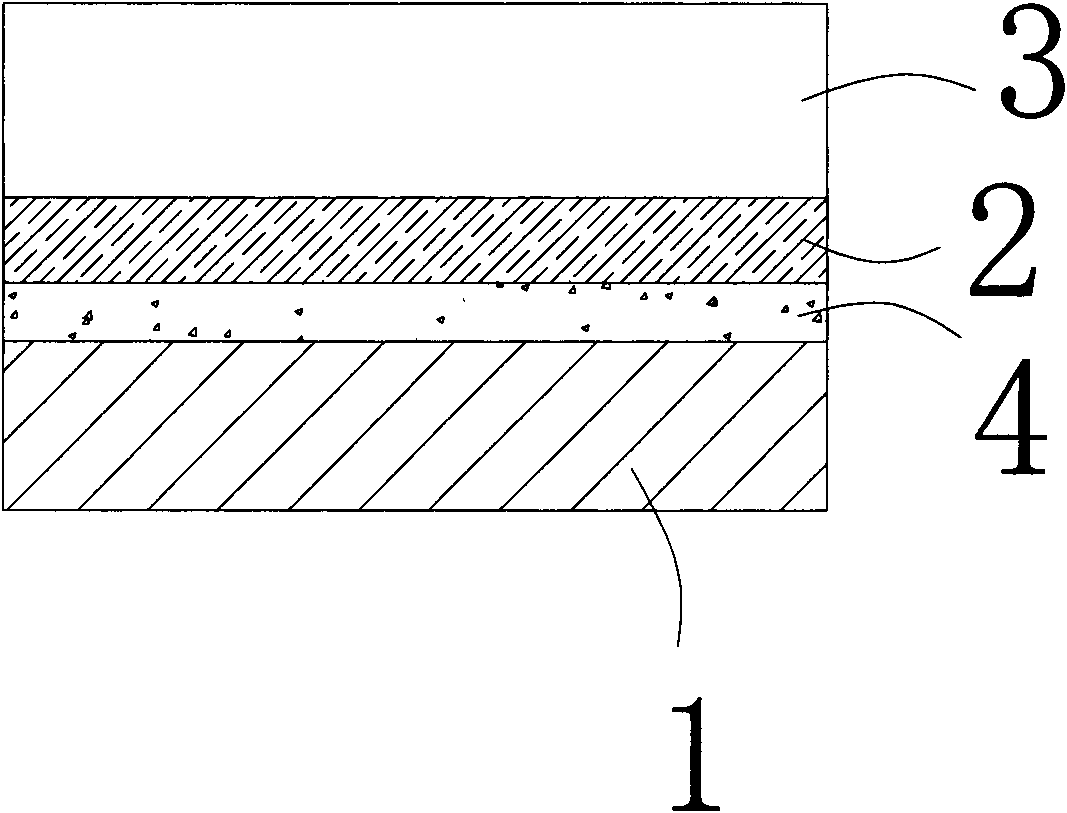

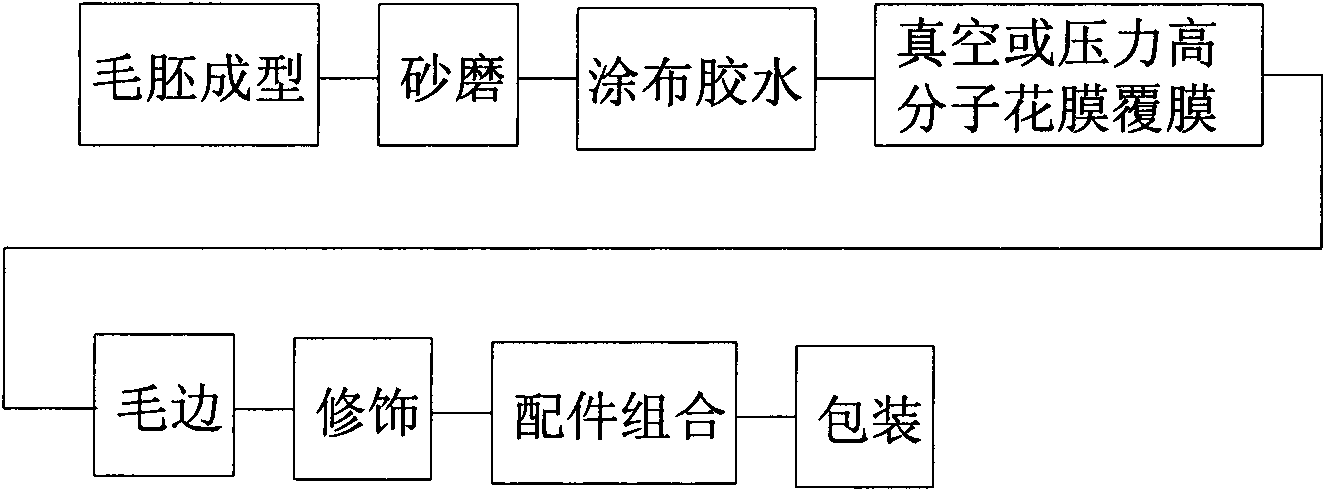

Toilet cover and surface coating technique thereof

InactiveCN101664289ASave storage spaceEasy to rule outDecorative surface effectsSpecial ornamental structuresEngineeringRoughcast

The invention relates to a toilet cover and a surface coating technique of other complete bathroom accessories. The technique comprises the following steps: rough machining, sanding, coating and gluing, vacuum coating or pressure high polymer printing film applying, burr trimming, decorating, accessories assembling and packaging. In respect of the production technique, the original high polymer printing film is taken as a production mold, thus causing the mold to be the external surface of a product, without painting for surface finishing and decorating. In such a way, environmental pollutionand impact on worker health caused by sanding and painting spraying and decorating can be avoided during the manufacturing process of a wooden closestool and other complete bathroom accessories, thuscompletely overcoming the disadvantages of sanding and spraying of traditional technique, simplifying production processes and beautifying the surface decoration of the product. An LED illuminant canalso be embedded to beautify the surface of the product.

Owner:周廷芳

Method for preparing lamellar FeAl-based composite plates

The invention discloses a method for preparing lamellar FeAl-based composite plates, which relates to a method for preparing composite plates and solves the problems of large brittleness and poor strength of the conventional iron-aluminum intermetallic compounds at room temperature. The preparation method comprises the following steps of: mixing aluminum substrate powder and ceramic granules uniformly, performing cold molding, and putting the mixture into a vacuum hot-pressing furnace to obtain ceramic granule-enhanced aluminum-based composite blanks; and rolling the ceramic granule-enhanced aluminum-based composite blanks to form thin plates, stacking alternately with pure iron plates, and performing hot pressing, hot rolling and heat treatment to obtain the lamellar FeAl-based composite plates. Interfaces of composites prepared by the method are flat and straight and high in combination; the broken bending strength of the composite plates at room temperature can reach 1,132 MPa and is about 1.4 times that of a substrate; and compared with that of the substrate, the yield strength of the composite plates at the temperature of 750 DEG C is improved substantially, namely is improved by about 26 percent.

Owner:HARBIN INST OF TECH

Manufacturing method of lost foam casting foaming mold

InactiveCN101554645ASimple designEasy to modifyFoundry mouldsFoundry coresComposite ceramicMetallurgy

The invention provides a manufacturing method of a lost-foam casting foaming mold. The invention is characterized in that the manufacturing method comprises the following steps: firstly, the three-dimensional CAD model of a casting part is manufactured, and a colophony prototype used for casting a blank of the foaming mold is manufactured through a rapid molding machine; secondly, a colophony prototype used for casting an electric spark working electrode is manufactured; thirdly, the inner cavity structure of the blank of the foaming mold is copied by using a colophony prototype with the same size with the casing part and silica gel; fourthly, the blank of the foaming mold is cast by using the composite ceramic shell casting technology; fifthly, the electric spark working electrode is cast by using the colophony prototype for enlarging the size of the casting part by 0.5-1.5 mm and the composite ceramic shell casting technology; and sixthly, the blank of the foaming mold is processed by using the electric spark and assembled to obtain the foaming mold. The invention is suitable for manufacturing the foaming mold with a complex-shaped inner cavity, can rapidly obtain the blank and the electrode of the foaming mold, enables the chrematistics of the arbitrary prototype with a complex shape through the rapid molding technology to be displayed more obvious as for the more complex shape and realizes the rapid manufacture of the lost-foam casting foaming mold.

Owner:SHANDONG UNIV OF TECH

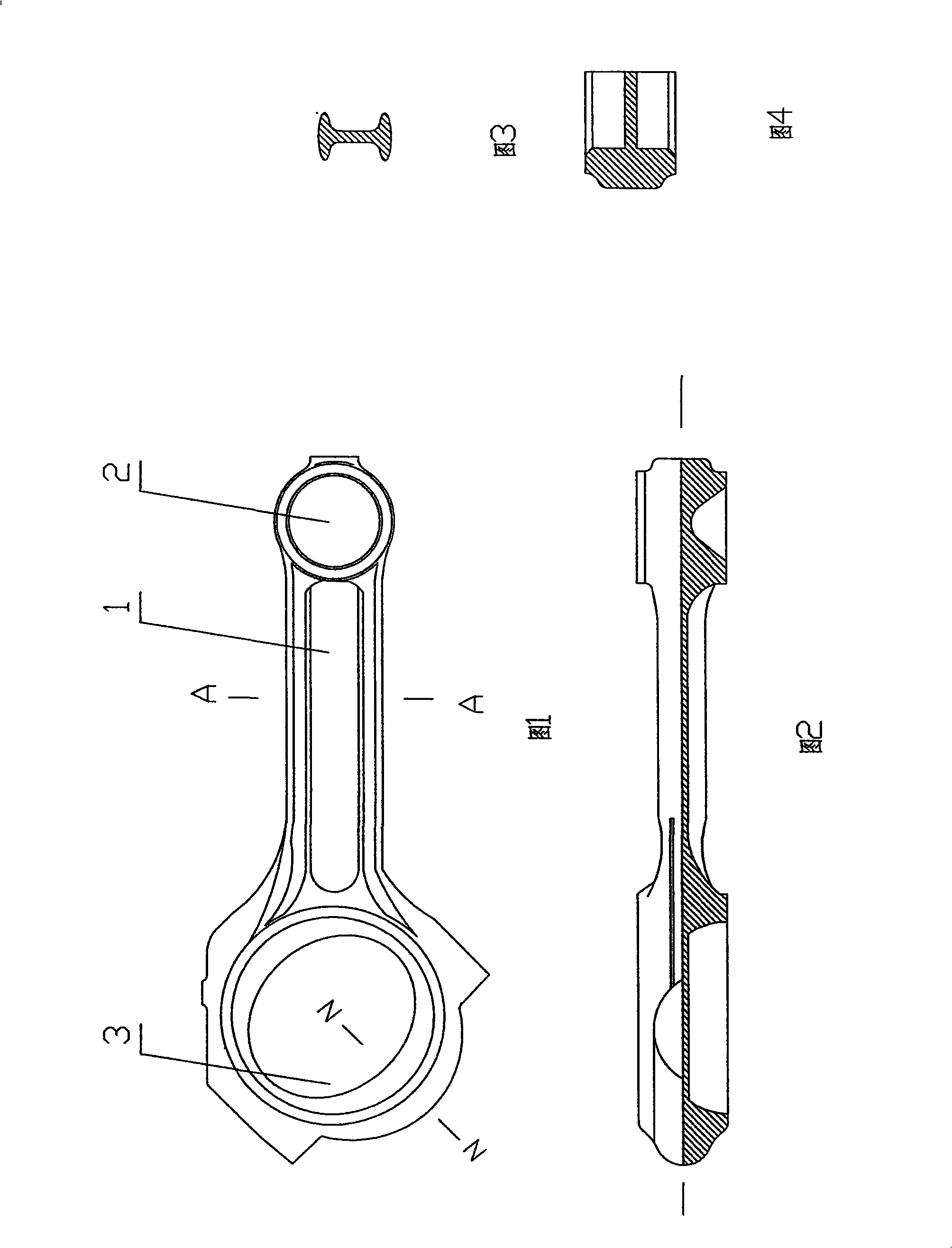

IC link rod manufacture process

InactiveCN101260903AAchieve fixed positionRealize installation positioningConnecting rodsEllipseEngineering

The invention relates to a process for manufacturing an internal-combustion engine connecting rod. The steps of the process are: forging, by a forging die, an integral blank of a connecting rod having a big end ad a small end, with the small end of the blank provided with opposite circular pits, the big end of the blank provided with opposite pits or a through hole, the edges of the pits or the hole on the big end being elliptical, the difference between a major axis and a minor axis being from 5 to 8mm, and the major axis superposing on the axis of the connecting rod or forming an included angle of 45 degrees with the axis of the connecting rod; subjecting the integral blank to blasting shot, flaw detection and phosphorization, then roughly milling two planes of the integral blank of the connecting rod, and machining an mounting hole for a piston pin on the small end; incising along the minor axis of the ellipse of the big end of the integral blank to form a blank of a connecting rod body and a blank of a connecting rod cover board, milling the incising junction surfaces; merging the junction surfaces, synchronously drilling the mounting jump-holes on the connecting rod body and the connecting rod cover board, and machining a crank mounting hole corresponding to the piston pin mounting hole on the big end; threading through the mount jump-holes on the connecting rod body, and machining a gap block position-limiting grooves in the connecting rod body and the connecting rod cover board; and removing burrs, and setting a positioning fixed bolt.

Owner:常州久弘金属材料有限公司

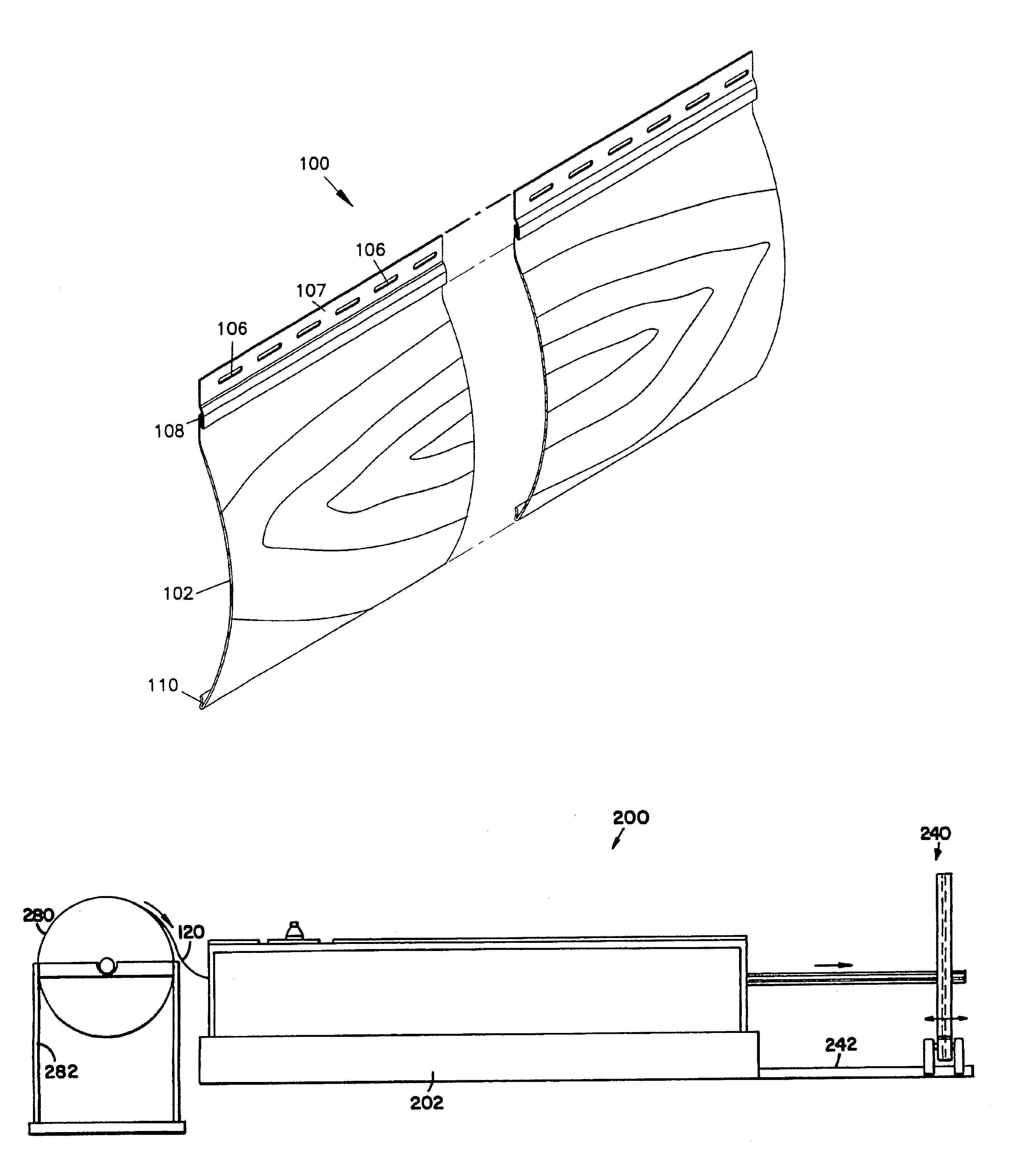

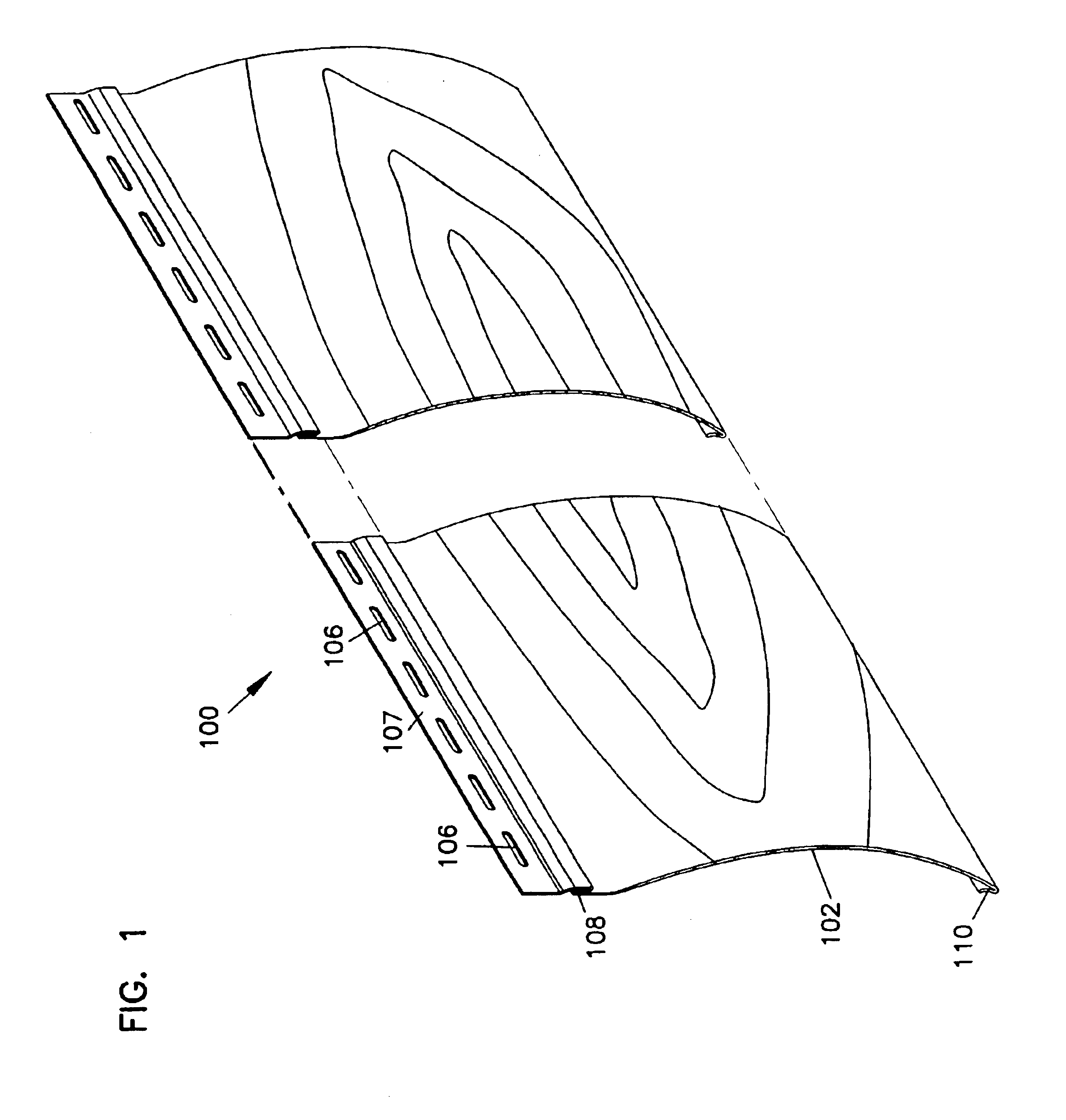

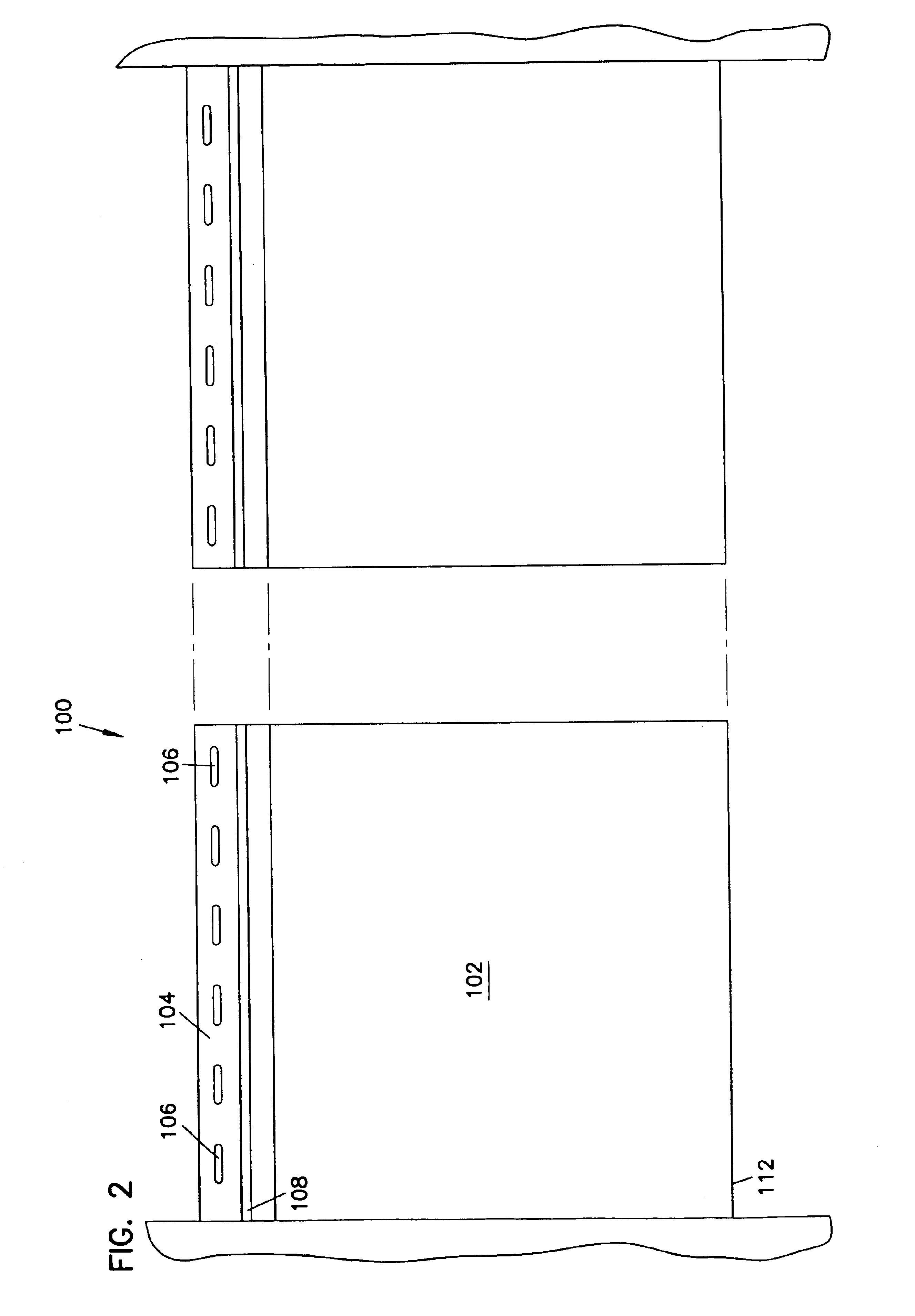

Apparatus for making seamless siding panel

InactiveUS6904780B2Improve textureImprove aestheticsRoof covering using tiles/slatesCovering/liningsEngineeringSurface plate

A siding system includes panels having a facing element with a convex front face portion. A first connecting portion extending along an upper edge and a second connecting portion at a lower edge is adapted to engage the first connecting portion of an adjacent lower siding panel. Mounting holes at a top edge of the facing element provide for mounting the siding panel to a vertical surface. A support element, such as foam insulation attaches to a rear surface of the facing element. A machine for making the metal siding panels has a feeder and multiple roller sets. First ones of the rollers have a concave portion and complementary second ones of the rollers have a convex portion. The concave portion first roller set has a larger radius profile than the last roller set to roll form the siding from a coil of blank material. Bending rollers form the mounting structure of the panels. Embossing rollers forming an embossed pattern on the face of the panels.

Owner:US SEAMLESS

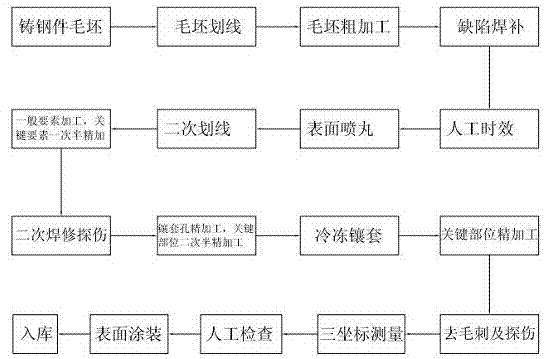

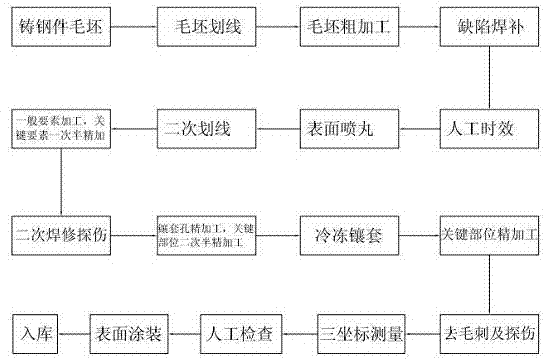

Process for controlling deformation of axle-hung box of locomotive

The invention relates to the technical field of processing of an axle-hung box of a locomotive, in particular to a process for controlling the deformation of the axle-hung box of the locomotive. The process comprises the following steps of: (1) performing rough machining on a cast steel blank; (2) performing fine machining on the cast steel blank; and (3) checking and storing into a storehouse: a, removing burrs and detecting flaws, b, measuring by using a three-dimensional coordinate, c, manually checking, and d, coating the surface and storing into the storehouse. By the process, burrs, a welding stress and a rough machining stress on thin-wall parts of the cast steel which are easy to deform are eliminated as much as possible; meanwhile, the machining sequence is arranged rationally; afixture is designed and used and a positioning and clamping point is set rationally, so the deformation of the fixture is reduced; and interference and influence of various factors on key elements can be eliminated by the final fine machining. The process guarantees the machining precision and the quality of a product.

Owner:CRRC QISHUYAN CO LTD

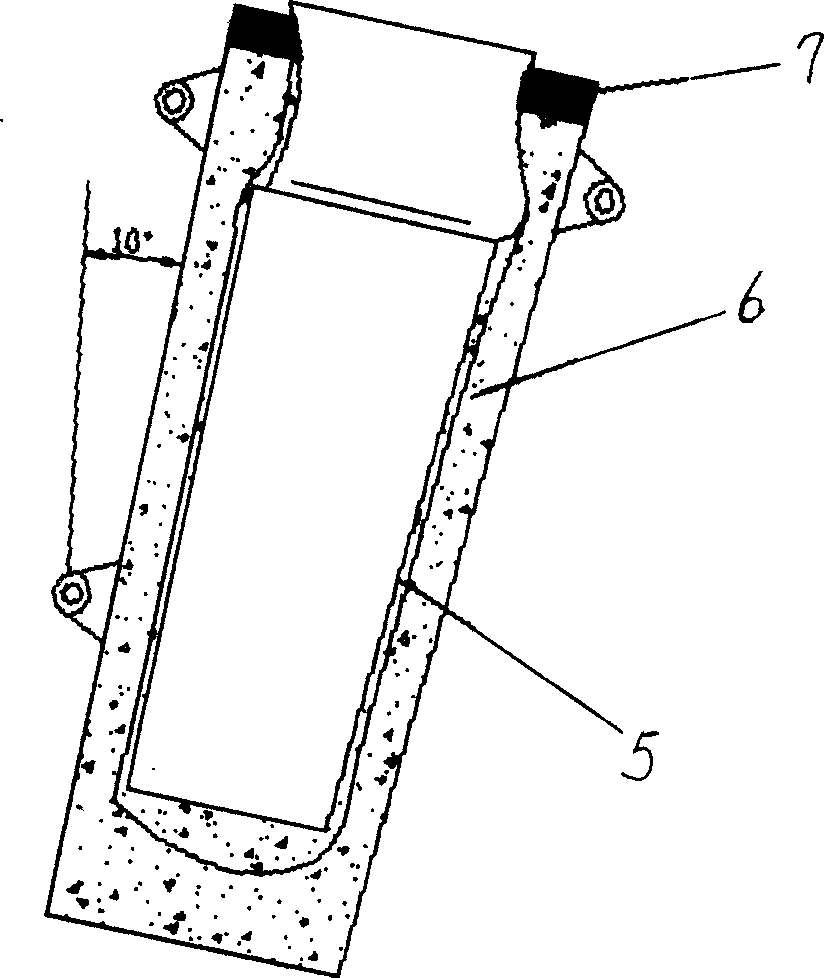

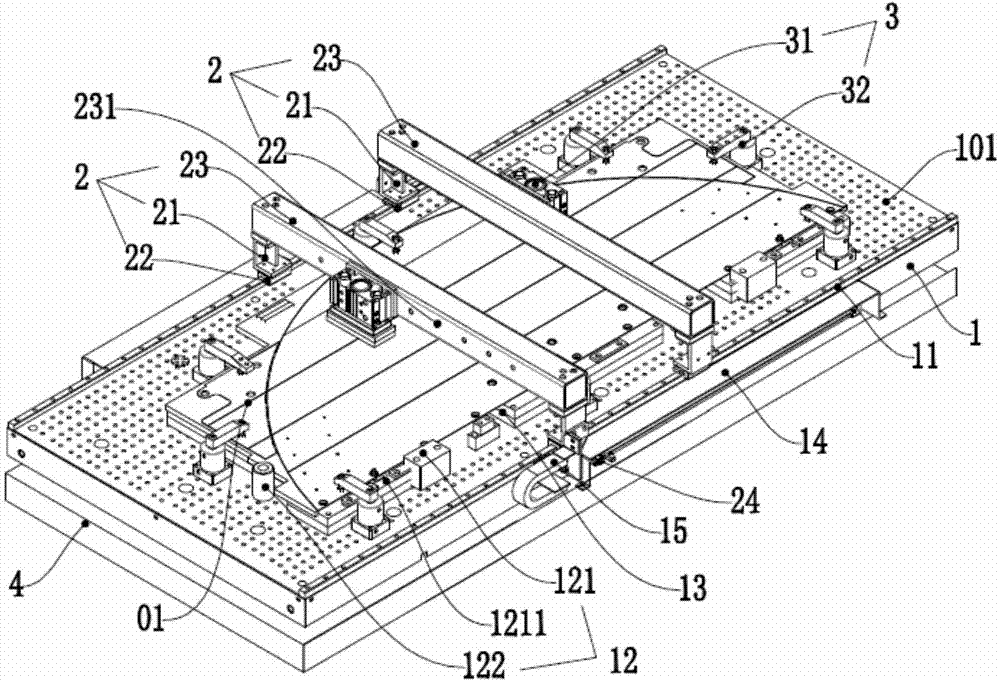

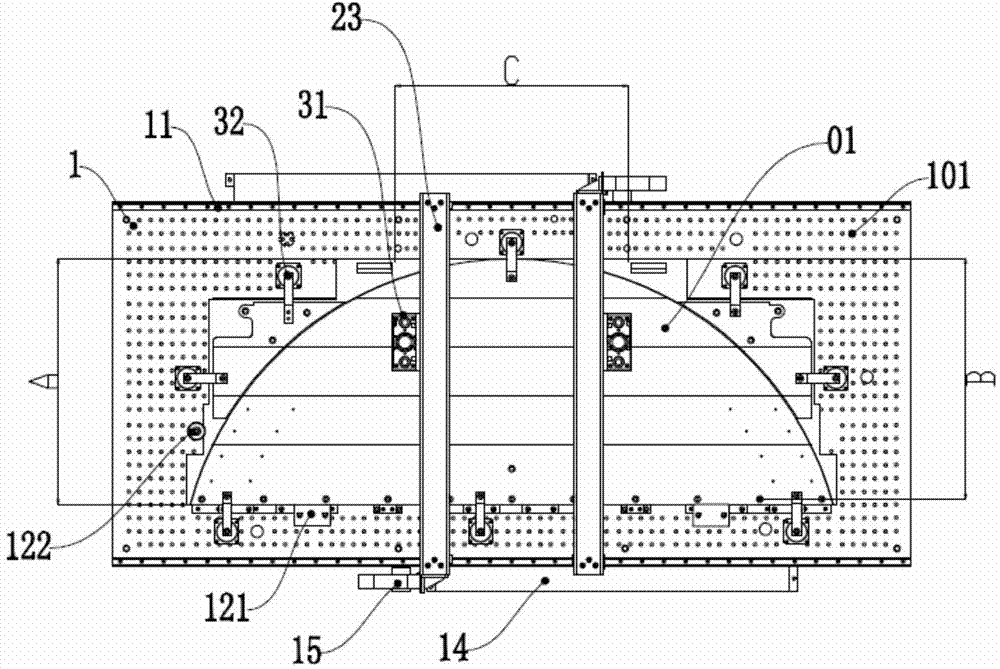

Base-adjustable fixture for elongated workpiece with outer contour needing to be milled

ActiveCN104842190AAvoid offsetGuaranteed stabilityWork clamping meansLarge fixed membersControl systemRoughcast

A base-adjustable fixture for an elongated workpiece with the outer contour needing to be milled comprises a base, movable portal devices, a positioning device and a control system. A transverse guide rail is mounted at each of the upper and lower edges of the base, and limiting devices for limiting a workblank are arranged on the upper surface of the base at intervals according to the shape of the outer contour of the workblank needing to be machined. Movement of a portal frame structure of each movable portal device along the transverse guide rails is controlled by a portal frame cylinder. The positioning device comprises a press-down positioning device and a plurality of rotatable angle positioning devices, wherein the press-down positioning device is used for pressing down the middle of the workblank, and the rotatable angle positioning devices are used for pressing down the outer contour of the workblank. The control system controls the movable portal devices to move according to machining movement trails of a cutter and controls single or multiple positioning device bodies in the positioning device to loosen to make way for a cutter path. The base-adjustable fixture for the elongated workpiece with the outer contour needing to be milled has the advantages that deformation of the elongated workpiece during machining is avoided, machining efficiency is improved, the positioning device can be controlled to make way for the machining path of the cutter, operation safety is improved and machining precision is high.

Owner:江苏普拉迪数控科技有限公司

Coating for sintering hard alloy product

The invention discloses a coating for sintering a hard alloy product, which comprises 14.7%-15.4% of high wear resistant C (carbon) powder, 8.4%-8.8% of coarse C powder, 6%-7.5% of Tween80, 2%-3% of normal butanol, 2.5%-5% of PEG (polyethylene glycol) 6000, 22%-25% of metal oxide powder and 37.5%-40% of deionized water, wherein the metal oxide powder includes titanium oxide powder, zirconium oxide powder or aluminum oxide powder, and the ratio of the high wear resistant C powder to the coarse C powder ranges from1.6:1 to 1.8:1. The coating is applicable to sintering of all low-weight hard alloy blanks with the weight less than 250g and cobalt content lower than or equal to 25%, the surface of a boat has no gathered particles after the coating is painted, the coating is not adhered to the boat in sintering, and the sintered product is free of carburization and decarburization and has no dent. Besides, the labor intensity of workers spraying the boat is reduced, dependence of final product quality on manual boat spraying quality is technically and greatly reduced, and the coating is economical.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

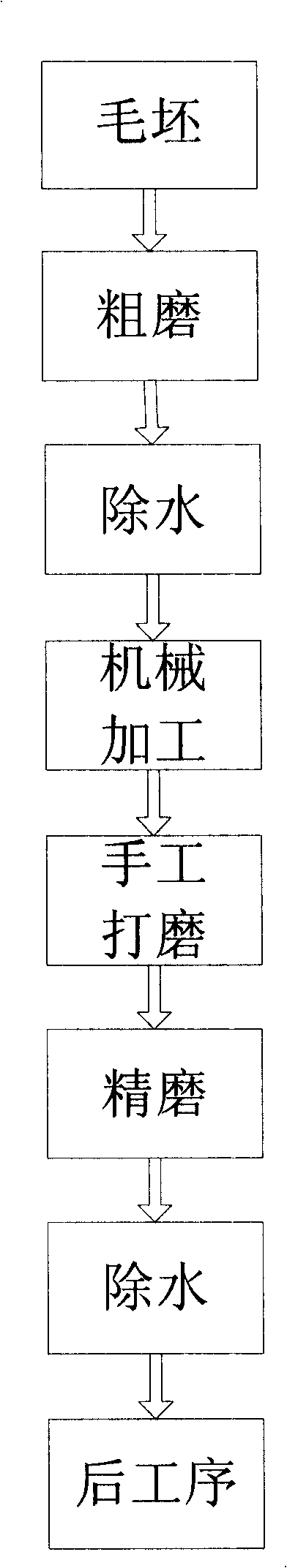

Surface finish method for magnesium alloy parts

InactiveCN101244524ANo problems with poor surface qualityStable and good surface qualityPolishing machinesLapping machinesSurface finishRoughcast

The invention provides a surface machining method of magnesium alloy component, which is characterized in that: the method comprises coarse grinding to the roughcast of the magnesium alloy component firstly and then fine grinding to the roughcast, wherein the coarse grinding and the fine grinding comprises that the roughcast of the magnesium alloy component, the grinding medium and the grinding liquid with water are put into the grinding vessel of the muller to grind under the condition of the coarse grinding and the fine grinding respectively; after the coarse grinding and the fine grinding, the water on the surface of the roughcast, which is left by the coarse grinding and the fine grinding, is eliminated in 20 minutes. The surface machining method of magnesium alloy component has advantages that: the work efficiency is increased obviously and the problem that the quality of the magnesium alloy component surface comes to bad caused by the contact reaction of magnesium and water is avoided.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com