Autoclaved aeolian sand aerated concrete building block and wallboard

A technology of aerated concrete and concrete block, which is applied in the field of wallboard, aerated concrete block and autoclaved aerated sand aerated concrete block, can solve the problems of poor gradation, poor shear resistance, difficult forming, etc. , to achieve the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

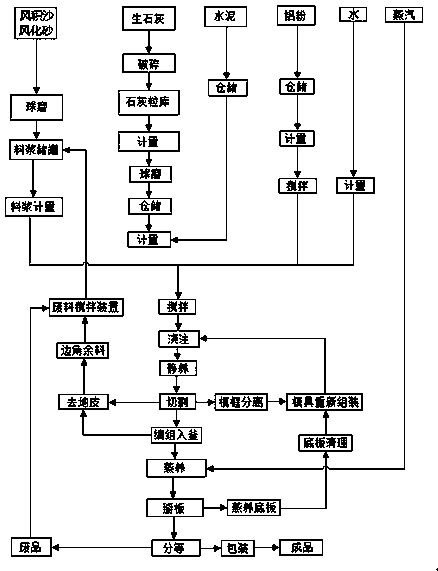

Method used

Image

Examples

preparation example Construction

[0027] Aluminum powder is used in the preparation process of the concrete blocks and wallboards of the present invention: the main purpose of the aluminum powder is that the aluminum powder reacts with silicon dioxide and quicklime to release gas during the production process, so that the produced concrete blocks are formed porous structure. Put the aluminum powder into the aluminum powder slurry mixing tank and stir well, then put it into the pouring mixer together with quicklime, gypsum, mortar and other raw materials. The concrete slurry expands to form a porous structure. So that the general weight of the produced air-entrained concrete blocks is 400-700kg / m 3 , which is only equivalent to 1 / 4 to 1 / 5 of the weight of clay bricks, and 1 / 5 of the weight of ordinary concrete, which is a lighter type of concrete.

[0028] In addition, the use of aluminum powder can also make the aerated concrete block have the following effects.

[0029] 1. Sound insulation effect, because ...

Embodiment 1

[0037] Ball mill aeolian sand to obtain a slurry with a concentration of 50% by mass. The particle size of solid particles in the slurry is 80-120 mesh; crush quicklime and ball-mill it into quicklime powder with a particle size of 150-180 mesh; stir aluminum powder; Percentage, respectively take 10% of cement, 75% of slurry and 15% of quicklime powder, mix them to form a base material, and then press 1m 3 Add 0.5kg of aluminum powder to the base material, add the stirred aluminum powder into the base material; take gypsum according to 5% of the base material weight, add the taken gypsum into the base material, stir evenly, and obtain the finished slurry; According to the existing method for producing autoclaved aerated concrete blocks, pouring, static curing, and cutting are carried out to form a green body. After removing the waste on the green body, the green body is marshaled into the still; Steam curing, board breaking, classification, etc., qualified products are package...

Embodiment 2

[0040] Ball mill the aeolian sand to obtain a slurry with a concentration of 60% by mass. The particle size of the solid particles in the slurry is 80-120 mesh; crush quicklime and ball-mill it into quicklime powder with a particle size of 150-180 mesh; stir aluminum powder; Percentage, respectively take 18% of cement, 70% of slurry and 12% of quicklime powder, mix them to form a base material, and then press 1m 3 Add 0.5kg of aluminum powder to the base material, add the stirred aluminum powder into the base material; take gypsum according to 4% of the weight of the base material, add the taken gypsum into the base material, stir evenly, and obtain the finished slurry; According to the existing method for producing autoclaved aerated concrete blocks, pouring, static curing, and cutting are carried out to form a green body. After removing the waste on the green body, the green body is marshaled into the still; Steam curing, board breaking, classification, etc., qualified produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com