Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155 results about "Extremely Poor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A subjective response indicating that something is extremely poor.

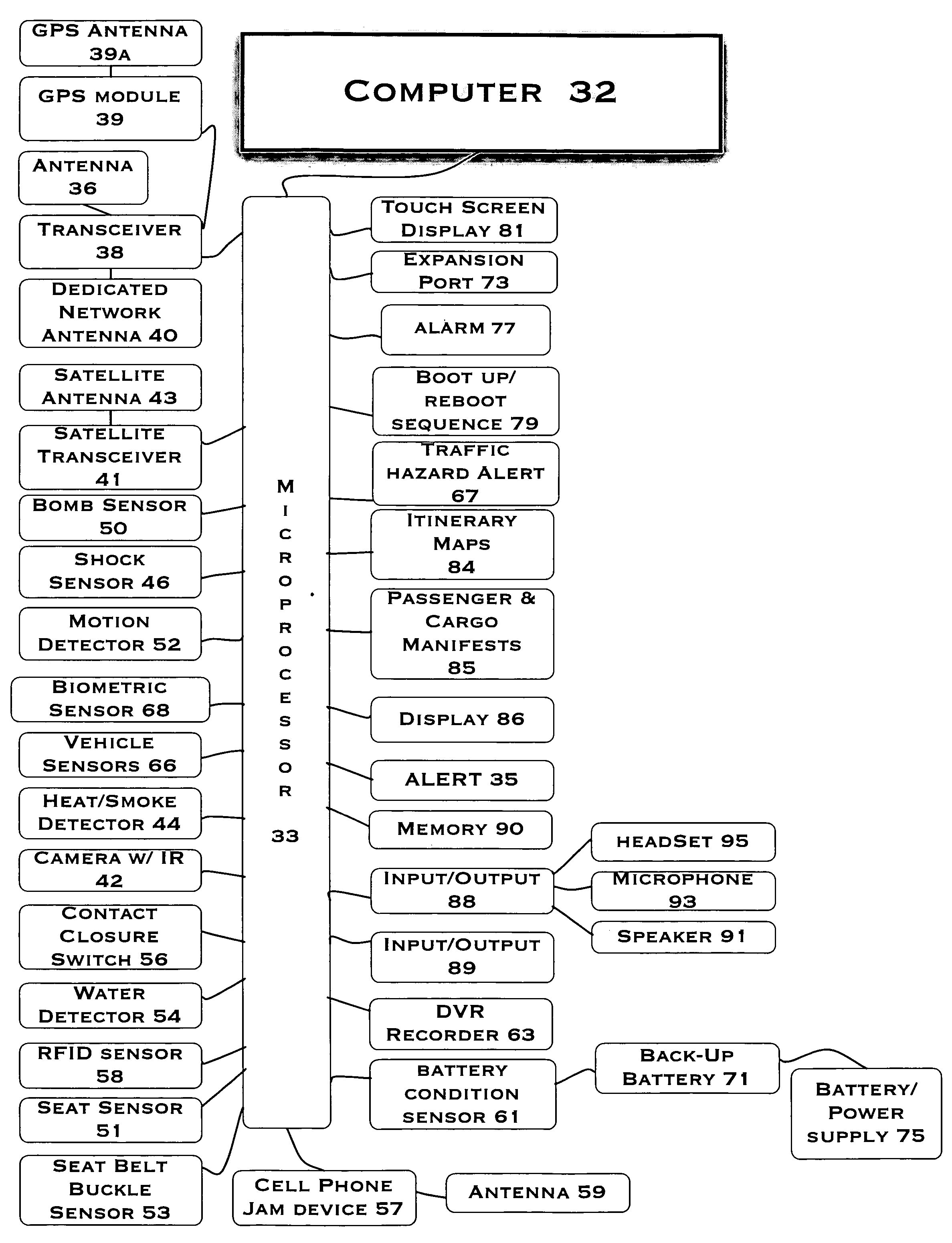

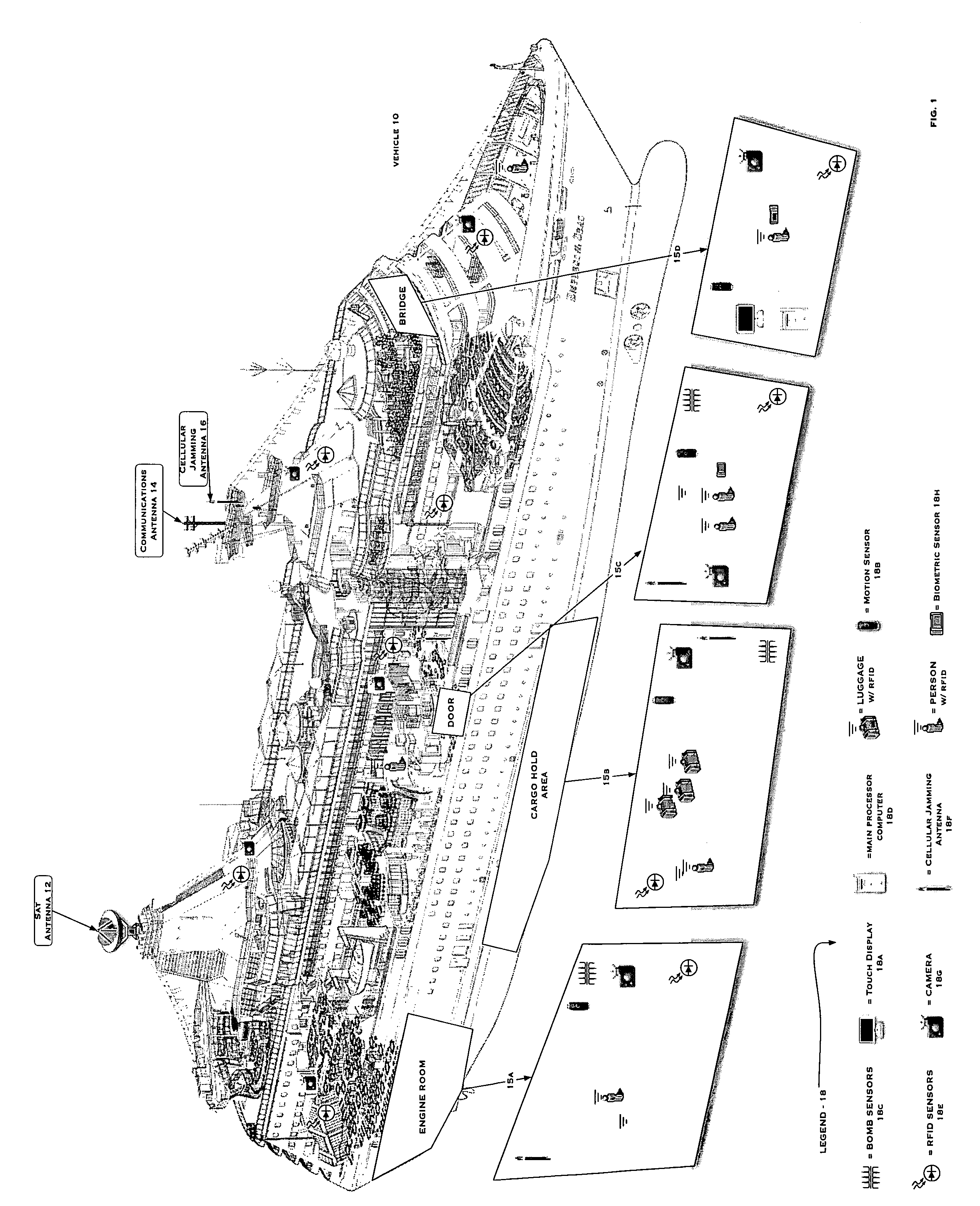

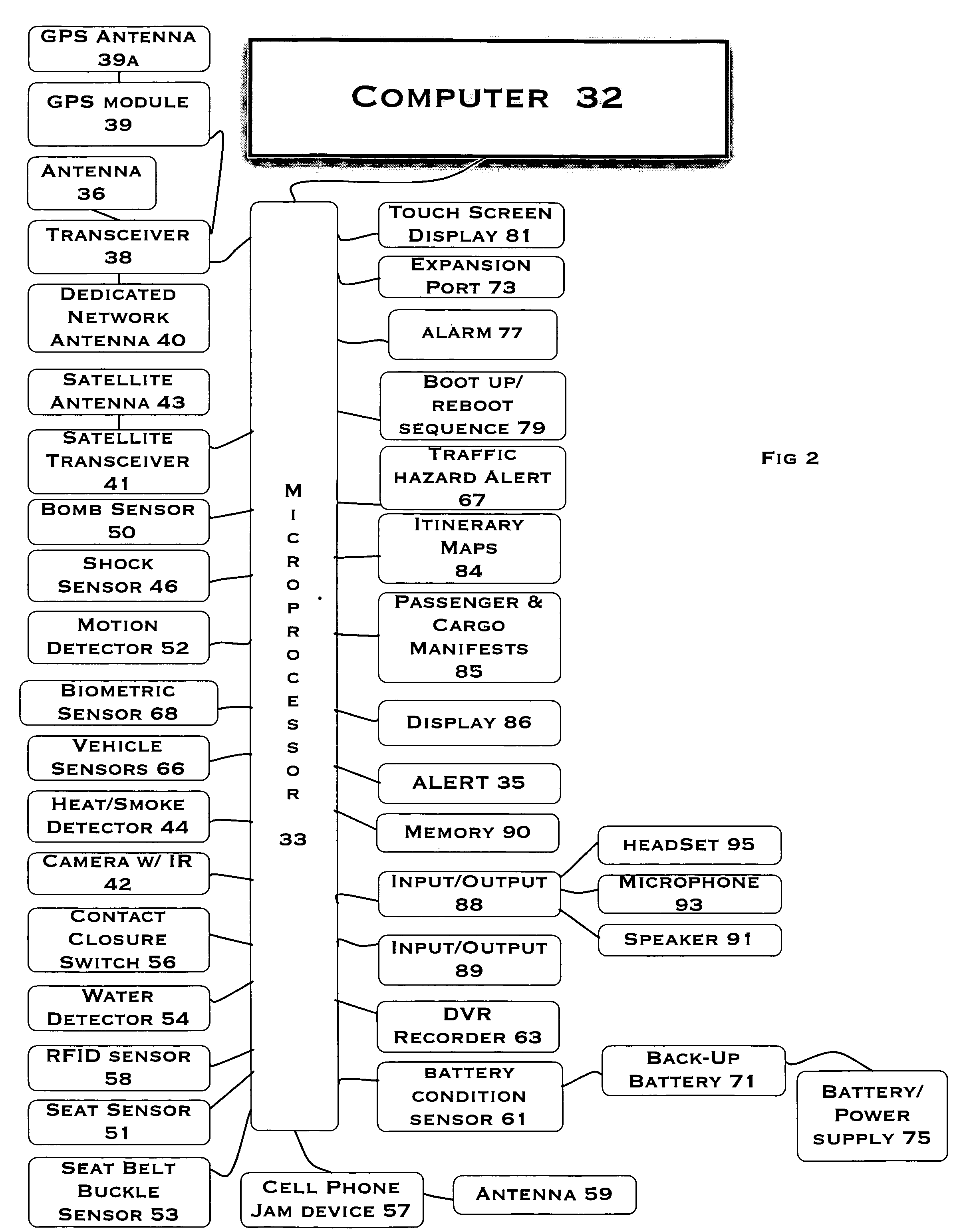

Security system for mass transit and mass transportation

InactiveUS20070040672A1Avoid disasterEasy to implementAnalogue computers for vehiclesAnalogue computers for trafficTelecommunications linkVoice communication

A security system and method for mass transit and mass transportation whereby high capacity mobile vehicles such as ships, buses, planes, trains and subways transporting large numbers of passengers or cargo, are continuously monitored and secured. Sensors are utilized to detect and alert the presence of radioactive or explosive materials on board as well as within close proximity of the vehicle. Sensors are also used to identify and track cargo and people, such as drivers, operators, employees, crew, and passengers, and provide continuous location and tracking thereof from the point of initial entry to the final point of exit. Additionally, a global positioning system (GPS) provides location data, and wireless data and telecommunications link provides two-way data and voice communication with any designated remote location by using one of several modes of wireless telecommunication. Cameras provide visual observation within designated viewable areas, and may be activated by any detection of motion, and are infrared or night vision capable allowing viewing even in extremely poor light conditions. DVR recording allow a huge amount of video content from the cameras to be digitally recorded, then played back later for further analysis. Finally, the Security System may optionally have an Internet Protocol (IP) address thereby allowing authorized persons to access the system from secured Internet connection.

Owner:CHINIGO ANDREW

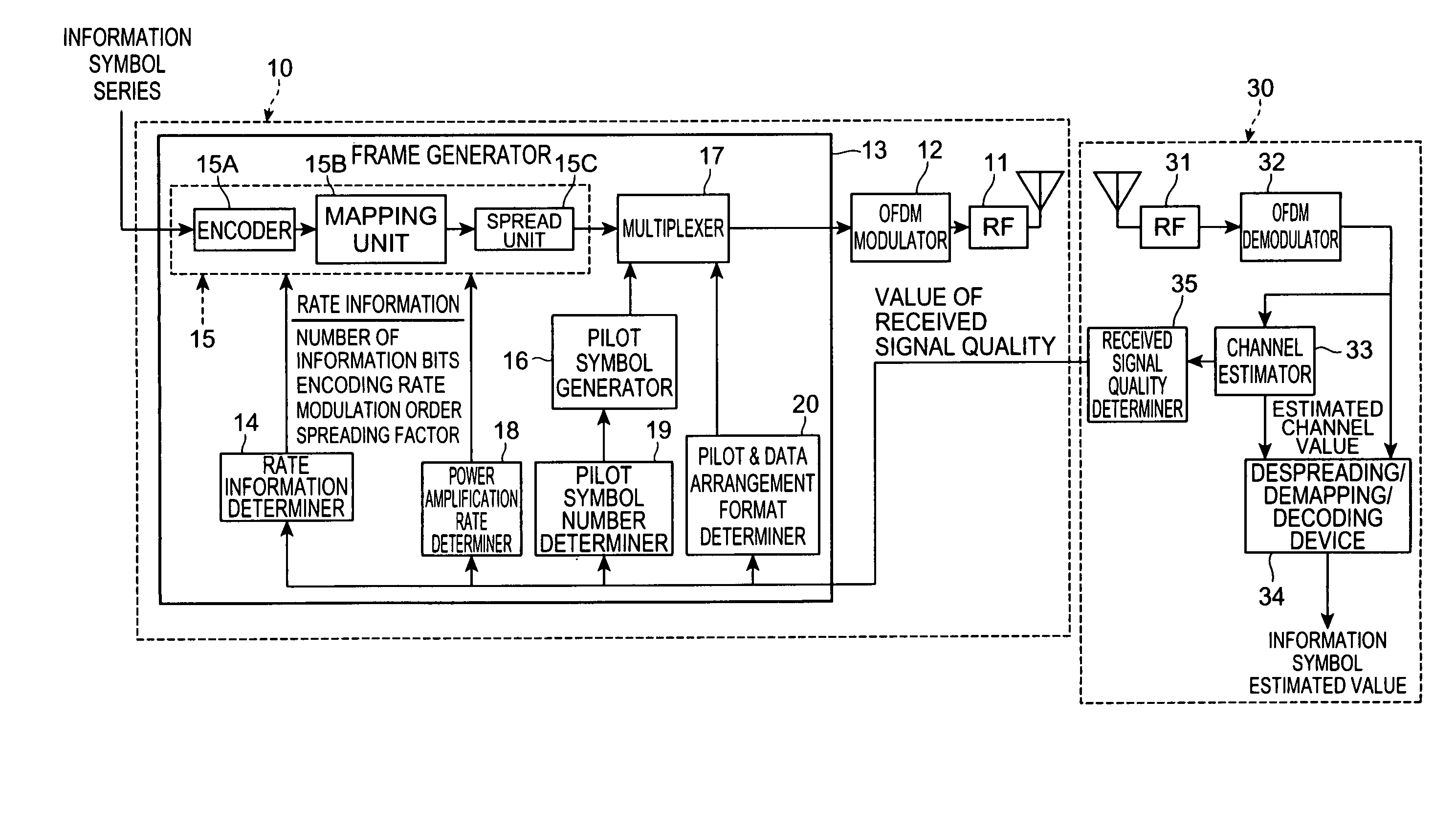

OFDM signal frame generator, transmitter, signal transmission system and OFDM signal frame generating method

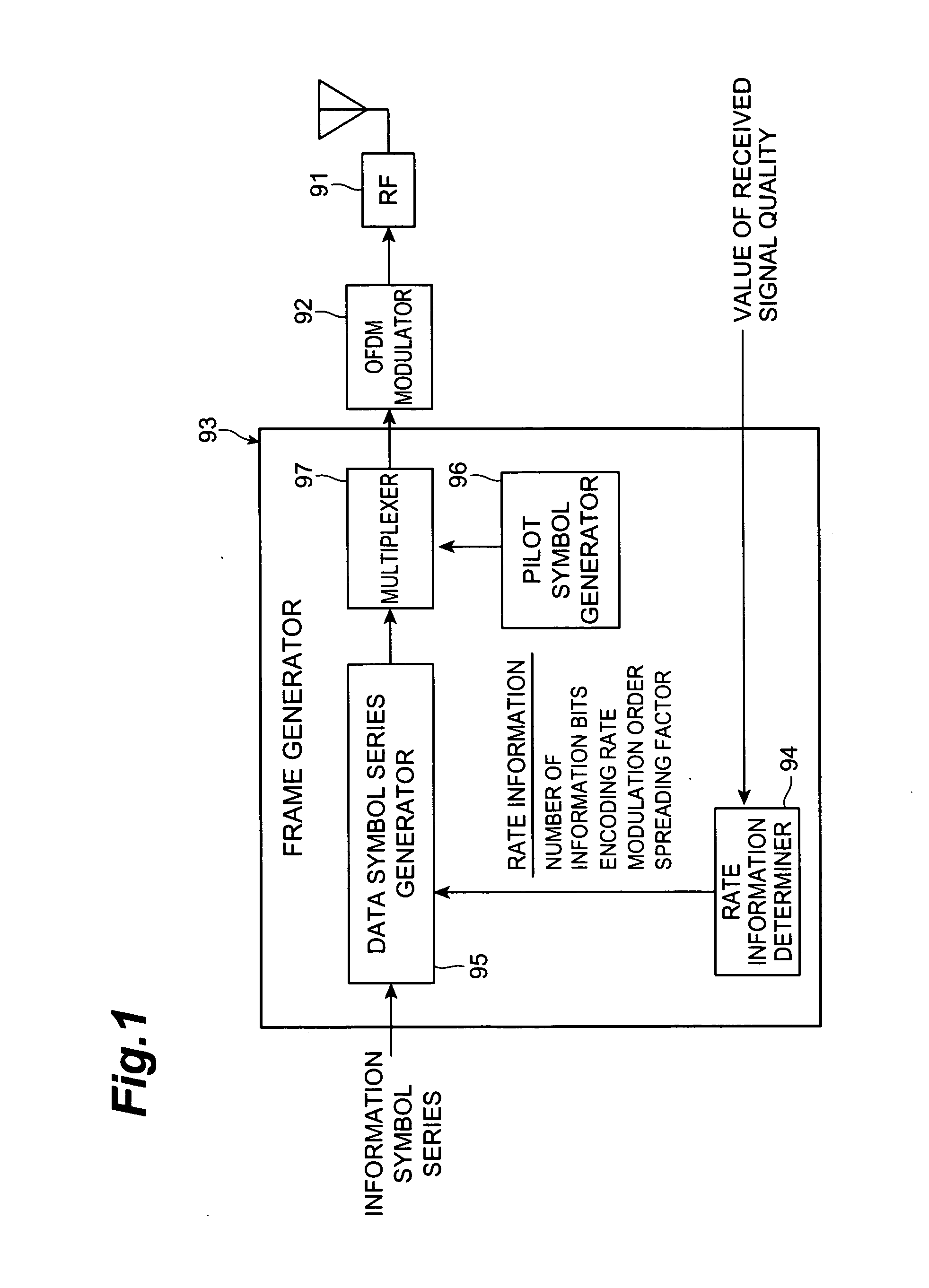

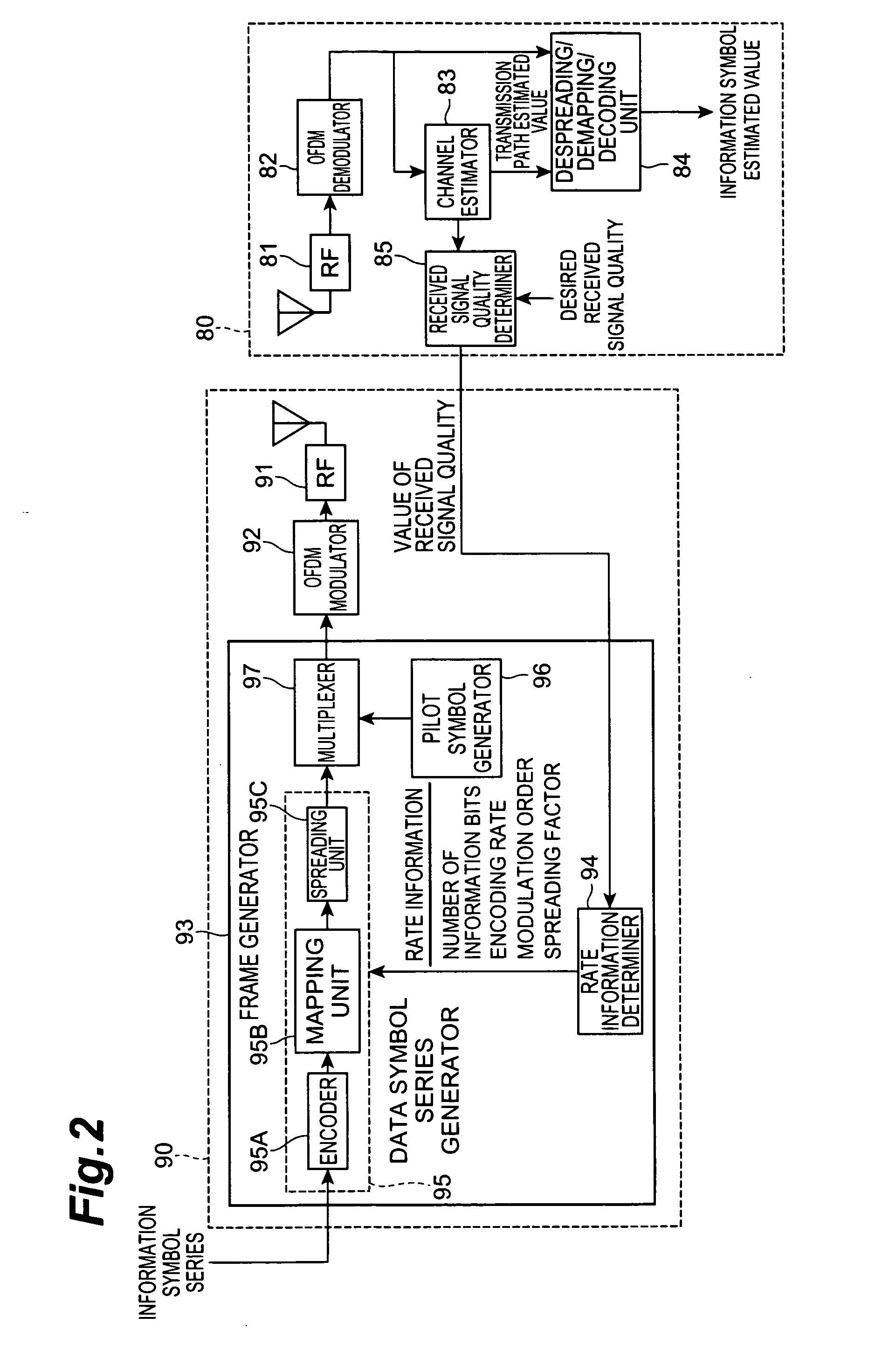

InactiveUS20050094552A1Prevent stateTransmission rate is satisfactorilyTransmission control/equlisationFrequency-division multiplex detailsSignal qualityTransfer system

An object of the present invention is, in a communication path of which received signal quality is extremely poor, to prevent such a state of the communication failure. To a frame generator 13 in a transmitter 10, which transmits OFDM signal, a pilot & data arrangement format determiner 20, which determines pilot & data arrangement format of an OFDM signal based on the value of received signal quality at a receiver 30, a pilot symbol number determiner 19, which determines the number of pilot symbols based on the value of received signal quality, and a power amplification rate determiner 18, which determines power amplification rate based on the value of received signal quality, are newly provided. Thereby, it is possible to change the pilot & data arrangement format, the number of pilot symbols and the power amplification rate depending on the value of received signal quality to generate transmission signal frame of the OFDM signal. Owing to this, even in a channel of which received signal quality is poor, it is possible to satisfactorily reduce the transmission rate using adaptive modulation technique and maintain the channel estimation accuracy to a satisfactory level, and thus it is possible to prevent such a state of the communication failure.

Owner:NTT DOCOMO INC

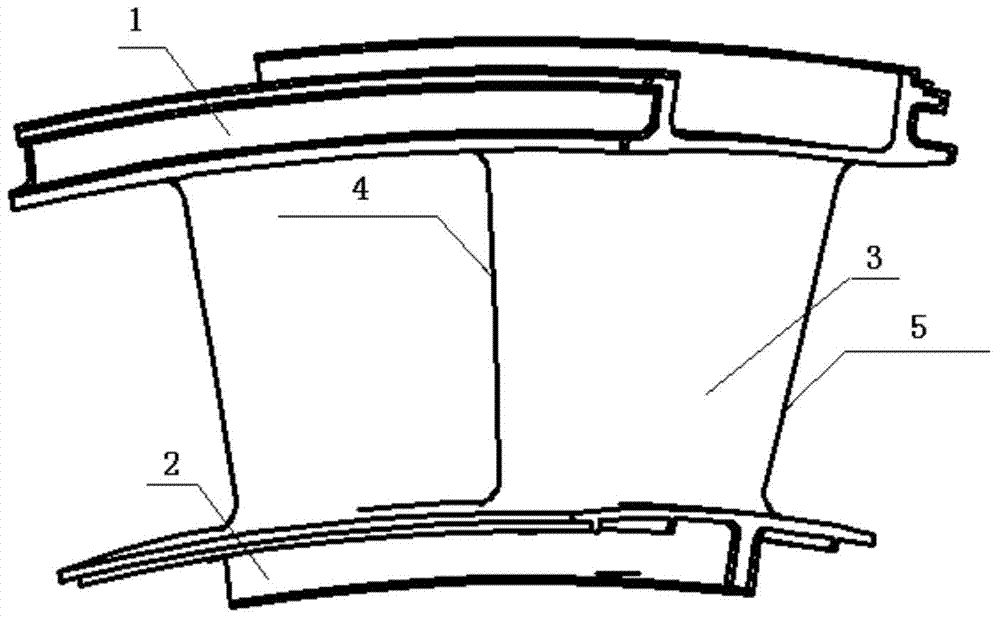

NC (numerical control) processing method for special-shaped joint part

InactiveCN101767264ASolve processing deformationMeet the design requirementsNumerical controlMachining process

The invention provides an NC (numerical control) processing method for a special-shaped joint part. The profile surface of a tee joint is divided into the following parts: a side wall 1, an upper-lower profile 2, an upper-part circular arc 3, a through-connection circular arc 4, a profiled groove 5, a spigot outer wall 6, a root part 7 and a technical chuck 8. The NC processing method is characterized in that: a part blank is adopted to reserve the technical chuck, so as to solve the problem of clamping deformation of the part; the outer profile surface is first processed through NC milling and then the inner profile surface is processed through NC linear cutting. The NC processing method overcomes the disadvantage that the part is difficult to meet the requirement of the special-shaped profile surface for the wall thickness due to having extremely poor rigidity during the processing. The NC processing method in the invention can be applied for manufacturing the special-shaped joint part of a stress application main pipe of a certain machine, and can solve the deformation problem without stress processing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

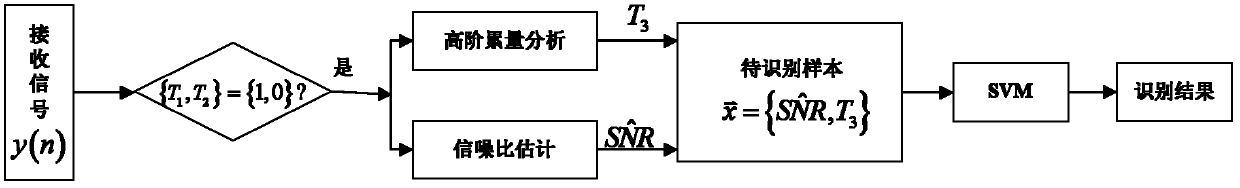

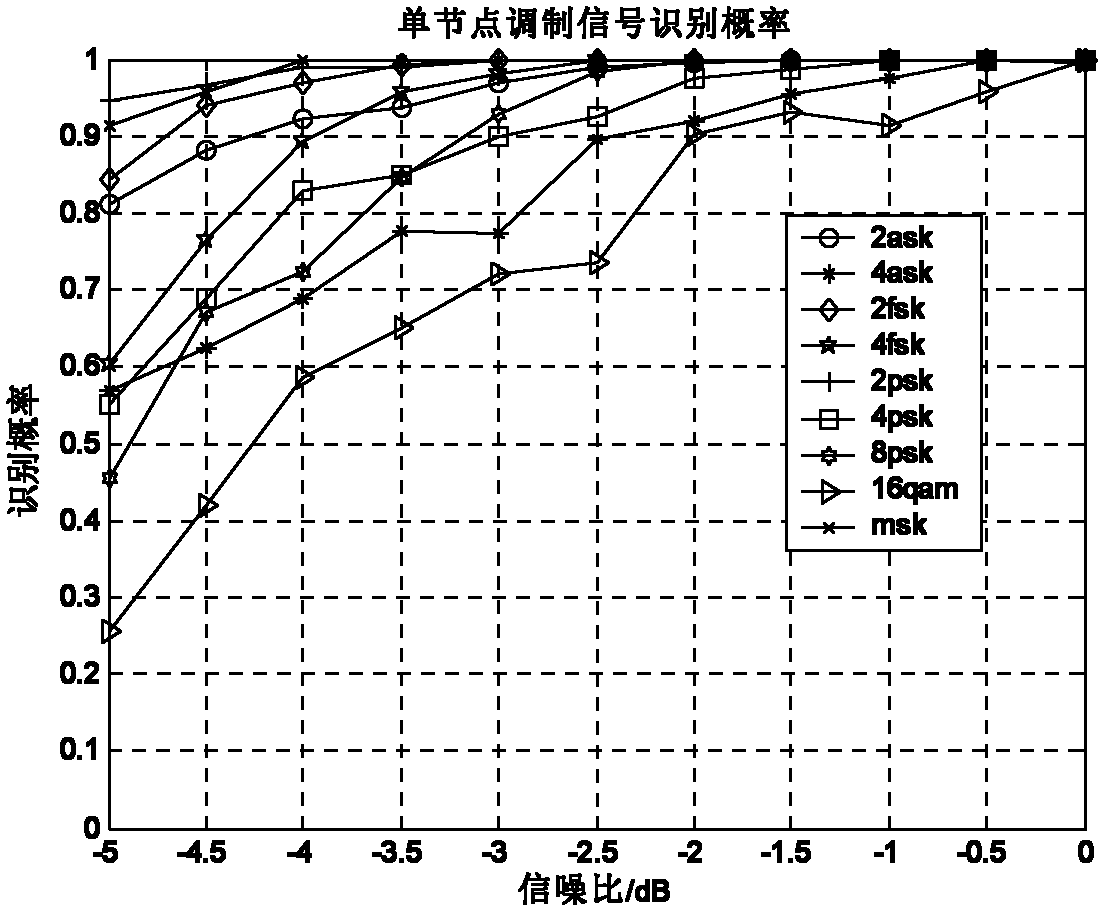

Distributed collaborative signal identification method based on blind estimation of higher order statistics and signal to noise ratio

InactiveCN102571230AImprove recognition rateAccurate identificationBaseband system detailsTransmission monitoringFusion centerNODAL

A distributed collaborative signal identification method based on blind estimation of higher order statistics and signal to noise ratio includes the following steps: establishing feature space; enabling collected features and estimated signal to noise ratio to be input as smart volume management (SVM) aiming at modulating signals of special types, and establishing a modulation signal recognition classifier; and the third step is that each sensor node makes blind estimation for signal to noise ratio of received signals and transmits characteristic parameters together with the signal to noise ratio to a fusion center, and the fusion center distributes weights for each sensor node by utilizing the signal to noise ratio, obtains fused characteristic parameters and thus performs modulation type identification. Compared with the prior art, as for a single sensor node, the algorithm is capable of maintaining high identification probability on the condition of low signal to noise ratio, identified signals are rich in variety, and by making blind estimation for the signal to noise ratio and performing fusion at a feature level, identification accuracy rate of target signals still can be maintained on the premise that a plurality of sensor node channels have extremely poor conditions.

Owner:NO 63 RES INST HEADQUARTERS OF THE GENERAL STAFF PLA

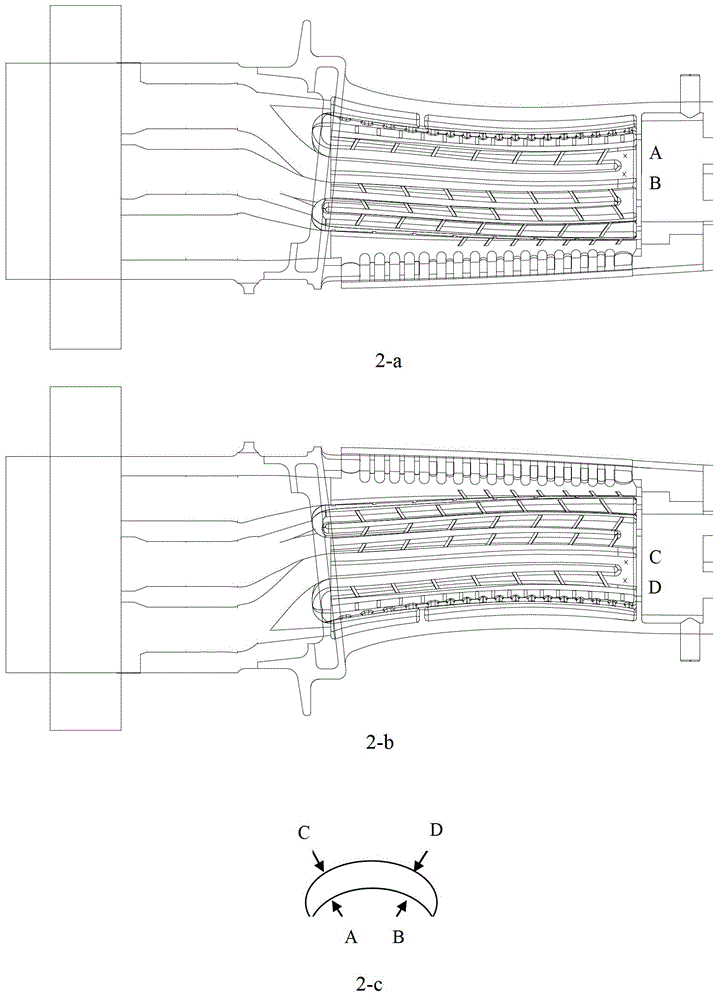

Fixing method of isometric crystal and columnar crystal ceramic mold core in mold shell

The invention relates to a precision casting production technology of a fired mold having a complex hollow blades, and particularly relates to a fixing method of an isometric crystal and columnar crystal ceramic mold core in a mold shell. The fixing method solves the fixing problem of the ceramic mold core in the mold shell when the complex inner cavity of the blades is formed by employing a preformed ceramic mold core technology, guarantees that the position of the ceramic mold core in the mold shell is relatively fixed during a metal liquid casting process, reduces or prevents the shift of the ceramic mold core, and for the ceramic mold core with relatively complex structure and relatively large core head space, effectively decreases the shift of the ceramic mold core caused by high-temperature creep of the ceramic mold core in a pouring process, thereby preventing the problems of core leakage or extremely poor wall thickness of the casting from generating. The method effectively improves the qualified rate of the investment casting of the complex hollow blades.

Owner:AECC AVIATION POWER CO LTD

Novel water-saving water closet pan and designing method

ActiveCN103556691ASolve wasting waterSolve the problem of easy clogging of sewersWater closetsFlushing devicesHuman wasteEngineering

The invention discloses a novel water-saving water closet pan and mainly relates to the technical field of water closet pans. As for pedestal pans and squatting pans in modern urban families and public places, water consumption is high, the water waste is extremely serious, unclean flushing sometimes occurs, and unfavorable influences on public hygiene are caused. As for modern rural toilets, old open-type flushing-free toilets are dominant, environmental hygiene is extremely poor, and high water consumption of modern flushing water closet pans is greatly related to the phenomenon. A piston of the water closet pan can move relatively to a water closet pan port (the piston reaches the lower portion of the water closet pan port), human body excrement can be directly moved to a thick channel of the water closet pan to be rotated, the flushing water pressure of the water closet pan is high, therefore, a lot of water is saved, the flushing of the water closet pan is clean, a sewer is not prone to be blocked, a lower port of the water closet pan is sealed by the pistonto be isolated from outside space and a sewer lineeffects of air sealing are better than those of keeping water and sealing peculiar smell by drain traps in traditional water closet pans, meanwhile, collection and usage of human body excrement are facilitated, and the water content of the excrement is greatly reduced so that the collected substance content can be increased, and the workload is reduced.

Owner:ZHEJIANG KEZHUDA MACHINERY TECH CO LTD

Sintered sliding material, sliding member, connection device and device provided with sliding member

The present invention provides a sintered sliding material, a sliding member and a connecting device that are excellent in baking resistance and wear resistance under extremely harsh lubrication conditions such as high surface pressure, low-speed sliding or swinging. The sintered sliding material of the present invention is composed of a sintered body containing 10 to 95% by mass of Cu or Cu alloy, the remainder being mainly Mo, and having a relative density of 80% or more.

Owner:KOMATSU LTD

Low-emission low-rotational-flow combustion chamber head structure for aircraft engine

ActiveCN103939946AGuaranteed stabilityGuaranteed combustion efficiencyContinuous combustion chamberCycloneAviation

The invention provides a low-emission low-rotational-flow combustion chamber head structure for an airascraft engine. The low-emission low-rotational-flow combustion chamber head structure comprises a pre-burning level and a main-burning level. The pre-burning level is designed with low rotational flow, that is the gas flow is divided into two parts through an inner ring of a cyclone, one part of the flow forms jet flow with the extremely-low rotational flow strength through a current limiting plate of a center channel, and the other part of the flow forms rotational jet flow with the large rotational flow strength through an outer-side cyclone. Pre-burning level fuel is ejected from a centrifugal nozzle and then enters the combustion chamber along with pre-burning level jet flow. A pre-film type air atomizing nozzle is adopted in the main-burning level for supplying oil, the fuel is sheared and atomized by rotational jet flow, ejected by a pre-burning level external cyclone, of fuel and rotational gas flow, ejected by a main-burning level cyclone and then enters the combustion chamber. Due to a low-rotational-flow flow field, the staying time of combustion products is reduced, generation of heating power type NOx is reduced, and the combustion chamber can work stably in extremely-poor conditions. Working can be achieved by replacing the combustion chamber head of the aircraft engine, the requirement for transforming the engine is extremely low, the pollution emission level in the whole landing-taking off circulation can be reduced, and earnings are obvious.

Owner:BEIHANG UNIV

Method and device for monitoring a cutting extraction machine

The invention relates to a method and to a device for monitoring the track of a cutting extraction machine (1), which is used in particular in coal mining and can be displaced during longwall mining in a longwall face equipped with face conveyors (9) and longwall advancing (12, 13) along the face (10). The underlying object of the invention is to create a method and a device which make it possible, despite extremely poor visibility conditions, for example in the track of the extraction machine, to detect present obstacles in the form of lowered canopies or drooping folding canopies, sliding canopies or other additions to the lining or overloads of the conveyor in order to take measures for avoiding interruptions in the operation in a timely manner. In order to achieve this object, according to the invention the track of the extraction machine (1) is scanned using a radar measuring device (14) associated with the extraction machine (1) and upon detection of an obstacle an alarm is triggered and / or an invention in the controller of the extraction machine (1) takes place.

Owner:EICKHOFF BERGBAUTECHN

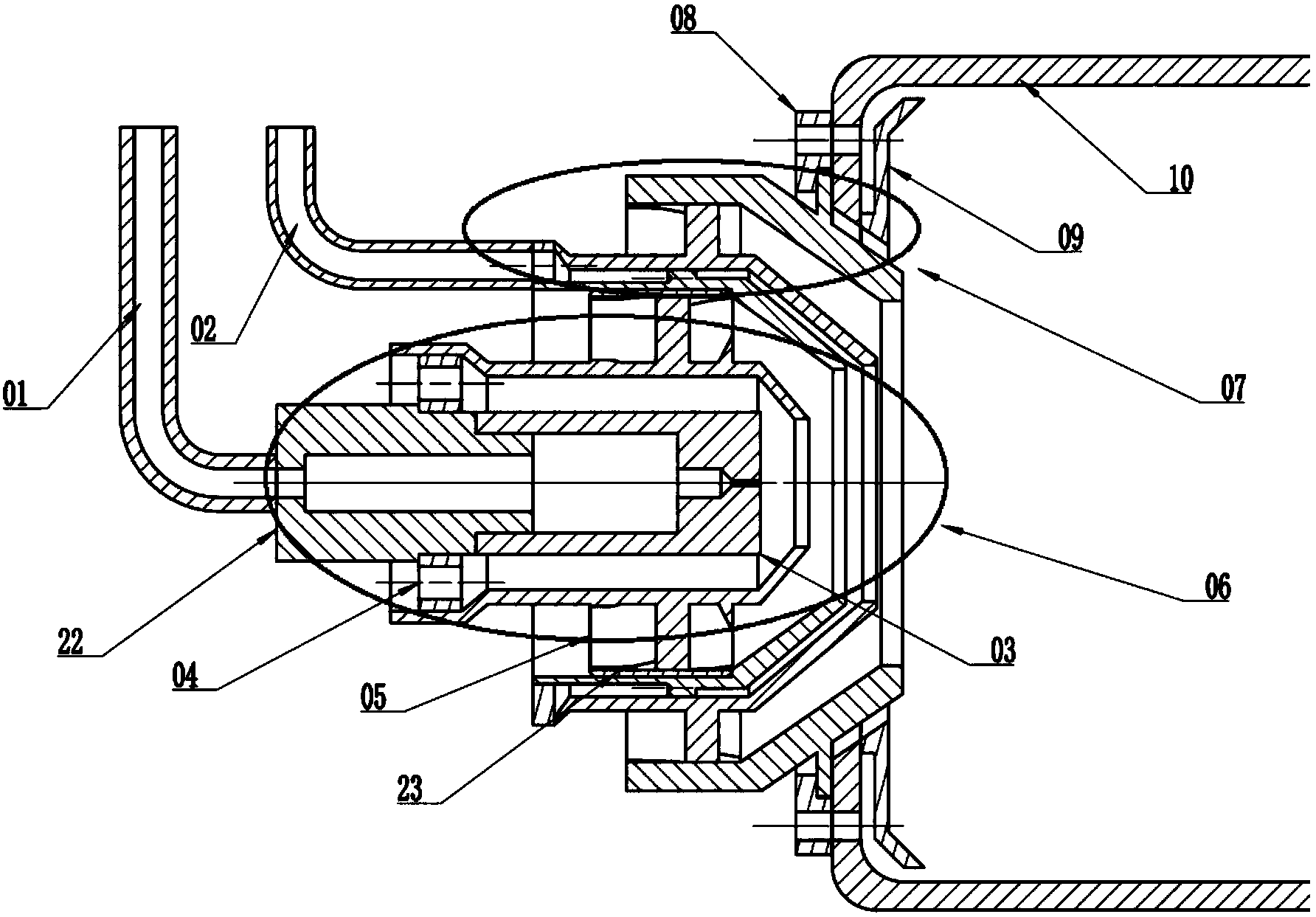

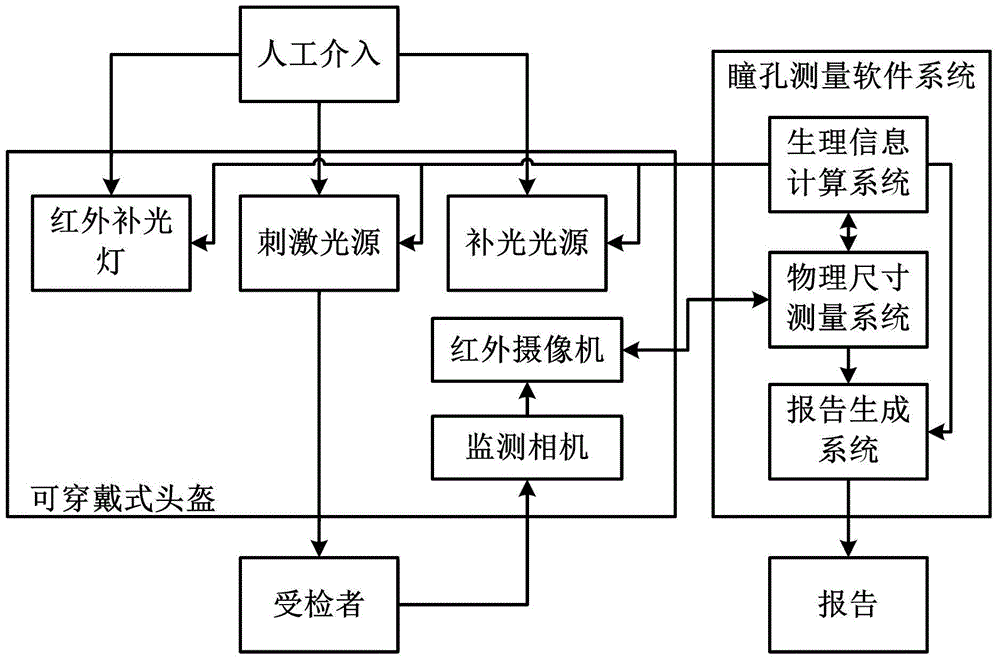

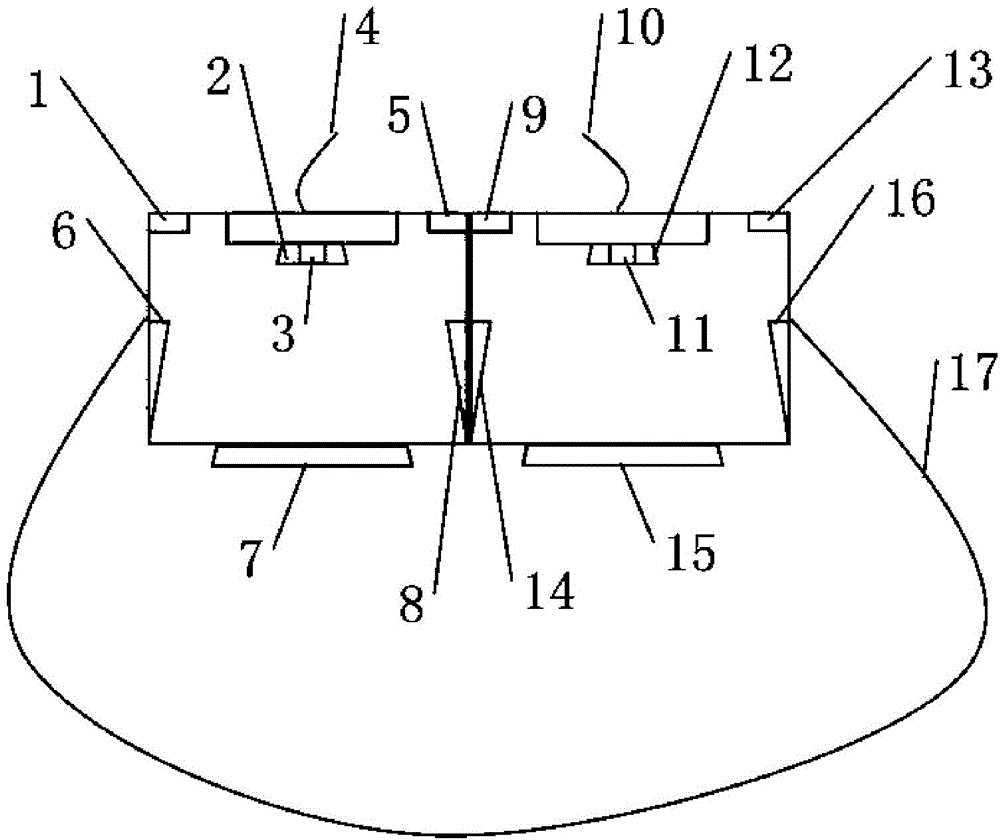

Wearable pupil light reflex measurement equipment

InactiveCN104545787AImprove portabilityIncrease flexibilityEye diagnosticsSoftware systemNeurosurgery

Owner:许昌红 +3

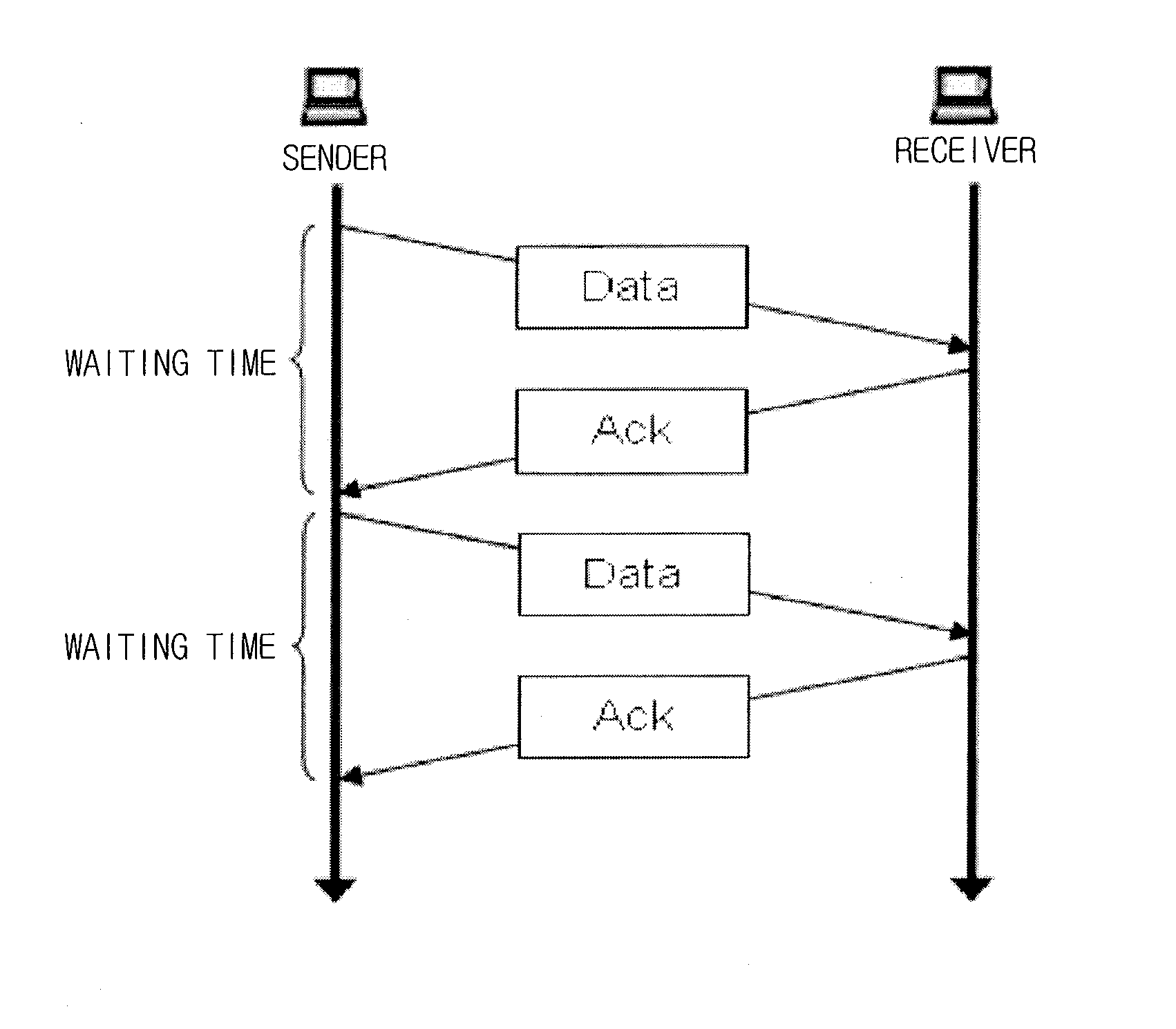

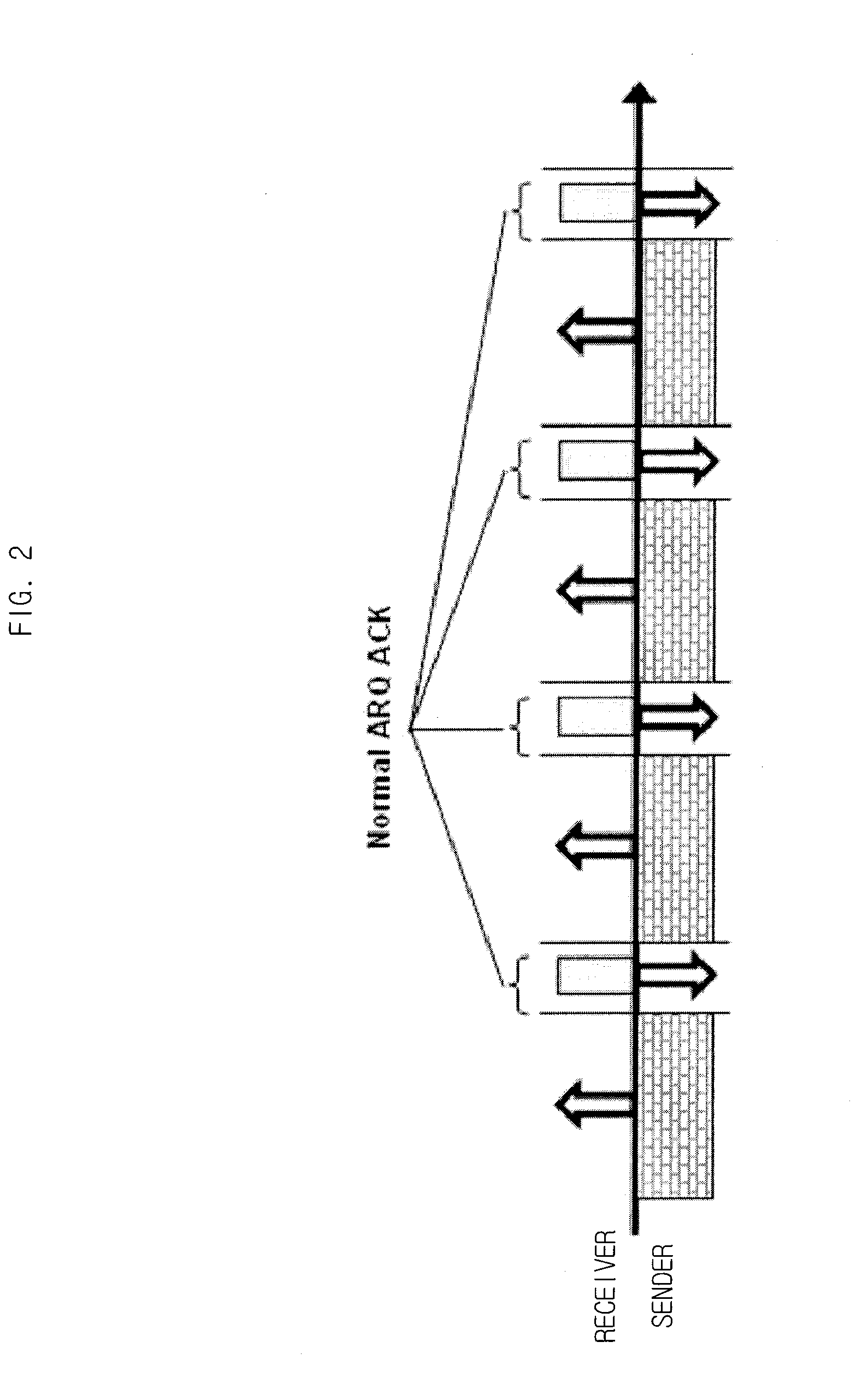

Method for transmitting wireless data and recording medium storing program for executing the method

InactiveUS20090292965A1Increase success rateImprove network efficiencyError prevention/detection by using return channelNetwork traffic/resource managementComputer hardwareWireless data

A method of transmitting wireless data and a recorded medium storing a computer program therefor. The method of transmitting data by a sender coupled to a receiver through a network can include transmitting a data frame having an Initiation field to the sender and transmitting a plurality of data frames corresponding to the Initiation field. The present invention can improve the completion rate of data transmission under an extremely-poor wireless environment.

Owner:GANGNEUNG WONJU NAT UNIV IND ACAD COOPERATION GROUP

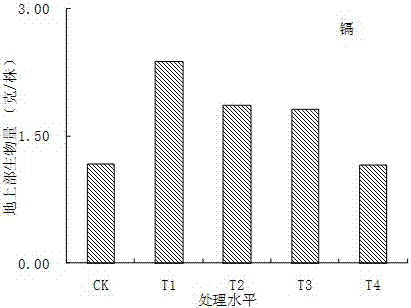

Application of artemisia stolonifera in repairing of heavy metal cadmium polluted soil

InactiveCN102172608AReduce contentNatural reproductive growthContaminated soil reclamationSoil heavy metalsPhytoremediation

The invention discloses feverfew artemisia stolonifera, and in particular relates to an application of the Artemisia stolonifera in repairing of heavy metal cadmium polluted soil, namely planting the artemisia stolonifera in the heavy metal cadmium polluted soil. The enrichment of the artemisia stolonifera to the heavy metal cadmium is utilized, the artemisia stolonifera is planted into the polluted soil, the heavy metal cadmium can be absorbed and accumulated, and most cadmium can be transferred to the overground part; and the overground part is subjected to ashing treatment to extract the heavy metal, thus the aim of repairing the heavy metal cadmium polluted soil is achieved. The artemisia stolonifera has strong fertility, can grow rapidly and can grow on extremely poor soil, and management is extensive in the growing process of the artemisia stolonifera, thus the cost is low, the operability is high, and a new plant resource specie used for repairing the heavy metal cadmium polluted soil is developed.

Owner:SICHUAN AGRI UNIV +9

Preparation method of combined type shell with heat insulating materials implanted therein

ActiveCN104325081AFix uneven growthSolve the problem of columnar grainsFoundry mouldsFoundry coresTurbine bladePrecision casting

The invention discloses a preparation method of a combined type shell in which heat insulating materials are implanted and mainly relates to a control method of the grain size of a precision-casting turbine blade which has the defects of large and wide margin plate, long blade, wide chord and large blade profile thickness difference. According to the preparation method, ceramic heat-preservation cotton is implanted in the shell, so that the defects in the prior art are effectively made up, the problem of extremely poor grain size of the exhaust side of the precision-casting turbine blade with the large and wide margin plate, the long blade, the wide chord and the large blade profile thickness difference is solved (primarily, the problem of columnar grains perpendicular to the exhaust side is solved), and uniform equiaxed grains are obtained. By adopting the preparation method, the problem of non-uniformity in growth of grains in a thin-wall area of a similar casting is completely solved, the qualified rate of the casting is increased from 30% before improvement to 70%, and the production cost is reduced.

Owner:AECC AVIATION POWER CO LTD

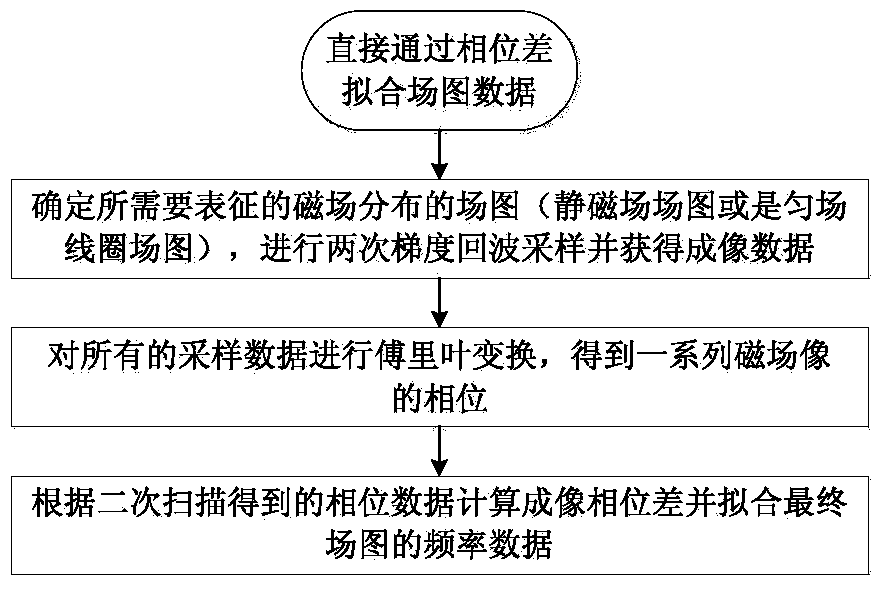

Gradient magnetic field shimming method based on regularization magnetic field distribution image reconstruction

ActiveCN104297709AIntegrity guaranteedSuppress noiseMagnetic measurementsSignal-to-noise ratio (imaging)Phase difference

The invention discloses a gradient magnetic field shimming method based on regularization magnetic field distribution image reconstruction. Compared with an existing phase difference imaging gradient magnetic field shimming technology, the image reconstruction optimization method obtains an initial field pattern through three times of phase difference scanning imaging, a penalized likelihood estimation function of field pattern data is built by a penalized likelihood estimation method with smooth and prior potential functions, function minimization is carried out through optimization transformation, and a final field pattern is obtained. By means of the method, on one hand, continuity of pixels can be effectively considered, and noise and image burrs are restrained; on the other hand, the target shape of the data can be estimated through the prior potential function, it is avoided that the direction is error in the optimization transformation process, and a good correcting effect is obtained for image distortion and winding caused by inhomogeneous magnetic fields. The method can ensure the integrity of the field pattern and improve the signal to noise ratio, so that a certain magnetic field shimming effect is obtained even under extremely poor magnetic field homogeneity conditions like a cold field.

Owner:武汉中科云楚科技有限公司

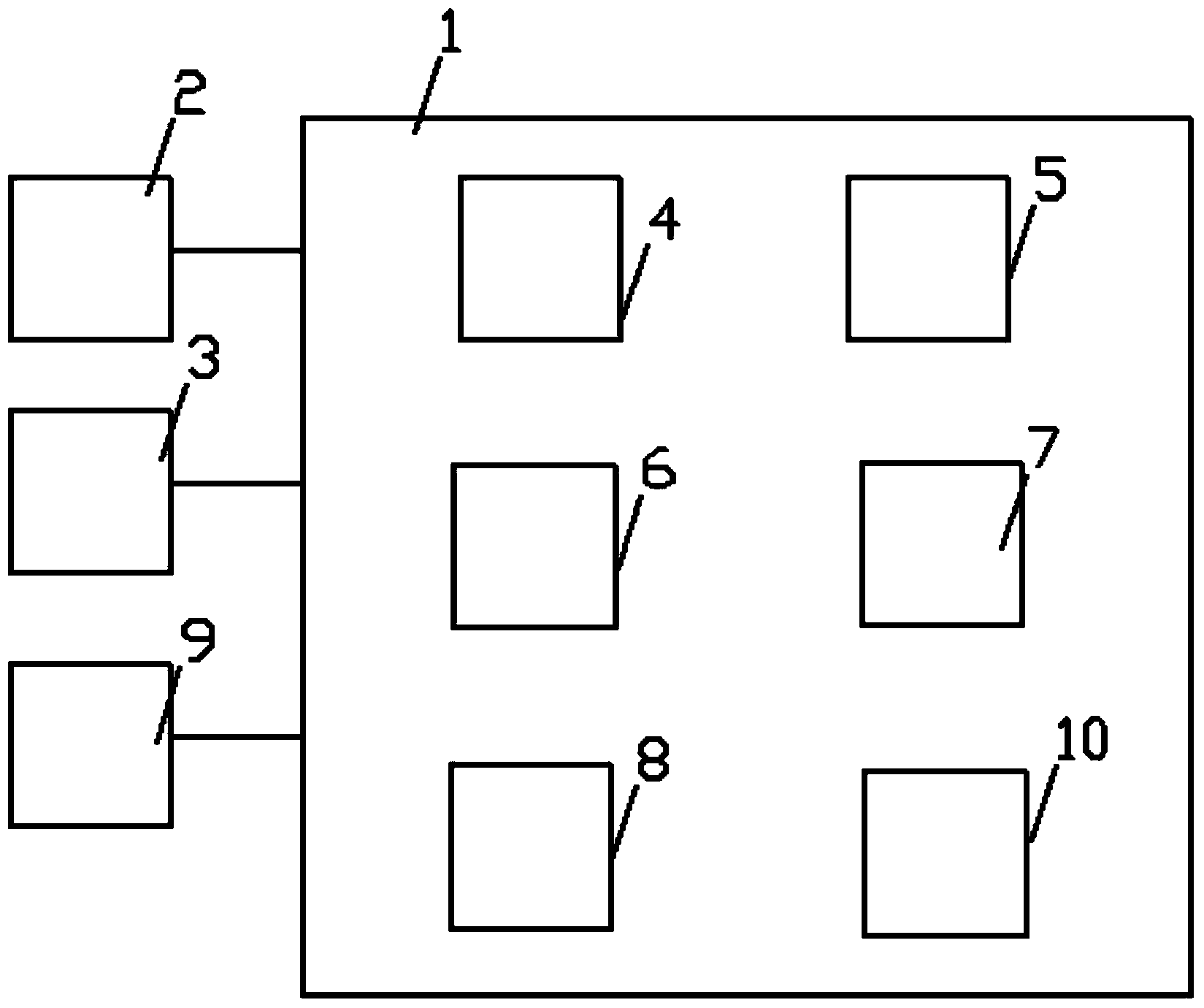

Indoor unit for air-conditioner

InactiveCN105444265AWith lighting functionReduce internal structureCondensate preventionLighting elementsEngineeringFlue

The invention provides an indoor unit for an air-conditioner. The indoor unit for the air-conditioner comprises an indoor unit shell, a lamp, a heat exchanger and a water receiving disc; a draught fan is arranged in the middle portion of the interior of the indoor unit shell, and an air flue extending from the draught fan to the four faces is arranged in the indoor unit shell; the lamp is arranged on the indoor unit shell; the heat exchanger is arranged in the air flue and located above the draught fan; and the water receiving disc is arranged in the manner of corresponding to the heat exchanger in position and located below the heat exchanger. By means of the indoor unit for the air-conditioner, the problem that in the prior art, an indoor unit for the air-conditioner is extremely poor in decoration performance, so that the indoor unit is difficultly fused into the decoration design is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

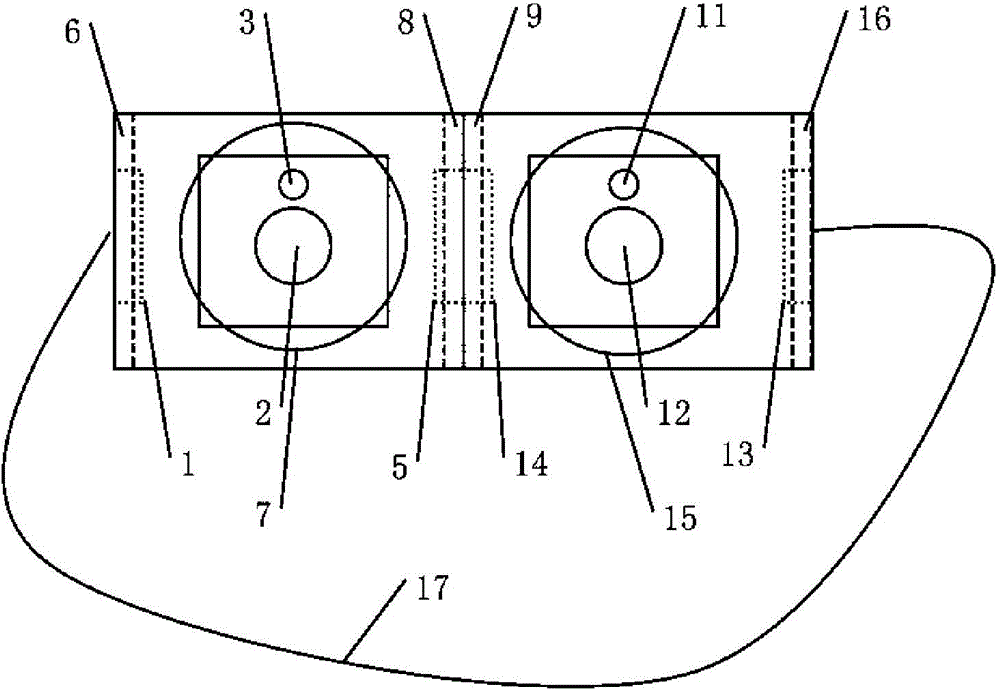

Double-shaft rack opposed engine

The invention relates to a double-shaft rack opposed engine which is used for providing power for automobiles, ships and the like. The double-shaft rack opposed engine aims to overcome the defects that old product crankshaft engines are complex in structure, high in weight, large in size, large in loss, low in efficiency and instable in power transmission. According to the technical scheme adopted by the double-shaft rack opposed engine, a crankshaft and a flywheel of a traditional engine are omitted, and innovative racks, pistons, gear sets and semicycle gears are adopted. Movement of the pistons is transmitted to a gear structure through the racks, the semicycle gears and the racks / gears work alternately, and back-and-forth movement of the racks is changed into circumferential movement. The structure is simplified; the weight is lowered, and the size is reduced; friction is reduced; the service life is prolonged; vibration is small and noise is low. Particularly, power arms of the gears are equal, the power, torque and speed are output linearly, in this way, the stability is extremely high, and the acting efficiency is high. The double-shaft rack opposed engine overcomes the defects that the power arms of the crankshaft of the traditional crankshaft engine change continuously, the power, torque and speed are output in a pulsed mode, in this way, the stability is extremely poor, and the acting efficiency is low.

Owner:孙书伟

Multi-modal online incremental access recognition system and recognition method thereof

Disclosed are a multi-modal online incremental access recognition system and a recognition method thereof. The multi-modal online incremental access recognition system comprises a computer terminal which is connected with a camera, a sound sensor and sound equipment, and a multi-modal online incremental access recognition module, an OPENCV (open source computer vision library), a first configuration document, a second configuration document, a face recognition model data storing file and a photo sum and photo classification object attribute sum storing document are arranged in the computer terminal. Being combined with the recognition method, the multi-modal online incremental access recognition system is capable of avoiding the defect, in the prior art, that due to the fact that a face recognition classifier cannot be corrected by means of interaction of other sensing approaches when in recognition errors, online incremental improvement on face recognition effect cannot be achieved and user experience is affected seriously, and avoiding the defect, in the prior art, that traditional voice recognition effect is extremely poor resulting from no grammar content in Chinese character content.

Owner:NANJING UNIV

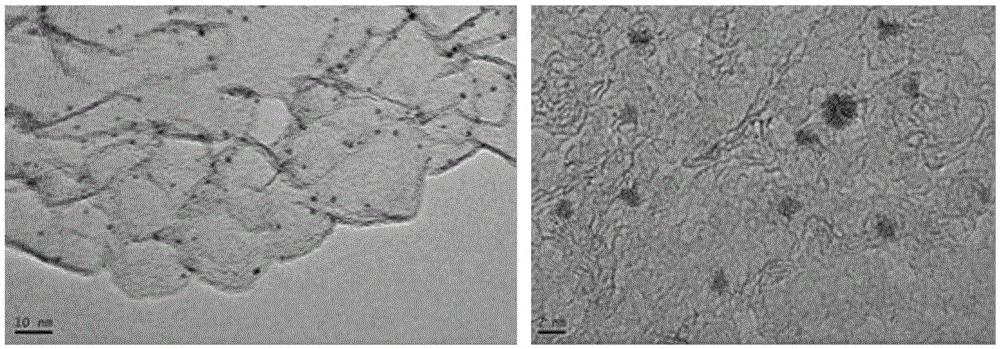

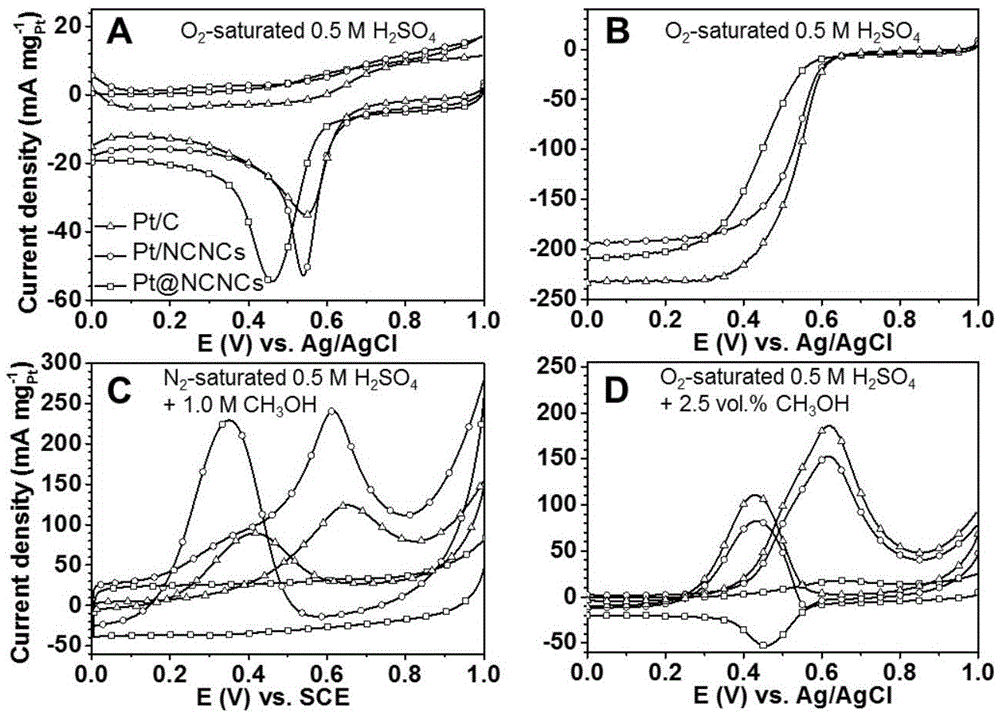

Preparation method of York-shell nitrogen-doped carbon nanocage-coated platinum nanoparticles oxygen-reduction electrocatalyst with high methanol tolerance

InactiveCN105609789AIncreased dispersionSmall particle sizeCell electrodesIntellectual propertyOxygen

The invention discloses nitrogen-doped carbon nanocage-coated platinum nanoparticles (Pt@NCNCs) as a methanol-tolerant oxygen-reduction electrocatalyst. With the NCNCs, which are uniform in nitrogen distribution, high in purity and high in quality and have independent intellectual property, prepared by a chemical vapor deposition method as a carrier, anchoring and coordination effects of nitrogen can be directly utilized without surface pretreatment on the carrier; and the Pt nanoparticles are extremely evenly coated with an NCNCs cage to form a York-shell catalytic material. The oxygen-reduction electrocatalyst is simple in preparation process and friendly to environment. The oxygen-reduction catalytic activity is equivalent to the best result reported by the existing literature. Remarkably, the catalyst has complete methanol tolerance while a commercial Pt / C catalyst and an NCNCs-loaded Pt metal nanoparticles catalyst are extremely poor in methanol tolerance. The stability performance is good and far better than that of the Pt / C catalyst and the Pt / NCNCs catalyst.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST

High-pressure gas multistage pre-splitting grouting transformation method for surrounding rock of deep soft rock roadways

ActiveCN105156134AGood injectabilityPrevent closureUnderground chambersFluid removalHigh pressureMechanical property

The invention relates to a high-pressure gas multistage pre-splitting grouting transformation method for surrounding rock of deep soft rock roadways. The high-pressure gas multistage pre-splitting grouting transformation method has the advantages that the surrounding rock of the deep soft rock roadways is subjected to multistage pre-splitting by the aid of high-pressure gas, special propping agent materials are added into popping agent containers when last-stage gas pre-splitting is carried out, the particle sizes of the propping agent materials are larger than those of cement particles, the propping agent materials are used for propping crack of the artificially pre-split expanded surrounding rock, the crack can be prevented from being closed again under the effect of deep high ground stress, the groutability of the surrounding rock can be improved, then the surrounding rock with the crack can be grouted and reinforced, weak surrounding rock structures and mechanical properties of the roadways can be greatly transformed, the surrounding rock of the deep soft rock roadways can be stably controlled, and difficult problems of closing of crack of existing surrounding rock of existing deep soft rock roadways, extremely poor groutability of the existing surrounding rock and poor grouting effects can be solved; the weak surrounding rock structures and the mechanical properties can be obviously transformed and enhanced, and the bearing capacity of the surrounding rock can be improved; high-pressure gas pre-splitting holes and grouting holes of the surrounding rock are combined with one another, and the high-pressure gas multistage pre-splitting grouting transformation method is easy to operate and implement in fields.

Owner:CHINA UNIV OF MINING & TECH

Method for evaluating fresh water fish meat quality

InactiveCN109406740APredict processing quality fairnessAccurate prediction of processing qualityComponent separationColor/spectral properties measurementsFresh water organismFresh fish

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Stage grinding and desliming, gravity separation, magnetic separation and floatation process for extremely poor hematite

ActiveCN102580842AReduce manufacturing costReduce the cost of beneficiationWet separationResource utilizationEngineering

The invention provides a stage grinding and desliming, gravity separation, magnetic separation and floatation process for extremely poor hematite. The process is characterized by comprising the steps of subjecting raw ore to first-stage closed grinding, subjecting a first-stage classified product to desliming, subjecting desliming bottom flow to rough spiral separation, subjecting rough spiral separation concentrate to fine spiral separation, subjecting rough spiral separation middling to middle magnetic scavenging, carrying out self-circulation on fine spiral separation middling, subjecting middle magnetic scavenging concentrate and fine spiral separation tailing to second-stage grinding, desliming a second-stage grinding product, subjecting bottom flow to recleaning rough spiral separation, subjecting recleaning rough spiral separation concentrate to recleaning fine spiral separation, carrying out self-circulation on recleaning fine spiral separation middling, subjecting recleaning fine spiral separation tailing, recleaning rough spiral separation tailing, rough spiral separation tailing and desliming overflow to primary concentration, subjecting ore pulp after primary concentration to strong magnetic treatment, carrying out secondary concentration on strong magnetic treatment concentrate, then subjecting to floatation, combining recleaning fine spiral separation concentrateand fine spiral separation concentrate to obtain final concentrate, and abandoning floatation, strong magnetic treatment and middle magnetic scavenging tailings. The process provided by the inventionis stable in operation, reduces ore concentration cost and improves resource utilization rate.

Owner:ANSTEEL GRP MINING CO LTD

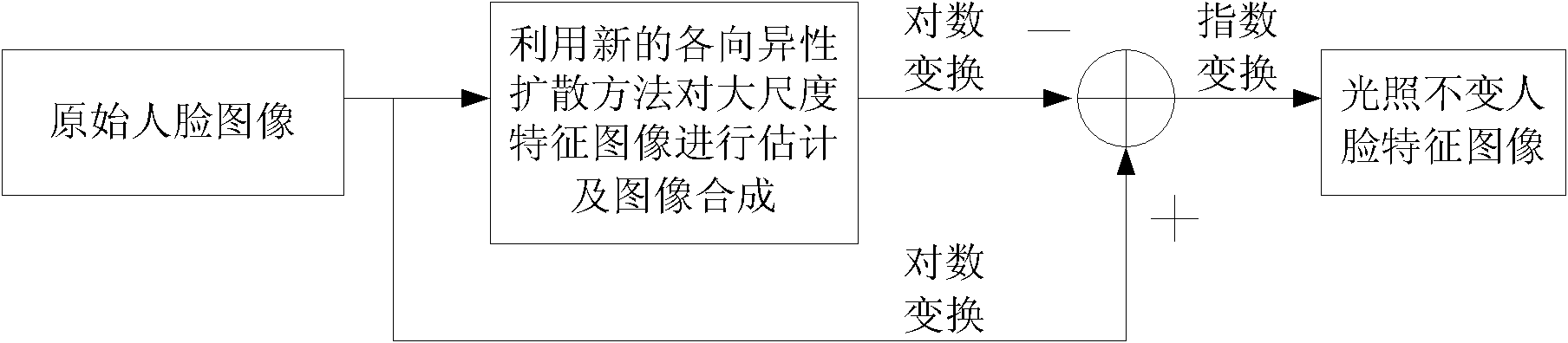

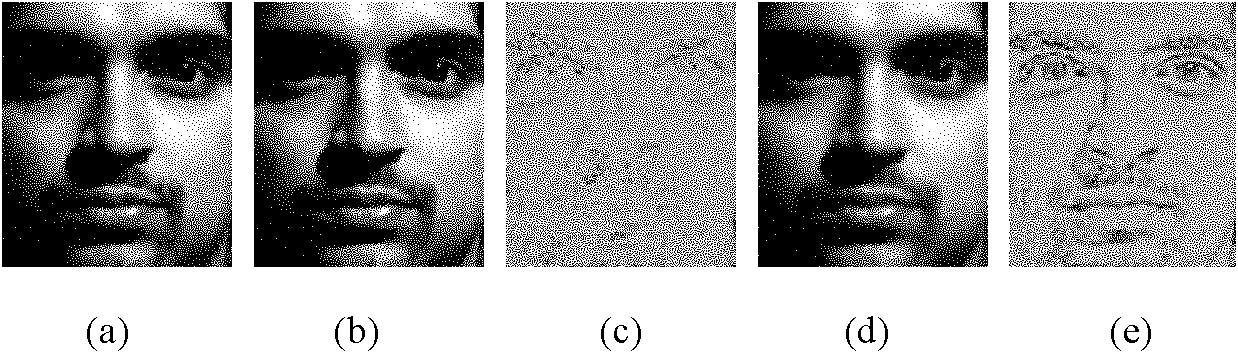

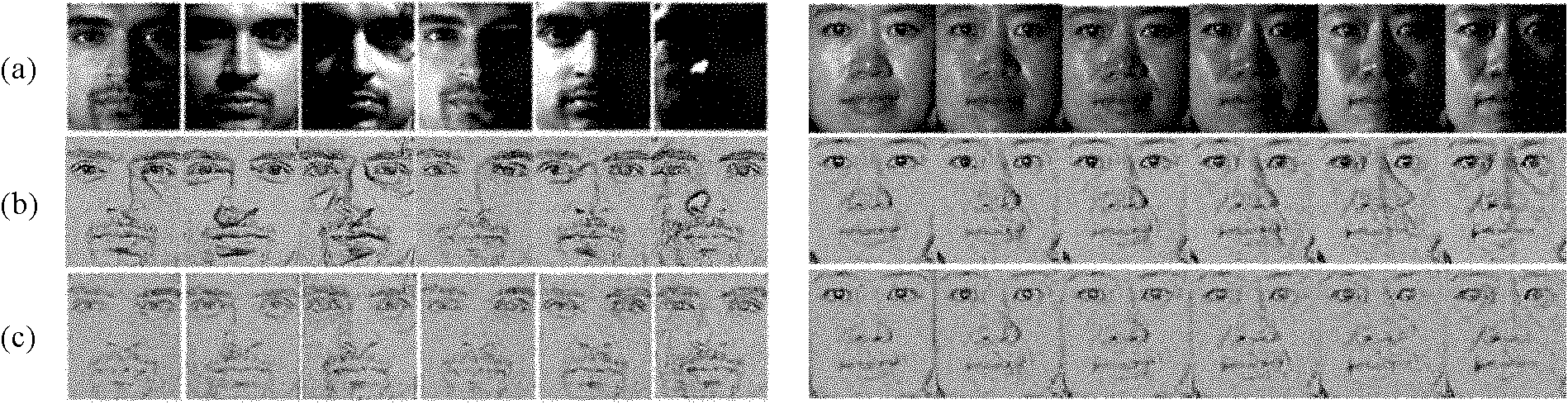

Method for obtaining human face illumination invariant images based on multiscale anisotropic diffusion

ActiveCN101957912AEnhanced edge retentionReduce the halo effectCharacter and pattern recognitionPattern recognitionHuman body

The invention relates to a method for obtaining human face illumination invariant images based on multiscale anisotropic diffusion, belonging to the field of image processing technologies. The invention is based on a Lambertian convex surface model for decomposing the human face image to a small-scale feature image and a large-scale feature image. The small-scale feature image can be regarded as the ideal human face illumination invariant feature image. The core is characterized in that new descriptors with inconsistent intervals are introduced for strengthening edge retention capability of an anisotropic diffusion algorithm to low frequency domain images so as to greatly weaken image halo effect of the algorithm; meanwhile, a new transfer coefficient is provided, and noised caused by edge sharpening is reduced; and an anisotropic diffusion constraint is introduced, and the method is more suitable for treating the illumination problem of the human body image. Experiments show that the invention can obtain good treatment effect even in extremely poor lighting conditions and can effectively improve robustness of face recognition or face certification to changes in lighting conditions.

Owner:CHONGQING UNIV

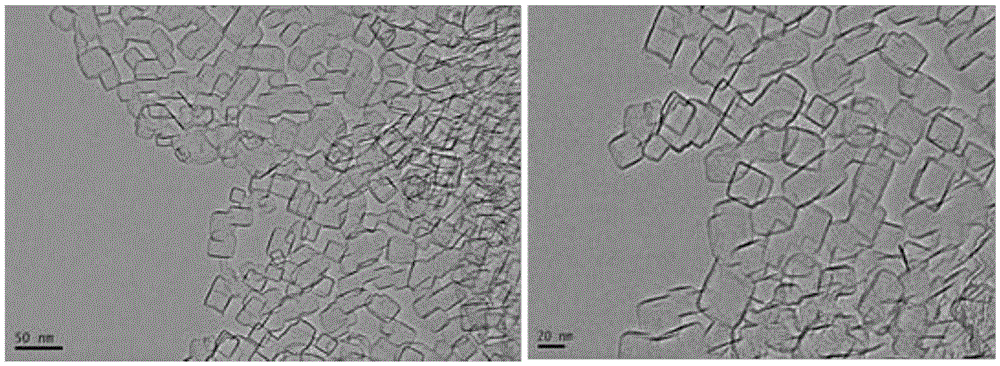

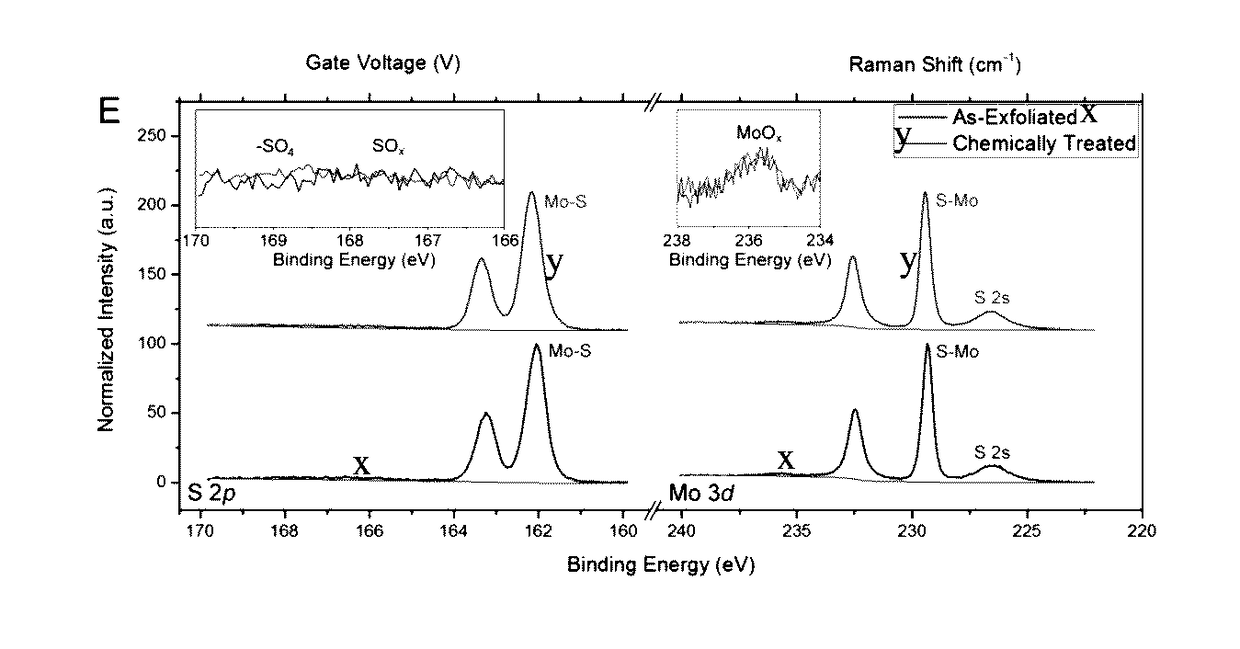

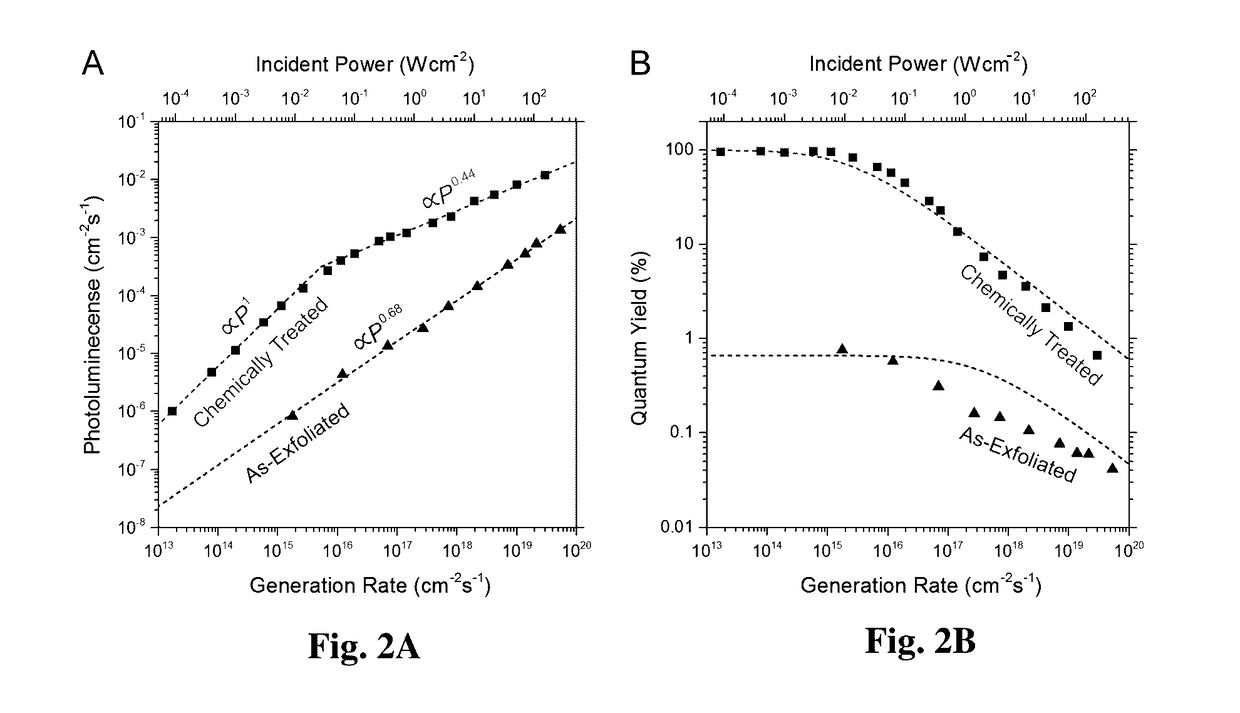

Near-Unity Photoluminescence Quantum Yield in MoS2

ActiveUS20170110338A1Laser detailsFinal product manufactureChemical treatmentLuminescence quantum yield

Two-dimensional (2D) transition-metal dichalcogenides have emerged as a promising material system for optoelectronic applications, but their primary figure-of-merit, the room-temperature photoluminescence quantum yield (QY) is extremely poor. The prototypical 2D material, MoS2 is reported to have a maximum QY of 0.6% which indicates a considerable defect density. We report on an air-stable solution-based chemical treatment by an organic superacid which uniformly enhances the photoluminescence and minority carrier lifetime of MoS2 monolayers by over two orders of magnitude. The treatment eliminates defect-mediated non-radiative recombination, thus resulting in a final QY of over 95% with a longest observed lifetime of 10.8±0.6 nanoseconds. Obtaining perfect optoelectronic monolayers opens the door for highly efficient light emitting diodes, lasers, and solar cells based on 2D materials.

Owner:RGT UNIV OF CALIFORNIA

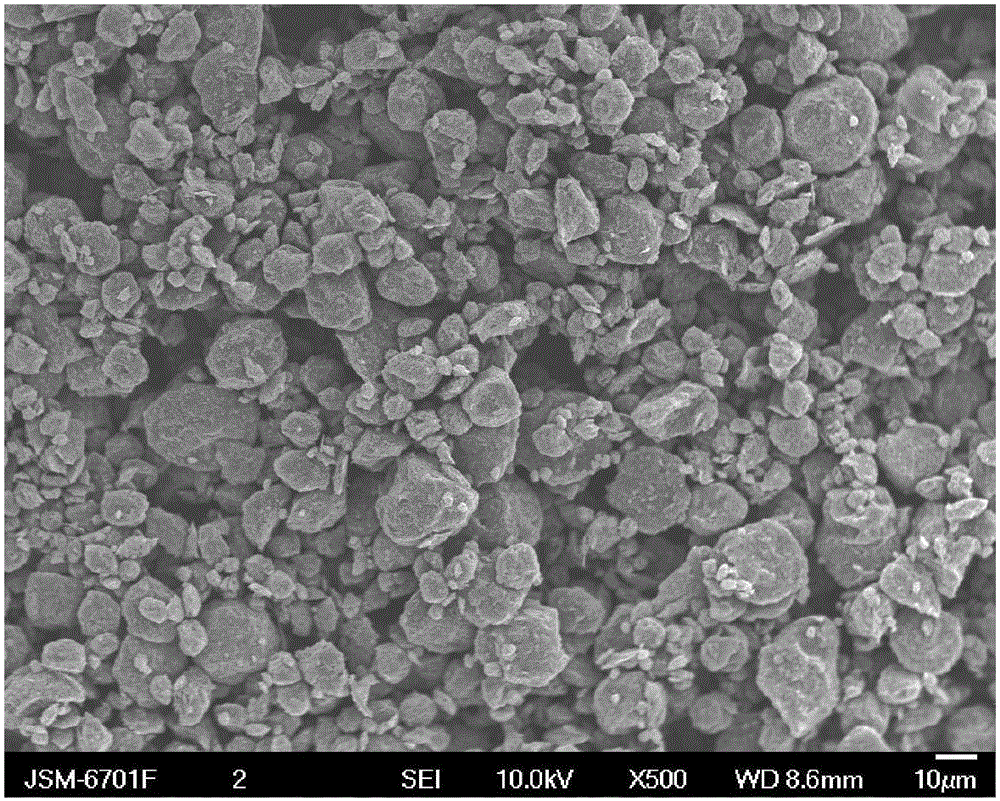

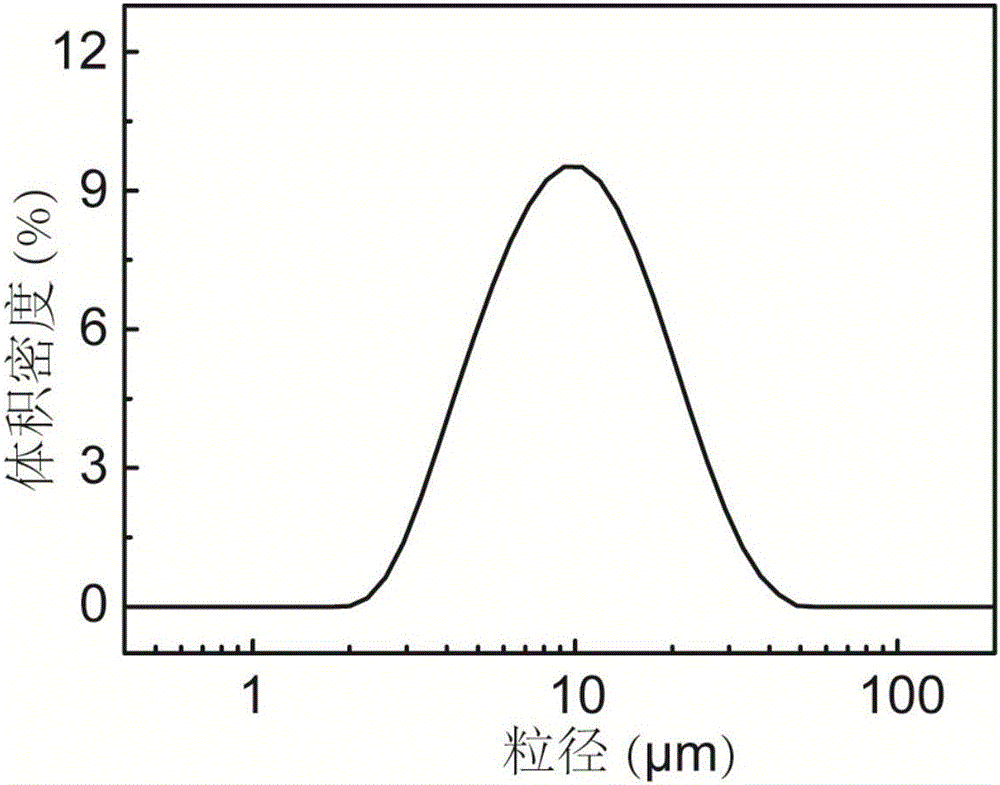

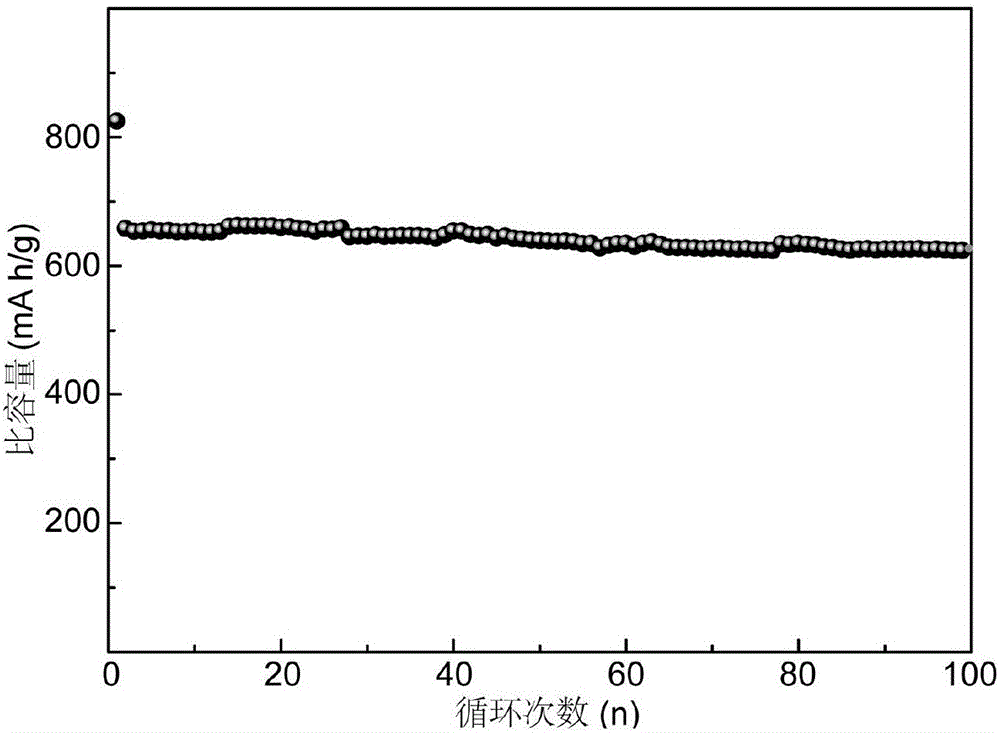

Silicon oxide/carbon/metal element composite material and preparation method and application thereof

ActiveCN105870415AWell mixedSolve the defect of poor conductivityCell electrodesSecondary cellsSilicon oxidePollution

The invention relates to an SiOx / C / M composite material and a preparation method and an application thereof. The SiOx / C / M composite material is prepared from an SiOx material, a carbon material and an M component and is prepared through a simple, efficient, low-cost and pollution-free production technology on a large scale. The composite material is taken as a negative electrode material for a lithium-ion battery, so that the electrochemical properties of the SiOx negative electrode material are significantly improved; and the defects that the SiOx negative electrode material is extremely poor in conductivity, poor in capacity development and relatively low in initial coulomb efficiency are overcome.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

An information pushing method and device

The invention discloses an information pushing method and device which relates to the technical field of information pushing, and used for solving the problems in the prior art that when the menus arerecommended to the users according to the foods, the recommended menus are inaccurate, and the user experience is extremely poor. The method provided by the invention comprises the following steps ofobtaining a food material image of a food material stored in a storage device and a geographic position of a user using the storage device, and performing image recognition on the food material imageto determine a stored food material, selecting a recommended recipe corresponding to the geographic position of the user and containing the stored food material from a preset recipe database, and sending the recommended recipe as push information.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

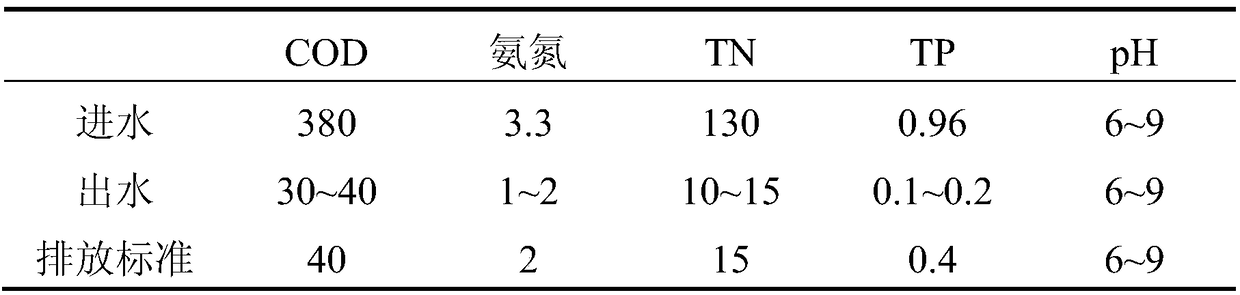

Deep treatment process and equipment of pharmaceutical waste water being stricter than class-A standards

InactiveCN108275835AImprove biodegradabilityGood removal effectWater contaminantsTreatment involving filtrationBiological filterOxidation pond

The invention belongs to the field of deep treatment of waste water and particularly relates to a deep treatment process and equipment of pharmaceutical waste water being stricter than class-A standards. The deep treatment equipment of the pharmaceutical waste water being stricter than class-A standards comprises an adjusting pond, a first-stage coagulating precipitation pond, a first-stage ozoneoxidation pond, a stabilizing pond, a hydrolytic acidification pond, an aerobic MBBR (Moving Bed Biofilm Reactor) pond, a secondary precipitation pond, a denitrifying biological filter, an aeration biological filter, a second-stage coagulating precipitation pond, a sand filter, a second-stage ozone oxidation pond and a disinfecting pond. The deep treatment process and equipment of the pharmaceutical waste water being stricter than the class-A standards has the advantages that according to the characteristics of complex components, high chromaticity, large toxicity and extremely poor biodegradability and the like of discharged water from a sewage treatment station of a pharmaceutical factory, physical and chemical processes, an advanced oxidation technology and a biological technology are reasonably combined and applied, and after treatment, the discharged water can meet the requirements of class-A local discharge standards.

Owner:CCCC TIANJIN ECO ENVIRONMENTAL PROTECTION DESIGN & RES INST CO LTD

Brazing method of SiO2 ceramic matrix composite material

ActiveCN105418135AReduce residual stressImprove wettabilitySoldering apparatusWelding/soldering/cutting articlesMetallic materialsThermal expansion

The invention provides a brazing method of a SiO2 ceramic matrix composite material and relates to a brazing method of a composite material. The invention aims at solving the problems that existing surface active brazing filler metal for the SiO2 ceramic matrix composite material is extremely poor in wettability, high-quality connection and even effective connection of composite components are difficult to realize, and a contact has great residual stress in a brazing process as thermal expansion coefficients of the SiO2 ceramic matrix composite material and a metal material are different when a brazing method is adopted for connecting SiO2 ceramic matrix composite material-metal components. The brazing method of the SiO2 ceramic matrix composite material comprises the following steps: firstly polishing, then mechanically perforating the surface of the SiO2 ceramic matrix composite material, then carrying out plasma treatment, and finally brazing the SiO2 ceramic matrix composite material with metal. The brazing method provided by the invention is applied to the SiO2 ceramic matrix composite material.

Owner:HARBIN INST OF TECH

Method for in-situ construction of electrode through electro-depositing super-stable metal thin films on ITO conductive glass surface

InactiveCN104132976AEasy to makeImprove stabilityMaterial electrochemical variablesMicroscopic scalePt element

The invention relates to a method for in-situ construction of an electrode through electro-depositing super-stable metal thin films on an ITO conductive glass surface, and relates to the electrochemical field. The method solves the problem of extremely poor stability of ITO surface deposited metal thin films, and at the same time, omits a large vacuum coating device required for constructing a complex electrode system, so as to greatly reduce the cost and time consumption for constructing a complex electrochemical device. According to the method, a three-electrode system is composed of the ITO as a working electrode, Ag-AgCl as a reference electrode and platinum as a counter electrode, and after the working electrode surface is subjected to reduction, stripping and roughening, the voltage is applied through a step pulse method or a current-time curve method for electro-depositing various super-stable metal thin films. The electrode preparation method is universal, simple and fast, also has double natures of macroscopic smoothness and microcosmic roughness, and greatly improves the stability and electrochemical active area of the electrode.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Application internet access processing method and device as well as terminal

InactiveCN104661322ASolve the problem of extremely poor user experienceImprove experienceAssess restrictionConnection managementInternet accessComputer terminal

The present invention provides an application Internet access processing method, apparatus, and terminal. In the method of the present invention, an Internet access routing manner corresponding to an application is determined according to the application, and application Internet access processing is performed on a network port corresponding to the Internet access routing manner, so that a problem in the prior art that normal processing of terminal services is affected and use experience of users is extremely poor because different Internet access routing manners cannot coexist, thereby achieving an effect of improving user experience.

Owner:ZTE CORP

Method for improving inversion accuracy of high greenhouse gas concentration

InactiveCN103760125ASelectiveImprove inversion accuracyMaterial analysis by optical meansSpecial data processing applicationsSystem structureGas concentration

The invention discloses a method for improving the inversion accuracy of high greenhouse gas concentration. The method has the beneficial effects that (1) a certain infrared spectrum screening rule is constructed so as to eliminate measurement spectrums with great influence caused by the cloud layer, aerosol and the like or extremely poor fitting effect, and compared with the prior art, a target spectrum is high in selectivity; (2) physical parameters are observed through a precise measurement spectrum to realize accurate modeling of the measurement spectrum, so that the reference spectrum precision is improved; (3) in a greenhouse gas concentration inversion process, a correction spectrum is added for fitting, so that a sun structure and a system structure are corrected, and the correction method adopting the correction spectrum is obviously better than a correction method in the prior art. According to the method, the Fraunhofer structure of the sun can be corrected, and the fixed structure of a system can be corrected; furthermore, the correction spectrum is obtained by fitting through a same spectrometer, so that an error caused by the performance difference of different instruments is avoided; by the use of the method, the same experiment device can obtain high greenhouse gas concentration inversion precision.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com