Preparation method of combined type shell with heat insulating materials implanted therein

A thermal insulation material and composite technology, which is applied in casting molding equipment, casting molds, cores, etc., can solve problems such as uneven grain formation, and achieve the effect of solving uneven growth and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] 2) Preparation of surface layer slurry

[0044] Mix silica sol, 325-mesh zircon powder, 270-320-mesh cobalt aluminate, penetrant "T" and analytically pure n-octanol, stir evenly and park for 12 hours to obtain the surface layer slurry; among them, The mass ratio of silica sol to zircon powder is 1:(5~5.5), the mass ratio of silica sol to penetrant "T" is 200:1, and the mass ratio of silica sol to analytically pure n-octanol is 100:1 ; Wherein, the prepared surface layer slurry has a specific gravity of 2.75 to 2.95 and a viscosity of 40S to 50S. Silica sol was purchased from Shangyu Yuda Chemical Co., Ltd., zircon powder was purchased from Australia Pan Asia Industrial Co., Ltd., cobalt aluminate was purchased from Prince Minerals, penetrant "T" was purchased from Shenyang Auxiliary Factory, and analytically pure n-octanol Purchased from Xi'an Chemical Preparation Factory.

[0045] 3) Preparation of remaining coating slurry

[0046] Take the ethyl silicate hydrolyzat...

Embodiment 1

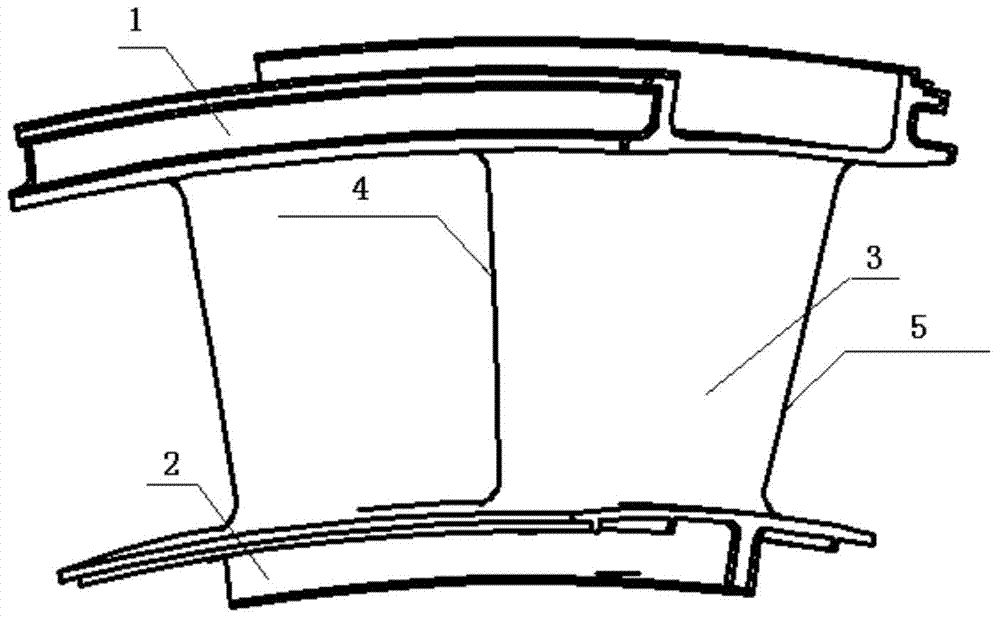

[0055] 1. Combined with the structure of the parts, formulate a reasonable wax model combination plan, and complete the module combination work according to the requirements of the combination plan, such as figure 1 shown; figure 1 It is the structure diagram of the blade, the upper edge plate 1 and the lower edge plate 2 are respectively located on both sides of the airfoil 3, the thickness of the intake edge 4 is 11.4mm, and the thickness of the exhaust edge 5 is 1.2mm.

[0056] 2. Configure the surface layer slurry, add grain inoculants and refiners (cobalt aluminate with a particle size of about 270 mesh to 320 mesh), and stir evenly according to the specific process requirements, and prepare for coating and hanging modules;

[0057] 3. Coat the surface layer slurry and hanging sand on the module, and carry out self-drying to complete the surface layer coating and hanging work;

[0058] 4. Complete 2-5 layers of coating and hanging work respectively, and ensure that the 5...

Embodiment 2

[0065] 1. Combined with the structure of the parts, formulate a reasonable wax model combination plan, and complete the module combination work according to the requirements of the combination plan, such as image 3 ; image 3 For the schematic diagram of implanting thermal insulation cotton into the shell after coating and hanging 5 layers, a layer of thermal insulation cotton 12 is pasted on the exhaust side 5 .

[0066] 2. Configure the surface layer slurry, add grain inoculants and refiners (cobalt aluminate with a particle size of about 270 mesh to 320 mesh), and stir evenly according to the specific process requirements, and prepare for coating and hanging modules;

[0067] 3. Coat the surface layer slurry and hanging sand on the module, and carry out self-drying to complete the surface layer coating and hanging work;

[0068] 4. Complete 2-6 layers of coating and hanging work respectively, and ensure that the 6th layer is dry;

[0069] 5. According to the length of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com