Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1024 results about "Octanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Octanols are alcohols with the formula C₈H₁₇OH. A simple and important member is 1-octanol, with an unbranched chain of carbons. Other commercially important octanols are 2-octanol and 2-ethylhexanol.

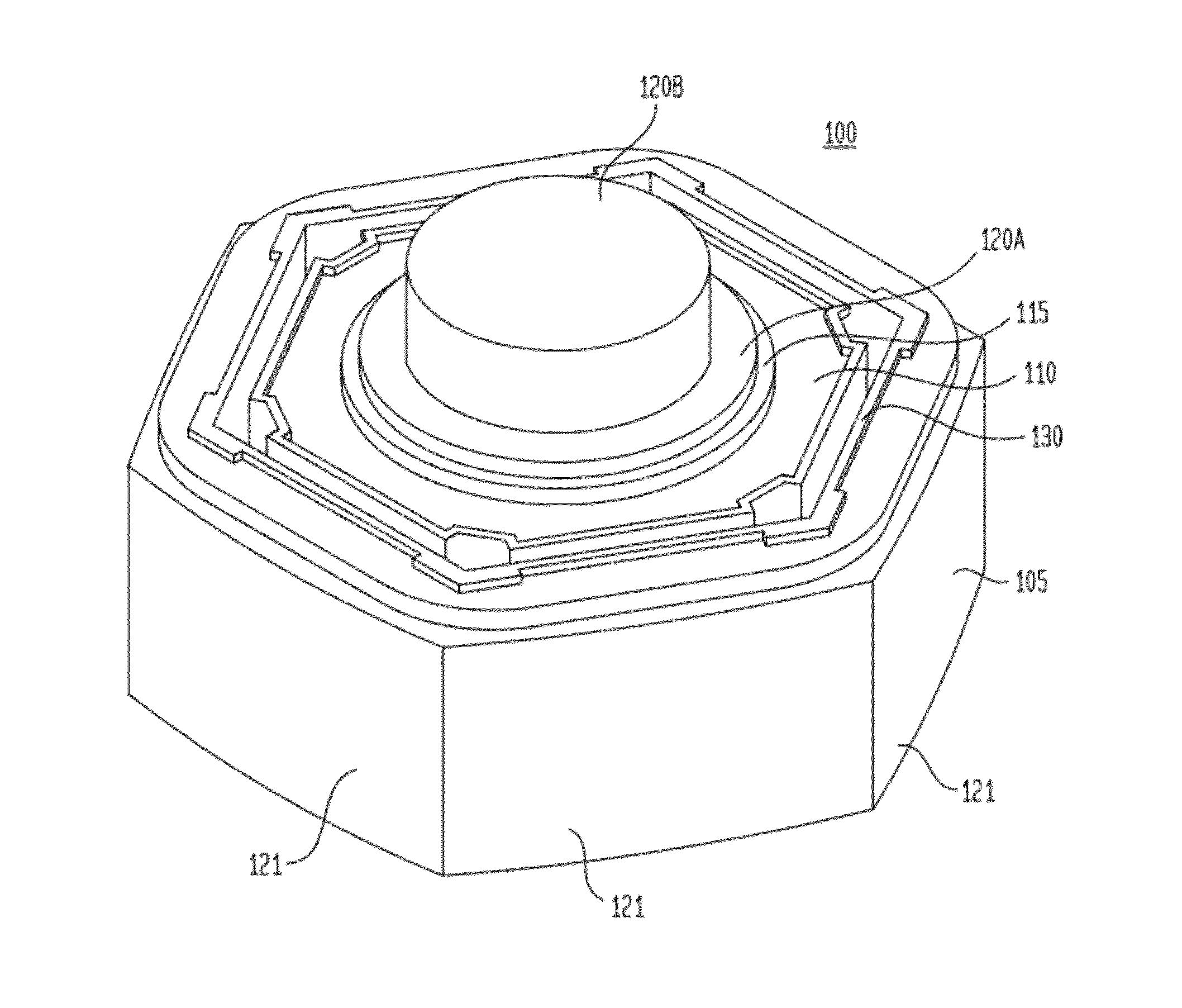

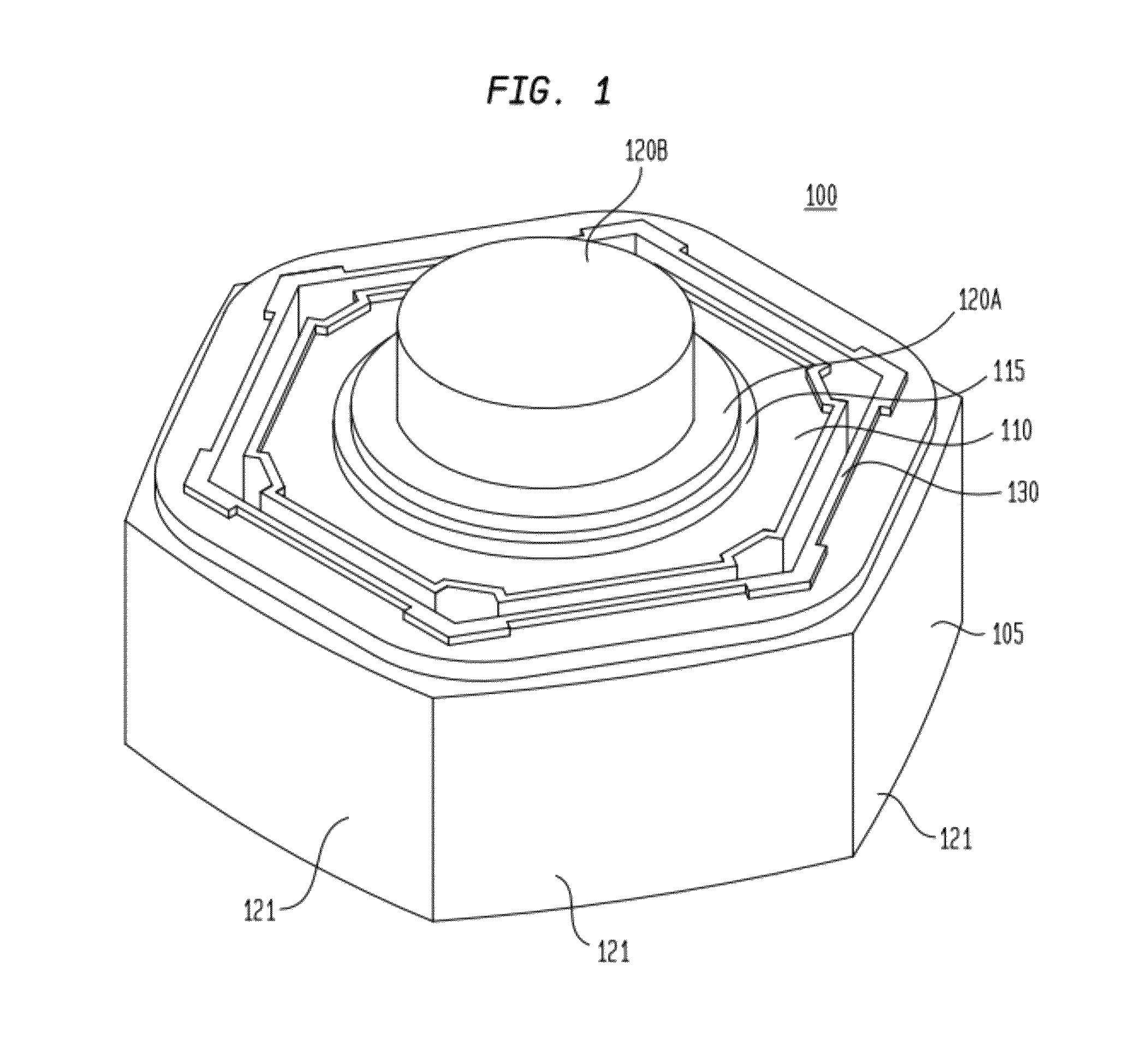

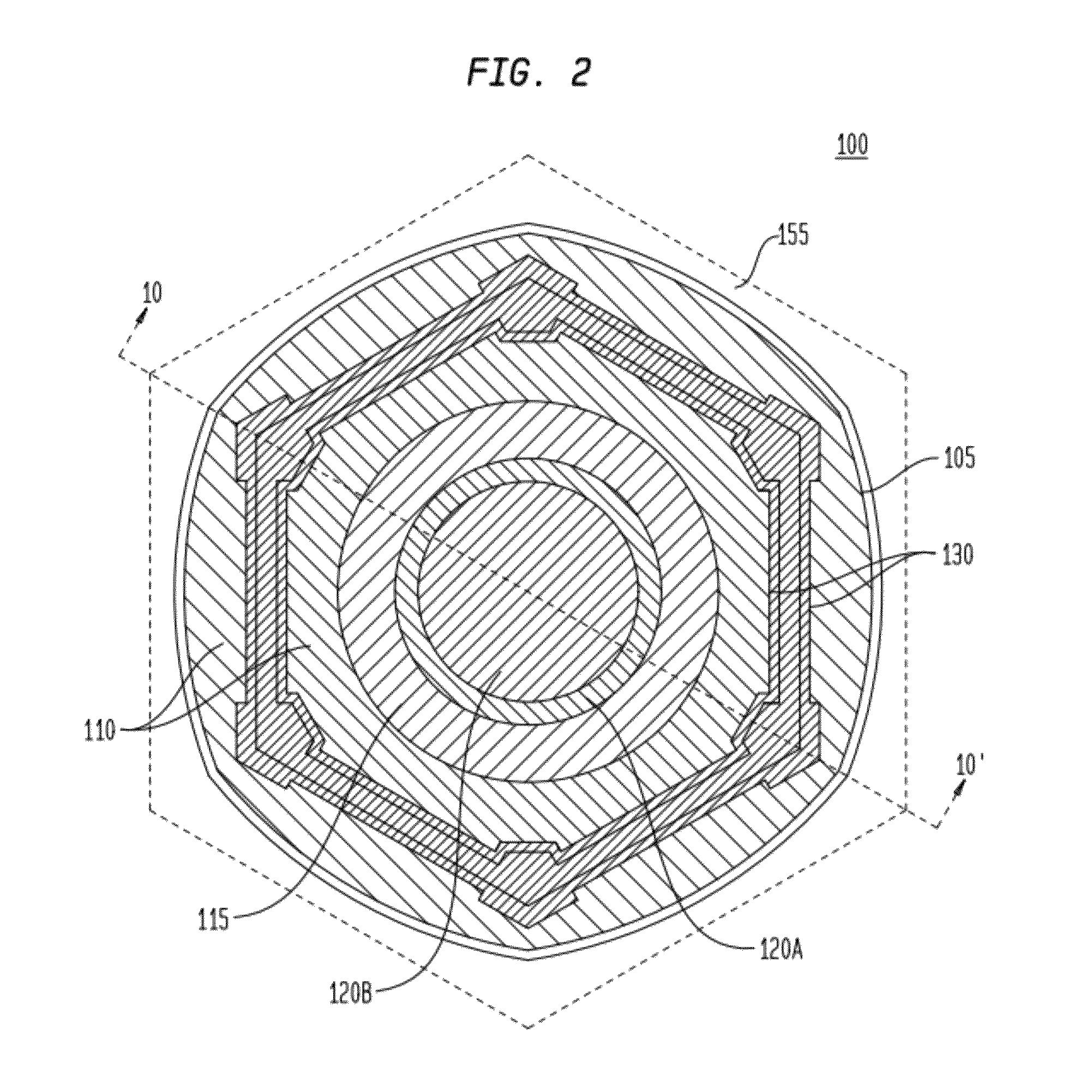

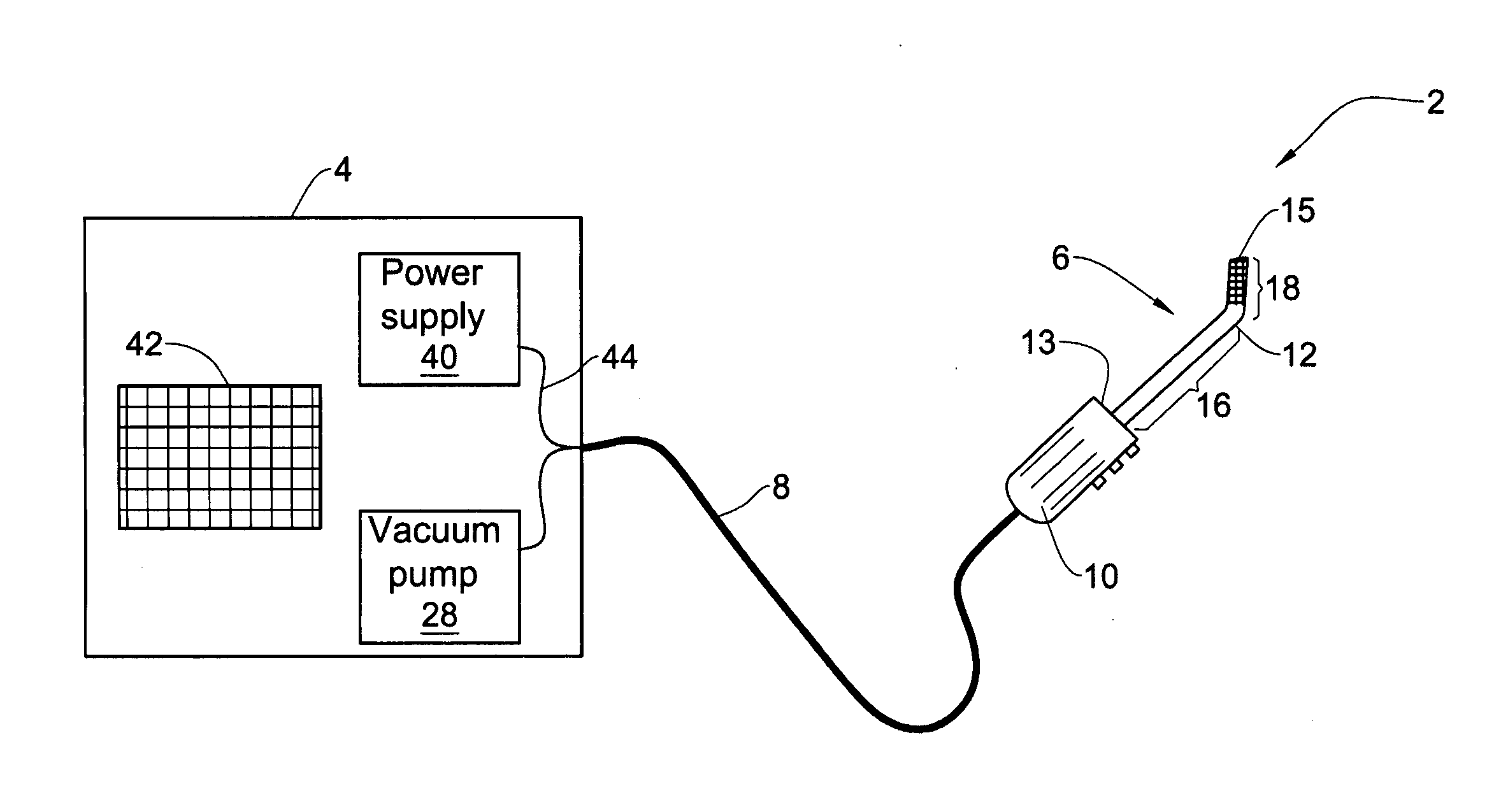

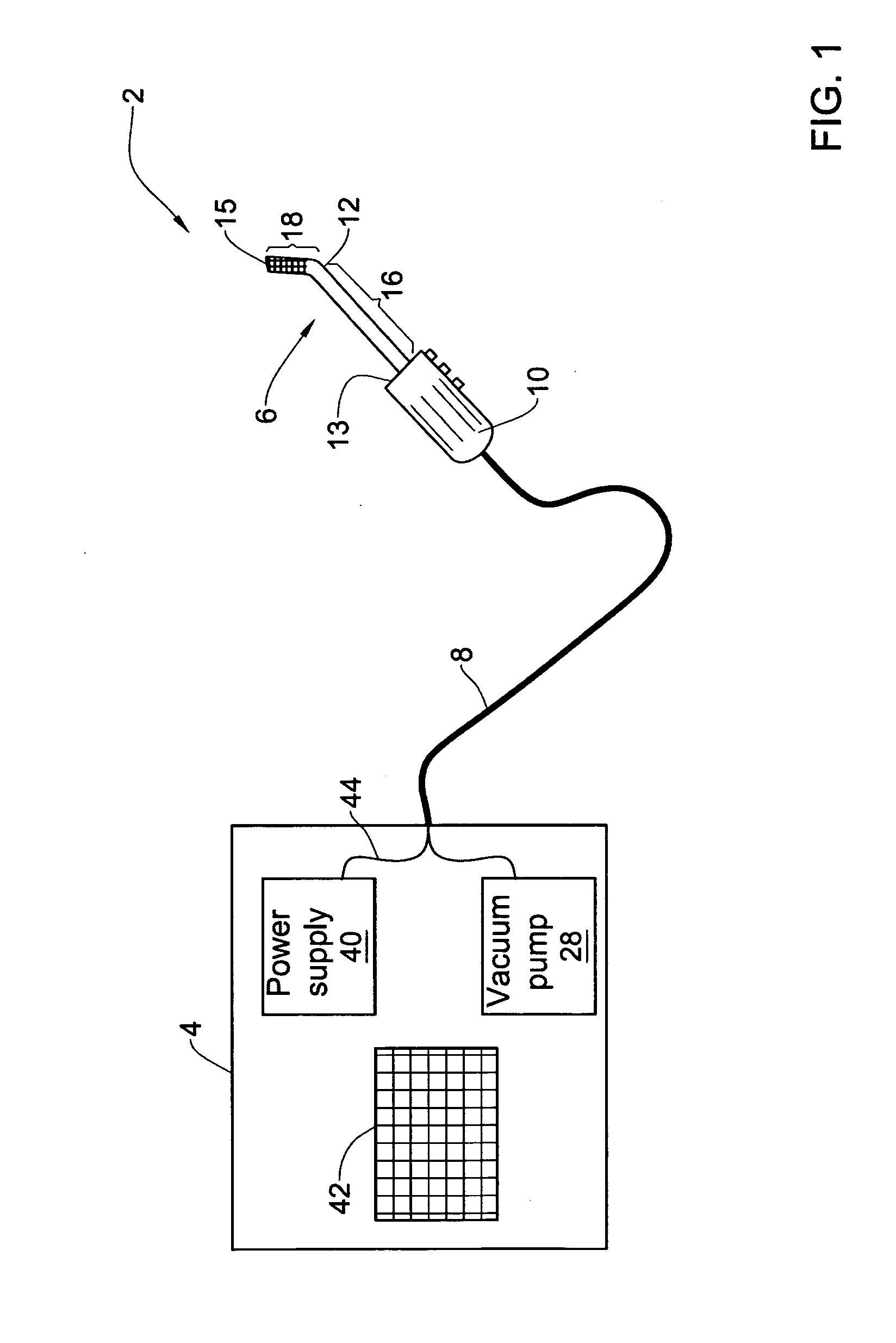

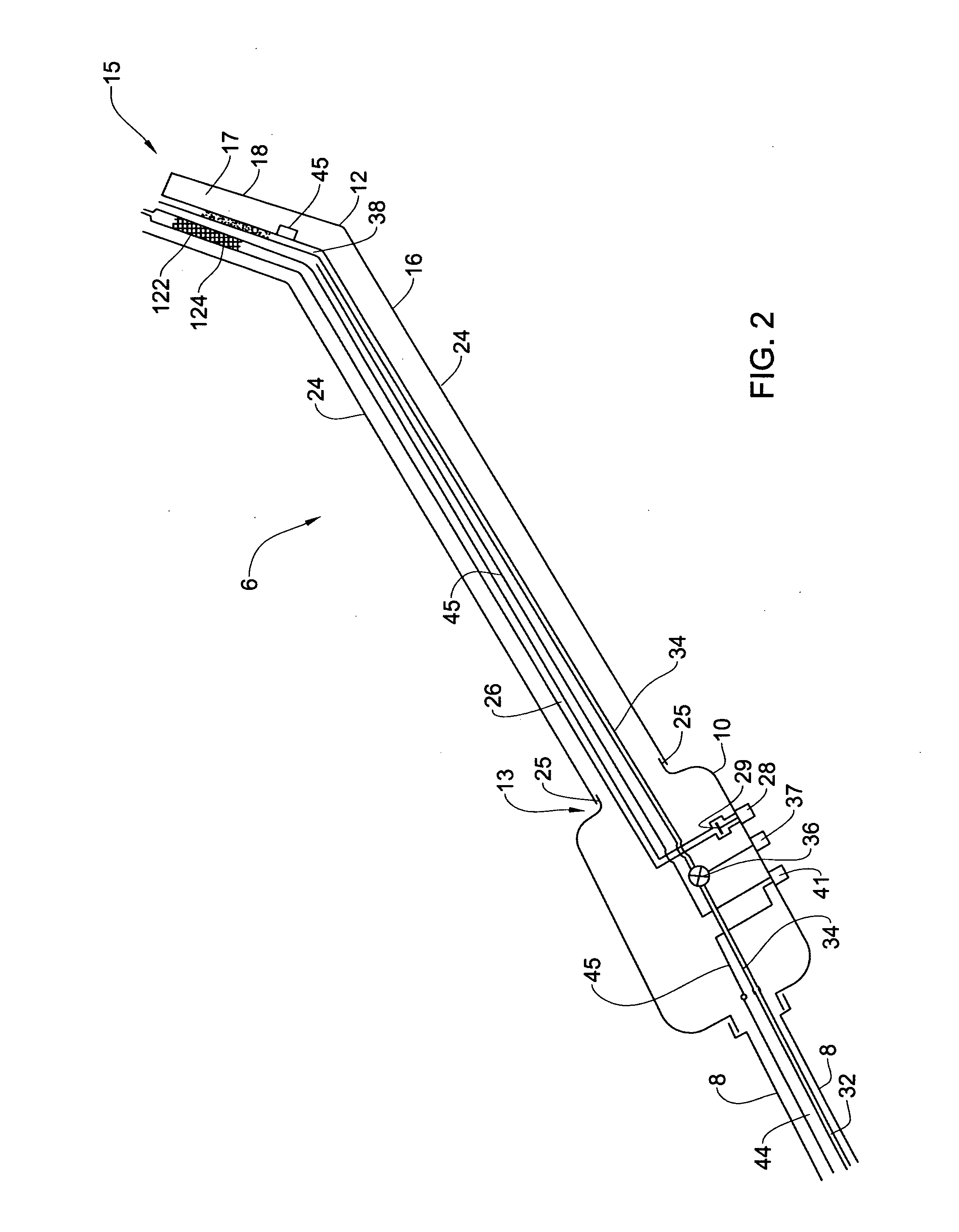

Apparatus for preparing a solid phase microparticulate composition

InactiveUS6042792ALow costImproved substantivityCosmetic preparationsComponent separationWaxMicroparticle

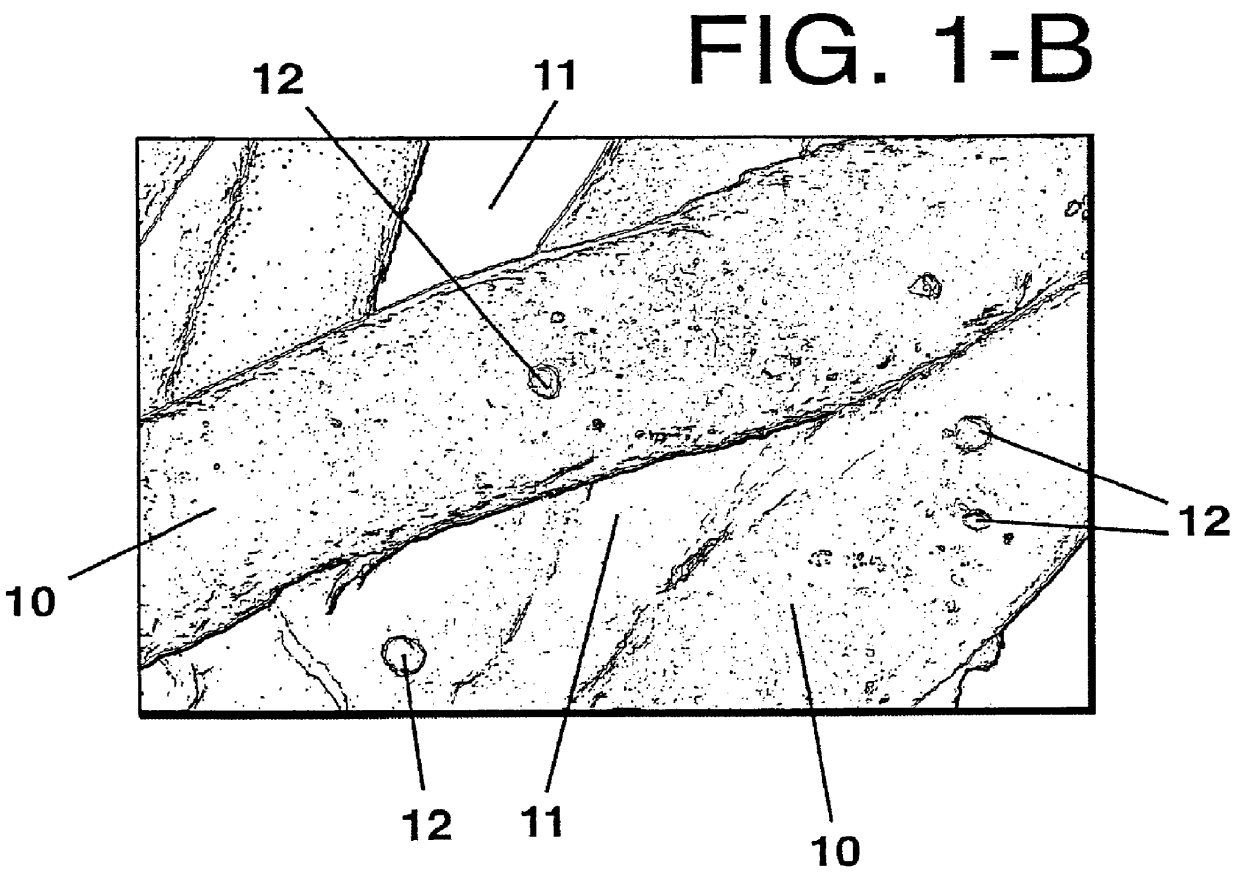

Described are controlled, time-release microparticulate active and bioactive compositions (including perfuming compositions) for targeted delivery to services such as skin, hair and fabric and the environment proximate thereto, where the active and bioactive materials have a calculated log10P values of between 1 and 8 (P being the n-octanol-water partition coefficient). Such compositions include the active or bioactive material in single phase, solid solution in a wax or polymer matrix also having coated thereon and / or containing a compatible surfactant. Also described are processes and apparatus for preparing such compositions and processes for using same. Furthermore, certain component(s) of the aforementioned compositions in combination with one another are novel, and other components have novel uses in increasing fragrance substantivity.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Transdermal Absorption Patch

It is intended to provide a transdermal absorption patch which is highly excellent in transdermal absorption properties and long-lasting drug effect even in the case where a drug-effect component contained in the transdermal absorption patch is a basic drug hardly soluble in a pressure-sensitive adhesive base, has a high stability of the drug contained therein with the passage of time and can achieve improvement in the compliance and simplification of the administration method. These problems can be solved by providing a transdermal absorption patch which contains a basic drug having an octanol / water partition coefficient (logarithm) in the free state of 3 or above, a pressure-sensitive adhesive base and a (meth)acrylic copolymer having carboxyl group.

Owner:HISAMITSU PHARM CO INC

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

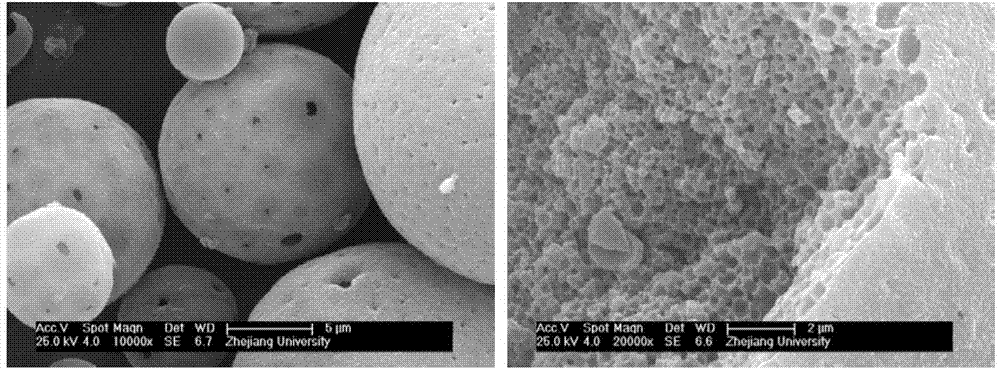

Preparation method of alumina porous microsphere

The invention discloses a preparation method of an alumina porous microsphere. The preparation method comprises the following steps: 1) dissolving a surfactant in deionized water, stirring the solution, and using the solution as a water phase; 2) mixing a chelating agent, an alumina precursor and octanol, stirring the materials, and using the mixture as an oil phase; 3) adding Span80 and a pore-forming agent to the oil phase, and stirring the materials; 4) pouring the clear oil phase obtained in the step 3) into the water phase, and continuously stirring and emulsifying the materials; 5) carrying out vacuum filtration on the product obtained in the step 4), and washing and then drying the obtained filter cake, thus obtaining the alumina porous microsphere. The microsphere has an internally closed macroporous structure and has a microsphere dimension of 1-100mu m and an internally closed pore diameter of 50nm-5mu m.

Owner:ZHEJIANG UNIV

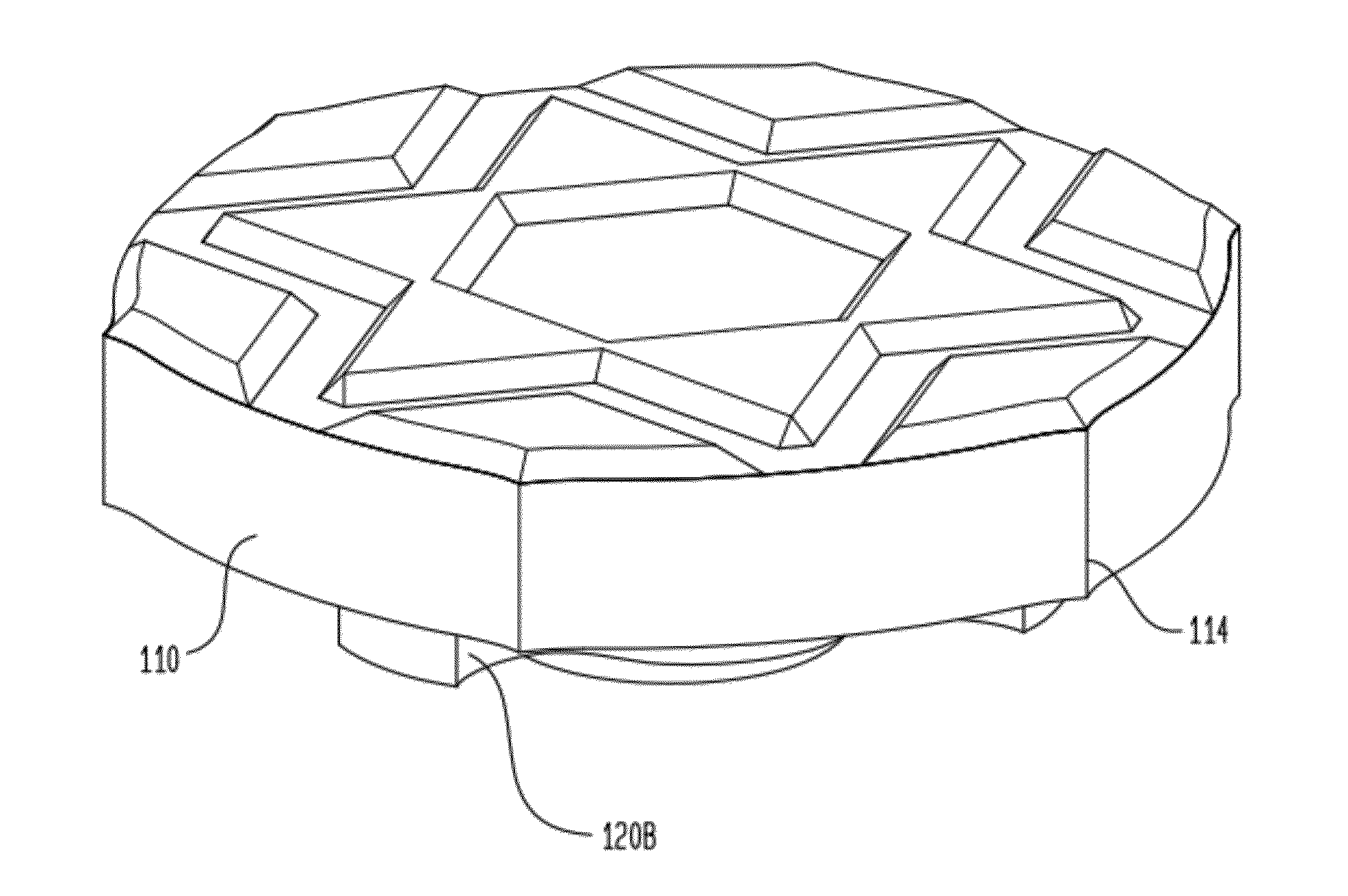

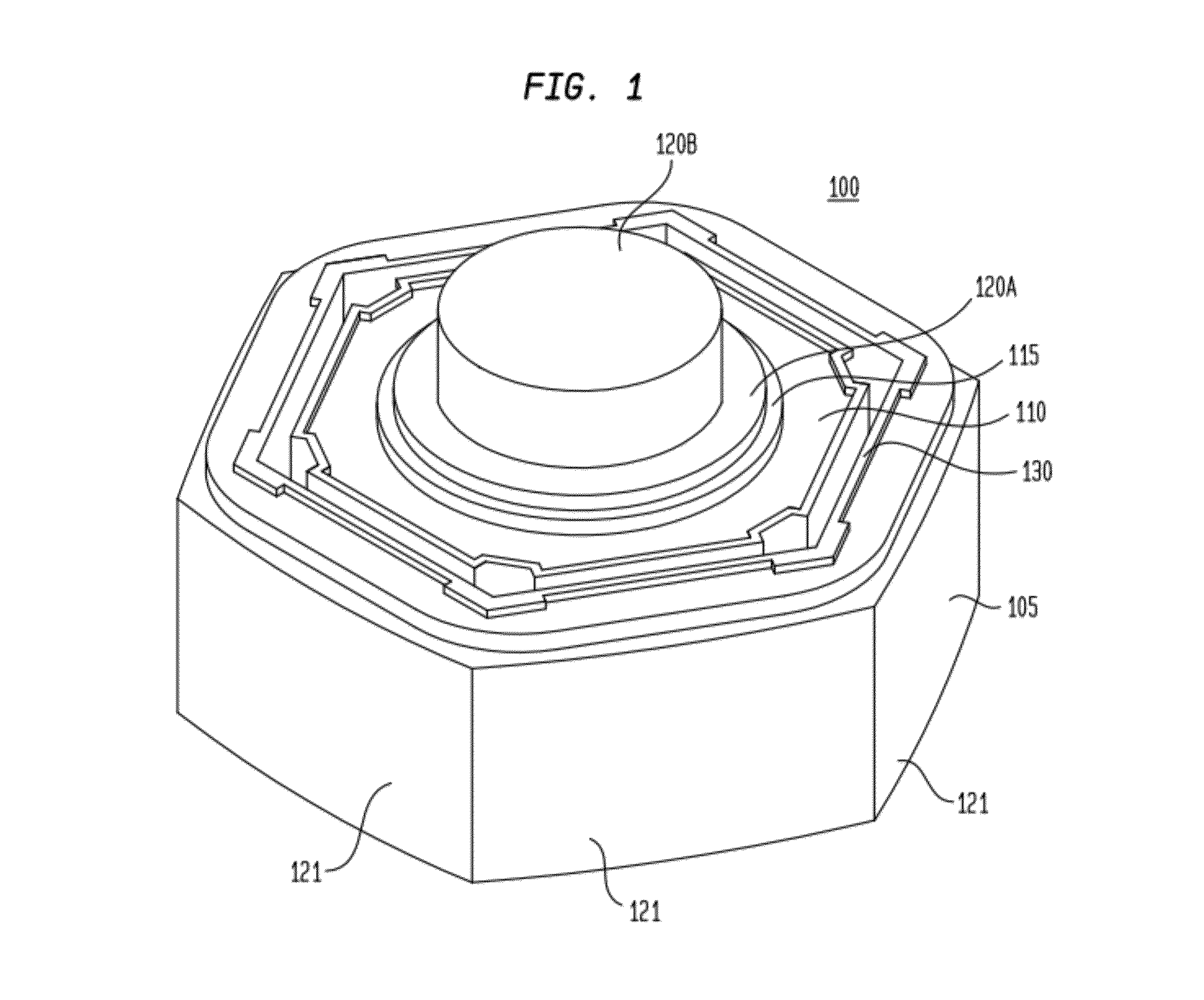

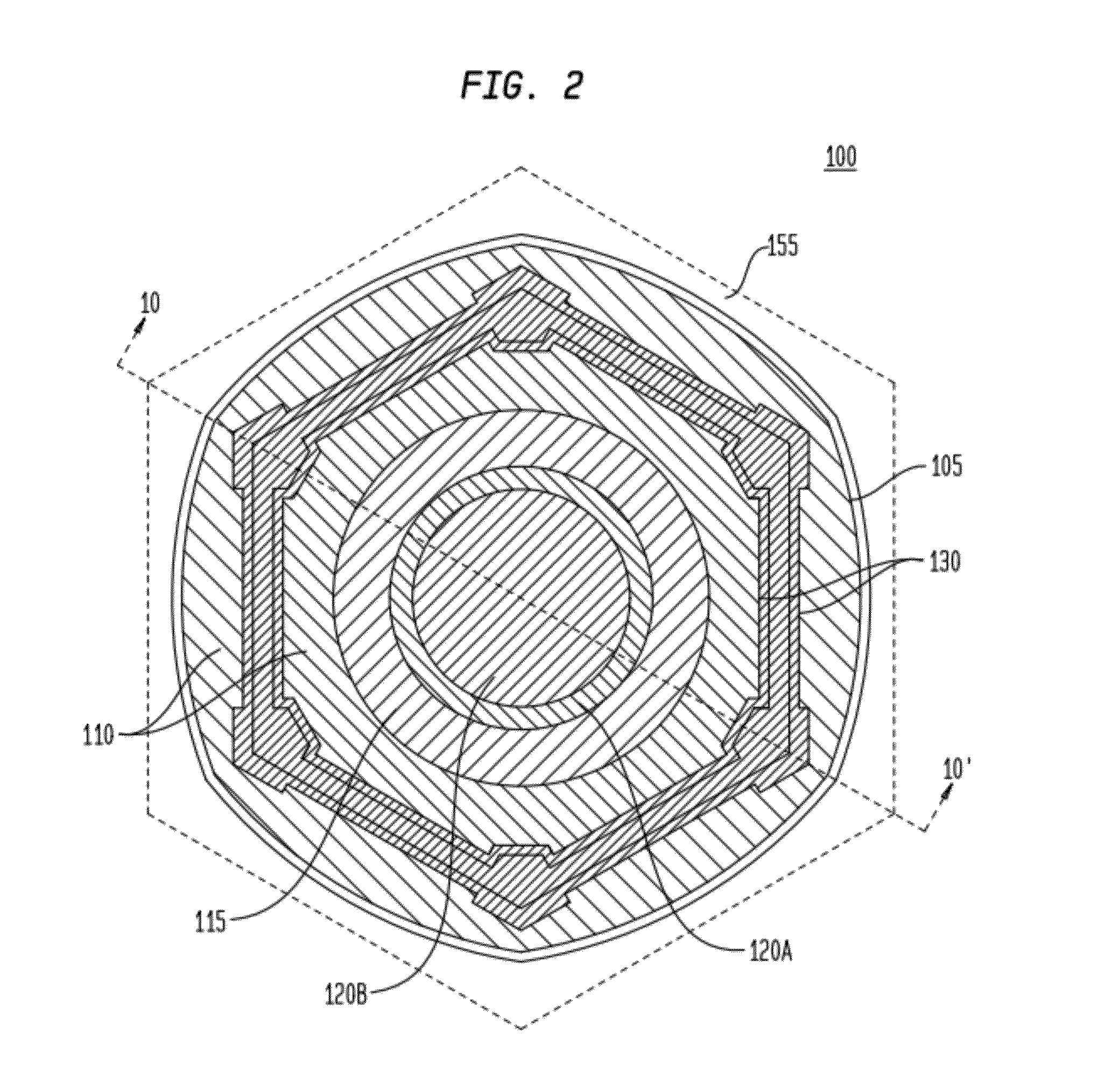

Printable Composition of a Liquid or Gel Suspension of Diodes

ActiveUS20120161195A1Solid-state devicesSemiconductor/solid-state device manufacturingOctanolSolvent

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

Process for producing aqueous fluoropolymer dispersion and aqueous fluoropolymer dispersion

ActiveUS20070135558A1Efficient productionLow total surfactant contentSemi-permeable membranesFibre treatmentPolymer scienceOctanol

The present invention provides a method of producing a fluoropolymer aqueous dispersion by which the fluorine-containing emulsifier contained in the fluoropolymer aqueous dispersion as obtained after polymerization can be efficiently removed as well as a fluoropolymer aqueous dispersion low in fluorine-containing emulsifier concentration. The present invention is a method of producing a fluoropolymer aqueous dispersion which comprises carrying out a concentration treatment comprising a concentration operation of a pretreatment fluoropolymer aqueous dispersion, wherein the pretreatment fluoropolymer aqueous dispersion is obtained by carrying out a polymerization in an aqueous medium in the presence of a fluorine-containing surfactant (A), the fluorine-containing surfactant (A) is a fluorine-containing surfactant having an octanol / water partition coefficient of 1.5 to 3.5.

Owner:DAIKIN IND LTD

Printable composition of a liquid or gel suspension of diodes

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

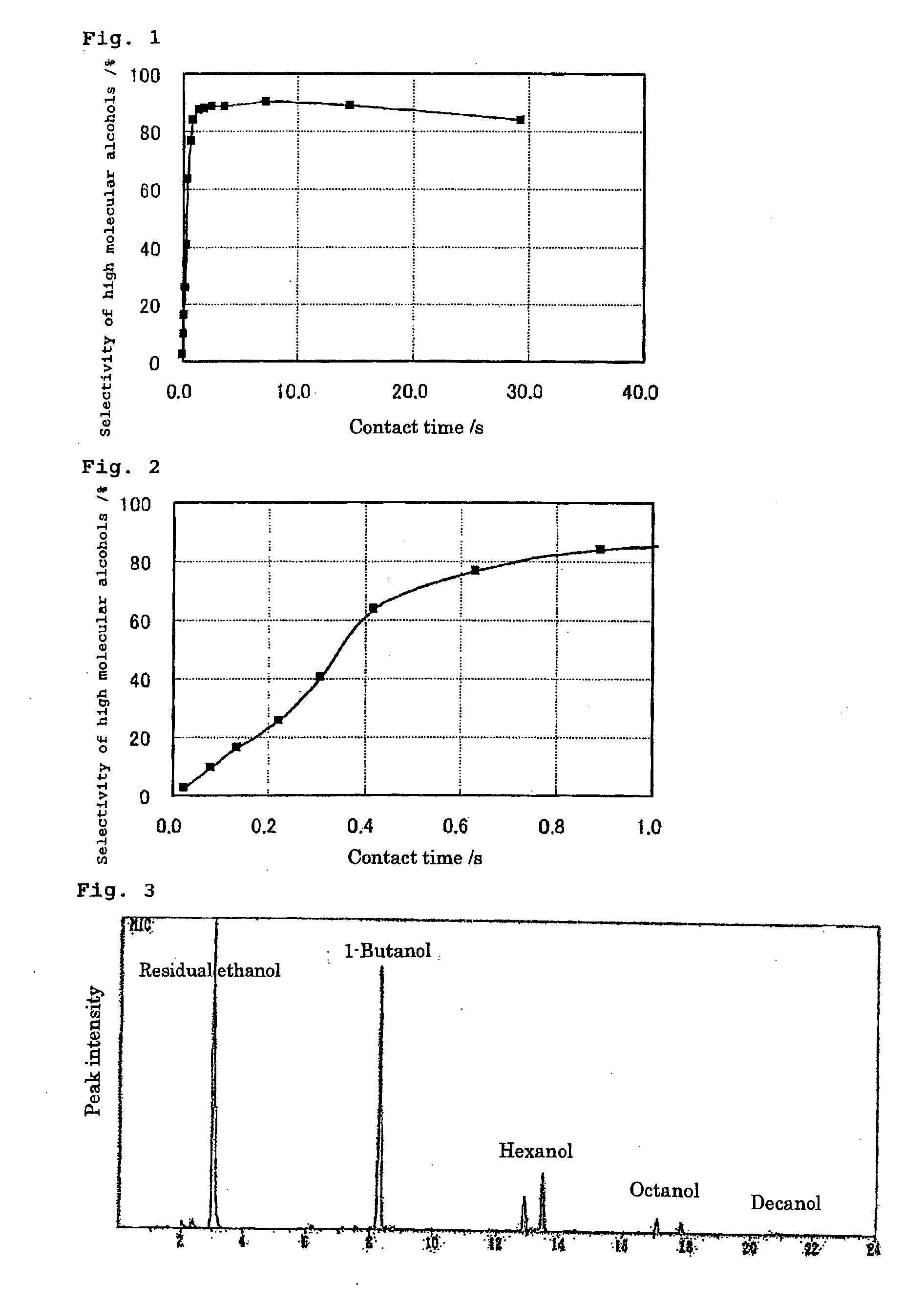

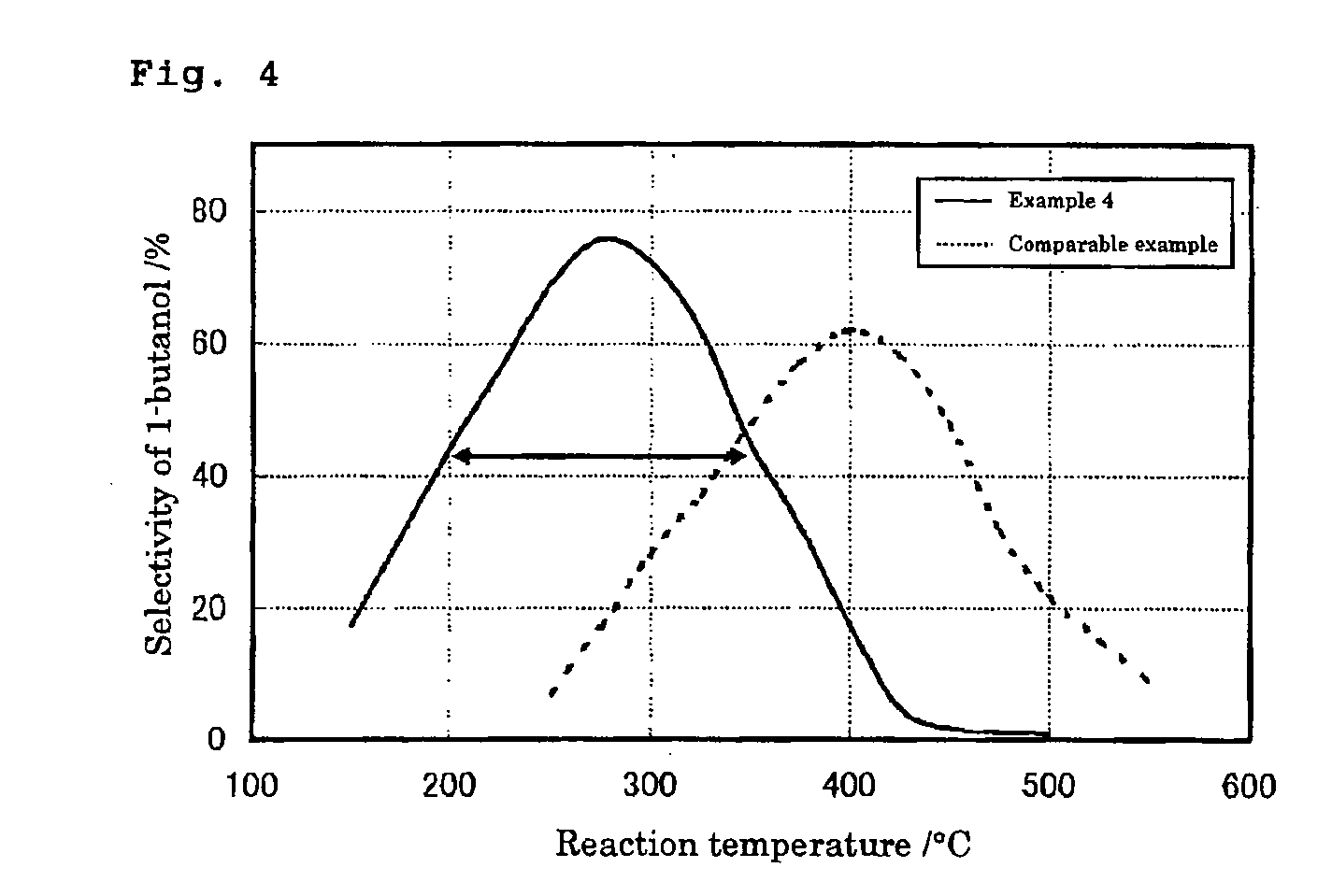

Method of Synthesizing Higher-Molecular Alcohol

ActiveUS20070255079A1Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationOctanolSynthetic Polymeric Macromolecules

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2.nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

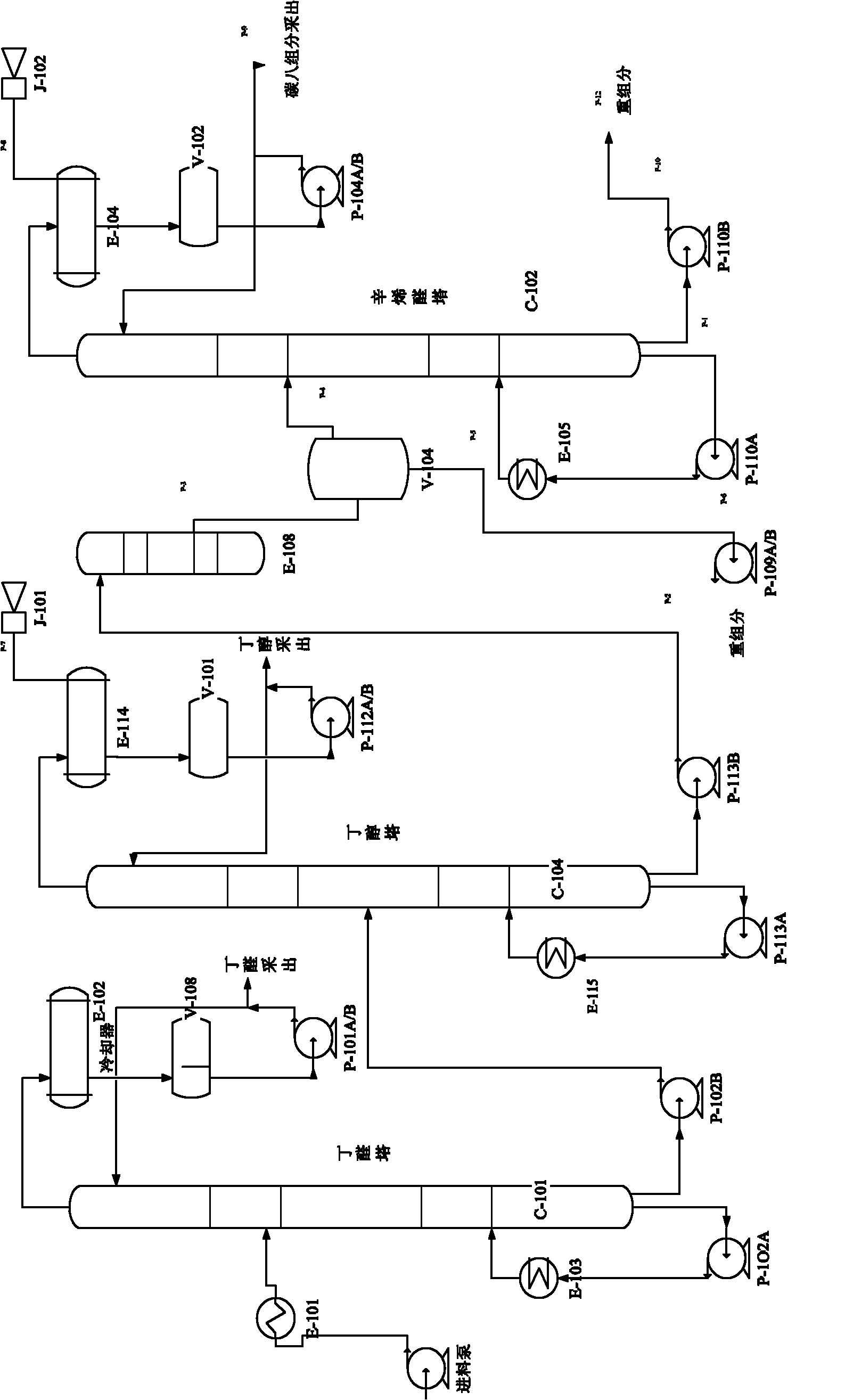

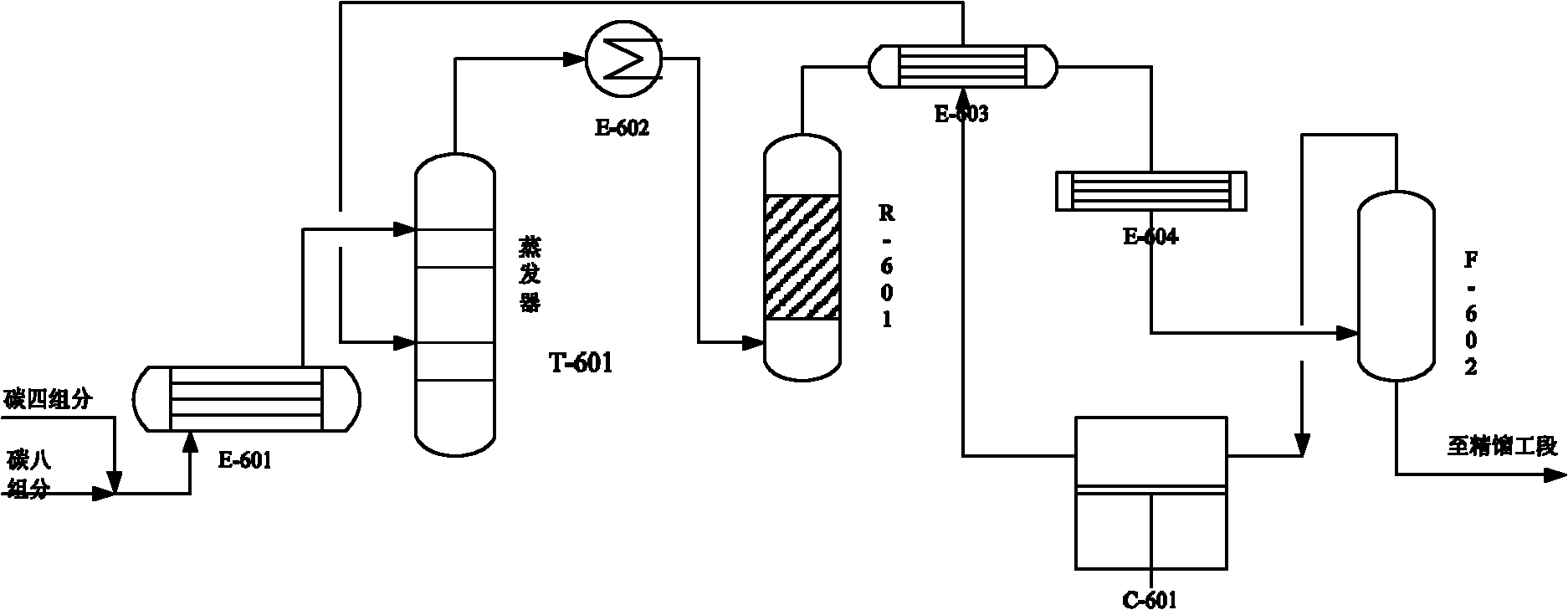

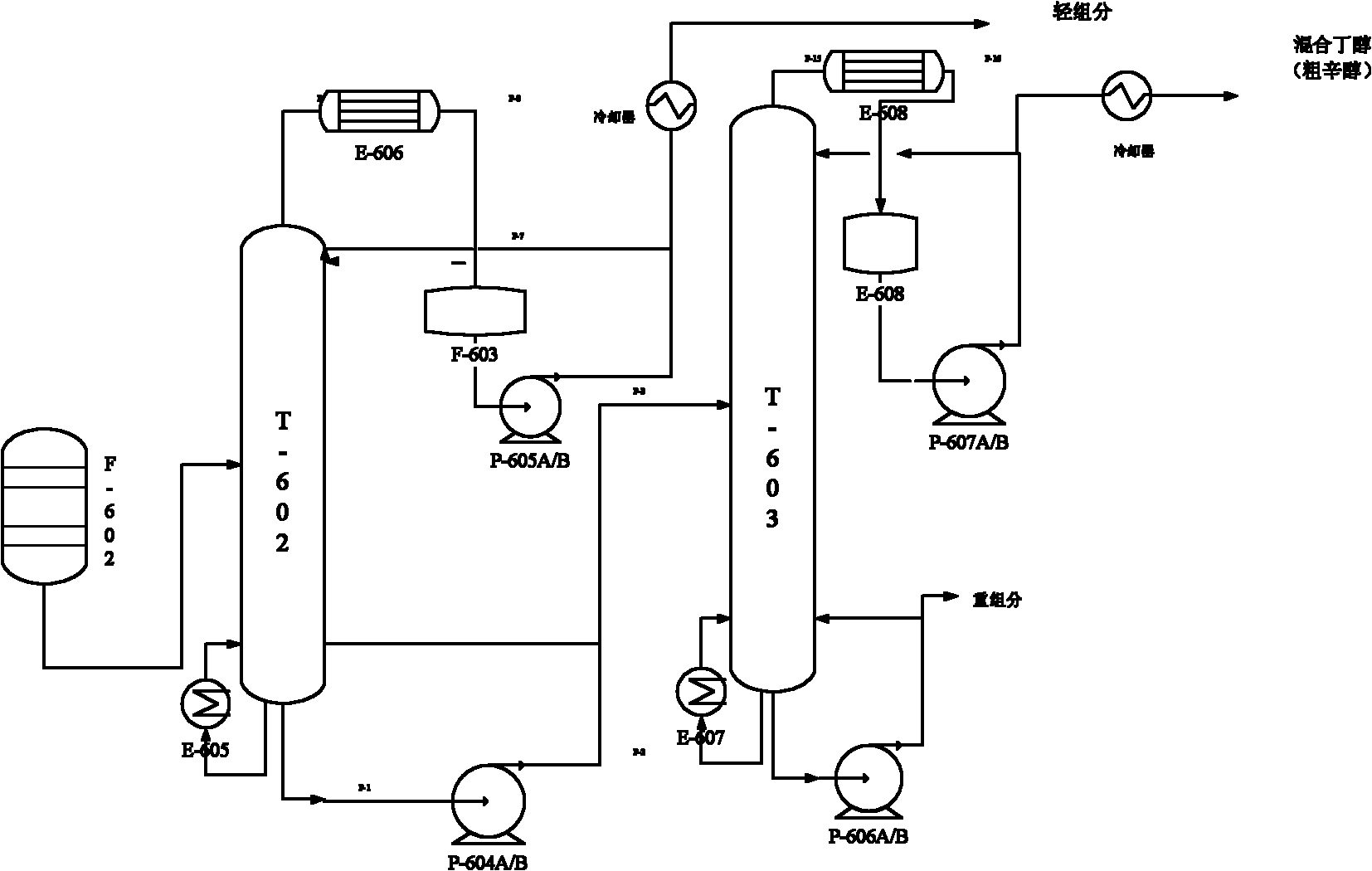

Method for producing mixed butanol and coarse octanol by using waste liquid discharged from octanol device as raw material

ActiveCN101973846AReduce loadReduce processing costsOrganic compound preparationPreparation by hydrogenationLiquid wasteDistillation

The invention discloses a method for producing mixed butanol and coarse octanol by using waste liquid discharged from an octanol device as a raw material, which belongs to a method for preparing acyclic monohydric alcohols, and is characterized by using a raw material fractionation unit, a hydrogenation synthesis unit and a product distillation unit, wherein the raw material fractionation unit comprises three fractionation devices: a butyraldehyde fractionation tower, a butanol fractionation tower and a C8 fractionation tower; the hydrogenation synthesis unit and the product distillation unit are suitable for hydrogenating and distilling a butyraldehyde fraction and a C8 fraction from the raw material fractionation unit alternately; and the product distillation unit comprises a light component removing tower device and a heavy component removing tower device. The method for producing the mixed butanol and coarse octanol by using the waste liquid discharged from the octanol device as the raw material, which is energy-saving and environmentally-friendly, can realize the recycling of the waste liquid discharged from the octanol device, reduce the waste water treatment cost of the octanol device and improves the technical indexes of treated water.

Owner:淄博诺奥化工有限公司

High-voltage power transmission line ice-covering-proof paint and preparation method thereof

InactiveCN102146249AImprove thermal conductivityImprove hydrophobicityEpoxy resin coatingsTransformerLow temperature curing

The invention discloses high-voltage power transmission line ice-covering-proof paint and a preparation method thereof. The preparation method comprises the following steps: using toluene diisocynate, tridecafluoro-octanol, butyl acetate, organosilicon modified epoxy resin, epoxy resin curing agent, organic solvent, nanographite and carbon nanotubes as raw materials to react and ensure that long-carbon-chain fluoro-alcohol is grafted in the molecular chain of epoxy resin, and adding nanographite and carbon nanotubes in the modified epoxy resin to prepare the paint with good hydrophobicity and thermal conductivity. The paint is mainly used in the coating of the high-voltage power transmission line and the coatings of equipment such as the insulator and the transformer case; and the paint has high coating adhesion, is ice-covering-proof and environmental friendly, has the advantages of corrosion resistance, ultraviolet resistance and aging resistance, and no pollution. Compared with the traditional acrylic paint, the paint has the advantages of simple preparation technology and excellent room temperature curing performance and low temperature curing performance, and is convenient to construct and operate.

Owner:甘肃省电力公司检修公司 +1

Lost foam casting cast iron coating for preventing carbon defects and preparation method thereof

InactiveCN101767184AGood suspensionImprove thixotropyFoundry mouldsFoundry coresPolyvinyl alcoholOctanol

The invention discloses a lost foam casting cast iron coating for preventing carbon defects, which comprises the following components by weight percent: 60.5%-64.5% of bauxite, 13.5-17.5% of kaolin, 3.5%-6.0% of talc powder, 1.7%-3.5% of attapulgite, 0.4%-0.8% of sodium lignosulphonate, 2.5%-6.0% of aluminum sulfate, 1.7%-3.5% of polyvinyl alcohol, 3.5%-5.0% of silica sol, 0.1%-0.2% of iron oxide powder and 0.01%-0.02% of n-octanol, and the sum of the components is 100%. The lost foam casting cast iron coating is prepared by respectively preparing water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, evenly mixing the bauxite, the kaolin, the talc powder and the iron oxide powder for preparing mixed powder material, mixing the water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, the silica sol and the refractory mixed powder material with the n-octanol, stirring and grinding. The coating has the advantages of good thixotropy, good coating property, high coating strength and good gas permeability; and the surface of a cast is smooth and has no wrinkles and other carbon defects.

Owner:NANTONG XINZHENGDA SPECIAL STEEL

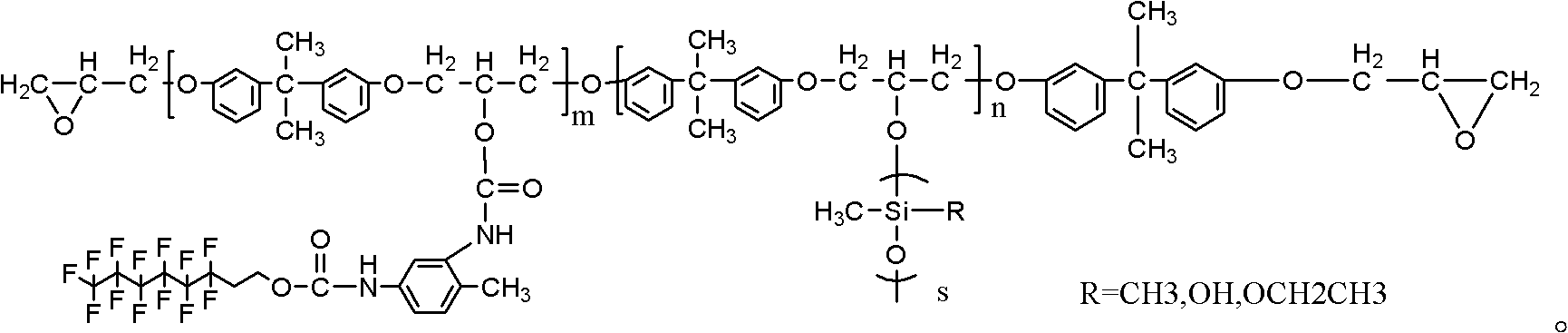

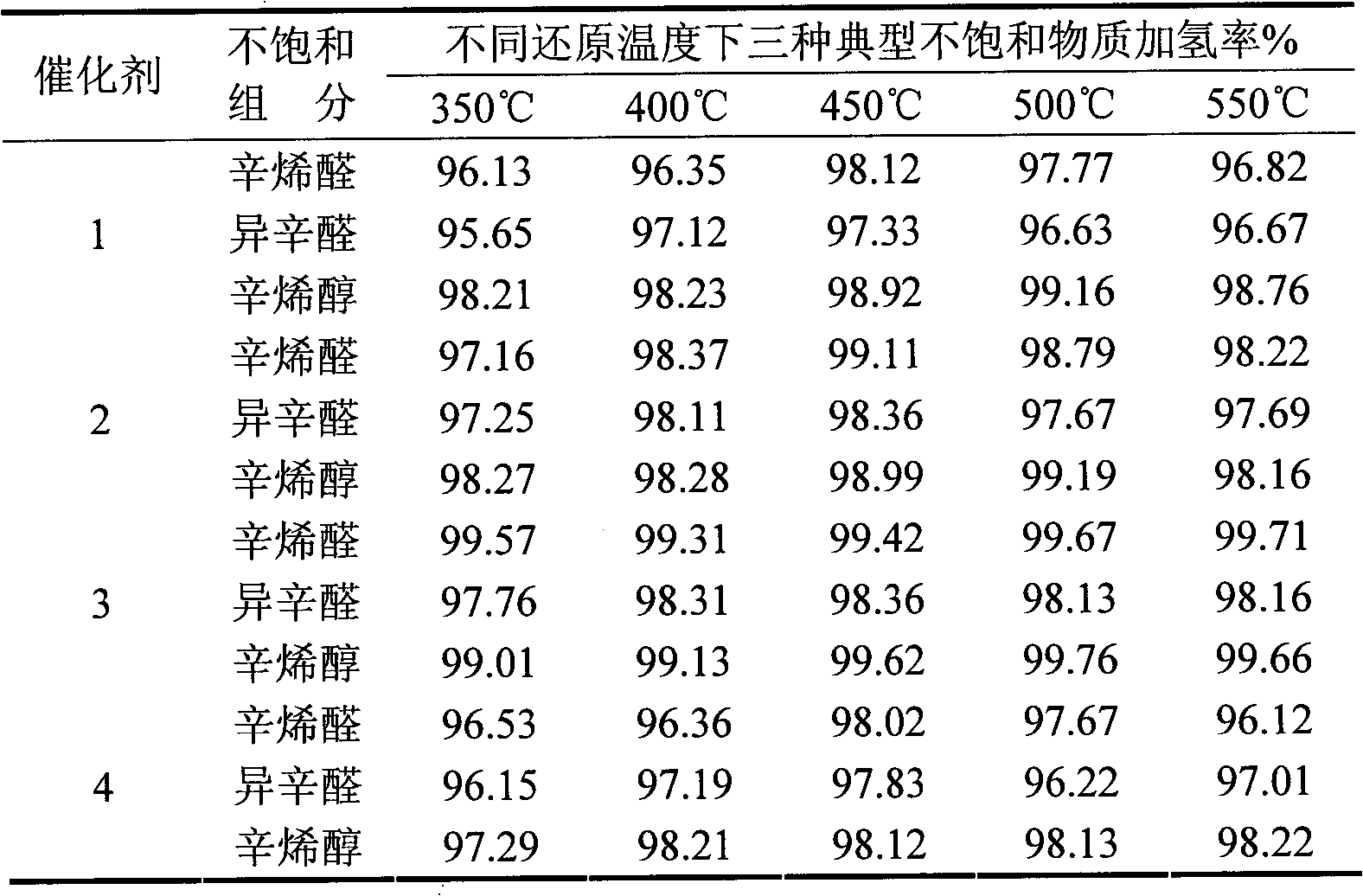

Lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof

ActiveCN102059121AReduce generationReduce coalescenceOrganic compound preparationHydroxy compound preparationReaction temperatureOctanol

The invention relates to a lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof. The catalyst is prepared by taking Gamma-Al2O3 as a carrier, taking lanthanum as an auxiliary agent, taking nickel-copper as a active component and adopting an immersion method; and the aluminum oxide accounts for 40-90%in the terms of 100% by mass, the content of nickel is 1-40% in the terms of NiO, the content of copper is 1-30% in the terms of CuO, and the lanthanum as the auxiliary agent is 0.1-10% in the terms of La2O3; and a hydrogenation evaluation result indicates that the catalyst is reduced at a temperature of 350-550 DEG C, and under the conditions that the reaction temperature is 120 DEG C, the reaction pressure is 2.5MPa, the volume ratio of hydrogen to liquid is 8:1 and the volume air speed is 3.0h<-1>, the hydrogenation rates of unsaturated substances such as octylene aldehyde, isooctyl aldehyde and octylene alcohol are all more than 95%.

Owner:PETROCHINA CO LTD +1

Matrix composition comprising surfactant and matrix useful for targeted delivery articles

InactiveUS6156826ALow costImproved substantivityCosmetic preparationsComponent separationWaxMicroparticle

Described are controlled, time-release microparticulate active and bioactive compositions (including perfuming compositions) for targeted delivery to surfaces such as skin, hair and fabric and the environment proximate thereto, where the active and bioactive materials have a calculated log10P values of between 1 and 8 (P being the n-octanol-water partition coefficient). Such compositions include the active or bioactive material in single phase, solid solution in a wax or polymer matrix also having coated thereon and / or containing a compatible surfactant. Also described are processes and apparatus for preparing such compositions and processes for using same. Furthermore, certain component(s) of the aforementioned compositions in combination with one another are novel, and other components have novel uses in increasing fragrance substantivity, particularly in hair care preparations such as hair gels and shampoos.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Treatment process for two stage recycling alkali waste liquid drained off by process system of synthesizing octanol

InactiveCN1462729AReduce liquiditySave investment costMultistage water/sewage treatmentWater/sewage treatment by neutralisationProcess systemsWastewater

A two-stage process for reclaiming the waste alkaline solution discharged by octanol synthesizing system includes "after-heat self-extracting" and "activated carbon adsorption" stages, that is, usingthe afterheat and inorganic acid to acidify the waste alkaline solution, extracting the organic components from waste solution by 2-ethylhexanol as the product of said octanol synthesizing system, adsorbing the residual phase by granular activated carbon, neutralizing by alkali, biochemical treating, and regenerating the used activated carbon. Its advantagesa re high effect etc.

Owner:SHANGHAI JIAO TONG UNIV

Pharmaceutical composition and system for permeabilizing fetal membranes

Provided is a pharmaceutical composition for permeabilizing fetal membranes including an active ingredient having a log K in the range of 2 to 4, where K is the octanol / water partition coefficient. The active ingredient may be, for example, bupivacaine, sodium lauryl sulfate or oleic acid. Further provided is a system for transfetal membrane transport. The system includes a probe unit adapted for insertion into a female reproductive tract and releasing a substance onto fetal membranes that permeabilizes the membranes. The system is also configured to apply ultrasound radiation to the fetal membranes to further increase the membrane permeability.

Owner:B G NEGEV TECH & APPL LTD

Formulation of surfactant oil displacement system for anionic and nonionic oil displacement

ActiveCN101705083ASignificant precipitation and oil increase effectImprove oil displacement efficiencyDrilling compositionAlkanePhosphate

The invention provides a composition of a surfactant oil displacement system for anionic and nonionic oil displacement. The composition consists of 18% C18 sodium alkyl benzene sulfonate, C16 fatty acid, 25% C2 alkanolamide, 7% C8 alkylphenol polyoxyethylene ether phosphate, 17% ethanol, 3% octanol, 30% water; the alkyl is a hydrocarbyl group with linear chain, branched chain and ring structures in a calibrated carbon atom range, and also can be substituted by one or more halogens, alkyls or alkoxys; the sodium sulfonates are formed by sulfonating different alkanes or arenes by SO3 or chlorosulfonic acid in chloroalkane environment and then neutralizing the sulfonate and sodium hydroxide; and the esterification derivatives are sulfates or phosphates. The formulation has highoil displacement efficiency, strong oil deposit adaptability and good popularization prospect.

Owner:DESHI ENERGY TECH GRP CO LTD

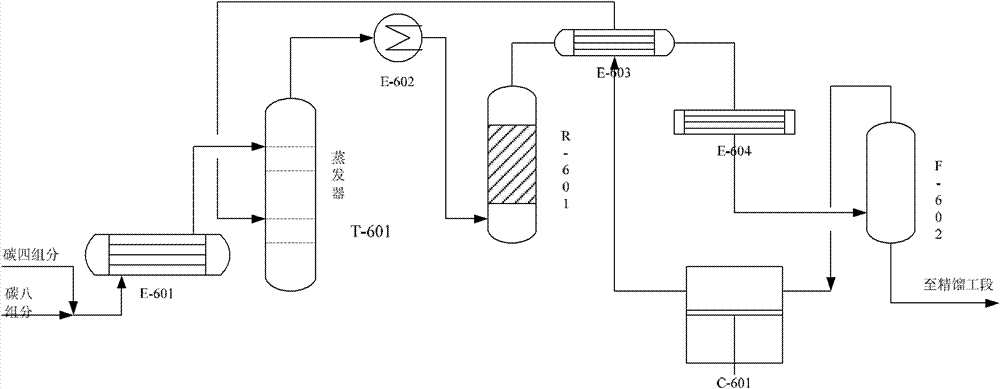

Treatment process of 2-ethyl hexanol liquid waste

InactiveCN103342625AAvoid crackingTake advantage ofOrganic compound preparationHydroxy compound preparationLiquid wasteSocial benefits

The invention discloses a treatment process of 2-ethyl hexanol liquid waste. The treatment process is suitable for processing the 2-ethyl hexanol liquid waste discharged by a 2-ethyl hexanol device. The treatment process comprises the following steps: heating the 2-ethyl hexanol liquid waste to 60-100 DEG C and then leading to a middle section of a first rectifying tower; removing moisture and light components from the top of the first rectifying tower under the effect of an entrainer; enabling tower kettle liquid of the first rectifying tower to enter the middle section of a second rectifying tower, so as to obtain a butanol product of which the purity is greater than 98% from the top of the second rectifying tower; enabling the tower kettle liquid of the second rectifying tower to enter the middle section of a third rectifying tower; removing C5-C7 and an octenal component from the top of the third rectifying tower; and enabling the tower kettle liquid of the third rectifying tower to enter the middle section of a fourth rectifying tower, so as to obtain an octanol product of which the purity is greater than 98% from the top of the fourth rectifying tower. The treatment process does not need any fuel; butanol and octanol, of which the purity is greater than 98%, can be effectively recovered, so that the useful components in the 2-ethyl hexanol liquid waste can be fully utilized; the resources are saved; the environmental pollution is also reduced; the treatment process has good economical benefits and social benefits.

Owner:SHANGHAI DONGHUA ENVIRONMENT ENG

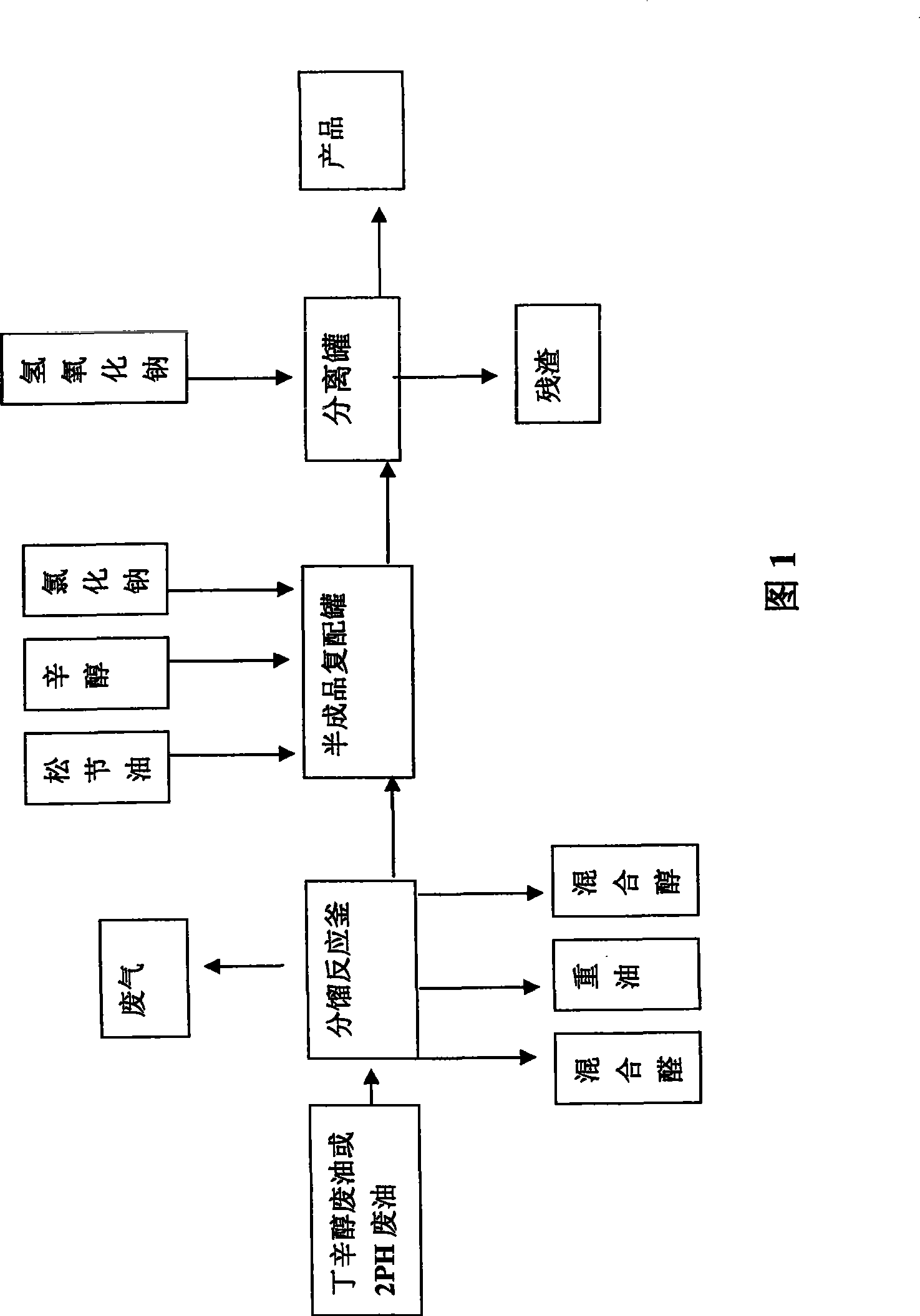

Butanol-octanol waste oil and 2-PH waste oil resource treatment method

The invention provides a resourceful treatment method for butanol-octanol waste oil and 2-PH waste oil, which can effectively recover useful compositions in the waste oil to produce an ore flotation agent and obtain a product with high added value, and has good economical benefit. In the method, the butanol-octanol waste oil is fractionized under normal pressure or pressure reduction to obtain mixed alcohol and heavy oil, and then auxiliary materials such as octanol are added to compound to obtain a flotation agent product. Industrial waste gas produced during wastewater esterification and fractionization processes is cleaned and then is sent into the prior incinerator for incineration treatment along with waste residues produced by neutralization and separation after the compounding, and heat energy in flue gas is recovered to produce steam for a production device for use. A production technology does not produce production sewage.

Owner:NANJING FUCHANG ENVIRONMENTAL PROTECTION

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Octanol hydrorefining catalyst and preparation method thereof

InactiveCN101791556AHigh surface active sitesIncreased surface active sitesOrganic compound preparationPreparation by hydrogenationRare-earth elementNickel salt

The invention discloses an octanol hydrorefining catalyst, which belongs to the field of hydrorefining catalytic materials. The prepared catalyst is used for modifying a carrier by using a rare earth element, reducing the amount of an active component of a nickel ion entering a carrier framework and improving the content of surface nickel species; the active component is loaded by adopting a hydrothermal deposition method, the dispersion of nickel salts on the surface of a carrier pore canal by using hydrothermal high-temperature and high-pressure conditions and forming nickel precipitation with proper size at the loading initial period of the active component by using a deposition reaction, so the invention can effectively control the amount of the nickel ions entering the carrier, improve the content of the surface nickel species and simultaneously can avoid the growth of nickel oxide particles; and the catalyst greatly increases the surface nickel active site, effectively improves the utilization rate of the active component of nickel and has higher catalytic reaction activity during hydrorefining the octanol at higher airspeed. The result shows that the hydrogenation rate of an unsaturated substance in crude octanol reaches over 90 percent when the temperature is 120DEG c, the pressure is 2.5MPa, the ratio of hydrogen to liquid for feeding is 8:1 and the airspeed is 30<-1>hour.

Owner:UNIV OF SCI & TECH BEIJING

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Hard Surface Cleaners Comprising Low VOC, Low Odor Alkanolamines

InactiveUS20130196893A1Organic detergent compounding agentsDetergent solventsSurface cleaningOctanol

Hard surface cleaning compositions comprise: A. Surfactant, e.g., a nonionic ethoxylated alcohol; B. Solvent, e.g., propyleneglycol n-butyl ether; C. Low VOC, low odor, alkanolamine selected from the group consisting of tris(hydroxymethyl)amino methane; 2-amino-2-methyl-1,3-propanediol; 2-amino-2-ethyl-1,3-propanediol; 2-amino-2-methyl-1-propanol; N,N-dimethylamino-2-methyl-1-propanol; and 3-amino-4-octanol; D. Water, and E. Optionally, one or more of an alkaline agent, builder, fragrance, preservative, biocide, colorant, dye and rheology modifier.

Owner:BUSBY MOLLY I +1

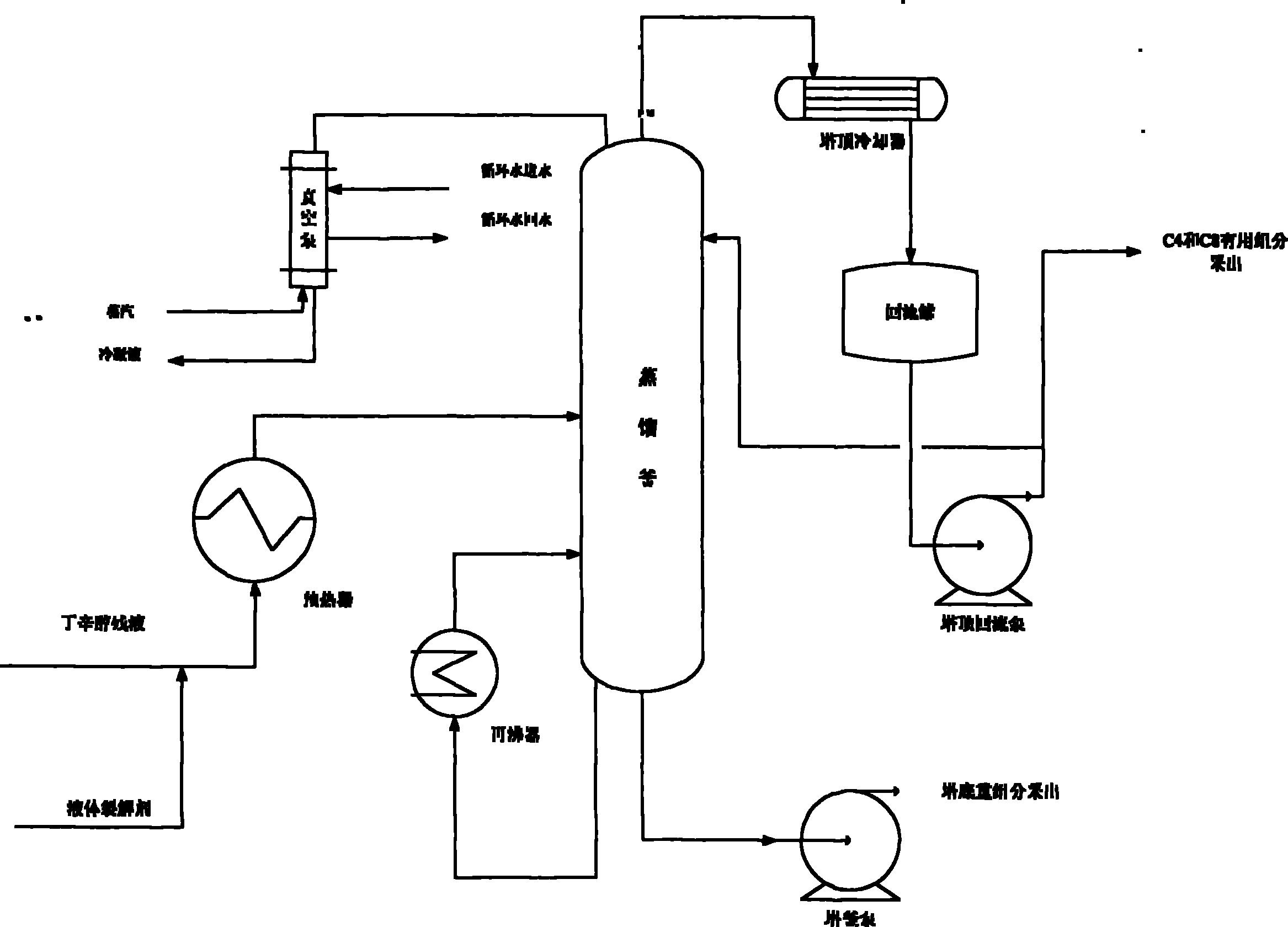

Production technology for cracking butyl octanol residual liquid into C4 and C8 by means of alkaline liquid cracking agent

ActiveCN101892066AReasonable useEmission reductionThermal non-catalytic crackingFractionationPotassium hydroxide

The invention relates to production technology for cracking butyl octanol residual liquid into C4 and C8 by means of an alkaline liquid cracking agent. The technology is characterized by comprising the following steps of: preparing the alkaline liquid cracking agent, wherein the alkaline liquid cracking agent consists of sodium hydroxide, potassium hydroxide, water, isopropanol, ethylene glycol, potassium permanganate, ethanol, barium nitrate and diboron trioxide; preheating the alkaline liquid cracking agent and the butyl octanol residual liquid through a preheater and adding into a distilling still, wherein the tower bottom temperature of the distilling still is between 200 and 280 DEG C, the tower top temperature is between 130 and 190 DEG C, and the tower top pressure is between 0.08 and 0.1Mpa below zero; and extracting the C4 and C8 generated by cracking from the tower top of the distilling still, pumping the C4 and C8 into a fractionating column at the downstream for fractionation, and extracting a small amount of uncracked heavy components from a tower bottom pump. The production technology has the advantages of high production capacity, high cracking selectivity, high content of the cracked useful components, low cost, simple process, and batch distillation or continuous distillation.

Owner:山东瑞利尔石油装备有限责任公司

Method for producing mixed butanol and coarse octanol by using waste liquid discharged from octanol device as raw material

ActiveCN101973846BSave energyReduce loadOrganic compound preparationPreparation by hydrogenationAlcoholDistillation

The invention discloses a method for producing mixed butanol and coarse octanol by using waste liquid discharged from an octanol device as a raw material, which belongs to a method for preparing acyclic monohydric alcohols, and is characterized by using a raw material fractionation unit, a hydrogenation synthesis unit and a product distillation unit, wherein the raw material fractionation unit comprises three fractionation devices: a butyraldehyde fractionation tower, a butanol fractionation tower and a C8 fractionation tower; the hydrogenation synthesis unit and the product distillation unitare suitable for hydrogenating and distilling a butyraldehyde fraction and a C8 fraction from the raw material fractionation unit alternately; and the product distillation unit comprises a light component removing tower device and a heavy component removing tower device. The method for producing the mixed butanol and coarse octanol by using the waste liquid discharged from the octanol device as the raw material, which is energy-saving and environmentally-friendly, can realize the recycling of the waste liquid discharged from the octanol device, reduce the waste water treatment cost of the octanol device and improves the technical indexes of treated water.

Owner:淄博诺奥化工有限公司

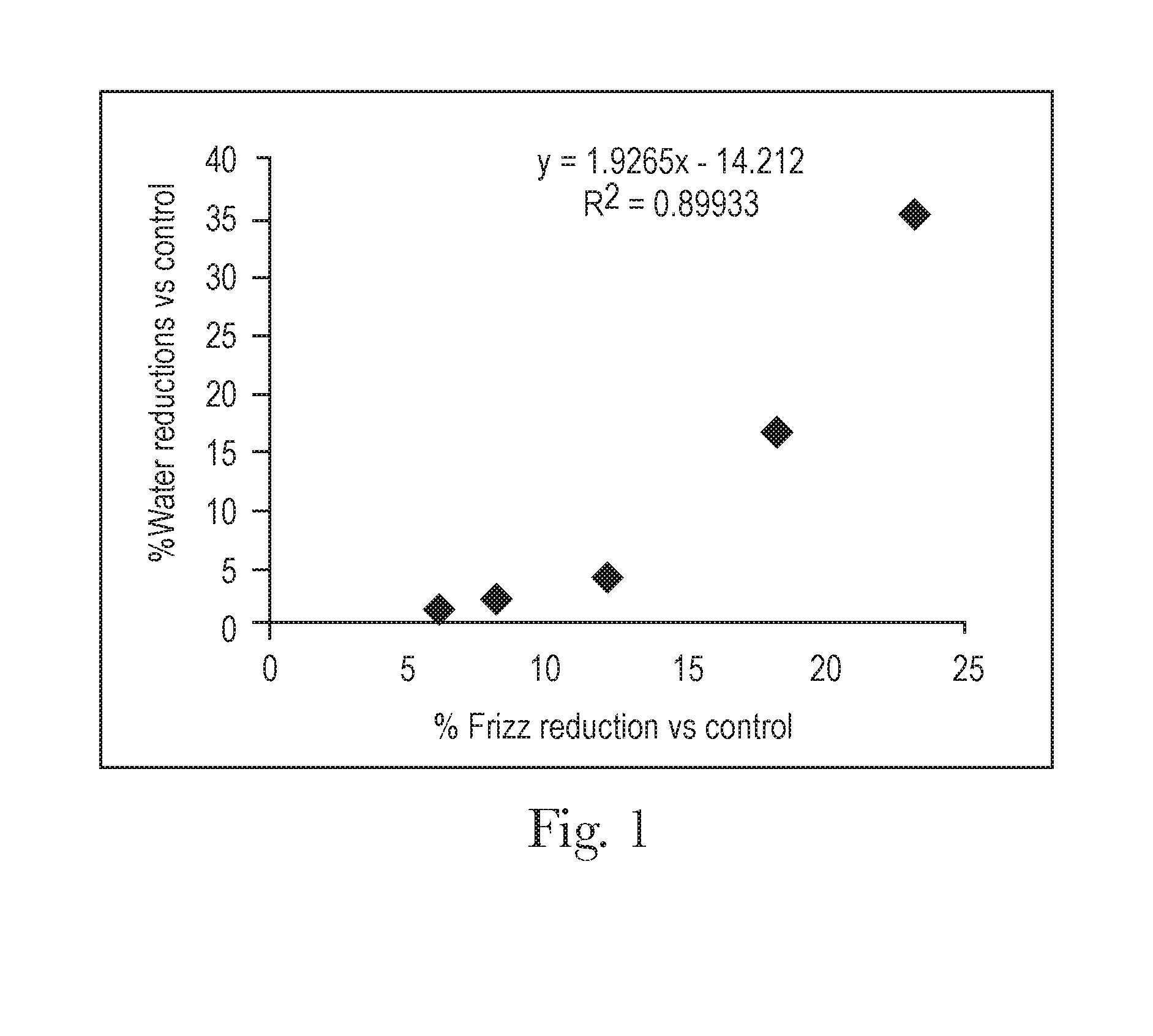

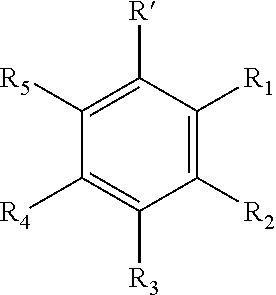

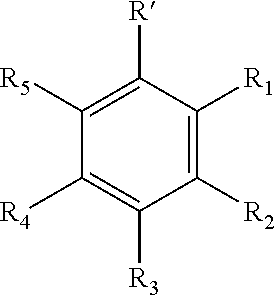

Composition for hair frizz reduction

ActiveUS20160158128A1Excellent frizz performanceNegatively affecting hair feelCosmetic preparationsHair removalSulfonateMeth-

The present invention is directed to a rinse-off conditioner composition for hair frizz reduction comprising from about 0.2% to about 20% of a moisture control material or mixture of moisture control materials wherein the moisture control material is selected from one or more of the following:wherein R′ is —COOY, sulfonic acid, or C═CH—COOY, Y is hydrogen or a metal ion, R1, R2, R3, R4, R5 is hydrogen, methyl, ethyl, propyl, vinyl, allyl, methoxy, ethoxy, hydroxyl, halogen, sulfate, sulfonate, nitro, or —CH═CH—COOR, and wherein the moisture control material is an acidic material and further wherein the moisture control material has a % Protein binding higher than 20 and Molecular Volume lower than 500 and Partition coefficient octanol to water (log P) lower than 3 and hydrogen binding higher than 10 and pKa lower than 5.0; and at least about a 4% fizz reduction vs. a control composition without the moisture control material.

Owner:THE PROCTER & GAMBLE COMPANY

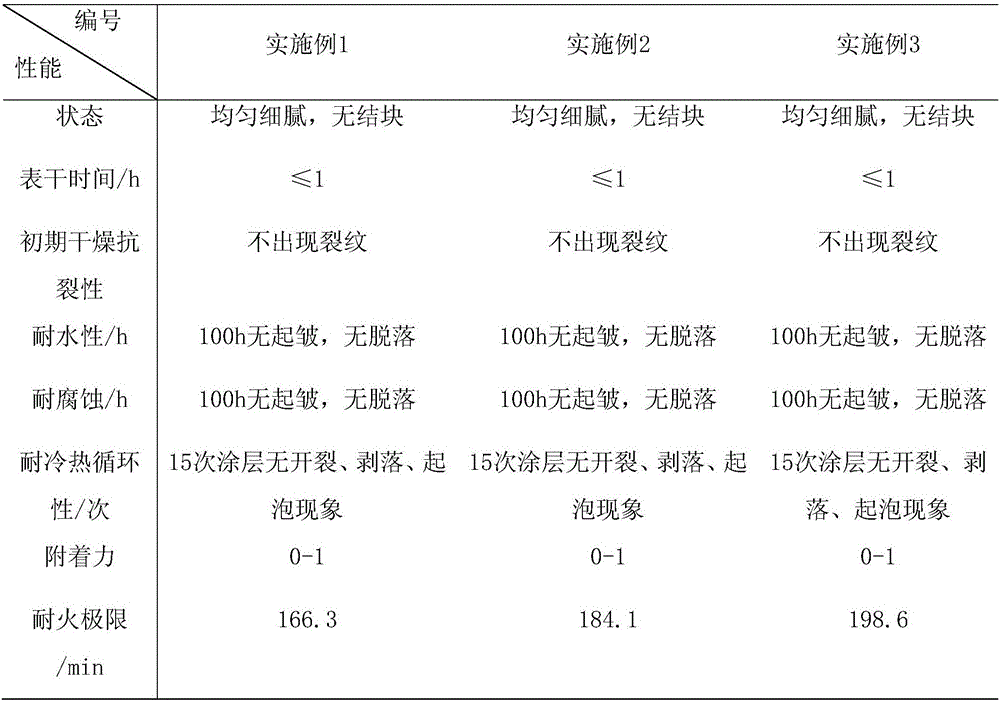

Microencapsulated water-based fire retardant coating and preparation method thereof

ActiveCN105925168AImprove the problem of hydrophilic migrationGood compatibilityFireproof paintsAnti-corrosive paintsEnvironmental resistanceWater based

The invention discloses a microencapsulated water-based fire retardant coating. The coating is prepared from an epoxy-modified water-based polyurethane emulsion, melamino-formaldehyde resin microencapsulated ammonium polyphosphate, polyurethane microencapsulated inorganic particles, hydroxyethyl cellulose, a dispersing agent, a defoaming agent, a mildewproof agent, n-octanol and water. According to the microencapsulated water-based fire retardant coating, a carbon source and an air source are subjected to resinification, the total adding amount of fire retardant is reduced, and due to that fact that too much fire retardant is added, physical damage to obtained materials is reduced; microencapsulation treatment is conducted on ammonium polyphosphate, hygroscopicity and water solubility of hydrophilic fire retardant are reduced, migration of APP is blocked, and the durability of the coating is increased; microencapsulation to inorganic filler is achieved, compatibility of the inorganic filler and a high polymer material is enhanced, the defects of being prone to agglomeration and migration are overcome, and the mechanical property of fire retardant composite material is improved; the obtained coating has the advantages of being green, environmentally friendly, efficiency, durable, stable, attractive and the like, and a related preparation method is simple and suitable for application and popularization.

Owner:湖北合聚高分子材料有限公司

Pyrophillite lost foam casting coating and preparation method thereof

InactiveCN101444827AGood suspensionImprove thixotropyFoundry mouldsFoundry coresSoluble glassOctanol

The invention discloses a pyrophillite lost foam casting coating and a preparation method thereof. The coating comprises the following components by the mass percentage: 90% to 95.8% of pyrophillite refractory powder, 0.2% to 0.7% of sodium carboxymethyl cellulose, 1.9% to 4.4% of swell soil, 1.9% to 5.3% of soluble glass, 0.1% to 0.18% of polyethylene alkyl polyol ether, and 0.05% to 0.1% of N-octanol, and the mass percentage of the components is 100% in total, wherein, pyrophillite refractory powder is pyrophillite or mixture of pyrophillite and other refractory materials. The invention has the advantages that the pyrophillite lost foam casting coating has favorable suspension property and thixotropy, as well as excellent ventilation property and relatively high surface strength; and the preparation technology is simple, the operation is convenient, the raw material is abundant and the production cost is low. The invention is mainly used for producing refractory material on the surface of foam plastic mould of lost foam pieces.

Owner:HAIAN HENGYE SILK

Method for removing chlorine from solution of zinc sulfate

The invention discloses a method for chlorine from solution of zinc sulfate, which mainly comprises the following: 1, a step of extraction, in which tributylamine is used as an extractant, kerosene or para-octanol is used as diluent, clear liquid of zinc sulfate is mixed with an organic phase for extraction, and chlorine in a water phase is transferred to an organic phase; 2, a step of back extraction, in which back extraction is performed by using ammonia water or solution of sodium hydroxide, chlorine in the organic phase is retransferred to the water phase, and the organic phase is recycled; 3, a step of organic phase regeneration, in which 5 to 10 percent solution of sodium hydroxide is mixed with the organic phase which ages after being used for a certain period of time in a ratio of 1:0.9 to 1:2.5, and the mixture is stirred by an electromagnetic siterr at a high speed for 8 to 15 minutes for regenerating the organic phase; and 4, a step of deoiling, in which raffinate is subjected to active carbon absorption or ultrasonic demulsification so as to remove the organic phase in the raffinate. In the invention, the organic phase and the raffinate can be used circularly, the dechlorination rate is over 85 percent, the electrolytic operation environment is improved, the process flow is simple, and the method can be used for dechlorinating solution of zinc sulfate from wet-method zinc smelting plants and can also be used for dechlorinating wastewater.

Owner:ZHUZHOU SMELTER GRP

Extraction process for preparing electronic-grade cobalt sulfate from cobalt-containing waste material

ActiveCN101974687AHigh recovery rateGuaranteed growthProcess efficiency improvementCobalt saltOctanol

The invention discloses an extraction process for preparing electronic-grade cobalt sulfate from a cobalt-containing waste material, and relates to an extraction method for cobalt salt. The process comprises the following steps of: performing acidolysis; filtering and separating; removing iron and copper; preparing rough Co material liquid; removing impurities by P204 extraction; and separating Co and Ni by P507 extraction; and the process is characterized in that an N235 extracting agent is prepared from 8 to 12 volume percent of N235, 8 to 12 volume percent of 2-octanol and 76 to 84 volume percent of 206 solution oil; and the prepared N235 extracting agent is added into raffinate of the P204 extraction and is subjected to six stages of extraction, two stages of hydrochloric acid washing, six stages of washing, three stages of ammonia water washing and one stage of sulfuric acid washing. The process has good impurity removal effect; compared with the prior art, the process has the advantages that: one order of magnitude is reduced, particularly, impurities such as cadmium, lead and the like which are difficult to remove are removed by P204 extraction and the P507 extraction, and the impurities reach an extremely low degree. The process has short flow, the comprehensive recovery rate of cobalt is high and the production cost is lower than the average cost of the same domestic industry.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

Method for preparing environment-friendly plasticizer by recycling waste resources

ActiveCN104496819AImprove qualityAvoid wastingOrganic compound preparationCarboxylic acid esters preparationFiltrationOctanol

The invention relates to a method for preparing an environment-friendly plasticizer by recycling waste resources. The method comprises the following steps of transferring alkali-reduction wastewater containing sodium terephthalate into an acid precipitation tank with a stirring device and adding sulfuric acid to further precipitate terephthalic acid (PTA) solids; carrying out plate-frame filtration on the mixed solution to obtain a crude PTA material; adding the recovered crude PTA material into an esterification reactor with an alcohol-water separation device, adding iso-octanol, heating and dehydrating, adding tetrabutyl titanate as a catalyst and carrying out esterification reaction; after water is no longer produced, stopping reaction and dealcoholizing to obtain a crude DOTP (Dioctyl Terephthalate) product; rectifying the prepared crude DOTP product in a packing-type rectifying tower to obtain a rectified product, adding the rectified product into a neutralization reaction kettle, adding sodium hydroxide lye, stirring and washing with alkali; standing, precipitating and discharging the aqueous solution in the lower layer, adding hot water, stirring and washing with water, standing, precipitating and discharging the moisture in the lower layer, carrying out temperature-raising dehydration, adding an inorganic filter aid and filtering to obtain the pure DOTP product. By the method, the recycling of the waste resources is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com