Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1251 results about "Cryolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

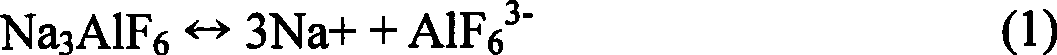

Cryolite (Na₃AlF₆, sodium hexafluoroaluminate) is an uncommon mineral identified with the once large deposit at Ivigtût on the west coast of Greenland, depleted by 1987. It was historically used as an ore of aluminium and later in the electrolytic processing of the aluminium-rich oxide ore bauxite (itself a combination of aluminium oxide minerals such as gibbsite, boehmite and diaspore). The difficulty of separating aluminium from oxygen in the oxide ores was overcome by the use of cryolite as a flux to dissolve the oxide mineral(s). Pure cryolite itself melts at 1012 °C (1285 K), and it can dissolve the aluminium oxides sufficiently well to allow easy extraction of the aluminium by electrolysis. Substantial energy is still needed for both heating the materials and the electrolysis, but it is much more energy-efficient than melting the oxides themselves. As natural cryolite is too rare to be used for this purpose, synthetic sodium aluminium fluoride is produced from the common mineral fluorite.

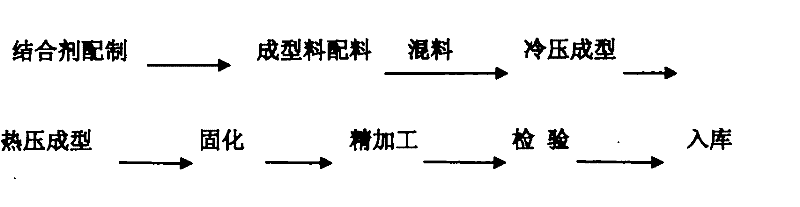

Method for treating aluminum electrolysis waste cathode carbon block using acid and alkali combination method

A method for treating aluminum electrolytic waste cathode carbon blocks by an acid and alkali combination method is characterized by comprising the following steps: (1) aluminum electrolytic waste cathode is added to concentrated basic solution for reaction; a filtered solid phase is obtained by filtering and is added to concentrated acid for reaction; and carbon powder is obtained after filtration; (2) filtrates are mixed and dropwise added with the concentrated basic solution, the pH value thereof is adjusted to 9, the obtained mixture is kept standing and filtered to obtain cryolite; (3) the filtrate is added with saturated bleach solution, kept standing and filtered to obtain calcium fluoride; (4) the fourth filtrates is heated, evaporated and crystallized to obtain sodium chloride solid. With the purposes of waste utilization and environmental protection, the method successfully provides the process for treating aluminum electrolytic waste cathode by the acid and alkali method, which causes the waste cathode to not be the conventional waste and pollutant and to become artificial mineral resources. The method solves the problem of waste utilization in aluminum electrolysis industry, improves benefit, and improves the comprehensive level of the aluminum electrolysis industry of China.

Owner:NORTHEASTERN UNIV +1

Method of producing aluminium scandium alloy by electrolysis

The invention relates to the method for producing the alloy of aluminium and scandium by using oxides of aluminium and scandium as the raw materials. Fused salt electrolysis process is adopted to electrolyze and separate out aluminium and scandium so as to form the alloy. The weight ratio of the electrolyte of fused cryolite is as following: alumina 1%-10%, scandium oxide 0.1%-10%, cryolite as the rest and the unavoidable impurities. The ratio between sodium fluoride and aluminium fluoride is 2-3. The relevant parameters are as following: temperature of electrolysis 900-990 deg.C, operating voltage of the electrobath 3.0V-6.5V and the electrode distance 2.0cm-7.0 cm. The invention possesses the features of no need of high pure metal scandium, shortened technological flow and high metal yield so as to reduce the cost of the alloy greatly.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

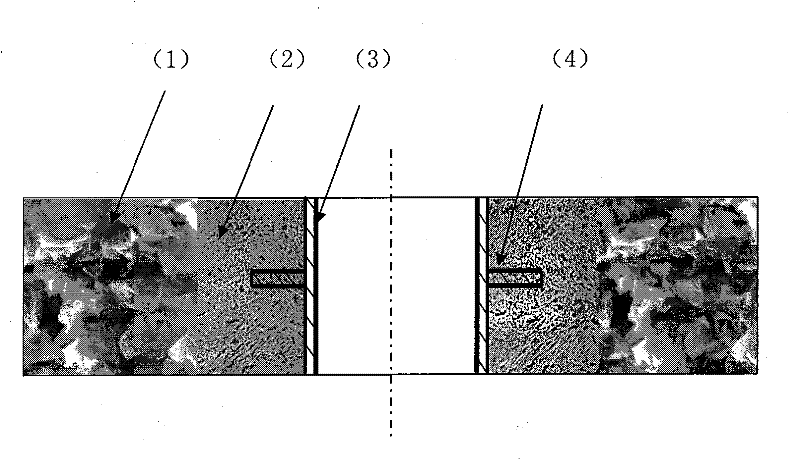

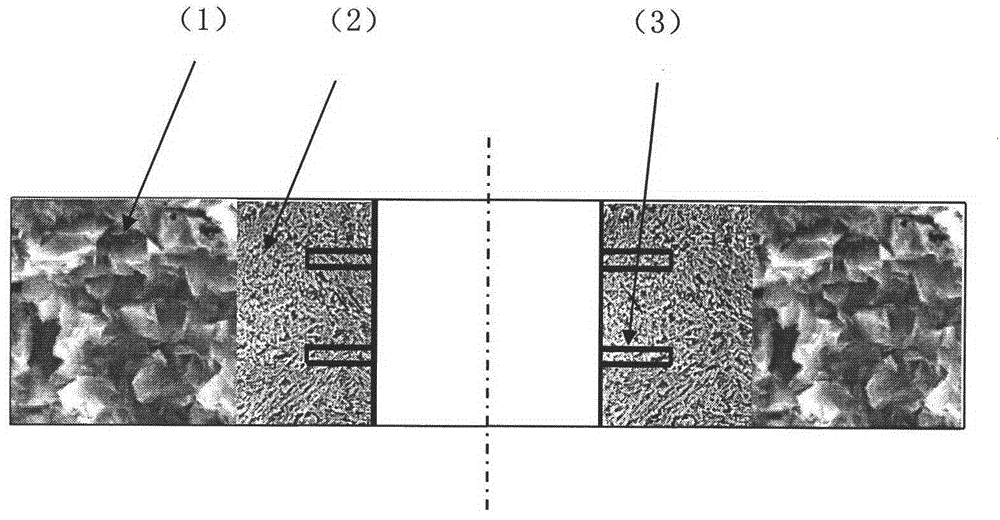

High-speed resin heavy-load grinding wheel

InactiveCN102161183AImprove mechanical propertiesImprove automationAbrasion apparatusGrinding devicesFiberZirconia alumina

Owner:江苏华东砂轮有限公司

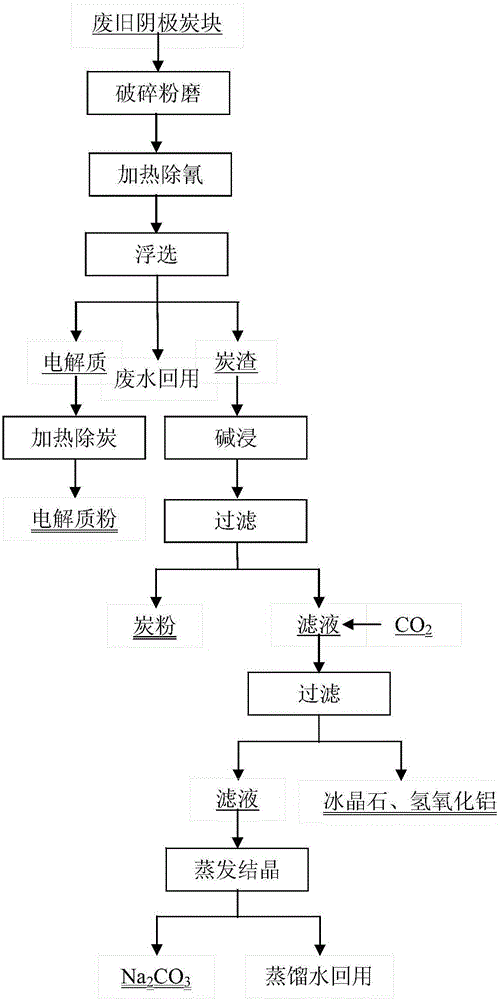

Comprehensive recovery method of waste and old cathode charcoal block of aluminium electrolytic tank

ActiveCN106064813AReduce consumptionShorten the alkaline leaching timeAluminium fluoridesAluminium oxides/hydroxidesRecovery methodElectrolysis

The invention relates to a comprehensive recovery method of waste and old cathode charcoal block of an aluminium electrolytic tank, and belongs to the technical field of comprehensive utilization of industrial solid waste resources. The method is as below: crushing and grinding waste and old cathode charcoal block of the aluminium electrolytic tank at 200-400 DEG C, insulating, removing cyanide, conducting flotation separation on the material with cyanide removed to obtain carbon slag and electrolyte slag, heating the electrolyte slag at 550-800 DEG C to remove carbon impurities, so as to obtain an electrolyte powder, removing to soluble substances in the electrolyte slag by alkali leaching to obtain a carbon powder with high purity, and precipitating a mixture of cryolite and aluminium hydroxide form the alkali leaching liquid by CO2. The invention has the advantages of reasonable process design, simple process, high treatment efficiency, high recovery rate and recycling rate of each material and no secondary pollution, and is applicable to large-scale industrial application.

Owner:CENT SOUTH UNIV

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

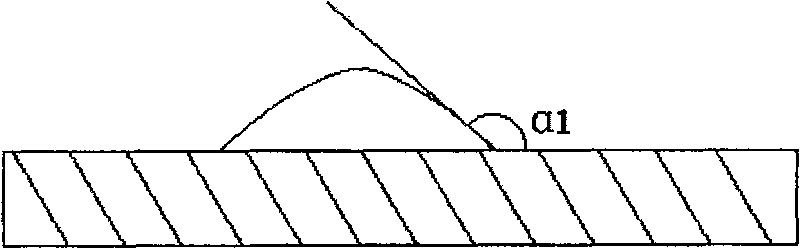

Nickel-base welding rod

InactiveCN101745759AGood production technologyImprove yieldWelding/cutting media/materialsSoldering mediaSlagManganese

The invention relates to a welding material technology, in particular to a nickel-base welding rod. The welding rod uses a SNi6062 welding wire as a core wire. The electrode coating comprises the following solid ingredients in percentage by mass: 36-50% of rutile, 2-7% of titanium pigment, 20-30% of fluorite, 3-8% of cryolite, 2-4% of phlogopite, 2-4% of zircon sand, 0.5-1.5% of sodium carbonate, 5-10% of manganese metal, 2-4% of ferrotitanium containing 25-35% of Ti, and 2-4% of ferroniobium containing 50-60% of Nb. The nickel-base welding rod has the advantages of favorable performance of production technique, smooth welding rod surface, high yield, stable eccentricity; during welding, the nickel-base welding rod has the advantages of stable electric arc, basically no splash, favorable slag detachability and outstanding operating performance; and the appearance of the welding seam is beautiful, the height of a weld bead is moderate, the wetting angle of a welding seam is moderate, and the strength and plasticity of deposited metals are moderate.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

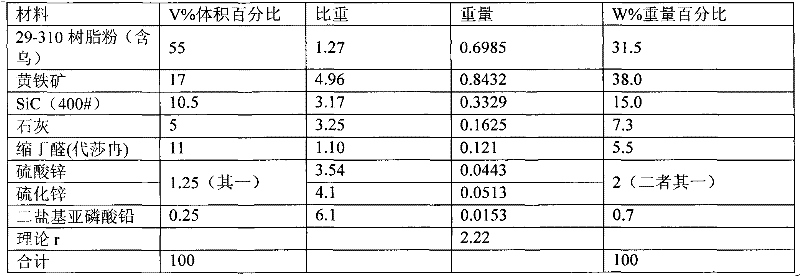

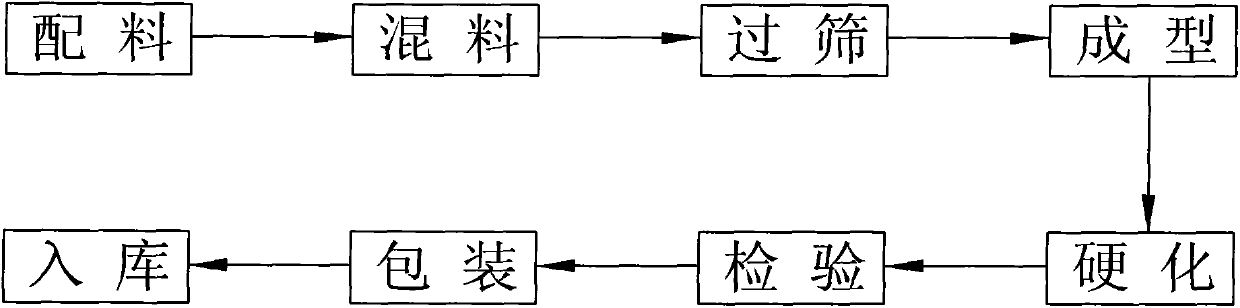

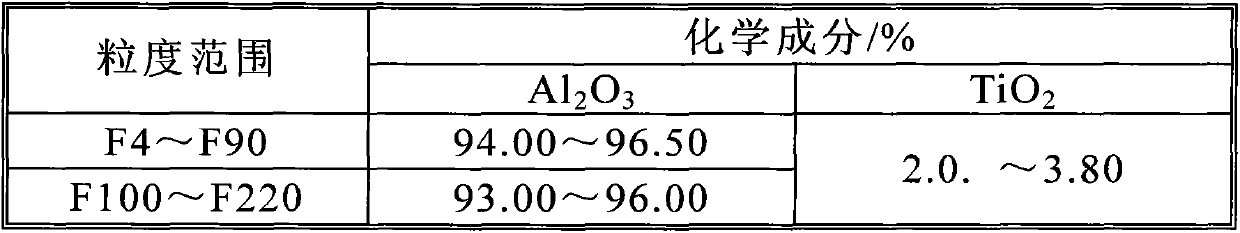

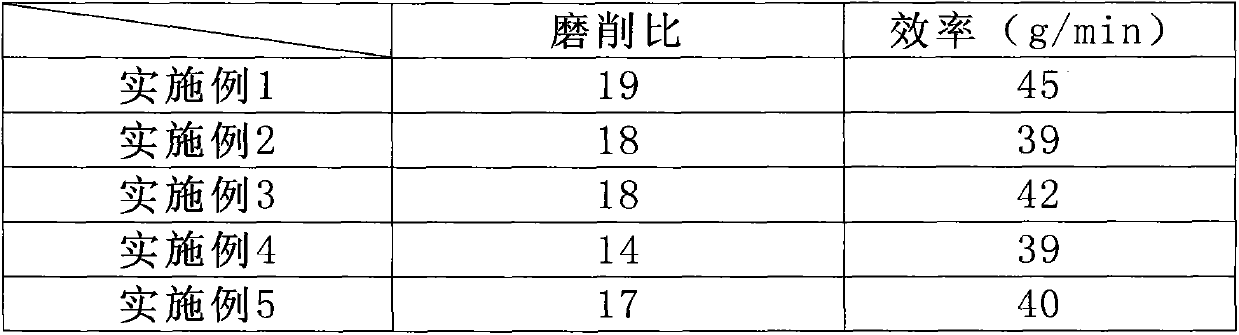

Resin rough grinding wheel and preparation method thereof

ActiveCN103465179AImprove grinding efficiencyIncrease roughnessAbrasion apparatusGrinding devicesPyriteAlumina zirconia

The invention relates to a resin rough grinding wheel and a preparation method thereof. The resin rough grinding wheel comprises a grinding body and reinforcing meshes, wherein the reinforcing meshes are arranged inside the grinding body to enhance the revolving strength of the grinding body. The grinding body is composed of 115-150 parts of grinding materials, 5-15 parts of liquid phenolic resin, 25-45 parts of phenolic resin powder and 15-35 parts of filling, wherein the grinding materials comprise 30-40 parts of microcrystal corundum, 80-100 parts of fused alumina zirconia and 5-10 parts of garnets, the filling is composed of 9-21 parts of pyrite, 1-3 parts of cryolite, 1-3 parts of ferric oxide, 1-3 parts of quick lime and 3-5 parts of fluorite. The resin rough grinding wheel is prepared through the steps of preparation, mixing, sifting, shaping, hardening, testing, packaging and storing, has high strength, good abrasive resistance and self-sharpening performance, high grinding efficiency, good roughness and low workpiece burning possibility; meanwhile, the surface of the grinding wheel is not easy to block and has good breathability, good tenacity and high security performance.

Owner:NINGBO DAHUA GRINDING WHEEL

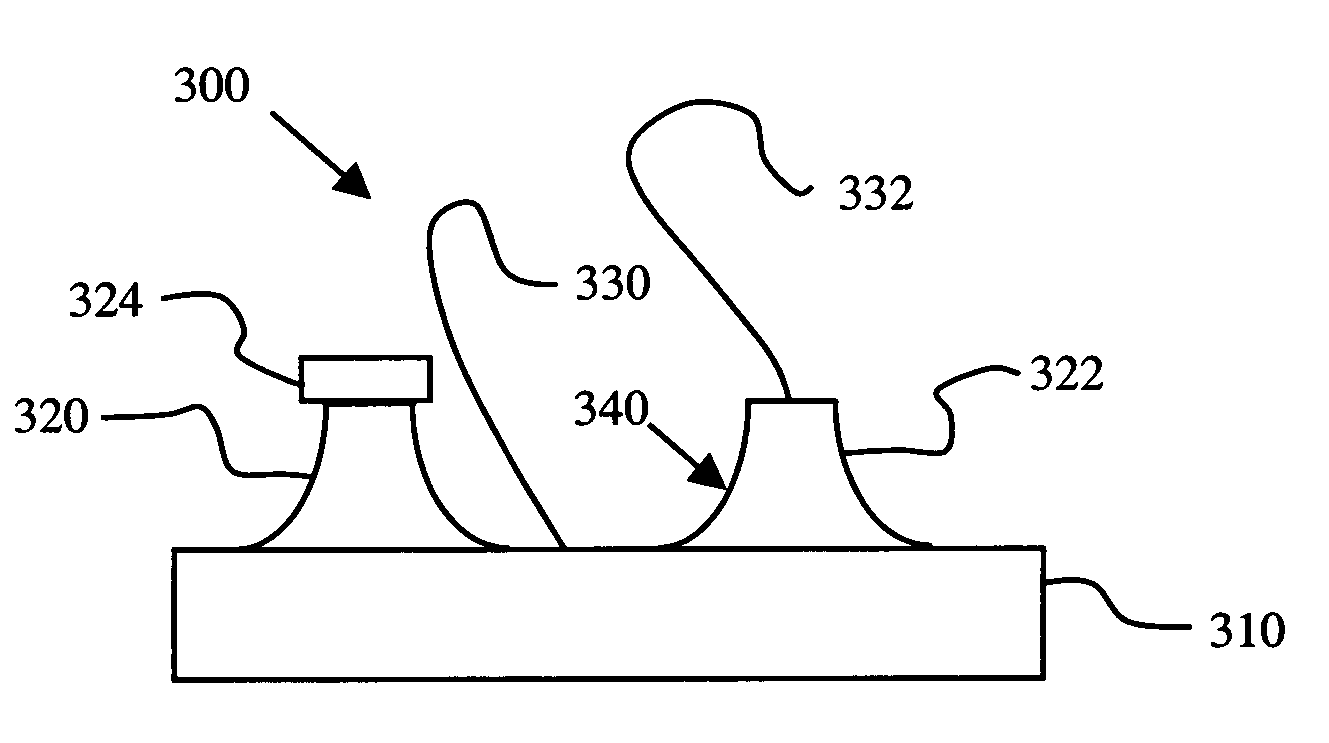

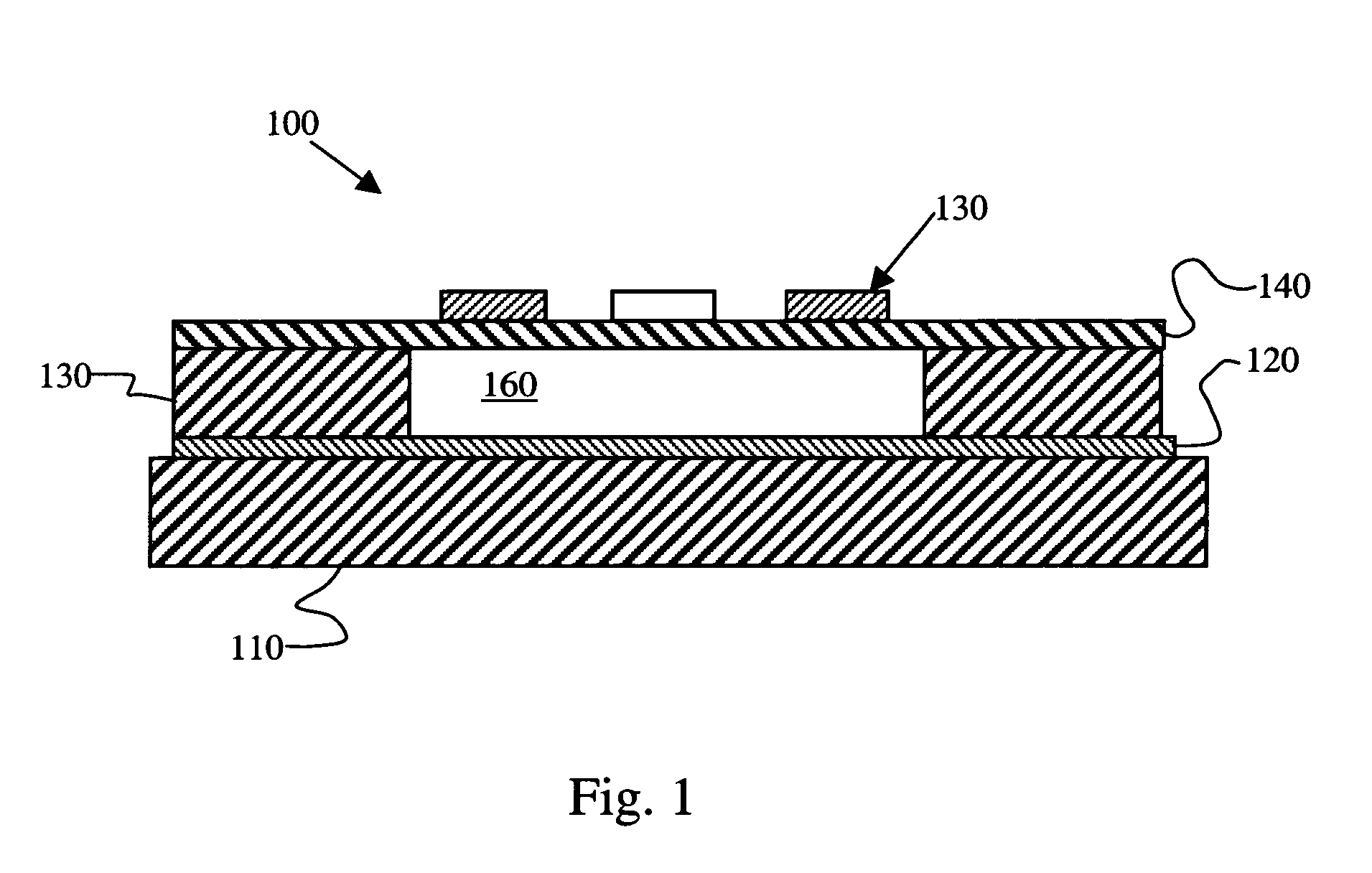

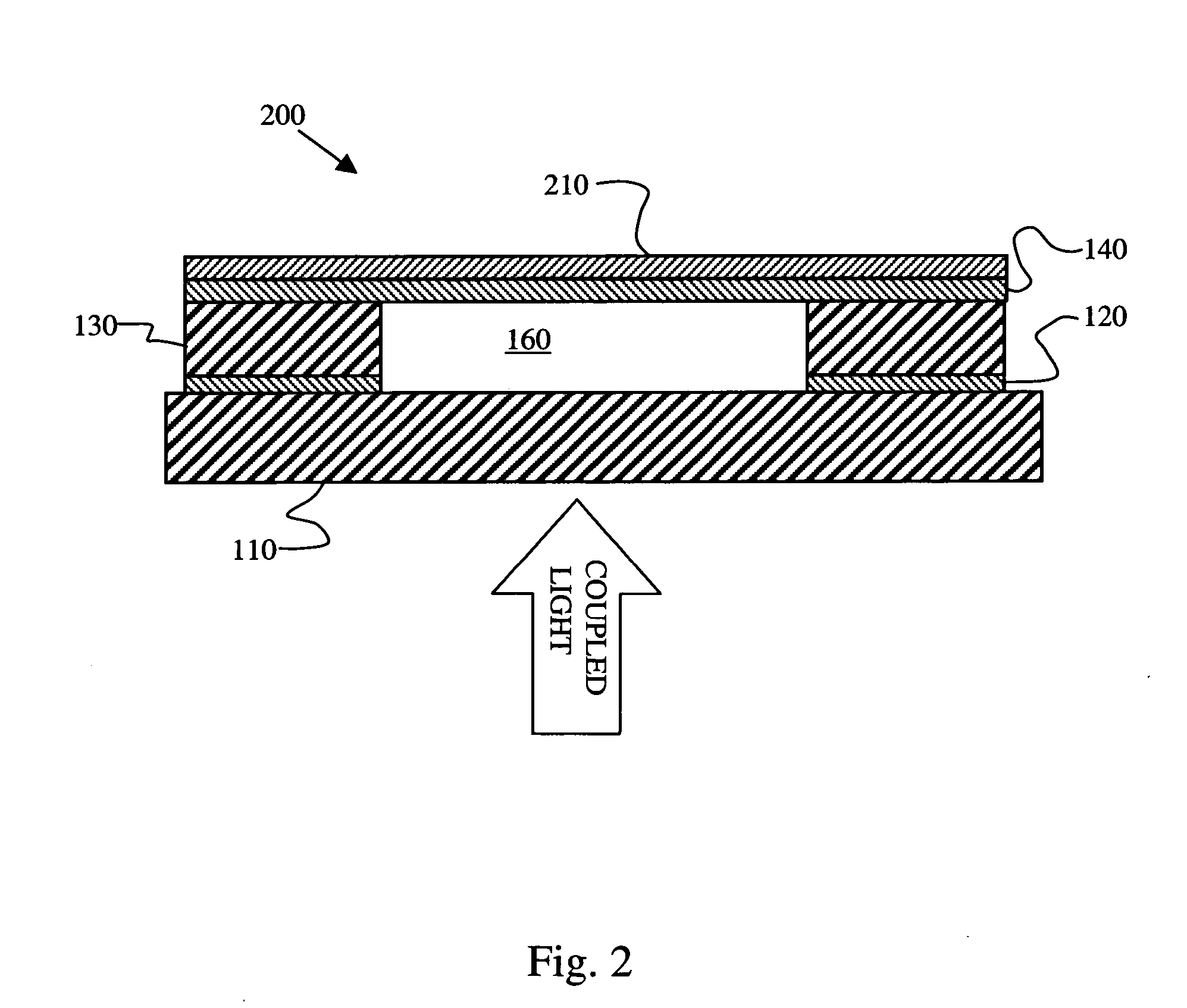

Etchant, method of etching, laminate formed thereby, and device

ActiveUS20060289386A1Decorative surface effectsFluid pressure measurement by electric/magnetic elementsEtchingCelsius Degree

An etchant including a halogenated salt, such as Cryolite (Na3AlF6) or potassium tetrafluoro borate (KBF4), is provided. The salt may be present in the etchant in an amount sufficient to etch a substrate and may have a melt temperature of greater than about 200 degrees Celsius. A method of wet etching may include contacting an etchant to at least one surface of a support layer of a multi-layer laminate, wherein the support layer may include aluminum oxide; or contacting an etchant to at least one surface of a support layer of a multi-layer laminate, wherein the etchant may include Cryolite (Na3AlF6), potassium tetrafluoro borate (KBF4), or both; and etching at least a portion of the support layer. The method may provide a laminate produced by growing a crystal onto an aluminum oxide support layer, and chemically removing at least a portion of the support layer by wet etch. An electronic device, optical device or combined device including the laminate is provided.

Owner:SLT TECH

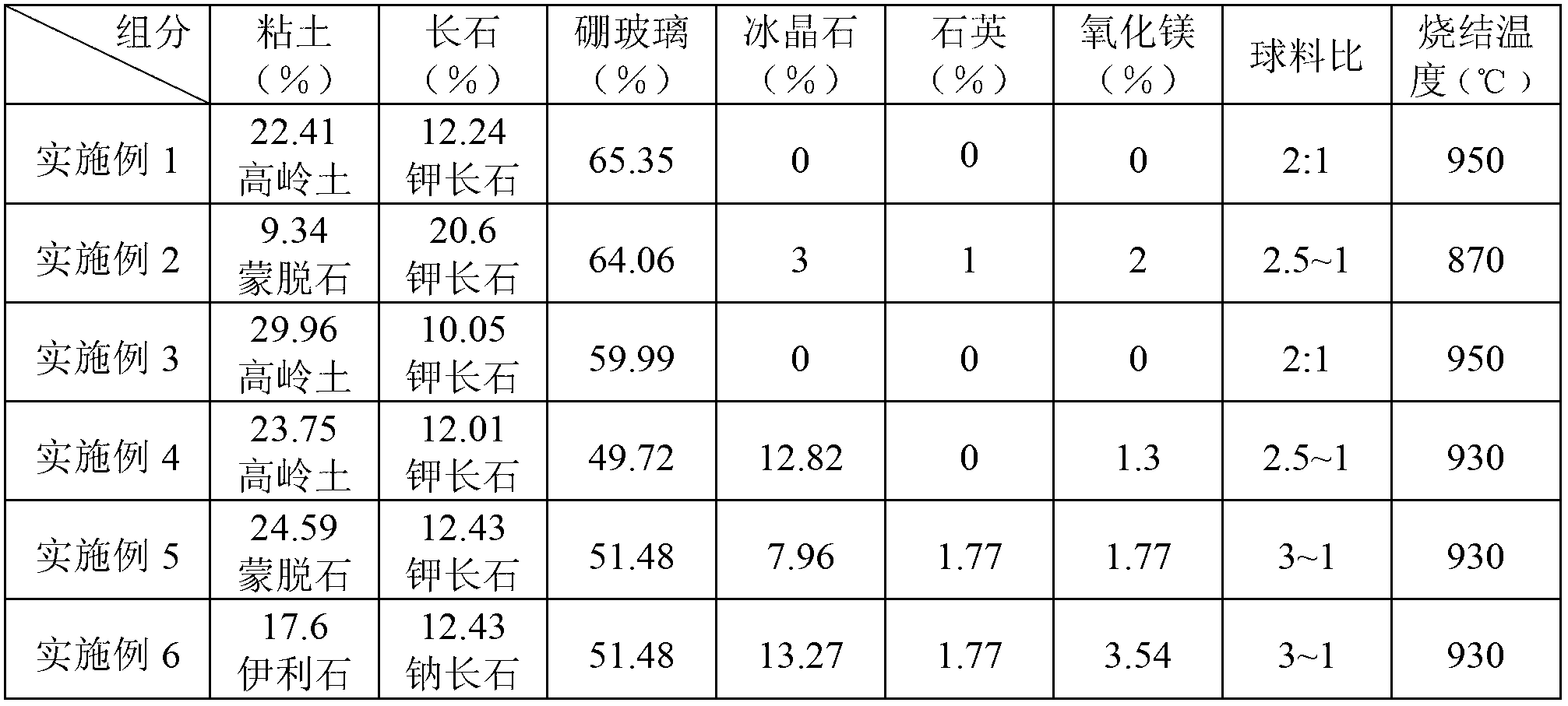

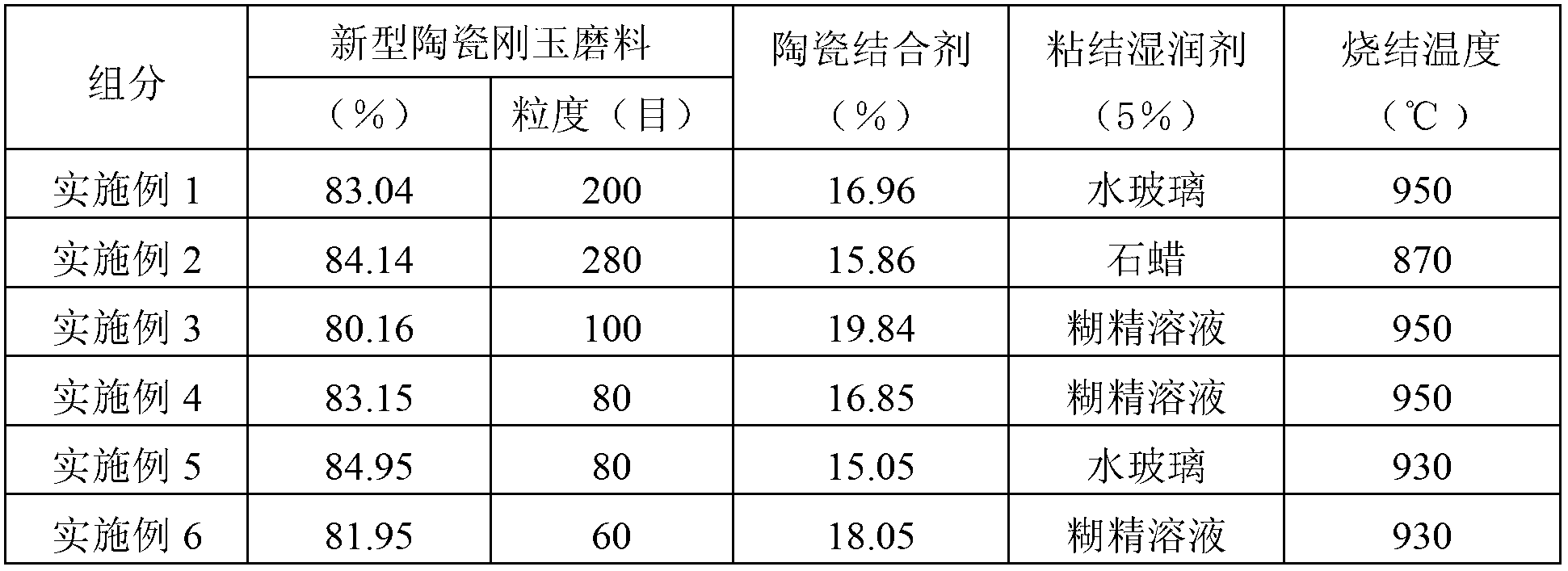

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

Flux-cored wire for austenitic stainless steel all-position welding

ActiveCN102229029AGood workmanshipGood slag removalWelding/cutting media/materialsSoldering mediaElectrolysisPotassium

The invention relates to a flux-cored wire for austenitic stainless steel all-position welding, and the flux-cored wire is composed of a flux core and an external stainless steel belt, wherein, the flux core accounts for 22-24wt% of the flux-cored wire, and the flux core comprises the following components in percentage by weight: 20-23% of metal chromium powder, 7-8.5% of metal nickel powder, 2-4% of electrolytic manganese metal, 3-4% of aluminium powder, 0.5-1% of ferrotitanium, 32-34% of rutile, 1-2% of quartz, 2-4% of zircon sand, 4-6% of albite, 2-4% of potassium feldspar, 1-1.5% of cryolite, 1-1.5% of lithium carbonate, 0.1-0.5% of bismuth oxide and the balance of iron powder. The ratio of the albite to the potassium feldspar in the flux core is 1.2-2, the sum of the albite and the potassium feldspar is not more than 10wt% of the flux core, the external stainless steel belt is the austenitic stainless steel 304L, the carbon content is less than 0.025wt%, the diameter of the flux-cored wire is 0.9-1.2mm, and the flux-cored wire can be used for realizing the austenitic stainless steel all-position welding.

Owner:北京远达国际工程管理咨询有限公司 +1

Process for controlling the alumina content of the bath in electrolysis cells for aluminum production

InactiveUS6033550AImprove Faraday efficiencyPollution problemStatic indicating devicesCapillary burnersElectrolysisMaterials science

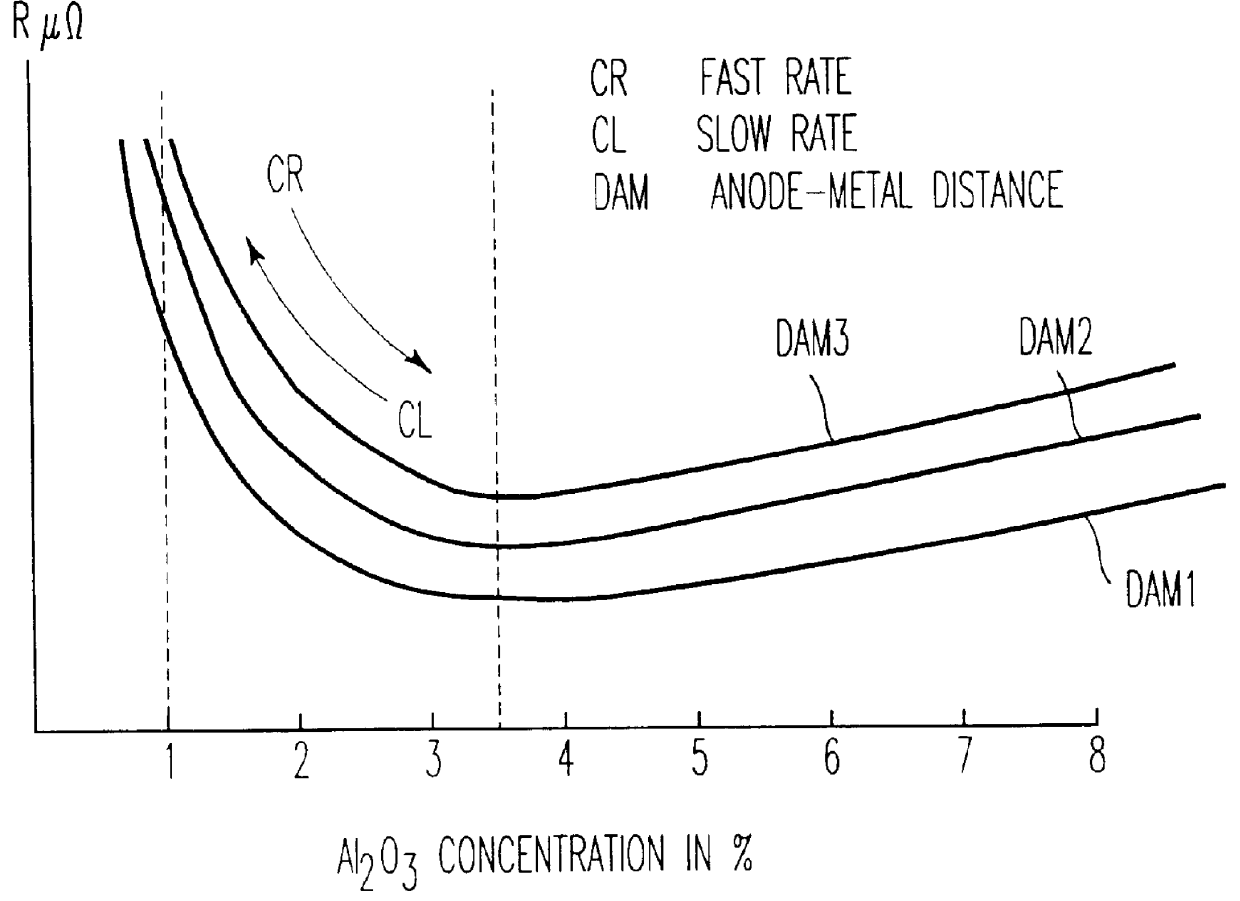

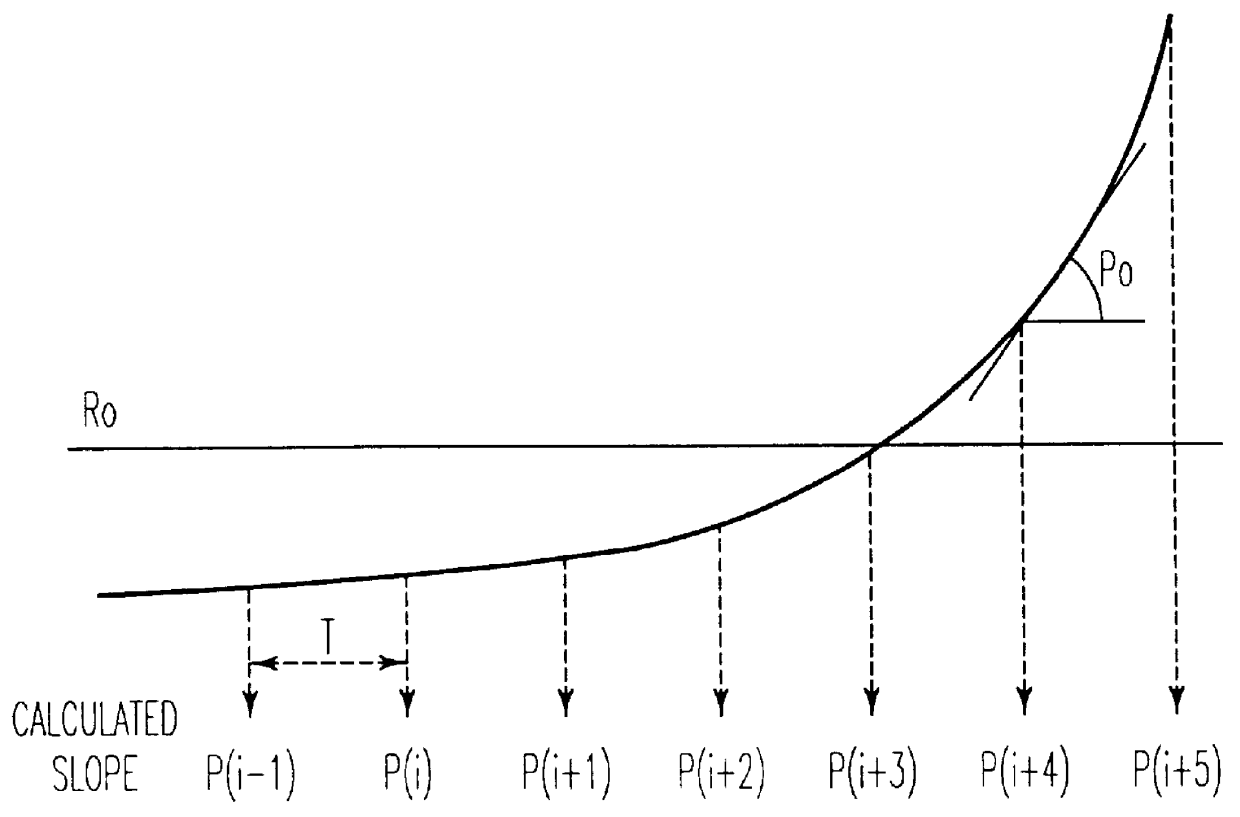

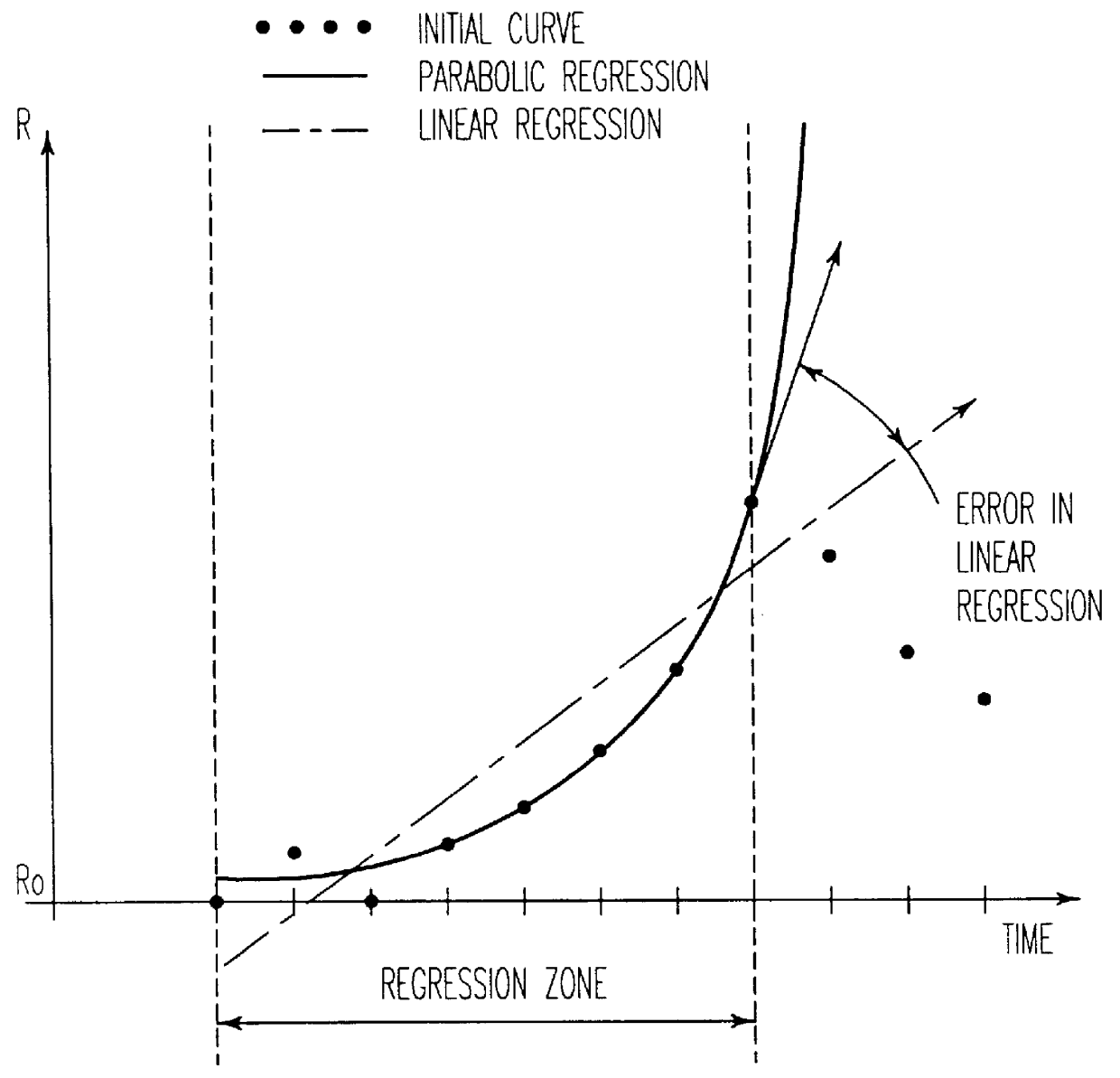

A process for control of the alumina content of the bath in a cell for production of aluminum by electrolysis of alumina dissolved in a molten cryolite-base salt, consisting of alternation of phases of alumina underfeeding and phases of alumina overfeeding compared with a theoretical mean rate of alumina consumption of the cell, the said alternation being a function of values, calculated at the end of each control cycle i of duration T, of the mean resistance R(i) measured at the cell electrode terminals, of the rate of change of this resistance or resistance slope P(i), of the rate of change of the resistance slope or curvature C(i) and of the extrapolated slope PX(i)=P(i)+C(i)xT, these values being compared respectively with reference values Po, Co and PXo in order to modulate, according to an appropriate control algorithm, the alumina content of the bath in a very narrow concentration range between 1.5 and 3.5%.

Owner:ALUMINUM PECHINEY

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Separation and purification method of electrolytic aluminum scraps

ActiveCN101818253ASolve stubborn problemsImprove the effect of magnetic separationProcess efficiency improvementPurification methodsIron fluoride

The invention discloses a separation and purification method of electrolytic aluminum scraps, characterized by comprising the following steps of: crushing electrolytic aluminum scraps in a wet type, floating and magnetically separating, firstly removing iron and silicon and separating to obtain carbon powder and another raw material A; and putting the raw material A in an electric furnace, electrifying to dissolve fluoride salt, restoring harmful impurities in the scraps into an elementary substance metal state by utilizing metal aluminum, precipitating at the bottom of the electric furnace and secondarily removing the iron and the silicon to obtain an electrolyte B. The invention has the advantages that metal aluminum particles in electrolytic aluminum scraps in the electric furnace is utilized as a low-cost reducing agent to restore and precipitate iron, silicon and other harmful impurities at the bottom of the furnace when the fluoride salt is in a dissolved state so as to solve the problem that iron fluoride with high stability is hard to remove, and the reducing agent is utilized in the floatation process to improve the magnetic separation effect. For a product obtained in an electric furnace melting system, an acid-method process is adopted to convert alumina into cryolite, thirdly remove silicon and obtain a byproduct of ammonium bicarbonate.

Owner:周俊和 +1

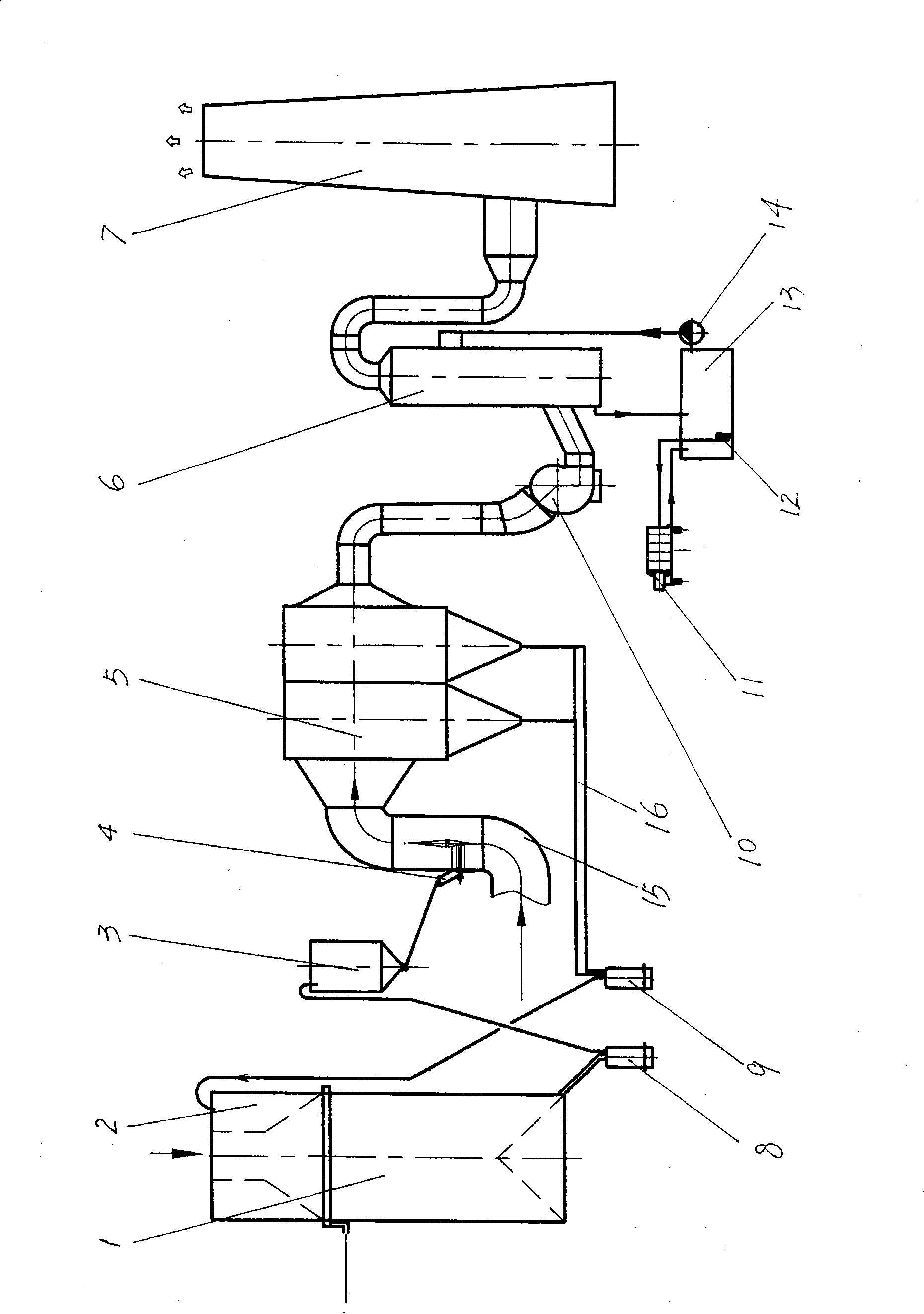

Dry and wet methods combined aluminum electrolysis flue gas deep treatment process

InactiveCN101348924ALow running costEmission reductionDispersed particle separationLiquid wastePartial oxidation

A novel process for realizing deep treatment of electrolytic aluminum flue gas through combining a dry-wet method is characterized in that flue gas of each electrolytic cell is fully contacted with fresh alumina powder inside a VIR reactor; after fluorine is absorbed, the alumina powder and the flue gas enter an electrostatic dust collector so as to remove most alumina powder and alumina powder dust; waste gas enters an absorption tower of a wet system, and is in counter current contact with an absorption liquid so as to remove alumina powder, dust, hydrogen fluoride and sulfur dioxide in the waste gas; and the purified tail gas is exhausted into the atmosphere. The novel process has the advantages that the process turns the prior dry bag-type dust removal into electrostatic dust removal, thereby substantially reducing the investment of dry dust removal and the operating cost of the entire environmental protection system; then, wet treatment is adopted so as to reach the goal of deep treatment; meanwhile, SO2 with flue gas removed is absorbed, thereby greatly reducing the emission of pollutants during aluminum electrolysis; through the organic combination of the dry-wet technology, the process ensures that fluoride inside the wet system is directly synthesized into cryolite and is reclaimed, thereby solving the problems that the prior wet purification process needs to adopt a villaumite recovery device and that villaumite liquid wastes are difficult to treat.

Owner:商丘市丰源铝电有限责任公司

Ultrasonic-assisted alkaline pickling treatment method of aluminum electrolysis spent cathode carbon blocks

The invention relates to an ultrasonic-assisted alkaline pickling treatment method of aluminum electrolysis spent cathode carbon blocks. The ultrasonic-assisted alkaline pickling treatment method of the aluminum electrolysis spent cathode carbon blocks belongs to the technical field of aluminum electrolysis solid waste resource recovery, and comprises the following steps of smashing the aluminum electrolysis spent cathode carbon blocks, adding the aluminum electrolysis spent cathode carbon blocks into alkaline liquor for leaching, and filtering to obtain carbon powder and first filter liquor; carrying out alkaline pickling under the ultrasonic environment; leading CO2 into the first filter liquor, crystallizing out, filtering to obtain cryolite, an aluminum hydroxide mixture and second filter liquor, and recycling the second filter liquor. The ultrasonic-assisted alkaline pickling treatment method of the aluminum electrolysis spent cathode carbon blocks is simple in process, and convenient to operate; and through the synergistic effect of ultrasonic wave and alkaline pickling, the reaction rate is accelerated, the purity of the product carbon powder is improved, the maximum purity of the carbon powder is 97.92 percent, and the production cycle is 70min.

Owner:CENT SOUTH UNIV

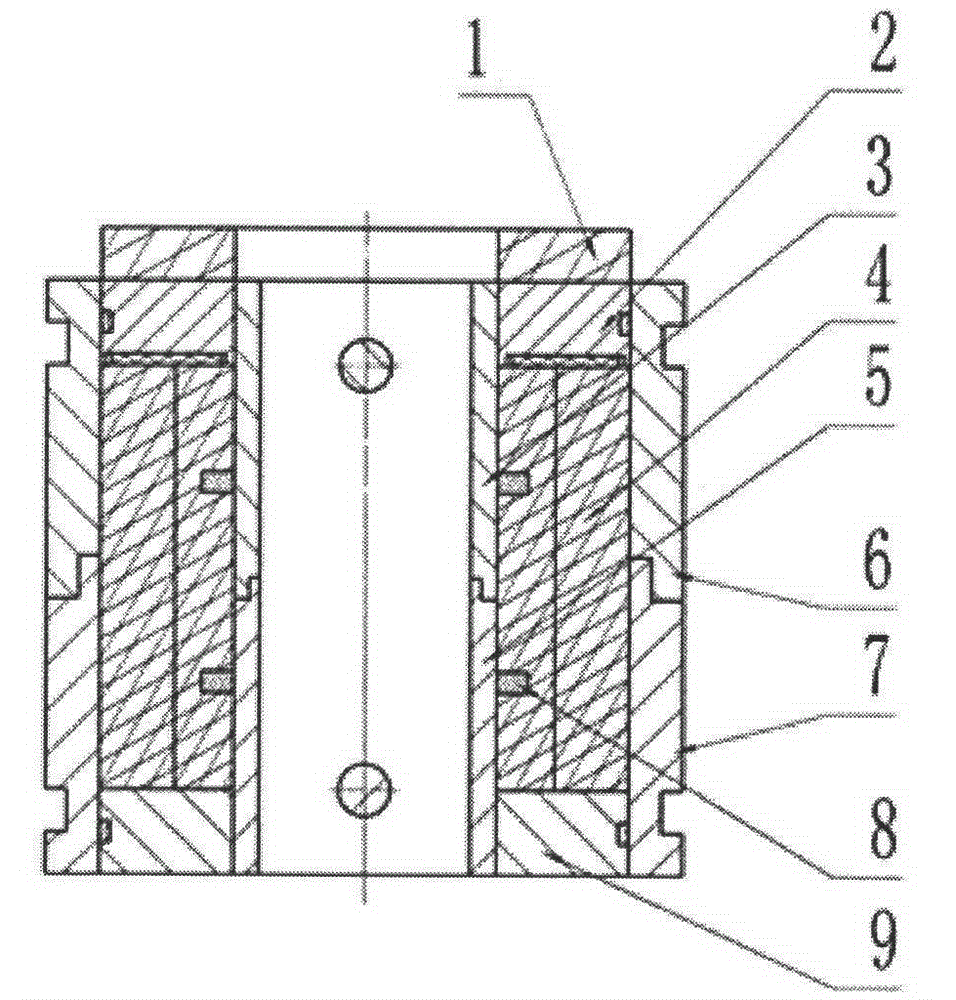

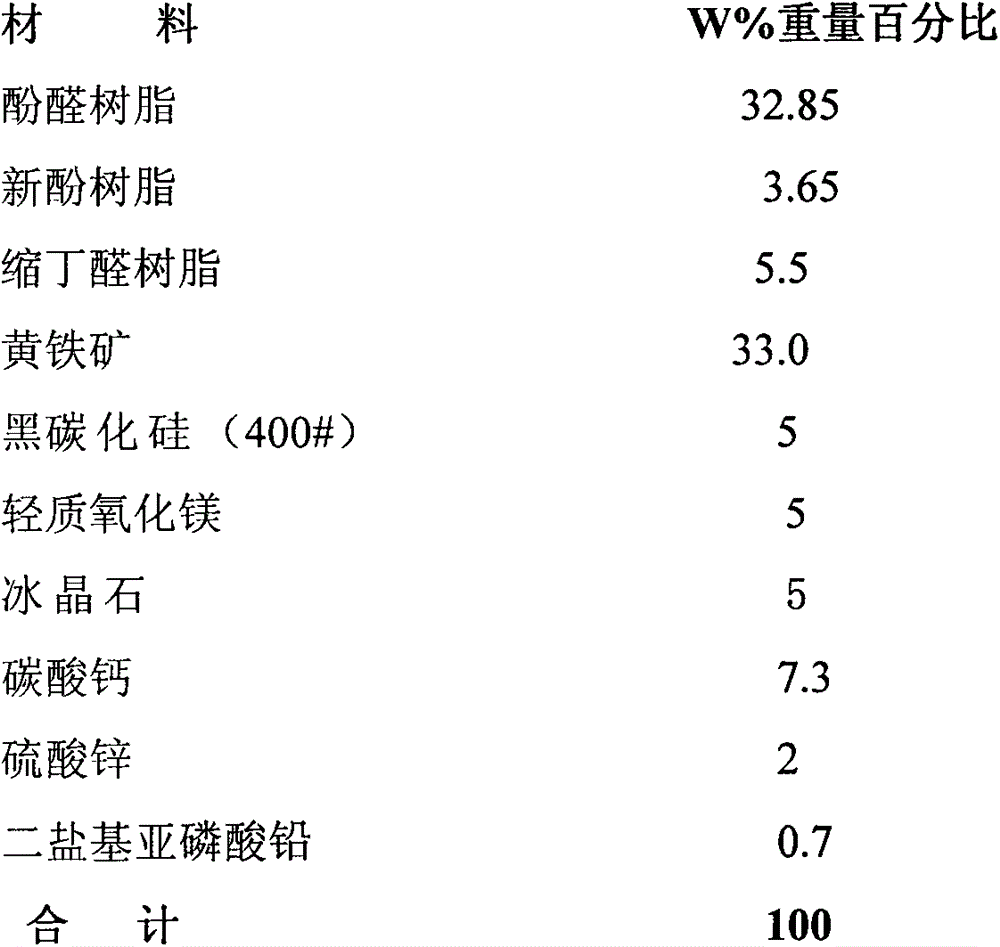

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

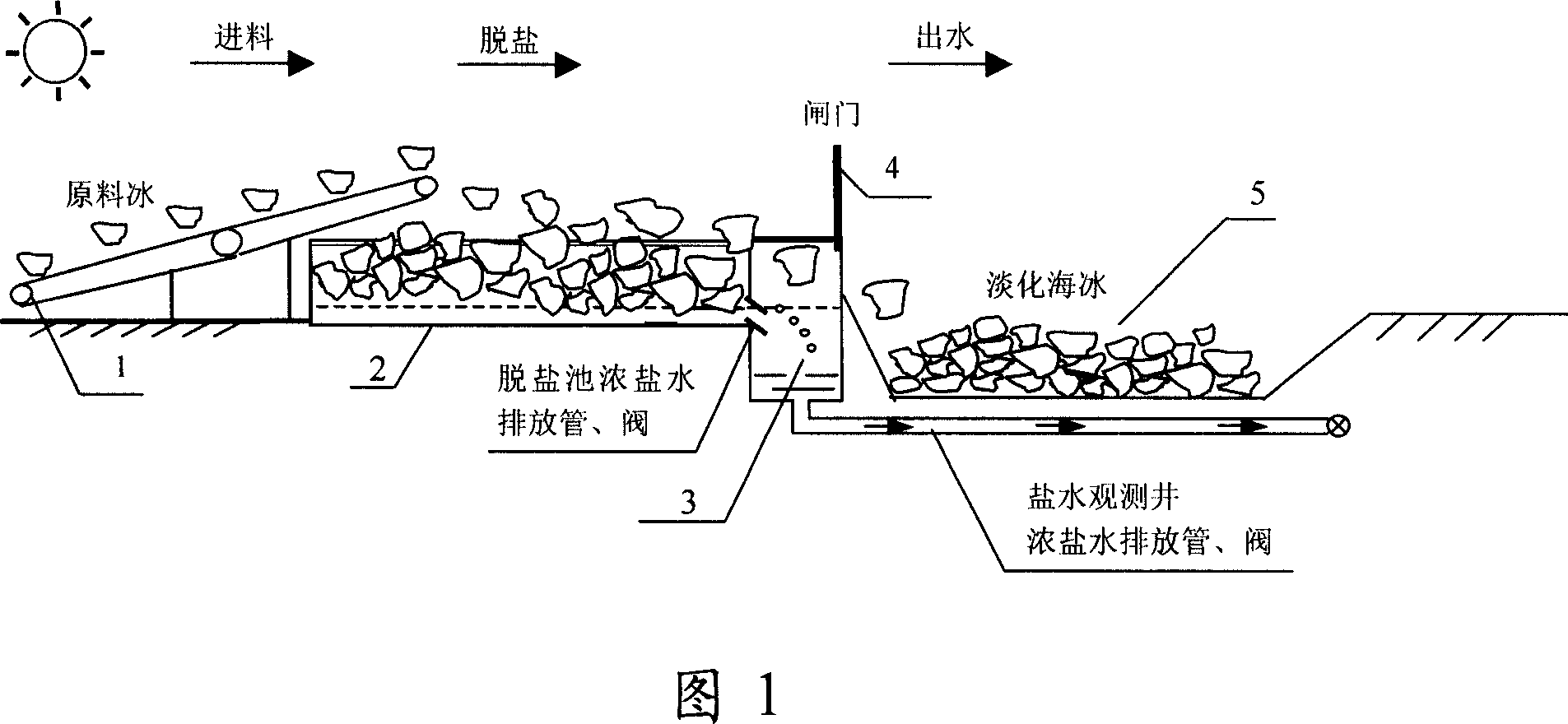

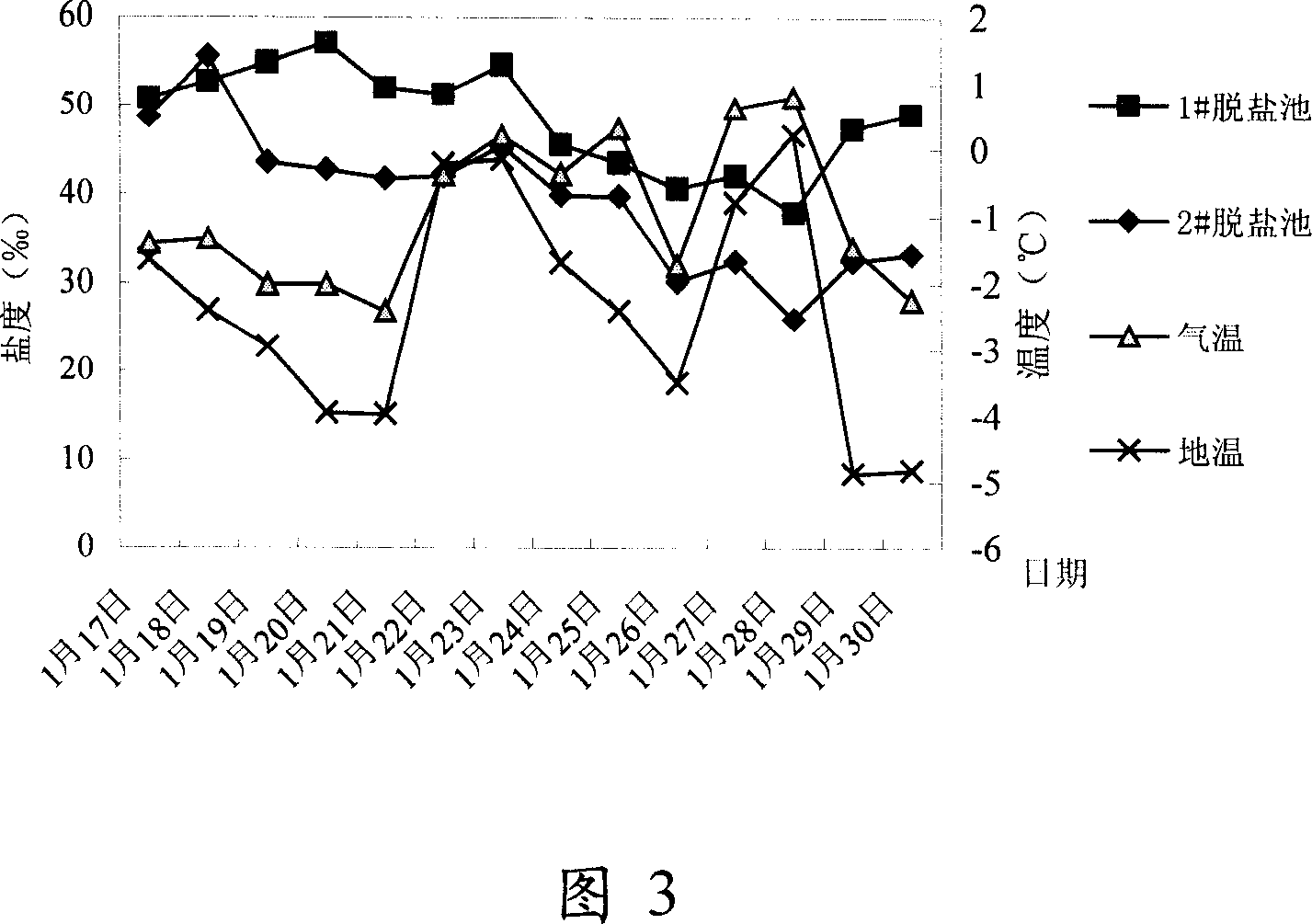

Sea ice desalinization facilities with gravity method and sea ice solid-state gravity desalinization method

ActiveCN1919742AIncrease profitReduce energy consumptionSeawater treatmentWater/sewage treatmentWater desalinationSea ice

The invention discloses a sea ice solid gravity desalinizing method, which comprises the following parts: feed device, gravity desalinization pool, salt water observing pump, product transmitting device and reservoir, wherein the sea ice solid gravity desalinizing method comprises the following steps: fetching sea ice in the gravity desalinizing pool through feed device; discharging bittern in the ice part acted by gravity; collecting solid cryolite; transmitting in the reservoir; melting naturally.

Owner:BEIJING NORMAL UNIVERSITY

Special flux-cored wire for surfacing repair of BD roller

InactiveCN101804530AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaHigh carbonManganese

The invention discloses a special flux-cored wire for surfacing repair of a BD roller, which consists of a tube skin and a flux core, wherein the tube skin is an H08A steel strip, and the flux core comprises the following components by weight percent: 15-25% of high-carbon ferrochrome, 2-10% of micro-carbon ferrochrome, 5-7% of metal manganese, 6-12% of ferromolybdenum, 3-10% of ferrotungsten, 5-10% of ferrovanadium, 0.5-6% of ferrotitanium, 0.3-5% of yttrium-based rare-earth, 1-3% of ferrocolumbium, 4-10% of cryolite and 10-50% of ferrous powder, wherein the filling coefficient is 30-45%. The special flux-cored wire selects a Cr-Mo-W-V alloy system with optimal alloy matching and carries out Ti-Nb-Re micro-alloy grain refinement, thereby leading a surfacing repair layer to have the advantages of high hardness, high wear resistance, high toughness and high anti-cold and hot alternating thermal fatigue performance, and exponentially prolonging the service life of the BD roller after surfacing repair in comparison with the BD roller after the ordinary roller flux-cored wire repair.

Owner:邯郸市永固冶金备件有限公司

Low-temperature steel flux-cored wire

InactiveCN101450426AExcellent Oxygen Content Diffusion Hydrogen ContentOxygen Diffusion Good Hydrogen ContentWelding/cutting media/materialsSoldering mediaArc stabilitySlag

The invention discloses a low-temperature steel flux cored wire. Flux core of the flux cored wire comprises the following raw materials by weight percentage: 28 to 33 percent of rutile, 1 to 3 percent of aedelforsite, 14 to 18 percent of silicon-manganese alloy, 16 to 21 percent of ferrous powder, 2 to 4 percent of nickel powder, 1 to 2 percent of cryolite, 5 to 7 percent of feldspar, 1.5 to 2.5 percent of ferrotitanium, 0.5 to 1 percent of ferroboron, 5 to 6 percent of mid-carbon ferromanganese, 2.5 to 4 percent of magnesite, 4 to 6 percent of quartz and 1.5 to 3.5 percent of fluorite. Compared with the similar product of the prior art, the flux cored wire belongs to the meta-acid slag series, and has the advantages of good electric arc stability, less splash, easy slag removal, good low-temperature impact ductility, good low-temperature crack resisting performance, high efficiency and low cost.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

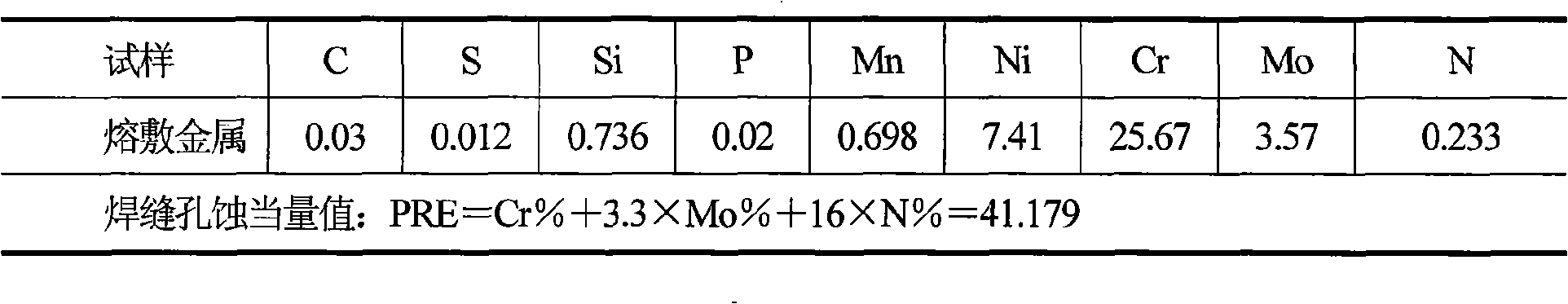

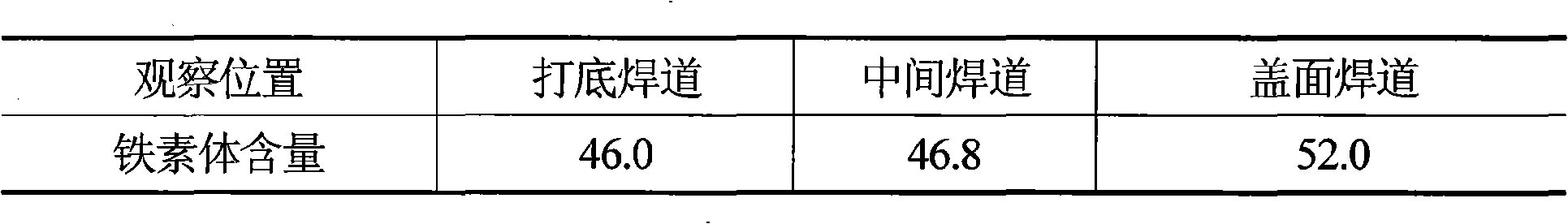

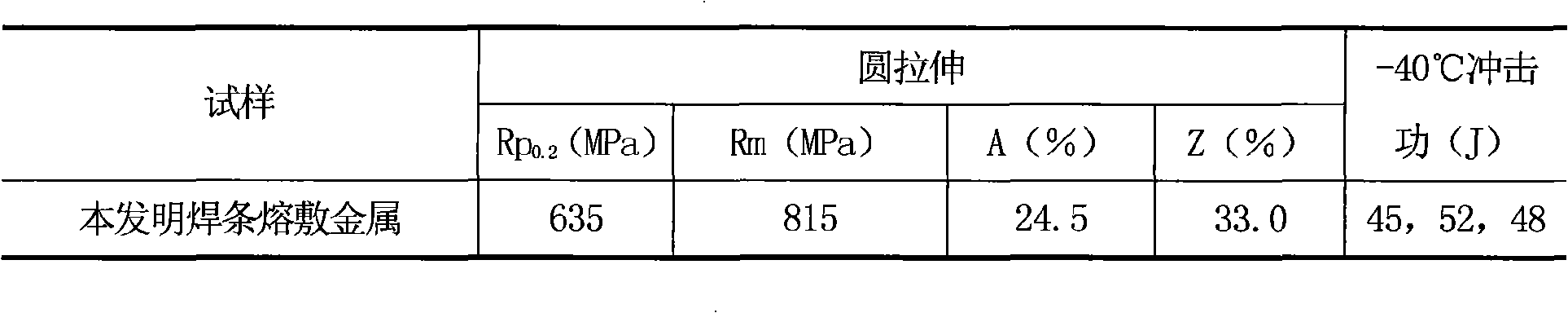

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

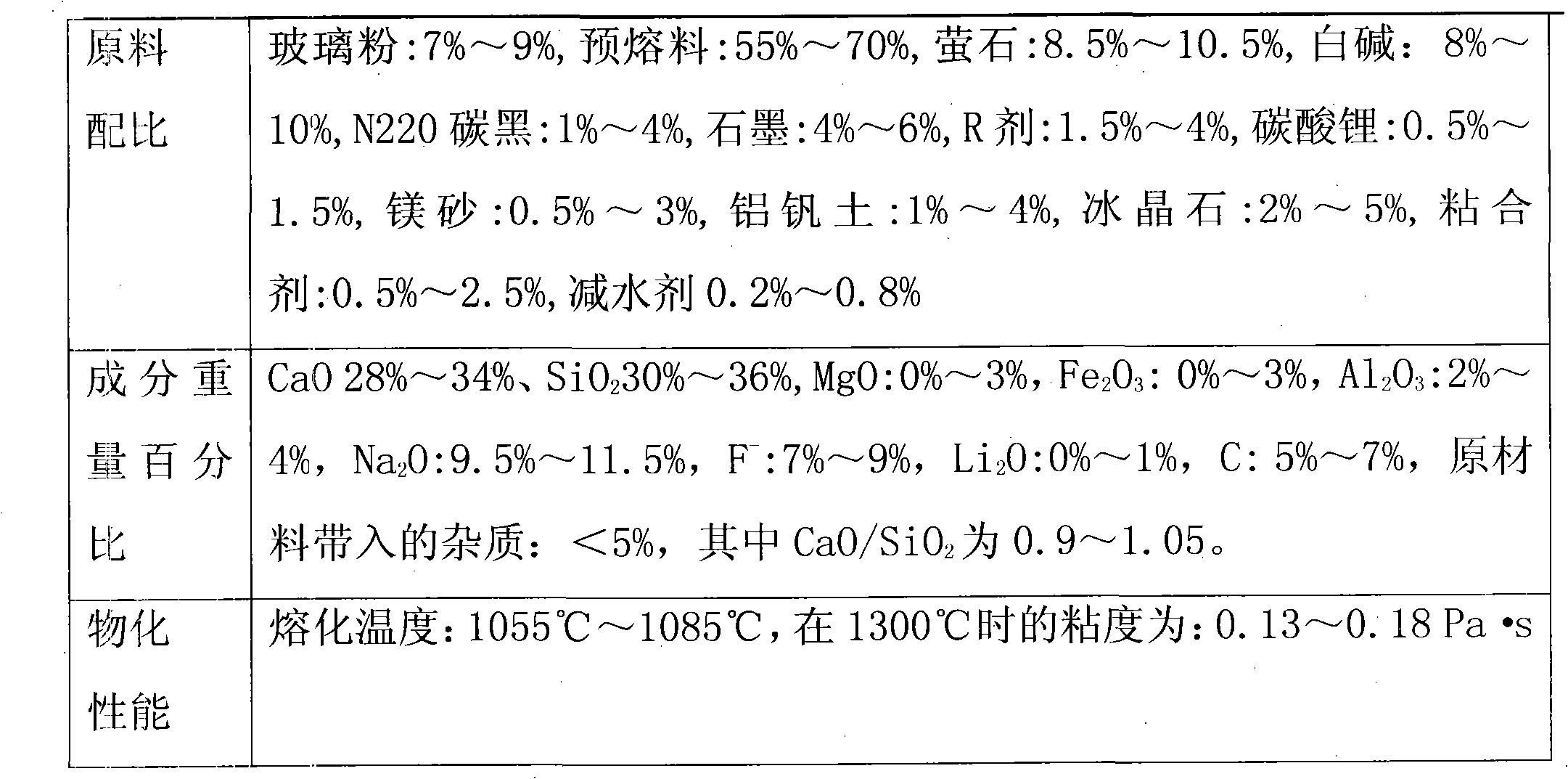

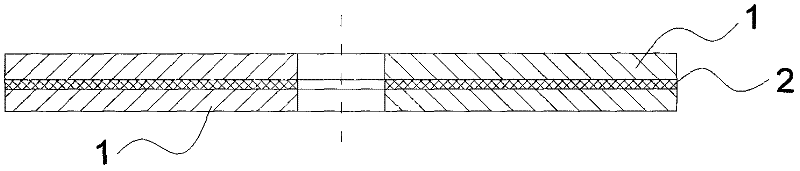

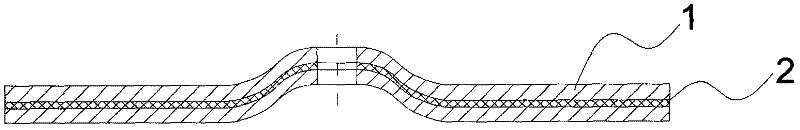

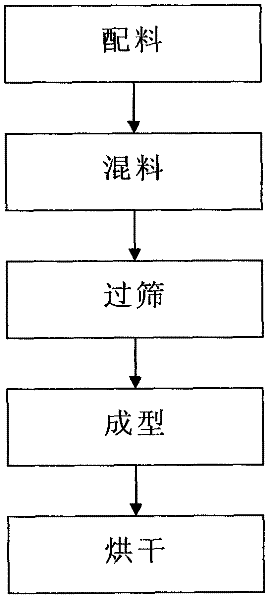

High-viscosity continuous casting protective slag for solving slag inclusion on surface of low-carbon steel

The invention discloses high-viscosity continuous casting protective slag for solving slag inclusion on the surface of low-carbon steel. The protective slag comprises the following raw materials by weight percent: 0%-7% of glass powder, 50%-70% of premelting material, 5.5%-8.5% of fluorite, 4%-8% of dietary alkali, 3% of N330 carbon black, 3.5% of graphite, 0%-3% of R agent, 0.5-2% of lithium carbonate, 2%-5% of manganese carbonate, 2%-5% of magnesite, 3%-7% of bauxite, 1%-3% of cryolite, 1%-3% of adhesive, and 0.3%-1% of water-reducing agent. By utilizing the high-viscosity continuous casting protective slag, mainly on the basis of CaO and SiO2, a certain amount of fluxing agents such as the lithium carbonate, the fluorite, the dietary alkali and the like and a certain amount of carbon materials such as carbon black and graphite are externally added, thus the viscosity is improved and the surface tension is increased; and under the same technique condition, slag inclusion on the surface of a steel billet can be effectively prevented.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Resin grinding wheel and manufacturing method thereof

ActiveCN102363287AStrong grinding forceImprove grinding forceAbrasion apparatusGrinding devicesPyriteEngineering

The invention provides a resin grinding wheel and a manufacturing method thereof, which belong to the field of grinding tools and are used for solving the problem of the production of harmful sulfur dioxide by pyrite serving as a lubricating agent existing in the conventional resin grinding wheel. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body for enhancing the revolving strength of the grinding body, wherein 90-105 parts by mass of corundum is taken as a grinding material the grinding body; 2-8 parts by mass of phenolic aldehyde resin liquid and 6-25 parts by mass of phenolic aldehyde resin powder are taken as bonding agents; and 1-10 parts by mass of cryolite and 1-5 parts by mass of polytetrafluoroethylene powder are taken as fillers. The invention further provides a manufacturing method of the resin grinding wheel. In the grinding wheel, the polytetrafluoroethylene powder instead of pyrite is taken as a lubricating agent, so that sulfur dioxide is not produced and other pollution is avoided in the using process.

Owner:NINGBO DAHUA GRINDING WHEEL

Full-position soldering biphase stainless steel flux-cored wire

InactiveCN101134271AEasy to remove slagArc stabilizationWelding/cutting media/materialsSoldering mediaWeld seamMaterials processing

The flux cored wire for all position welding of two-phase stainless steel has flux core comprising metal Cr powder 35-40 wt%, metal Mo powder 11-15 wt%, metal Ni powder 2-4 wt%, metal Mn powder 3-5 wt%, Al-Mg alloy 2-5 wt%, cryolite 1-4 wt%, quartz 4-9 wt%, feldspar 2-8 wt%, rutile 21-30 wt%, Al2O30.5-4 wt%, zirconite 1-5 wt%, Bi2O30.5-3 wt%, and manganese nitride 0.5-3 wt%. Welding two-phase stainless steel with flux cored wire can form weld seam with excellent corrosion resisting performance and high impact toughness, and the flux cored wire has excellent welding performance and all position welding adaptability.

Owner:栗卓新

Method for conducting ultrasonic-assisted acid leaching treatment on aluminum electrolytic waste cathode carbon blocks

The invention relates to a method for conducting ultrasonic-assisted acid leaching treatment on aluminum electrolytic waste cathode carbon blocks and belongs to the technical field of aluminum electrolytic solid waste resource recovery. The method comprises the steps that the aluminum electrolytic waste cathode carbon blocks are crushed and added into acid liquor to be subjected to leaching, and powdered carbon and filtrate are obtained through filtration; acid leaching is carried out in an ultrasonic environment; and the pH value of the filtrate is adjusted to be neutral, crystals are separated out through evaporative crystallization, a cryolite and aluminum hydroxide mixture is obtained through filtration, and distilled water is utilized repeatedly. The method is simple in process, operating is convenient, the cyclic utilization rate of materials is high, environmental pollution is little, the reaction speed is increased through the synergistic effect of ultrasonic waves and acid leaching, and the purity of powdered carbon products is improved. The method is suitable for treatment of aluminum electrolytic waste cathode carbon blocks with the carbon content higher than 50%, and the purity of obtained powdered carbon can reach up to 98.47%.

Owner:CENT SOUTH UNIV

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Low-temperature molten salt system for aluminum electrolysis and method for carrying out aluminum electrolysis by same

The invention relates to the field of molten salt electrolysis of nonferrous metal metallurgy and provides a novel molten salt electrolyte system which can be applied to the aluminum electrolysis industry. The molten salt as an electrolyte system of aluminum electrolysis can greatly reduce the electrolysis temperature, and the electrolyte system also presents a favorable dissolving performance onAl2O3 in the process of electrolysis. The novel molten salt electrolyte system comprises ternary or multivariant salt, such as KF, KCl, NaF, NaCl, AlF3, MgF2, CaF2, LiF, BaF2, Al2O3, and the like. Theelectrolyte system has a lower primary crystal temperature and the favorable dissolving performance on the Al2O3. The problems of low Al2O3 solubility and low dissolving speed brought by reducing theelectrolyte primary crystal temperature through reducing the NaF / AlF3 ratio in a sodium cryolite system are solved. In addition, the low-temperature electrolyte system is particularly suitable for adopting an inert anode of metal ceramics or metal alloy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Grinder of bullet train tread cleaner and production method thereof

ActiveCN102432978AAvoid stressAvoid heat cracksOther chemical processesVehicle cleaningIron powderGraphite

The invention provides a grinder of a bullet train tread cleaner, wherein the grinder is made of a composite material; the composite materials comprises modified phenolic resin 6818, iron powder, copper fibres, steel fibres, sepiolite, potassium feldspar, graphite, cryolite and aluminium oxide; the invention further provides a production method of the grinder.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +1

Polyimide resin diamond grinding wheel and preparation method thereof

ActiveCN102814763AHigh mechanical strengthImprove heat resistanceAbrasion apparatusGrinding devicesCorundumPolyimide

The invention discloses a polyimide resin diamond grinding wheel and a preparation method of the polyimide resin diamond grinding wheel. The polyimide resin diamond grinding wheel is prepared from the following components in parts by weight: 50-60 parts of diamond grinding material, 5-10 parts of white corundum grinding material, 5-10 parts of garnet sand, 5-15 parts of polyimide resin powder, 2-6 parts of furfuryl alcohol, 1-2 parts of trioctyl trimellitate, 5-10 parts of cryolite, 5-10 parts of gypsum powder, 2-5 parts of nano siliceous shale powder and 2-5 parts of copper powder. According to the polyimide resin diamond grinding wheel and the preparation method of the polyimide resin diamond grinding wheel, as polyimide resin serving as a binding agent has higher mechanical strength and excellent heat resistance, the durability of the prepared resin grinding wheel is improved greatly; as ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, and cracks formed by rigid grinding are reduced, thereby the use efficiency and service life of the resin grinding wheel are improved further; and in addition, since copper power is added, fast heat dissipation effect is achieved, a great deal of heat generated in a cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is achieved.

Owner:安徽威铭耐磨材料有限公司

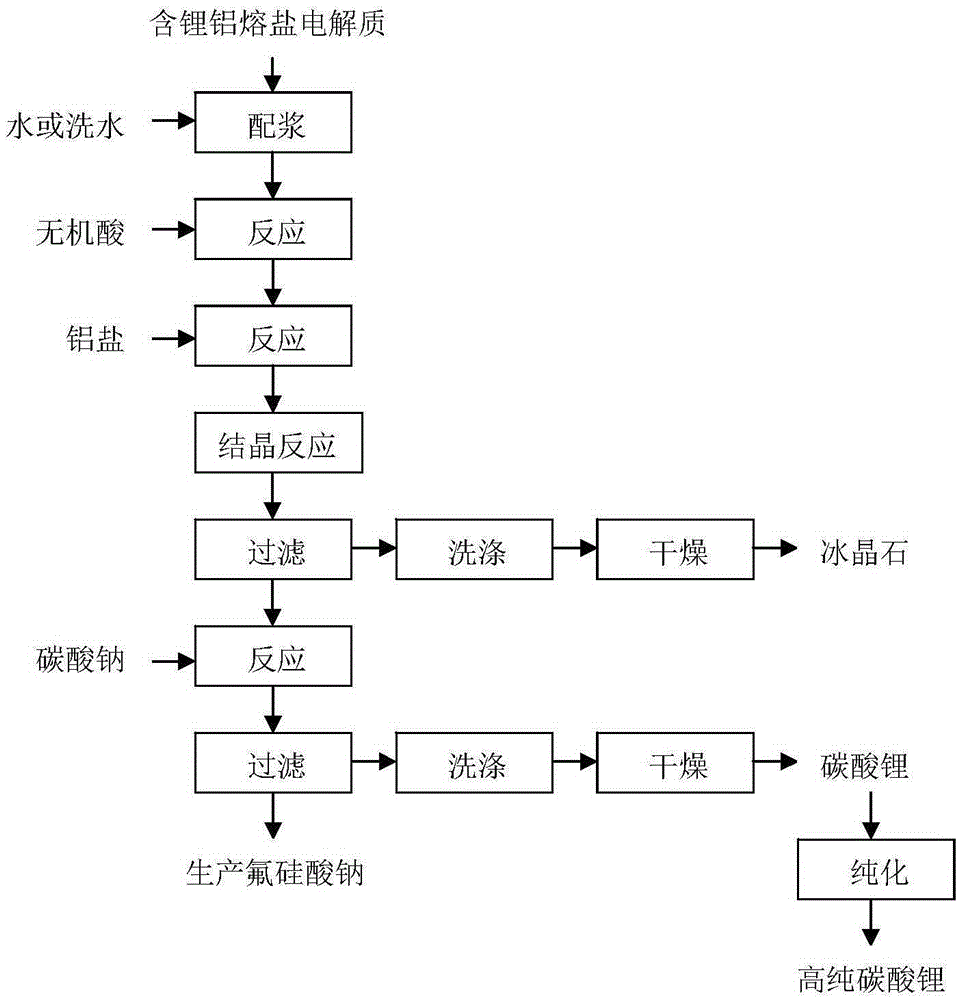

Lithium-aluminum-contained electrolyte comprehensive recycling method

ActiveCN105349786AImprove qualityRunning balance and stabilityProcess efficiency improvementLithiumSlurry

Owner:DO FLUORIDE CHEM CO LTD

Alkali-type dissolving method of carbon powder in electrolytic aluminum scraps

The invention discloses an alkali-type dissolving method of carbon powder in electrolytic aluminum scraps, characterized by comprising the following steps: crushing electrolytic aluminum scraps in a wet type, floating and magnetically separating to remove iron and silicon and obtain carbon powder A; putting the carbon powder A in an alkali solution to dissolve; dissolving fluoride in the carbon powder A; and then, adding carbon dioxide to separate out cryolite B. The invention adopts the technical scheme that the theory that fluoride has a certain solubility in caustic soda is utilized to design an alkali-method process, i.e. carbon powder primarily separated at normal pressure is dissolved in an alkali type, and CO2 generated in the product-drying process is utilized to carbonize so as to separate out the cryolite. Tested by the proposer to the product, high-purity cryolite achieving the national standard can be obtained. Iron and silicon in the carbon powder can be eliminated by the secondary floatation of the carbon powder because the fluoride carrier is damaged, and the processed carbon powder (with 1-2 percent of ash content) can reach a high-purity carbon powder level.

Owner:贵州铝城铝业原材料研究发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com