Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

293 results about "Phase ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase ratio is a simple ratio of the volumes of the column and the thickness of the film coated on the inside wall of the column. A high phase ratio represents a column which has a large column-to-stationary-phase volume, and therefore will show relatively little retention.

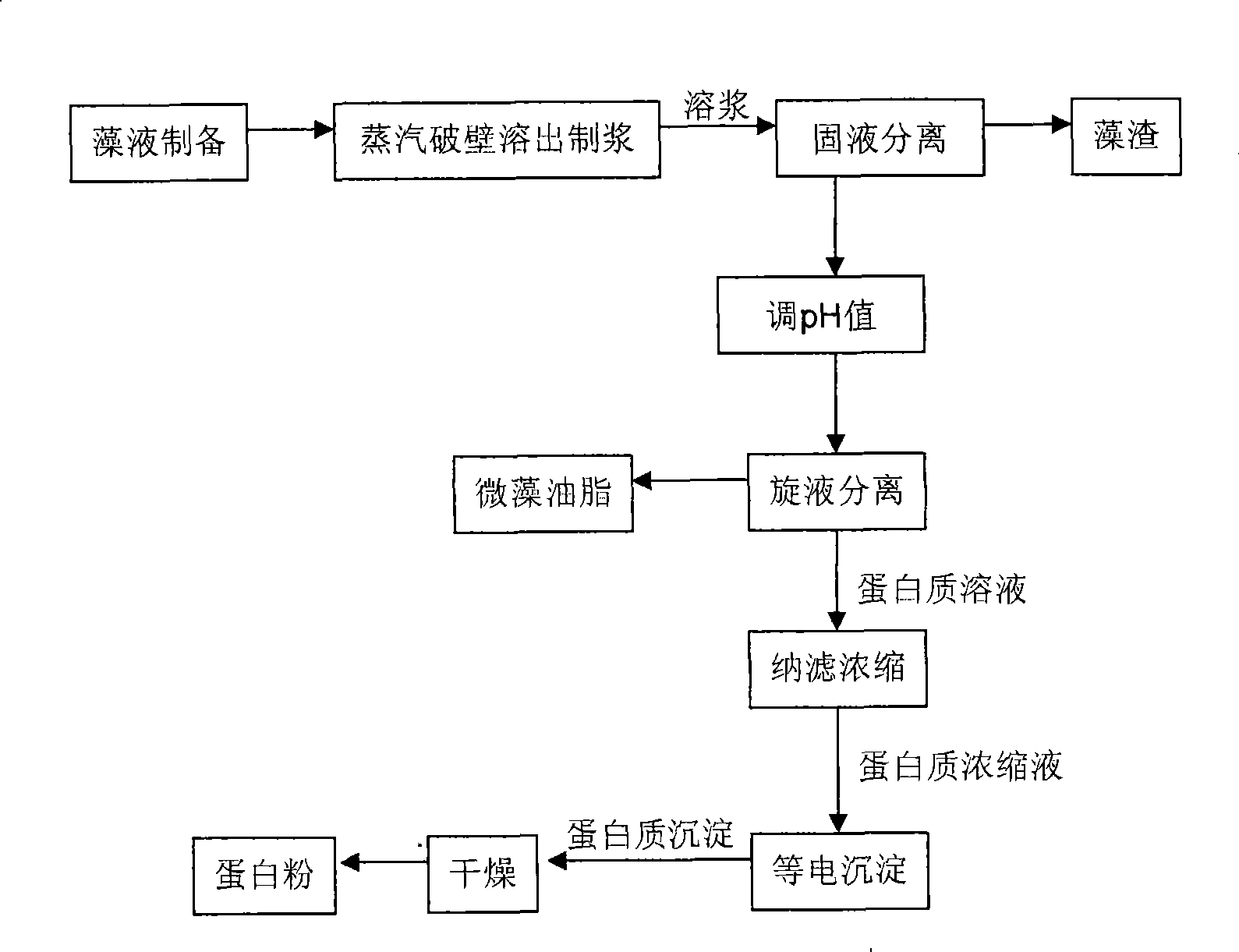

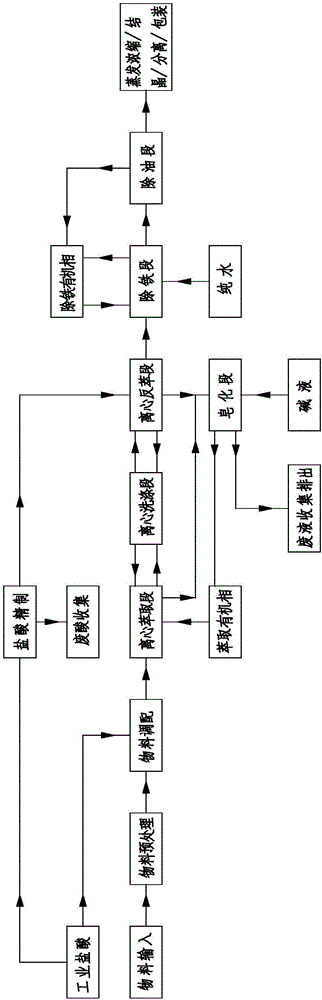

Method for simultaneously extracting lipid and protein from microalgae

ActiveCN101429467AHigh yieldPrevent drynessPeptide preparation methodsFatty-oils/fats productionOil and greaseFreeze-drying

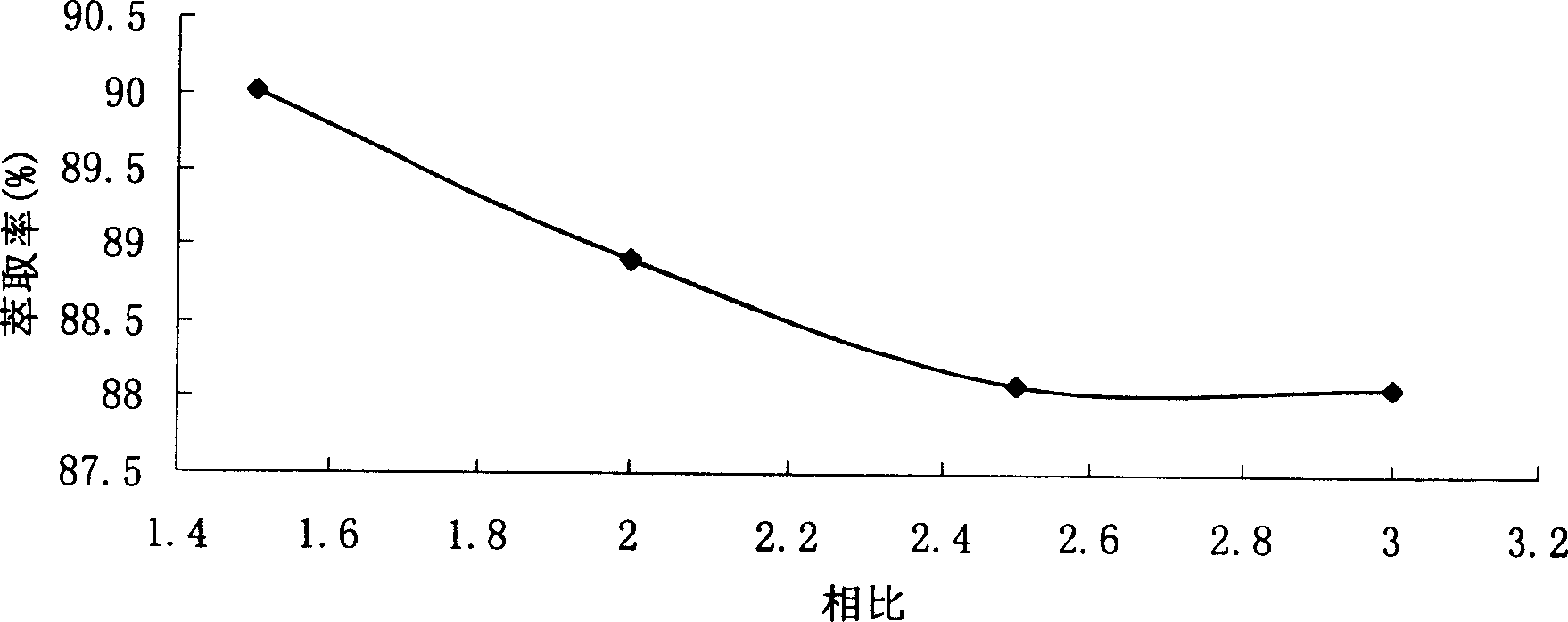

The invention relates to a method for simultaneously extracting grease and proteins from microalgae, which takes wet algae mud as a raw material, adjusts the pH value to be alkaline or slightly alkaline, and performs wall breaking of microalgae cells and dissolution of the grease and the proteins through vapor. The method is as follows: dissolved microalgae slurry is filtered for removal of cell residue, and a mixture of the grease and the proteins is obtained; a hydrocyclone is utilized for oil-water separation, and microalgae grease is obtained; and a protein aqueous solution is subjected to nano-filtration, condensation, isoelectric precipitation and freeze drying or spray drying, and protein powder is obtained. The method utilizes the water-bearing microalgae cells as the raw material, saves the energy consumption for drying the algae cells, adopts a slightly alkaline or alkaline algae cell liquid to realize vapor wall breaking and simultaneous dissolution of the grease and the proteins, and has good wall breaking effect, high dissolution rate, low energy consumption and easily widened process. The method adopts vortex hydrocyclone separation to well solve the problem of difficult oil-water separation under the condition of low phase ratio and realize simultaneous extraction of the microalgae grease and the proteins. Moreover, the method has the advantages of simple process, economy, low energy consumption, and easy realization of industrialization.

Owner:云南中科雨虹生物科技有限公司

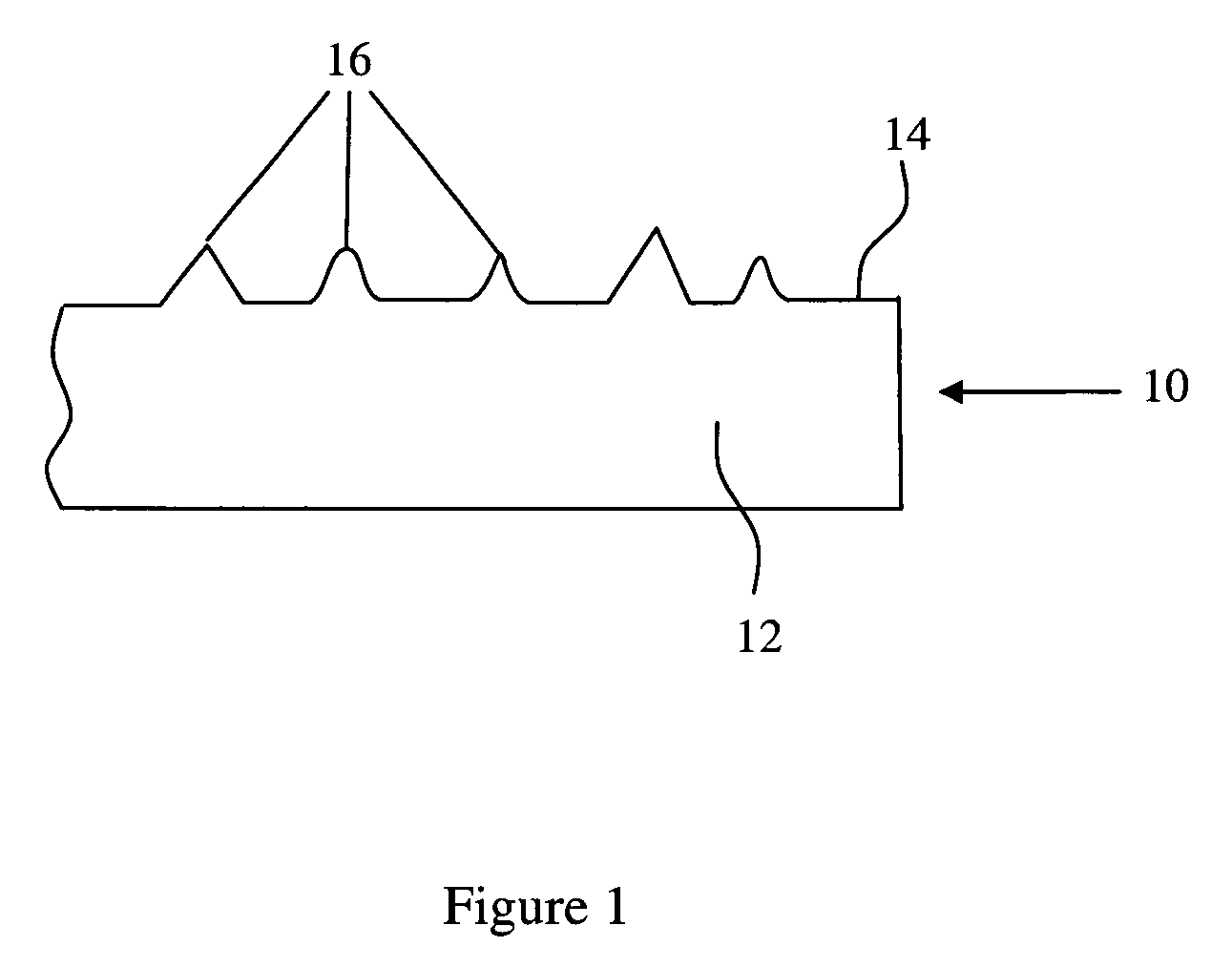

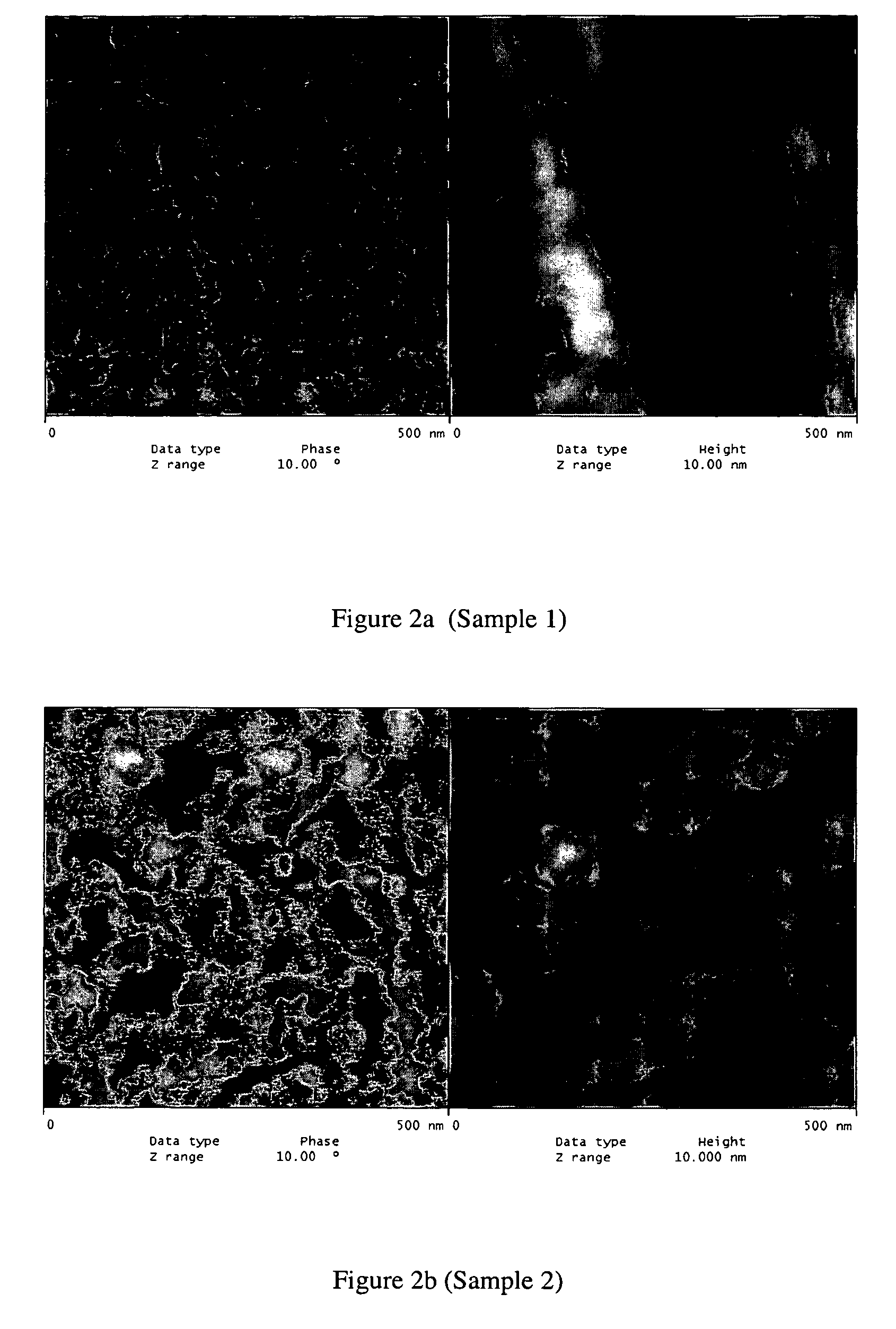

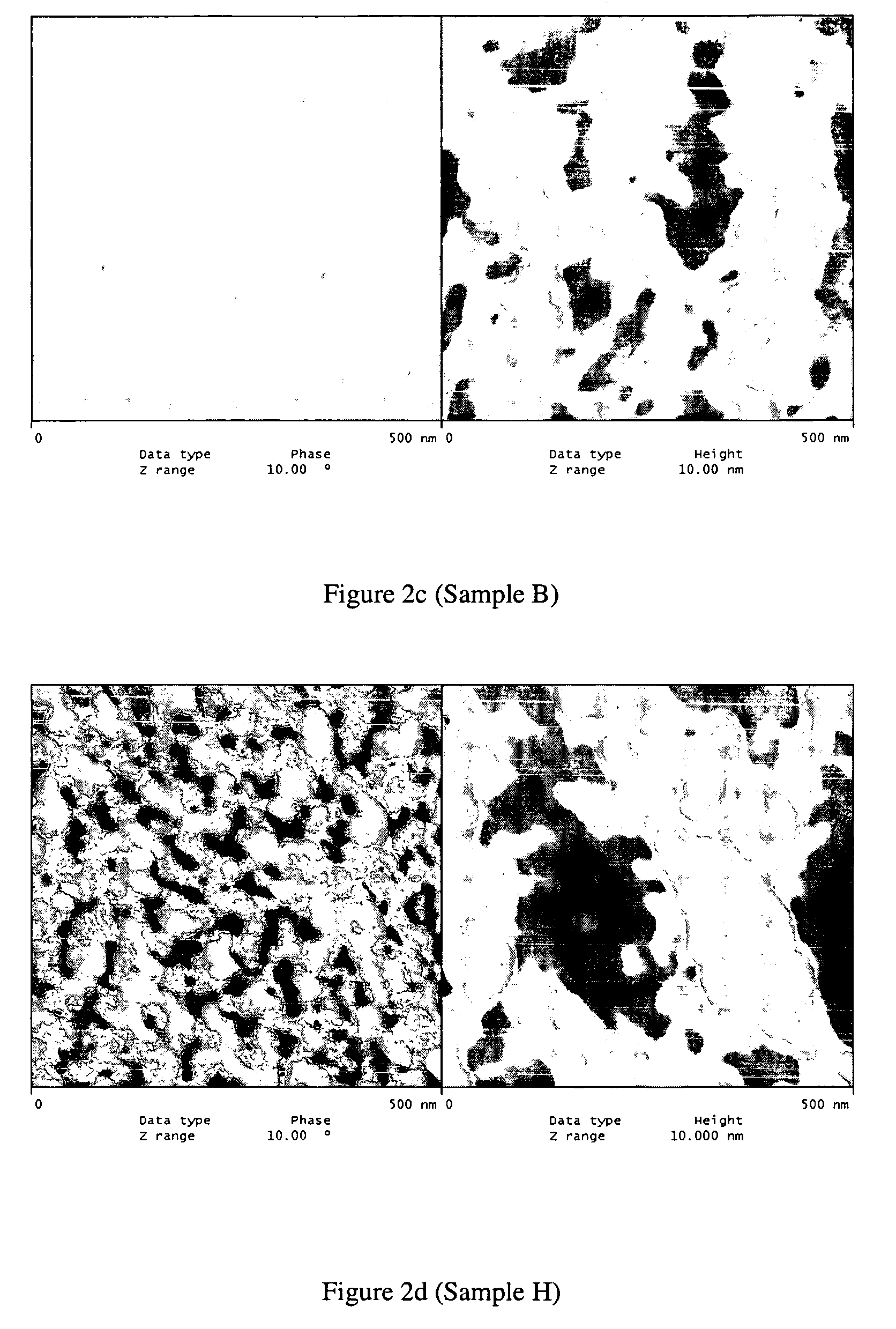

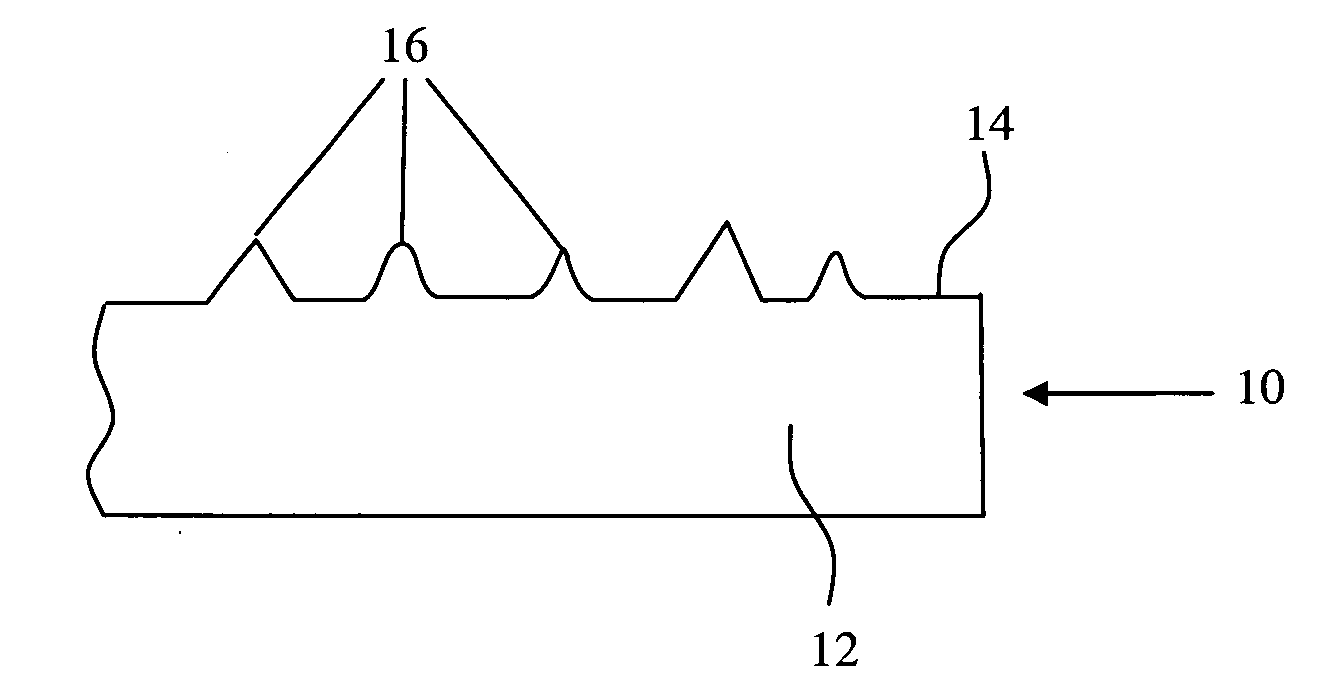

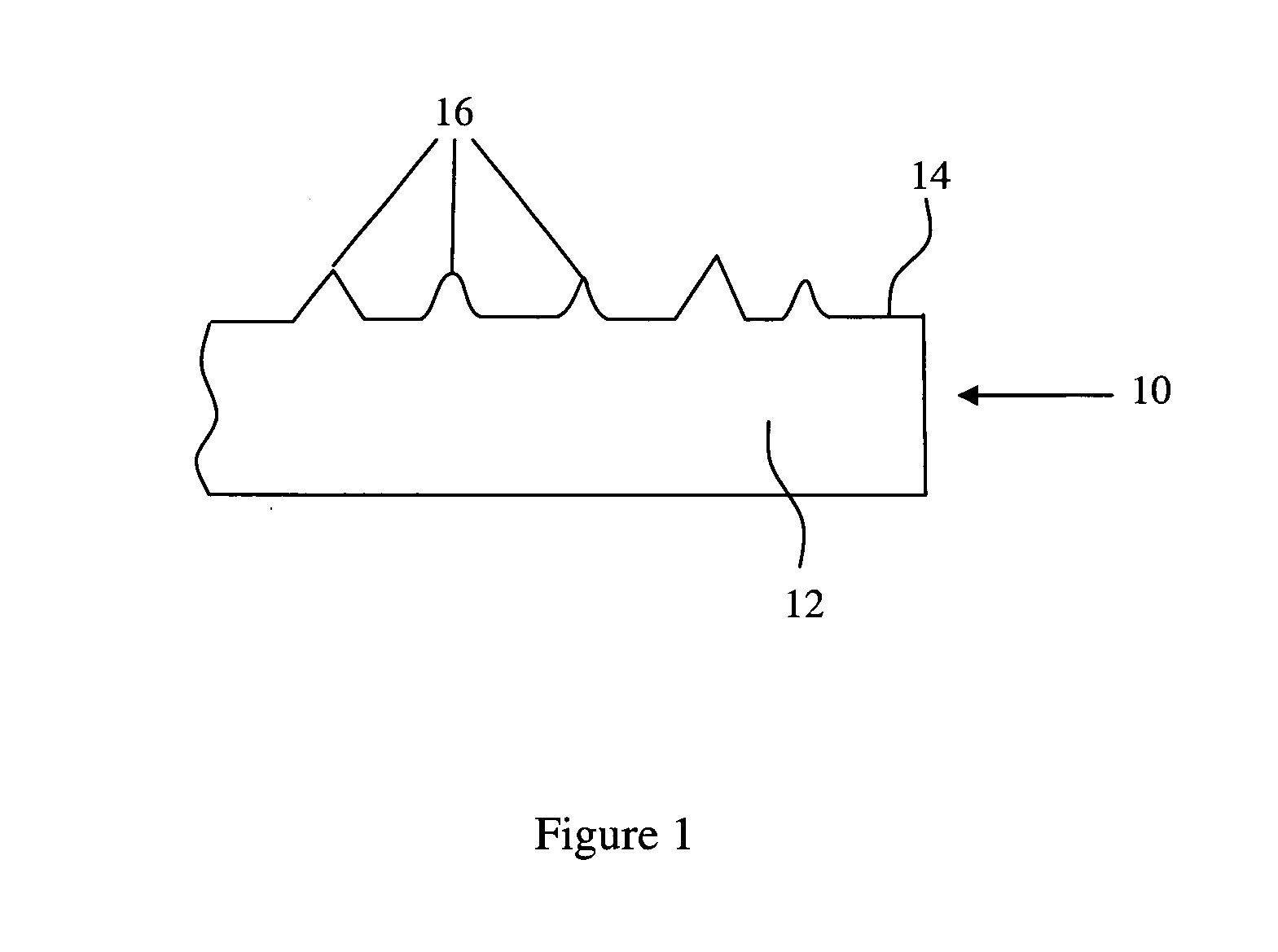

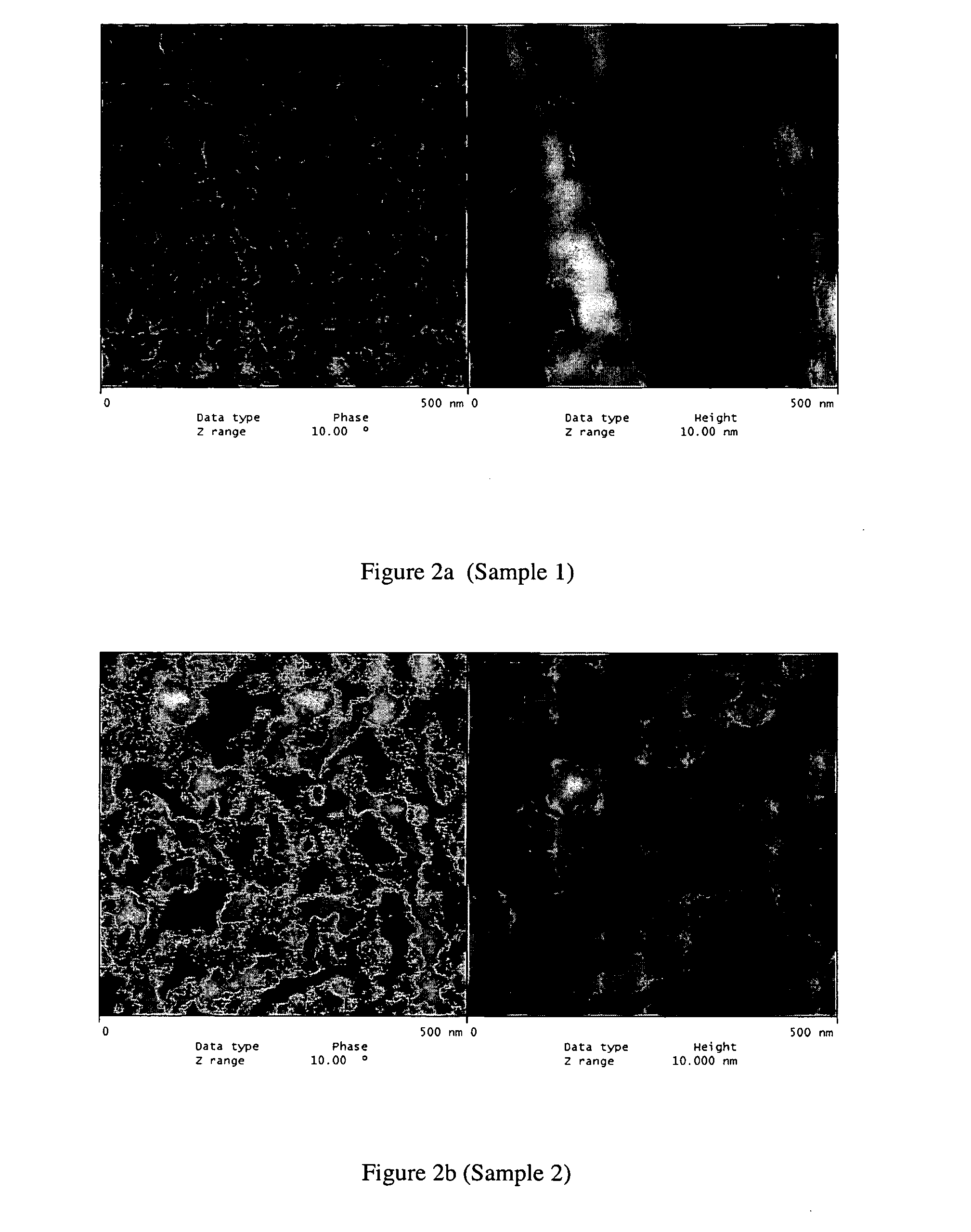

Chemical mechanical polishing pad

ActiveUS7445847B2Synthetic resin layered productsAbrasion apparatusPhase ratioUltimate tensile strength

The invention provides a polishing pad suitable for planarizing at least one of semiconductor, optical and magnetic substrates. The polishing pad includes a polymeric matrix having a top polishing surface. The top polishing surface has polymeric polishing asperities or forms polymeric polishing asperities upon conditioning with an abrasive. The polymeric polishing asperities are from a polymeric material having at least 45 weight percent hard segment and a bulk ultimate tensile strength of at least 6,500 psi (44.8 MPa). And the polymeric matrix has a two phase structure, a hard phase and a soft phase with an average area of the hard phase to average area of the soft phase ratio of less than 1.6.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

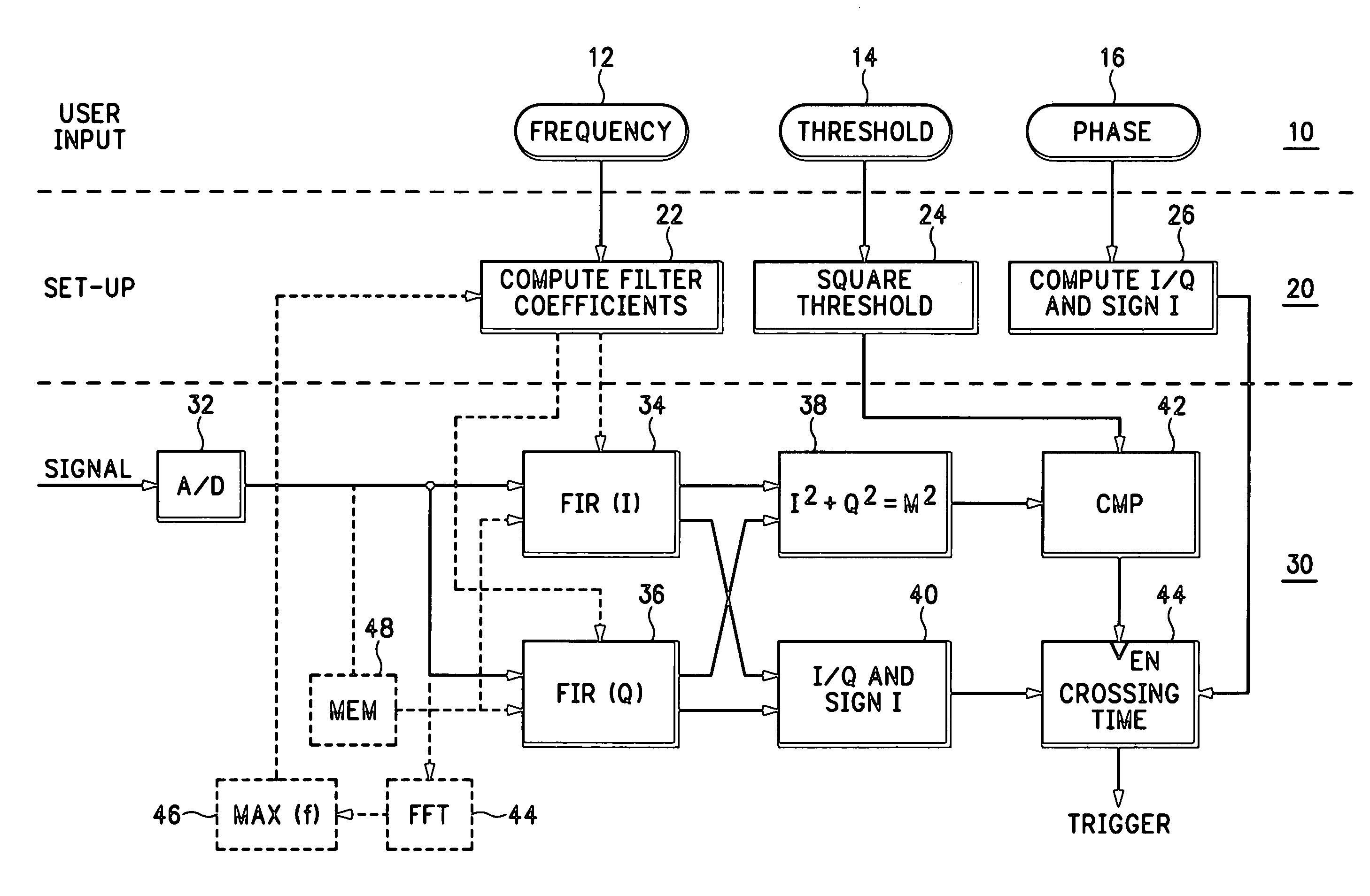

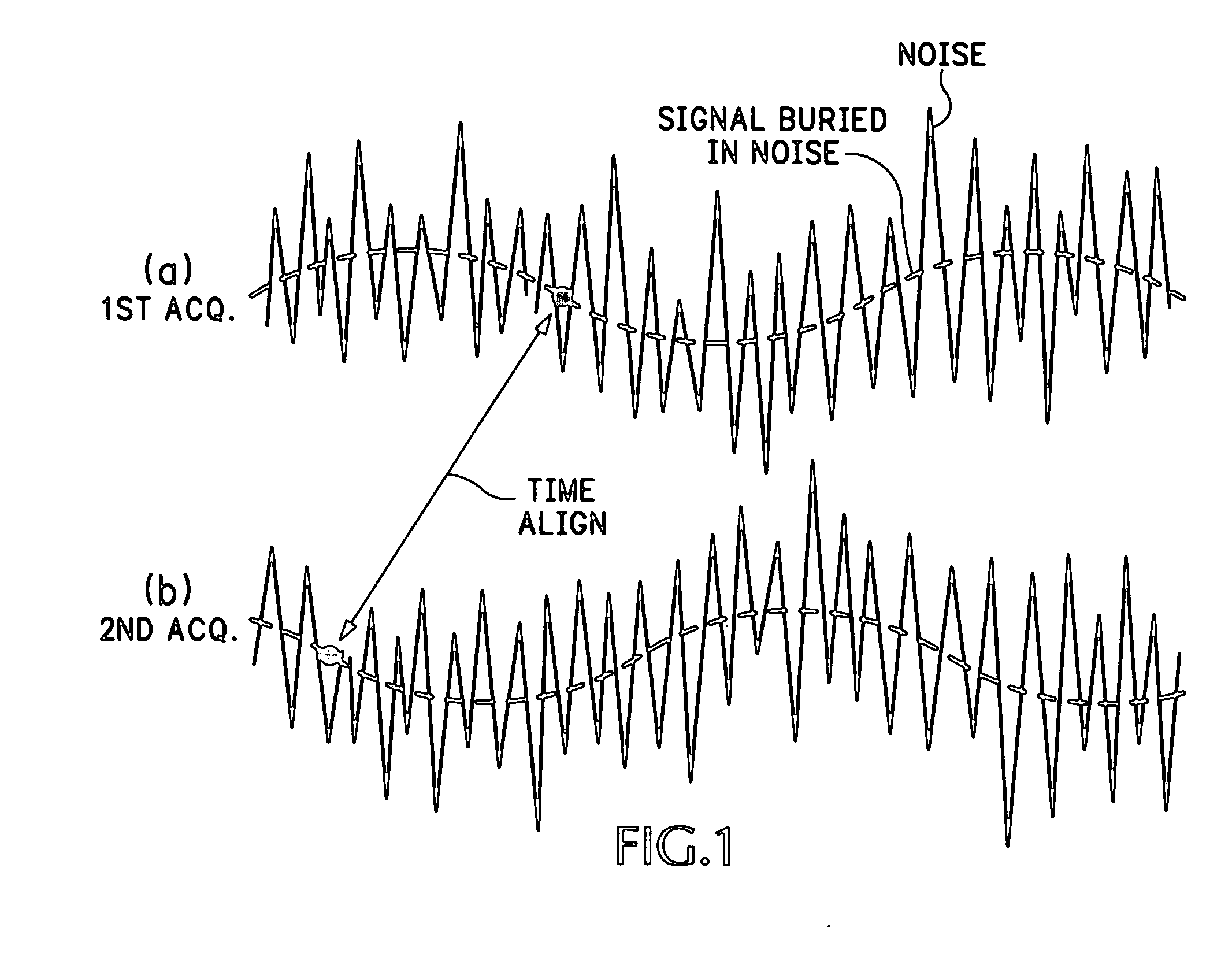

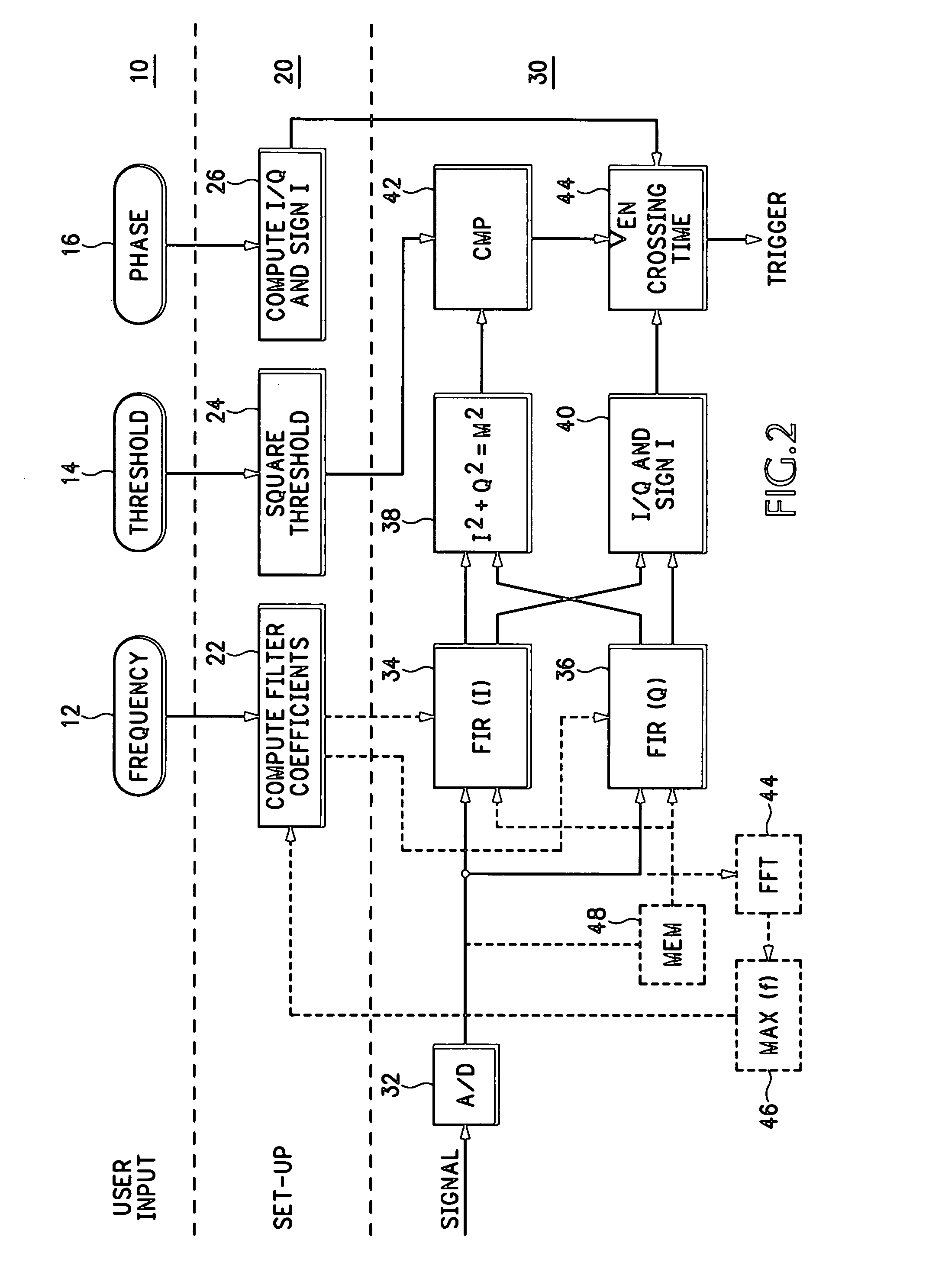

Realtime spectrum trigger system on realtime oscilloscope

InactiveUS20080082278A1Spectral/fourier analysisDigital variable displayFrequency spectrumUser input

A realtime spectrum trigger system on a realtime oscilloscope considers both the magnitude and phase of an input signal having a periodic component so that successive acquisitions of the input signal are time aligned. A user inputs a frequency, threshold and phase for triggering on the periodic component. Input signal samples are filtered by quadrature filters according to the frequency input to produce quadrature signal components. The square of the magnitude of the input signal is computed from the quadrature signal components, as well as the phase ratio and sign, for comparison with calculated values. When enabled by the magnitude of the input signal, a phase crossing determinator compares the phase ratio and sign with calculated values to determine the phase crossing to generate a trigger, resulting in successive acquisitions of the input signal being in time alignment.

Owner:TEKTRONIX INC

Recovery method of copper indium gallium selenide thin-film solar panel

ActiveCN103184338ASimple processEasy to operatePhotography auxillary processesProcess efficiency improvementRecovery methodElectrolysis

The invention provides a recovery method of a copper indium gallium selenide thin-film solar panel. The method comprises the steps that: the copper indium gallium selenide thin-film solar panel is crushed into pieces; the pieces are soaked by using a H2SO4+H2O2 system, such that a soaking liquid is obtained; the soaking liquid is filtered, such that a first leachate is obtained; with a first phase ratio of 1, the first leachate is extracted by using an extraction agent; separation is carried out, such that a first extraction liquid and a first raffinate are obtained; the extraction agent is composed of 30% of P2O4 and 70% of kerosene by volume percentage, the extraction and balance time is 5-20min; an HCl solution is adopted as a stripping agent, and the first extraction liquid is striped by using a second phase ratio, such that In and stripping residual liquid are obtained; a reducing agent is added into the first raffinate; when a reduction reaction is finished, crude Se and a second leachate are obtained by filtering; alkali is added into the second leachate, and a pH value is regulated such that the pH value is constantly higher than 14; when a reaction is finished, filtering is carried out, such that a filtering slag comprising a hydroxide of Cu and a water solution comprising Ga are obtained; the alkali is NaOH, the pH value adjustment process is to add the NaOH in the reaction process after pH=14 so that the pH is always kept more than 14 during the reaction process, and the reaction time is kept for 0.5-2h; and the water solution is electrolyzed.

Owner:FIRST SEMICON MATERIALS

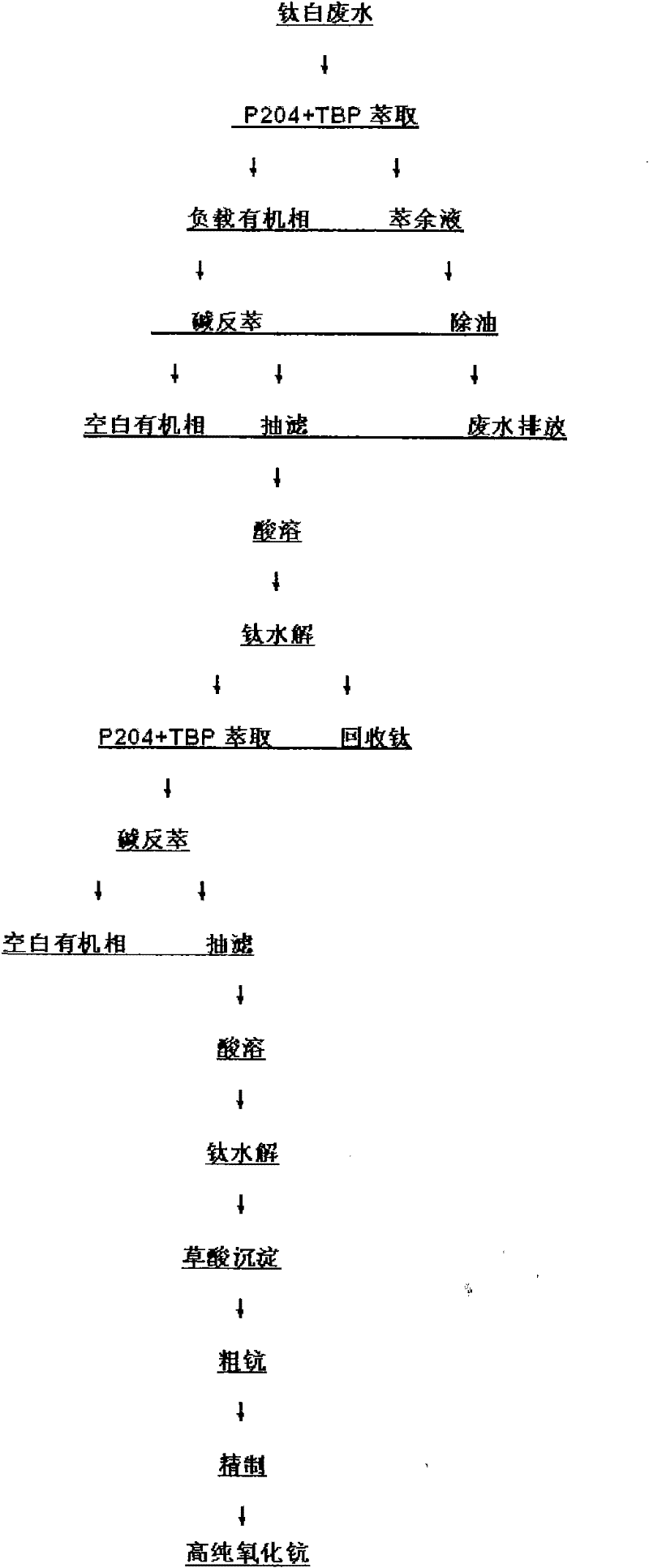

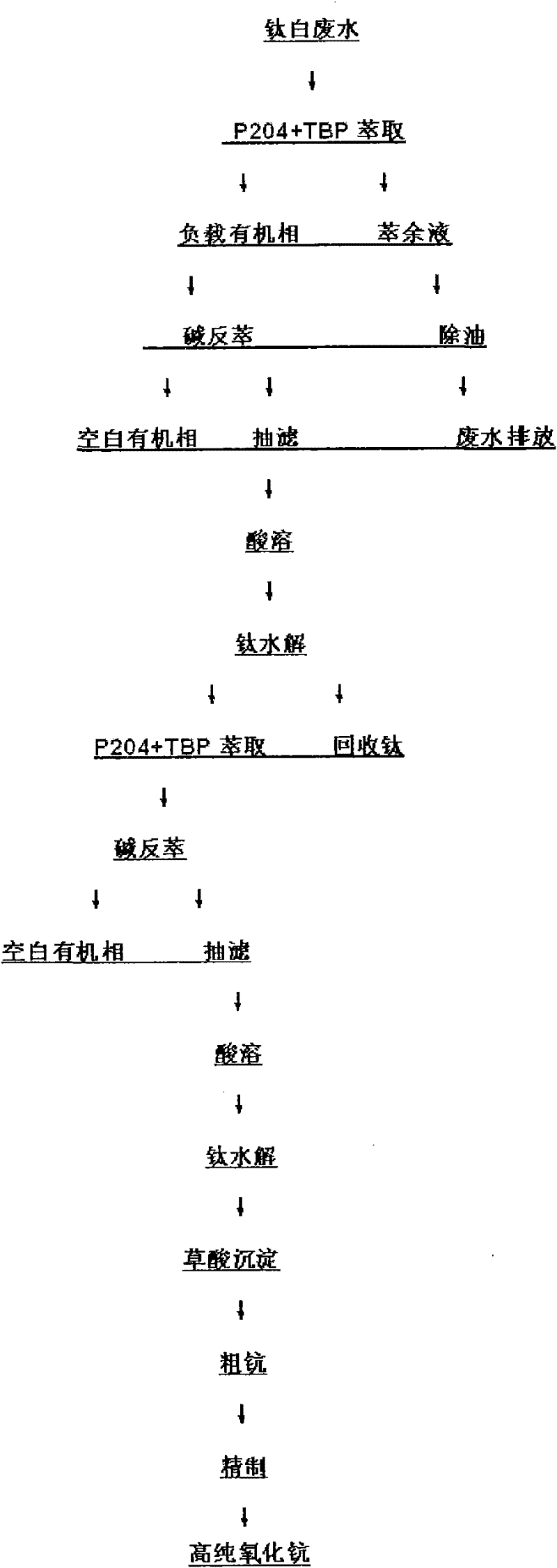

Method for recovering scandium and titanium in titanium white wastewater

ActiveCN102127641AOrganic phase content is smallReduce pollutionProcess efficiency improvementKeroseneEmission standard

The invention discloses a method for recovering scandium and titanium from wastewater in the production of titanium white powder. The method comprises the following steps of: carrying out single stage extraction in titanium white wastewater with P2O4, TBP and kerosene, wherein a phase ratio O / A is 1:50 to 1:10, and balance time is 10-20 min; then, stripping with alkali, filtering and dissolving a stripped substance with acid; heating a solution in a reaction kettle, adjusting a pH value, hydrolyzing titanium, filtering and recovering titanium, repeating the above process to process supernatant fluid, secondarily extracting and dissolving a stripped substance alkali cake with acid; precipitating scandium with oxalic acid and burning to obtain scandium oxide with the purity of 95 percent; and further refining to obtain high-pure scandium oxide. In the invention, titanium is recovered under the condition of ensuring scandium recovery without adopting a titanium washing process of sulfuric acid and hydrogen peroxide, and a hydrolysis mode is adopted to recover titanium, and the recovery cost of scandium is decreased. In addition, a degreasing device and oil-absorbing felt are adopted in waste liquid generated after extraction. The invention has the advantages of environmental protection and simple process, the wastewater contains the organic phase of less than 50 mg / l and reaches an emission standard.

Owner:河南荣佳钪钒科技有限公司

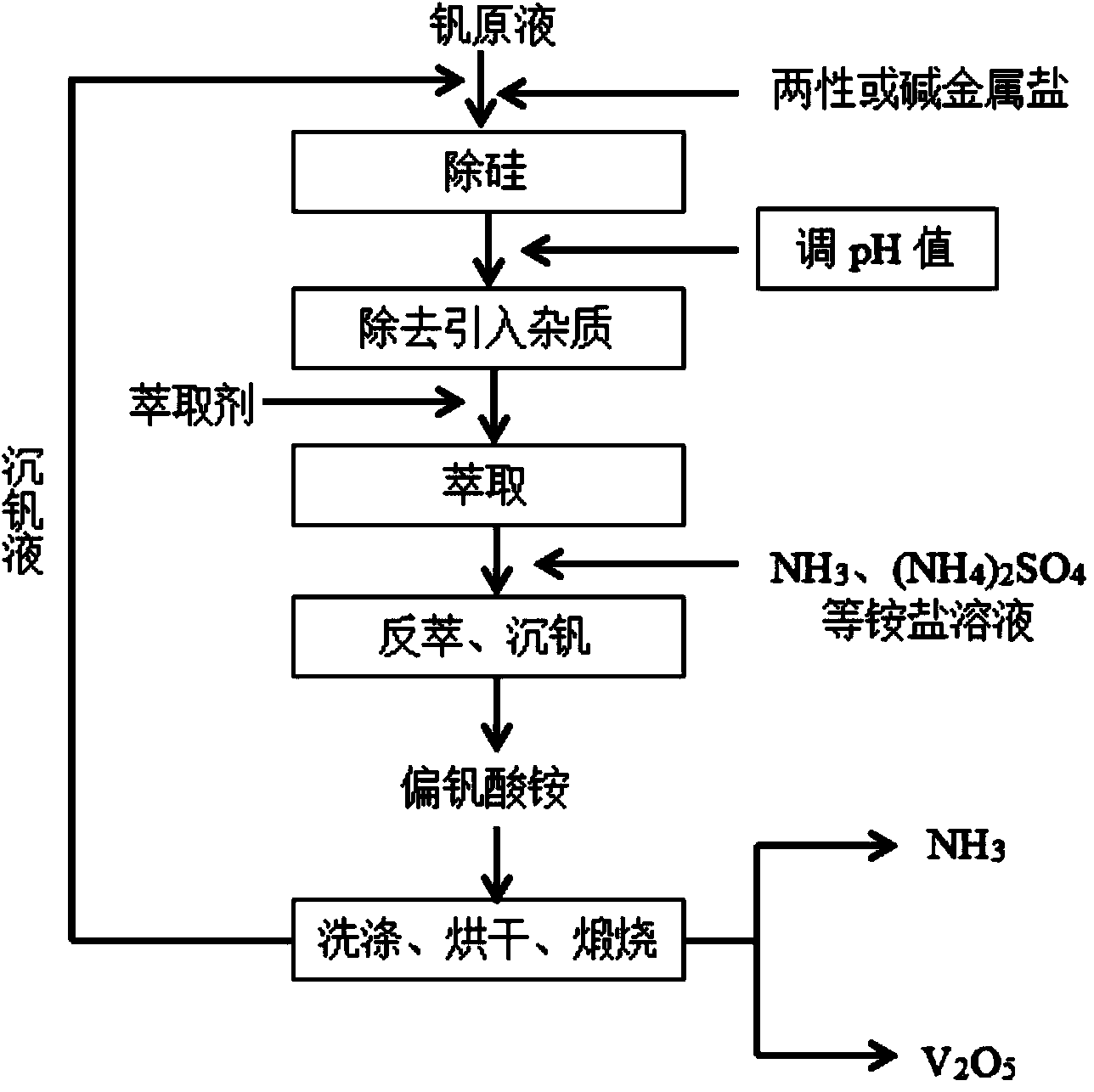

Method for preparing low-silicon vanadium pentoxide from solution containing vanadium, chromium and silicon

ActiveCN103937998AImprove removal efficiencyReduce silicon contentVanadium oxidesProcess efficiency improvementBrickPhase ratio

The invention discloses a method for preparing high-purity low-silicon vanadium pentoxide (V2O5) from a mixed solution containing vanadium, chromium and silicon. The method mainly comprises the following steps: firstly removing the silicon from the solution containing the vanadium, the chromium and the silicon by utilizing amphoteric metal salt and / or alkali metal salt, then also removing other introduced impurities by regulating the pH value of the solution and performing solid and liquid separation; afterwards, selectively extracting most of the vanadium into an organic phase according to a certain phase ratio by use of a primary amine extraction system, then also reversely extracting the vanadium in the organic phase rich in the vanadium by use of an alkaline solution containing ammonium salt, precipitating ammonium metavanadate, filtering or centrifuging the reversely-extracted water phase to obtain a high-purity ammonium metavanadate solid, washing, drying and calcining under a certain temperature to obtain a brick-red substance V2O5, wherein the purity of the V2O5 is above 99.9%, the content of silicon is smaller than 0.007% and no interlayer is formed during the extraction-reverse extraction process. The method disclosed by the invention is used for preparing the high-purity low-silicon V2O5 through processes of intensified silicon removal, extraction, reverse extraction and vanadium precipitation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

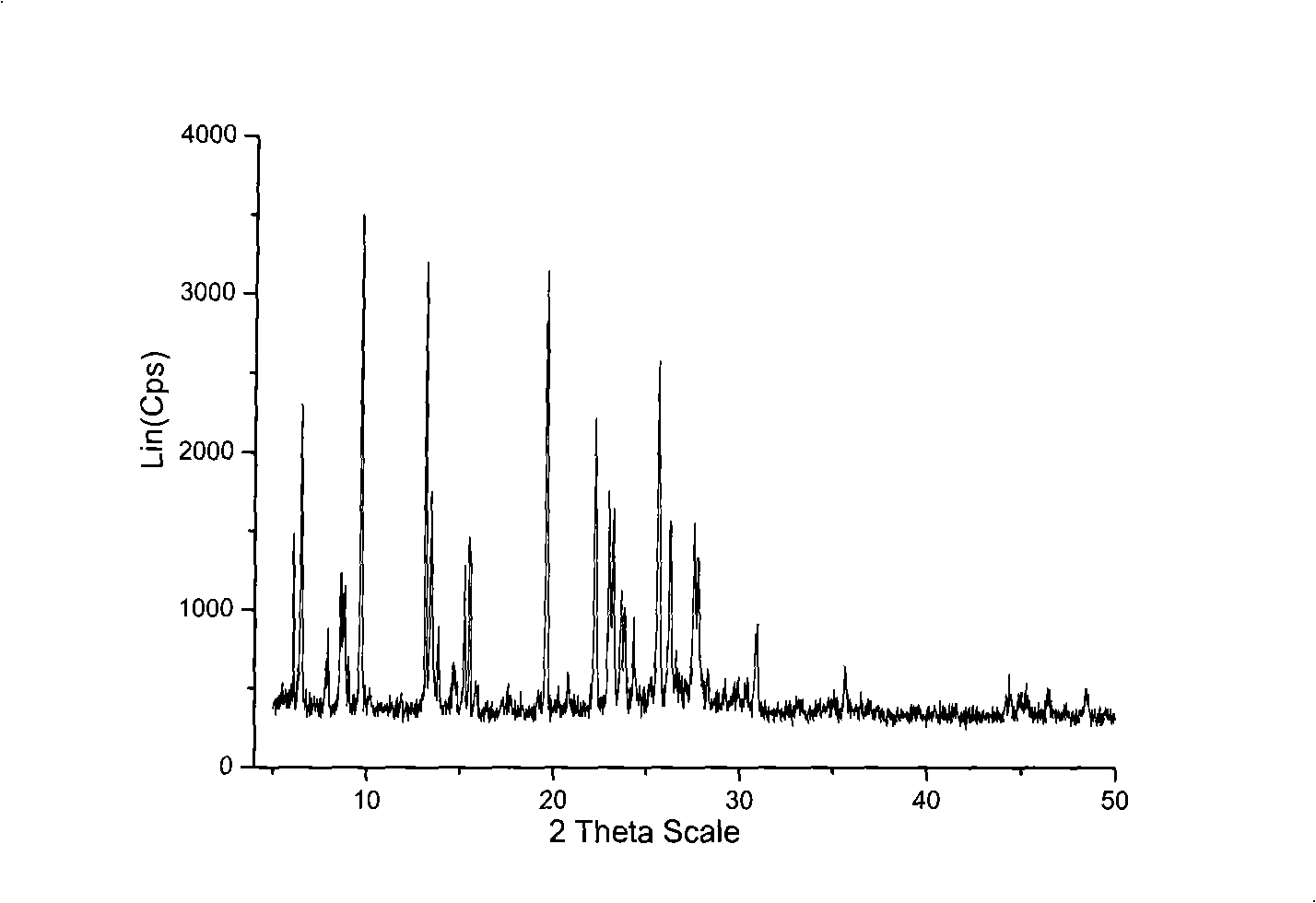

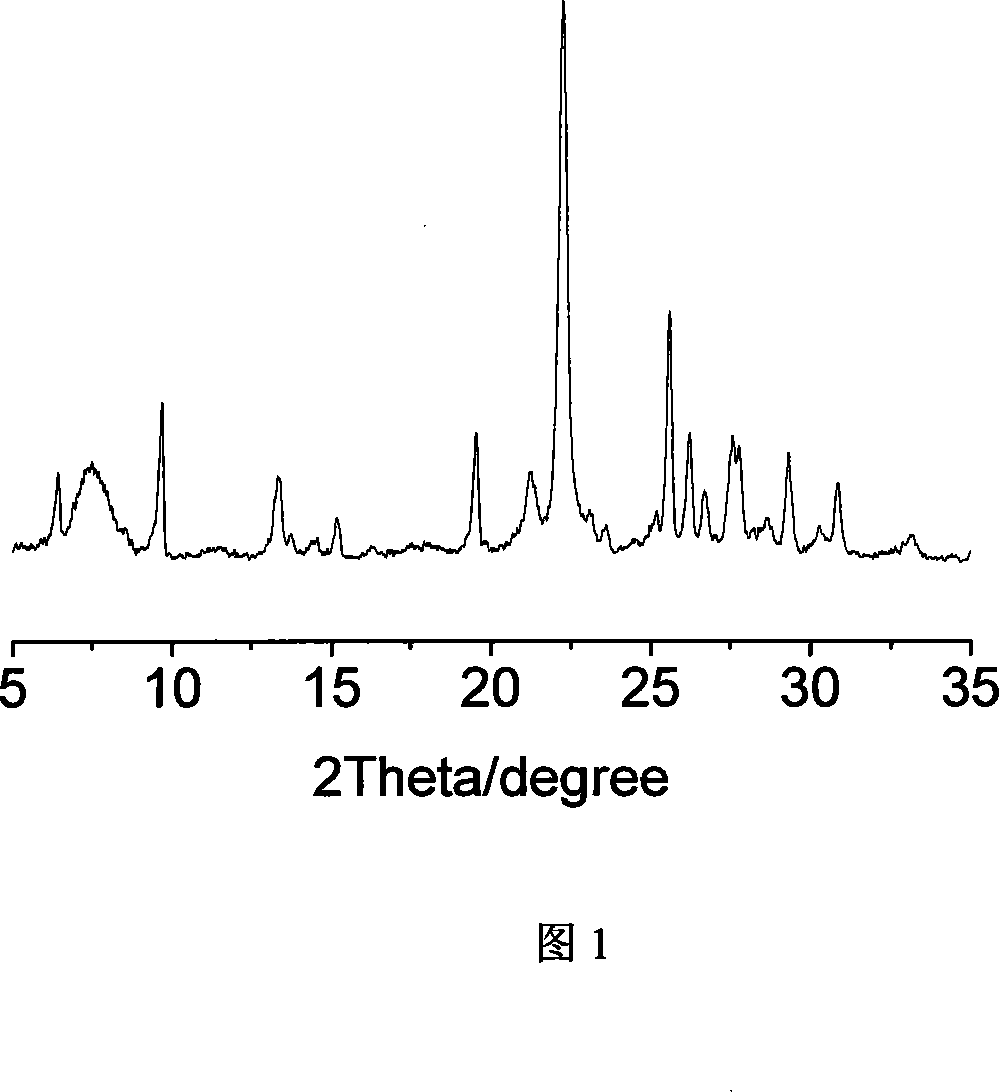

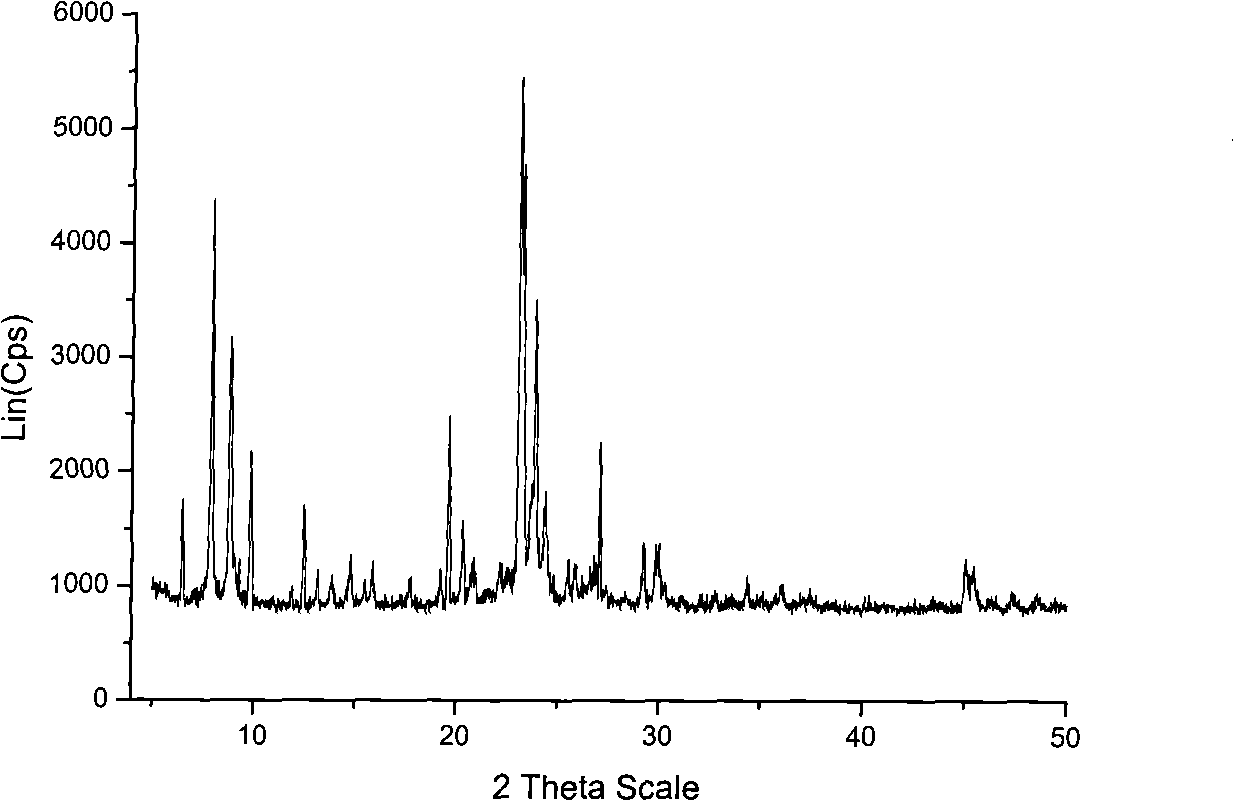

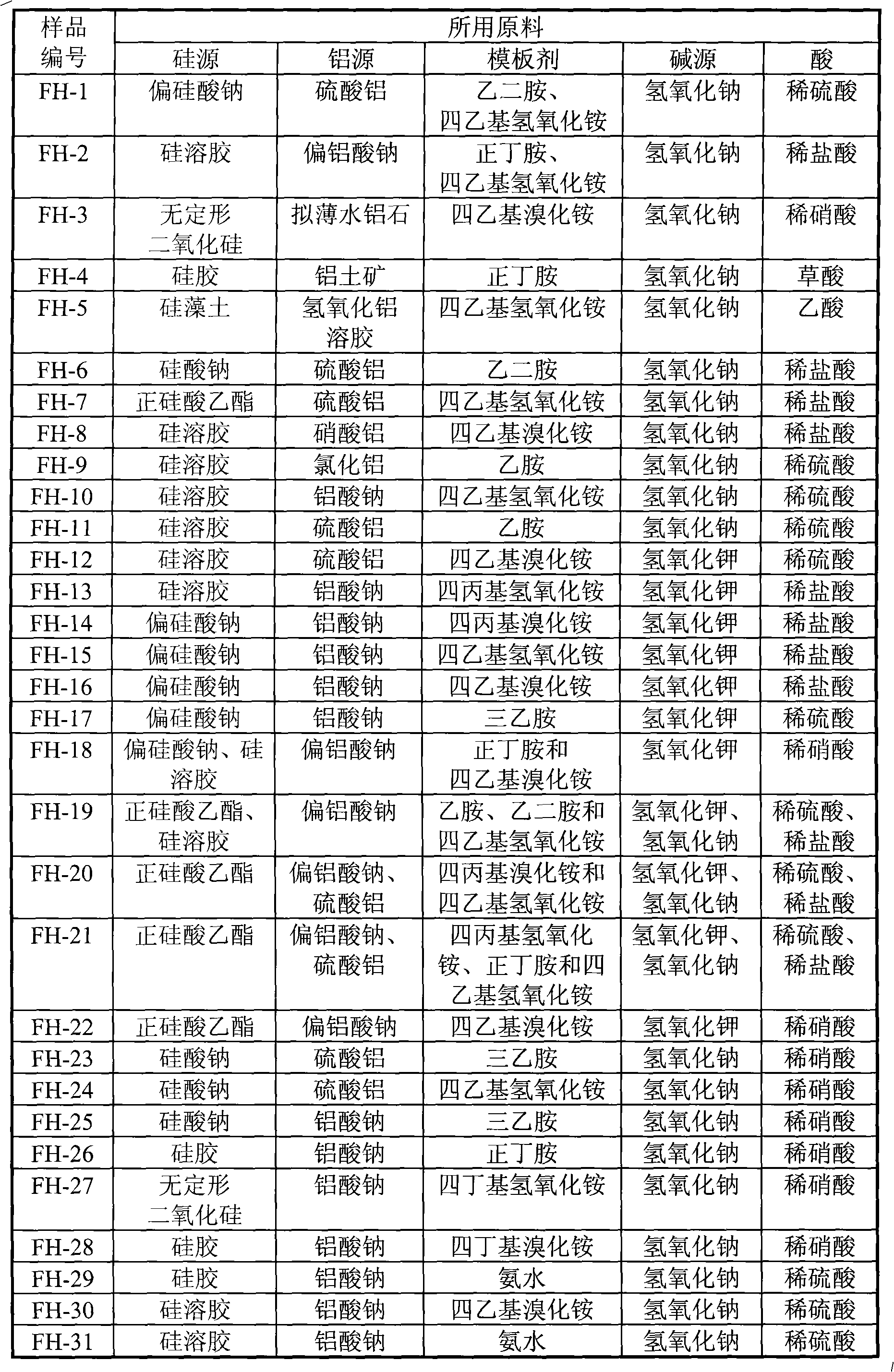

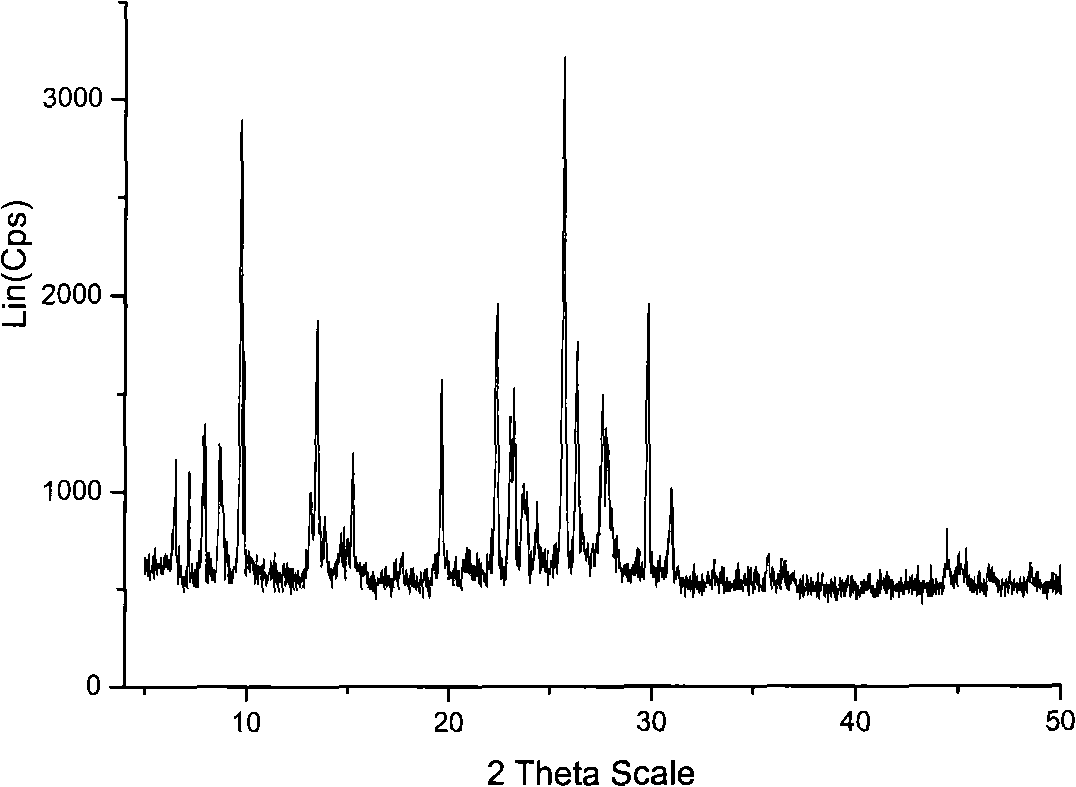

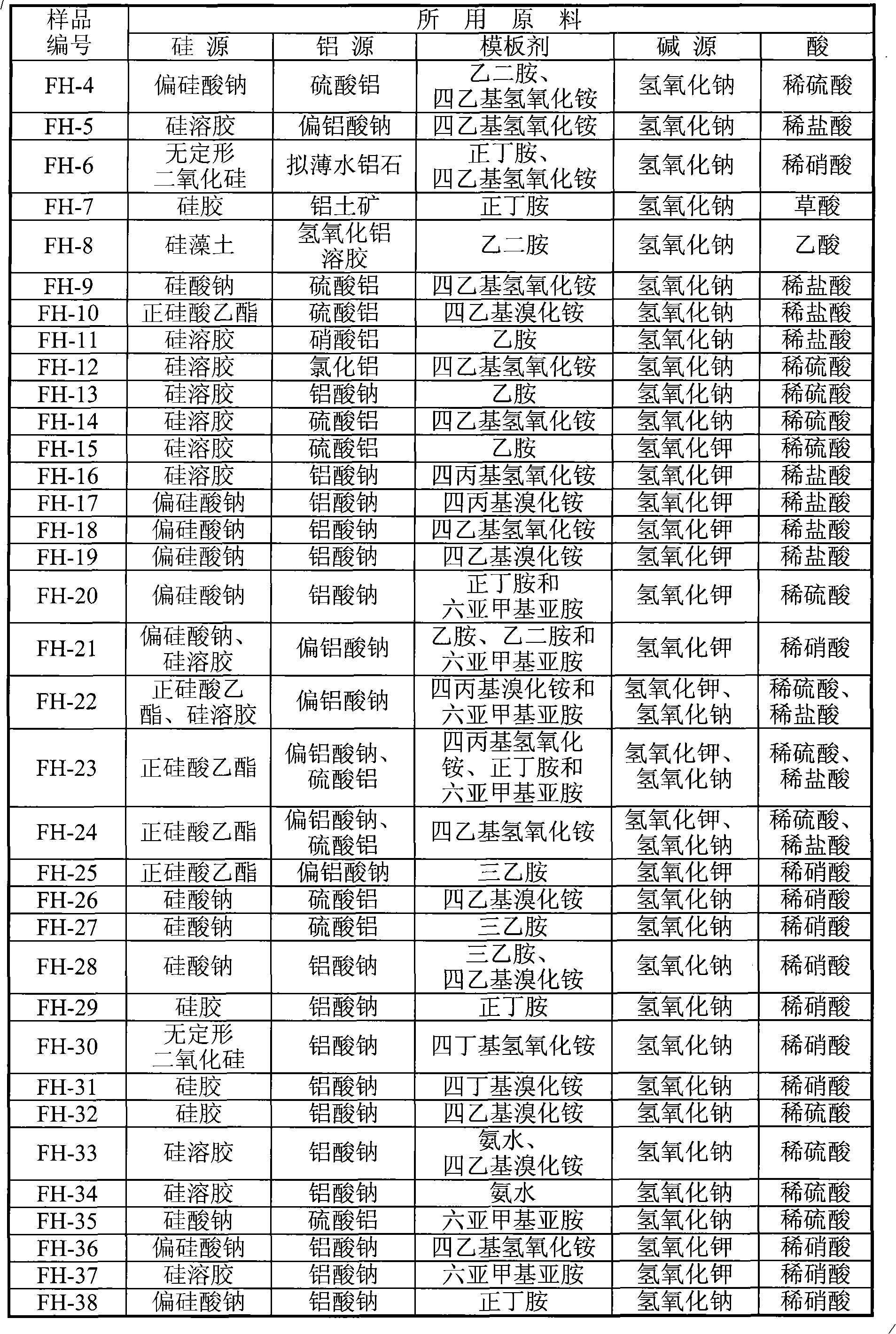

Mordenite/Y zeolite coexisting molecular sieve and method for synthesizing same

ActiveCN101514008AIncrease acidityStrong acidFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteMolecular sieveCatalytic pyrolysis

The invention relates to a mordenite / Y zeolite coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / Y zeolite coexisting molecular sieve by adding a seed crystal containing a Y zeolite precursor and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of mordenite. The coexistence phase ratio of the mordenite / Y zeolite coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 4 and 400; the coexisting molecular sieve has more than two phases, the XRD diffraction pattern of the coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.05 and 14.52+0.05 A, 13.52-0.05 and 13.52+0.05 A, 8.96-0.05 and 8.96+0.05 A, 8.83-0.05 and 8.83+0.05 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71 +0.1 A, 4.51-0.1 and 4.51+0.1 A, 3.98-0.1 and 3.98+0.1 A, 3.78-0.05 and 3.78+0.05 A, 3.47-0.1 and 3.47+0.1 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

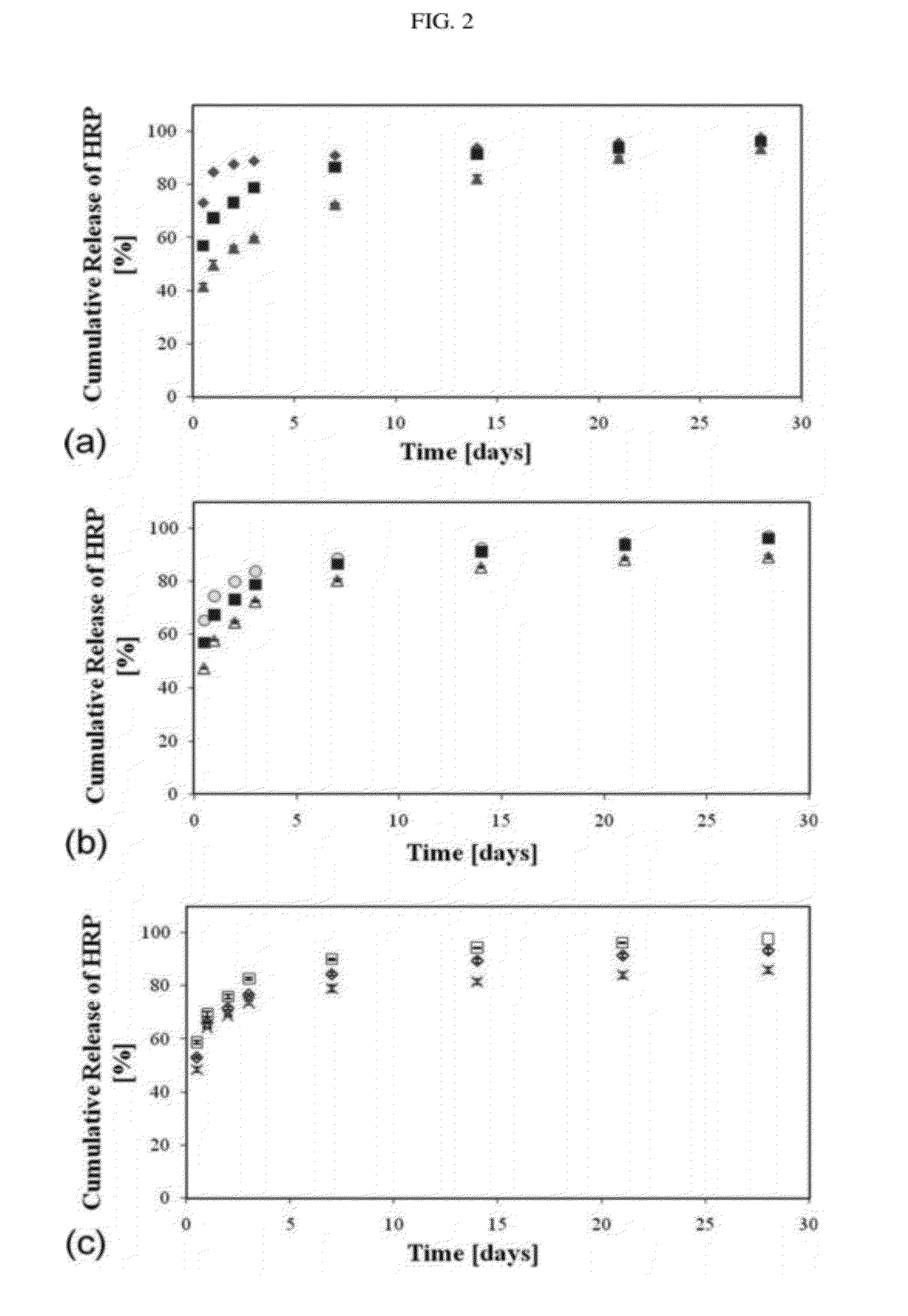

Drug-eluting films

InactiveUS20120027833A1High burst releaseLow burst releaseAntibacterial agentsBiocideActive agentFreeze-drying

Polymeric porous films, capable of eluding a bioactive agent when coming in contact with a physiological medium according to a pre-determined and controlled release profile suitable for particular type of drug and indication, and medical devices including the same are disclosed. Also disclosed are processes for producing the polymeric porous films by freeze-drying an inverted emulsion formulation in which the polymer's composition, the polymer's concentration, the polymer's initial molecular weight, the concentration and / or the type of a surfactant, the homogenization rate and / or the oil phase to aqueous phase ratio (O:A) are selected so as to impart a desired release profile of the bioactive agent from the polymeric film.

Owner:ZILBERMAN MEITAL

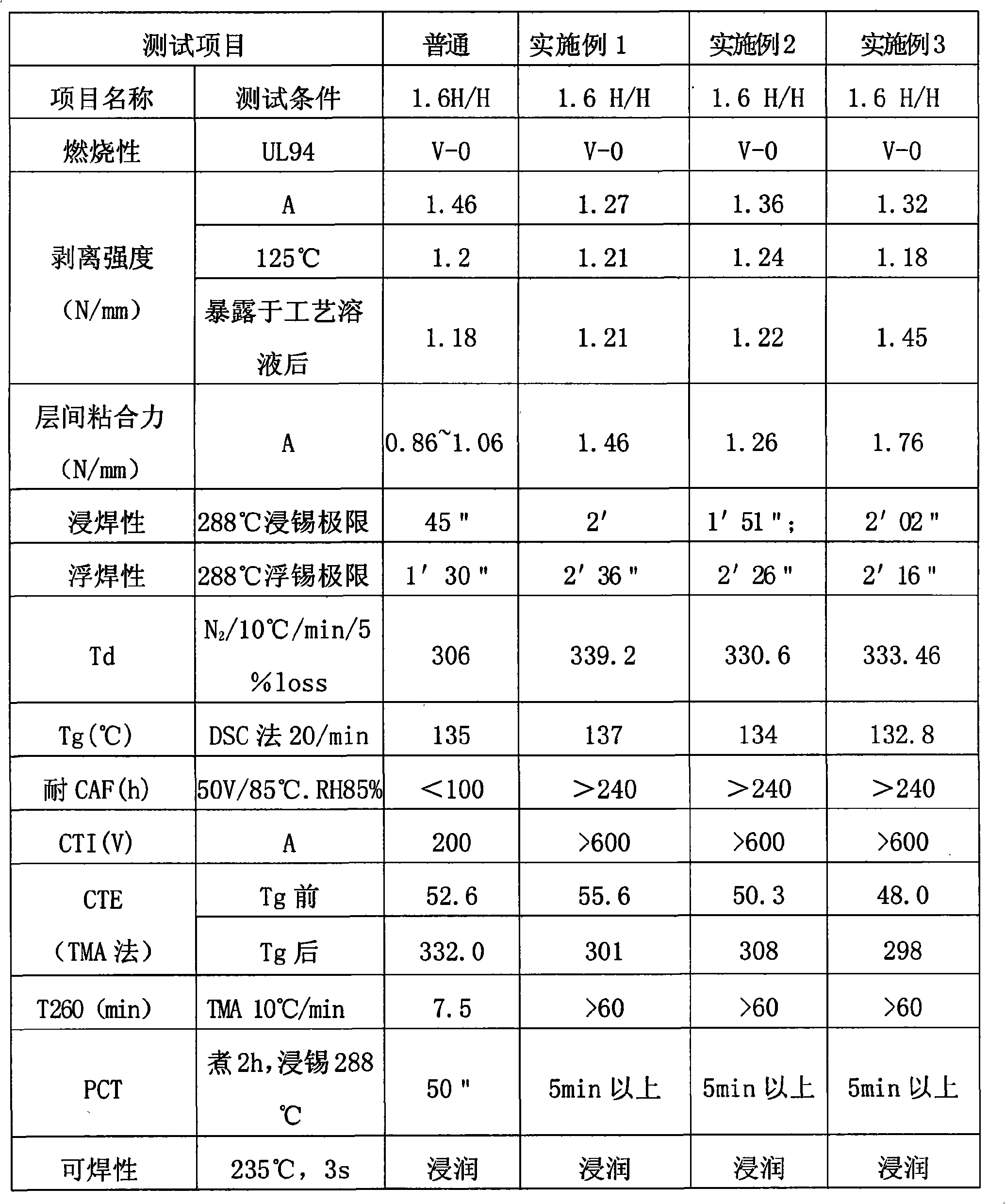

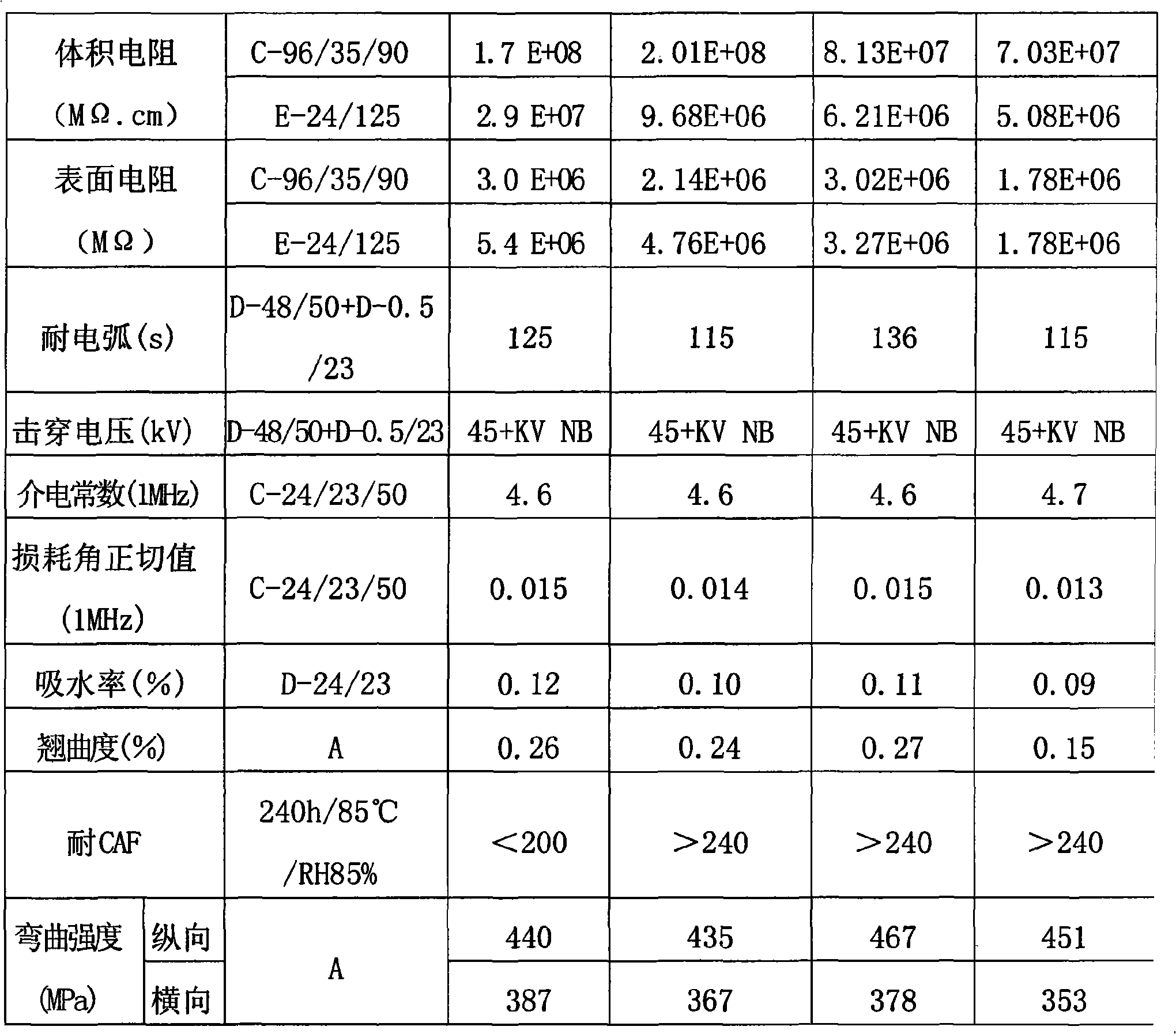

Method for preparing high phase ratio electric leakage resistant tracking index leadless compatible CEM-3 copper-clad laminate

ActiveCN101578010AImprove heat resistanceGood resistance to CAFNon-macromolecular adhesive additivesLamination ancillary operationsGlass fiberBromine

The invention discloses a method for preparing a high phase ratio electric leakage resistant tracking index leadless compatible composite base copper-clad laminate CEM-3, which comprises the following process steps: using low brominated epoxy resin / phenolic aldehyde as a main curing agent, adding a filling material to prepare core material glue impregnated glass fiber paper, and preparing a core material by making the glass fiber paper in a semi-solidified state at a temperature of between 130 and 210 DEG C; adding aluminum hydroxide or magnesium hydroxide as the filling material into the epoxy resin / phenolic aldehyde to prepare a plus material glue impregnated glass fiber cloth, and preparing the plus material by making the glass fiber cloth in a semi-solidified state at a temperature of between 130 and 210 DEG C; and superposing 1 to 20 sheets of the core material, pasting the plus material on the surface of the core material, cladding a copper foil on the plus material, and performing hot press molding at a temperature of between 80 and 200 DEG C, a pressure of between 10 and 60 Kg / cm and a vacuum degree of -60 mmHg. The CEM-3 copper-clad laminate prepared by the method simultaneously has CT1 more than or equal to 600V, higher heat resistance and excellent CAF resistance, and overcomes the defects that a CEM-3 plate prepared by the prior art has the CT1 between 175 and 249 V and poor heat resistance and CAF resistance, thus the CEM-3 copper-clad laminate is more adaptive to long-term operations under wet conditions and has high heat resistance and electric reliability.

Owner:SHAANXI SHENGYI TECH

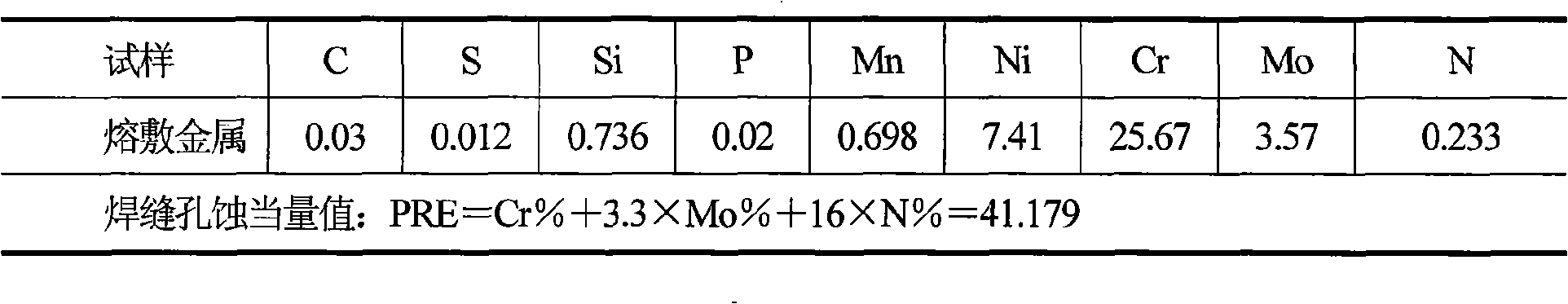

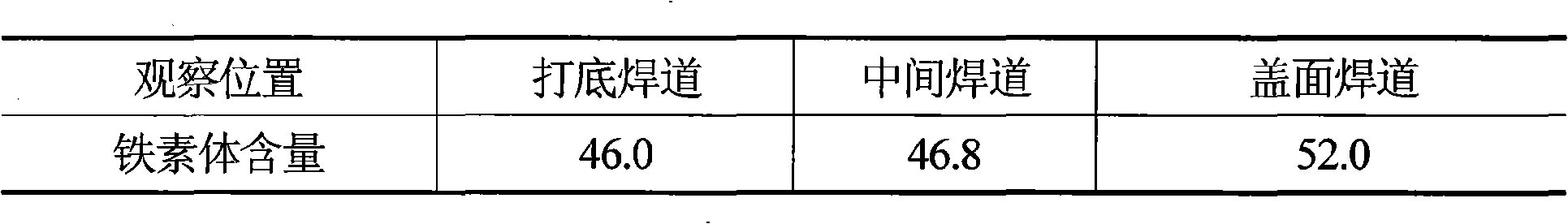

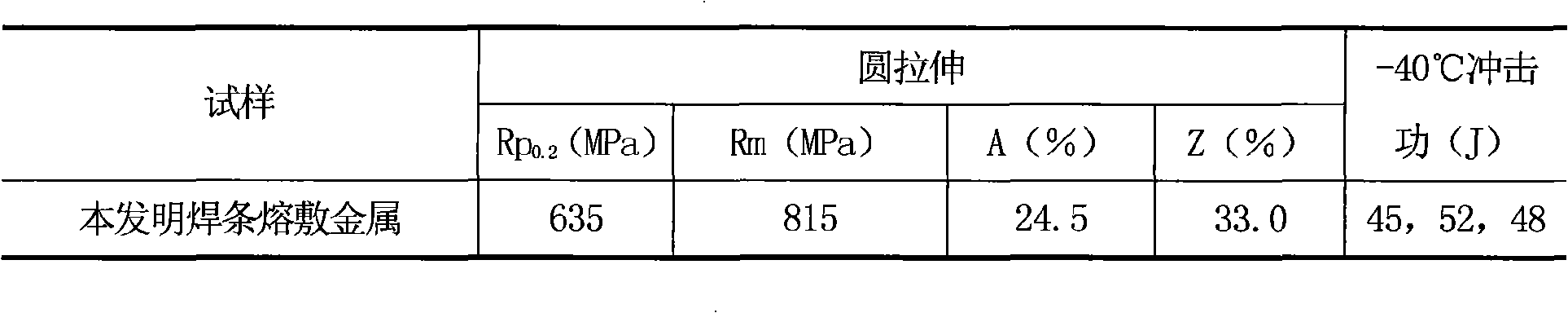

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

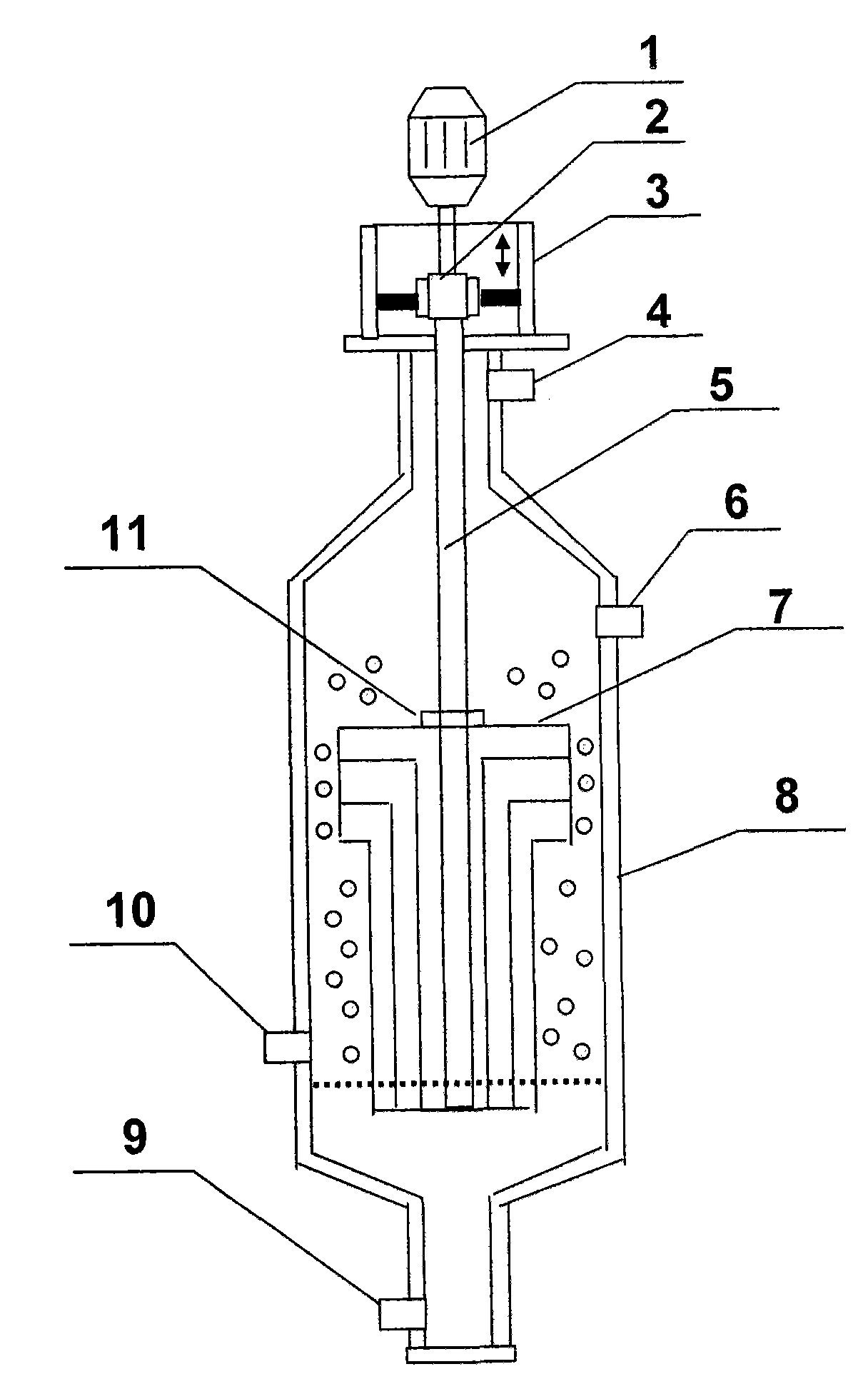

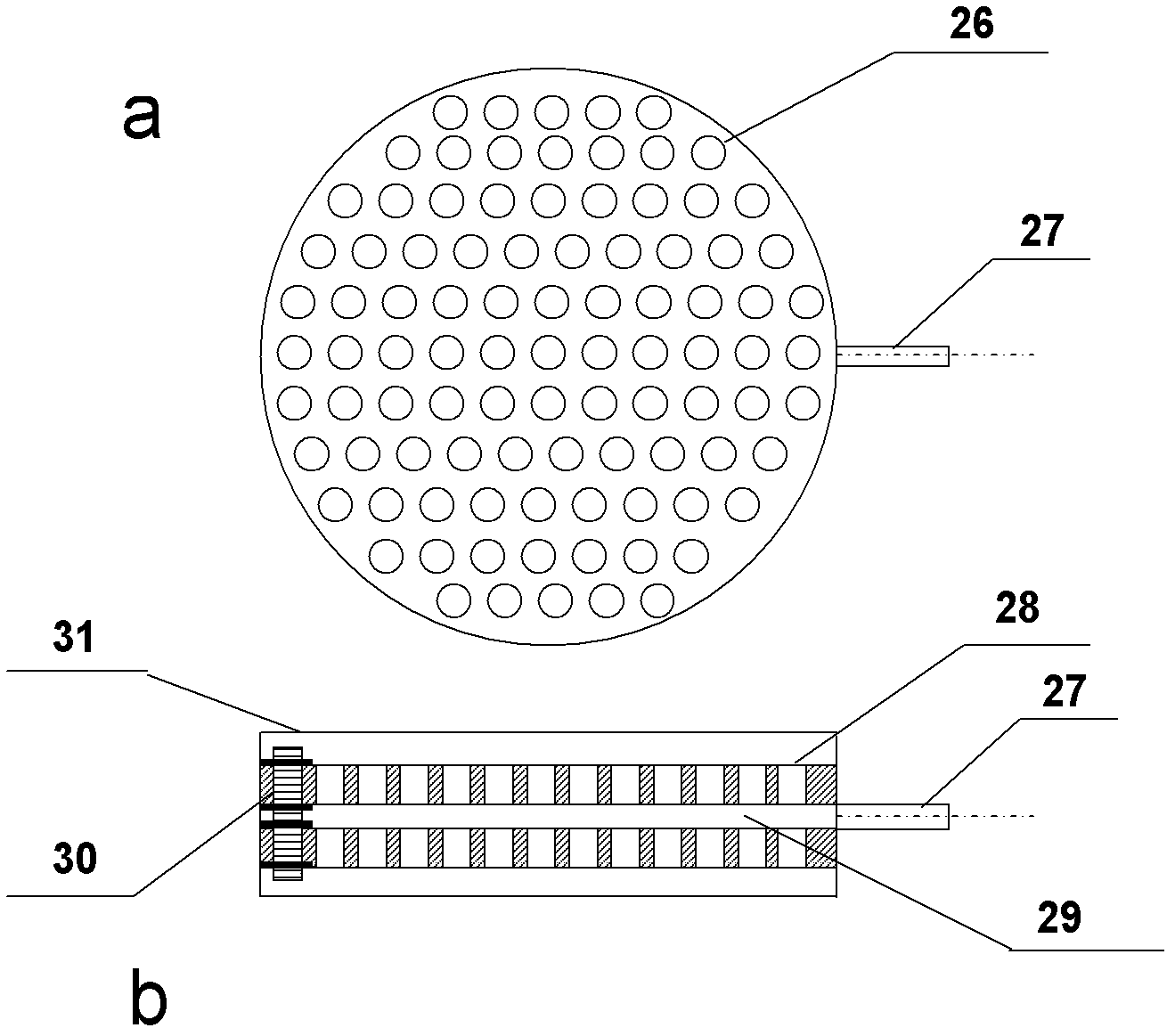

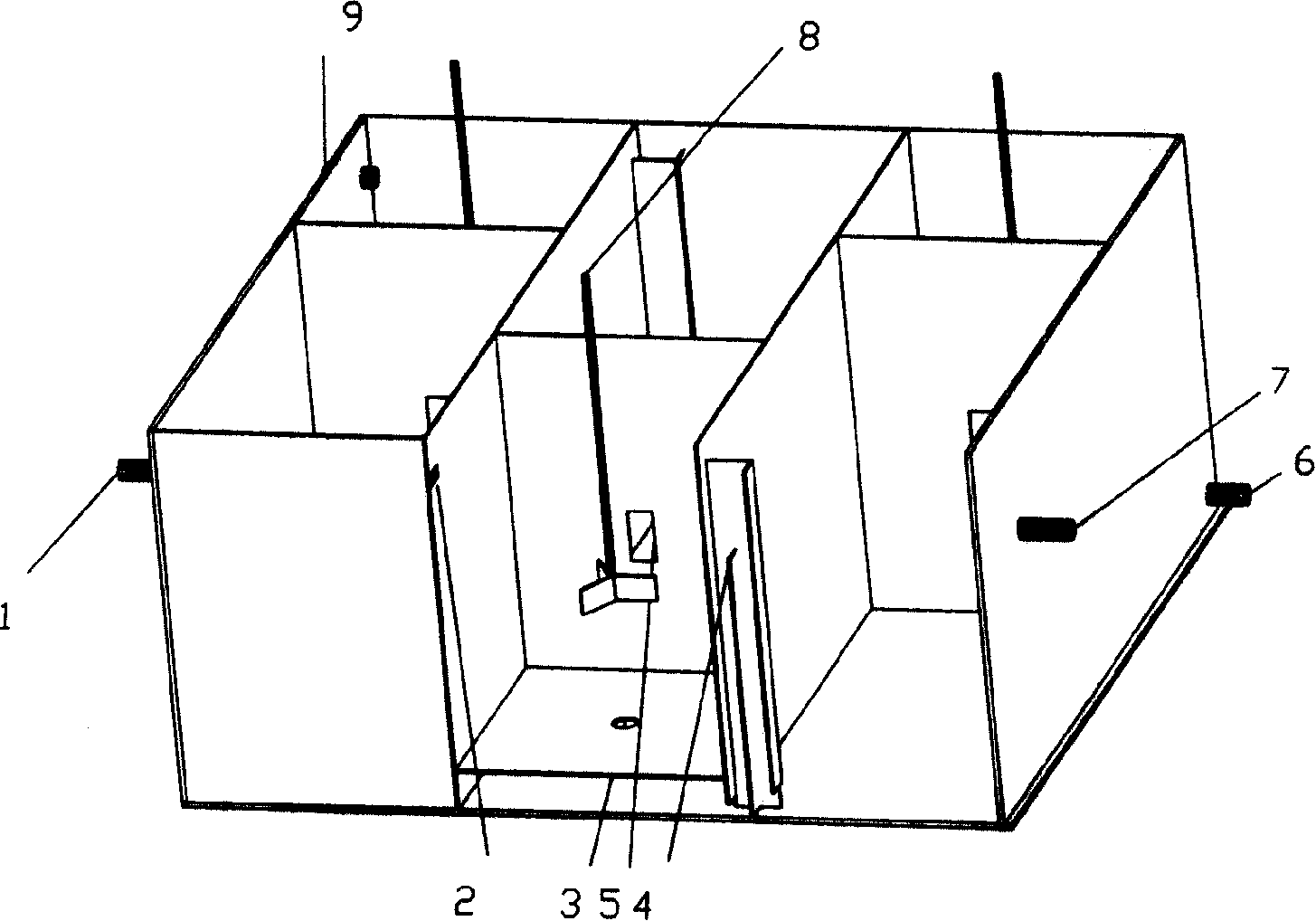

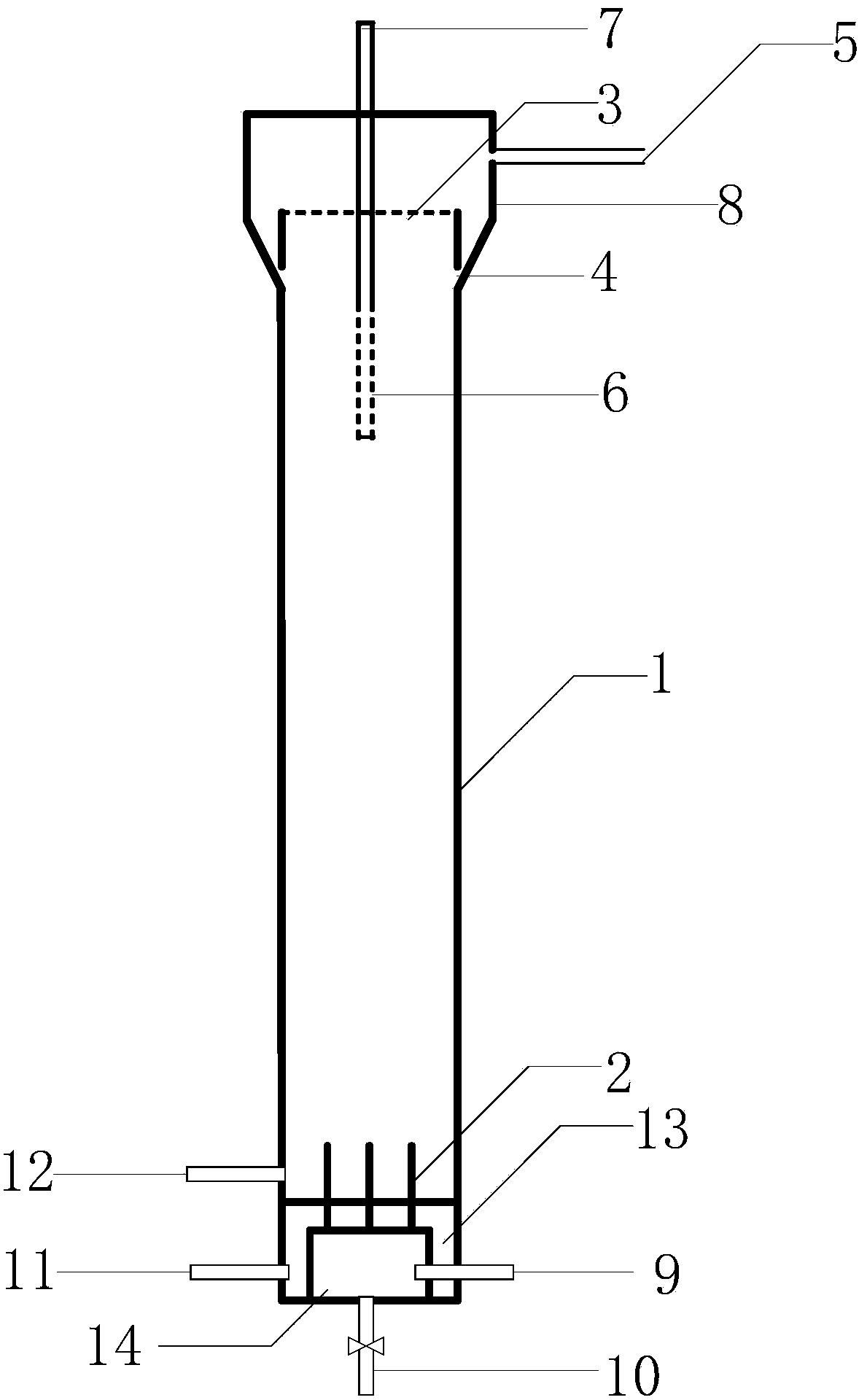

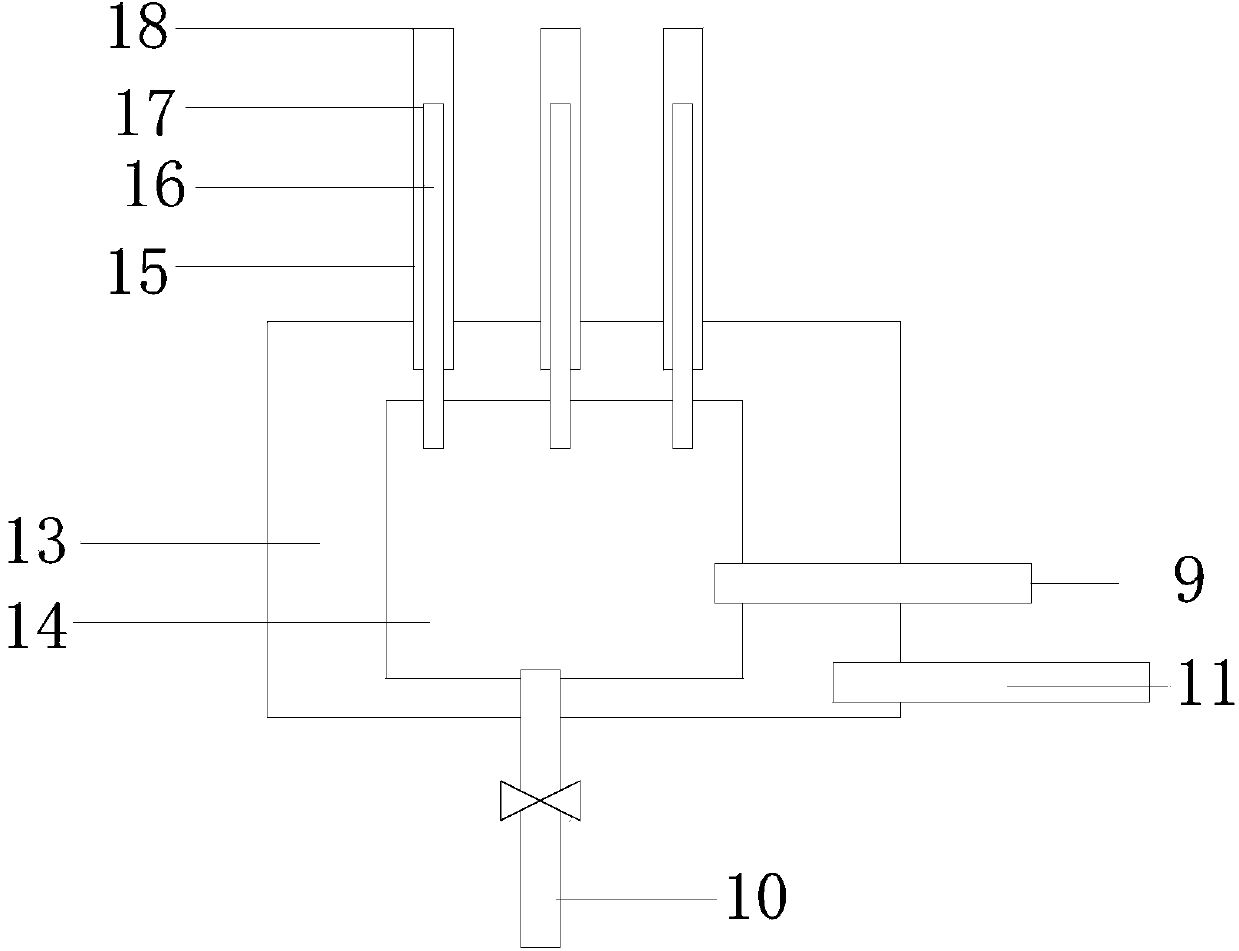

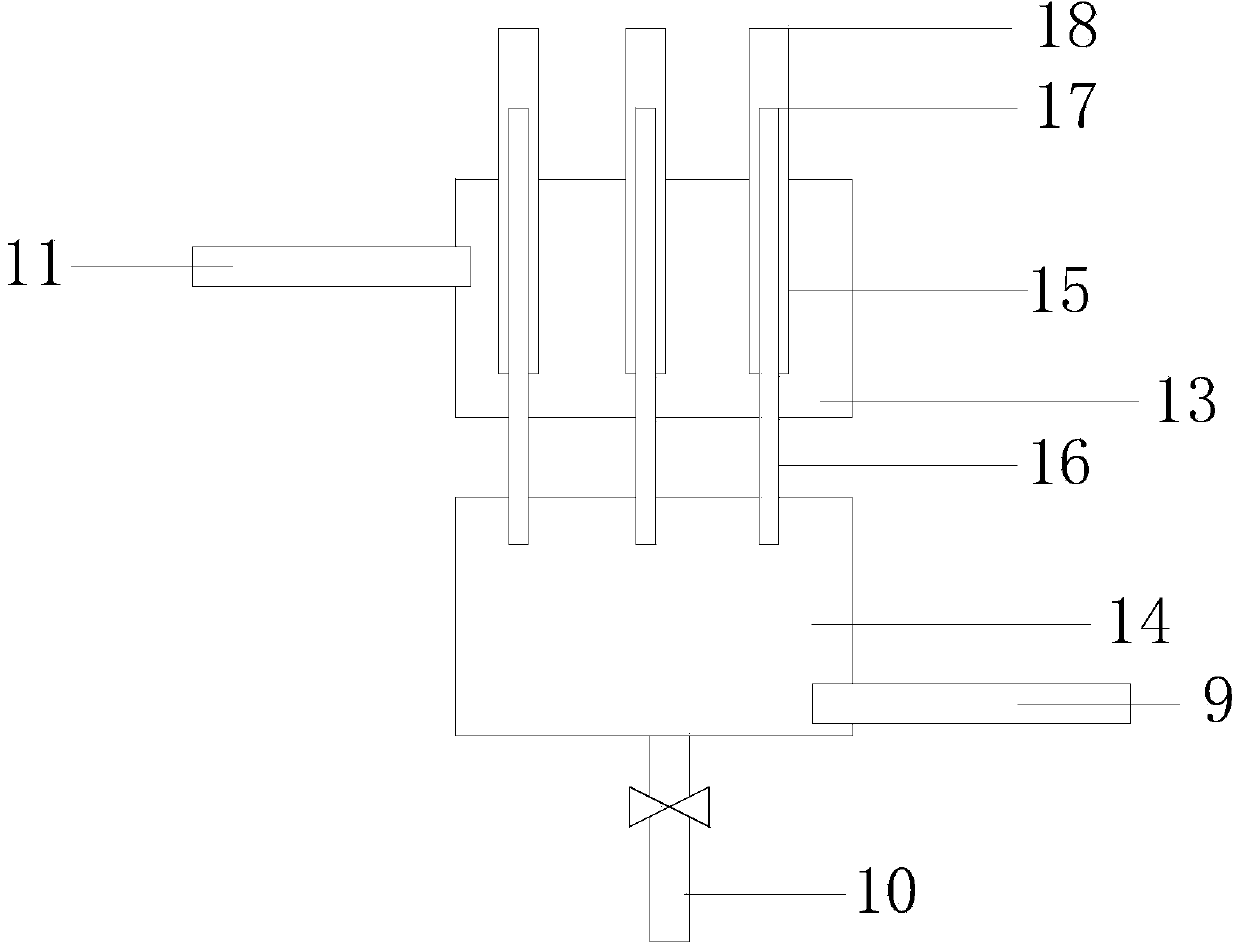

Clarifying chamber-free continuous extracting device of large-phase ratio easy emulsifying system and operating method

InactiveCN101862549ASimple structureEasy to zoom inLiquid solutions solvent extractionPhase ratioEngineering

The invention relates to a clarifying chamber-free continuous extracting device of a large-phase ratio easy emulsifying system and an operating method, which belong to the technical field of chemical liquid-liquid solvent extraction. The device comprises a tower body, a liquid phase disperser, a main shaft, a lifting mechanism, a motor, and the like, wherein the liquid phase disperser comprises a series of hollow concentric cylinders, and spiral type flow guide plates are arranged on the inner walls of the cylinders; and the liquid phase disperser can be used for uniformly dispersing one liquid phase in the other liquid phase by tiny particles at lower rotating speed. Because the shearing force is small when the liquid phase disperser rotates and is difficult to cause the larger turbulence of two phases of liquid flow, phenomena of unbalanced shearing force and easy emulsifying generation in the stirring process of a common stirrer are effectively avoided. The two-phase clarifying speed is high, and the phase continuity is easy for control. The spiral type flow guide plates can assist the self-absorbing type stirring and pumping process, and solves the problems of difficult full dispersion of a small-volume liquid phase and difficult large-phase ratio operation of the traditional stirring way. The device has simple structure, easy amplification and multistage series connection and realizes continuous countercurrent extracting operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Core-shell structural dibasic composite zeolite and preparation method thereof

InactiveCN101177276AEmission reductionSave raw materialsMolecular sieve catalystsMordenite aluminosilicate zeoliteHydrogenMordenite

A binary composite zeolite with a core-shell structure and a preparation method thereof, which belong to the field of inorganic synthesis and catalyst preparation, specifically relate to a binary composite zeolite with a Beta core and a mordenite shell structure and a preparation method thereof. The material will contain two phases of Beta zeolite and mordenite at the same time, and the ratio of the two phases and the surface L / B acid can be adjusted. Directly add aluminum, organic template agent tetraethylammonium bromide and alkali, and use Beta zeolite as the silicon source for mordenite synthesis to prepare a binary composite zeolite material with a double microporous core-shell structure, which is transformed by amine exchange After forming hydrogen form, it is used as a catalyst for the conversion of methanol to prepare dimethyl ether. At a weight space velocity of 2.26 (g / g) h-1, a partial pressure of methanol of 11.4Kpa and a reaction temperature of 300°C, after 72 hours of reaction, methanol The conversion rate still remains above 80%, and the selectivity of dimethyl ether is above 99%.

Owner:TAIYUAN UNIV OF TECH

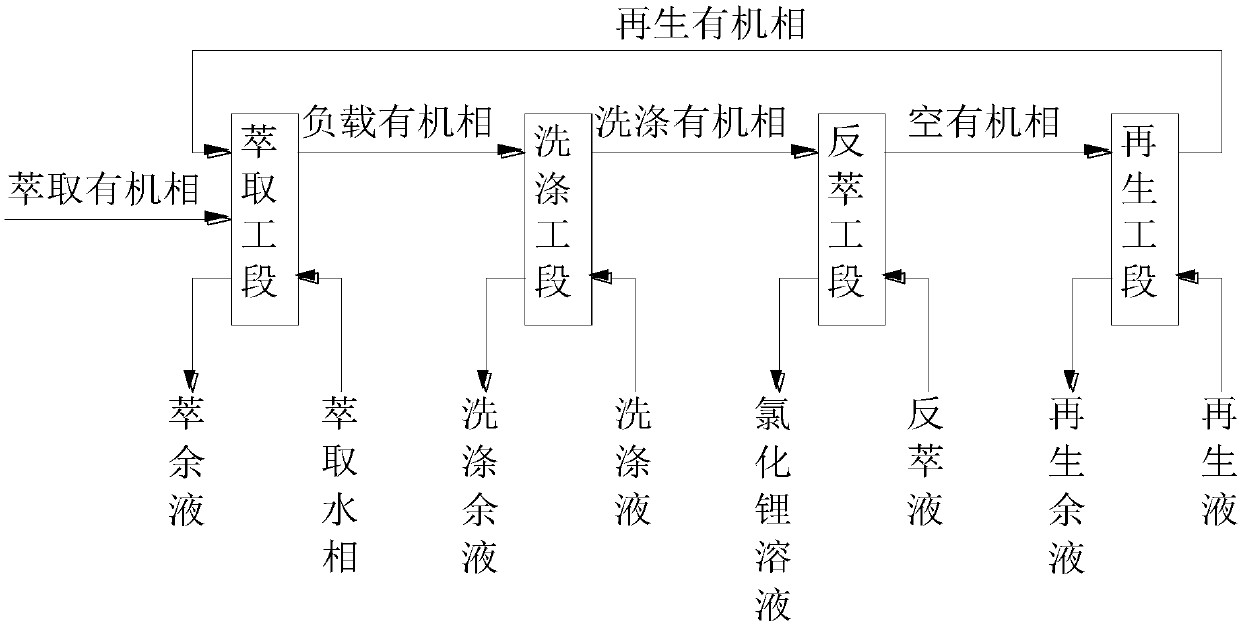

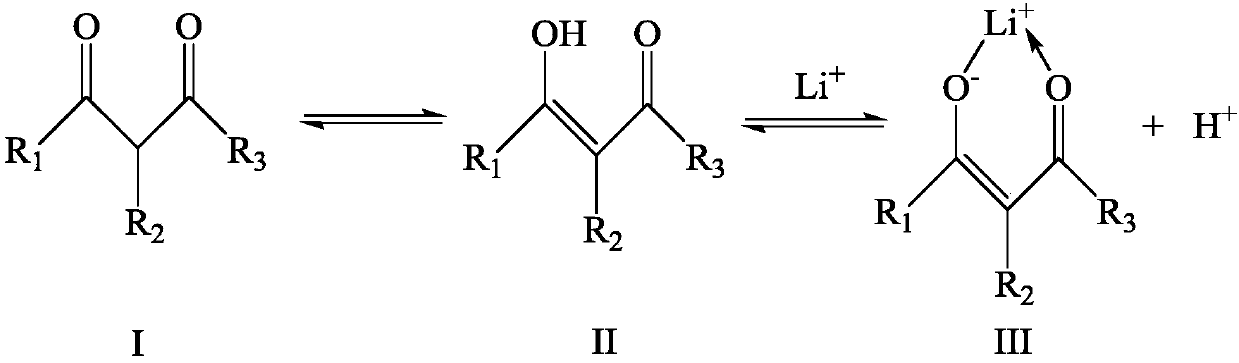

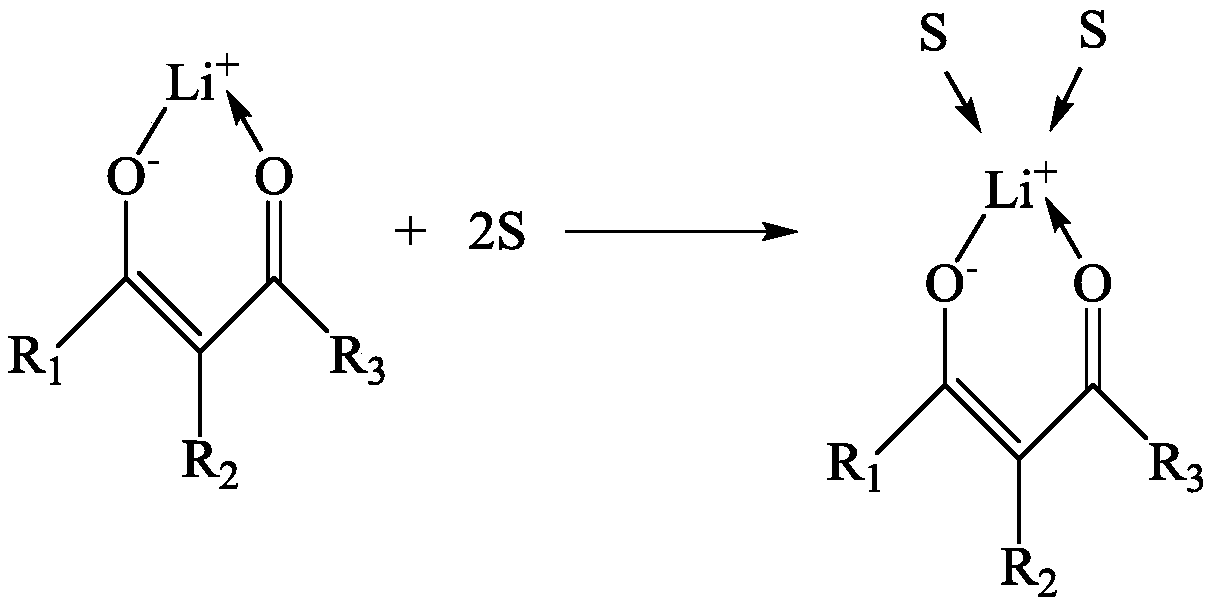

Technology for extracting lithium from alkaline bittern

ActiveCN107779612AReduce usageLow water solubilityProcess efficiency improvementLithium chlorideLithium carbonate

The invention discloses a technology for extracting lithium from alkaline bittern. The technology comprises the following steps of supplying an aqueous phase extraction, supplying an organic phase extraction, extracting, washing, reverse extracting and regeneration. The technology adopts an extraction system different from the tradition, and can extract lithium from an alkaline bittern system, meanwhile a complete process comprising the steps of extraction, washing, reverse extraction and regeneration is determined for the first time while not staying at basic researching of an extraction section, technology parameters such as the series of each section, the phase ratio and the concentration of each agent matched with the extraction system are finally determined, and a basic technology route is provided for industrialized expanded production. The technology for extracting lithium from the alkaline bittern is particularly suitable for a system that filter liquid is generated in the preparation process of a lithium carbonate product by using a lithium chloride solution, so that lithium is further extracted from the alkaline filter liquid bittern system where lithium carbonate is saturated, accordingly rear comprehensive cyclic utilization of salt lake bittern can be achieved, and the technology has practical meaning.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Mordenite/beta zeolite/analcime porous coexisting material and method for synthesizing same

ActiveCN101514010AIncrease acidityStrong acidMordenite aluminosilicate zeoliteCatalytic pyrolysisMolecular sieve

The invention relates to a mordenite / beta zeolite / analcime porous coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the porous coexisting material by well controlling the nucleating and growing process of a molecular sieve during a synthesis process of porous material. The coexistence phase ratio of the porous coexisting material is adjustable, and a mole relation of the components of the synthesized porous coexisting material is nSiO2 :Al2O3, wherein n is between 4 and 400; the porous coexisting material has more than three phases; the XRD diffraction pattern of the porous coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 13.52-0.1 and 13.52+0.1 A,11.32-0.1 and 11.32+0.1 A, 9.47-0.1 and 9.47+0.1 A, 8.96-0.1 and 8.96+0.1 A, 7.07-0.1 and 7.07+0.1 A, 6.71-0.1 and 6.71+0.1 A, 4.51-0.1 and 4.51+0.1 A, 4.15-0.1 and 4.15+0.1 A, 3.98-0.05 and 3.98+0.05 A, 3.76-0.05 and 3.76 +0.05 A, 3.65-0.05 and 3.65+0.05 A, 3.53-0.02 and 3.53+0.02 A, 3.47-0.02 and 3.47+0.02 A, 3.31-0.05 and 3.31+0.05 A, and 3.02-0.05 and3.02+0.05 A; therefore, the problems are solved well. The mordenite / beta zeolite / analcime porous coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

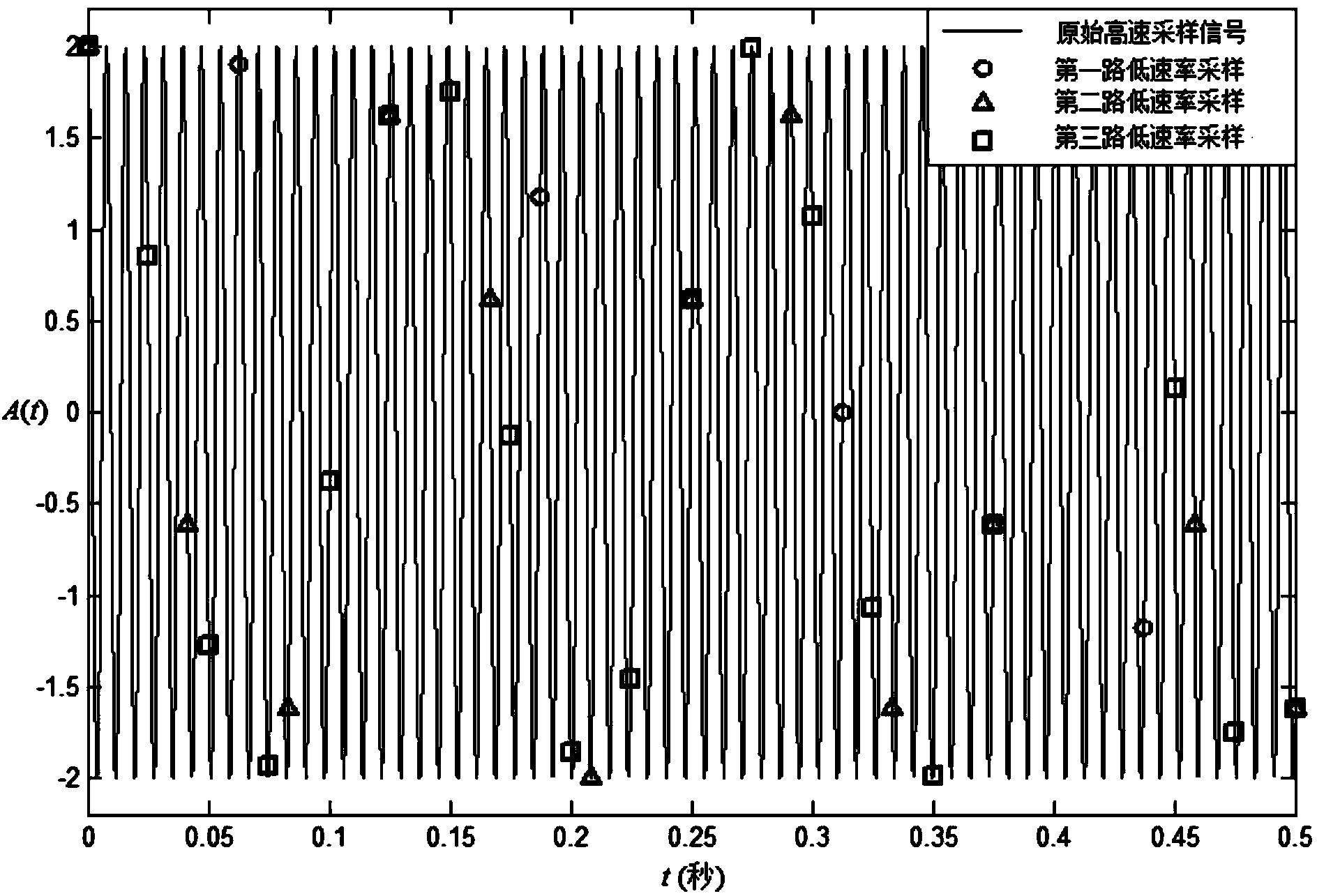

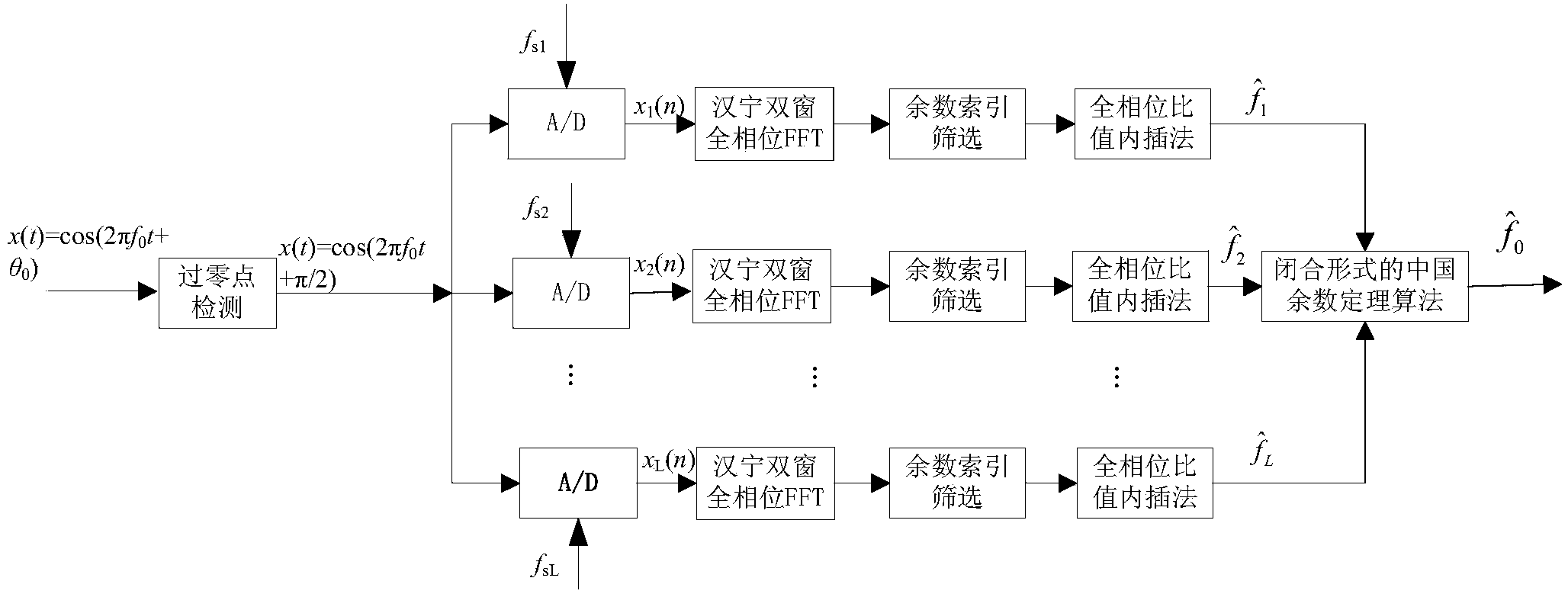

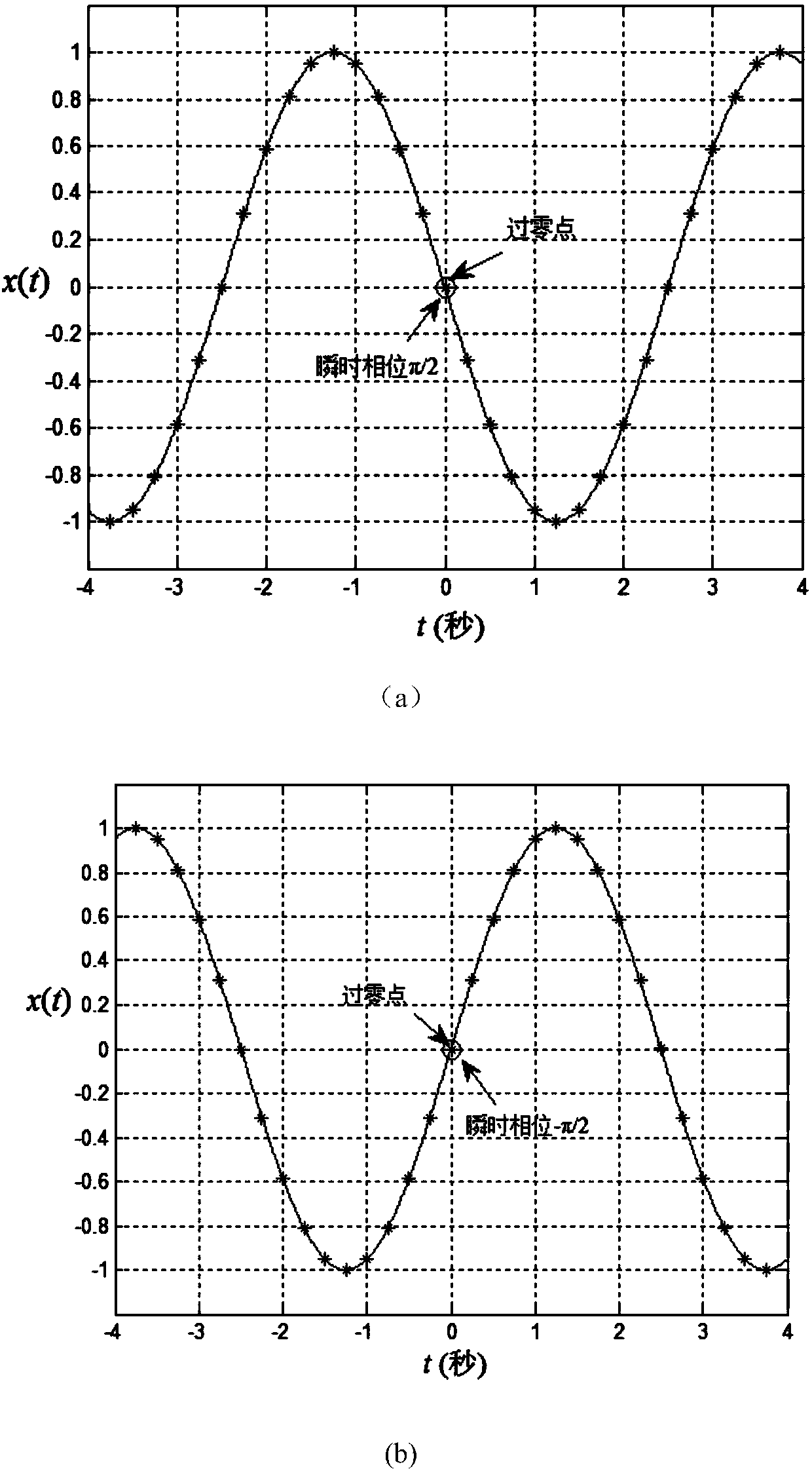

Method and device for measuring frequencies of high-frequency cosine signals under undersampling rate

InactiveCN103941087ARealize measurementExpand the measurement rangeFrequency measurement arrangementDigital signal processingFrequency spectrum

The invention discloses a method and device for measuring the frequencies of high-frequency cosine signals under the undersampling rate, and relates to the field of digital signal processing. By combining the type of the zero crossing point with the distribution characteristic of apFFT phase spectrums, L spectrum position index values are selected from 2L peak value magnitude spectrum positions; according to the remainder selecting result, each apFFT phase spectrum is corrected through the all-phase ratio interpolation method so that the frequency of the apFFT phase spectrum can be estimated; the frequency estimation value obtained after each apFFT phase spectrum is corrected is used as a remainder, the remainders are processed according to the Chinese remainder theorem of the closed analysis form, and the frequencies of the original high-frequency signals are reconstituted through the frequency estimation values. According to the method and the device, the frequencies of the multiple paths of high-frequency cosine signals under the undersampling rate are measured, and the measuring range of the frequencies of the high-frequency signals is greatly widened; the novel spectrum correction method is adopted, and therefore the measuring accuracy of the frequencies of the high-frequency cosine signals is improved, and novel anti-noise performance of the high-frequency cosine signals under the low undersampling rate is ensured.

Owner:TIANJIN UNIV

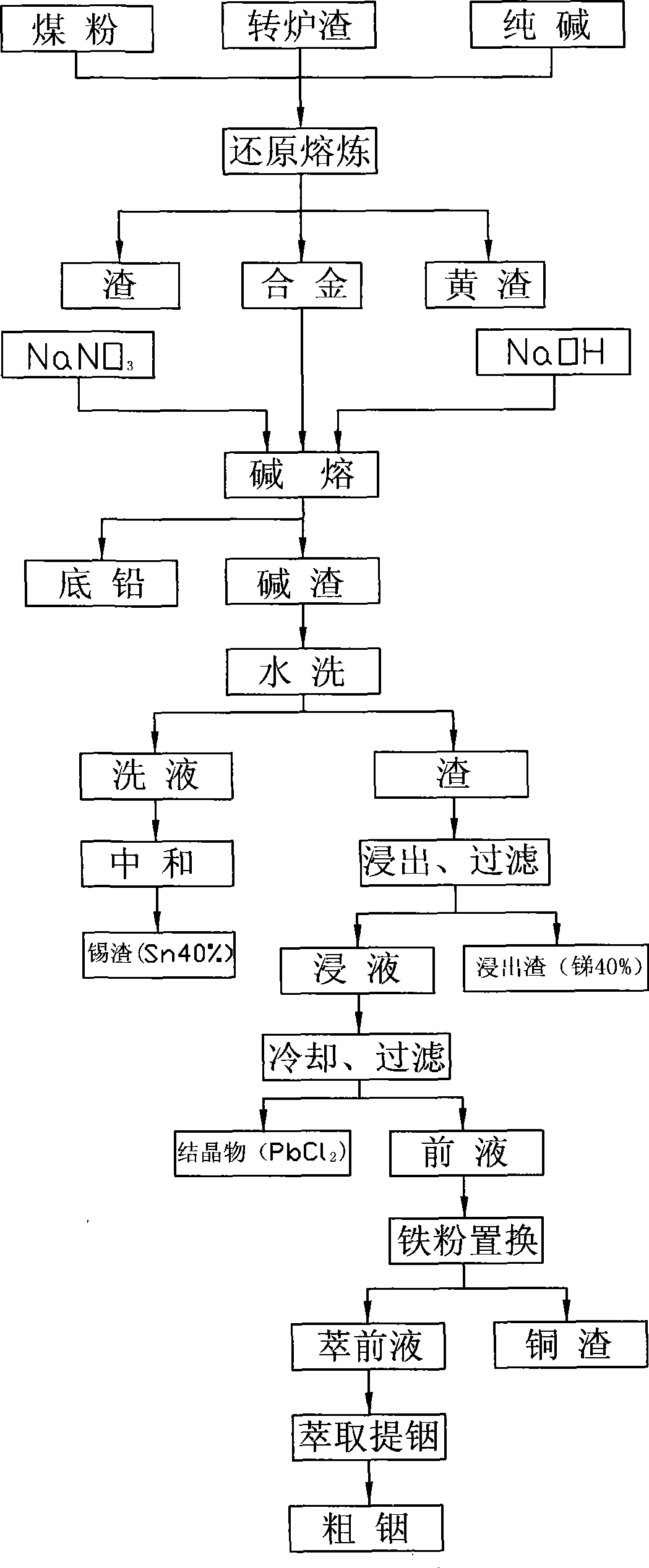

Technology of extracting and separating valuable metals such as Pb, In, Sb, Cu and Sn from lead smelting converter slags

The invention relates to a technology of extracting and separating valuable metals such as Pb, In, Sb, Cu and Sn from lead smelting converter slags, comprising the following steps: adding carbonaceous reducing agent in raw materials which are produced in the process of crude lead smelting and contain Pb, In, Sb, Cu and Sn; smelting the raw materials and the carbonaceous reducing agent in an electric furnace or a reverberatory at the temperature over 1000 DEG C, reducing the Pb, Cu, Sb, Sn, In and the like into metals and forming alloy, sorting out silicon and other components as slags; mixing sodium hudroxide with weight accounting for 40-60% of the alloy weight into the alloy, adding oxidizer and copper removal agent with weight accounting for 5-20% of the alloy weight, oxidizing the In, Sn, Sb and Cu for slagging and extracting the metallic lead; washing oxidizing slags to extract Sn, neutralizing the Sn by adding acid through washing water, regulating pH value to 3-4 and obtaining tin slags; obtaining stibium slags after acid leaching and separating of washing slags; obtaining copper sponge by replacement with ferrous powder by pickle liquor; extracting indium from replaced liquid and extracting organic phase by adopting TBP+octanol+karaffin oil, with extraction phase ratio of O / A equal to 1:1. The direct yield and recovery rate of metallic In, Pb, Sn and Sb are respectively over 90% and 95%.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

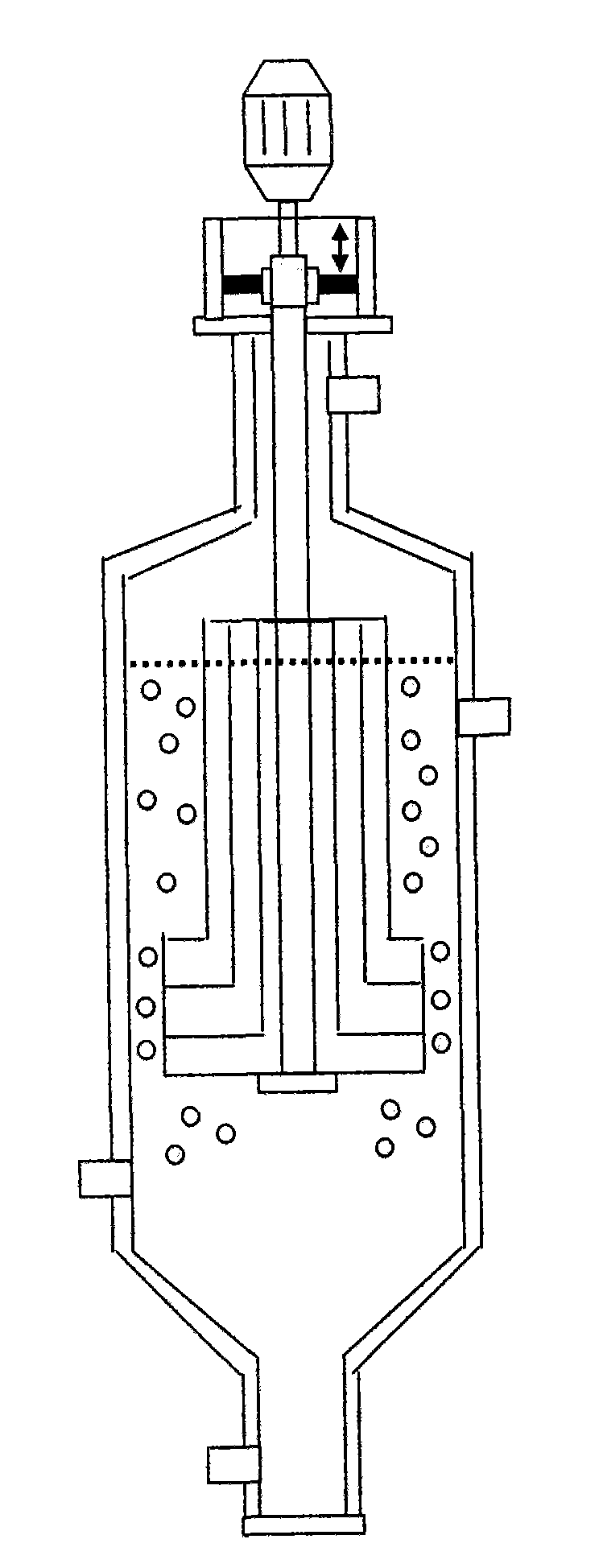

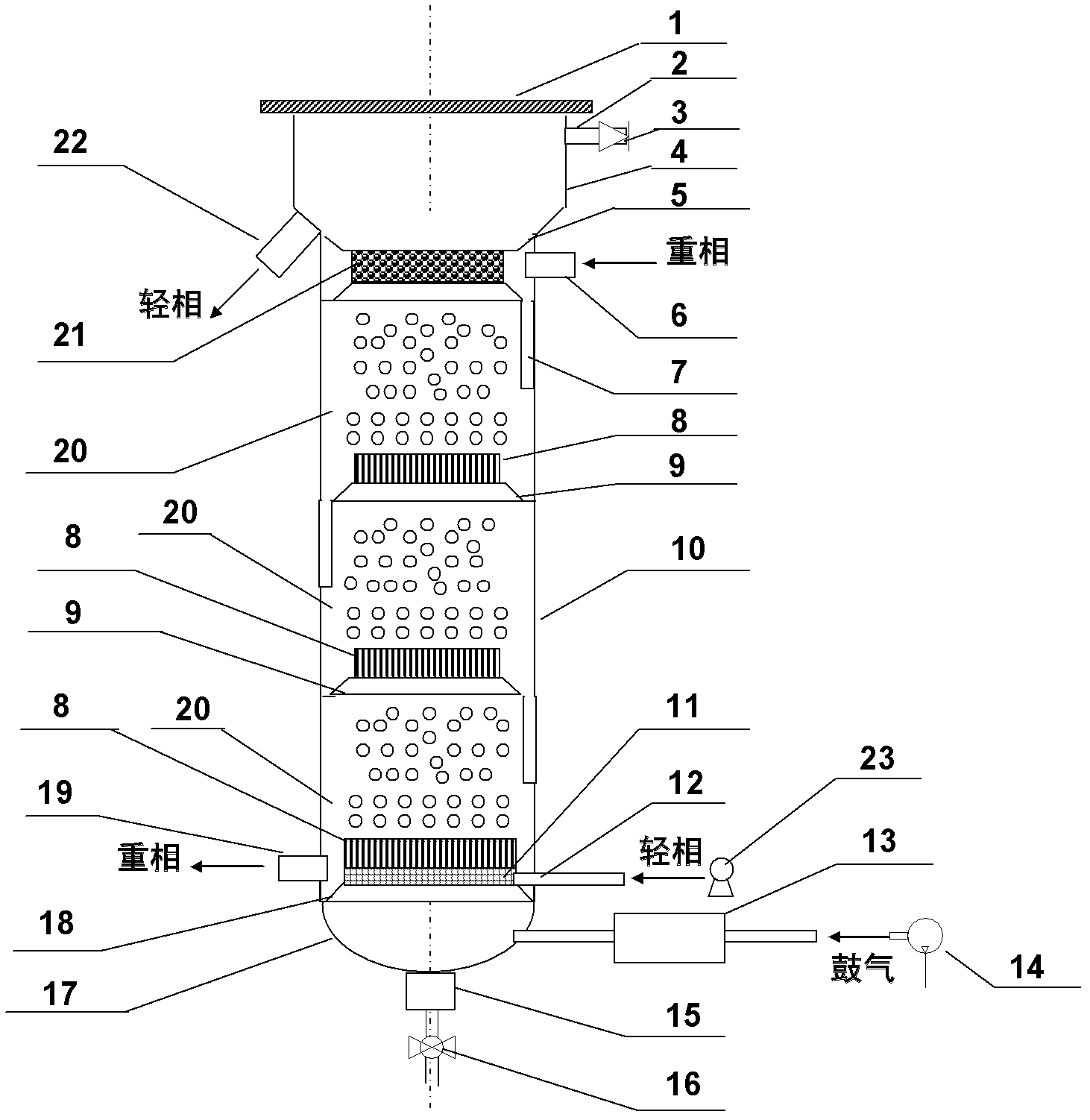

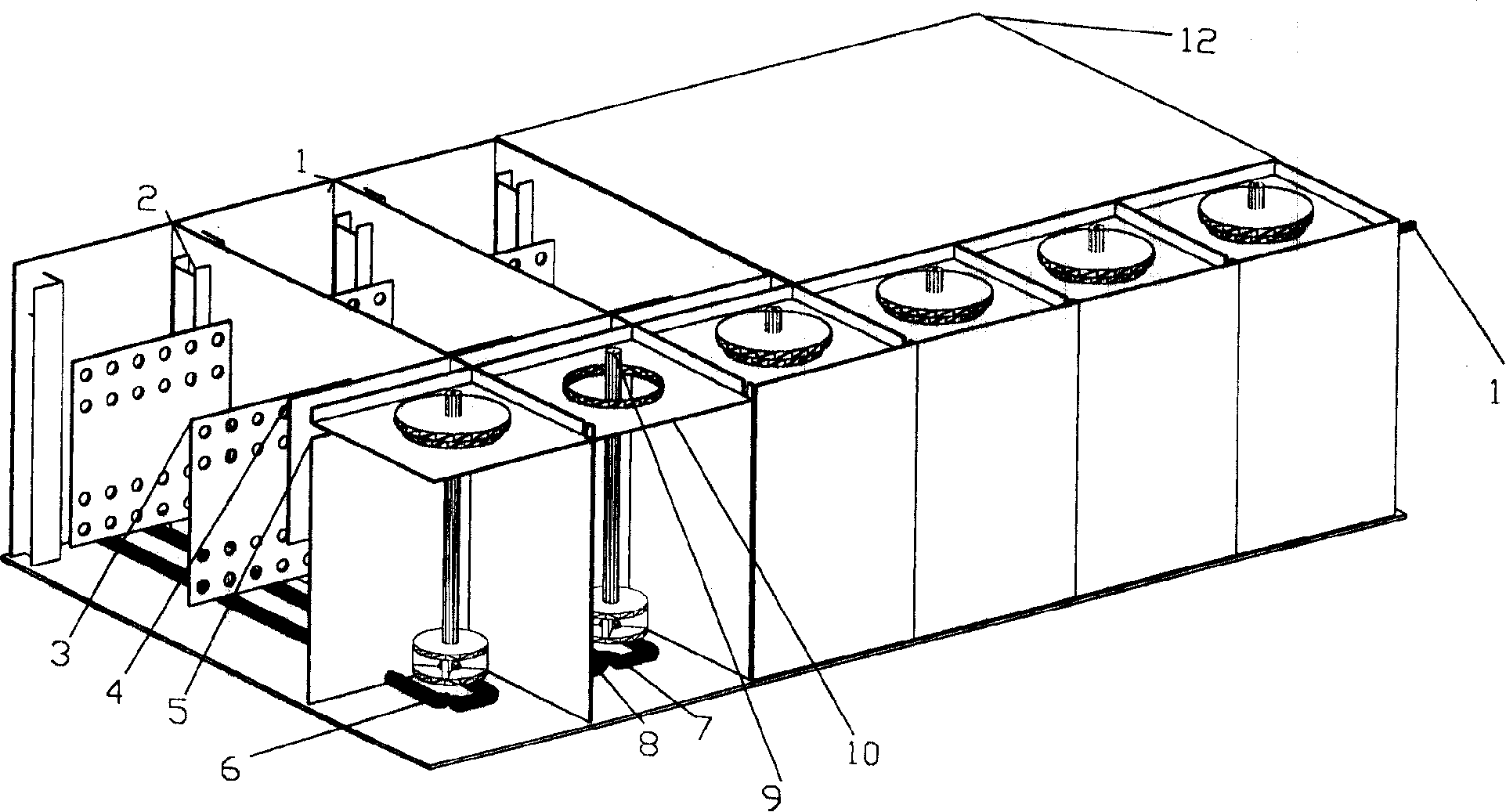

Large phase ratio liquid-liquid two-phase continuous extraction apparatus

ActiveCN102512848APrevent backmixingImproved stage efficiency for unit mass transfer heightsLiquid solutions solvent extractionPhase ratioEngineering

A large phase ratio liquid-liquid two-phase continuous extraction apparatus belongs to the field of liquid-liquid extraction and separation. The apparatus contains a tower body, a gas buffer chamber, a liquid film aggregation device, liquid film dispersers, a liquid film distributor, an air-pressure chamber and the like. The liquid film dispersers and the liquid film distributor can be combined together to realize dispersion of small-volume organic phase by the use of tiny bubbles, thus solving the problem that it is not easy to fully disperse small-volume organic phase by a traditional stirring mode. The phase ratio of a light phase to a heavy phase flowing upstream in the tower body can be adjusted by the interlayer gap of the liquid film distributor. The light phase and the heavy phase can be operated by counter current under the condition of super-large phase ratio. A liquid film disperser and a bubble connection cap are arranged at intervals in the tower body, so as to realize repeated coagulation and dispersion of rising bubbles and achieve high stage efficiency of height of mass transfer unit. A liquid film aggregation device on the top of the tower can be used for bubble coagulation and demulsification and is suitable for extraction operation of an easily-emulsified system. The apparatus provided by the invention is applicable to continuous countercurrent operation under the condition of multi-stage series connection.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Chemical mechanical polishing pad

ActiveUS20070275226A1Synthetic resin layered productsAbrasion apparatusCompound (substance)Phase ratio

The invention provides a polishing pad suitable for planarizing at least one of semiconductor, optical and magnetic substrates. The polishing pad includes a polymeric matrix having a top polishing surface. The top polishing surface has polymeric polishing asperities or forms polymeric polishing asperities upon conditioning with an abrasive. The polymeric polishing asperities are from a polymeric material having at least 45 weight percent hard segment and a bulk ultimate tensile strength of at least 6,500 psi (44.8 MPa). And the polymeric matrix has a two phase structure, a hard phase and a soft phase with an average area of the hard phase to average area of the soft phase ratio of less than 1.6.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Mixed settler extractor

InactiveCN101219289AEliminate pollutionQuick layeringLiquid solutions solvent extractionSingle stagePhase ratio

The invention relates to a mixer settle extraction tank that is applicable to the extraction of high flow rate solvent, in particular to an extraction case combined by single-stage mixer settle extraction tanks. A two-phase mixer is stirred and driven by a turbine and the stirring has a pumping effect for two-phase fluid. Two phases are induced to a place below a stirring axial center by a diversion tube in a mixing chamber. The mixed phases are layered in a settling chamber, wherein, a light phase flows into a light phase box and enters a next stage mixing chamber through the diversion tube and a heavy phase gets across an overflow plate of a heavy phase box and enters a former stage mixing chamber and the two phases form an adverse current mode in a cascade stage device. The settling chamber is provided with a return line to be communicated with the mixing chamber to guarantee that the mixing phase ratio of the two phases in the mixing chamber is less than 4 when the flow rate of the two phases is high. A heat protection layer is coated around the extraction case, a cover board is arranged at the upper part and temperature in the tank body is constant. Water sealing is used at the top part of the mixing chamber of the extraction tank, thus organic gas evaporated from the extraction tank can be recovered.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Technology for preparing high-purity anhydrous lithium chloride through centrifugal extraction of salt lake brine

InactiveCN106337138AImprove extraction efficiencyContinuous processProcess efficiency improvementLithium chloridePhase ratio

The invention discloses a technology for preparing high-purity anhydrous lithium chloride through centrifugal extraction of salt lake brine. The technology solves the technical problem that in the prior art, the preparing purity is poor and comprises the steps of impurity removal, hydrochloric acid blending, multistage counterflow centrifugal extraction, multistage counterflow washing, multistage counterflow reverse extraction, saponification, iron removal, oil removal, final evaporation and concentration, crystallization, separation, drying, packaging and obtaining 99.995% high-purity sewage lithium chloride products. Compared with the prior art, the technology has the beneficial effects that before lithium extraction, the saponification working procedure is set, an extraction organic phase containing amide complexing extractants is regenerated, and a frequency converter closed-loop flow control system is introduced for precisely controlling the flow; the backflow of the stage is adopted for solving the problem that the contact face is small due to large-phase-ratio feeding; a centrifugal extraction machine is arranged, the technology is automatically switched, and continuity and reliability of production can be ensured.

Owner:深圳市捷鑫资产管理有限公司

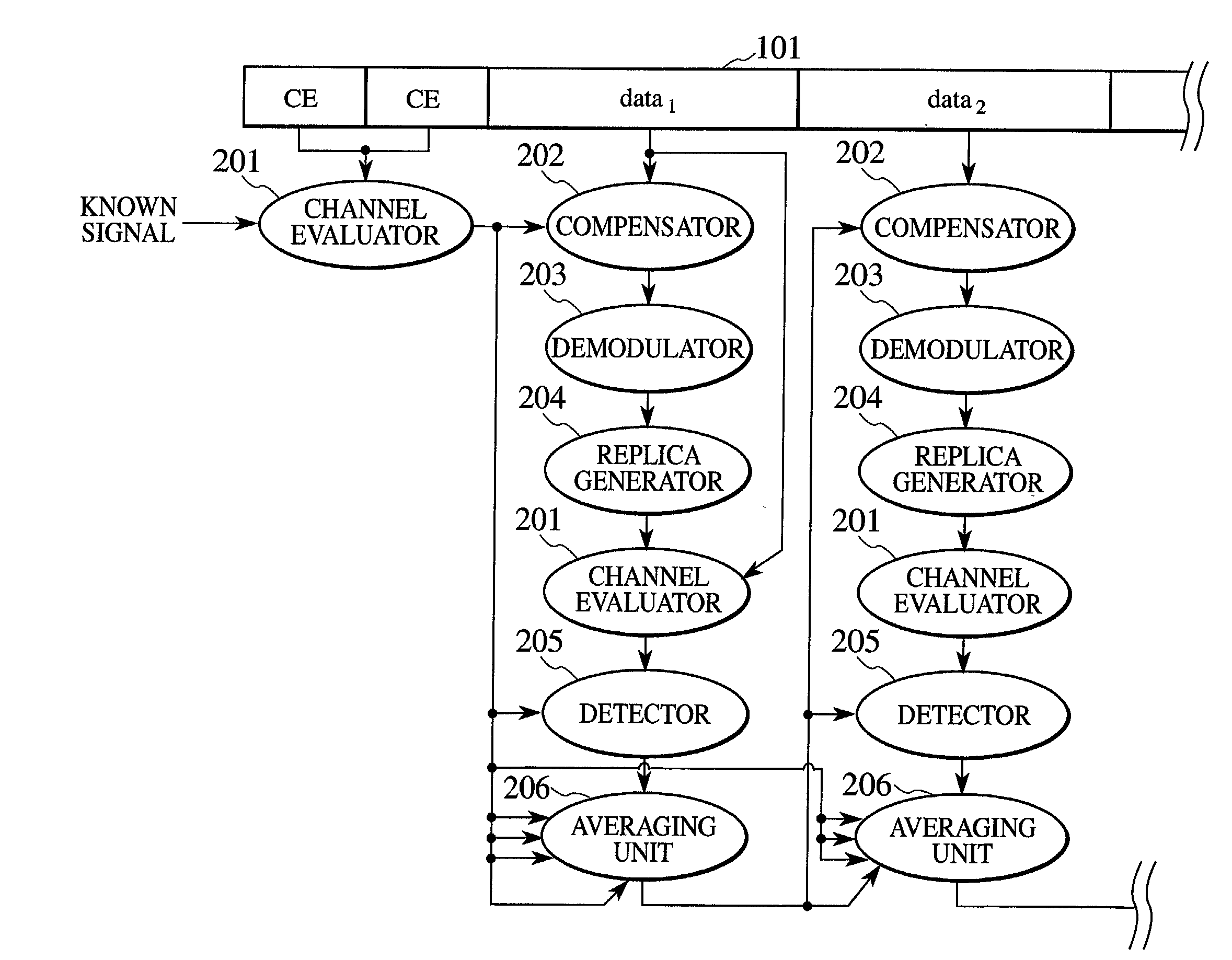

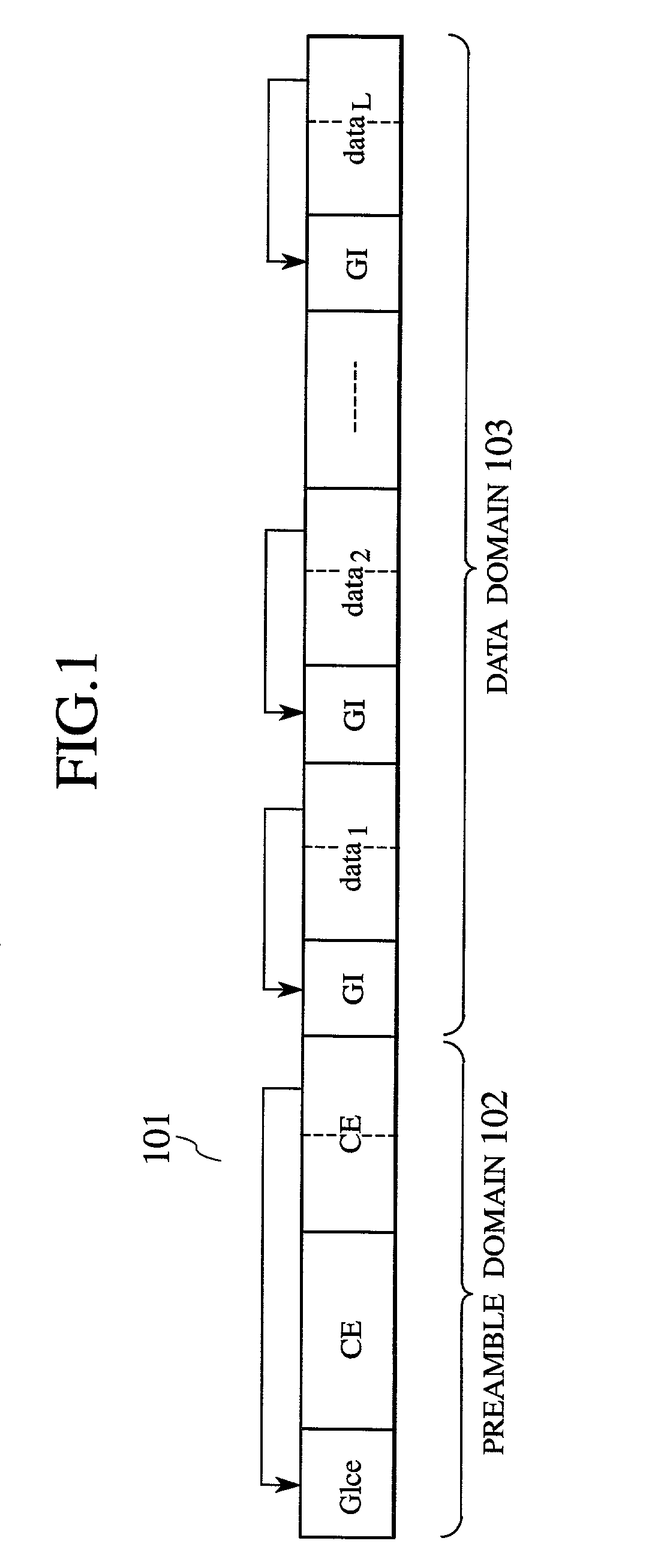

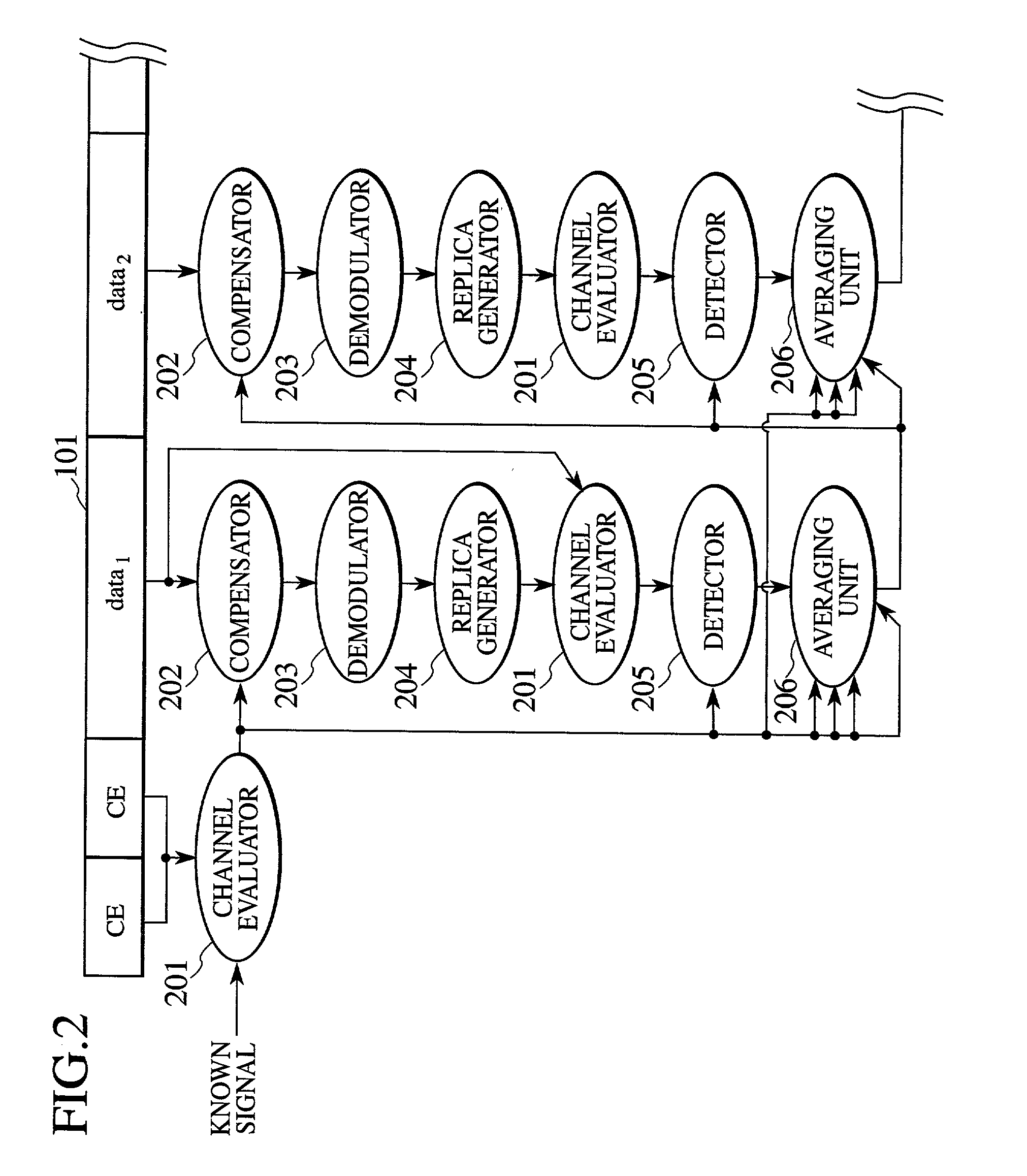

Receiving apparatus, receiving method, program and information recording medium

A channel evaluator acquires a change predicted value from a known symbol, and a compensator compensates for a first symbol using the change predicted value. A demodulator restores a portion corresponding to this symbol with another subcarrier. A replica generator acquires a transmission replica of the restored symbol. The channel evaluator performs complex division on the replica with the symbol to acquire an amplitude phase ratio. A detector compares the amplitude phase ratio with an amplitude phase ratio acquired immediately previously. In case where an elimination condition is satisfied, the detector disregards the amplitude phase ratio acquired currently and uses an immediately previous value instead, an averaging unit averages amplitude phase ratios to acquire a next change predicted value, and the compensator compensates for a next symbol using the change predicted value. Hereinafter, the sequence of processes is repeated.

Owner:NAT INST OF INFORMATION & COMM TECH +1

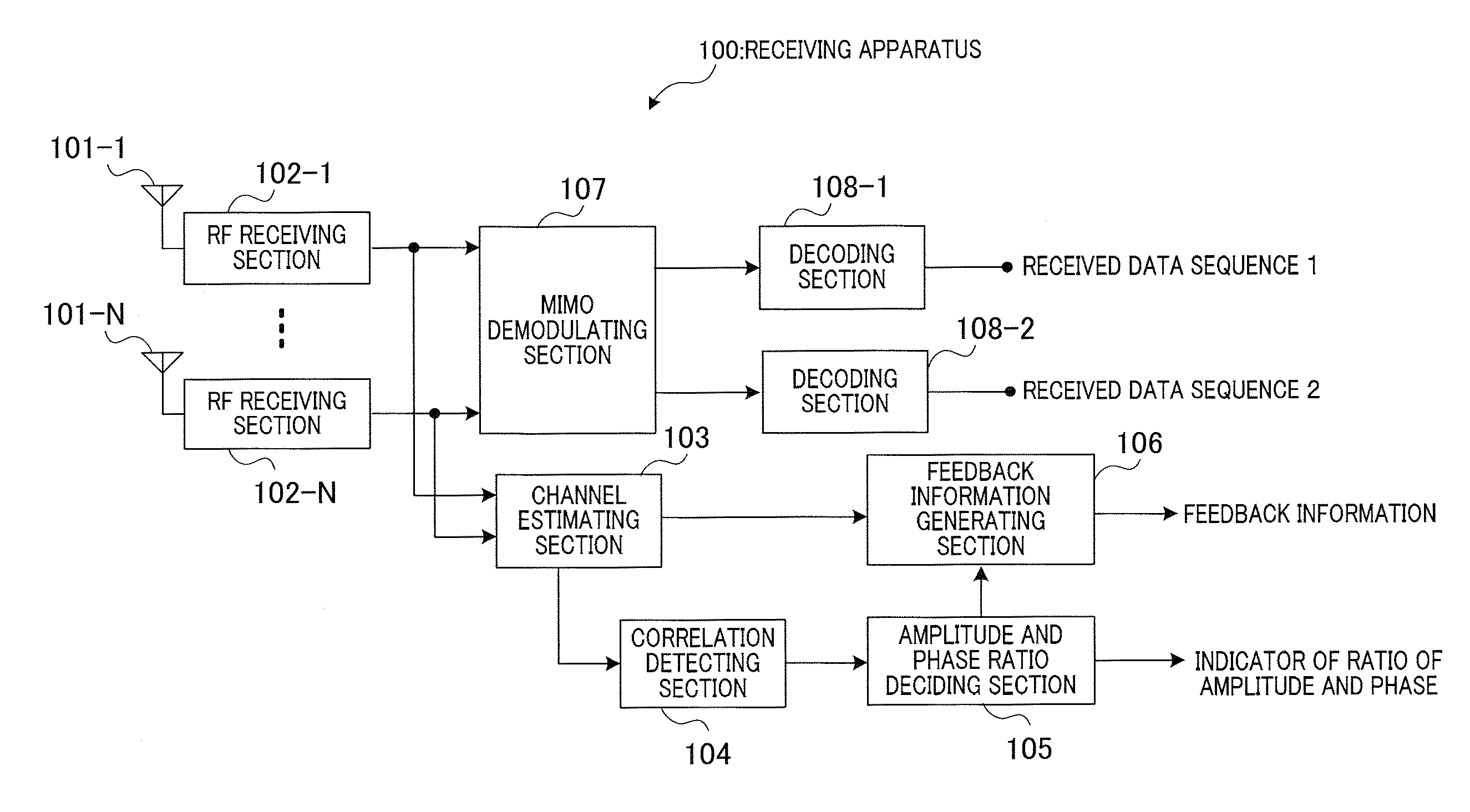

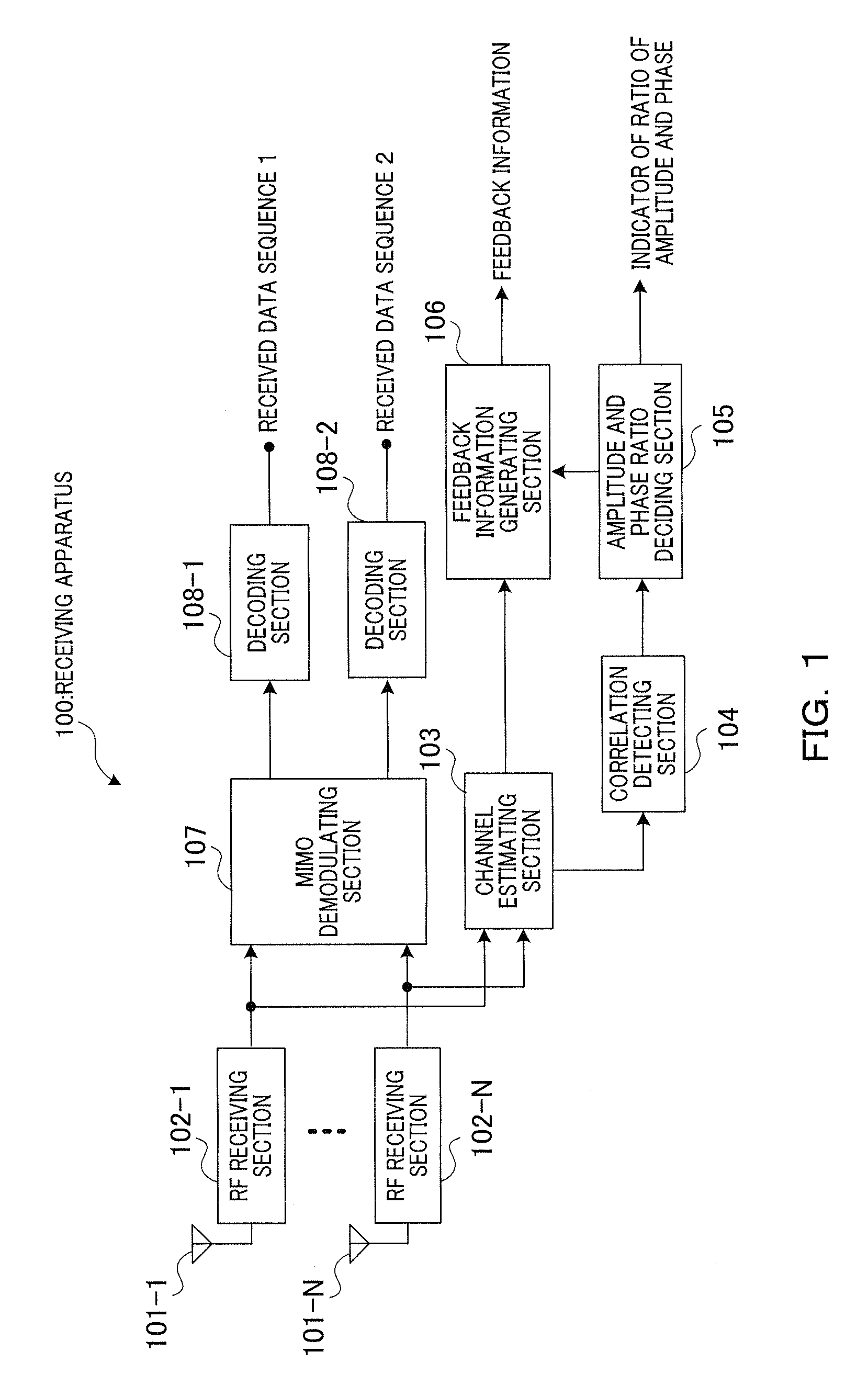

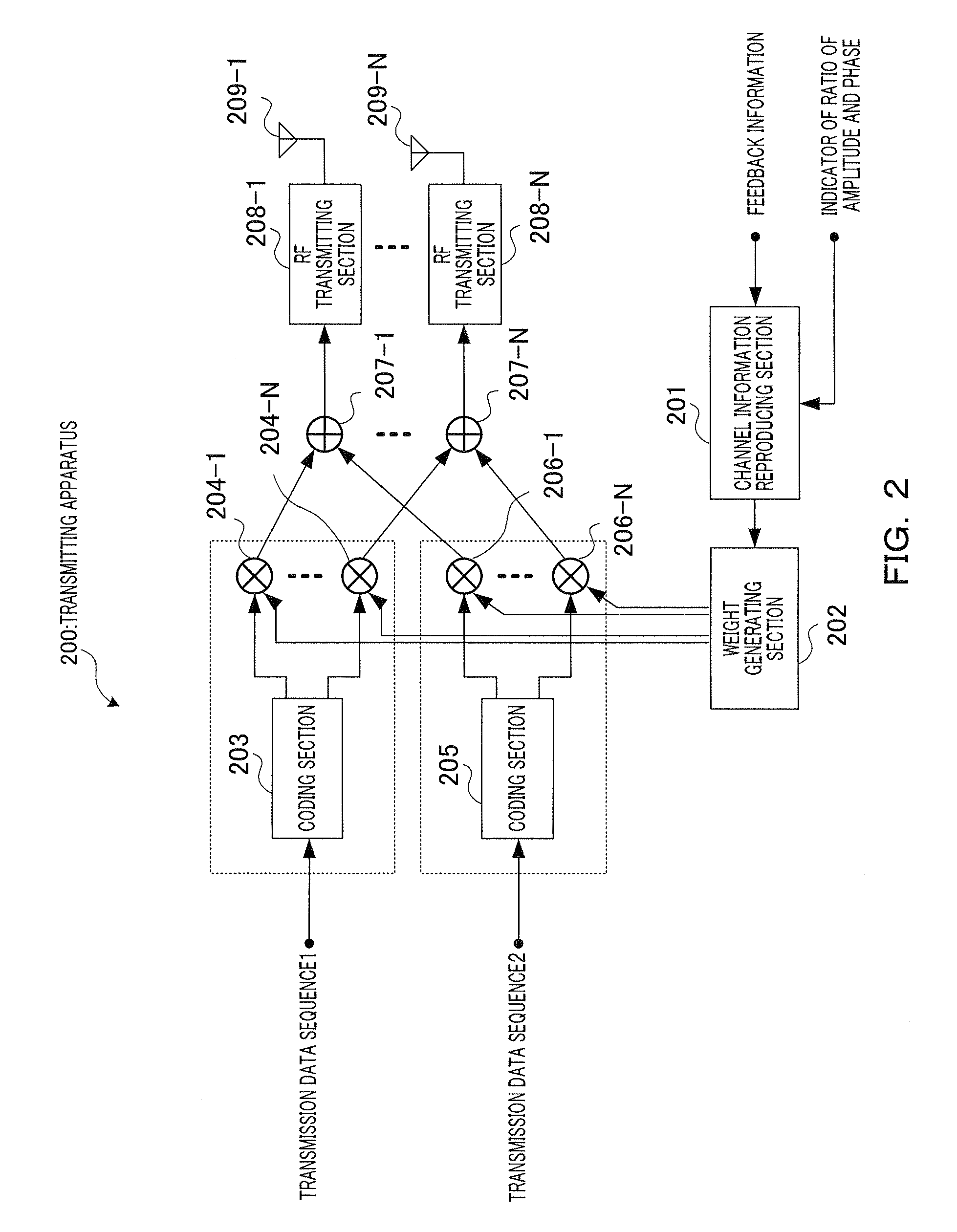

Wireless communication apparatus, and feedback information generating method

InactiveUS20090060082A1Exact reproductionReduce in quantityMultiplex communicationDiversity/multi-antenna systemsChannel state informationPhase ratio

A wireless communication apparatus that allows channel information to be reproduced with high precision at a transmitting end without increasing feedback information amount. In this apparatus, a channel estimating part (103) uses received pilot signals to perform channel estimation for each channel. A correlation detecting part (104) uses the result of the channel estimation to obtain correlation values between the channels, thereby detecting correlation values of all channels. An amplitude / phase ratio determining part (105) determines, based on the correlation values, the quantization bit ratio of the amplitude and phase of channel information to be used when those amplitude and phase are quantized. A feedback information generating part (106) quantizes the channel information in accordance with the determined ratio of the amplitude and phase.

Owner:PANASONIC CORP

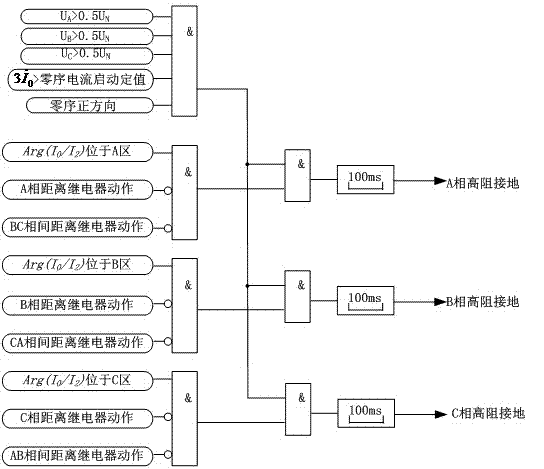

High-resistance grounding phase selection method for longitudinal zero-sequence protection of line protection device

ActiveCN102769279ARealize phase selection tripEmergency protective circuit arrangementsHigh resistanceUltra high voltage

The invention discloses a high-resistance grounding phase selection method for longitudinal zero-sequence protection of a line protection device. The method comprises the following steps of: firstly, when a line fails, detecting whether the failure is a line grounding failure, and determining the failure type of the line grounding failure according to a phase ratio criterion method; and secondly, according to criteria of the motion direction of a zero-sequence directional element and three phase voltage values and a one-way phase determination criterion method, determining that the failure type is the phase of a single-phase high-resistance grounding failure. By adoption of the phase selection method for the longitudinal zero-sequence protection during high-resistance grounding, the phase of the single-phase high-resistance grounding failure of the longitudinal zero-sequence protection can be conveniently and quickly obtained, and the phase selection tripping of the longitudinal zero-sequence protection is realized, so the line protection device is applicable to an ultra-high-voltage line employing a single-phase re-turn-on mode and has a good application prospect.

Owner:NARI TECH CO LTD +1

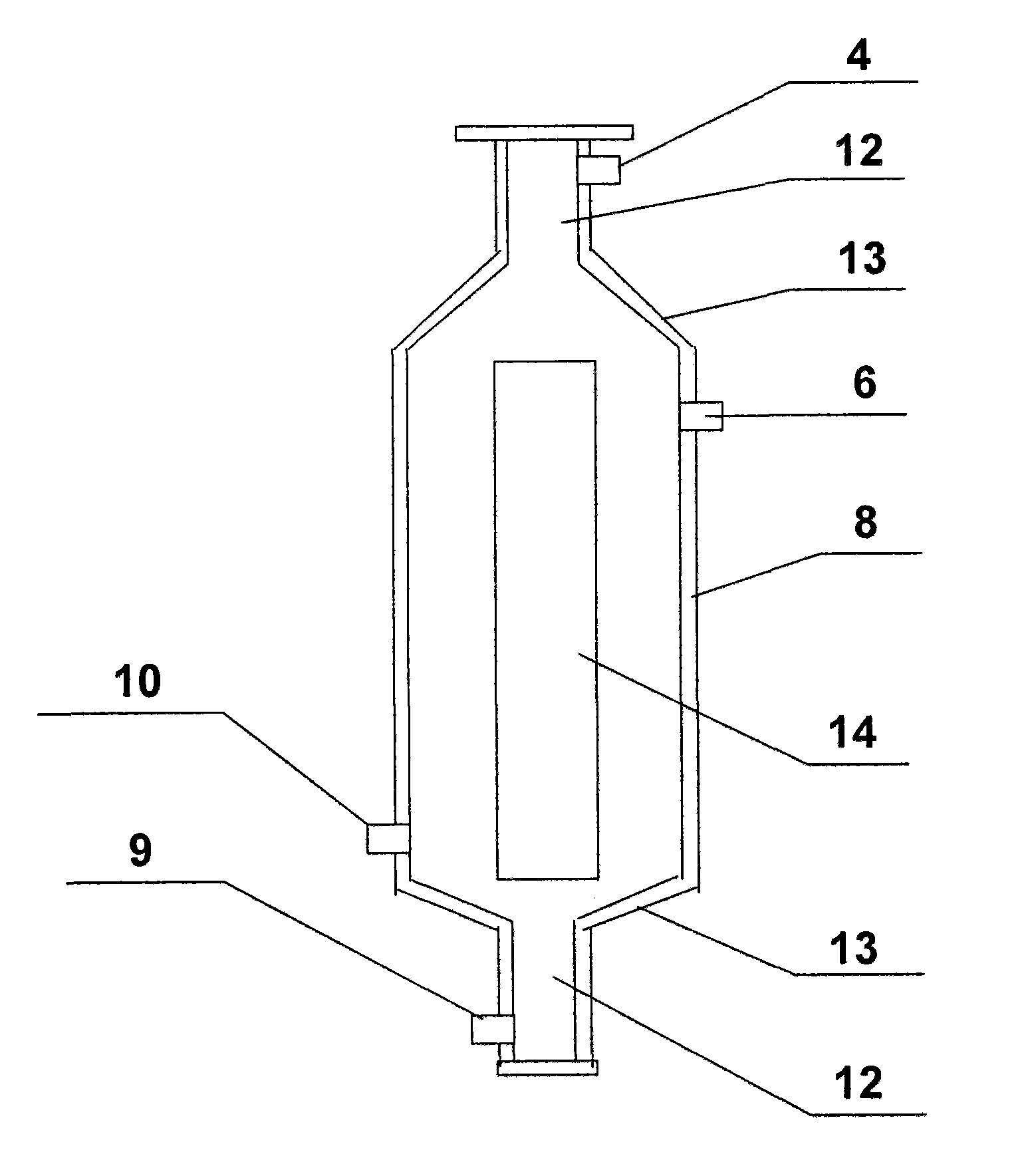

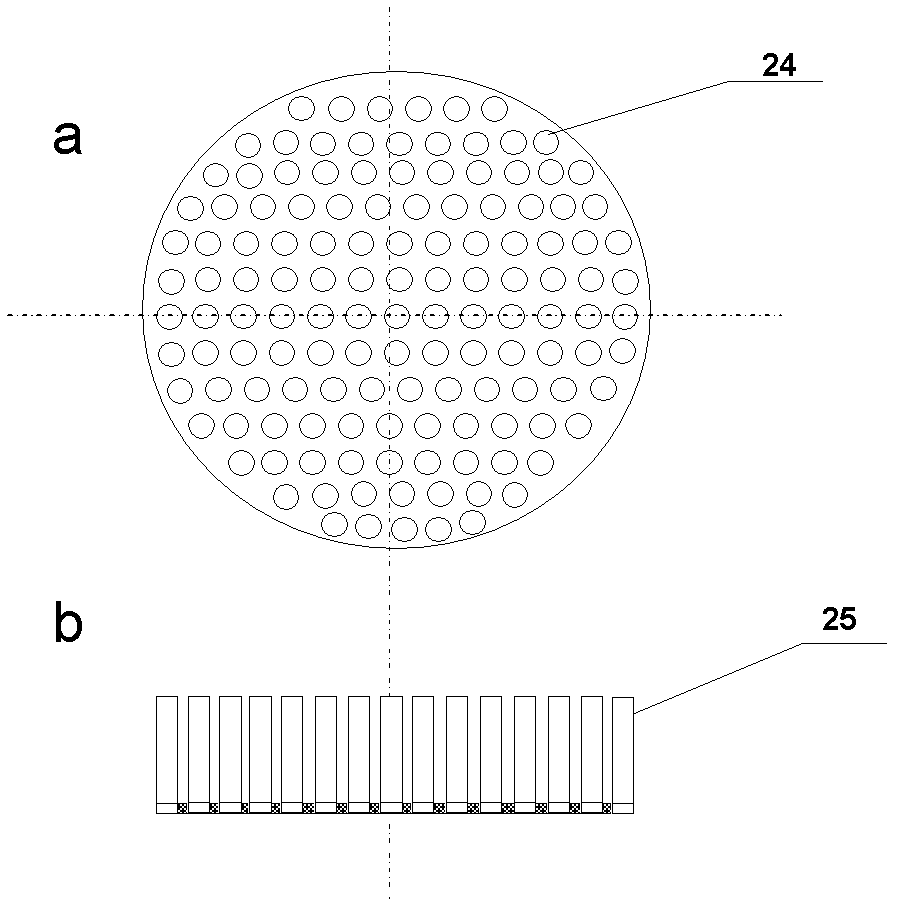

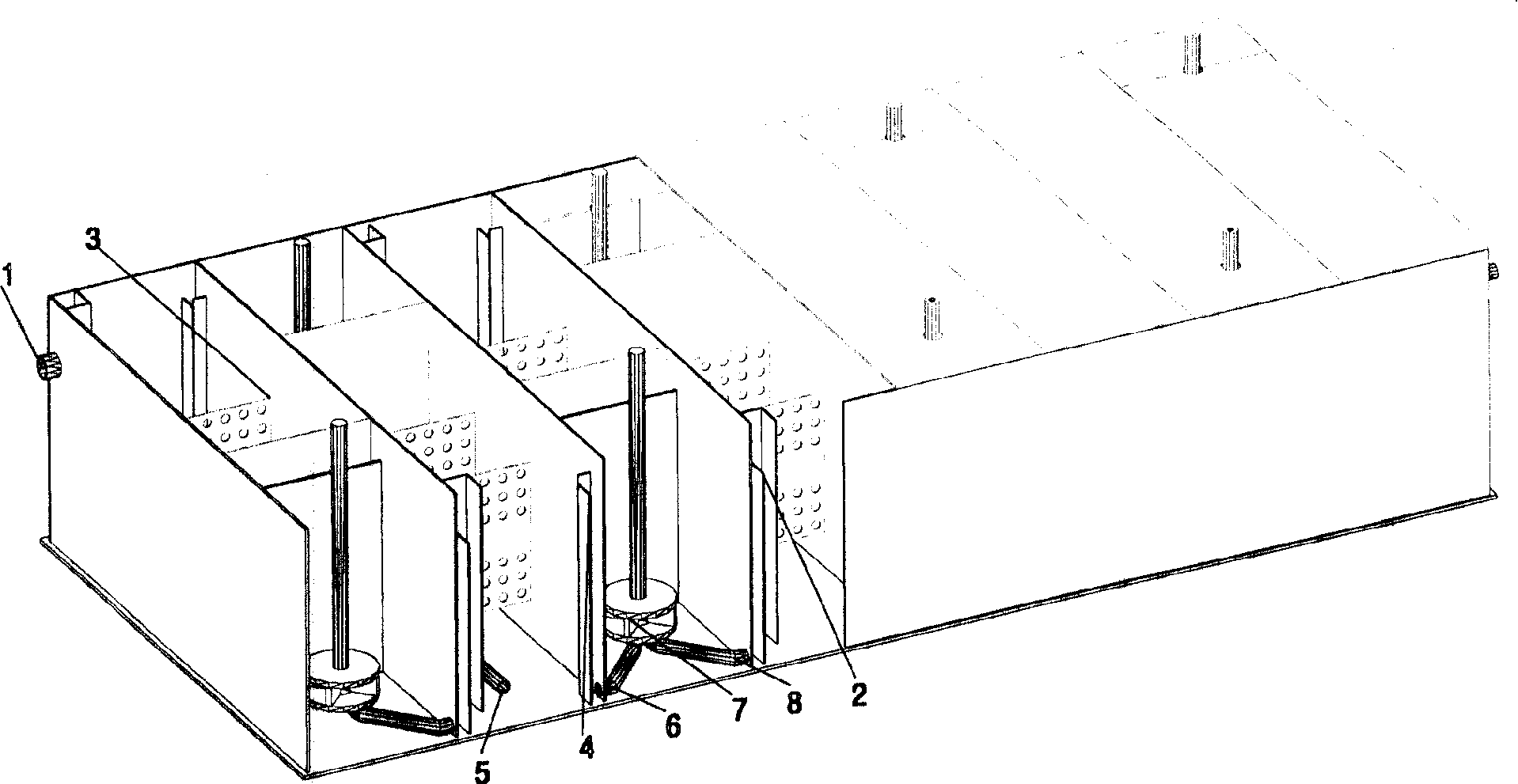

Large-phase-ratio extraction device for organic liquid film on bubble surface

ActiveCN103736295AGuaranteed working conditionUniform sizeLiquid solutions solvent extractionPhase ratioEngineering

The invention relates to a large-phase-ratio extraction device for an organic liquid film on a bubble surface. The large-phase-ratio extraction device comprises a column body, an expansion section and an oil-phase bubble distributor, wherein the expansion section is connected with the top of the column body; the oil-phase bubble distributor is connected with the bottom of the column body and comprises at least one oil-phase distribution head; each oil-phase distribution head comprises an outer tube and an inner tube embedded inside the outer tube; the outer diameter of the inner tube is smaller than the inner diameter of the outer tube; an inner-outer tube annular space is formed between the inner tube and the outer tube; the inner tube extends downward below the lower end opening of the outer tube; the mounting position of the upper end opening of the inner tube is lower than the mounting position of the upper end opening of the outer tube; an oil-phase collector is arranged inside the expansion section connected with the top of the column body; a hole is formed in the top end face of the expansion section; a water-phase inlet pipeline enters from the hole; an oil-phase outlet is formed in the lateral wall of the top of the expansion section. With the adoption of the large-phase-ratio extraction device, a small-volume organic oil phase is dispersed in a large-volume continuous water phase when the oil phase volume is very small, and then target components with ultralow concentration in water-phase material liquid can be extracted and enriched through the organic liquid film on the bubble surface.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Boron extraction technology

The invention discloses a boron extraction technology. Brine water after extracting lithium from salt lake is used as raw paderial and 2-thyl-1,3-hexanediol respectively with mixture alcohol of isooctal alcohol and isoamyl alcohol extracts borone from the brine water and optimum processing condition for extracting boron from brine water using the mixture alcohol is obtained after performing experiments from the aspects of extractant volume fraction, acidity, phase ratio, extraction time, extraction temperature, saturation extraction volume, back washing agent concentration and back washing time: extractant volume fraction 30%, water phase pH 3, phase ratio 1:1, extraction time 10min, maximum saturation capacity 61.4g / L(B2O3).

Owner:于网林

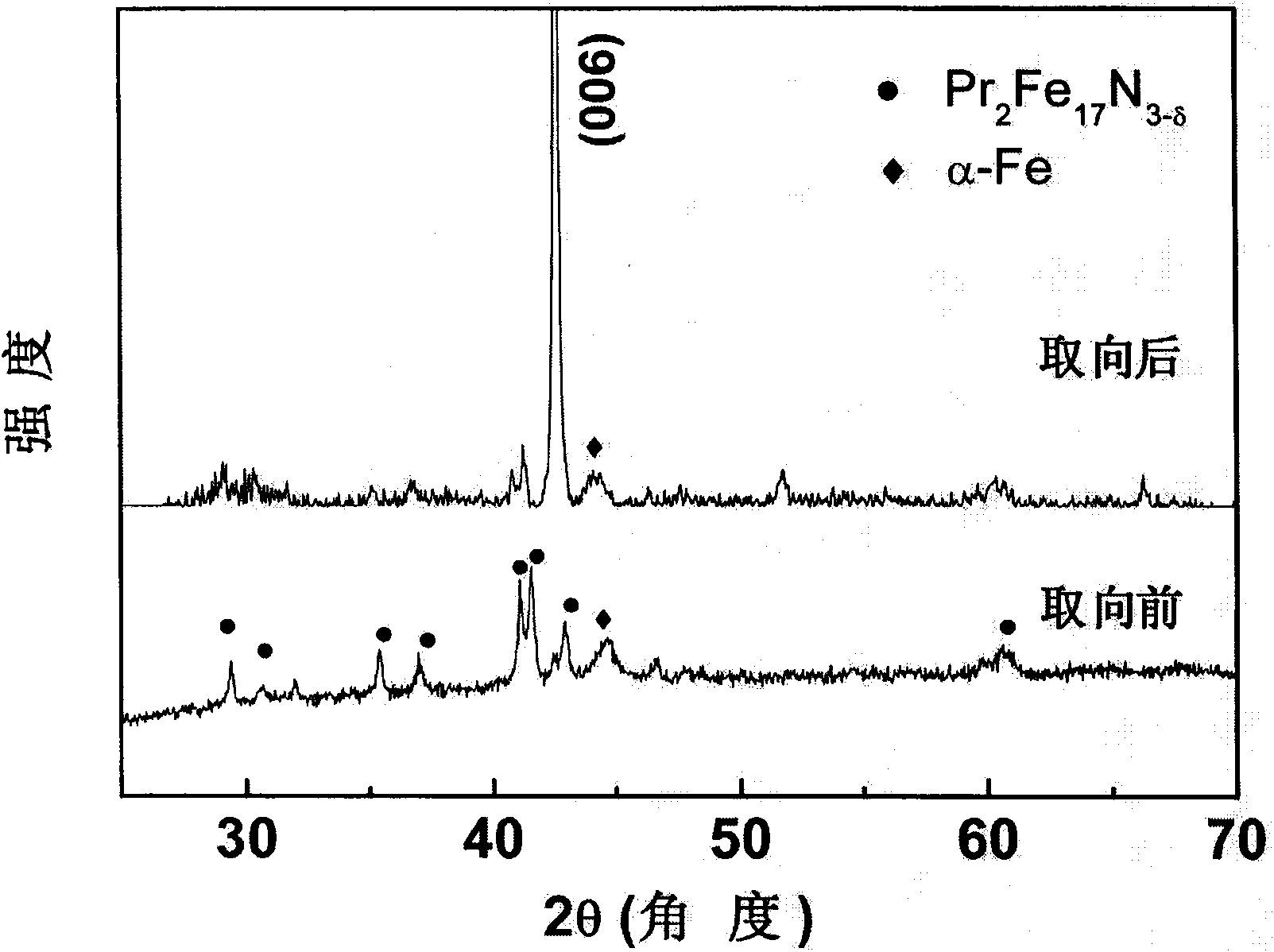

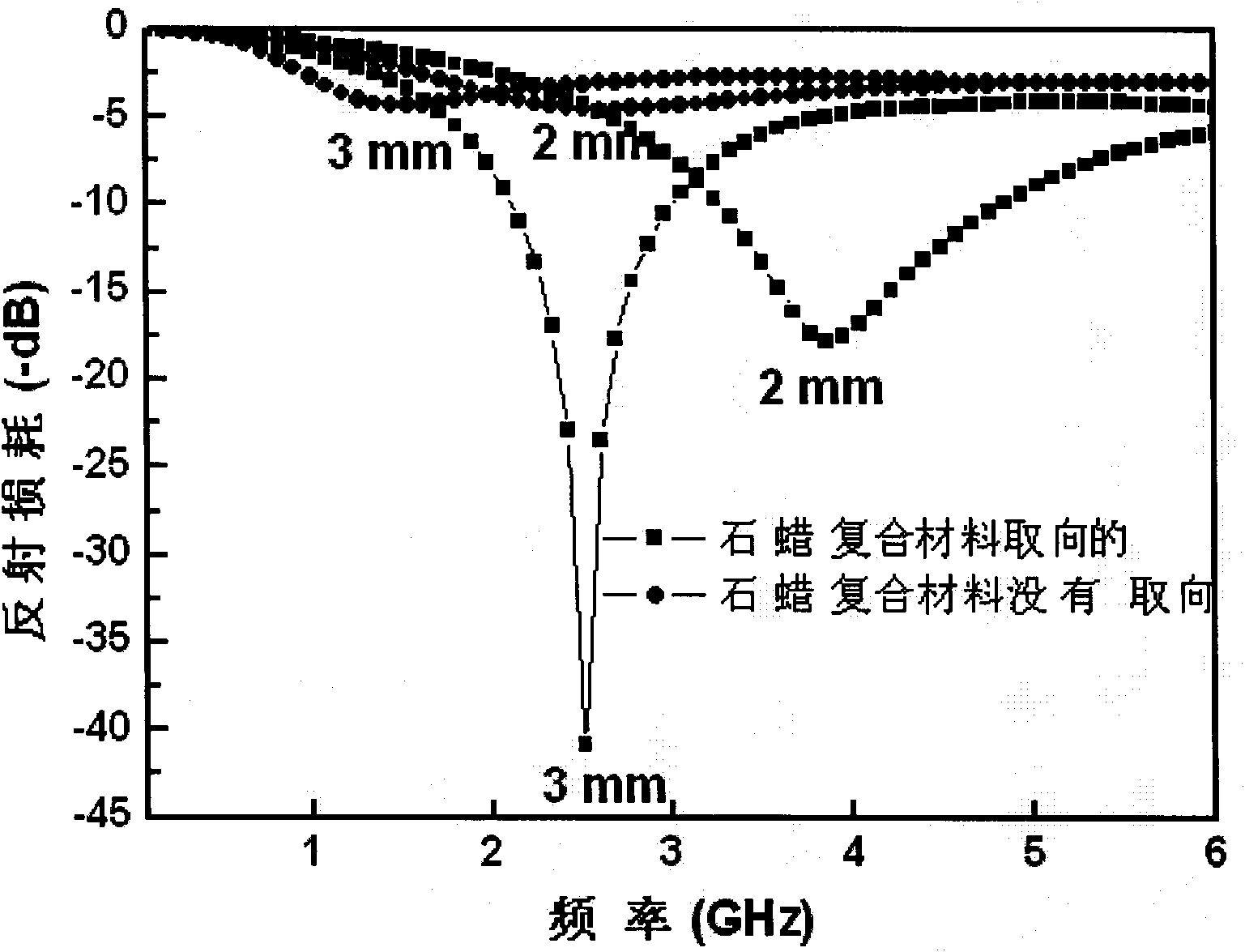

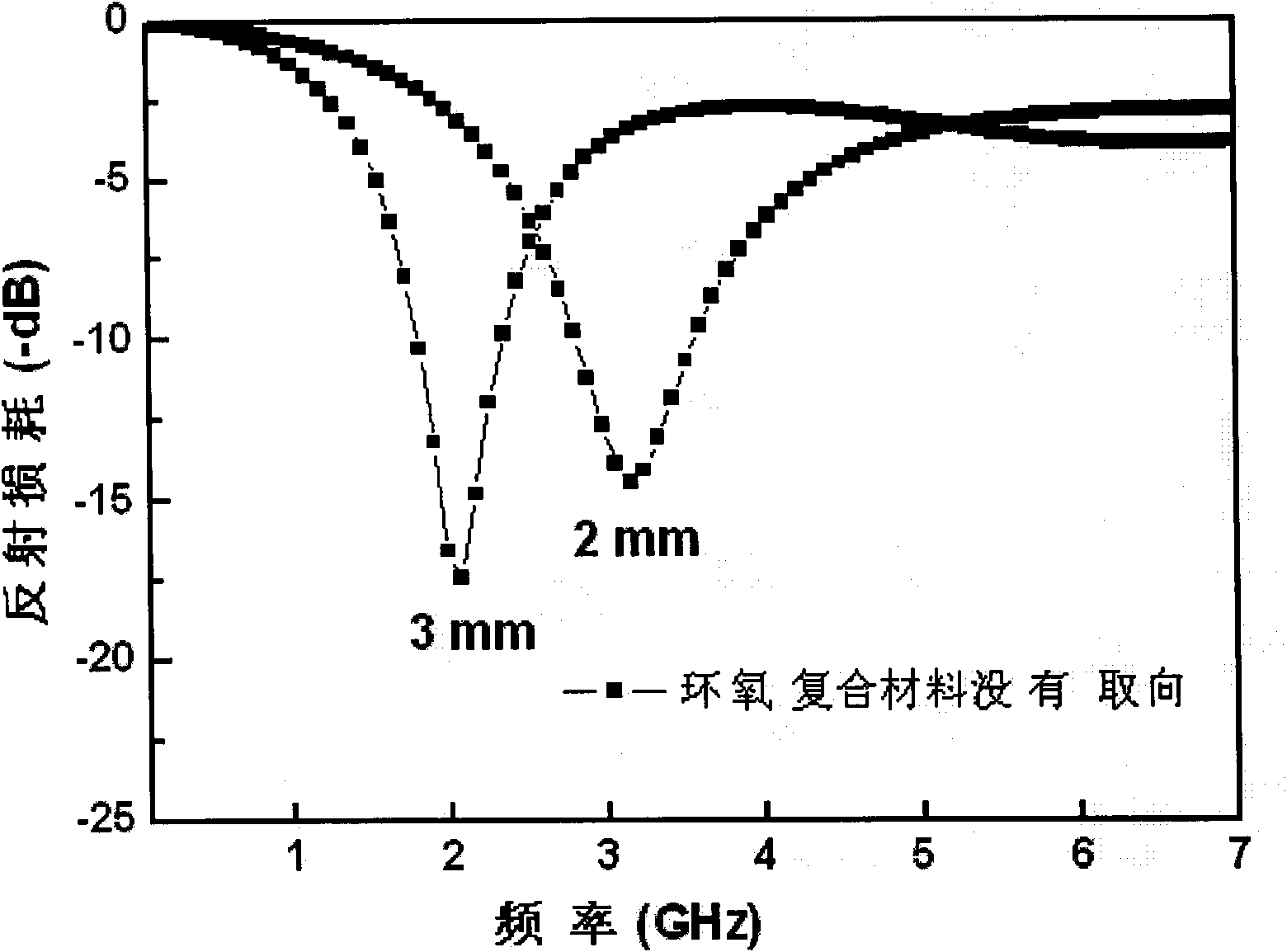

Electromagnetic wave absorbing material

InactiveCN101886214AMatching thickness thinMeet miniaturizationMagnetic/electric field screeningInorganic material magnetismRare-earth elementMagnetization

The invention discloses a material which comprises rare earth elements and iron nitrogen according to a phase ratio of 2:17 and has high capability of absorbing high-frequency electromagnetic radiation from 1G to 100G and an electromagnetic wave absorbing composite material which is made of the material and has better wave absorbing properties. The general formula of the electromagnetic wave absorbing material is R2Fe17N3-delta, and the preferred magnetization direction of the material meeting the general formula needs to be perpendicular to the C axis. In the general formula, R is one or a combination of any two of Y, Ce, Nd, Pr, Gd, Tb, Dy, Ho, Er, Tm and Lu. The method for preparing the electromagnetic wave absorbing material comprises the following steps of: adding the materials in an uncured binding material, thoroughly and uniformly mixing, then putting into a mold made of non-magnetic materials, and finally placing the mold in a magnetic field for orientation treatment.

Owner:LANZHOU UNIVERSITY

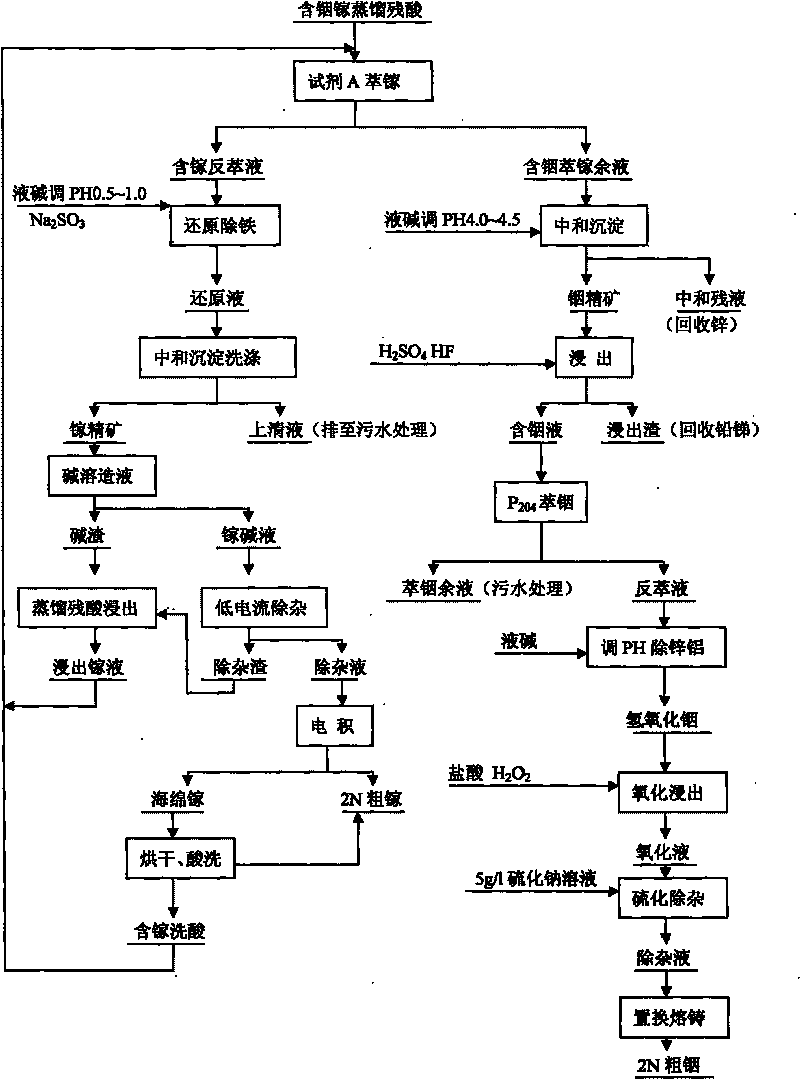

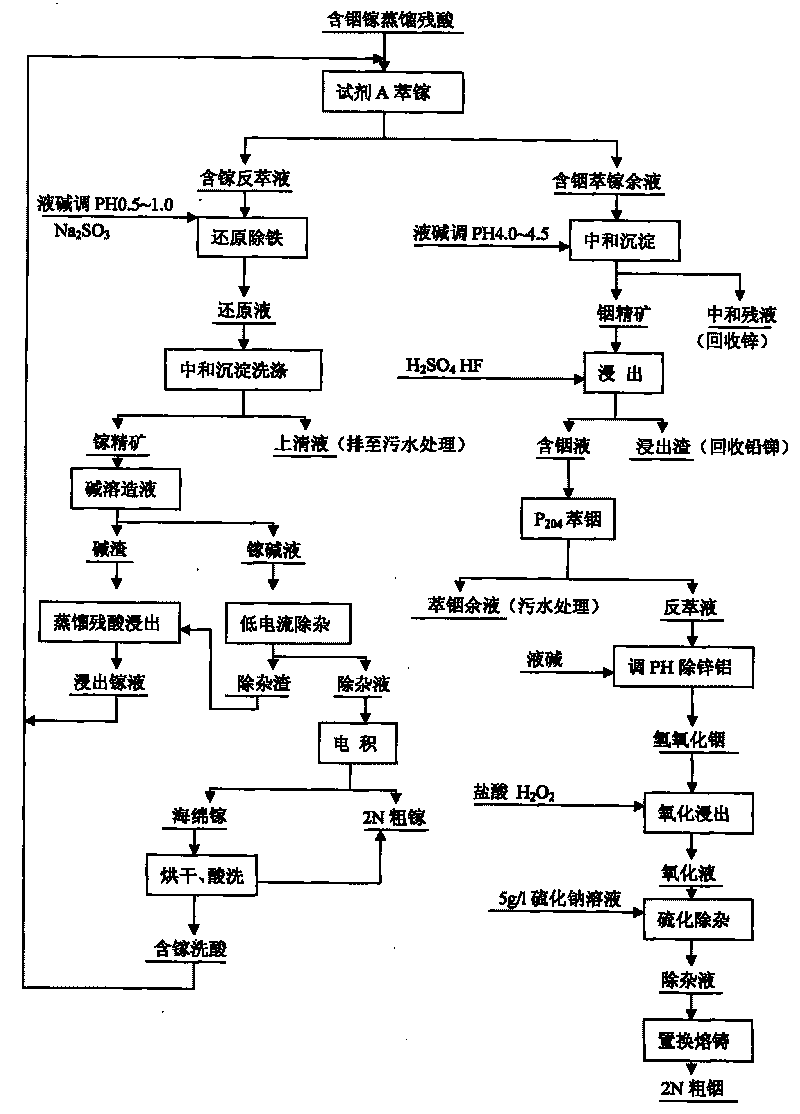

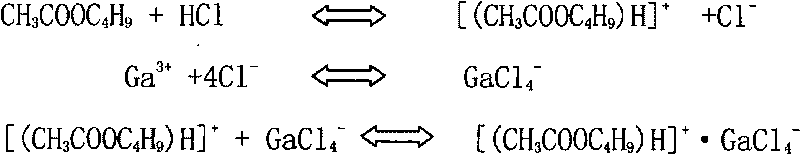

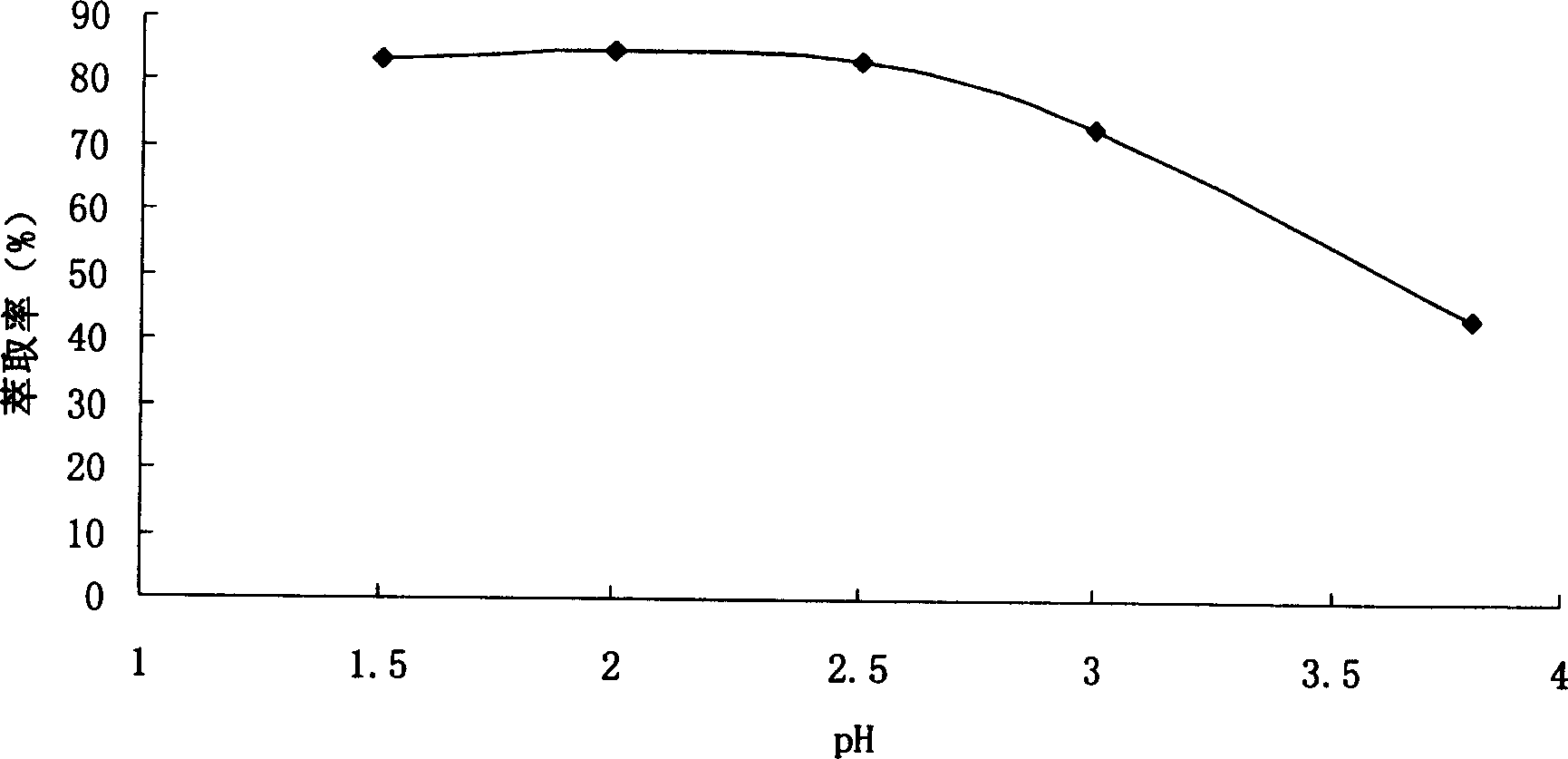

Method for comprehensively recovering indium and gallium from distilled waste acid containing indium and gallium

InactiveCN101717868ASimple processGood effectPhotography auxillary processesProcess efficiency improvementIndiumKerosene

The invention discloses a method for comprehensively recovering indium and gallium from distilled waste acid, wherein the process for recovering gallium comprises the following steps of: adopting ethyl acetate as an extracting reagent and adopting kerosene as diluent; extracting at two grades in an intermittent type extracting way, quantitatively supplementing new ethyl acetate every day and maintaining the phase ratio of a water phase and an organic phase to be 2-3:1; extracting and stirring for five minutes; standing, demixing and then discharging extracted residual liquid in a neutralizing pond to carry out the enrichment and recovery of indium; washing and mechanically mixing a loaded organic phase by hydrochloric acid with 4-6N and then reversely extracting by diluted hydrochloric acid with 1-1.5N; standing, demixing and then separating a deficient organic phase from reversely extracted liquid; carrying out neutralized enrichment on the reversely extracted liquid twice to form gallium concentrated ore, washing and removing impurities to obtain high-purity gallium; in addition, the process for recovering indium comprises the following steps of: neutralizing and depositing the gallium extracting residual liquid by liquid alkali; then leaching for three times, extracting indium, purifying, removing impurities, replacing and founding to obtain rough indium with stable quality.

Owner:南京中锗科技有限责任公司

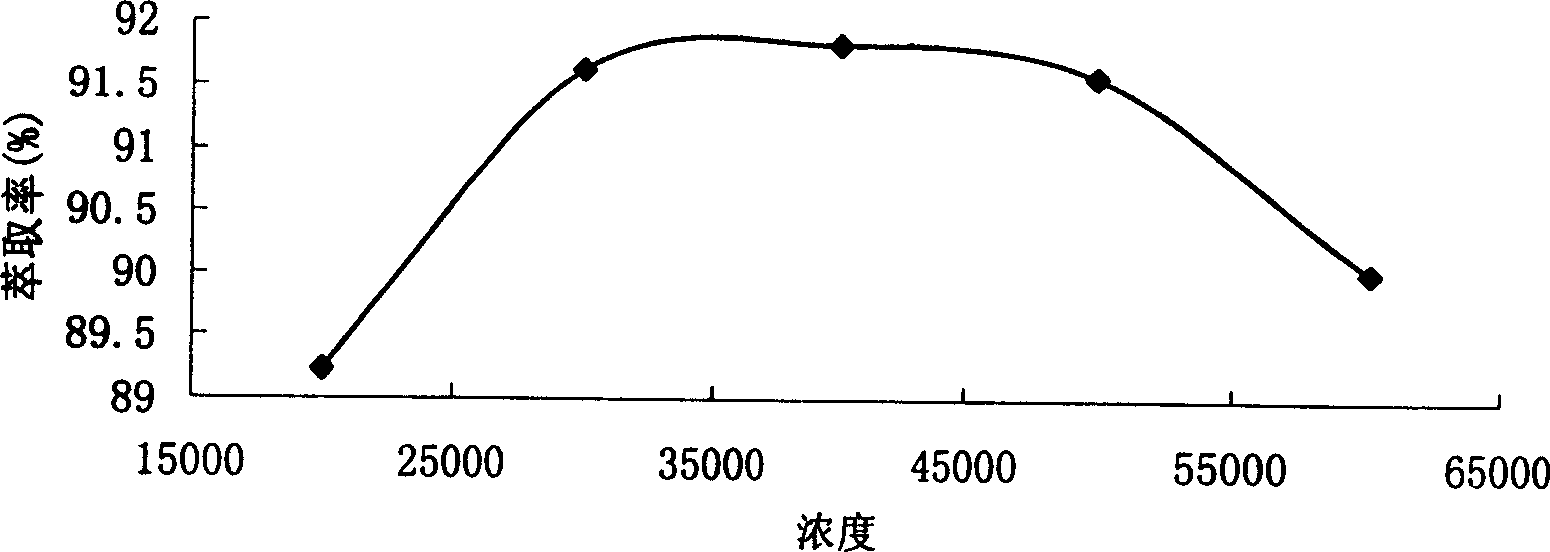

Method of ion liqid extraction for separating penicillin

InactiveCN1563008ALow priceOvercome problems such as emulsificationOrganic chemistrySingle stagePenicillin

This invention relates to method for extracting penicillin by ion-liquid extract. In this invention, determinations are: extraction procedures, pH value, phase ratio, extration rate affected by penicillin concentration. Extraction types are; single stage extraction, cross current extraction and counter current extraction. Said extract ion-liquid is [BMIM]PF6(1-ethyl-3-methyl imidazole hexafluorophosphate. This invention determines back-extraction method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Mordenite/beta zeolite/MCM-22 triphase coexisting molecular sieve and method for synthesizing same

ActiveCN101514011AIncrease acidityStrong acidMordenite aluminosilicate zeoliteMolecular sieveCatalytic pyrolysis

The invention relates to a mordenite / beta zeolite / MCM-22 triphase coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the porous coexisting material by adding a seed crystal containing an MCM-22 precursor and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of triphase coexisting molecular sieve. The coexistence phase ratio of the triphase coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized triphase coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 4 and 400; the triphase coexisting molecular sieve has more than three phases; the XRD diffraction pattern of the triphase coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 13.58-0.1 and 13.58+0.1 A, 12.35-0.1 and 12.35+0.1 A, 11.32-0.1 and 11.32+0.1 A, 11.08-0.1 and 11.08+0.1 A, 8.83-0.05 and 8.83+0.05 A, 8.96-0.05 and 8.96+0.05 A, 6.71-0.1 and 6.71+0.1 A, 6.17-0.1 and 6.17+0.1 A, 4.51-0.1 and 4.51+0.1 A, 4.15-0.05 and 4.15+0.05 A, 3.90-0.05 and 3.90+0.05 A, 3.42-0.05 and 3.42+0.05 A, 3.29-0.04 and 3.29+0.04 A, 3.19-0.04 and 3.19+0.04 A, and 3.02-0.1 and 3.02+0.1 A; therefore, the problems are solved well. The triphase coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

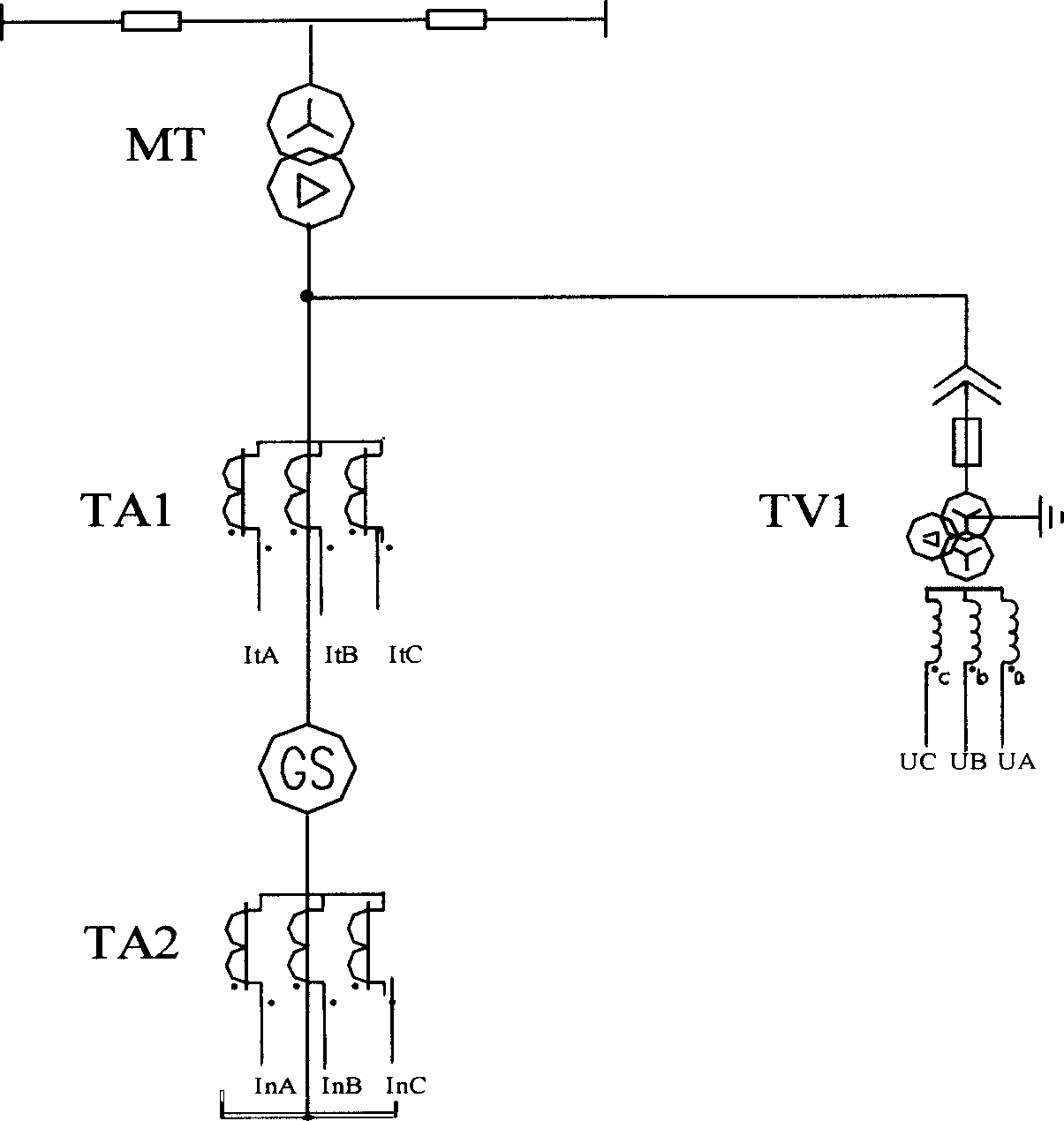

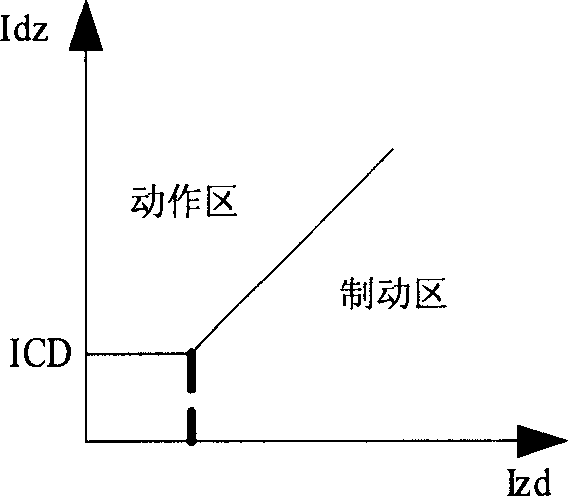

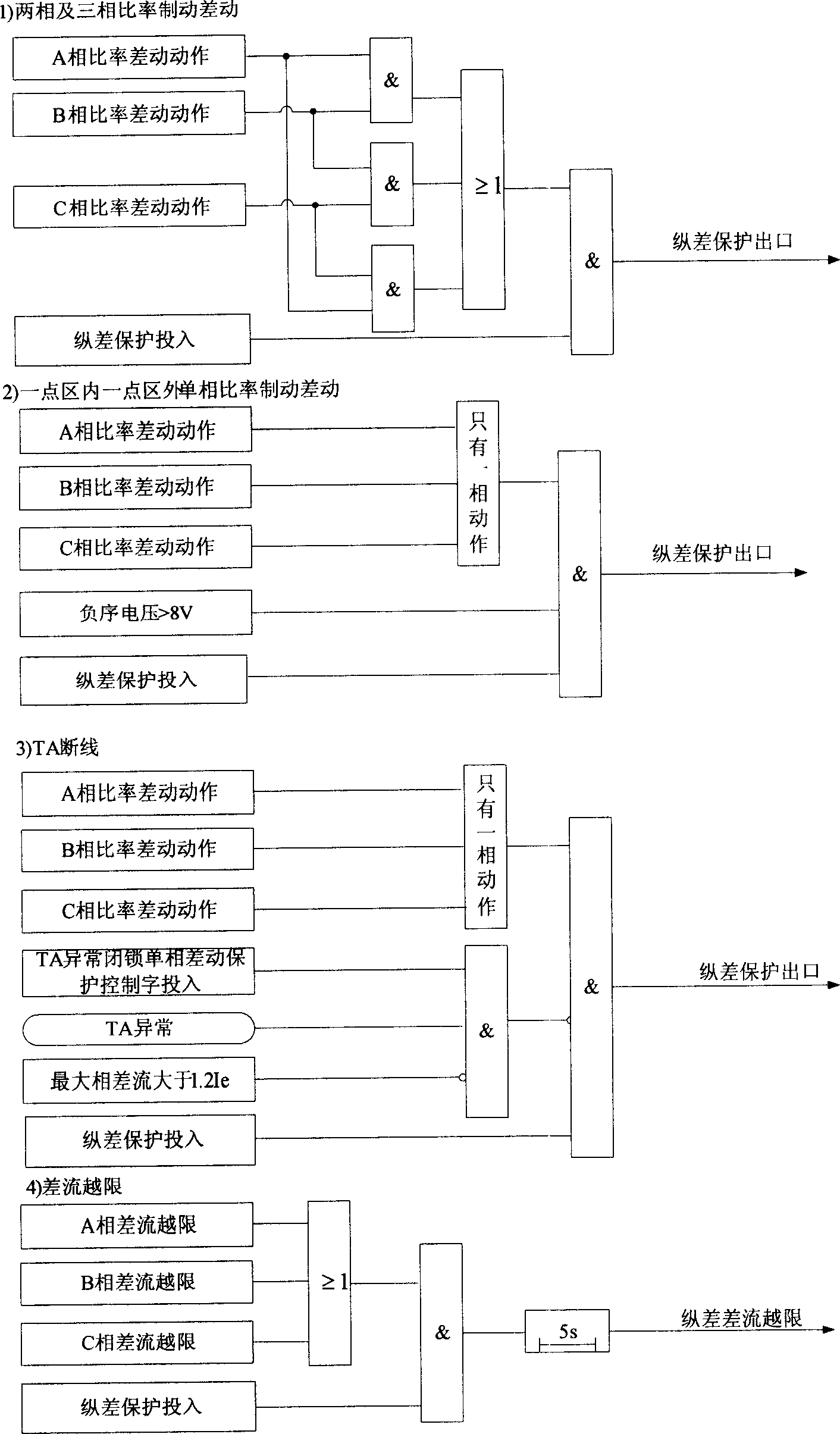

Anti-TA transient imbalance differential protection for generator

ActiveCN1632997AImprove securityImprove reliabilityEmergency protective circuit arrangementsElectricityTransient state

This invention relates to a relay protection method in power system, which discloses an unbalanced transient state generator differential protection method of a TA composed of phase ratio brake property and multiple constant value sampled ratio brake open criteria and applies the algorism of varying data windows and a cyclic block theory. This invention also has the criteria of interconnected detection, out of the zone fault detection, interspaced wire breakage of the current mutual inductor second loop at both sides of the generate and TA saturation.

Owner:BEIJING SIFANG JIBAO AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com