Technology of extracting and separating valuable metals such as Pb, In, Sb, Cu and Sn from lead smelting converter slags

A technology of lead, indium, antimony, copper, tin, and valuable metals, which is applied in the field of non-ferrous metal extraction, and can solve the problems of less recycling of tin and antimony and less consideration of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

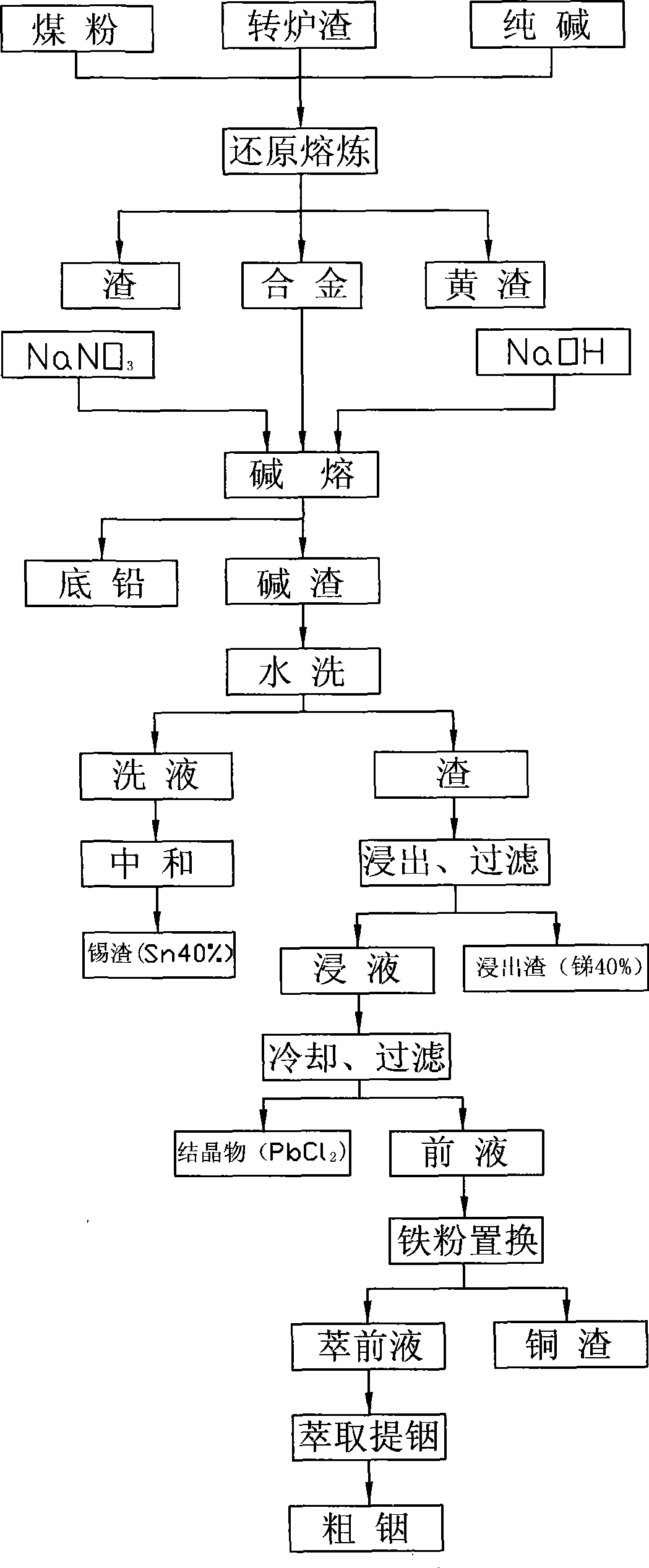

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0012] see figure 1 , a process for extracting and separating valuable metals of lead, indium, antimony, copper, and tin from lead smelting converter slag. The raw material is crude copper that is blown in a converter to produce oxide slag containing indium, lead, antimony, copper and tin. The main metals and their contents in the raw material are respectively Is: Pb15~23%, In0.15~0.3%, Sn4.5~6.5%, Sb4.7~5.87%, Cu4.2~8.92%, first of all, the material is mixed with soda ash and anthracite, and the proportion is converter slag : soda ash: anthracite = 1000:12:8; smelting in an electric furnace at 1100°C for 2 hours to obtain an alloy with a content of: In1-3%, Pb45-60%, Sn10-20%, Sb5-15%, Cu10-20% , The direct recovery rate of indium in this process is about 90%, and that of other metals is above 90%.

[0013] Then in the reverberatory furnace at 600-650°C, add ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com