Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228 results about "Reverberatory furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term reverberation is used here in a generic sense of rebounding or reflecting, not in the acoustic sense of echoing.

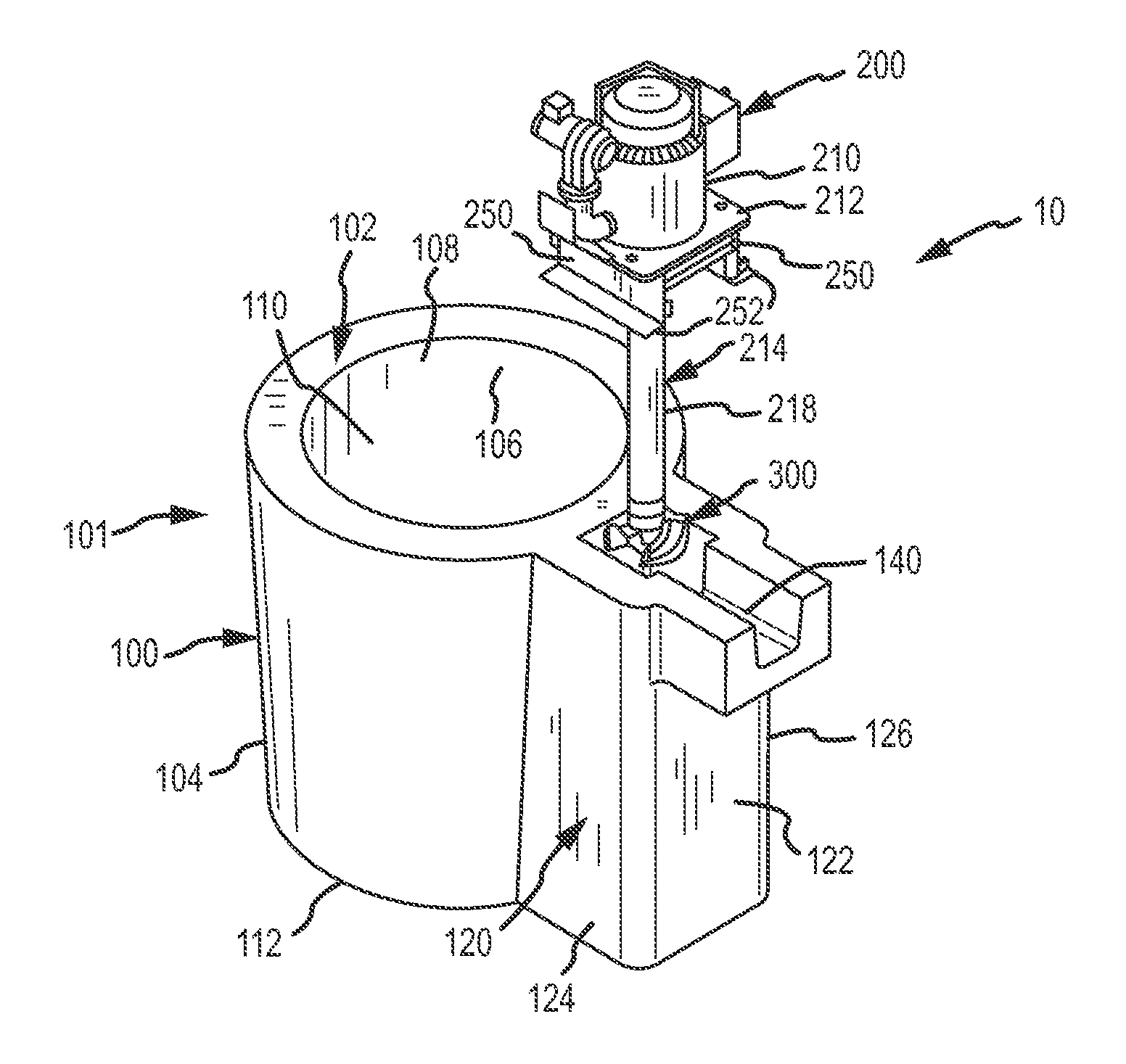

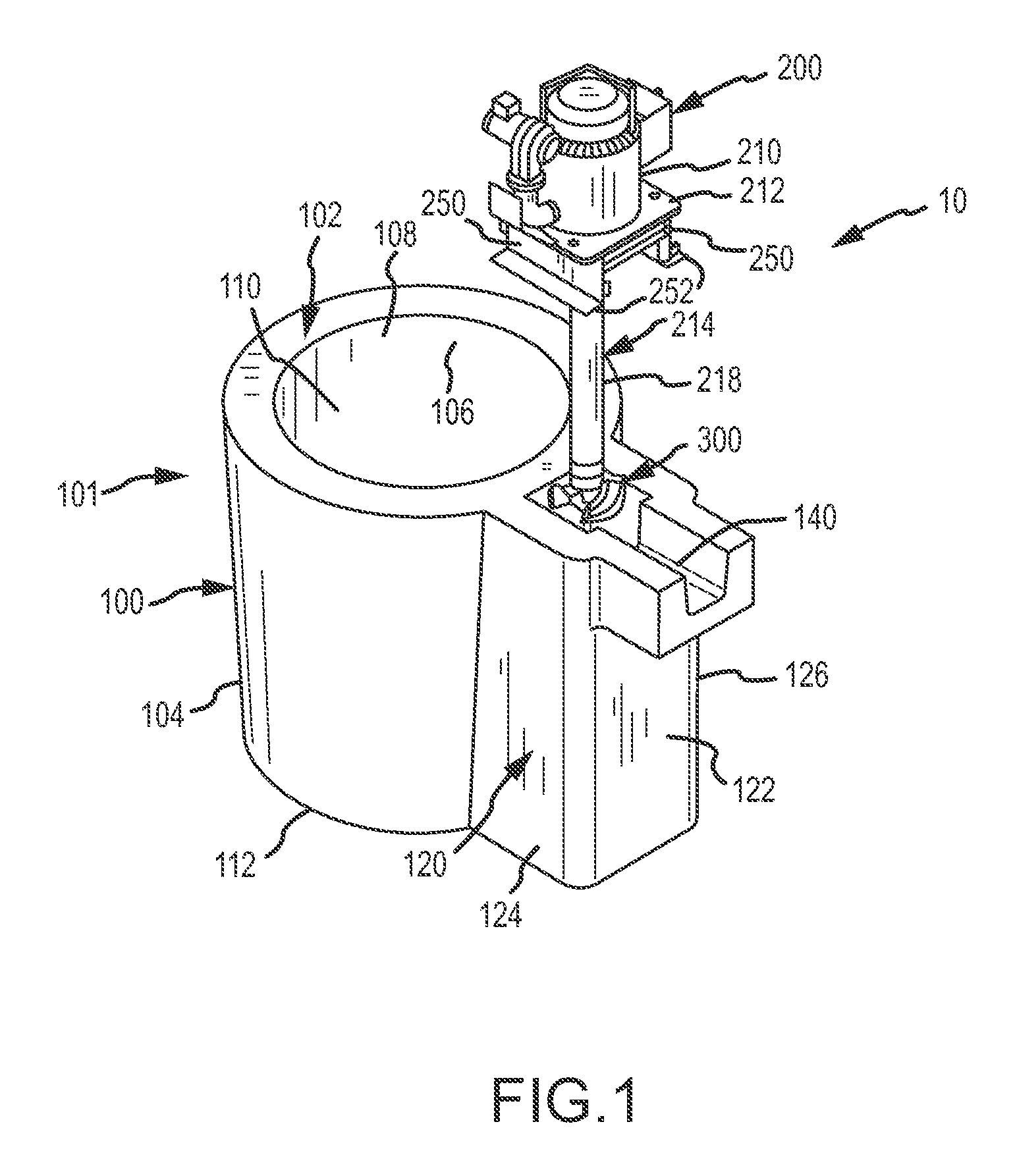

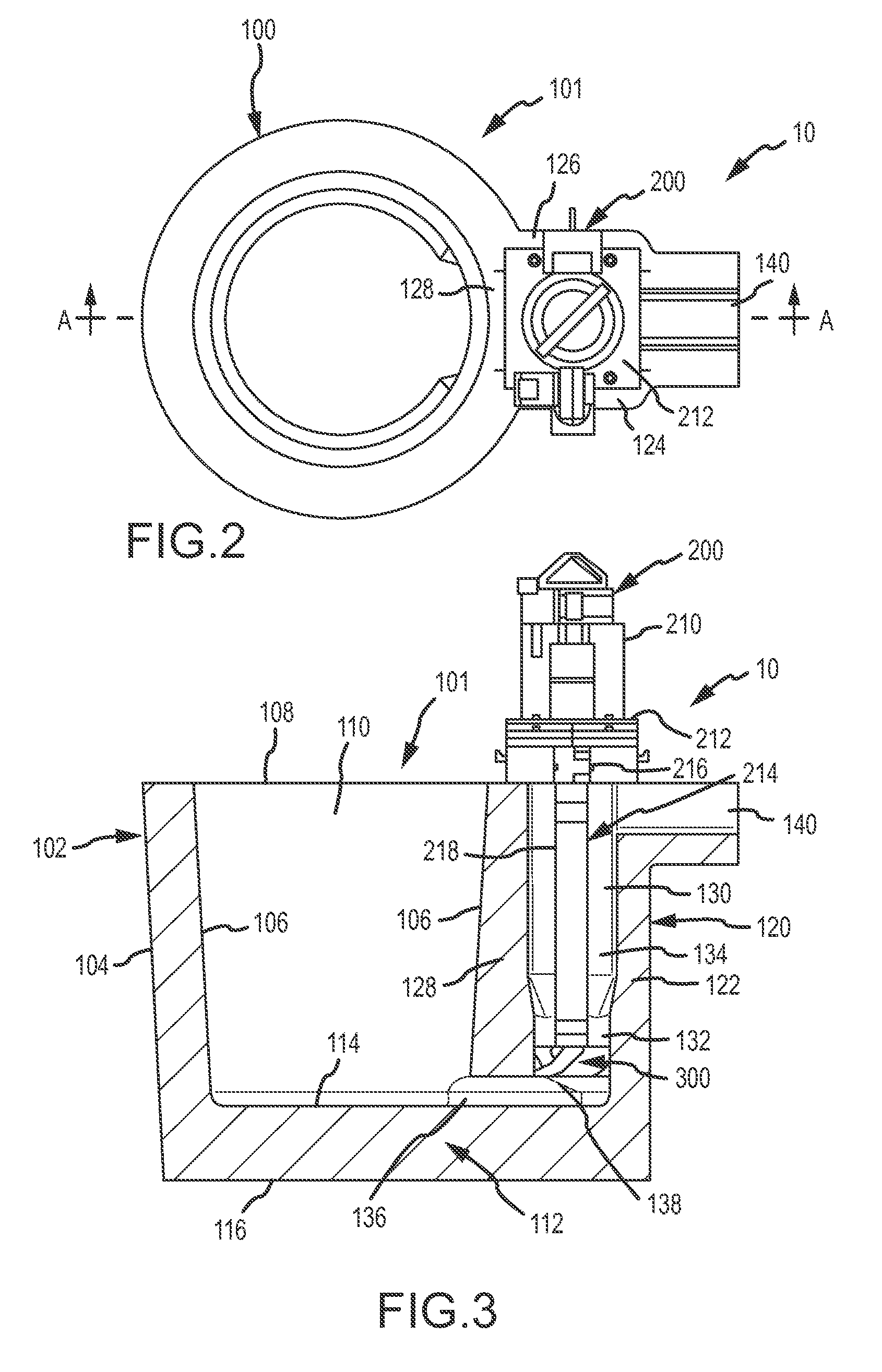

Ladle with transfer conduit

ActiveUS9011761B2Reduce the amount requiredReduce formationMelt-holding vesselsMolten metal supplying equipmentsMarine engineeringGuide tube

Disclosed is a transportable vessel for use in a factory for processing molten metal. The vessel is not connected to a reverbatory furnace and can be moved to different locations in the factory. The vessel includes a transfer conduit in communication with a cavity of the vessel. A molten metal pump can be positioned in the transfer conduit to move molten metal out of an outlet in communication with the transfer conduit and into another vessel without the need to tip or tilt the transportable vessel.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

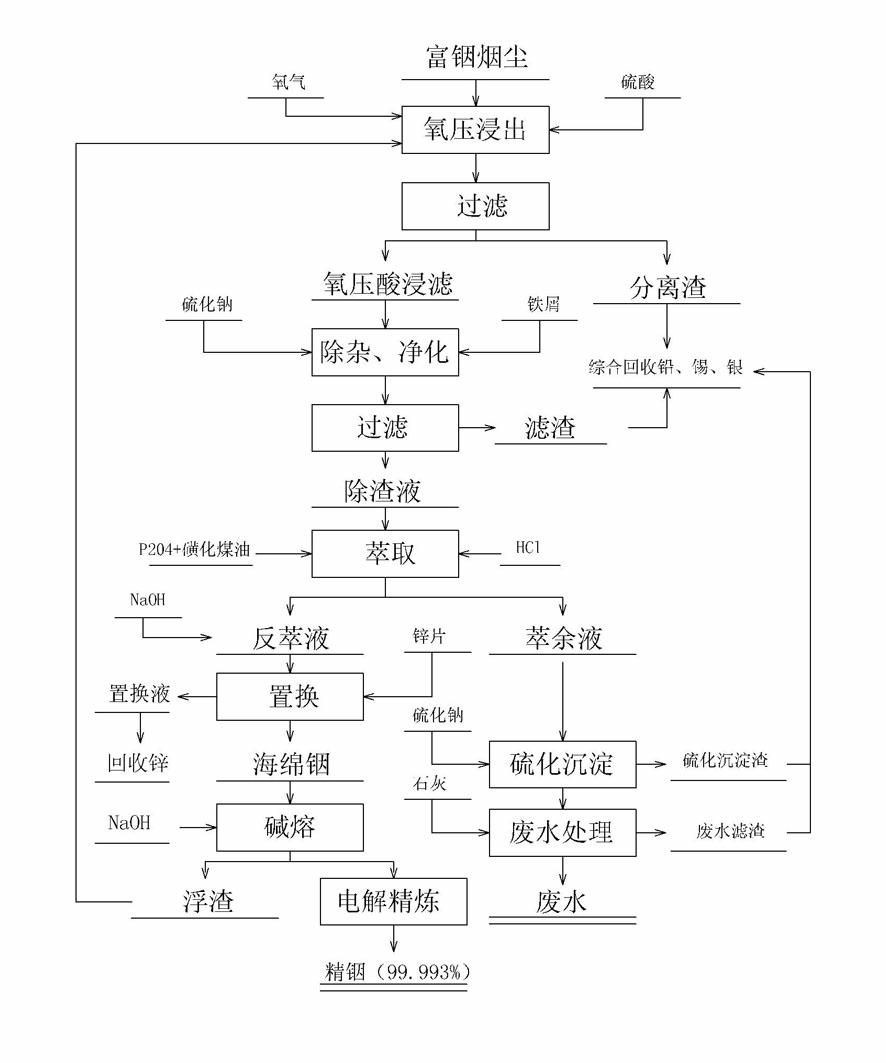

Method for extracting indium from indium-rich smoke dust by using oxygen pressure technology

The invention provides a method for extracting indium from indium-rich smoke dust by using an oxygen pressure technology. The method is characterized by comprising the following steps of: carrying out leaching indium extraction of the difficult-to-handle indium-rich smoke dust of a Pb-Sn reverberatory furnace by adopting a wet-process metallurgical oxygen pressure acid leaching technology, and highly enriching and recycling valuable metals in the raw material; and purifying to remove impurities of leachate, and carrying out extraction, replacement and electrolytic refining, thereby obtaining greater than 99.995% of electrical indium products. The technology method has the advantages that the indium leaching rate of the indium-rich smoke dust of the Pb-Sb reverberatory furnace and the enrichment rate of the valuable metals can be obviously increased, and the comprehensive recycling effect can be achieved, thereby waster water of indium smelting can be discharged up to the standard after being processed with low cost, the environmental pollution in the indium extraction process is eliminated. In the process, the leaching rate of the indium is more than 97%, leaching residues containless than 0.01% of indium, the enrichment rate of plumbum, tin, bismuth and zinc is more than 98%, the quality of refined indium products is more than 99.995%, and plumbum enriching slag containing greater than 60% of Pd is obtained. The technical scheme can independently form a system, can also be used for improving and perfecting old technologies and has higher popularization and application value.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Calcium titanium-aluminate prefabricated part for vanadium smelting reverberatory furnace lining and preparation method thereof

The invention relates to a calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace lining and a preparation method thereof. According to the technical scheme, 60-75 wt% of calcium titanium-aluminate particles, 10-20 wt% of calcium titanium-aluminate fine powder, 2-7 wt% of titanium dioxide micro powder, 5-10 wt% of alpha-Al2O3 micro powder and 1-6 wt% of rho-Al2O3 micro powder are used as raw materials; 0.05-0.30 wt% of water reducing agent and 3.5-6.0 wt% of water of the raw materials are added; stirring is conducted for 5-8 minutes, vibration forming is achieved, maintenance is carried out for 18-24 hours under the natural condition, demolding is performed, heat preservation is conducted for 18-24 hours at the temperature of 90-110 DEG C, and accordingly the calcium titanium-aluminate prefabricated part for the vanadium smelting reverberatory furnace lining is obtained. The calcium titanium-aluminate prefabricated part has the advantages of being low in production cost, and capable of saving resources and protecting the environment. The obtained calcium titanium-aluminate prefabricated part for a vanadium smelting reverberatory furnace is high in high-temperature strength, good in acidity vanadium slag corrosion resistance and good in permeability.

Owner:WUHAN UNIV OF SCI & TECH

Apparatus and method for reclaiming scrap metal

An apparatus and method for reclaiming contaminated scrap metal, more particularly an improved reverberatory furnace designed for melting scrap. The amount of hydrocarbons volatilized from the melting of contaminated scrap is measured and the fumes are passed into the main hearth for burning. As the amount of fuel value contained within the fumes increases, the amount of fuel provided to the burner is proportionally reduced while the amount of oxygen is kept constant. This will ensure that the amount of fuel and the amount of oxygen present within the furnace is completely burned without excessive free oxygen or unburned fuel building up within the furnace or furnace exhaust. The burner will be operating under lean fuel conditions or under fuel rich conditions such that the flame temperature is lower than at stoichiometric firing, whereby the burners create reduced NOx.

Owner:ANTARES CAPITAL LP AS AGENT

Ultra-fine grain aluminum alloy gold welding wire and preparation method thereof

InactiveCN104722945AQuality improvementImprove welding effectWelding/cutting media/materialsSoldering mediaMisch metalIngot casting

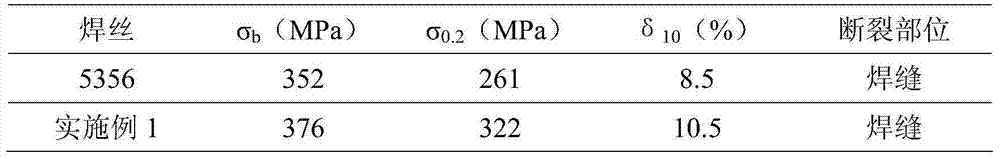

The invention relates to an ultra-fine grain aluminum alloy gold welding wire and a preparation method of the ultra-fine grain aluminum alloy gold welding wire. The ultra-fine grain aluminum alloy gold welding wire includes the following components: SC 0.05%-0.8%, Er 0.05%-0.6%, misch metal 0.01%-0.8%, B 0.01%-0.5%, Ti 0.1%-0.3%, Cr 0.05%-0.4%, Zr 0.05%-0.2%, Mn 0.1%-0.6%, Zn 0.2%-1.0%, Mg 4%-8%, and the rest is Al. The preparation method is as follows: adding an aluminum ingot or the molten aluminum into a semi-closed reverberatory furnace firstly; adding Mn, Ti, Zr, Cr and Zn; adding B and the misch metal; conducting the furnace refining on the alloy melt; slagging the alloy melt after the refining; pressing Mg into the alloy melt after stewing; adjusting the temperature of the melt for standby; pouring the melt in an electromagnetic continuous casting machine; preparing an aluminum alloy ingot casting; lifting up the aluminum alloy ingot casting for homogenizing annealing and scalping for standby; putting the aluminum alloy ingot casting into an extrusion die for extrusion, extruding an aluminum alloy wire disc; and conducting wire drawing till the specification and the diameter reach the standard and using. The ultra-fine grain aluminum alloy gold welding wire can effectively improve the structural strength of a welding structure and the welding performance, and overcomes the welding defects of the low strength of an aluminum alloy welding joint and welding cracks.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

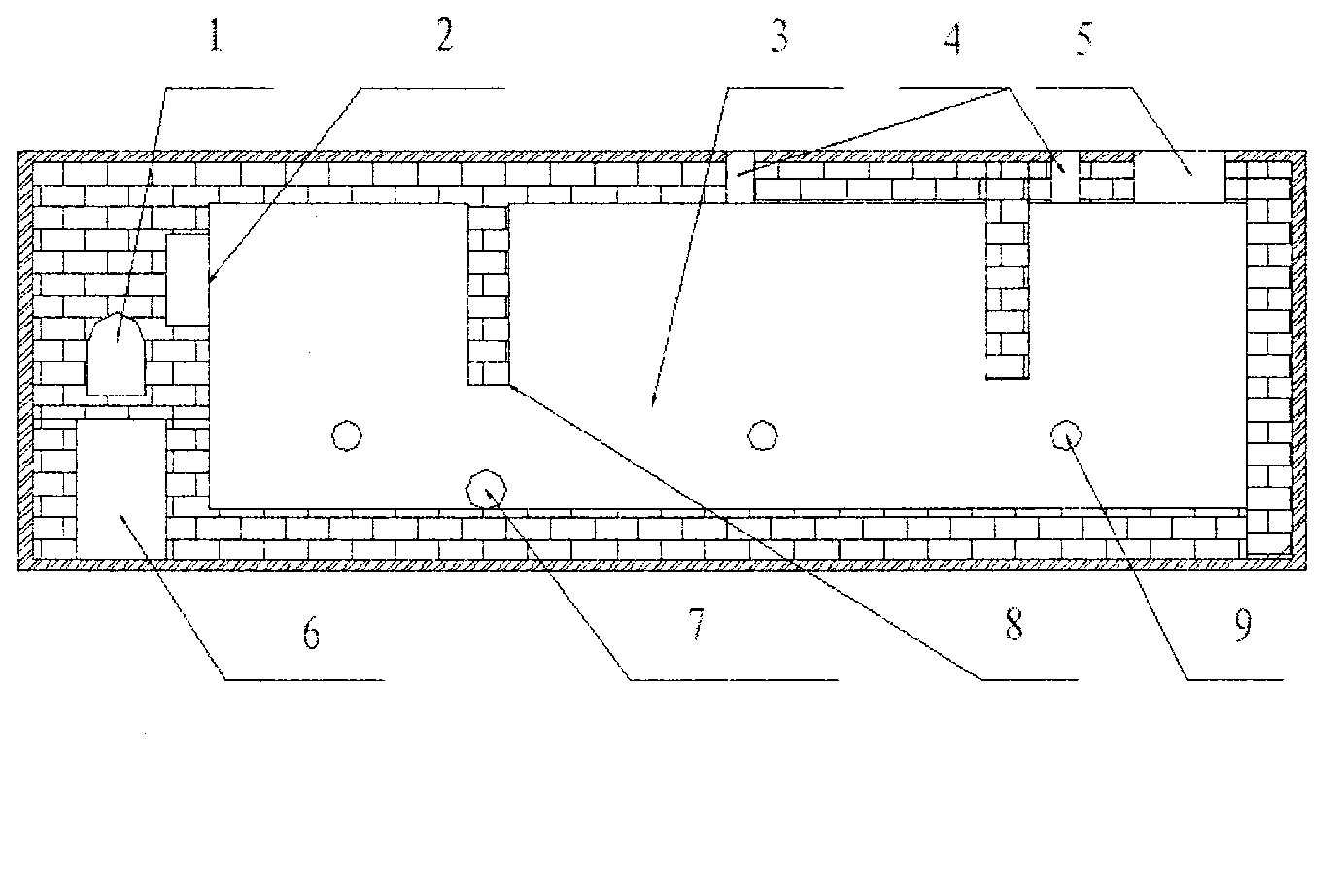

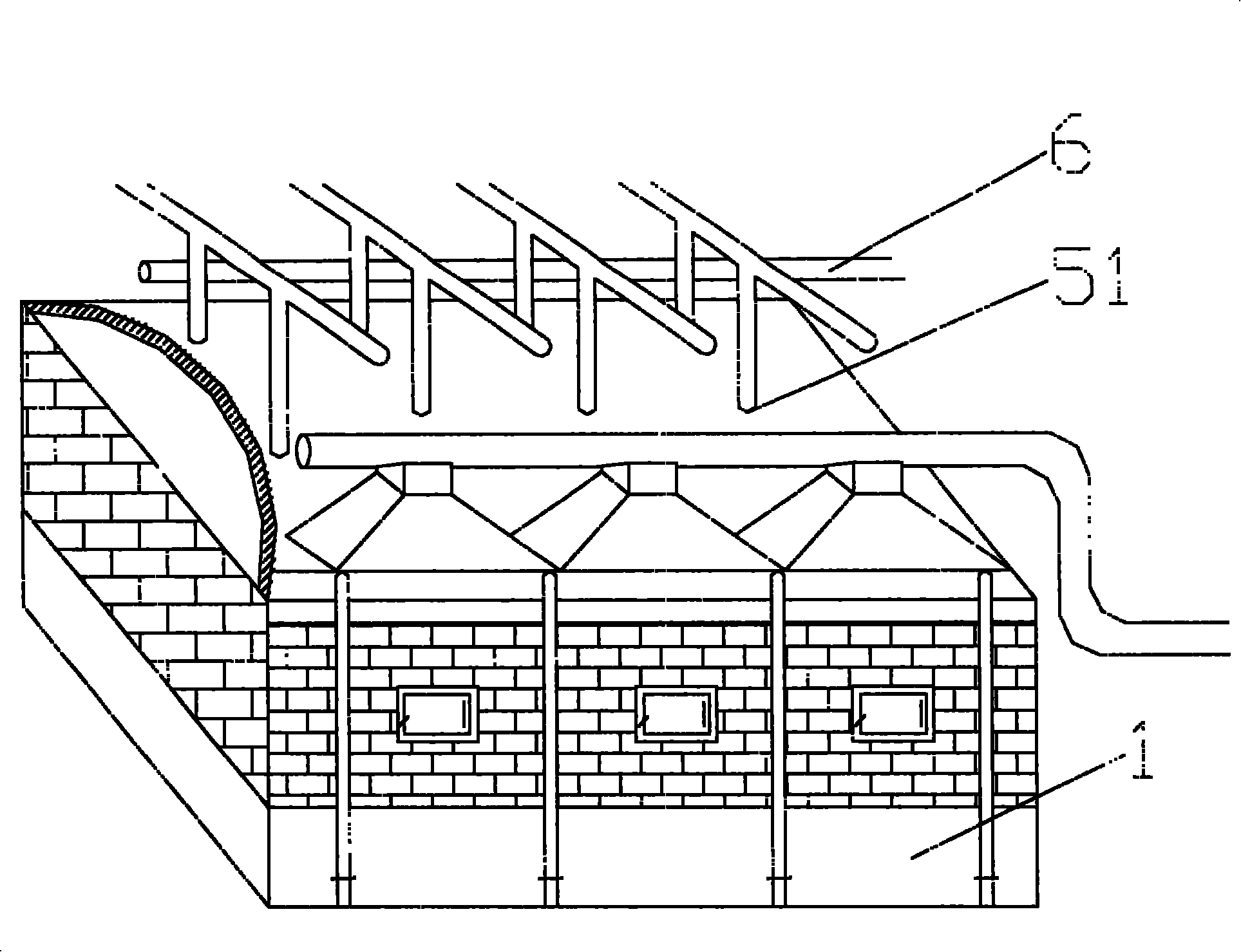

Process for smelting tin-lead alloy by tin enriched slag reduction and reduction-smelting reflecting furnace

InactiveCN101701295AImprove insulation effectImprove heat utilizationLighting and heating apparatusProcess efficiency improvementCombustion chamberBrick

The invention relates to a process for smelting tin-lead alloy by tin enriched slag reduction and a reduction-smelting reflecting furnace, which belong to the technical field of smelting of tin-lead alloy. The process adopts discontinuous type smelting operation, is carried out by furnaces and comprises the operation processes of furnace baking, mixing, charging, reduction smelting and tin-lead alloy placing and slag discharging. The fuel of the reduction-smelting reflecting furnace is changed into bituminous coal from diesel oil, and an air pipe of the reduction-smelting reflecting furnace, which is connected between a blower and a furnace body, form an air preheating return stroke around the outer wall of a flue; a combustion chamber is added to a furnace body, and an inverted arch furnace bottom, a furnace wall and a furnace top above a furnace bottom packing layer in a hearth are rebuilt; a brick body of the slag line part is changed into a chrome-magnesite brick from a high-aluminum brick, the depth of a smelting pool is reduced to 280-460mm from 510mm, and the clearance height of the hearth is lowered to 600-1,000mm from 1,040mm. The invention smelts the tin enriched slag by the reduction-smelting reflecting furnace and obviously reduces cost.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Preparation method of high-purity zinc powder

The invention provides a preparation method of high-purity zinc powder. In the method, clean energy natural gas is taken as a heating source to heat and melt zinc for a zinc melting furnace. The temperature of the zinc melting furnace is controlled between 520 DEG C to 580 DEG C, zinc fluid is then introduced to a reverberatory furnace or a refining furnace, and the heating source of the natural gas is turned on to 460 DEG C to 500 DEG C, and then, stands for 24 to 36 hours until melt is layered. The upper layer of the melt is melt refining zinc. After then, the melt refining zinc passes through a lead tower and a cadmium tower respectively to realize the separation of zinc and impurity elements. At last, zinc vapor is introduced into a condenser for rapid cooling, and the zinc vapor is changed into the zinc powder to fall into a powder hopper, and then, the zinc power passes through a mixer and a grader to obtain finished product, i.e. high-purity zinc powder. The cleaning method can be used for preparing the high-purity zinc powder, of which the zinc content is higher than or equal to 99.99wt%, and the high-purity zinc powder can reach the standards of the high-purity zinc powder of zinc-1 and zinc-0 brand. The invention has the advantages of simple process, easy control of furnace temperature and high production efficiency, which is especially suitable for large-scale industrial production.

Owner:JIANGSU YEJIAN ZINC IND CO LTD +1

Method for depleting refining slag of copper

The invention discloses a method for depleting refining slag of copper. The method comprises the following steps of: adding recovered waste copper into a reverberatory furnace, heating and melting, inserting a blast pipe into molten copper to blow air, and stirring for oxidization with blasting to ensure that impurities are oxidized and partial copper is oxidized into cuprous oxide; taking a molten copper sample for observation, and adding quartz sand in an amount which is 1.2 to 1.4 percent of the weight of the total charging material for slagging when the section is brick red so as to ensure that the oxidized impurities in the molten copper such as Fe, Pb, Sn and the like and quartz react to form silicate slag; covering a carbonaceous reducing agent in an amount which is 0.13 to 0.17 percent of the total amount of the charged waste copper on the slag, inserting the blast pipe into the molten copper to blow the air, and stirring for 5 to 10 minutes, wherein a considerable amount of copper which enters a slag phase is reduced and enters a molten copper phase because copper is reduced more easily than other impurity elements. About 35 percent of copper content in the slag is reduced, and the method is favorable for recycling reclaimed copper resources. The production process is easy to operate, and the conventional production equipment can be directly utilized.

Owner:NINGBO JINTIAN SMELTING +1

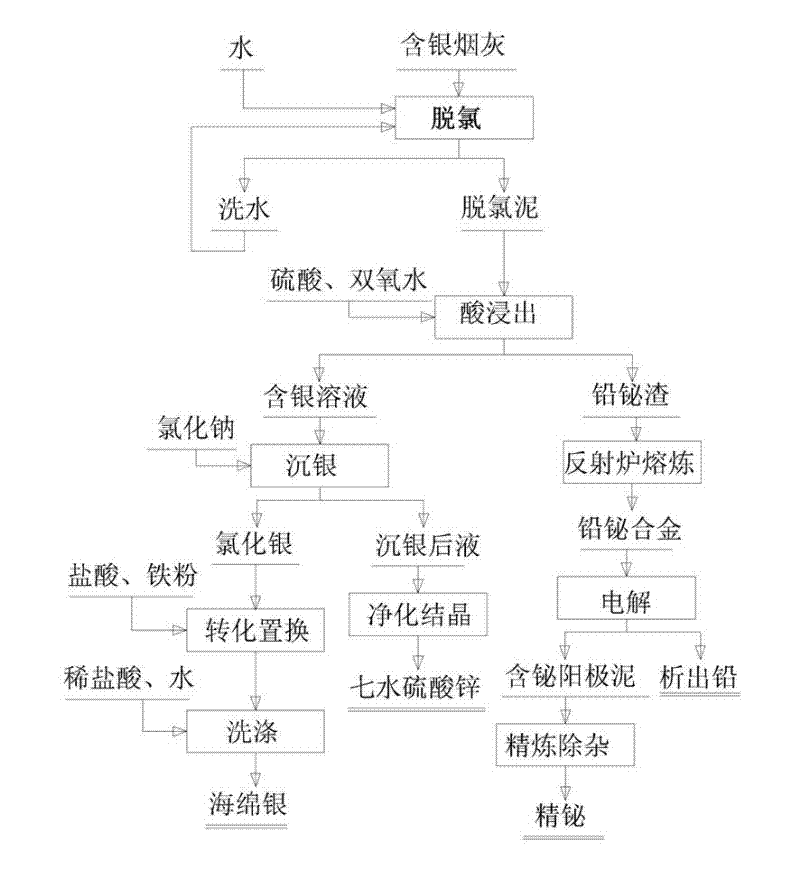

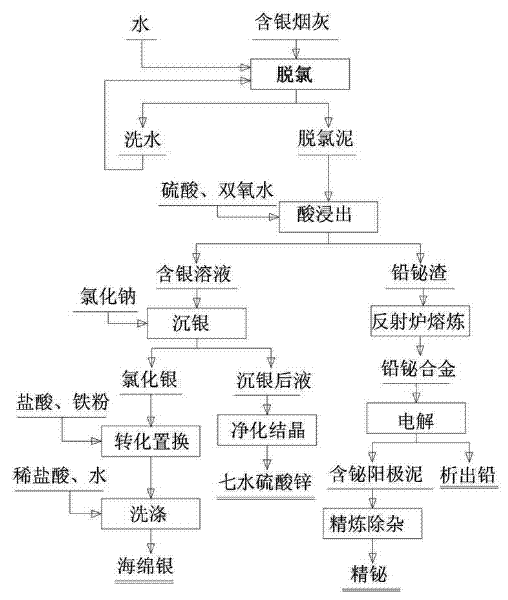

Process for recovering silver, lead and bismuth from silver-bearing soot comprehensively

InactiveCN102363839AFaster turnaroundProcess environmental protectionProcess efficiency improvementReverberatory furnaceSoot

The invention relates to a process for recovering silver, lead and bismuth from silver-bearing soot comprehensively, and belongs to the technical field of comprehensive recovery of noble metals. The process comprises the following steps of: removing chlorine from silver soot by using clear water, and performing acid leaching on the silver in the silver soot by using sulfuric acid and an oxidizing agent; adding sodium chloride into silver-bearing solution to obtain pure silver chloride, and performing the conversion of hydrochloric acid, iron powder metathesis and the washing of acidized purified water on the silver chloride to obtain high-purity sponge silver; after the silver is precipitated, purifying solution, removing impurities and crystallizing to obtain zinc sulfate heptahydrate; and smelting the lead and bismuth which are left in lead bismuth dregs to form a lead bismuth alloy by reverberatory furnace, electrolyzing to obtain precipitated lead and bismuth-bearing anode mud, and refining the bismuth-bearing anode mud and removing impurities to obtain refined bismuth. The process is suitable for processing the silver-bearing soot of which the silver content is over 0.8 percent; and compared with the prior art, the process has the advantages of environment friendliness, silver direct yield of more than or equal to 99.2 percent, high recovery rate, low machining cost and quick capital turnover.

Owner:郴州雄风环保科技有限公司

Smelting process for aluminum-silicon master alloy

InactiveCN102618738ATake advantage ofNo need to increase investmentSmelting processReverberatory furnace

The invention relates to a smelting process for an aluminum-silicon master alloy. 75 percent of industrial pure aluminum ingot with the aluminum content being more than or equal to 99.7 percent and 12.5 to 13 percent of 6063 aluminum remelted regenerable ingot, which are measured according to a weight percent, are added into a reverberatory furnace at the temperature of 1000 to 1200 DEG C, 12 to 12.5 percent of well-measured pure silicon is added into the reverberatory furnace after the ingot is completely smelted to generate aluminum-silicon master alloy melt, and the aluminum-silicon master alloy melt is made into the aluminum-silicon master alloy through a smelting technique, a casting technique and a sawing technique. On the premise of not increasing equipment investment, the existing aluminum alloy smelting reverberatory furnace with an environment-friendly device system, a deep well and a casting system capable of continuously casting multiple cylindrical ingots at a time are used for smelting and casting the aluminum-silicon master alloy cylindrical ingot so as to substitute a traditional outdated production technique of the aluminum-silicon master alloy adopting a small-sized ground furnace to smelt and adopting a manual pouring way and an automatic cooling way of ingot molds, so that the energy can be saved, the environment can be protected, the production efficiency can be greatly improved, the labor intensity can be alleviated, the balance of silicon content in the aluminum-silicon master alloy and adequate chemical combination of aluminum and silicon as well as refining of the crystal grains can be better guaranteed, and the transformation, upgrading and development of enterprises can be promoted.

Owner:东莞市奥达铝业有限公司

Recovery and processing technique for waste lead acid accumulator

InactiveCN101197458ACause secondary pollutionFully meltedSolid waste disposalWaste accumulators reclaimingAtmospheric airReverberatory furnace

The invention discloses a process for recovering old and useless lead-acid storage batteries, comprising the steps of dismantling of a storage battery, processing of waste liquid, shell processing, smelting of coarse lead, deslagging of cast ingots, sedimentation of swirling flow, collecting and dust removal, dust removal of water film, etc. The invent adopts a marble acidproof and leakproof sewage pool for dealing with waste water, so the acid liquor can not permeate into and contaminate the earth; the smelting of coarse lead and deslagging of cast ingots are carried out by using a coal gas producer for gas combustion, with a plurality of coal gas nozzles providing enough fire to thoroughly smelt lead containing materials. The coal gas nozzles are arranged in the front of a reverberator the rear end of which is provided with an air exhaust opening to move the fire in the front constantly backward to thoroughly smelt lead containing materials at the back, thereby saving energy resource; a flue is formed in a S-shape, so the gas stays for a long time in the flue with a good sedimentation effect; as cloth-bag dust removal followed by the dust removal of water film is adopted, the dust is completely removed, so the discharged gas causes no pollution to the atmosphere. The invention has a perfect processing which leads to no secondary pollution to the environment.

Owner:许兴义

Method for producing continuous casting, and tandem rolling copper rod from all of copper scrap

InactiveCN1958182AQuality improvementReduce distanceMetal rolling stand detailsMetal rolling arrangementsReverberatory furnaceElectric consumption

A conticasting-tandem rolling technology for manufacturing copper rod with rejected copper material features that the molten copper top is arranged on the back of reflection furnace for shortening the flow launder, the molten copper is tapped at lower temp for improving its quality, the volume of cast strand is increased for shortening the casting time and decreasing electric consumption, the 14 passes of rolling frame is decreased to 12 passes for higher quality, and gas instead of coal is used as fuel for less pollution.

Owner:潘德君

Preparation method and application of artificial water-soluble silicon

InactiveCN103359750AImprove permeabilitySimple processAlkali metal silicatesWater solubleReverberatory furnace

The invention belongs to the technical field of food production, and in particular relates to a preparation method and application of artificial water-soluble silicon. The preparation method specifically comprises the following steps of: (1) uniformly mixing 36-70% of silicon dioxide powder and 30-64% of sodium carbonate powder in percentage by weight; (2) heating the powder mixed in the step (1) to 1050-2000 DEG C in a reverberatory furnace, and calcining to generate molten sodium silicate; (3) pouring the molten sodium silicate generated in the step (2) out of a discharge port of the reverberatory furnace, and cooling to prepare a blocky sodium silicate solid preparation for later use; (4) pouring the molten sodium silicate generated in the step (2) out of the discharge port of the reverberatory furnace, putting the molten sodium silicate into a water-quench tank, and smashing the molten sodium silicate into a 1-5mm sodium silicate particle solid preparation for later use; and (5) continuously grinding the sodium silicate particles generated in the step (4) to form a sodium silicate powder solid preparation for later use. The artificial water-soluble silicon can be used for large-scale production and has a wide application range.

Owner:叶卫斌

Technique for producing low-oxygen copper pole

InactiveCN101434024AImprove reduction efficiencyReduce consumptionMetal rolling arrangementsSlagReverberatory furnace

The invention discloses a technique for manufacturing a low-oxygen copper rod, which is characterized by comprising the following steps: firstly, pretreating waste copper; secondly, throwing the waste copper into a reverberatory furnace; thirdly, removing slag at a low temperature; fourthly, stopping blast and fire and oxidating at a high temperature; fifthly, melting slag; sixthly, stopping blast and fire and polling at a high temperature; and seventhly, continuously casting and rolling reduced copper and preparing the low-oxygen copper rod finished product. The technique for manufacturing the low-oxygen copper rod has the advantages of high efficiency, energy conservation and good product quality.

Owner:汨罗市长江铜业有限公司

Semi-vertical reverberatory furnace for preparing sodium sulfide and process thereof

InactiveCN101565173AAvoid cloggingReduce the temperatureEnergy inputAlkali metal sulfides/polysulfidesReverberatory furnaceCombustion chamber

The invention discloses a semi-vertical reverberatory furnace for preparing sodium sulfide and a technique thereof. The semi-vertical reverberatory furnace comprises a combustion chamber, a forehearth part, a vertical furnace and an aeration tower. The technique comprises the following steps: anhydrous sodium sulphate or glauber salt and pulverized anthracite are briquetted and then put into the semi-vertical reverberatory furnace; by utilizing reaction waste heat, the pallets flow through a packing layer and then enter the forehearth part in a melting state; fused mass of the forehearth part is heated by the combustion chamber, and the reaction is finished; and the steps of leaching, filtering, evaporating and concentrating are carried out after the reaction is finished so as to obtain the product, namely industrial sodium sulfide. Compared with the reverberatory furnace and the converter in the traditional process, as tail gas is adopted to heat and melt solid materials, the coal consumption for annealing and reducing is reduced by more than 25 percent; and compared with the common short convertor, the invention has the advantages of low coal consumption, less investment, easy maintenance, pollution reduction, high mechanization degree and continuous production.

Owner:孔凡逸

Method for removing impurity during copper and copper alloy melting process

The invention discloses a method for removing impurity during copper and a copper alloy melting process, which comprises the following steps: 1)a micro oxidation phase: introducing oxygen in a copper and copper alloy melt in a cored induction melting furnace, or a coreless induction melting furnace, or a shaft furnace, or a reverberatory furnace, or adding one or more from CuO, MnO2 and KMnO4 as an oxidizing agent for a slagging reaction; 2)a micro reduction phase: using one or more from metal Mg, Cr, Zr, B as a reducing agent, reducing and recovering the valuable metals in the oxidation process; and 3)a harmful impurity element harmlessness processing phase; adding one or more from Li, Ca, Zr, Mn for removing harmful impurity. The method can use the raw materials with low cost and low quality, or uses the outshot which has standard-exceeding impurity and harmful element, a simple micro oxidation-micro reduction-harmlessness processing is carried out on the current cored induction melting furnace, the coreless induction furnace or the shaft furnace, so that products with high quality can be produced.

Owner:XINJIANG UNIVERSITY

Al-Mg alloy welding wire and preparation method thereof

The invention discloses an Al-Mg alloy welding wire and a preparation method thereof. The composition of the welding wire is as follows in percentage by weight: magnesium: 4.5 to 5.5, chromium: 0.05 to 0.20, manganese: 0.05 to 0.20, titanium: 0.06 to 0.20, beryllium: 0.0001 - 0.0003, yttrium: 0.03 - 0.15, and the balance aluminum. The preparation method is as follows: after an aluminum ingot is added into a gas reverberatory furnace, a magnesium ingot is added in, melted and a reside-crash agent is added for deslagging; and then AlCr10, Mn99, AlTi10, AlBE3 and AlY10 are added in; after 35min, a refining agent is added under an argon protection state, a refining product stays still for 30min and is horizontally and continuously cast into an aluminum alloy wire rod; and after a plurality of times of drawing, the refining product is processed into continuous discoid welding wires with various specifications. Compared with the prior art, the invention has simple preparation method, easily controlled operation and little volatilization, oxidation or burning in melting; and the prepared welding wire has good welding toughness, strength and thermal crack resistance.

Owner:桂林市银箭焊接材料有限公司

Method for directly separating antimony and arsenic from flue dust containing antimony and arsenic

InactiveCN102233229AThe process of smelting is simpleLess investment in productionDispersed particle separationAntimony compoundsSmelting processTemperature difference

The invention relates to a method for directly separating antimony and arsenic from flue dust containing the antimony and the arsenic. The method is characterized in that: the flue dust containing the antimony and the arsenic is conveyed in a reverberatory furnace and is separated to obtain arsenic trioxide and antimony trioxide by using temperature difference; the temperature for separating the arsenic trioxide is 680 DEG C; the arsenic trioxide passes through a air discharge cooling apparatus, and is insufflated in a bag chamber through a fan and collected; the remaining antimony raw material is heated to a temperature of 850 DEG C to carry out a reduction reaction to collect the antimony trioxide. According to the present invention, the collection efficiency of the arsenic trioxide is 98-98.5%, and the collection efficiency of the antimony trioxide is 98-99.8%; the smelting process method is simple; production investment is less; factory constructing and commissioning are quick.

Owner:HUNAN TAOJIANG YAOXING CHEM

Shredder dust feeding device, reverberatory furnace provided with this feeding device, and furnace for burning shredder dust

InactiveUS20020195754A1Increasing the proportion of the oxidizing gasImprove combustion efficiencyTuyeresBell-and-hopper arrangementCombustorReverberatory furnace

The present invention relates to a device for feeding shredder dust to a furnace such as a reverberatory furnace. This device comprises a feeding chute that passes to the inside of the reverberatory furnace and is fitted to the ceiling of the reverberatory furnace. Shredder dust can be fed from this feeding chute which also allows oxygen enriched air to be supplied to the feeding chute and fed to the inside of the reverberatory furnace. Further, the present invention relates to a reverberatory furnace in which a burner is able to be installed in a wall portion of one end side thereof. A plurality of feeding ports to which are connected the feeding chutes of the shredder dust feeding devices are provided at the one end side in the ceiling portion thereof forming a plurality of staggered rows facing the other end side.

Owner:ONAHAMA SEIREN

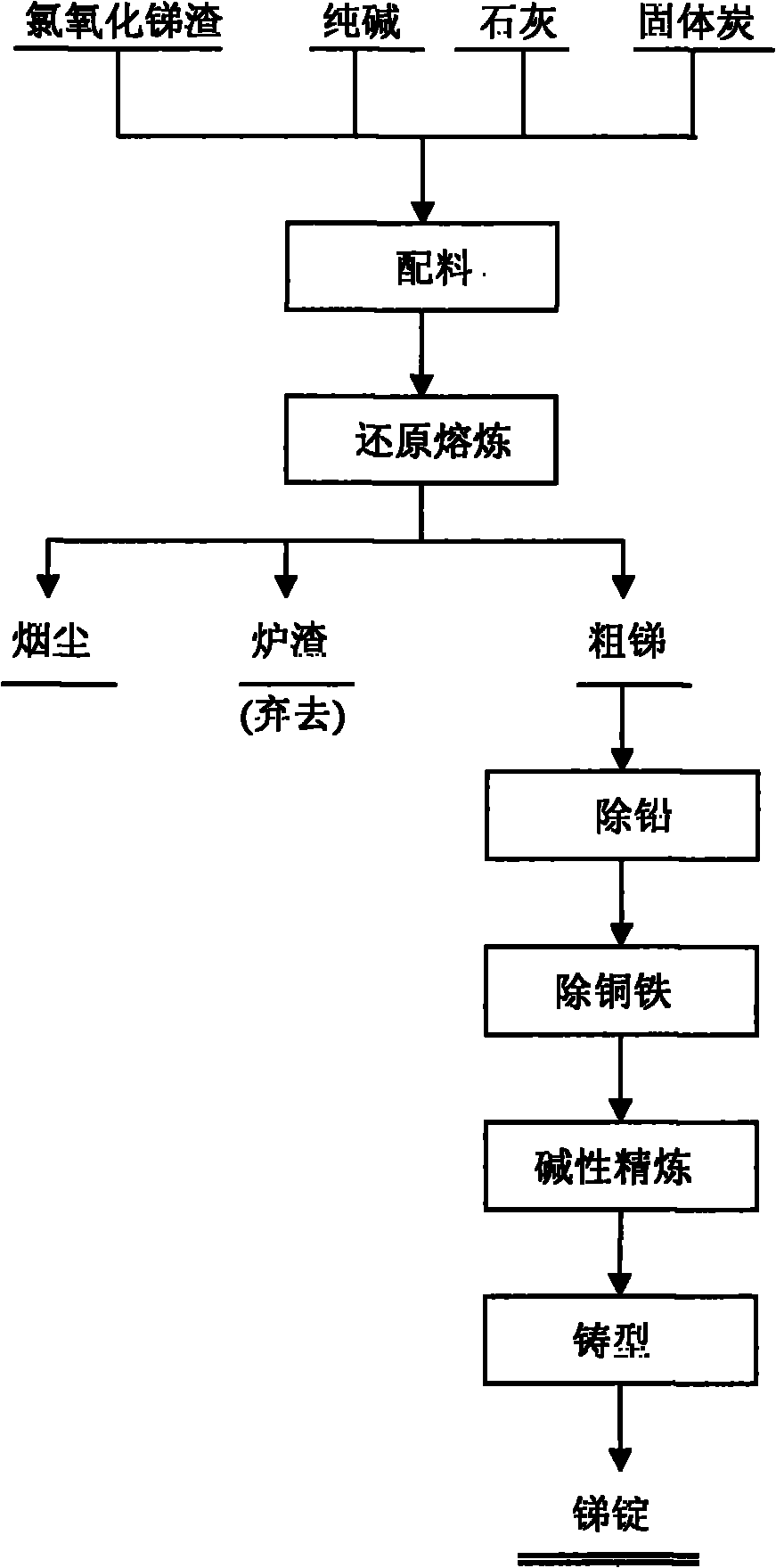

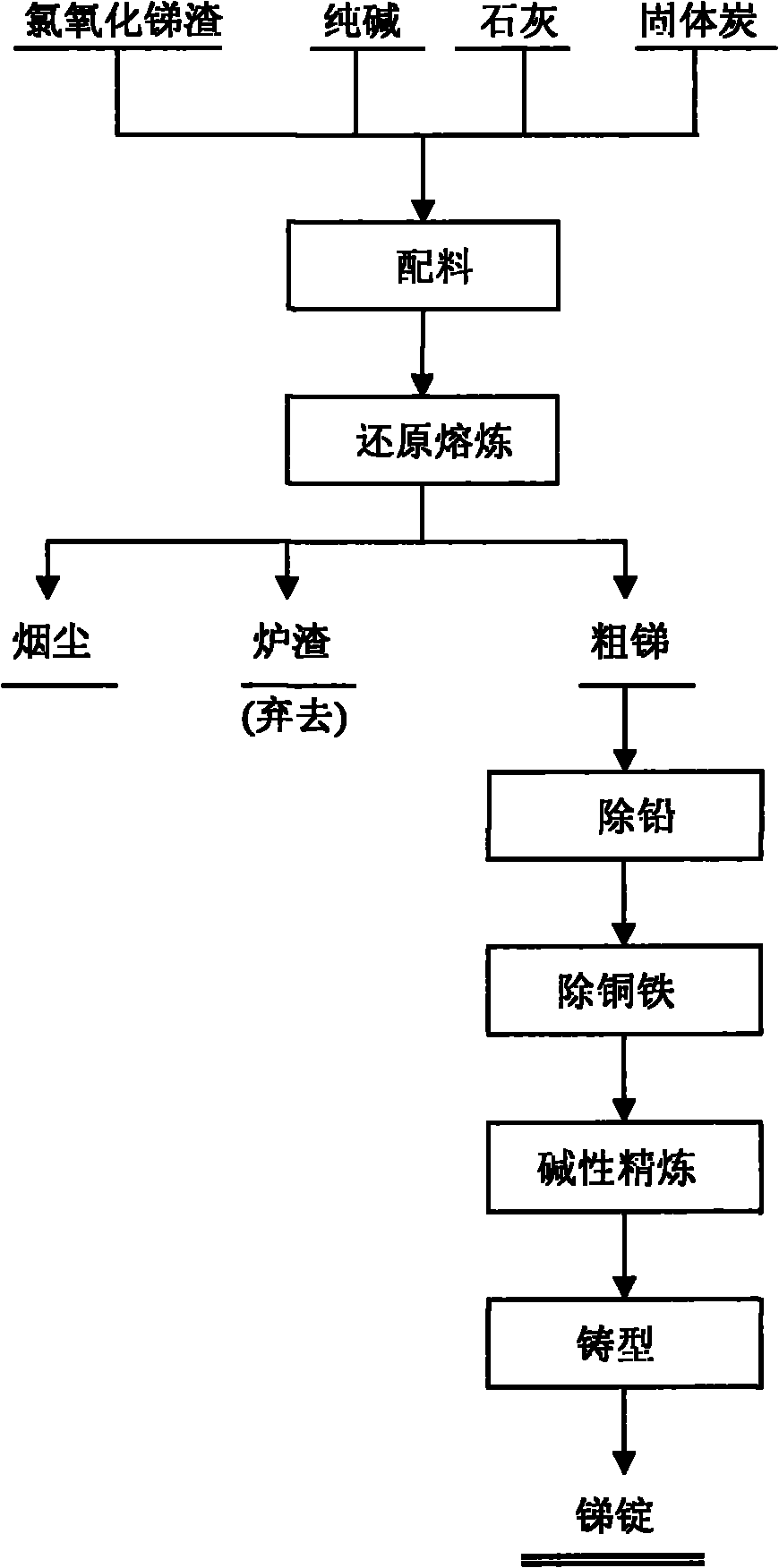

Production method for recovering antimony from antimonyoxychloride

ActiveCN101818266AHigh recovery rateHigh economic feasibilityProcess efficiency improvementReverberatory furnaceSulfide

The invention relates to a method for recovering antimony from antimonyoxychloride, which comprises the steps of furnace drying, reducing and smelting, coarse antimony refining and casting. The method is characterized in that in the step of reducing and smelting, antimonyoxychloride slag, soda ash, lime and solid carbon are mixed in a certain proportion, the mixture is added into a reverberatory furnace batch by batch, the temperature of the furnace is raised to 1,100 to 1,200 DEG C, the smelting time of each batch is 8 to 12 hours and the pressure in the furnace is kept between 20 and 50Pa. The step of coarse antimony refining comprises adding ammonium dihydrogen phosphate to remove lead, adding sulfur to remove copper and iron and alkaline refining, namely adding ammonium dihydrogen phosphate to remove lead according to a conventional method first, then adding antimony sulfide or sodium sulfide according to copper and iron content to remove the copper and iron, and finally adding soda ash and introducing compressed air to remove arsenic, copper, iron and sulfur and the like. Compared with the prior art, the method has the advantages of short process flow, relatively low cost and over 94 percent of antimony recovery rate.

Owner:ZHUZHOU SMELTER GRP

Forging method of Grade R5 mooring chain accessory swivel shackle

ActiveCN102688976ALarge machining allowanceIncreased forging temperatureEngine componentsReverberatory furnaceEngineering

Disclosed is a forging method of a Grade R5 mooring chain accessory swivel shackle, comprising the steps of: blanking raw materials according to design requirements of drawings; carrying out nondestructive testing on the materials with a flaw detector; heating the materials in a box-type reverberatory furnace; controlling the forging temperature between 900 and 1100 DEG C; using a 3-ton belt drop hammer to beat a forge piece into a cuboid and its both ends into a step, putting a molding die into the forge piece, and forging into a shape; placing the forge piece into a tempering furnace and tempering at a controlled temperature of 620-650 DEG C; and carrying out nondestructive testing on the forge piece with the flaw detector. The forging method provided by the invention appropriately raises initial forging temperature and final forging temperature of the Grade R5 mooring chain accessory swivel shackle, appropriately raises forging temperature as surface crack will emerge when Grade R5 swivel shackle is being forged, and increases working allowance of forging machines. Furthermore, relevant requirements of classification societies for surface and internal structures of the Grade R5 mooring chain accessory are reached, and product quality is ensured.

Owner:JIANGSU ASIAN STAR ANCHOR CHAIN +1

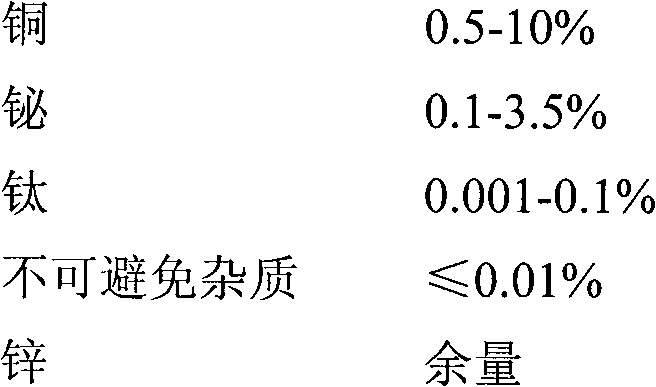

Easy-cutting zinc-copper-base wrought zinc alloy and preparation method thereof

The invention relates to an easy-cutting zinc-copper-base wrought zinc alloy and a preparation method thereof. The easy-cutting zinc-copper-base wrought zinc alloy is characterized by comprising the following components in percentage by weight: 0.5-10% of copper, 0.1-3.5% of bismuth, 0.001-0.1% of titanium, at most 0.01% of inevitable impurity and the balance of zinc. The alloy fusion casting technique comprises the following steps: smelting in a line frequency furnace, intermediate frequency or reverberatory furnace, and carrying out continuous casting or metal mold casting to obtain a casting blank; and carrying out hot extrusion at 180-400 DEG C, and finally carrying out cold drawing to obtain various sizes of rods, wires and section products. The obtained products can be used in the fields of automatic lathes, drill presses, instrument lathes and the like. Compared with the prior art, the alloy provided by the invention has the characteristics of favorable cutting property, moderate mechanical properties and the like, and is easy for processing and electroplating.

Owner:NINGBO POWERWAY ALLOY MATERIAL

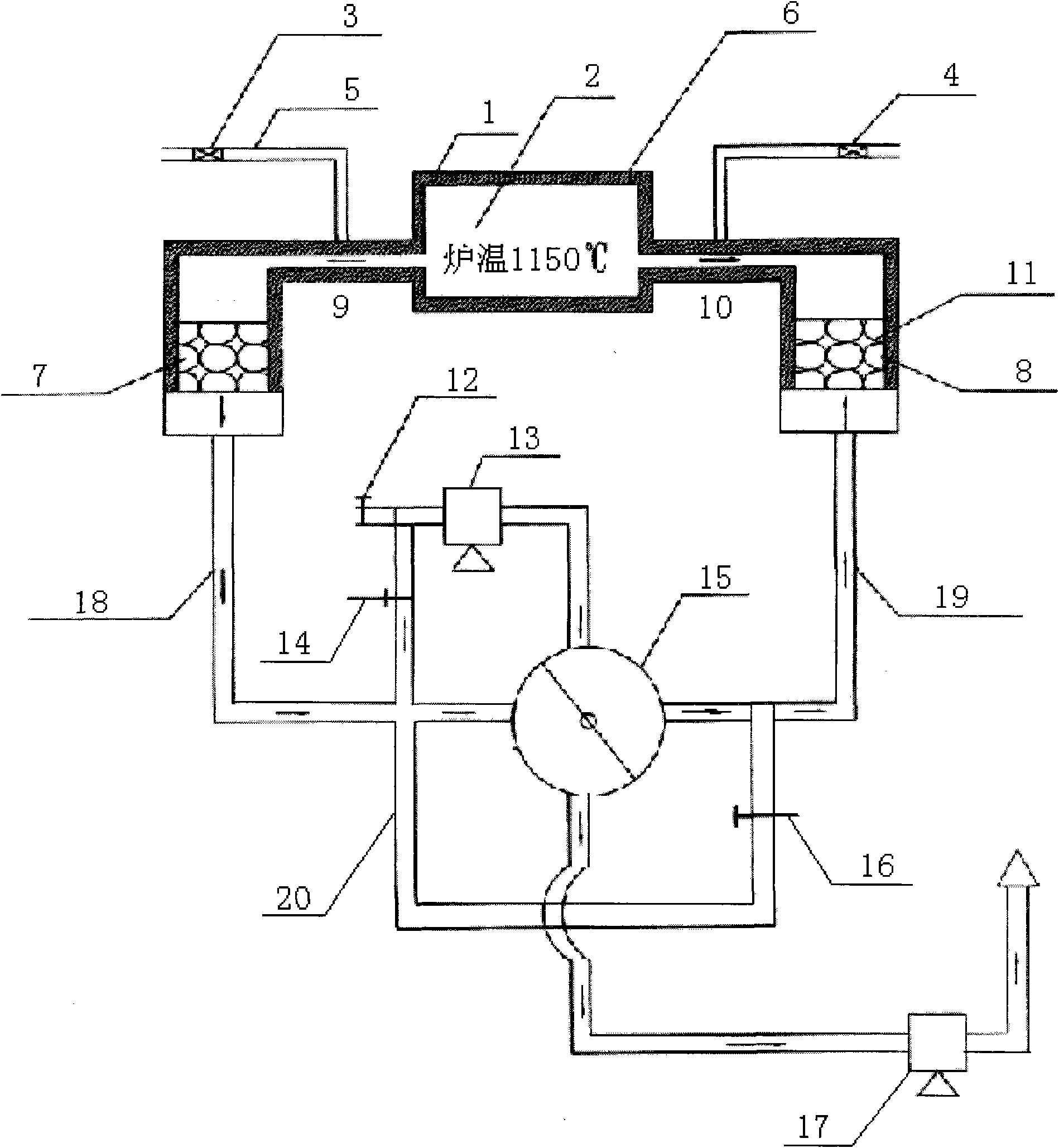

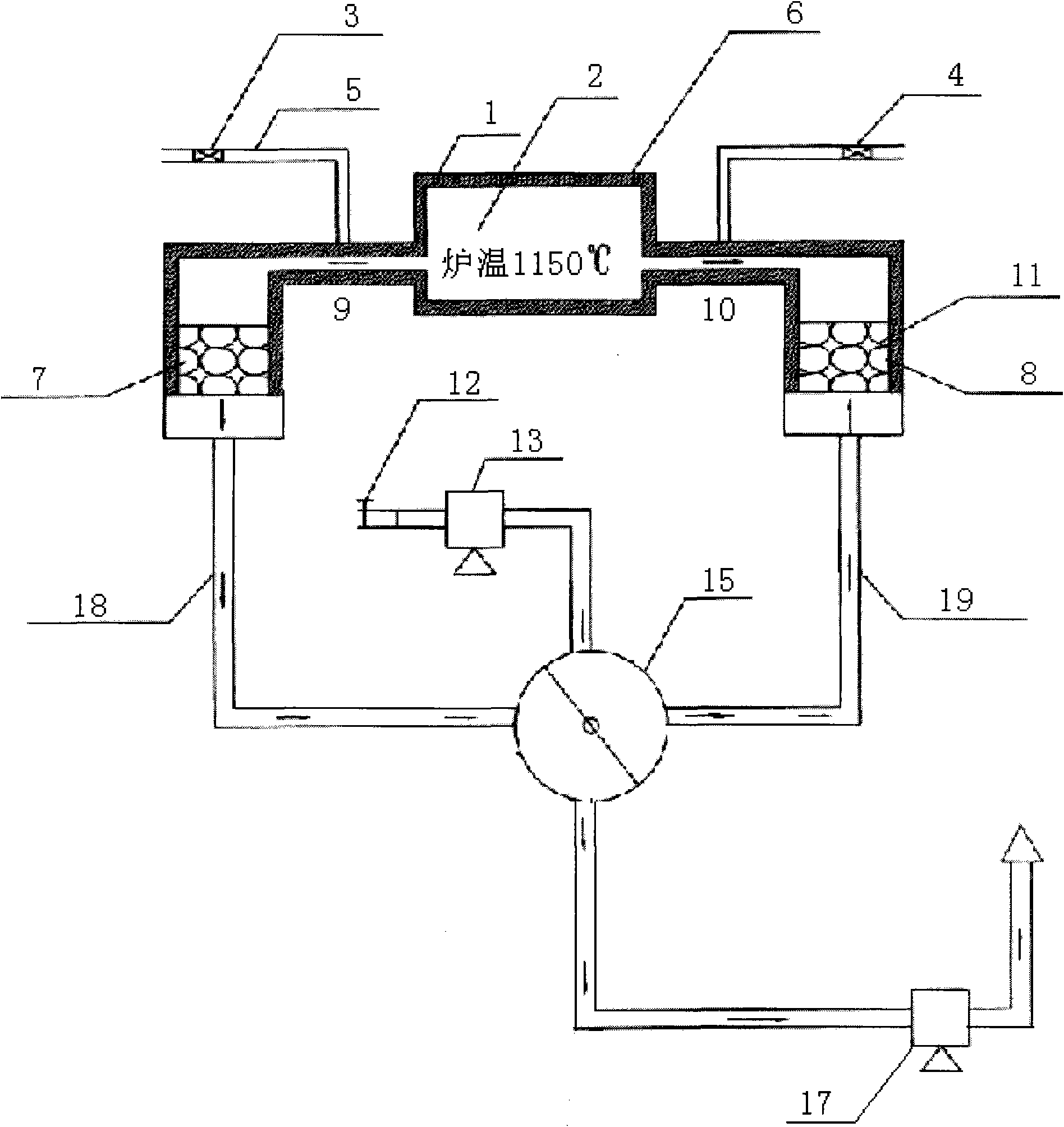

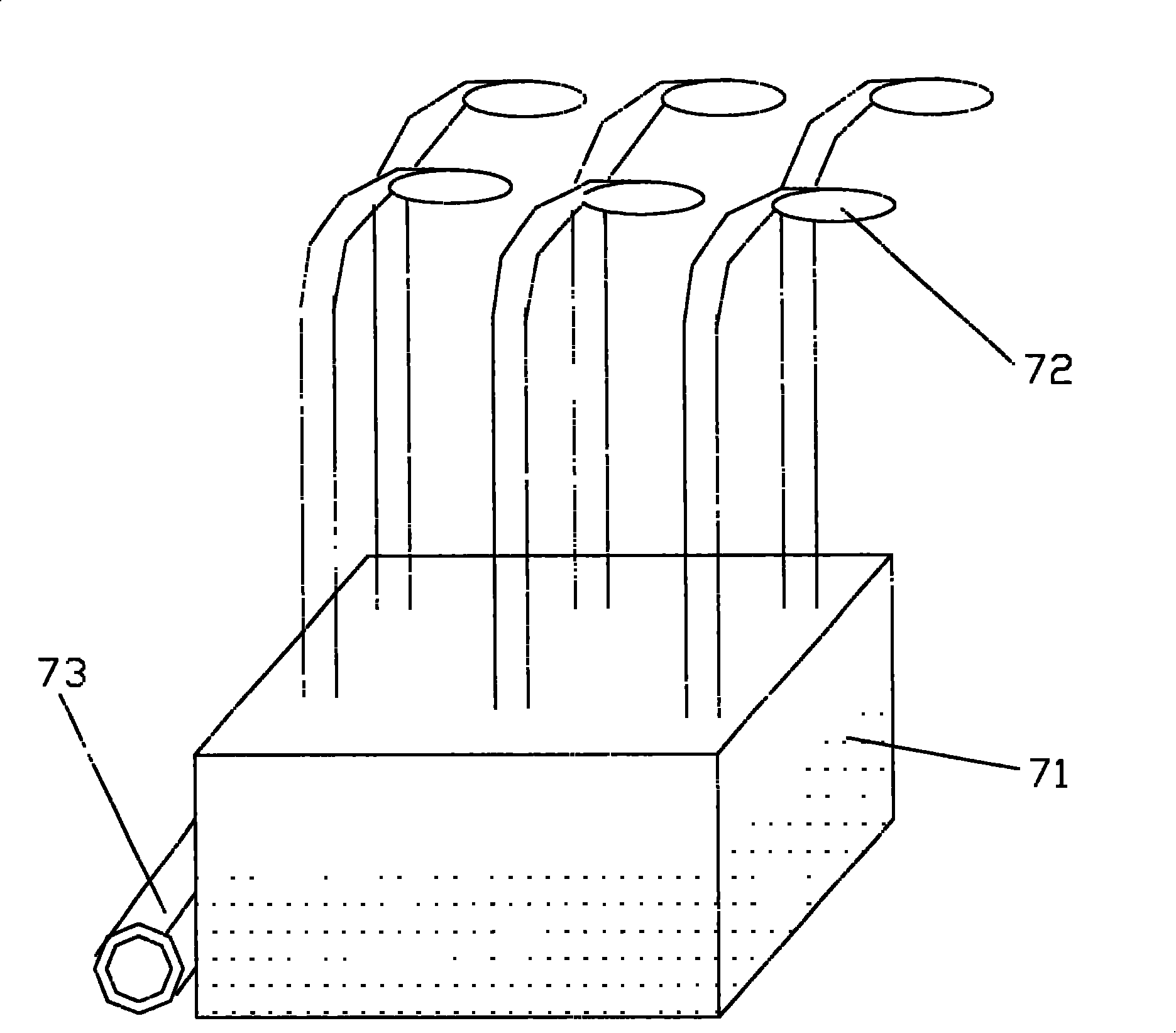

Method for regulating oxygen atmosphere in fuel oil (gas) reverberatory furnace by using recovered fume

InactiveCN101915502AReduce burning lossReduce production efficiencyLighting and heating apparatusCombustion chamberProcess engineering

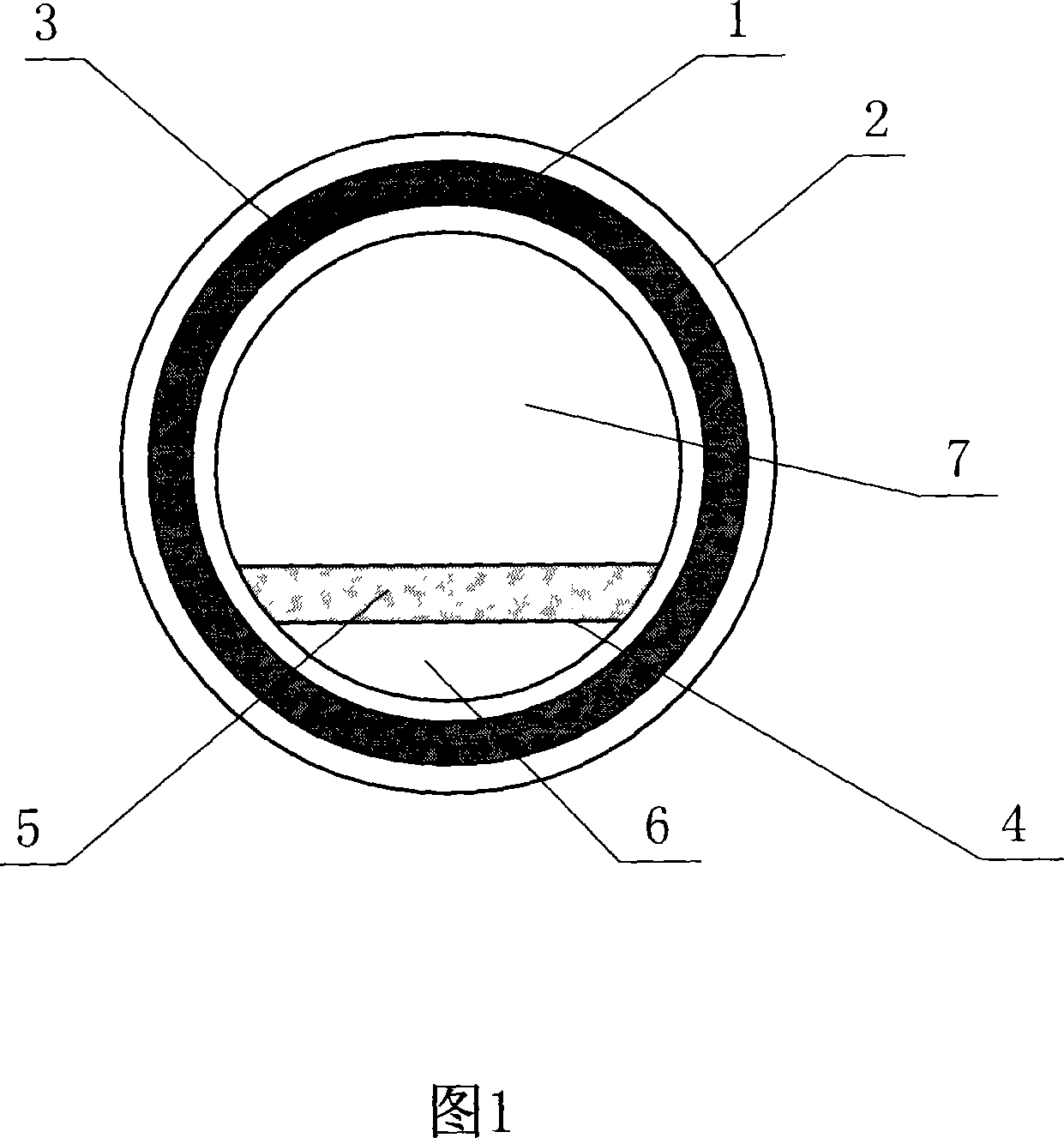

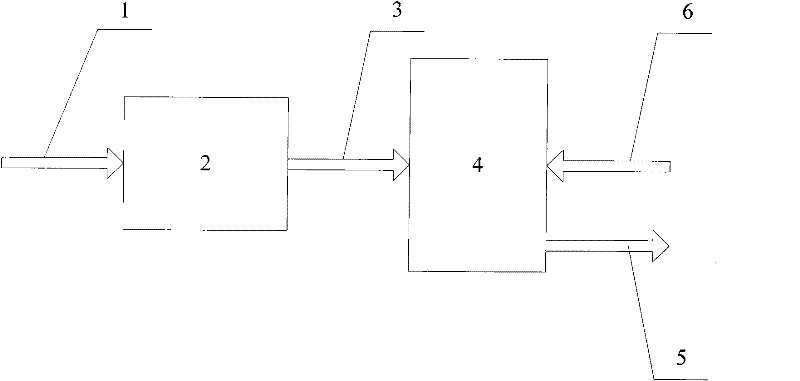

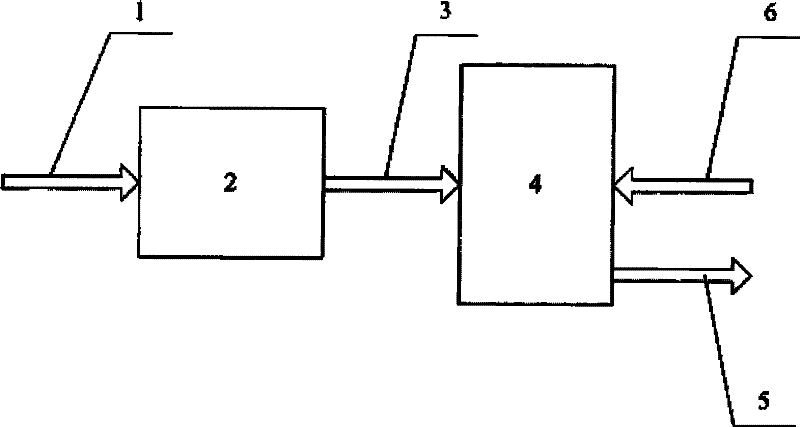

The invention relates to a method for regulating oxygen atmosphere in a fuel oil (gas) reverberatory furnace by using recovered fume. The method is implemented by a reverberatory furnace regulating the fuel oil (gas) by using the recovered fume. The reverberatory furnace regulating the fuel oil (gas) by using the recovered fume comprises a furnace body 1, a nozzle, heat accumulators (7 and 8), fume pipelines (18 and 19), a reversing adjusting valve 15, an air blower 13 and the like, and is characterized in that: a fume recovering pipeline with a fume adjusting valve is arranged between a heat accumulator A (7) and a heat accumulator B (8) and regulates the oxygen atmosphere in a combustion chamber of a reaction furnace by using the recovered fume to ensure that the oxygen is fully burned; a pipeline arranged between low-temperature pipelines below the heat accumulators is a low-temperature fume recovering pipeline (20); a pipeline arranged between high-temperature pipelines above the heat accumulators is a high-temperature fume recovering pipeline; and the oxygen atmosphere in the combustion chamber can be regulated by one of the low-temperature fume recovering pipeline and the high-temperature fume recovering pipeline as required.

Owner:江西宏成铝业有限公司

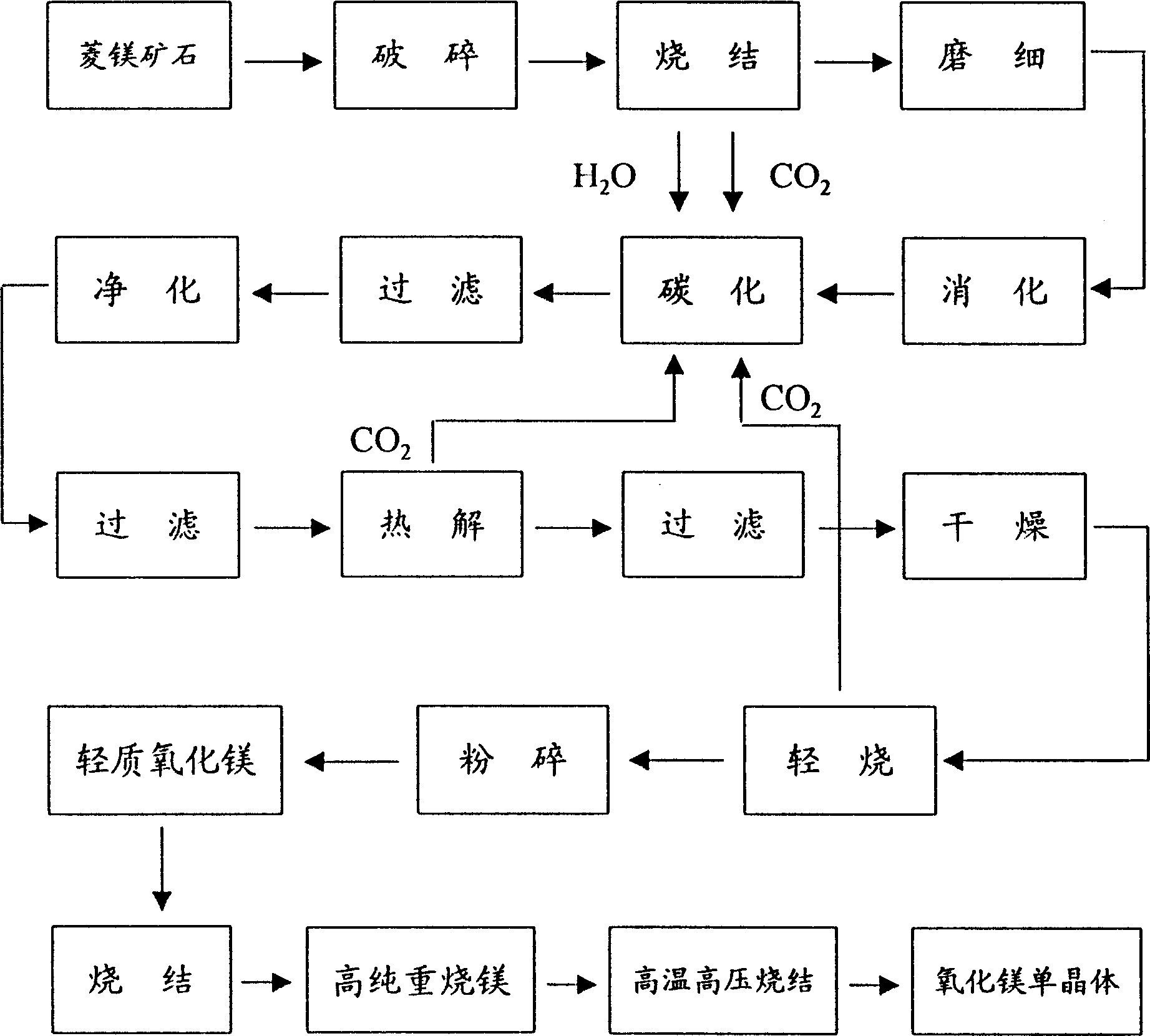

Process for producing high purity magnesium oxide monocrystal using waste magnesite ore

The production process of high purity magnesia monocrystal with magenesite ore of 35-44 % purity includes baking in reverberatory furnace to obtain light burnt magnesia, cooling and ball milling, digesting via adding water andp umping to carbonating pressure tank, adding water and CO2 gas while maintaining the temperature, stirring to slight acid, filtering before and after adding purifying agent in a storage tank, decomposing with hot vapor and separating deposit; filtering, depositing and stoving to obtain light magnesia; pressing to form balls and incineration to obtain heavy magnesia monocrystal material; crushing and sintering at high temperature and high pressure to obtain magnesia monocrystal.

Owner:吕佳成

Method for producing pig iron and phosphate using ferro-phosphorus

InactiveCN102796838AIncrease the speed of oxidation reactionSave heating energyPhosphoric acidPhosphateReaction temperature

A method for producing pig iron and phosphate using ferro-phosphorus is characterized in that: the ferro-phosphorus is arranged in a reverberatory furnace, and performs quick air refining reaction with air or oxygen-rich air, thus the phosphor in the ferro-phosphorus is oxidized into P2O5 gas, and the reaction furnace gas is subjected to heat exchange, dust removal, and P2O5 hydration absorption to obtain rough phosphoric acid, and the rough phosphoric acid is refined and purified to obtain a technical grade phosphoric acid product. While the phosphorus element is oxidized, part of the ferro element is oxidized into ferric oxide, and then the ferric oxide is reacted with the newly-added ferro-phosphorus, thus the phosphorus element is oxidized into the P2O5 gas, and the ferric oxide is reduced into the ferro by phosphorus; when the phosphorus content in the iron solution in the reverberatory furnace is smaller than 4%, the iron solution is arranged in a converter and processed by pig iron smelting after adding refining agent such as burned lime powder as dephosphorization agent, and the eligible pig iron solution is then processed by injection moulding to obtain a pig iron product. The best material reaction temperature in the reverberatory furnace is 1300-1600 DEG C.

Owner:黄靖元

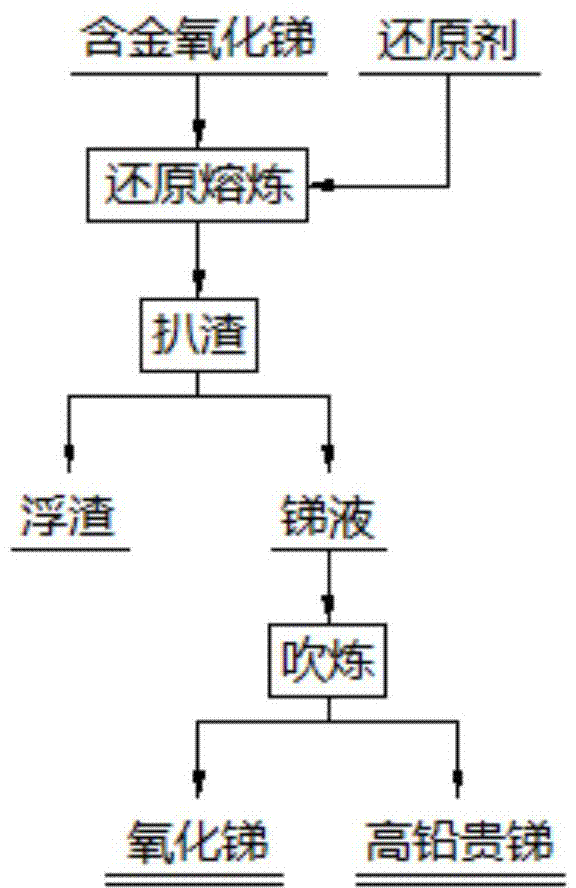

One-step technique for separating antimony from gold and lead in gold-containing antimony oxide smoke dust

ActiveCN104120270AReduce incorporationHigh removal rateProcess efficiency improvementSmelting processGold content

The invention discloses a one-step technique for separating antimony from gold and lead in gold-containing antimony oxide smoke dust, which comprises the following steps: adding a reducer into antimony oxide smoke dust with the gold content of 30g / t, carrying out reduction smelting at 1000-1250 DEG C, removing scum, blowing air or oxygen from the side of a reverberatory furnace at the rate of 50-250 m<3> / minute, converting at the converting temperature of 700-700 DEG C so that the antimony is oxidated and volatilized in the form of antimony oxide and the gold and lead are settled in a concentrated bottom water antimony solution, and obtaining the antimony oxide (in which the gold content is at most 0.5g / t, the lead content is at most 0.5 wt% and the antimony content is at least 73 wt%) and the bottom water antimony solution (in which the gold content is 80-150g / t, the lead content is 8-15 wt% and the antimony content is 84-89 wt%), thereby implementing one-step separation of the antimony from the gold and lead. The technique implements one-step separation of gold and lead in the antimony smelting process, and is suitable for industrial production.

Owner:HUNAN CHENZHOU MINING CO LTD

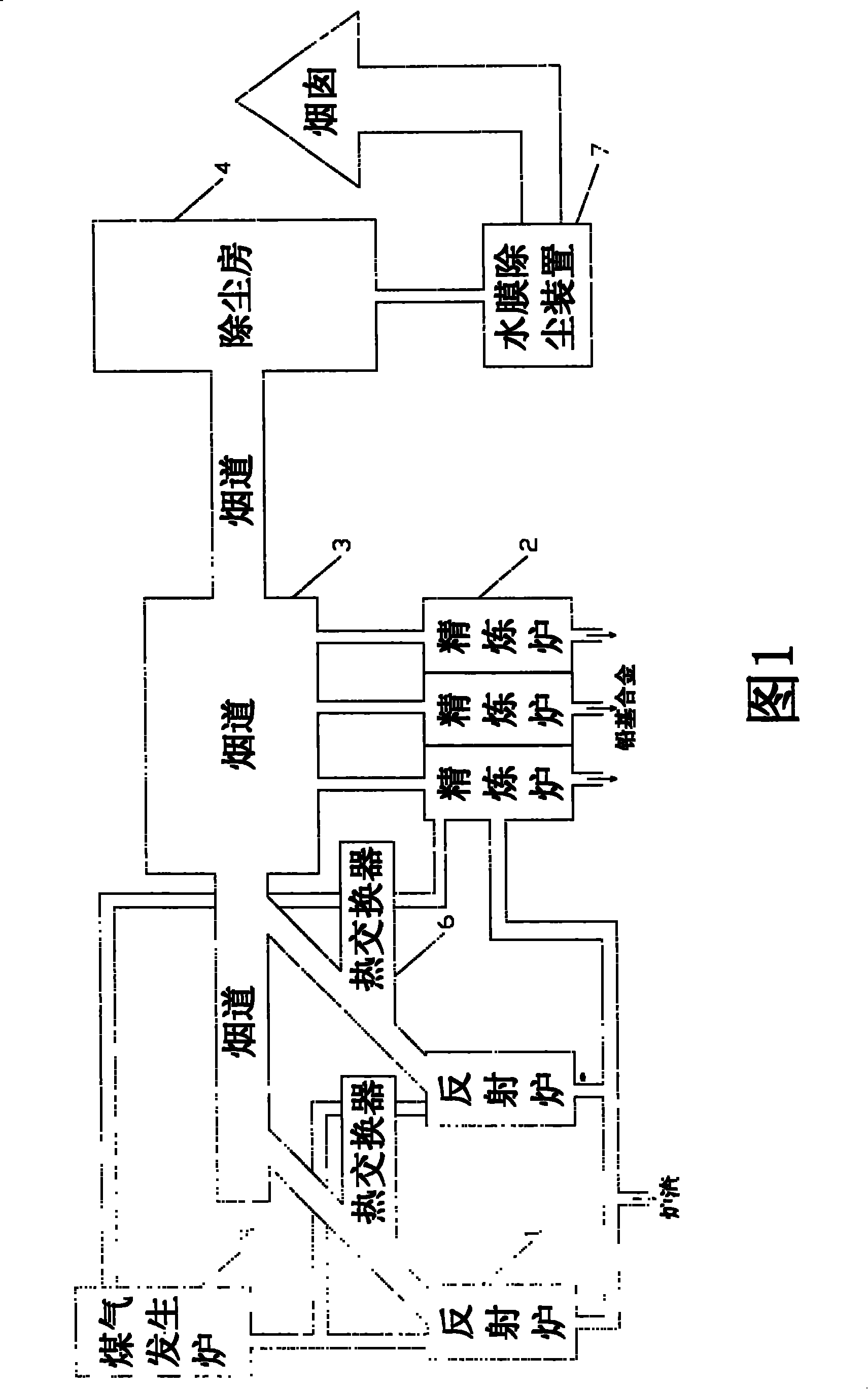

Solid waste recovery and processing system of waste lead acid accumulator

InactiveCN101197459AFully meltedBurn fullySolid waste disposalWaste accumulators reclaimingAtmospheric airReverberatory furnace

The invention discloses a system for recovering the solid waste in old and waste lead-acid storage batteries, comprising a reverberator, a finery, a flue, a dust removal house and a coal gas producer, wherein the finery is connected to the back end of the reverberator; the outlet flues of the reverberator and the finery are communicated with the front end of the flue; the dust removal house is communicated with the back end of the flue; the coal gas producer is connected with the reverberator and the finery. The invention adopts the gas combustion in the coal gas producer to heat both the reverberator and the finery and adopts a plurality of coal gas nozzles to provide enough fire to thoroughly smelt lead containing materials, with the fire in the front moving constantly backward to thoroughly smelt lead containing materials at the back, thereby saving energy resource; a heat exchanger is arranged for secondary combustion to provide big fire, thereby the smelting takes less time for completely smelting the lead containing materials; as cloth-bag dust removal followed by the dust removal of water film is adopted, the dust is completely removed, so the discharged gas causes no pollution to the atmosphere. The invention allows the lead containing solid waste to be burnt thoroughly and the dust to be removed completely.

Owner:许兴义

Fired-coal furnace and its additive

ActiveCN101029736AImprove insulation effectIncrease profitFurnace componentsSolid fuelsIr reflectionMetallurgy

This invention provides a coal burning furnace and additive in the domain of heat engineering. There is heat protection layer outside the furnace and the far IR reflection layer inside the furnace. The under-part of the inside furnace sets grate and the up-part forms the burning coal layer. The under-part and inside furnace consist the gas-supplying waste-out tune and the up-part of the burning coal layer forms burning heat supplying tune. The burning coal additive is added to the burning coal. The heat protection layer outside the furnace protects heat well and the inside far IR reflection layer can reflect the transferring heat to radiation heat so as to improve the heat utilization. The additive of the burning coal can let the coal burn efficiently and improve the burning rate and heat productivity. This furnace can be used to the industrial burning coal sinter, bake and calcinations.

Owner:颐珑达绝热材料技术(北京)有限公司

Light burning system and method of magnesite

ActiveCN102190449AHigh degree of automationImprove labor productivityLime productionRefractoryEngineering

The invention relates to a light burning system of magnesite, particularly to a magnesite light burning system and a light burning method in the refractory industry. The magnesite light burning system comprises an ore crushing and grinding system which sends ores into a calcinator system through material-charging and conveying equipment. The calcinator system, connected to a fuel supply system, outputs lightly-burnt magnesia powders by material-discharging and conveying equipment. The system of the invention has the advantages of: low heat consumption, with 44%-56% energy saved compared with a reverberatory furnace; great capacity of production; lower dust concentration of less than or equal to 50mg / Nm3 in exhaust emissions, about 90%-95% lower than the dust concentration of a reverberatory furnace; good quality of products; low labor intensity; high labor productivity which is more than 49 times of the productivity of a reverberatory furnace; high utilization of magnesite, for a reverberatory furnace only being capable of lightly burning lump ore materials, but a gaseous suspension calcinator, a fluidized flash calcinator or a circulating calcinatory being able to lightly burn fine ore materials.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Arsenic alkaline slag pyrogenic processing method

InactiveCN101386914ASimple processOperating conditions are easy to controlProcess efficiency improvementSlagEconomic benefits

The invention discloses a method for carrying out pyrogenic attack to arsenic alkali slag by using the prior antimony smelting reverberatory furnace. The method is characterized by comprising the following steps: the arsenic alkali slag is crushed and is added with oxygen in the reverberatory furnace and is melted down and stirred; NaOH is added to alloy liquid for removing arsenic; and a deleading agent is added to the alloy liquid for removing lead. The method has simple process flow, is easy to control the operating condition, can totally convert the arsenic alkali slag into a useful product for utilization or selling; the reclaiming rates of antimony and arsenic reach over 99 percent; the reclaiming rate of lead is close to 100 percent; and the method has remarkable economic benefit and environmental benefit.

Owner:湖南宏大锑铅有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com