Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1816 results about "Oxygen atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

While normal atmosphere contains between 20.8 and 21 percent oxygen, OSHA defines as oxygen deficient any atmosphere that contains less than 19.5 percent oxygen, and as oxygen enriched, any atmosphere that contains more than 22 percent. Oxygen-deficient atmospheres may be created when oxygen is displaced by inerting gases, such as carbon dioxide,...

Fabrication methods of a ZnO thin film structure and a ZnO thin film transistor, and a ZnO thin film structure and a ZnO thin film transistor

ActiveUS20070241327A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingOptoelectronicsFilm structure

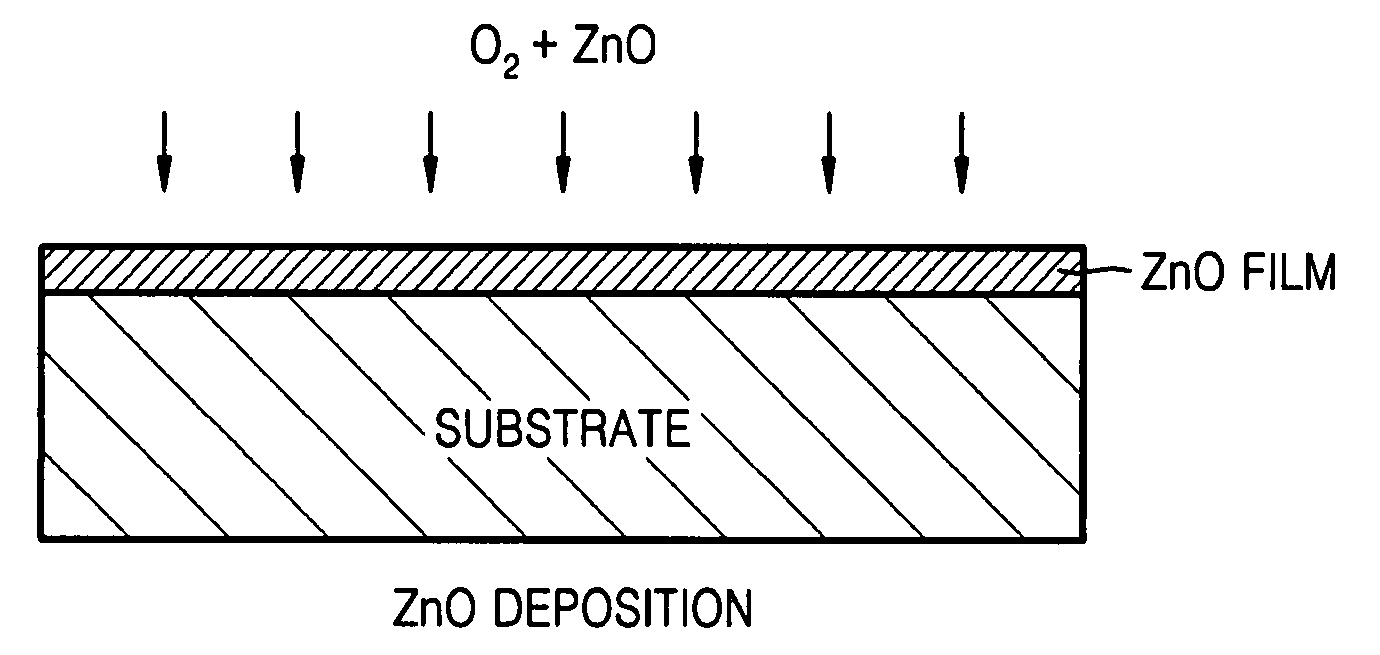

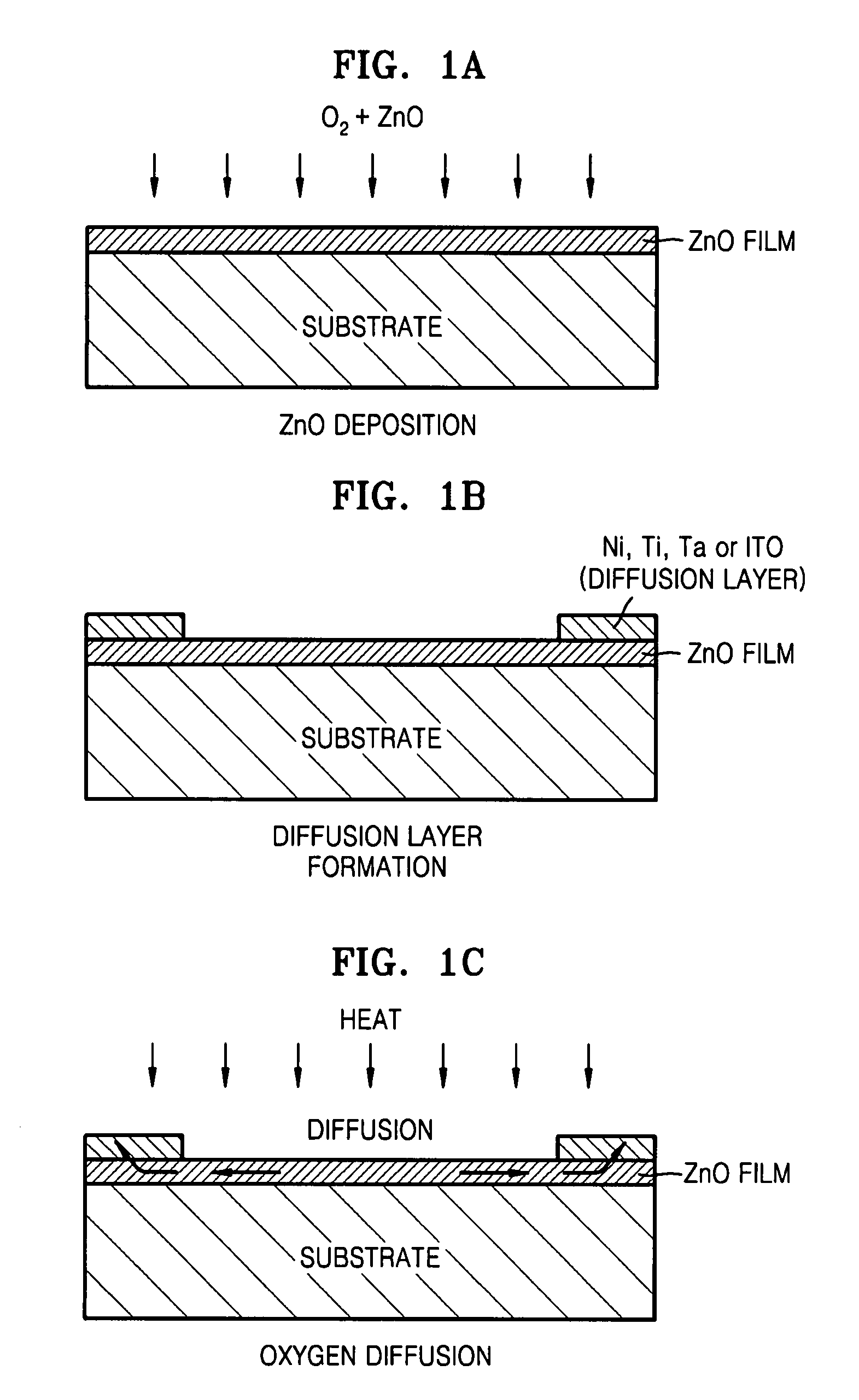

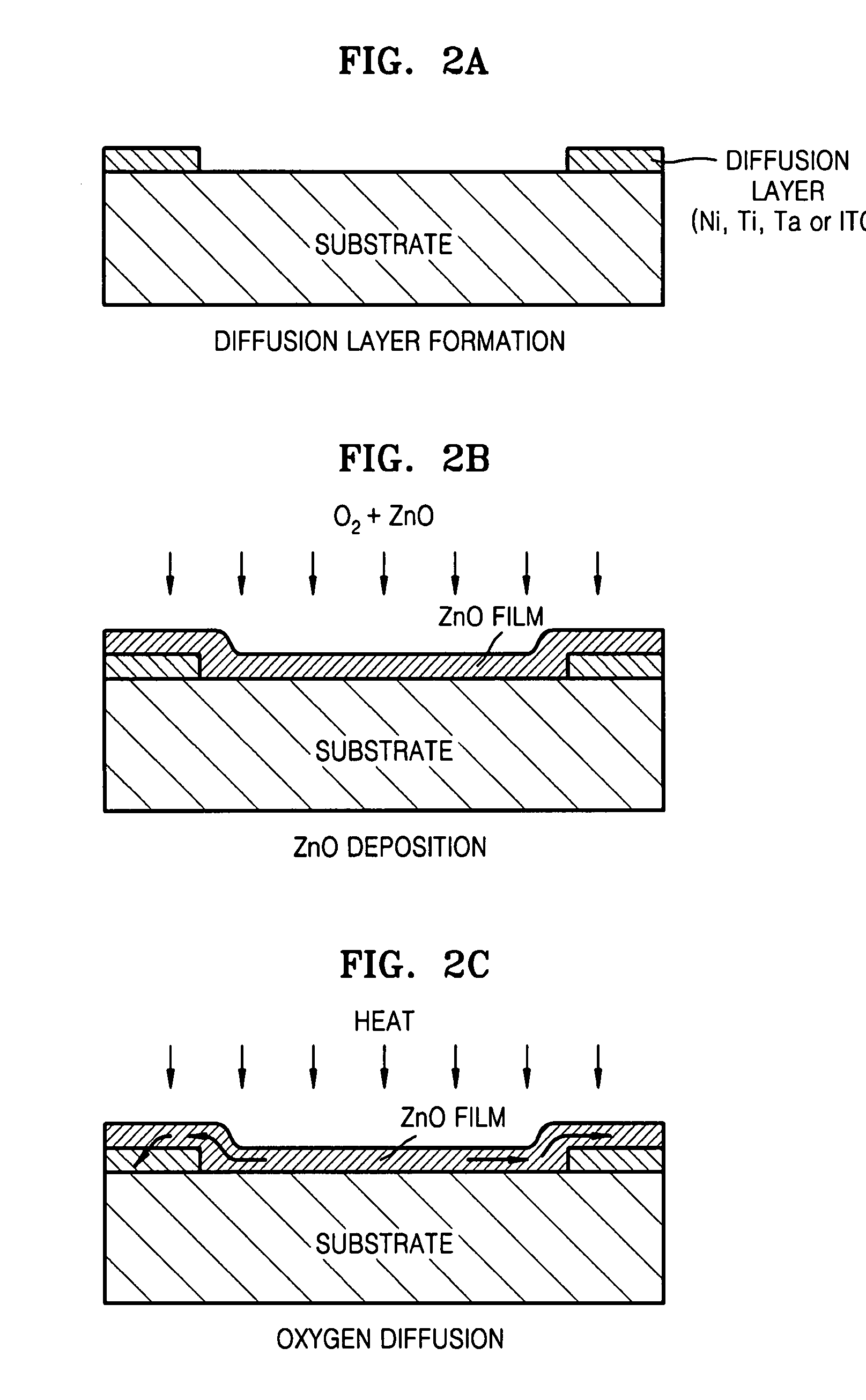

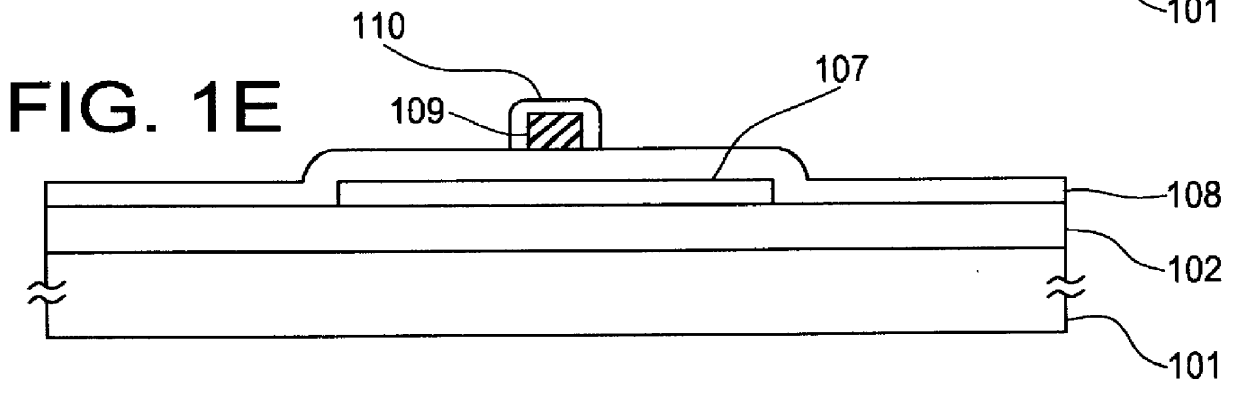

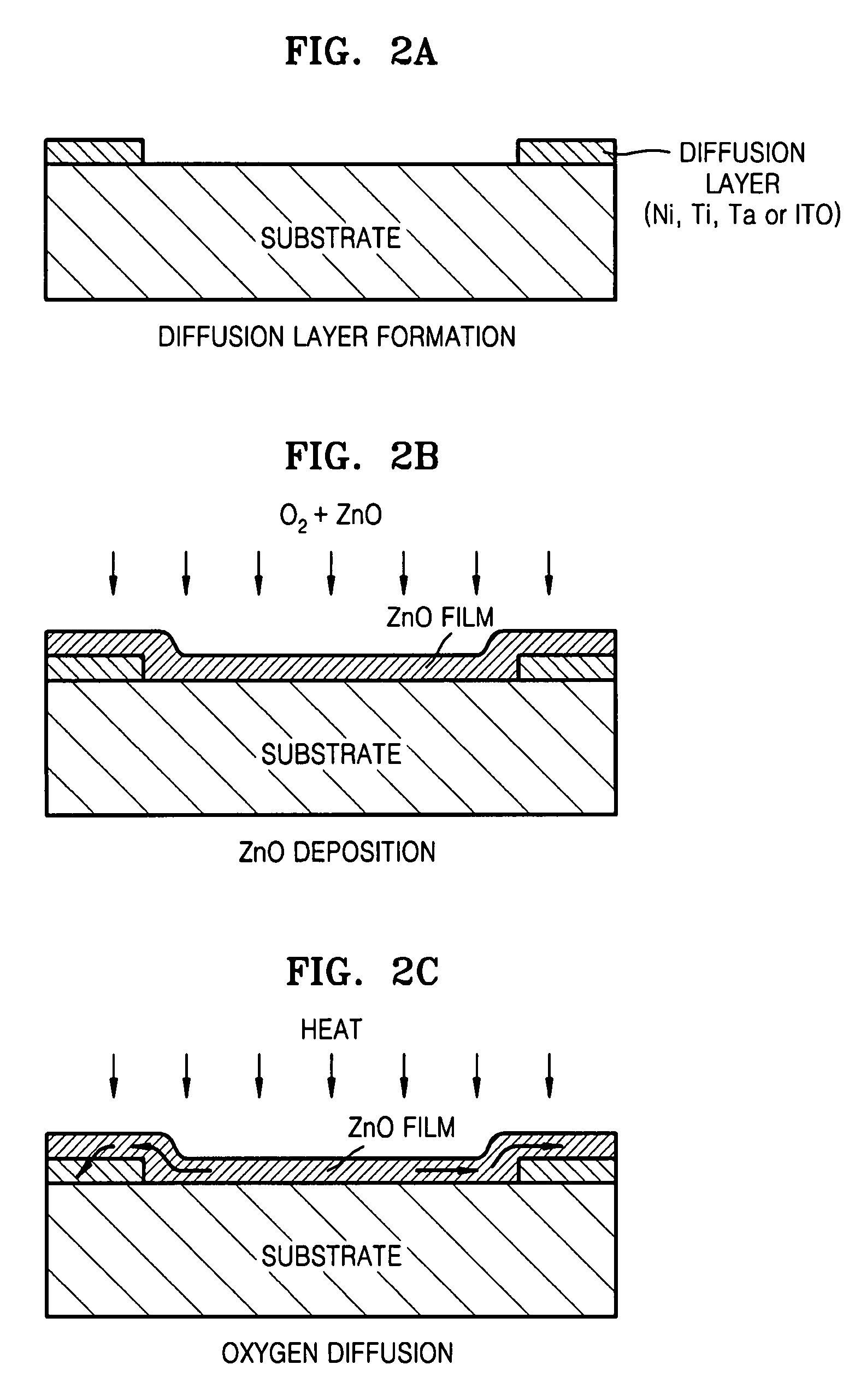

Provided is a method of fabricating a ZnO thin film structure and a ZnO thin film transistor (TFT), and a ZnO thin film structure and a ZnO thin film transistor. The method of fabricating a ZnO thin film structure may include forming a ZnO thin film on a substrate in an oxygen atmosphere, forming oxygen diffusion layers of a metal having an affinity for oxygen on the ZnO thin film and heating the ZnO thin film and the oxygen diffusion layers to diffuse oxygen of the ZnO thin film into the oxygen diffusion layers.

Owner:SAMSUNG ELECTRONICS CO LTD

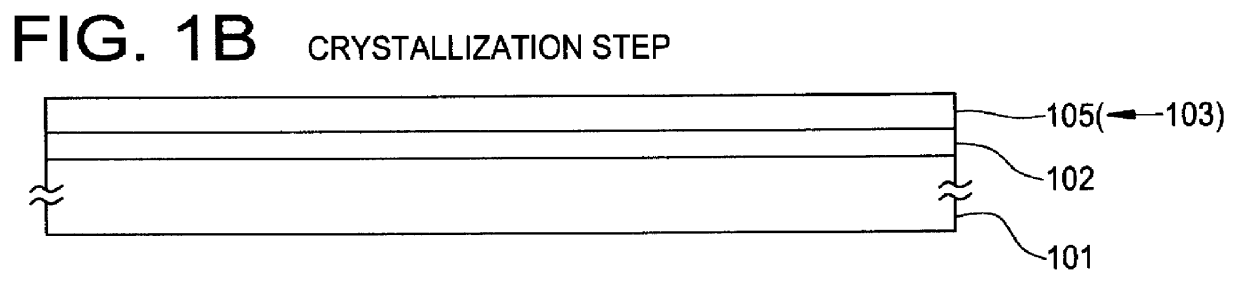

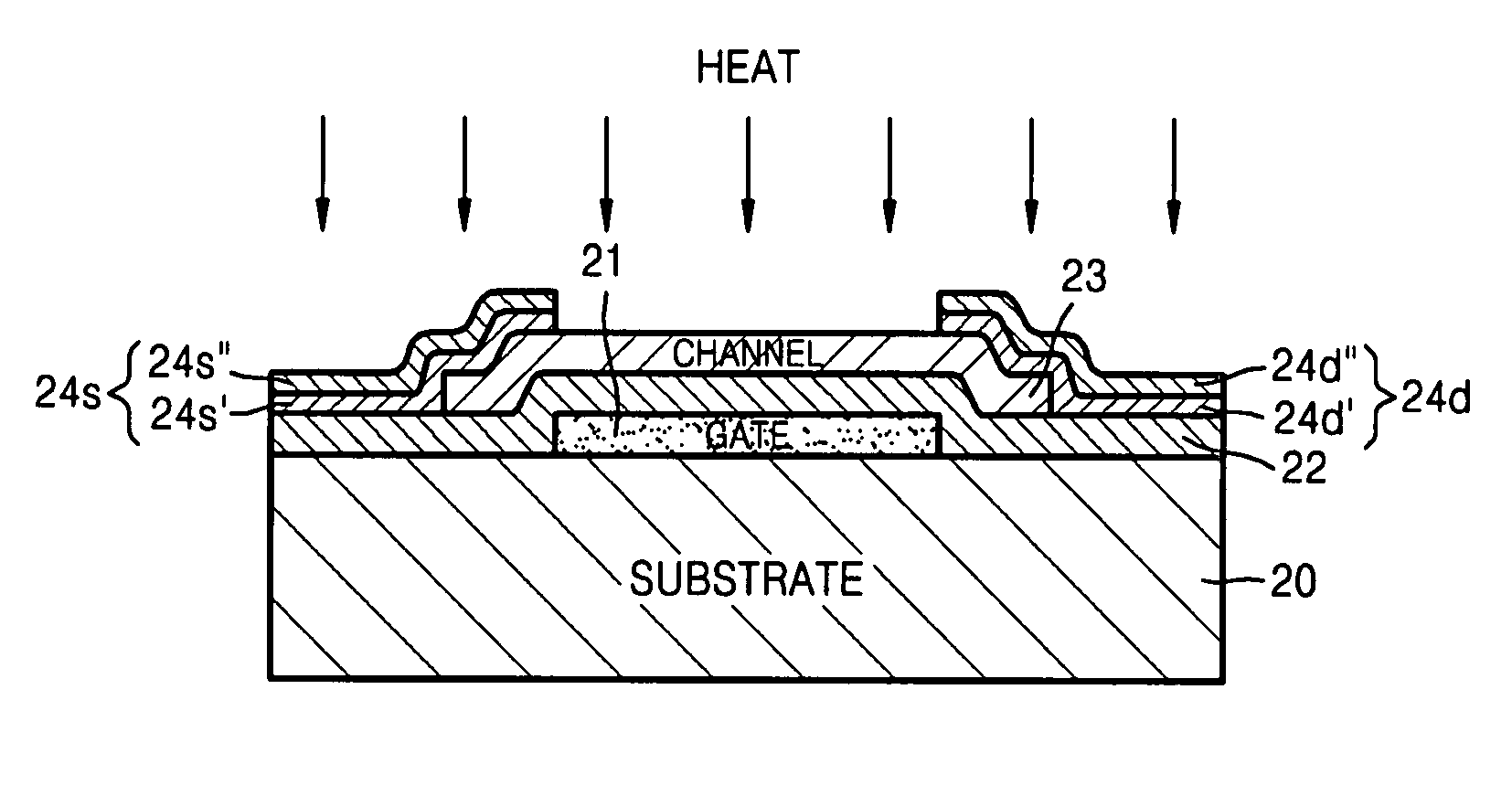

Method of manufacturing a thin film transistor involving laser treatment

InactiveUS6063654AImprove reliabilityEnhancing reliability and characteristicTransistorSolid-state devicesHydrogenAmorphous silicon

Defects at the grain boundaries of a crystal silicon film, which has been crystallized from an amorphous silicon film, are passivated without using a hydrogen plasma treatment. An underlying film and a crystal silicon film which has been crystallized from an amorphous silicon film are formed on a glass substrate. A thermal oxide film is grown on the surface of the crystal silicon film by heating in an oxygen atmosphere into which NF3 gas has been added. As the thermal oxide film is grown, non-coupled Si is generated. The defects at the grain boundaries of the crystal silicon film are passivated by the additional Si. Then, the thermal oxide film is removed and the crystal silicon film is patterned into an island shape to form an active layer of a TFT. A gate insulating film, a gate electrode and the like are then formed sequentially to complete the TFT.

Owner:SEMICON ENERGY LAB CO LTD

Nucleation and deposition of PT films using ultraviolet irradiation

InactiveUS6204178B1Semiconductor/solid-state device manufacturingPretreated surfacesPlatinumReactive gas

A method of depositing a platinum based metal film by CVD deposition includes bubbling a non-reactive gas through an organic platinum based metal precursor to facilitate transport of precursor vapor to the chamber. The platinum based film is deposited onto a non-silicon bearing substrate in a CVD deposition chamber in the presence of ultraviolet light at a predetermined temperature and under a predetermined pressure. The film is then annealed in an oxygen atmosphere at a sufficiently low temperature to avoid oxidation of substrate. The resulting film is free of silicide and consistently smooth and has good step coverage.

Owner:MICRON TECH INC

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

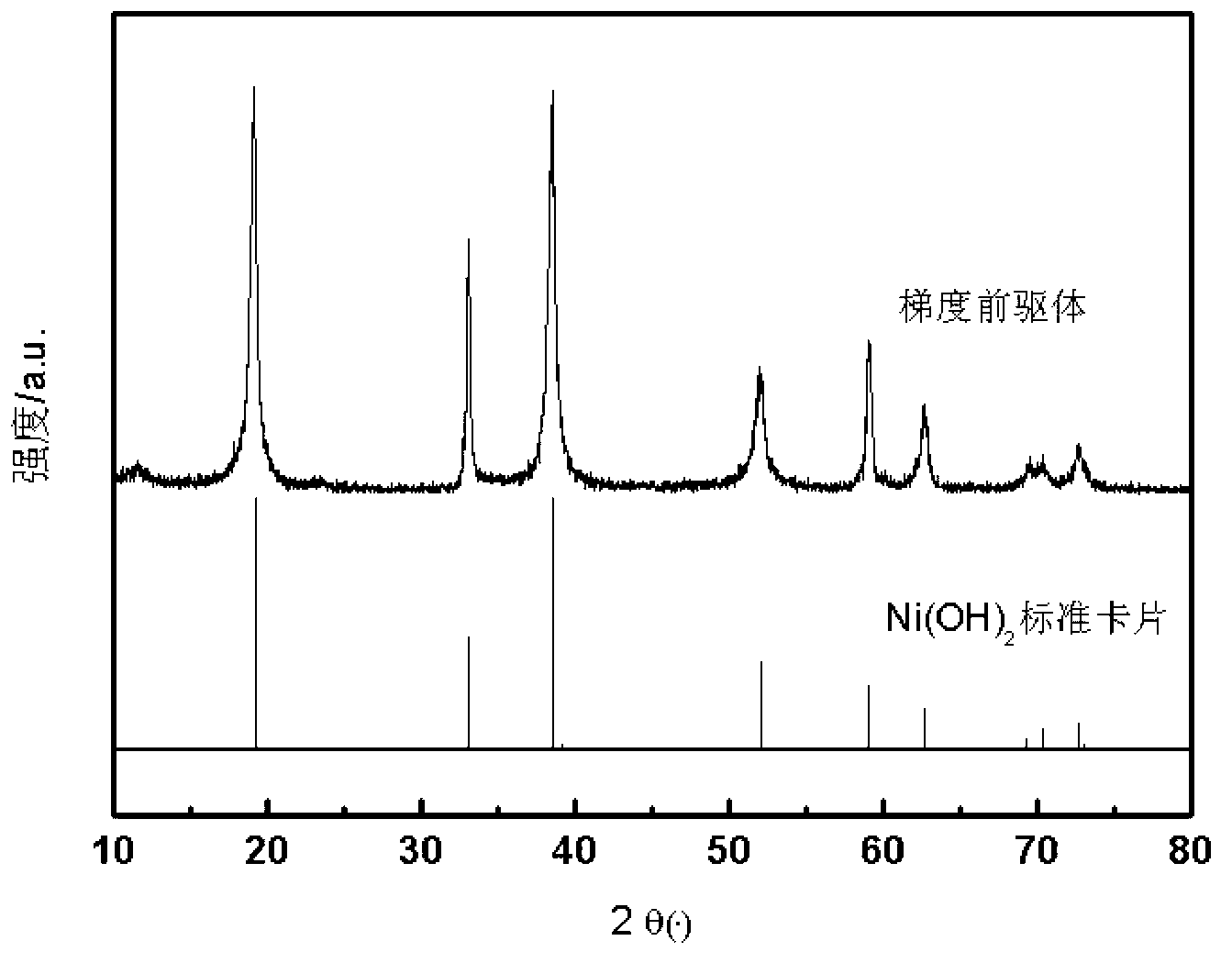

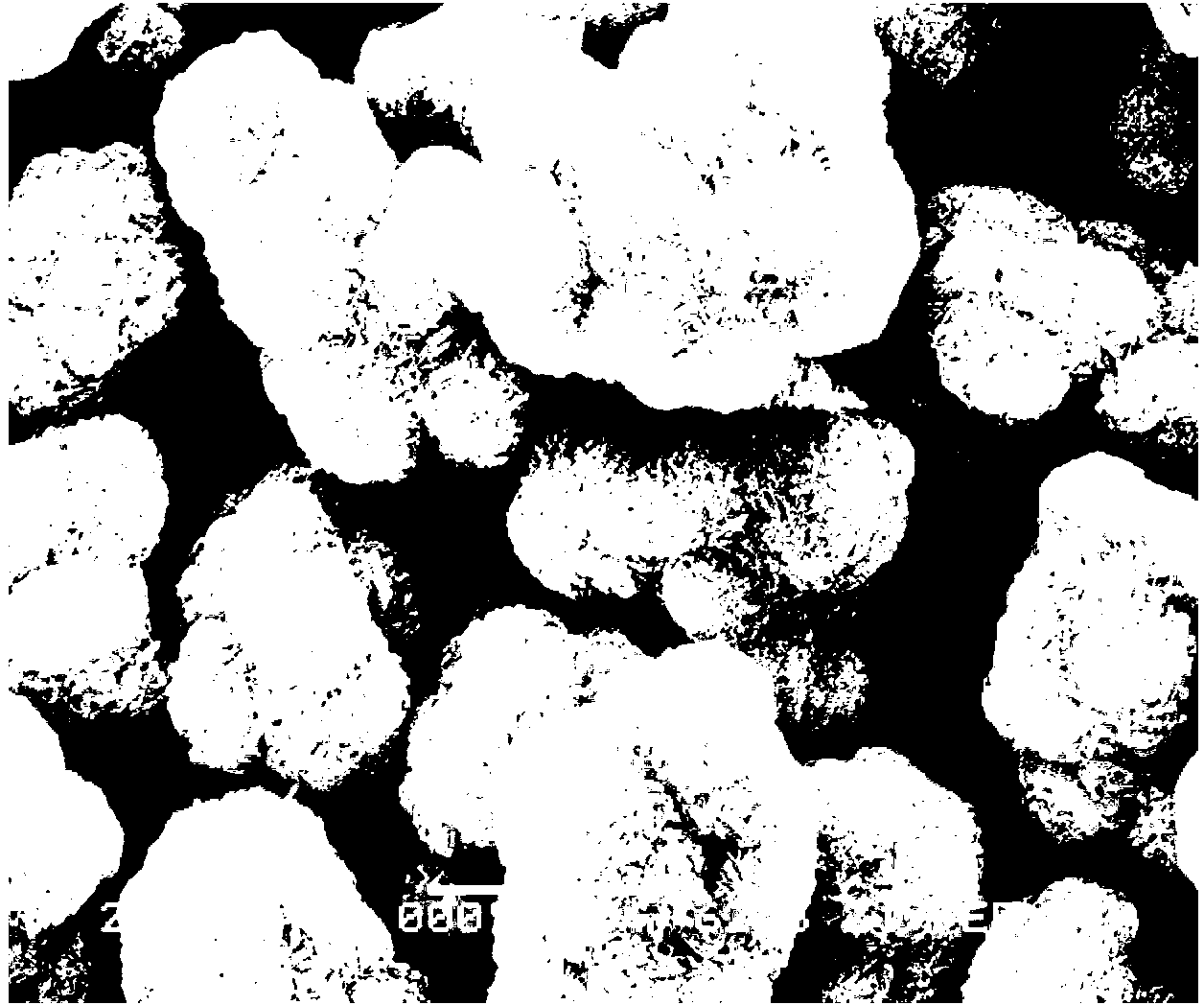

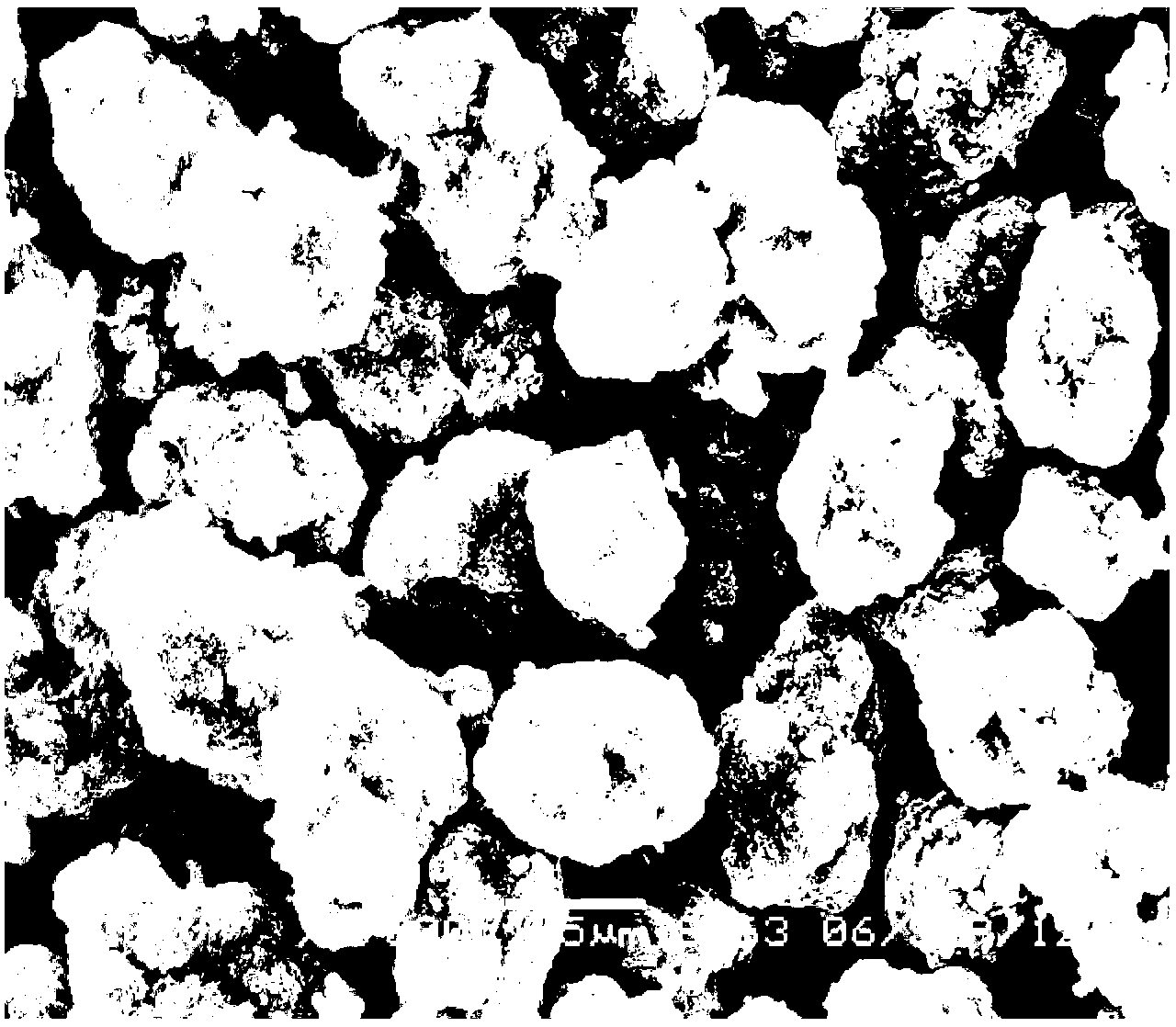

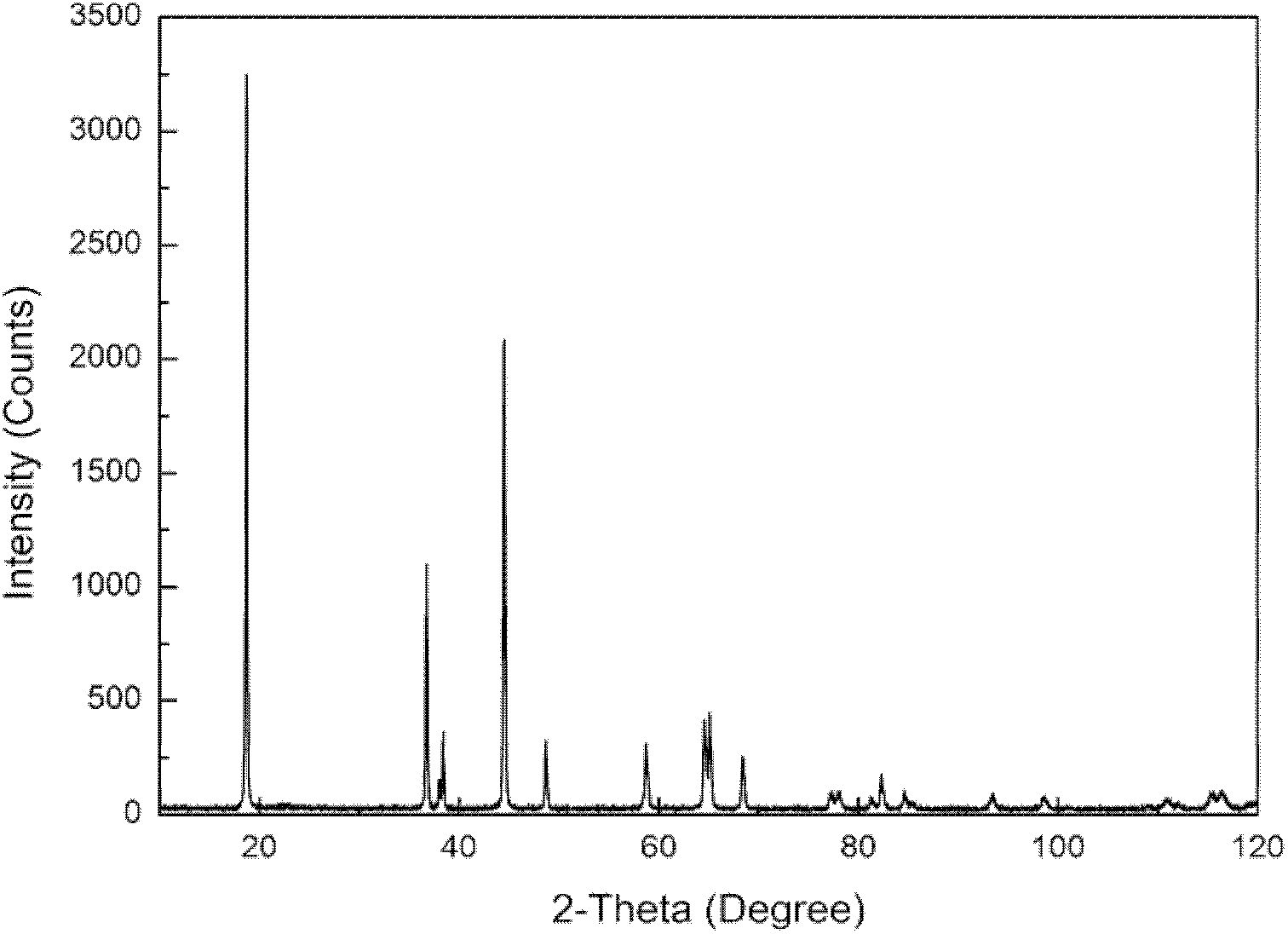

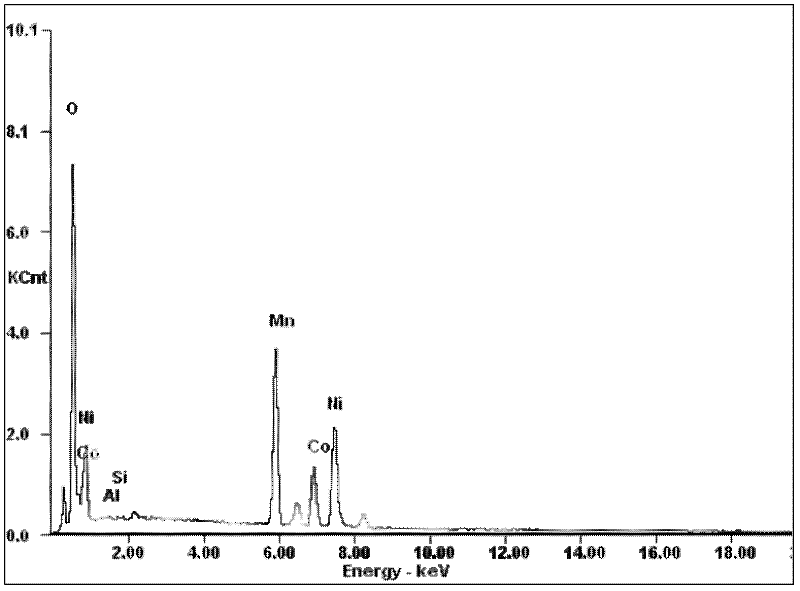

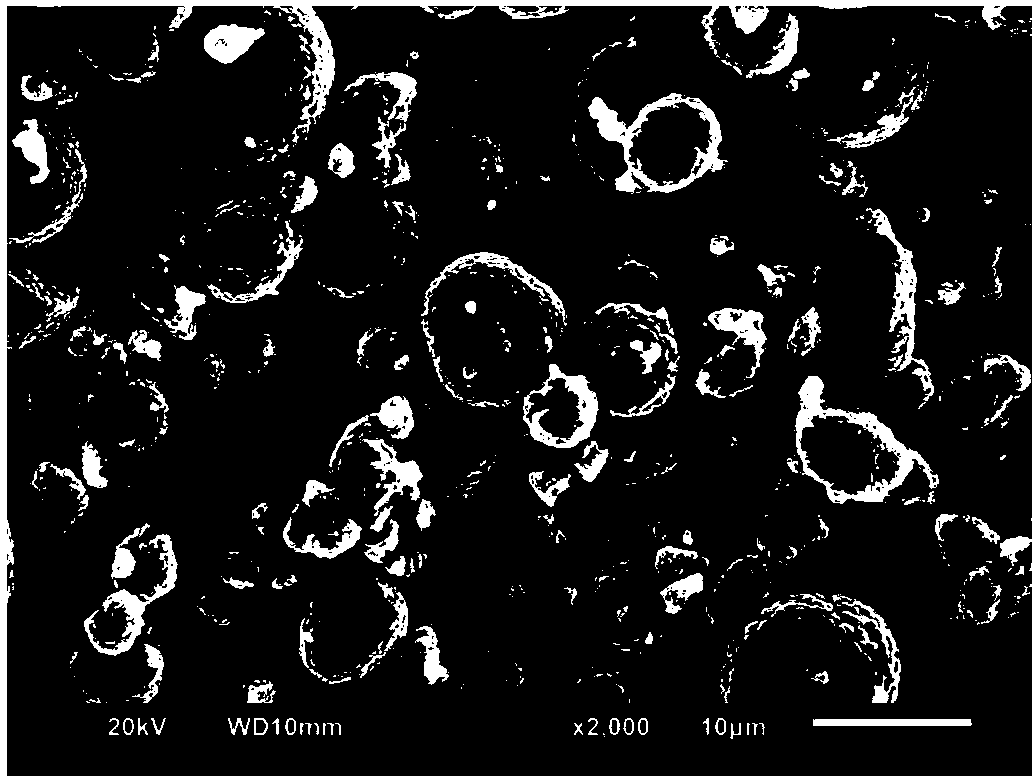

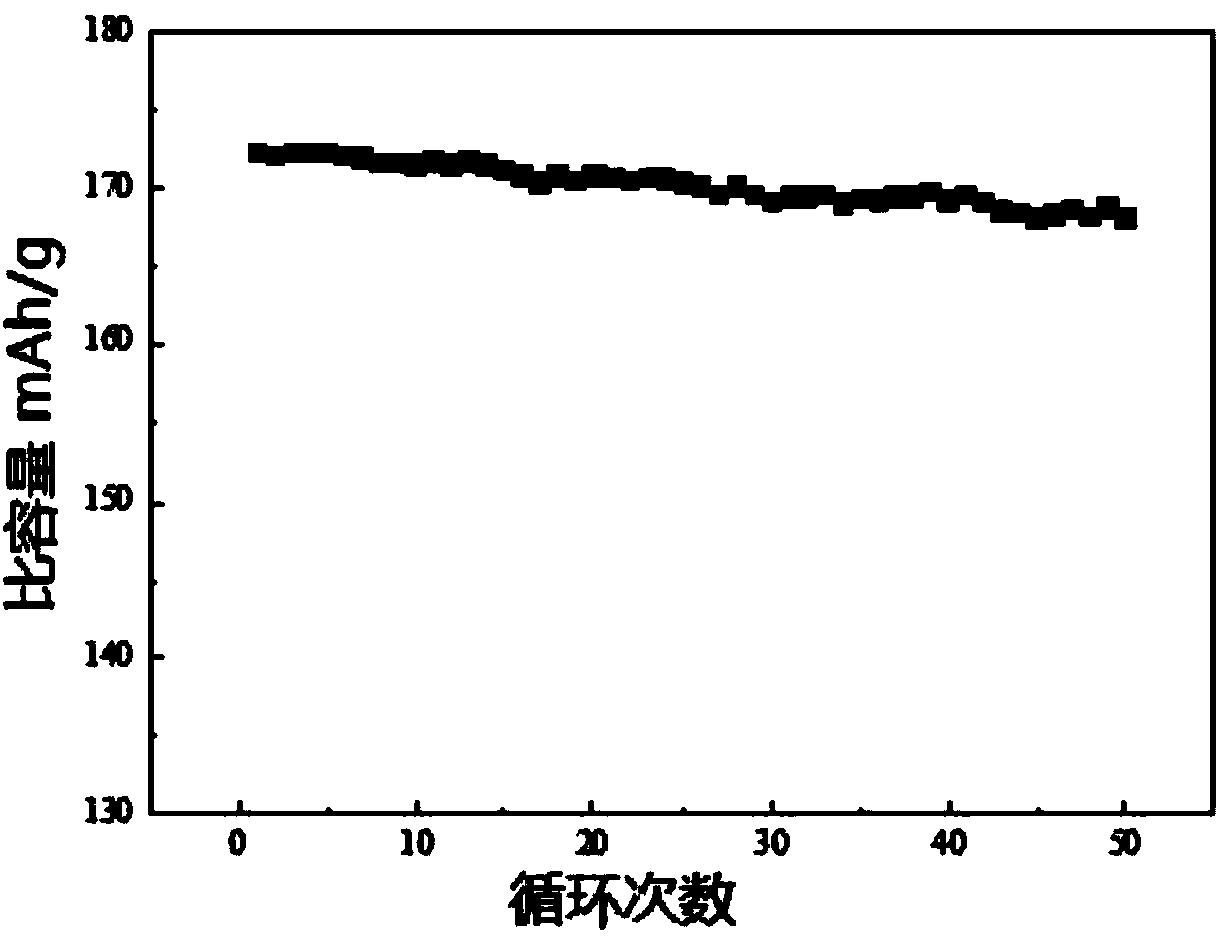

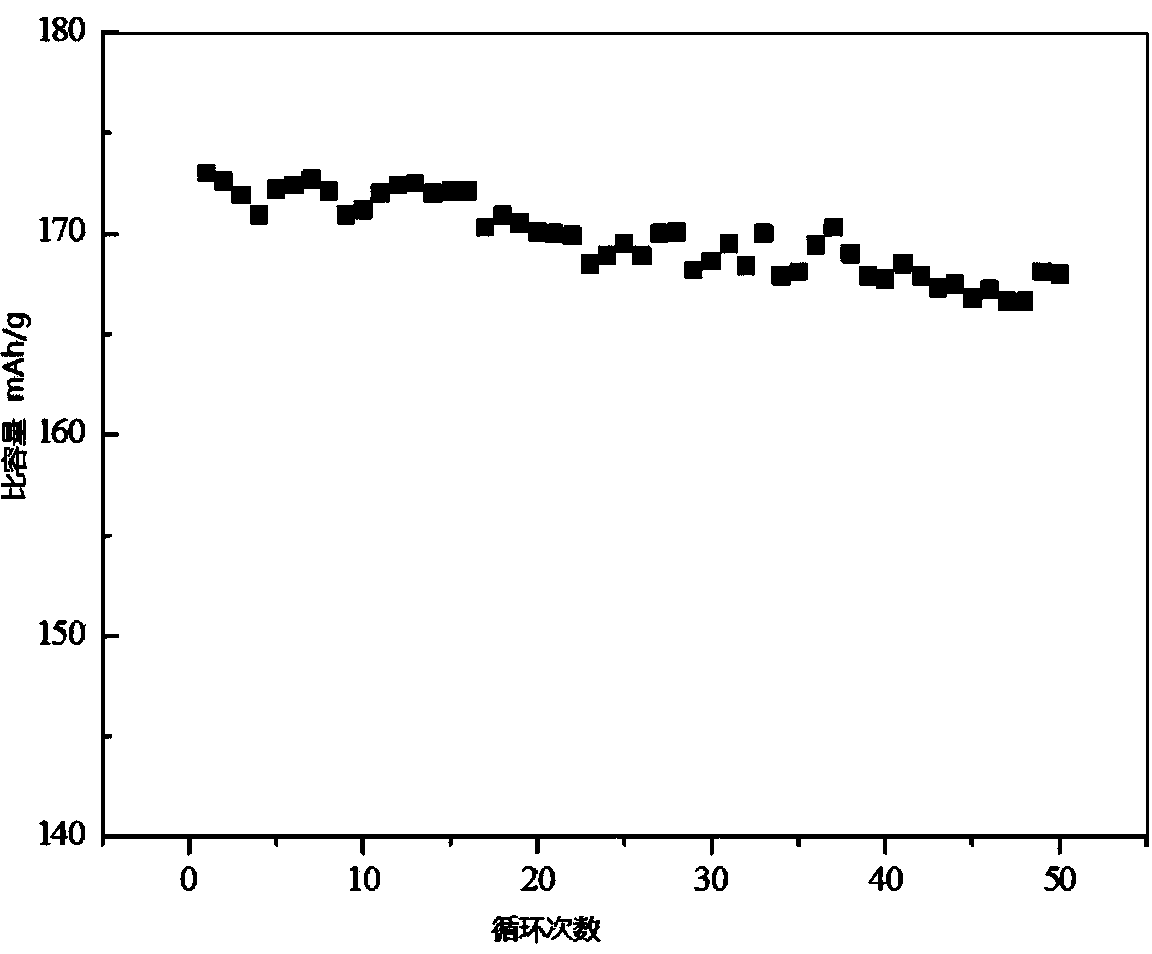

Gradient coated LiNiO2 material and preparation method

InactiveCN103078109AHigh electrochemical capacityInhibit sheddingCell electrodesSource materialManganese

The invention discloses a preparation method for gradient coated LiNiO2 for lithium ion battery positive pole material, so as to solve the problem of bad circulating performance of conventional LiNiO2. The molecular formula of the LiNiO2 is LiNi 1-xMxO2, wherein, the x is less than or equal to 0.3 and greater than 0, the M is adulterated metal ions and is one or more selected from magnesium, nickel, Fe, titanium, zinc, Co, manganese, aluminum, Nb and vanadium, the gradient coat refers to that concentration gradient hydroxide coprecipitate provided with nickel and other metallic elements is coated on the surfaces of spherical nickelous hydroxide material, and then the precursor is mixed with lithium-source material and roasted under high temperature in an oxygen atmosphere furnace, so as to obtain high-performance modified LiNiO2. The gradient coated LiNiO2 obtained in the invention has the characteristics of high specific capacity, excellent circulating performance, excellent high-temperature property and the like, and is suitable for the application field of high- capacity lithium ion batteries.

Owner:CENT SOUTH UNIV

Fabrication methods of a ZnO thin film structure and a ZnO thin film transistor, and a ZnO thin film structure and a ZnO thin film transistor

Provided is a method of fabricating a ZnO thin film structure and a ZnO thin film transistor (TFT), and a ZnO thin film structure and a ZnO thin film transistor. The method of fabricating a ZnO thin film structure may include forming a ZnO thin film on a substrate in an oxygen atmosphere, forming oxygen diffusion layers of a metal having an affinity for oxygen on the ZnO thin film and heating the ZnO thin film and the oxygen diffusion layers to diffuse oxygen of the ZnO thin film into the oxygen diffusion layers.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method of high-yield biochar

ActiveCN104371748AHigh specific surface areaImprove pore structureProductsReagentsPorosityCarbonization

The invention discloses a preparation method of high-yield biochar, which mainly comprises the following steps: (1) putting a collected biomass raw material into a catalyst solution, stirring and impregnating at normal temperature, and filtering to obtain the biomass raw material containing moisture and catalyst, the moisture weight percentage is 50-150%, and the catalyst weight content is 0.5-5%; and (2) heating the biomass raw material containing moisture and catalyst in an oxygen-free or limited-oxygen atmosphere to 100-180 DEG C at the rate of 0.5-2 DEG C / minute, keeping the temperature for 1-2 hours, heating to 240-300 DEG C at the rate of 0.5-3 DEG C / minute, keeping the temperature for 1-3 hours, heating to 500-900 DEG C at the rate of 10-50 DEG C / minute, keeping the temperature for 1-4 hours, and cooling to obtain the biochar, wherein the yield of the biochar is greater than 40 wt% of the biomass raw material. The method does not need drying in the biochar preparation process; the biomass raw material containing moisture and catalyst and the multi-step carbonization technique are utilized to achieve the goal of enhancing the biochar yield; and the biochar has the characteristics of energy saving, large specific area and high porosity, and can be widely used in the fields of water treatment, functional textiles and the like.

Owner:DONGHUA UNIV

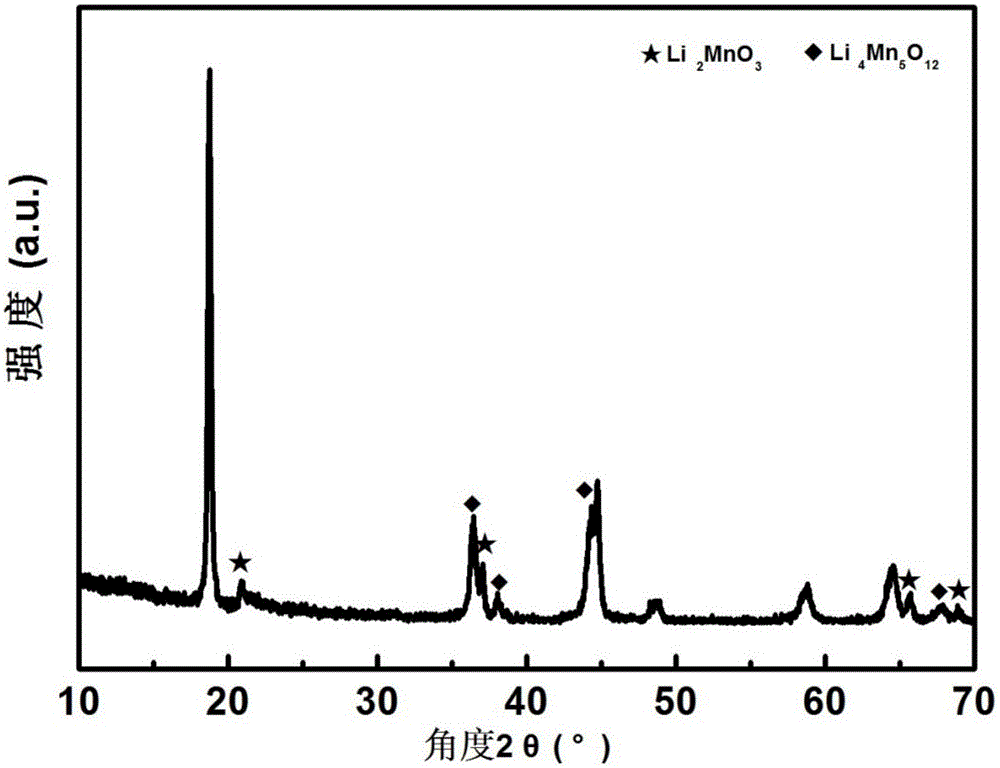

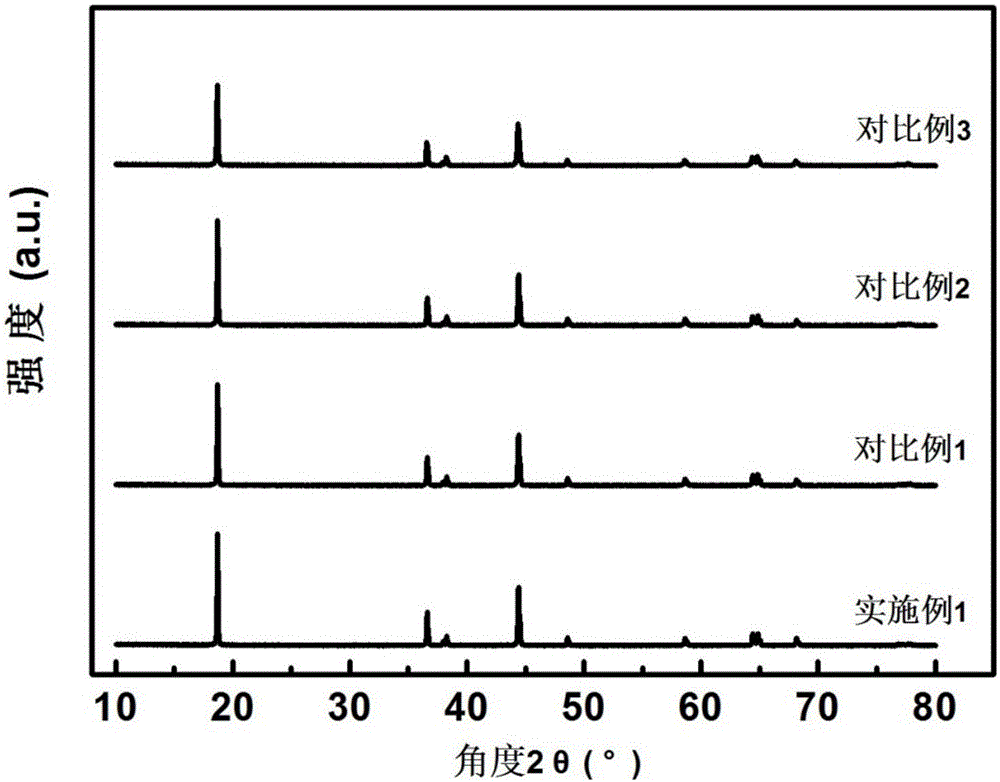

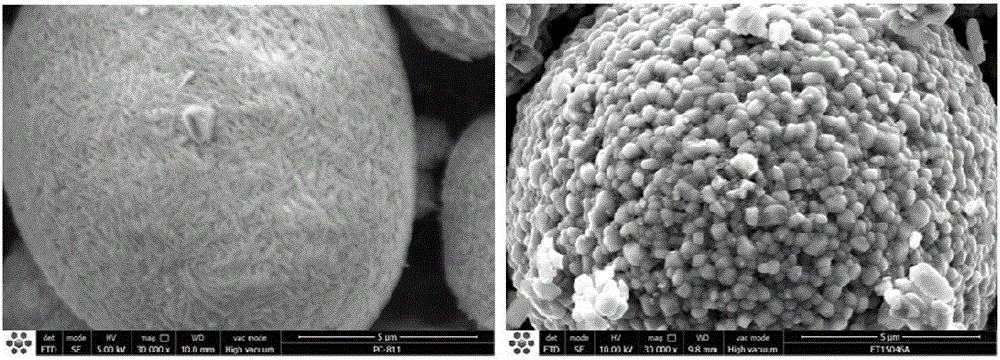

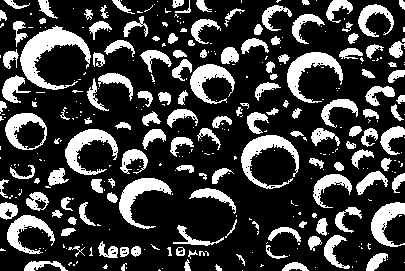

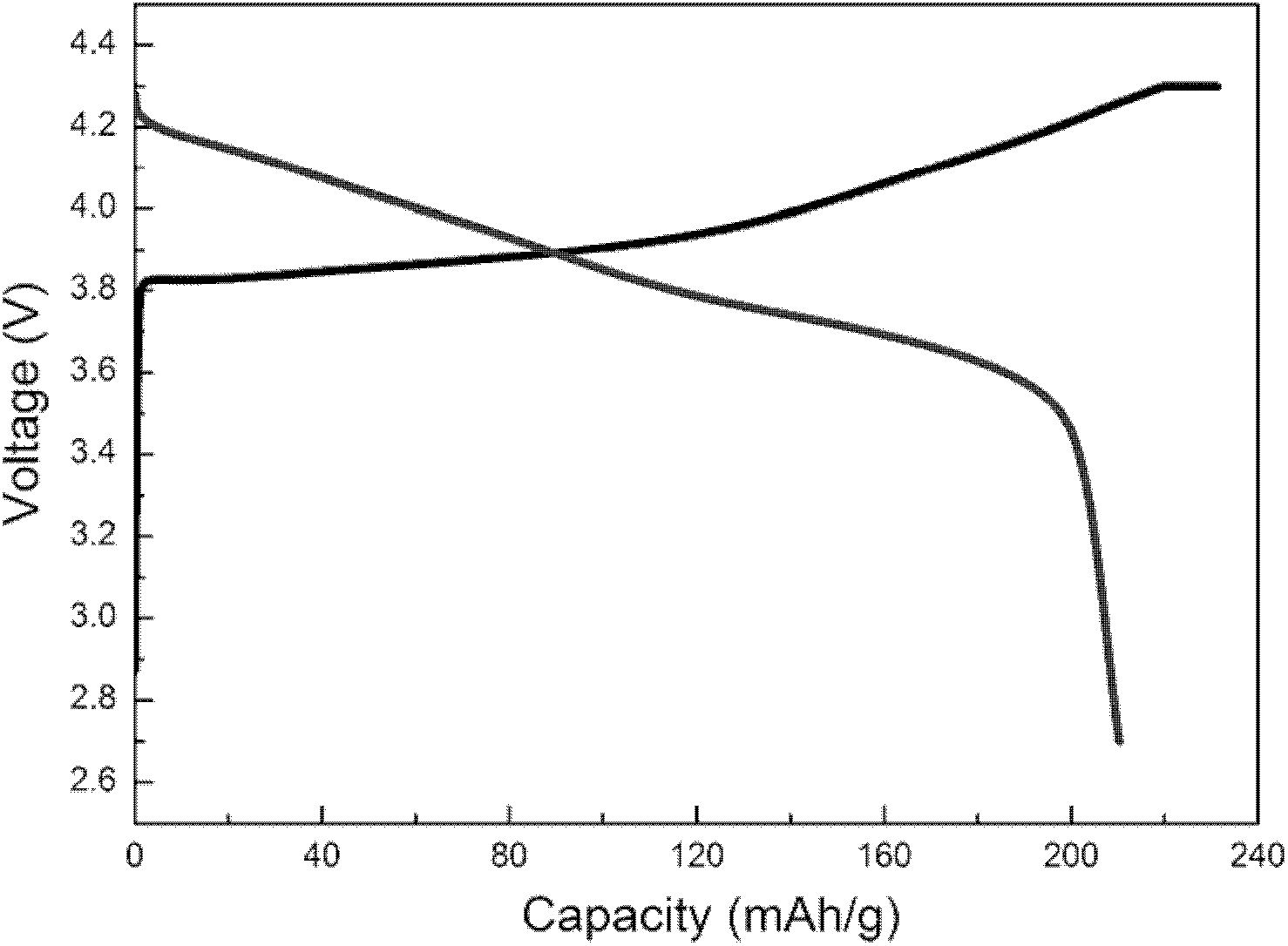

Polycrystal high-nickel positive electrode material used for lithium ion battery and preparation method for polycrystal high-nickel positive electrode material

InactiveCN105958062AExtended storage timeReduce lithiumCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

Disclosed is a polycrystal high-nickel positive electrode material used for a lithium ion battery. The polycrystal high-nickel positive electrode material comprises a base material with a layered structure and a coating layer which is arranged outside the base material and has a spinel structure; the general formula of the base material is LiNi<1-x-y>Co<x>M<y>O<2>, wherein M is at least one kind of Mn and Al; the coating layer is lithium manganese oxide; the mass percentage of the total impurity lithium on the surface of the base material is less than 0.085% based on the total mass percentage of the base material; the preparation method for the positive electrode material comprises the following steps of weighing Ni<1-x-y>Co<x>M<y>(OH)<2>, and mixing with a lithium source, then carrying out thermal treatment, cooling, crushing and sieving to obtain the base material; measuring the content of the residual impurity Li<2>CO<3> and LiOH on the surface of the base material, adding into the metal Mn compound according to the measurement result, and carrying out low-temperature thermal treatment in an oxygen atmosphere to obtain the polycrystal high-nickel positive electrode material used for the lithium ion battery. The polycrystal high-nickel positive electrode material provided by the invention has the advantages of low material alkalinity, low inflatable degree, excellent processing property and cycling performance, and the like.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

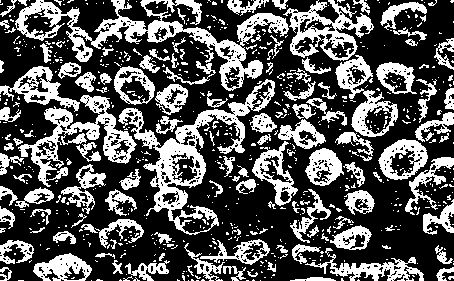

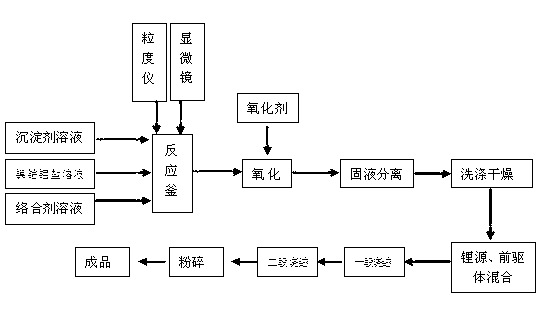

Method for preparing nickel cobalt lithium aluminate cathode material

The invention discloses a method for preparing a nickel cobalt lithium aluminate cathode material. The method comprises the following steps of: uniformly mixing a nickel salt solution, a cobalt salt solution and an aluminum salt solution in a certain mole ratio of metal ions; adding a complexing agent solution, a precipitator solution and a metal salt solution together into a high-speed stirring reaction kettle with a base solution, and performing precipitation reaction; after complete reaction, performing oxidizing reaction on discharged slurry and an oxidizing agent with certain concentration in an alkaline environment; after the oxidizing reaction is finished, performing solid liquid separation on the slurry, washing in pure water, and drying to obtain a nickel cobalt aluminum hydroxyl oxide precursor of a lithium ion battery cathode material; fully mixing the precursor with a lithium source, and performing multi-step sintering in an oxygen atmosphere; and performing crushing and subsequent treatment on a material obtained by sintering, and thus obtaining the nickel cobalt lithium aluminate cathode material. The method is low in equipment requirement, simple in flow, low in energy consumption and low in waste. The produced material is high in tap density and high in capacity.

Owner:HUNAN SOUNDDON NEW ENERGY

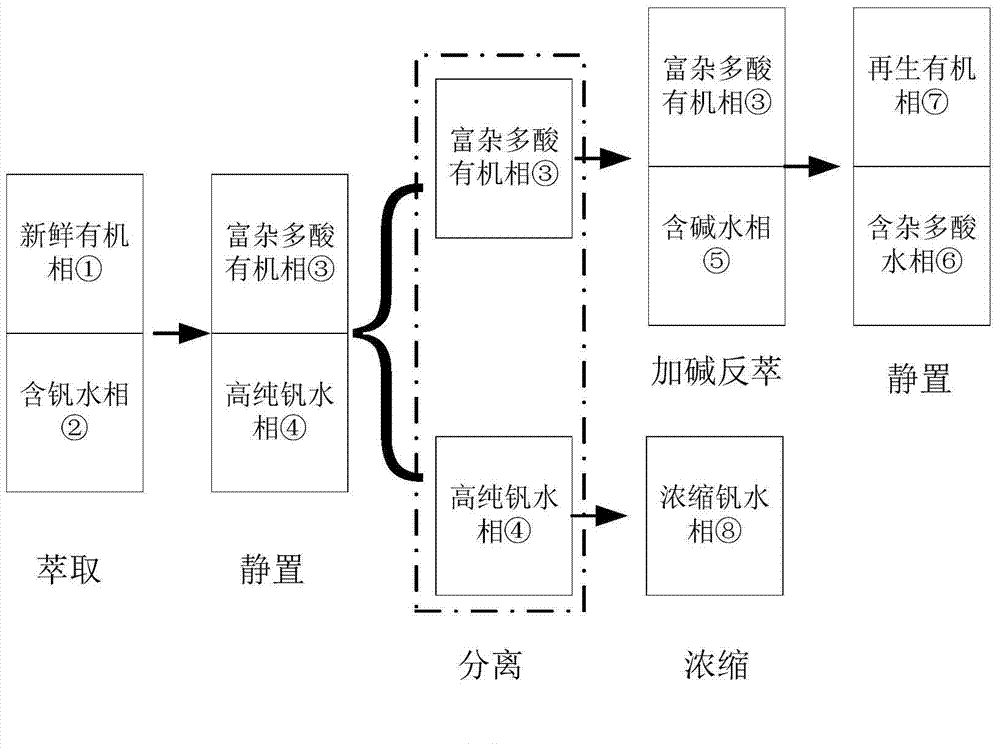

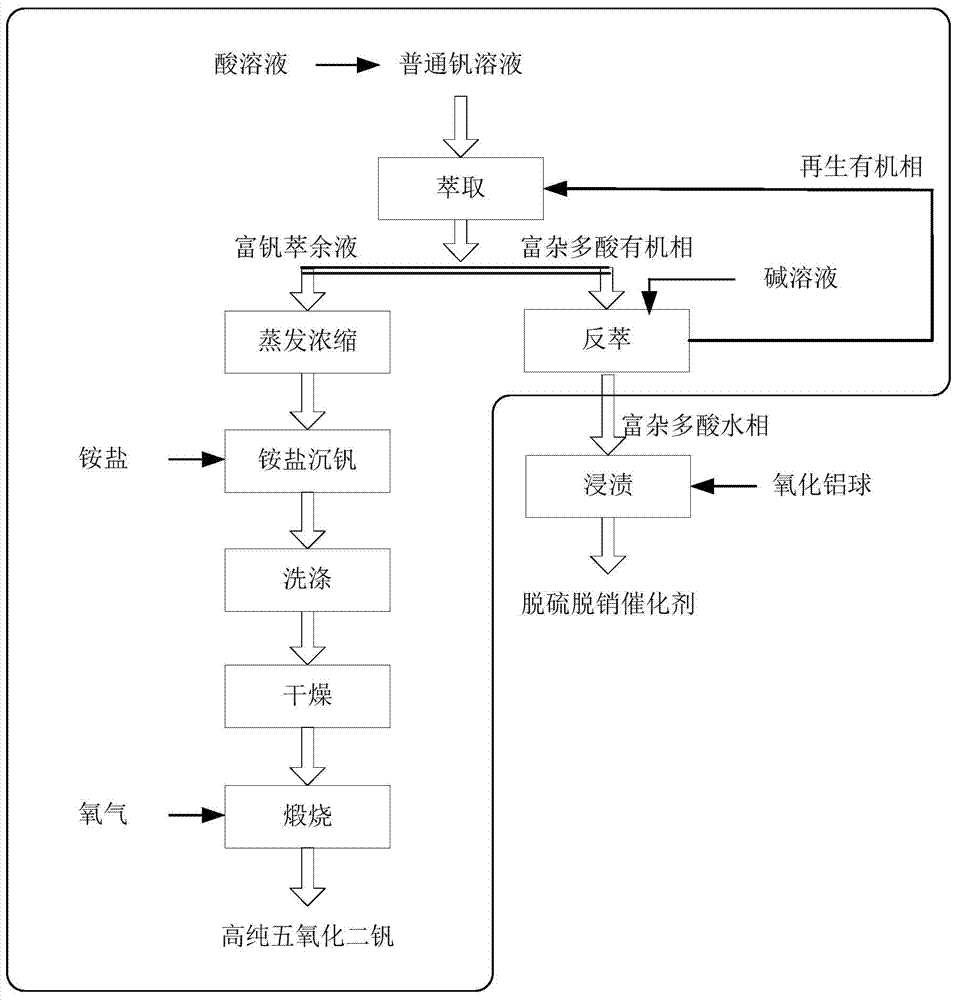

Method for preparing high-purity vanadium from heteropolyacid impurity in amine extraction mode

ActiveCN103540745AIncrease added valueImprove thermal stabilityProcess efficiency improvementAmmonium metavanadateRaffinate

The invention relates to a method for preparing high-purity vanadium from heteropolyacid impurities in an amine extraction mode. Generally an ordinary vanadium solution is doped with impurities such as chromium, silicon, phosphorus, tungsten, molybdenum and arsenic, if acid is added into the solution, heteropolyacids such as phosphorus tungsten, phosphorus vanadium tungsten, silicon tungsten, phosphorus molybdenum tungsten, silicon molybdenum tungsten, molybdenum vanadium arsenic and tungsten arsenic can be formed, the impurities in the solution are removed by carrying out compounding synergic extraction on the heteropolyacids in the ordinary vanadium solution by using amines and a synergist so as to obtain a purified vanadium-containing raffinate, subsequently the vanadium-containing raffinate is evaporated and concentrated to be the concentration that each liter of the solution contains 40g vanadium, ammonium salt is further added into the concentrated liquid to obtain ammonium metavanadate solid, vanadium pentoxide with the purity greater than 99.9% is obtained through washing in pure water, drying and calcining in an oxygen atmosphere, the organic phase after the heteropolyacid is extracted is subjected to reverse extraction by using an alkali solution so as to form a heteropolyacid water phase, and the organic phase is recycled and circulated. The method has low requirement on equipment, and is simple to operate, key extraction agents are good in thermal stability and not sensitive in acid and alkali, and a recycling and circulating method is simple and easy to be industrialized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

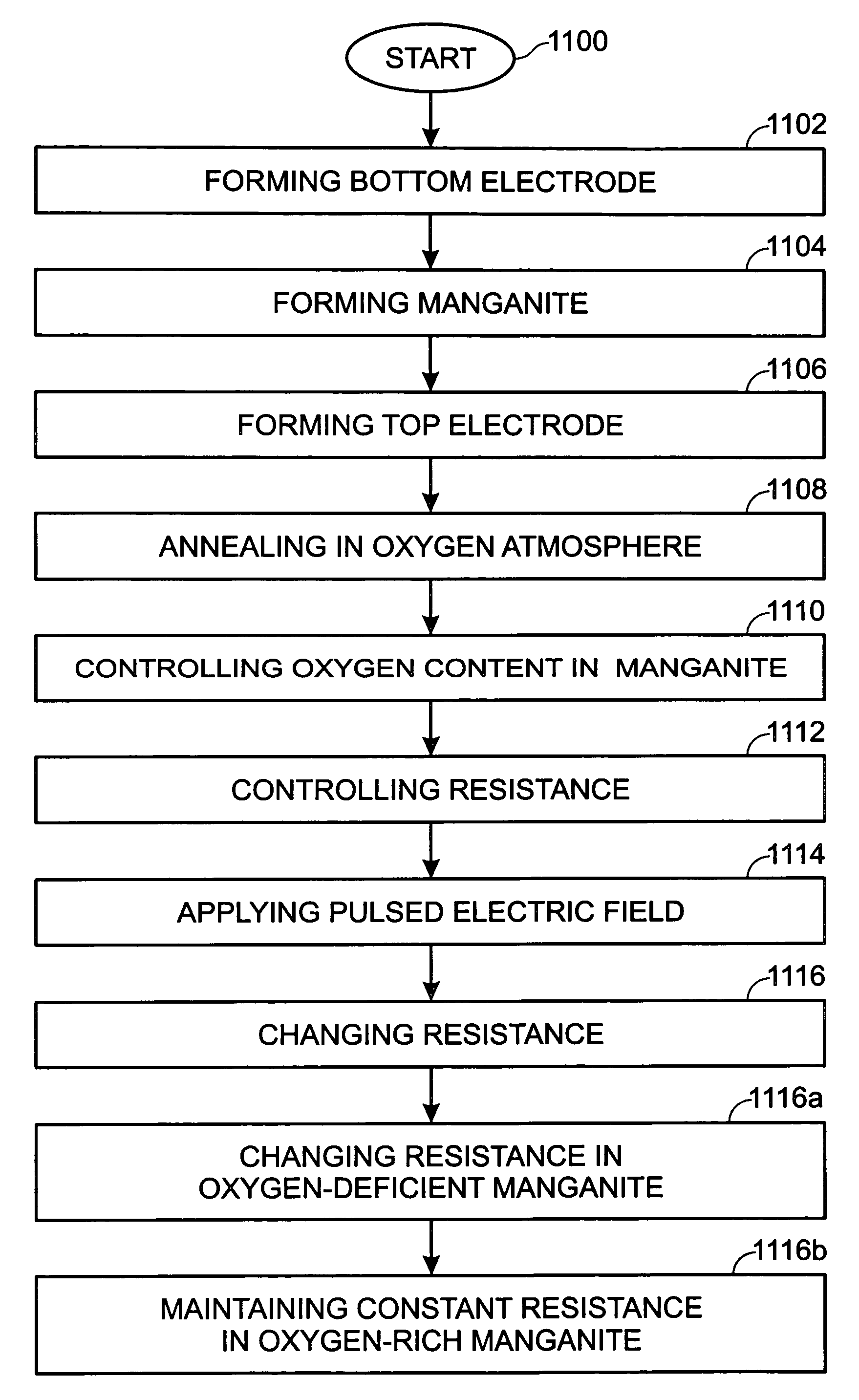

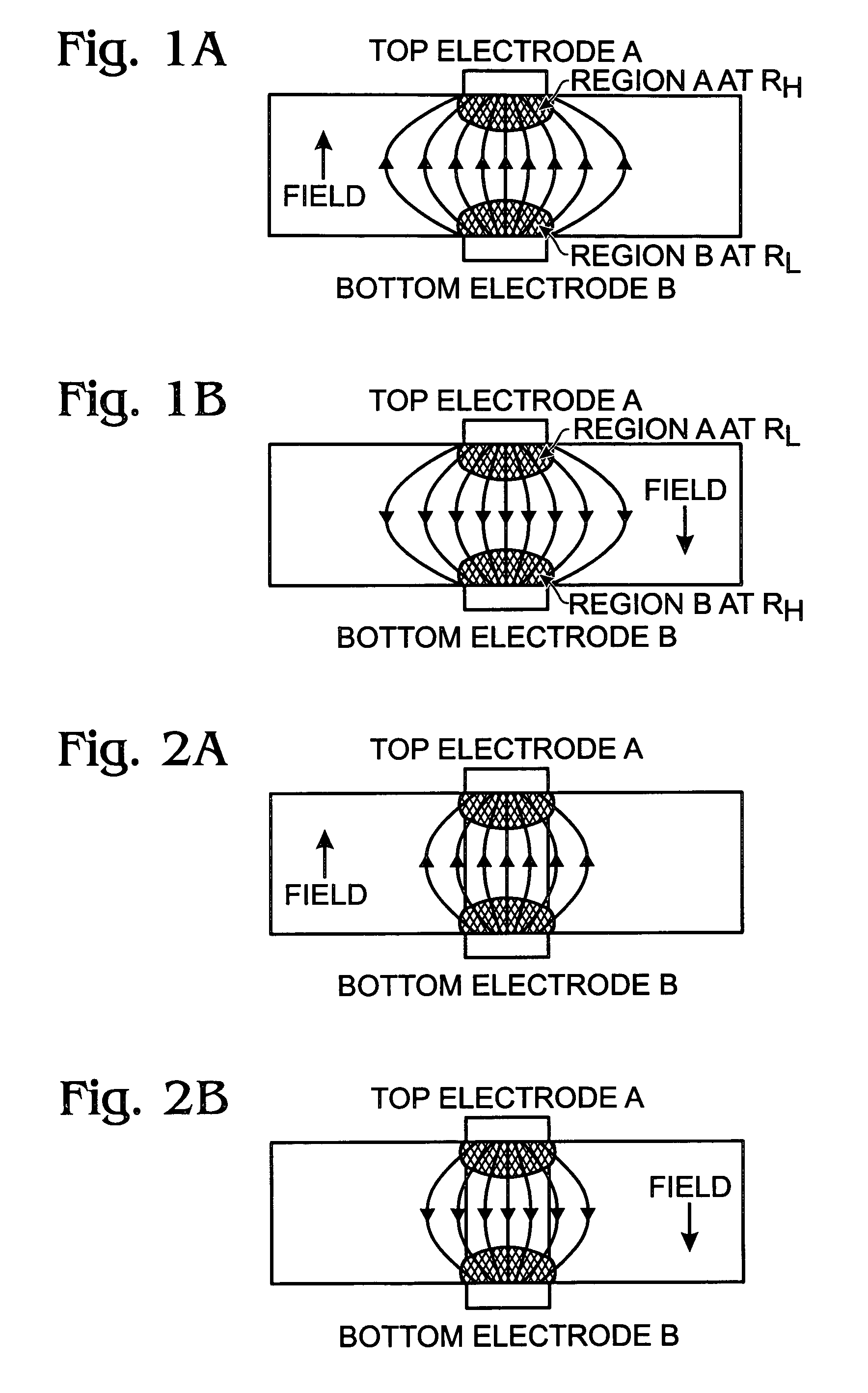

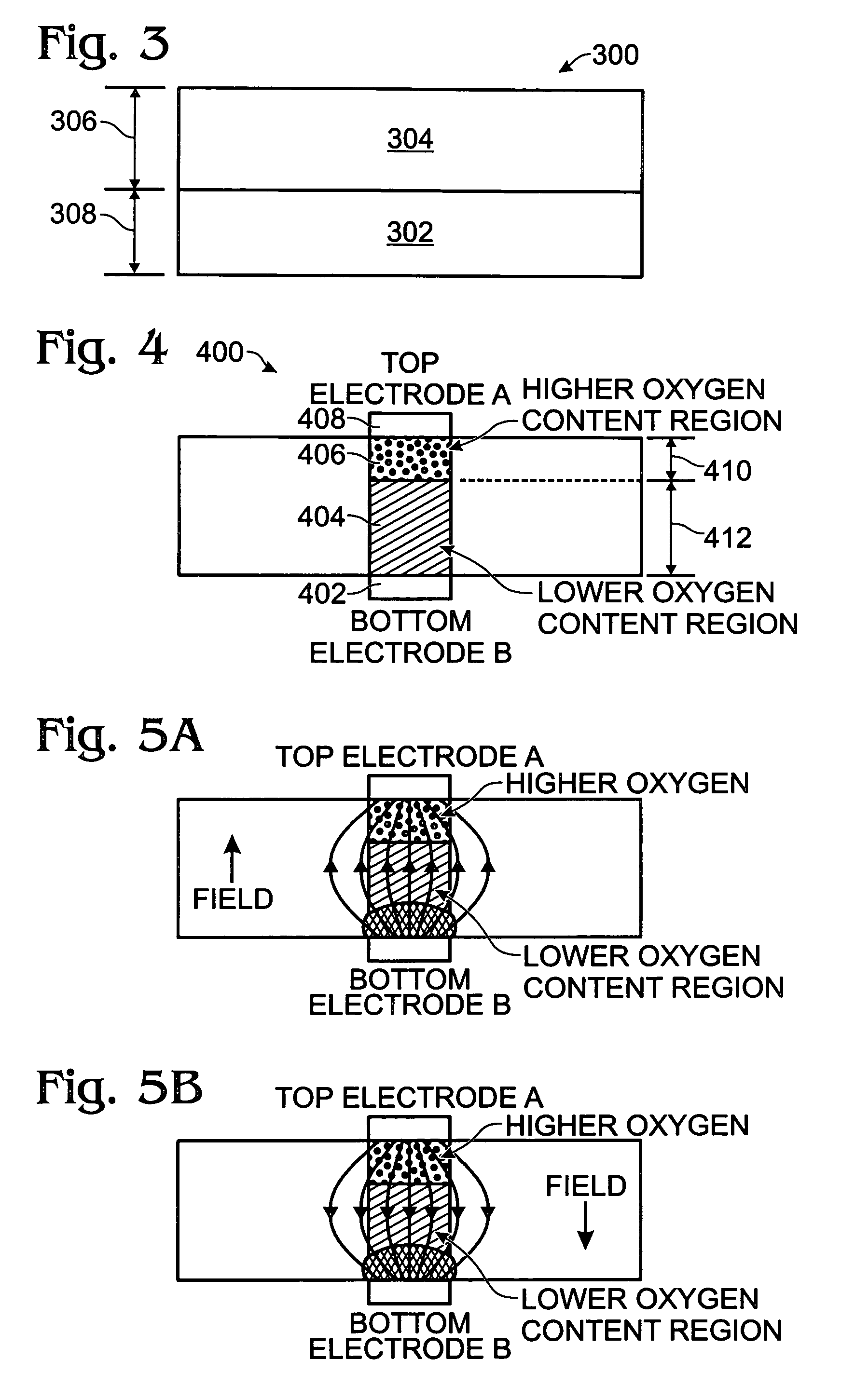

Oxygen content system and method for controlling memory resistance properties

ActiveUS6972238B2Reliably programmedCombustion-air/fuel-air treatmentSolid-state devicesHigh resistanceManganese oxide

A memory cell and method for controlling the resistance properties in a memory material are provided. The method comprises: forming manganite; annealing the manganite in an oxygen atmosphere; controlling the oxygen content in the manganite in response to the annealing; and, controlling resistance through the manganite in response to the oxygen content. The manganite is perovskite-type manganese oxides with the general formula RE1-xAExMnOy, where RE is a rare earth ion and AE is an alkaline-earth ion, with x in the range between 0.1 and 0.5. Controlling the oxygen content in the manganite includes forming an oxygen-rich RE1-xAExMnOy region where y is greater than 3. A low resistance results in the oxygen-rich manganite region. When y is less than 3, a high resistance is formed. More specifically, the process forms a low resistance oxygen-rich manganite region adjacent an oxygen-deficient high resistance manganite region.

Owner:XENOGENIC DEV LLC

Method for forming Ta2O5 dielectric layer using plasma enhanced atomic layer deposition

InactiveUS20020086476A1Enhance layeringImprove propertiesTransistorSemiconductor/solid-state device manufacturingElectric propertiesAtomic layer deposition

A method for forming a Ta2O5 dielectric layer using plasma enhanced atomic layer deposition, which can improve the quality of a layer and its electric property by forming a Ta2O5 dielectric layer using a plasma enhanced atomic layer deposition. The method for forming a Ta2O5 dielectric layer using plasma enhanced atomic layer deposition, comprising the steps of: a) flowing Ta(OC2H5)5 source gas in a chamber and generating plasma; b) depositing a Ta2O5 layer by using the plasma; c) purging the chamber; d) repeatedly performing the steps a) to c) in order to form a Ta2O5 dielectric layer; e) thermally treating the surface of the Ta2O5 dielectric layer in an oxygen atmosphere; and f) crystallizing the Ta2O5 dielectric layer.

Owner:INTELLECTUAL DISCOVERY CO LTD

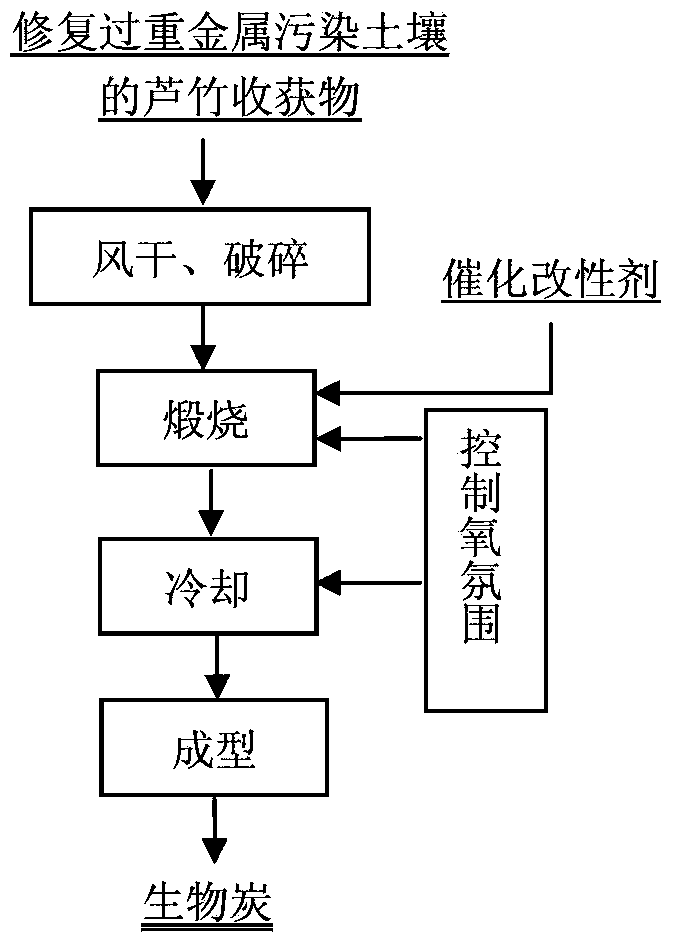

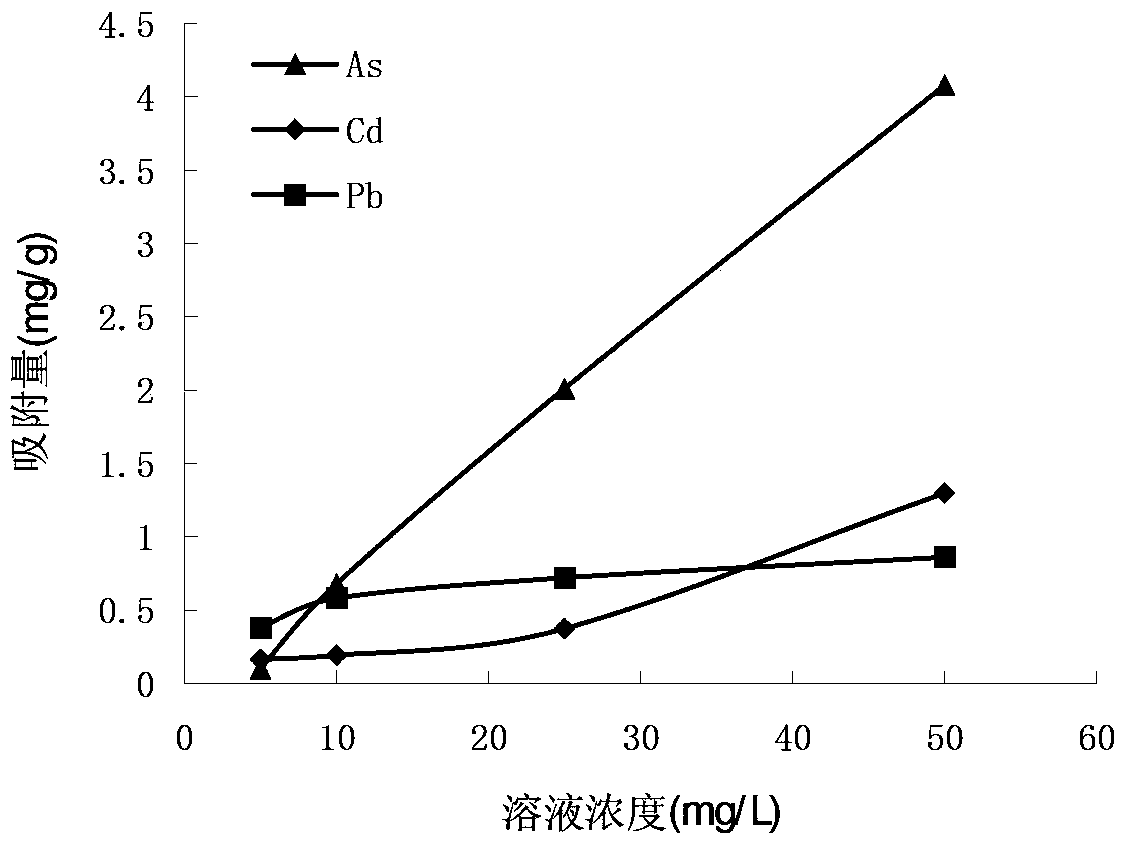

Resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil

ActiveCN103464101APrevent proliferationRealize deep purificationOther chemical processesDispersed particle separationResource utilizationBiochar

The invention discloses a resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil. The method comprises the following steps: air-drying and crushing the harvested plant bamboo reed used for restoring heavy metal contaminated soil, adding a catalytic modifier under a condition of controlling oxygen atmosphere, calcining the plant bamboo reed at 200-800 DEG C for 0.5-4 h, and cooling the plant bamboo reed to obtain charcoal, wherein the yield of the bamboo reed charcoal is 25-75%. When the bamboo reed charcoal is used for adsorbing heavy metals and compounds thereof in contaminated soil, wastewater or waste gases, the adsorption capacity reaches 0.4-6.0 mg / g; meanwhile, the bamboo reed charcoal can be used as an energy source raw material or a reducing agent to be comprehensively utilized by metallurgy enterprises. The invention provides an engineering approach for biomass resource utilization of contaminated soil restoring plants and solving the problem of potential secondary pollution.

Owner:CENT SOUTH UNIV

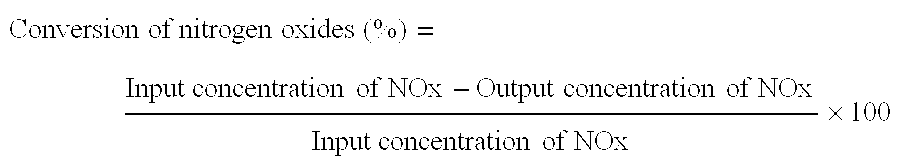

Method for preparing noble metal-supported zeolite catalyst for catalytic reduction of nitrogen oxide

InactiveUS6528031B1High activityMolecular sieve catalystsExhaust apparatusOrganic compoundReducing agent

The present invention provides a method for preparing a catalyst for the reduction of nitrogen oxides by the use of natural gas as a reducing agent in an excess oxygen atmosphere, which comprises of filling zeolite with an organic compound having molecular weight of 100~250 prior to loading catalytically active noble metal components on a zeolite. Since the method according to the present invention supports catalytic active noble metal components on a zeolite under the condition that the pores of zeolite are filled with organic compounds, the noble metal component, which is essential for forming highly active NOx reduction catalyst, can be supported precisely on the desired positions of zeolite pores. Therefore, the NOx reduction catalysts prepared by the present invention are very useful for the purification of exhaust gas in an excessive oxygen atmosphere such as gas turbines, boilers or lean-burn automobiles.

Owner:KOREA RES INST OF CHEM TECH

Method for producing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveCN102933496AImprove compactnessHigh strengthConductive layers on insulating-supportsTantalum compoundsPhysical chemistryThermal treatment

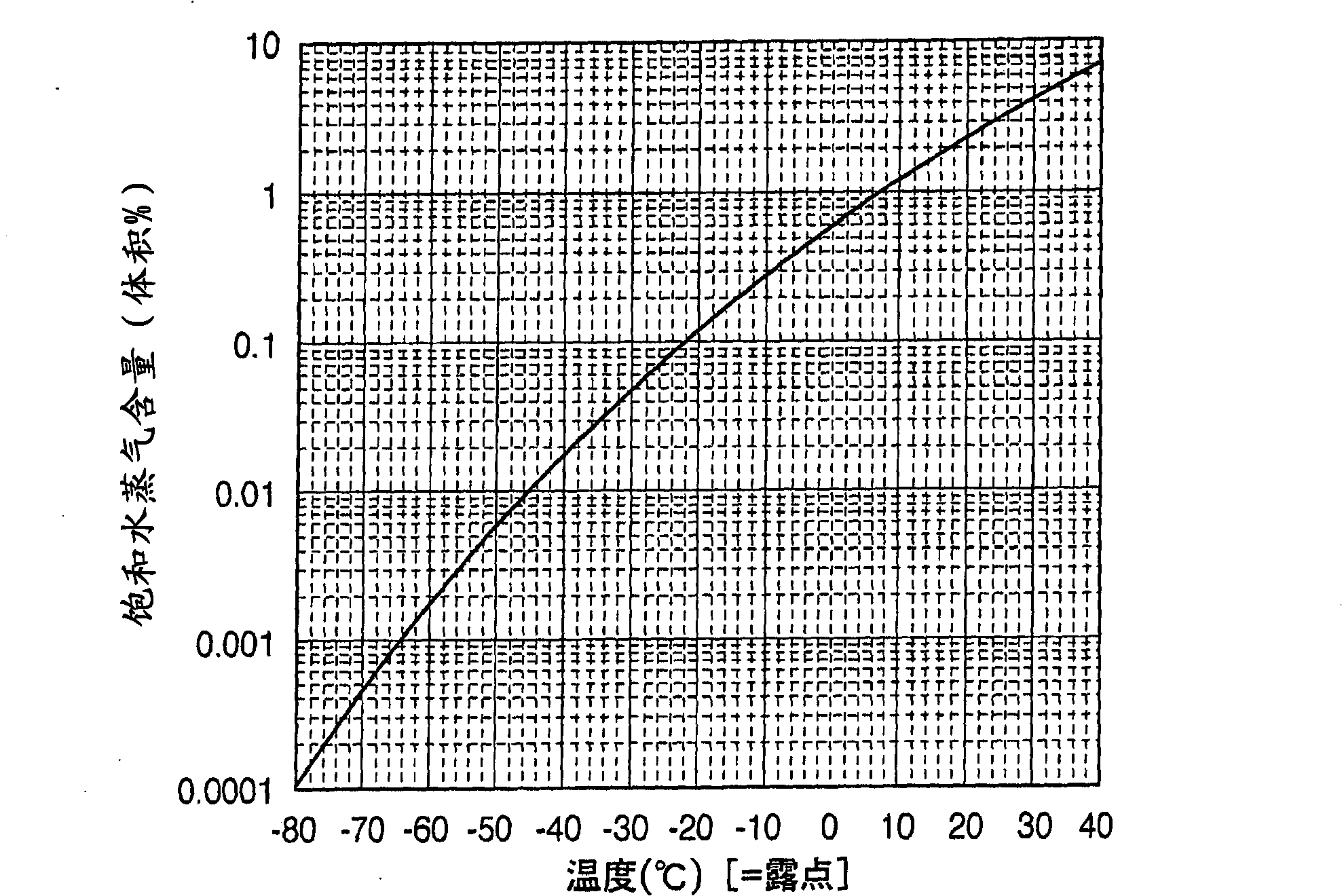

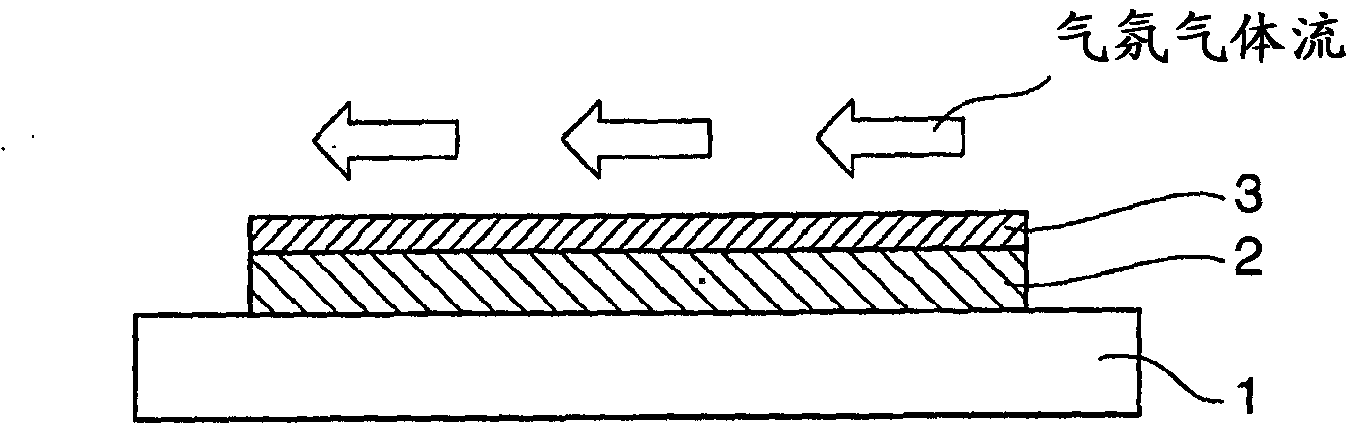

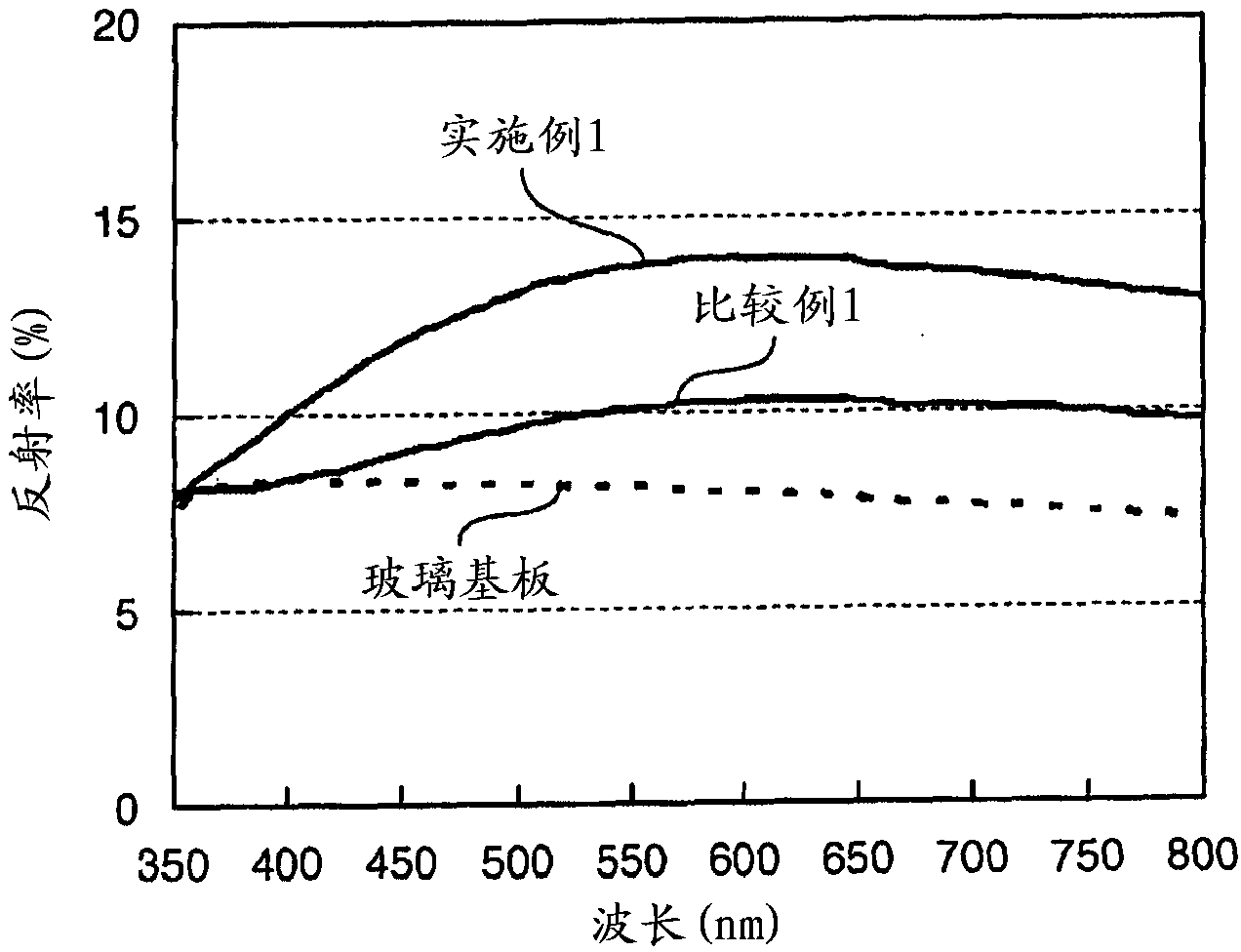

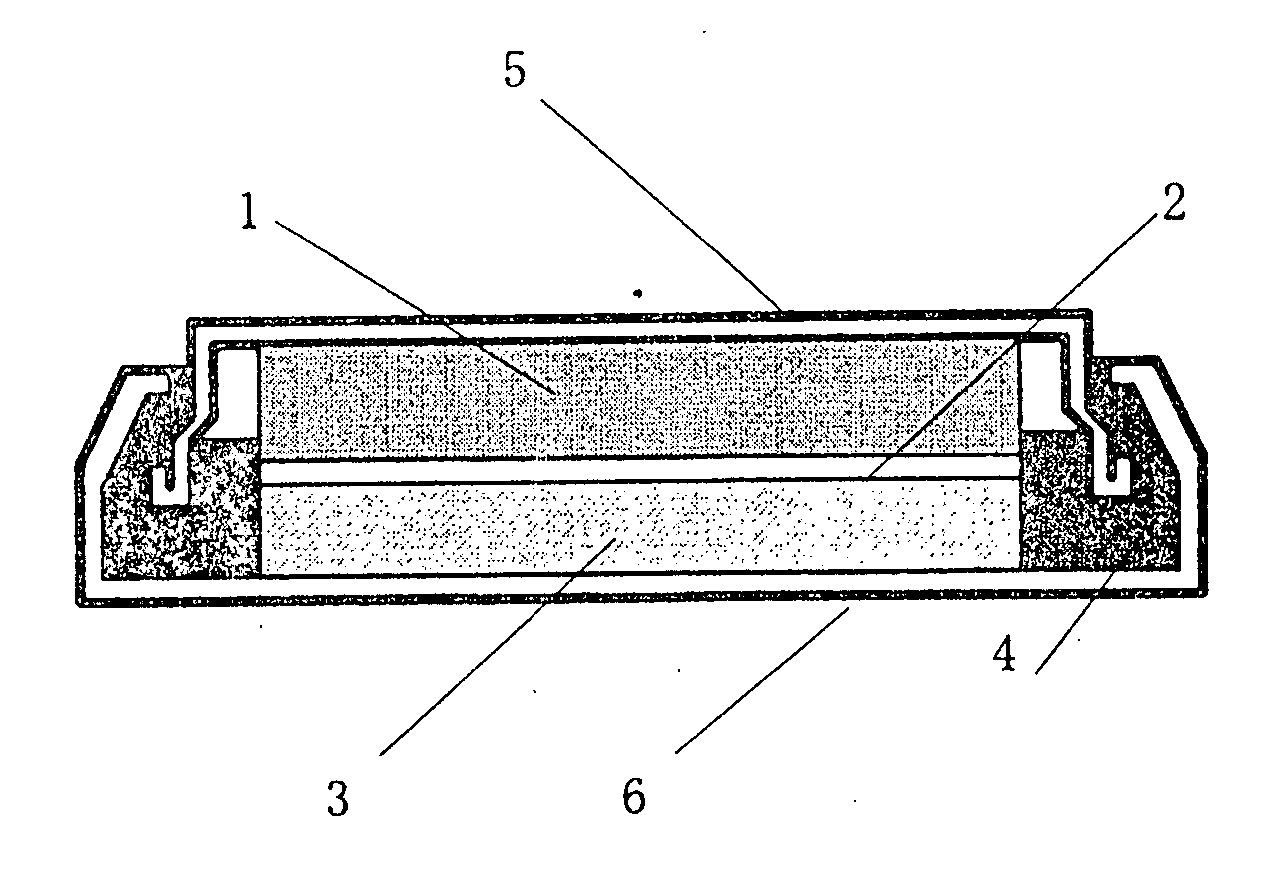

Disclosed are: a metal oxide film, which is formed by a coating method that is one of the methods for producing a metal oxide film, and which has a good balance between excellent transparency and high electrical conductivity, while having excellent film strength; and a method for producing the metal oxide film. Specifically disclosed is a method for producing a metal oxide film, which comprises: a coating step wherein a coating film is formed on a substrate using a metal oxide film-forming coating liquid that contains various organic metal compounds; a drying step wherein the coating film is changed into a dry coating film; and a heating step wherein an inorganic film is formed from the dry coating film. The method for producing a metal oxide film is characterized in that in the heating step, the dry coating film, which is mainly composed of the various organic metal compounds, is heated to a temperature at which at least mineralization of organic metal compound components occurs or higher in an oxygen-containing atmosphere at a temperature not higher than the temperature that is lower by 10 DEG C than the dew point, so that the organic components in the dry coating film are removed by thermal decomposition or combustion, or by thermal decomposition and combustion, thereby forming a metal oxide fine particle layer which is densely filled with metal oxide fine particles that are mainly composed of various metal oxides.

Owner:SUMITOMO METAL MINING CO LTD

Positive electrode active material for non-aqueous electrolyte-based secondary battery, production method therefor and non-aqueous electrolyte-based secondary battery using the same

ActiveUS20070231691A1Large capacityLow costNon-aqueous electrolyte accumulatorsActive material electrodesAir atmosphereHeat stability

The present invention provides a positive electrode active material for a non-aqueous electrolyte-based secondary battery, composed of a lithium / nickel composite oxide with high capacity, low cost and excellent heat stability, an industrially suitable production method therefor, and a high safety non-aqueous electrolyte-based secondary battery. A lithium / nickel composite oxide is produced by the following steps (a) to (c): (a) Nickel hydroxide or nickel oxyhydroxide having a specified component is prepared at a temperature of 600 to 1100° C., under air atmosphere. (b) Fired powders are prepared after mixing said nickel oxide and a lithium compound, and then by firing at a maximal temperature range of 650 to 850° C., under oxygen atmosphere. (c) Obtained fired powders are washed with water within a time satisfying the following equation (2) and then filtered and dried. A<B / 40 (2) wherein, A represents washing time represented by unit of minute; and B represents slurry concentration represented by unit of g / L).

Owner:SUMITOMO METAL MINING CO LTD +1

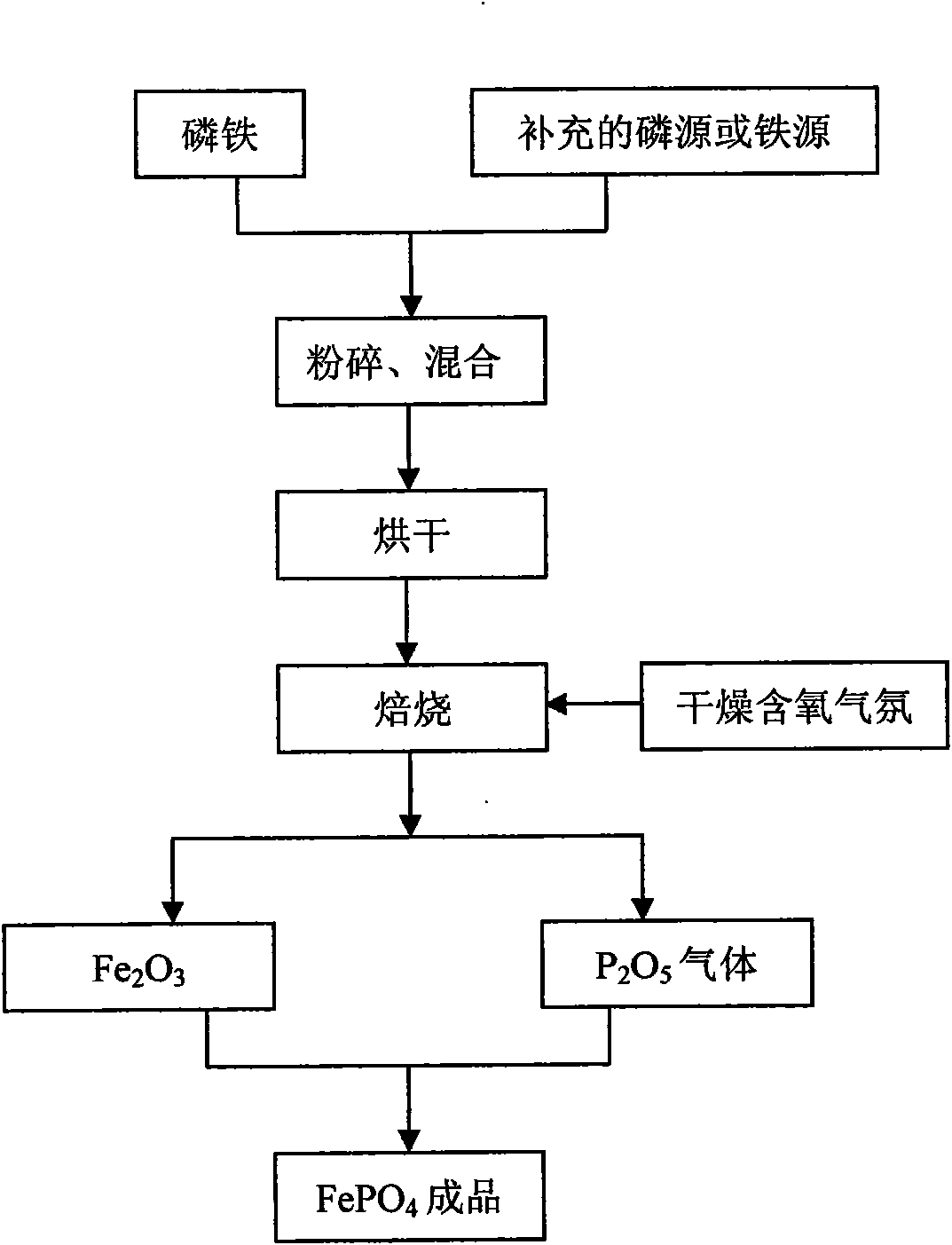

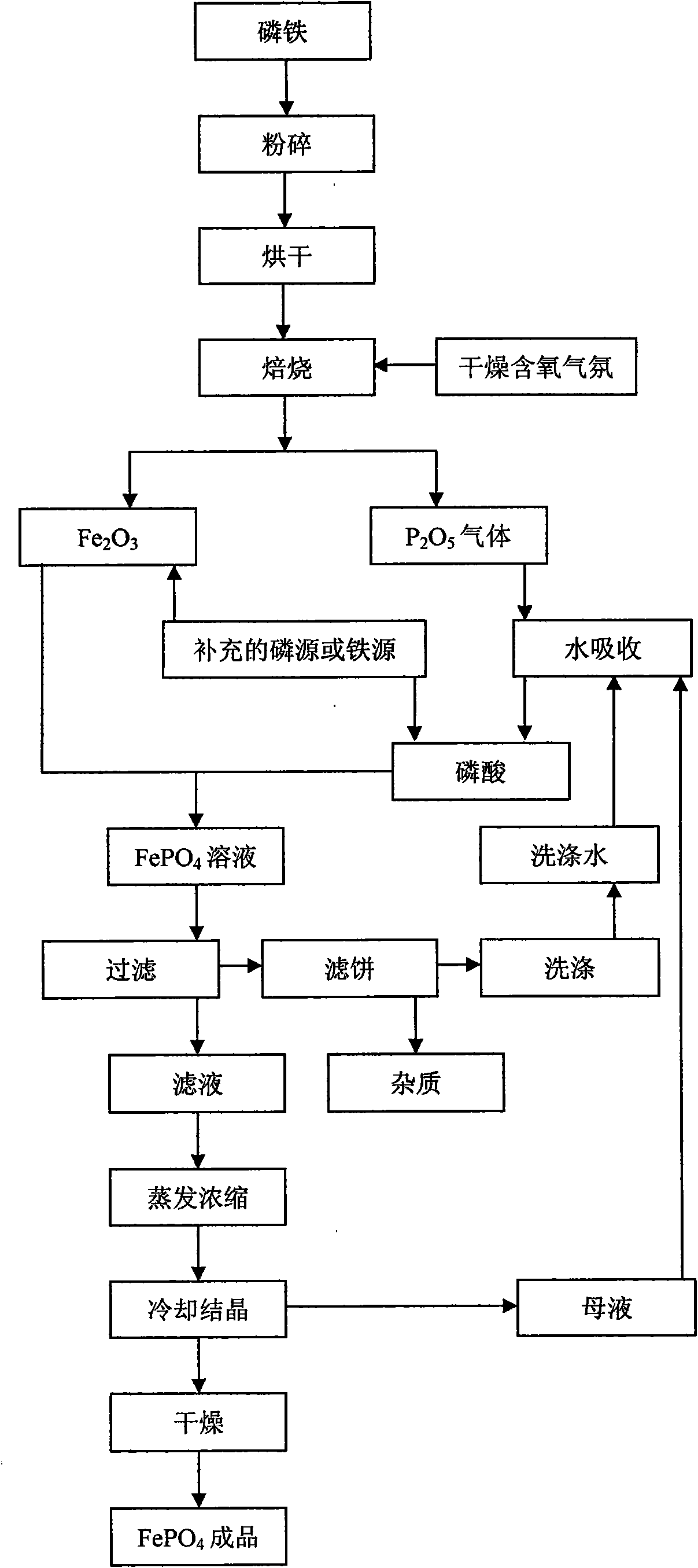

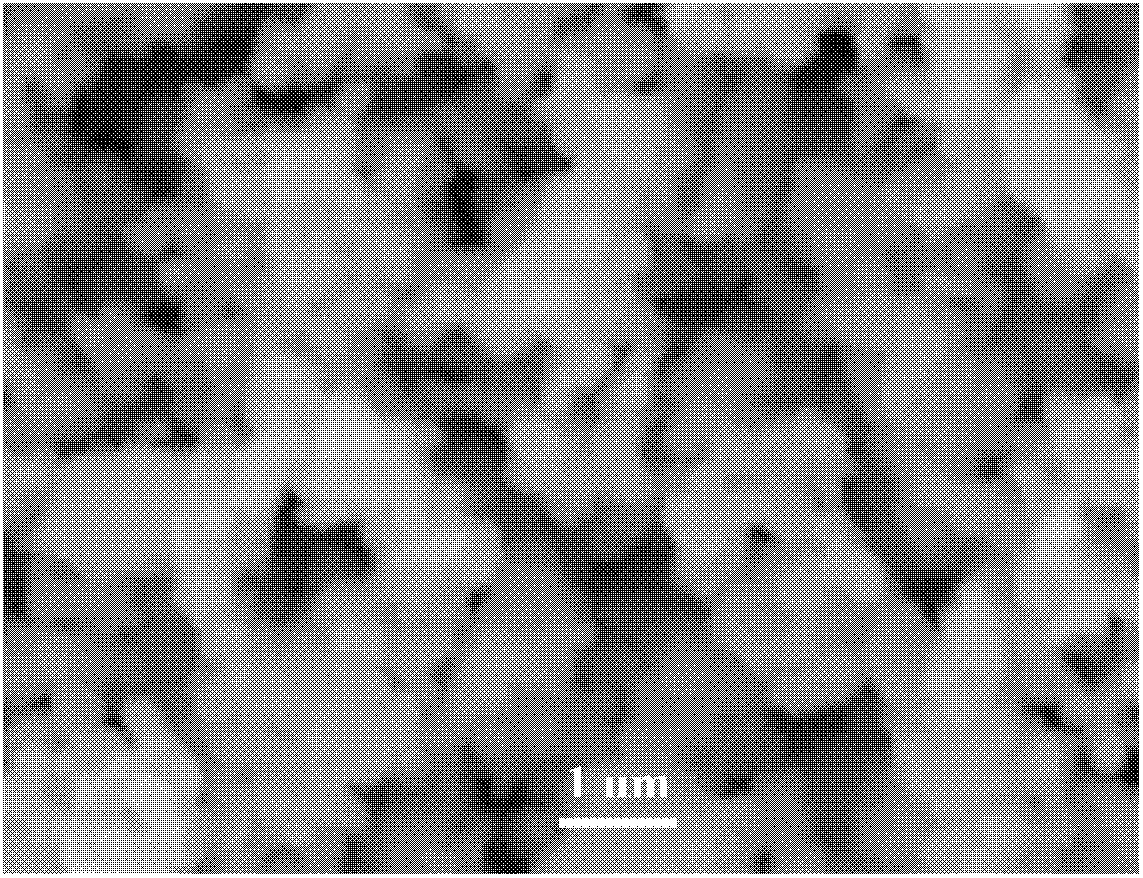

Method for preparing iron phosphate from ferrophosphorus

InactiveCN101659406AOvercome the problem of difficult ratioWide variety of sourcesPhosphorus compoundsLow demandResource utilization

The invention relates to a method for preparing iron phosphate from ferrophosphorus. The ferrophosphorus is used as a part or the whole of a phosphorus source and an iron source for preparing the ironphosphate. The phosphorus source or the iron source is supplemented according to a mol ratio of (0.8-1.2):1.0 between total phosphorus elements and total iron elements. The ferrophosphorus is roastedin a dry and oxygen-containing atmosphere. The iron phosphate product is obtained by means of dry or wet oxidation product reaction. The method adopts the ferrophosphorus as the raw material for preparing the iron phosphate, makes full use of elements in the ferrophosphorus and creates a novel preparing process of iron phosphate. In addition, as the reaction process can be used for weakening or eliminating the influence of impurity elements in the ferrophosphorus on the iron phosphate product, the method indirectly purifies the ferrophosphorus and eliminates the influence of the impurities inthe ferrophosphorus and the problem of severe corrosion caused by the existence of water during the roasting of ferrophosphorus. The reaction process has relatively low demand on apparatuses. The preparing method has simple process, short production flow and low production cost, is clean and environment-friendly, realizes high resource utilization rate, low investment and good benefit and is suitable for large-scale, industrial, low-cost and clean preparation of iron phosphate.

Owner:SICHUAN UNIV

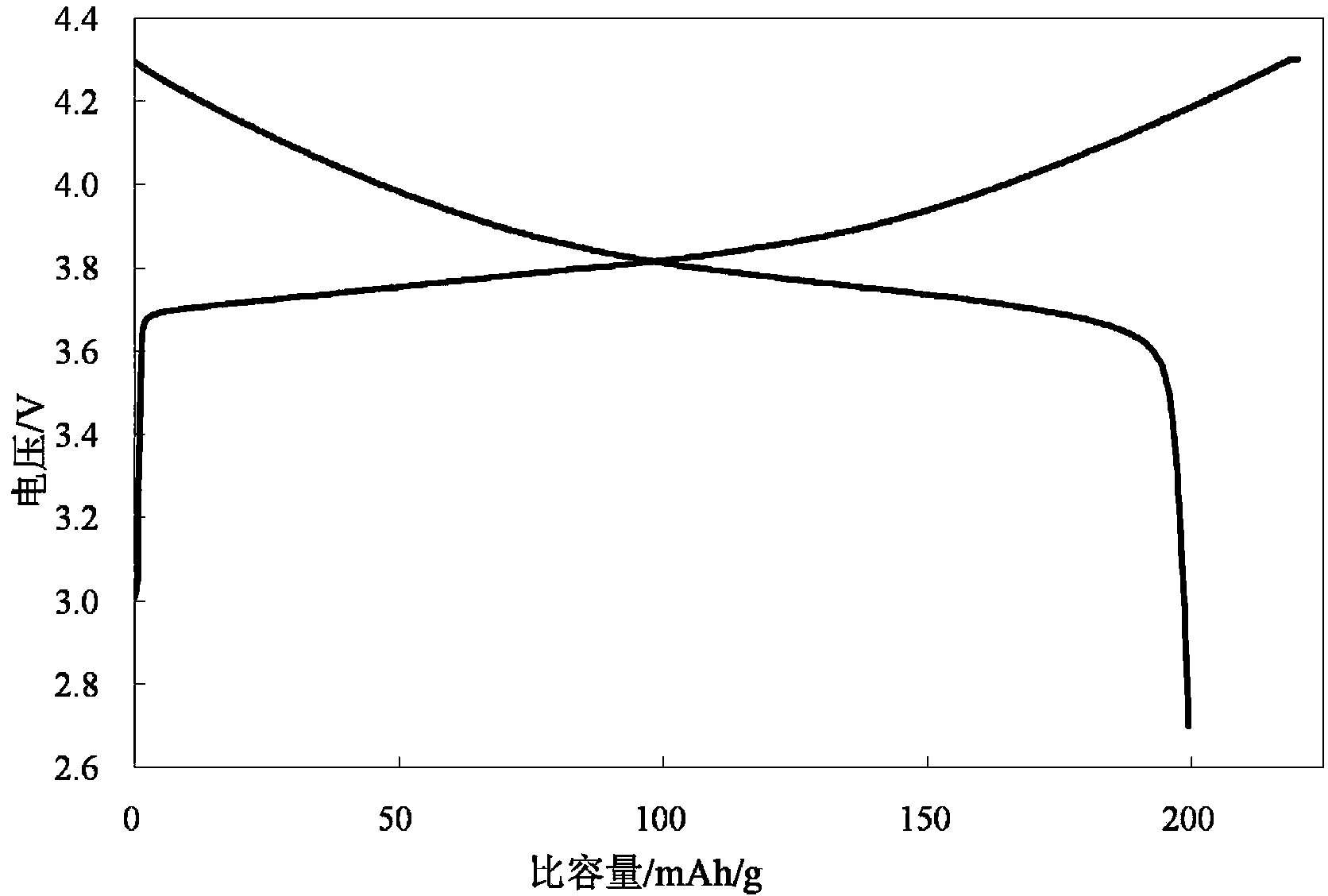

Method for preparing ternary complex anode material (LiNixCoyMn1-x-yO2)

The invention discloses a method for preparing a ternary complex anode material (LiNixCoyMn1-x-yO2), which is characterized in that the lithium ion battery anode material (LiNixCoyMn1-x-yO2) is prepared by adopting a coprecipitation-silicon cladding-high temperature sintering-desilicication integrated method, and specifically comprises the following steps: mixing a nickel source and a cobalt source with a manganese source according to molar ratio of nickel-cobalt-manganese: x:y:(1-x-y), adding with water, stirring to form a solution, adding with a certain amount of ammonia water and a sodium hydroxide solution to generate a uniform NixCoyMn1-x-y(OH)2 ocyhydrate precursor, washing and filtering the precursor, adding with a certain amount of polyvinylpyrrolidone, stirring for a certain period, adding with a certain quantity of organosilicon reagents, stirring continuously to obtain an ocyhydrate precursor wrapped by organosilicon reagent-polyvinylpyrrolidone, washing, filtering, drying and then mixing the ocyhydrate precursor with a lithium source, calcining the mixture under air or an oxygen atmosphere under the temperature of 450-950 DEG C for 2-48 hours, and removing a silicon wrapping layer on a product by the utilizing a sodium hydroxide solution, thus obtaining the nanoscale or standard nanoscale lithium ion battery ternary complex anode material (LiNixCoyMn1-x-yO2). The particle size of the anode material prepared by the invention ranges from 80nm-180nm, the initial charging / discharging performance achieves 194.4-210.3mAh / g, and the electrochemical performance is excellent.

Owner:CENT SOUTH UNIV

Modified nickel-cobalt lithium aluminate positive electrode material and preparation method thereof

ActiveCN103972499ASuppression of shufflingImprove electrochemical performanceCell electrodesSecondary cellsNickel saltLithium aluminate

The invention relates to a modified nickel-cobalt lithium aluminate positive electrode material and a preparation method of the material. The chemical general formula of the material is LiNi(1-a-b)CoaAlbO2 / TiO2, wherein a is greater than 0.1 and less than 0.3; b is greater than 0.01 and less than 0.2; 1-a-b is greater than 0 and less than 1; the TiO2 layer is a coating layer; the preparation method of the material comprises the following steps: preparing soluble metal nickel salt, cobalt salt and aluminium salt into a mixed salt solution, preparing the mixed salt solution, NaOH and ammonia water into a mixed alkali solution for reacting, filtering, washing, drying and then roasting the mixed alkali solution for 5-10 hours at the temperature of 400-600 DEG C in the oxygen atmosphere, then carrying out ball milling and uniformly mixing with lithium salt, roasting the mixed alkali solution for 6-16 hours at the high temperature of 800-1000 DEG C in the oxygen atmosphere, coating the mixed alkali solution by titanium dioxide to prepare the modified nickel-cobalt lithium aluminate positive electrode material. The prepared modified ternary positive electrode material of the lithium ion battery is good in electrochemical performance; the dry coating process is free of waste liquid and high-temperature sintering, so that the energy consumption and the cost are reduced.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

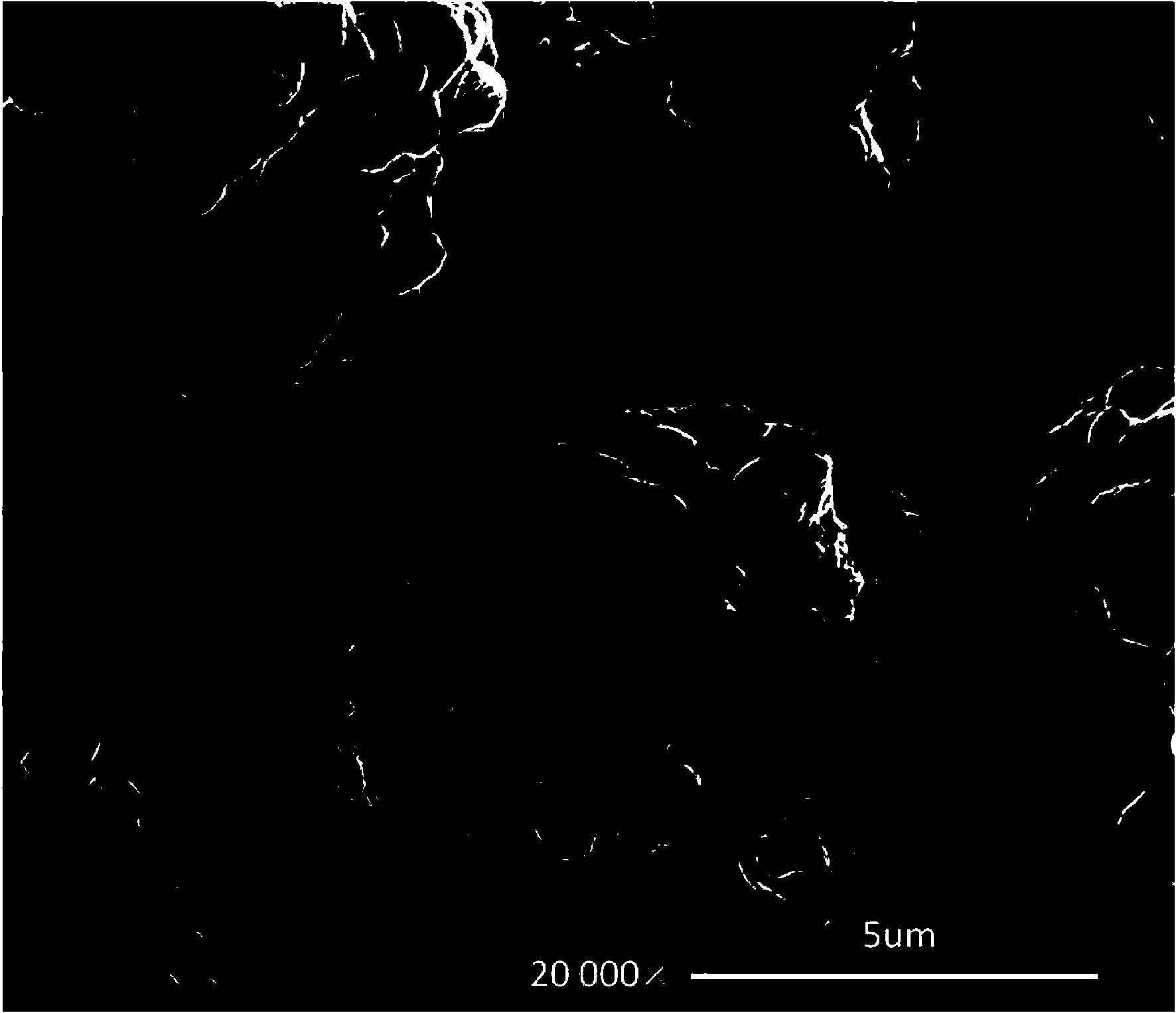

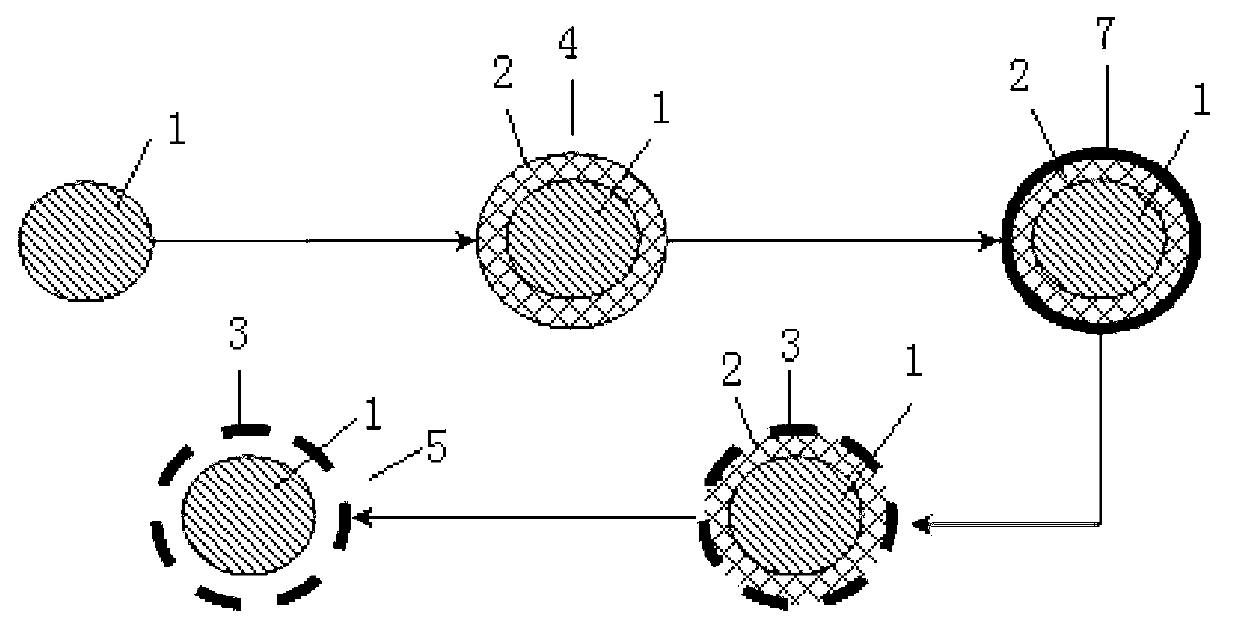

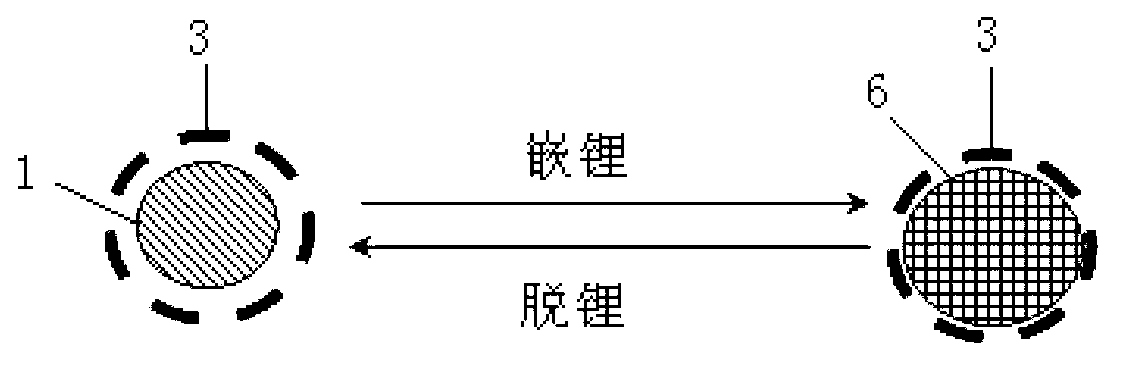

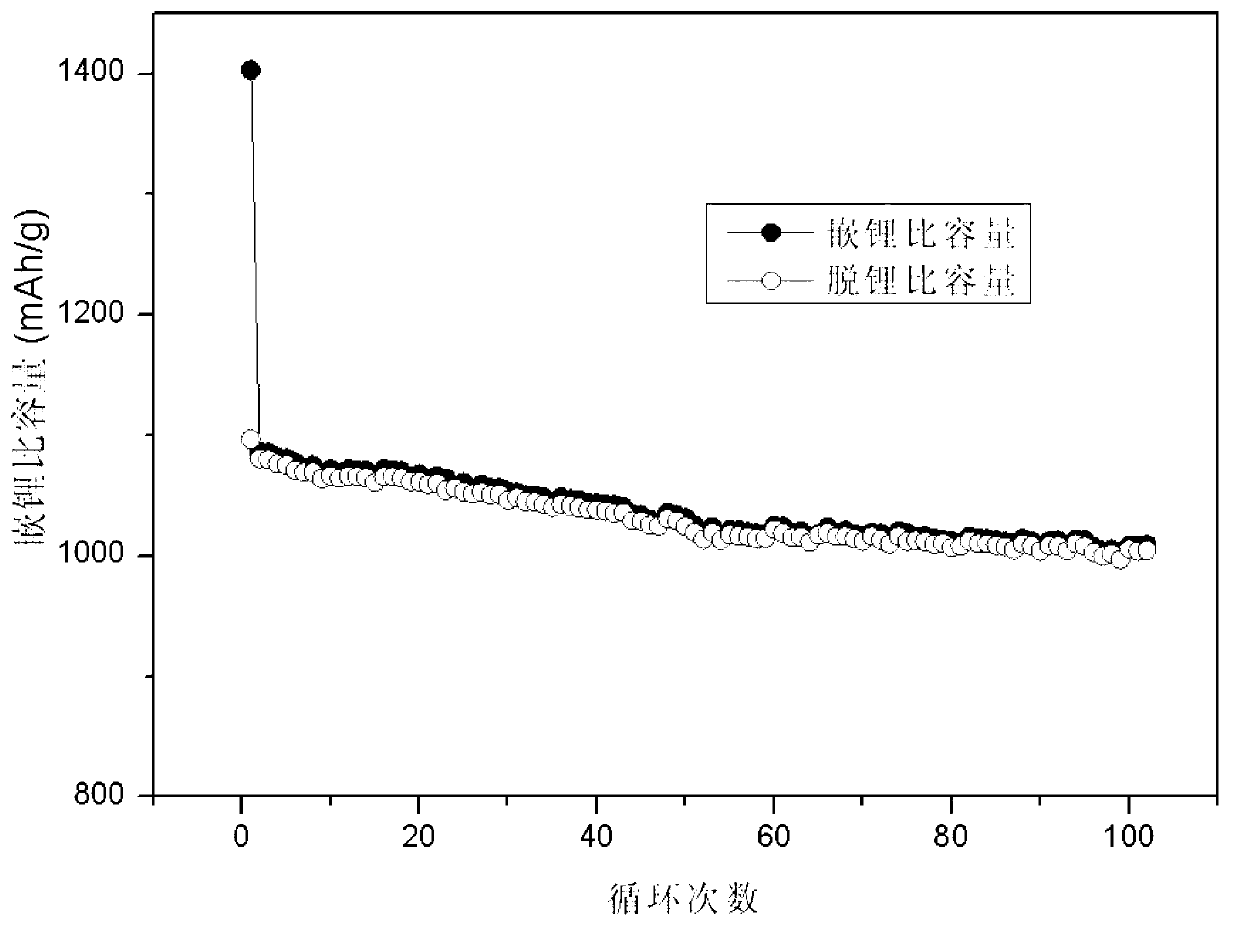

Si-C composite material and preparation method thereof and lithium ion battery containing same

ActiveCN103107317APossesses electrochemical reversible intercalation and delithiation performanceAlleviate chalking and sheddingElectrode manufacturing processesSecondary cellsCarbon compositesElectrical battery

The invention discloses a preparation method of a Si-C composite material. The preparation method comprises the following steps of: (1) cauterizing Si powder in an oxygen-containing atmosphere to obtain a SiO2-coated Si composite material; (2) mixing the SiO2-coated Si composite material with a carbohydrate, coating the SiO2-coated Si composite material with a carbon precursor by a hydrothermal method, and heating and carbonizing in an inert atmosphere to obtain a carbon-coated composite material which is coated on the SiO2-coated Si composite material; and (3) corroding SiO2 with excessive hydrofluoric acid to obtain the Si-C composite material. The Si-C composite material provided by the invention has electrochemical reversible lithium embedding / extraction property so as to effectively prevent chalking and dropping of the active particles in the charge / discharge process, and also has high lithium storage capacity property of the Si-based material as well as high cycling stability of the C-based material. Therefore, a battery prepared by the Si-C composite material has better cycling performance.

Owner:CHERY AUTOMOBILE CO LTD

Supported chromium catalyst and its use for preparing homopolymers and copolymers of ethylene

A process for preparing supported, titanized chromium catalysts is disclosed. The process comprises A) bringing a support material into contact with a protic medium comprising a titanium compound and a chromium compound; B) optionally removing the solvent; C) optionally calcining the precatalyst obtained after step B); and D) optionally activating the precatalyst obtained after step B) or C) in an oxygen-containing atmosphere at from 400° C. to 1100° C.

Owner:BASELL POLYOLEFINE GMBH

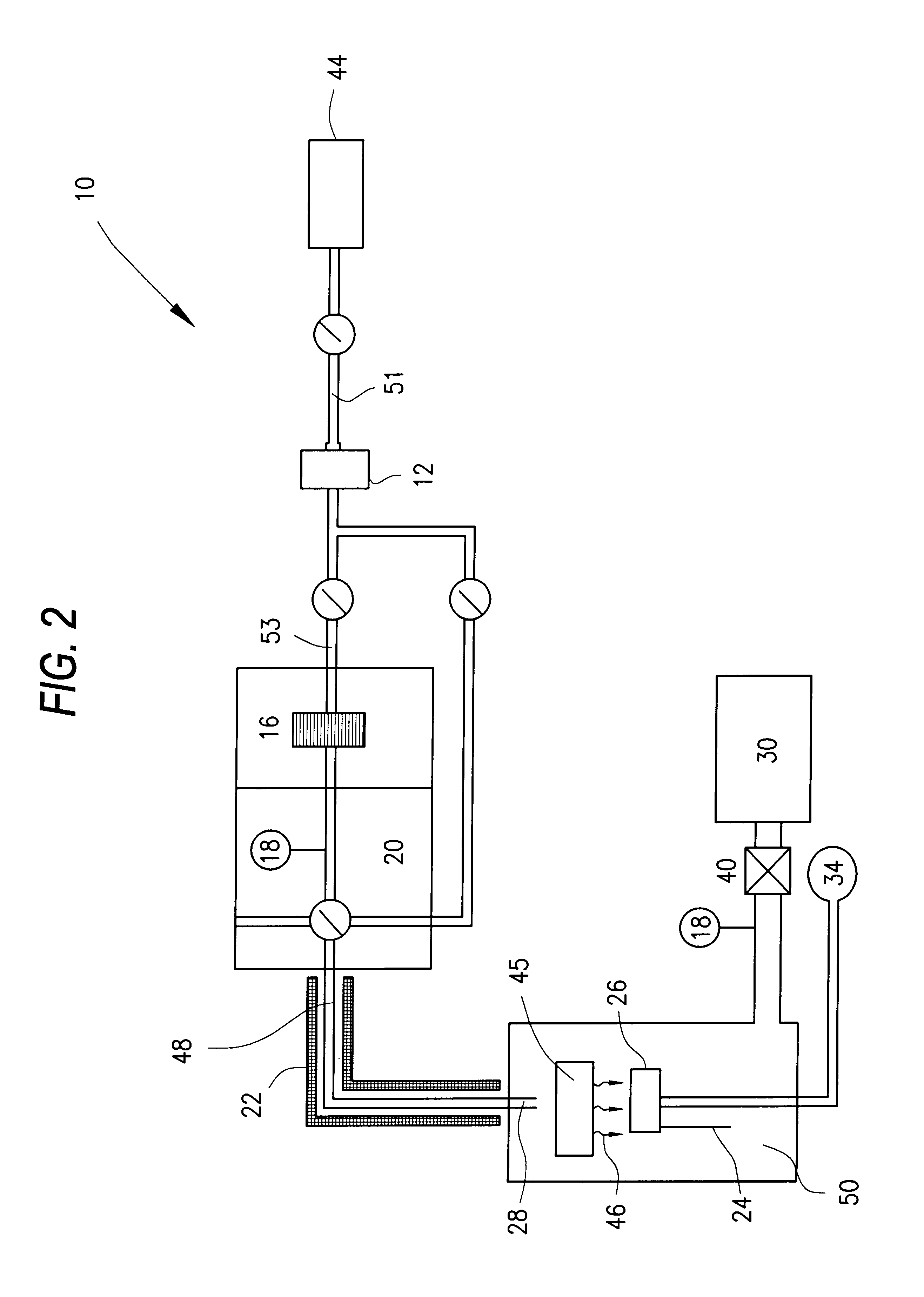

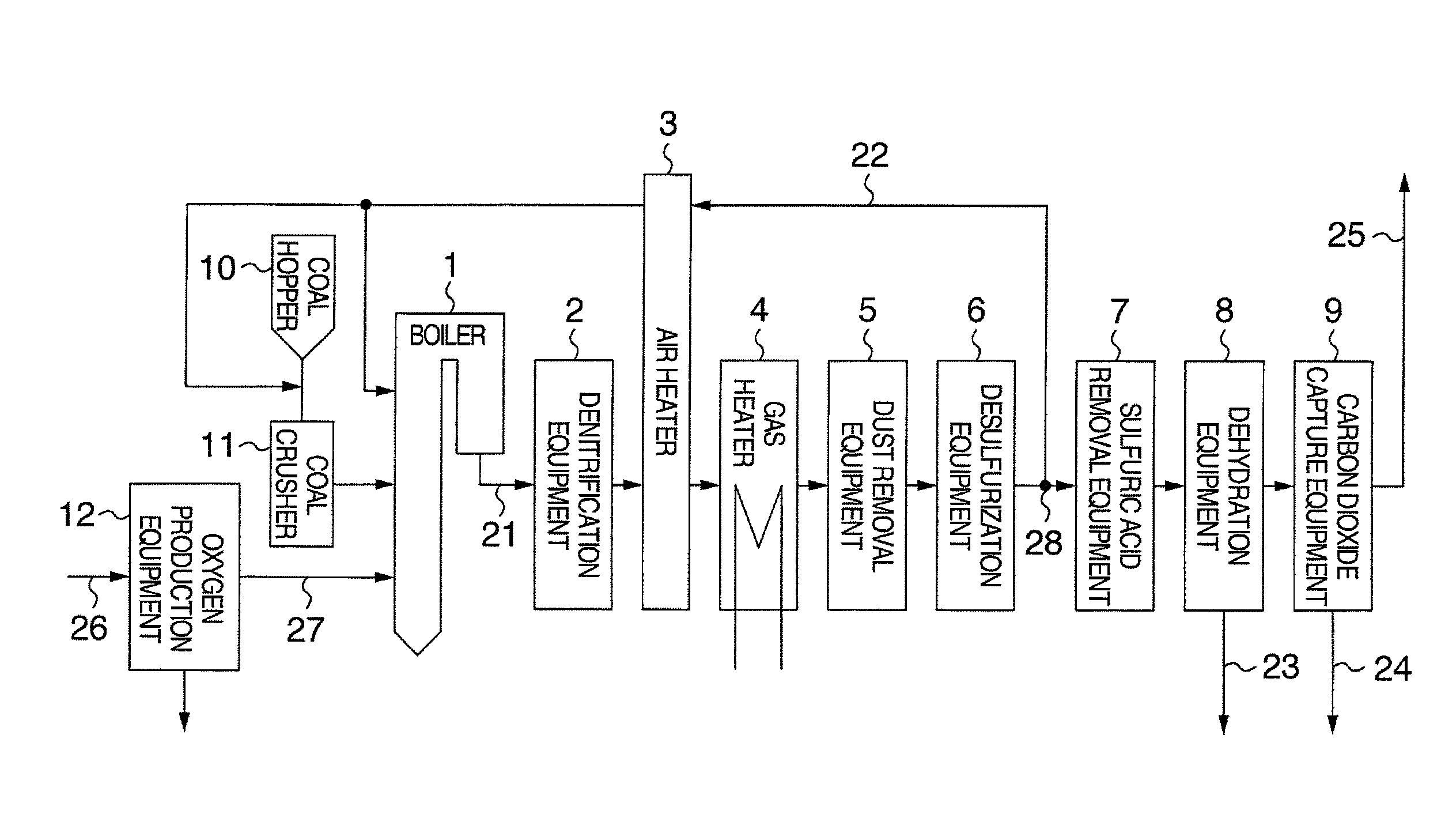

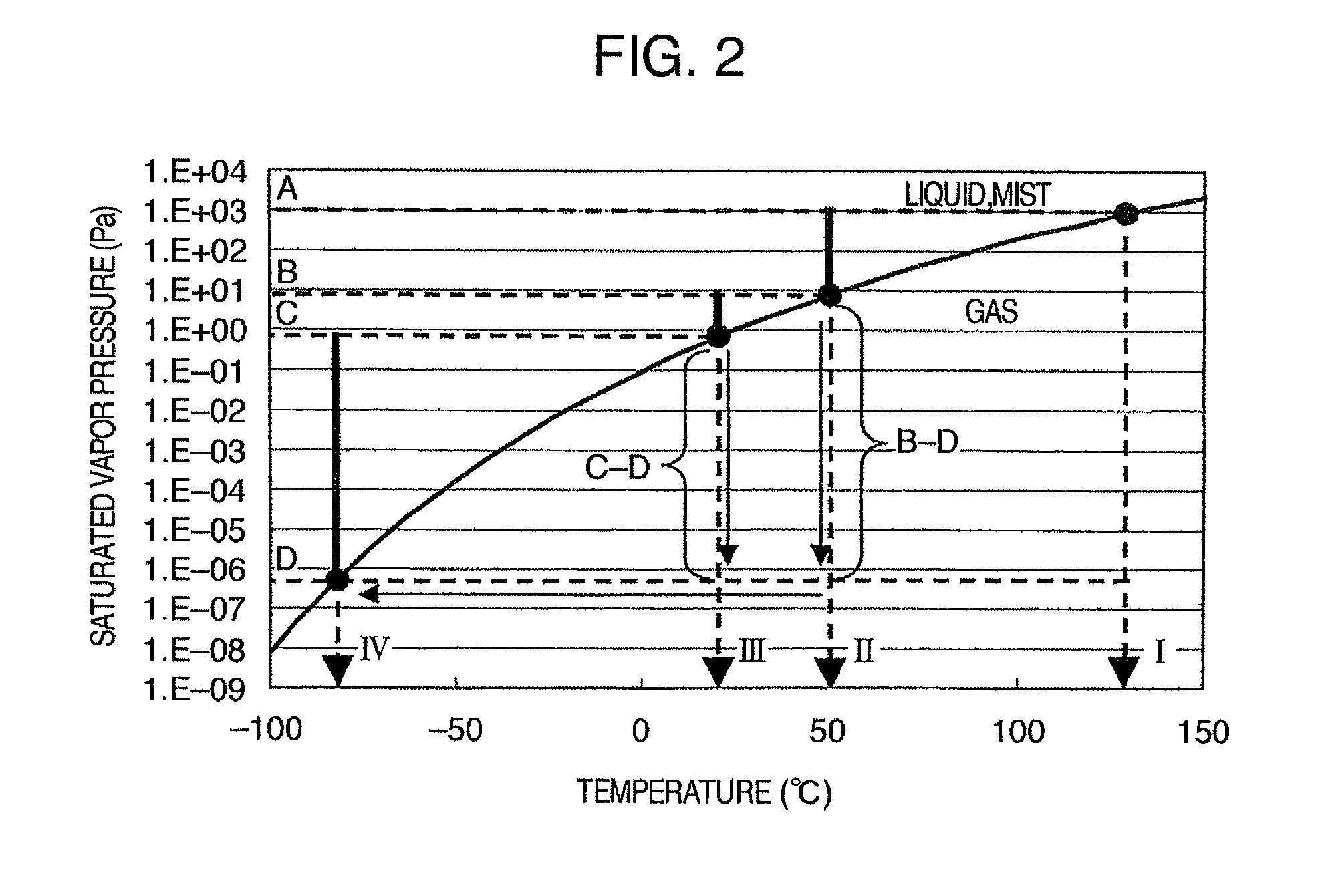

Carbon dioxide capture power generation system

ActiveUS8500881B2Corrosion of the members by long run can be preventedCombination devicesExhaust apparatusCombustionSulfur

Owner:MITSUBISHI POWER LTD

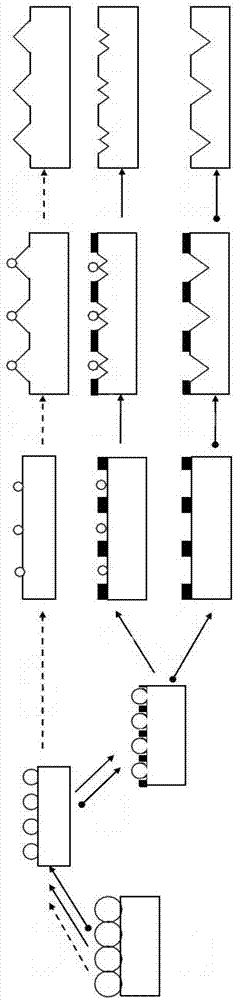

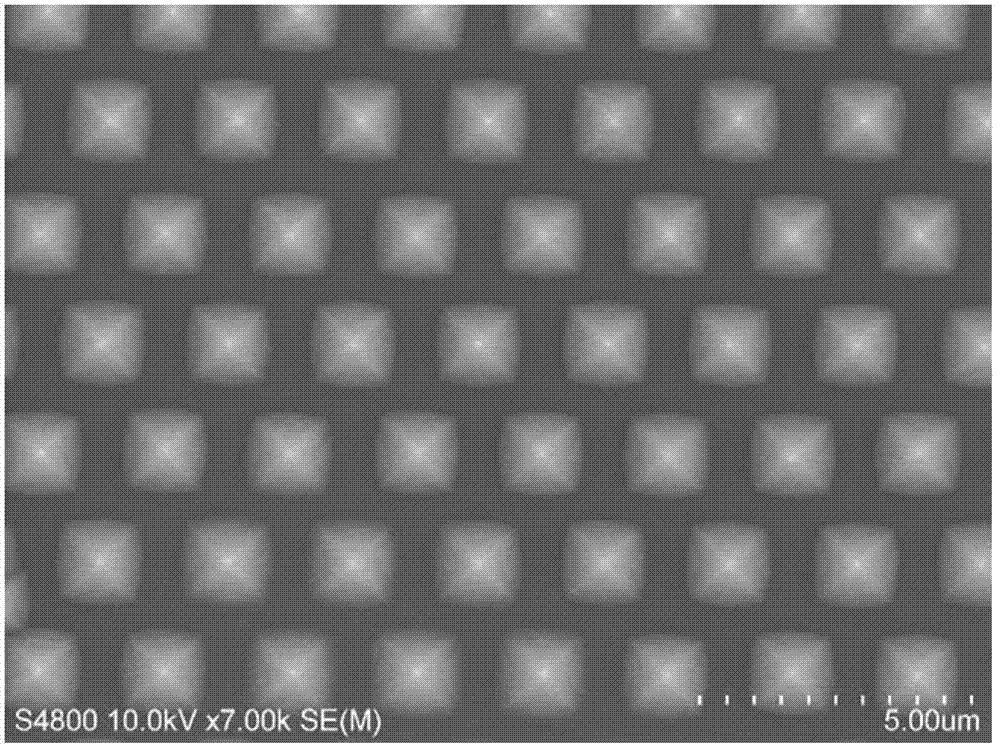

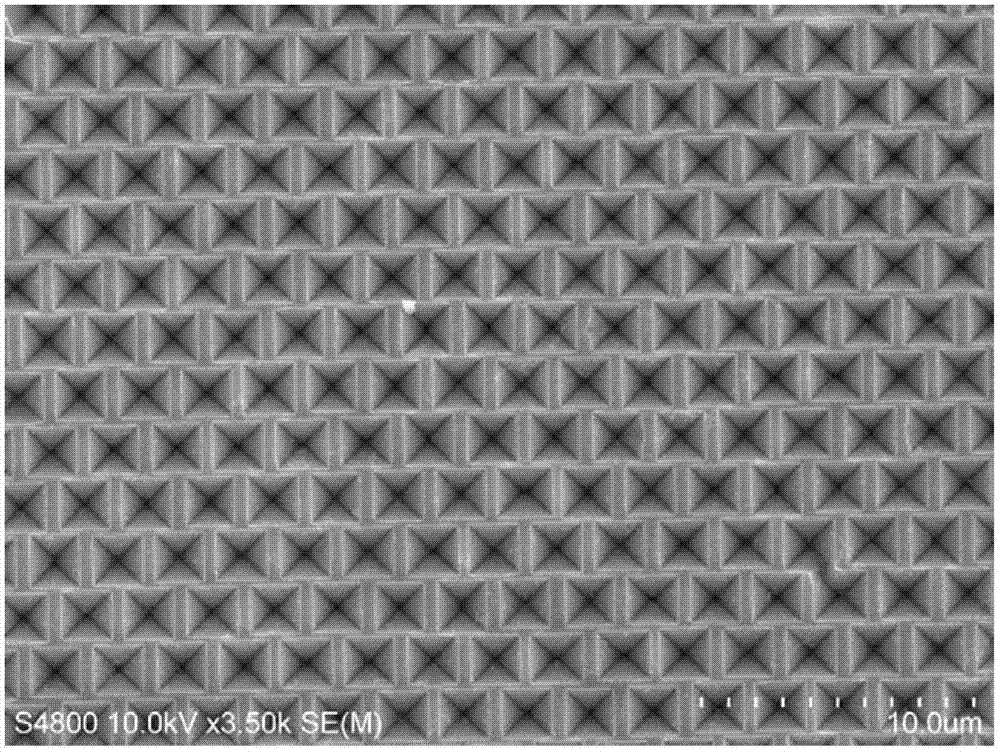

Method for preparing pyramid array on monocrystalline silicon substrate

ActiveCN103112816ALow costEasy to operateDecorative surface effectsChemical vapor deposition coatingMicrosphereGas phase

The invention relates to a method for preparing a pyramid array on a monocrystalline silicon substrate, and belongs to the technical field of manufacture of photovoltaic and semiconductor devices. The method comprises the following steps of: covering microballons in periodic arrangement on the surface of a monocrystalline silicon piece, and annealing near the glass transition temperature point of the microballoon; in oxygen atmosphere, obtaining a microballoon array in separation arrangement after etching by use of inductive coupling plasma; depositing a metallic titanium membrane on the monocrystalline silicon piece uniformly by a physical vapor deposition manner; and putting a silicon wafer with a masking film into an alkaline solution containing a surfactant for corrosion so as to obtain the pyramid array in order arrangement. The method is simple in process, short in preparation period and mature in technology; and three structures such as a positive pyramid array, an inverted pyramid array and a positive and inverted pyramid combined array can be obtained by a method for preparing a template through selecting and fine turning. The method has wide application value in the fields of photovoltaic, magnetic memory devices, nano photoelectric devices, nano sensors, surface raman enhancement and surface plasma effect and the like.

Owner:HUANGSHAN AKENT SEMICON TECH

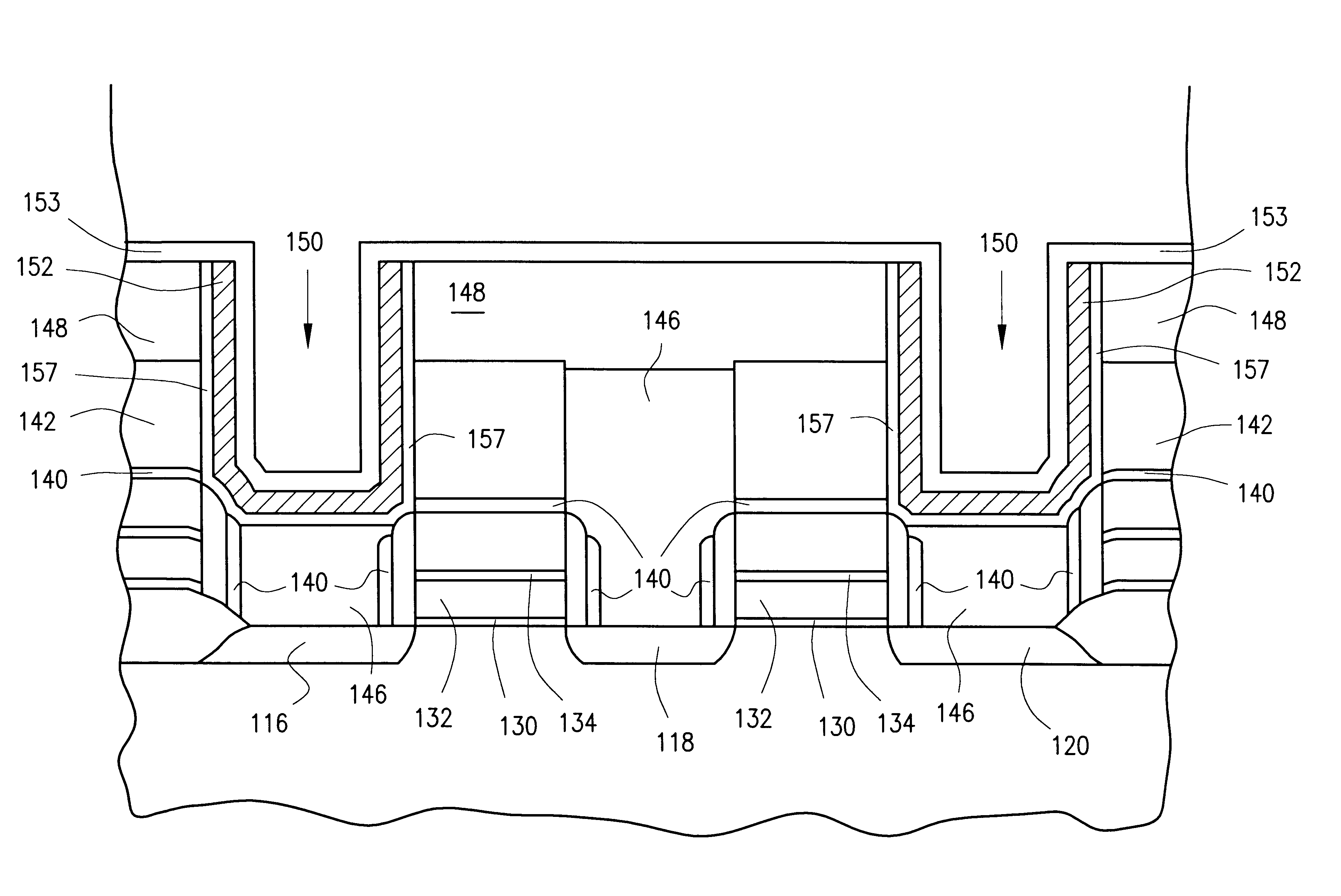

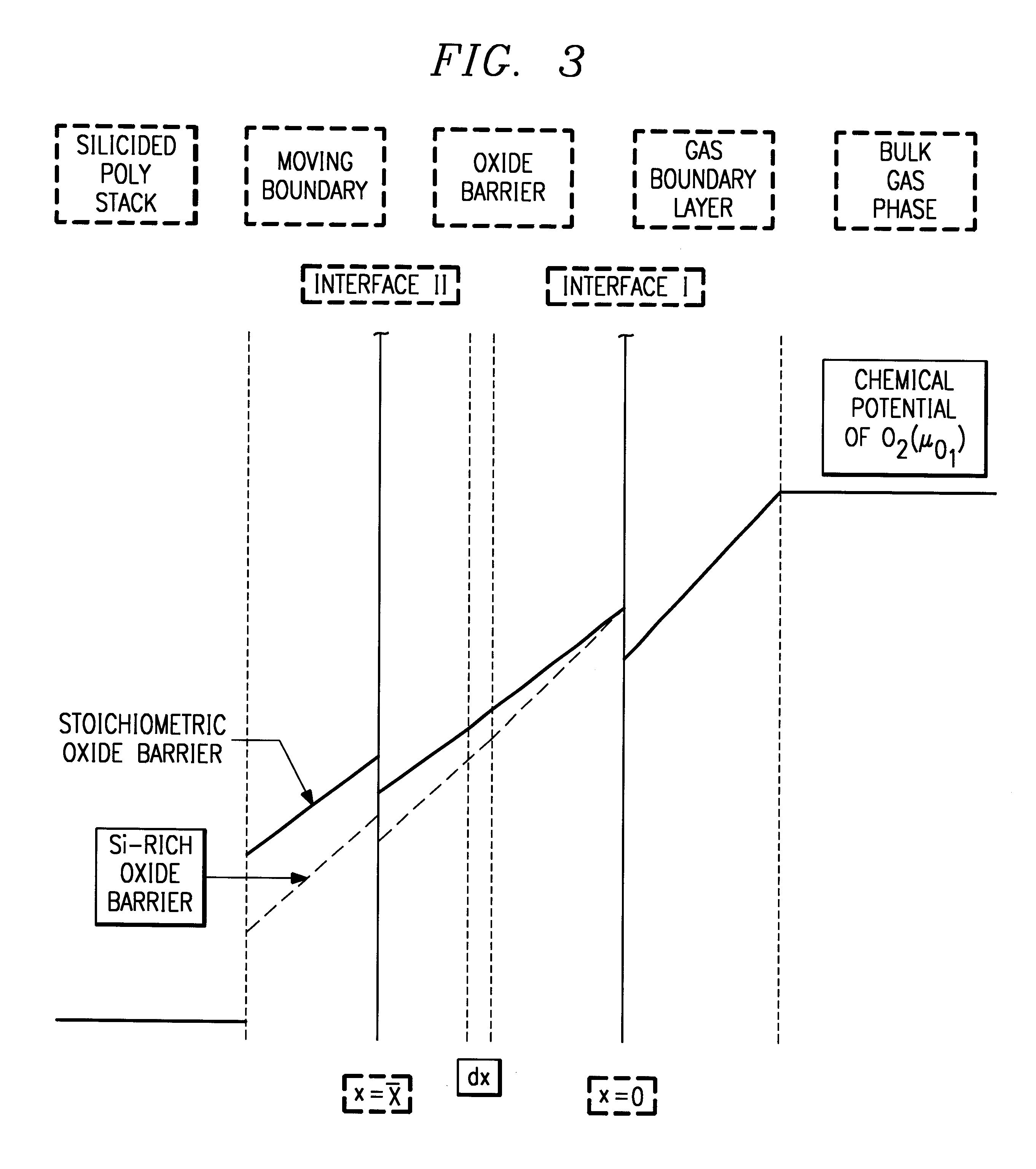

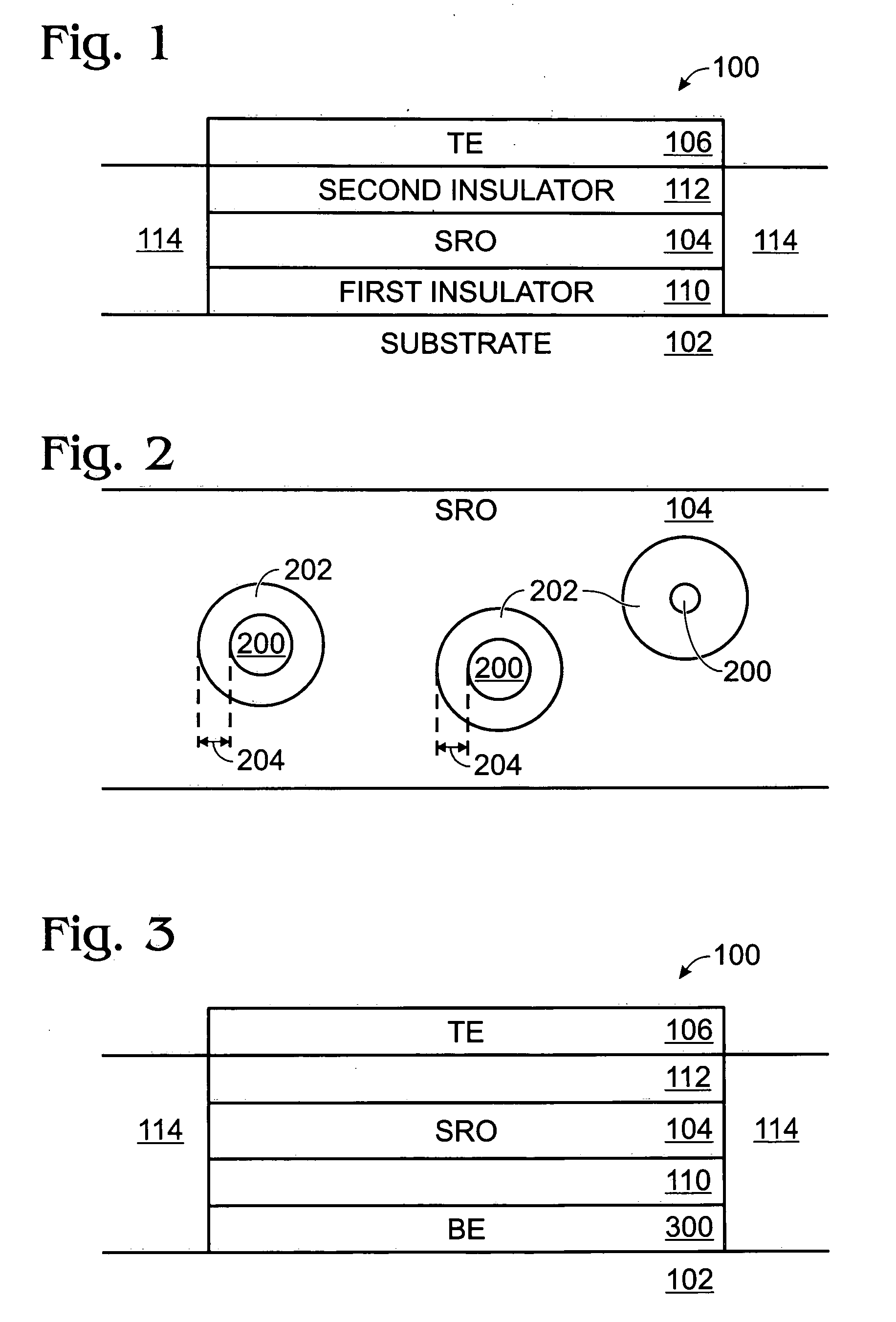

Use of Si-rich oxide film as a chemical potential barrier for controlled oxidation

InactiveUS6274429B1Easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingLow temperature depositionSilicon oxide

An oxidation process for reducing the data retention loss (DRL) in a FAMOS device comprising the steps of (1) low temperature deposition of a silicon-enriched silicon oxide (130) over a FAMOS transistor gate stack (116) and (2) annealing said silicon-enriched oxide (130) at a high temperature in oxygen atmosphere to convert said silicon-enriched oxide (130) to a thermal oxide. The silicon enriched oxide (130) acts as both an oxygen getter and diffusion barrier during the annealing step.

Owner:TEXAS INSTR INC

Method for preparing self-doping nitrogen grading porous oxide by using biomass template

InactiveCN101249952AWide variety of sourcesSelf-doping is effectively achievedOxide/hydroxide preparationDistilled waterHierarchical porous

Disclosed is a process for preparing nitrogen self-doped hierarchical porous oxide in the technical field of functional material by employing biological templates, steps of which comprises 1) selecting fresh biomaterial to fix in glutaraldehyde PBS stationary liquid, 2) soaking the biomaterial, after being rinsed by pure water and fixed, in HCl, then rinsing the biomaterial by distilled water for a plurality of times, soaking the biomaterial in salt solution of metal M, 3) rinsing the biomaterial obtained from step 2) by pure water, soaking in the salt solution of metal M, 4) rinsing the obtained biomaterial from step 3) to obtain biomaterial which is naturally dried, then heating within the range of 500-1000 DEG C in an oxygen atmosphere and insulating to obtain the nitrogen-doped porous oxide N-MxOy. The nitrogen self-doped porous oxide prepared by the invention not only is provided with a biological porous structure, but also effectively realizes nitrogen self-doping, and has the obviously strengthened advantage of capturing and absorbing light wave with different wave ranges.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of aluminum-doped material of cathode of lithium ion battery with solid phase process

The invention relates to a preparation method of an aluminum-doped material of a cathode of a lithium ion battery with a solid phase process. The preparation method comprises the following steps: controlling certain reaction conditions to prepare a precursor of a nickel, cobalt and / or manganese hydroxide; uniformly mixing the precursor with a lithium salt and a nanometer aluminum compound; and carrying out high temperature processing for a certain period of time in an air or oxygen atmosphere, cooling, and crushing to obtain the aluminum-doped material of the cathode of the lithium ion battery with the solid phase process. The aluminum-doped material of the cathode of the lithium ion battery with the solid phase process which can substantially improve the safety performance and the cycle characteristic of the lithium ion battery at a high temperature can be applied to power batteries.

Owner:山东天骄新能源有限公司

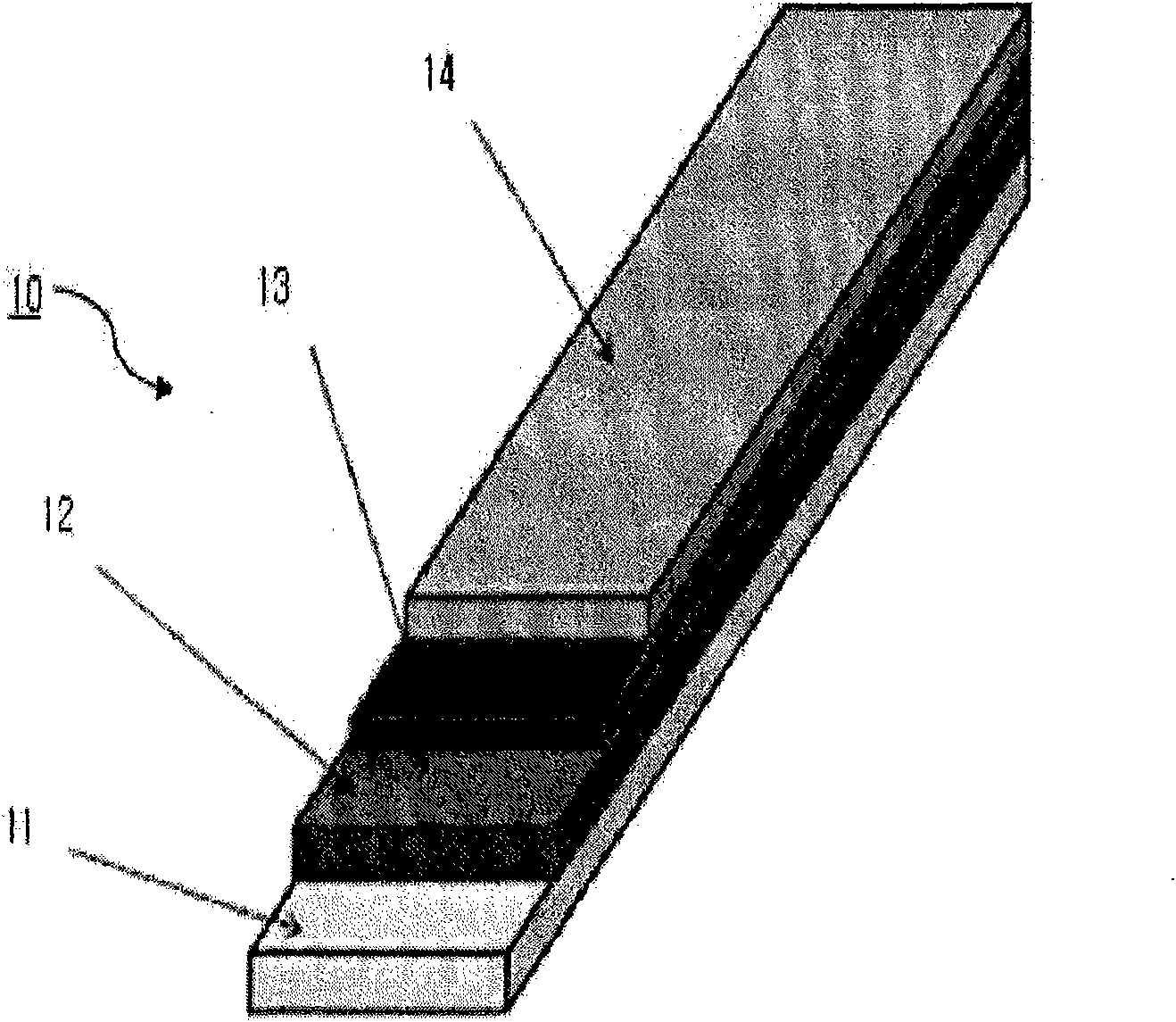

Method for joining second-generation high-temperature superconducting wires by melting diffusion

InactiveCN101971273ALower eutectic pointSuperconductors/hyperconductorsSuperconductor detailsHigh-temperature superconductivityHot Temperature

The present invention relates to a welding method for a second generation high temperature superconducting wire including a substrate, a buffer layer, a superconductor layer, and a stabilizing material layer, wherein parts of the stabilizing material layers contained in two strands of the second generation high temperature superconducting wire are removed, the superconductor layers of two strands of the second generation high temperature superconducting wire exposed by the removal of the stabilizing material layer abut each other and are heated to the melting point of the superconductor layer to melt-diffuse the abutting superconductor layers and weld two strands of the second generation high temperature superconducting wire together. Subsequently, the welded portion is oxygenation-annealed under an oxygen atmosphere to recover superconducting properties of the second high temperature superconducting wire. The above-described configuration of the present invention enables superconductor layers to directly abut each other and to be melt-diffused without using a mediator, thus producing a wire having a full length with a rare junction resistance as compared to a normal conduction junction method. Specifically, the present invention brings a partial oxygen pressure to a nearly vacuum state to lower the melting point, thereby enabling junction processes to be performed without melting a stabilizing material layer containing silver (Ag).

Owner:K·约恩

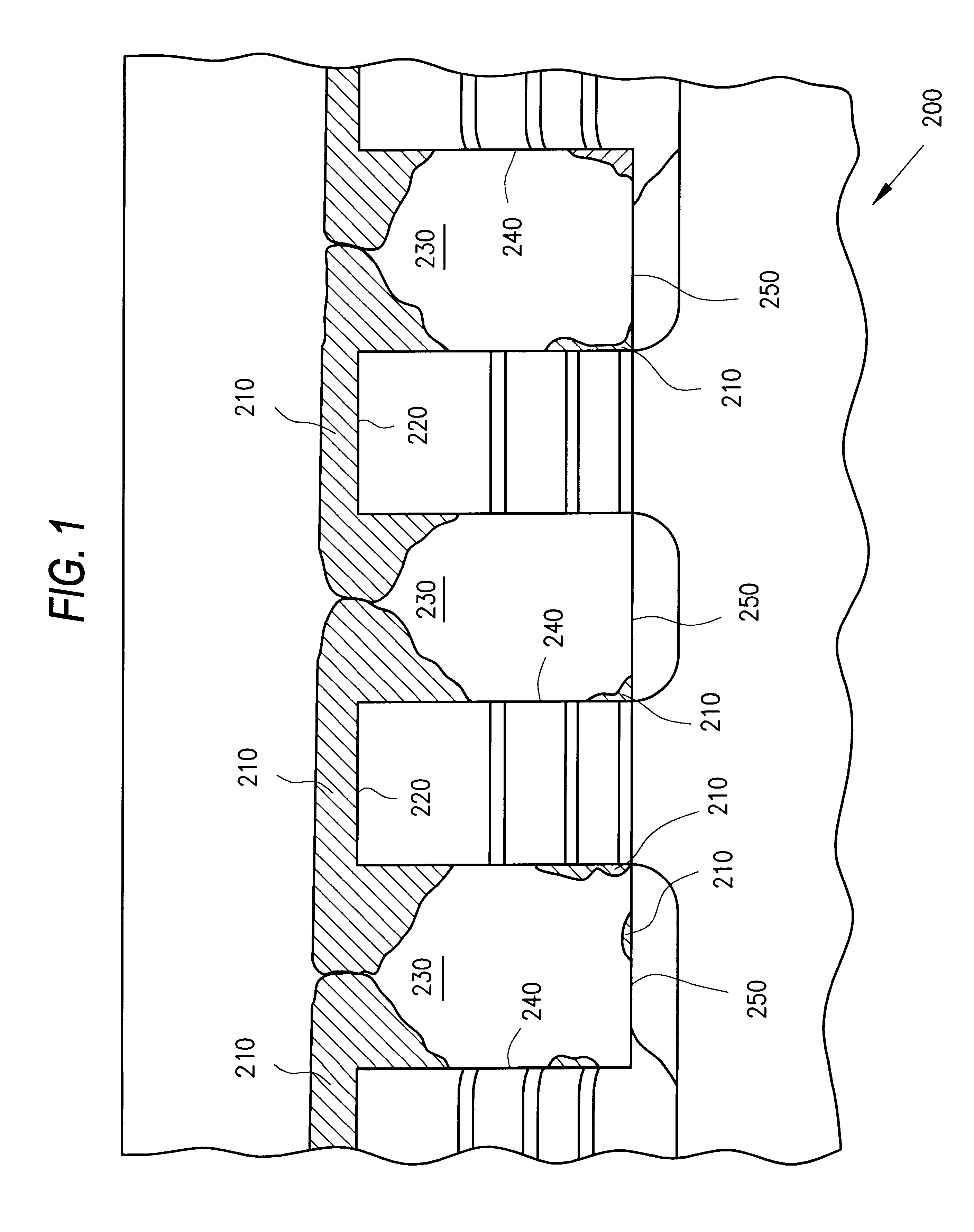

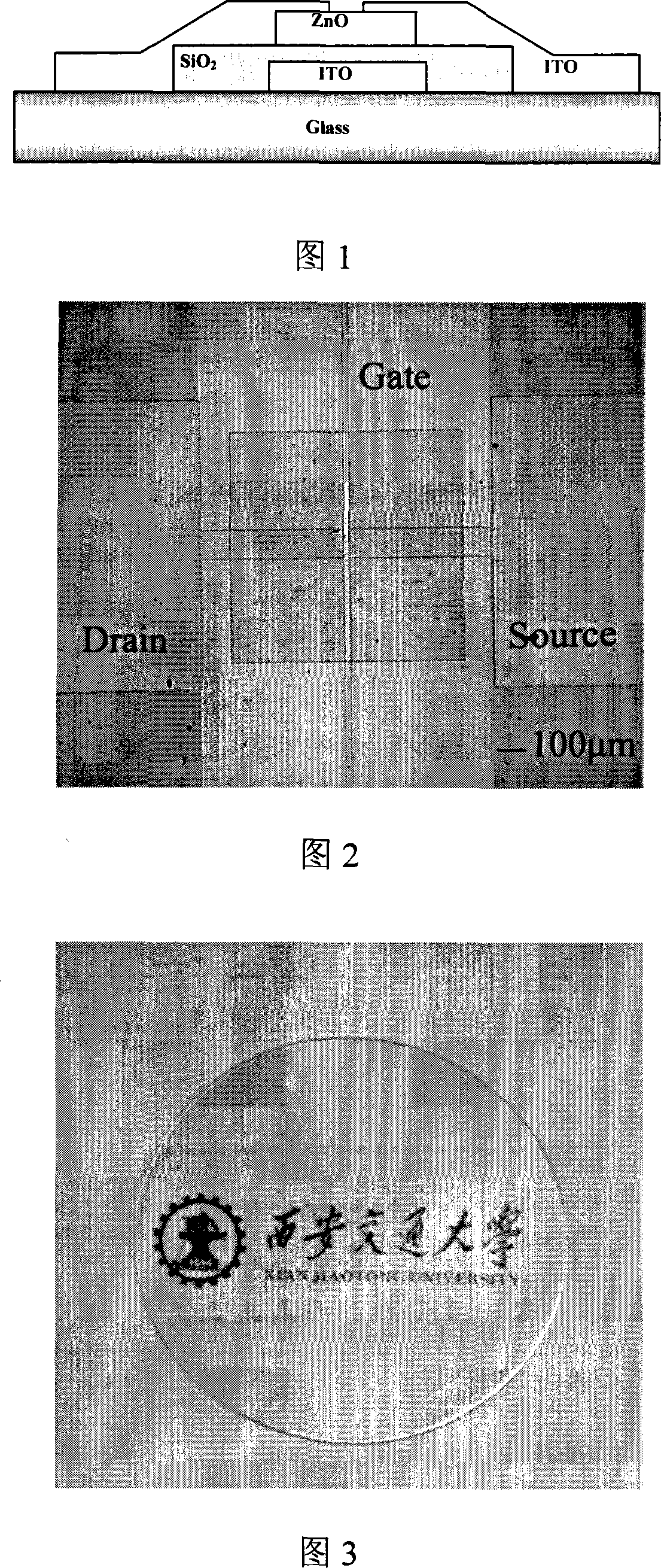

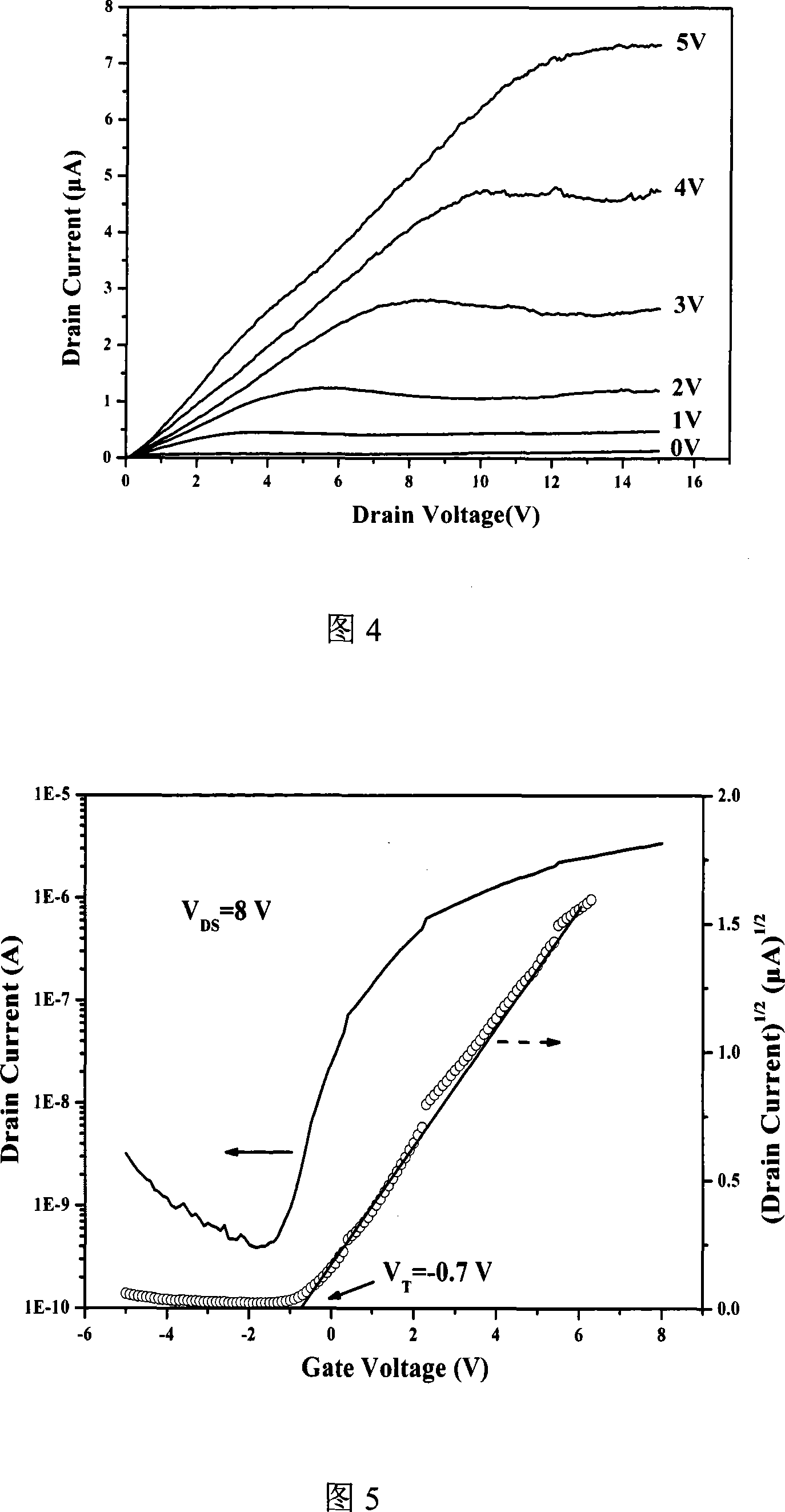

Method of producing ZnO based transparent film transistor array

InactiveCN101183667ASemiconductor/solid-state device manufacturingNon-linear opticsTransistor arrayRadio frequency magnetron sputtering

The invention discloses a method for preparing a transparent ZnO-based thin film transistor array. The method adopts a preparation process of four peeling processes, uses radio frequency magnetron sputtering technology to grow a ZnO-based thin film, and anneals the ZnO-based thin film in oxygen to obtain improve its electrical properties. The thin film transistor array uses transparent conductive films such as ITO, ZnO:Al or ZnO:Ga as gate, source and drain electrodes, and uses SiO2, Al2O3, SiNX and other films as insulating layers. The experiment shows that the transmittance of the ZnO-based thin film transistor array in the visible light band reaches 85%, which provides a new way for the development of high-performance flat panel display arrays.

Owner:XI AN JIAOTONG UNIV

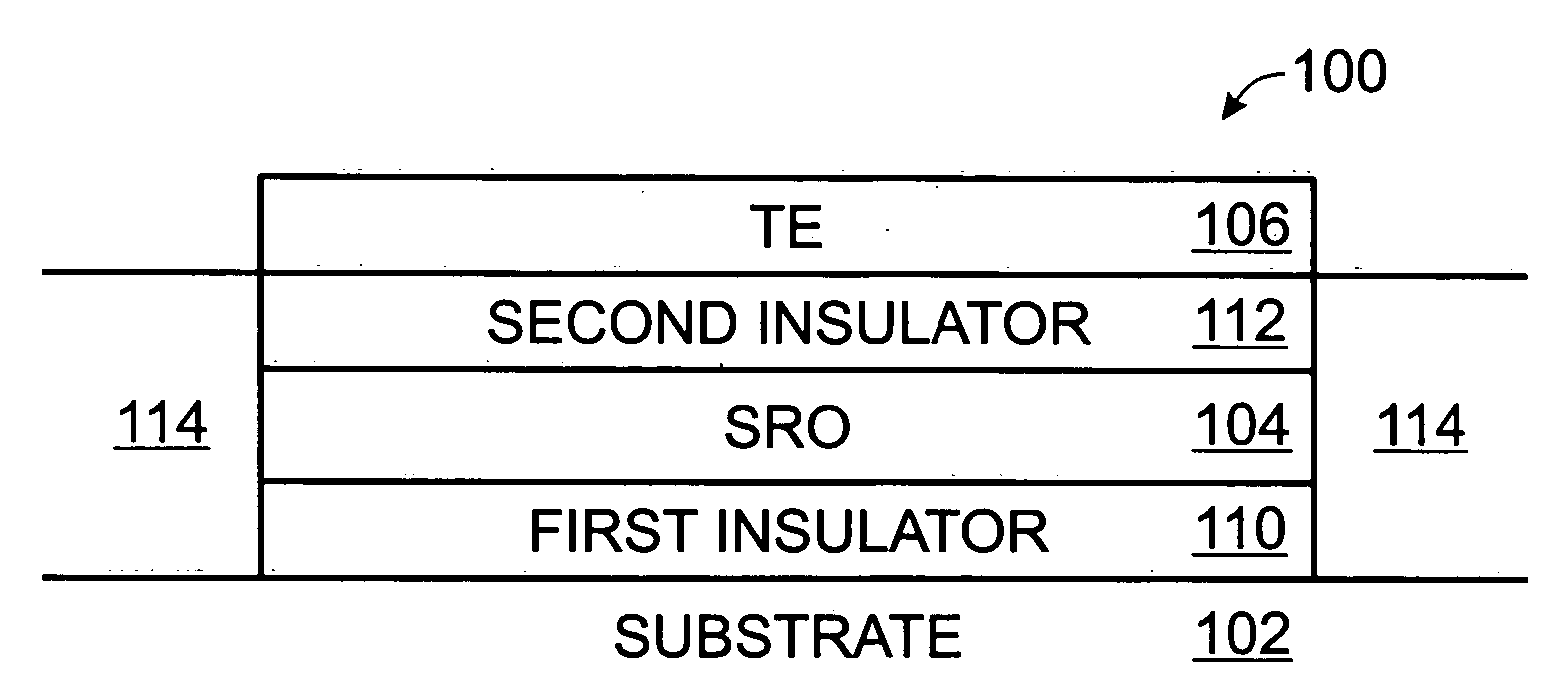

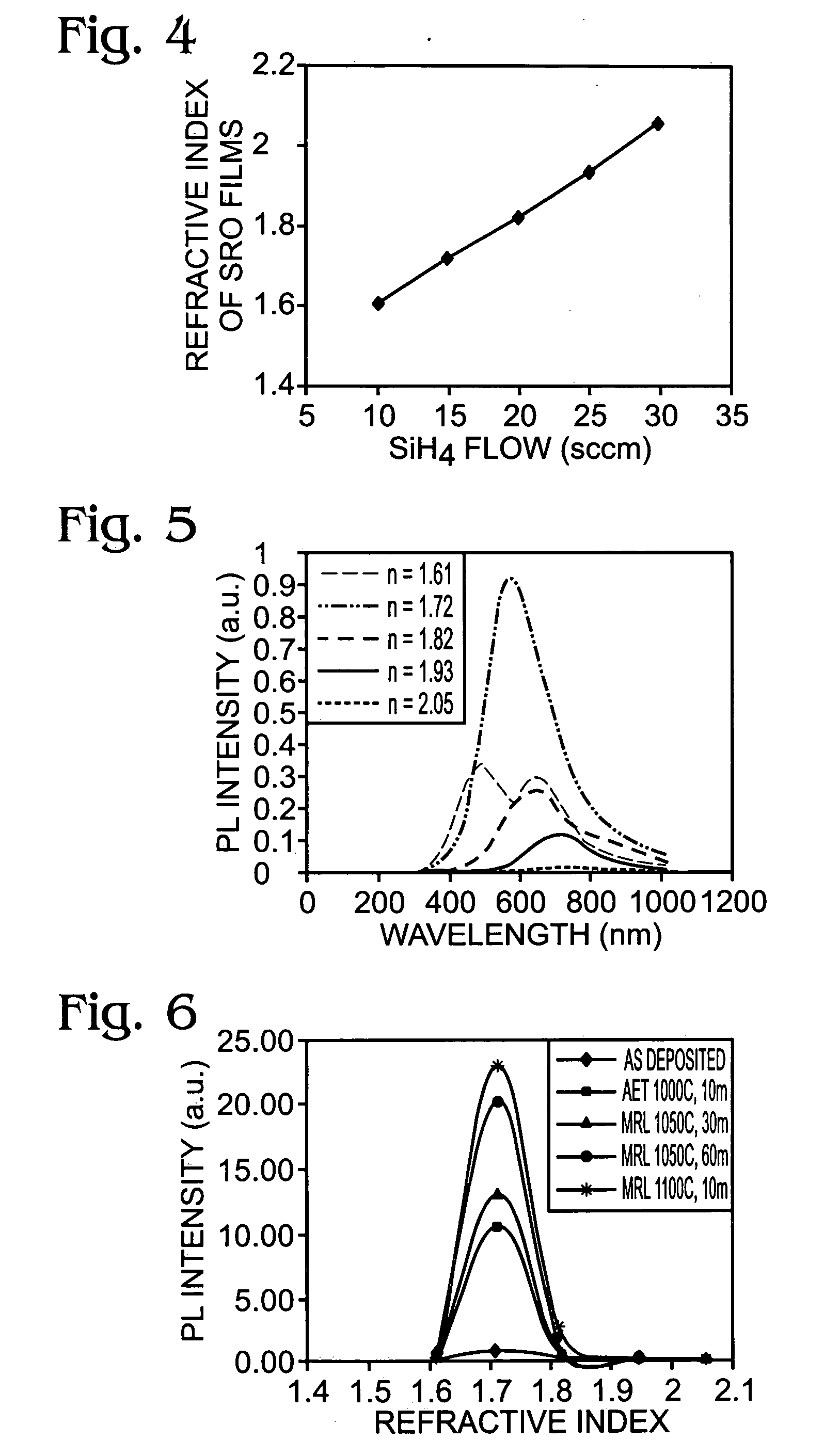

High-luminescence silicon electroluminescence device

InactiveUS20060189014A1Enhance homogeneous oxidation of nano-SiFacilitated DiffusionFinal product manufactureSemiconductor/solid-state device detailsPorosityRefractive index

A method for forming a high-luminescence Si electroluminescence (EL) phosphor is provided, with an EL device made from the Si phosphor. The method comprises: depositing a silicon-rich oxide (SRO) film, with Si nanocrystals, having a refractive index in the range of 1.5 to 2.1, and a porosity in the range of 5 to 20%; and, post-annealing the SRO film in an oxygen atmosphere. DC-sputtering or PECVD processes can be used to deposit the SRO film. In one aspect the method further comprises: HF buffered oxide etching (BOE) the SRO film; and, re-oxidizing the SRO film, to form a SiO2 layer around the Si nanocrystals in the SRO film. In one aspect, the SRO film is re-oxidized by annealing in an oxygen atmosphere. In this manner, a layer of SiO2 is formed around the Si nanocrystals having a thickness in the range of 1 to 5 nanometers (nm).

Owner:SHARP KK

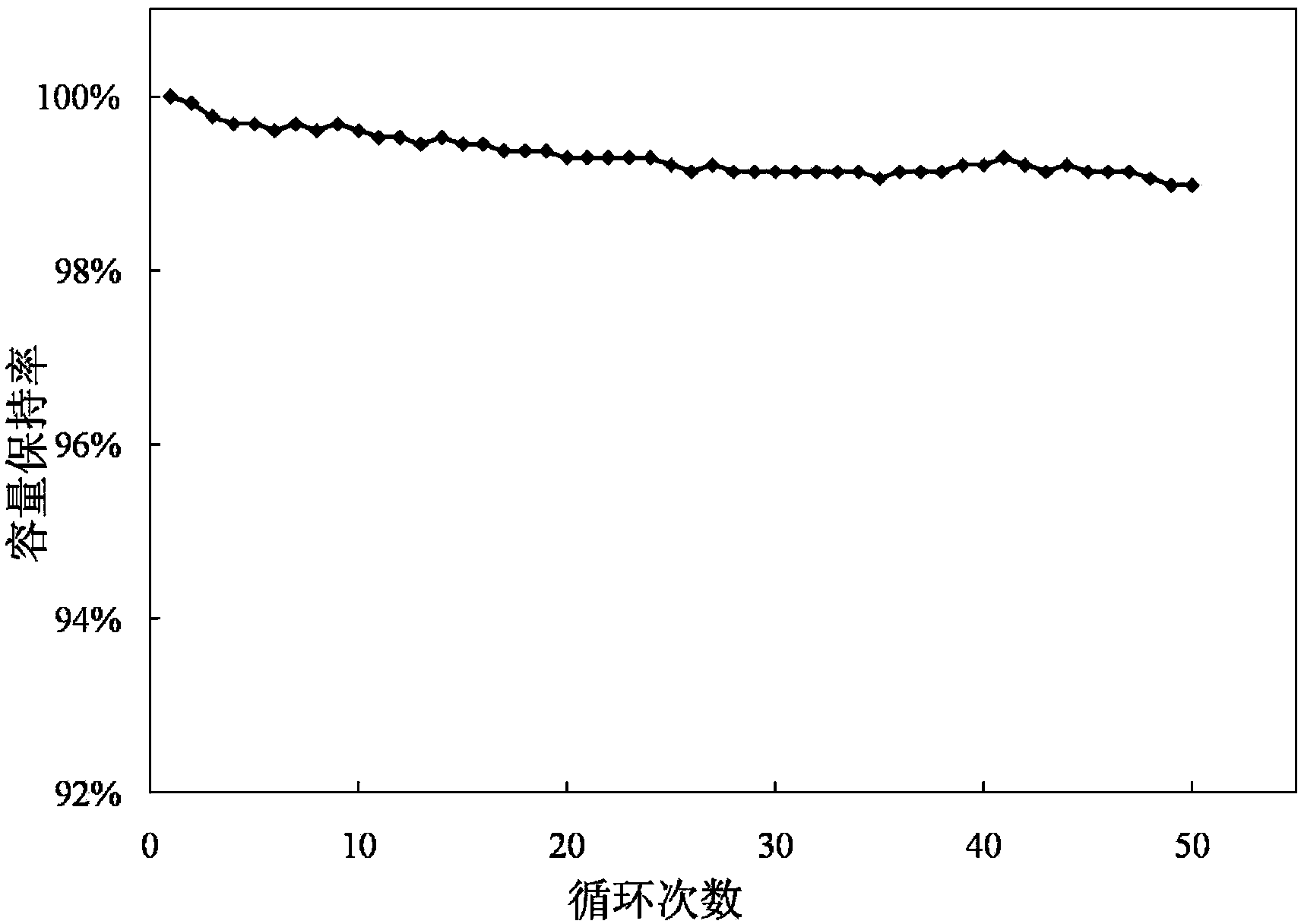

Method for preparing high-nickel ternary cathode material of lithium ion battery

ActiveCN104201378AEasy to getEasy to operateCell electrodesSecondary cellsHigh concentrationManganese

The invention discloses a method for preparing a high-nickel ternary cathode material of a lithium ion battery. According to the method, under the existence, a lithium source and a nickel-cobalt-manganese hydroxide / a nickel-cobalt-aluminum hydroxide are used as reaction substrates and are calcined in an oxygen atmosphere to prepare the high-nickel ternary cathode material of the lithium ion battery. According to the method, the dependency on high-concentration oxygen in a preparation process can be reduced; by the use of low-concentration oxygen, the oxygen cost can be lowered, and a requirement on the sealing property of calcining equipment is also reduced, so that the cost is lowered; meanwhile, compared with the high-nickel ternary cathode material of the lithium ion battery, which is prepared by the common method, the high-nickel ternary cathode material of the lithium ion battery, which is prepared by the method disclosed by the invention, is higher in circulating performance and higher in specific capacity.

Owner:北京盟固利新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com