Method for preparing pyramid array on monocrystalline silicon substrate

A single-crystal silicon and single-crystal silicon wafer technology, which is applied in the field of preparing pyramid arrays, can solve the problems of difficulty in preparing nanoscale photolithography masks, complicated processes, limited applications, etc., and achieves excellent light trapping effect, simple operation, top-end smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

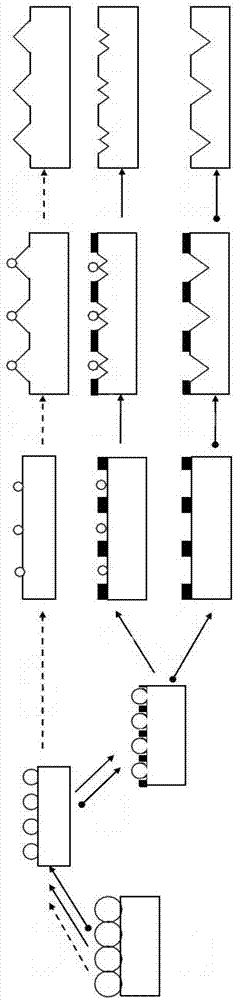

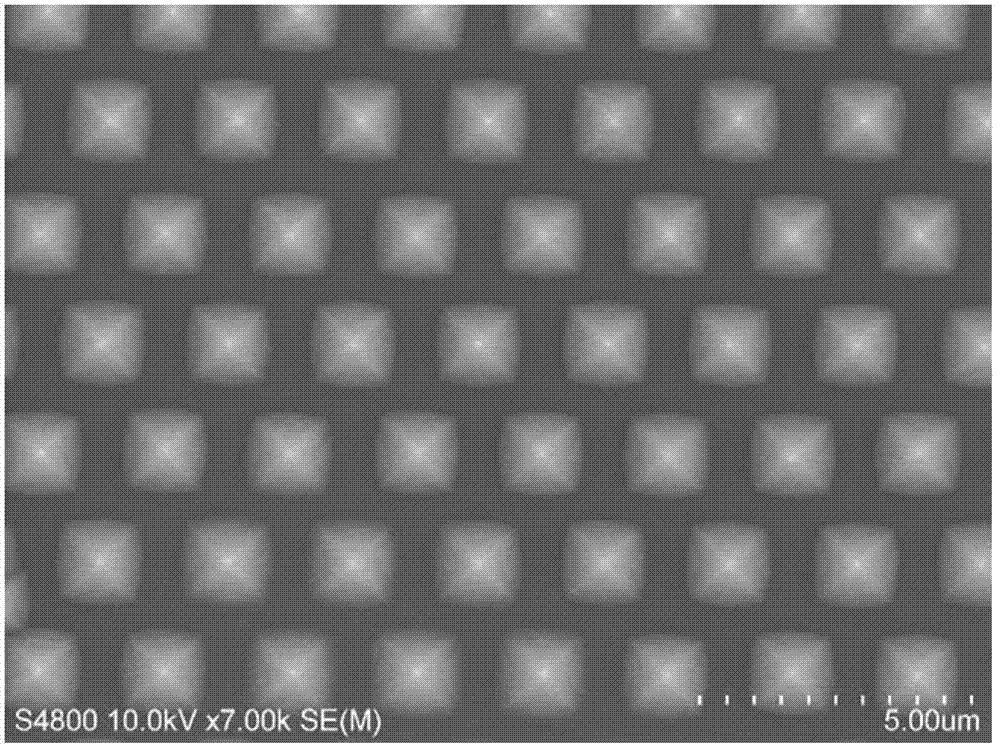

[0065] Preparing a positive pyramid array on a single crystal silicon substrate comprises the following steps:

[0066] (1) Arrange a layer of hexagonal close-packed polystyrene colloidal microspheres on the monocrystalline silicon wafer substrate by the vertical pulling method, and the pulling speed is 1 μm / s. The sheet was dried naturally in the air for 1 hour, and then subjected to rapid thermal annealing, the annealing temperature was 115°C, the glass transition temperature of polystyrene microspheres was 120°C, and the annealing time was 2 minutes and 30 seconds;

[0067](2) Using the inductively coupled plasma etching method, the microspheres are etched in an atmosphere of oxygen, so that the microspheres closely packed on the surface of the single crystal silicon wafer are separated from each other, and the diameter of the etched microspheres is determined by the The etching parameters and etching time are determined, the etching power is 150 watts, and the etching time...

Embodiment 2

[0072] Preparing a positive pyramid array on a single crystal silicon substrate comprises the following steps:

[0073] (1) Arrange a layer of hexagonal close-packed polystyrene colloidal microspheres on the monocrystalline silicon wafer substrate by vertical pulling method at a pulling speed of 2.5 μm / s. The sheet was dried naturally in the air for 1 hour, and then subjected to rapid thermal annealing, the annealing temperature was 125°C, the glass transition temperature of polystyrene microspheres was 120°C, and the annealing time was 1 minute and 30 seconds;

[0074] (2) Using the inductively coupled plasma etching method, the microspheres are etched in an atmosphere of oxygen, so that the microspheres closely packed on the surface of the single crystal silicon wafer are separated from each other, and the diameter of the etched microspheres is determined by the The etching parameters and etching time are determined, the etching power is 200 watts, and the etching time is 1 ...

Embodiment 3

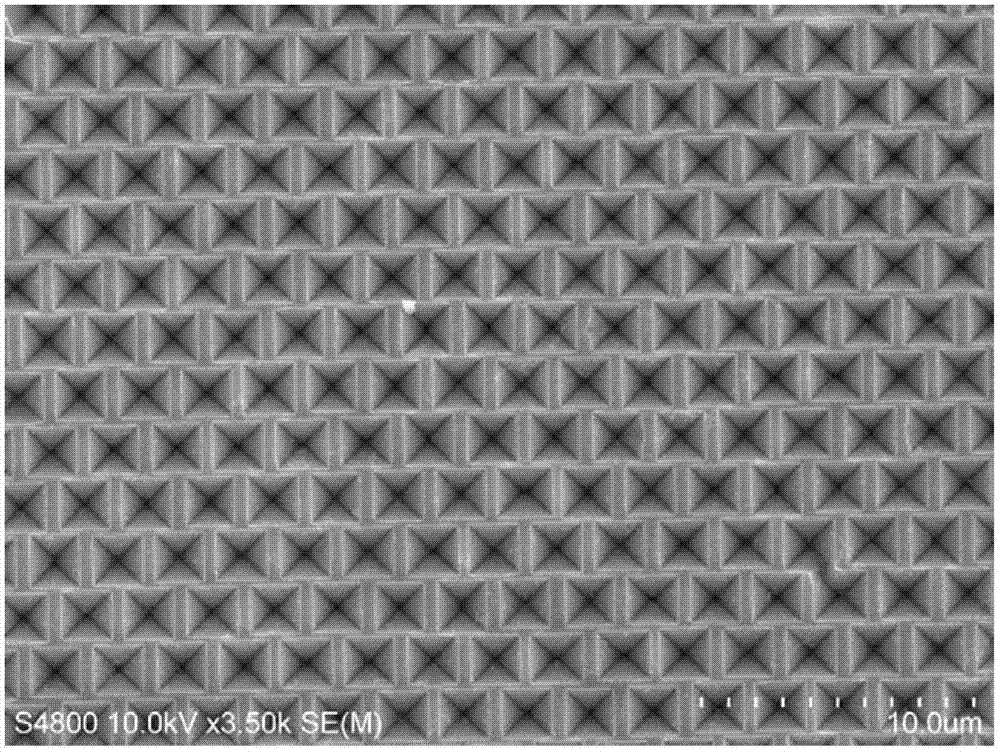

[0079] Prepare an array of inverted pyramids on a single crystal silicon substrate, comprising the following steps:

[0080] (1) Arrange a layer of hexagonal close-packed polystyrene colloidal microspheres on the monocrystalline silicon wafer substrate by vertical pulling method at a pulling speed of 1.3 μm / s. The sheet was dried naturally in the air for 1 hour, and then subjected to rapid thermal annealing, the annealing temperature was 115°C, the glass transition temperature of polystyrene microspheres was 120°C, and the annealing time was 2 minutes;

[0081] (2) Using the inductively coupled plasma etching method, the microspheres are etched in an atmosphere of oxygen, so that the microspheres closely packed on the surface of the single crystal silicon wafer are separated from each other, and the diameter of the etched microspheres is determined by the The etching parameters and etching time are determined, the etching power is 125 watts, and the etching time is 3 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com