Method for preparing high-nickel ternary cathode material of lithium ion battery

A high-nickel ternary material and lithium-ion battery technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as difficult equipment implementation, and achieve the effects of reducing production costs, easy industrialization, and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Lithium hydroxide and nickel cobalt manganese hydroxide Ni 0.8 co 0.1 mn 0.1 (OH) 2 mixed, where Ni 0.8 co 0.1 mn 0.1 (OH) 2 The mass of is 100g, and the precursor mixture is prepared,

[0064] (2) Add 5 g of potassium permanganate to the precursor mixture, ball mill, and roast in an oxygen atmosphere at a temperature of 780 ° C for 20 h to obtain a nickel-cobalt-manganese lithium-oxygen compound,

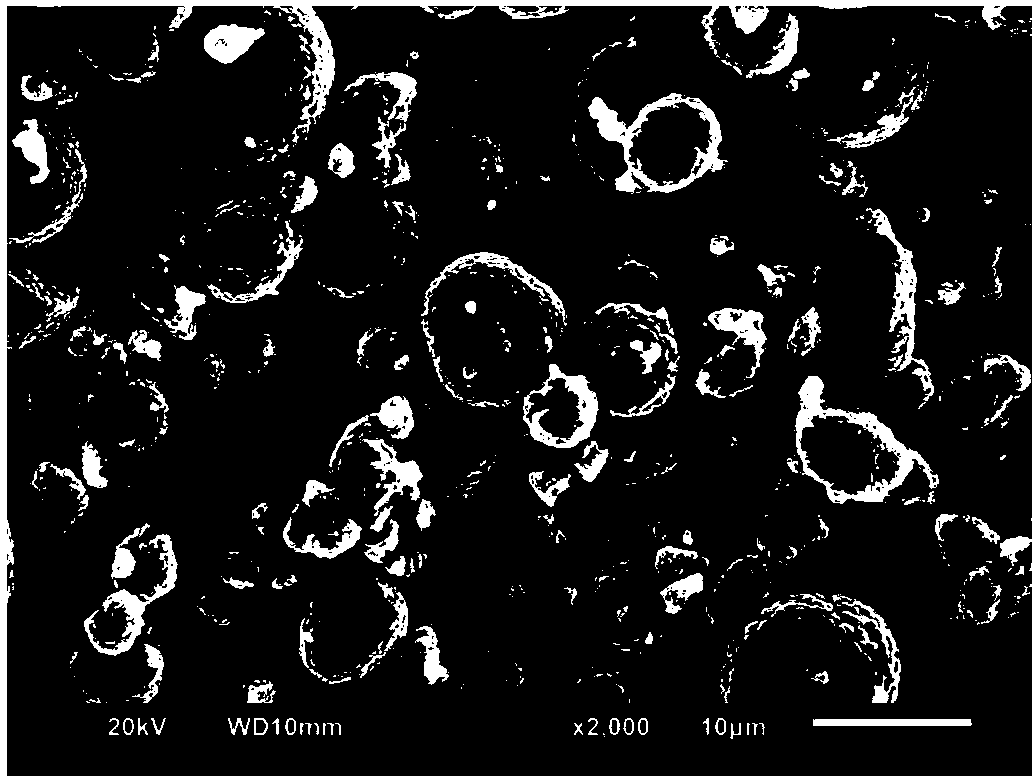

[0065] (3) After the nickel-cobalt-manganese lithium oxygen compound is cooled, it is pulverized, and the product LiNi is obtained through a 300-mesh sieve. 0.8 co 0.1 mn 0.1 o 2 , its sulfate content is 2800ppm, and the D50 of particle size is 10.6μm.

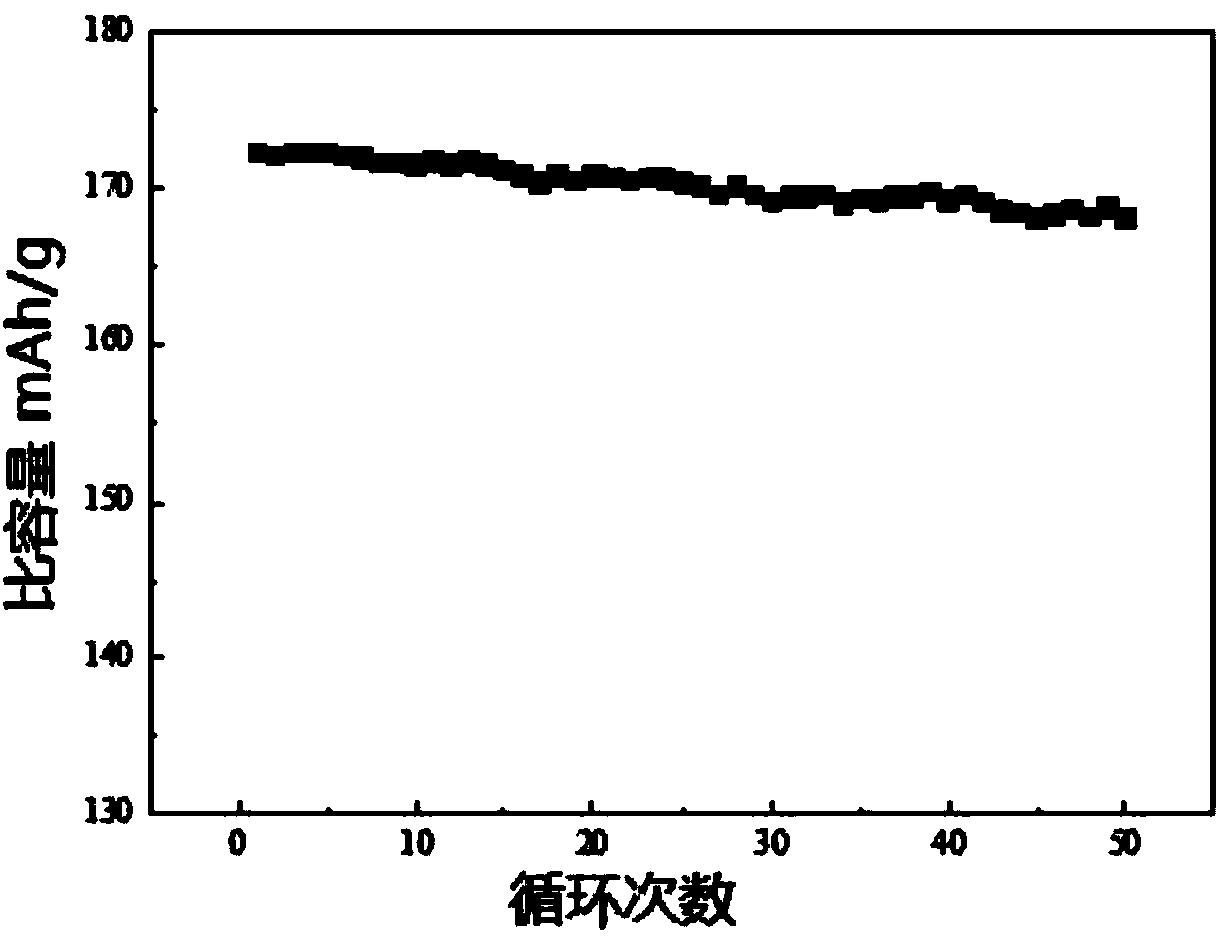

[0066] Using the obtained material as the positive electrode and the lithium sheet as the negative electrode, assemble it into a button battery, and charge and discharge it in the voltage range of 3.0-4.3V. The first reversible discharge specific capacity of the material is measured to be 172.3mAh / g, 50 times ...

Embodiment 2

[0068] (1) Lithium hydroxide and nickel cobalt manganese hydroxide Ni 0.8 co 0.15 al 0.05 (OH) 2 mixed, where Ni 0.8 co 0.15 al 0.05 (OH) 2 The mass of is 200g, and the precursor mixture is prepared,

[0069] (2) Add 10 g of ammonium nitrate to the precursor mixture, ball mill, and roast at a temperature of 800 ° C for 20 h in an oxygen atmosphere to obtain a nickel-cobalt-aluminum-lithium-oxygen compound,

[0070] (3) pulverize after cooling, and get the product LiNi through a 300-mesh sieve 0.8 co 0.15 al 0.05 o 2 , and its sulfate content is 2660ppm.

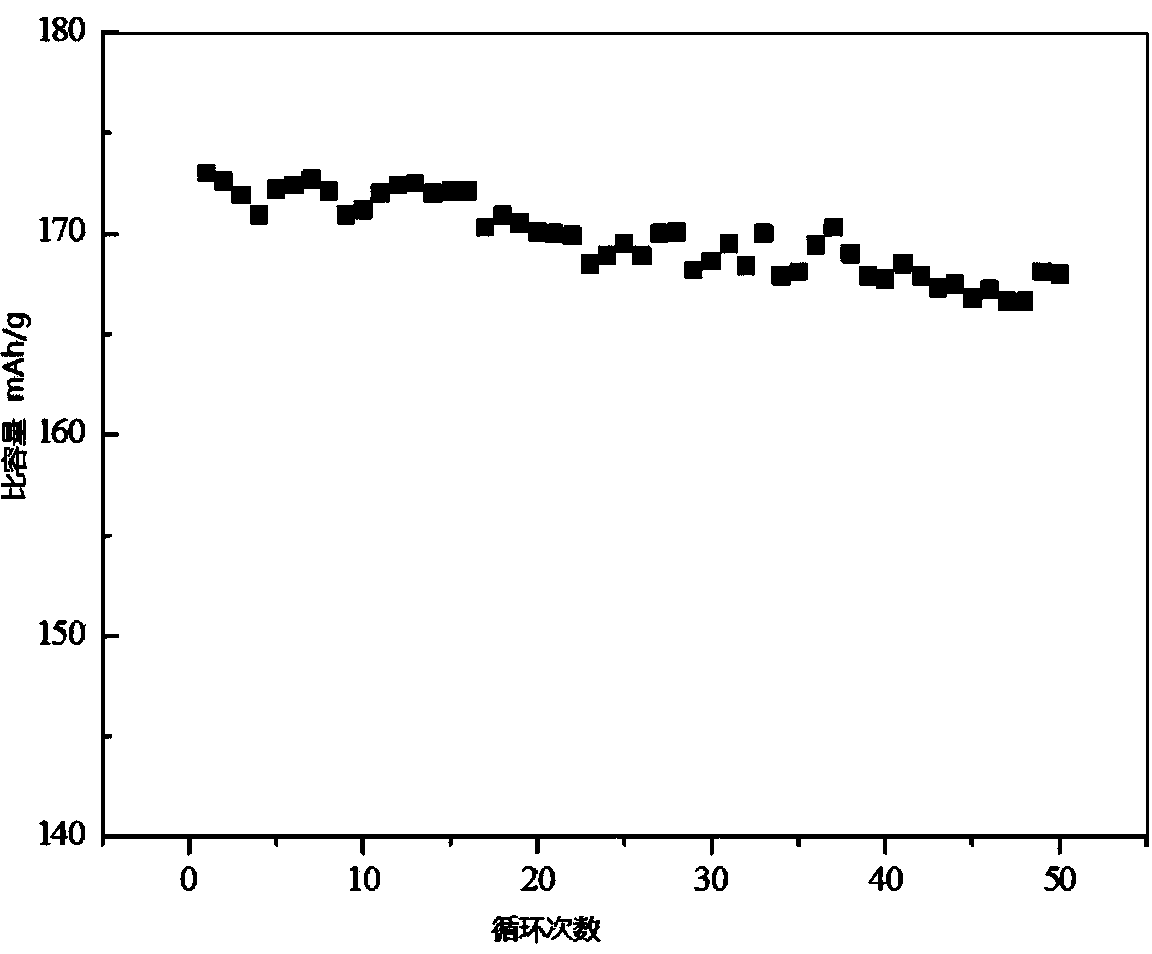

[0071] Using the obtained material as the positive electrode and the lithium sheet as the negative electrode, assemble it into a button battery, and charge and discharge it in the voltage range of 3.0-4.3V. The first reversible discharge specific capacity of the material is measured to be 173.3mAh / g, 50 times The cycle retention rate is 97.1%, and its cycle curve is as follows image 3 shown.

Embodiment 3

[0073] (1) Lithium hydroxide and nickel cobalt manganese hydroxide Ni 0.7 co 0.15 mn 0.15 (OH) 2 mixed, where Ni 0.7 co 0.15 mn 0.15 (OH) 2 The mass of is 200g, and the precursor mixture is prepared,

[0074] (2) Add 2 g of sodium nitrate to the precursor mixture, ball mill, and roast in an oxygen atmosphere at a temperature of 850 ° C for 20 hours to obtain a nickel-cobalt-manganese lithium-oxygen compound,

[0075] (3) pulverize after cooling, and get the product LiNi through a 300-mesh sieve 0.7 co 0.15 mn 0.15 o 2 , and its sulfate content is 3180ppm.

[0076] Using the obtained material as the positive electrode and the lithium sheet as the negative electrode, assemble it into a button battery, and charge and discharge it in the voltage range of 3.0-4.3V. The first reversible discharge specific capacity of the material is measured to be 166.4mAh / g, 50 times The cycle retention rate is 98.7%, and its cycle curve is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com