Method of producing ZnO based transparent film transistor array

A technology of transistors and thin films, which is applied in the field of preparation of ZnO-based transparent thin film transistor arrays, can solve the problems of affecting the charge storage characteristics of liquid crystal pixels, improving the mobility of amorphous silicon thin film transistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

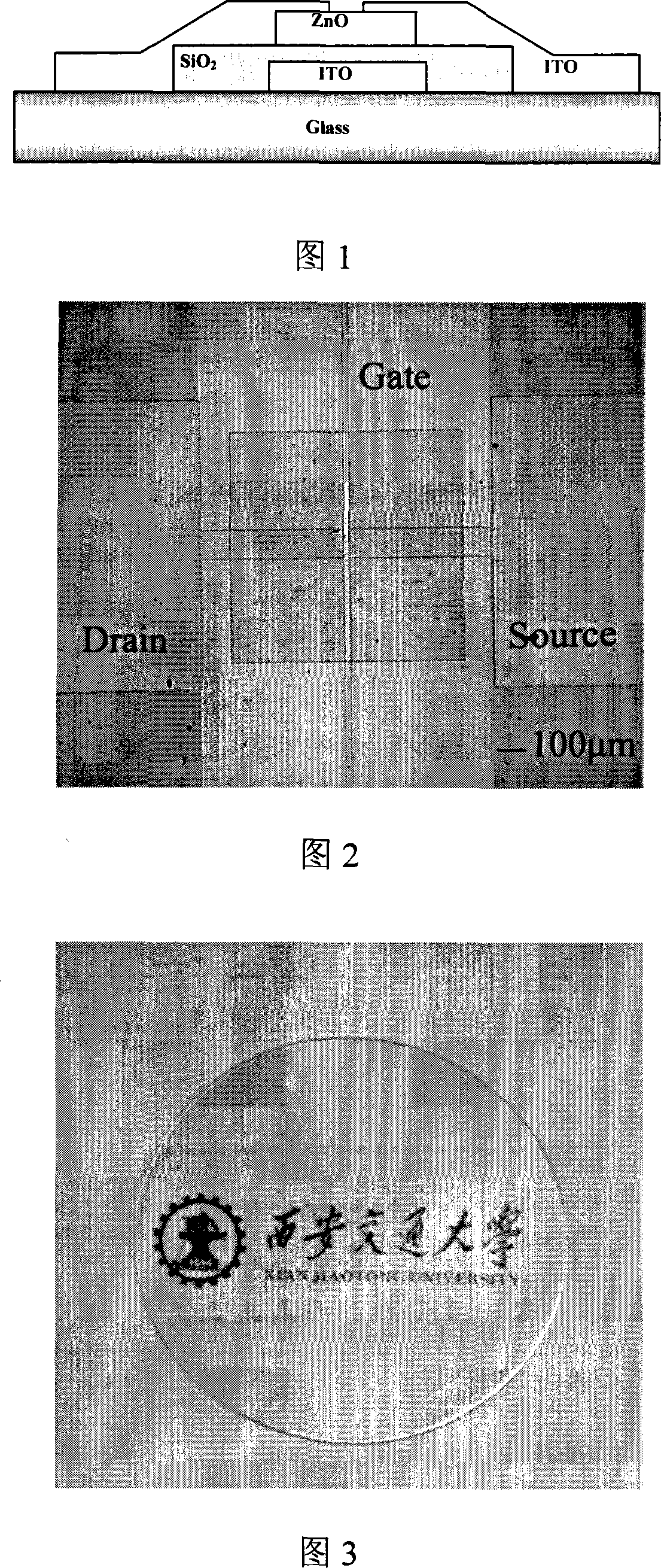

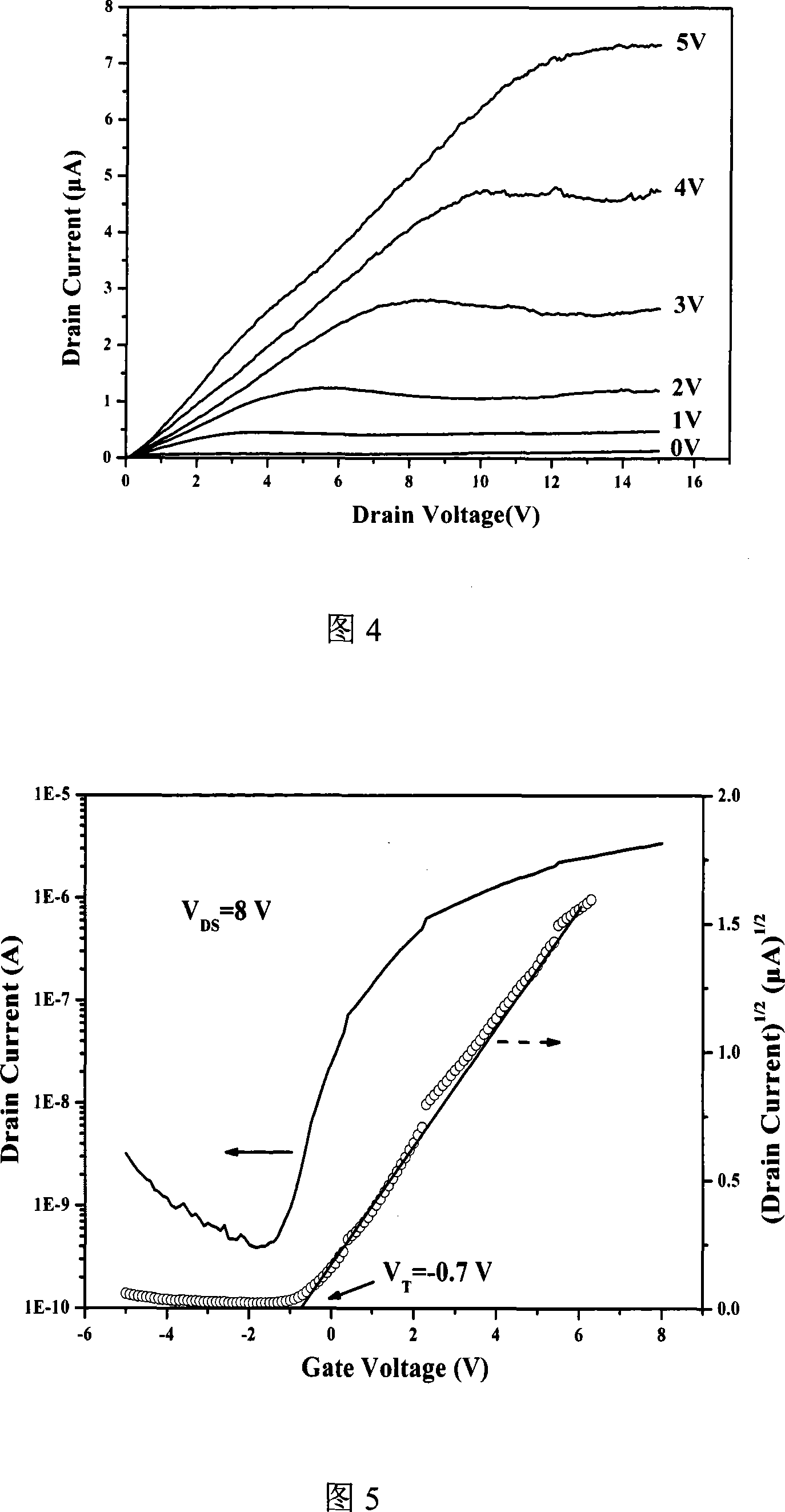

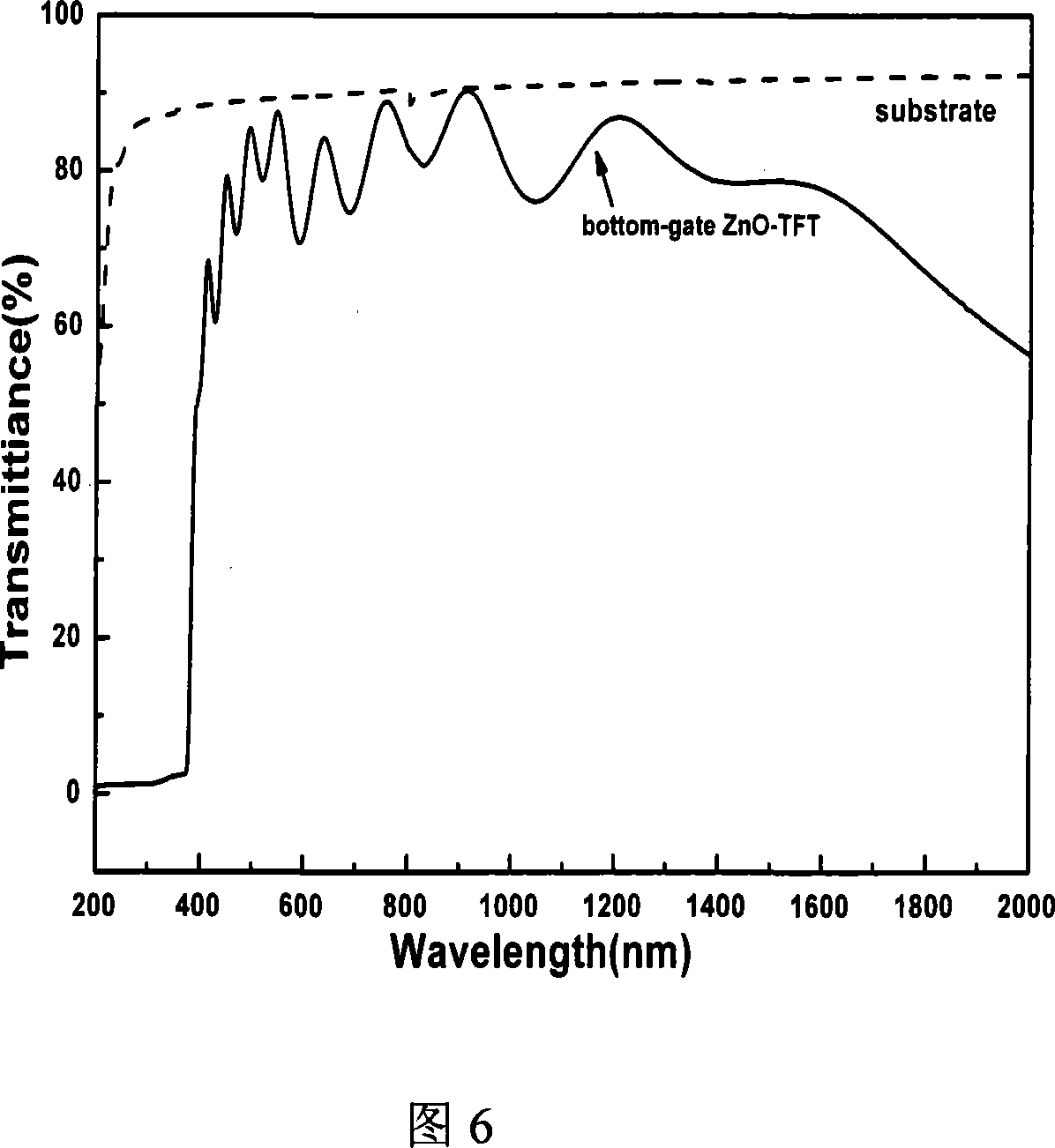

[0026] This embodiment is to prepare a ZnO channel layer transparent thin film transistor array, and the specific implementation steps are:

[0027] 1. Lithographically engrave the gate pattern on the ordinary glass or quartz substrate, then grow the ITO transparent conductive film by magnetron sputtering, take out the sample and ultrasonically in the acetone solution for several minutes to form the gate pattern, the thickness of the gate film is about 200nm;

[0028] 2. Overlay the insulating layer pattern on the ITO gate twice, and grow SiO by magnetron sputtering 2 The thin film is used as an insulating layer, and the excess photoresist is partially peeled off in acetone ultrasonically;

[0029] 3. Overlay the channel layer pattern on the insulating layer film, and grow the ZnO film by magnetron sputtering, and then remove the excess photoresist by ultrasonic in acetone;

[0030] 4. Anneal the sample in an oxygen atmosphere at 500°C for 1 hour;

[0031] 5. On the ZnO chan...

Embodiment 2

[0035] The difference between this example and Example 1 is that the ITO film in Step 1 and Step 5 is replaced by a transparent conductive film such as ZnO:Al or ZnO:Ga, and a transparent ZnO-TFT array can also be prepared.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is that the SiO in step 2 2 Thin film replaced by HfO 2 、Al 2 o 3 or Y 2 o 3 Etc. transparent insulating layer film, other are all the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com