Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1652results about How to "Improve pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance ultracapacitors with carbon nanomaterials and ionic liquids

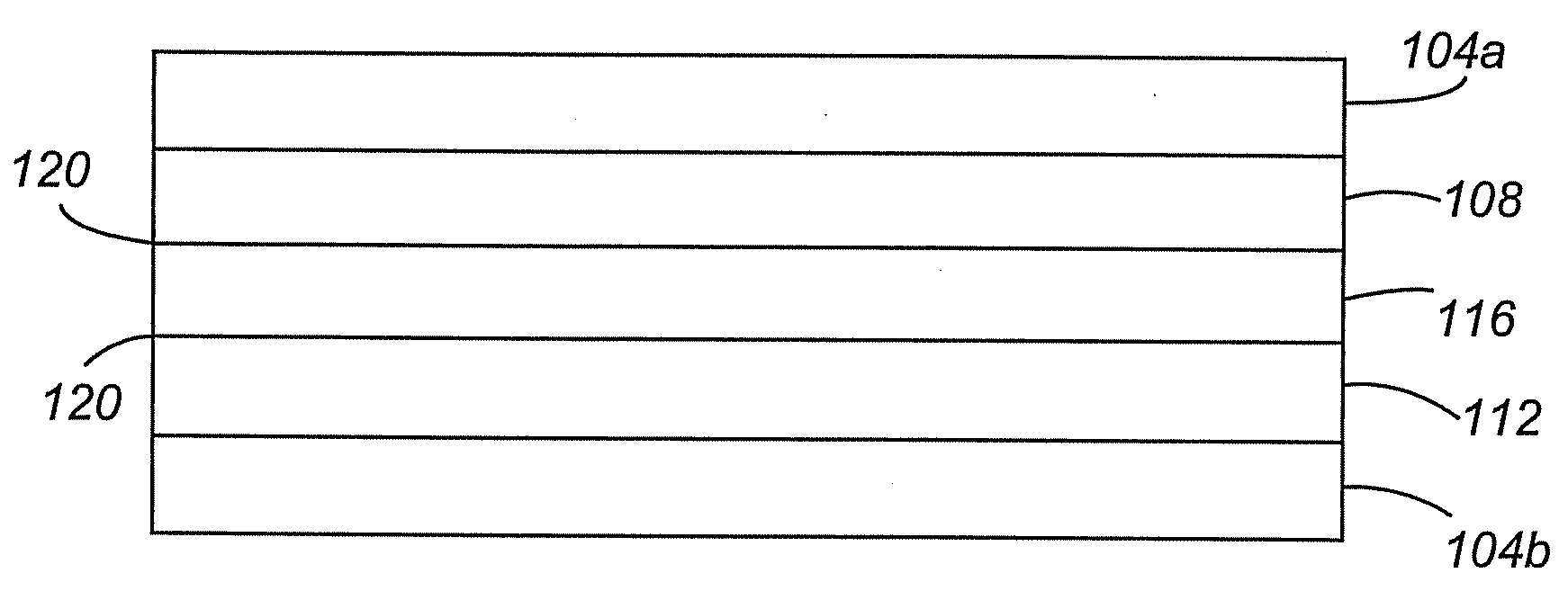

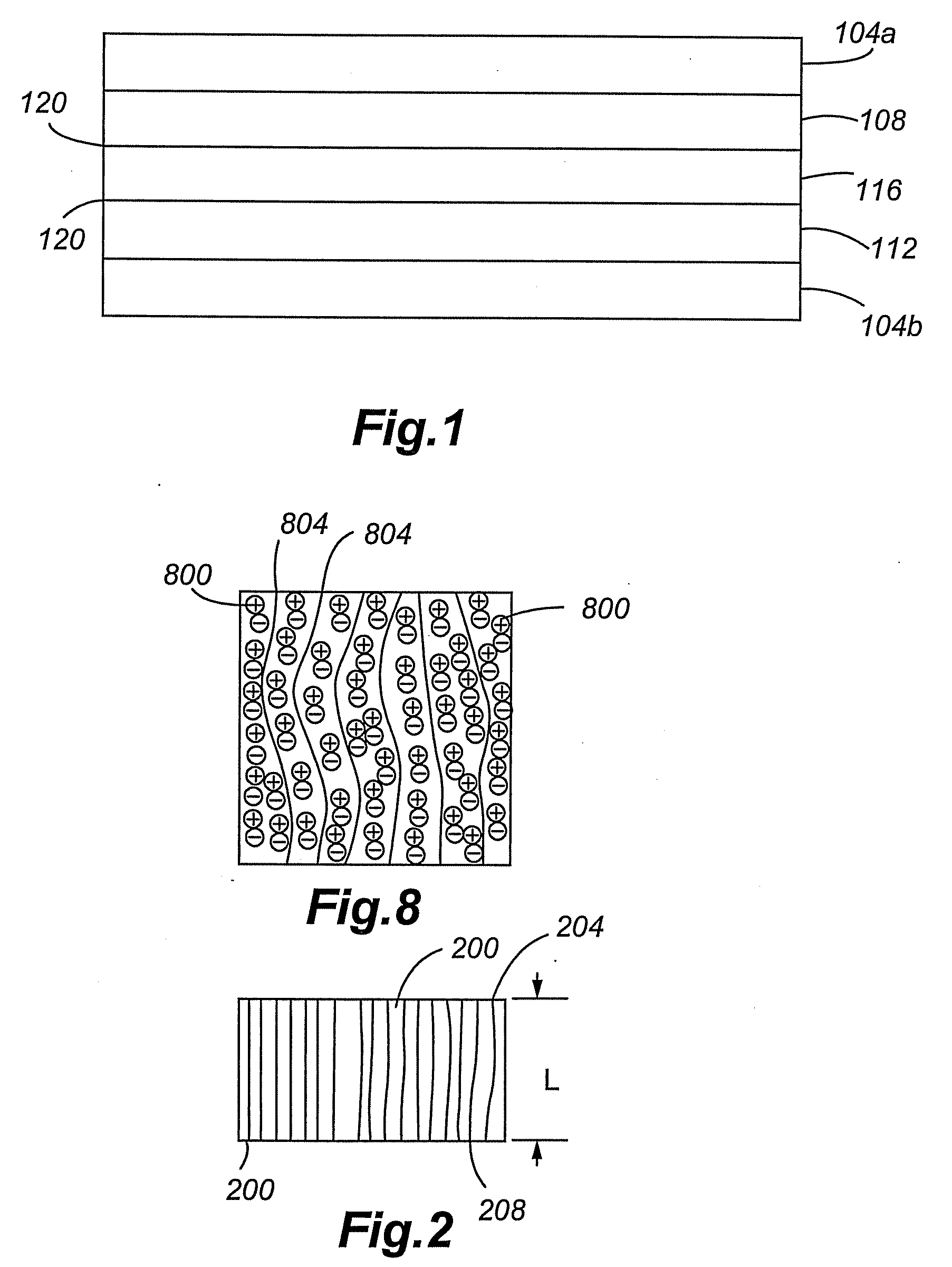

InactiveUS20080192407A1Excellent electrolyte accessibilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsSupercapacitorCarbon nanomaterials

The present invention is directed to the use of carbon nanotubes and / or electrolyte structures comprising ionic liquids in various electrochemical devices, such as ultracapacitors.

Owner:ADA TECH

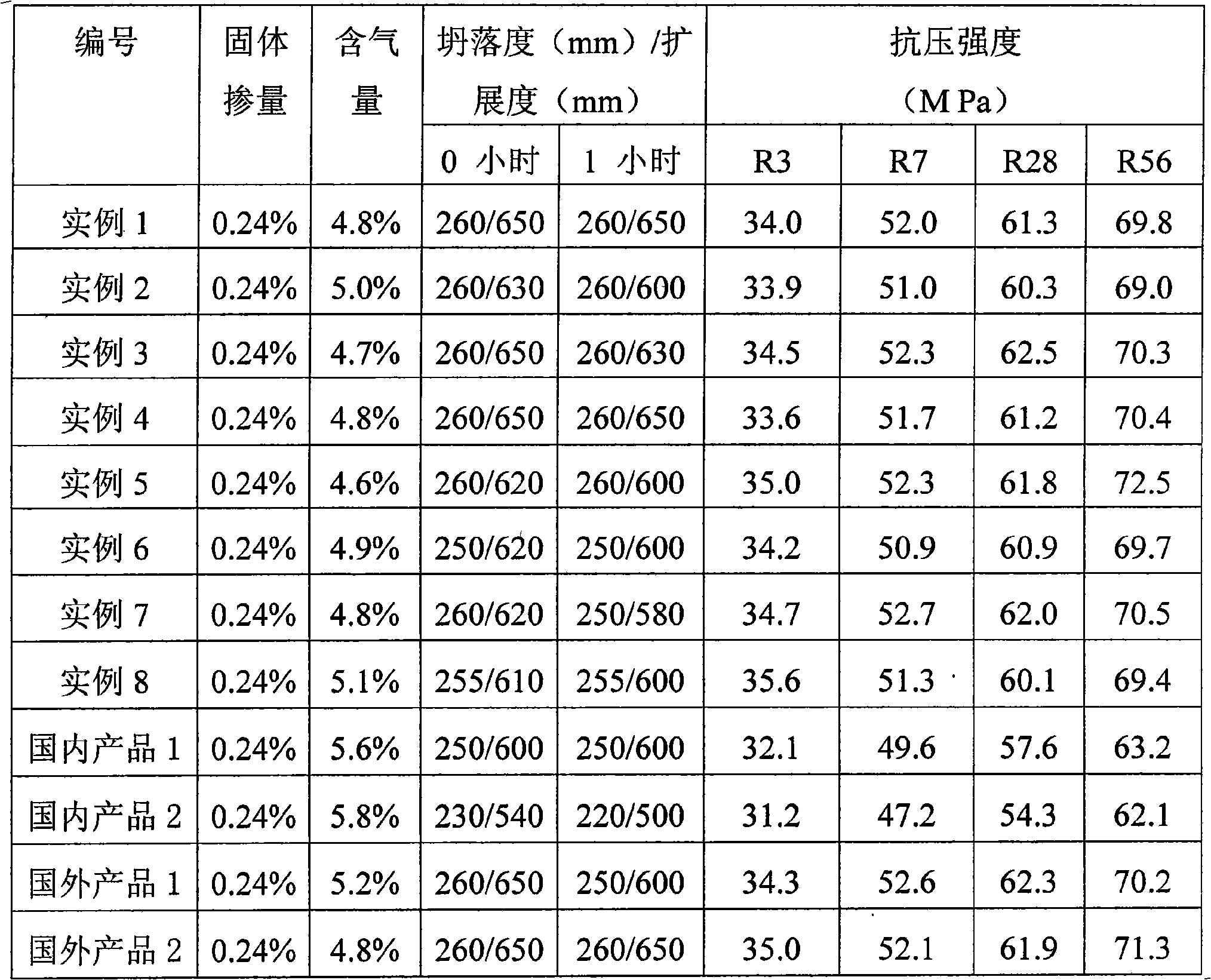

Polyether class polycarboxylic acid high-efficiency water reducing agent and preparation method thereof

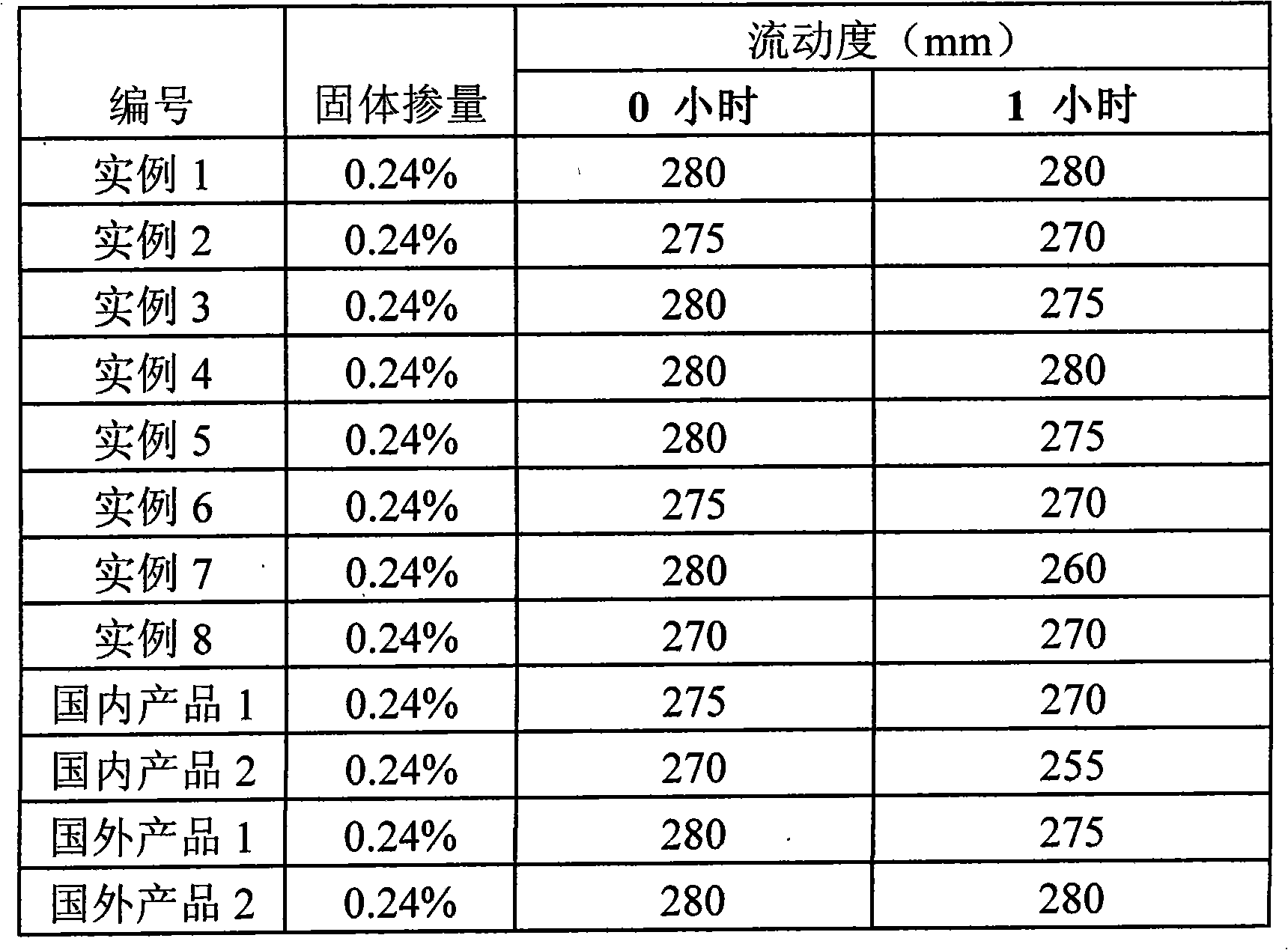

The invention relates to a polyether class polycarboxylic acid high-efficiency water reducing agent and a preparation method thereof, belonging to the field of concrete materials, structures and engineering of building materials. The polyether class polycarboxylic acid high-efficiency water reducing agent raises the temperature of water solutions of 15-55 mass percent of allyl polyethenoxy ether and 0-6 mass percent of chain transfer agent is raised to 50-90 DEG C, one side is dropwise added with a water solution of 0.01-0.9 mass percent of an evocating agent, one side is dripwise added with miscible liquids of 3-15 mass percent of unsaturated acids and one or more than one derivative thereof, the temperature is kept unchanged, and the water solution and the miscible liquids are completely dropped within 2-6 hours, the temperature is preserved for 1-6 hours and naturally cooled to room temperature, and the mixed solution is neutralized by sig water till a PH value reaches 6.8-7.2 so as to obtain the polyether class polycarboxylic acid high-efficiency water reducing agent. The polyether class polycarboxylic acid high-efficiency water reducing agent and the preparation method thereof have simple technique, low cost and good property, can effectively reduce the water-cement ratio of concrete, improves the compaction rate of a pore structure of the concrete, enhances the strength and the durability of the concrete and has great significance on enhancing the engineering quality, prolonging the service life, reducing the engineering cost, reducing the environment pollution, and the like.

Owner:大连华健科技有限公司

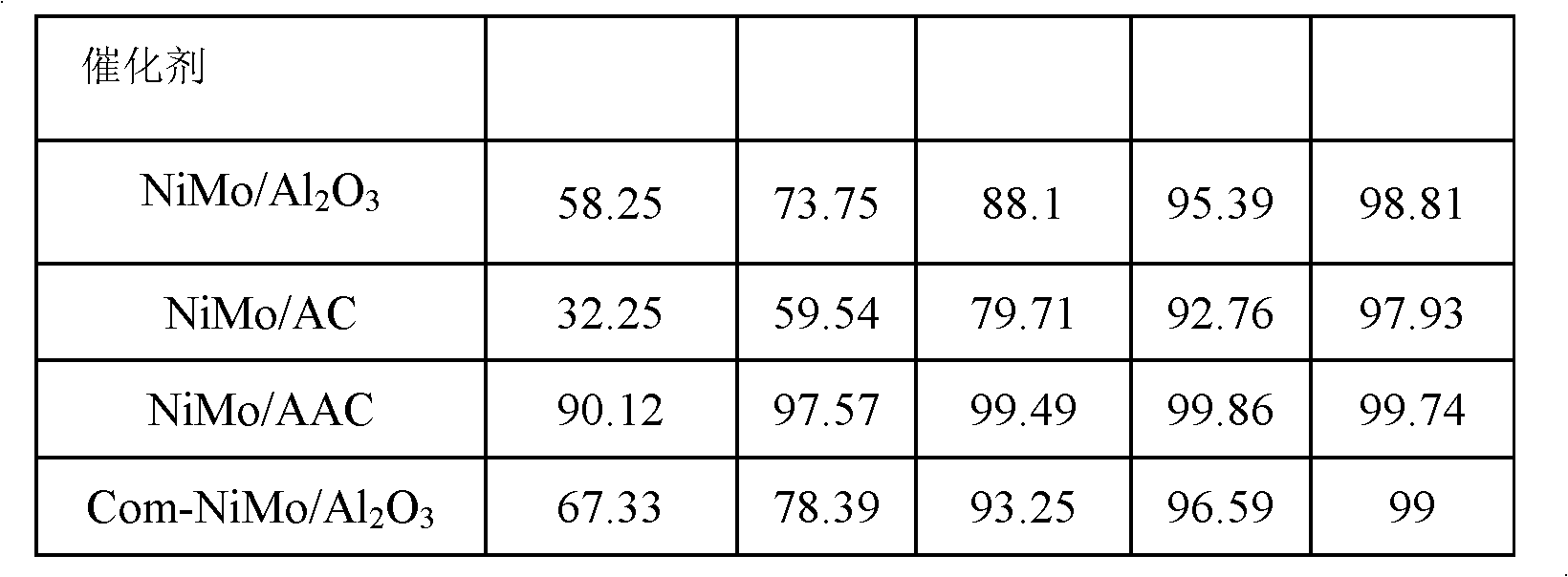

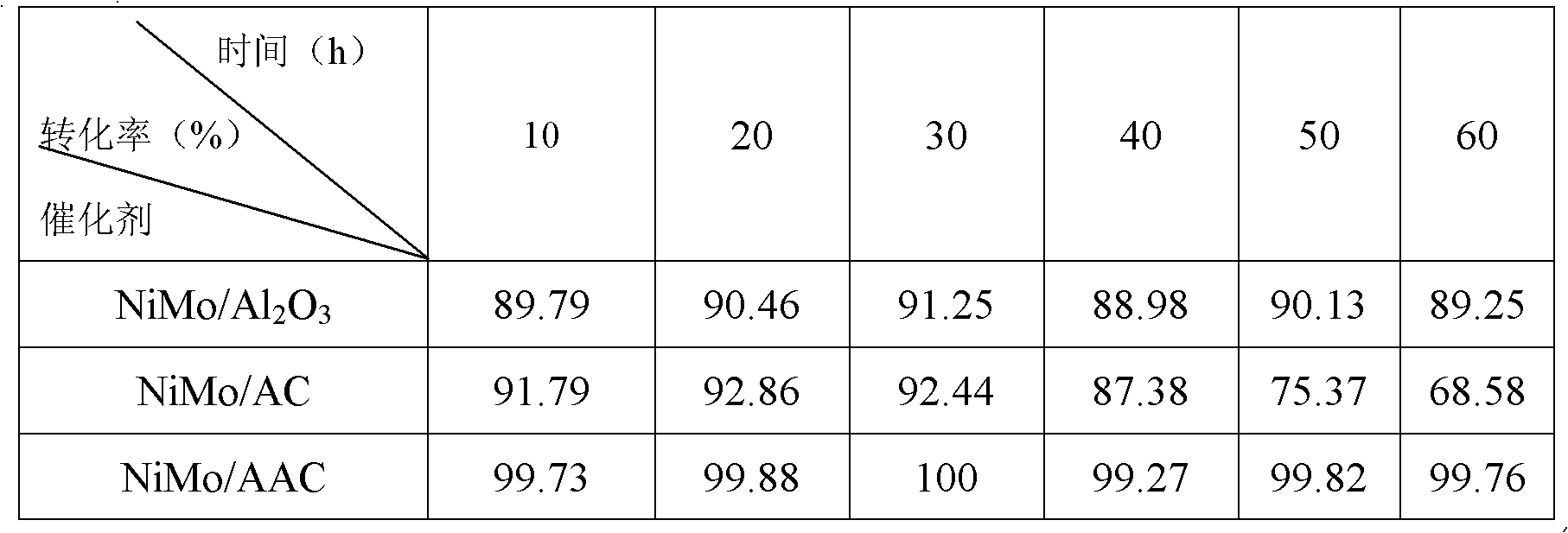

Aluminum oxide-activated carbon composite carrier, preparation method and prepared catalyst

InactiveCN101862684AImprove pore structureMeet the compressive strengthCatalyst carriersCatalyst activation/preparationActivated carbonPtru catalyst

The invention discloses an aluminum oxide-activated carbon composite carrier, a preparation method and a prepared catalyst. The carrier is characterized by having a specific surface area of 70 to 300 m<2> / g, a most probable pore diameter of 3 to 25 nm and the side compression strength of 80 to 200 N / mm; the activated carbon content of the carrier is 10 to 30 mass percent, while aluminum oxide content is 70 to 90 mass percent; and the carrier is prepared by kneading, molding and calcining aluminum oxide, activated carbon and an auxiliary material. The hydrogenation and desulfurization catalyst is prepared by loading Ni-Mo or Co-Mo or Ni-W onto the carrier by an impregnation method. The carrier of the invention has a well-developed mesopore structure and high mechanical strength. The catalyst of the invention has hydrogenation and desulfurization activity higher than that of the catalyst prepared by taking the aluminum oxide and the activated carbon independently as the carriers.

Owner:DALIAN UNIV OF TECH

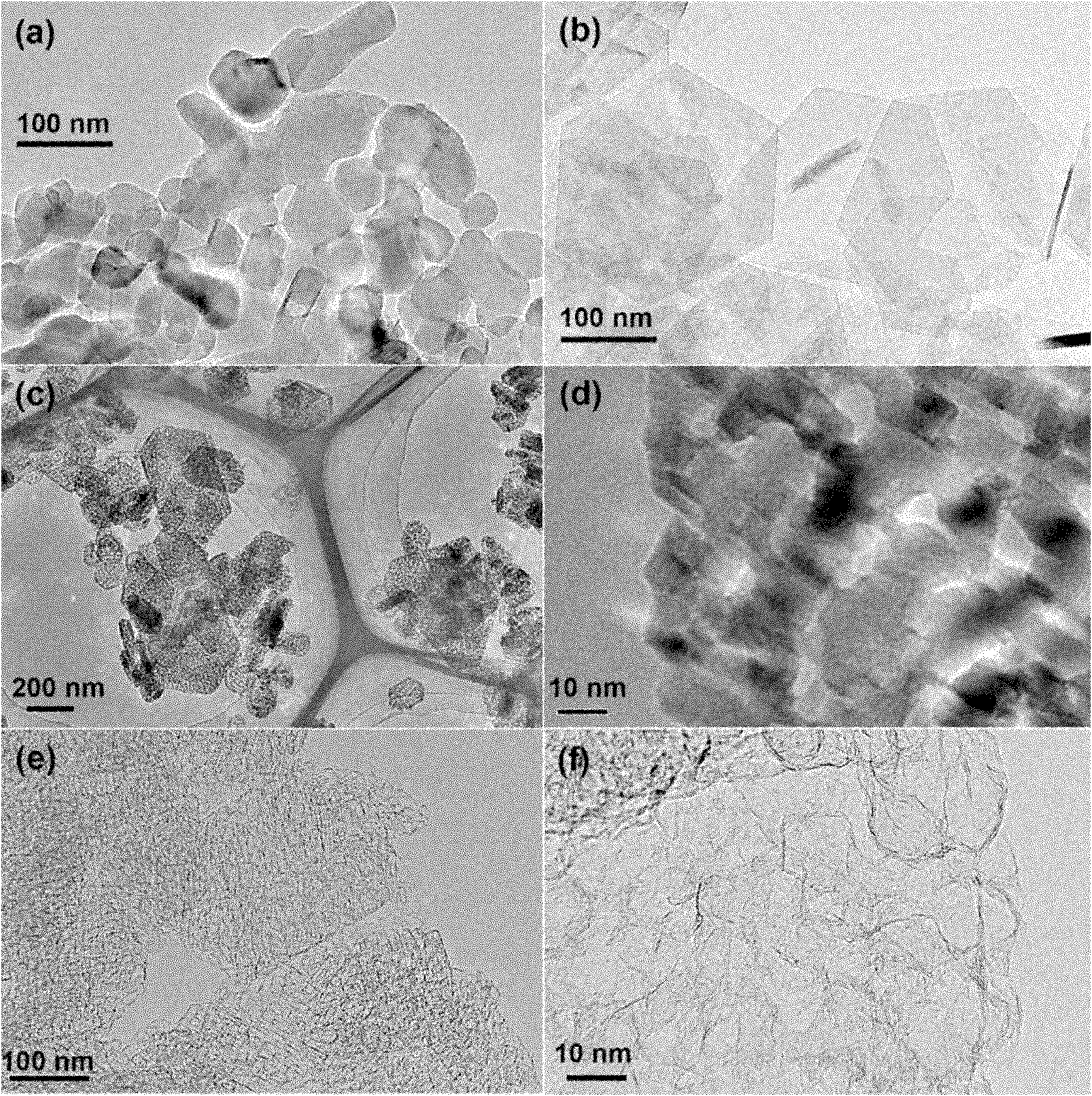

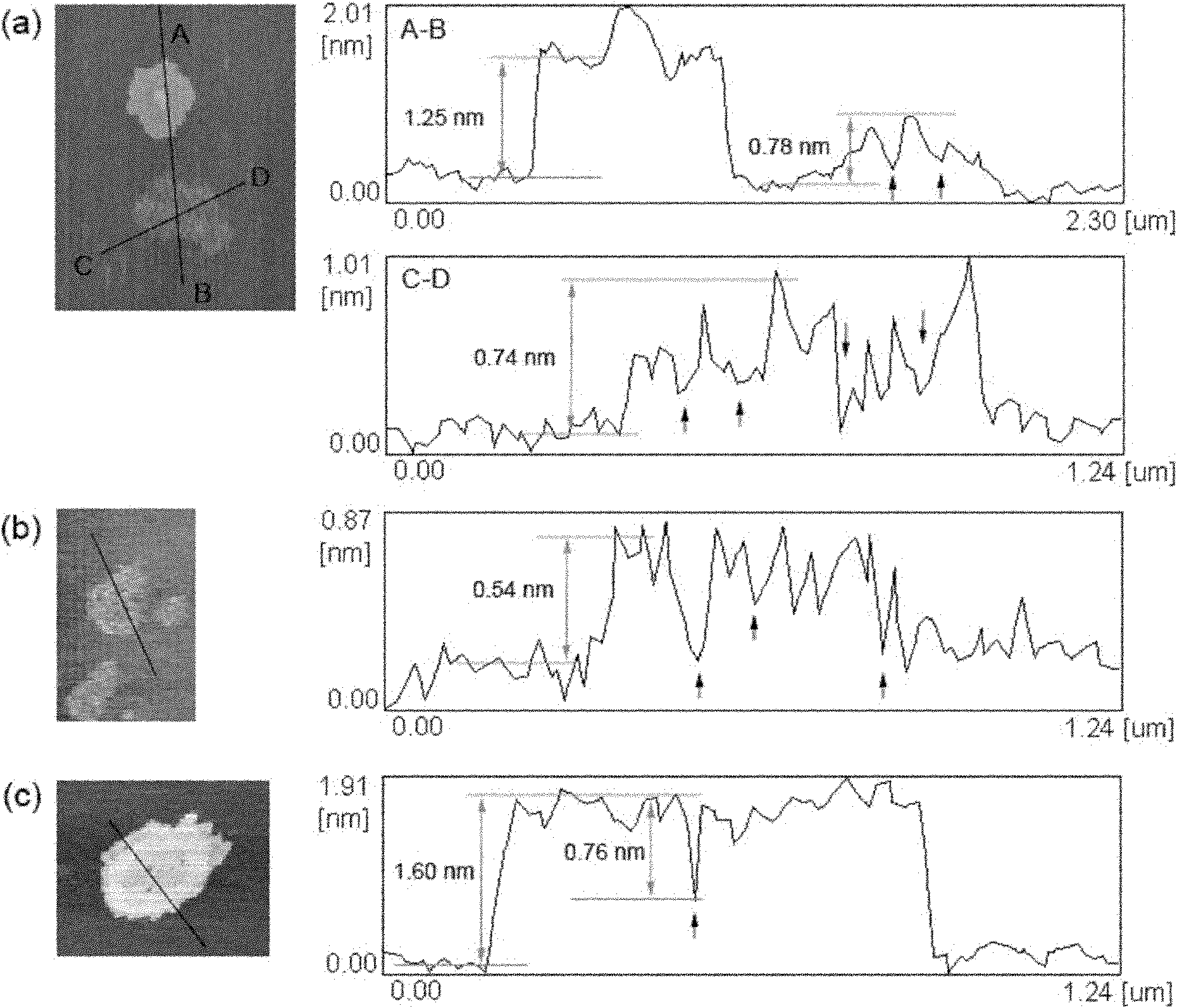

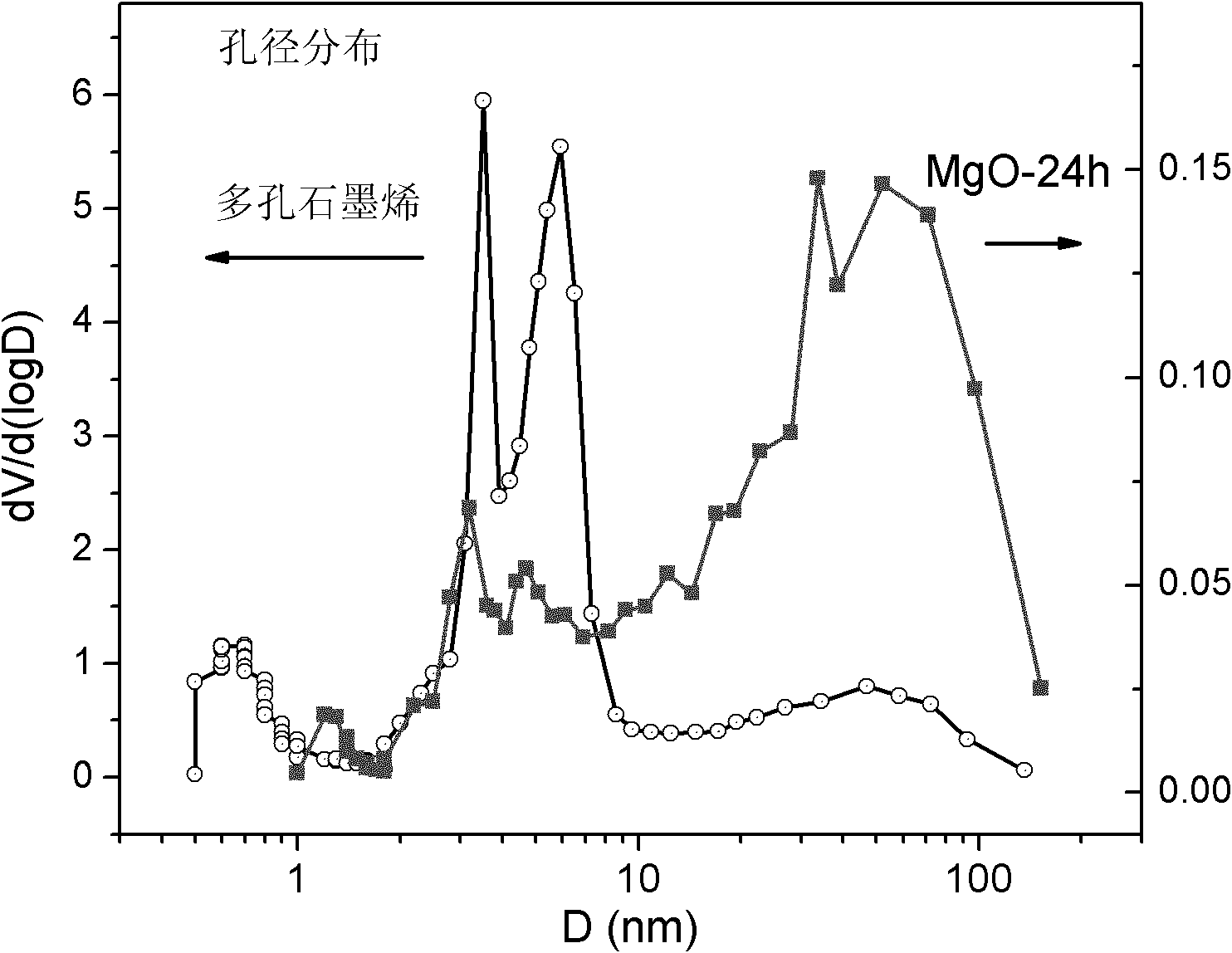

Graphene with porous structure and preparation method of graphene

The invention discloses a graphene with a porous structure and a preparation method of the graphene. The porous grapheme consists of a single-layer or multi-layer graphene structure unit, the single-layer or multi-layer grapheme structure unit has a pore-shaped structure (pore diameter is 0.1-200 nm) and a large specific surface area (300-2000 m<2> / g), thus the graphene has potential application value in the aspects of super-capacitors, conductive filling materials and the like. The preparation method of the porous grapheme is characterized in that MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as catalysts, or MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as carriers so as to further load one or more active components of Fe, Co, Ni and Mo and then the obtained substance is used as the catalyst ( the pore diameter of the catalyst is 1-200 nm, and the specific surface area is 10-300 m<2> / g); and then at the temperature of 300-1000 DEG C, the graphene is prepared by using inert gases such as nitrogen, argon, helium and the like and using a hydrocarbon chemical gas phase deposition method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

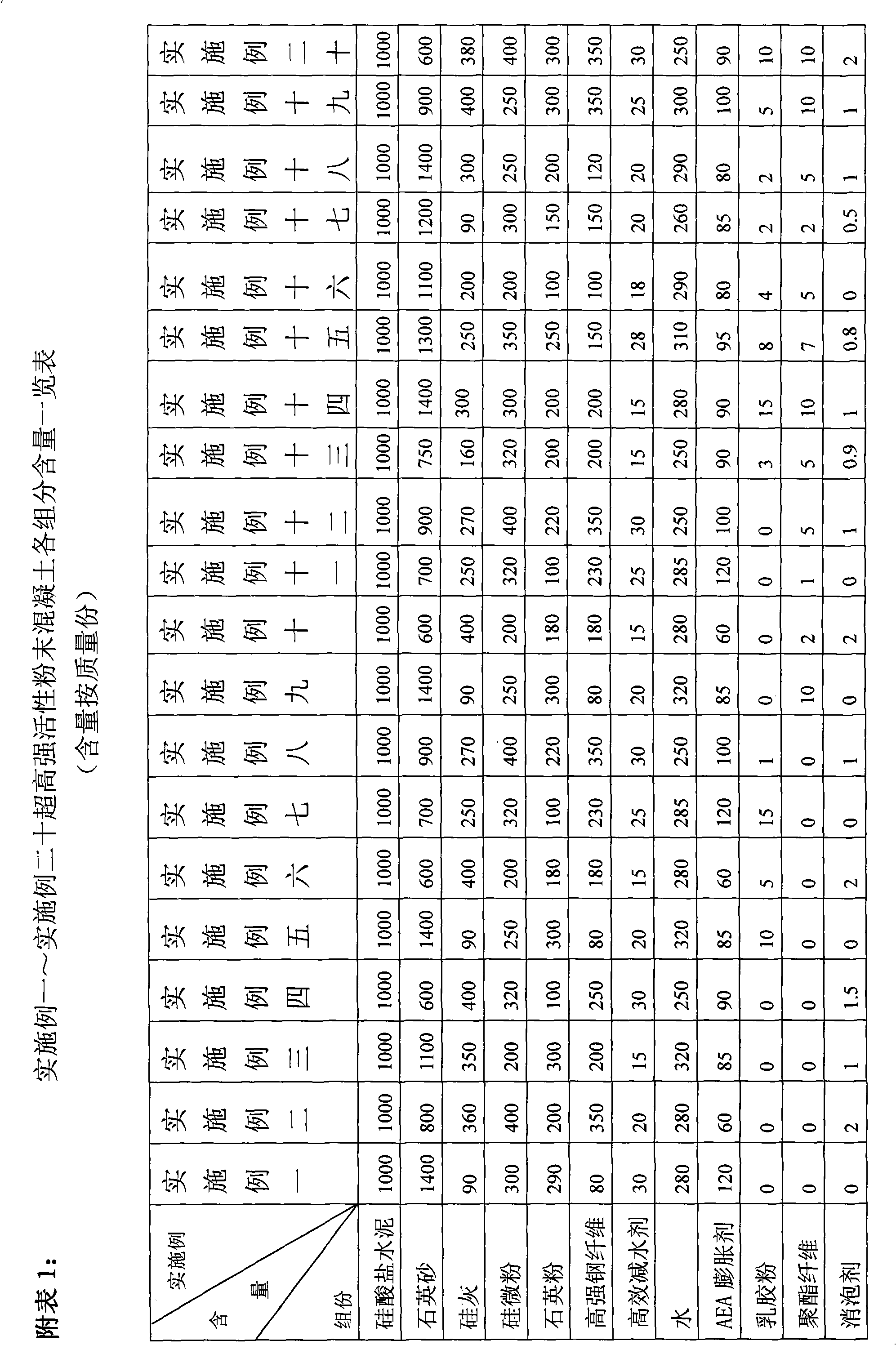

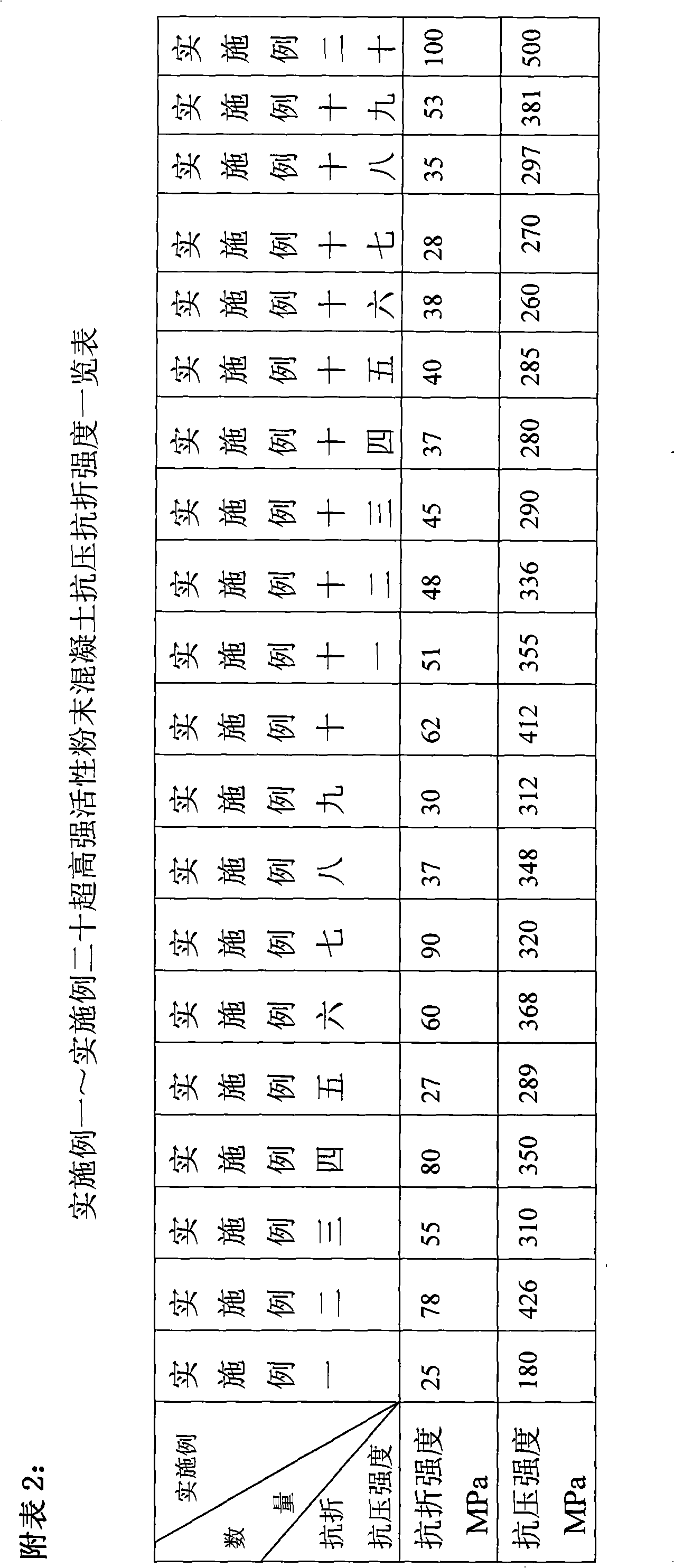

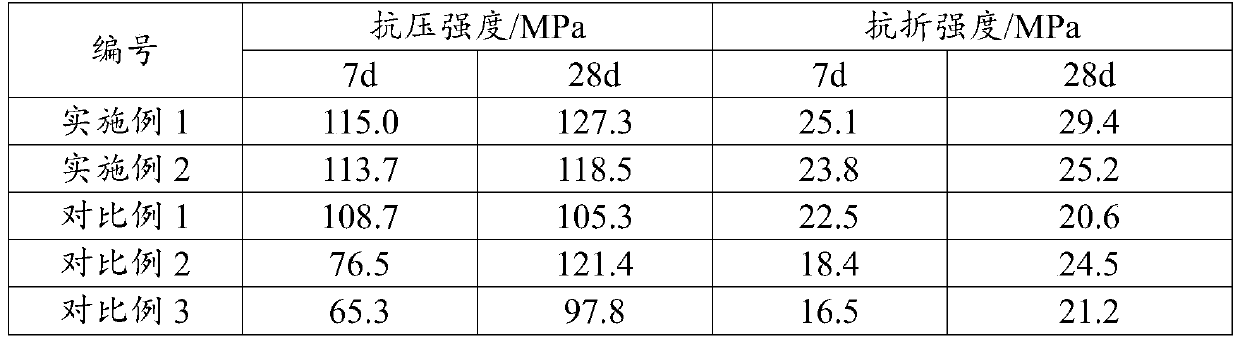

Ultrahigh-strength active powder concrete and preparation method thereof

An ultrahigh-strength active powder concrete is a mixture prepared by mixing the following materials according to weight portion: 1000 portions of Portland cement, 600-1400 portions of quartz sand, 90-400 portions of siliceous dust, 200-400 portions of silicon powder, 100-300 portions of quartz powder, 80-350 portions of high-strength steel fiber, 15-30 portions of high-efficiency water reducing agent, 250-320 portions of water, 60-120 portions of AEA expanding agents, 0-15 portions of latex powder, 0-10 portions of polyester fiber and 0-2 portions of antifoam agents. The preparation method comprises the following steps: preparing the materials according to the weight proportion, firstly mixing water, cement, quartz sand, siliceous dust, silicon powder, quartz powder, AEA expanding agents, high-efficiency water reducing agent, latex powder, polyester fiber, and antifoam agents into pasty state; then adding high-strength steel fiber, and mixing for 4-6 minutes. The prepared active powder concrete has super-high compressive and bending strengths, high mechanical property and high durability.

Owner:LIUZHOU OVM MASCH CO LTD

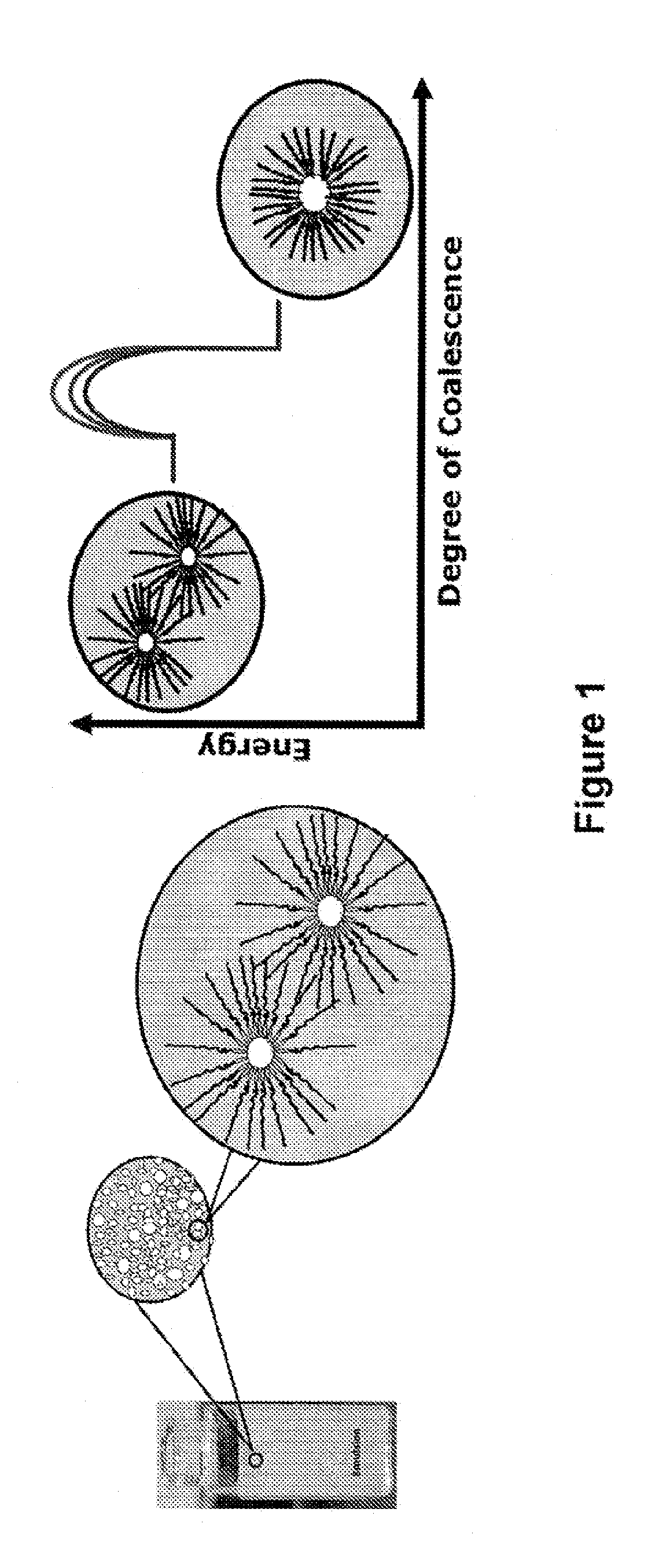

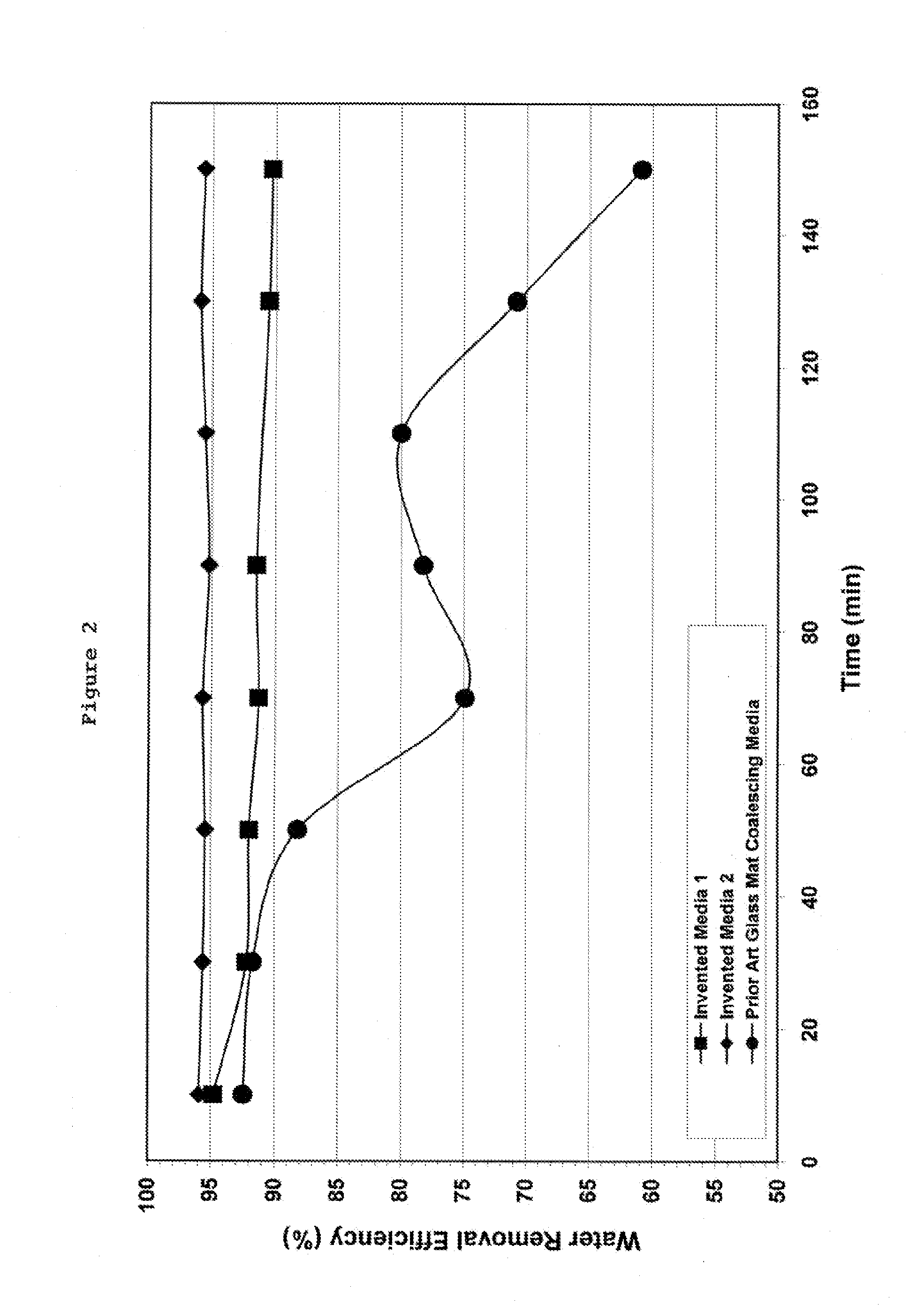

Coalescence media for separation of water-hydrocarbon emulsions

ActiveUS20110147299A1Low energyHigh surface areaLoose filtering material filtersGravity filtersNatural fiberMicrofiber

A coalescence media for separation of water-hydrocarbon emulsions comprises an emulsion-contacting sheet formed of: (a) at least one component of the group consisting of natural fibers, cellulose fibers, natural-based fibers, and cellulose-based fibers, at least one component of the group consisting of high-surface-area fibrillated fibers, surface-area-enhancing synthetic material, glass microfibers, and nanoceramic functionalized fibers; and (c) at least one component of the group consisting of a dry strength additive, and a wet strength additive, wherein the fibrous components of the media constitute at least about 70% of the media. In preferred embodiments, the coalescence media comprises kraft fibers, fibrillated lyocell fibers, glass microfibers or nanoceramic functionalized fibers, a wet strength additive, and a dry strength additive. Preferably, the coalescence media is formed as a single, self- supporting layer from a wet-laid process using a homogenously distributed, wet-laid furnish. It may also be formed as a multi-layer structure.

Owner:A AHLSTROM CORP

Method for preparing nitrogen-doped porous carbon nanofiber cloth

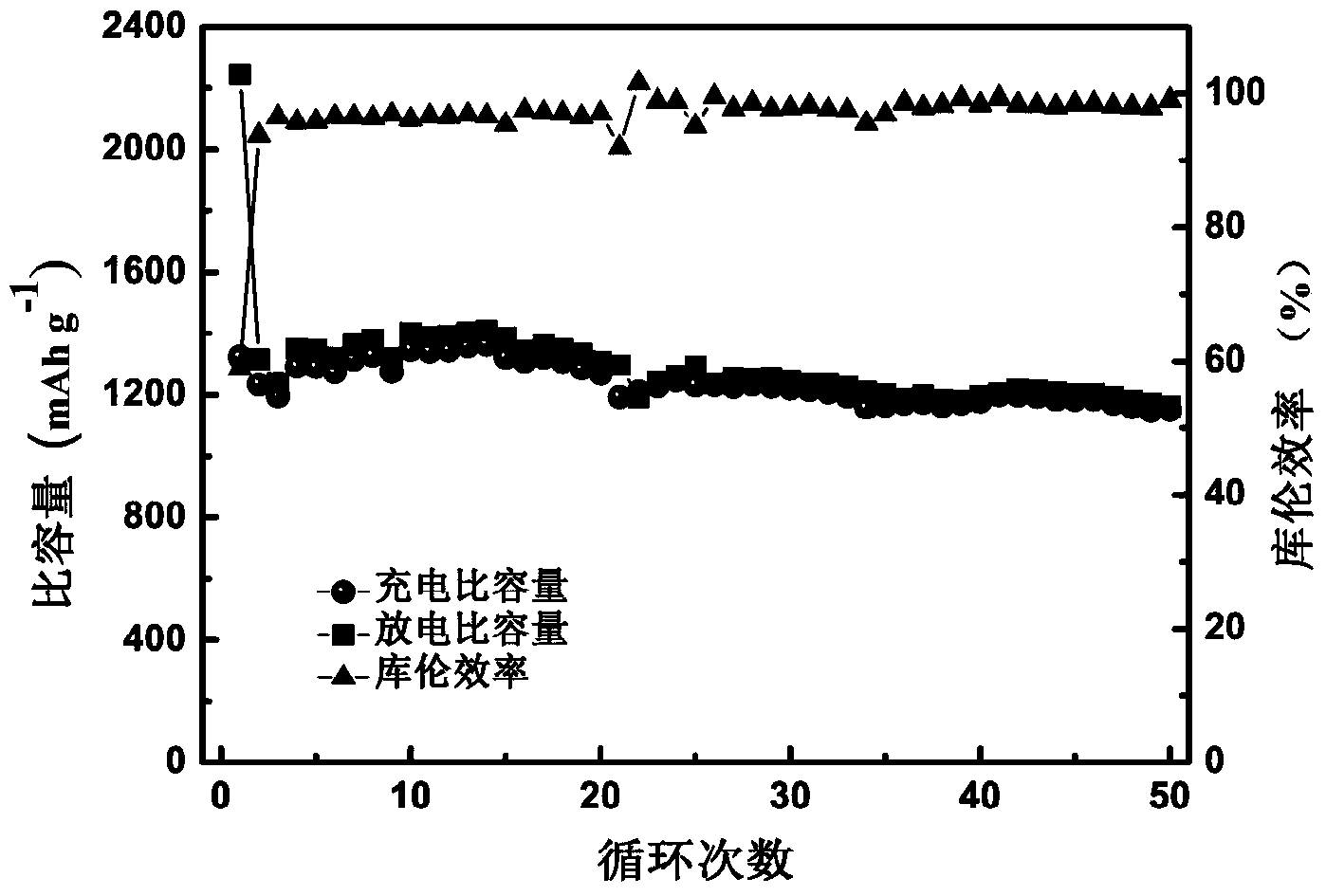

ActiveCN103855361ALow costGood spinnabilityMicroscopic fiber electrodesSecondary cellsLithium electrodeCarbon nanofiber

The invention relates to a method for preparing nitrogen-doped porous carbon nanofiber cloth. The nitrogen-doped porous carbon nanofiber cloth is prepared by adding a nitrogen-rich compound into an organic solution, electrospinning and subsequent carbonizing-activating, has a self-support structure, omits preparation steps of size mixing, coating and the like, needs no conductive agent or binder, and can be directly used as the negative electrode of a lithium ion battery. The electrochemical performance of the negative electrode material of the lithium ion battery is improved by doping nitrogen and activating and forming pores; compared with a commercial graphite lithium ion battery negative electrode material, the nitrogen doping porous carbon nanofiber cloth used as the negative electrode material of the lithium ion battery has simple steps for preparing the electrode, has higher specific capacity, good power performance and circulatory stability. The method also can be used as the electrode material of super capacitors and other novel batteries.

Owner:TSINGHUA UNIV

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

Preparation method of high-yield biochar

ActiveCN104371748AHigh specific surface areaImprove pore structureProductsReagentsPorosityCarbonization

The invention discloses a preparation method of high-yield biochar, which mainly comprises the following steps: (1) putting a collected biomass raw material into a catalyst solution, stirring and impregnating at normal temperature, and filtering to obtain the biomass raw material containing moisture and catalyst, the moisture weight percentage is 50-150%, and the catalyst weight content is 0.5-5%; and (2) heating the biomass raw material containing moisture and catalyst in an oxygen-free or limited-oxygen atmosphere to 100-180 DEG C at the rate of 0.5-2 DEG C / minute, keeping the temperature for 1-2 hours, heating to 240-300 DEG C at the rate of 0.5-3 DEG C / minute, keeping the temperature for 1-3 hours, heating to 500-900 DEG C at the rate of 10-50 DEG C / minute, keeping the temperature for 1-4 hours, and cooling to obtain the biochar, wherein the yield of the biochar is greater than 40 wt% of the biomass raw material. The method does not need drying in the biochar preparation process; the biomass raw material containing moisture and catalyst and the multi-step carbonization technique are utilized to achieve the goal of enhancing the biochar yield; and the biochar has the characteristics of energy saving, large specific area and high porosity, and can be widely used in the fields of water treatment, functional textiles and the like.

Owner:DONGHUA UNIV

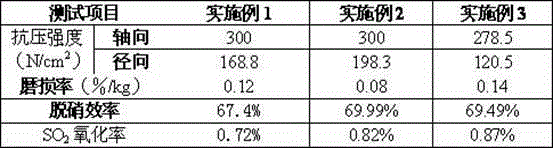

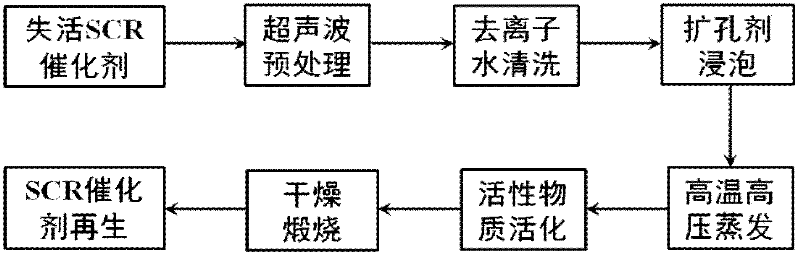

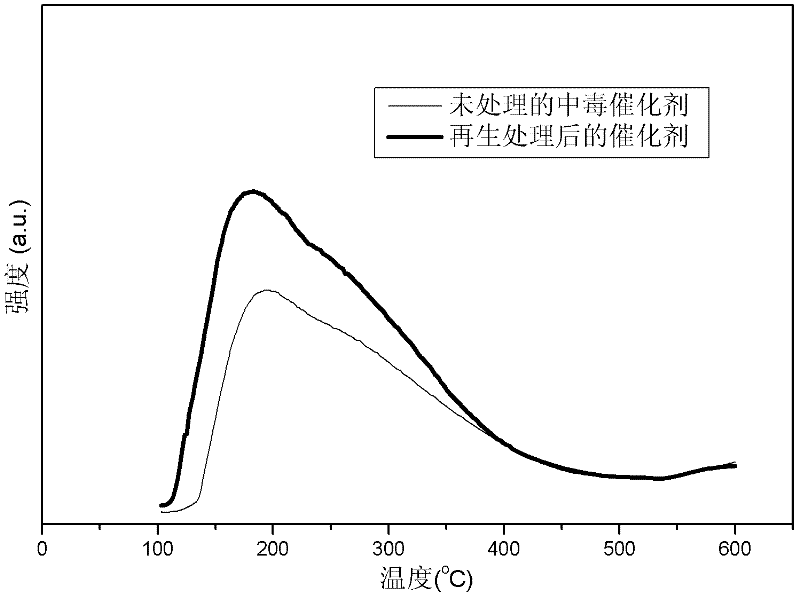

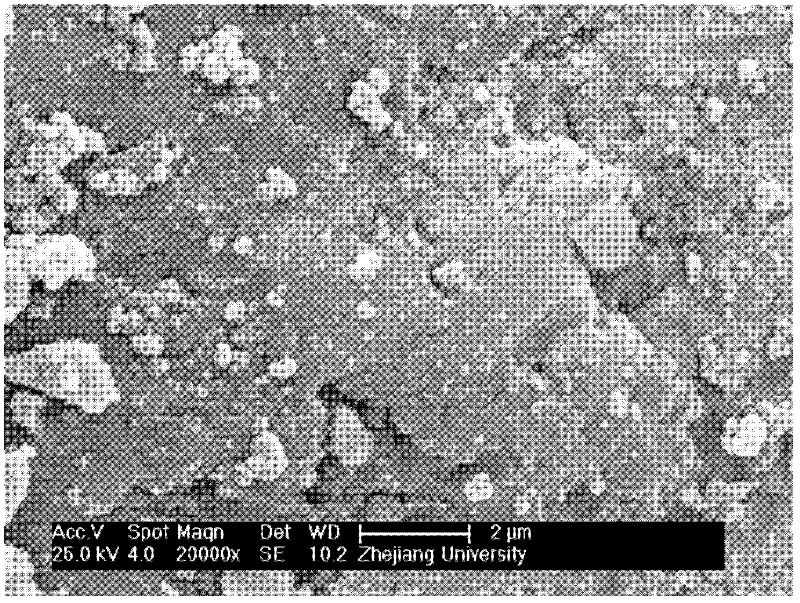

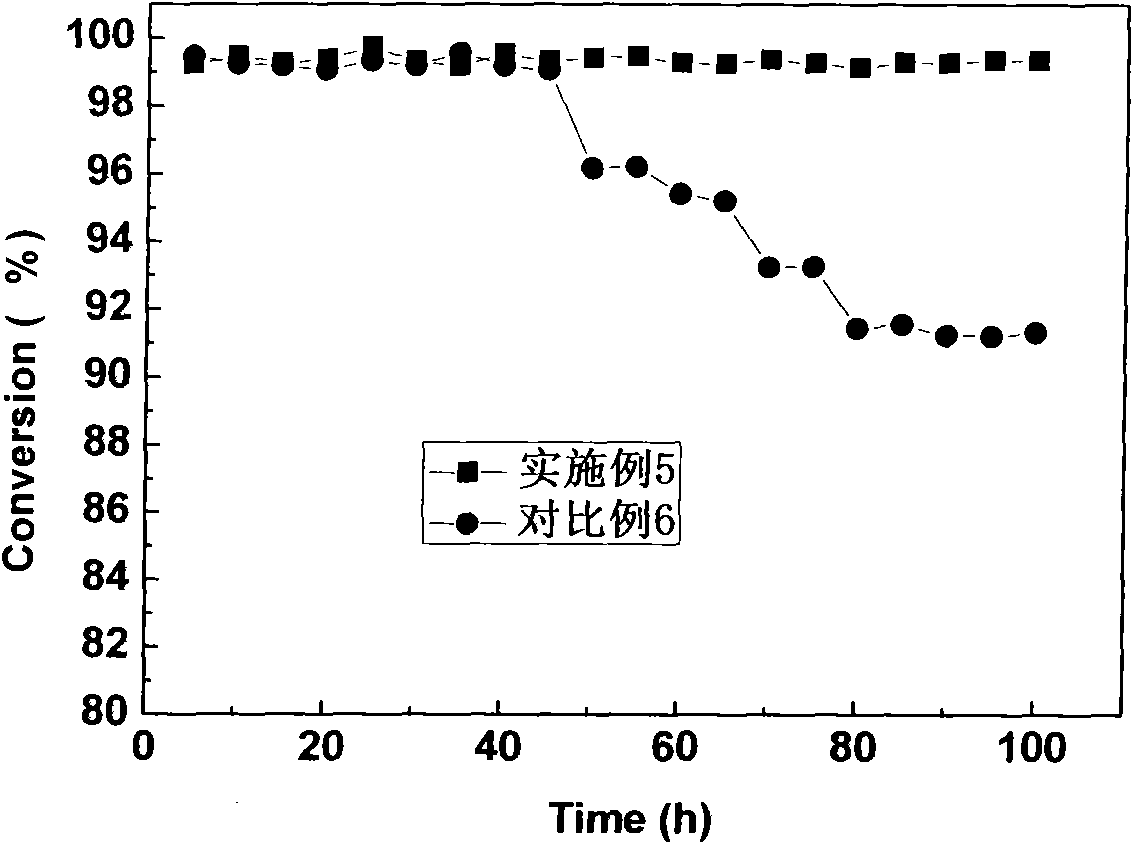

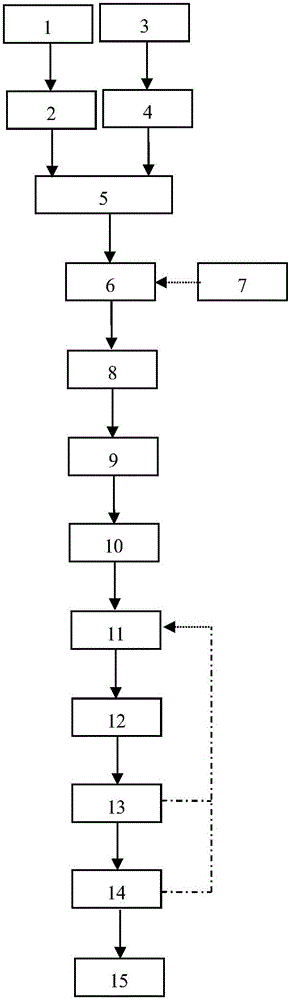

A regeneration method and device for a selective catalytic reduction denitrification catalyst

ActiveCN102266723AImprove pore structureImprove surface conditionDispersed particle separationMuffle furnacePre treatment

The invention discloses a regenerating method and a regenerating device for a selective catalytic reduction de-nitration catalyst. In the regenerating method, the industrially applied poisoned SCR (Selective Catalytic Reduction) de-nitration catalyst is subject to ultrasonic pretreatment, de-ionized water rinsing, chambering agent soaking, high-temperature high-pressure evaporation, active material activation and burning in sequence, thereby regenerating the catalyst. The regenerating device comprises a purging pool, a soaking cleaning pool, a high-pressure kettle, an oscillation water bath kettle, a drying box and a muffle furnace. The regenerating method and the regenerating device have the advantages that pore channels are loosened, the pore structure of the catalyst is obviously optimized, the surface appearance of the catalyst is obviously improved, the activity of the regenerated catalyst is greatly promoted, the practical running demand in industry is met, the raw material is easily acquired in the regeneration process, the process is simple, and the production cost of the enterprise using the SCR de-nitration catalyst is greatly lowered.

Owner:ZHEJIANG UNIV

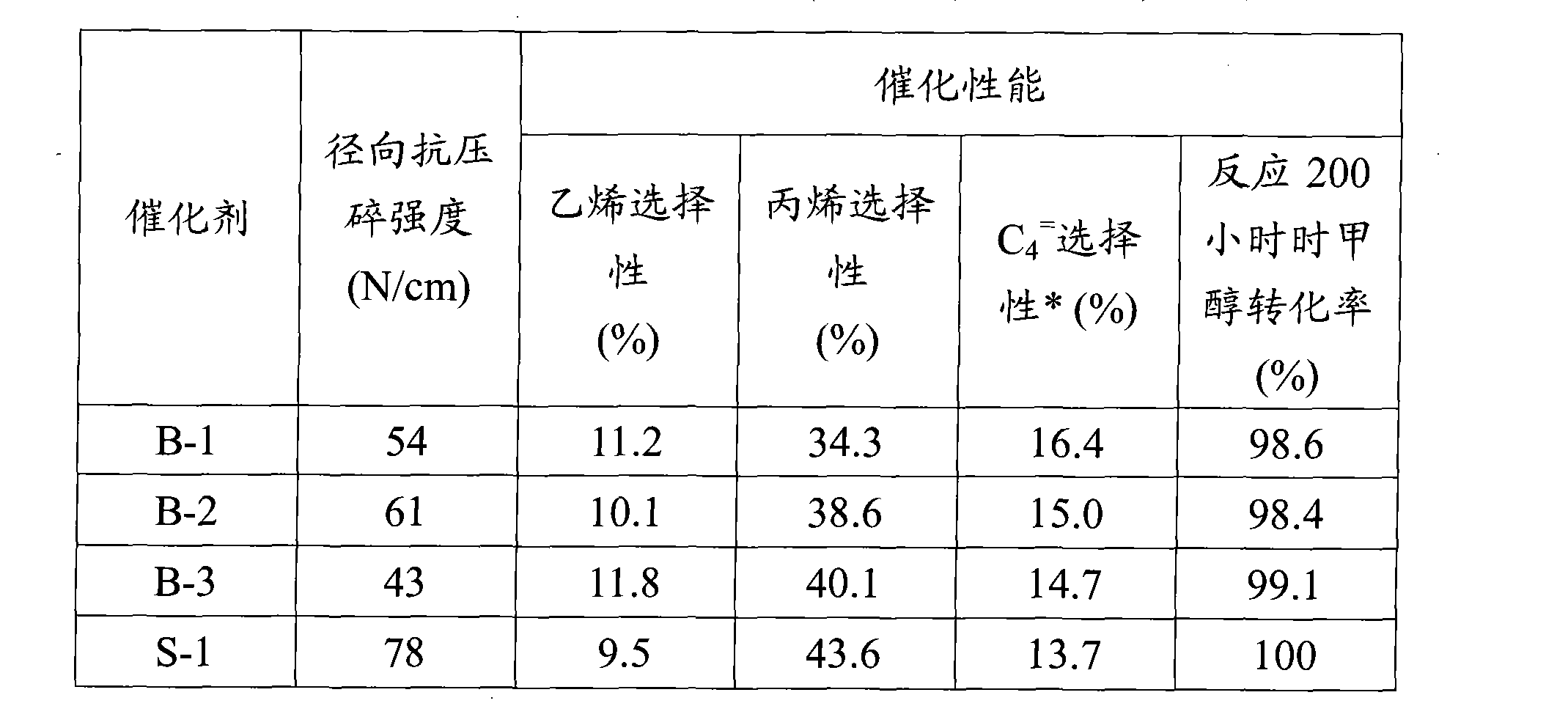

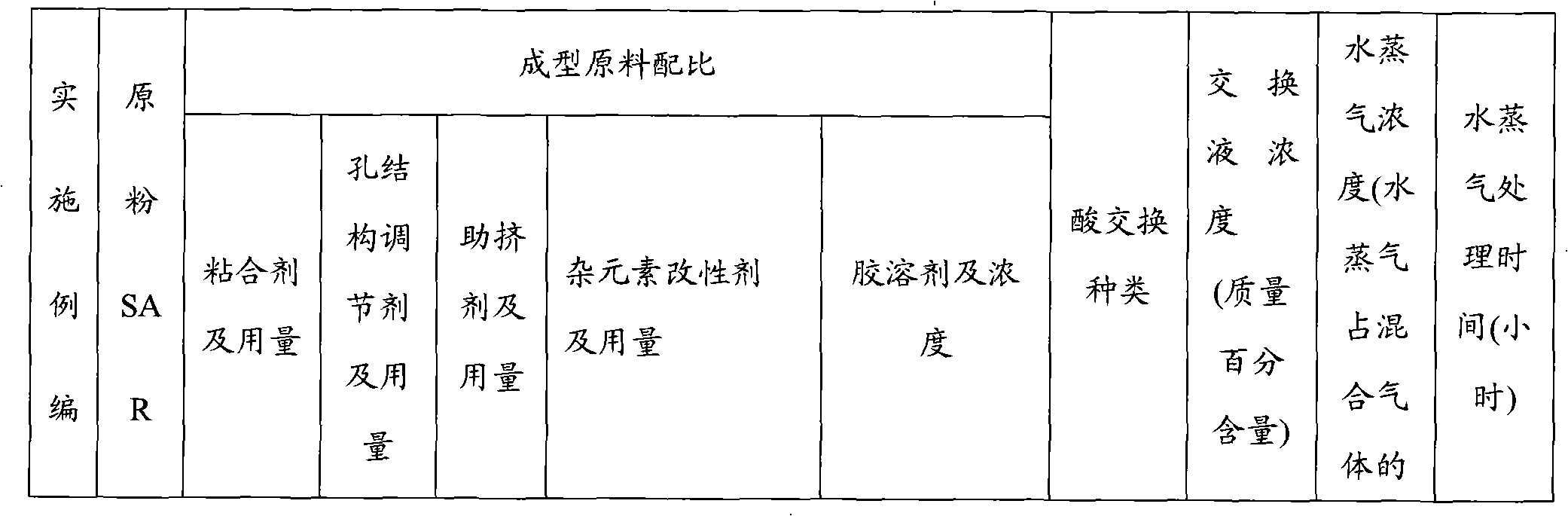

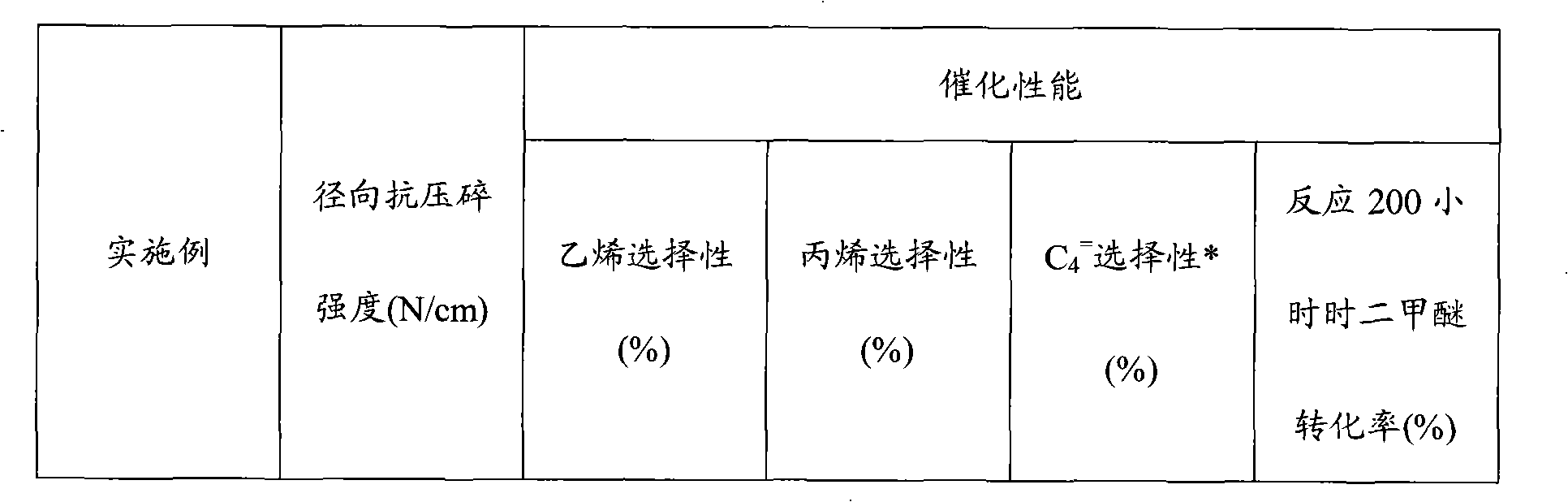

Molecular sieve catalyst for preparing low-carbon olefin and preparation method thereof

ActiveCN101628242ATotal pressure is smallSimplify production stepsMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHigh activity

The invention provides a molecular sieve catalyst for preparing low-carbon olefin, and the catalyst comprises the following raw materials by parts by weight: 30-93.7 parts of Na-ZSM-5 zeolite, 5-40 parts of bonding agent, 0.1-10 parts of modifier of mixed elements, 1-15 parts of hole structure regulator and 0.1-5 parts of extrusion assistant, and the modifier of the mixed elements is a soluble substance containing one or a plurality of elements of B, P, La, Ca, Mg, Sr, Zn, Cu, Mn, Cd, Ga and In. The invention further provides a prepration method of the catalyst. The molecular sieve catalyst adopts the extrusion assistant and adds an appropriate amount of hole structure regulator, thereby improving product strength and hole structure, effectively improving diffusion performance of the catalyst and further improving selectivity of the low-carbon olefin. The catalyst has the advantages of appropriate strength, high hydrothermal stability, high activity and high selectivity of propylene.

Owner:DATANG INT CHEM TECH RESINST

Anti-cracking low-shrinkage-deformation fiber-cement product and production method thereof

InactiveCN102785423AIncreased durabilityExtended service lifeWater-setting substance layered productEngineeringUltimate tensile strength

The invention relates to an anti-cracking low-shrinkage-deformation fiber-cement product and a production method thereof. Concretely, a novel fiber-reinforced cement product with an excellent anti-cracking function and low shrinkage deformation is realized through an ultra-short fiber, low-elasticity-modulus short fiber and high-elasticity-modulus long-fiber composite reinforced-cement base material by simultaneously adopting high-efficiency additives (a high-efficiency water-reducing agent, a thickening agent, an expanding agent and the like). The product comprises a flexible anti-cracking surface layer and a fiber-reinforced cement structural layer, has a simple and resaonable structure, is convenient and easy in production construction and can be applied to projects, such as building external-wall decorative enclosure, indoor engineering construction as well as roads, bridges and the like with higher requirements on the strength and the durability of the cement base material.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

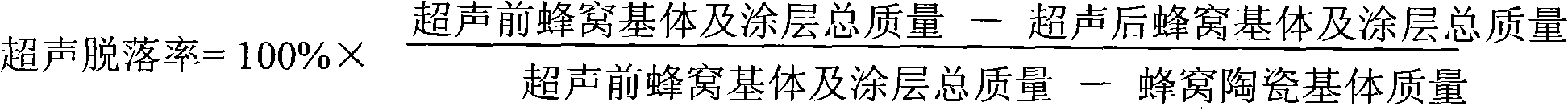

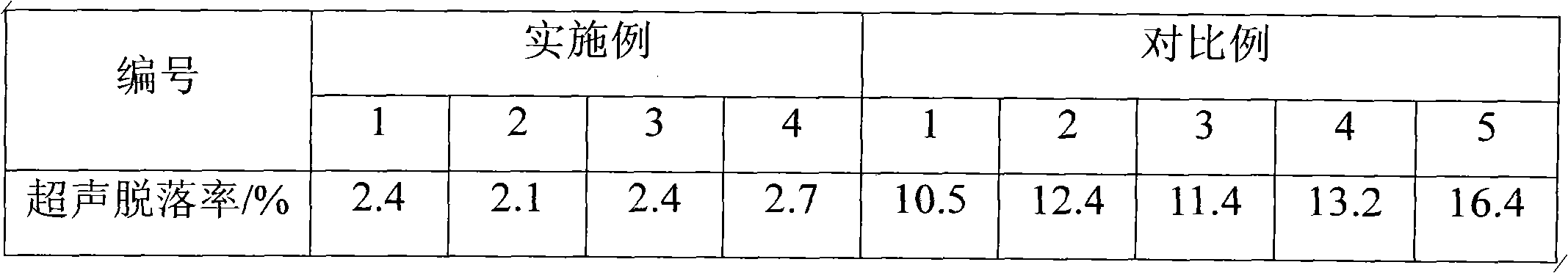

Preparation method of catalytic combustion catalyst

ActiveCN102049312ASimple preparation processEasy to operateDispersed particle separationCatalyst activation/preparationOperational performanceAirflow

The invention discloses a preparation method of a catalytic combustion catalyst. The method comprises the following steps: firstly, performing hydrothermal pretreatment on a honeycomb ceramic matrix; secondly, soaking the honeycomb ceramic matrix with alumina sol; and finally, loading additives and precious metal active components. The catalyst coating obtained by the method of the invention has high bonding degree with the matrix, is difficult to crack and peel off and has less dosage of additives. Thus, the catalyst has good operational performance and activity stability and can maintain higher activity under the scouring of high space velocity airflow and thermal shock, so that the long-term stable operation of the catalyst can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-base desulfurizer for catalyzing, translating and absorbing carbonyl sulfur at middle-low temperature and preparation thereof

InactiveCN101054538AHigh breakthrough sulfur capacityHigh precisionCombustible gas purificationSyngasSecondary component

The invention relates to a preparation of catalyzing and transforming-absorbing Fe-desulphurizer by high accuracy carbonyl sulfur at medium and low temperature, which has a good hydrogenation effect to the carbonyl sulfur and absorbs the produced carbonyl sulfur. The invention can be used to accurately remove the carbonyl sulfur in the ammonia material gas, coke oven gas, natural gas and composed gas. The desulphurizer is provided with primary active components Fe2O3, CeO2, MnO2, Ni2O3, and secondary components CuO, ZnO, MgO, K2O and etc, and the carriers are Al2O3, ZrO2, and residual binding agent and expanding drilling agent, and water. The process has a reacting temperature of 150-350 DEG C, an airspeed of 500-2000h-1, a carbonyl sulfur concentration in the gas from minim to 5000ppm. The inventive desulphurizer has a high catalytic transforming capacity with a carbonyl sulfur converting ratio more than 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

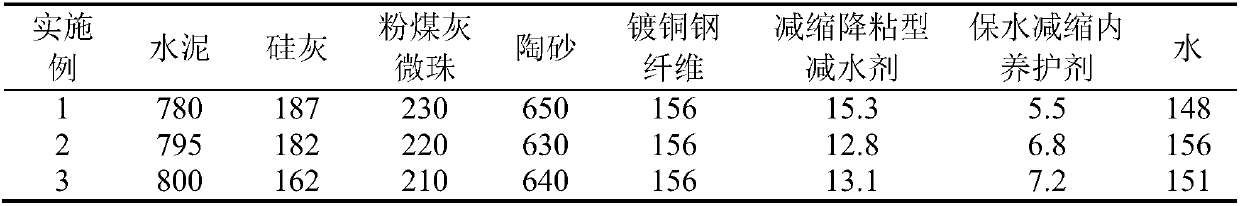

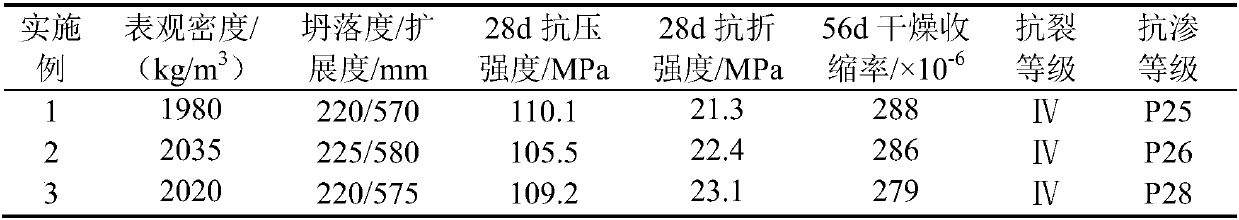

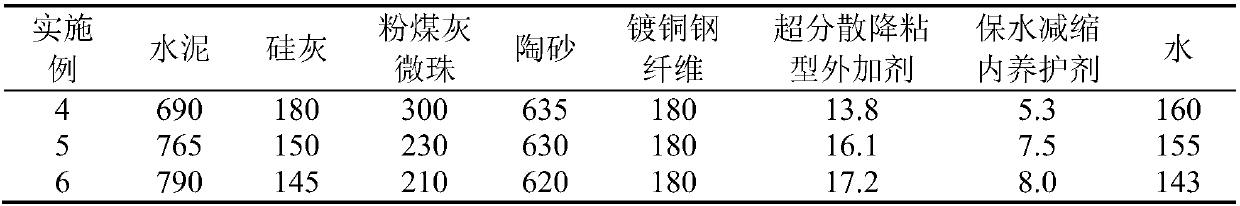

Light low-shrinkage super-high performance concrete and preparation method thereof

The invention discloses light low-shrinkage super-high performance concrete which is prepared from cement, coal ash beads, silica fume, pottery sand, a brass coated steel fiber, shrinkage and viscosity reduction type water reduction agent, a water-retention shrinkage-reduction inner curing agent and water as main raw materials. According to the concrete, the pottery sand is adopted as aggregate, the self weight of the concrete is reduced, and a high-strength and dense 'arch housing' interface area is formed on the surface of the pottery sand by using a pre-mixing process, so that the interfacestrength is improved, and the mechanical properties and the anti-penetrability performance of the concrete are improved; due to the adoption of the shrinkage and viscosity reduction type water reduction agent and the coal ash beads, the working performance and the density of the concrete are improved; due to the adoption of the pre-wetted pottery sand and the developed water-retention shrinkage-reduction inner curing agent, reduction of wetness inside the concrete is retarded, the self-shrinkage and the drying shrinkage of the concrete are reduced, and the volume stability of the concrete isimproved. While the self weight of the concrete is reduced, the light low-shrinkage super-high performance concrete disclosed by the invention is good in working performance, mechanical property, anti-penetrability and durability, and has significant practical application values.

Owner:WUHAN UNIV OF TECH

Alumina support containing silicon and titanium and preparation method thereof

ActiveCN1768945AImprove pore structureLarge specific surface areaCatalyst carriersPore distributionAluminium hydroxide

The invention discloses property-transformation alumina carrier which contains titanium and silica agent and its relative preparing method. Said silica agent is added in the sol process of aluminum hydroxide to improve the specific surface, pore diameter and pore capacity of alumina; after the sol process, individually using acid agent and alkali agent to adjust the pH value of mixed paste solution for several times to make the attained alumina with more centralized pore distribution; the titanium agent is added after the sol process and before the aging process, to improve the surface acid property, surface acid amount and B acid amount of carrier. In addition, the surface of alumina is modified by titanium to decrease the interactive condition between active metal and carrier, which can apply the diffusion of active metal components in the catalyst. The property transformation of said invention can be used as catalysis material when processing oil, especially as the catalyst carrier of hydrogenation treatment and hydrogenation transformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

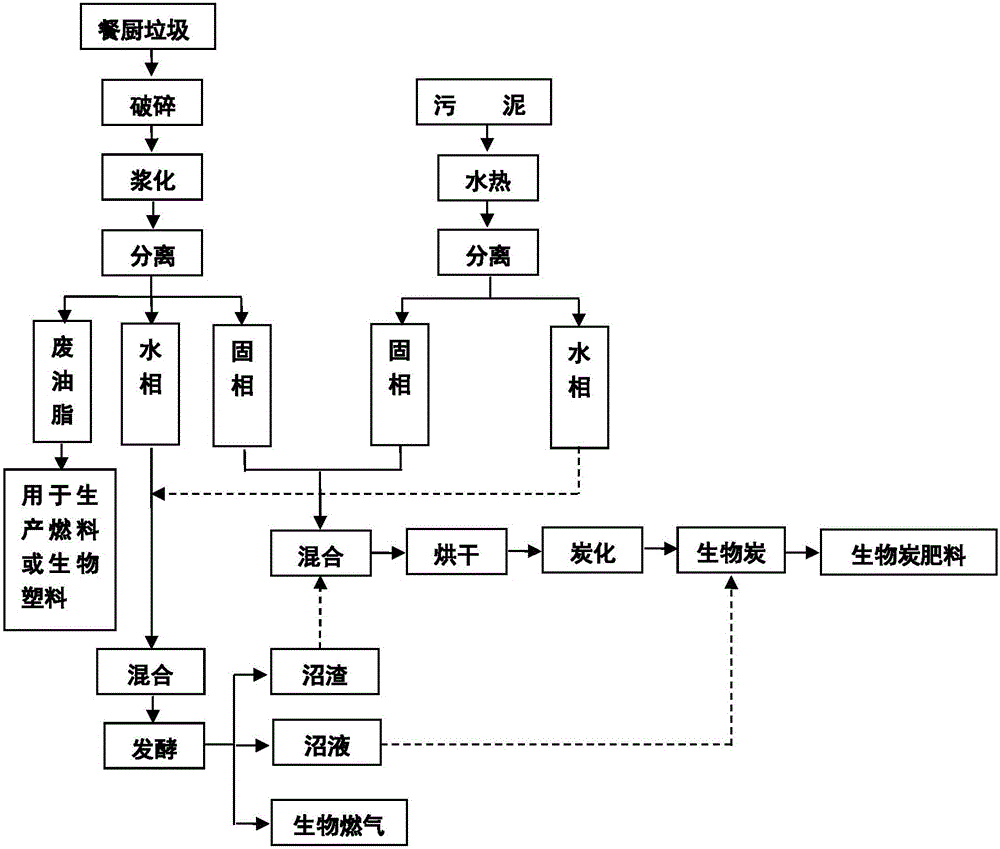

Method for processing sludge and kitchen wastes

ActiveCN105855275AImprove system stabilityLow running costSludge treatment by de-watering/drying/thickeningSolid waste disposalFertilizerNutrient

The invention relates to a method for processing sludge and kitchen wastes. The method comprises the following steps: by utilizing sludge and kitchen wastes as principal raw materials; separating waste oil from kitchen wastes to be taken as the raw material of fuel or bioplastics; taking biological fuel gas, which takes methane as main material and is generated through fermentation, as an external fuel supply; absorbing the nutrient in biogas slurry by the charcoal generated through pyrolysis and then taking the charcoal as a charcoal fertilizer. The method for processing sludge and kitchen wastes provided by the invention meets the increasingly urgent requirement of processing the sludge and kitchen wastes in China at present; the method can be used for efficiently solving the problems of separately processing sludge and kitchen wastes; the classification and valuable utilization of by-products are realized; various by-products are low-carbon high-efficient cleanly utilized; the purposes of best use, energy conservation, environment protection and cost lowering are achieved; the method has excellent economic benefit and environmental benefit.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

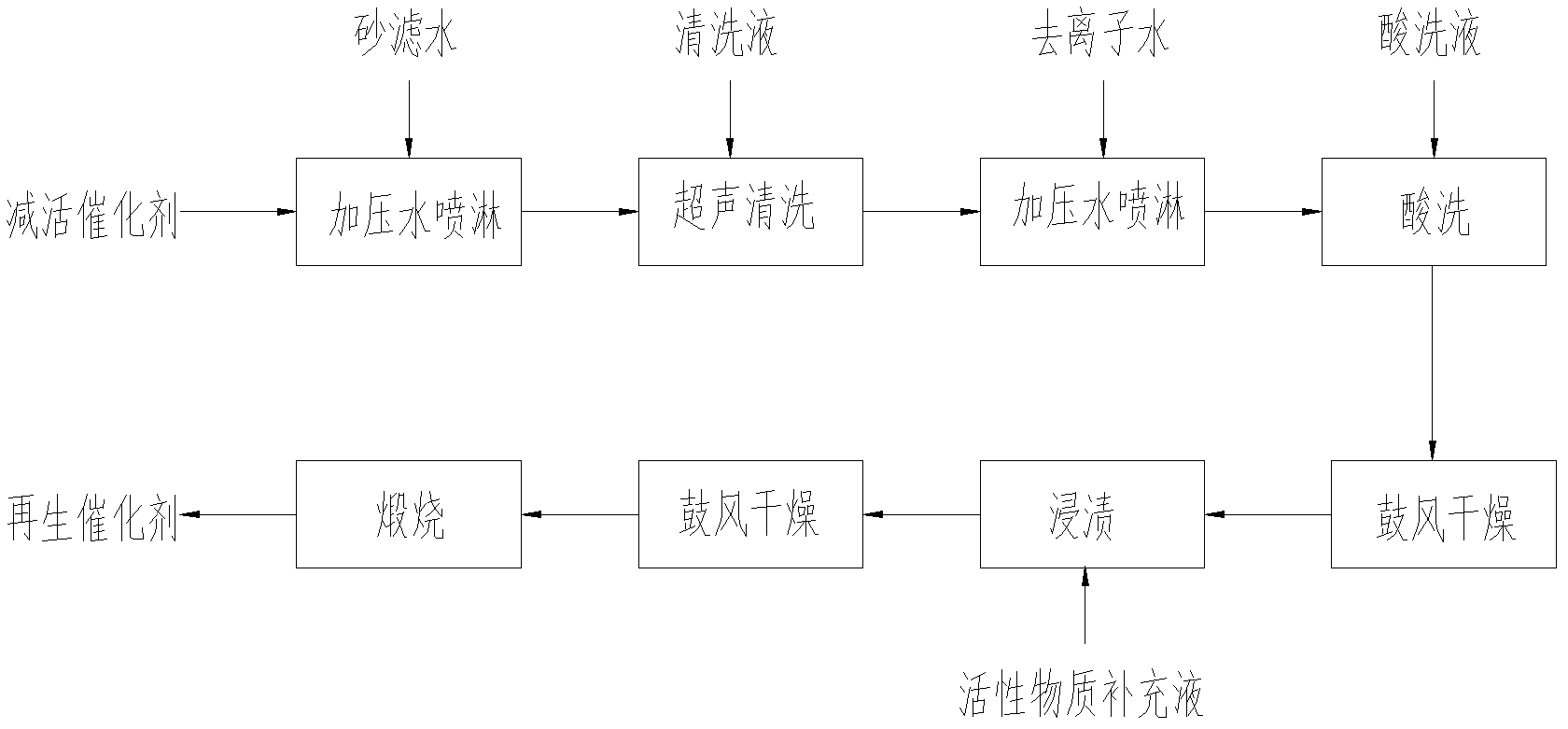

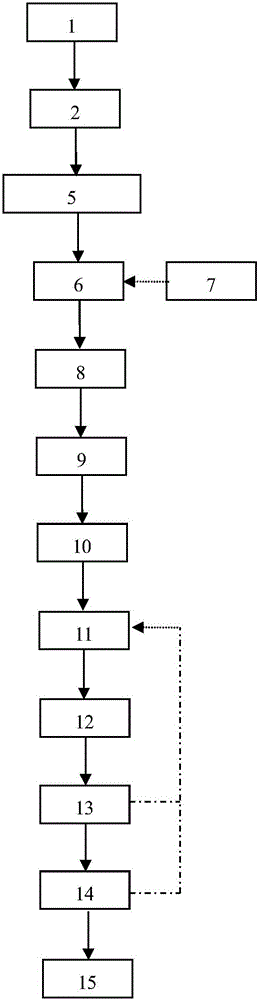

Regeneration technology of V-Ti-based honeycomb SCR denitration catalyst, and apparatus thereof

InactiveCN102658170AGuaranteed structural strengthImprove surface conditionDispersed particle separationCatalyst regeneration/reactivationActive componentHoneycomb

The invention discloses a regeneration technology of a V-Ti-based honeycomb SCR denitration catalyst, and an apparatus thereof. A deactivated catalyst in the technology is regenerated through steps of pressurized water spraying, ultrasonic cleaning, secondary pressurized water spraying, air blow drying, active component supplement, secondary air blow drying, step calcining, and the like. Parameters of the regeneration technology, which comprise components of a cleaning solution, a pickling solution and an active supplement solution, are provided. By adopting the technology, the denitration activity of the deactivated catalyst is recovered, the structural strength of the catalyst is maintained, and the SO2 oxidation frequency is reduced. The apparatus used for realizing the technology comprises a pressurized water spraying pool, an ultrasonic cleaning pool, a secondary pressurized water spraying pool, a pickling pool, an air blow drying pool, an active component supplement pool, a secondary air blow drying pool, a calciner and the like which are sequentially arranged, and the device can realize the hoisting transport regeneration of a regeneration module, and has the characteristics of simplicity, convenient operation, and high efficiency.

Owner:XI AN JIAOTONG UNIV

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

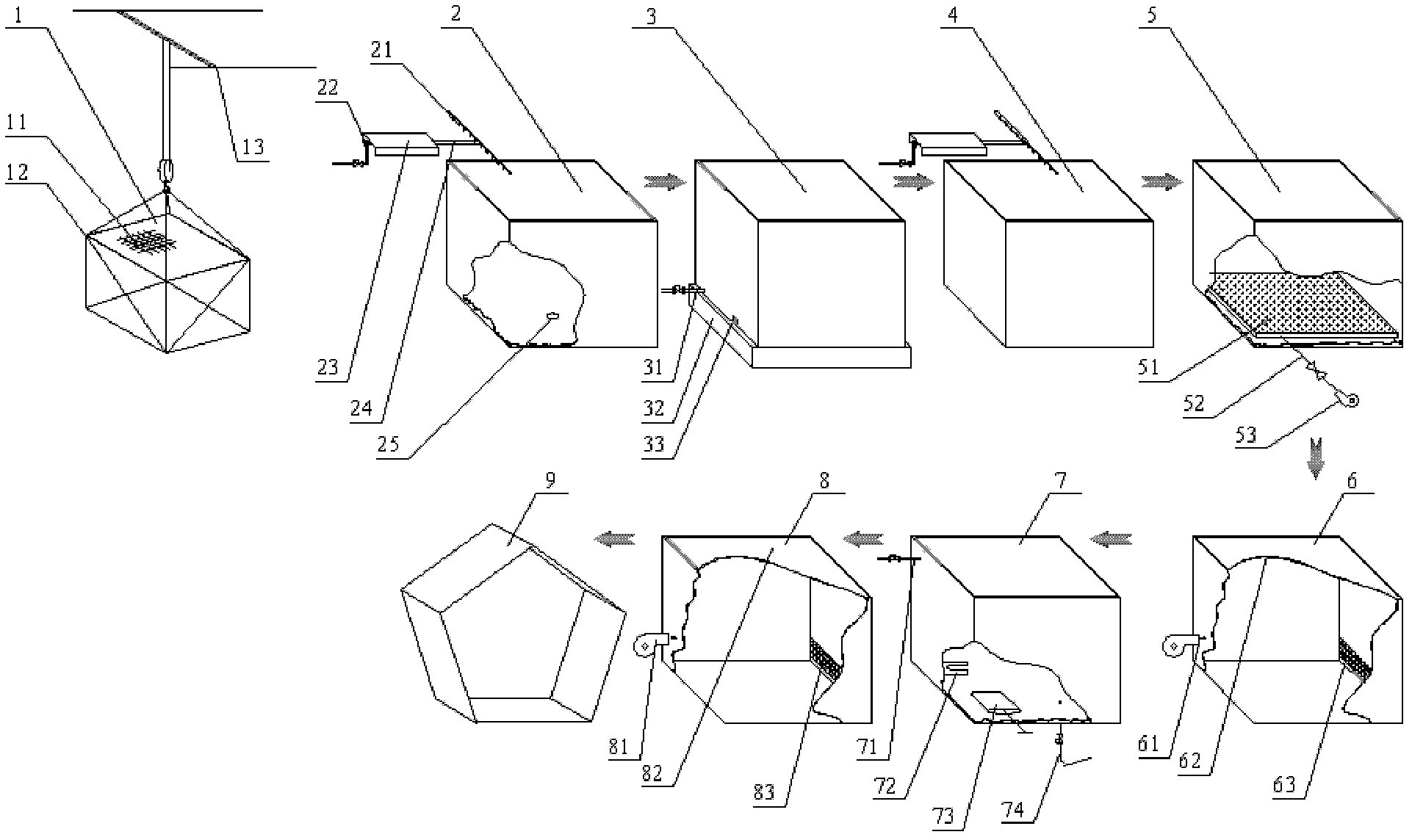

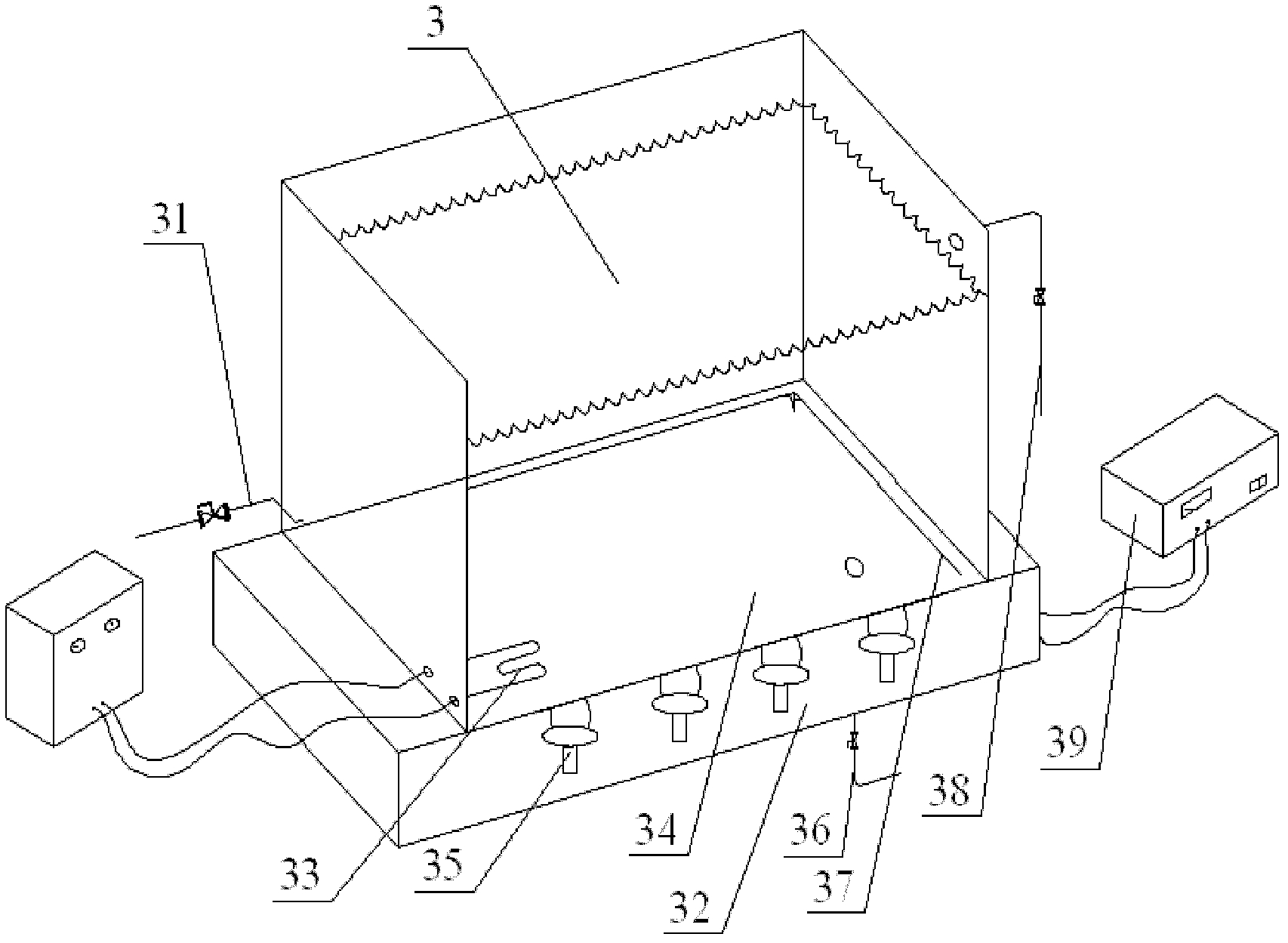

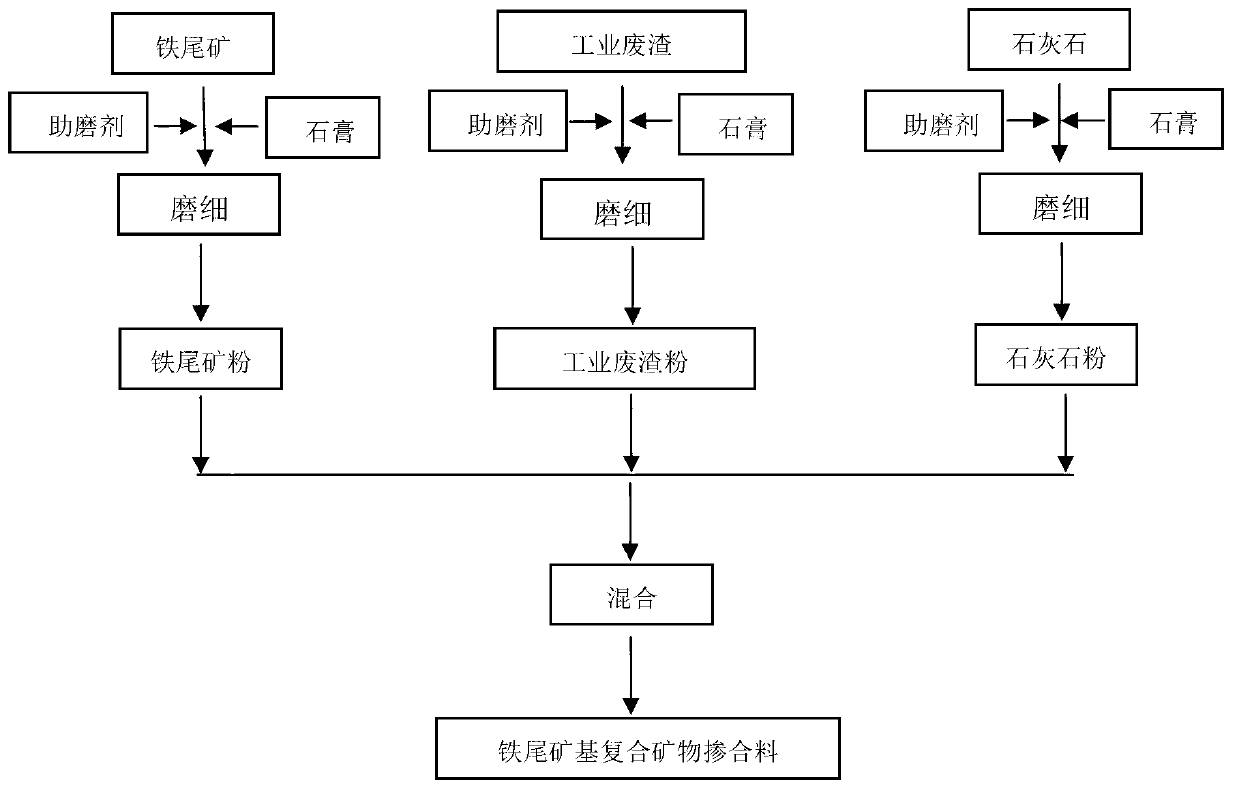

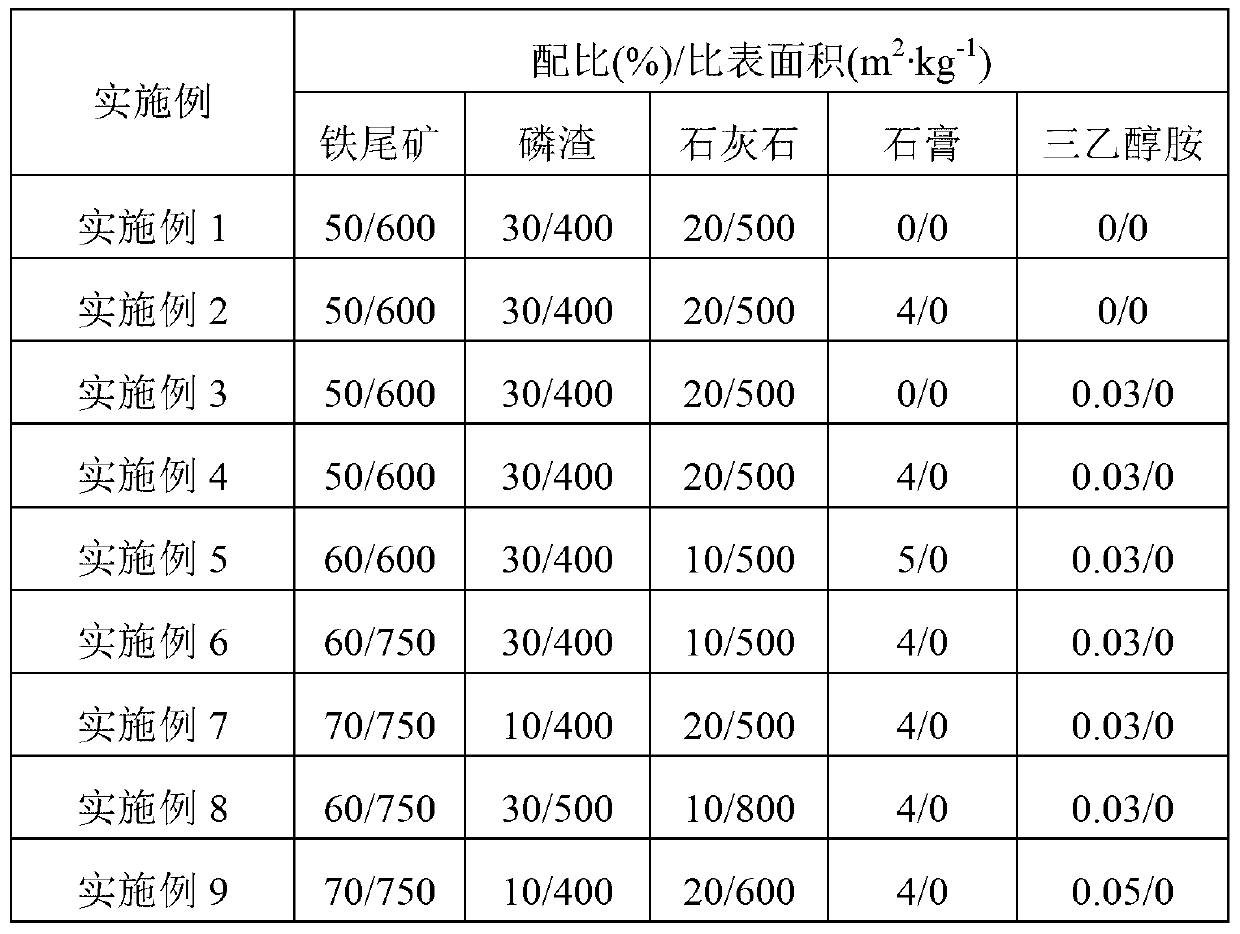

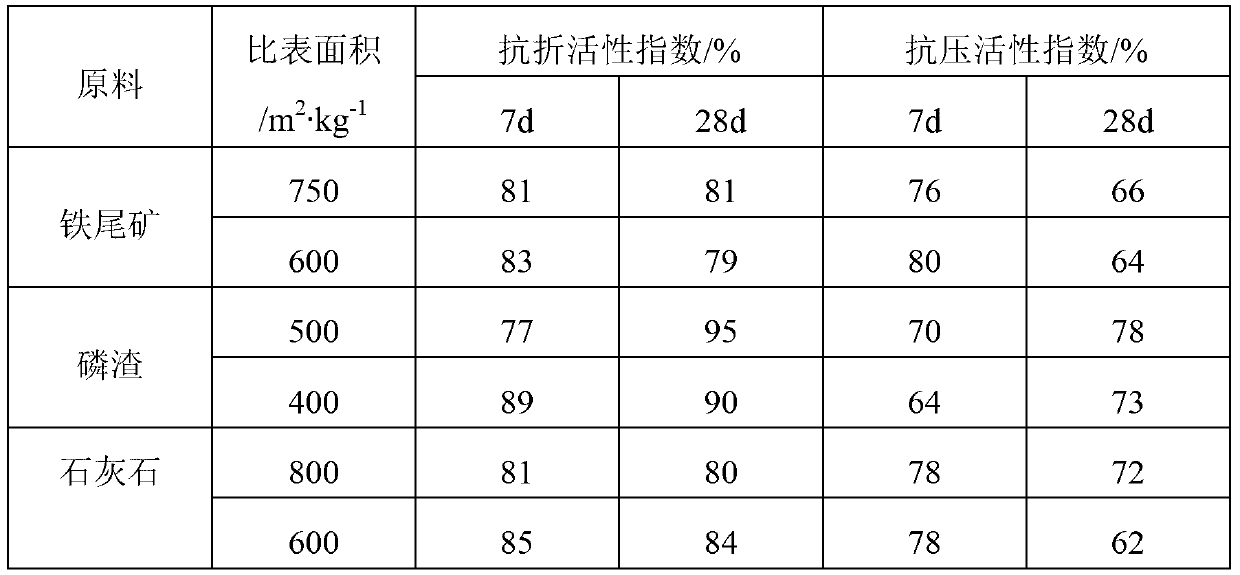

Iron tailing-based complex mineral admixture and preparation process thereof

InactiveCN103342491AExcellent performanceImprove pore structureSolid waste managementWater contentSlag

The invention relates to an iron tailing-based complex mineral admixture and a preparation process thereof. The preparation process comprises the following steps of: respectively drying iron tailing sand, industrial waste slag and limestone till water content is not more than 1% for later use; adding gypsum to match with iron tailings, the industrial waste slag and the limestone after drying, then sending into a ball grinding machine to perform powder grinding, and adding grinding aids during the powder grinding process; and uniformly mixing the obtained iron tailing powder, industrial waste slag powder and limestone powder to obtain the iron tailing-based complex mineral admixture. The iron tailing-based complex mineral admixture disclosed by the invention has the beneficial effects that 1) the iron tailings are matched with other industrial waste slag, the admixture for concrete is prepared by simple mechanical fine grinding, and the performance is better; 2) the performance is good, and the iron tailing-based complex mineral admixture can be used for preparing the concrete with the strength grade of C50-C80; 3) a variety of industrial wastes are scientifically and effectively compounded, the activity and particle size synergy of each component against cement and the concrete can be fully exerted to enable the advantages of all the components to complement each other, and the over-superimposed effect is further realized; and 4) the production process is simple and conductive to industrial production, popularization and application.

Owner:WUHAN UNIV OF TECH

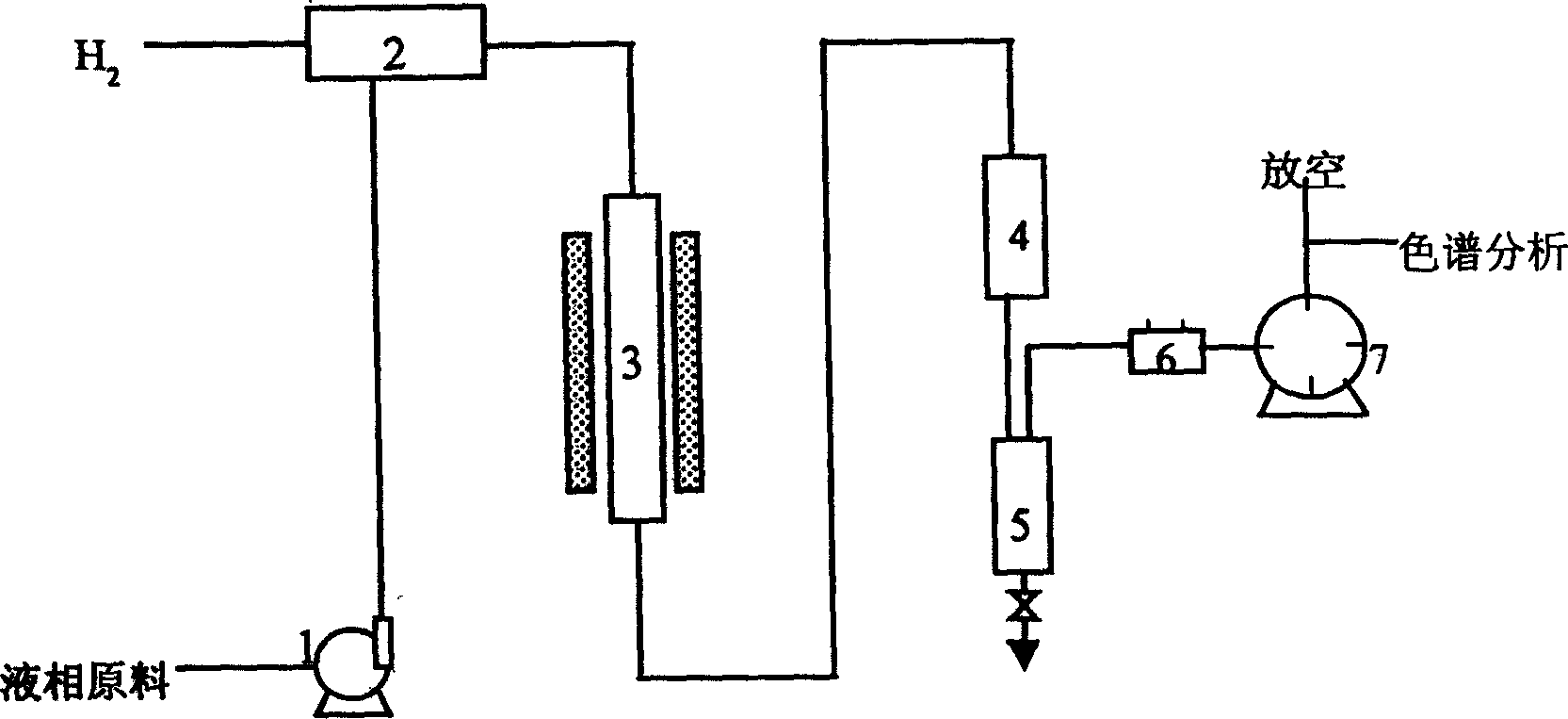

Technology of hydrogenatioin to produce iso octanol using iso octaldehyde mixture and its catalyst

InactiveCN1478596AStrong abilityImprove hydrogenation activityCatalyst activation/preparationPreparation by oxygen reductionAldehydeNickel

A process and catalyst for preparing isooctanol by liquid-phase hydrogenation of the mixture of isooctanal and octylene alcohol is disclosed. Said catalyst is prepared from metallic Ni, alkali-earth metal oxide and / or alumina, and Si-contained compound as carrier through code position of Ni and carrier, kneading, and calcining at 300-800 deg.C. Its advantages are good porous structure, and high strength, hydrogenating activity, and output rate of isooctanol.

Owner:CHINA PETROLEUM & CHEM CORP

Method of preparing silicon dioxide delustrant by large pore volume gel

ActiveCN101407324AHigh mattingHigh transparencySilicaPigment treatment with macromolecular organic compoundsFiltrationSilicon dioxide

The invention relates to a preparation method of a silicon dioxide flatting agent used for coating flatting with a large pore volume gelatin method, which comprises the following steps of: adding a sodium silicate water solution in a reaction kettle; at the temperature of 26 DEG C and under stirring, adding 30% sulphuric acid until forming gelatin in the kettle; then stirring for 15min, raising the temperature to 50 DEG C and continually adding the sulphuric acid until pH value being up to 3; when no gelatin block by stirring, slowly adding 30% sodium hydroxide into the reaction kettle, regulating the pH value to be 5-6, and then regulating the pH value to be 9-10 by using ammonia water; and raising the temperature to 98 DEG C, ageing for 1 hour, adding water for cooling to the temperature of 75 DEG C, filtration washing, slurrying, sponging drying and crashing classifying to obtain the finished product. The product has the characteristics of large pore volume, large specific surface area, high purity, moderate DBP absorption value, good dispersion performance, high transparency and the like as well as the advantages of reasonable technology and high production efficiency. The product can be added with wax for carrying out surface treatment, thus leading the surface paint film of the coating to be smooth, and improving scratch resistance and precipitate resistance.

Owner:通化双龙化工股份有限公司

Method and device for preparing ceramsite from sludge pyrolytic biochar

ActiveCN106007776AAchieving mass utilizationEfficient curingCeramic materials productionCeramicwareSludgeBiochar

The invention discloses a method and device for preparing ceramsite from sludge pyrolytic biochar. The method includes the steps that powder grinding, humidifying, pelleting, low-temperature drying, middle-temperature presintering, high-temperature sintering and cooling are carried out on the sludge pyrolytic biochar to obtain the ceramsite. The device comprises a quantitative feeding device, a water adding device, a humidifying device, a forming and pelleting device, a drying device, a middle-temperature presintering device, a high-temperature sintering device and a cooling device. The sludge pyrolytic biochar is used for preparing the ceramsite, large-scale utilization of the sludge pyrolytic biochar is achieved, heavy metal element in the sludge pyrolytic biochar is further efficiently solidified and passivated, potential heavy metal accumulated pollution of the sludge pyrolytic biochar in the land using process is avoided, and the method and device are particularly suitable for resource utilization of sludge pyrolytic biochar with heavy metal content exceeding standard. The method is simple, practical, low in equipment investment and low in cost and has good economic benefits and environmental benefits.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

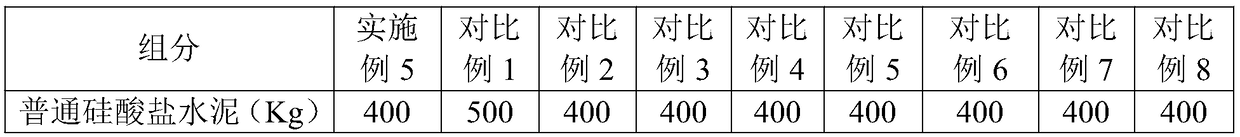

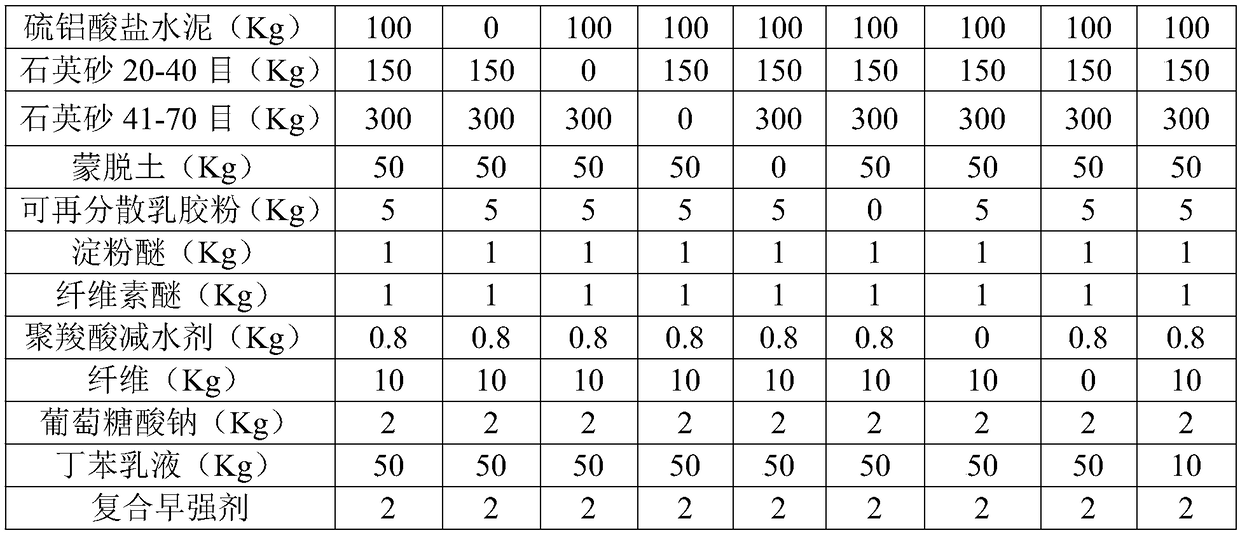

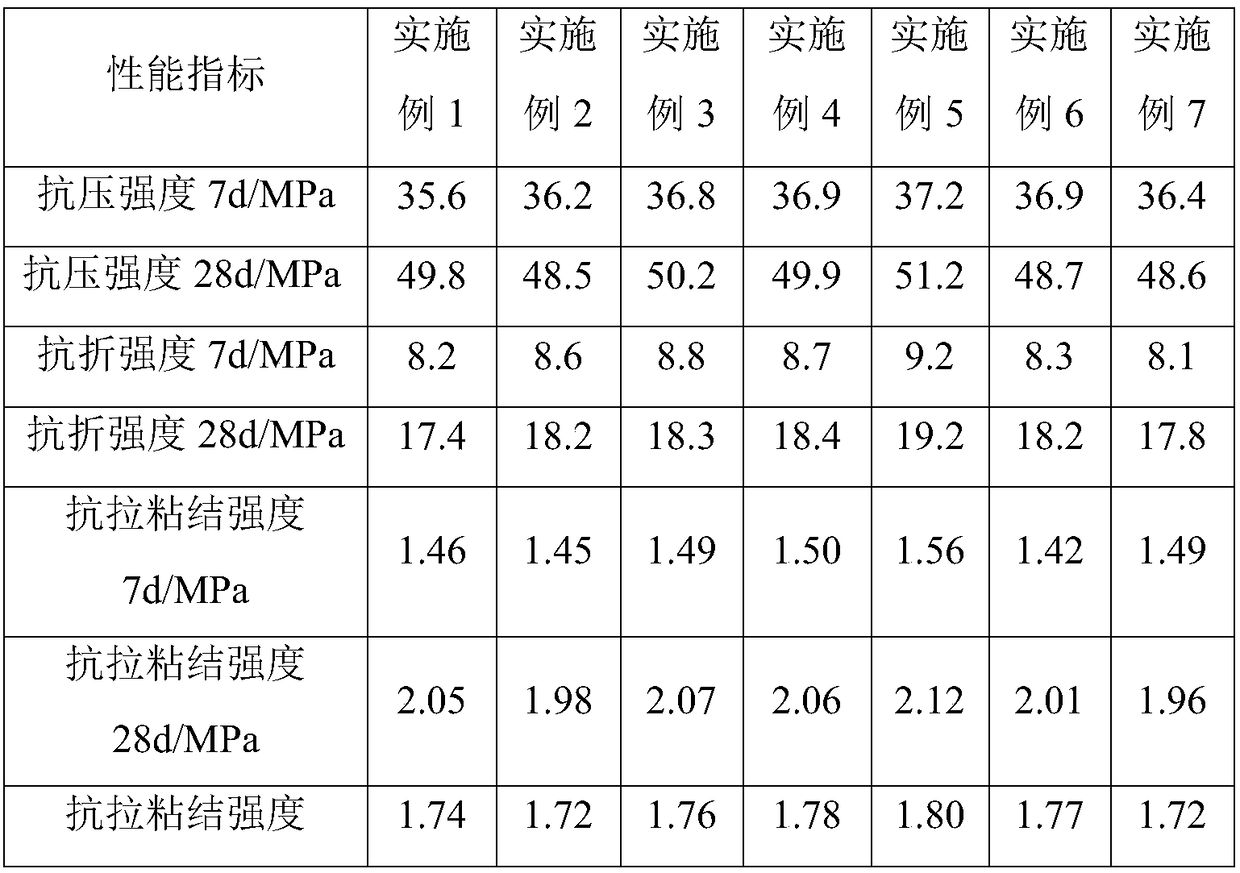

Special repair mortar for structure and preparation method thereof

The invention discloses special repair mortar for a structure. The mortar is prepared from the following components in parts by weight: 350-500 parts of common silicate cement, 50-150 parts of sulphate aluminum cement, 100-200 parts of 20-40-mesh quartz sand, 300-350 parts of 41-70-mesh quartz sand, 20-50 parts of montmorillonite, 30-50 parts of a styrene-butadiene rubber latex, 1-10 parts of redispersible latex powder, 1-5 parts of starch ether, 1-5 parts of cellulose ether, 0.5-2 parts of a polycarboxylate superplasticizer, 1-3 parts of a retarder, 1-10 parts of fibers and 1-5 parts of a compound early strength agent. According to the special repair mortar for the structure, by selecting and proportioning the components in proportion, comprehensively excellent utilizing performance of the components, the components draw on strengths of each other and act jointly, so that the shrinking percentage of the mortar is low. Mechanical properties of relatively high bonding strength, tensileand crush resistances and the like are obtained, and the cost performance is high.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

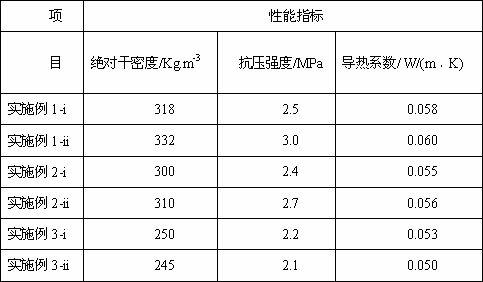

Low-thermal-conductivity aerated concrete and preparation method thereof

ActiveCN102167619ASolve insulation problemsSolve coordination problemsSolid waste managementCeramicwareFoaming agentThermal bridge

The invention discloses low-thermal-conductivity aerated concrete and a preparation method thereof, which belong to the technical field of material science and engineering science and are used for solving the key technical problem of enhancement of extra light aerated concrete. The preparation method comprises the following steps of: stirring a compound foaming agent component and a silicate substrate sizing agent according to a certain weight part ratio; molding; standing; performing autoclave curing; and cutting to obtain a hardened hydrated silicate substrate, wherein the rubber hole ratioof the obtained hardened hydrated silicate substrate is more than 0.95, the porosity is less than 3 percent, the volume ratio of a calcium hydrosilicate crystal to colloid is 1-2.5, self-heat-preserving performance and appropriate intensity of a product are realized, and when the thermal conductivity coefficient is less than 0.06 W / (m.K) and the absolute dry volume density is less than 250 kg / m<3>, the compressive strength of the aerated concrete is still higher than 2Mpa. The low-thermal-conductivity aerated concrete can be applied to self-heat-preserving wall bodies with the energy saving rates of more than 70 percent, fire-proof isolation belts for outer heat-preserving systems of polystyrene plate thin plastered outer walls, treatment of wall body heat bridge positions, shear wall heat-preserving systems and roof heat preserving.

Owner:HOHAI UNIV

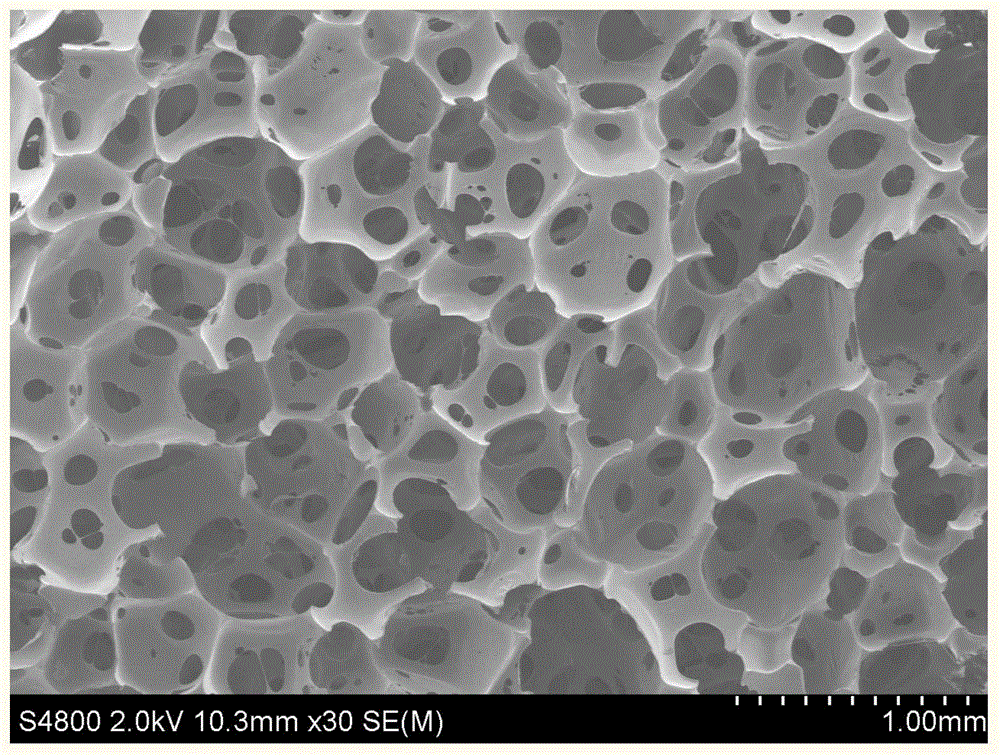

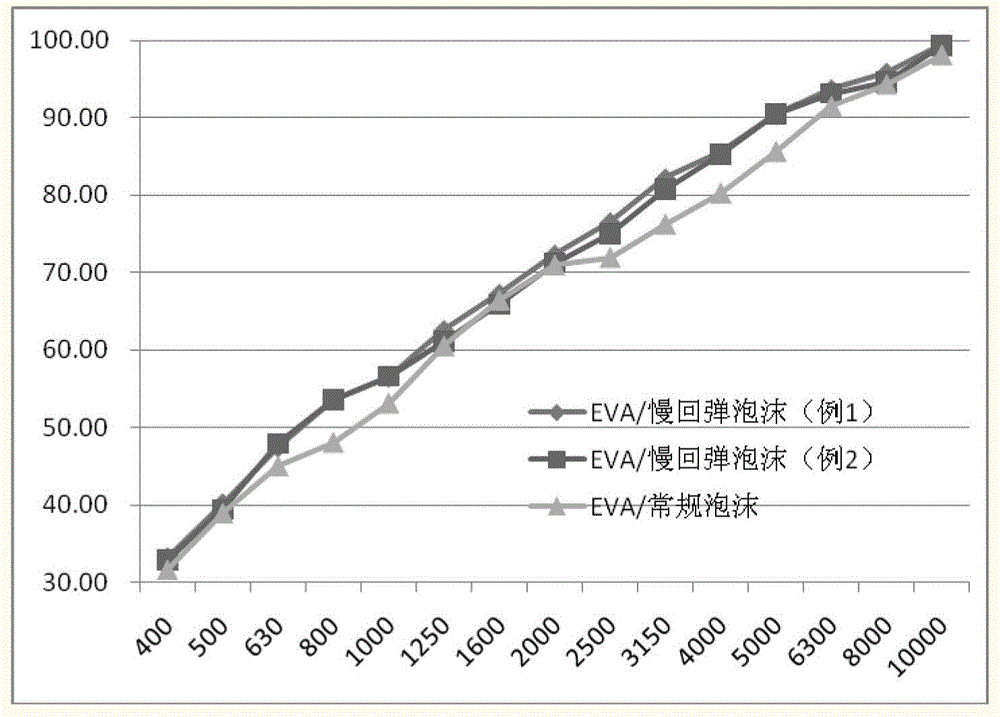

Vehicle-used slowly-springback polyurethane foam composite material

ActiveCN104149455AHigh reactivityGood physical propertiesSynthetic resin layered productsEnvironmental resistanceSilicone oil

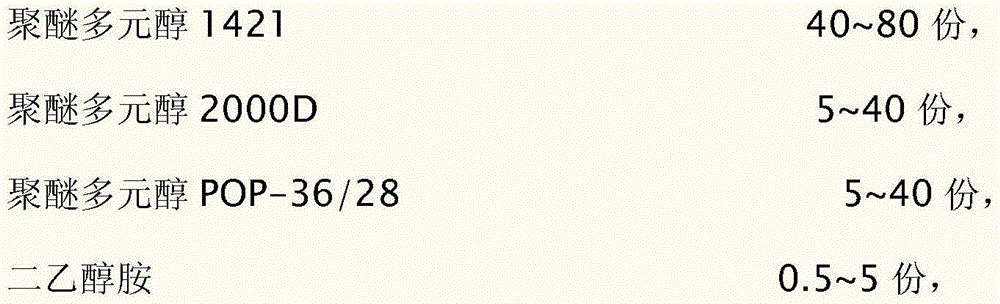

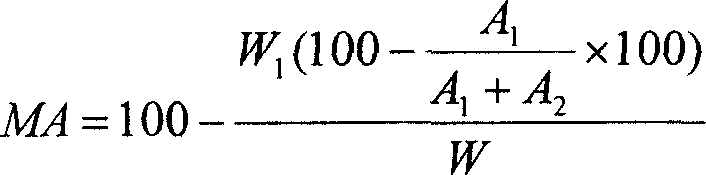

The invention discloses a vehicle-used slowly-springback polyurethane foam composite material which is compounded from slowly-springback polyurethane foam and an ethylene-vinyl acetate copolymer. The slowly-springback polyurethane foam is prepared from following components including, by weight, an A material: 40-80 parts of a polyether polyol 1421, 5-40 parts of a polyether polyol 2000D, 5-40 parts of a polyether polyol POP-36 / 28, 0.5-5 parts of diethanolamine, 1-6 parts of water, 0.1-1.5 parts of a catalyst EF-600, 0.1-0.5 parts of a catalyst ZF-10 and 1-6 parts of a silicone oil L-580; a B material: 40-80 parts of a modified MDI. During preparation of the slowly-springback polyurethane foam, a weight usage amount ratio of the A material to the B material is 100:40-80. The vehicle-used slowly-springback polyurethane foam is high in reaction activity, is low in toxicity, is environmental-protective, is high in damp loss factor, is high in sound-insulation performance and is free of addition of a foam-forming agent.

Owner:NINGBO TUOPU GROUP CO LTD

Method for modifying kaolinite

ActiveCN101045202ALarge specific surface areaLarge pore volumeCatalytic crackingPhysical/chemical process catalystsKaoliniteSlurry

A process for modifying kaolinite includes such steps as proportionally mixing kaolinite, dispersing modifier, acid solution and deionized water, beating, calcining, cooling, and washing with deionized water. The modified kaolinite has large specific surface area and pore volume, and high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graphene oxide ultra-high performance concrete with low cement consumption and preparation method thereof

InactiveCN111377687AImprove early strengthIncrease late strengthBreaking strengthUltimate tensile strength

The invention provides graphene oxide ultra-high performance concrete with low cement consumption, which belongs to the technical field of building materials. The concrete comprises the following components in parts by weight: 100 parts of cement, 30-50 parts of silica fume, 60-120 parts of fly ash, 10-50 parts of slag powder, 80-120 parts of quartz sand, 30-50 parts of water, 20-50 parts of steelfiber, 2-10 parts of a water reducing agent and 1-10 parts of graphene oxide. The invention also provides a preparation method of the ultra-high performance concrete. The graphene oxide is compoundedwith the steel fiber concrete doped with the mineral fine powder, and the graphene oxide can promote cement hydration, improve the early and later strength of the concrete, improve the interface conditions of a matrix and steel fibers and improve the binding strength of the matrix and the steel fibers, so that the breaking strength of the concrete is improved. The graphene oxide can improve the pore structure of the concrete, so that the concrete is denser, the strength of the concrete is improved, concrete strength shrinkage caused by steam curing is avoided, and the durability of the concrete is further improved.

Owner:重庆高途新材料科技有限公司

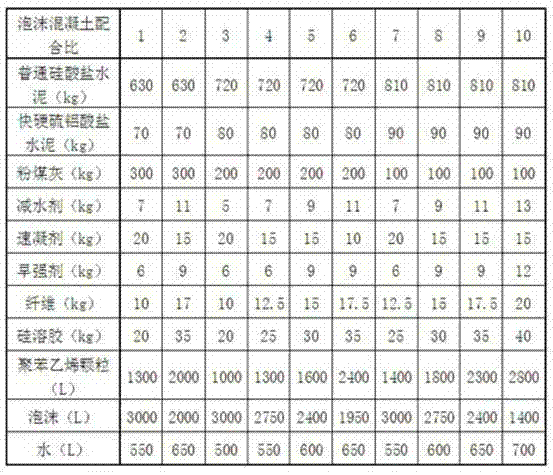

Foam concrete with large-dosage polystyrene particles and preparation method thereof

ActiveCN102503526AImprove thermal insulation performanceHigh electrical insulationCement mixing apparatusCeramicwareFoam concreteAluminate

The invention provides a foam concrete with large-dosage polystyrene particles and a preparation method thereof, which solve problems of water leakage and frost resistance of the foam concrete. The foam concrete comprises components in part as follows: 63-81 parts of ordinary portland cement, 63-81 parts of quick-hardening sulphoaluminate cement, 10-30 parts of coal ash, 0.5-1.3 parts of water reducing agent, 1-2 parts of accelerating agent, 0.6-1.2 parts of early strength agent, 1-2 parts of fiber, 2-4 parts of silica sol, and 50-70 parts of water. The percentage in volume (liter) of the polystyrene particles in added water is 200-400percent, and the percentage in volume (liter) of foam in the added water is 100-600percent. In the preparation process, the treated polystyrene particles stand for 10 min, and the foam can be added after standing uniformly-stirred cement slurry for 20 min. On the premise of ensuring the intensity, the foam cement disclosed by the invention has the advantages of higher heat preservation and heat-shielding performance, higher electric insulating performance, lower volume weight and lower water absorption. The problems of the water leakage and the frostresistance of the foam cement can be solved.

Owner:SHENYANG JIANZHU UNIVERSITY

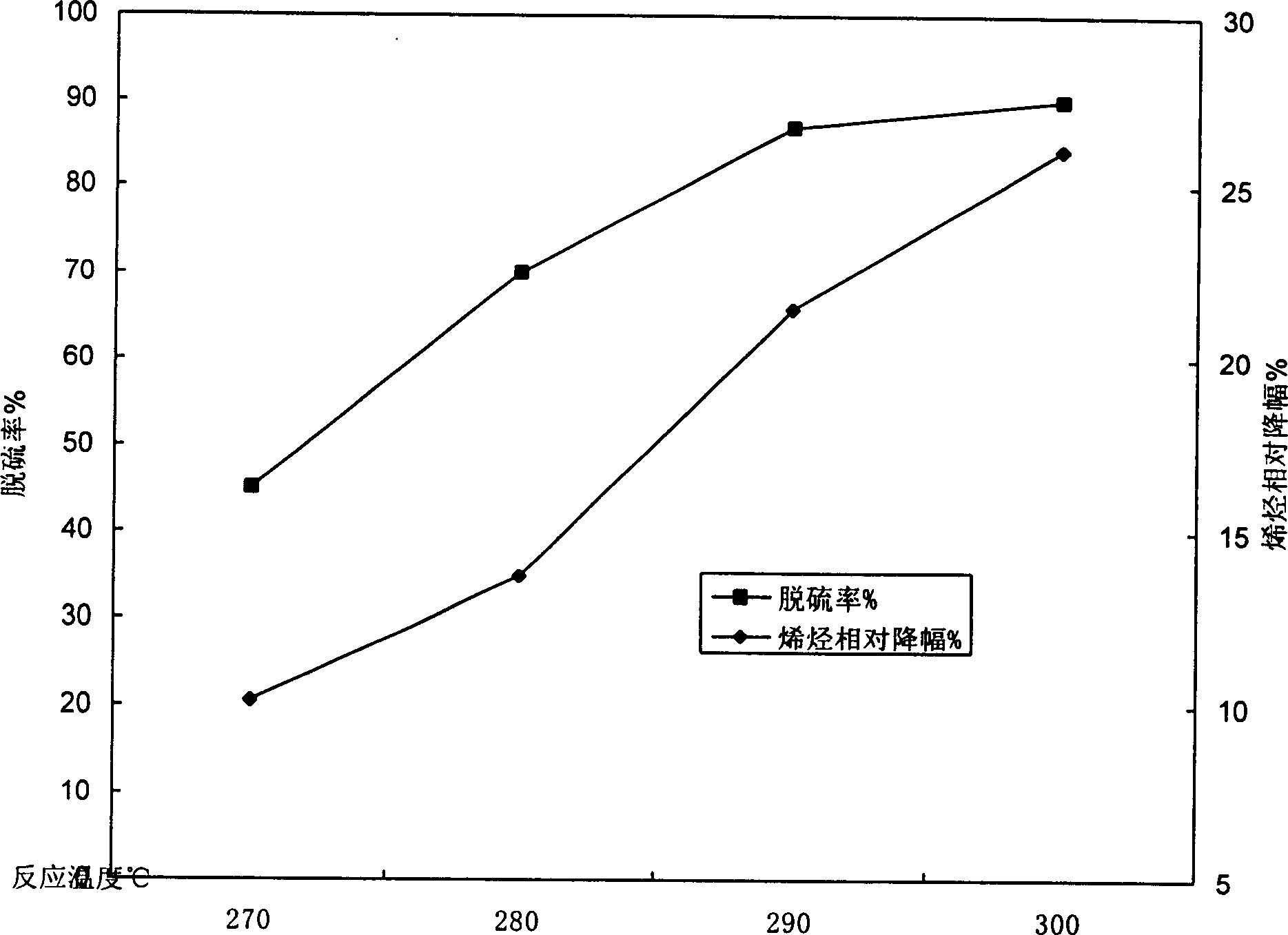

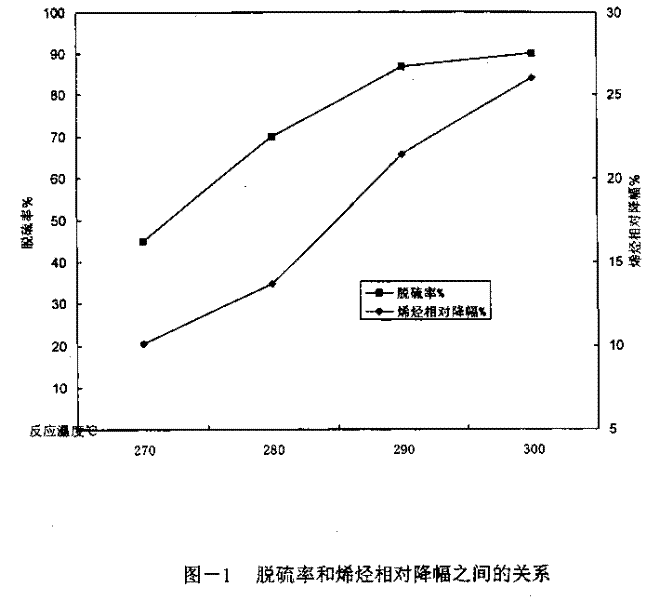

Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

InactiveCN1448471AImprove anti-coking performanceHigh activityRefining to eliminate hetero atomsLiquid productActive component

The gasoline hydrogenating catalyst includes the components of carrier with TiO2 in 20-90 wt%; active component A of VIII metal oxide in 0.1-8 wt%; active component B of VIB metal oxide in 1-13 wt%; and adhesive in the rest content. After being pre-sulfurized, the catalyst of the present invention is used to process FCC gasoline in condition of mild hydrogenation and exhibits very high hydrodesulfurization activity and selectivity. Compared with traditional hydrogenation catalyst, the catalyst of the present invention has less loss of gasoline octane number and higher liquid product yield, up to 99 wt%, in the condition of same hydrodesulfurization level.

Owner:BEIJING HAISHUNDE TITANIUM CATALYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com