Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2307 results about "Foam concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

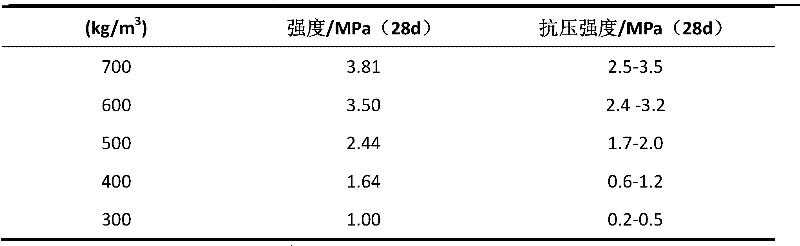

Foam concrete, also known as Lightweight Cellular Concrete (LCC), Low Density Cellular Concrete (LDCC), aircrete, foamed concrete, foamcrete, cellular lightweight concrete or reduced density concrete, is defined as a cement based slurry, with a minimum of 20% (per volume) foam entrained into the plastic mortar. As mostly no coarse aggregate is used for production of foam concrete the correct term would be called mortar instead of concrete; it may be called "foamed cement" as well. The density of foam concrete usually varies from 400 kg/m³ to 1600 kg/m³. The density is normally controlled by substituting fully or part of the fine aggregate with foam.

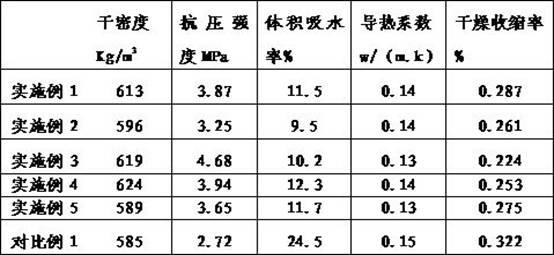

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Foam concrete and preparation method

The invention discloses a foam concrete and a preparation method, belonging to the technical field of building materials and construction, comprising the following components of cement, ore powder, fly ash and water, and further comprising a waterproof agent, fibers, an accessory and a foaming agent. The preparation method comprises the following steps of: adding 50-200 parts by weight of the cement, 10-100 parts by weight of the ore powder, 10-150 parts by weight of the fly ash, 60-250 parts by weight of the water, 0-3 parts by weight of the waterproof agent, 0.3-1 part by weight of fiber and 0.1-3 parts by weight of accessory to a container, evenly stirring the components by a stirring machine, adding 6-20 parts by weight of the foaming agent, mixing and stirring the mixture, quickly paving the obtained material on the construction surface for natural smoothing, standing for finishing foaming within 2-30min to obtain the desired strength after 24h, and maintaining to form the formed foam concrete. The invention has high strength, light quantity, low head conductivity coefficient, simple formula, convenient construction and low cost due to the utilization of industrial and mining waste materials, and the invention can partially replace polyvinyl benzene foam boards, extruded sheets and slurry particle insulating boards of a heat insulating system; in addition, the invention is applied to the field construction of a foam concrete heat insulating system of floors and roofs and the production of the foam concrete blocks and heat insulating slabs in a factory by using moulds.

Owner:CHENGDU XIYA TECH DEV

Lightweight aggregate foam concrete and production method thereof

The invention discloses a lightweight aggregate foam concrete which is composed of the following materials in parts by weight: 100-300 parts of cement, 1-150 parts of admixture, 60-250 parts of water, 1-10 parts of additive and 1-11 parts of foaming agent, as well as a lightweight material by a dosage accounting for 5%-60% of the total volume. The admixture comprising PC32.5 cement, coal ash and the like is produced from industrial waste materials such as coal ash, slag powder and clinker, so that discharge and bulk deposition of the industrial waste materials are effectively reduced and the environmental pollution is greatly reduced; therefore, good environmental protection benefit and social benefit are achieved. More importantly, expensive sulfoaluminate cement is replaced by low-cost materials, so that the cost of producing the lightweight aggregate foam concrete is greatly reduced; the performance effect of the product is extremely obvious and the physical properties of the cement is greatly improved; as a result, the outside erosion resisting capability of the concrete is effectively improved.

Owner:河南华泰新材科技股份有限公司

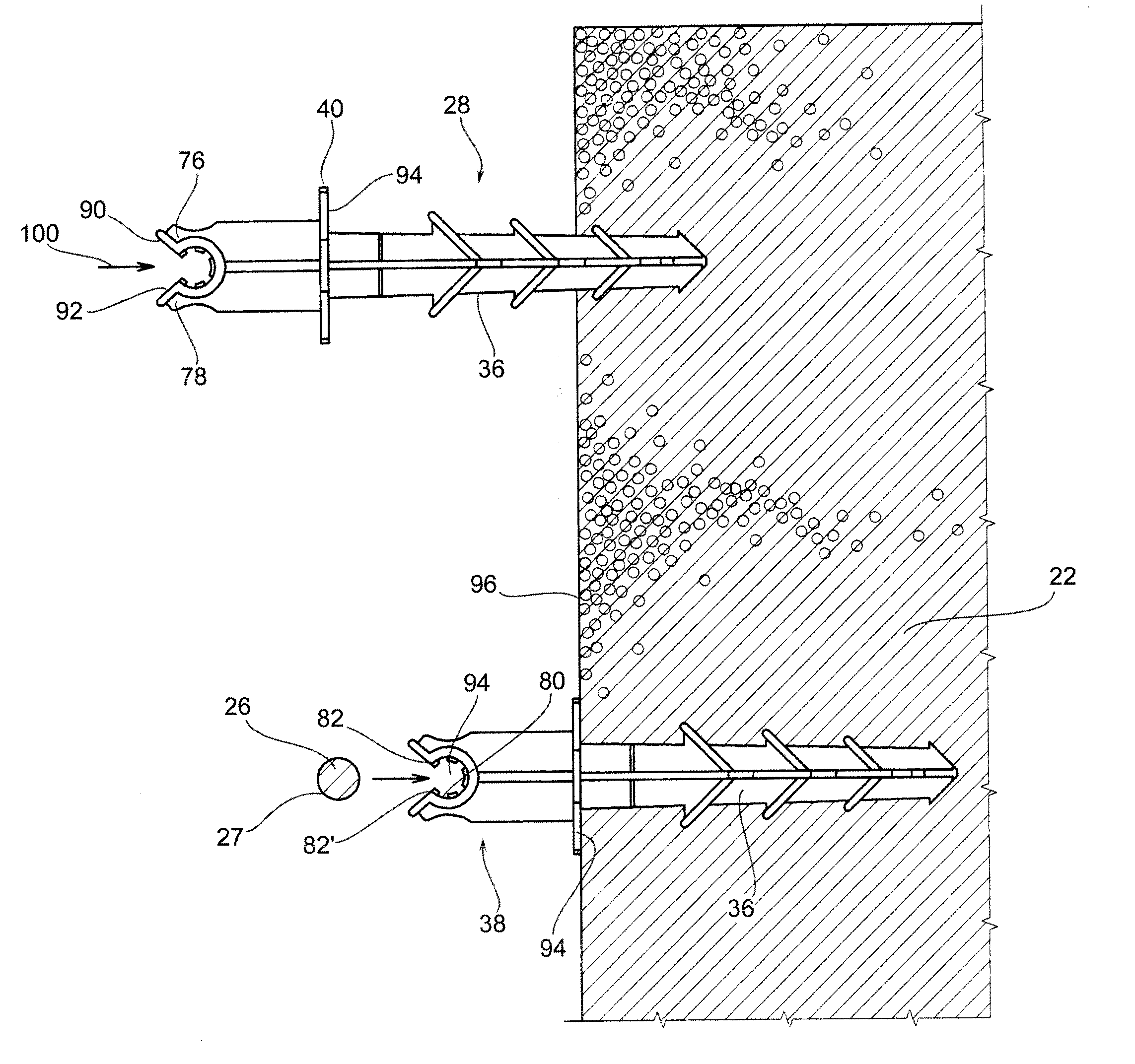

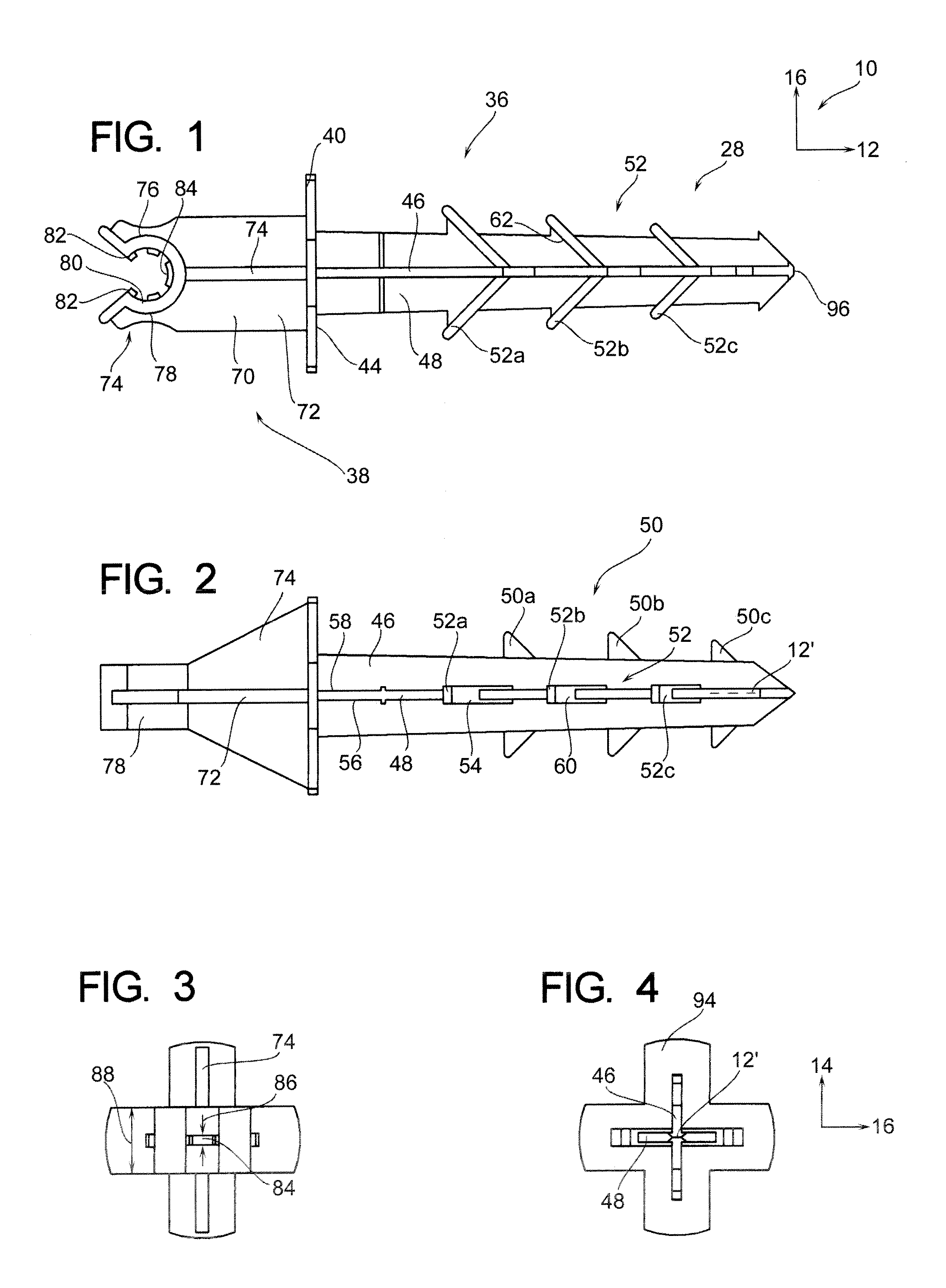

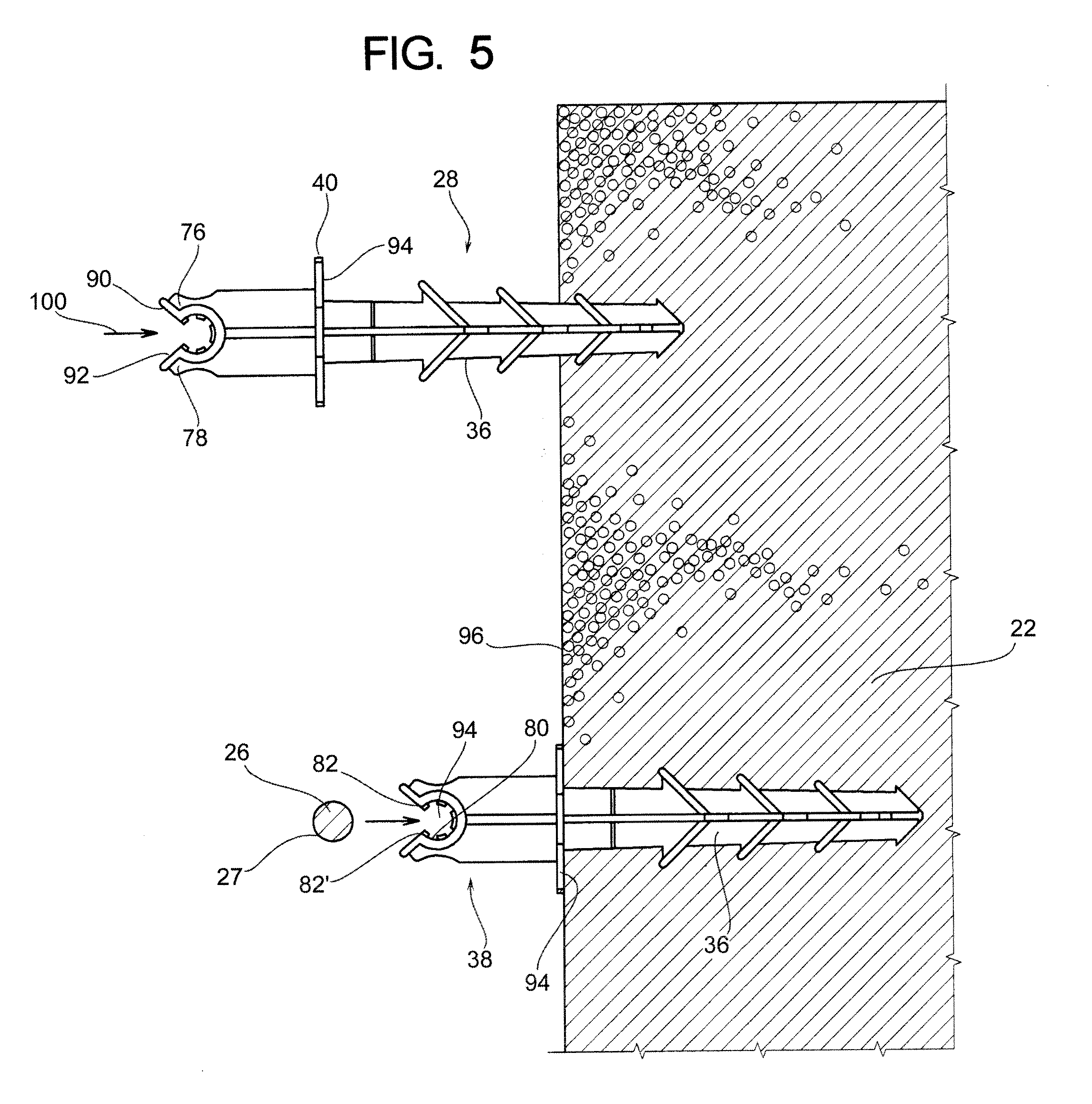

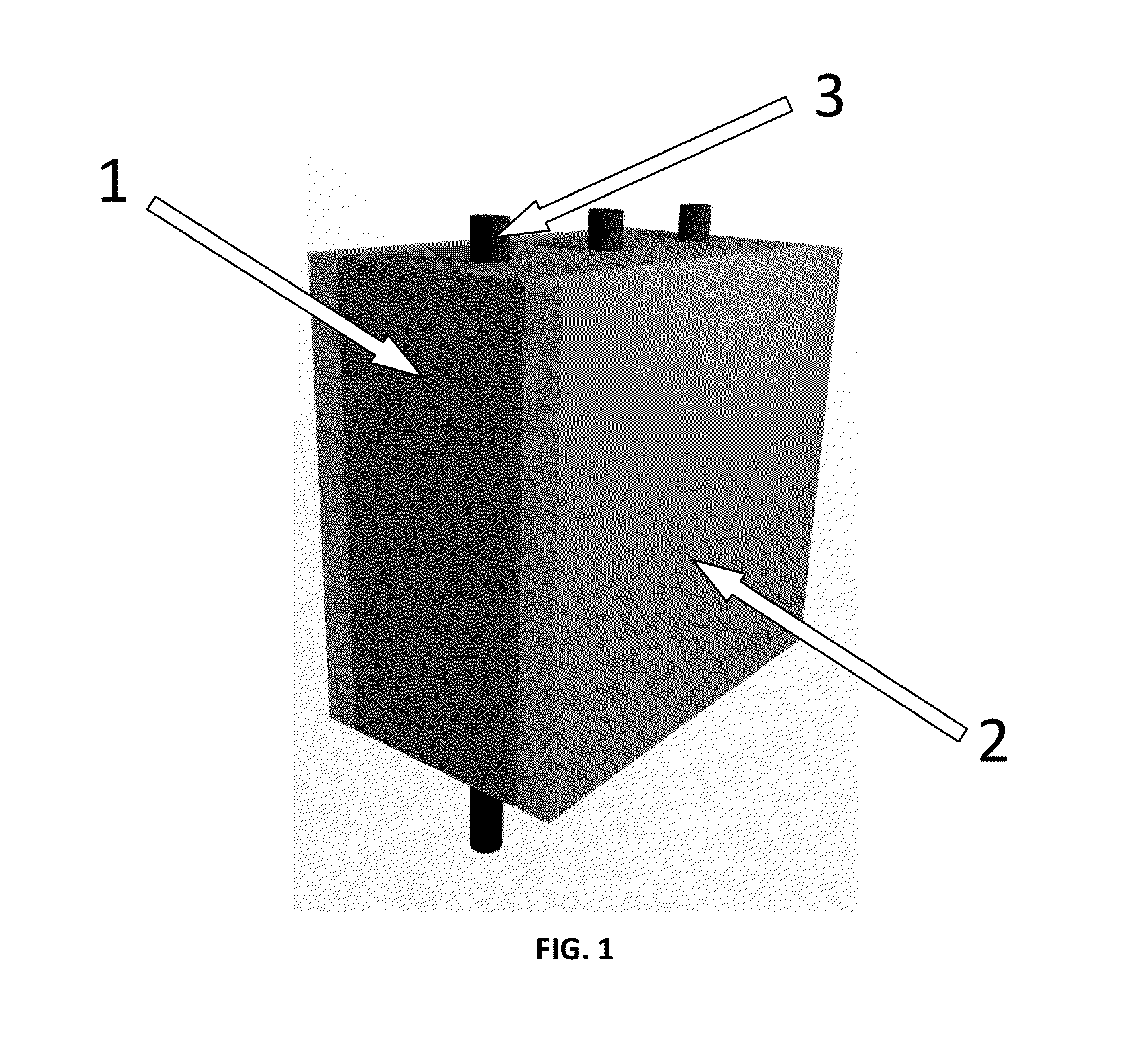

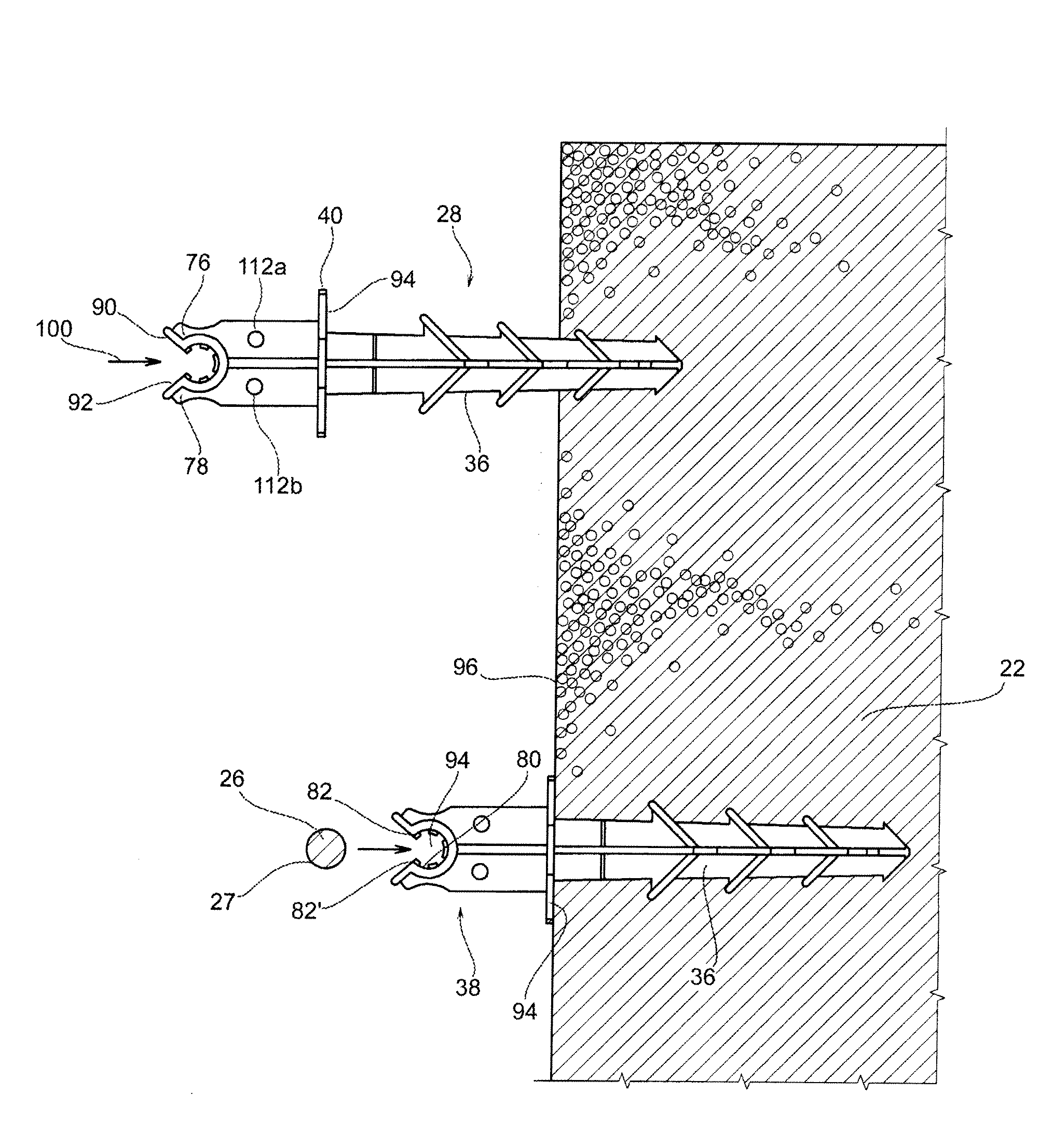

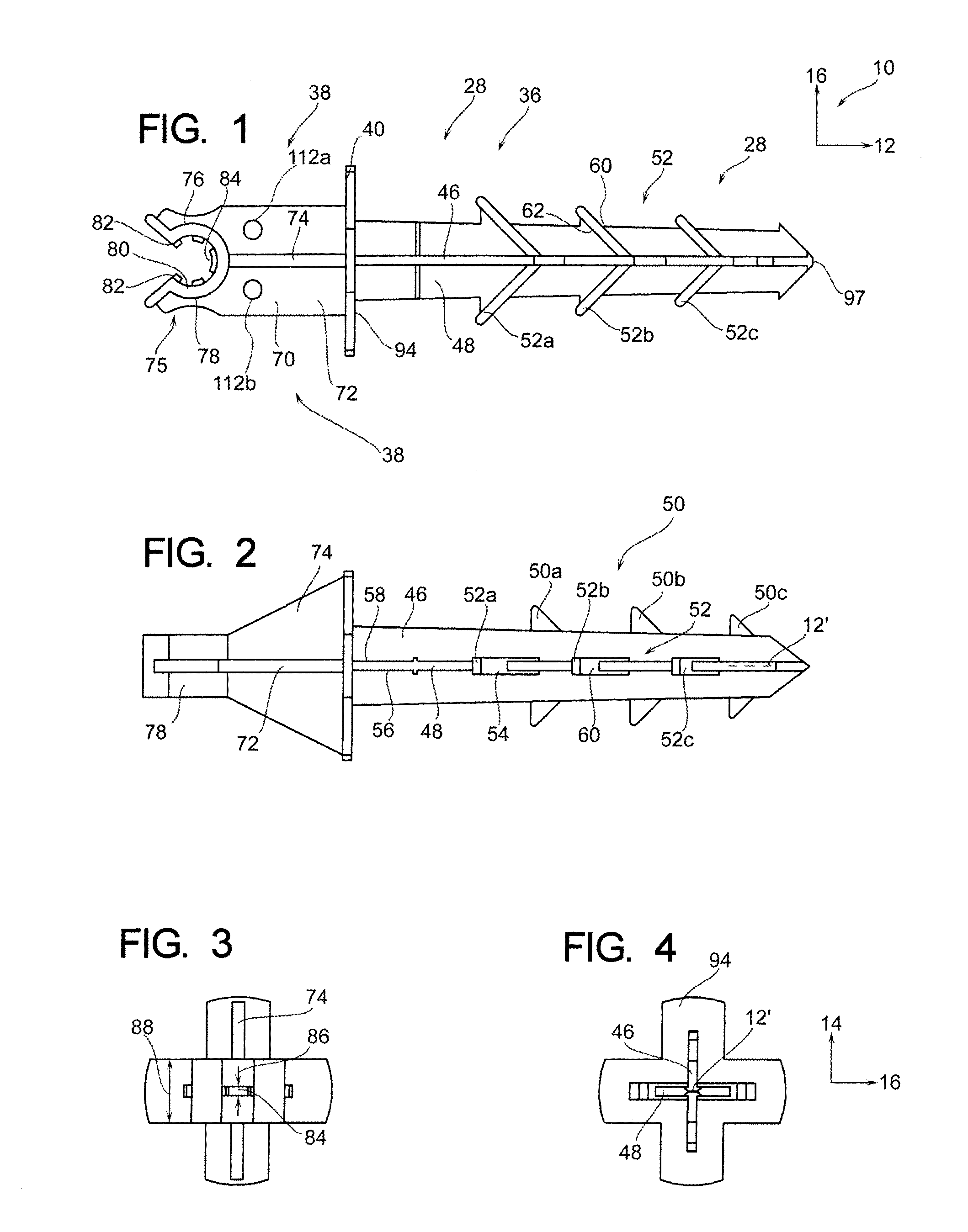

Foam-concrete rebar tie

InactiveUS20090229214A1Improve rigidityPrevent rotationBuilding reinforcementsFoam concreteArchitectural engineering

A fastener is disclosed having a an extension portion configured to be inserted into a first construction material such as foam, and having a stirrup portion configured to retain portion of a second construction material, such as rebar at a distance from the first construction material. A third construction material such as concrete can then be inserted (poured) in contact with the first construction material and surrounding the second construction material such that the second construction material is not directly in contact with the first construction material.

Owner:NELSON STEVEN J

Foamed concrete composition and process

InactiveUS6153005AExcellent and highly desirable performance attributesEnhance resilienceSurface-active detergent compositionsCeramicwareFoam concreteSURFACTANT BLEND

Owner:MACH IV L L C

Foam concrete composite lightweight partition batten and preparation method thereof

ActiveCN105601323ALimit drying shrinkageSolve the shortcomings of high hygroscopicityConstruction materialCeramicwareCalcium silicateFoam concrete

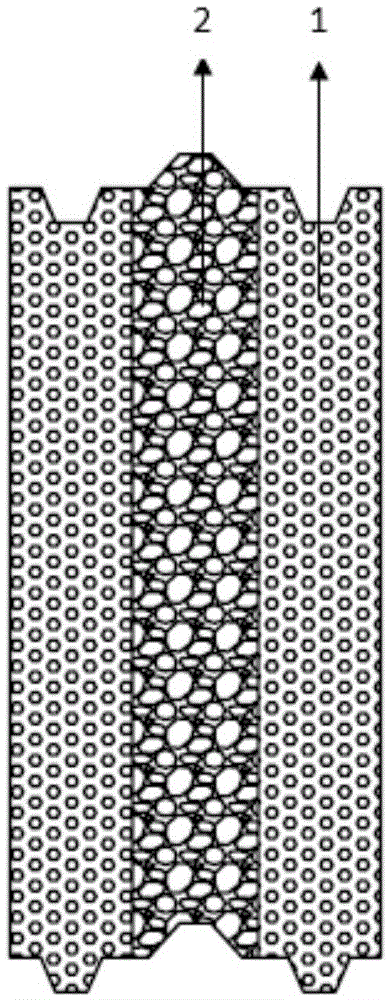

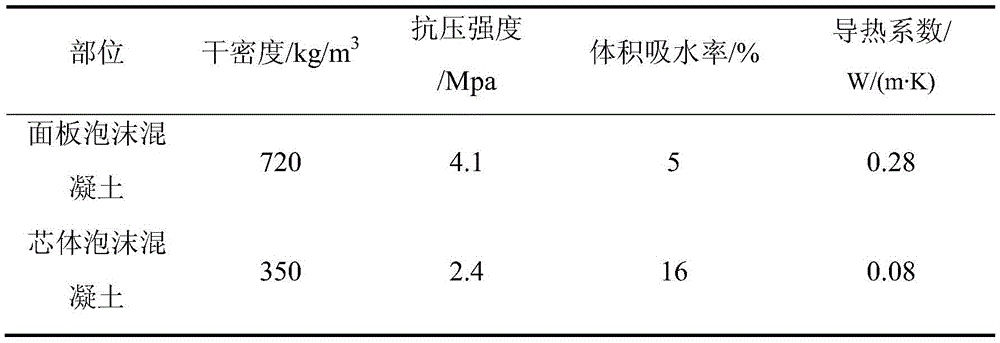

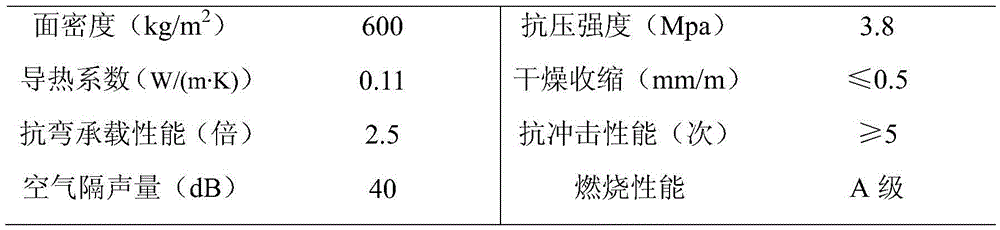

The invention discloses a foam concrete composite lightweight partition batten, which comprises a panel foam concrete and a core foam concrete. The panel foam concrete is symmetrically arranged on both sides of the core foam concrete, and has the bulk density of 600-900kg / m<3>; and the core foam concrete has density of 150-500kg / m<3>. The present invention uses foam concrete layers with different densities and functions to design the composite lightweight partition batten, uses foam concrete with high density and high strength grade to substitute a traditional calcium silicate board panel structure, uses the core foam concrete with relatively low density and low strength to fill the middle of the composite wall. The method can effectively reduce the use of calcium silicate board, reduce the production cost of lightweight composite partition batten, and simplify the production process; and the obtained foam concrete composite lightweight partition batten has excellent performances of waterproofness, thermal insulation, fireproofness, sound insulation and phase change energy storage, and has broad application prospects.

Owner:THE FIRST SINCERITY CONSTR TECH CO LTD

Heat-preservation sound-proof low-density foamed concrete

The invention discloses heat-preservation sound-proof low-density foamed concrete. The heat-preservation sound-proof low-density foamed concrete is characterized by being prepared from, by weight, 40-100 parts of cement, 5-40 parts of carbide slags, 5-40 parts of active powder, 1-20 parts of foaming agents, 0.1-8 parts of foam stabilizers, 0-8 parts of water reducing agents, 0-8 parts of coagulation accelerator, 0-25 parts of waterproof agents, 0.1-5 parts of anti-cracking agents and 25-150 parts of water, and the foamed concrete is prepared from the materials through mixing, foam molding and maintenance. The heat-preservation sound-proof low-density foamed concrete has the advantages of being low in dry density, low in heat conductivity coefficient, high in strength, wide in raw material source, low in cost, simple in preparation technology, convenient to prefabricate in factories or pour on site and the like; the heat-preservation sound-proof low-density foamed concrete is suitable for building exterior wall heat-preservation engineering, roof heat-preservation engineering, floor heating heat-preservation engineering, composite heat-preservation wall engineering, backfilling engineering, retaining wall slab engineering and the like.

Owner:株洲大禹恒基新材料有限公司

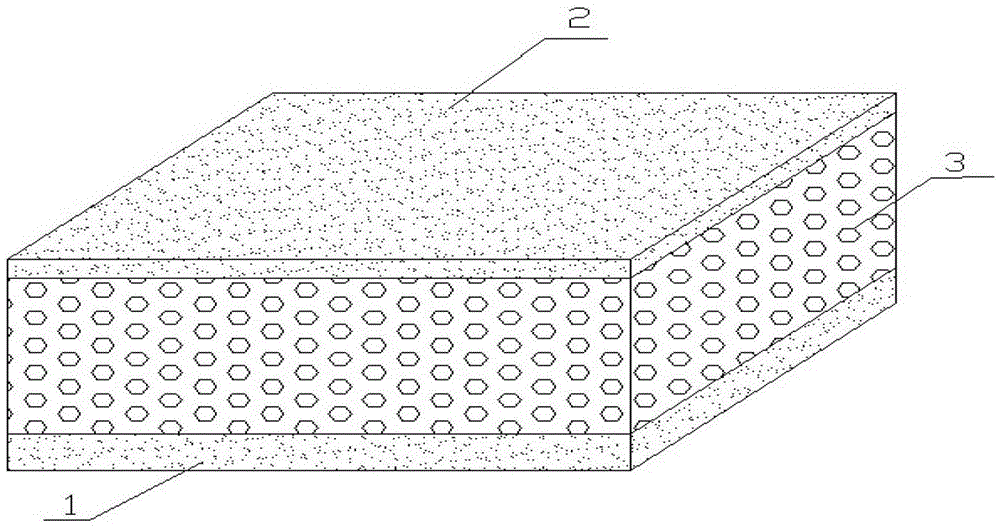

Nano foamed concrete, reinforced insulation wallboard and preparation method of reinforced insulation wallboard

ActiveCN103359997AAvoid interferenceAvoid pollutionBuilding componentsFoam concreteAdditive ingredient

The invention belongs to the field of building materials and construction technologies and relates to nano foamed concrete, a reinforced insulation wallboard and a preparation method of the reinforced insulation wallboard. The nano foamed concrete disclosed by the invention is prepared from the following ingredients in parts by weight: 100 parts of cement, 0.1-5 parts of desulfurized oil coke ash residue, 0.012 part of waterproofing agent, 10-30 parts of fly ash, 0.1-6 parts of superplasticizer, 50-200 parts of water, 1-20 parts of foamer and 0.01-5 parts of nano wave absorbing agent. Thus, when a wallboard product, prepared by embedding steel wire meshes in the nano foamed concrete disclosed by the invention, is applied nearby airports, docks, navigation marks, television stations and receiving stations or applied to concrete-based retaining walls of electromagnetic wave interference preventing scientific research departments, precise instrument plants and information leakage prevention high-grade buildings of national confidential units and the like, the most basic physical, mechanical, heat preservation and heat insulation properties are guaranteed on one hand, and the wallboard product has the capabilities of lowering noise and insulating sound on the other hand.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

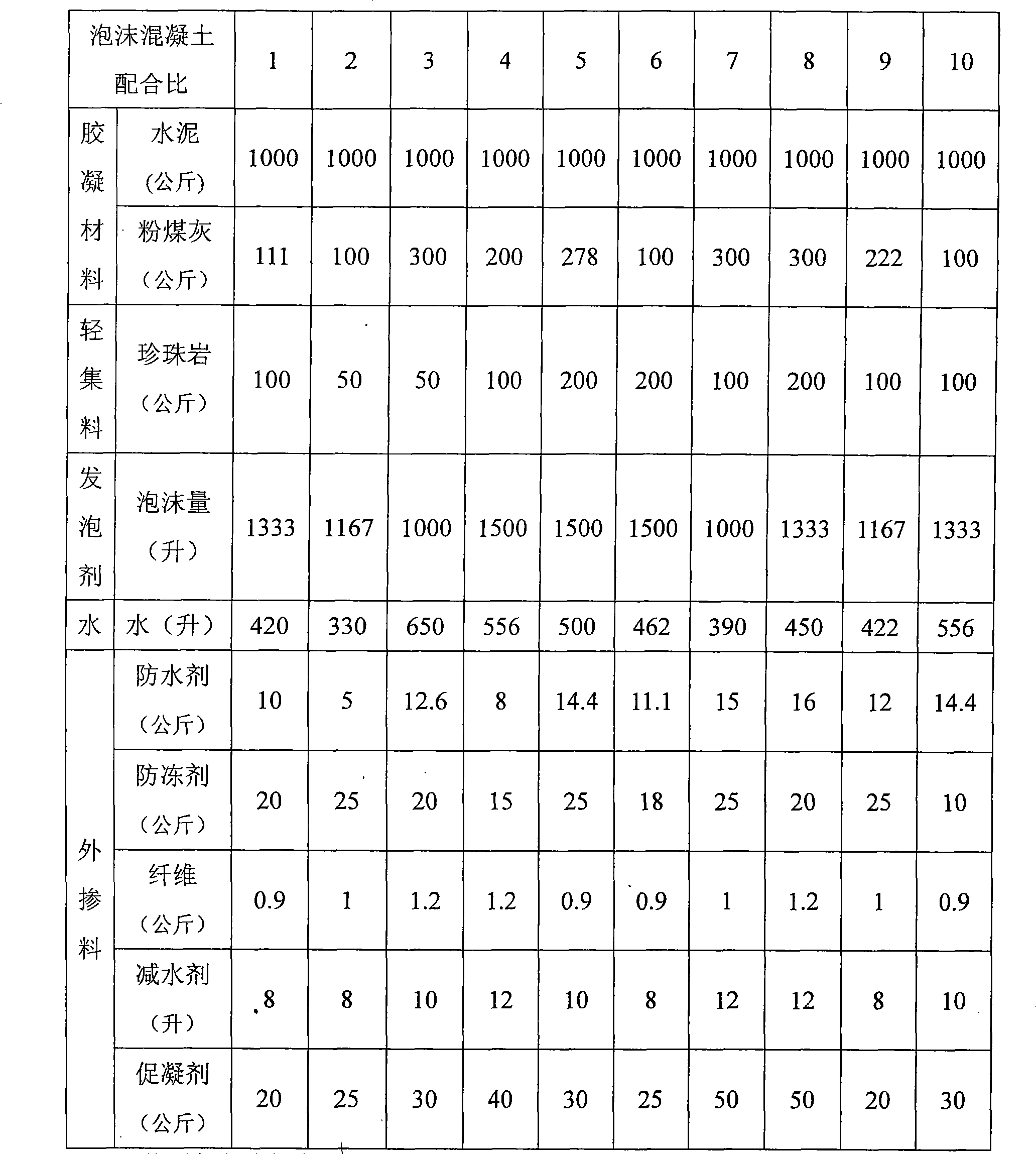

Foam concrete and preparing process thereof

InactiveCN101497533AHigh strengthLight weightCeramic shaping apparatusCement mixing apparatusFoam concreteFiber

The invention discloses foam concrete and a preparation method thereof. The foam concrete comprises a gelling material, light aggregate, water, admixture and foaming agent. The preparation method comprises the following steps: (1) pre-treating raw materials to prevent hard lumps and hard grains in the raw materials from depositing in foam slurry; (2) weighing each component according to a proportion; (3) preparing and adding foaming solution; (4) loading and stirring, namely, adding water into a stirrer, starting the stirrer, and adding cement, coal ash, perlite, waterproof agent, anti-freezing agent, water reducing agent and fiber into the stirrer in turn; (5) foaming, namely, foaming at the same time of stirring the slurry, sealing a valve firstly and then pressurizing the valve by an air compressor; (6) adding foam, namely, after the gelling slurry is well prepared, adding the foam into the gelling slurry under the state of stirring without stopping the stirrer; and (7) casting and molding, namely, when the slurry surface has no floating foam, finishing the preparation of the foam slurry. The foam concrete has the functions of light weight, water proofing, fire resistance, heat insulation, freezing resistance, cracking resistance, shock resistance and the like, and is particularly suitable for engineering insulating layers in cold areas and water-blocking and shock-resistant layers of underground engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

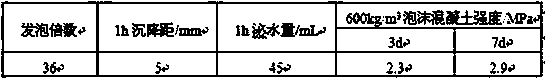

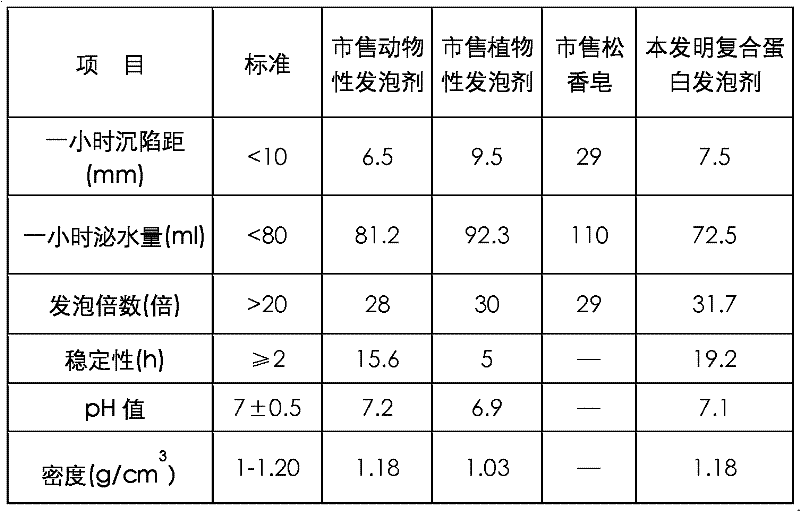

Early-strength composite foam concrete foaming agent and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to an early-strength composite foam concrete foaming agent and a preparation method thereof. The early-strength composite foam concrete foaming agent comprises the following components in percentage by mass: 40%-80% of composite foaming components, 1.0%-5.0% of foam stabilizing components, 3.3%-22% of early-strength components and 10%-45% of water, wherein the composite foaming components are formed by compounding synthesized surface active agent foaming agents and protein foaming agents. The early-strength composite foam concrete foaming agent prepared through the method disclosed by the invention has the advantages of high foam expansion, excellent foam stability and good compatibility with general cement pastes; the early-strength composite foam concrete foaming agent disclosed by the invention is applied to foam concrete; the prepared foam concrete has no recess phenomenon and is fast enhanced in early strength, and the foam concrete with a density grade equal to 300 kg / m<3> or above is more easily prepared.

Owner:中建商品混凝土(福建)有限公司 +1

Composite wall panel with low thermal conductivity and sufficient strength for structural use

ActiveUS20130216802A1Improve insulation effectImprove barrier propertiesSolid waste managementWallsThermal insulationRebar

The present invention provides a composite wall panel with good thermal insulation and sufficient strength for structural use which is designed for the fabrication of energy efficient building. The composite wall panel of the present invention comprises a foamed concrete core with sufficient compressive strength and low thermal conductivity which is sandwiched between two lightweight ductile fiber reinforced cementitious composite (FRCC) protective layers with low thermal conductivity, good barrier resistance to moisture / chloride ion / gas, multiple cracking as well as certain amount of steel reinforcements. These composite wall panels are useful in a variety of buildings in both cold and hot regions.

Owner:NANO & ADVANCED MATERIALS INST

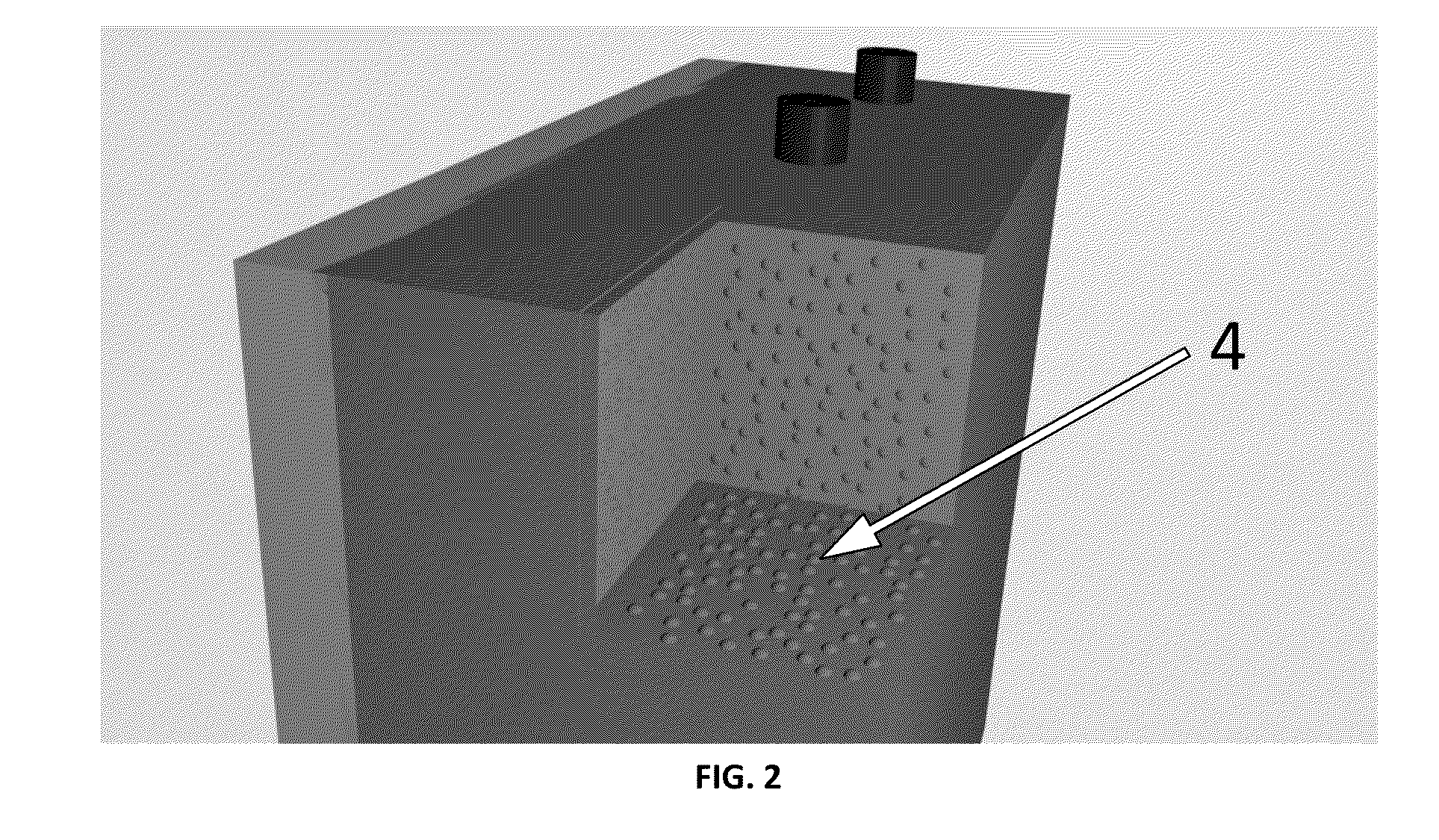

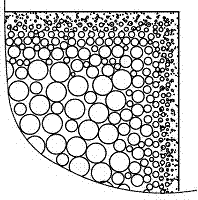

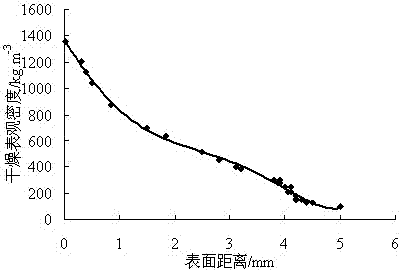

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of large-mixing-amount fly ash non-autoclaved ultra-light foamed concrete

ActiveCN103524091AImprove performanceReduce dosageSolid waste managementCeramicwareFoam concreteFiber

The invention provides a preparation method of large-mixing-amount fly ash non-autoclaved ultra-light foamed concrete. The preparation method comprises the steps of preparing the following raw materials in percentage by weight: 25-35% of cement, 25-47% of fly ash, 0-5% of silica fume, 0-2% of attapulgite clay, 1-5% of a chemical foaming agent, 0.03-2% of a foam stabilizer, 0-4% of fibers, 0.5-3% of a waterproof agent, 0-2% of a reinforcing agent, 0-4% of an accelerator, 0.1-0.4% of a water reducing agent, 0.1-4% of an expansion agent, 0-3% of quicklime and 22-30% of water, and then mixing, stirring and foaming the raw materials. The main properties of the foamed concrete prepared by the preparation method are superior to those of commonly used foamed concrete, the apparent density of the foamed concrete is 160-280kg / m<3>, the thermal conductivity is lower than 0.06W / (m.K), and the specific absorption of volume is not more than 10%; besides, the ratio of fly ash doped in the foamed concrete reaches 47%, the preparation method is good in process stability and high in finished product ratio, and the foamed concrete is suitable for large-scale production and can be used for outer wall external insulation works, roof insulation works, floor heating engineering, energy-saving composite materials and the like.

Owner:BEIJING BUILDING TECH DEV

Foam concrete with desulfurized gypsum as main cementing material and preparation method of foam concrete

The invention belongs to the technical field of building materials, in particular relates to foam concrete with desulfurized gypsum as a main cementing material. The foam concrete comprises desulfurized gypsum, slag powder, coal ash, cement, a foaming agent, a foam stabilizer, an alkali-activator, an early strength agent, water glass, a water reducer and polypropylene fibre. The desulfurized gypsum in the foam concrete is uncalcined desulfurized gypsum; by using the foam concrete, the desulfurized gypsum can be recycled, a great number of industrial wastes such as slag powder and coal ash canbe digested, and a favorable environmental benefit is achieved. In addition, the foam concrete provided by the invention has the excellent performances such as light weight, heat insulation, noise isolation and absorption, flame retardance, seismic resistance and energy adsorption, can be used for casting in situ and producing blocks and plates and is suitable for casting a roof heat insulating layer, a floor heating heat insulating layer, a light wall heat insulating building block, a road absorbent lined barrier and the like in situ.

Owner:TONGJI UNIV

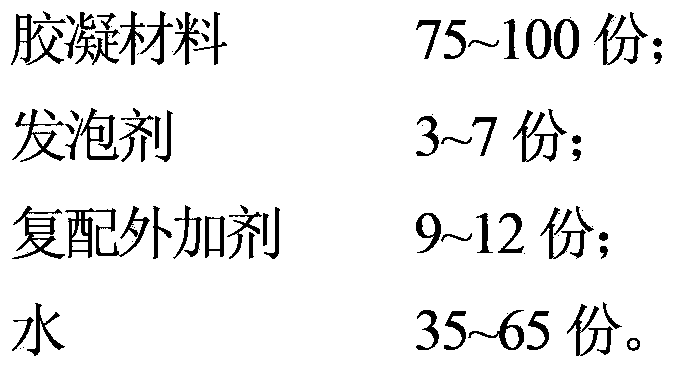

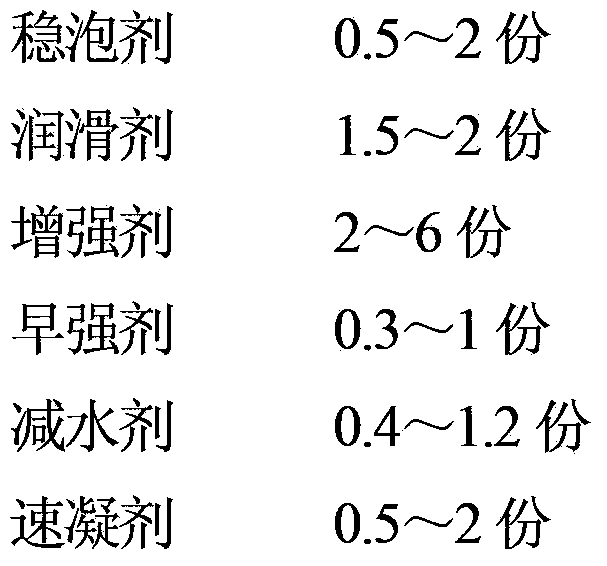

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

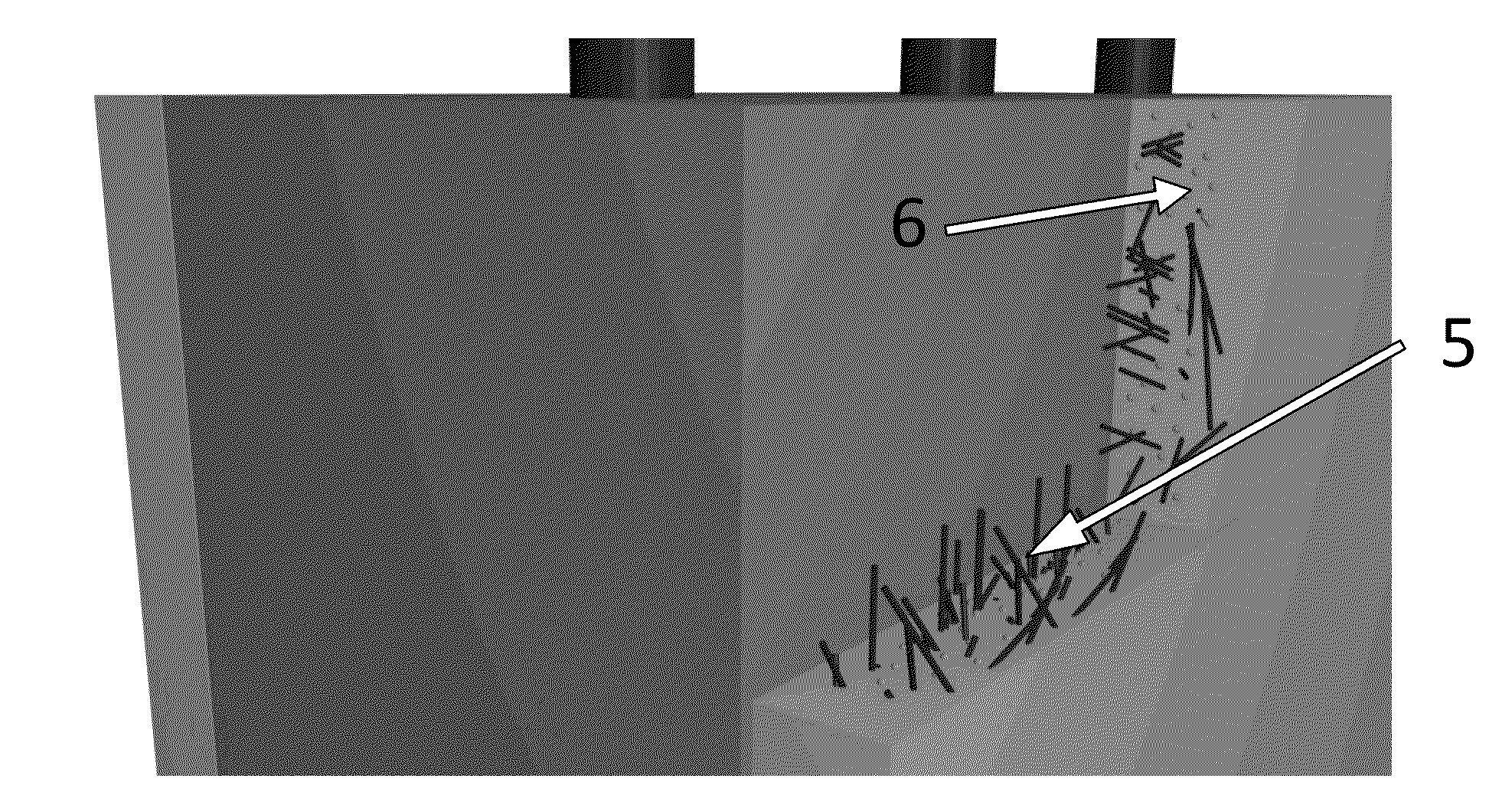

Explosion-proof heat-preservation multifunctional sheet material of foaming concrete sandwich and preparation method of material

InactiveCN102747789AWith anti-knock abilityStrong anti-knock abilityHeat proofingWater-setting substance layered productFoam concreteUltimate tensile strength

The invention discloses an explosion-proof heat-preservation multifunctional sheet material of a foaming concrete sandwich and a preparation method of the material. The sheet material comprises an outer wall heat-preservation sheet material core body; and explosion-proof light mortar outer protection plates are respectively spliced on the surfaces of the two sides of the outer wall heat-preservation sheet material core body. The explosion-proof heat-preservation multifunctional sheet material of the foaming concrete sandwich has stronger explosion-proof capability and can be used for protecting the safety and stability of a main body structure of a building under the effect of protecting an explosive load; and the heat-preservation, heat-insulation, fireproof, environmentally-friendly performances and the like of the explosion-proof heat-preservation multifunctional sheet material are better than those of like products. The method comprises the following steps of: A, preparing an explosion-proof and light-weight mortar outer protection plate; and B, preparing a foaming concrete core body. The heat-preservation, heat-insulation, fireproof, environmentally-friendly performances and the like of the explosion-proof heat-preservation multifunctional sheet material are better than those of like products and the construction process is simple. Panels on the two sides of the explosion-proof heat-preservation multifunctional sheet material of the foaming concrete sandwich are made of high-strength and light-weight mortar and the strength of the panels is higher. When the panels are cast and molded, a metal grid reinforcing layer is additionally arranged so that the panels have stronger anti-explosion capability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Foam-concrete rebar tie

InactiveUS20100319295A1Improve rigidityPrevent rotationBuilding reinforcementsFoam concreteArchitectural engineering

A fastener is disclosed having a an extension portion configured to be inserted into a first construction material such as foam, and having a stirrup portion configured to retain portion of a second construction material, such as rebar at a distance from the first construction material. A third construction material such as concrete can then be inserted (poured) in contact with the first construction material and surrounding the second construction material such that the second construction material is not directly in contact with the first construction material.

Owner:NELSON STEVEN J

Foamed concrete and preparation method thereof

ActiveCN103304200AReduce voidsImprove waterproof performanceCeramicwareIsolation effectFoam concrete

The invention provides foamed concrete and a preparation method thereof, and belongs to the technical field of building materials. The foamed concrete provided by the invention consists of the following components in percentage by mass: 25-55 percent of a gel material, 18-50 parts of light aggregate, 13-36 parts of water, 0.5-5 parts of a foaming agent, 0.03-0.5 part of a thickening agent and 0.03-0.5 part of enhanced fiber, wherein the gel material consists of cement and coal ash or superfine slag powder; the light aggregate consists of coarse light aggregates and fine light aggregates; the foaming agent is a hydrogen peroxide solution or an ammonium hydrogen carbonate; the thickening agent is powdered carboxymethylcellulose; the enhanced fiber is a lignin fiber or a polypropylene fiber or an alkali resistance glass fiber which is 5-20 mm long. The water prevention, sound isolation and heat isolation effects of the foamed concrete prepared by the invention are better than those of the existing foamed concrete. According to the method, the foaming process of processing various batches and scales of foamed concrete can be precisely controlled by in-situ foaming; the method can be suitable for large-scale production of high-quality foamed concrete.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

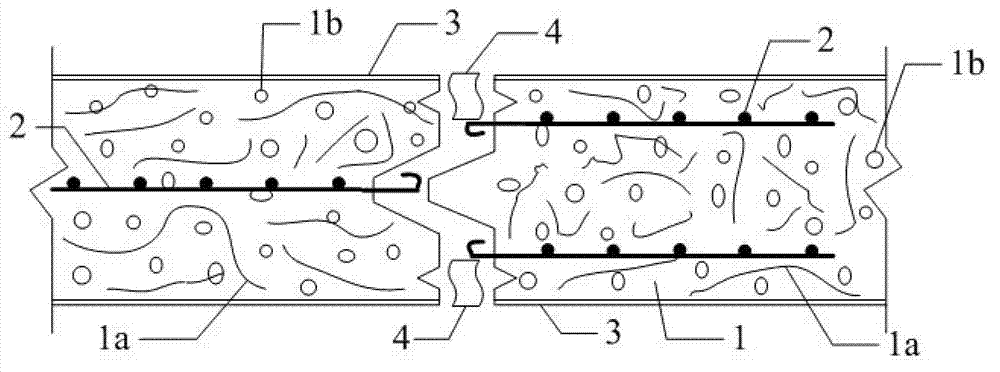

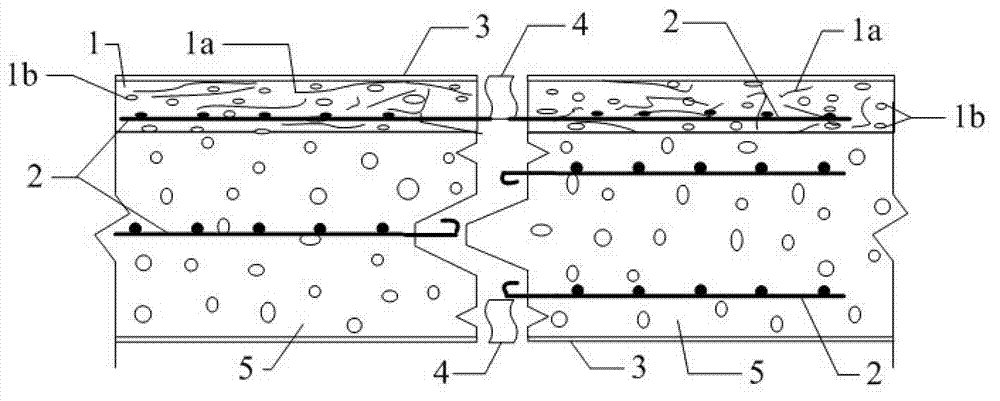

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

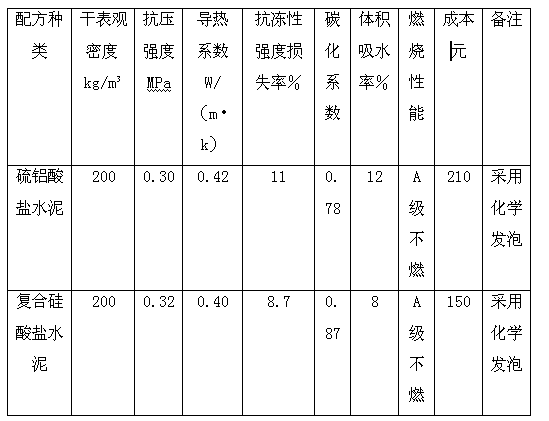

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

Method for preparing light foam concrete by using compound protein foaming agent

ActiveCN102515827AImprove foam stabilityNo autoclaving requiredCeramicwareFoam concreteActivated sludge

The invention relates to a method for preparing light foam concrete by using a compound protein foaming agent. The light foam concrete comprises 1-10 weight parts of foaming agent, 20-50 weight parts of concrete, 25-60 weight parts of fly ash, 1-10 weight parts of lime, 1-5 weight parts of gypsum, 0.5-2 weight parts of additive, and 27-40 weight parts of water, wherein the foaming agent comprises2.5-25 weight parts of activated sludge protein with a mass concentration 15-25 %, 0.1-1 weight parts of vegetable protein with a mass concentration of 20-40 %, 0.1-0.5 weight parts of stabilizing agent, and 73.5-97.3 weight parts of water. According to the invention, the compound protein foaming agent uses activated sludge protein and vegetable protein as the main components, and the stabilizingagent is used for modification, thus the foam stability of the protein foaming agent is raised. The preparation method has no need of steam pressure curing.

Owner:天津市裕川环境科技有限公司

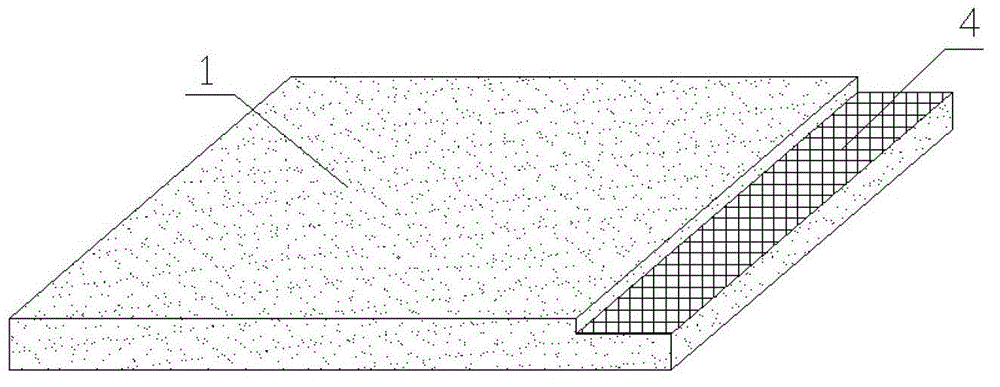

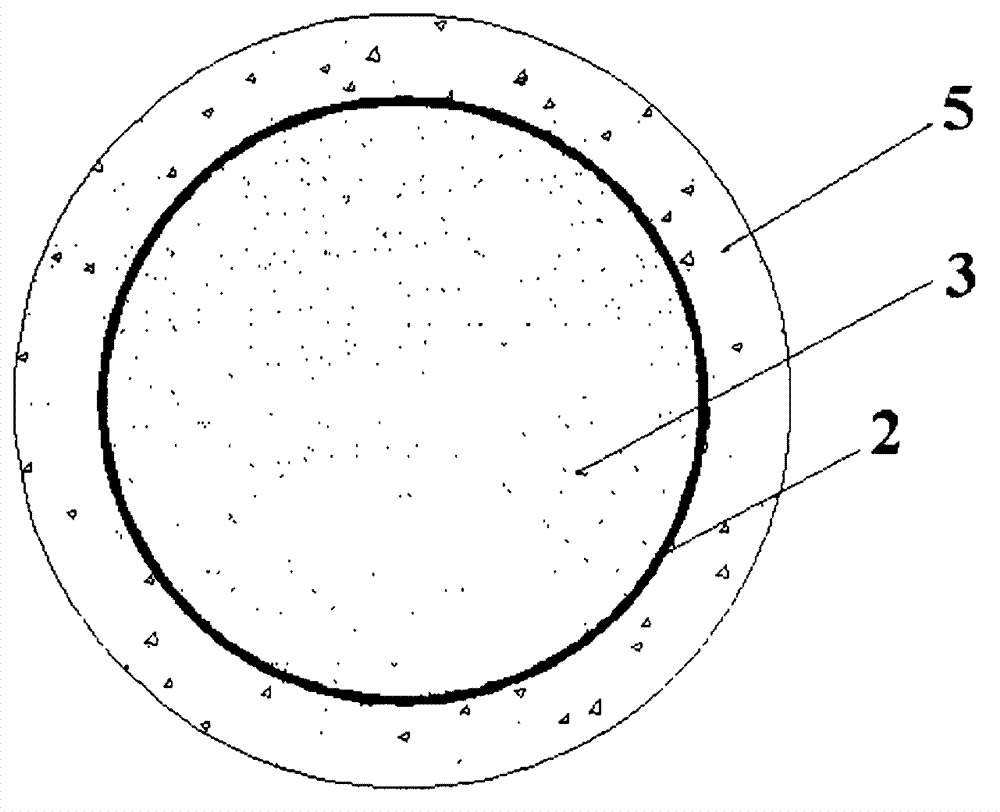

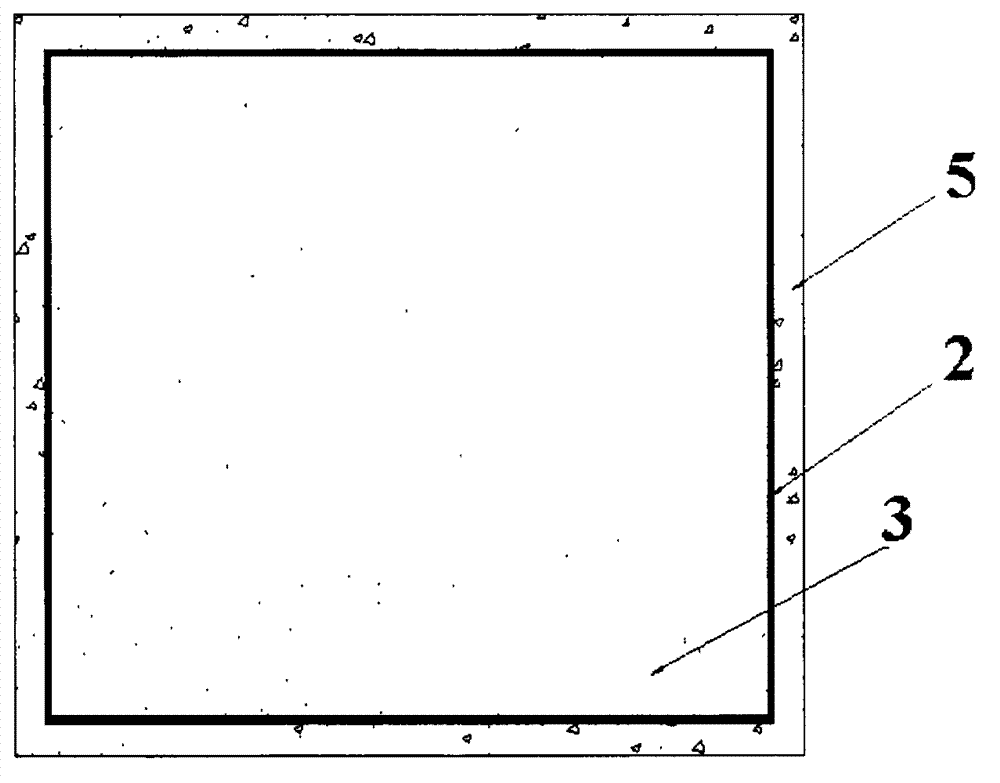

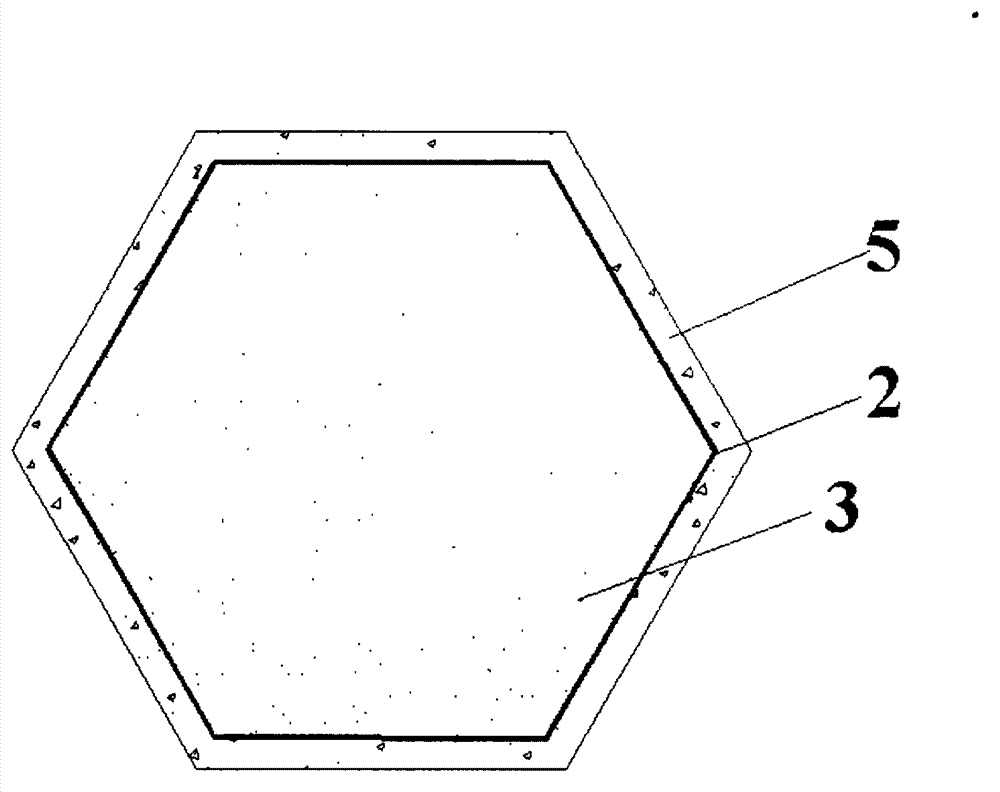

Steel tube foam concrete combined upright column and construction method thereof

InactiveCN103088964ASmall shrinkage deformationIncreased load-bearing capacityStrutsCeramicwareFoam concreteExpanded clay aggregate

The invention relates to a steel tube foam concrete combined upright column and a construction method of the steel tube foam concrete combined upright column. The steel tube foam concrete combined upright column comprises an upright column body, wherein the upright column body comprises steel tubes (2), foam concrete (3), reinforcing meshes (4) and outer wrapped concrete layers (5), wherein the foam concrete (3) is poured into the steel tubes (2); the reinforcing meshes (4) are arranged on the outer walls of the steel tubes; the steel tubes are connected by virtue of flange discs (6) and flange sockets (7); and a gasket (8) is arranged between each flange disc (6) and each flange socket (7). The foam concrete in the steel tube foam concrete combined upright column can adopt coal ash foam concrete or ceramsite foam concrete. The steel tube foam concrete combined upright column has a simple structure, and is high in shock resistance, high in carrying capability, good in economical performance and easy to construct, and suitable for main support columns and support parts of house structures, industrial building structures, recreational and athletic building structures and other structures.

Owner:HEFEI UNIV OF TECH

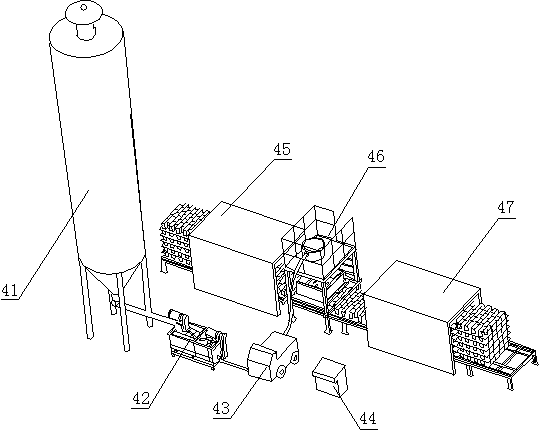

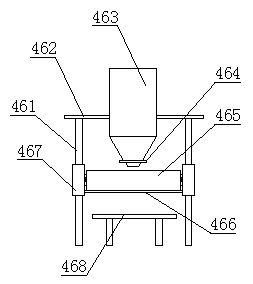

Production line for self-heat-insulation building blocks for walls

ActiveCN103128848AReduce waste lossEasy maintenanceCeramic shaping plantsProduction lineFoam concrete

The invention discloses an equipment production line for self-heat-insulation building blocks for walls. The equipment production line comprises a hollow brick production system, a steam curing system, a transfer system, a foam concrete pouring system and an automatic control system. The steam curing system is respectively connected with the hollow brick production system and the foam concrete pouring system by the transfer system, and the automatic control system is connected with the hollow brick production system, the steam curing system, the foam concrete pouring system and the transfer system by control circuits. Compared with the traditional production line, the equipment production line has the advantages that the steam curing efficiency is greatly improved, the energy cost is greatly saved, and the production cost is reduced; and distances from a filling plate and a filling groove to hollow bricks can be adjusted via lifting mechanisms, so that slurry can be effectively prevented from flowing out of the hollow bricks during pouring when the quantity of slurry in the filling groove is excessively high, waste of the slurry is reduced, and accordingly the production cost is saved.

Owner:河南华泰新材科技股份有限公司

High-performance cast-in-place foam concrete and preparation method thereof

The invention belongs to the technical field of an energy-saving building material, and relates to high-performance cast-in-place foam concrete and a preparation method thereof. The high-performance cast-in-place foam concrete is prepared from the following raw materials in parts by weight: 100-520 parts of cement, 25-180 parts of admixture, 80-320 parts of lightweight aggregate, 0.8-6.4 parts of foaming agent, 75-300 parts of water, 1.6-12 parts of additive and 2-28 parts of modifier in a mixing manner. The foam concrete prepared by the preparation method is light in weight, high in strength, excellent in waterproofness, good in heat preservation effect, free of poison, durable and the same as a building in service life, and is suitable for casting internal and external wall bodies in place, roof and ground heat preservation and foundation pit backfill of a pier pavement and the like.

Owner:沈阳红姗石新型建材有限公司

Composite fiber reinforced foam concrete and preparation method thereof

InactiveCN102199044APrevent shrinkage crackingImprove flexural strengthSolid waste managementCeramicwareFoam concreteFoaming agent

The invention relates to composite fiber reinforced foam concrete and a preparation method thereof. The foam concrete comprises the following components in parts by weight: 0-400 parts of fly ash, 100-900 parts of cement, 500-1000 parts of sands, 300-600 parts of water, 0.4-1 part of organic fiber, 1-3 parts of plant fiber, 0.2-15 parts of early strength agent, 3-20 parts of foaming agent, 0.5-4 parts of water reducing agent and 0.5-2 parts of water retention agent. The preparation method of the foam concrete comprises the following steps of: generating foams by using the foaming agent, adding the foams to fully stirred cement mortar containing composite fibers and the like and keeping stirring so that the foams are dispersed in the mortar uniformly, measuring the volume weight and carrying out casting forming or coating forming and carrying out standard curing for 28 days. In the invention, industrial and agricultural wastes, such as fly ash, plant fiber and the like, are used, shrinkage crack of the foam concrete is inhibited obviously, and the composite fiber reinforced foam concrete has low price; and the foam concrete has simple formula, good workability, long foam stabilizing time, light weight and low coefficient of thermal conductivity and is suitable for exterior wall thermal insulation, roof thermal insulation and non-load-bearing wall manufacturing.

Owner:TONGJI UNIV

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

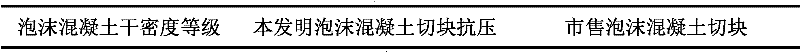

Light aggregate foam concrete building blocks and method for manufacturing same

The invention discloses a lightweight aggregate cellular concrete block and a preparation method thereof. The lightweight aggregate cellular concrete block comprises cement, lightweight aggregate, water, a foaming agent and an additive. The lightweight aggregate is multihole lightweight aggregate with the stacking density of less than 1200kg / m3. The foaming agent is the substance, with which foam is formed in a material, thus forming a material in a closed pore or a connected pore structure. The additive is one, several or none of concrete common additives and mineral additives. In the preparation method, the cement, the additive, the chemical foaming agent (or not involved) and water are weighted and fed into an agitator, and beaten into a mixed cement paste; the mixed cement paste is manufactured into a foamed cement paste through a foaming device; after the lightweight aggregate is added to the foamed cement paste, the mixture is beaten and poured. Subsequently, the mixture is moulded at one step and cured. The manufacturing cost of the lightweight aggregate cellular concrete block is low; the manufacturing process is simple and easy to control; regions, which are able to invest on the production of the lightweight aggregate cellular concrete block, are wider.

Owner:王格

A kind of foam concrete and preparation method thereof

The invention relates to a foamed concrete and a preparation method thereof. The foamed concrete adopts a chemical foaming method, and a foam stabilizer, an early strength agent, and a water reducer are respectively added to ordinary Portland cement slurry and stirred evenly, and then chemical foaming agent is added. The foaming agent is fully stirred evenly, then injection molded, cured at room temperature, and hardened. The dry apparent density range of the foamed concrete prepared by this method is 150-300kg / m3, the corresponding compressive strength is 0.10-0.50MPa, and the thermal conductivity is lower than 0.10W / mK. It can be used as roof insulation project, floor heating project, light Cushion material, especially suitable for external wall insulation system, energy-saving composite panels, etc. used in building energy-saving projects.

Owner:NANJING UNIV OF TECH

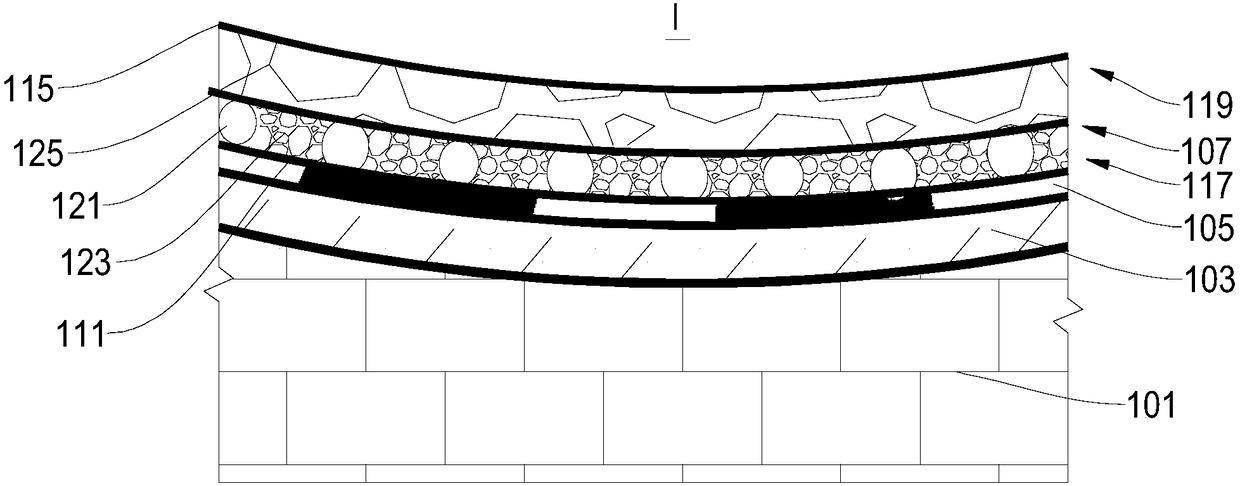

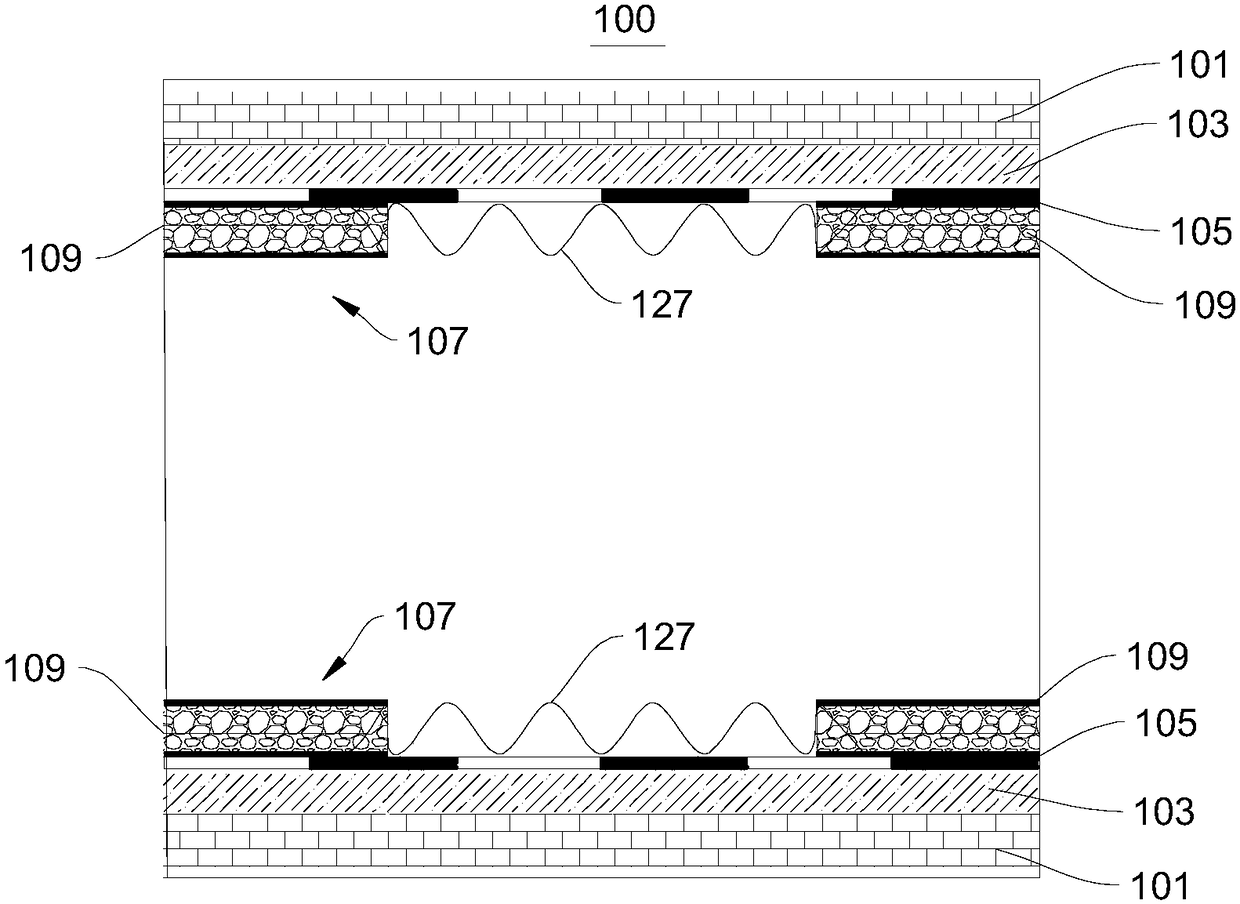

Tunnel-assembled lining structure and tunnel across large-scale active fault zone in strong earthquake zone

InactiveCN108119166AGuaranteed stabilityGuarantee unimpededUnderground chambersTunnel liningFoam concreteStructure of the Earth

The invention relates to a tunnel-assembled lining structure and a tunnel across a large-scale active fault zone in a strong earthquake zone, and relates to the field of transportation infrastructureconstruction. The structure comprises an initial support layer, a spray film waterproof layer, an assembly type concrete-filled steel tube lining layer and a flexible joint; the assembly type concrete-filled steel tube lining layer is provided with a plurality of concrete-filled steel tube lining sections, each section is provided with a first steel tube sheet, a second steel tube sheet and a third steel tube sheet which are arranged from outside to inside, a first lining layer is arranged between the first steel tube sheet and the second steel tube sheet, and a second lining layer is arrangedbetween the second steel tube sheet and the third steel tube sheet. The first lining layer includes a plurality of hollow steel tubes arranged at intervals and lightweight foam concrete for filling gaps, the second lining layer comprises high compressibility concrete, and the lining sections are connected through the steel plate spring type flexible joint. The structural stability under dislocation and strong earthquakes can be ensured, and the tunnel-assembled lining structure has functions of quick installation, replacement and quick repair; the principle of stiffness matching is fully considered in the structure, and multiple measures are combined to 'lead the earthquake'.

Owner:SOUTHWEST JIAOTONG UNIV

Straw fiber reinforced foam concrete and preparation method thereof

ActiveCN104130006AUniform porous structureReduce voidsSolid waste managementCeramicwareFoam concreteFoaming agent

The invention discloses straw fiber reinforced foam concrete and a preparation method thereof, and belongs to the technical field of building materials. The straw fiber reinforced foam concrete comprises the following components by mass: 40-80 parts of a cementitious material; 1-20 parts of a fine lightweight aggregate; 0.05-0.6 part of straw fiber; 2-8 parts of a chemical foaming agent; 0.5-4 parts of a physical foaming agent; 0.02-0.14 part of a foam stabilizing agent; 0.1-0.8 part of a catalyst; 0.05-0.6 part of a thickening agent and 15-30 parts of water. The preparation method is as follows: mixing and stirring the cementitious material, the straw fiber and the thickening agent, then adding the water, the chemical foaming agent, the foam stabilizing agent and the catalyst, stirring to obtain a slurry mixture, then adding expanded vermiculite, stirring to obtain chemically foamed foam concrete; adding the physical foaming agent into the chemically foamed foam concrete, stirring, pouring into a mould, and demoulding after concrete is solidified and hardened to prepare the straw fiber reinforced foam concrete. The straw fiber reinforced foam concrete has a more uniform multihole structure, and the water proof, sound insulation and heat insulation effects are better than that of foam concrete in the prior art.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

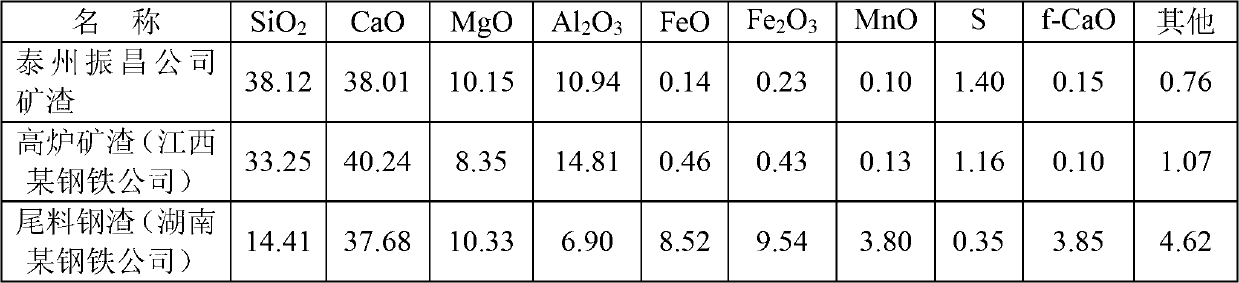

Aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and production method of aerated concrete block

The invention provides an aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and a production method of the aerated concrete block. The aerated concrete block is produced through the following steps: adding an additive A, an additive B and water in components as follows: 40 to 50% of specially-made mineral waste residue obtained in a such way that cinder is obtained through the production process of recycling steel slag discharged from Taizhou Zhenchang Industrial Waste Residue Comprehensive Utilization LTD and metallurgical and chemicalferrous waste residue, and then is water-quenched, 35 to 45% of tailings steel slag, 2 to 4% of cement clinker, 1 to 3% of gypsum, and 8 to 12% of modified wood, wherein the grain size of the specially-made mineral waste residue is less than or equal to 5 mm, the grain size of the tailings steel slag is less than or equal to 20 mm, the additive A accounts for 1% of the total weight of the components, the additive B accounts for 0.05% of the total weight of the components, and water accounts for 0.5 to 0.6 times of the total weight of the components; and conducting mixing, heating, air-entrapping, steaming and pressing, and curing in sequence. The aerated concrete block produced by adopting the production method is high in strength, and small in drying shrinkage value, and can meet the block standards of the A3.5 grade and the B09 grade in the JC1062-2007 foam concrete block standard.

Owner:TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com