Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Cementitious composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

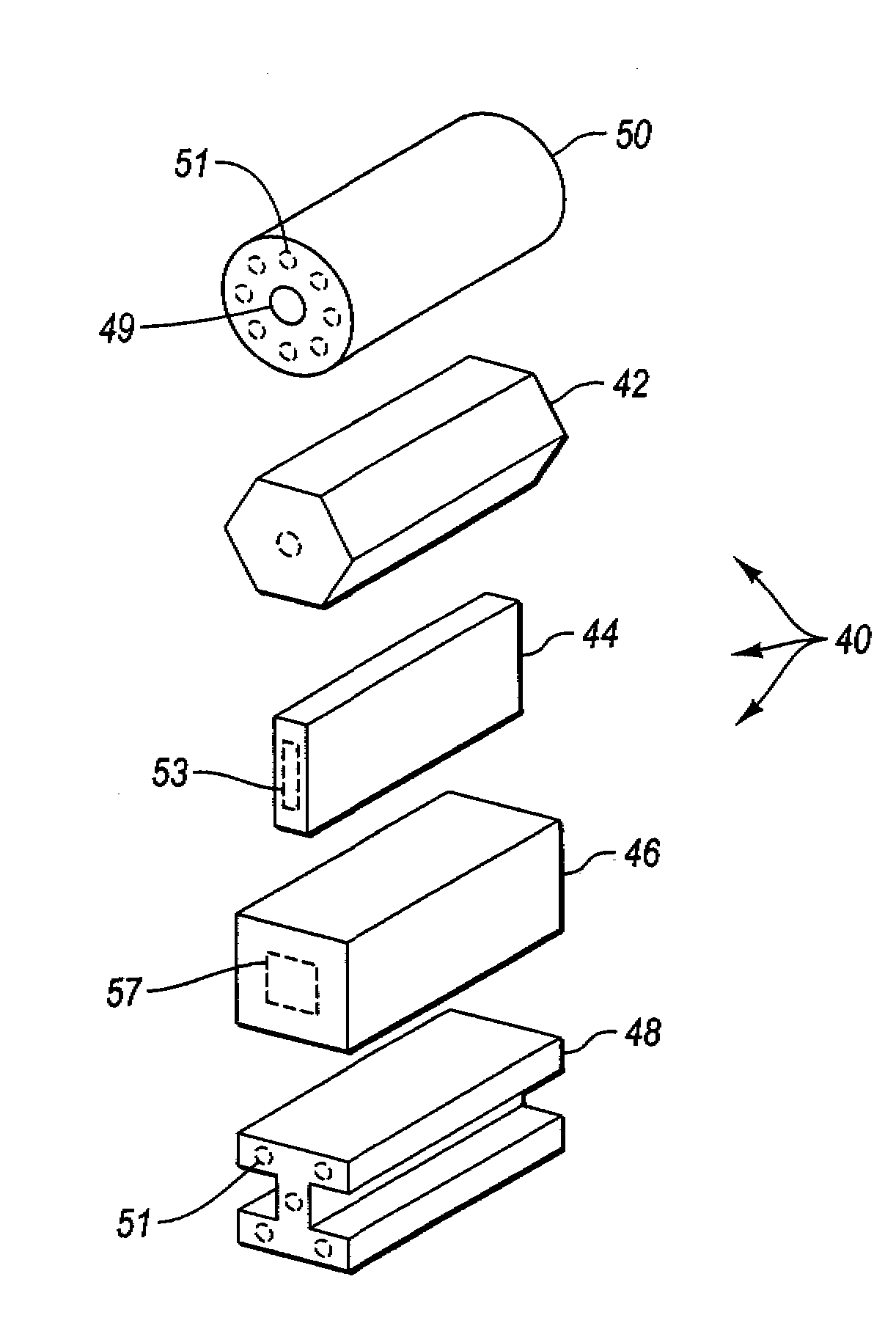

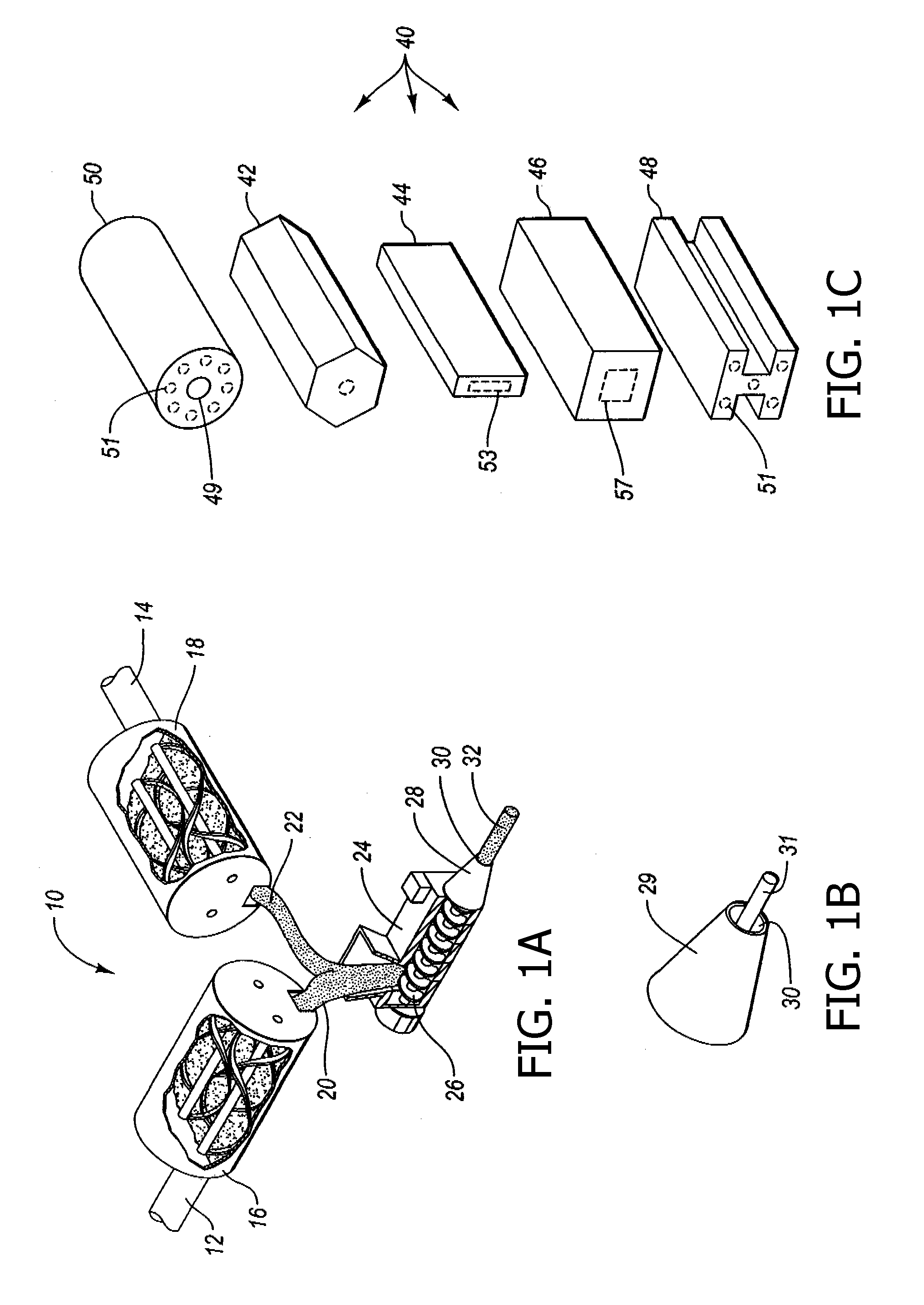

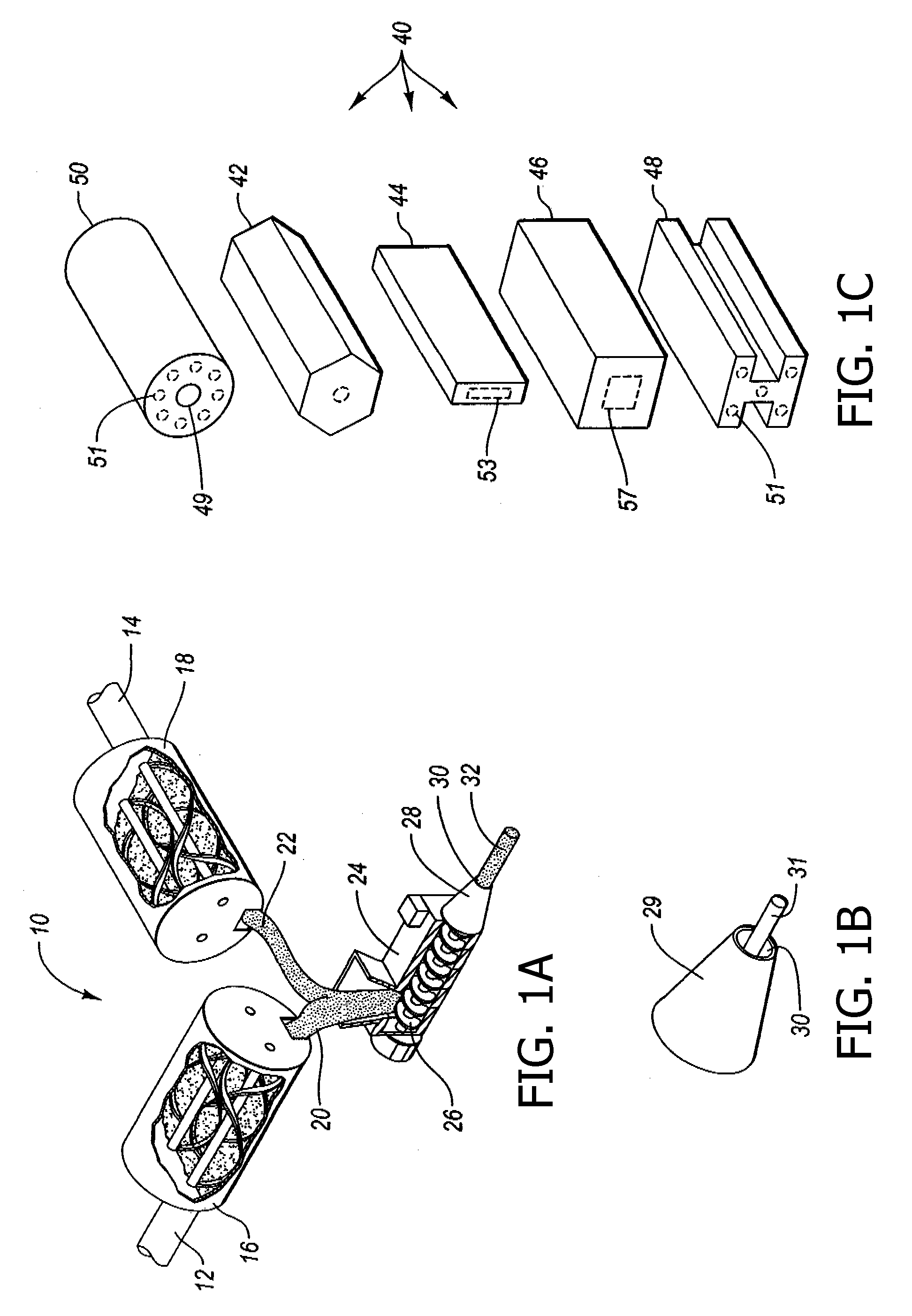

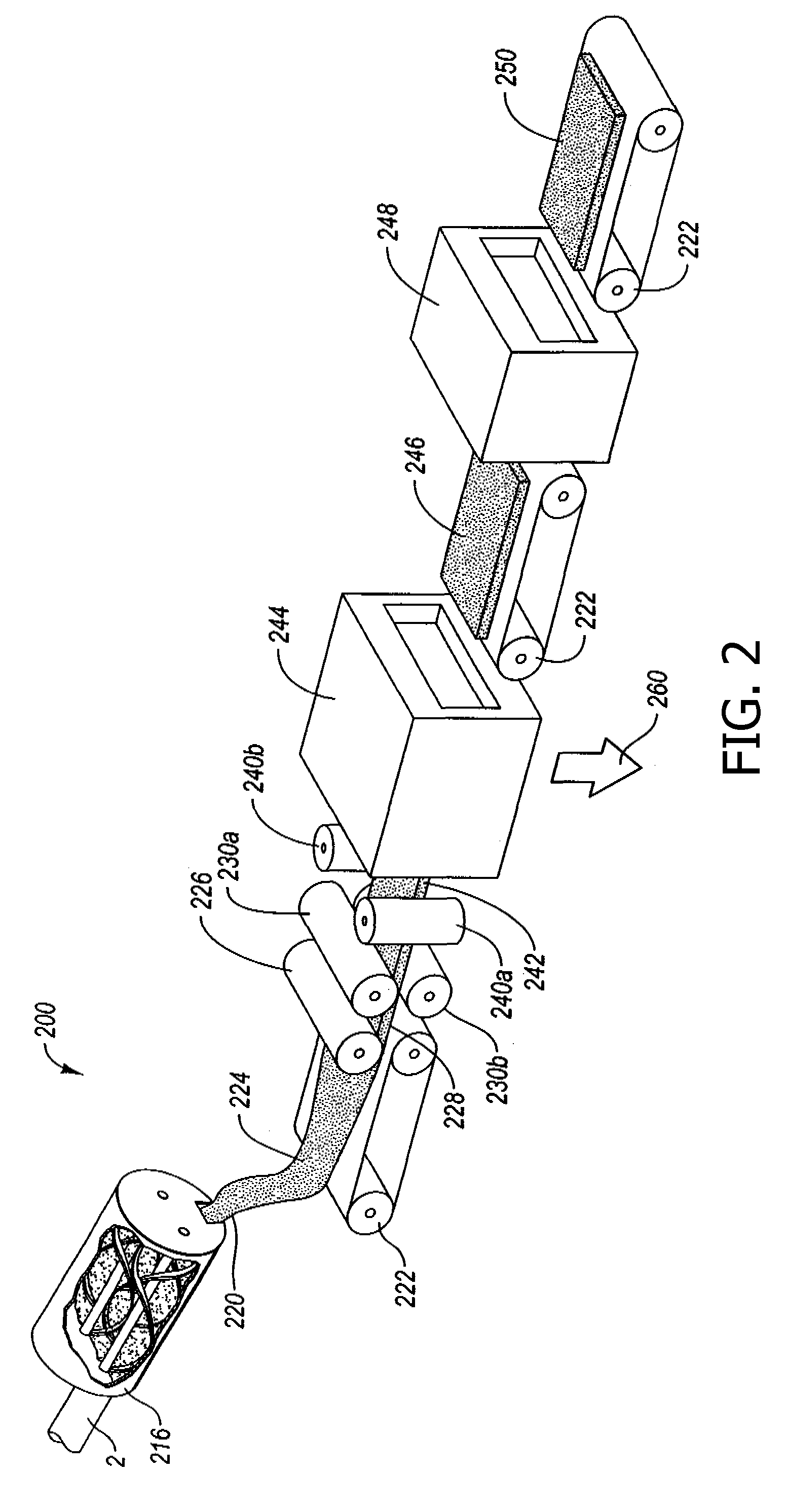

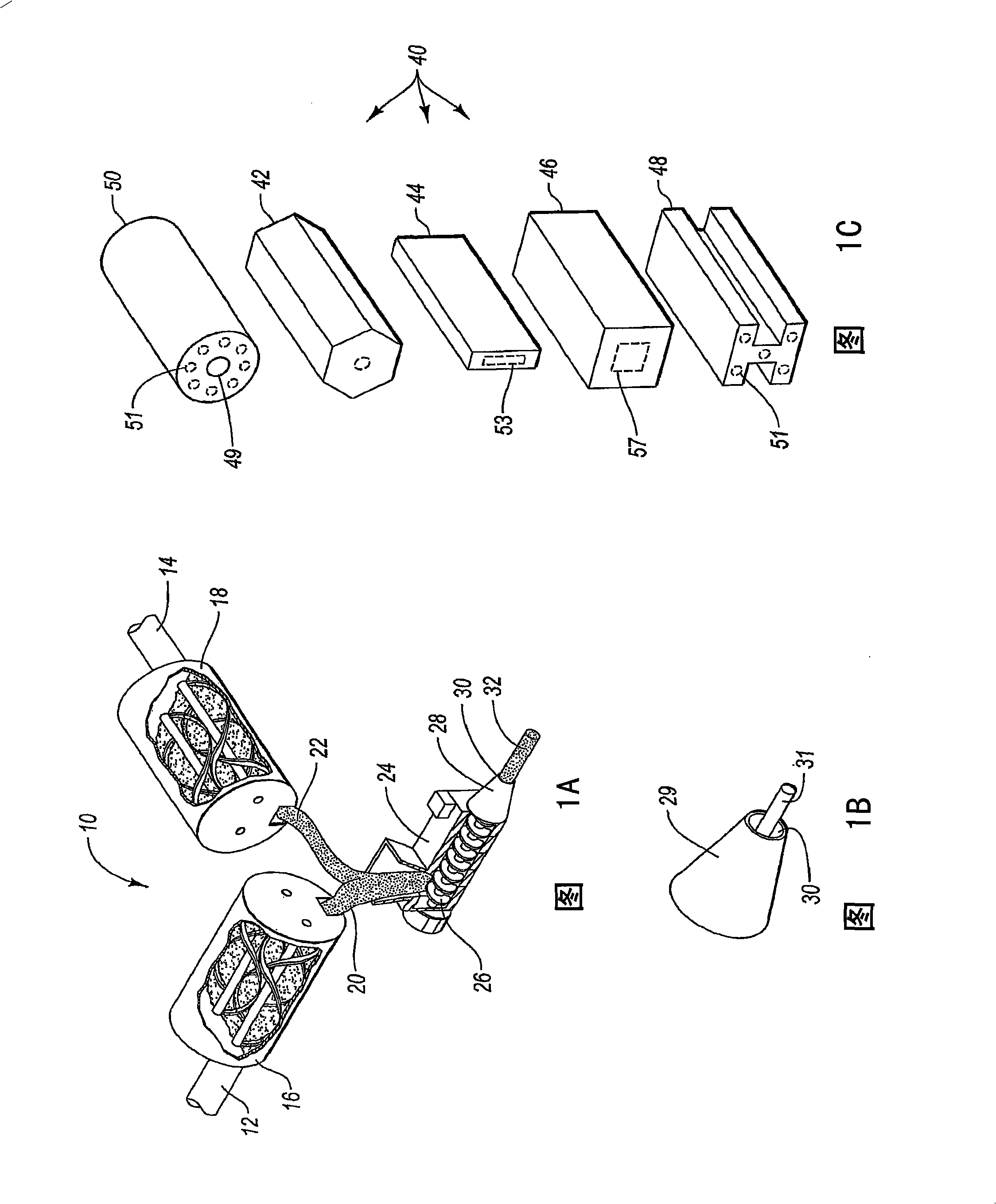

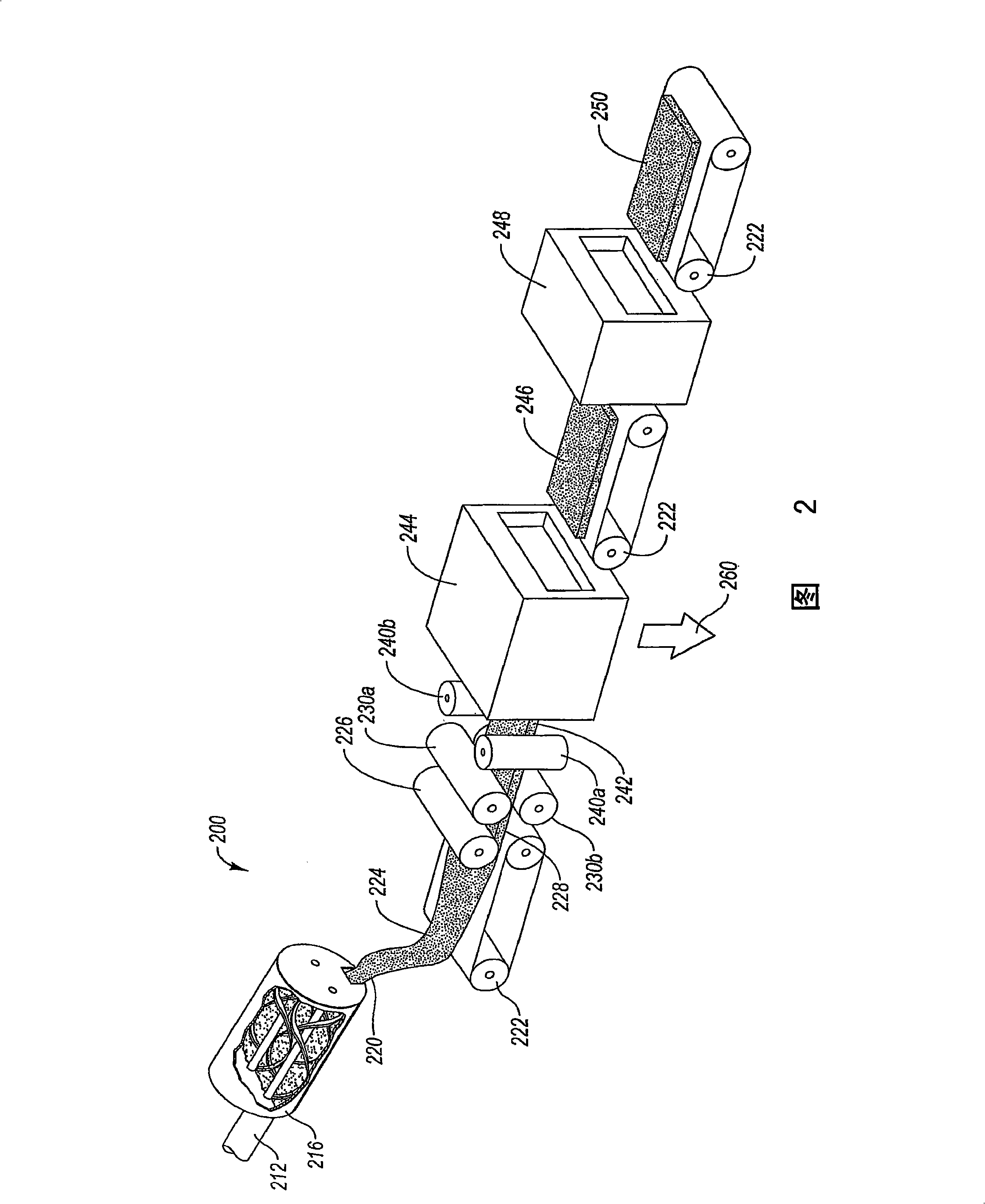

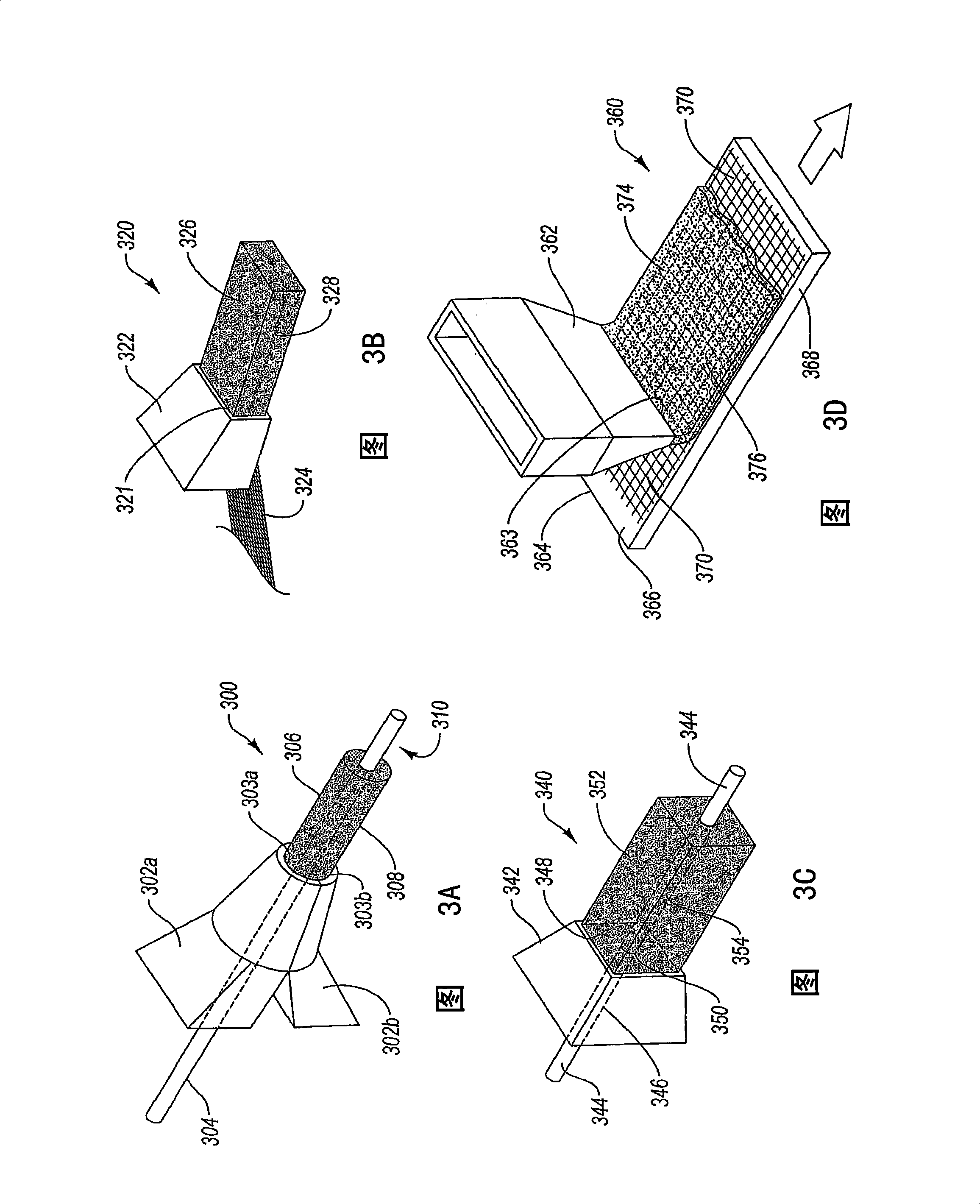

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

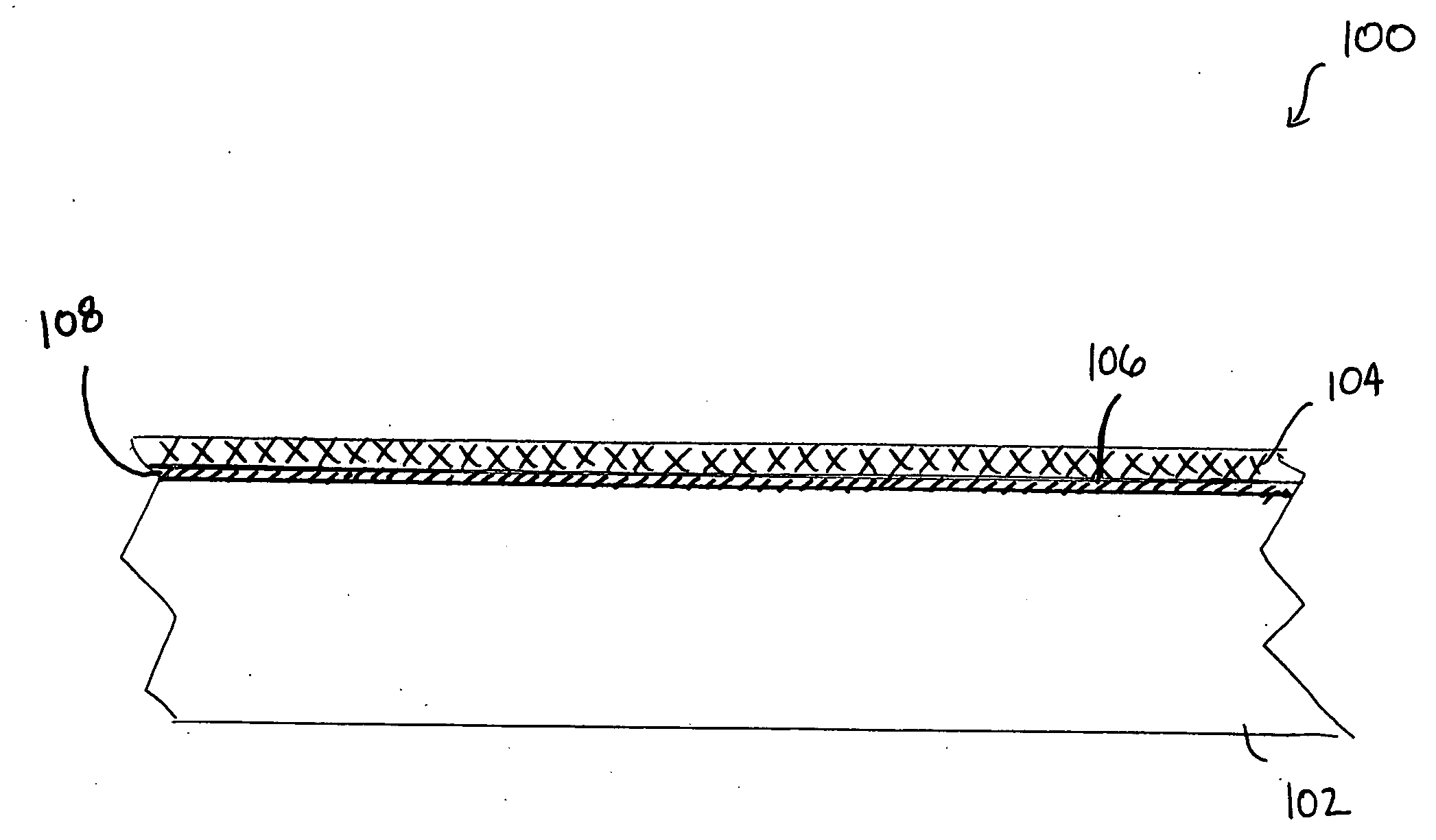

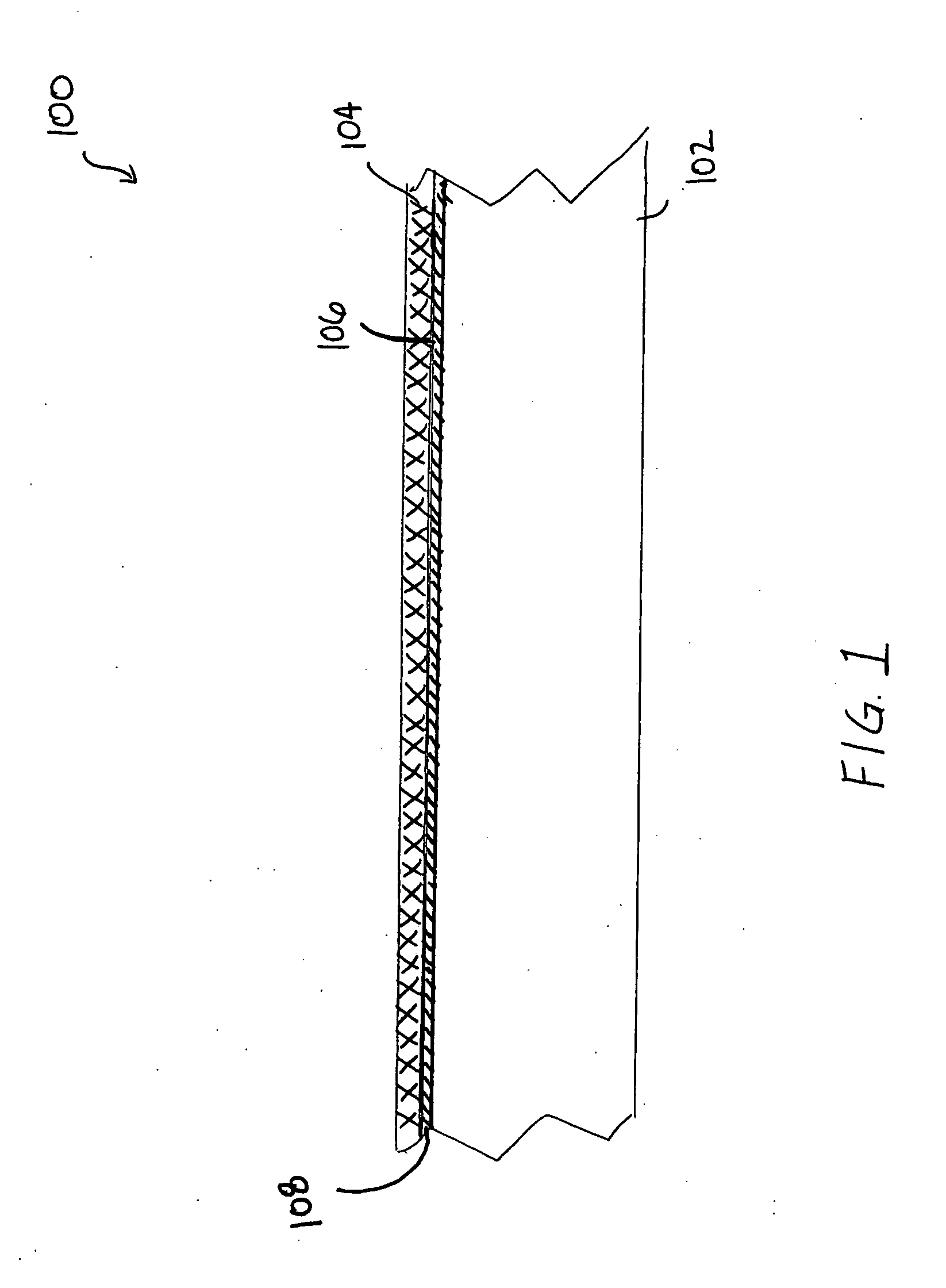

Mat-Faced Cementitious Article and Method for Preparing Same

InactiveUS20100143682A1Solid waste managementSynthetic resin layered productsCement compositesVolumetric Mass Density

A cementitious composite article comprising (a) a cementitious core, (b) a skim coat cementitious layer in contact with the cementitious core having a density greater than the cementitious core, and (c) a fibrous mat comprising (i) microfibers and (ii) continuous fibers having a length of about 0.6 cm or more, wherein the fibrous mat comprises an inner surface in contact with the skim coat cementitious layer; as well as a method for manufacturing same.

Owner:UNITED STATES GYPSUM CO

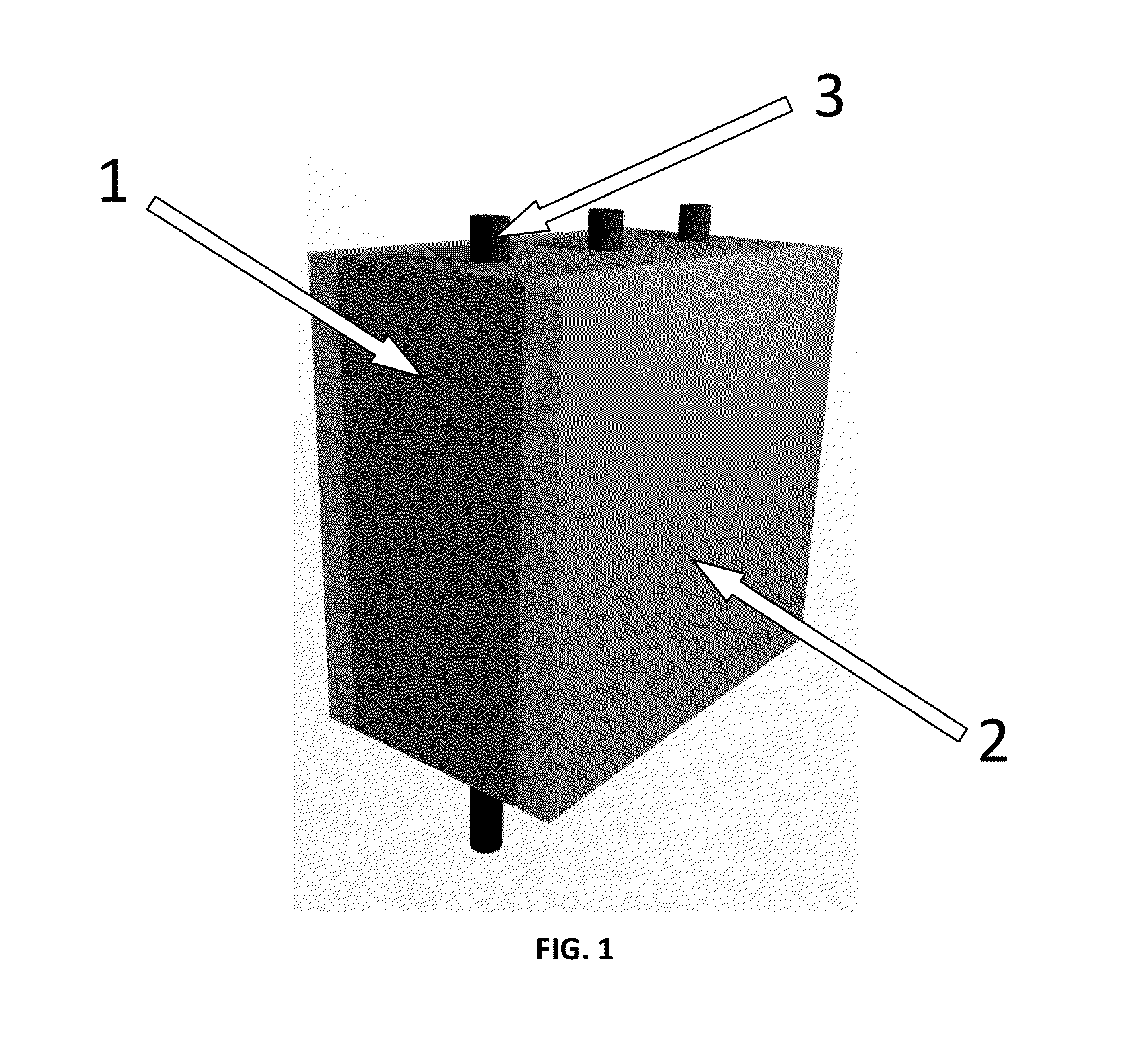

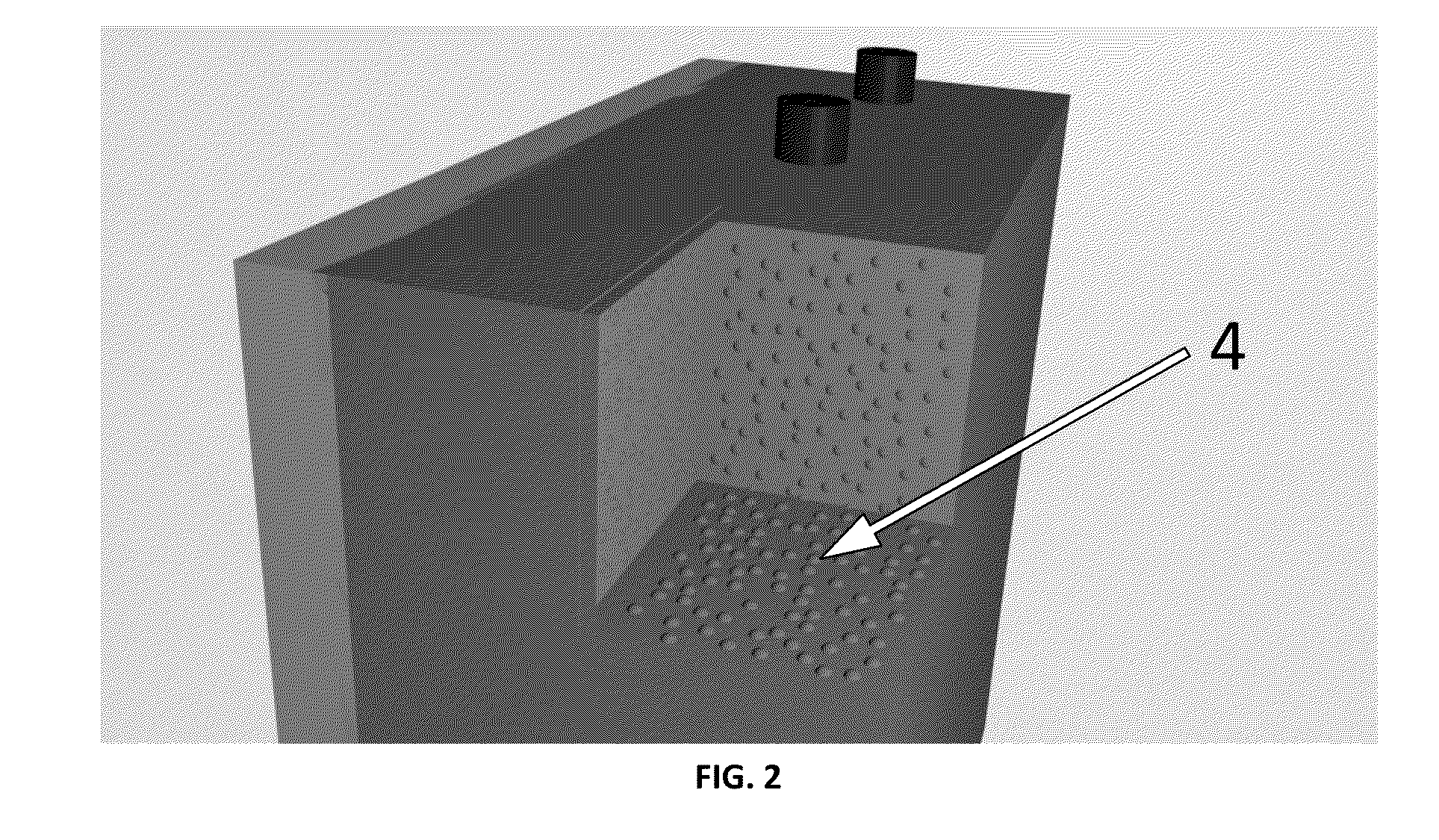

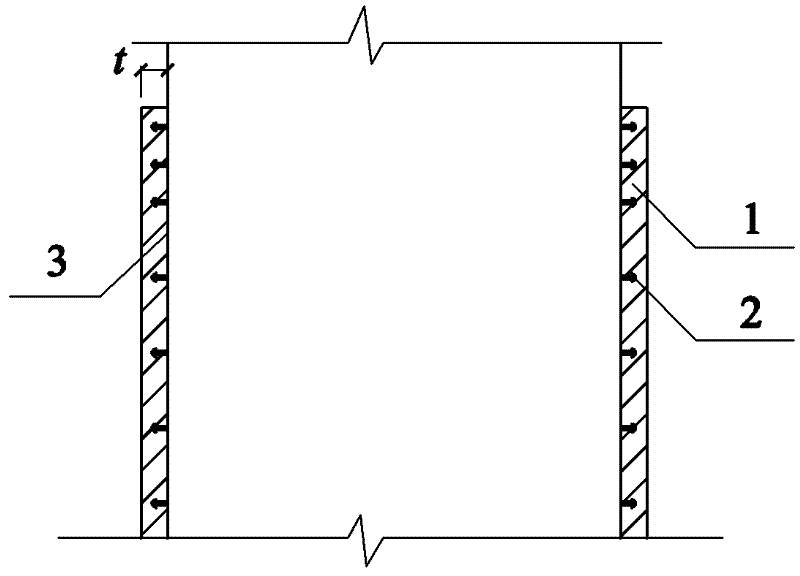

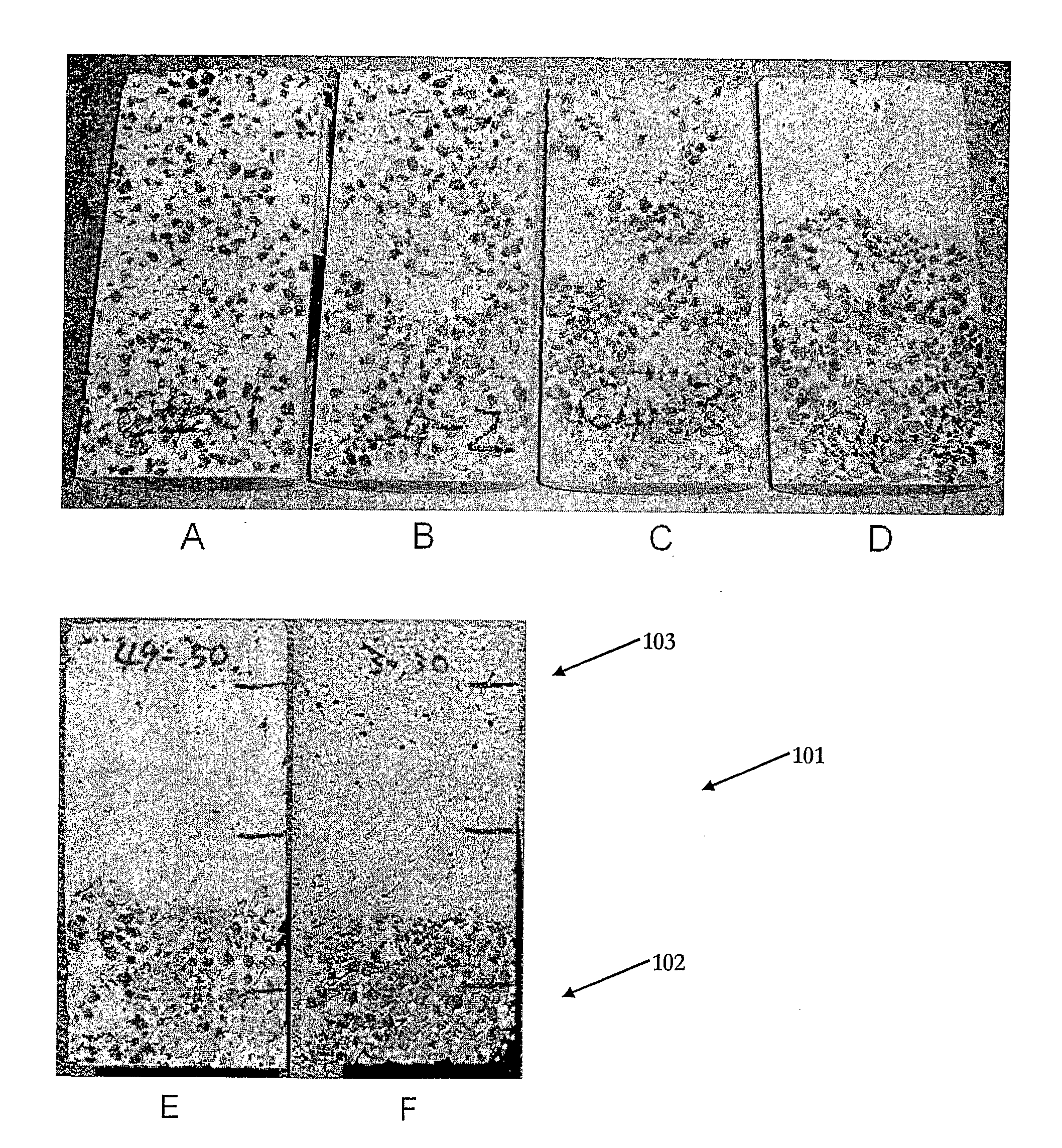

Composite wall panel with low thermal conductivity and sufficient strength for structural use

ActiveUS20130216802A1Improve insulation effectImprove barrier propertiesSolid waste managementWallsThermal insulationRebar

The present invention provides a composite wall panel with good thermal insulation and sufficient strength for structural use which is designed for the fabrication of energy efficient building. The composite wall panel of the present invention comprises a foamed concrete core with sufficient compressive strength and low thermal conductivity which is sandwiched between two lightweight ductile fiber reinforced cementitious composite (FRCC) protective layers with low thermal conductivity, good barrier resistance to moisture / chloride ion / gas, multiple cracking as well as certain amount of steel reinforcements. These composite wall panels are useful in a variety of buildings in both cold and hot regions.

Owner:NANO & ADVANCED MATERIALS INST

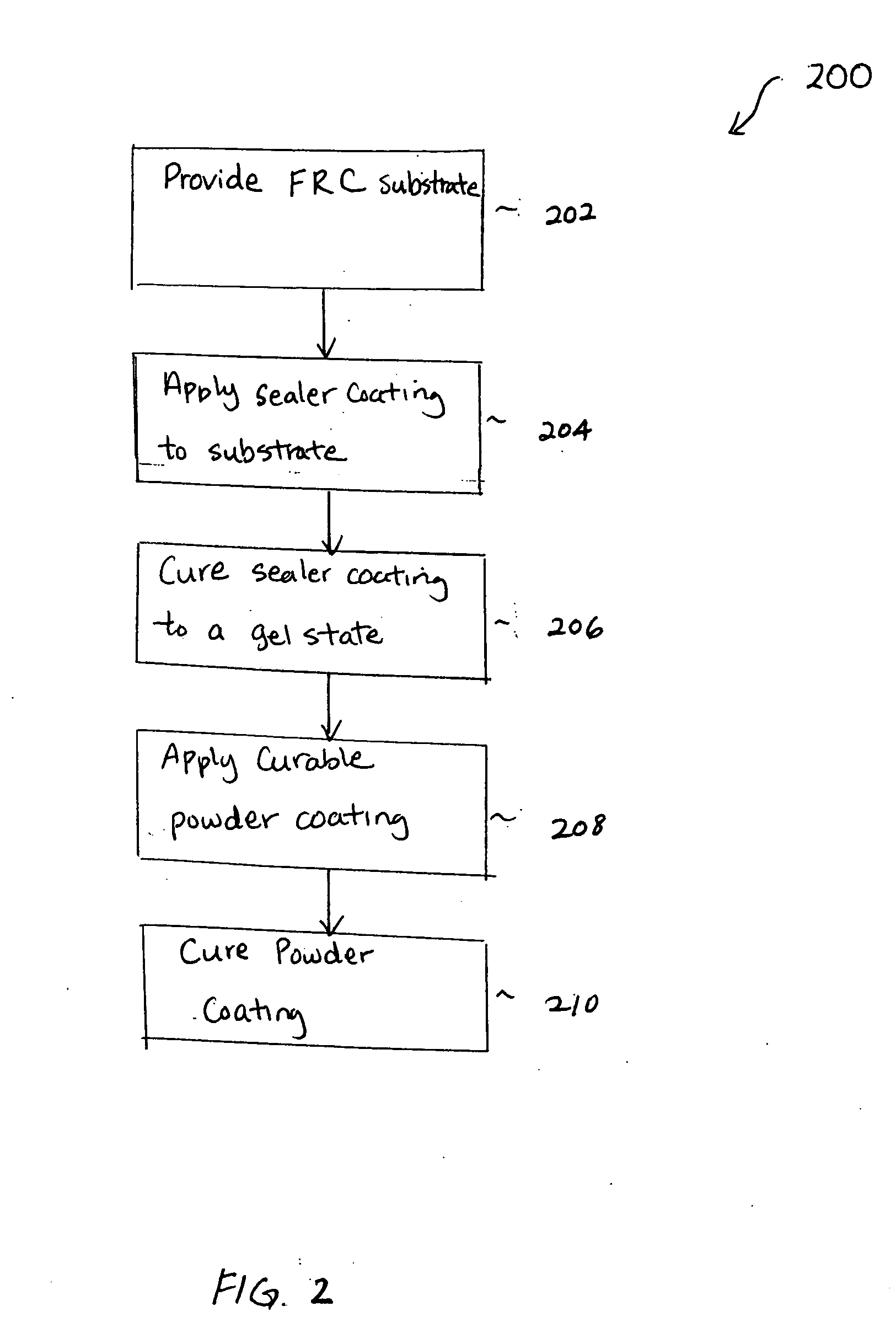

Composite cement article incorporating a powder coating and methods of making same

A cementitious composite article incorporating a powder coating on at least one surface is provided. The composite article includes a surface treatment adapted to facilitate application of the powder coating onto the article. The surface treatment can include modifications to surface porosity, surface, and / or application of a sealer to the surface so as to make the cementitious surface more conducive to powder coating. One method of manufacturing the cementitious composite article includes first applying a sealer coating to a surface of a fiber cement substrate, partially curing the substrate to a gel-like state, applying a powder coating to the article, processing the article to a curing device in which the powder coating and sealer coating are co-cured to form a hardened film.

Owner:JAMES HARDIE TECH LTD

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20120276310A1Low densityReduce hardnessEnvelopes/bags making machineryCeramic extrusion diesPorosityBuilding product

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

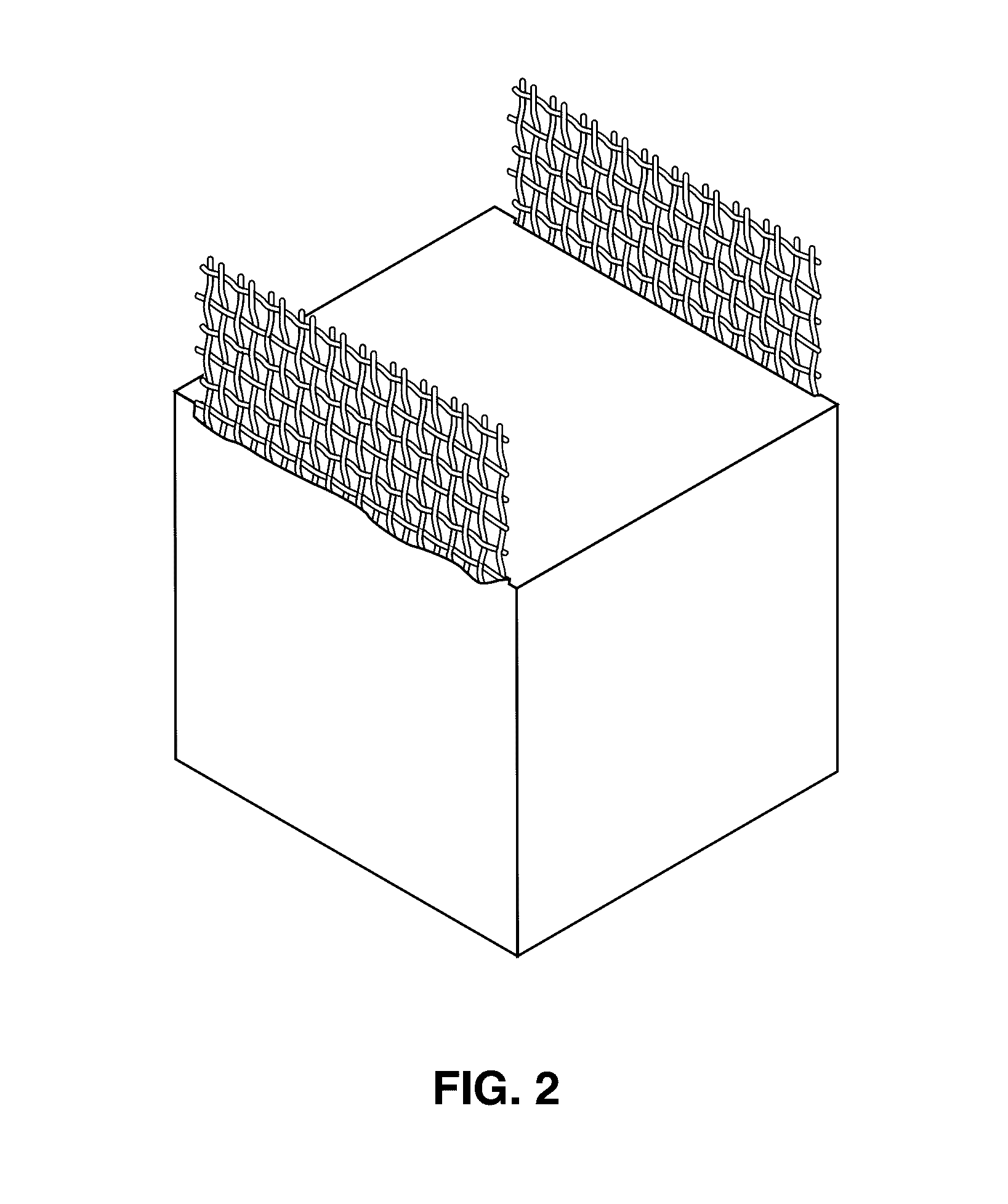

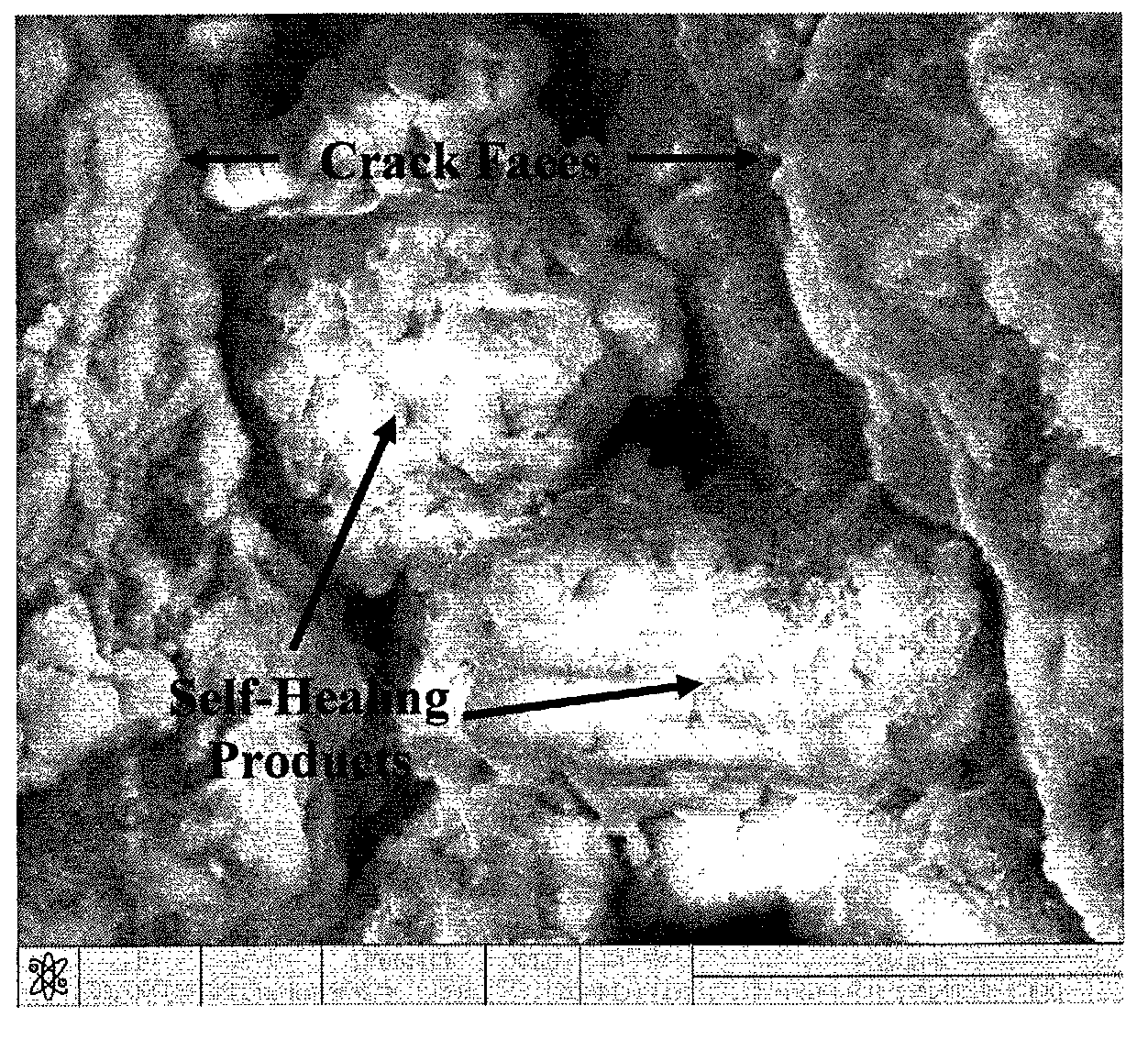

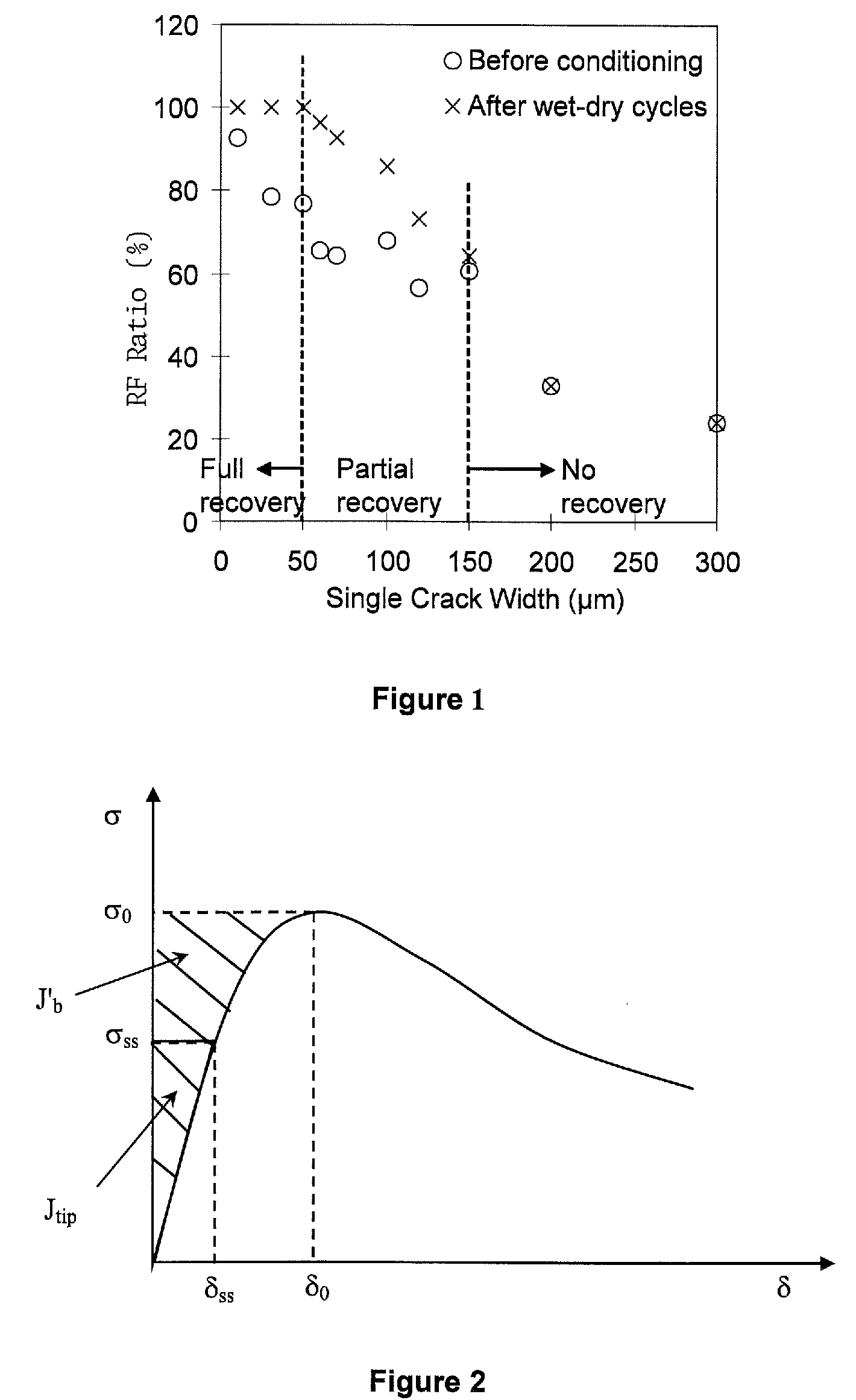

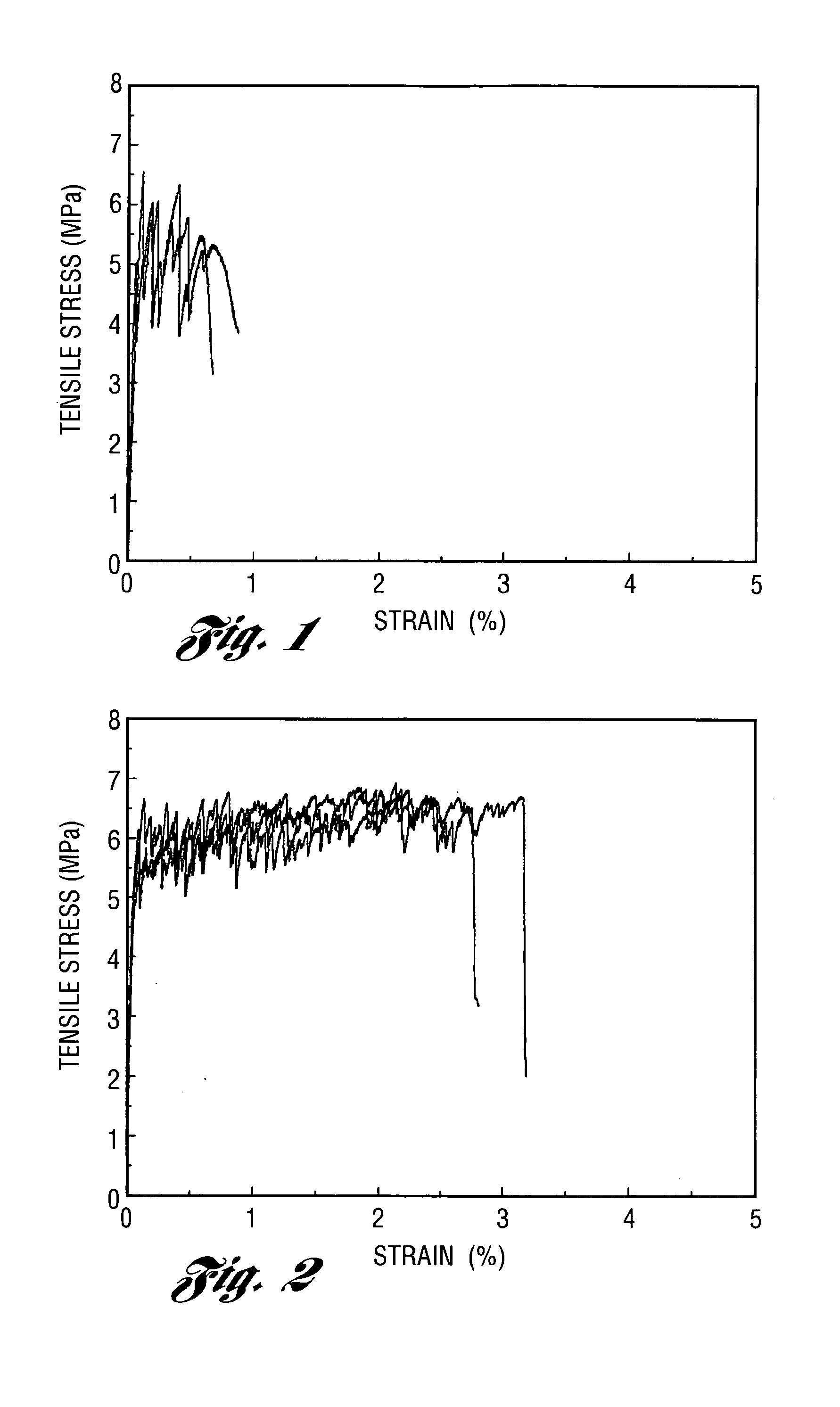

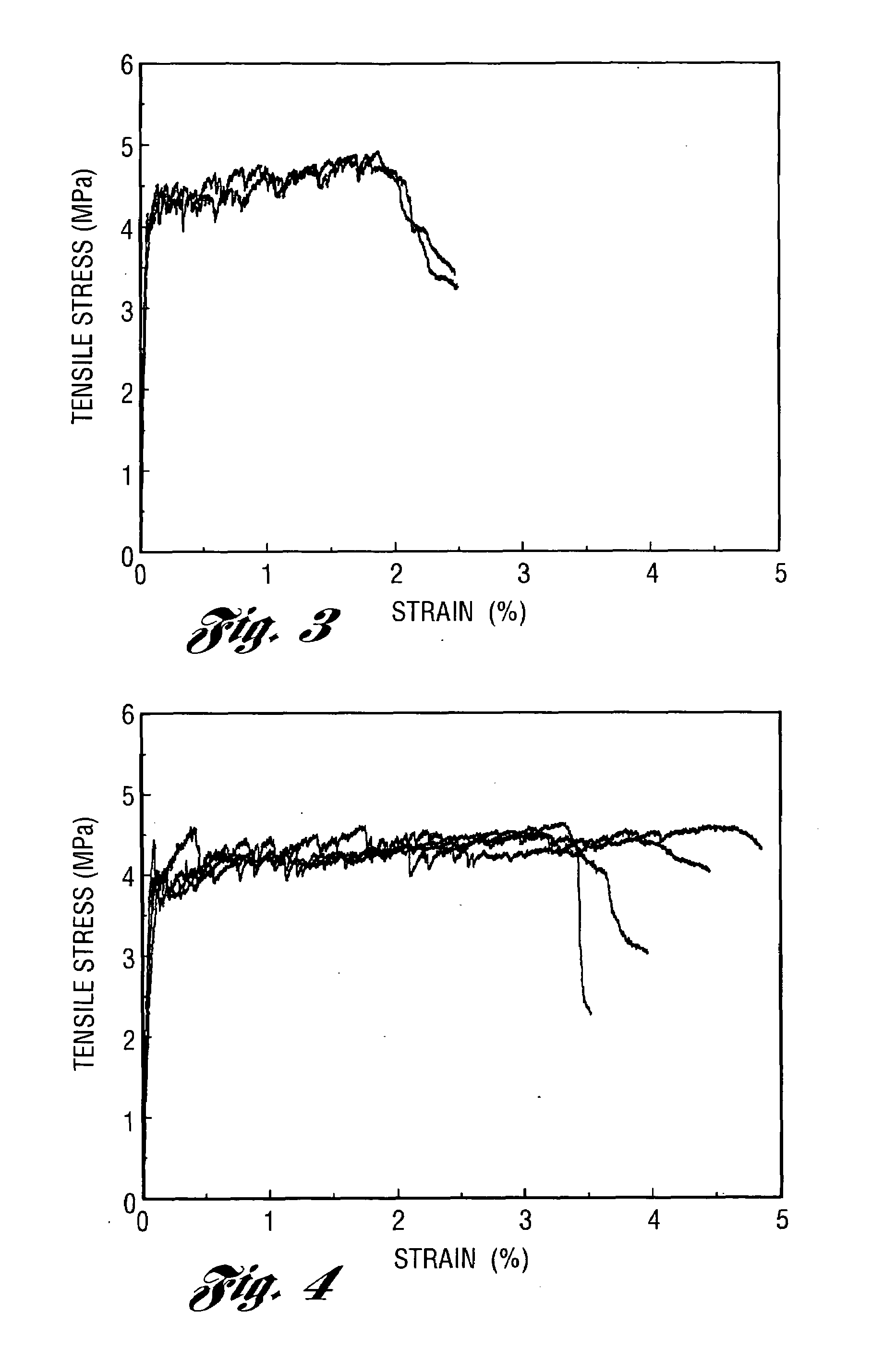

Engineered self healing cementitious composites

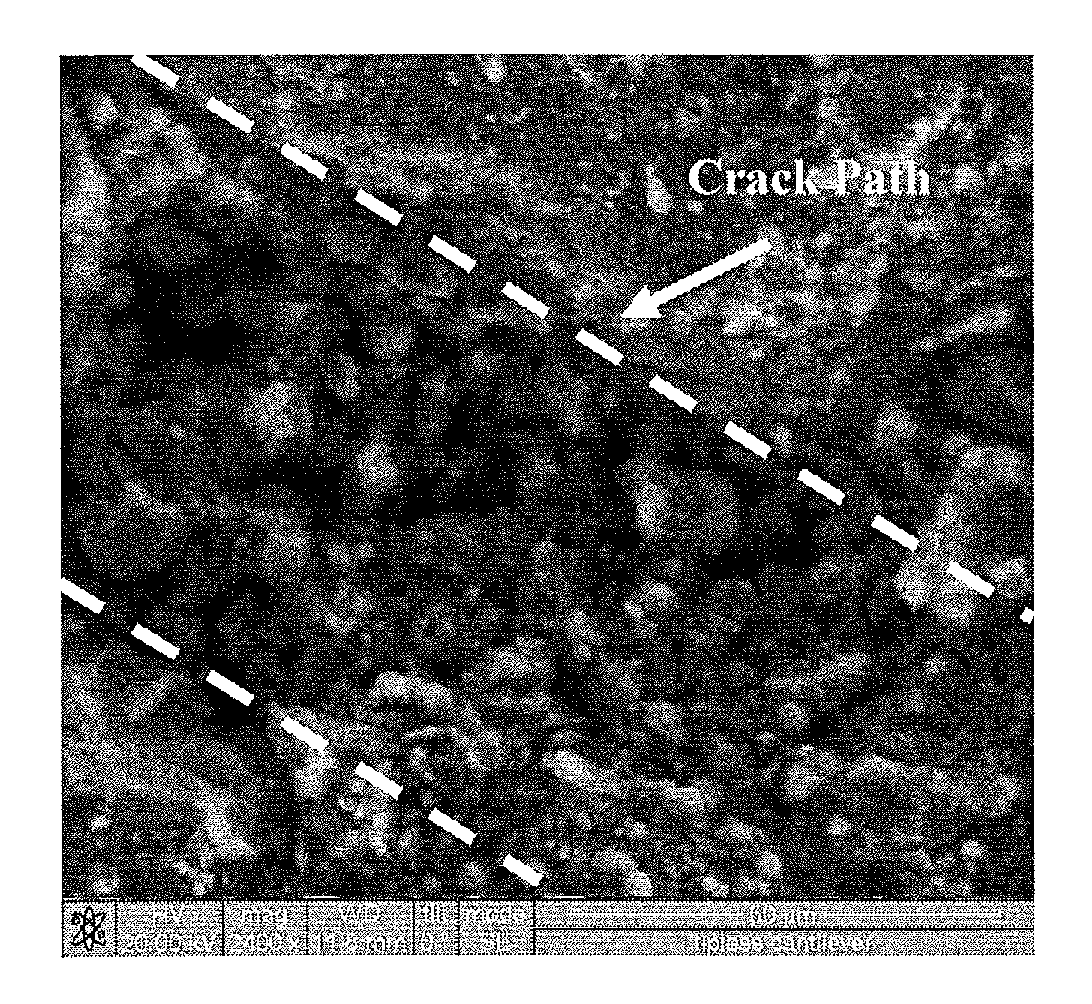

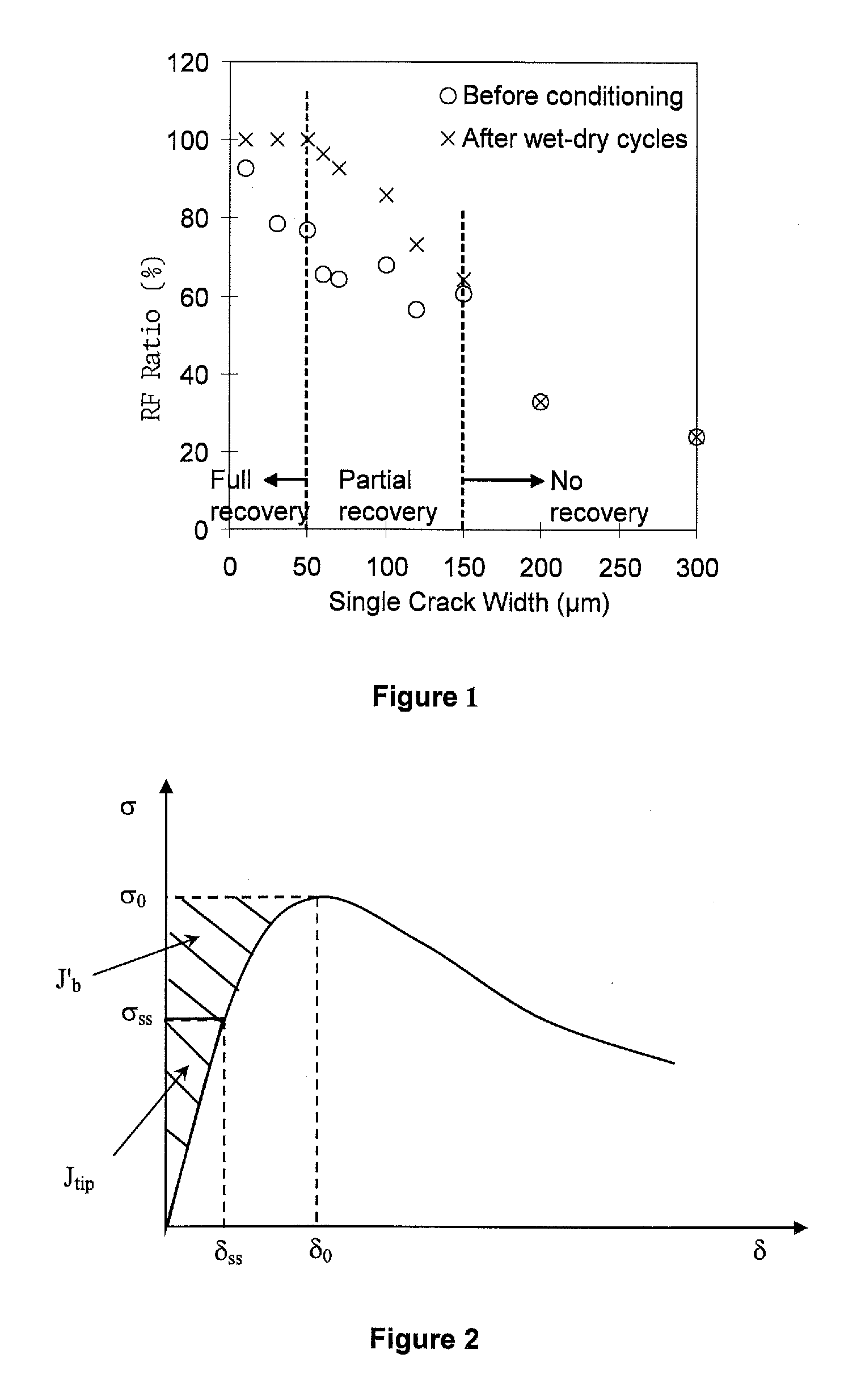

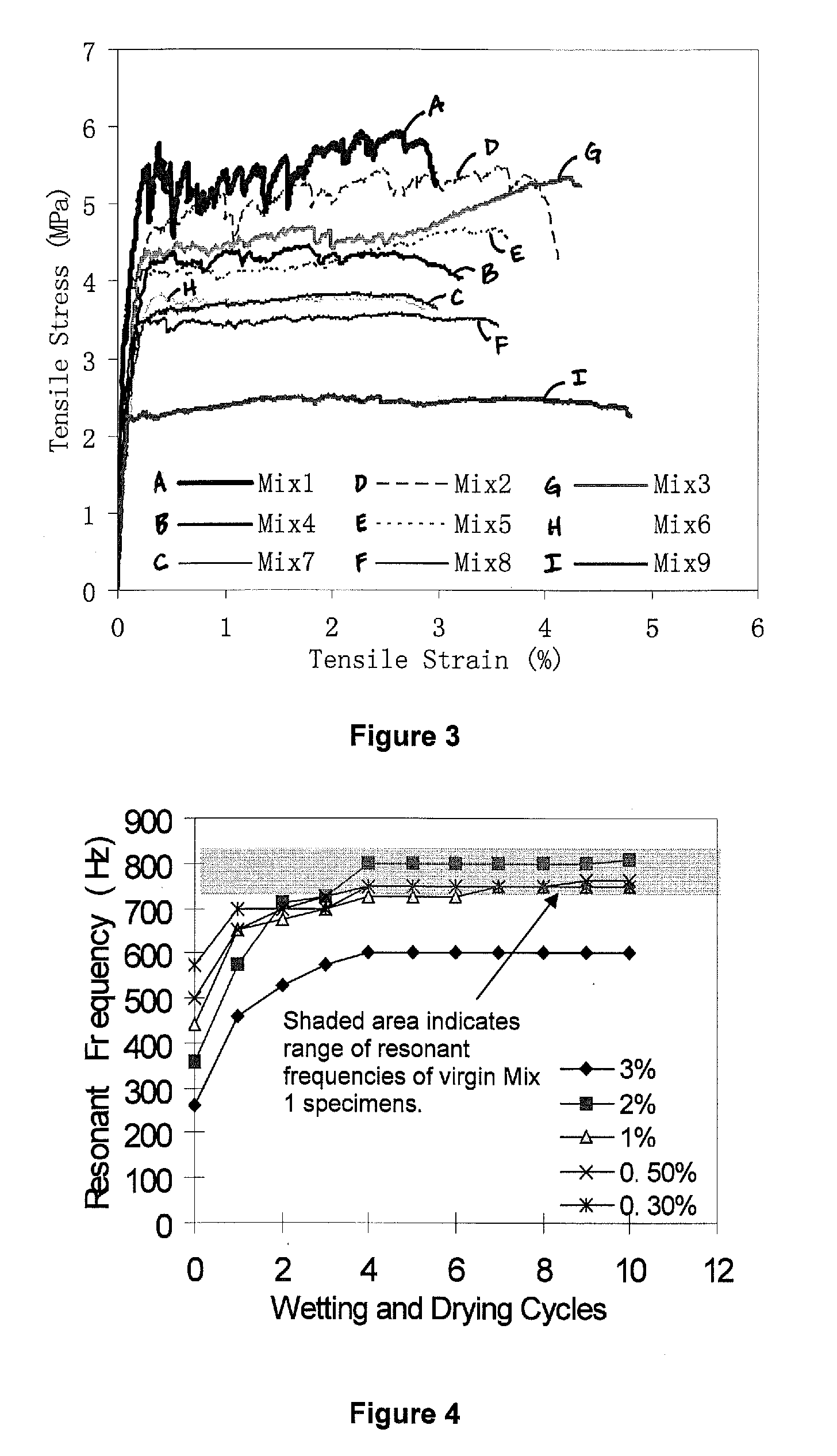

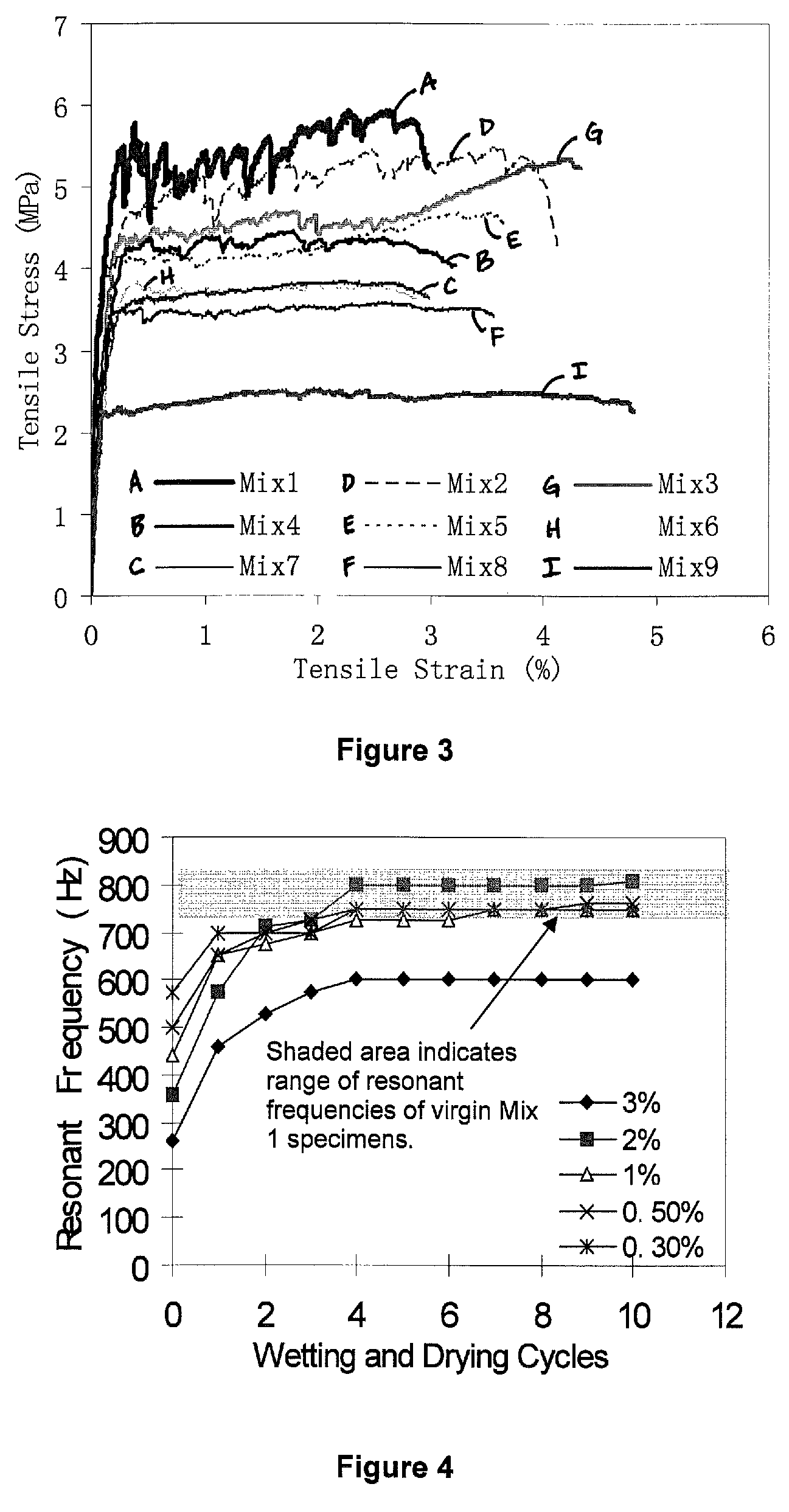

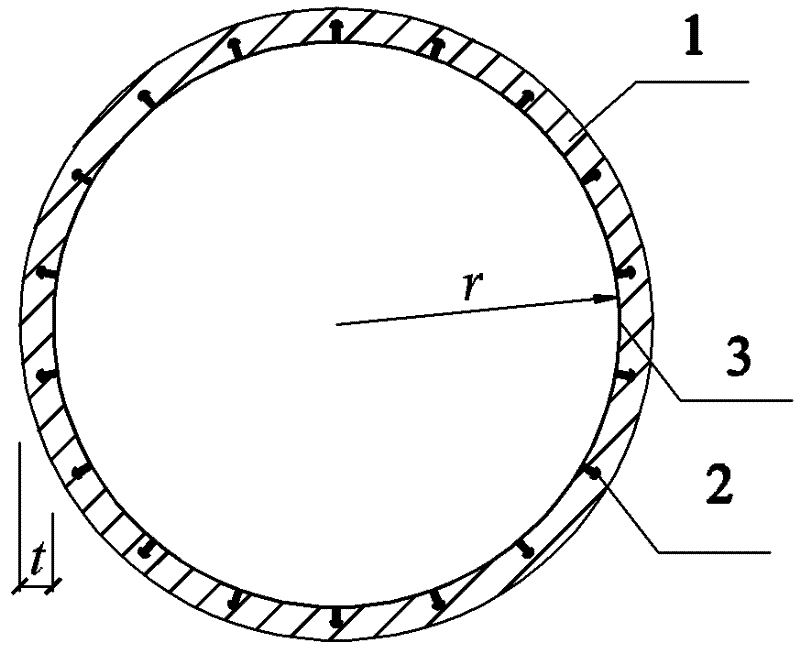

ActiveUS20080261027A1Highly controlled crack widthPreferable flowabilitySolid waste managementSynthetic resin layered productsSelf-healingCement composites

Cementitious composites engineered for self-healing, combining self-controlled tight crack width and extreme tensile ductility. Self-healing takes place automatically at cracked locations without external intervention. In the exemplary embodiment, fiber-reinforced cementitious composites with self-controlled tight crack width less than 50 μm and tensile ductility more than 2% are prepared. Self-healing in terms of mechanical and transport properties recovery of pre-damaged (by pre-cracking) composite is revealed in a variety of environmental exposures, include wetting and drying cycles, water permeation, and chloride submersion.

Owner:RGT UNIV OF MICHIGAN

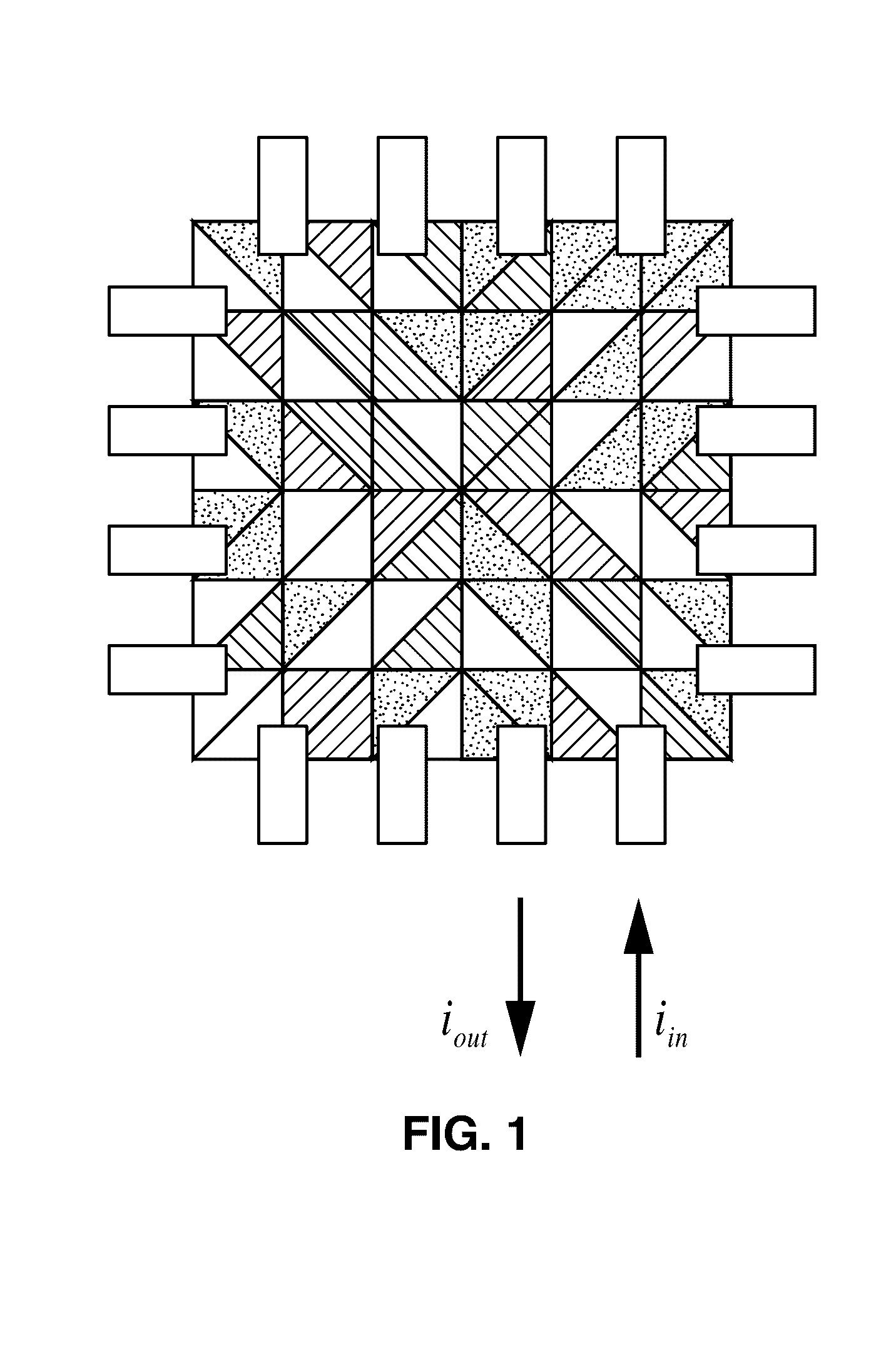

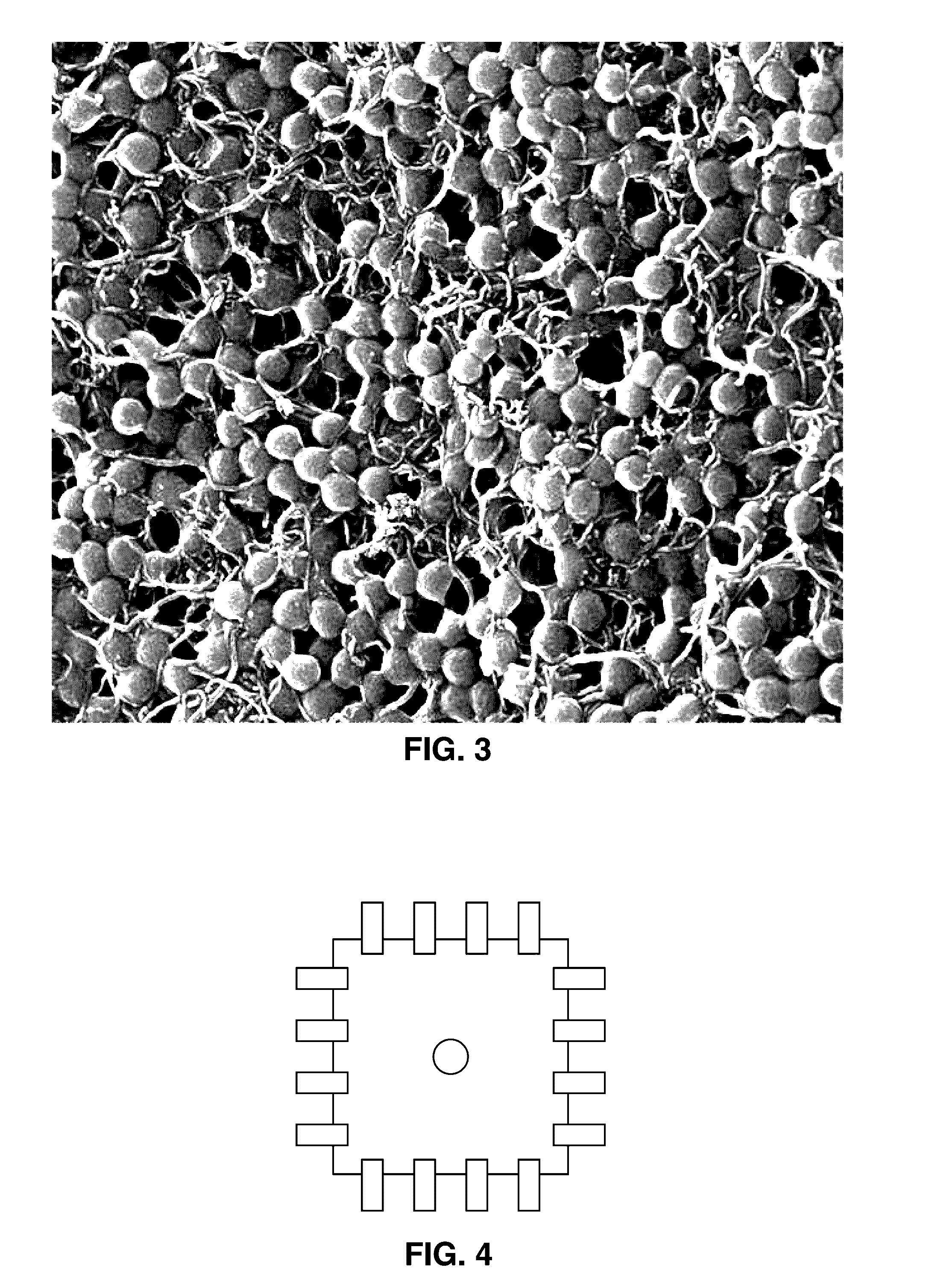

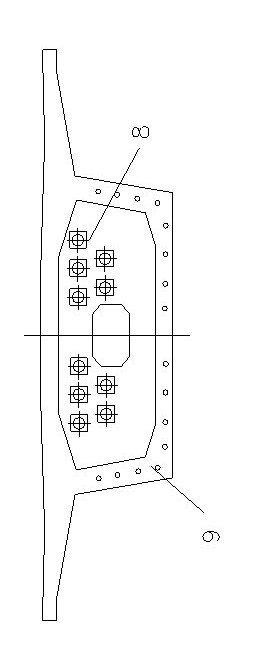

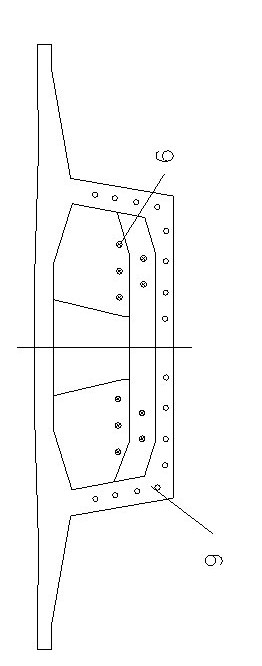

Multifunctional cement composites with load-bearing and self-sensing properties

ActiveUS20160340245A1Enhances ability to sense damageMaterial resistanceElectrical impedance tomographyCarbon nanotube

A method for creating multifunctional cementitious composites that provide load-bearing and self-sensing properties. The method involves dispersing conductive nanomaterials (e.g., multi-walled carbon nanotubes) into a polymer (e.g., latex) material from which a thin film is created and deposited (e.g., sprayed) onto aggregates, which after drying, can be incorporated with cementitious materials and desired liquids and cast, along with sufficient number of electrodes, into a form for curing. After curing, the resultant structure can be electrically tested through the electrodes, for structural characteristics, including determination of damage severity and location using back-calculation utilizing electrical resistance tomography (ERT), or electrical impedance tomography (EIT), to generate a spatial resistivity map (distribution).

Owner:RGT UNIV OF CALIFORNIA

Engineered self healing cementitious composites

ActiveUS7572501B2Reduce capacityReduce stiffnessSolid waste managementSynthetic resin layered productsSelf-healingCement composites

Owner:RGT UNIV OF MICHIGAN

Radiation-curable coating compositions, composite and plastic materials coated with said compositions and methods for their preparation

InactiveUS20080286592A1Impression capsSynthetic resin layered productsCeramic compositeCement composites

Owner:FINISHES UNLTD

Synthetic fibers and cementitious systems including same

InactiveUS20060188719A1Superior basic hydrolysis resistanceReduce cohesionConstruction materialYarnCement compositesCementitious composite

Owner:SELIVANSKY DROR

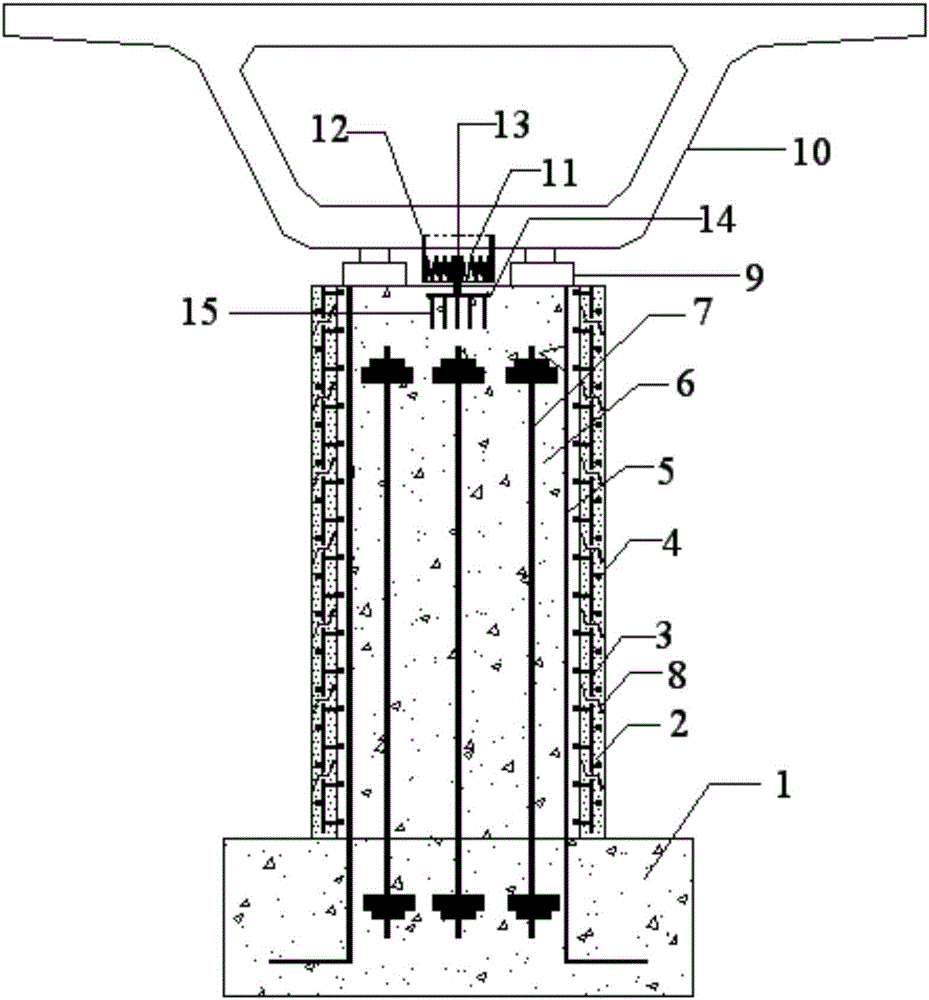

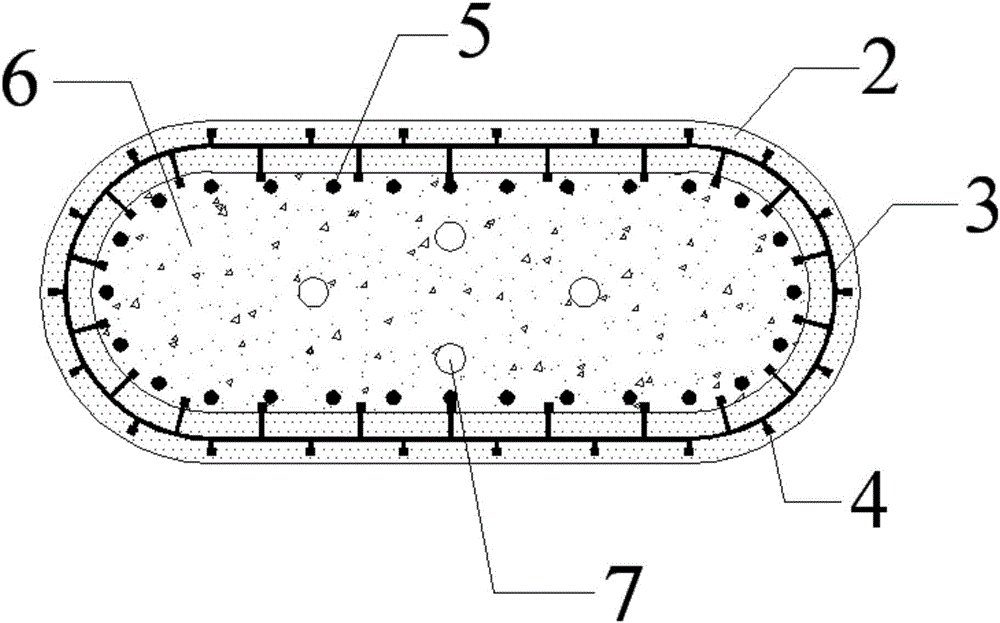

Method for repairing and reinforcing pile foundations in ocean splash zones

The invention provides a method for repairing and reinforcing pile foundations in ocean splash zones. The method is characterized by comprising the following steps: firstly carrying out interface treatment on the splash zones and the zones needing repair near the splash zones aiming at different pile body types, fixing end hoops for bearing upper construction loads on the lower edges of the repaired zone, installing external molds and then continuously pouring a self-compaction ultra high toughness cementitious composite (UHTCC). The method has the following beneficial effect: erosion of dry-wet alternation and chloride ion permeation in the splash zones, temperature difference and sea wave impact effect can be effectively resisted, thus ensuring the durability of pile bodies under the environmental condition of severe corrosion.

Owner:浙江固邦新材料有限公司

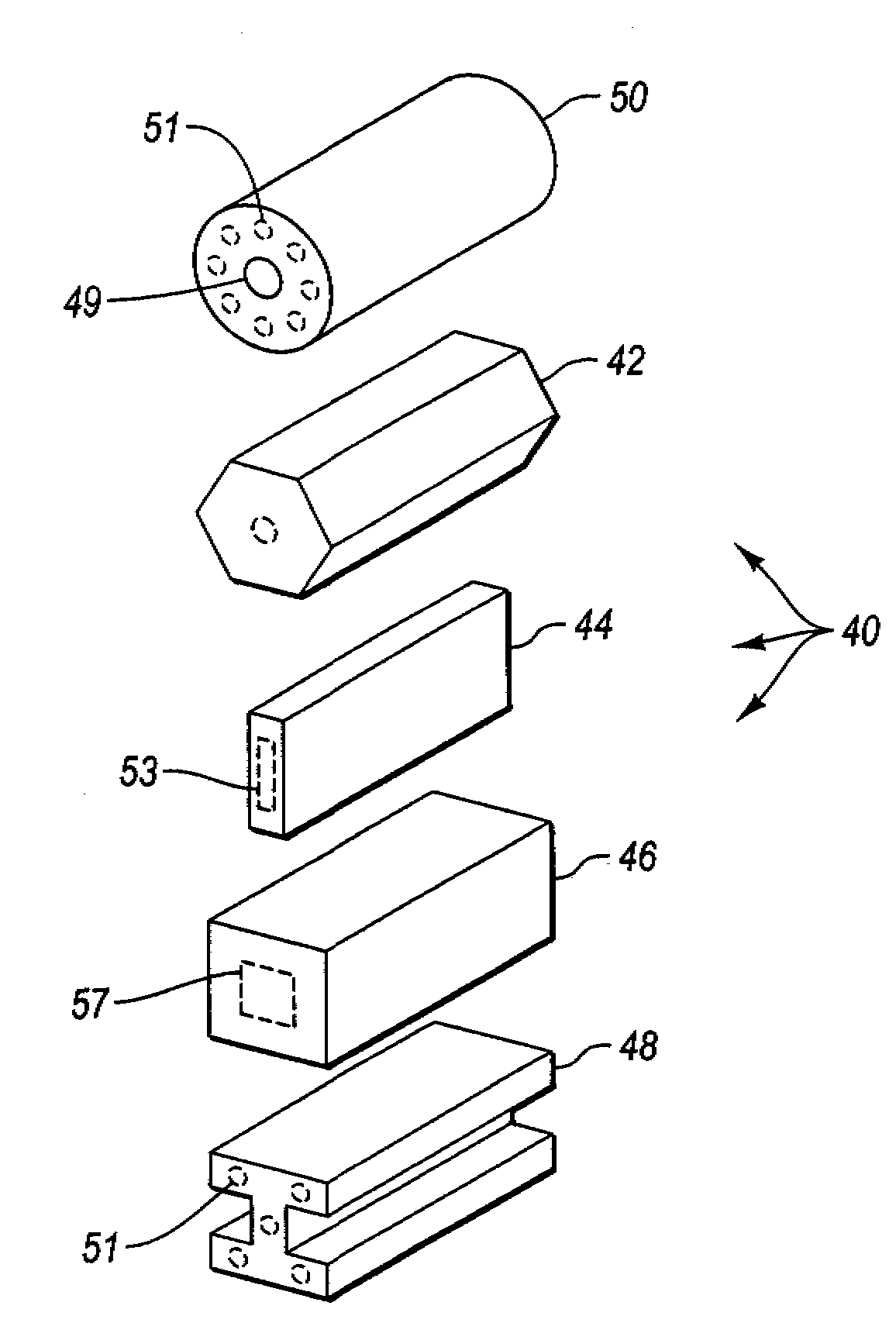

Cementitious composites having wood-like properties and methods of manufacture

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

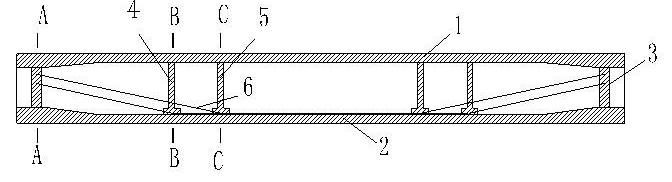

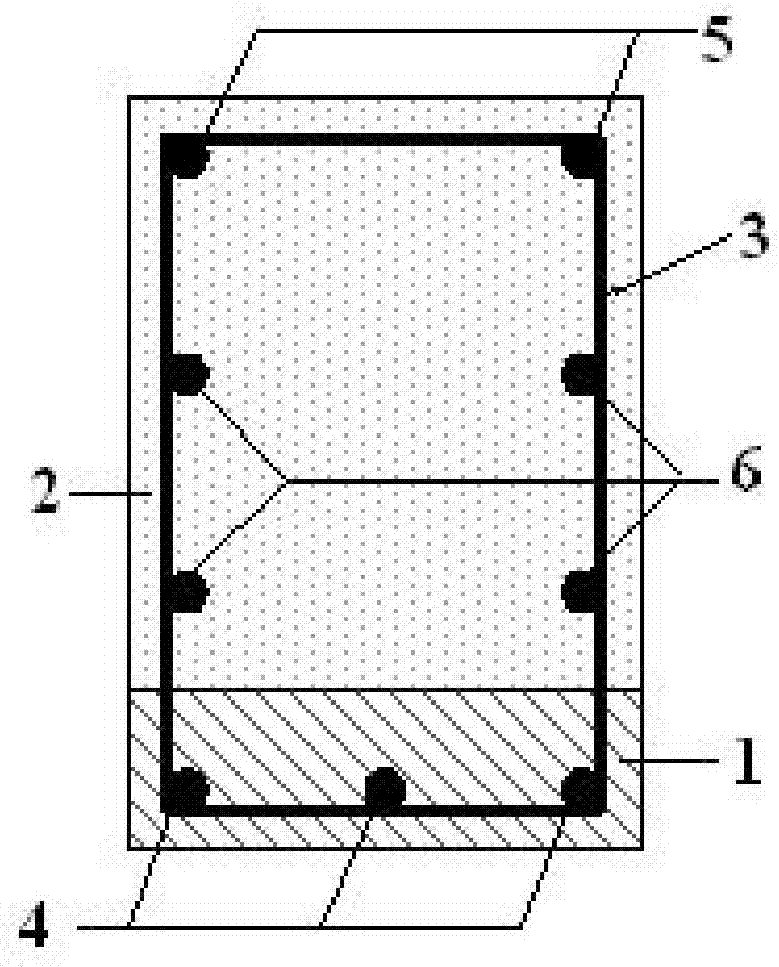

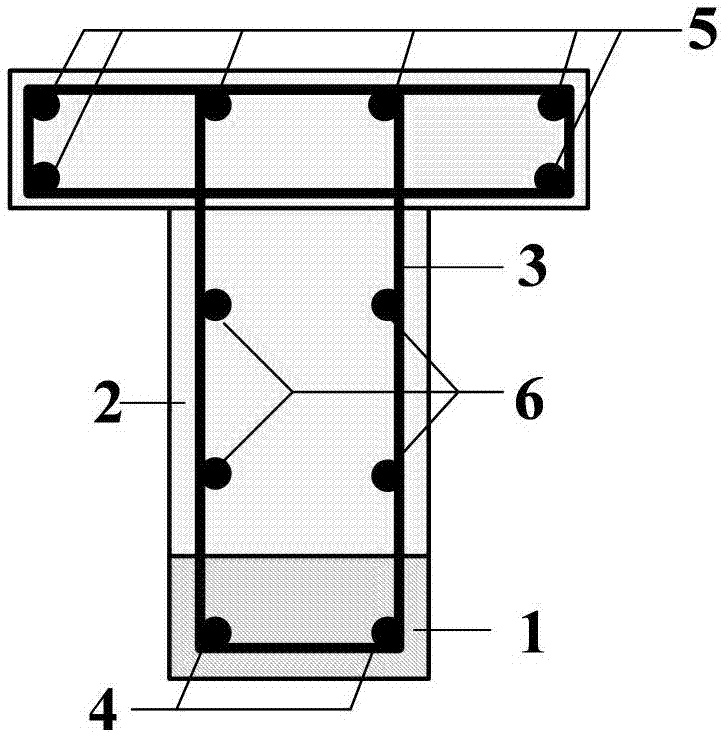

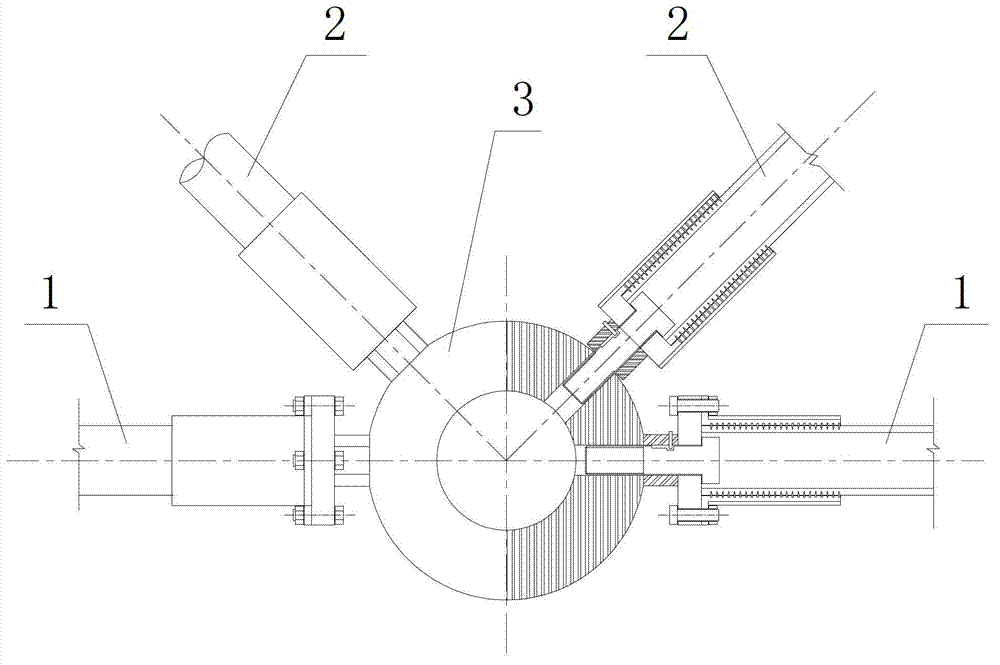

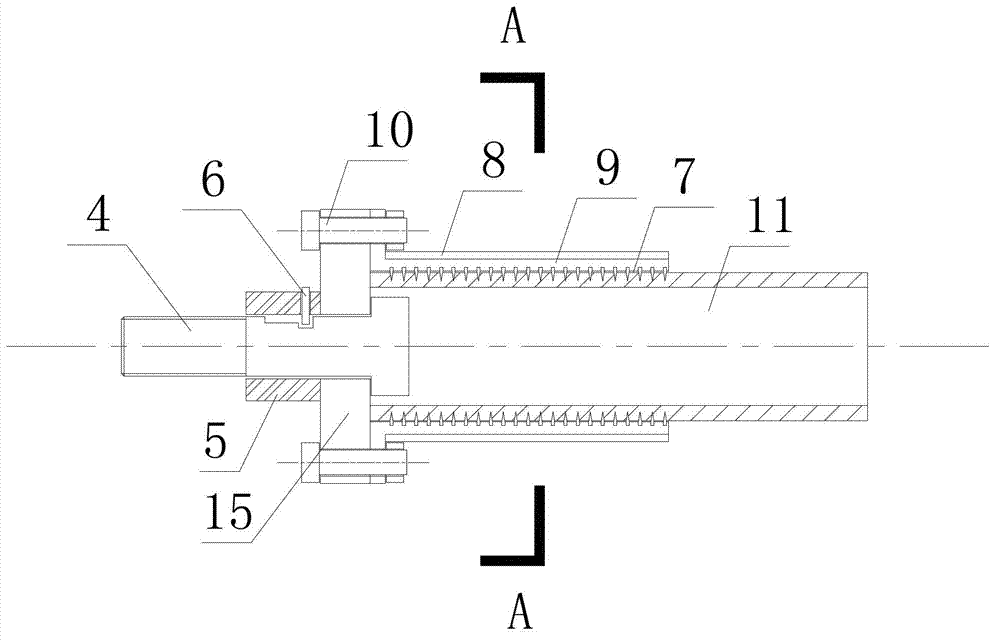

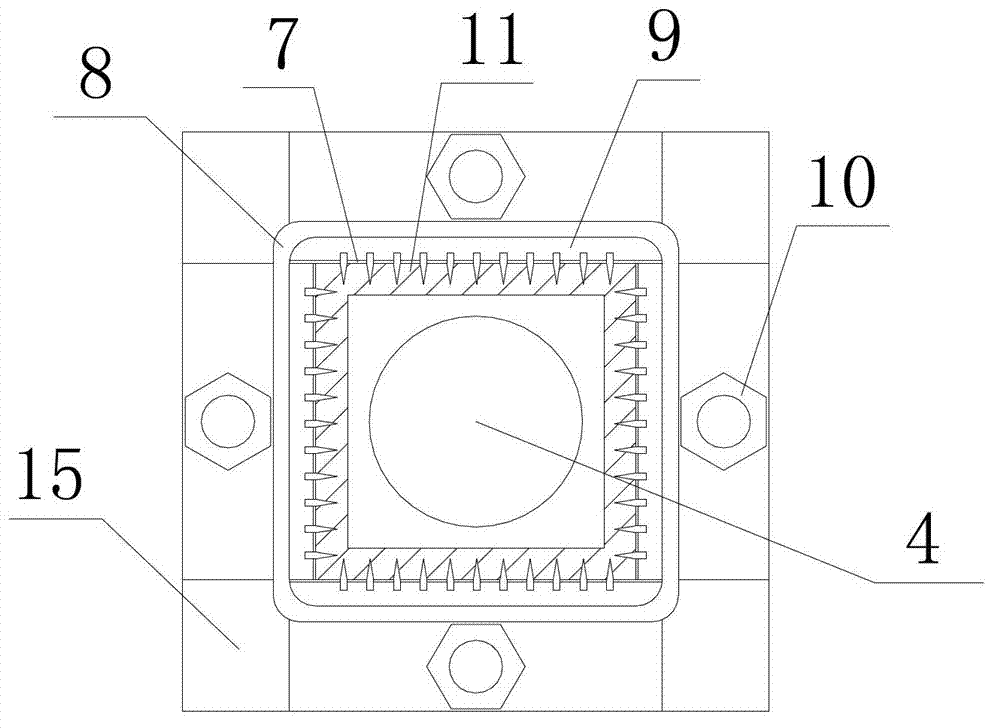

Partial external prestressed and fine-grain reinforcing steel bar fiber reinforced cementitious composite (FRCC) railway box girder

The invention discloses a partial external prestressed and fine-grain reinforcing steel bar fiber reinforced cementitious composite (FRCC) railway box girder. The partial external prestressed and fine-grain reinforcing steel bar FRCC railway box girder comprises a hollow beam frame body consisting of a top plate and a webplate, wherein the top plate and the webplate are made from an FRCC material; an anchoring toothed plate and an anchoring diaphragm plate are symmetrically arranged on the two sides of the center in the hollow beam frame body; an anchor is arranged on the anchoring toothed plate; a diverter is arranged on the anchoring diaphragm plate; an external prestressed rib is arranged between the anchoring toothed plate and the anchoring diaphragm plate; and one end of the external prestressed rib is fixed on the anchor, and the other end of the external prestressed rib is fixed in the diverter. At the same time, an external prestressed technique has the advantages that: the partial external prestressed and fine-grain reinforcing steel bar FRCC railway box girder is convenient to construct, detect and change; and the friction loss of the prestressed rib is low, and the like. The webplate of the box girder is shrunk; the strength of the materials used by the box girder is improved; and the FRCC is used for substituting the conventional C50-grade concrete, the bearing capacity of the girder body is not reduced but increased, so that the box girder has an extremely wide application prospect.

Owner:SOUTHEAST UNIV +1

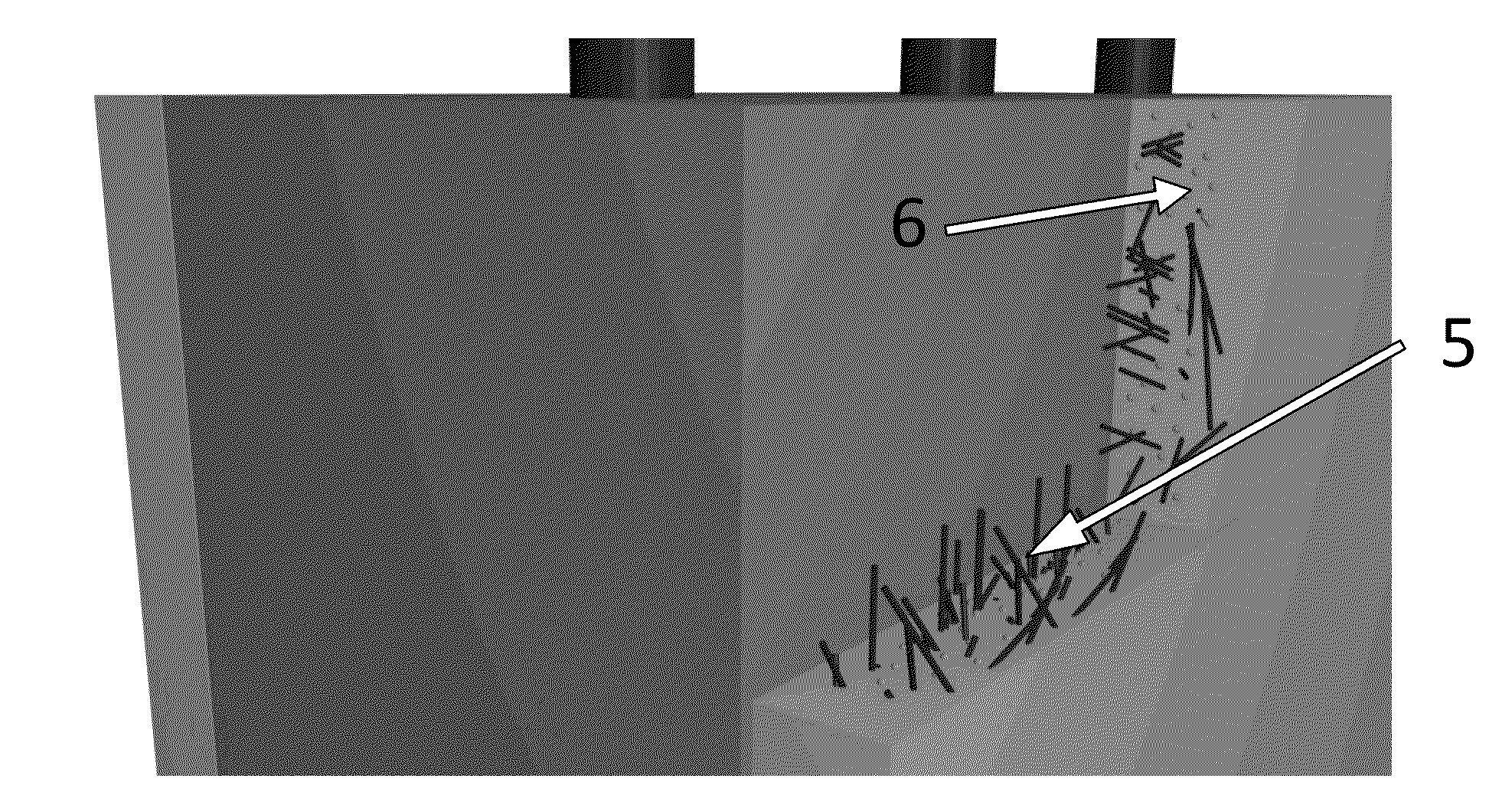

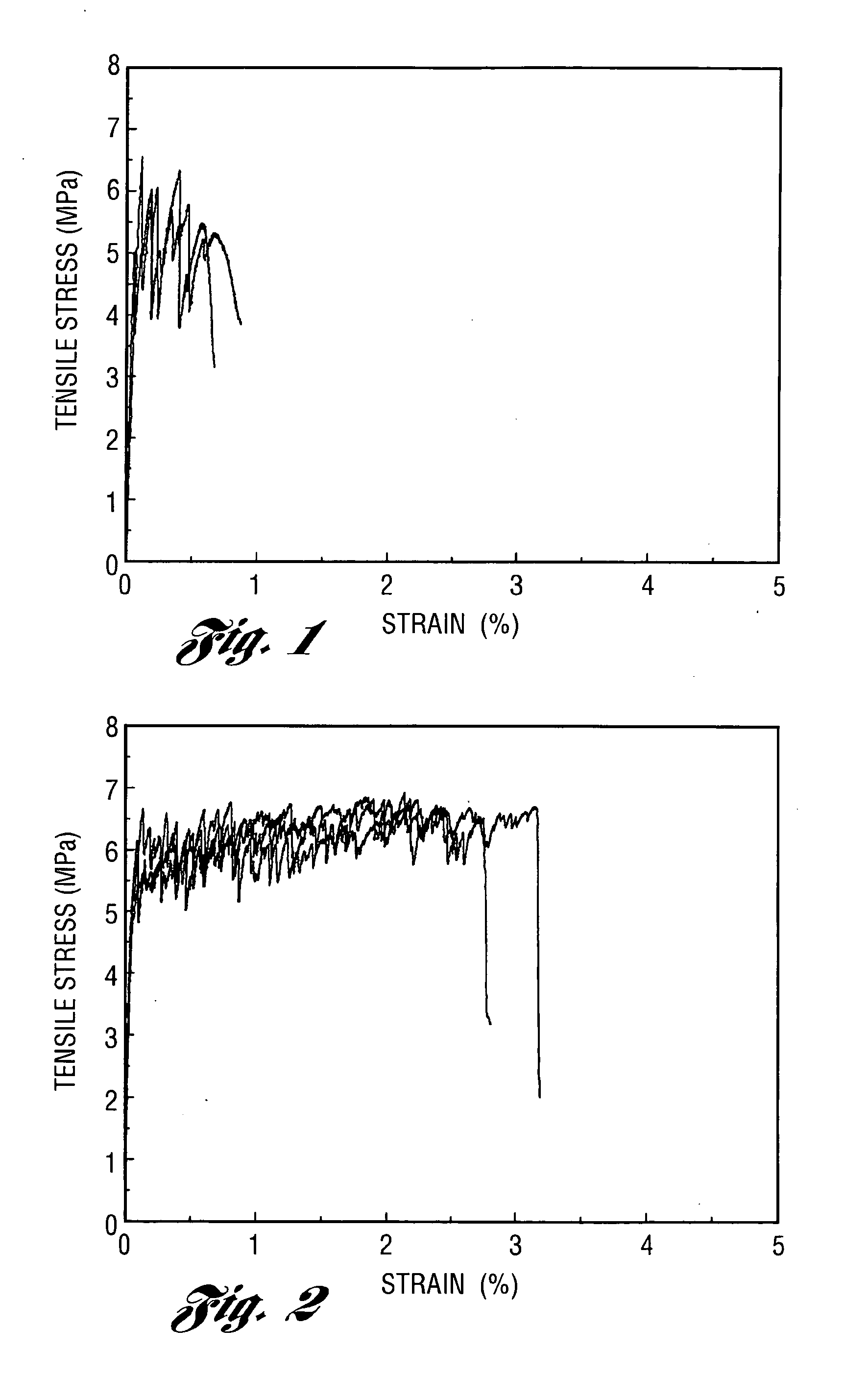

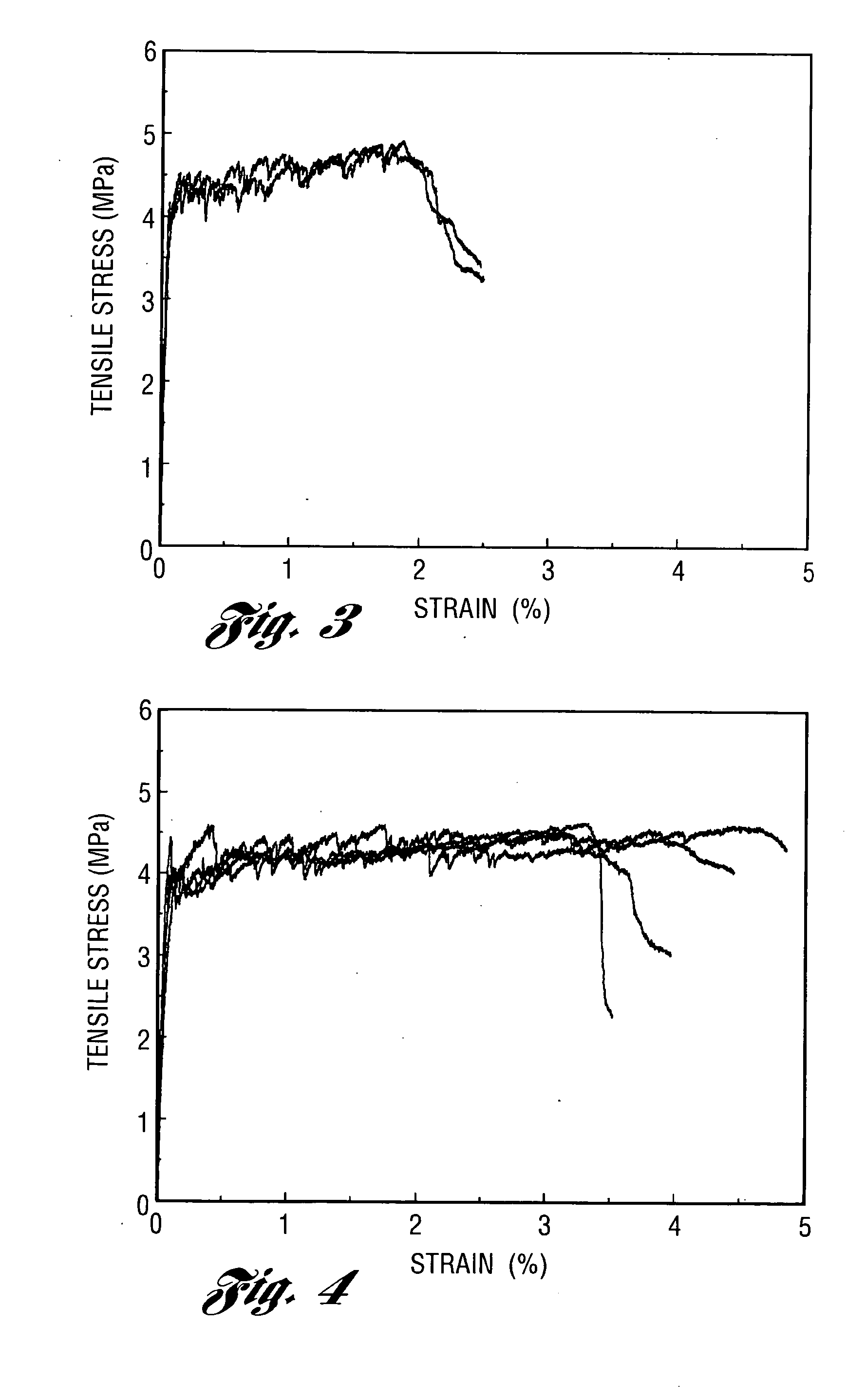

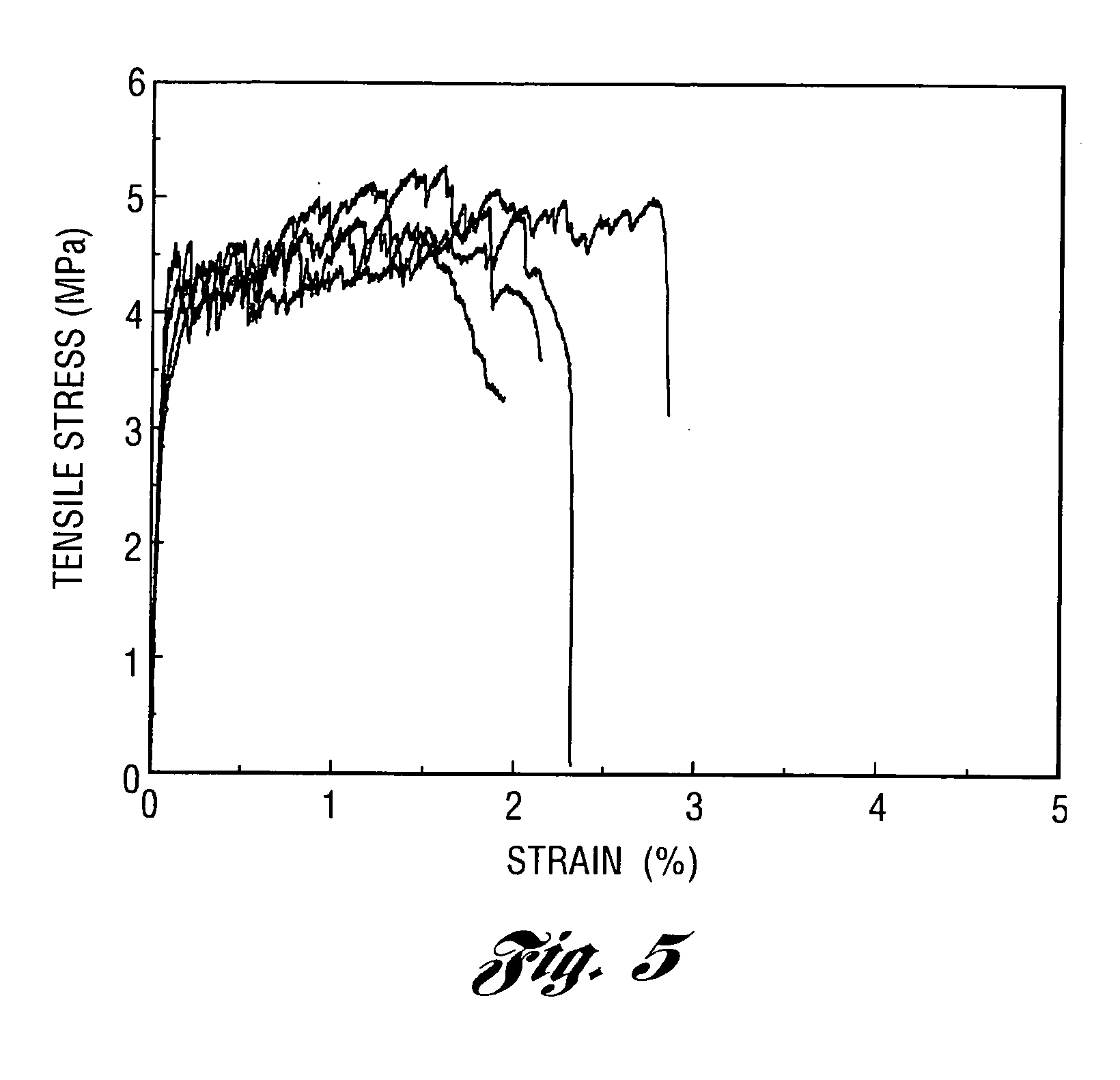

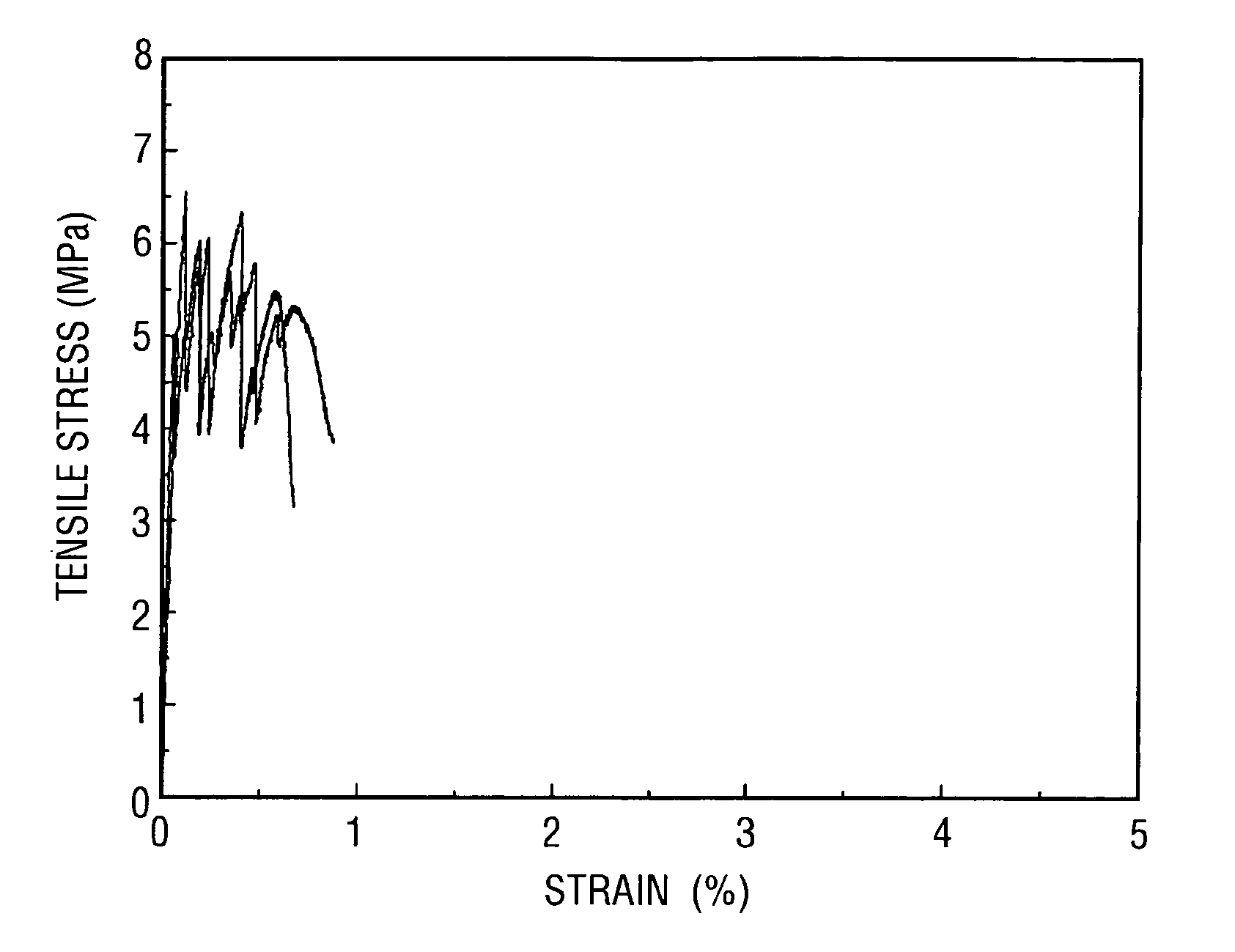

Process for increasing the ductility of high performance fiber-reinforced brittle matrix composites, and composites produced thereby

Purposeful addition of crack-initiating voids in the form of low tensile strength particulates, particulates having low matrix interaction, or gas bubbles formed by chemical reaction, in a size range of 0.5 mm to about 5 mm, and preferably of a size commensurate with or larger than naturally occurring crack-initiating gaseous voids, to fiber-reinforced strain hardening cementitious composites generates controlled and uniform cracking which increases strain hardening behavior in conventionally dense cementitious compositions.

Owner:RGT UNIV OF MICHIGAN

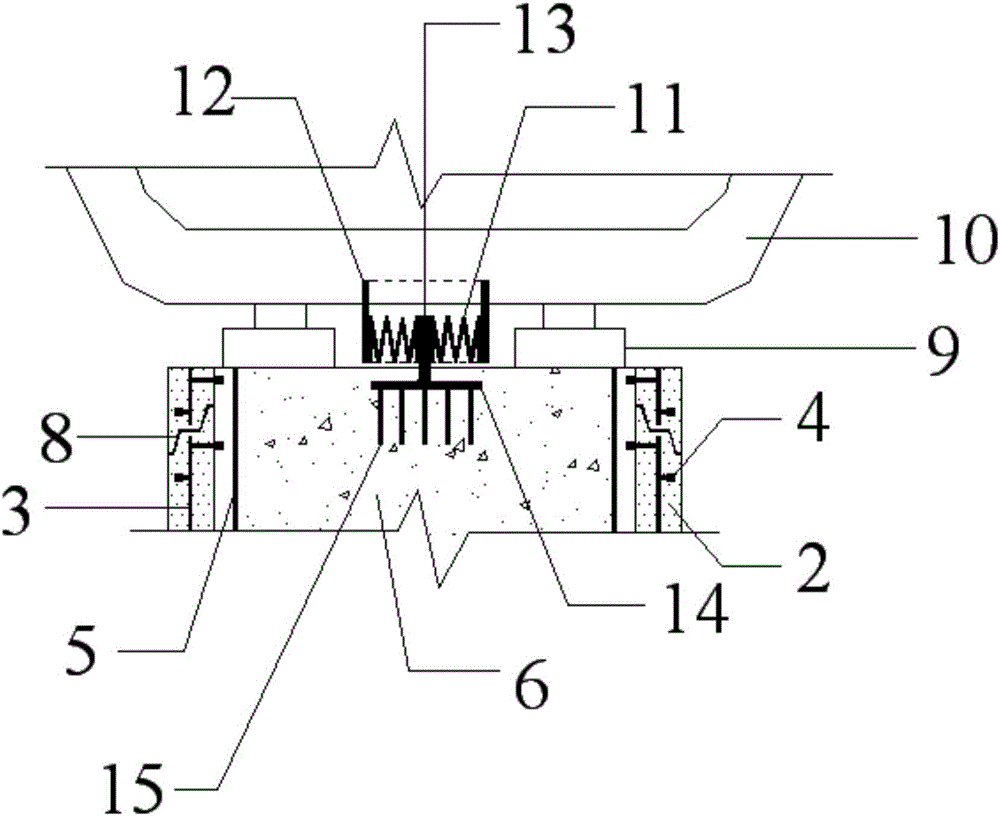

Earthquake control system of high-speed railway bridge

ActiveCN106351113AEnsure driving safety after earthquakeGuaranteed post-earthquake repairabilityClimate change adaptationBridge structural detailsControl systemPre stress

The invention discloses an earthquake control system of a high-speed railway bridge, comprising a prefabricating shell wall composed of high ductility cementitious composite (ECC)-steel plate to form a pier, wherein a vertical unbonded tendon is set in the pier. The top of the pier is connected with a main beam at the upper part by two movable supports; and a shape memory alloy (SMA) spiral spring is set between the top of the pier and the main beam. The SMA spiral spring is respectively connected with a steel sleeve and a square steel rod. The upper part of the steel sleeve is embedded into the bottom of the main beam; the lower part of the square steel rod is embedded into the top of the pier. The prefabricating shell wall becomes the template of inner concrete construction in the pier; the shearing strength and ductility energy consumption of the pier are provided; the crack damage under the earthquake can be reduced; and the residual displacement of the pier is reduced by the unbonded tendon. SMA spiral spring can provide the level rigidity under the normal operation as well as energy consumption under the earthquake and self-resetting ability of the main beam. The movable support can provide vertical rigidity and bearing capacity.

Owner:INST OF DISASTER PREVENTION

Toughened cementitious composites

InactiveUS7192643B2Improve fracture toughnessReduce crack propagationLiquid surface applicatorsFilament/thread formingCementitious compositeToughness

The present invention relates to the field of toughening and reinforcing brittle matrix materials, and more specifically to the structural fibers made from an oriented film, which enhance the toughness of matrix materials such as concrete, cement, and other cementitious products.

Owner:3M INNOVATIVE PROPERTIES CO

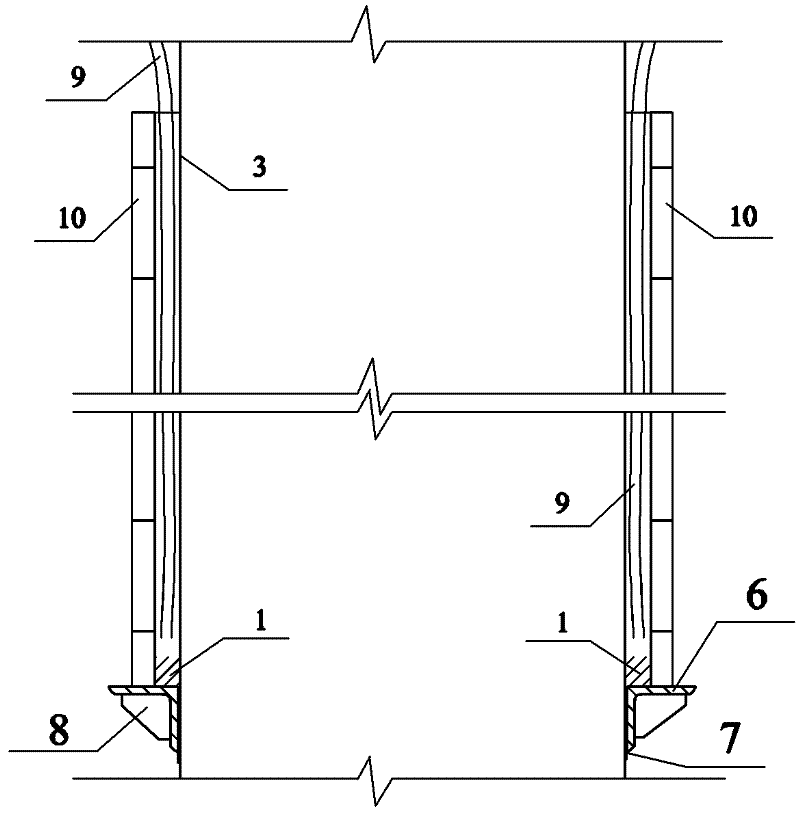

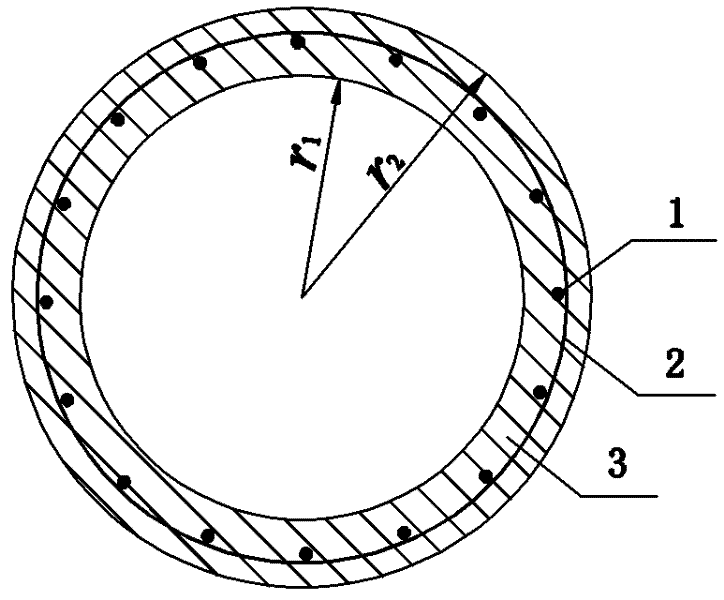

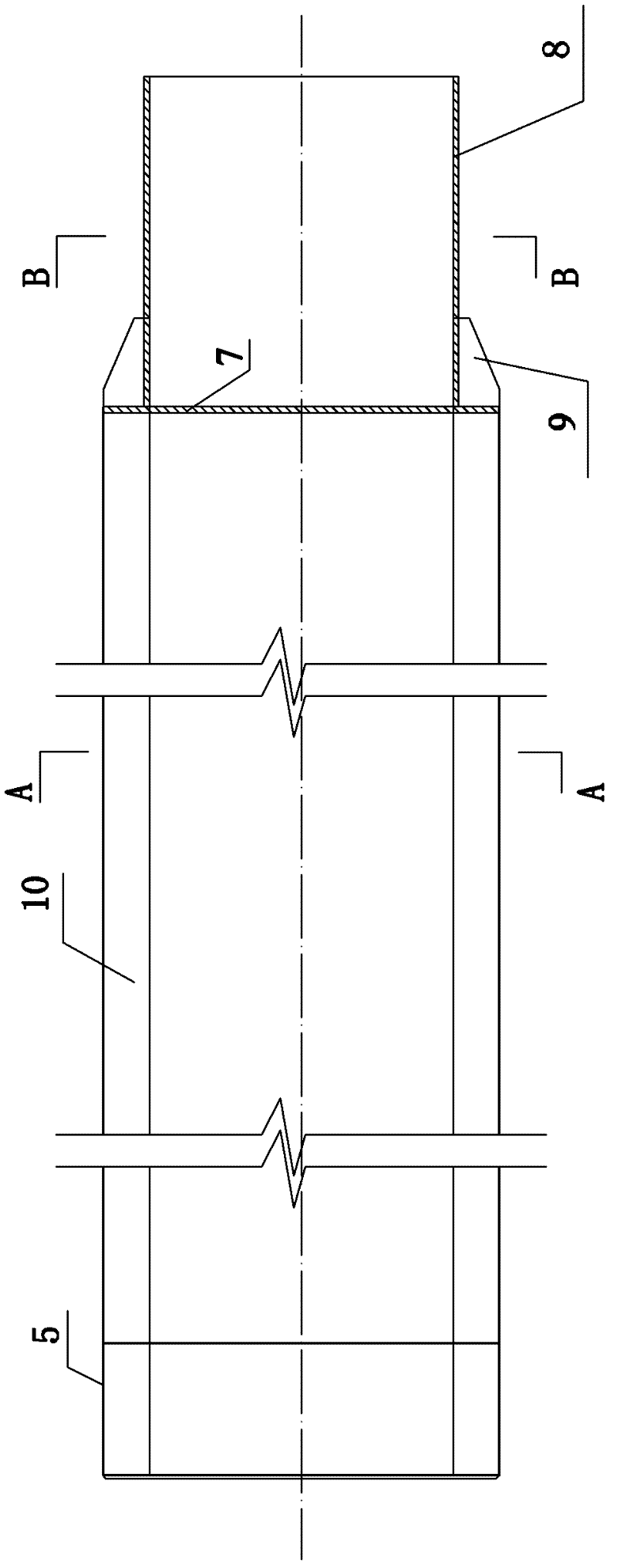

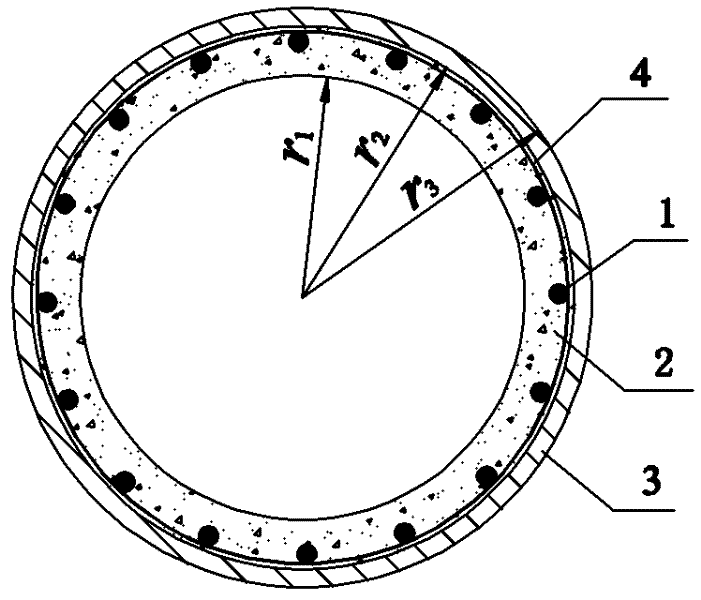

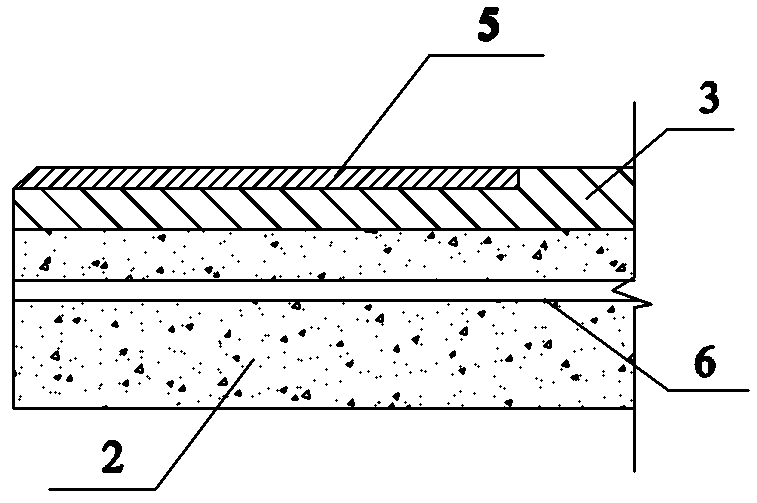

High-toughness pipe pile and manufacturing method thereof

InactiveCN102392440AStrong impact resistanceExtended service lifeShaping reinforcementsBulkheads/pilesRebarCementitious composite

The invention provides a high-toughness pipe pile firstly, each pipe section uses an ultrahigh-toughness cementitious composite (UHTCC) as a pipe pile substrate, vertical rebars are provided in the pipe wall along the length direction of the pipe pile, and spiral stirrups are provided around the vertical rebars, steel end plates and steel hoops are provided on both end parts of each pipe section, the vertical rebars are welded to the steel end plates in way of plug welding, and all pipe sections are connected together via the steel end plates on the end parts in way of welding. The high-toughness pipe pile combines with common advantages of steel pipe pile and prestressed concrete pipe pile well, and guarantees endurance quality of pipe pile in marine environment with serious erosion.

Owner:浙江固邦新材料有限公司

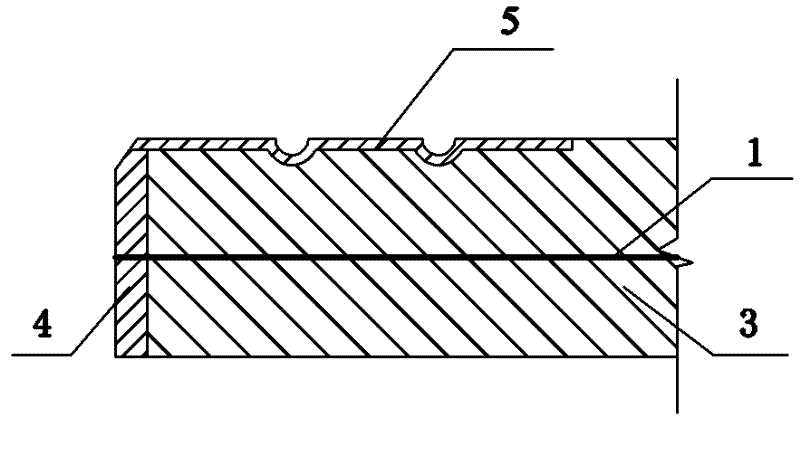

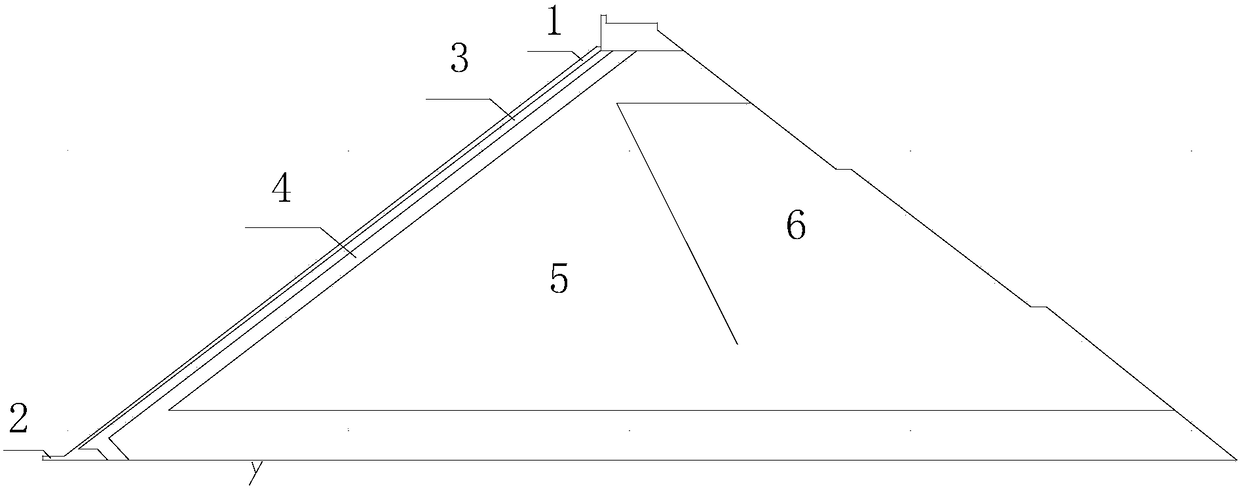

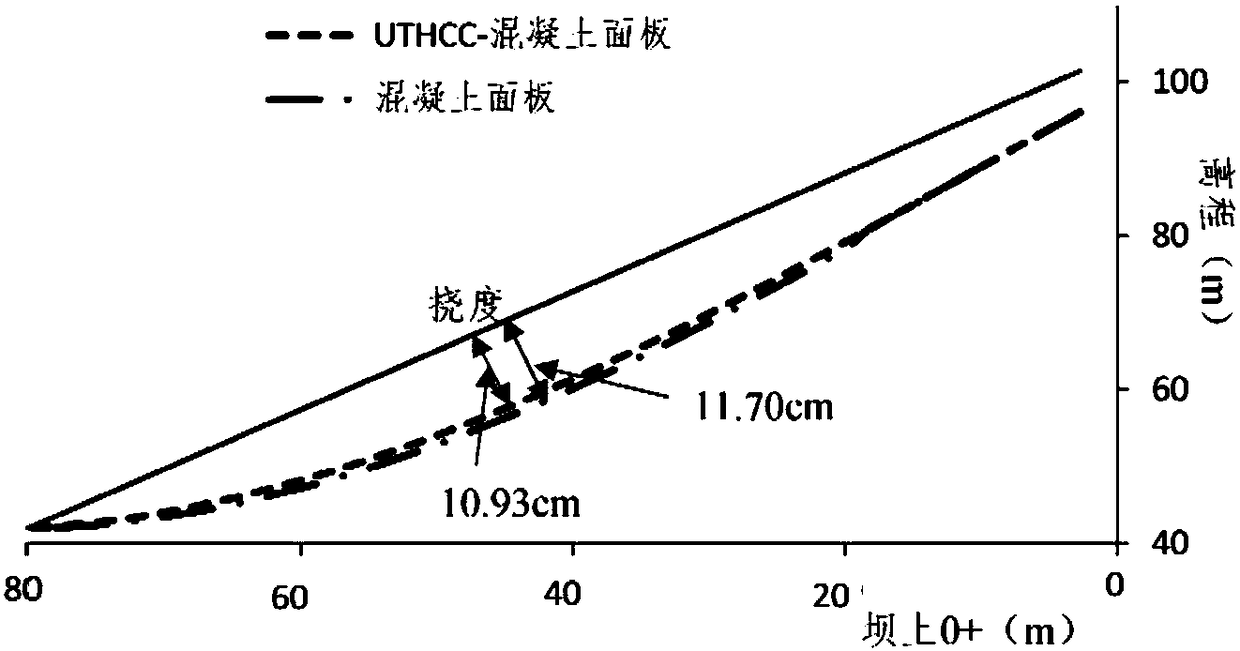

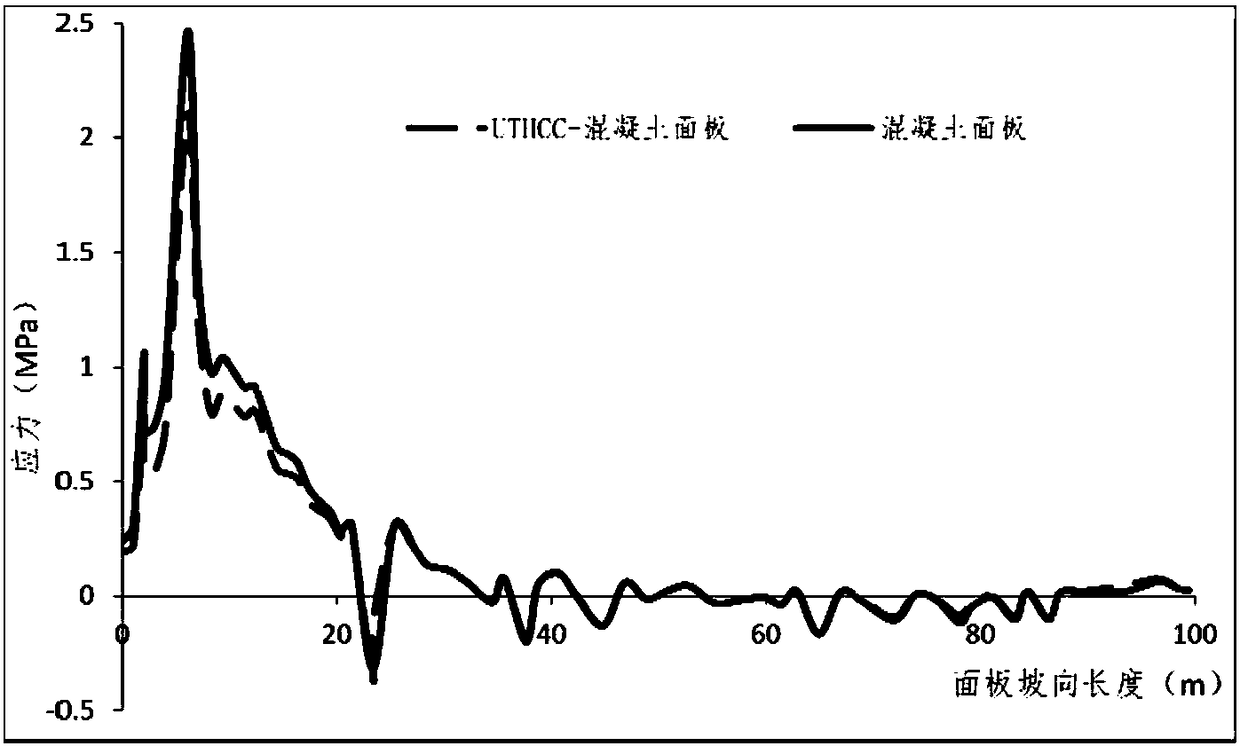

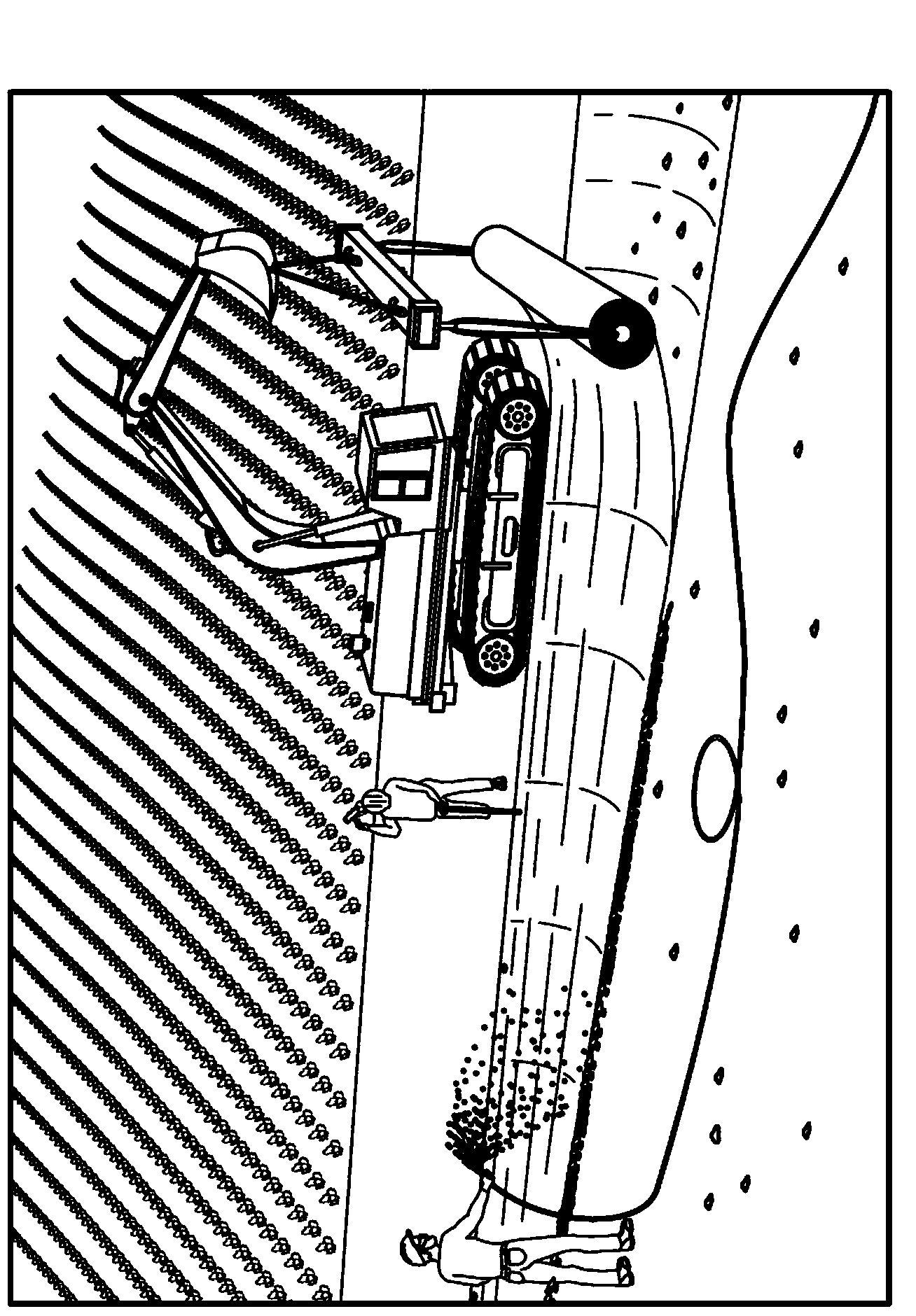

Method for reinforcing rock-fill dam concrete face through ultra high toughness cementitious composites

ActiveCN108316251AIncrease the ultimate tensile strain valueHigh ability to adapt to deformationEarth-fill damsRock-fill damsStress distributionCrack resistance

The invention discloses a method for reinforcing a rock-fill dam concrete face through ultra high toughness cementitious composites (UHTCC for short). The method comprises the steps that a three-dimensional finite element model of a concrete face rock-fill dam is built, and stress distribution of the concrete face under the design operation water level is calculated; on the basis of the finite element model calculation, an ultra high toughness cementitious composite reinforcing layer is added in the area where face concrete stress is larger than concrete cracking stress, the face concrete calculation stress is smaller than cracking stress by constantly adjusting the range and thickness of the reinforcing layer, and therefore the optimal reinforcing range and thickness of the ultra high toughness cementitious composites are determined; and after the reinforcing range of the face and the thickness of the reinforcing layer are calculated and determined, a jet technology is adopted for reinforcing the concrete face. The advanced calculation method and the jet reinforcing measure adopting the ultra high toughness cementitious composites are adopted, the cracking resistance of the composite face can be remarkably improved, and the application prospect is wide.

Owner:ZHEJIANG UNIV

Process for increasing the ductility of high performance fiber-reinforced brittle matrix composites, and composites produced thereby

Purposeful addition of crack-initiating voids in the form of low tensile strength particulates, particulates having low matrix interaction, or gas bubbles formed by chemical reaction, in a size range of 0.5 mm to about 5 mm, and preferably of a size commensurate with or larger than naturally occurring crack-initiating gaseous voids, to fiber-reinforced strain hardening cementitious composites generates controlled and uniform cracking which increases strain hardening behavior in conventionally dense cementitious compositions.

Owner:RGT UNIV OF MICHIGAN

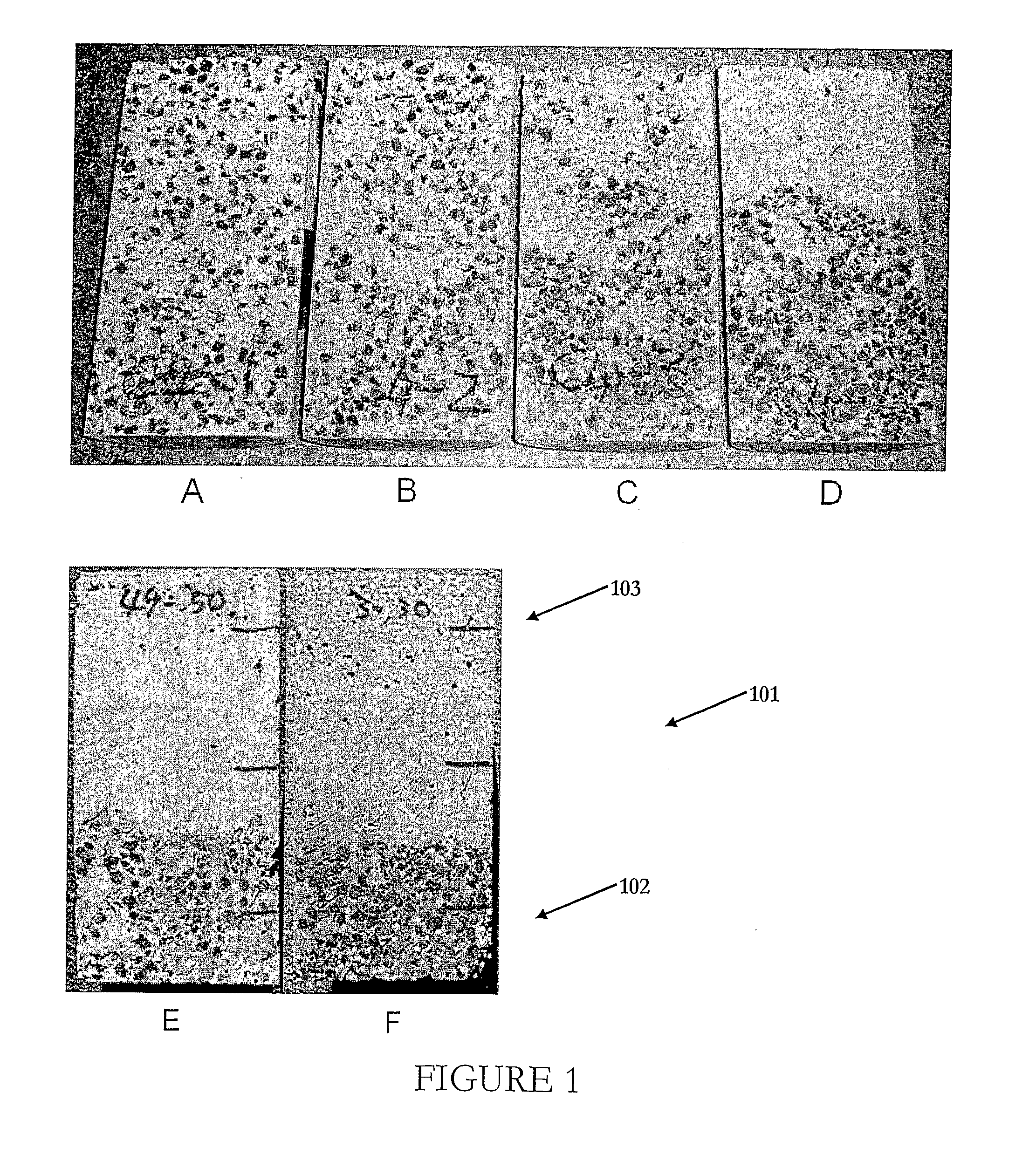

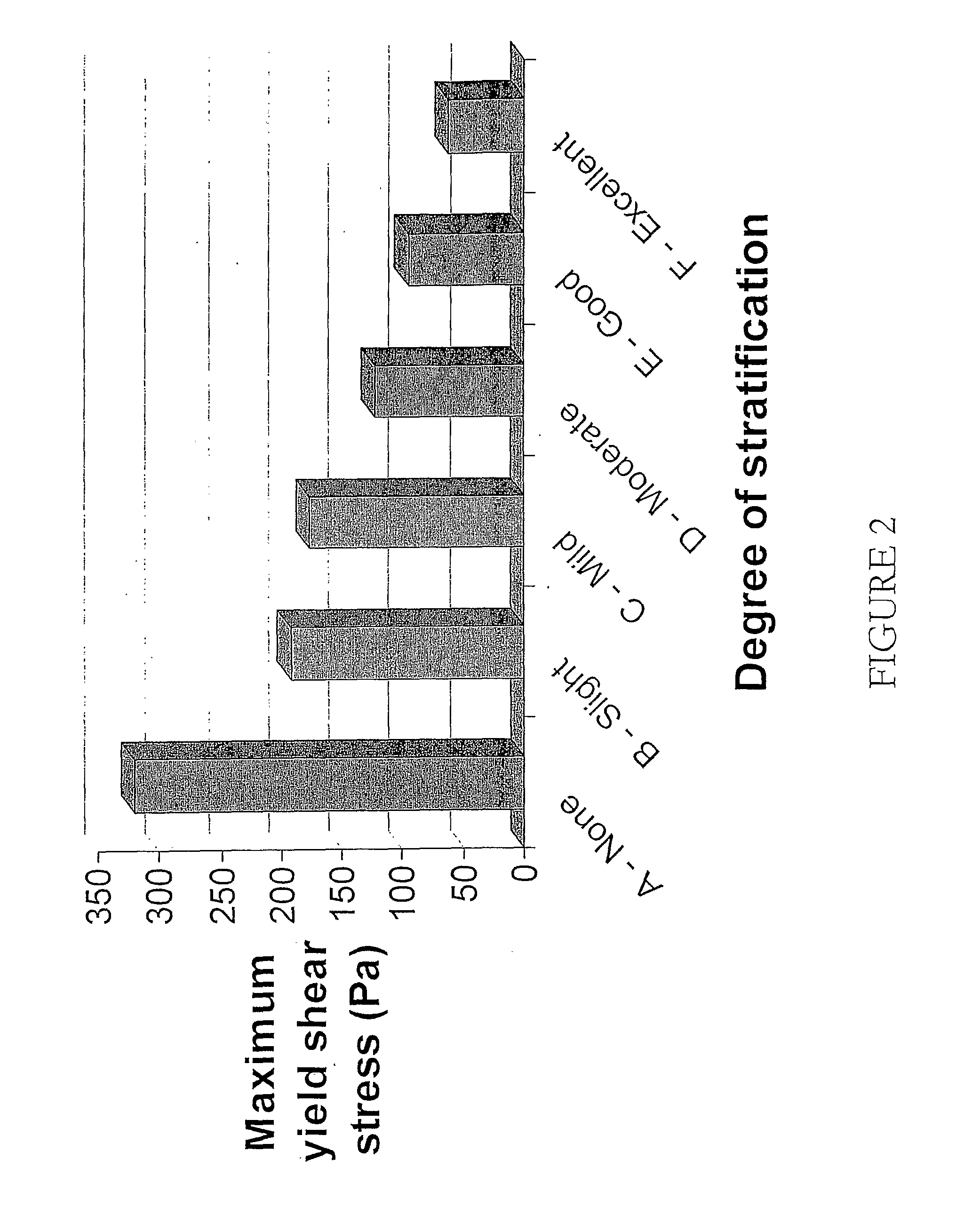

Stratified cementitious composite

The present invention relates to a method for forming a stratified cementitious body comprising placing a cementitious slurry comprising a cementitious binder, to form the body in a single pour and curing the slurry to form a stratified cementitious body. The method may also comprise the steps of mixing a cementitious binder and at least one aggregate material with water to form a slurry, pouring the slurry into a mould, allowing the slurry to stratify into layers under the influence of gravitational forces and / or buoyancy forces, optionally applying vibrations to the slurry to encourage the slurry to stratify into layers, and curing the slurry to form a stratified cementitious body.

Owner:BELLAMY LARRY ARTHUR +2

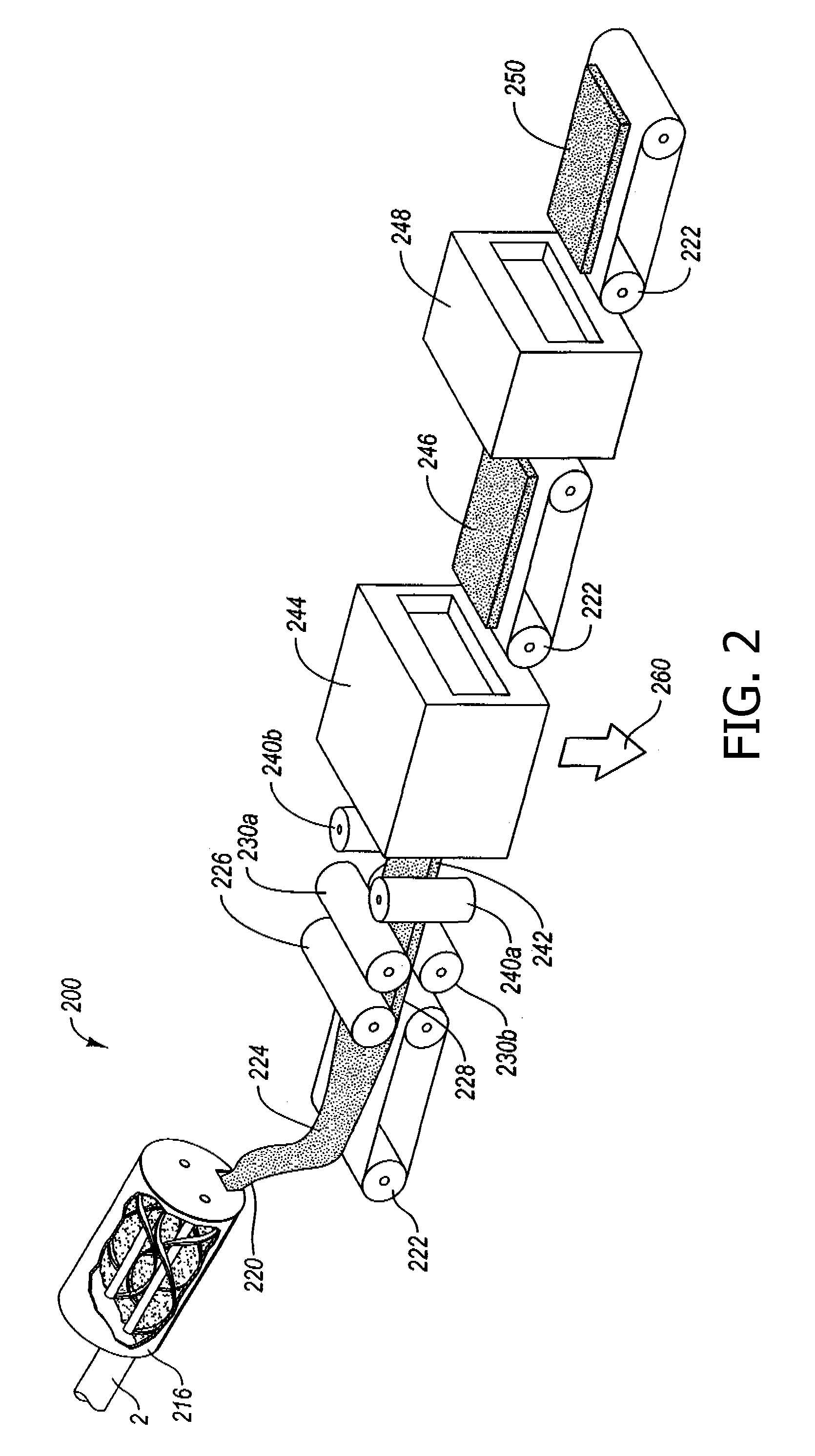

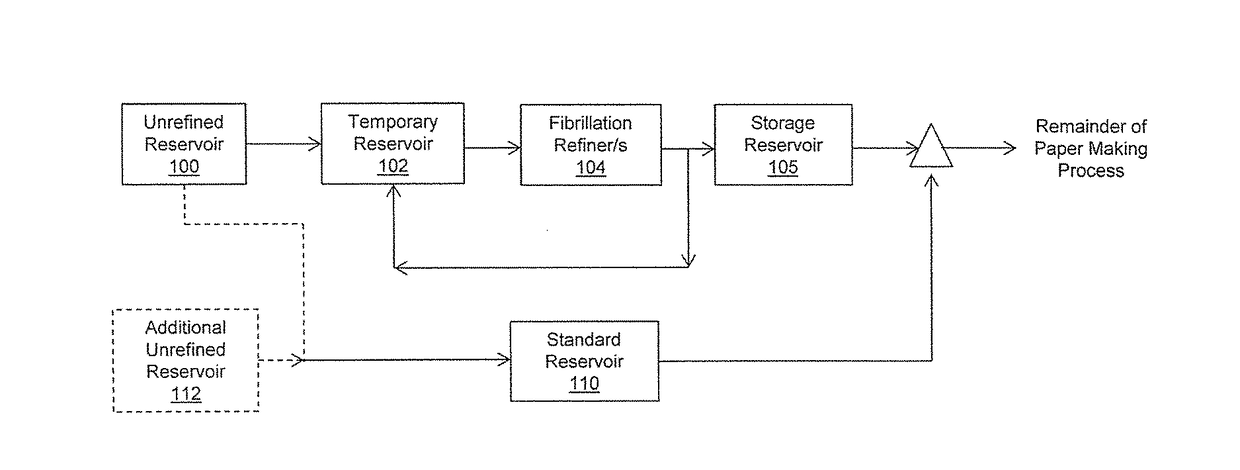

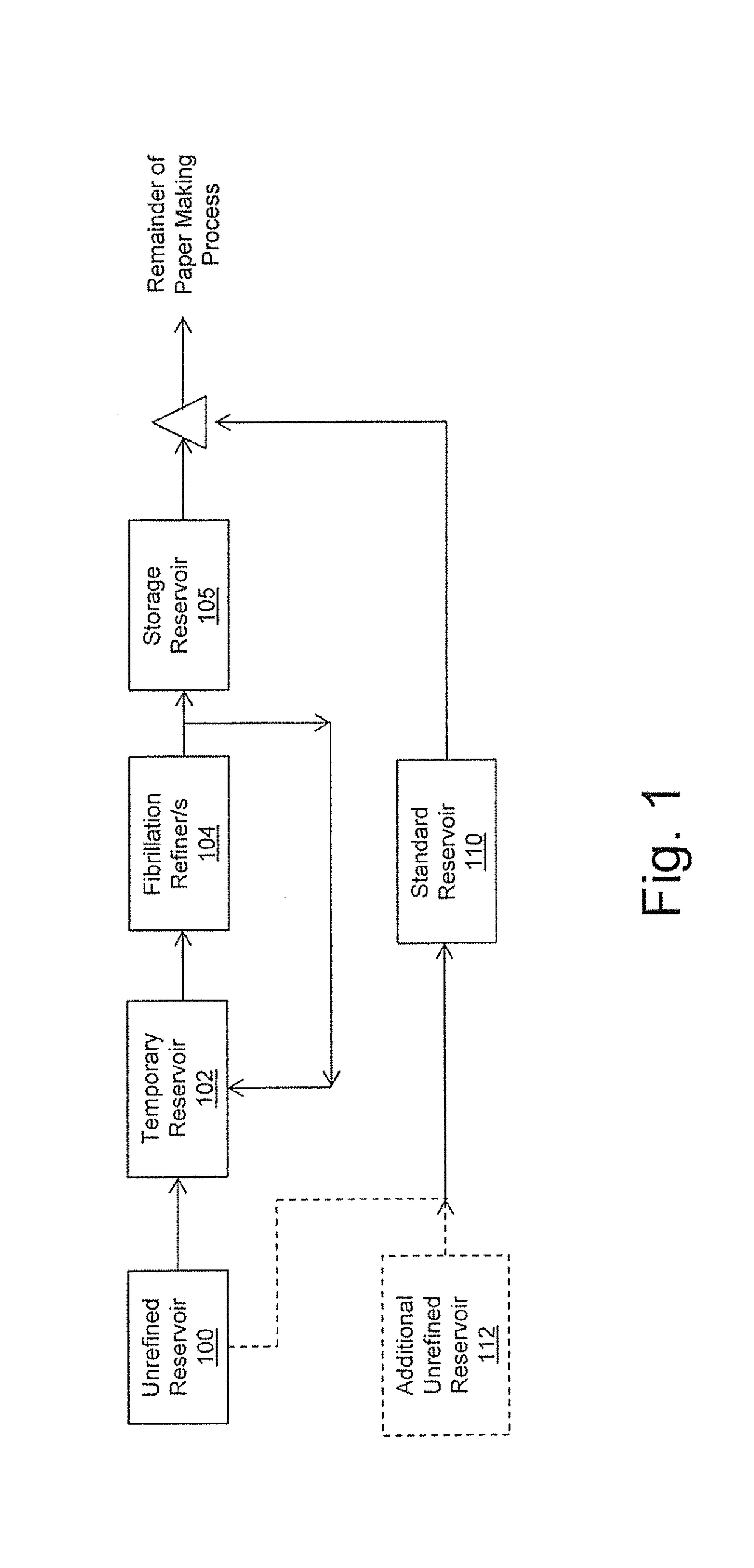

Surface enhanced pulp fibers in fiber cement

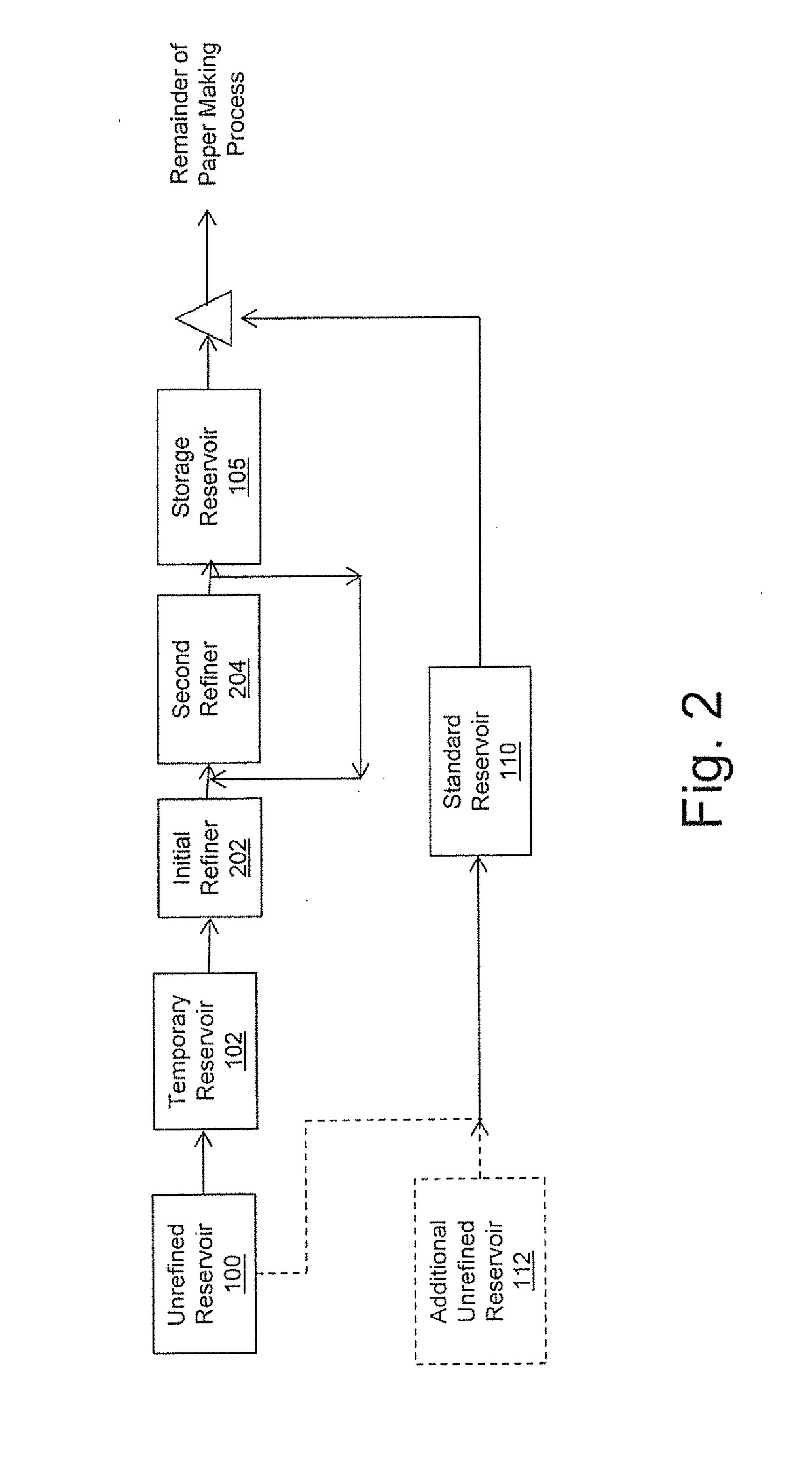

ActiveUS20170226009A1Wide applicabilityGood processing characteristicsSolid waste managementCement compositesPresent method

The present invention relates to a method of making a fiber-reinforced cementitious composite material which finds widespread applicability in a variety of construction and related applications. The composite comprises cellulosic fibrous material in order to provide the composite with the desired performance characteristics. Notably, at least a portion of the cellulosic fibrous material comprises surfaced enhanced pulp fiber, which desirably enhances the processing characteristics of the material, as well enhancing the characteristics of the finished composite product. The method of making a fiber-reinforced cementitious composite comprising the steps of providing a cementitious composition, and providing cellulosic fibrous material. The present method further includes blending the cementitious composition and the cellulosic fibrous material to form the cementitious composite. The surface enhanced pulp fiber preferably comprises approximately 1-10%, by weight, of the cellulosic fibrous material, and the cellulosic fibrous material exhibits an enhanced Bauer-McNett long fiber fraction. The cellulosic fibrous material preferably exhibits at least a 10% increase in length-weighted average fiber length (LWAFL), in comparison to a cellulosic fibrous material which is devoid of surface enhanced pulp fiber. The cellulosic fibrous material requires relatively reduced refining energy, in comparison to a cellulosic fibrous material which is devoid of surface enhanced pulp fiber, to reach a predetermined freeness CSF (Canadian Standard Freeness) value.

Owner:DOMTAR PAPER COMPANY

Full FRP (Fiber Reinforced Plastics) bar reinforced ECC-concrete combined beam component and preparation method thereof

InactiveCN107217788AImprove ductilityImprove energy consumptionClimate change adaptationGirdersHigh energyCementitious composite

The invention provides a full FRP (Fiber Reinforced Plastics) bar reinforced ECC-concrete combined beam component and a preparation method thereof. FRP bars, high ductility cementitious composite materials ECC and concrete are combined. The full FRP bar reinforced ECC-concrete combined beam component comprises an ECC layer on the lower part, a concrete layer on the upper part and an FRP bar framework, wherein the FRP bar framework is formed by a longitudinal tensile FRP bar, an FRP bar hoop, an FRP bar web bar and a longitudinal erection FRP bar; the longitudinal tensile FRP bar is placed on the bottom part of the beam component and is located on the inner side of the FRP bar hoop; the FRP bar erection bar is placed on the top part of the beam component and is located on the inner side of the FRP bar hoop; the FRB bar web bar is placed in the middle of the beam component and is attached to the inner side of the FRP bar hoop; the longitudinal tensile FRP bar, the FRP bar erection bar and the FRP bar web bar are respectively bound with the FRP bar hoop. The full FRP bar reinforced ECC-concrete combined beam component provided by the invention has the advantages of good ductility, high energy-dissipating capacity, good durability, light weight and the like, and can be applied to beam components in buildings, bridges and port structures.

Owner:ZHENGZHOU UNIV

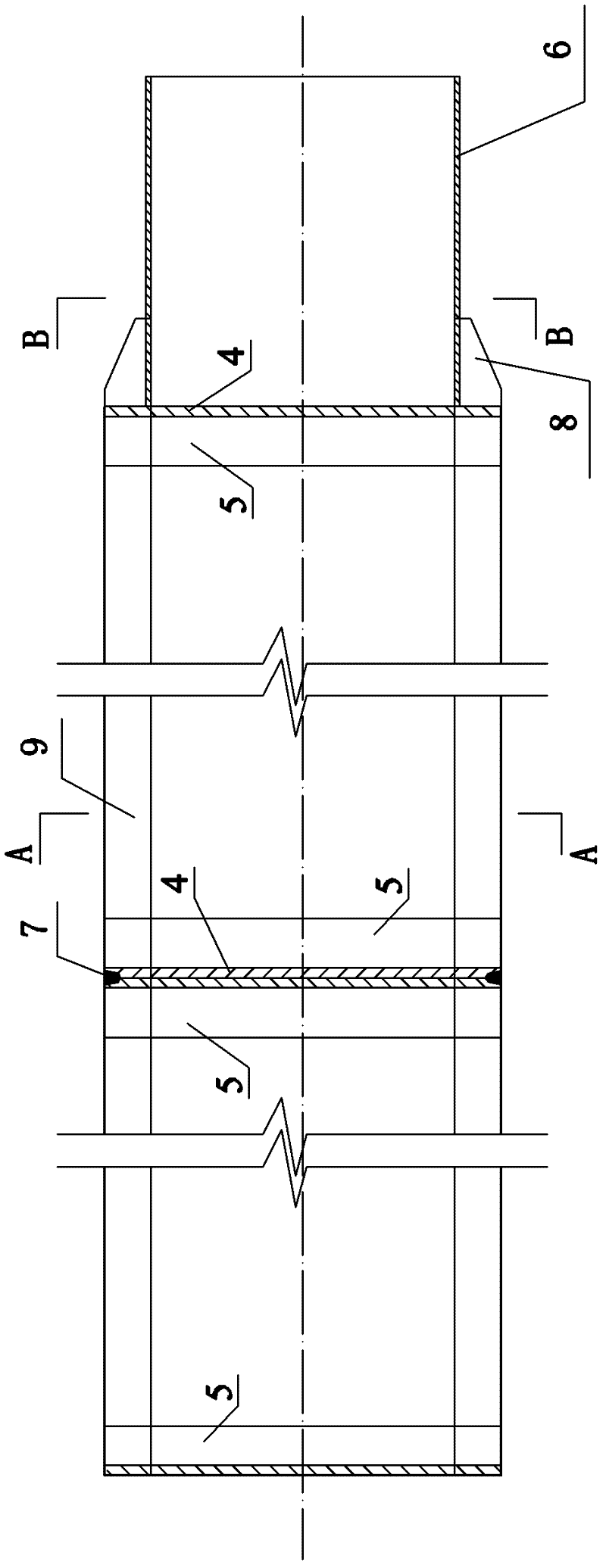

Composite crack control prestressed concrete big tube pile and manufacturing method thereof

InactiveCN102392441AExtended service lifeImprove cracking momentShaping reinforcementsBulkheads/pilesDaily operationCrack resistance

The invention provides a composite crack control prestressed concrete big tube pile which comprises a steel pipe pile tip and a plurality of tube sections. A substrate of each tube section is made of concrete. The periphery of each tube section is provided with a UHTCC (Ultra High Toughness Cementitious Composites) crack control protective layer for replacing concrete; the outer circumference of the top of the tube section at the pile top is provided with a steel plate hoop; the bottom end of the tube section at the pile bottom is provided with a flange plate; a screw hooping is matched and a longitudinal reserved pore passage is arranged inside the tube pipe of each tube section; the tube sections are spliced into one whole body by tensioning longitudinal prestressed tendons passing through the reserved pore passages; the reserved pore passages are tightly filled through injection molding cement paste after the tensioning of the longitudinal prestressed tendons is completed; and the steel pipe pile tip is connected with the flange plate of the tube section at the pile bottom by a welding mode. Not only are the crack resistance, the crack control capability and the anti-erosion capacity of a pile body improved and the integrity of the pile body in the pile sinking process is ensured, but also the maintenance cost during the daily operation is obviously reduced, the service life of the tube pile is prolonged, and the composite crack control prestressed concrete big tube pile has obvious economic benefits.

Owner:浙江固邦新材料有限公司

Lightweight cementitious composite material

InactiveUS7255738B2Liquid surface applicatorsAlkali metal silicate coatingsParticulatesCement composites

A lightweight cementitious composite material includes expanded synthetic polymer particulate having a particle size of between 0.0625 and 0.5 inches. A dispersant coating on said particulate suppresses electrostatic attraction between particulate particles. A matrix surrounds the particulate and is present from 0.25 to 1 pound per gallon of dispersant coated particulate.

Owner:MOS

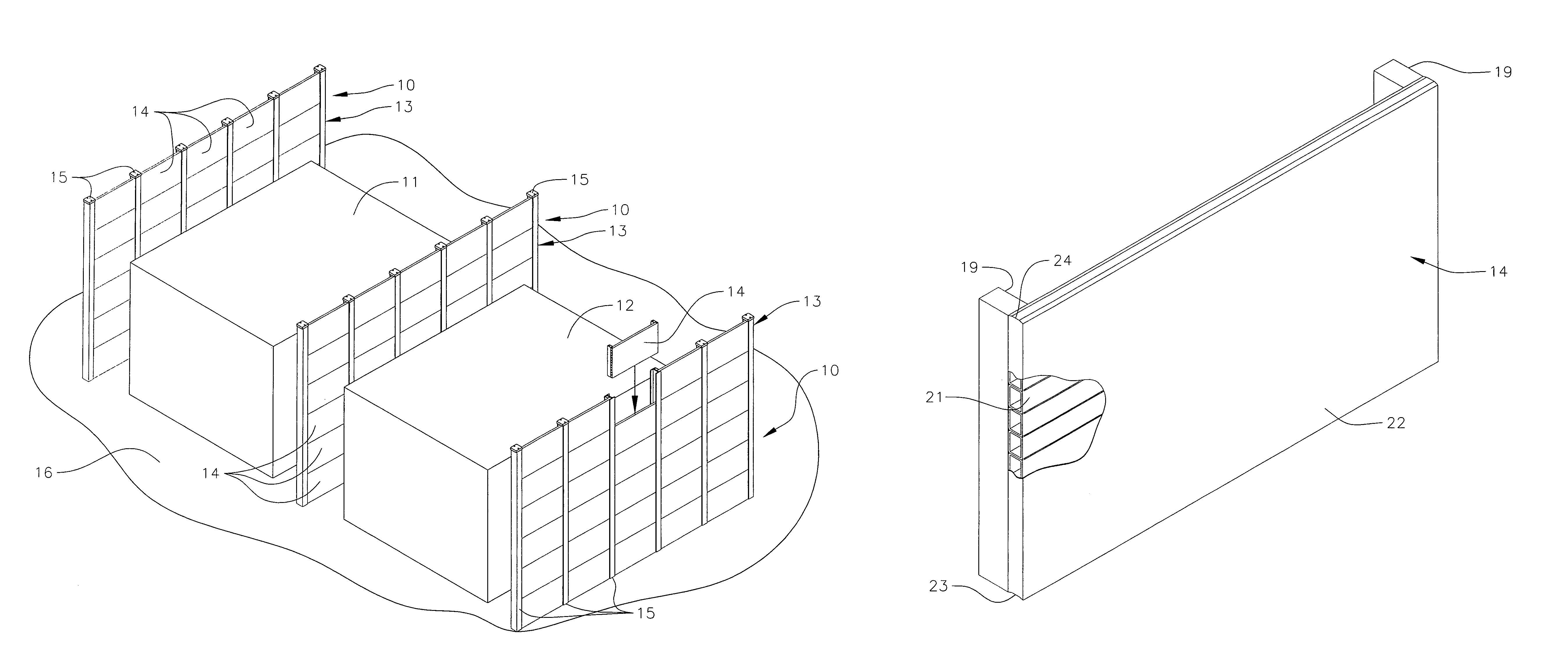

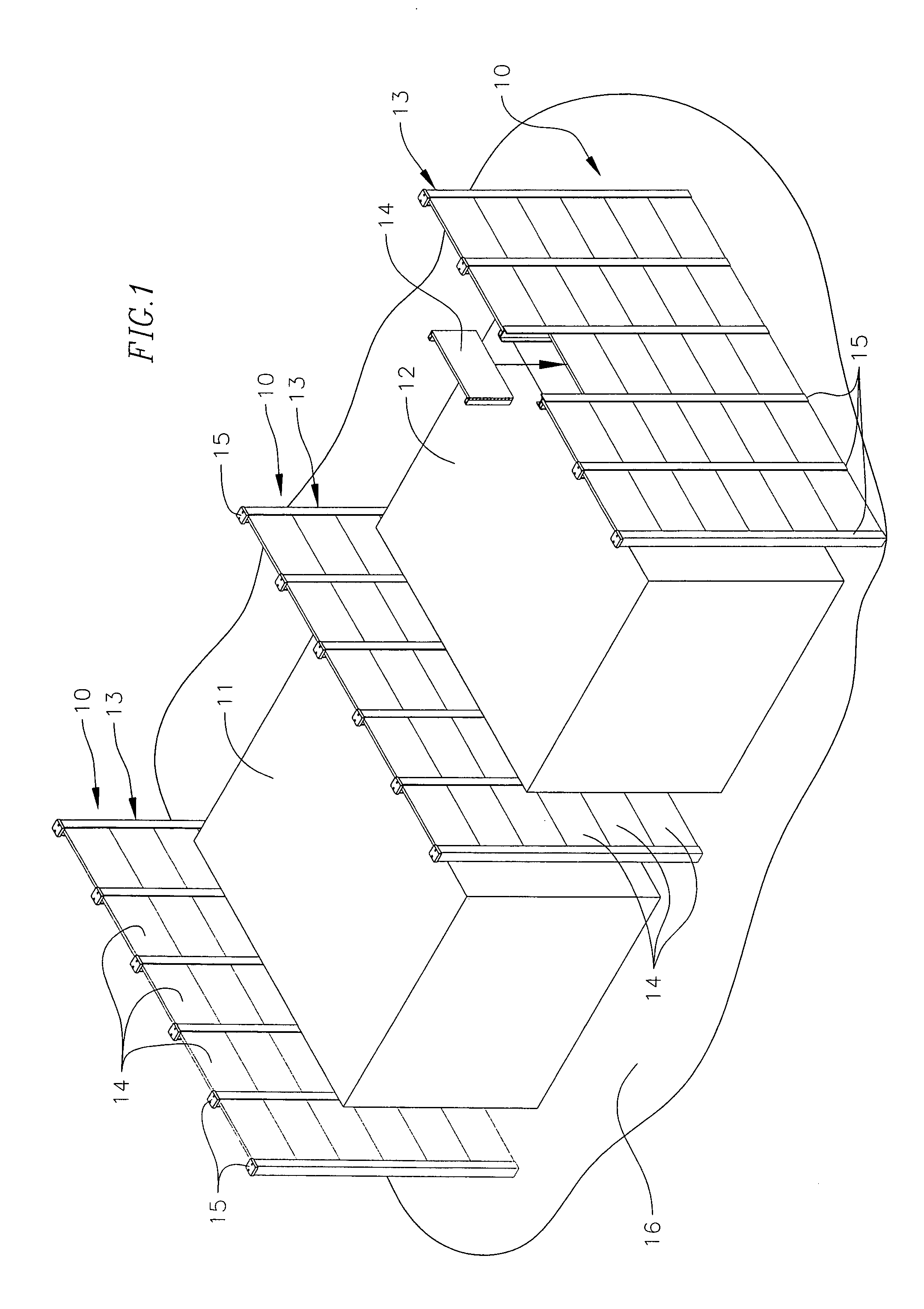

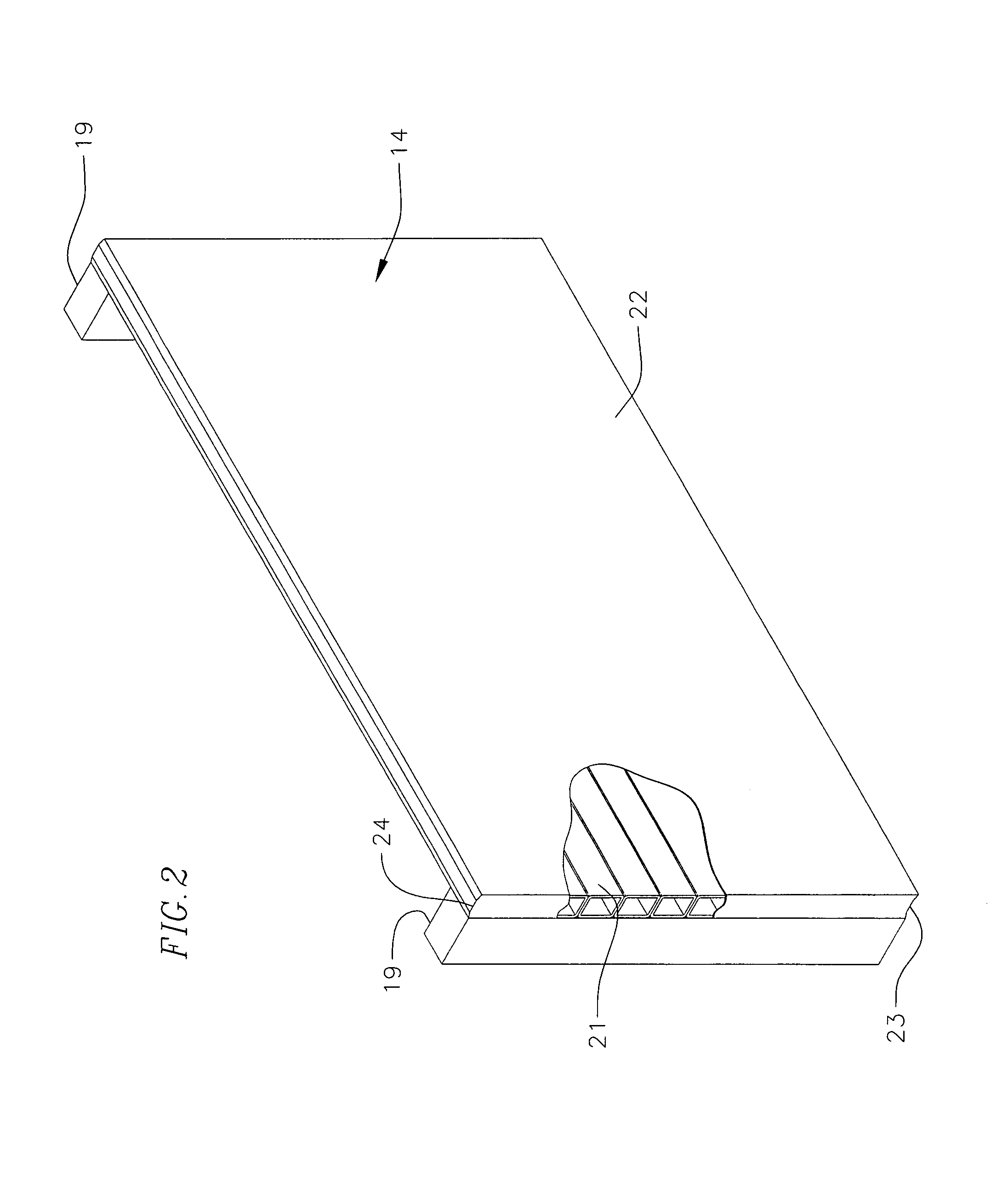

Fire-protection walls of cementitious composite materials

A highly protective firewall (13) supported between upstanding columns or beams (15). The firewall is made of an inorganic cementitious material which is preferably inorganic phosphate cement. In one form, the firewall comprises a group of vertically stacked panels (14) made of such material, and the panels are in turn formed by a plurality of elongated and vertically stacked hollow members (21) of the same material.

Owner:COMPOSITE SUPPORT & SOLUTIONS

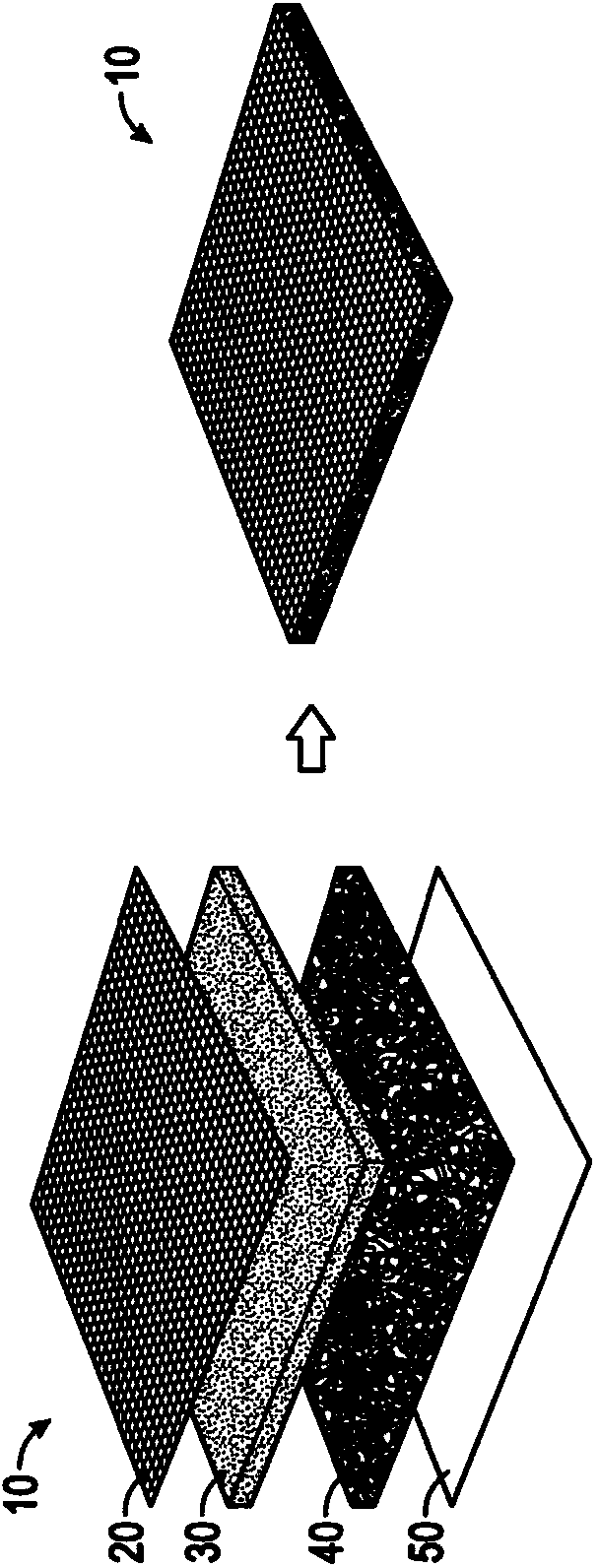

Composite wall panel with low thermal conductivity and sufficient strength for structural use

ActiveUS9249053B2Improve barrier propertiesImprove insulation effectConstruction materialSolid waste managementFoam concreteThermal insulation

The present invention provides a composite wall panel with good thermal insulation and sufficient strength for structural use which is designed for the fabrication of energy efficient building. The composite wall panel of the present invention comprises a foamed concrete core with sufficient compressive strength and low thermal conductivity which is sandwiched between two lightweight ductile fiber reinforced cementitious composite (FRCC) protective layers with low thermal conductivity, good barrier resistance to moisture / chloride ion / gas, multiple cracking as well as certain amount of steel reinforcements. These composite wall panels are useful in a variety of buildings in both cold and hot regions.

Owner:NANO & ADVANCED MATERIALS INST

Lightweight cementitious composite material

InactiveUS20050058832A1Liquid surface applicatorsAlkali metal silicate coatingsParticulatesCement composites

A lightweight cementitious composite material includes expanded synthetic polymer particulate having a particle size of between 0.0625 and 0.5 inches. A dispersant coating on said particulate suppresses electrostatic attraction between particulate particles. A matrix surrounds the particulate and is present from 0.25 to 1 pound per gallon of dispersant coated particulate.

Owner:MOS

Composite material space truss joint and method

ActiveCN103397702AFirmly connectedTroubleshoot node connectivity issuesBuilding constructionsPre stressEngineering

The invention discloses composite material space truss joint and method. The composite material space truss joint comprises composite material square tube connectors, composite material circular tube connectors and a bolt-sphere joint. The composite material square tube connectors and the composite material circular tube connectors are connected with the bolt-sphere joint through high-strength bolts. The composite material space truss joint covers reliable connection of two closed sections of most frequently used circular tubes and square tubes in the space truss structure, joint form is complete, and the problem of the joint of the composite material closed sections in the application of the space truss structure is basically solved. Steel slabs and the cementitious composite connecting mode can provide joint strength as required in the structure, and the advantages of high strength of composite materials can be effectively exerted. Winding of aramid fiber cloth helps improve the overall performance of the joint, so that the joint strength is further improved, and anti-corrosion area in joint regions are reduced. Joint production is completed in factories that guarantee production precision, on-site assembly is fast, assembly fee is low, and time limit is short. Prestress application is omitted during the production, and bearing capacity degradation caused by creep of the composite materials is no need to worry about.

Owner:SOUTHEAST UNIV

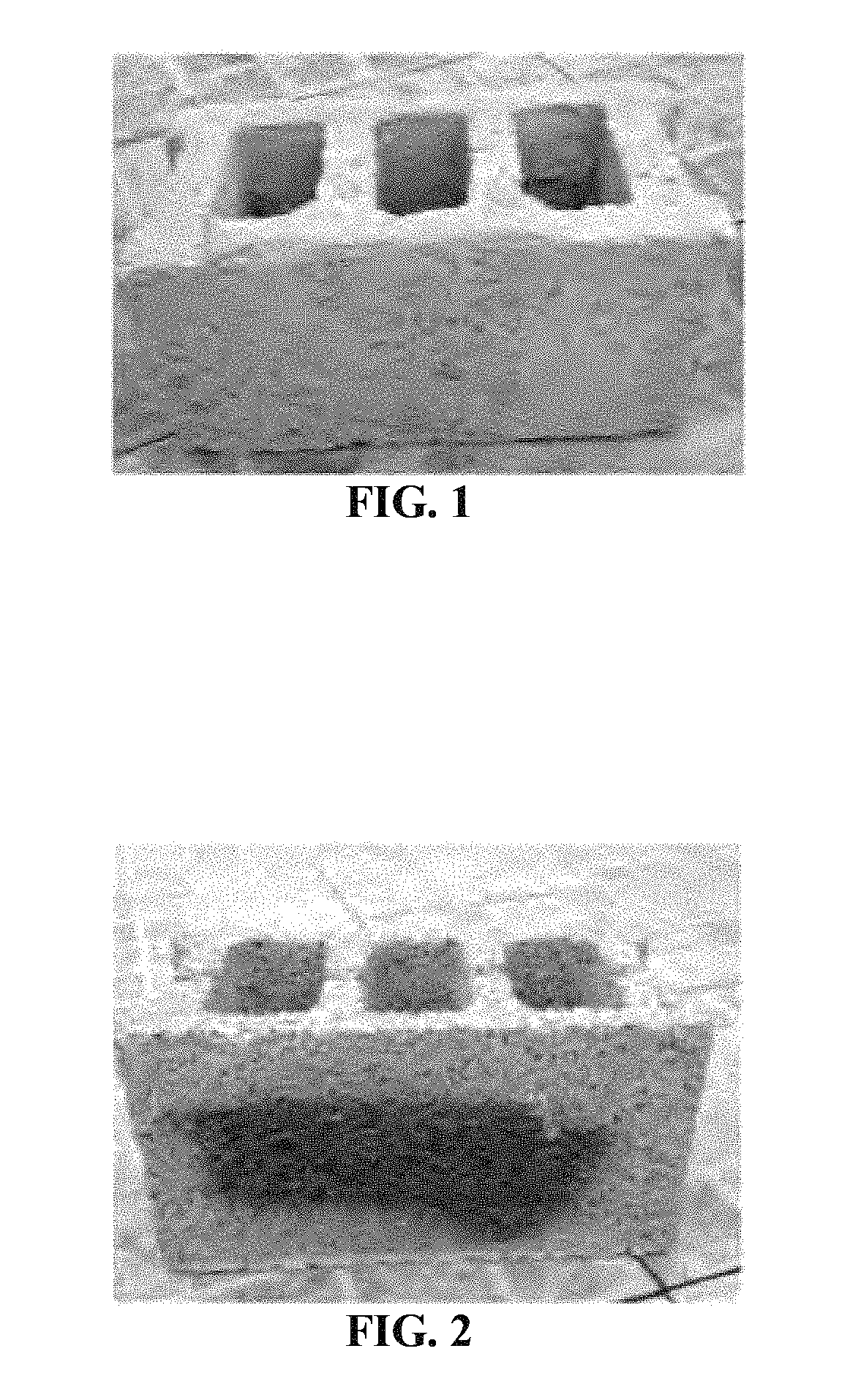

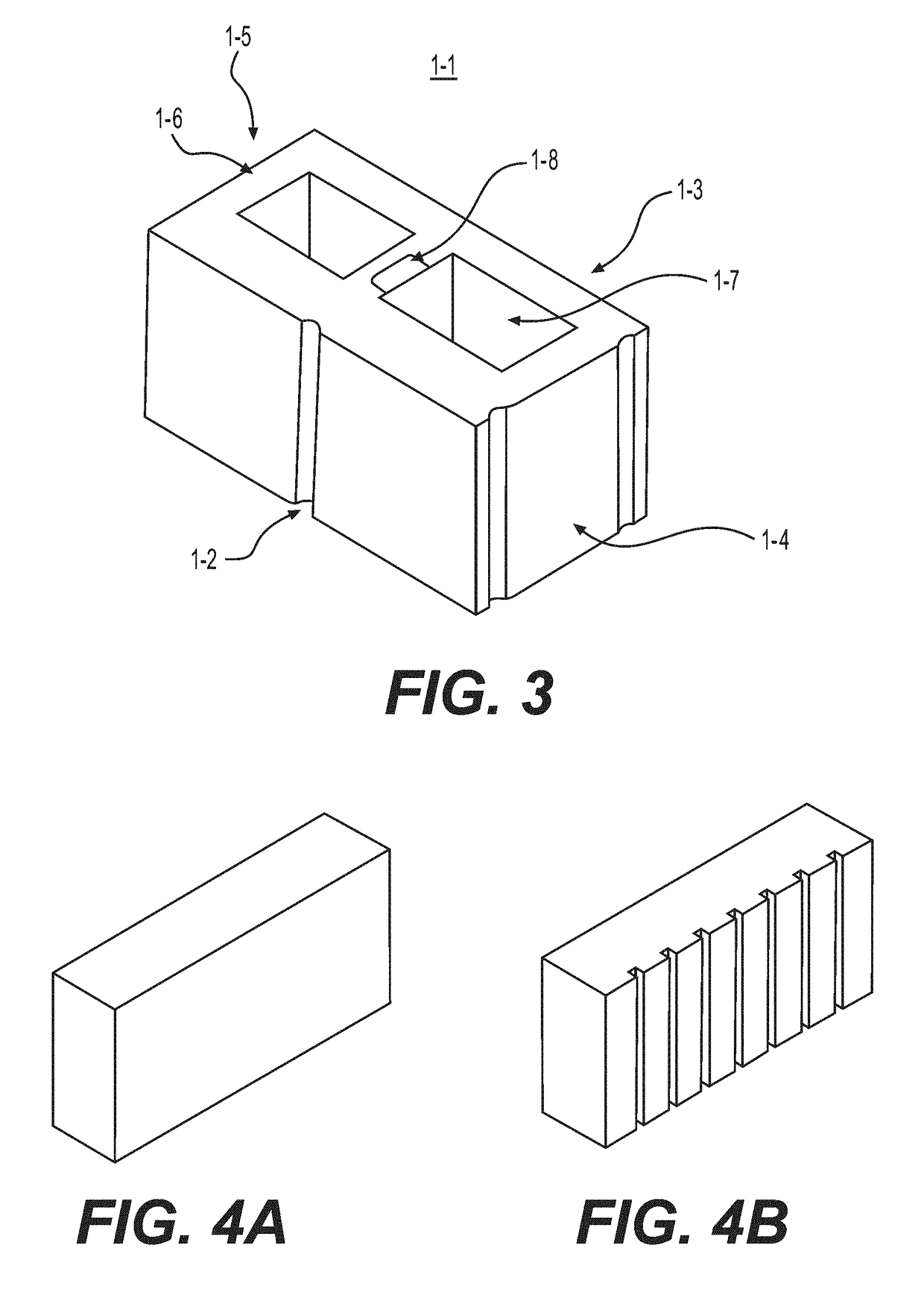

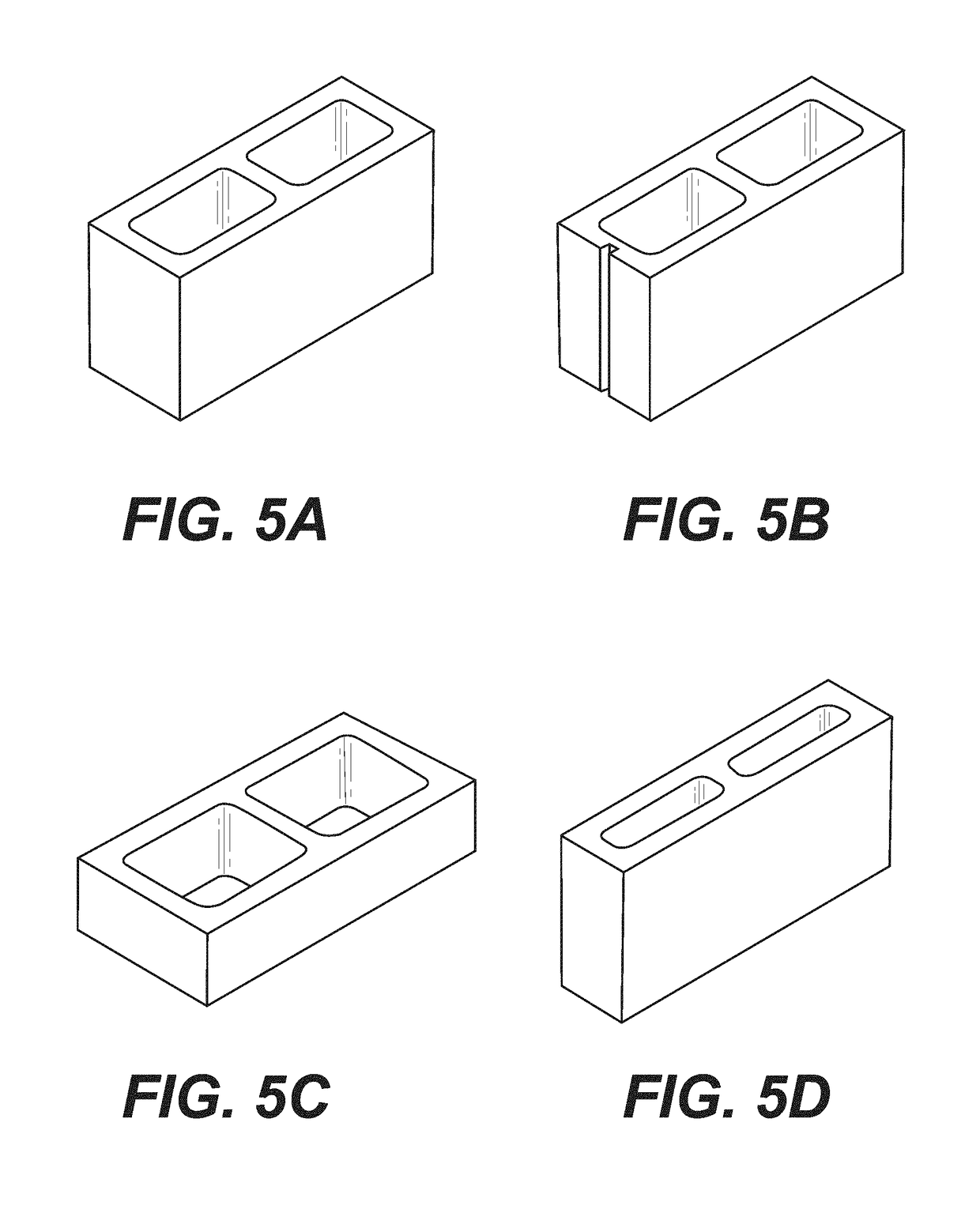

Crumb rubber-containing composites and masonry blocks thereof

A cementitious composite and cured masonry block made from the cementitious composite. The cementitious composite contains a cement, a non-rubber aggregate, a crumb rubber and at least one of cement kiln dust and limestone powder. The crumb rubber aggregate is extracted from scrap tires after being processed and then mixed in specified percentages with the aggregate, the cement and water, then cured in forms to make the masonry blocks. In the present disclosure sand, which is used in conventional masonry blocks, is at least partially replaced with crumb rubber to produce a sand-free or sand-reduced masonry block that contains crumb rubber. The crumb rubber masonry blocks satisfy the ASTM non-load bearing requirements. The use of crumb rubber decreases the unit weight and increases thermal resistance of the masonry blocks. The use of cement kiln dust or limestone as a partial replacement of cement will lead to decrease in the cost. The use of industrial waste materials, such as crumb rubber, limestone powder and cement kiln dust, will lead to economic and environmental benefits.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

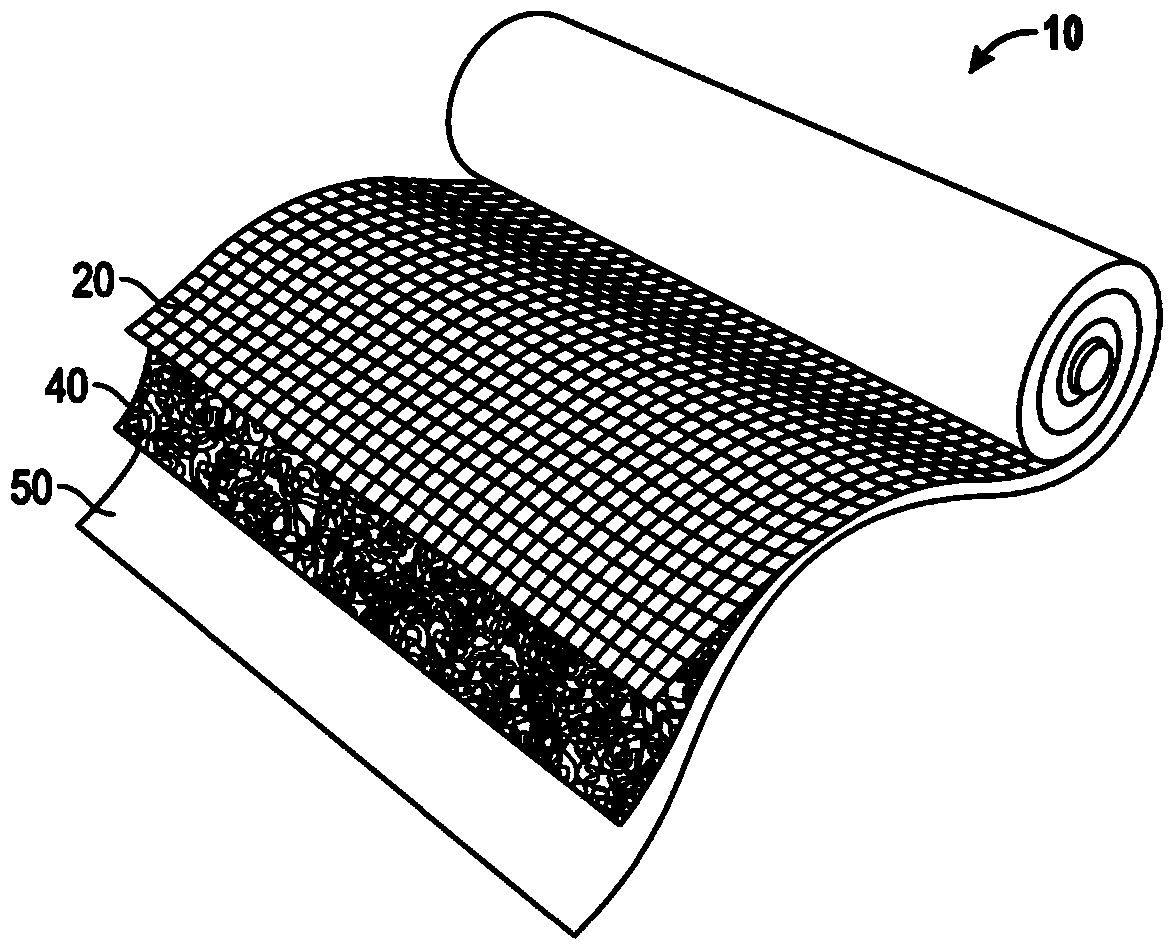

Nonwoven cementitious composite for in-situ hydration

Owner:CORTEX COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com