Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1722 results about "Friction loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In fluid flow, friction loss (or skin friction) is the loss of pressure or “head” that occurs in pipe or duct flow due to the effect of the fluid's viscosity near the surface of the pipe or duct. In mechanical systems such as internal combustion engines, the term refers to the power lost in overcoming the friction between two moving surfaces, a different phenomenon.

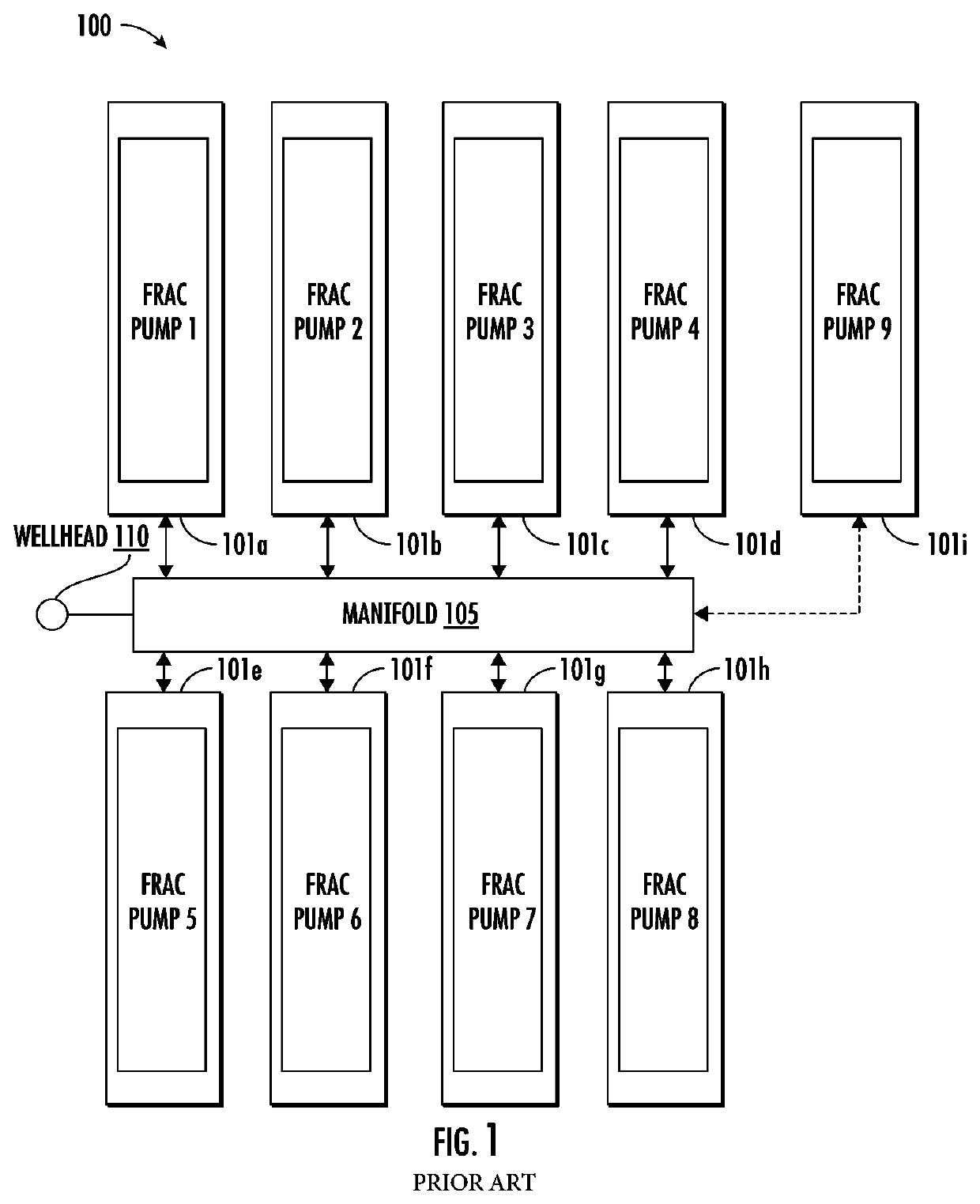

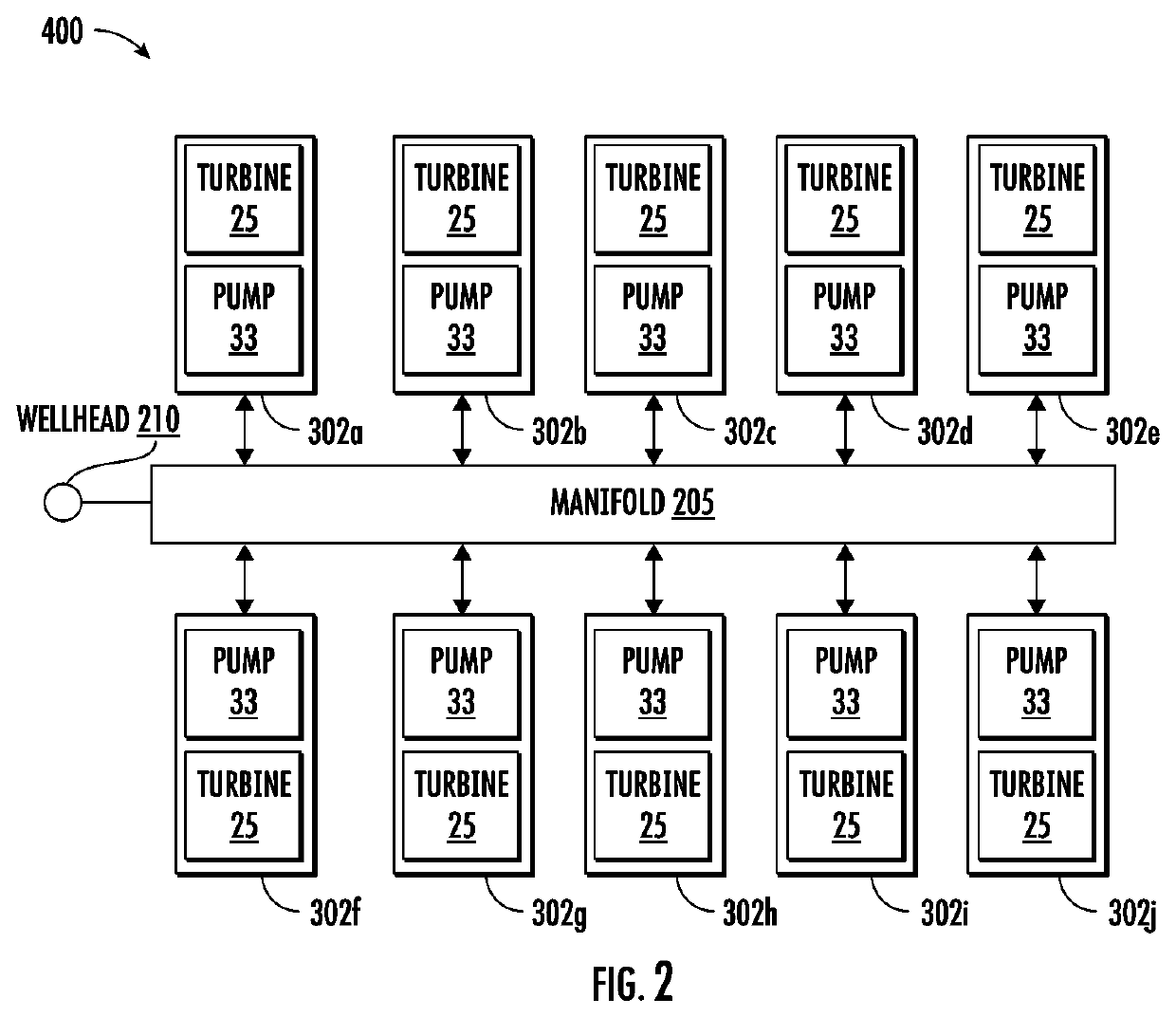

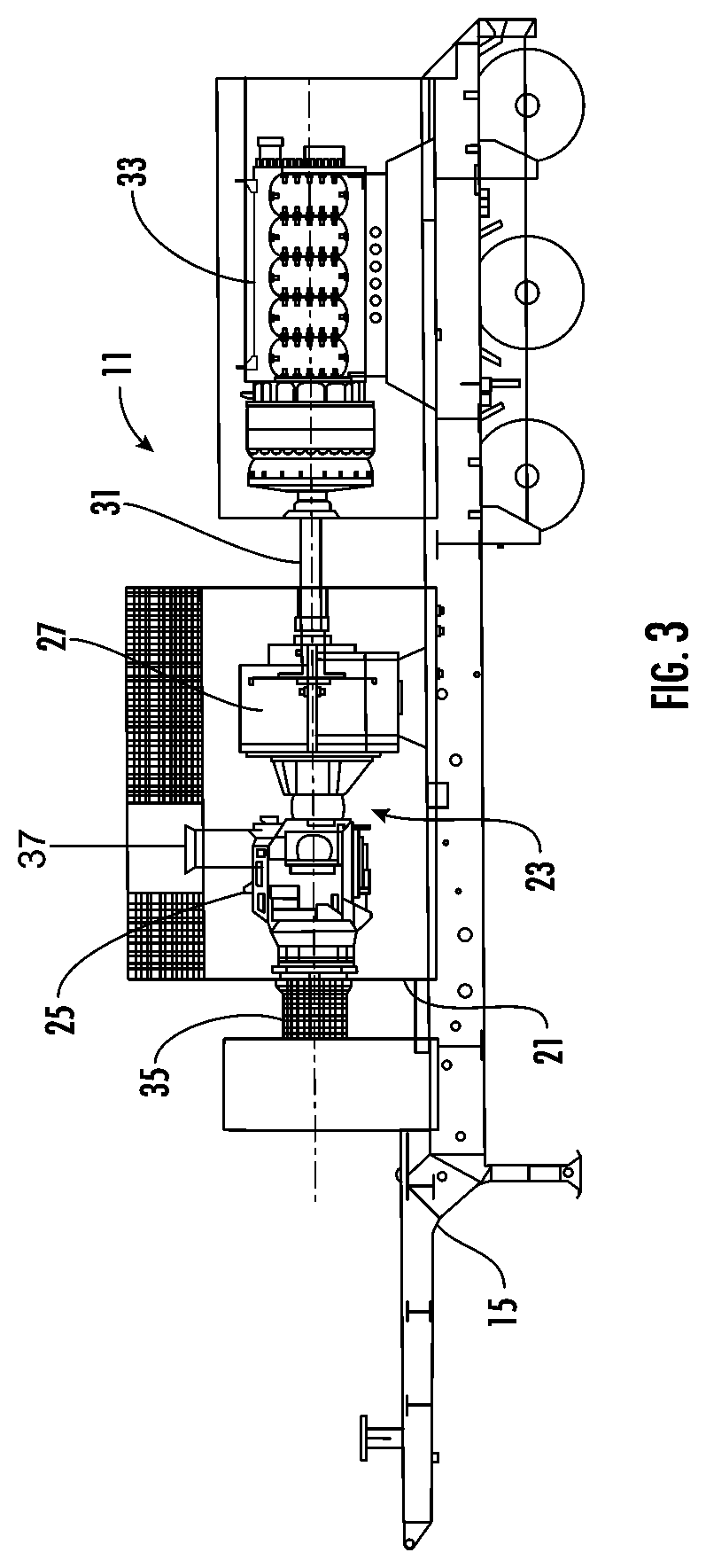

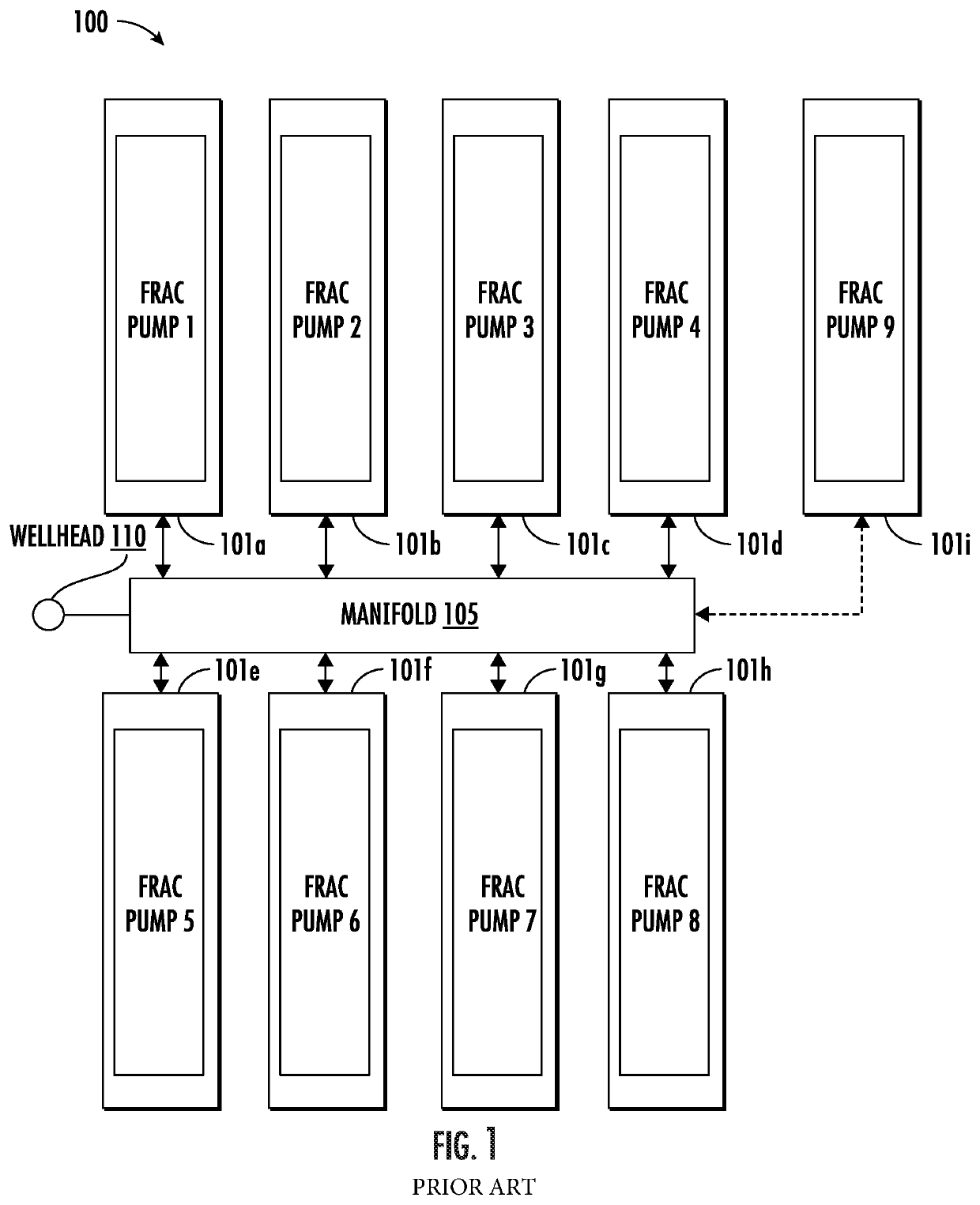

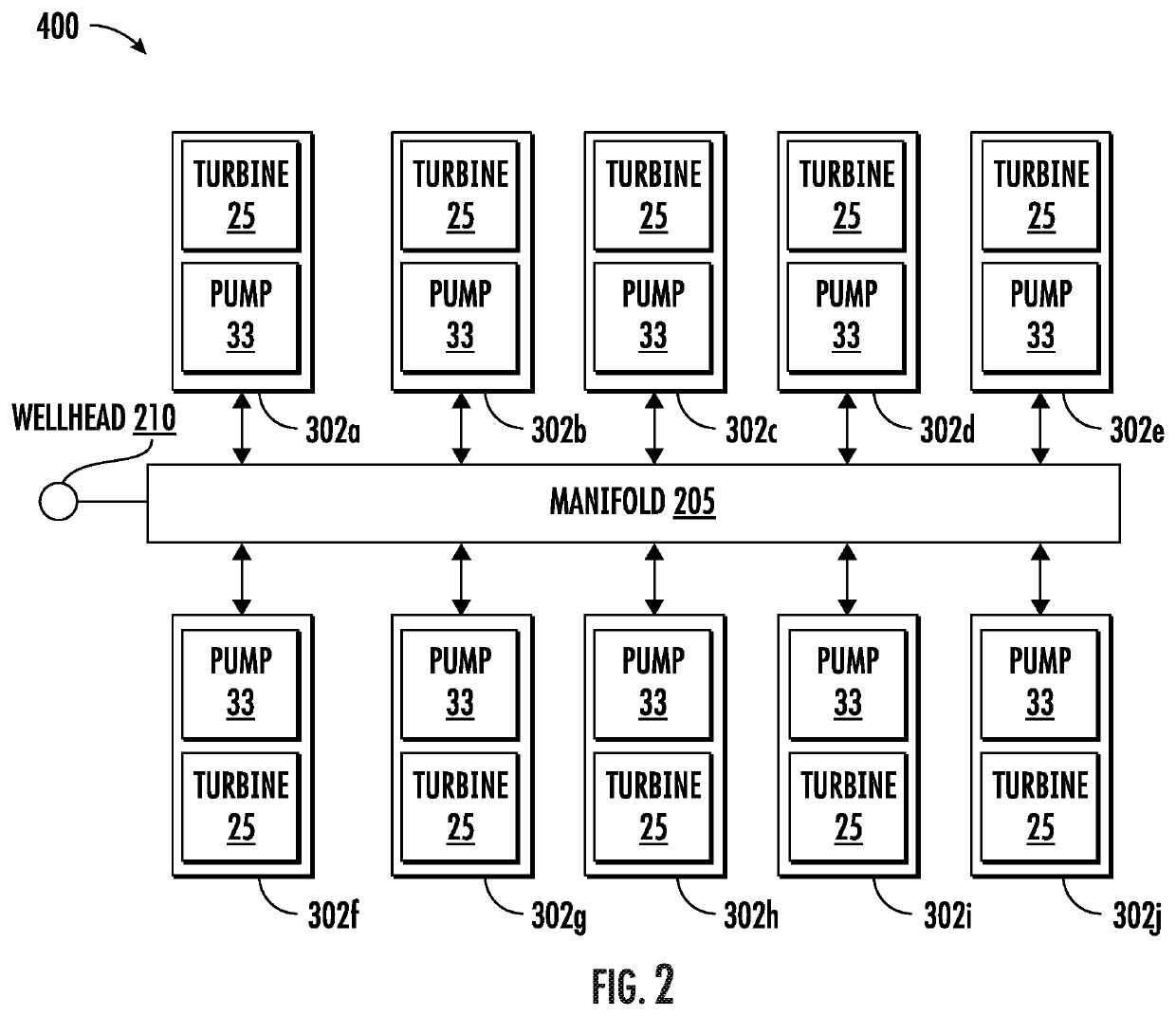

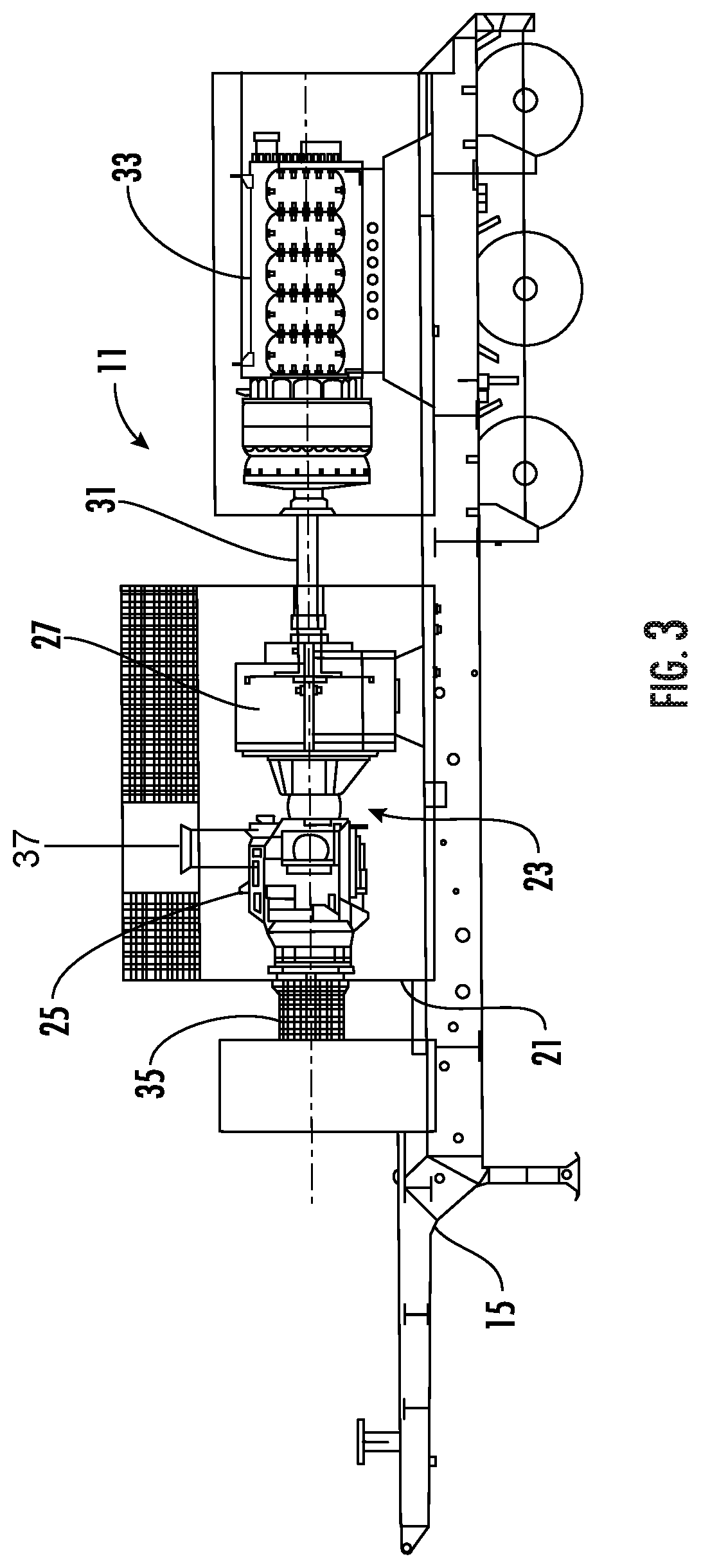

Methods and systems for operating a fleet of pumps

A system and method for operating a fleet of pumps for a turbine driven fracturing pump system used in hydraulic fracturing is disclosed. In an embodiment, a method of operating a fleet of pumps associated with a hydraulic fracturing system includes receiving a demand Hydraulic Horse Power (HHP) signal. The demand HHP signal may include the Horse Power (HP) required for the hydraulic fracturing system to operate and may include consideration for frictional and other losses. The method further includes operating all available pump units at a percentage of rating below Maximum Continuous Power (MCP) level, based at least in part on the demand HHP signal. Furthermore, the method may include receiving a signal for loss of power from one or more pump units. The method further includes operating one or more units at MCP level and operating one or more units at Maximum Intermittent Power (MIP) level to meet the demand HHP signal.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

Methods and systems for operating a fleet of pumps

A system and method for operating a fleet of pumps for a turbine driven fracturing pump system used in hydraulic fracturing is disclosed. In an embodiment, a method of operating a fleet of pumps associated with a hydraulic fracturing system includes receiving a demand Hydraulic Horse Power (HHP) signal. The demand HHP signal may include the Horse Power (HP) required for the hydraulic fracturing system to operate and may include consideration for frictional and other losses. The method further includes operating all available pump units at a percentage of rating below Maximum Continuous Power (MCP) level, based at least in part on the demand HHP signal. Furthermore, the method may include receiving a signal for loss of power from one or more pump units. The method further includes operating one or more units at MCP level and operating one or more units at Maximum Intermittent Power (MIP) level to meet the demand HHP signal.

Owner:BJ ENERGY SOLUTIONS LLC

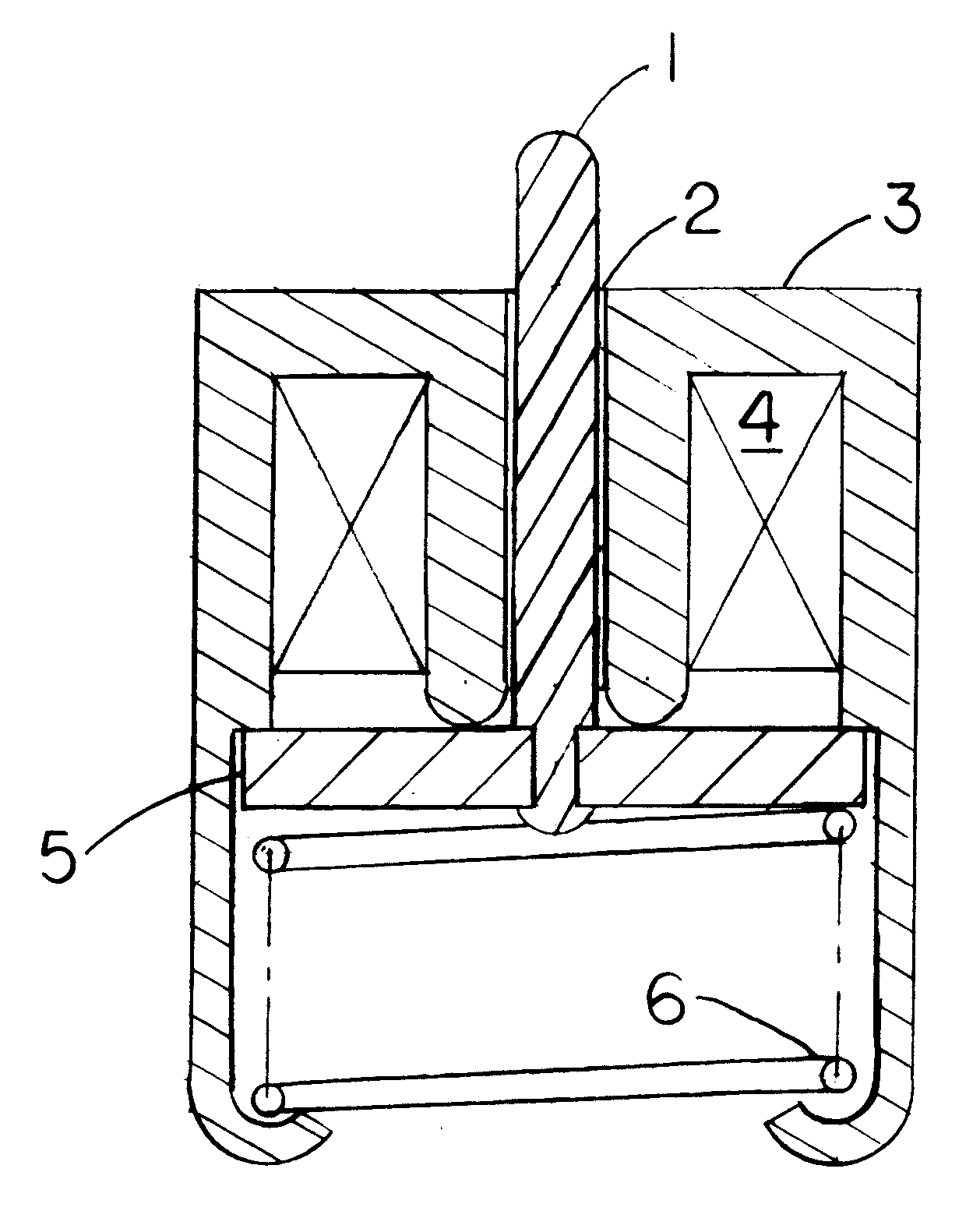

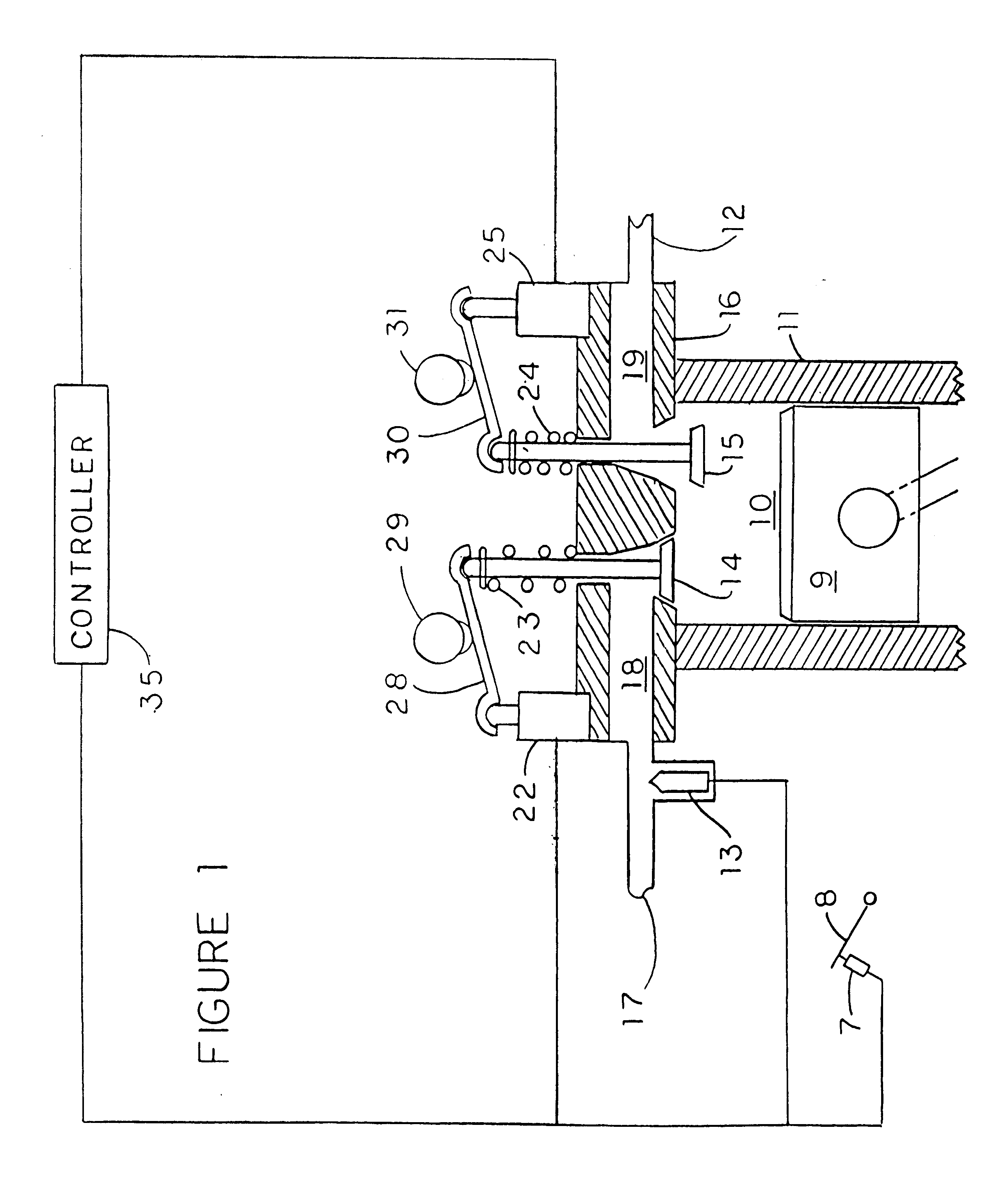

Engine valve disabler

A method for improving efficiency and reducing emissions of an internal combustion engine. Variable displacement engine capabilities are achieved by disabling engine valves during load changes and constant load operations. Active cylinders may be operated at minimum BSFC by intermittently disabling other cylinders to provide the desired net torque. Disabling is begun by early closing of the intake valve to provide a vacuum at BDC which will result in no net gas flow across the piston rings, and minimum loss of compression energy in the disabled cylinder; this saving in engine friction losses is significant with multiple disablements.

Owner:MOYER DAVID F

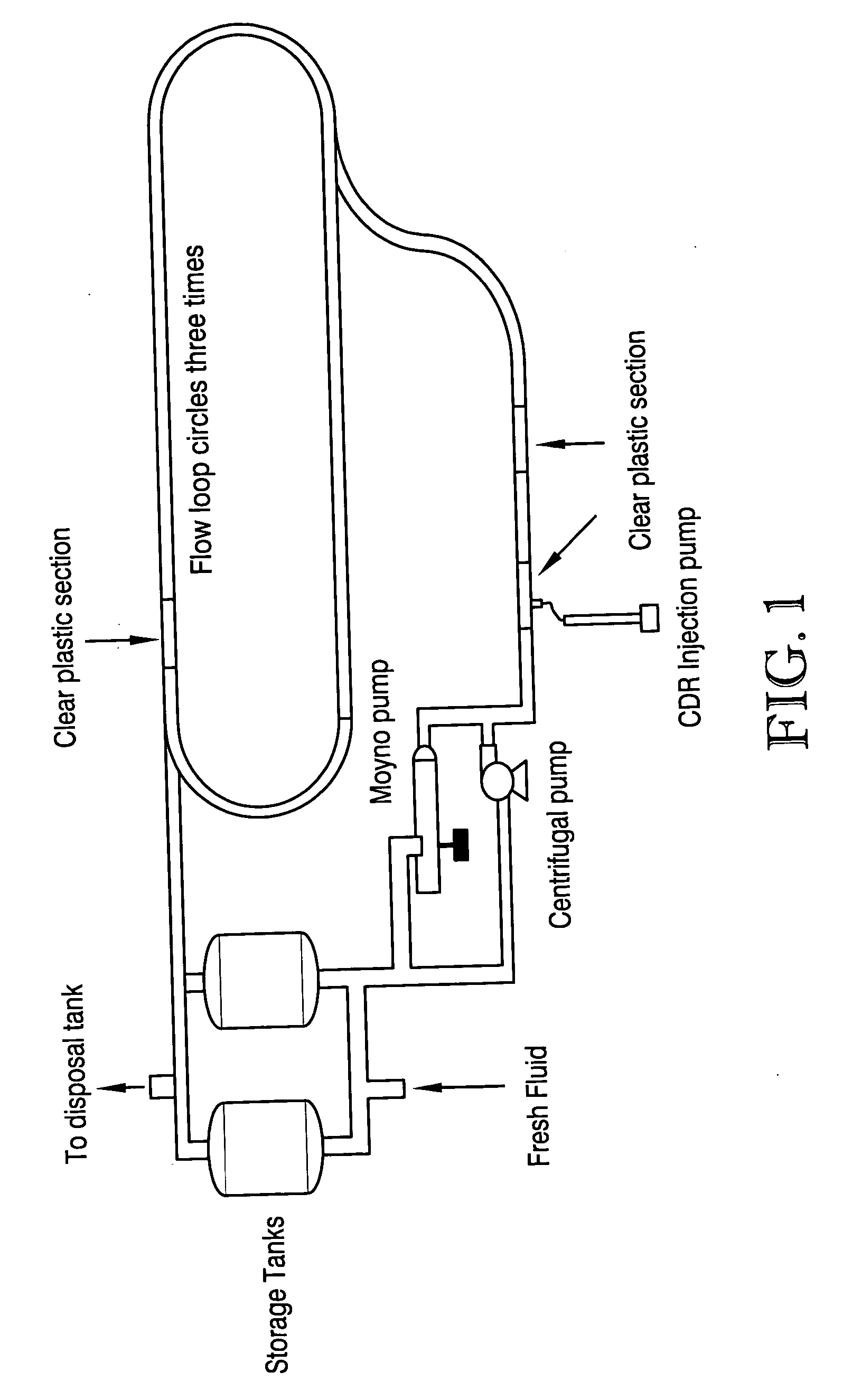

Modified latex drag reducer and processes therefor and therewith

ActiveUS20060148928A1Stable latex drag reducerOther chemical processesPipeline systemsFriction lossSolvent

A modified latex drag reducer and methods of making and using the drag reducer in order to reduce friction losses resulting from turbulent fluid flow through a conduit. Particularly, the modified latex drag reducer is formed from an initial latex which is a product of an emulsion polymerization reaction. The initial latex is then modified, preferably by admixing with at least one low HLB surfactant or at least one solvent, or both, to form a modified latex with an enhanced dissolution rate in a hydrocarbon stream over the initial latex.

Owner:LIQUIDPOWER SPECIALTY PROD INC

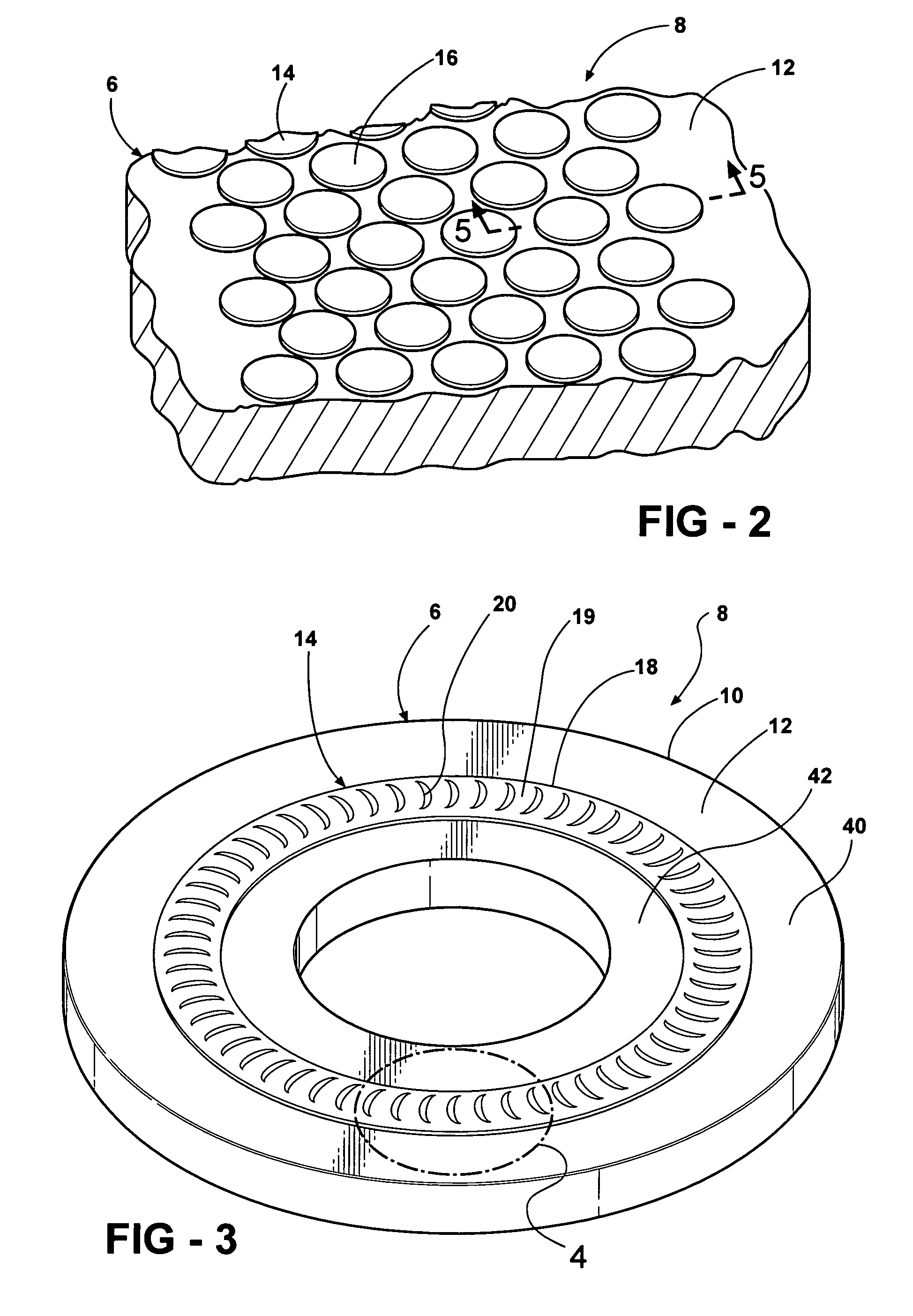

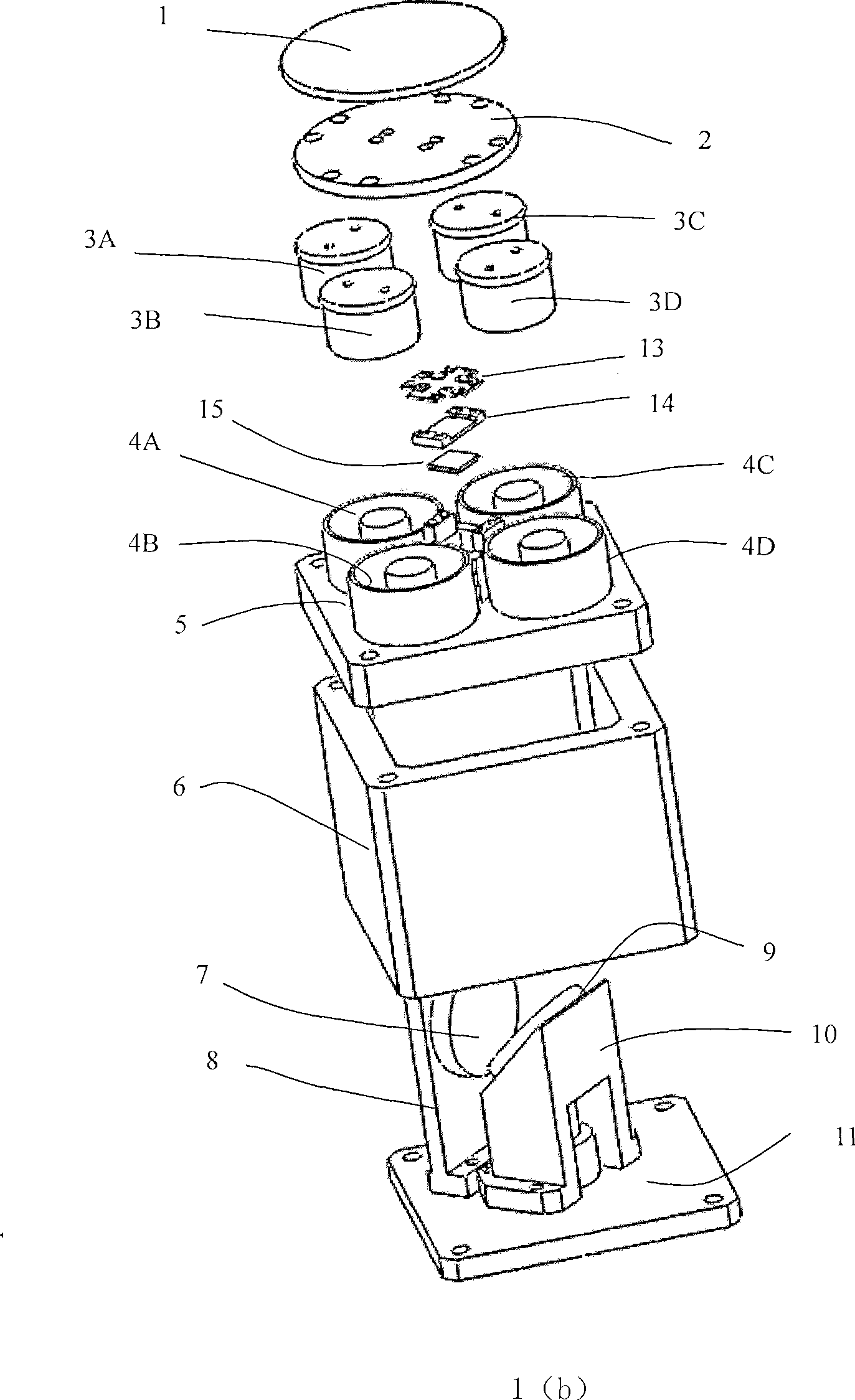

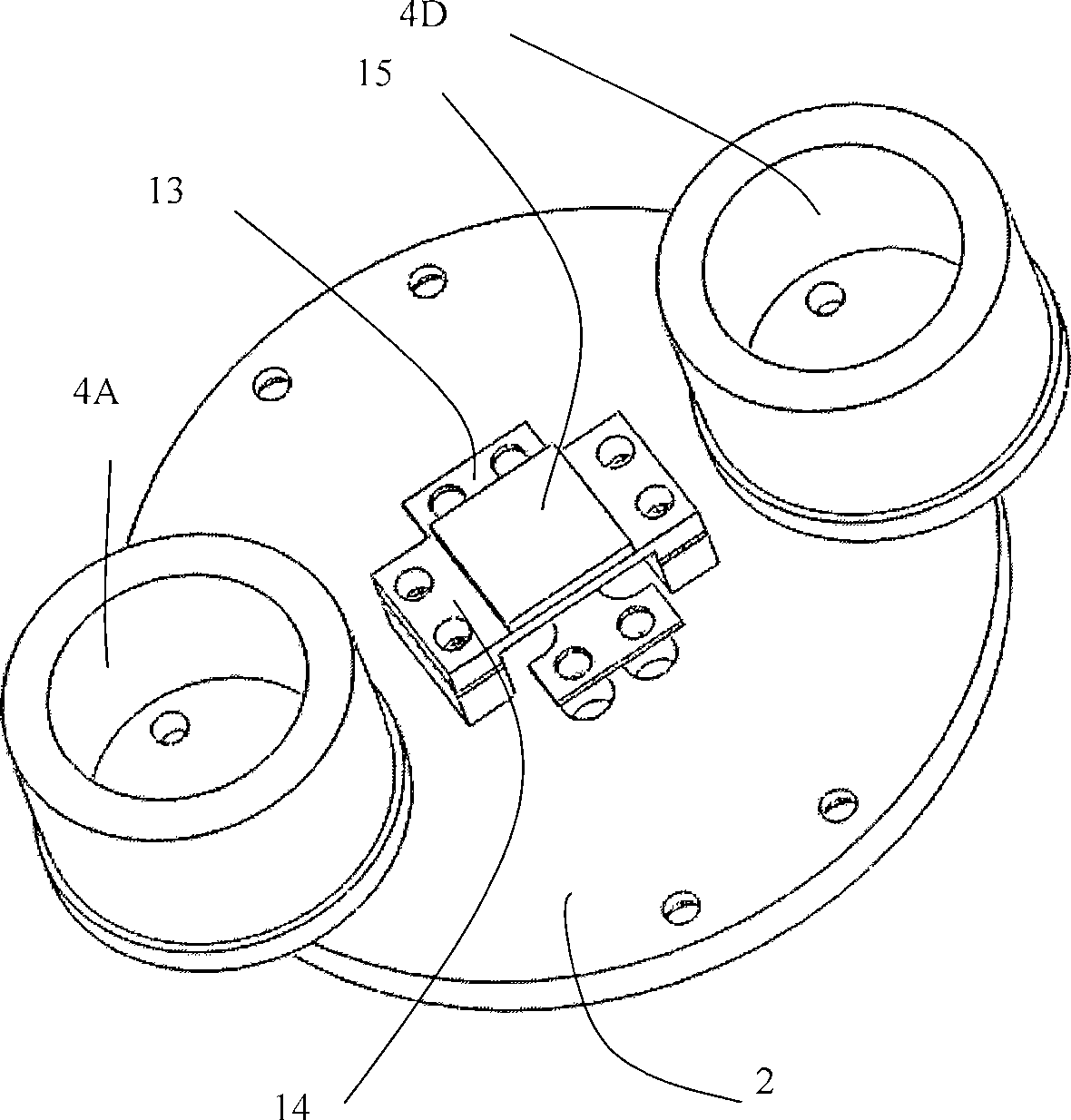

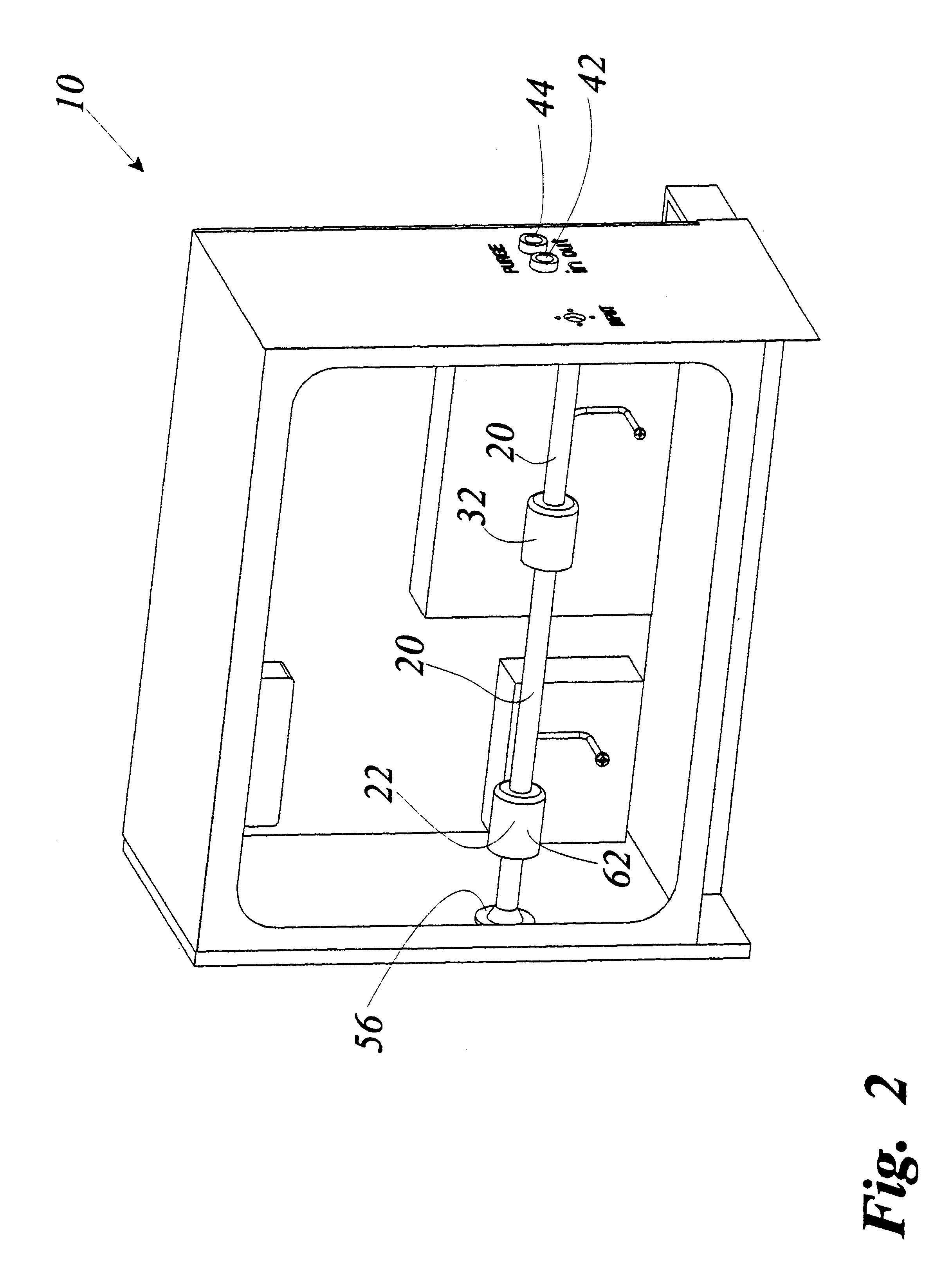

Friction and wear tester

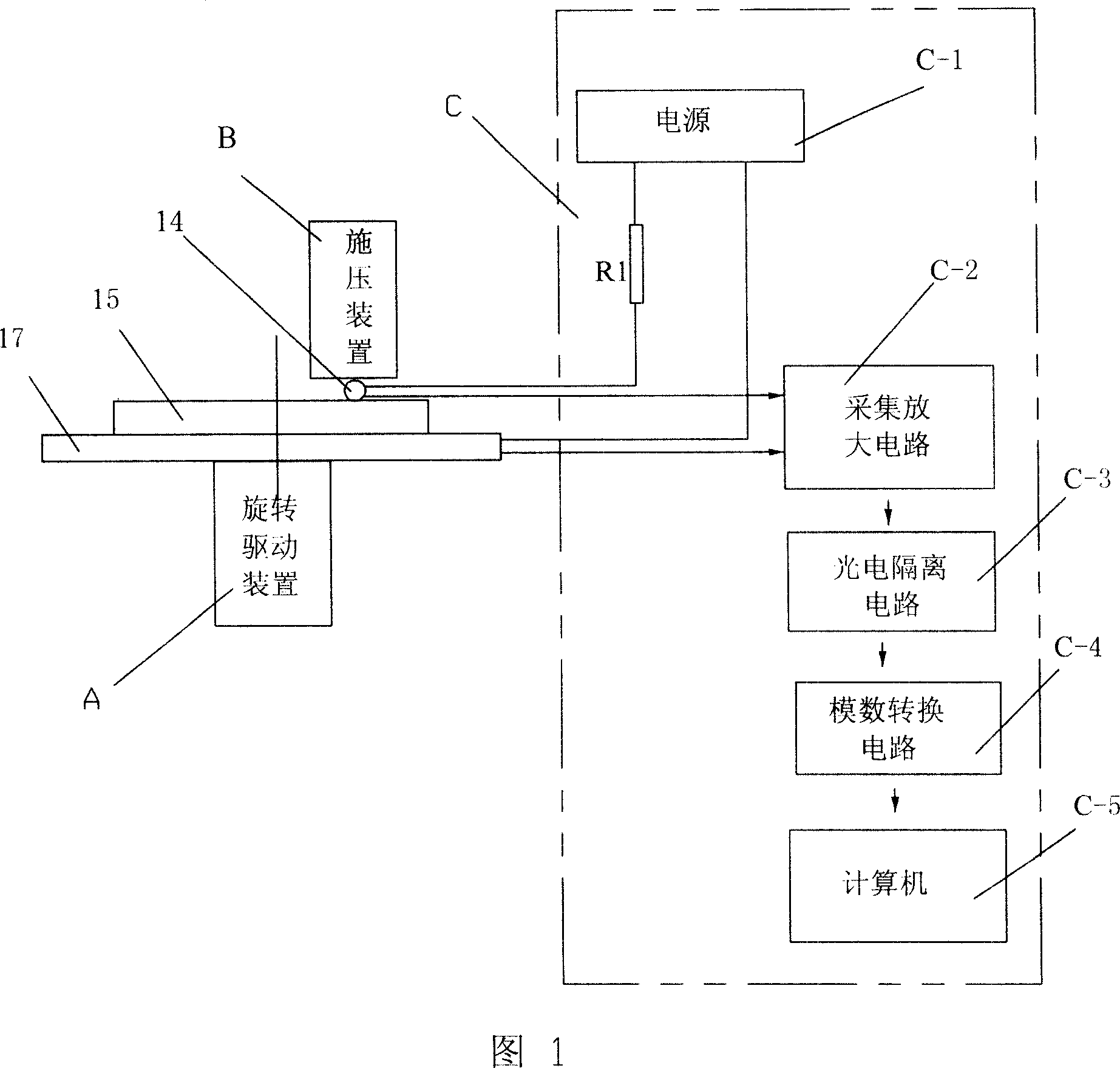

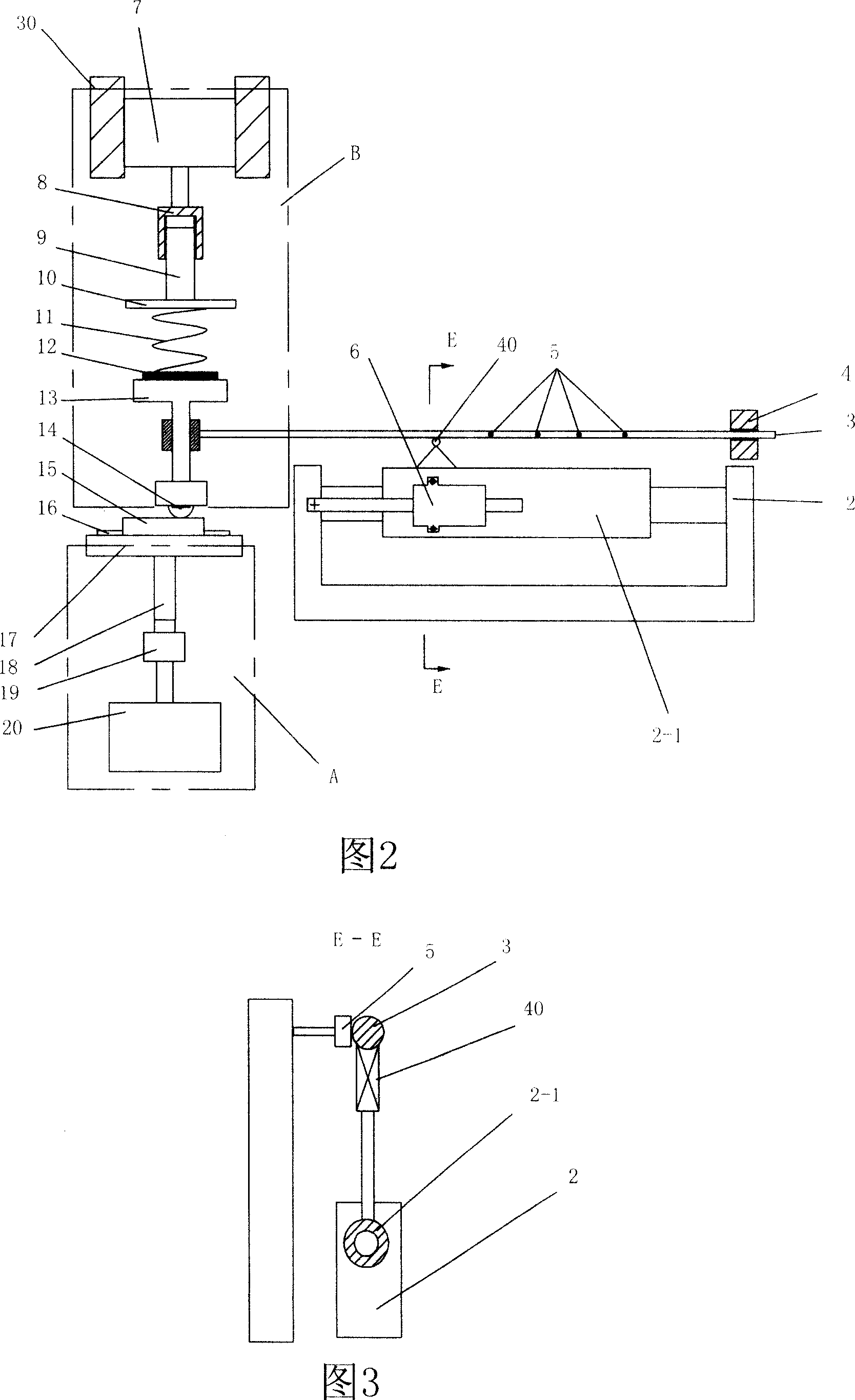

InactiveCN101008598AAvoid errorsHigh degree of automationUsing mechanical meansInvestigating abrasion/wear resistanceElectrical resistance and conductanceTest sample

This invention relates to one friction loss process analogue and test device, which comprises rotation disc, rotation drive device, steel ball and pressure device and test sample resistance test circuit, wherein, the test resistance value test circuit is composed of power, resistance, sample and amplification circuit, photoelectrical isolation circuit, A / D conversion circuit and computer, wherein, the rotation drive device and rotation disc down end are connected; the steel ball top end is fixed on pressure device with one output end fixed on steel ball with other output end connected to rotation disc; two input ends of collection and amplification circuit are fixed on steel balls and rotation disc.

Owner:HARBIN INST OF TECH

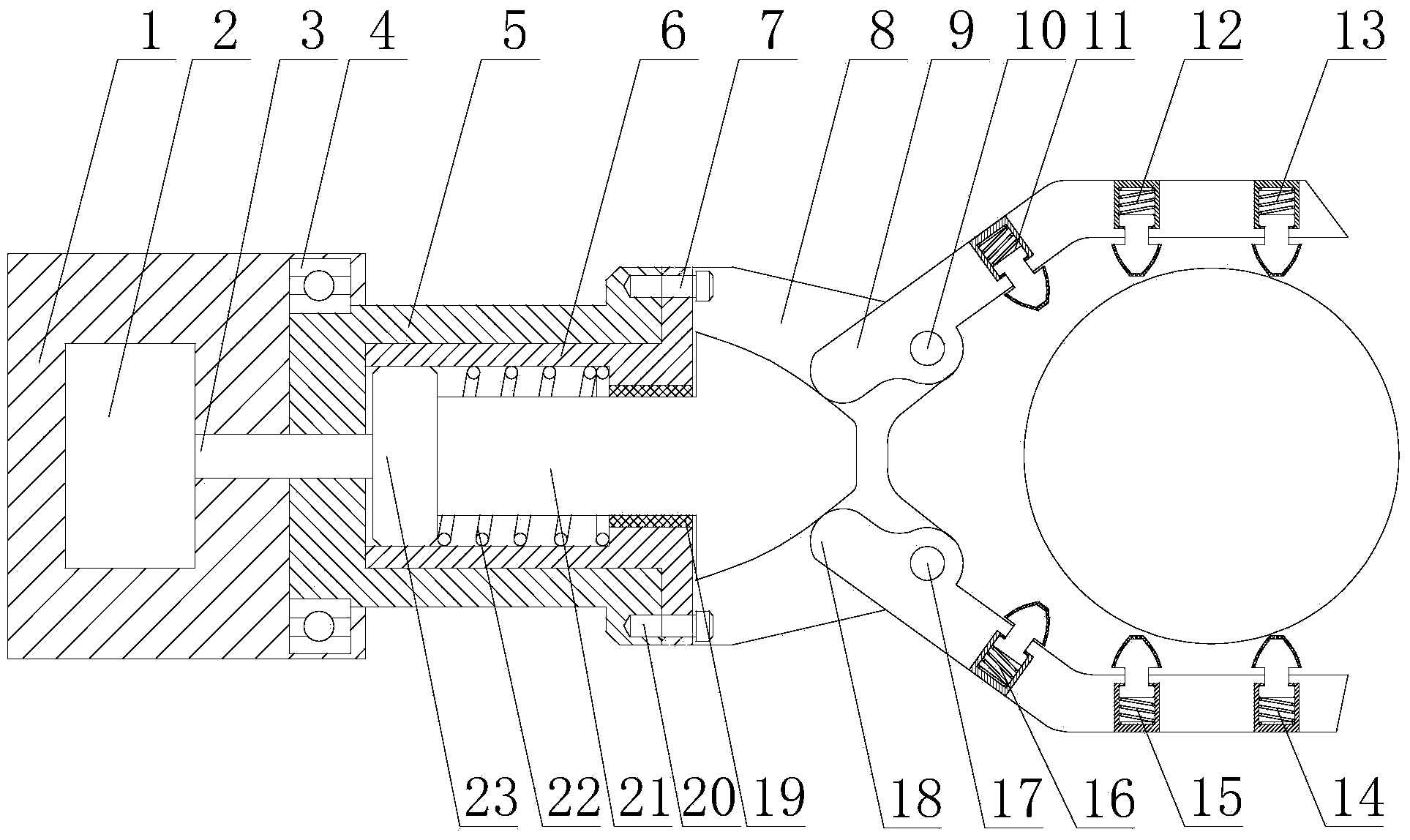

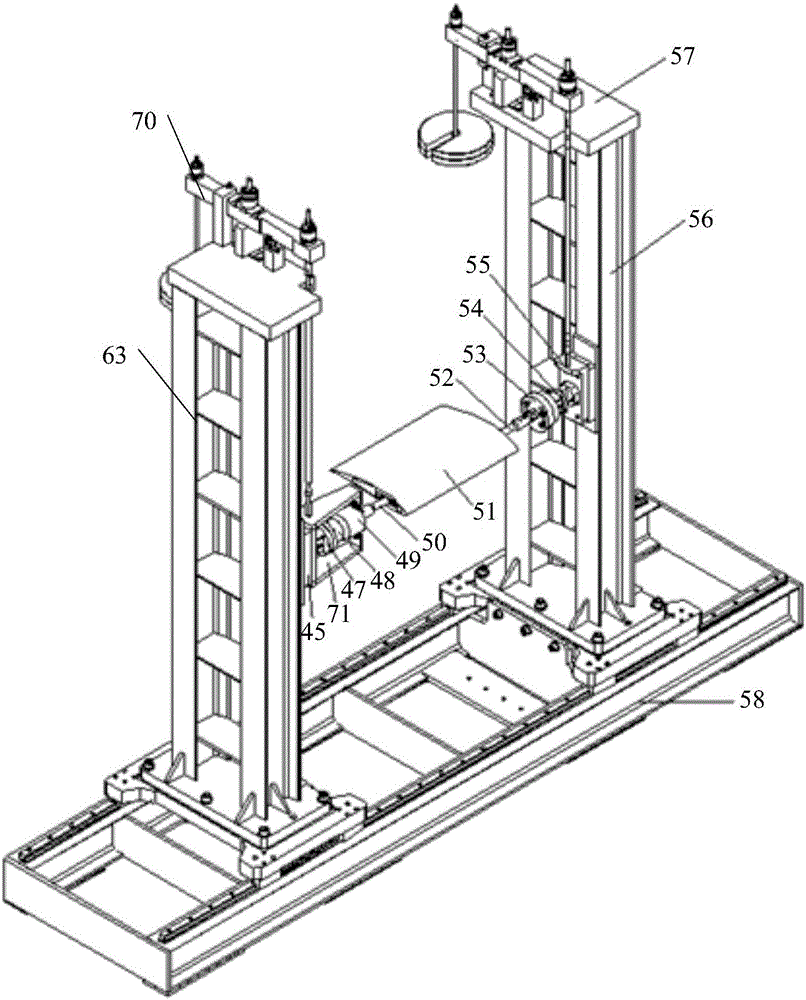

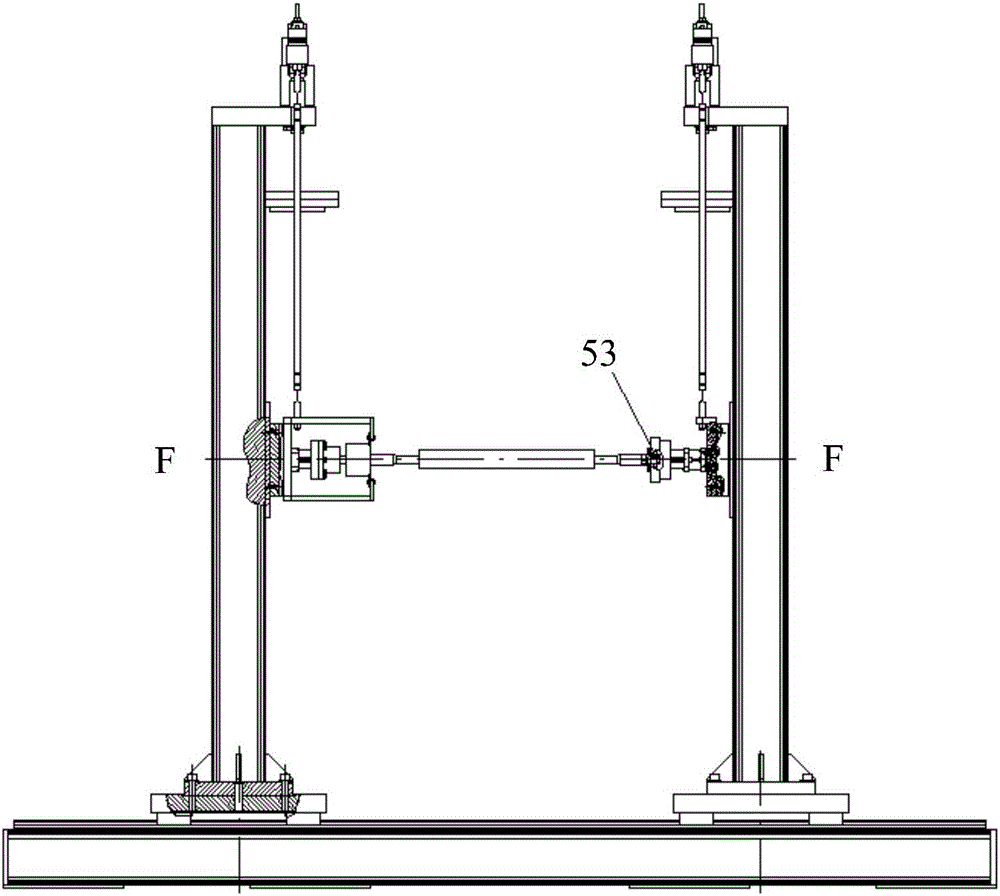

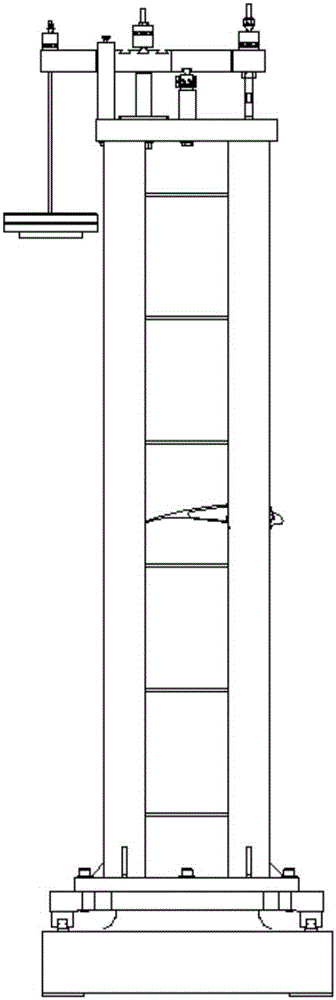

Friction-loss and vibration analog experimental equipment for main motion components of IC engine

InactiveCN1940523AMonitor temperature in real timeReal-time monitoring of abrasive compositionInternal-combustion engine testingInvestigating abrasion/wear resistancePiston ringFriction loss

A tester used for simulating wear-out and vibration of main movable parts on internal combustion engine consists of master driving system formed by air cylinder, piston ring, piston, crankshaft, inlet and outlet of high pressure air; state monitoring system formed by pressure transducer and vibration transducer on bearing base, oil monitoring transducer and temperature transducer as well as vibration transducer on machine rack, and dynamic transducer on crankshaft. It is featured as utilizing high pressure air to simulate explosion pressure in air cylinder and to simulate operation condition causing wear-out and vibration of cylinder sleeve and piston ring pair in said engine.

Owner:WUHAN UNIV OF TECH

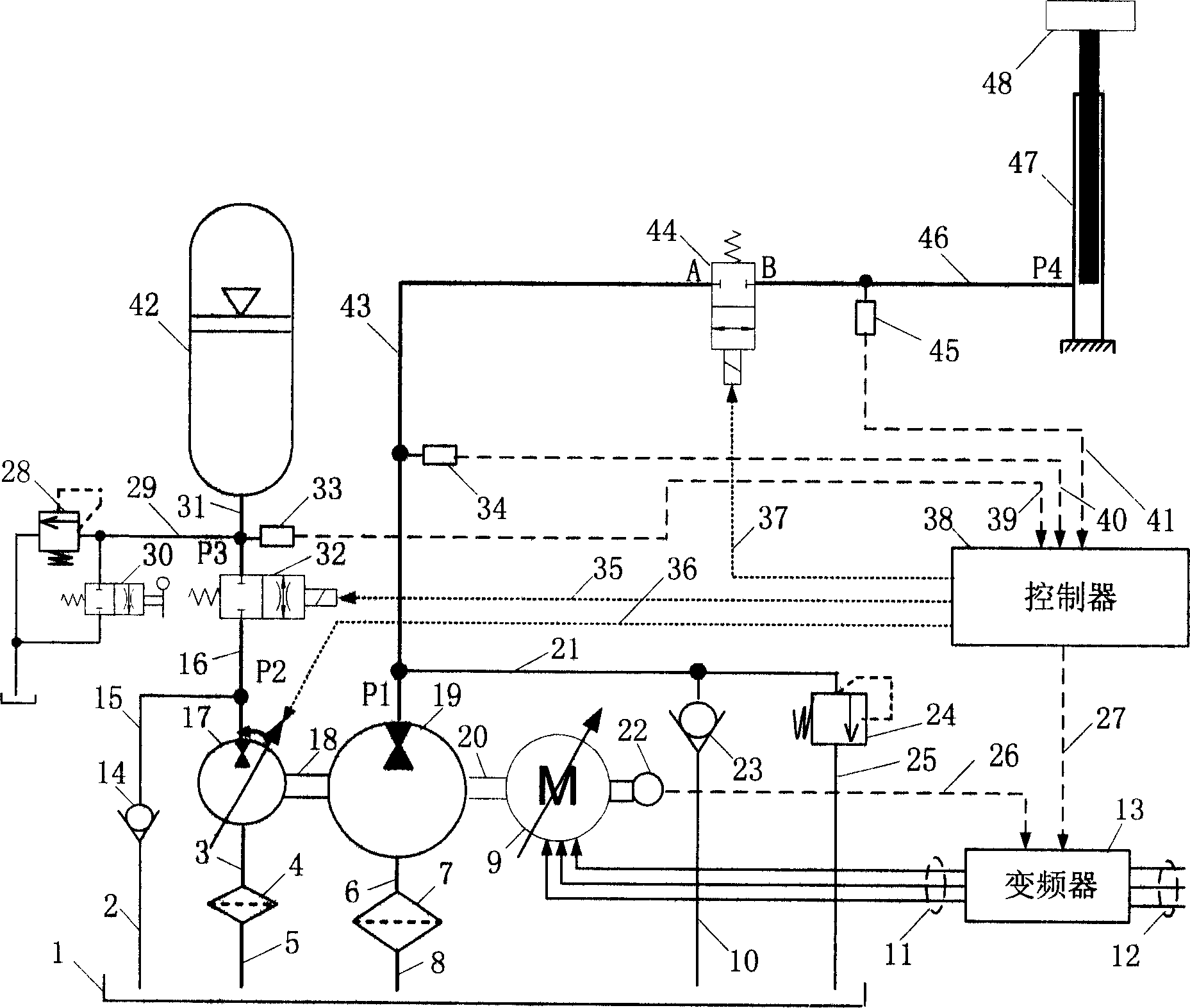

Energy saving hydraulic lifting system of variable hydraulic counterweight

InactiveCN1987124ANo wasteReduce installed powerServomotorsElevatorsFrequency changerHydraulic motor

An energy-saving hydraulic lift system with variable hydraulic counterweight for the real-time match with load is composed of a primary loop consisting of frequency variator, AC asynchronous motor, quantitative pump / motor, and hydraulic cylinder or hydraulic motor, and a secondary loop consisting of hydraulic energy accumulator (hydraulic counterweight) for recovering the all energy generated by lowering load and variable pump / motor. Said asynchronous motor provides the only energy needed by system efficiency and friction loss.

Owner:ZHEJIANG UNIV

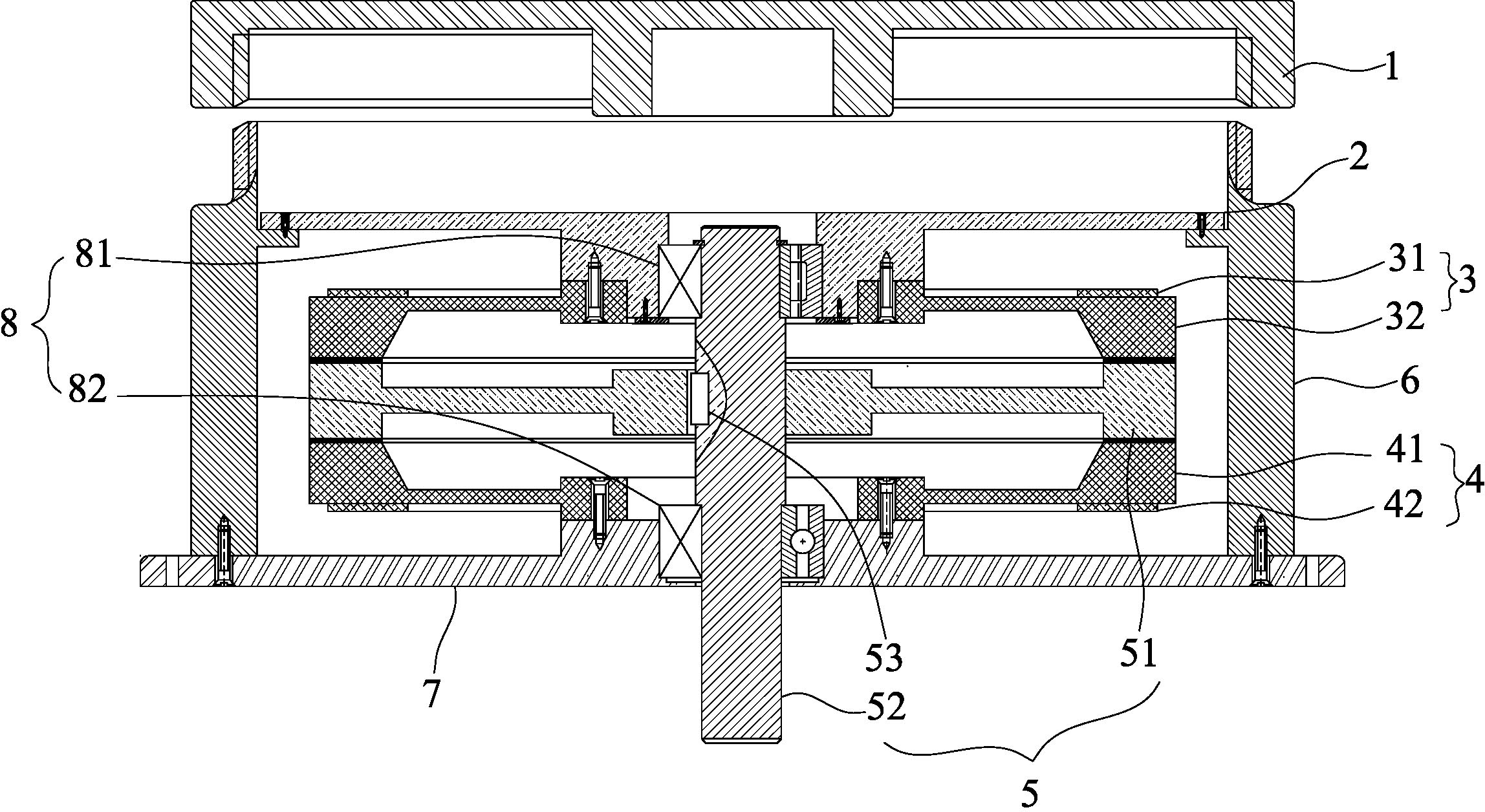

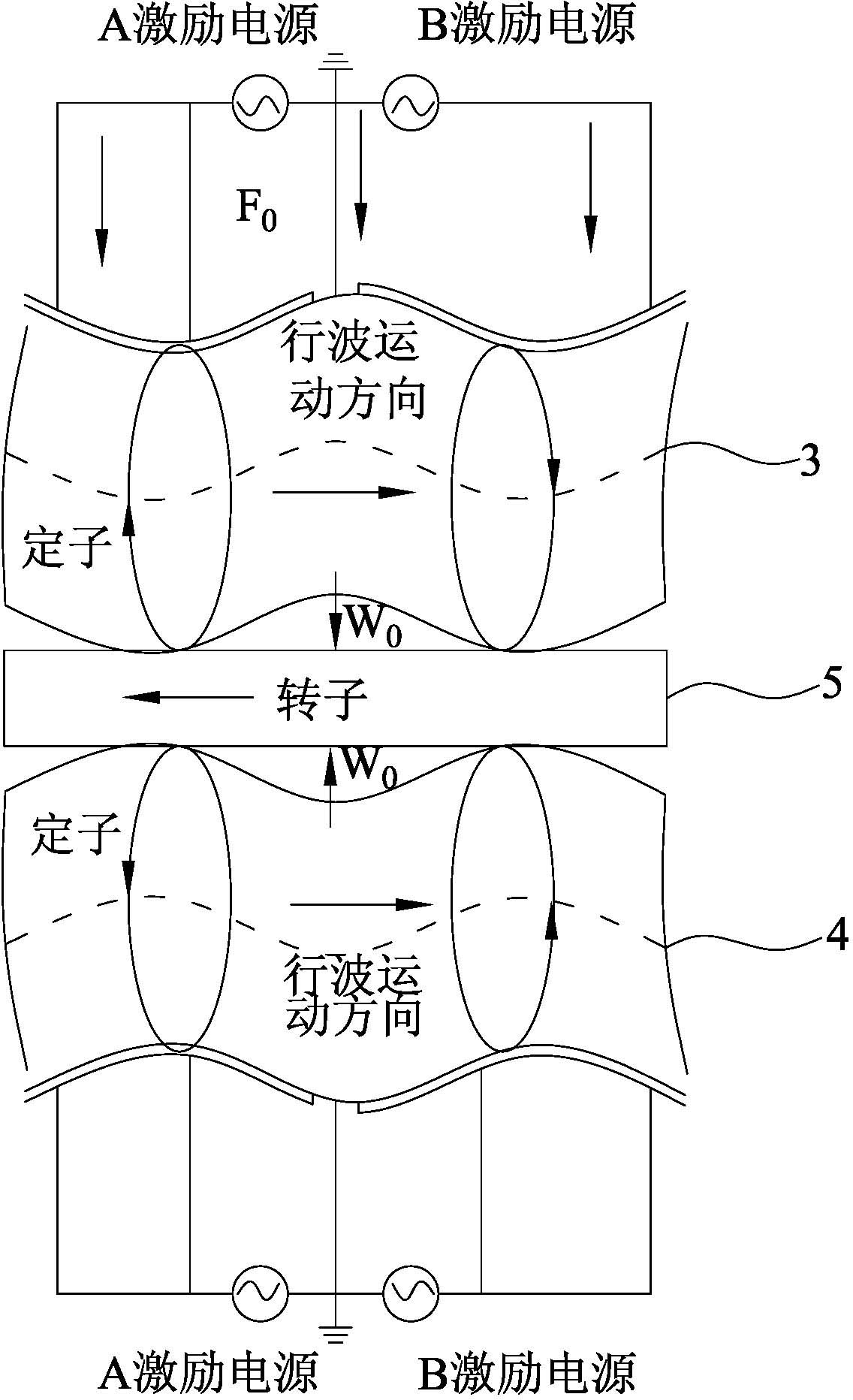

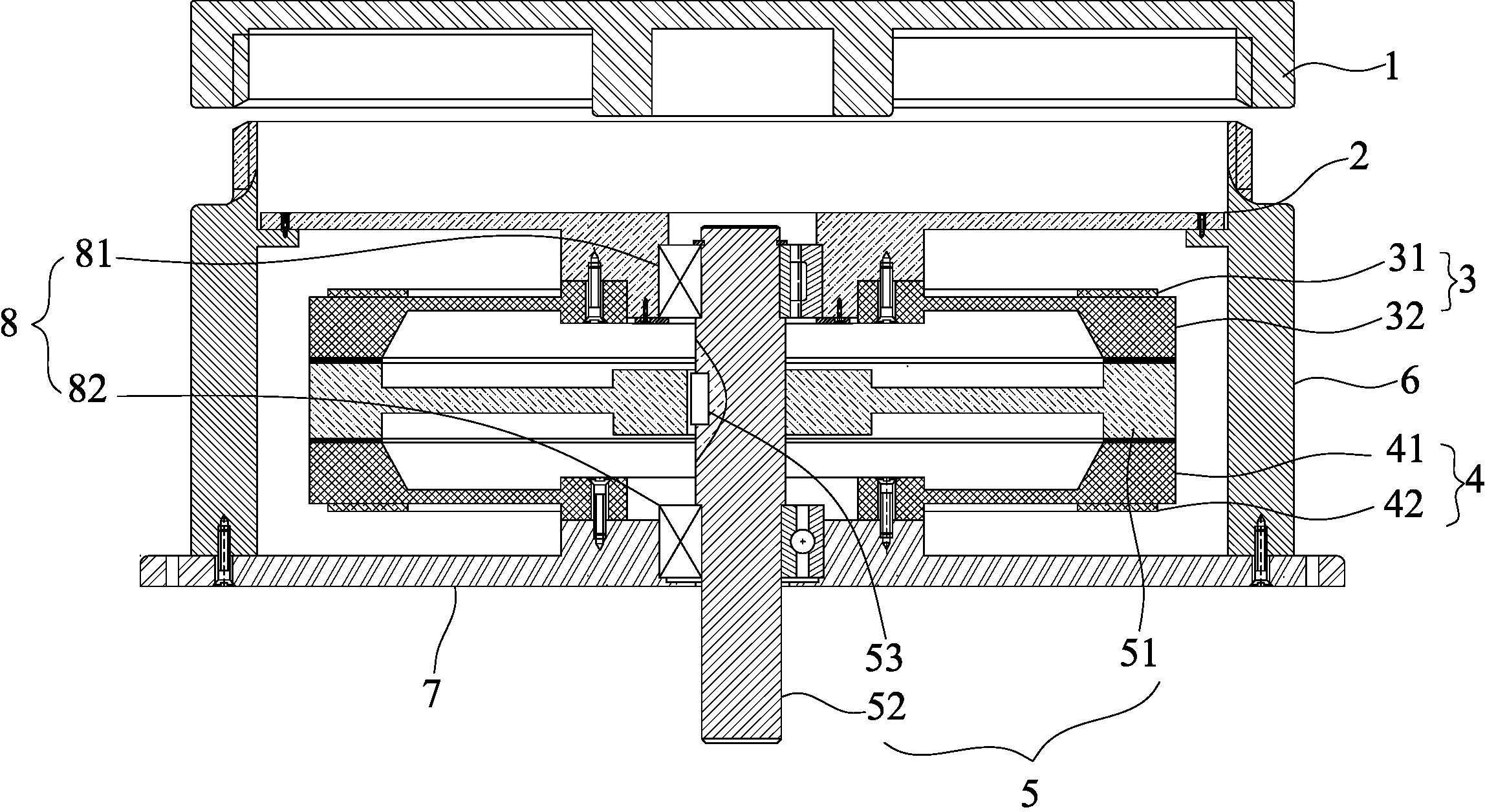

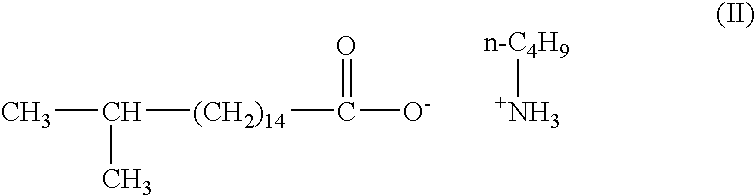

Novel rotating travelling-wave ultrasonic motor

InactiveCN102437787AIncrease the maximum output torqueImprove efficiencyPiezoelectric/electrostriction/magnetostriction machinesElectric machineFriction loss

The invention discloses a novel rotating travelling-wave ultrasonic motor. The ultrasonic motor comprises the following main parts: two stators, a rotor, a pedestal, a friction pad, a check ring, a bearing and the like. The two stators which are in a same shape are symmetrically arranged and compact on two end faces of the rotor. Working faces of the two stators can be parallelly contacted with a surface of the rotor so that a contact surface of the stators and the rotor bears stress evenly. In a current rotating travelling-wave ultrasonic motor based on a single stator structure, radial contact between the stator and the rotor is nonuniform, a contact scope is small, and radial sliding friction losses and other defect are existed in the stator and the rotor. By using the ultrasonic motor of the invention, the above defects can be overcome. A maximum output torque and an efficiency of the rotating travelling-wave ultrasonic motor can be increased and a service life of the rotating travelling-wave ultrasonic motor can be prolonged.

Owner:JIMEI UNIV

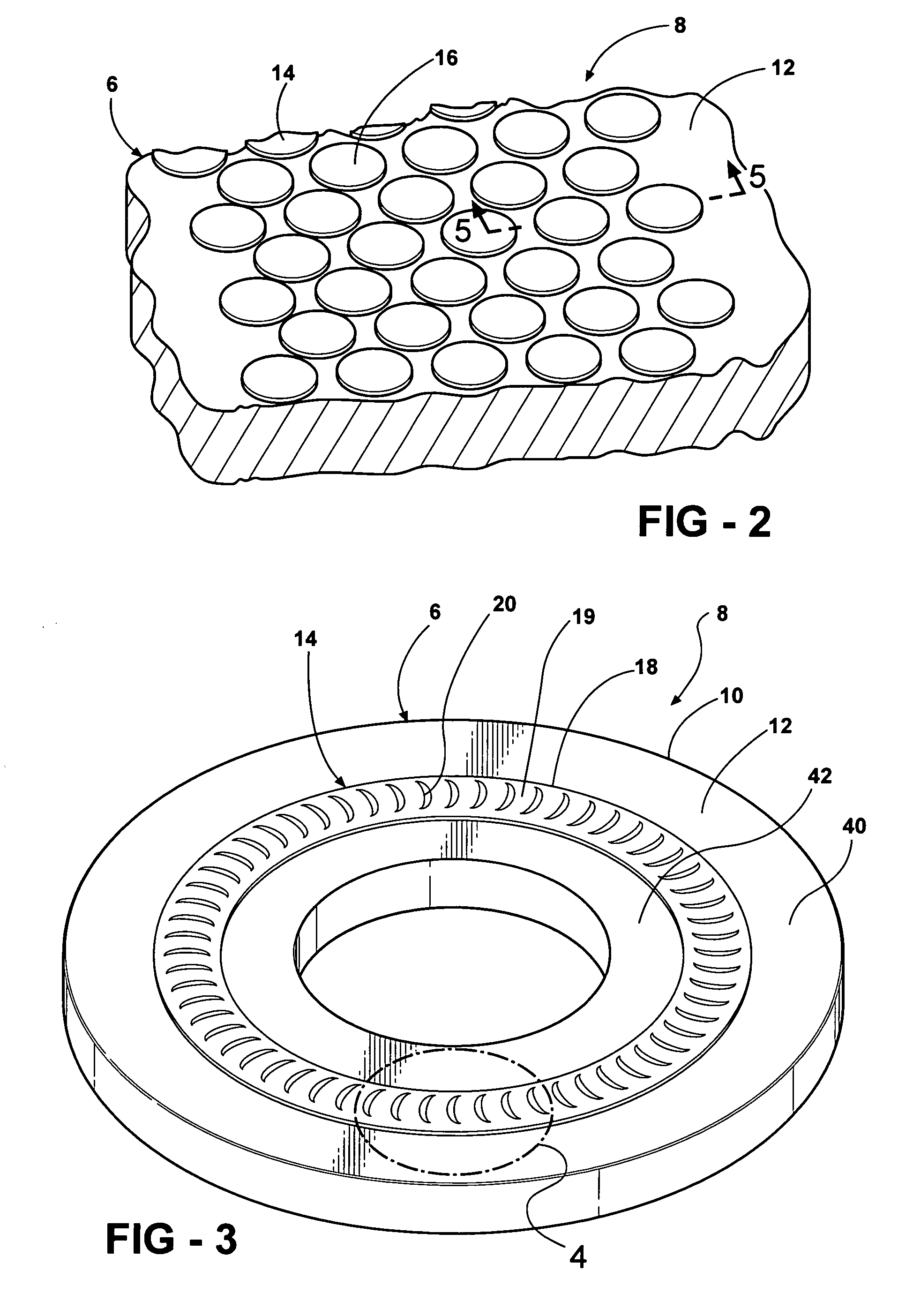

Method of making a sliding bearing

InactiveUS7458158B2Improve performanceCompromising performanceCrankshaftsBearing assemblyEffective surfaceFriction loss

This invention introduces a new category of engineered surfaces and corresponding production processes for better wear resistance and lower friction loss. The structured surfaces can be applied on many automobile components with frictional surfaces. The composite structure settles the usual conflicts between surface functions and stresses. Two sets of multiple-step processes are introduced to achieve high production efficiency and low cost. Unlike traditional surface technologies that generate single and uniform layers on the whole part surface, the new technology processes the part surface selectively for more effective surfaces with versatile functions.

Owner:FEDERAL MOGUL WORLD WIDE LLC

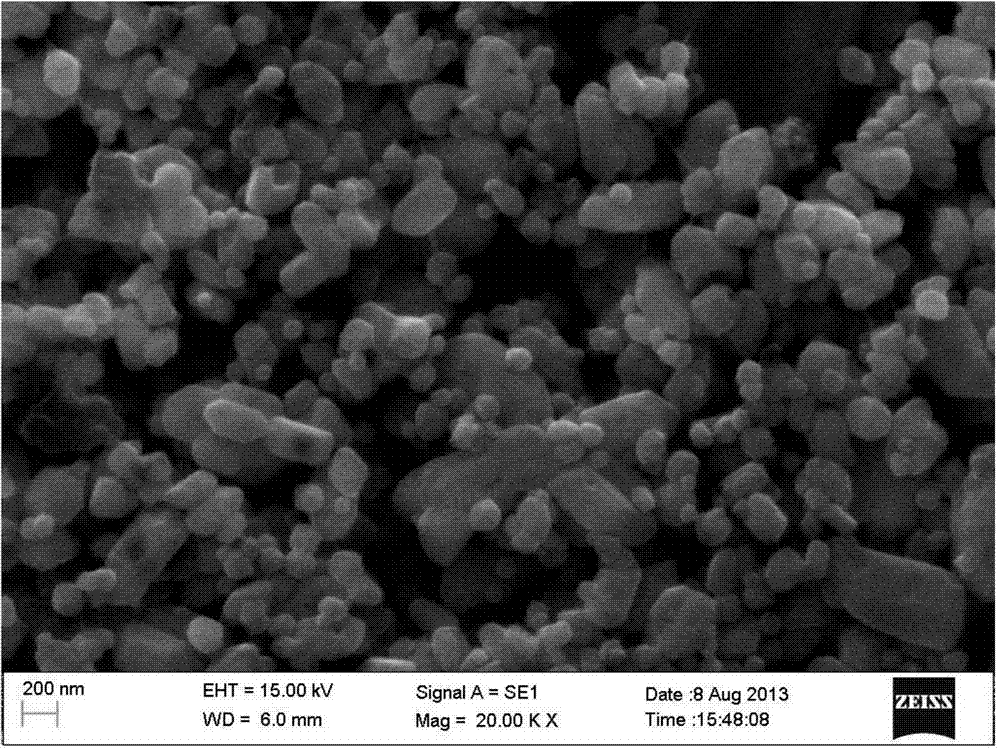

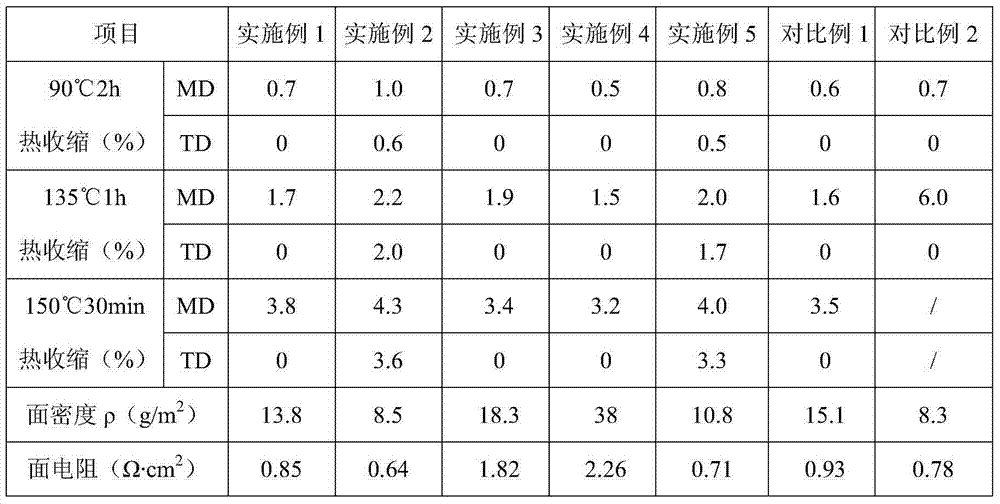

Lithium ion battery diaphragm with polymer inorganic coating and preparation method for lithium ion battery diaphragm

ActiveCN103618059ALower internal resistanceImprove performanceCell component detailsWater basedPolyolefin

The invention relates to the field of processing of lithium ion battery diaphragms, and discloses a lithium ion battery diaphragm with a polymer inorganic coating. The diaphragm comprises a macroporous polyolefin membrane and a coating layer on one side or two sides of the macroporous polyolefin membrane, wherein the coating layer consists of 20 to 60 weight percent of coating composition and 40 to 80 weight percent of water; the coating composition comprises 0.1 to 5 weight parts of water-soluble polymer thickener, 0.1 to 5 weight parts of water-based dispersing agent, 10 to 90 weight parts of polymer particles, 9.7 to 70 weight parts of ceramic particles and 0.1 to 10 weight parts of water-based latex. The invention also discloses a method for preparing the lithium ion battery diaphragm with the polymer inorganic coating. The lithium ion battery diaphragm has the advantages of low mechanical equipment friction loss, uniform and consistent coating thickness and favorability for large-scale continuous production.

Owner:SHENZHEN SENIOR TECH MATERIAL

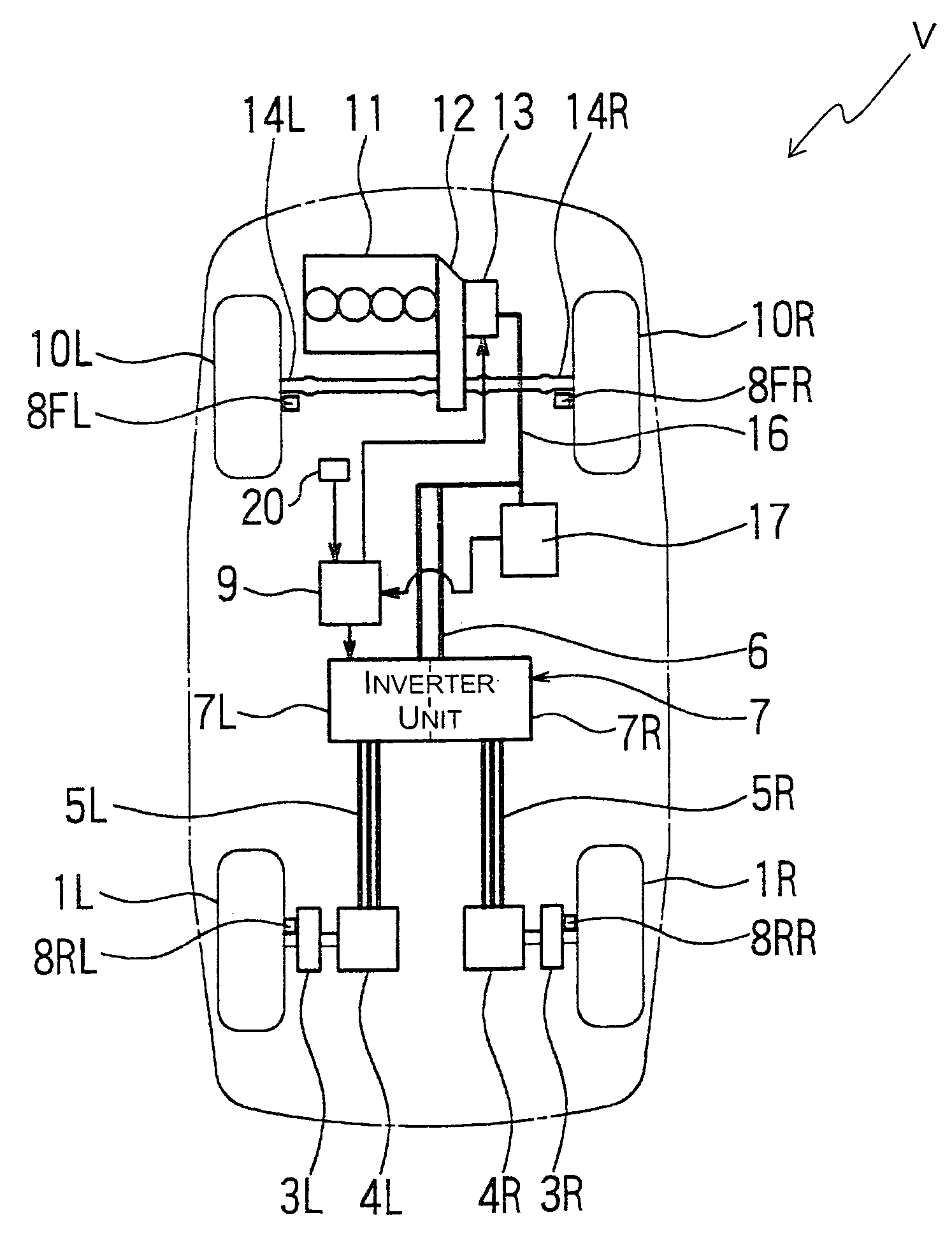

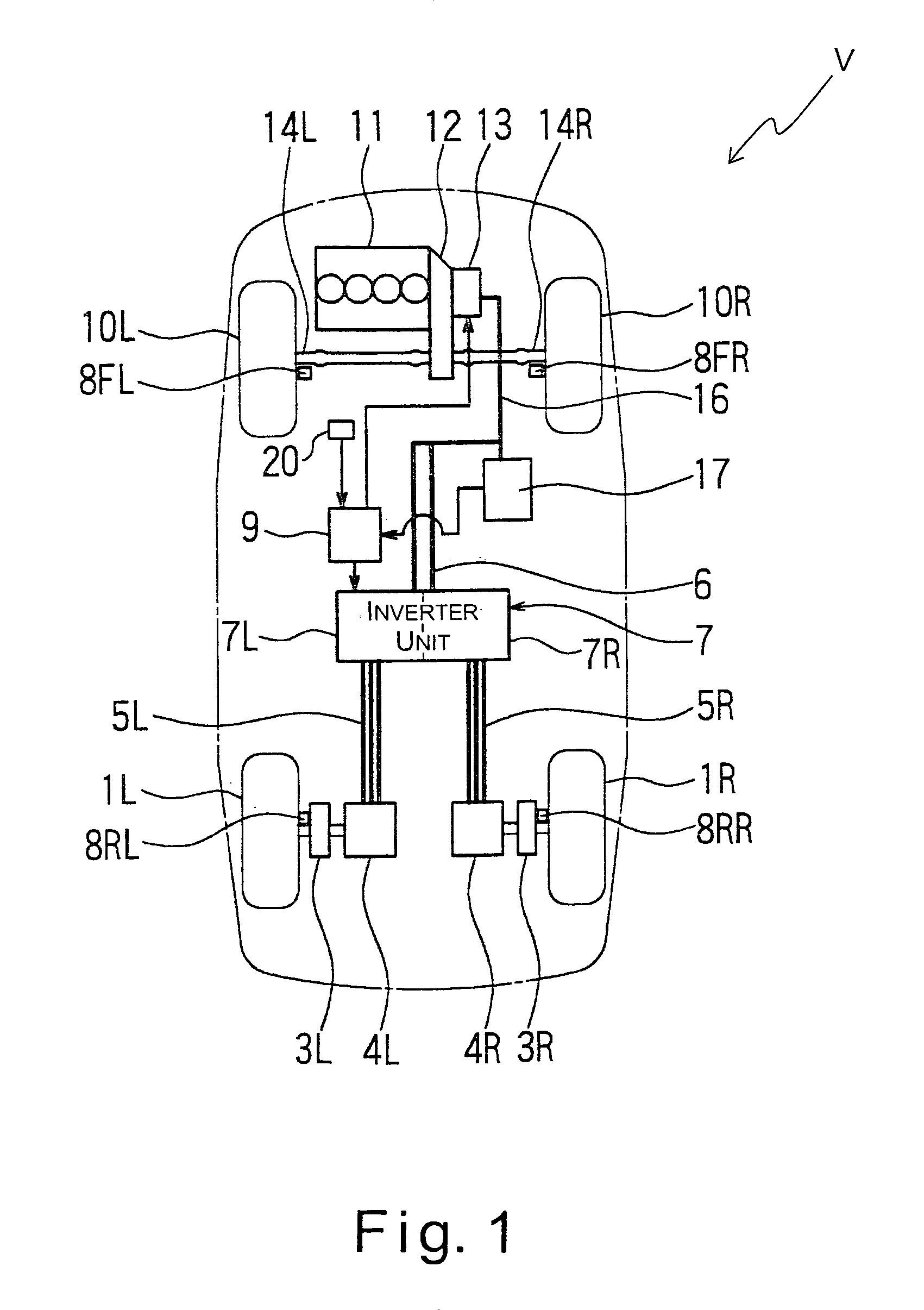

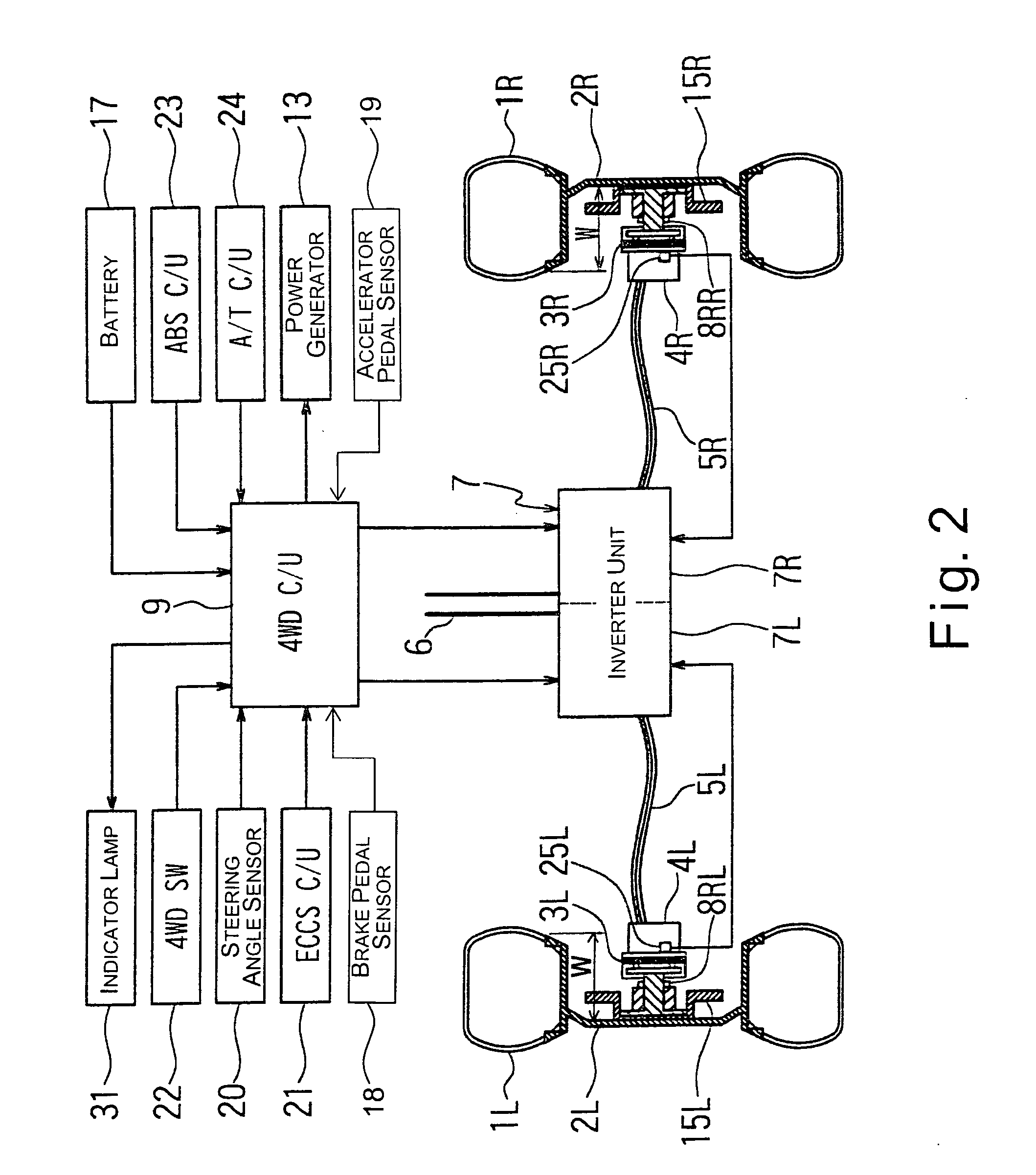

Drive apparatus for vehicle

InactiveUS7195087B2Weight increaseImprove fuel efficiencyInternal combustion piston enginesPropulsion using ac induction motorsDrive wheelFriction loss

A drive apparatus basically comprises left and right drive units each including at least a reduction gear, an electric motor without a permanent magnet, and a brake disc. Each of the left and right drive units is housed substantially within a rim of each of rear wheels which are driven wheels. A 4WD control unit is configured to control a pair of inverters to separately drive the electric motors when a vehicle speed is in a range between a standing start speed and a prescribed vehicle speed, and to stop driving the electric motors when the vehicle speed is equal to or greater than the prescribed vehicle speed to place the rear wheels in a driven state. Accordingly, a friction loss due to a cogging torque encountered in a conventional permanent magnet-type motor is eliminated, and a lightweight drive apparatus is obtained. Fuel efficiently is accordingly improved.

Owner:NISSAN MOTOR CO LTD

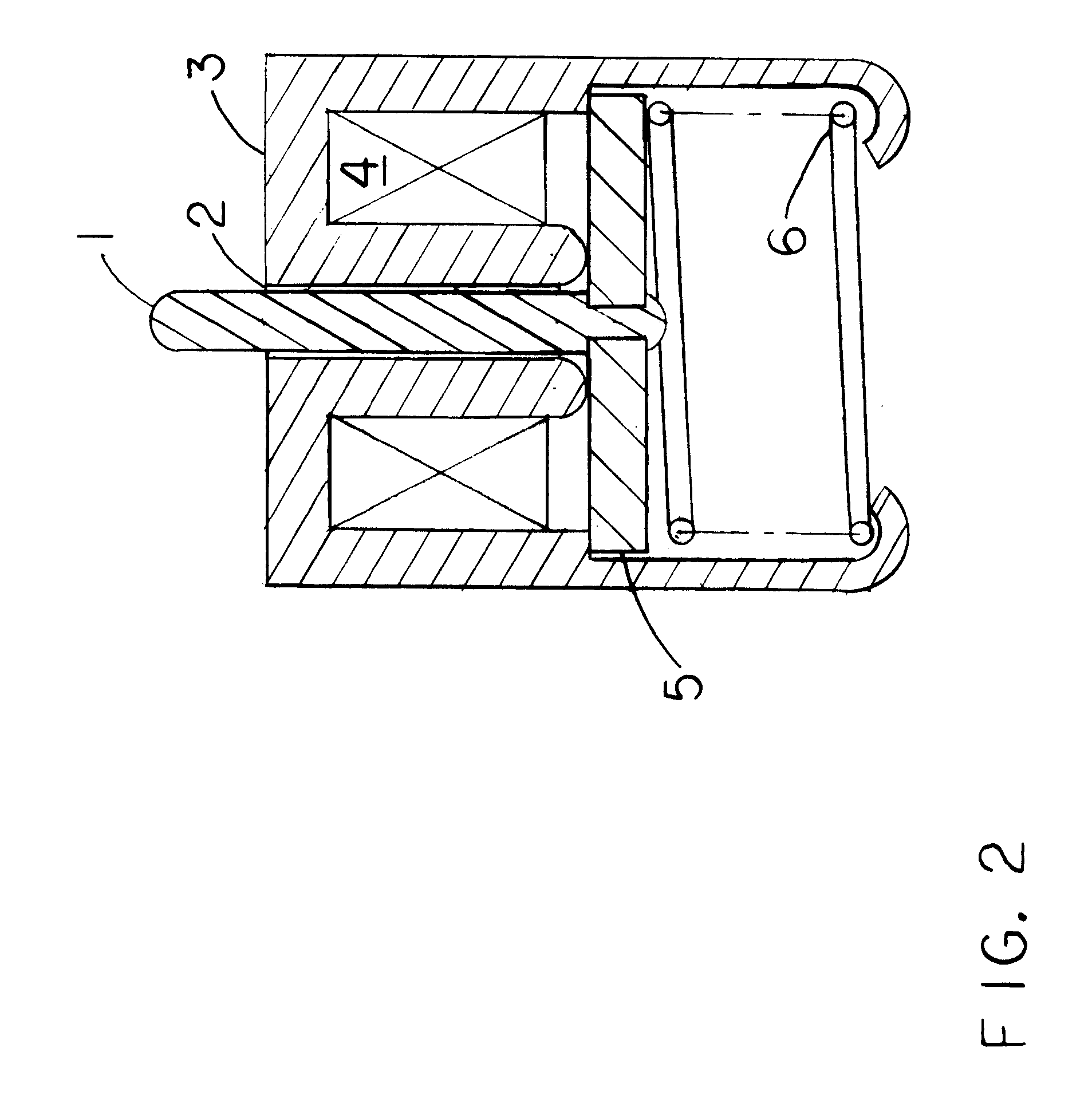

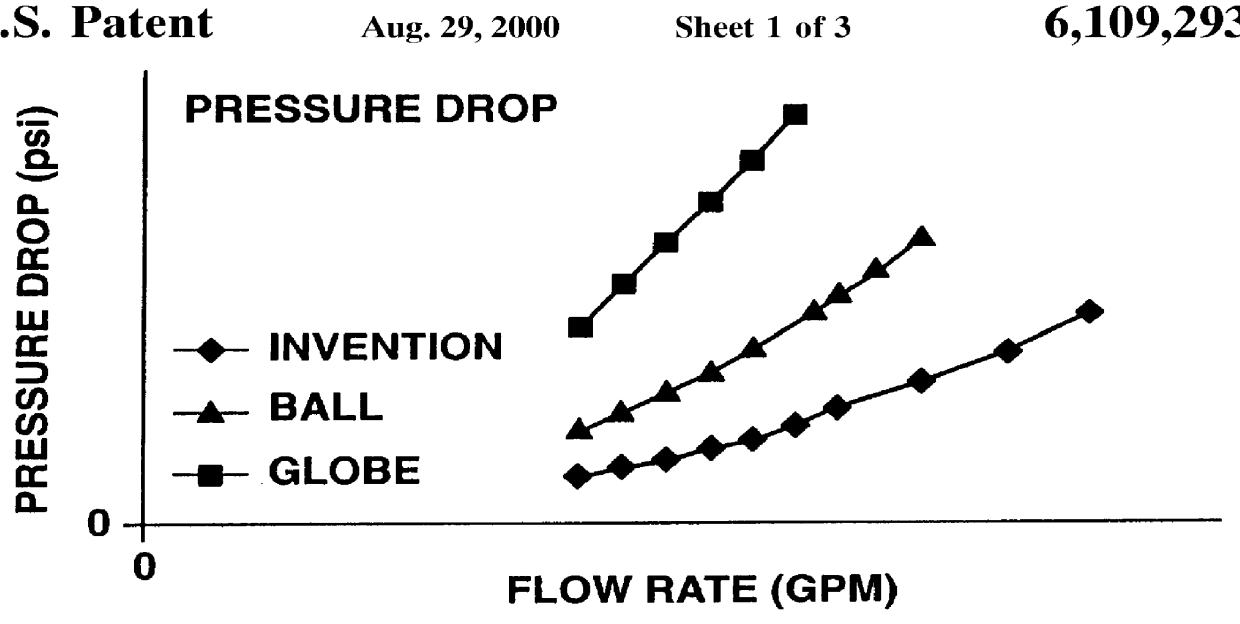

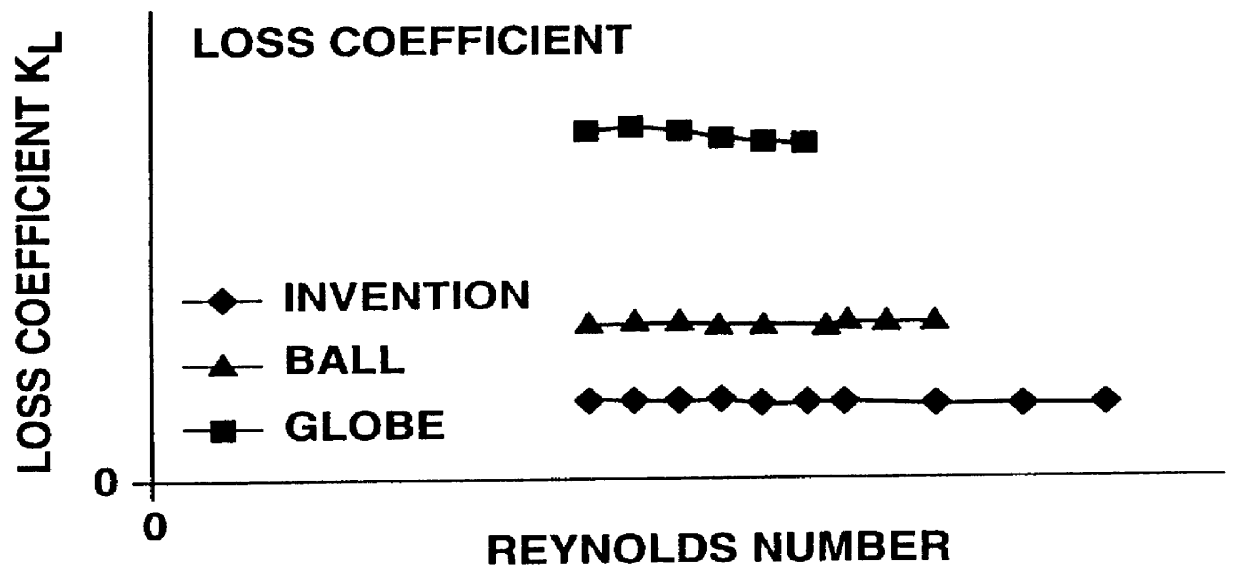

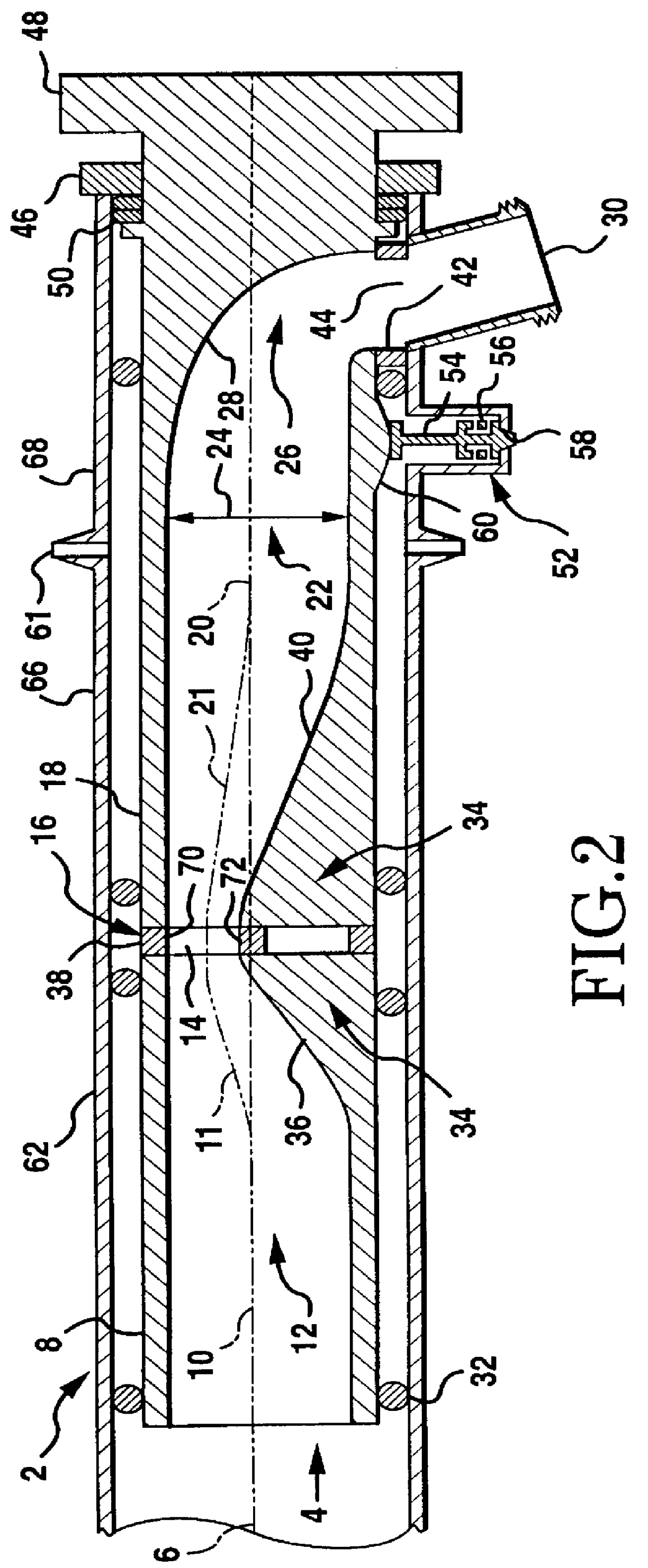

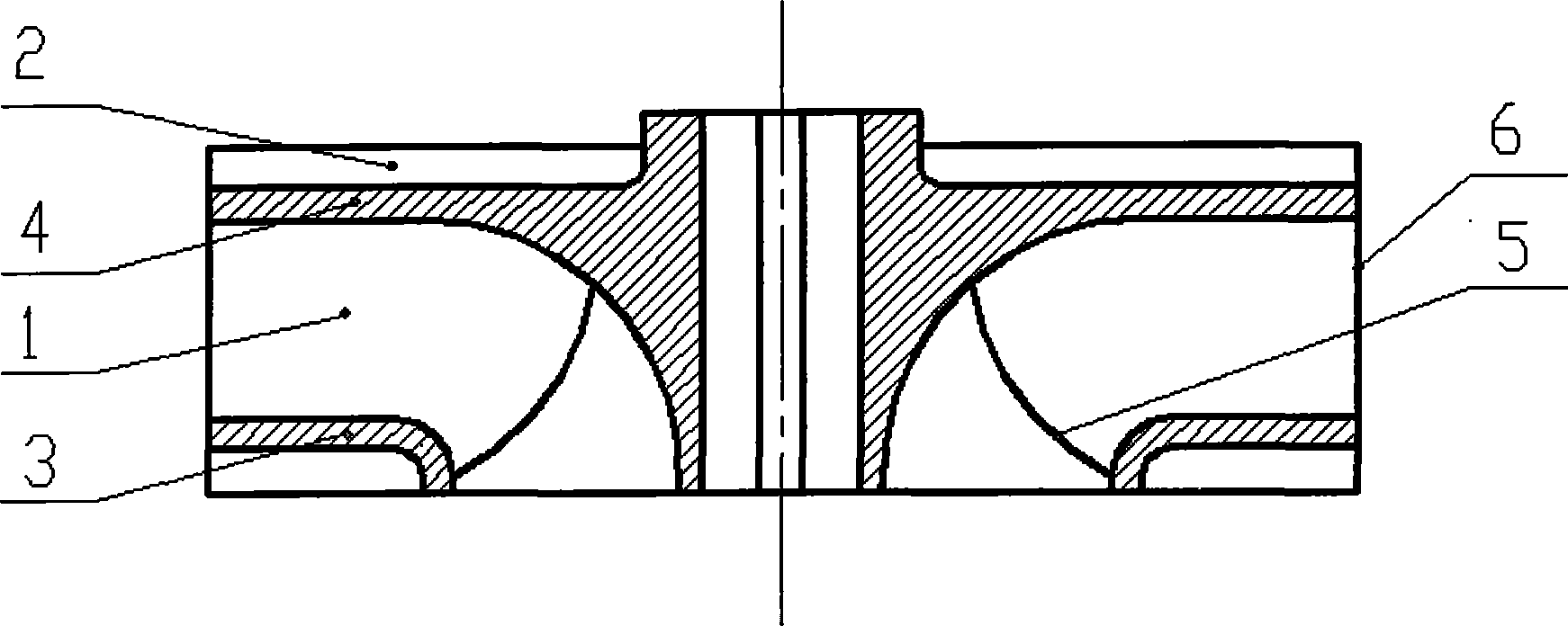

Split venturi, axially-rotated valve

InactiveUS6109293AIncrease flow rateReduce manufacturing costPlug valvesPipesCavitationValve actuator

The present invention provides an axially-rotated valve which permits increased flow rates and lower pressure drop (characterized by a lower loss coefficient) by using an axial eccentric split venturi with two portions where at least one portion is rotatable with respect to the other portion. The axially-rotated valve typically may be designed to avoid flow separation and / or cavitation at full flow under a variety of conditions. Similarly, the valve is designed, in some embodiments, to produce streamlined flow within the valve. A typical cross section of the eccentric split venturi may be non-axisymmetric such as a semicircular cross section which may assist in both throttling capabilities and in maximum flow capacity using the design of the present invention. Such a design can include applications for freeze resistant axially-rotated valves and may be fully-opened and fully-closed in one-half of a complete rotation. An internal wide radius elbow typically connected to a rotatable portion of the eccentric venturi may assist in directing flow with lower friction losses. A valve actuator may actuate in an axial manner yet be uniquely located outside of the axial flow path to further reduce friction losses. A seal may be used between the two portions that may include a peripheral and diametrical seal in the same plane.

Owner:BIG HORN VALVE INC

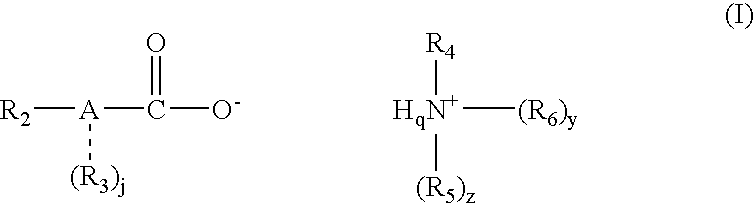

Friction modifier additives for fuel compositions and methods of use thereof

InactiveUS6866690B2Improve fuel economyFriction lossLiquid carbonaceous fuelsAdditivesCombustionFriction loss

A friction modifier for combustible fuels is provided that is prepared by combining a saturated carboxylic acid and an alkylated amine. Furthermore, there also is an additive concentrate for use in fuels, especially in gasoline for internal combustion engines, comprising (a) a friction modifier comprising of a branched saturated carboxylic acid salt of an alkylated amine, such as n-butylamine isostearate; (b) a detergent package, as well as the combustible fuels containing this additive concentrate. The particular selection of friction modifier (a) enables a stable additive concentrate to be formulated providing a significant benefit in friction loss when incorporated in gasoline used to fuel an internal combustion engine, and hence an improvement in fuel economy. Moreover, the use of the friction modifier (a) in combination with a detergent package permits increased fuel efficiency to be obtained without increasing the incidence of IVD deposits in combustion engines running on a fuel modified with the additive concentrate.

Owner:AFTON CHEM INTANGIBLES

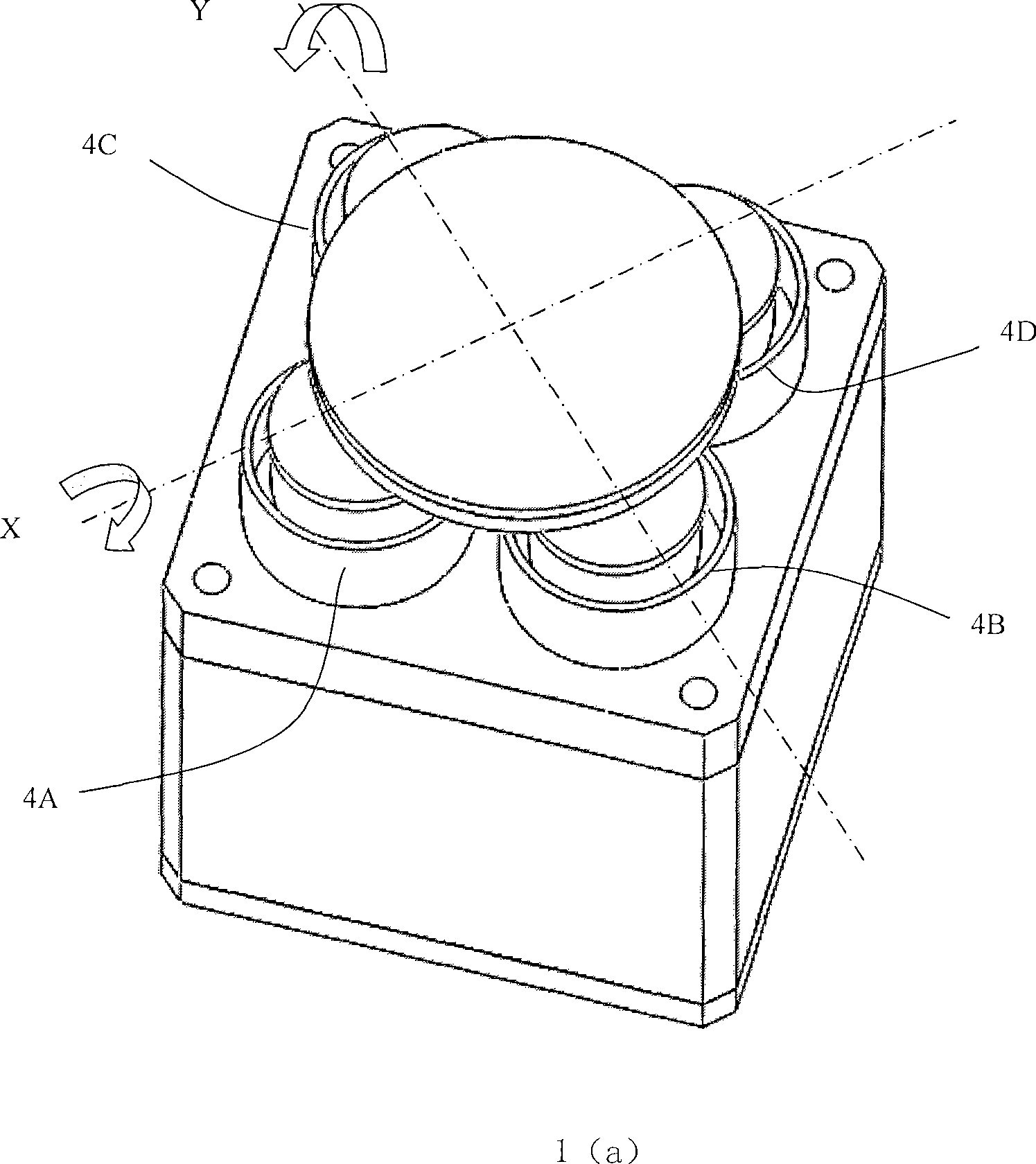

Split second control reflecting mirror

The invention discloses a fast steering mirror. An upper support frame is sequentially connected with an auxiliary mirror bracket and a main mirror bracket by an elastic bracing frame, and the main mirror bracket and the auxiliary mirror bracket are respectively fixed with a main mirror and an auxiliary mirror; four linear voice coil motors are symmetrically arranged on the surface of the upper bracing frame, and the center is provided with a through hole; a semiconductor laser, a position sensitive detector and a spectroscope tilting 45 degrees are respectively arranged under the upper bracing frame, wherein, laser emitted from the semiconductor laser passes through the spectroscope and the through hole and reaches the auxiliary mirror, the auxiliary mirror reflects the laser back to the spectroscope, and then the spectroscope reflects the laser to the position sensitive detector. The fast steering mirror has the advantages of compact structure, high angle control precision, no friction loss and high resonance frequency, can be widely used in the fields such as space optical communication, adaptive optical compensation, laser processing, laser radar and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of making a sliding bearing

InactiveUS20060288579A1Improve performanceImprove structural strengthCrankshaftsBearing assemblyEffective surfaceFriction loss

This invention introduces a new category of engineered surfaces and corresponding production processes for better wear resistance and lower friction loss. The structured surfaces can be applied on many automobile components with frictional surfaces. The composite structure settles the usual conflicts between surface functions and stresses. Two sets of multiple-step processes are introduced to achieve high production efficiency and low cost. Unlike traditional surface technologies that generate single and uniform layers on the whole part surface, the new technology processes the part surface selectively for more effective surfaces with versatile functions.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Low friction, high durability ringless piston and piston sleeve

InactiveUS20050214540A1Improve engine performanceReduce frictionVacuum evaporation coatingSputtering coatingGas phaseFriction loss

A cylinder liner and ringless piston adapted to be combined therewith in an internal combustion engine are provided that have superior wear resistance, superior scuffing resistance, and superior properties for abating friction loss between the inside surface of the cylinder and the sliding surface of the ringless piston. These embodiments can also include a cylinder liner which has at least some portion of the inner circumferential surface coated with an iron oxide film, a metallic nitride film, or other physical vapor deposition or chemical vapor deposition film, combined with a ringless piston with at least some portion of the exterior surface being coated with a metallic nitride film or other vapor deposition film.

Owner:MASLAR DAVID

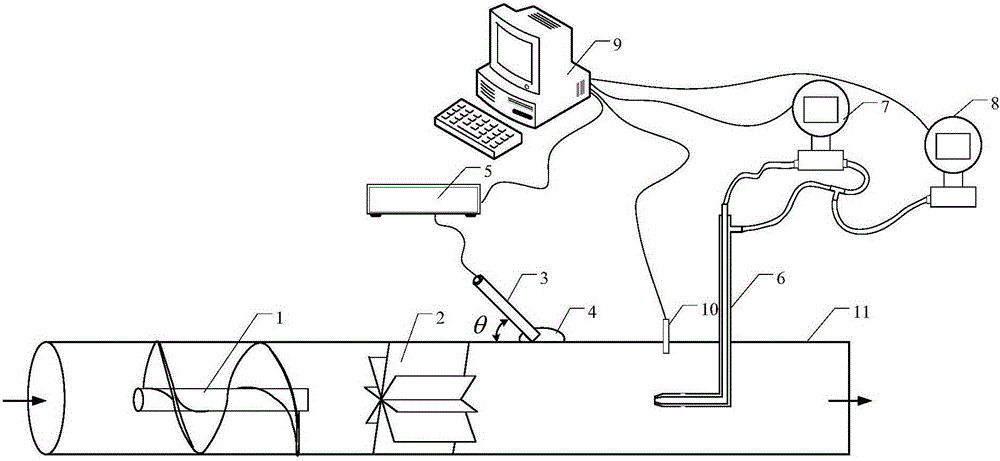

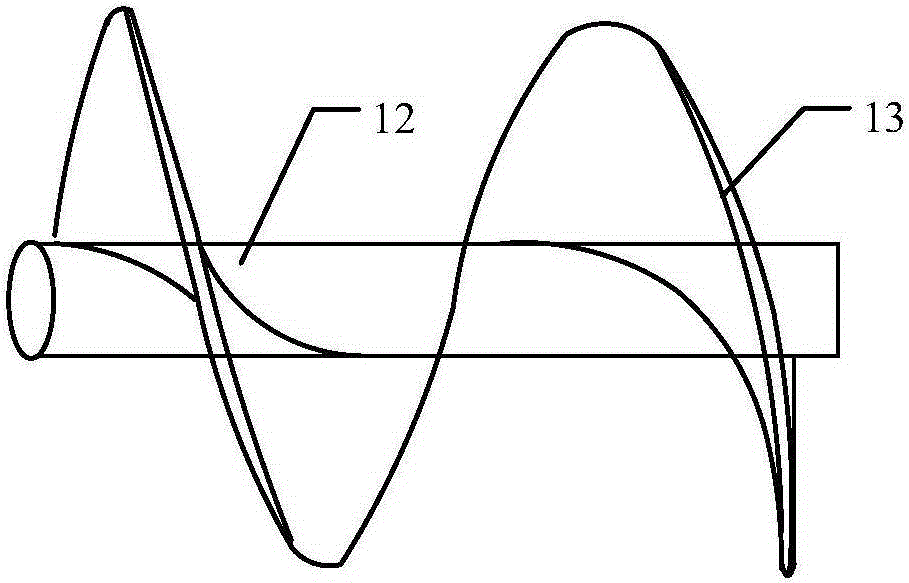

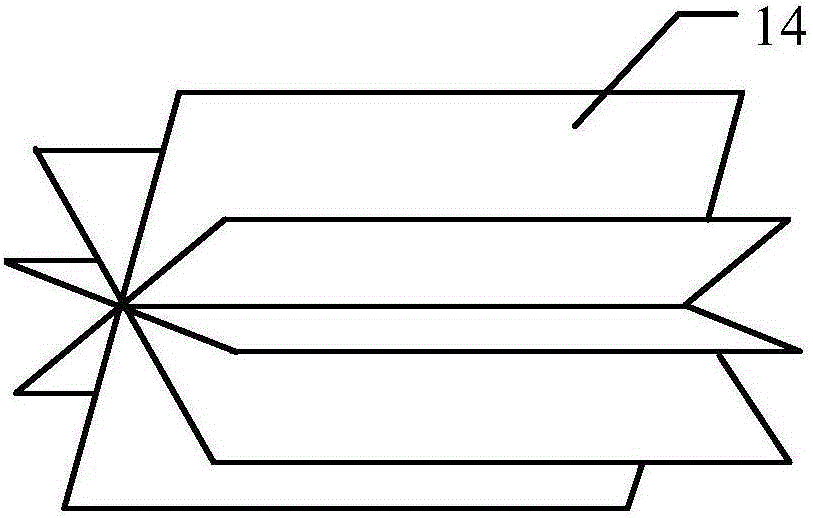

Gas-liquid two-phase flow metering device and method

InactiveCN105222831AEliminate measurement effectsHigh measurement accuracyMeasurement devicesDifferential pressureFriction loss

The invention provides a gas-liquid two-phase flow metering device, which mainly comprises a cyclone, a rectifier, an ultrasonic probe, an ultrasonic Doppler velocimeter, a Pitot tube, a differential pressure transducer, a pressure transducer, a temperature transducer, a data acquisition computer, and the like. A flow metering method provided by the invention comprises the steps of separating a gas-liquid two-phase flow in a tube by means of the cyclone to form an annular liquid film region and a central gas region, measuring the liquid flow in a liquid film by means of the ultrasonic Doppler velocimeter, and measuring the gas flow by means of the Pitot tube. Compared with a multiphase flowmeter in the prior art, the above gas-liquid two-phase flow metering device is small in size, compact in structure, small in resistance loss, wide in measurement range, and high in measurement precision.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

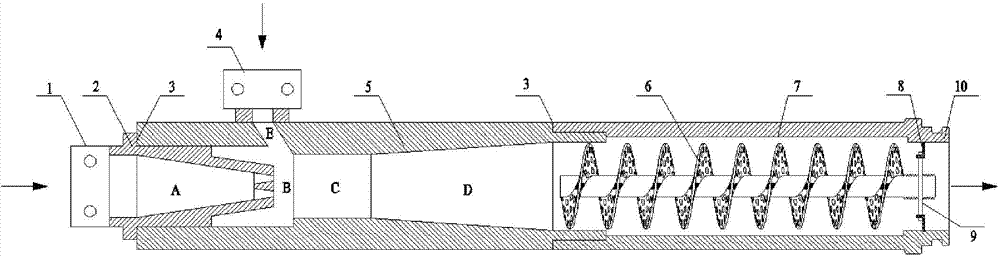

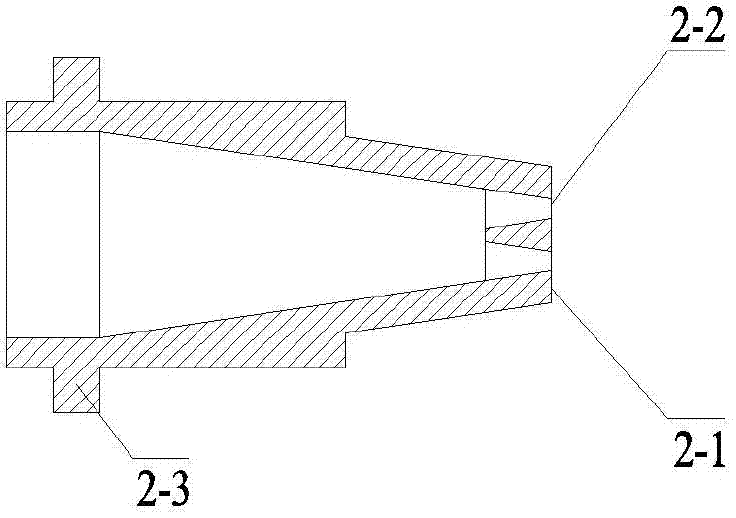

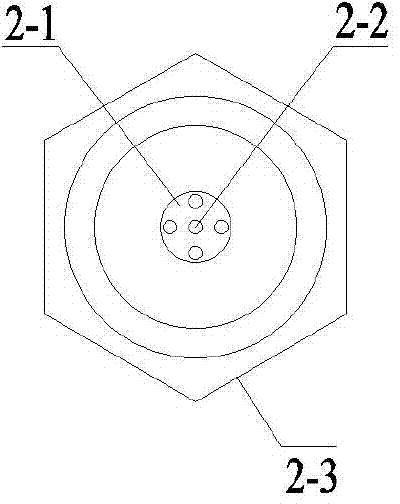

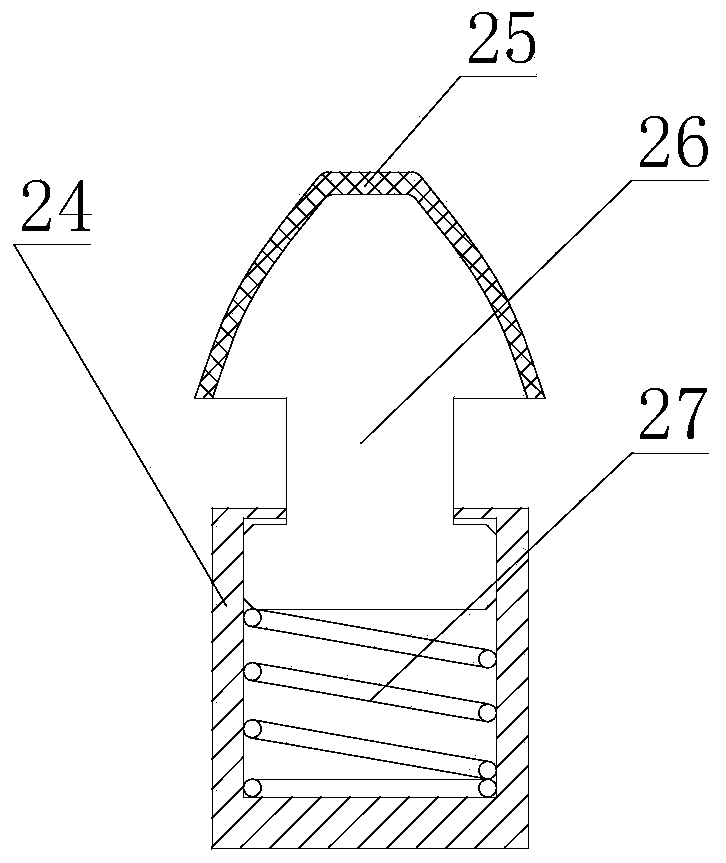

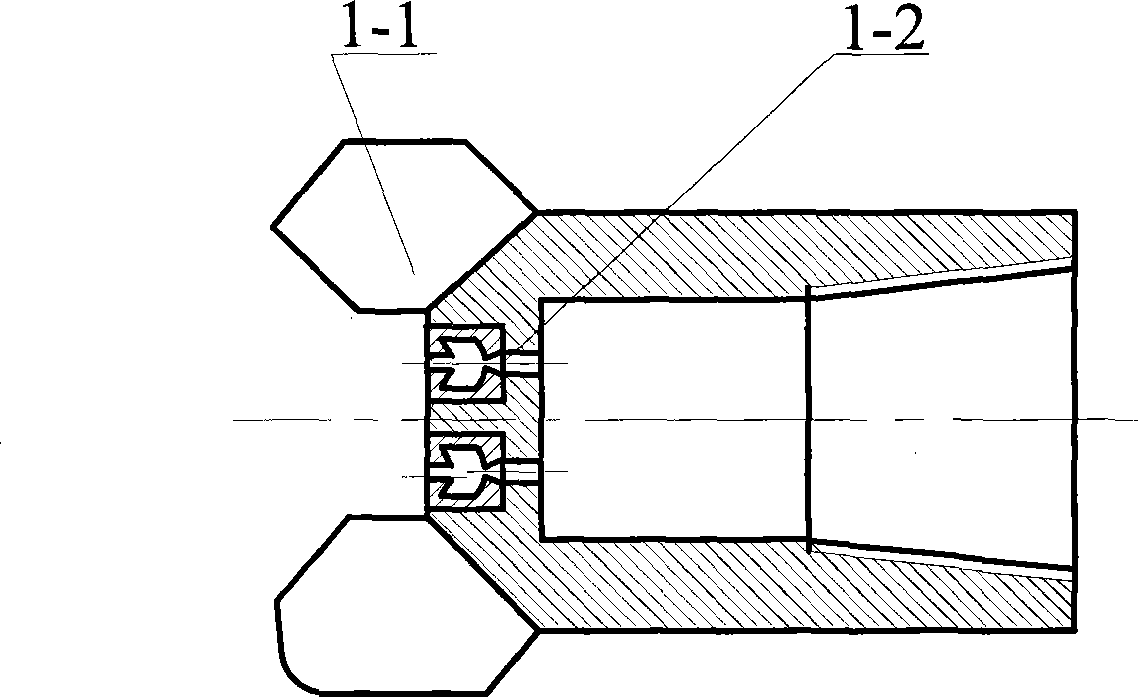

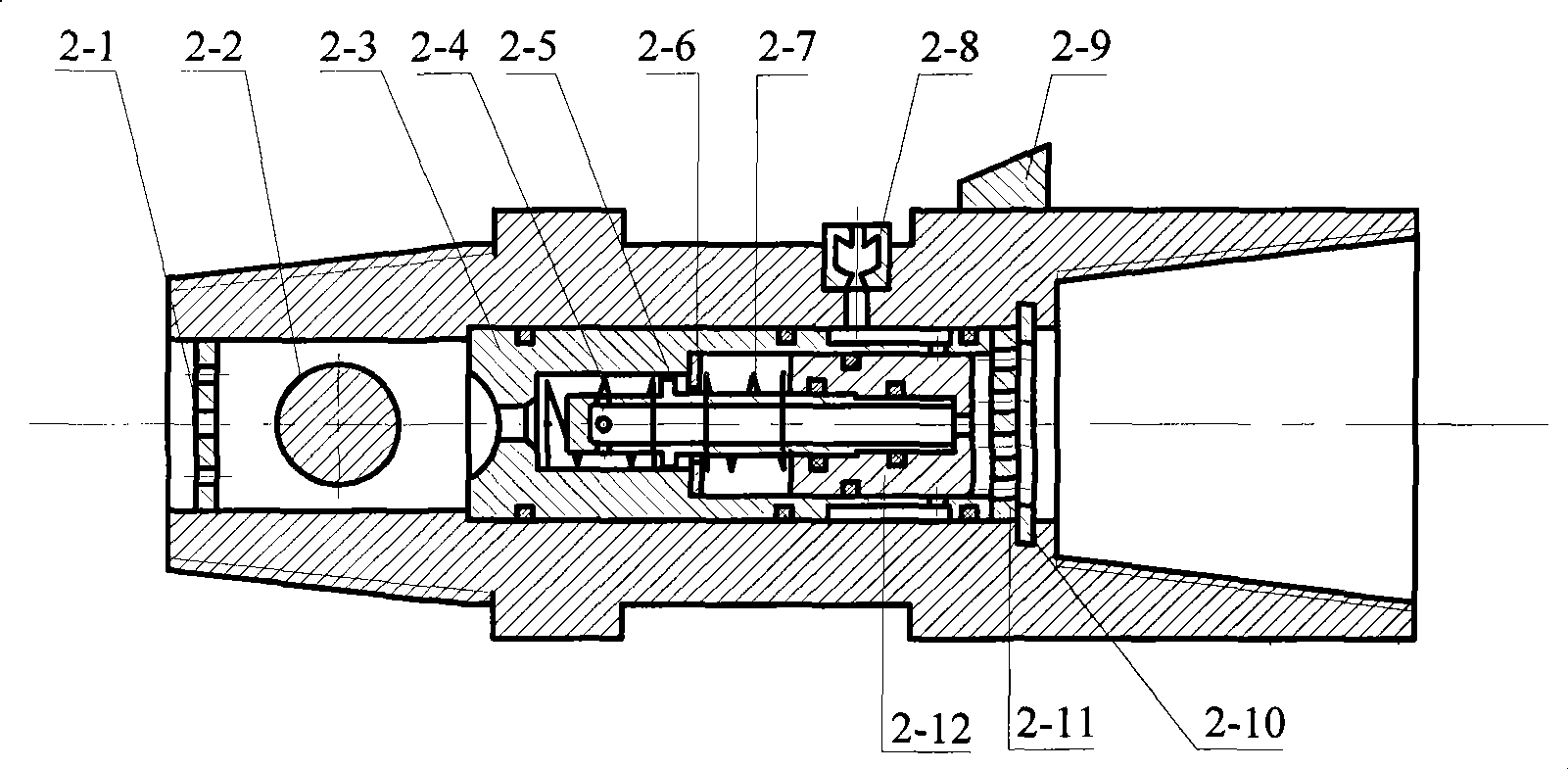

Mining porous spiral-type foam generating device

The invention discloses a mining porous spiral-type foam generating device. The mining porous spiral-type foam generating device comprises a compressed air joint (1), a nozzle body (2), a gas-liquid mixing chamber (5), porous spiral-type foamers (6), a foaming cylinder body (7) and a foam outlet joint (10), wherein the rear end of the nozzle body (2) is provided with at least one outlet nozzle; a nozzle cavity in the nozzle body (2) is of a circular truncated cone contracted shape; the compressed air joint is connected with the nozzle body; the nozzle body is installed at the inner side of the front end of the gas-liquid mixing chamber; the porous spiral-type foamers are installed in the foaming cylinder body. A multi-nozzle jet flow structure provided by the invention can achieve low-resistance high-efficiency mixing of a gas phase and a liquid phase. A wire surface high-multiple foaming and spiral low-resistance high-efficiency heat transfer mass transfer coupling mechanism is adopted for foaming, so that the foaming performance of the device is improved greatly; the generated foam is low in wind to foam ratio, is high in foaming quantity and is high in foam forming ratio; the resistance loss in the mixing and foaming process is reduced; the driving pressure of the device is improved; easily damage moving components in a turbulent flow foaming device are discarded; the device foaming reliability is improved.

Owner:CHINA UNIV OF MINING & TECH +1

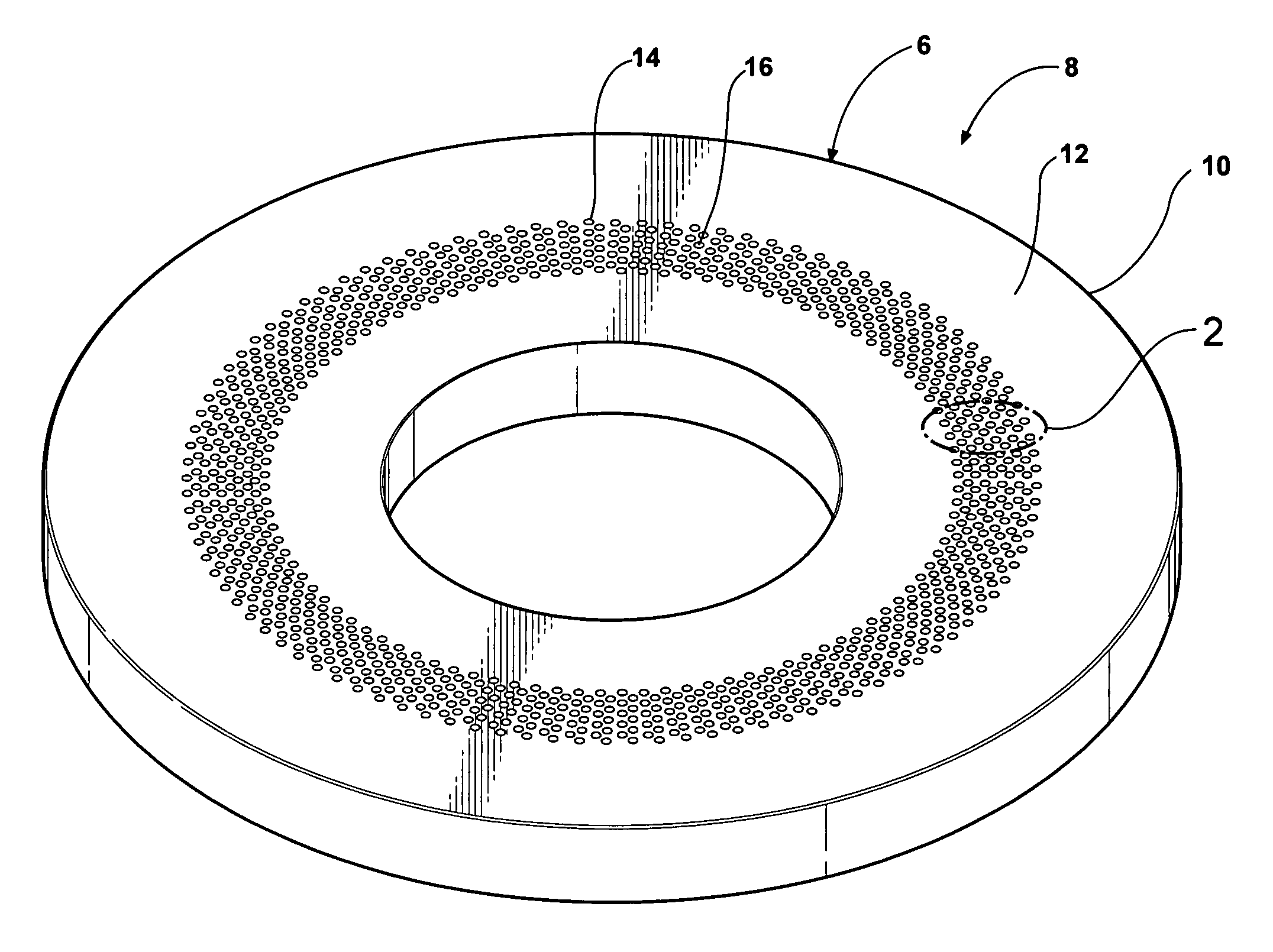

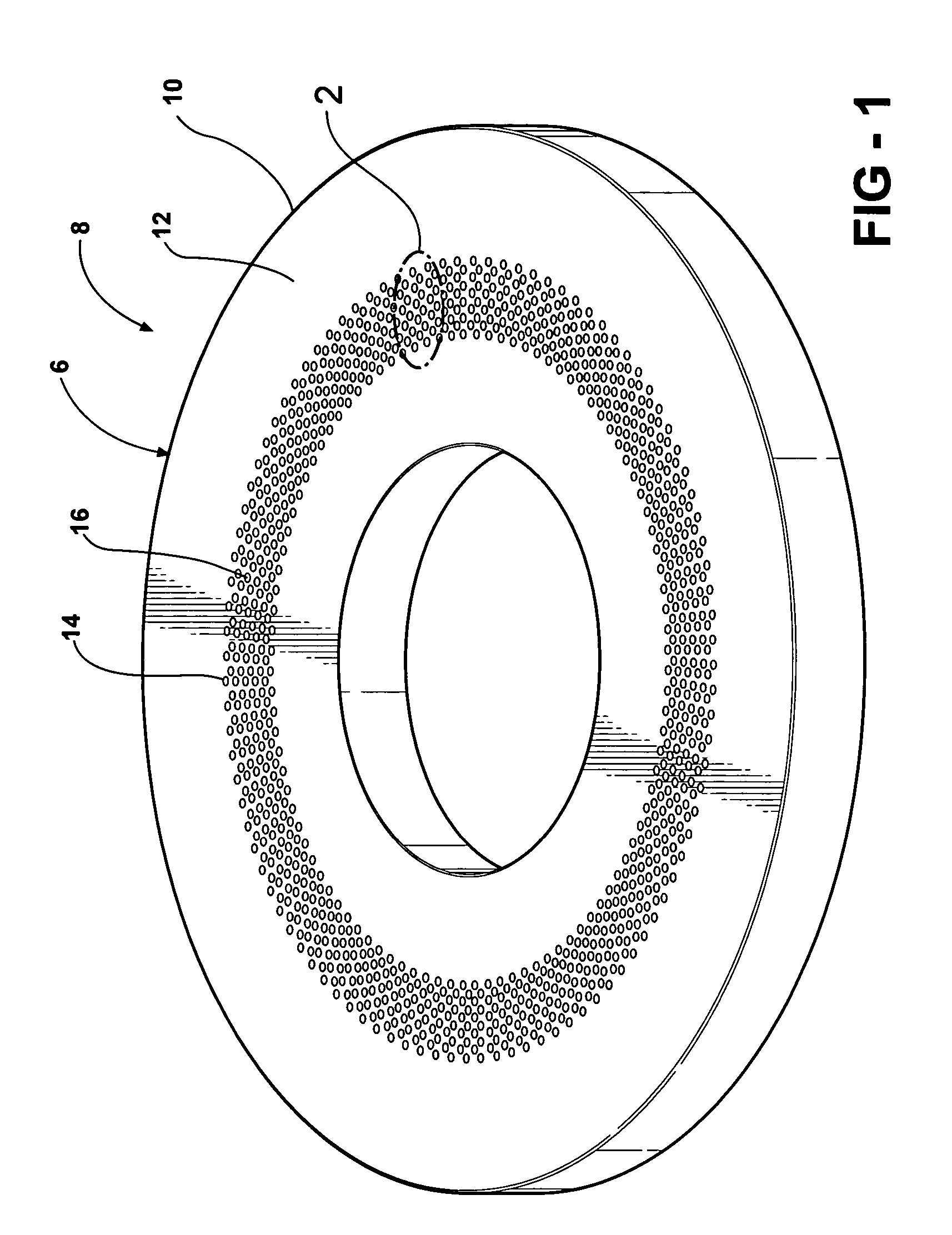

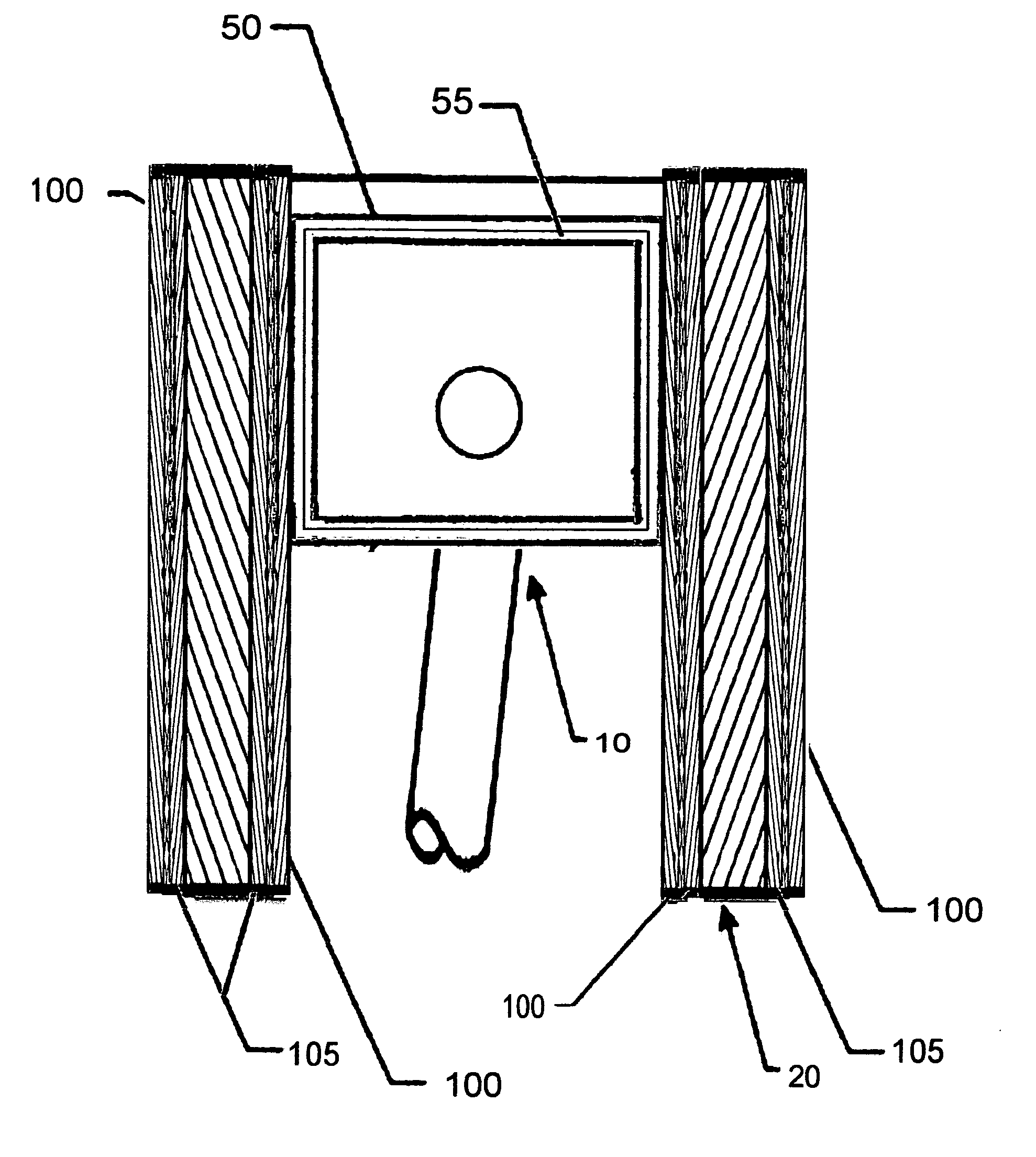

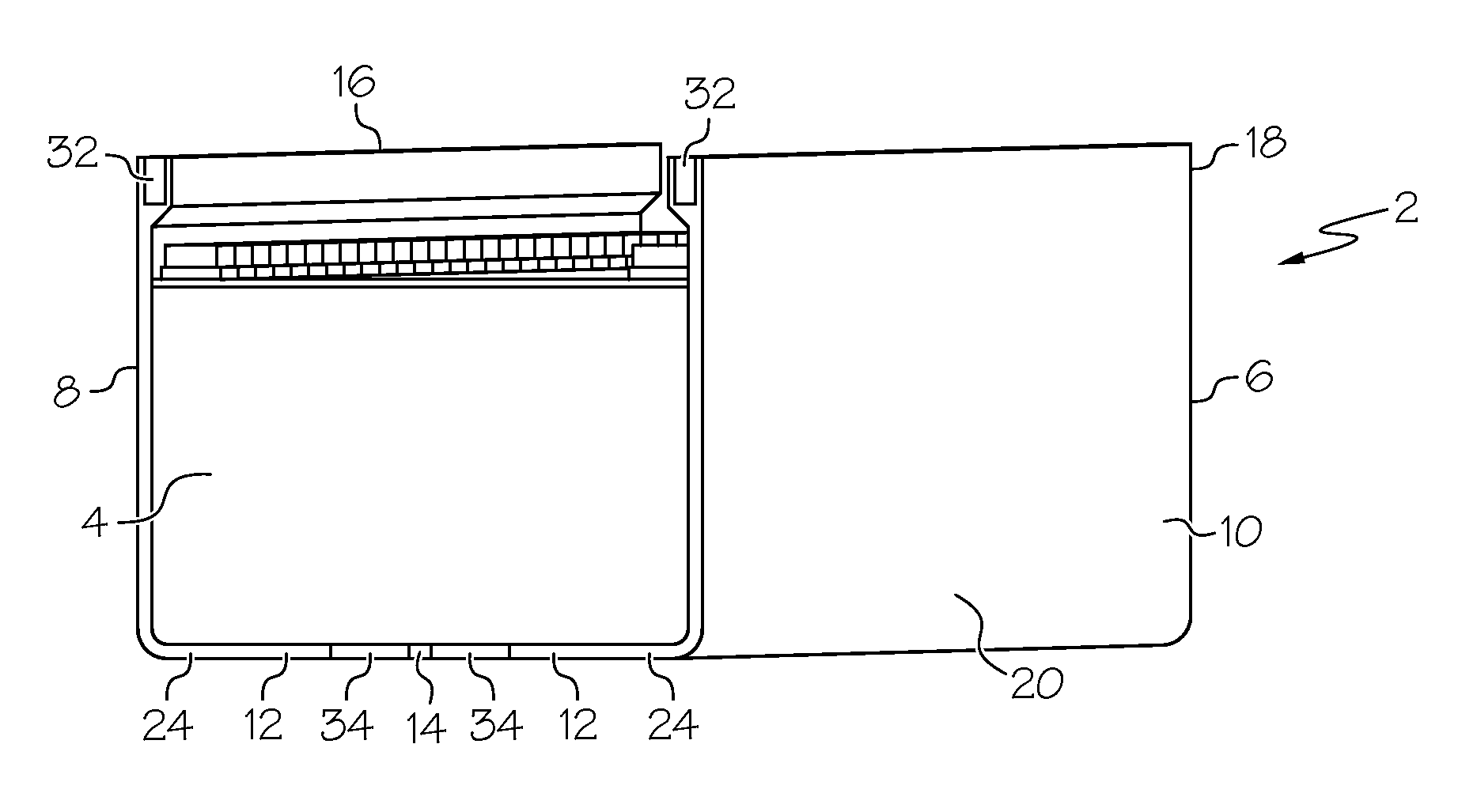

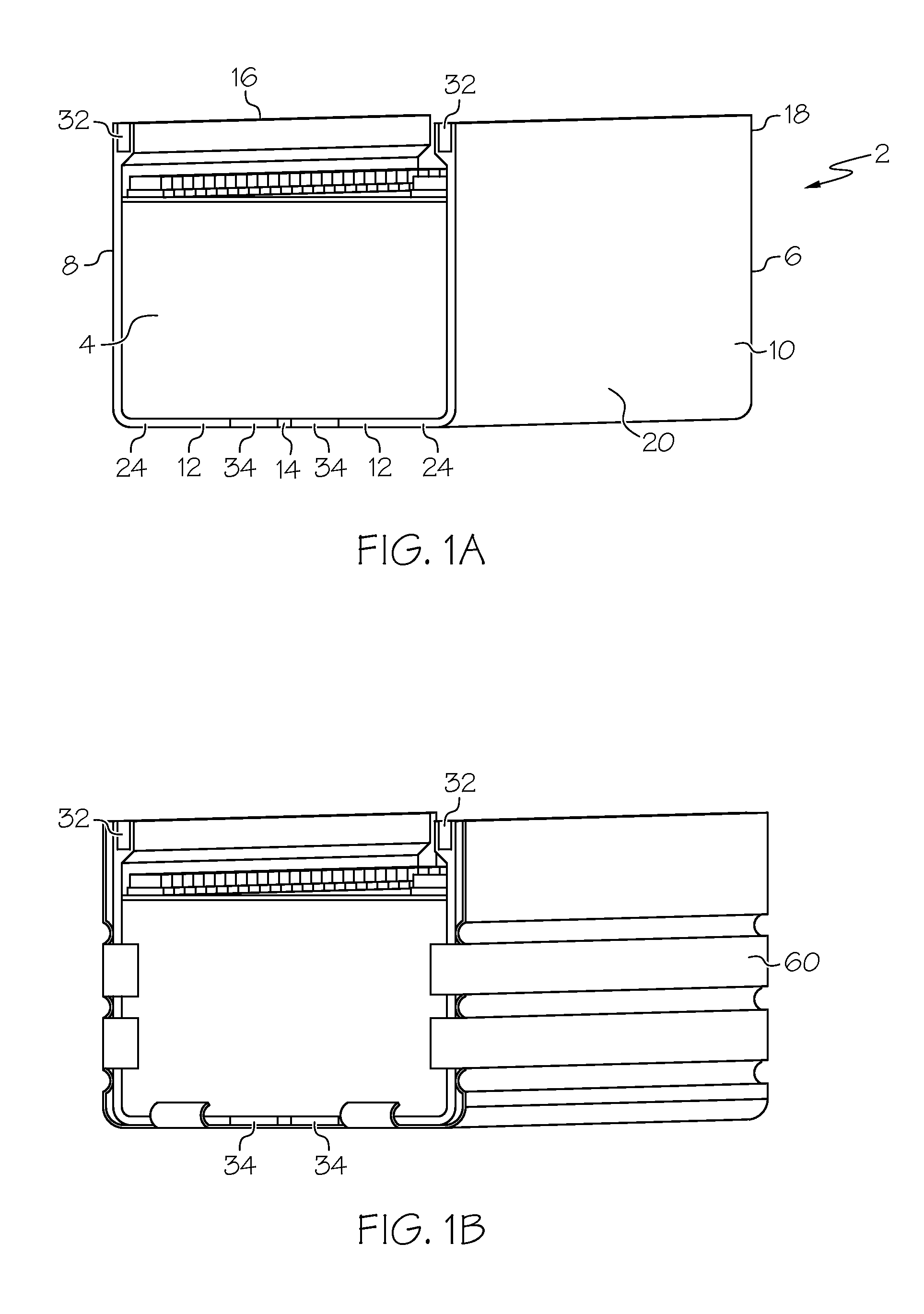

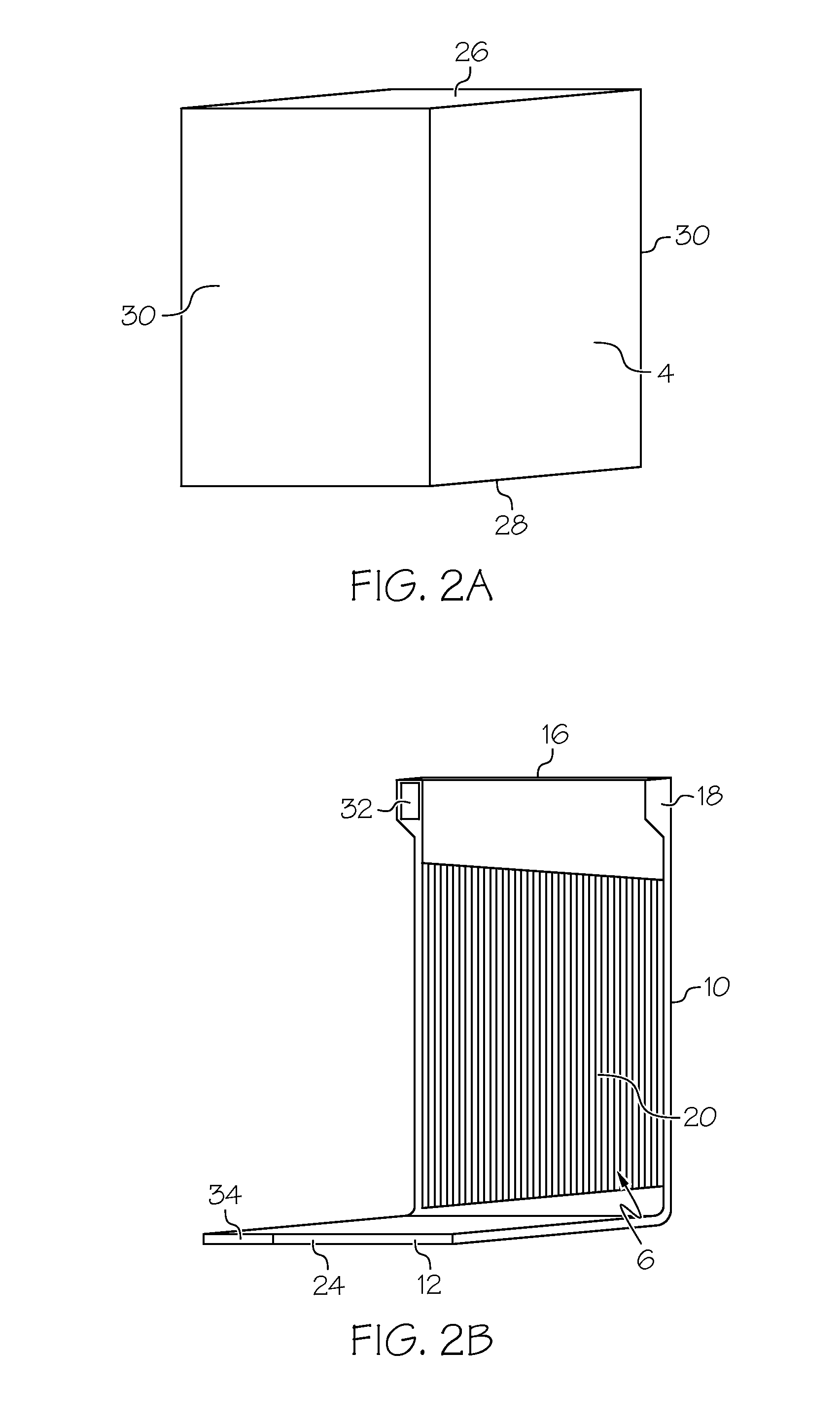

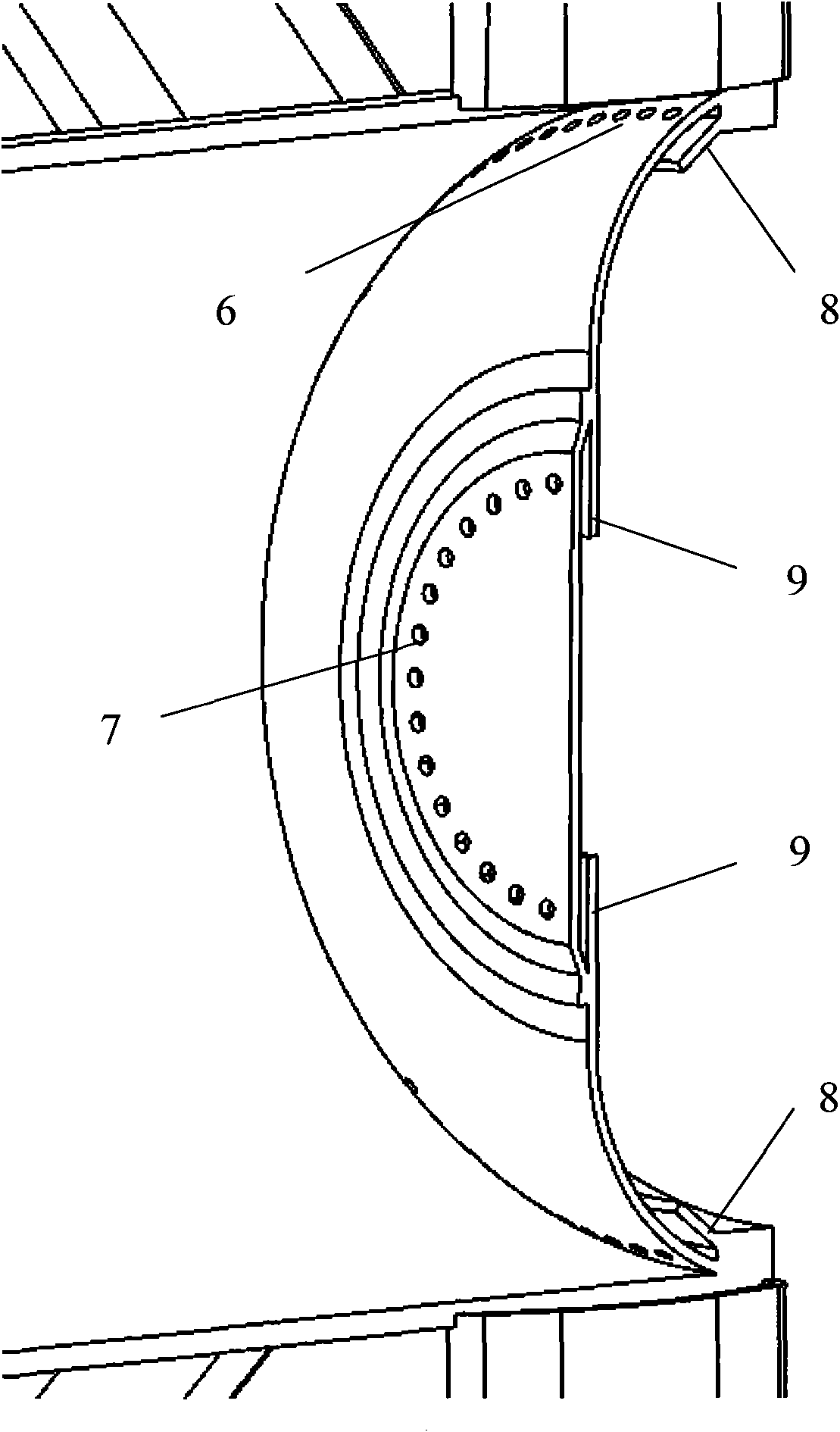

Liquid-cooled battery module

InactiveUS20140272513A1Reduce temperature changesLower overall pressure dropCell temperature controlPrimary cellsCoolant flowFriction loss

A battery module having a cooling plate assembly made from two non-contiguous cooling plates is provided. Each cooling plate has a side panel contiguous with a base panel, and the cooling plates are disposed opposite one another such that the base panels are coplanar and separated by a gap. An inlet duct runs along an upper edge of each side panel, and a manifold having coolant channels in fluid communication with the inlet duct is located in each side panel. The base panels have an outlet duct in fluid communication with the manifold. The cooling plate is designed to decrease friction loss as coolant flows through the inlet duct, manifold and outlet cut, and coolant channels in the manifold are designed to maintain a uniform flow rate across the manifold. Individual cells are disposed in the assembly such that the cell sides and bottoms are in heat-transfer contact with the plate side and base panels, respectively. The design of the battery module reduces operational temperature variation in the cells across the battery module and within each battery cell. Methods for reducing coolant flow friction loss, for establishing a more uniform coolant flow rate, and for reducing temperature variation are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

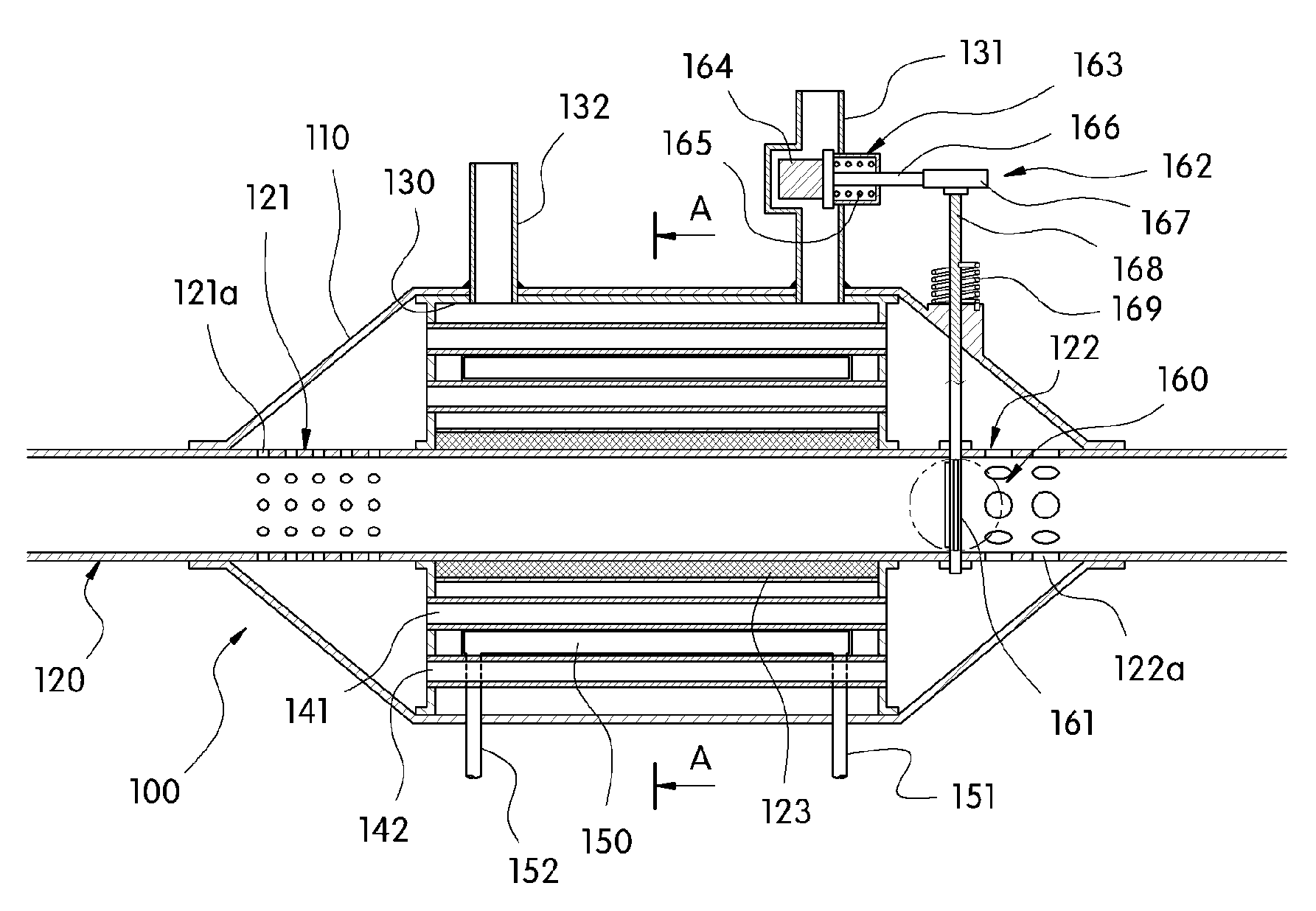

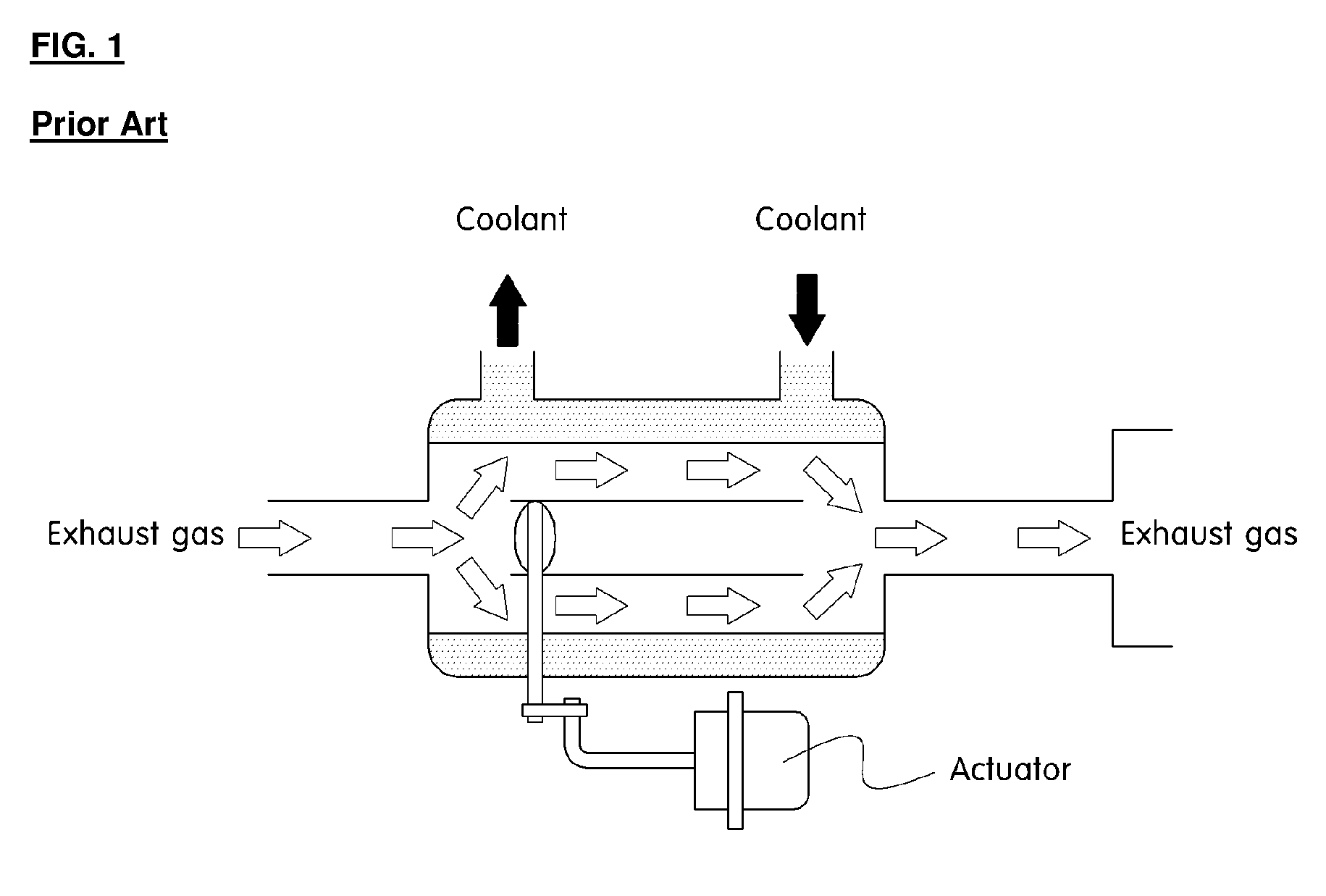

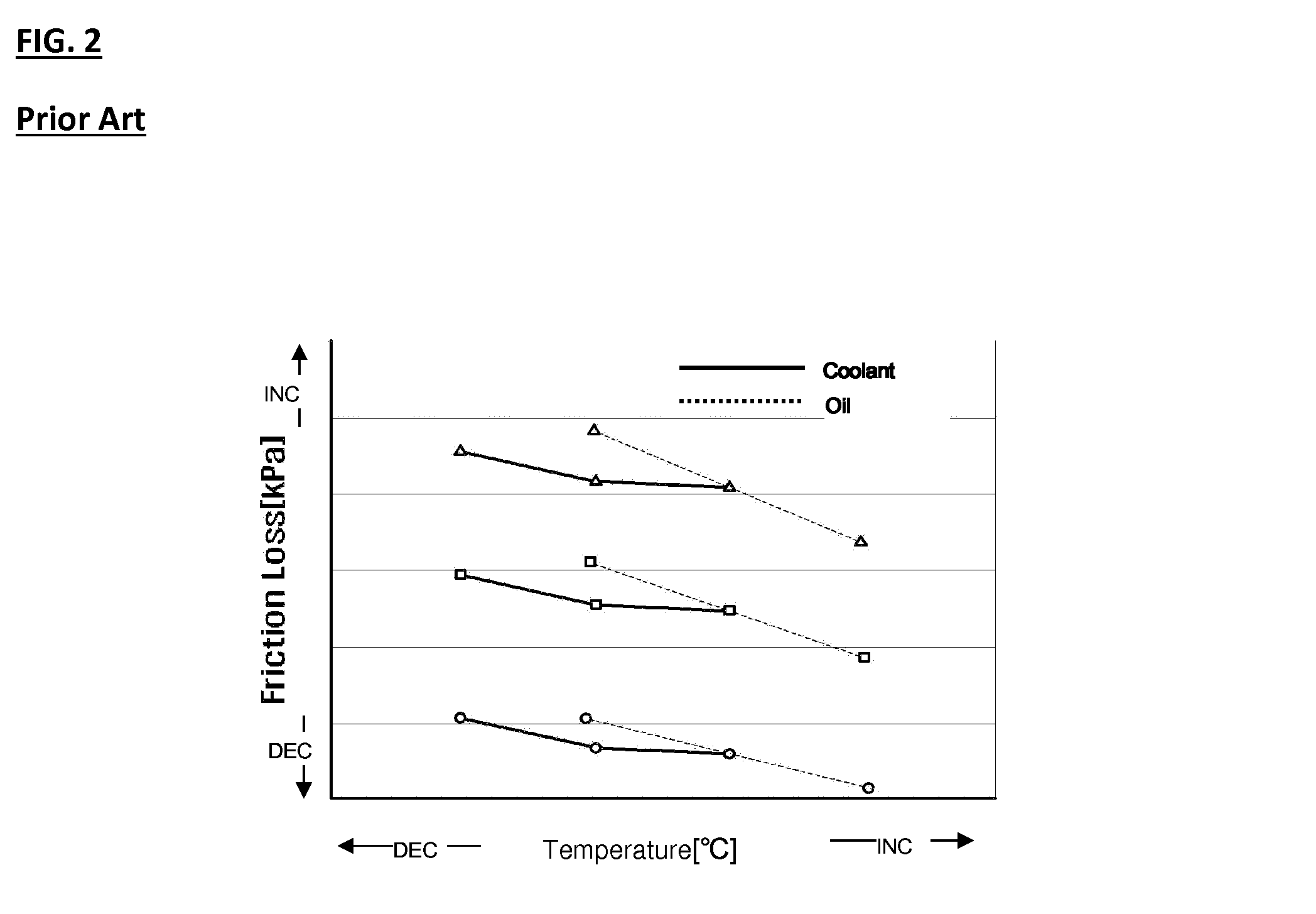

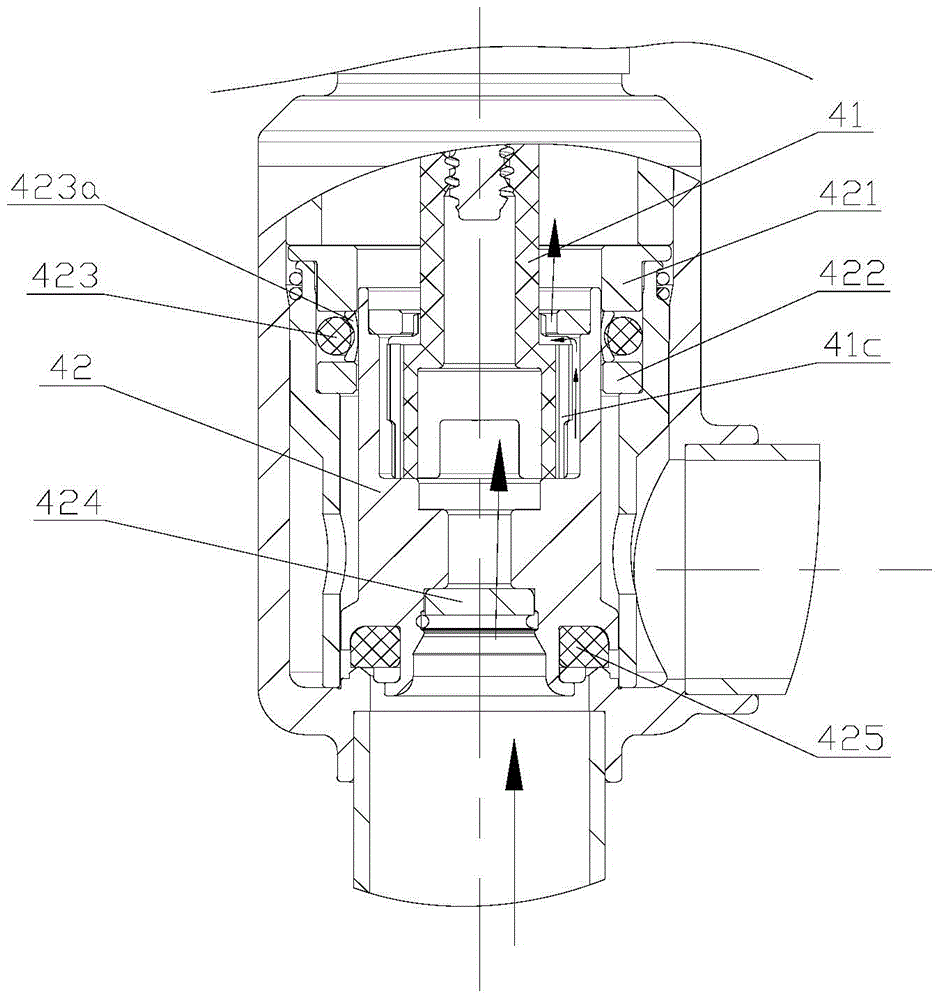

Exhaust heat recovery device

ActiveUS8522537B2Increase temperatureReduce friction lossInternal combustion piston enginesRecuperative heat exchangersFriction lossFuel efficiency

The present invention provides an exhaust heat recovery device configured to perform heat exchange between three media such as, exhaust gas, coolant, and oil. According to preferred embodiments of the present invention, the exhaust heat recovery device is configured such that the heat of exhaust gas discharged from an engine is transmitted to the coolant and the oil at the same time and direct heat exchange between the coolant and the oil is made, thereby simultaneously increasing the temperature of the coolant and the oil during the initial start-up of the engine (fast warm-up). As a result, it is possible to reduce friction loss of powertrain, thereby improving fuel efficiency. Accordingly, an object of the present invention is to provide an exhaust heat recovery device which is configured to perform the integral heat exchange between the exhaust gas, the coolant, and the oil.

Owner:HYUNDAI MOTOR CO LTD +1

Tubular column mechanical hand

InactiveCN103659809AAutomatically adjust the elongationIncrease grip areaProgramme-controlled manipulatorGripping headsHydraulic cylinderFriction reduction

A tubular column mechanical hand comprises a hydraulic outer shell, a hydraulic cylinder, a hydraulic rod, a bearing, a rotating outer shell, an end cover, a reset spring, a piston, a mechanical hand support, and ejector rod, an upper mechanical hand, a lower mechanical hand, grabbing telescopic rods and grabbing teeth. The hydraulic outer shell is connected with the rotating outer shell through the bearing, the hydraulic cylinder is mounted in the hydraulic outer shell, the hydraulic cylinder is connected to the hydraulic rod, the hydraulic rod is connected to the piston and the ejector rod, and the ejector rod is sleeved with a guide sleeve. The rotating outer shell is fixed to the end cover through fixing nuts, the upper mechanical hand and the lower mechanical hand are connected on the mechanical hand support through a rotating pin respectively, the upper mechanical hand and the lower mechanical hand are respectively provided with three grabbing teeth, and pressure springs and the grabbing telescopic rods are arranged in the grabbing teeth. By means of the tubular column mechanical hand, the contact area of the mechanical hand and tubular column type goods can be enlarged, the tubular column mechanical hand has the functions of anti-sliding and reducing friction loss, and improves grabbing force.

Owner:GUANGXI UNIV

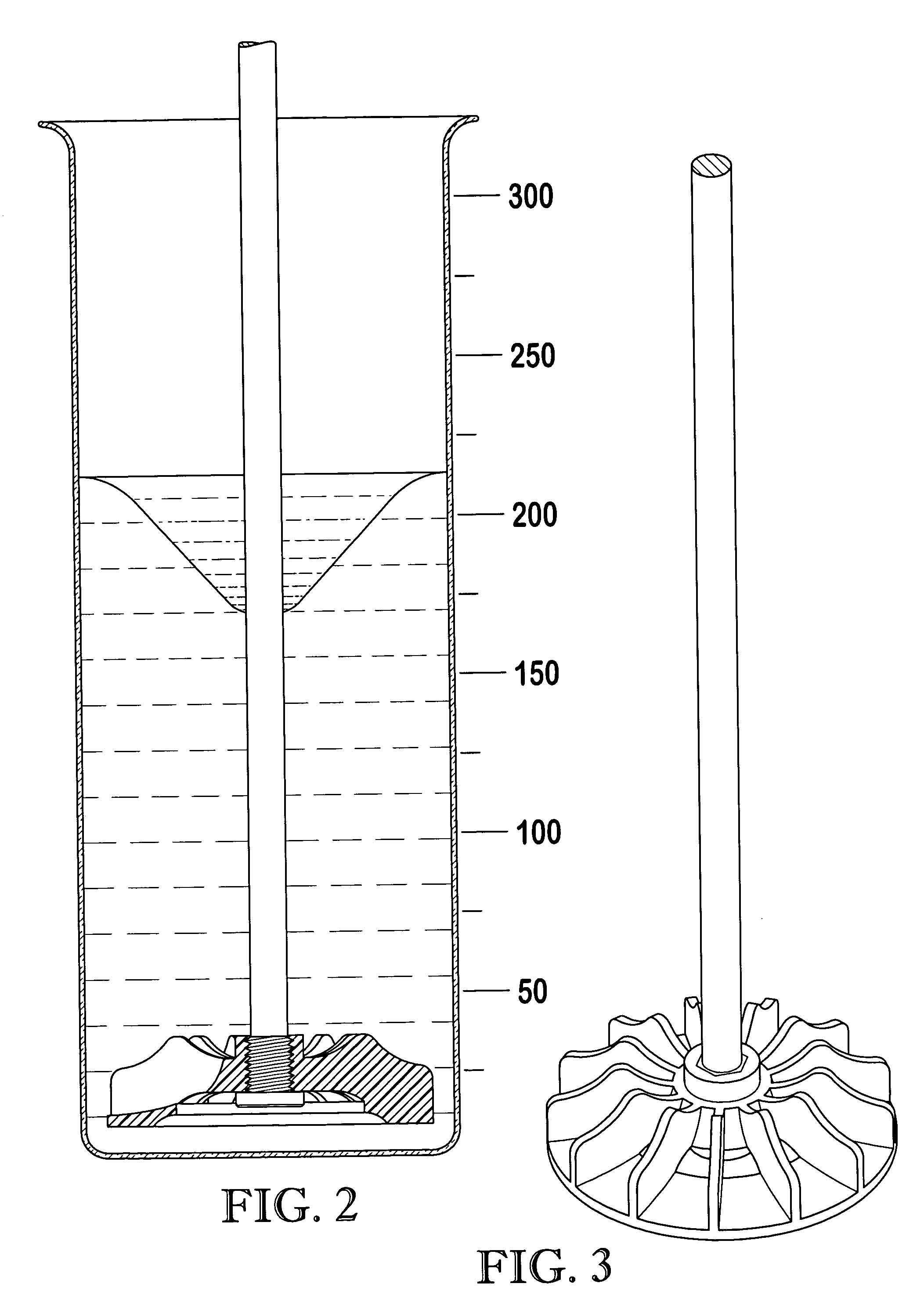

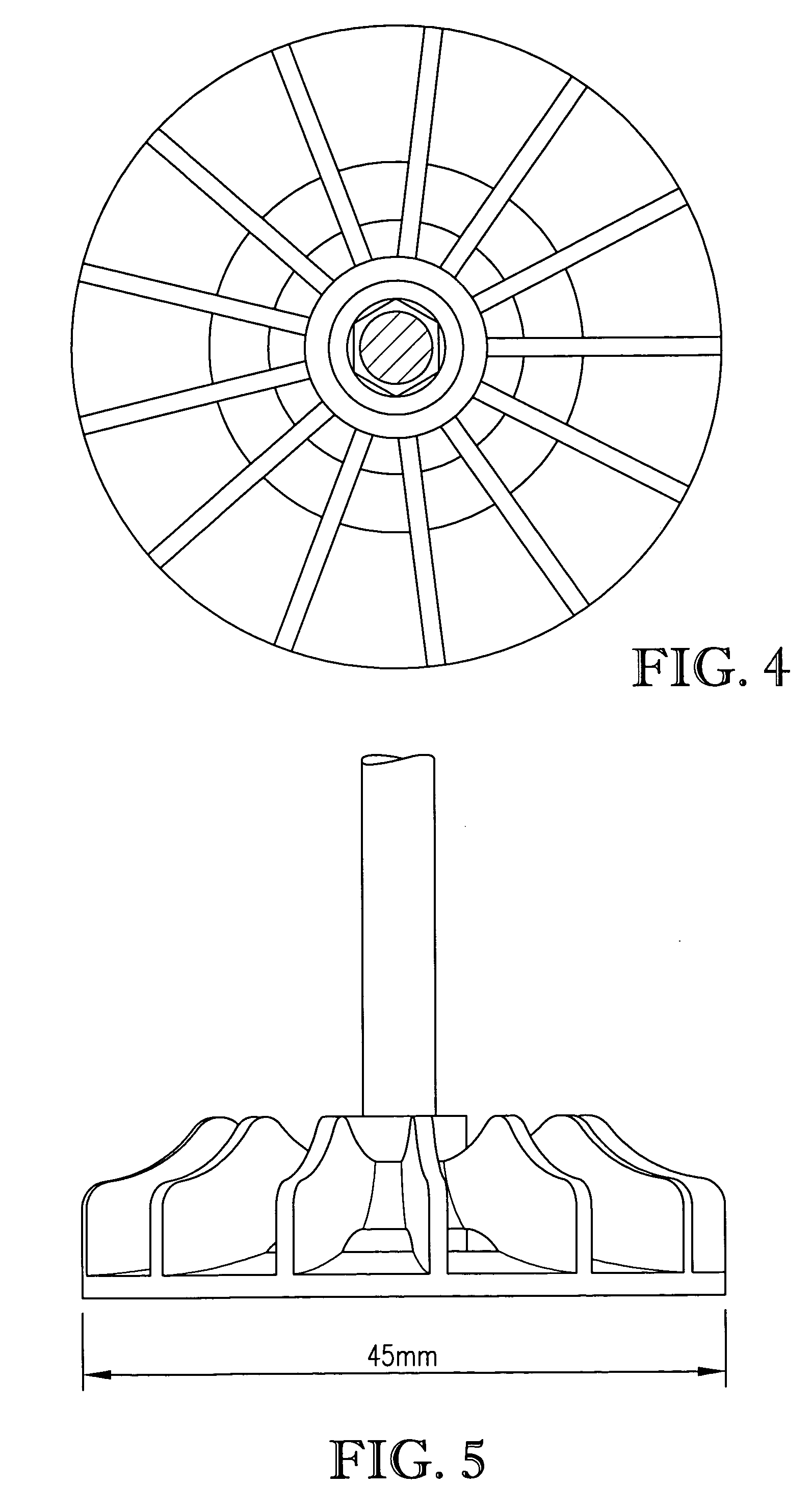

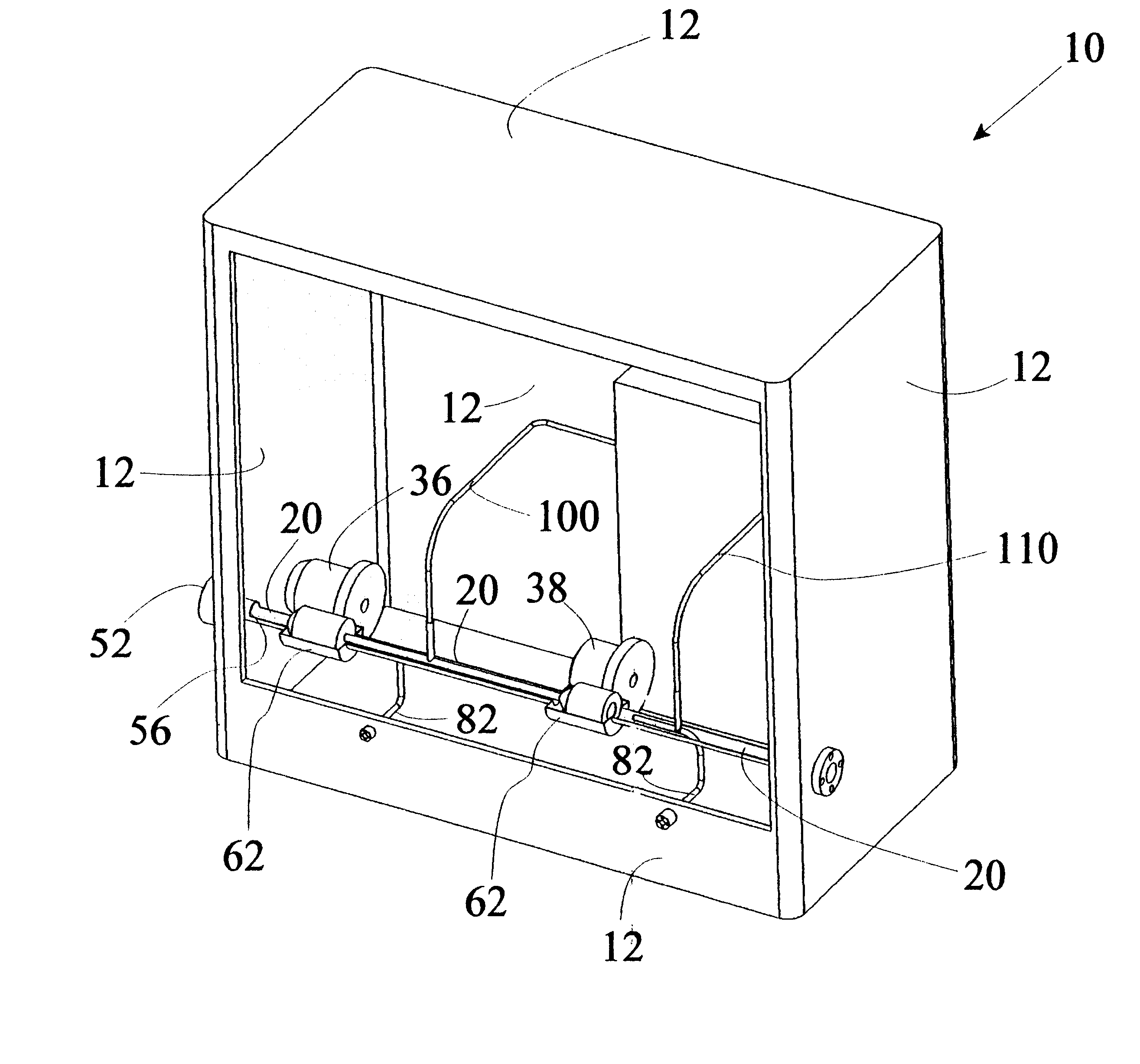

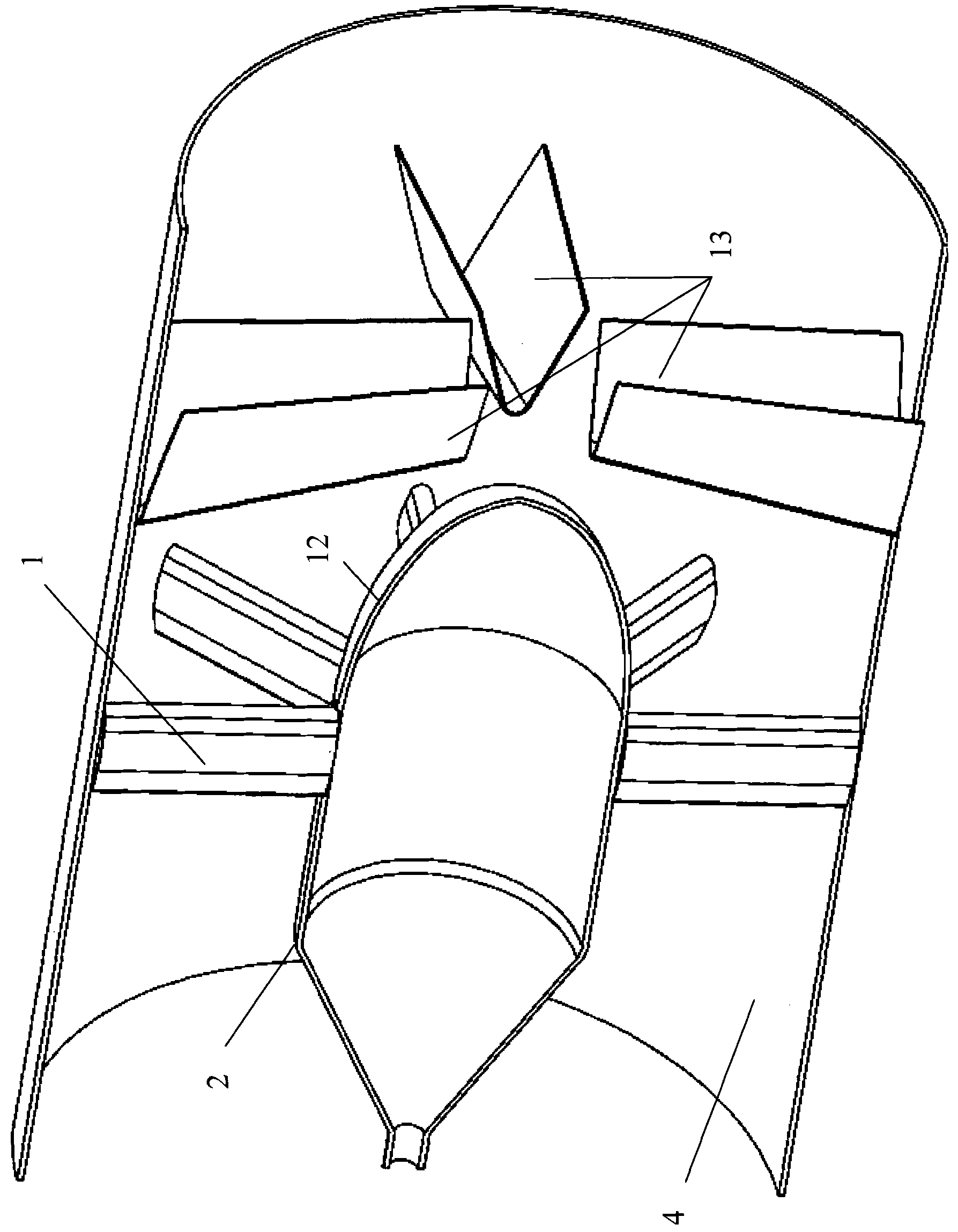

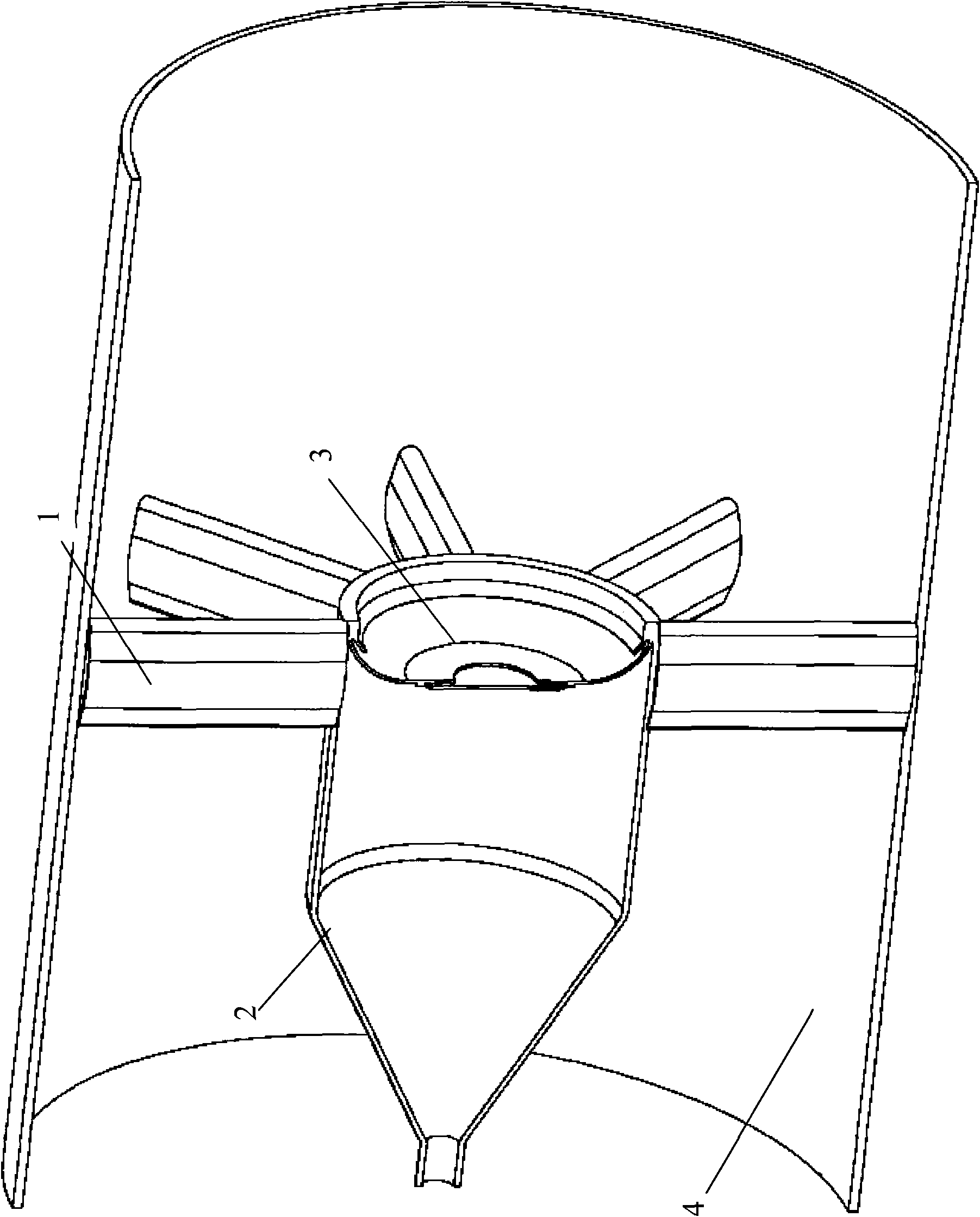

Apparatus with voraxial separator and analyzer

InactiveUS6248231B1Maximum separation resultReduce lossesLiquid separation auxillary apparatusRotary centrifugesFriction lossRotation velocity

A voraxial separator and analyzer apparatus includes a composite fluid passing tube having a tube upstream segment and a tube downstream segment; a rotation acceleration vane structure rotationally mounted within the tube upstream segment and being oriented to deliver angular acceleration to a composite fluid within the tube about the longitudinal axis of the tube for separating the fluid into radially stratified component layers within the tube in the order of component density and to propel the fluid toward and through the tube downstream segment; an acceleration vane drive mechanism drivably connected to the rotation acceleration vane structure; a rotation maintenance vane structure rotationally mounted within the tube downstream segment and being oriented to deliver angular acceleration to a composite fluid within the tube about the longitudinal axis of the tube for maintaining the rotational velocity of the fluid imparted by the rotation acceleration vane structure against friction losses; and a maintenance vane drive mechanism drivably connected to the rotation maintenance vane structure.

Owner:SCHLUMBERGER TECH CORP

Flame stabilizer with jet injection

InactiveCN101776283AReduce weightGood Burn ProgramContinuous combustion chamberCombustion chamberJet injection

The invention provides a flame stabilizer for an after-combustion chamber of a gas turbine engine. In the device, which is characterized in that turbine rear frames are integrated, a radial flame stabilizer and a center cone in the prior art are omitted, and the an upstream concave structure and the a jet injection gas flow are used for forming a vortex system to form a necessary backflow region for flame stabilization, thereby reducing the amount of parts, shortening the total length of the combustion chamber, lightening the structural weight, reducing the resistance loss, and enabling the thrust-weight ratio of the engine to have great expansion lifting space.

Owner:BEIHANG UNIV

Airfoil model force measurement system

InactiveCN106289710AReduce distortionImprove support stiffnessAerodynamic testingMeasurement deviceFriction loss

The invention discloses an airfoil model force measurement system comprising a pair of supports, a pair of connecting bases, a drag measurement scale, a drag and pitch moment measurement scale, a pair of connecting rods, and a pair of lift measurement devices. The supports are arranged vertically. The connecting bases are respectively arranged on the supports in such a way that the connecting bases can slide along the supports without friction loss. The drag measurement scale is connected to one connecting base. The drag and pitch moment measurement scale is connected to the other connecting base. One end of one connecting rod is connected to the drag measurement scale, one end of the other connecting rod is connected to the drag and pitch moment measurement scale, and the other ends of the connecting rods are connected to the front end of an airfoil model to support the airfoil model between the supports. The lift measurement devices are respectively arranged on the supports, and the lift transfer components of the lift measurement devices are respectively connected to the connecting bases. A double-support system is adopted, and the airfoil model is supported between the supports. The system is of high support rigidity, and the airfoil model has little deformation under the action of gravity and wind load.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

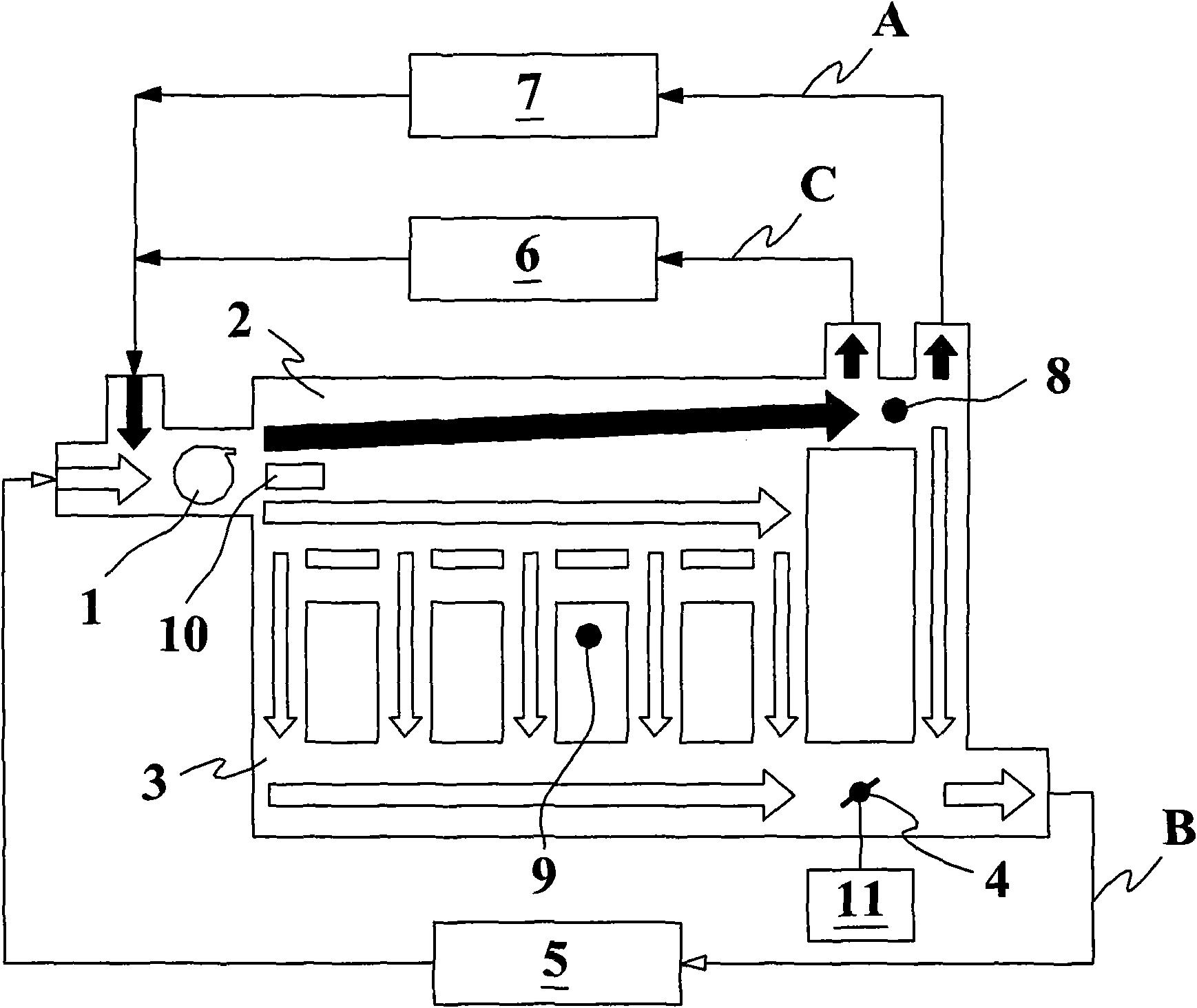

An engine cooling system and a cooling method

InactiveCN102733921AReduce fuel consumptionIncrease fuel consumptionLiquid coolingCoolant flow controlExpansion tankFriction loss

The invention relates to an engine cooling system, comprising a radiator, an expansion water tank, a pump unit, and a water jacket of a cylinder cover and a water jacket of a cylinder body that are communicated with each other. An outlet of the pump unit is communicated with an inlet of the water jacket of the cylinder cover to input cooling liquid; the input cooling liquid is arranged to be two flow paths for respectively cooling the cylinder cover and the cylinder body of the engine, wherein the first flow path is a loop where the cooling liquid outflows from an outlet arranged on the cylinder cover via the water jacket of the cylinder cover, and enters into an inlet of the pump unit after passing through the expansion water tank; the second flow path is a loop where the cooling liquid outflows from an outlet arranged on the cylinder body via the water jacket of the cylinder body, and enters into the inlet of the pump unit after passing through the radiator. The invention also relates to an engine cooling method. By utilizing the engine cooling system and the cooling method, temperatures of the cylinder cover and the cylinder body can be controlled and maintained in a more reasonable way, and therefore a temperature of lubricating oil can be notably improved, friction loss can be lowered, fuel consumption can be more efficient, and emission can be lowered.

Owner:SAIC GENERAL MOTORS +1

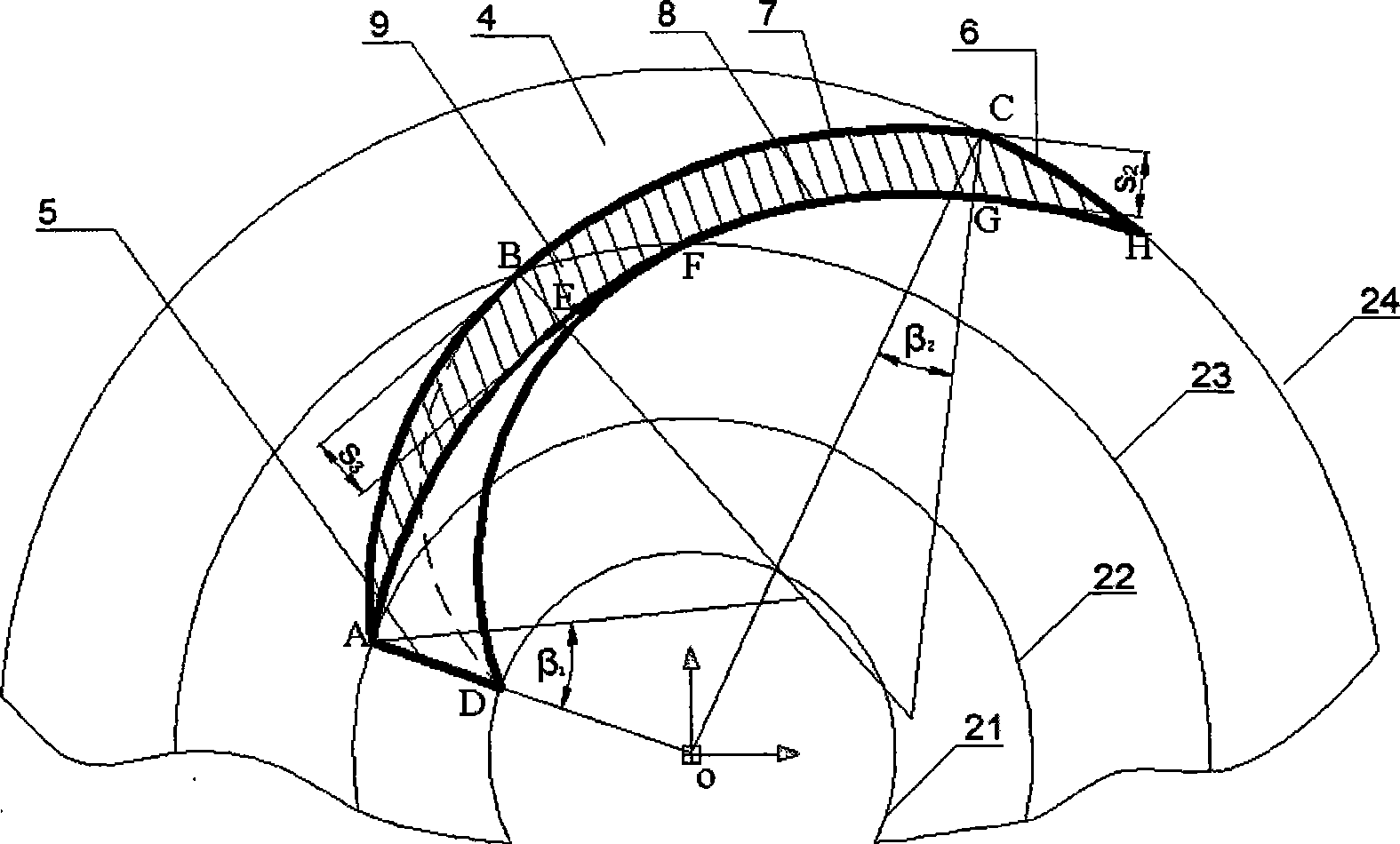

Design method of two phase flow pump impeller

InactiveCN101368574AAdhere to flow characteristicsThe angle of attack of the water flow changes evenlySpecific fluid pumpsPump componentsImpellerFriction loss

The invention discloses the design method of a two-phase flow pump; the two-phase flow pump comprises a slurry pump, a mud pump, a diving slurry pump, a diving mud pump and a diving two-phase pump; the impeller includes a main impeller and an auxiliary impeller; the main impeller mainly comprises a main vane, an auxiliary vane, a front cover plate and a back cover plate; the impeller is mainly arranged on an impeller shaft; the main vane is inclined to the front cover plate and the back cover plate through the vane inlet segment; the vane outlet segment is vertical to the front cover plate and the back cover plate to form a semi-twisted vane; the vane contour line on the impeller front cover plate has smooth transition to the vane contour line on the impeller back cover plate to form the surface of the semi-twisted vane. The auxiliary vane of the impeller and the auxiliary impeller construct a dynamic sealing device. Based on the semi-twisted vane in the invention, the water power loss and the friction loss are smaller than that of the cylindrical vane; the vibration and noise of the pump are reduced; the pump efficiency is improved; the service life of the impeller is prolonged; meanwhile, the operation of the pump become more stable.

Owner:许洪元

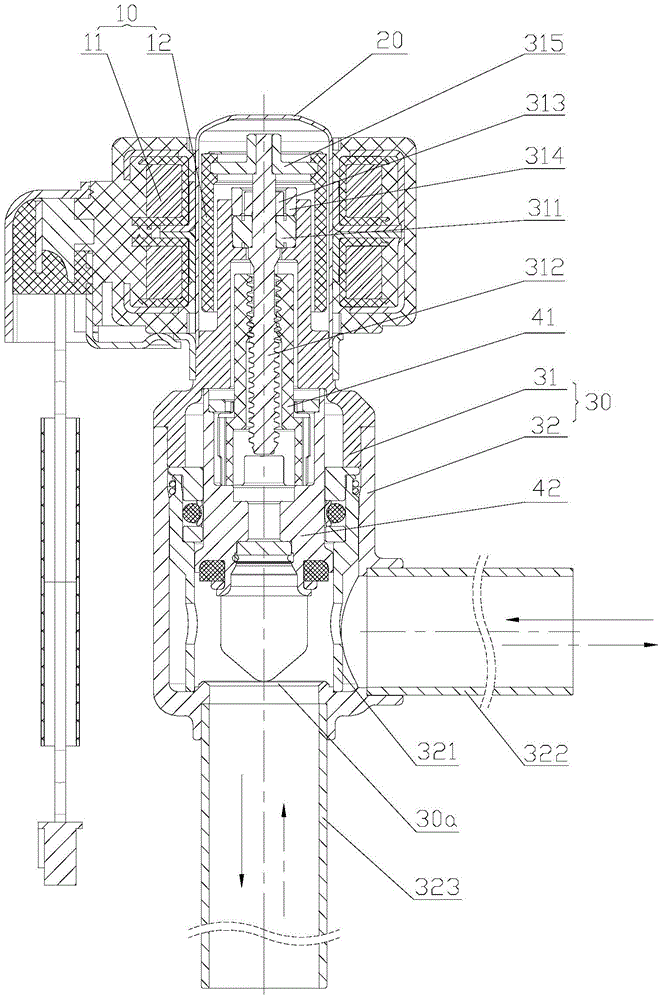

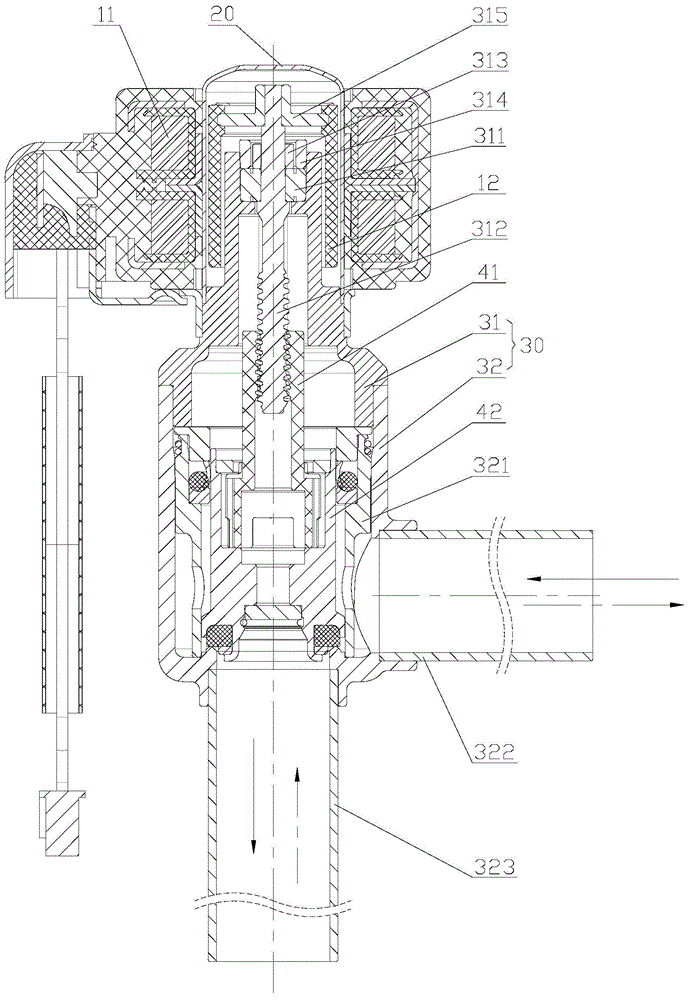

Direct-acting type electric valve

The invention discloses a direct-acting type electric valve. The direct-acting type electric valve comprises a valve seat with a valve cavity, a motor and a lead screw, wherein the motor and the lead screw are mounted at the upper end of the valve seat. The lead screw is connected with a nut in a thread fit manner, and the nut is connected with a valve element; a rotor of the motor and the axial position of the valve seat are relatively fixed, and the upper end of the lead screw is fixedly connected with the rotor; the valve element is driven by the nut to move in the axial direction of the valve cavity to open or close a valve opening in the valve seat; the valve element is of cylindrical structure with a balance channel, and a sealing part for dividing the valve cavity into two independent cavity bodies is arranged on the periphery of the valve element. According to the structure, a gear system is eliminated, and unnecessary transmission is reduced; and friction losses are reduced, and the response is direct, reliable and sensitive. The rotor and the axial position of the valve seat are fixed, that is, in the working process, the opposite positions of the rotor and the coil component are fixed, so that driving force is stable; obviously, for the valve opening of the same size, the size of the motor in the scheme is smaller than that of a motor in the prior art, and the miniaturization large-capacity requirements can be met.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

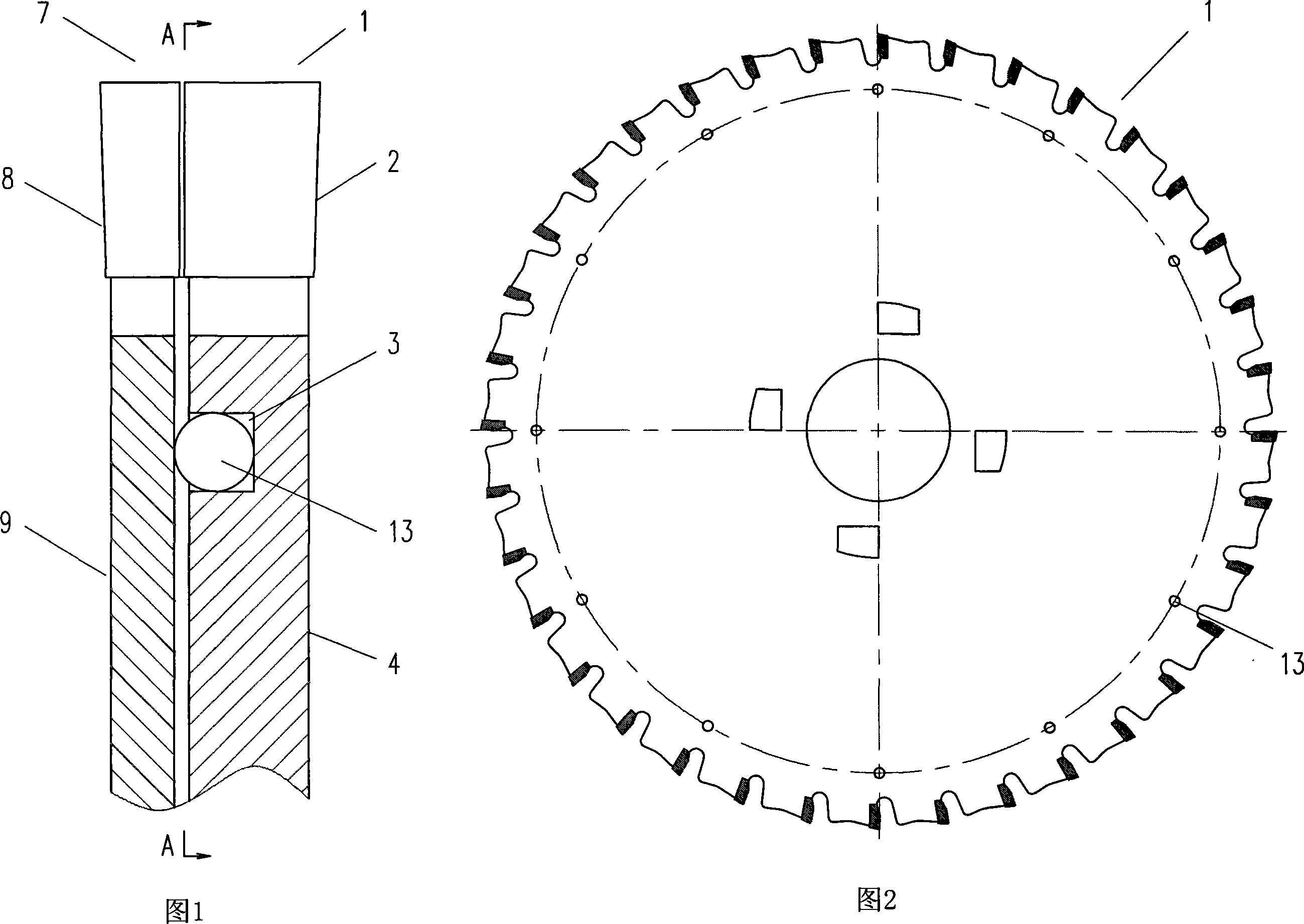

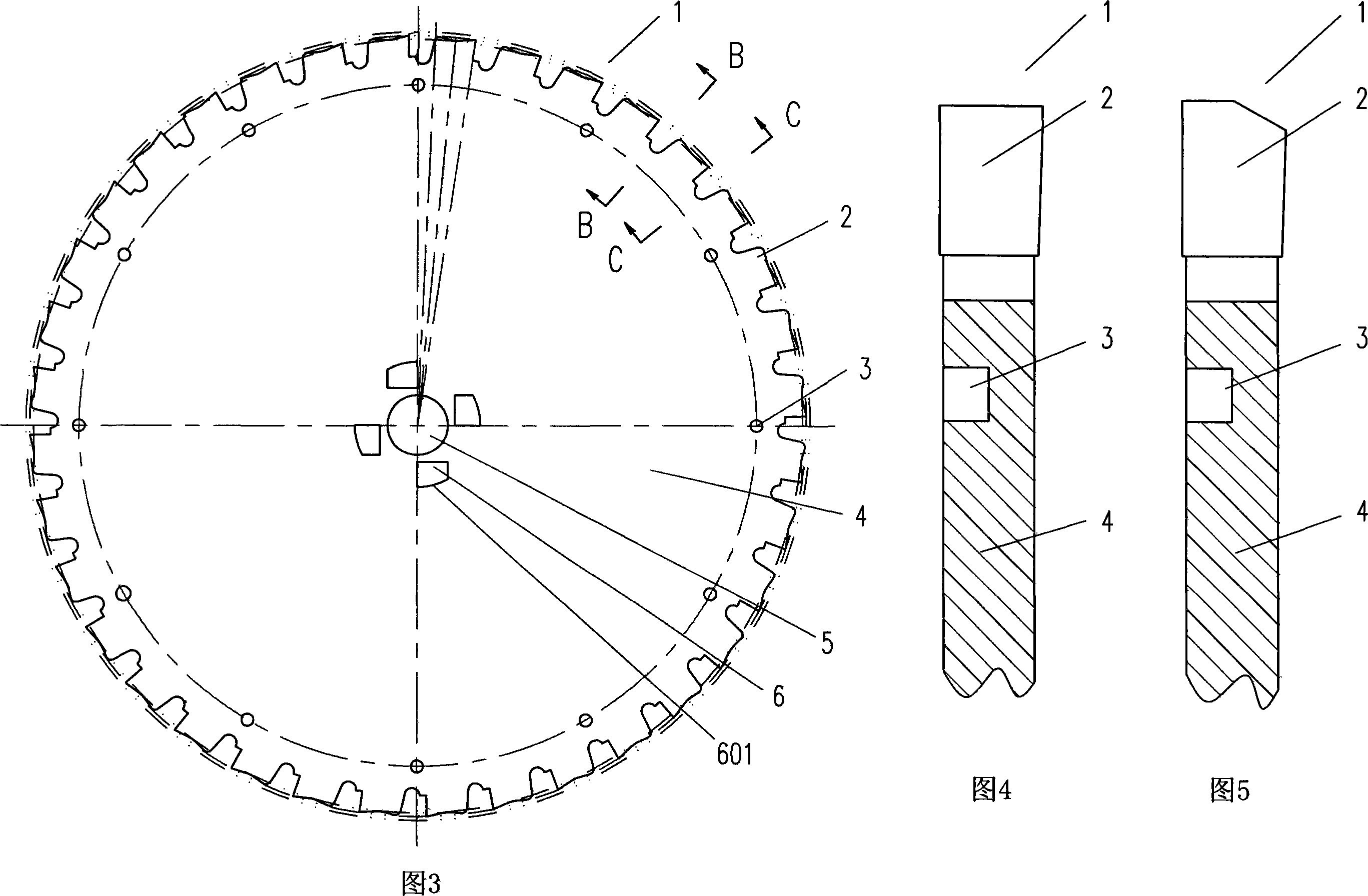

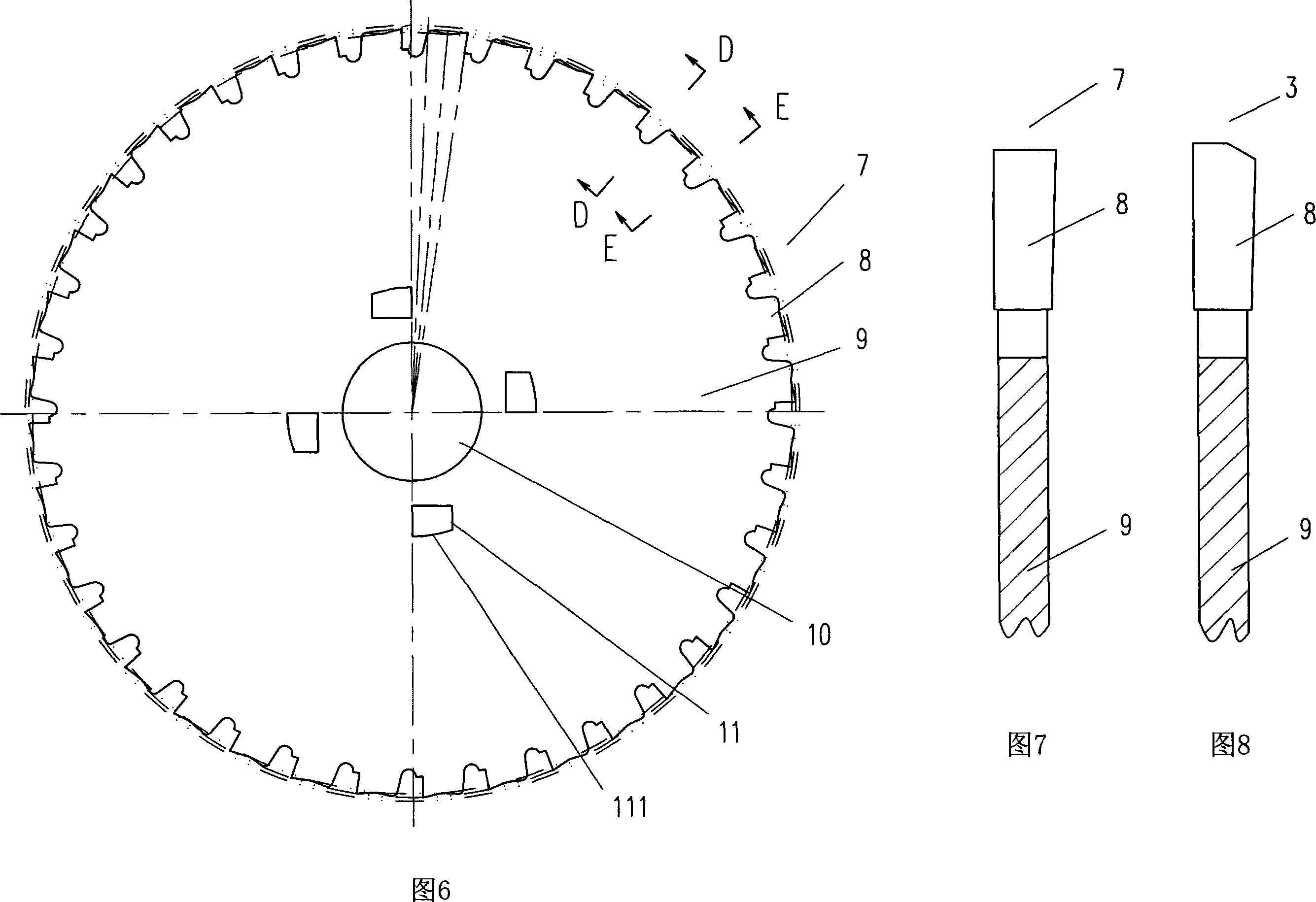

Sawblades in couple

InactiveCN101116919AReduce frictionEasy maintenanceMetal sawing devicesMetal sawing toolsFriction lossEngineering

The invention discloses a double saw blades, which consists of a first saw blade which rotates around the axes and a second saw blade which rotates reversely around the axes. Every saw blade has a saw blade body and a cutting element arranged on the surrounding of the saw blade body. Two saw blades approach in parallel each other in rotating state. The invention is characterized in that an interval piece which guarantees the corresponding rolling and the gap of two saw blades is arranged between two saw blades. Because the double saw blades of the invention adopt the rolling distance piece, therefore, the friction loss is greatly decreased and the working efficiency is improved. The product is convenient to installation and replaced, thereby prolonging the life-span of product.

Owner:郭一文

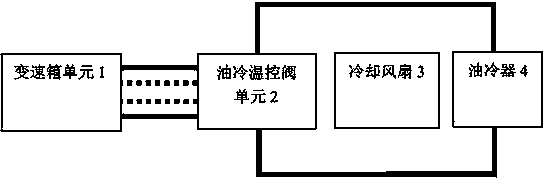

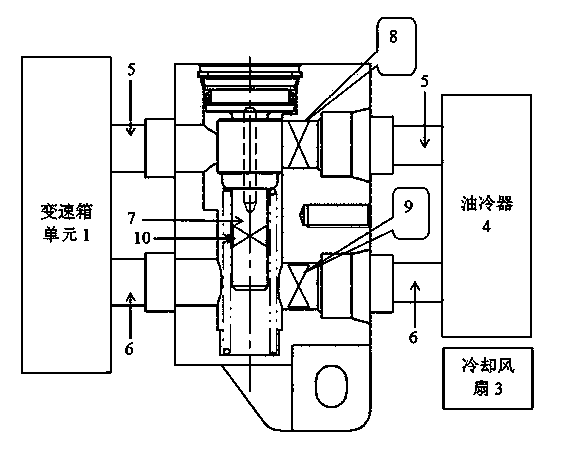

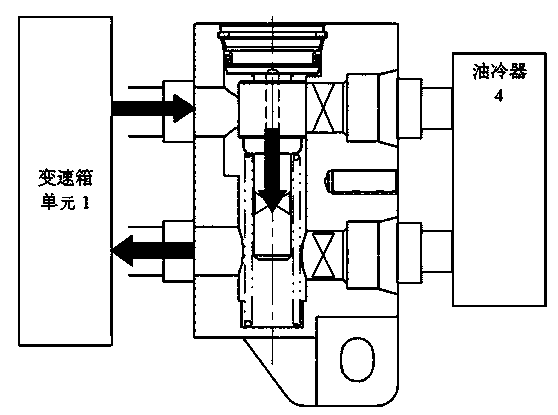

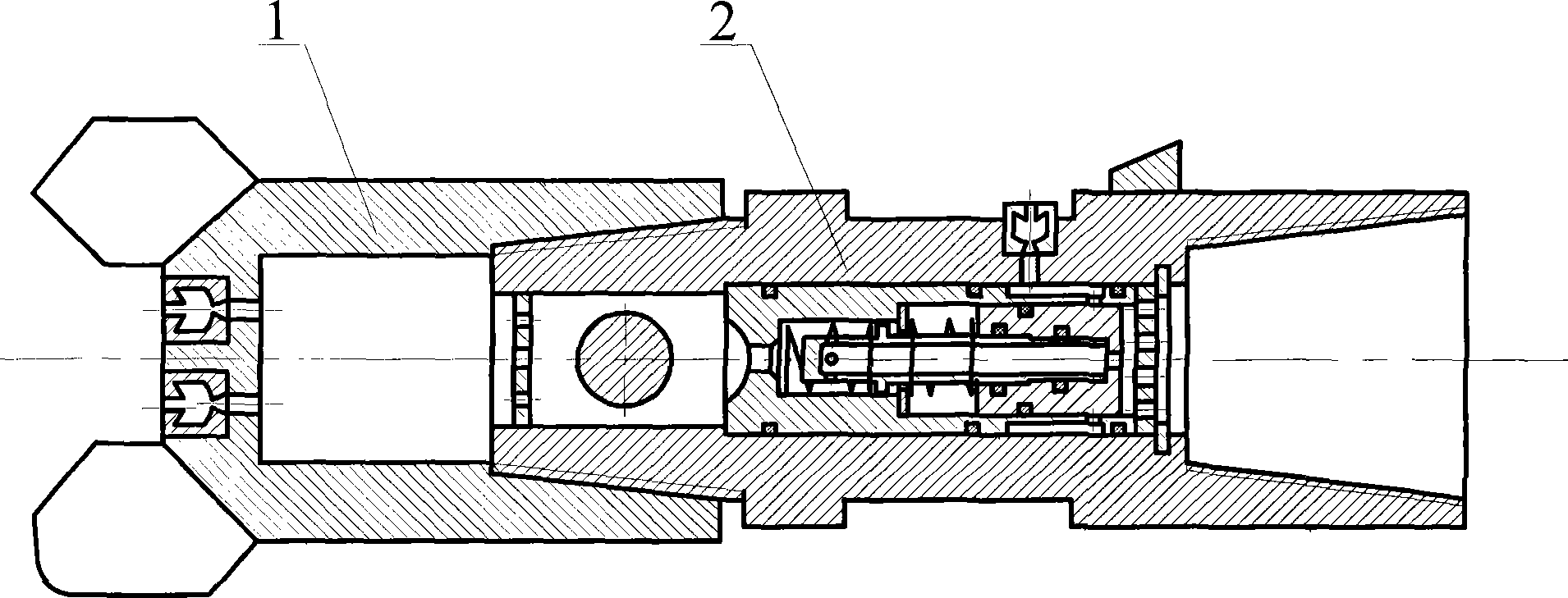

Hybrid power automobile gearbox unit cooling system and cooling method

ActiveCN104279306AImprove cooling effectGuaranteed uptimeGear lubrication/coolingTransmission elementsTemperature controlFriction loss

The invention provides a hybrid power automobile gearbox unit cooling system and cooling method. An oil incoming pipe, an oil discharging pipe and a returning pipe communicating the oil incoming pipe and the oil discharging pipe are arranged in an oil cooling temperature control valve unit, the oil temperature sensing information of a gearbox unit is combined, and valves of oil pipes are controlled to open and close dynamically; on the idling condition, oil from the gearbox unit flows back to the gearbox from the oil cooling temperature control valve unit directly, time for the oil flowing back the gearbox is shortened, oil pressure can be established rapidly, and the gearbox and a coupled mechanism thereof operate at the proper temperature rapidly; when an engine operates in high speed and the gearbox is under high load, oil friction heat is increased sharply, oil of the gearbox flows to an oil cooler completely through the oil cooling temperature control valve, waste heat is radiated through the oil cooler, and the coil flows back to the gearbox unit, so that the accurate control of the oil temperature of the gearbox is implemented, friction loss, oil consumption and discharging are reduced, service life of the gearbox unit is prolonged, and shift quality is guaranteed.

Owner:奇瑞控股集团有限公司

Multifunctional self-oscillation flow jet flow drill

InactiveCN101413380AImprove permeabilitySimple structureLiquid/gas jet drillingVibration drillingJet flowSelf-oscillation

The invention relates to a multifunctional self-oscillation jet drill bit. The prior similar product not only has shallow drilling depth and complex structure but also has large resistance loss and short service life of a drill bit, can not repeatedly switch drilling and groove cutting during the drilling process, and limits the application scope. A crushing blade and a valve body are arranged inside a cutting head body of the drill bit; a first offsetting spring in the valve body is matched with a valve core A in the form of sliding; a valve core B is matched with a second offsetting spring for operation under the action of a lined ring, a washer and the valve body together; and the valve core and a limber hole of the valve body are matched for use with a self-oscillation nozzle. The multifunctional self-oscillation jet drill bit adopts high-pressure water as power to realize repeated switching between drilling and groove cutting of coal seam and terrane, not only has a simple structure and is flexible to switch but also can promote development of coal seam fissure through oscillation jet generated by the nozzle, strengthens the permeability of the coal seam, improves the gas extraction rate, particularly has obvious effect on low-permeability coal seam, and widely promotes and applies the fluid technology of the high-pressure water in the fields of drilling and gas extraction of the low-permeability coal seam.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com