Mining porous spiral-type foam generating device

A foam generating device and spiral technology, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve problems such as difficult to determine energy loss, poor reliability of the overall structure, difficult disassembly and maintenance, etc., to improve reliability, The effect of simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

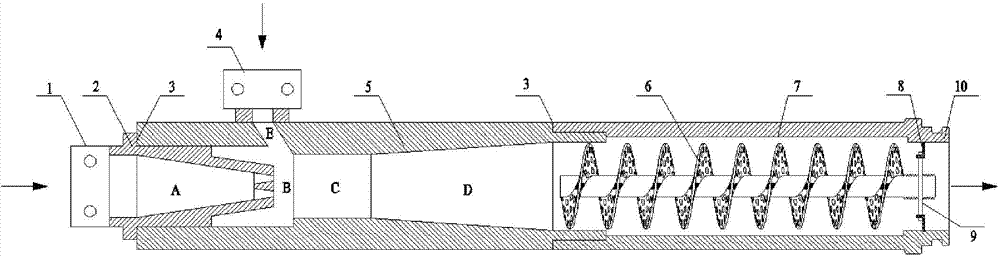

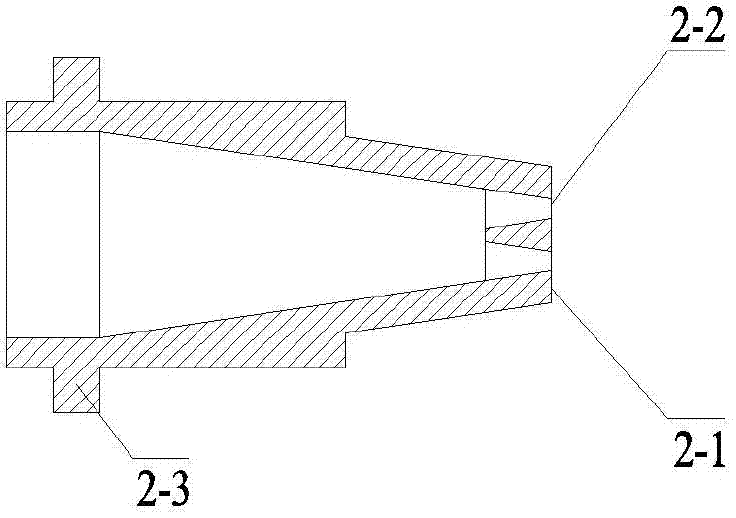

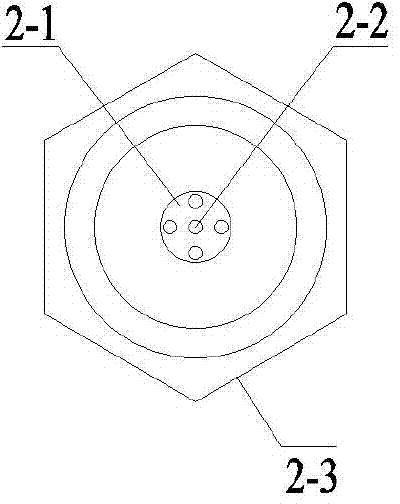

[0024] Such as figure 1 As shown, a mine porous spiral foam generating device of the present invention includes a compressed air joint 1, a nozzle body 2, a gas-liquid mixing chamber 5, a porous spiral foamer 6, a foaming cylinder 7 and a foam outlet joint 10 The outer edge of the front end of the nozzle body 2 is provided with a deck 2-3, and the rear end is provided with at least one outlet nozzle 2-2; the nozzle chamber A in the nozzle body 2 is constricted; The front ends of the nozzle body 2 are connected; the nozzle body 2 is installed inside the front end of the gas-liquid mixing chamber 5; a liquid suction chamber E is opened on the front side wall of the gas-liquid mixing chamber 5; the liquid suction chamber E is installed There is a liquid inlet joint 4; the rear end of the gas-liquid mixing chamber 5 is connected to the front end of the foaming cylinder 7, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com