Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2710results about "Specific fluid pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

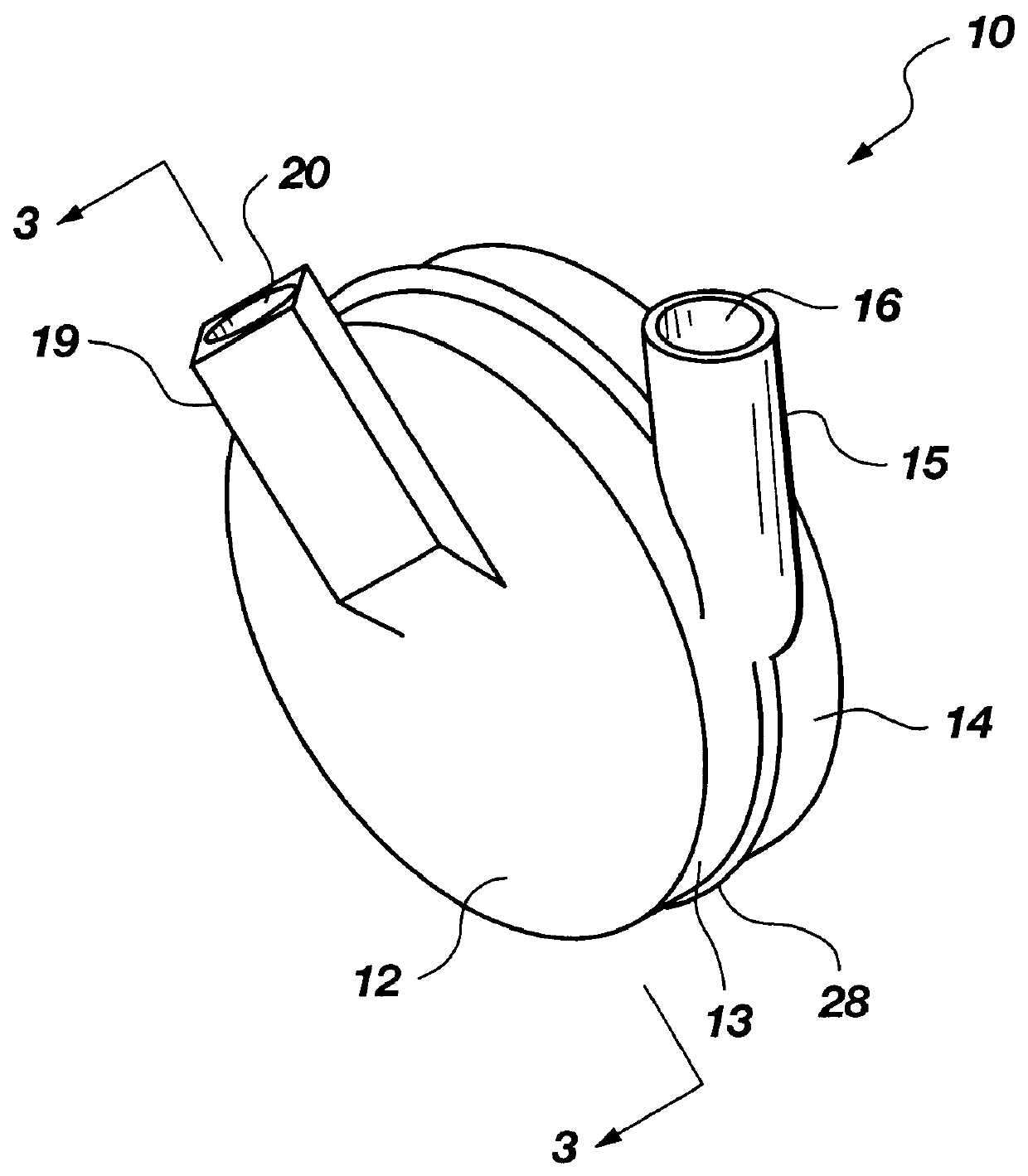

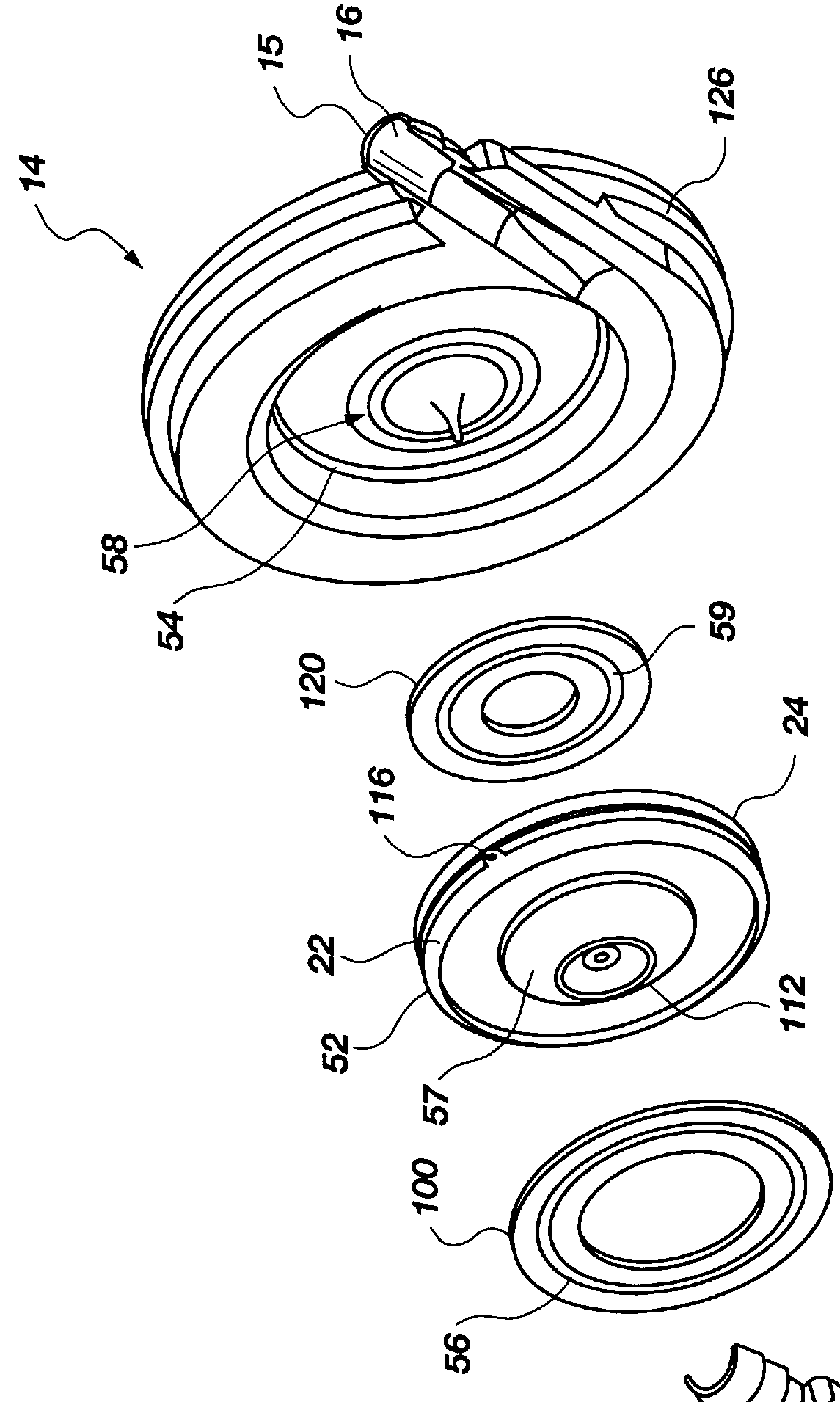

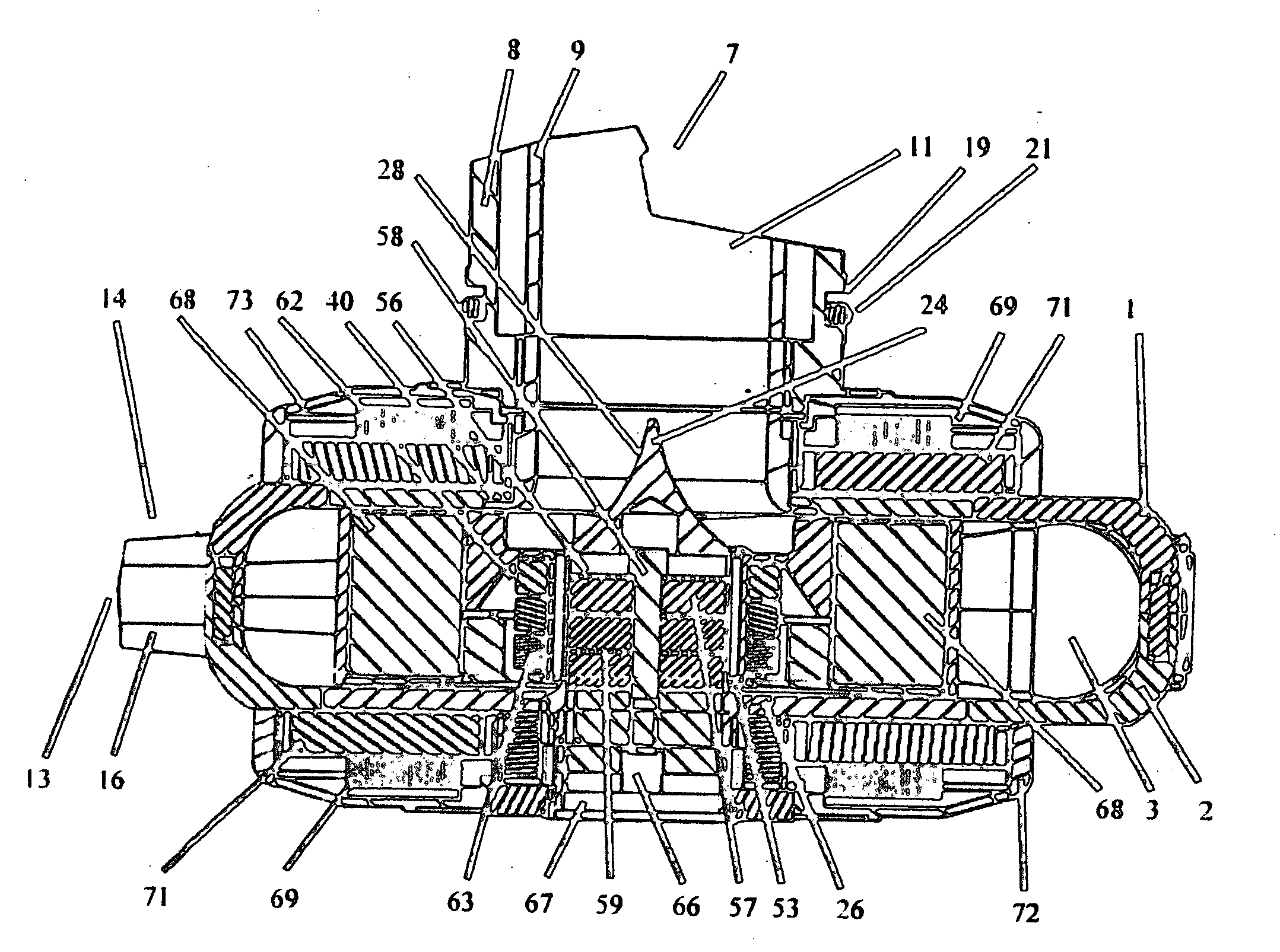

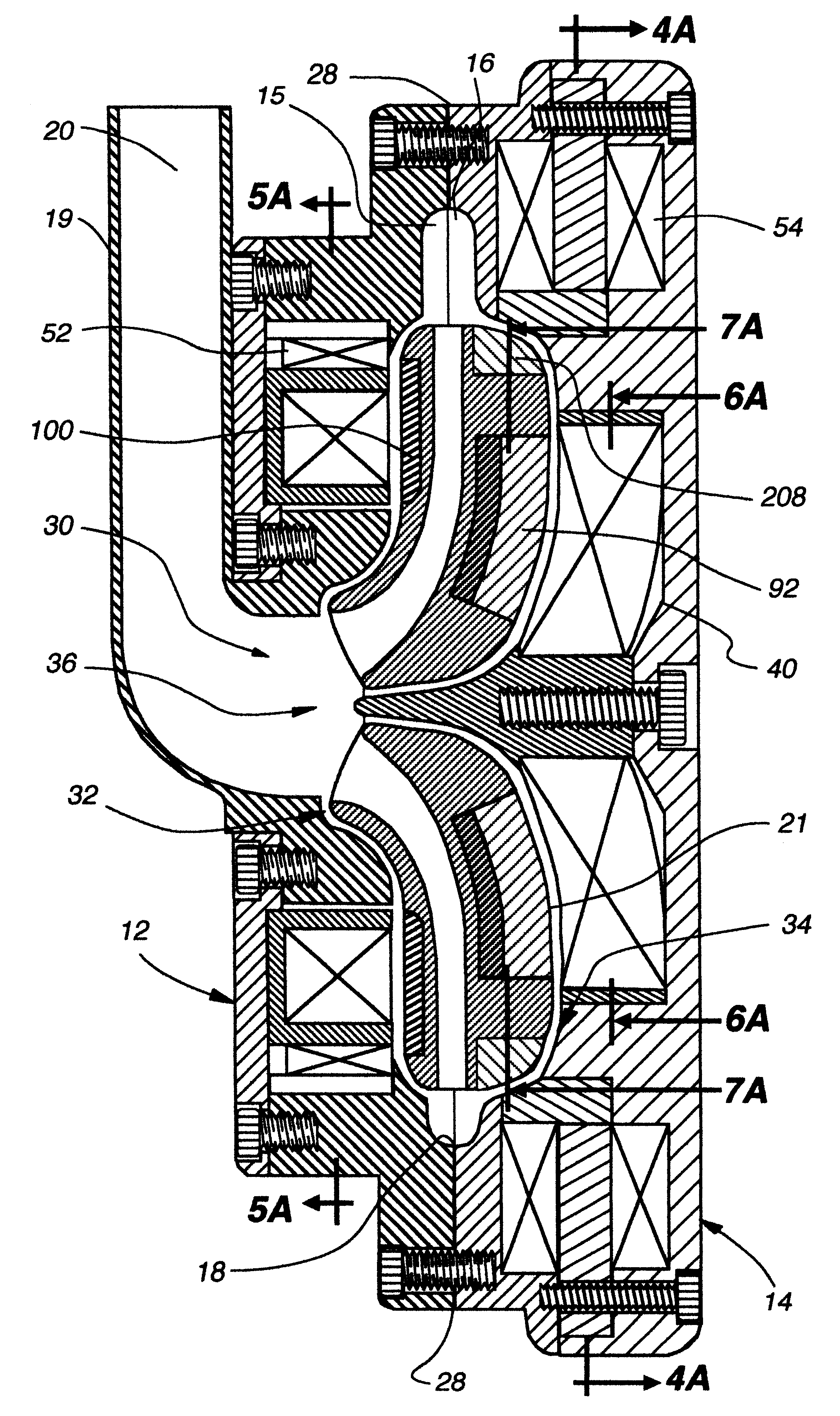

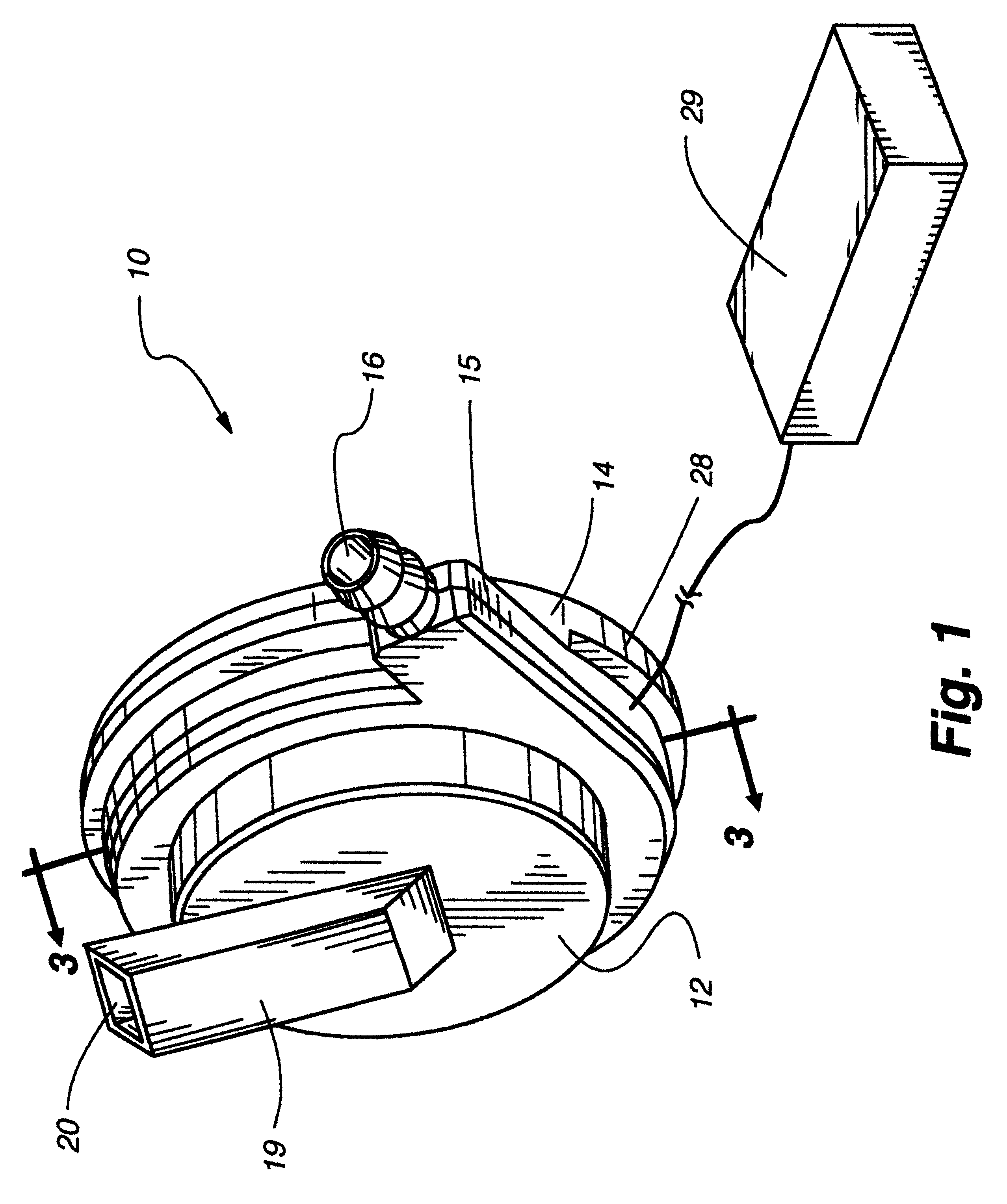

Hybrid magnetically suspended and rotated centrifugal pumping apparatus and method

InactiveUS6074180AAvoid displacementEfficient startSpecific fluid pumpsPump componentsMotor speedRotary pump

An apparatus and method for a centrifugal fluid pump for pumping sensitive biological fluids, which includes (i) an integral impeller and rotor which is entirely supported by an integral combination of permanent magnets and electromagnetic bearings and rotated by an integral motor, (ii) a pump housing and arcuate passages for fluid flow and containment, (iii) a brushless driving motor embedded and integral with the pump housing, (iv) a power supply, and (v) specific electronic sensing of impeller position, velocity or acceleration using a self-sensing method and physiological control algorithm for motor speed and pump performance based upon input from the electromagnetic bearing currents and motor back emf-all fitly joined together to provide efficient, durable and low maintenance pump operation. A specially designed impeller and pump housing provide the mechanism for transport and delivery of fluid through the pump to a pump output port with reduced fluid turbulence.

Owner:WORLD HEART +2

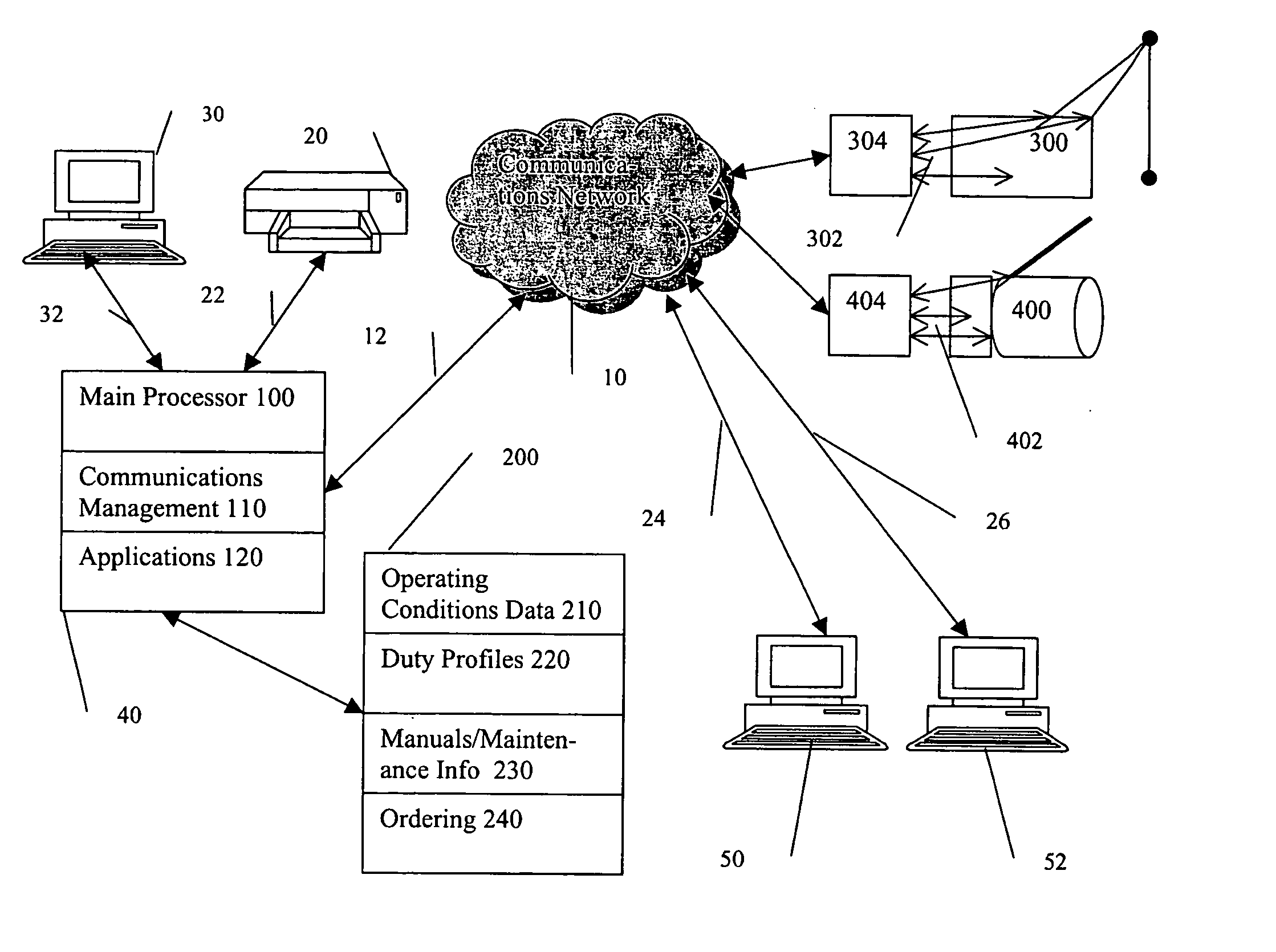

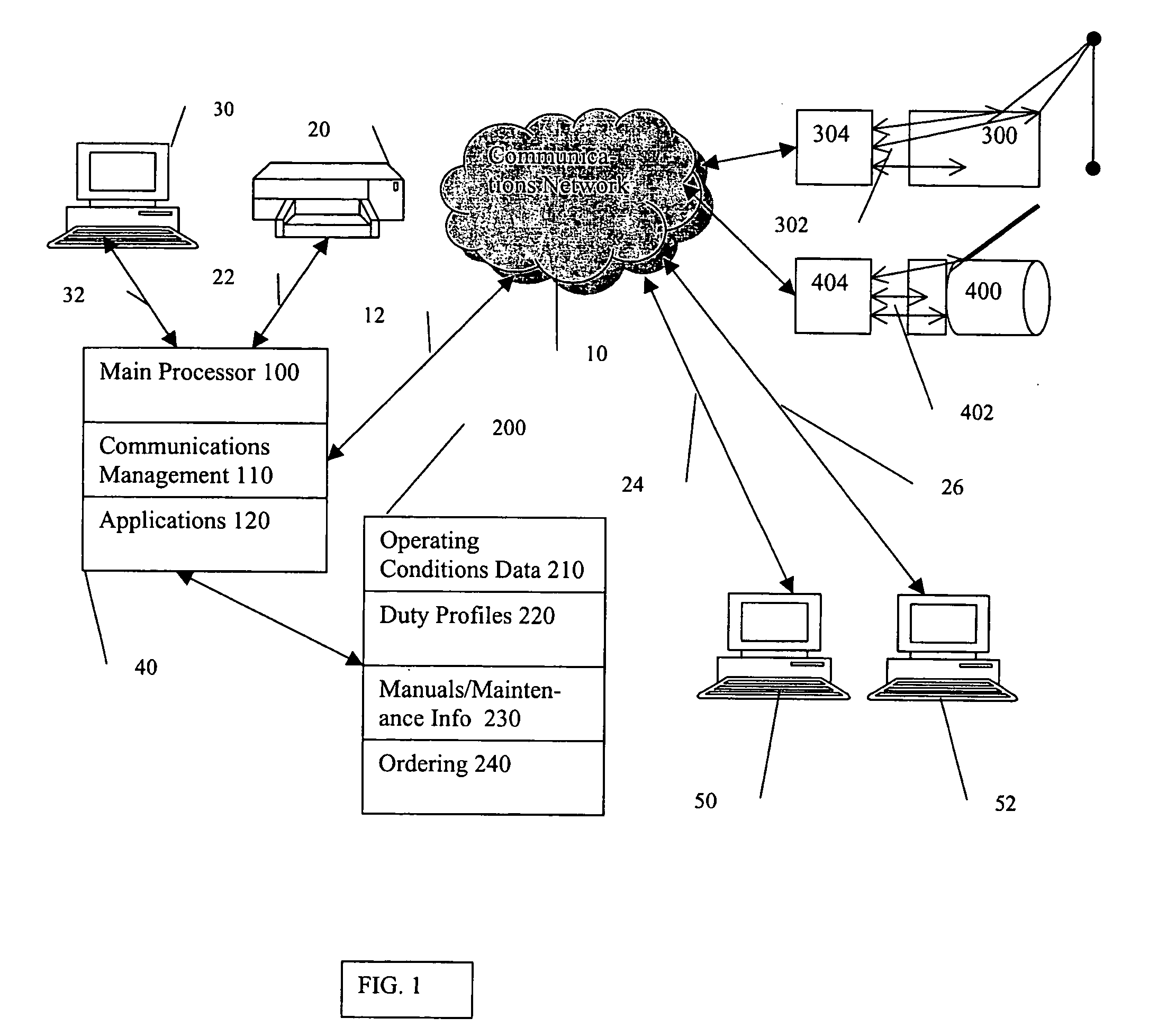

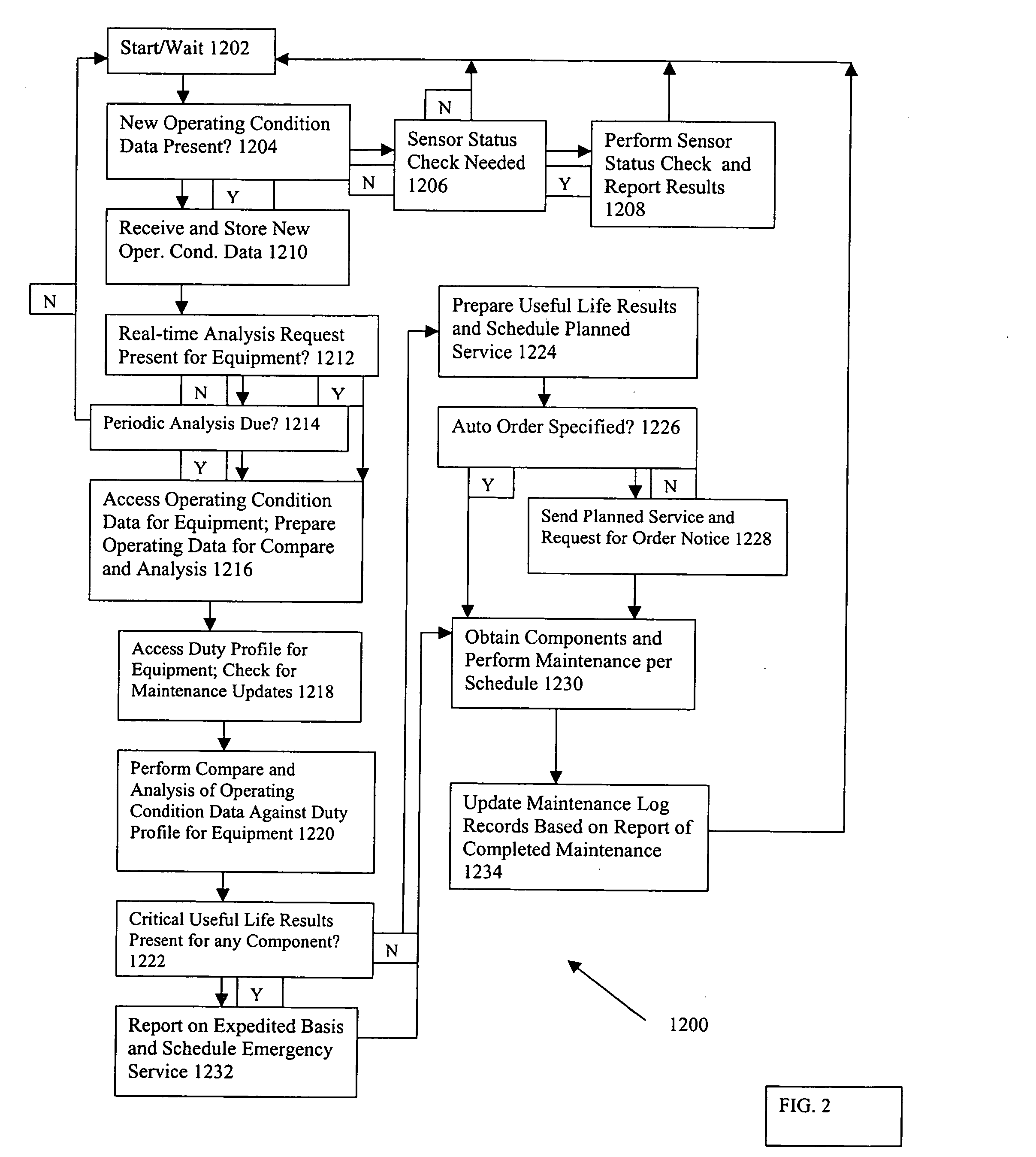

Equipment component monitoring and replacement management system

ActiveUS20050143956A1Improve performanceGood interpretationPlug gaugesMachine part testingComputer scienceOperant conditioning

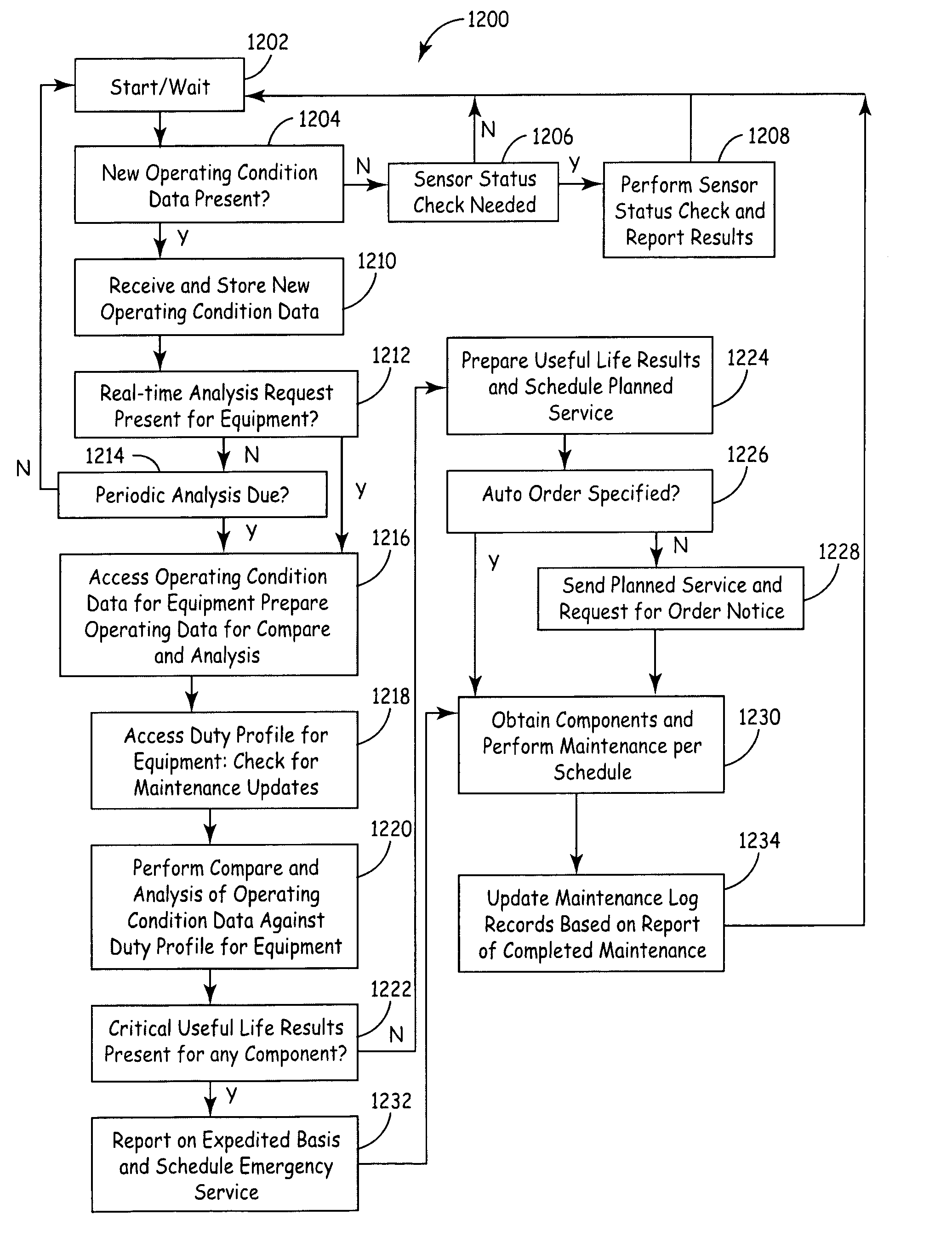

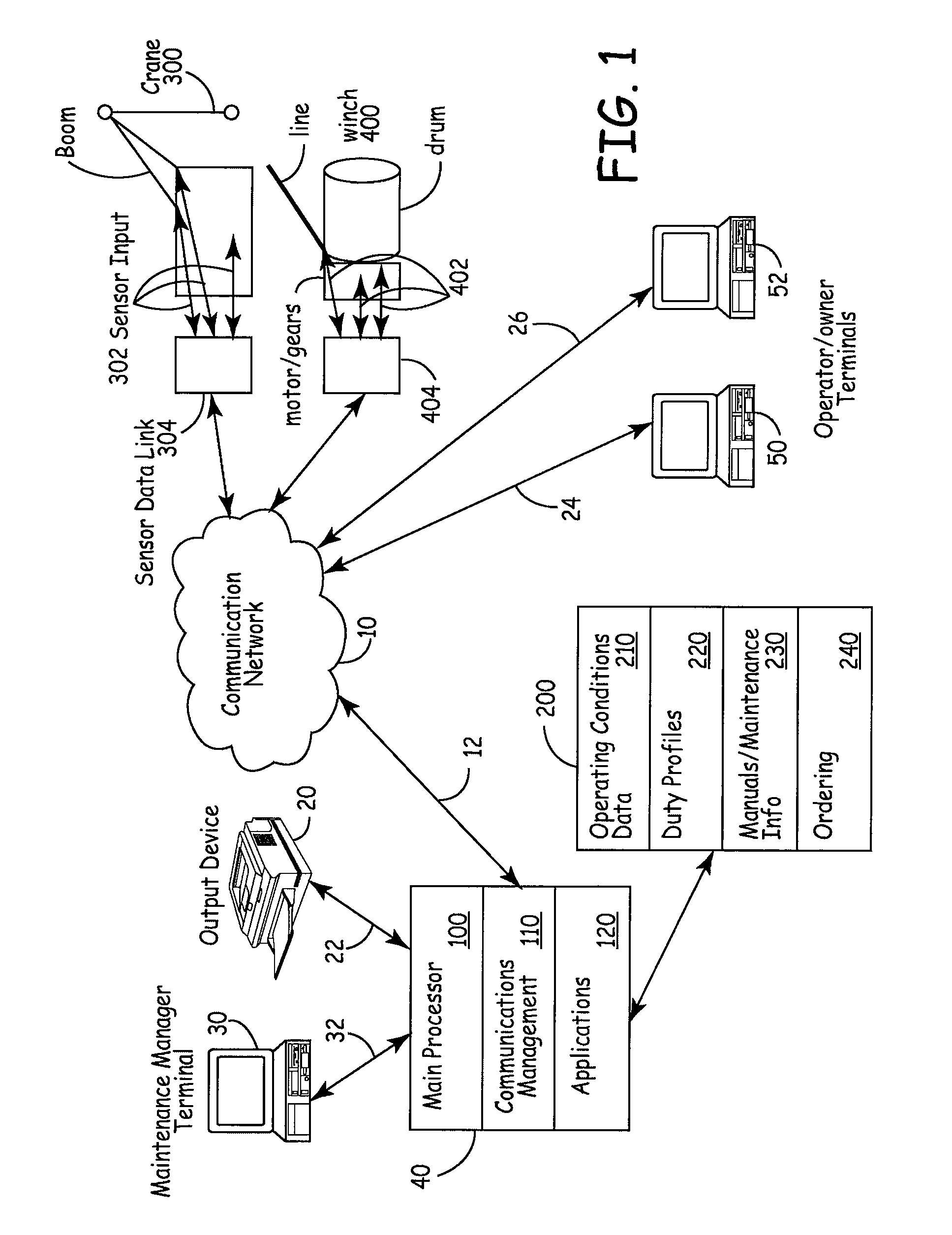

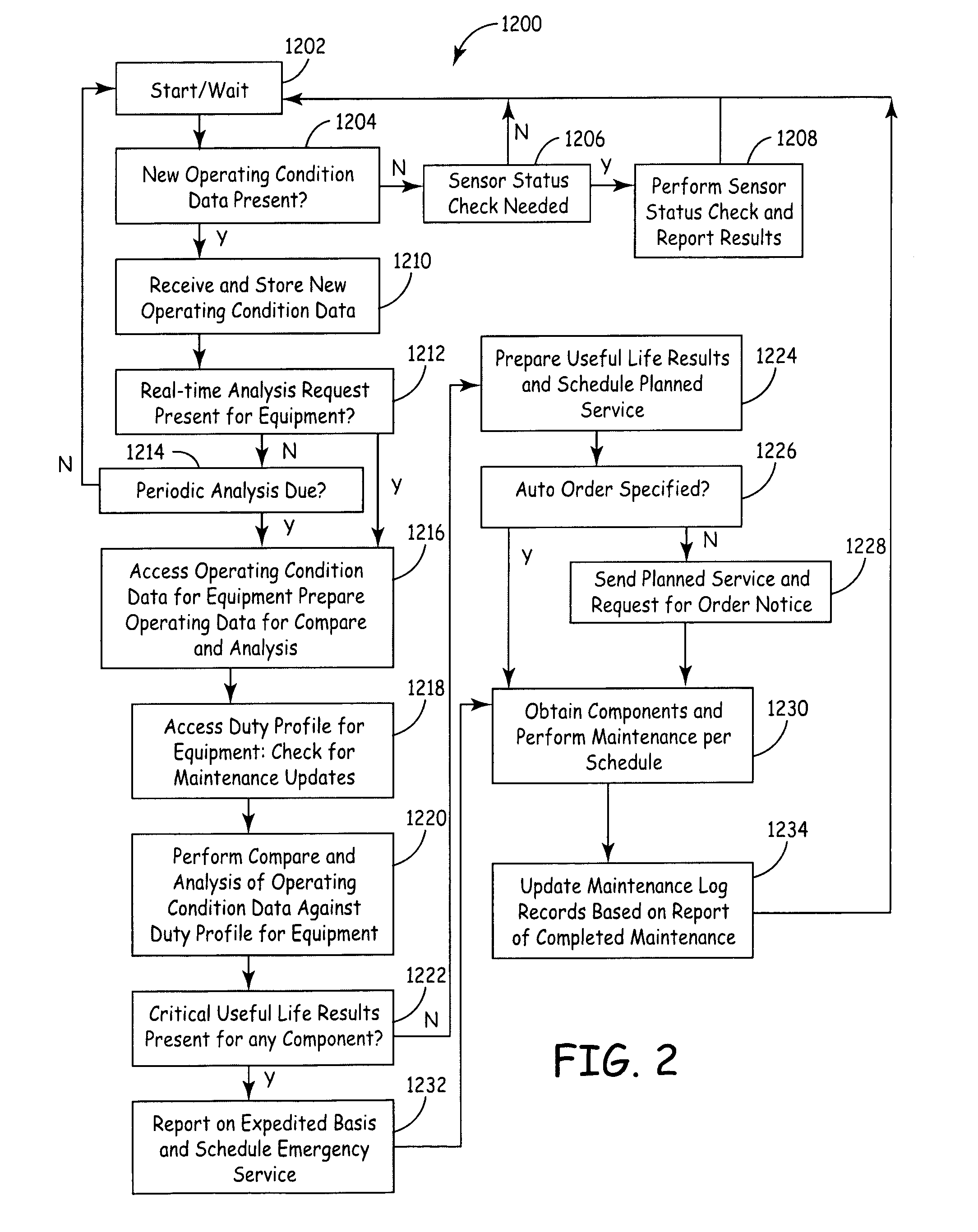

A system for managing replacement components for equipment having a plurality of components each with a limited useful life has a computer with a processor. The system includes a computer program module for defining a duty profile comprising a plurality of usage cases for the equipment, each usage case involving two or more of the plurality of components and specified operating conditions assumed to be experienced by the involved components during the execution of each of the usage cases. There are also a computer program module for determining a theoretical useful life for each component involved in a duty profile, the theoretical useful life being based on component useful life data under the specified operating conditions; and sensors for determining and monitoring the occurrence of equipment operation corresponding to a usage case and measuring the actual operating conditions experienced in the operation and the number of such operations. A further computer program module computes an adjusted theoretical useful life for a component that has experienced one or more operations, based on a comparison of actual operating conditions to operating conditions assumed to be experienced in the operation of the usage case.

Owner:HYDRALIFT AMCLYDE INC

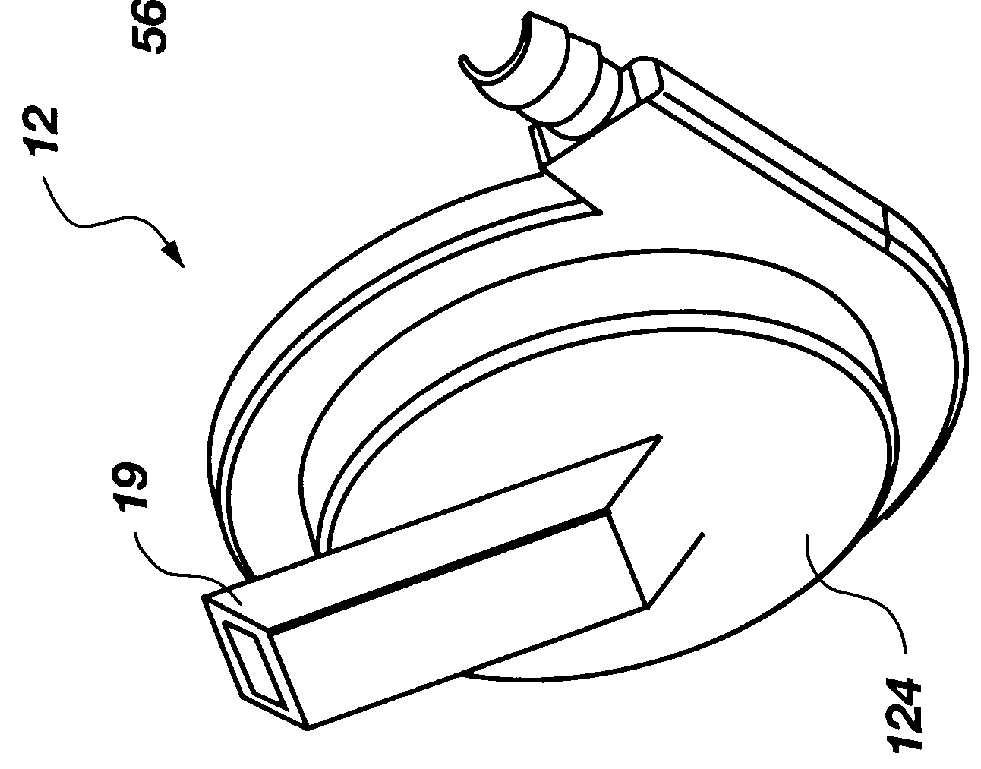

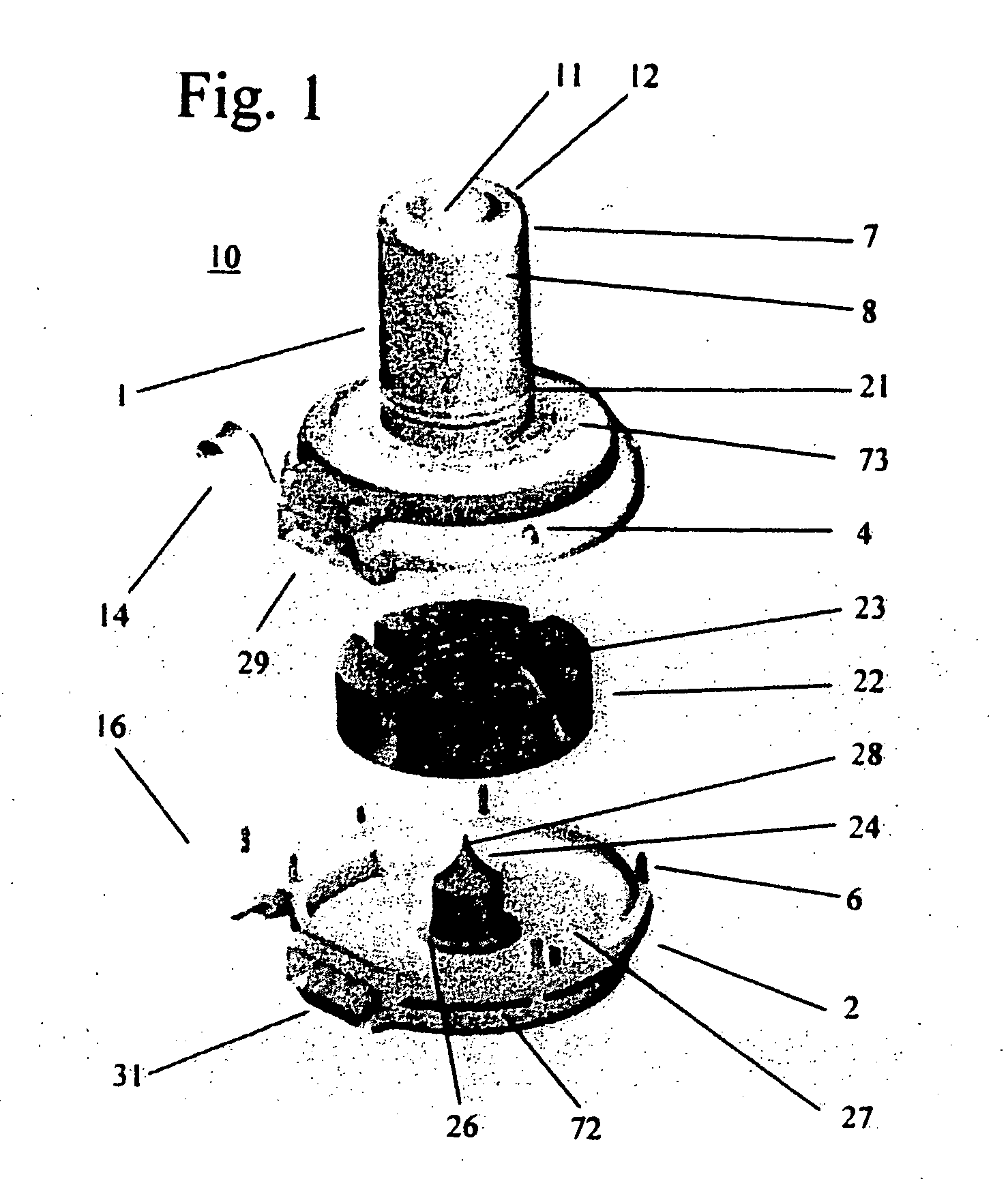

Stabilizing drive for contactless rotary blood pump impeller

ActiveUS20080021394A1Good for healthSpeed up the flowSpecific fluid pumpsPump componentsImpellerCoupling

A rotary blood pump includes a casing defining a pumping chamber. The pumping chamber has a blood inlet and a tangential blood outlet. One or more motor stators are provided outside of the pumping chamber. A rotatable impeller is within the pumping chamber and is adapted to cause blood entering the pumping chamber to move to the blood outlet. The impeller has one or more magnetic regions. The impeller is radially constrained in rotation by magnetic coupling to one or more motor stators and is axially constrained in rotation by one or more hydrodynamic thrust bearing surfaces on the impeller.

Owner:HEARTWARE INC

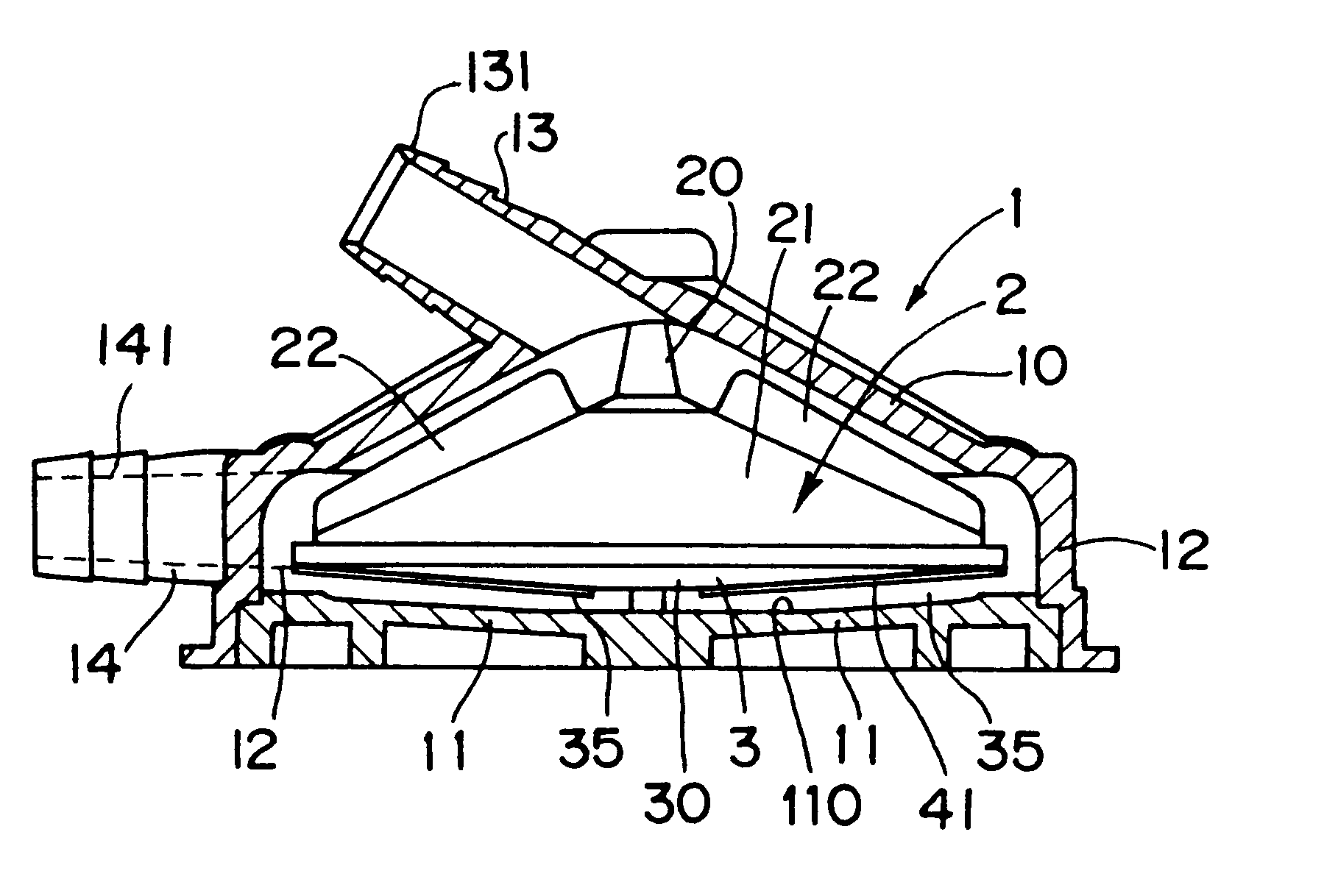

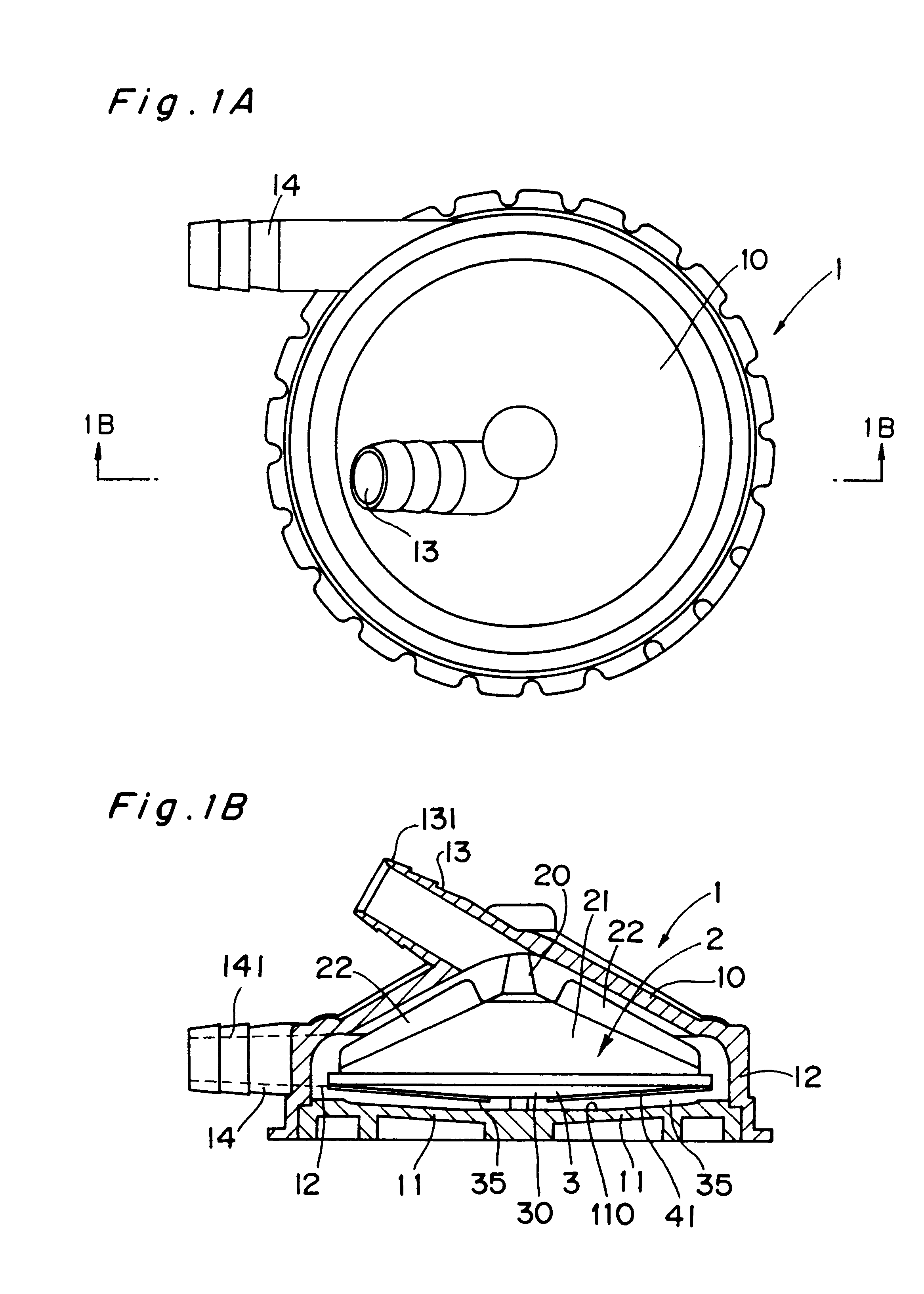

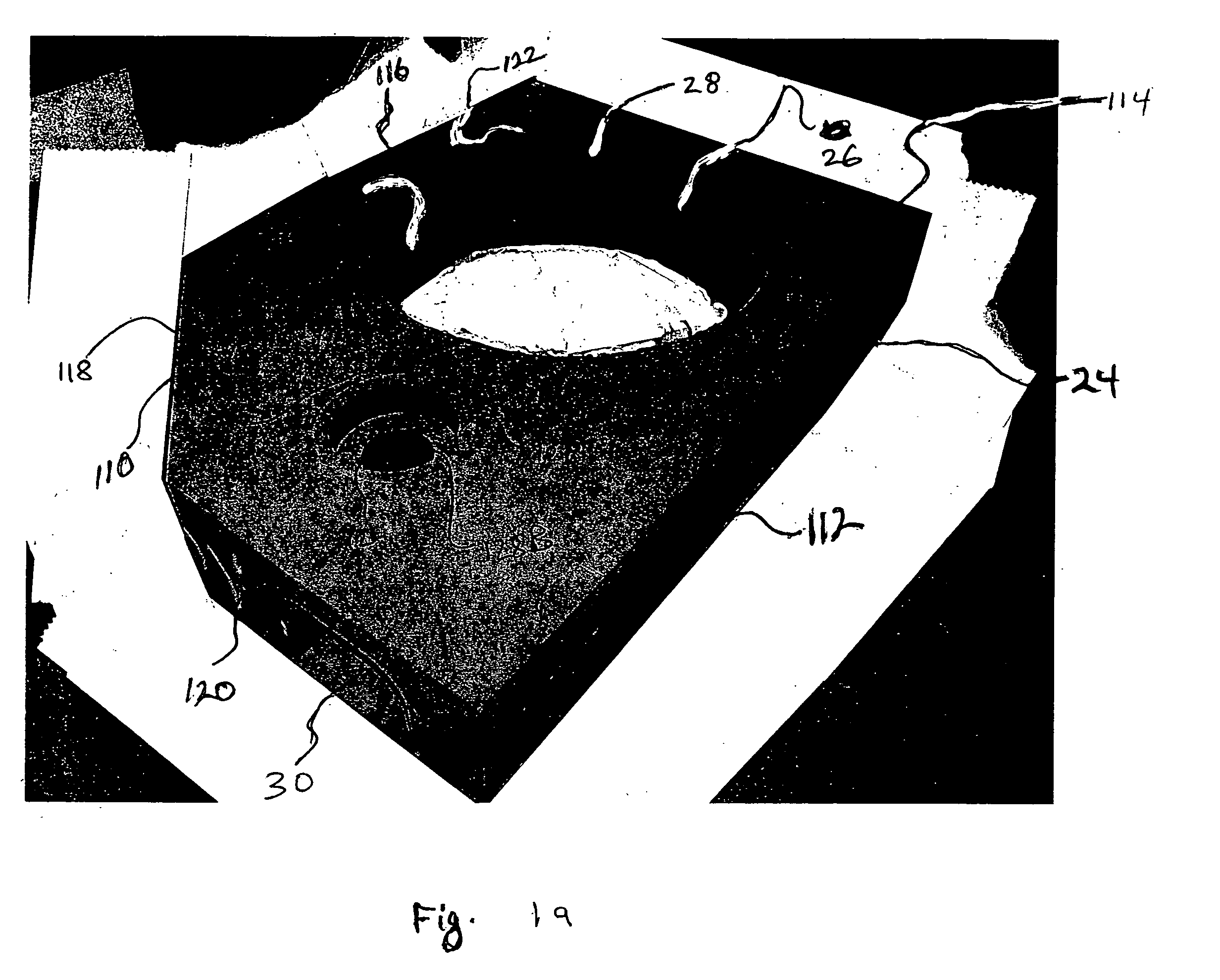

Electromagnetically suspended and rotated centrifugal pumping apparatus and method

InactiveUS6302661B1Increase energy lossIncrease frictionSpecific fluid pumpsPump componentsElectric machineryEngineering

An apparatus and method for a centrifugal pump for pumping sensitive biological fluids which includes (i) an integral impeller and rotor which is electromagnetically supported and rotated, (ii) a pump housing and arcuate passages for fluid flow and containment, (iii) a brushless driving motor embedded and integral with the pump housing, (iv) a power supply, and (v) specific electronic sensing and control algorithms-all fitly joined together to provide efficient, durable and low maintenance pump operation. A specially designed impeller and pump housing provide the mechanism for transport and delivery of fluid through the pump to a pump output port with reduced fluid turbulence.

Owner:WORLD HEART

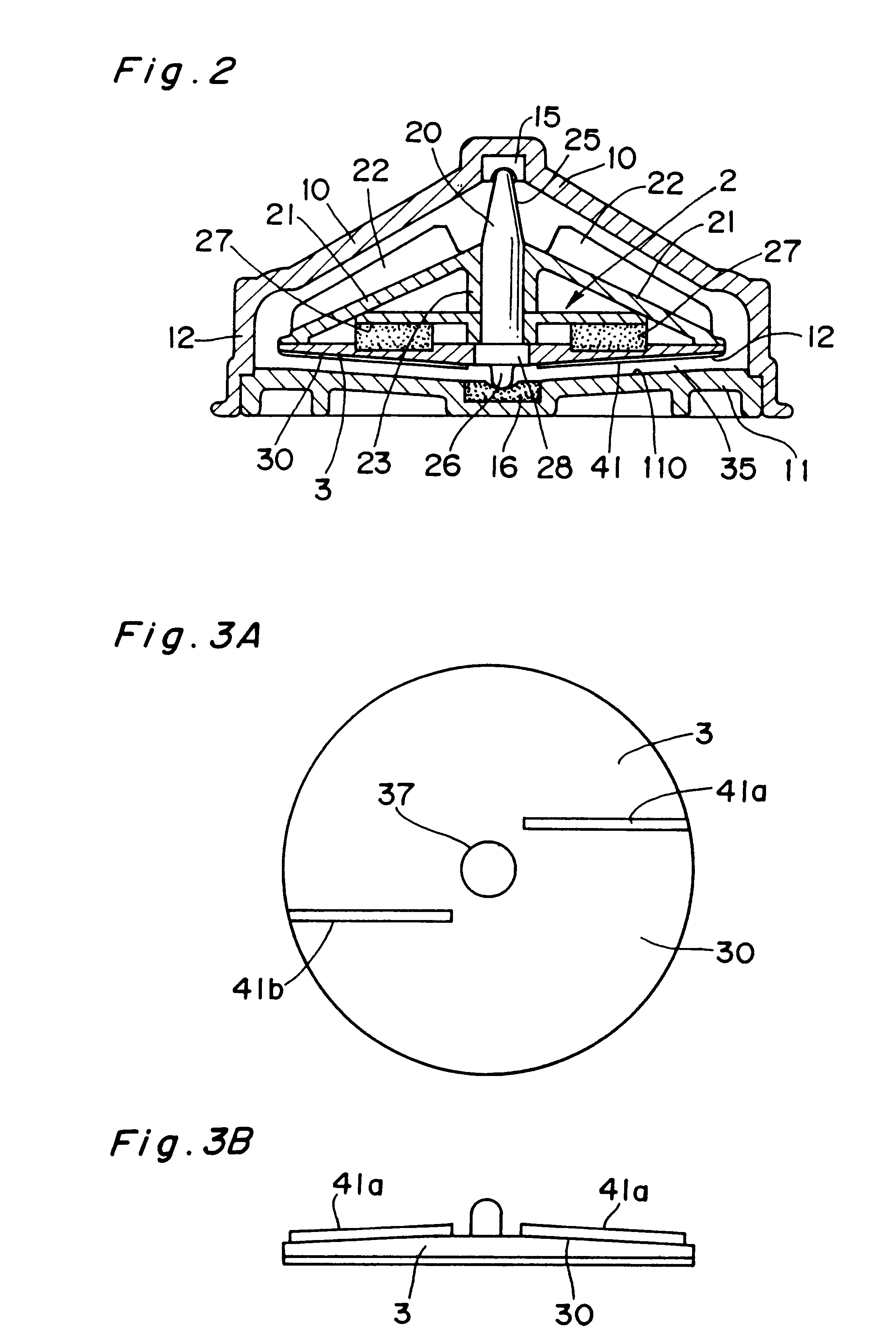

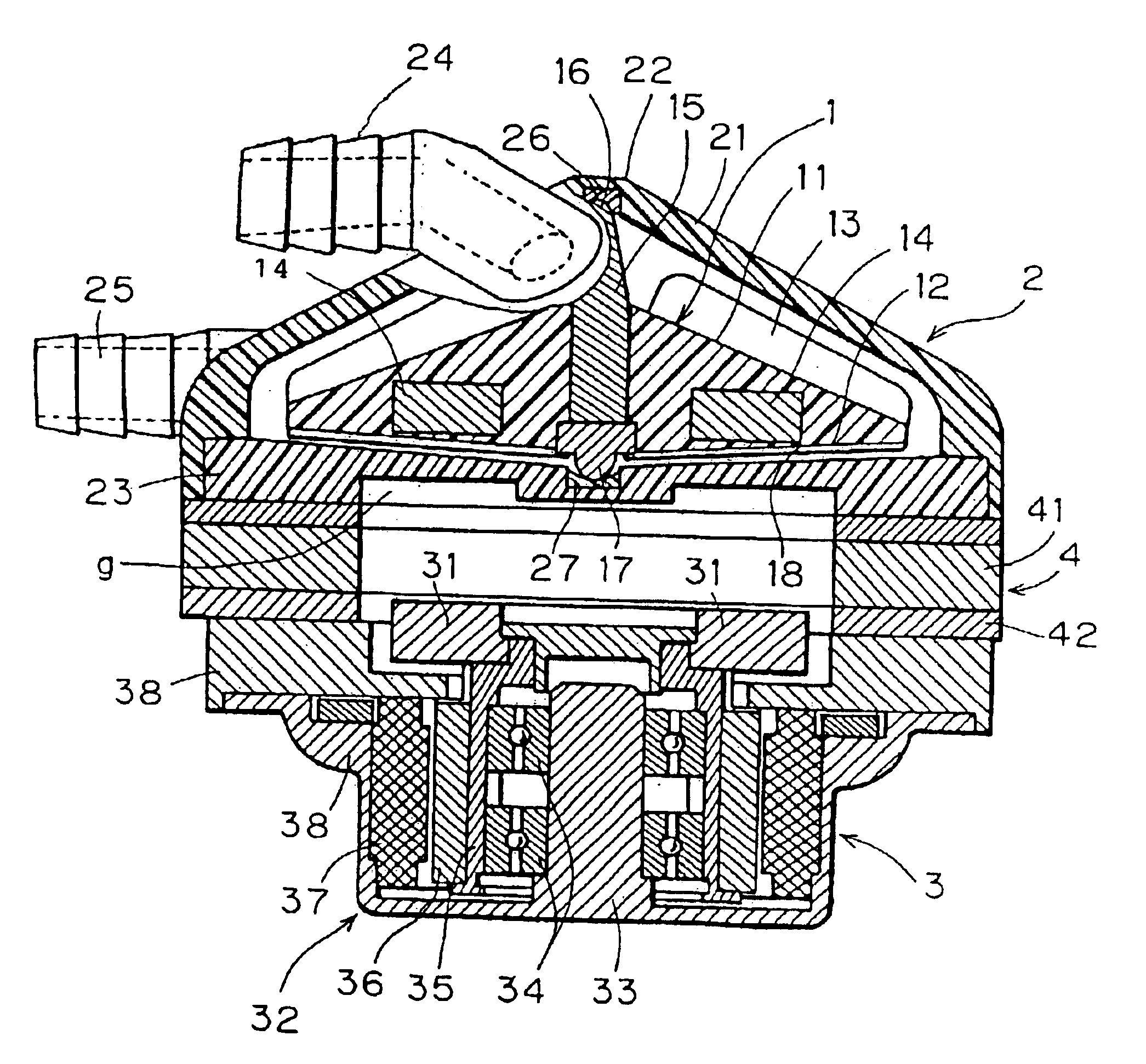

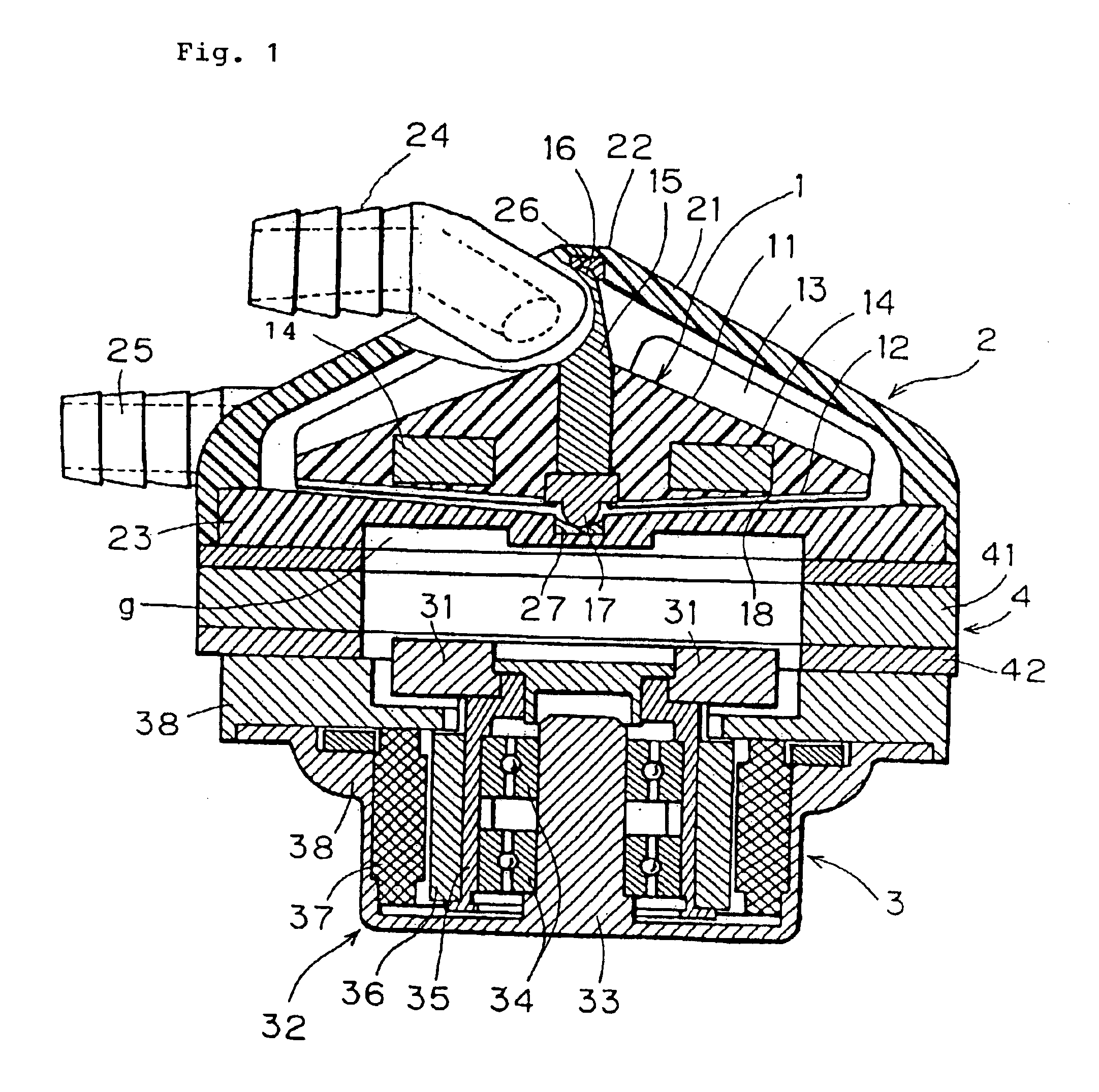

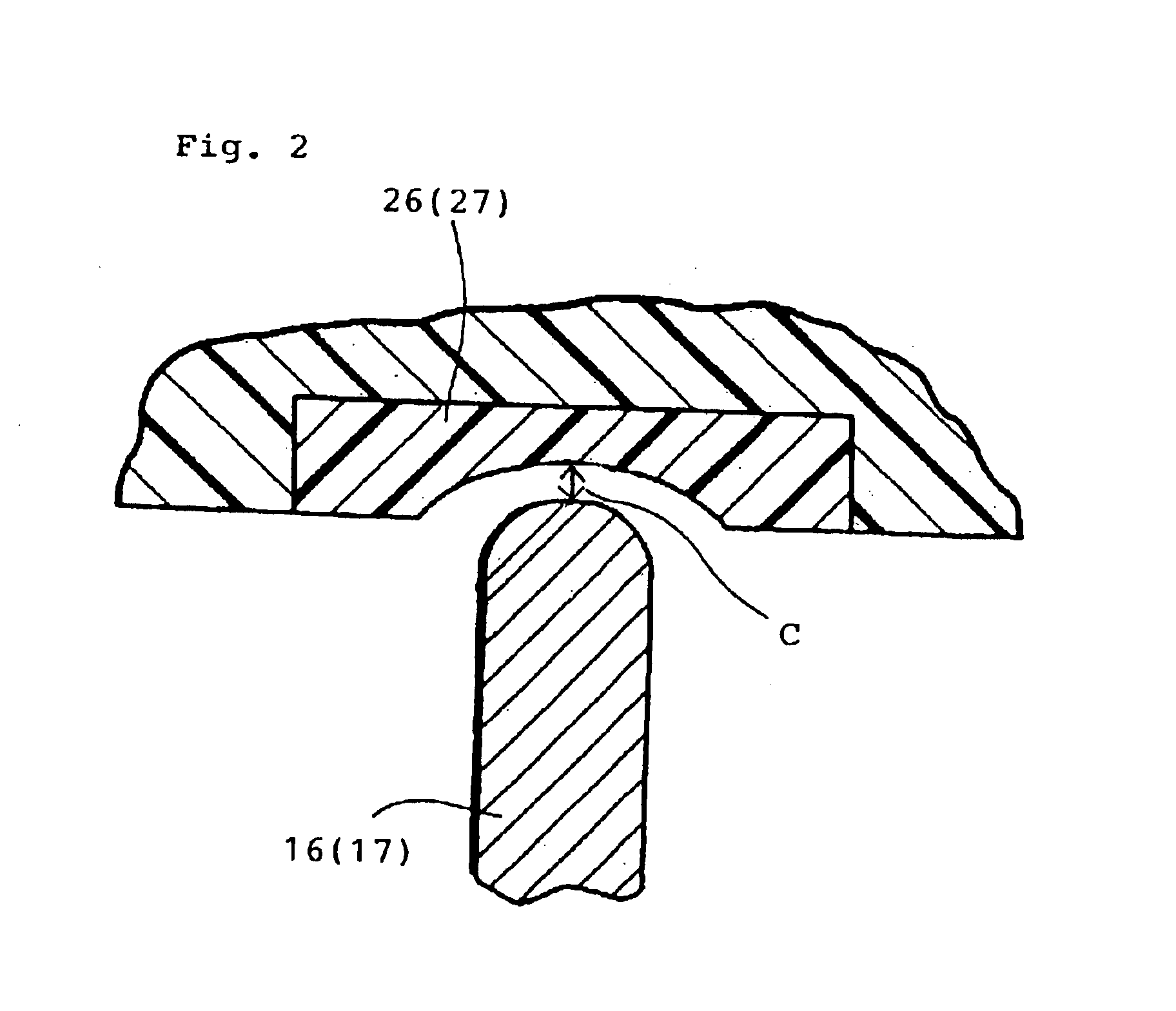

Centrifugal blood pump

The present invention provides a blood pump capable of substantially completely preventing thrombus from attaching to the inner bottom portion of the casing without lowering the anti-hemolytic characteristic of blood. A centrifugal blood pump in accordance with the present invention comprises a pump casing, a suction inlet disposed at the central portion on the upper side of the casing, a delivery outlet disposed at the bottom peripheral portion of the casing, a main impeller (D in diameter) for forming a centrifugal flow of blood supplied from the suction inlet in the range from the central portion to the peripheral portion to feed the blood to the delivery outlet, wherein the main impeller is provided with an stirring impeller, the surface of which is provided with one or more stirring elements (L in entire length) having the shape of a fin or a groove, and the dimensions of the stirring elements are determined to satisfy inequality (1): 0.43<LD<1.30 and inequality (2) 0.03<S / A<0.21, where S is the surface area of the blood contact surfaces of the stirring elements.

Owner:KYOCERA CORP +1

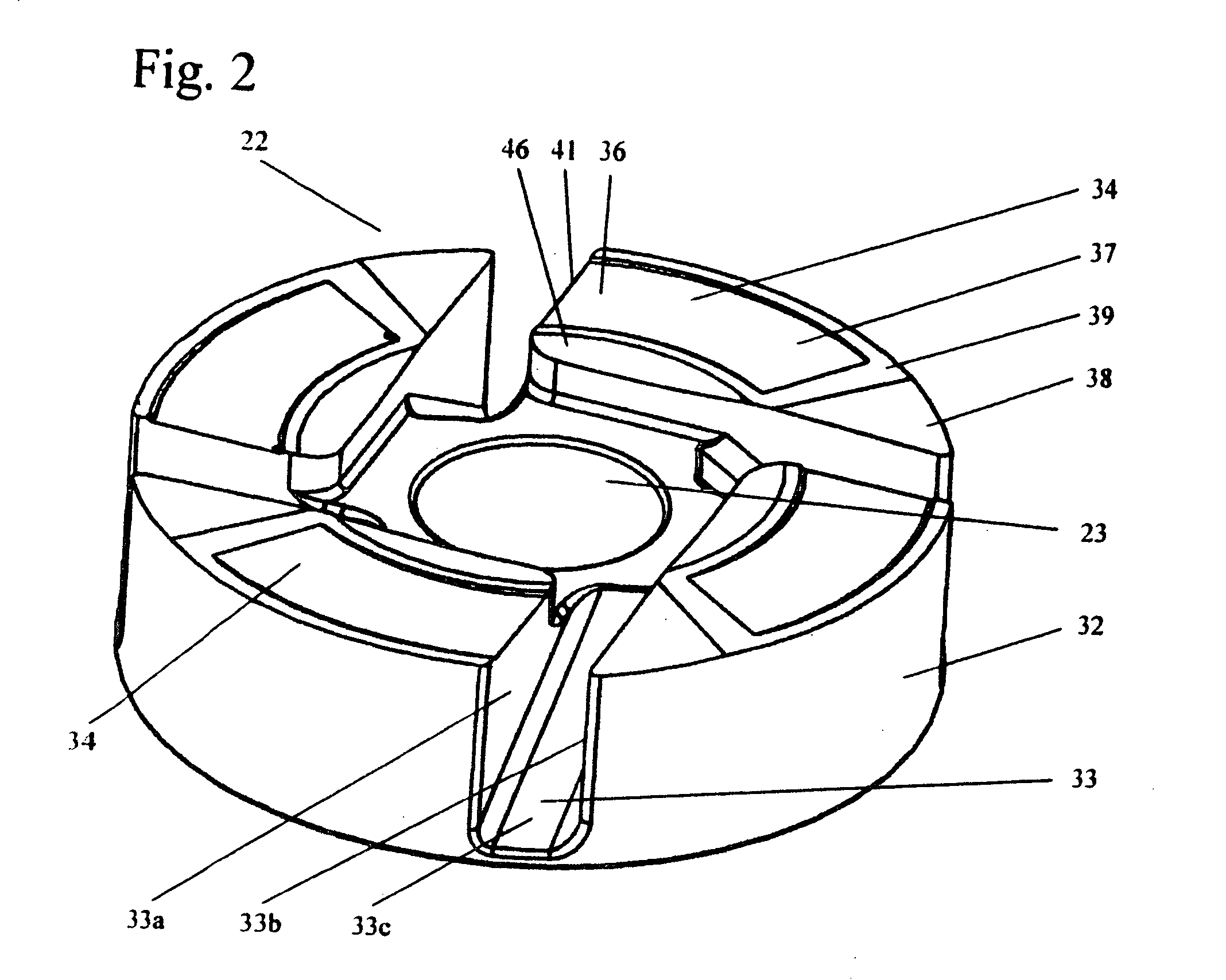

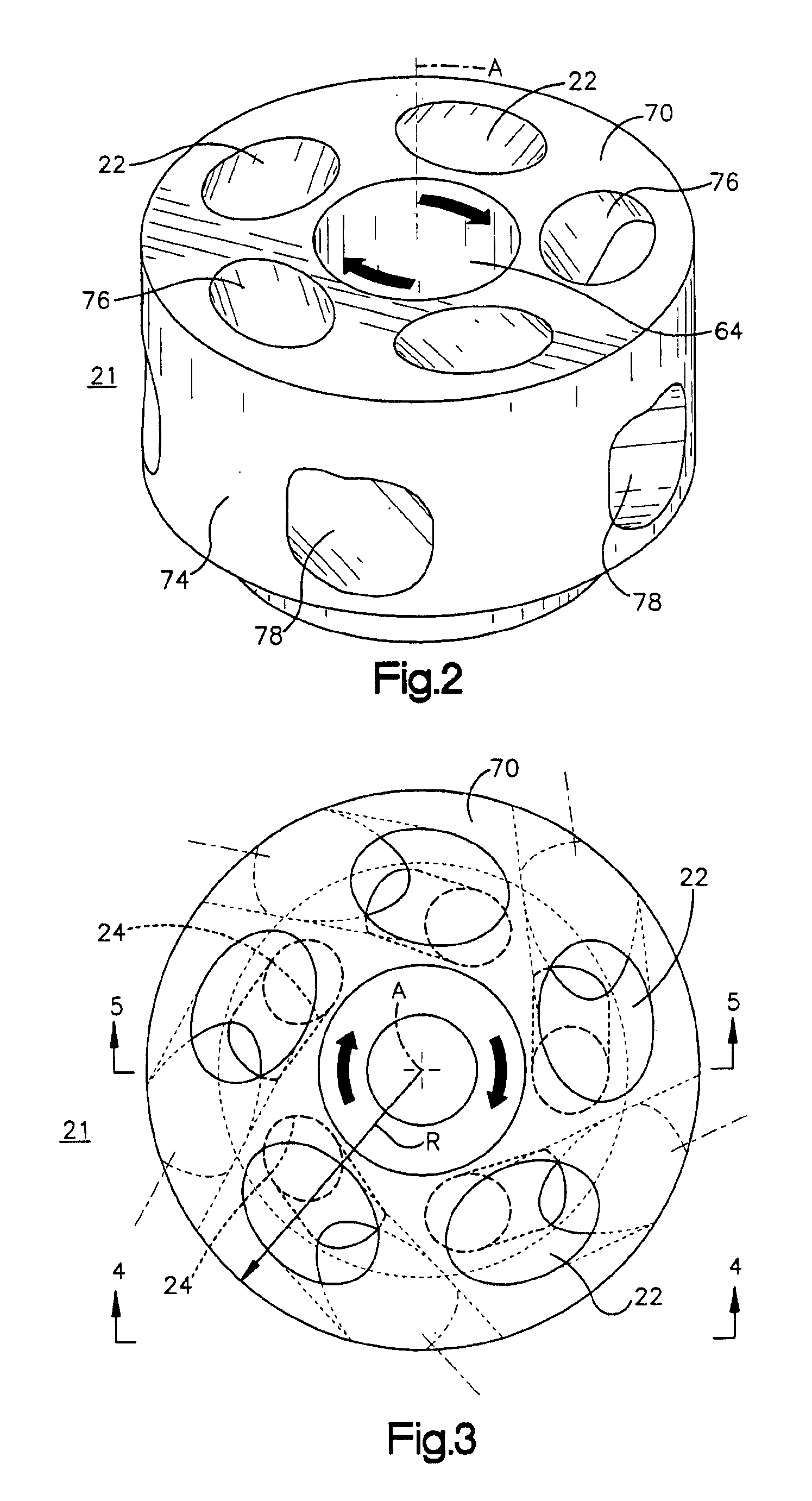

Pump with rotating inlet

A device for use in a molten metal pump helps alleviate jams between a rotating rotor and stationary inlet. The device includes an inlet structure including one or more openings and a displacement structure that preferably includes one or more rotor blades. The inlet structure and displacement structure are connected to one another (preferably, but not necessarily, as a unitary piece), thus enabling them both to rotate. A pump including the device is also enclosed. The invention further includes a bearing surface for an impeller or for a device according to the invention, wherein the bearing surface includes grooves that help reduce molten metal build up between the bearing surface of the impeller or device and the bearing surface of a pump chamber.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

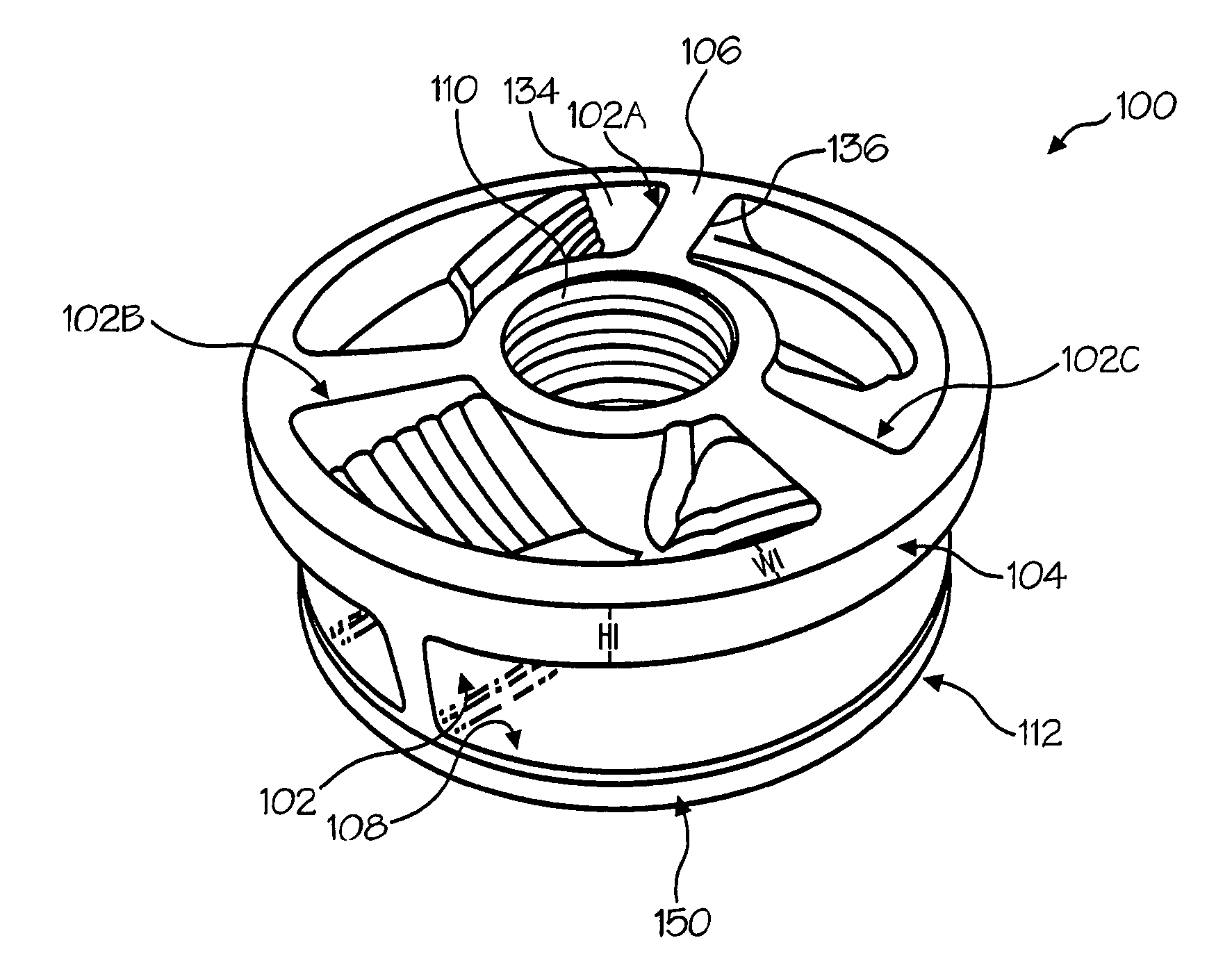

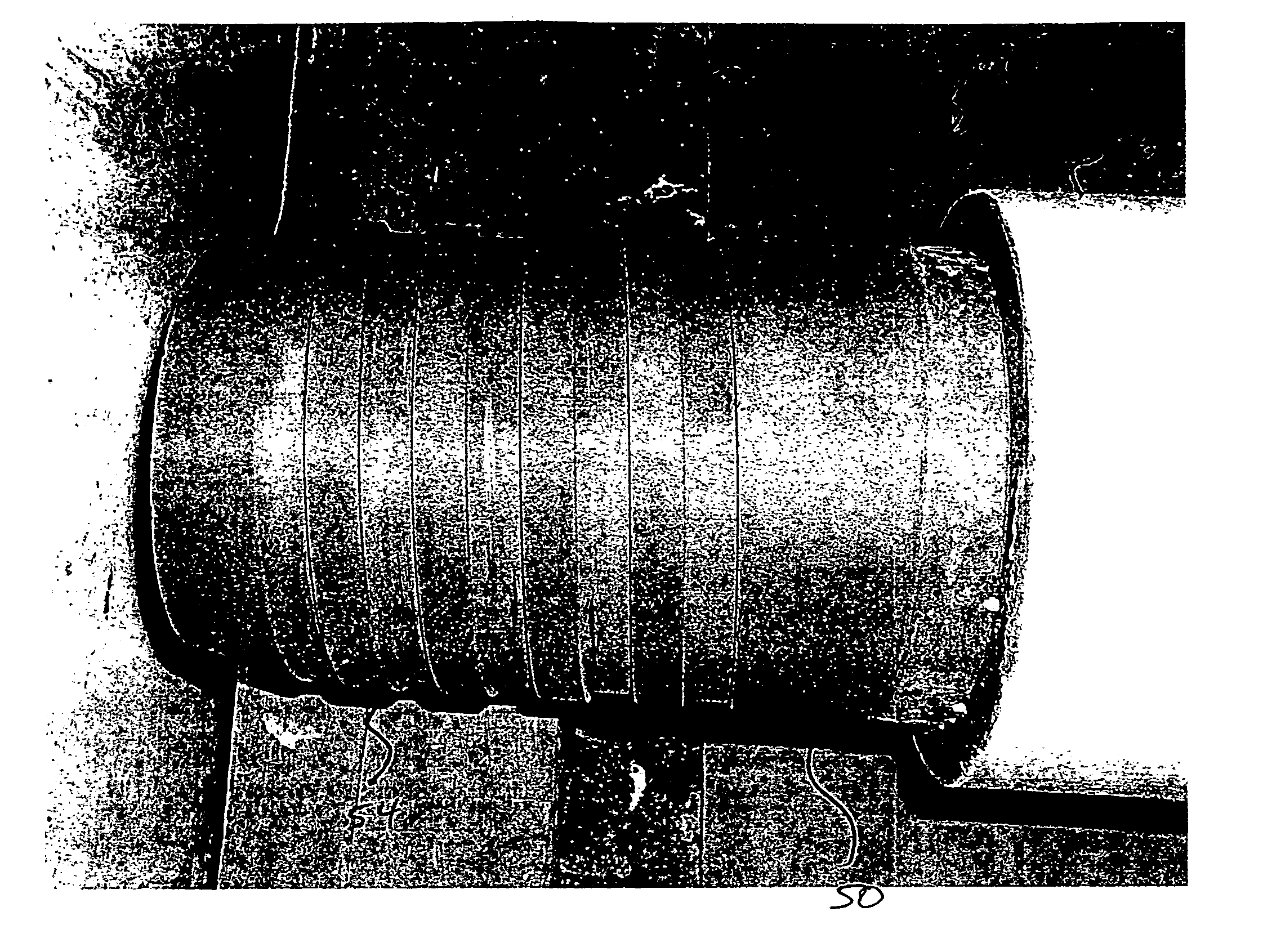

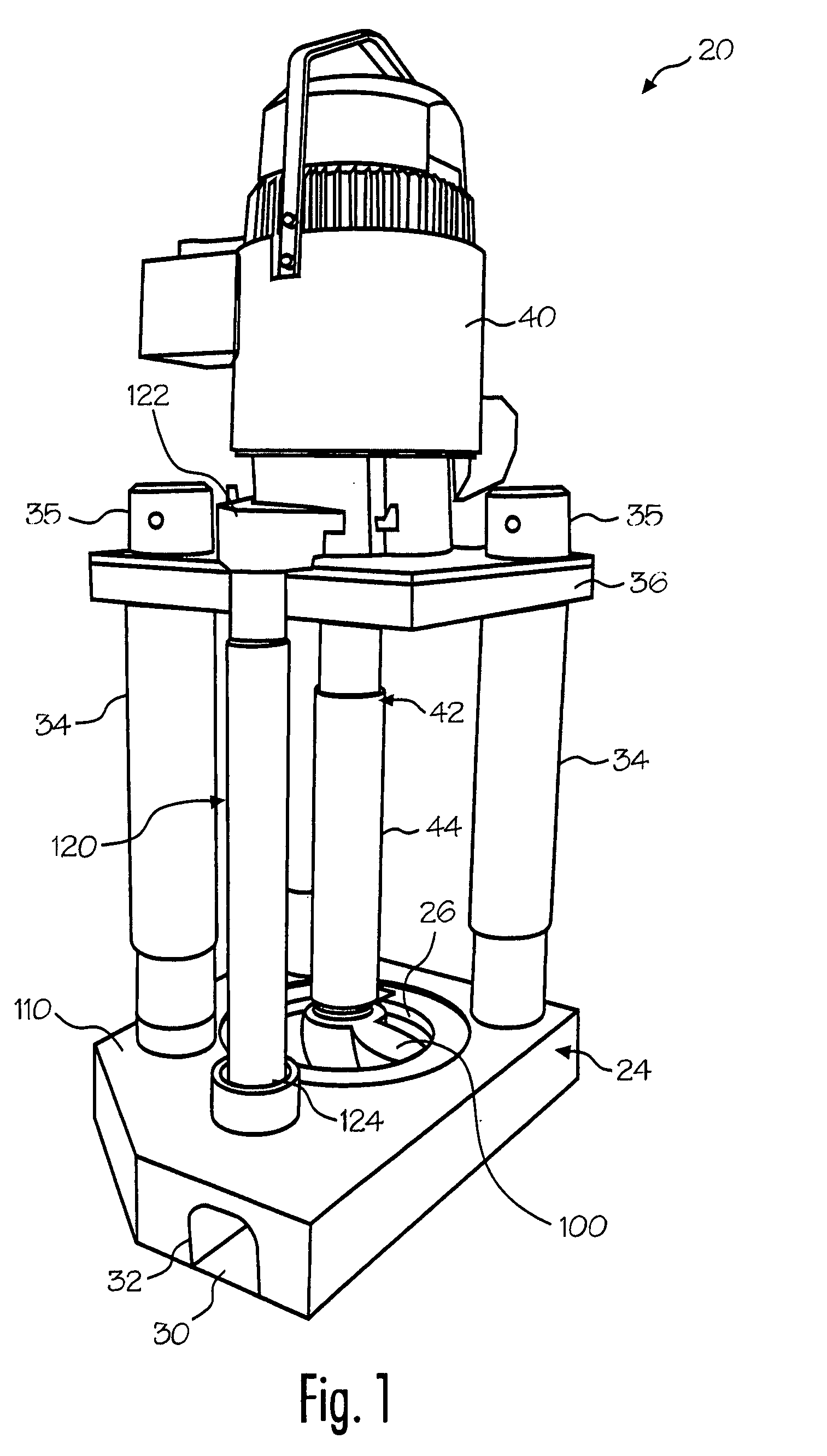

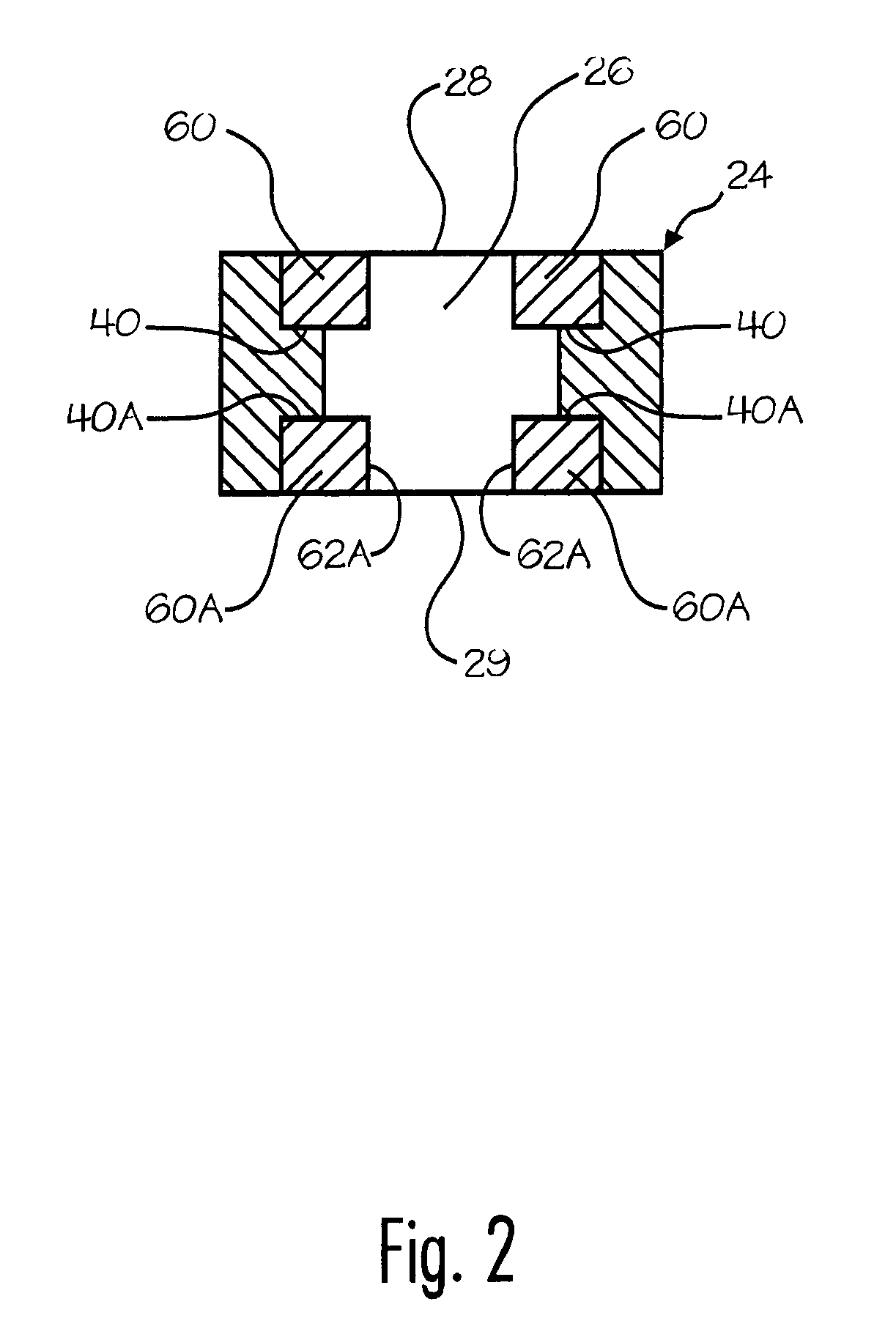

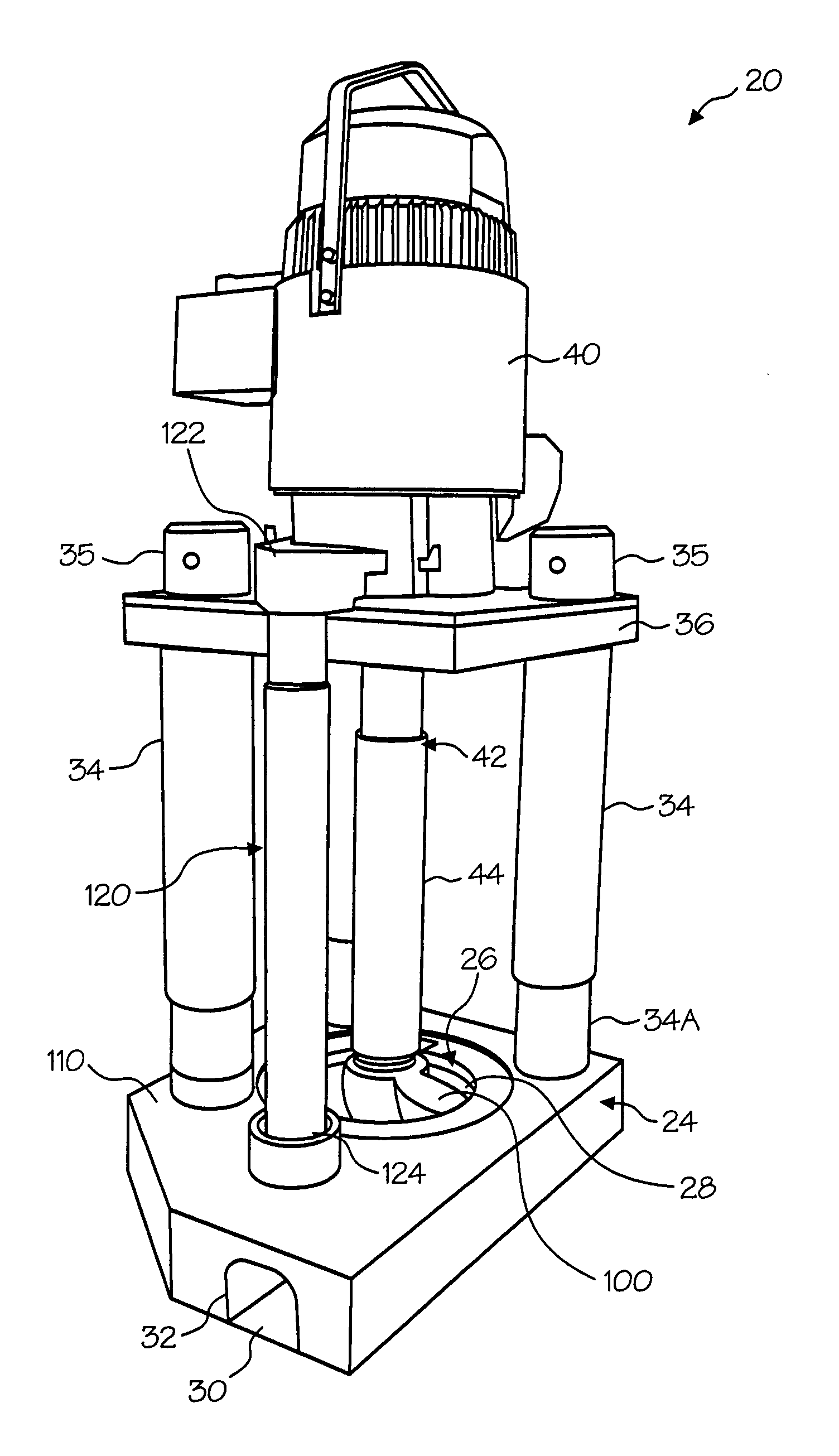

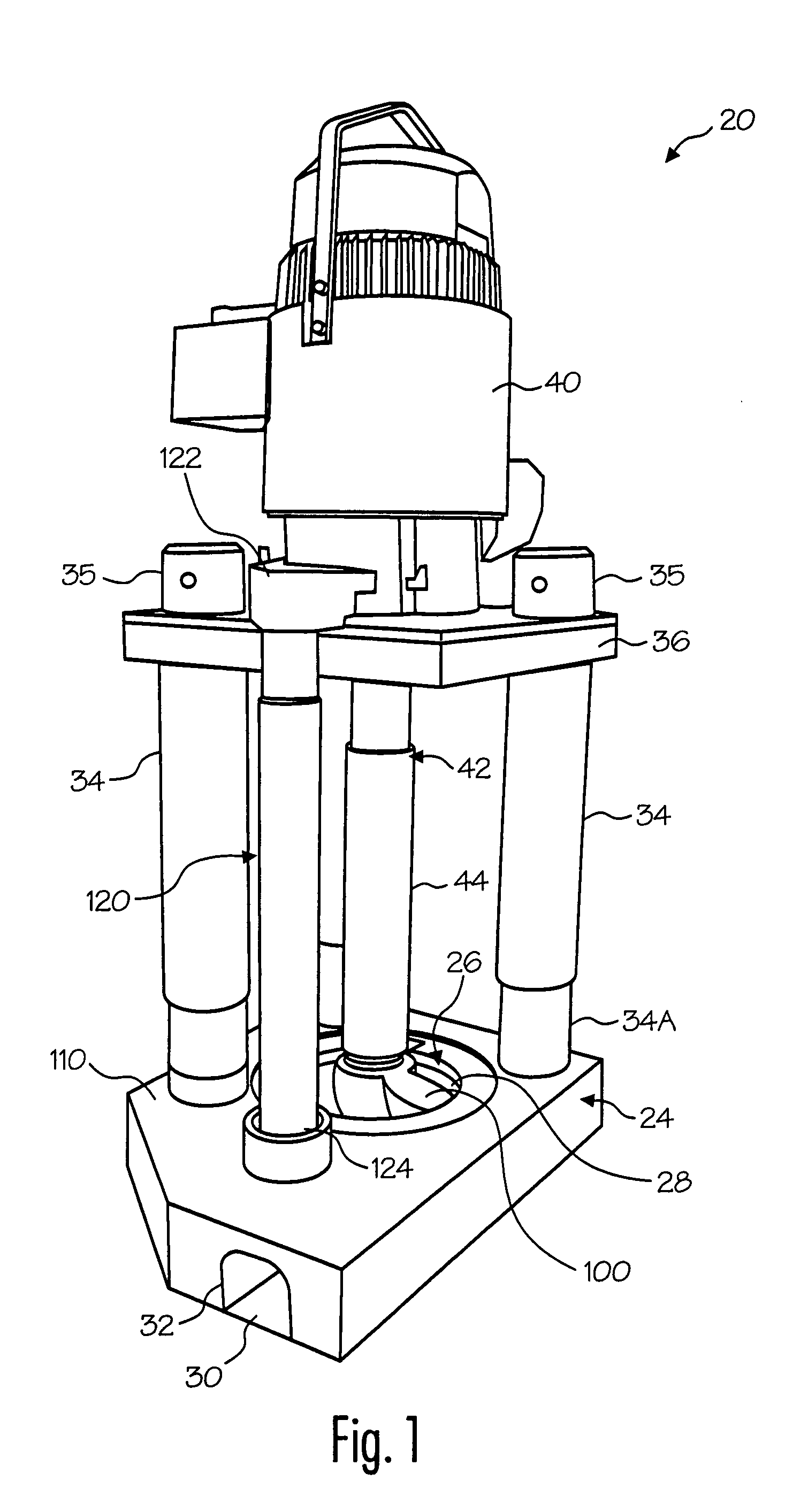

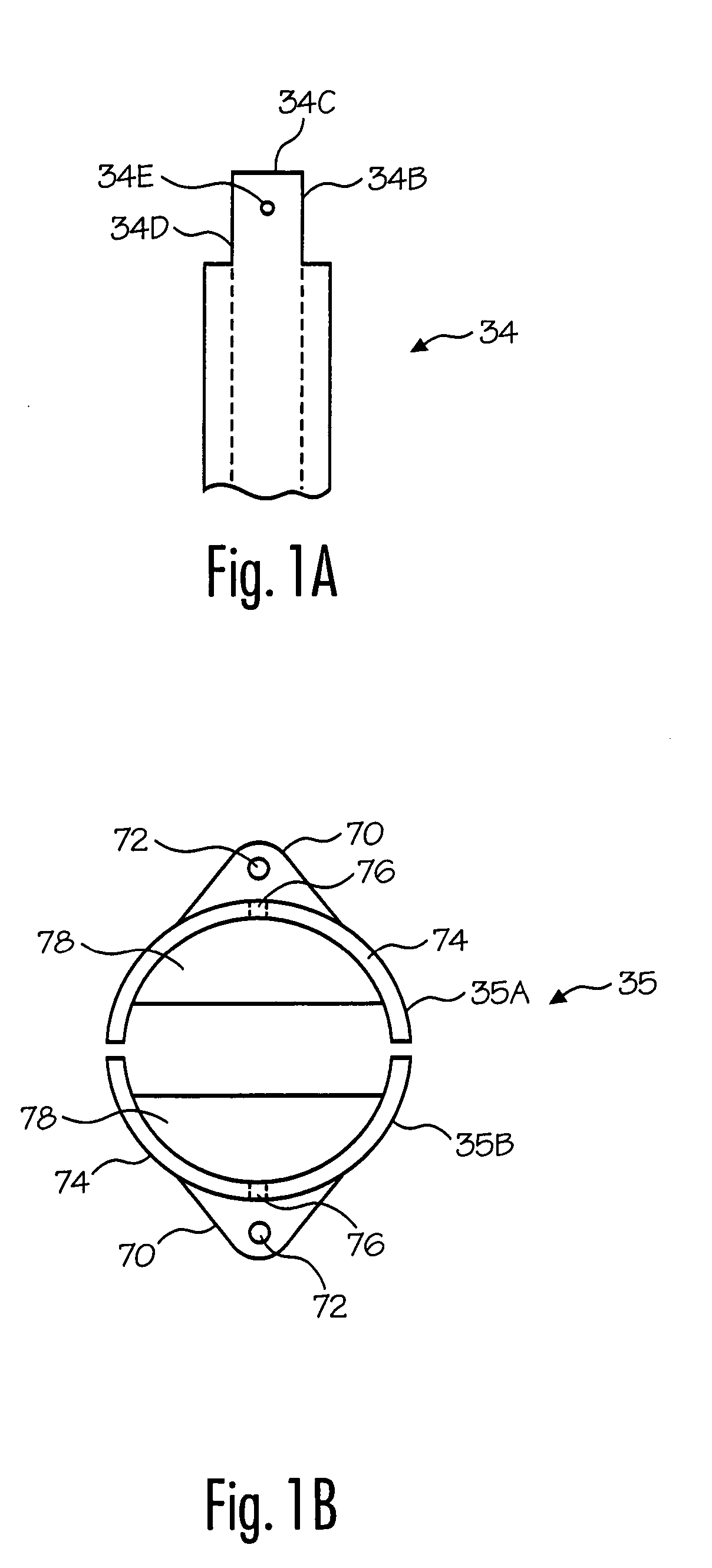

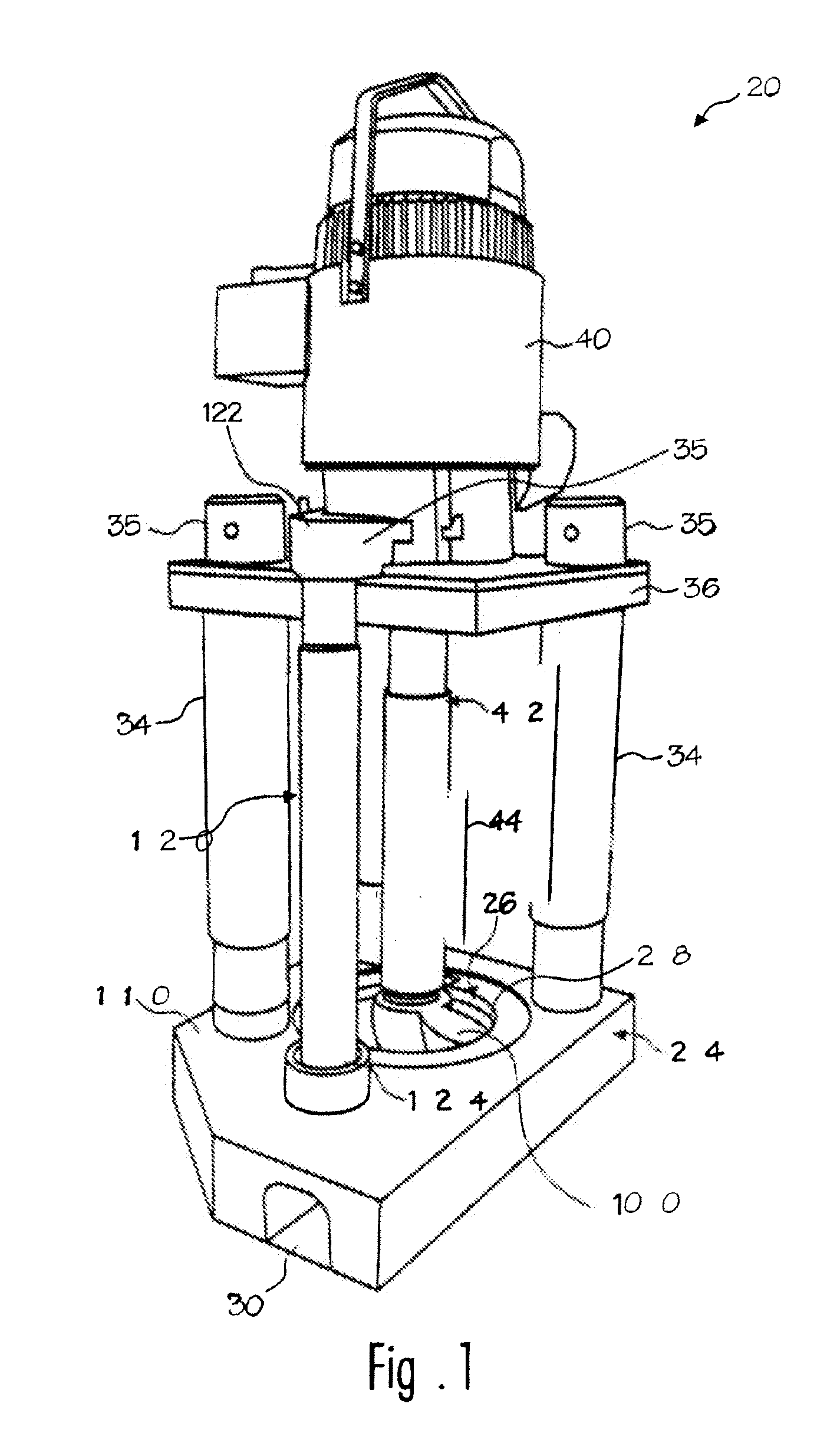

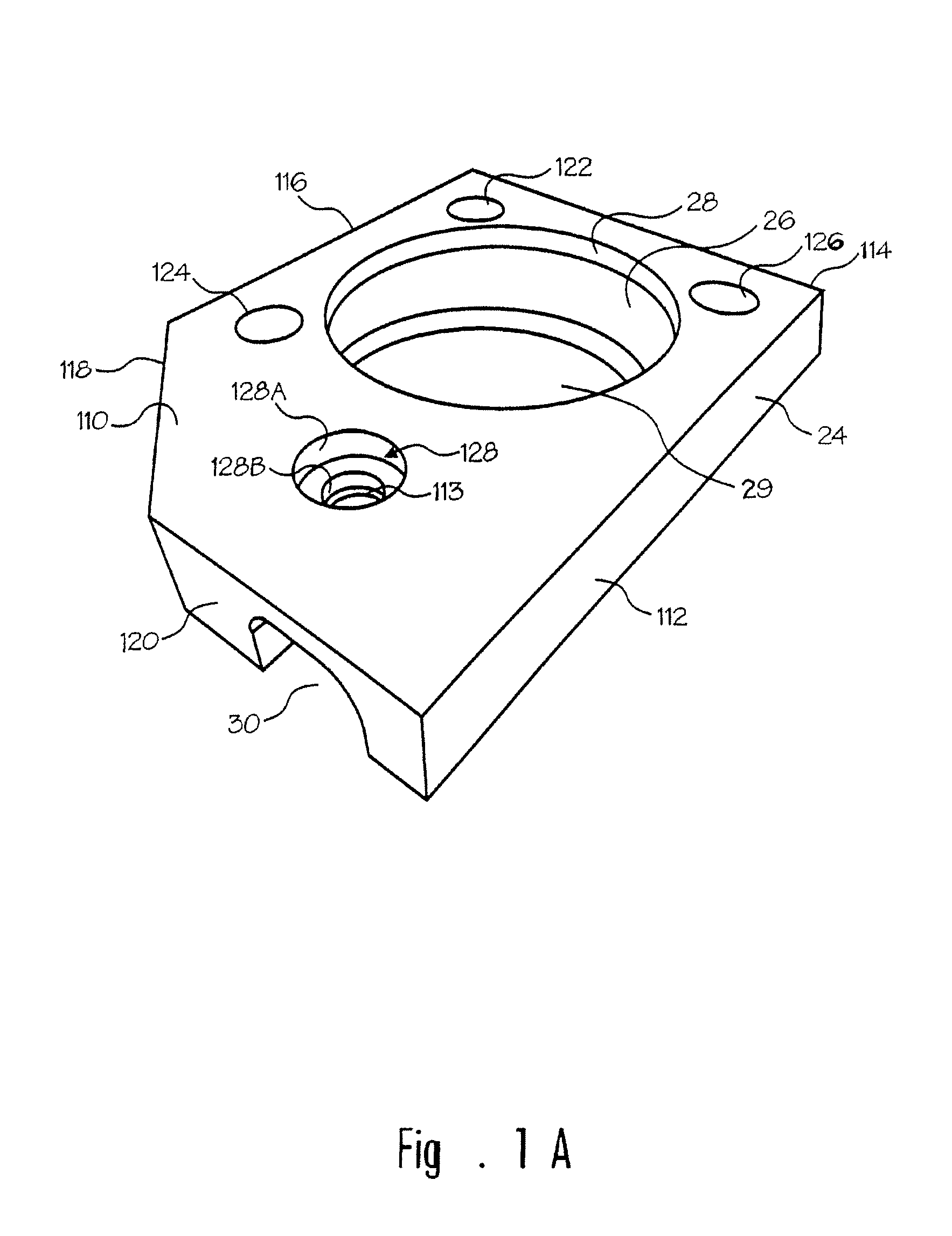

Molten metal pump components

Improved components for a molten metal pump include a coupling for connecting a rotor shaft to a motor shaft, a rotor shaft and a rotor. The rotor shaft has a first end and a second end wherein the first end optionally has a vertical keyway formed in the outer surface of the shaft. The second end optionally has flat, shallow threads. The coupling can be one-piece or multi-piece, includes a cavity for receiving the first end of the rotor shaft and, if the first end of the rotor shaft has a keyway, the coupling includes a projection in the cavity for being received at least partially in the keyway. The rotor includes a connective portion that connects to the second end of the rotor shaft. If the second end of the rotor shaft includes flat, shallow threads, the connective portion is essentially a bore having flat, shallow threads configured to receive the second end of the rotor shaft. Optionally, the first end of the rotor shaft may have flat, shallow threads in which case the coupling would have a cavity that receives the first end of the rotor shaft, wherein the cavity has flat, shallow threads.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

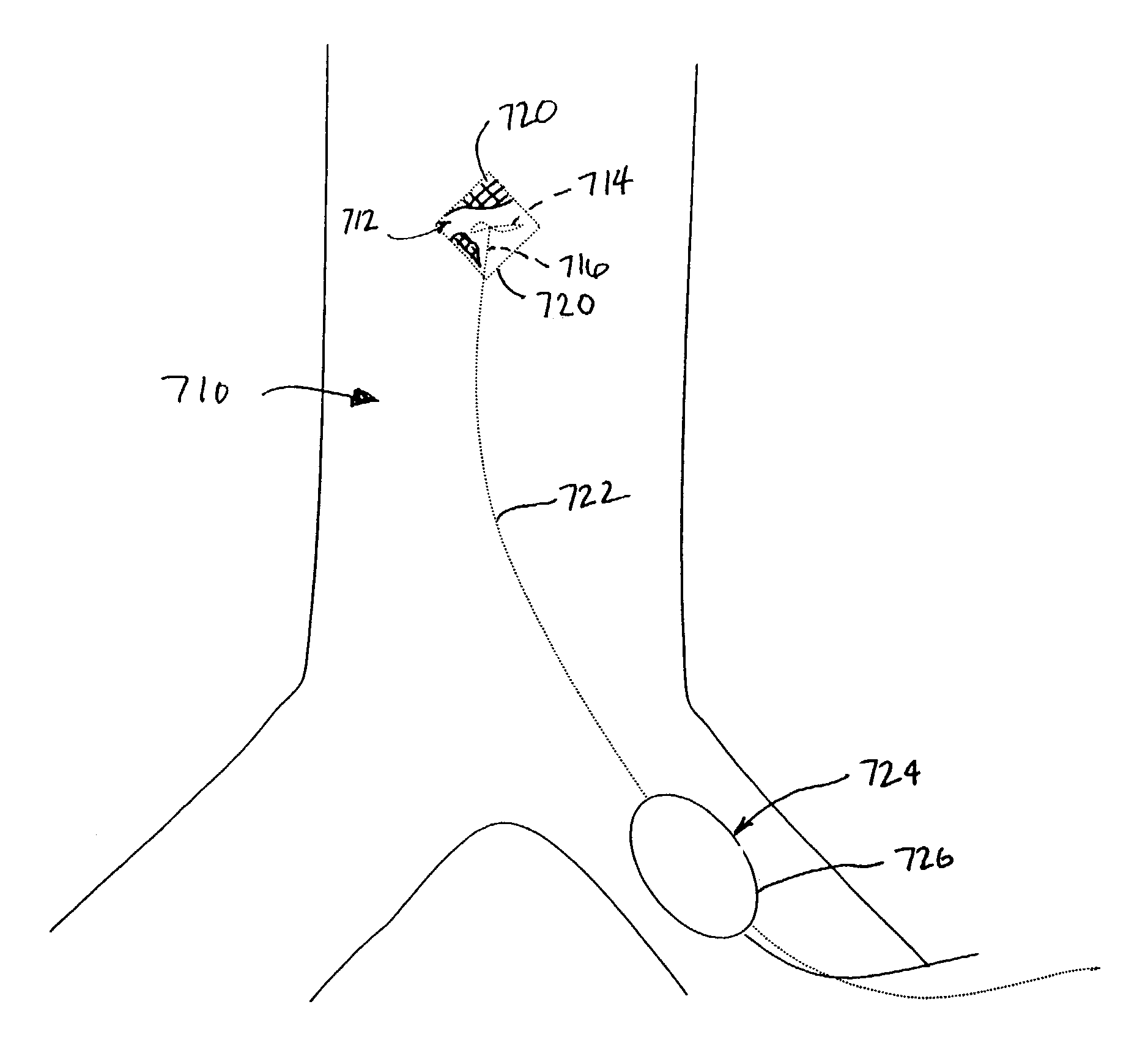

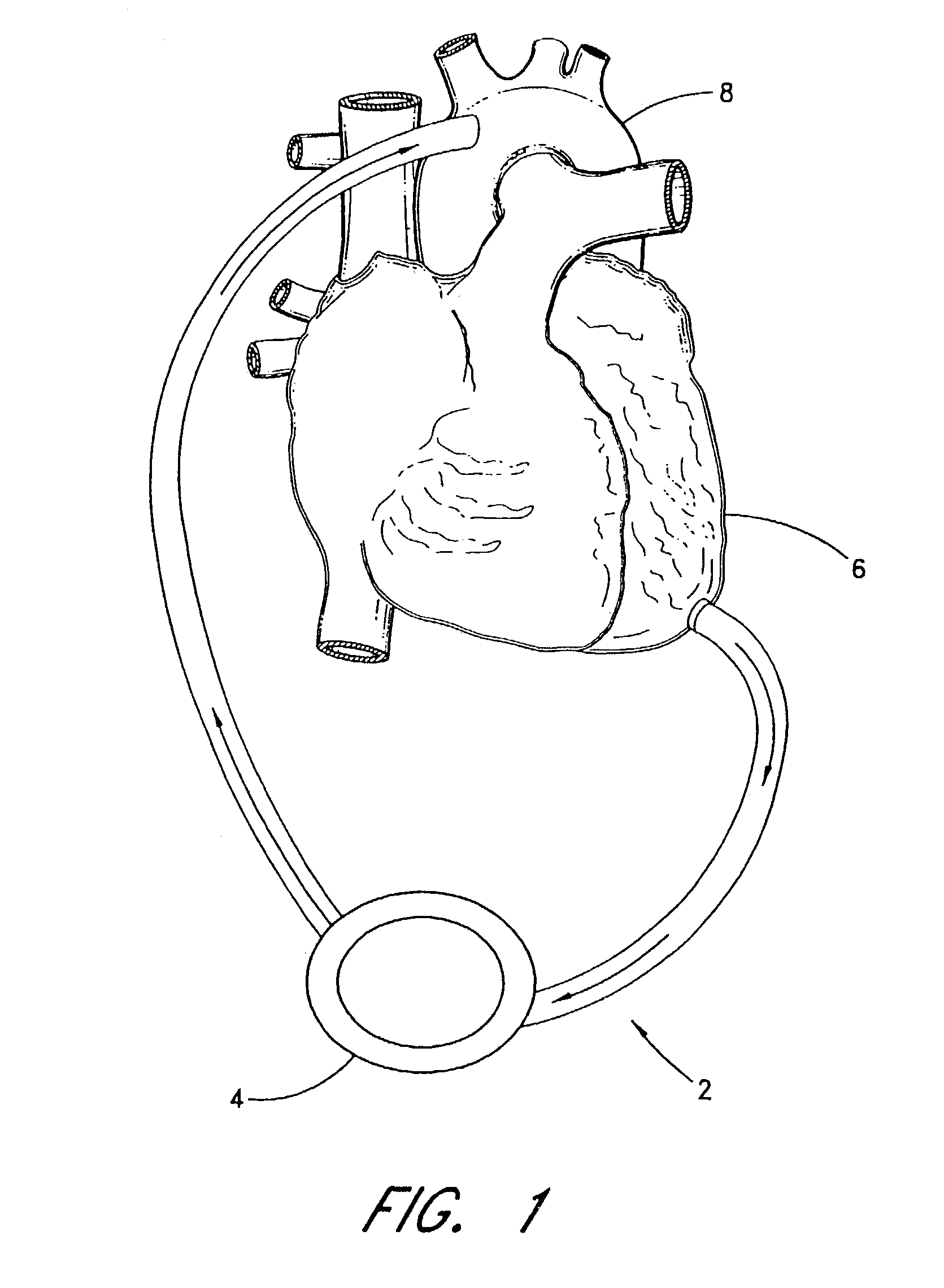

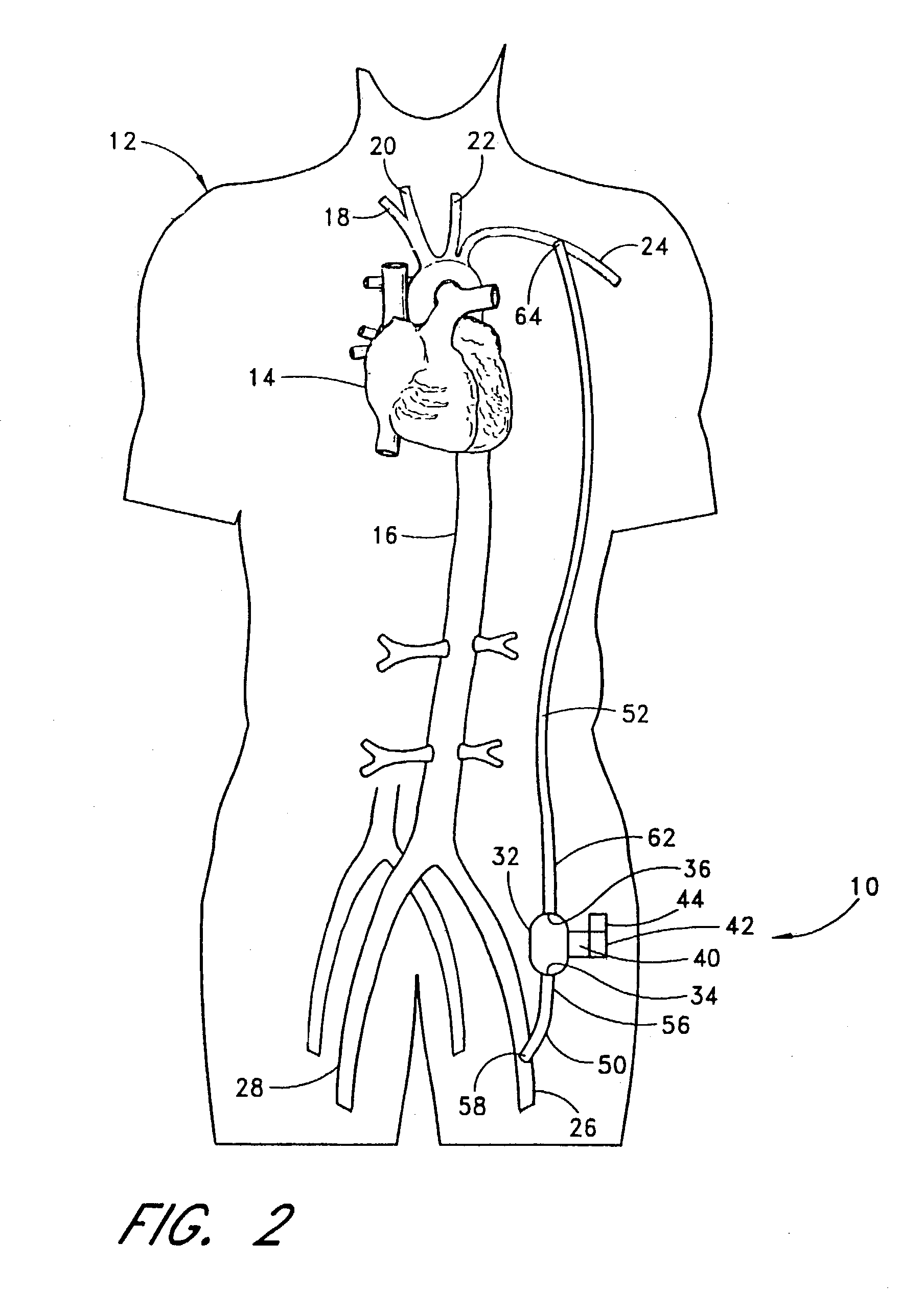

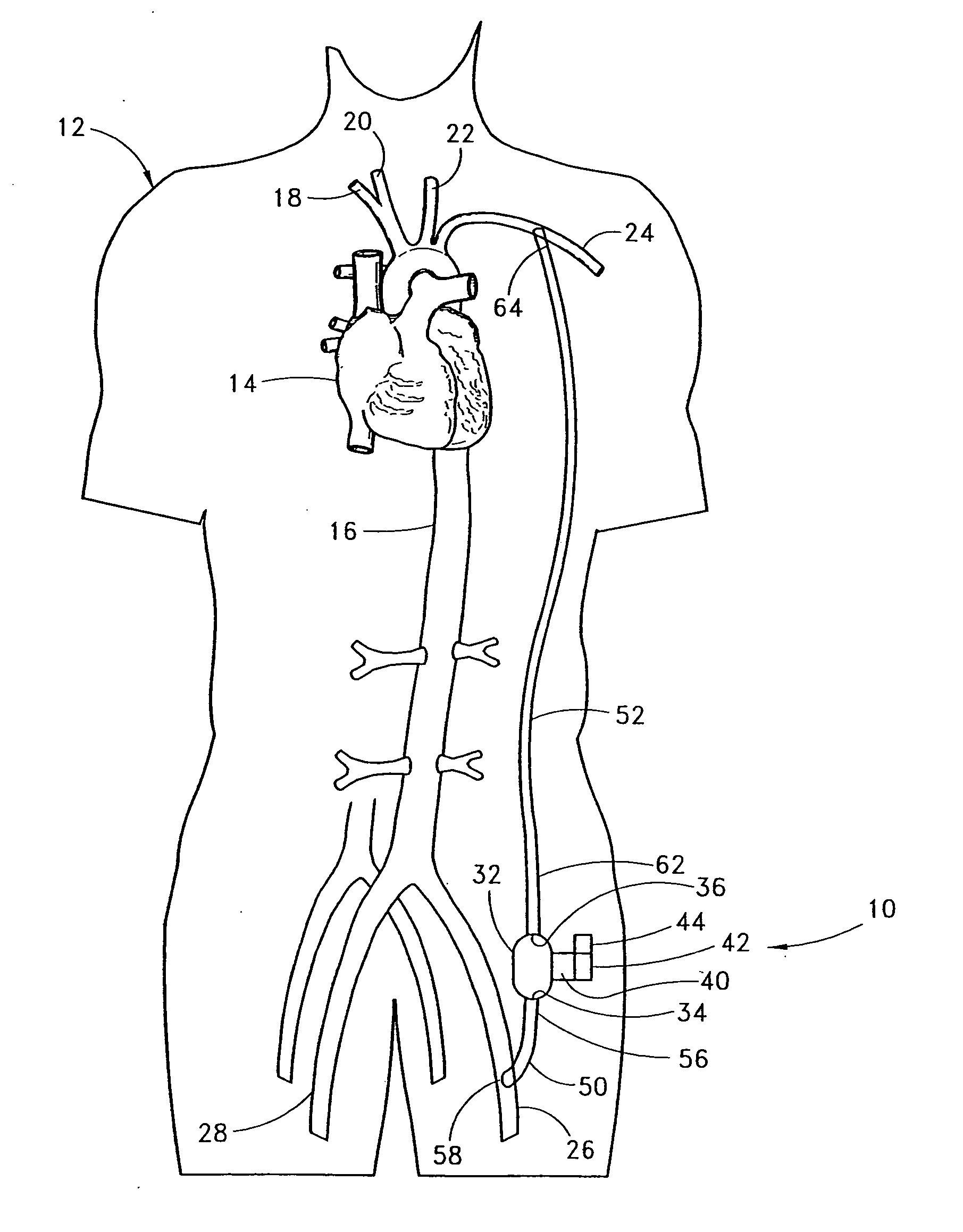

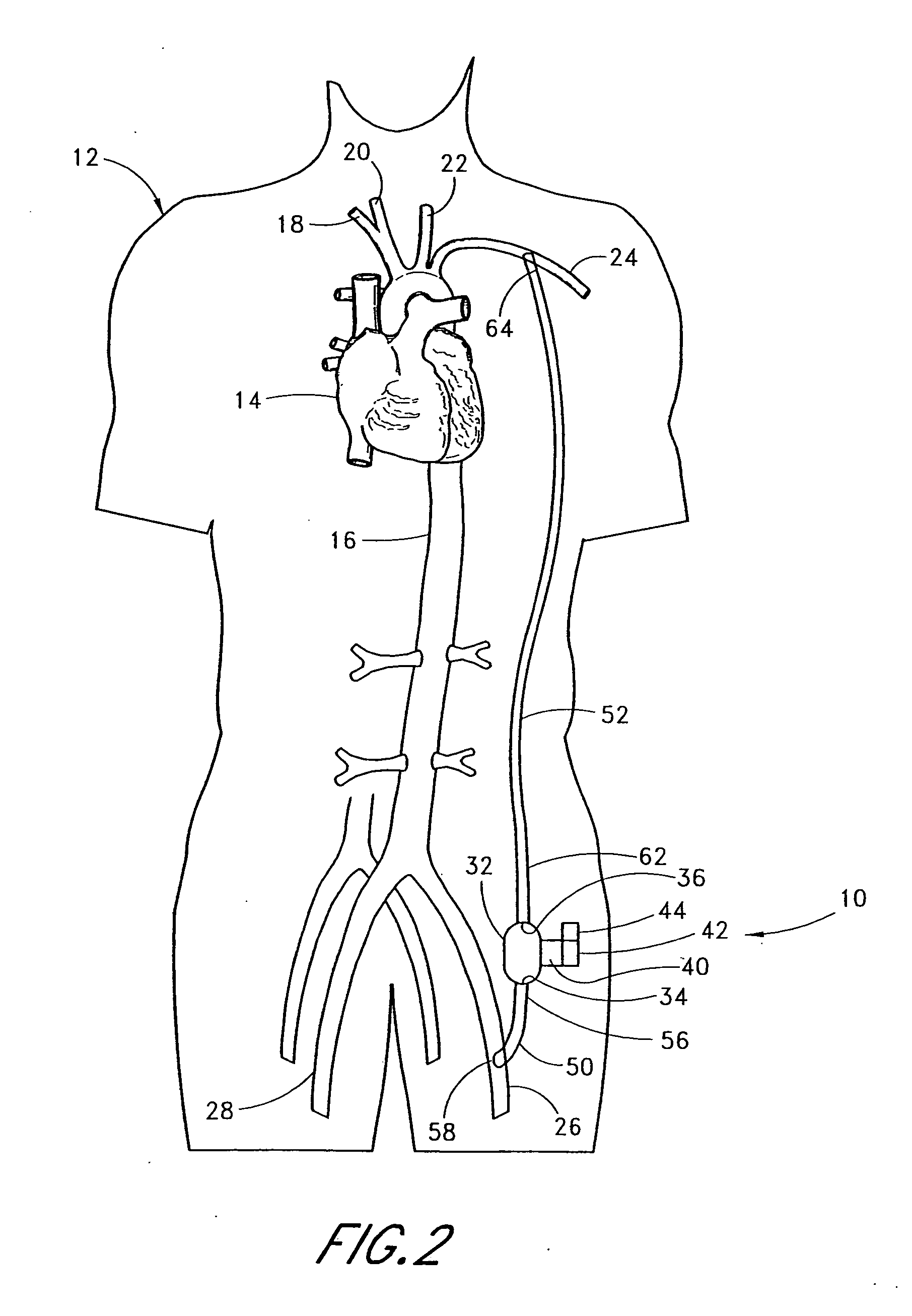

Implantable heart assist system and method of applying same

InactiveUS7125376B2RevitalizeReduce energy inputSpecific fluid pumpsOther blood circulation devicesAfterloadCatheter

An extracardiac pumping for supplementing the circulation of blood, including the cardiac output, in a patient without any component thereof being connected to the patient's heart, and methods of using same. One embodiment of the intravascular extracardiac system comprises a pump with inflow and outflow conduits that are sized and configured to be implantable intravascularly through a non-primary vessel, whereby it may positioned where desired within the patient's vasculature. The system comprises a subcardiac pump that may be driven directly or electromagnetically from within or without the patient. The pump is configured to be operated continuously or in a pulsatile fashion, synchronous with the patient's heart, thereby potentially reducing the afterload of the heart. In another embodiment, the system is positioned extracorporeally, with the inflow conduit and outflow conduit applied percutaneously to a non-primary vessel for circulating blood to and from the non-primary vessel or between the non-primary vessel and another blood vessel within the patient's vasculature.

Owner:TC1 LLC

High flow/dual inducer/high efficiency impeller for liquid applications including molten metal

A centrifugal pump has a pump base with inlet inducer openings that receive molten metal into an impeller chamber. An impeller structure in the impeller chamber passes the metal in a radial direction through an outlet inducer opening into a volute passage for discharge into the pool of metal in which the pump is located.

Owner:MORANDO JORGE A

Blood pump

InactiveUS6884210B2Good biocompatibilityPrevent thrombosisSpecific fluid pumpsBlood pumpsImpellerThrombus

It is an object of the present invention to realize a small and light blood pump that can control thrombosis and moreover, endure a prolonged use.A blood pump comprising an impeller, a casing having a suction inlet and a delivery outlet and rotatably encasing the impeller, a magnetic drive means for rotating the impeller by magnetically acting from outside of the casing on a magnet that the impeller includes, a magnetic attraction force adjustment means for adjusting the attraction force by said magnetic action, a control means for rotating speed of said magnetic drive means, and a pair of pivot bearings for supporting pivots at both ends of the impeller rotation shaft, wherein the distance between bearing faces of said both pivot bearings is set longer than the length of the rotation shaft of the impeller and the rotation speed of the impeller is controlled to a predetermined speed by said control means for rotating speed so as to levitate the impeller in the blood flow in the casing and to maintain out of contact between the pivots at both ends of the rotation shaft of the impeller and the bearing face of said both pivot bearing.

Owner:HITMAC USA +1

Impeller for molten metal pump with reduced clogging

InactiveUS6881030B2Improve impeller efficiencyAvoid cloggingSpecific fluid pumpsPropellersImpellerEngineering

One aspect of the invention is directed to an impeller made of a non-metallic, heat resistant material, comprising a generally cylindrical shaped body, first and second generally planar end faces and a side wall extending between the first and second faces. A plurality of passages have inlets circumferentially spaced apart from each other on the first face, outlets at the impeller sidewall, and connecting portions extending between the inlets and the outlets transverse to the central axis. Another aspect of the invention is directed to an impeller comprising a central hub portion and first and second impeller bases, including end faces, transverse to a central axis. Vanes extend from the central hub portion between the impeller bases. Cavities are formed between the impeller bases and between adjacent vanes. Molten metal inlets on the end faces for molten metal to reach the cavities. Pumps are also disclosed using the inventive impellers.

Owner:THUT BRUNO H

Molten metal pump system

A molten metal pump system which generally provides a refractory connection joint for connecting a refractory pump post to a pump base, the pump post including a refractory post with a first end, the first end including an internal joint peg aperture; a refractory base with a post aperture configured to receive the first end of the refractory post, and with a peg aperture contiguous with the post aperture; and a joint peg with a first end and a second end, the joint peg including a retention shoulder, the joint peg configured to insert through the peg aperture in the refractory base with a retention bar or bolt inserted through an aperture in the joint peg of refractory post, and the retention shoulder engaging the refractory base.

Owner:PYROTECK INC

Pump for molten materials with suspended solids

InactiveUS6551060B2Improve sealing propertiesPrecise alignmentSpecific fluid pumpsPropellersImpellerUniversal joint

A molten material pump includes an impeller housed within a base member of the pump. A plurality of grooves are defined in a peripheral sidewall of the impeller for either drawing a molten material into the base member's chamber or pushing molten material out of the base member's chamber. The impeller is rotated by a rotatable shaft connected to an upper surface of the impeller. The rotatable shaft includes a non-circular shaped lower end dimensioned to be received within a cooperating opening in the impeller. The molten material pump further includes a connecting assembly for interconnecting components of the molten material pump. The connecting assembly includes a first mounting member attached to a first pump component that is dimensioned to be fitted within a cooperating recess of a second mounting member attached to a second pump component. In another embodiment of the invention, a stub shaft connects an upper shaft portion of the shaft to the impeller. The stub shaft includes a universal joint that is not rigidly connected to the upper shaft portion. In addition, the universal shaft is configured to allow the stub shaft and impeller to pivot. A floating deflector block weighs on an upper sealing block of the pump for enhancing the seal at the pump's bearing surfaces.

Owner:PYROTECK INC +1

System for releasing gas into molten metal

InactiveUS20050013715A1Reduce amountReduce stressSpecific fluid pumpsEngine manufactureMetallurgyGas release

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:COOPER PAUL V

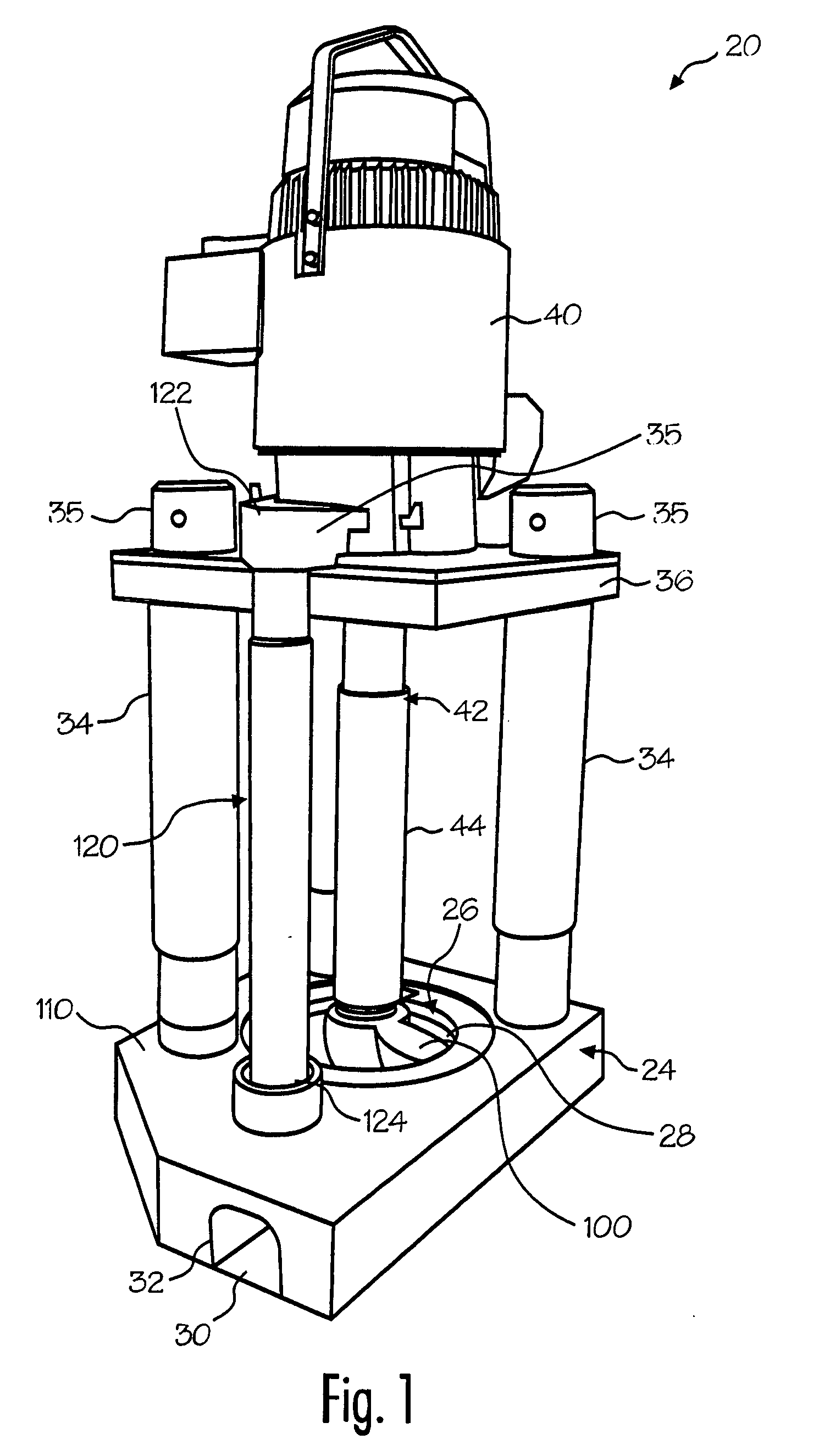

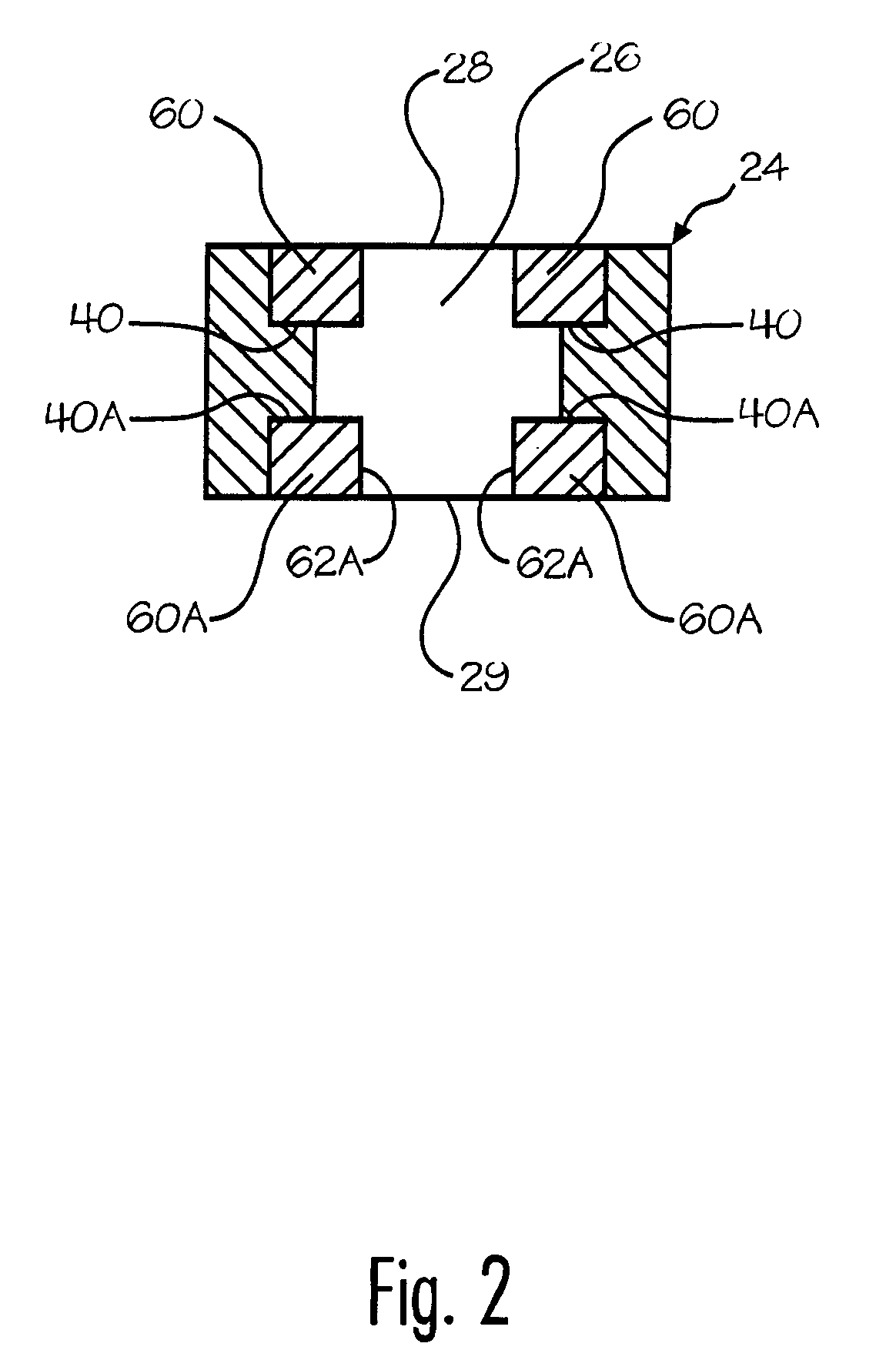

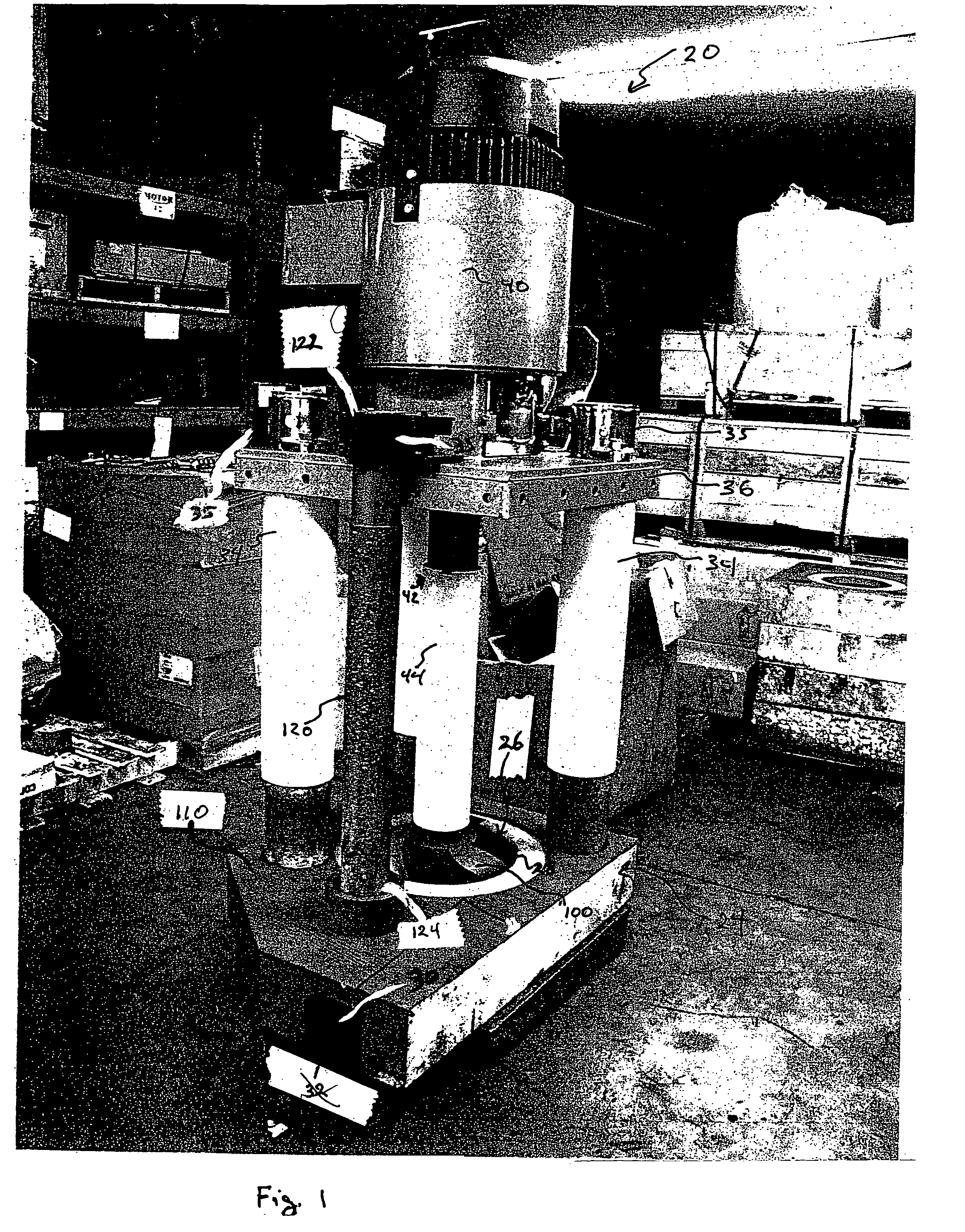

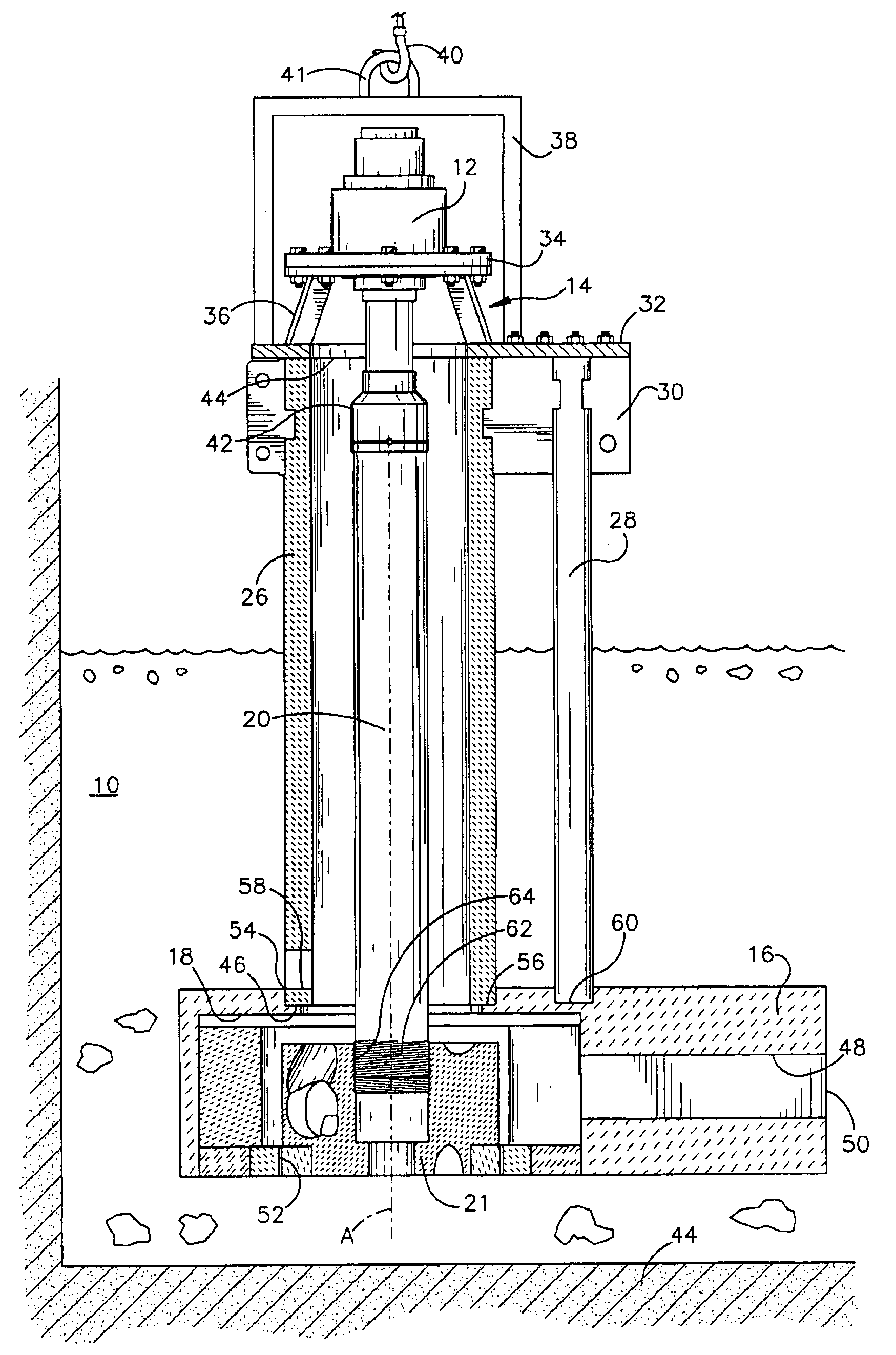

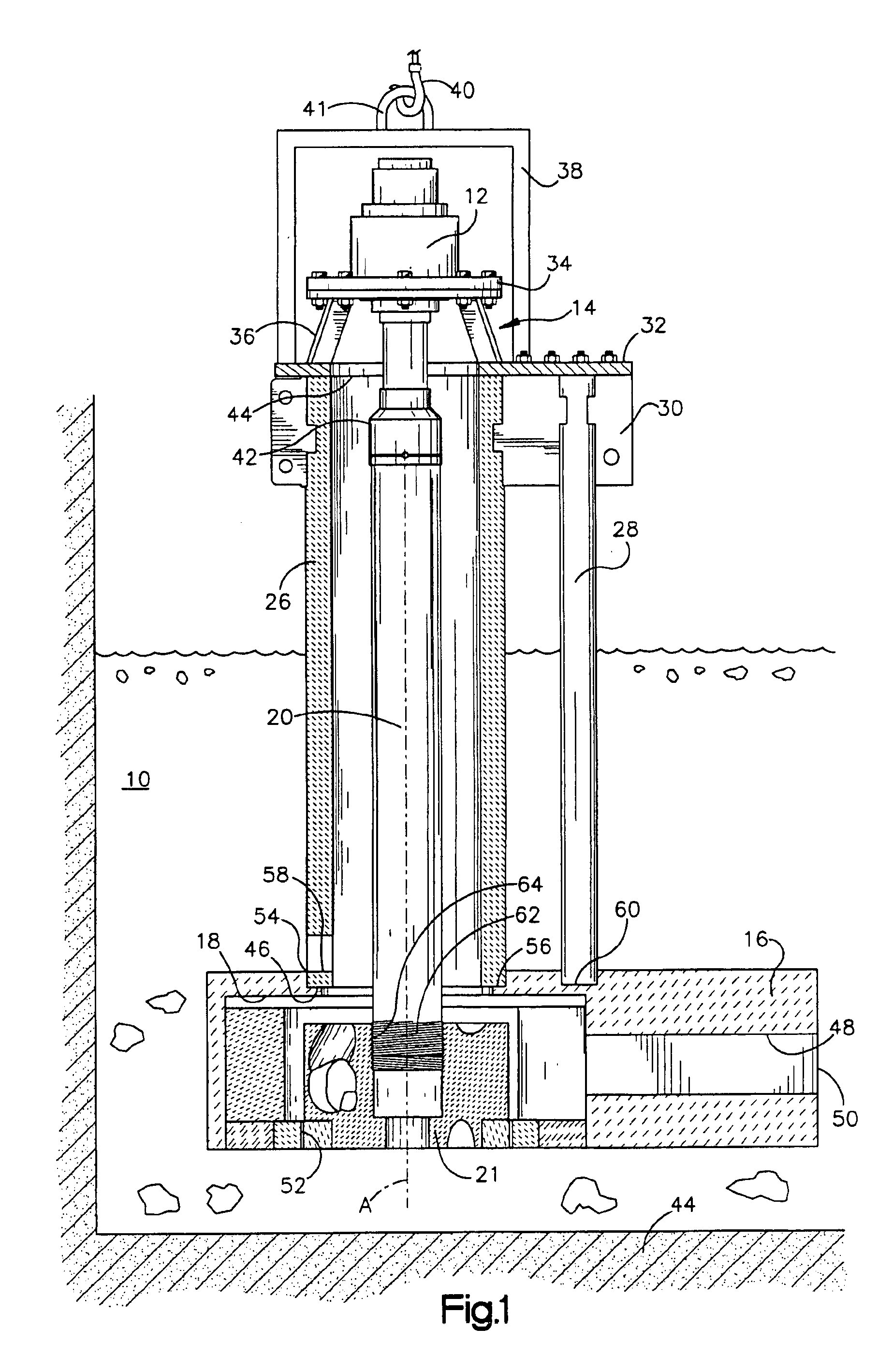

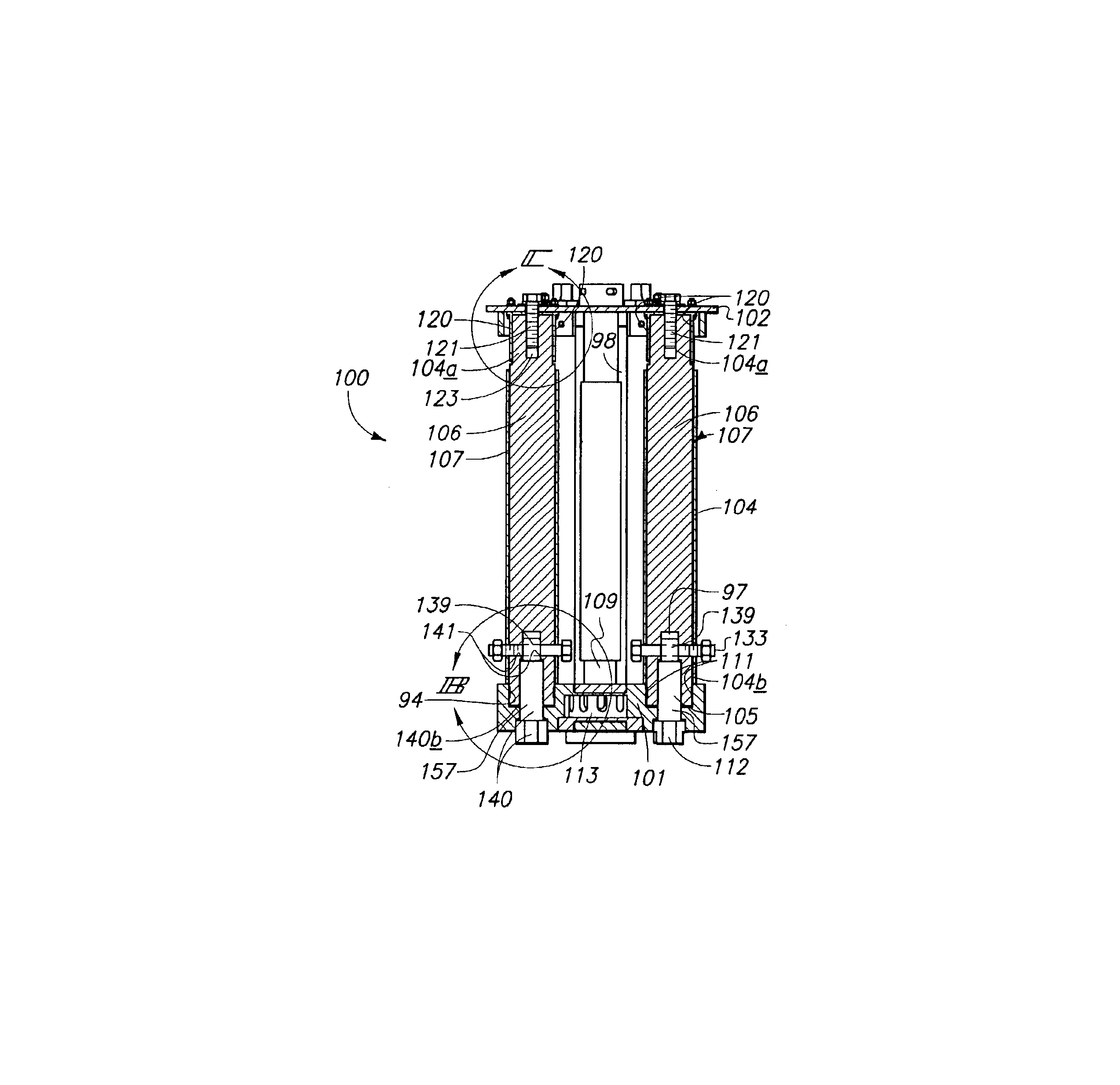

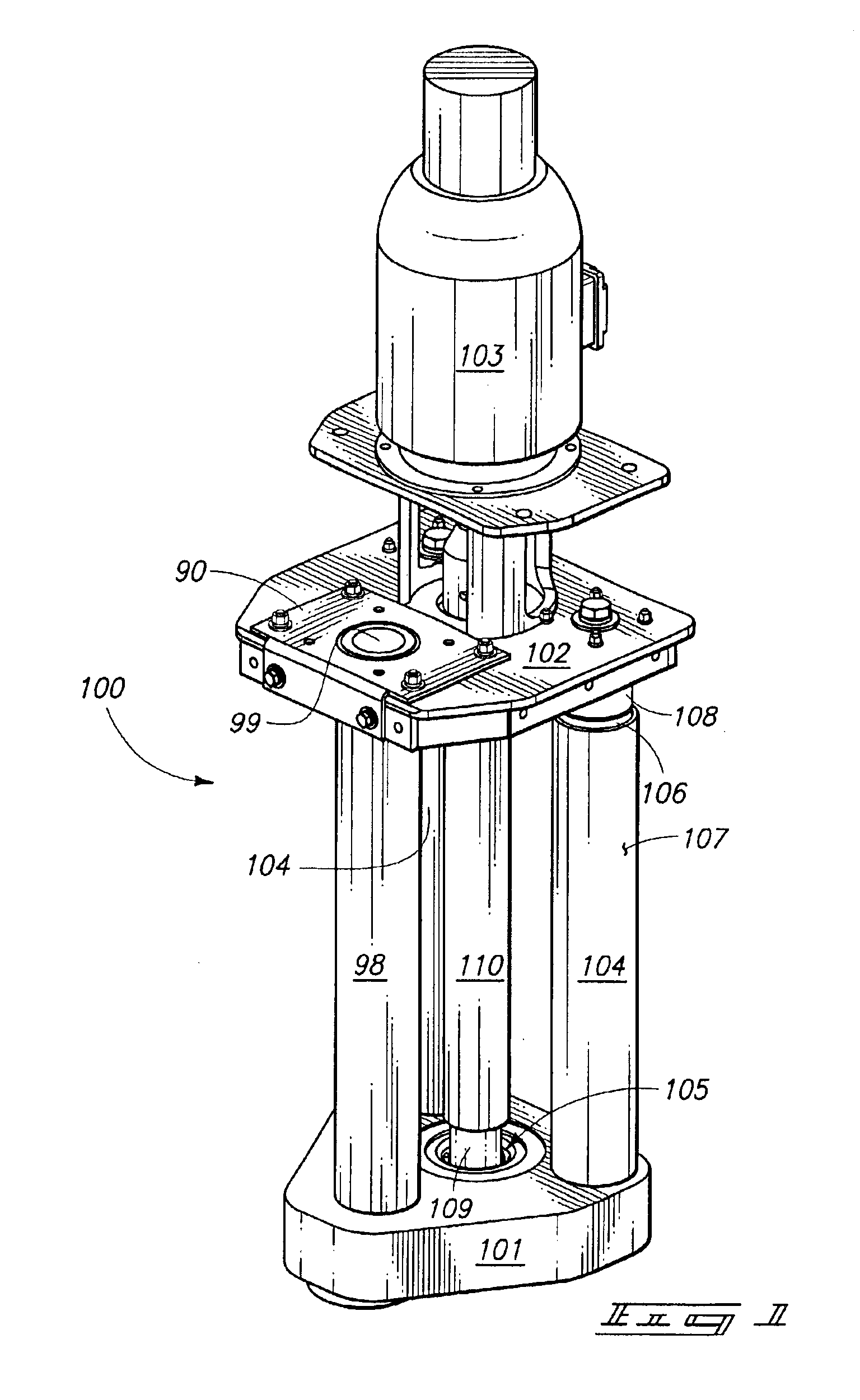

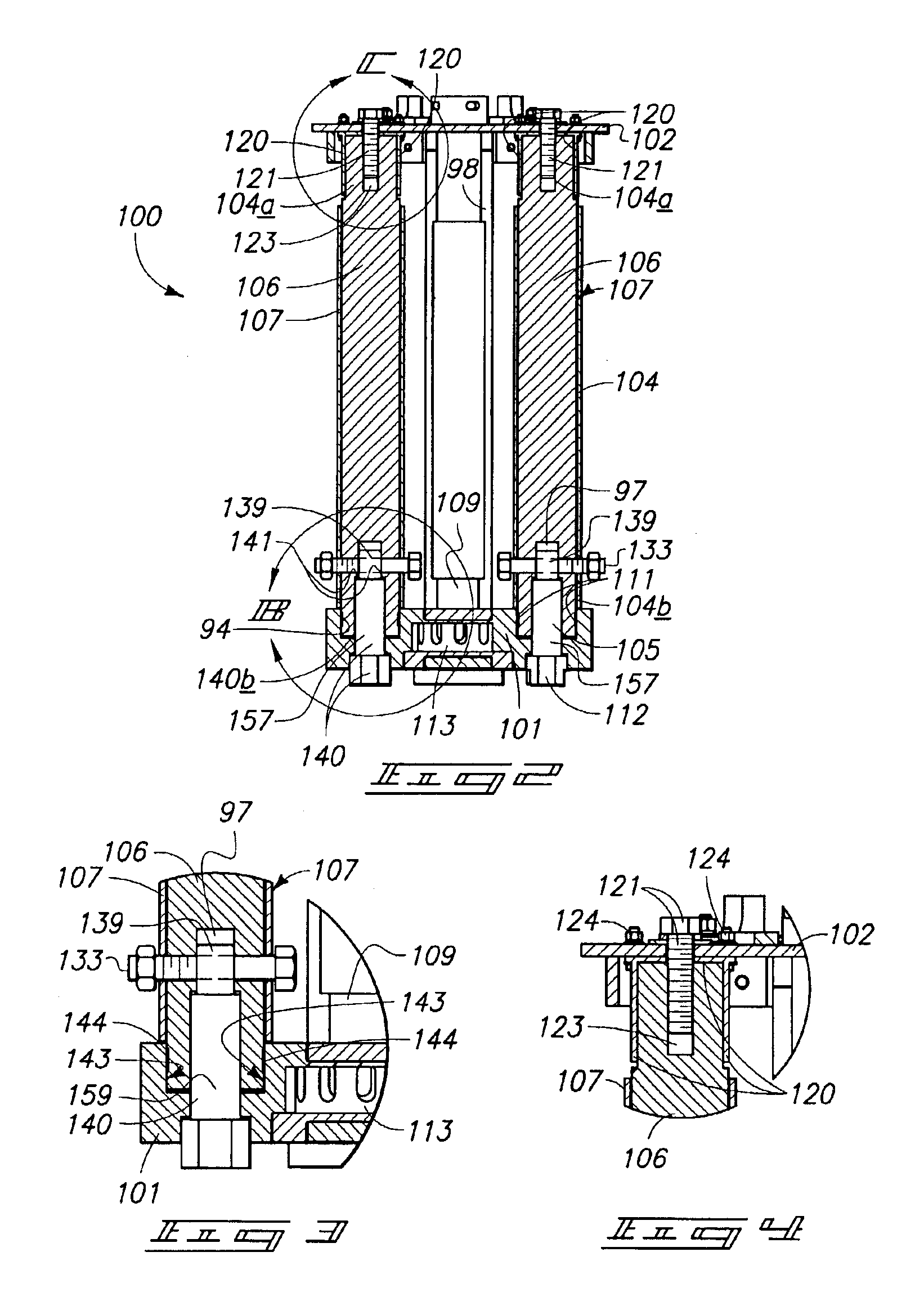

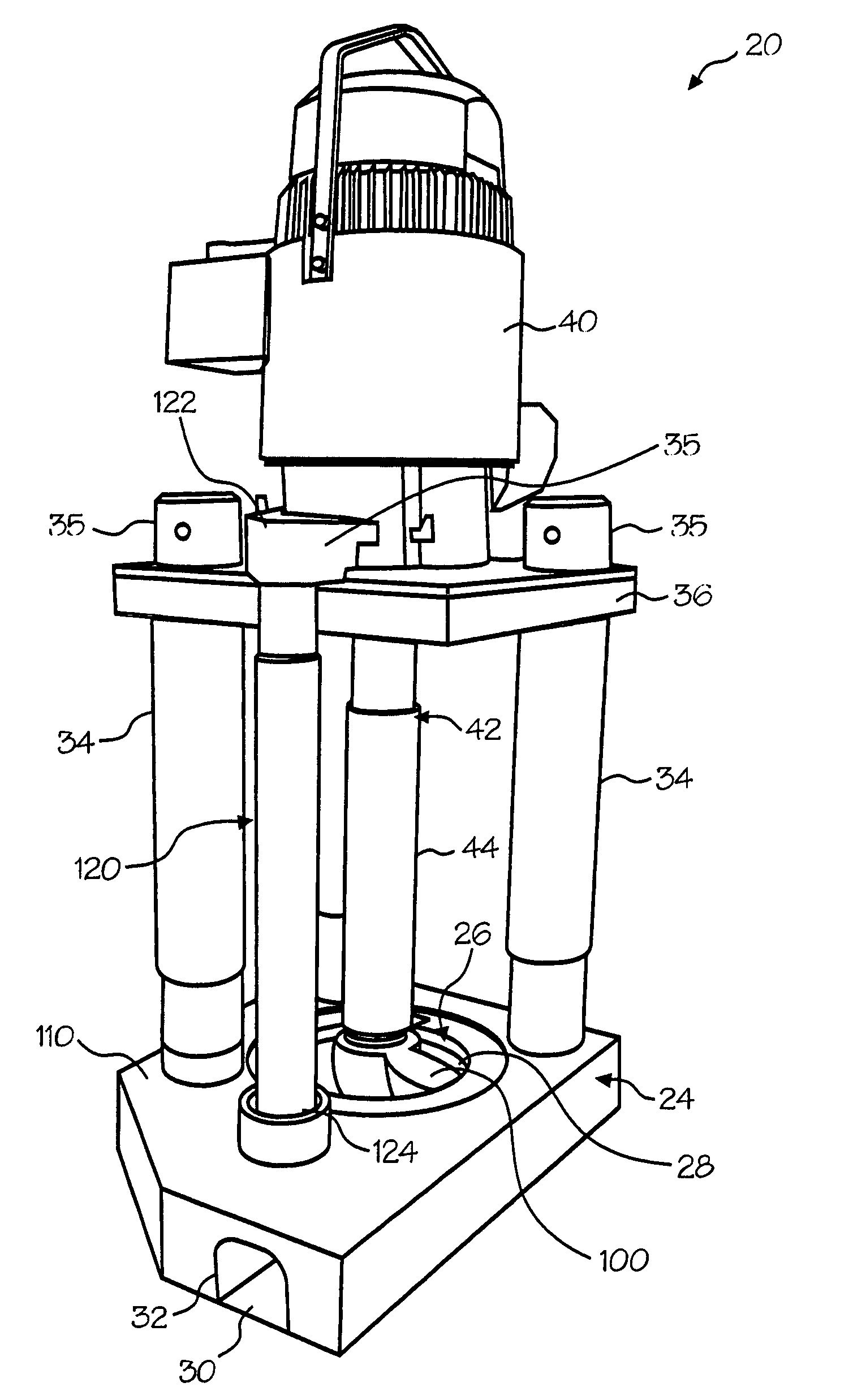

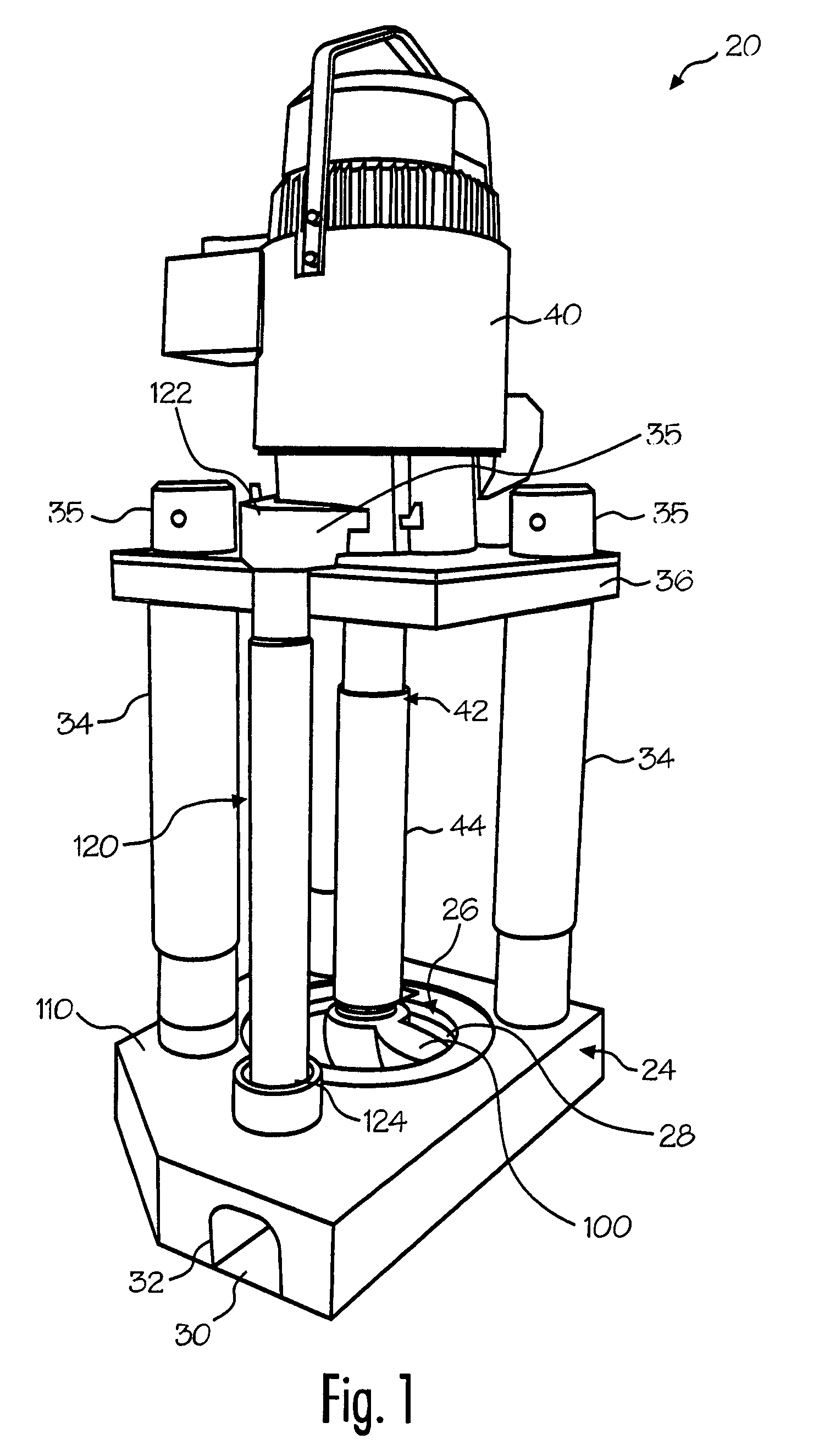

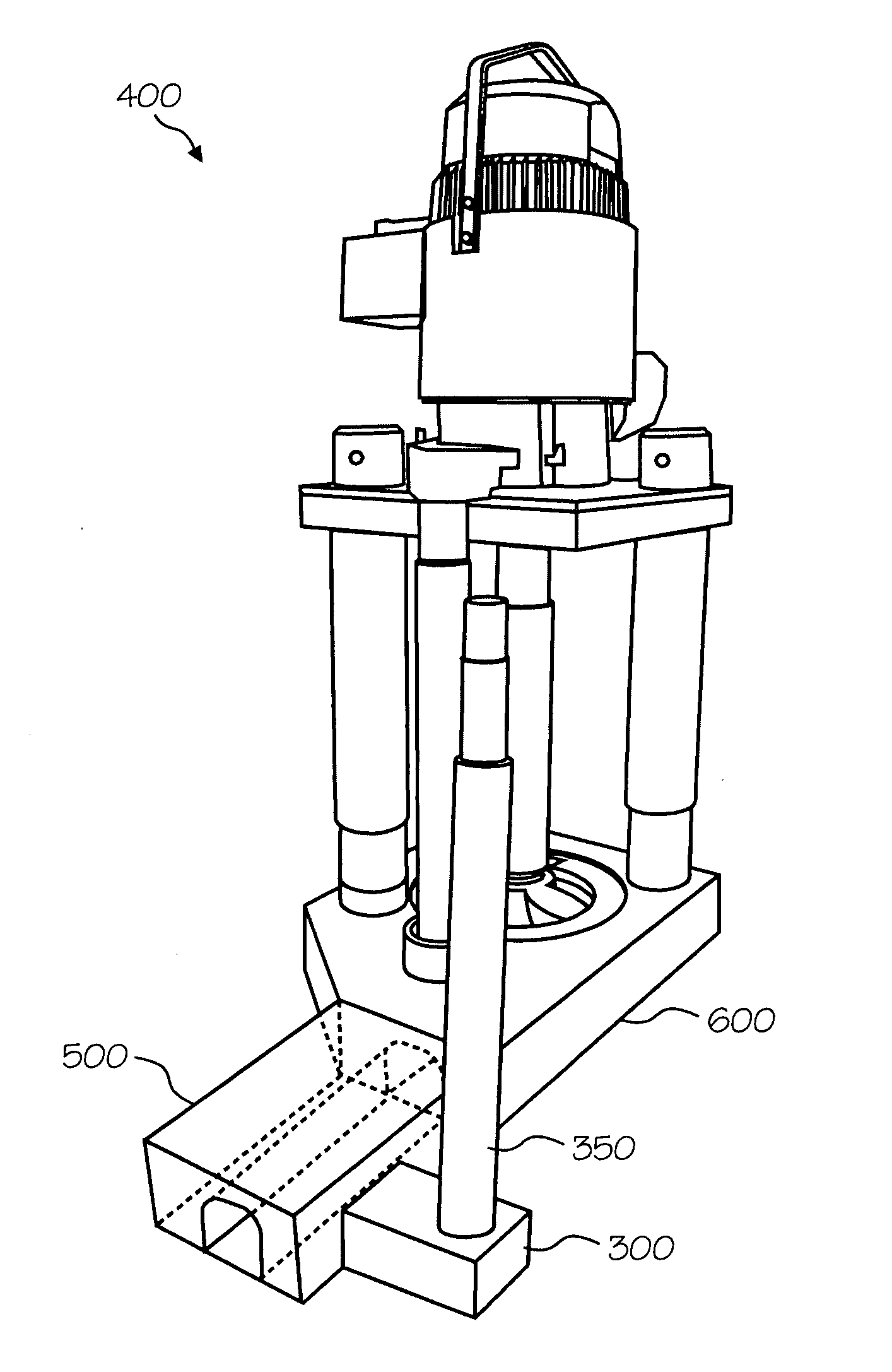

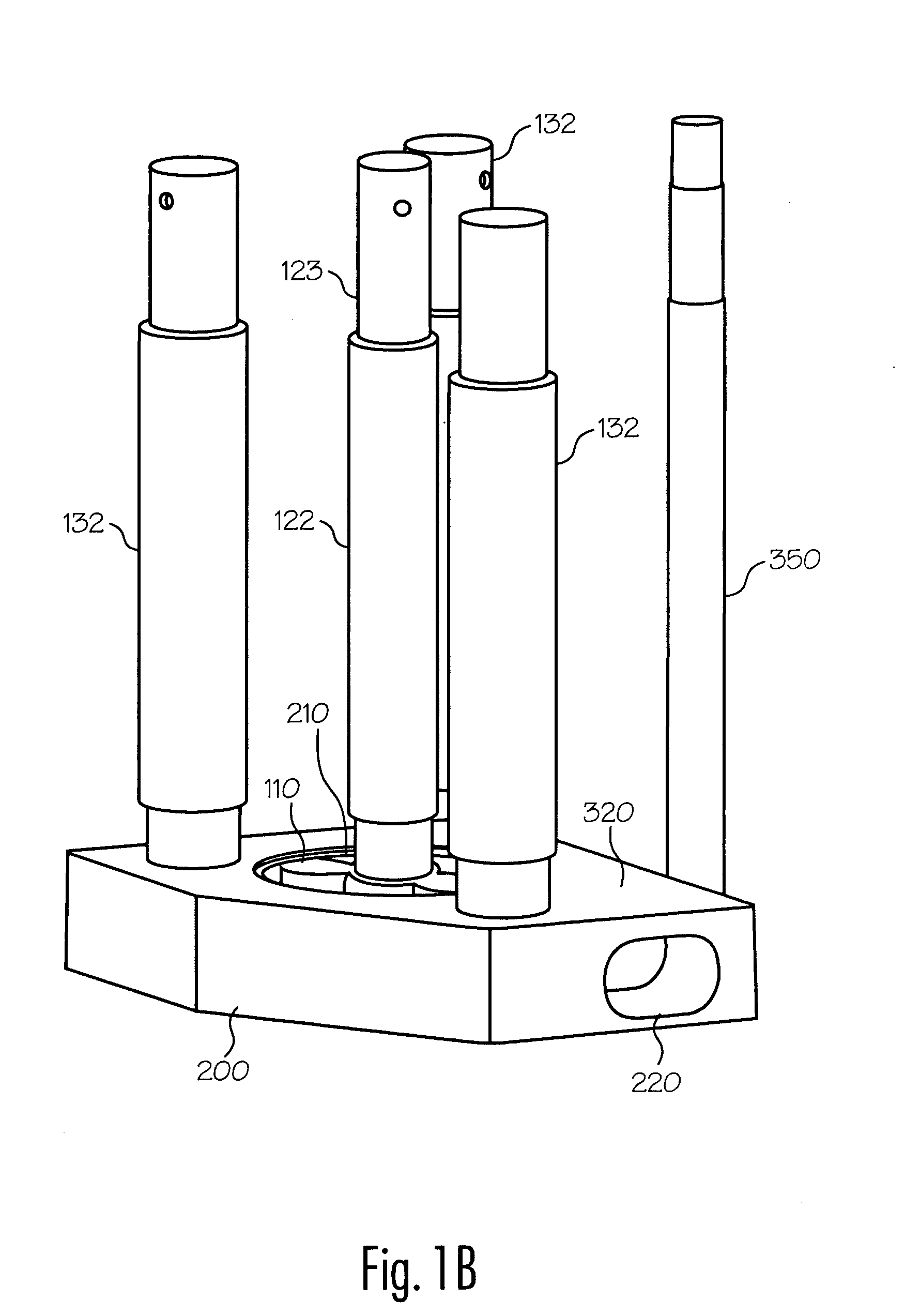

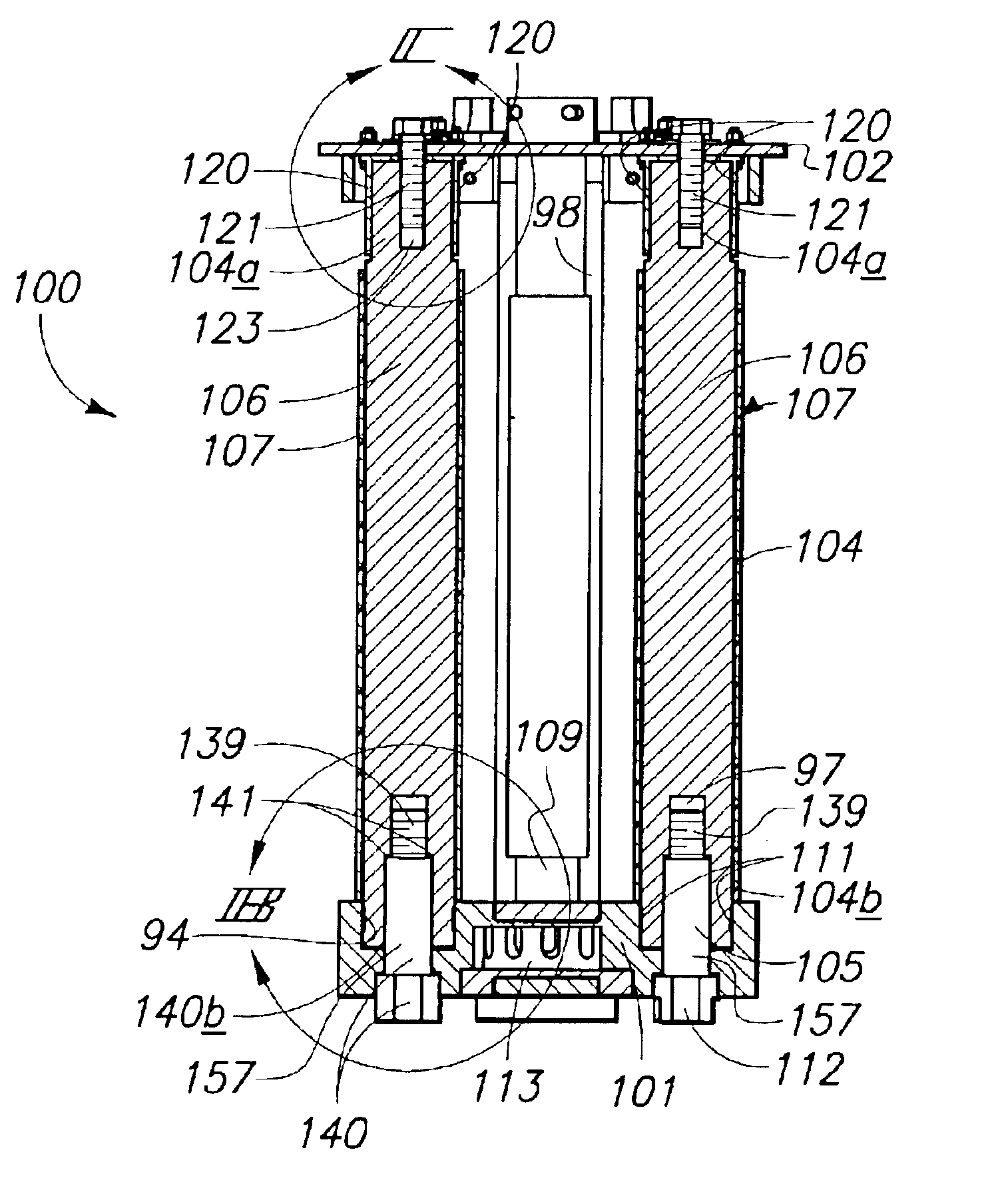

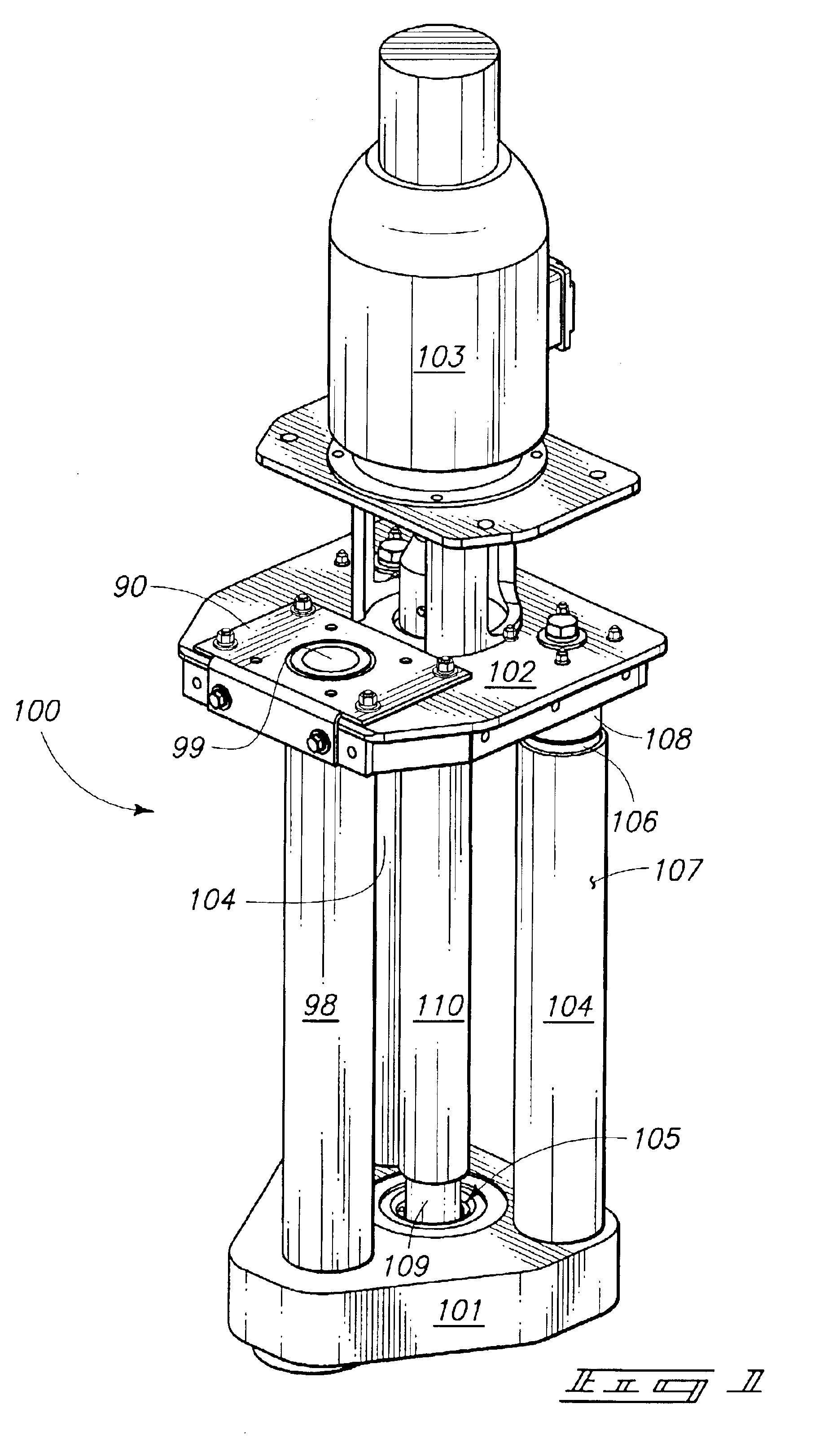

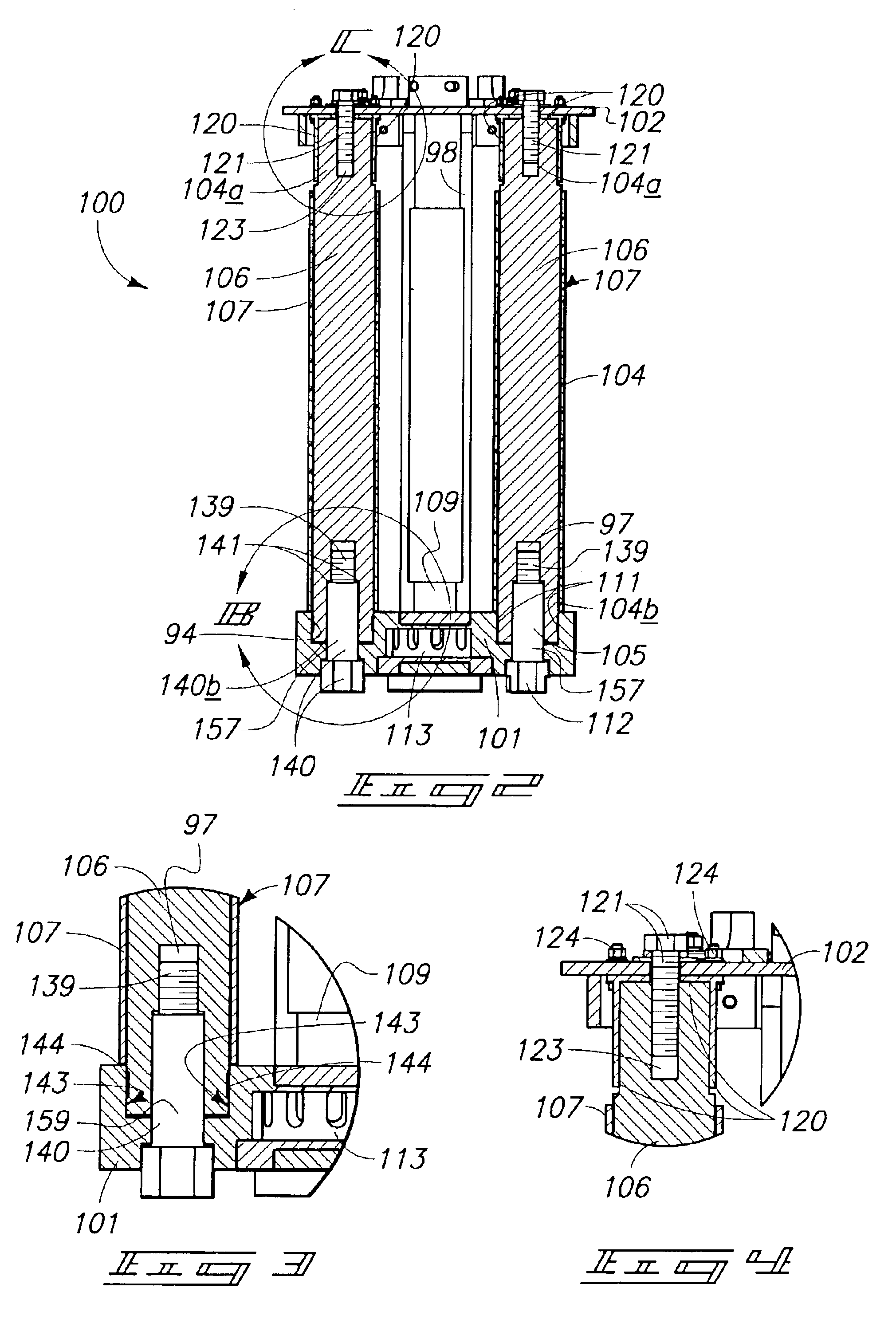

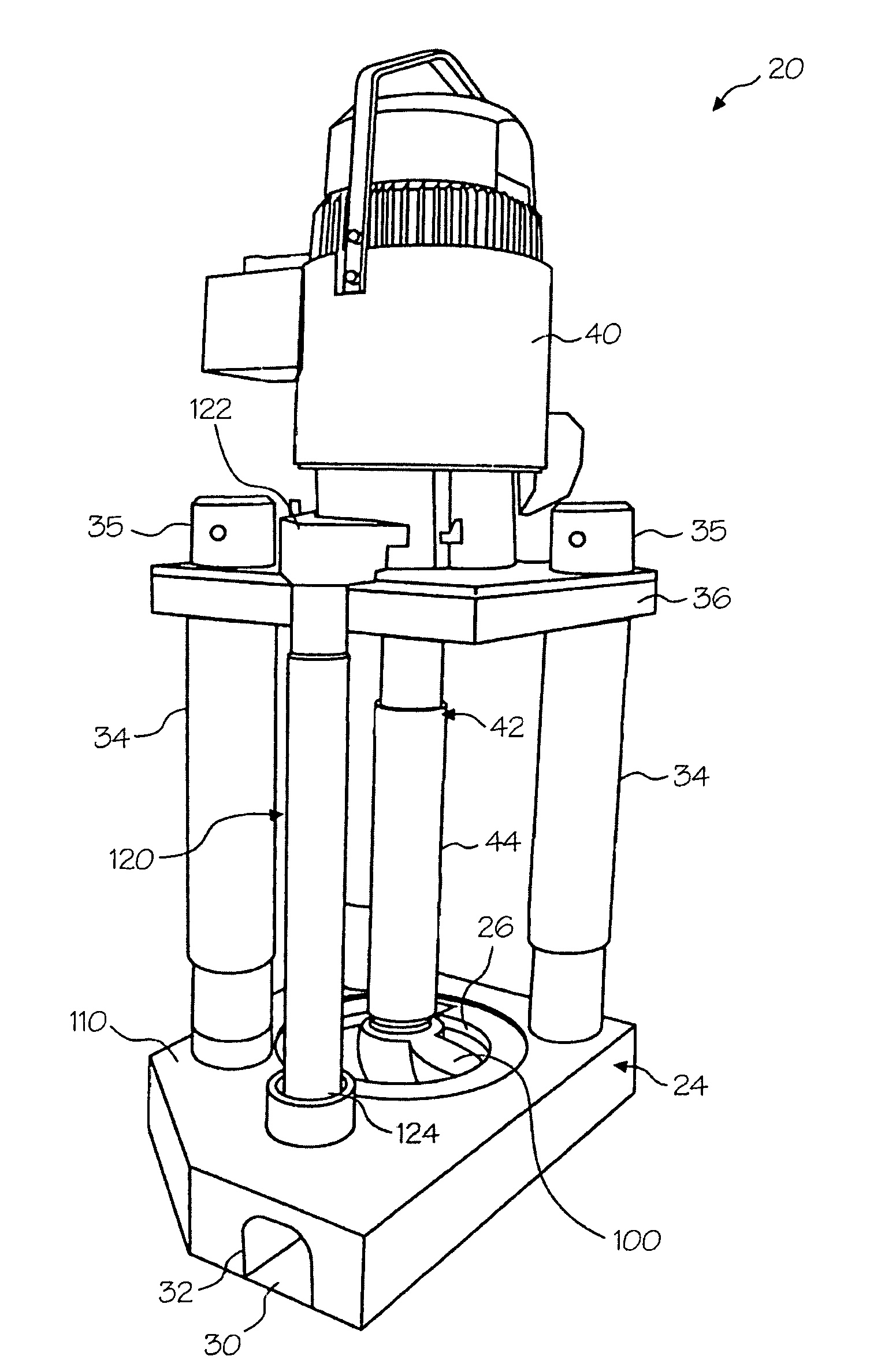

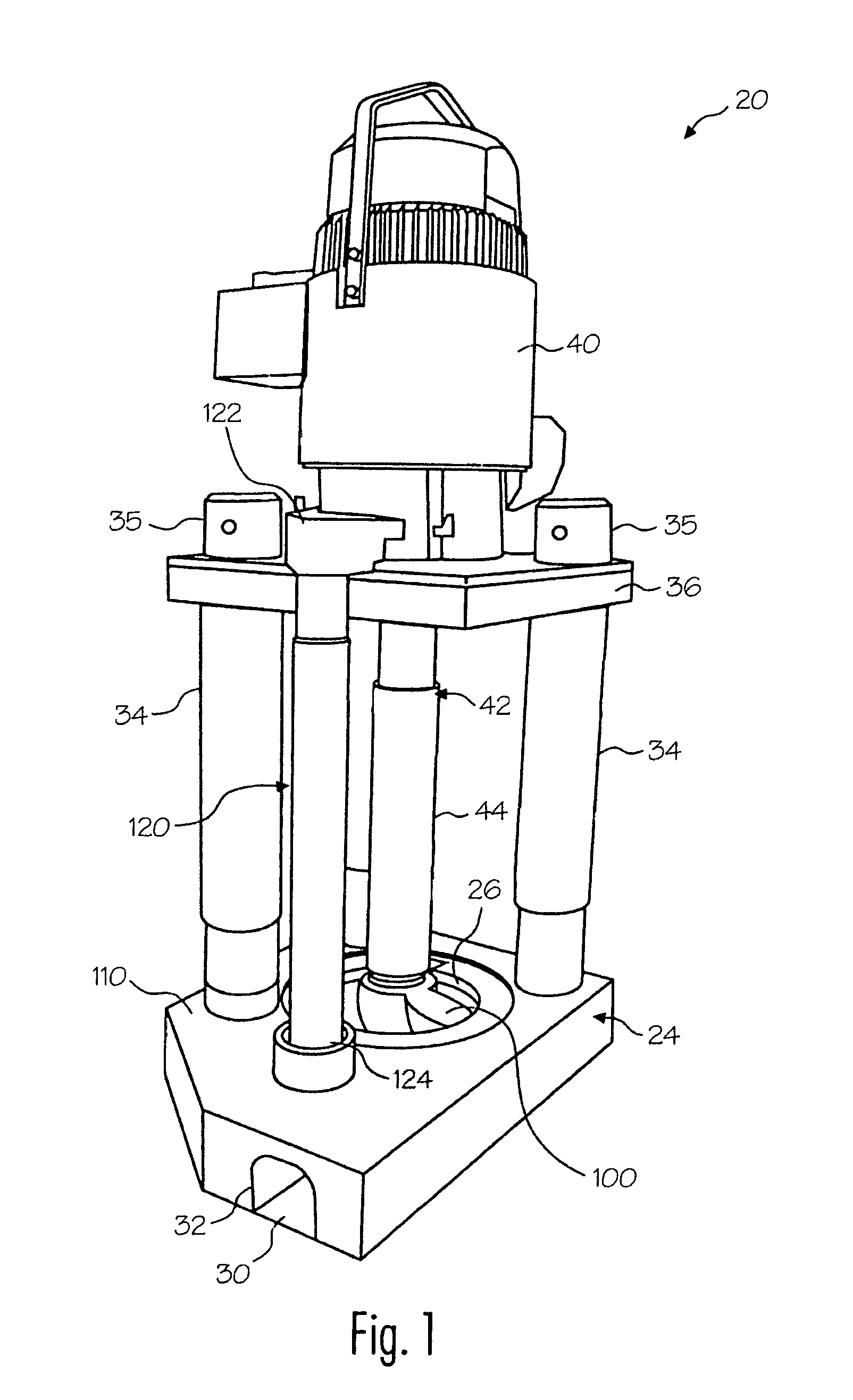

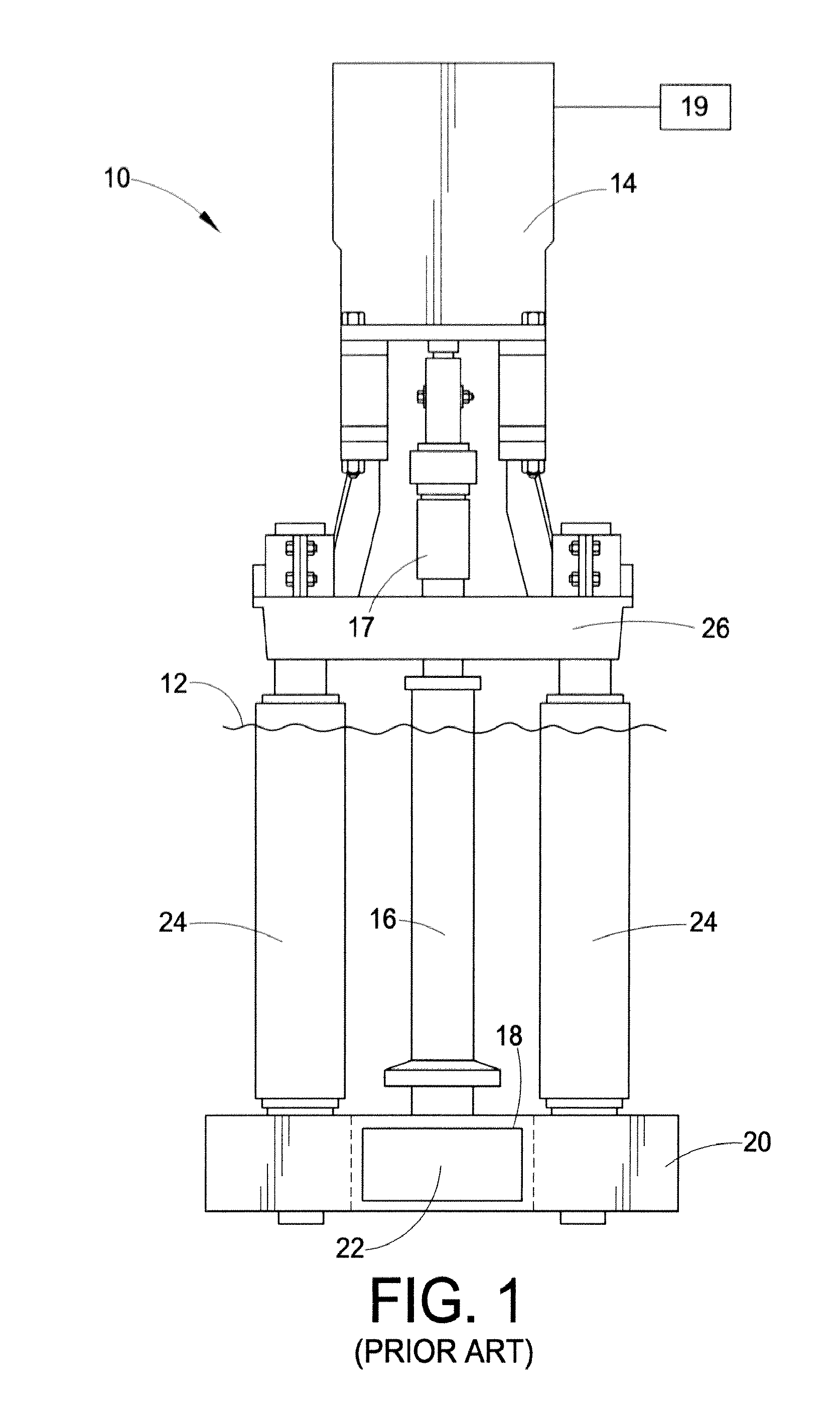

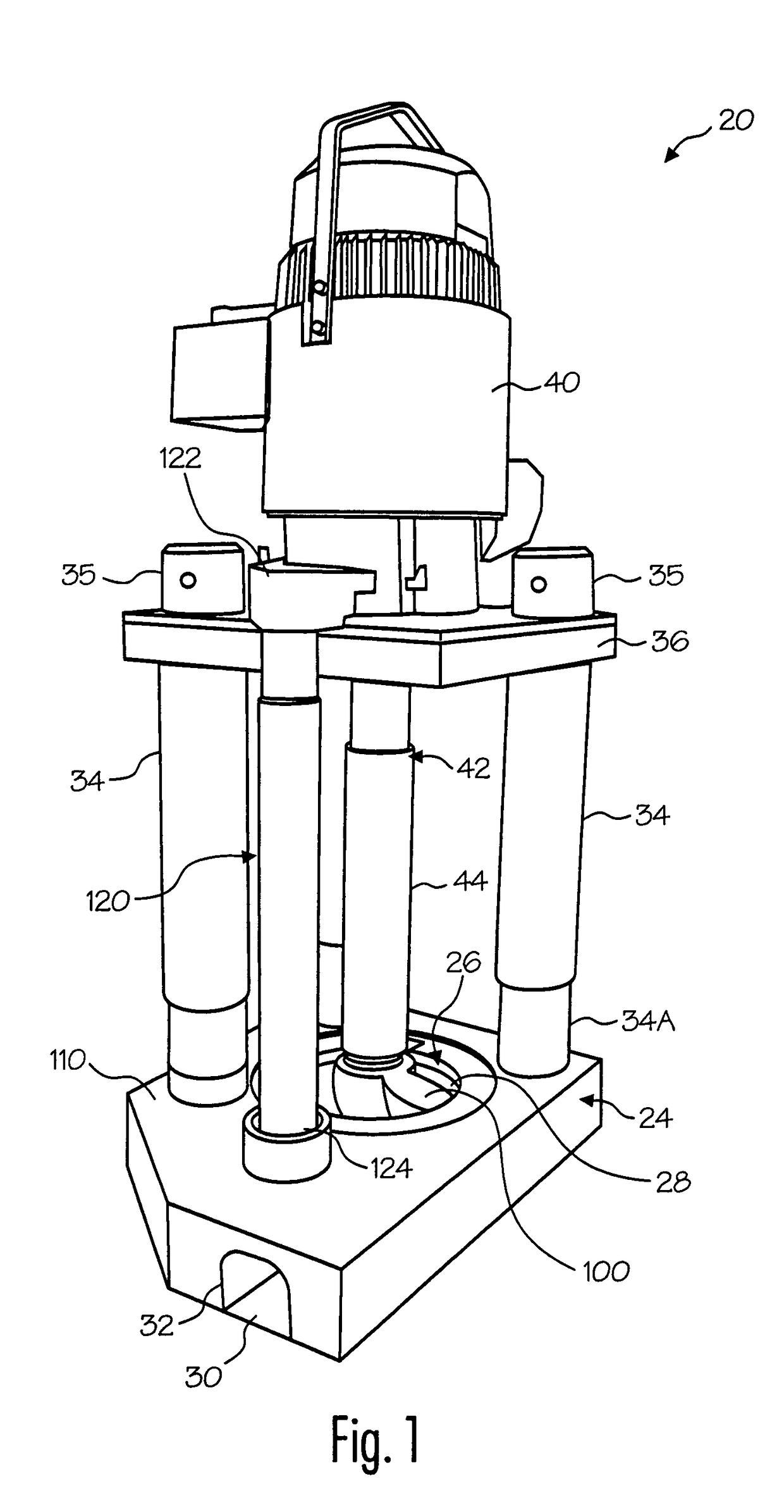

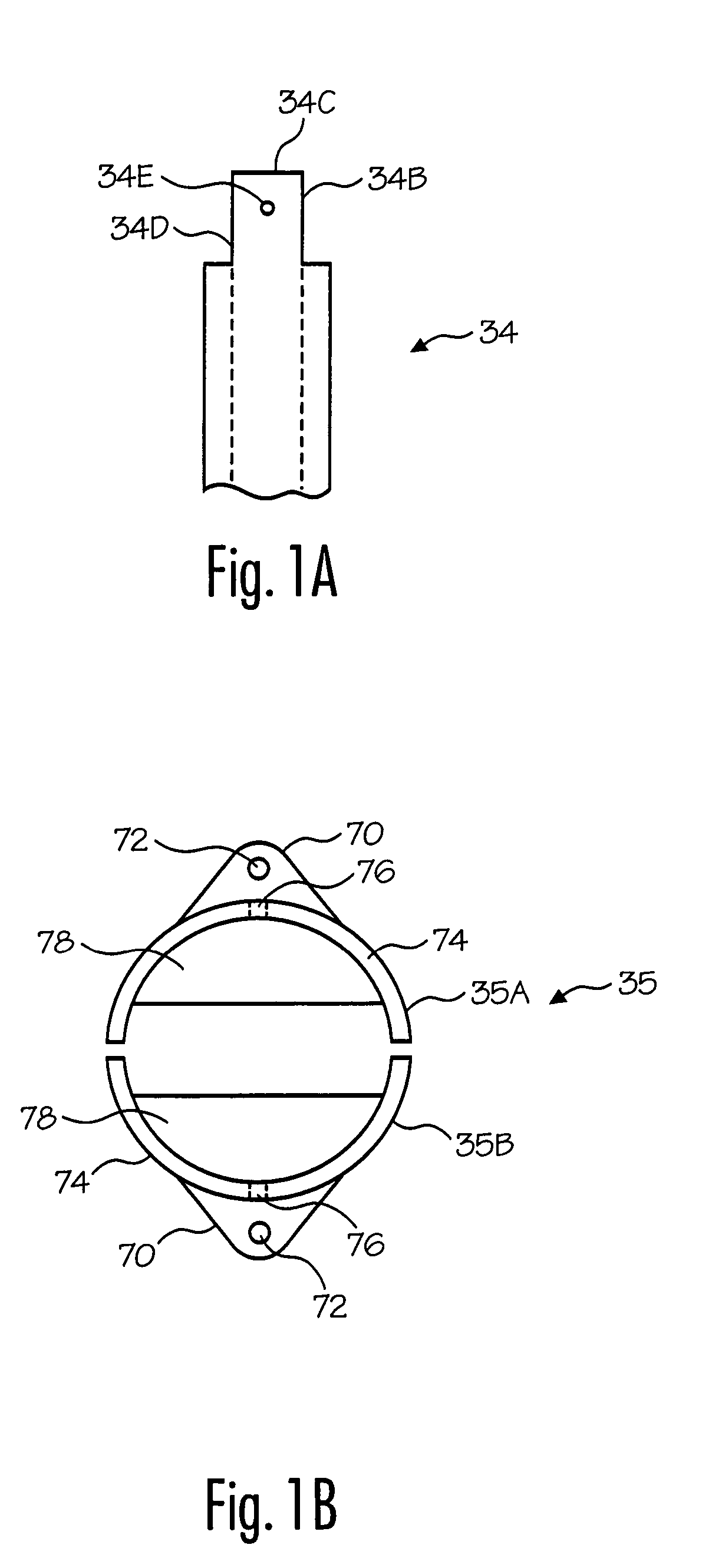

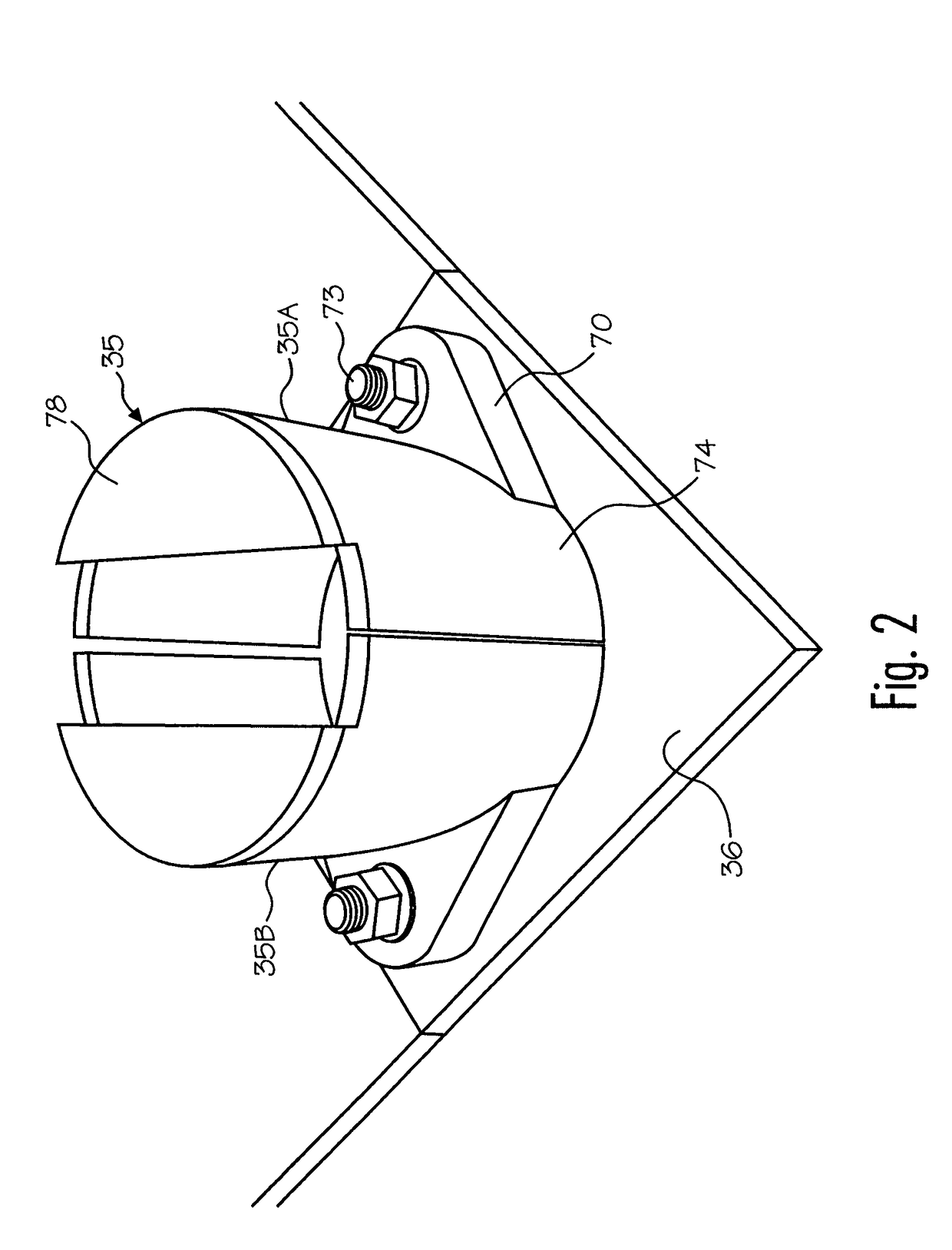

Support post system for molten metal pump

ActiveUS20050053499A1Specific fluid pumpsPositive displacement pump componentsEngineeringMechanical engineering

An improved post clamp for a molten metal pump includes a support post clamp that supports the weight of a pump superstructure on the top of the support posts. The clamp preferably includes (a) a bottom flange for connecting to the pump superstructure, (b) a cavity for receiving an end of a support post, wherein the end has a top surface, and (c) a top flange for being positioned above the top surface. In operation the top flange rests on the top surface of the support post thereby supporting at least part of the weight of the superstructure. It is preferred that a plurality of support posts and post clamps according to the invention be used with a molten metal pump wherein the top surface of each support post supports some of the weight of the superstructure. Also disclosed are novel support posts that may be used with the post clamp, and a pump in which the post clamp and / or support posts may be used.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Pump with rotating inlet

A device for use in a molten metal pump helps alleviate jams between a rotating rotor and stationary inlet. The device includes an inlet structure including one or more openings and a displacement structure that preferably includes one or more rotor blades. The inlet structure and displacement structure are connected to one another (preferably, but not necessarily, as a unitary piece), thus enabling them both to rotate. A pump including the device is also enclosed. The invention further includes a bearing surface for an impeller or for a device according to the invention, wherein the bearing surface includes grooves that help reduce molten metal build up between the bearing surface of the impeller or device and the bearing surface of a pump chamber.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Equipment component monitoring and replacement management system

A computer system for managing replacement components for equipment having a plurality of components, each component having a limited useful life, has a computer program module defining a duty profile comprising a plurality of usage cases for the equipment, each usage case involving two or more of the components and specified operating conditions for the involved components during execution of the usage cases. A further program module determines a theoretical useful life for each component involved in a duty profile, based on component useful life data under specified operating conditions; and sensors determine and monitor the occurrence of equipment operation corresponding to a usage case and measur actual operating conditions and number of operations. A further program module computes an adjusted theoretical useful life for a component experiencing operations, based on a comparison of actual operating conditions to those assumed for the usage case.

Owner:HYDRALIFT AMCLYDE INC

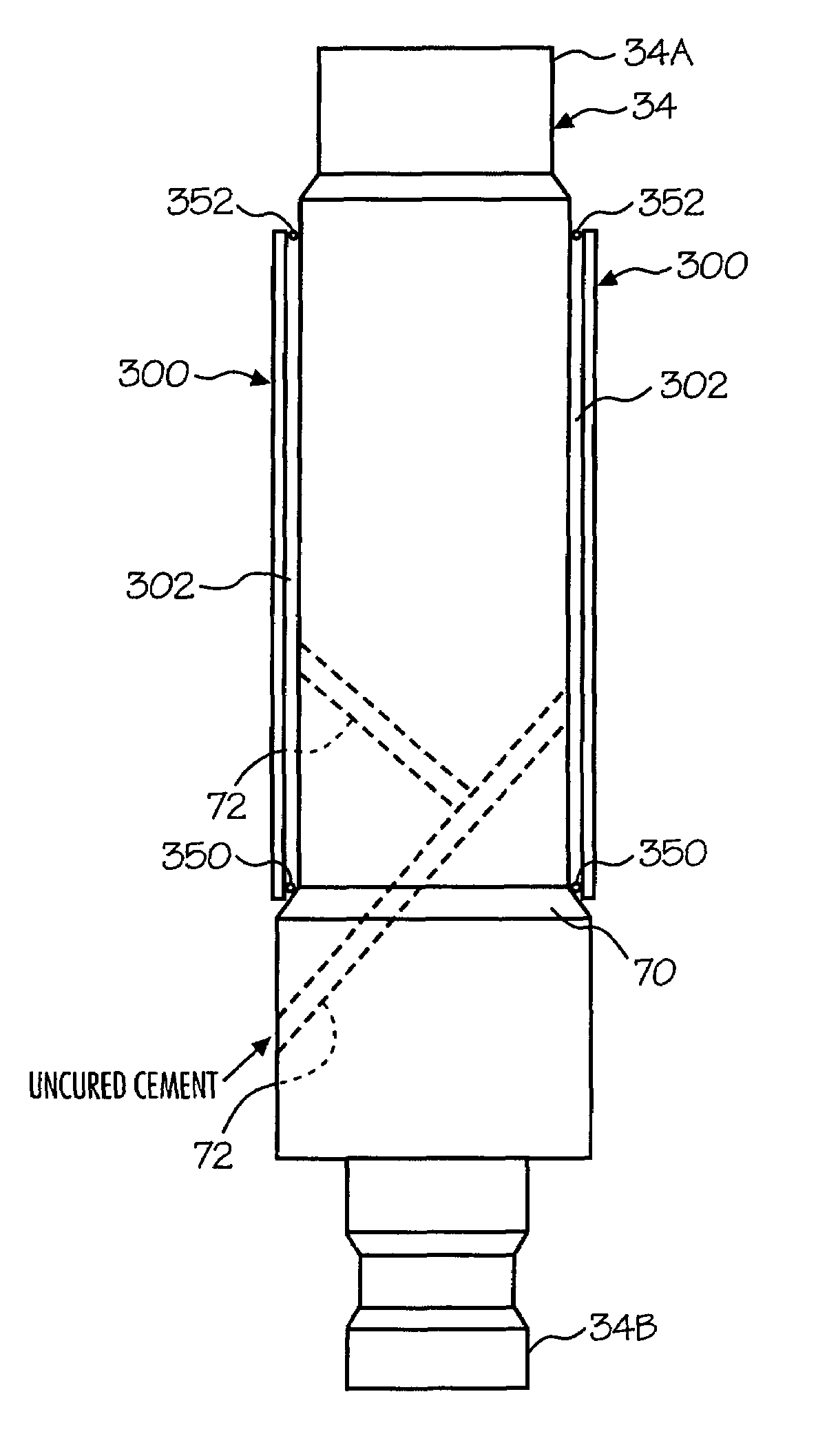

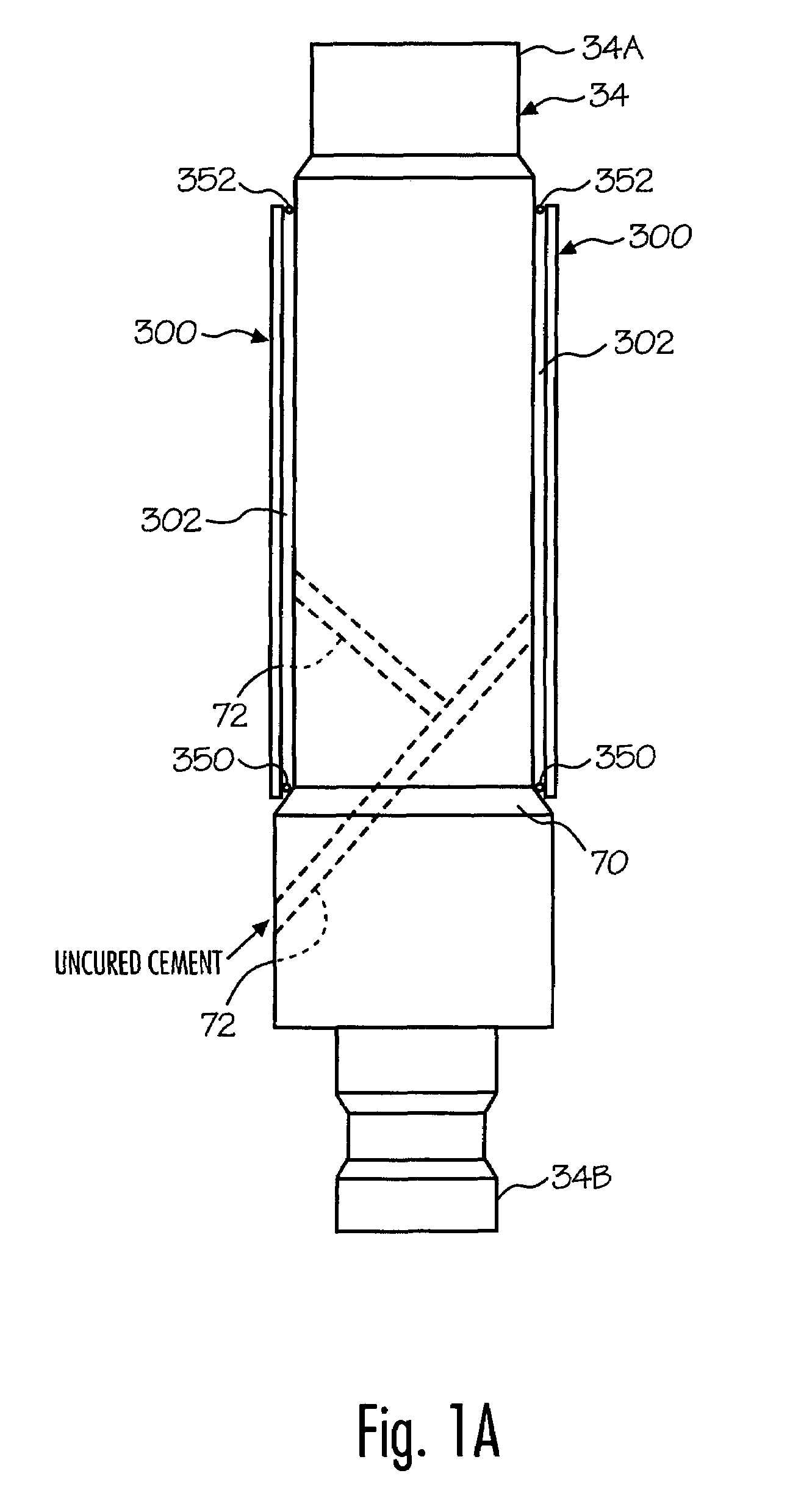

Protective coatings for molten metal devices

ActiveUS7507367B2Reduce componentsPrecise positioningSpecific fluid pumpsPump componentsMolten metalCoating

Disclosed are components covered with a protective coating for use in a molten metal bath (or comparable environment) and devices including such components. The protective coating is preferably a ceramic sleeve adhered to a non-coated component by cement. A component with the protective coating is more resistant to degradation in molten metal than is the component without the coating, and may be manufactured by the process of (a) placing the protective coating over the non-coated component, and (b) injecting cement into the space between the non-coated component and protective coating, wherein at least some of the cement is injected through a passage in either the non-coated component or the protective coating.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Gas-transfer foot

The present invention includes a molten metal pump and associated components that enable gas to be released into a stream of molten metal. The gas may be released into the molten metal stream (preferably into the bottom of the stream) flowing through a passage. Such a stream may be within the pump discharge and / or within a metal-transfer conduit extending from the pump discharge. The gas is released by using a gas-transfer foot that is positioned next to and is preferably attachable to the pump base or to the metal-transfer conduit. Preferably, the conduit (and / or discharge) in which the gas is released comprises two sections: a first section having a first cross-sectional area and a second section downstream of the first section and having a second cross-sectional area, wherein the second cross sectional area is larger than the first cross-sectional area. Preferably, the gas is released into or near the second section so that the gas is released into an area of relatively lower pressure.

Owner:COOPER PAUL

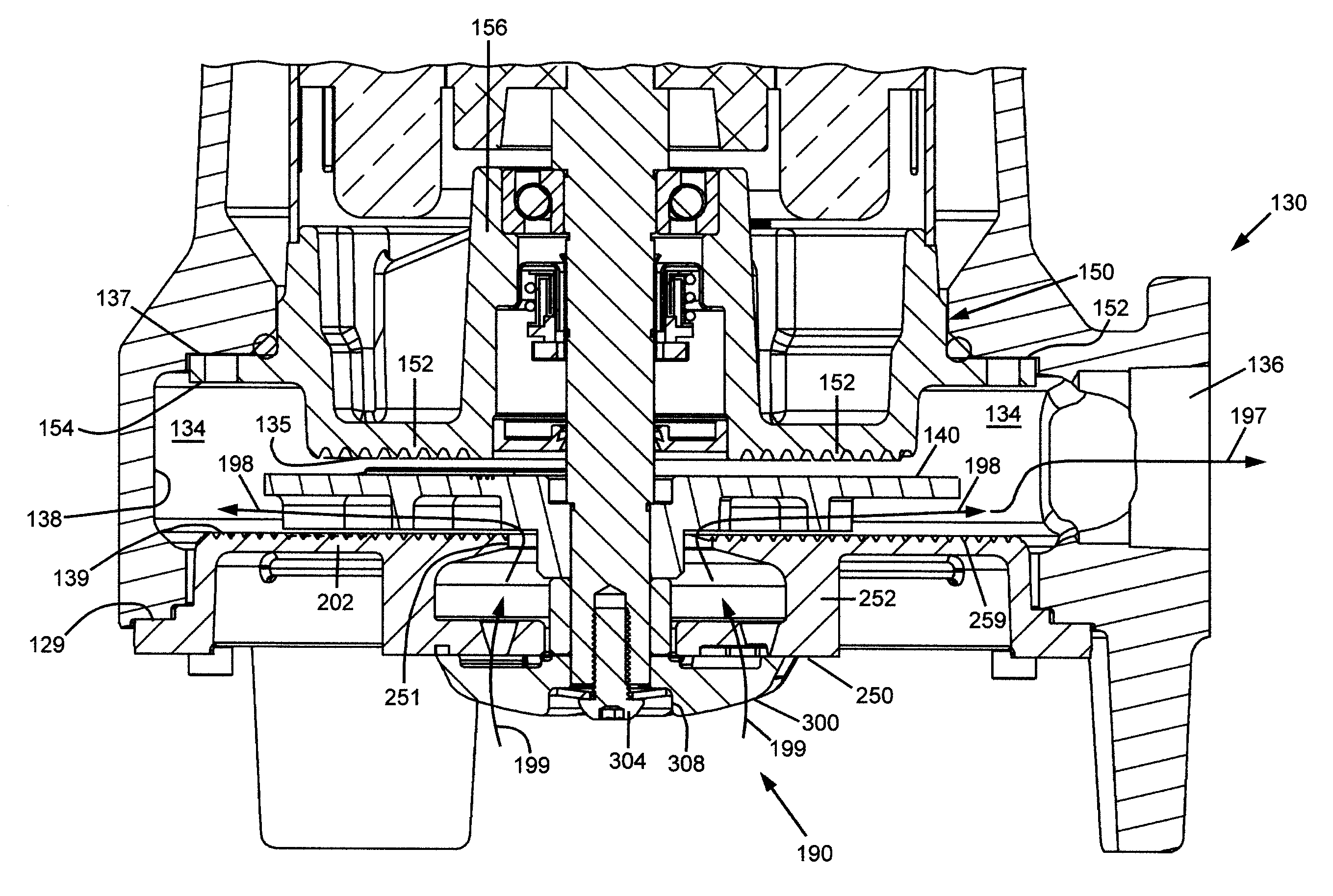

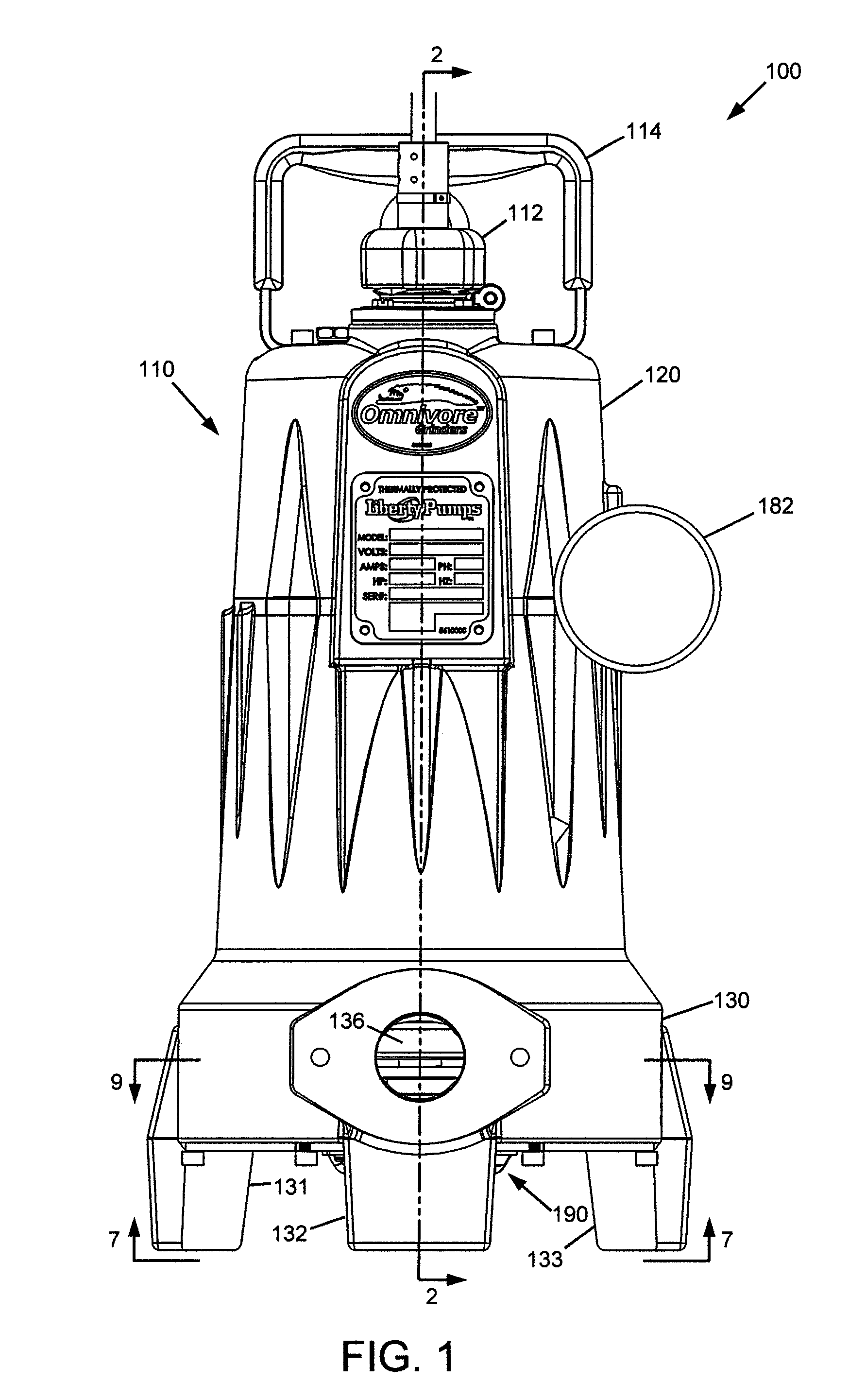

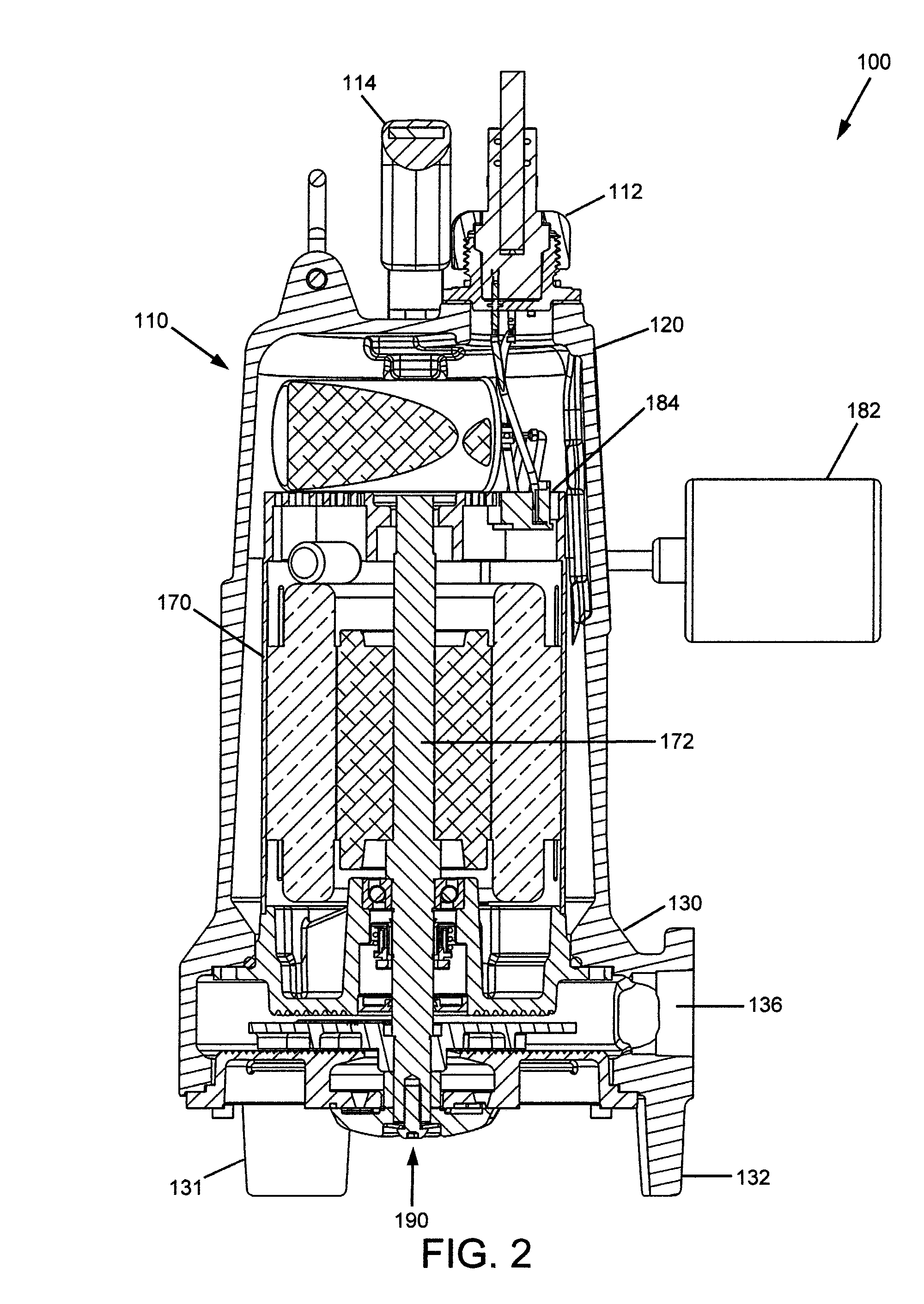

Cutter assembly for a grinder pump

A cutting assembly for a grinder pump comprised of a rotary cutter rotatable against an opposing plate cutter. The cutting edges of the plate cutter include a plurality of V-slice cutting teeth, which create bridging spaces to pinch material which is being sucked in to ports and begin cutting along the V-slice and then for cut material to pass through and onward into the volute of the pump. The rotary cutter has a ground edge with a rake angle which shears the gathered material in cooperation with the cutting edges of the plate cutter. A grinder pump including the cutter assembly is also disclosed.

Owner:LIBERTY PUMPS

Molten metal pump system

A molten metal pump system which generally provides a refractory connection joint for connecting a refractory pump post to a pump base, the pump post including a refractory post with a first end, the first end including an internally threaded joint screw aperture; a refractory base with a post aperture configured to receive the first end of the refractory post, and with a screw aperture contiguous with the post aperture; and a joint screw with a first end and a second end, the joint screw including a threaded external surface and a retention shoulder, the joint screw configured to insert through the screw aperture in the refractory base with the threaded external surface engaging the internally threaded joint screw aperture of the refractory post, and the retention shoulder engaging the refractory base.

Owner:PYROTECK INC

Molten metal pump components

Improved components for a molten metal pump include a coupling for connecting a rotor shaft to a motor shaft, a rotor shaft and a rotor. The rotor shaft has a first end and a second end wherein the first end optionally has a vertical keyway formed in the outer surface of the shaft. The second end optionally has flat, shallow threads. The coupling can be one-piece or multi-piece, includes a cavity for receiving the first end of the rotor shaft and, if the first end of the rotor shaft has a keyway, the coupling includes a projection in the cavity for being received at least partially in the keyway. The rotor includes a connective portion that connects to the second end of the rotor shaft. If the second end of the rotor shaft includes flat, shallow threads, the connective portion is essentially a bore having flat, shallow threads configured to receive the second end of the rotor shaft. Optionally, the first end of the rotor shaft may have flat, shallow threads in which case the coupling would have a cavity that receives the first end of the rotor shaft, wherein the cavity has flat, shallow threads.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Implantable heart assist system and method of applying same

InactiveUS20060264695A1Reduce loadPermitting the heart to recover during useSpecific fluid pumpsOther blood circulation devicesAfterloadCatheter

Owner:VIOLE ANTHONY +7

System for releasing gas into molten metal

InactiveUS20080213111A1Reduce amountIncrease the cross-sectional areaSpecific fluid pumpsEngine manufactureMetallurgyGas release

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

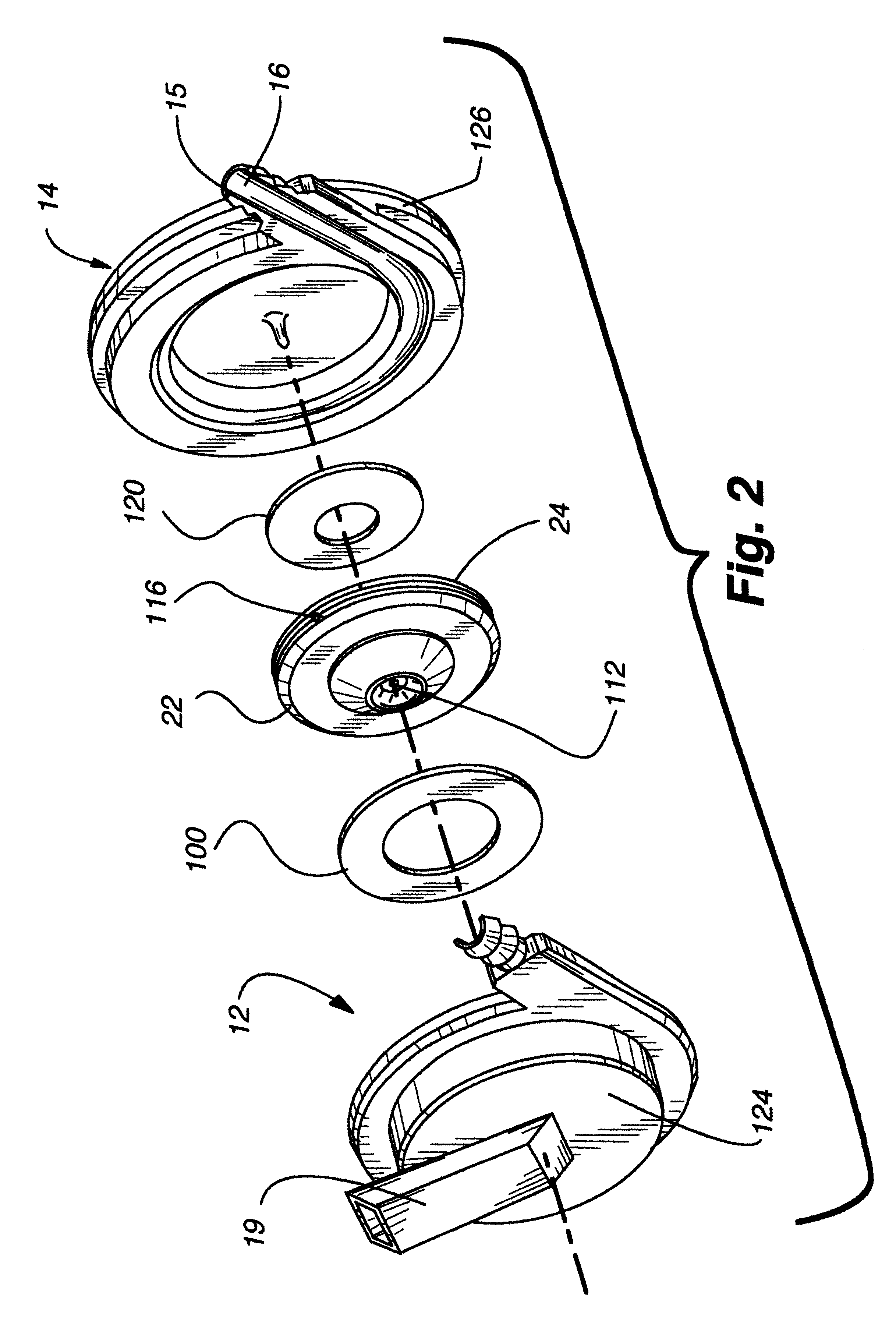

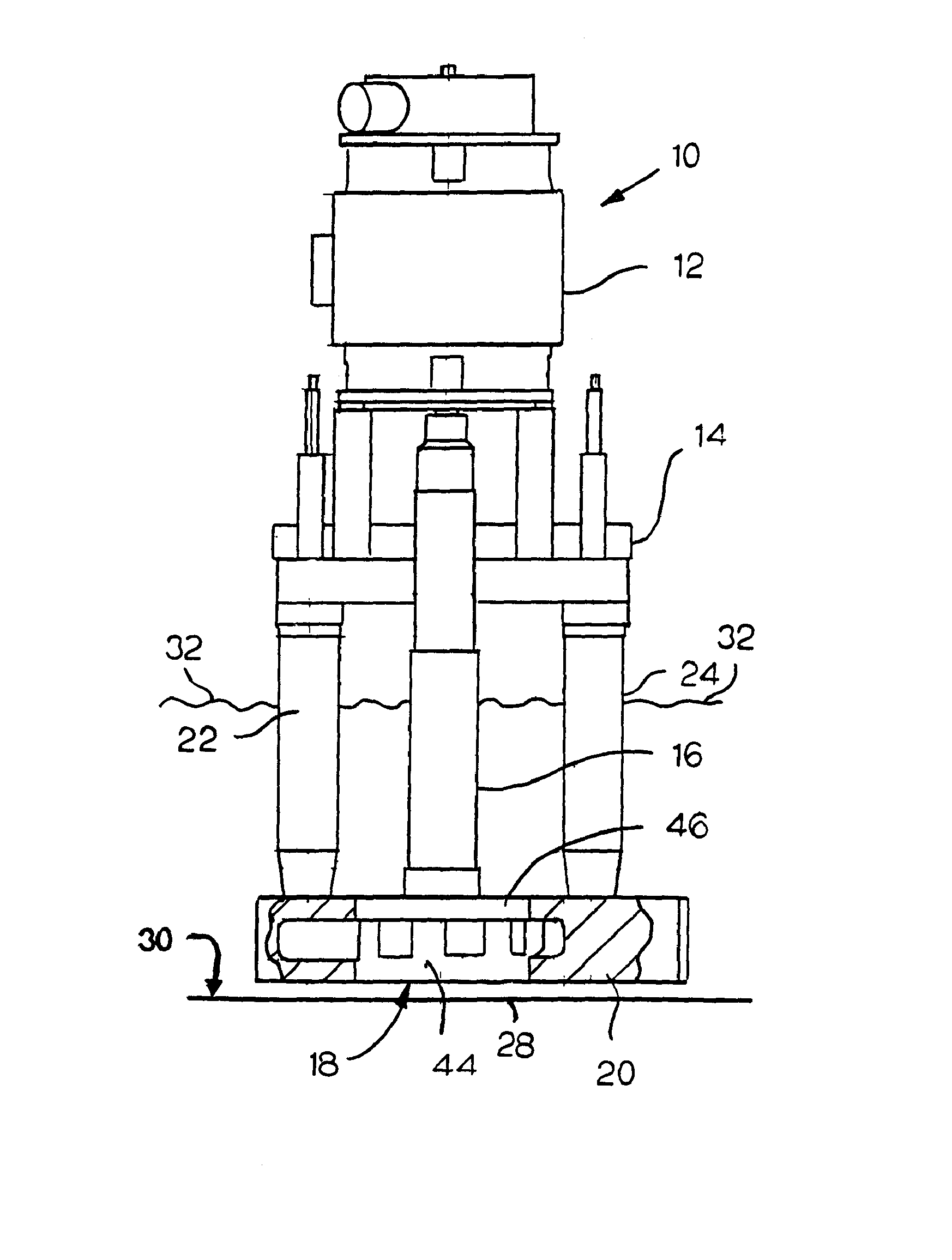

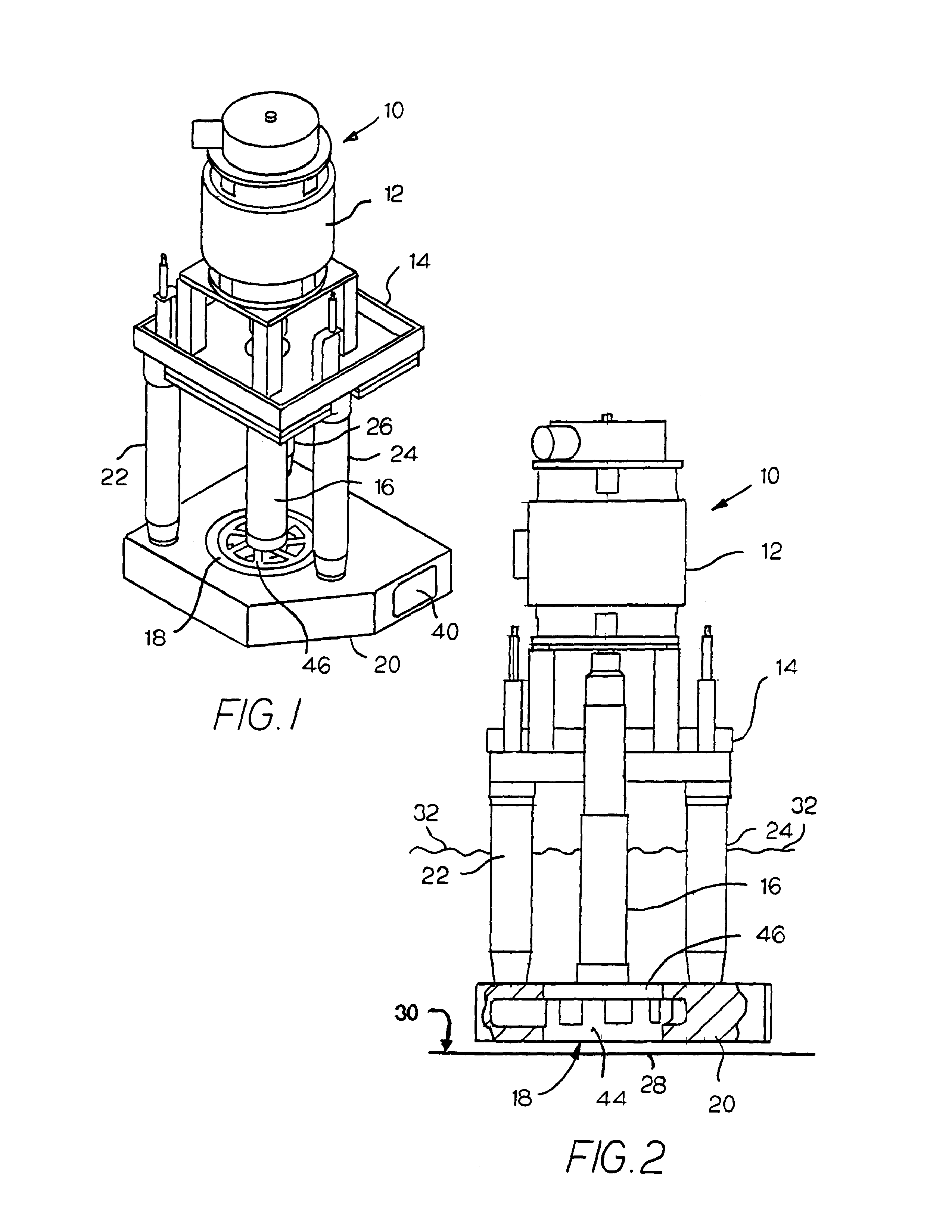

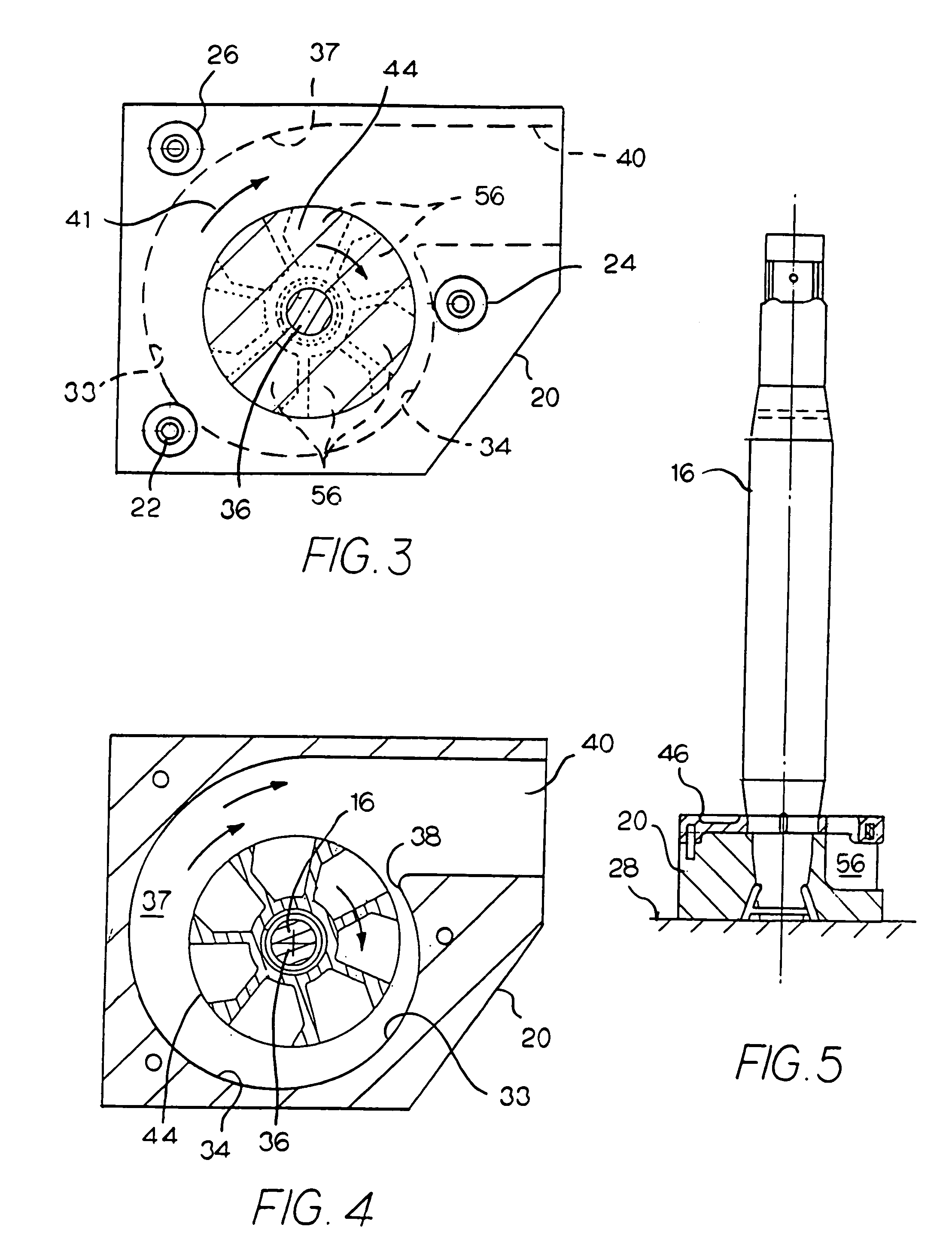

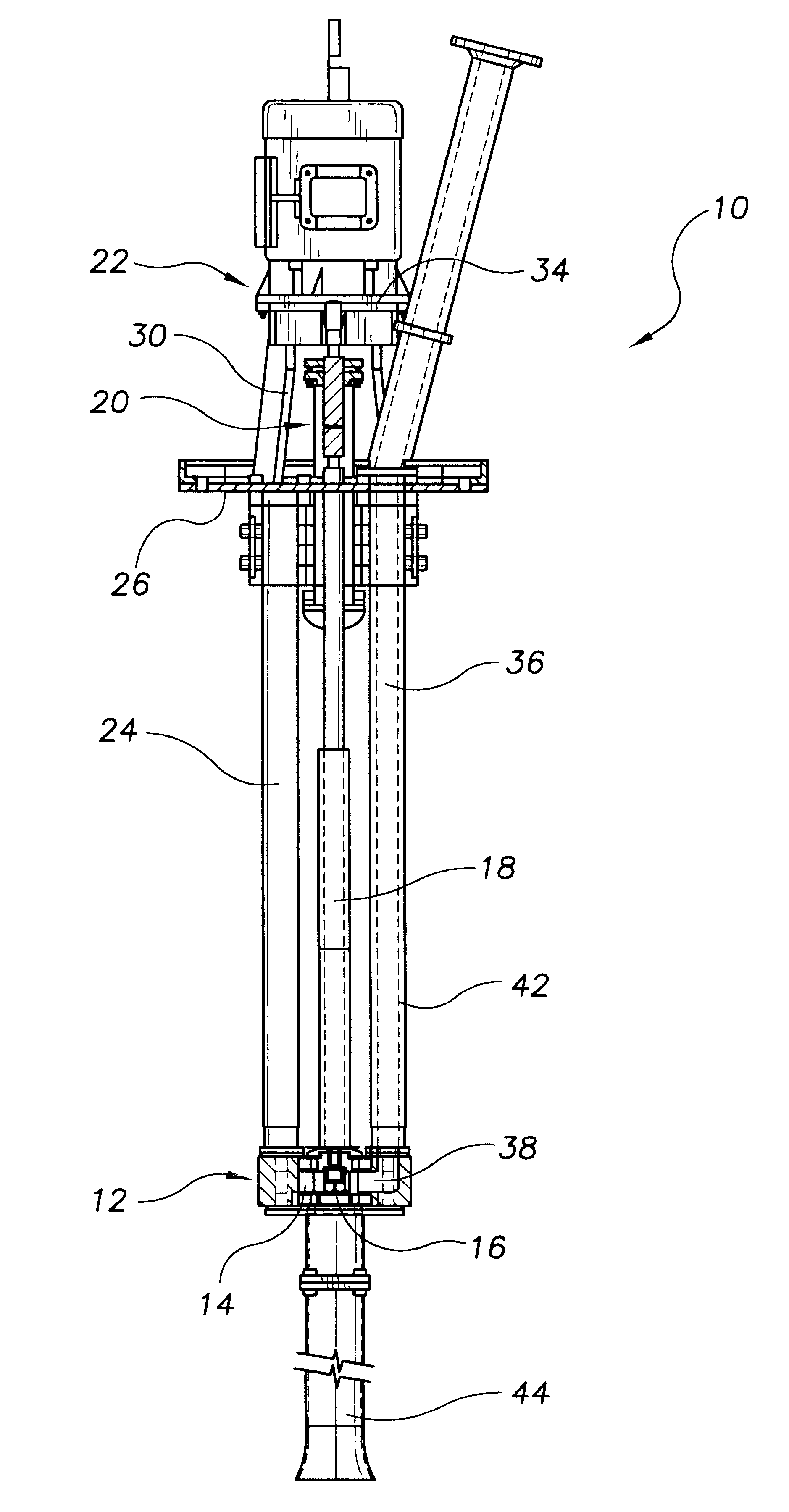

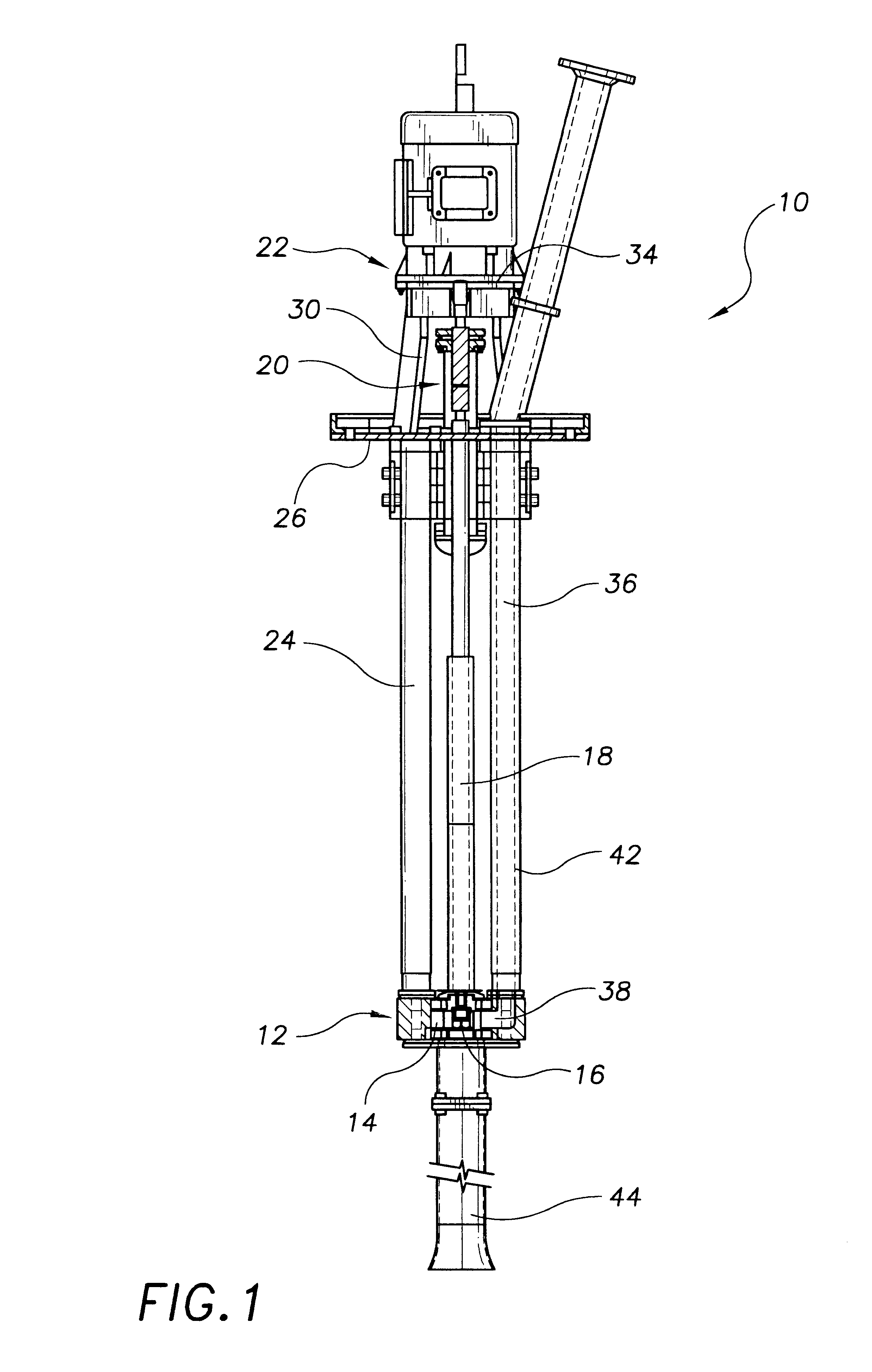

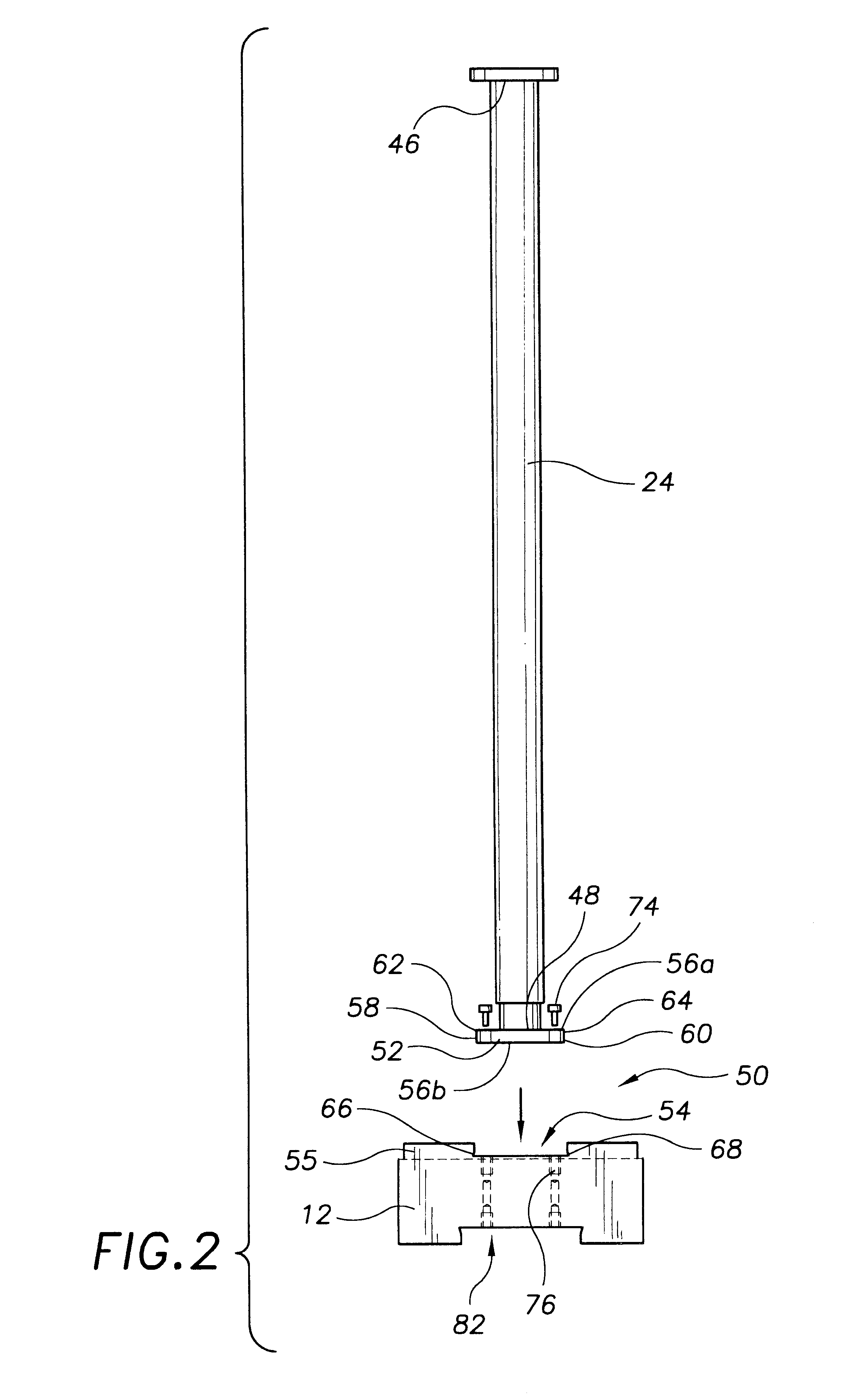

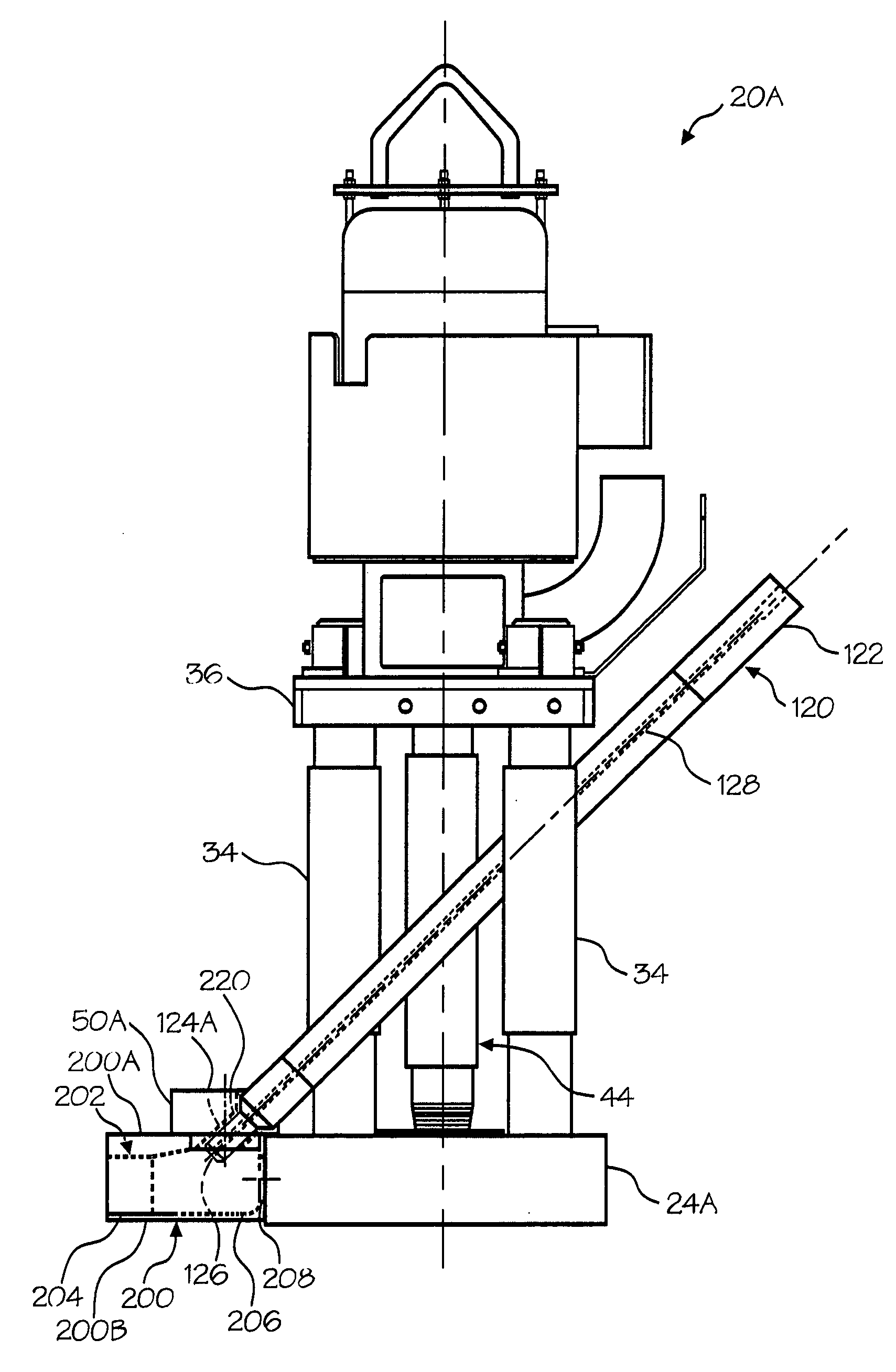

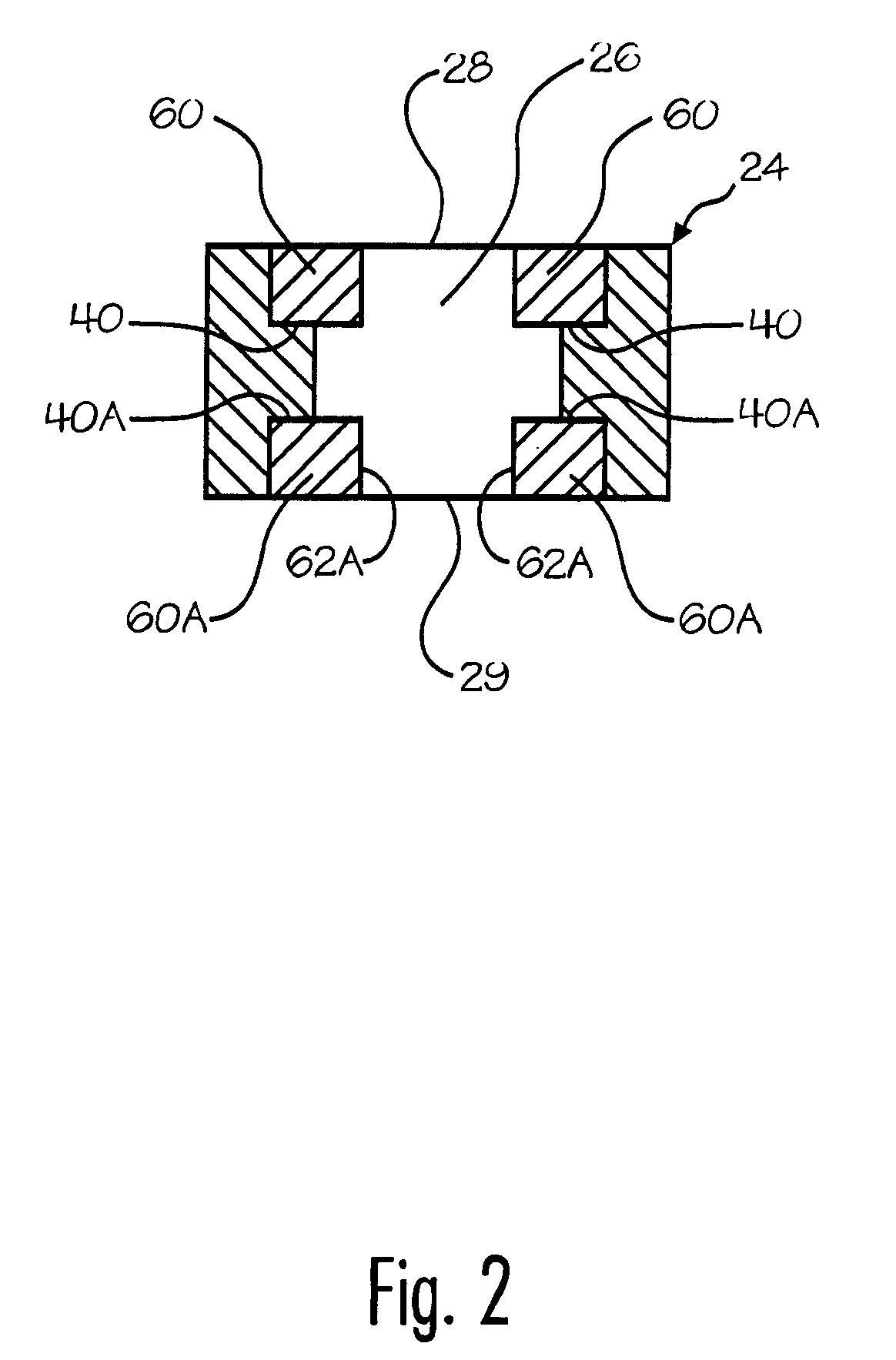

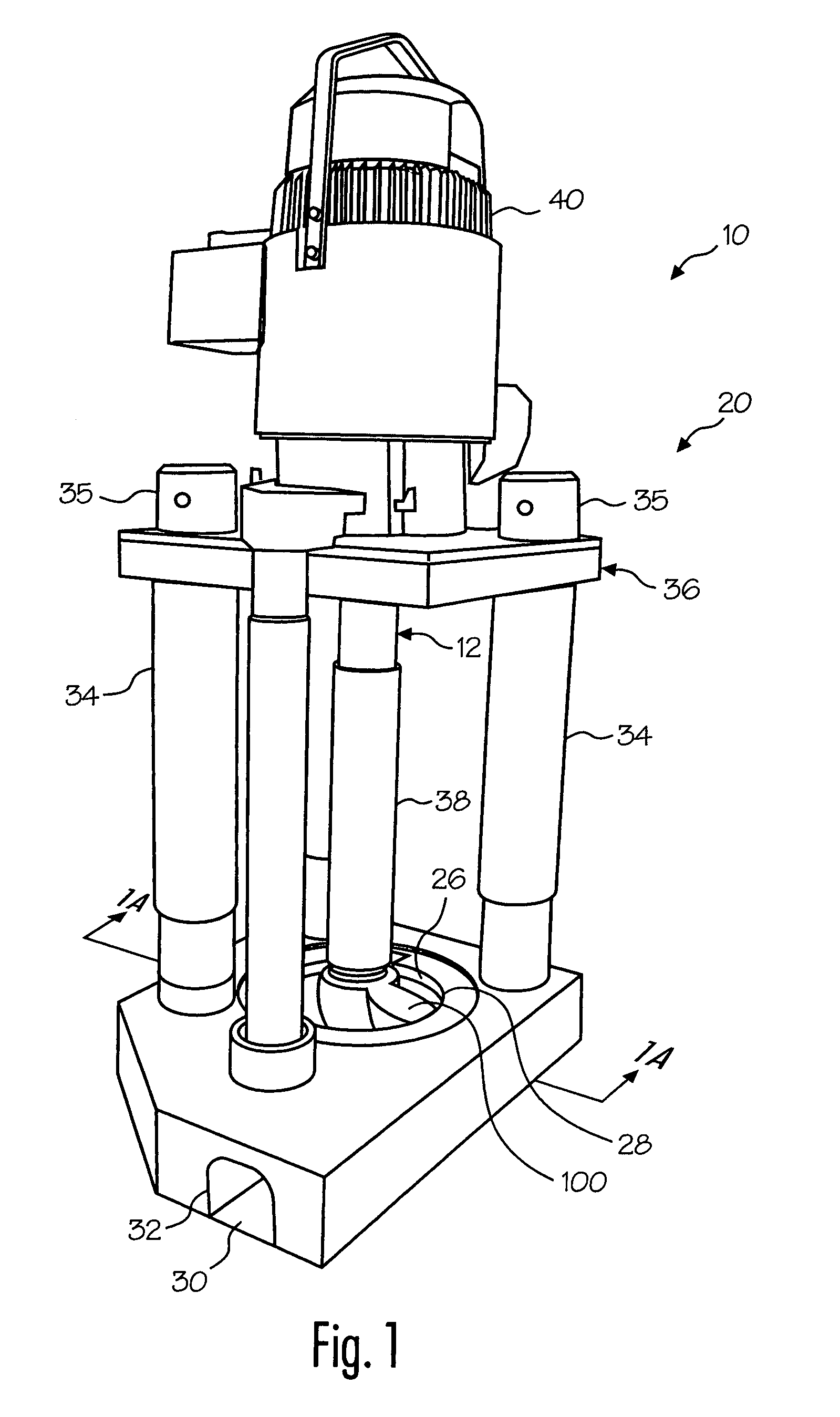

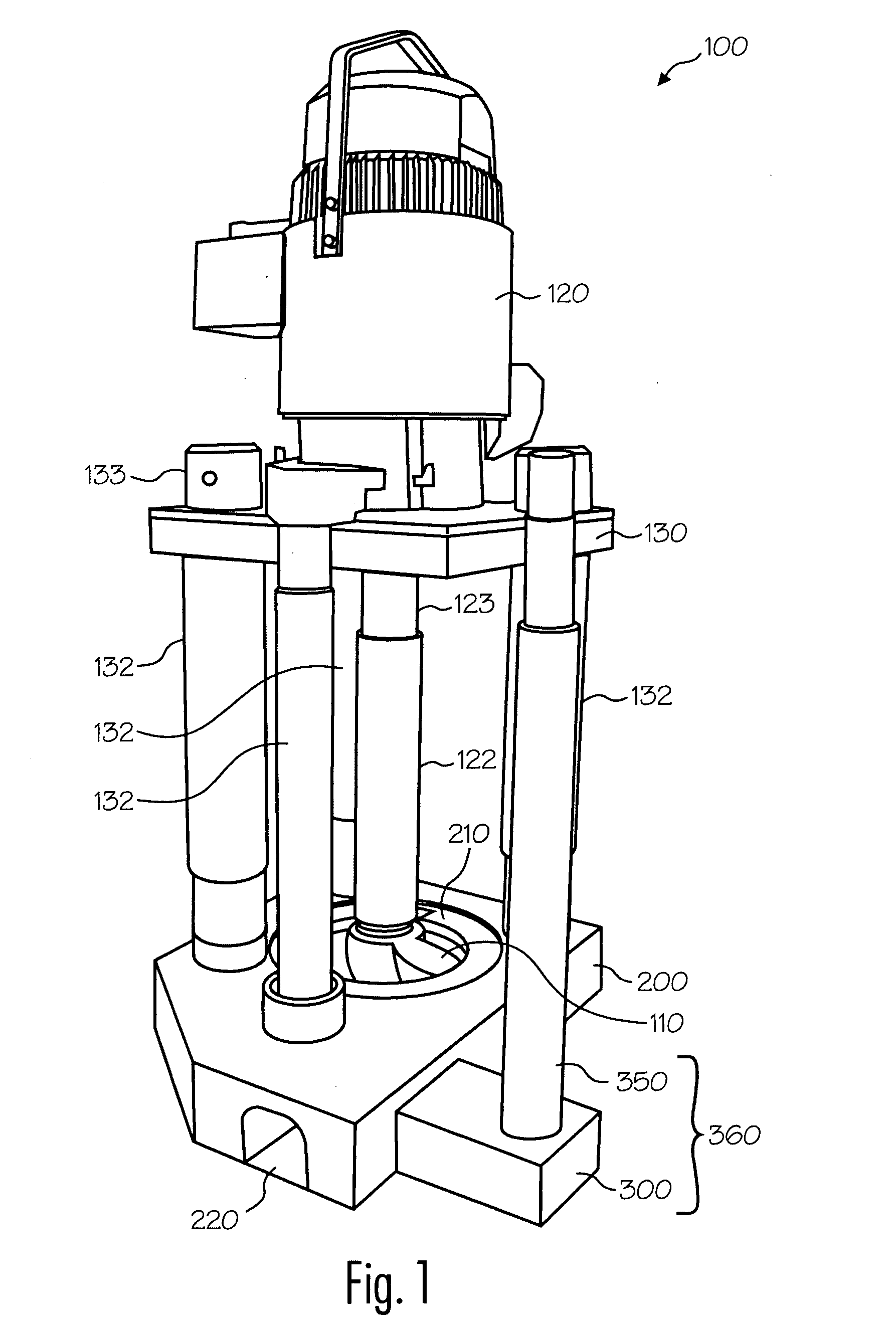

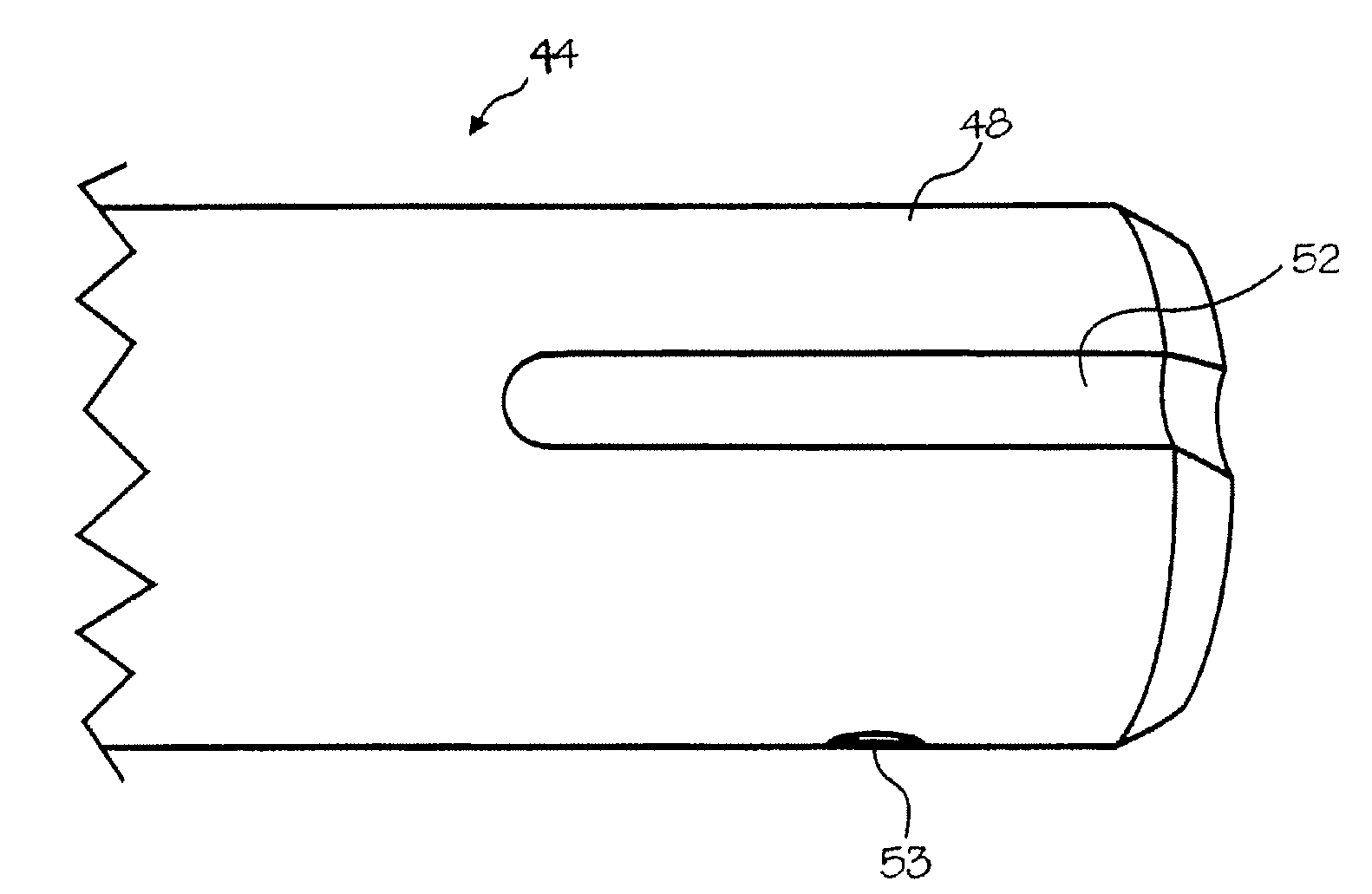

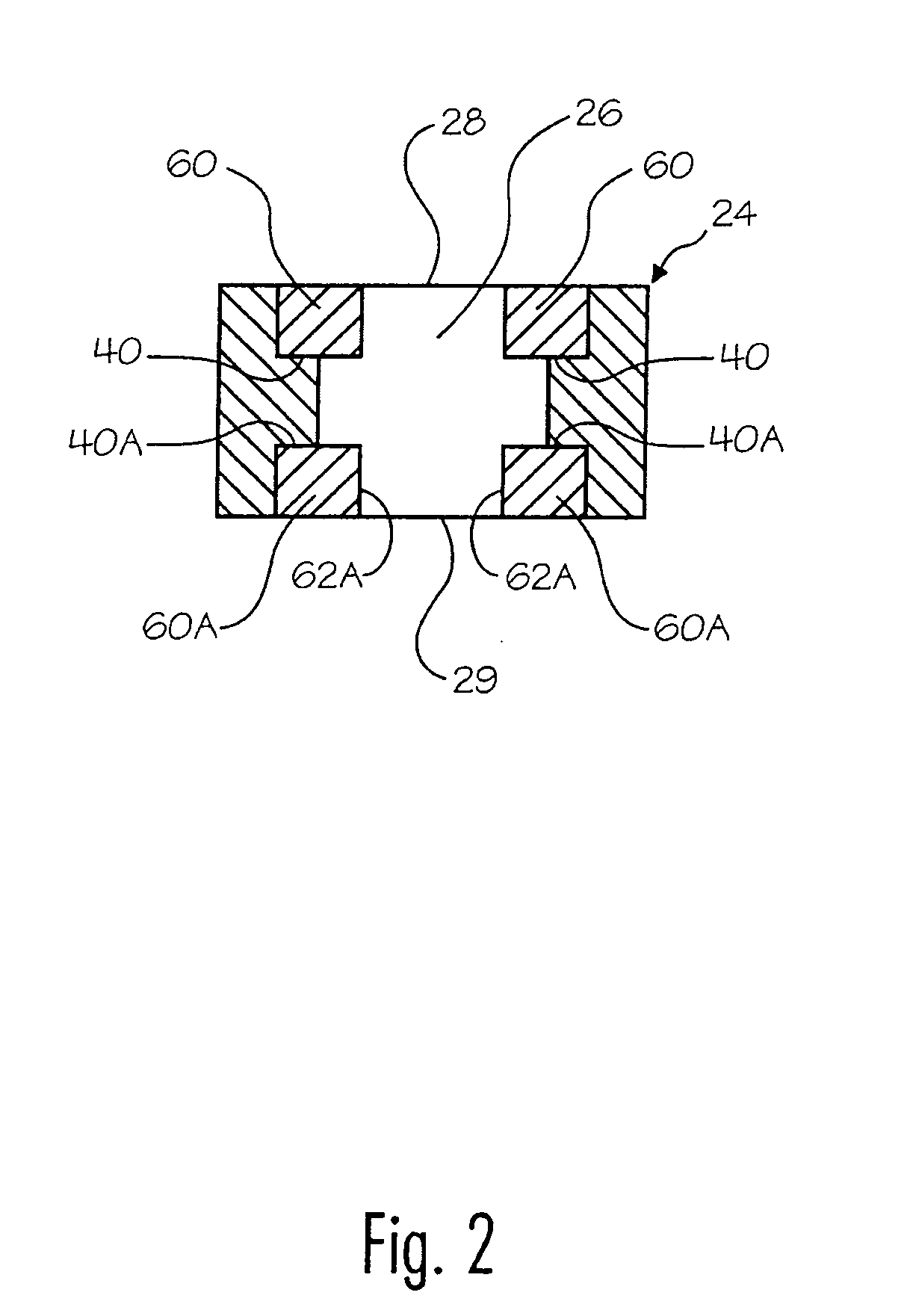

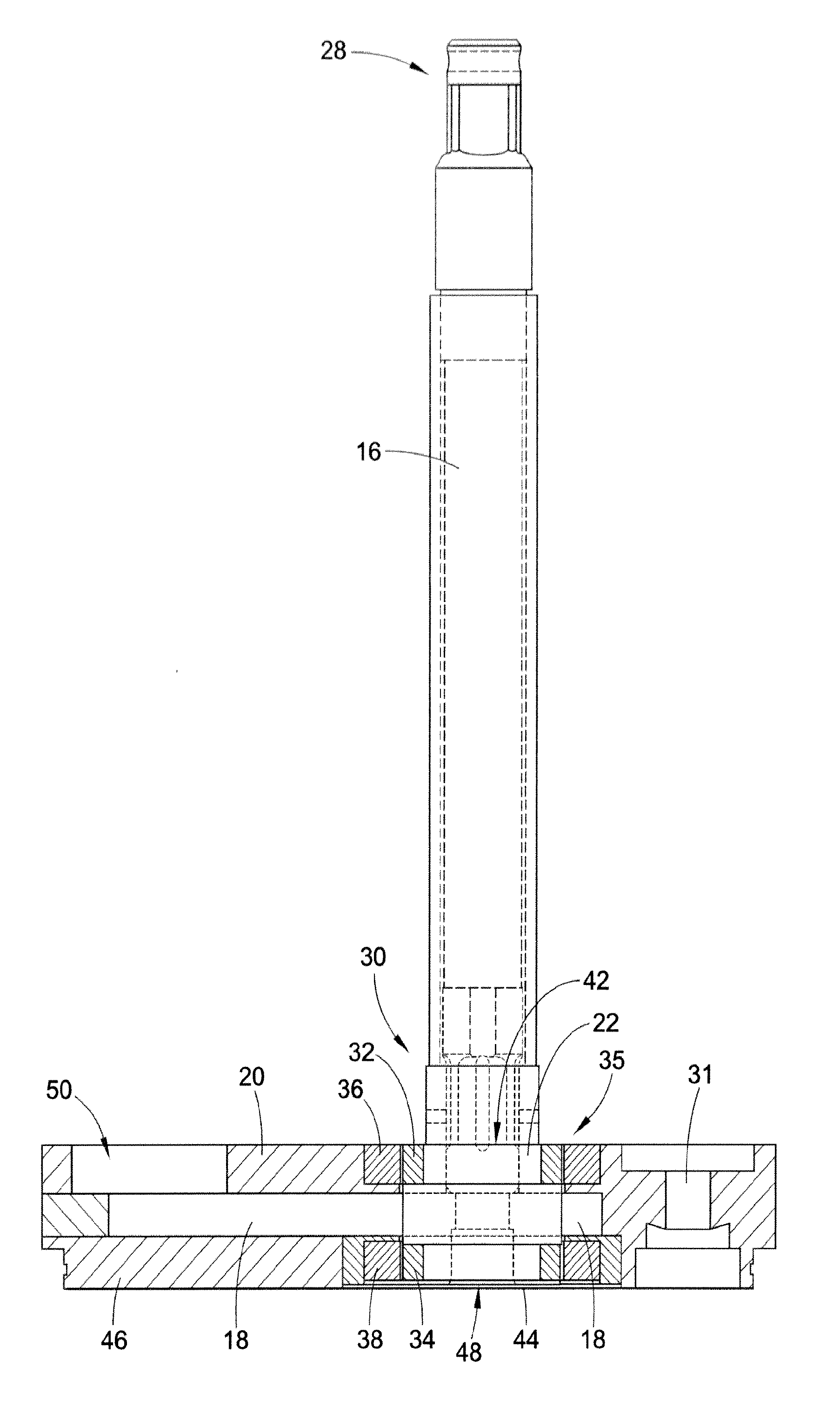

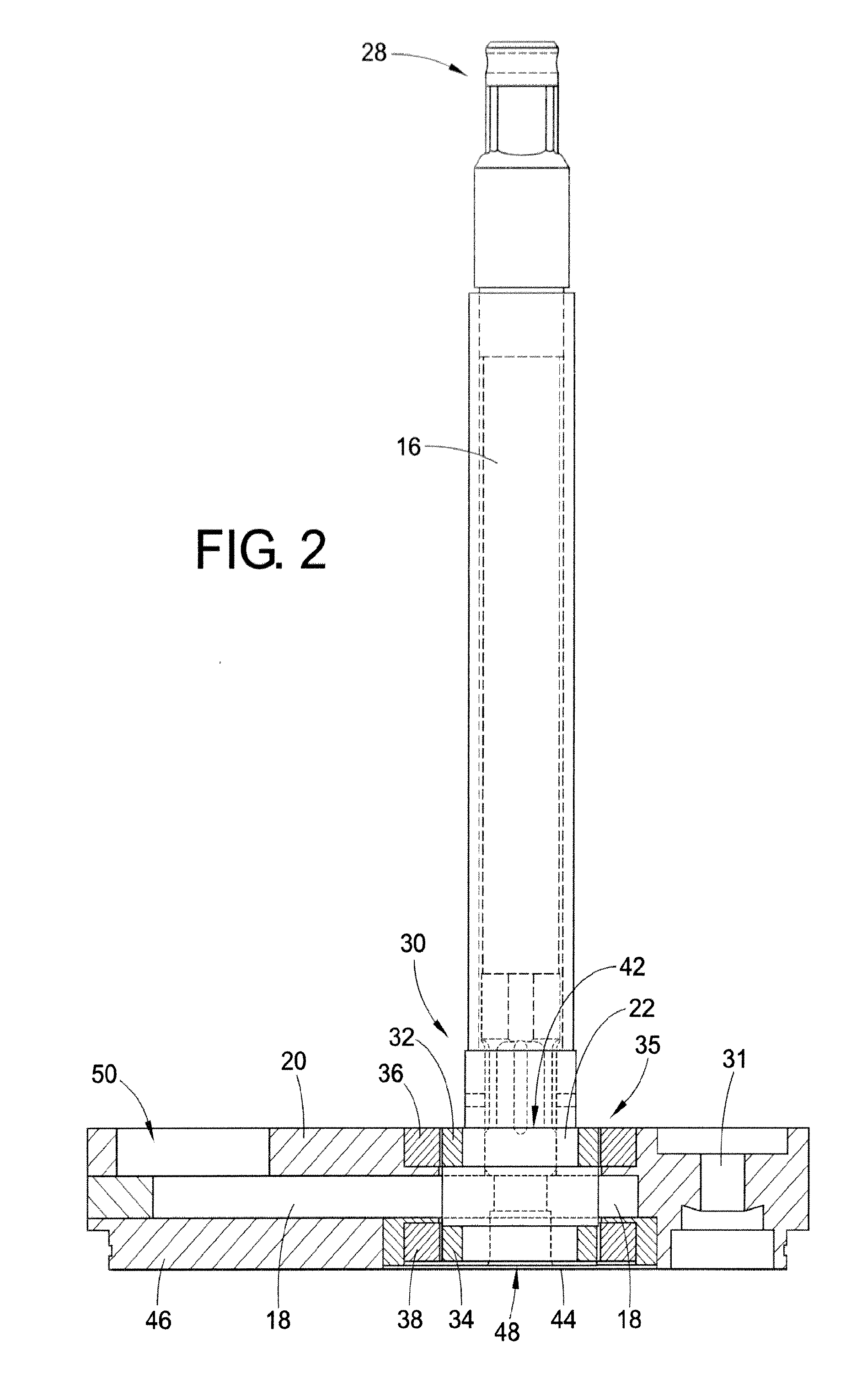

Mold pump assembly

ActiveUS20140044520A1Easy to tunePrecise flow controlSpecific fluid pumpsPump componentsImpellerEngineering

A molten metal pump assembly (10) and method to fill complex molds with molten metal, such as aluminum. The pump assembly includes an elongated shaft (16) connecting a motor (14) to an impeller (22). The impeller is housed within a chamber (18) of a base member such that rotation of the impeller draws molten metal into the chamber at an inlet (48) and forces molten aluminum through an outlet (50). A first bearing (36) is adapted to support the rotation of the impeller at a first radial edge (32) and a second bearing (38) is adapted to support the rotation of the impeller at a second radial edge. A bypass gap (60) is interposed between the second bearing and the second radial edge. Molten metal leaks through the bypass gap at a predetermined rate to manipulate a flow rate and a head pressure of the molten metal such that precise control of the flow rate is achieved.

Owner:PYROTECK INC

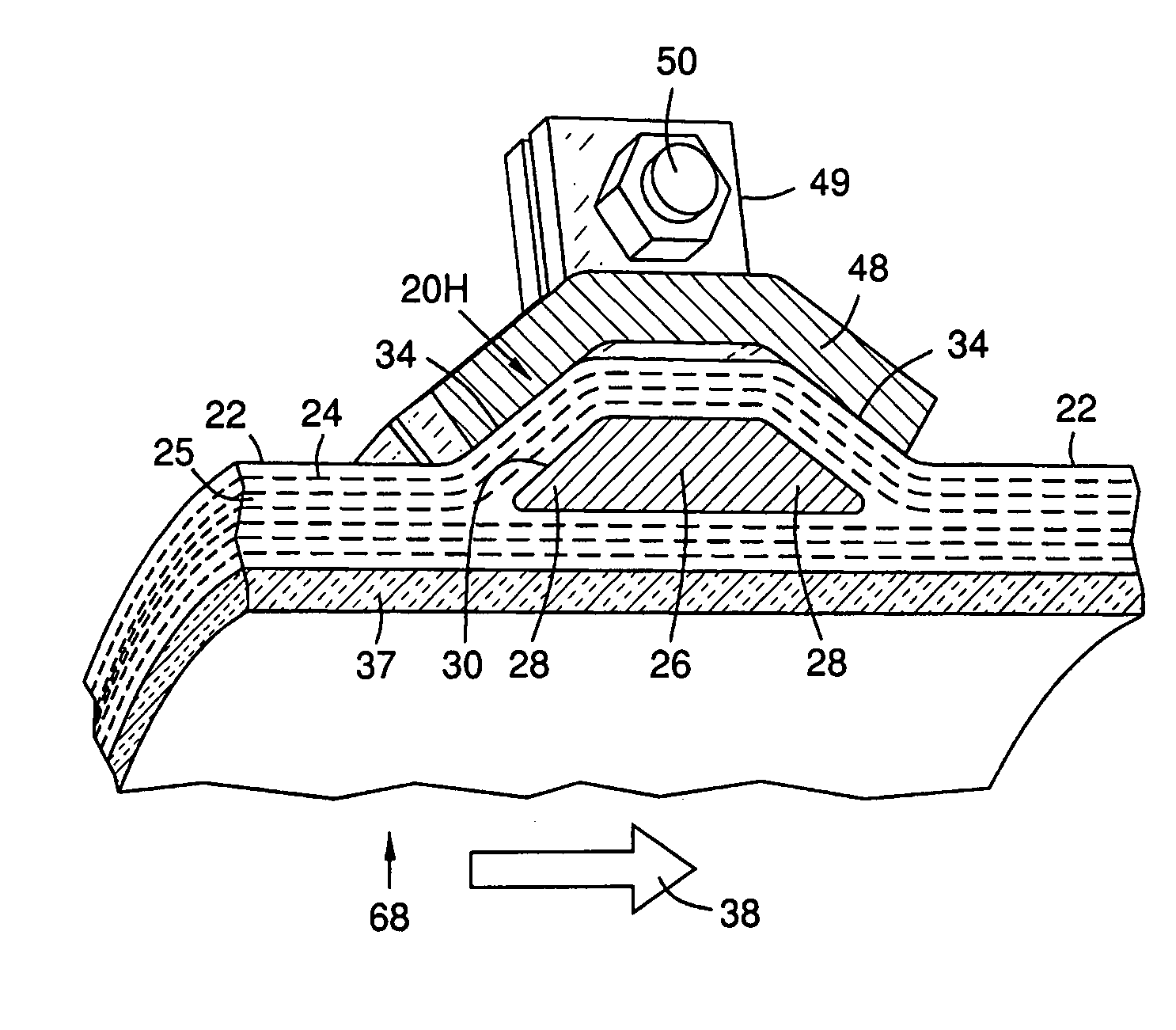

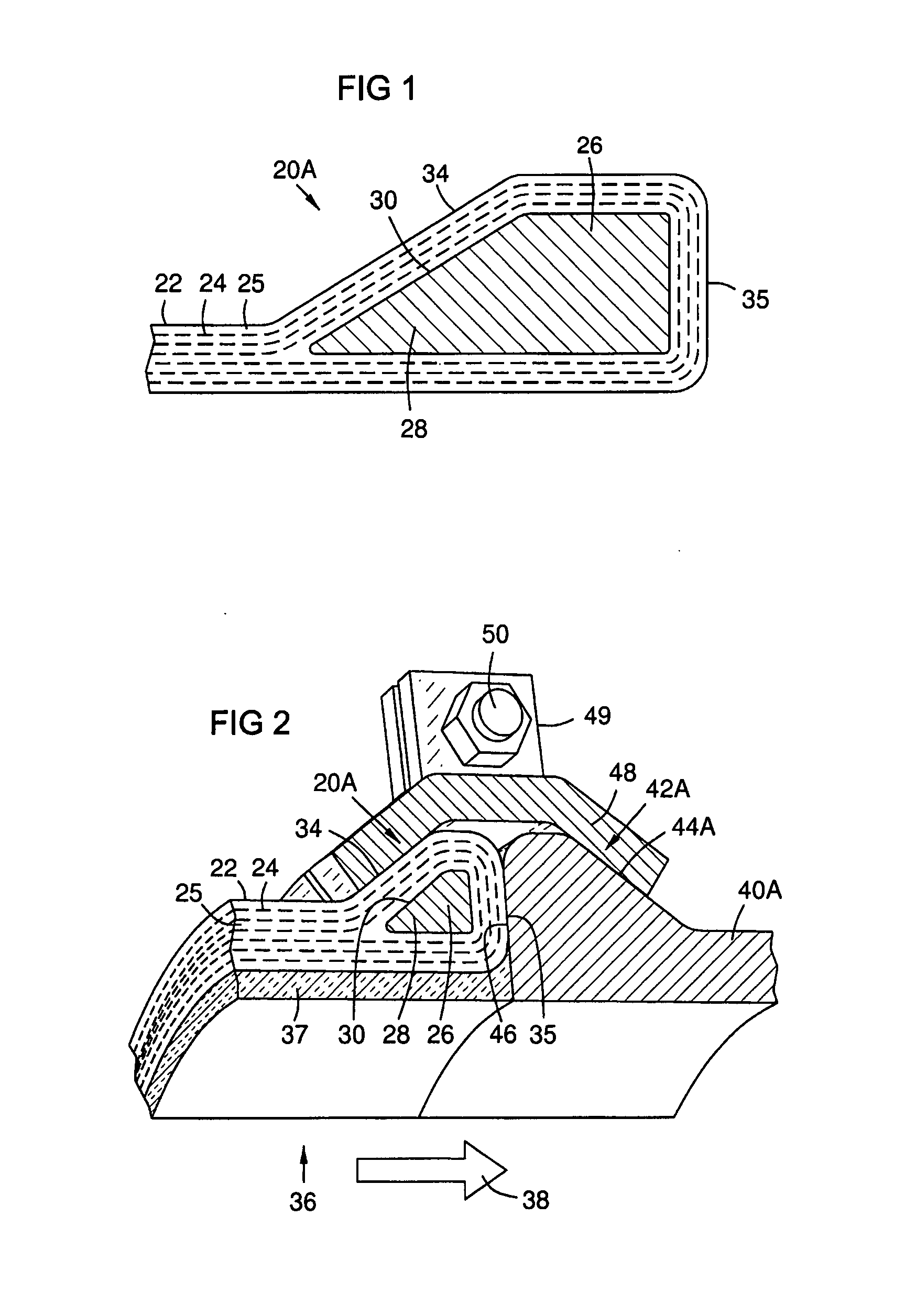

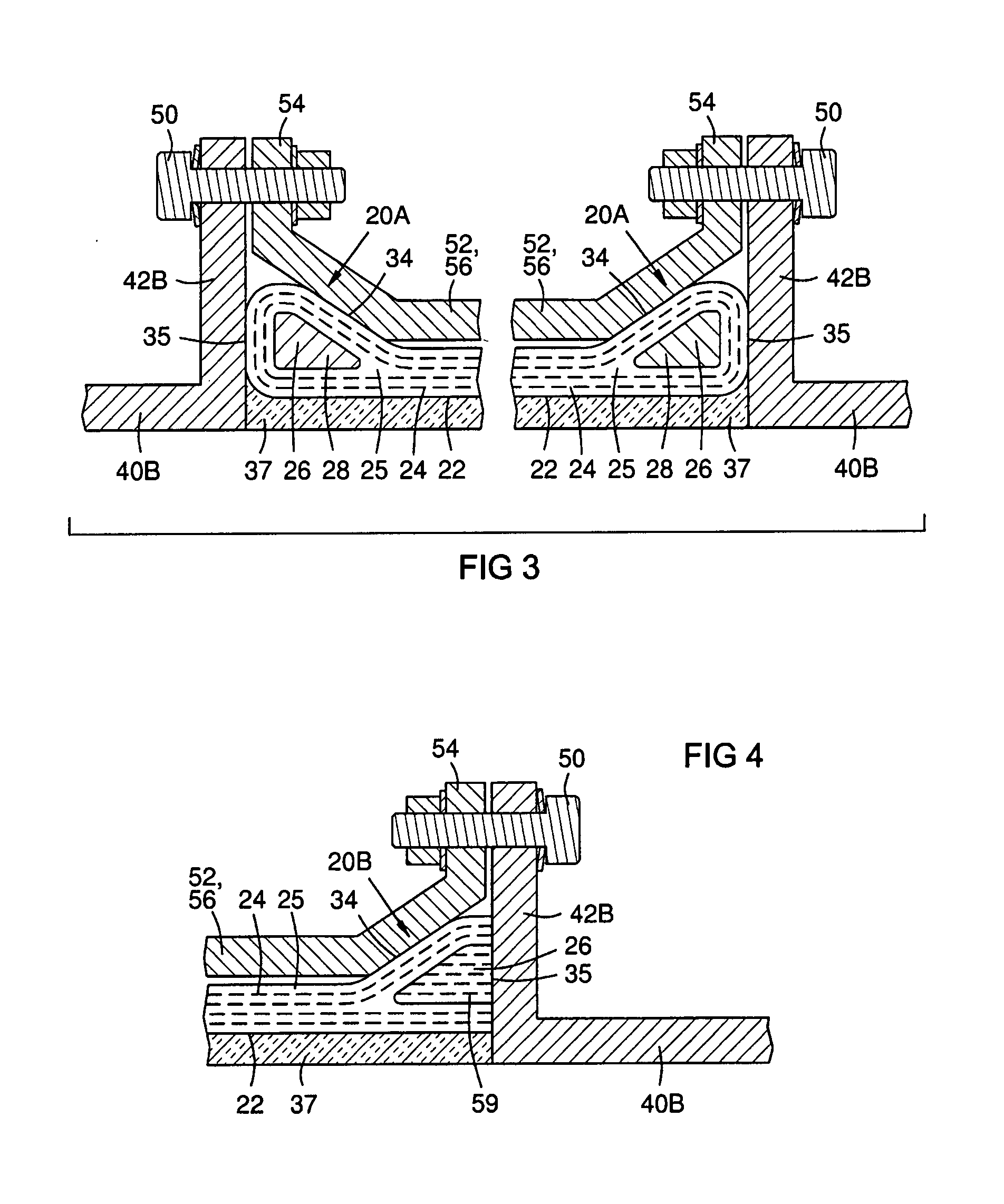

Ceramic matrix composite attachment apparatus and method

An attachment method and flange for connecting a ceramic matrix composite (CMC) component, such as a gas turbine shroud ring (36, 68), to a metal support structure. A CMC flange (20A) may be formed by attaching a wedge-shaped block (26) of a ceramic material to a CMC wall structure (22), and wrapping CMC layers (24) of the wall structure (22) at least partly around the block (26), forming the flange (20A) with an inner oblique face (34) and an outer face (35) normal to the wall structure. An adjacent support structure, such as a metal support ring (40A), may abut the outer face (35) of the CMC flange (20A) and be clamped or bolted to the CMC flange (20A).

Owner:SIEMENS ENERGY INC

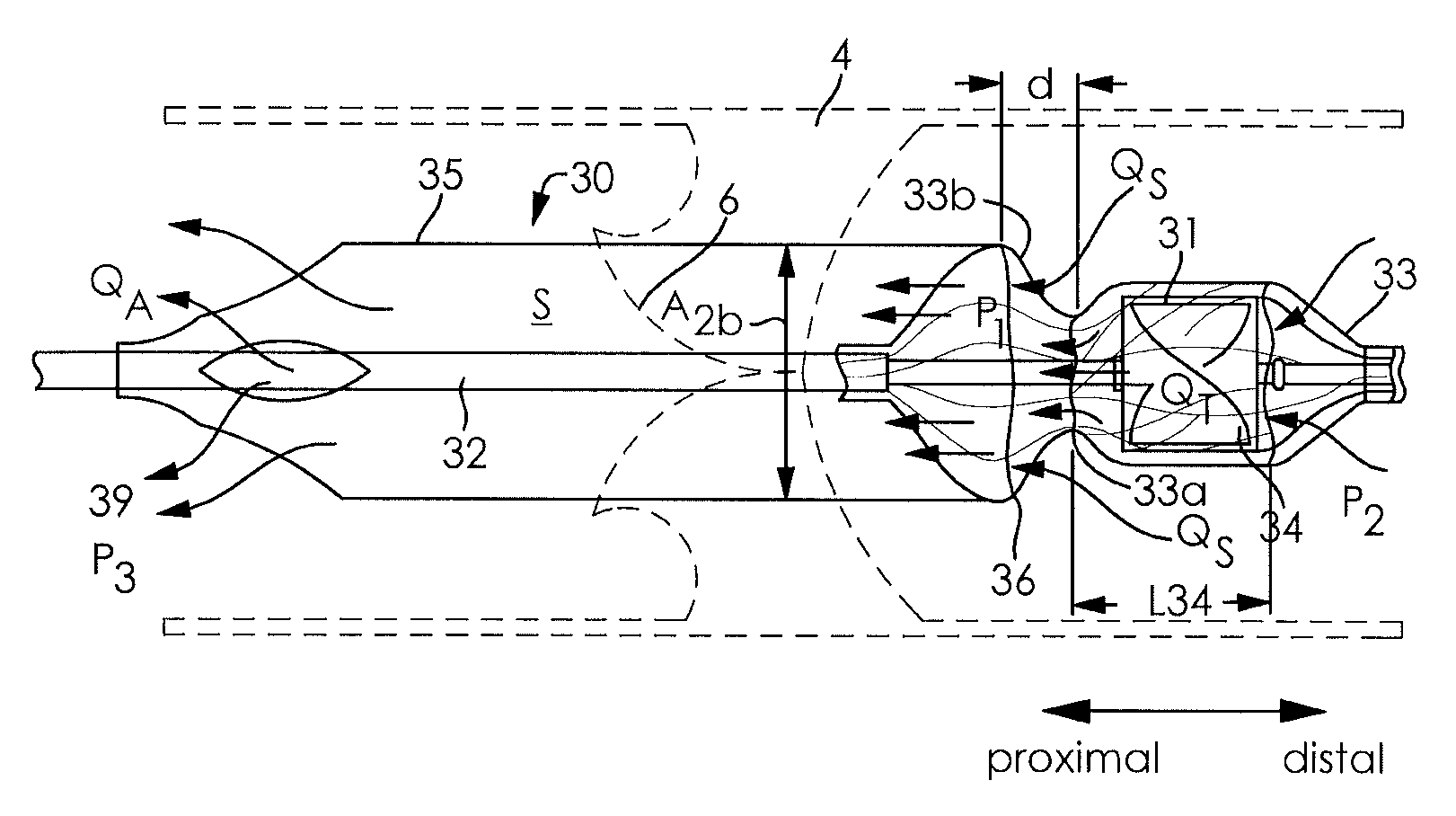

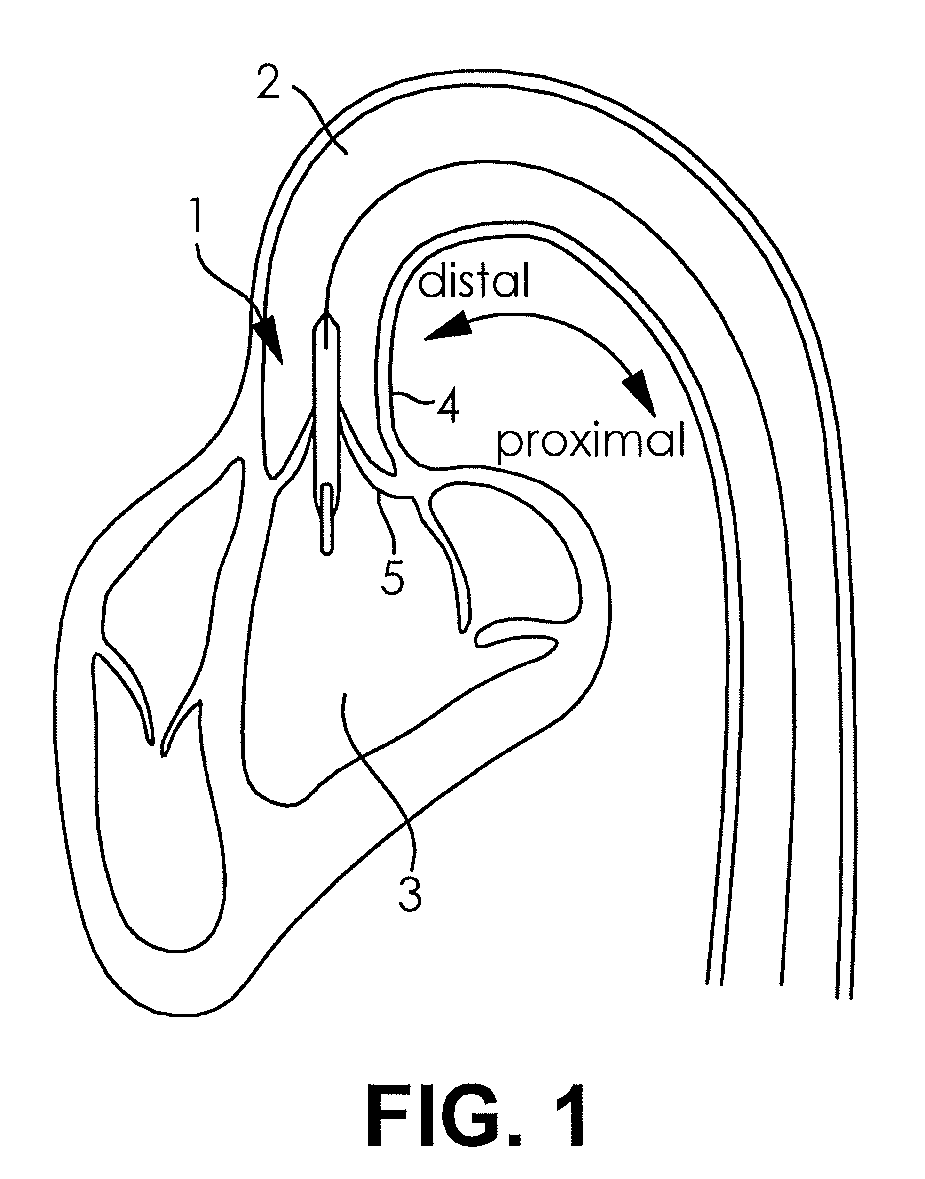

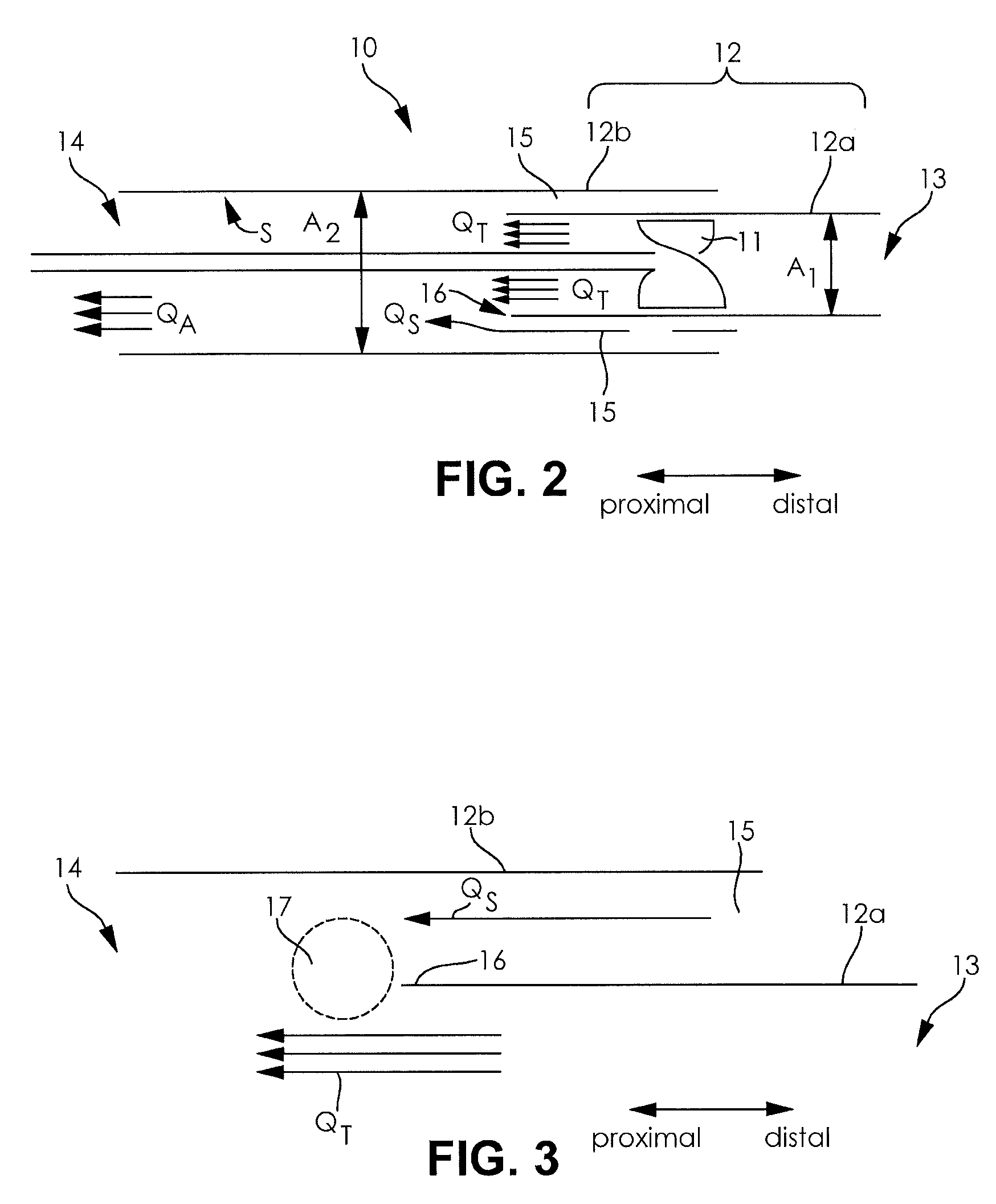

Pump arrangement

ActiveUS9328741B2Light introductionReduce riskSpecific fluid pumpsPump componentsSubject matterEngineering

The subject matter of the present invention is a pump arrangement, in particular for use in the body's own vessels, having a pump and a sheath receiving the pump, bounding a flow passage and having a distal intake opening and a proximal outflow opening for producing a driving flow by means of the pump, wherein the pump is arranged in a first fluid-tight section having the distal intake opening and a second fluid-tight section includes the proximal outflow opening. In accordance with the invention, a further inlet opening is present between the first section, and the second section and is arranged between the intake opening and the outflow opening, with the first section and the second section being arranged with respect to one another such that the inlet opening opens into the flow proximal to the pump.

Owner:ECP ENTWICKLUNGSGMBH

Support post system for molten metal pump

ActiveUS7906068B2Specific fluid pumpsPositive displacement pump componentsSupporting systemEngineering

An improved post clamp for a molten metal pump includes a support post clamp that supports the weight of a pump superstructure on the top of the support posts. The clamp preferably includes (a) a bottom flange for connecting to the pump superstructure, (b) a cavity for receiving an end of a support post, wherein the end has a top surface, and (c) a top flange for being positioned above the top surface. In operation the top flange rests on the top surface of the support post thereby supporting at least part of the weight of the superstructure. It is preferred that a plurality of support posts and post clamps according to the invention be used with a molten metal pump wherein the top surface of each support post supports some of the weight of the superstructure. Also disclosed are novel support posts that may be used with the post clamp, and a pump in which the post clamp and / or support posts may be used.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

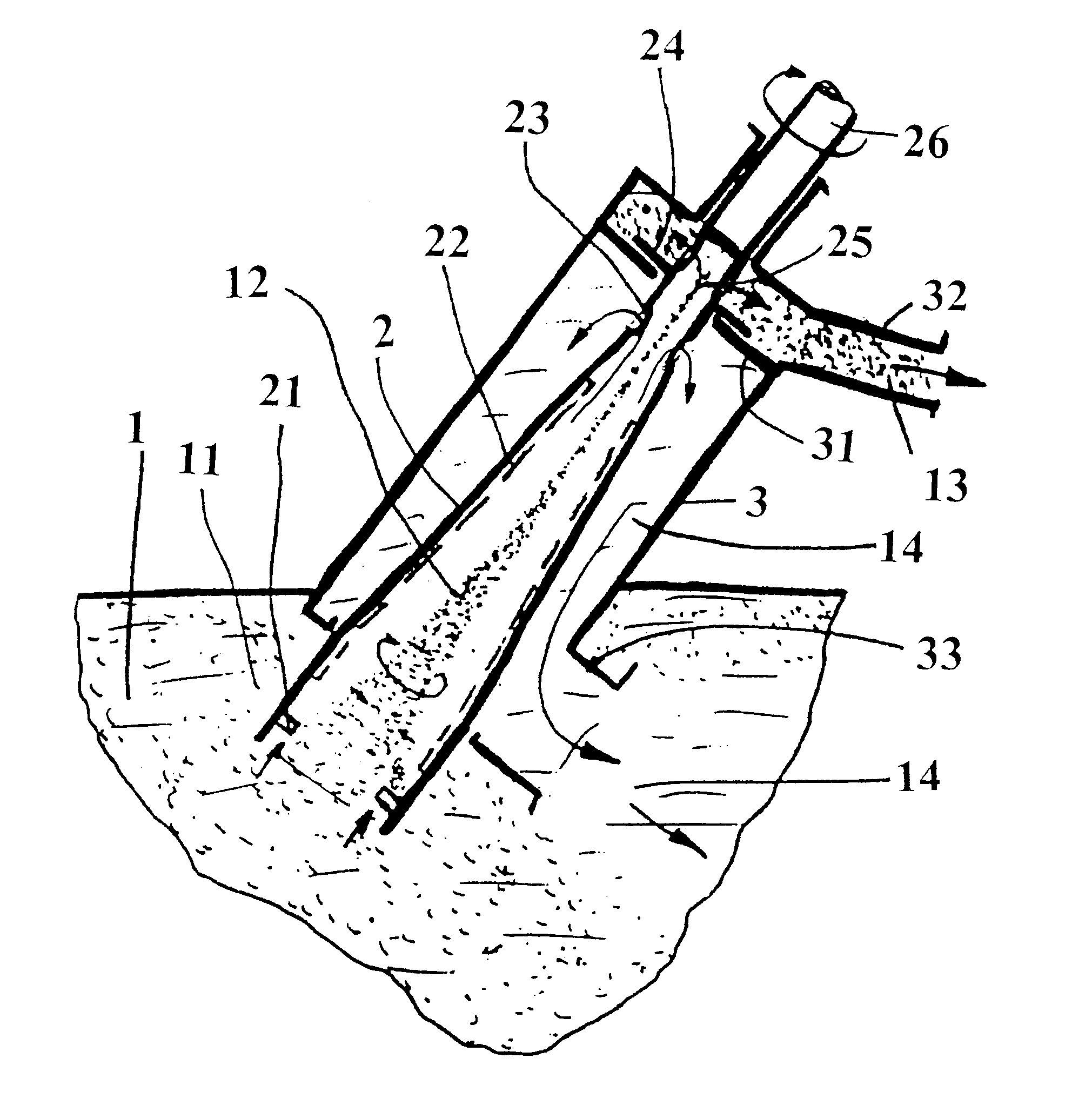

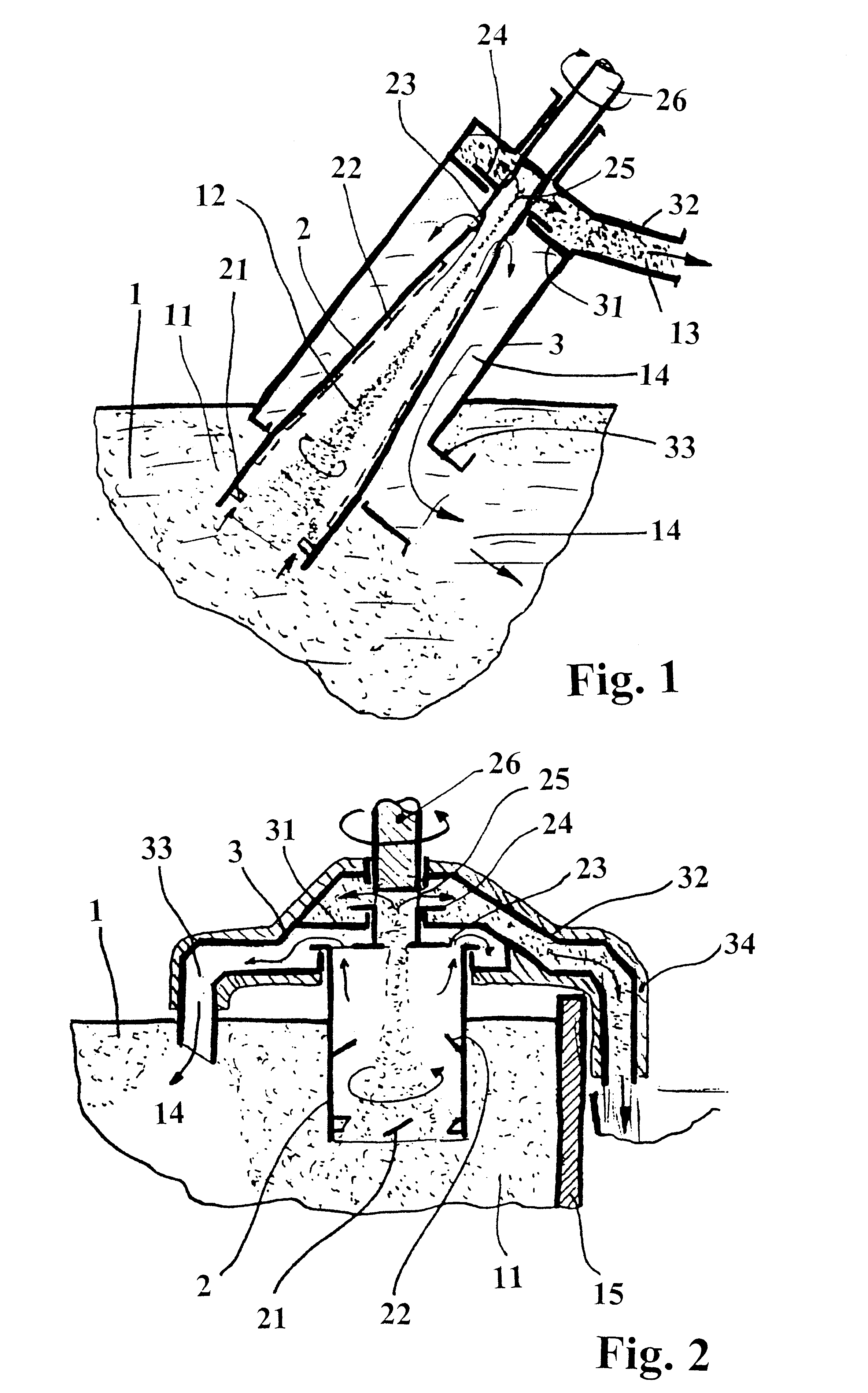

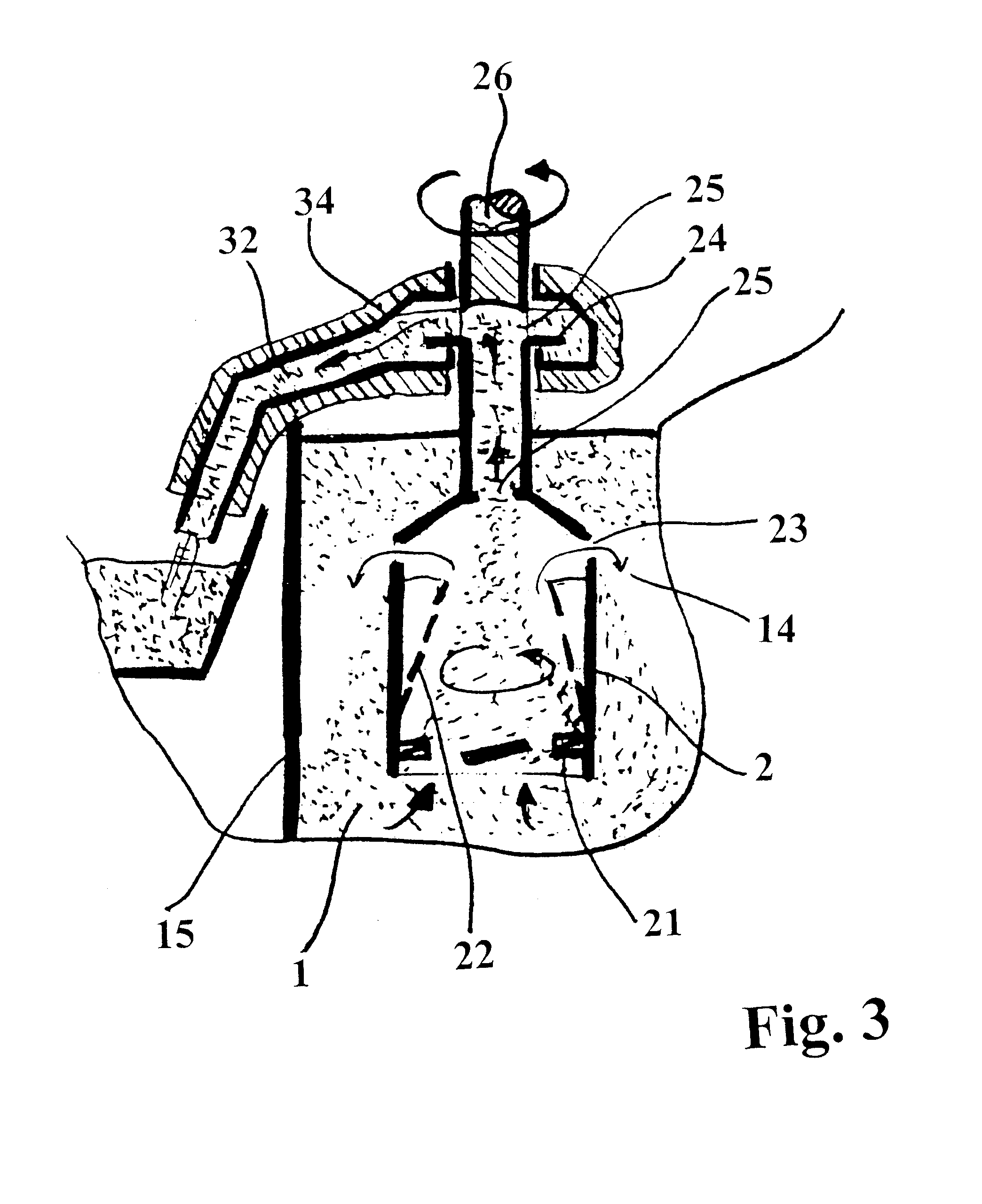

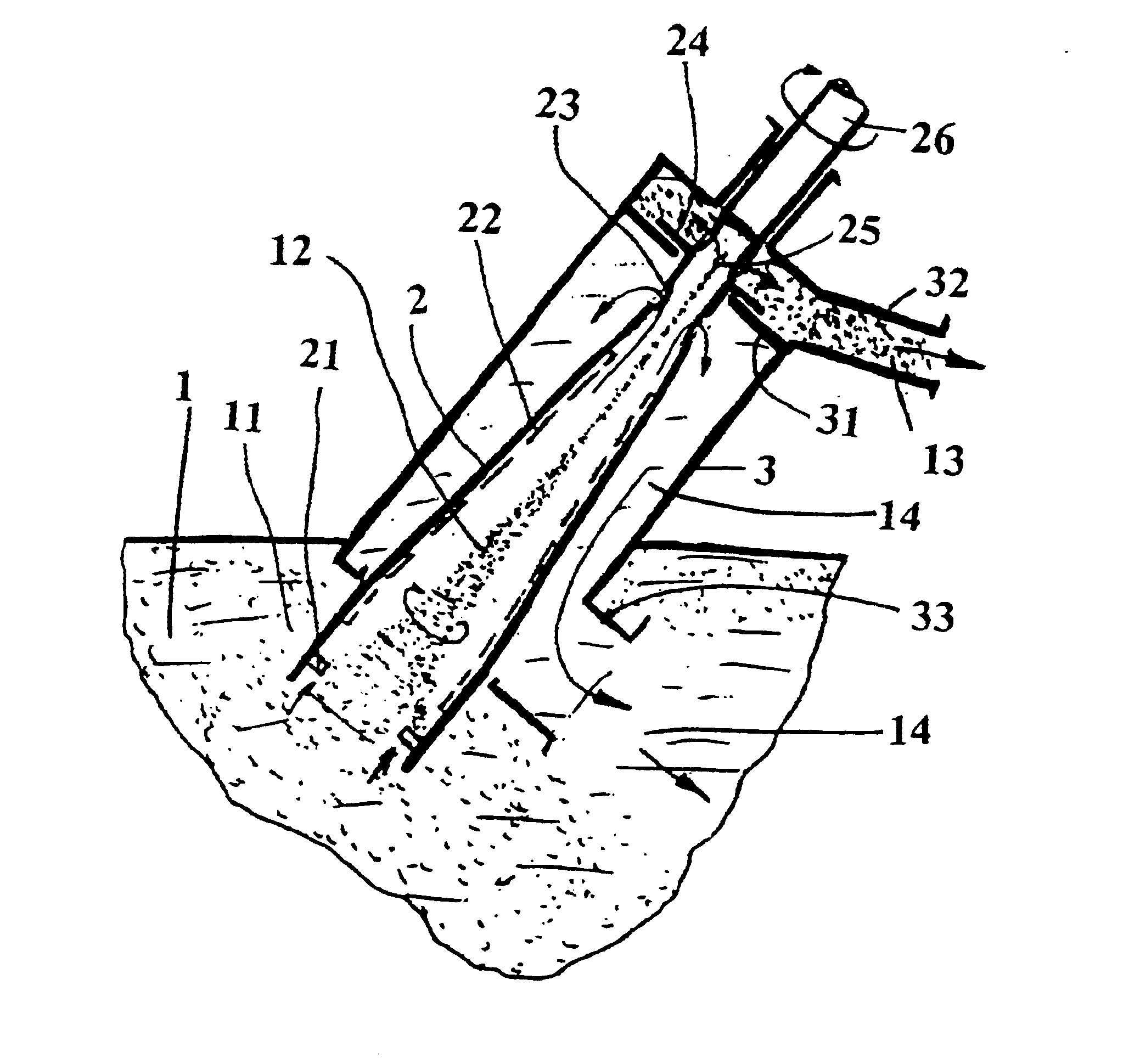

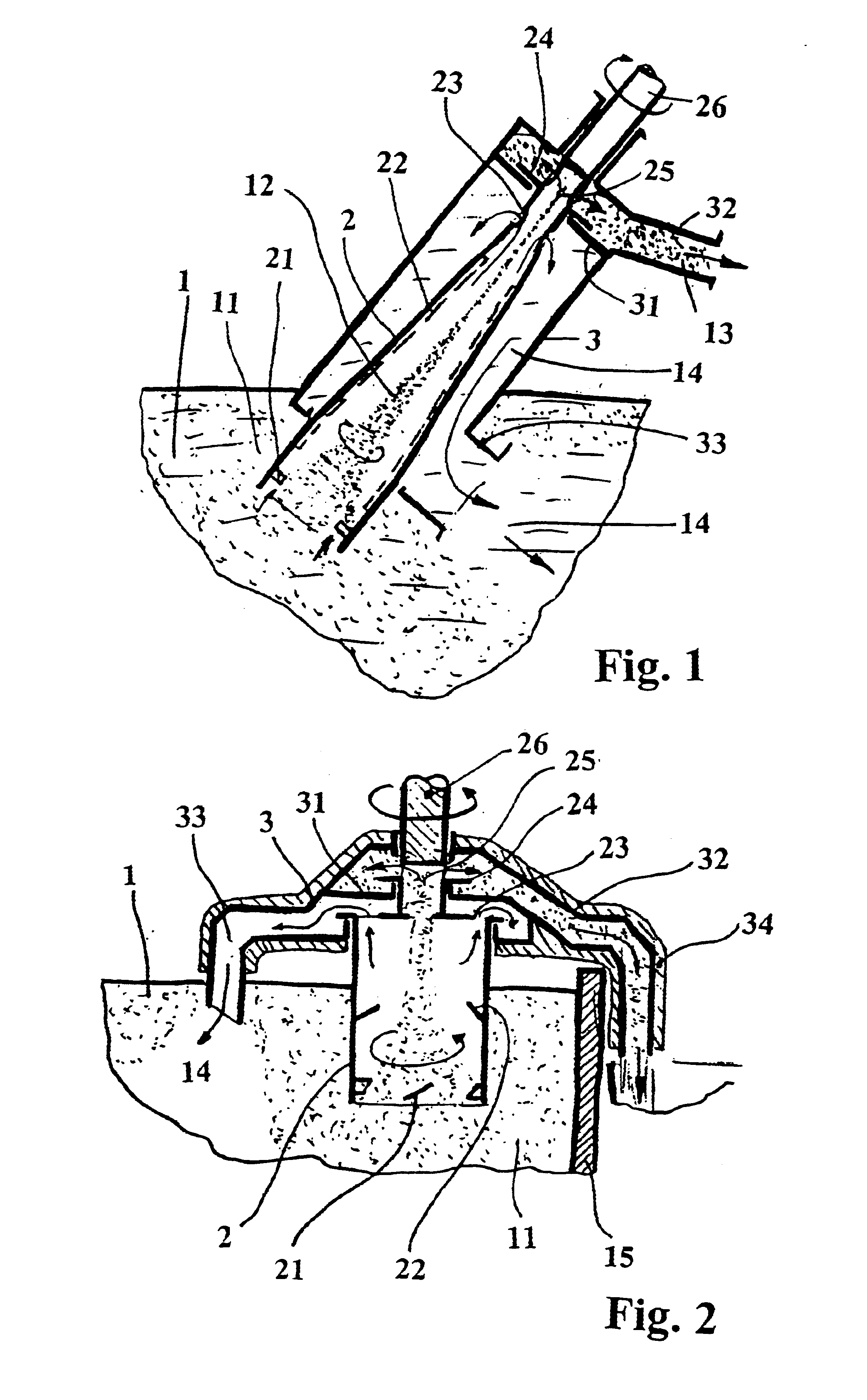

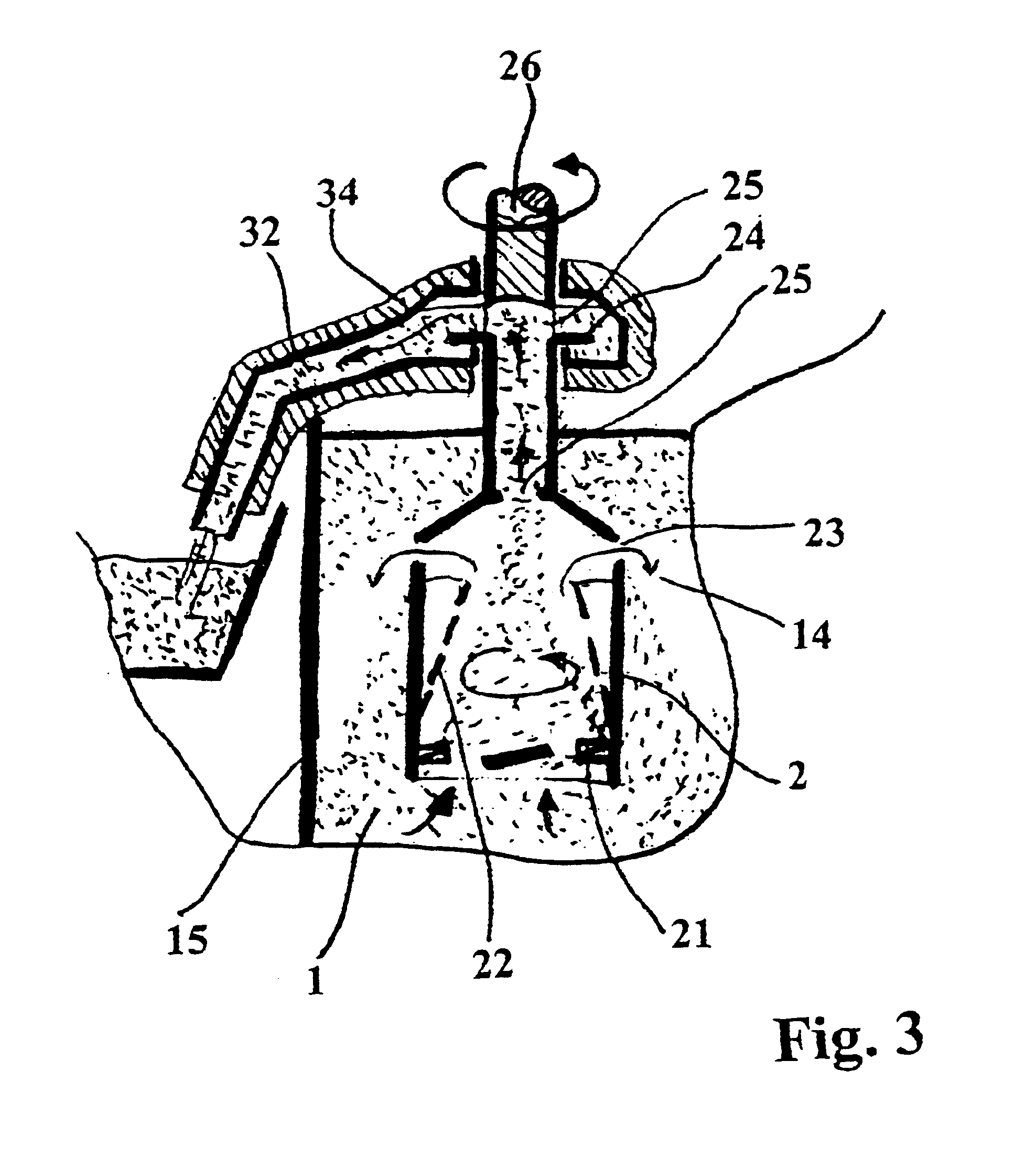

Process for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6364930B1High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsZinc metalLiquid metal

A process and device are disclosed for precipitating solid compounds from the liquid zinc or liquid zinc-based alloys of a metal bath. According to the disclosed process, partial amounts of the metal phase containing the compound(s) are exposed to an acceleration higher than the acceleration due to gravity and at least partially dissociated thereby into fractions containing heavier and / or lighter components. The molten mass depleted of solid compounds is returned to the metal bath and the part of the molten mass enriched with the desired compounds is discharged. The disclosed device is substantially characterized in that a hollow rotary body (2) is introduced into the molten mass (1). The hollow rotary body (2) can be driven about an axis and is fitted in the submerged or lower area with conveyor means (21) which project into the cavity. In its discharge or upper area, the hollow rotary body (2) is provided with at least one discharge opening (23) for the depleted molten mass (14) eccentrically arranged in its wall and with at least one further discharge opening (25) for the liquid metal enriched with the desired compounds centrally arranged and / or eccentrically arranged on the discharge side. At least one of the upper molten mass discharge openings (23, 24) in the rotary body (2) opens into a discharge area of a housing (3) which at least partially surrounds the rotary body (2).

Owner:ANDRITZ PATENTVERW GES

Process and device for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6656415B2High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsLiquid stateZinc metal

Process and device for precipitating solid compounds from zinc metal baths. Partial amounts of the metal phase containing these compounds are exposed to an acceleration higher than gravity and dissociated into fractions containing heavier or lighter components. The molten mass depleted of solid compounds is returned to the metal bath. The device has a hollow rotary body for introduction into the molten mass and provided with a discharge opening for the depleted molten mass and a discharge opening for the liquid metal enriched with the solid compounds.

Owner:ANDRITZ PATENTVERW GES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com