Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

369 results about "Zinc metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc, a shiny metal known for its bluish-white color, occurs naturally in the environment. It is mined mainly from North America, Northern South America, Australia, and Central-East Asia. ... Zinc is often a component of a nickel-copper alloy known as nickel silver, which is used to make silverware. The name “nickel silver” is a misnomer, as the alloy contains no silver.

Catalyzer for the oxalic ester hydrogenation synthesizing of ethylene glycol and method of preparing the same

A catalyst for hydrogenated synthesis of glycol with oxalate and a preparation method for the catalyst belong to the glycol preparation technical field. The catalyst of the present invention uses the copper metal as the main active component, and zinc as the promoter, and is manufactured with the method of deposition. A carrier of the catalyst is the modified silica sol. The select content of the copper metal is 5 to 45 percent of the carrier weight, and the optimal content of the copper metal is 10 to 40 percent. The content of zinc metal is 0.1 to 15 percent of the carrier weight, and the optimal content of zinc metal is 1 to 8.0 percent. The select specific surface area of the carrier is 90-350m2 / g, and the optimal is 150-300m2 / g. Proven by experiments, the catalyst is provided with the very high reaction activity and glycollate selectivity in the reaction to synthesize glycollate with oxalate and hydrogen Moreover, the catalyst is provided with the long usable life and the stable reaction performance, and can be easily controlled.

Owner:TIANJIN UNIV +1

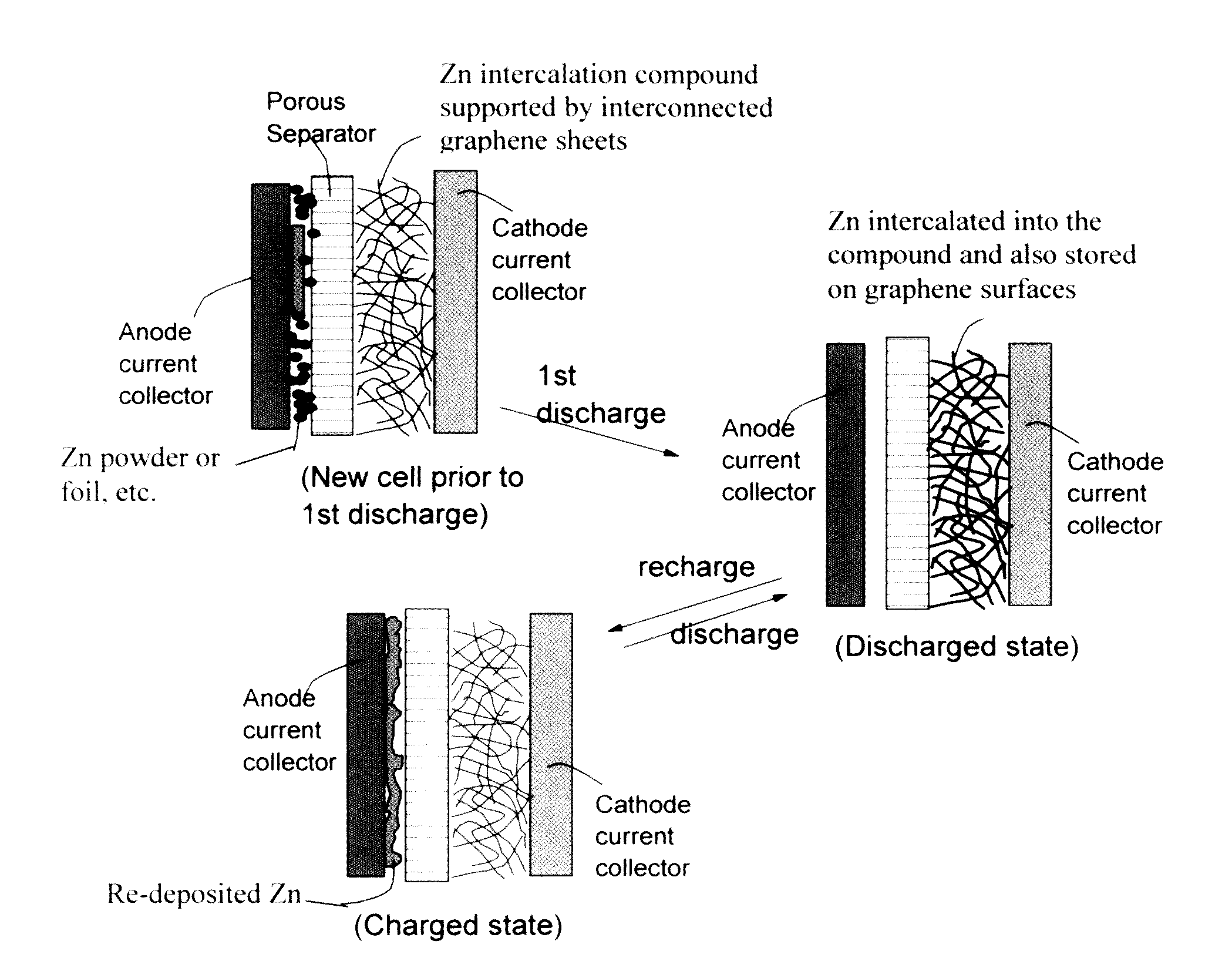

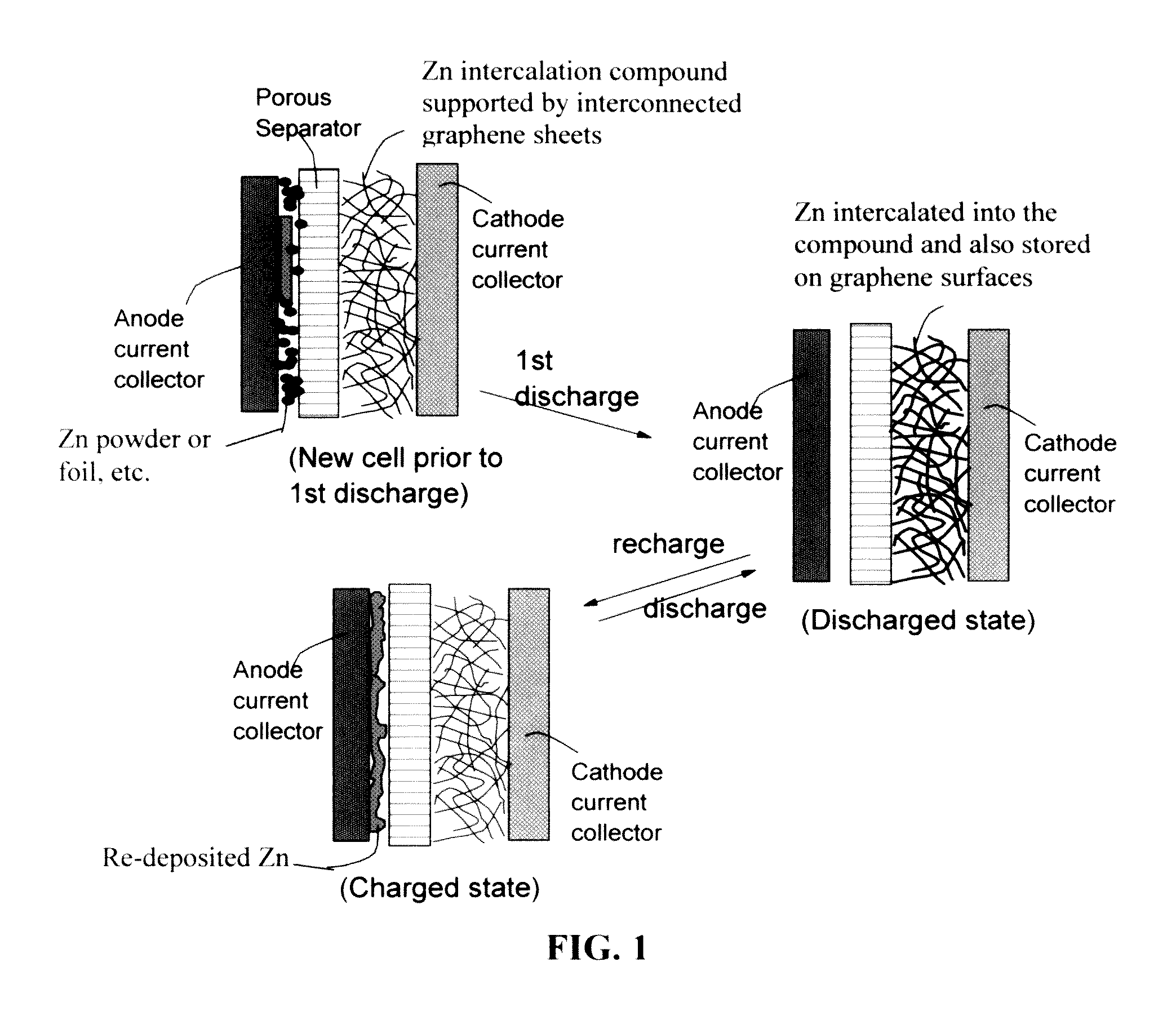

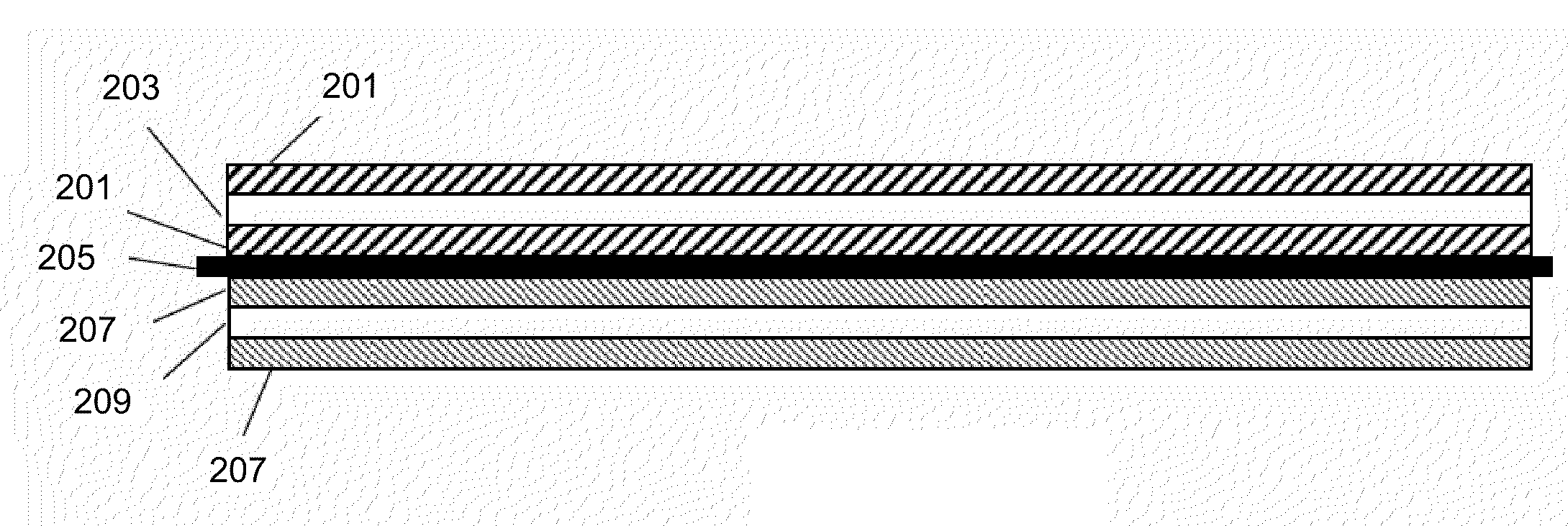

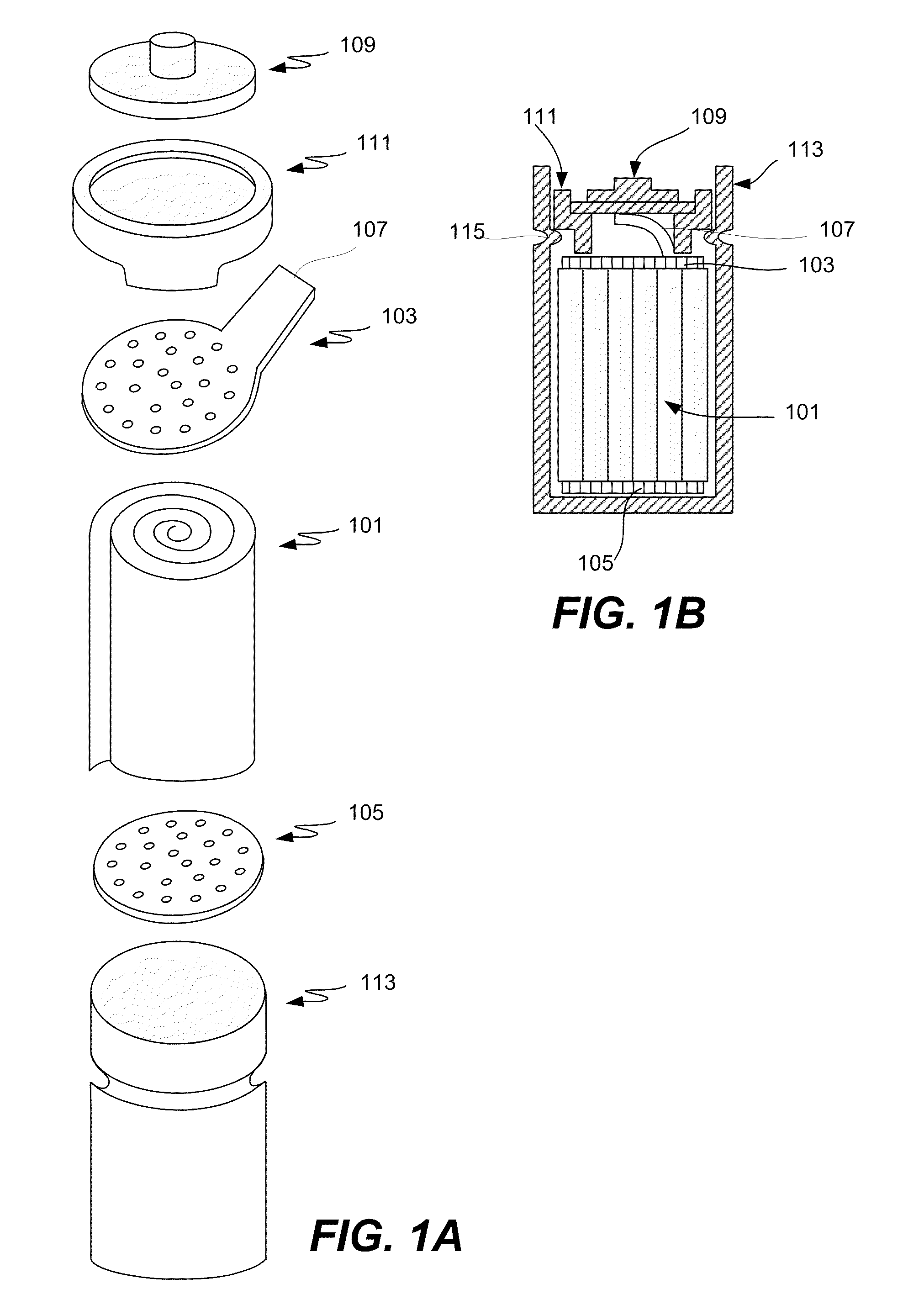

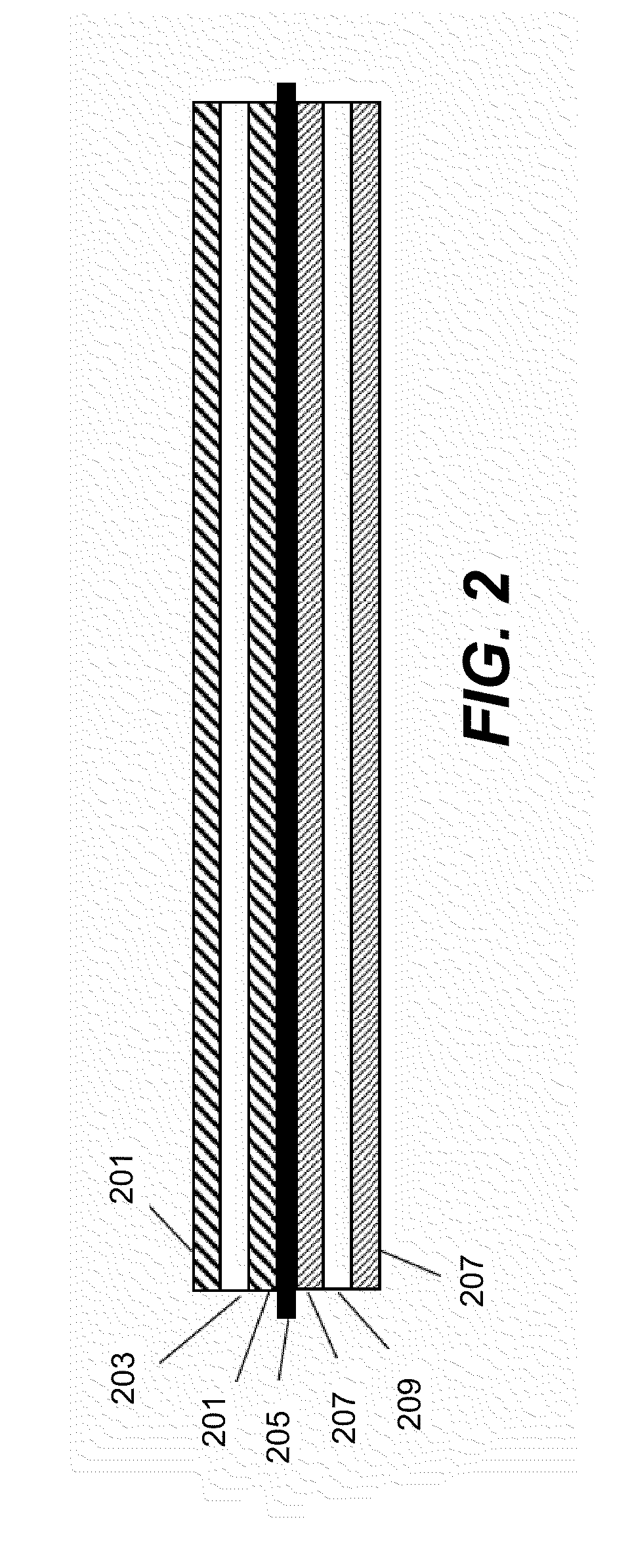

Zinc Ion-Exchanging Energy Storage Device

ActiveUS20160301096A1Quick releaseRapid depositionHybrid capacitor electrolytesAlkaline accumulatorsChemical treatmentZinc metal

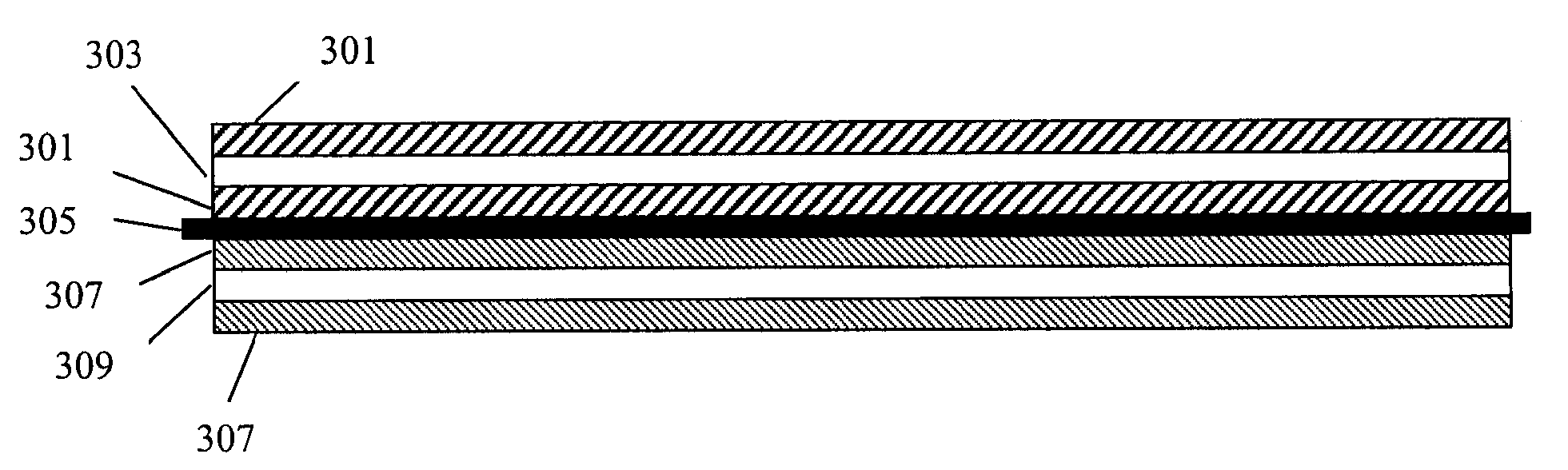

A zinc ion-exchanging battery device comprising: (A) a cathode comprising two cathode active materials (a zinc ion intercalation compound and a surface-mediating material); (B) an anode containing zinc metal or zinc alloy; (C) a porous separator disposed between the cathode and the anode; and (D) an electrolyte containing zinc ions that are exchanged between the cathode and the anode during battery charge / discharge. The zinc ion intercalation compound is selected from chemically treated carbon or graphite material having an expanded inter-graphene spacing d002 of at least 0.5 nm, or an oxide, carbide, dichalcogenide, trichalcogenide, sulfide, selenide, or telluride of niobium, zirconium, molybdenum, hafnium, tantalum, tungsten, titanium, vanadium, chromium, cobalt, manganese, iron, nickel, or a combination thereof. The surface-mediating material contains exfoliated graphite or multiple single-layer sheets or multi-layer platelets of a graphene material.

Owner:GLOBAL GRAPHENE GRP INC

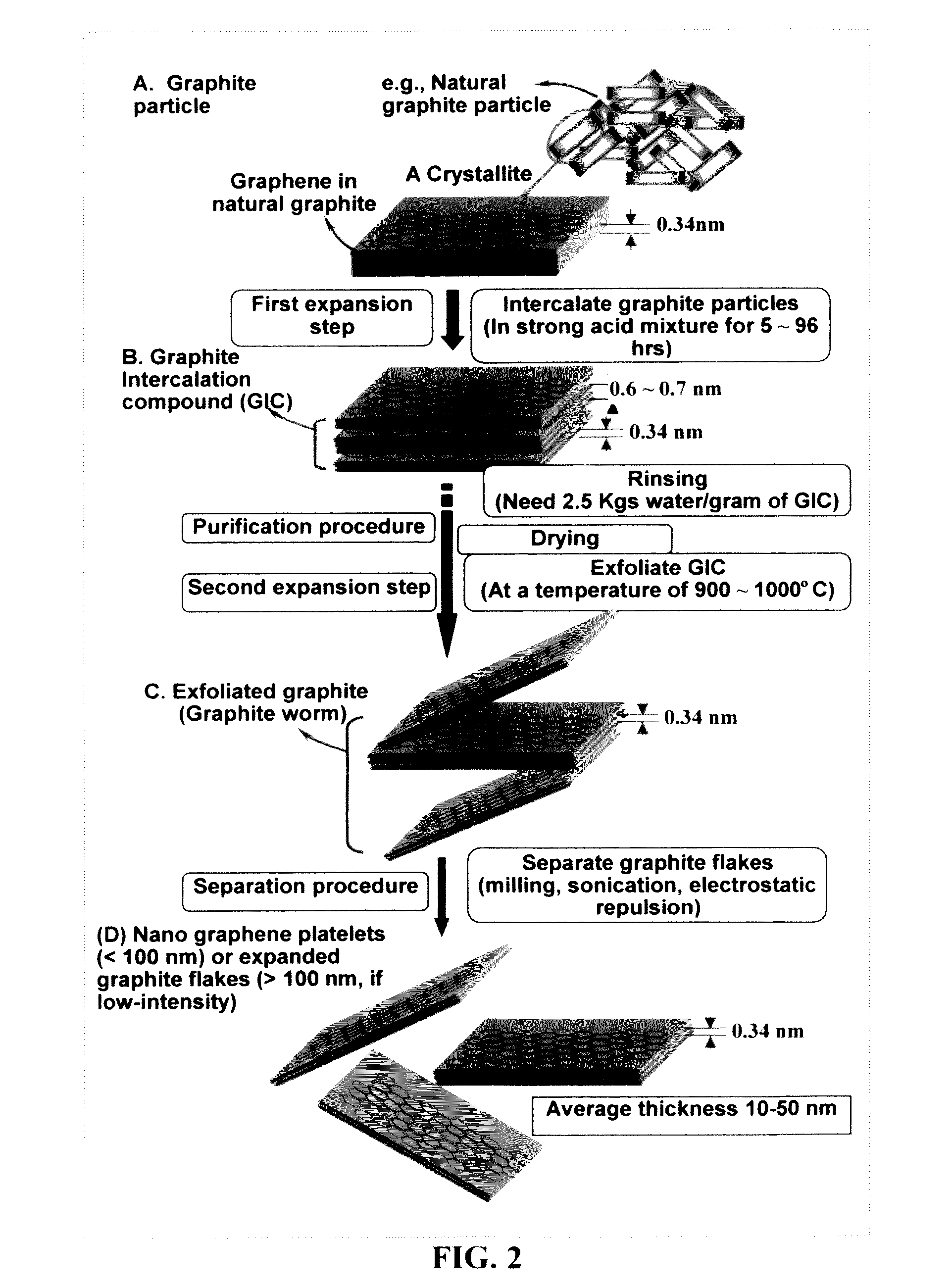

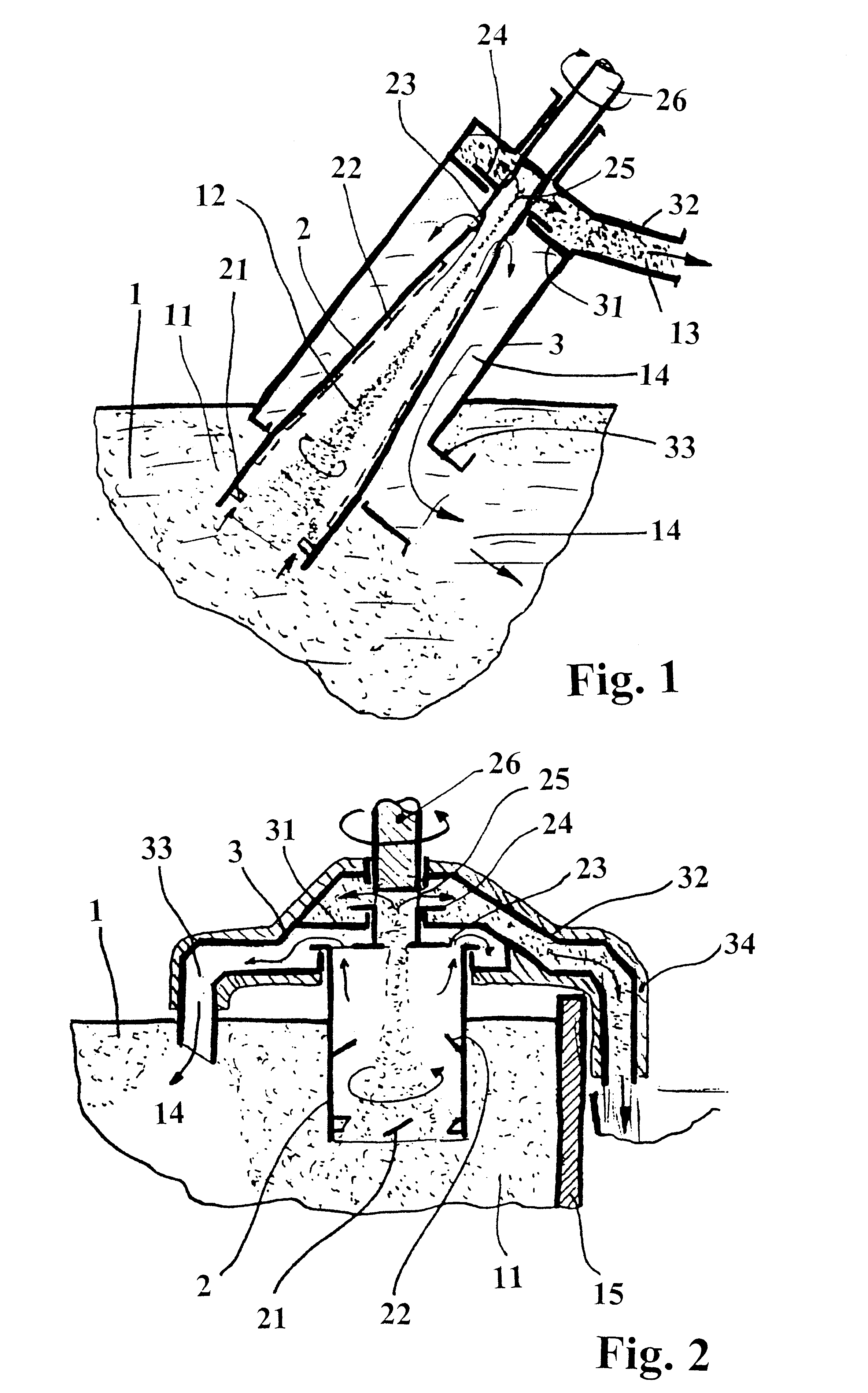

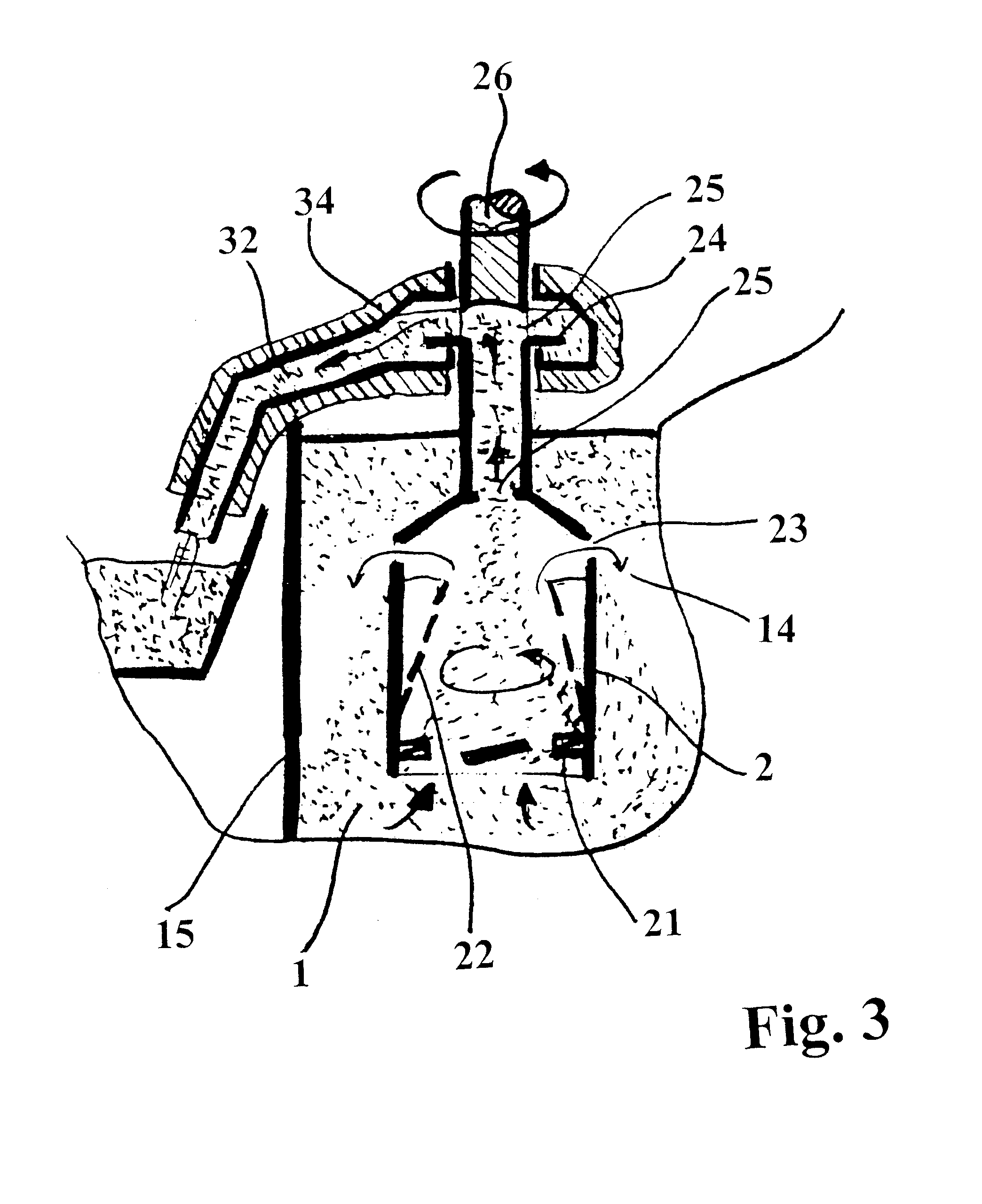

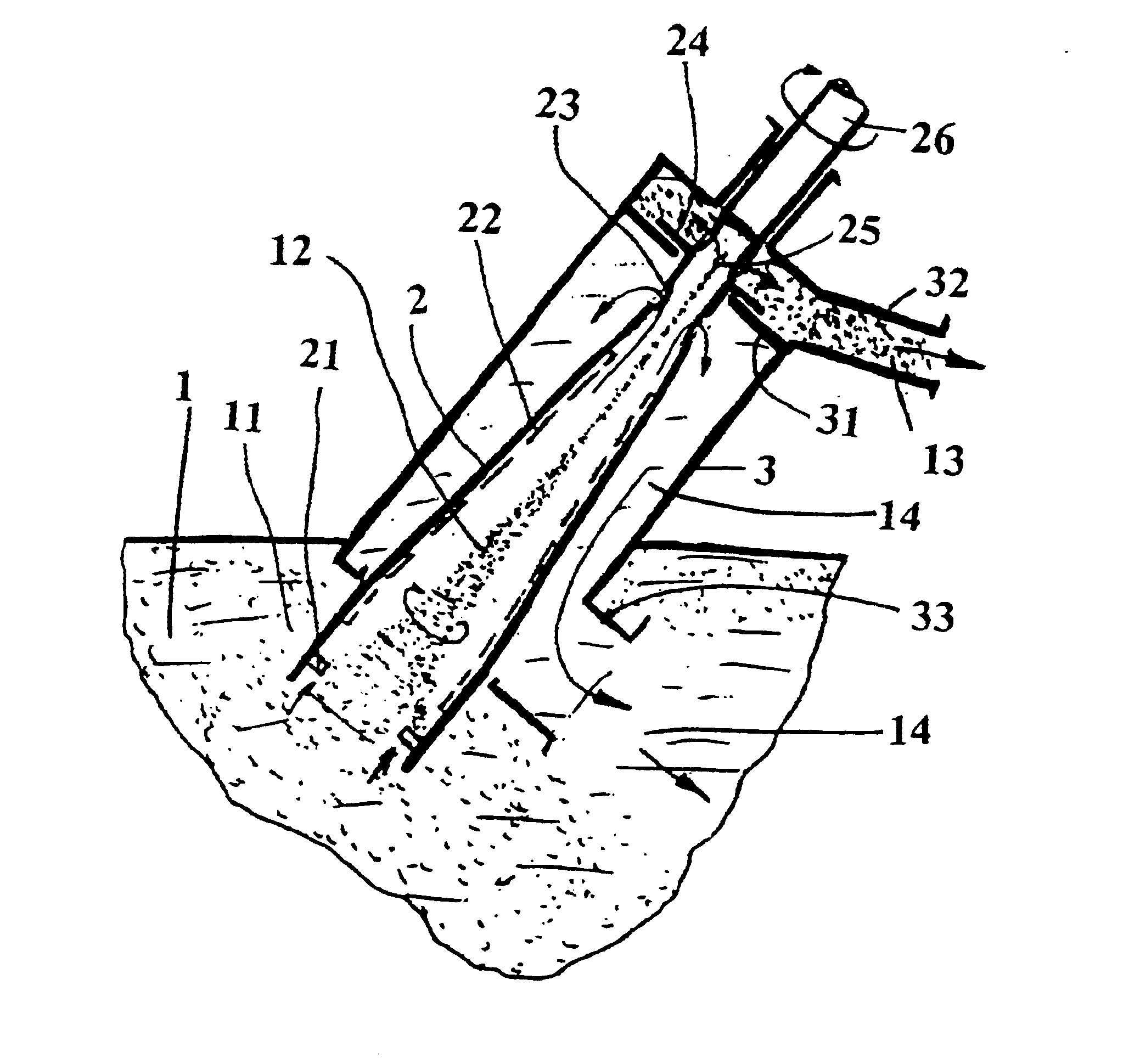

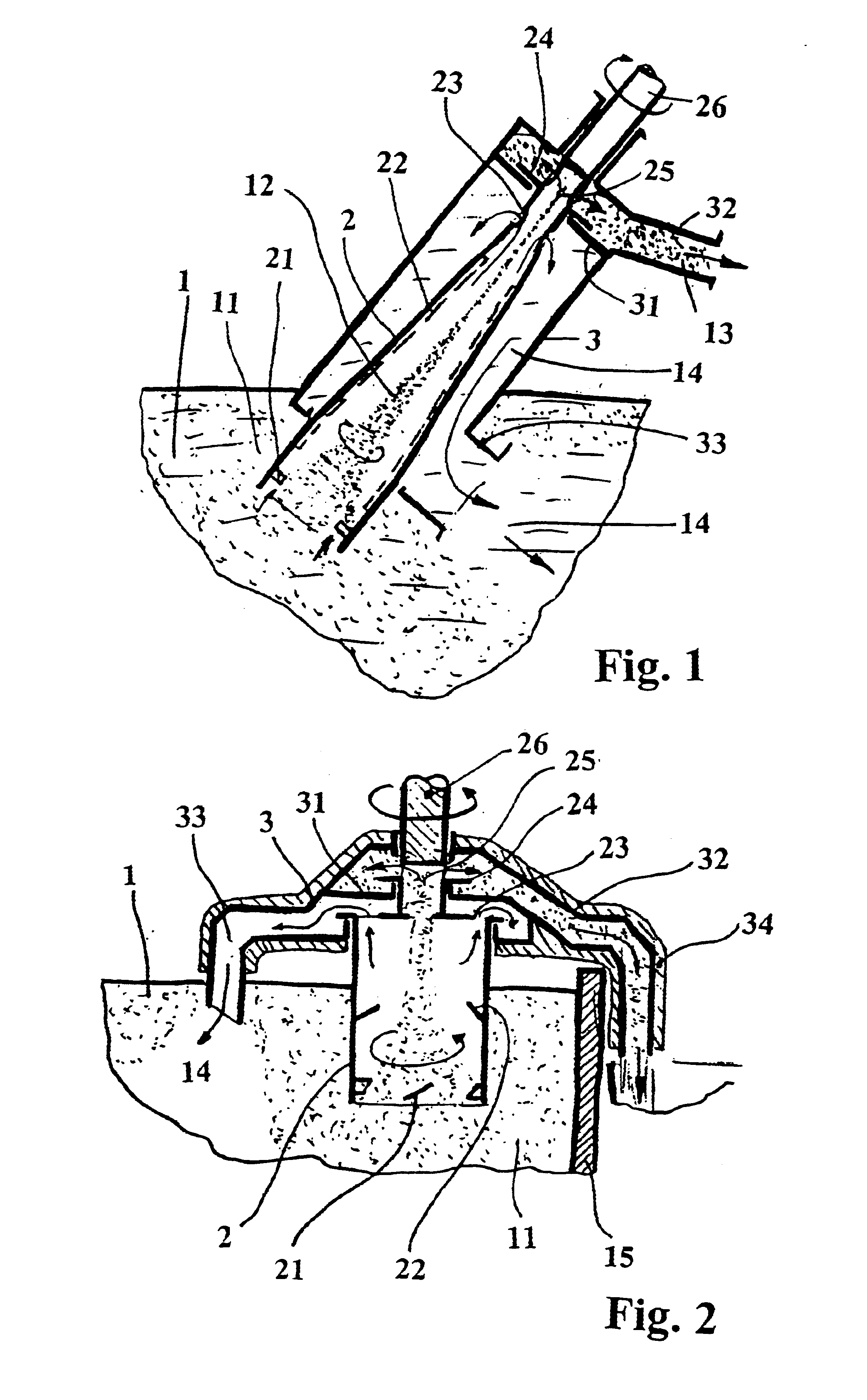

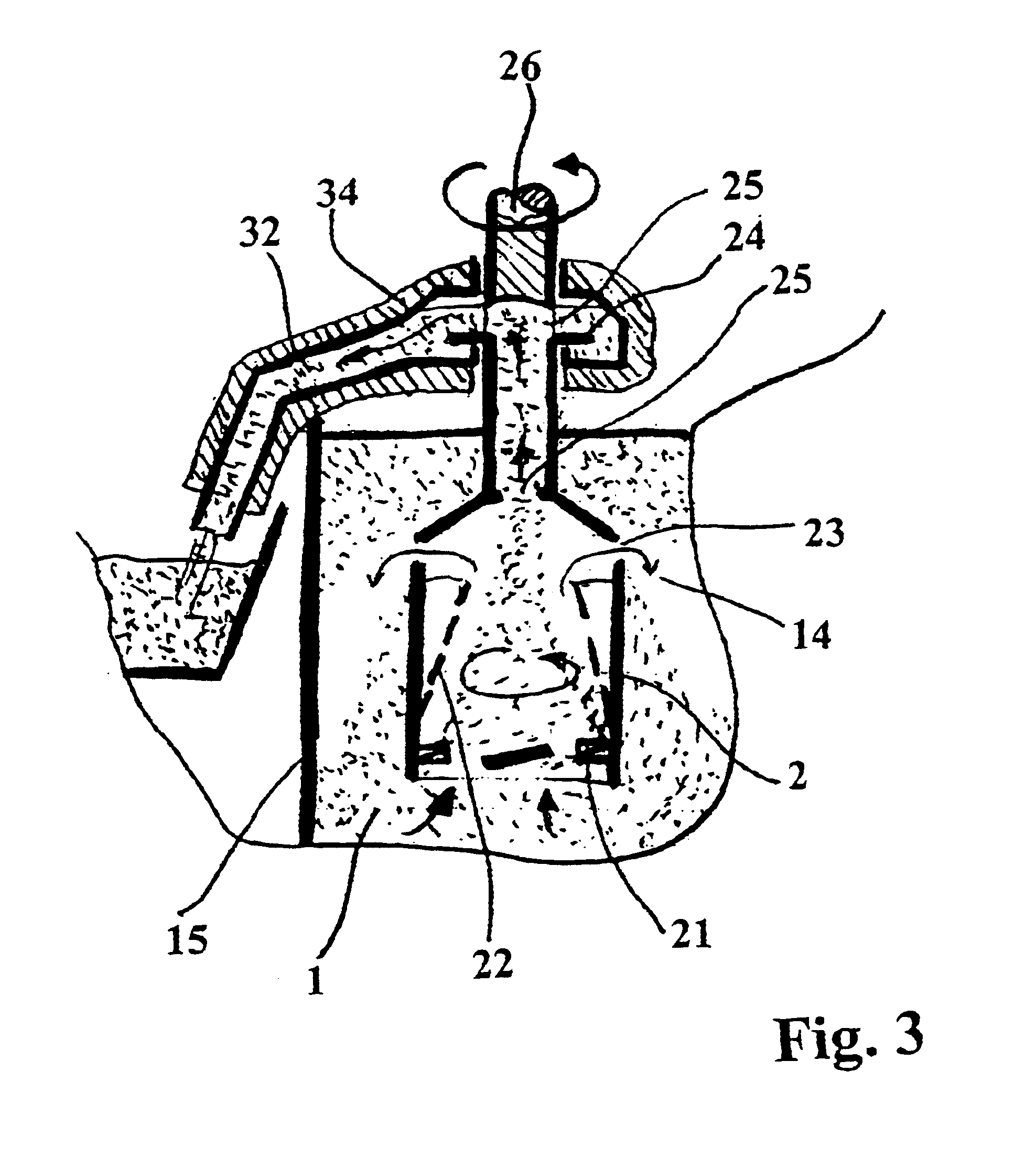

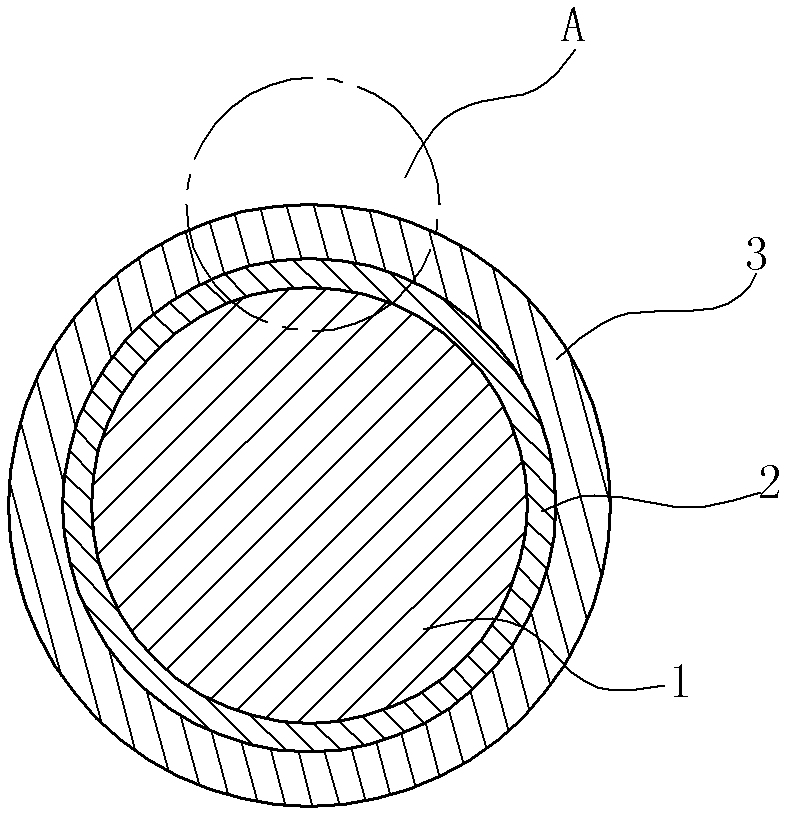

Process for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6364930B1High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsZinc metalLiquid metal

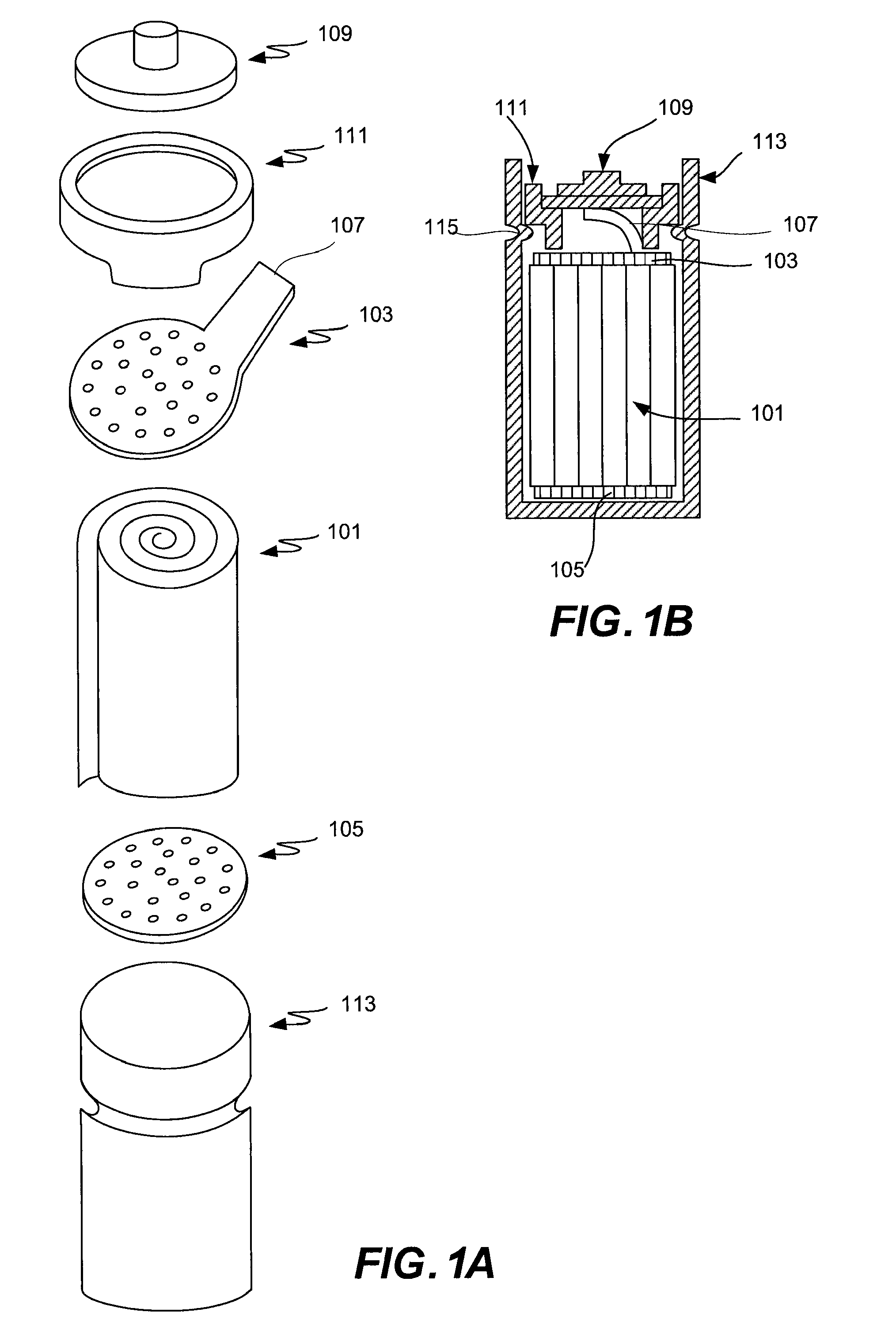

A process and device are disclosed for precipitating solid compounds from the liquid zinc or liquid zinc-based alloys of a metal bath. According to the disclosed process, partial amounts of the metal phase containing the compound(s) are exposed to an acceleration higher than the acceleration due to gravity and at least partially dissociated thereby into fractions containing heavier and / or lighter components. The molten mass depleted of solid compounds is returned to the metal bath and the part of the molten mass enriched with the desired compounds is discharged. The disclosed device is substantially characterized in that a hollow rotary body (2) is introduced into the molten mass (1). The hollow rotary body (2) can be driven about an axis and is fitted in the submerged or lower area with conveyor means (21) which project into the cavity. In its discharge or upper area, the hollow rotary body (2) is provided with at least one discharge opening (23) for the depleted molten mass (14) eccentrically arranged in its wall and with at least one further discharge opening (25) for the liquid metal enriched with the desired compounds centrally arranged and / or eccentrically arranged on the discharge side. At least one of the upper molten mass discharge openings (23, 24) in the rotary body (2) opens into a discharge area of a housing (3) which at least partially surrounds the rotary body (2).

Owner:ANDRITZ PATENTVERW GES

Process and device for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6656415B2High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsLiquid stateZinc metal

Process and device for precipitating solid compounds from zinc metal baths. Partial amounts of the metal phase containing these compounds are exposed to an acceleration higher than gravity and dissociated into fractions containing heavier or lighter components. The molten mass depleted of solid compounds is returned to the metal bath. The device has a hollow rotary body for introduction into the molten mass and provided with a discharge opening for the depleted molten mass and a discharge opening for the liquid metal enriched with the solid compounds.

Owner:ANDRITZ PATENTVERW GES

Thermoplastic resin compositions suitable for use in laminated safety glass

The present invention is a polymeric resin composition having improved toughness, suitable for use in transparent glazing, comprising an at least partially neutralized ethylene acid copolymer metal carboxylate resin, wherein the metal carboxylate consists essentially of zinc metal counter-ions.

Owner:DOW GLOBAL TECH LLC

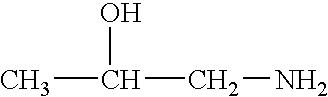

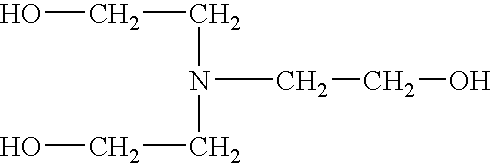

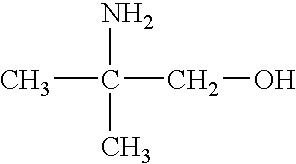

Pyrithione biocides enhanced by zinc metal ions and organic amines

InactiveUS6908912B2Improve the bactericidal effectAntibacterial agentsHeavy metal active ingredientsSodium PyrithioneMicroorganism

The present invention is directed to a stable, soluble, antimicrobial composition concentrate comprising pyrithione or a pyrithione complex in an amount of from about 0.5% to about 30 weight percent, a zinc source in an amount of from about 0.1% to about 10%, and an organic amine component in an amount of from about 30% to about 80%, said percents being based upon the total weight of the composition concentrate. The invention is also directed to methods of controlling the growth of free-living microorganisms or biofilms using the antimicrobial composition of the invention, and products made using the antimicrobial composition of the invention.

Owner:ARCH CHEM INC

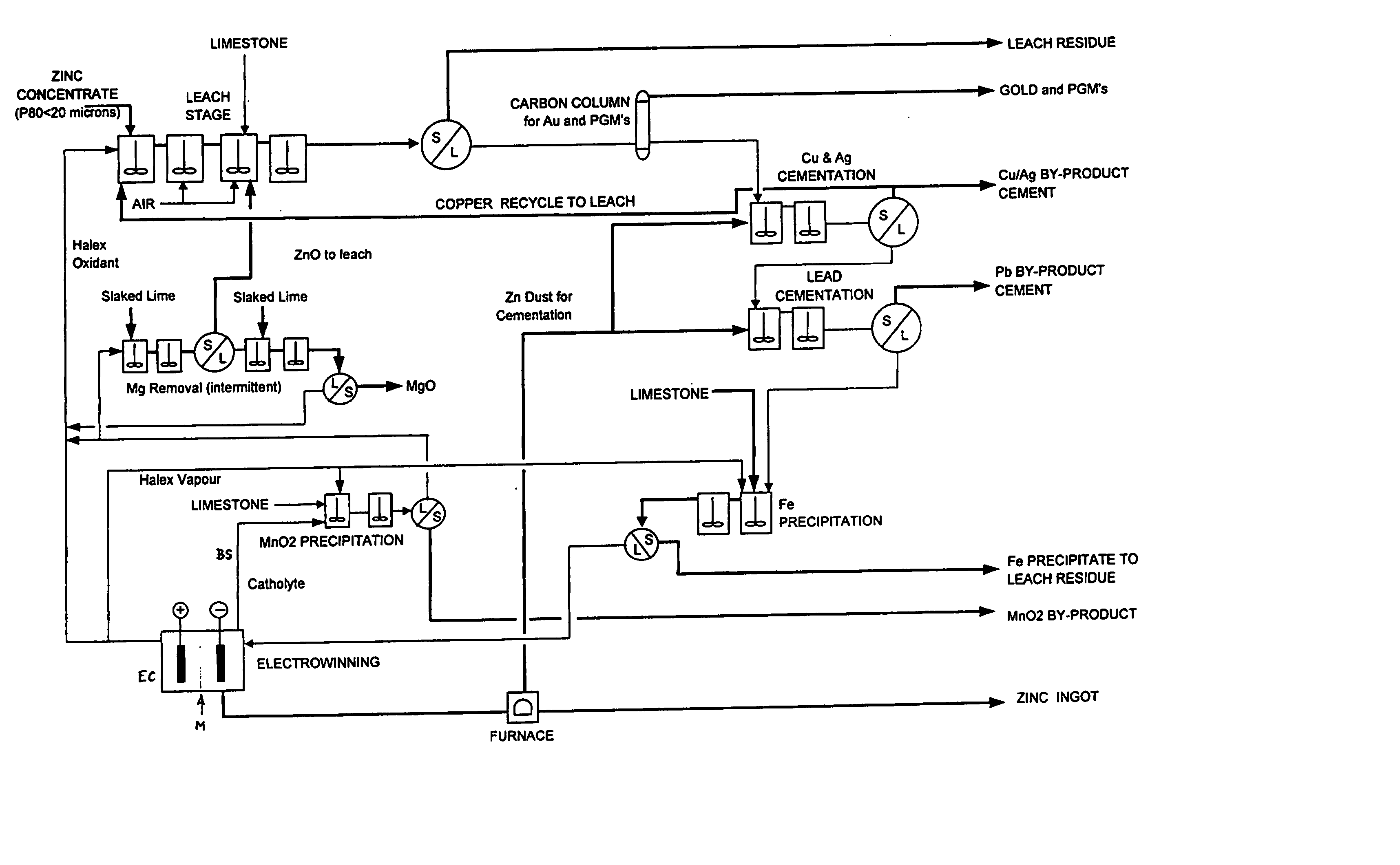

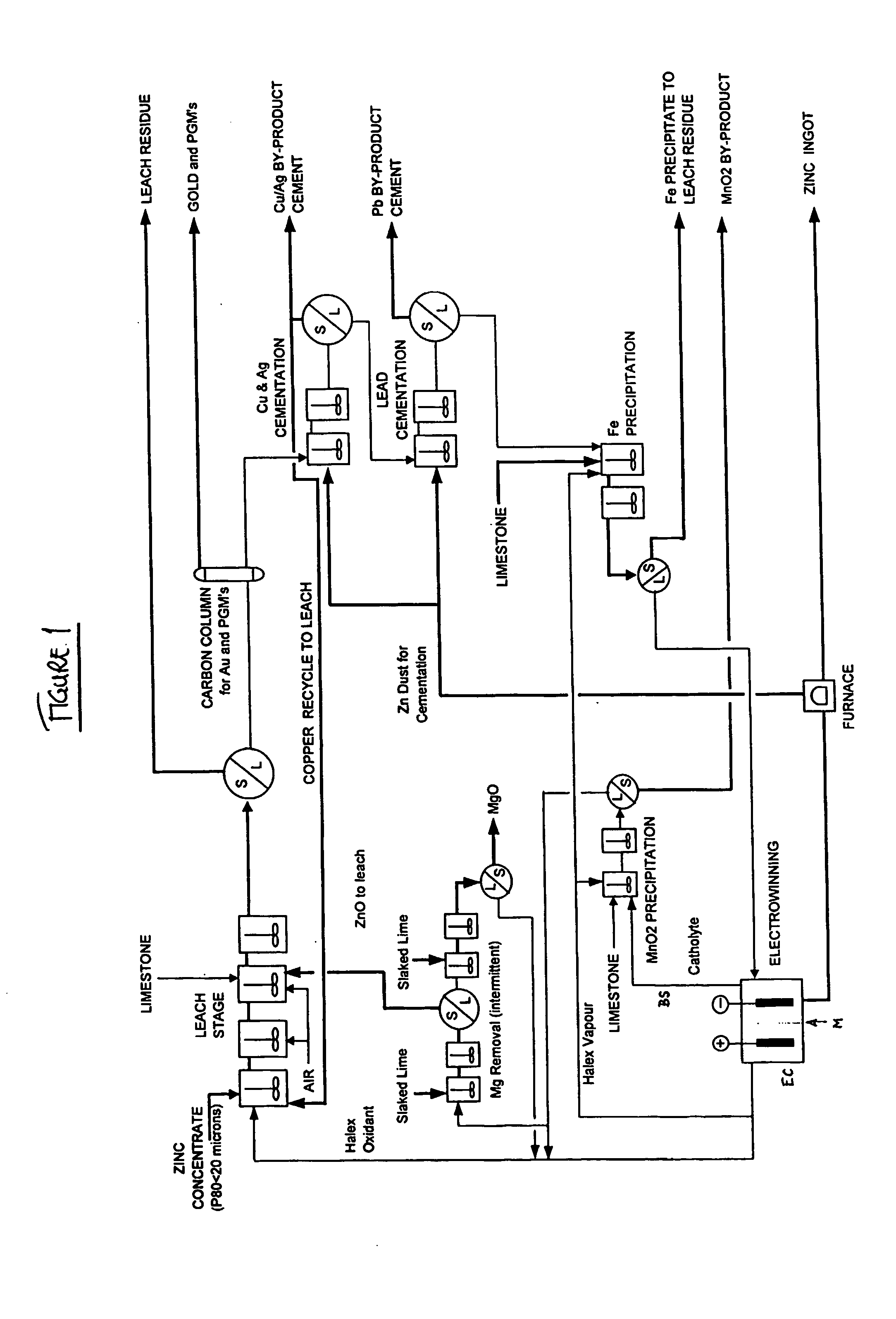

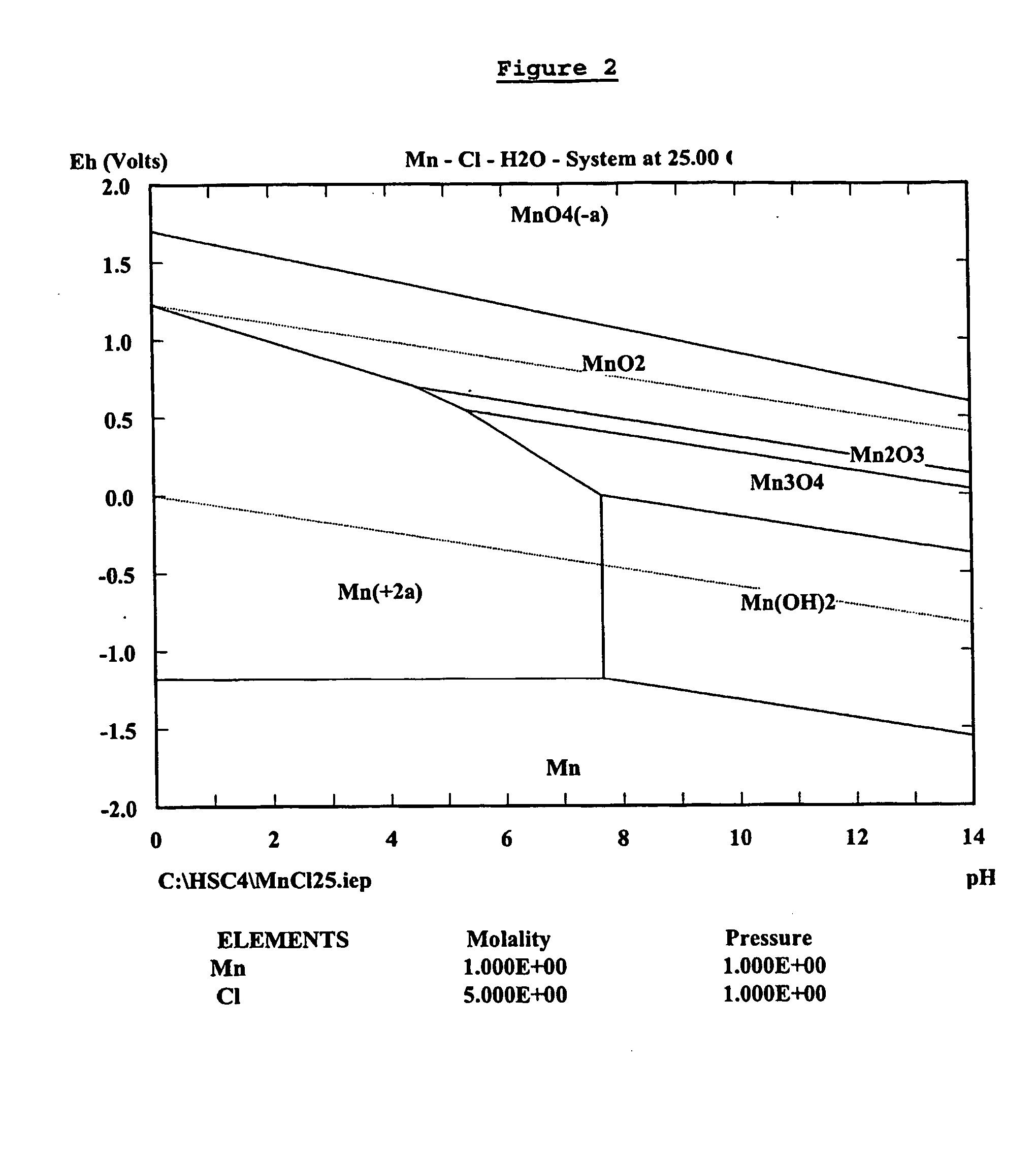

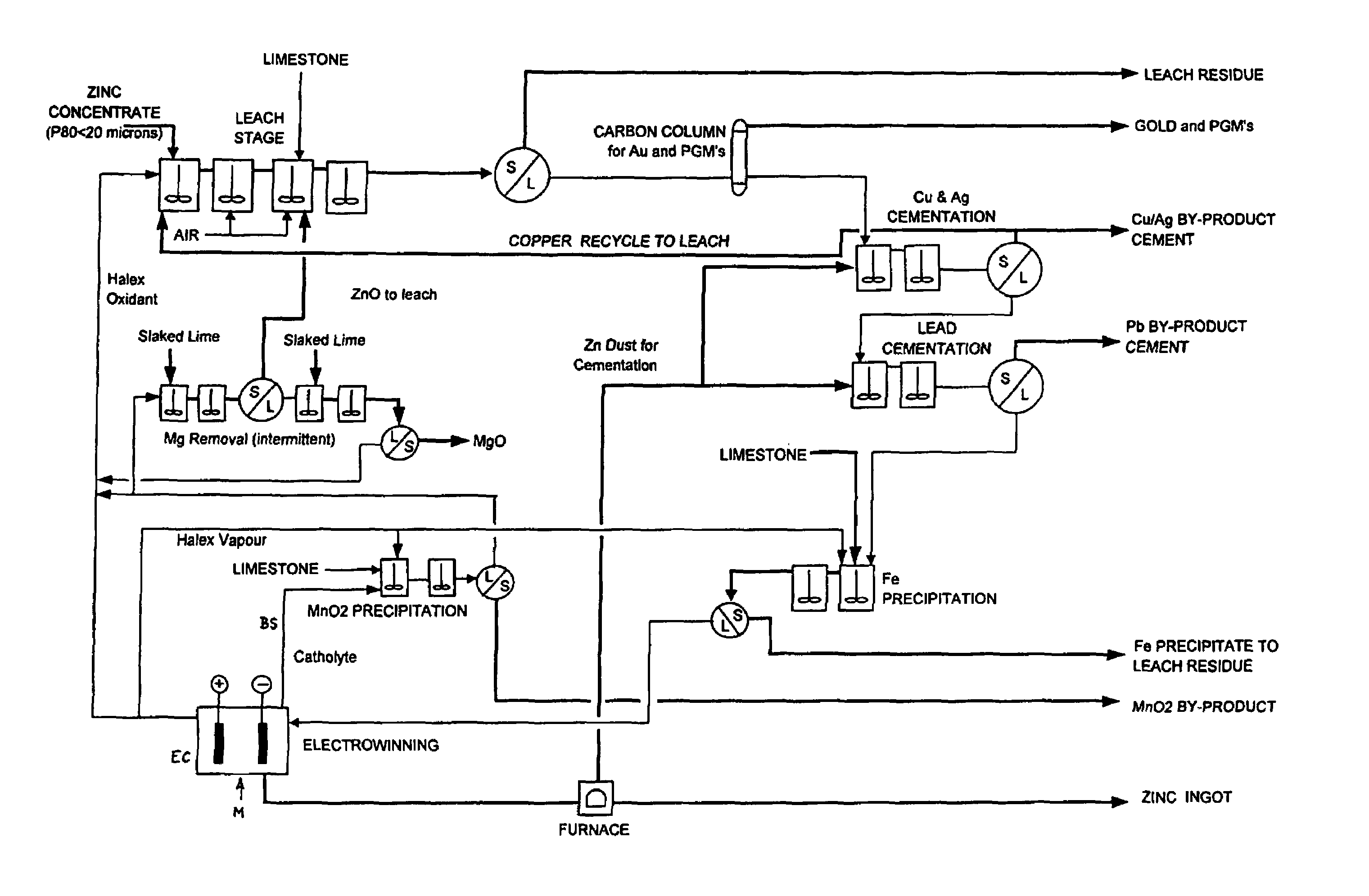

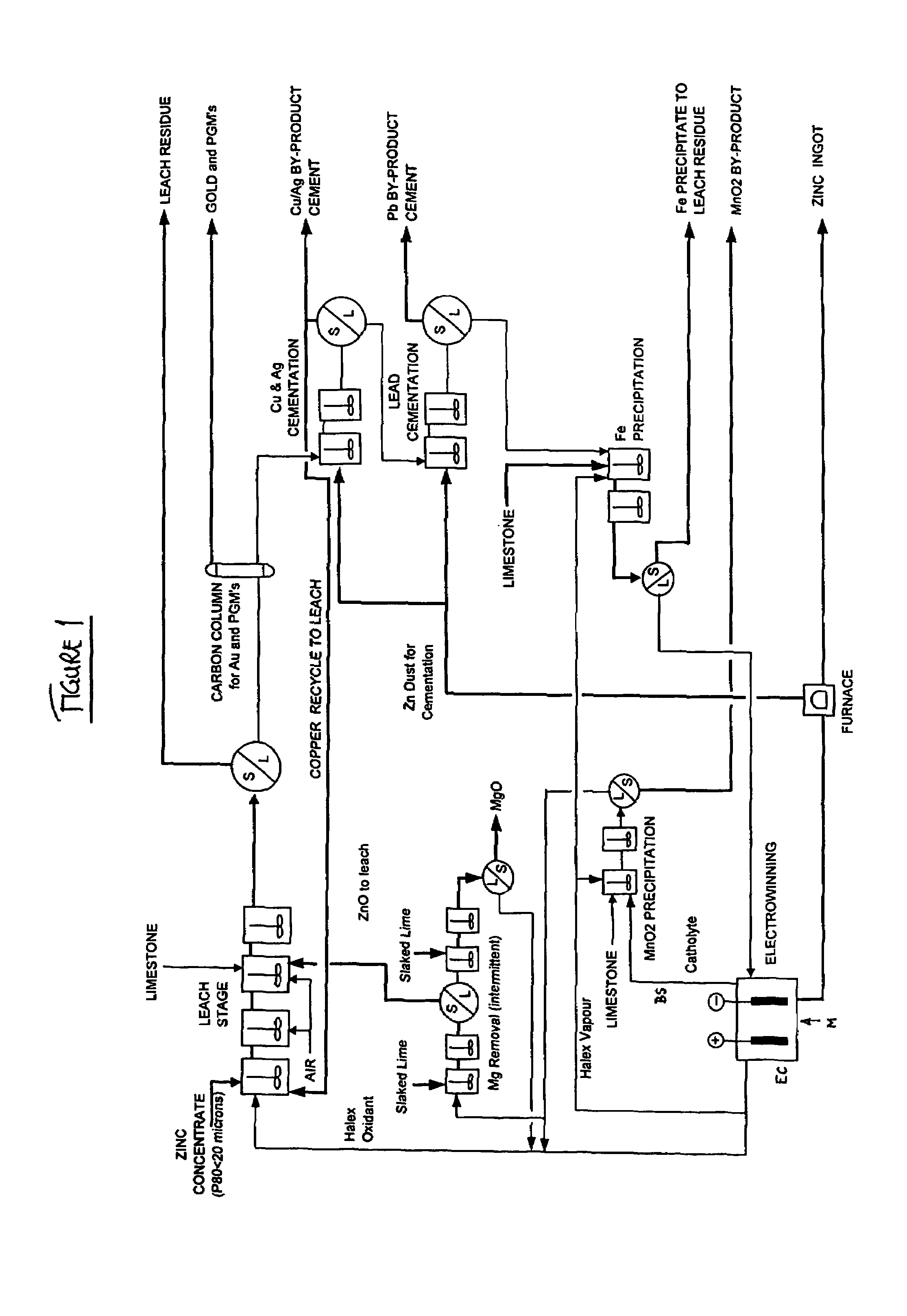

Zinc recovery process

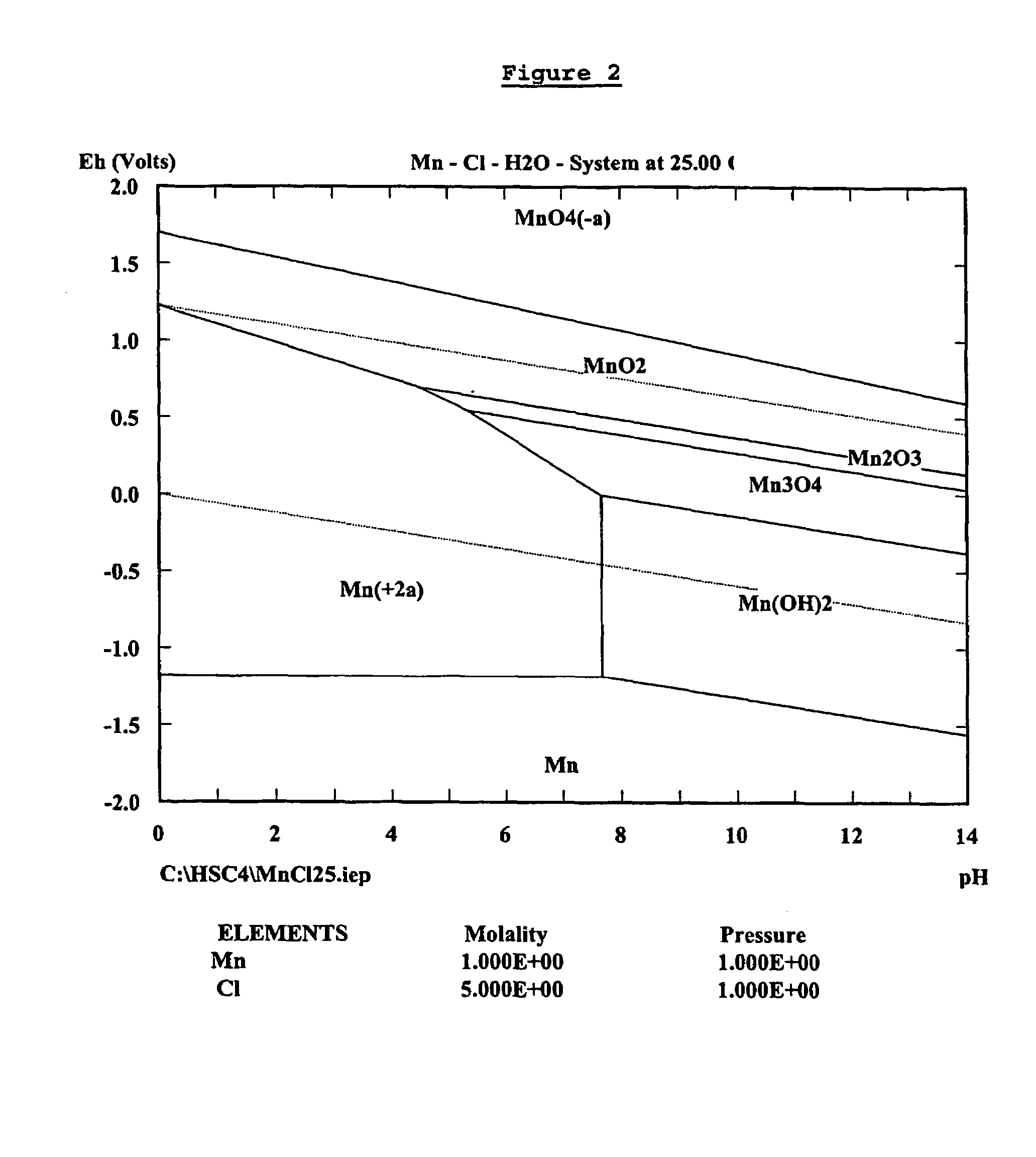

InactiveUS20040237720A1Improve filtering effectEh is decreasedPhotography auxillary processesSolvent extractionZinc metalManganese

A process for the recovery of zinc metal from a zinc mineral includes the steps of leaching the zinc mineral in a solution including a halide species formed from two or more different halides, to leach the zinc into the solution. The zinc-bearing solution is then electrolysed to yield zinc metal and to generate the halide species. The electrolysed solution including the halide species is then returned to the leaching step. A portion of the electrolysed solution can be removed as a bleed stream from a cathode compartment of an electrolytic cell of the electrolysis process and processed to remove manganese as manganese dioxide precipitate by adding thereto limestone, and the halide species from an anode compartment of the electrolysis process. In this regard, the pH and Eh of the solution can regulated in a manner that favours the formation of the manganese dioxide precipitate over the formation of a precipitate of zinc.

Owner:INTEC INT PROJECTS

Pasted zinc electrode for rechargeable nickel-zinc batteries

ActiveUS20100291439A1High viscositySimple working processFinal product manufacturePrimary cellsZinc metalSlurry

Active material for a negative electrode of a rechargeable zinc alkaline electrochemical cell is made with zinc metal particles coated with tin and / or lead. The zinc particles may be coated by adding lead and tin salts to a slurry containing zinc particles, a thickening agent and water. The remaining zinc electrode constituents such as zinc oxide (ZnO), bismuth oxide (Bi2O3), a dispersing agent, and a binding agent such as Teflon are then added. The resulting slurry / paste has a stable viscosity and is easy to work with during manufacture of the zinc electrode. Further, the zinc electrode is much less prone to gassing when cobalt is present in the electrolyte. Cells manufactured from electrodes produced in accordance with this invention exhibit much less hydrogen gassing, by as much as 60-80%, than conventional cells. The cycle life and shelf life of the cells is also enhanced, as the zinc conductive matrix remains intact and shelf discharge is reduced.

Owner:ZINCFIVE POWER INC

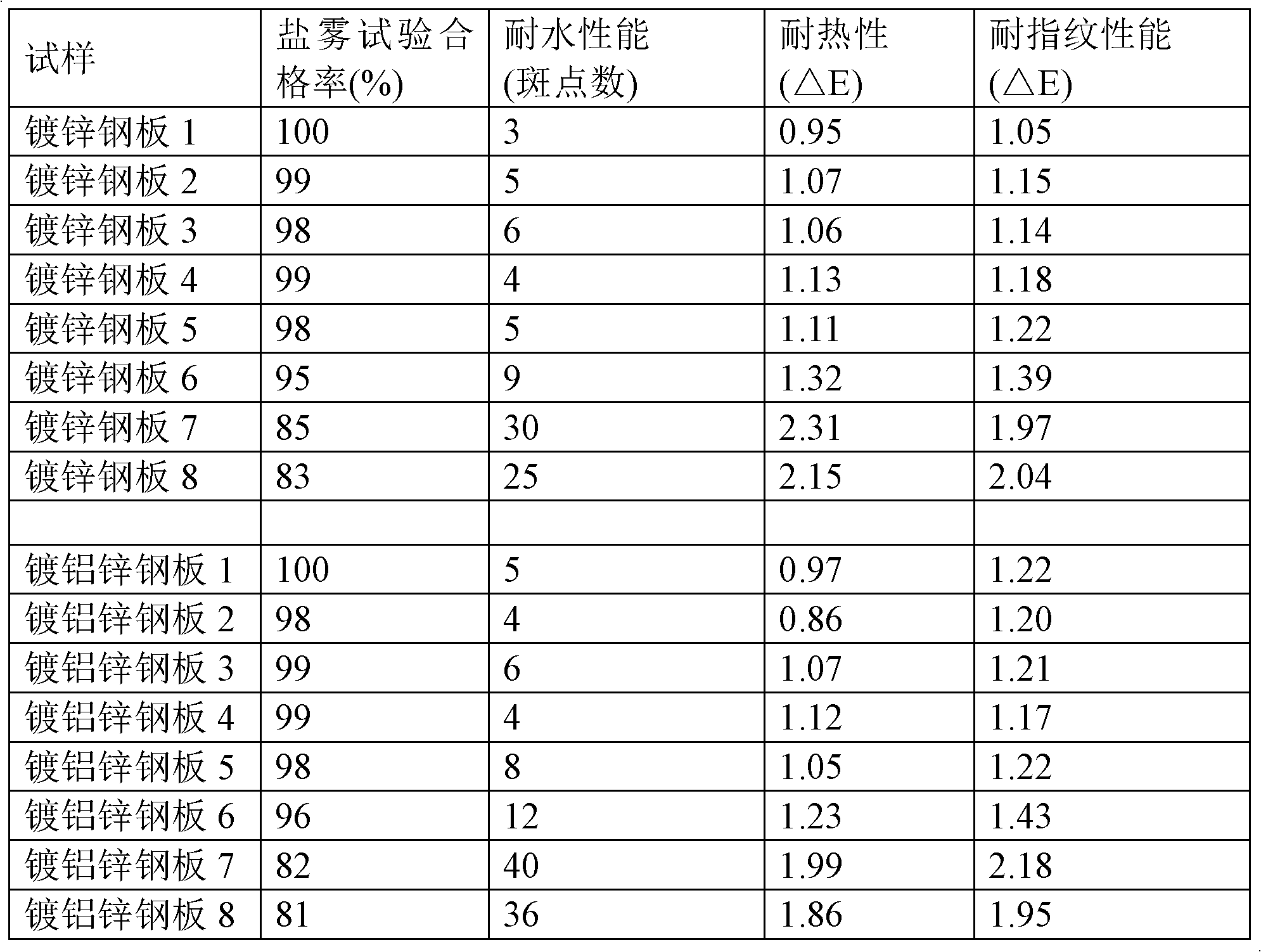

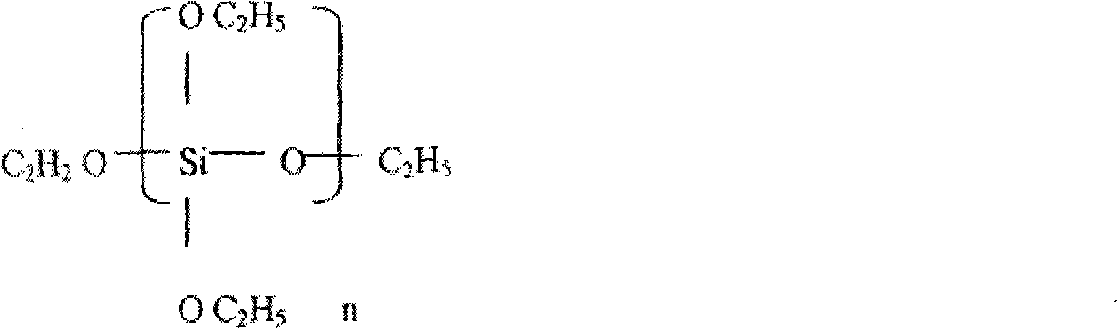

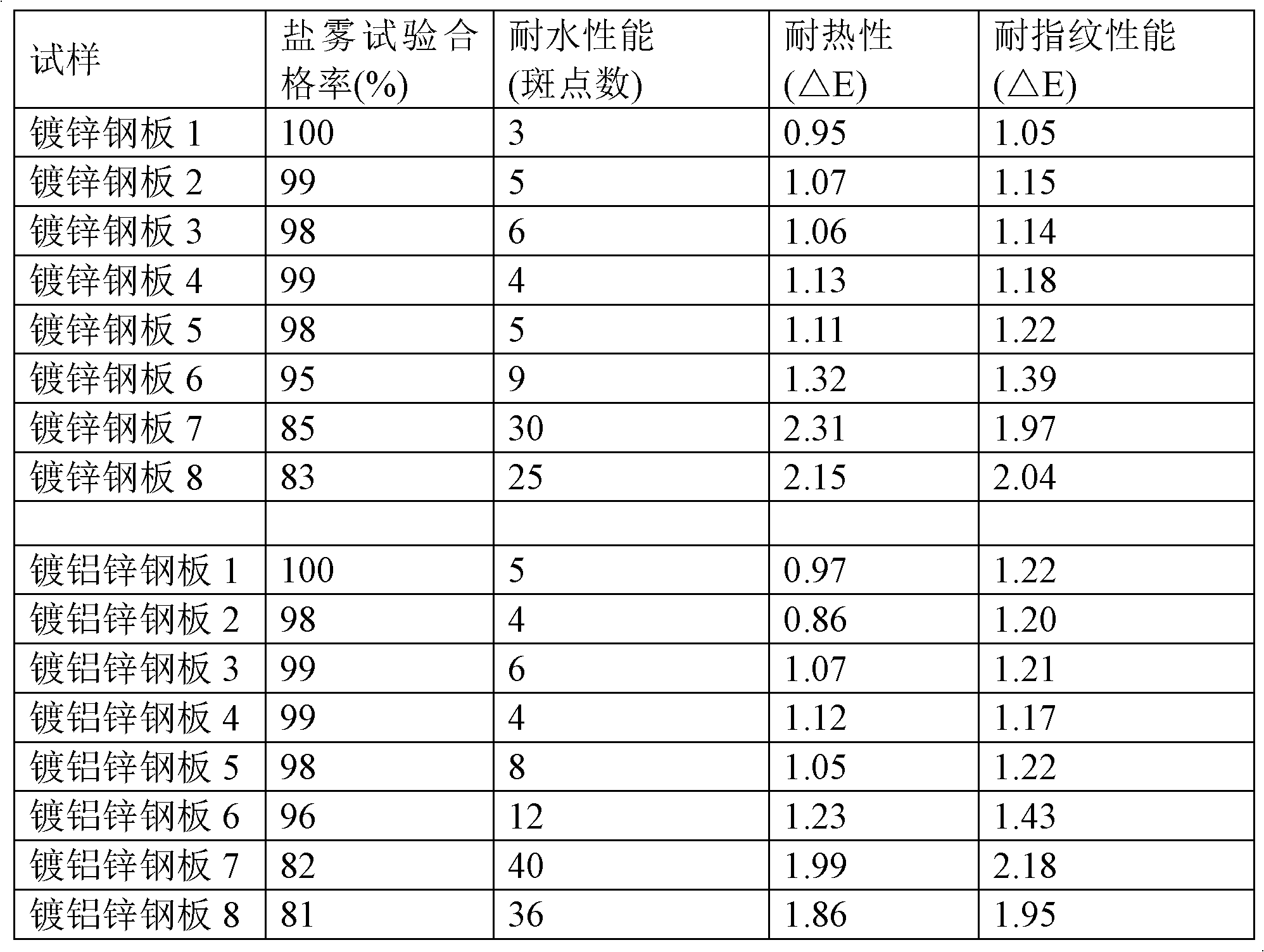

Metal protective coating and hot galvanizing metal material and hot dip aluminum-zinc metal material

ActiveCN103031043AImprove corrosion resistanceImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesThiourea

The invention provides metal protective coating, which is obtained by uniformly mixing a raw material mixture. The raw material mixture contains water soluble silicate, an accelerant, a silane coupling agent, a silicon oxide filler, a water soluble film-forming resin and water; the accelerant is thiourea and / or urea; and the silane coupling agent contains a first silane derivative represented by the formula (1), wherein R1, R2 and R3 are respectively either a methoxy group or an ethyoxyl group, and n is an integer from 1 to 4. The invention further provides a hot galvanizing metal material and a hot dip aluminum-zinc metal material. The protective film prepared by the metal protective coating provided by the invention is excellent in corrosion resistance, water resistance, heat resistance and fingerprint resistance. Formula (1).

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Zinc metallic coating

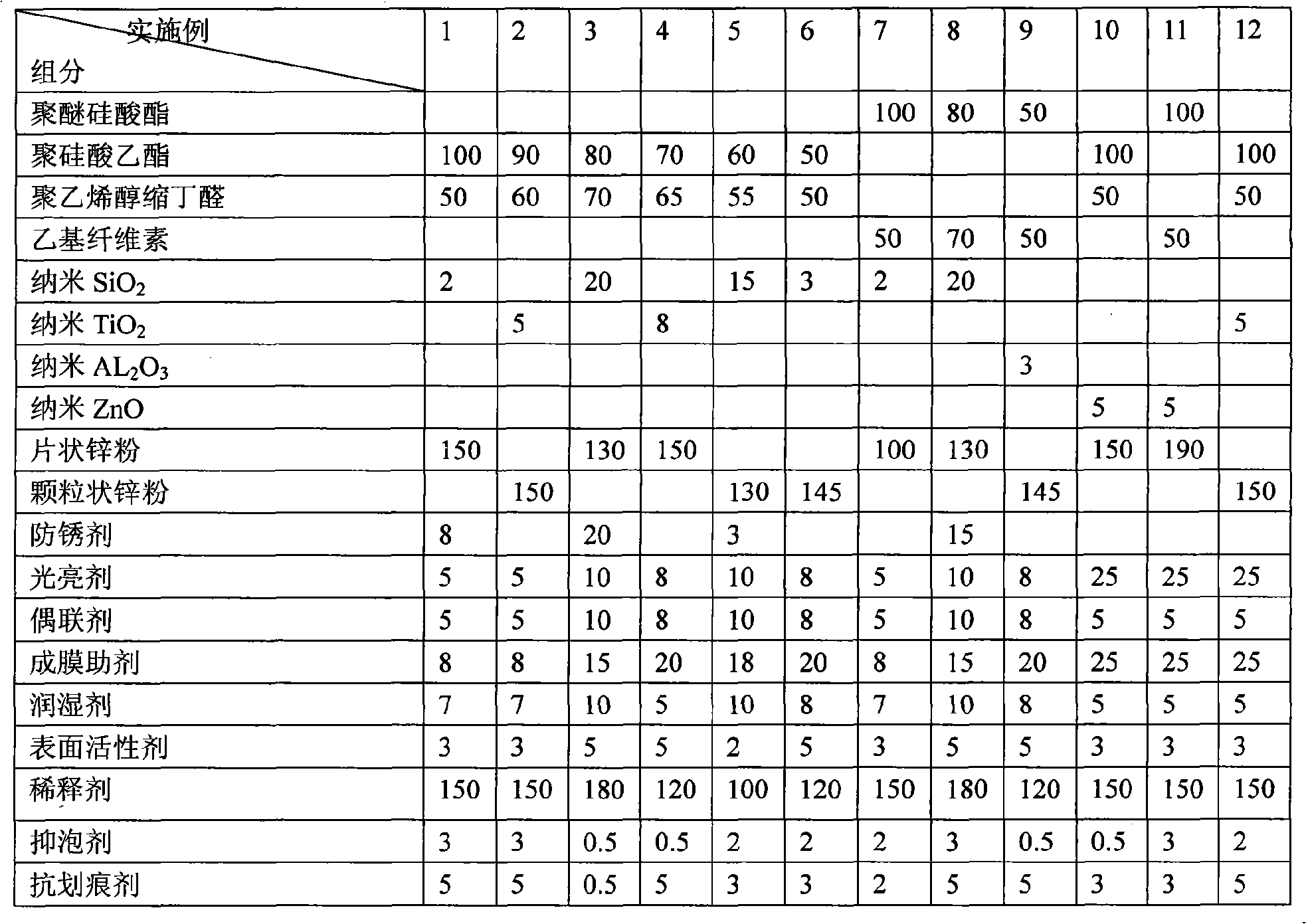

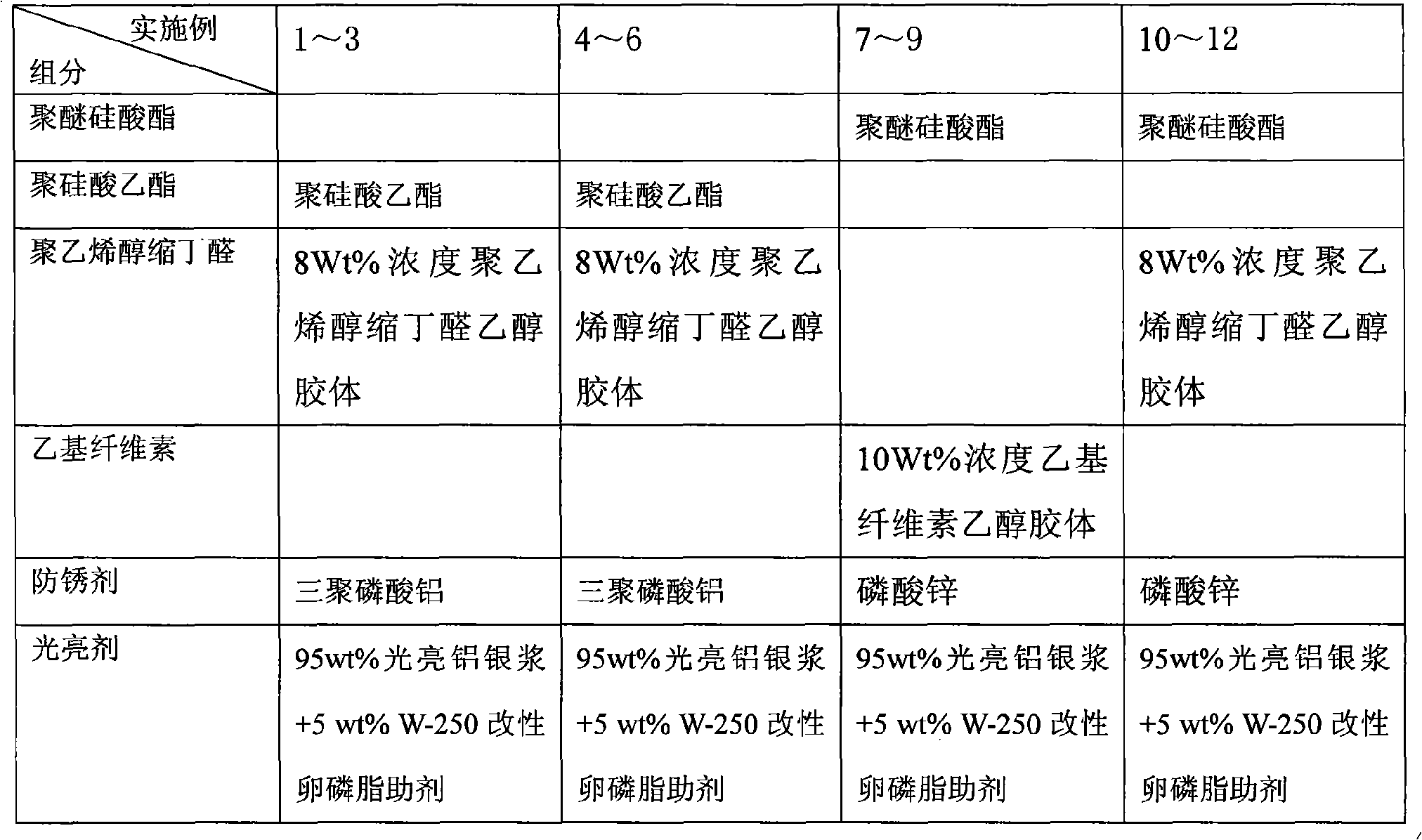

The invention discloses a zinc metal coating layer, the zinc metal coating is characterized in that when being calculated according to the parts by weight, the components of the the zinc metal coating are as follows: 50 parts to 100 parts of polyether silicate ester or polymerized silica acid ester, 50 parts to 100 parts of polyvinyl butyral or ethyl cellulose, 1 part to 20parts of one or a plurality of component (s) among nanometer silicon dioxide, nanometer titanium dioxide, nanometer molybdenum dioxide, or nanometer zinc oxide, 80 parts to 200 parts of zinc powder, 0 to 20 parts of rust preventing agent,, 5 parts to 100 parts of coupling agent, 5 parts to 25 parts of brightening agent, 8 parts to 250 parts of film forming auxiliary agent, 5 parts to 10 parts of wettinh agent, 1 part to 5 parts of surface activating agent, 100 parts to 200 parts of thinning agent, 0.5 part to 3 parts of anti-foaming agent and 0.5 part to 5 parts of anti-scratching agent. The bright metal zinc coating layer related by the invention can be taken as the anti-corrosive oxidation resistant zinc metal coating layer of metal product, particularly the black metal product, which can replace the commonly adopted galvanizing technology. The bright zinc metal coating layer of the invention can very conveniently and effectively paint a zinc metal coating layer the binding of which is firm on the metal product, particularly the black metal product.

Owner:胡仲寅

Preparation method of nano particles with high refractive index and polymer nano composite film material

The preparation method of nano composite film material by using nano microparticles with high refractive index and polymer includes the following three steps: preparing ZnS nano microparticles for surface modification, preparing organic polymer monomer and polymer with high refractive index and preparing nano composite film. In the organic solvent of zinc metal salt the organic small molecule surface modifier with function group is added, and the hydrogen sulfide gas is introduced to synthesize ZnS nano colloidal microparticles, and the polymer base material for combining ZnS nano microparticles can be polymethyl methacrylate, polybutyl methacrylate, polystyrene, epoxyresin, polymer large monomer, optimally can be polyurethane oligomer and polyurethane acrylate large monomer with high refractive index, finally the above-mentioned materials can be made into the invented nano composite film.

Owner:JILIN UNIV

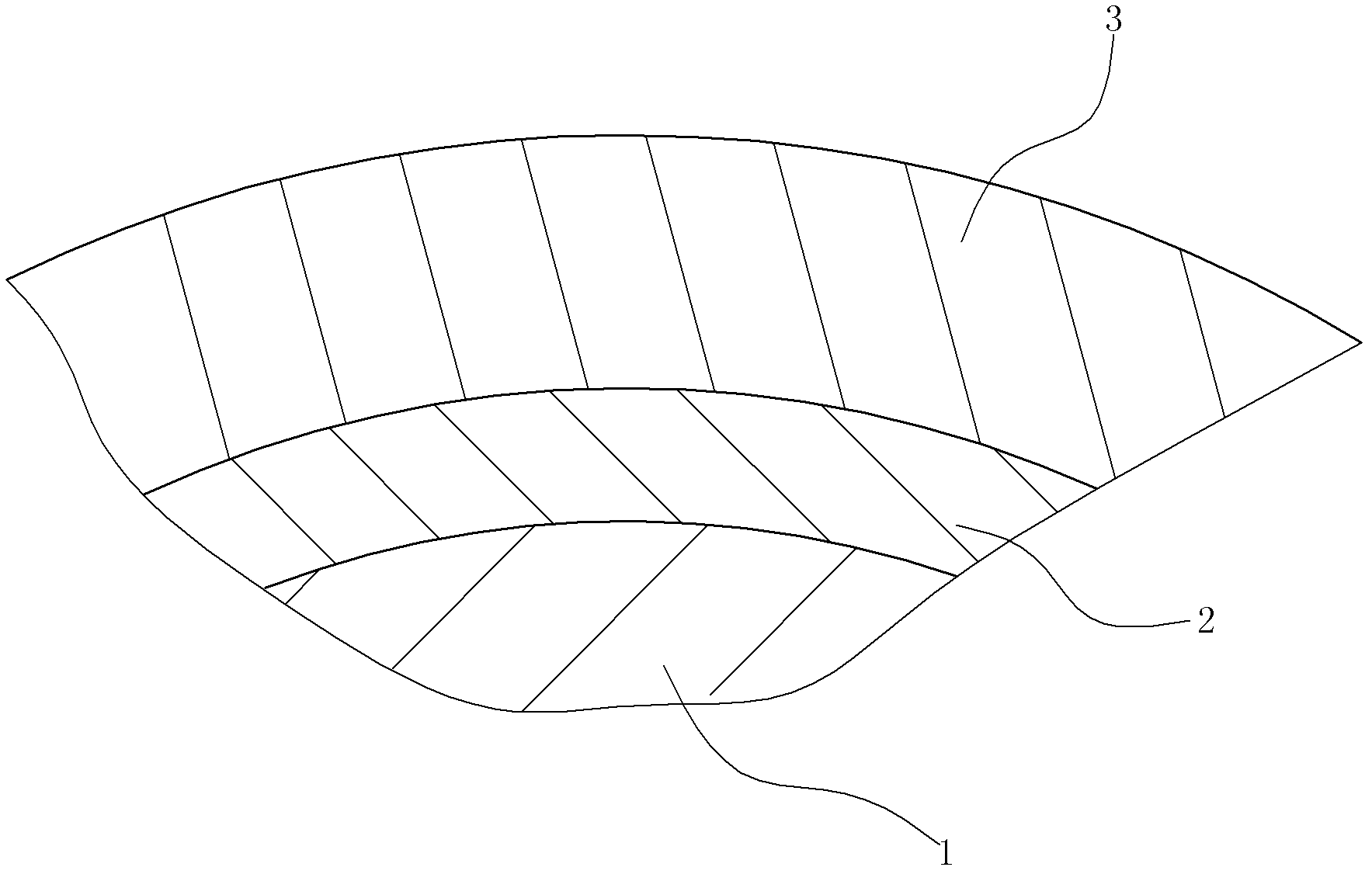

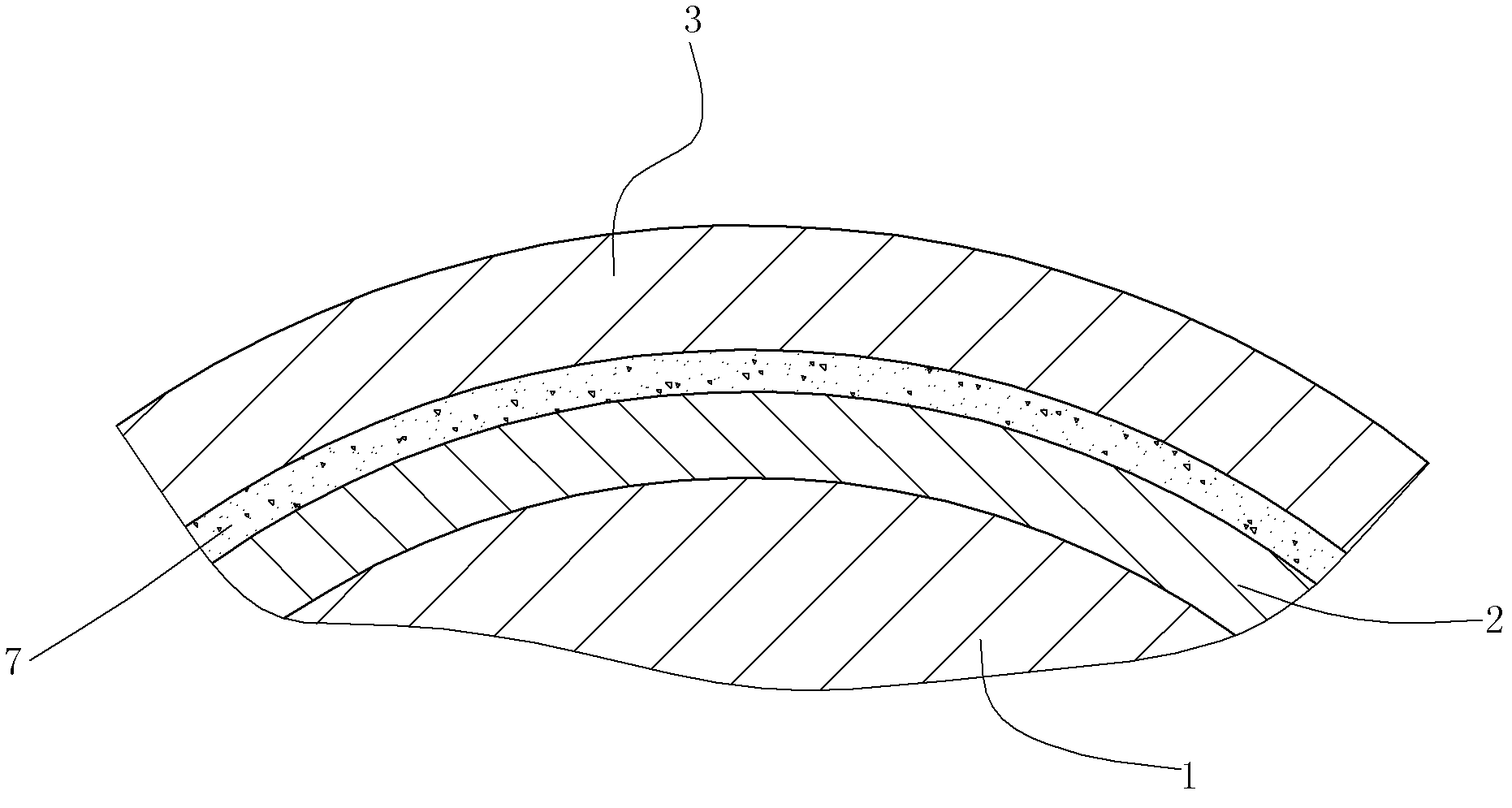

Hot press-formed article and a method for its manufacture

ActiveUS20060121305A1Improve corrosion resistanceNot readily peel offAnodisationHot-dipping/immersion processesSolderabilitySolid solution

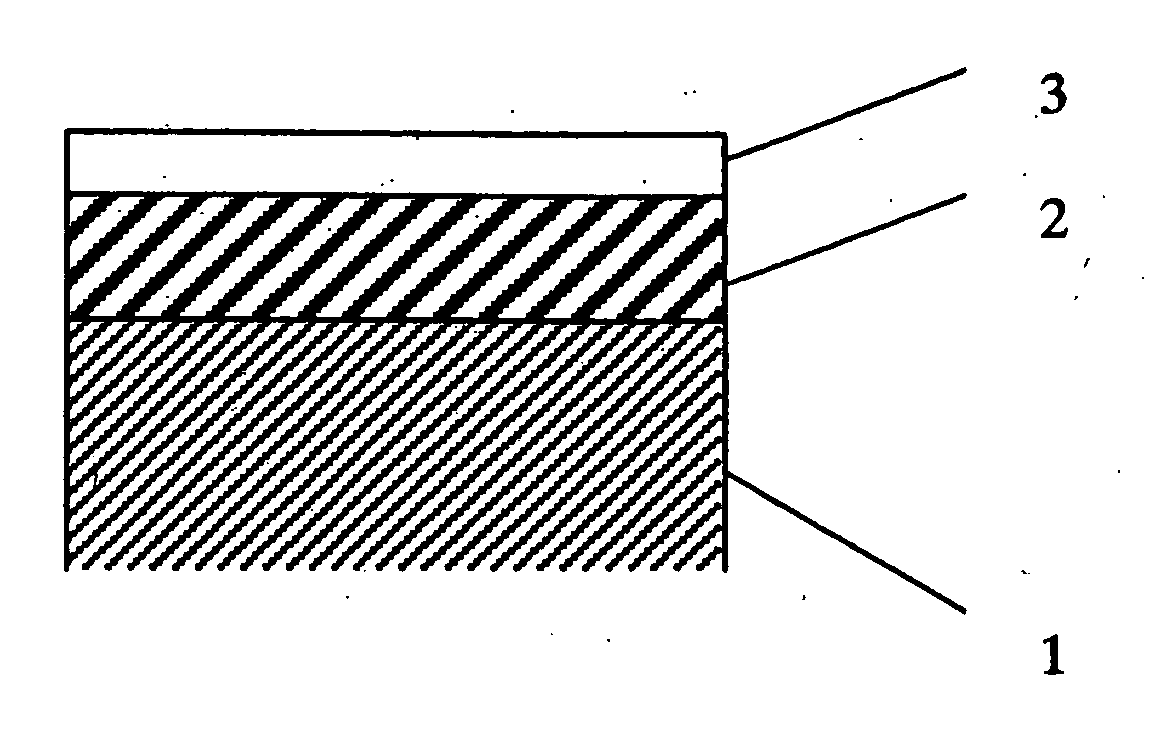

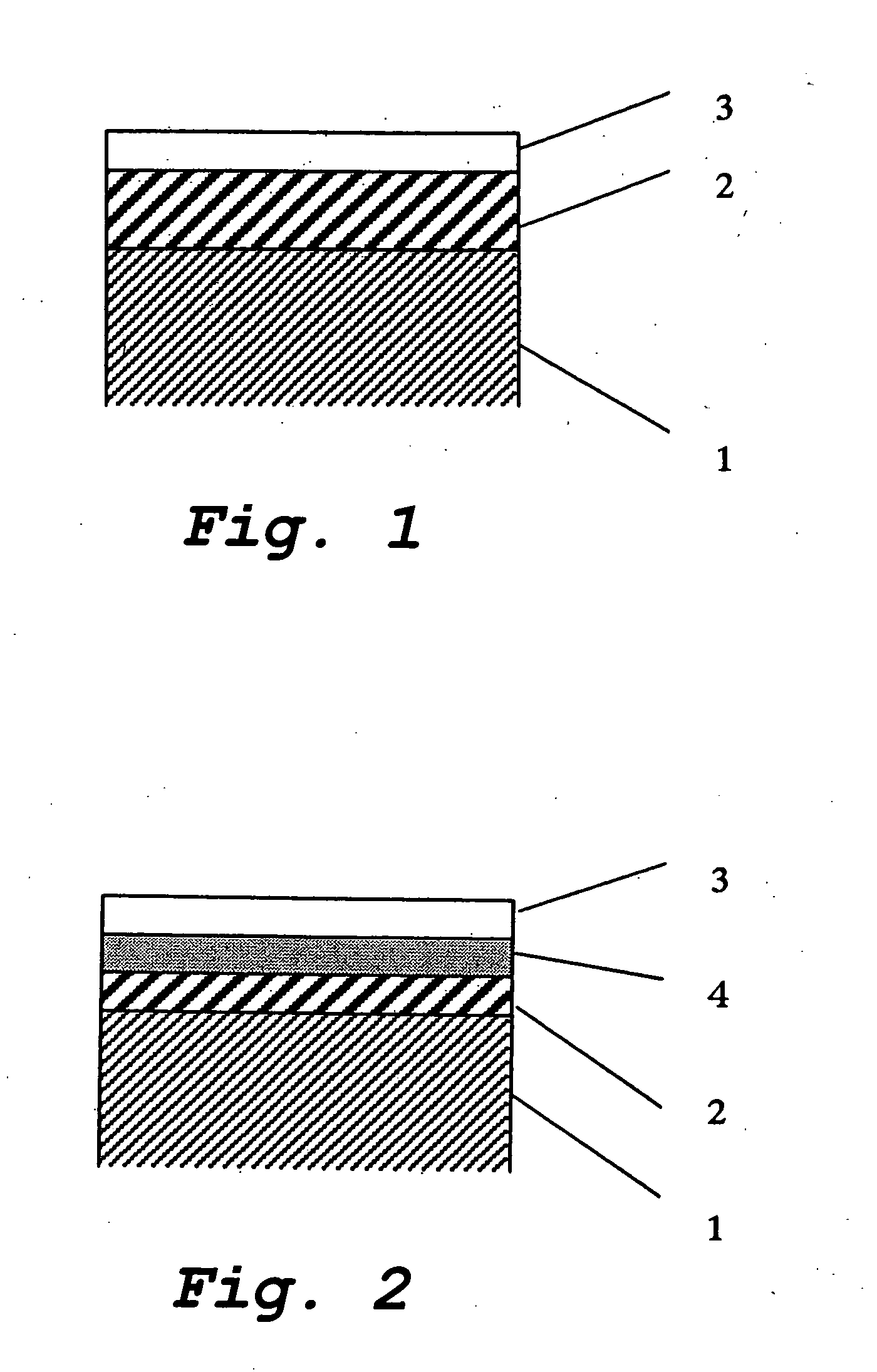

A hot press-formed article having improved corrosion resistance and coating adhesion when coated is obtained by hot press forming of a zinc-based plated steel material. It has a zinc-based plating layer comprising an iron-zinc solid solution phase and atop it a zinc oxide layer. The average thickness of the zinc oxide layer which is the outermost layer is at most 2 μm. A hot press-formed article having a good appearance and excellent corrosion resistance, coating adhesion, post-coating corrosion resistance, and weldability has a layer (2) consisting essentially of an iron-zinc solid solution phase atop a base material steel sheet (1). It also has a zinc oxide layer (3) with an average thickness of at most 5 μm as an uppermost layer, but it does not have a substantial amount of an iron-zinc intermetallic compound phase. The total amount of Al contained in the iron-zinc solid solution layer (2) and the zinc oxide layer (3) is at most 0.5 g / m2, and / or the total amount of Al oxides contained in these layers is at most 5 mg / m2.

Owner:NIPPON STEEL CORP +2

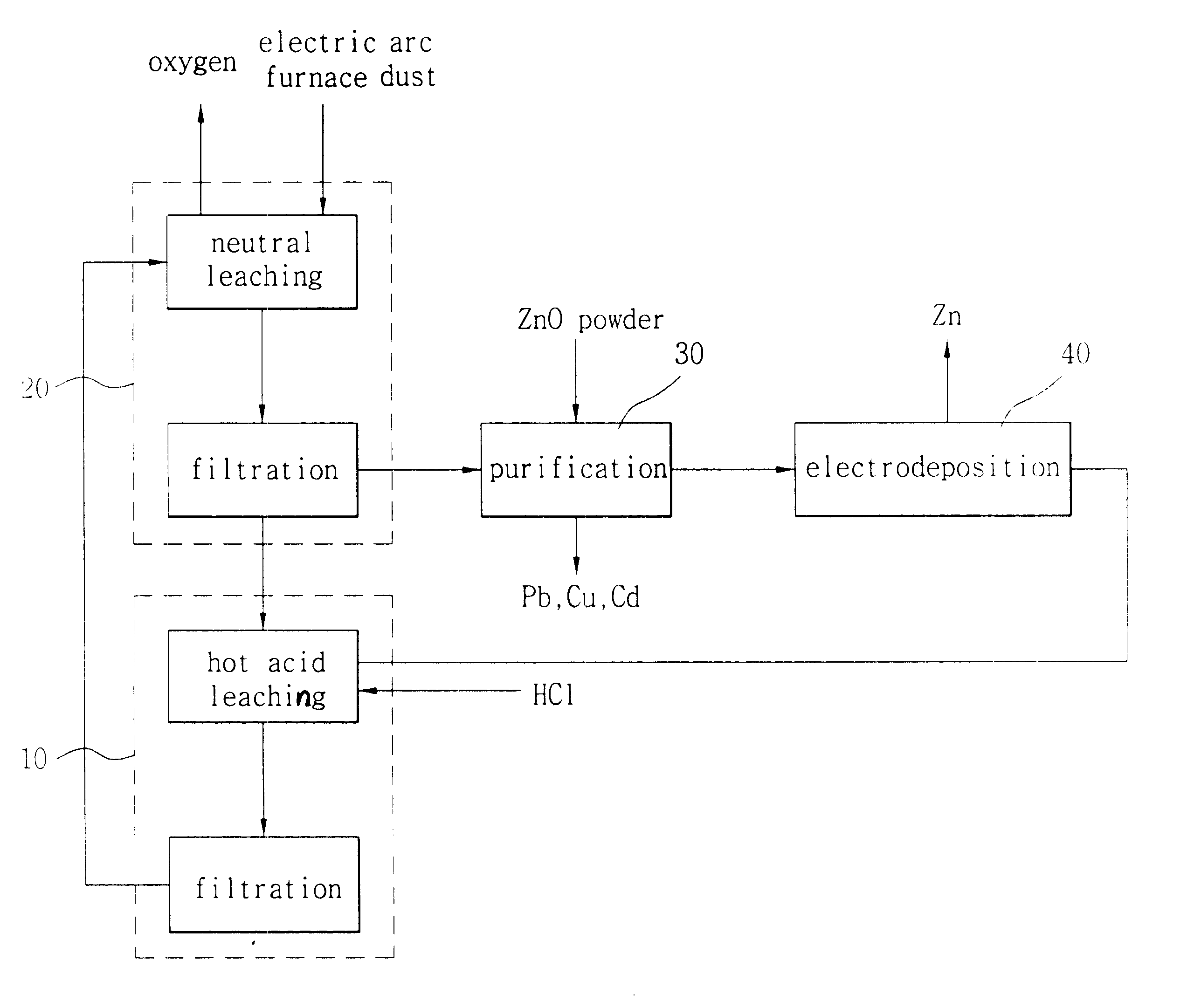

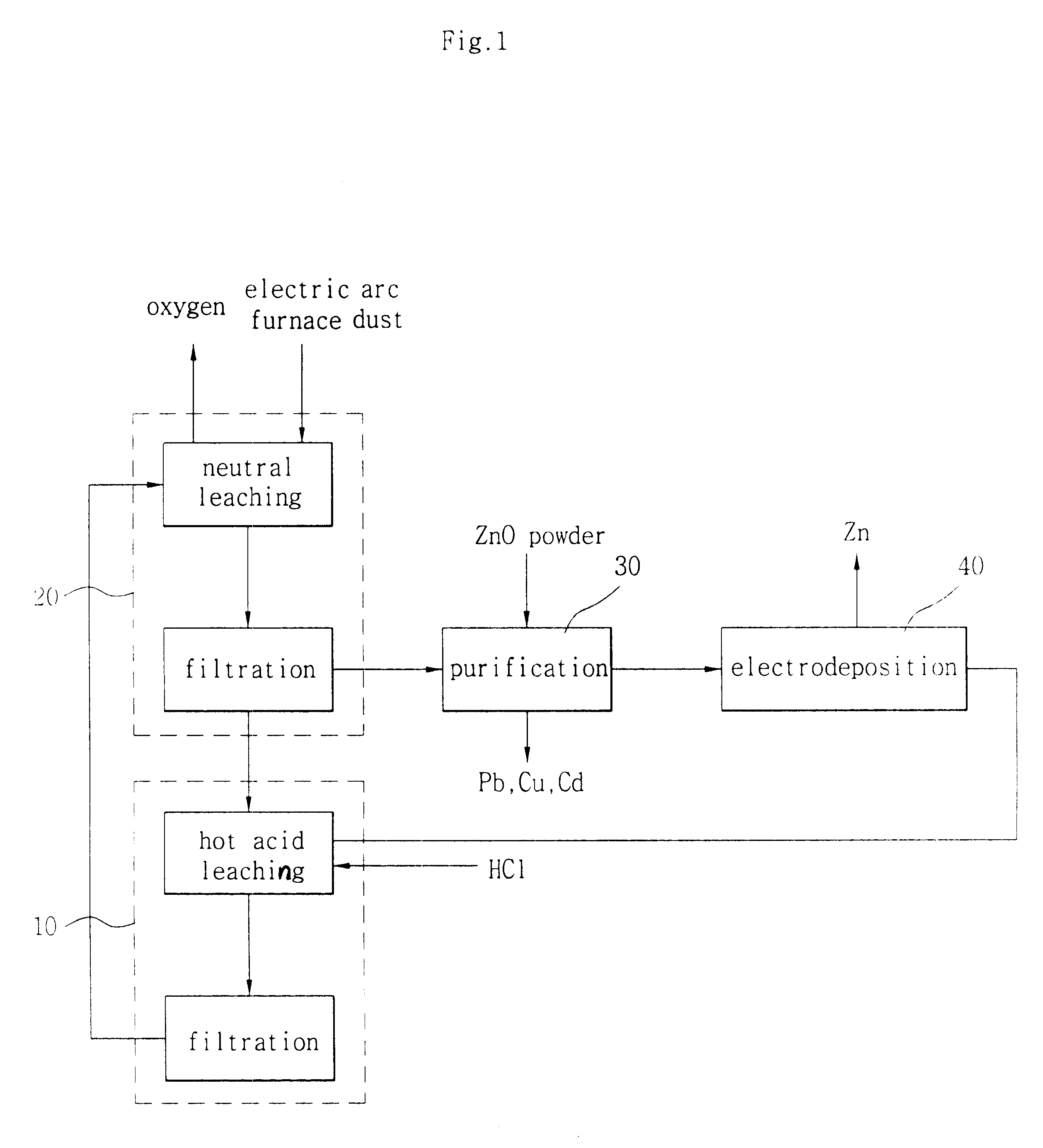

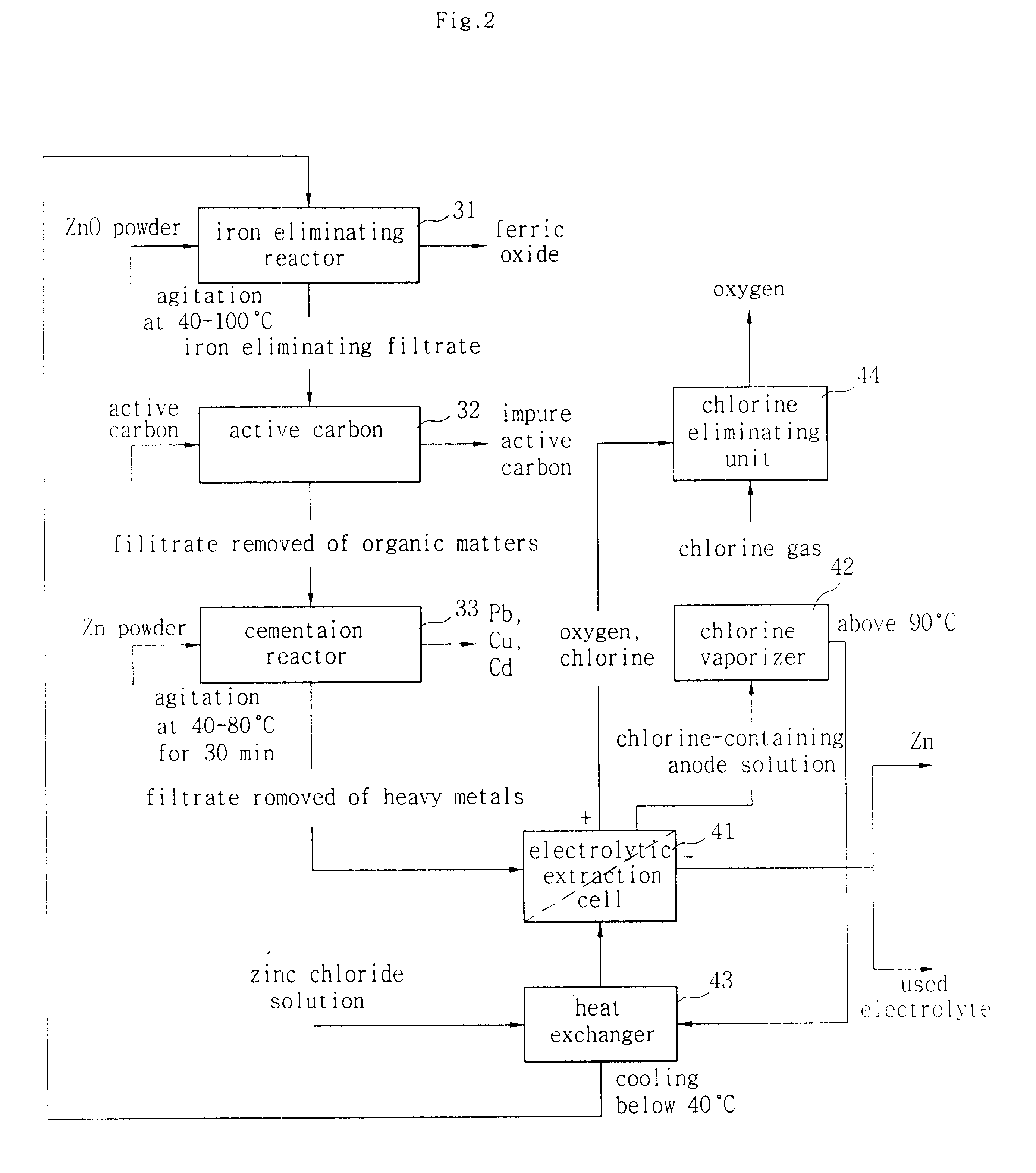

Hydrometallurgical method for recovery of zinc from electric arc furnace dust

InactiveUS6338748B1Current efficiency is deterioratedLow costPhotography auxillary processesSolvent extractionMembrane currentElectric arc furnace

The process uses hydrochloric acid solutions to extract zinc from electric arc furnace dusts containing zinc oxide and zinc ferrite. To selectively leach zinc and minimize iron dissolution by precipitating as FeO.OH and Fe2O3, hot acid leaching with the aqueous solution containing 37 g / l-74 g / l HCl and 104 g / l-270 g / l ZnCl2 is used. New dust is introduced to remove iron from the filtrate of the hot acid leaching. The zinc chloride solutions purified by activated carbon and metallic zinc powder is electrolysed in electrowinning cells which had cation exchange membrane to produce high purity zinc metal and to regenerate hydrochloric acid. Electrolysing an aqueous solution of zinc chloride with Zn concentration of 50-130 g / litre below 40° C. in a cell divided by cation exchange membrane, whereby coherent zinc is yielded at the cathode with high current efficiency of exceeding 90%. HCl is directly regenerated with a very small loss below 2% and low energy consumption below 5.0 kWh / kg-Zn during Zn-electrodeposition at a cathodic current density in the range of 300-2000 A / m2, and a membrane current density in the range of 750-2000 A / m2. The spent electrolyte with 1-2N HCl is used to leach the residue in the hot acid leaching vessel.

Owner:SANGWON ENC +1

Efficient multilayer composite electrode wire and preparation method thereof

InactiveCN102528190AFast cutting speedImprove cutting efficiencyElectrical-based machining electrodesComposite electrodeBeta phase

The invention relates to an efficient multilayer composite electrode wire, which comprises a core part and a wrapper wrapped on the core part. The electrode wire is characterized in that: the core part is provided with a brass wire core formed by performing diffusion annealing, water cooling and continuous drawing and continuous retracting treatment on a brass core wire, and the metallographic structure of the brass wire core is mainly an alpha-phase structure; and the wrapper is a diffused alloy layer formed by performing diffusion annealing, water cooling and continuous drawing and continuous retracting treatment on a copper metal coating and a zinc metal coating which are sequentially plated on the brass core wire, and the metallographic structure of the diffused alloy layer is mainly a beta-phase structure. The electrode wire is prepared by the following steps of: plating the copper and zinc metal coatings on the core wire, then performing diffusion annealing, water cooling and continuous drawing and continuous retracting treatment, drawing, and thus obtaining the electrode wire. Compared with the prior art, the invention has the advantages that: the cutting efficiency of the efficient multilayer composite electrode wire is remarkably higher than that of a common galvanized wire, the comprehensive cutting cost of the efficient multilayer composite electrode wire is lower than that of the common galvanized wire, and the efficient multilayer composite electrode wire has good universality.

Owner:NINGBO BODE HIGHTECH CO LTD

Zinc recovery process

InactiveUS7465334B2Improve filtering effectEh is decreasedPhotography auxillary processesSolvent extractionZinc metalProcess engineering

A process for the recovery of zinc metal from a zinc mineral includes the steps of leaching the zinc mineral in a solution including a halide species formed from two or more different halides, to leach the zinc into the solution. The zinc-bearing solution is then electrolyzed to yield zinc metal and to generate the halide species. The electrolyzed solution including the halide species is then returned to the leaching step. A portion of the electrolyzed solution can be removed as a bleed stream from a cathode compartment of an electrolytic cell of the electrolysis process and processed to remove manganese as manganese dioxide precipitate by adding thereto limestone, and the halide species from an anode compartment of the electrolysis process. In this regard, the pH and Eh of the solution can regulated in a manner that favors the formation of the manganese dioxide precipitate over the formation of a precipitate of zinc.

Owner:INTEC INT PROJECTS

Method for producing high-purity zinc from zinc oxide ore

InactiveCN1482263AHigh extraction rateReduce loss rateProcess efficiency improvementLiquid wasteElectrolysis

The present invention relates to smelting technology and is wet smelting process of producing high purity zinc metal from zinc oxide ore. The technological process includes the steps of: leaching zinc oxide ore with alkali solution; adding sulfide separating agent into filtrate after leaching; filtering to separate lead-containing filtered residue and electrolyzing the filtrate to produce zinc.The present invention has simple technological process, low production cost, high in zinc leaching out rate, reuse of waste liquid and low alkali loss.

Owner:YUXI YOUTH INDGROUP YUNNAN

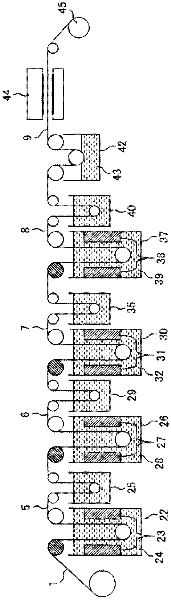

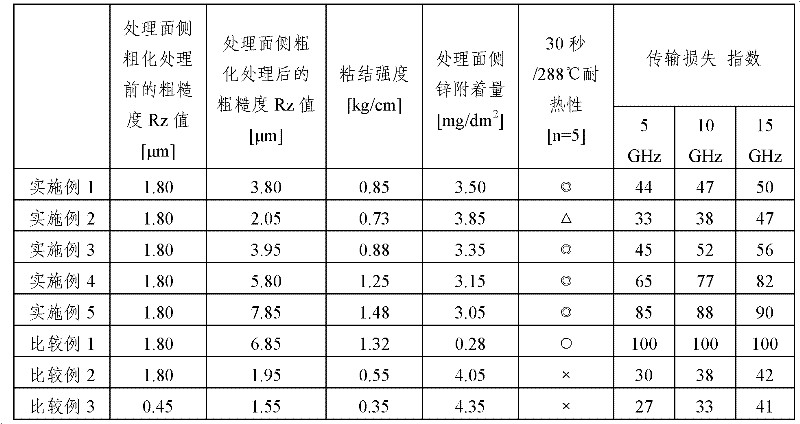

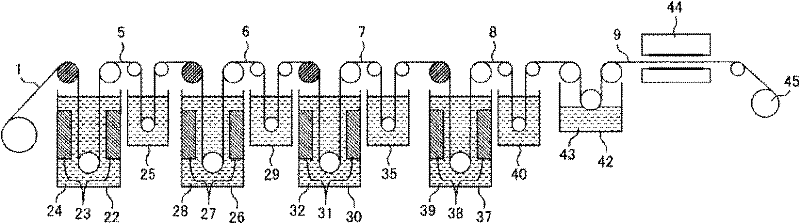

Heat-resistant copper foil and method for producing same, circuit board, and copper-clad laminate board and method for manufacturing same

ActiveCN102482795AHigh peel strengthImprove heat resistanceChromatisationPrinted circuit aspectsSurface layerZinc metal

Disclosed is a copper foil which has excellent high frequency characteristics and heat resistance, while achieving high heat-resistant adhesion to a resin substrate at the same time. Specifically disclosed is a heat-resistant copper foil which has a configuration wherein a primary roughened surface layer which has been subjected to a primary roughening process by copper metal, a secondary roughened surface layer which has been subjected to a secondary roughening process by copper metal, and a tertiary processed surface layer which has been subjected to a tertiary processing process by zinc metal are sequentially provided on one surface of an unprocessed copper foil. Also specifically disclosed are: a circuit board which is obtained by laminating the heat-resistant copper foil on a flexible resin substrate or a rigid resin substrate; and a method for manufacturing a copper-clad laminate board wherein the heat-resistant copper foil and a heat-resistant resin substrate are thermally pressure-bonded and the tertiary processed surface layer, which is composed of the roughened copper metal and the zinc metal, is alloyed.

Owner:FURUKAWA ELECTRIC CO LTD

Method of Recovering Valuable Metals from IZO Scrap

InactiveUS20100288645A1Good effectIncrease productivityPhotography auxillary processesProcess efficiency improvementElectrolysisIndium

Provided is a method of recovering valuable metals from IZO scrap in which valuable metals are recovered as indium and zinc metals or suboxides by performing electrolysis using an insoluble electrode as an anode and an IZO scrap as a cathode. Specifically, this method enables the efficient recovery of indium and zinc from IZO scrap such as an indium-zinc oxide (IZO) sputtering target or IZO mill ends that arise during the manufacture of such a sputtering target.

Owner:JX NIPPON MINING & METALS CORP

Metallic zinc-based current collector

ActiveUS20100092857A1Raise the ratioLower performance requirementsFinal product manufactureElectrode carriers/collectorsZinc metalZinc alloys

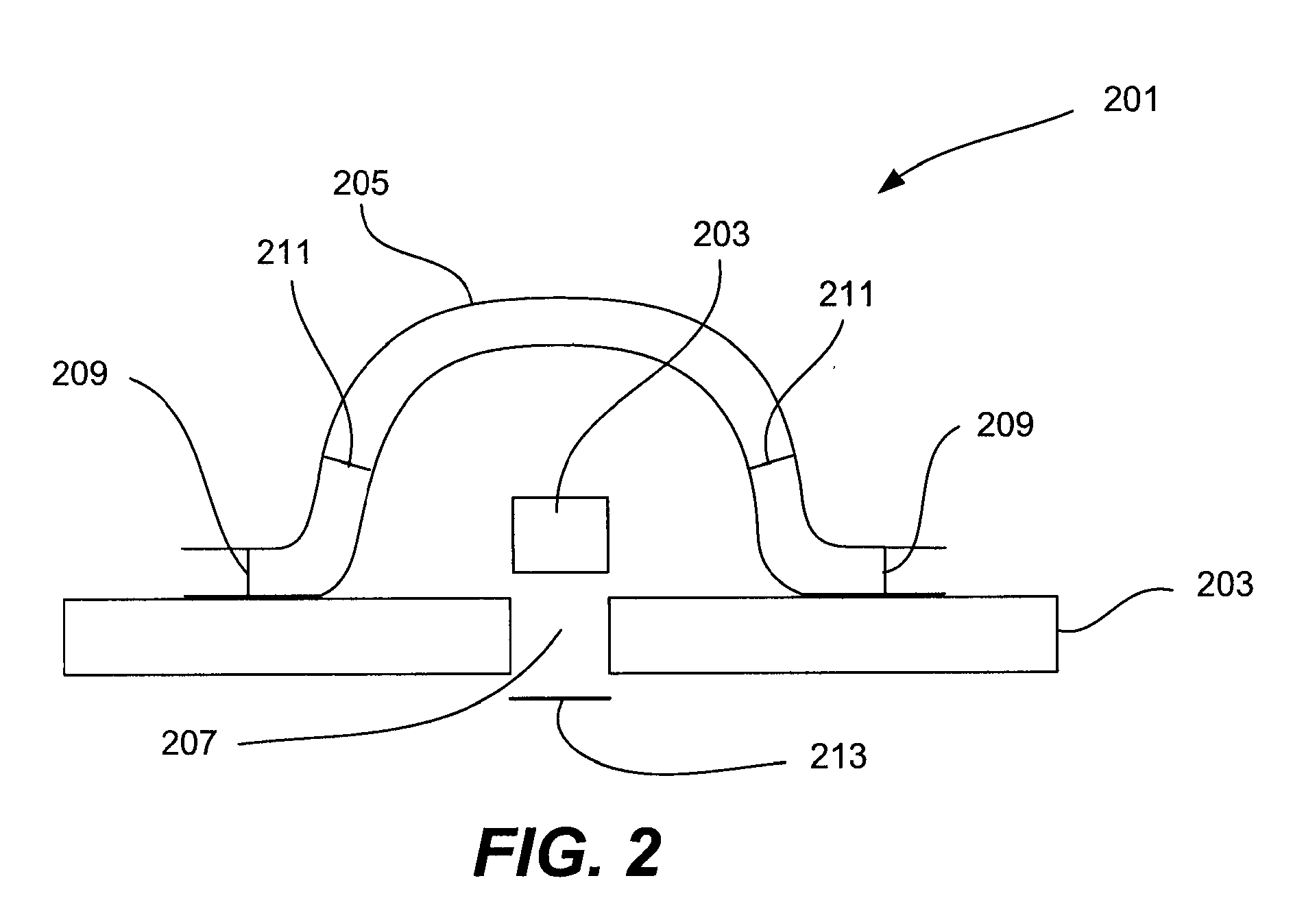

A nickel zinc battery cell includes a metallic zinc-based current collection substrate as a part of the negative electrode. The metallic zinc-based current collector may be made of or be coated with a zinc metal or zinc alloy material and may be a foil, perforated, or expanded material. Battery cells incorporating the zinc-based current collector exhibit good cycle lifetime and initial charge performance.

Owner:POWERGENIX SYST SHENZHEN +1

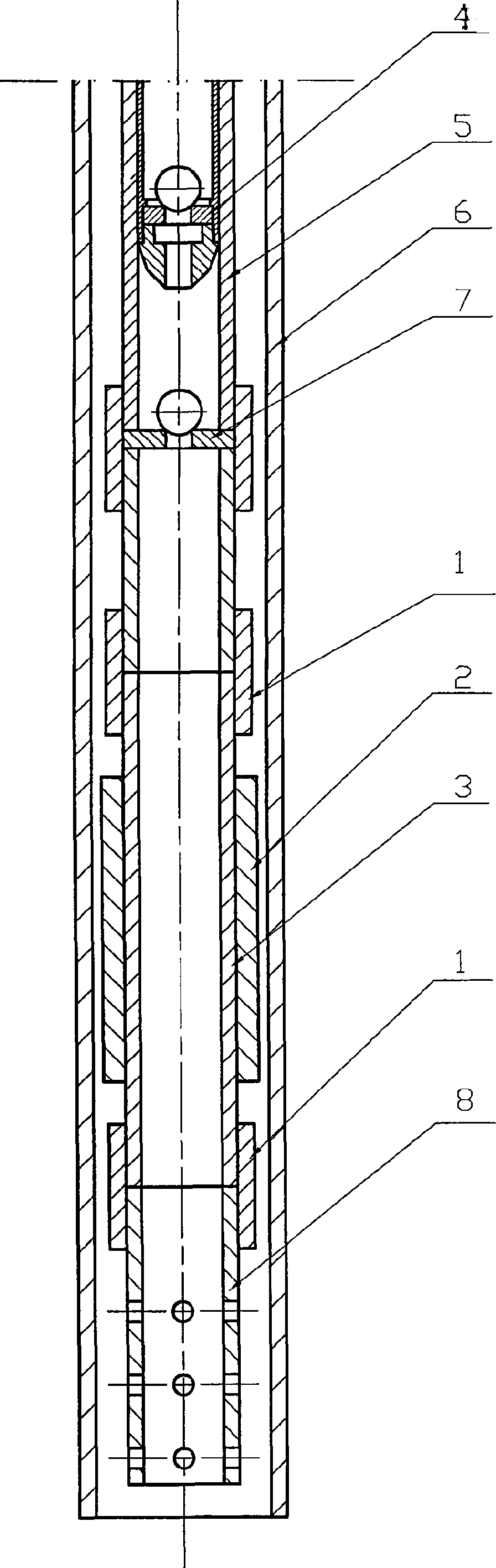

Sacrificial anode and protective cathode-oil-well pump anti-corrosive apparatus

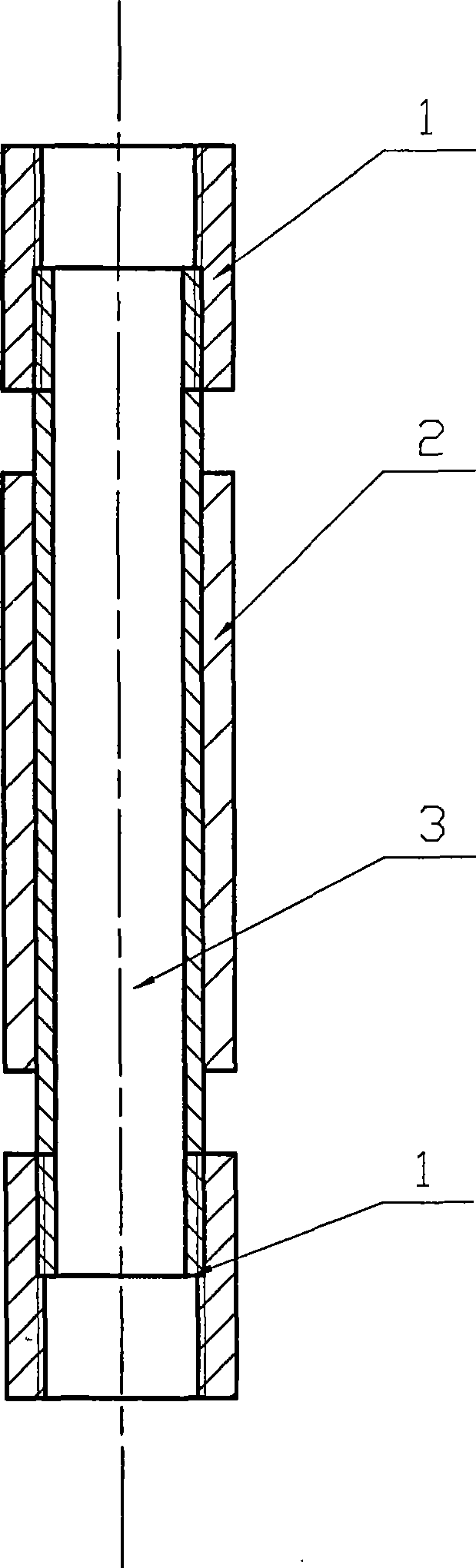

InactiveCN101397672AReduce consumptionEliminate accidentsFlexible member pumpsPositive-displacement liquid enginesZinc metalThermal insulation

The invention relates to a corrosion resistant device for an oil well pump which utilizes a sacrificial anode to protect a cathode. The corrosion resistant device utilizes the principle of protecting the cathode by sacrificing the anode in electrochemistry and takes zinc, lead, magnesium and other active metals as the anode of the oil well pump. The production method is as follows: the nipple of the oil well pump is processed according to the technical specification of the oil well pump firstly and the length of the nipple is 400mm to 500mm; then the nipple is put into a specially designed rod cavity; magnesium or aluminium or zinc metal blocks are converted into liquid by heating and melting and then cast into the nipple cavity of a special oil well pump; and shaping, thermal insulation, slow cooling, mold unloading and mechanical processing are carried out, a coarse blank is processed into a smooth revolution body, thread at the two ends of the oil well pump is processed, and collars are installed, therefore, the anode assembly of the oil well pump is formed. The instillation method is as follows: during the process of putting down the oil well pump, the anode of the pumping rod is connected in series with the collar at the lower end of the oil well pump and collar is screwed.

Owner:HENAN XINYU PETROLEUM MACHINERY MFG

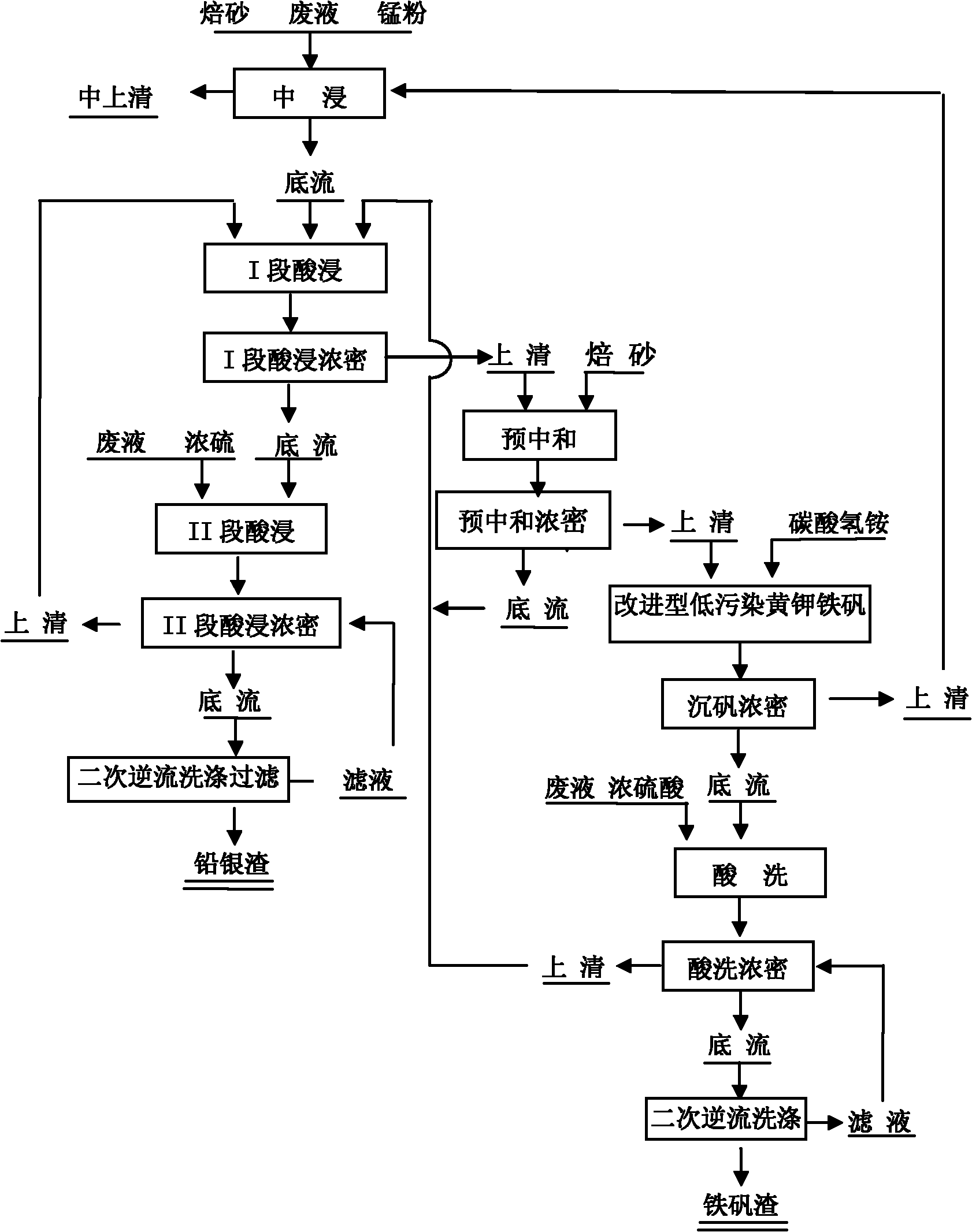

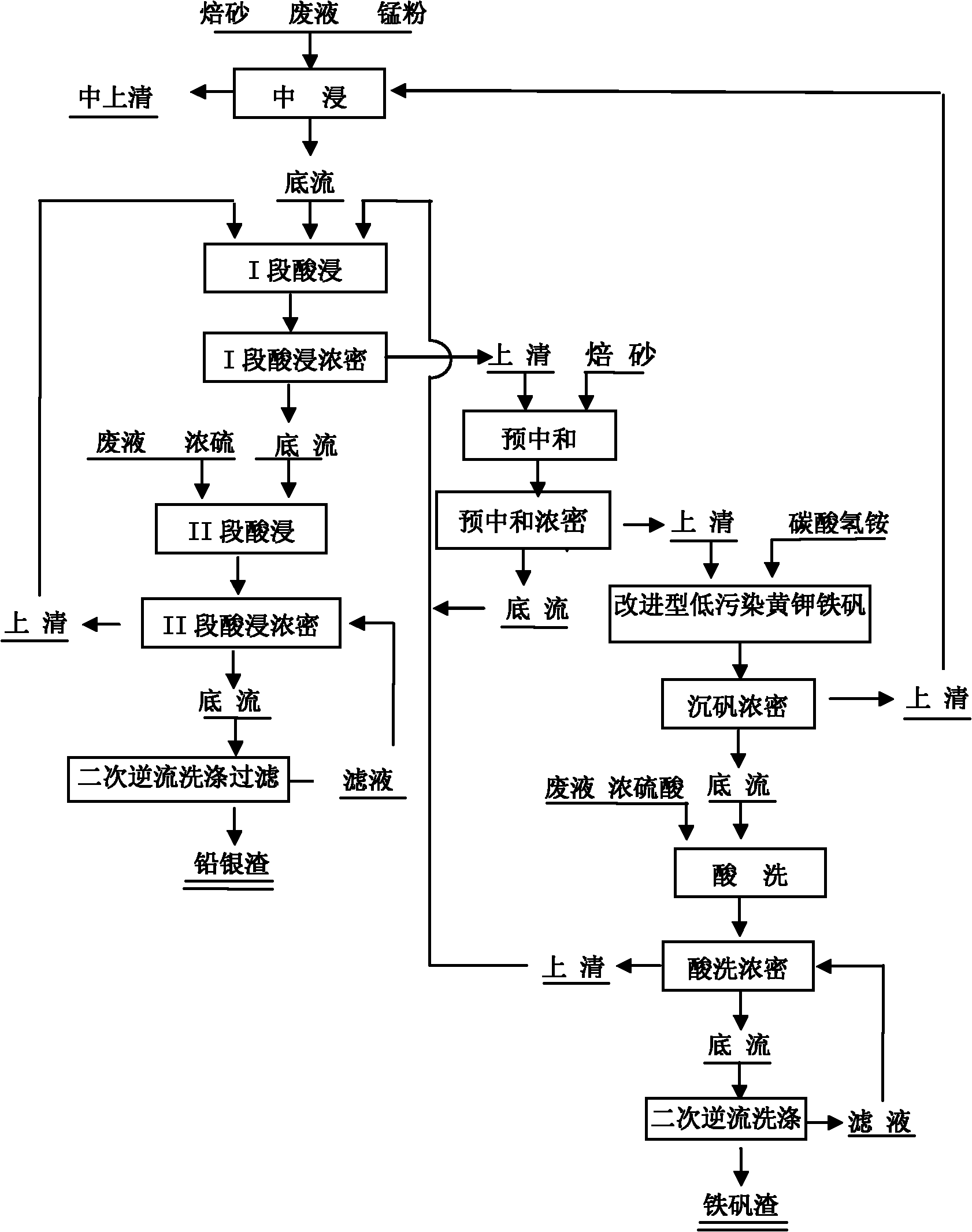

Process for smelting zinc with wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling by two stages

InactiveCN102094126AImprove leaching rateHigh recovery rateProcess efficiency improvementSlagZinc metal

The invention provides a process for smelting zinc with a wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling at two stages, belonging to the technical field of non-ferrous metal smelting. The process comprises the following steps of neutral leaching, acid leaching at the first stage, acid leaching at the second stage, pre-neutralizing, settling vitriol and pickling to obtain zinc metal with a high recovery rate. The total recovery rate of zinc metal is 94.45%. The loss of valuable metal in iron vitriol slag is less, the recovery rate of metal is high, and the pollution of vitriol slag to the environment is improved.

Owner:BAIYIN NONFERROUS GROUP

Particulate metal alloy coating for providing corrosion protection

InactiveUS7078076B2Improve coating adhesionGood storage stabilityPigmenting treatmentAlkali metal silicate coatingsWater basedZinc metal

Coatings containing particulate metal alloy are disclosed. The coatings provide corrosion protection to a substrate, such as a metal substrate. The coatings contain zinc-metal-containing alloy in flake form, most particularly an alloy flake of zinc and aluminum. The coating can be from compositions that are water-based or solvent-based. The compositions for providing the coating may also contain a substituent such as a water-reducible organofunctional silane, or a hexavalent-chromium-providing substance, or a titanate polymer, or a silica substance constituent. The coating may desirably be topcoated.

Owner:NOF METAL COATINGS NORTH AMERICA INC

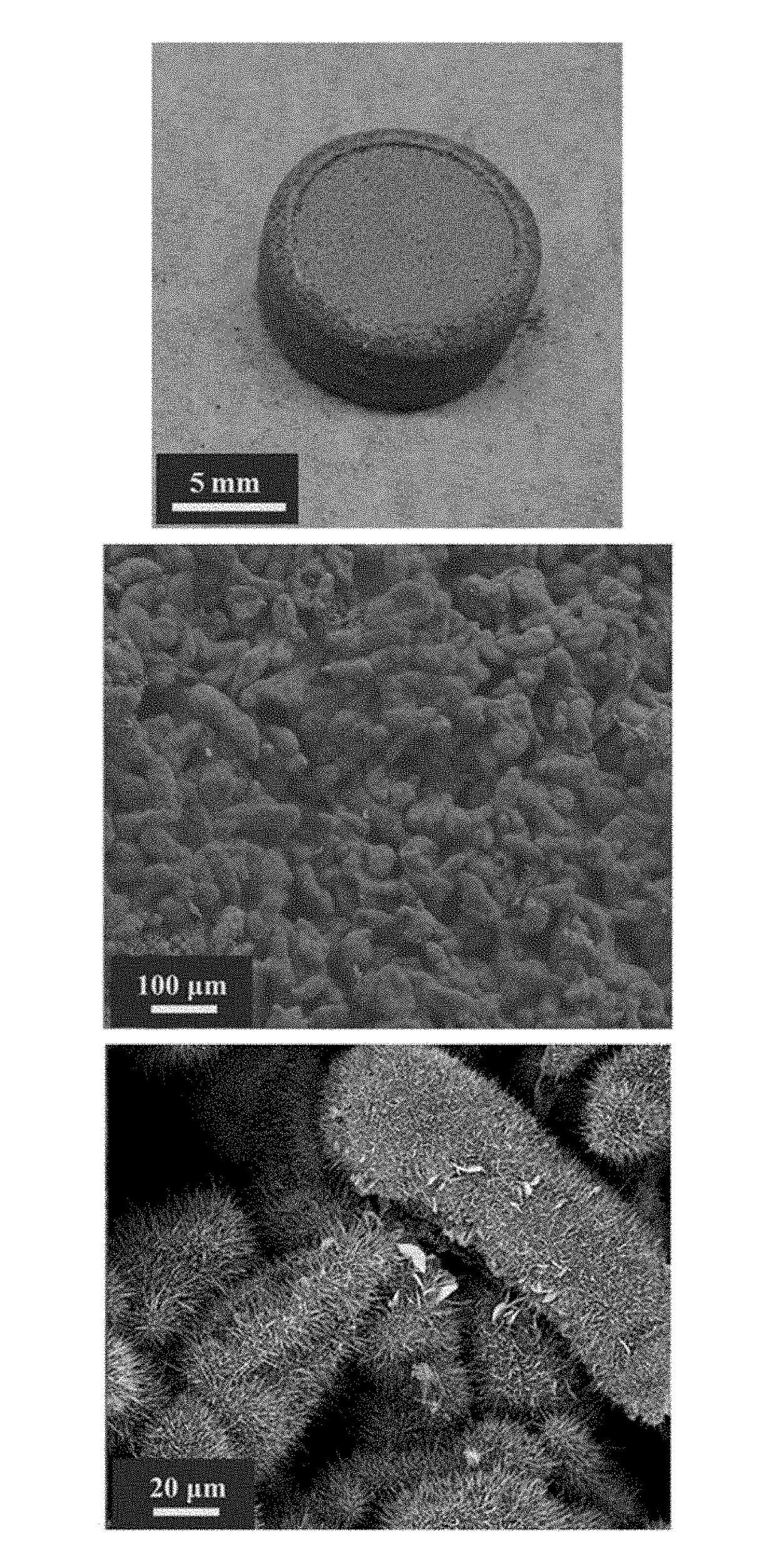

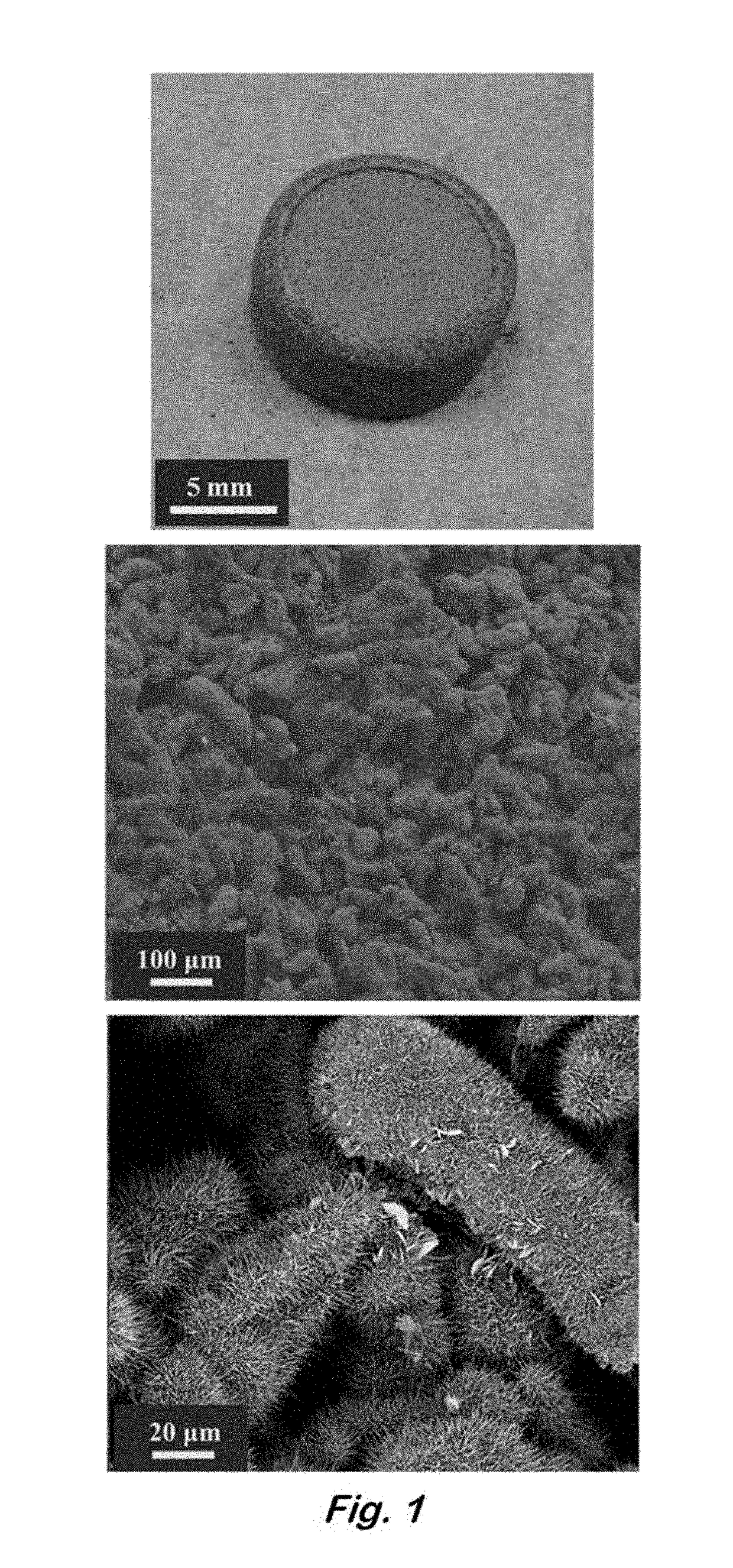

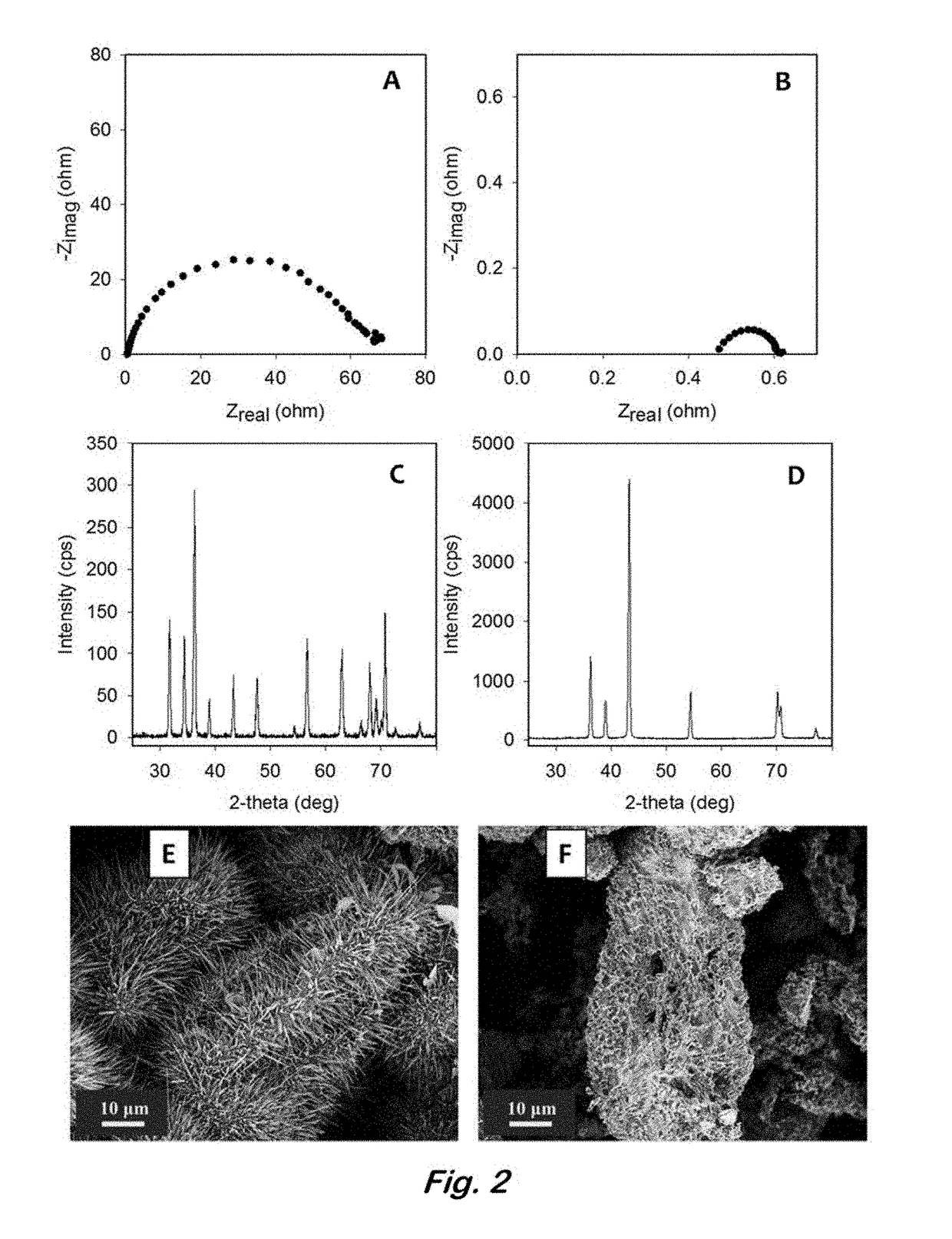

Zinc Electrodes for Batteries

An article having a continuous network of zinc and a continuous network of void space interpenetrating the zinc network. The zinc network is a fused, monolithic structure. A method of: providing an emulsion having a zinc powder and a liquid phase; drying the emulsion to form a sponge; annealing and / or sintering the sponge to form an annealed and / or sintered sponge; heating the annealed and / or sintered sponge in an oxidizing atmosphere to form an oxidized sponge having zinc oxide on the surface of the oxidized sponge; and electrochemically reducing the zinc oxide to form a zinc metal sponge.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

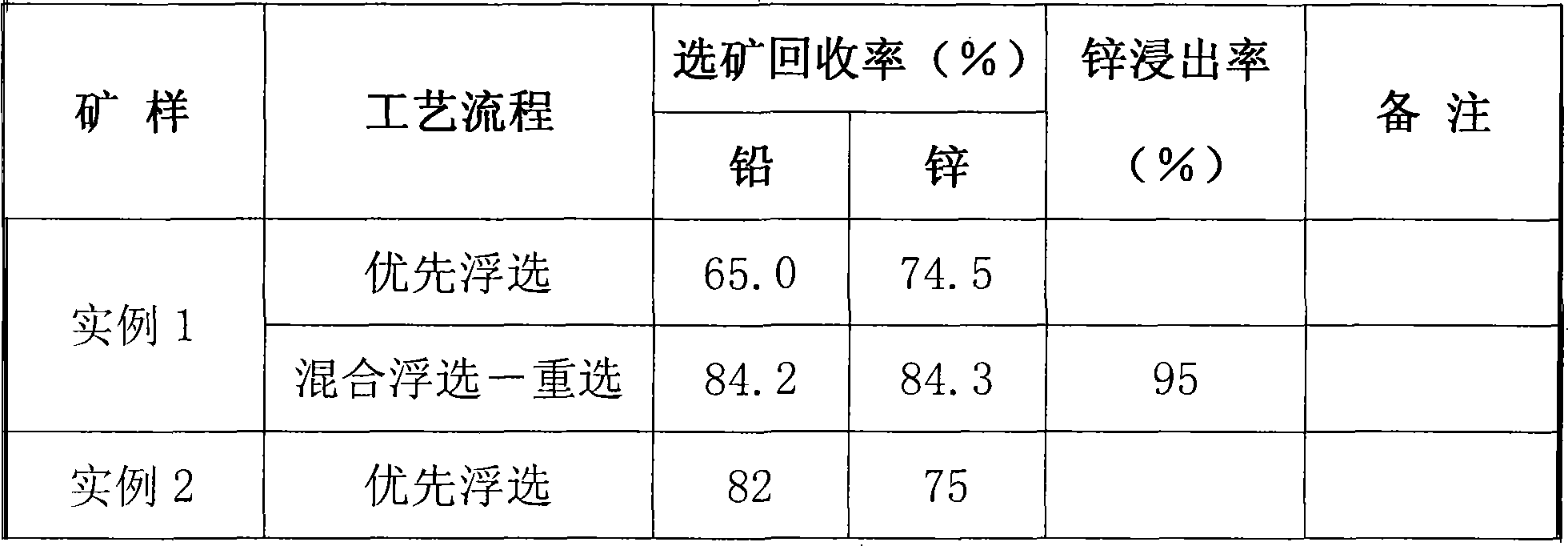

Selecting-smelting method for processing complex hard-washing low ore grade pulmbous sulfide zincium mine

InactiveCN101245407AHigh recovery rateReduce total usageFlotationProcess efficiency improvementLead smeltingZinc metal

The invention relates to a method for treatment of dressing and smelting low-grade lead-zinc sulphur ore with complex dressing and pertains to the filed of metallurgy. The specific steps of the method comprise that the low-grade lead-zinc sulphur ore with complex dressing is selected, the lead-zinc crude mixed concentrate is obtained by adopting a flotation technique and is then selected by adopting a gravity dressing technique so as to obtain part of lead concentrate and lead-zinc sulphur mixed concentrate; the lead-zinc sulphur mixed concentrate is added with acid to mix slurry after being treated with fine grinding and then done with acid pickling in a high-pressure kettle with high temperature and high pressure and oxygen and then the solid-liquid separation is carried out; leaching solution is used for producing zinc metal by the conventional technique of zinc hydrometallurgy, while leaching slag is used for recycling lead and silver metal with the conventional pyrometallurgical technique of lead smelting. The method of the invention adopts less species of additive medicine and dosage thereof and has higher recovery rate of lead and zinc products and lower production cost; meanwhile, tail water can be directly recycled with benefit for environmental protection. In addition, the smelting process of the method is characterized by shorter process, lower production cost and no smoke emission benefiting environmental protection.

Owner:YUNNAN METALLURGICAL GROUP

Method for making cracking rock core

InactiveCN101435331AThe method of making fractured core is simpleBorehole/well accessoriesRock coreZinc metal

The invention relates to a manufacturing method of a fractured rock core, which comprises the steps of manufacturing a mould of the core, sand, clay, aluminium phosphate and a zinc sheet. The method is characterized in that the sand, clay and aluminium phosphate with the weight ration of 50 to 80 : 10 to 40 : 10 to 30 are mixed together, stirred evenly and put into a cylindrical or rectangular mould; then the zinc sheet simulating the fracture strike, shape, width and thickness of the core is put into the simulation position in the mould which is then placed on a pressing machine for shaping at the pressure of 1 to 50MPa by pressing; the sheet is placed in a high temperature furnace for baking after demoulding, the vapourizing temperature of the zinc metal sheet is reached when the temperature is more than 910 DEG C which is maintained for more than 10min; then the furnace is shut down till the zinc sheet is completely vaporized into gas; and when the temperature drops, the fractured rock core is taken out and manufactured.

Owner:中国石化股份胜利油田分公司地质科学研究院

Particulate metal alloy coating for providing corrosion protection

Owner:NOF METAL COATINGS NORTH AMERICA INC

Metal protective coating and hot galvanizing metal material as well as hot-dip aluminium-zinc metal material

ActiveCN103013337AImprove corrosion resistanceImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesZinc metal

The invention provides metal protective coating. The metal protective coating is obtained by uniformly mixing raw material mixture, wherein the raw material mixture contains water soluble silicate, a promoter, a silane coupling agent, silicon oxide filler, water soluble film forming resin and water; the promoter is at least one of pyrrolidone, N-methyl pyrrolidone, and N-ethyl pyrrolidone; and the silane coupling agent contains first silane derivatives shown in formula (1) described in the specification, wherein R1, R2 and R3 are methoxyl or ethoxyl respectively, and n is an integral number ranging from 1 to 4. The invention also provides a hot galvanizing metal material and a hot-dip aluminium-zinc metal material. A protective film formed by the metal protective coating provided by the invention has excellent corrosion resistance, water resistance, heat resistance and fingerprint resistance. Formula (1) is described in the specification.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

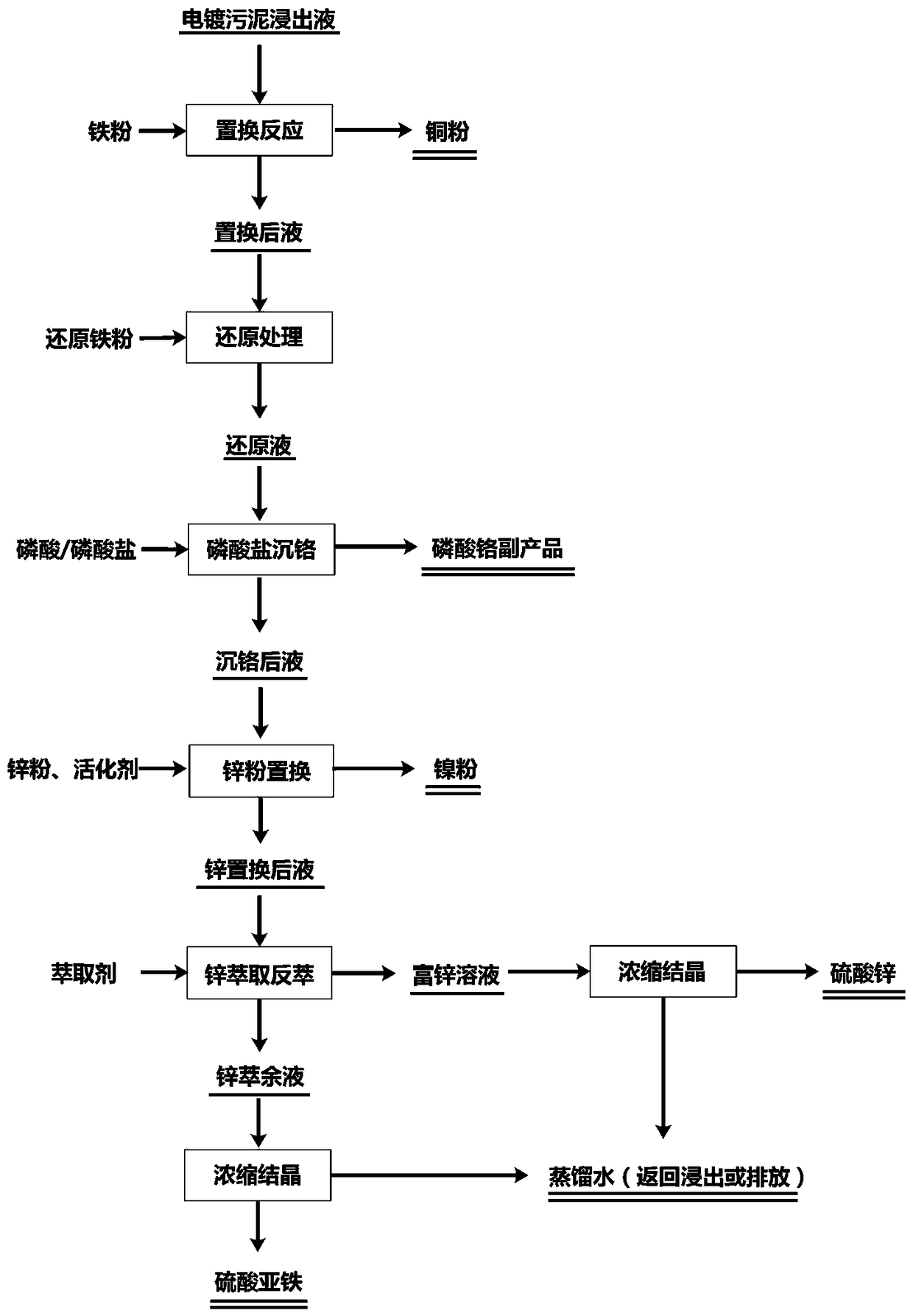

Method for separating iron, chromium, nickel, copper and zinc from high-iron high-chromium electroplating sludge leachate

The invention provides a method for separating iron, chromium, nickel, copper and zinc from high-iron high-chromium electroplating sludge leachate. The method comprises the following steps: (1) addingiron powder into the leachate to obtain a copper powder product and replaced liquid; 2) adding iron powder into the replaced liquid to obtain reduced liquid; (3) adding a chromium precipitating agentinto the reduced liquid, and carrying out filtering to obtain chromium-precipitated liquid and a chromium precipitate; (4) adding the activator antimony salt and zinc dust into the chromium-precipitated liquid, carrying out a reaction, and then carrying out filtering to obtain nickel powder and nickel-removed liquid; (5) adding an acidic phosphate extraction agent into the nickel-removed liquid to extract zinc, then carrying out reextraction by using dilute sulfuric acid, subjecting a zinc-rich solution to concentration and crystallization to prepare a zinc salt product, and subjecting zinc raffinate to subsequent treatment; and (6) subjecting the zinc raffinate to concentration and crystallization to prepare ferrous sulfate heptahydrate, and returning distilled water for leaching. The separation method of the invention has the advantages of short process and high efficiency, and can effectively solve the problem difficulties in separate separation of chromium, iron, nickel, copper and zinc metals in the high-iron high-chromium electroplating sludge leachate.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

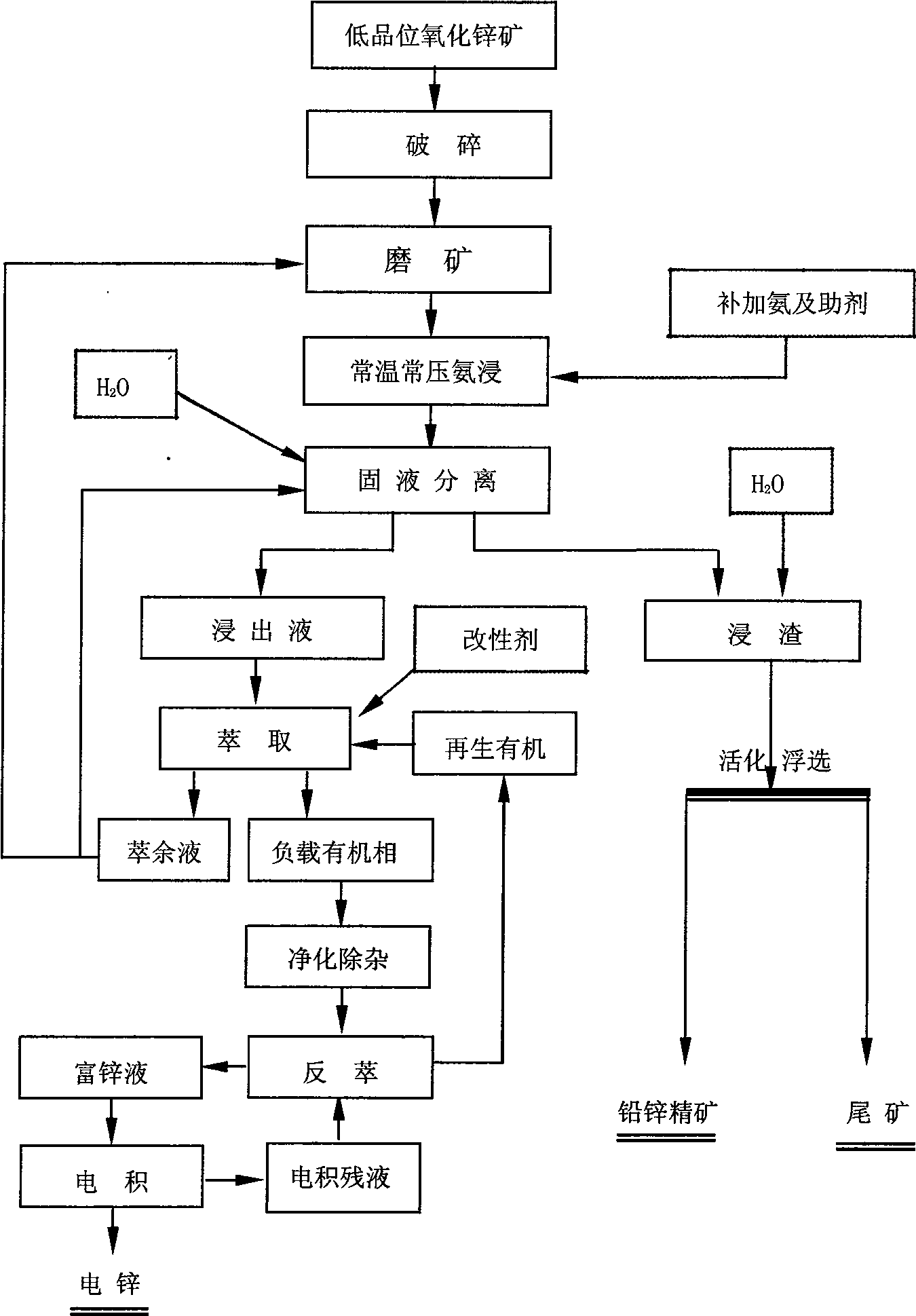

Method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration

InactiveCN101530826AHigh recovery rateReduce the amount of dissolutionWet separationZinc metalResource utilization

The invention provides a method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration, comprising the processing techniques of ammonia leaching under normal temperature and pressure-extraction-electrodeposition-leaching floatation, which not only gives full play to the advantage of wet method melting technique in recovering zinc in the oxidized lead zinc ore but also gives full play to the advantage of floatation technique in recovering vulcanized lead zinc; what is more, the advantages in the two aspects are organically combined and have shared complementary advantages, thus realizing integrated optimization of concentration technique, forming a brand-new combined process for concentration of low-grade zinc oxide ore, improving recovery rate of lead and zinc metal and achieving the effect of improving resource utilization rate and saving energy, lowering energy consumption and reducing pollutants discharge on the whole.

Owner:KUNMING UNIV OF SCI & TECH

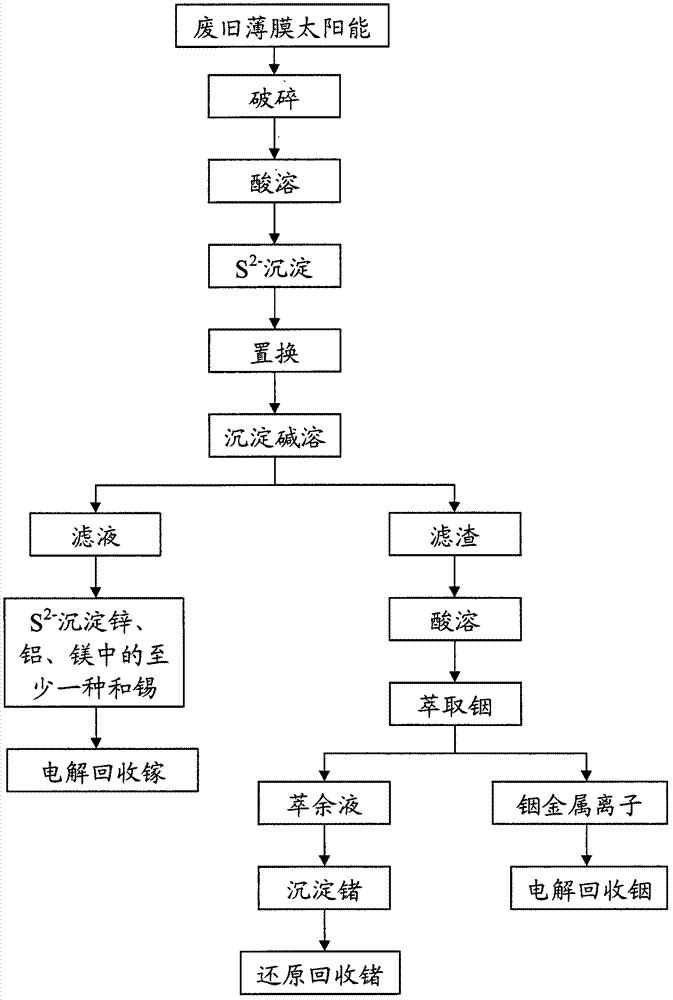

Method for recycling gallium, indium and germanium from wasted thin-film solar cells

ActiveCN103199148AHigh purityReduce recycling costsFinal product manufactureElectronic waste recyclingIndiumCopper

The invention provides a method for recycling gallium, indium and germanium from wasted thin-film solar cells. The method includes the steps: obtaining first separation liquid containing metal ions of the gallium, the indium, the germanium, cadmium, copper, tin and zinc; obtaining second separation liquid; obtaining filter residues containing the gallium, the indium, the germanium and the tin; obtaining fourth separation liquid and an indium and germanium metal solid which is not dissolved in a lye solution; conducting the steps of recycling gallium metal; conducting the steps of recycling indium metal; and conducting the steps of recycling germanium metal. According to the method for recycling the gallium, the indium and the germanium from the wasted thin-film solar cells, various dissipated metal such as the gallium, the indium and the germanium can be respectively recycled step by step, recycling cost can be effectively reduced, the recycling efficiency is improved, and the method is simple in process and is suitable for industrial production. In addition, through the method for recycling the gallium, the indium and the germanium from the wasted thin-film solar cells, the various dissipated metal such as the gallium, the indium and the germanium is high in purity, and the purity can reach up to 99.99%.

Owner:GEM CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com