Efficient multilayer composite electrode wire and preparation method thereof

A multi-layer composite, electrode wire technology, applied in the direction of electrode manufacturing, electric processing equipment, manufacturing tools, etc., can solve the problems of unsatisfactory cutting speed, poor cutting stability, multiple phases disorder, etc., to achieve comprehensive cutting. Low cost, improved cutting efficiency, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

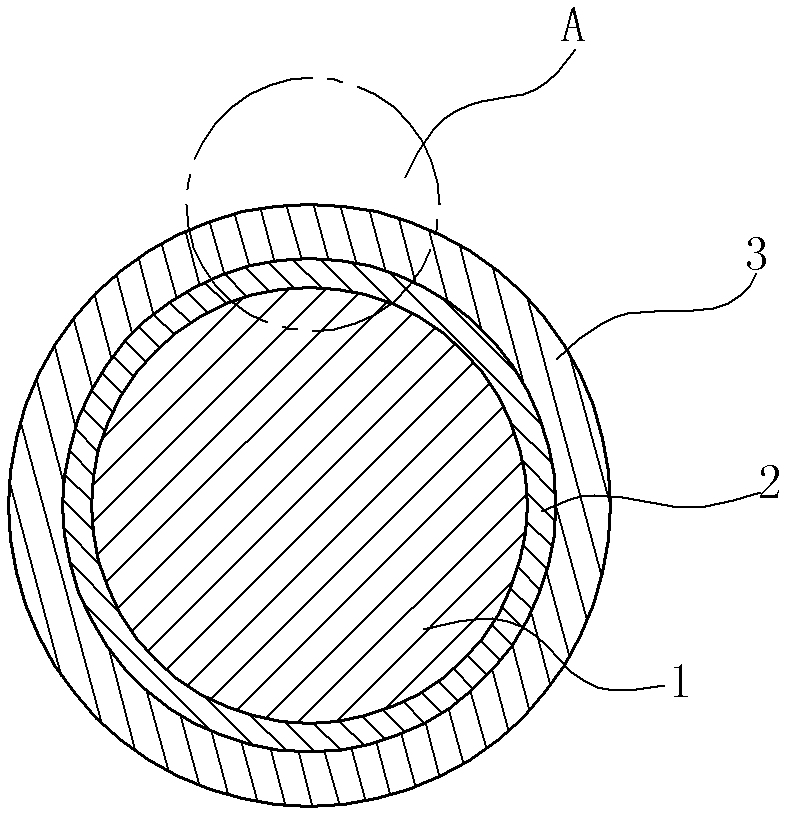

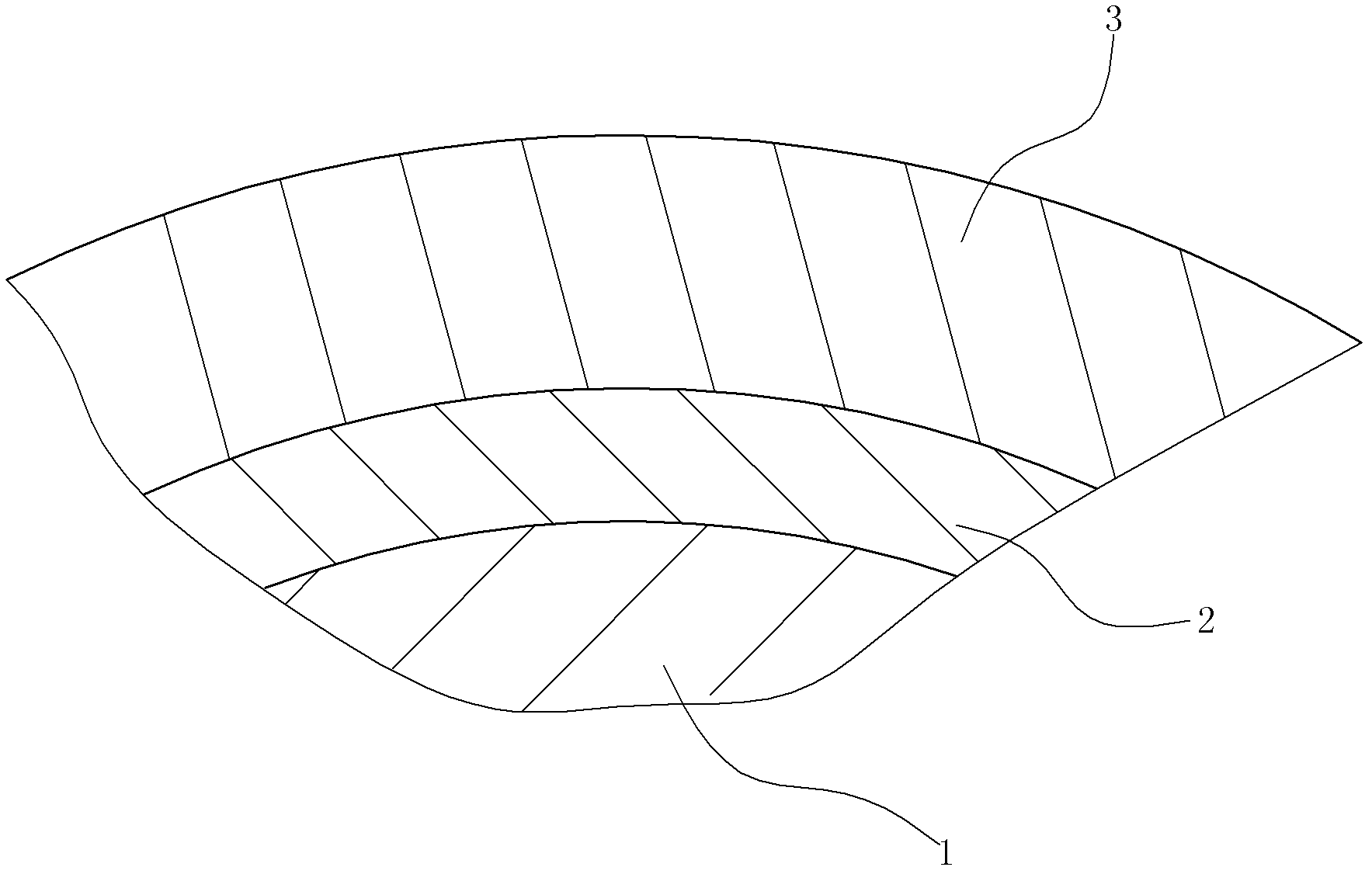

[0037] A core wire 1 with a diameter of 0.6mm is selected, and a layer of copper metal coating 2 with a thickness of 3 μm is electroplated on the core wire according to a conventional method, and then a layer of zinc metal coating 3 with a thickness of 9 μm is electroplated on the copper metal coating 2 , to obtain the first wire blank 4. Such as figure 1 and figure 2 shown.

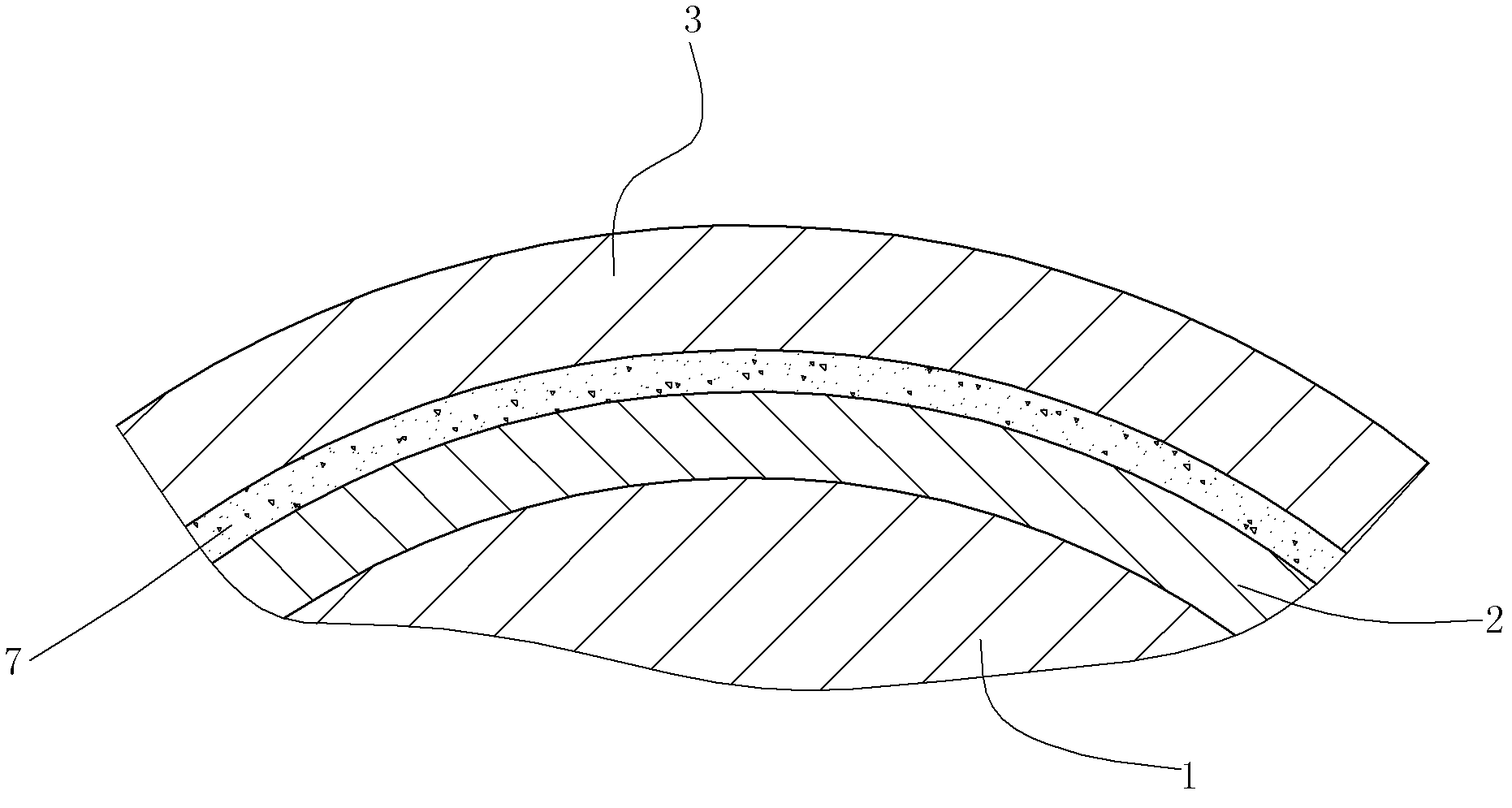

[0038] Diffusion annealing treatment is performed on the first wire blank, the diffusion annealing temperature is 450° C., and the diffusion annealing time is 20 seconds. The changes of the metallographic structure of the core wire and the two metal coatings during the diffusion annealing process are as follows: Figure 3 to Figure 7 shown.

[0039] in image 3 After the diffusion annealing starts, the interdiffusion between the copper metal coating and the zinc metal coating forms β, β′, γ and other tissue layers 7 . With increasing annealing time, as Figure 4 As shown, the continuous diffusion...

Embodiment 2

[0047] A core wire with a diameter of 0.8 mm is selected, and a copper metal coating with a thickness of 3 μm and a zinc metal coating with a thickness of 9 μm are sequentially electroplated to obtain a first wire blank.

[0048] Diffusion annealing treatment is performed on the first wire blank, the diffusion annealing temperature is 475° C., and the diffusion annealing time is 15 seconds.

[0049] After the diffusion annealing, the second wire billet is water-cooled, and the cooling temperature is 50°C.

[0050] The second wire billet was subjected to continuous drawing and continuous annealing processing to produce a high-efficiency multilayer composite electrode wire with a diameter of 0.15 mm and a thickness of the foreskin of 2.25 μm.

[0051] The scanning electron microscope photo of the high-efficiency multilayer composite electrode wire is as follows: Figure 9 As shown, the mass percentage of the metal at the surface layer is Cu: 29.4%, Zn: 70.6%.

[0052] Its comp...

Embodiment 3

[0054] A core wire with a diameter of 1.0 mm was selected, and a copper metal coating with a thickness of 5 μm and a zinc metal coating with a thickness of 6 μm were electroplated sequentially from the inside to the outside to obtain the first wire blank.

[0055] Diffusion annealing treatment is performed on the first wire blank, the diffusion annealing temperature is 500° C., and the diffusion annealing time is 10 seconds.

[0056] After the diffusion annealing, the second wire billet is water-cooled, and the cooling temperature is 40°C.

[0057] The second wire billet is subjected to continuous drawing and continuous retreat processing to produce a high-efficiency multi-layer composite electrode wire with a diameter of 0.3 mm and a thickness of the foreskin of 3.3 μm.

[0058] The scanning electron microscope photo of the high-efficiency multilayer composite electrode wire is as follows: Figure 10 As shown, the mass percentage of metal at the surface layer is Cu: 27.6%, Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com