Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7578 results about "Composite coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A composite coating is the combination of two or more substances that offer protection against corrosion. This special type of coating is chiefly based on epoxy and polyurethane as well as resin. It is produced through state-of-the-art resin technology in order to meet the requirements of various industries.

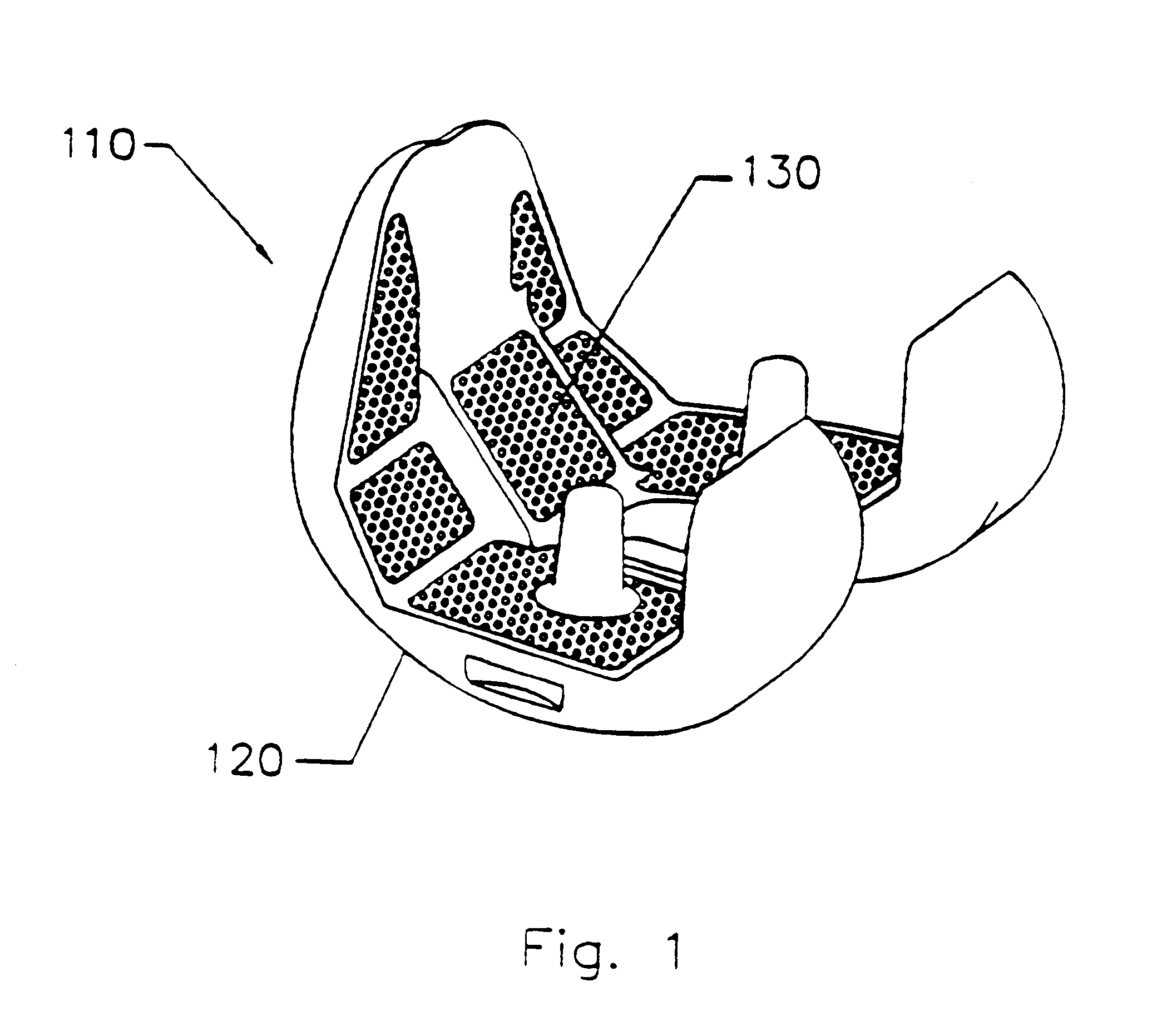

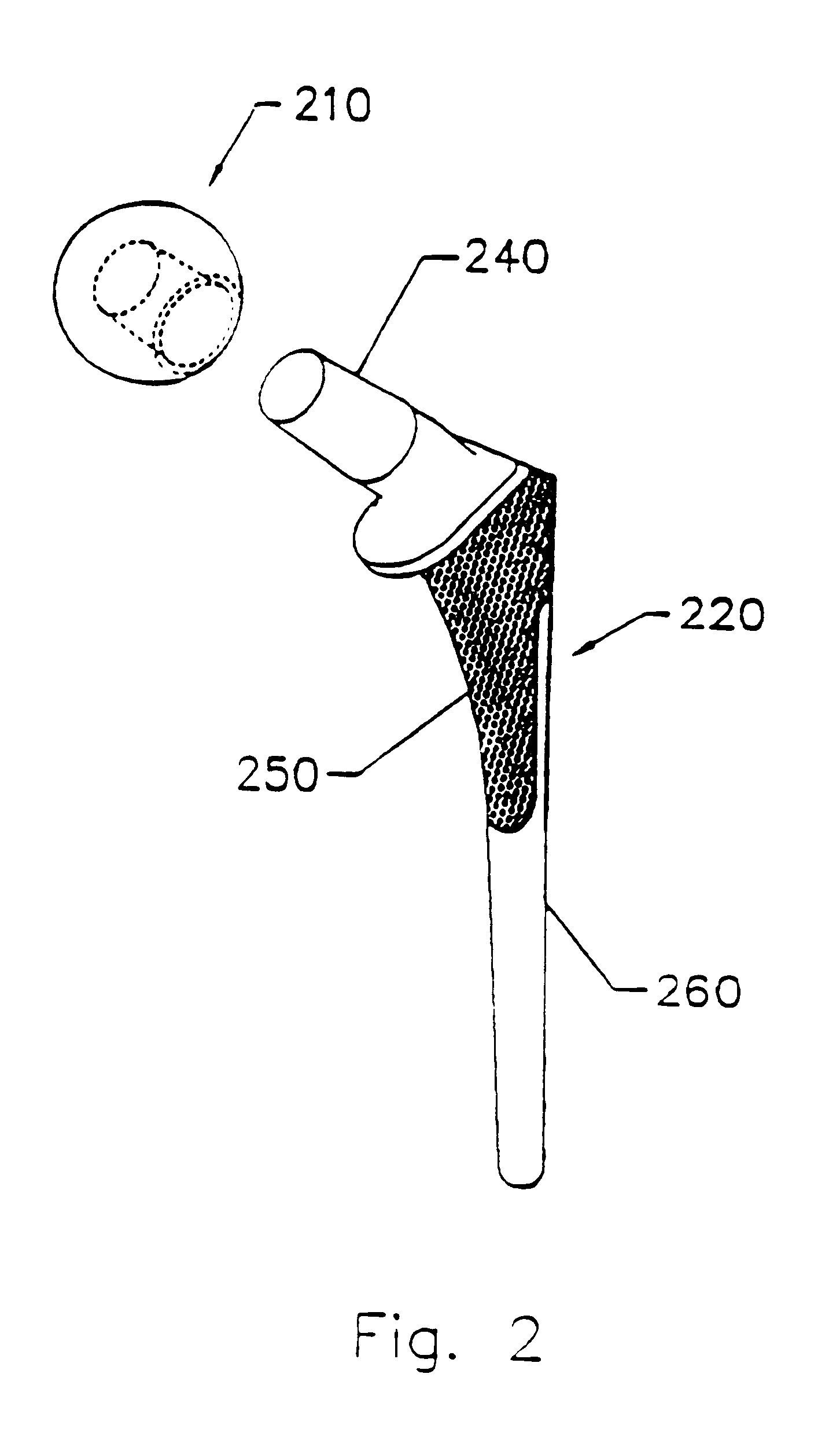

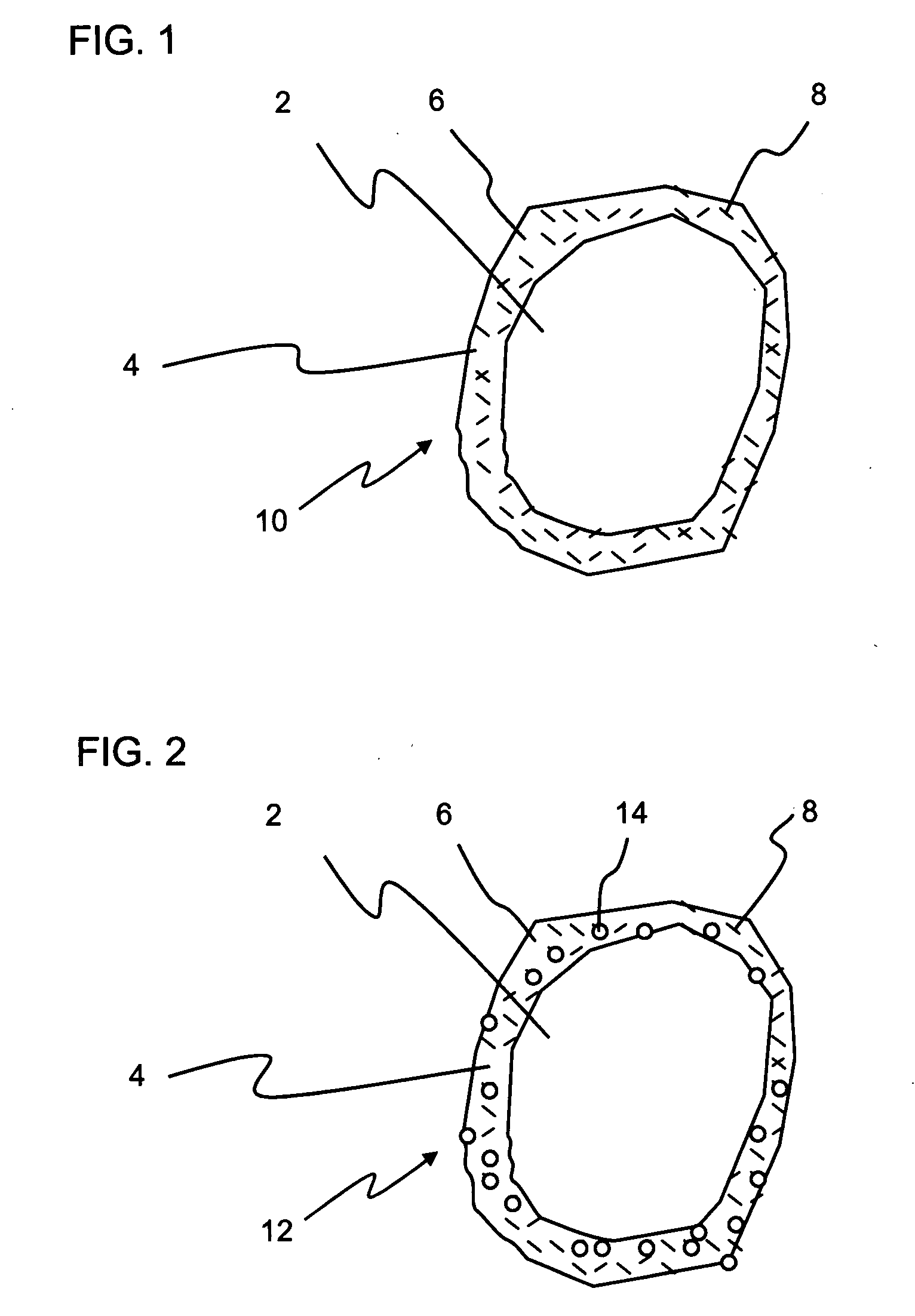

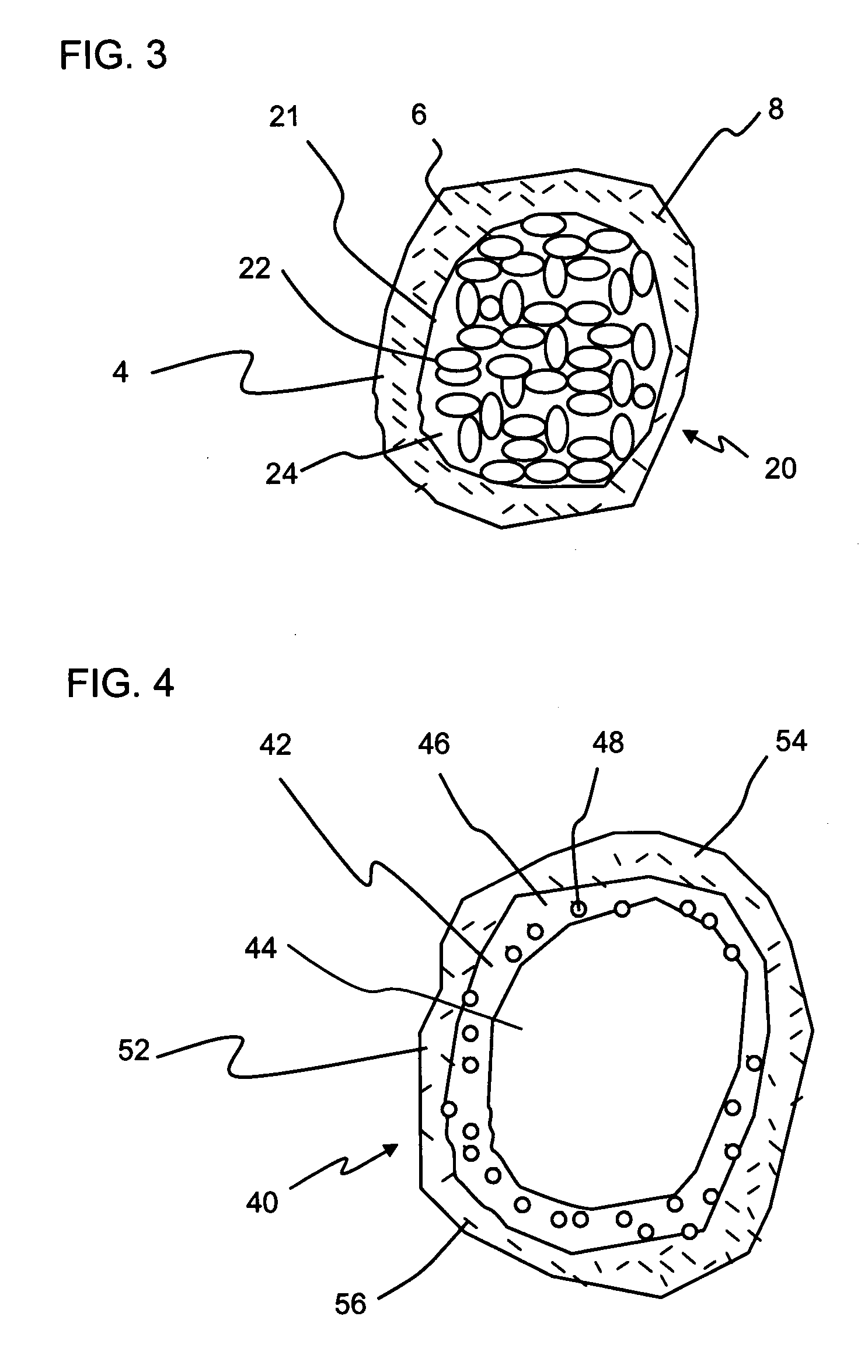

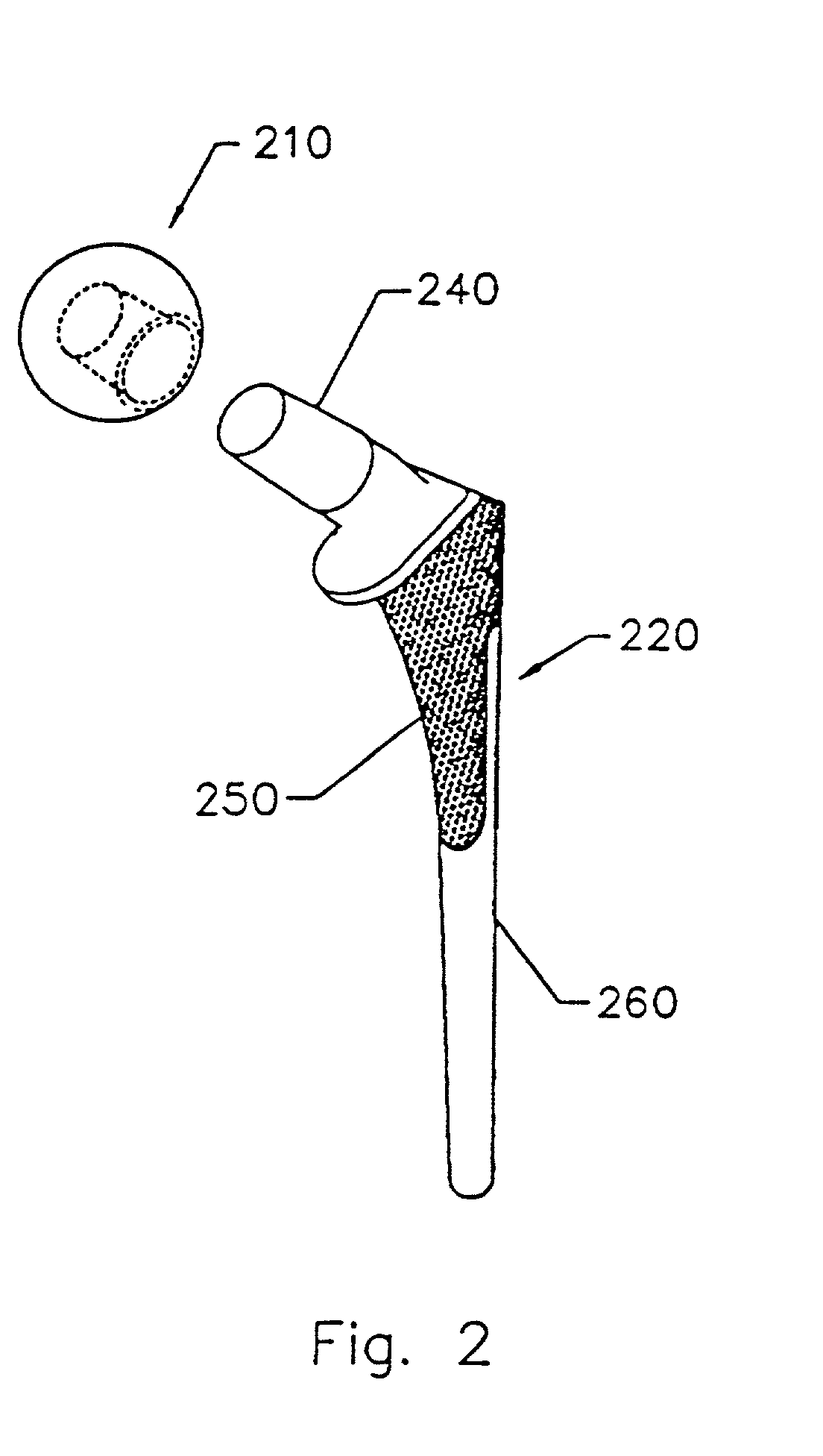

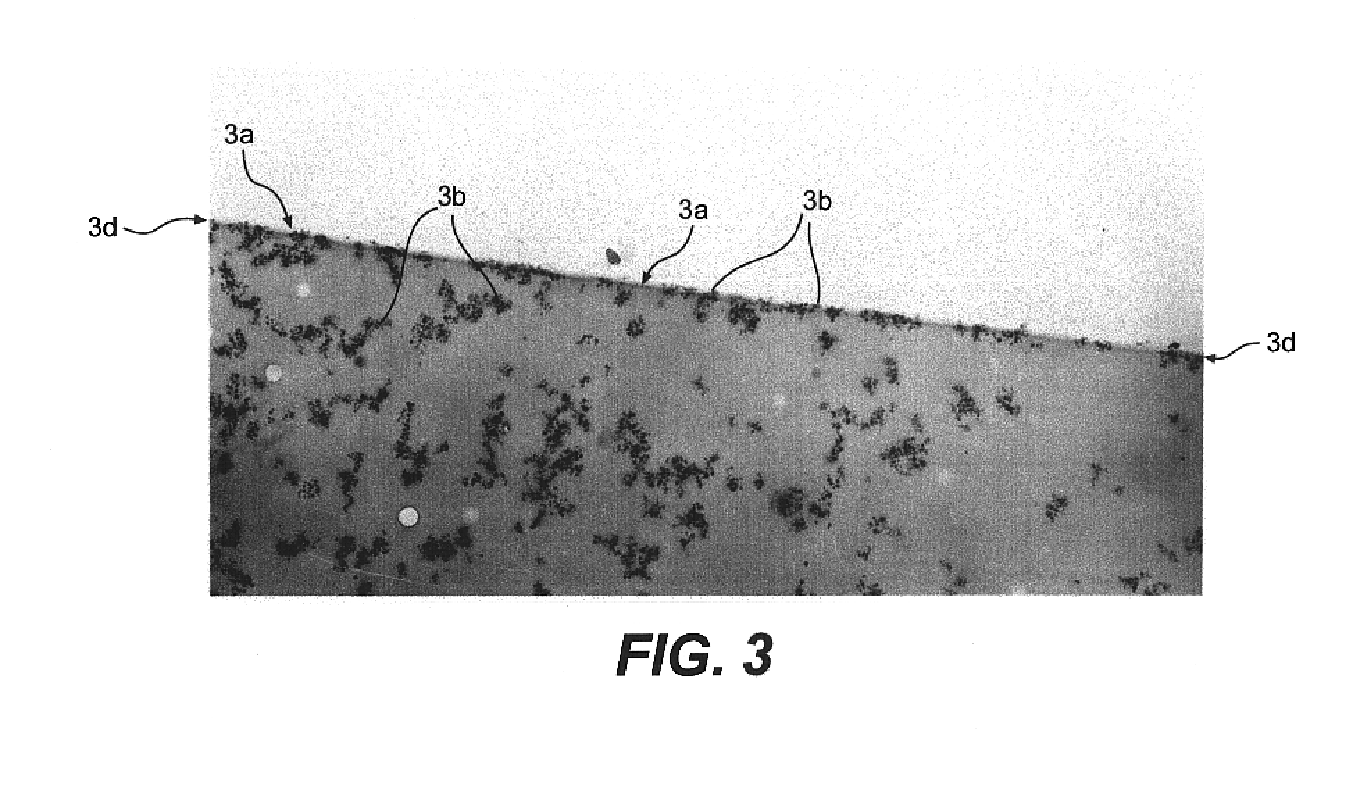

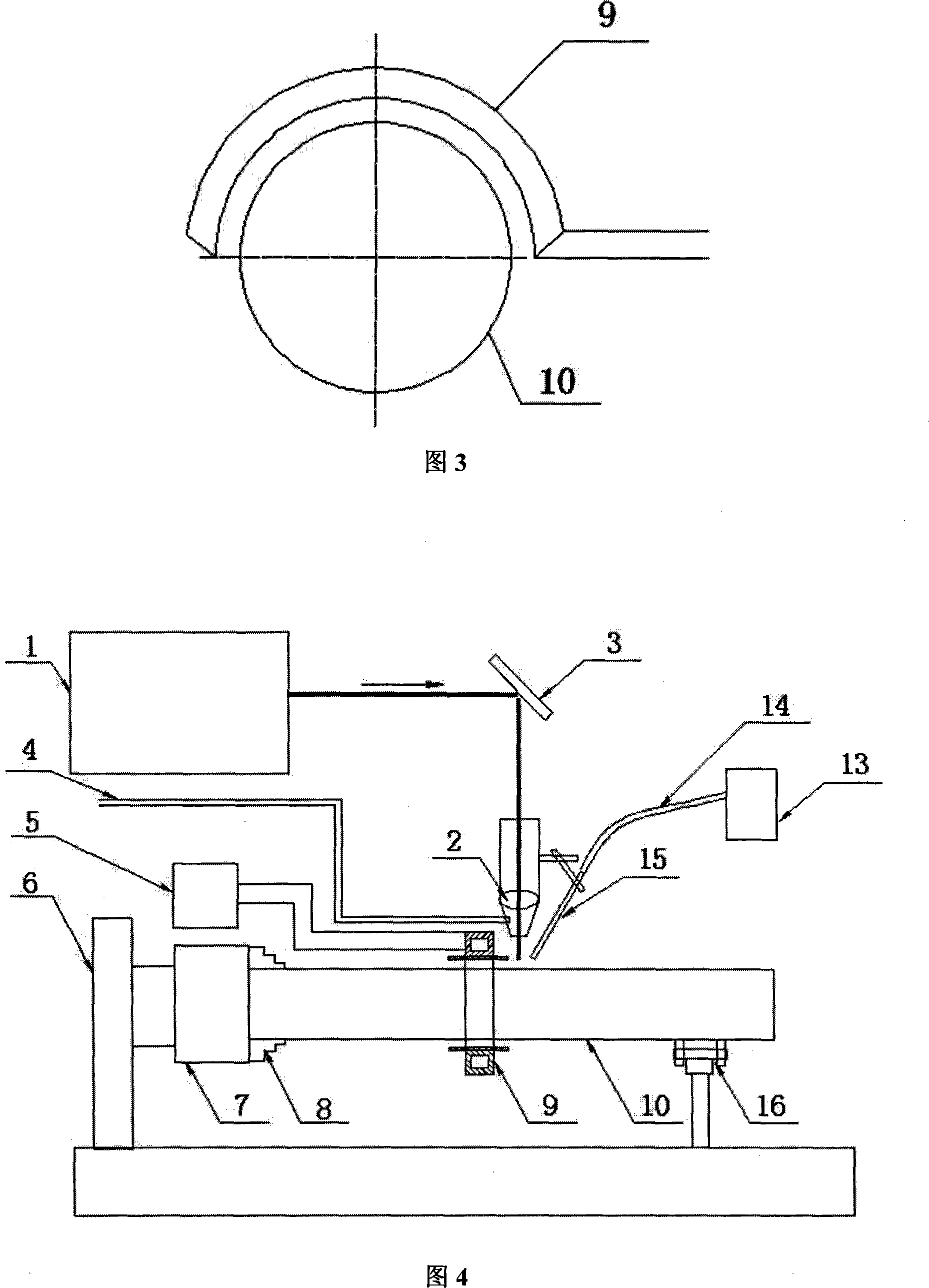

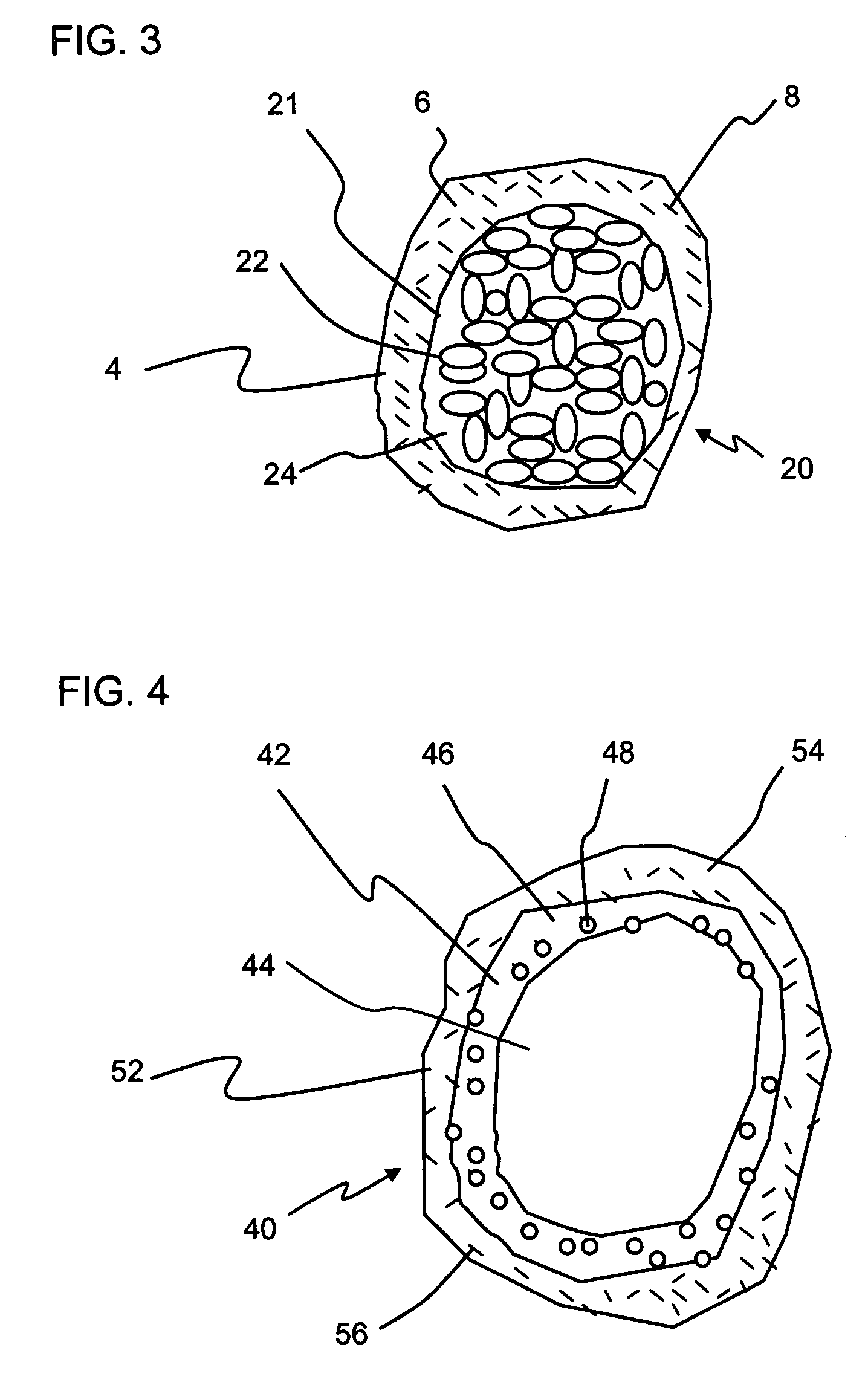

Implant with composite coating

InactiveUS6261322B1High strengthCost effectiveImpression capsBone implantBiocompatible coatingBiocompatibility Testing

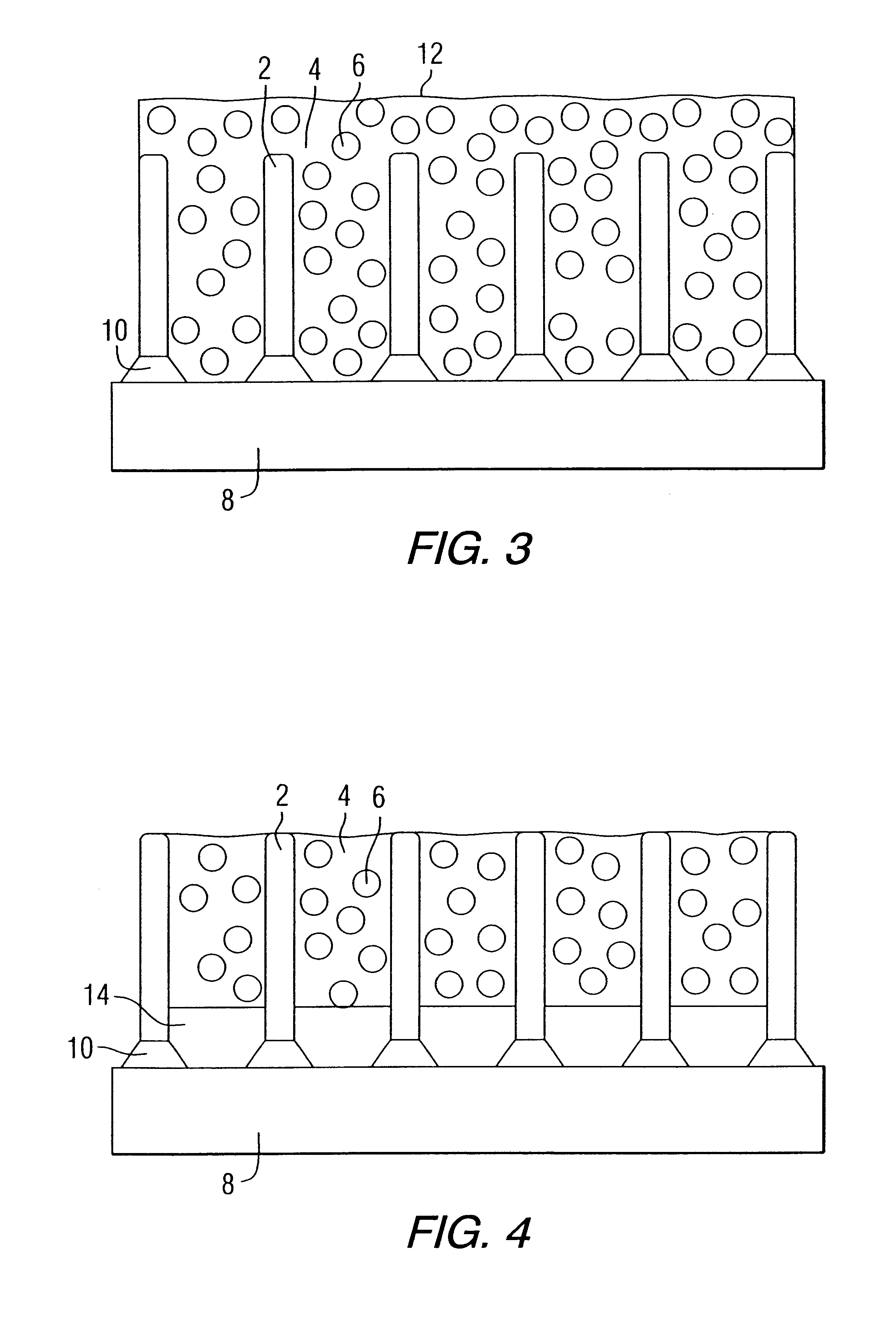

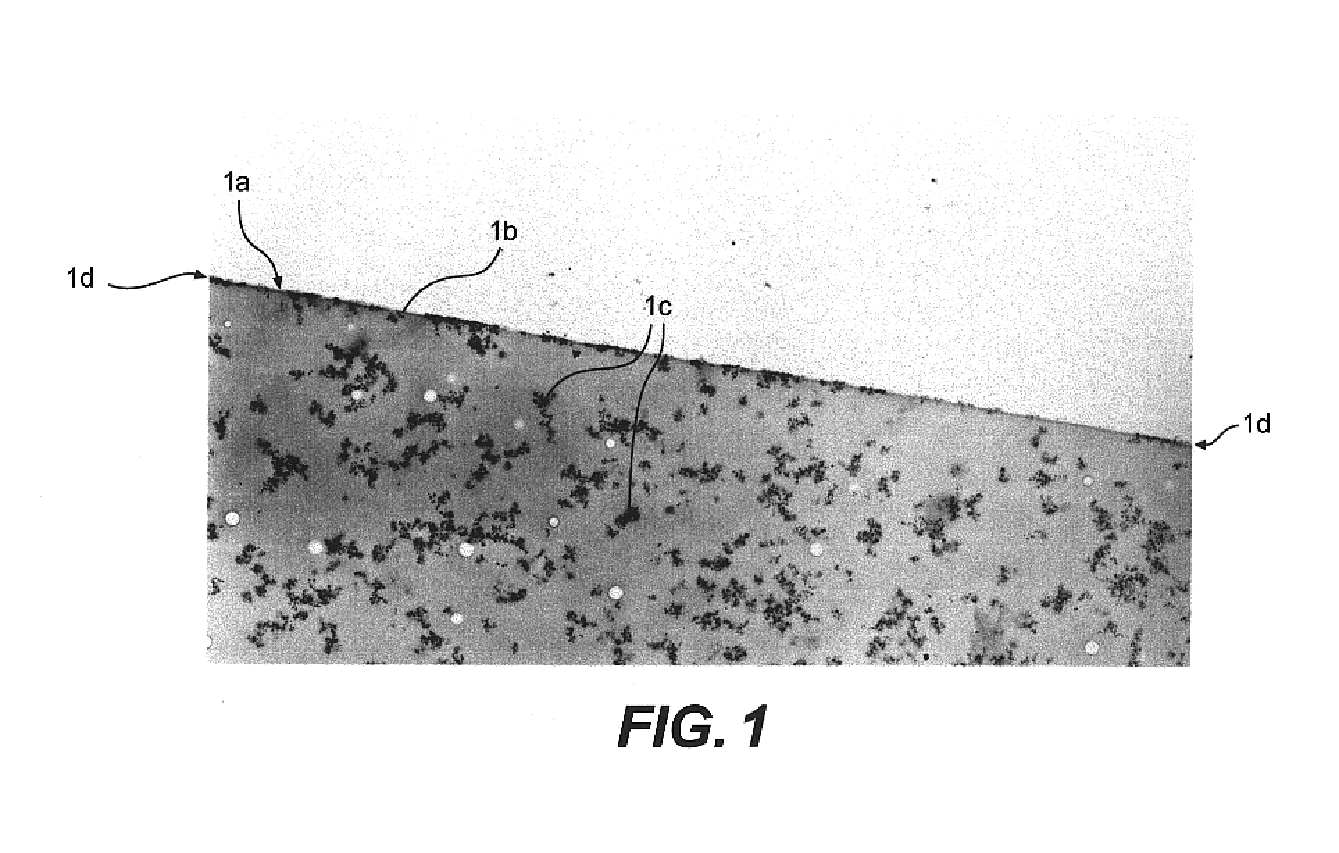

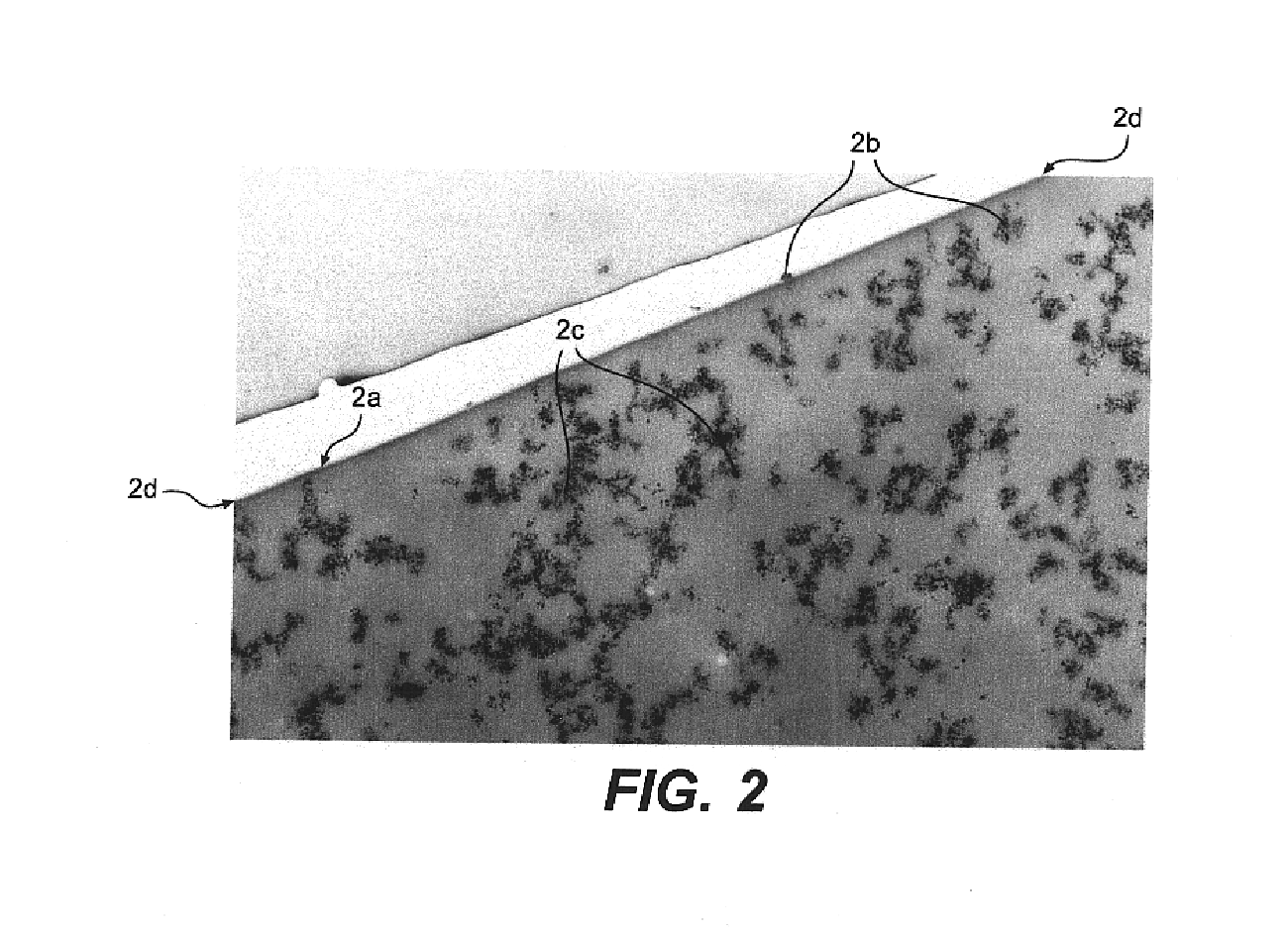

Systems and methods are described for implants with composite coatings to promote tissue in-growth and / or on-growth. An implant includes: a substrate; a structured surface formed on at least a portion of the substrate; and a biocompatible coating deposited on at least a fraction of the structured surface. The systems and methods provide advantages in that the implant has good biocompatibility while the biocompatible coating has good strength.

Owner:SHALBY ADVANCED TECH INC

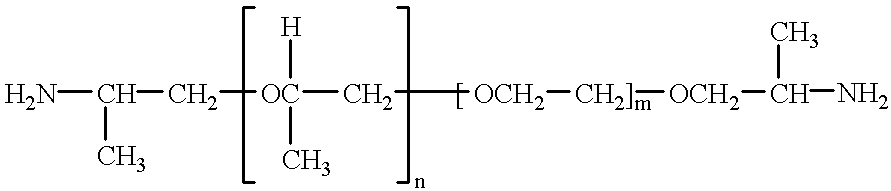

Multi-component coatings that include polyurea coating layers

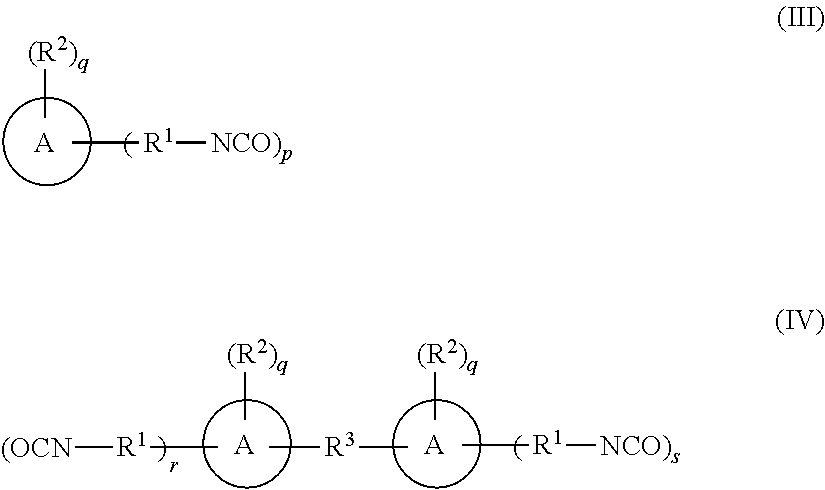

ActiveUS20060046068A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

A polyurea composition, a multi-component composite coating and articles formed therefrom, and methods of forming the same are disclosed. The coating composition is formed from a reaction mixture comprising an isocyanate-functional component and an amine-functional component. The ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 while the volume mixing ratio of the isocyanate-functional component to the amine-functional component is capable of being applied to a substrate at 1:1.

Owner:PPG IND OHIO INC

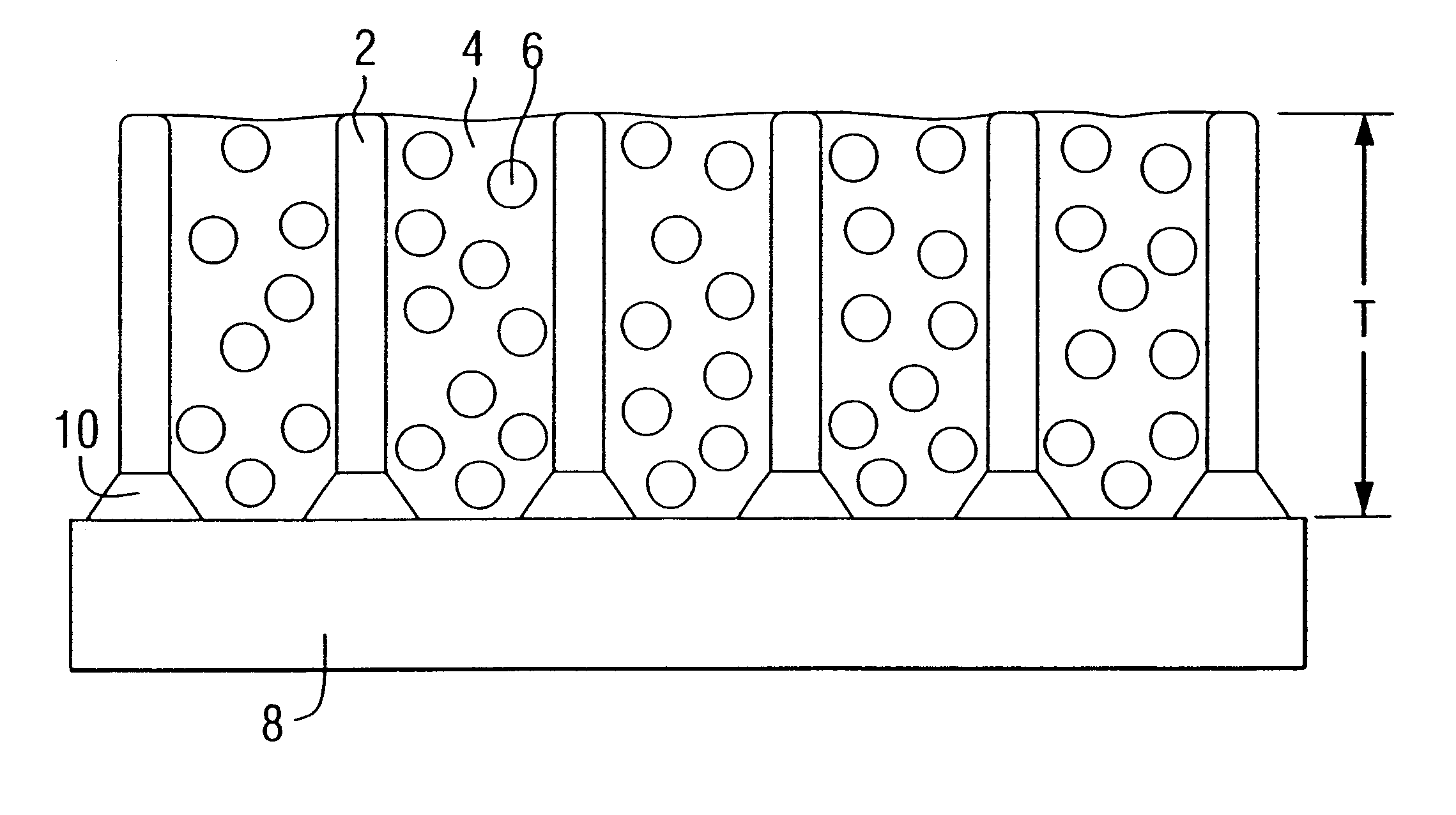

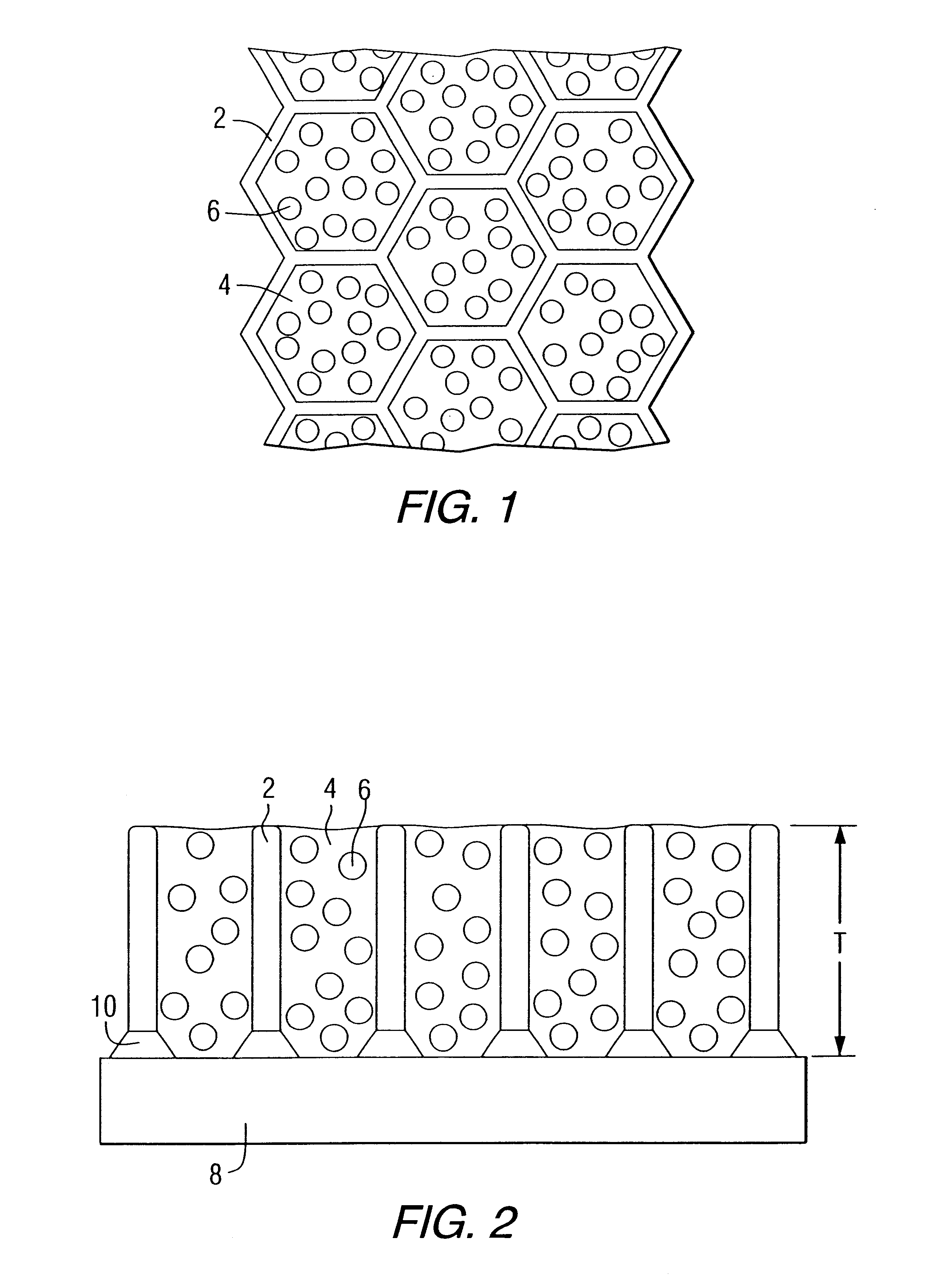

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

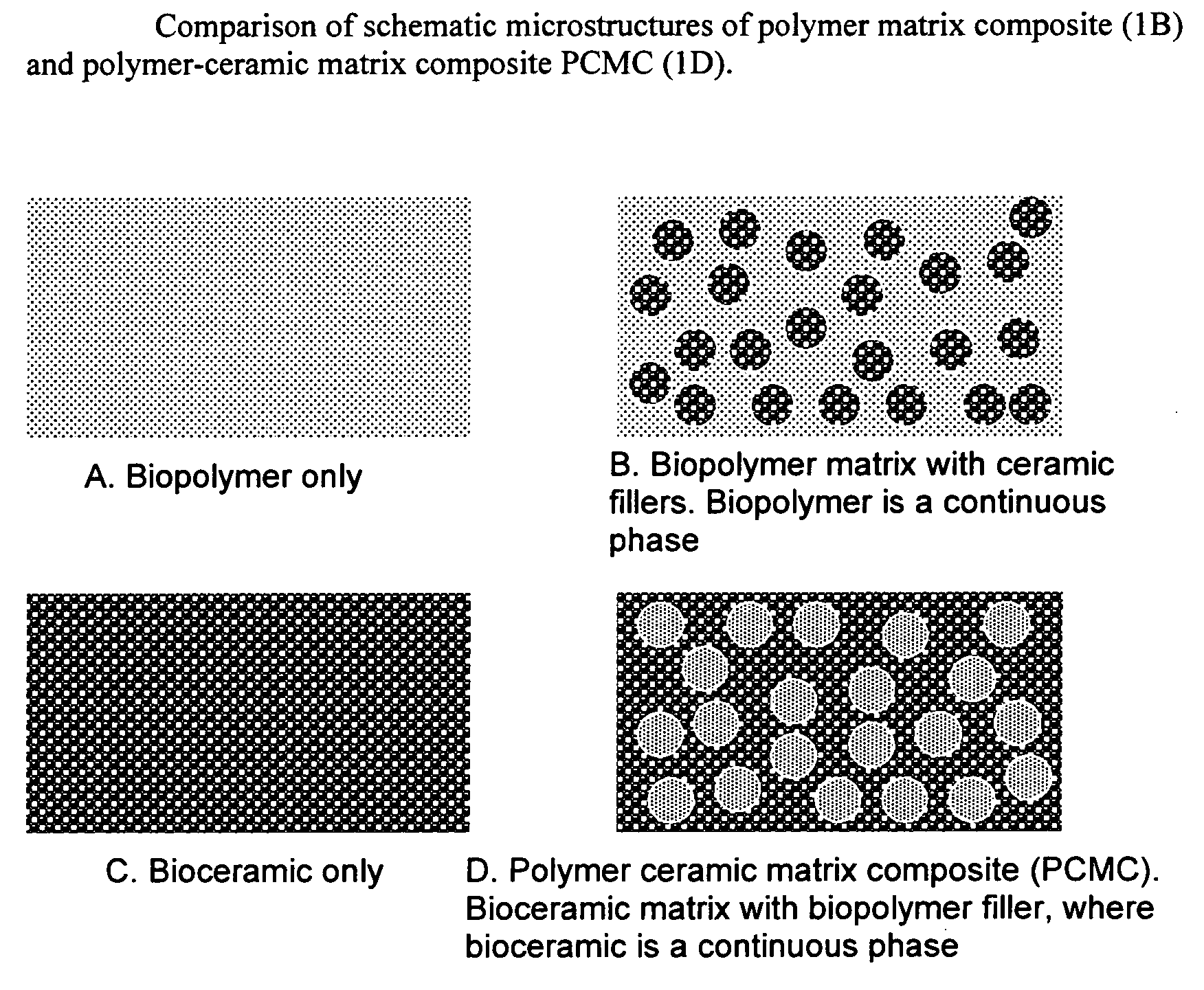

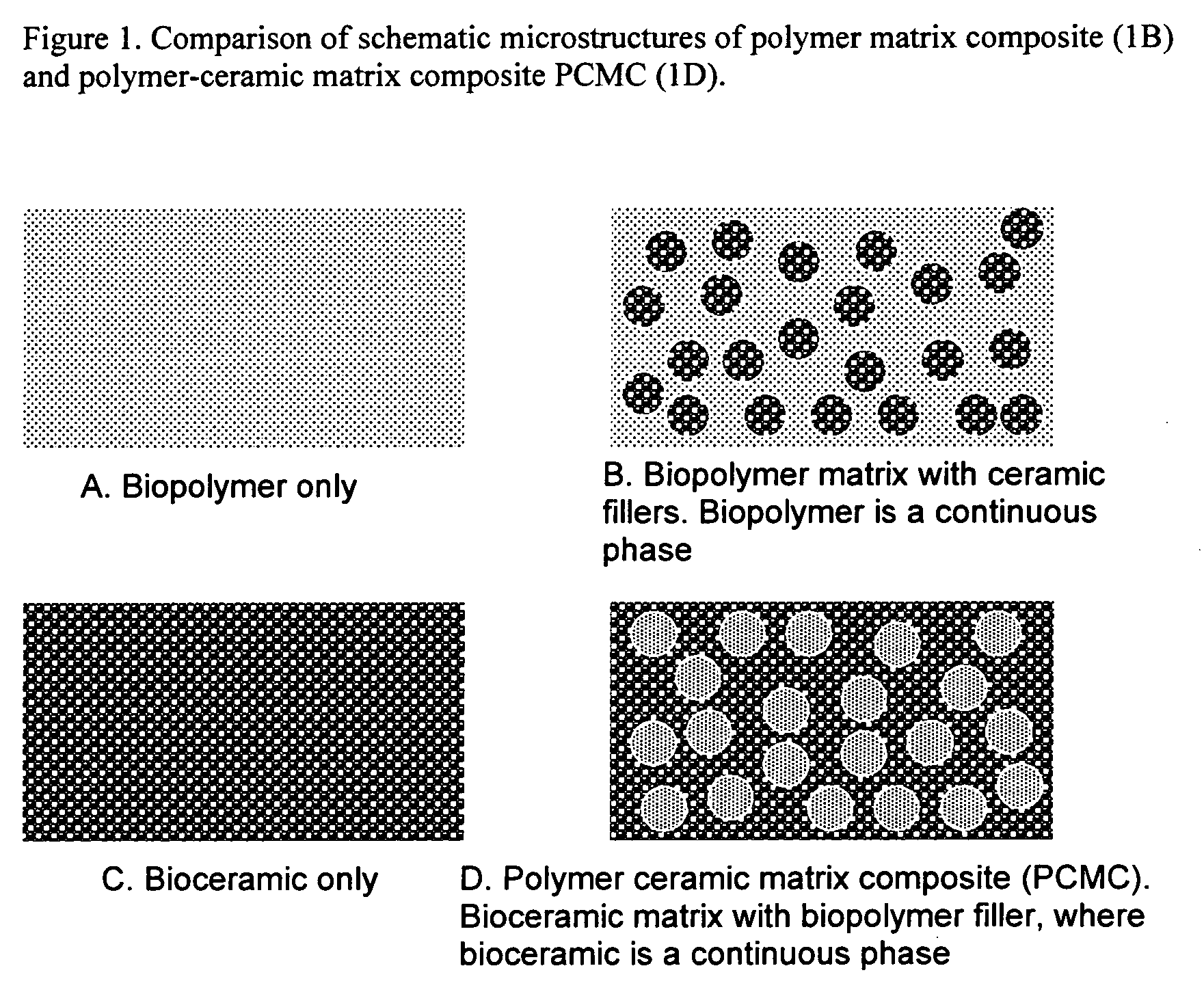

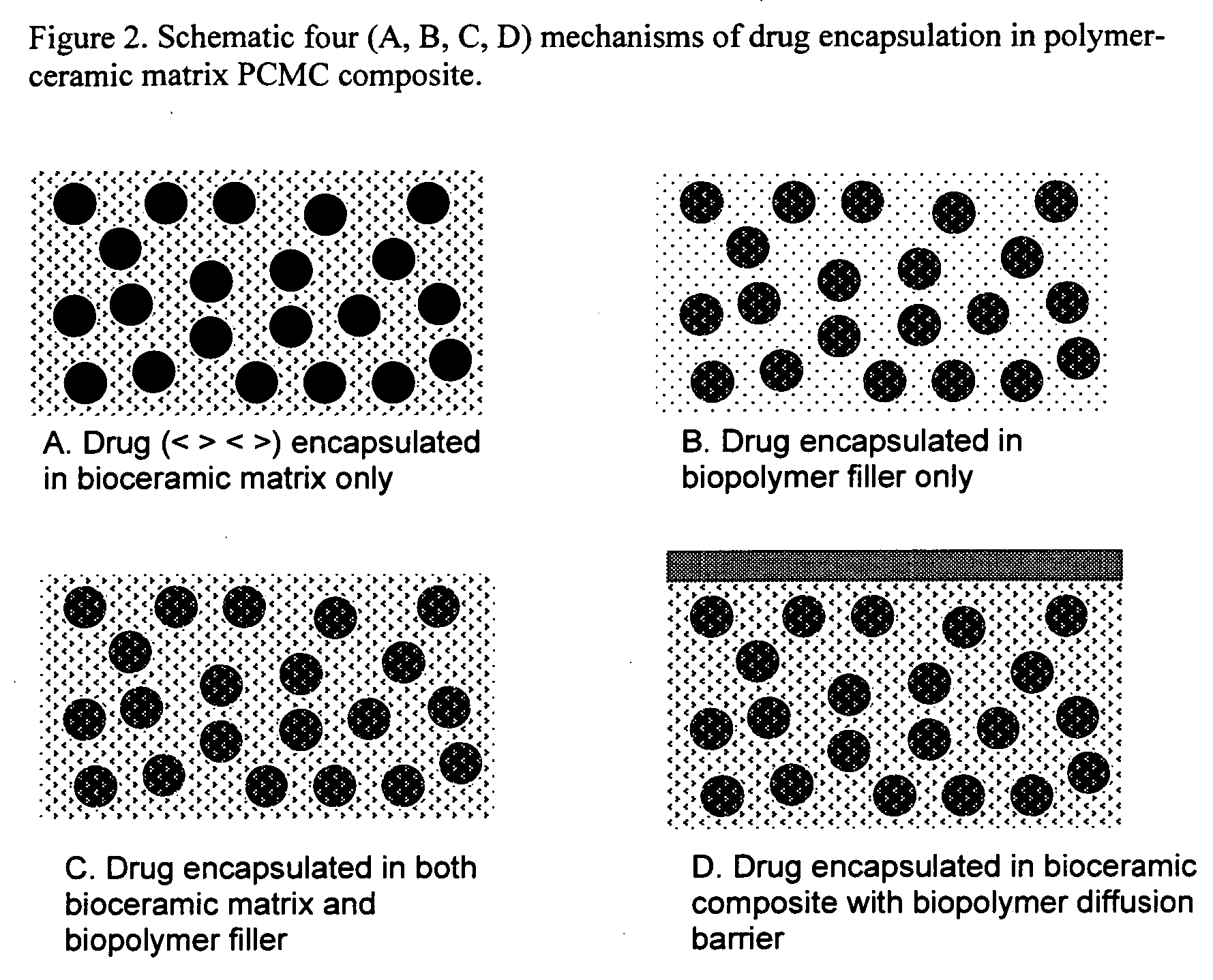

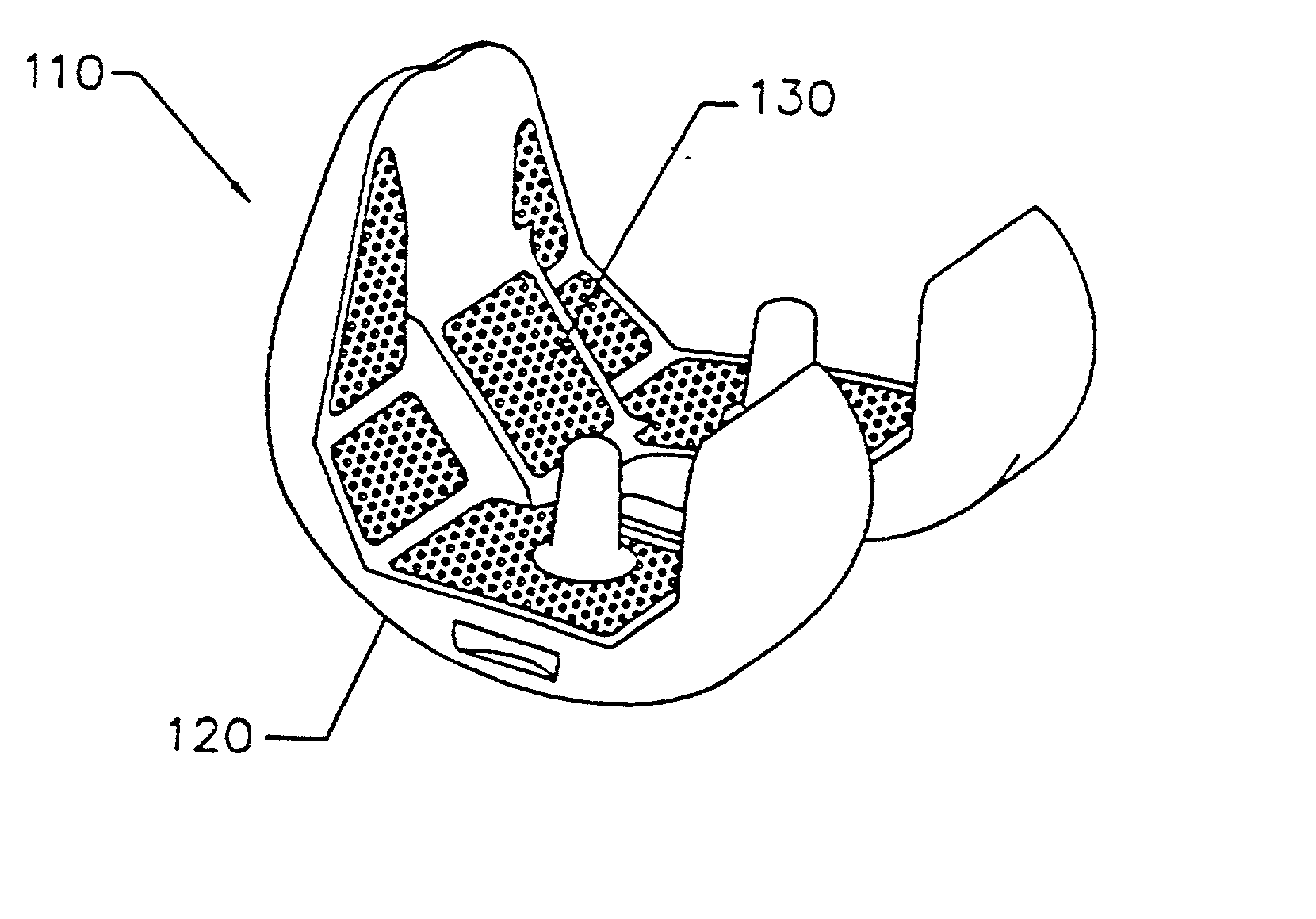

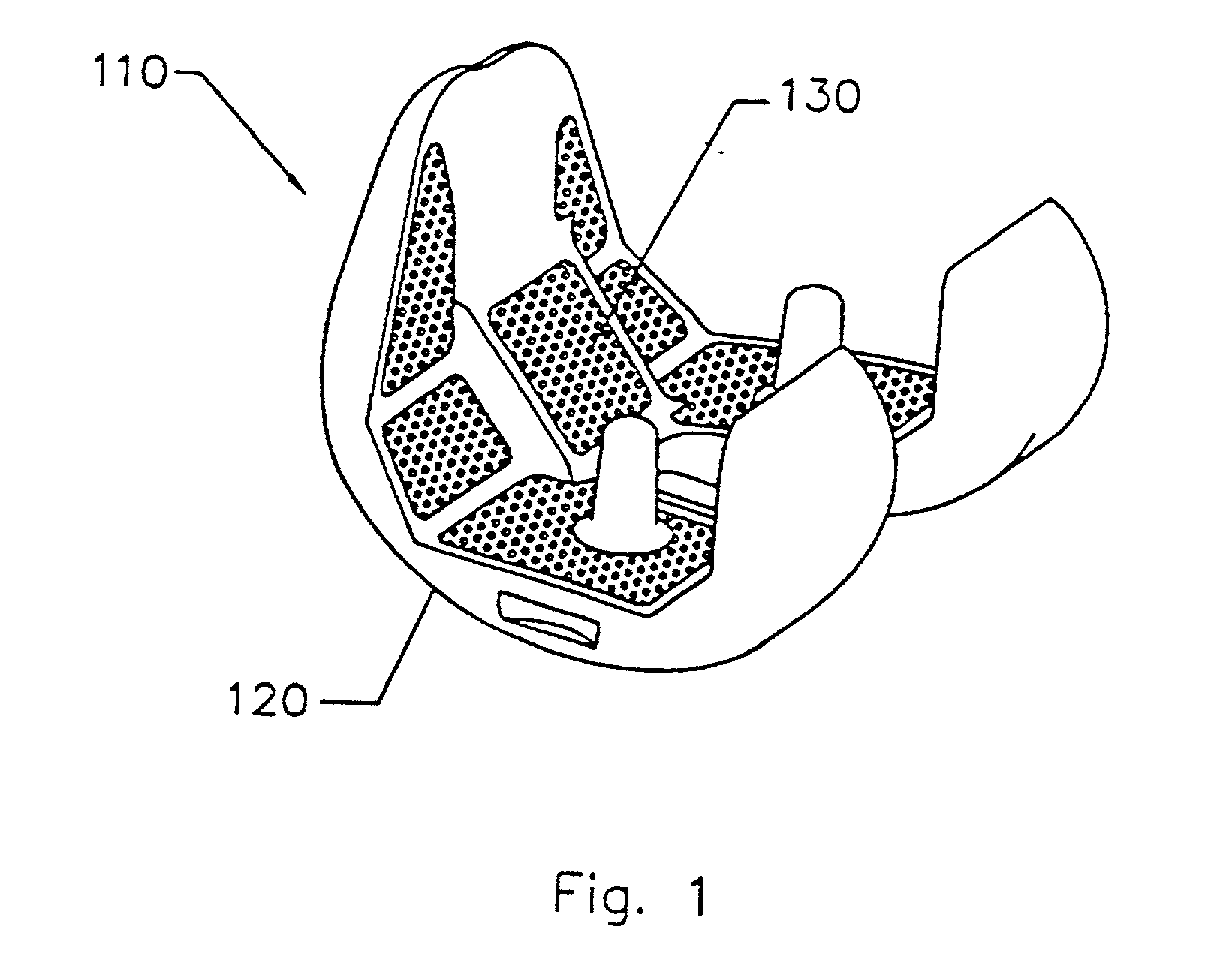

Bioceramic composite coatings and process for making same

The present invention discloses novel polymer-ceramic matrix composites and processes for making same. The composites can be used in biomedical applications, in particular, coatings of implants and other medical devices, where both the ceramic phase and the polymer phase are bio-compatible. The composites combine a reinforcing polymer phase with a continuous ceramic matrix to create materials with properties that are new and superior to polymer or ceramic phases alone. The composites can incorporate a bioactive agent.

Owner:THE UNIV OF BRITISH COLUMBIA

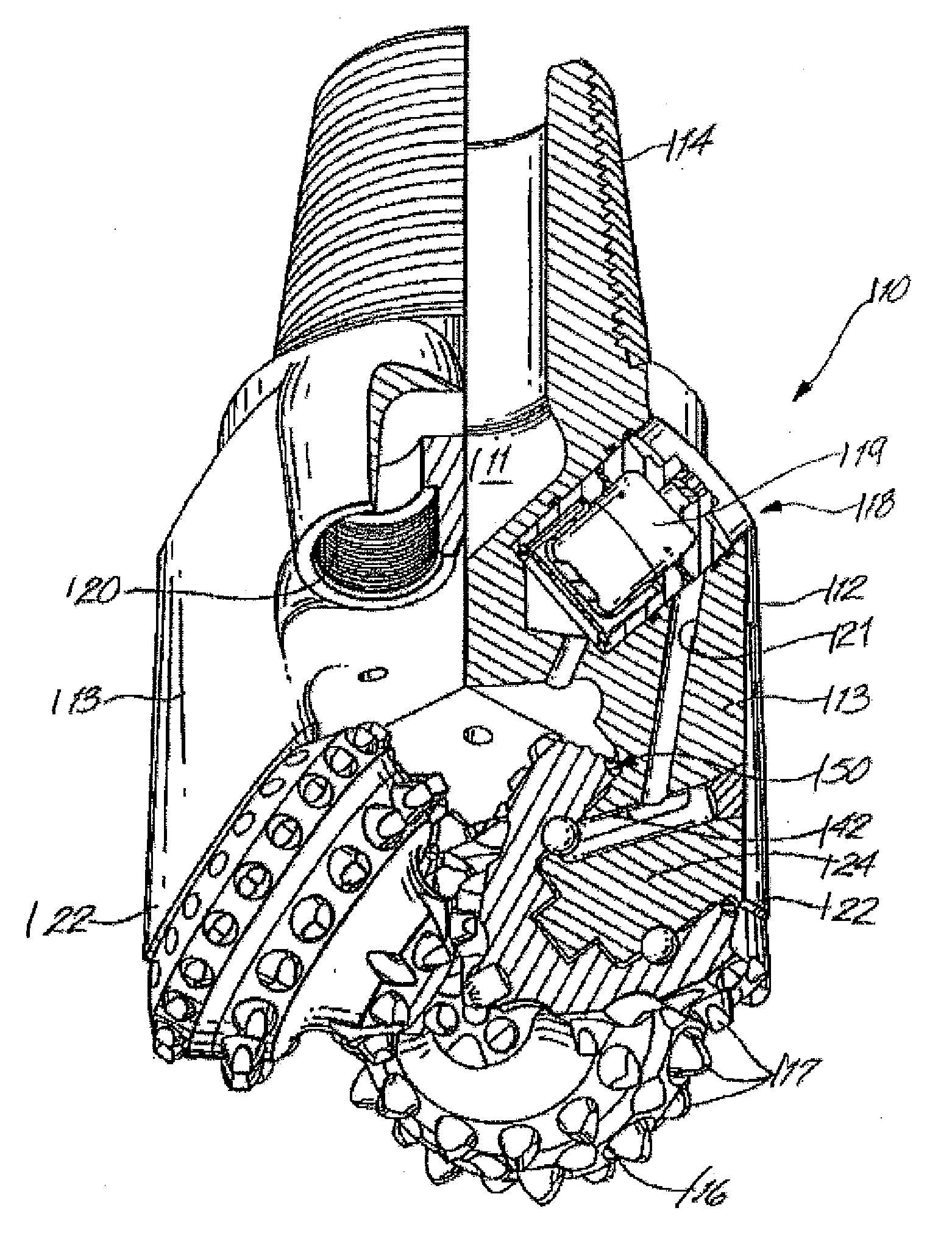

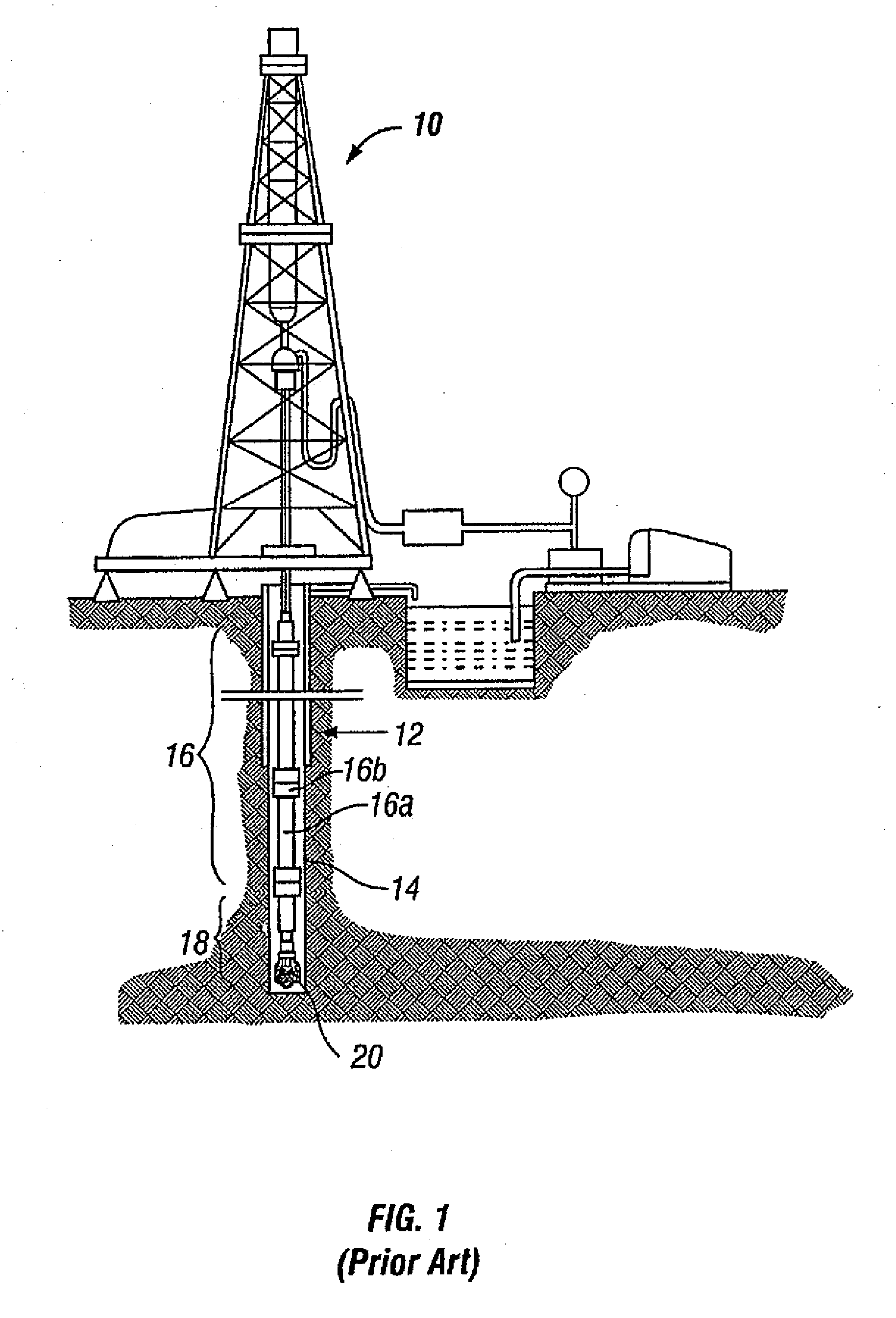

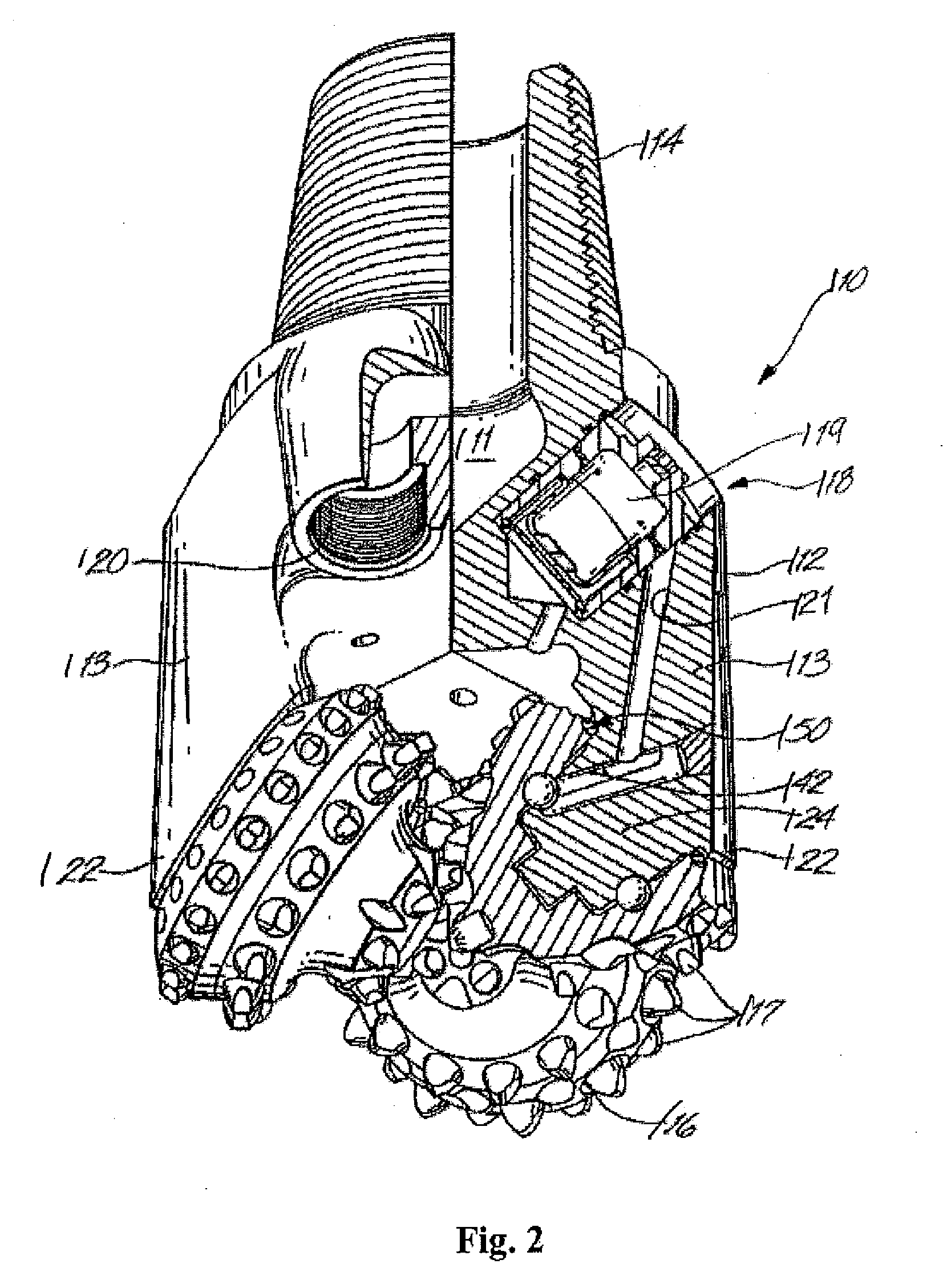

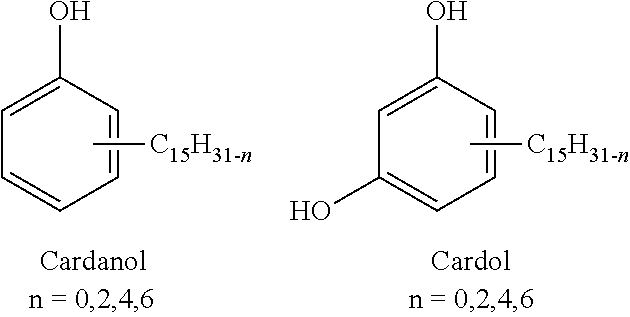

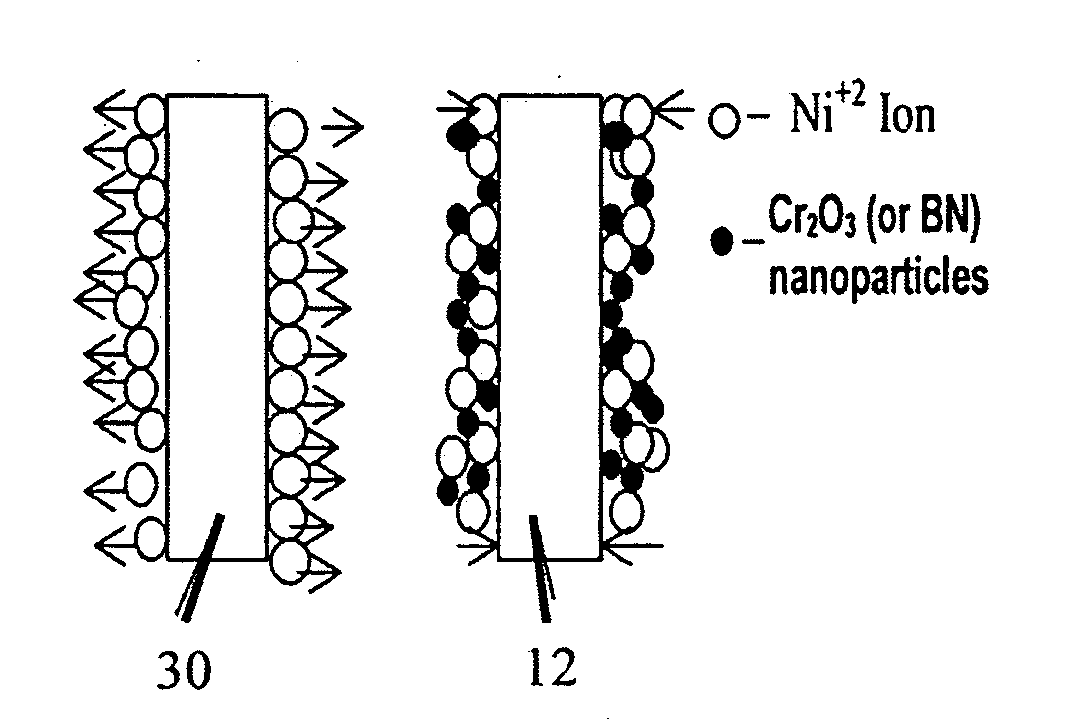

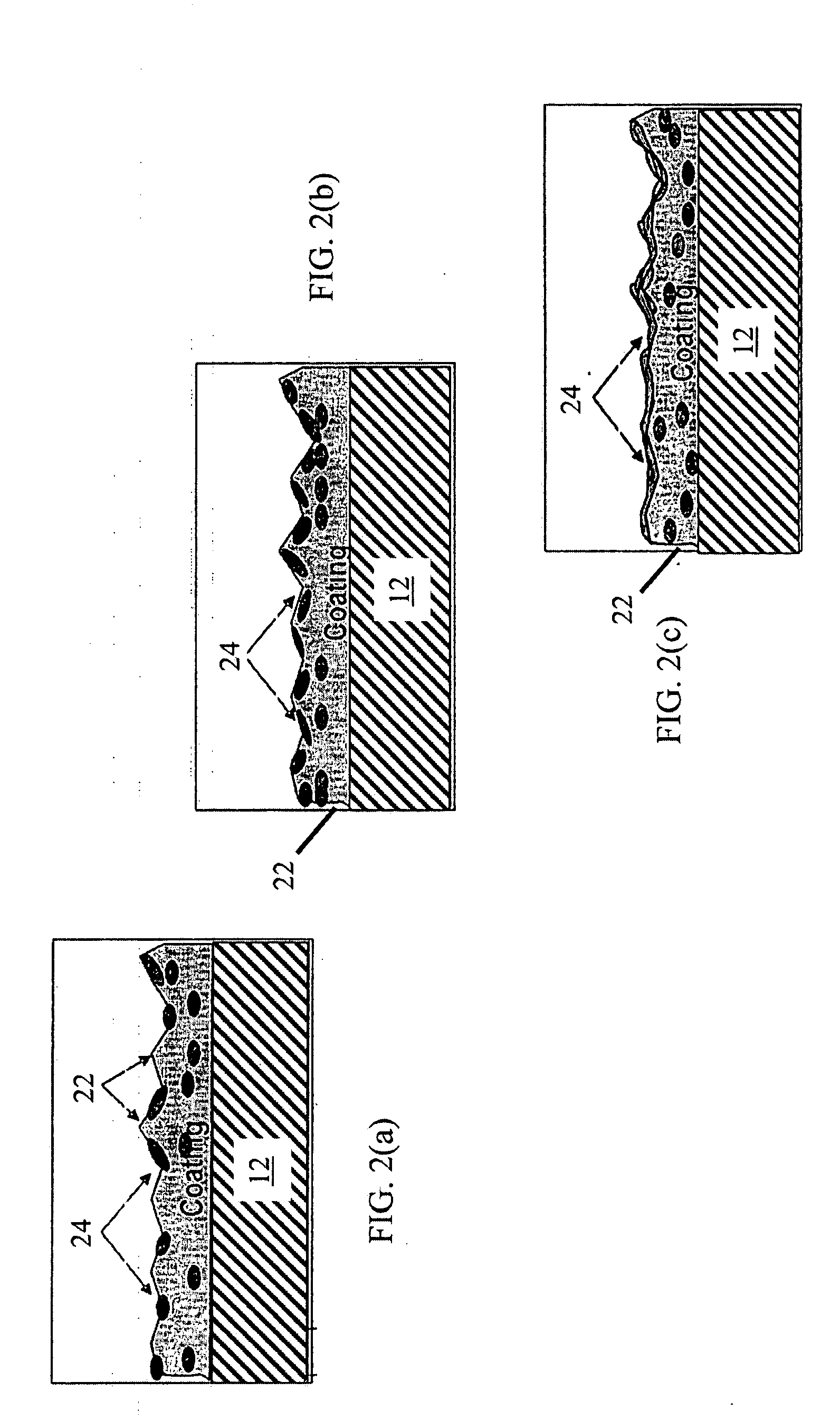

Composite coating with nanoparticles for improved wear and lubricity in down hole tools

Owner:SMITH INT INC

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS20080230223A1Improves unconfined compressive strength propertyImprove performanceLiquid surface applicatorsSynthetic resin layered productsPolyesterParticulates

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including resole resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include resole resin, novolak resin, polyester, acrylic and / or urethane. A method including applying a coating including the continuous phase including resole resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

Implant with composite coating

InactiveUS20020016635A1High strengthCost effectiveImpression capsBone implantBiocompatible coatingBiocompatibility Testing

Systems and methods are described for implants with composite coatings to promote tissue in-growth and / or on-growth. An implant includes: a substrate; a structured surface formed on at least a portion of the substrate; and a biocompatible coating deposited on at least a fraction of the structured surface. The systems and methods provide advantages in that the implant has good biocompatibility while the biocompatible coating has good strength.

Owner:CONSENSUS ORTHOPEDICS

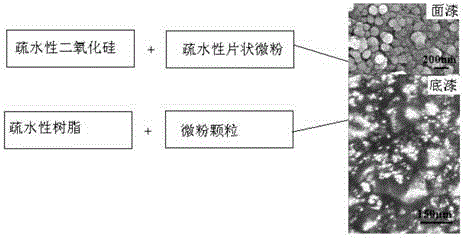

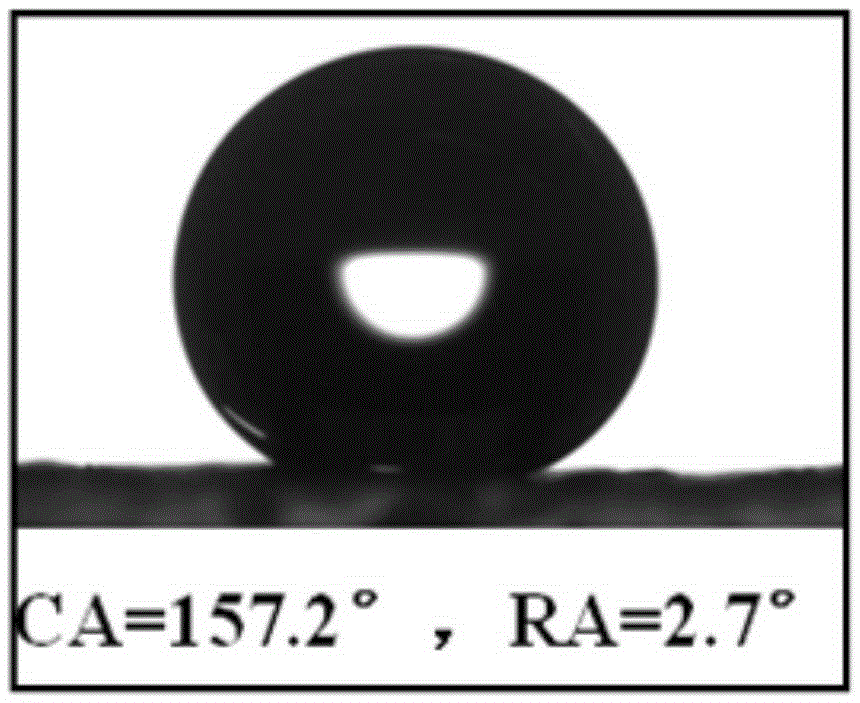

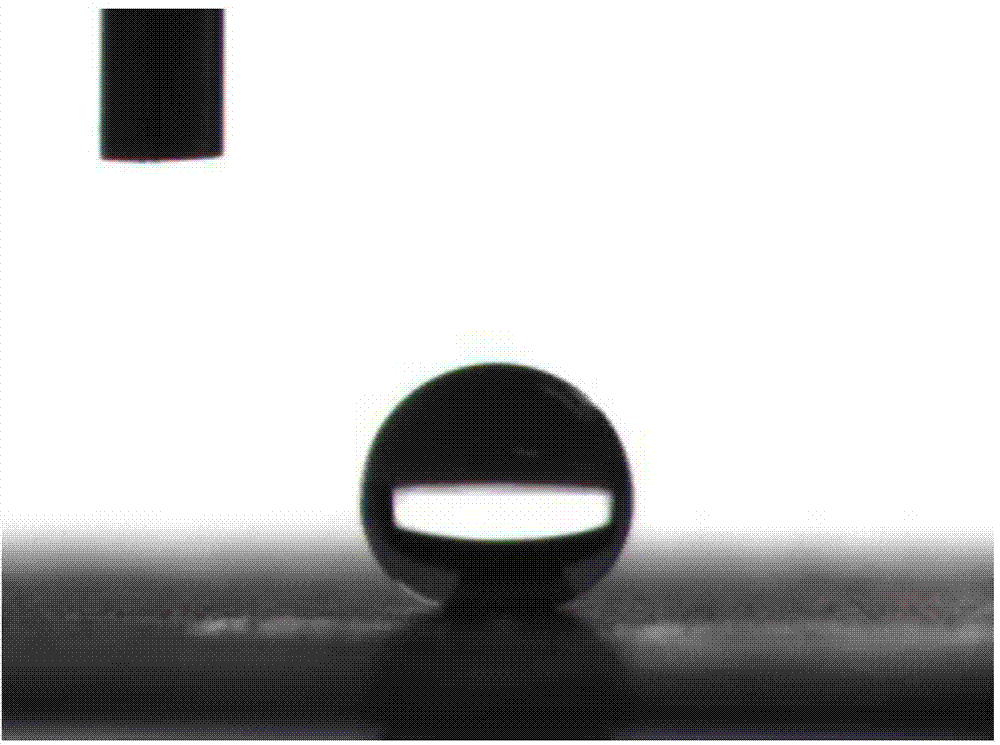

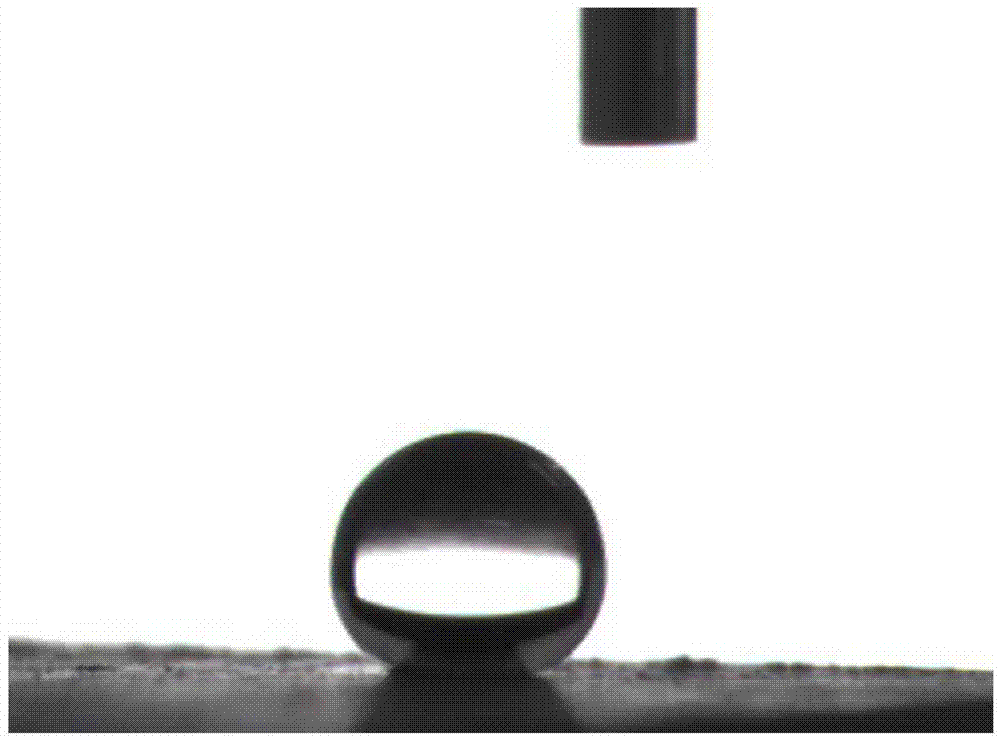

Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

The invention discloses a highly-wear-resistant super-hydrophobic composite coating and a preparation method thereof. The preparation method includes the steps that the surface of a base is coated with hydrophobic resin primer containing compound micropowder through a brush coating or spray coating method, the surface of the resin primer is sprayed with hydrophobic organic / inorganic hybrid nano-paint after semi-curing, and the highly-wear-resistant super-hydrophobic composite coating is obtained after complete curing. The highly-wear-resistant super-hydrophobic composite coating and the preparation method thereof have the advantages that equipment and the process are simple, operation is easy and cost is low, and have the industrial mass production prospect. The prepared super-hydrophobic composite coating can be applied to various hard / soft bases such as glass, copper, aluminum, stainless steel, exterior wall tiles, wood, paper and cloth and can bear damage of external force such as sanding.

Owner:SOUTHEAST UNIV

Coating compositions having improved scratch resistance, coated substrates and methods related thereto

InactiveUS7005472B2Improve scratch resistanceGood lookingMaterial nanotechnologyNanostructure manufacturePolymer sciencePolymer chemistry

Coating compositions are provided which are formed from components comprising (a) at least one polysiloxane comprising at least one reactive functional group; (b) at least one reactant comprising at least one functional group that is reactive with at least one functional group selected from the at least one reactive functional group of the at least one polysiloxane and at least one functional group of at least one reactant; and (c) a plurality of particles, wherein each component is different, and wherein the at least one reactive functional group of the at least one polysiloxane and the at least one functional group of the at least one reactant are substantially nonreactive with the particles. A multi-component composite coating composition formed from a basecoat and a topcoat deposited from the curable coating composition also is provided. The multi-component composite coating compositions of the invention provide highly scratch resistant color-plus-clearcoatings capable of retaining scratch resistance after weathering.

Owner:PPG IND OHIO INC

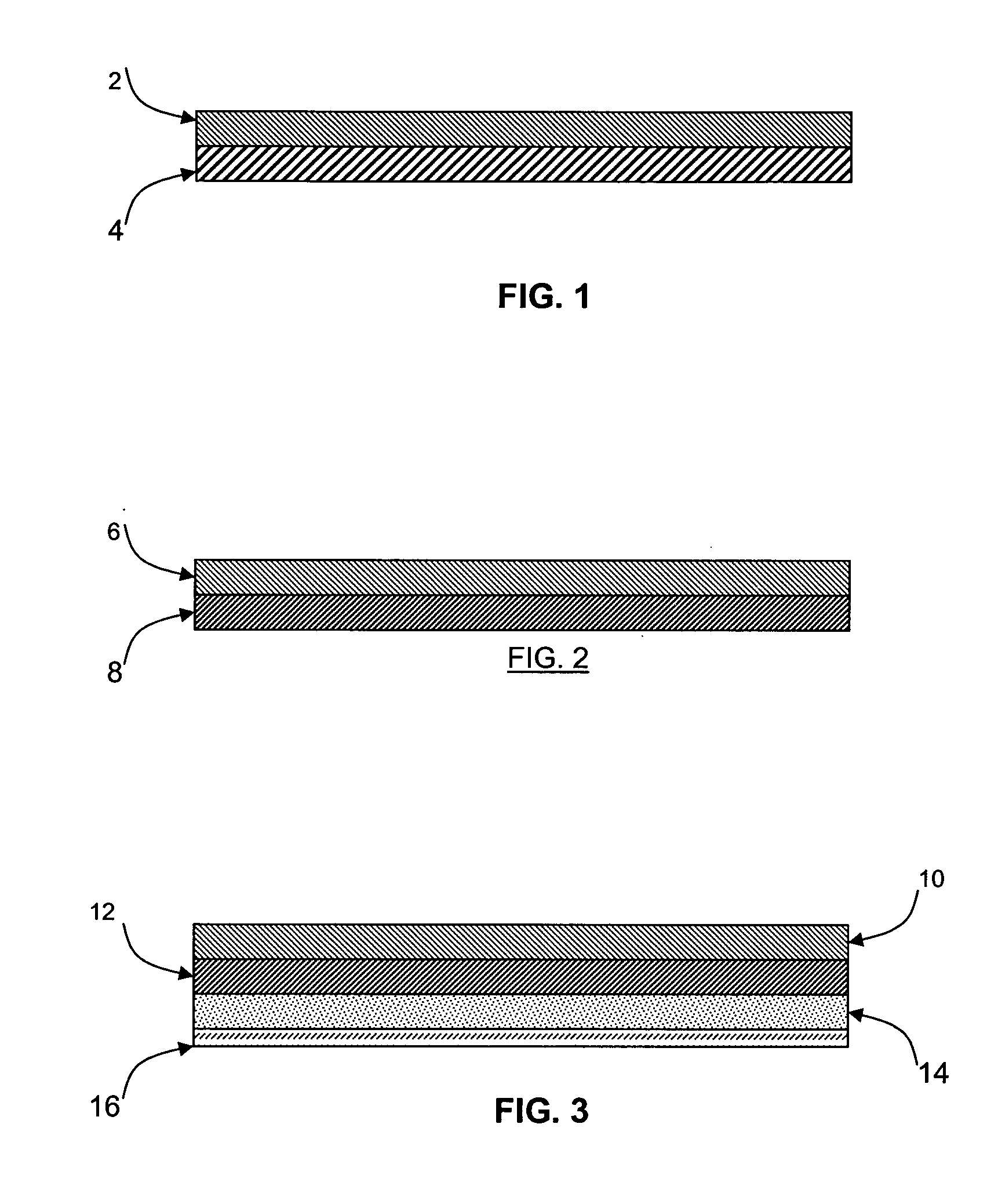

Process for forming a two-coat electrodeposited composite coating the composite coating and chip resistant electrodeposited coating composition

InactiveUS6248225B1Electrolysis componentsVolume/mass flow measurementPolyurethane coatingAqueous dispersion

A process for applying two electrodeposited coatings, one on top of the other, to an electrically conductive substrate is provided. An electrically conductive first coating is applied to provide for corrosion resistance and a second polyurethane-based coating is applied to the first coating to provide chip resistance. Also, aqueous dispersions of the polyurethane coating compositions are disclosed.

Owner:PPG IND OHIO INC

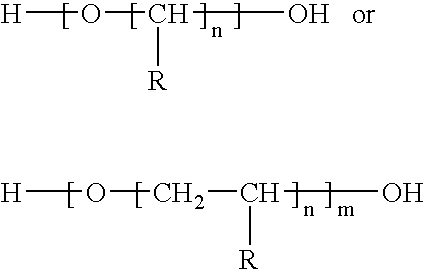

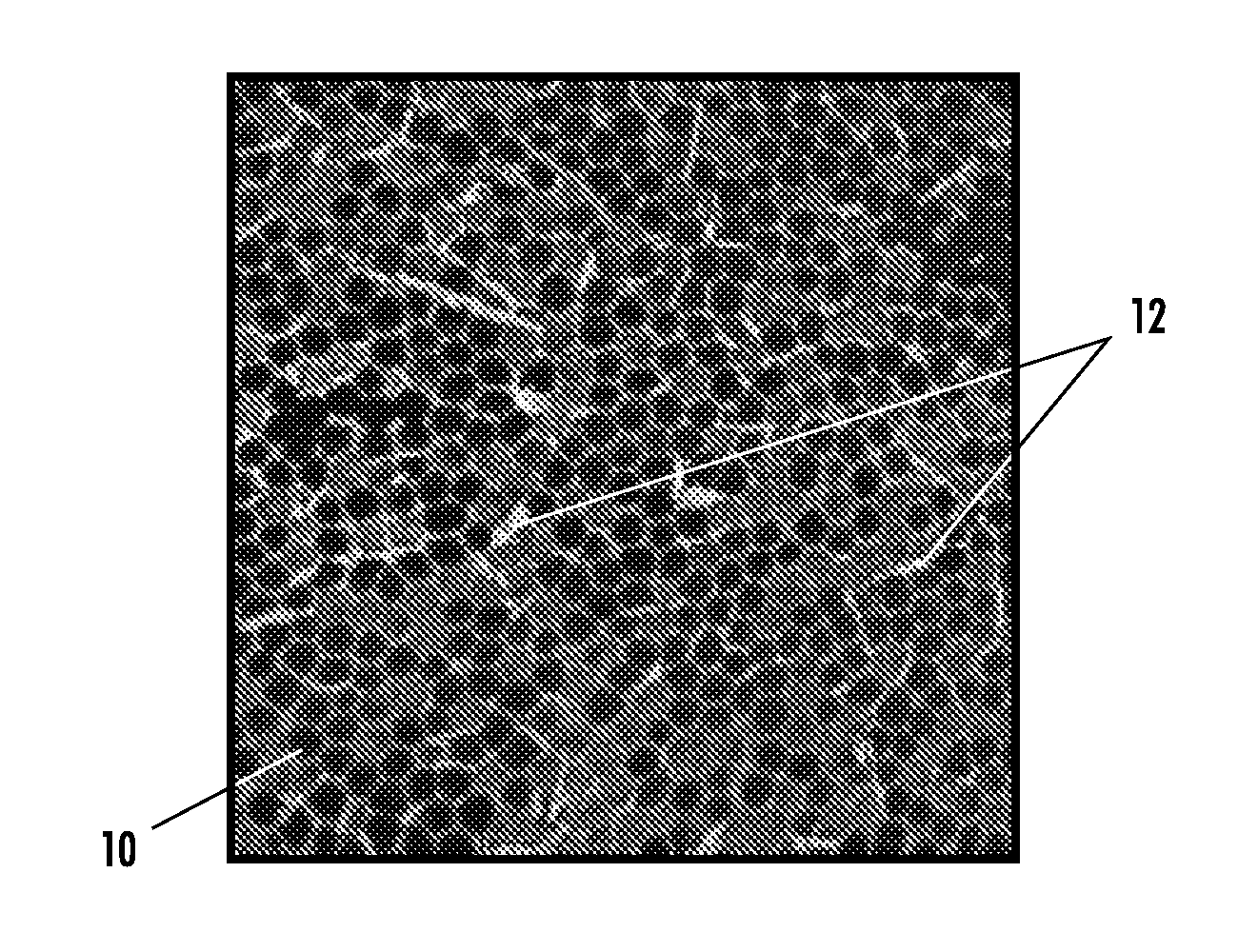

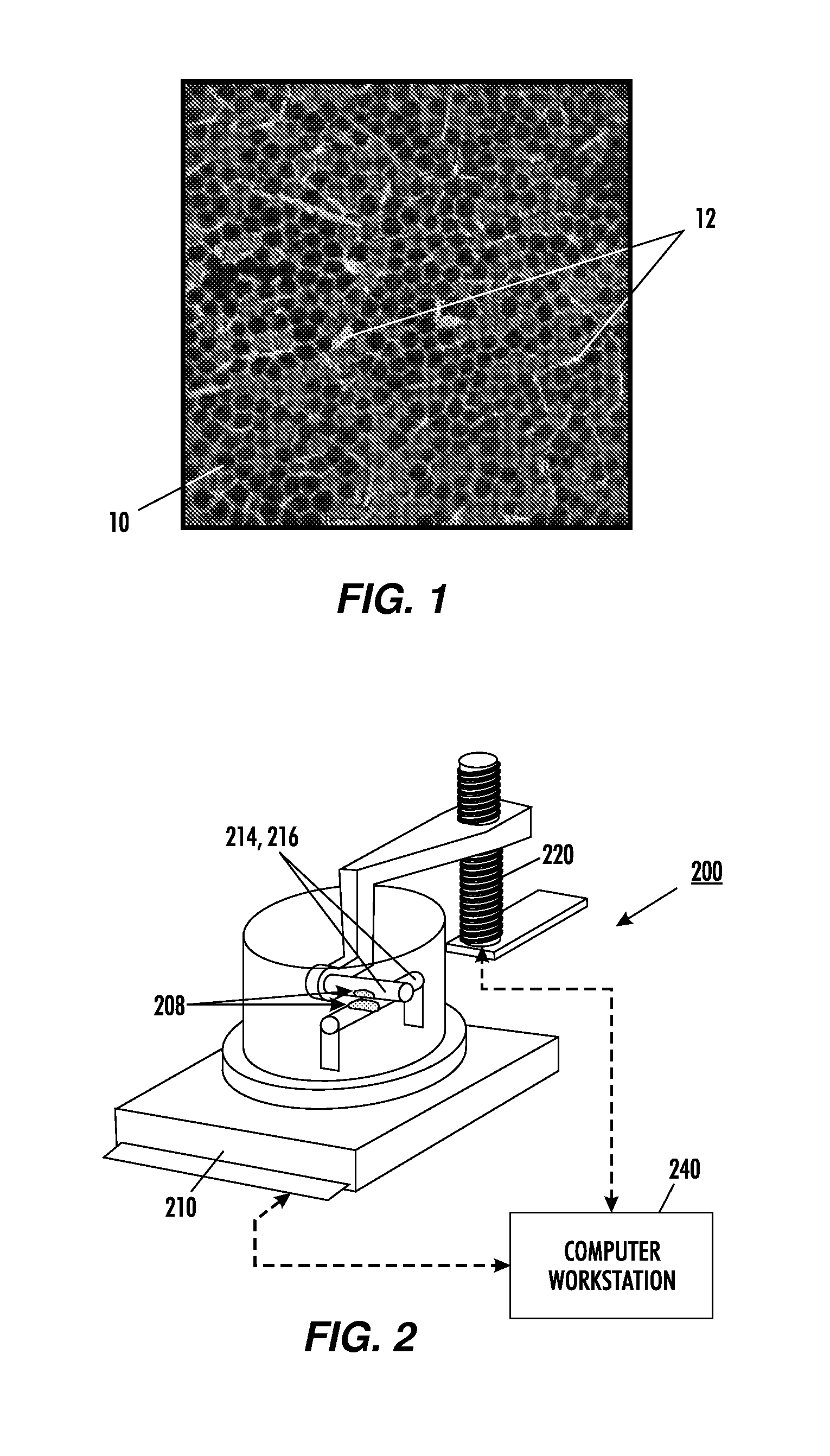

Nanoparticle compositions, coatings and articles made therefrom, methods of making and using said compositions, coatings and articles

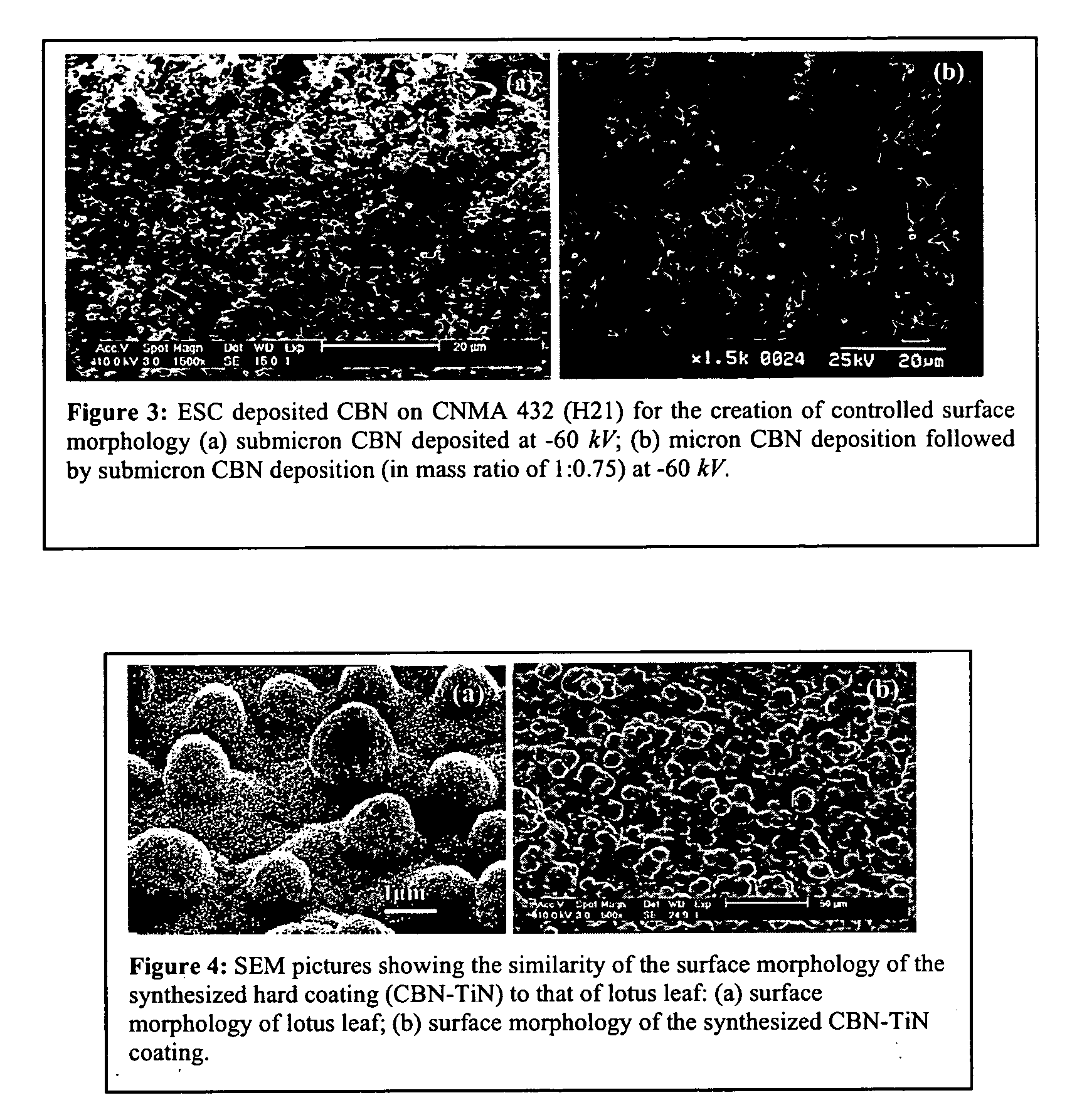

Compositions comprising nanoparticles, microparticles, and combinations thereof, the particles may be overcoated particles. Composite coatings and coated articles made therefrom, the coatings comprising mono or multi layers having a textured outer surface morphology, the layers may be continuous and / or discontinuous and may comprise different particle phases. Methods of making and using said compositions, coatings and coated articles.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

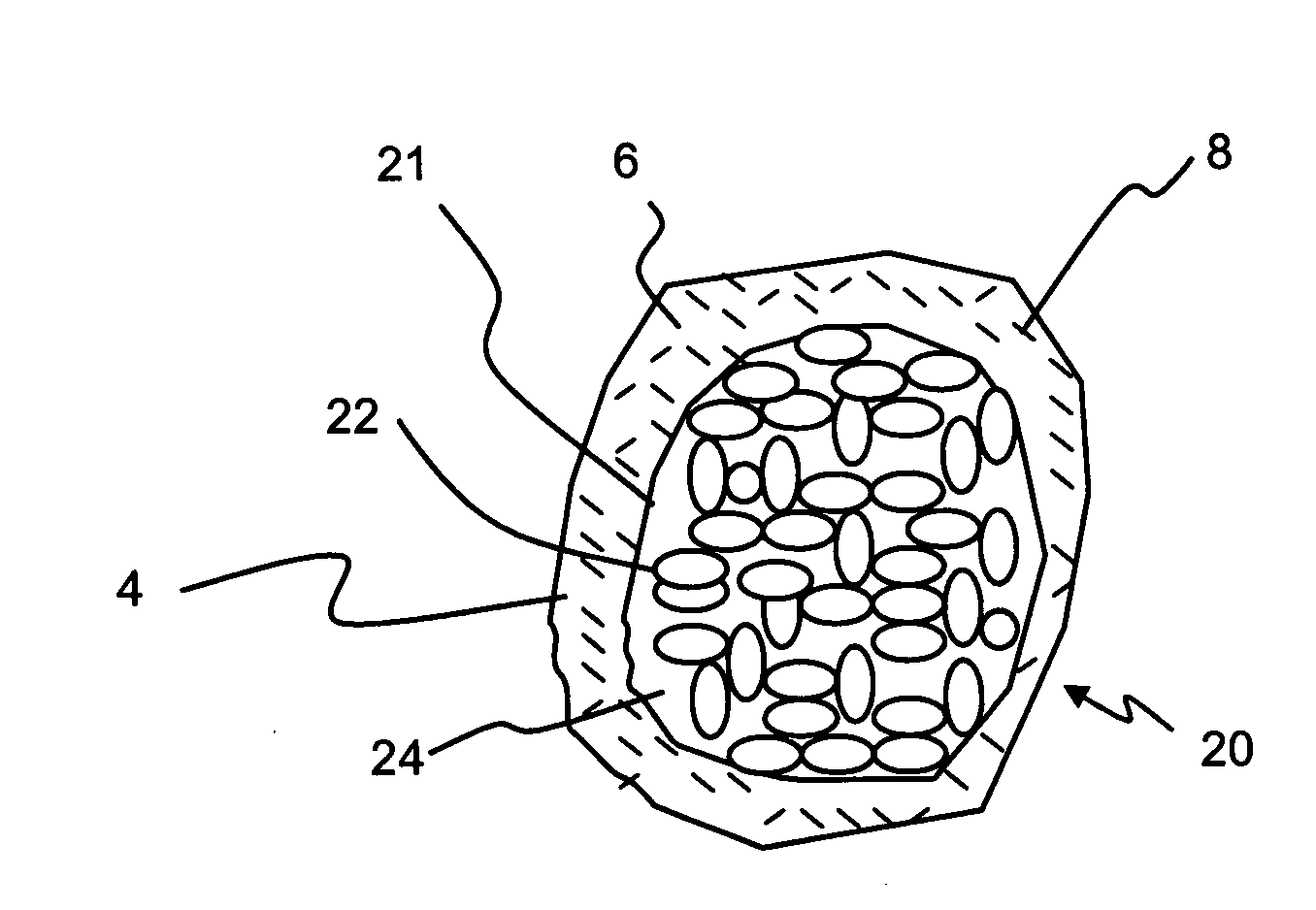

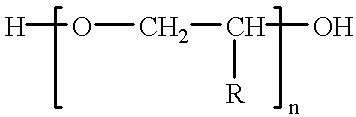

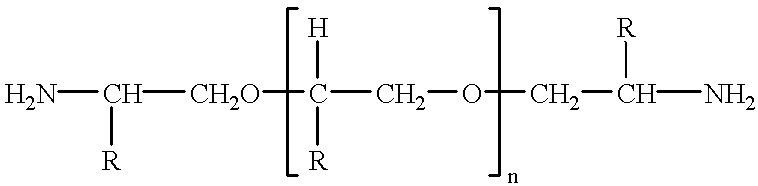

Proppant with composite coating

ActiveUS20140162911A1Improve crush resistanceEnhanced level of hardnessFluid removalFlushingParticulatesChemical Linkage

Proppants for hydraulic fracturing of oil and gas wells have a polymeric coating that is strengthened with reinforcing particulates that are reactive with, or chemically bonded to, the polymeric proppant coating. Preferably, these particulates are added into the coating during the coating process. In one embodiment, functionalized particulates are used that become grafted into the polymer of the proppant coating through the chemical functionality imparted to the particulates. If non-functionalized particulates are used, a coupling agent is preferably added to enhance the bond strength between the added particulates and the polymeric matrix of the proppant coating.

Owner:PREFERRED TECH

Lubricant-hard-ductile nanocomposite coatings and methods of making

InactiveUS20090155479A1Liquid surface applicatorsMolten spray coatingNanocomposite coatingWear resistance

Lubricant-hard-ductile composite coating compositions and methods of making the same are provided. In embodiment, a composite coating composition comprises: a lubricant phase for providing lubrication to a surface; a hard ceramic phase for providing structural integrity and wear resistance to the surface; and a ductile metal phase for providing ductility to the surface.

Owner:INFRAMAT CORPORATION

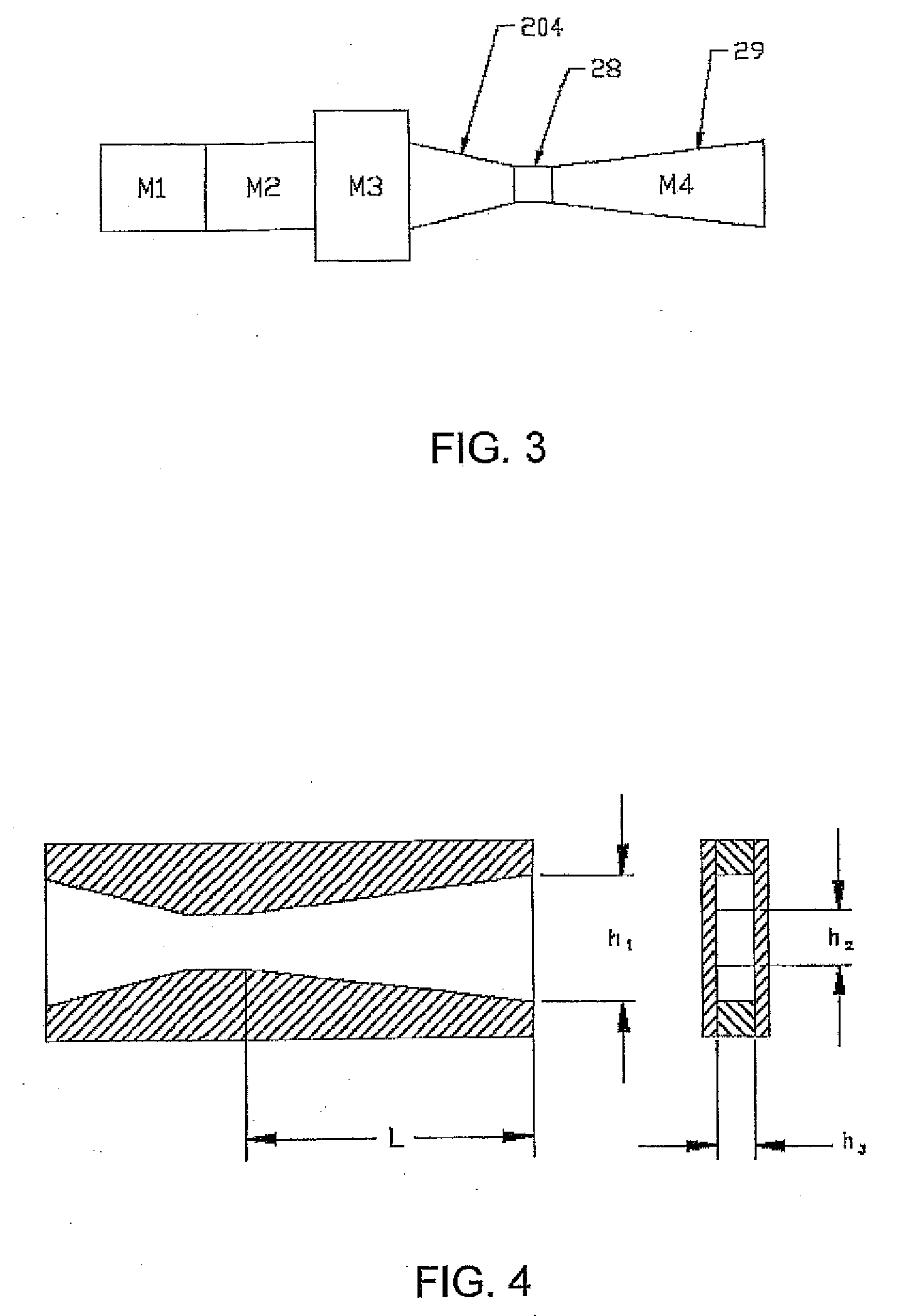

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

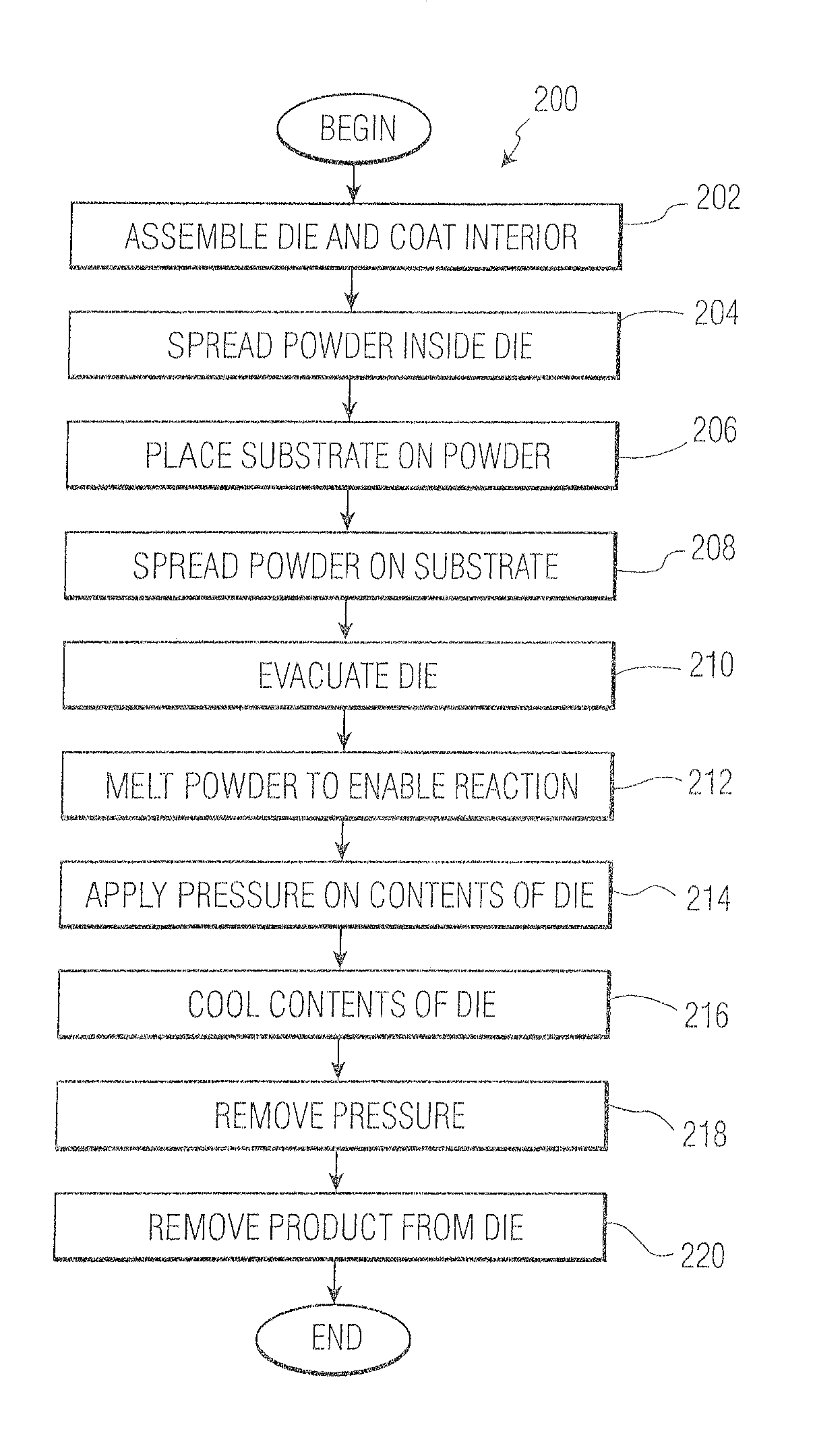

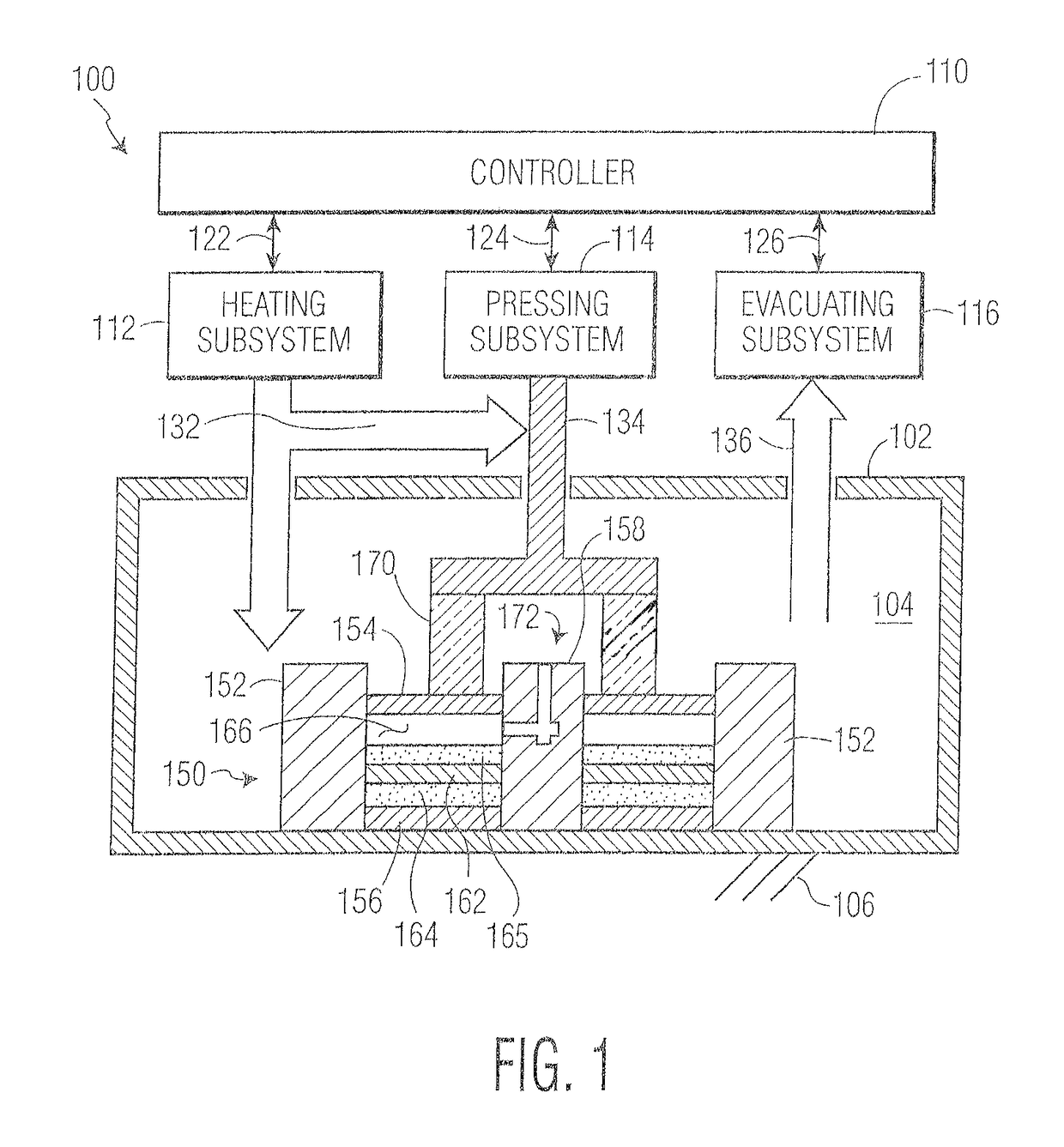

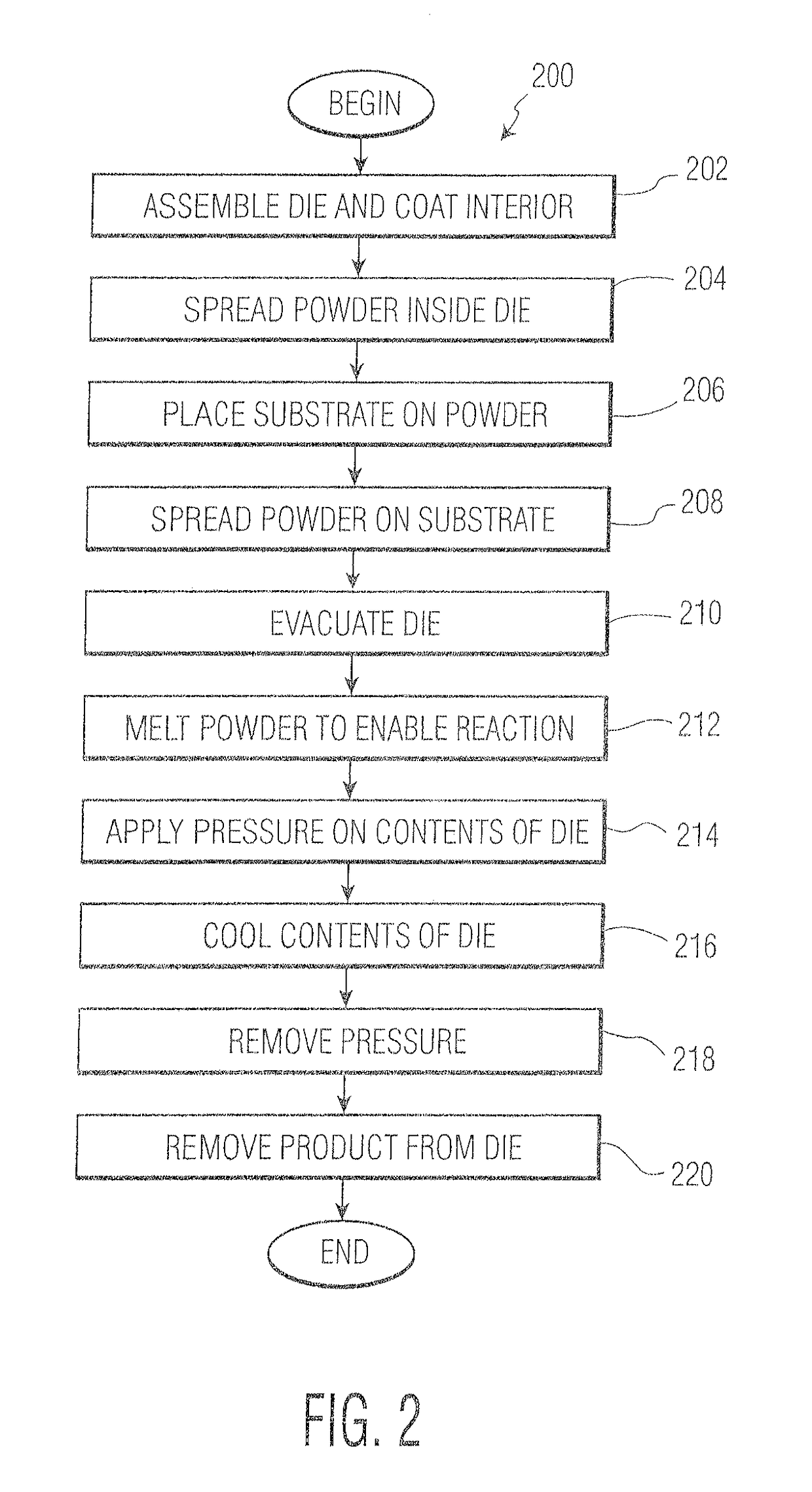

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

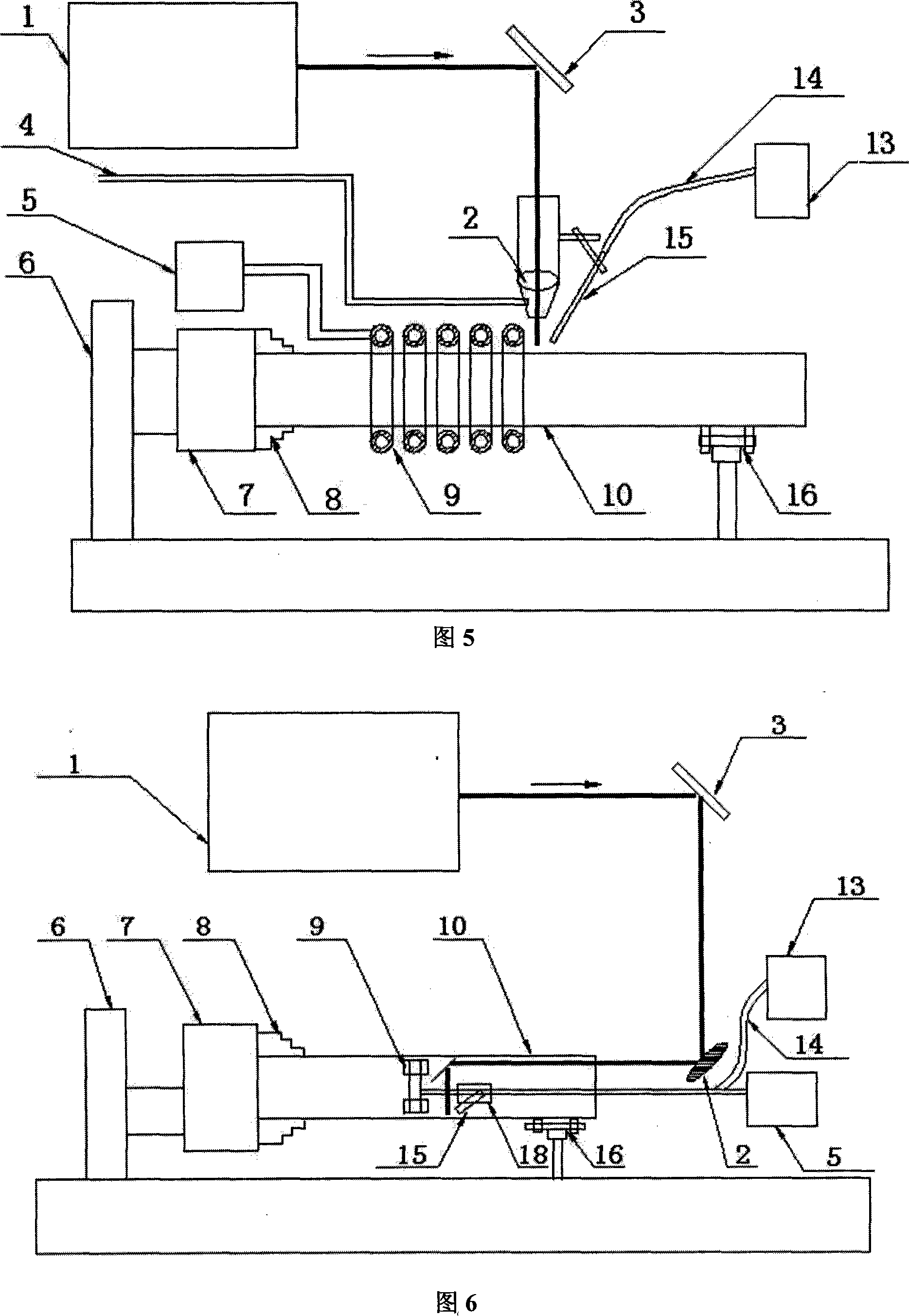

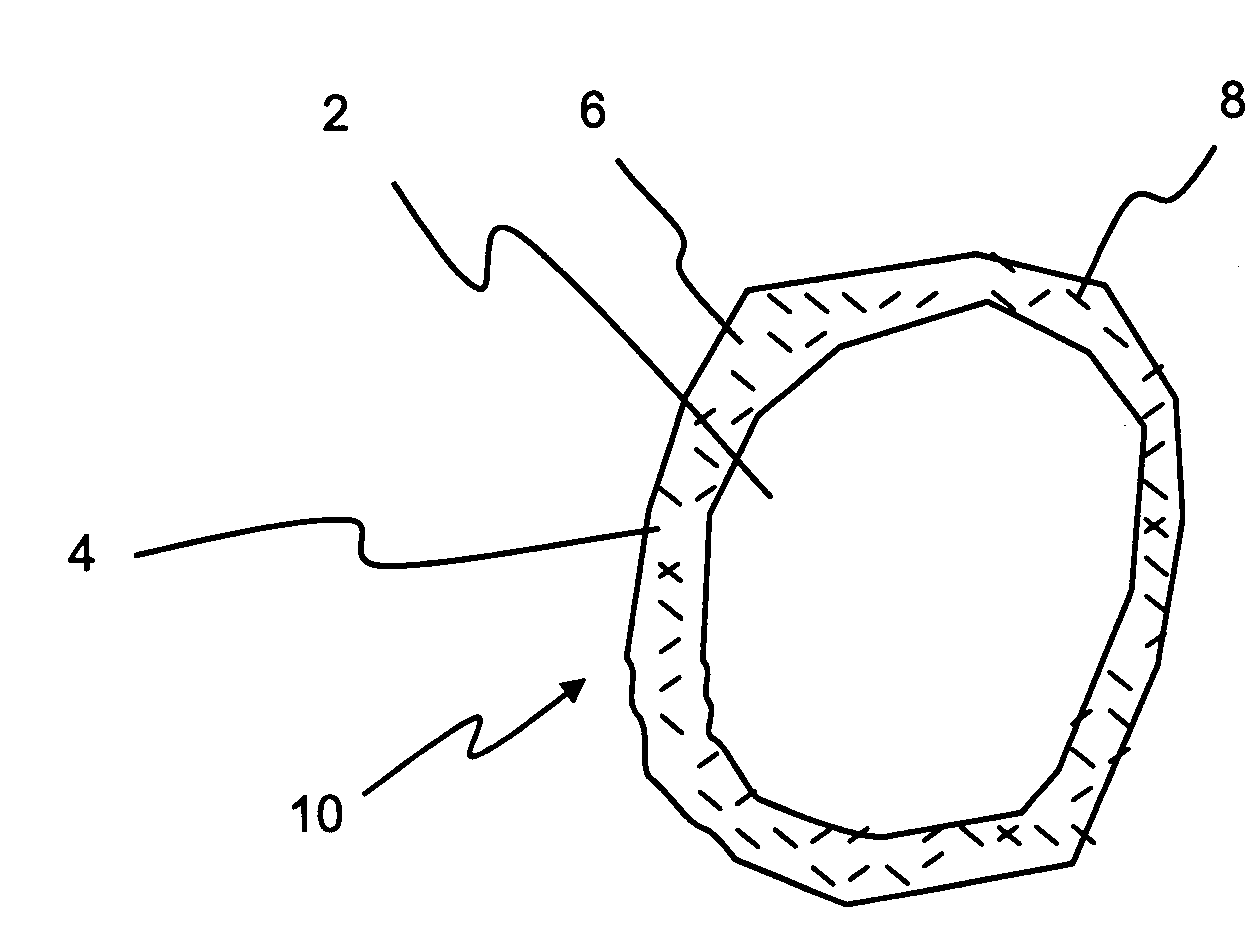

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

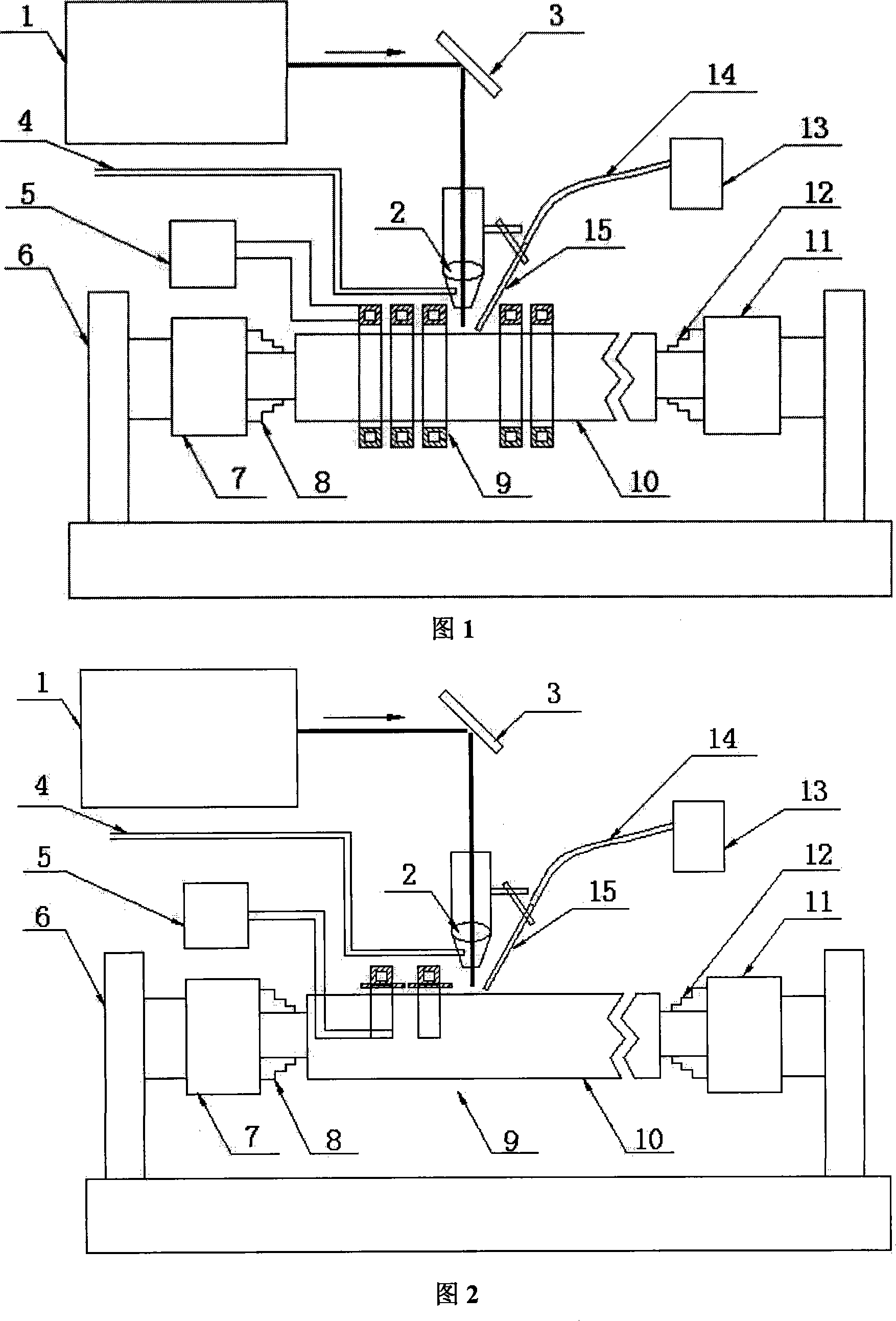

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS7624802B2Improves unconfined compressive strength propertyImprove performanceLiquid surface applicatorsSynthetic resin layered productsPolyesterParticulates

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including resole resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include resole resin, novolak resin, polyester, acrylic and / or urethane. A method including applying a coating including the continuous phase including resole resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

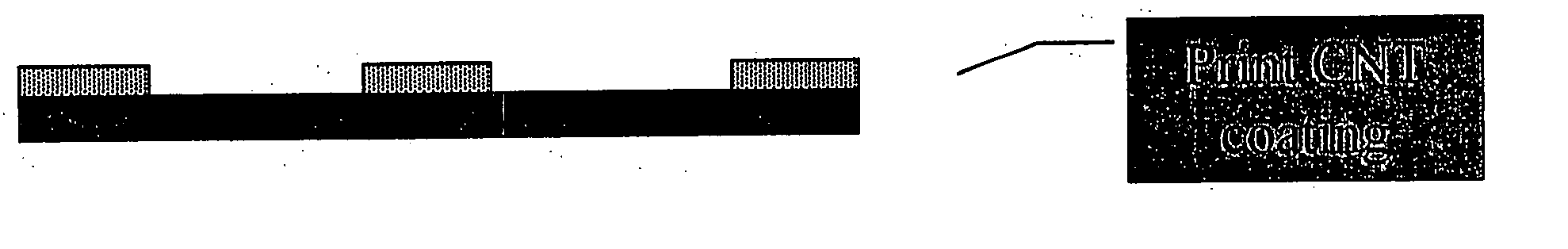

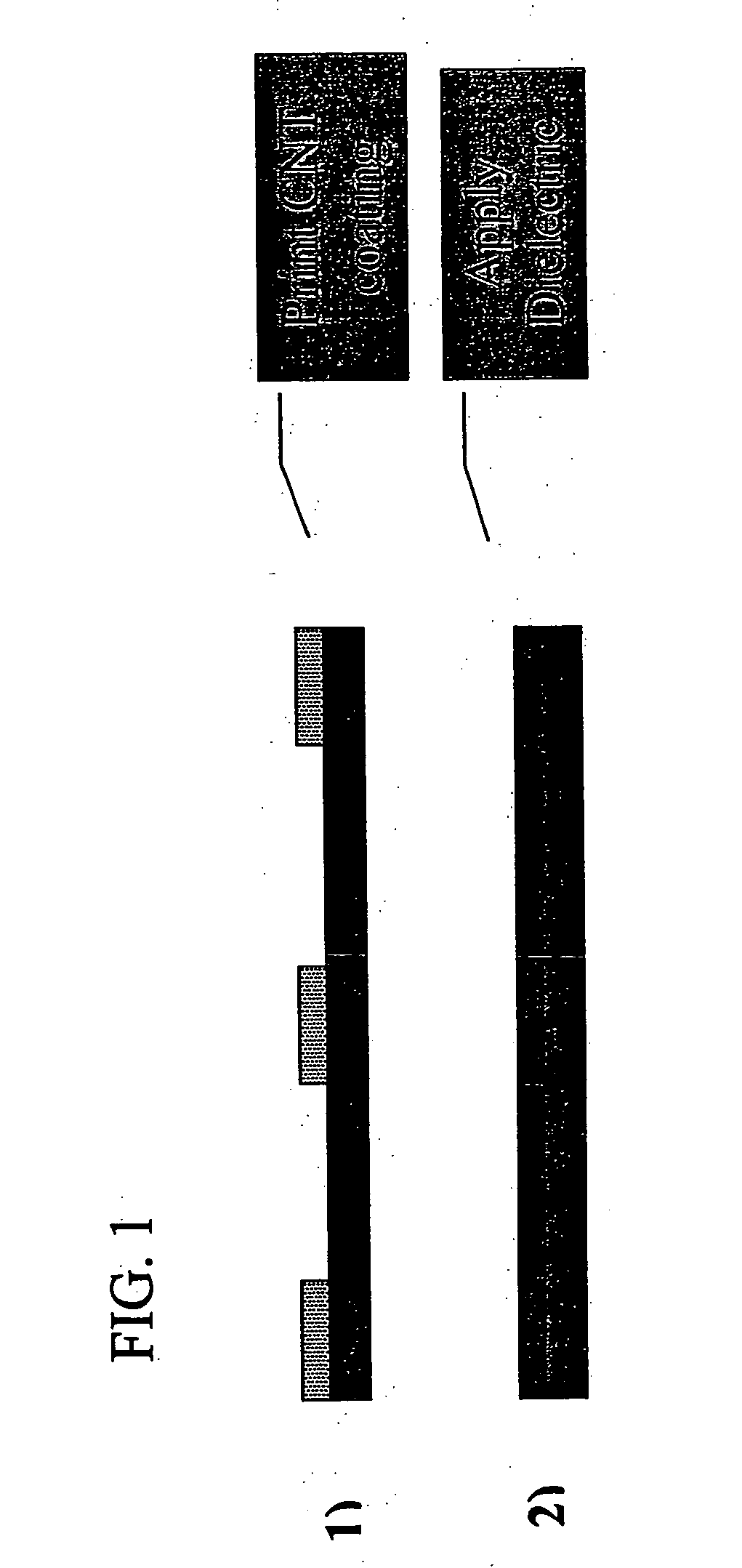

Method for patterning carbon nanotube coating and carbon nanotube wiring

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:ARTHUR DAVID J +1

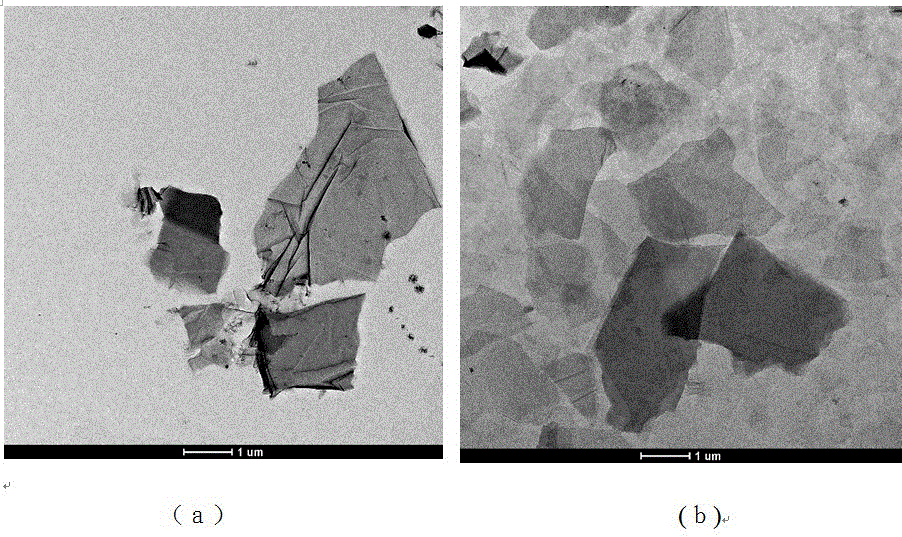

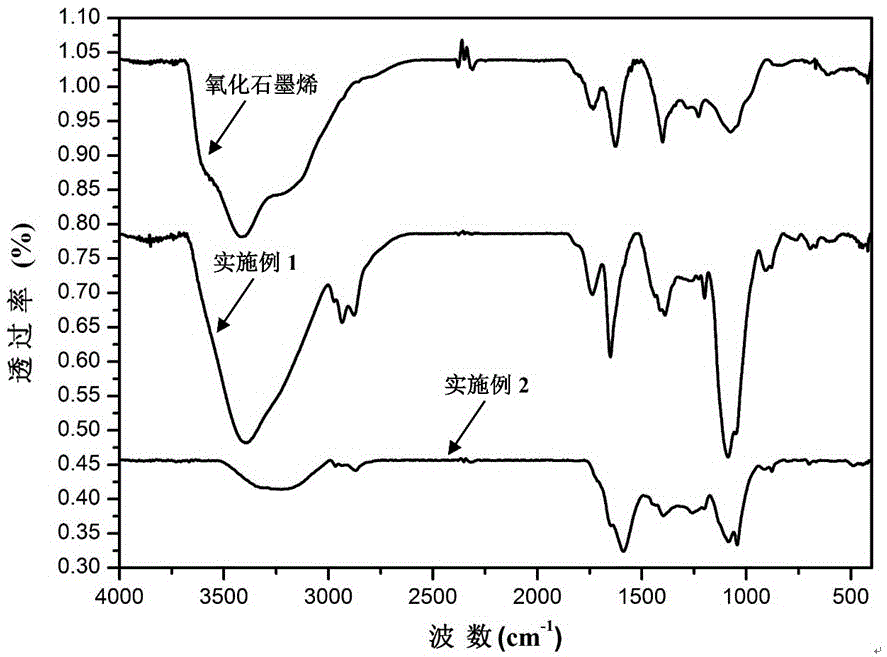

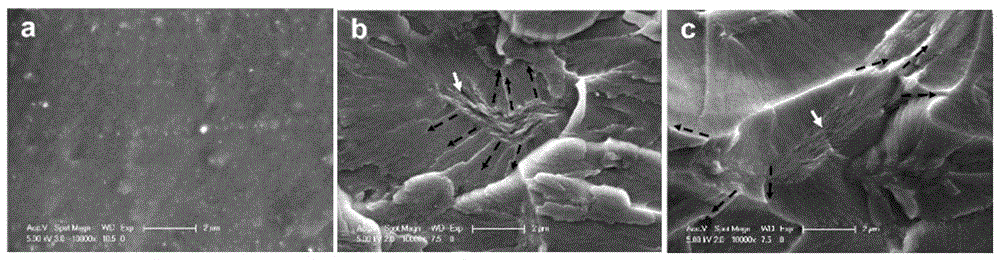

Epoxy resin-oxidized graphene composite coating and application method thereof

InactiveCN104356860AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCoated surface

The invention provides an epoxy resin-oxidized graphene composite coating. The composite coating is prepared by using oxidized graphene as a packing and adding the packing to epoxy resin coating. A coating layer prepared on the surface of a matrix by utilizing the composite coating is excellent in binding force of the matrix, and further greatly improved in corrosion resistance, so as to effectively obstruct a corrosive medium from penetrating from the surface of the coating layer to the path of the matrix. Therefore, the epoxy resin-oxidized graphene composite coating is good in application prospect, and in particular suitable for the matrix in a highly-corrosive severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

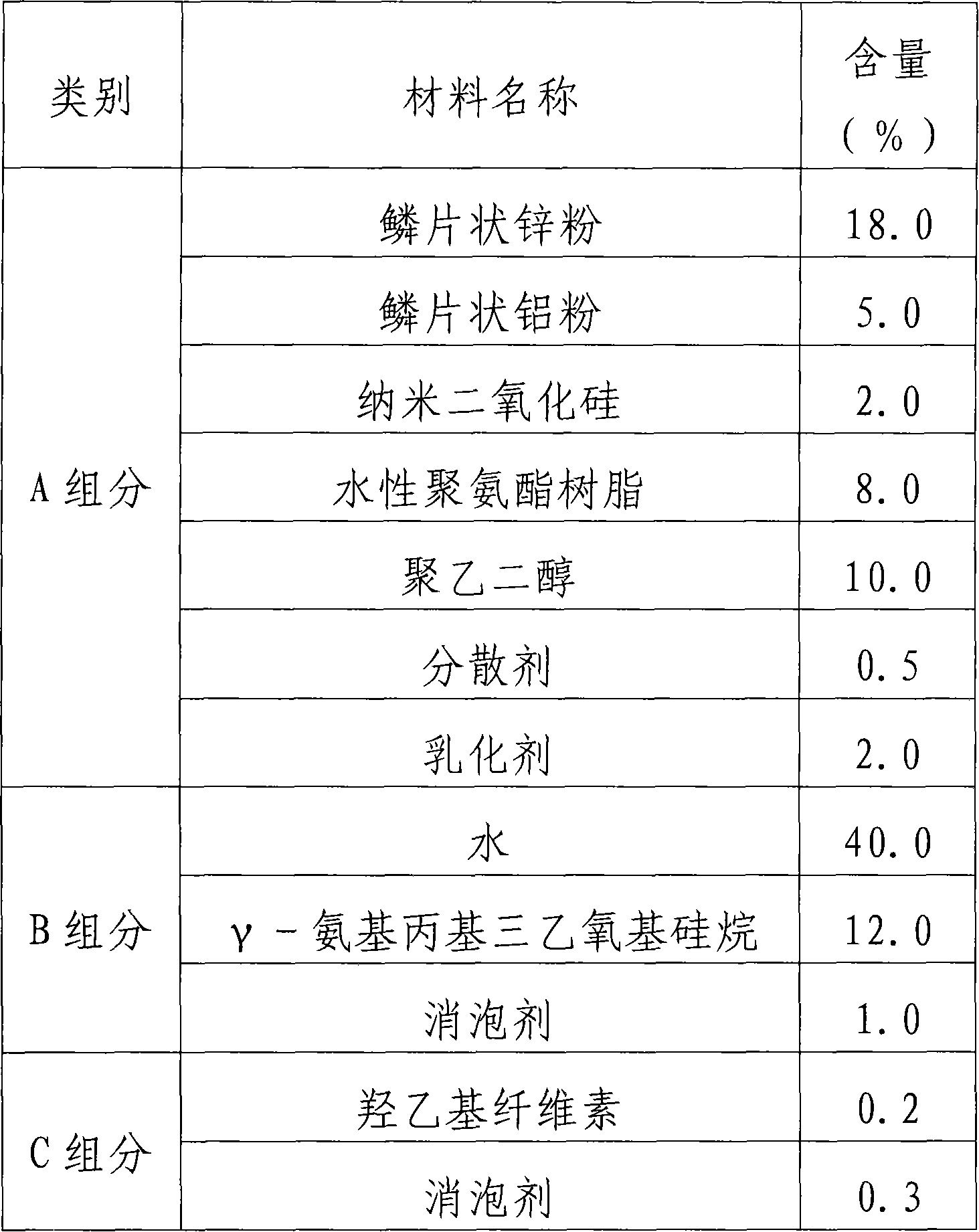

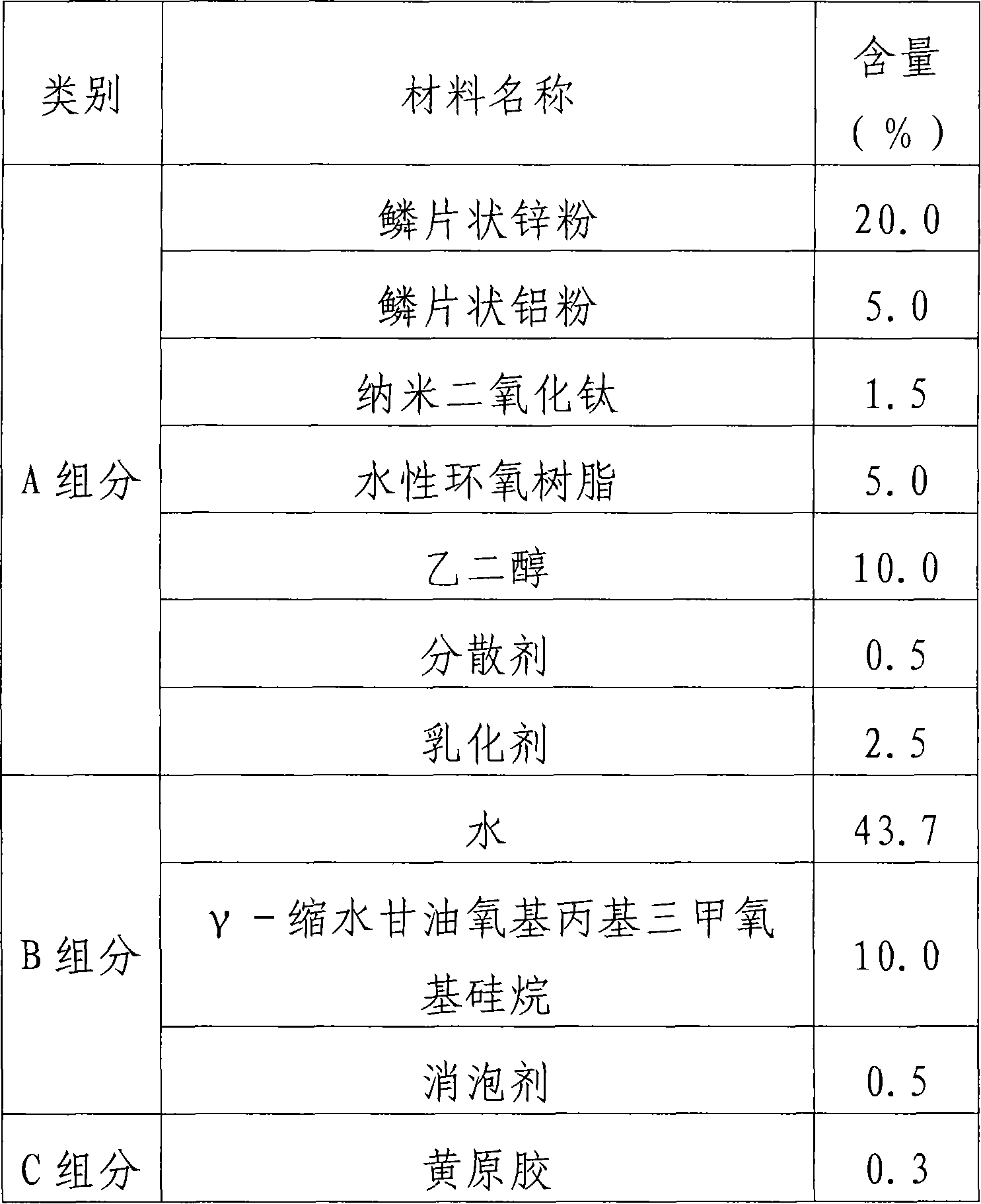

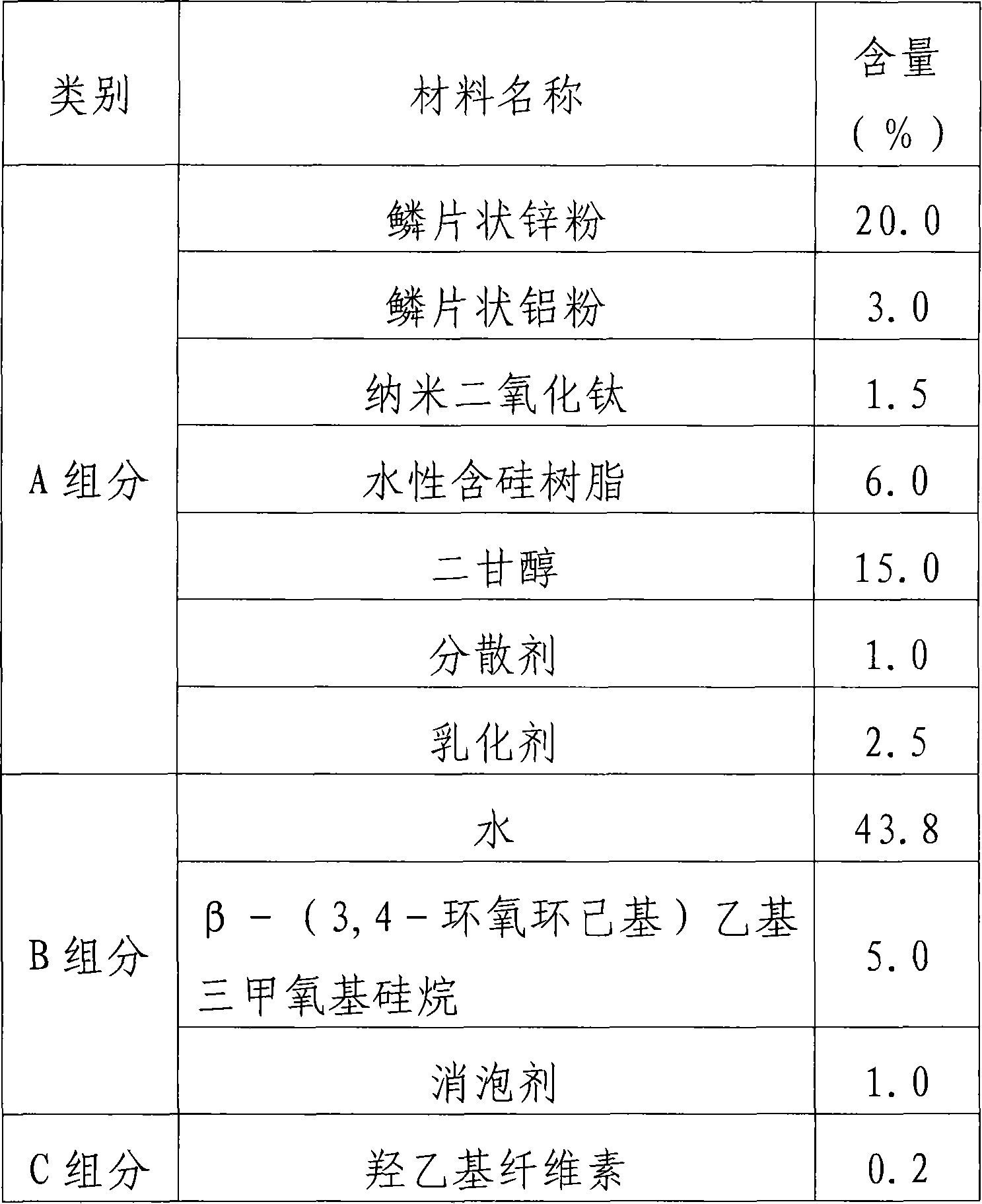

Hydrophilic nano zinc based composite coating

InactiveCN101613559AStrong weather resistanceNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesSolvent

The invention belongs to the technical field of chemical engineering coatings and particularly relates to a hydrophilic nano zinc based composite coating used for preventing corrosion on the surfaces of the metal parts. The coating comprises an emulsifier, a dispersant, an antifoaming agent, scaly metallic powder, nano oxides, a silane coupler, an alcohol-type solvent, a high-molecule organic material, a thickener and 30.0 to 60.0 percent of water serving as a disperse medium. The coating can be coated by spraying, brushing, soaking and soaking-centrifugal coating and other methods, and the coating can be formed by being roasted at a temperature of about 200 DEG C for 20 minutes. Neutral salt spray corrosion resistant tests show that the neutral salt spray corrosion resistant time is more than 800h, the binding force is proved to be above level 4 (by an adhesive band test). The coating has the advantages of environmental pollution prevention, excellent metallic corrosion resistant property, economy and practicability and convenient use; and moreover, the coating can be widely used for the corrosion resistant treatment of the surface of metal parts made of iron, aluminum, copper and magnesium alloy and the like, particularly the corrosion resistant treatment of metal parts with complex geometric shapes.

Owner:YUNNAN GREAT IND DEV

Graphene/polysiloxane composite coating material and preparation method thereof

ActiveCN106752926AImprove scratch resistanceImprove wear resistanceFireproof paintsAnti-corrosive paintsEpoxyResin-Based Composite

The invention provides a graphene / polysiloxane composite coating material and a preparation method thereof. The method comprises the following steps: modifying the graphene surface with active groups by a chemical modification technique to obtain modified graphene, mixing the modified graphene with a silane compound, a dispersion medium, a non-essential comonomer and a non-essential accelerator, and carrying out hydrolytic condensation or hydrolytic condensation-free radical polymerization to generate a graphene / polysiloxane composite resin in situ; and mixing the resin with a non-essential blend resin, a non-essential curing agent, a non-essential solvent, a non-essential pigment and filler and a non-essential aid, and carrying out physical blending, amino epoxy addition reaction, Michael addition reaction and the like to form a film, thereby obtaining the graphene / polysiloxane composite coating material. The uniformly dispersed graphene lamellae and polysiloxane have strong interface effects, also have the gas / liquid barrier and heat shielding effects, and endow the coating with excellent corrosion resistance, flame retardancy and the like, thereby greatly enhancing the mechanical properties, corrosion resistance, scratch resistance, wear resistance and the like of the coating.

Owner:FUDAN UNIV

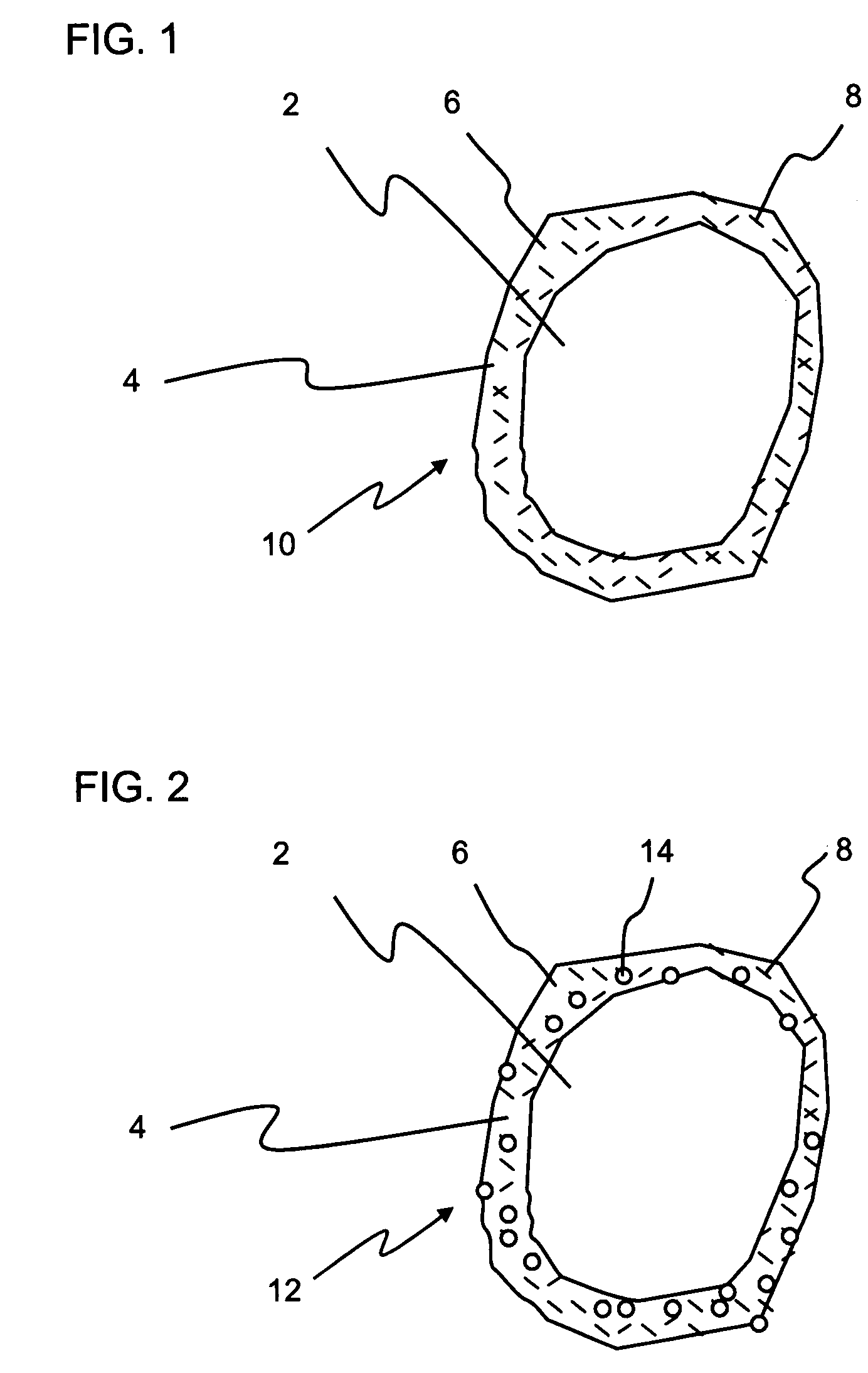

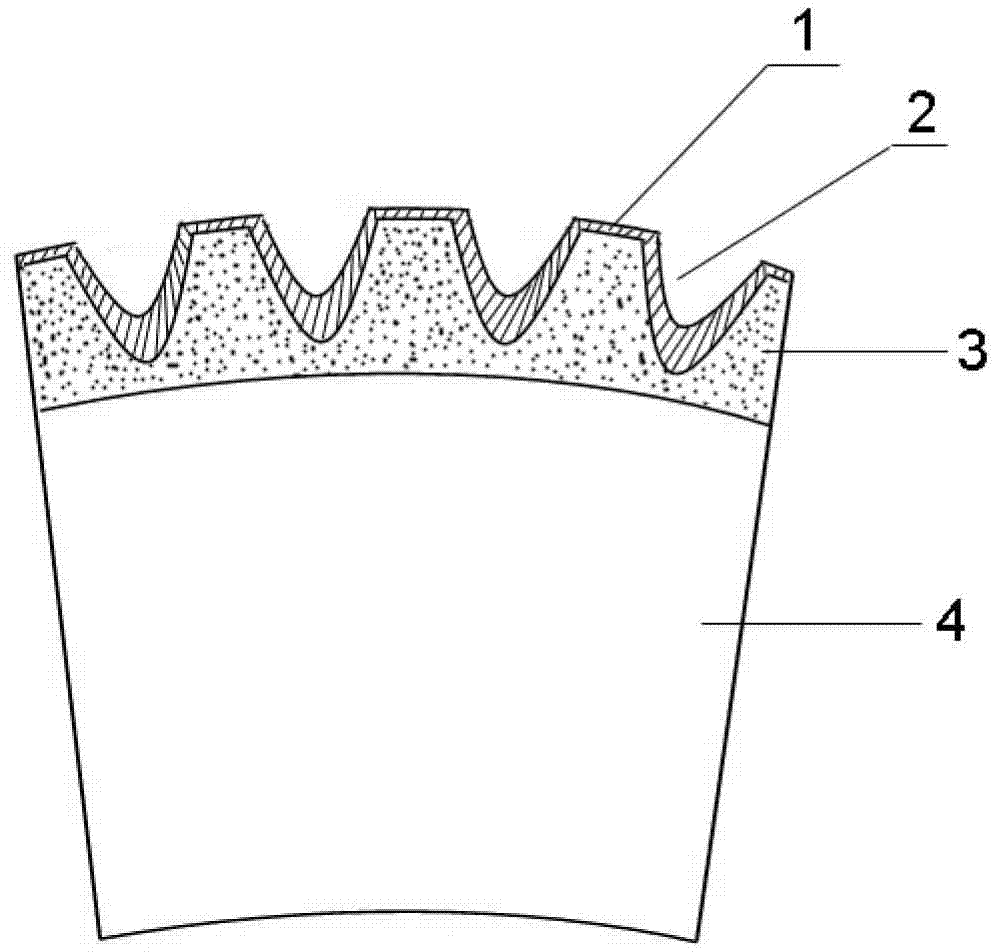

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

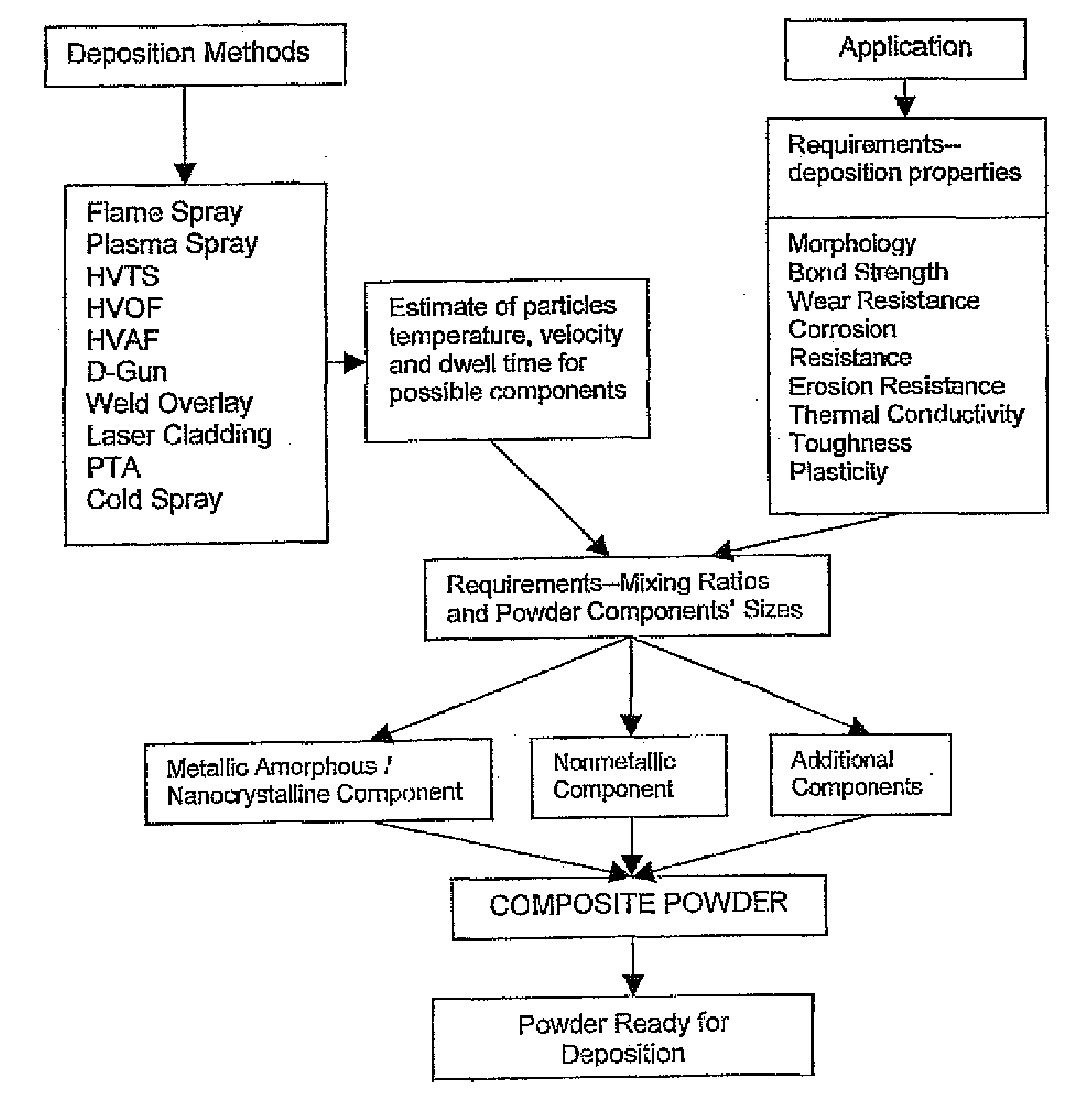

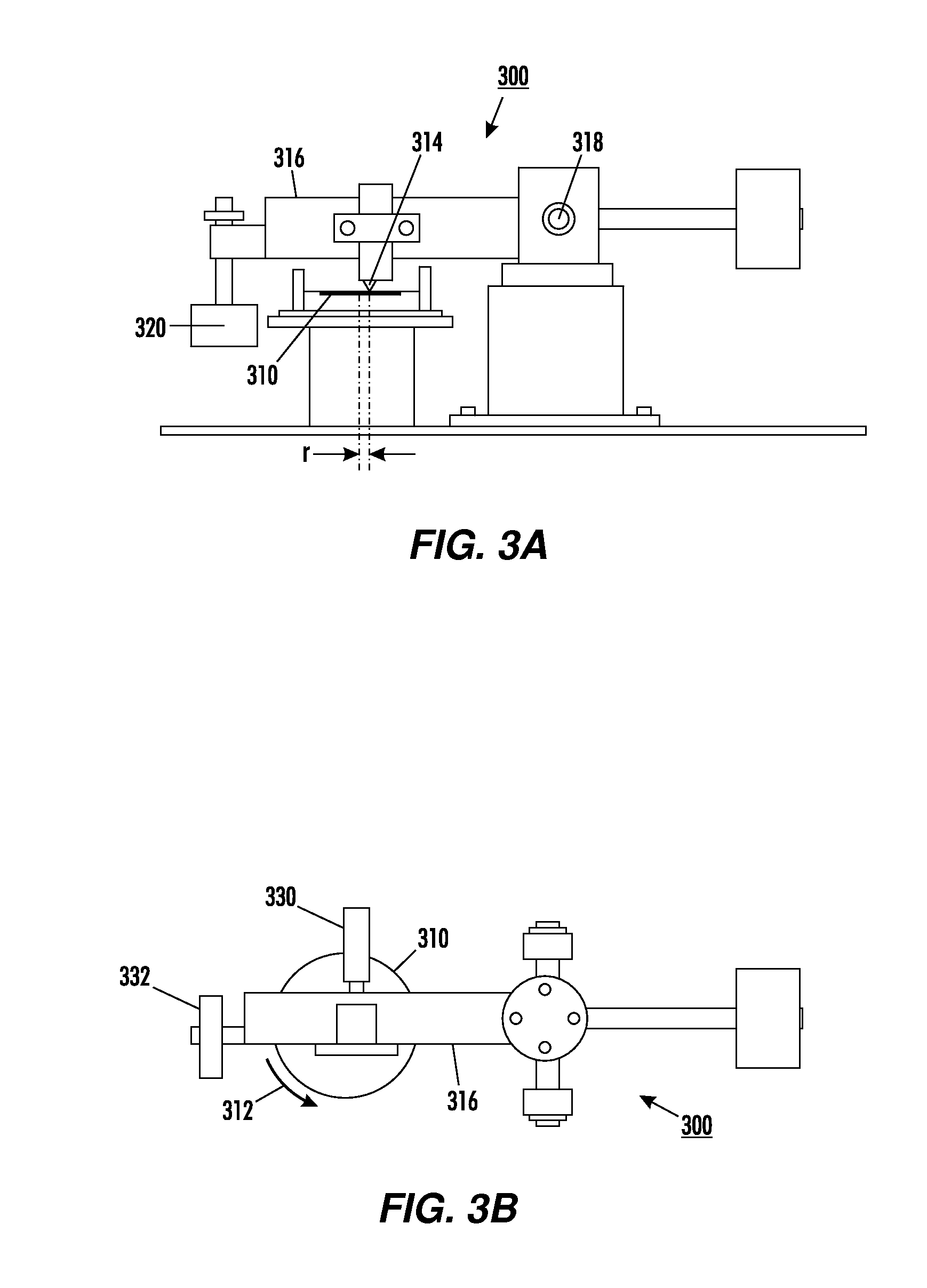

Deposition System, Method And Materials For Composite Coatings

InactiveUS20070243335A1Improve corrosion resistanceImprove structural performanceMolten spray coatingMetal-working apparatusHigh wear resistanceNanocrystal

A composite powder for a deposition of a composite coating comprises a nonmetallic component and a metallic component, the metallic component having an amorphous structure or a nanocrystalline structure. The metallic component may include an amorphous metallic alloy. The metallic alloy may include constituents having the amorphous structure. The metallic component may include a combination of the metallic alloy existing in the amorphous state and constituents of the amorphous metallic alloy in the amorphous state. The composite metal-ceramic powders are used for depositing composite coatings on a selected surface. Disclosed are several methods and systems for producing such composite powders. Disclosed are also several methods and systems for depositing composite coatings. Advantageously, the deposited coatings exhibit high corrosion resistance, high wear resistance, and excellent structural properties.

Owner:BELASHCHENKO VLADIMIR E

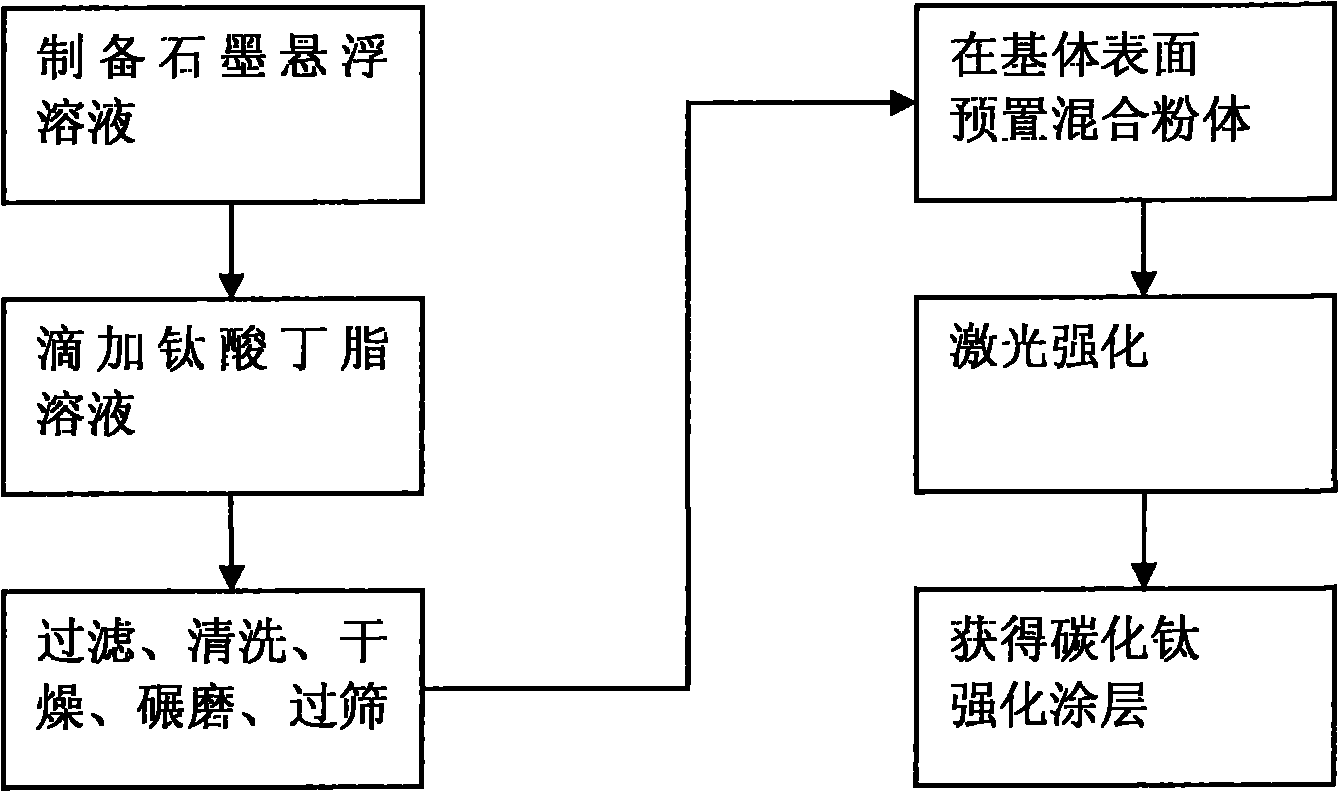

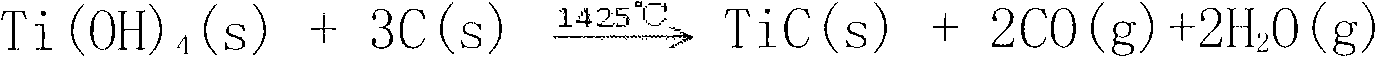

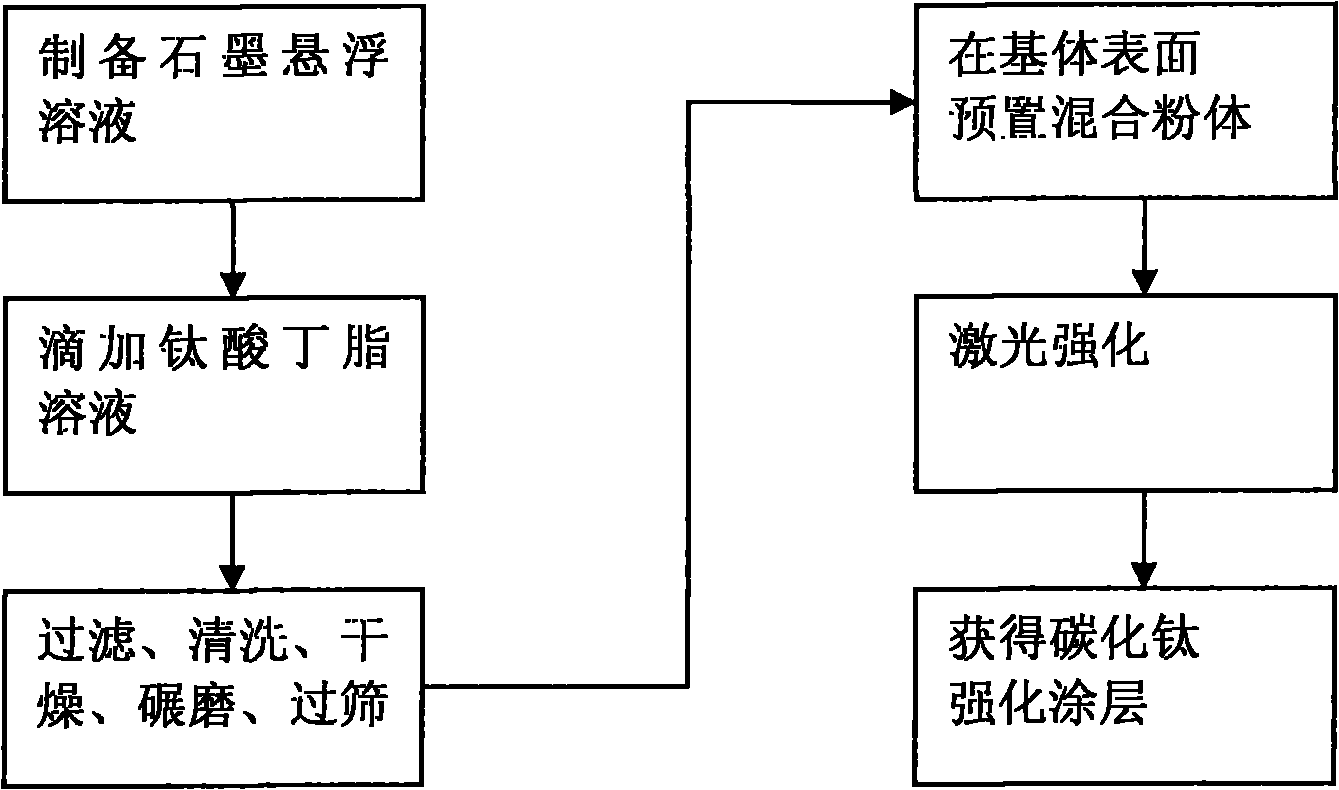

Method for preparing metal surface laser strengthened coat

InactiveCN101812684AIncrease profitImprove the strengthening effectMetallic material coating processesChemical reactionArgon atmosphere

The invention discloses a method for preparing a metal surface laser strengthened coat, which comprises the following steps: preparing uniformly mixed powder of titanium dioxide hydrate and graphite powder by using a wet chemistry method; pre-placing the mixed powder on the surface of a basal body; and irradiating the surface of the basal body by using laser as a heat source under an argon atmosphere to form a molten pool, performing a carbon-thermal chemical reaction on the pre-placed mixed powder under a high-temperature environment to generate titanium carbide, and finally forming a titanium carbide composite coat on the surface of the basal body. In the same way, the method is also suitable for preparing a TiN enhanced composite coat by mixing hydrated oxide thereof and graphite by the wet chemistry method, then mixing the mixture and urea to form pre-placed powder and cladding the pre-placed powder on the basal body by laser. The surface of the enhanced coat prepared by the technical scheme is smooth, and has no cracks or pores; enhancing particles are uniformly distributed in the coat; the enhanced coat and the basal body are metallurgically combined; and the mixed powder prepared by adopting the wet chemistry method is uniformly mixed, ensures complete reaction, and is suitable for industrial popularization and application.

Owner:姚建华

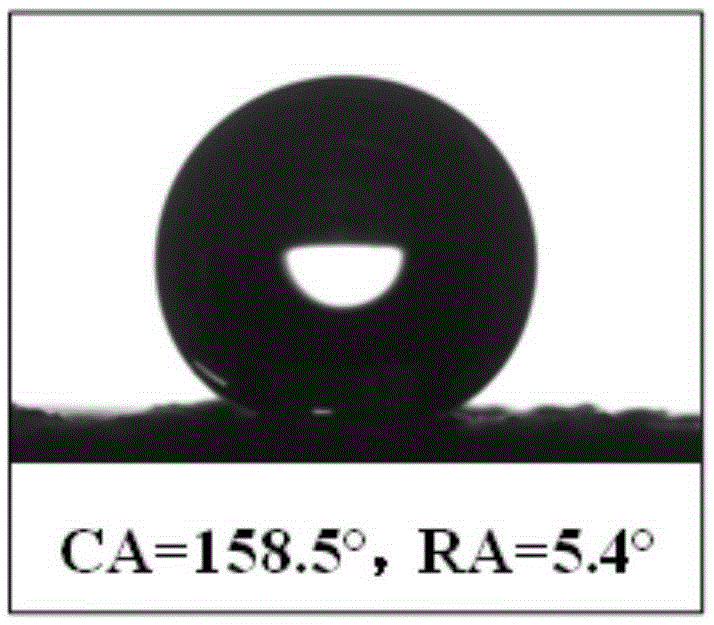

Super-hydrophobic and oleophobic composite coating and preparation method thereof

InactiveCN104745045AImprove hydrophobicity and oleophobicityHydrophobic and oleophobicPretreated surfacesEpoxy resin coatingsGas phaseSolvent

The invention discloses a super-hydrophobic and oleophobic composite coating which comprises a super-hydrophobic and oleophobic primer coat layer and a super-hydrophobic and oleophobic finishing coat layer. The coating is characterized in that the super-hydrophobic and oleophobic finishing coat layer is located on the super-hydrophobic and oleophobic primer coat layer; the super-hydrophobic and oleophobic primer coat layer is coated by a super-hydrophobic and oleophobic primer coat which is a composition containing epoxy resin, an auxiliary A, extinction powder and a solvent; the super-hydrophobic and oleophobic finishing coat layer is coated by a super-hydrophobic and oleophobic finishing coat which is a composition containing fumed silica, an auxiliary B, an auxiliary C, a mixed solution A and a mixed solution B. Compared with the prior art, the super-hydrophobic and oleophobic composite coating disclosed by the invention not only has a super-hydrophobic performance, but also can resist greasy dirt and has a super-oleophobic performance as well as good wear resistance and stability; the preparation process is simple, and realization of industrialized production is facilitated.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

High-temperature wearable composite dope for electric power boiler flue

The invention relates to a high-temperature wear-resistant composite coating for the flue of an electrical furnace, belonging to the high-temperature coating field. The invention enhances the strength and toughness of the material, improves the high-temperature performance of the material and forms mullite net compound structure under high temperature condition by using modern composite material principle and a coupling method by particle enhancing and fiber toughness increasing and adding high-performance material and using nano-compound powder as bonding and using hard high-strength particle as enhancer, further, the invention can also improves the volume stability and the rear resistant performance in high temperature, and prolongs service life. The invention is especially suitable for the flue of a furnace, and has the advantages of high refractoriness, wear-resistant performance, excellent high temperature performance, stable volume, high strength, good toughness, prolonging service life of the material, reducing maintenance times for the flue, and labor saving.

Owner:LUOYANG KENAI HIGH TEMPERATURE MATERIAL

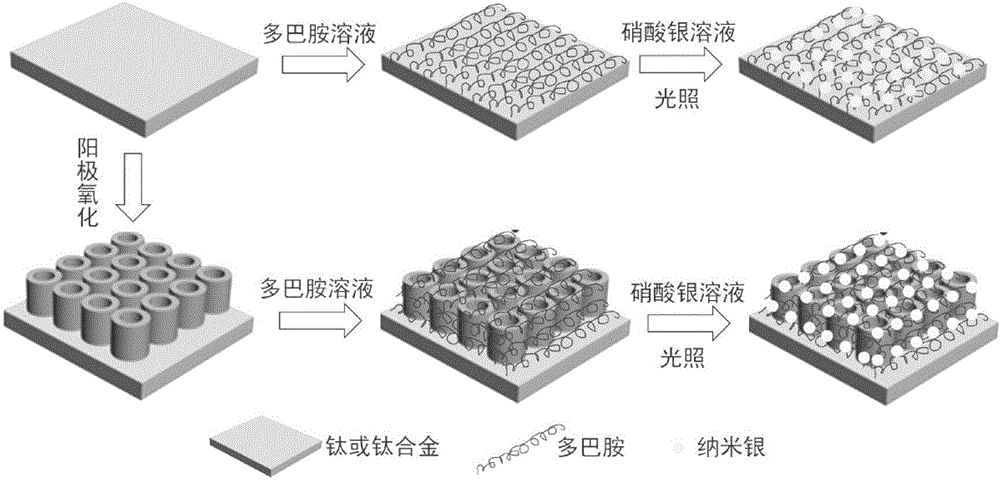

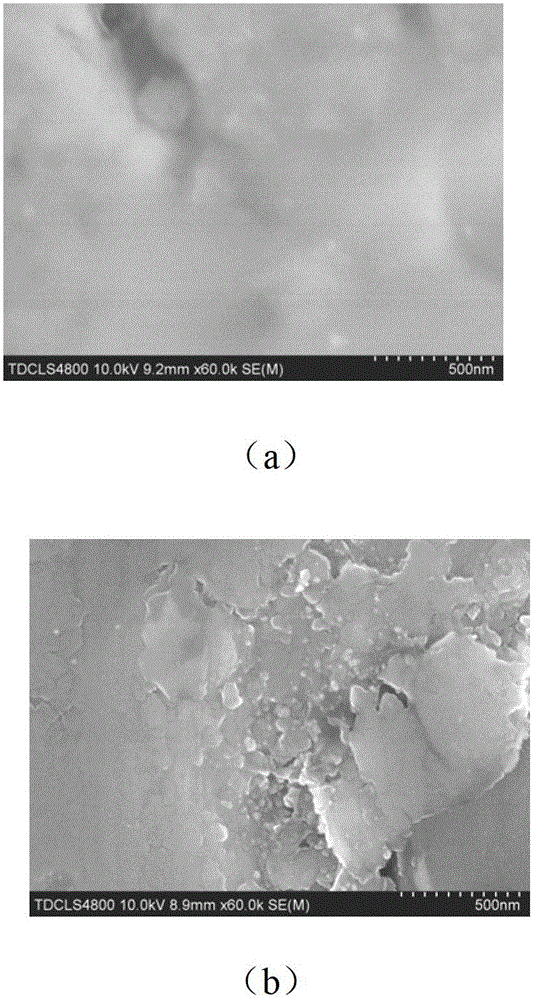

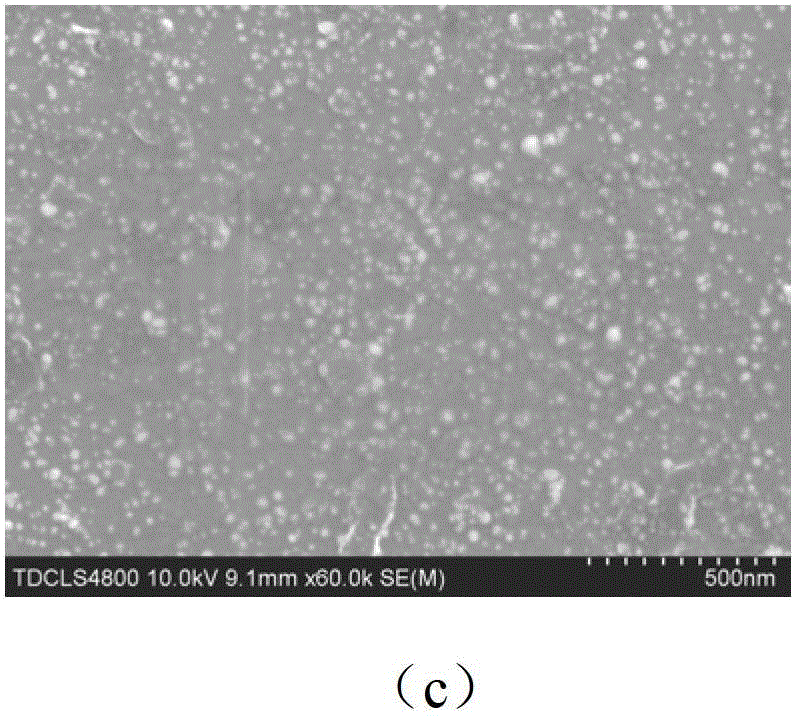

Dopamine-nanosilver composite coating and preparation method thereof

The invention discloses a dopamine-nanosilver composite coating and a preparation method thereof. Firstly, pure titanium or a titanium alloy with titanium dioxide nanotube arrays grown on the surface of the titanium alloy is put in a dopamine buffer solution, then the pure titanium loaded with the dopamine or the titanium alloy with the titanium dioxide nanotube arrays grown on the surface of the titanium alloy is put in a silver nitrate solution, and nanosilver particles are obtained by photoreduction. According to the dopamine-nanosilver composite coating and the preparation method thereof, the chelating property of the dopamine and metal ions and the reducibility in an auto polymerization process are utilized, and the antibacterial performance of material is improved by preparing the nanosilver coating on the surface of the titanium alloy, which has important application value and guiding significance for developing novel functional metal implant material.

Owner:TIANJIN UNIV

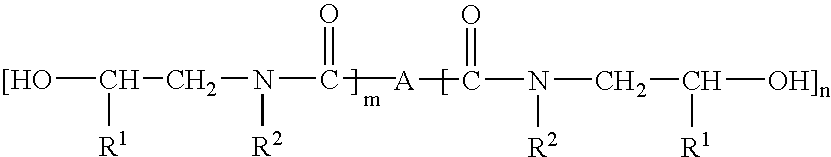

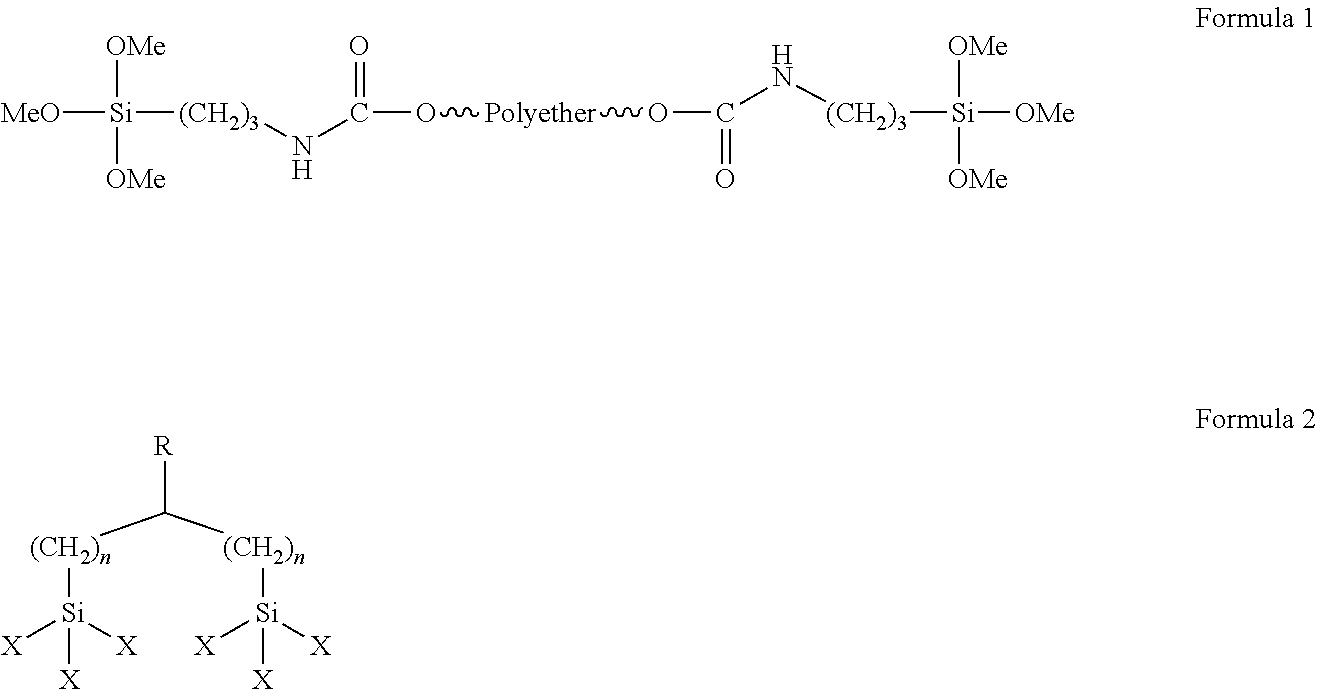

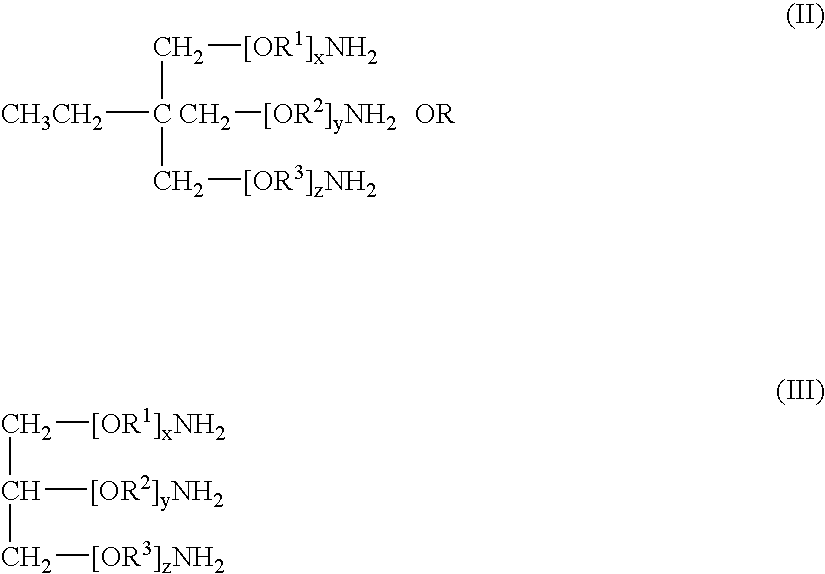

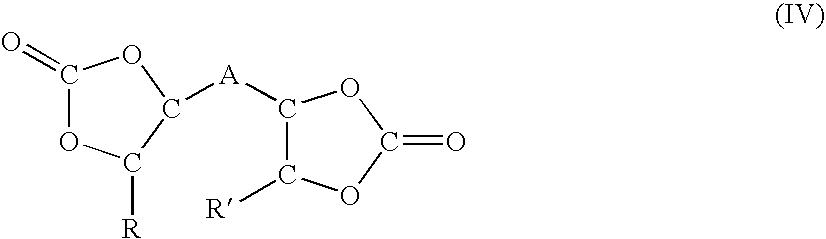

Polyether carbamate compounds, compositions containing such compounds, and methods related thereto

Owner:PPG IND OHIO INC

Polymeric coatings including nanoparticle filler

InactiveUS20080248201A1Reduce load levelIncreases potential for homogeneous dispersionPretreated surfacesSpecial surfacesHalloysiteNanoparticle

Disclosed is a novel polymeric composite coating including a nanoparticle filler, where the filler may be suitable to alter one or more characteristics of the coating. More particularly, one embodiment of the present invention provides a novel halloysite nanoparticle filler which has the general configuration of a cylinder or a rolled scroll-like shape, and a polymer protective coating containing the halloysite nanoparticle or equivalent nanotubular filler.

Owner:NATURALNANO RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com