Dopamine-nanosilver composite coating and preparation method thereof

A technology of composite coating and dopamine, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve problems such as failure of implanted materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

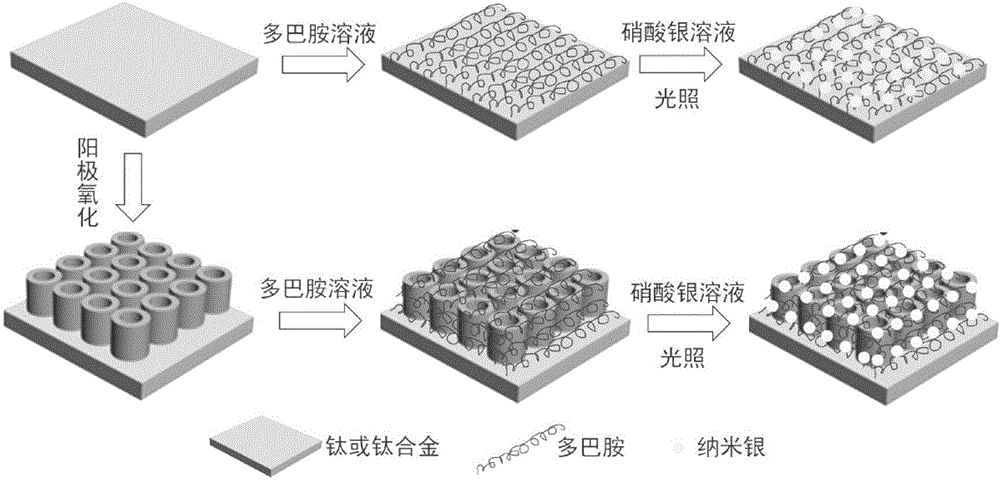

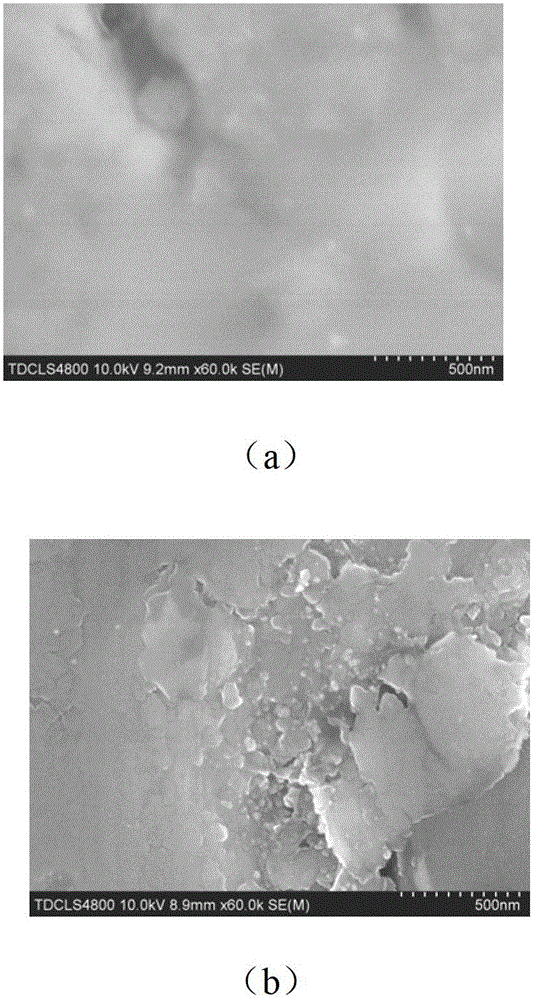

[0024] Nano-silver antibacterial coating is prepared with pure titanium as the substrate, and nano-silver particles are prepared by using the chelating and reducing properties of dopamine. The said pure titanium as the substrate is a pure titanium plate with a size of 10*10*6mm. The Ti sheet is cleaned with deionized water, and dried with absolute ethanol for 5 minutes before being used.

[0025] Said nano-silver particles are prepared by dopamine reduction method, the Ti sheet is placed in the dopamine Tris solution for 24 hours, and then placed in silver nitrate (AgNO 3 ) solution by light reaction, the sample was taken out and ultrasonically cleaned with absolute ethanol to obtain evenly distributed nano-silver particles on the Ti surface.

[0026] The process parameters for preparing nano-silver are:

[0027] Tris concentration: 0.3mg / ml

[0028] Dopamine concentration: 0.1mg / ml

[0029] Silver nitrate solution concentration: 0.01mol / L

[0030] Lighting time: 10min

Embodiment 2

[0032] Nano-silver antibacterial coating is prepared with pure titanium as the substrate, and nano-silver particles are prepared by using the chelating and reducing properties of dopamine. The said pure titanium as the substrate is a pure titanium plate with a size of 10*10*6mm. The Ti sheet is cleaned with deionized water, and dried with absolute ethanol for 5 minutes before being used.

[0033] Said nano-silver particles are prepared by dopamine reduction method, the Ti sheet is placed in the dopamine Tris solution for 24 hours, and then placed in silver nitrate (AgNO 3 ) solution by light reaction, the sample was taken out and ultrasonically cleaned with absolute ethanol to obtain evenly distributed nano-silver particles on the Ti surface.

[0034] The process parameters for preparing nano-silver are:

[0035] Tris concentration: 0.3mg / ml

[0036] Dopamine concentration: 0.2mg / ml

[0037] Silver nitrate solution concentration: 0.01mol / L

[0038] Lighting time: 10min

Embodiment 3

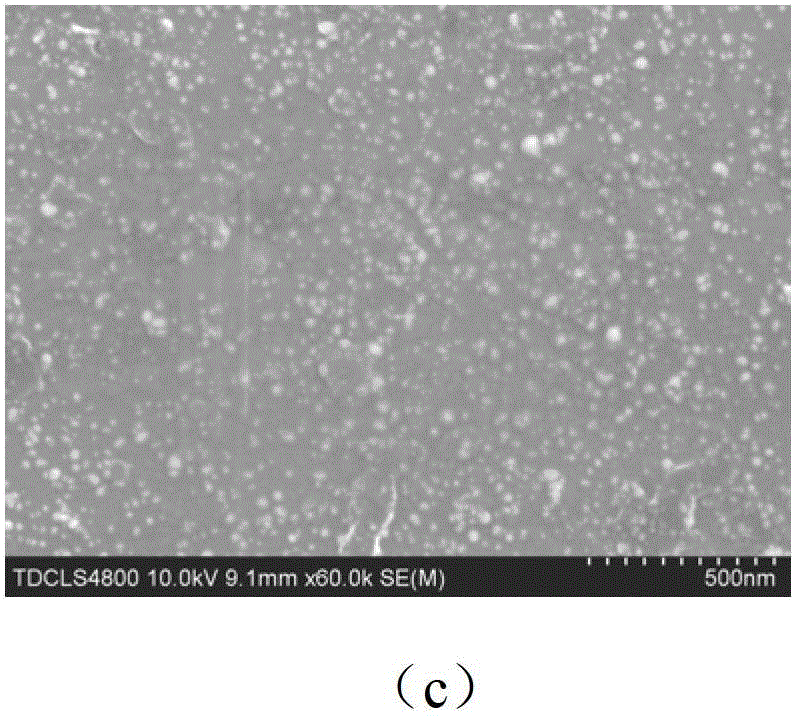

[0040] Nano-silver antibacterial coating is prepared with pure titanium as the substrate, and nano-silver particles are prepared by using the chelating and reducing properties of dopamine. The said pure titanium as the substrate is a pure titanium plate with a size of 10*10*6mm. The Ti sheet is cleaned with deionized water, and dried with absolute ethanol for 5 minutes before being used.

[0041] Said nano-silver particles are prepared by dopamine reduction method, the Ti sheet is placed in the dopamine Tris solution for 24 hours, and then placed in silver nitrate (AgNO 3 ) solution by light reaction, the sample was taken out and ultrasonically cleaned with absolute ethanol to obtain evenly distributed nano-silver particles on the Ti surface.

[0042] The process parameters for preparing nano-silver are:

[0043] Tris concentration: 0.3mg / ml

[0044] Dopamine concentration: 0.3mg / ml

[0045] Silver nitrate solution concentration: 0.01mol / L

[0046] Lighting time: 10min

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com