Copper-nickel alloy nanowire/titanium dioxide composite material as well as preparation method and application thereof

A technology of copper-nickel alloy and titanium dioxide, which is applied in the field of nano-composite materials with new binary metal alloy semiconductor heterostructure and its preparation, can solve the problem of low Schottky barrier and photocatalytic activity at the metal-semiconductor heterojunction. , easy deactivation and denaturation of materials, etc., to achieve the effect of inhibiting recombination rate, improving photocatalytic activity, and highly uniform and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation of organic solvent dispersion of copper-nickel alloy nanowires. The copper-nickel alloy nanowire is dispersed in a dispersant (organic solvent), and a uniform and stable copper-nickel alloy nanowire dispersion liquid with a certain concentration is obtained after ultrasonic dispersion. Specifically, the copper-nickel alloy nanowires obtained by reducing copper acetylacetonate were first washed three times with isopropanol, then washed three times with ethanol, and finally ultrasonically dispersed in a dispersant to obtain uniform and stable copper-nickel alloy nanowires. line dispersion. The dispersant of the copper-nickel alloy nanowire dispersion liquid can be an organic solvent, preferably at least one of ethanol, methanol, isopropanol, ethylene glycol, toluene and acetone. In addition, the preparation method of the copper-nickel alloy nanowires in the present invention includes but not limited to the method of reducing copper acetylacetonate (see patent...

Embodiment 1

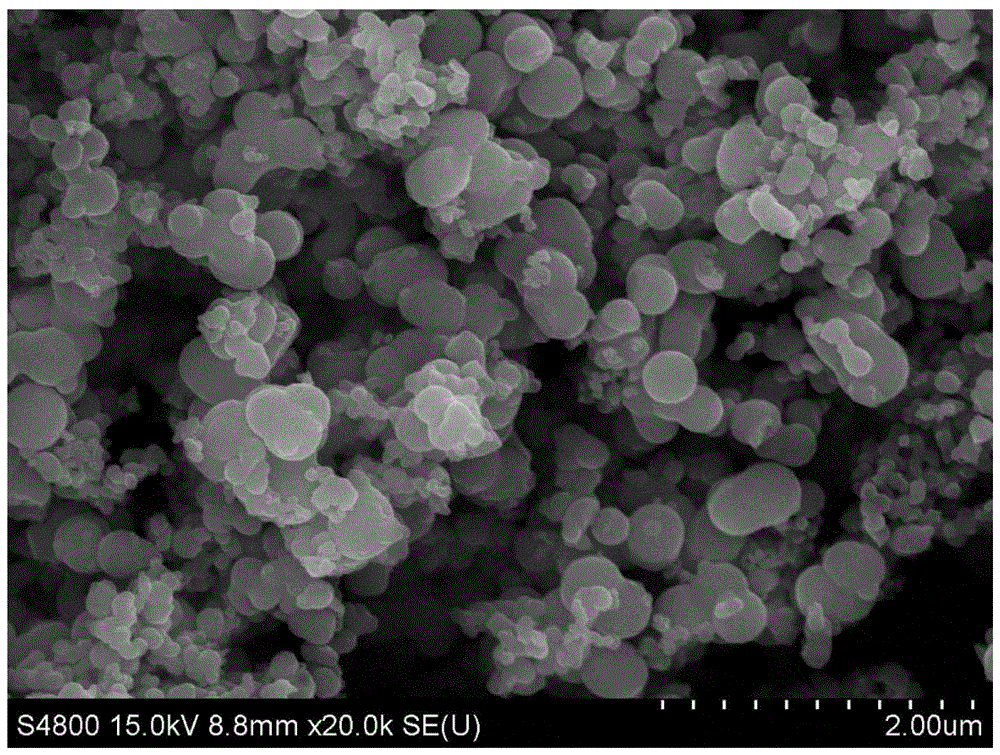

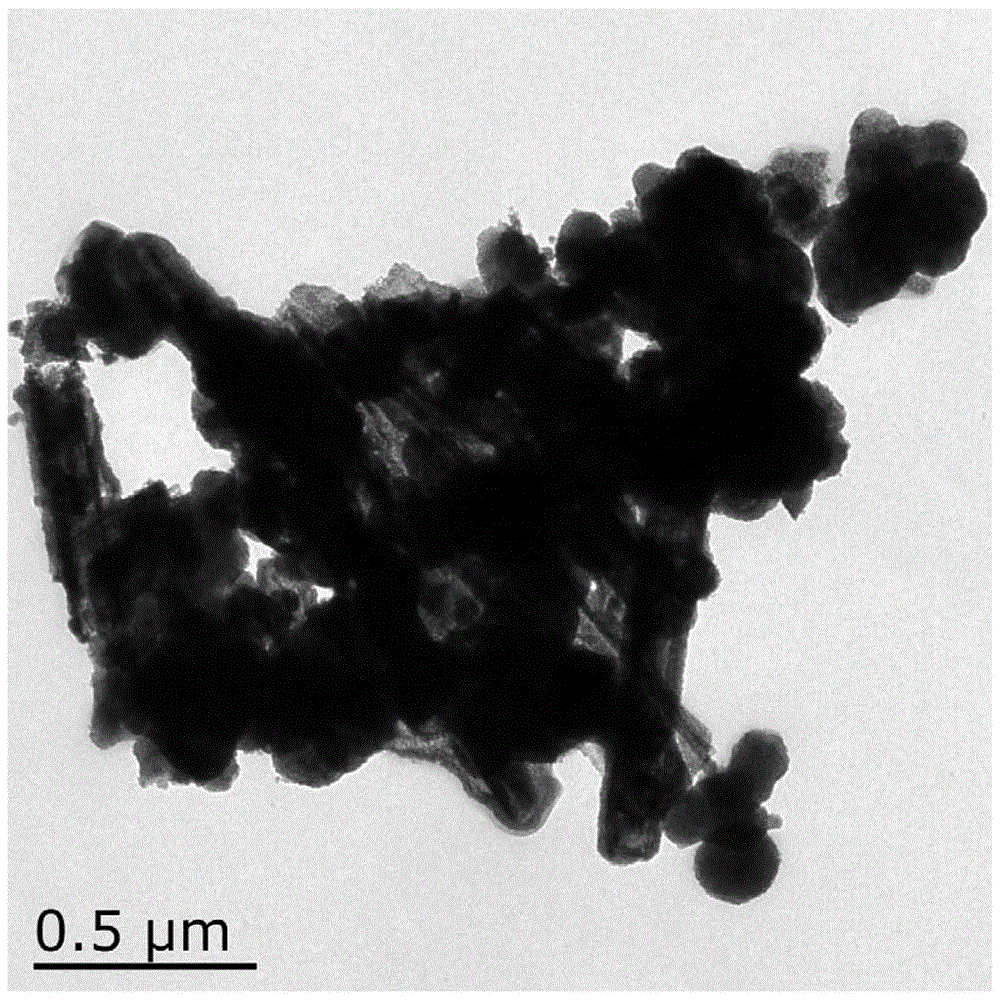

[0068] Disperse 0.0272g of copper-nickel alloy nanowires in 100ml of ethanol and ultrasonically disperse for 30 minutes to obtain a uniform and stable dispersion of copper-nickel alloy nanowires with good dispersion. Add 10ml of deionized water to the dispersion, continue stirring and then drop 10.06ml of titanium isopropoxide, continue to stir for 1h, after fully stirring, centrifuge and wash 4 times with alcohol at a speed of 4000rpm, put it in a vacuum oven at 60°C for 12h, and then place the obtained powder precursor in an argon atmosphere After annealing at 400° C. for 3 hours, a copper-nickel alloy nanowire / titanium dioxide composite material powder is obtained, wherein the weight ratio of the copper-nickel alloy nanowire is 1%. see image 3 , Figure 4 , which shows the SEM image and TEM image of the obtained copper-nickel alloy nanowire / titanium dioxide composite material powder, from which it can be seen that the obtained copper-nickel alloy nanowire / titanium dioxide...

Embodiment 2

[0072] Disperse 0.0412g of copper-nickel alloy nanowires in 100ml of ethanol and ultrasonically disperse for 30 minutes to obtain a uniform, stable and well-dispersed copper-nickel alloy nanowire dispersion. Add 10ml of deionized water to the dispersion, continue stirring and then drop 4. 978ml of titanium isopropoxide, continue to stir for 1h, after fully stirring, centrifuge and wash 4 times with alcohol at a speed of 4000rpm, put it in a vacuum oven at 60°C for 12h, and then place the obtained powder precursor in an argon atmosphere After annealing at 400° C. for 3 hours, a copper-nickel alloy nanowire / titanium dioxide composite material powder is obtained, wherein the weight ratio of the copper-nickel alloy nanowire is 3%. see Figure 5 , 6 , which shows the SEM image and TEM image of the obtained copper-nickel alloy nanowire / titanium dioxide composite material powder, from which it can be seen that the obtained copper-nickel alloy nanowire / titanium dioxide composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com