Photocatalyst and application thereof to efficient photocatalysis degradation on different gas phase organic contaminants

A technology of organic pollutants and photocatalysts, applied in physical/chemical process catalysts, chemical/physical processes, chemical instruments and methods, etc., can solve the problem of poor adsorption capacity of organic pollutants, difficult gas degradation, and weak catalytic activity. problem, to achieve the effect of easy industrial production, good photocatalytic performance, and low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

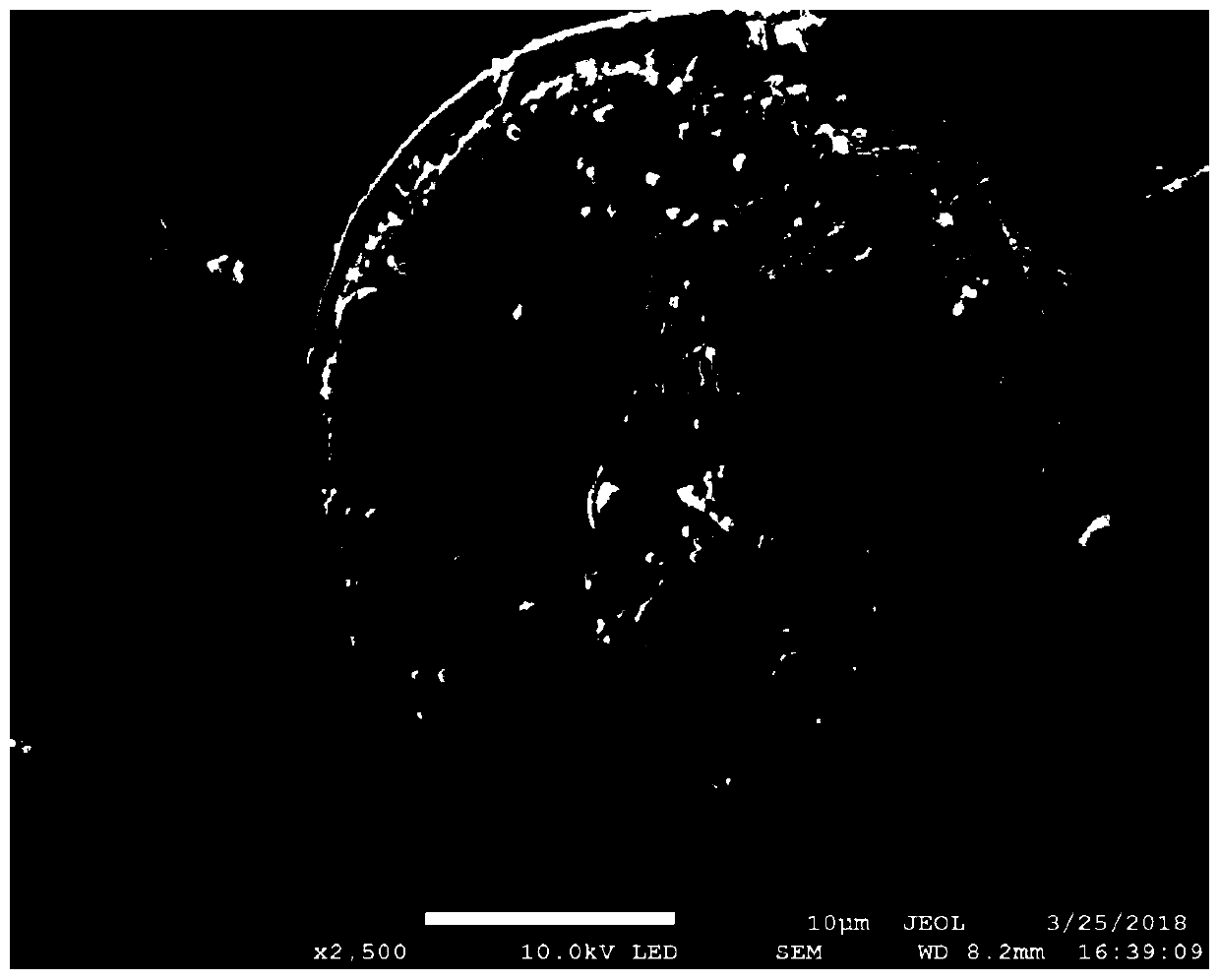

Embodiment 1

[0032] A. Add 50.00 mL of absolute ethanol to the three-necked flask, place it in an ice-water bath and stir for 20 minutes. Under the condition of stirring, slowly add 2.00 mL of titanium tetrachloride to the three-necked flask, and then take 0.50 mL of water with a pipette gun Add it and continue to stir until the yellow transparent solution;

[0033] B. Weigh 4.00g of diatomaceous earth and place it in a 100mL reaction kettle, transfer the yellow transparent solution obtained in step A to the reaction kettle, stir the yellow transparent solution and diatomite in the reaction kettle evenly, and put it into an oven at 200 ℃ reaction 12h;

[0034] C. After the reaction is completed, wash with absolute ethanol and deionized water for 4 times, rinse until the pH is about 7, and then dry in an oven at 80°C for 10 hours to obtain a photocatalyst.

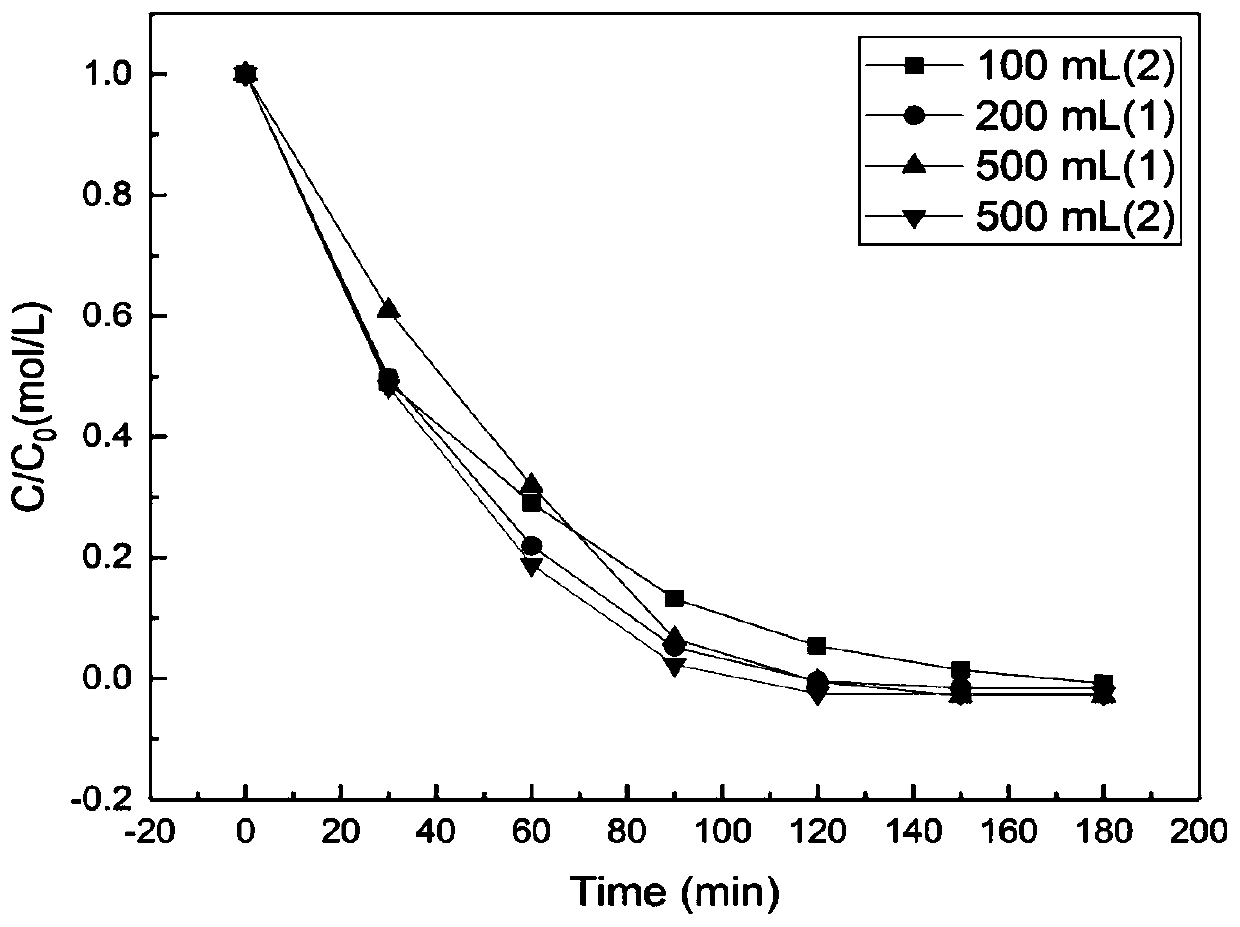

[0035] The photocatalyst prepared by the above method was subjected to photocatalytic degradation. Weigh 0.05 g of the photocatalyst...

Embodiment 2

[0038] A. Add 50.00 mL of absolute ethanol to the three-necked flask, place it in an ice-water bath and stir for 20 minutes. Under the condition of stirring, slowly add 2.00 mL of titanium tetrachloride to the three-necked flask, and then take 0.50 mL of water with a pipette gun Add it and continue to stir until the yellow transparent solution;

[0039] B. Weigh 4.00g of diatomaceous earth and place it in a 100mL reaction kettle, transfer the yellow transparent solution obtained in step A to the reaction kettle, stir the yellow transparent solution and diatomite in the reaction kettle evenly, and put it into an oven at 200 ℃ reaction 12h;

[0040] C. After the reaction is completed, wash with absolute ethanol and deionized water for 4 times, rinse until the pH is about 7, and then dry in an oven at 80°C for 10 hours to obtain a photocatalyst.

[0041] The photocatalyst prepared by the above method was subjected to photocatalytic degradation. Weigh 0.05 g of the photocatalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com