Concrete material having function of purifying gas-solid pollutants and preparation method thereof

A concrete and pollutant technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of unfavorable popularization and application, high cost, short photocatalytic life of road surface, etc., and achieve improved photocatalytic efficiency and low cost , the effect of enhancing the photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

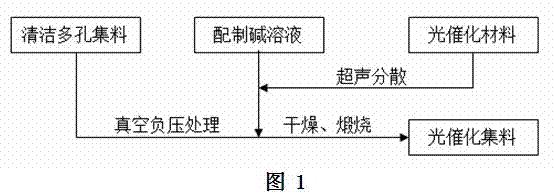

Method used

Image

Examples

Embodiment 1

[0051] Select river sand with a fineness modulus of 2.6 and dry it for later use; select 400-grade shale ceramsite loaded with photocatalytic materials (that is, the following aggregates with photocatalytic properties, or coarse aggregate-loaded photocatalytic materials, or photocatalytic aggregates, or coarse aggregates loaded with photocatalysts), placed in water for 24 hours to make it saturated with water, and then placed in a freezing environment to freeze, so that the pores on the surface and the adsorbed water on the surface freeze to obtain Pretreated photocatalytic aggregates, ready for use; using water as the medium, ultrasonically disperse Degussa P25 (photocatalyst TiO 2 5g / m 2 ), this mixture is named A, and it is reserved; the raw materials are weighed according to the following content: 32.5 ordinary Portland cement 260 kg / m 3 , silica fume 29kg / m 3 , sand rate 45% (coarse aggregate ceramsite in sand rate 255kg / m 3 ), effective water 155kg / m 3 , water reduce...

Embodiment 2

[0056] Select machine-made sand with a fineness modulus of 2.9 and dry it for later use; select 600-grade clay ceramsite loaded with photocatalytic materials, place it in water for 24 hours to make it saturated, and then freeze it in a freezing environment to make its surface porosity and the adsorbed water on the surface is frozen, and the photocatalytic aggregate is pretreated for use; using water as the medium, ultrasonically disperse Hombikat UV100 (ie TiO 2 14g / m 2 ), this mixture is named B, and it is reserved; the raw materials are weighed according to the following content: 32.5 ordinary Portland cement 280.5 kg / m 3 , fly ash 49.5 kg / m 3 , sand rate 30%, water 180kg / m 3 , superplasticizer 2.64kg / m 3 (Naphthalene-based water reducer, powder, water reducing rate 25%), spare; the above raw materials (ie, ordinary Portland cement, fly ash, pretreated photocatalytic aggregate, machine-made sand, water, water reducer) mixed Fill it into the test mold after stirring, and ...

Embodiment 3

[0060] Select ceramic sand with a fineness modulus of 3.4, place it in water for 24 hours to make it saturated, and set aside; select 800-grade fly ash ceramsite loaded with photocatalytic materials, place it in water for 24 hours to make it saturated, and then place Freeze in a freezing environment to freeze the pores on the surface and the adsorbed water on the surface to obtain pretreated photocatalytic aggregates for use; use water as the medium to ultrasonically disperse Anatase, and name this mixture C for use; weigh it according to the following content Raw materials: 32.5 ordinary Portland cement 330 kg / m 3 , silica fume 11 kg / m 3 , fly ash 99 kg / m 3 , sand rate 35%, effective water 200 kg / m 3 , water reducer 4.4 kg / m 3 (Melamine-based water-reducing agent, powder, water-reducing rate 25%), spare; the above-mentioned raw materials (ie, ordinary Portland cement, silica fume, fly ash, pretreated photocatalytic aggregates, ceramic sand, effective water, Water reducer)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com