Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2251 results about "Anatase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

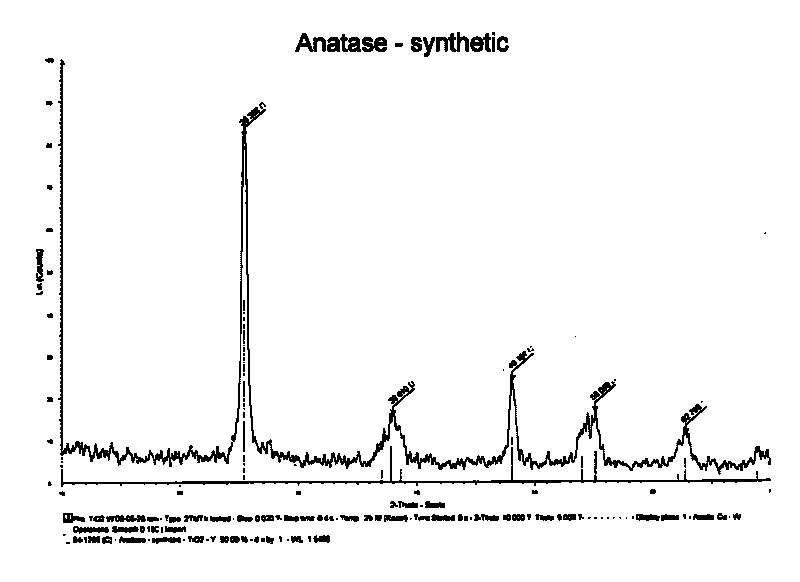

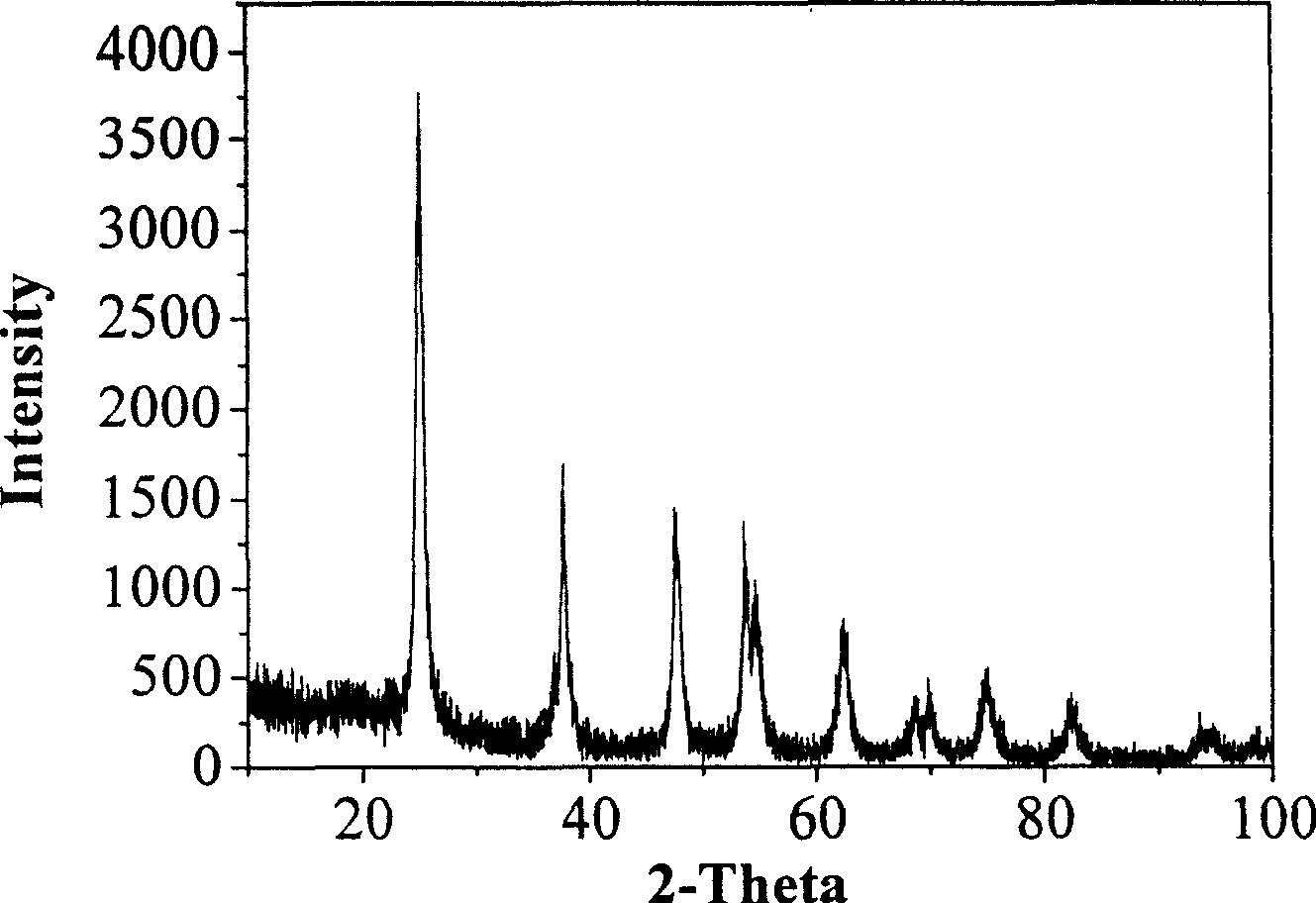

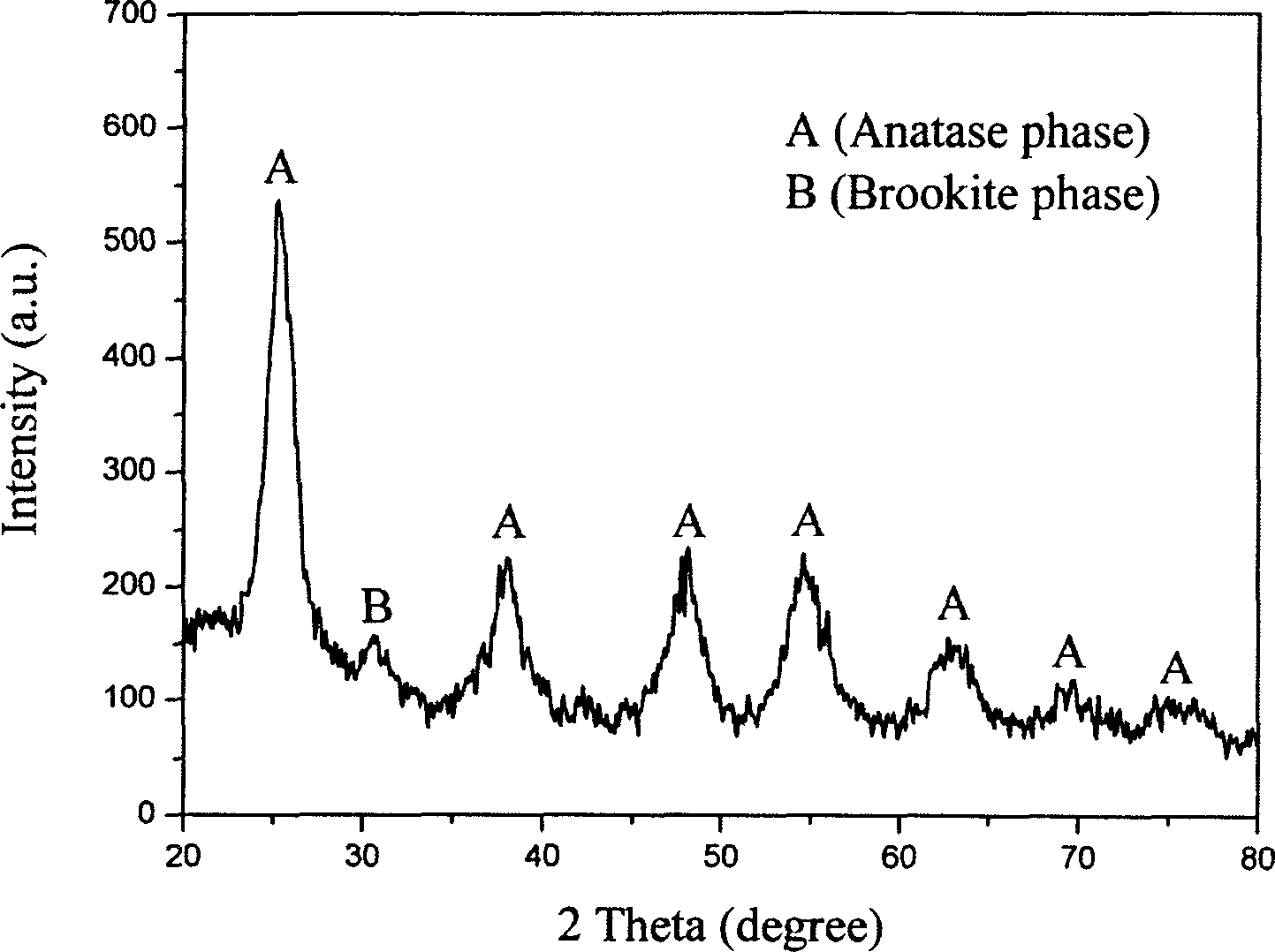

Anatase is a metastable mineral form of titanium dioxide (TiO₂). The mineral in natural forms is mostly encountered as a black solid, although the pure material is colorless or white. Two other naturally occurring mineral forms of TiO₂ are known, brookite and rutile.

Titanium-containing materials

The invention relates to a method of preparing a solution containing colloidal particles which contain crystalline titanium dioxide wherein one or more hydrolysable titanium-containing compound(s) is stabilised by oxalic acid in a reaction medium. The reaction further relates to the preparation of titania materials (including particulate materials, coating solutions and films) which comprise or include anatase phase titania, and so are suitable in photocatalytic applications. The invention also deals with a method of preparing B-phase titania.

Owner:IND RES LTD

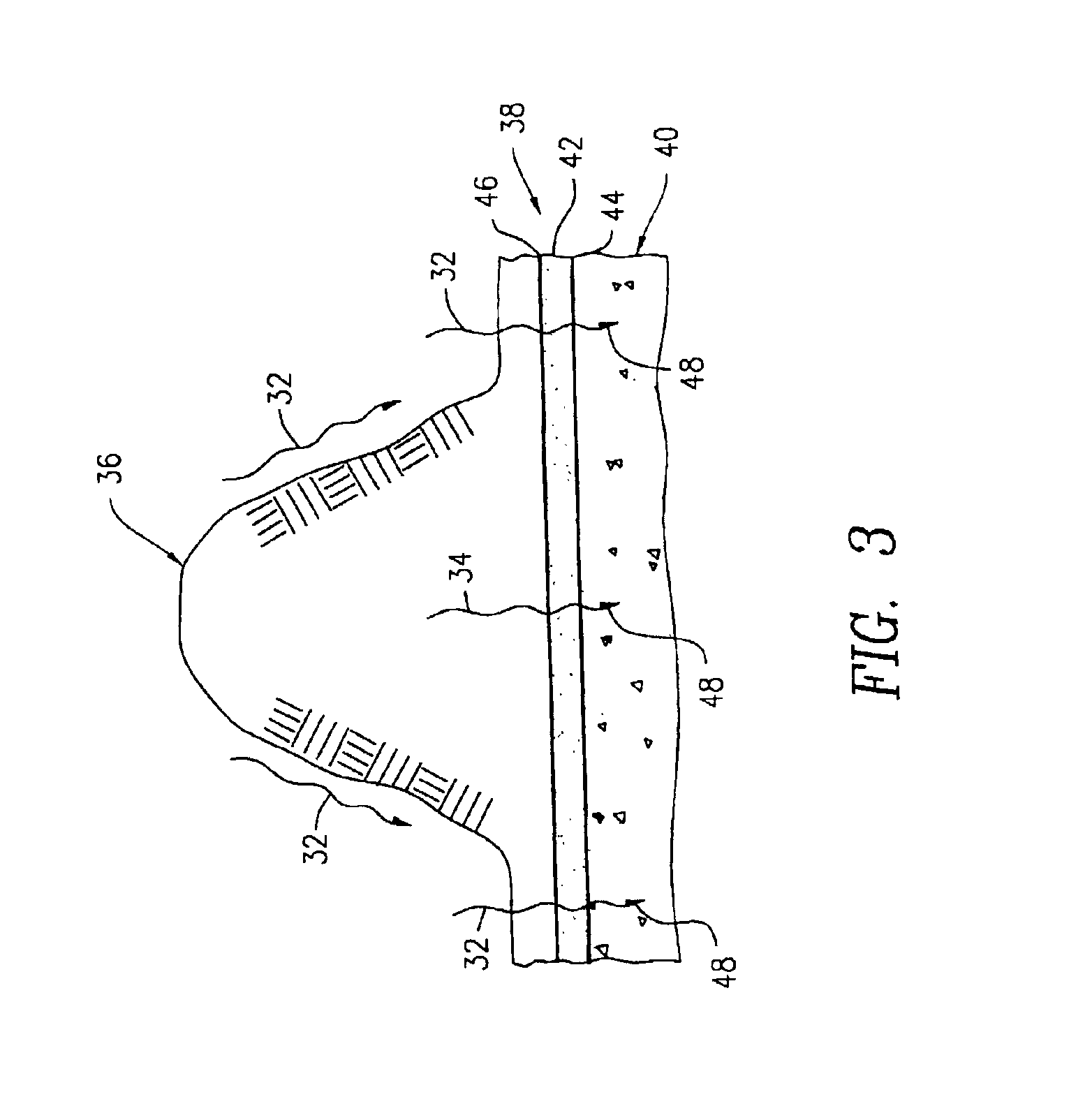

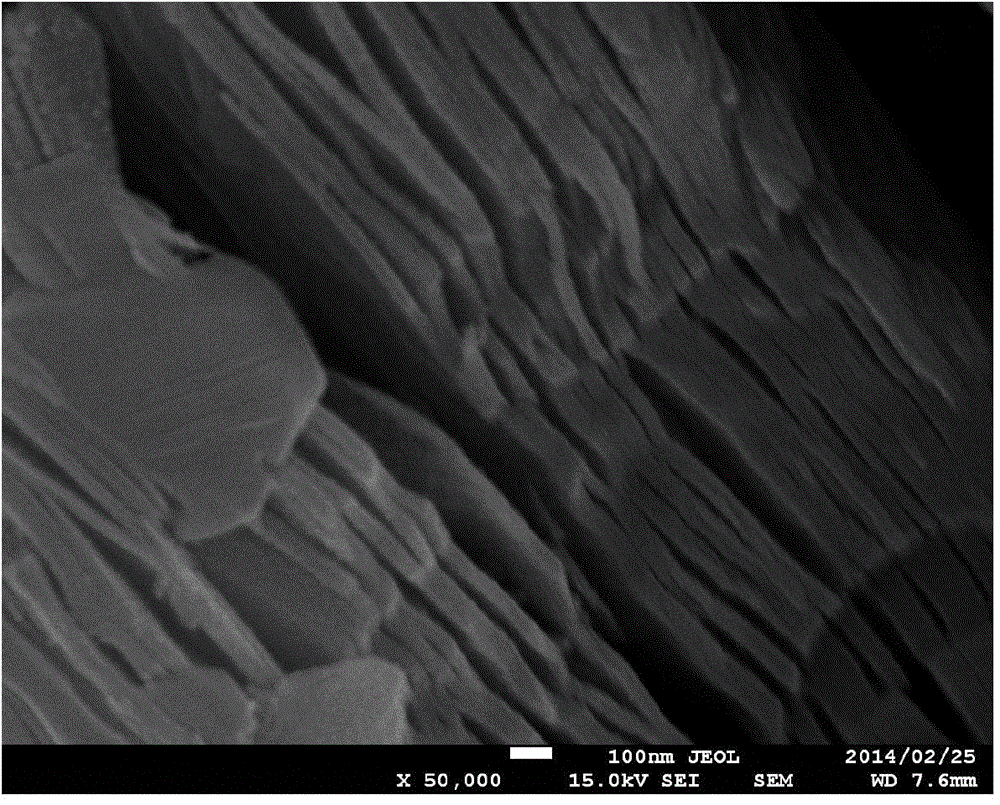

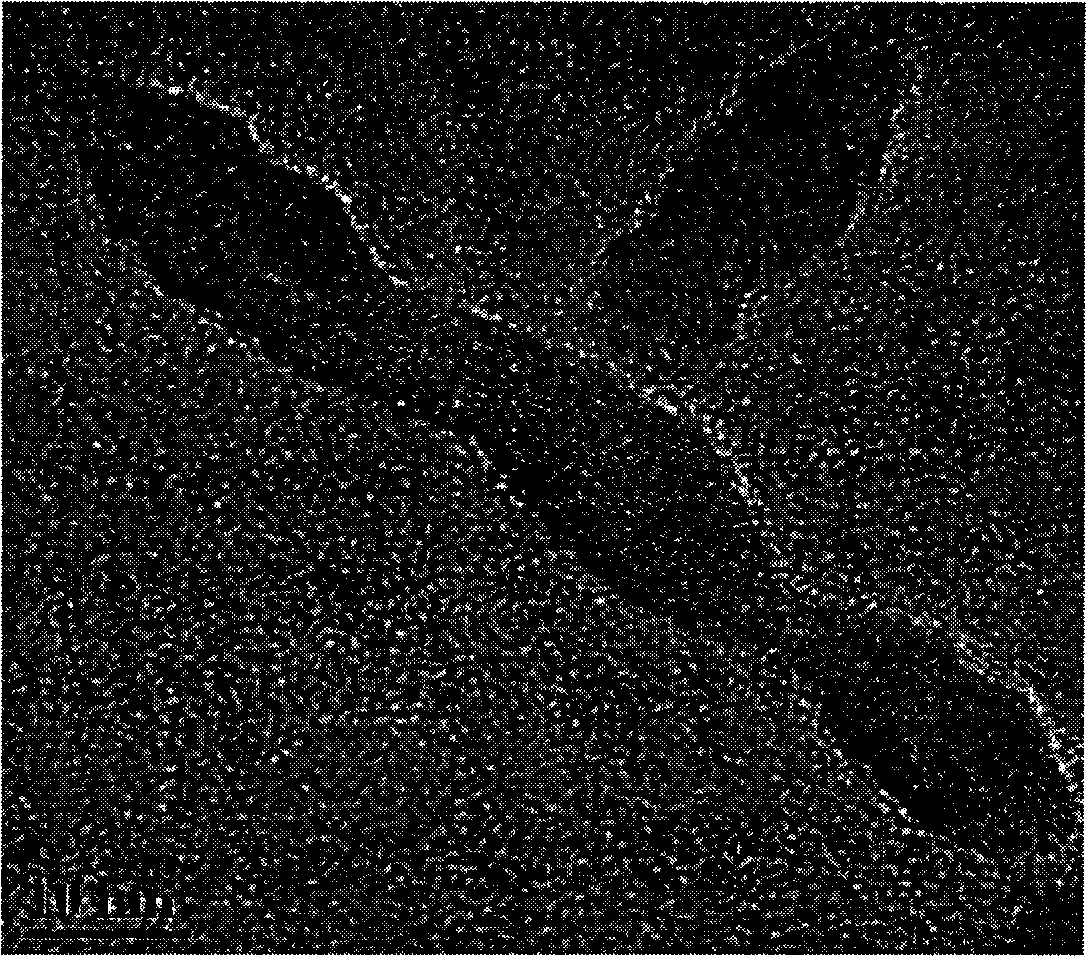

Process for preparing titanium dioxide nano-belts

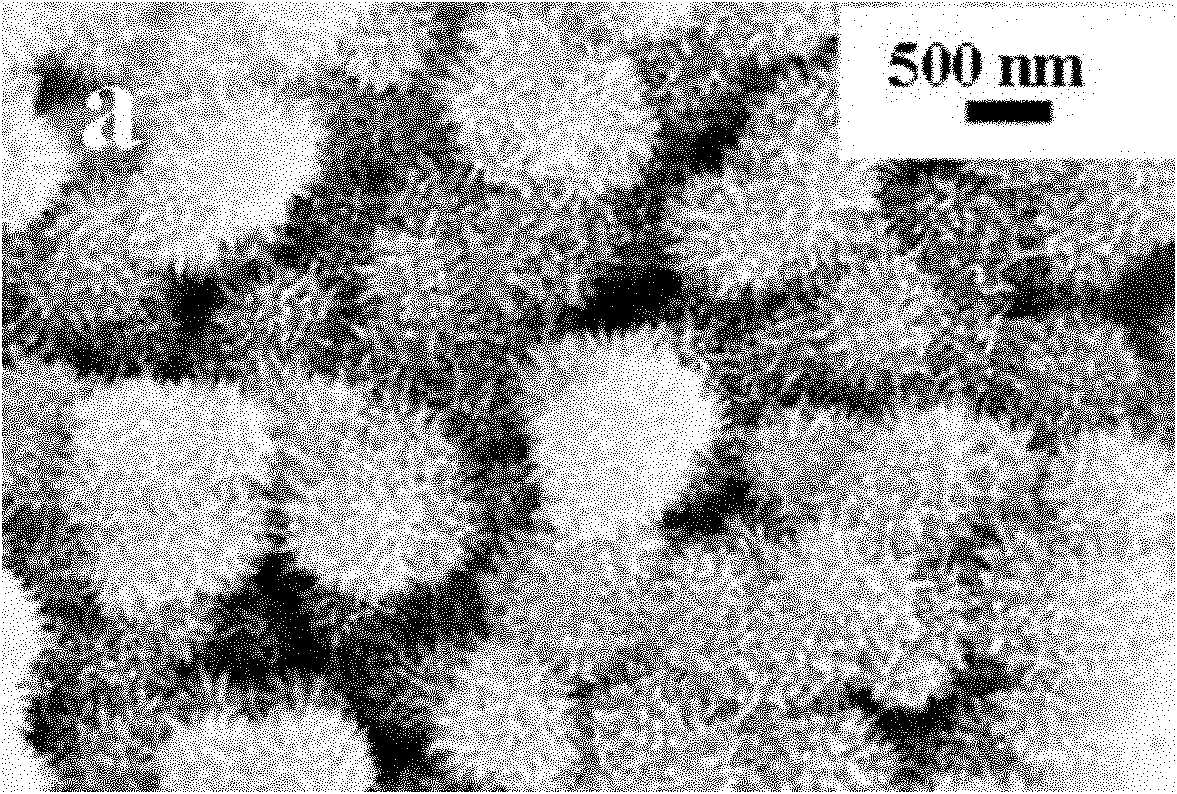

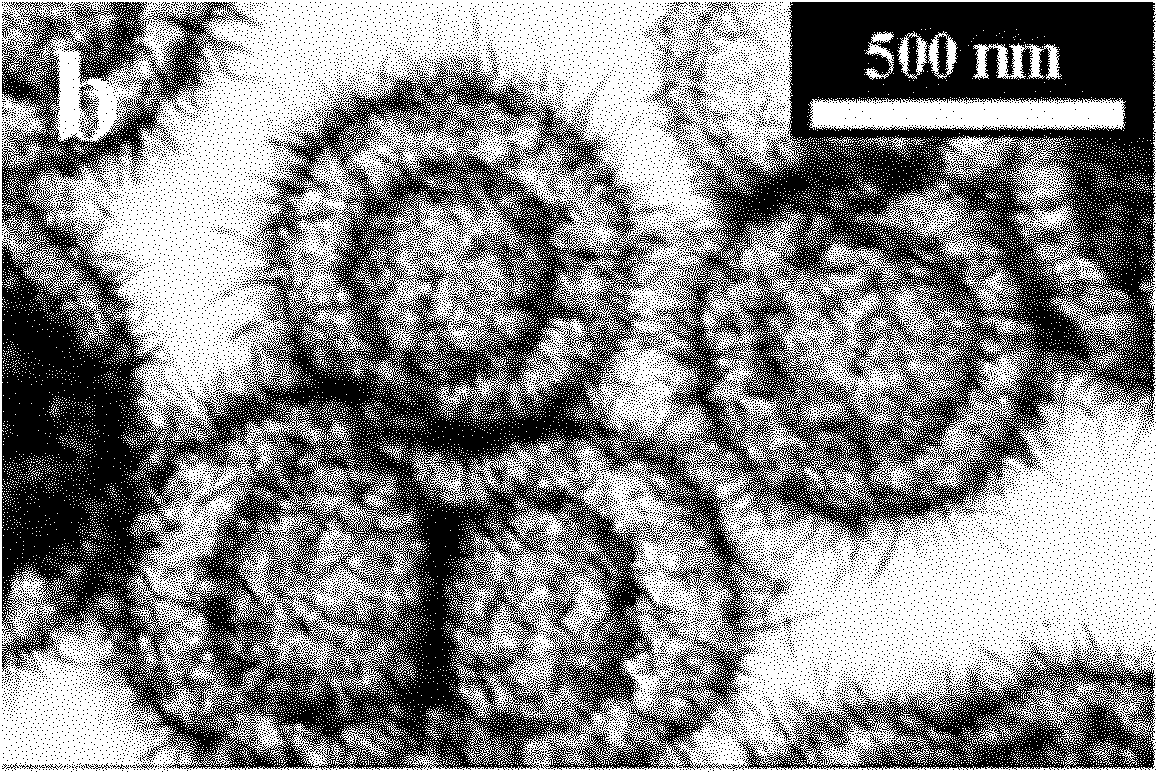

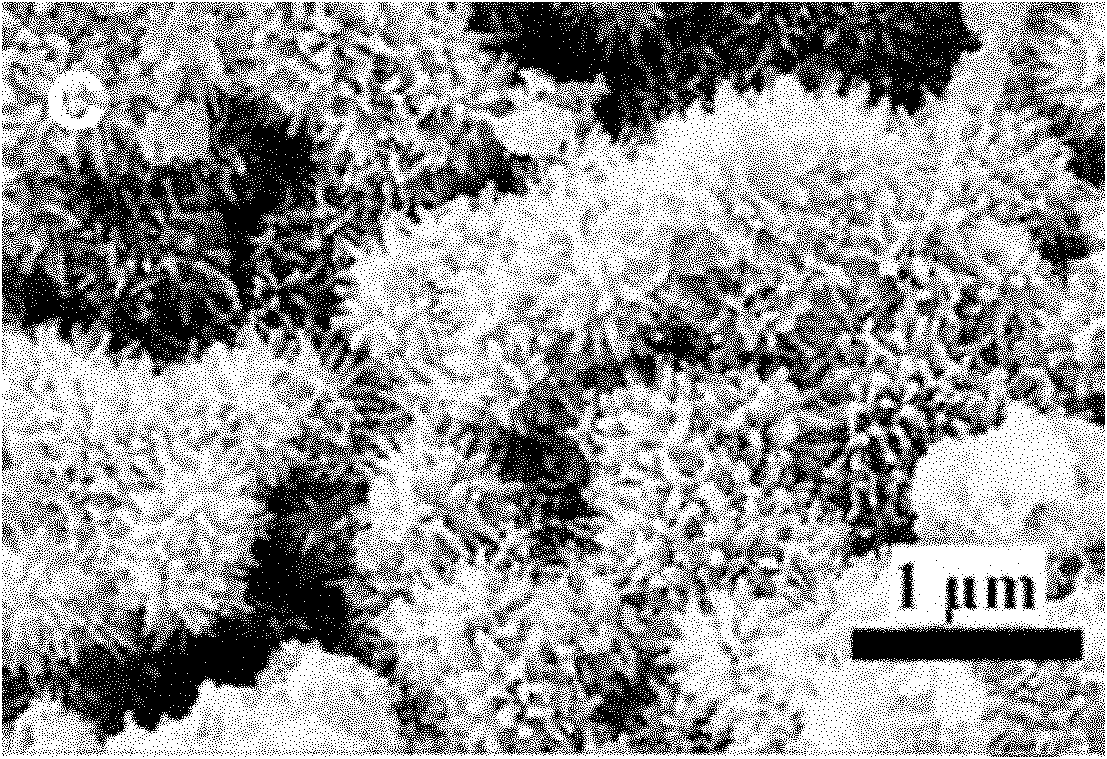

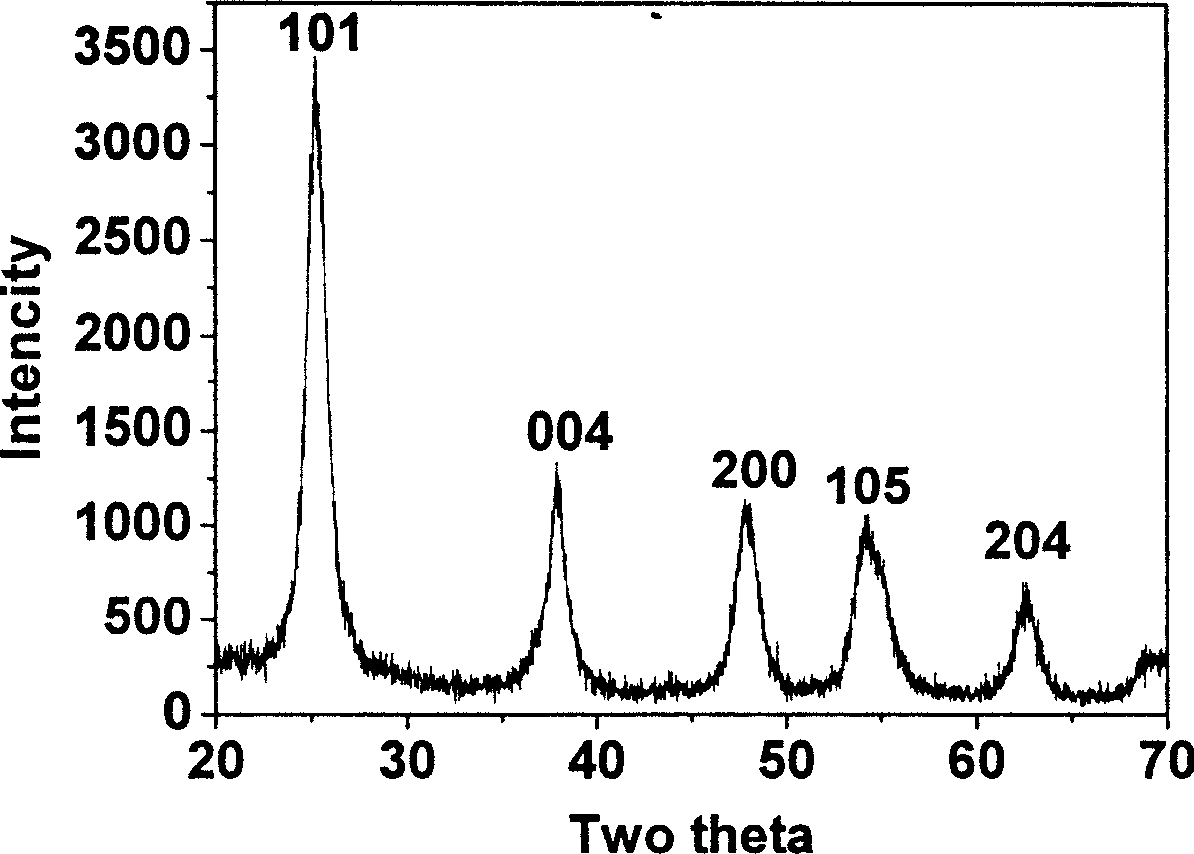

The invention provides a method for preparing a titanium dioxide nano belt, belonging to the nano material technical field. The prior methods for preparing the titanium dioxide nano belt comprise the hydro-thermal method and the combination method of the sol-gel method and the hydro-thermal method. The prior electrostatic spinning method is applied to the preparation of nano fibers. The invention comprises three steps that: 1. a spinning solution is prepared; the mixture of polymethylmethacrylate and vinylpyrrolidone is used as a macromolecule template, and the mixture of chloroform and N,N-dimethylformamide is used as a solvent; 2. a titanium alkoxide / macromolecule template compound nano belt is prepared; the electrostatic spinning method is used, and the technical parameters are as follows: the voltage is between 15 and 25kV and the curing distance is between 15 and 30cm; 3. a TiO2 nano belt is prepared; the heat treatment method is used, and the technical parameters are as follows: the rate of temperature rise is between 0.5 and 2 DEG C / min and the heat preservation time at the temperature of between 500 and 900 DEG C is between 10 and 15h; for the TiO2 nano belt prepared, the width is between 5 and 15mu m, the thickness is between 30 and 60nm and the length is more than 200mu m; the TiO2 nano belt comprises a pure phase anatase type TiO2 nano belt and a pure phase rutile type TiO2 nano belt.

Owner:CHANGCHUN UNIV OF SCI & TECH

Methods of preparing a surface-activated titanium oxide product and of using same in water treatment processes

InactiveUS6919029B2Inhibit dissolution and migrationMaterial nanotechnologyOther chemical processesHigh rateTitanium

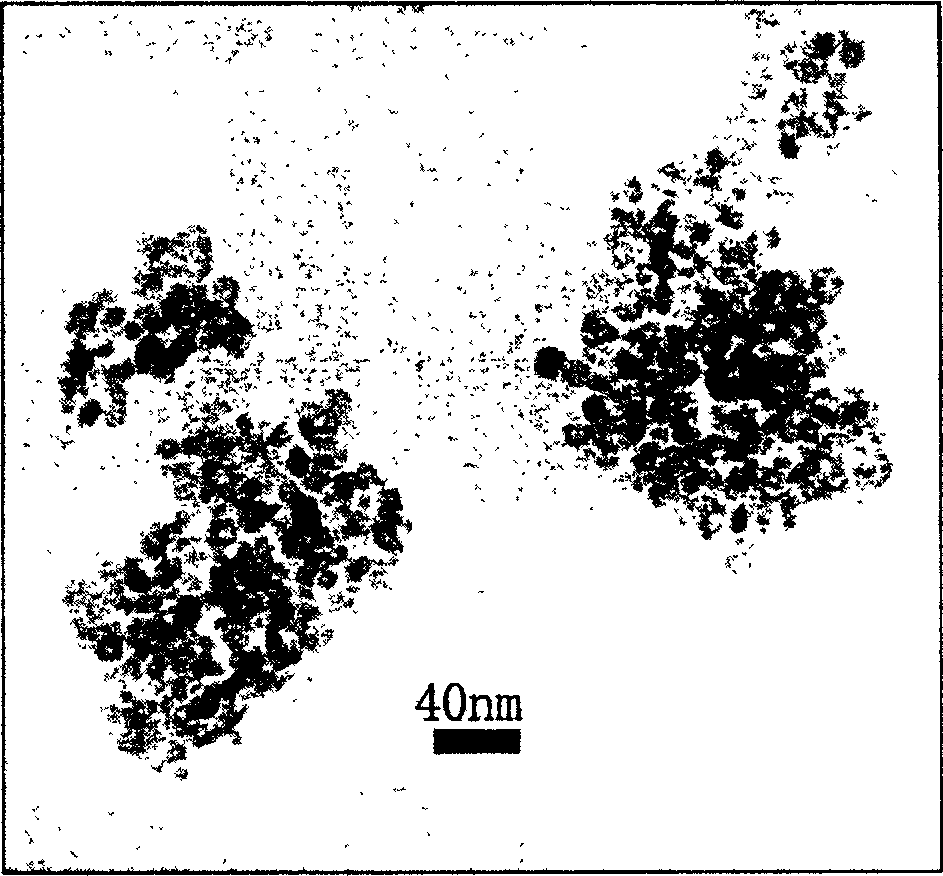

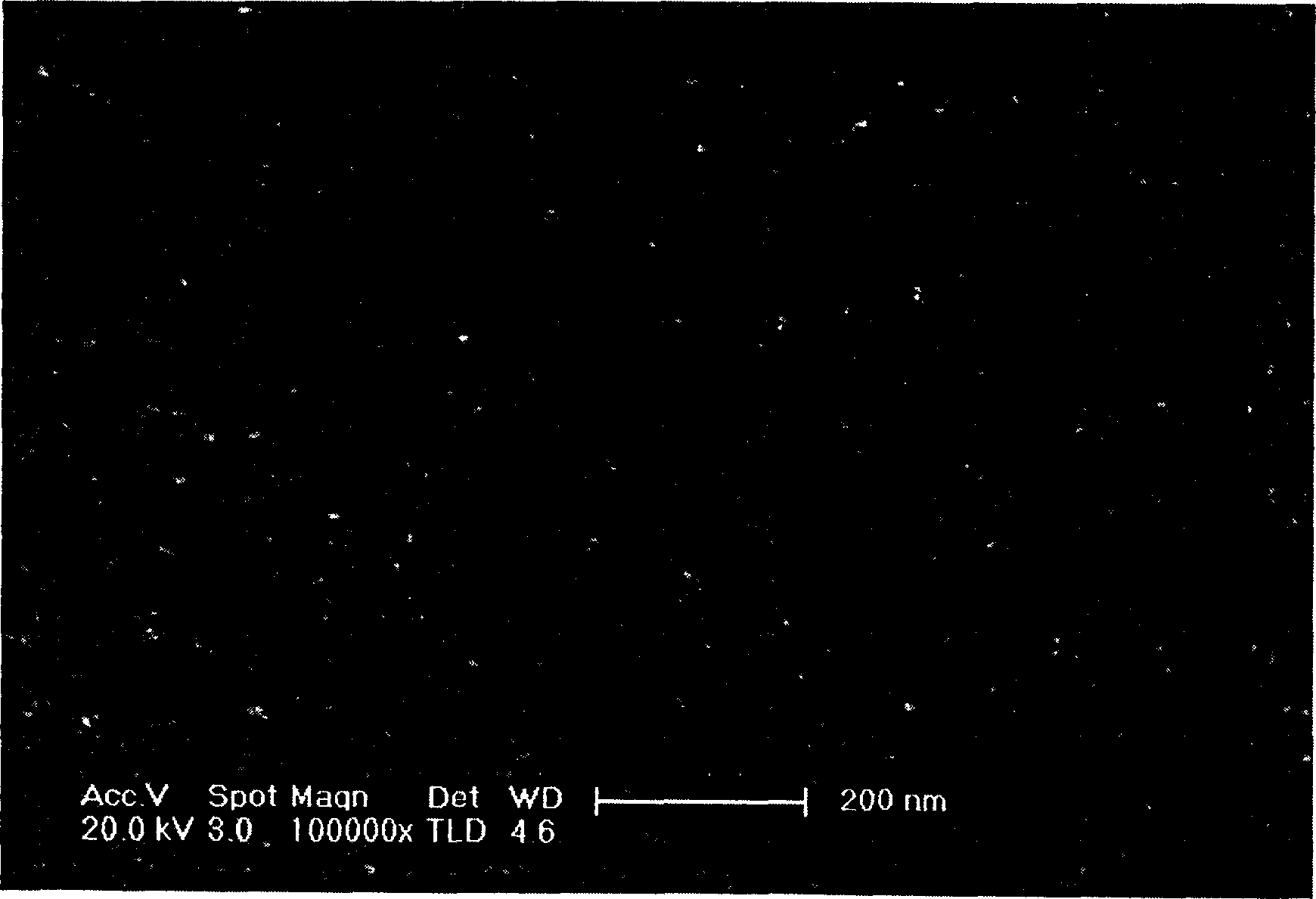

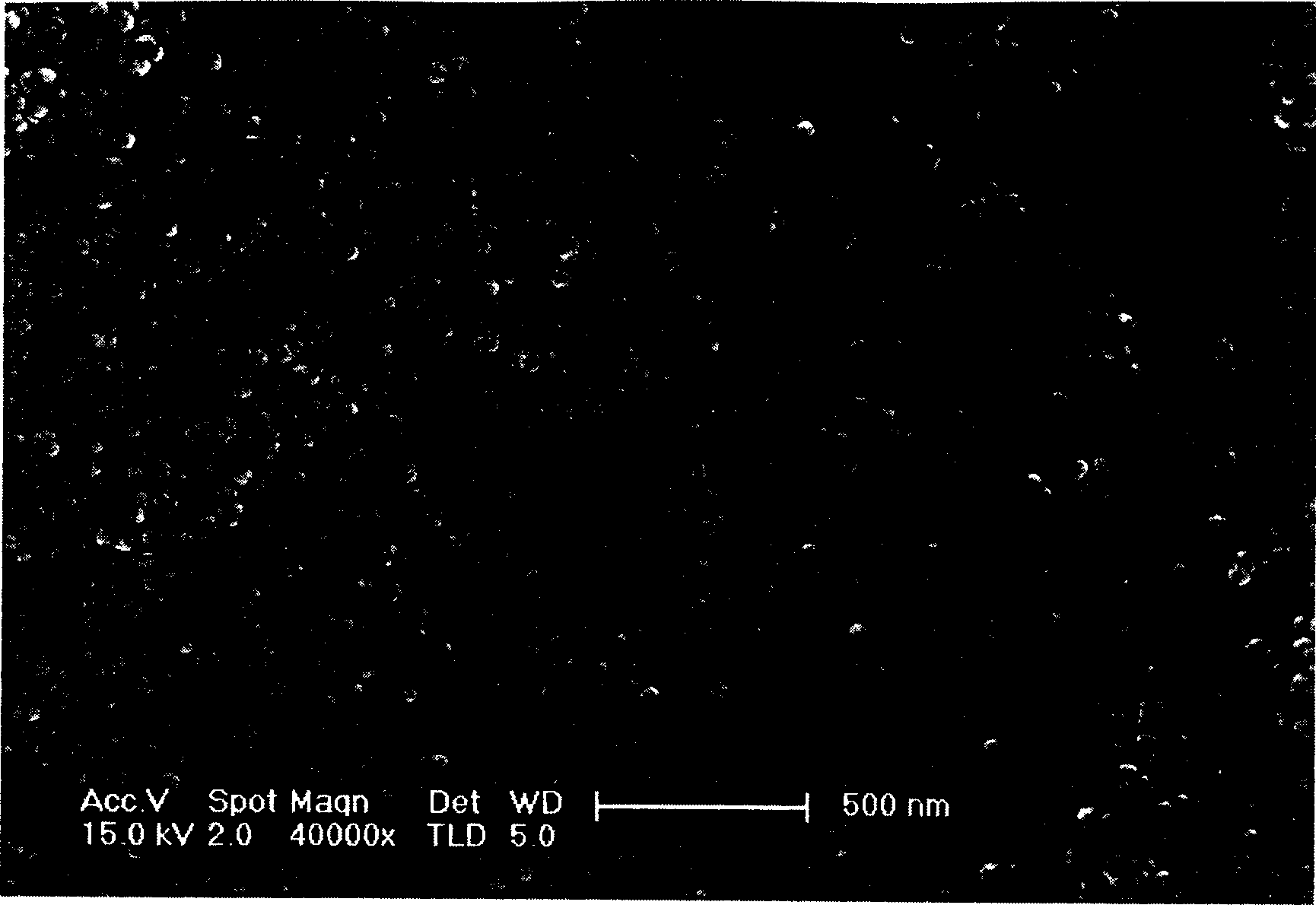

A method for producing a surface-activated crystalline titanium oxide product having a high adsorptive capacity and a high rate of adsorption with respect to dissolved contaminants includes the steps of preparing a titanium oxide precipitate from a mixture comprising a hydrolysable titanium compound and heating the precipitate at a temperature of less than 300° C., without calcining the precipitate. Preferably, the titanium oxide product includes crystalline anatase having primary crystallite diameters in the range of 1-30 nm. The surface-activated crystalline titanium oxide product is used in methods to remove dissolved inorganic contaminants from dilute aqueous streams by suspending the product in an aqueous stream or by filtering an aqueous stream through a bed of the product. In another method, a hydrolysable titanium compound is added to an aqueous stream so that titanium oxides form as a co-precipitate with dissolved contaminants within a bed of particulate material.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

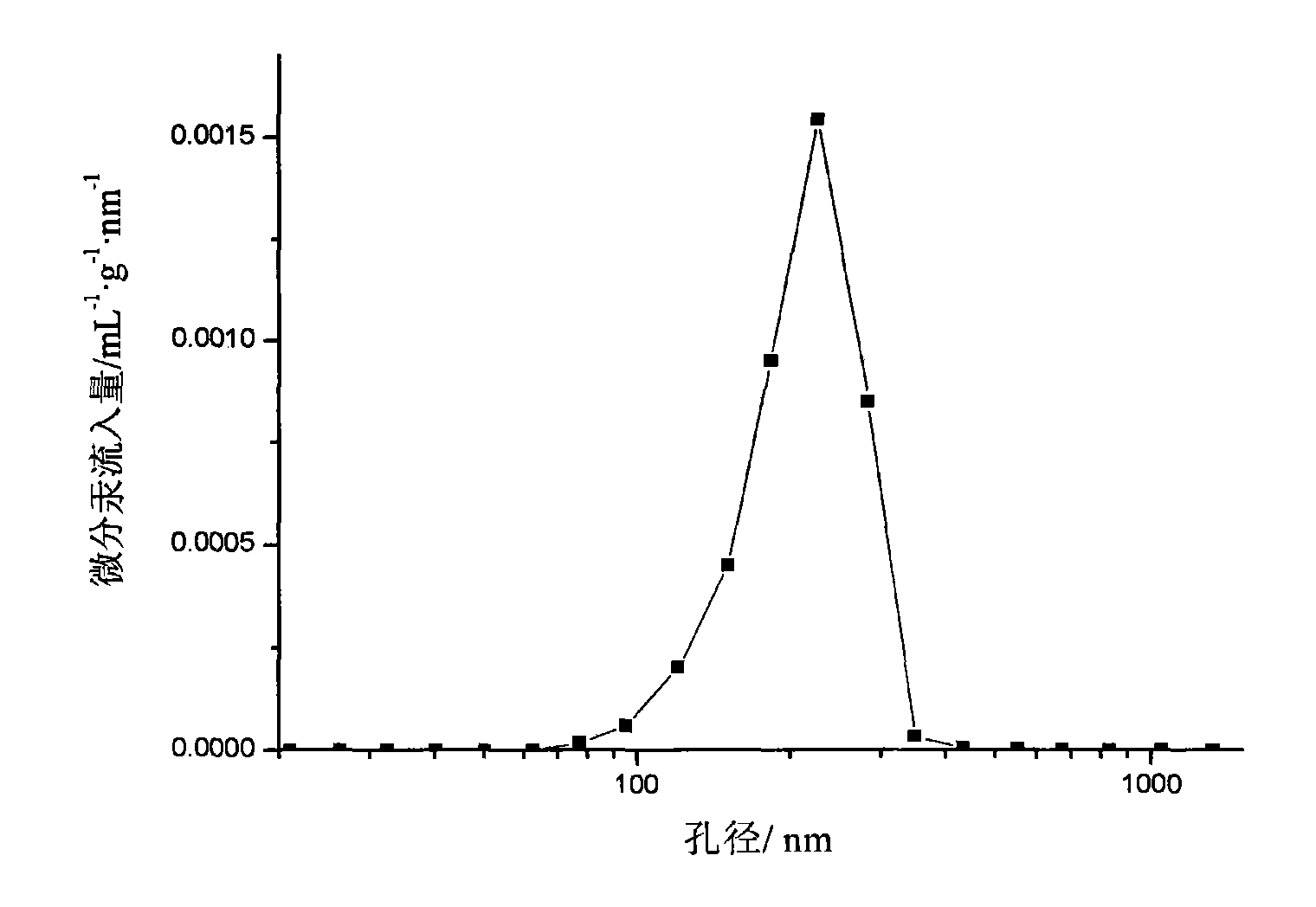

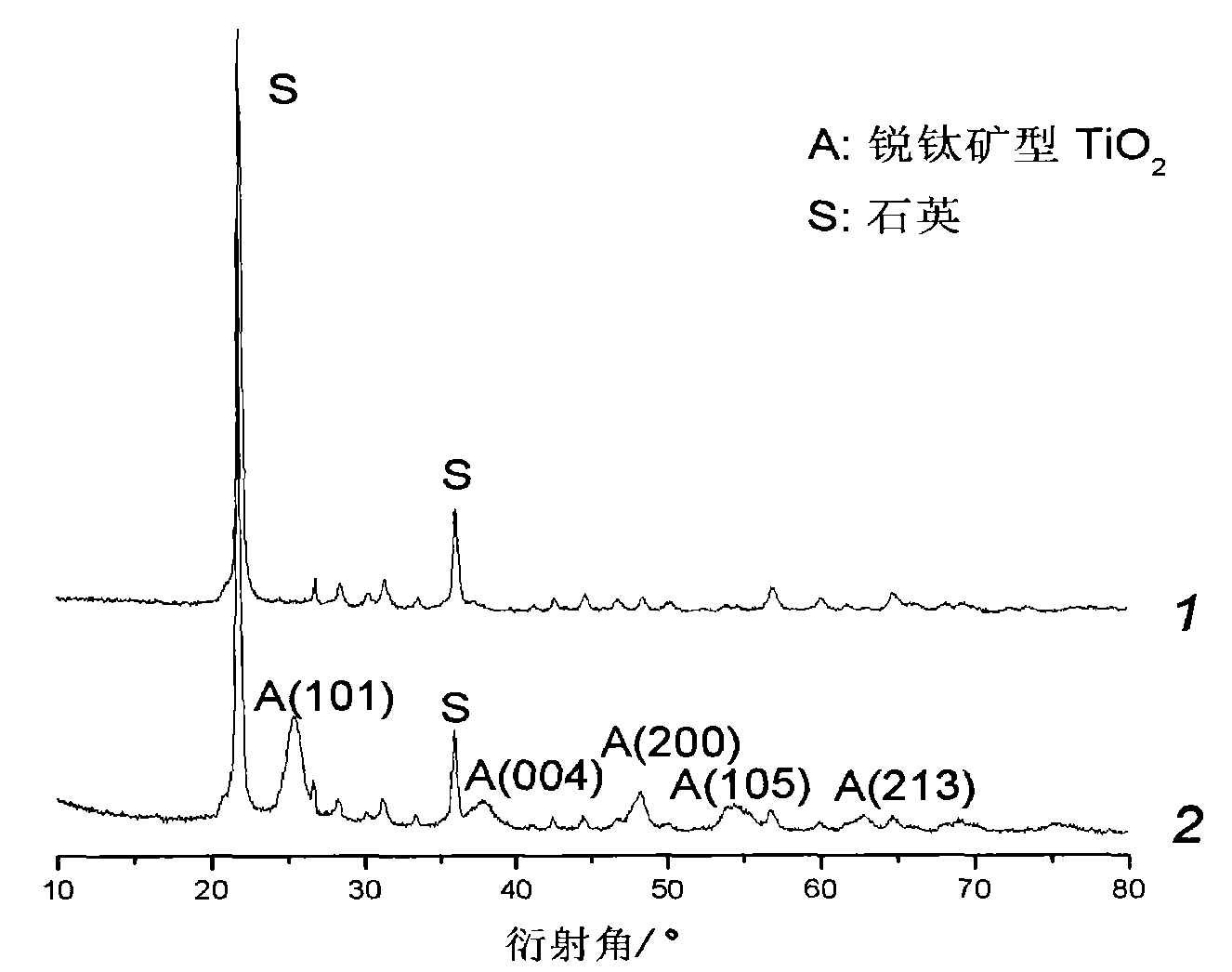

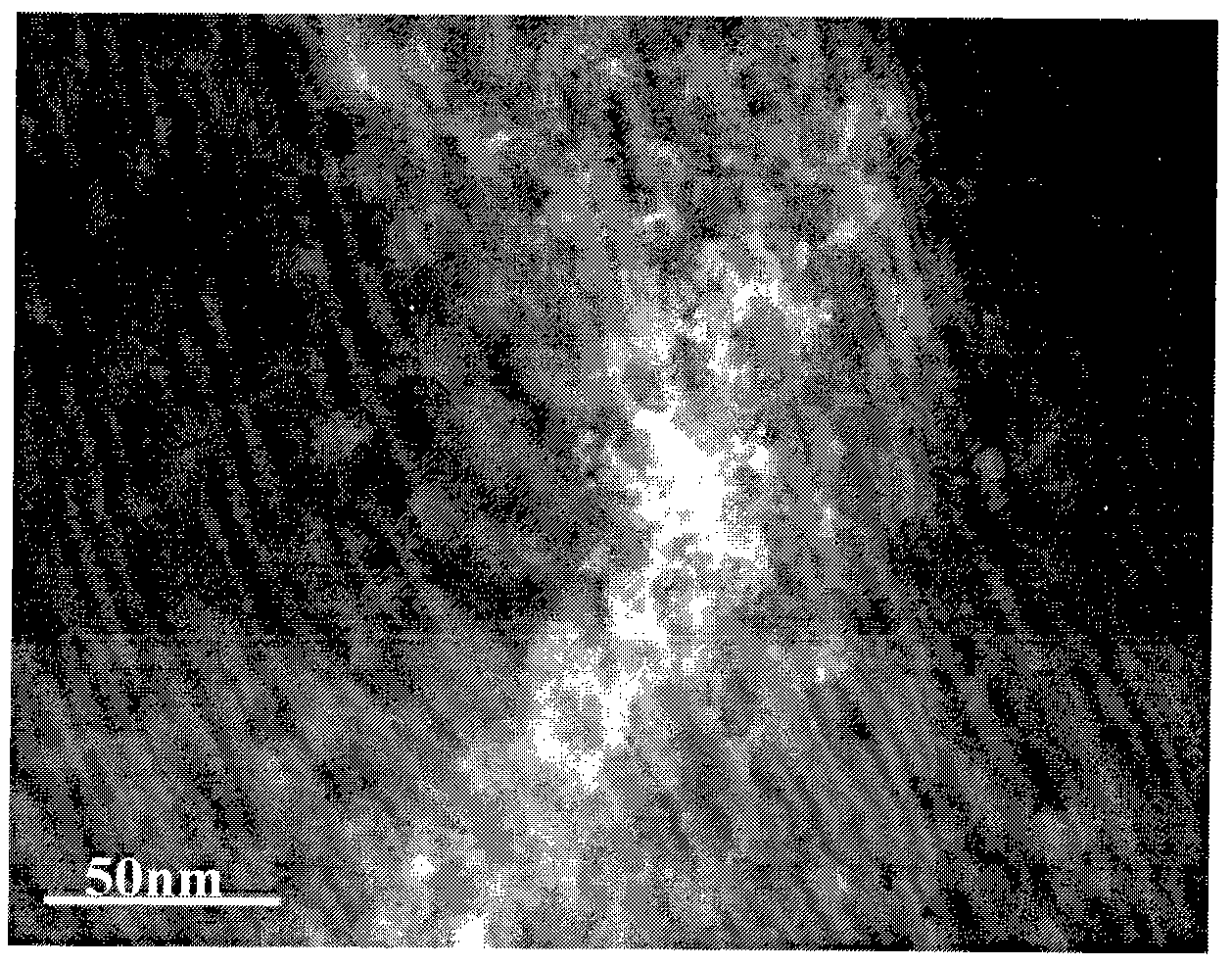

Kieselguhr-based porous ceramics and method for loading Ag doped with nano TiO2 on same

The invention relates to a kieselguhr-based porous ceramics, a preparation method thereof and a method for loading Ag doped with nano TiO2 on the same, belonging to the technical field of a kieselguhr inorganic material. The kieselguhr-based porous ceramics is made from kieselguhr, a sintering auxiliary agent, a dispersing agent, a binder and water in the weight ratio of 60-92:8-40:0.01-2:0:001-1:100-450. The kieselguhr-based porous ceramics has functions of absorption and filtration, and can absorb granules in fluid when the fluid passes through the lieselguhr-based porous ceramics. Ag doped with nano TiO2 is loaded on the kieselguhr-based porous ceramics to generate kieselguhr-based porous ceramics loading the Ag doped with TiO2. The laden anatase-type nano TiO2 has large specific surface area. The effects of filtration, photochemical catalysis and sterilization of the kieselguhr-based porous ceramics loading the Ag doped with nano TiO2 are greatly increased.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

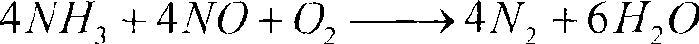

Catalyst for denitration of power plant soot fume SCR and preparation method thereof

InactiveCN101422728AImprove wear resistanceStrong anti-poison abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporWorking temperature

The invention relates to a catalyst carrier, an SCR denitrifying catalyst of electric plant flue gas that is prepared by the catalyst carrier and a preparation method of the SCR denitrifying catalyst. The invention adopts purple mud clay and anatase TiO2 to form the carrier; by weight, the content of the TiO2 is 50 to 99 percent and the content of the purple mud clay is 1 to 50 percent. The catalyst carrier can further contain active carbon, CaSO4 and ammonia-typed Y molecular sieve, which respectively account for 0 to 20 percent of the weight of the catalyst carrier. The active ingredients of the catalyst comprise V2O5 accounting for 1.0 to 6.0 percent of the weight of the catalyst, WO3 accounting for 4.0 to 10.0 percent of the weight of the catalyst, MoO3 accounting for 0 to 9.0 percent of the weight of the catalyst, and CeO2 accounting for 0 to 2.0 percent of the weight of the catalyst. The working temperature of the catalyst is 200 to 500 DEG C, has high catalytic activity, large specific surface and strong toxin immunity, hardly has inactivation phenomenon in long-time running, and is insensitive to vapor and sulfur dioxide.

Owner:HARBIN INST OF TECH

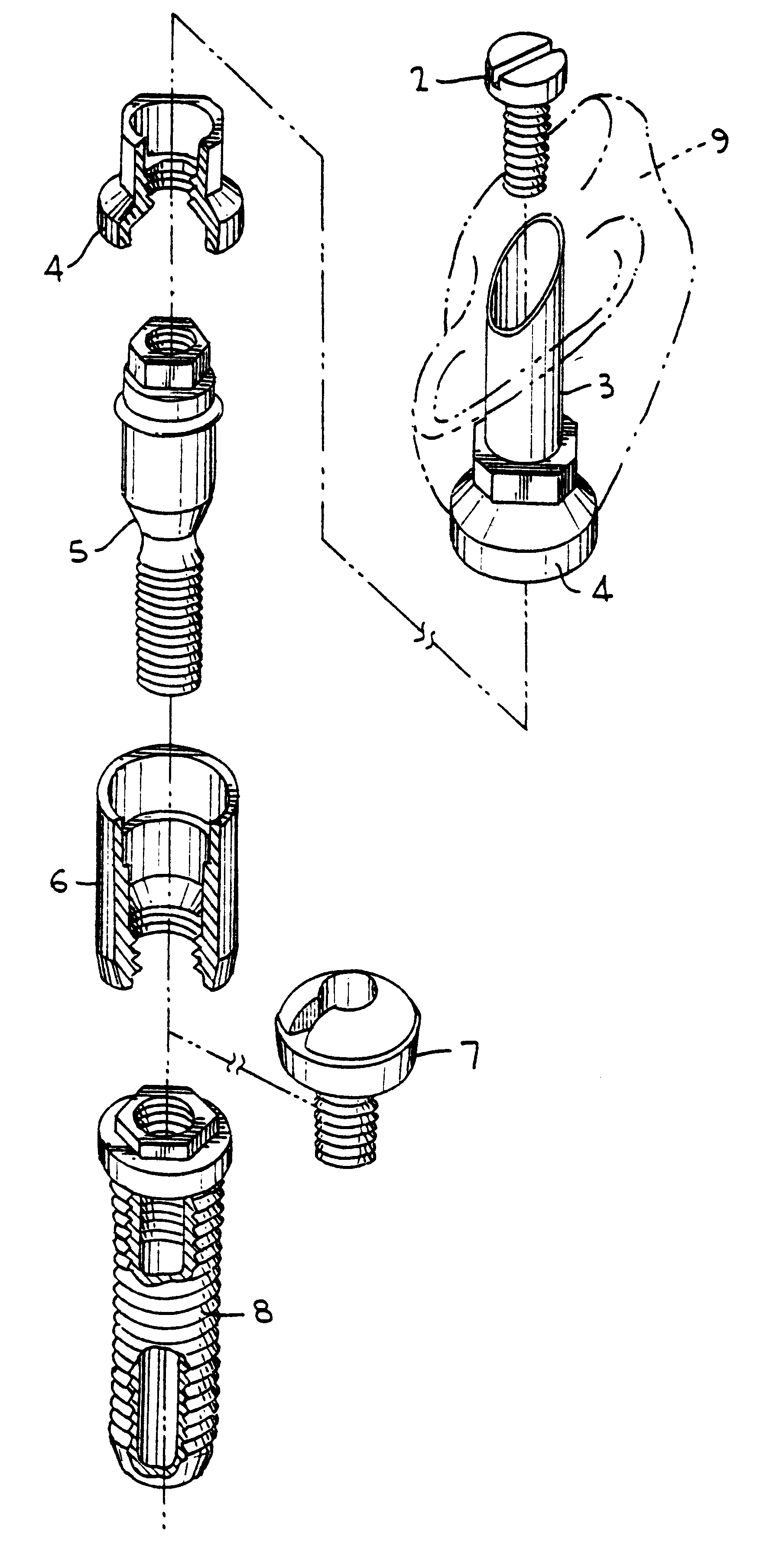

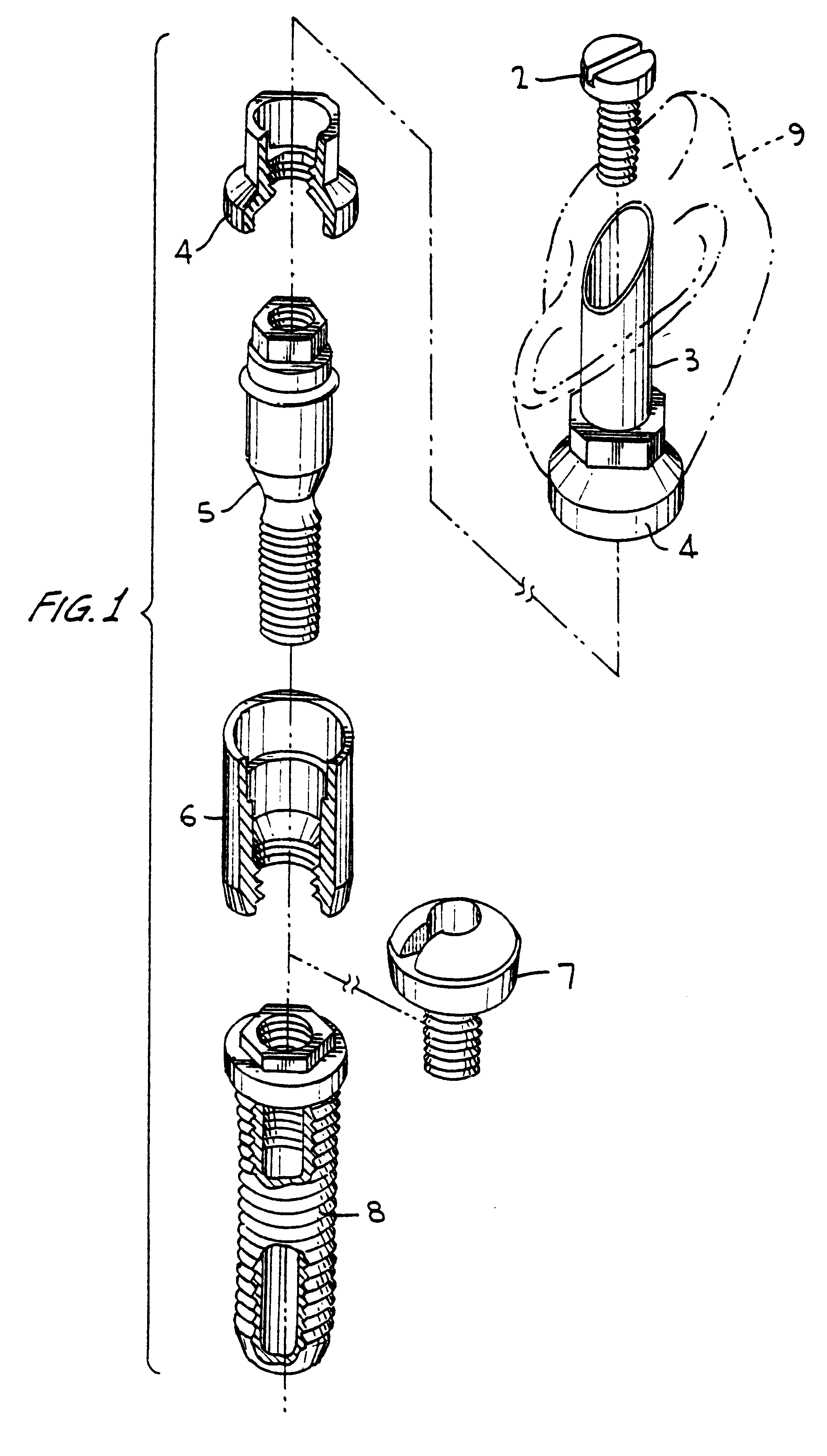

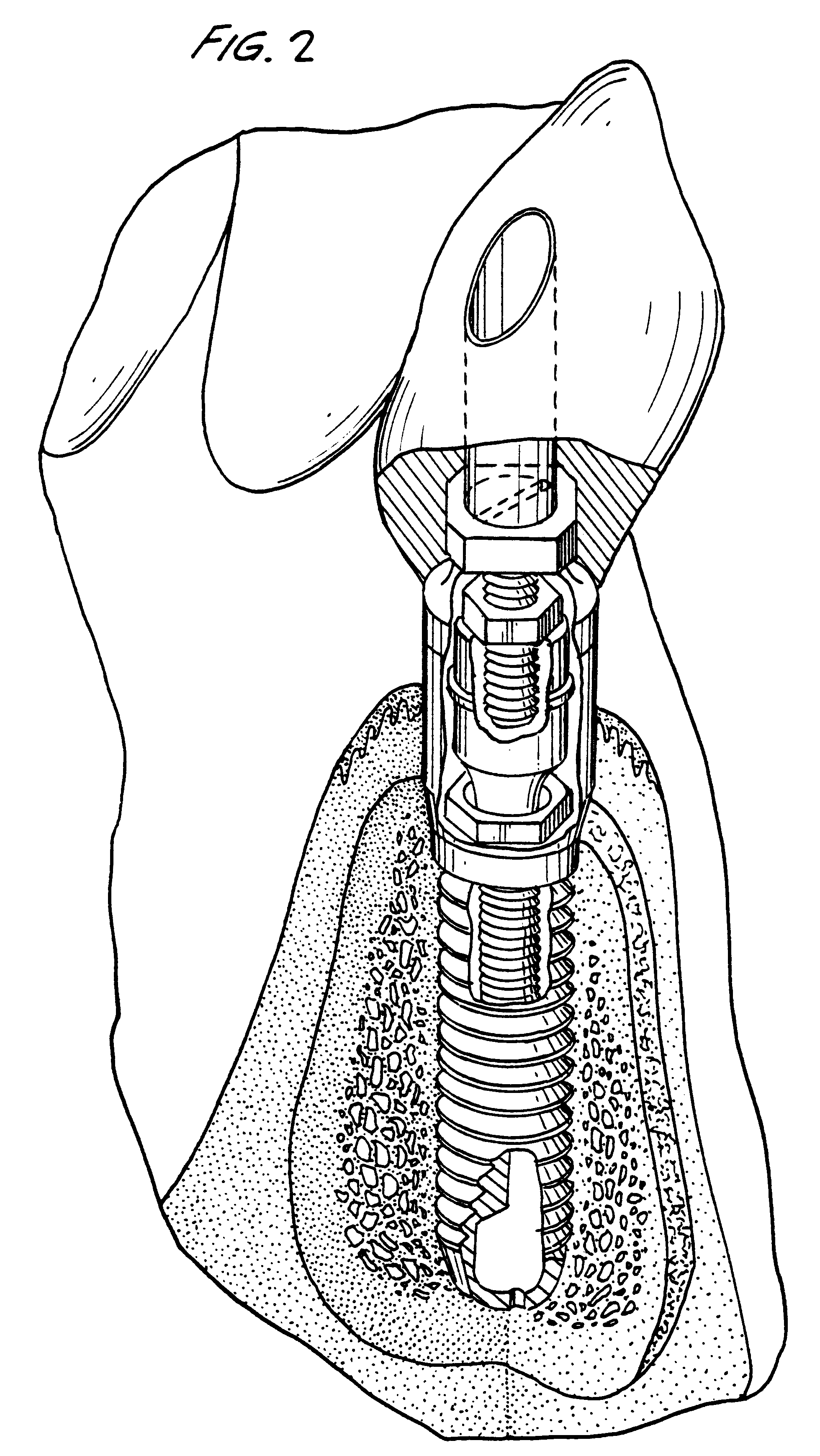

Titanium material implants

One of many universal requirements of dental or orthopedic implants, wherever they are used in the vital body, is that the implant system should be biologically functioning. To achieve the biological functionality, the implant should meet several requirements for compatibility. These include biological compatibility and mechanical compatibility. It has now been recognized that morphological compatibility and crystallographic compatibility should be added to these two compatibility requirements. Hence, the present invention provides a method of forming a certain type of crystalline structure of titanium oxide and controlled surface roughness to meet both morphological and crystallographic compatibilities. It has been further determined that a chemical treatment (using sodium hydroxide) alone or followed by in-air oxidation, or acid treatment (a mixed aqueous solution of hydrofluoric acid and nitric acid), followed by sodium hydroxide treatment, furthermore followed by in-air oxidation provide for advantageous surface modifications to create a complex mixture of rutile with anatase and / or brookite types of titanium oxide and provide a most favorable surface for wettability and an acceptable range of surface roughness.

Owner:OSHIDA YOSHIKI

Method for producing fine particles of metal oxide

A method for producing fine particles of metal oxide characterized in that metal halide is hydrolyzed in the presence of organic solvent. According to this invention, under hydrolysis of titanium tetrachrolide, anatase type titanium oxide can be obtained by selecting hydrophilic organic solvent, and rutile type titanium oxide can be obtained by selecting hydrophobic organic solvent.

Owner:SHOWA DENKO KK

Photocatalytic body and method for making same

An amorphous titanium peroxide sol made by a process which includes adding an alkali hydroxide to an aqueous titanium salt solution and reacting the resulting amorphous titanium hydroxide with an aqueous hydrogen peroxide solution to obtain an amorphous titanium peroxide sol. The amorphous titanium peroxide sol is afterward raised to a temperature sufficient to obtain an anatase titanium oxide sol. The resulting anatase titanium oxide sol can thereafter be heated to a temperature sufficient to obtain anatase titanium oxide. The claimed compositions are useful as binders to support the particles of a photocatalyst on a variety of substrates.

Owner:SAGA KEN

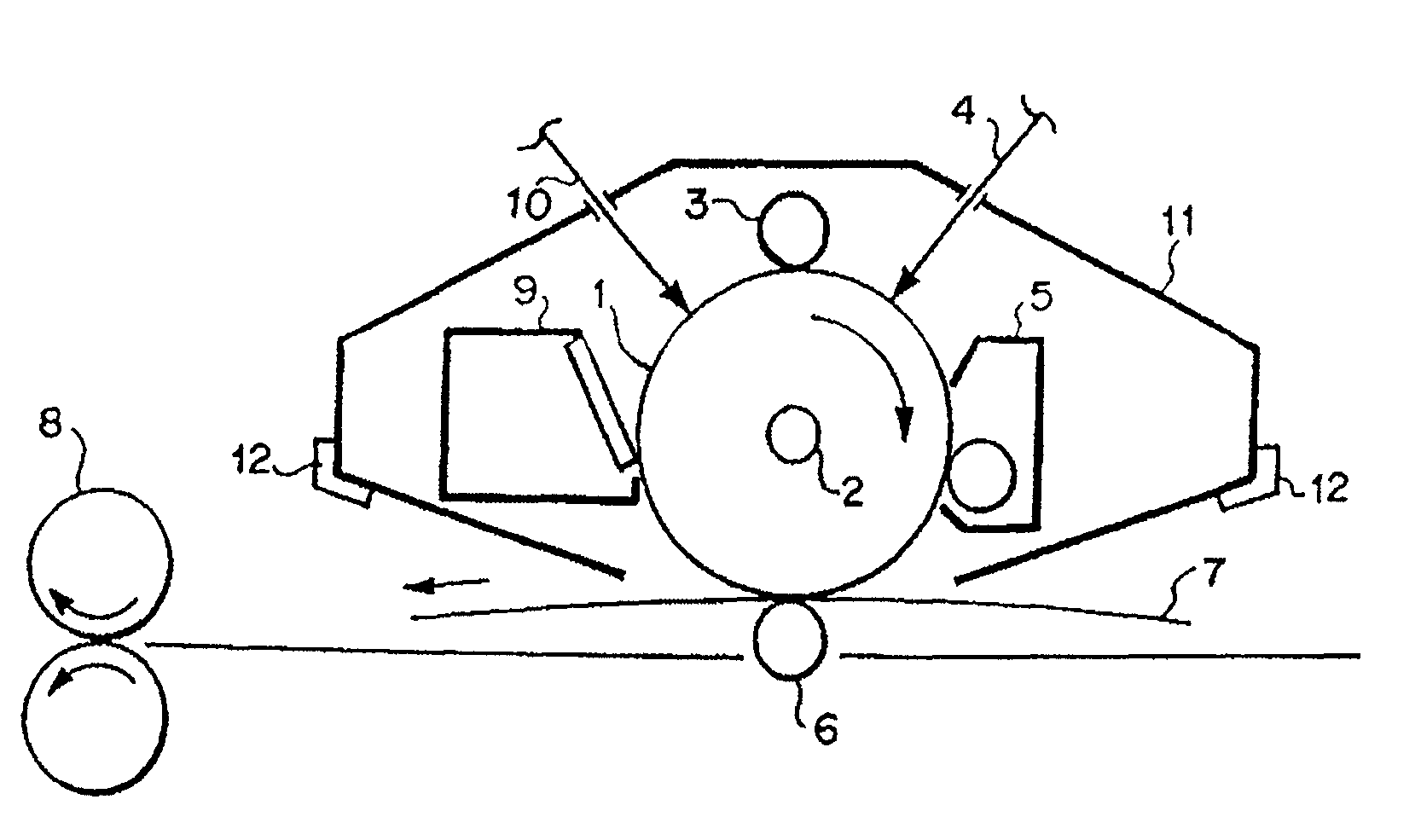

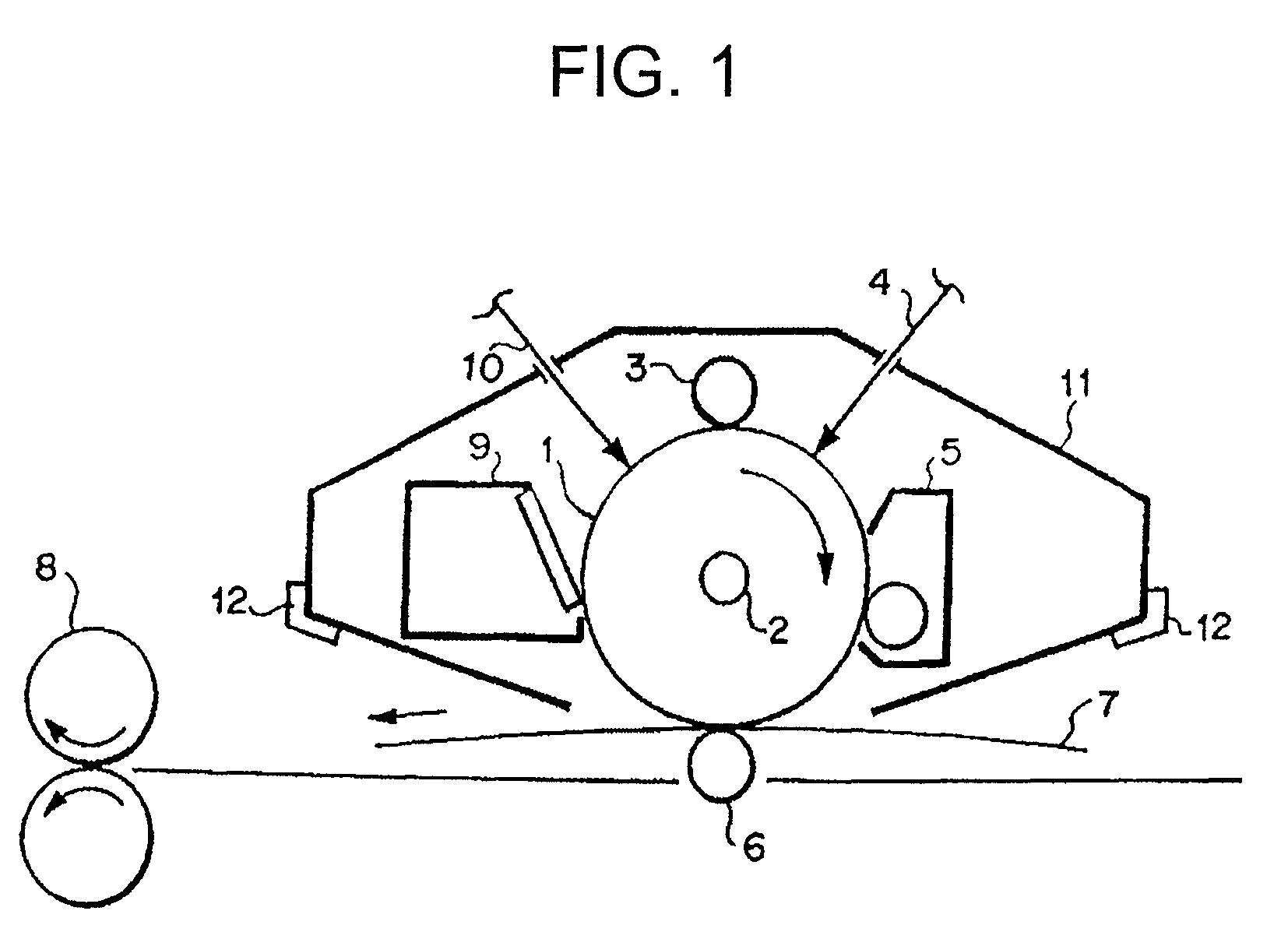

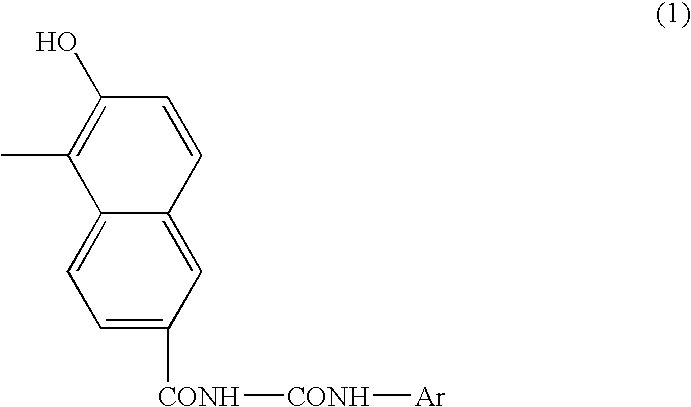

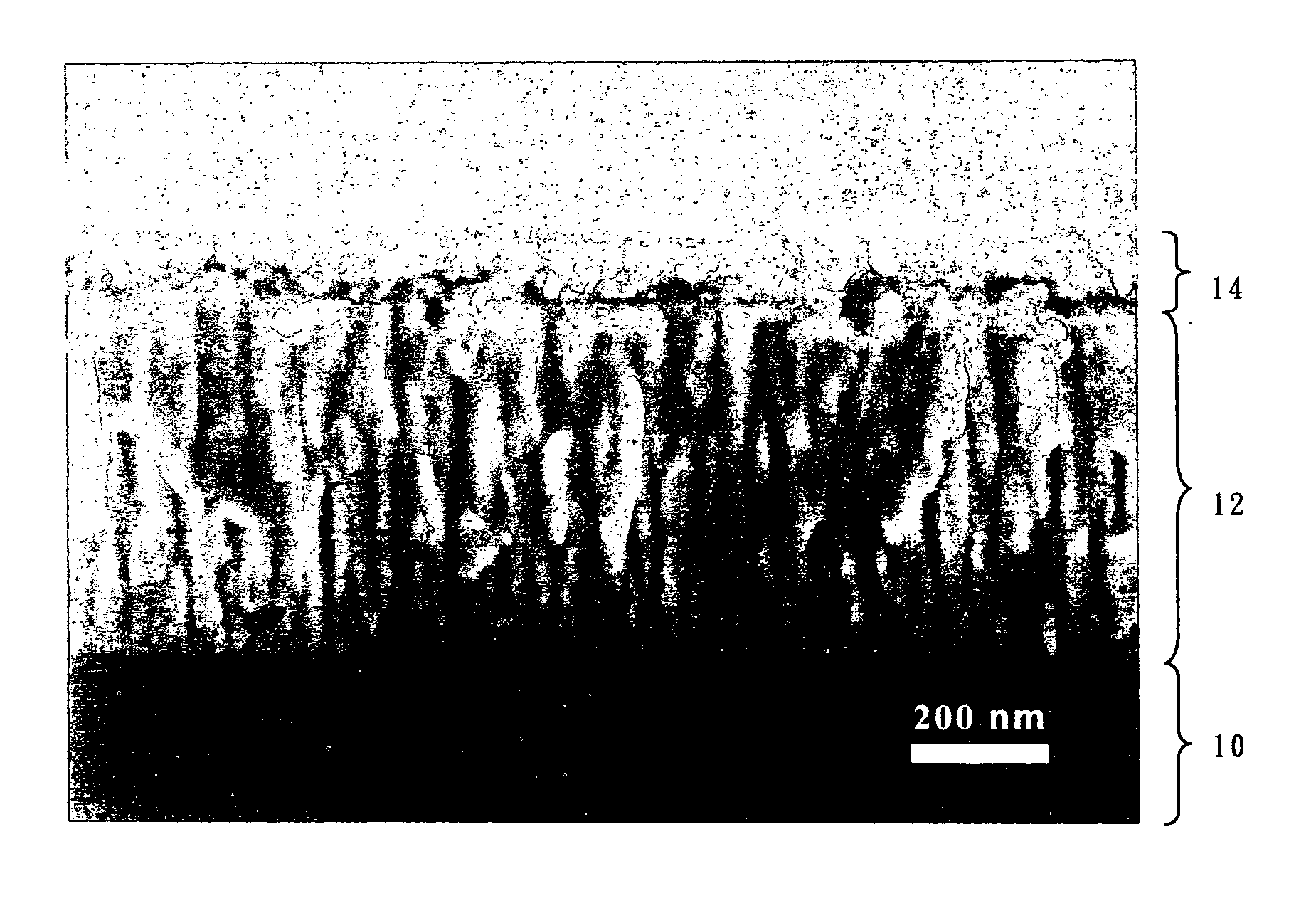

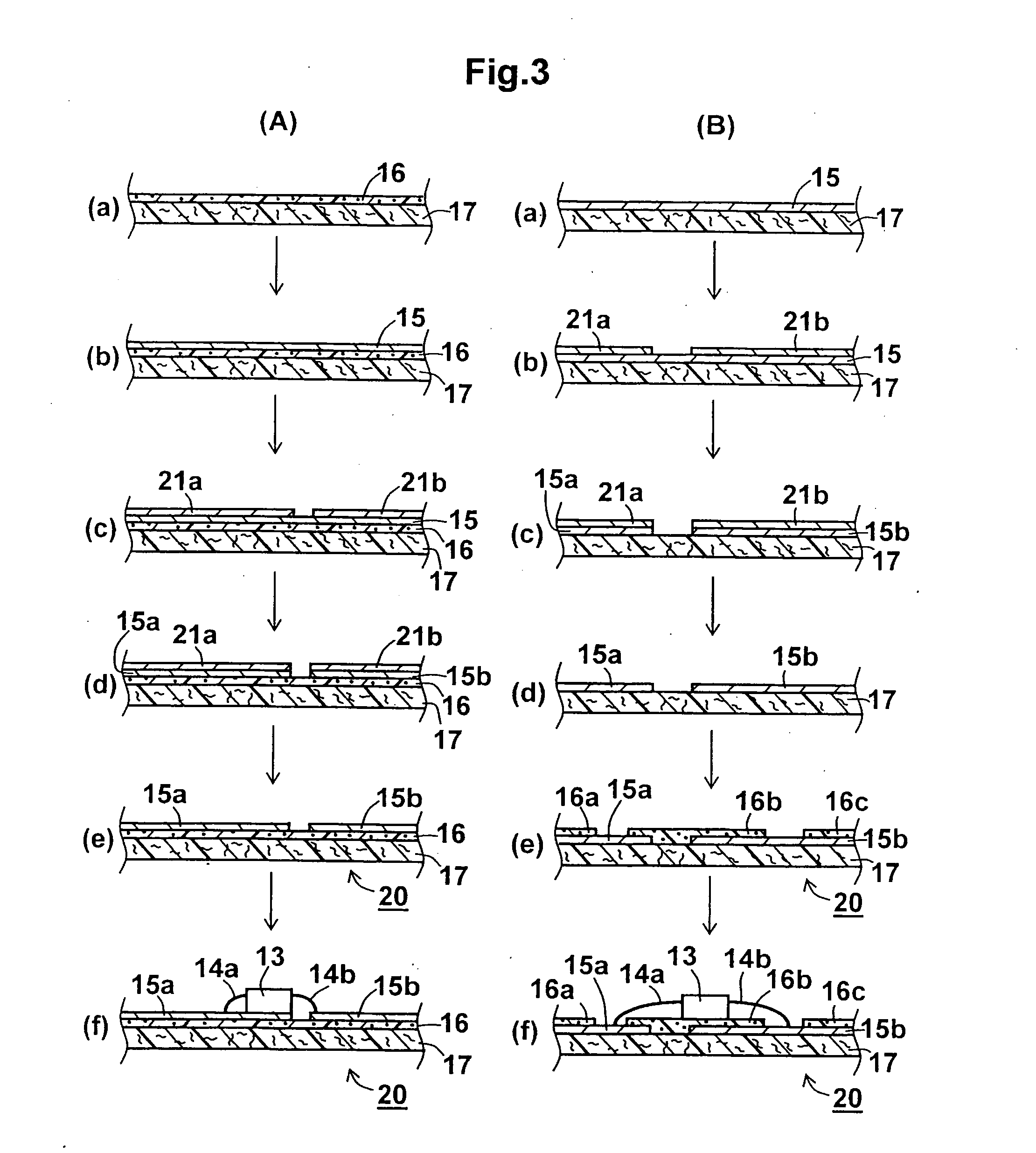

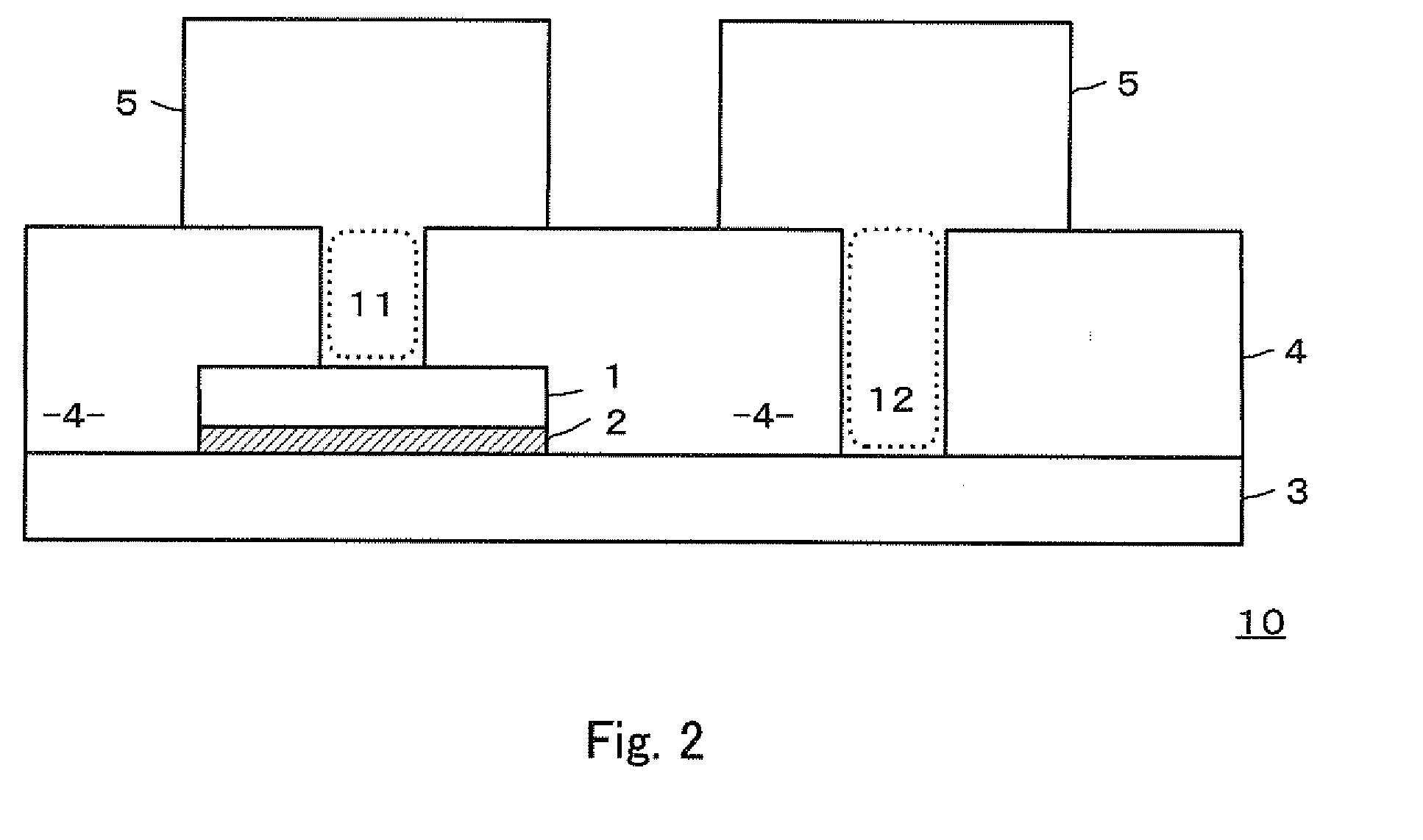

Electrophotographic photosensitive member, method of producing electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

InactiveUS7910274B2Increase speedPotential variationElectrographic process apparatusCoatingsInter layerEngineering

An electrophotographic photosensitive member is provided in which both a potential variation over a long time period and a potential variation within a short time period are suppressed. A method of producing the electrophotographic photosensitive member, and a process cartridge and an electrophotographic apparatus each having the electrophotographic photosensitive member are also provided. In the electrophotographic photosensitive member, an intermediate layer is a layer formed by coating and drying a coating liquid for an intermediate layer, containing an acidic titania sol and an organic resin, and the acidic titania sol is an acidic sol containing anatase-type titanium oxide crystal particles having an average primary particle diameter of 3 nm or more and 9 nm or less.

Owner:CANON KK

Titanium dioxide film synthesizing method and the product thereof

InactiveUS20050103639A1Surface reaction electrolytic coatingElectrochemical anodizationRoom temperature

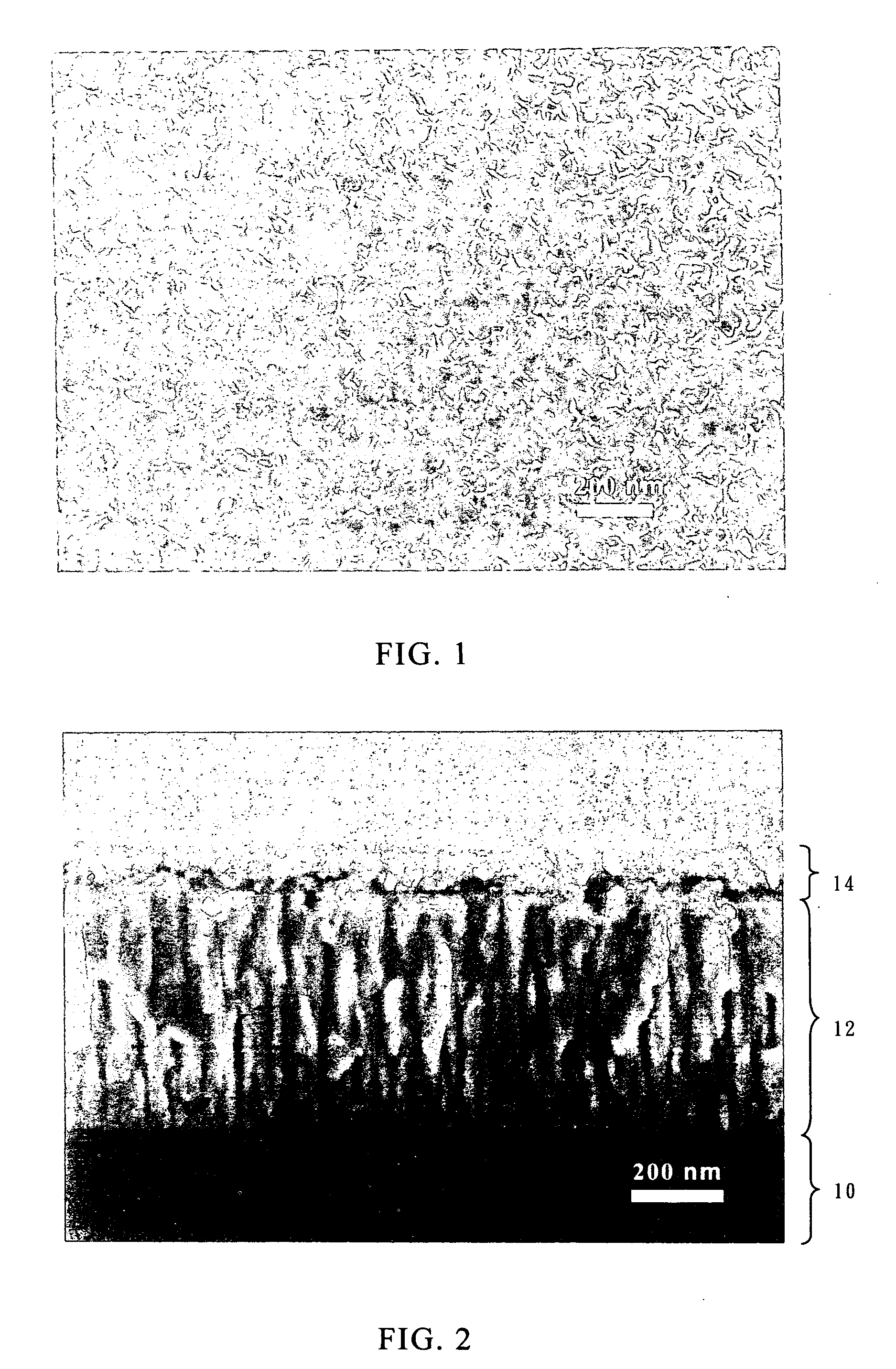

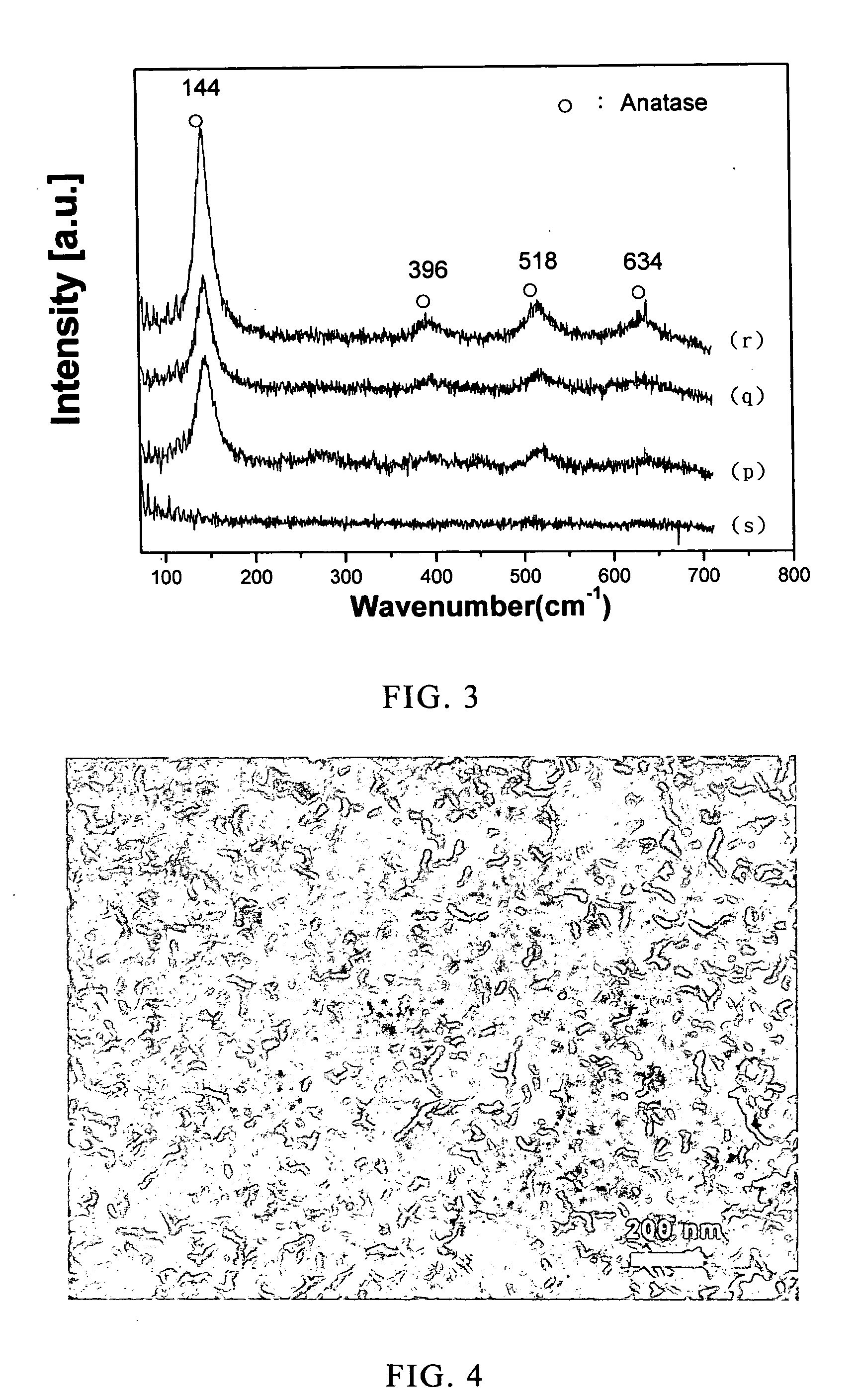

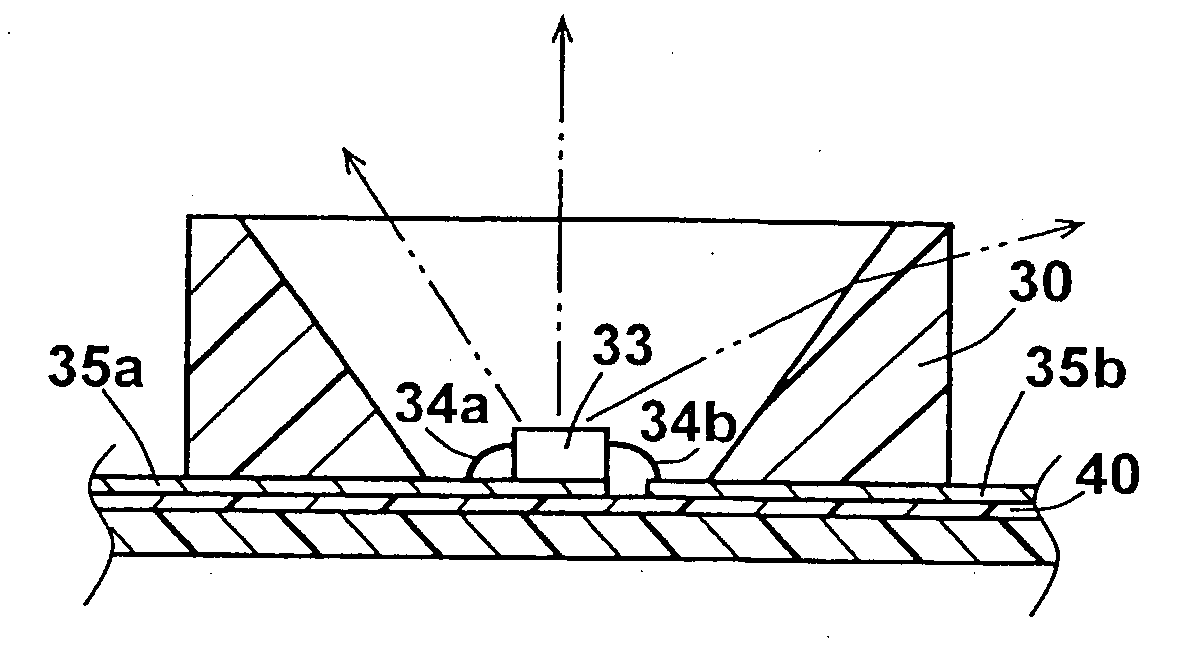

A titanium dioxide films synthesizing method includes the step of coating a titanium film on the surface of a homogenous (or heterogeneous) substrate, and the step of using the titanium-coated substrate as anode in an electrolyte to synthesize an nano-structured titanium dioxide film with single anatase phase on the surface of the titanium film by employing electrochemical anodic oxidation at room temperature.

Owner:LU FU HSING +1

White color reflecting material and process for production thereof

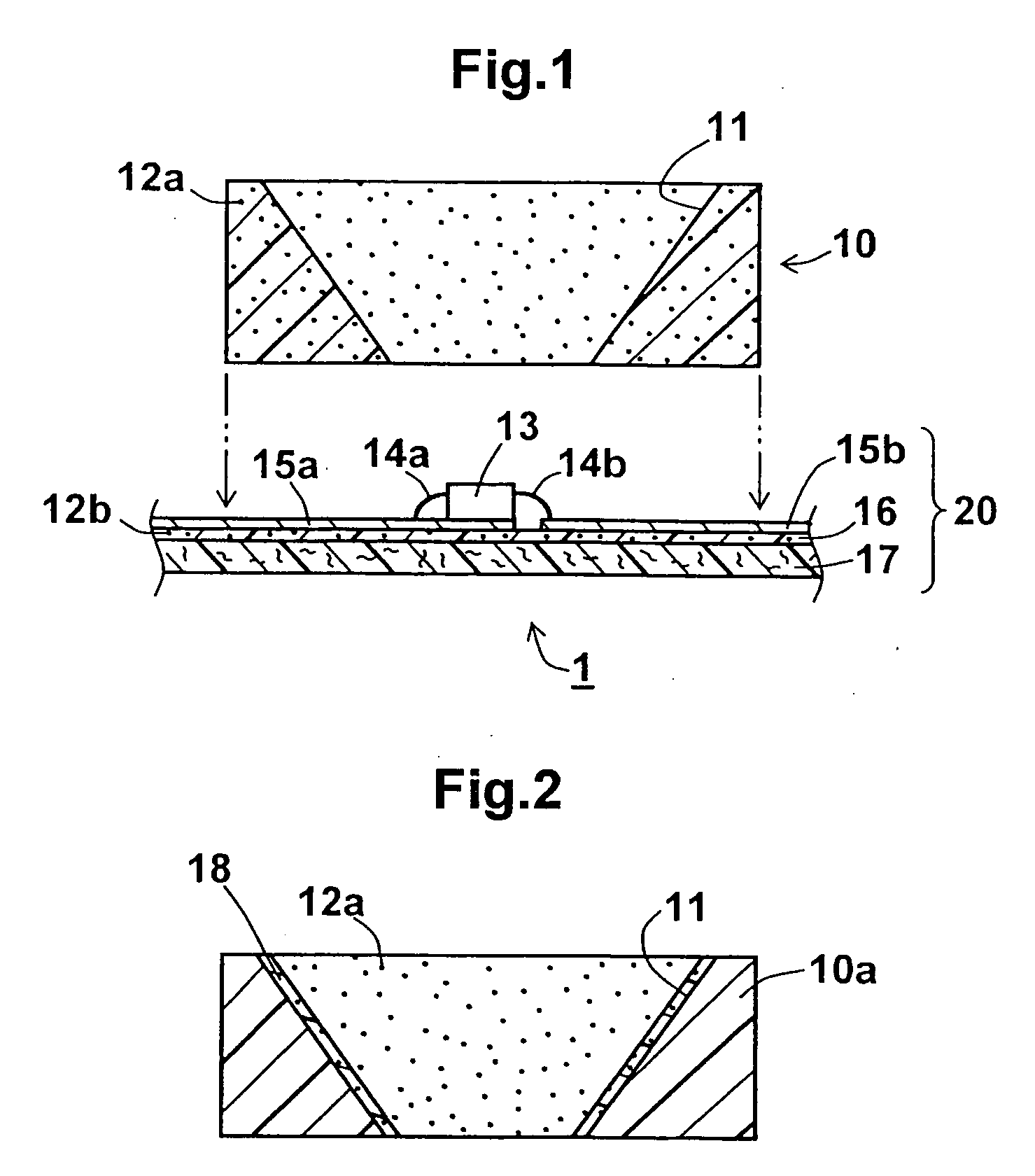

ActiveUS20120138997A1Improve heat resistanceImprove light resistanceDiffusing elementsSolid-state devicesUltravioletRutile

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by plating, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflecting material in a film shape is also provided. The white color reflecting material comprises; a silicone resin or silicone rubber formed from titanium oxide-containing silicone composition, in which anatase-type or rutile-type titanium oxide particles are dispersed.

Owner:ASAHI RUBBER

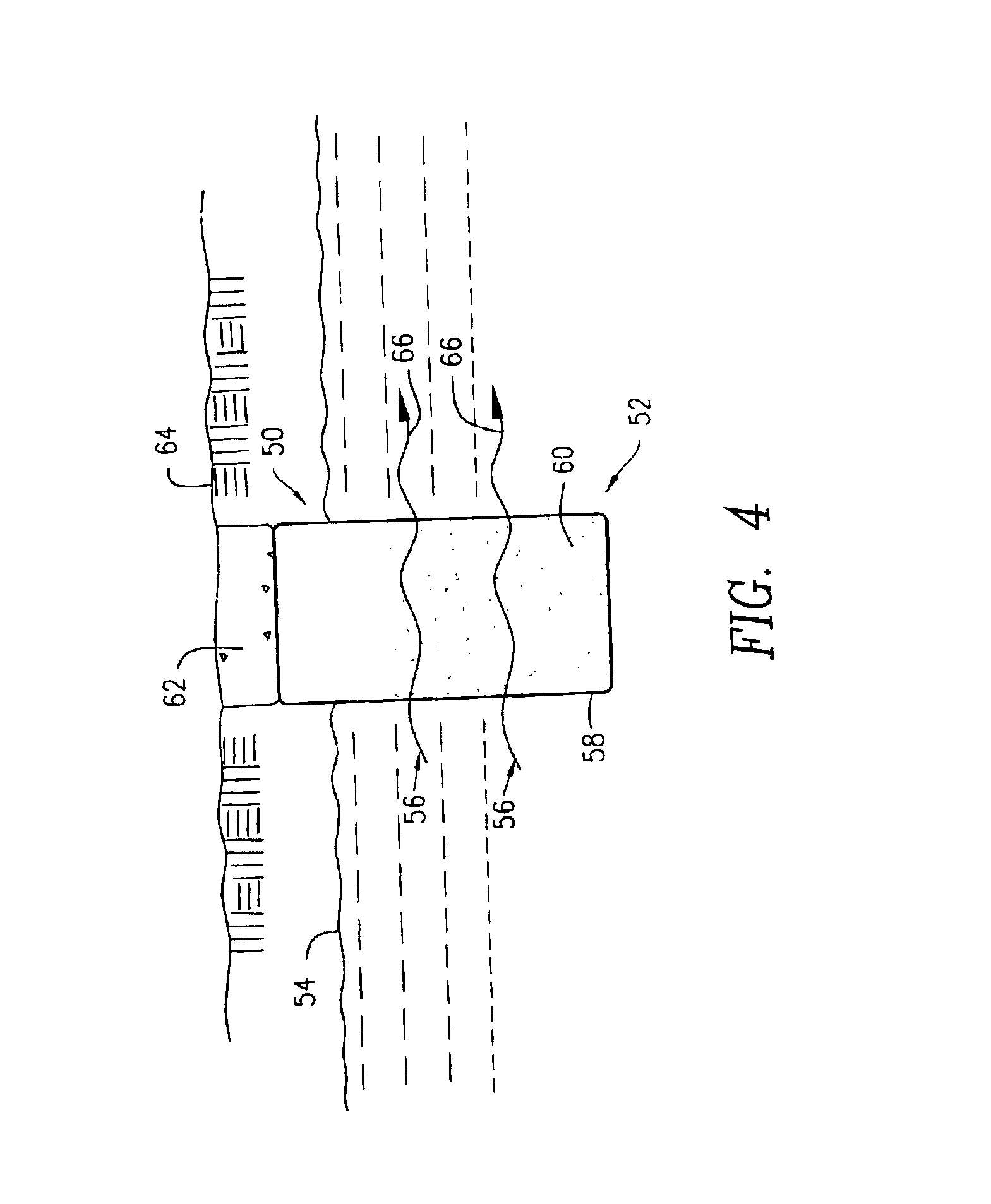

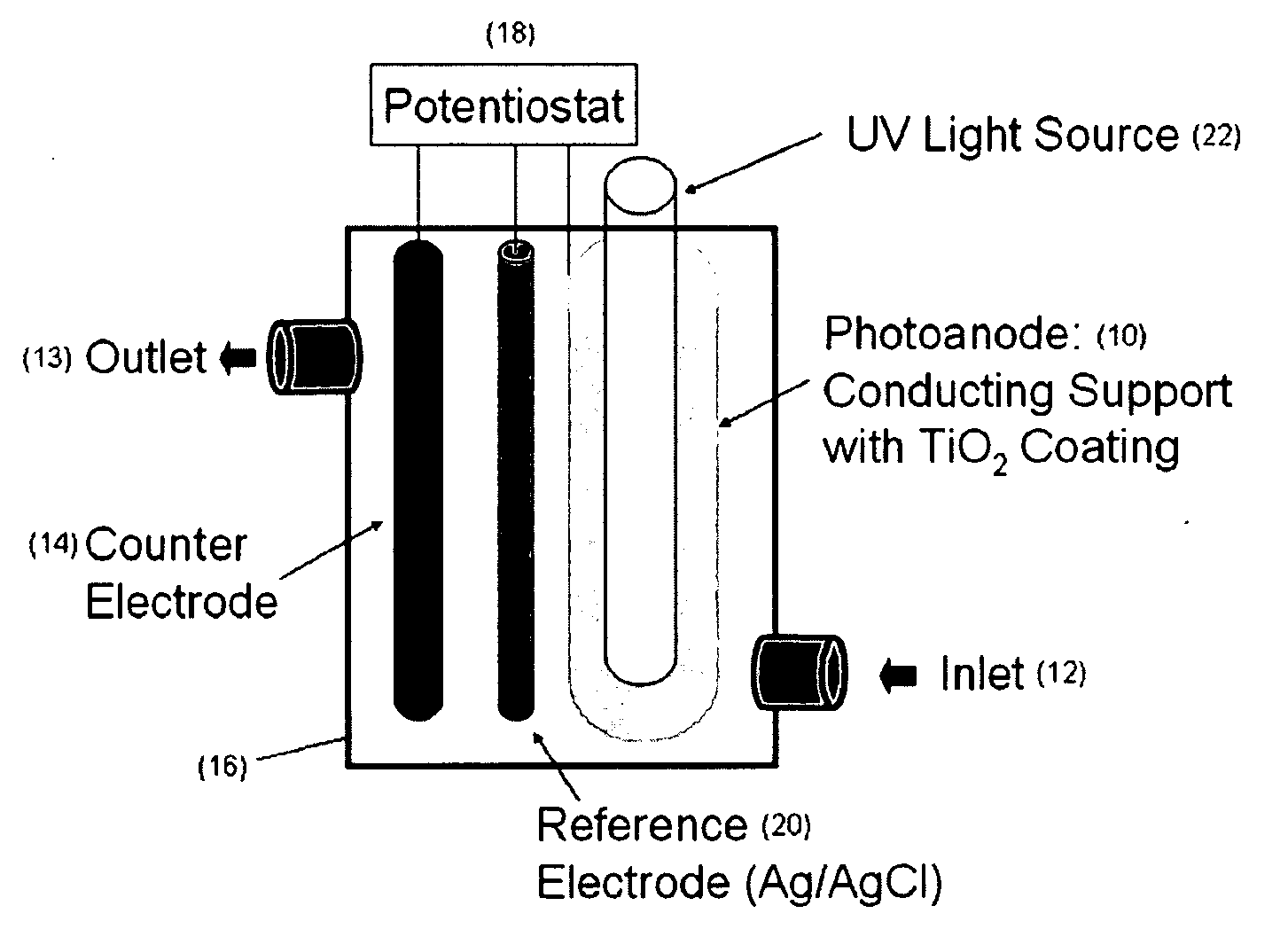

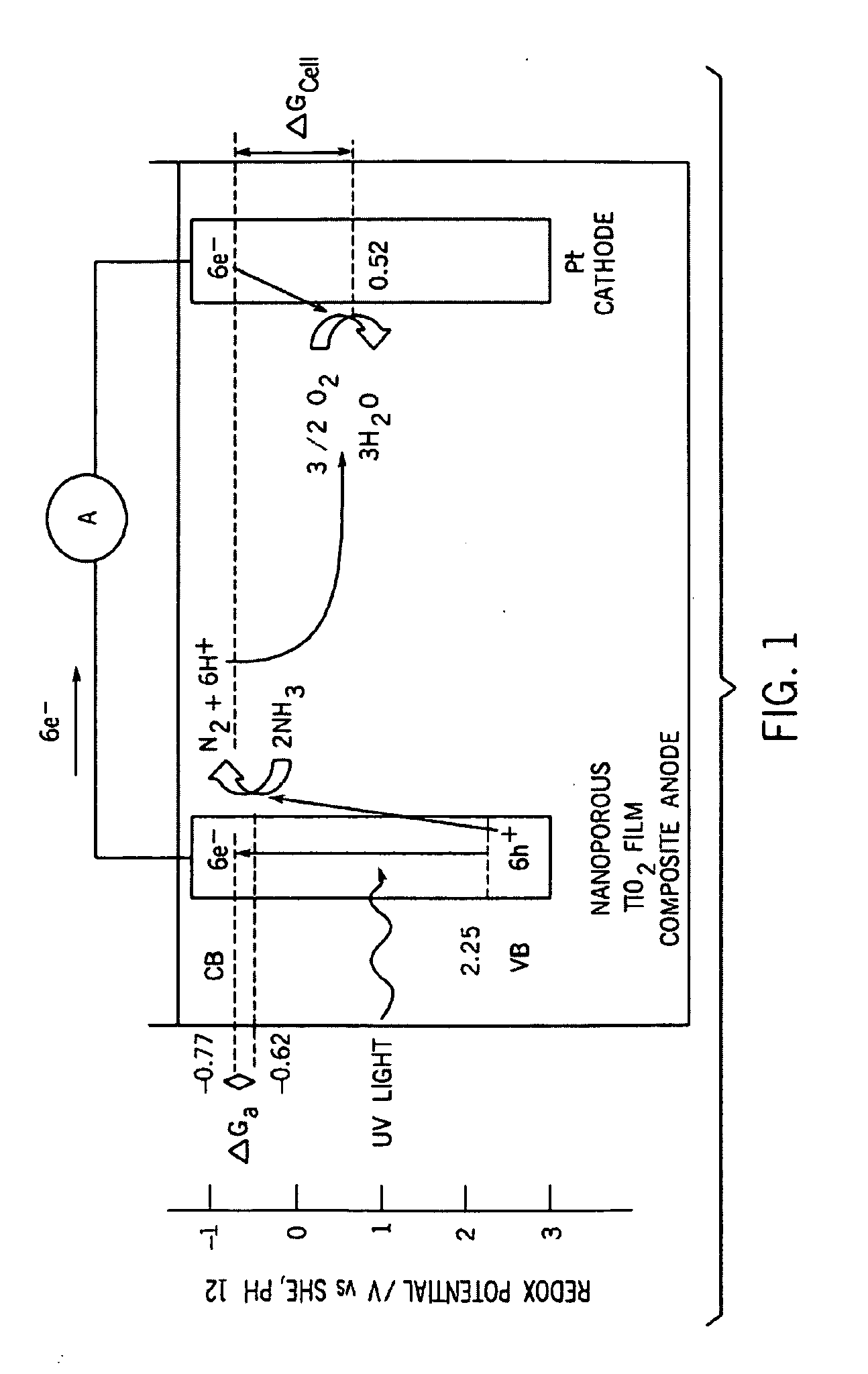

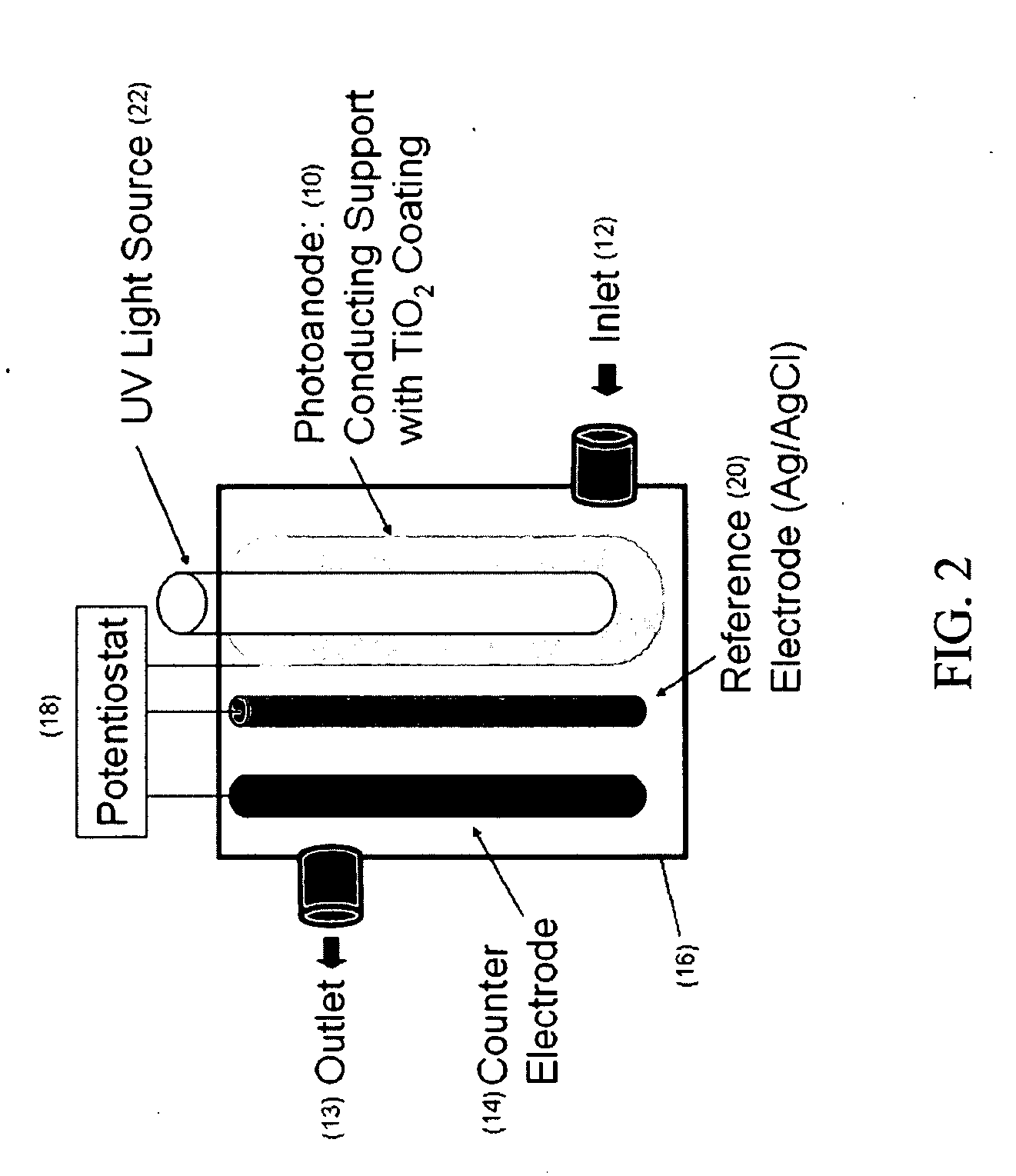

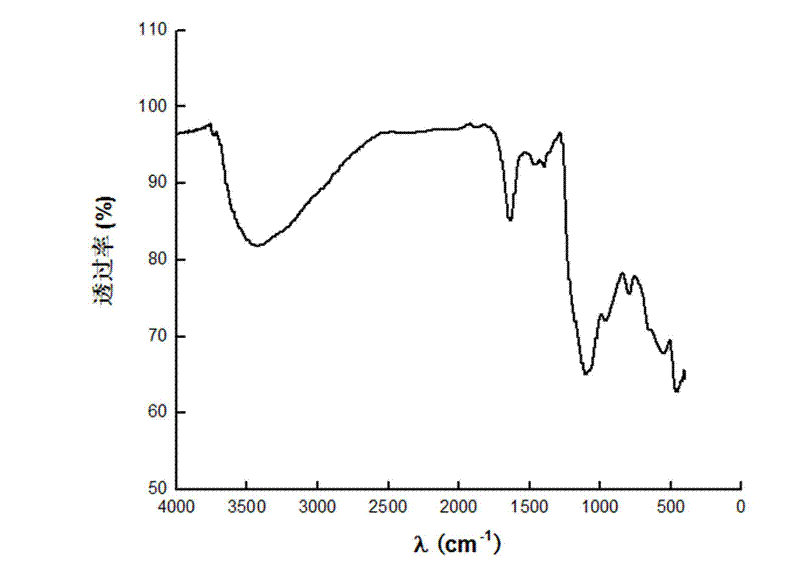

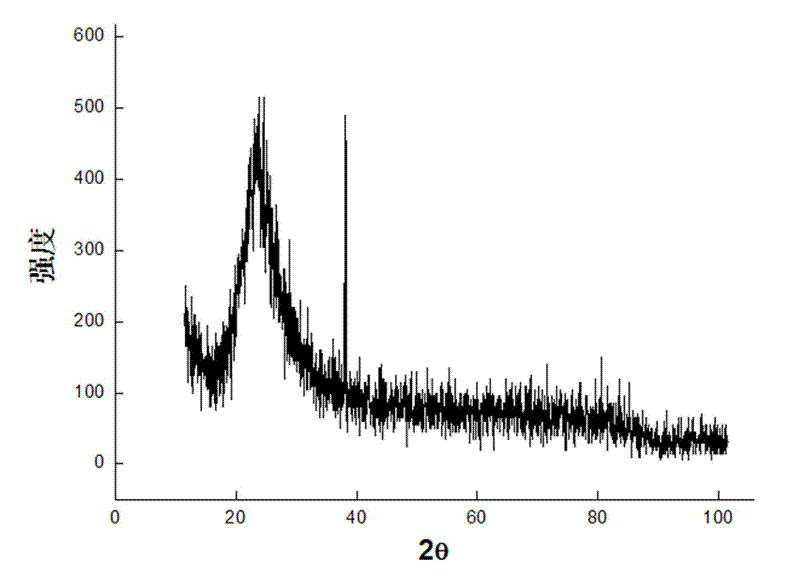

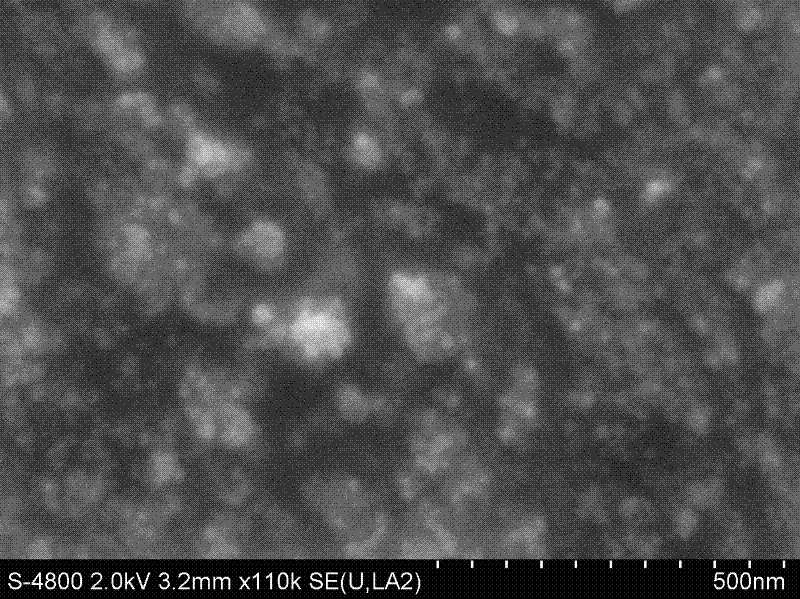

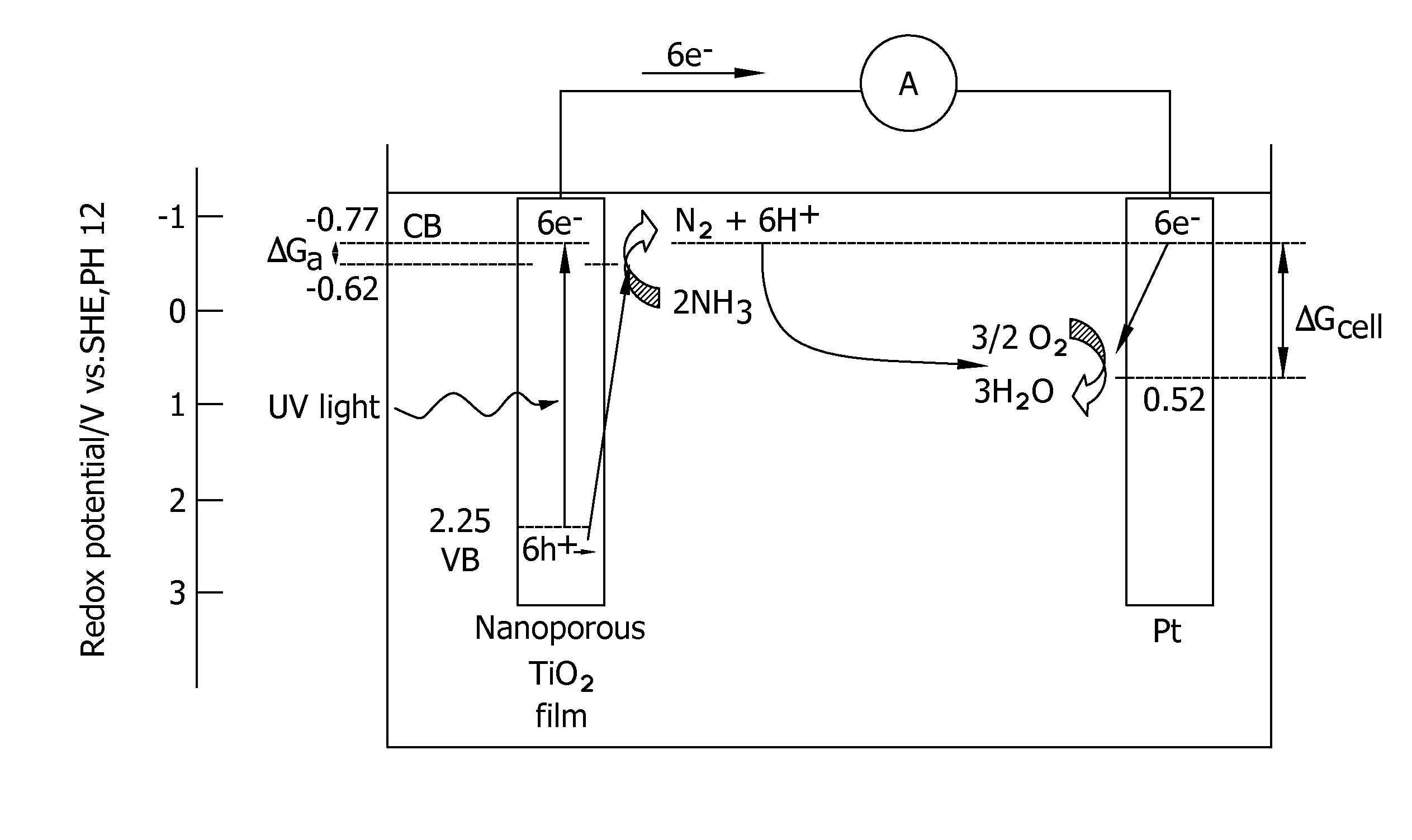

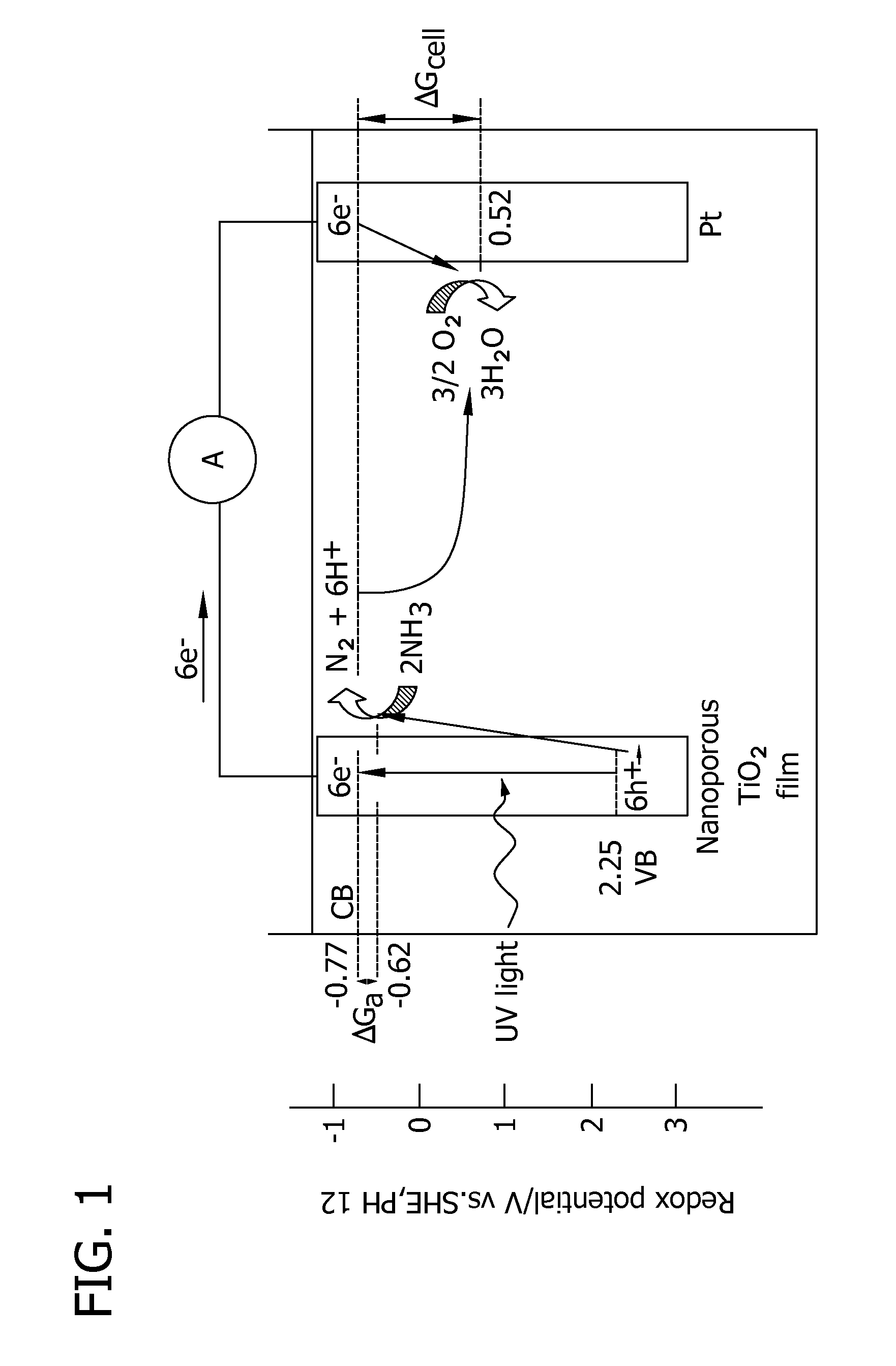

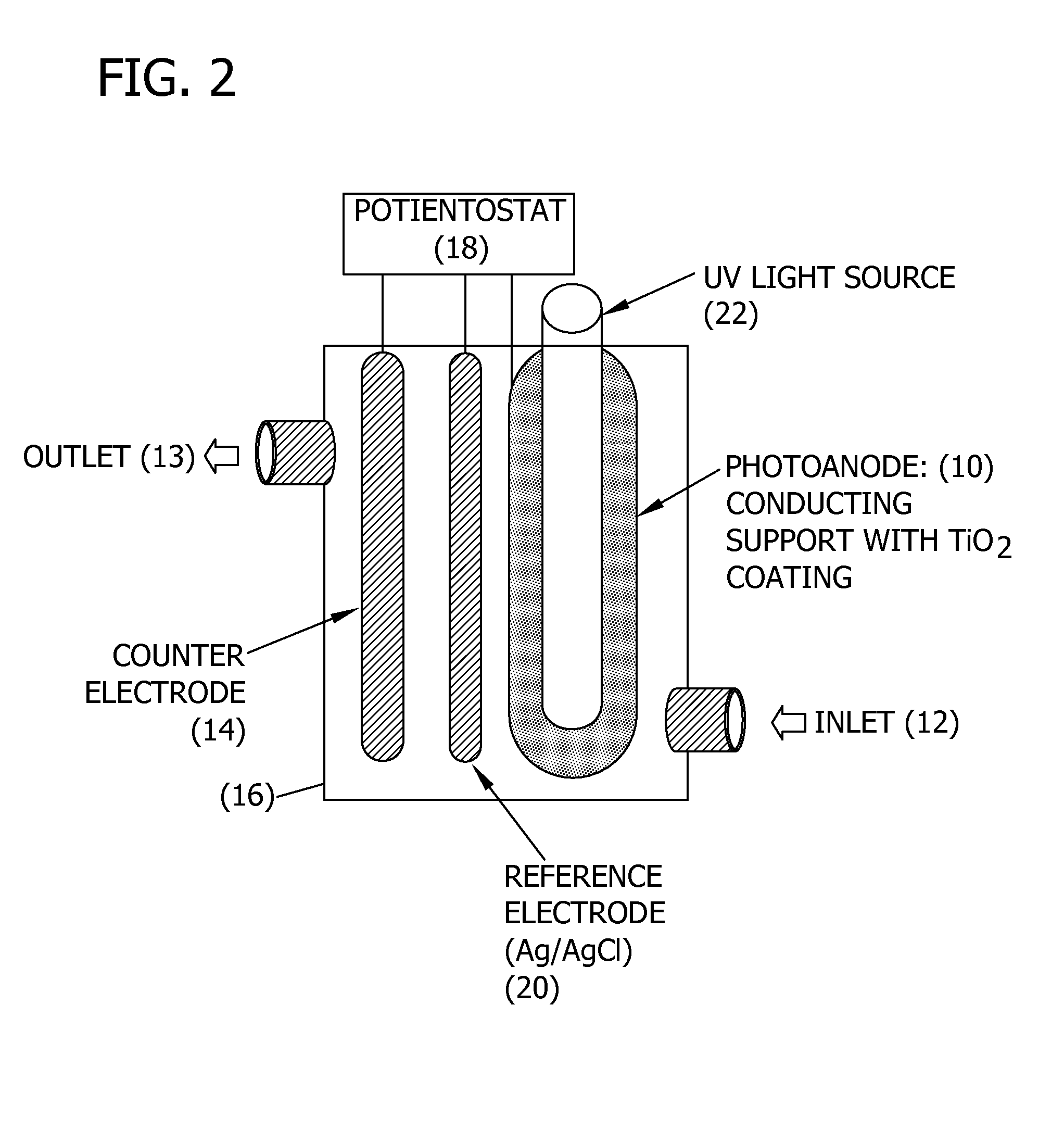

PHOTOELECTROCATALYTIC OXIDIZER DEVICE HAVING COMPOSITE NANOPOROUS TiO2 COATED Ti PHOTOANODE AND METHOD OF REMOVING AMMONIA FROM WATER IN AQUARIA AND RECIRCULATION AQUACULTURE SYSTEMS

InactiveUS20090314711A1Improve performanceWater treatment parameter controlElectrolysis componentsComposite electrodeNanoporous membrane

A photoelectrocatalytic oxidizing device having a photoanode being constructed from an anatase or rutile polymorph of Ti as the support electrode. Alternatively, the photoanode is a composite electrode comprising an anatase or rutile polymorph of Ti as the support electrode coated with a thin film of sintered nanoporous TiO2 derived from a stable, dispersed suspension of nanoparticulate TiO2. The device being useful for removing ammonia, protein and other contaminants from water in aquariums and aquacultures thereof. The device being cylindrical in shape and having a flow-through configuration. The method being directed at reducing the amount and concentration of ammonia in an aquarium or aquaculture system comprising providing an aqueous solution comprising water, NH3, NH4+ and 1 ppb to 200 g / L NaCl, and, photoelectrocatalytically oxidizing the NH3 and NH4+ to produce N2 gas, NO2− and NO3−, wherein the NH3 and NH4+ are oxidized on the surface of a photoanode constructed from an anatase polymorph of Ti, a rutile polymorph of Ti, or a nanoporous film of TiO2.

Owner:WISCONSIN ALUMNI RES FOUND

Environment protectional photocatalyzed paint for inner wall

The invention relates to an environment-friendly photocatalysis inner wall paint and process for preparation, wherein the weight percent of raw material constituents are, one or two of acrylic-styrene emulsion and polyacrylic ester emulsion or their mixed liquor 10-35%, silicasol 5-15%, or mixed phase titanium oxide particles of octahedrite phase and rutile phase, or surface treated titanium oxide composite particles, the paint comprises photocatalyst 2-15%, pigment, filling material and other additive 10-20%, and water for the rest. The invention can effectively degrade the contaminant in the surrounding air.

Owner:SHANGHAI UNIV

Preparation method and use of hydrophilic automatically-cleaning coating with photocatalytic activity

The invention provides a preparation method of a hydrophilic automatically-cleaning coating with photocatalytic activity, and belongs to the technical field of chemical engineering. The preparation method is characterized in that butyl titanate and ethyl orthosilicate are utilized as precursors; nanoscale TiO2 / SiO2 sol is formed through a sol-gel method; and the nanoscale TiO2 / SiO2 sol is coated on the surface of an object and is naturally dried at normal temperature to form an anatase nanoscale TiO2 / SiO2 composite film with photocatalytic activity. When the anatase nanoscale TiO2 / SiO2 composite film with photocatalytic activity is coated on a solar photovoltaic panel, a vehicle window glass plate or a building glass plate at a normal temperature, the anatase nanoscale TiO2 / SiO2 composite film with photocatalytic activity can fast form a hydrophilic coating. Under natural light irradiation, the hydrophilic coating can decompose greasy dirt adhered to the hydrophilic coating into inorganic pollutants, and through rainwater flushing or artificial washing, the inorganic pollutants are removed so that the solar photovoltaic panel or the vehicle window glass plate or the building glass plate is kept as clean as a new one for a long time. The preparation method provided by the invention reduces a production management cost and improves solar photovoltaic panel generating efficiency.

Owner:NORTH WEST YONGXIN GROUP

Methods for removing contaminants from aqueous solutions using photoelectrocatalytic oxidization

InactiveUS20110180423A1Improve performanceImprove photoanode performanceWater treatment compoundsSpecific water treatment objectivesComposite electrodeNanoporous membrane

A photoelectrocatalytic oxidizing device having a photoanode being constructed from a conducting metal such as Ti as the support electrode. Alternatively, the photoanode is a composite electrode comprising a conducting metal such as Ti as the support electrode coated with a thin film of sintered nanoporous TiO2. The device is useful in methods for treating an aqueous solution such as groundwater, wastewater, drinking water, ballast water, aquarium water, and aquaculture water to reduce amounts of a contaminant. The method being directed at reducing the amount and concentration of contaminants in an aqueous solution comprising providing an aqueous solution comprising at least one contaminant, and, photoelectrocatalytically oxidizing the contaminant, wherein the contaminant is oxidized by a free radical produced by a photoanode constructed from an anatase polymorph of Ti, a rutile polymorph of Ti, or a nanoporous film of TiO2.

Owner:WISCONSIN ALUMNI RES FOUND

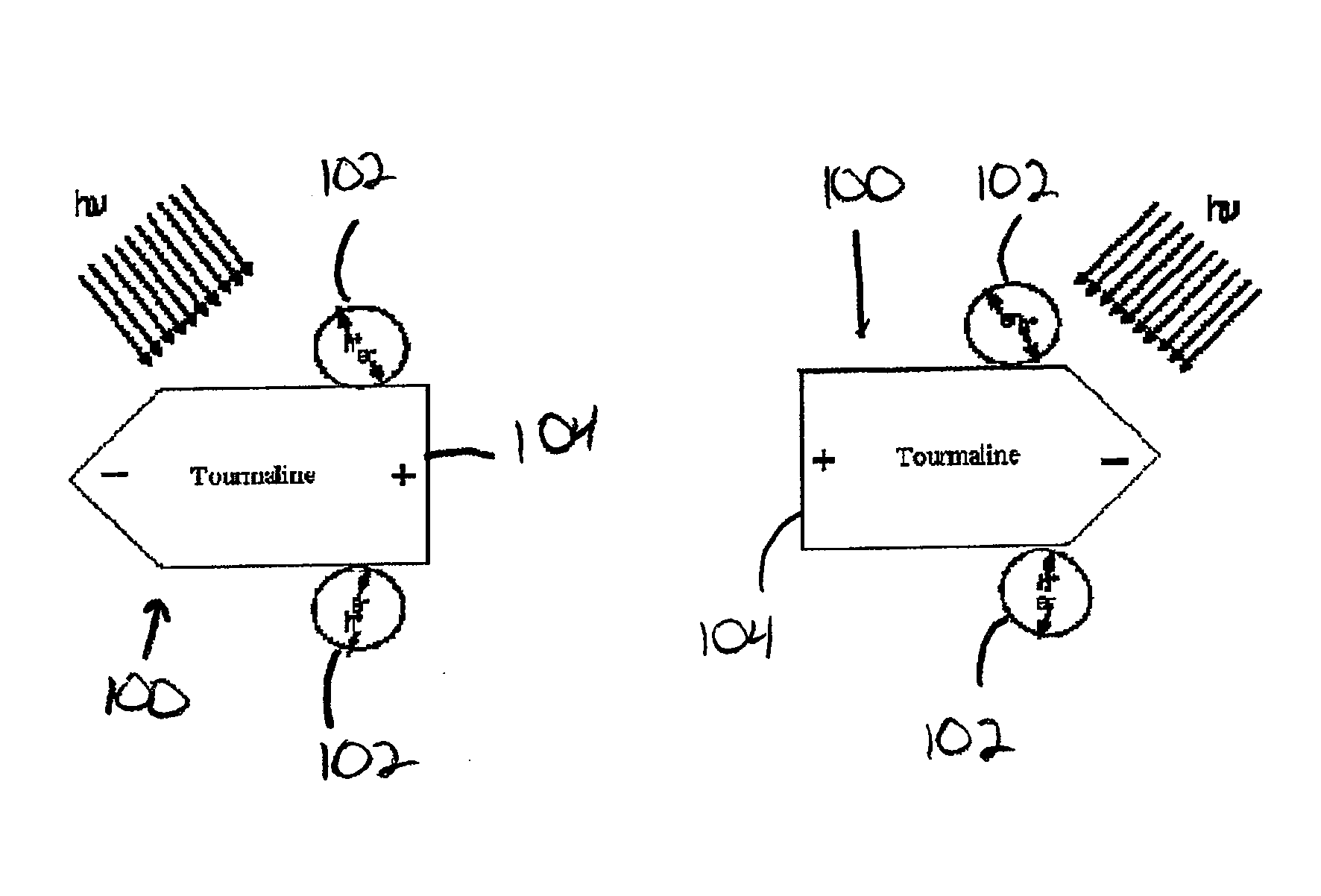

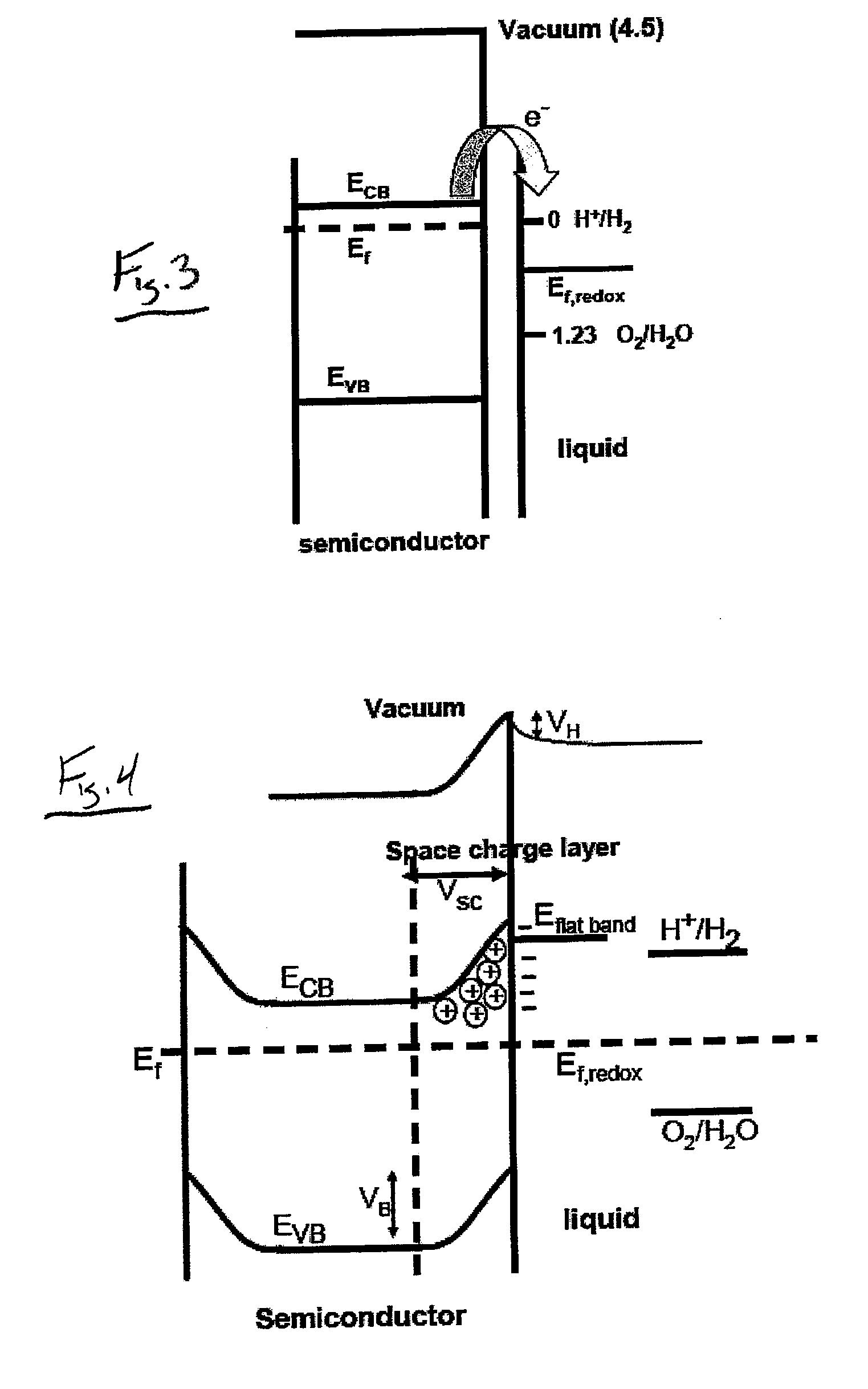

Photocatalyst Having Improved Quantum Efficiency and Method for Use in Photocatalytic and Photosynthetic

InactiveUS20080223713A1Easy to separateImprove quantum efficiencyHydrogenGas treatmentPhotocatalytic reactionNanostructure

The present invention involves increasing the quantum efficiency in titania photocatalysts for photocatalytic (oxidation of acetaldehyde) and photosynthetic (photosplitting of water) reactions by integrating the titania photocatalyst with a polar mineral having surface electrical fields due to pyroelectric and piezoelectric effects, and by adjusting the nanostructure of the photocatalyst materials. The photocatalytic reactivity of titania powder is increased due to the effect of electric field present on the surface of polar mineral material on the photocatalytic effect of commercial titania with respect to photolysis of water. Additionally, the photocatalytic performance of pure phase rutile and anatase nanostructures with well defined morphologies was found to improved with respect to certain photocatalytic reactions in comparison with non-structured titania.

Owner:XU HUIFANG +2

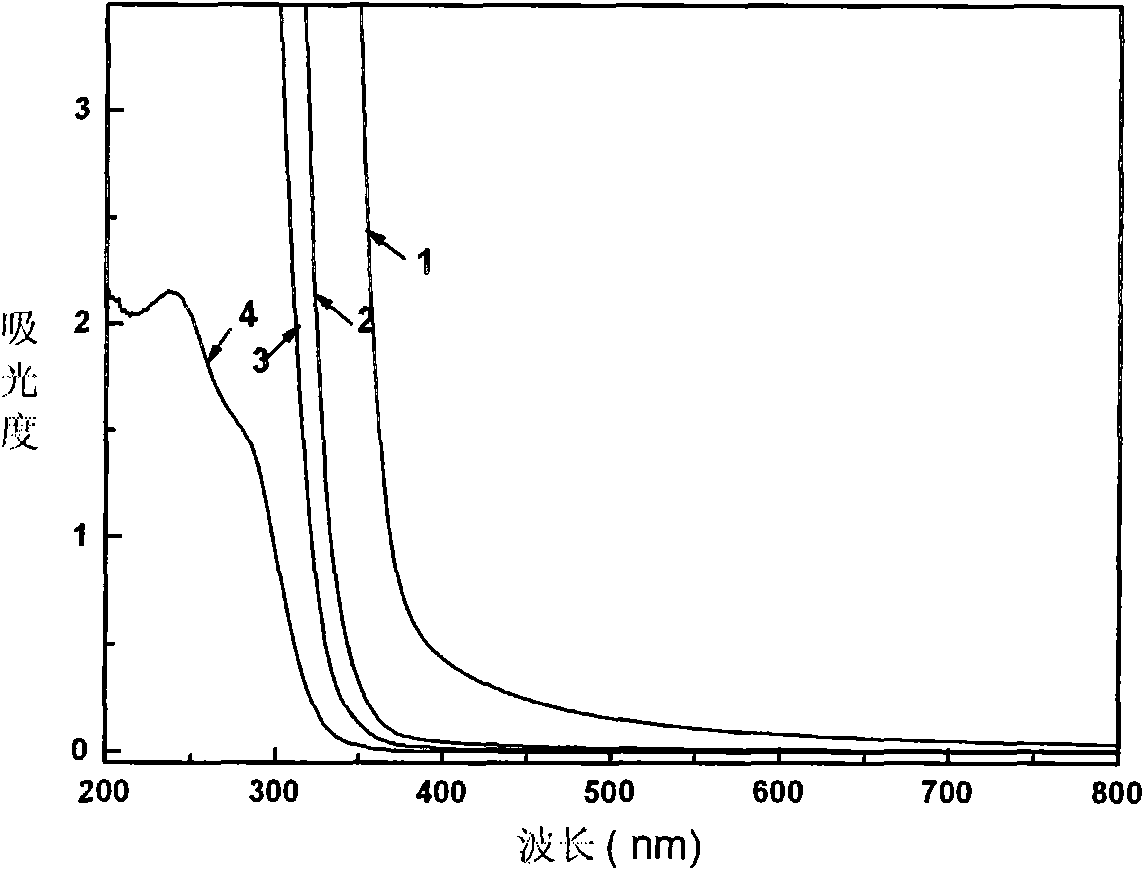

Prepn process of nanometer composite titania/silica photocatalyst sol and transparent photocatalyzing film

InactiveCN101088606AWide variety of sourcesLow pricePhysical/chemical process catalystsDispersed particle separationTitaniumHardness

The present invention belongs to the field of inorganic metal oxide, and is especially process of preparing nanometer titania / silica photocatalyst sol and transparent photocatalyzing film. The anatase type nanometer titania / silica photocatalyst sol is prepared with inorganic low concentration titanium compound solution as material at normal pressure and 40-100 deg.c. The sol has high hydrophilicity, high photocatalyzing activity, high transparency and particle size of 15-30 nm. The sol may be painted onto substrate of different properties to form self-cleaning transparent photocatalyzing film with high hardness and high antifouling and antiseptic performance. The sol has high stability, small and homogeneous size and high performance; and the preparation process has low cost and simple operation and is suitable for large scale production and application.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

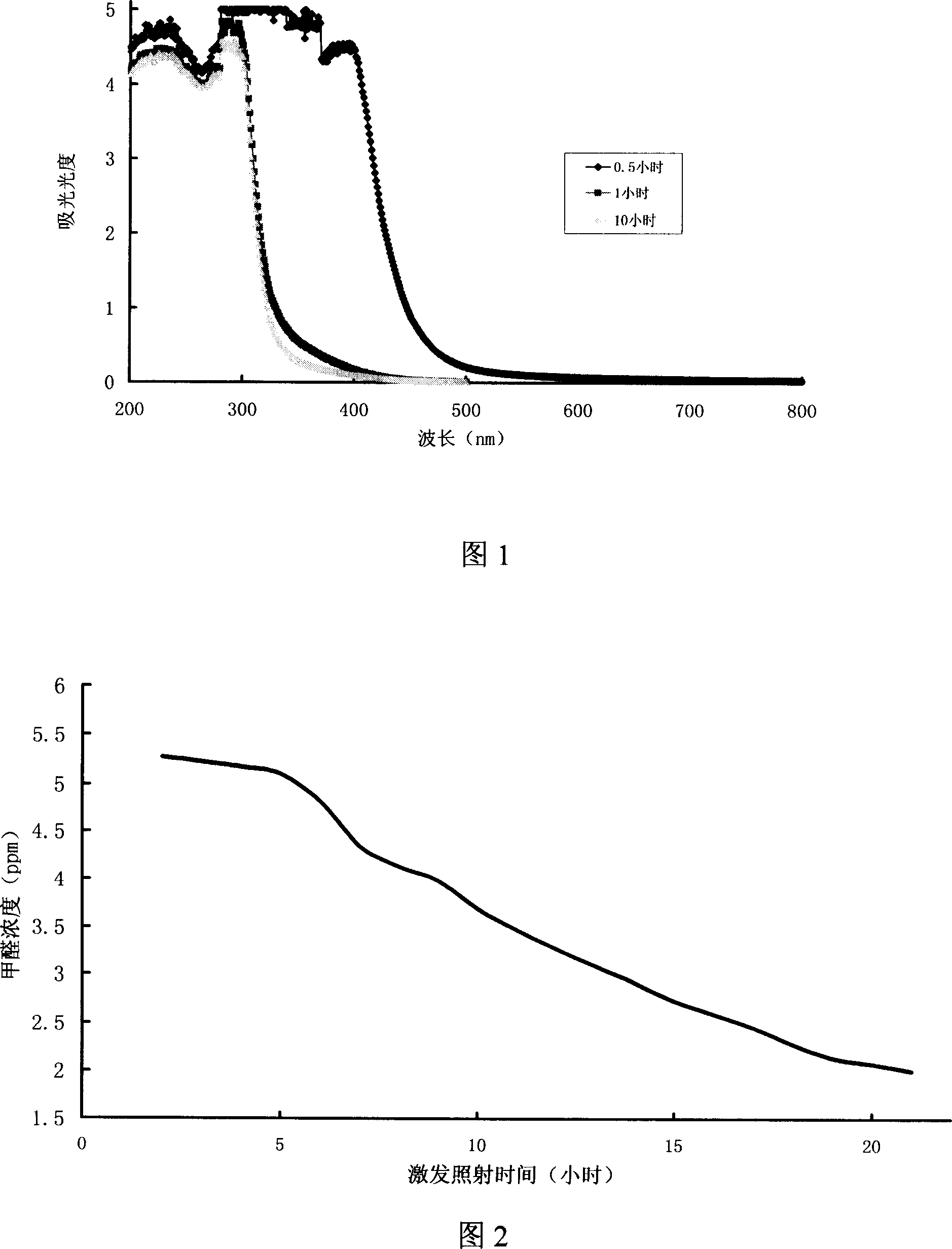

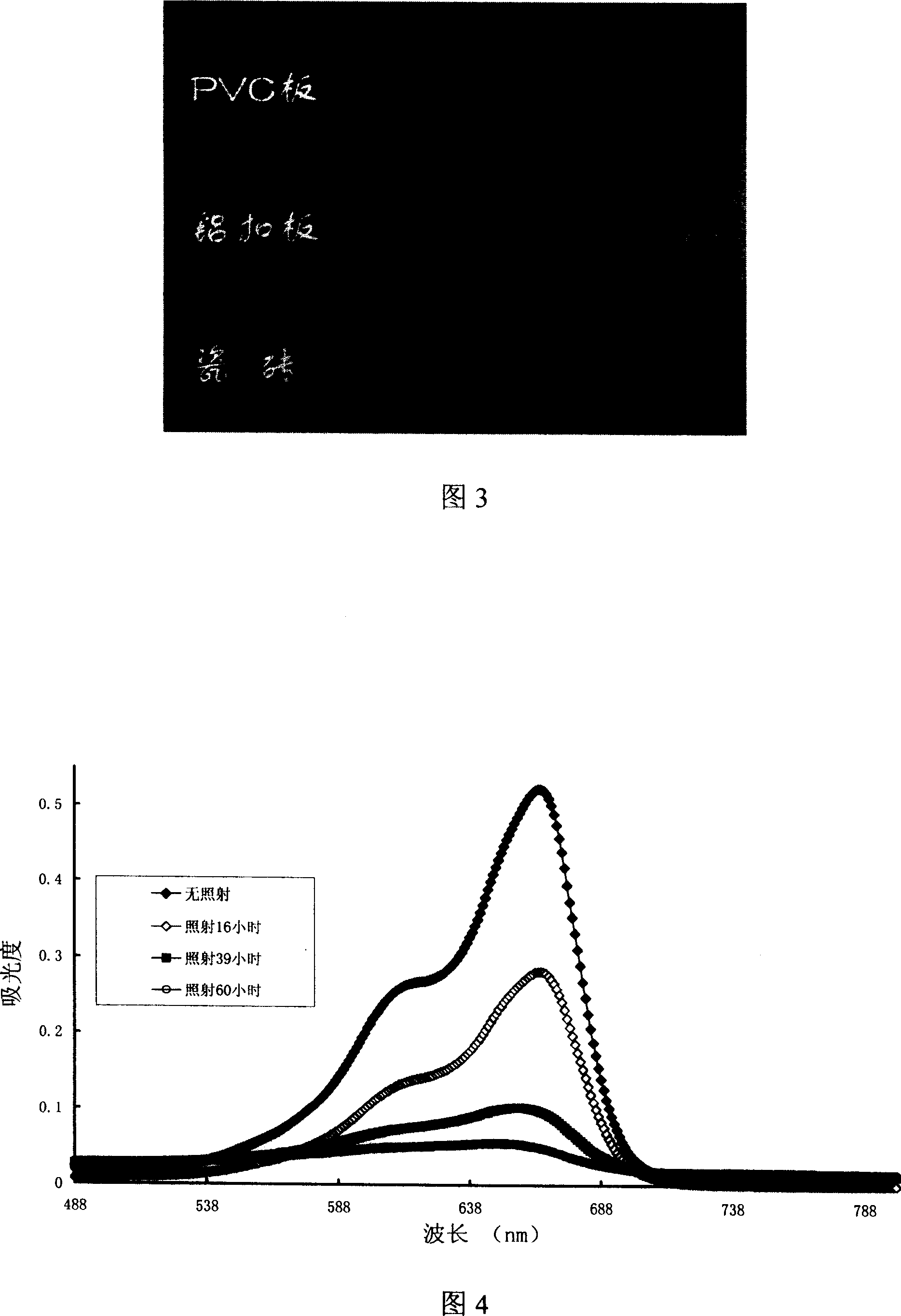

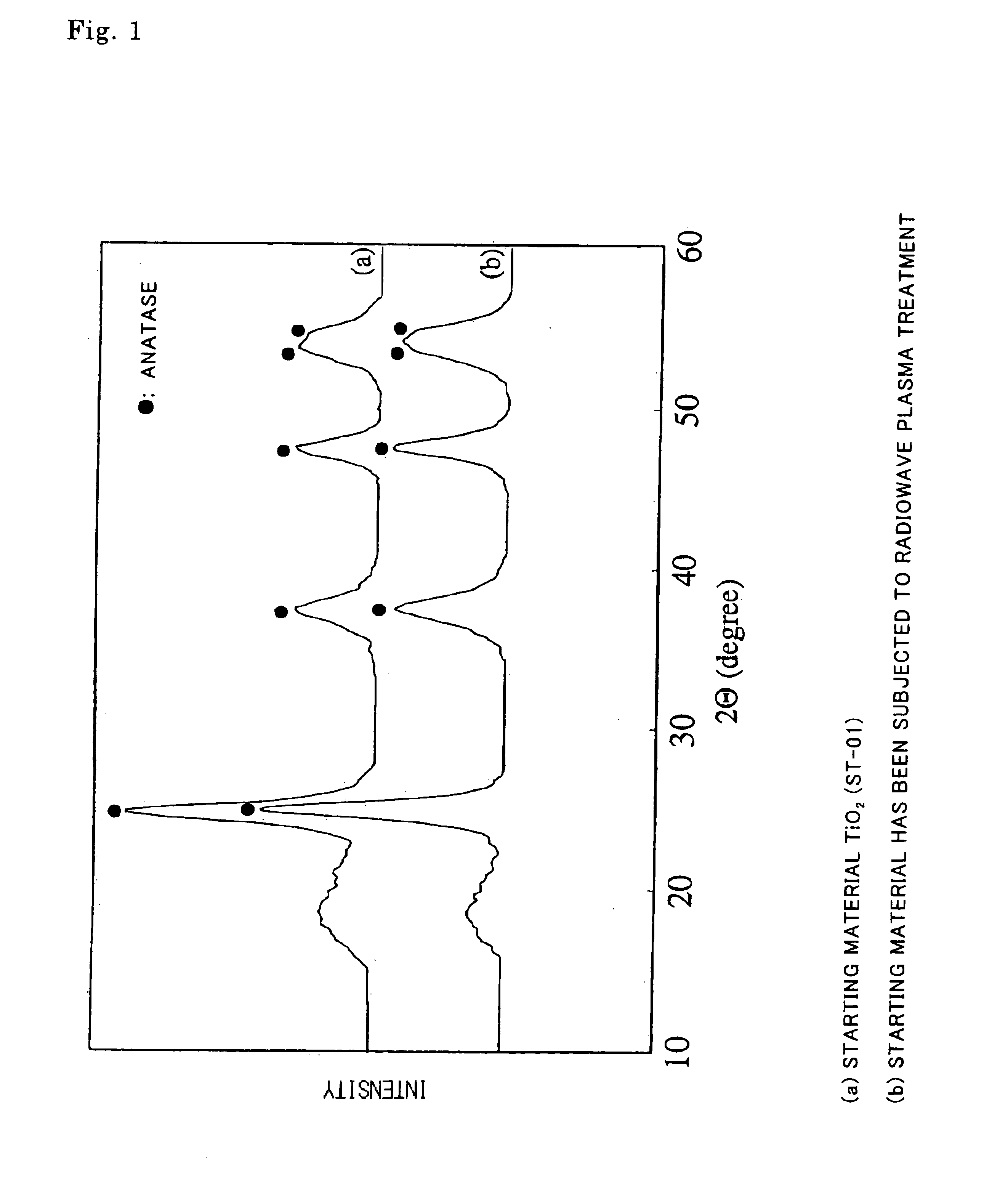

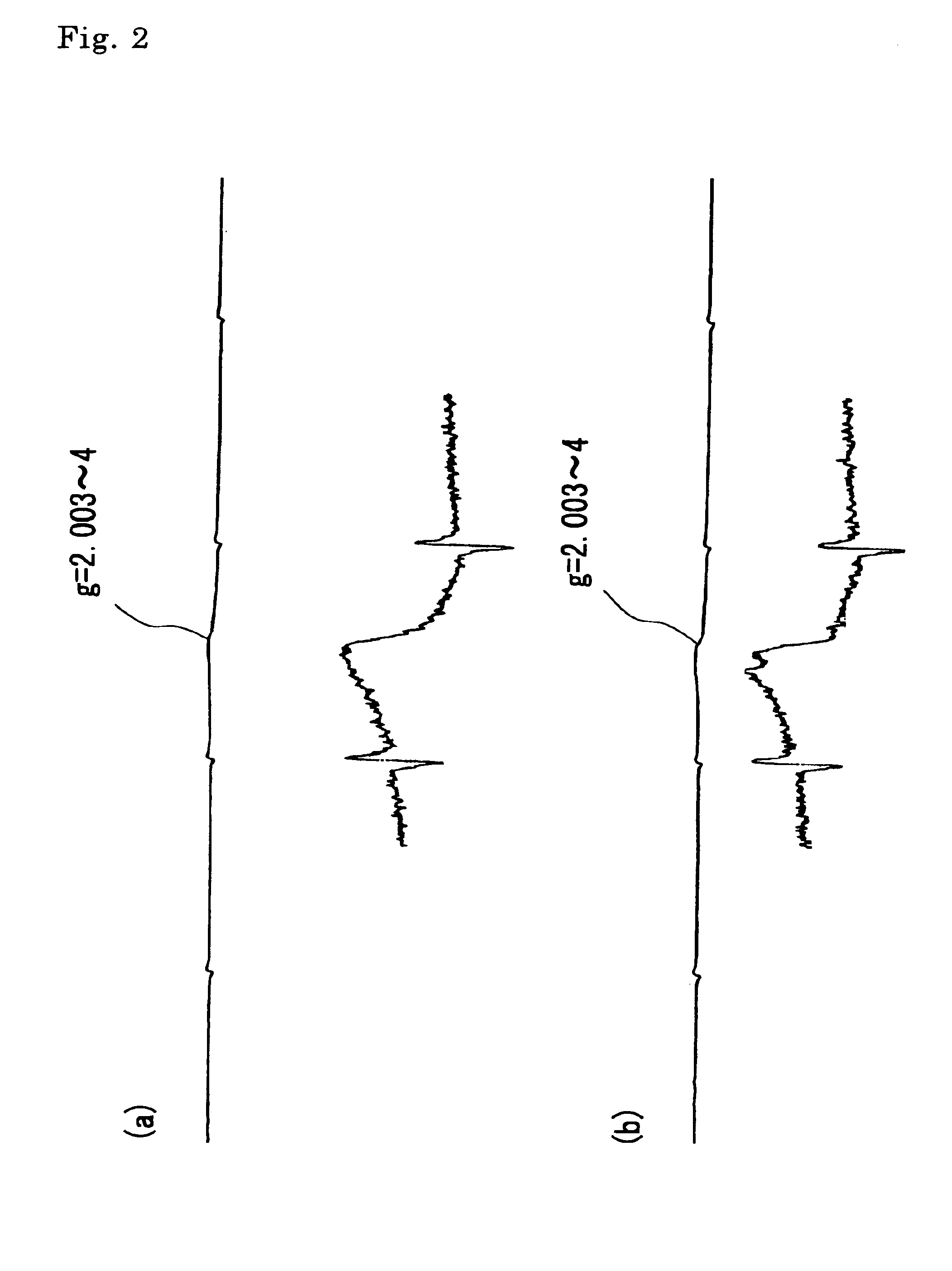

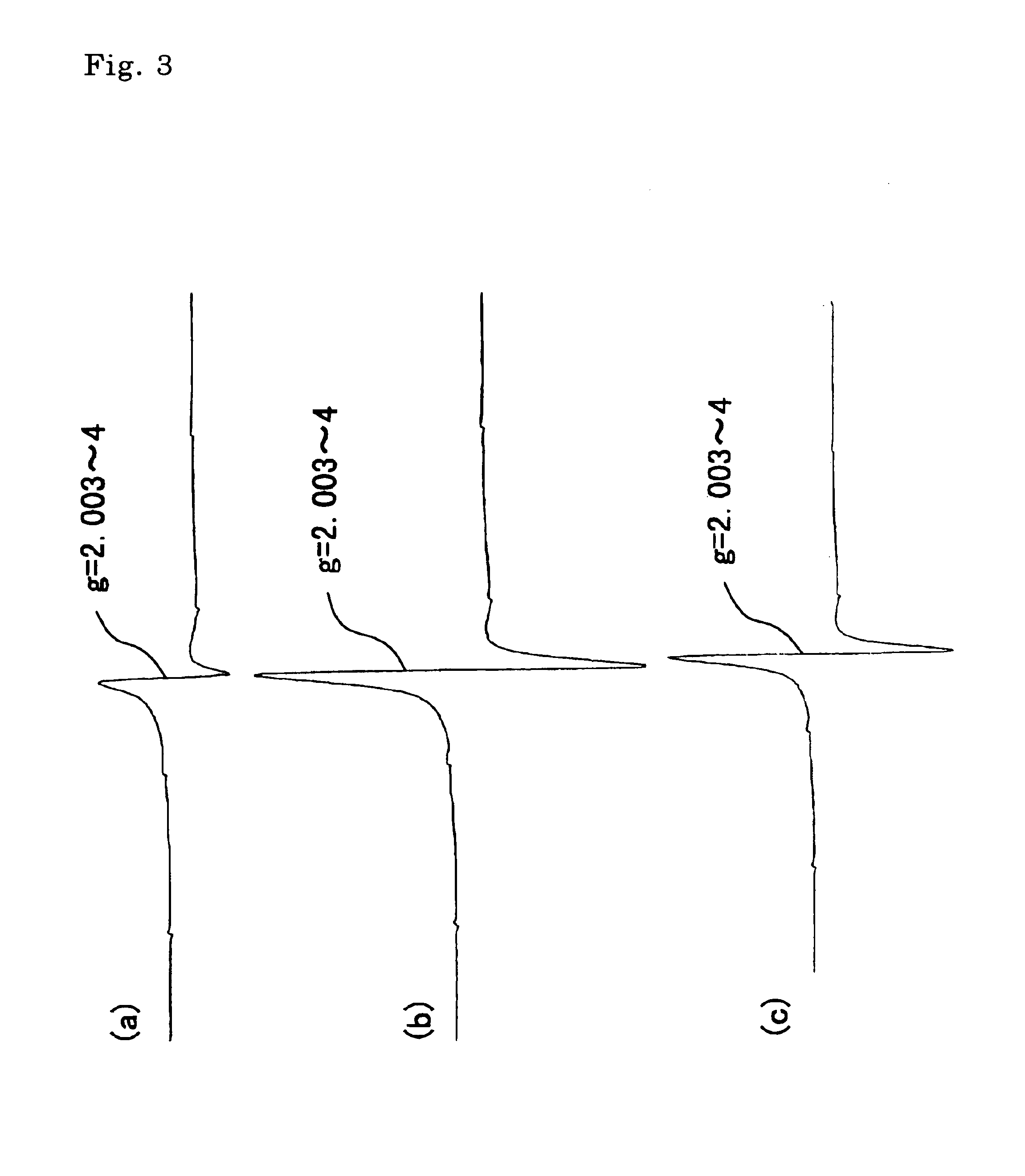

Visible radiation type photocatalyst and production method thereof

The invention is directed to a catalyst having activity under the irradiation of a visible light, the catalyst being an oxide semiconductor such as an anatase type titanium dioxide, having stable oxygen defects. A method for producing a catalyst having activity under the irradiation of a visible light which comprises treating an oxide semiconductor with hydrogen plasma or with a plasma of a rare gas element, comprising performing the treatment in a state substantially free from the intrusion of air into the treatment system is also provided. An article comprising a base material having the catalyst above provided on the surface thereof and a method for decomposing a substance, comprising bringing an object to be decomposed into contact with the catalyst above under the irradiation of a light containing at least a visible radiation are disclosed. A novel photocatalyst which enables use of a visible radiation is provided, as well as a method utilizing the photocatalyst for removing various substances containing an organic matter or bacteria by photodecomposition.

Owner:ASUKATEC

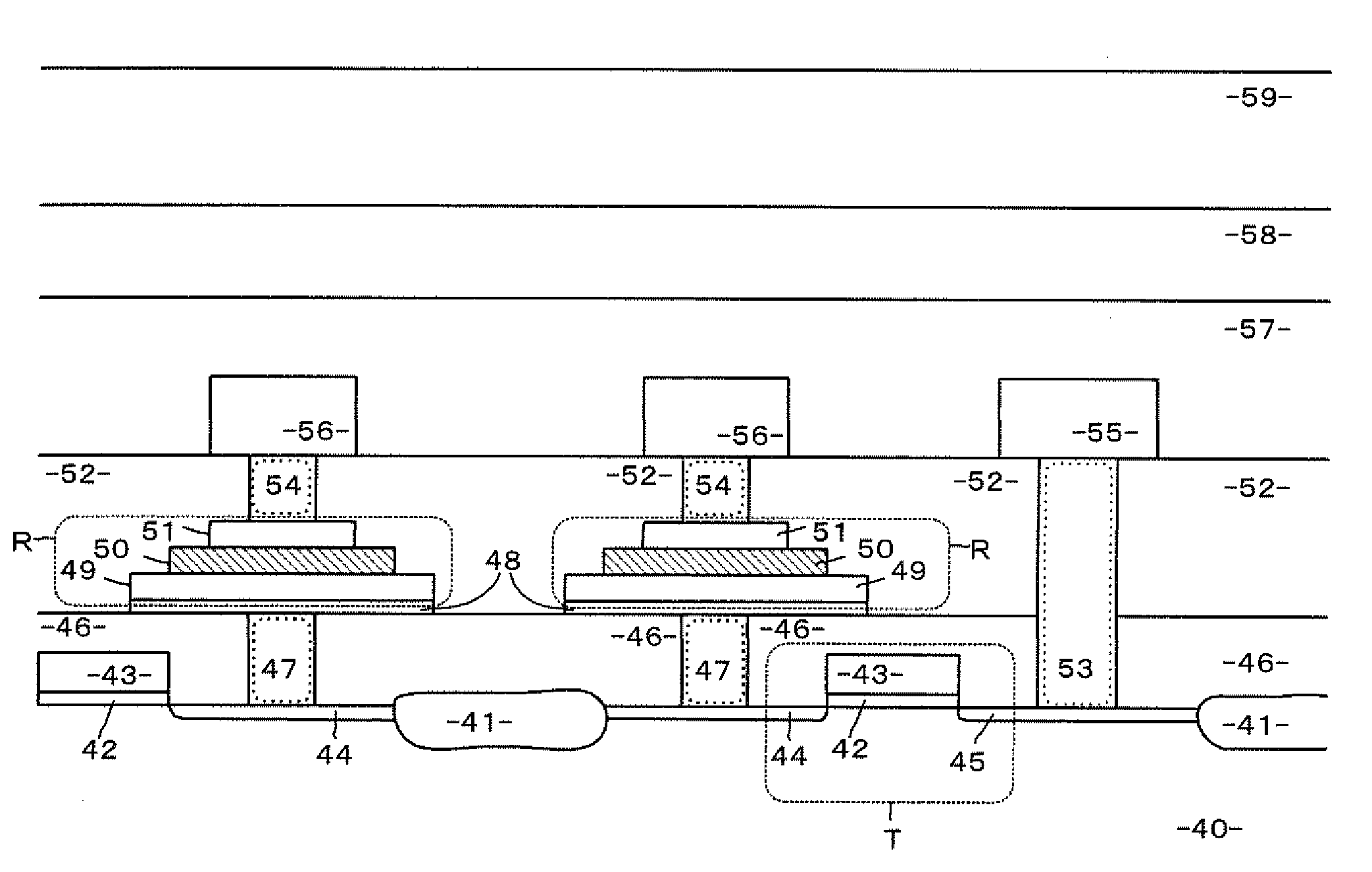

Variable resistance element, its manufacturing method and semiconductor memory device comprising the same

InactiveUS20090097300A1Stable switching operationFavorable data retention characteristicCurrent responsive resistorsSolid-state devicesElectrical resistance and conductanceVoltage pulse

Provided is a variable resistance element capable of performing a stable resistance switching operation and having a favorable resistance value retention characteristics, comprising a variable resistor 2 sandwiched between a upper electrode 1 and lower electrode 3 and formed of titanium oxide or titanium oxynitride having a crystal grain diameter of 30 nm or less. When the variable resistance 2 is formed under the substrate temperature of 150° C. to 500° C., an anatase-type crystal having a crystal grain diameter of 30 nm or less is formed. Since the crystalline state of the variable resistor changes by applying a voltage pulse and the resistance value changes, no forming process is required. Moreover, it is possible to perform a stable resistance switching operation and obtain an excellent effect that the resistance fluctuation is small even if the switching is repeated, or the variable resistance element is stored for a long time under a high temperature.

Owner:SHARP KK

Preparation method of ultra-thin titanium dioxide nanosheet

InactiveCN102010002AWide choiceEasy to makeNanostructure manufactureTitanium dioxideNew energyTitanium

The invention relates to a preparation method of an ultra-thin titanium dioxide nanosheet. The ultra-thin titanium dioxide nanosheet is synchronized by using a wet chemical method. The synchronized titanium dioxide nanosheet is of an anatase titanium type and mainly square, rectangular and other irregular shapes, and the thickness of the ultra-thin titanium dioxide nanosheet in the [001] crystallographic orientation is 0.5-5.0 nanometers; and (001) crystal surfaces with high reactivity are arranged on the upper bottom surface and the lower bottom surface of the ultra-thin titanium dioxide nanosheet. The titanium dioxide nanosheet with the structure has important application in the fields of environmental science and new energy.

Owner:EAST CHINA UNIV OF SCI & TECH

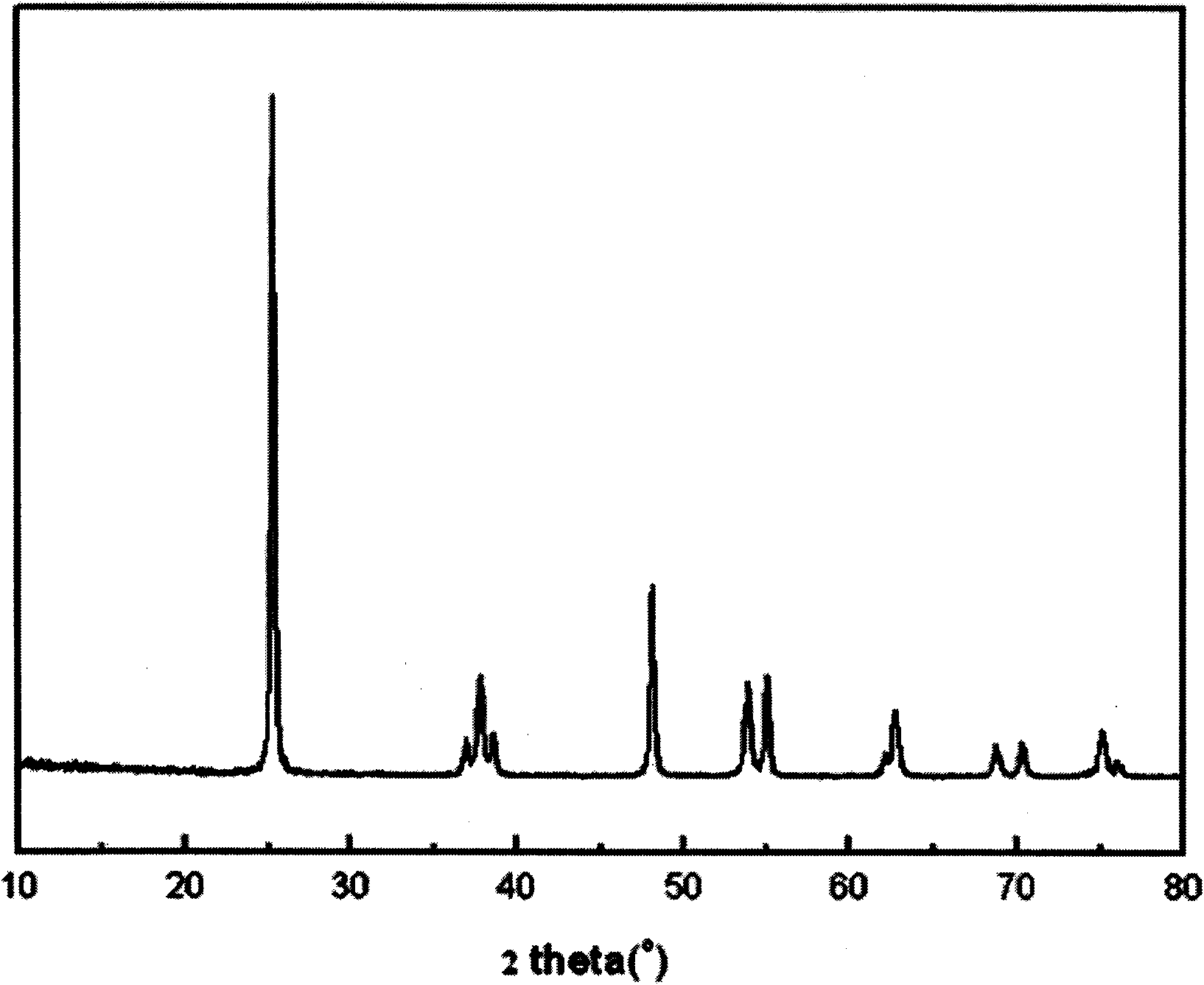

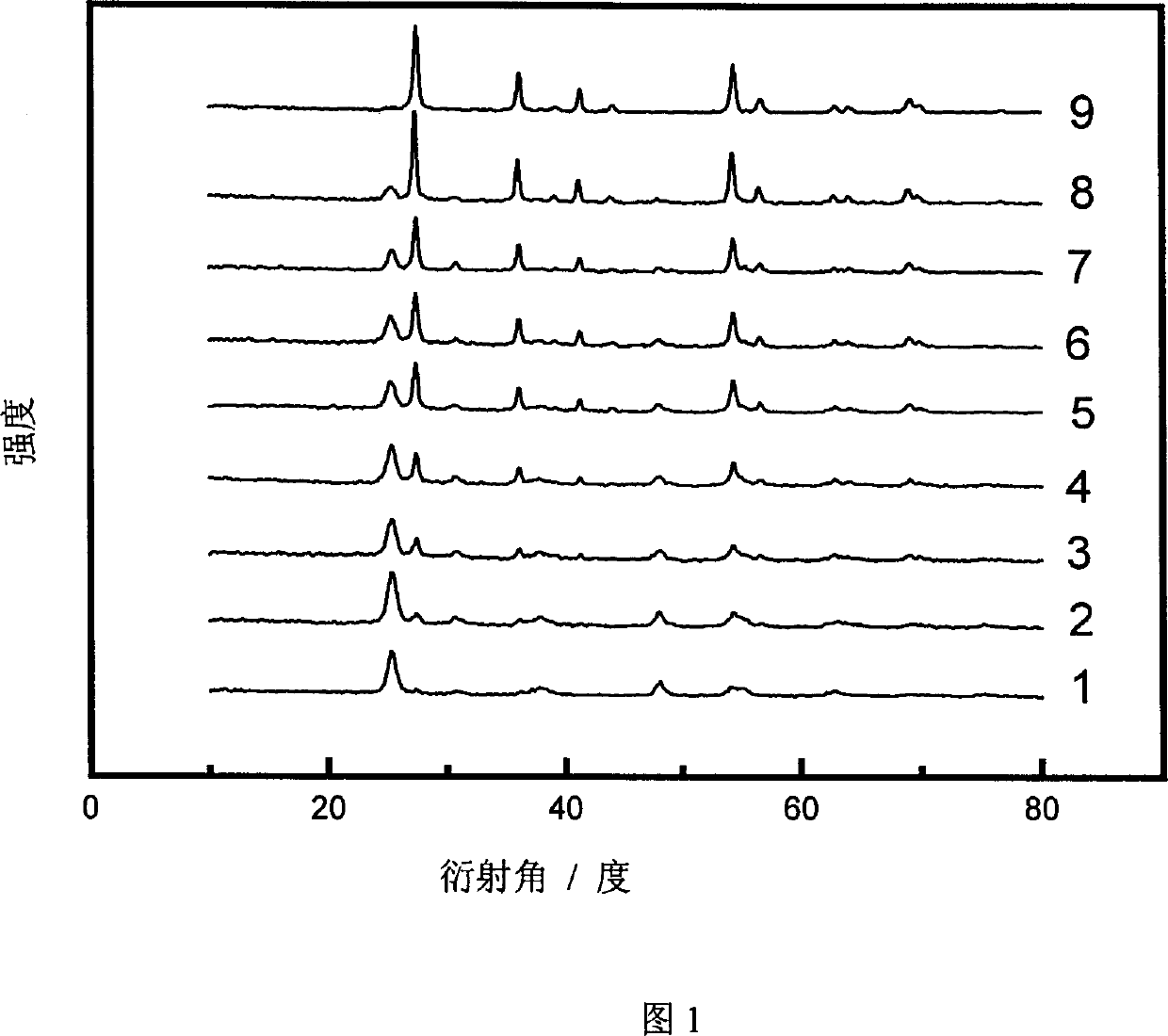

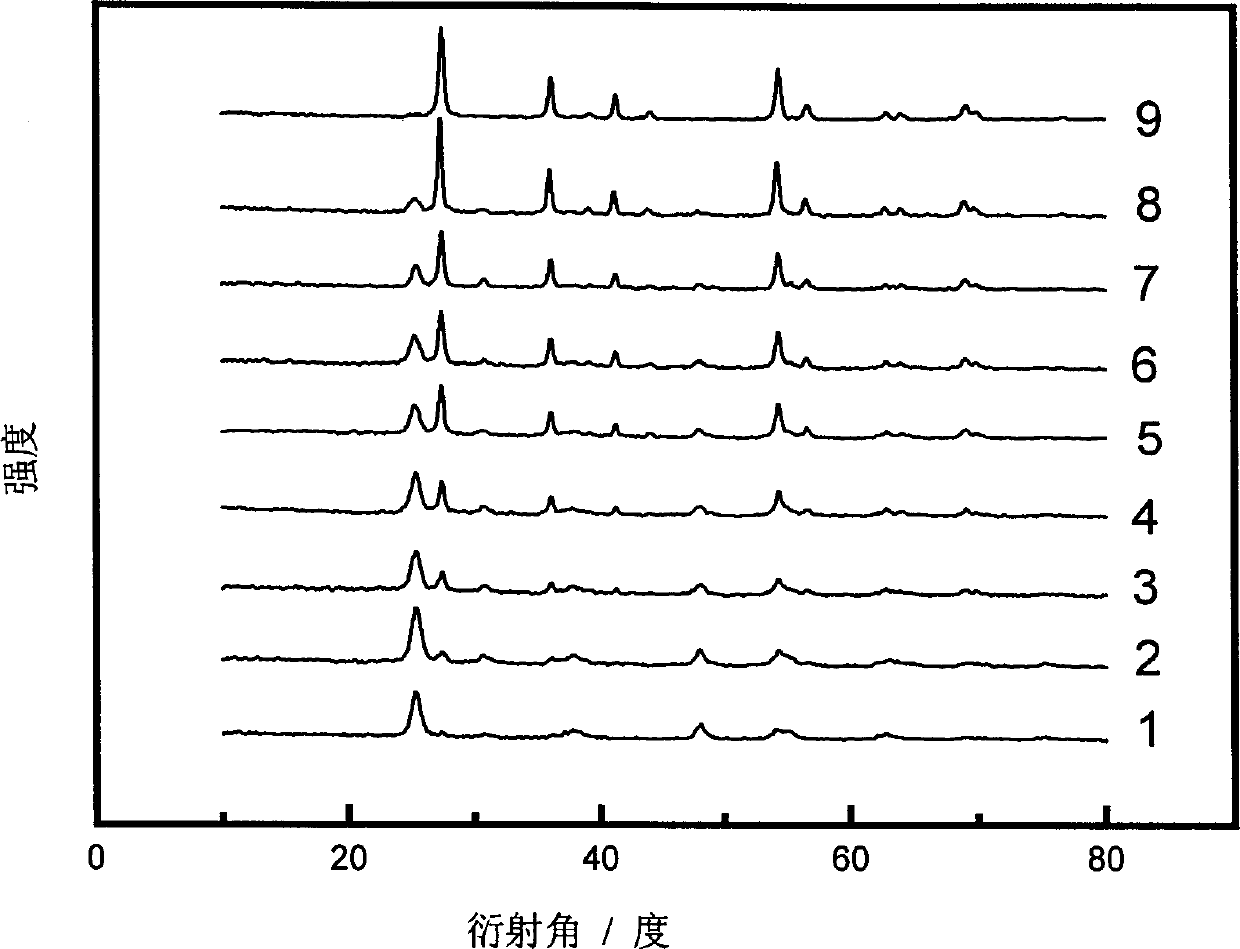

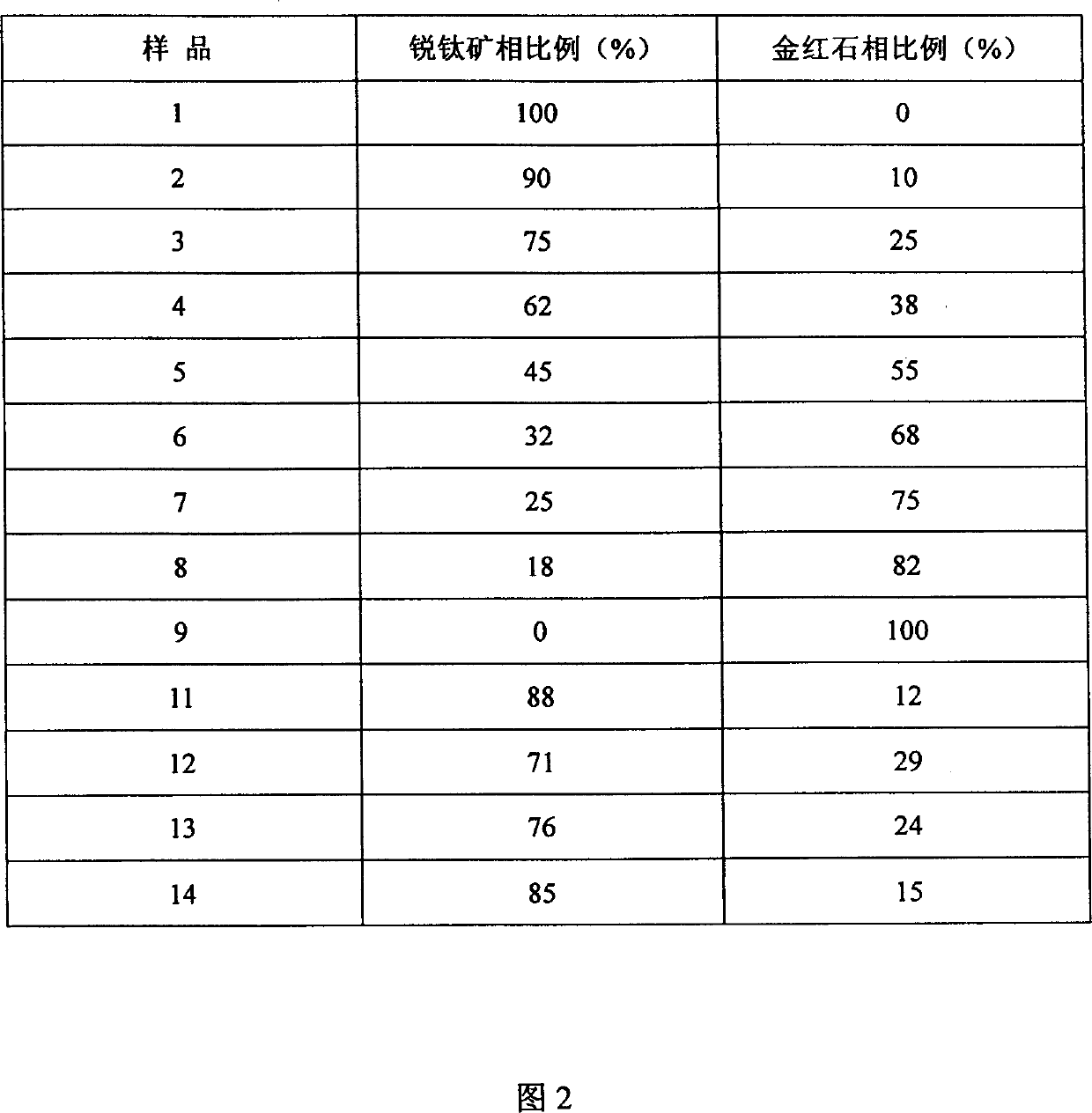

Preparation method of crystal phase controllable titanium dioxide nanometer crystal

InactiveCN1478725AMild preparation conditionsSimple preparation equipmentTitanium dioxideAlcoholTitanium

A process for preparing the crystal phase controllable TiO2 nanocrystals includes such steps as hydrolyzing the Ti-cotnained compound in the aqueous solution of alcohol to obtain amorphous TiO2 powder, adding inorganic acid, hydrothermal treating, filtering, washing and drying. Its resultant TiO2 nanocrystal has the continuously regulatable ratio of anatase phase to rutile phase.

Owner:FUDAN UNIV

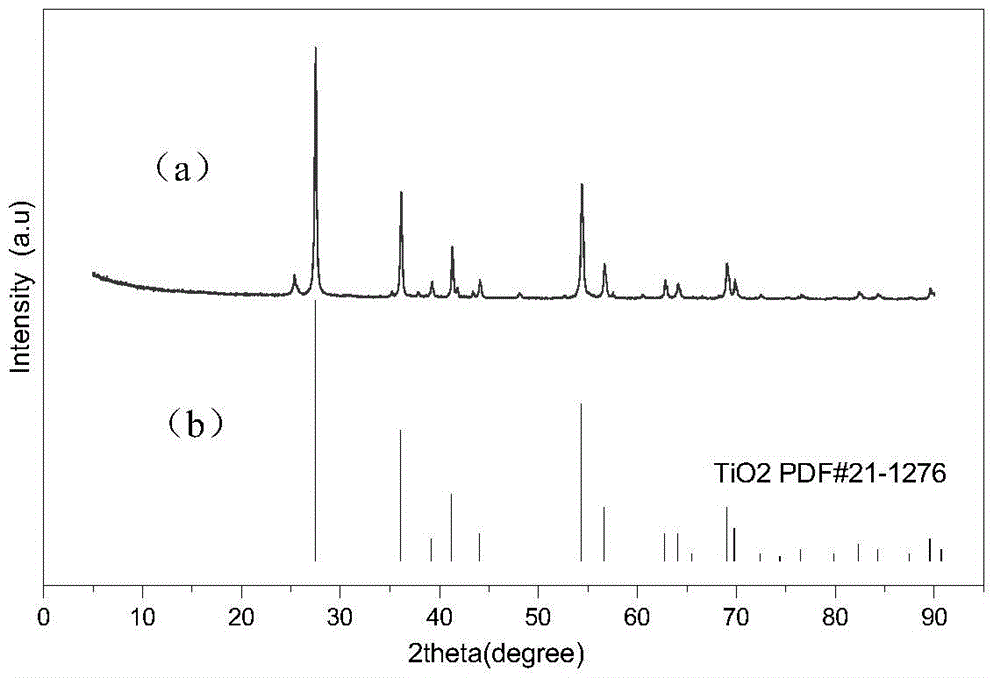

Preparation method for two-dimensional sheet-shaped titanium dioxide nanosheet material

InactiveCN104085920AHigh purityHigh crystallinityMaterial nanotechnologyTitanium dioxideCrystallinityRutile

The invention discloses a preparation method for a two-dimensional sheet-shaped titanium dioxide nanosheet material. The preparation method comprises the following steps: soaking three-dimensional laminated Ti3AlC2 powder in an aqueous solution of HF at a room temperature, and removing an Al atom layer by use of a chemical liquid-phase dissection method to prepare a two-dimensional Ti3C2 nanosheet with laminated characteristics still kept; then, placing Ti3C2 in a tubular furnace, ventilating a gas mixture of flowing oxygen gas and argon gas after vacuumizing, realizing in-situ oxidization of the two-dimensional Ti3C2 nanosheet at a high temperature, then cooling, taking out powder, and grinding to obtain the TiO2 nanosheet. According to the preparation method disclosed by the invention, any organic solvent and additive are not needed to be added in the preparation process, process parameters are stable, the procedure is simple, the process is controllable, the efficiency is high and the cost is low; the prepared two-dimensional titanium dioxide nanosheet has transverse dimension of 5-10 microns, and single-layer average thickness of 50 nanometers; the prepared rutile type titanium dioxide nanosheet is high in purity and good in degree of crystallinity, and only contains very little antase phase.

Owner:HOHAI UNIV

Titanium dioxide powder containing tungsten for preparing honeycomb SCR DeNOx catalyst and preparation method thereof

InactiveCN101757907ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSlurryAnatase

The invention relates to titanium dioxide powder containing tungsten for honeycomb SCR DeNOx catalyst and a preparation method thereof; the powder is characterized by comprising anatase crystal and TiO2-WO3 two components, and containing 85 to 95 percent of TiO2. and 5 to 15 percent of WO3.; the preparation method comprises the following steps that: intermediate metatitanic which is used to prepare anatase titanium dioxide through a sulfuric acid method is prepared into serum, the content of titanium dioxide is 200 to 800g / L, and serum A is prepared; simultaneously, tungsten is dissolved into deionized water, the content of tungsten is 440g / L, and serum B is prepared; and then the serum B is calculated and added into the serum A, ammonia is used to regulate the pH value to be 8; and titanium tungsten composite denitrification powder is prepared after spray drying and calcining for 3 to 7 hours at 300DEG C to 550DEG C.

Owner:河北晶锐瓷业有限公司

Method for preparing extrafine anatase titanium dioxide nano rods

InactiveCN101559979ADopingTransparent highNanostructure manufactureTitanium dioxideHydrolysisUltrasonic dispersion

The invention relates to a method for preparing extrafine anatase titanium dioxide nano rods, which comprises that: (1) titanium containing inorganic substances are hydrolyzed, the temperature is raised to be between 20 and 100 DEG C, inorganic base solution is added for heat preservation and hydrolysis and neutralizes pH to between 7 and 8, and precipitation of hydrous titanium dioxide is obtained; (2) the precipitation is repeatedly washed, added with oxyful, stirred and subjected to ultrasonic dispersion, the temperature is raised to be between 0 and 50 DEG C and the heat is preserved for 1 to 24 hours; and (3) water solution of pertitanic acid is diluted by deionized water, then filled into a hydrothermal reaction kettle, subjected to hydrothermal treatment at a temperature between 100 and 250 DEG C for 2 to 48 hours, and cooled to room temperature. The preparation method is simple; the obtained sol does not contain organic stabilizer; and the titanium dioxide in the sol is anatase, has a rod-shaped structure and high length-diameter ratio, and can form extrafine rod-shaped nanocrystal titanium dioxide.

Owner:DONGHUA UNIV

Titanium white for dry acrylic spinning delustering its preparing method

InactiveCN1858309ADry spinning methodsPigment treatment with organosilicon compoundsWeather resistanceWhite powder

The present invention discloses a kind of titanium white powder for extinction in dry spinning acrylic fiber and its preparation process. The titanium white powder is prepared with anatase type titanium white as material and through pulping, sanding milling, grading, purifying and other steps to eliminate coarse grains and impurity ions, coating with compact Al2O3 to obtain high weather resistance, water washing and coating with organic material. It has excellent dispersivity in spinning solution for dry spinning acrylic fiber and is used for extinction. It can result in excellent filtering performance and spinnability, low end breakage, high tow strength, high whiteness and high dyeability.

Owner:EAST CHINA UNIV OF SCI & TECH

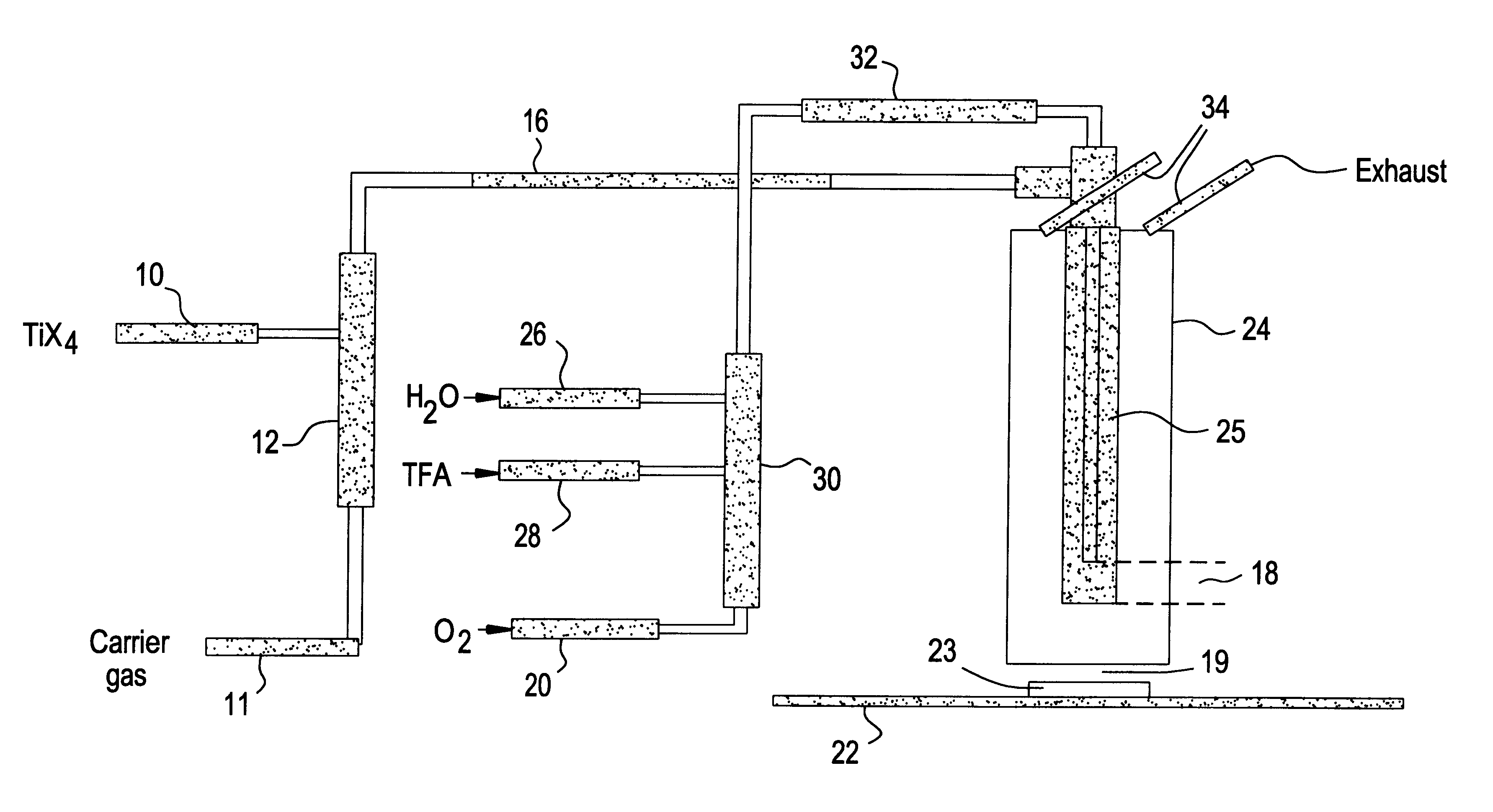

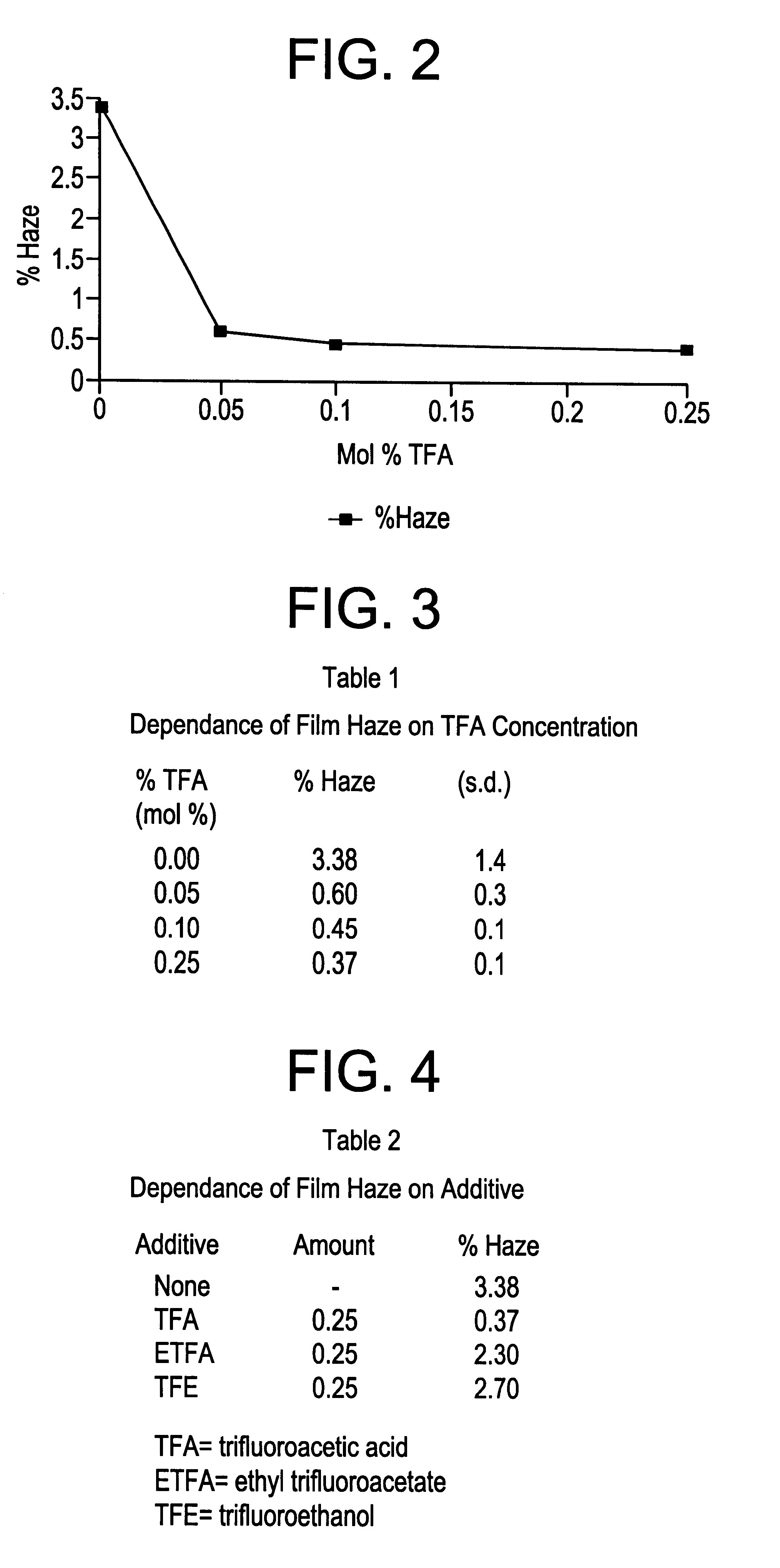

Preparation of fluorine modified, low haze, titanium dioxide films

InactiveUS6268019B1Improve propertiesDegradation of optical propertySpecial surfacesChemical vapor deposition coatingGas phaseRefractive index

The present invention concerns the deposition of fluorine modified, titanium dioxide films (TiO2) onto hot glass by atmospheric pressure chemical vapor deposition (APCVD) using TiCl4 vapor. The invention is also suitable for depositing other metallic oxide films from their metallic halides such as SnCl4, GeCl4, and VCl4. The present invention provides a process that deposits a novel, fluorine modified, titanium dioxide film (TiO2) onto hot glass by atmospheric pressure chemical vapor deposition using TiCl4 vapor. The process uses injection of TiCl4 into a hot, nonoxygen containing carrier gas and blends the carrier gas and TiCl4 vapor with an oxygen containing gas stream containing a haze reducing quantity of a fluorine containing compound before contacting a surface of hot glass with the blended mixture. The process is capable of depositing a fluorine modified, TiO2 film at deposition rates exceeding 900 Å per second. The crystalline phase of the fluorine modified film is essentially anatase. The film has a haze of less then 1% and a refractive index of greater than or equal to about 2.48. Also provided is an apparatus for practicing the process and a novel coated glass.

Owner:ATOCHEM OF NORTH AMERICA INC

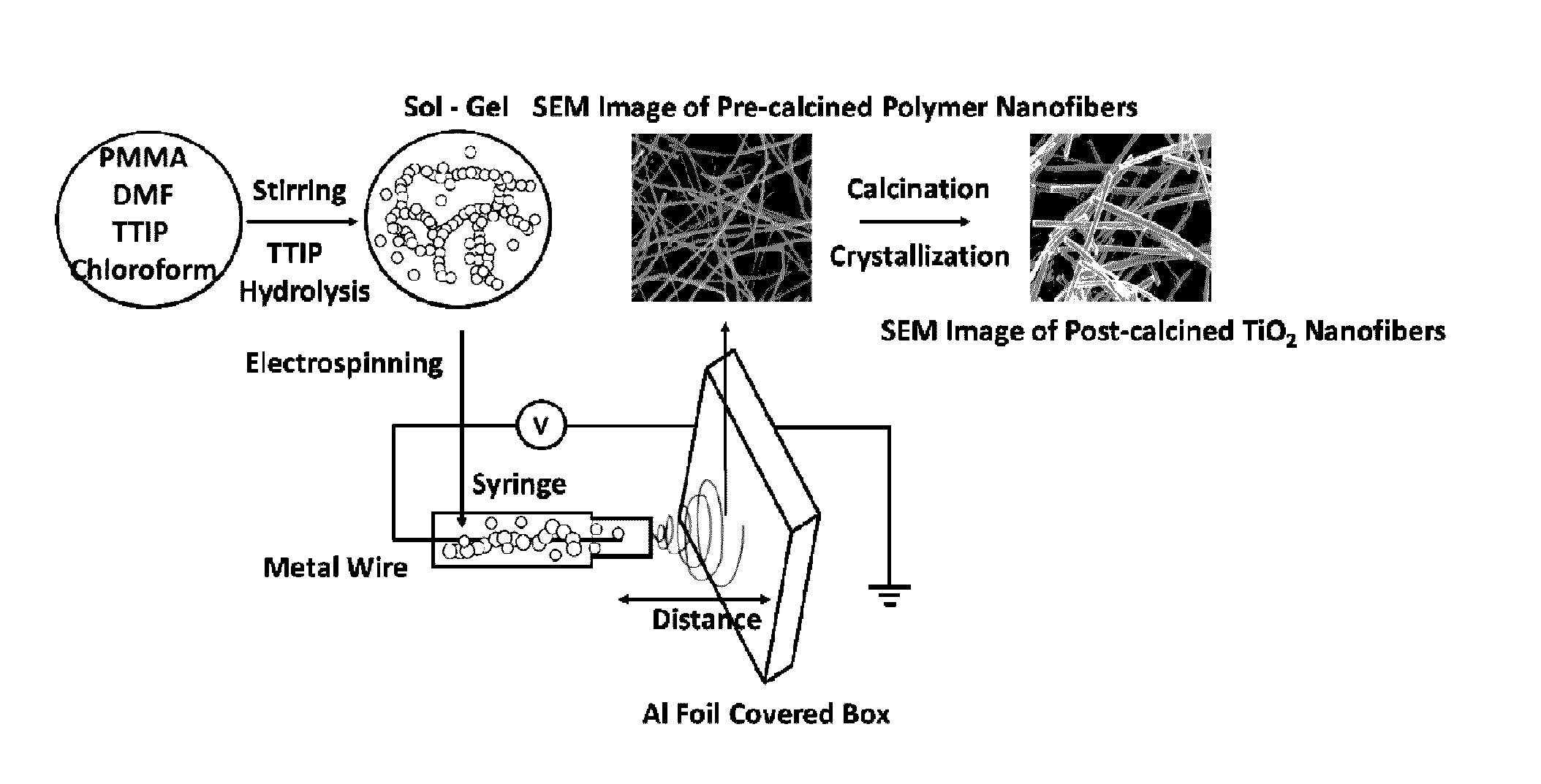

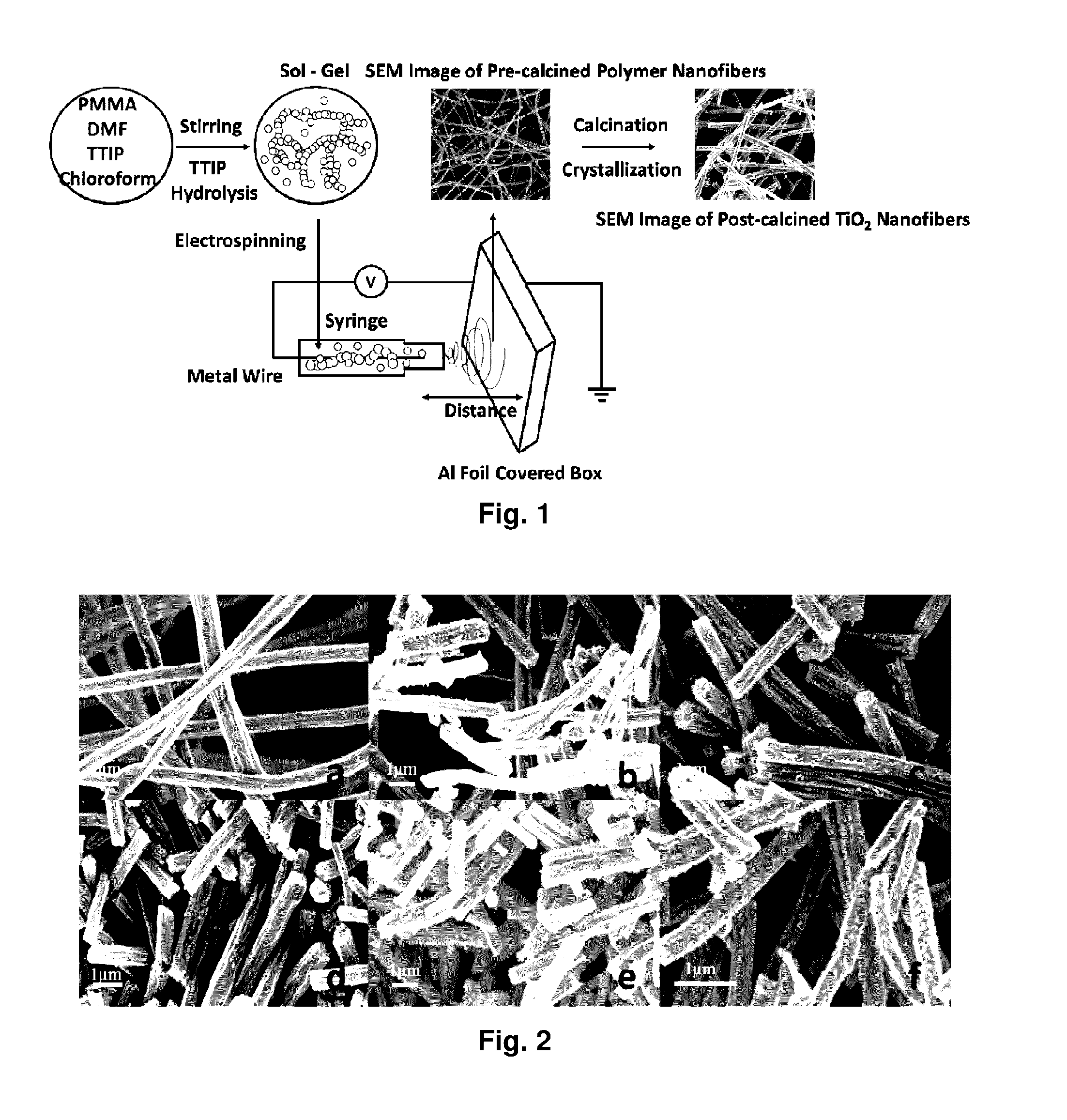

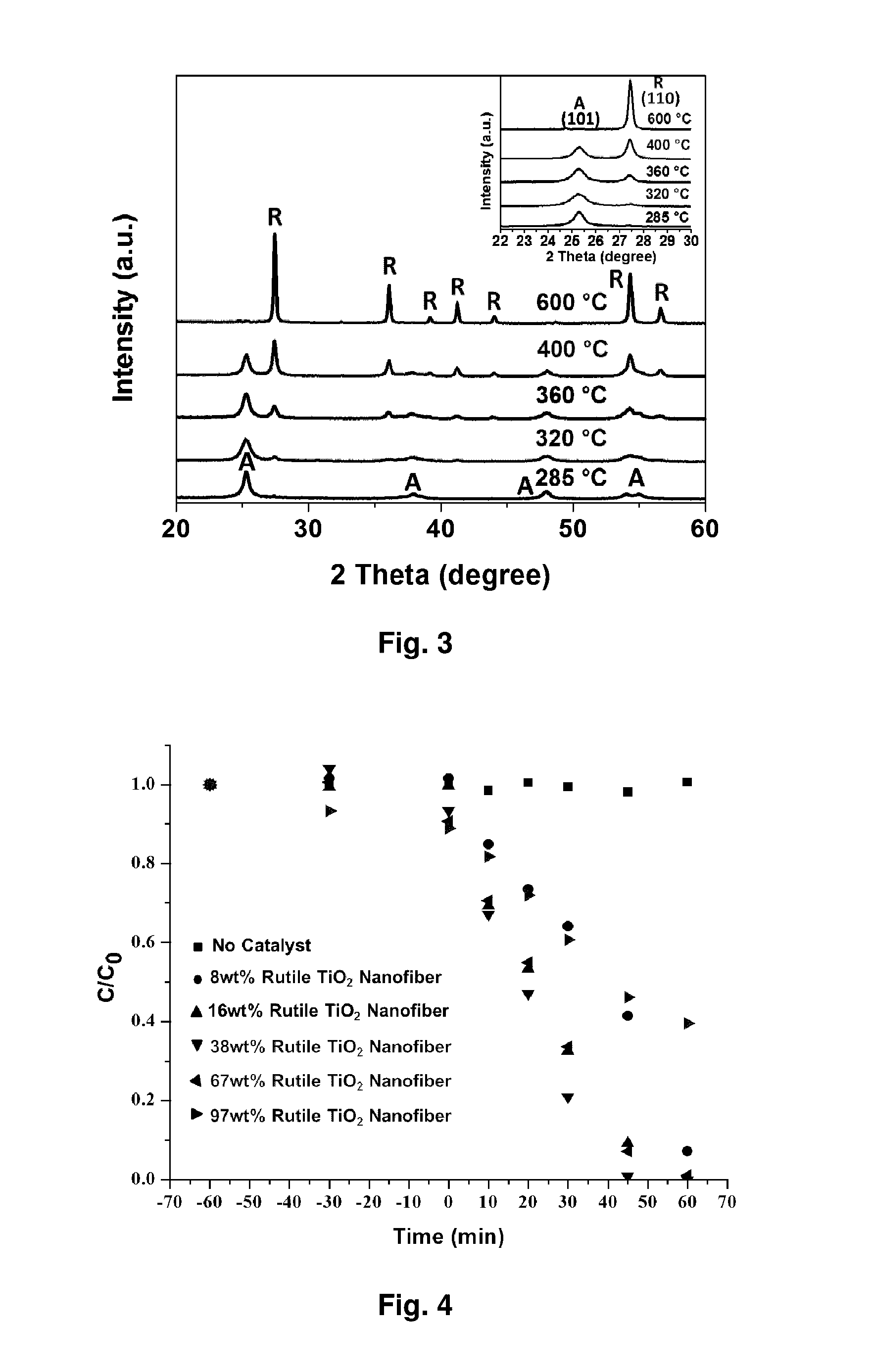

Metal oxide nanofibrous materials for photodegradation of environmental toxins

ActiveUS20170056873A1Rapid and inexpensiveAccelerated photodegradationWater/sewage treatment by irradiationWater treatment compoundsFiberRutile

Mixed-phase TiO2 nanofibers prepared via a sol-gel technique followed by electrospinning and calcination are provided as photocatalysts. The calcination temperature is adjusted to control the rutile phase fraction in TiO2 nanofibers relative to the anatase phase. Post-calcined TiO2 nanofibers composed of 38 wt % rutile and 62 wt % anatase exhibited the highest initial rate constant of UV photocatalysis. This can be attributed to the combined influences of the fibers' specific surface areas and their phase compositions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Preparation method of echinoid titanium dioxide microspheres in single/double layer cavity structure

InactiveCN101941736ALarge specific surface areaEasy to shapeTitanium dioxideMicrosphereSilicon dioxide

The invention relates to a preparation method of echinoid titanium dioxide microspheres in single / double layer cavity structure, belonging to the field of nano composite materials. The method comprises the following steps: (1) preparing monodisperse silicon dioxide microspheres with uniform particle size; (2) by using silicon dioxide as a template, coating a titanium dioxide layer on the surface of the silicon dioxide microspheres by using a sol-gel method to obtain core-shell type silicon dioxide / titanium dioxide composite microspheres; (3) regulating the concentration of sodium hydroxide solution, the hydrothermal reaction time and other conditions, and preparing echinoid titanium-base microspheres in the single / double layer cavity structure in a controllable way; and (4) treating the echinoid titanium-base microspheres in the single / double layer cavity structure with hydrochloric acid with a certain concentration, and calcining at high temperature to obtain anatase-type echinoid titanium dioxide microspheres in the single / double layer cavity structure. The material prepared by the method has the high-activity pure-phase titanium dioxide crystal structure, and has the advantages of large specific area, complete appearance and high yield; the technical process is controllable and easy to operate; and the invention also has the advantages of low preparation cost, no pollution and low energy consumption.

Owner:UNIV OF SCI & TECH BEIJING

Production of nitrogen-doped anatase-type nanometer titanium dioxide

InactiveCN1712128ALarge specific surface areaControllable grain sizePhysical/chemical process catalystsAlcoholHydrothermal synthesis

A process for preparing the nitrogen doped anatase-type TiO2 by hydrothermal synthesis includes such steps as proportionally mixing Ti source, precipitant, nitrogen source and water, loading in high-pressure reactor with teflon liner, hydrothermal reacting, alcohol washing, water washing, and drying.

Owner:UNIV OF SCI & TECH BEIJING

Process for preparing anatase type TiO2 sol

InactiveCN1699181AReduce energy consumptionImprove bindingPhysical/chemical process catalystsTitanium dioxideAlcoholDecomposition

The invention discloses a process for preparing anatase type TiO2 sol which comprises preparing alcoholic solution of titanium compounds from titanium compounds and alcohols by the mol ratio of 1:1.42-12, agitating and dropping the alcoholic solution of titanium compounds into the water solution of acid with pH=1.0-4.0 for hydrolytic decomposition, the mol ratio of titanium compounds and water in the aqueous solution of acids being 1:76-151, inversing flow for 6-48 hours at 65-85 deg. C, evaporating the obtained sol at 50-55 deg. C to remove the alcohols, thus obtaining octahedrite type titanium dioxide collosol.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com