Titanium dioxide powder containing tungsten for preparing honeycomb SCR DeNOx catalyst and preparation method thereof

A denitration catalyst, titanium dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as inability to prepare, and achieve improved thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

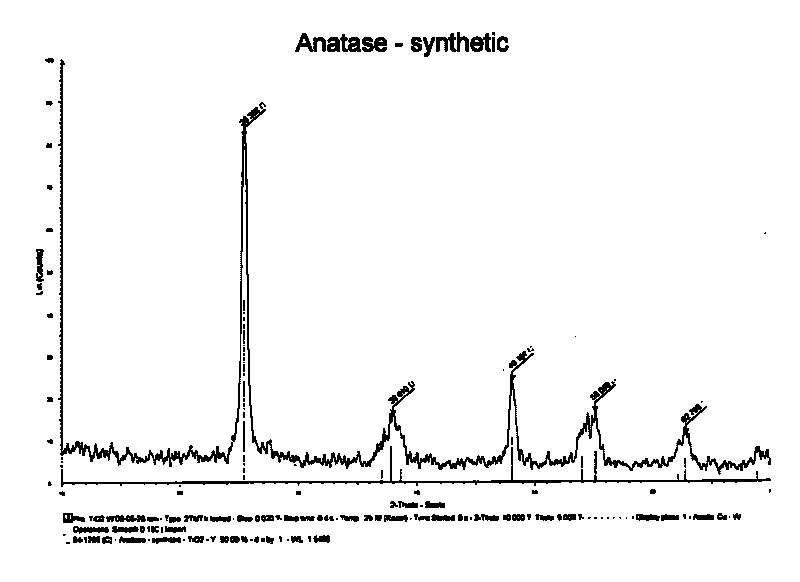

Image

Examples

Embodiment 1

[0025] 1. Preparation of metatitanic acid slurry A

[0026] The intermediate metatitanic acid prepared by the sulfuric acid method is selected, and the metatitanic acid is commercially available, which can shorten the process flow. Metatitanic acid is preferably washed. In this way, metatitanic acid can be made into slurry A.

[0027] To measure the solid content of metatitanic acid, add 88L deionized water into a stirring tank equipped with a stirrer. Weigh 35.2 kg of metatitanic acid (dry basis), add it into a stirring tank, and stir for 60 minutes to prepare metatitanic acid slurry A with a slurry concentration of 400 g / L.

[0028] 2. Preparation of tungsten solution B

[0029] Add 12L of deionized water at a temperature of 40-65°C to another dissolving tank, then take 5.28kg of high-grade pure ammonium paratungstate, and add it into the dissolving tank while stirring. Stir to obtain tungsten solution B whose concentration of tungsten solution is 440g / L.

[0030] 3. Mi...

Embodiment 2

[0042] 1. Preparation of metatitanic acid slurry A

[0043] The intermediate metatitanic acid prepared by the sulfuric acid method is selected, and the metatitanic acid is commercially available, which can shorten the process flow. Metatitanic acid is preferably washed. In this way, metatitanic acid can be made into slurry A.

[0044] To measure the solid content of metatitanic acid, add 90L deionized water into a stirring tank equipped with a stirrer. Weigh 36.0 kg of metatitanic acid (dry basis), add it into a stirring tank, and stir for 60 minutes to prepare metatitanic acid slurry A with a slurry concentration of 400 g / L.

[0045] 2. Preparation of tungsten solution B

[0046] Add 10L of deionized water at a temperature of 40-65°C into another dissolving tank, then take 4.40 kg of superior pure ammonium paratungstate, and add it into the dissolving tank while stirring. Stir to obtain the tungsten solution B whose concentration of the tungsten solution is 440g / L.

[00...

Embodiment 3

[0059] 1. Preparation of metatitanic acid slurry A

[0060] The intermediate metatitanic acid prepared by the sulfuric acid method is selected, and the metatitanic acid is commercially available, which can shorten the process flow. Metatitanic acid is preferably washed. In this way, metatitanic acid can be made into slurry A.

[0061] To measure the solid content of metatitanic acid, add 92L of deionized water into a stirring tank equipped with a stirrer. Weigh 36.8 kg of metatitanic acid (dry basis), add it into a stirring tank, and stir for 60 minutes to prepare metatitanic acid slurry A with a slurry concentration of 400 g / L.

[0062] 2. Preparation of tungsten solution B

[0063] Add 8L of deionized water at a temperature of 40-65°C to another dissolving tank, then take 3.52 kg of high-grade pure ammonium paratungstate, and add it into the dissolving tank while stirring. Stir to obtain the tungsten solution B whose concentration of the tungsten solution is 440g / L.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com