Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2136 results about "Sal ammoniac" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sal ammoniac or Salammoniac, is a rare naturally occurring mineral composed of ammonium chloride, NH₄Cl. It forms colorless, white, or yellow-brown crystals in the isometric-hexoctahedral class. It has very poor cleavage and a brittle to conchoidal fracture. It is quite soft, with a Mohs hardness of 1.5 to 2, and it has a low specific gravity of 1.5. It is water-soluble. Sal ammoniac is also the archaic name for the chemical compound ammonium chloride.

Method for preparing nickel-coated alumina powder

The invention relates to a preparation method of nickel-coated alumina oxide powder, in particular to the preparation method of nickel-coated aluminum oxide powder for thermal spraying in aviation, aerospace and military fields. The invention is characterized in that: a suspension is made from a mixing liquid of nano-aluminum oxide and dispersant, stirred and added with nickel salt solution at the same time, and the obtained mixture liquid is dropped with ammonium water after being fully stirred, added with distilled water, when dark blue mixing solution C of nickel ammonia complex ([Ni (NH3)) 2+and alumina oxide is obtained; the mixing solution C is aged by water, filtered, washed and dried, and a green middle coated product is obtained; the green middle coated product is further reduced and roasted, finally, black nickel-coated aluminum oxide powder is prepared. The nickel-coated aluminum oxide powder prepared through the invention has uniform granularity, with average size less than or equal to 1.0Mum, and can enhance the application performance of nano-alumina and expand the application of nano-aluminum oxide; the product is mainly used for aviation, aerospace and military materials and other high-tech fields. The method of the invention is simple, reproducible and easy to be industrialized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

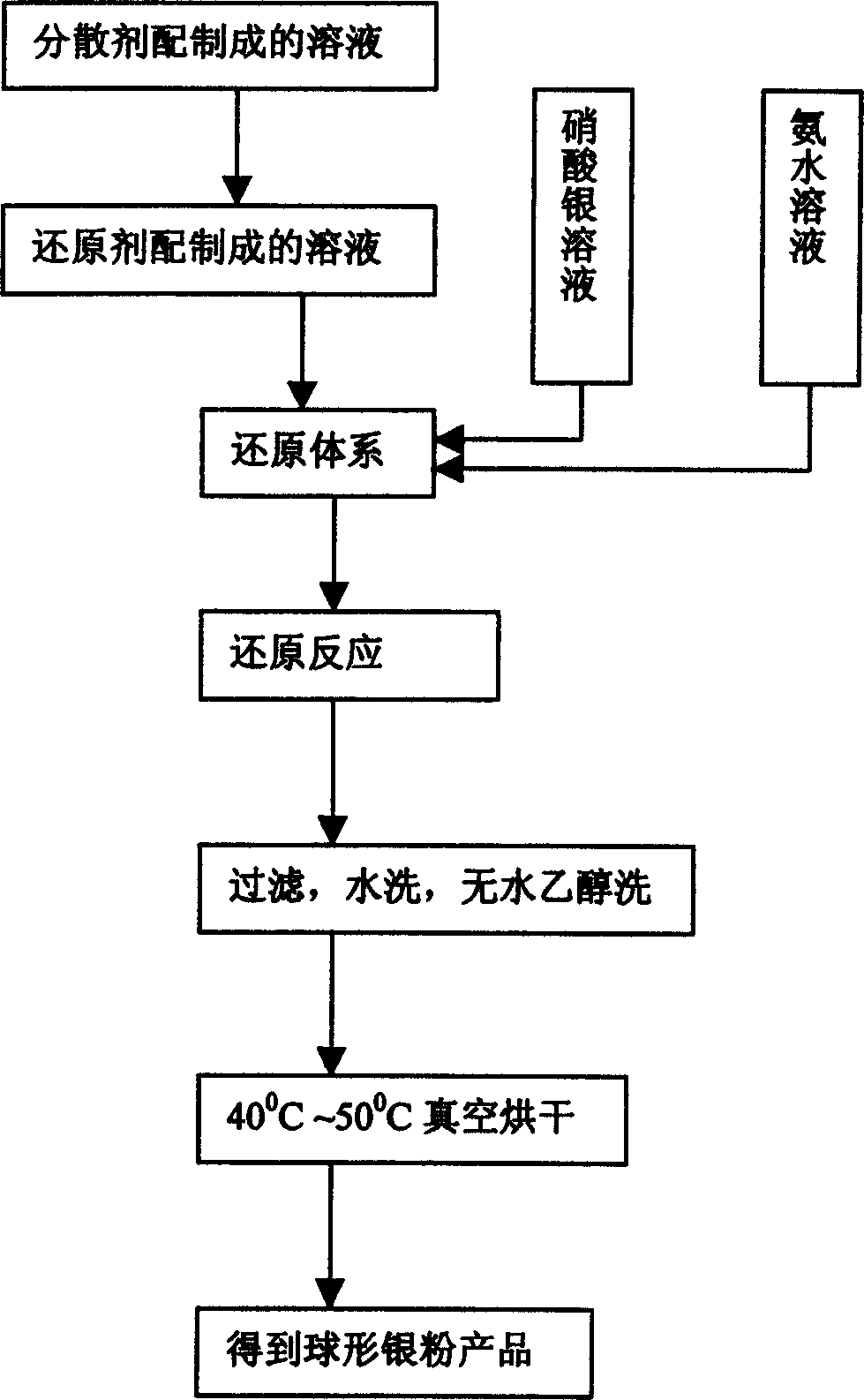

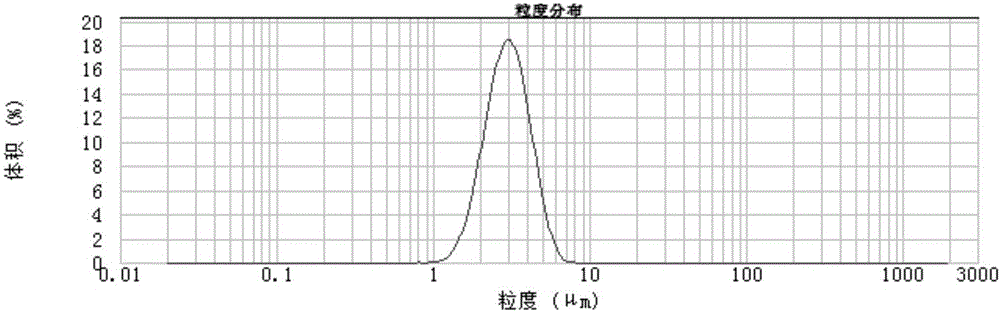

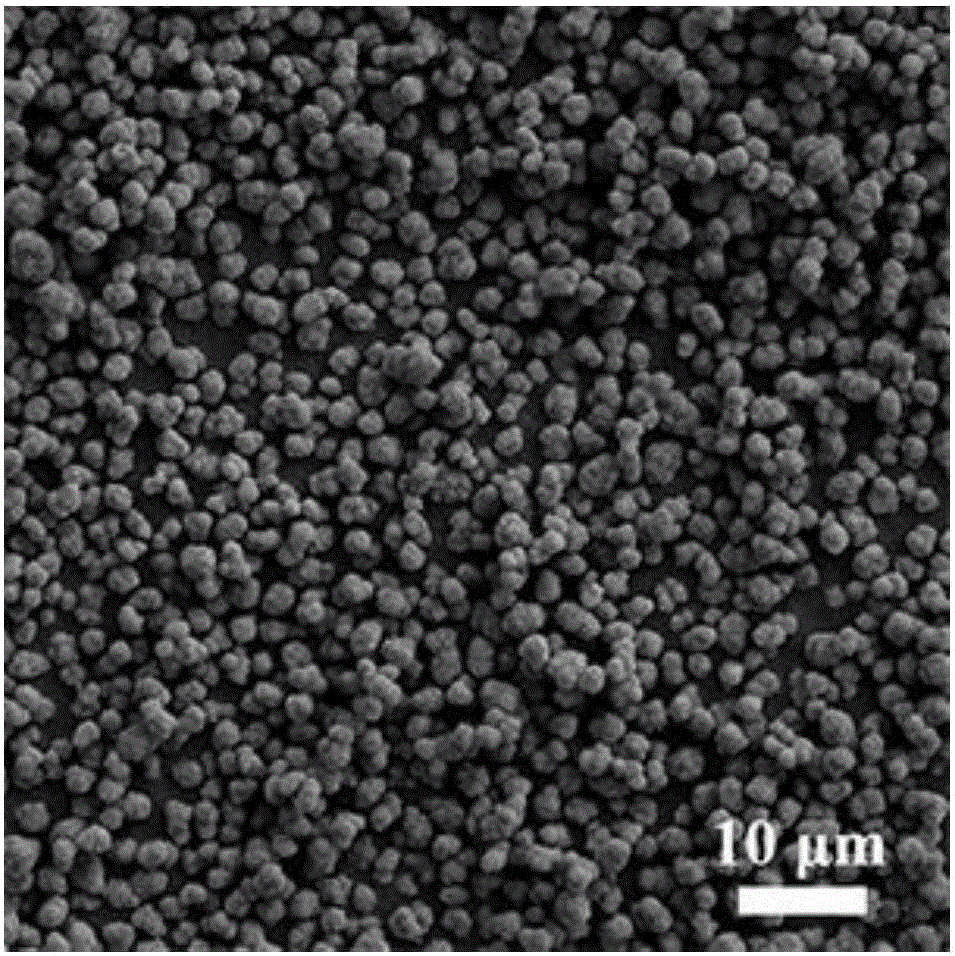

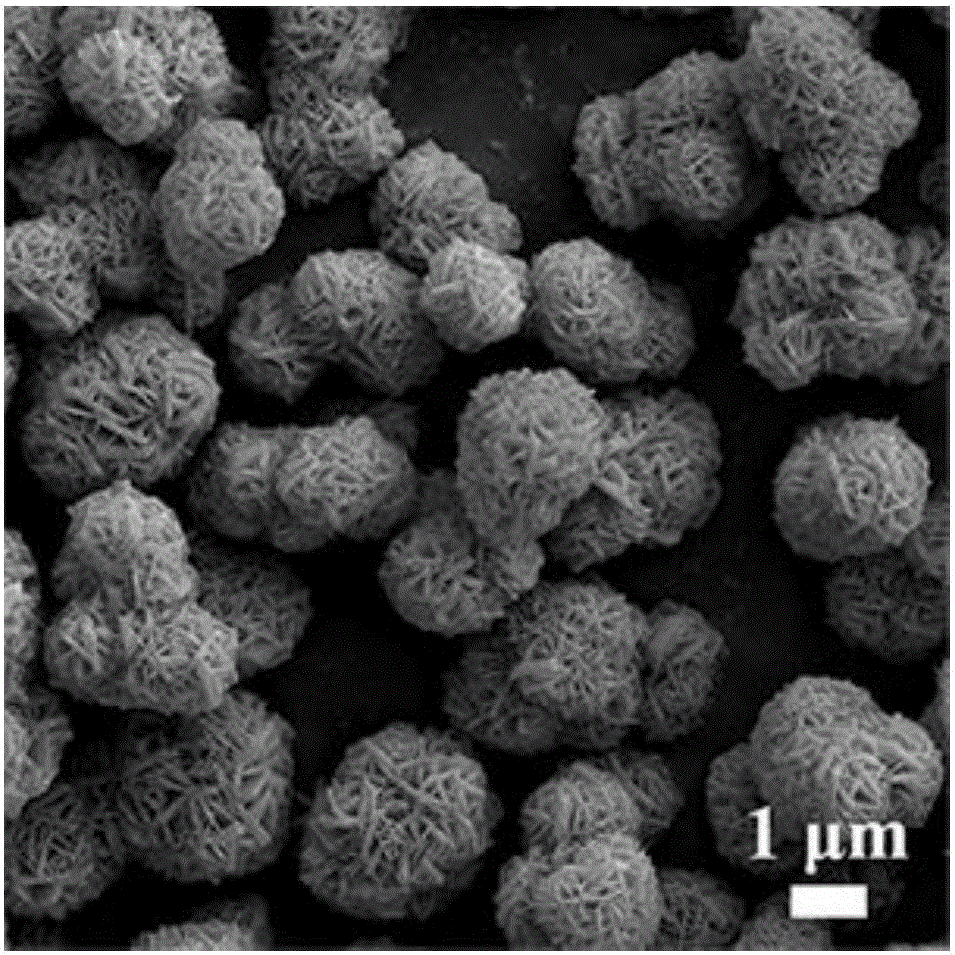

Preparation method of micron grade ball shape silver powder for conductive silver paste

A process for preparing the micron-class spherical silver powder used for electrically conductive Ag slurry features that in the redox procedure, the silver nitrate solution is dripped into reducer and disperser while the ammonia water is used to regulate the pH value of solution, and the kind of disperser, stirring speed, and reaction temp and time are regulated.

Owner:SOUTHEAST UNIV

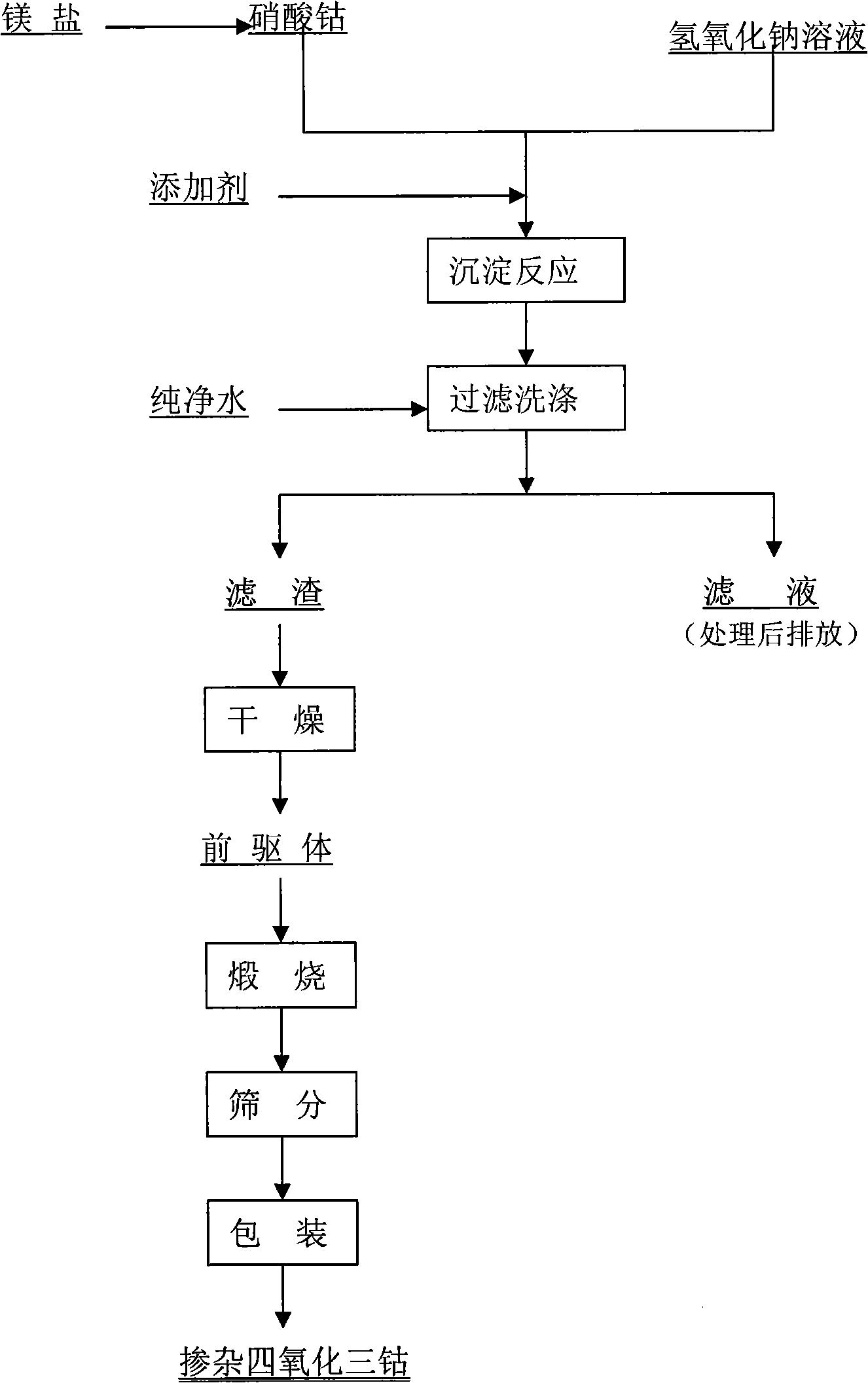

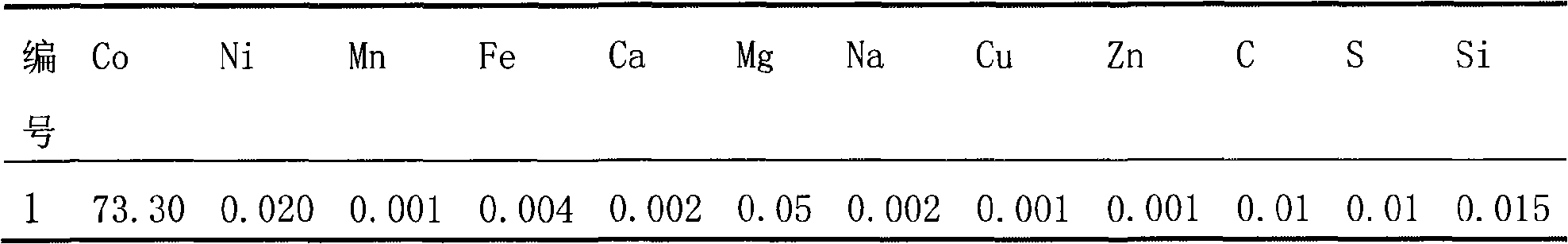

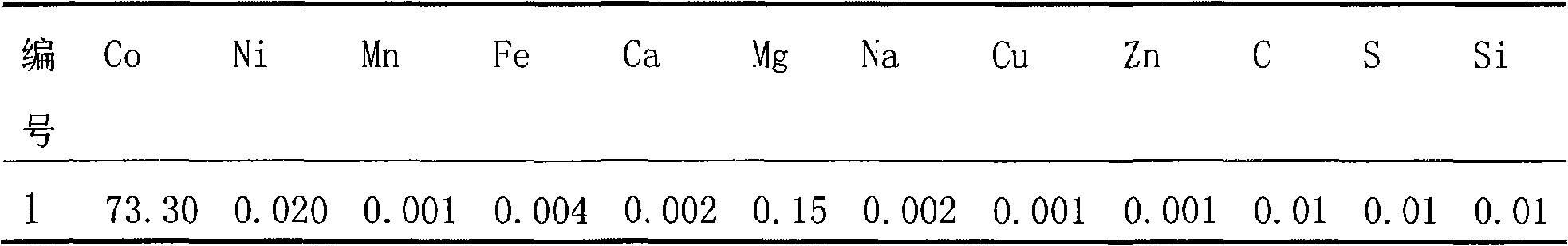

Preparation of doped cobaltic-cobaltous oxide

InactiveCN101279771AImprove stabilityImprove electrochemical performanceCobalt oxides/hydroxidesSal ammoniacNitrate

Disclosed is a process for preparing a doping cobaltosic oxide, which relates to a method for the production of a modified cobaltosic oxide used for a Lithium-ion battery anode material. The method is characterized in that the preparation process comprises: 1) mixing a cobalt nitrate solution containing doped chemical ions with a mixed precipitator solution containing ammonia and sodium hydroxide and making the mixture react for eight to twenty hours at a pH value of between 8.4 to 10 and a temperature of between 40 and 80 DEG C so as to prepare a cobalt hydroxide precipitation containing doped chemical; and 2) washing and drying the cobalt hydroxide precipitation containing the doped chemical and then burning the precipitation for two to six hours at a temperature of between 500 and 800 DEG C so as to obtain the doping cobaltosic oxide. The method of the invention can get even particles with regular shapes after the reaction, the particle sizes of the doping cobalt hydroxide are controllable in a certain range, and the doping cobaltosic oxide can be obtained by calcinations. The method of preparation is characterized in that a magnesium source, an aluminum source, a titanium source, etc. are induced to the cobalt nitrate solution directly, and the process and operation are simple and easy.

Owner:JINCHUAN GROUP LIMITED

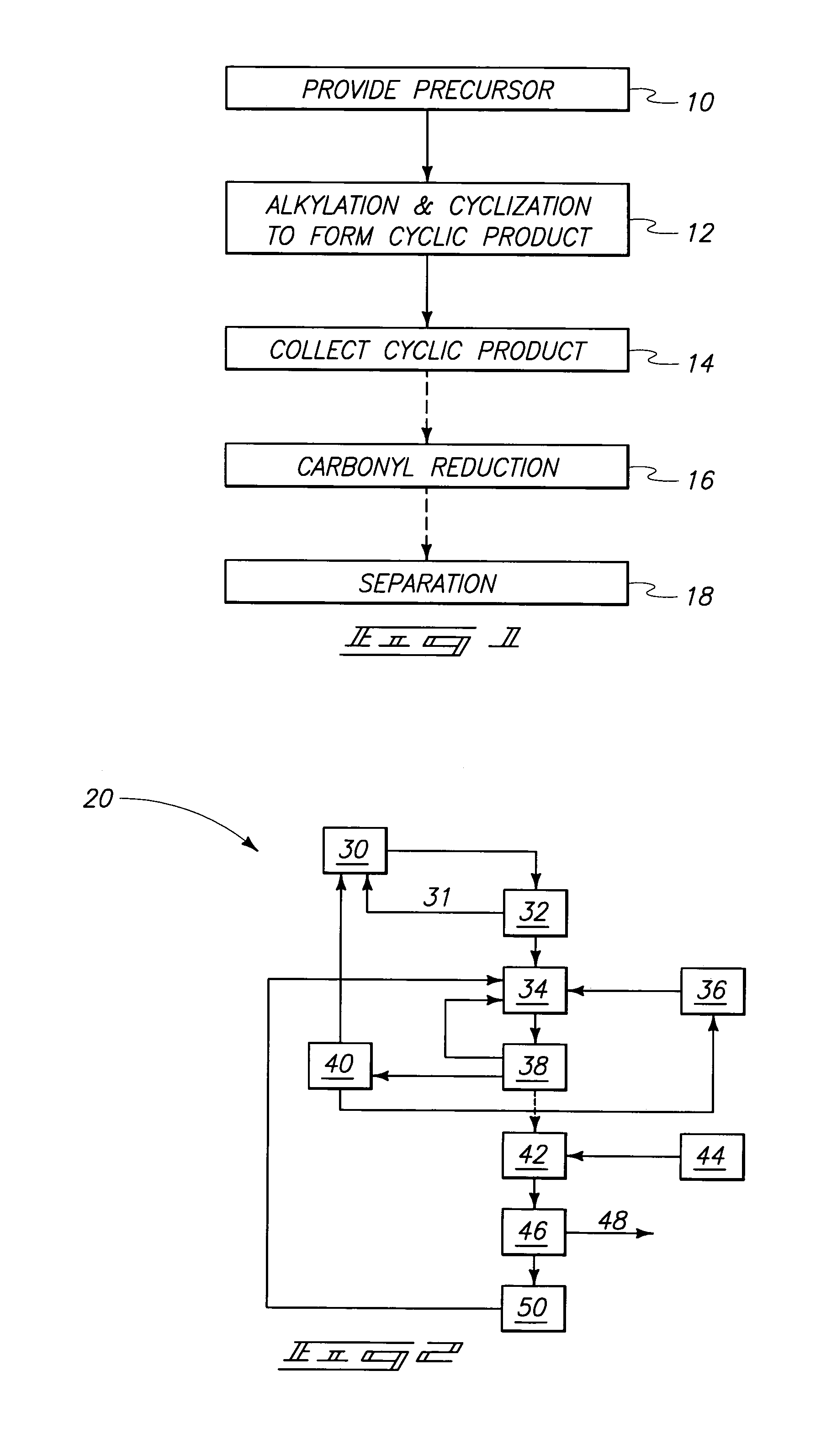

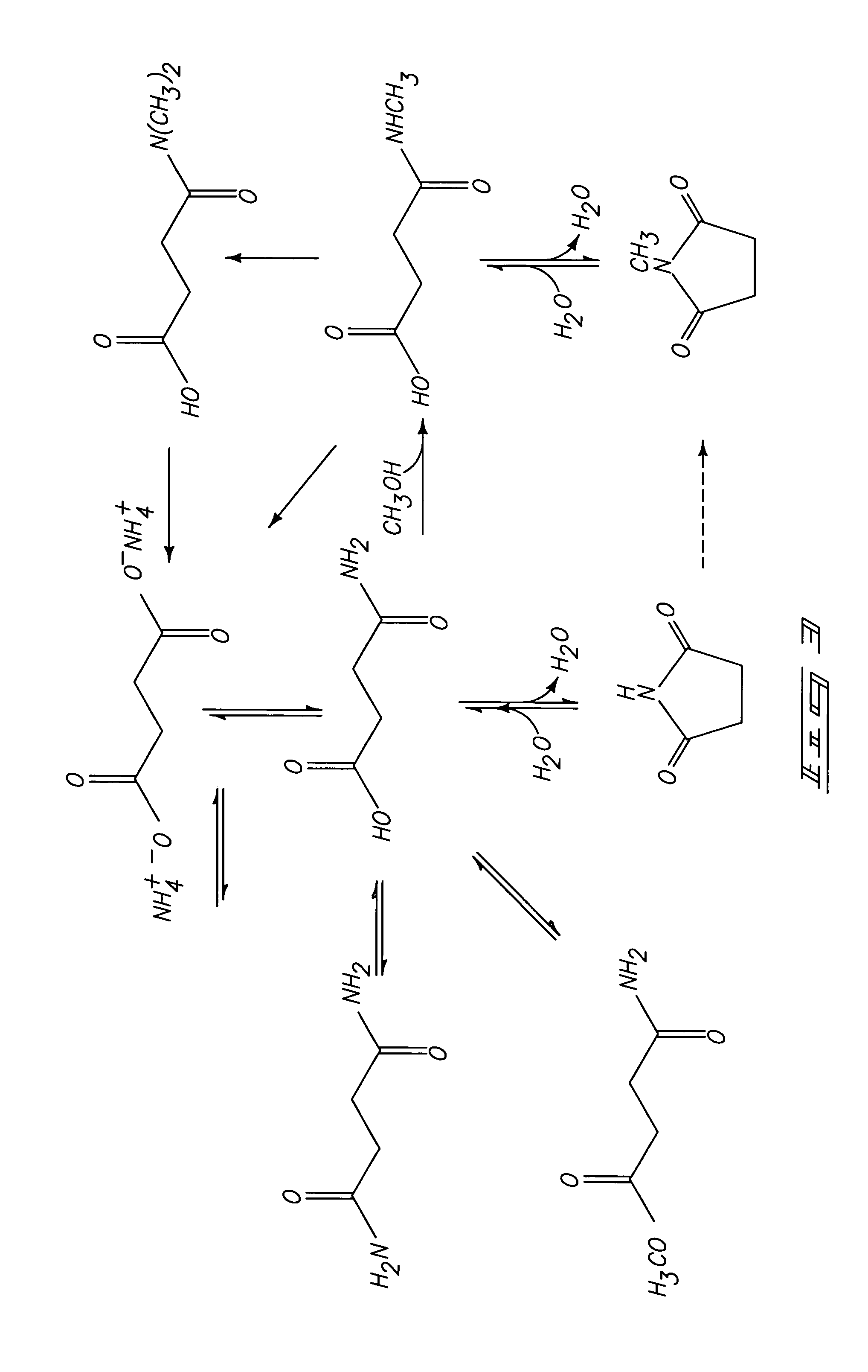

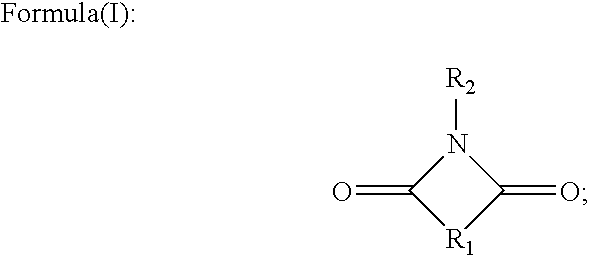

Process for producing cyclic compounds

The invention includes methods of processing an initial di-carbonyl compound by conversion to a cyclic compound. The cyclic compound is reacted with an alkylating agent to form a derivative having an alkylated ring nitrogen. The invention encompasses a method of producing an N-alkyl product. Ammonia content of a solution is adjusted to produce a ratio of ammonia to di-carboxylate compound of from about 1:1 to about 1.5:1. An alkylating agent is added and the initial compound is alkylated and cyclized. The invention includes methods of making N-methyl pyrrolidinone (NMP). Aqueous ammonia and succinate is introduced into a vessel and ammonia is adjusted to provide a ratio of ammonia to succinate of less than 2:1. A methylating agent is reacted with succinate at a temperature of from greater than 100° C. to about 400° C. to produce N-methyl succinimide which is purified and hydrogenated to form NMP.

Owner:BATTELLE MEMORIAL INST

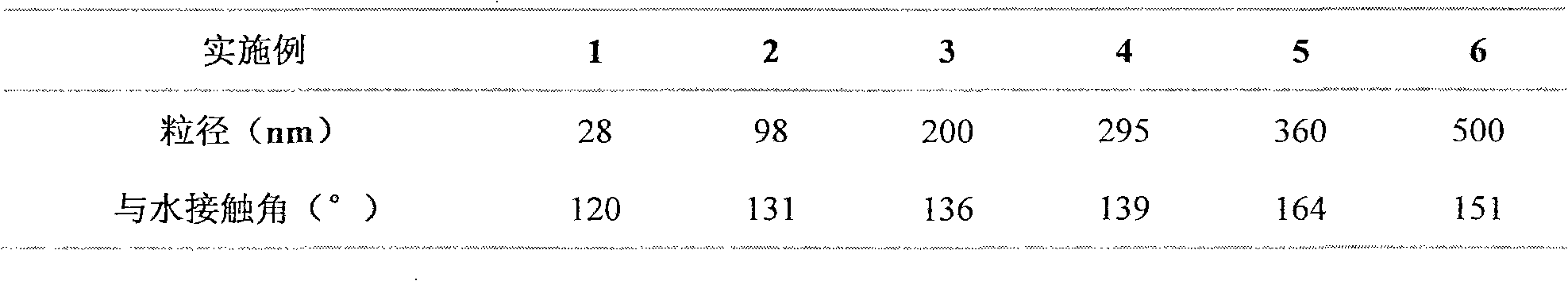

Method for preparing hydrophobic nano-silica with controllable grain diameter

InactiveCN101880478AGood dispersionHydrophobicPigment treatment with organosilicon compoundsSal ammoniacReaction temperature

The invention discloses a method for preparing hydrophobic nano-silica with a controllable grain diameter. The method comprises the following steps of: adding ammonia water and water into absolute ethanol and stirring the mixture for 0.5 to 1 hour at the temperature of between 20 and 70 DEG C; under an alkali condition, performing hydrolytic polycondensation to obtain nano-silica by using the absolute ethanol as solvent and tetraethoxysilane as a raw material; and preparing the hydrophobic nano-silica with the grain diameter in the range of between 20 and 500 nm by using a silane coupling agent as a hydrophobic modifier, wherein the using amount of ammonia water is 40 to 100 percent of the weight of the tetraethoxysilane; the using amount of the absolute ethanol is 12 to 25 times the weight of the tetraethoxysilane; and the using amount of the water is 30 to 150 percent of the weight of the tetraethoxysilane. The preparation method has the advantages of simpleness, easy operation and mild reaction condition. The hydrophobic nano-silica with the controllable grain diameter can be prepared by adjusting proportion and technological parameters of the materials.

Owner:SOUTH CHINA UNIV OF TECH

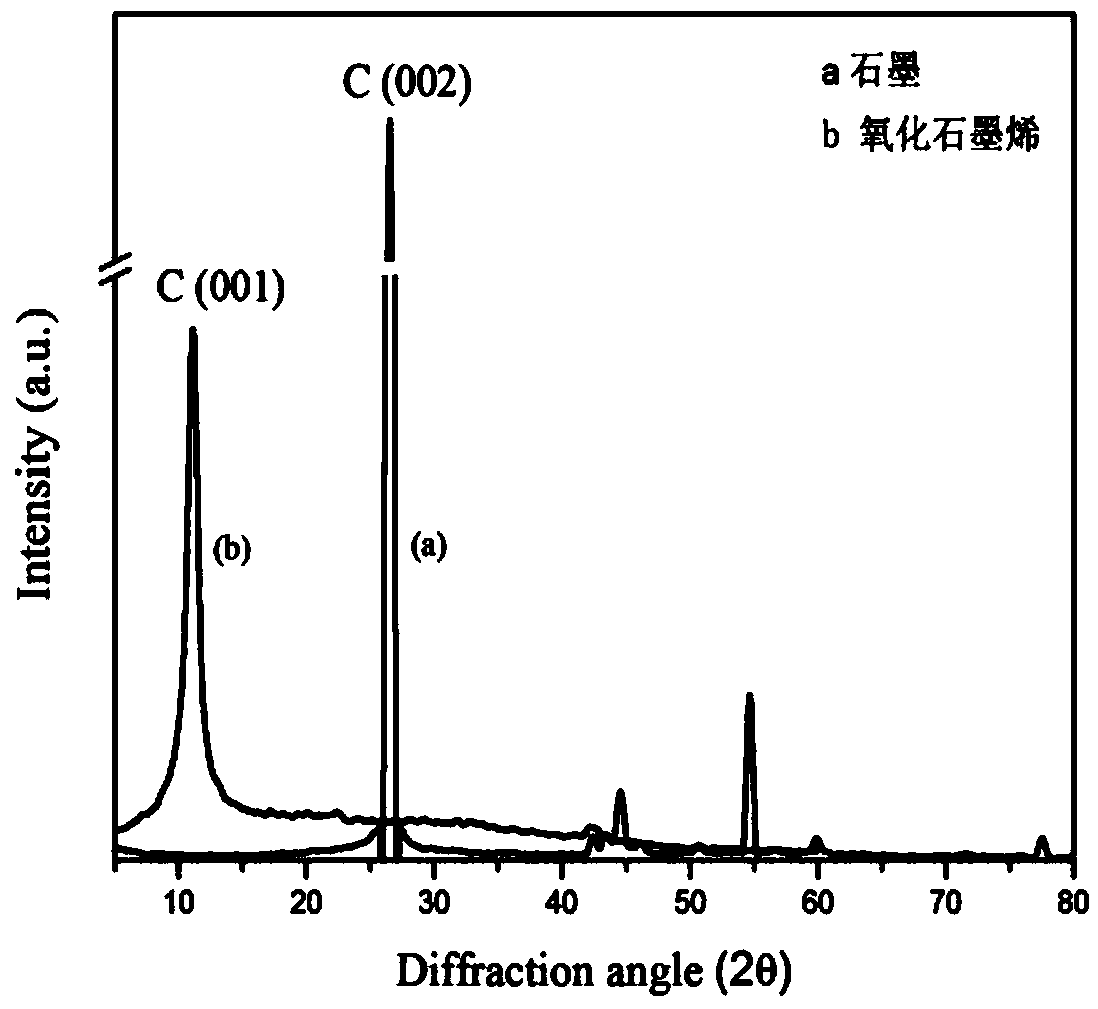

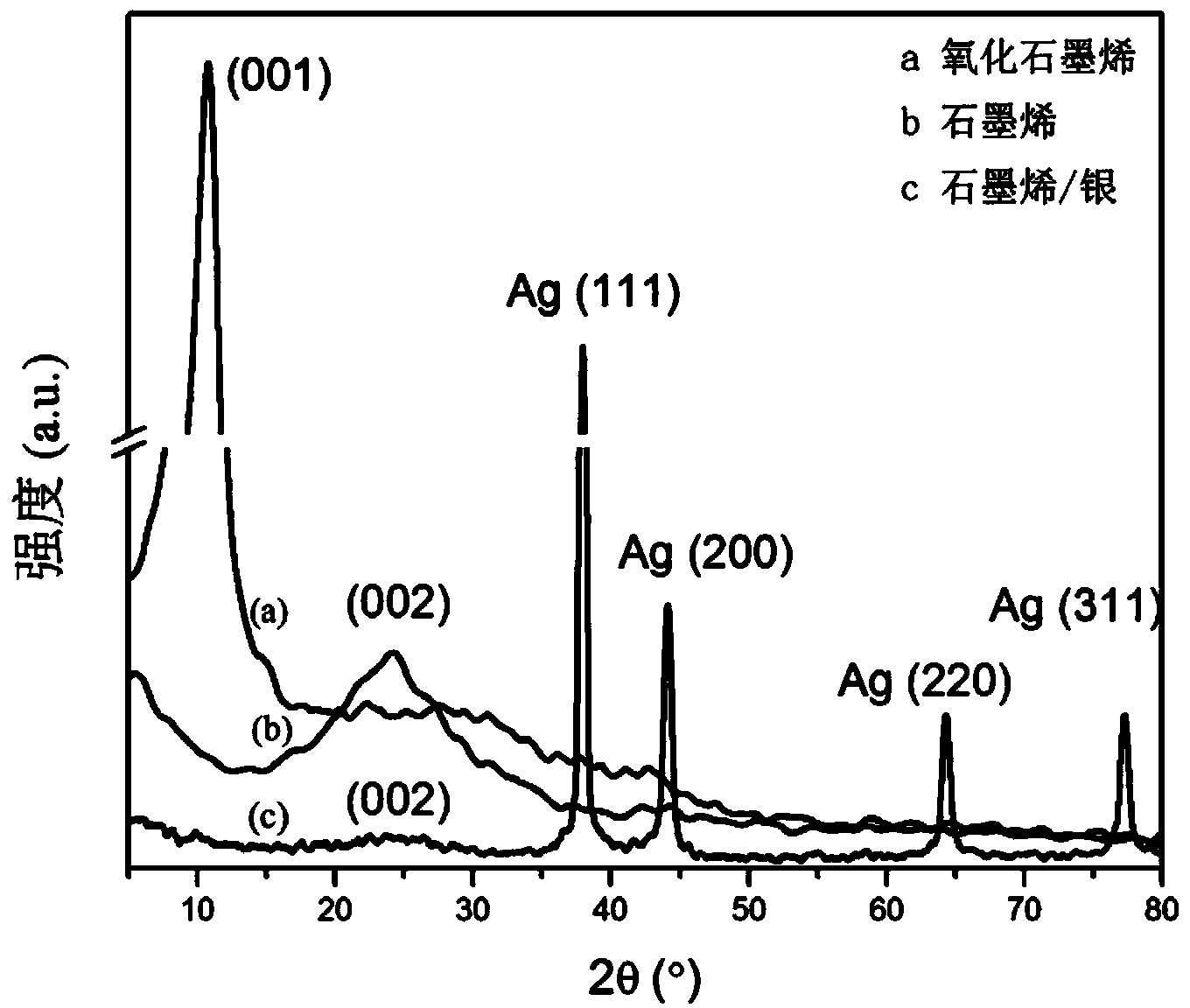

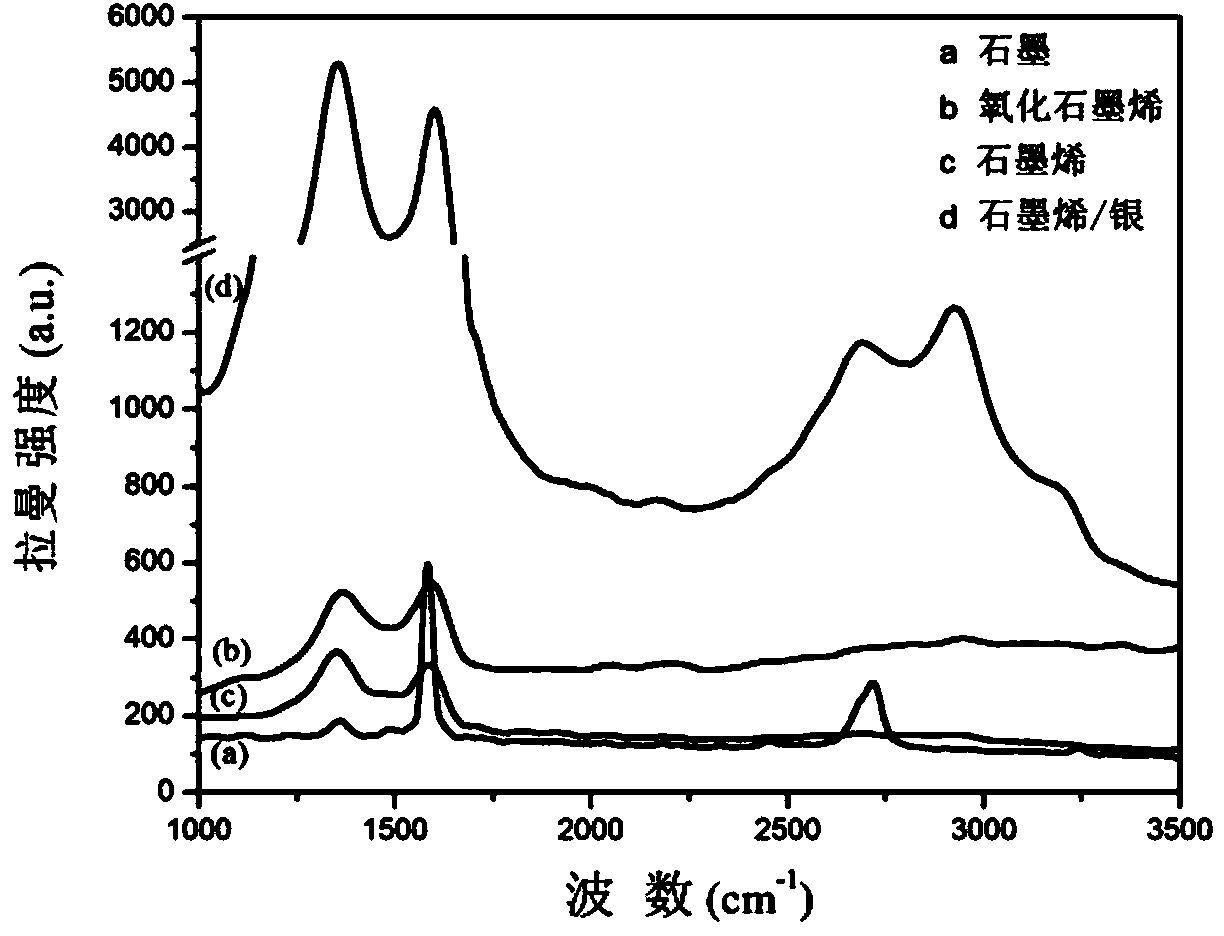

Preparation method for high-conductivity graphene and silver nanoparticle composite materials

ActiveCN103639421AEnhanced surface contactGuaranteed electrical conductivityMaterial nanotechnologyFreeze-dryingHydrazine compound

The invention relates to a preparation method for high-conductivity graphene and silver nanoparticle composite materials. The method comprises the steps that graphene oxide is prepared at first; a graphene oxide water solution is prepared; silver nitrate is added into the obtained graphene oxide water solution, the temperature is risen to be 90+ / -10 DEG C, sodium citrate is added in the solution, and stirring and reaction are conducted; ammonium hydroxide and hydrazine hydrate are added into the obtained solution, and stirring and reaction are conducted at the temperature of 90+ / -10 DEG C; deionized water and ethyl alcohol are adopted to clean the reaction product, vacuum freeze drying is conducted on the cleaned reaction product, and then the conductive graphene and silver nanoparticle composite materials are obtained. The conductivity of the composite materials is 3.71-18.32S / cm, the graphene and silver nanoparticle composite materials prepared based on the method can greatly improve the conductivity of graphene, and can be further applied in the field of printed electronics.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Preparation method of low-sulfur small-particle-size nickel-cobalt-manganese hydroxide

The invention belongs to the technical field of synthesis of lithium ion battery ternary anode material precursors, and particularly relates to a preparation method of a nickel-cobalt-manganese hydroxide. The method comprises the following steps: preparing a small-particle-size nickel-cobalt-manganese hydroxide by a nucleation / crystallization isolation method: introducing a nickel-cobalt-manganese mixed metal solution, sodium hydroxide and ammonia water under the condition of a high pH value at the same time for nucleation, adding a certain amount of additive at the end of nucleation to help a crystal nucleus to be dispersed rapidly, and entering a crystal nucleus growing stage to obtain a spherical particular nickel-cobalt-manganese hydroxide with D50 being equal to 2 to 3 mum, high dispersity and high degree of sphericity; controlling the washing condition, so that the sulfur content of the nickel-cobalt-manganese hydroxide is as low as 1,500ppm. The method has the advantages of easiness and convenience in operation, high flexibility, no need of modifying a reaction kettle, easiness for expanded production and the like.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Chromium-free composite passivator for hot-dip galvanized steel sheet and preparation and application methods of composite passivator

ActiveCN104178757AImprove corrosion resistanceUniform appearanceMetallic material coating processesWater basedChromium free

The invention relates to a chromium-free composite passivator for a hot-dip galvanized steel sheet. The passivator is prepared from the following raw materials in percentage by weight: 2.20-2.30% of water-base resin, 2.60-2.65% of main salt compound, 0.10-0.15% of organic silane, 0.07-0.09% of sulfate, 0.11-0.13% of inorganic zircon salt, 0.09-0.12% of inorganic acid and the balance of water. A preparation method of the passivator comprises the following steps: firstly, dissolving the organic silane in water; stirring till the organic silane is fully dissolved and adding the main salt compound; after the main salt compound is dissolved, adding the inorganic acid to measure the pH value; then, adding the sulfate and the inorganic zircon salt in the stirring state; after the sulfate and the inorganic zircon salt are fully dissolved, adding the water-base resin; stirring till the water-base resin is fully dissolved; adjusting the pH value to 3-4 by virtue of ammonium water; and standing for later use. An application method of the passivator comprises the following steps: firstly, degreasing the hot-dip galvanized steel sheet by virtue of an alkaline degreaser during use; then, respectively washing by using tap water and deionized water; and after drying, coating the composite passivator on the surface of the hot-dip galvanized steel sheet. The passivator provided by the invention is free from chromium and non-toxic and harmless. The thickness of a passivation film can reach 8-1.0mg / m<2>, and the corrosion resistance is close to that of a hexavalent chromium passivating liquid.

Owner:唐山正元管业有限公司

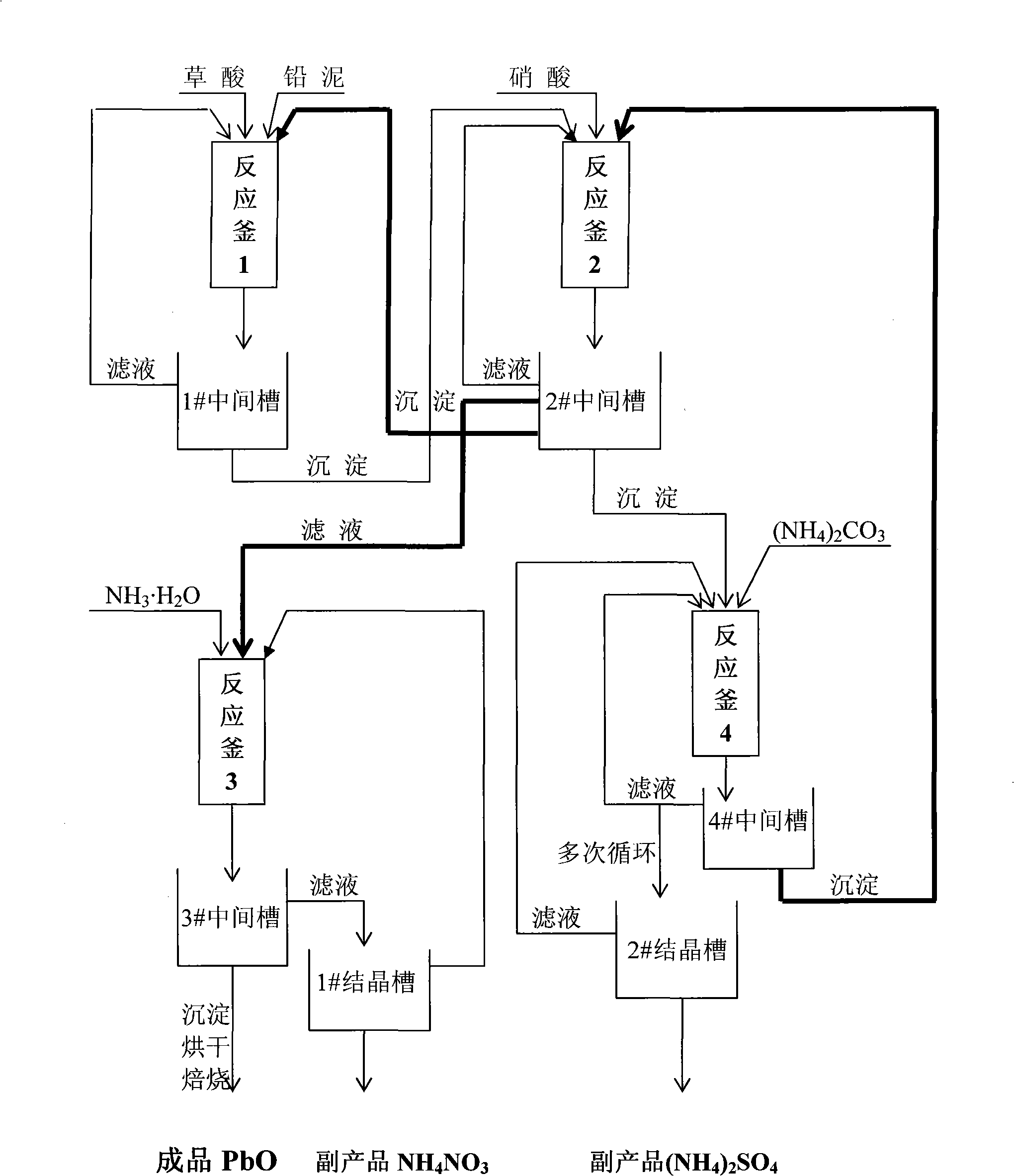

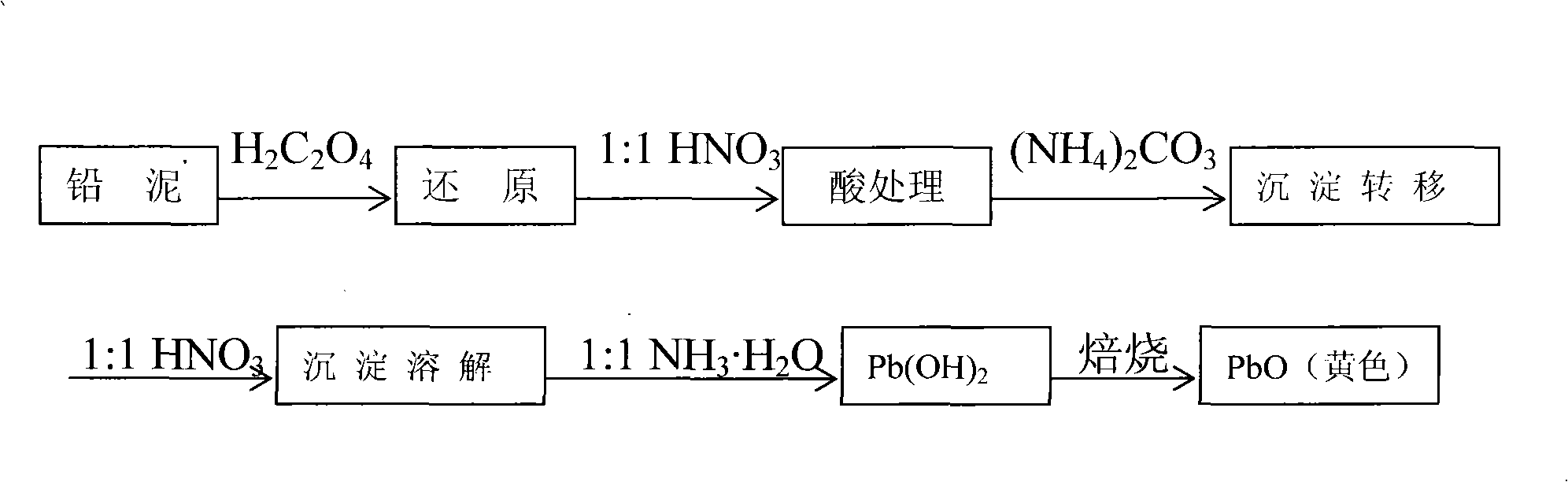

Method for recovering lead oxide by waste lead-acid storage battery

InactiveCN101514395AReduce energy consumptionReduce pollutionProcess efficiency improvementLiquid wasteFiltration

A method for recovering lead oxide by a waste lead-acid storage battery is disclosed. The waste lead-acid storage battery is crushed together with lead slime subsequent to acid cleaning, a grid plate and a filler comprising the lead slime are obtained by screening, the grid plate is fused-cast to an alloy ingot, the filler and the lead slime are ball-milled, and fine stuff is added with saturated oxalic acid solution for reaction at 25-65 DEG C and then for filtering and depositing; the deposition is then treated by excessive 30% nitric acid at the temperature of 40-45 DEG C for subsequent filtration and deposition, and the deposition is reacted with 4wt% sal volatile at the temperature of 25-65 DEG C for subsequent filtration and deposition; the deposition is added into recovered HNO3 to be dissolved at the temperature 40-45 DEG C until no bubble is generated, the filtered filtrate is added with 25% ammonia for reaction, filtration, washing and deposition to be neutral, and the lead oxide is obtained by drying and roasting. Recoverable nitramine and ammonium sulfate are recycled in all the filtrates in the technologies; thereby discharging no waste liquid. The utilization rate of raw material is 90.1-92.1%, the yield is 95.0-96.7%, and the content of PbO is 98.0-98.9%.

Owner:DALIAN WUHUATIANBAO TECH DEV

Eggshell type nickel-based catalyst

ActiveCN101890351AHigh activityHigh selectivityMolecular sieve catalystsCatalyst activation/preparationSal ammoniacNickel salt

The invention discloses an eggshell type nickel-based catalyst and a preparation method and application thereof, belonging to the technical field of nickel-based catalysts and aiming at developing the eggshell type nickel-based catalyst for meeting the demand. The research shows that the eggshell type nickel-based catalyst can be prepared by dissolving nickel salt into ammonia water solution, loading the mixed solution on a catalyst carrier by adopting a spraying or immersing mode, drying, roasting and reducing. The active component of nickel is mostly centralized in an area from the surface of the carrier to the part of 0.7mm below the surface and can remarkably improve the conversion rate and the selectivity of the catalyst. The invention can be applied to the technical fields of hydrogen addition and trace amount of carbon monoxide removal from hydrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super paramagnetic ferric oxide composite nanometre particle preparation method

InactiveCN1736881AReduce nucleationReduced growth rateNanostructure manufactureFerric oxidesSal ammoniacNanoparticle

The invention discloses a preparation method for composite nano particcle of superparamagnetic ferric oxide. Wherein, adding ammonia and sodium citrate synchronously and speed controlled to make ions of Fe3+ and Fe2+ coprecipitate and form Fe3O4 nano particle with water-phase dispersion surface adsorbed by citric acid radical that can be substituted by multi chemical functional group on basic condition as crystal seed for sodium citrate-goden chloric acid reduction reaction and form SPION nano particle.

Owner:HUAZHONG UNIV OF SCI & TECH

High active and high stable catalyst of ferro manganese Fischer-Tropsch synthesis and preparation method

ActiveCN1562476AHigh strengthHigh mechanical strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSal ammoniacManganese

A Fe-Mn catalyst with high activity and stability for Fischer-Tropsch synthesis contains Fe, Mn, Ca, K and SiO2. It is prepared through codepositing of the assistant containing Fe, Mn and Ca, silicon sol and ammonia water, feeding the deposit slurry and the catalyst slurry prepared from potassium carbonate solution in drier, drying and calcining.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

Method for preparing nano hydroxyapatite powder

InactiveCN101734635ANo pollution in the processNo harmNanostructure manufacturePhosphorus compoundsWater bathsPolyethylene glycol

The invention relates to a method for preparing nano hydroxyapatite powder, belonging to the field of the biomedical material. The method for preparing the nano hydroxyapatite powder comprises the following steps: adding the organic polymer of polyethylene glycol to the initial reactants of calcium nitrate and diammonium phosphate solution to adjust and control the morphologies of the products of reaction; adding aqueous ammonia to adjust the pH values of the products of reaction, and making the aqueous ammonia react with the products of reaction at different water bath temperature to synthesize nano hydroxyapatite precipitate, wherein the agglomeration of the synthesized nano hydroxyapatite precipitate can be inhibited by the polyethylene glycol functioning as the dispersant; freezing and drying synthesized nano hydroxyapatite precipitate slurry to obtain dry nano hydroxyapatite powder which contains by-products of reaction and polyethylene glycol, and calcinating the dry nano hydroxyapatite powder at high temperature to remove the by-products of reaction and the polyethylene glycol which are contained in the dry nano hydroxyapatite powder to obtain the nano hydroxyapatite powder which is in the shape of the ball or the rod and in the particle size of 10-100 nm and has high yield and good dispersion. The method for preparing the nano hydroxyapatite powder is simple, needs short preparing period, causes no poison and pollution and is suitable for industrial production.

Owner:SICHUAN UNIV

Chemical method for silver coating on copper powder surface

The invention relates to a method for copper powder surface chemical plating silver, belonging to field of chemical silver plating. Said method comprises following steps: putting copper powder into diluted acid of 5-10% to remove oxide on surface of copper powder; adding disperser of 1-30% of copper powder by weight, stabilizer of 10-60% of copper powder by weight into deionized water to form reducing liquid, adding copper powder and stirring; adding silver nitrate into deionized water, adding ammonia, stirring and adding sodium-hydroxide and getting silver amine solvent; adding silver amine solvent into reducing liquid under stirring, finishing chemical silver plating of copper surface 10-50 minutes later; filtering, separating and washing, vacuum drying and getting silver-coated copper powder. The process is characterized by simple preparation and raw material, reduced silver-plated layer on container wall by adding silver amine solvent into reducing liquid, high silver converting rate. The electrical resistance of got copper powder is smaller than 2*10-4 omegacm.

Owner:TSINGHUA UNIV

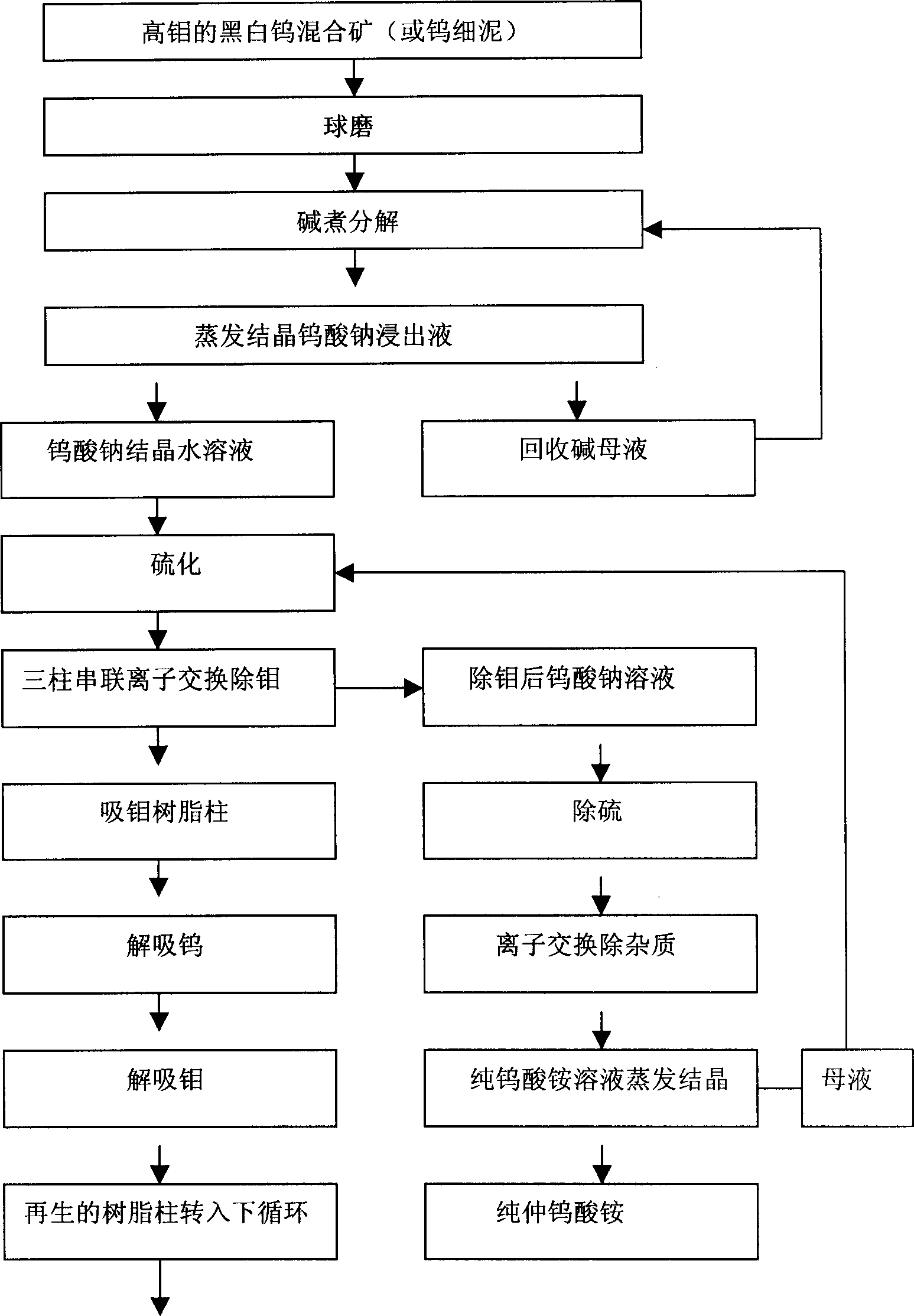

Process for preparing high purity ammonium para-tungstate using hihg-molybdenum tungsten ore

The present invention provides a method of treating high-molybdenum tungsten mineral or tungsten slime by means of three-ion column exchange molybdenum-eliminating technology so as to obtain ammoniumpara-tungstate with high purity at low cost. The treating process includes grinding, alkali leaching, filtering and concentration to obtain sodium tungstate crystal; water dissolving, filtering and sulfurizing sodium tungstate; ion exchange to eliminate molybdenum; desulfurizing sodium tungstate liquid; ion exchange to elimiante impurity and desorbing tungsten with ammonia water and ammonium chloride solution to prepare ammonium tungstate solution; and evaporation to obtain ammonium para-tungstate crystal. The present invention has low cost.

Owner:王旭升 +1

Method for producing fine spherical particles of carbonate or hydroxide of nickel, cobalt or copper

InactiveUS6197273B1Amino compound purification/separationOxide/hydroxide preparationSal ammoniacCobalt metal

The invention provides a process for production of fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper which comprises: dissolving a carbonate or a hydroxide of nickel, cobalt or copper having the general formula (I)wherein M represents Ni, Co or Cu, and x and y are numerals satisfying the followings: 0<=x<=2, 0<=y<=2 and x+y=2, in aqueous ammonia, converting the resulting solution to a W / O emulsion containing droplets of the solution in a non-aqueous medium, and then removing volatile components including ammonia from within the droplets, thereby precipitating a basic carbonate or a hydroxide of a metal selected from nickel, cobalt and copperin the droplets.The fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper obtained according to the process of the invention are especially useful as a precursor for the manufacture of uniform, fine spherical particles of nickel, copper or cobalt metal, as well as useful as themselves as a catalyst for use in organic synthesis, a carrier, a pigment, a filler or a glaze.

Owner:SAKAI CHEM IND CO LTD

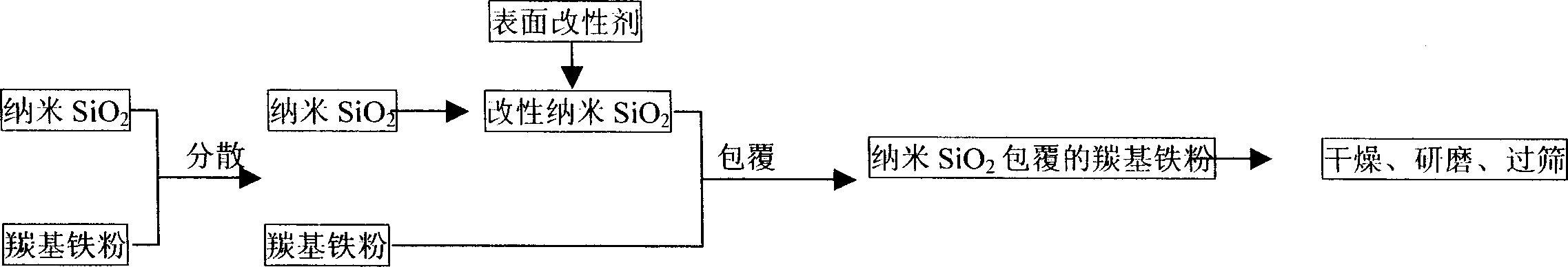

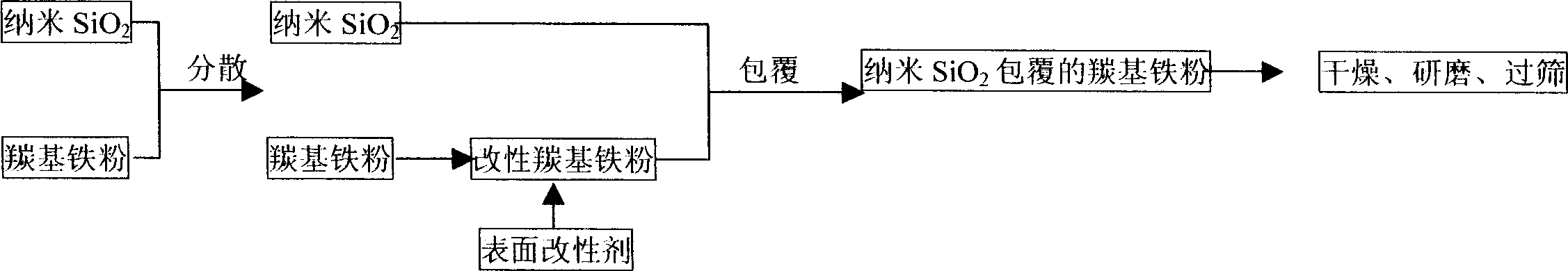

Production of nano-SiO2 for coating carbonyl iron powder

A process for preparing the nano-SiO2 coated carbonyl iron particles includes such steps as dispersing SiO2 nanoparticles and carbonyl iron particles by grinding, modifying the surface polarity of both particles by soluble caustic substance, coating the SiO2 nanoparticles on the surface of each carbonyl iron particle by physical adsorption, backing in vacuum or protective atmosphere, grinding, sieving and packing.

Owner:JIANGSU TIANYI ULTRA FINE METAL POWDER

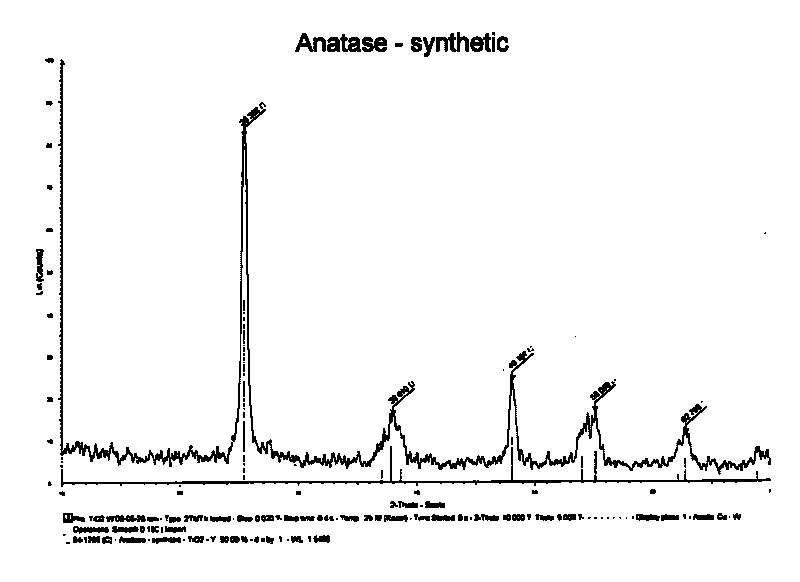

Titanium dioxide powder containing tungsten for preparing honeycomb SCR DeNOx catalyst and preparation method thereof

InactiveCN101757907ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSlurryAnatase

The invention relates to titanium dioxide powder containing tungsten for honeycomb SCR DeNOx catalyst and a preparation method thereof; the powder is characterized by comprising anatase crystal and TiO2-WO3 two components, and containing 85 to 95 percent of TiO2. and 5 to 15 percent of WO3.; the preparation method comprises the following steps that: intermediate metatitanic which is used to prepare anatase titanium dioxide through a sulfuric acid method is prepared into serum, the content of titanium dioxide is 200 to 800g / L, and serum A is prepared; simultaneously, tungsten is dissolved into deionized water, the content of tungsten is 440g / L, and serum B is prepared; and then the serum B is calculated and added into the serum A, ammonia is used to regulate the pH value to be 8; and titanium tungsten composite denitrification powder is prepared after spray drying and calcining for 3 to 7 hours at 300DEG C to 550DEG C.

Owner:河北晶锐瓷业有限公司

Nano mirror spray coating

InactiveCN1944710AExtended use timeImprove adsorption capacityLiquid/solution decomposition chemical coatingPotassium borohydrideSpray coating

The nanometer mirror spraying process includes the following steps: 1. eliminating surface dust; 2. spraying primer; 3. sensitizing and activating treatment; 4. spraying solution A comprising silver nitrate solution, ammonia water solution and sodium hydroxide solution and solution B comprising sodium borohydride, potassium borohydride or p-methylaminophenol sulfate solution in the volume ratio of 1 to 1-1.7 to produce reduction; 5. shaping and developing; 6. blowing to dry; and 7. drying. The present invention has the advantages of diversified products, high corrosion resistance, suitability to mass production, high hardness, low cost, etc.

Owner:方宏亮

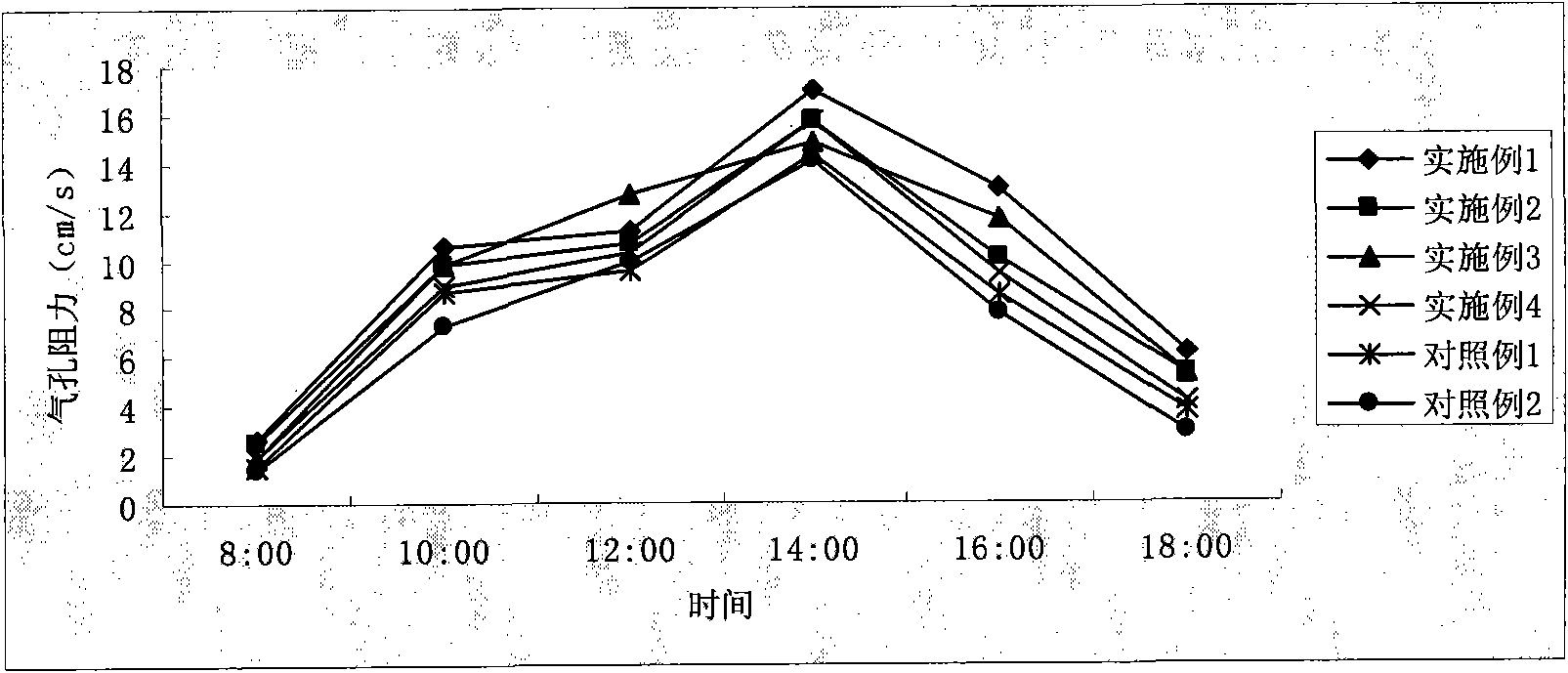

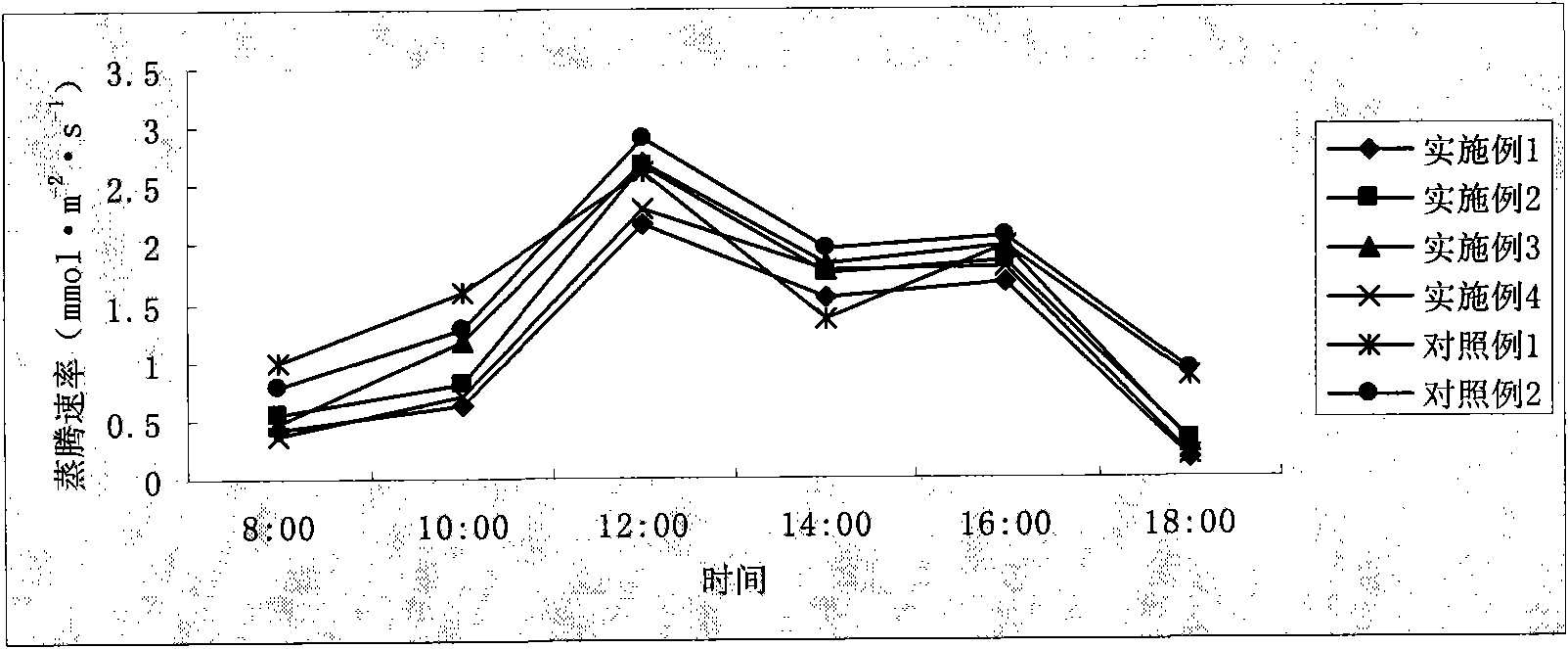

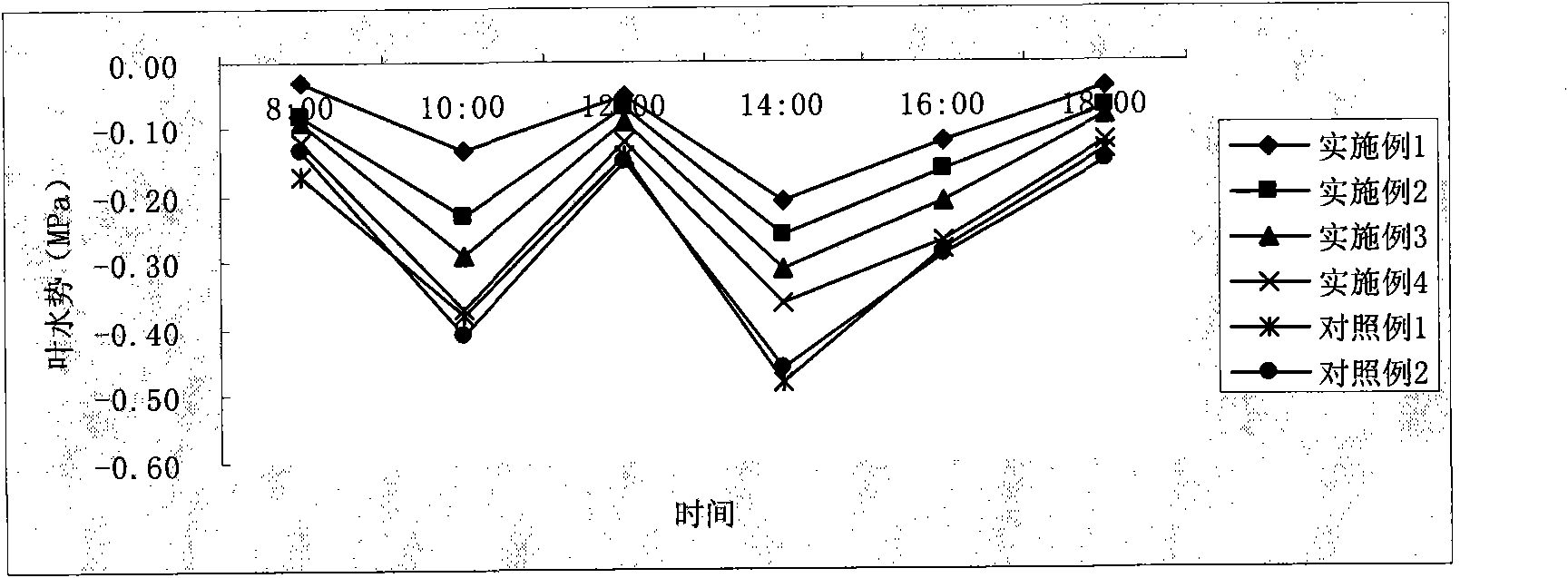

Antitranspirant foliar fertilizer and preparation method thereof

ActiveCN101913941AThe ratio is scientific and reasonableImprove solubilityFertilizer mixturesMicrobial agentMonopotassium phosphate

The invention discloses an antitranspirant foliar fertilizer and a preparation method thereof. The antitranspirant foliar fertilizer comprises the raw materials of copper sulfate, ethylene diamine tetraacetic acid, monopotassium phosphate, zinc sulfate, ferrous sulphate, manganese sulphate, ammonium molybdate, composite rare earth, boric acid, sodium dodecyl sulphonate, urea, fulvic acid, hexanoic acid 2-(diethylamino) ethyl ester, compound amino acid, magnesium sulfate, calcium nitrate, ethylene diamine tetraacetic acid, microbial agent, azone and ammonia water. The antitranspirant foliar fertilizer provides nutrient elements and microbial agents which are required by the growth of plants, the rare earth and amino acid and other beneficial elements, can promote the growth of the plants, improve the yield, the quality, the stress resistance of the plants and the absorbing and operating capabilities on trace elements, simultaneously can effectively reduce the transpiration of the plants and is applied to afforesting in arid regions.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

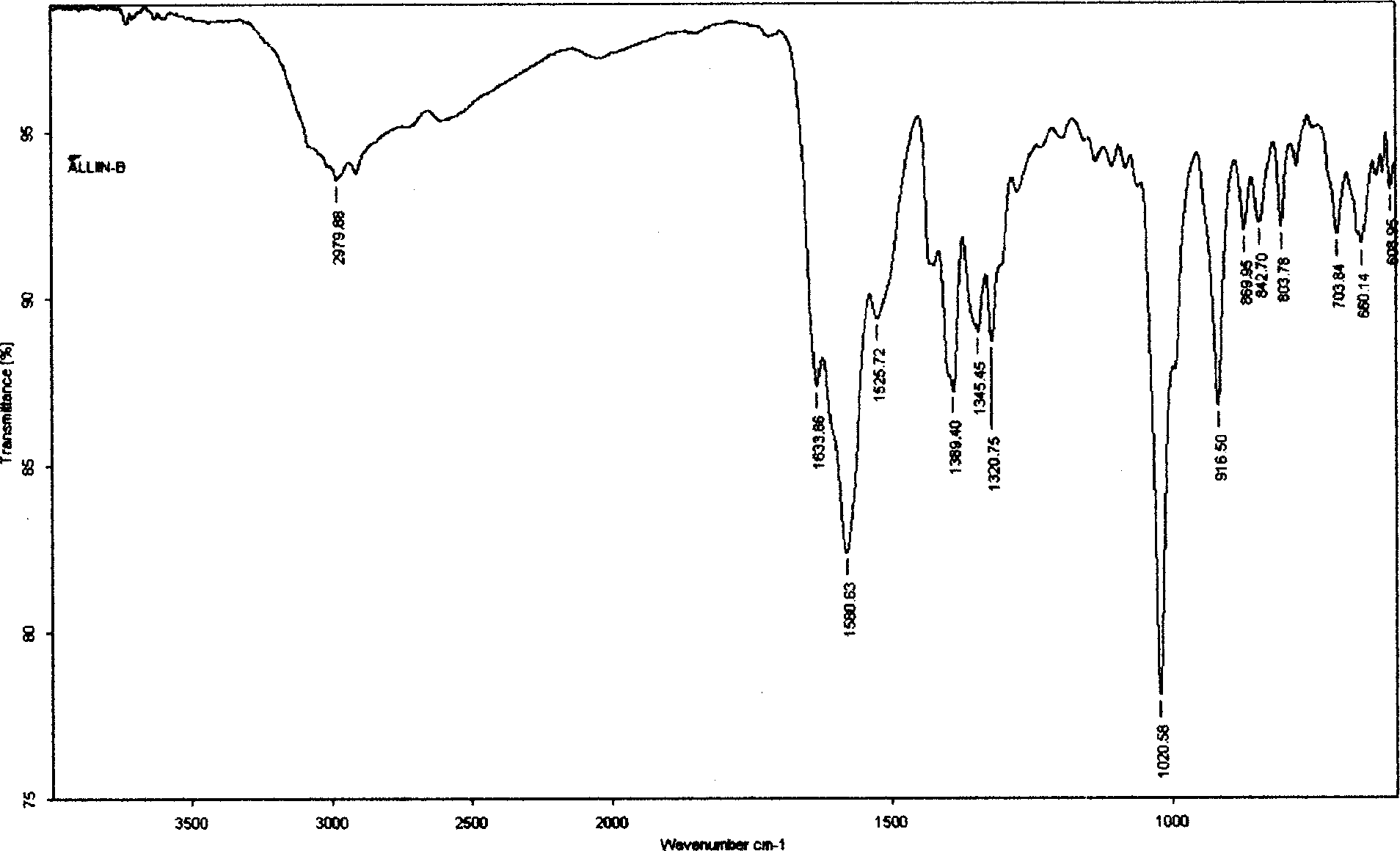

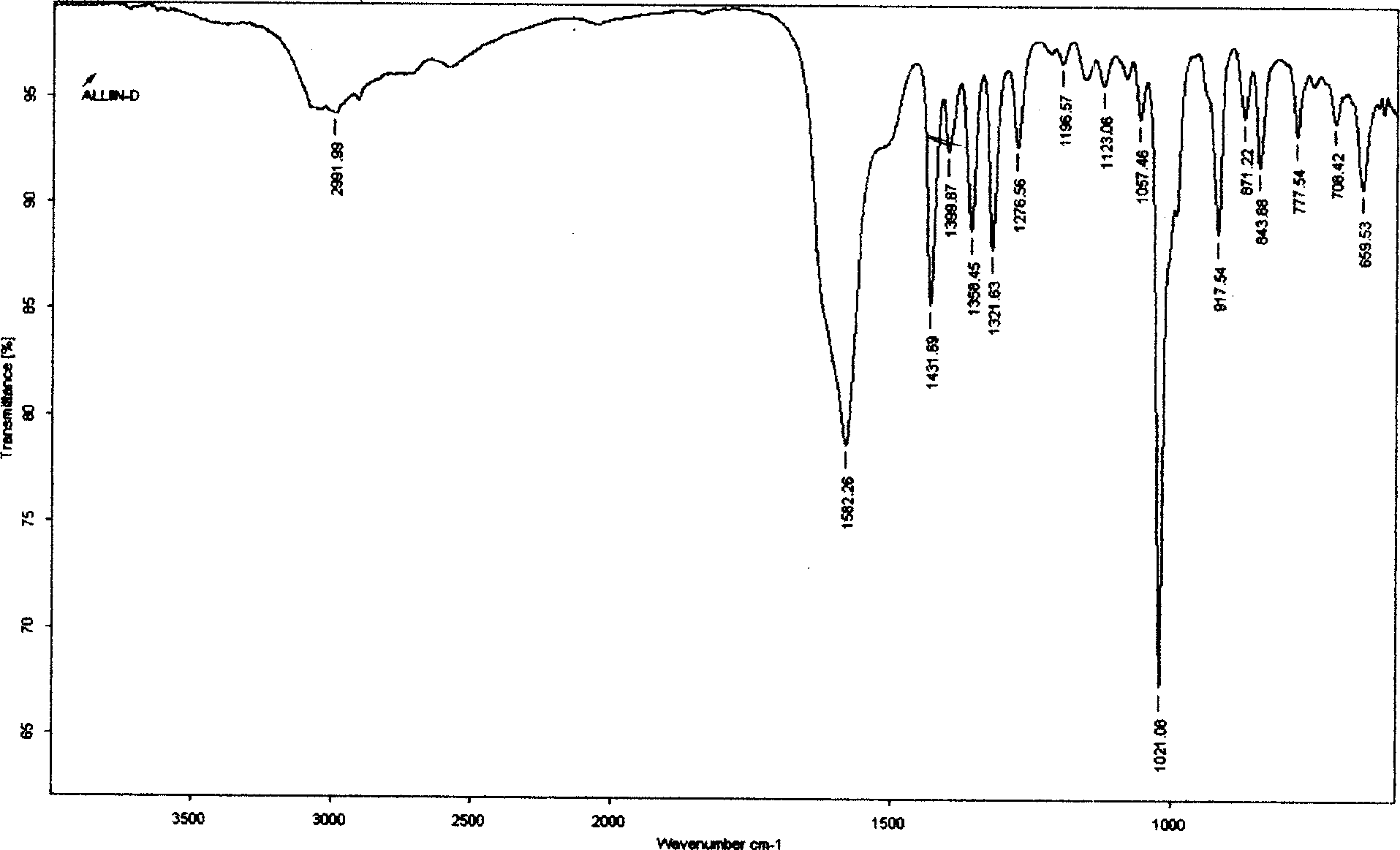

Process for extracting alliin from fresh garlic

The extraction process of alliin from fresh garlic includes the steps of: pre-treatment to kill enzyme of garlic with microwave; organic extraction through ginding garlic into slurry, ethanol extraction, separating extractive liquid and depression concentration; cationic exchange resin adsorption of alliin from concentrated extractive liquid; ammonia water desorption of alliin; and obtaining alliin crystal. The said process has alliin yield of 0.1% and product has alliin content of 91.2%.

Owner:XINJIANG AILEXIN PHARMA

Method for reclaiming metal palladium and palladium chloride from waste loading palladium hydrogenation catalyst

InactiveCN101078054AAvoid increasing difficultyHigh investment costProcess efficiency improvementSal ammoniacAmmonium hydroxide

A method to recover Pd and Palladium Chloride from waste Pd loading hydrogenation activator, the patent provides a method to reclaim Pd and Palladium Chloride with high purity from waste activator, especially form Lindla activator. The organic substance impurity adhere to the surface of the waste Pd loading hydrogenation activator will be get rid by solution, the activator, which has been treated, will be added acid to decompose and get rid of the carbonate in the carrier, and the raw Pd will be gained. The raw Pd will be oxidized and dissolved to produce chorosub-palladium acid by hydrochloric acid-double oxygen water, and Pd solution can be gained. Ammonia will be added into the Pd solution to aminate, and the inorganic impurity such as Pb and Bi will be filtrated and get rid as deposit. Reducing agent will be used to deoxidize and deposit the cavernous Pd with high purity from Palladium-ammonia solution. The cavernous Pd will be oxidized and dissolved with hydrochloric acid-double oxygen water, and then will be evaporated to dryness to produce palladium chloride with high purity.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

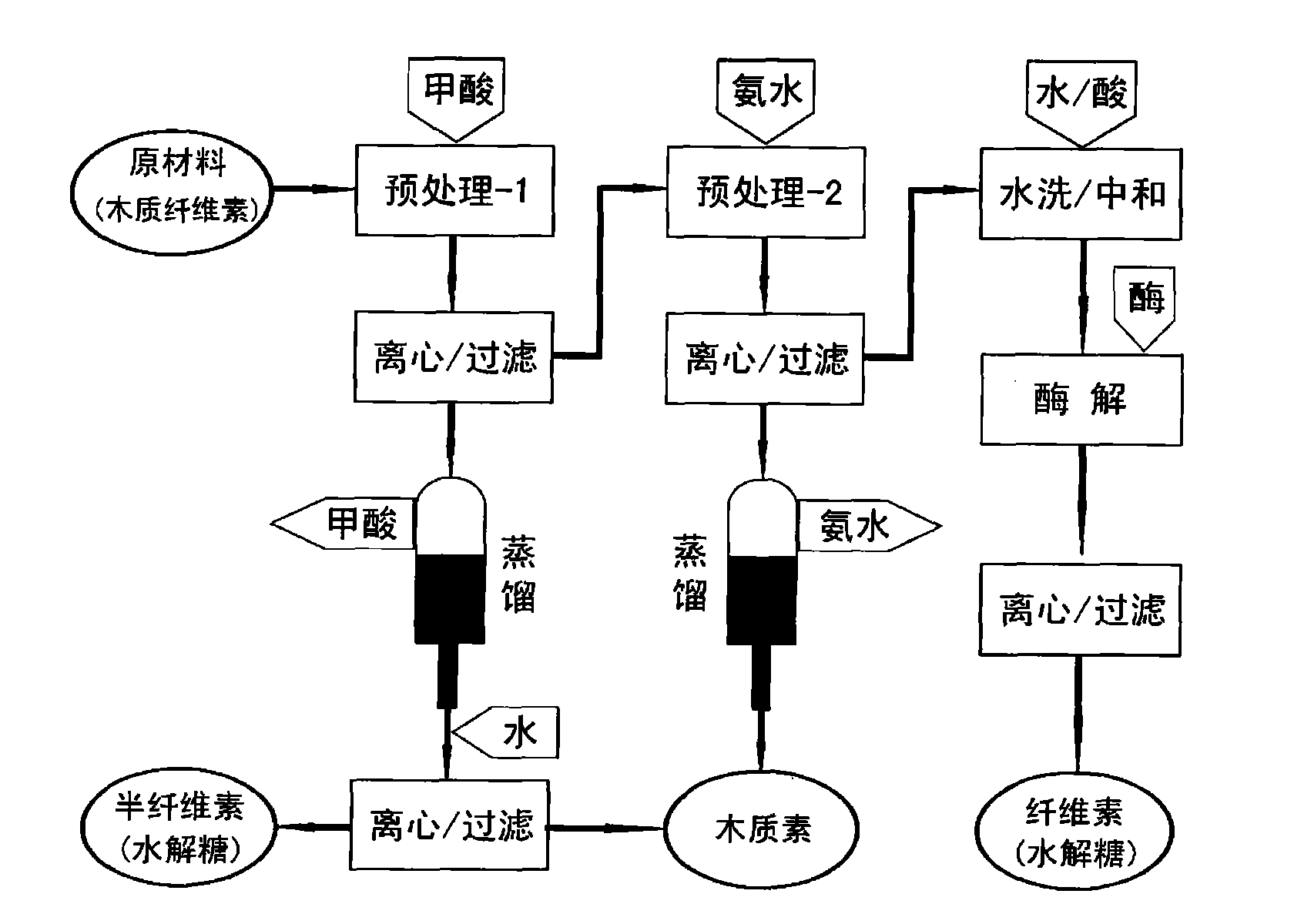

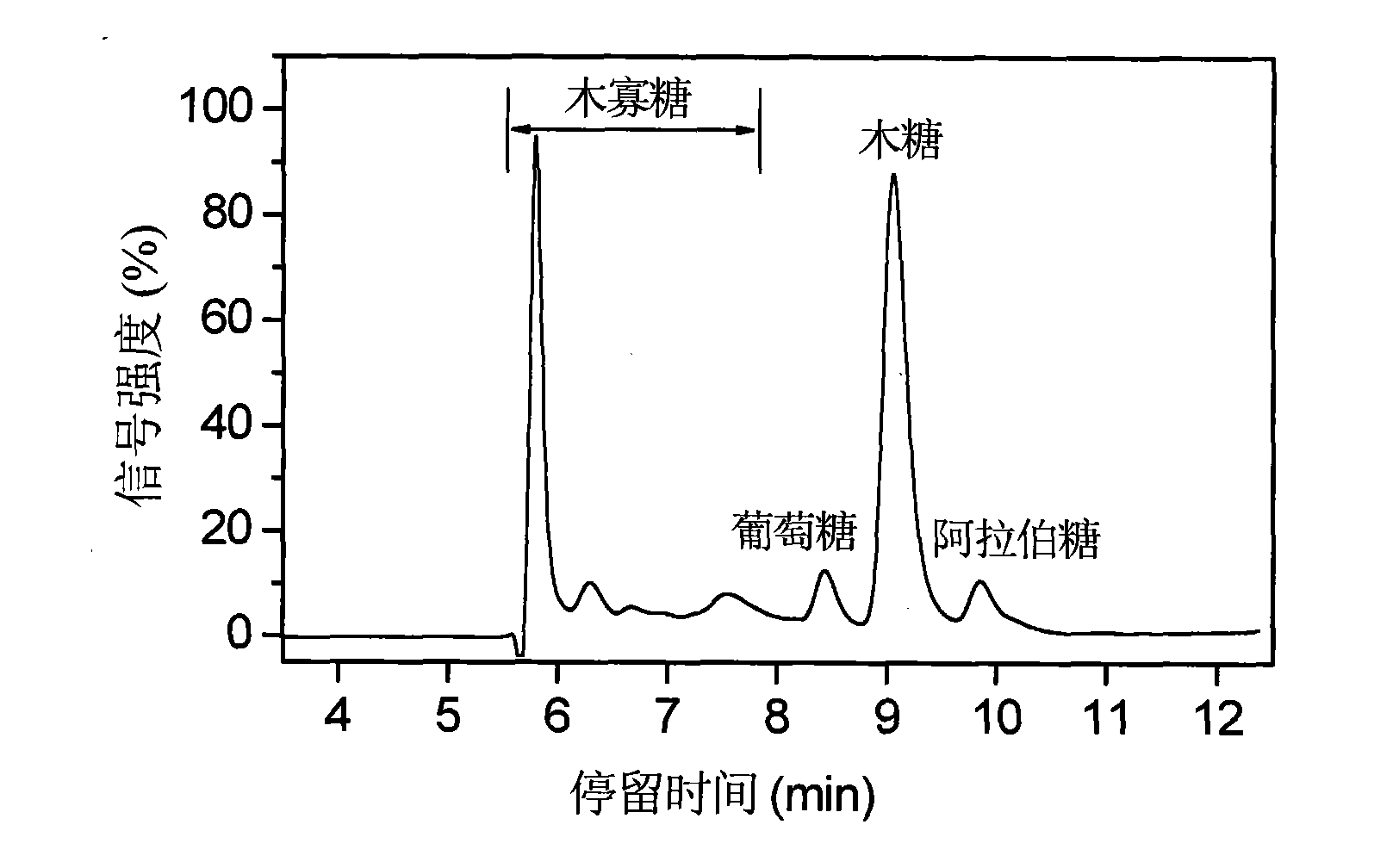

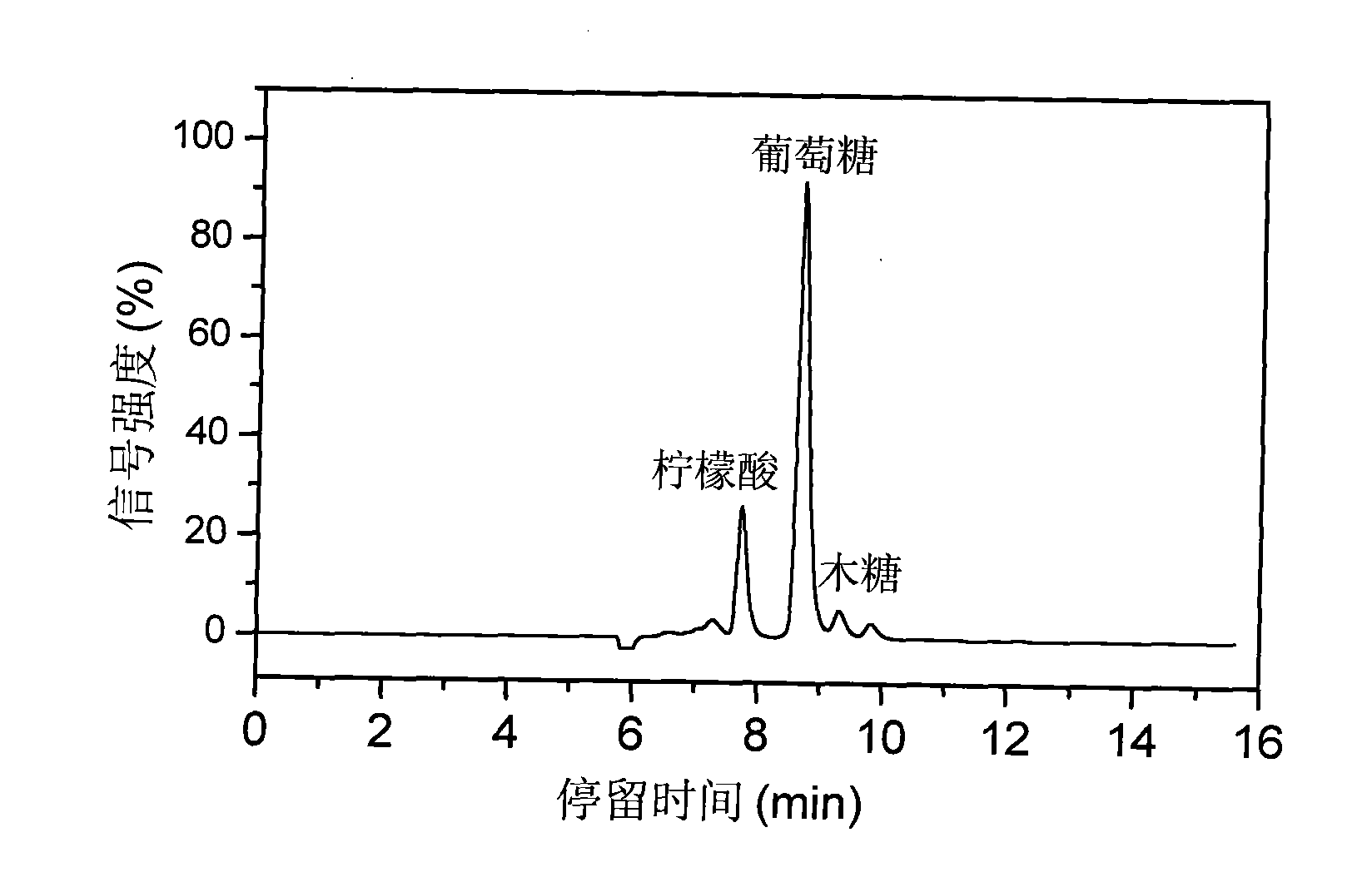

Lignocellulose acid/alkali coupling pretreatment method

InactiveCN102153763ARealize the separation of all componentsHigh purity of componentsFermentationSaccharides productionSolid componentPretreatment method

The invention relates to a lignocellulose acid / alkali coupling pretreatment method. Lignocellulose is separated into cellulose, hemicellulose and lignin by acid / alkali coupling pretreatment; and simultaneously, lignocellulose components are separated and subjected to high-efficiency enzymolysis and saccharification. The method comprises the steps of lignocellulose pretreatment, component separation, cellulose enzymolysis, solvent recovery and the like. The lignocellulose material is pretreated by formic acid or dilute sulphuric acid and is then subjected to solid-liquid separation, wherein the liquid component is used for recovering hemicellulose hydrolyzed sugar and part of lignin; and the solid component is further treated by ammonia water or a sodium hydroxide solution and is then subjected to solid-liquid separation, the liquid component is used for recovering lignin, and the solid component (cellulose) is subjected to enzymolysis and saccharification. By converting the lignocellulose into cellulose hydrolyzed sugar (glucose), hemicellulose hydrolyzed sugar (xylose and xylooligosaccharide) and lignin, the invention provides a basis for full-biomass utilization and develops a green process route for recovering the pretreatment solvent.

Owner:TIANJIN UNIV

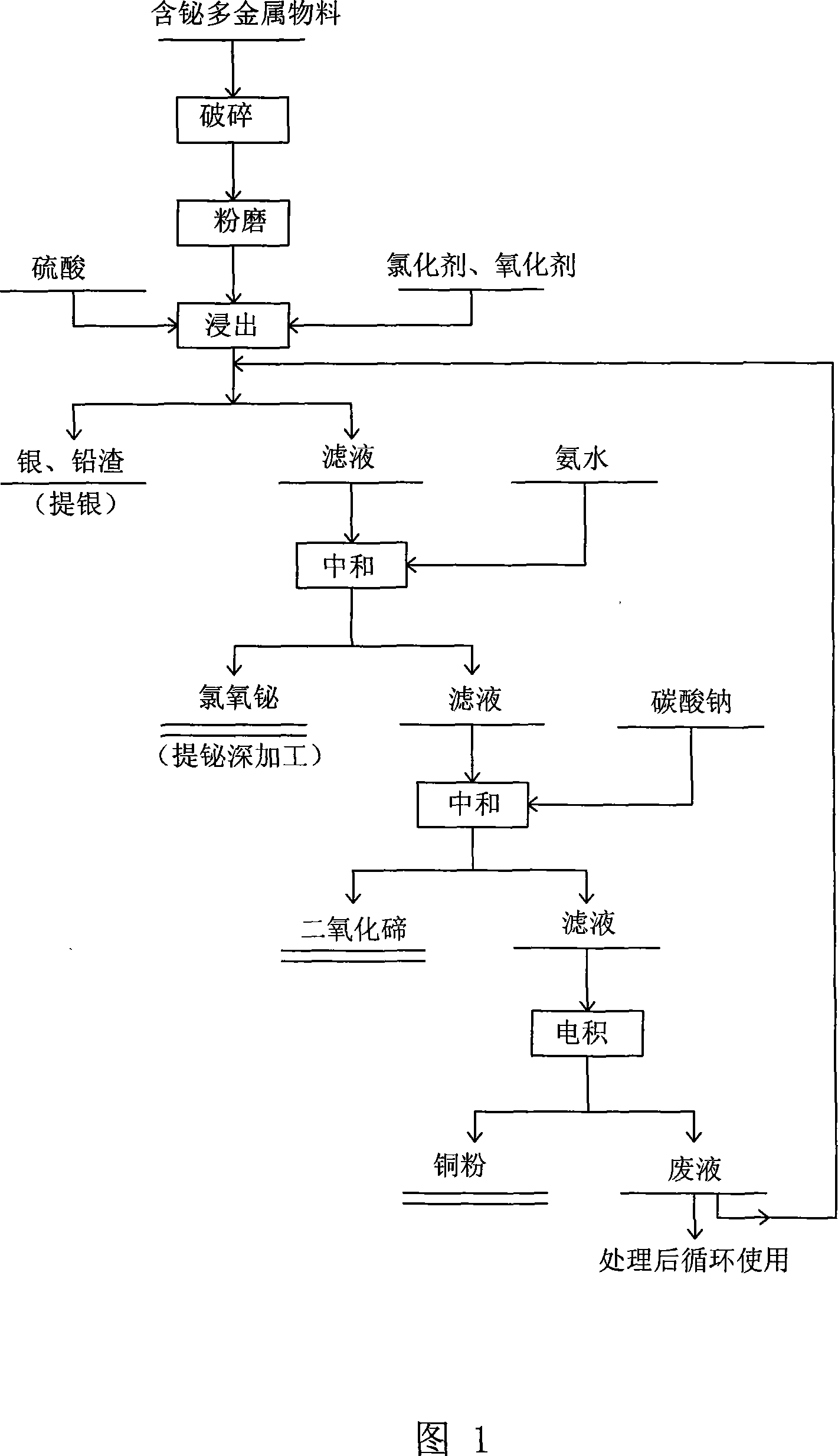

Comprehensive extraction of valent metal from bismuth-containing polymetallic material

InactiveCN101029353AHigh recovery rateImprove product added valuePhotography auxillary processesProcess efficiency improvementSesquioxideTe element

A method for extracting metal from bismuth-contained multi-metal material is carried out by leaching out copper and tellurium from bismuth-contained multi-metal by sulfuric acid, adding into chlorinating agent and oxidant to leach out metal bismuth, extracting silver from leaching-out slag with AgCl, PbSO4 and PbC12, adding ammonia water into leaching-out liquid, adjusting pH value to 1.5 to obtain bismuth oxychloride slag with 70% bismuth content, smelting into coarse bismuth by firing method or machining to obtain high-purity bismuth sesquioxide, adjusting pH value to 4.5 by Na2CO3, depositing tellurium to obtain tellurium dioxide and copper-contained solution, and electrically depositing to obtain copper powder with copper-contained content90%. It adopts wetting and firing metallurgical technology, has higher metal recovery rate and excellent leaching-out separation effect and effluent circulating utilization and no environmental pollution.

Owner:HUNAN JINWANG BISMUTH

Method for extracting rhenium from eluate of flue ash generated by baking enriched ore of molybdenum

This invention relates to a method for extracting Re from flue dust and tail gas rinsing solution of Mo concentrate calcination. The method comprises: (1) adding water to flue dust, leaching out Re in the flue dust to obtain Re-containing leaching solution; (2) adjusting the pH value of the Re-containing leaching solution and tail gas rinsing solution to 5 with ammonium bicarbonate so that Mo, Fe, Cu and Zn ions are converted into hydroxides, separated from Re and precipitated, and filtering to obtain Re-containing solution for extraction; (3) extracting with extractant so that Re enters into the extractant, which is named enriched oil; (4) back-extracting the enriched oil with 3 N ammonia solution so that Re enters into the back extraction solution; (5) adding the back extraction solution into an ion exchange system so that Re is adsorbed onto the resin; (6) preparing 5-10% ammonium thiocyanate solution, adding ammonia solution to adjust the pH value to 8-9, and desorbing Re adsorbed onto the resin to obtain Re-containing desorption solution; (7) evaporating the desorption solution, concentrating, and crystallizing to obtain ammonium perrhenate product.

Owner:锦州沈宏实业集团有限公司

Method for reclaiming metals from molybdenum-containing waste catalyst

ActiveCN102051483APrevents the problem of easy leachingSolve pollutionProcess efficiency improvementFiltrationImpurity

The invention discloses a method for reclaiming metals from a molybdenum-containing waste catalyst, which comprises the following steps of: mixing the waste catalyst and a magnesium-containing compound, roasting, degreasing, removing carbon, then crushing, mixing the powder and sodium carbonate, roasting the mixture, and leaching the roasted materials by using aqueous solution, wherein ammonium salt or aqueous ammonia is added in the aqueous solution leaching step, the molybdenum in the waste catalyst enters the solution in a form of sodium molybdate or ammonium molybdate, the impurities such as silicon, phosphorus and the like entering the aqueous solution form sediment, and the sediment is kept in solid residue in a filtration step; and after the solid is separated, performing acidification, extraction, re-extraction and the like to reclaim the molybdenum and other metals. The method solves the pollution problem caused by sulfur dioxide in the discharged gas in the roasting, degreasing and carbon removal processes; and the salts formed by the reclaimed sulfur and magnesium can play a role in removing impurities in the subsequent steps so as to save the consumption of chemical reagents in the metal reclaiming process and reduce the cost. In addition, the method reduces the operation steps, reduces equipment, improves the operation effect, and also can improve the molybdenum yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

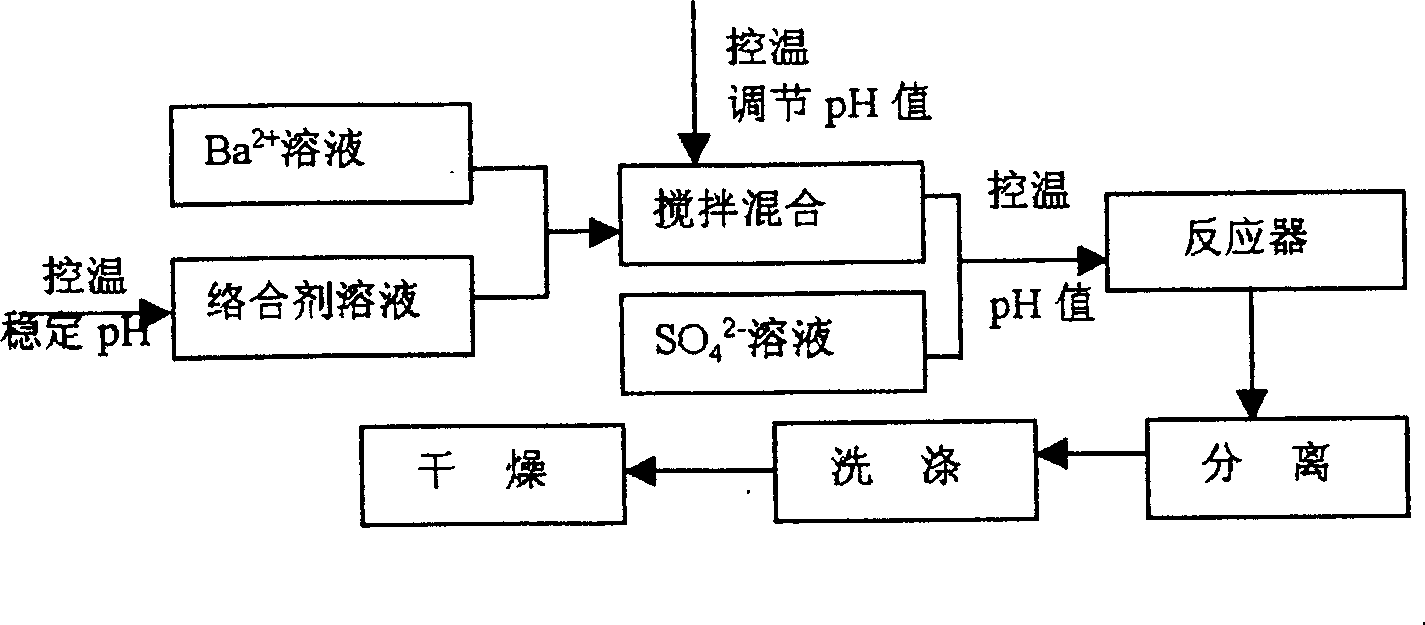

Prepn of nano barium sulfate

InactiveCN1398789AStable operating conditionsGood resolubility and dispersibilityMaterial nanotechnologyCalcium/strontium/barium sulfatesSal ammoniacSulfate radicals

The present invention belongs to the field of chemical technology and is especially a complexing process of preparing nanometer BaSO4. The process includes two main steps of complexing reaction and deposition reaction. Specifically. Ba2+ ion solution and EDTA complexing agent solution produce complexing reaction in a reactor to produce complex solution with certain stability and ammonia water being used for regulating system pH value. The complex solution is made to react with sulfate radical solution while stirring to prepare nanometer level BaSO4 particles as precipitate. The nanometer level BaSO4 product is hexagonal crystal and blue in color, and has grain size of 20-40 nm and average grain size of 25 nm. The process is stable in operation, and the product has high quality and dispersivity.

Owner:ZHONGBEI UNIV

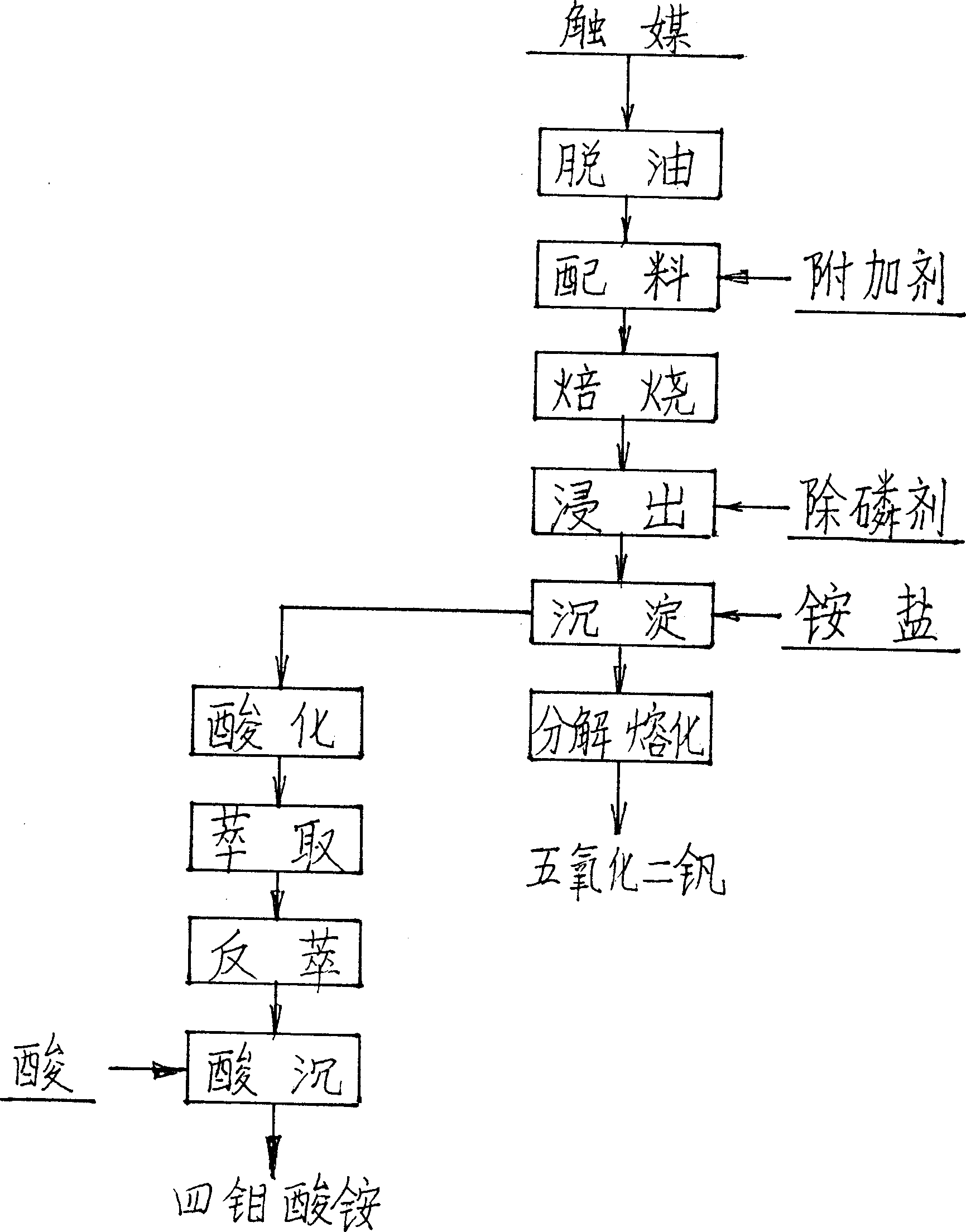

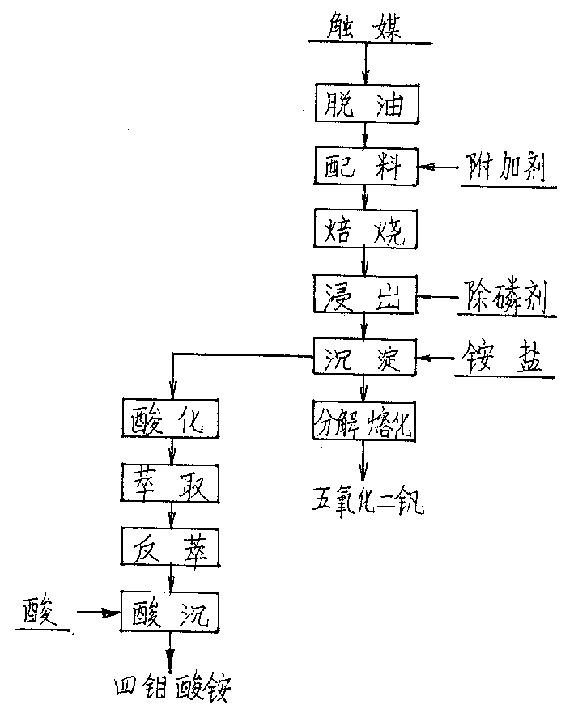

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

Low temperature CO oxidation non-noble metal catalyst

InactiveCN101143321AHave substantive characteristicsLow costCatalyst carriersDispersed particle separationNickel saltIron salts

The invention provides an oxidation catalyst to purify CO in room temperature, which is prepared in coprecipitation method or deposition-precipitation method. The catalyst consists of non precious metal active components and carrier, wherein the loading of the active components is 5 to 80 percent of the conversion value of metal element. The active components come from cobalt salt liquid, iron salt liquid, nickel salt liquid, manganese salt liquid, copper salt liquid, zinc salt liquid, tin salt liquid and cerium salt liquid. The carrier comes from alumina, silica, molecular sieve, honeycomb ceramics, wire fence, cobalt oxide, iron oxide, manganese oxide, copper oxide, zinc oxide, tin oxide and cerium oxide. The precipitant is Na2CO3, K2CO3, sodium hydroxide, urea or ammonia. The catalyst preparation solution needs to be fully stirred for 1 to 8 hours and the retrogradation duration is 1 to 16 hours. The dried solution needs to be treated in in-situ remediation in air, oxygen, and hydrogen or nitrogen atmosphere in temperature from 100 to 500 degrees centigrade. The catalyst disuses precious metal as active component, so the cost is low and the preparation process is simple.

Owner:NO 63971 TROOPS PLA

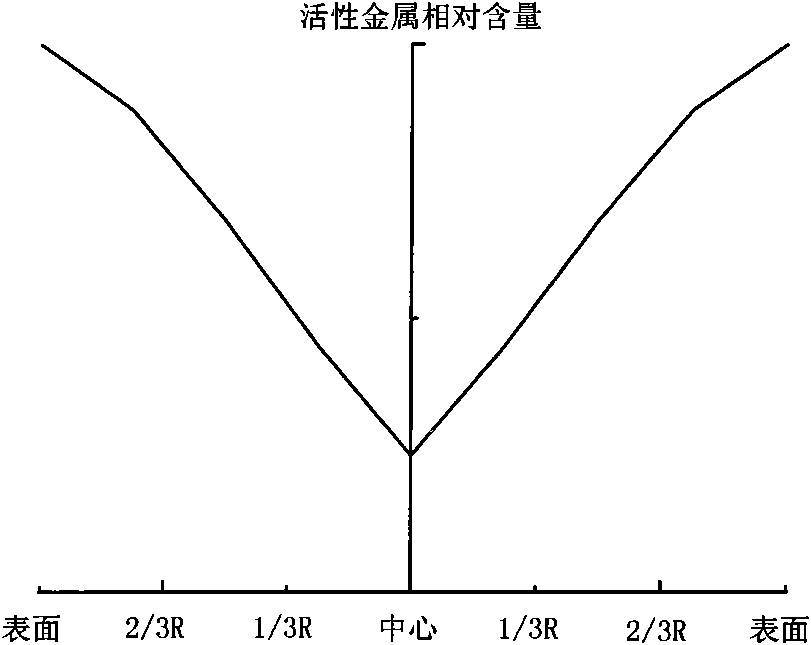

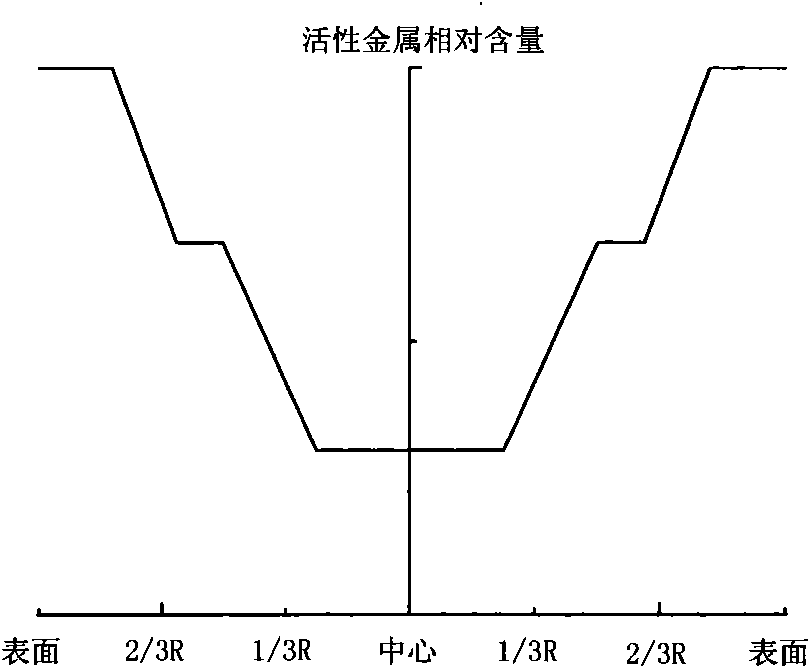

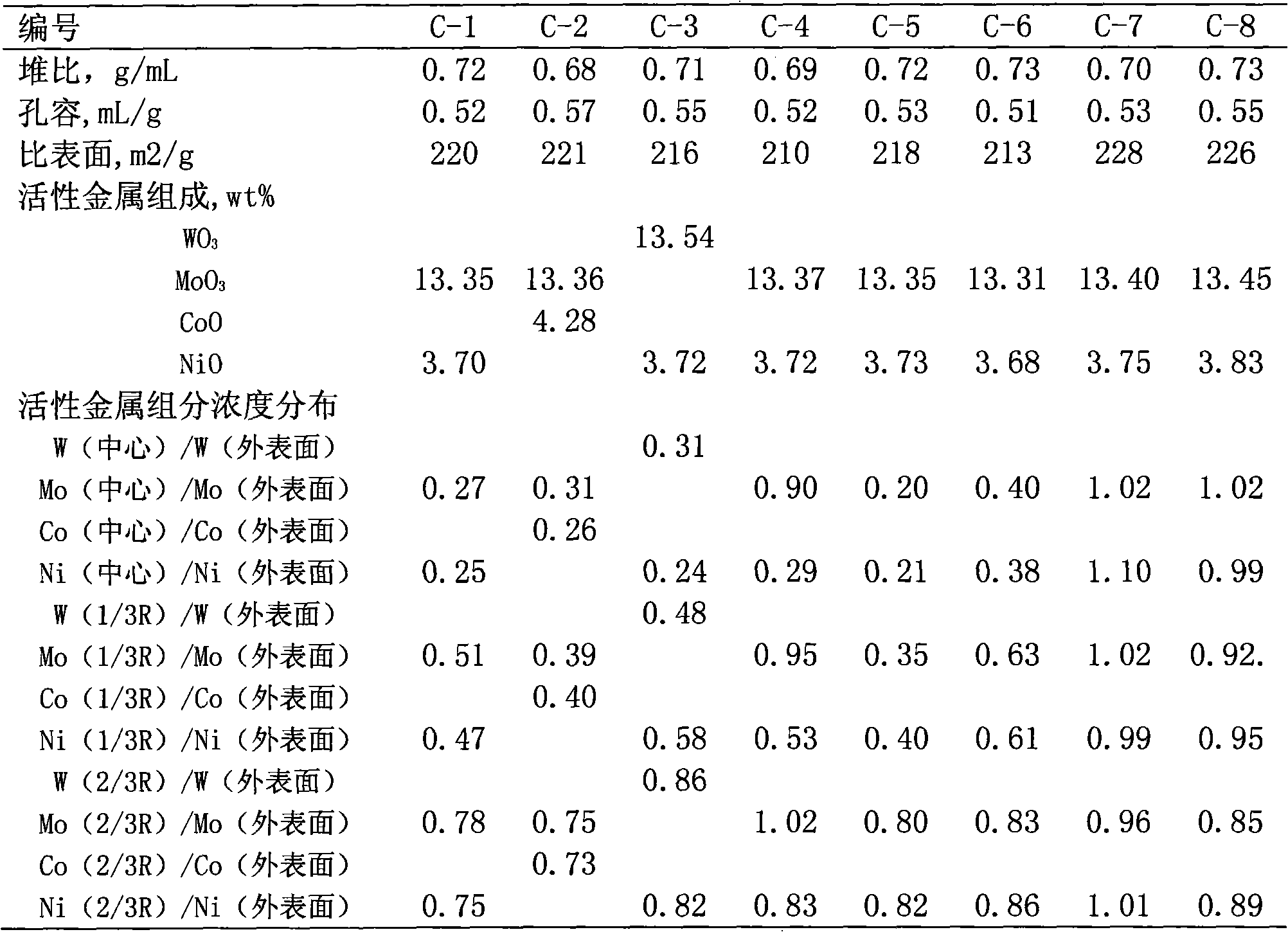

Hydrogenation catalyst with active metal component concentration in gradient increase and distribution and preparation method thereof

ActiveCN101927169AImprove desulfurizationPromote denitrificationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSal ammoniacHigh concentration

The invention relates to a hydrogenation catalyst with active metal component concentration in gradient increase and distribution and a preparation method thereof. The preparation method comprises the following steps of: mixing compounds of metal in VIB and / or VIII family with deionized water or ammonia to prepare a metal impregnating solution by using Al2O3 or Al2O3 containing SiO2, TiO2 and ZrO2 as a vector; preparing the hydrogenation catalyst by using a saturated impregnation method; gradually adding denser metal solution for saturated impregnation of the vector by preparing more dilute solutions of metal in VIB and / or VIII family or deionized water; or impregnating the vector first with the metal impregnating solution with low concentration and then with the metal impregnating solution with high concentration by preparing metal solutions of different concentrations; drying for 1 to 8 hours at 80 DEG C to 150 DEG C; and baking for 2 to 6 hours in an air of 300 DEG C to 650 DEG C. The catalyst has the advantages of high desulfurization, denitrification, residual carbon removing activity and stability, simple preparation and lower preparation cost and is suitable for the field of heavy oil hydrogenation.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com