Process for preparing high purity ammonium para-tungstate using hihg-molybdenum tungsten ore

A technology of pure ammonium paratungstate and high molybdenum tungsten ore, which is applied in the field of metallurgy and chemical industry, can solve the problems of high processing cost, influence on popularization and application, and high cost of pH adjustment method, and achieve good and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

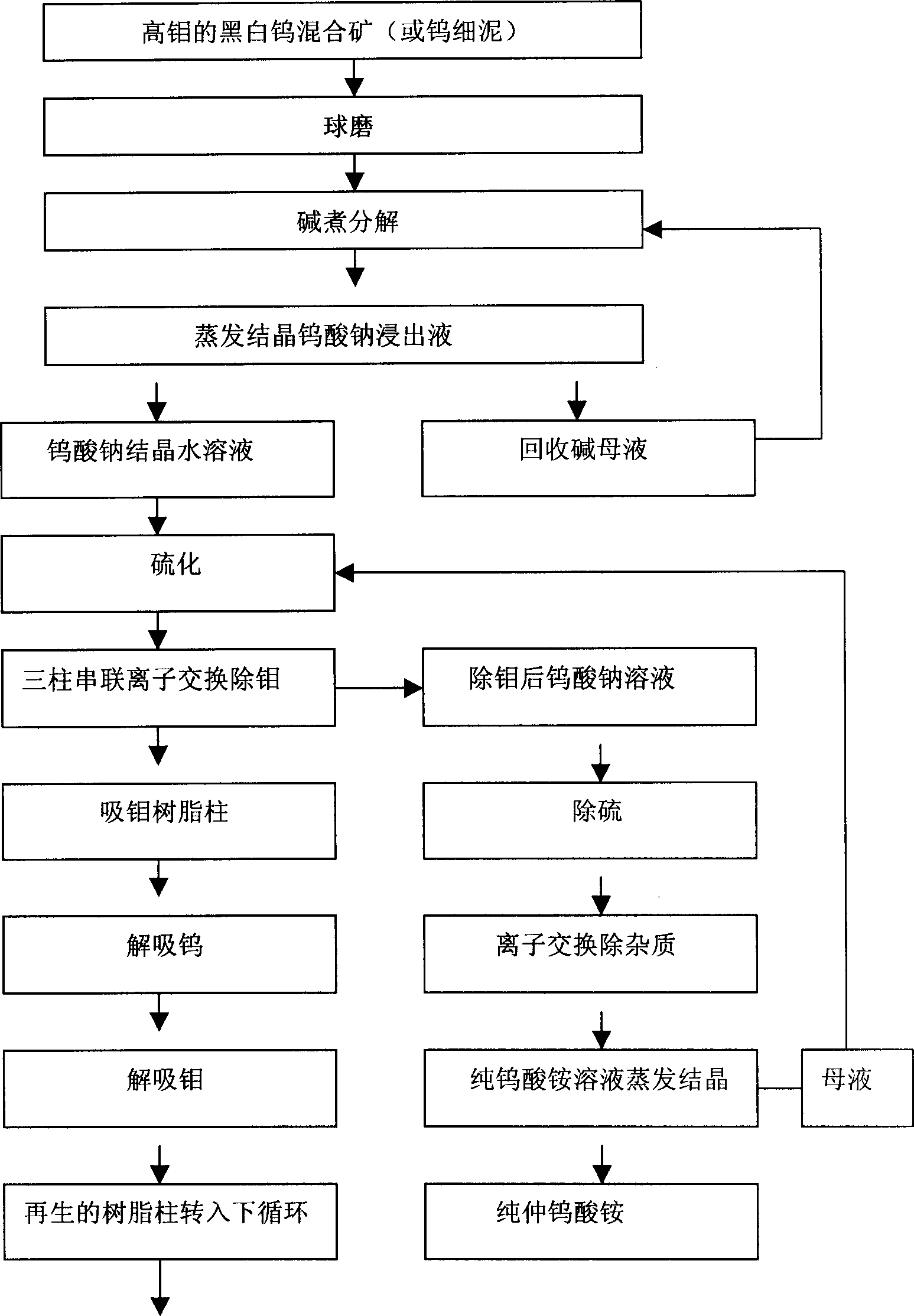

[0018] Below in conjunction with the flow chart of the process principle of the present invention, the specific implementation of the present invention is described: (1), black and white tungsten ore or tungsten fine mud ball mill, alkali boiling leaching, filtration, concentrated sodium tungstate crystallization:

[0019] After the high-molybdenum tungsten minerals are discharged by alkaline pressure cooking, the pressure filtration should control the WO 3160-190g / l, the mother liquor is processed by alkali recovery, and the crude sodium tungstate is evaporated and crystallized and filtered to dry up; (2), water-soluble filtered sodium tungstate, vulcanized:

[0020] a. Sodium tungstate solution to adjust PH

[0021] Water-soluble sodium tungstate solution controls WO 3 130-180g / l, alkalinity 1-5g / l, the mother liquor of crystalline ammonium paratungstate is used to roughly adjust the alkalinity of sodium tungstate solution, according to the production volume, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com