Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

261 results about "Tungsten ore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten ore is a rock from which the element tungsten can be economically extracted. The ore minerals of tungsten include wolframite, scheelite, and ferberite. Tungsten is used for making many alloys.

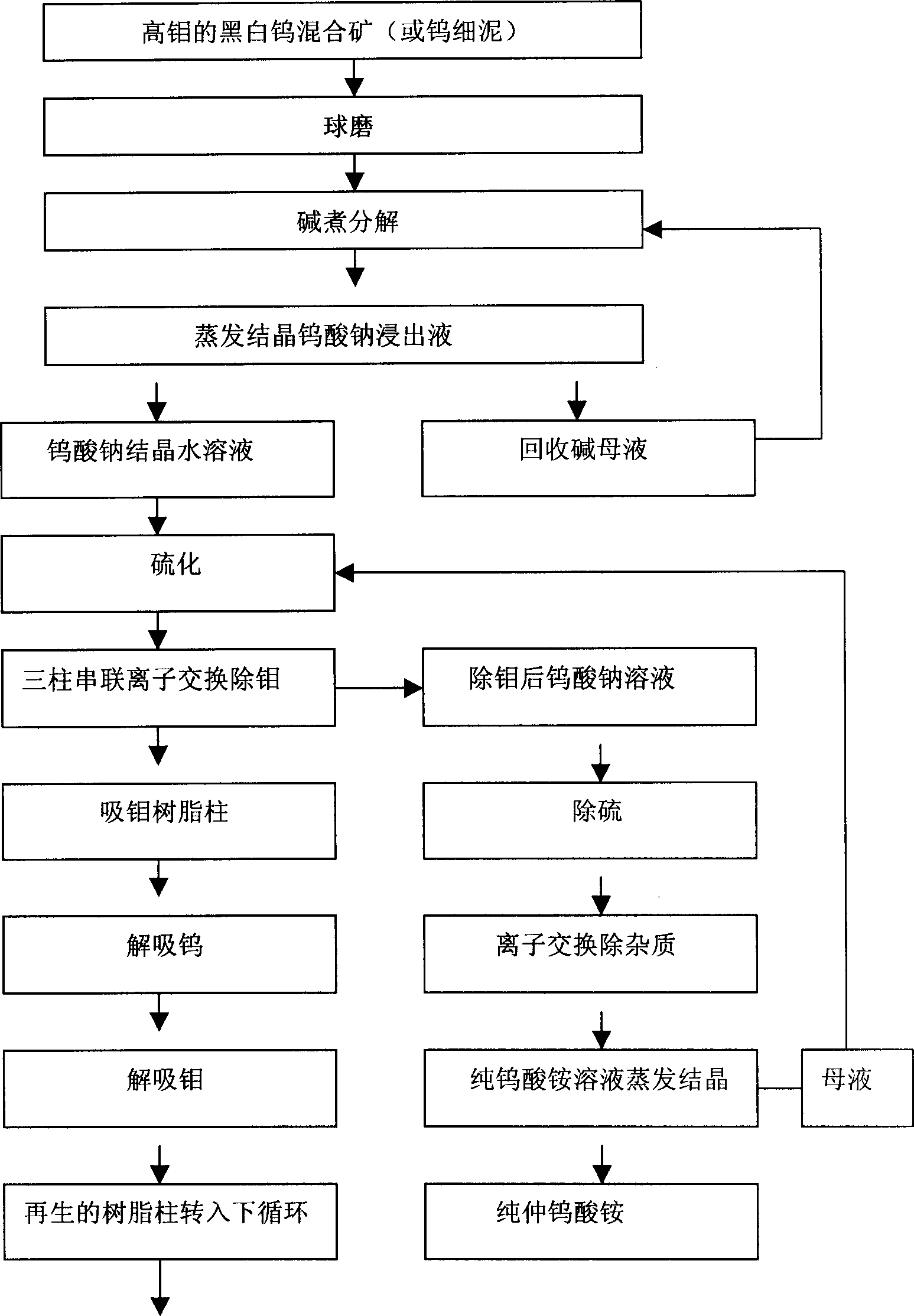

Process for preparing high purity ammonium para-tungstate using hihg-molybdenum tungsten ore

The present invention provides a method of treating high-molybdenum tungsten mineral or tungsten slime by means of three-ion column exchange molybdenum-eliminating technology so as to obtain ammoniumpara-tungstate with high purity at low cost. The treating process includes grinding, alkali leaching, filtering and concentration to obtain sodium tungstate crystal; water dissolving, filtering and sulfurizing sodium tungstate; ion exchange to eliminate molybdenum; desulfurizing sodium tungstate liquid; ion exchange to elimiante impurity and desorbing tungsten with ammonia water and ammonium chloride solution to prepare ammonium tungstate solution; and evaporation to obtain ammonium para-tungstate crystal. The present invention has low cost.

Owner:王旭升 +1

Method for extracting tungsten from scheelite

ActiveCN102021328AReduce lossesLow costProcess efficiency improvementWater dischargeReaction temperature

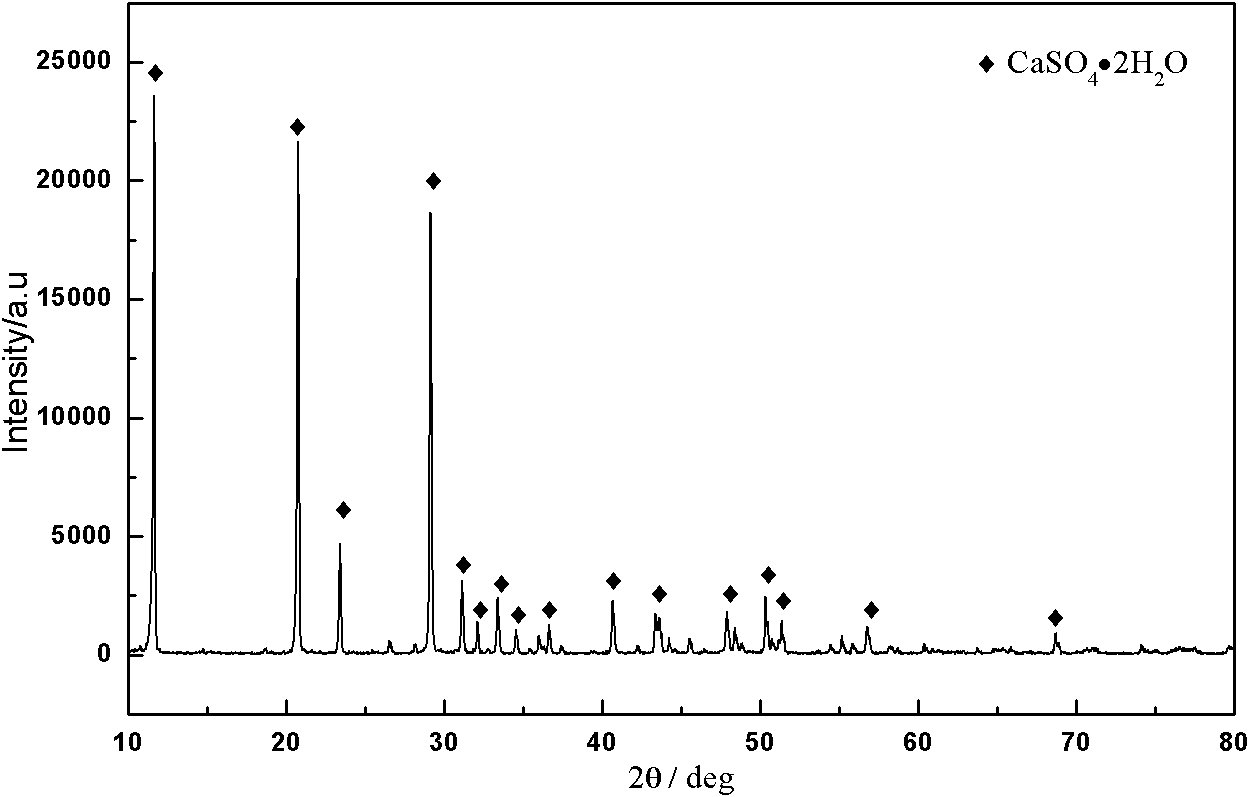

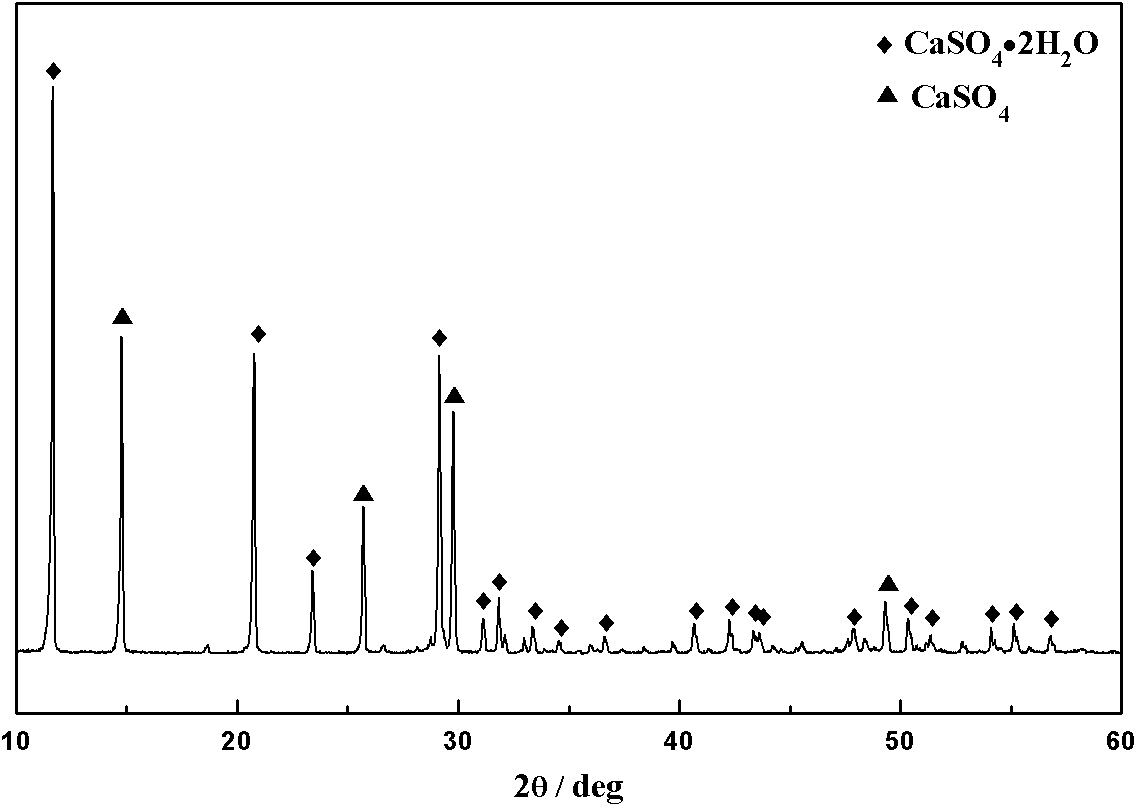

The invention discloses a method for extracting tungsten from scheelite, comprising the following steps of: mixing the scheelite with a mixed solution of phosphoric acid and sulfuric acid for reaction, adding dihydrate gypsum as seed crystals, and controlling the concentration of SO4<2->, the content of P2O5 and the reaction temperature to obtain the dihydrate gypsum with good filtering and washing properties. The invention has the advantages that one-step efficient normal pressure leaching of the scheelite is achieved, thus resources and energy consumption are saved, and the resolution ratio of the scheelite is up to above 98%; the problems of Cl<-> corrosion and serious HCl volatilization are overcome; the cyclic utilization of phosphoric acid is basically achieved, and the leaching cost and waste water discharge are greatly reduced; leaching equipment is simple, is convenient for operation and is easy to realize industrialization; the single and stable dihydrate gypsum is obtained, the filter efficiency of the dihydrate gypsum is high, the washing property of the dihydrate gypsum is good, and the P2O5 content in the washed dihydrate gypsum is reduced to be below 2%, thereby reducing the loss of phosphoric acid; and the passivation phenomenon of calcium sulfate solid film when the tungsten ore is leached is avoided.

Owner:CENT SOUTH UNIV

Method for comprehensively recovering tungsten and phosphorus from high phosphorus white tungsten ores

ActiveCN102080161ARealize comprehensive utilizationEasy to separate by filtrationProcess efficiency improvementPhosphorus compoundsWater dischargeDecomposition

The invention discloses a method for receiving tungsten and phosphorus from high phosphorus white tungsten ores, which comprises: decomposing the ores by using mixed acid of phosphoric acid and sulfuric acid, wherein phosphorus-containing ore are converted into phosphoric acid, tungsten-containing ore are converted into phosphotungstic acid, and both the phosphorus and the tungsten enter solution; when the total P2O5 mass content in circular leaching filtrate surpasses 30 percent, extracting tungsten from the circular leaching filtrate, extracting phosphoric acid by using a solvent extraction method, reducing P2O5 mass content in the circular leaching filtrate by controlling the extraction rate of phosphoric acid, resupplying sulfuric acid, and returning to newly leached high phosphorus white tungsten ores; and thus, recovering tungsten and phosphoric acid from the leaching filtrate respectively. The method has the advantages of comprehensively recovering tungsten and phosphorus from ores, lowering requirements on tungsten ore raw material, reducing pressure in ore dressing step, ensuring over 98 percent decomposition rate of the white tungsten ore, recycling leaching agent, greatly reducing leaching cost and waste water discharge, along with simple leaching equipment, convenient operation and easy industrialization implementation.

Owner:CENT SOUTH UNIV

Method for comprehensively recovering tungsten and fluorine from minerals

InactiveCN102586632AHigh recovery rateImprove solubilitySilicaProcess efficiency improvementDecompositionApatite

The invention provides a method for comprehensively recovering tungsten and fluorine from minerals, namely a mixed acid of phosphoric acid and sulfuric acid is adopted for decomposing complex calcium-containing minerals containing fluorite, scheelite, apatite, and calcite, wherein the fluorite is decomposed to fluorine hydride or silicon tetrafluoride to escape, and absorption treatment is performed for preparing hydrofluoric acid or a fluoride salt; and the scheelite is transformed to phosphotungstic acid to enter into a solution, and filtrate after filtration is supplemented into the consumed sulfuric acid and the phosphoric acid after extraction of the tungsten and returned to the new-round mineral leaching. The method disclosed by the invention has the advantages of comprehensively recovering the fluorine and the tungsten from the minerals, reducing the requirements on the fluorite or the tungsten ore raw material, reducing the pressure on a mineral dressing link, improving the comprehensive recovery rate and simultaneously ensuring the decomposition rate of the fluorite and the scheelite, wherein the decomposition rate of the fluorite is above 98%, and WO3 contained in decomposition slag is reduced to below 0.5%; furthermore, a leaching agent can be recycled, so that leaching cost and wastewater emission are greatly reduced; and the method also has the advantages of simple leaching equipment, convenience in operation and easiness in realization of industrialization.

Owner:CENT SOUTH UNIV

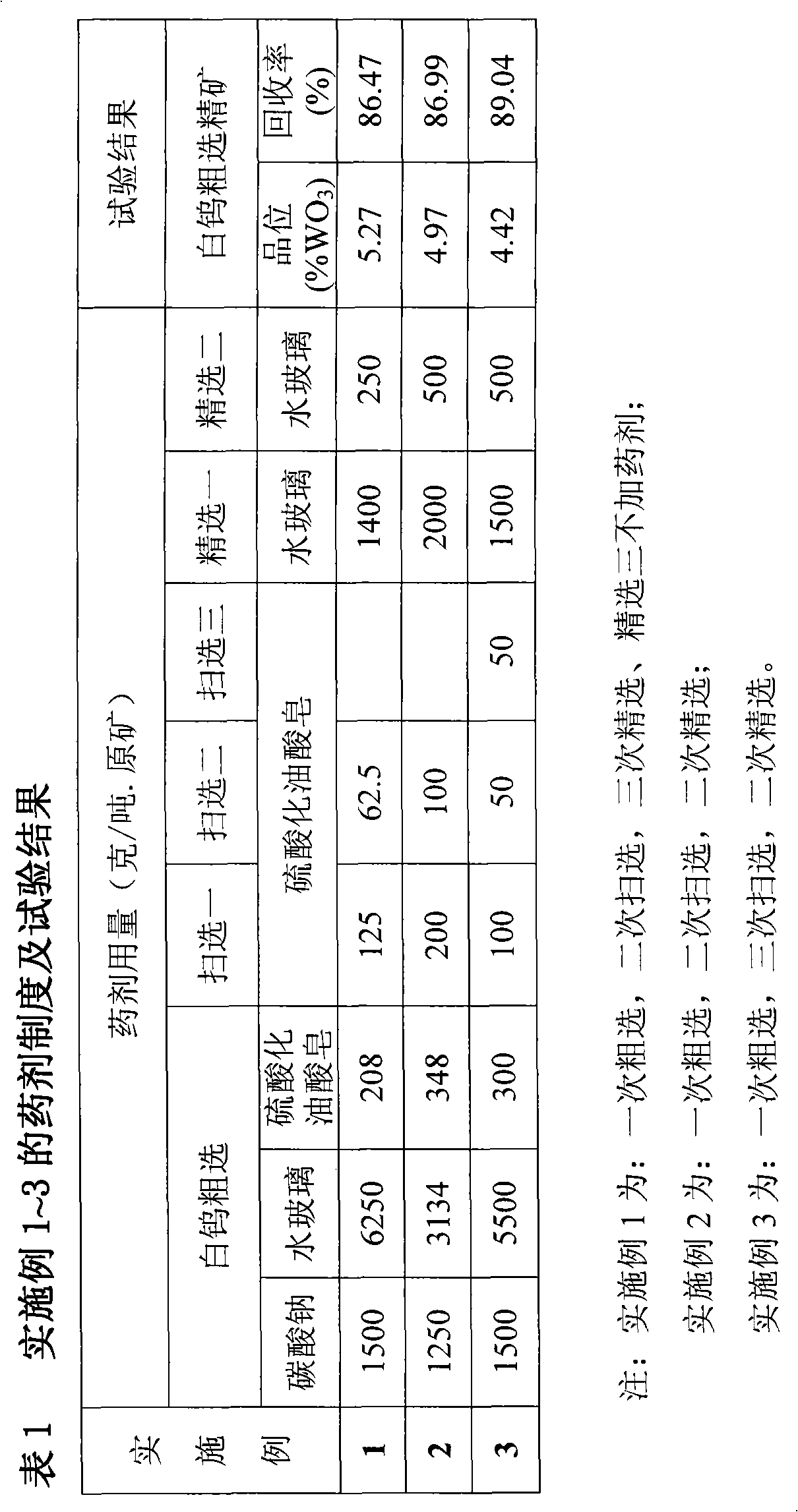

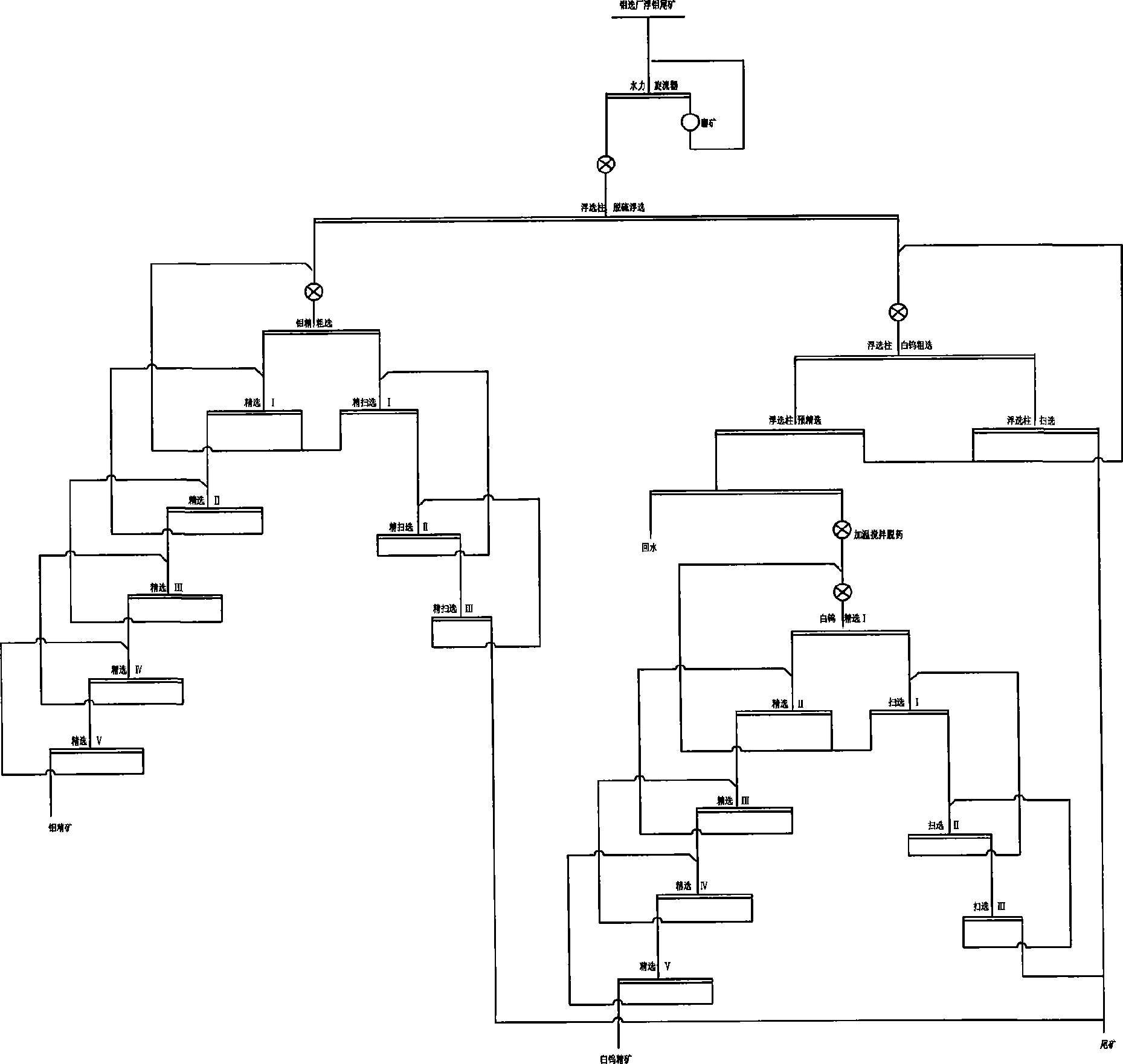

Method for separating black and white tungsten bulk flotation rough concentrates

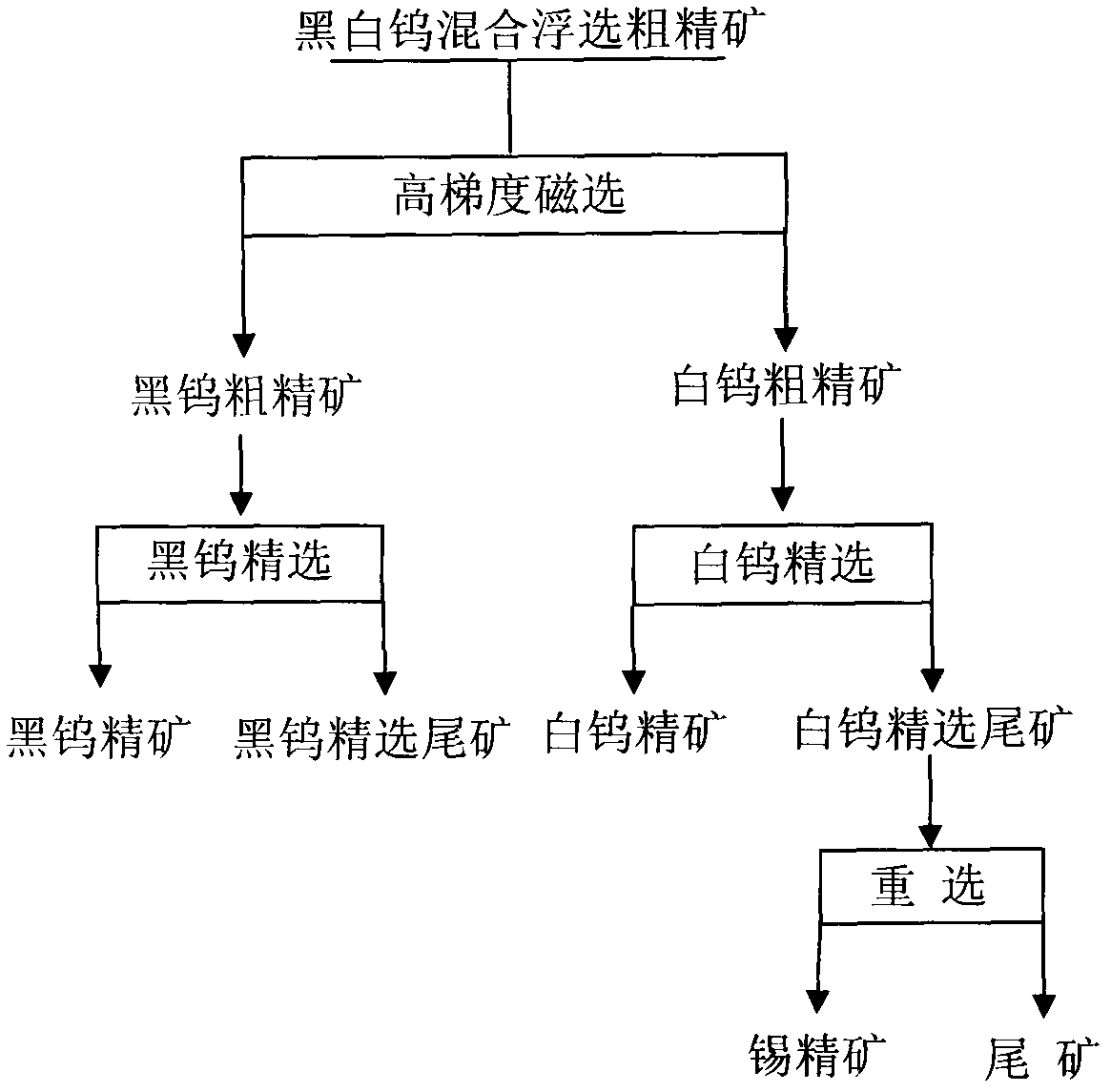

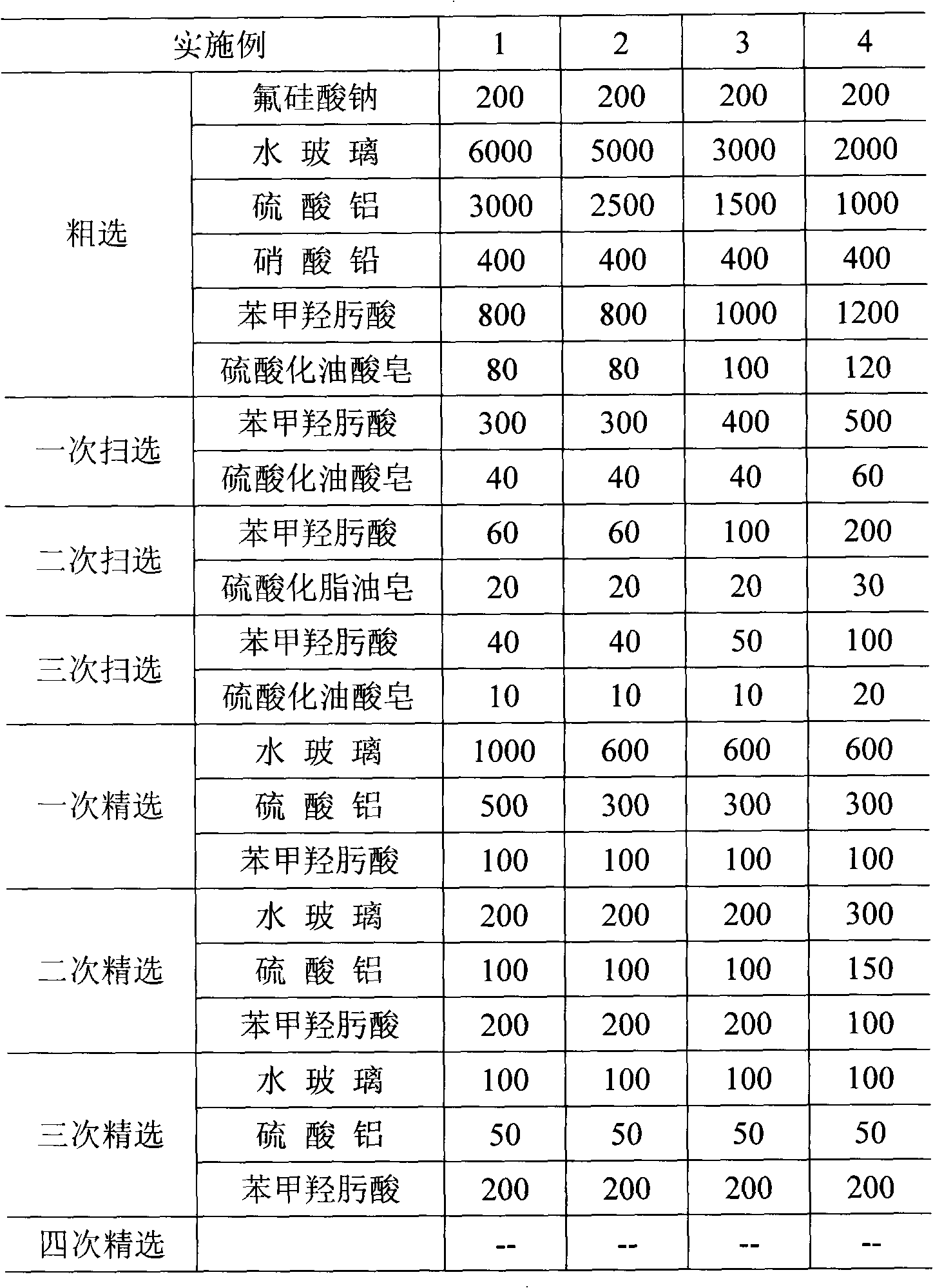

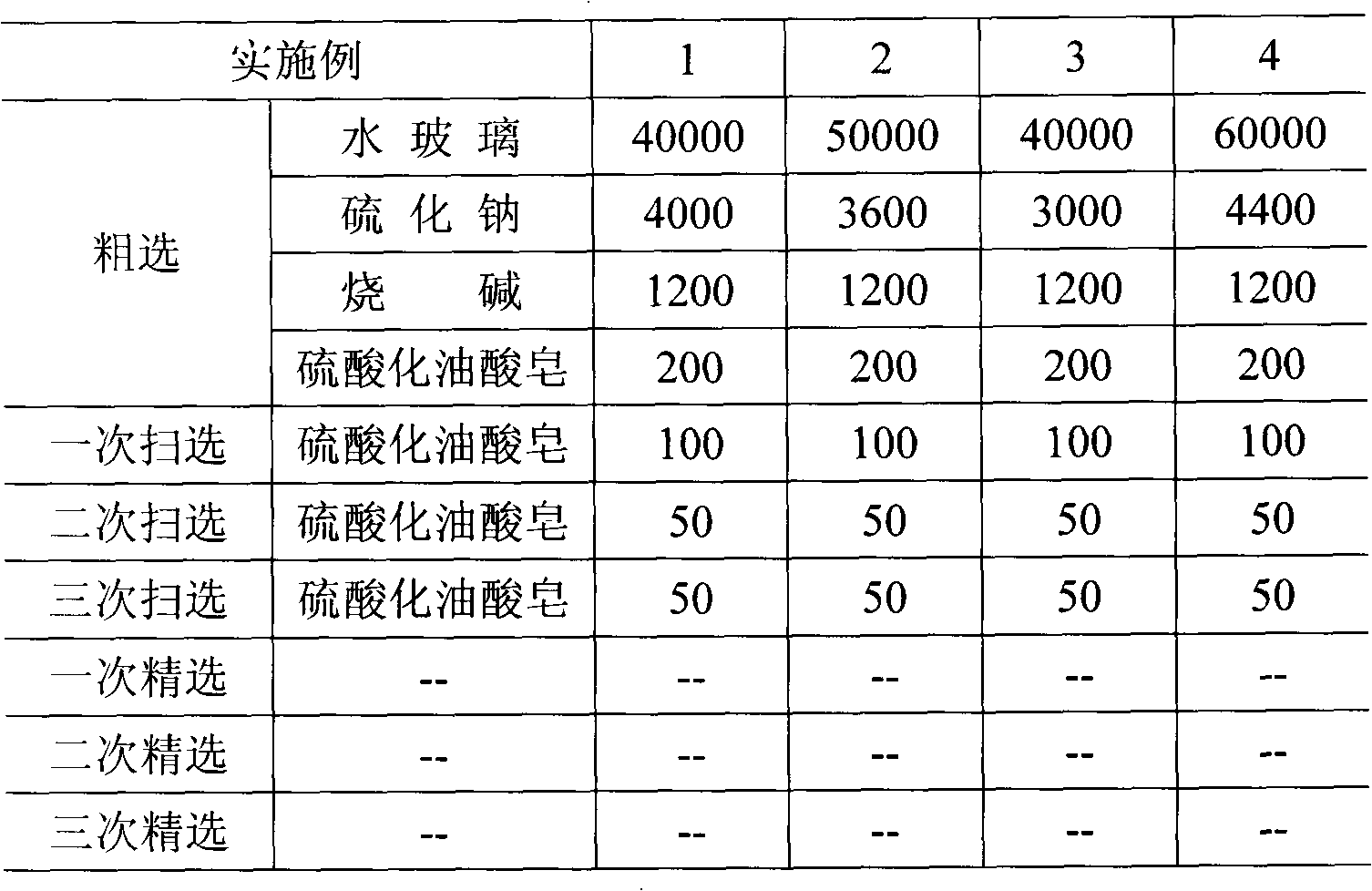

ActiveCN102211053AHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

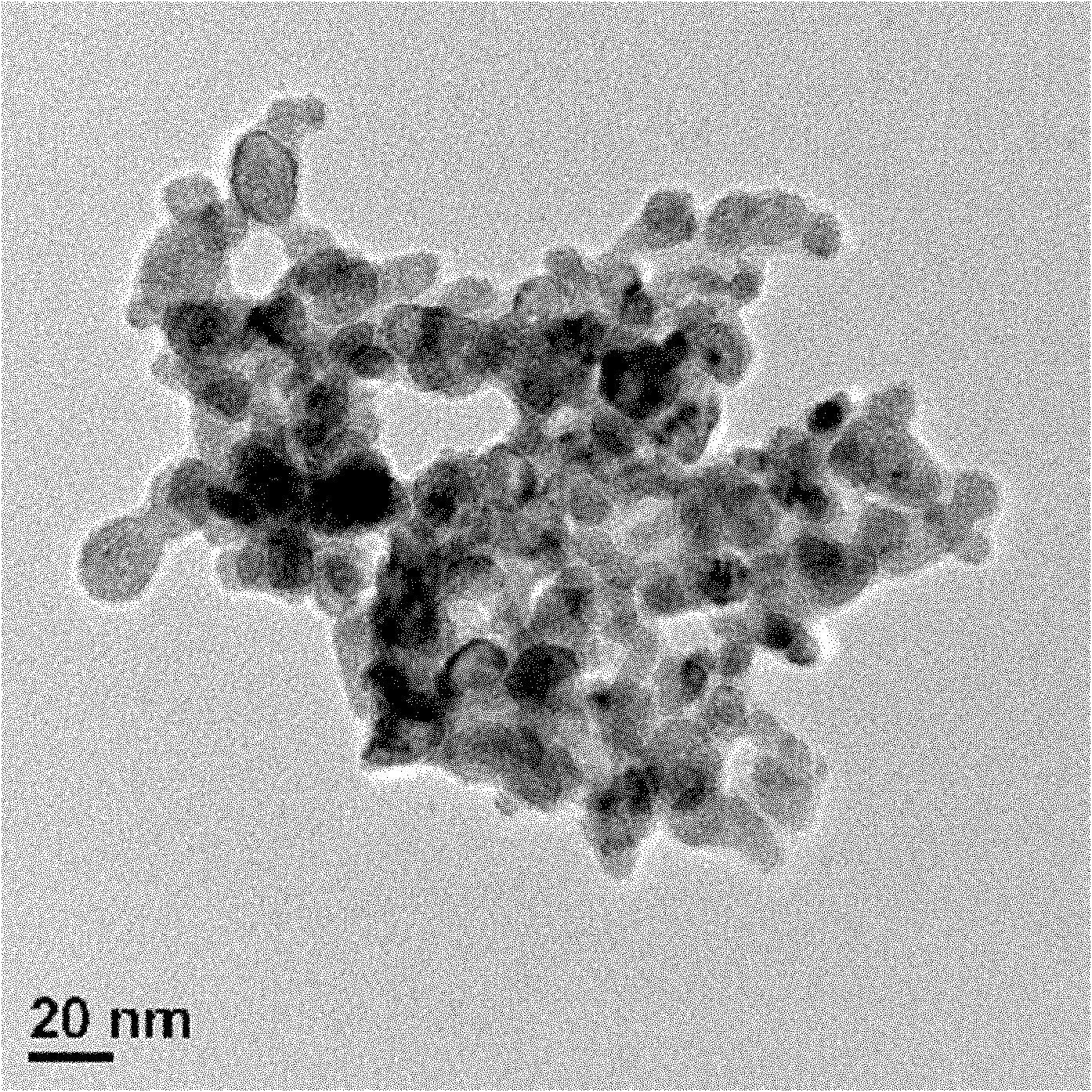

Preparation method of nano-tungsten powder

InactiveCN102019429ASimple preparation processThe preparation process is practicalAir atmosphereAmmonium metatungstate

The invention discloses a preparation method of nano-tungsten powder. The preparation method comprises the following steps: preparing ammonium metatungstate and citric acid into clear mixed aqueous solution; performing complex reaction at the temperature of 60 to 90 DEG C; filtering and drying to obtain the precursor of tungsten oxide; calcining in air to obtain tungsten oxide (WO3) powder; introducing ammonia gas to the tungsten oxide powder for nitridation to obtain tungsten nitride (W2N) powder; and finally performing thermal treatment on the tungsten nitride powder to obtain the nano-tungsten powder. The preparation process disclosed by the invention is simple and practical and has the high operability and is easy in implementation of scale production; the prepared powder has small particle size of which the average particle size is 20-50 nm; the particle size distribution is uniform; and the degree of aggregation is low and high sintering activity is realized. The technology disclosed by the invention can promote the progress of high-quality tungsten material in China and the performance level, and provide means for transforming advantages in tungsten ore resources into industrial and economical advantages.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

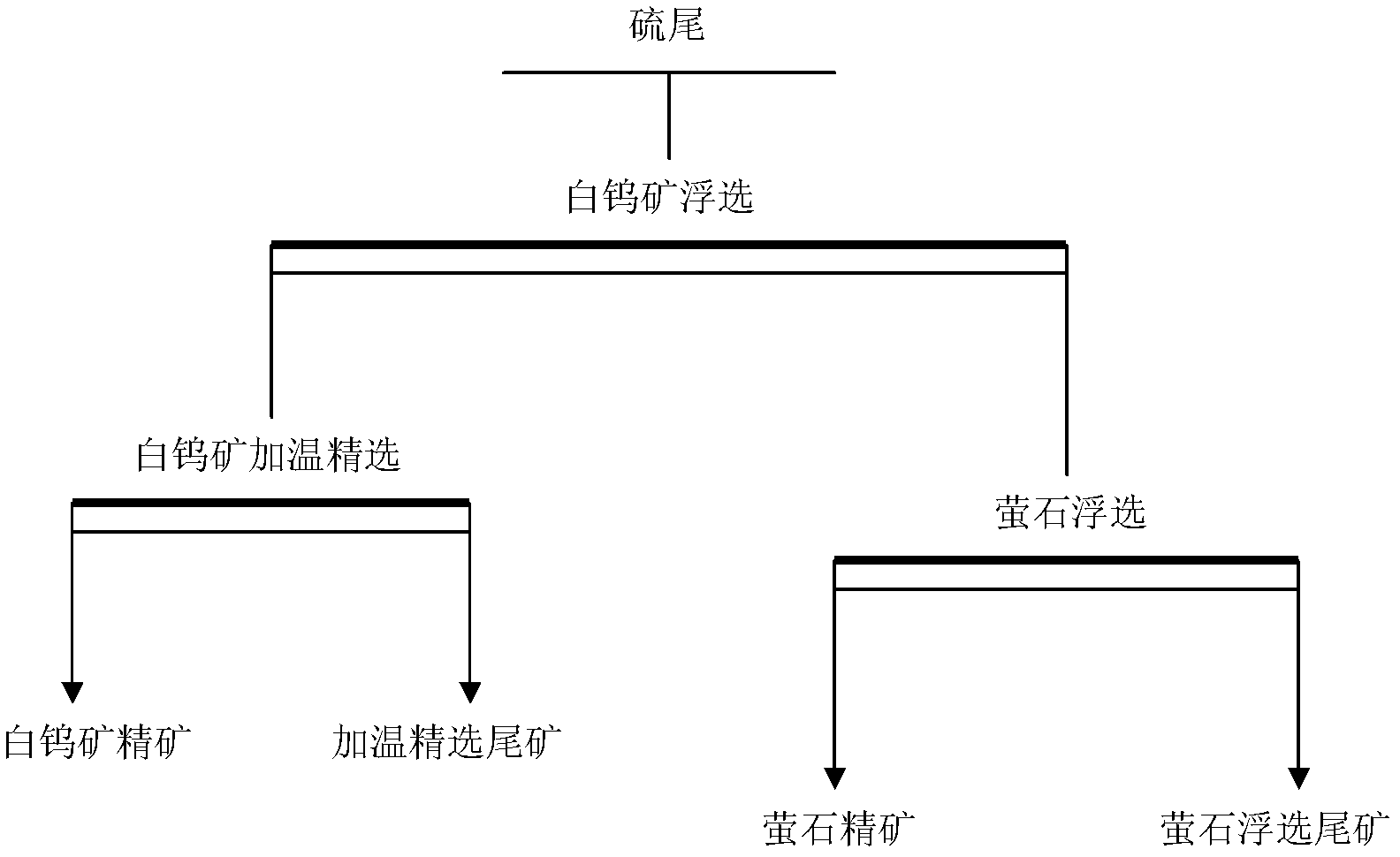

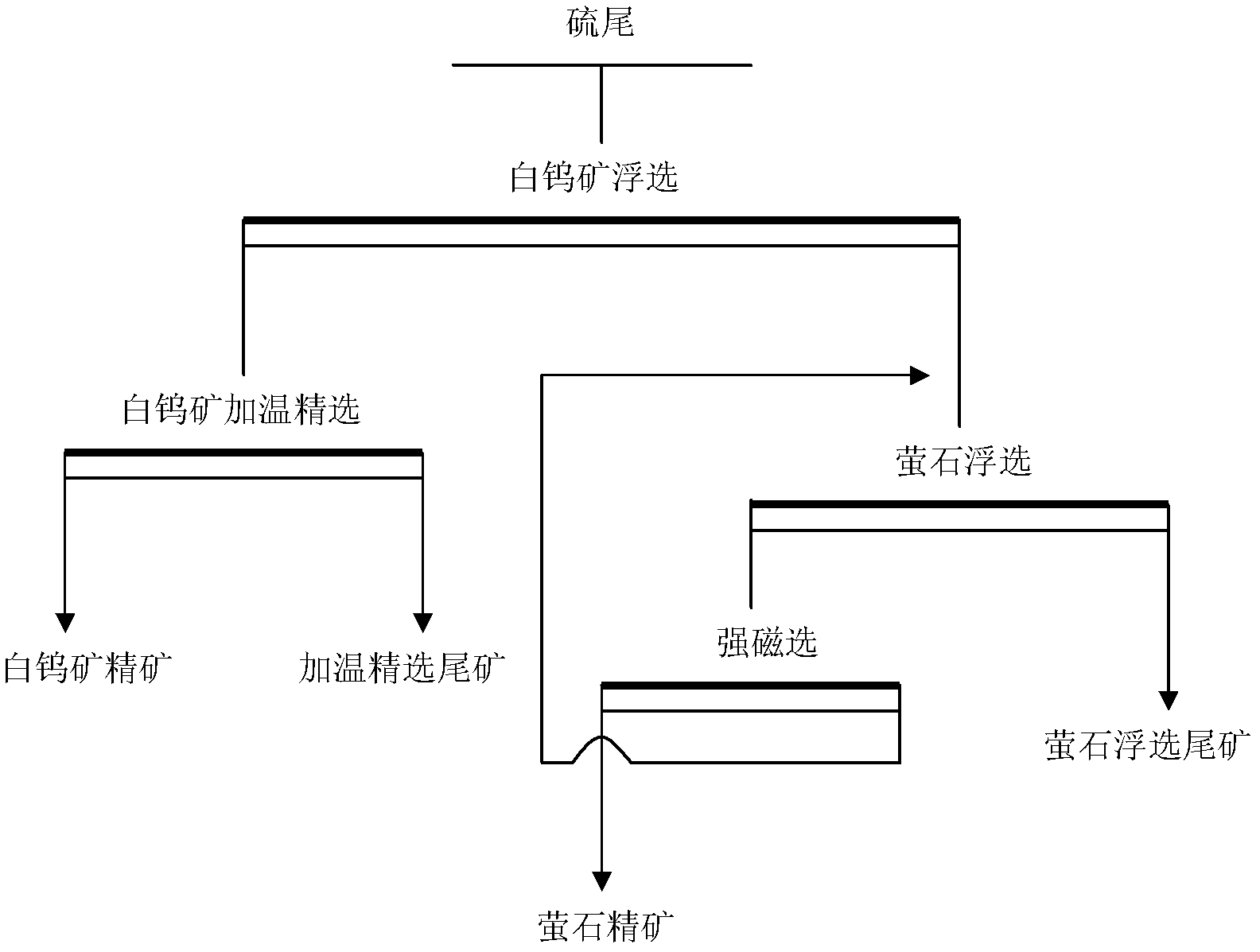

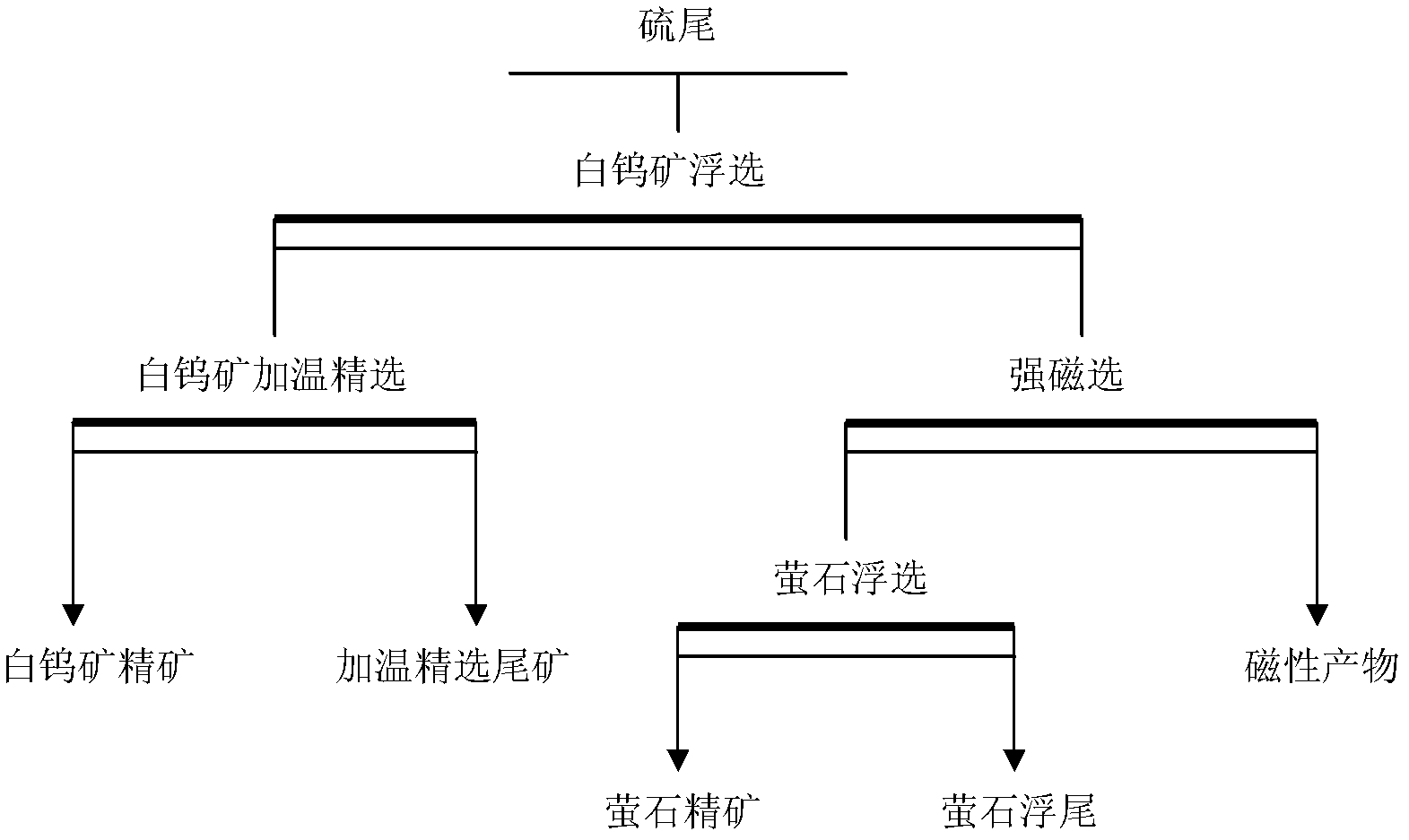

Ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore

InactiveCN102489393AReduce acid consumptionReduce drug consumptionGlass recyclingSolid separationSulfurMaceral

The invention discloses an ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore. The ore dressing method can eliminate the shortcomings caused by a preferential flotation process in the prior art by simultaneously performing bulk flotation on the scheelite and the fluorite and further separating the scheelite from the fluorite, further significantly improve the recovery rate of the scheelite and the fluorite and realize high-efficient recovery of two minerals, namely the scheelite and the fluorite in the polymetallic ore.Furthermore, the scheelite and the fluorite are dressed through a rough concentration bulk flotation and fine concentration separation two-stage process, so that indexes in various stages of operations are convenient to stipulate and control, and quantification of the indexes of the ore dressing process of the scheelite and the fluorite and operation management can be effectively realized.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

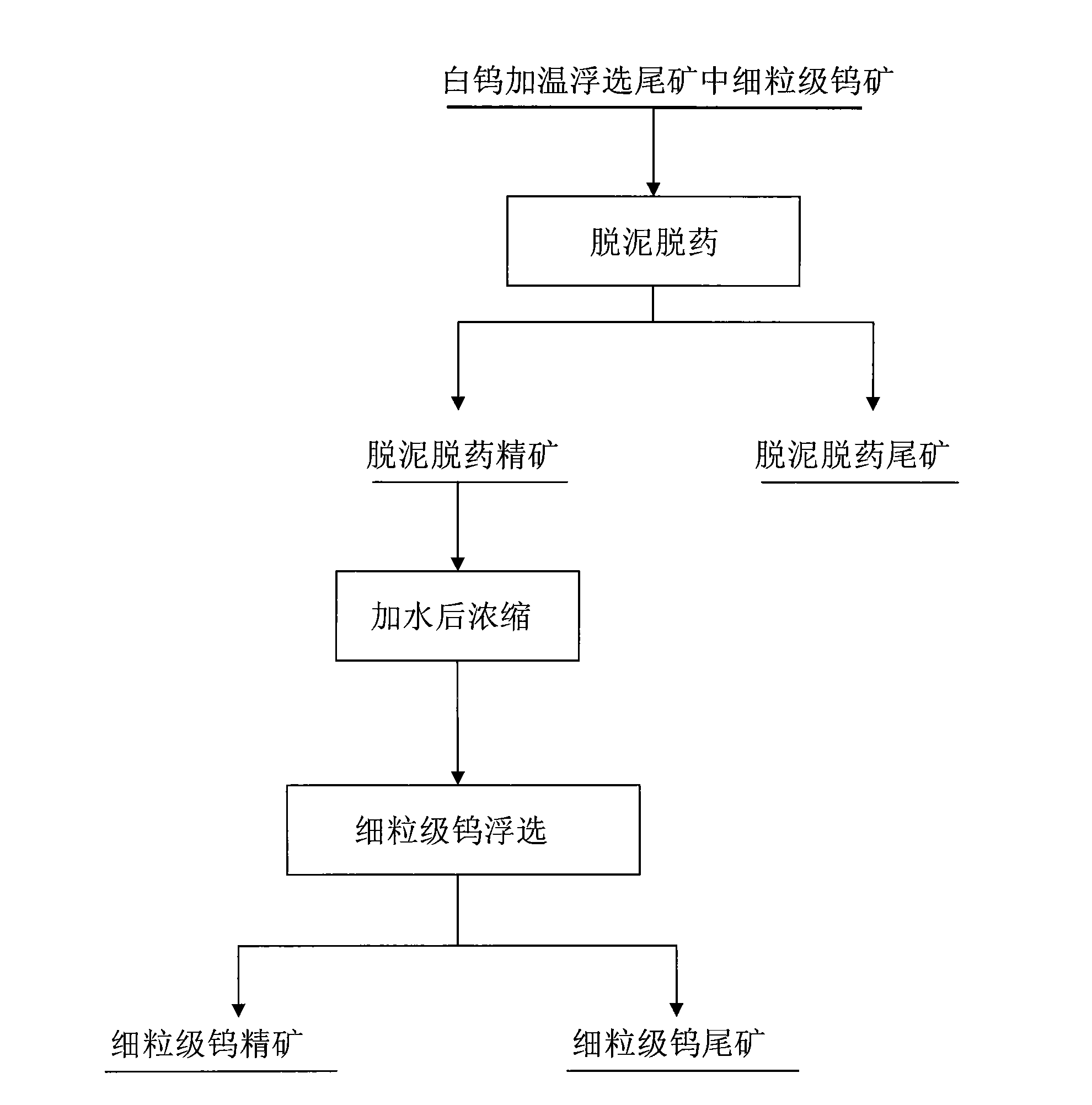

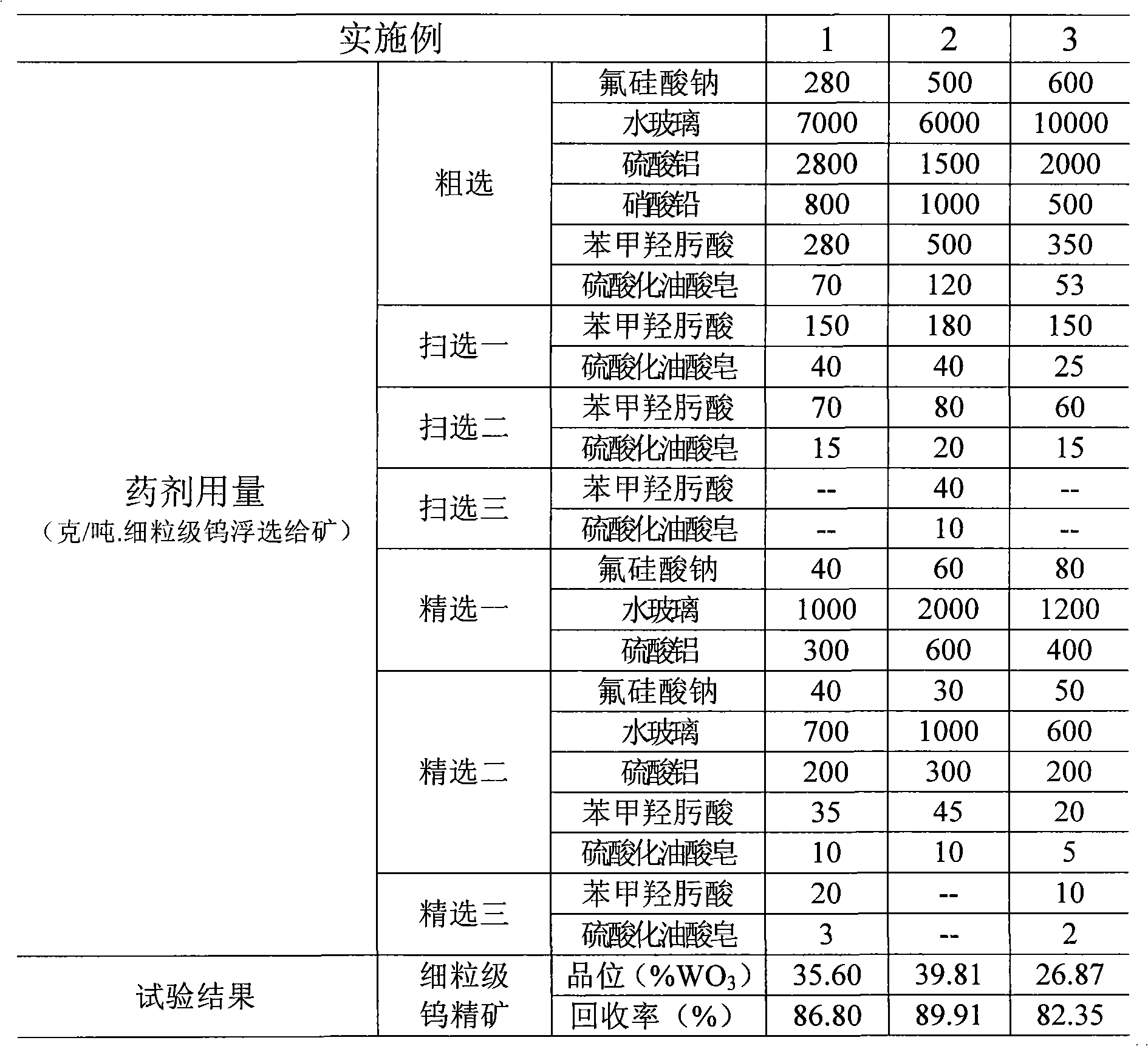

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

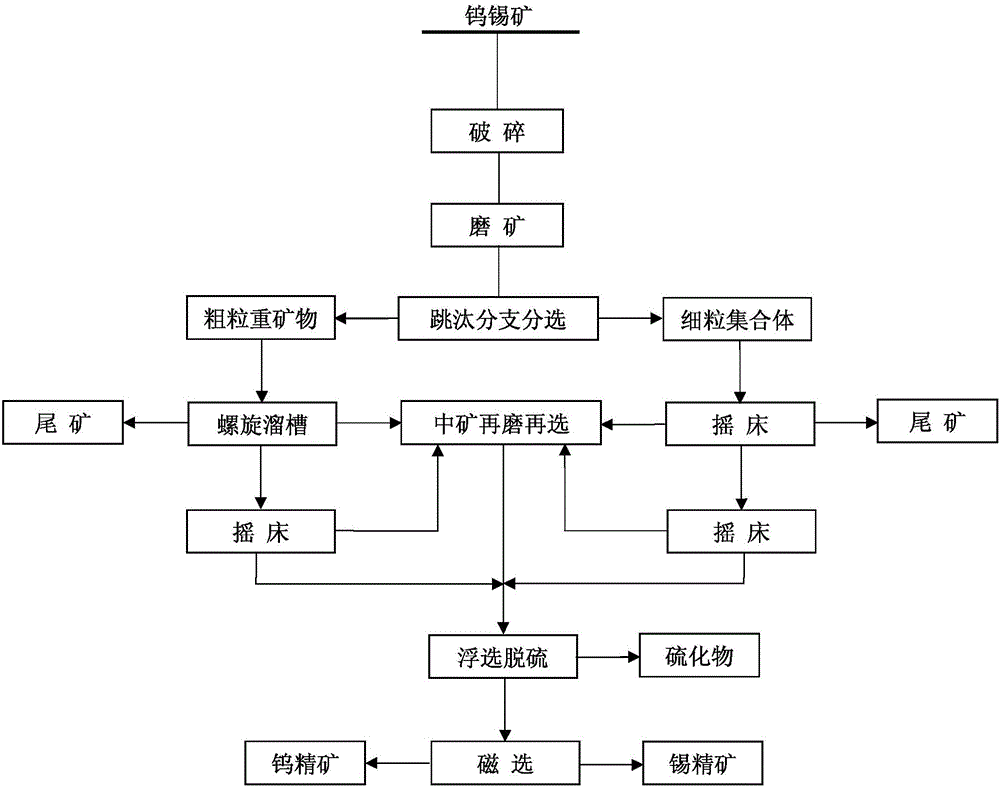

Tin-tungsten ore selection method

InactiveCN105057087AGuaranteed RecoveryEfficient recyclingWet separationSeparation technologyGranularity

Disclosed is a tin-tungsten ore selection method. The method comprises the following steps that tin-tungsten ore is ground to achieve partial monomer separation, and then the jigging branch separation technology is adopted for ore separation to obtain coarse grain heavy ore and fine grain aggregation, wherein the coarse grain heavy ore is monomer tin-tungsten ore with the coarse granularity and rich aggregation with the large specific gravity, and the fine grain aggregation is monomer tin-tungsten ore with the fine granularity and lean aggregation with the small specific gravity; then, separation is performed on the coarse grain heavy ore and the fine grain aggregation, and reselection and recycling of tin and tungsten are achieved. By the adoption of the tin-tungsten ore selection method, tin-tungsten ore can be effectively prevented from being excessively ground or excessively powdered; the technical problems that the main metal ore level is low, the insetting grain size thickness is not uniform and separation is hard are solved; and the fine ore quality and the tin-tungsten recycling rate are better considered, and the high fine ore level and the ore selection recycling rate are obtained.

Owner:广西冶金研究院有限公司 +1

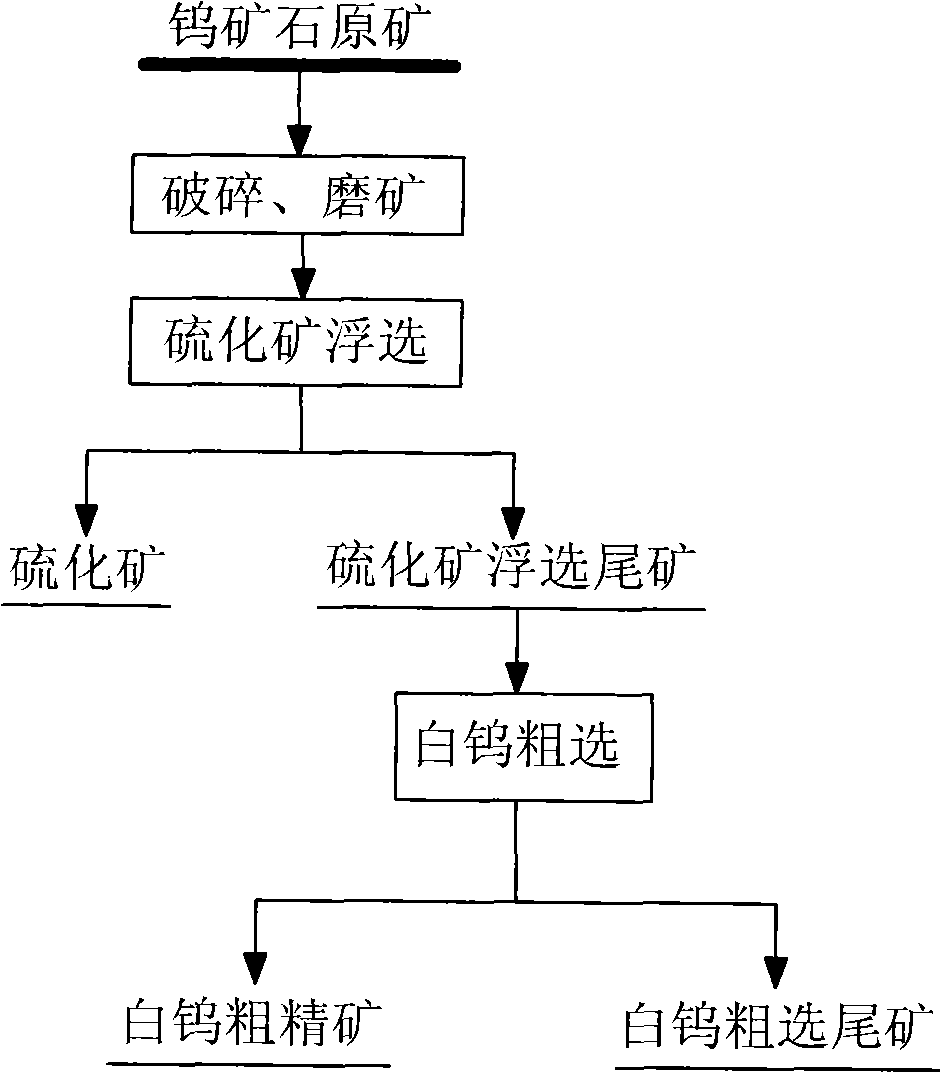

Beneficiation method for recycling scheelite from tungsten ore rich in mispickel

InactiveCN101269353AReduce dosageImprove rough selection indexFlotationSodium silicateMaterials science

The invention relates to an ore dressing method for recycling scheelite from tungsten ore which is rich in arsenopyrite. The method is characterized in that: (1) the flotation of sulphide ore is performed: the tungsten ore is crushed, ground and floated so as to obtain the sulphide ore and sulphide ore flotation tailing which are mainly composed of arsenopyrite; (2) the rough flotation of scheelite is performed: the sulphide ore flotation tailing is mixed with sodium carbonate and sodium silicate, then is added with a collector, namely, sulfating nascent soap; the scheelite concentrate and the coarse ore and the scheelite coarse flotation tailing are obtained by stirring, rough flotation, fine flotation and scavenging. The method provided by the invention is characterized in that the process is simple, the beneficiation reagent has low cost, the recovery rate of tungsten is high, and scheelite concentrate and coarse ore with the recovery rate of tungsten ranging from 80 to 90 percent and containing WO3 which accounts for 4 to 10 percent is obtained.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

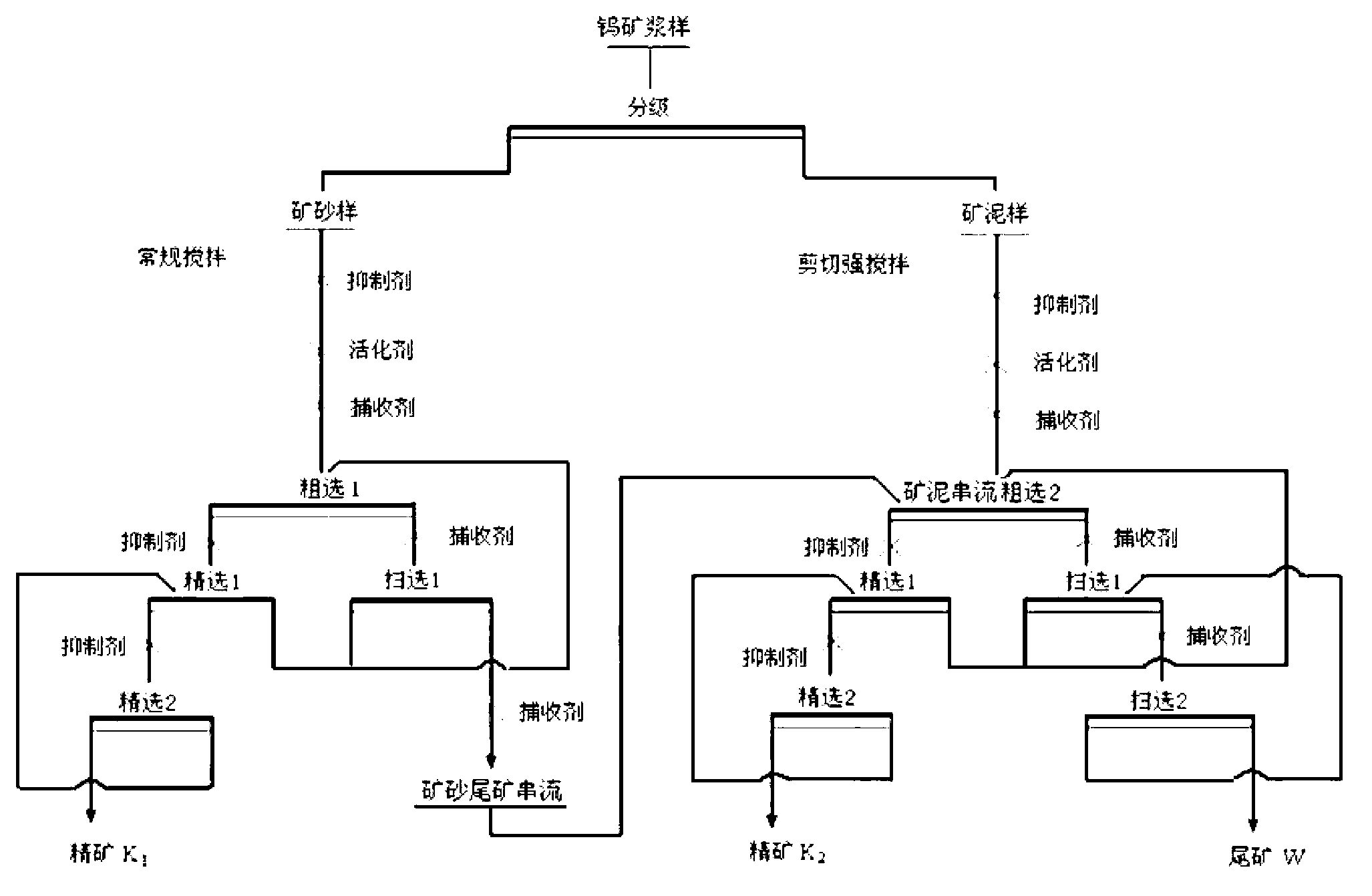

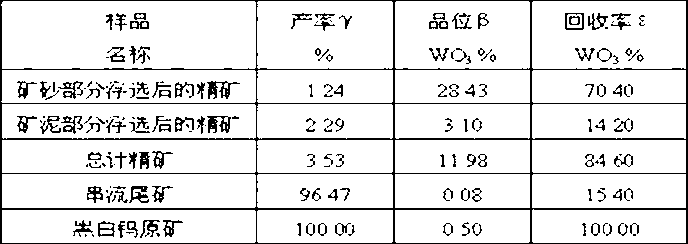

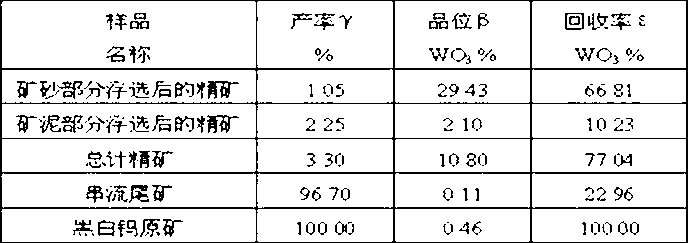

Grading and branching streaming flotation method of tungsten ore

ActiveCN103301946AImprove flotation technical indicatorsImprove sorting indexFlotationRed mudLower grade

The invention discloses a grading and branching streaming flotation method of tungsten ore. The grading and branching streaming flotation method of the tungsten ore comprises the following steps: firstly, finely grinding the tungsten ore; secondly, grading ore pulp of the ground tungsten ore into an ore sand part with a high flotation speed and an ore mud part with a low flotation speed by using grading equipment; thirdly, floating the ore sand part to obtain medium-grade tungsten concentrate and ore sand tailing; and finally, streaming the ore sand tailing to the ore mud part for floating, and obtaining low-grade tungsten concentrate and streamed tailing. By the grading and branching streaming flotation method of the tungsten ore, the size fraction for floating the ore pulp can be improved and the flotation performance and flotation indexes of the ore mud part can be improved.

Owner:中钨共享服务(湖南)有限公司

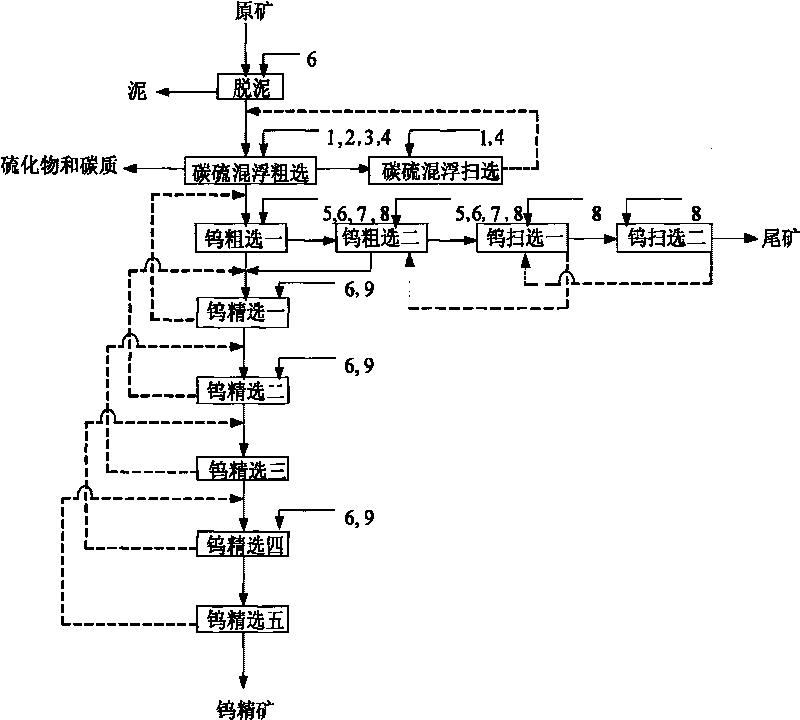

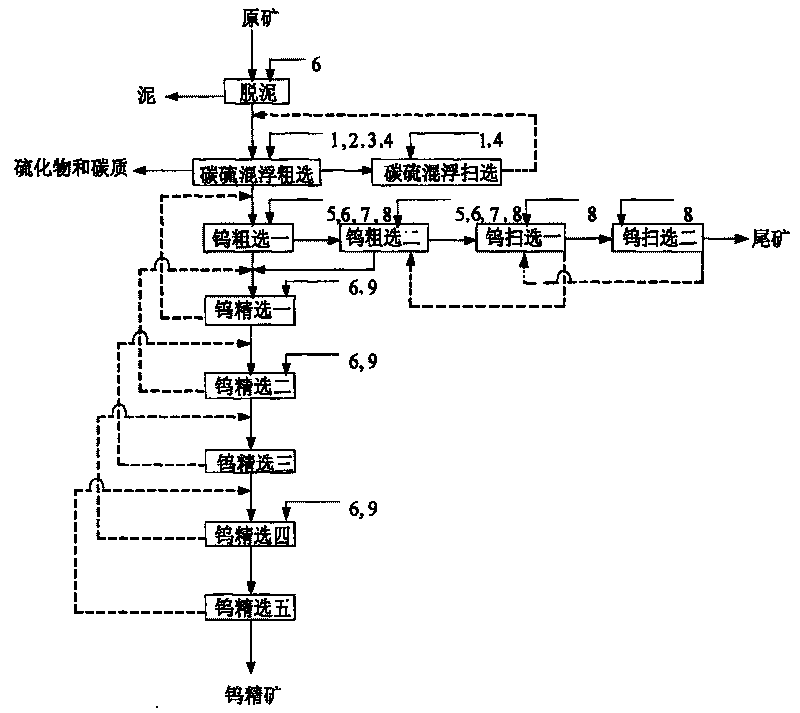

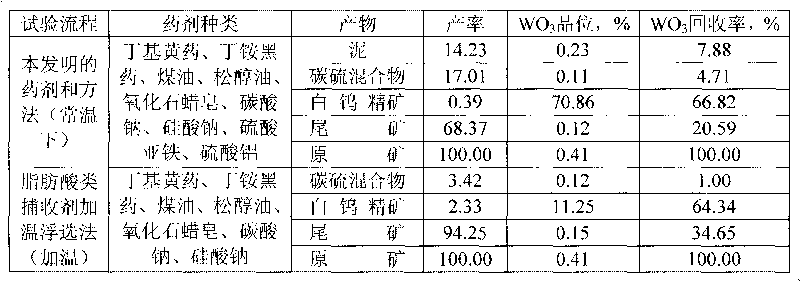

Beneficiation reagent and method for separating scheelite from complex tungsten ore

The invention relates to a beneficiation reagent and a method for separating scheelite from complex tungsten ore; the beneficiation reagent adopts oxidized paraffin soap, kerosene, butyl xanthate, dithiophosphate BA as collectors, adopts sodium carbonate as modifier and terpenic oil as foaming agent, and also adopts one or the combination of Sodium silicate and ferrous sulfate or aluminum sulfate as inhibitor; the method employing the beneficiation reagent for separating scheelite from complex tungsten ore includes: desliming in normal temperature, carbon-sulfide bulk rough floatation, secondary tungsten rough floatation and quintic tungsten concentration, so tailings and tungsten concentrate product are obtained; besides, the invention has the advantages of high sorting efficiency, high yield rate, wide reagent resource, low price, low cost and dosage, simple and reliable process, easy operation and normal temperature working, and is particularly applicable to the beneficiation application of complex tungsten ores.

Owner:ZIJIN MINING GROUP

Method for extracting tungsten from wolframite or scheelite and wolframite mixture ore through adding of high-phosphorus scheelite

The invention provides a method for tungsten from wolframite or scheelite and wolframite mixture ore through adding of high-phosphorus scheelite. In the ore grinding process of tungsten mineral raw materials (wolframite or scheelite and wolframite mixture ore), the high-phosphorus scheelite is added, fine grinding and pulp mixing are carried out, and obtained ore pulp is decomposed through phosphoric acid-sulfuric acid; after the reaction is finished, the tungsten is extracted from an obtained leaching agent, then, sulfuric acid is supplemented again, and mineral leaching is carried out again. The method has the advantages that the limitation that a sulfuric acid-phosphoric acid mixing system cannot treat the wolframite and the scheelite and wolframite mixture ore is broken through, and the wolframite and the scheelite and wolframite mixture ore is efficiently decomposed at the constant temperature and constant pressure under the system; phosphorus in the high-phosphorus scheelite can be comprehensively utilized, and meanwhile, the decomposing rate of the tungsten ore can reach more than 97 percent; the added phosphorus can generate phosphoric acid in the decomposing process, the method can be used for making up the phosphoric acid consumed in the decomposing process, energy is saved, and the leaching cost is reduced; and the whole technological process is convenient to operate, and the industrialization is easily achieved.

Owner:CENT SOUTH UNIV

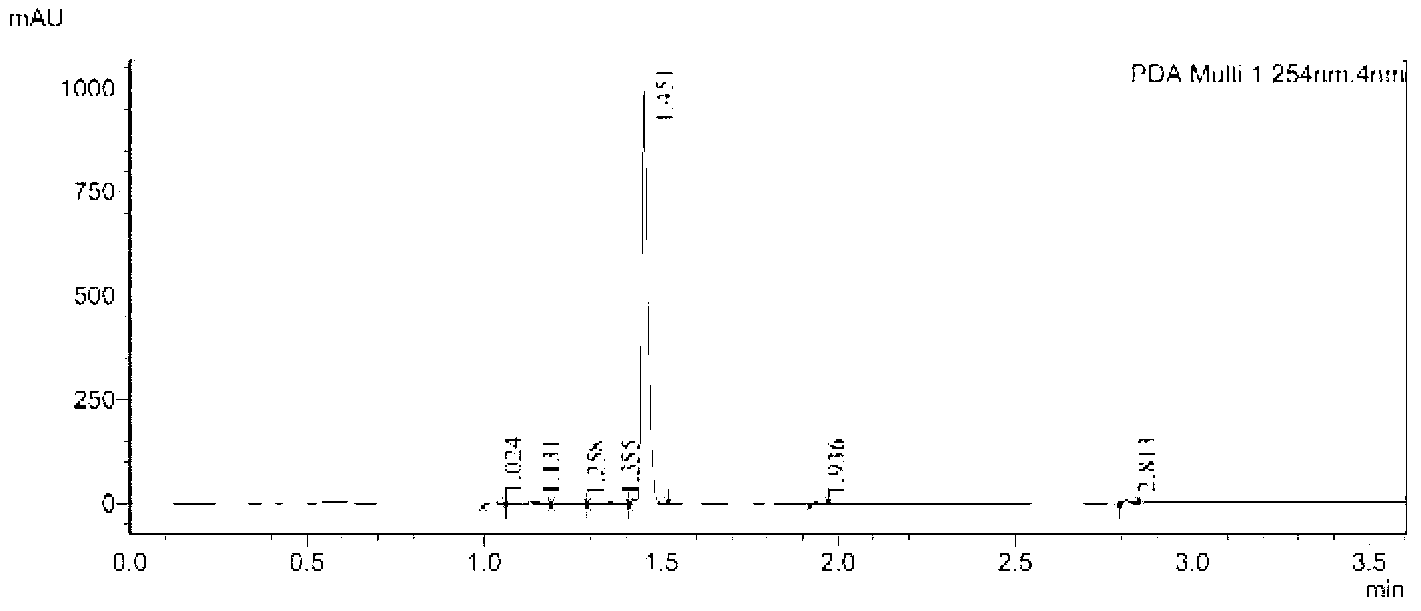

6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301953AStrong harvesting abilityImprove flotation recoveryFlotationPotassium hydroxideSodium hydroxide

The invention discloses a 6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof. 6-aryl amido hexyl hydroximic acid represented by a formula (I) is taken as a collecting agent and utilized in flotation of tungsten ore, tombarthite ore, tin ore or bauxite, wherein R represents H or C1-8 alkyl. 6-aryl amido hexyl hydroximic acid and sodium hydroxide, potassium hydroxide or ammonium hydroxide are put into water to prepare an aqueous solution of 6-aryl amido hexyl hydroxyoximate; a flotation reagent is added for size mixing during an ore grinding and / or flotation process, the added reagent at least contains the aqueous solution of 6-aryl amido hexyl hydroxyoximate, and the dosage of 6-aryl amido hexyl hydroximic acid ranges from 100g / t to 3,500g / t; and useful metallic minerals are floated out through a froth flotation method, and the flotation recovery rate can be increased by 2%-5%.

Owner:CENT SOUTH UNIV

Method for extracting tungsten from wolframite or scheelite and wolframite mixed ores

ActiveCN104878223AEfficient decompositionEasy to operateProcess efficiency improvementDecompositionPhosphoric acid

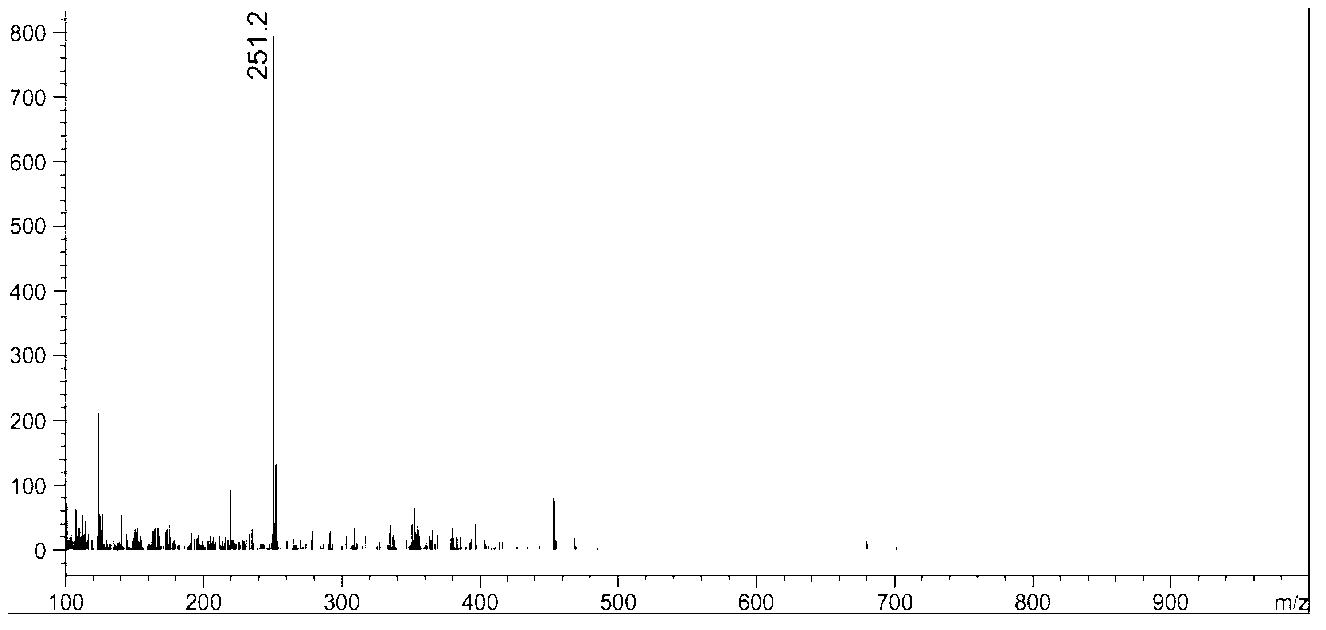

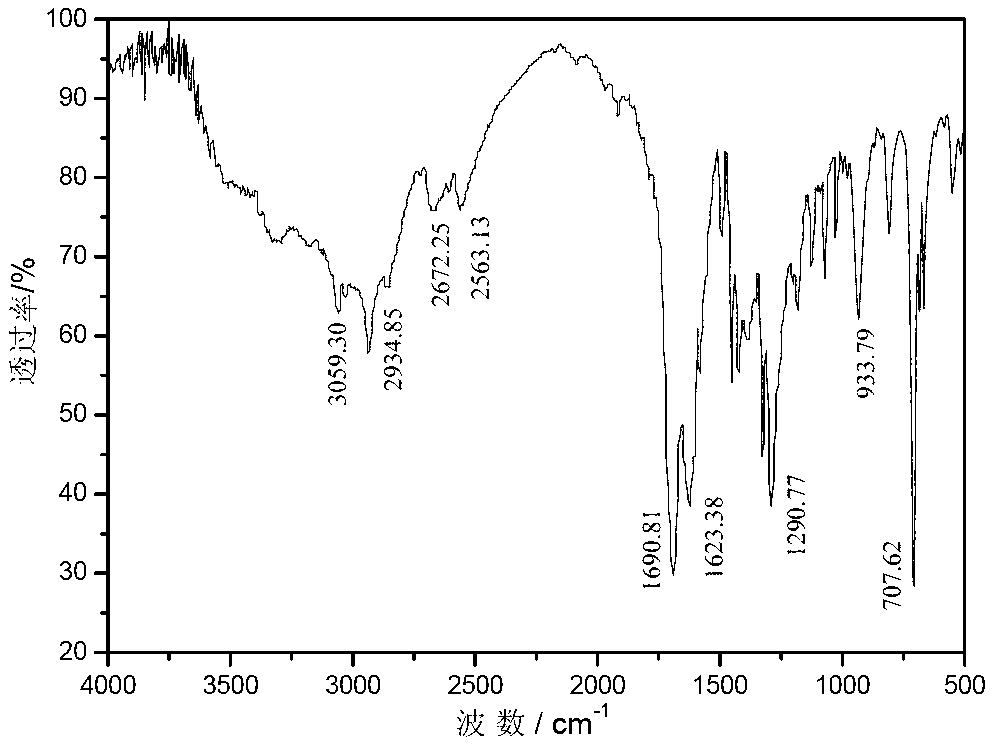

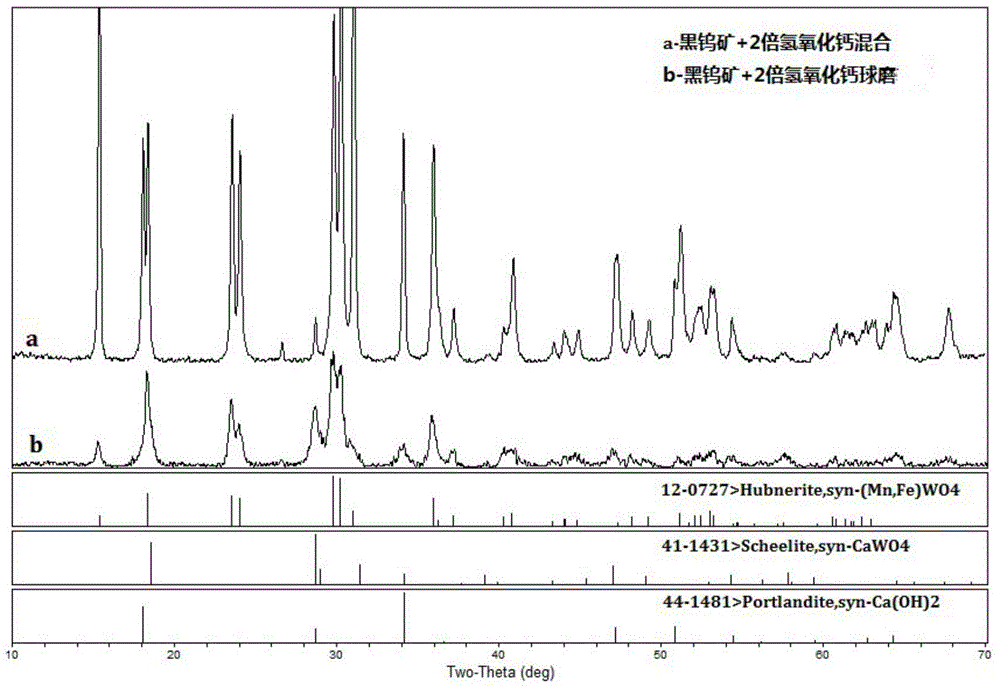

The invention provides a method for extracting tungsten from wolframite or scheelite and wolframite mixed ores. In the process of grinding the tungsten ores (wolframite, scheelite and wolframite mixed ores or tungsten fine silt), an alkaline calcium-containing substance is blended and fine grinding and pulp blending are performed, and then the obtained ore pulp is decomposed by use of phosphoric acid-sulfuric acid. The method has the advantages that the restriction that a sulfuric acid-phosphoric acid mixed system fails in treating the wolframite is broken through, the normal-temperature and normal-pressure efficient decomposition of the wolframite and the scheelite and wolframite mixed ores in the system is realized, and the requirements of the method on the raw material are reduced; for the wolframite, the decomposition rate can be above 98%, and for the scheelite and wolframite mixed ores, the decomposition rate can be above 97%; and the whole process is convenient to operate and prone to industrialization.

Owner:CENT SOUTH UNIV

Tungsten ore floatation collecting agent and application thereof

ActiveCN101757983AIncreased critical micelle concentrationImprove surface activityFlotationAdditive ingredientPhosphoric acid

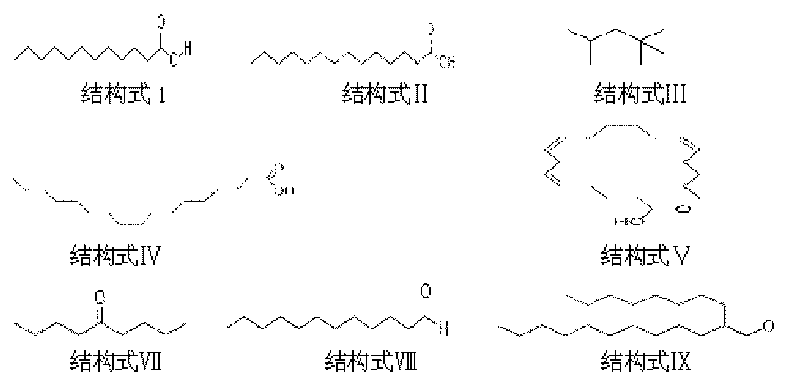

The invention relates to a tungsten ore floatation collecting agent and application thereof. The collecting agent is prepared from the following ingredients in mass percent: 15 to 20 percent of lauric acid, 15 to 20 percent of myristic acid, 10 to 15 percent of isooctane, 20 to 30 percent of oleic acid, 10 to 15 percent of arachidonic acid, 5 to 10 percent of 5-nonanone, 5 to 10 percent of dodecyl aldehyde and 5 to 10 percent of isomer 20 ether. The floatation collecting agent is applicable for wolframine and scheelite floatation. When being used, the floatation collecting agent is added intoraw ore according to the proportion of 200 to 500g / ton. The organic mixture improves the selective collecting capability of fatty acid type medicine agents to the tungsten ore. Compared with oxidizedore collecting agents of alkyl sulfonic acid (alkyl sulfonate), phosphoric acid and swelling acid, the invention can not cause environment pollution. Compared with hydroximic acid, the invention has the advantages that the cost is low, and the pipeline can not be blocked for causing the operation difficulty and the mineral dressing index influence. When being used in the scheelite floatation, theinvention has the predominant collecting performance, and belongs to the high-efficient floatation collecting agent for the wolframine and the scheelite.

Owner:CENT SOUTH UNIV

Low-grade scheelite in molybdenum floatation tailings

InactiveCN101417267AHigh enrichment ratioReduce the number of operationsFlotationLower gradeLow graded

The invention discloses a recycling method of low grade white tungsten in molybdenum selection tailing, after molybdenum selection tailing is floated and desulfurized, white tungsten rougher flotation adopts one rougher flotation, one scavenging and one preconcentration to replace one rougher flotation, scavenging for three times and preconcentration for three times, and rough concentrate with about 1.2 percent of WO3 is obtained. The method reduces scavenging twice and preconcentration twice, the rougher flotation has high recovery rate which can achieve 75 percent, and is about 10 percent higher than the recovery rate of a flotation machine method; and the used device has high processing capacity and small occupied area, thus greatly reducing the operating personnel and labor intensity.

Owner:CINF ENG CO LTD

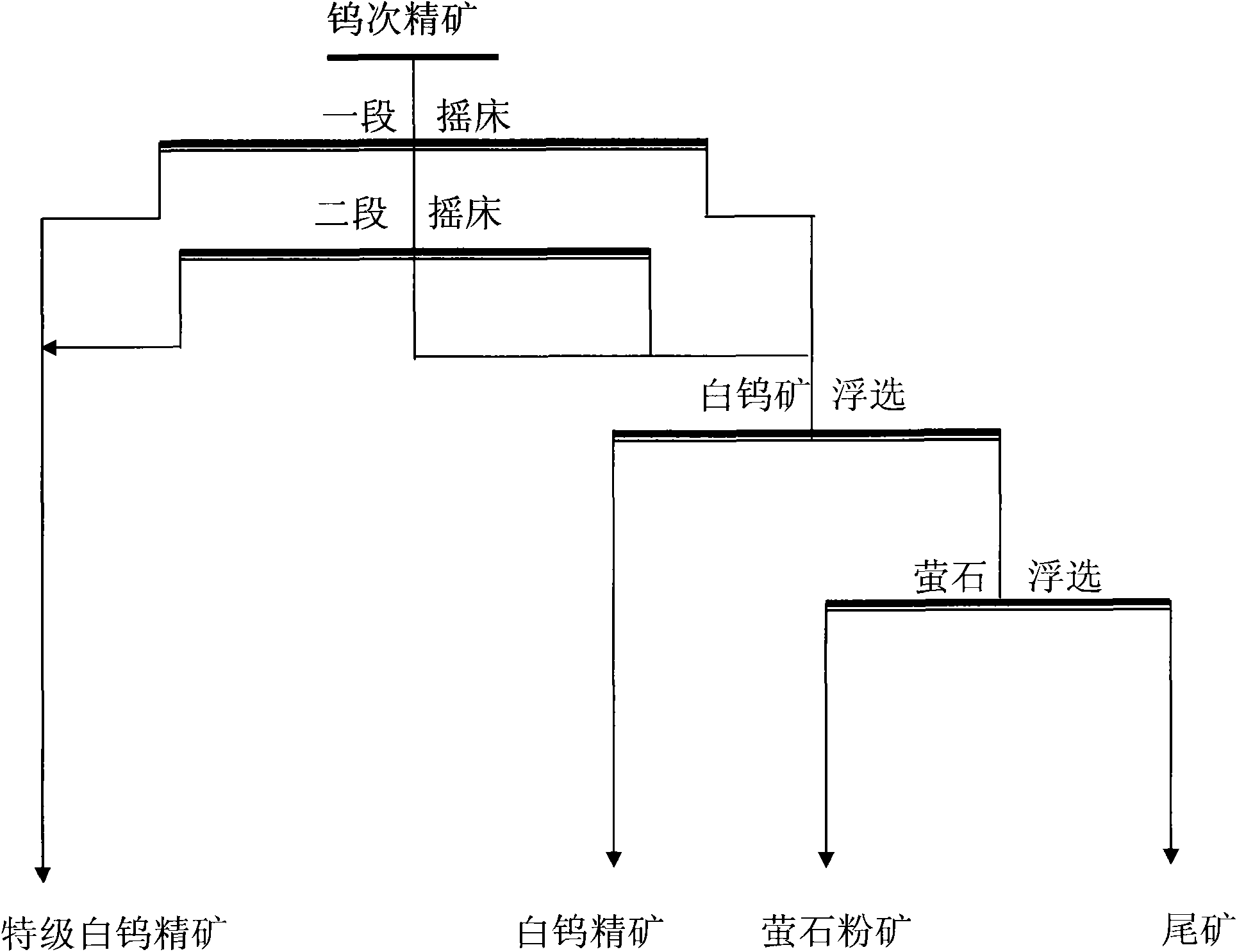

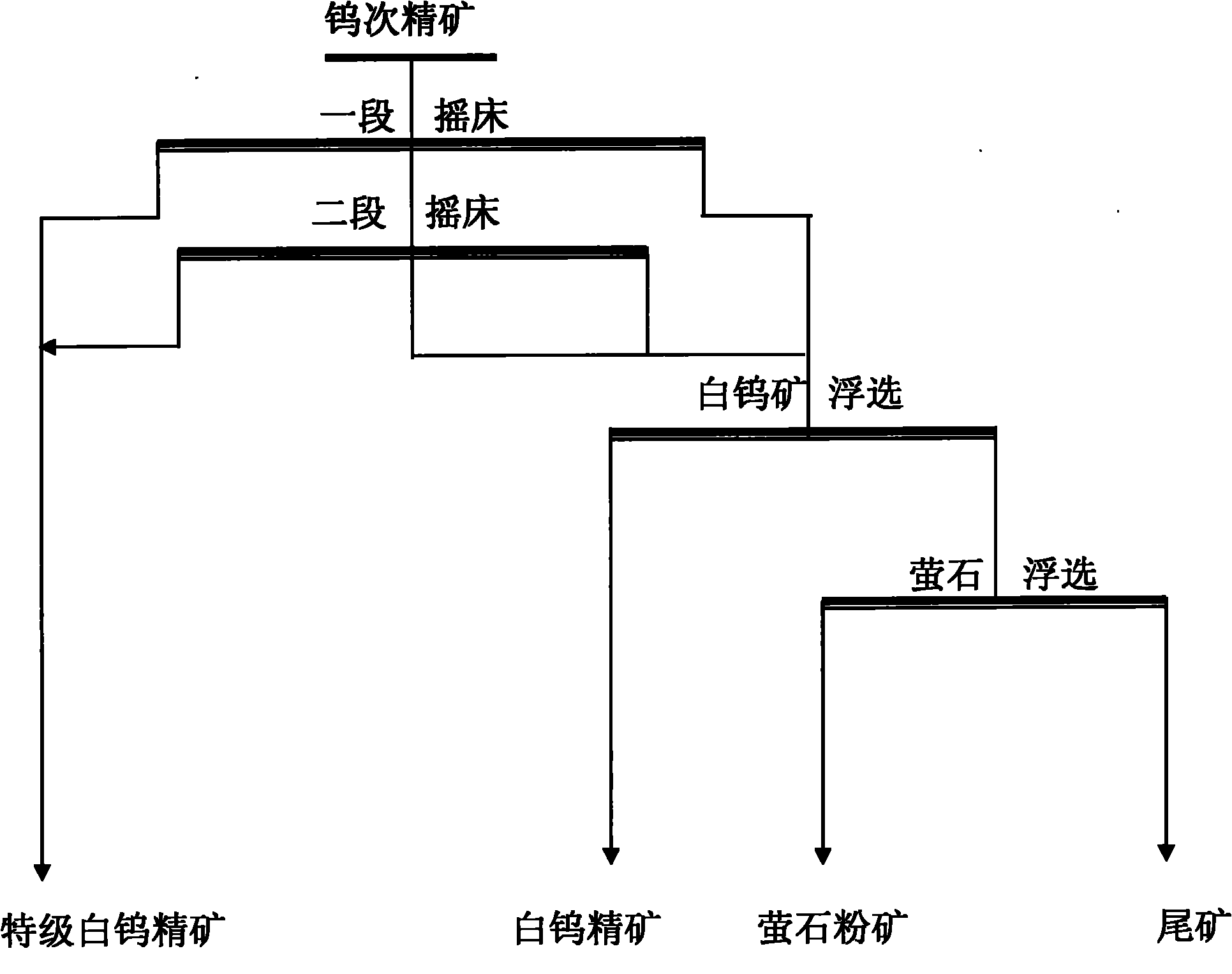

Method for separating scheelite from fluorite

InactiveCN101979145AReduce contentLow fluorine contentFlotationWet separationAmmonium paratungstateTungsten trioxide

The invention relates to a method for separating scheelite from fluorite and belongs to the technical field of mineral dressing of metal mines. The method comprises the following steps of: preparing ore pulp from tungsten secondary concentrate ore containing 30 to 60 weight percent of tungsten trioxide; carrying out two stages of separation by adopting shaking tables; then making middlings of a first-stage shaking table enter a second-stage shaking table to be separated so as to produce special grade white tungsten concentrate ore products containing over 70 weight percent of tungsten trioxide; concentrating the middlings and tailings, which are separated by the shaking tables, to 50 to 60 weight percent in a centralizing mode, then adding water glass and TN into the concentrated middlings and tailings, and uniformly stirring the mixture in a stirring barrel for flotation; diluting flotation pulp to 20 to 30 weight percent, regulating the pH of the diluted flotation pulp to 9 to 10, and adding an inhibitor KJ and a collector YY to produce white tungsten concentrate ore containing over 65 weight percent of tungsten trioxide; and further carrying out flotation on the flotation tailings to obtain fluorite powder ore containing over 85 percent of calcium fluoride. The method has the advantages of high mineral dressing index, simple process, low production cost, environmental protection and capability of better solving the environmental problems of ammonium paratungstate manufacturing enterprises, which are caused by high fluorine content of raw materials.

Owner:YUNNAN TIN GROUP HLDG

Method of treating scheelite

ActiveCN108754123AReduce the difficulty of leachingImprove leaching efficiencyTungstateMagnesium salt

The invention discloses a method of treating scheelite, comprising: mixing scheelite and a magnesium salt, and roasting at high temperature; washing the roasted product via water; performing acid leaching or alkali leaching to obtain tungstic acid or tungstate solution. The magnesium salt is utilized in the method to convert CaWO4, difficult to extract by acid or alkali leaching, in scheelite intoMgWO4 easy to extract by acid or alkali leaching; tungsten ore leaching rate is increased. The method helps solve the problem tungsten is difficult to extract directly from calcium tungstate.

Owner:CENT SOUTH UNIV

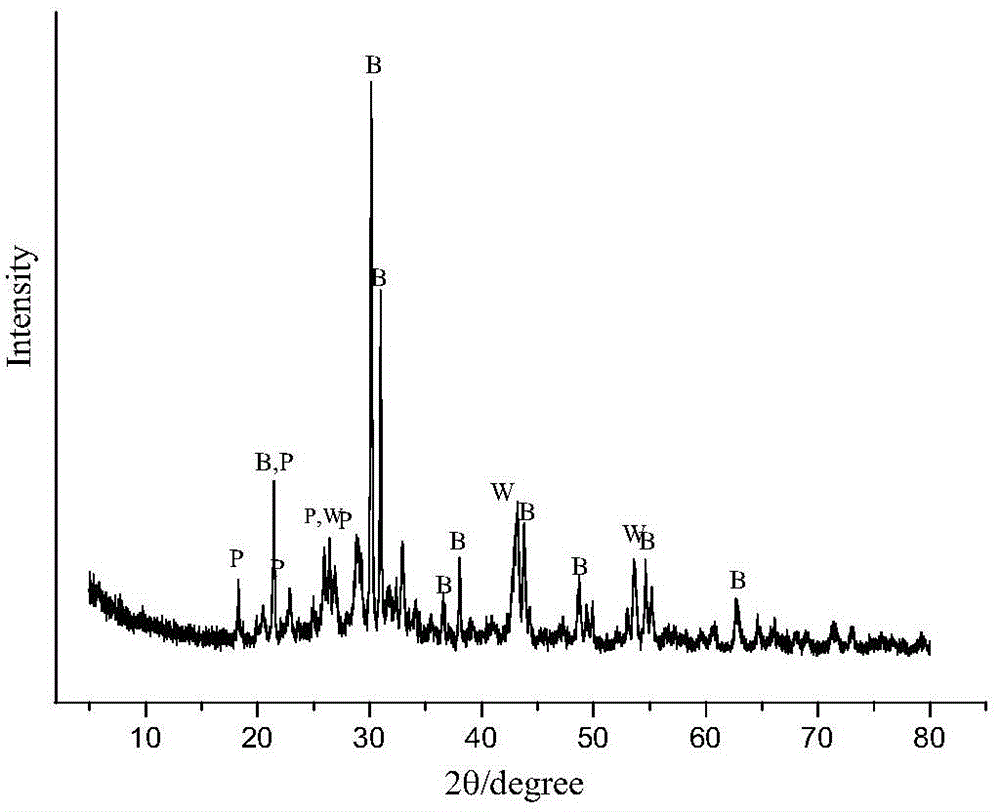

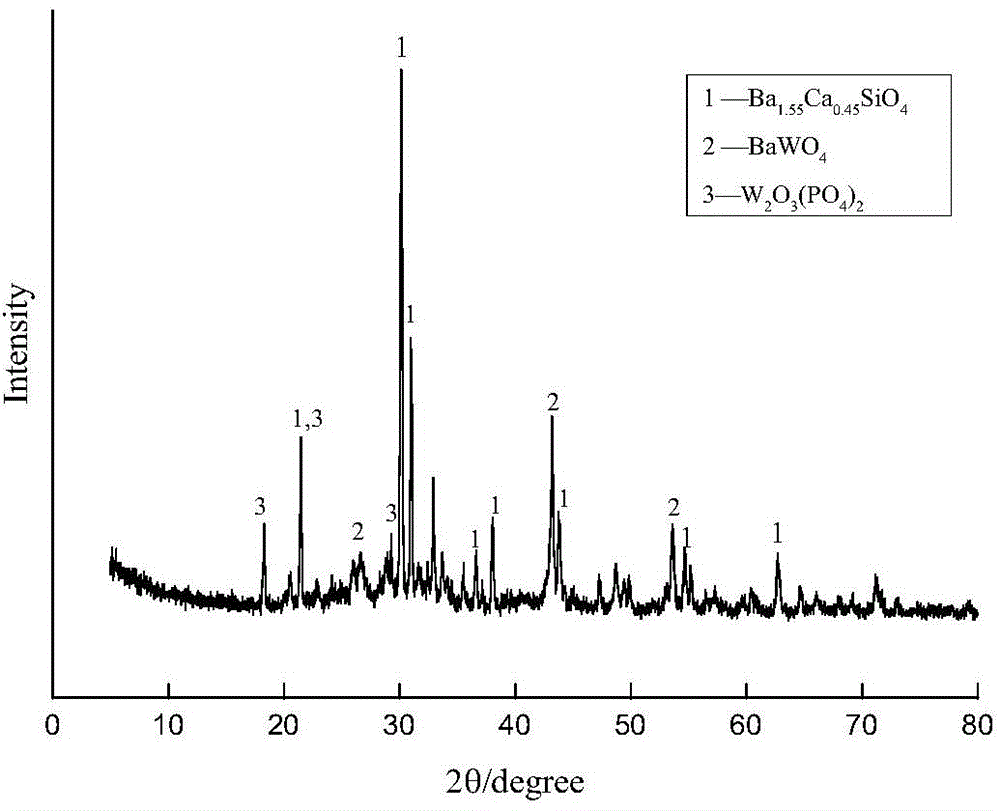

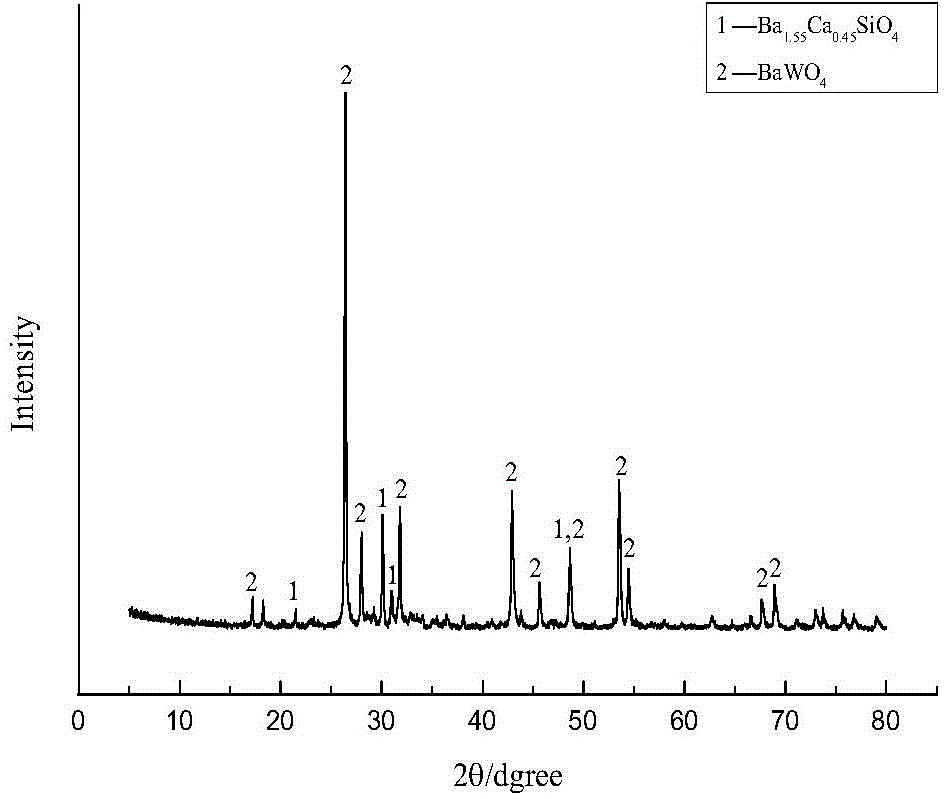

Method of extracting tungsten from high-barium tungsten ore

InactiveCN104372169ASolve the low leaching ratePrevent precipitationProcess efficiency improvementHigh concentrationSlag

The invention discloses a method of extracting tungsten from high-barium tungsten ore. The method includes: mixing the high-barium tungsten ore and a certain amount of SiO2 and Na2CO3 to obtain mixture, roasting the mixture at the high temperature, and leaching roasting slag with Na2CO3 to obtain tungsten. By roasting the Na2CO3 and SiO2, the structure of the high-barium tungsten ore is fully broken to obtain stable (Ba or Ca)2SiO4 slag which is leached with high-concentration Na2CO3, water-soluble calcium and barium ions in roasting material are deposited, deposition of tungsten ions is prevented, leaching rate of the tungsten is greatly increased, reaching greater than 95%, and the problem that the high-tension alkaline leaching methods of the prior art fail to break the barite structure, leading to low leaching rate, is solved. The method according to the technical scheme is simple to operate, raw materials are cheap, processing can be performed with traditional equipment, and the method fully satisfies industrial production.

Owner:CENT SOUTH UNIV

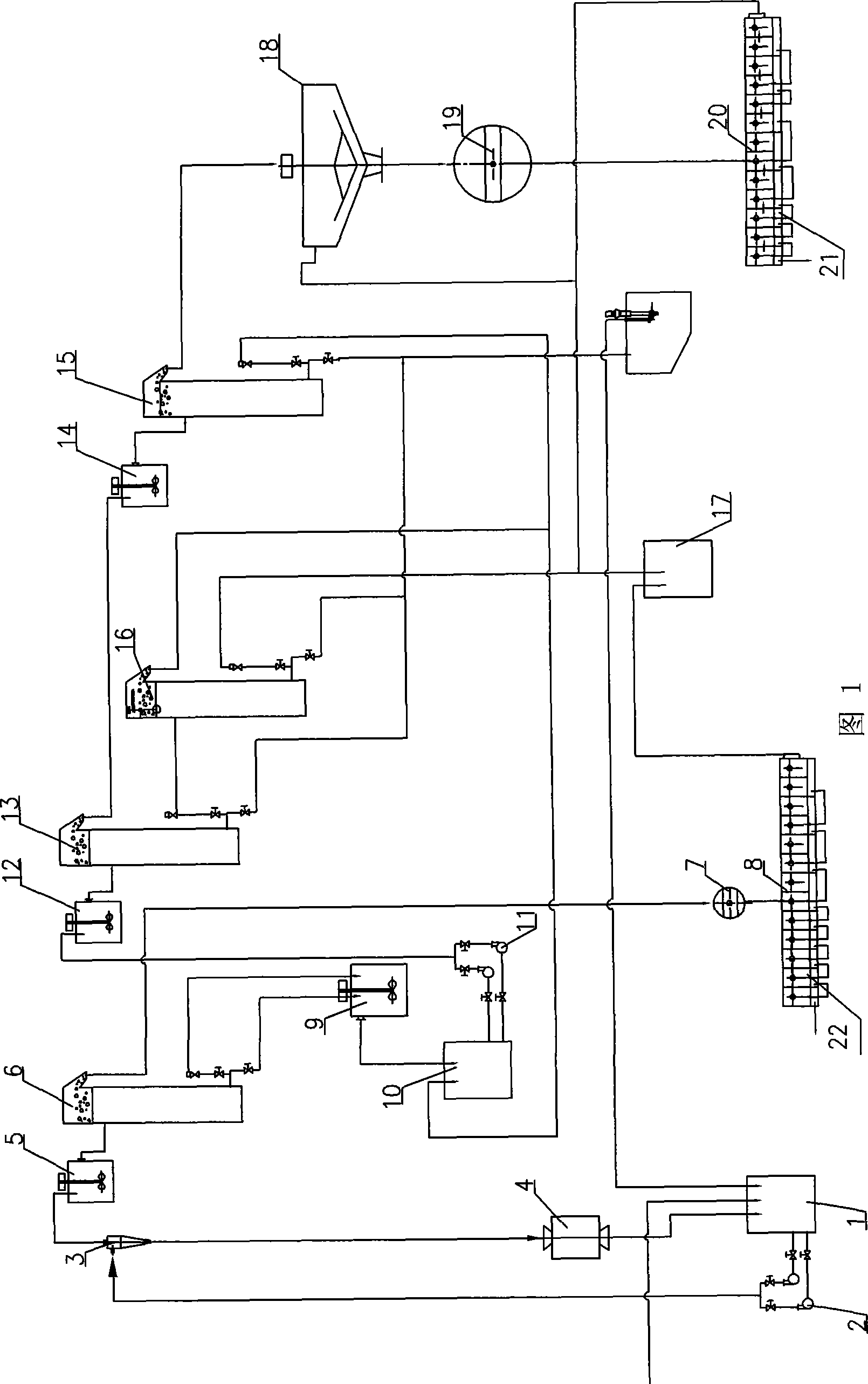

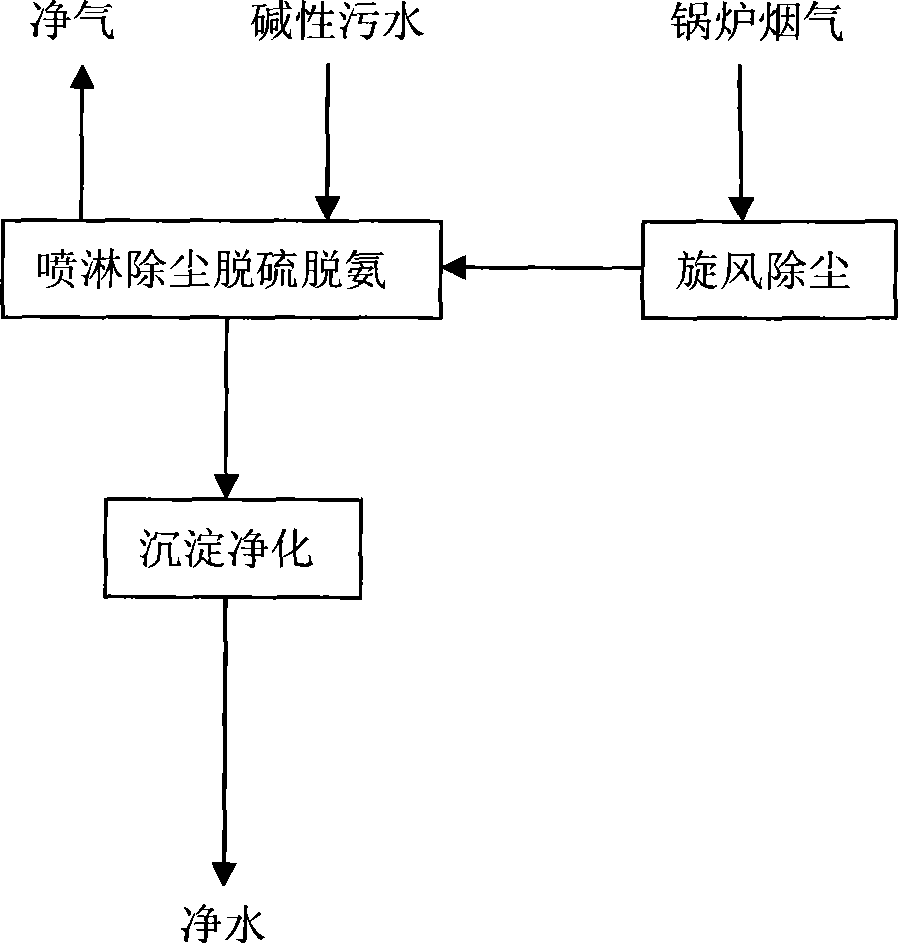

Method for processing waste water/gas from tungsten smelting and a device thereof

InactiveCN101530737AReduce consumptionSave waterDispersed particle separationWater/sewage treatment by neutralisationCycloneAir volume

The invention relates to a method for processing waste water / gas from tungsten smelting and a device thereof. The method is to directly implement the processing of the waste water / gas by utilizing alkali waste water, which is generated by extracting ammonium tungstate from tungsten ores by an ion exchange method, and by utilizing smoke gas generated by a boiler furnace, and the method comprises the following steps of: cyclone dust removal, spray dust removal, desulfurization, deamination, controlling the temperature of the primarily dust-removed smoke gas of the boiler furnace in a range from 140-200 DEG C, diffusing from bottom to top the air quantity of 13000-18000 m<3> / H and controlling the flow quantity from top to bottom in a range from 13-15 m<3>H, spraying the alkali waste water for exchange absorption for removing fine particle dusts and SO2 in the smoke gas and free ammonia in the alkali waste water, exhausting net gas after the spraying absorption to the air and discharging purified water after deposition; the device for realizing the method for processing waste water / gas from tungsten smelting comprises; a water pump, a multitubular cyclone dust extractor, a dust-removing desulfurization deamination nitrogen column and a water processing pond. The invention has the advantages of simple technological steps, small investment of the device, easy operation, low processing cost and primary standard exhaust of the waste water / gas.

Owner:FUJIAN JINXIN TUNGSTEN

Beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore

InactiveCN106076590AEliminate the need for deslimingThe beneficiation process is simpleFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Iron mine oxidized ore flotation green collector and production process thereof

The invention relates to an iron mine and oxidized ore beneficiation and flotation agent and a production method thereof and specifically discloses an iron ore and oxidized mine flotation anion collector; the main preparing agents of the anion collector are fatty acid modifier and derivatives thereof; assisting agents of the collector also comprise fatty alcohol, emulsifier and water. The production method of the collector comprises the following steps of compounding the main agents by organic action, then weighting rest components according to certain mass fractions, mixing according to a certain sequence, and uniformly stirring to prepare the micro-emulsion homogeneous phase viscous liquid. The collector has the advantages of strong collecting capacity, strong argillization resistance, low production cost, hard water resistance, stable performances, small agent use level, good selectivity, environment friendliness, safety and adaptivity to low temperature. By changing the variety and use level of the main agents, the series of collectors can be used for the flotation of diversified iron mines, phosphorite mines, fluorites, tungsten mines, rare earth mines, ilmenites and diversified oxidized mines.

Owner:肖国光 +1

Ore selecting method for recovering scheelite from gneiss-type ore

The invention provides an ore selecting method for recovering a scheelite from a gneiss-type ore. the flotation process is used, the method comprises the steps of ore grinding, roughing separation, fine separation and scavenging and is characterized in comprising the following specific steps of: regulating a PH (Potential of Hydrogen) value of ore pulp to 7-9 by using a regulation agent in floatation gneiss-type ore raw pulp of which the mass concentration is 25-60 percent when the roughing separation is performed, and then adding polyacrylamide according to 0.01-0.05 percent of an ore solid mass in the ore pulp and adding sulfoleate according to 2-10 percent of the solid mass in the ore pulp; and obtaining an ore concentrate of the scheelite after performing the fine separation and the scavenging. According to the method provided by the invention, only the polyacrylamide and the sulfoleate are added in the traditional flotation pulp-mixing process without changing the traditional flotation process flow; the operation is convenience; the production cost is low; the ore selecting recovery rate and the ore concentrate grade are high; and the total recovery rate is over 85 percent.

Owner:KUNMING UNIV OF SCI & TECH

Method for smelting high-speed steel by employing oxide ore

The invention discloses a method for smelting high-speed steel by employing oxide ore. During the smelting process, tungsten ore, molybdenum oxide and vanadium oxide are added at the same time to alloy smelting high-speed steel, and the alkalinity and the blowing oxygen and fluxing are controlled; the direct alloying rate can be that W(tungsten)% plus Mo(molybdenum)% plus V(vanadium)% is equal to 13%; the yield rate of alloy elements is higher than that of the method of the ferroalloy alloying high-speed steel and alloying smelting high-speed steel by less than two oxide ores. The invention can realize direct production of the alloying smelting high-speed steel by entirely adopting of the oxide ore, and has the advantages of short smelting time, fast alloy element reduction speed, high directly alloying ratio and high alloy yielding, and the smelting cost and the comprehensive energy consumption are low, leading to good economical benefit.

Owner:CENT IRON & STEEL RES INST

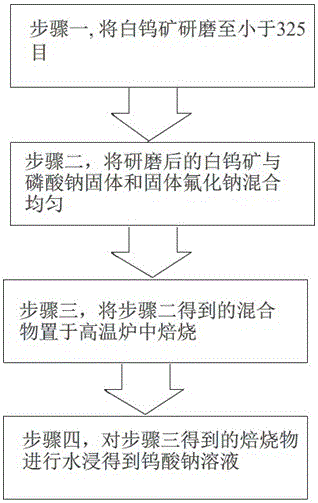

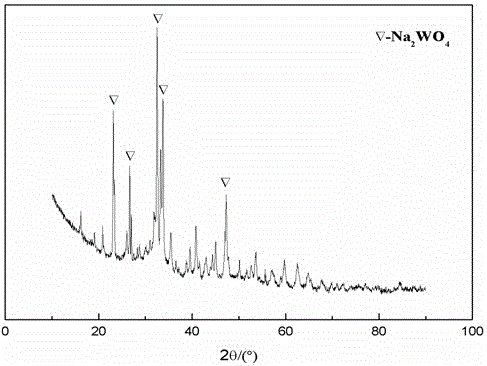

Method for extracting tungsten from scheelite

ActiveCN105969977AFacilitate continuous productionEasy to operateProcess efficiency improvementSodium phosphatesHigh pressure

The invention relates to a method for extracting tungsten from scheelite. The method comprises steps as follows: Step 1: the scheelite is ground to have the mesh number smaller than 325; Step 2: the ground scheelite is mixed with solid sodium phosphate and solid calcium fluoride, and a mixture is obtained; Step 3: the mixture is placed in a high-temperature furnace for calcination, and a calcination material is obtained; Step 4: the calcination material is subjected to water leaching treatment, a sodium tungstate solution is obtained, and the tungsten is extracted from the scheelite. According to the method for extracting the tungsten from the scheelite, reactions can be conducted in a normal-pressure environment, high-pressure equipment is not required, continuous production can be realized easily, and the method is more convenient and safer to operate.

Owner:赣州海盛钨业股份有限公司

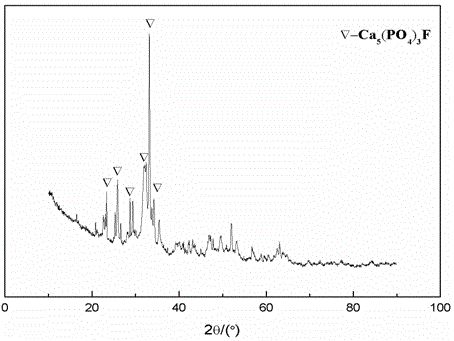

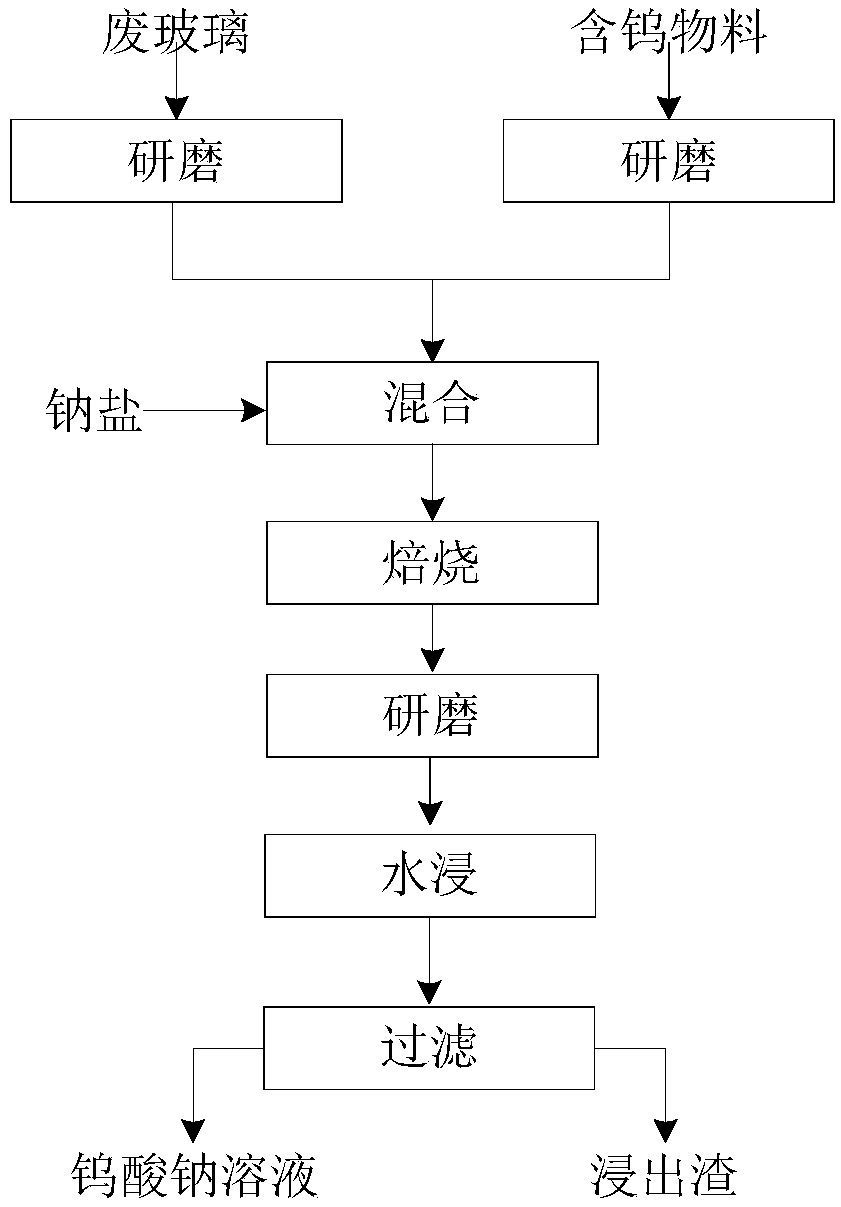

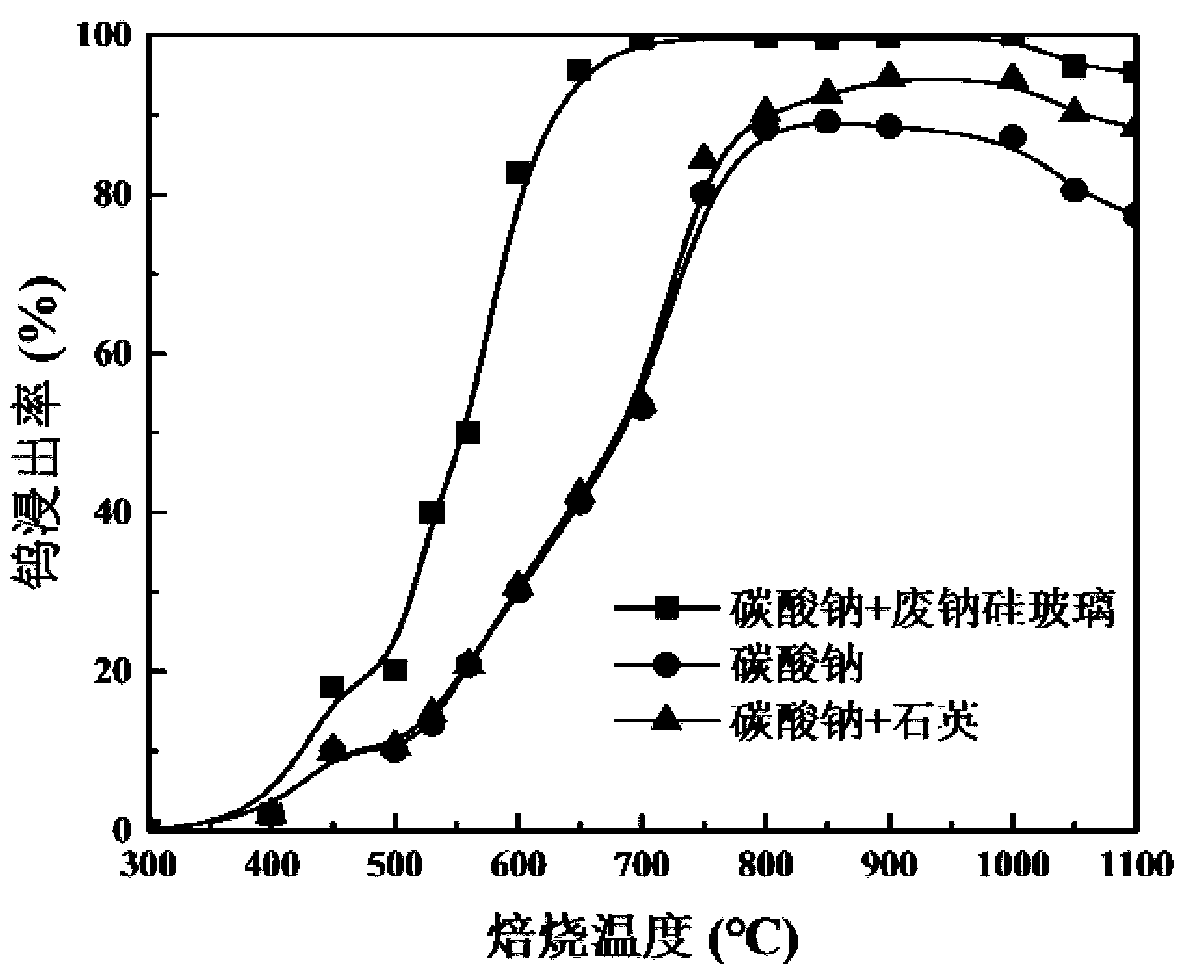

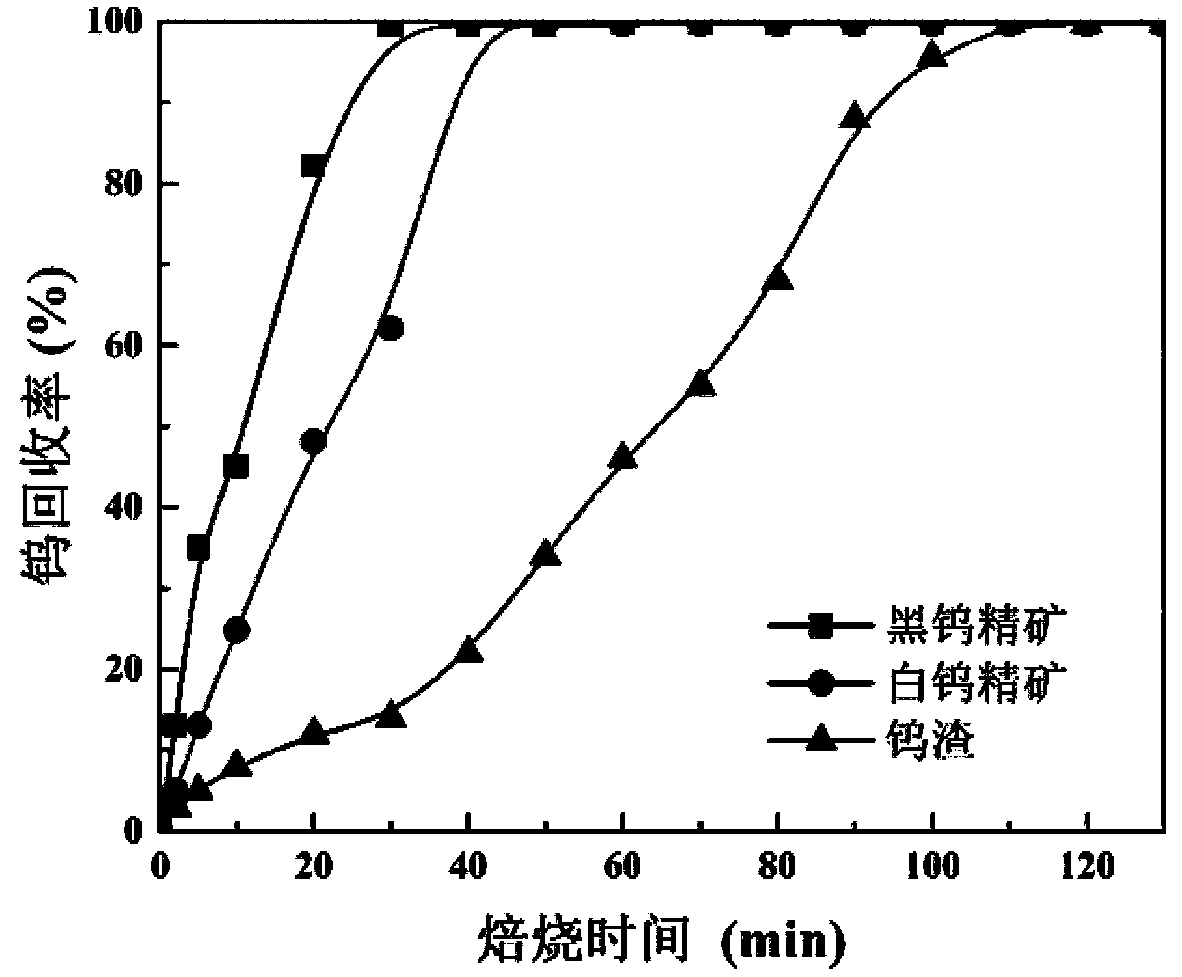

Method for extracting tungsten from tungsten-containing raw material through waste glass

The invention discloses a method for extracting tungsten from a tungsten-containing raw material through waste glass. The method includes the steps that the tungsten-containing material and the wasteglass are ground and smashed and then mixed with sodium salt, the mixture is roasted, and a sintered material is obtained; and after being ore-ground, the sintered material is leached with water, andtungsten-containing extract is obtained. According to the method, quartz used in the traditional tungsten ore thermometallurgy process is replaced with the waste glass, the tungsten leaching rate canbe increased, the operation is easy, the requirements on the raw material are low, the operating cost is low, the problem of low efficiency of fixing of calcium and magnesium by the quartz in the traditional sodium salt roasting process is solved, and the method is also an effective means for consuming the waste glass on a large scale.

Owner:CENT SOUTH UNIV

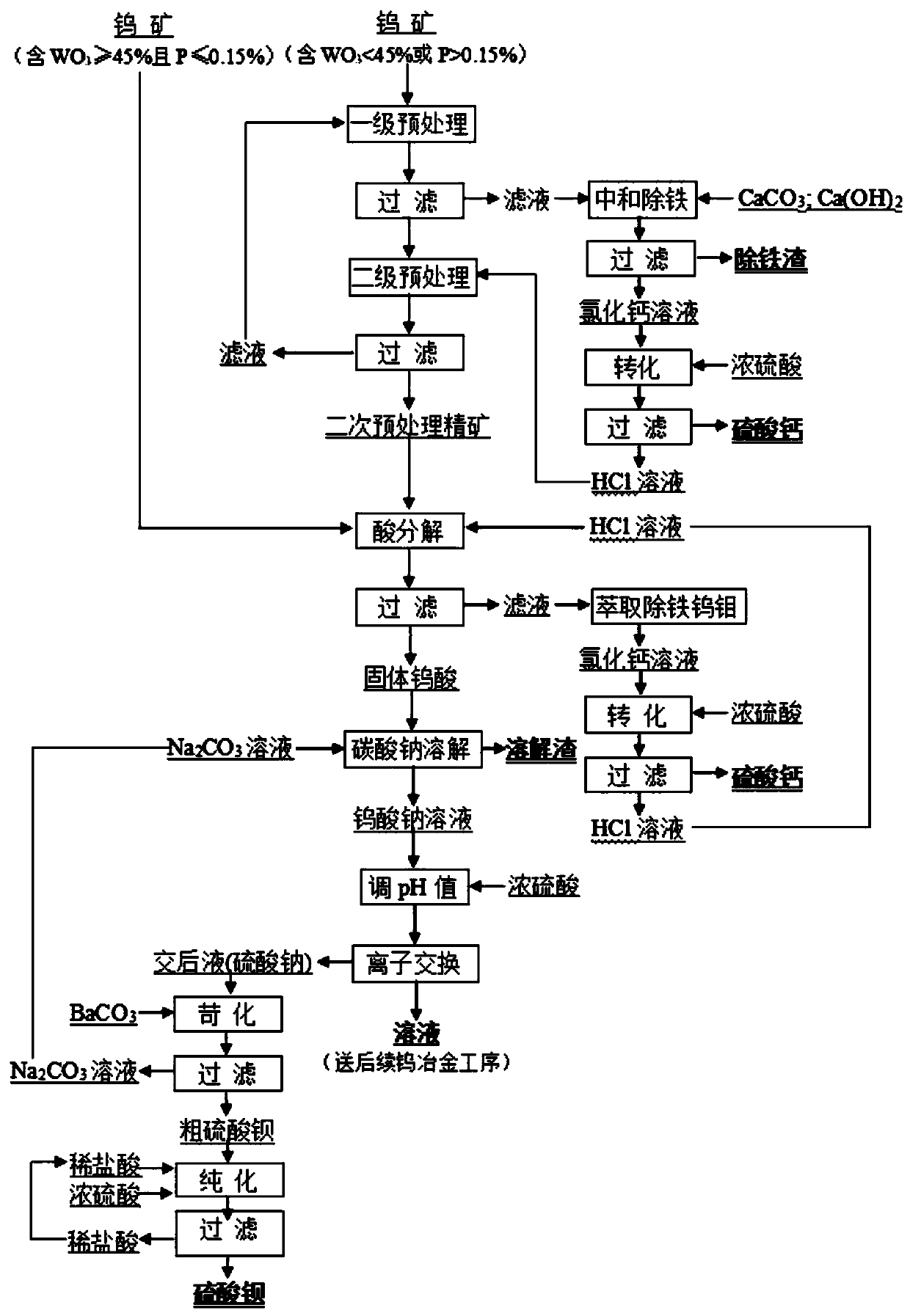

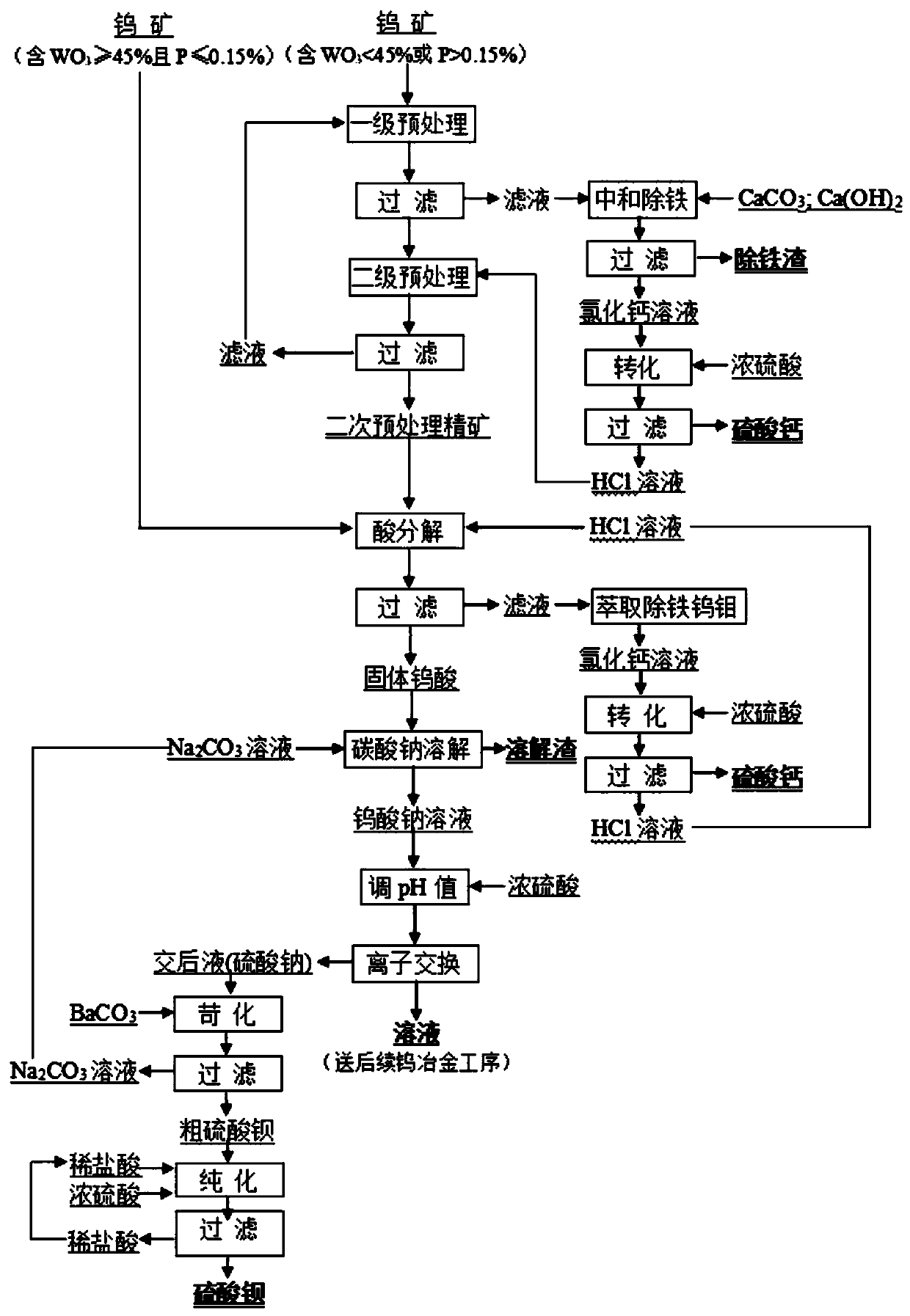

Acid-alkali combination method for extracting tungsten from tungsten minerals

The invention relates to an acid-alkali combination method for extracting tungsten from tungsten minerals. The method comprises the following steps of step 1, decomposing acid, specifically mixing a tungsten ore with a hydrochloric acid solution, adding H2O2 to carry out a stirring reaction to obtain a solid tungstic acid and an acid decomposition mother solution; step 2, dissolving the solid tungstic acid by using sodium carbonate, specifically mixing the solid tungstic acid with a sodium carbonate solution to carry out the stirring reaction, and after the reaction is finished, filtering to obtain dissolved slag and a sodium tungstate solution; step 3, carrying out resin ion exchange treatment on the sodium tungstate solution, specifically neutralizing the sodium tungstate solution obtained in the step 2 with sulfuric acid until the pH value is 3-6 to serve as a pre-exchange solution, adsorbing the tungsten in pre-exchange solution through macroporous weak-alkaline anion exchange resin, washing the macroporous weak-alkaline anion exchange resin adsorbing the tungsten by using deionized water; after washing is completed, carrying out desorption to obtain ammonium tungstate desorption liquid by using ammonia water as a desorption agent, and further, removing impurities, evaporating and crystallizing to obtain ammonium paratungstate. The method has the advantages that the technological process is simplified, and meanwhile, the recovery rate of the tungsten is ensured.

Owner:CENT SOUTH UNIV

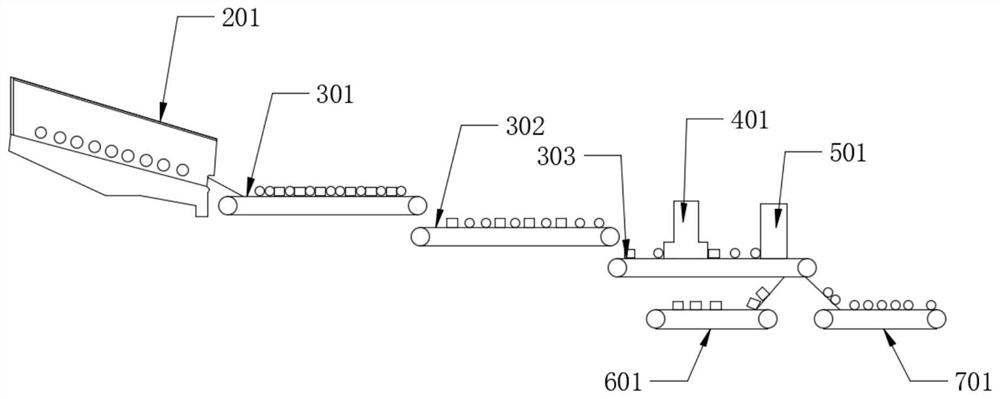

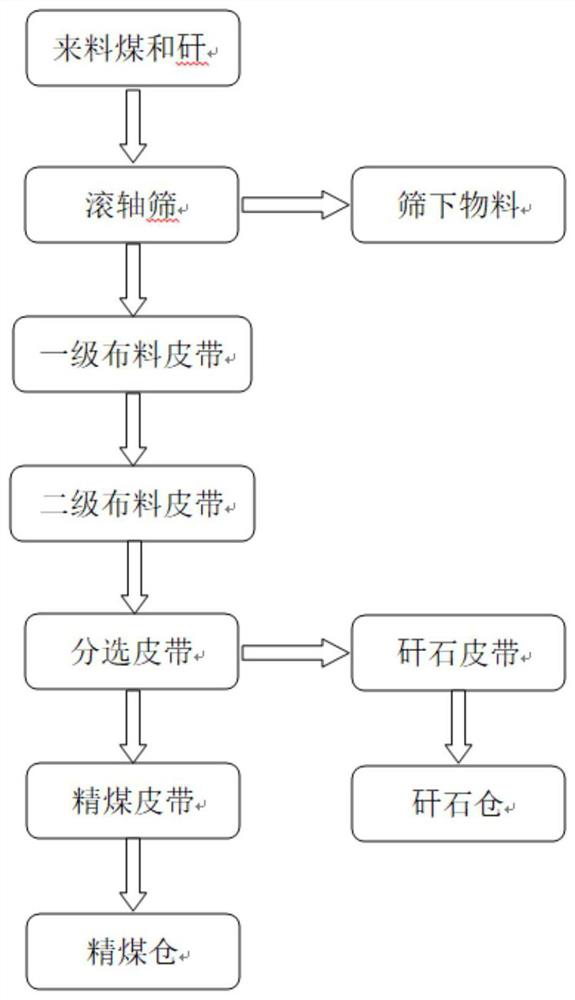

Intelligent automatic sorting system for coal

PendingCN111617987AEvenly distributedAccurate sortingSievingScreeningControl systemProcess engineering

The invention discloses an intelligent automatic sorting system for coal. The intelligent automatic sorting system comprises a roll screen, a first-grade distribution belt conveyor, a second-grade distribution belt conveyor, a sorting belt conveyor, a recognition system, an execution system, a gangue belt conveyor and a clean coal belt conveyor; and the roll screen is used for screening supplied materials, small materials are removed, and meanwhile, materials distribution is completed. The first-grade distribution belt conveyor, the second-grade distribution belt conveyor and the sorting beltconveyor are sequentially connected, and uniform distribution of the materials is realized. The intelligent automatic sorting system for the coal can be used for realizing efficient and automatic material sorting, sorting of the coal and gangue is included, and sorting of gold ores, tungsten ores, iron ores and other ores is further included. The dry method sorting of the materials is realized through the recognition of the radial recognition system and the calculation of a centralized control system.

Owner:BIRTLEY TIANJIN IND EQUIP

Mineral separation technique for fine-grain tungsten-tin associated minerals

InactiveCN107617508AHigh recovery rateGuaranteed concentrate gradeFlotationMagnetic separationPre selectionMagnetic separation

The invention discloses a mineral separation technique for fine-grain tungsten-tin associated minerals. The mineral separation technique includes the following specific steps that (1) secondary slurrygenerated by quartz vein type tungsten-tin associated minerals or tailings generated by floatation of sulphide ore of polymetallic ore are crushed; (2) enrichment via gravity concentration is carriedout, specifically, tailings are discarded via gravity concentration, and the gangue tailing discarding amount is 60%-85%; (3) silicone is removed through reverse floatation, specifically, regulatorsinclude a sodium carbonate solution and a starch solution, and collecting agents include one or more of an ether amine solution, a lauryl amine solution and an octadecylamine solution; and (4) tungsten-tin minerals are separated through magnetic separation, specifically, concentrate obtained after magnetic separation is wolframite, and tailings obtained after magnetic separation are tinstone concentrate. For fine-grain tungsten-tin minerals, the technique that gravity-concentration tailing discarding is adopted for pre-selection, sulfur and silicon are removed through reverse floatation, and wolframite and tinstone are separated through magnetic separation is utilized, on the premise of guaranteeing the concentrate grade, the recovery rates for wolframite and tinstone are increased, and the mineral separation technique is mainly applied to comprehensive recovery of tungsten and tin in tungsten-tin associated minerals and nonferrous-metal associated tungsten-tin minerals.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com