Method of extracting tungsten from high-barium tungsten ore

A technology of barium tungsten and solution, which is applied in the field of tungsten extraction, can solve the problems of inapplicability, and achieve the effect of cheap auxiliary materials and additives, inhibiting tungsten precipitation, and preventing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 500g of a certain high-barium tungsten ore (its composition analysis is shown in Table 1), grind it until the particle size is in the range of 74-200μm, and 270gNa 2 CO 3 and 40gSiO 2 After mixing evenly, put it into a corundum crucible and bake it in a muffle furnace at 850°C for 3h. After the calcined sand is cooled and crushed to a particle size of 0.1mm-1mm, it is mixed with 10g / L NaCO 3 solution, the liquid-solid ratio was controlled at 5mL / g, and leached at 60°C for 1h. The obtained sodium tungstate solution extracts tungsten by ion exchange or extraction.

[0026] Table 1 Composition / % of high barium scheelite concentrate

[0027]

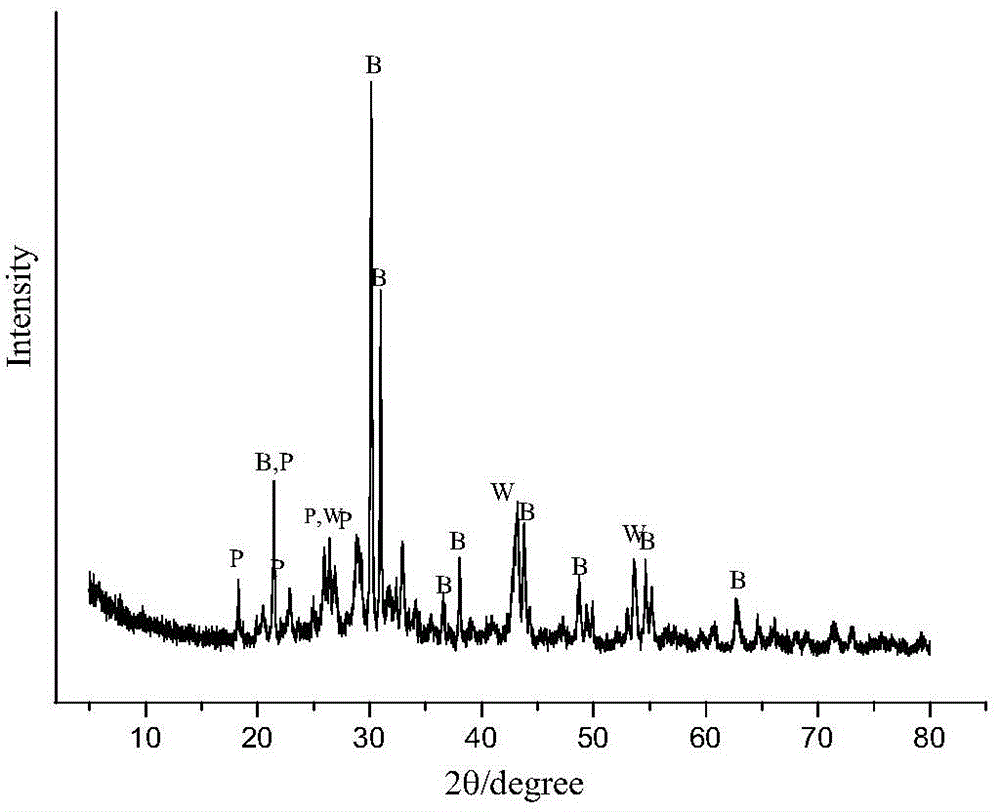

[0028] After leaching, analyze the W content in the leaching solution and leaching slag, the leaching solution composition is shown in Table 2, the tungsten leaching rate is 95.96%, and the XRD pattern of leaching slag is as follows figure 1 . Ca, Ba and Si form relatively stable (Ca, Ba) during the roasting process. 2 ...

Embodiment 2

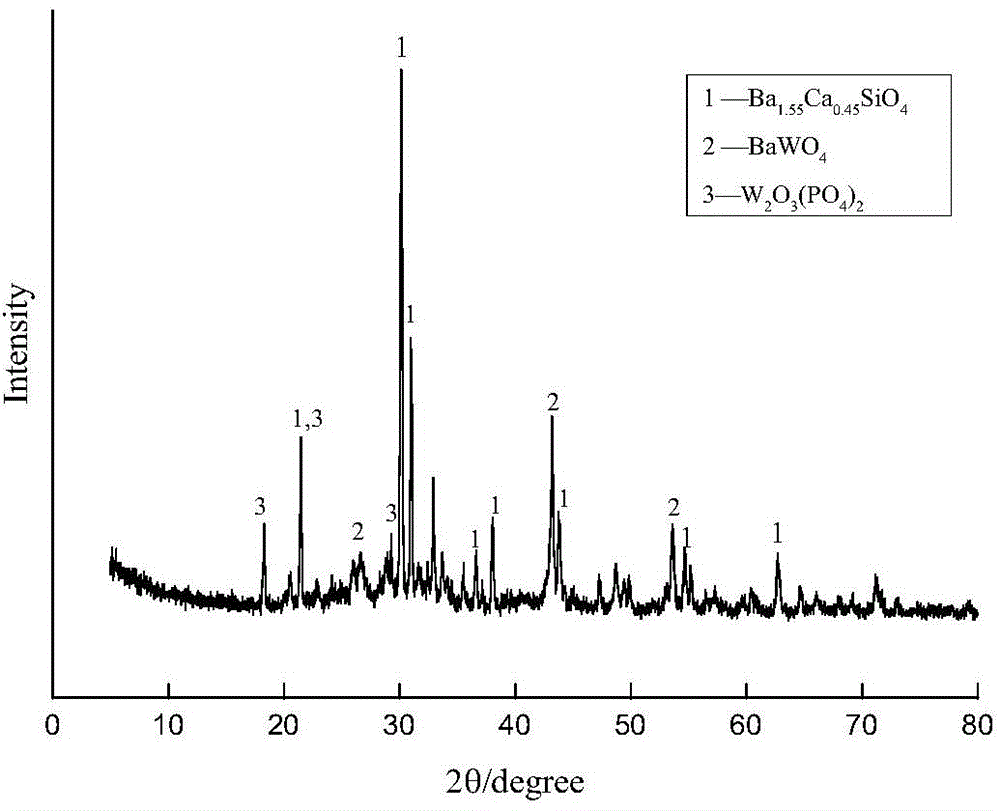

[0032] Take 500g of a certain high-barium tungsten ore (its composition analysis is shown in Table 1), grind it until the particle size is in the range of 74-200μm, and 270gNa 2 CO 3 and 70gSiO 2 After mixing evenly, put it into a corundum crucible and bake it in a muffle furnace at 950°C for 2h. After the calcined sand is cooled and crushed to a particle size of 0.1mm-1mm, it is mixed with 20g / L NaCO 3 solution, the liquid-solid ratio was controlled at 4mL / g, and leached at 60°C for 1h. After leaching, analyze the W content in the leaching liquid and leaching slag, the obtained leaching rate is 96.76%, and the XRD pattern of the leaching slag is as follows: figure 2 . The obtained sodium tungstate solution extracts tungsten by ion exchange or extraction methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com