Ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore

A technology for separation and recovery of polymetallic ores, applied in the field of beneficiation, can solve the problems of difficulty in increasing the total recovery rate of fluorite, affecting the recovery rate of fluorite, and fluorite easily falling out of the tank, so as to solve the problem of heating and beneficiation, reduce acid The effect of reducing the consumption and drug consumption and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

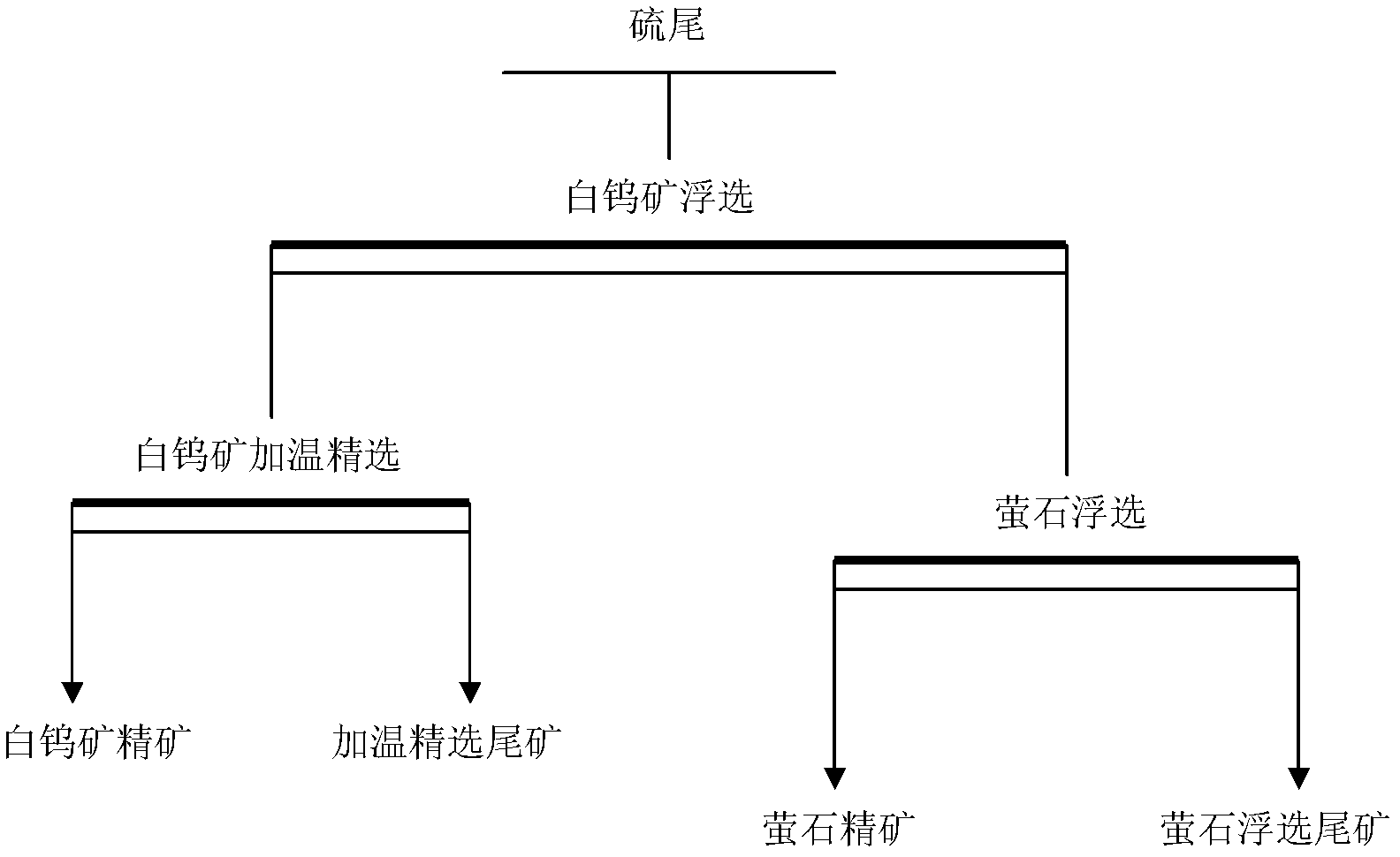

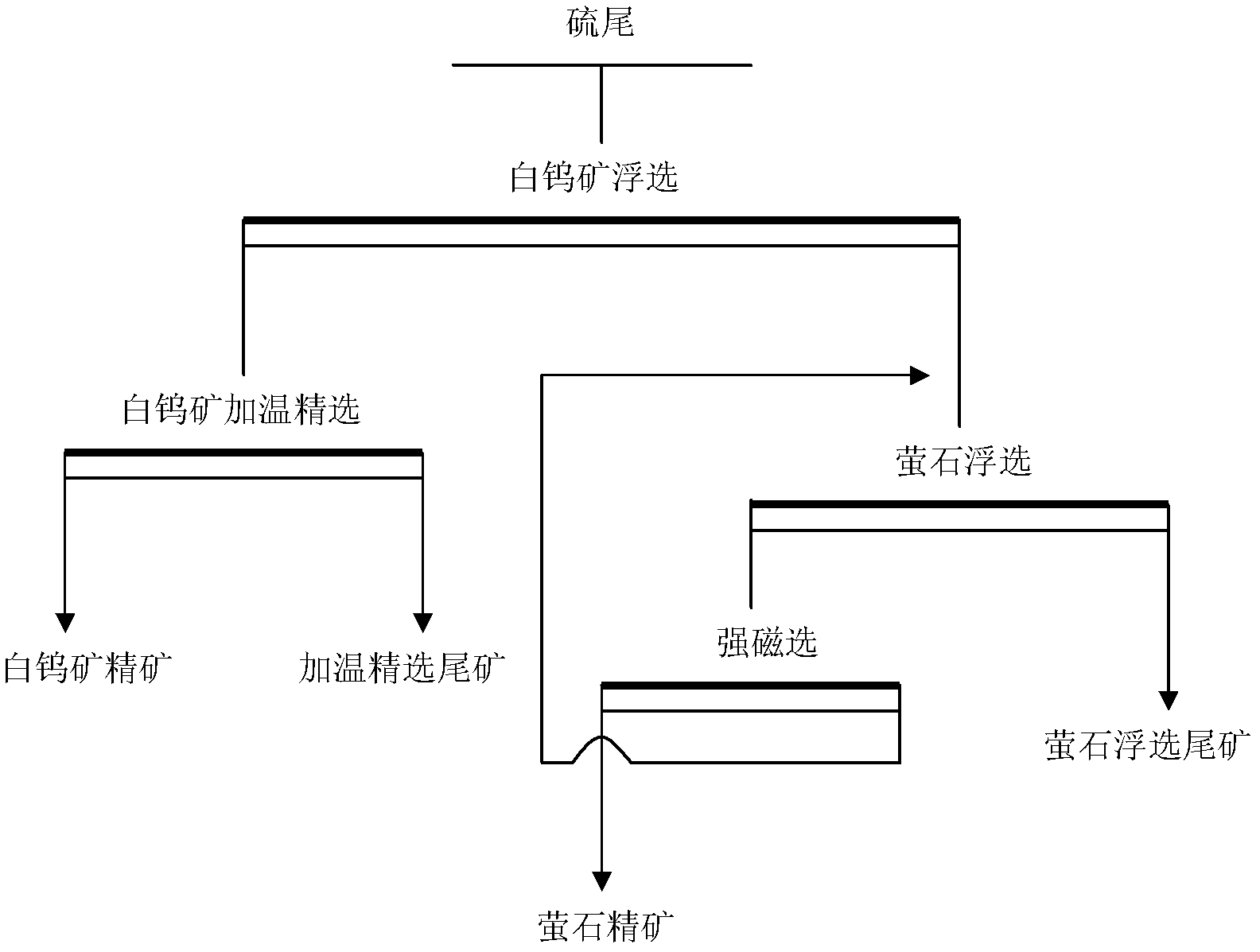

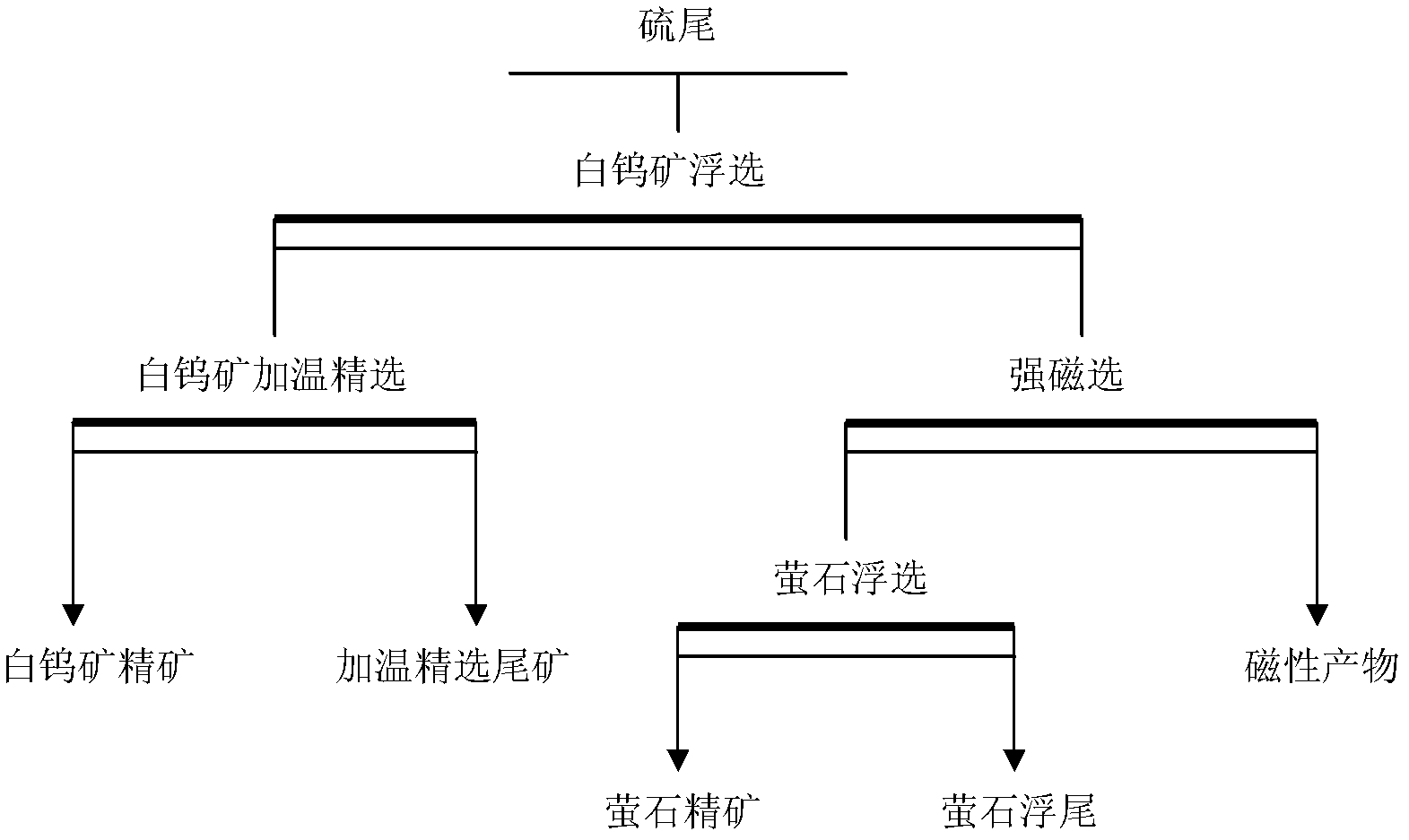

[0045] In this embodiment, the above-mentioned floating sulfur tailings are used as ore feed, and the mineral processing method for separating and recovering scheelite and fluorite is as follows: Figure 4 As shown, the steps are as follows:

[0046] (1) Mixed flotation of scheelite and fluorite with floating sulfur tailings (rough selection section)

[0047] The ore feeding particle size is -200 mesh 82%, adding water glass as a gangue inhibitor, and the collector is oleic acid fat in parts by weight: sodium carbonate=1: 0.2 modified fatty acid, under the condition of pH 9, through a rough Two rough one scan one fine process (see Figure 5 ), the total time is 14 minutes, and the foam product obtained is the mixed rough concentrate of scheelite and fluorite;

[0048] (2) Fluorite flotation of mixed coarse concentrate of scheelite and fluorite (concentrated section)

[0049] With water glass in parts by weight: sulfuric acid: sodium hexametaphosphate: oxalic acid=1: 0.3: 0....

Embodiment 2

[0055] This embodiment differs from Embodiment 1 in that:

[0056] 1, step (1), the ore feeding granularity is-200 order 85%, and collector is the modified fatty acid of oleic acid fat in parts by weight: sodium carbonate=1: 0.1; Total time is 20 minutes.

[0057] 2, step (2), with water glass by weight: sulfuric acid: sodium hexametaphosphate: oxalic acid=1: 0.1: 0.2: 0.25 composite acidic water glass as scheelite inhibitor; Total time is 25 minutes.

[0058] 3. In step (3-1), the grinding particle size of the fluorite coarse concentrate regrinding is -400 mesh 85%; the total time is 15 minutes.

[0059] 4. In step (4), the ore feeding concentration of the shaking table is 30%.

Embodiment 3

[0061] This embodiment differs from Embodiment 1 in that:

[0062] 1, step (1), feed particle size is-200 order 90%, collector is by weight oleic acid fat: the modified fatty acid of sodium carbonate=1: 0.3; Flotation under the condition of pH 8.5, total time for 10 minutes.

[0063] 2, step (2), with water glass by weight: sulfuric acid: sodium hexametaphosphate: oxalic acid=1: 0.5: 0.25: 0.1 composite acidic water glass as scheelite inhibitor; Total time is 15 minutes.

[0064] 3. In step (3-1), the grinding particle size of the fluorite coarse concentrate regrinding is -400 mesh 75%; the total time is 5 minutes.

[0065] 4. In step (4), the ore feeding concentration of the shaking table is 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com