Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "No rust spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pickling solution containing compounded passivating agent, and preparation method thereof

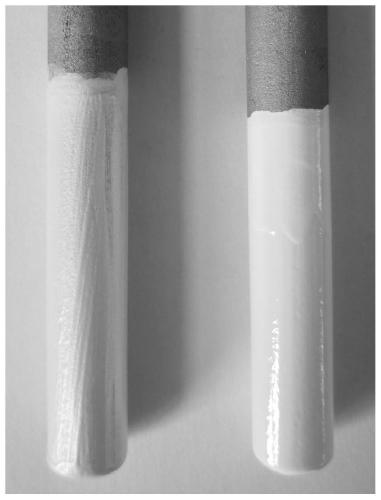

The invention belongs to the stainless steel casting cleaning field, and relates to a passivating pickling solution obtained through adding an organic substance to an HNO3-HF base acid solution and compounding. The pickling solution comprises 3.3-37.5mass% of HNO3, 0.7-7.5mass% of HF, 1.3-13.5mass% of the compounded passivating agent, and the balance water. A polluted stainless steel casting is cleaned by the pickling solution to recover the metal luster originally possessed by the casting. The pickling solution forms a compact passivating film on the surface of the casting, so bright beauty maintenance and no rusty spot are realized after the casting is stored for a long term. The pickling solution has the characteristics of very small acid mist, benefiting for the environmental protection and the body health of an operation personnel, large pickling amount, and low pickling cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-efficient rust-proofing agent

InactiveCN1854345AImprove permeabilityAccelerated reduction reactionSodium molybdateSodium phosphates

A high efficient antirust which consists of the following component by weight ratio: water 200-300 share, orthophosphoric acid 80-160 share, sodium nitrate 0.5-4 share, zinc oxide 1-6 share, ammonium bichromate 1-5 share, tertiary sodium phosphate 1-8 share, sodium molybdate 0.01-1 share, hydroxypropyl methylcellulose 1-8 share, divinyl ether 1-4 share. It's high efficient antirust with great performance, strong penetrability and strong adhesive power.

Owner:晏雄立 +1

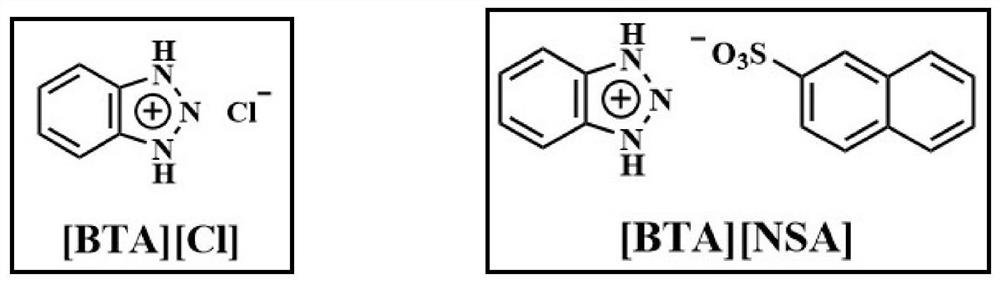

Anti-flash-rust agent for water-based paint and preparation method thereof

ActiveCN111876006AOvercoming toxicityOvercome environmental problemsAnti-corrosive paintsPolyurea/polyurethane coatingsAdsorptive membranePhosphate

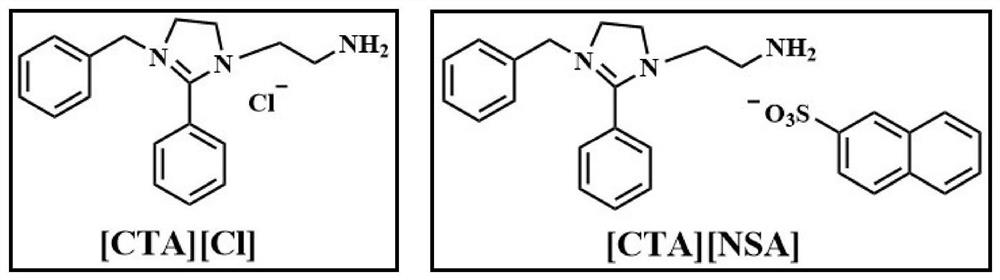

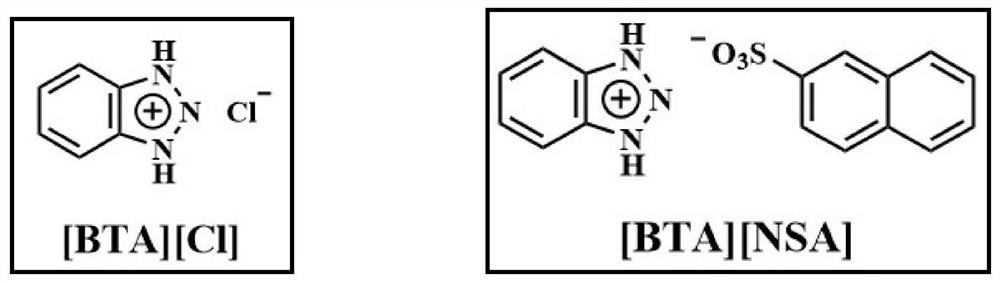

The invention discloses an anti-flash-rust agent for water-based paint and a preparation method of the anti-flash-rust agent. The anti-flash-rust agent is formed by compounding imidazoline ionic liquid, triazole ionic liquid, quaternary ammonium salt ionic liquid, organic phosphate, alkynol and deionized water according to the mass ratio of 20-60 : 20-60 : 20-60 : 4-25 : 4-25 : 1000. According tothe method, a uniform and compact adsorption film is easily formed on the metal surface, electrochemical corrosion on the metal surface is effectively prevented, and the effect of inhibiting corrosionis achieved. The anti-flash-rust agent is applied to the water-based paint, the anti-flash-rust performance is good, the use amount is small, and it can be guaranteed that rust spots do not appear onthe metal surface only by adding 0.7 to 1.2 wt% of the anti-flash-rust agent.

Owner:HUAQIAO UNIVERSITY

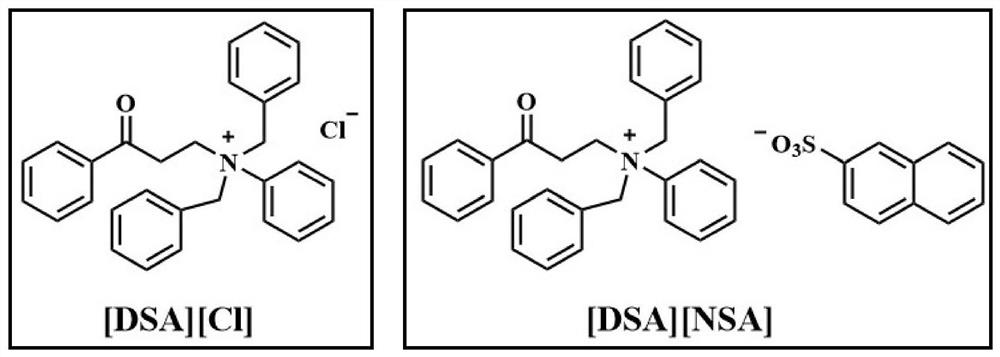

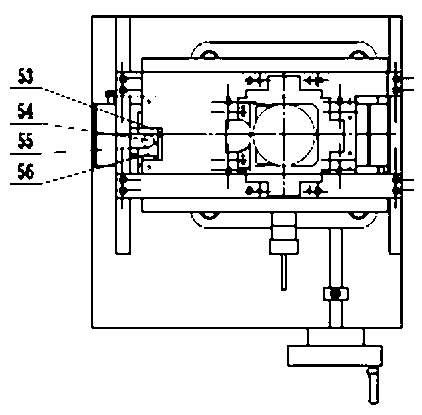

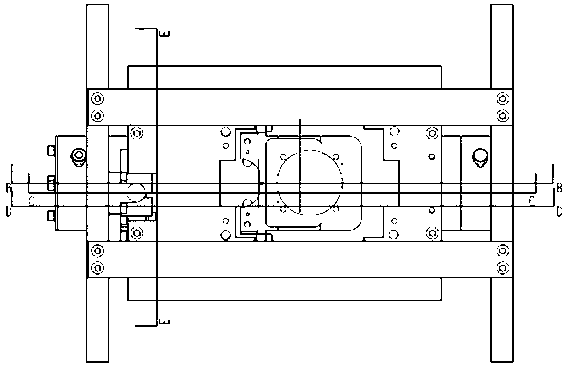

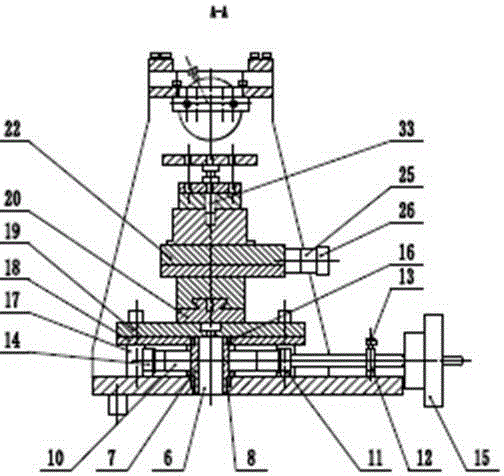

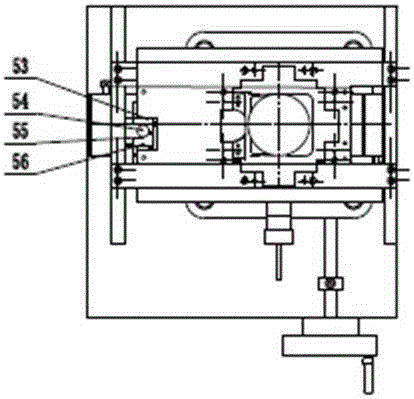

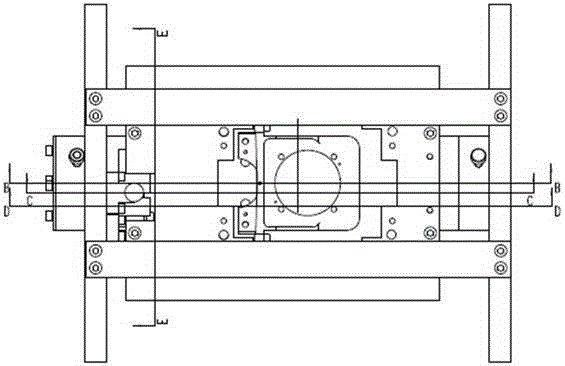

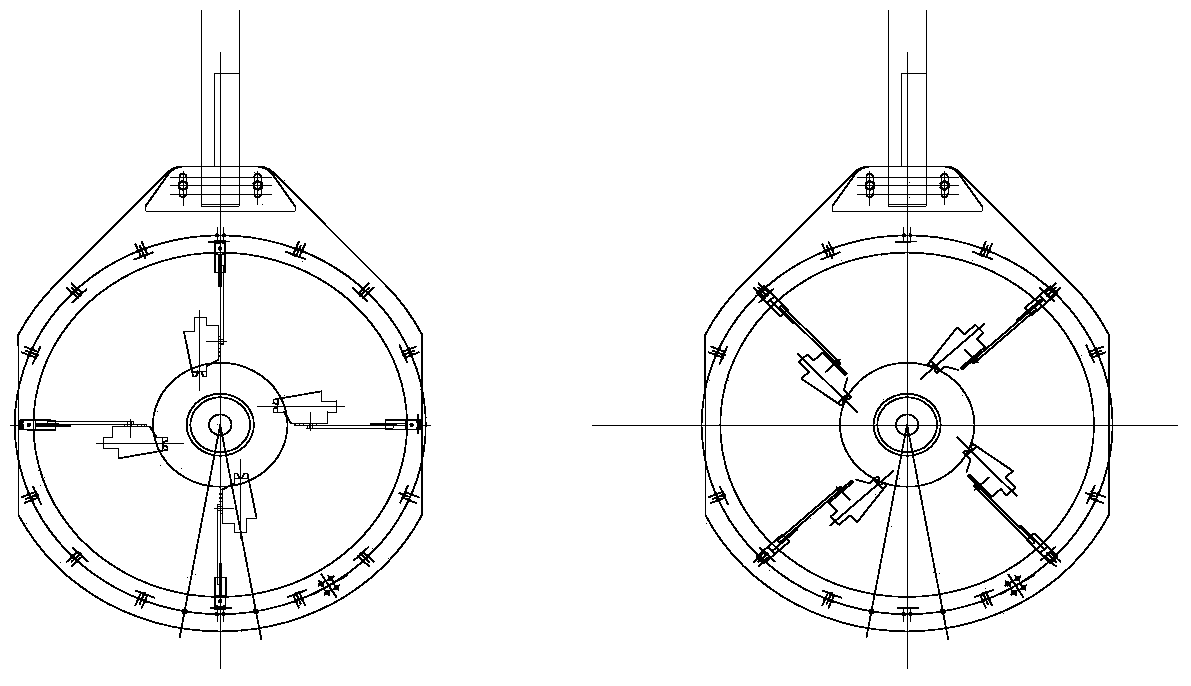

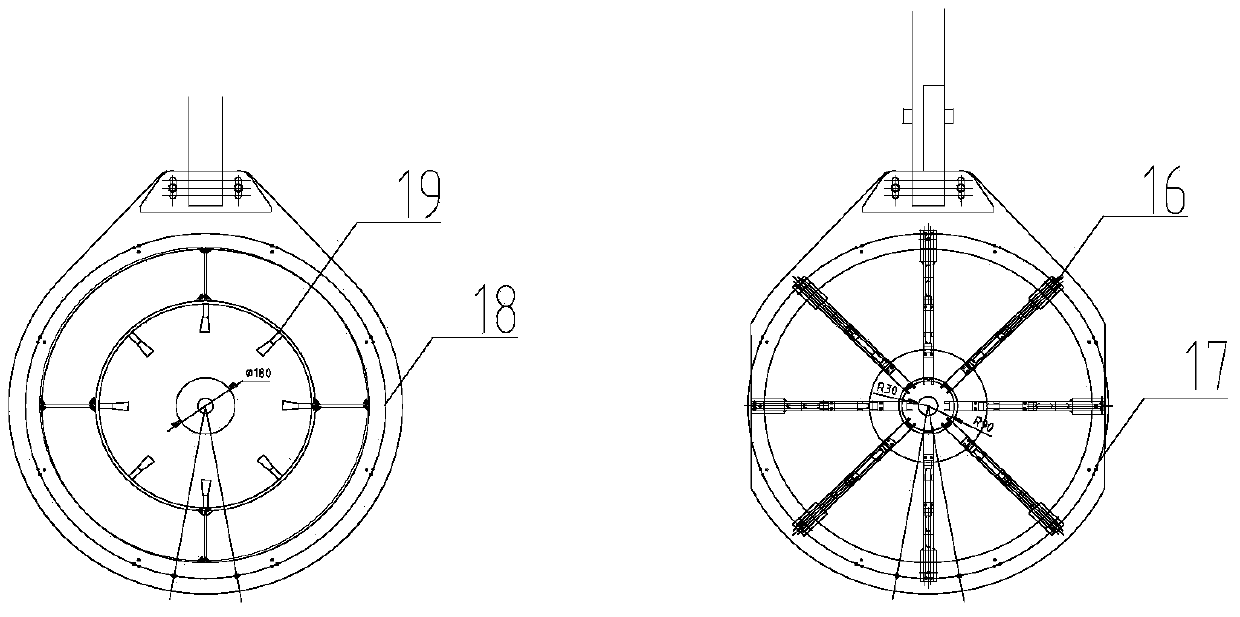

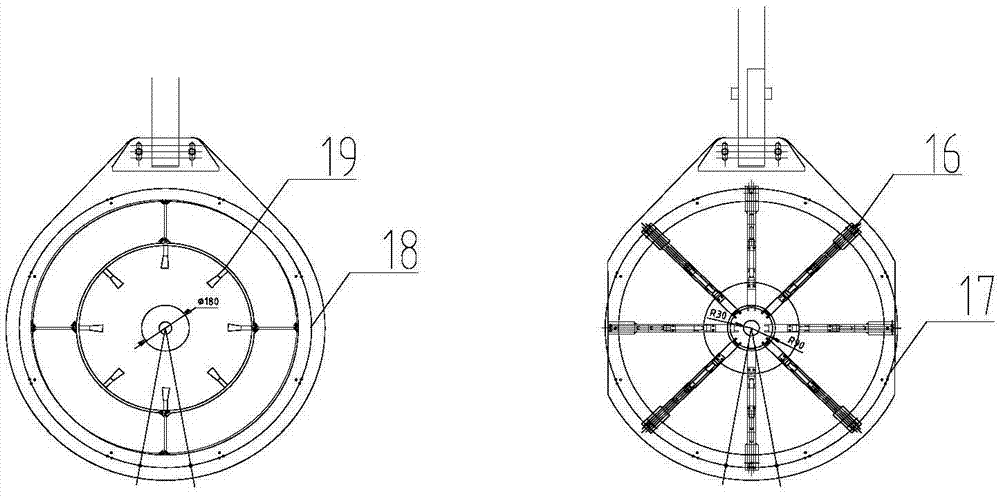

Five degree of freedom butt joint tightness debugging equipment provided with connector

ActiveCN103134642AAchieve free spinsEasy to operateMachine part testingFluid-tightness measurement using fluid/vacuumFree rotationButt joint

Five degree of freedom butt joint tightness debugging equipment provided with a connector is characterized in that a connecting device is arranged at one end of a machine frame, and the end of the machine frame is provided with a fixed connector. The connecting device comprises a lifting device, a cross axial movement device and a rotating device. The machine frame which is used for driving the connecter to lift up and down, move in a cross mode and rotate in a horizontal mode is provided with an angle turnover device of the five degree of freedom butt joint tightness debugging equipment which is provided with the connector. A turnover plate is provided with a connecting structure which is used for connecting the other end of the connector. The five degree of freedom butt joint tightness debugging equipment provided with the connector has the advantages of freely rotating around six shafts, being capable of imitating deviation produced by the connector when a work object is connected through butt joint, accurately controlling deviation of an angle and displacement and clearly mastering the size of the adjustment of the angle due to the fact that an adjustment stick is adopted, and being high in reliability. Due to the fact that the whole equipment is connected through stainless screws, and stainless pins which match with the stainless screws are arranged, the five degree of freedom butt joint tightness debugging equipment provided with the connector is easy to dismantle and reset, guarantees assembling accuracy, is good in stability and free from producing rusty spots due to the fact that the whole equipment except of a circular dividing table and a cross-shaped working table is made of 2 Cr13 stainless materials.

Owner:柳州市鑫鑫农业科技有限公司

Waterborne epoxy low-surface treatment anticorrosive paint, preparation method and application thereof

InactiveCN110964406AHarm reductionReduce pollutionAntifouling/underwater paintsPaints with biocidesPolymer scienceFirming agent

The invention discloses a waterborne epoxy low-surface treatment anticorrosive paint, a preparation method and application thereof. The paint is composed of 80-85 weight parts of matrix coating, 10-12weight parts of a curing agent and 3-6 weight parts of deionized water. Specifically, the matrix coating is prepared from waterborne epoxy resin, a nano composite liquid, a rust conversion agent, titanium dioxide, an antirust pigment, micron basalt scales, a wetting dispersant, a leveling agent, a defoaming agent and deionized water. The matrix coating, the curing agent and the distilled water are added into a clean container according to a weight ratio of 80-85:10-12:3-6 and are mixed uniformly, and then curing is carried out for 5-10min, thus obtaining the paint applicable to coating. The paint disclosed by the invention can be applied to large steel structures like bridges, pipelines and complex equipment without thorough rust removal, and has excellent corrosion resistance.

Owner:WUXI HUADONG ZINDN TECH

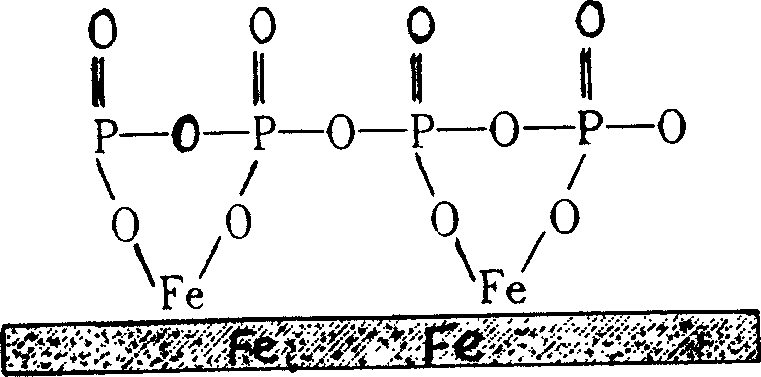

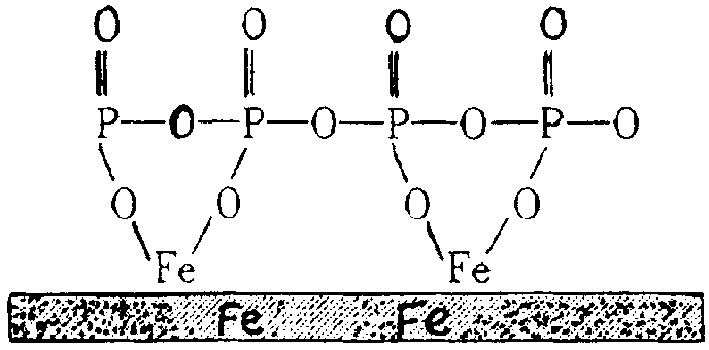

Water-latex tye rust removing and rust protection liquid as well as its preparation method

InactiveCN1480559AEasy to produceEasy to useMetallic material coating processesEmulsionAluminium phosphate

An aqueous emulsion type rust-removing and anti-rust liquid is prepared from H3PO4, Al powder, NH4NO3, Alk(SO4)2, and water through proportioning, mixing H3PO4 with Al powder, reaction to obtain aluminium phosphate solution, mixing it with others, and regulating pH value to 0.5-1. Its advantages are high effect, no damage to human body, and no environmental pollution.

Owner:黄奇伟

Corrosion-resistant metal coating and preparation method thereof

InactiveCN106046882ANo rust spotsImprove corrosion resistanceAnti-corrosive paintsZno nanoparticlesCerium oxide

The invention discloses a corrosion-resistant metal coating and a preparation method thereof. The corrosion-resistant metal coating comprises raw materials in parts by weight as follows: 10-50 parts of nano-zinc oxide, 10-50 parts of manganese dioxide, 50-60 parts of cerium oxide, 40-80 parts of castor oil polyoxyethylene ether, 10-20 parts of aluminum, 20-30 parts of copper, 20-100 parts of 2-hydroxyethyl methacrylate, 10-50 parts of 2-ethylene pyrrolidine and 20-30 parts of sorbic acid. The preparation method of the corrosion-resistant metal coating comprises the steps as follows: nano-zinc oxide, manganese dioxide, cerium oxide, aluminum, copper, 2-hydroxyethyl methacrylate, 2-ethylene pyrrolidine and sorbic acid are heated for 20-30 h at the temperature of 40-60 DEG C, then castor oil polyoxyethylene ether is added, the materials are mixed uniformly, a mixture is obtained, a metallic matrix is uniformly coated with the mixture and is dried, and the corrosion-resistant metal coating is obtained. The corrosion-resistant metal coating has excellent corrosion resistance.

Owner:WUXI EPIC TECH

Corrosion-resistant electronic element coating

InactiveCN106752710AStructural properties are stableImprove protectionAnti-corrosive paintsPolyether coatingsEpoxyMetallic Nickel

The invention discloses a corrosion-resistant electronic element coating. The corrosion-resistant electronic element coating consists of the following components in parts by weight: epoxy resin 50-70 parts, graphite powder 3-5 parts, aluminium powder 80-85 parts, zinc powder 2-4 parts, nickel powder 1-3 parts, tin oxide 6-12 parts, sodium tripolyphosphate 2-6 parts, acetone 10-18 parts, methylcellulose 1.5-2.5 parts, castor oil polyoxyethylene ether 40-80 parts and sorbic acid 20-30 parts. A stable coating structure is formed, weather fastness, radiation protection ability and anti-static ability are excellent, the structure of the coating is stable in property and can protect an electronic element for a long time, and damage of foreign elements to the electronic element is reduced. The corrosion-resistant electronic element coating is excellent in corrosion resistance, and the metal surface does not have rusty spots even if the corrosion-resistant electronic element coating soaks in sodium chloride for 300-400 hours due to the fact that the corrosion resistance of the corrosion-resistant electronic element coating is improved to a certain degree by sorbic acid.

Owner:钦州太平电子科技有限公司

Marine anti-corrosion inorganic coating and preparation method thereof

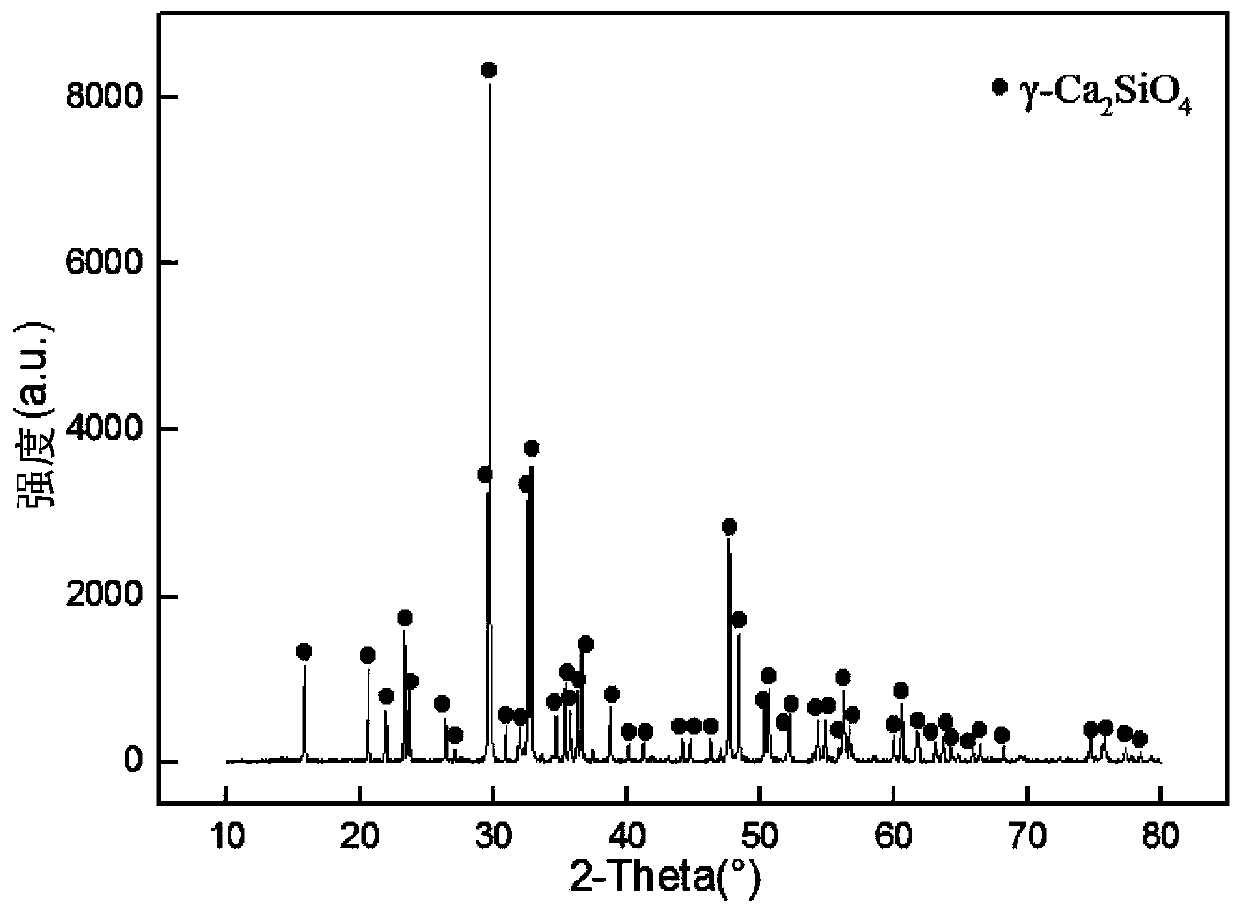

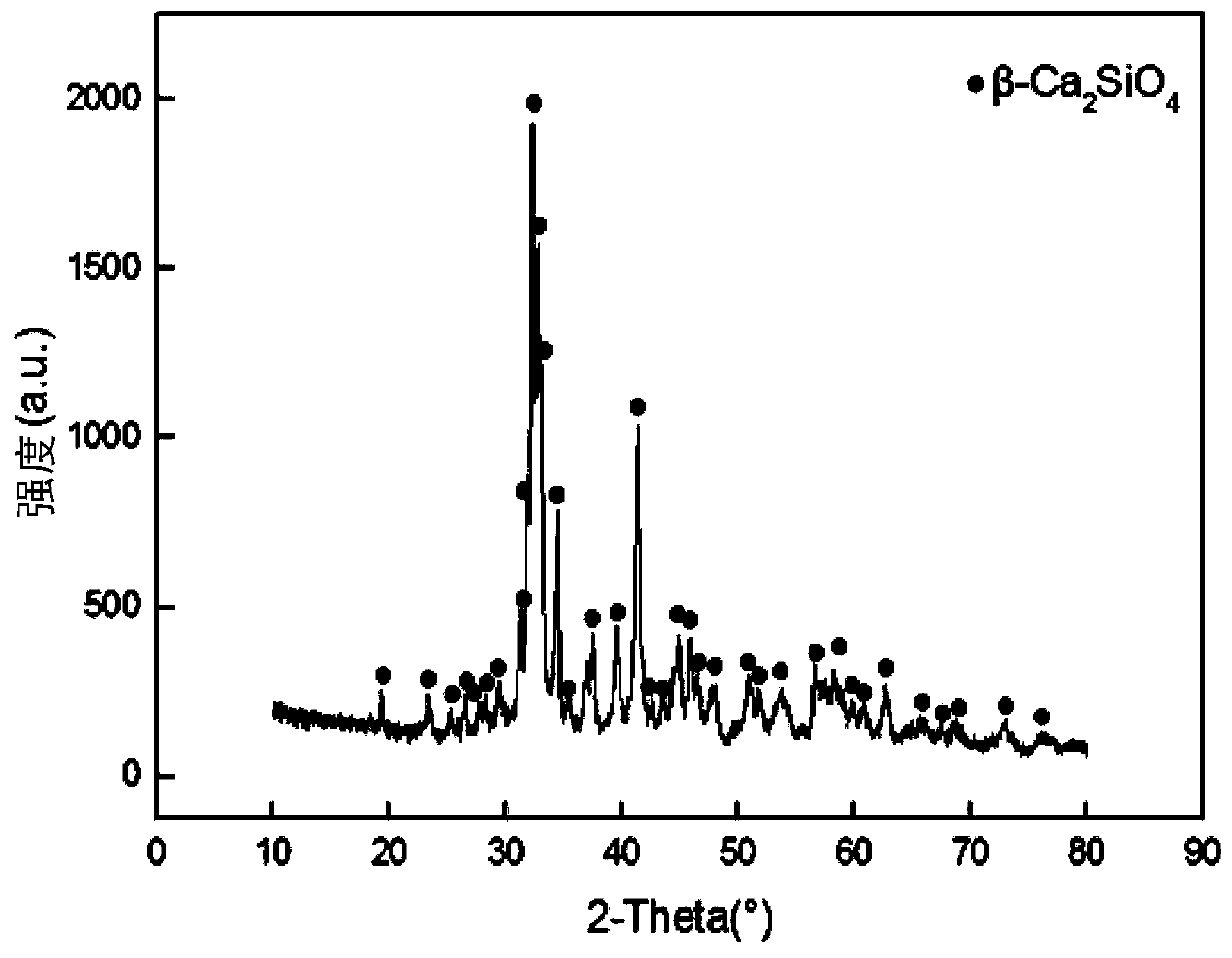

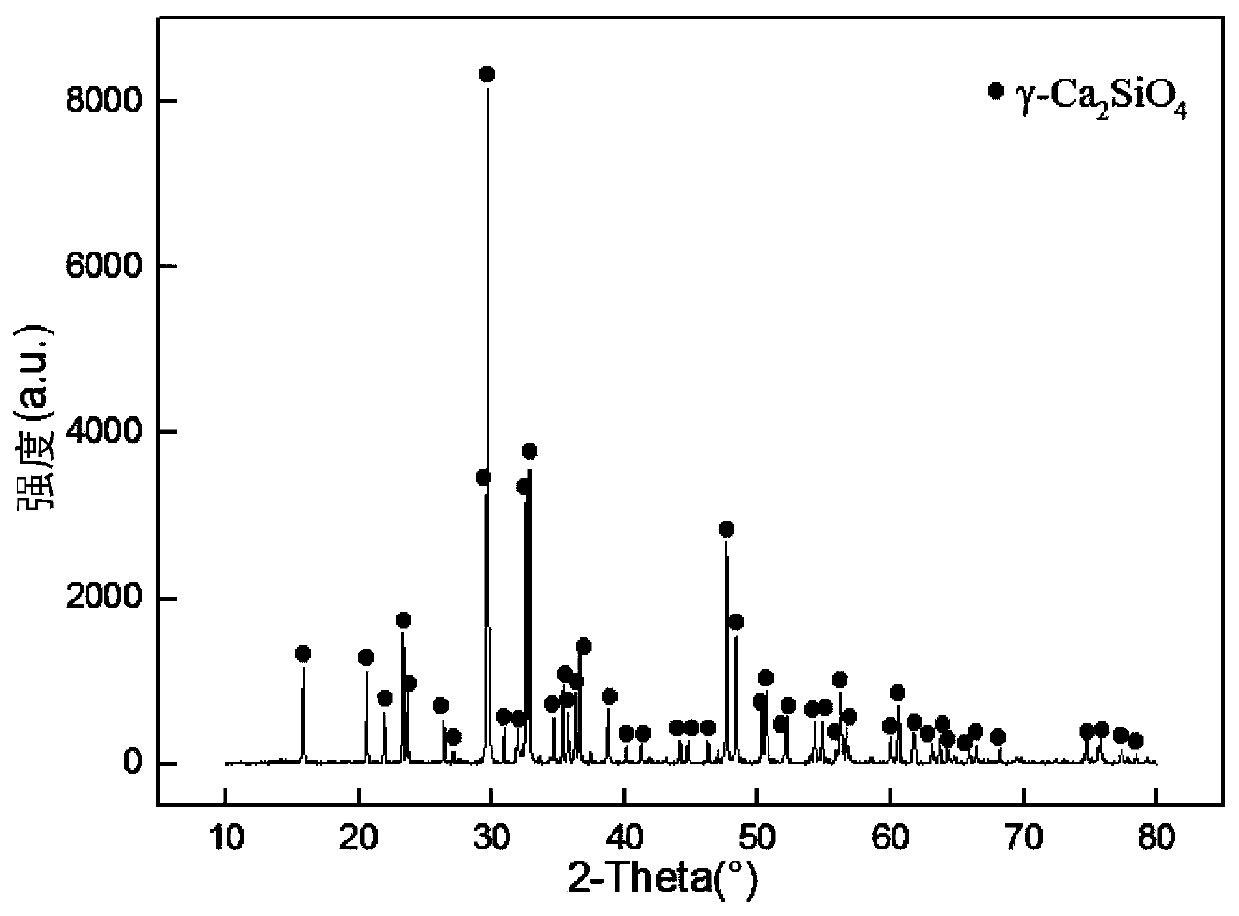

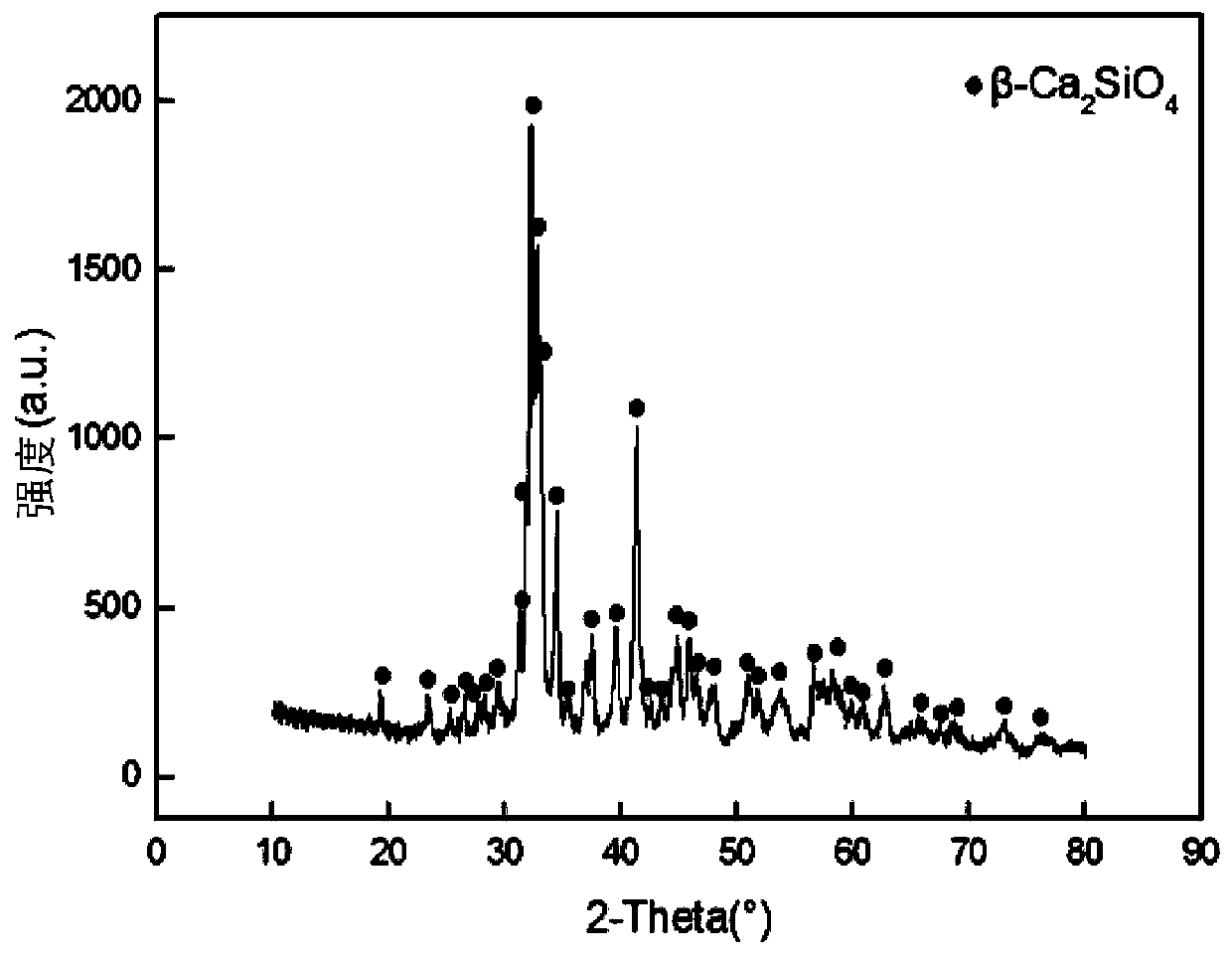

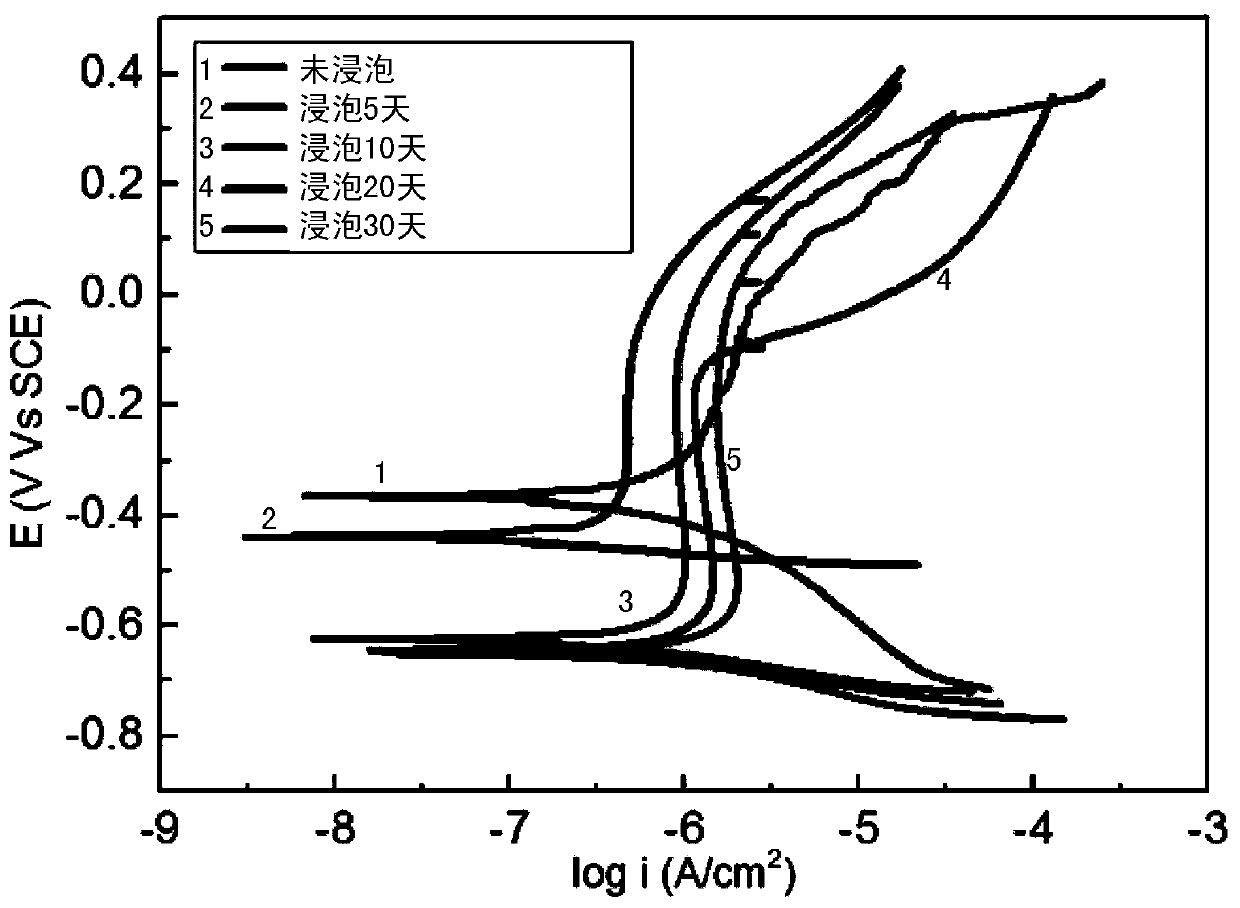

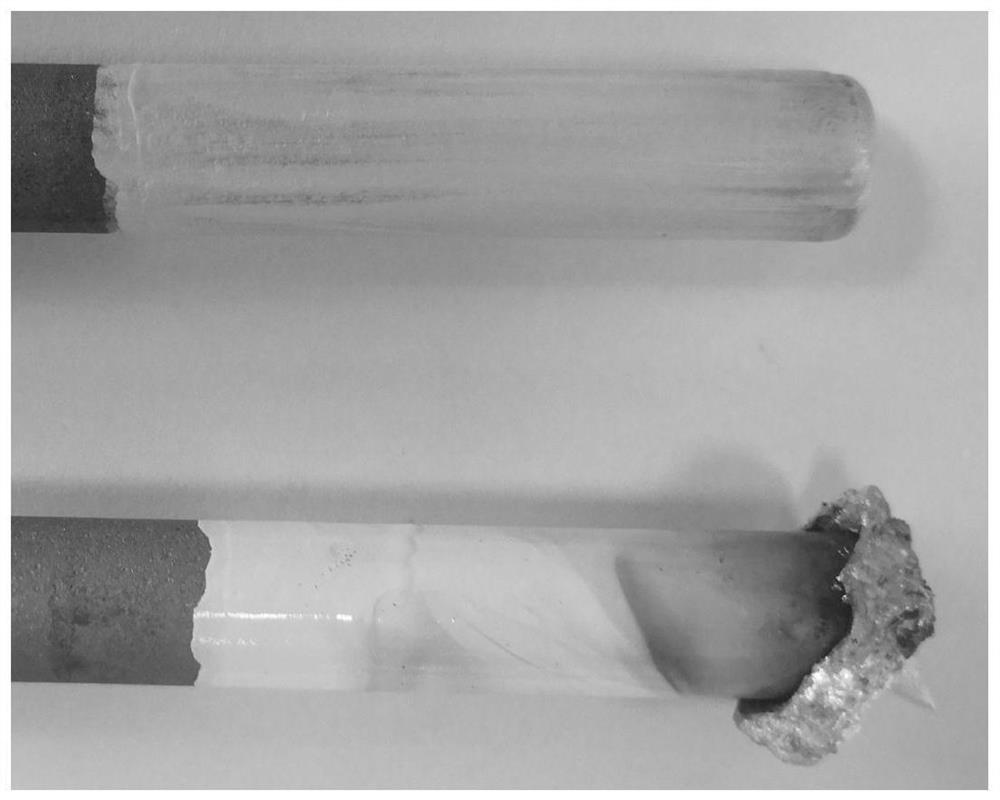

ActiveCN107620024AReduce heat of hydrationStem shrinkMolten spray coatingUltimate tensile strengthMaterials science

The invention relates to a marine anti-corrosion inorganic coating and a preparation method thereof. The marine anti-corrosion inorganic coating comprises a beta-dicalcium silicate ceramic layer formed on a base material. In the marine anti-corrosion inorganic coating and the preparation method thereof, the beta-dicalcium silicate ceramic layer is hardened when making contact with water to form C-S-H gel, the later-period strength is large, dicalcium silicate is low in hydration heat, small in air shrinkage, resistant to temperature, resistant to freezing, good in size stability, resistant tochemical erosion and good in abrasion resistance, and thus the marine anti-corrosion inorganic coating can protect marine facilities such as ship bodies for a long time to prevent the marine facilities from being corroded.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Aqueous paint printing ink anti-flash-rust agent, preparation method therefor and applications

ActiveCN105419439AImprove rust resistancePrevents galvanic corrosion reactionsInksAnti-corrosive paintsNitritePrinting ink

The invention relates to the antirust agent technology field, and concretely relates to an aqueous paint printing ink anti-flash-rust agent, a preparation method therefor and applications. The anti-flash-rust agent is composed of the following raw materials, by weight, 0.5-20% of imidazoline compounds, 1-10% of alkyl benzotriazol, 0-15% of nitrite, 1-8% of EDTA compound and 0.1-5% of alkylamine, the balance being deionized water. For the anti-flash-rust agent, rust points are not easy to generate, and the antirust performance is good. For the preparation method, the technology is simple, processing is convenient, the production cost is low, and the method facilitates large-scale production. The anti-flash-rust agent is applied in aqueous paint printing ink, the dosage is low, printing ink is not easy to generate rust points after construction, and the antirust performance is good.

Owner:江西省龙海化工有限公司

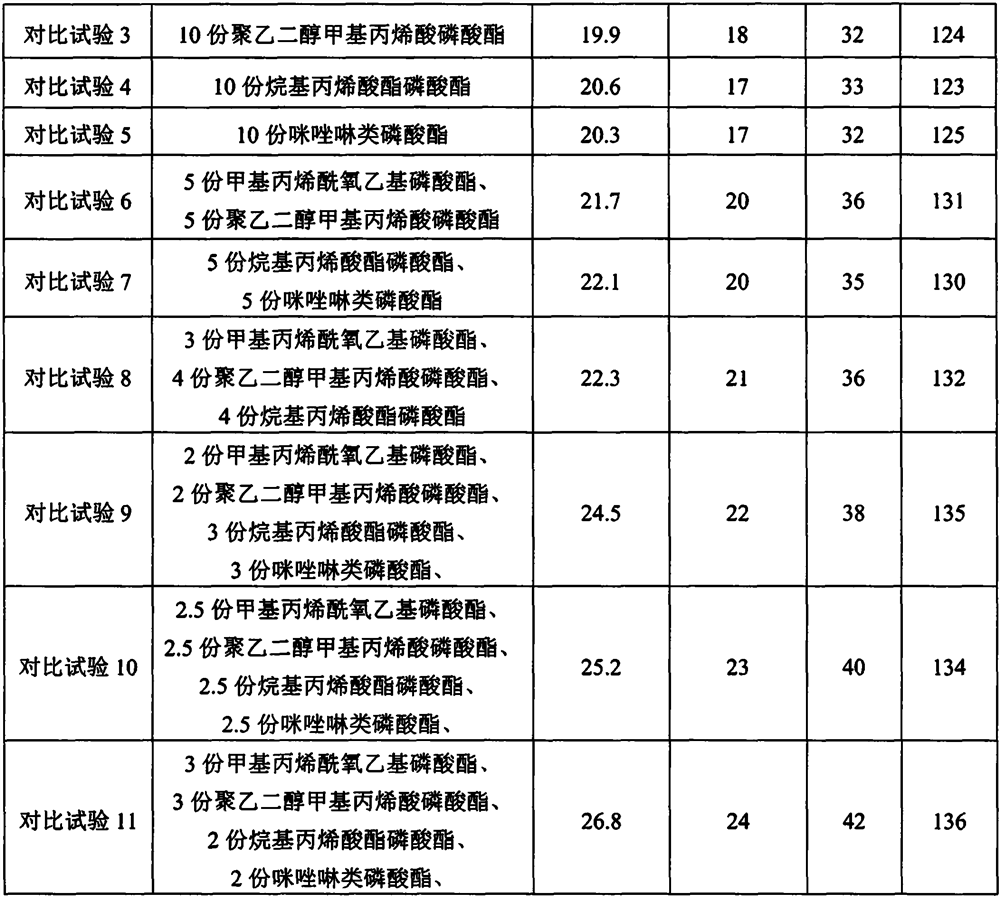

Packaging material with high adhesive force no magnesium-aluminum alloy and preparation method of packaging material

The invention provides a packaging material with high adhesive force on magnesium-aluminum alloy and a preparation method of the packaging material. The packaging material is prepared from a main agent A and a curing agent B, wherein the main agent A is prepared from the following components in parts by weight: 35 to 80 parts of an acrylic monomer, 10 to 30 parts of a toughening agent, 5 to 15 parts of a phosphate functional monomer, 1 to 10 parts of an accelerant, 1 to 5 parts of a stabilizer, 0.1 to 3 parts of a corrosion inhibitor and 0.1 to 3 parts of a silane coupling agent; the curing agent B is prepared from 5 to 50 parts of an initiator, 30 to 80 parts of a toughening agent and 0.5 to 5 parts of a thickening agent. The phosphate functional monomer and the corrosion inhibitor are added into the main agent A, the phosphate functional monomer can increase the adhesive force of the structural adhesive oo the magnesium-aluminum alloy, the corrosion inhibitor can reduce corrosion ofthe structural adhesive on the magnesium-aluminum alloy, and the packaging and corrosion inhibition effects on the magnesium-aluminum alloy are improved through the combined action of the phosphate functional monomer and the corrosion inhibitor.

Owner:常州汉索电子材料科技有限公司

Engineering oil cylinder coating method

ActiveCN103071610AFlat and smooth appearanceNo whiteningPretreated surfacesCoatingsEpoxyWrinkle skin

The invention discloses an engineering oil cylinder coating method which is characterized by consisting of the following steps of polishing, oil pre-removal, oil removal, four-in-one phosphorization, phosphating film drying, the spraying of red iron oxide epoxy primer TNE-HD001, the preparation of working lacquer liquid, the adoption of the red iron oxide epoxy primer, the spraying of the primer, napping, sootblowing and the spraying of finish; a product paint film has level and smooth appearance, and has no such quality defects as particles, bottom exposure, bubbles, needle holes, heat rash particles, wrinkled skin, flood and flying paint misty edges; and the paint film is fine, full and the color consists with that on a standard color disk. According to the engineering oil cylinder coating method, the total adhesive force of the paint film is less than or equal to Level 1 (GB / T9286-88); and no whitening, bubbles or rust spots occur 720 hours after a neutral salt spray resistance test of the paint film is taken.

Owner:CNHTC CHENGDU WANGPAI COMML VEHICLE

Double-layer chemical nickel plating solution and process for improving corrosion resistance of magnesium-containing aluminum alloy

InactiveCN104313551AImprove bindingNo rust spotsLiquid/solution decomposition chemical coatingSalt spray testSodium phosphates

The invention discloses a double-layer chemical nickel plating solution and process for improving corrosion resistance of a magnesium-containing aluminum alloy. The nickel plating solution comprises a neutral fluorine-containing chemical nickel plating solution which comprises the following components: sodium hypophosphite, basic nickel carbonate, ammonium citrate, lactic acid, ammonium acetate, ammonium bifluoride and the balance of water. The double-layer chemical nickel plating process comprises the following steps: 1) performing zinc dipping treatment on the magnesium-containing aluminum alloy twice; 2) performing neutral fluorine-containing chemical nickel plating treatment on the aluminum alloy after performing the zinc dipping treatment twice; and 3) performing high-phosphorus chemical nickel plating treatment on the aluminum alloy after the treatment in the previous step. According to the process disclosed by the invention, the zinc dipping treatment is firstly performed on the magnesium-containing aluminum alloy twice, the neutral fluorine-containing chemical nickel plating treatment and the high-phosphorus chemical nickel plating treatment are further performed, a salt spray test is performed on a workpiece after the treatment for 24-28h, and the results show that no rust points appear on the surface of the workpiece and the corrosion resistance is very good; furthermore, the phenomenon of decomposition of the plating solution is avoided in the nickel plating process; and in addition, after double-layer nickel plating treatment, a plated layer has relatively strong binding force with a matrix of the workpiece.

Owner:GREATOO INTELLIGENT EQUIP INC +1

Technology for inlaying aluminum alloy in magnesium alloy in pressure casting manner

InactiveCN110576291AImprove antioxidant capacityNo rust spotsDetails for portable computersPressure castingAluminum can

The invention discloses a technology for inlaying an aluminum alloy in a magnesium alloy in a pressure casting manner. The technology for inlaying the aluminum alloy in the magnesium alloy in the pressure casting manner includes the following steps that S1, pressure casting forming of the magnesium alloy is conducted; S2, local inlaying of the aluminum alloy is conducted; S3, CNC machining is conducted; S4, formation is conducted; S5, surface paint spraying is conducted; S6, drilling cutting highlighting is conducted; S7, salt spray testing is conducted; and S8, complete inspection packaging is conducted. By means of the technology for inlaying the aluminum alloy in the magnesium alloy in the pressure casting manner, due to the fact that the aluminum alloy is inlaid in a magnesium alloy shell and the antioxidant effect of the aluminum alloy is better than that of the magnesium alloy, it can be ensured that the highlighted part of a metal notebook computer face shell does not generate rust; due to the fact that a dovetail-shaped aluminum engaging structure is arranged, the aluminum alloy can be better engaged with the magnesium alloy firmly; and due to the fact that the aluminum engaging structure is made into a dovetail shape, the dovetail structure of aluminum can be completely wrapped by magnesium during pressure casting, and disengagement of the inlaid aluminum part is prevented.

Owner:重庆百钰顺科技有限公司

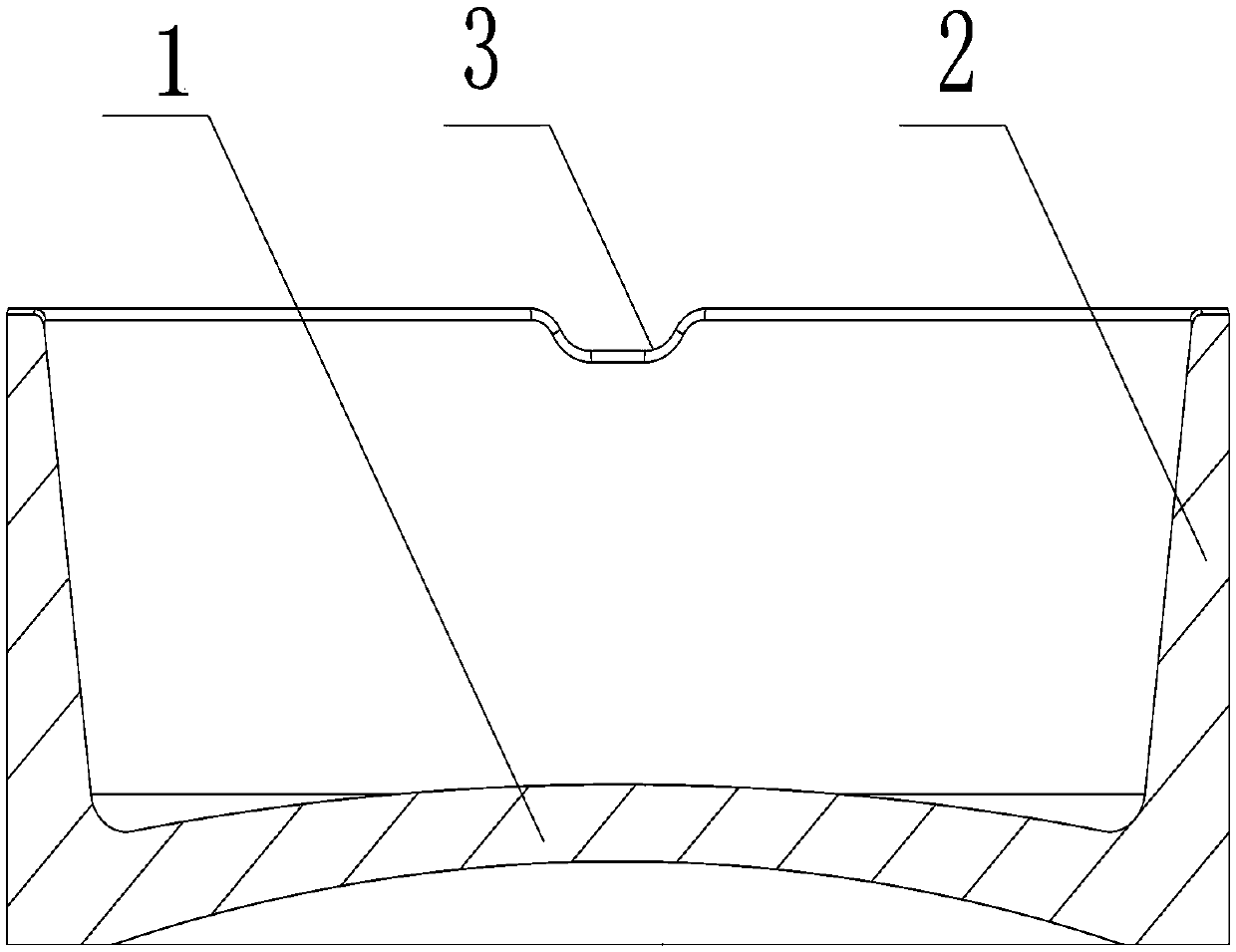

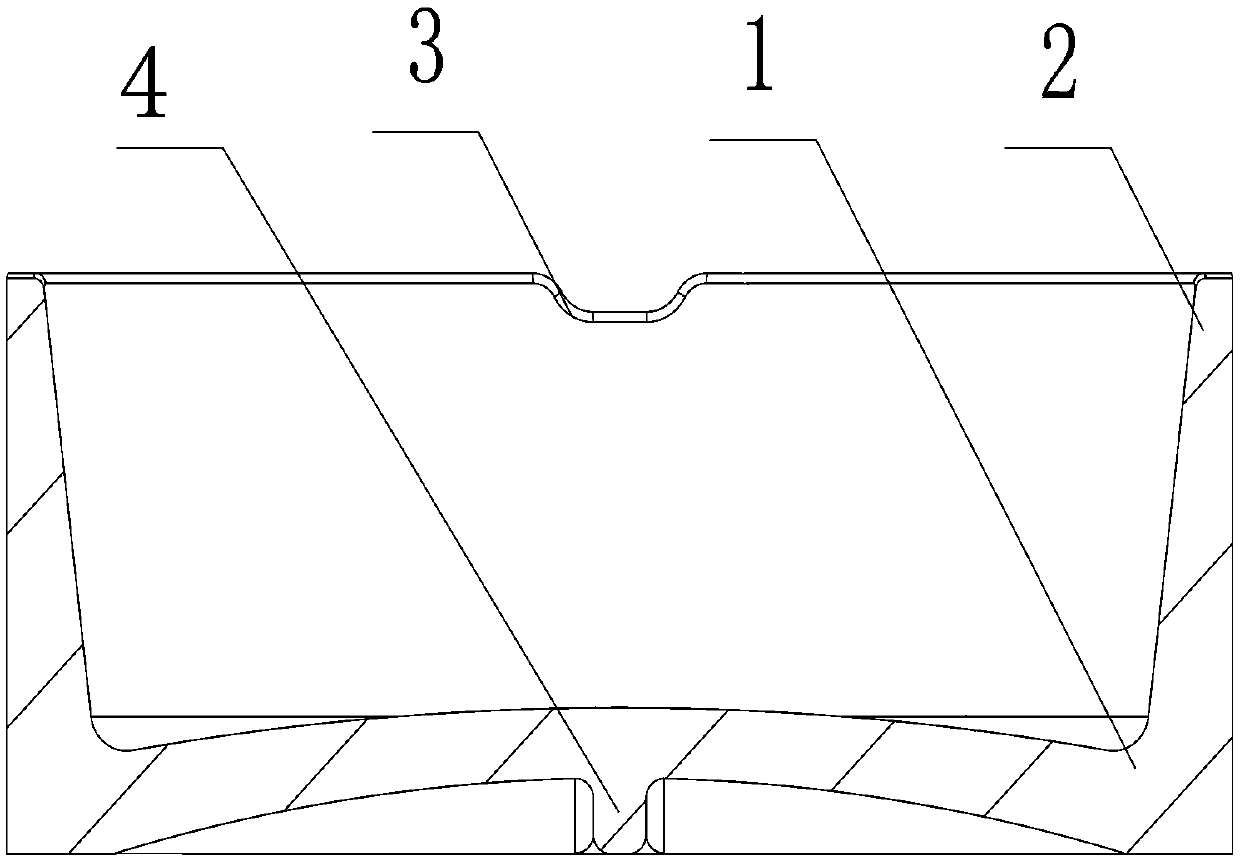

Saggar and method for producing abrasive material through saggar

The invention provides a saggar. The saggar is provided with a saggar base (1) and a saggar wall (2), wherein the saggar base (1) is provided with an upward groove, two or more air holes (3) are uniformly formed in the top of the saggar wall (2), and therefore the ability of the saggar to resist deformation at high temperature is improved, and the heat conduction and air permeation performance of material in the saggar is improved through the structure. The invention further provides a method for producing abrasive material through the saggar. The method comprises the steps of loading the abrasive material into the saggar, stacking the saggar on a kiln car for high-temperature calcination, cooling the abrasive material to the indoor temperature and then obtaining finished products of the abrasive material. The method has the advantages that the process is simple, the energy consumption is small, and the strength and the machinability of the abrasive material are improved.

Owner:ZHENGZHOU HONGJI ABRASIVE TECH CO LTD

Self-lubricating non-stick molten aluminum environment-friendly coating, coating film and preparation method of self-lubricating non-stick molten aluminum environment-friendly coating

ActiveCN111590017AEasy to prepareStable temperature resistanceFoundry mouldsFoundry coresDipropylene glycolAluminium

The invention discloses a self-lubricating non-stick molten aluminum environment-friendly coating, a coating film and a preparation method of the self-lubricating non-stick molten aluminum environment-friendly coating. The preparation method comprises the following steps of mixing a silane coupling agent containing amino or epoxy groups, deionized water and tetramethylammonium hydroxide, and carrying out ultrasonic dispersion and hydrolysis to prepare a polysiloxane oligomer aqueous solution I; conducting stirring continuously, and sequentially adding dipropylene glycol butyl ether, boron nitride, talcum powder, low-temperature glass powder and Al2O3 for dispersing; adding gas-phase SiO2 for dispersing so as to prepare water-based slurry II; and mixing the polysiloxane oligomer aqueous solution I and the slurry II, and carrying out ultrasonic dispersion to prepare the self-lubricating non-stick molten aluminum environment-friendly coating. The coating film prepared from the coating hasthe advantages of stability, reliability, no toxicity, no powder falling, cracking, discoloration and gasification on the surface at 800 DEG C, self-lubricating property, no adhesion of molten aluminum, capability of being used as an environment-friendly, clean and efficient release agent for cast aluminum, the simple preparation process, convenience in construction, environmental friendliness and the like.

Owner:陕西宝塔山油漆股份有限公司 +1

Joint five-degree-of-freedom docking sealing debugging equipment

ActiveCN103134642BAchieve free spinsEasy to operateMachine part testingFluid-tightness measurement using fluid/vacuumFree rotationButt joint

Five degree of freedom butt joint tightness debugging equipment provided with a connector is characterized in that a connecting device is arranged at one end of a machine frame, and the end of the machine frame is provided with a fixed connector. The connecting device comprises a lifting device, a cross axial movement device and a rotating device. The machine frame which is used for driving the connecter to lift up and down, move in a cross mode and rotate in a horizontal mode is provided with an angle turnover device of the five degree of freedom butt joint tightness debugging equipment which is provided with the connector. A turnover plate is provided with a connecting structure which is used for connecting the other end of the connector. The five degree of freedom butt joint tightness debugging equipment provided with the connector has the advantages of freely rotating around six shafts, being capable of imitating deviation produced by the connector when a work object is connected through butt joint, accurately controlling deviation of an angle and displacement and clearly mastering the size of the adjustment of the angle due to the fact that an adjustment stick is adopted, and being high in reliability. Due to the fact that the whole equipment is connected through stainless screws, and stainless pins which match with the stainless screws are arranged, the five degree of freedom butt joint tightness debugging equipment provided with the connector is easy to dismantle and reset, guarantees assembling accuracy, is good in stability and free from producing rusty spots due to the fact that the whole equipment except of a circular dividing table and a cross-shaped working table is made of 2 Cr13 stainless materials.

Owner:柳州市鑫鑫农业科技有限公司

Antirust coating for building steel bars and construction method thereof

The invention discloses a building steel bar antirust coating which is composed of following raw materials including, by mass, 55-70 parts of cement, 15-25 parts of chloroprene rubber latex, 3-7 parts of a latex regulating agent, 2-4 parts of a rust inhibitor, 0.3-1 part of a defoamer and 5-10 parts of water. Total amount of the components is 100 parts. The coating is a modified antirust coating that can prevent rust on steel bars in construction sites, remove iron rust and enhance gripping force between the steel bar and concrete. The invention also discloses a construction method of the coating.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

A kind of pickling solution containing compound passivating agent and preparation method thereof

The invention belongs to the field of cleaning stainless steel castings, and relates to a pickling solution with passivation effect obtained by adding organic substances to HNO3 and HF basic acid solution. It is composed of nitric acid and hydrofluoric acid, compound passivating agent and water, and its mass content is respectively: 3.3%~37.5% for nitric acid, 0.7%~7.5% for hydrofluoric acid, and 1.3~13.5% for compound passivating agent , Water is the balance. Clean the polluted stainless steel castings to restore the metallic luster of the castings. And a dense passivation film is formed on the surface of the casting, so that the casting can still keep silver bright and beautiful without rust spots after long-term storage. Another feature of the present invention is that the acid mist is very small, which is beneficial to environmental protection and the health of operators, the pickling amount is large, and the acid treatment cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion-resistant cutting fluid and preparation method thereof

InactiveCN105670761ASimple materialImprove cooling and lubrication effectLubricant compositionArray data structureCavitation

The invention discloses a corrosion-resistant cutting fluid which is composed of the following components in parts by mass: 10-15 parts of polyvinyl alcohol, 5-10 parts of stearic acid, 3-6 parts of triethanolamine, 5-8 parts of sodium carbonate, 3-5 parts of sodium cumenesulfonate, 120-140 parts of diluted cucumber juice, 1-3 parts of preservative, 0.1-0.5 part of bactericide, 0.1-0.3 part of softener and 0.03-0.06 part of defoaming agent. By selecting excellent materials and adopting the scientific processing method, the corrosion-resistant cutting fluid solves the problems of corrosion, deterioration and smelliness for the machine tool in the past cutting fluid, and can prevent the corrosion, cavitation corrosion and scaling on the machine tool internal surface and form a protective layer. The corrosion-resistant cutting fluid has favorable cooling and lubricating effects, generates fewer precipitates in the use process, and ensures the workpieces to be clean and acceptable. Nitrites and phosphorus and sulfur compounds are eliminated in the product formula, and the cucumber juice is added; and thus, the product is green and environment-friendly. The properties of the product are not changed; and the product has the advantages of high economy, low cost, no toxicity and no adverse effect on skin.

Owner:周紫阳

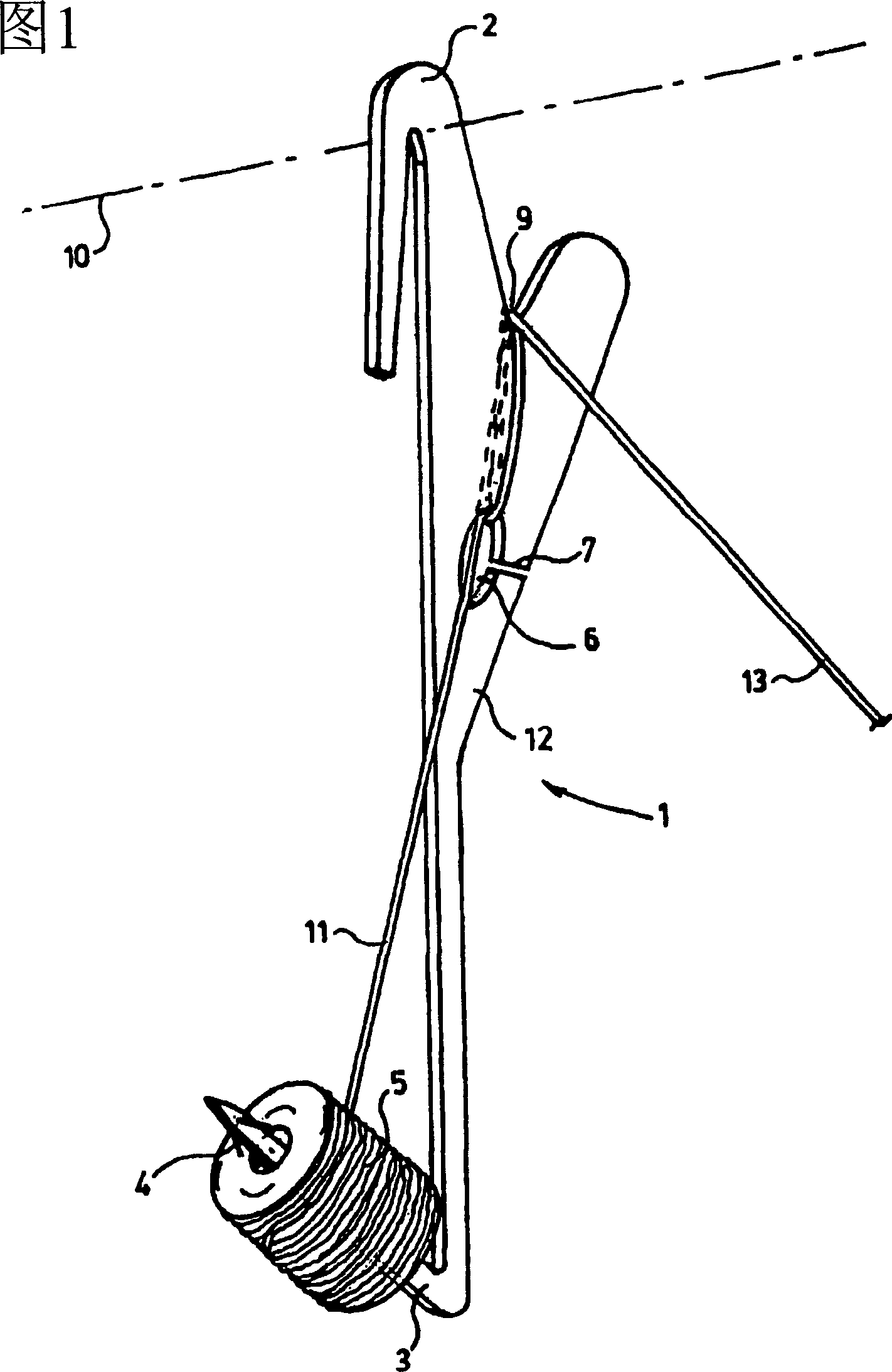

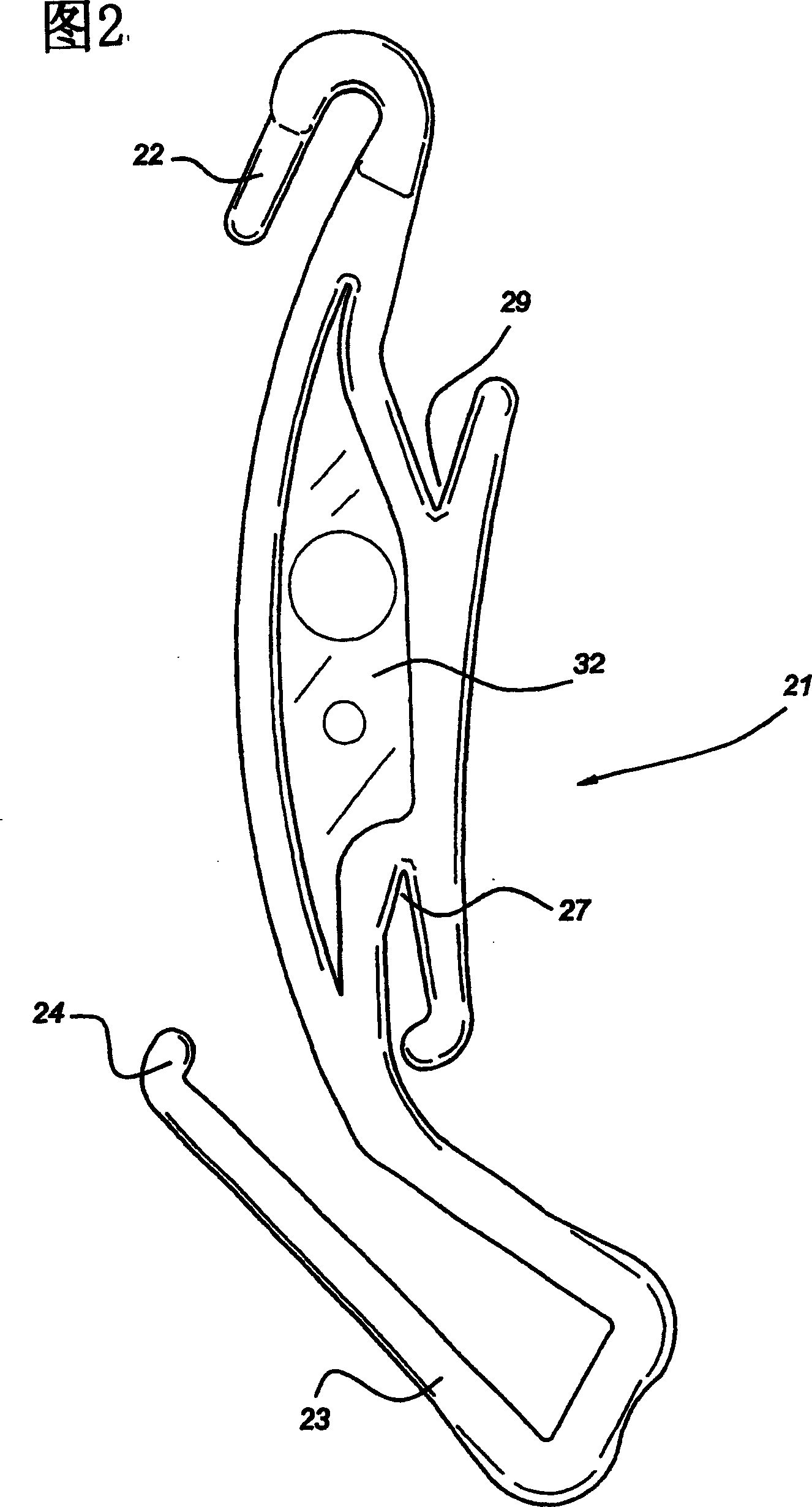

Suspension hook

InactiveCN1317939CEasy to recycleEasy to produceCultivating equipmentsPlant supportsBobbinEngineering

Suspension hook (1) for plants, comprising a plate-like body (12) provided with a support (3) which is of stub-like design and on which a bobbin (5) bearing plant cord can be held. There are locking means (9) for fixing the plant cord with respect to the suspension hook (1) and thus supporting the plant in question. A suspension part (2) is present for securing to the surroundings.

Owner:CORSA BEHEER BV

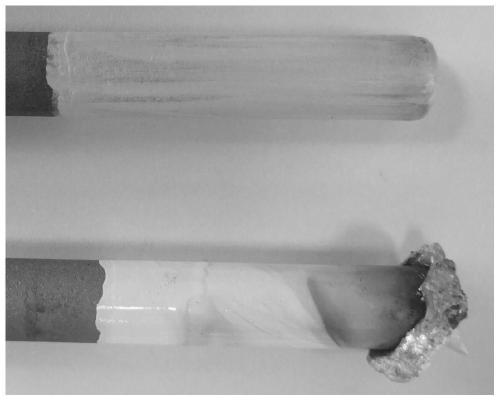

A process method for anticorrosion by spraying oil casing with black uv paint

ActiveCN107127119BMake up for the shortcomings of incomplete curingFully absorbedPretreated surfacesCoatingsHalogen lampAnti-corrosion

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

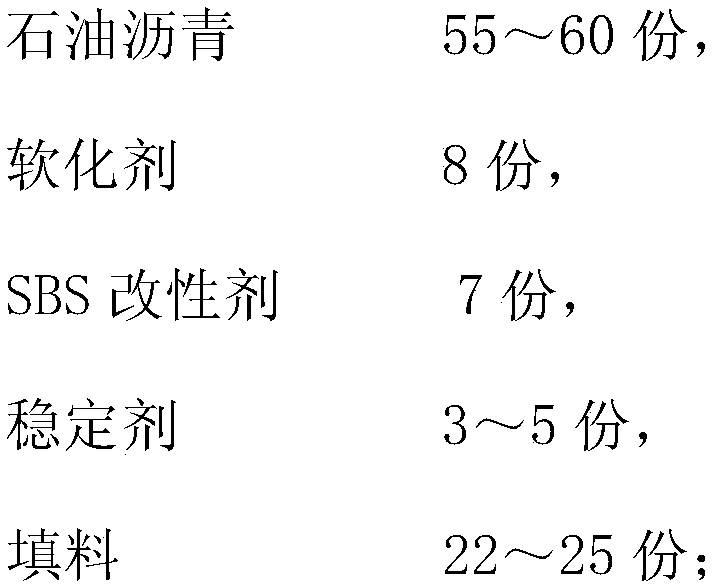

A kind of modified asphalt for waterproof membrane and preparation method thereof

ActiveCN105885441BImprove stabilityImprove aging resistanceBuilding insulationsSocial benefitsBituminous waterproofing

A modified asphalt used for waterproofing membranes and a preparation method thereof, the modified asphalt is composed of the following components in parts by mass: 50-60 parts of petroleum asphalt, 5-8 parts of softener, 5 parts of SBS modifier ~8 parts, 1~5 parts of stabilizer, 20~30 parts of filler; wherein, the softener is polyethylene glycol, glycerol, pentaerythritol oleate or pentaerythritol acrylate. The invention also includes the preparation method of the modified asphalt used for the waterproof coiled material. The modified asphalt waterproofing membrane prepared by using the novel softener in the present invention has greatly improved storage low-temperature flexibility stability and aging resistance compared with modified asphalt prepared by petroleum hydrocarbon softeners, and the preparation steps are simple and the production investment is small. It has significant economic and social benefits.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

A kind of anti-flash rust agent for water-based paint and preparation method thereof

ActiveCN111876006BMeet the requirements of green environmental protectionAvoid Galvanic CorrosionAnti-corrosive paintsPolyurea/polyurethane coatingsPhosphateEngineering

The invention discloses an anti-flash rust agent for water-based coatings and a preparation method thereof. 20‑60: 20‑60: 4‑25: 4‑25: 1000 mass ratio compounded. The invention can easily form a uniform and dense adsorption film on the metal surface, effectively prevent the electrochemical corrosion of the metal surface, and play the role of inhibiting corrosion. The invention is applied to the water-based paint, has good anti-flash rust performance and less dosage, and only needs to add 0.7-1.2wt% of the anti-flash rust agent to ensure that no rust spots appear on the metal surface.

Owner:HUAQIAO UNIVERSITY

A kind of anti-flash rust agent for water-based paint ink and its preparation method and application

ActiveCN105419439BImprove rust resistanceImprove performanceInksAnti-corrosive paintsWater basedNitrite

Owner:江西省龙海化工有限公司

Technological method of carrying out corrosion protection by adopting black UV paint to spray oil casing

ActiveCN107127119AMake up for the shortcomings of incomplete curingFully absorbedPretreated surfacesCoatingsCouplingLength measurement

The invention discloses a technological method of carrying out corrosion protection by adopting black UV paint to spray an oil casing. Original transparent UV paint is poor in covering property and low in adhesive force, which results in the problems that the product appearance is worse, and rust, grinding traces and blots can not be covered. The technological method adopts the black UV paint for corrosion protection. The technological method comprises the steps of weighing, length measurement, marking, painting and sign spraying. Through delay control spraying, a coupling is prevented from being sprayed excessively, and the color of the coupling is protected; and a metal halid lamp is adopted and is matched with the black UV paint for solidification, so that the solidification is complete, the painting quality is ensured, and the product quality of the oil casing is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A packaging material with high adhesion to magnesium and aluminum alloys and its preparation method

Owner:常州汉索电子材料科技有限公司

A kind of marine anti-corrosion inorganic coating and preparation method thereof

ActiveCN107620024BWide range of substratesImprove coating qualityMolten spray coatingCalcium silicateUltimate tensile strength

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of self-lubricating non-stick aluminum-melting environment-friendly coating and coating film and preparation method thereof

ActiveCN111590017BEnvironmentally friendlyHigh temperature resistanceFoundry mouldsFoundry coresBoron nitrideSlurry

The invention discloses a self-lubricating and non-stick aluminum-melting environment-friendly coating, a coating film and a preparation method thereof, comprising mixing a silane coupling agent containing an amino group or an epoxy group, deionized water, and tetramethylammonium hydroxide, and ultrasonically Disperse, hydrolyze, and prepare polysiloxane oligomer aqueous solution I; disperse deionized water and dispersant, and add dipropylene glycol butyl ether, boron nitride, talc powder, low-temperature glass powder, Al 2 o 3 Disperse it; then add gas phase SiO 2 , disperse, that is, prepare the water-based slurry II; mix the polysiloxane oligomer aqueous solution I and the slurry II, and ultrasonically disperse, that is, prepare an environmentally friendly coating with self-lubricating non-stick melting aluminum. The coating film prepared by this coating is stable and reliable at 800°C, non-toxic, free from powder removal, cracking, discoloration, and gasification on the surface, self-lubricating, non-sticky and molten aluminum liquid, and can be used as an environmentally friendly, clean and efficient coating for casting aluminum The release agent has the characteristics of simple preparation process, convenient construction, and environmental protection.

Owner:陕西宝塔山油漆股份有限公司 +1

Engineering oil cylinder coating method

The invention discloses an engineering oil cylinder coating method which is characterized by consisting of the following steps of polishing, oil pre-removal, oil removal, four-in-one phosphorization, phosphating film drying, the spraying of red iron oxide epoxy primer TNE-HD001, the preparation of working lacquer liquid, the adoption of the red iron oxide epoxy primer, the spraying of the primer, napping, sootblowing and the spraying of finish; a product paint film has level and smooth appearance, and has no such quality defects as particles, bottom exposure, bubbles, needle holes, heat rash particles, wrinkled skin, flood and flying paint misty edges; and the paint film is fine, full and the color consists with that on a standard color disk. According to the engineering oil cylinder coating method, the total adhesive force of the paint film is less than or equal to Level 1 (GB / T9286-88); and no whitening, bubbles or rust spots occur 720 hours after a neutral salt spray resistance test of the paint film is taken.

Owner:CNHTC CHENGDU WANGPAI COMML VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com