Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

522results about How to "Reduce acid consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

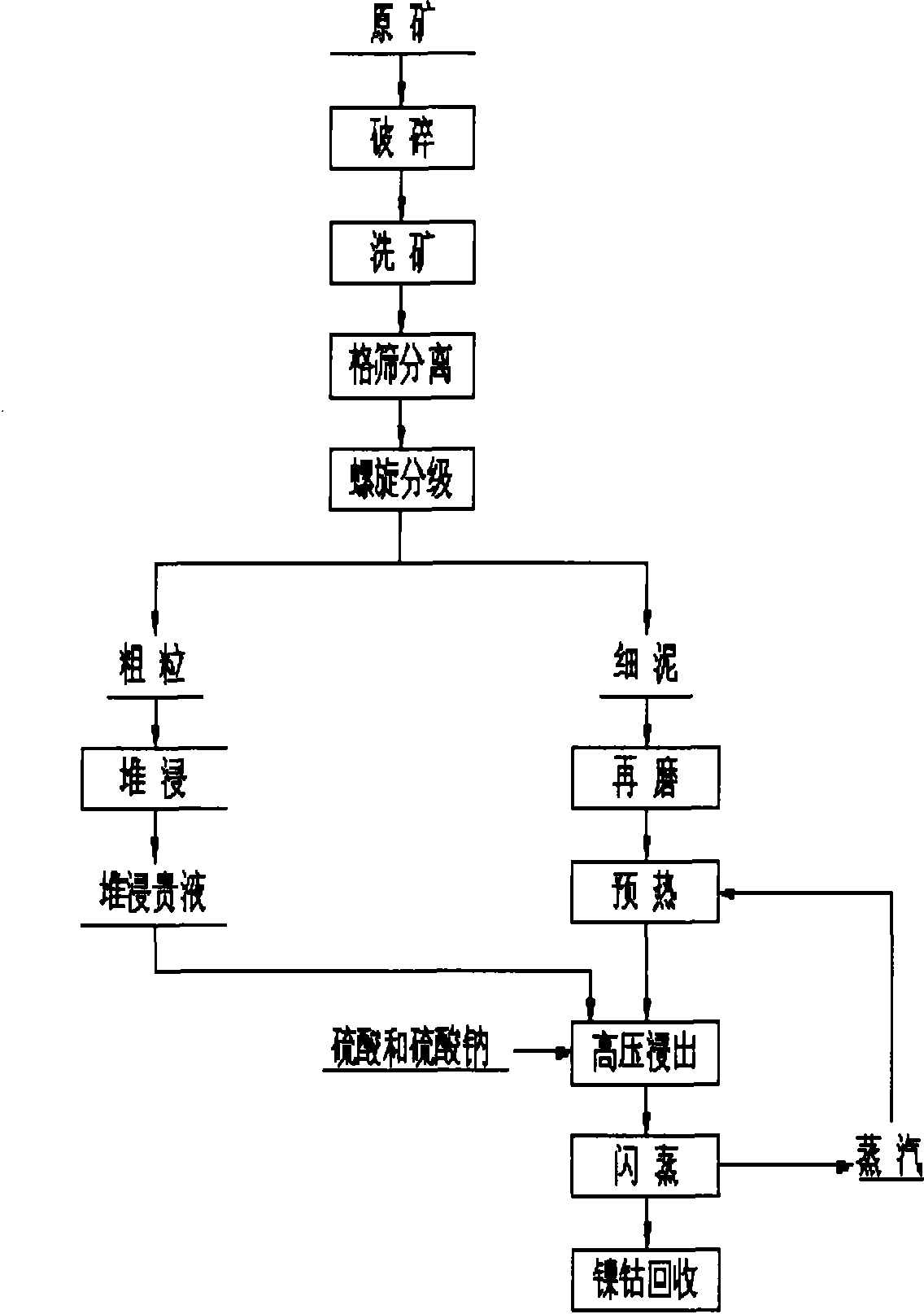

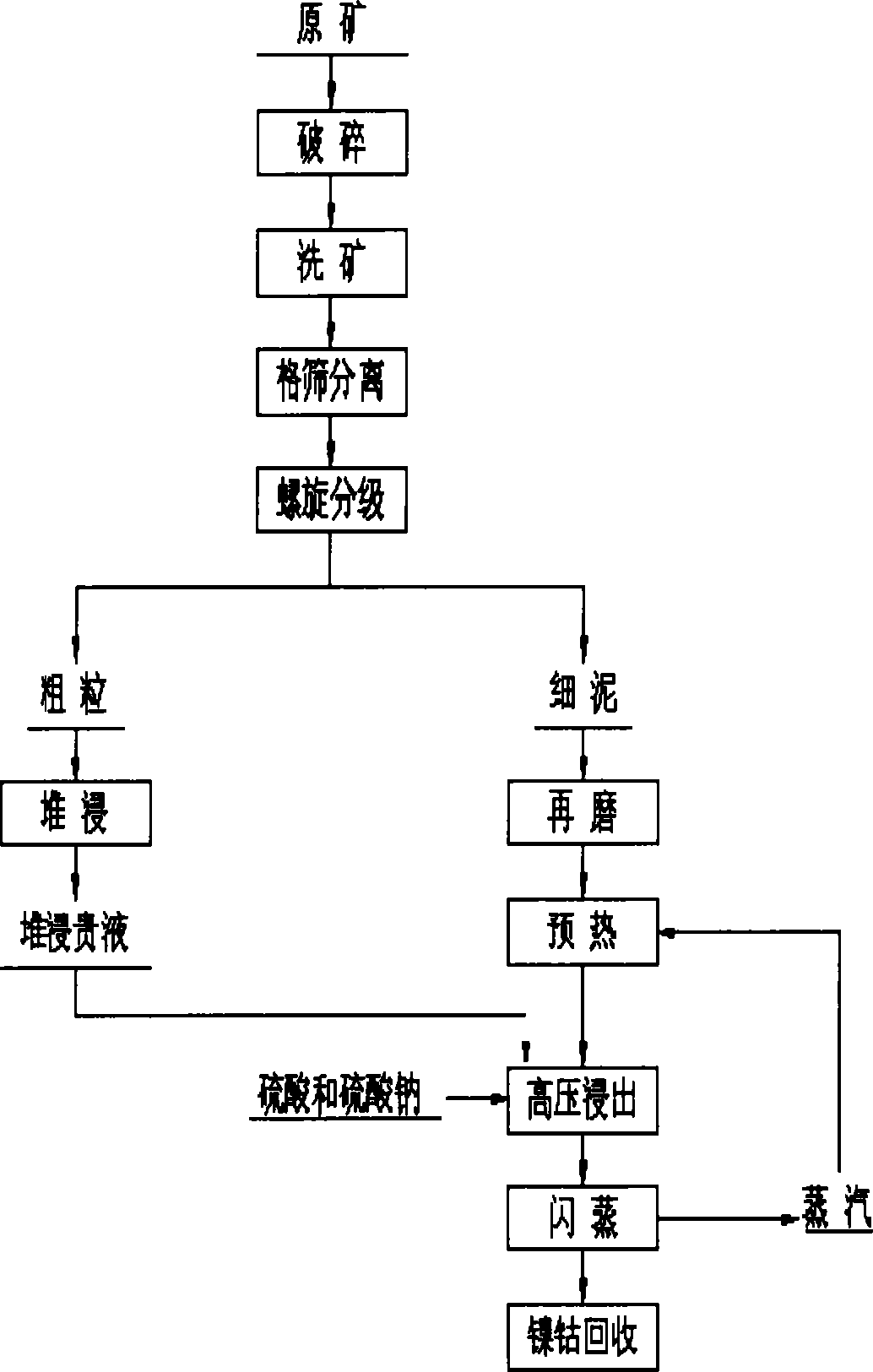

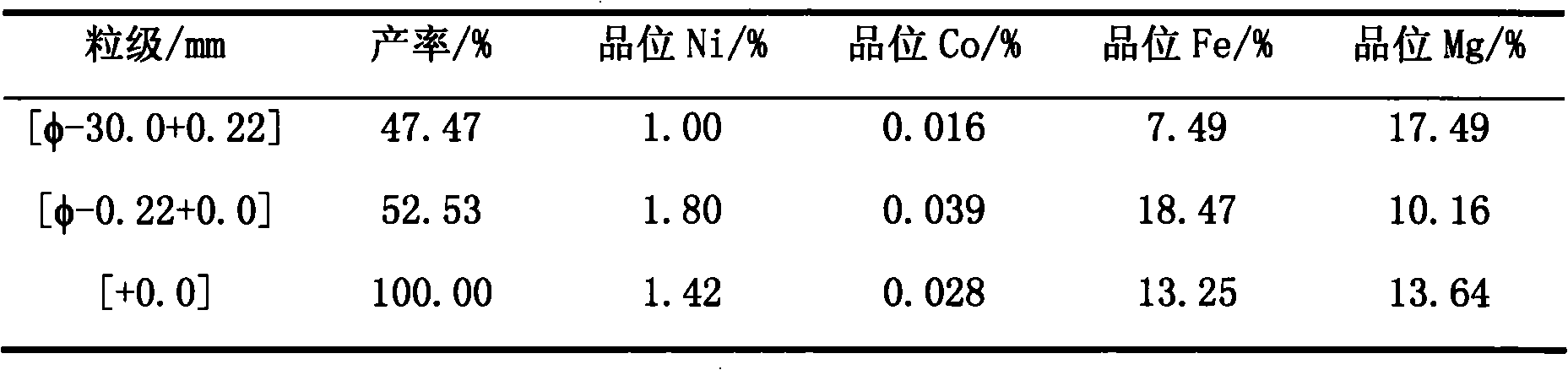

Method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore

InactiveCN101768665AReduce acid consumptionReduce consumptionProcess efficiency improvementHigh pressureLaterite

The invention discloses a method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore, which combines the heap leaching technology with the high-pressure leaching technology to reduce acid consumption during the treatment of nickel laterite ore; residual sulfuric acid in coarse particle immersion of limonite heap is sufficiently utilized and sodium sulfate is added during the stage of high-pressure leaching so that sulfuric acid is generated while yellow natrojarosite is formed, thereby further reducing the consumption of sulfuric acid during the stage of high-pressure leaching.

Owner:厦门紫金矿冶技术有限公司

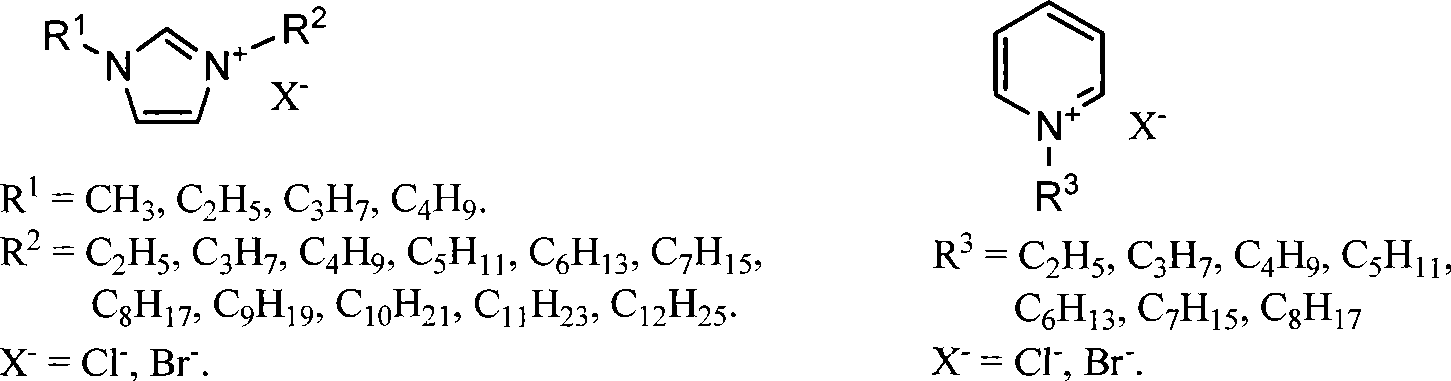

Process for effectively hydrolyzing cellulose in ion liquid

InactiveCN101289817ALower catalyst costsReduce acid consumptionCation exchanger materialsOrganic anion exchangersIonSolvent

The invention relates to cellulosic hydrolysis, in particular to a method for high-efficiently hydrolyzing celluloses in ionic liquid. In the method, the ionic liquid in which celluloses are dissolved is used as solvent, and water, the equivalent weight of which is more than or equal to 1 mol, is used as reactant, and inorganic acids, the catalytic amount of which is the stoichiometric amount, are used as catalyst, and celluloses are reacted under the conditions of the normal pressure and the temperature of between 70 to 100 DEG C for 2min to 9hr; after the reaction is over, celluloses undergo the cold water quenching reaction and the alkali neutralization reaction, and the cellulose hydrolysate is obtained; total reducing sugar and glucose in the cellulose hydrolysate are taken with quantitative chemical analysis, and results of which show that the highest yield of reducing sugar is 73 percent, and correspondingly the yield of glucose is 53 percent. Compared with the conventional hydrolysis method, the method of the invention has the advantages of unnecessary pretreatment, mild reaction conditions, high hydrolytic activity, quick reaction speed, little acid consumption, low requirement on corrosion resistance of a reactor and easy tracking and controlling of the extent of reaction; the method opens a new road for resolving the lasting problem of the complete utilization of lignocelluloses.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

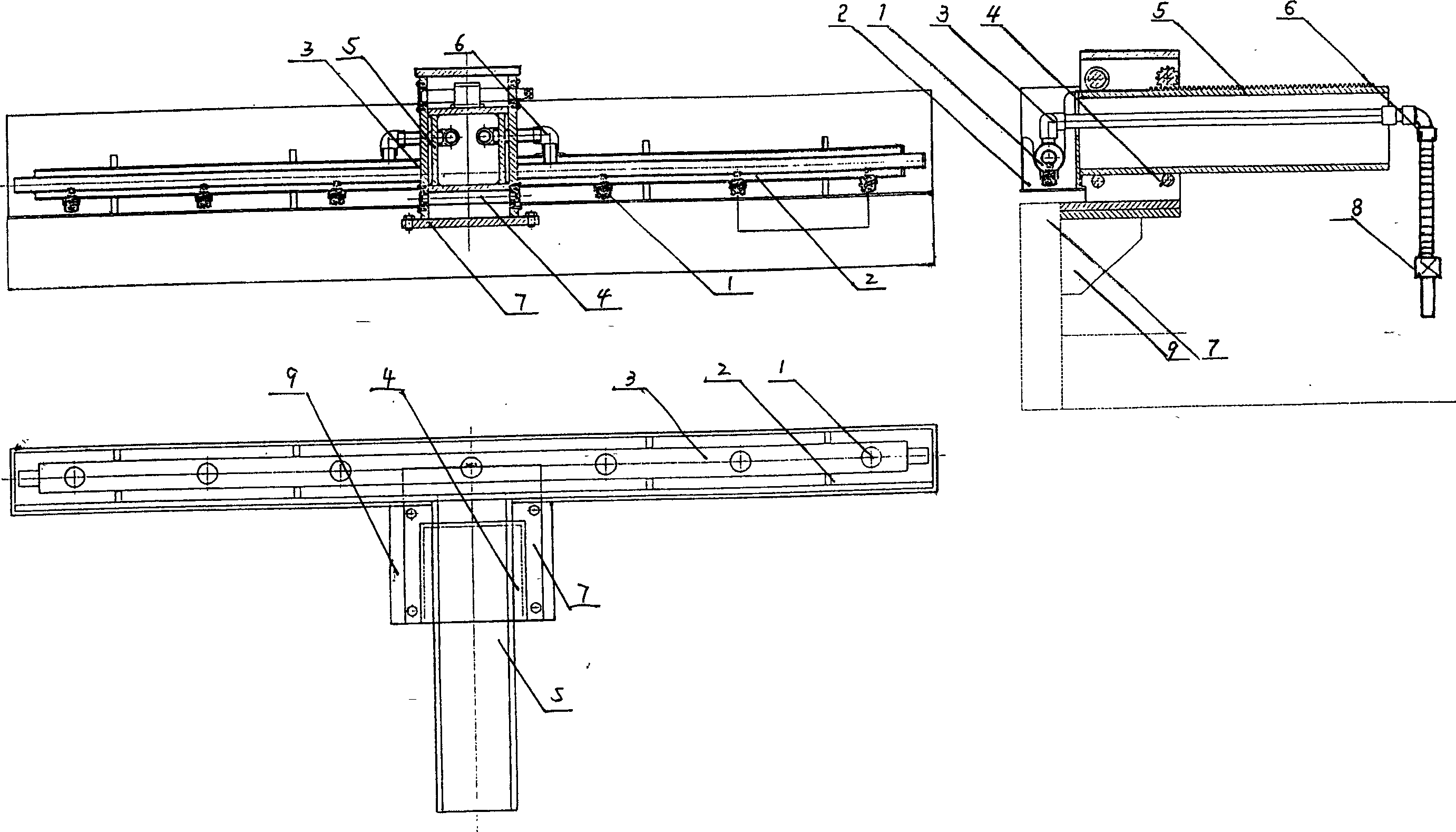

Stelmo line gas spray cooling device and method for high-speed wire rod mill

InactiveCN1603021AControllable water volumeWater pressure adjustableWork treatment devicesMetal rolling arrangementsForced-airEngineering

The invention simultaneously solves building the contact organization, the performance is uneven question. The invention has provides a kind of gas spray cooling system and the method, namely after the spinning machine, style touches in front of the air blower a section of air cooled table place above, two sides symmetrical establishes the gas spray chiller, first builds above the contact from the coil, key to builds the contact to leave the atomization to cool, then style touches the forced-air cooling line again from the underneath forced-air cooling, and uses the' good spirit installment concentratly blowing the contact place. The intensity difference between the line material build contact through the gas spray cooling system and the no build contact is fall to 5~7MPa; The overall intensity of the line material may enhance 20~25MPa; Improves the surface quality; Simultaneously decreases the ambient temperature, improves the operating environment.

Owner:UNIV OF SCI & TECH LIAONING

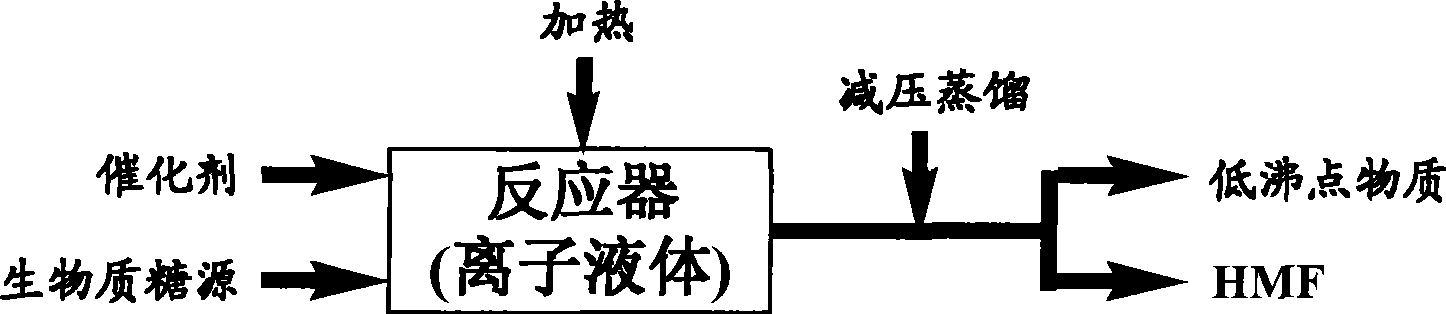

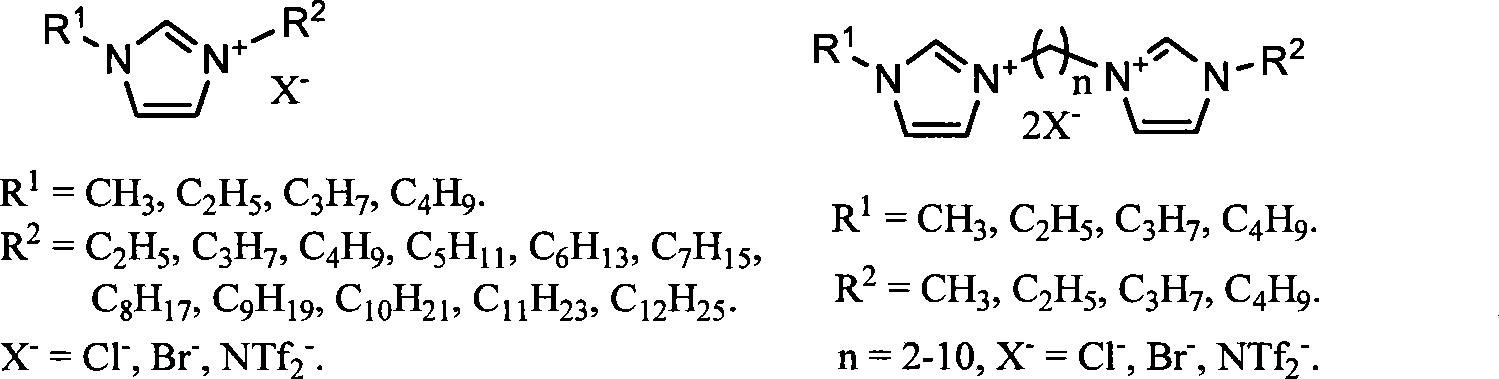

Method for preparing 5-hydroxymethyl-furfural

InactiveCN101386611ALow costCorrosion resistance requirements are not highOrganic chemistryAlternative fuelsSolvent

The invention relates to a method for transforming biomass sugar source into 5-hydroxymethyl-furfural, in particular to a method for preparing the 5-hydroxymethyl-furfural. The method comprises the following steps: using ionic liquid as a solvent, hexose or hexose source biomass as raw material substrates, and 0.5 to 50 percent (relative to the mass of the biomass sugar source) of acidic ionic liquid, inorganic acid or organic acid as a catalyst, and performing the reaction of materials for 1.5 minutes to 23 hours at normal pressure and at a temperature of between 80 DEG C and 100 DEG C to efficiently generate HMF. The method has the advantages of high HMF selectivity, less acid consumption, moderate operating conditions, fast reaction, reusable ionic liquid, simple process, environment protection and the like, and opens up a new approach for preparing commodity chemicals and replacing fuels starting from renewable biological resources.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 5-hydroxymethyl-furfural

InactiveCN101456850ALow costCorrosion resistance requirements are not highOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlternative fuelsSolvent

The invention relates to a method for preparing 5-hydroxymethylfurfural (HMF) by transforming a biomass saccharine source. The method comprises the following concrete steps: using an ionic liquid as a solvent, hexose or hexose source biomass as a raw material substrate, and acid as a catalyst, heating the mixture to react for 5 minutes to 20 hours at normal pressure, and then depressurizing and distilling the mixture under the condition that an operation temperature is not higher than 180 DEG C to obtain the HMF after the reaction is ended; and after the distilled remainder is cooled, directly adding the remainder into the biomass saccharine source, and repeating the processes of reaction and separation to obtain the HMF, so as to realize recycling of an ionic liquid catalyst system and semi-continuous preparation of the HMF. By using the method, once through yield of the HMF reaches as high as 94 percent. The method has the advantages of high selectivity, low acid consumption, mild condition, quick reaction, reusability of the ionic liquid, low cost, simple process, environmental protection, semi-continuous production and the like, and provides new technology for industrialized production of the HMF by transforming the biomass saccharine source, so as to develop a new path for preparing common chemicals in a large scale by using biomass resources and replacing fuels.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

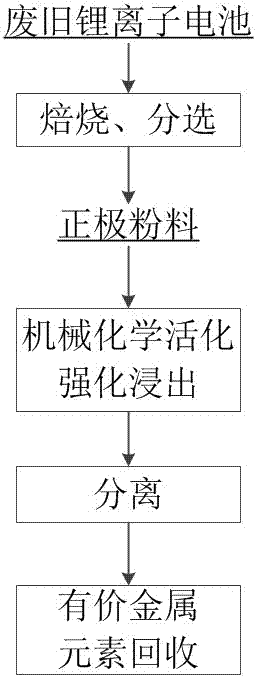

Method for enhancing metal recovery of waste lithium ion battery

PendingCN107083483AReduce acid consumptionHigh cost of solutionWaste accumulators reclaimingProcess efficiency improvementLeaching rateMechanical force

The invention provides a method for enhancing metal recovery of a waste lithium ion battery. The method for enhancing the metal recovery of the waste lithium ion battery comprises the steps that firstly, the waste lithium ion battery is calcinated, smashed and sorted so that positive electrode powder materials can be obtained; and then, wet leaching is conducted on the positive electrode powder materials, and mechanical and chemical activation is achieved through a high-energy ball mill in the leaching process, wherein mechanical and chemical activation is executed during leaching, so that the obtained leach liquor can be further used for recovery of valuable metal elements. By the adoption of the method for enhancing the metal recovery of the waste lithium ion battery, the procedure is simple, the operability is high, under the cooperative action of mechanical force and chemical activation, the leaching time of the positive electrode powder material can be greatly shortened, the leaching rate of the metal elements is improved, cost is reduced, and the market prospect is good.

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

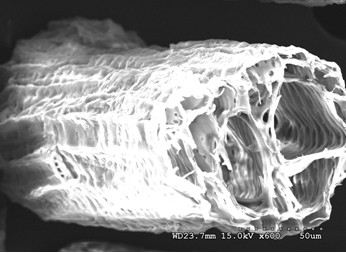

Short fiber food waste residue-based nano cellulose and preparation method thereof

InactiveCN102182089AFine granularityThe compactness of the crystal region is weakPretreatment with water/steamWashing/displacing pulp-treating liquorsFood additiveFiber

The invention relates to the field of processing of agricultural products, in particular to short fiber food waste residue-based nano cellulose and a preparation method thereof. The preparation method comprises three parts of pretreatment of short fiber food waste residues, acid hydrolysis of food residue fibers and homogenization. The nano cellulose prepared by the method has the granularity of 50-300nm, is short bar-shaped or microsphere-shaped and can be widely used for preparing a food additive or medicament excipient, and the like. In the method, acid hydrolysis is combined with high-pressure homogenization, thus the acid consumption and hydrolysis time are reduced, the granularity uniformity of the nano cellulose is improved; and the invention is suitable for mass production.

Owner:SOUTHWEST UNIV

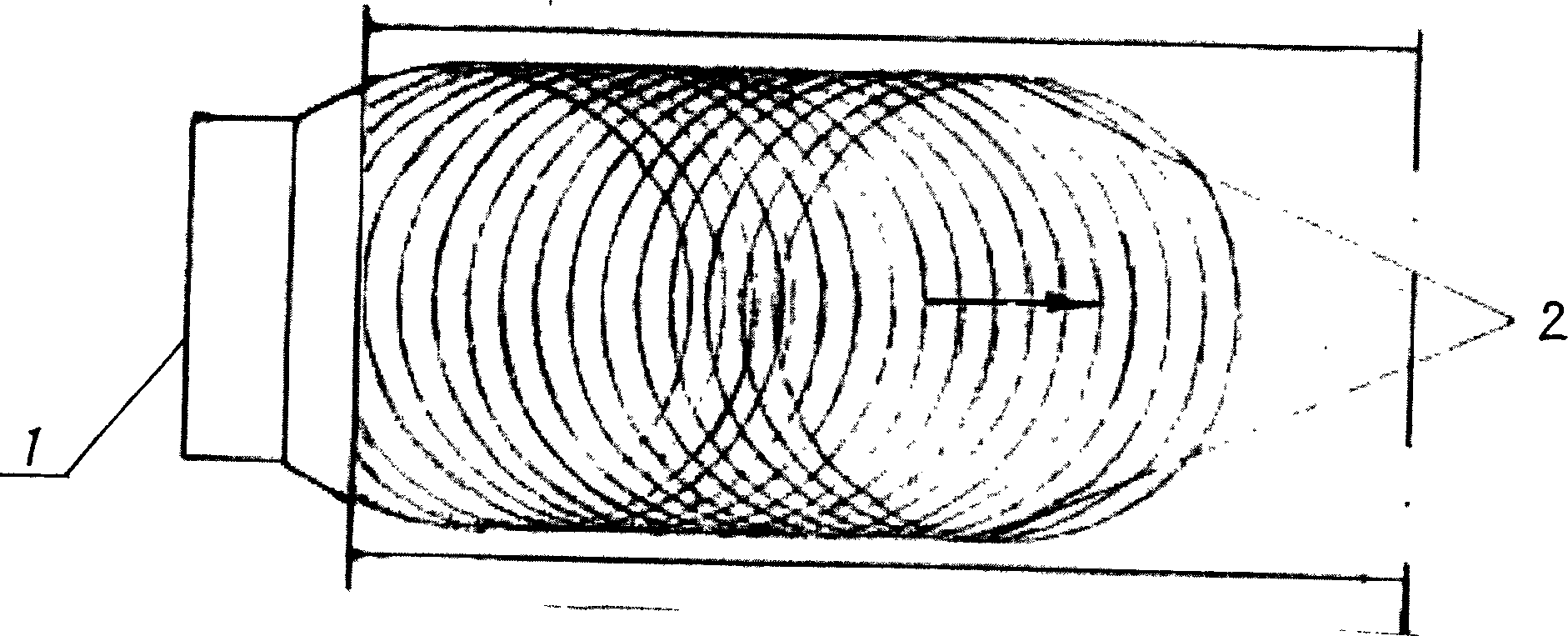

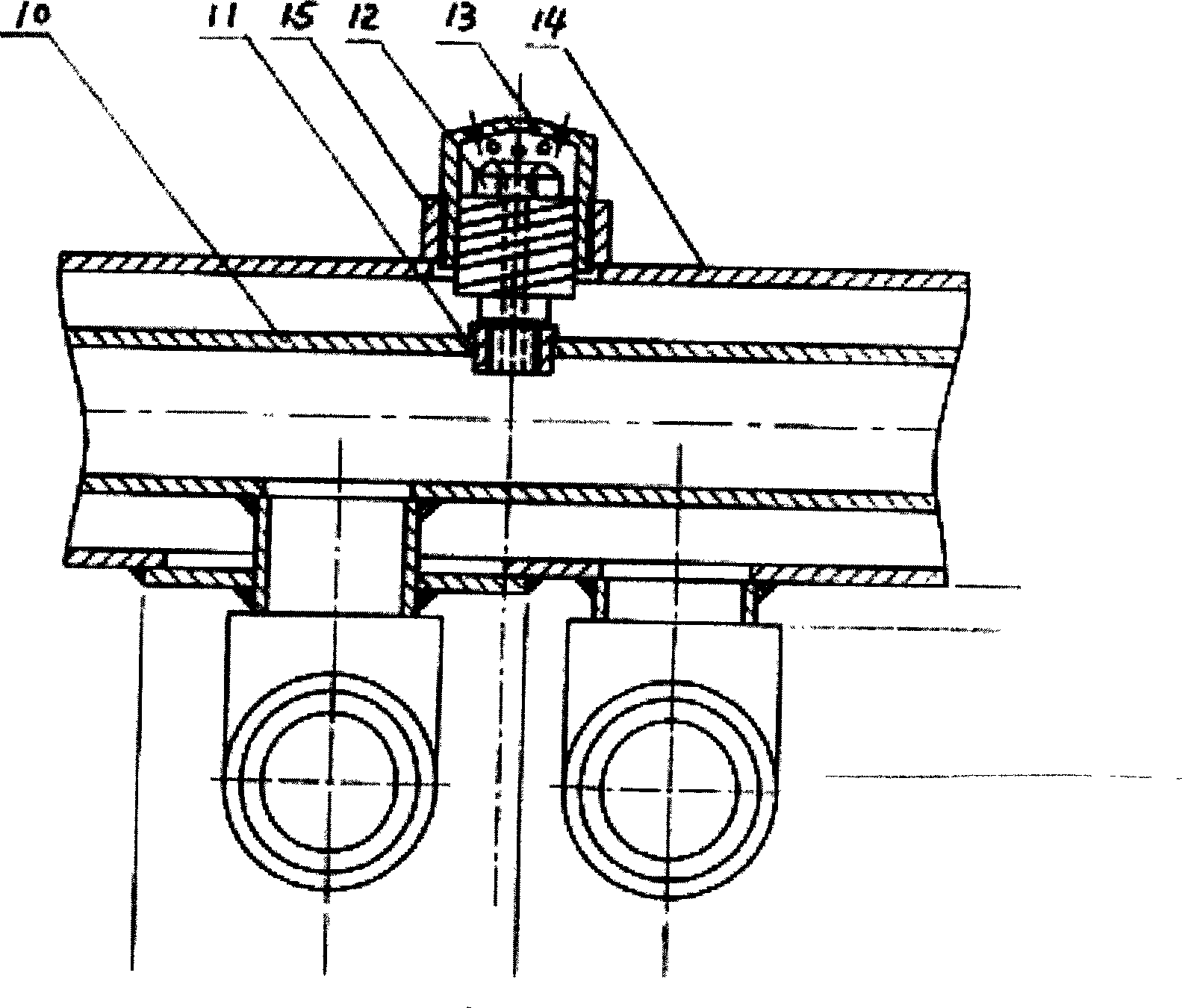

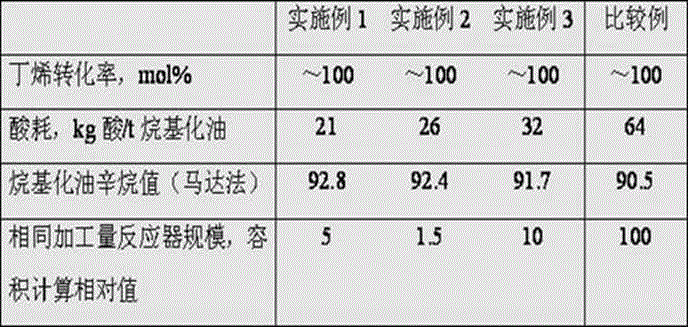

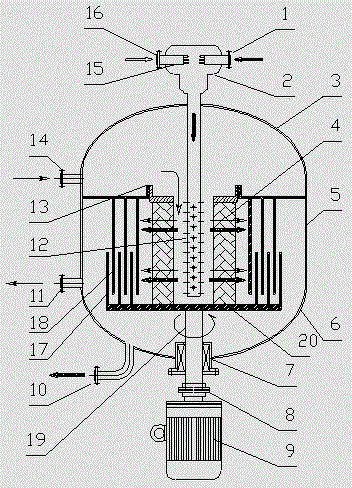

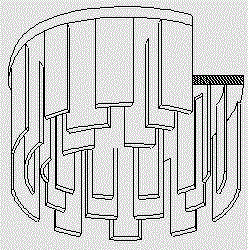

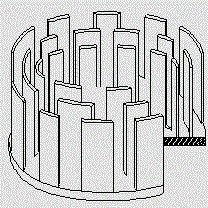

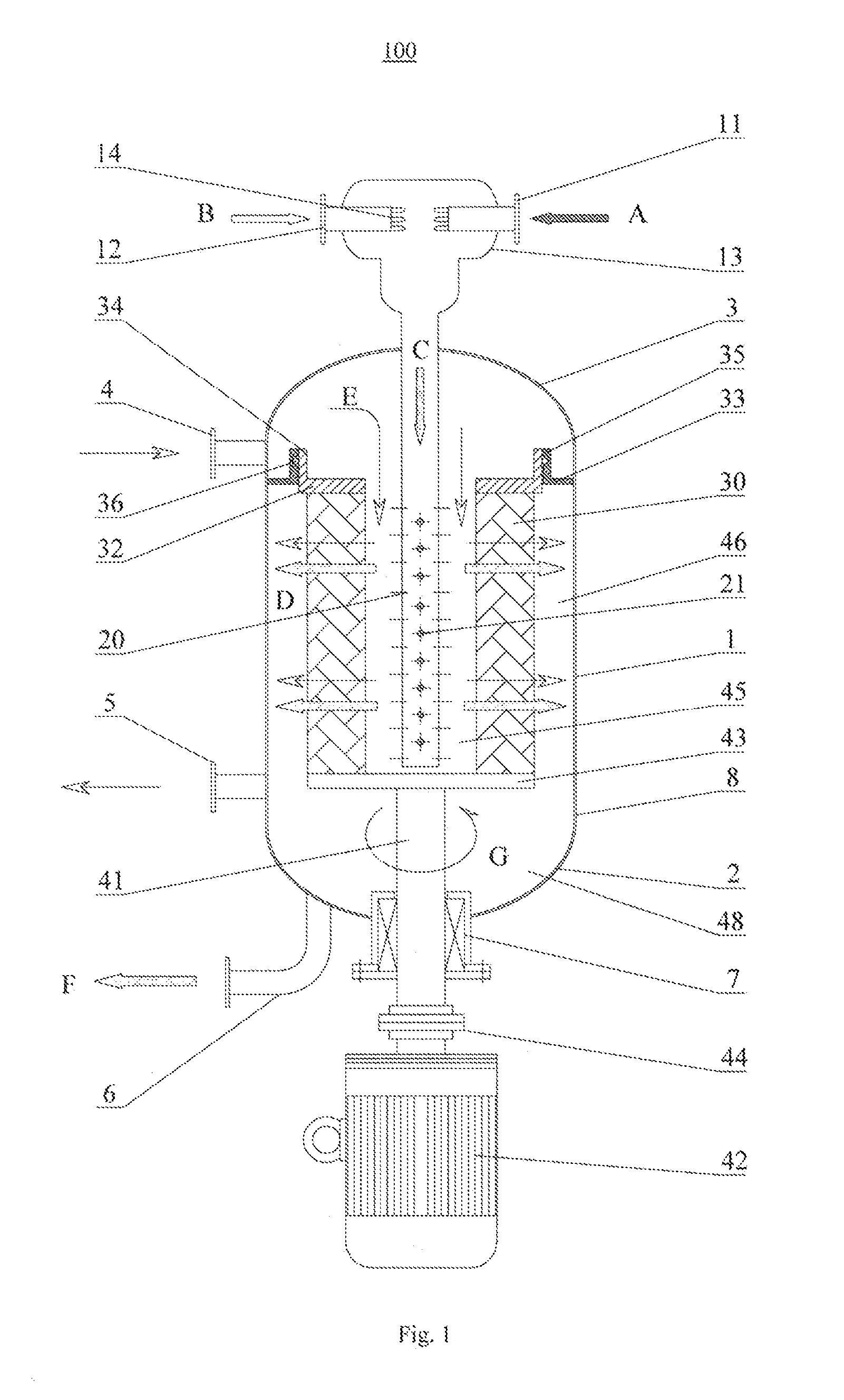

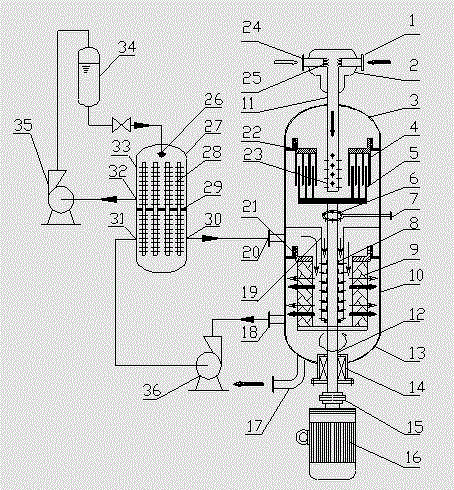

Alkylation reactor and alkylation process method

The invention discloses an alkylation reactor and an alkylation process method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigeration system and a circulating cooling gas outlet, wherein a closed reactor shell body is formed by the reactor tube body and the closure heads, and the revolving bed is vertically located at the internal middle part of the shell body; a sealing member is arranged between the upper part of the revolving bed and the reactor shell body, the upper part of the revolving bed and the sealing member are of rotatable connection, the circulating cooling gas inlet and the circulating cooling gas outlet are respectively formed in the shell body at the upper and lower sides of the sealing member, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation process method, the alkylation reaction can be carried out at low temperature, the acid consumption is low, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating valuable metals from lead anode mud

InactiveCN101798629AHigh recovery rateEasy to separateProcess efficiency improvementAlkali metal chloridesCopperBismuth

The invention discloses a method for separating valuable metals from lead anode mud, aiming to provide a new method for separating valuable metals in lead anode mud by using a wet method. The invention is characterized in that the purpose of more thoroughly separating the valuable metals in the lead anode mud is achieved through several steps of acid leaching, hydrolyzing to deposit antimony, hydrolyzing to deposit bismuth, vulcanizing to deposit copper and concentrating to crystallize. Meanwhile, compared with the traditional method, the method has simple flow, small environmental pollution and high metal recovery rate. The invention is mainly used for non-ferrous enterprises to separate the valuable metals from the lead anode mud.

Owner:ZHUZHOU SMELTER GRP

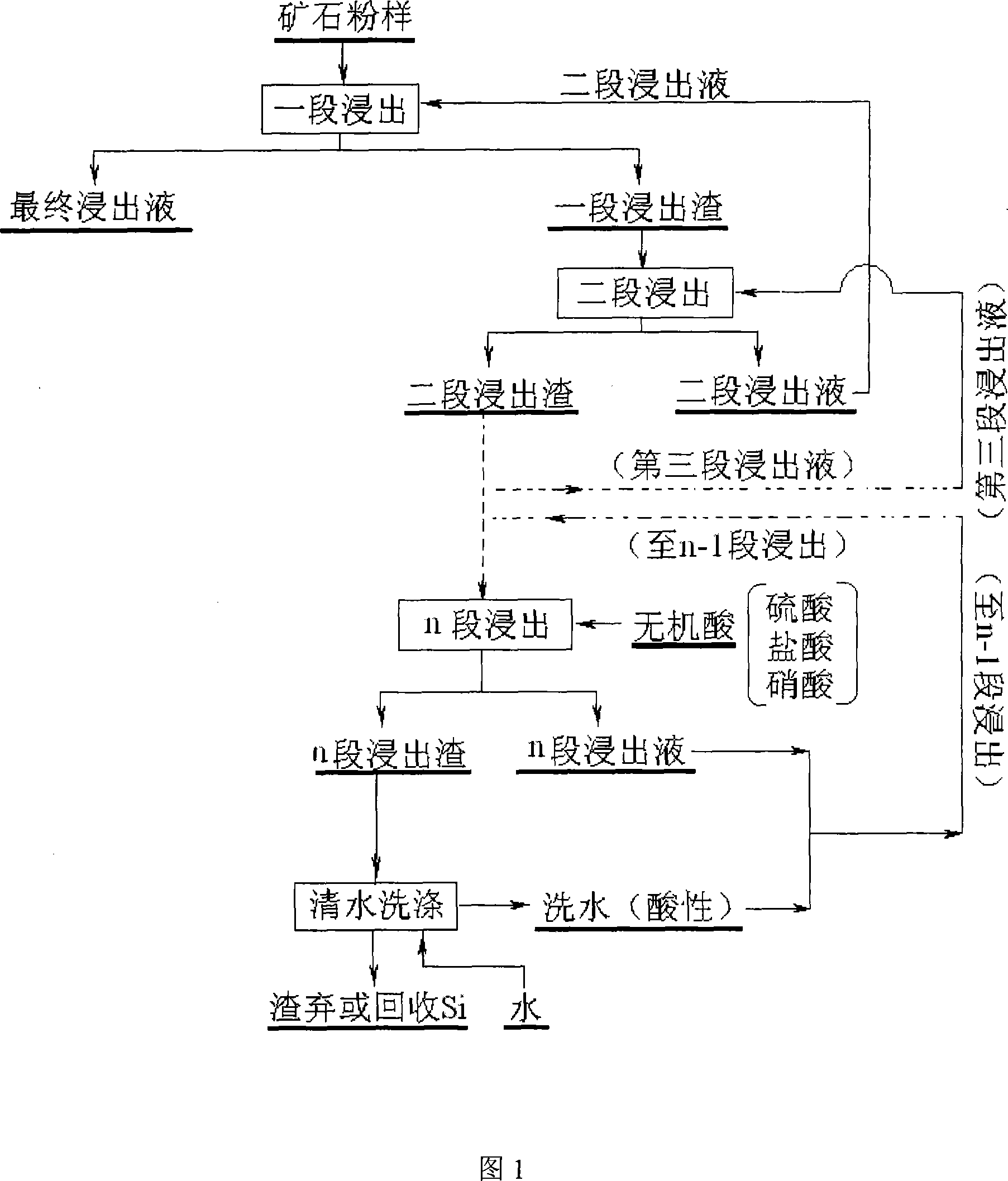

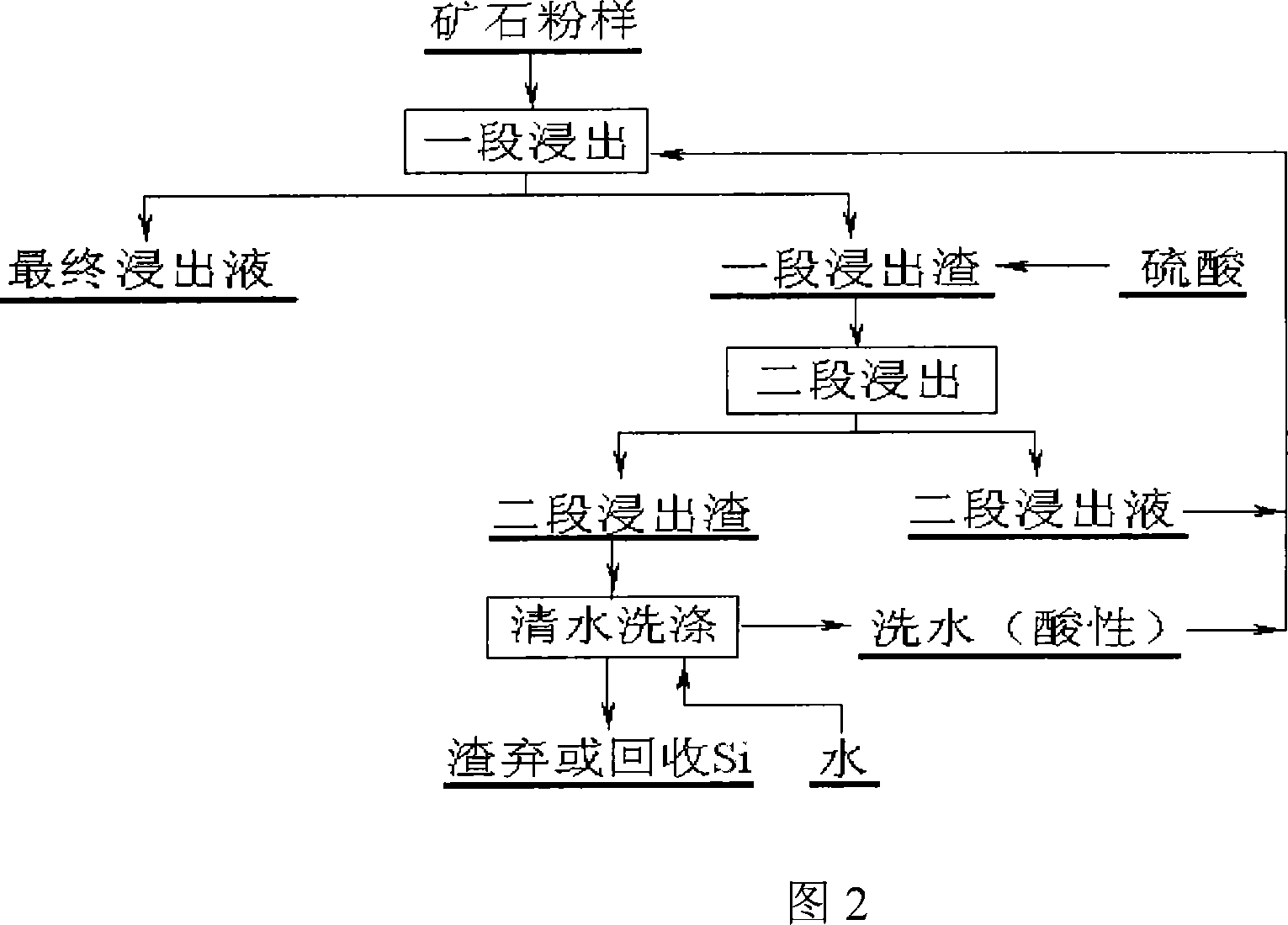

Multistage counter current acid leaching process containing nickel serpentine ore

InactiveCN101058852AReduce leachingReduce consumptionProcess efficiency improvementPregnant leach solutionReverse current

The invention discloses a nepouite with the multi-stage reverse-current acid-dipping technology, which comprises the following steps : grinding the nepouite; reacting with mixing the primary immersion liquid and water; reacting the leach residues a plurality of times endlessly; getting the K extract after finishing filtering the reaction of the k times; making the K extract liquor and the K extract react cyclically the k+1 times; regarding the k extract liquor as the extract liquor of the k-1 leaching reaction; regarding a corrosive acid as the extract liquor of the last leaching reaction; regarding the last extract liquor as a liquor containing Ni and Mg after n times reaction (k is between 1 and n and n is not less than 2). The invention reduces the cost, which recovers the Ni and Mg highly effectively.

Owner:CENT SOUTH UNIV

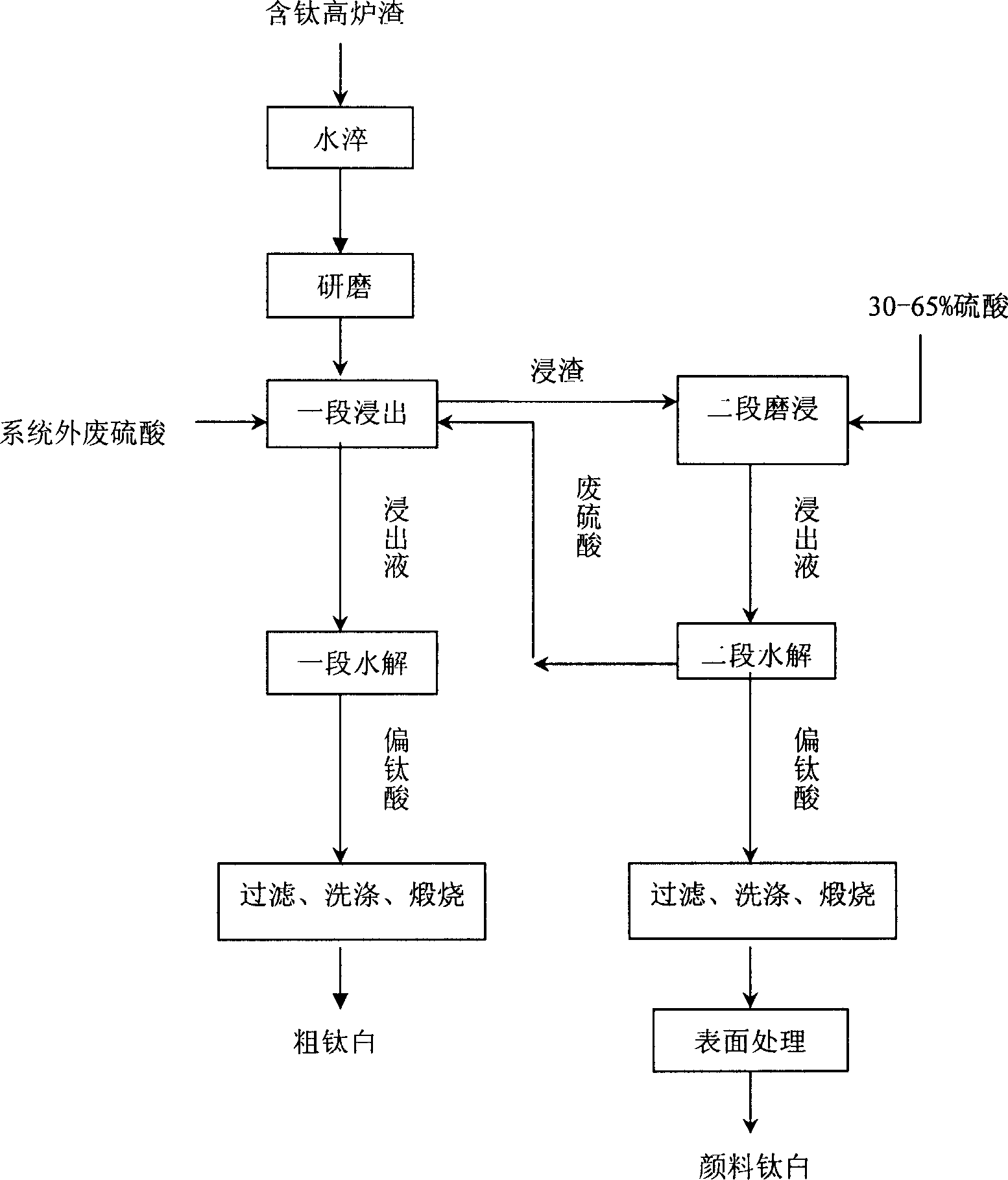

Method for preparing pigment-level titanium powder and coarse titanium white from blast slag containing titanium

InactiveCN1743386AReduce acid consumptionReduce the temperaturePigmenting treatmentTitanium dioxideQuenchingSlag

A method for preparing pigment-class titanium white powder and coarse titanium white utilizing titanium-contained blast furnace slag comprises the following process steps: water quenching, water cooling molten state titanium-contained blast furnace slag; grinding, grinding the slag into fine particles; single leaching, leaching the slag using sulfuric acid, pressure, normal pressure,temperature,60-90deg.C,mass concentration of sulfuric acid,5-35%,sulfuric acid dosage,0.6-1.0 theoretic value; two stage grinding-leaching, acid decomposing leached slag obtained by single leaching using grinding-leaching manner, pressure, normal pressure,temperature,50-100deg.C,mass concentration of sulfuric acid,30-65%,sulfuric acid dosage,1.0-1.5 theoretic value; preparing pigment-class titanium white powder, hydrolyzing leach solution from two stage grinding-leaching, filtering, washing, calcinating and surface treating to obtain pigment-class titanium white powder; preparing coarse titanium white, hydrolyzing leach solution from single leaching, filtering, washing, calcinating to obtain coarse titanium white.

Owner:SICHUAN UNIV

Flotation method of low ore grade manganous carbonate ore

The invention relates to a process that raw mine is ground into powder which is added with water to be prepared into pulp. Under certain pH value, inhibitor of carboxymethylcellulose nano solution, industrial water glass and tannin solution are added proportionally for absorbing calcium, magnesium and silicate. Then, sodium oleate is added as a collector for closed circuit circulation floating. Foam products after the floatation are flushed by water and then enter a sedimentation tank for the sedimentation or the pressure filtration. Thus, manganese concentrate fines above 20 percent are obtained. In the process, floatation is implemented on low grade poor manganese mine containing 10-14 percent of manganese, carbonaceous rock with the manganese content of 4-9 percent and electrolytic manganese leached slags with the manganese content of 1-3 percent to obtain manganese ore fines, the manganese content of which reaches above 20 percent. The recovery of manganese is more than 85 percent. And non-manganese emission for tailings can be realized. The manganese resources are lead to have extremely high utilization rate. Produced products can also lower acid consumption and ammonia consumption for electrolytic manganese production of downstream industry of manganese mines.

Owner:HUAYUAN QIANGHUA MINING

Extraction system for extracting alkaline metals or alkaline-earth metals and application of extraction system

ActiveCN105331817AReduce usageAvoid pretreatment such as acidificationProcess efficiency improvementLithiumAlkaline earth metal

The invention discloses an extraction system for extracting alkaline metals or alkaline-earth metals. The extraction system comprises an extraction agent and a synergistic extraction agent, wherein the extraction agent is a diketone compound, and the synergistic extraction agent is a neutral phosphoric-oxygenic compound. The invention further discloses a method for extracting lithium ions from an alkaline metal solution and extracting alkaline-earth metals from a mixed solution of alkaline metals and alkaline-earth metals through the extraction system. The extraction system has excellent effects for extracting and separating alkaline metals or alkaline-earth metals; and meanwhile, a synergistic extraction agent, ferric trichloride, in the prior art is avoided in the extraction system, so that problems such as high acidity caused by the ferric trichloride and the like can be avoided, the acid dosage and the cost can be reduced, and the corrosion to devices can be reduced as well. After lithium ions or alkaline-earth metal irons are extracted by using the extraction system, the reverse extraction and regeneration processes are simple, and the operation is facilitated.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

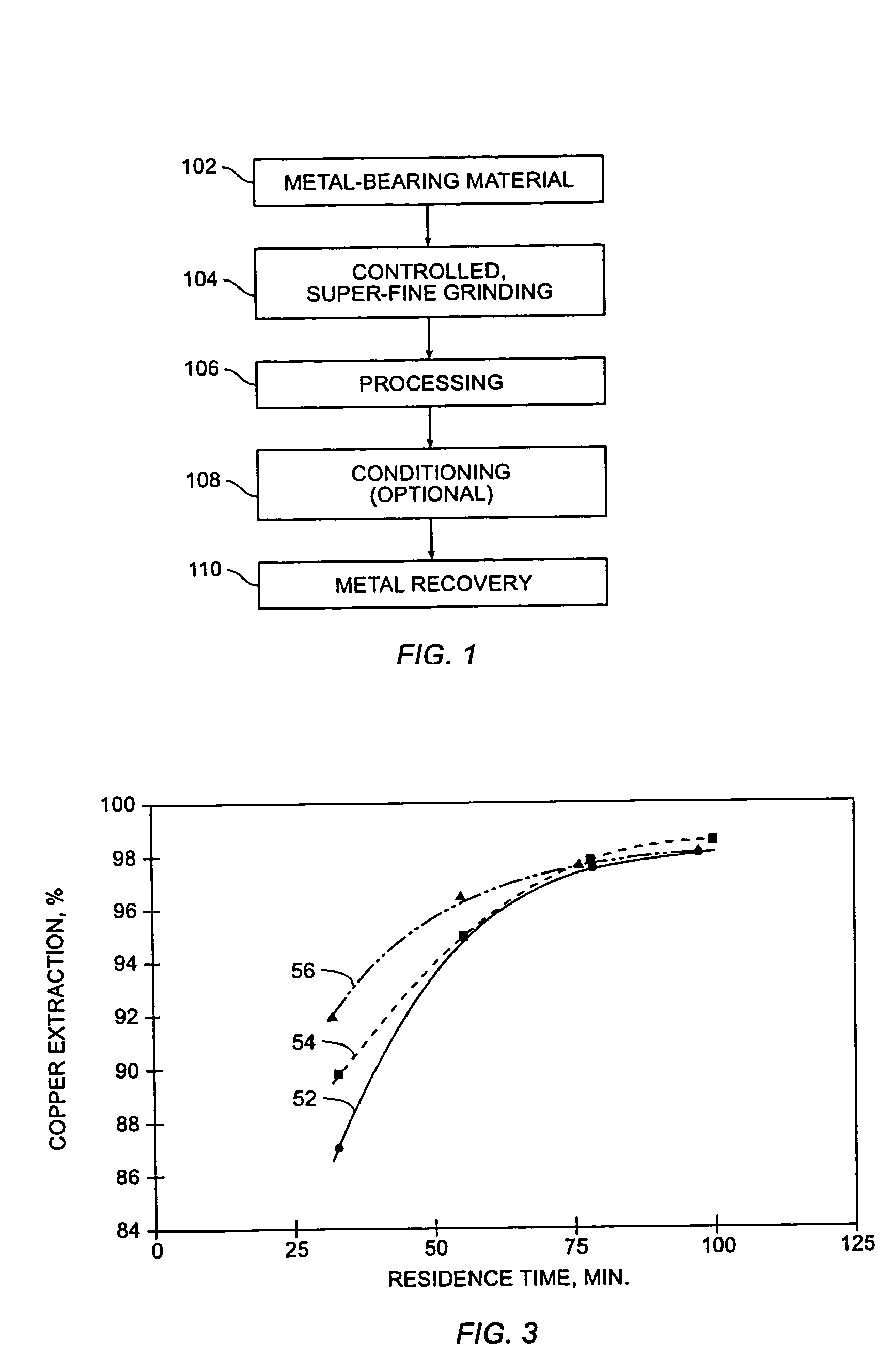

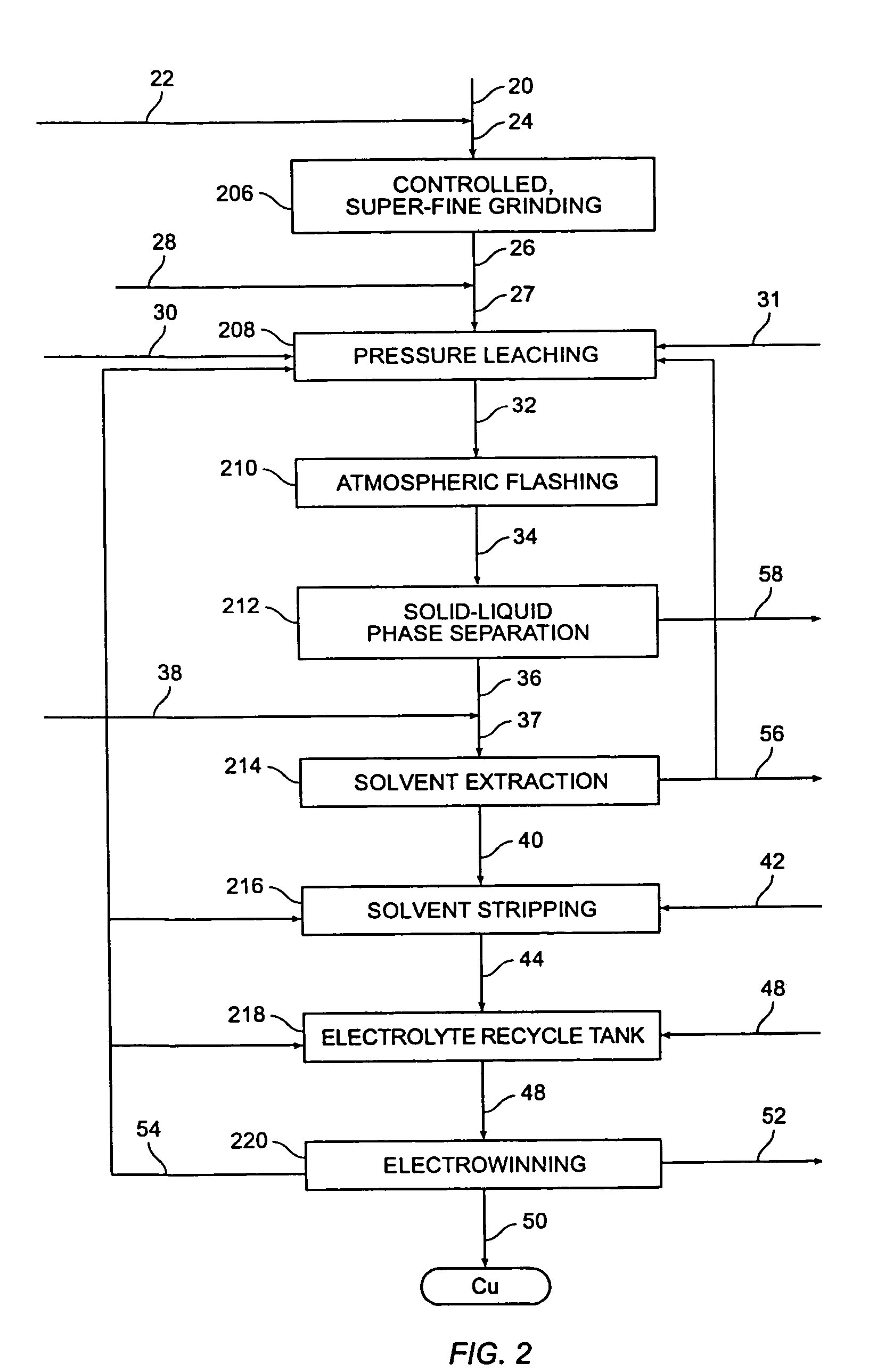

Method for recovery of metals from metal-containing materials using medium temperature pressure leaching

InactiveUS7341700B2Promote recoveryEnhanced metal value recoveryBiocideChromium compoundsRheniumMetallic materials

The present invention relates generally to a process for recovering copper and other metal values from metal-containing materials using controlled, super-fine grinding and medium temperature pressure leaching. Processes embodying aspects of the present invention may be beneficial for recovering a variety of metals such as copper, gold, silver, nickel, cobalt, molybdenum, rhenium, zinc, uranium, and platinum group metals, from metal-bearing materials, and find particular utility in connection with the extraction of copper from copper sulfide ores and concentrates.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

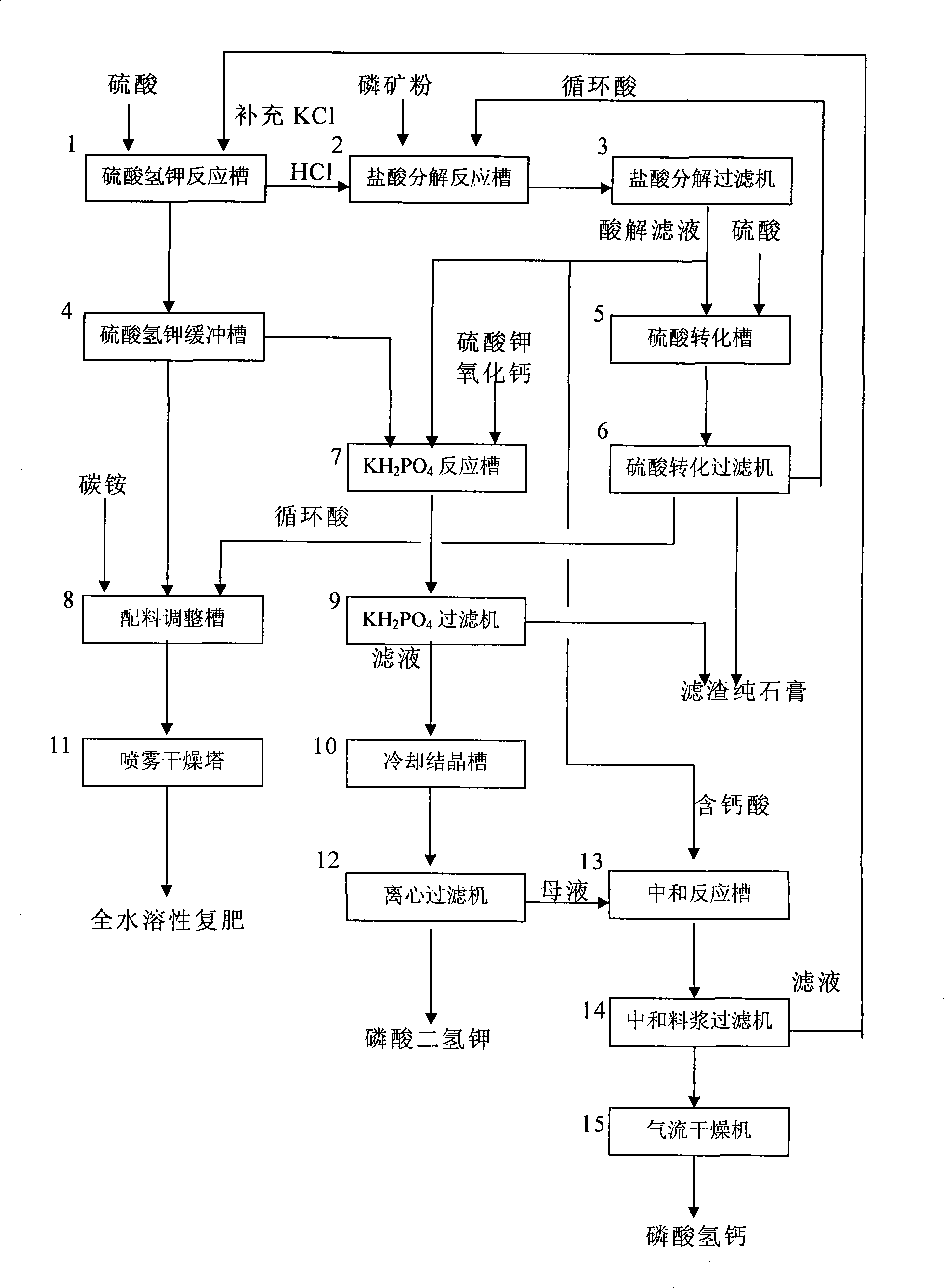

Process for disassembling phosphate ore by mixed acid and coproducing potassium dihydrogen phosphate, hydrogen phosphate and combined fertilizer

InactiveCN101337657ASolve processing problemsSolving Phosphogypsum ProblemsChlorine/hydrogen-chlorideSulfate/bisulfate preparationSolubilitySlurry

A method for the joint production of monopotassium phosphate, calcium hydrophosphate and compound fertilizers through by subjecting phosphorite to mixed acid resolution is characterized in that the method comprises the steps of taking sulphuric acid and potassium chloride to prepare chlorine hydride and acid potassium sulfate; conducting acidolysis reaction after phosphorite slurry absorbs chlorine hydride; preparing monopotassium phosphate through the reaction between an acidolysis filtrate and calcium oxide and lemery; agitating a mixture of the acidolysis fitrate with monopotassium phosphate crystallization mother liquor to neutralize and prepare calcium hydrophosphate; preparing recycle acid through the reaction between the acidolysis filtrate with sulphuric acid; preparing full water-solubility compound fertilizers through the reaction between recycle acid and an acid potassium sulfate solution and ammonium hydrogen carbonate or ammonia, etc. The method can successfully solve the impurity interference problem in the production of phosphate by using phosphorite of middle-low grade, and increase the reclaim rate of phosphorus pentoxide to approximate 100%. The method has the advantages of fully utilizing resources, simplifying process and devices, reducing corrosion, saving energy, reducing acid consumption and cost, eliminating pollution, and achieving good technical and economic effects.

Owner:黄明科 +1

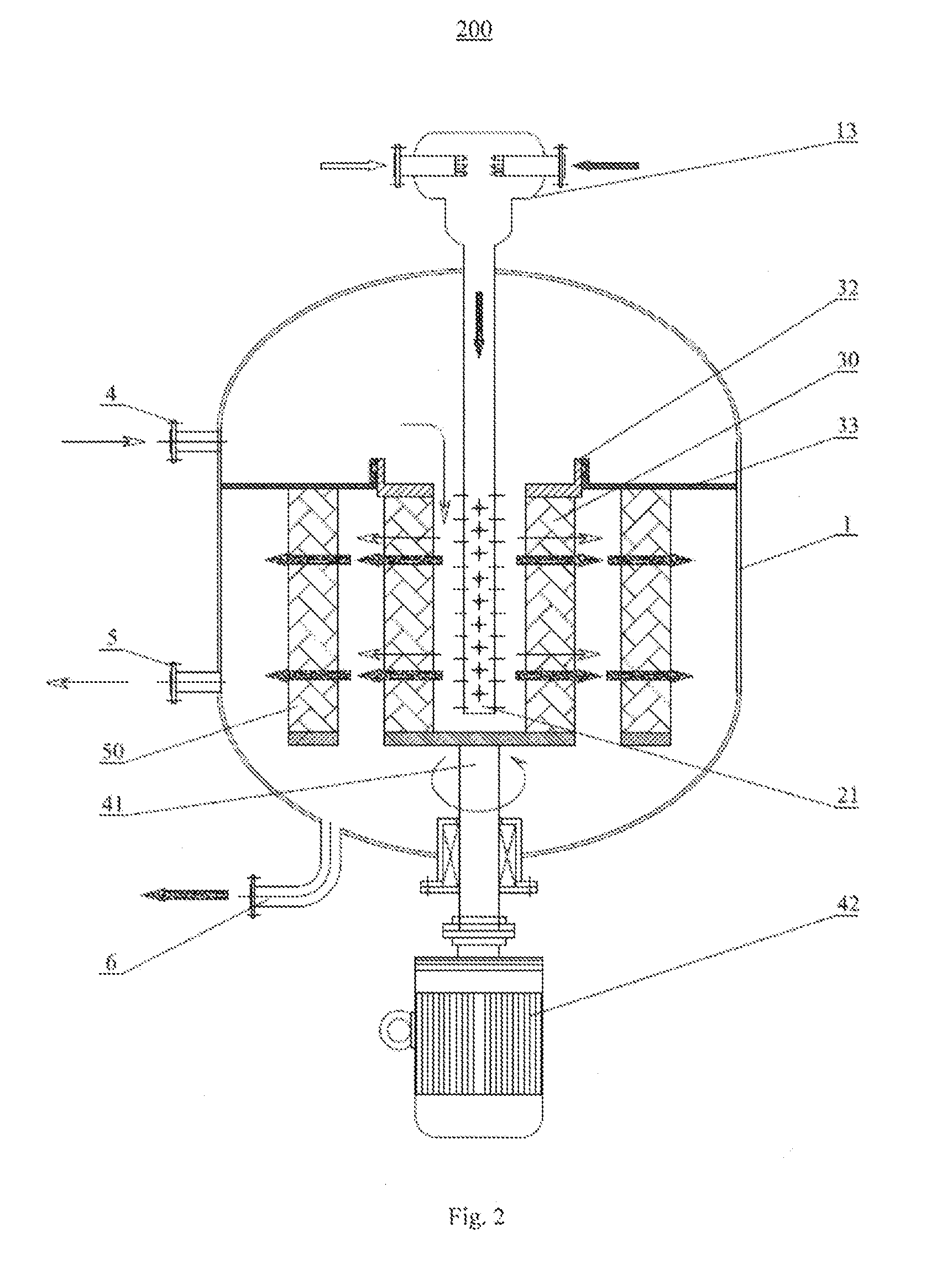

Alkylation reactor and alkylation reaction method

ActiveCN104549110ALow powerFully dispersedLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystProcess engineering

The invention discloses an alkylation reactor and an alkylation reaction method. The reactor comprises a reactor tube body, closure heads, a revolving bed, a charging pipe, a charge distribution pipe, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas outlet and a circulating cooling gas refrigeration system, wherein a shell body is formed by the reactor tube body and the closure heads, the revolving bed is arranged at the internal middle part of the shell body and is connected with a driving device through a revolving shaft, the charge distribution pipe is arranged in a hollow tube structure of the center of the revolving bed and is communicated with the charging pipe, the discharging opening is formed in the lower part of the shell body of the reactor, a sealing member is arranged between the upper part of the revolving bed and the shell body, static components and revolving components are sequentially arranged at the radial outer side of the revolving bed, and the circulating cooling gas refrigeration system is located between the circulating cooling gas inlet and the circulating cooling gas outlet. According to the alkylation reaction method disclosed by the invention, alkylation reaction is carried out by taking concentrated sulfuric acid as a catalyst and taking isobutane and alkene as raw materials. According to the alkylation reactor and the alkylation reaction method, the alkylation reaction can be carried out at relatively low temperature, the acid consumption is low, the quality of products is high, and the equipment scale is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reactor and Alkylation Process Using the Reactor

ActiveUS20140128654A1High catalytic efficiencyLower reaction temperatureHydrocarbons from unsaturated hydrocarbon additionCatalystsAlkyl transferEngineering

The present disclosure provides a reactor for at least two liquid materials, comprising an enclosed reactor housing; a feeding tube having liquid material inlets for receiving corresponding liquid materials respectively; a distribution tube communicating with the feeding tube and extending into the reactor housing, the distribution tube being provided with a plurality of distribution holes in the region thereof extending into the reactor housing; a rotating bed in form of a hollow cylinder, which is disposed in the reactor housing via a fixing mechanism, thus dividing inner cavity of the reactor housing into a central area and an outer area, the rotating bed being capable of rotating driven by a driving mechanism; and a material outlet provided in a lower portion of the reactor housing for outputting product after reaction. The distribution tube extends into the central area spaced from inner surface of the rotating bed, so that materials can enter into the outer area from the central area through the rotating bed and can be output via the material outlet.

Owner:CHINA PETROCHEMICAL CORP +1

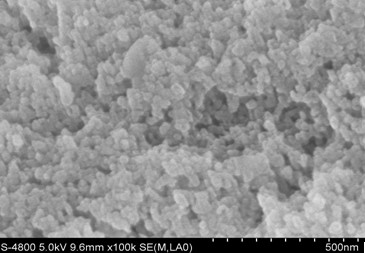

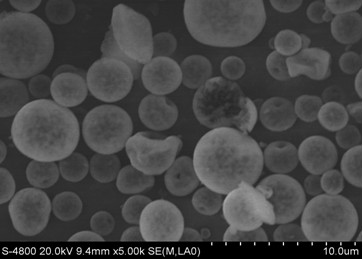

Preparation method for nano-microcrystalline cellulose

ActiveCN104293858AReduce the amount of acid usedSimplify the operation processFermentationAlgluceraseGlucanase

The invention discloses a preparation method for nano-microcrystalline cellulose. The method comprises: preparation and treatment of a nano-microcrystalline cellulose raw material, enzyme treatment, acid hydrolysis and deacidification treatment. The raw material is one of a wood fiber raw material, a non-wood fiber raw material, and a microbial fiber raw material, and the raw material is treated by grinding equipment. The enzyme used for enzyme treatment can be one of or a composition of several of endoglucanase, exoglucanase and beta-glucosidase. Cellulose is added into a slurry system, when reaction of a cellulose-slurry system ends, the solid phase and the liquid phase are separated by a filter screen, and then the solid phase is transferred to an acid hydrolysis reaction kettle to carry out acid hydrolysis treatment and follow-up deacidification treatment. The prepared nano-microcrystalline cellulose has a spherical, ellipsoidal or clavate shape, the particle length is 50nm-500nm, the width is 10nm-30nm, and the particle size distribution is uniform. The acid dose for acid treatment is only 5wt%-40wt%, which is 7.7%-61.5% of that of the traditional method, thus reducing the preparation cost and being beneficial to environmental protection.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

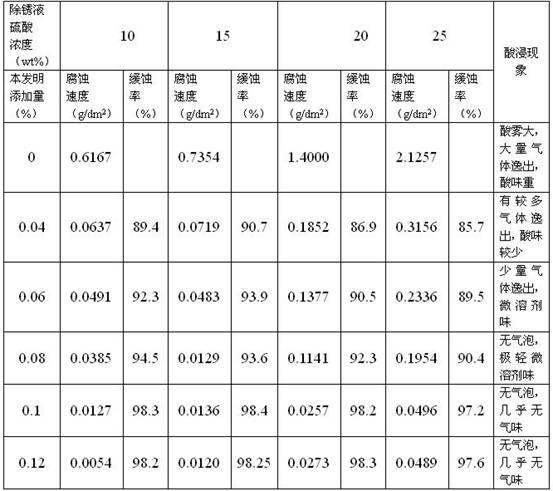

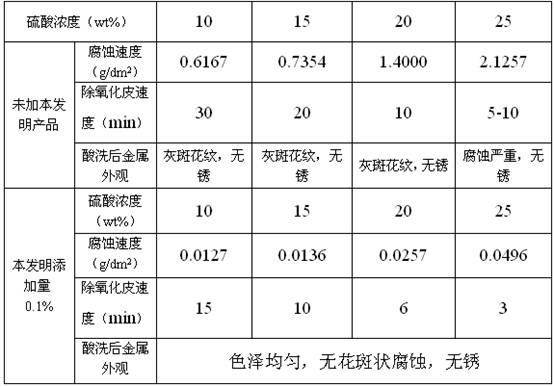

Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

InactiveCN101851761AThe effect of suppressing acid mist is obviousThe effect of acid mist is obviousEthylenediamineGallic acid ester

The invention discloses a sulfuric acid washing corrosion-retarding fog inhibitor and a preparation method thereof. The sulfuric acid washing corrosion-retarding fog inhibitor comprises an inhibitor, a complexing agent and a wetting agent, wherein the inhibitor comprises di-o-tolyl-thiourea, o-toluidine, sulfonated protein and ethylene diamine tetraacetic acid; the complexing agent comprises sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid; and the wetting agent comprises sodium sulfonate, sodium carboxylate, L-548 and OP-10. The sulfuric acid washing corrosion-retarding fog inhibitor can retard the excessive corrosion of sulfuric acid to steel matrix, also can be used as an acid washing fog inhibitor, and has good stability at high temperature; and the capability of inhibiting acid fog can reach over 95 percent, the highest corrosion-retarding capability can reach over 98 percent, and the stability is no less than 5 hours.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

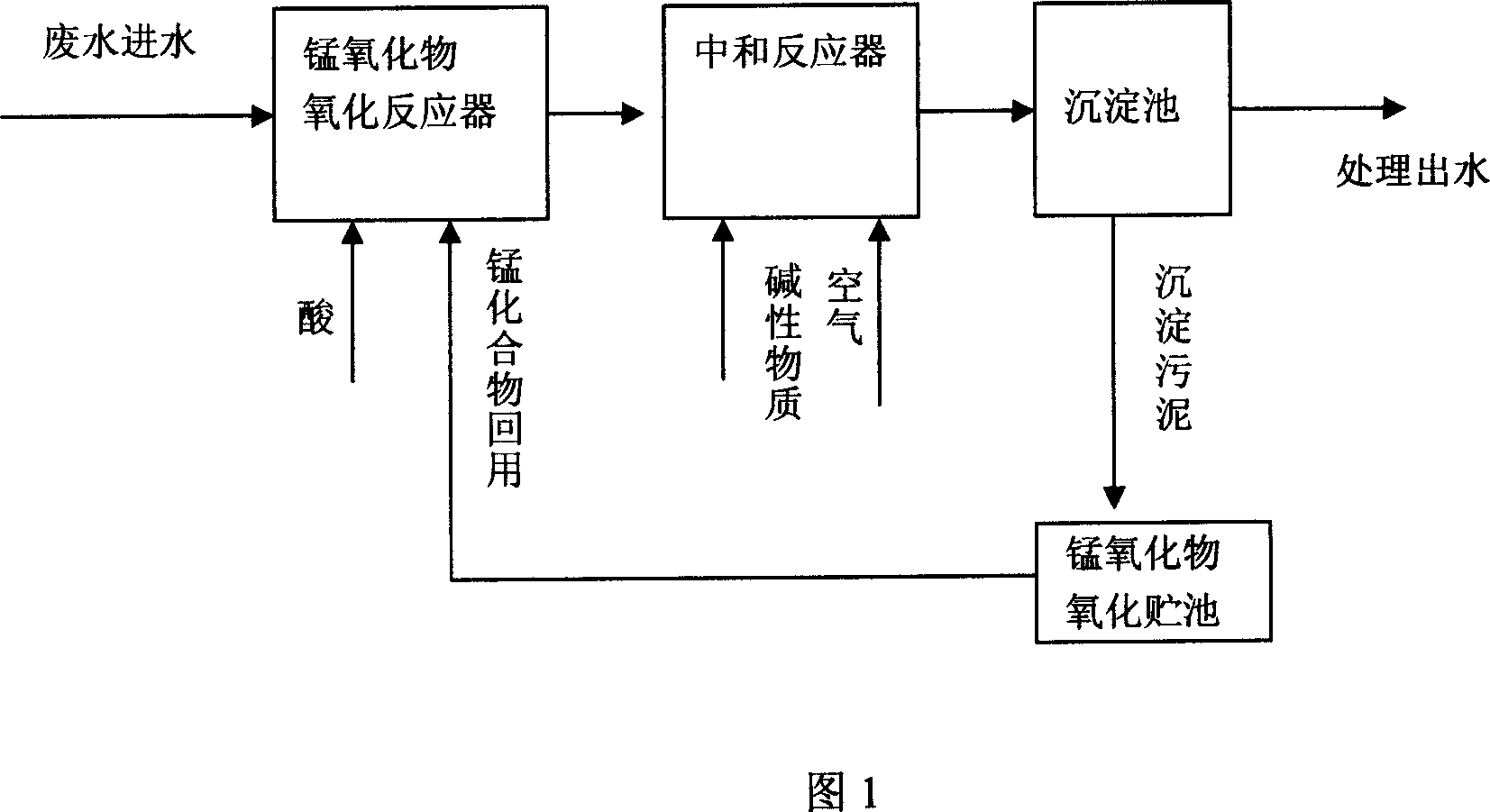

Method of processing organic contaminant waste-water difficult to biochemical degradation using tetravalent manganese compounds

InactiveCN1919755AWide concentration rangeImprove removal efficiencyMultistage water/sewage treatmentManganesePollution

The invention discloses disposing method of difficult biochemical decomposable organic polluted waste water, which is characterized by the following: oxidizing to decompose organic pollution in the quadravalent manganese compounds; reducing to generate bivalent manganese compounds; producing carbon dioxide and water; dehydrating bivalent manganese ion; sedimenting; oxidizing to generate quadravalent manganese compounds under weak caustic solution; recycling the waste water in the disposing course.

Owner:HEFEI UNIV OF TECH

Process for extracting rare earth from phosphate concentrate

InactiveCN102796888AImprove extraction efficiencyEfficient recyclingProcess efficiency improvementRare-earth elementDecomposition

The invention belongs to the field of rare earth metallurgy, and particularly relates to a full-flow process for extracting a rare earth element from rare earth-containing phosphate concentrate. According to the process, phosphate containing 0.05-0.3 percent of REO (Rare Earth Oxide) is used as a raw material, and decomposition is performed once by using low-concentration hydrochloric acid, so that most of impurities in the phosphate concentrate enter solution and the decomposition of the rare earth is effectively suppressed; primary residue is decomposed by using nitric acid, so that valuable metals such as rare earth enter the solution and secondary decomposition solution which meets a subsequent extraction process is prepared; and rare earth extraction is directly performed in a high-acid phosphate secondary decomposition solution system with complex impurity components by using a neutral extraction agent without adding a salting-out agent, and the rare earth is separated in one step under assistance of a washing measure to further separate phosphorus from the rare earth. The purity of the prepared rare earth enrichment is greater than 90 percent and the total rare earth recovery rate is over 90 percent.

Owner:贵州黔鸿瑞磷稀土分裂开发有限公司 +1

Method for recovering phosphorus from phosphorite tailings and preparing light magnesium oxide

The invention relates to a method for recovering phosphorus from phosphorite tailings and preparing light magnesium oxide. The method comprises the following steps of: calcining the phosphorite tailings; digesting calcined products to obtain digestion slurry and digestion products; separating the digestion products by using a table concentrator to obtain concentrates, middlings and tailings, wherein the concentrates are phosphorus concentrates and the middlings and the tailings are magnesium-enriched products; performing acid leaching on the magnesium-enriched products to obtain magnesium-enriched leachate and leaching slag; mixing the magnesium-enriched leachate and the digestion slurry, removing impurities, and carbonizing to prepare the light magnesium oxide; and recovering rich phosphorus pentoxide in the phosphorus concentrates and the leaching slag. By the method, phosphorus-containing ores in the phosphorite tailings are recovered effectively, and the light magnesium oxide is prepared, so that the aim of comprehensively utilizing the phosphorite tailings is fulfilled; and the total recovery rate of the phosphorus pentoxide is 98.88 percent, the content of magnesium oxide in the light magnesium oxide prepared by treating the leachate and the digestion slurry is 93.09 percent, and the quality of the light magnesium oxide meets the requirements for qualified products in the standard HG / T2573-94.

Owner:贵州贵达元亨环保科技有限公司

Biological-chemical metallurgy method by jointly utilizing oxidized ore and sulfide ore

InactiveCN101608260AHigh recovery rateUniversalProcess efficiency improvementMineral SourcesBiological oxidation

The invention belongs to the field of mineral resource comprehensive utilization, and relates to methods for reduced leaching of oxidized ore and oxidation leaching of sulfide ore through biological and chemical catalysis, in particular to a biological-chemical metallurgy method by jointly utilizing the oxidized ore and the sulfide ore. The reduced leaching of the metal oxidized ore and the oxidation leaching of the metal sulfide ore are realized by utilizing auxoautotrophs, auxohetertrophs or a mixture thereof under mild conditions; and the mixture ratio of the metal oxidized ore to the metal sulfide ore can be adjusted by adding organic biomass. The leachate is purified, concentrated and crystallized into metal sulfates which are then reduced and thermally decomposed into products of sulfur dioxide and metal oxides; and the sulfur dioxide is subjected to biological oxidation to prepare sulphuric acid for recycling.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for removing arsenic and antimony from zinc smelting leach liquor

InactiveCN103911512AEfficient use ofStable physical and chemical propertiesProcess efficiency improvementIndium metalPregnant leach solution

The invention discloses a method for removing arsenic and antimony from zinc smelting leach liquor, and relates to a method for removing arsenic and antimony from a solution produced during zinc smelting by purifying. The method is characterized by comprising the following steps: comprehensively recovering valuable components of zinc, indium, iron and the like by purifying in an arsenic and antimony removing process consisting of pre-reduction, neutralization of precipitated indium and a hematite process under the condition that zinc smelting low-acid leach liquor is taken as a raw material; turning high-valence iron into low-valence iron by taking zinc concentrate, zinc sulfite, sulfur dioxide and the like as reducing agents in the low-acid leach liquor, wherein the content of high-valence iron (Fe<3+>) in the reduced liquor is lower than 2g / L; performing two-stage neutralization by using lime, limestone, secondary zinc oxide, calcined sand and zinc oxide to regulate the pH value of reduced liquor to 4.0-5.4 in order to enrich indium precipitate; and removing arsenic and antimony from indium-precipitated liquor to fulfill the aim of efficiently cleaning and purifying the solution. The method has the advantages of high indium metal recovery rate, high arsenic and antimony removing rates, small residue amount, stable performance and environmental friendliness.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

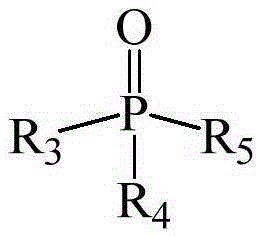

Process for extracting rare earth element by non-saponifiable phosphorous mixing extractant

ActiveCN1804063AImprove stripping efficiencyReduce acid consumptionProcess efficiency improvementRare-earth elementMaterial consumption

The extraction and separation method for rare-earth element comprises: with rare-earth solution contained a plurality of rare-earth elements as material, preparing mixed extractant with the non-saponifiable P204 and one or two from P507, P229, P350, TBP, C272, C301, C302 and HEOPPA; in the mixed solution with rare-earth sulfate solution, or rare-earth sulfate and rare-earth chloride solution and rare-earth nitrate solution, extracting and separating rare-earth elements. This invention eliminates saponification to overcome pollution, reduces acidity to improve rare-earth concentration, and decreases the main material consumption more than 30% compared with the technique with NH4HCO3 and P507.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for recycling industrial waste sulfate slag

InactiveCN101554613ANo change in physical propertiesHigh recovery rateSolid waste disposalWet separationSocial benefitsSlag

The invention provides a method for recycling industrial waste sulfate slag, which comprises the steps of sieving, stirring, magnetic separation, acid dipping, rinsing and drying to obtain iron-bearing materials. The method not only reallocates the available resource of the sulfate slag which is difficult to be processed and has high pollution, but also reduces the severe contamination of the sulfate slag to the environment and simultaneously lowers the production cost greatly; the metal recovery rate is 50 to 82 percent, high quality iron concentrate with the grade of iron being larger than 60 percent, the grade of sulfur being smaller than 0.3 percent and the grade of arsenic being smaller than 0.1 percent is obtained; simultaneously the recovery processing capacity is large, the equipment is simple, the investment is small, the operation is convenient, the sulfate slag material is not limited, both the sulfate slag with high iron content and the sulfate slag with low iron content can be recycled, and the method has good social benefit and remarkable economic effect.

Owner:房志强 +1

Alkylation reactor and alkylation reaction method

ActiveCN104667856ASmall scaleFast scaleLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsPtru catalystEmulsion

The invention discloses a sectional feeding alkylation reactor and an alkylation reaction method. The reactor comprises a reactor barrel, seal heads, a partition plate, an upper bed layer, a lower bed layer, a feeding pipe, a feeding distributing pipe, a rotary shaft, a supplementing material inlet, a discharging opening, a circulating cooling gas inlet, a circulating cooling gas refrigerating system and a circulating cool gas outlet. The invention further provides the alkylation reaction method. The method comprises the following steps: as the sectional feeding alkylation reactor is adopted, firstly forming an acidic hydrocarbon emulsion in the upper bed layer from iso-butane and concentrated sulfuric acid; and then carrying alkylation reaction on the acidic hydrocarbon emulsion and mixed hydrocarbon entering from the supplementing material inlet in a lower bed layer rotary bed. According to the alkylation method disclosed by the invention, by taking the concentrated sulfuric acid as a catalyst and the iso-butane and olefin as raw materials, the alkylation reaction is carried out. The alkylation reaction disclosed by the invention can be carried out at a low temperature, so that the reactor is low in acid consumption and small in equipment scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

Leaching method capable of reducing leached acid consumption of uranium ores

The invention provides a leaching method capable of reducing leached acid consumption of uranium ores, which comprises the following steps: leaching uranium ores by using the mixed solution of sulfuric acid and polyferric sulfate aluminium as the leaching agent, wherein if adopting an agitation leaching mode, the amount of the sulfuric acid in the mixed solution is 6-12% by mass of uranium ores, the amount of the polyferric sulfate aluminium is 0.3-0.7% by mass of uranium ores, and the mass proportion (liquid to solid ratio) of the leaching agent to the uranium ores is (1-2):1; and if adopting a heap leaching mode, the concentration of the sulfuric acid in the mixed solution is 5-10 g / L, and the amount of the polyferric sulfate aluminium is controlled, so that the concentration of Fe<3+> in the mixed solution is 3.0-8.0 g / L, and the concentration of Al<3+> is 0.2-0.8 g / L. On the premise of not affecting the leaching of uranium ores, the polyferric sulfate aluminium selectively inhibits the principal acid-consuming elements and the reaction of sulfuric acid, lowers the leaching rate and reduces the leached acid consumption of ores, thereby lowering the processing cost for uranium ore heap leaching.

Owner:BEIJING RES INST OF CHEM ENG & METALLURGY

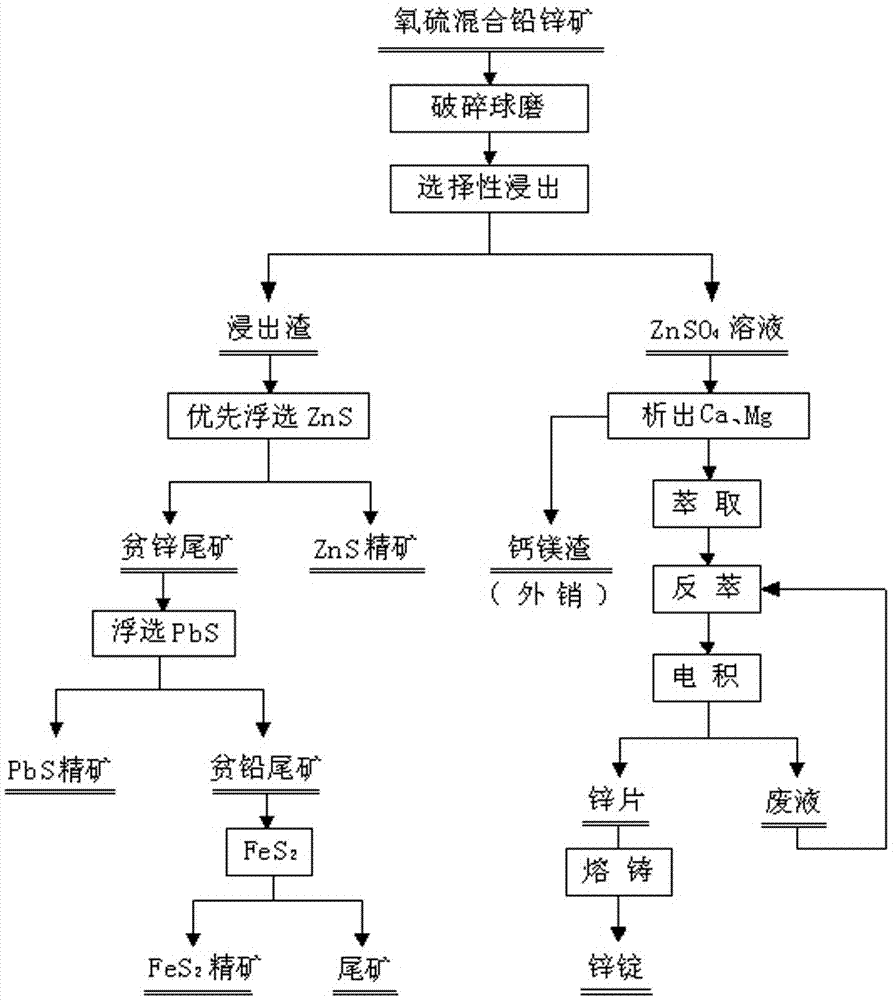

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

Pickling solution containing compounded passivating agent, and preparation method thereof

The invention belongs to the stainless steel casting cleaning field, and relates to a passivating pickling solution obtained through adding an organic substance to an HNO3-HF base acid solution and compounding. The pickling solution comprises 3.3-37.5mass% of HNO3, 0.7-7.5mass% of HF, 1.3-13.5mass% of the compounded passivating agent, and the balance water. A polluted stainless steel casting is cleaned by the pickling solution to recover the metal luster originally possessed by the casting. The pickling solution forms a compact passivating film on the surface of the casting, so bright beauty maintenance and no rusty spot are realized after the casting is stored for a long term. The pickling solution has the characteristics of very small acid mist, benefiting for the environmental protection and the body health of an operation personnel, large pickling amount, and low pickling cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com