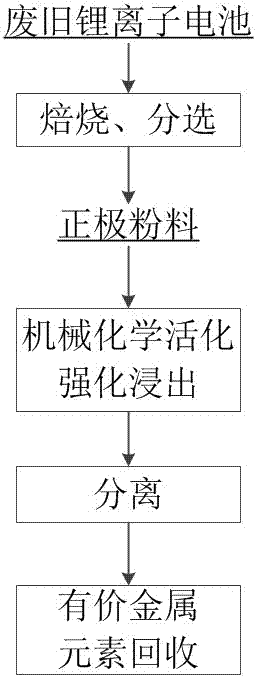

Method for enhancing metal recovery of waste lithium ion battery

A lithium-ion battery and waste technology, which is applied in the field of strengthening the metal recovery of waste lithium-ion batteries, can solve the problems of low leaching efficiency, secondary pollution, a large amount of waste liquid, etc., so as to improve the leaching efficiency, reduce the large acid consumption, and solve the problem of high cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The waste lithium-ion battery is broken into pieces of 1~20mm × 1~20mm, calcined at 600 ° C for 2 hours, and the positive electrode powder is obtained after sorting. 100g of positive electrode powder was added to the leaching solution of sulfuric acid and citric acid containing a reducing agent, wherein the concentration of sulfuric acid was 3 mol / L, the addition ratio of citric acid was 30 vol.%, the reducing agent was sodium sulfite, and the mass concentration of the reducing agent was 2%. The ratio is 150g / L. Add ZrO with a particle size of 2 mm to the leaching mixture 2 pellets, ZrO 2The mass ratio of pellets to cathode powder was 3:1, and high-speed stirring ball milling was carried out at a temperature of 75 °C, wherein the stirring speed was controlled at 500 rpm, and the leaching time was 15 min. The leaching solution containing cobalt, nickel and lithium metal ions was obtained, and the cobalt leaching rate was >98%, the nickel leaching rate was >99%, and the...

Embodiment 2

[0042] The waste lithium-ion battery is broken into pieces of 1~20mm×1~20mm, roasted at 800°C for 2h, and the positive electrode powder is obtained after sorting. 100g of positive electrode powder was added to the mixed acid leaching solution of nitric acid and trichloroacetic acid containing a reducing agent, wherein the acid concentration was 3 mol / L, the addition amount of trichloroacetic acid was 25 vol.%, the reducing agent was hydrogen peroxide, and the reducing agent mass concentration is 2%, and the leaching solid-liquid ratio is 250g / L. Add MgO pellets with a particle size of 2 mm to the leaching mixture, the mass ratio of MgO pellets to positive electrode powder is 7:1, and perform high-speed stirring at a temperature of 75°C, wherein the stirring speed is controlled at 500rpm, and the leaching time is 20min . A leaching solution containing cobalt, nickel and lithium metal ions was obtained, and the cobalt leaching rate was >98%, the nickel leaching rate was >99%, a...

Embodiment 3

[0044] The waste lithium-ion battery is broken into pieces of 1~20mm×1~20mm, roasted at 800°C for 2h, and the positive electrode powder is obtained after sorting. 100 g of positive electrode powder was added to the hydrochloric acid-sulfuric acid mixed acid leaching solution containing a reducing agent, wherein the acid concentration was 3 mol / L, the reducing agent was hydrogen peroxide, the reducing agent mass concentration was 2%, and the leaching solid-liquid ratio was 300 g / L. Add Al with a particle size of 3 mm to the leaching mixture 2 O 3 small ball, Al 2 O 3 The mass ratio of pellets to positive electrode powder was 5:1, and high-speed stirring was performed at a temperature of 75 °C, wherein the stirring speed was controlled at 500 rpm, and the leaching time was 20 min. The leaching solution containing cobalt, nickel and lithium metal ions was obtained, and the cobalt leaching rate was >98%, the nickel leaching rate was >99%, and the lithium leaching rate was >99%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com