Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

959results about How to "High cost of solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

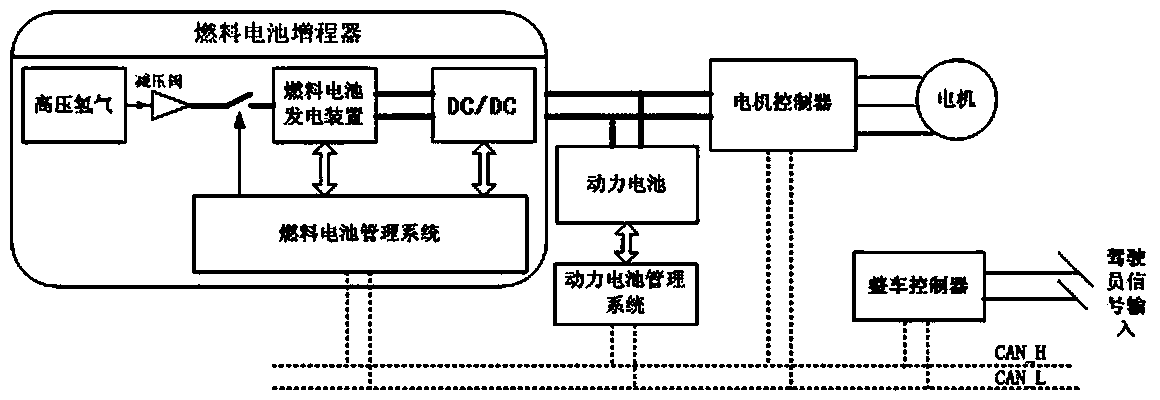

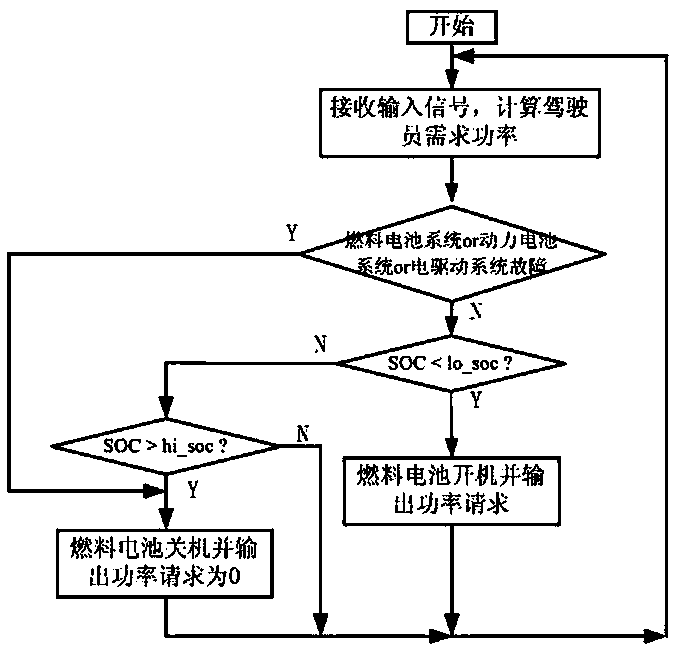

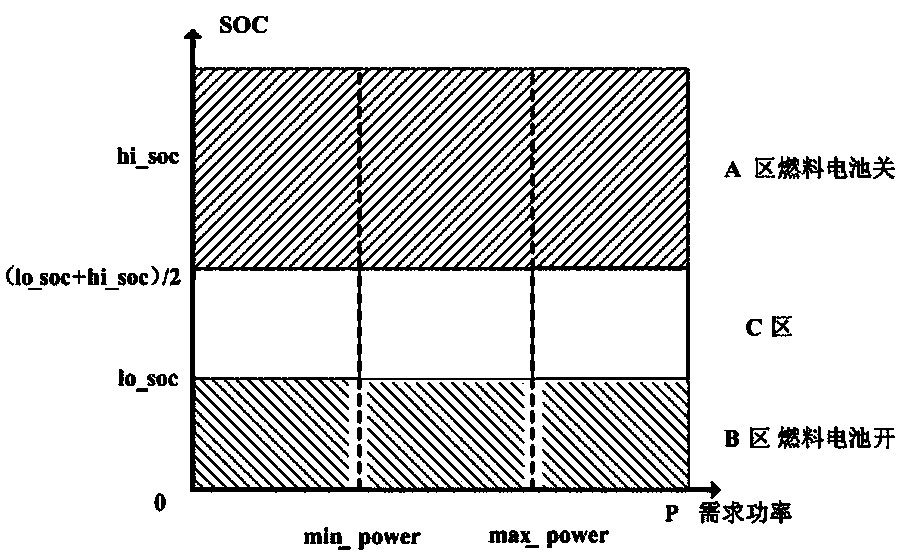

Control system and control method of fuel cell range extender

InactiveCN104139709AHigh cost of solutionImprove operational efficiencyElectric devicesVehicular energy storageFuel cellsNew energy

The invention provides a control system and a control method of a fuel cell range extender and belongs to the technical field of new energy electric vehicles. A power cell is taken as driving energy, a fuel cell is taken as auxiliary range extending energy, in efficiency and the power ranges of the power cell, times of start of the fuel cell range extender are reduced to the greatest extent, damage to the range extender due to frequent start and the effect caused by frequent charge and discharge of the power cell on the service life are reduced, after the energy of the power cell is utilized greatly, the fuel cell is started, the output power of the fuel cell is controlled according to the required power, and the driving range is extended. According to the control system and the control method, the operating efficiency of the fuel cell and the power cell is optimized, the problems of the short driving range of the power cell and the high cost of the fuel cell are solved, meanwhile, service lives of the power cell and the fuel cell are prolonged, and the power property and the economic efficiency are unified efficiently.

Owner:ZHONGBEI UNIV

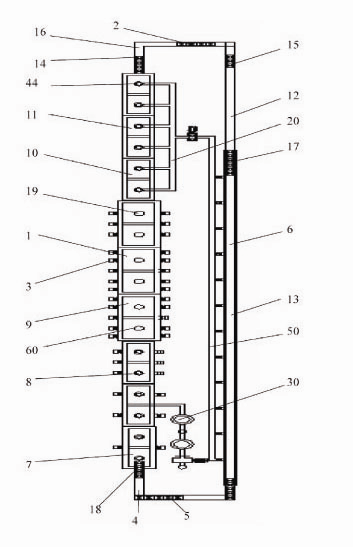

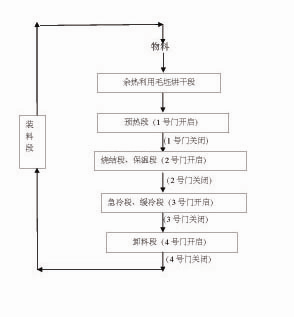

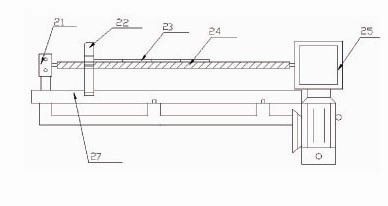

Fully-closed industrial microwave high-temperature roller continuous sintering kiln

InactiveCN102042749AConsistent shrinkageGood size consistencyMaintainance of heating chambersFurnace typesEnvironmental resistanceEngineering

The invention discloses a closed microwave high-temperature sintering roller kiln, in particular a tunnel roller kiln with length of 10 to 50meters, and hearth sectional area of 0.06 to 0.3m<2>. The kiln comprises a main kiln body, a microwave transmission system, a turning channel mechanism, a roller power system, and a kiln door interlocking opening and closing system; the main kiln body is formed by connecting a water draining section, a preheating section, a sintering section, a heat preservation section, a quick cooling section, and a slow cooling section in turn; the turning channel mechanism is mainly formed by a material loading and unloading section and a residual-heat utilization blank drying section and comprises a turning channel, a turning channel roller, and a power system; the power system can poke a pushing plate from the outlet of the main kiln body onto the turning channel and feed the pushing plate into the inlet of the main kiln body through the residual-heat utilization blank drying section; and an inner roller for transmitting the material pushing plate, which is driven by the roller power system, is arranged on the bottom of an inner cavity of the main kiln body. The closed microwave high-temperature sintering roller kiln saves energy and reduces consumption and is environmental-friendly, the shrinkage of the sintered products is consistent and the sintered products have high size consistency, the yield is high, the production efficiency is high and the production cost is low.

Owner:湖南航天有限责任公司

Foam cement insulation material for exterior wall and preparation method thereof

InactiveCN102942380AShorten the setting timeStrong synergistic effect is obviousCeramicwareSilica fumePortland cement

The invention belongs to the technical field of insulation material for building, and particularly relates to a foam cement insulation material for exterior wall and a preparation method thereof. The foam cement insulation material for exterior wall is prepared from raw materials comprising ordinary portland cement, sulphoaluminate cement, fly ash, silica fume, an expansive agent, a coagulating enhancer, a tackifier, a water-reducing agent, a waterproofing agent, a foaming agent, a foam stabilizer, fiber and water. The preparation method comprises the following steps: (1) first conducting dry mixing on ordinary portland cement, sulphoaluminate cement, fly ash, silica fume and the expansive agent, adding coagulating enhancer, tackifier, water-reducing agent, waterproofing agent, foam stabilizer, water and fiber, and stirring to obtain a slurry; and (2) adding the foaming agent in the slurry, and filling the foamed slurry into a mold. The foam cement insulation material for exterior wall has good fire resistance, long service life, good insulation property, light weight, high strength, low water absorption and good crack resistance.

Owner:刘巧玲

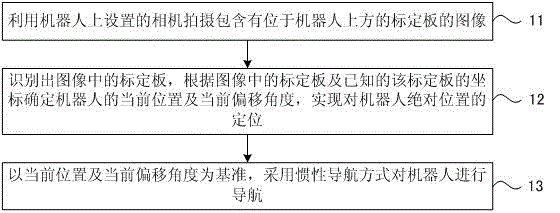

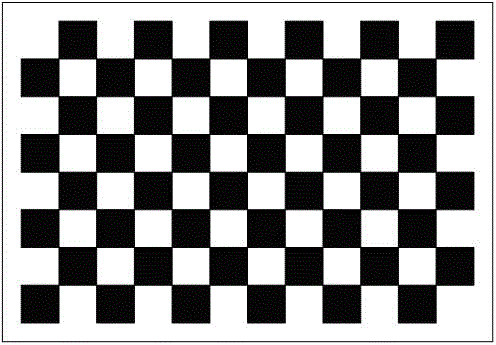

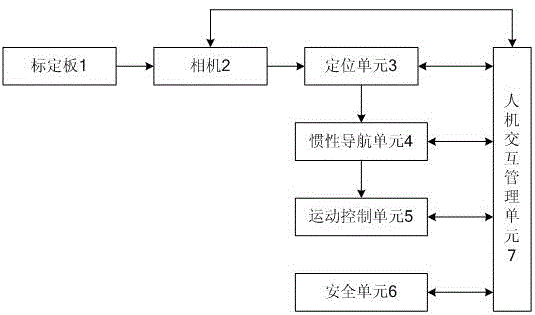

Indoor robot positioning navigation method and device

ActiveCN105486311AImprovement error is largeOvercome high costNavigational calculation instrumentsNavigation by speed/acceleration measurementsRobot positionMarine navigation

The invention discloses an indoor robot positioning navigation method and device. The method comprises using a camera on a robot to shoot an image containing a calibration plate positioned above the robot; using an image processing technology to recognize the calibration plate in the image, determining a current position and a current deviation angle of the robot according to the calibration plate in the image and known coordinates of the calibration plate, and positioning absolute positions of the robot; by taking the current position and the current deviation angle as a reference, navigating the robot by adopting an inertia navigation manner. By using the invention, problems of low positioning precision, high cost, inconvenient use and narrow use range of the existing positioning navigation method are solved.

Owner:苏州海通机器人系统有限公司

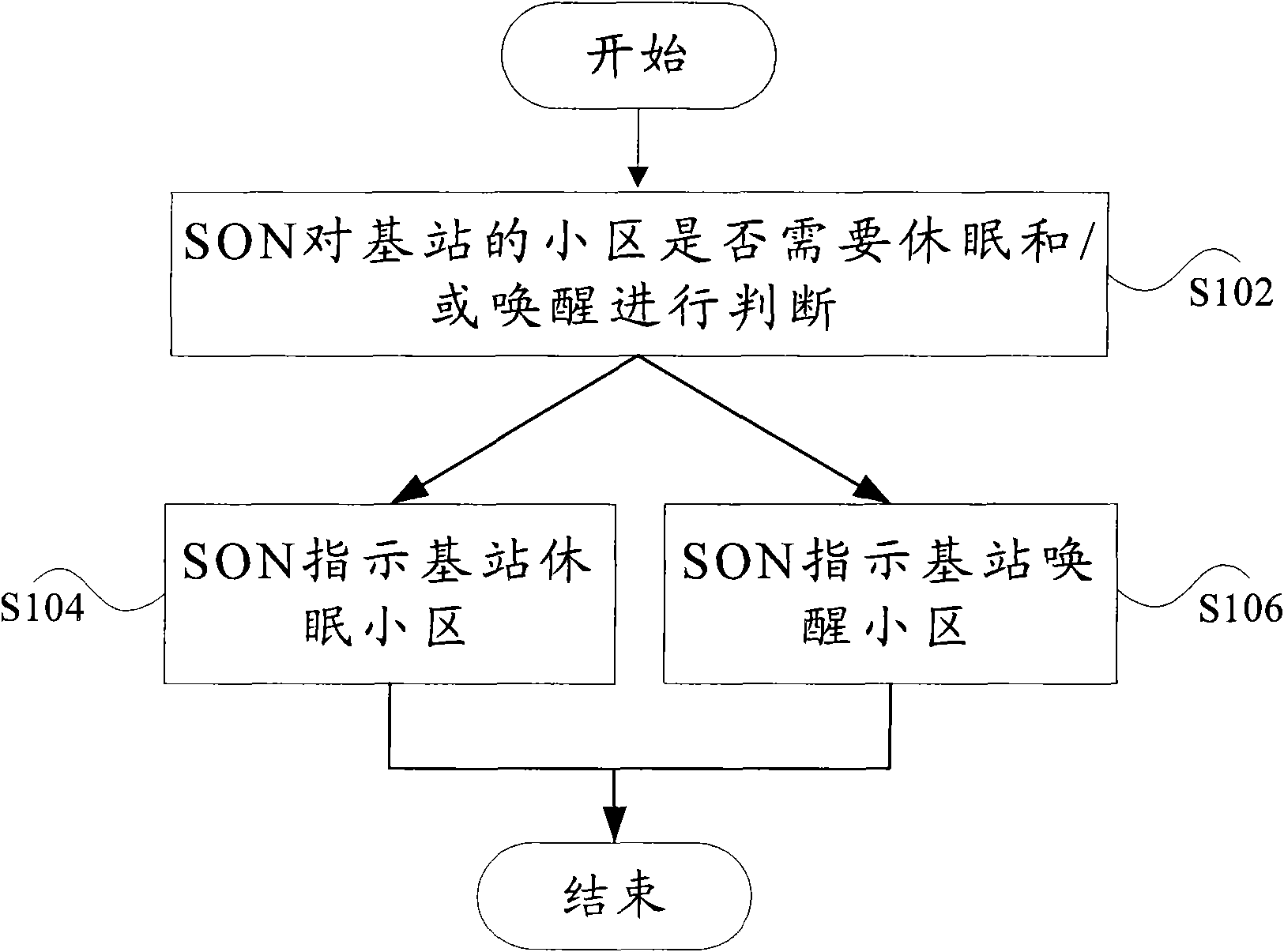

Method and device for controlling carrier power

ActiveCN101873677AEasy accessQuick exitEnergy efficient ICTPower managementCarrier signalPilot channel

Owner:ZTE CORP

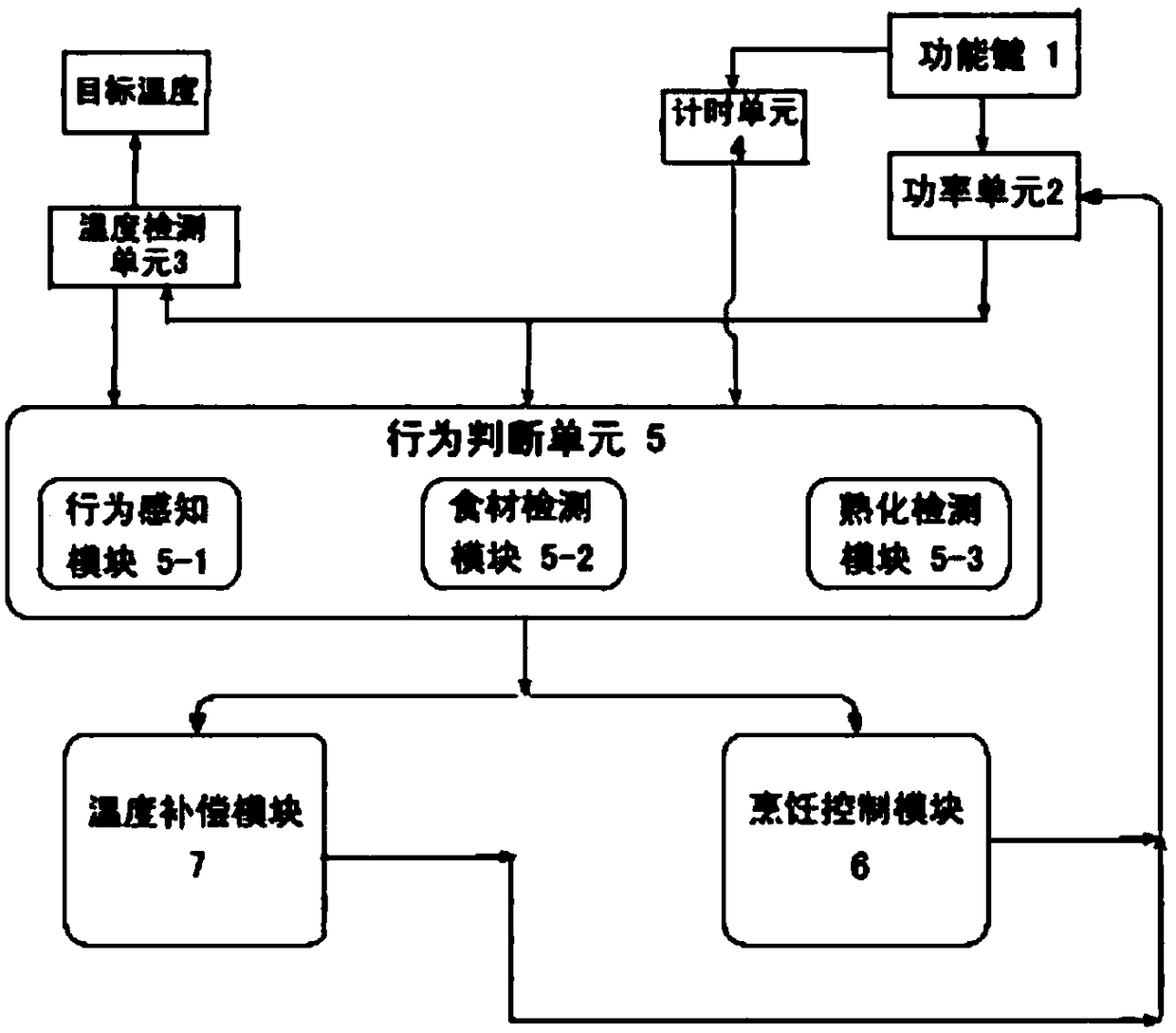

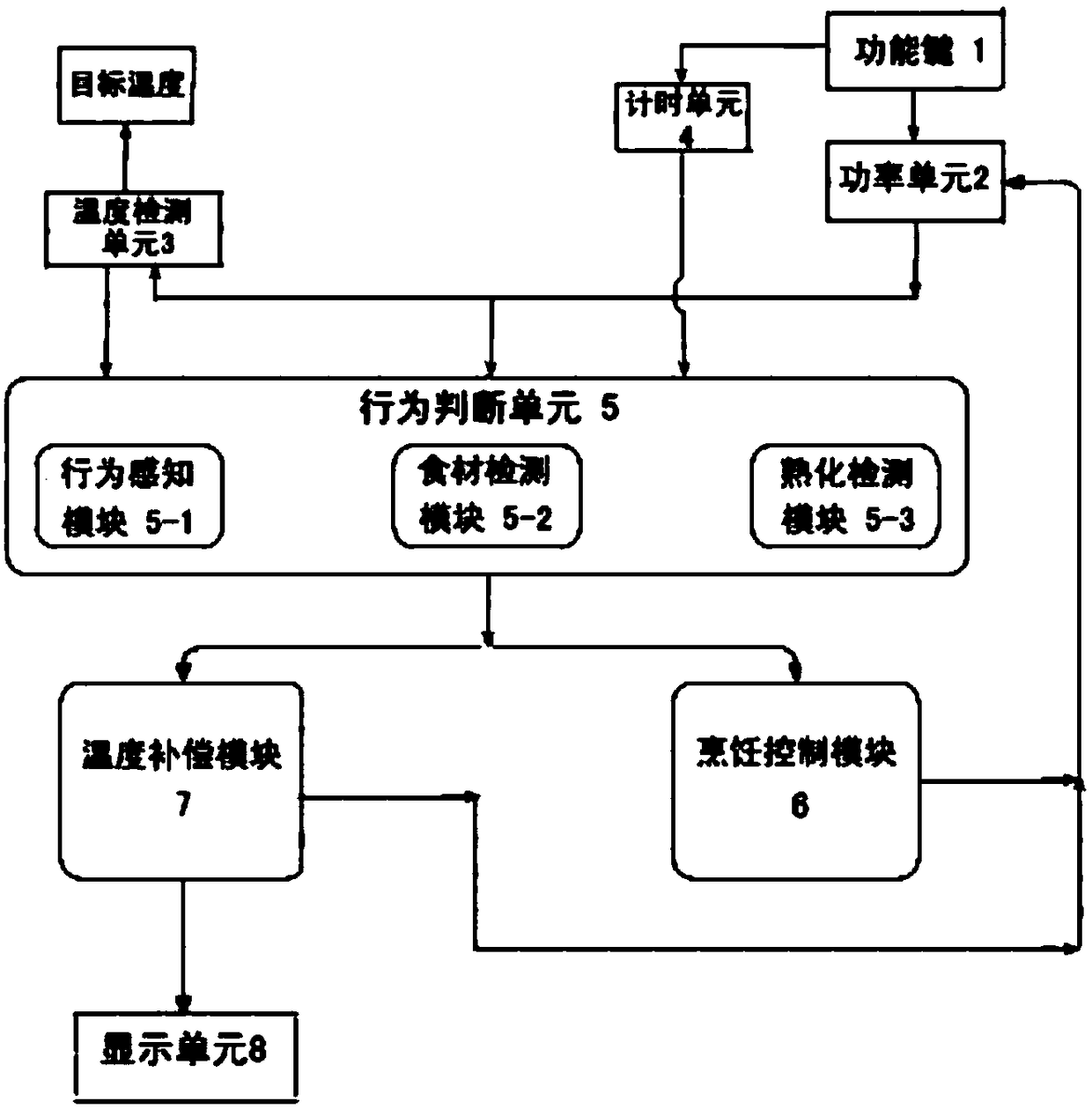

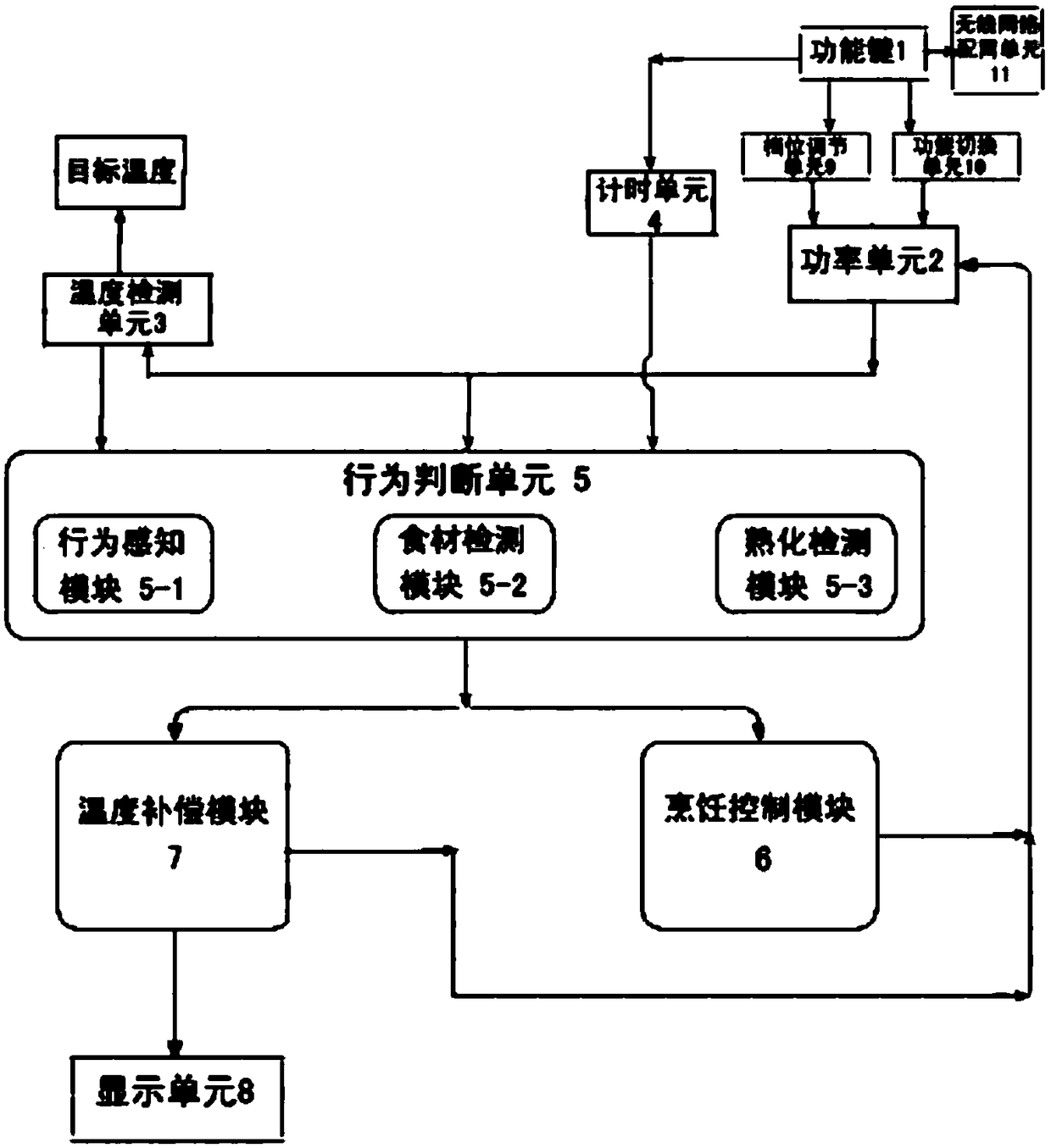

One-key intelligent cooking induction cooker with

PendingCN108731035AHigh cost of solutionSolve problems that cannot meet user needsDomestic stoves or rangesLighting and heating apparatusControl signalEngineering

The invention relates to a one-key intelligent cooking induction cooker comprising a cooker body. The one-key intelligent cooking induction cooker is characterized in that the cooker body is providedwith a function key; the cooker body is internally provided with a power unit, a temperature detection unit, a timing unit, a behavior judgment unit, a cooking control unit and a temperature compensation unit, and the signal output end of the function key is connected to the control signal input end of the power unit and the signal input end of the timing unit; the signal output end of the temperature detection unit and the signal output end of the timing unit are each connected to a signal input end of the behavior judgment unit, and the signal output end of the behavior judgment unit is connected to the input end of the cooking control unit and the input end of the temperature compensation unit; the output end of the cooling control unit is connected to the feedback input end of the power unit, so that a close control loop is formed; the behavior judgment unit is provided with a logical judgment structure for sensing cooking behaviors, types of cooking ingredients and food cooking degree, so that a one-key intelligent cooking structure is formed. The one-key intelligent cooking induction cooker has the characteristics of the simple structure, easy operation, various dishes and the like.

Owner:深圳酷平方科技有限公司

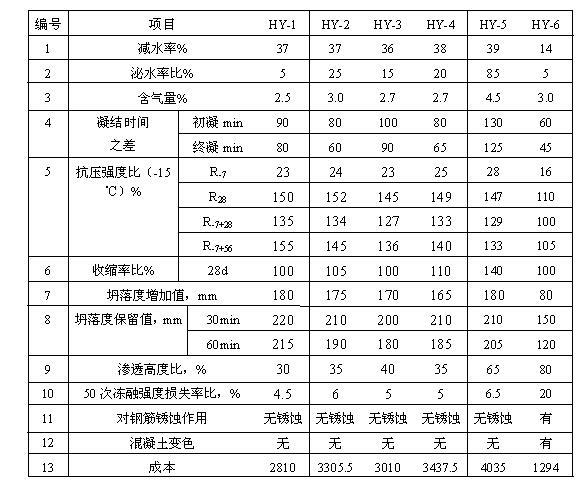

Low-cost concrete antifreezing pumping aid and preparation method thereof

The invention relates to the concrete pumping aid field, in particular to a low-cost concrete antifreezing pumping aid and a preparation method thereof. The concrete pumping aid comprises the following raw materials by weight percent: 20-30% of polycarboxylic acid water reducing agent of which solid content is 40%, 0.3-0.4% of air entraining agent, 0.9-2% of retarder, 11-15% of sulfonated acetone-formaldehyde condensate of which solid content is 36%, 6-10% of sodium lignin sulfonate, 2-4% of antifreezing component and the balance of water. The preparation method comprises the following steps: adding water, air entraining agent, polycarboxylic acid water reducing agent and sulfonated acetone-formaldehyde condensate in a container to heat to 45-55 DEG C, and stirring evenly; adding sodium lignin sulfonate in the container to stir, centrifuging to remove precipitate; and adding retarder and antifreezing component to stir evenly. The low-cost concrete antifreezing pumping aid has good performance; the composite indicators such as the antifreezing property, the pumping property, the water reducing ratio and the ratio of compressive strength are better than that of the antifreezing pumping aid which uses polycarboxylic acid water reducing agent or sulfonated acetone-formaldehyde condensate alone; and the antifreezing pumping aid in the invention has higher adaptability and good cost performance.

Owner:安徽海螺材料科技股份有限公司

Macrophomina beauveria bassiana HFW-05 bacterial strain and uses thereof

InactiveCN101245319AImprove the effect of prevention and controlGood control effectBiocideFungiMacrophominaTreatment effect

The invention discloses a Beauveria bassiana HFW-O5 bacterial strain CGMCC No.2356. The bacterial strain is separated from the Bemisia tabaci corpse in the tomato greenhouse in the suburb of Baoding city. The bacterial strain has no harmful effects for the human beings and the survival environment of the human beings and has very high toxic effects for the Bemisia tabaci, small white butterflies, aphids and other pests, the field efficacy trials for the field prevention and treatment of Bemisia tabaci, small white butterflies, aphids and other pests prove that the prevention and the treatment effects of the three pests of Bemisia tabaci, small white butterflies and aphids can achieve more than 70 percent.

Owner:INST OF PLANT PROTECTION HEBEI ACAD OF AGRI & FORESTRY SCI

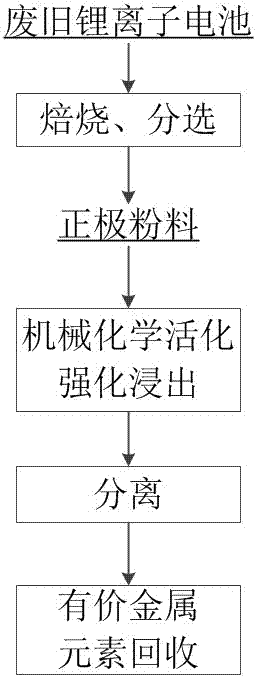

Method for enhancing metal recovery of waste lithium ion battery

PendingCN107083483AReduce acid consumptionHigh cost of solutionWaste accumulators reclaimingProcess efficiency improvementLeaching rateMechanical force

The invention provides a method for enhancing metal recovery of a waste lithium ion battery. The method for enhancing the metal recovery of the waste lithium ion battery comprises the steps that firstly, the waste lithium ion battery is calcinated, smashed and sorted so that positive electrode powder materials can be obtained; and then, wet leaching is conducted on the positive electrode powder materials, and mechanical and chemical activation is achieved through a high-energy ball mill in the leaching process, wherein mechanical and chemical activation is executed during leaching, so that the obtained leach liquor can be further used for recovery of valuable metal elements. By the adoption of the method for enhancing the metal recovery of the waste lithium ion battery, the procedure is simple, the operability is high, under the cooperative action of mechanical force and chemical activation, the leaching time of the positive electrode powder material can be greatly shortened, the leaching rate of the metal elements is improved, cost is reduced, and the market prospect is good.

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

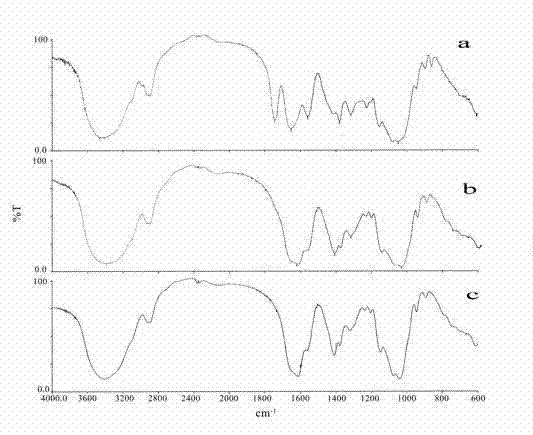

Method for preparing oligomeric hyalurate by digestion method, and oligomeric hyalurate and application thereof

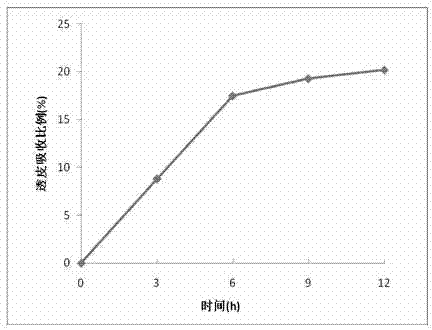

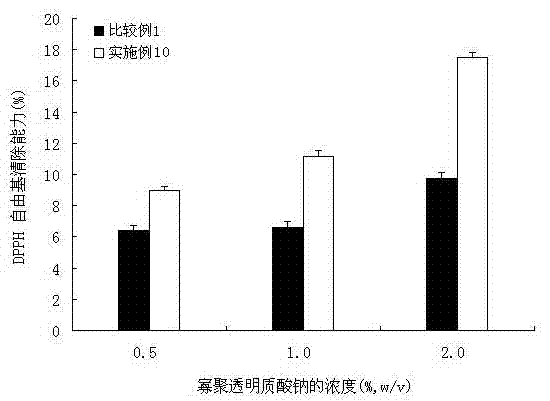

ActiveCN102876748ALow costImprove stabilityMicroorganism based processesFermentationAntioxidant capacityKetone

The invention discloses a method for preparing oligomeric hyalurate by a digestion method, and the oligomeric hyalurate and an application thereof. Bacillus hyaluronidase obtained through fermental cultivation of Bacillus sp. A50 CGMCC NO.5744 is used for degrading hyaluronic acid or a salt thereof, and the method comprises the steps of preparing the hyaluronic acid or the salt thereof, enzymolysis, inactivation, filtering, settling, dewatering and drying. According to the method, the hyaluronidase produced by the Bacillus is used for degrading the hyaluronic acid or the salt thereof, and the oligomeric hyalurate is prepared through dezymotizing, alcohol or ketone settling and dewatering and drying. The method is simple to operate and mild in condition, has no destroy on the product structure and no environmental pollution, the hyaluronidase for fermentation is low in cost and is suitable for large-scale industrial production, the prepared oligomeric hyalurate has the advantages of good percutaneous absorption capability, high purity, no cytotoxicity, strong oxidation resistance and the like, and can be used in fields such as cosmetics, foods and medicines.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

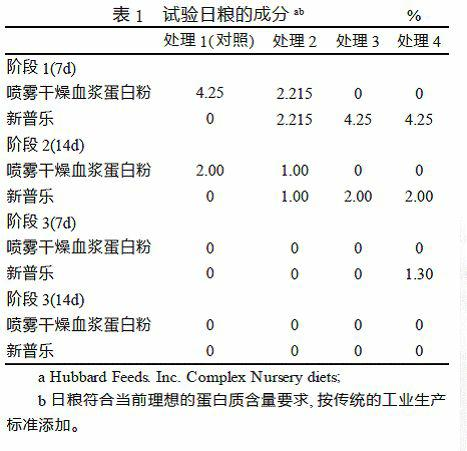

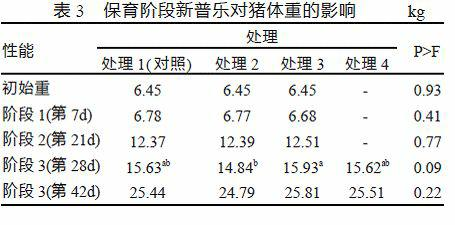

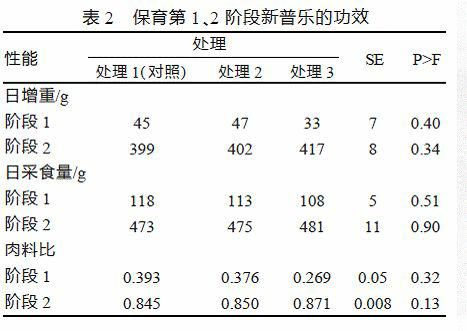

Sucking pig early compound feed and preparation method thereof

InactiveCN102318761AIncrease production capacityAdd lessAnimal feeding stuffAccessory food factorsAnimal scienceWheat germ

The invention provides a sucking pig early compound feed and a preparation method thereof, wherein the compound feed consists of the following raw materials in percentage by weight: 18-22% of puffing corn, 6-8% of corn, 13-17% of wheat, 13-17% of wheat germ, 11-15% of bean pulp, 5-10% of puffing soybean, 5-10% of whey powder, 3-5% of fish meal, 2-3% of amylaceum, 1-3% of pullersun, 1-2% of soybean oil, 1-2% of calcium hydrophosphate, 0.5-1% of mountain flour, 0.2-0.5% of acidulant, 0.2-0.5% of zinc oxide, 0.2-0.5% of vitamine premix compound for pigs, 0.2-0.5% of mineral premix compound for pigs, 0.2-0.4% of salt, 0.2-0.3% of lysine, 0.05-0.1% of methionine, 0.05-0.1% of treonine, 0.05-0.1% of choline chloride, 0.01-0.03% of tryptophan and 0.01-0.03% of antioxidant. All the raw materials are crushed so that 100% of the raw materials pass through a standard sieve of 30 meshes, 95% of the raw materials pass through a standard sieve of 40 meshes, granulation is carried out at 75 DEG C,and the gelatinization degree reaches 90%. In the invention, the nutrient requirements after the sucking pig weaning-post-weaning two weeks are satisfied, and a foundation is laid for piggy high growth performance.

Owner:贵阳新希望农业科技有限公司

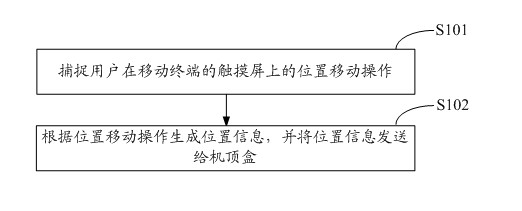

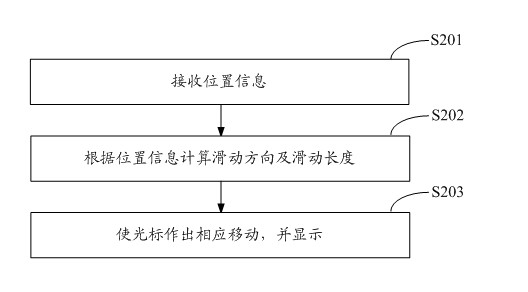

Method and system for controlling set top box by using mobile terminal

InactiveCN102096501AHigh cost of solutionTelevision system detailsColor television detailsControl setControl manner

The invention is suitable for the field of digital televisions, and in particular relates to a method and system for controlling a set top box by using a mobile terminal. The method comprises the following steps of: capturing a position moving operation of a user on a touch screen of the mobile terminal by the mobile terminal; generating position information by the mobile terminal according to the position moving operation, and sending the position information to the set top box; receiving the position information by the set top box; calculating the sliding direction and the sliding length by the set top box according to the position information; and controlling a cursor to make corresponding motion by the set top box, and displaying. In the invention, a UPNP (Universal Plug-n-Play) protocol is used as an interconnection protocol, a user carries out the position moving operation on the touch screen of the mobile terminal, the touch screen captures the position moving operation, the mobile terminal sends the position information to the set top box, and the set top box controls the cursor to move by corresponding position and displays the corresponding position so as to respond to the user operation. Therefore, the problem of higher cost caused by a special hardware device or element configured as required in the traditional control manner is solved.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

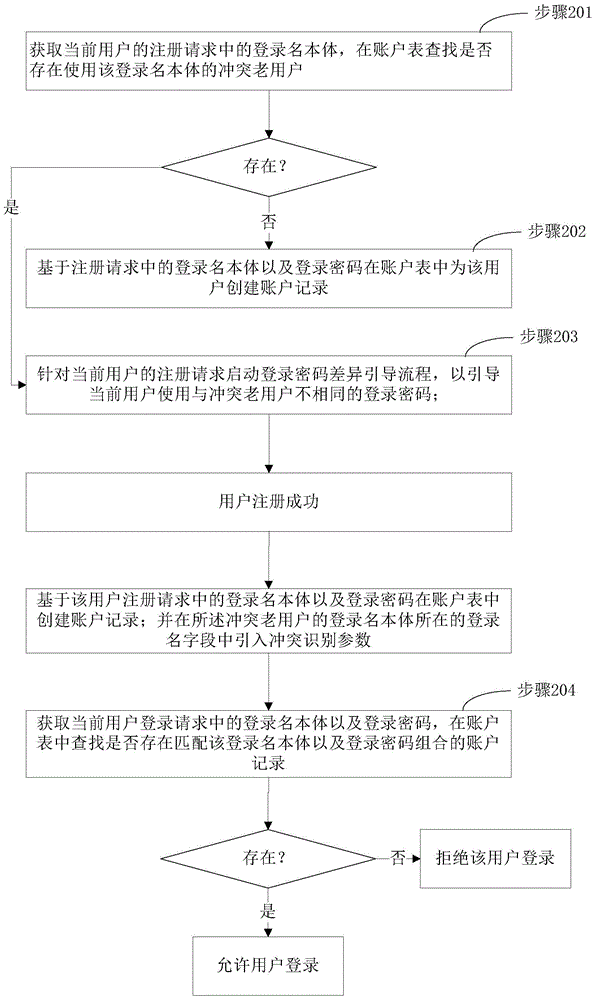

User account management method and device

ActiveCN105101196ASolve the decline of experienceHigh cost of solutionDigital data authenticationTransmissionLogin NameComputer science

Embodiments of the present application relate to a method and system for managing user accounts. The method includes receiving a registration request from a current user, wherein the registration request comprises a login name main part, determining, in a database, whether a conflicting old user exists, wherein a conflicting old user corresponds to another user that has a conflicting login name main part that is the same as the login name main part received in connection with the registration request, in the event that a conflicting old user exists, executing a login password differentiation process that requires a user to register a different login password that is different from a login password associated with the conflicting old user, and storing the different login password to the database in connection with a registration of the current user.

Owner:ADVANCED NEW TECH CO LTD

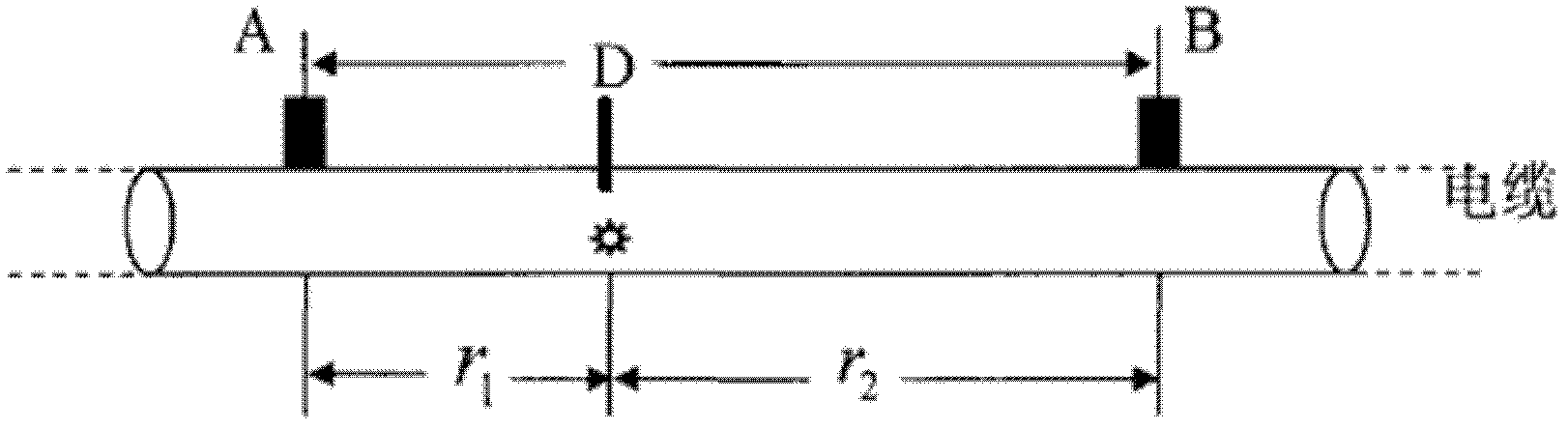

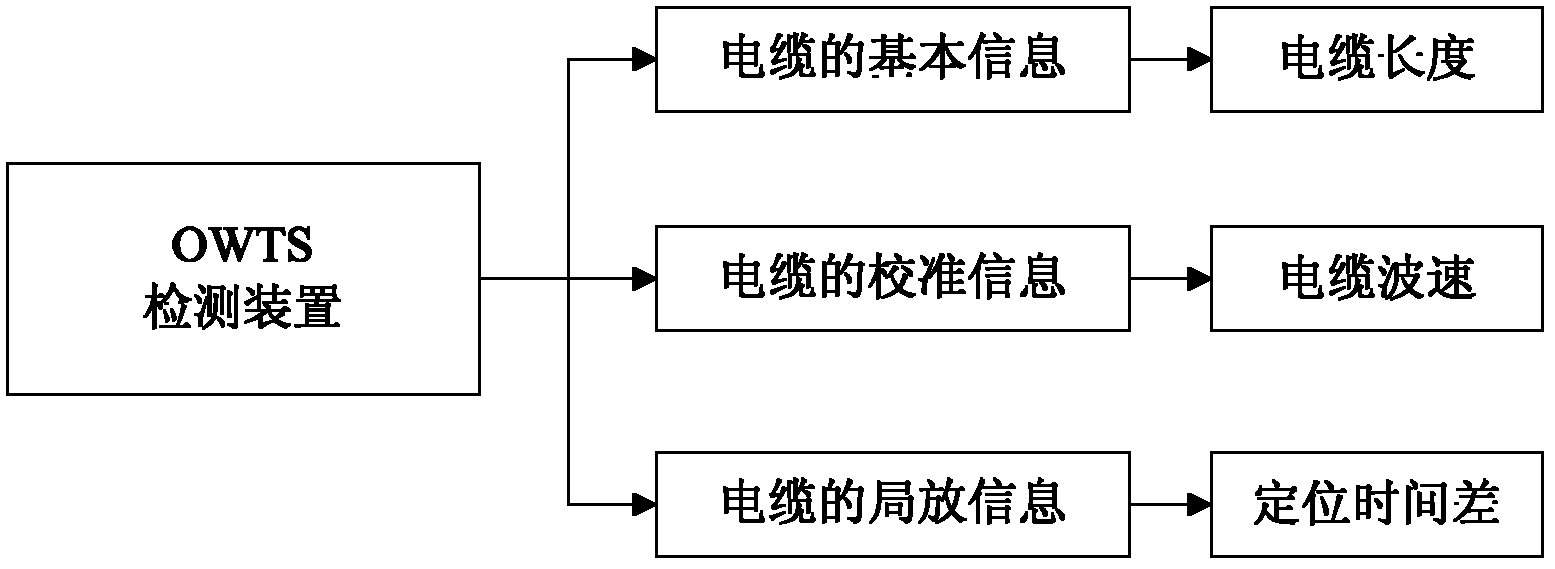

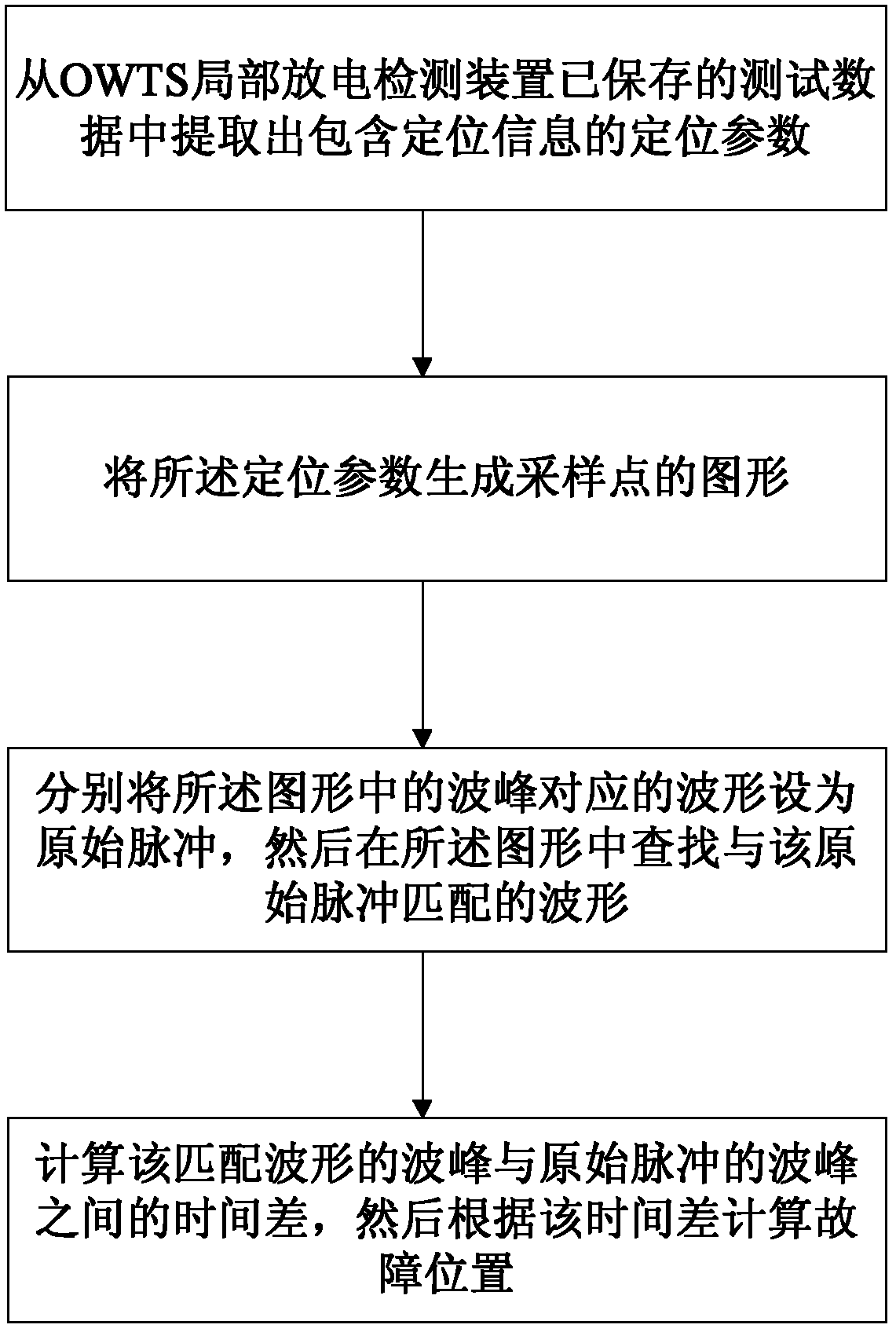

Automatic positioning method and system for cable local discharge single end of OWTS (Oscillating Wave Test System) detection device

ActiveCN102435924AReduce the presence of scatterPositioning analysis results are accurateTesting dielectric strengthFault locationWave crestTime difference

The invention discloses an automatic positioning method for a cable local discharge single end of an OWTS (Oscillating Wave Test System) detection device. The automatic positioning method comprises the following steps of: extracting a positioning parameter containing positioning information from test data saved in an OWTS local discharge detection device; enabling the positioning parameter to generate a graph of sampling points; respectively setting waveform sections corresponding to wave crests in the graph as original pulses; then searching the waveforms matched with the original pulses from the graph; calculating the time difference between the wave crests matched with the waveforms and the wave crests of the original pulse; and calculating the position of a fault according to the time difference. The invention also provides an automatic positioning system for the cable local discharge single end of the OWTS detection device. By using the technology disclosed by the invention, the fault pointing result of the cable is more intensive and scatter points are reduced, so that more accurate positioning analysis result is obtained, automatic analyzing and positioning can be carried out and costs of labor consumption and positioning are reduced.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD +1

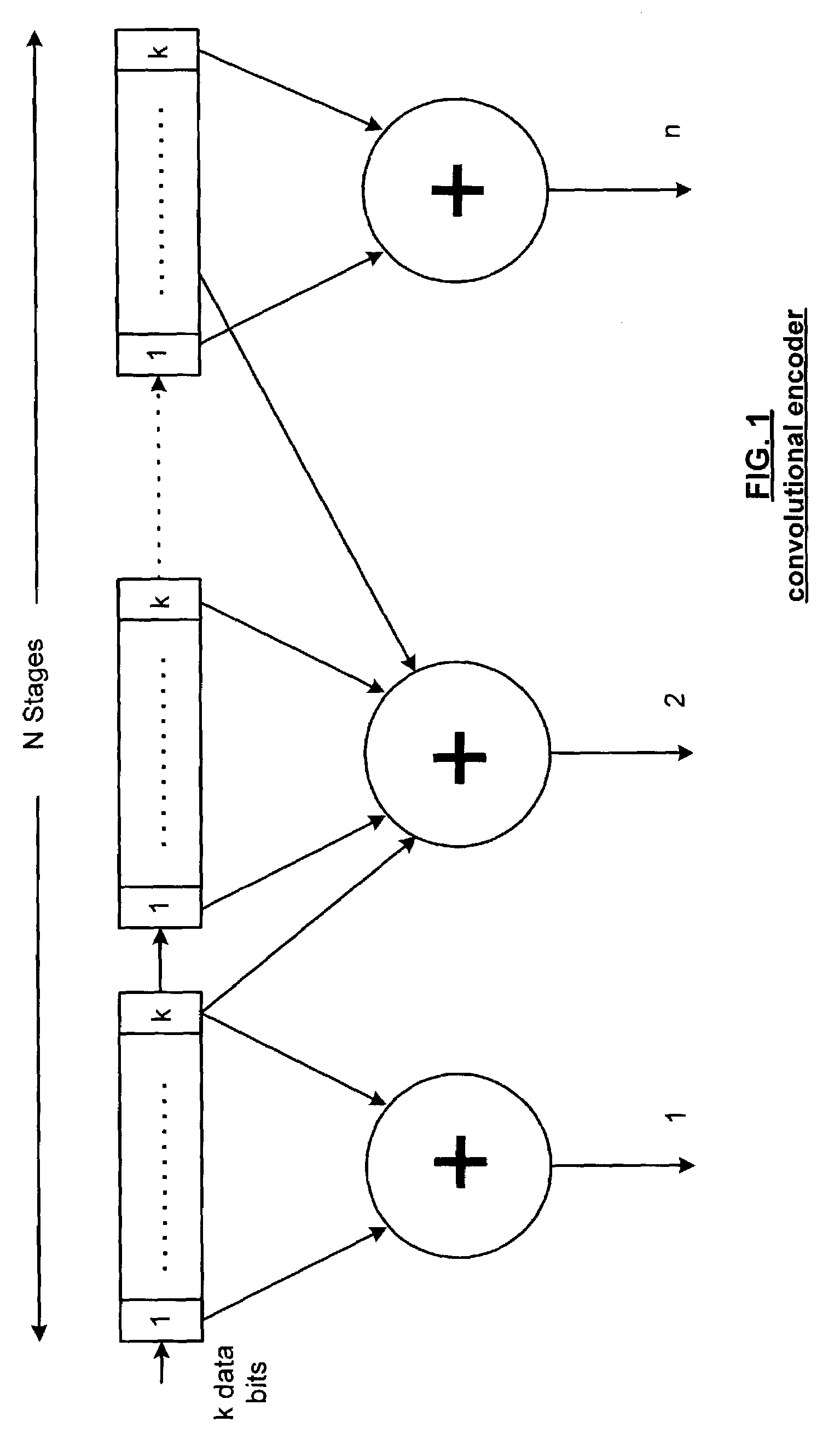

FPGA (Field Programmable Gate Array)-based micro-space oversampling direct-current balance serial deserializer

InactiveCN102340316AEasy to implementHigh cost of solutionParallel/series conversionPulse automatic controlDifferential signalingComputer module

The invention relates to an FPGA (Field Programmable Gate Array)-based micro-space oversampling direct-current balance serial deserializer, aiming to realize verification and design based on serial deserializer in an FPGA without built-in serial deserializer. The FPGA-based micro-space oversampling direct-current balance serial deserializer mainly comprises a clock data recovery (CDR) module, a 8B / 10B encoder, a 8B / 10B decoder an asynchronous FIFO (First In First Out) buffer module, a clock generation module, a parallel-to-serial conversion module, a serial-to-parallel conversion module, a framing module and a de-framing module. At a transmitting end, data are buffered by the asynchronous FIFO buffer module, input into the 8B / 10B encoder (by 8 bits in one frame) for encoding through the framing module, then processed by the parallel-to-serial conversion module and finally output in a differential manner. At a receiving end, a differential signal is accepted by a differential input module and input into the serial-to-parallel conversion module to be output, the output data are decoded by the 8B / 10B decoder, then input into the de-framing module, and finally output by the asynchronous FIFO buffer module in a buffer manner.

Owner:SHANGHAI UNIV

Method and apparatus for signal decoding in a diversity reception system with maximum ratio combining

InactiveUS7421046B2Reduce and eliminate complexity and redundancyHigh cost of solutionResonant long antennasSpatial transmit diversitySignal decodingDiversity scheme

A method signal for decoding in a diversity reception system can include converting the received RF signal into a plurality of digital baseband signals; phase aligning the plurality of digital baseband signals to produce a plurality of phase aligned digital baseband signals; determining a plurality of error terms from the plurality of phase aligned digital baseband signals; one of which corresponding to one of the plurality of phase aligned digital baseband signals; determining a plurality of weighting factors for the plurality of error terms based on characteristics of the plurality of digital baseband signals, one of which corresponding to one of the plurality of error terms; applying the plurality of weighting factors to the plurality of error terms to produce a plurality of weighted error terms; summing the plurality of weighted error terms to produce an error term for decoding.

Owner:VIXS SYSTEMS INC

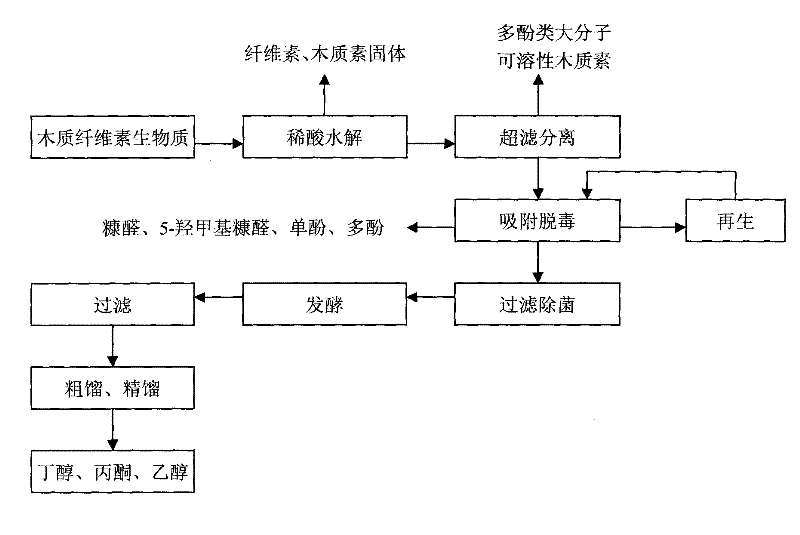

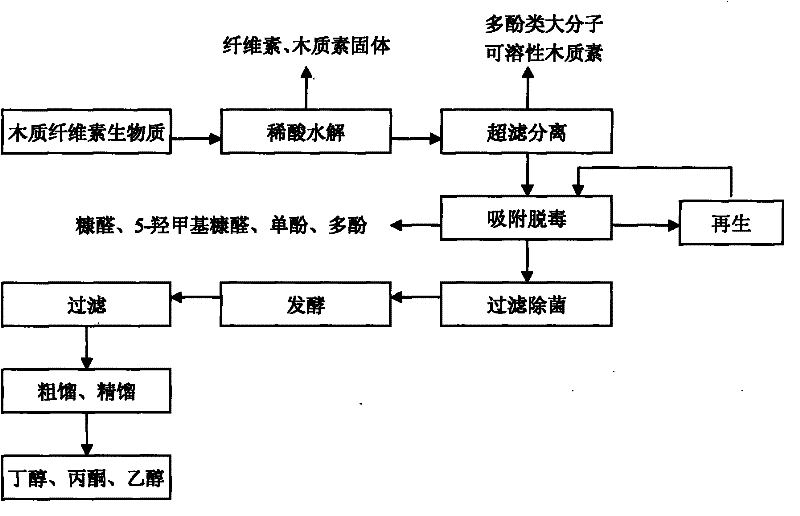

Method for fermenting and preparing biological butyl alcohol by using lignocellulose biomass as raw material

InactiveCN101748158AAvoid it happening againAvoid pollutionBiofuelsMicroorganism based processesAlcohol productionAdsorption separation

The invention discloses a method for fermenting and preparing biological butyl alcohol by using lignocellulose biomass as raw material. Dilute acid is used to hydrolyze lignocellulose biomass to prepare multi-component sugar solution; detoxication treatment and sterilization treatment are conducted to the multi-component sugar solution through membrane separation method and adsorption separation method, sterilization treatment is conducted to the multi-component sugar solution through the membrane separation method, then sterilization treatment is conducted to fermentation culture medium containing no carbon source under high temperature, and finally the sterilized multi-component sugar solution and the sterilized fermentation culture medium containing no carbon source are combined together to prepare fermentation culture medium; butyl alcohol production strains are inoculated in the fermentation culture medium and biological butyl alcohol is prepared through fermentation; and solid-liquid separation treatment is conducted to the fermented liquid and the liquid is distilled to obtain butyl alcohol, acetone and ethyl alcohol. The invention solves the problems of 'striving for grains with people and striving for land with grains' and high raw material cost existing in the traditional butyl alcohol fermentation and production method, and realizes the multiple utilization of lignocellulose biomass.

Owner:NANJING UNIV OF TECH

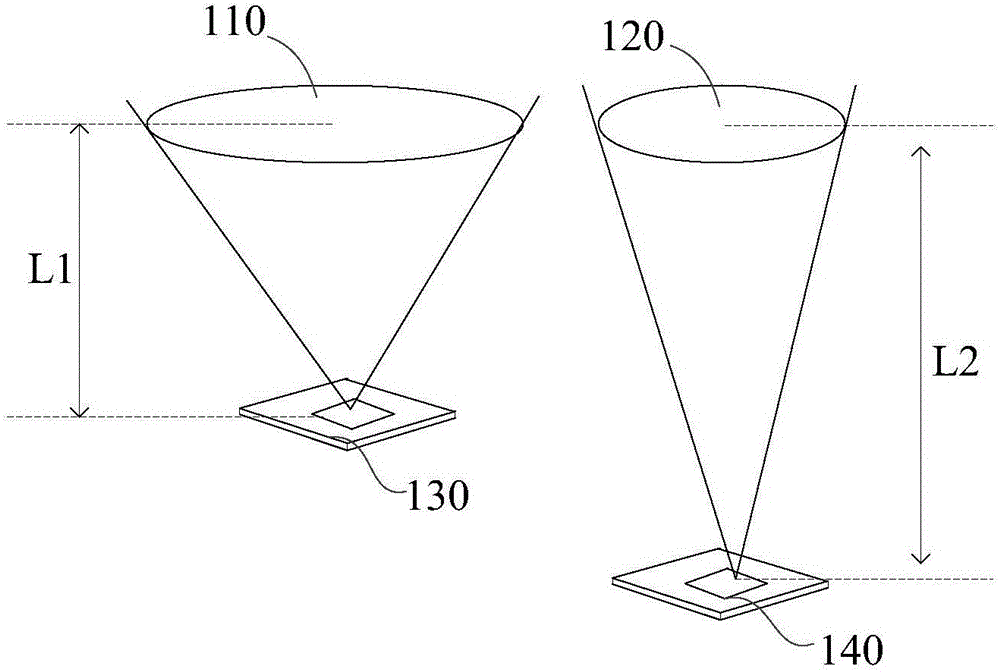

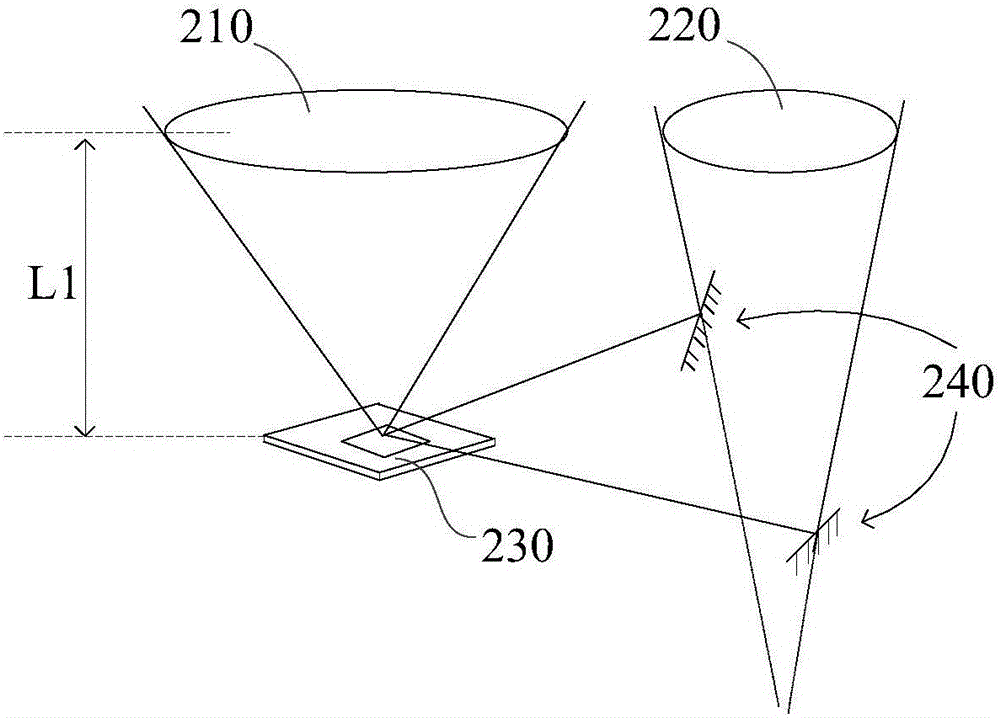

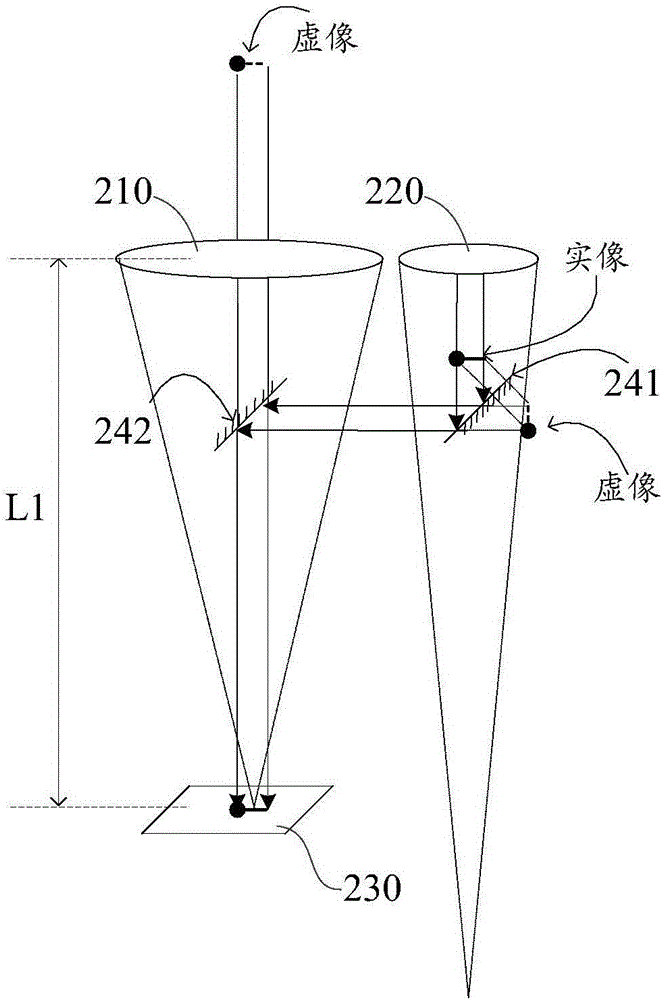

Photographing control method, camera module and mobile terminal

ActiveCN105959525AGuaranteed aestheticsImprove user experienceTelevision system detailsColor television detailsCamera lensImage sensor

The invention provides a photographing control method, a camera module and a mobile terminal. The camera module comprises a first lens group; a second lens group; an image sensor arranged at the imaging side of the first lens group and the second lens group; and multiple reflection elements of which reflection states are adjustable. The multiple reflection elements are arranged between the first lens group and the lens group, and the image sensor. Light rays of the second lens group and / or first lens group for photographing an image are reflected by the multiple reflection elements and then are projected on the image sensor for imaging. In this way, the problems that the cost is relatively high and the thickness of the module is relatively high due to the fact that independent image sensors are employed for double cameras in an existing camera module are solved; the beautiful appearance is ensured; and the user experience is improved.

Owner:VIVO MOBILE COMM CO LTD

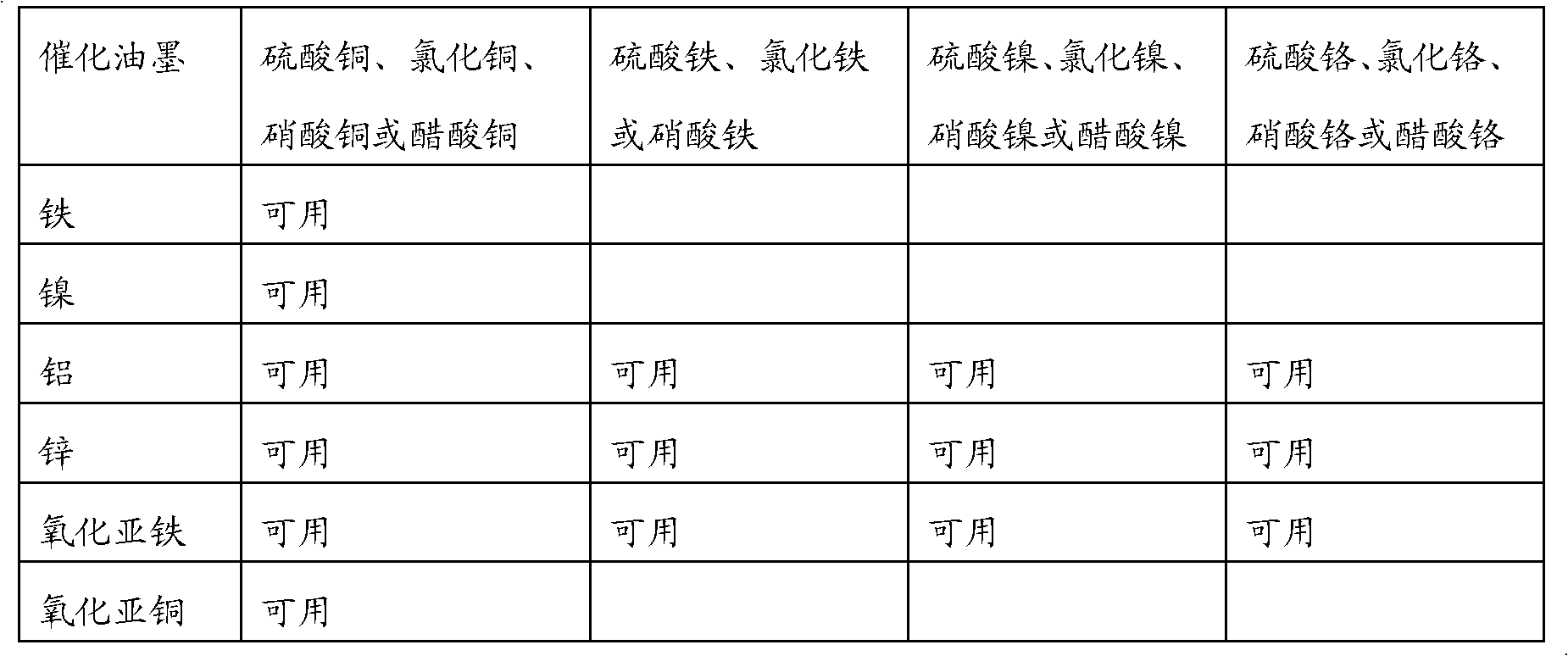

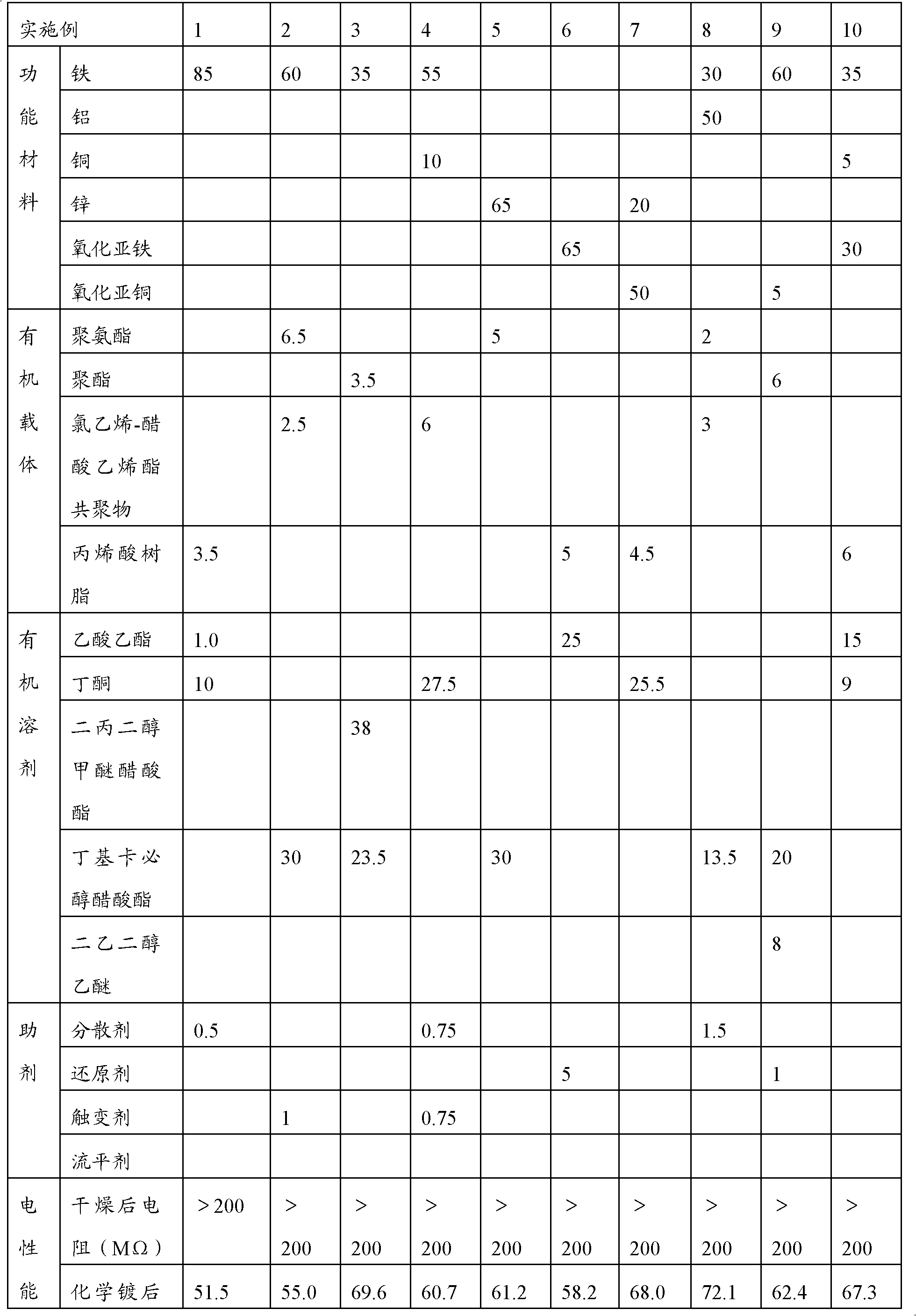

Method for utilizing base metal catalytic ink to manufacture printed circuit

InactiveCN102573313ALow priceReduce manufacturing costInksConductive pattern formationElectrical conductorDisplacement reactions

The invention provides a method for utilizing base metal catalytic ink to manufacture a printed circuit. The method is characterized in that: the ink mainly is composed of 10% to 90% of functional materials, 2% to 18% of organic carriers and 8% to 72% of organic solvents, wherein the functional materials are formed by metal or / and metal oxide powder, the metal is one selected from the group of iron, nickel, aluminum, and zinc, or a mixture of at least two metals in random mixing proportion selected from the group of iron, nickel, aluminum, zinc, and copper, and a metal oxide is selected from ferrous oxide or / and cuprous oxide. According to the invention, traditional printing modes of screen printing, gravure printing and the like can be employed to manufacture lines on insulation base material, and then the insulation base material is put into a replacement reaction solution for a displacement reaction to form a conductor printed circuit. The method has the following advantages: (1) the ink does not contain precious metals of silver, gold and the like, and manufacture cost of related products is greatly reduced; (2) the method is simple; (3) the manufactured printed circuit is reliable, electric conductivity is good, and application is wide.

Owner:SEMITEL ELECTRONICS

Incremental bending and forming method of hat-shaped member

InactiveCN103480704AHigh quality and precisionHigh forming precisionShaping toolsPunchingEngineering

Disclosed is an incremental bending and forming method of a hat-shaped member. Complex hat-shaped member with multi-arcs is formed through a simple mold matching with a plant bending machine. The method includes unfolding each arc of the complex hat-shaped member with the multi-arcs into a plane to determine the size of the plane blank; establishing a three-dimensional model according to the size of the plane blank, and dividing areas by adopting arcs as standards; performing numerical simulation on the forming process complex hat-shaped member with the multi-arcs, incremental bending arcs on two sides, then bending a central arcs, and finally bending boundaries of the areas; determining feeding amount of the plate blanks and downward punching amount of each step during the bending process according to the simulation result. By the aid of the method, the thickness of each part of a formed hat-shaped member is consistent basically, and surface quality and forming accuracy of the formed member can be guaranteed well; the process of controlling deformation is simple, and the method has the advantages of low cost and short period.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

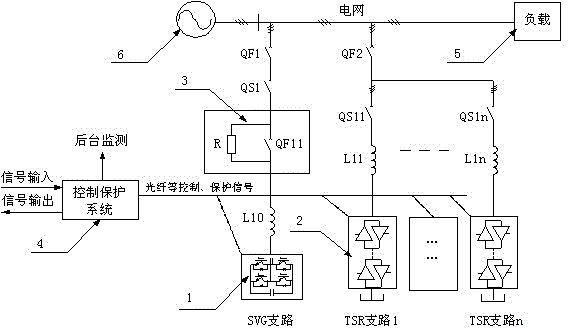

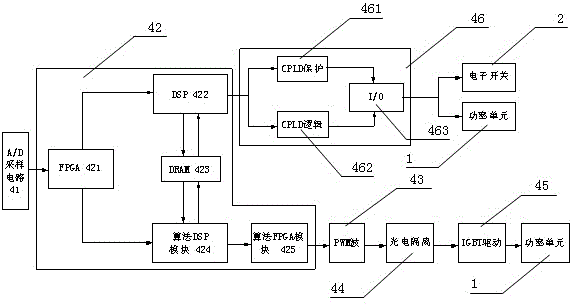

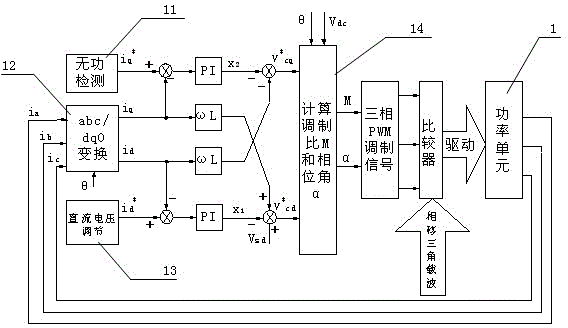

Railway power supply system comprehensive electric energy quality treatment device and method thereof

ActiveCN102882219AEasy to modularizeImprove good performanceFlexible AC transmissionReactive power adjustment/elimination/compensationThyratronPower grid

The invention discloses a railway power supply system comprehensive electric energy quality treatment device and method thereof. A static var generator comprises a power unit and an electric reactor and is connected with a pre-charge loop; the power unit is connected in series with the electric reactor; and the pre-charge loop is connected with a power side of a power grid through an AC (alternating current) switch. A thyristor switch electric reactor comprises more than two electric reactor branches; each electric reactor branch comprises an electric reactor and an electronic switch; the electric reactor is connected in series with the electronic switch; and the electric reactor branch is connected in parallel on a load side of the power grid through the electronic switch. A control protection system controls the investment of the electric reactor branches to compensate for the reactive power and controls the static var generator to compensate for the reactive power. The device and method disclosed by the invention overcome the technical shortcomings that the cost is high by using a static var generator only and the thyristor switch electric reactor can not realize continuous compensation, and also consider the advantages of high regulation speed, wide operation range, reactive power compensation and harmonic wave treatment of the static var generator and large capacity and low cost of thyristor switch electric reactor.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

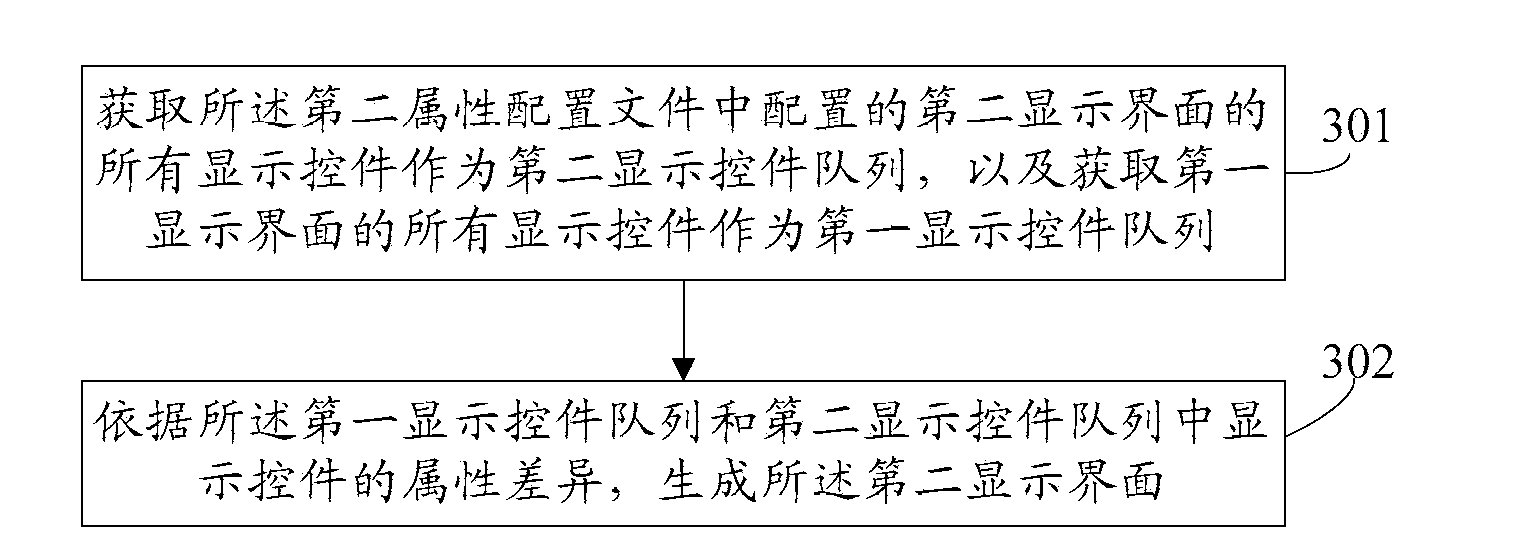

Method and device for switching interfaces dynamically

ActiveCN103809864AResources do not affectImprove user experienceInput/output processes for data processingMachine execution arrangementsSoftware engineeringDynamic switching

The invention provides a method and device for switching interfaces dynamically. The method includes the steps that a first attribute configuration file of the first display interface and a second attribute configuration file of the second display interface are pre-configured, and when a switching instruction of switching the first display interface displayed currently to the second display interface is received, the second attribute configuration file of the second display interface is acquired; the second display interface is loaded according to the difference between the display attribute of the second attribute configuration file and the display attribute of the first attribute configuration file; the first display interface displayed currently is switched to the second display interface to display the second display interface. By the adoption of the method or device for switching the interfaces dynamically, the performance of a computer system will not be affected, the sense of pausing existing in interface switching is avoided, so that user experience is improved. Meanwhile, interface codes are not needed for achieving interface switching, so that high cost caused by maintenance of the codes with complex structures is avoided.

Owner:ALIBABA GRP HLDG LTD

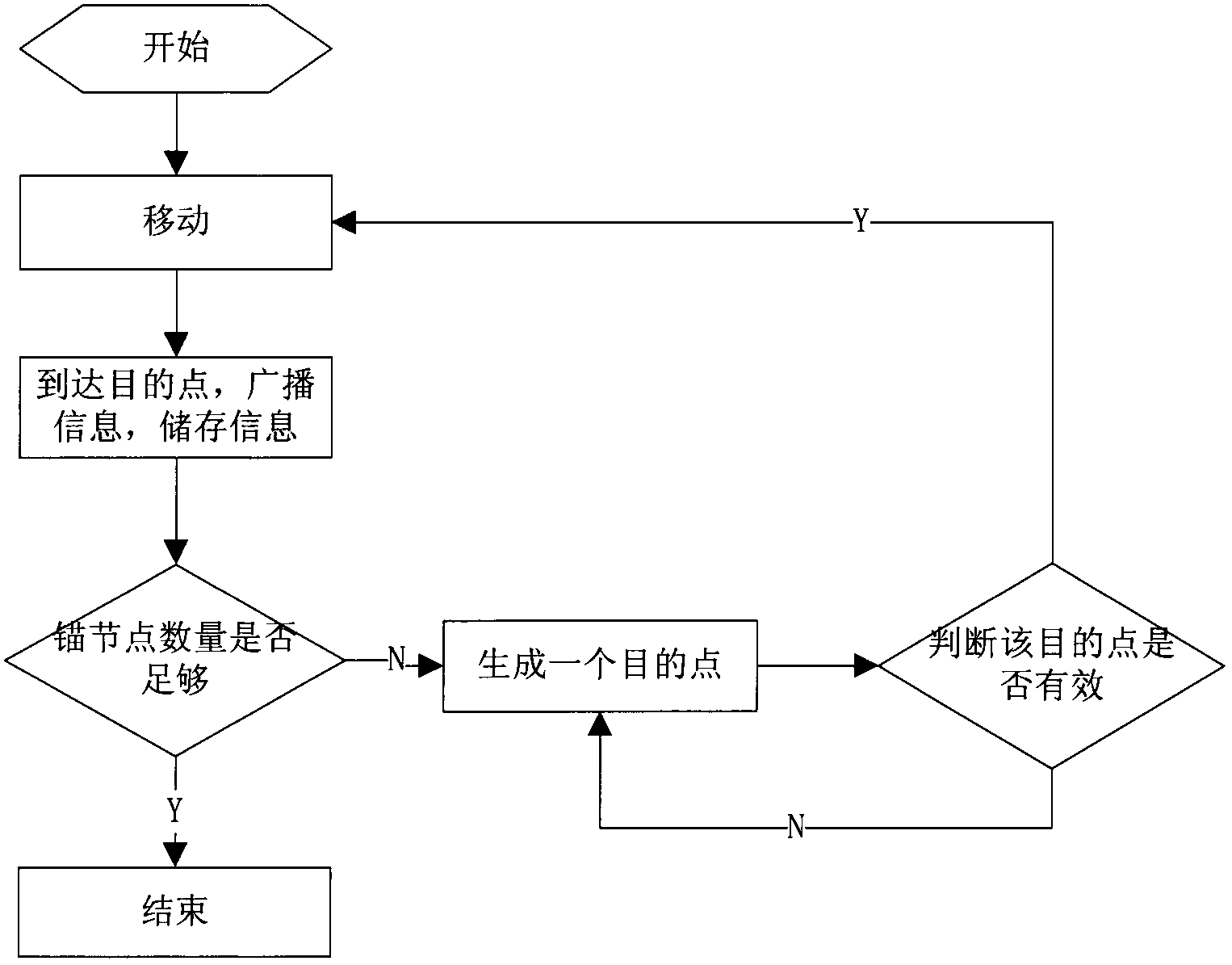

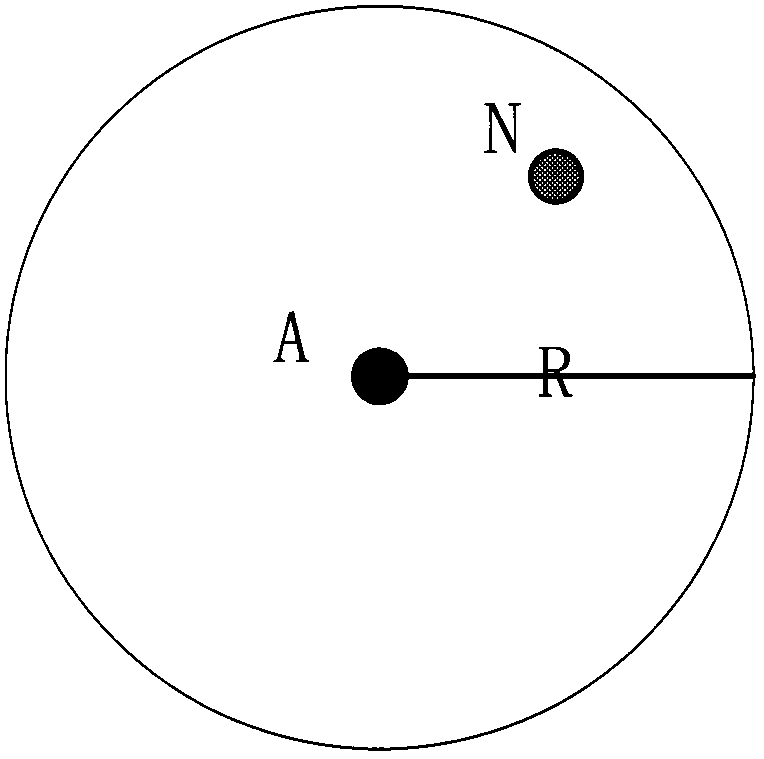

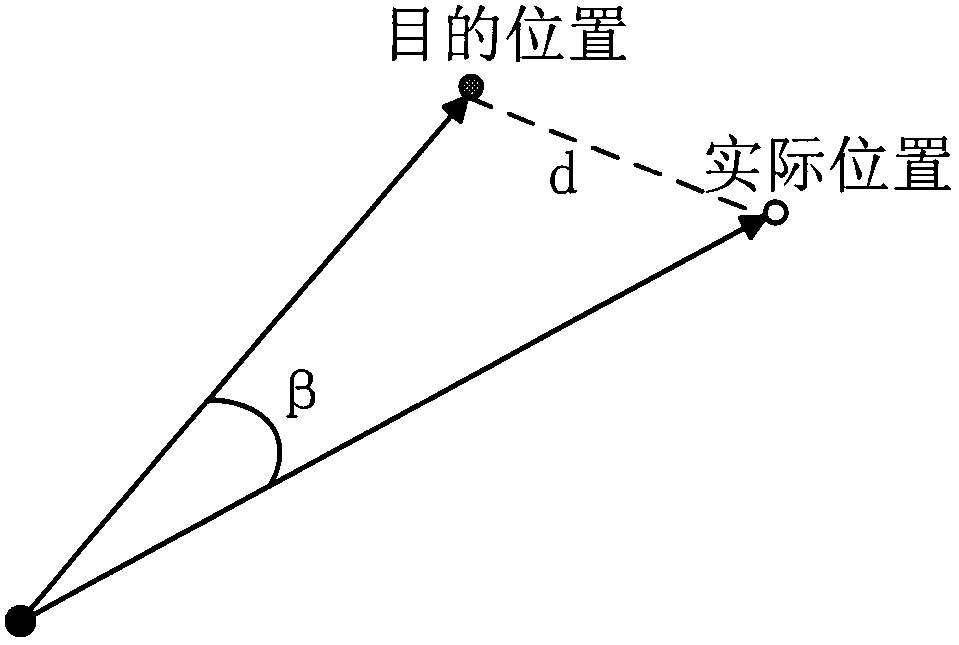

Mobile anchor node based weighted centroid locating method for wireless sensor network node

InactiveCN102680995AHigh cost of solutionLow costSatellite radio beaconingMobile wireless sensor networkWireless mesh network

The invention discloses a mobile anchor node based weighted centroid locating method for a wireless sensor network node and belongs to the field of application of the wireless sensor network and the random mobile technology and the wireless range finding technology. Since a mobile anchor node is utilized to substitute for a traditional anchor node, usage cost is reduced, and coverage rate for unknown nodes is increased. Locations of the unknown nodes can be obtained by scheduling moving path of the anchor node and by the aid of the weighted centroid algorithm. The mobile anchor node based weighted centroid locating method for the wireless sensor network node is low in cost, simple in algorithm, high in coverage rate of unknown nodes, accurate in locating, and applicable to practical use.

Owner:JIANGNAN UNIV

Carbon aerogel composite pair electrode used for dye-sensitized solar cell and preparation method thereof

InactiveCN101562077AImprove practicalityLow costLight-sensitive devicesSolid-state devicesHexafluoropropyleneSolar cell

The invention discloses a carbon aerogel composite pair electrode used for a dye-sensitized solar cell and a preparation method thereof. The carbon aerogel composite pair electrode is formed by coating carbon aerogel compound formed by mixing carbon aerogel (1) and polymer (2) on a conductive substrate (3). The preparation method of the carbon aerogel composite pair electrode comprises the steps: (1) the carbon aerogel is mixed with poly-dioxy ethyl thiophene / poly-p-styrenesulfonic acid water solution to obtain suspending liquid with the concentration of 5-40%, or the carbon aerogel is added into the suspending liquid of polyfluortetraethylene, polyvinylidene fluoride or polyvinylidene fluoride-hexafluoropropylene according to the mass ratio of 5:1-15:1 for ultrasonic dispersion for 10-20min, so that evenly mixed carbon aerogel / polymer compound can be obtained for standby application; (2) the conductive substrate is cleaned, and the carbon aerogel / polymer compound is coated on the cleaned conductive substrate and dried, finally, the carbon aerogel composite pair electrode used for the dye-sensitized solar cell can be prepared. The electrode has the characteristics of low cost, high electrical conductivity and catalytic activity as well as being capable of preparing flexible cells and the like, so as to promote the practicability of the dye-sensitized nano-crystalline solar cell.

Owner:XIANGTAN UNIV

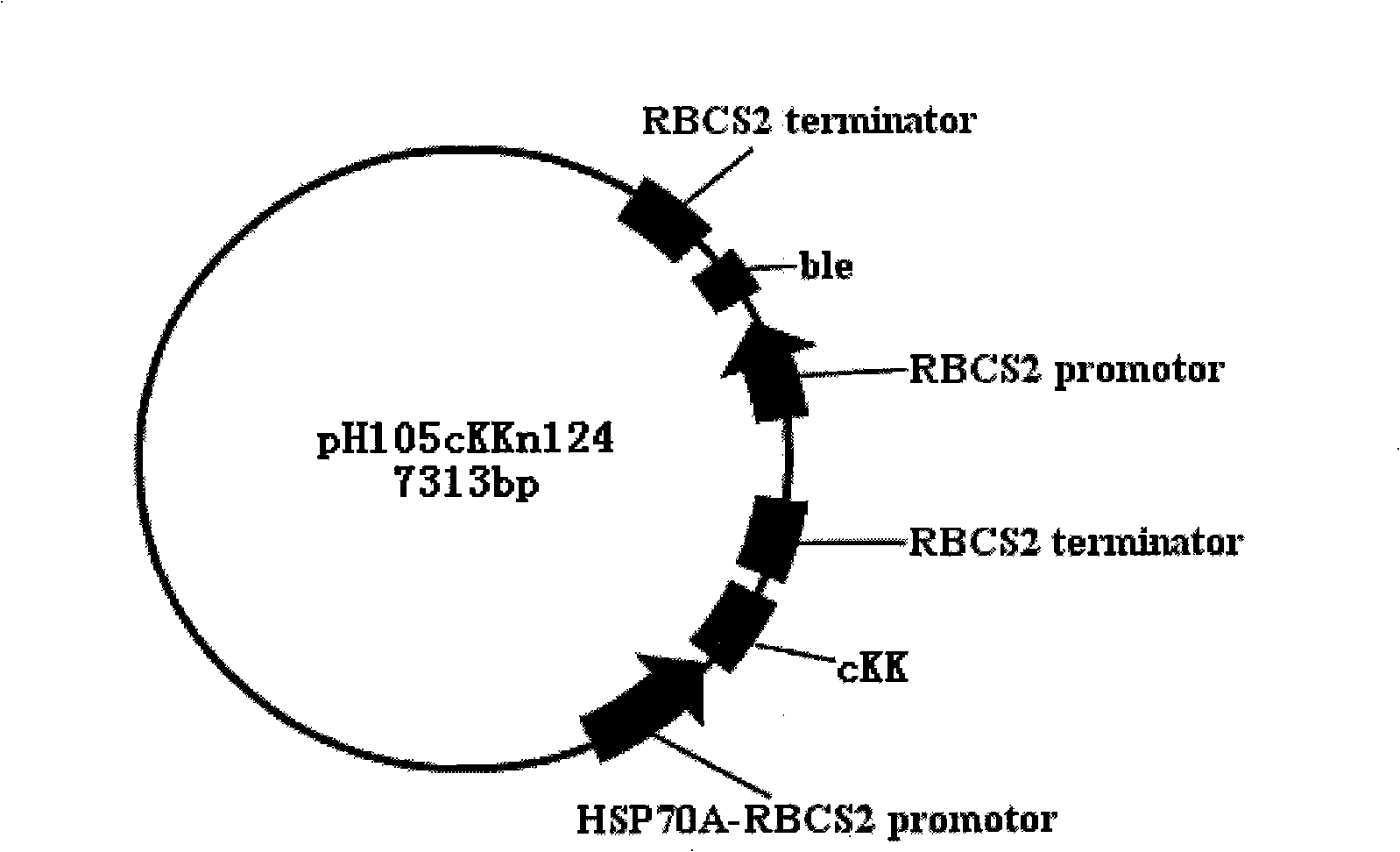

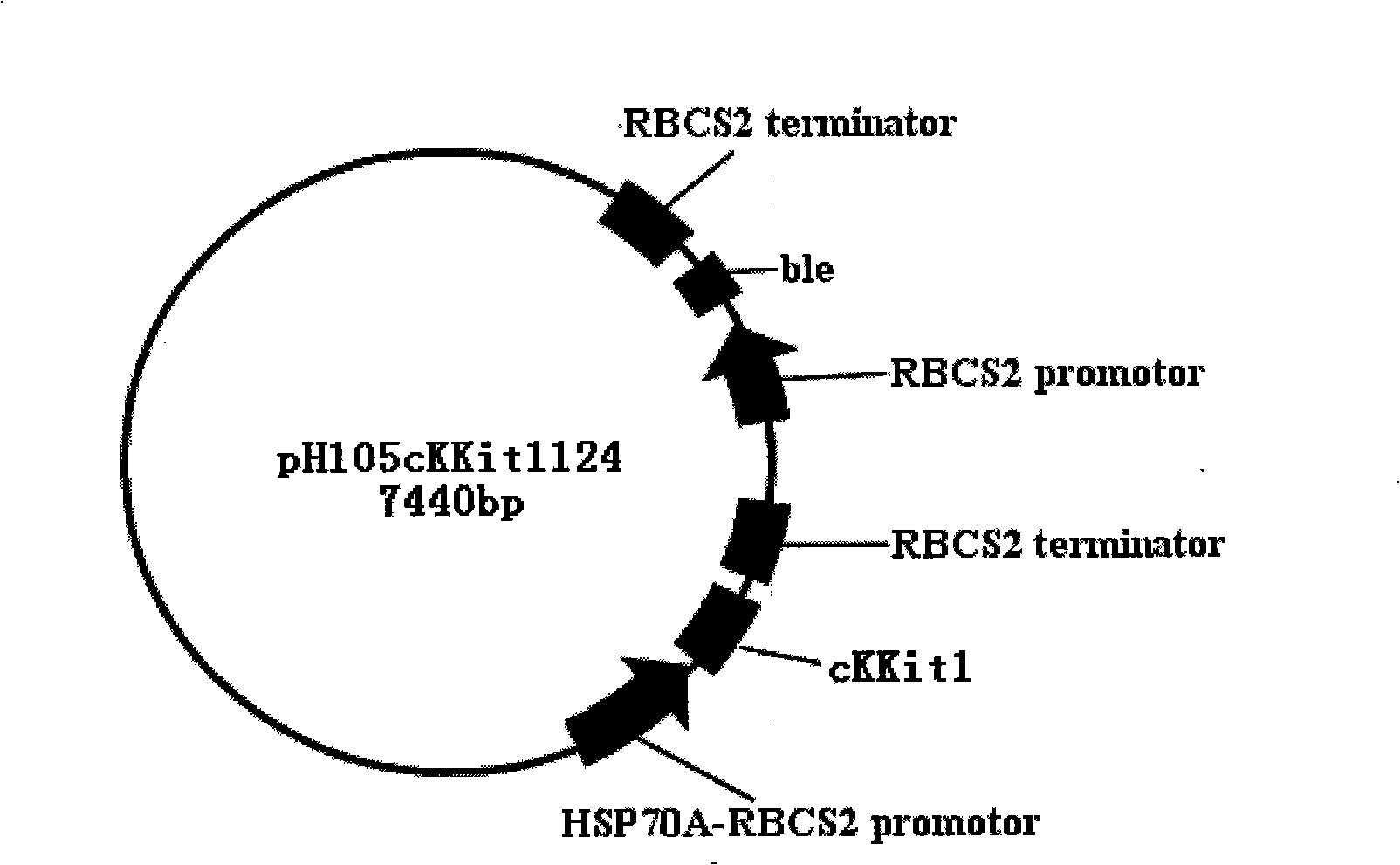

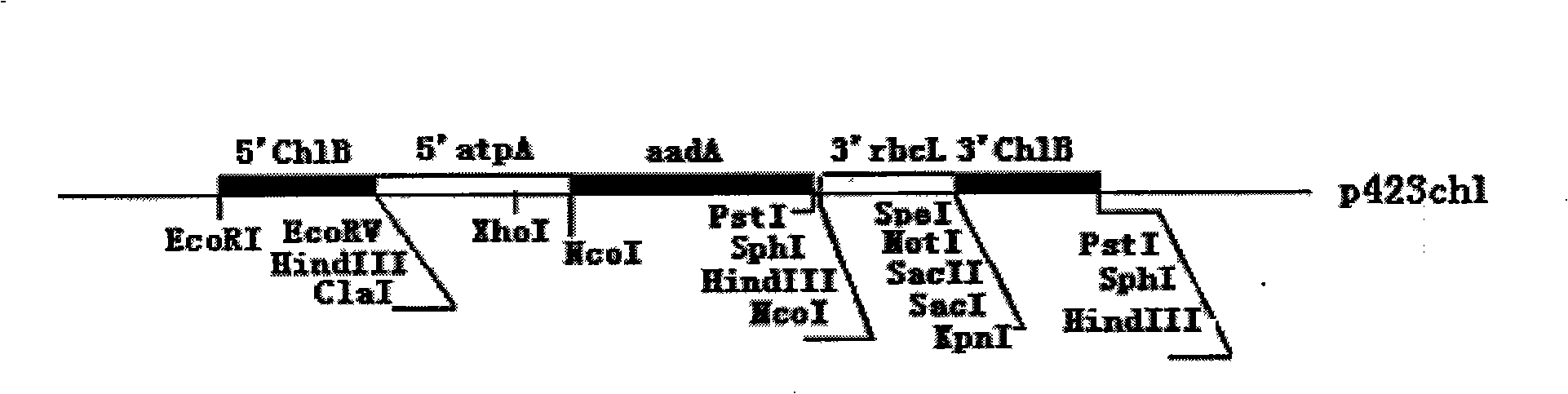

Construction method of transgenic chlamydomonas reinhardtii for expressing human tissue kallikrein

ActiveCN101255438ARich in nutrientsReasonable structureUnicellular algaeMicroorganism based processesDiseaseChlamydomonas reinhardtii

The invention is a constructing method of a genetic modified chlamydomonas reinhardtii to express kallikrein of human tissue. Firstly kallikrein gene sequence suitable for expression of chlamydomonas reinhardtii kernel genome or expression of chloroplast genome or expression of mitochondrial is designed according to kallikrein gene sequence of human tissue and preferred codon table of chlamydomonas reinhardtii, the gene sequence is synthesized by artificial synthesis, kallikrein gene of human tissue containing non-coded sequence is artificially synthesized, then expression vector of chlamydomonas reinhardtii kernel genome or expression vector of chlamydomonas reinhardtii chloroplast genome or expression vetor of chlamydomonas reinhardtii mitochondrial with mention foreign gene is constructed, then transformed into chlamydomonas reinhardtii by genetic transformation, and genetic modified algal strains capable of expressing kallikrein of human tissue is obtained after screening. The invention lays foundation of treating and preventing some diseases such as hypertention, glomerulonephritis with human original kallikrein gene chlamydomonas reinhardtii and products there.

Owner:深圳市微宇生物科技有限公司

High-titanium and low-silicon titanium-silicon-iron alloy and preparation method thereof

The invention discloses a high-titanium and low-silicon titanium-silicon-iron alloy and a preparation method thereof, which belong to the technical fields of vanadium-titanium resource comprehensive utilization and iron alloy smelting. The titanium-silicon-iron alloy is characterized in that: the titanium content is higher than 40 percent by weight, and contains 40-70 percent by weight of Ti, 8-40 percent by weight of Si, 3-15 percent by weight of Fe and unavoidable impurities. In preparation method of the titanium-silicon-iron alloy, the high-titanium and low-silicon titanium-silicon-iron alloy is prepared by adding an admixture into high-titanium blast furnace slag and undergoing a melting thermal reduction reaction, wherein the weight proportion of the high-titanium blast furnace slag to the admixture is 1:(0.4-0.8); the admixture comprises 40-80 percent by weight of a reducing agent; and the major component of the reducing agent is metal aluminum. The titanium-silicon-iron alloy disclosed by the invention instead of titanium and iron can be taken as a titanium alloy agent, and the popularization and application of the titanium-silicon-iron alloy can be promoted; and according to the method disclosed by the invention, improvement on the environment is facilitated, and the resource utilization ratio is increased.

Owner:PANZHIHUA GANGCHENG GROUP

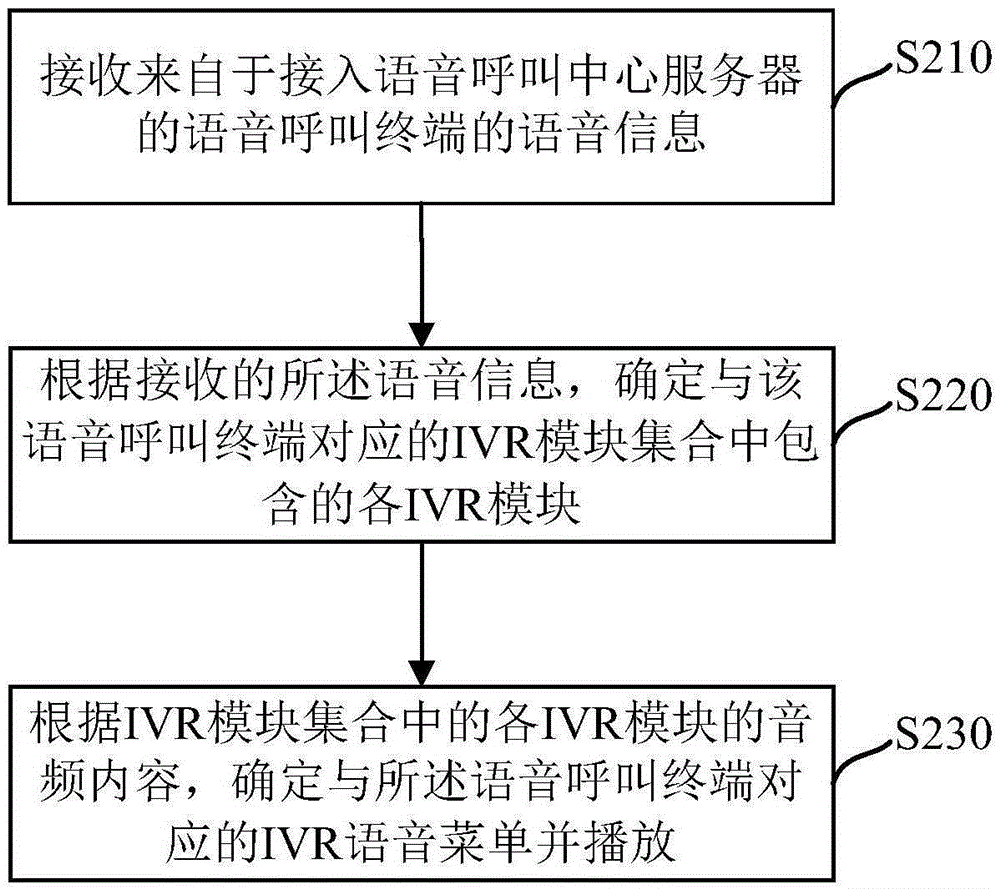

IVR voice menu determination method and apparatus

InactiveCN106572272AHigh cost of solutionSpecial service for subscribersComputer terminalSelf-service

The embodiment of the application discloses an IVR voice menu determination method and apparatus. The method comprises: acquiring user information corresponding to a voice call terminal getting access to a voice call center server; determining respective IVR modules included in an IVR module set corresponding to the voice call terminal according to the user information; according to the audio content of respective IVR modules in the IVR module set, determining and playing an IVR voice menu corresponding to the voice call terminal. The IVR voice menu determination method and apparatus may solve a problem that the IVR self-service voice menu service is fixed in the prior art but the cost of the enterprise and user in the manual service is high.

Owner:ALIBABA GRP HLDG LTD

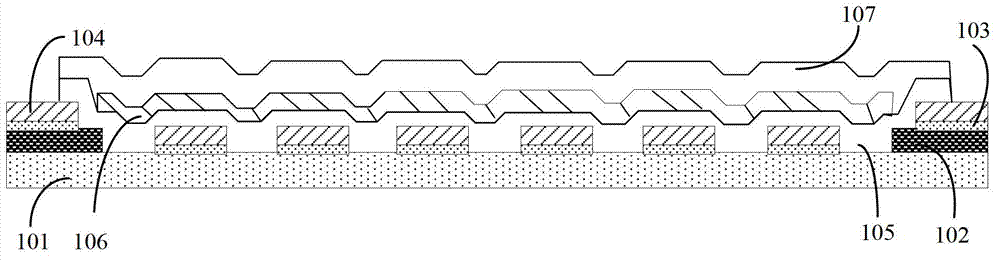

Touch sensor, manufacturing method thereof and display device

ActiveCN102955612AIncrease production capacityHigh cost of solutionInput/output processes for data processingDisplay deviceLithography

The invention provides a touch sensor, a manufacturing method thereof and a display device. A BM protection layer and a metal layer are provided with same patterns, so that five mask plates are needed in the technical process for producing the touch sensor, and the photoetching operation is implemented for five times, therefore the problem of low productivity caused by using the photoetching technique 6 times and the problem of high cost caused by using 6 mask plates in the production process of the touch sensor in the prior art are solved. The invention relates to the field of design and manufacturing of touch sensors.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Image defogging method and device

The invention relates to an image defogging method and device. The image defogging method comprises the steps as follows: (1) transforming a to-be-processed image from a RGB (red-green-blue) color space into an HSV (hue-saturation-value) color space; (2) extracting luminance components of the to-be-processed image; (3) performing homomorphic filtering processing on the luminance components of the to-be-processed image; (4) transforming the processed image from the HSV color space into the RGB color space; (5) outputting the processed image. The provided technical scheme has the advantages that the method is simple, requirements for hardware are not high, the cost for implementing the image defogging method is lower, and accordingly, the problem of higher cost during processing of fog images in the prior art is solved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

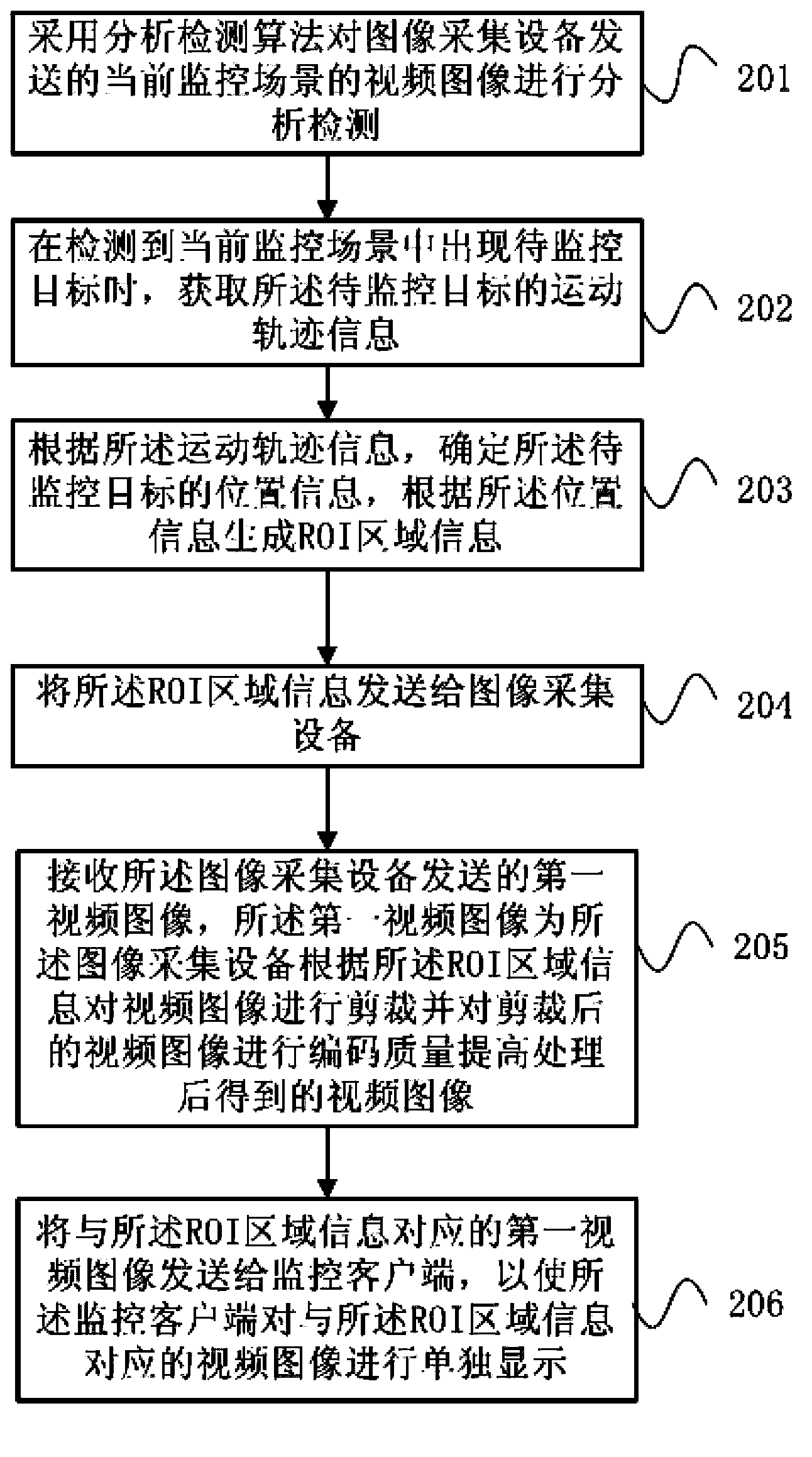

Video monitoring processing method, device and system thereof

InactiveCN104185078AHigh cost of solutionClosed circuit television systemsSelective content distributionVideo monitoringVideo image

An embodiment of the invention provides a video monitoring processing method, a device and a system thereof. The video monitoring processing method of the invention comprises the steps of: obtaining a region-of-interest ROI information which corresponds with a target to be monitored; transmitting the ROI information to image acquiring equipment; receiving a video image which is transmitted by the image acquiring equipment and corresponds with the ROI information; and transmitting the video image which corresponds with the ROI information to a monitored client so that the monitoring client singly displays the video image which corresponds with the ROI information. The video monitoring processing method realizes high-quality display on the video image which corresponds with the ROI information on condition of larger monitoring region through transmitting the video image that corresponds with the ROI information to the monitoring client.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com