Touch sensor, manufacturing method thereof and display device

A touch sensor and metal layer technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of high cost and low production capacity, and achieve the effect of improving production capacity and solving low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

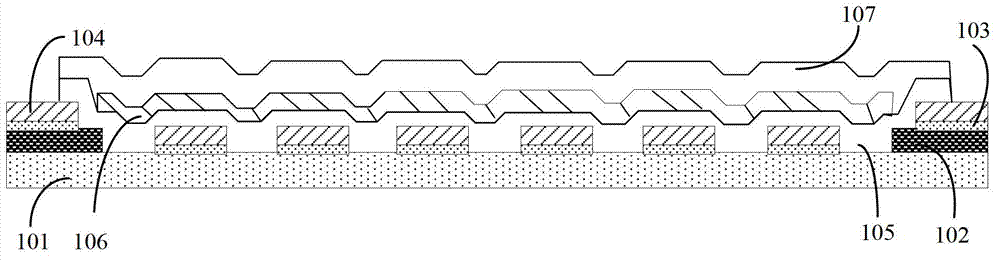

[0043] Based on the same inventive concept, an embodiment of the present invention also provides a method for manufacturing a touch sensor, the method includes the following steps: sequentially preparing a BM layer, a BM protective layer and a metal layer on a transparent substrate, wherein the BM protective layer and the metal layer steps such as Figure 4 As shown, it can be achieved through the following process:

[0044] S401, sequentially depositing a BM protection layer and a metal layer on the BM layer;

[0045] S402, using a mask to form the same pattern on the BM protection layer and the metal layer through a patterning process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com