Sublevel shrinkage caving stage open stope afterwards filling mining method

A filling mining method and caving technology, which is applied in ground mining, underground mining, special mining, etc., can solve the problems that the ground surface is not allowed to sink and cannot be used, and achieve the effect of low cost, large production capacity and high equipment level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment describe in detail:

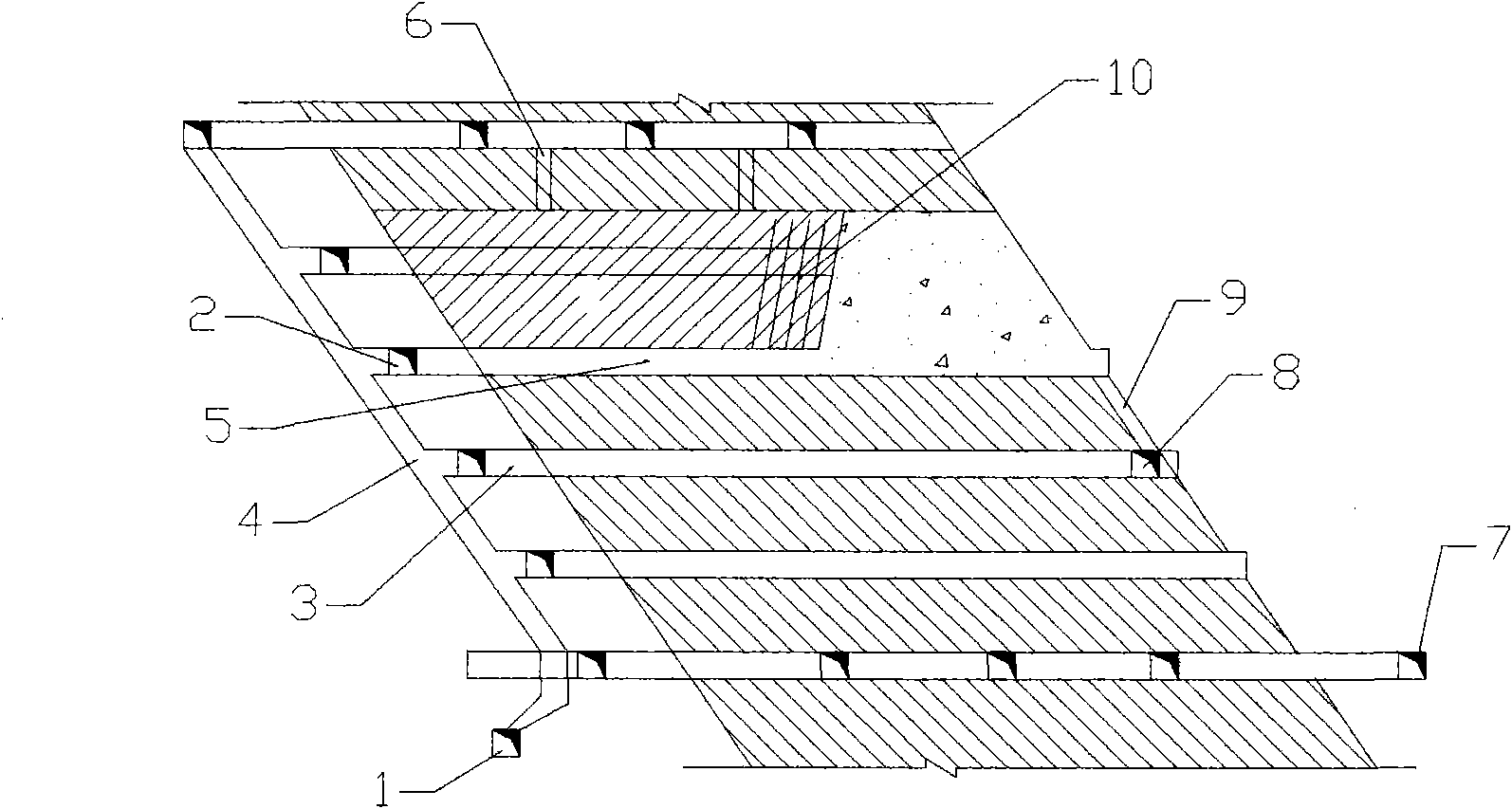

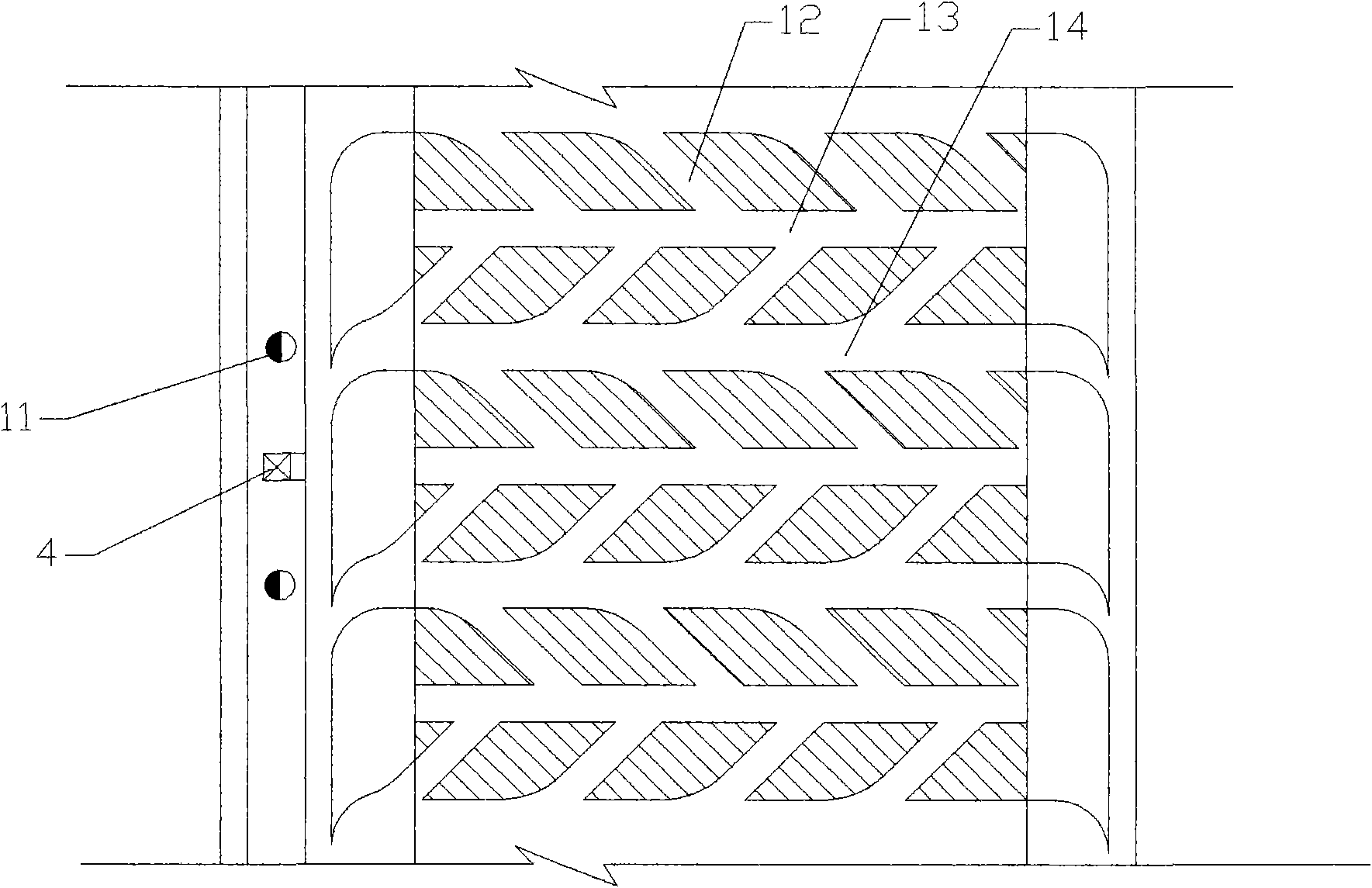

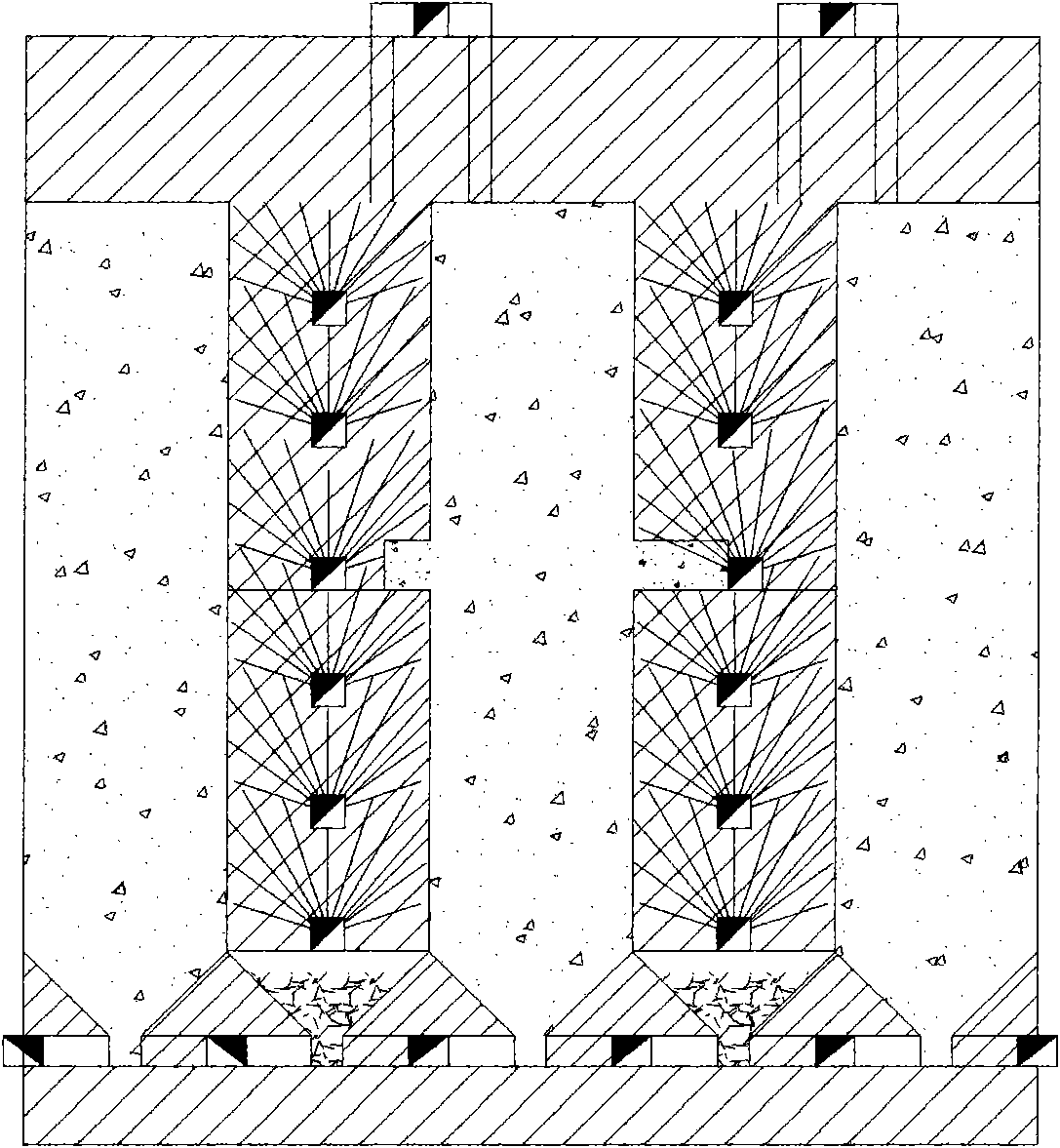

[0013] like figure 1 , figure 2 and image 3 As shown, excavate the footwall transport level roadway (1) at the footwall of the ore body, connect the roadway (3) in sections through the pedestrian ventilation shaft (4), and extend the construction recovery route (5) to reach the ore body hanging wall. Construction of cutting tunnels (8) and cutting patios (9) along the boundary of the hanging wall provides compensation space for ore mining, blasting is carried out sequentially from the hanging wall to the lower wall along the mining route (12), and parallel fan-shaped blastholes (10) are drilled , about 30% of the ore dropped by the explosion is transported out through the segmented roadway (2), and the remaining ore is left in the stope, and finally passes through the cutting ditch (13), the ore-out approach (12), and the ore-out roadway (14) And slip shaft (11) goes out ore.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com