Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12248 results about "Blast furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being "forced" or supplied above atmospheric pressure.

Alkali activated supersulphated binder

The invention describes an activated supersulphated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts, wherein the aluminosilicates are selected from the group consisting of blast furnace slag, clay, marl and industrial by-products such as fly ash with the proviso that the Al2O3 content is greater than 5% by weight, wherein blast furnace slag is present in an amount exceeding 35% by weight and clay, marl and / or fly ash is present in an amount exceeding 5% per weight and wherein cement kiln dust in an amount of from 3 to 10% by weight is added to the mixture as an activator and calcium sulphate is used in an amount exceeding 5% by weight.

Owner:HOLCIM

Activated aluminosilicate binder

An activated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts is disclosed. The aluminosilicates are selected from a group consisting of blast furnace slag, clay, marl and industrial by-products, such as fly ash, and has an Al2O3 content greater than 5% by weight. Blast furnace slag is present in an amount less than 35% by weight, and cement kiln dust, in an amount of from 1 to 20% by weight, is added to the mixture as an activator.

Owner:HOLCIM

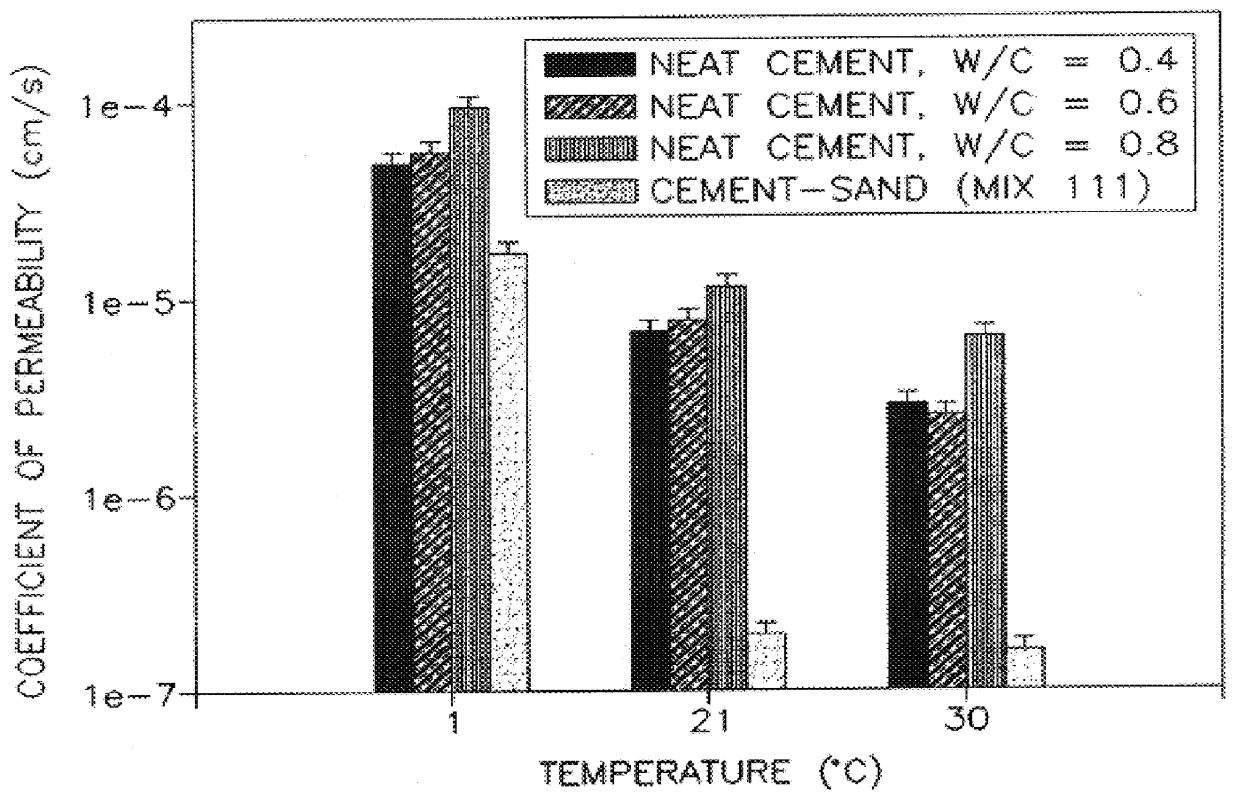

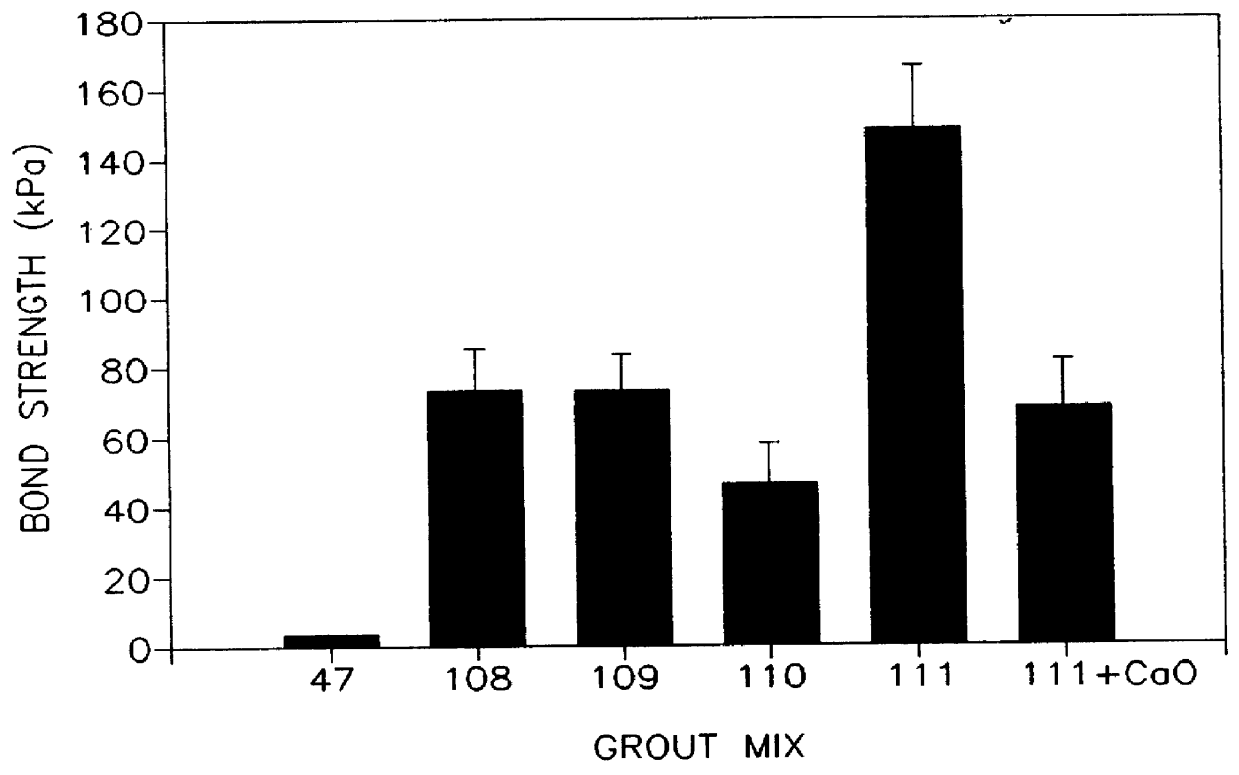

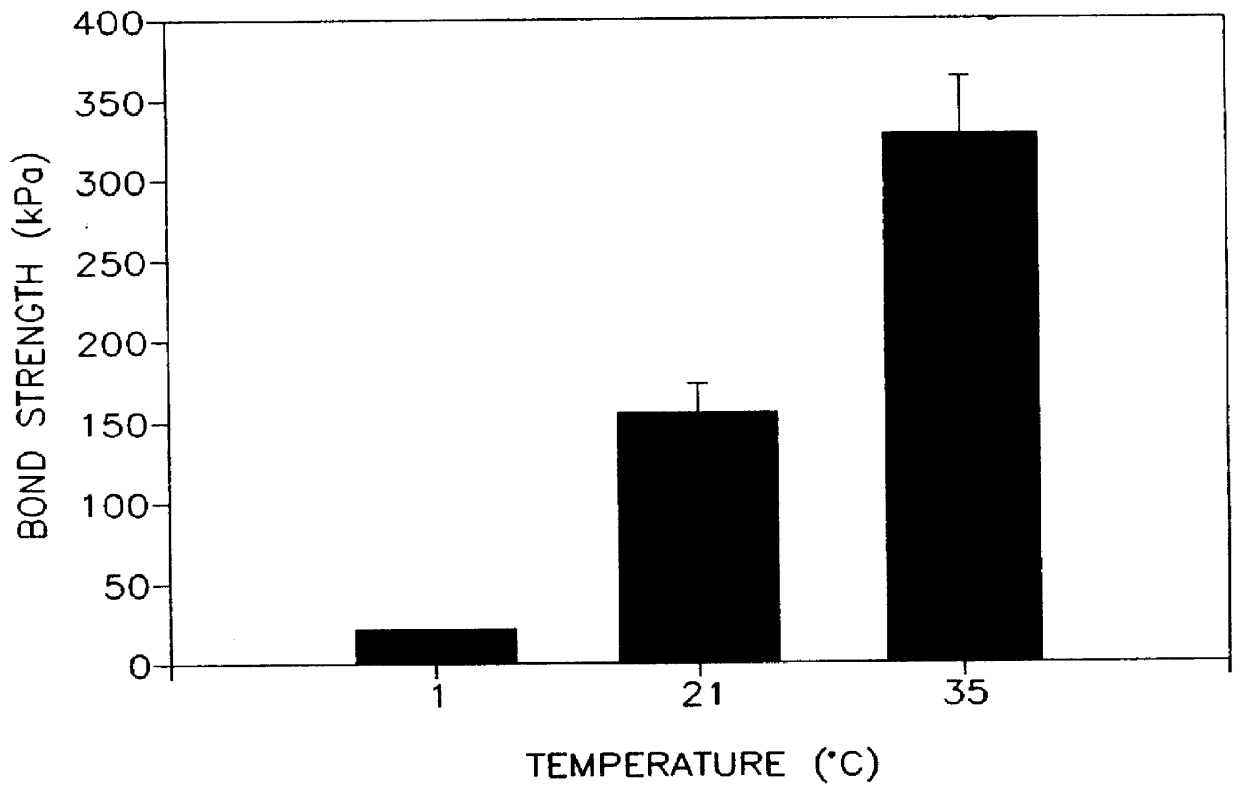

Thermally conductive cementitious grout for geothermal heat pump systems

A thermally conductive cement-sand grout for use with a geothermal heat pump system. The cement sand grout contains cement, silica sand, a superplasticizer, water and optionally bentonite. The present invention also includes a method of filling boreholes used for geothermal heat pump systems with the thermally conductive cement-sand grout. The cement-sand grout has improved thermal conductivity over neat cement and bentonite grouts, which allows shallower bore holes to be used to provide an equivalent heat transfer capacity. In addition, the cement-sand grouts of the present invention also provide improved bond strengths and decreased permeabilities. The cement-sand grouts can also contain blast furnace slag, fly ash, a thermoplastic air entraining agent, latex, a shrinkage reducing admixture, calcium oxide and combinations thereof.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

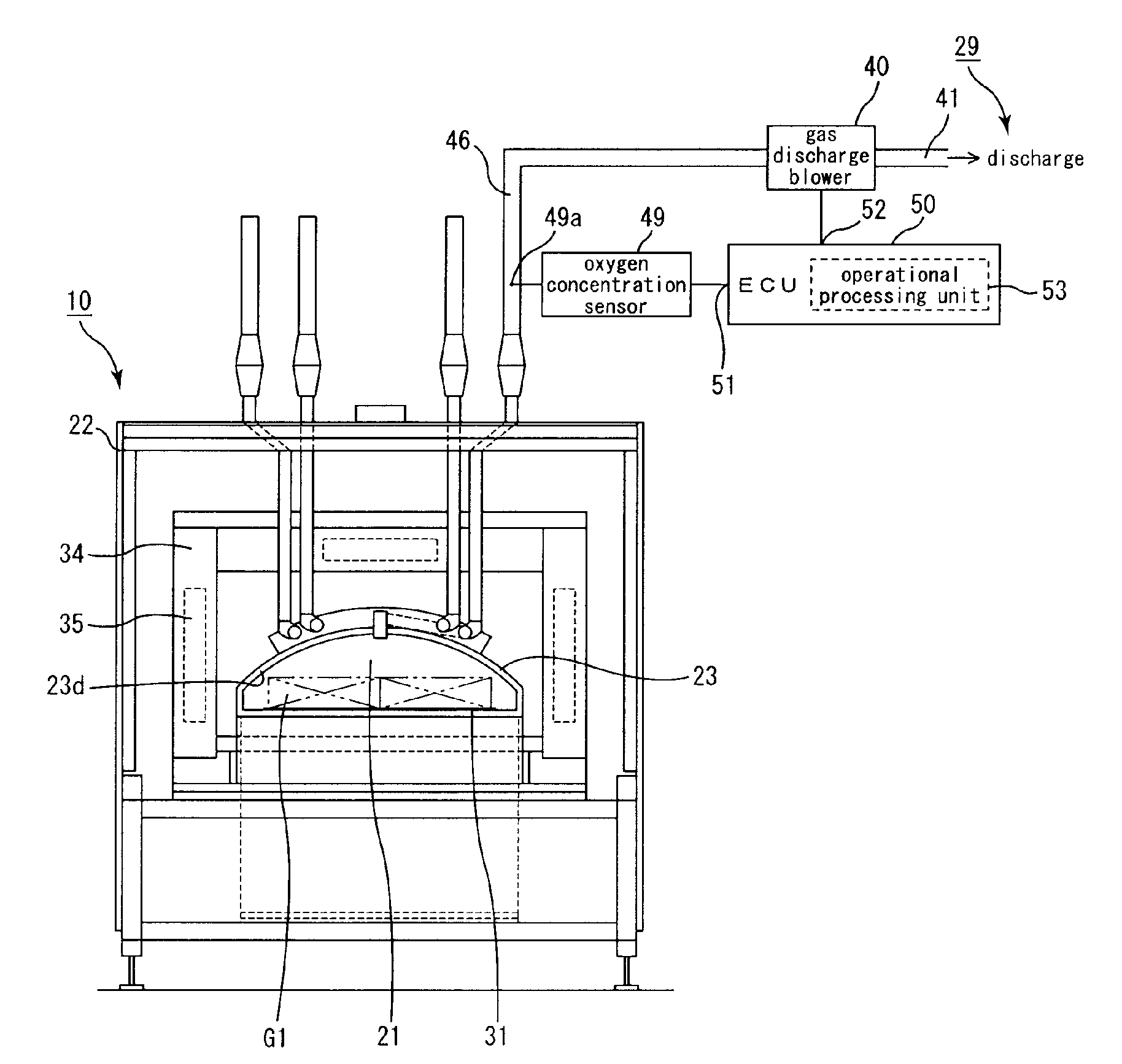

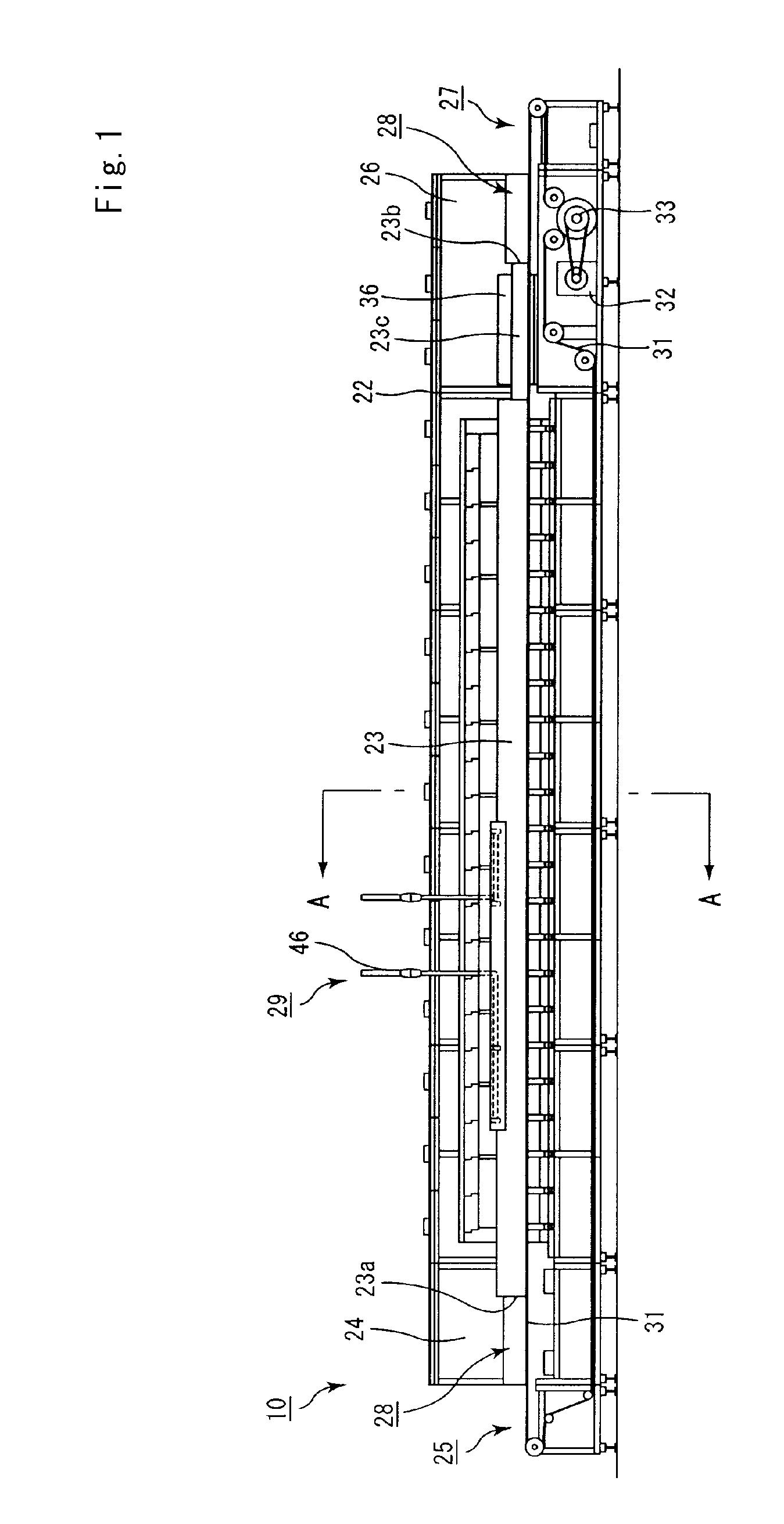

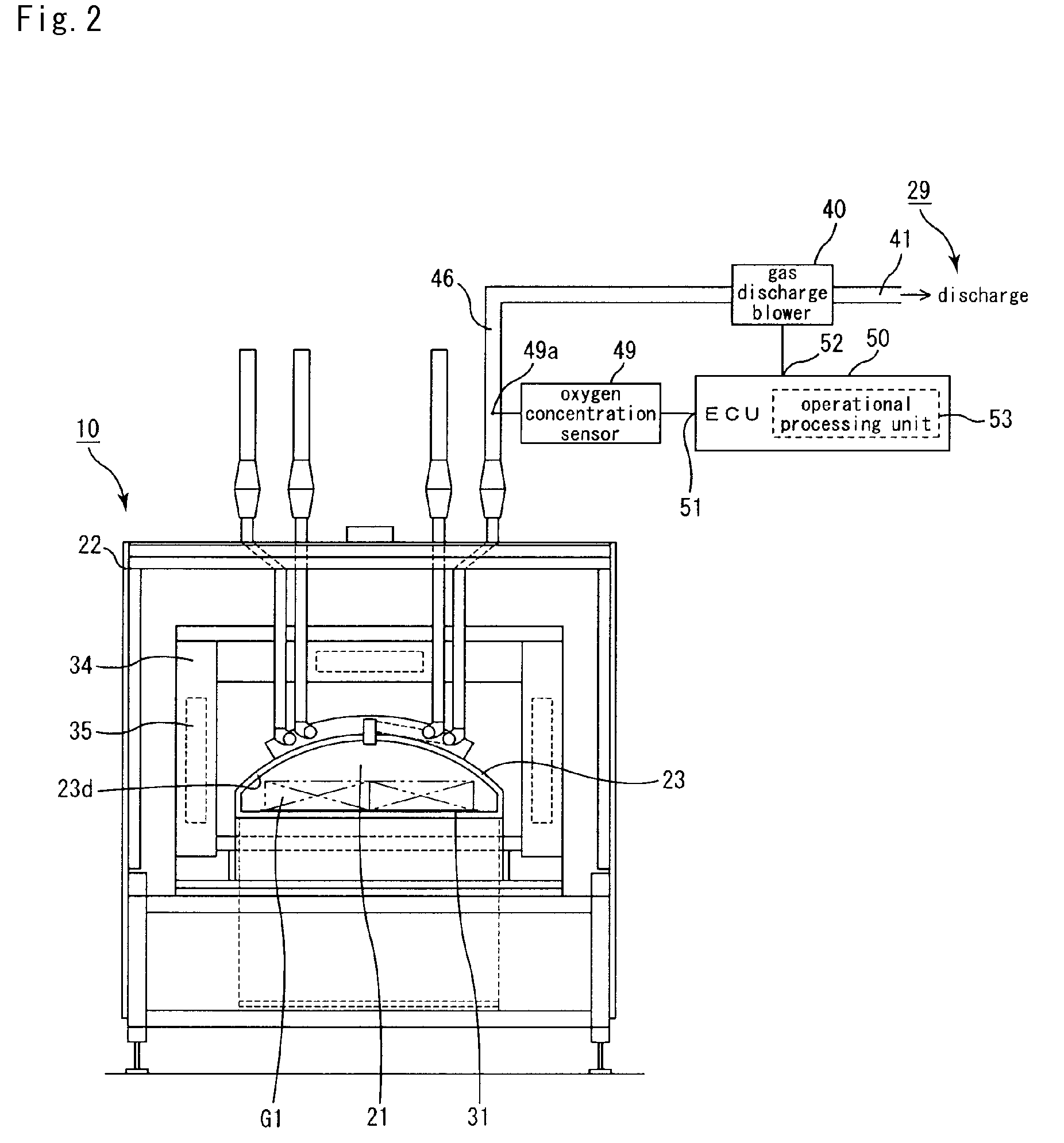

Heating furnace and method for manufacturing honeycomb structure

InactiveUS20080197544A1Increase temperatureMaintainance of heating chambersCeramic shaping apparatusMeasurement deviceHeating furnace

A heating furnace for calcining an object to be heated. The heating furnace includes a wall defining a furnace space and configured to receive the object in the furnace space, and a heating device configured to raise a temperature within the furnace space. The heating furnace also includes an oxygen supply channel configured to introduce gases containing oxygen into the furnace space. The oxygen supply channel is formed as an opening in a part of the wall surrounding the furnace space. The heating furnace further includes a gas discharge channel fluidly connected to the furnace space and configured to discharge gases in the furnace space to an outside of the furnace space, and a measurement device installed in the gas discharge channel and configured to measure properties of the gases passing through the gas discharge channel.

Owner:IBIDEN CO LTD

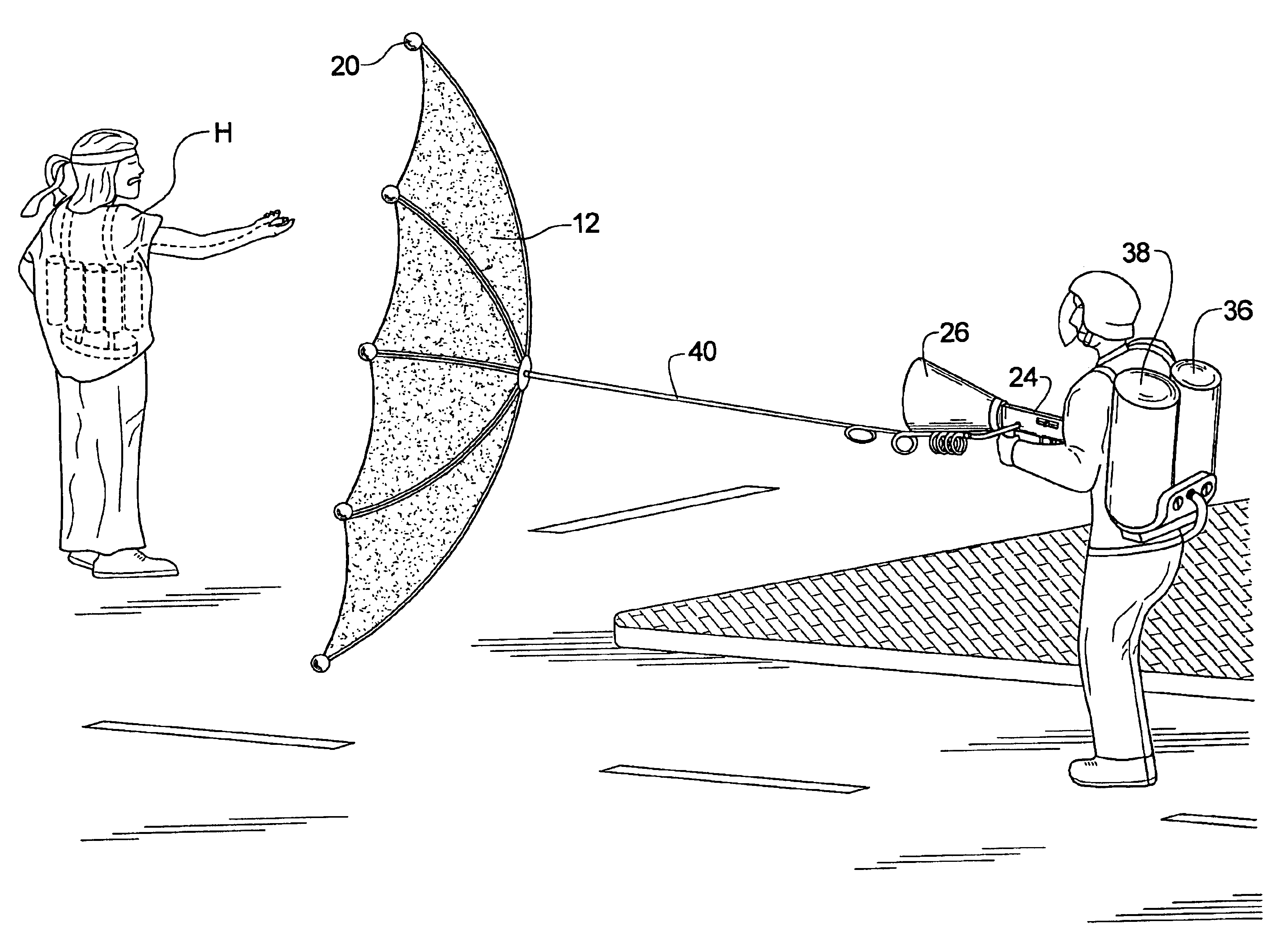

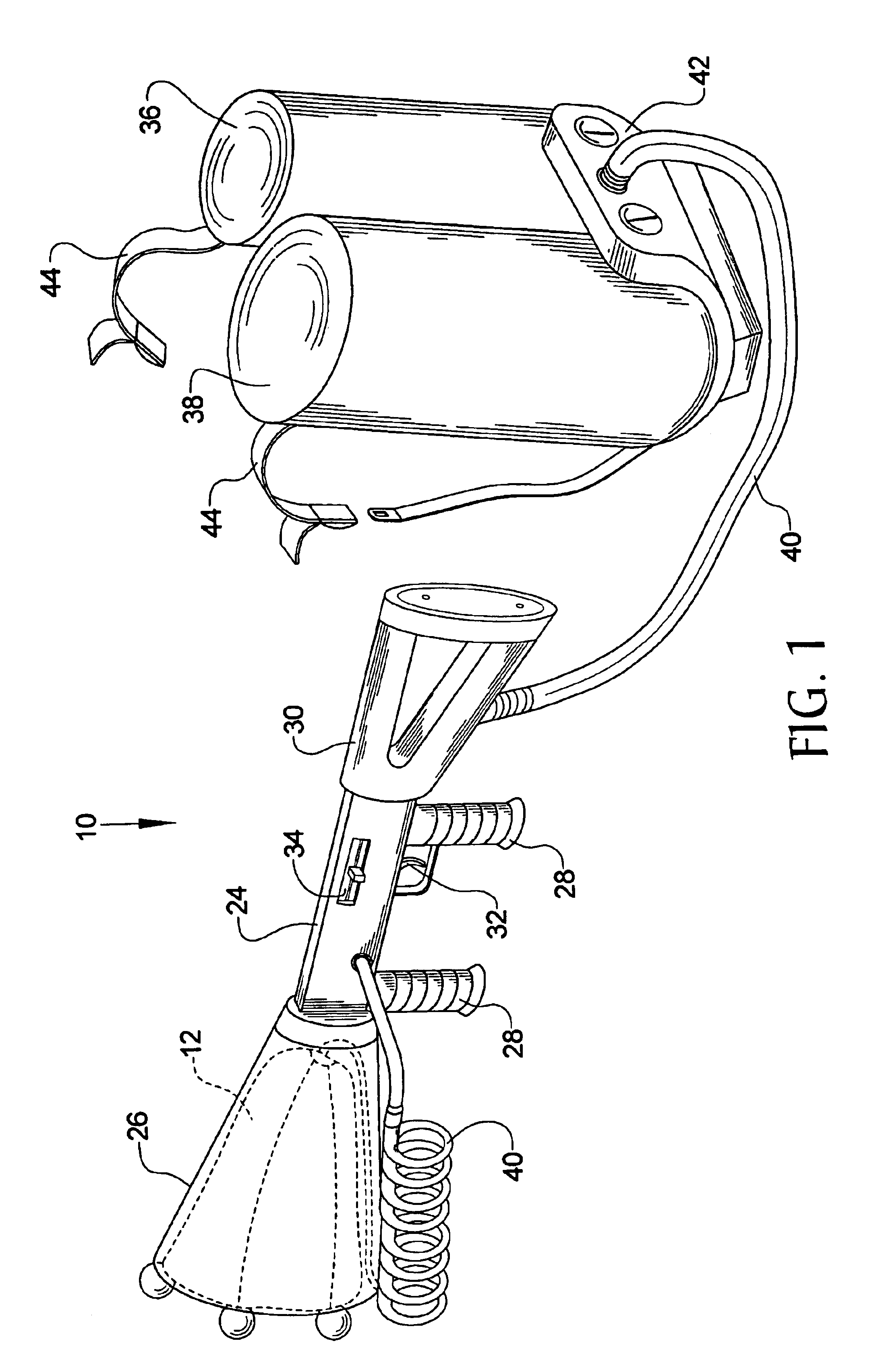

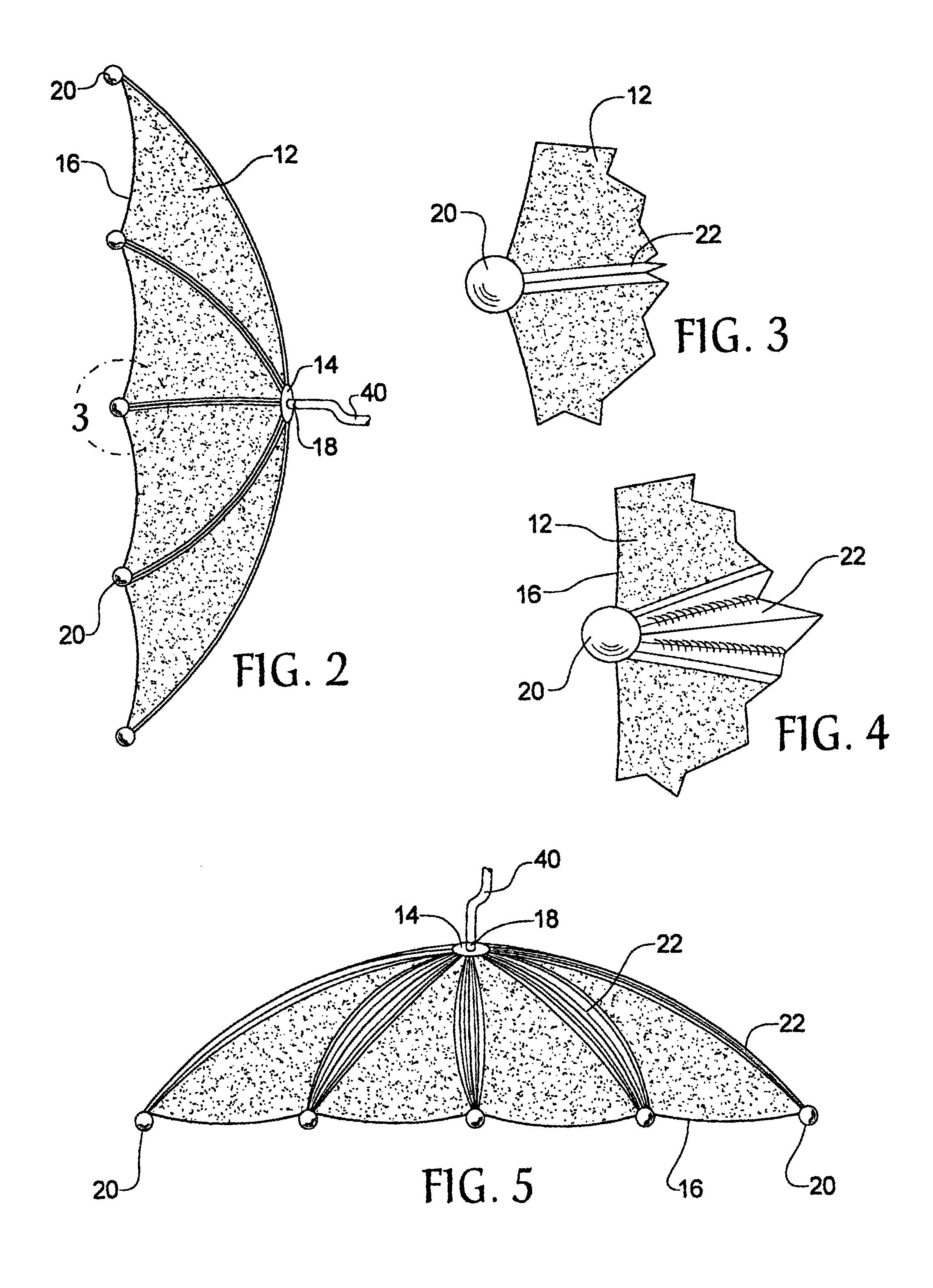

Explosion containment net

InactiveUS6854374B1Minimize and contain explosive blastPrevent serious injuryAmmunition projectilesTraining ammunitionHigh densityEngineering

A net is made from an explosive resistant material such as KEVLAR and is thrown over an explosive-laden device such that the net helps contain the blast force of the explosive-laden device. The net also has a nozzle that is fluid connected to a fire suppressant agent as well as a high density foam, each of which are discharged through the nozzle once the net is thrown over the explosive-laden device, the fire suppressant agent and the high density foam each helping to minimize the blast force of the explosive-laden device. The net can be thrown manually or can be fired from a gun that uses either pneumatic force or a firing cartridge to propel the net at its target.

Owner:BREAZEALE O ALAN

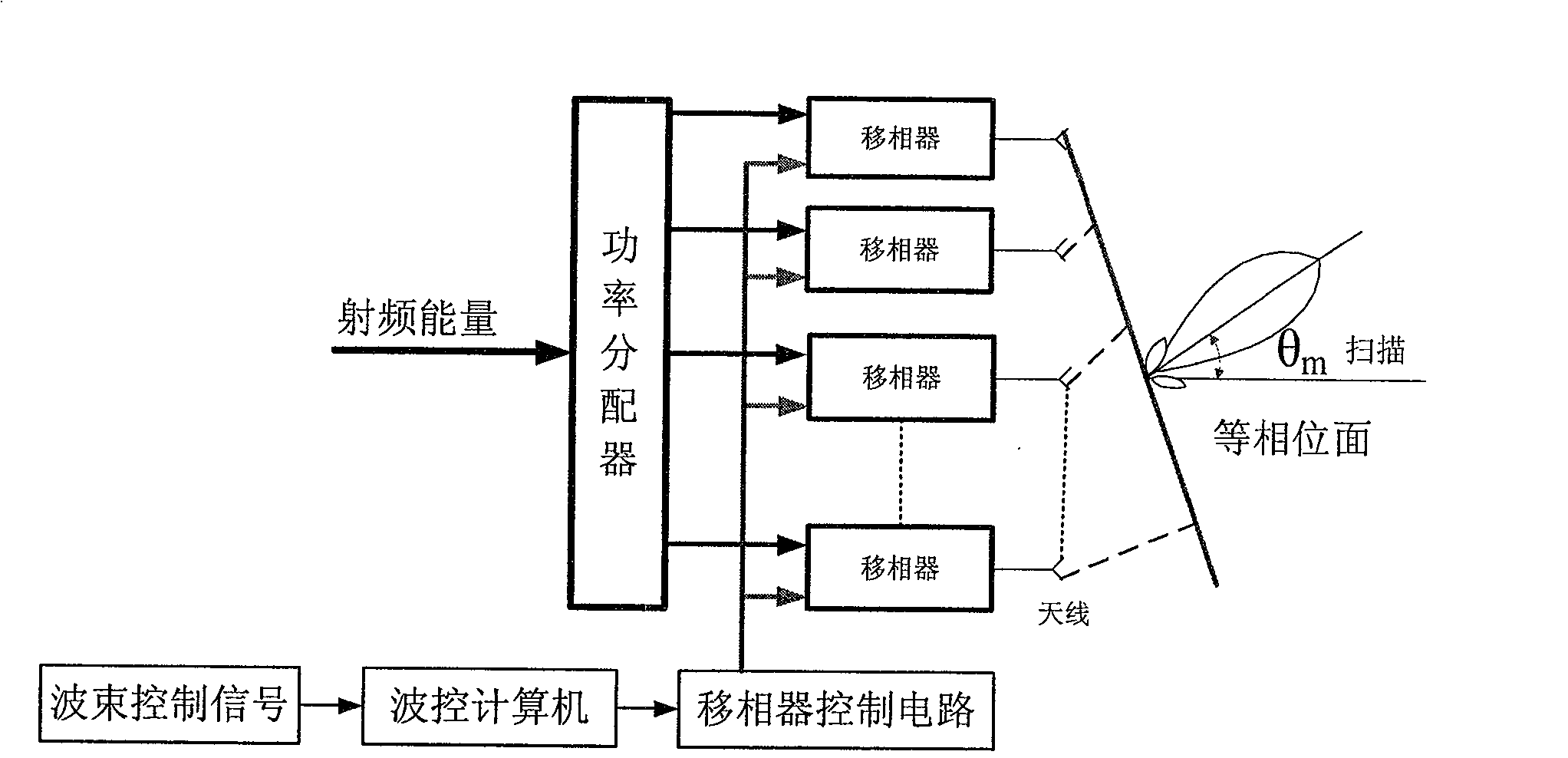

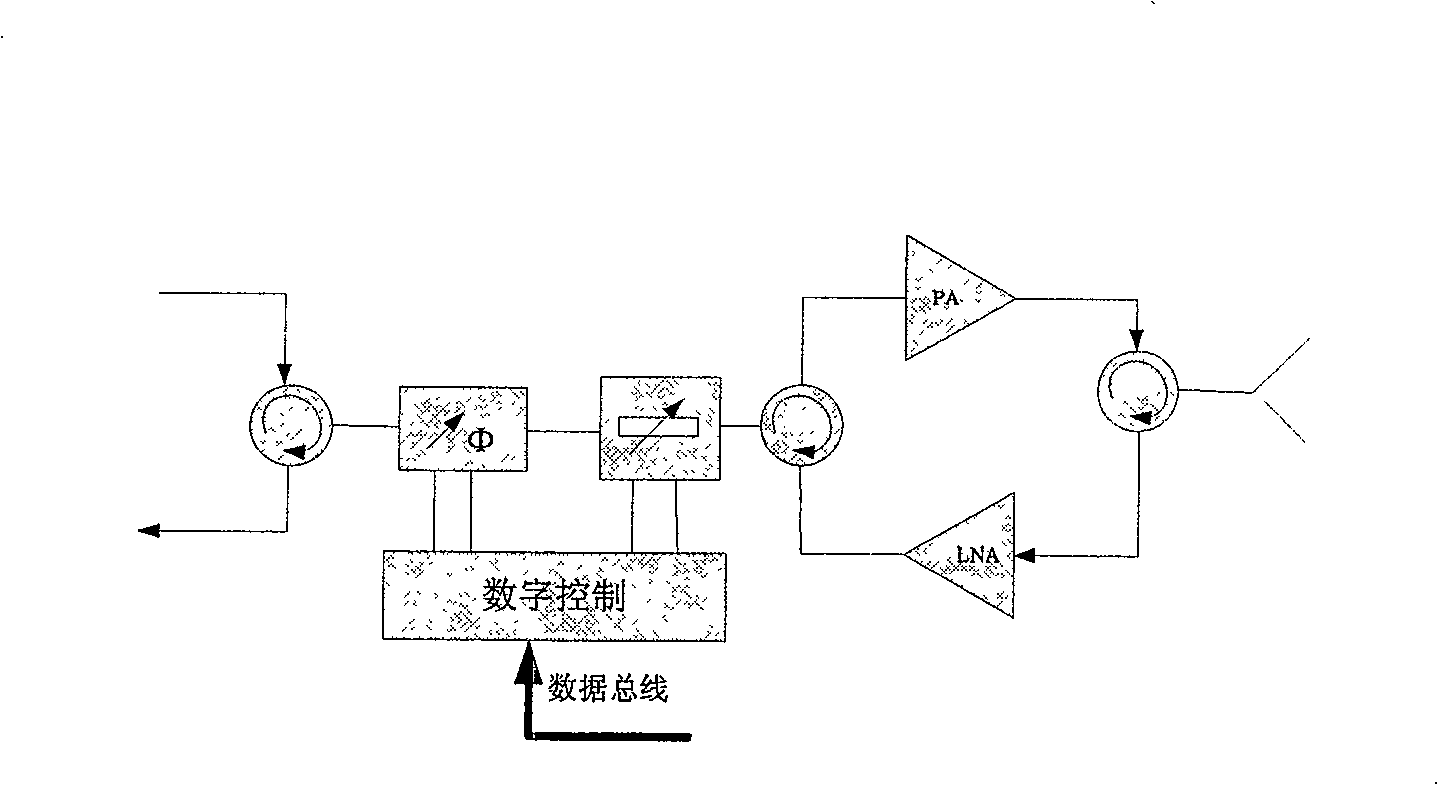

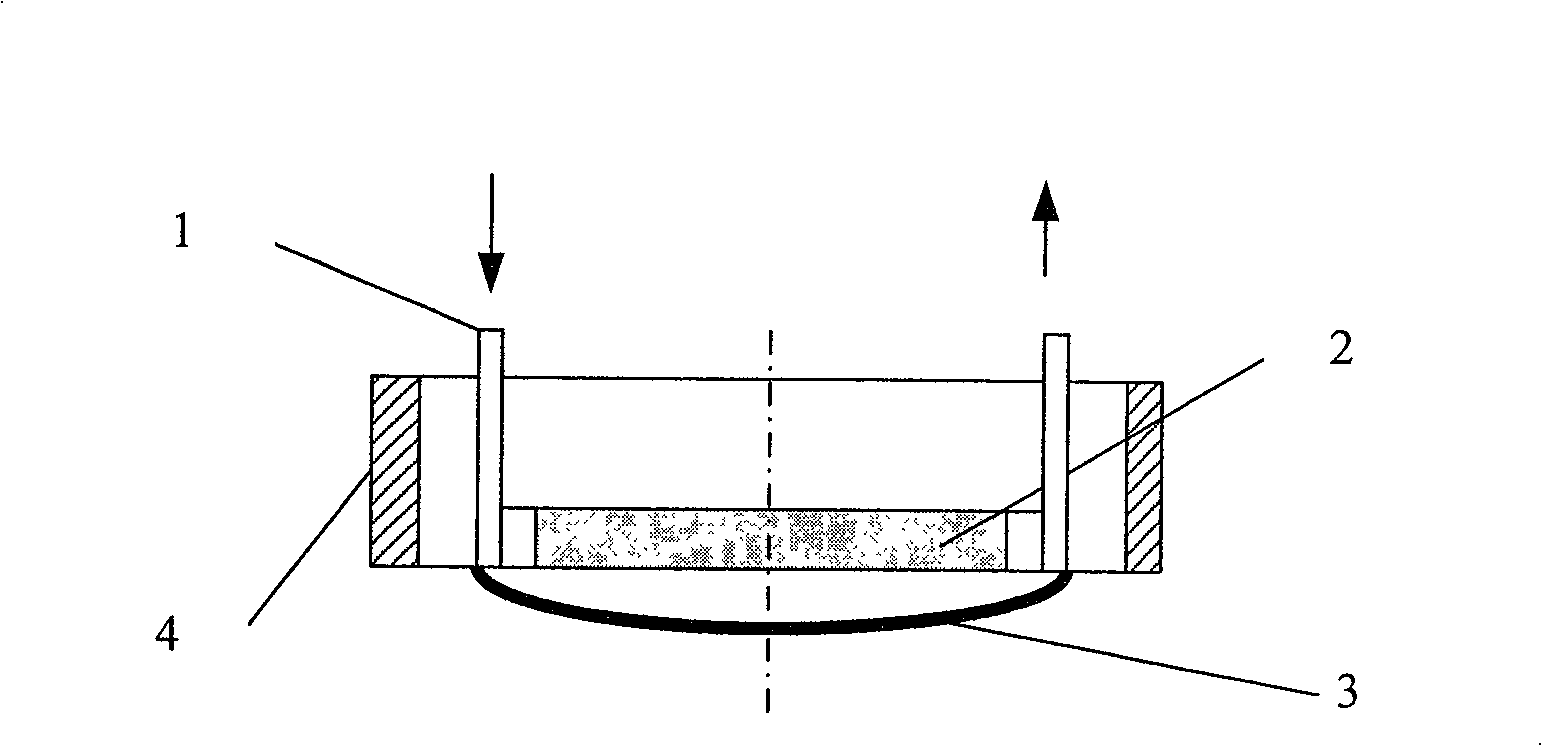

High furnace burden face measurement and control system based on industrial phased array radar

InactiveCN101492750ASolve bottlenecksFast scanningMachines/enginesLevel indicators3d imageControl system

A system for measuring and controlling blast furnace level based on an industrial phased array radar relates to the industrial phased array radar used in the fields of metallurgy, chemical engineering, cement building materials. The system includes an industrial phased array radar body, a radar electromagnetic shield and an interlock cloth control system; wherein the industrial phased array radar body is in charge of obtaining level information; the electromagnetic shield is in charge of protecting the industrial phased array radar body in a high-temperature and high-pressure dust atmosphere; and the interlock cloth control system is in charge of carrying out analysis and judgment and charging task according to the level height data transmitted by the interlock cloth control system to control the final level shape to be in a predetermined shape. The inventive system can be applied in severe atmosphere of darkness, high temperature and dustiness to precisely describe the height information of each solid level point and obtain the kind and time of charging at different moments by the interlock with PLC or DCS; so that the shapes of a plurality of level layers and 3D images of solid levels are obtained.

Owner:UNIV OF SCI & TECH BEIJING

Refractory spray coating with high steel fiber content and spraying method thereof

The invention discloses a refractory spray coating with high steel fiber content and a spraying method thereof, which belong to the technical field of refractory materials. The method comprises the following step of: 1, pneumatically conveying the refractory spray coating to a nozzle, adding water onto the nozzle, and spraying and bonding the coating on a wall; or 2, adding water or a liquid bonding agent into the refractory spray coating, stirring the mixture into mortar, conveying the mortar to the nozzle by a pumping method, spraying the mortar out of the nozzle by using high-pressure air,and bonding the mortar on the wall. The refractory spray coating comprises the following ingredients in part by weight: 30 to 80 parts of refractory aggregate, 30 to 50 parts of refractory powder, 5 to 20 parts of bonding agent, 0.5 to 15 parts of additive and 3 to 80 parts of steel fiber. The invention has the advantages that: by spraying the refractory spray coating on a blast furnace cooling wall, spraying on a blast furnace throat steel brick, spraying on various refractory linings with cold faces and hot faces and repairing, the service life of the refractory material for the inner wall of a blast furnace can be greatly prolonged, and the effects of protecting the environment, saving energy and reducing consumption are achieved.

Owner:北京联合荣大工程材料股份有限公司

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

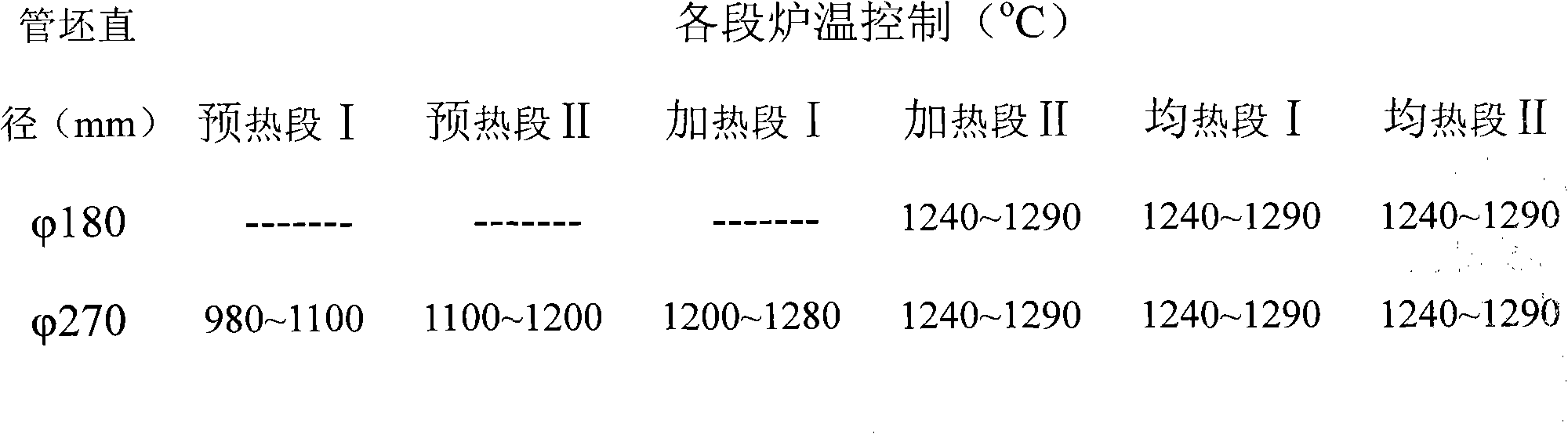

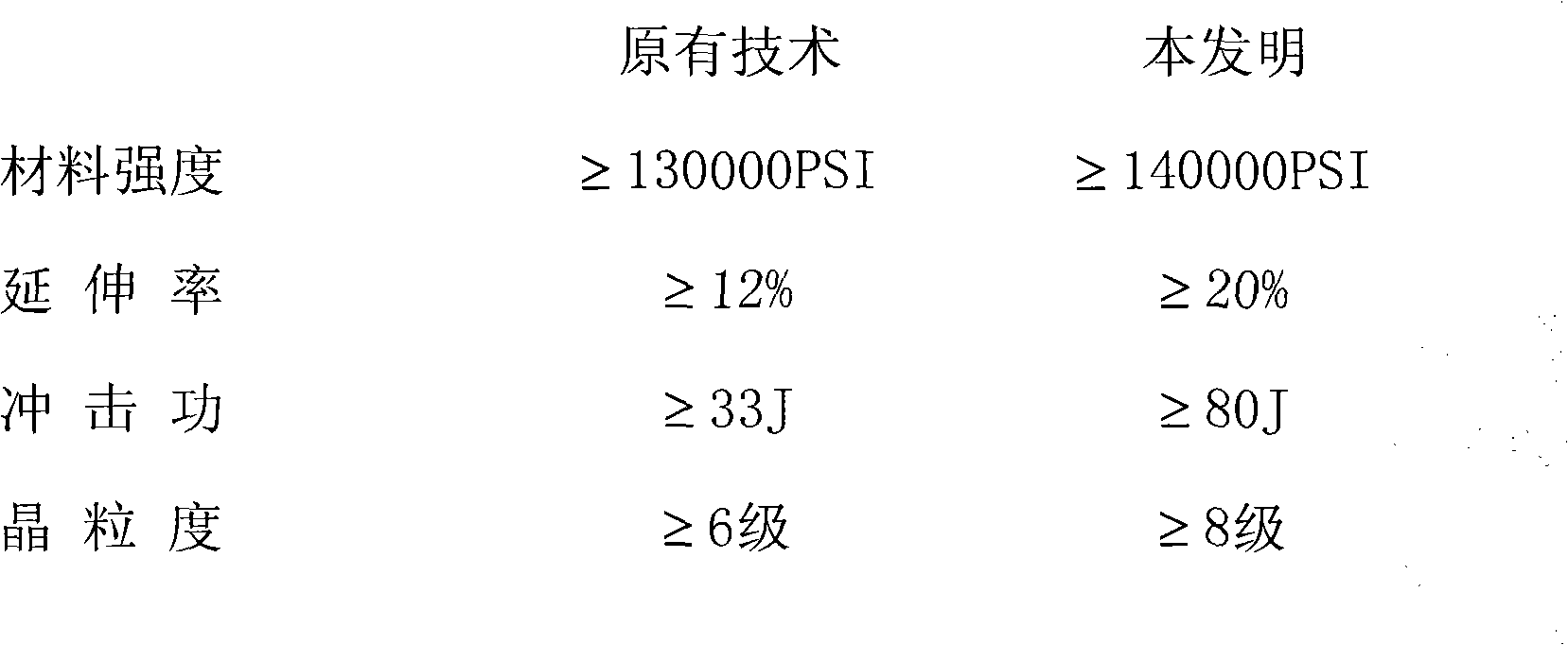

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-tenacity crack-control impervious fiber concrete

ActiveCN101665342AEvenly dispersedFully exerted tensile strengthSolid waste managementSlagPolyvinyl alcohol

The invention relates to a fiber concrete material belonging to the field of building materials. The fiber concrete material mainly contains cement, active mineral blending materials, aggregates, fibers and water and is characterized in that the active mineral blending materials adopt coal ash, siliceous dust, pelletization blast furnace slag and metakaolin; the fibers adopt polyvinyl alcohol fibers, polyethylene fibers and aromatic polyamide fibers; the maximum particle size of the aggregates is smaller than or equal to 0.5mm, and the ratio of the weight of the aggregates to the total weightof the cement and the active mineral blending materials is 1-70 percent; and the blending volume of the fibers accounts for 1.5-2.5 percent of the total volume of fiber concrete. The fiber concrete material has the advantages of high tenacity, higher deformation capability, tensile strength and bending strength, limit tension strain of 1.8-7.5 percent, tensile strength of 4-10MPa and bending strength of 10-20MPa, can control the width of a crack lower than 0.1mm, effectively enhance the integrity and the shock resistance of a structure and ensure the permeability resistance and the durabilityof the structure.

Owner:徐世烺

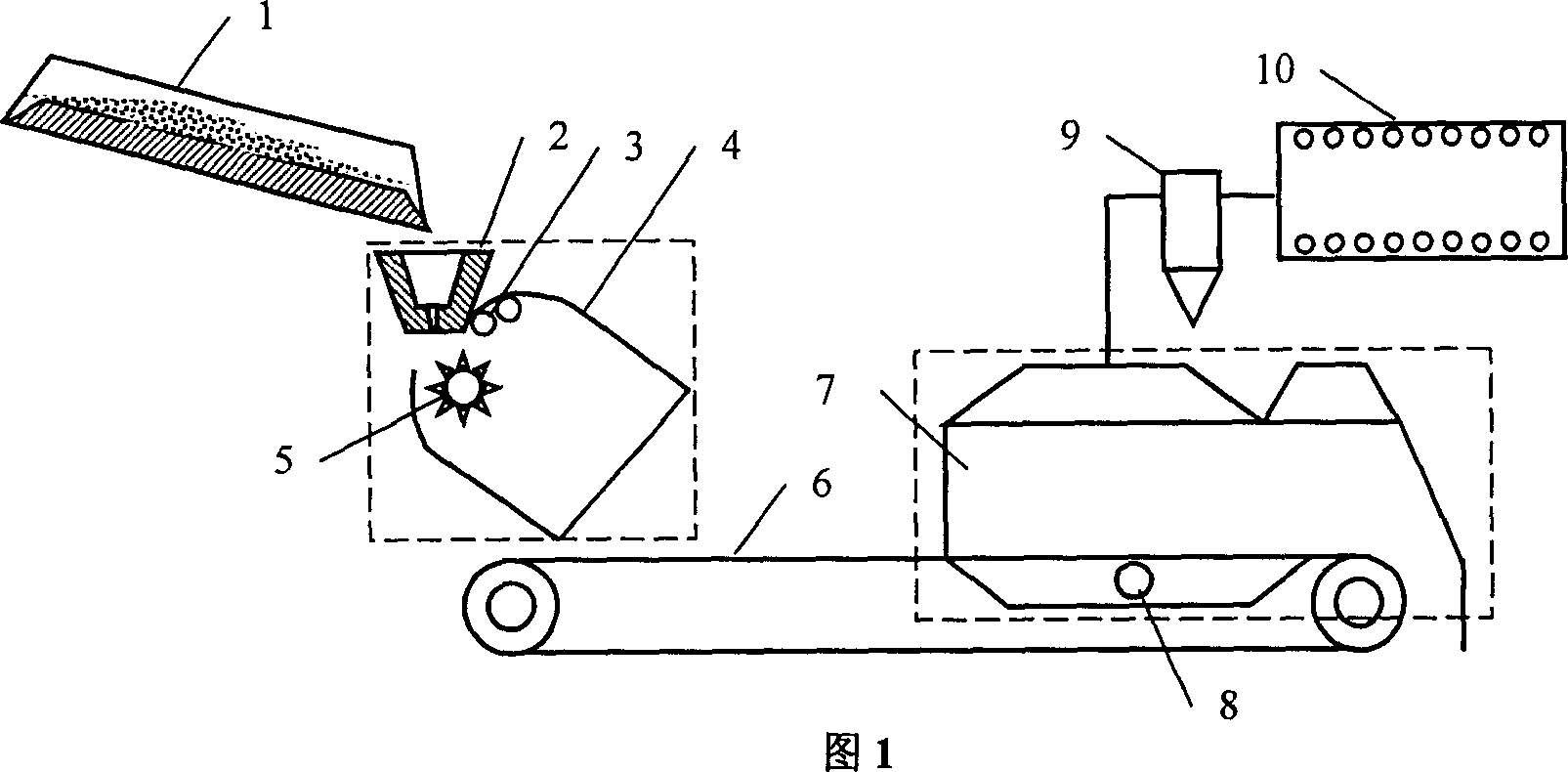

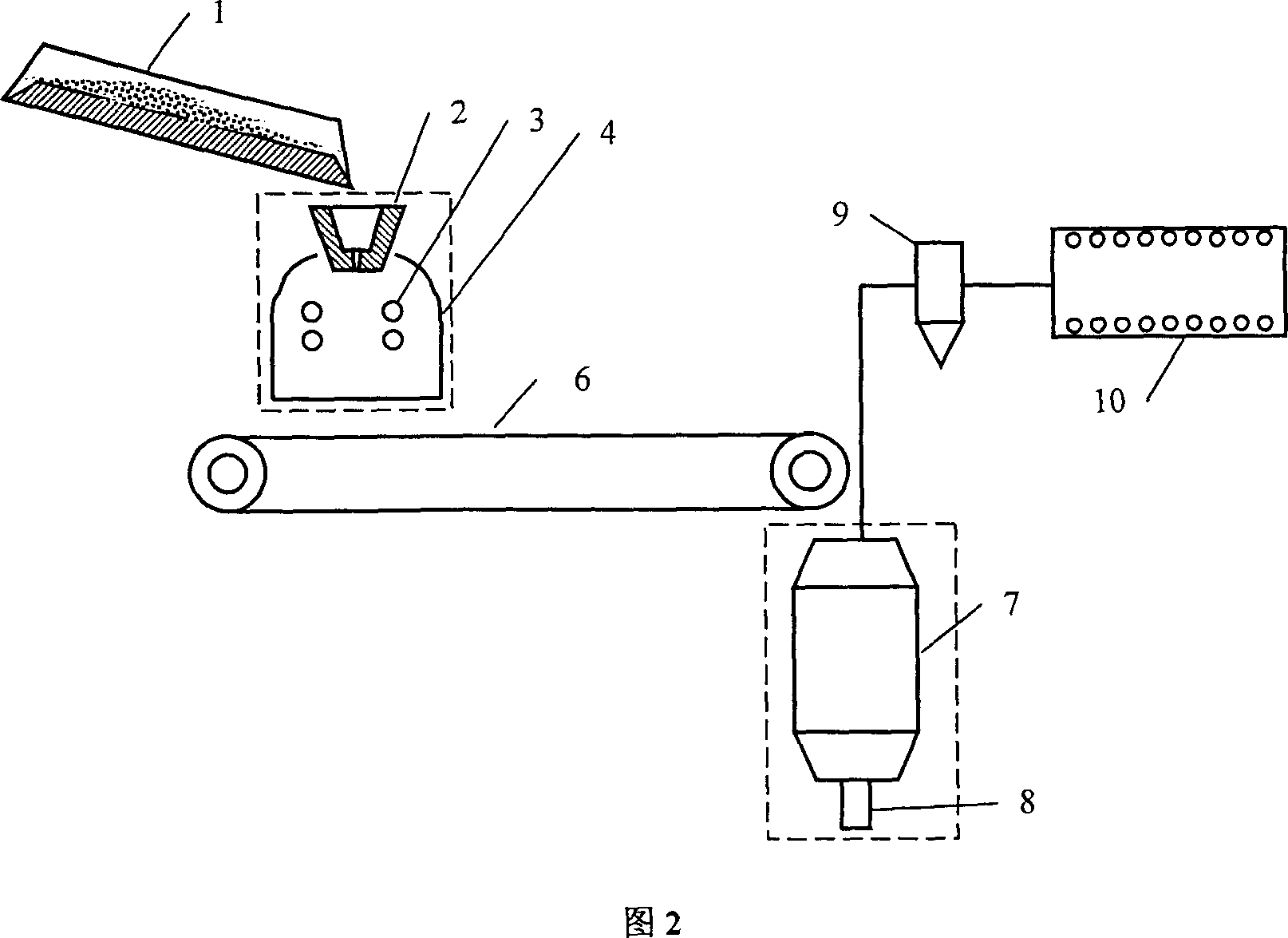

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

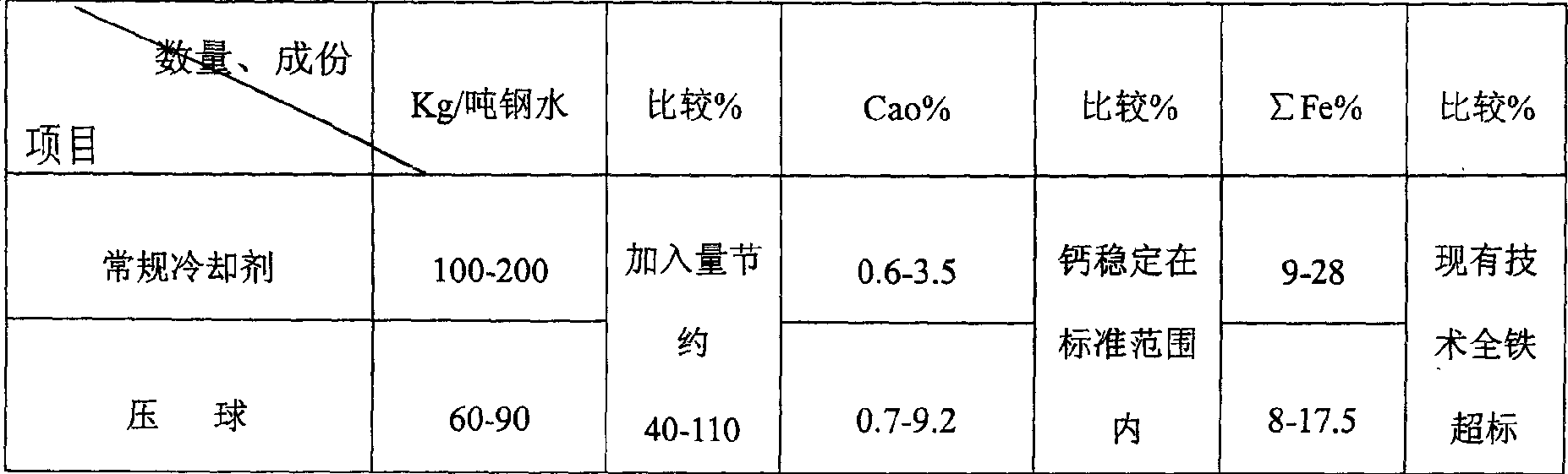

Molten iron vanadium-extracting calcium-controlling coolant and process therefor

The invention relates iron melt improving vanadium content and controlling calcium content cooling agent and the technology, specially relates the cooling agent of adjusting the proportion of cooling agent to stabilize calcium content in vanadium slag and the technology. The technology comprises the 56-60wt% iron scale, 30-40wt% iron concentrate powder containing vanadium, and 5-10wt% anchoring agent. The method stabilizes the calcium content and iron content in vanadium slag, and effectively solves the problems of great fluctuation of vanadium slag composition and superstandard calcium and iron. By controlling the thermoregulation material to meet the requirements of the improving vanadium temperature and calcium oxide content, the method improves the vanadium slag grade and extraction rate. The invention possesses the following characteristics: 1 shortening the converting time; 2 improving the vanadium slag grade and extraction rate, and stabilizing the calcium oxide content; 3 reducing the iron loss.

Owner:HEBEI LUANHE IND GROUP

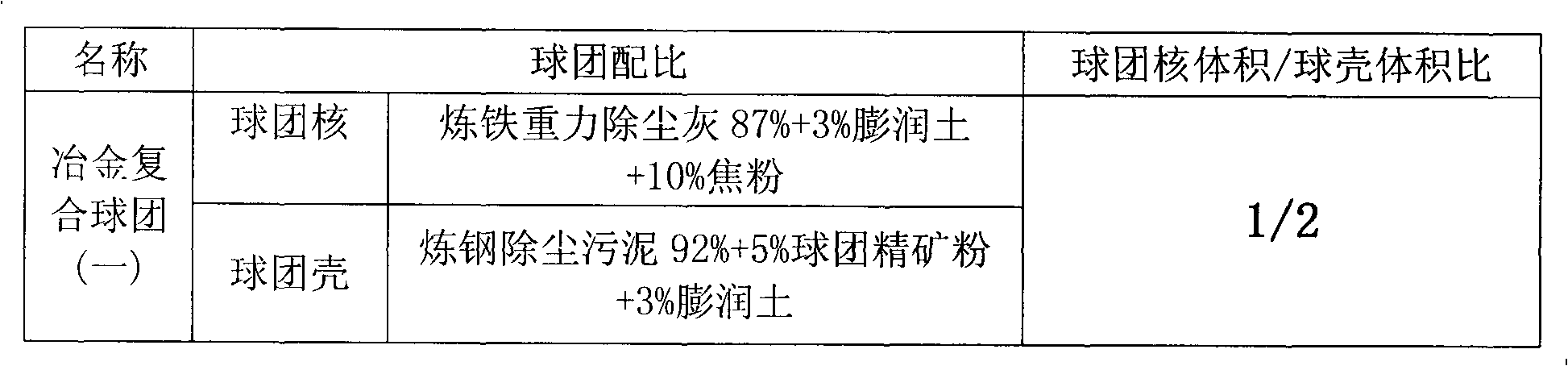

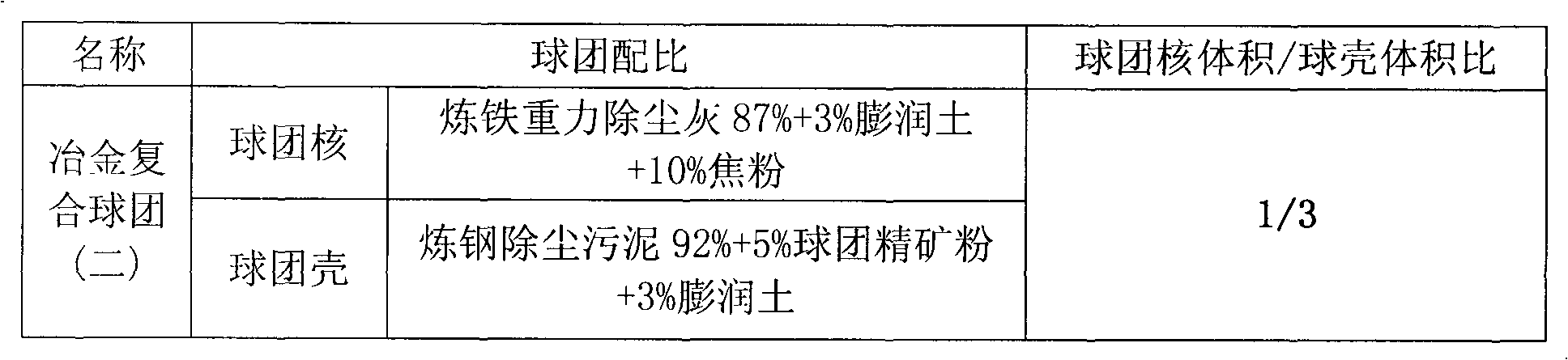

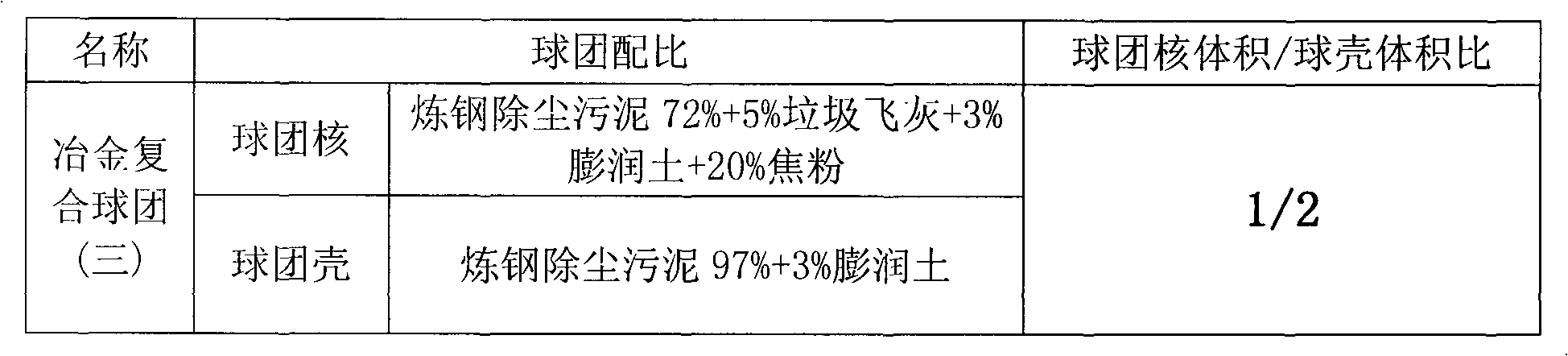

Metallurgical composite pelletizing prepared through twice pelletizing method, as well as preparation method and application thereof

ActiveCN101613800AImprove iron gradeIncrease valueBlast furnace detailsManufacturing convertersSocial benefitsAdhesive

The invention provides a metallurgical composite pelletizing prepared through a twice pelletizing method, as well as a preparation method and an application thereof. The pelletizing is provided with a pelletizing shell formed by a central pelletizing core and a pellet material coating the outside of the pelletizing core. The internal pelletizing core of the formed pelletizing is in a reducing atmosphere, the outside of the formed pelletizing is in an oxidizing atmosphere, and the metallurgical composite pelletizing undergoing twice pelletizing satisfies the metallurgical requirements. The pelletizing core takes an iron-containing material and reducing coal dust or coke powder as raw materials in which adhesive and waste fly dust are added, and is obtained by means of disk pelletization or pressure pelletization. The pelletizing shell takes the iron-containing material and the pelletizing core as raw materials in which the adhesive is added, and is obtained by means of disk pelletization and taking the pelletizing core as the center of the sphere. Various metallurgical performance indexes of the composite pelletizing are highly better than normal pellets. The composite pelletizing not only realizes the harmlessness and the recycling of the waste fly ash, but also can greatly improve the technical and economic indexes of iron making blast furnaces. In addition, the composite pelletizing not only achieves such social benefits as energy conservation, emission reduction, environment protection and environment pollution treatment, but also can create considerable economic benefits.

Owner:CHONGQING ANGRUIYUE SCI & TECH

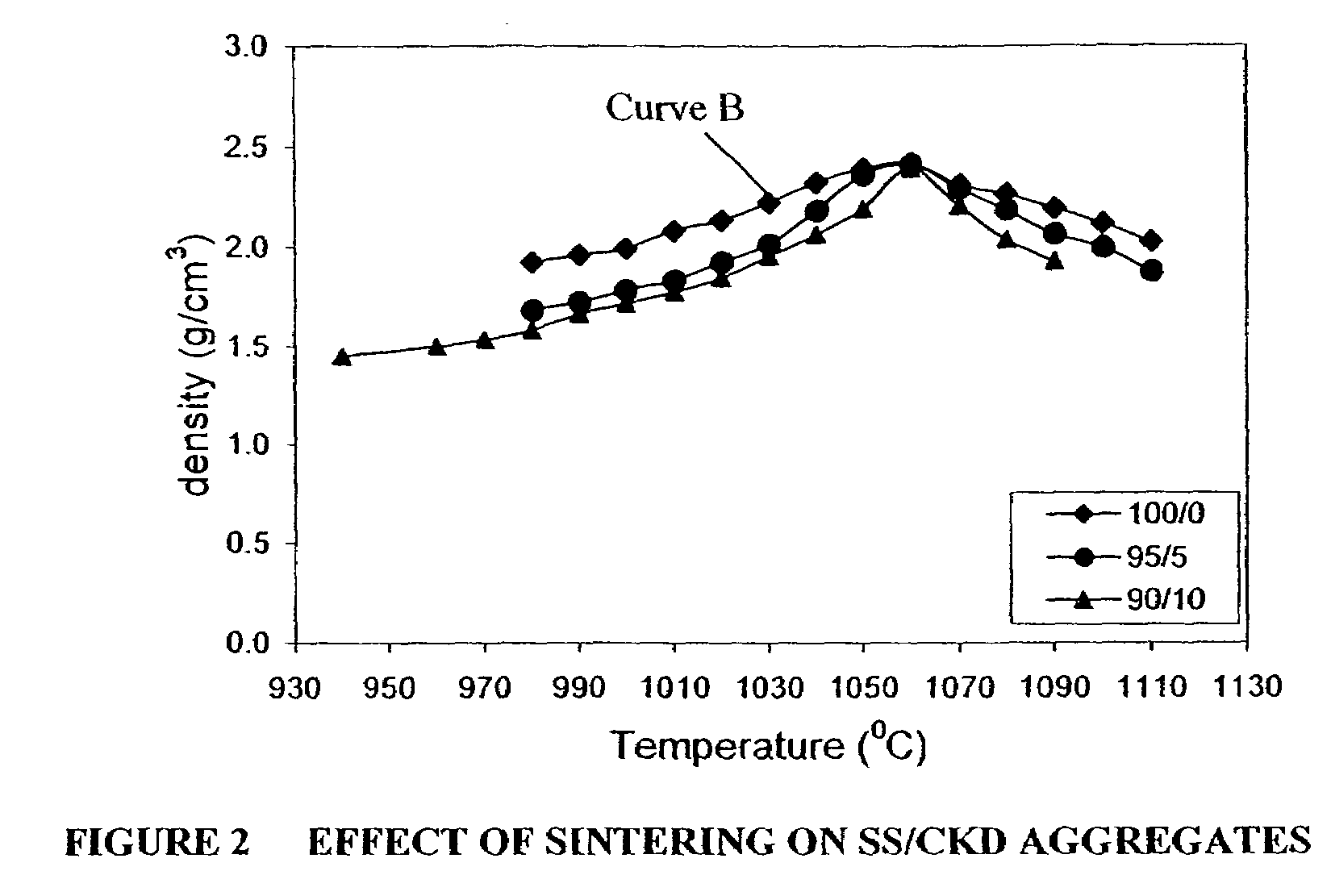

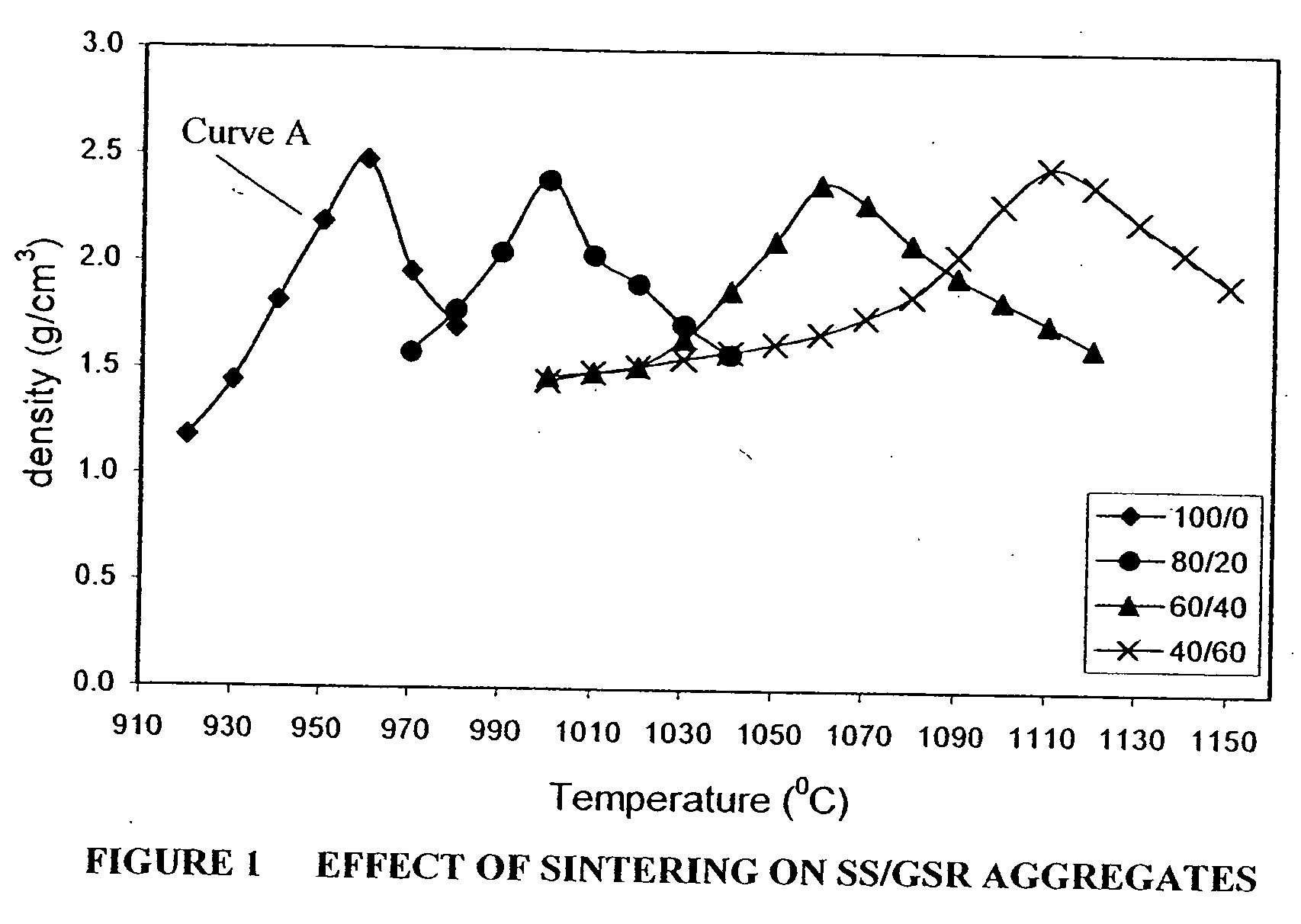

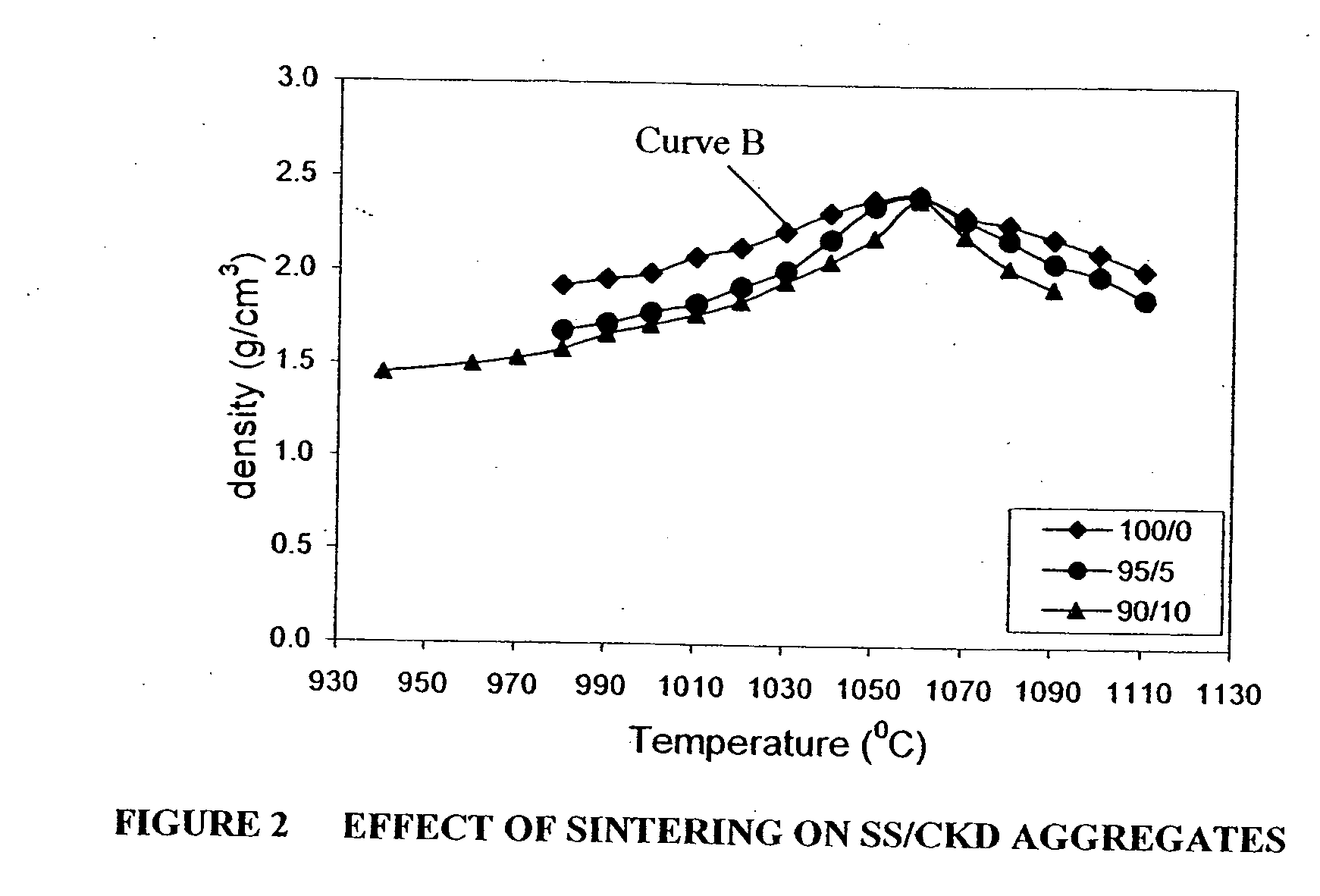

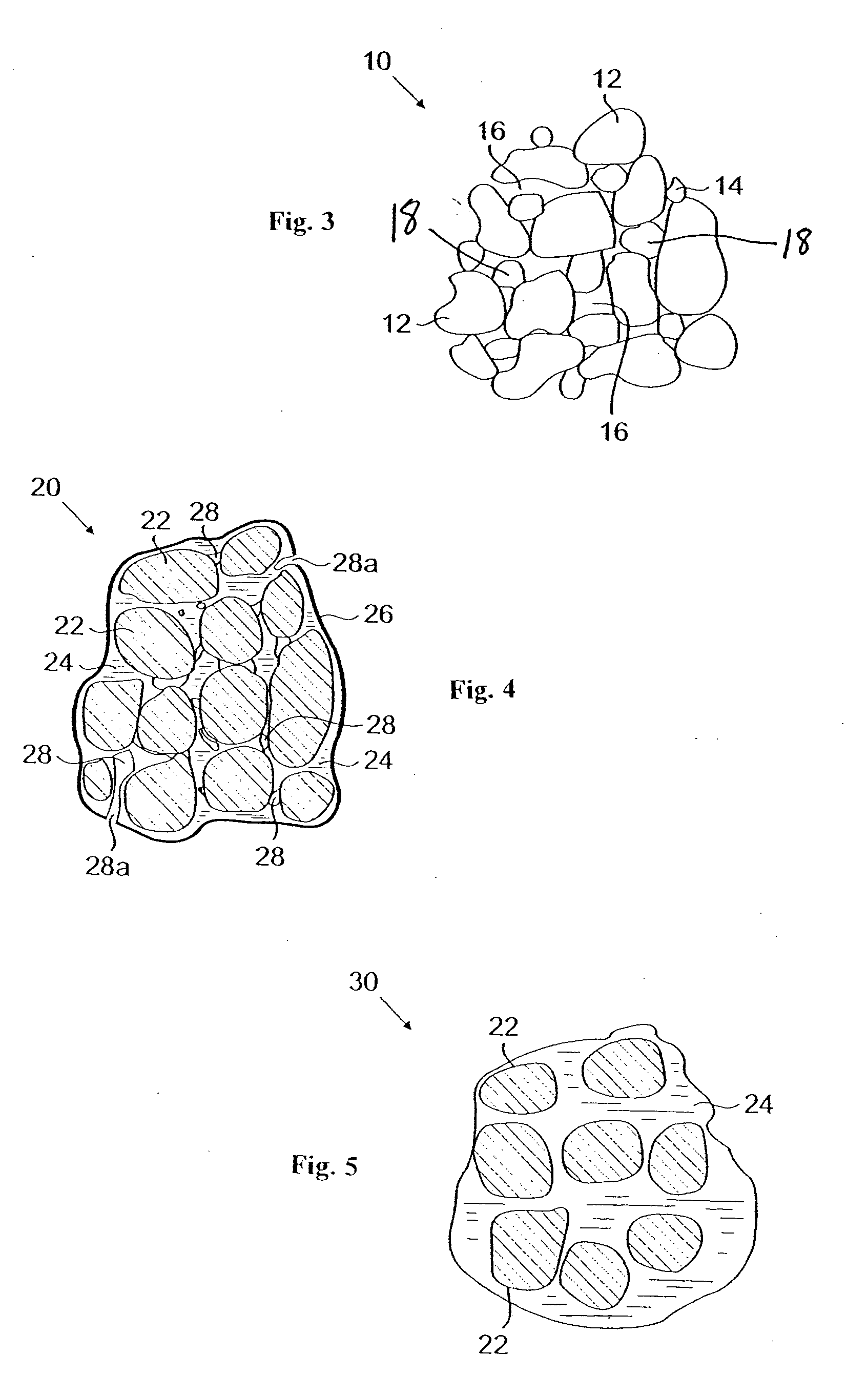

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

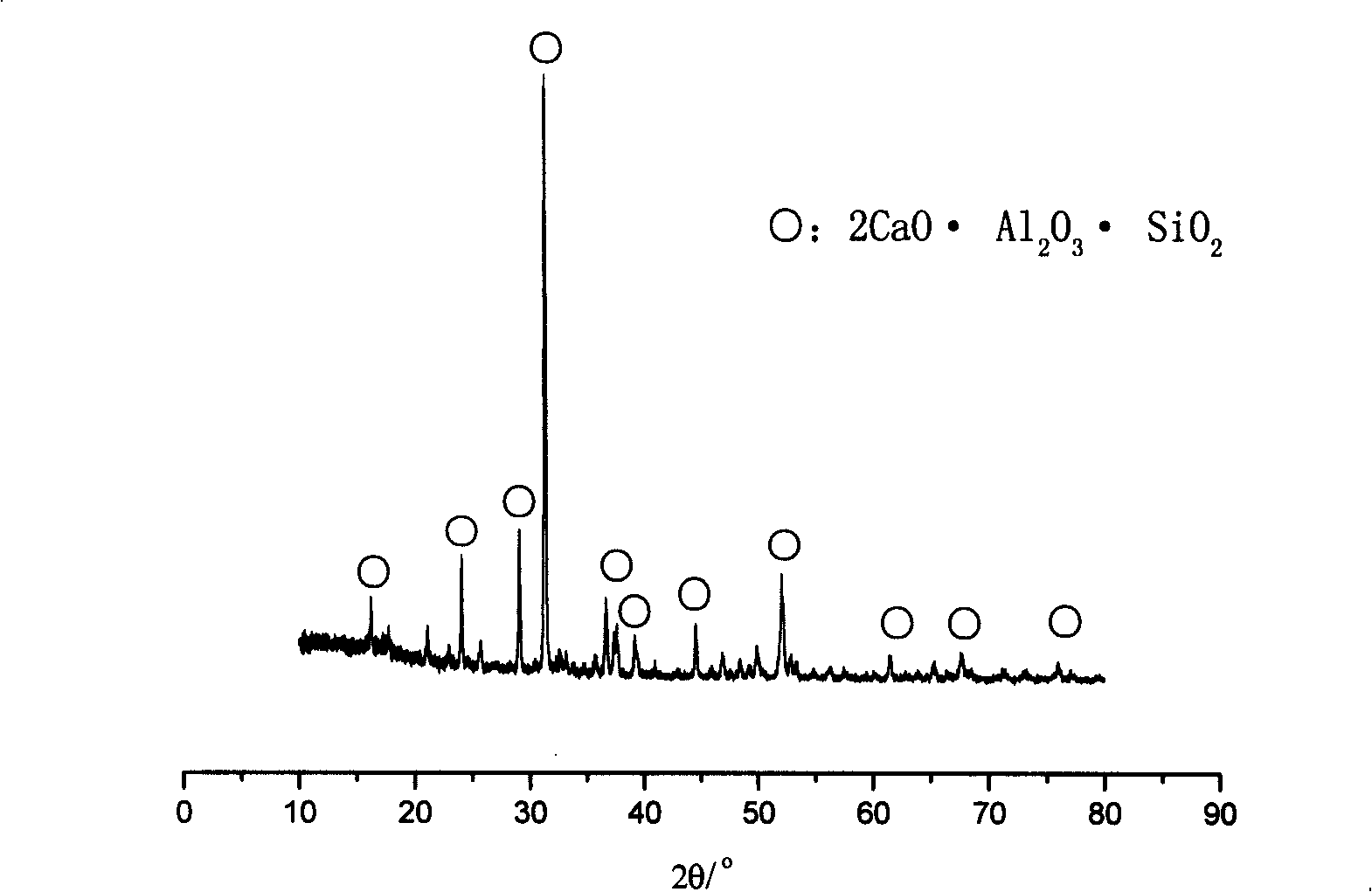

Method for preparing microcrystalline glass by using blast furnace slag

The invention discloses a method used for the preparation of microcrystalline glass by use of blast furnace slag, wherein blast furnace slag is crushed and sifted out and then is mixed with 0 to 10 wt percent of feldspar and 0 to 5 wt percent of zirconite to make mixed powder material with the weight proportion of blast furnace slag no less than 85 percent; then, the mixed powder material is made into slurry through ball milling mixing and agglomerant is added in after the slurry is dried to complete granulation; and finally, microcrystalline glass is made through direct tabletting crystallizing sintering. The method has the advantages that: (1) ironmaking blast furnace slag is adopted as main material with the addition amount of the blast furnace slag reaching more than 85 percent, which not only saves resources and reduces pollution, but also realizes cycle economy; (2) cheap silicate materials including zirconite and feldspar are adopted as additives; (3) powder tabletting sintering method is adopted to make microcrystalline glass, thereby omitting the complex process of casting moulding after high-temperature fusion of glass or sintering after fusion water quench in the prior glass process and sintering process.

Owner:ZHENGZHOU UNIV +1

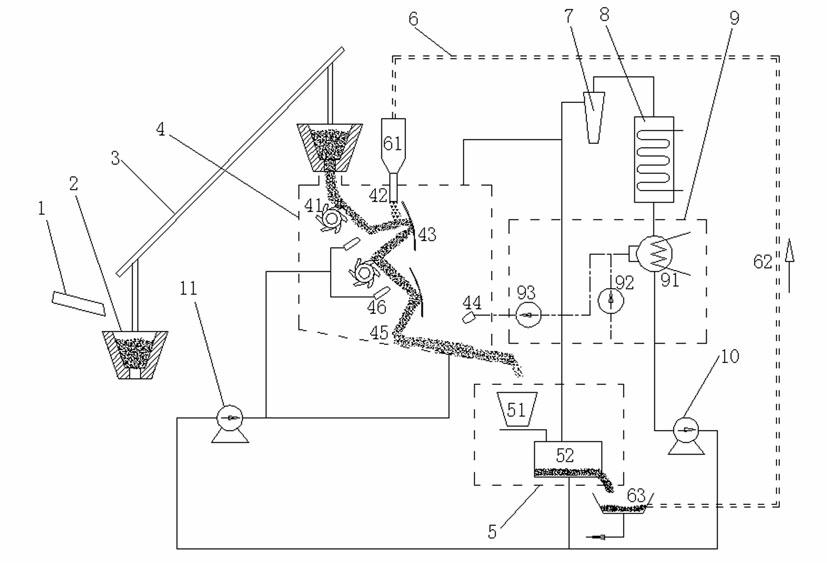

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

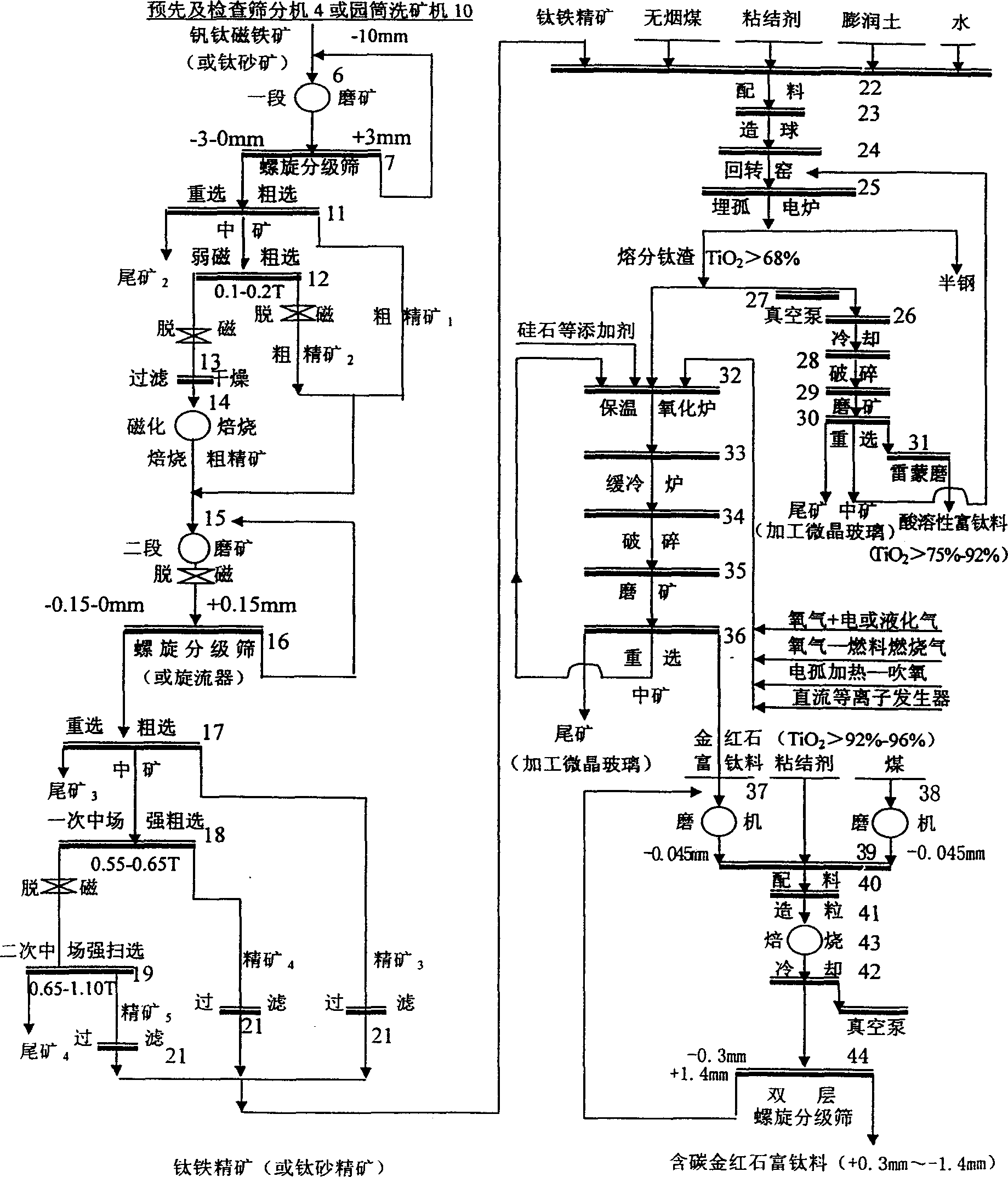

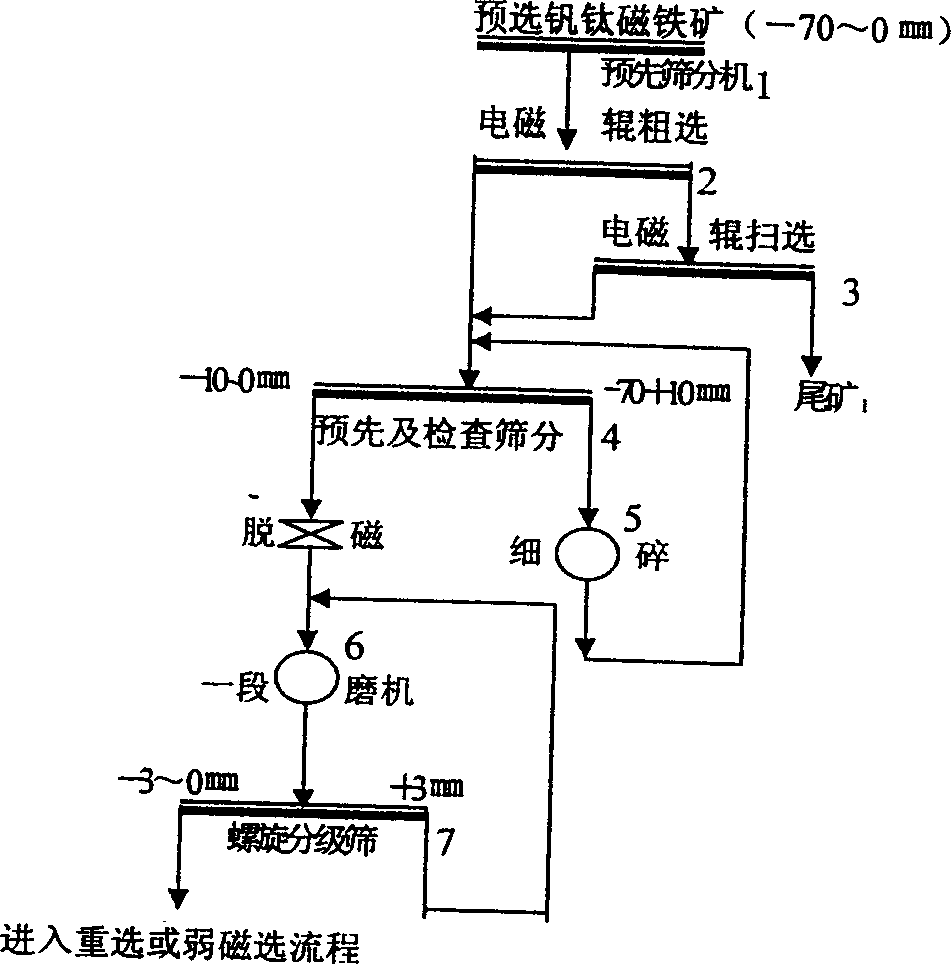

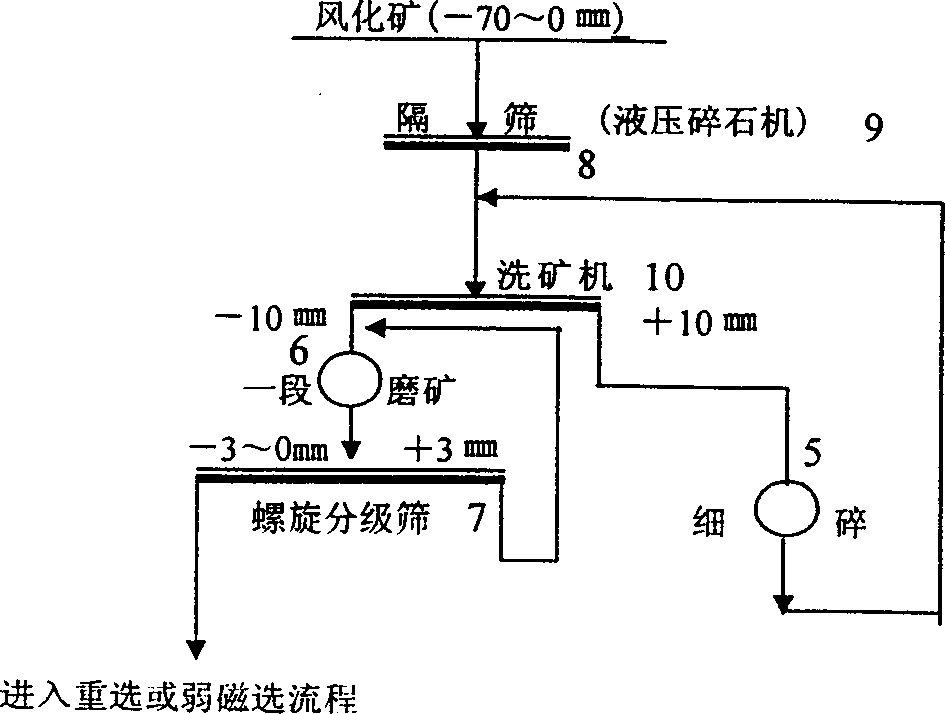

Method of producing titanium enriched material using titanium mineral

InactiveCN1429919AEfficient recyclingImprove resource utilization efficiencyMagnetic separationAdhesiveMagnetite

A process for preparing Ti-enriched material from V-Ti magnetite through preseparating to obtain Ti-Fe ore concentrate, proportionally mixing it with V-Ti-Fe core concentrate, adhesive and carbon reducer, smelting to obtain high-Ti slag and semi-steel, blowing V-Cr to melten alloy iron to obtain V-Cr contained steel slag, separating V and Cr, fire metallurge of high-Ti slag to obtain artificial rutile and microcrystal glass, ball grinding of artificial rutile and coal while adding adhesive to obtain C-contained Ti particles, calcining, cooling and classifying.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

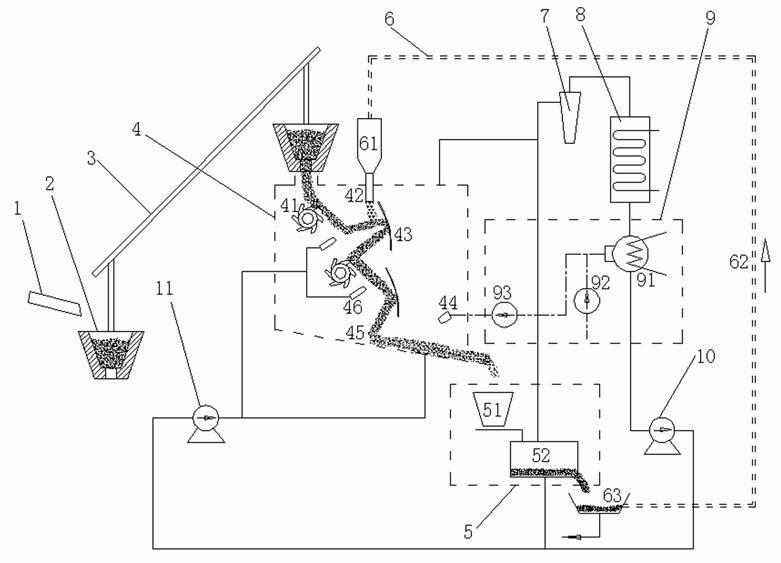

Blast-furnace cement sensible heat recovery system and its production process

InactiveCN1920380AReduce focal ratioRaise the hot air temperatureOther heat production devicesBlast furnace componentsSlagProduct gas

The invention relates to a blast furnace slag heat recycle system and relative production, wherein it is formed by cooling-breaking, gas-slag heat exchanger, and left-heat boiler units; the slag outlet has cooling-braking unit which will cool the slag to the solidify point 1200-1300Deg. C, to be broken into the slag particles whose diameter is less than 100mm; the transmitter is connected to the gas-slag heat exchanger to heat the air to 700-800Deg. C; the slag will be cooled under 150Deg. C; the heated air will be transmitted to the left-heat boiler; the water of heating tube of boiler will adsorb the heat of gas, to generate the steam whose pressure at 0.3-0.4MPa and temperature at 260-350Deg. C. The invention can improve the energy recycle efficiency more than 70%, to reduce the energy consumption of steel production, reduce the consumption of cooling water, and reduce the environment pollution.

Owner:ANGANG STEEL CO LTD +1

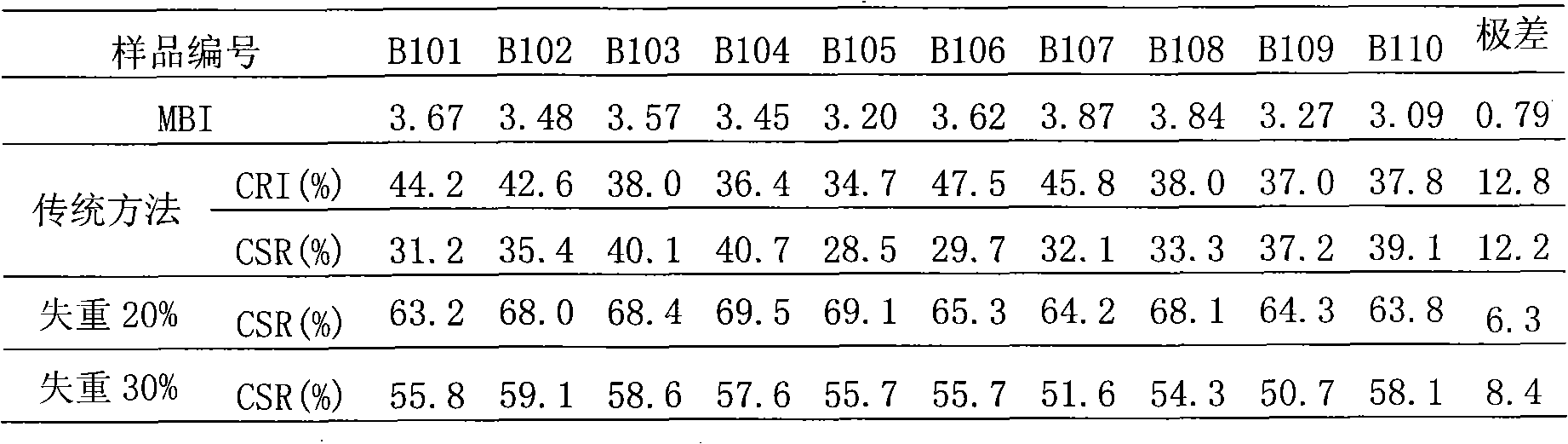

Coke coal blending ratio and coking method thereof

The present invention is one kind of coke coal blending ratio and coking process. The coke coal consists of fat coal 20-23 weight portions, coking coal 50-55 weight portions, 1 / 3 coking coal 15-20 weight portions, and lean coal 8-12 weight portions. The compounded coal has the quality including ash content 9-10 %, sulfur content 0.65-0.73 %, volatile component 24-26 %, G value 83-88, Ymm of 16-20, and Xmm of 20-30. The quality parameters, vitrinite reflectances and microscopic ingredients of the said four kinds of coal are specifically defined. During the coking process, the mixed coal material is sintered at 1200 deg.c for not less than 16 hr. The present invention can obtain coke with high strength.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for producing baking-free bricks by using phosphorous gypsum based cementitious material to solidify yellow phosphorous slags

InactiveCN101637936ASolve pollutionLow costSolid waste managementMixing operation control apparatusBrickSlag

Owner:KUNMING UNIV OF SCI & TECH

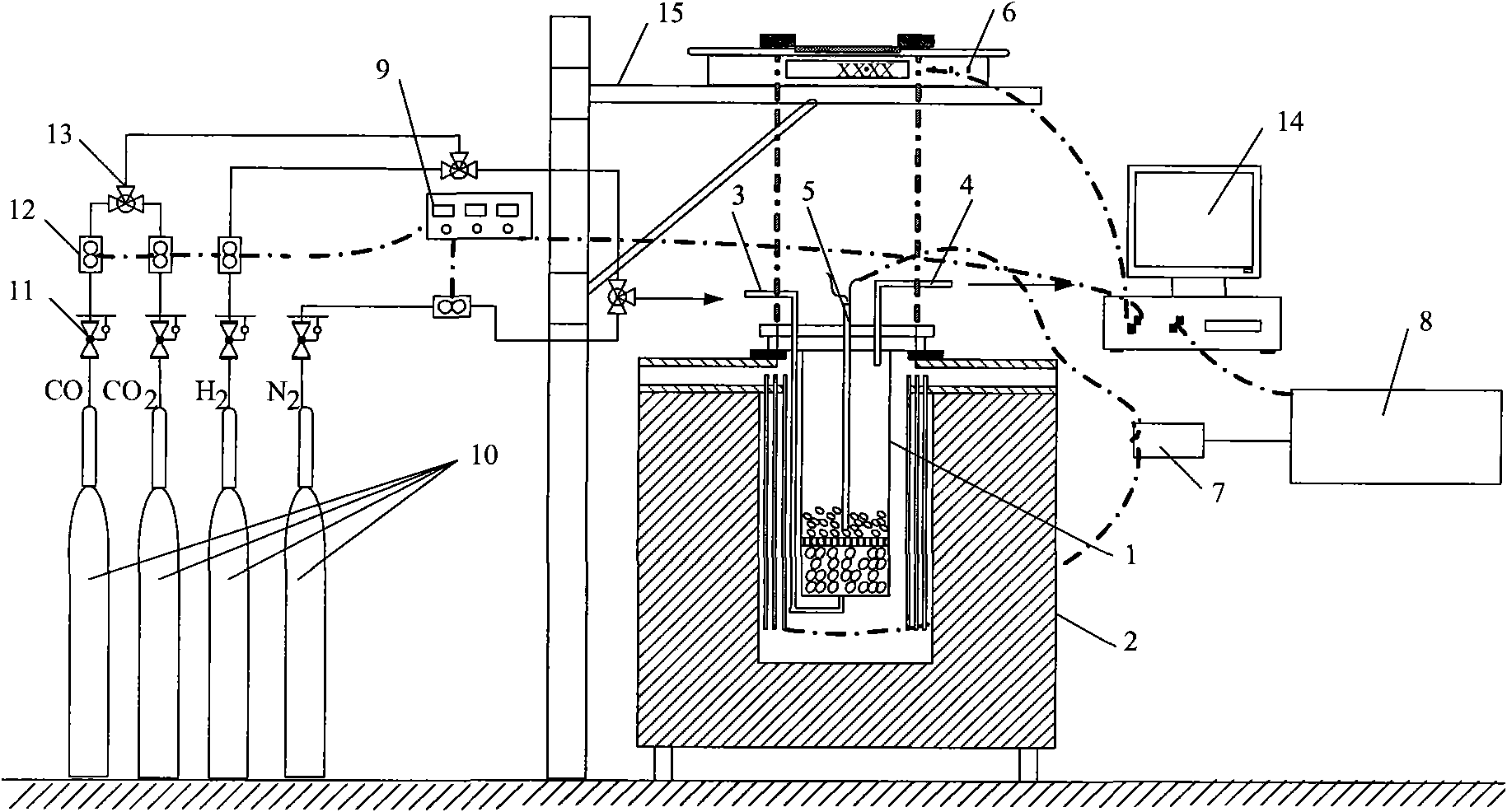

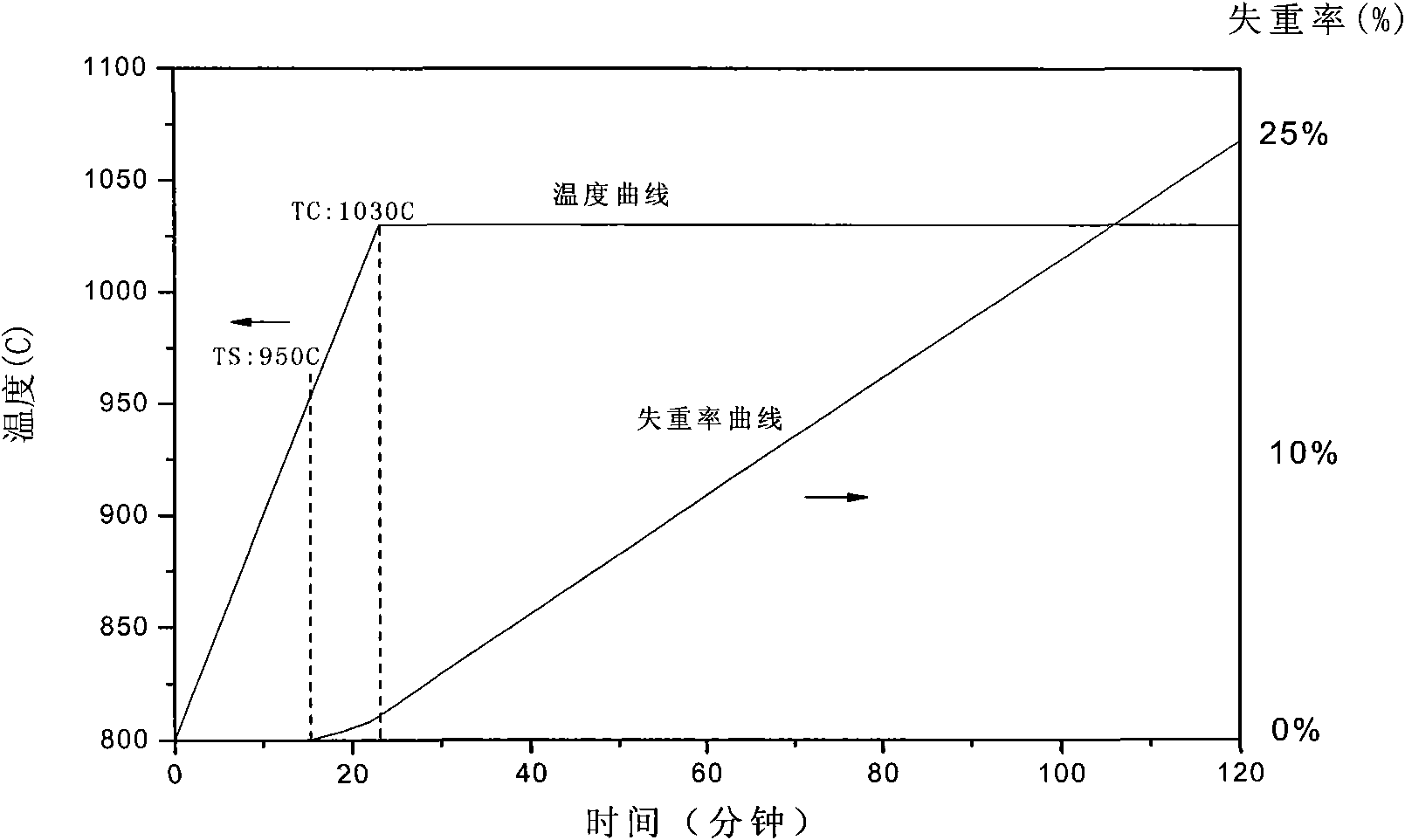

Strength determination method and device for reacted blast furnace coke

ActiveCN101936979ASolving thermal property evaluationSolve the situationFuel testingChemical methods analysisNitrogen gasInsertion reaction

The invention discloses a strength determination method for reacted blast furnace coke, which comprises the following steps of: (1) placing a coke sample in a reactor; (2) putting the reactor in an electric heating furnace; (3) inserting a temperature thermocouple into the coke in the reactor;(4) putting an electronic balance on a lifting table and connecting the electronic balance and the reactor through a chain; (5) regulating the electric furnace to heat through a temperature controller and introducing nitrogen when the temperature in the center of a material layer reaches 400 DEG C; (6) introducing carbon dioxide gas when the temperature in the center of the material layer reaches 780 DEG C; (7) cutting the nitrogen and introducing prepared mixed gas when the temperature in the centerof the material layer reaches a certain value, maintaining the temperature of the heating furnace, and when the loss ratio of the coke samples reaches the required value continuously introducing the carbon dioxide gas or the mixed gas, introducing the nitrogen and cooling after the carbon dioxide gas or the mixed gas reaches the specified dissolve loss quantity; and (8) stopping introducing the nitrogen and cooling naturally when below 100 DEG C. The invention more truly reflects the actual conditions of the coke in a blast furnace, and the prediction of the thermal properties of the coke is more accurate.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel synthetic fire-resistant hydraulic oil composition

The invention relates to a novel synthetic fire-resistant hydraulic oil composition. The composition is characterized in that the fire-resistant hydraulic oil composition is prepared by using low-viscosity ester oil as basic oil, little synthetic hydrocarbon component as a solubilizer and high-viscosity ester oil as a tackifier, and adding proper functional additives. The composition has lower volatility, excellent lubricating property, high and low temperature stability, wider using temperature range, excellent flame resistance, biodegradability, long service life and other excellent performance. The composition comprises the following components in percentage by weight: 40 to 70 percent of the low-viscosity ester oil, 10 to 20 percent of the synthetic hydrocarbon component, 0 to 10 percent of the high-viscosity ester oil, 2 to 10 percent of composite additive, and 10 to 200ppm of anti-foaming agent. The composition is mainly applied to steel continuous casting production line systems and hydraulic systems of blast furnaces, hot rolling, casting, power stations, coal mines and the like which require flame resistance and safe equipment.

Owner:益田润石(北京)化工有限公司

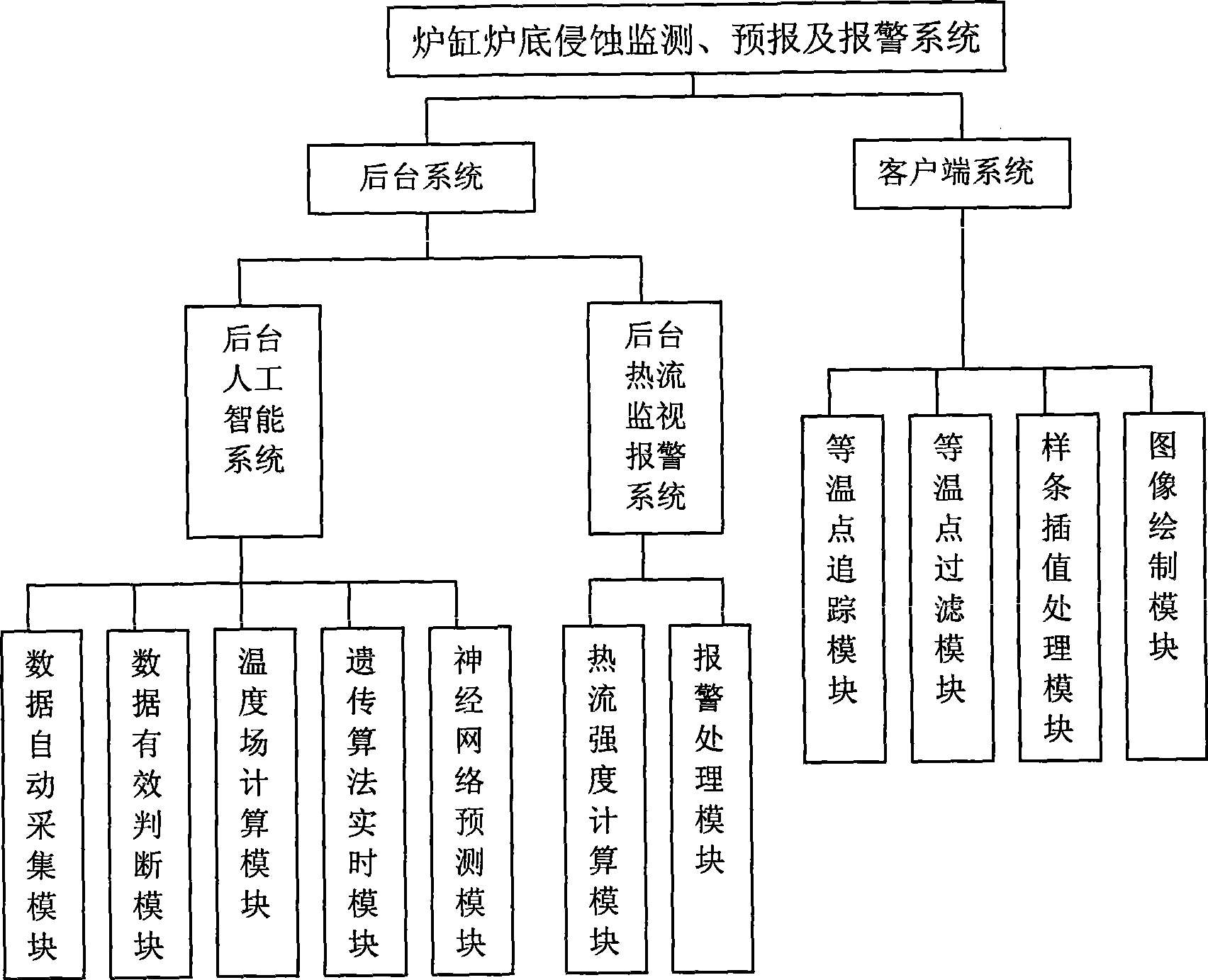

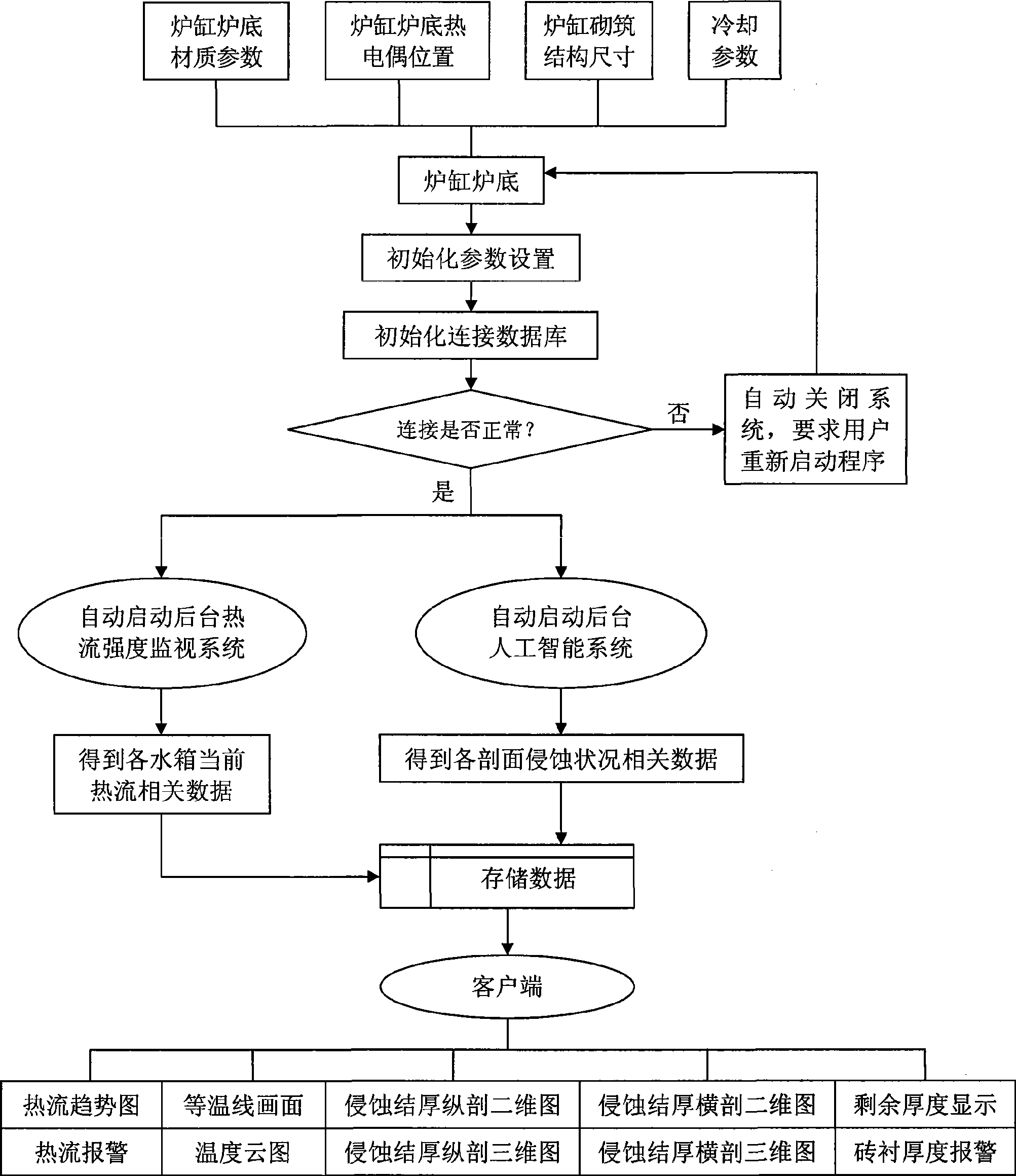

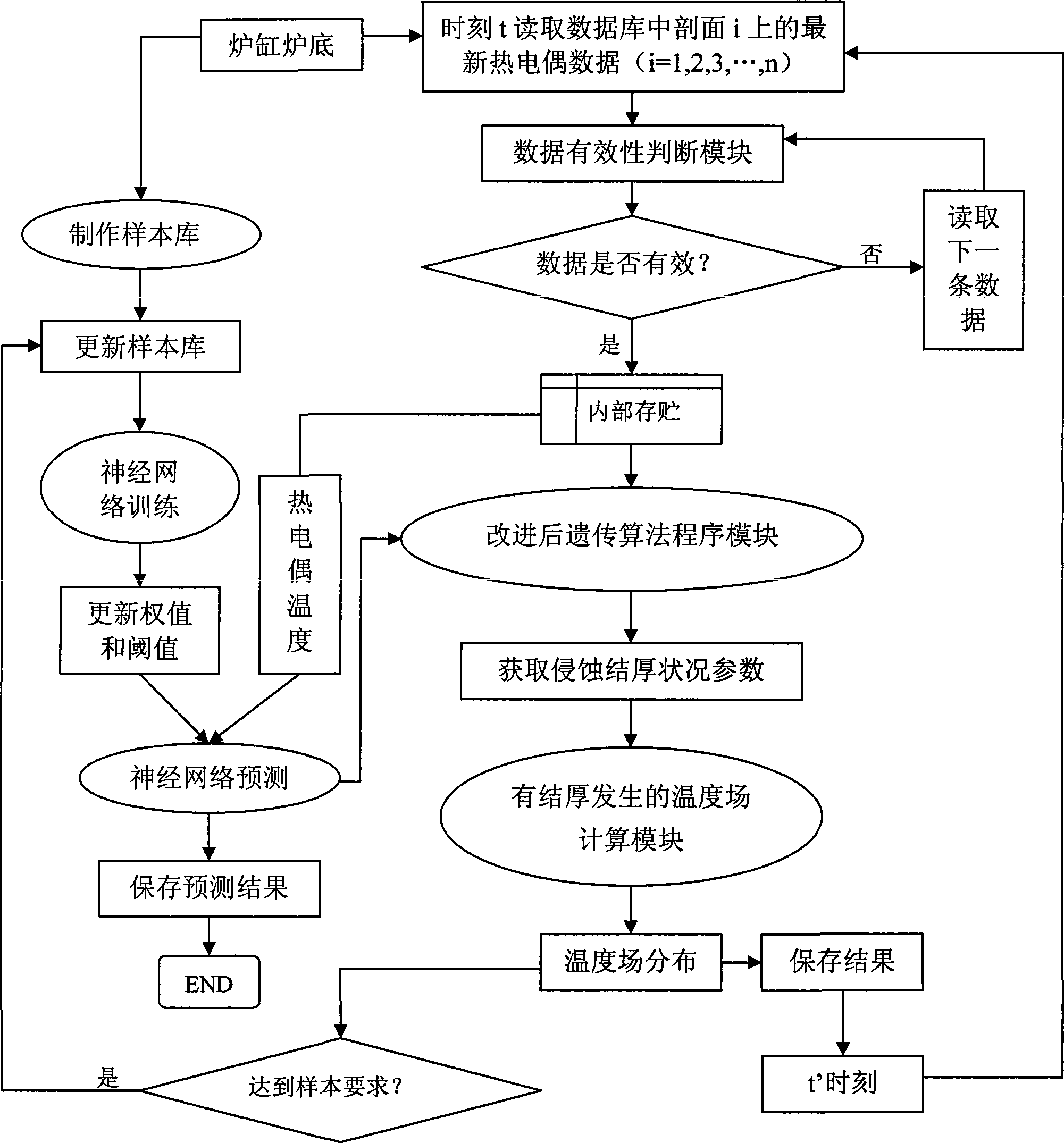

Monitoring, prediction and alarm system for blast furnace hearth and bottom

InactiveCN101457268ARealize online monitoring and alarmImplement storageThermometers using electric/magnetic elementsUsing electrical means3d imageData acquisition

A monitoring, forecasting and alarm system of the bottom and hearth of a blast furnace belongs to the longevity technical field of blast furnaces. The system comprises online monitoring and forecasting hardware and software processing modules; the online monitoring and forecasting hardware consists of a thermocouple and a cooling system which are laid at the furnace hearth and the furnace bottom, and a database of the blast furnace production process is connected by the Ethernet; the software processing modules comprise a data acquisition module, a data validity judgment module, a temperature field computation module, an improved genetic algorithm module, a B-P neural network module, a database, an isotherm, an erosion and thickening image display module, a 3D imaging module, a heat flow monitoring and alarm module and a historical data query module; and the software processing modules are operated on an industrial control computer. The monitoring, forecasting and alarm system has the advantages of low investment, reliability and visualization. The system provides an objective and quantized basis for the erosion and thickening erosion condition of the furnace hearth and the furnace bottom in the blast furnace ironmaking process, and helps a blast furnace operator timely know the condition of the furnace hearth and the furnace bottom and take effective furnace protection measures so as to prolong the service life of the blast furnace.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

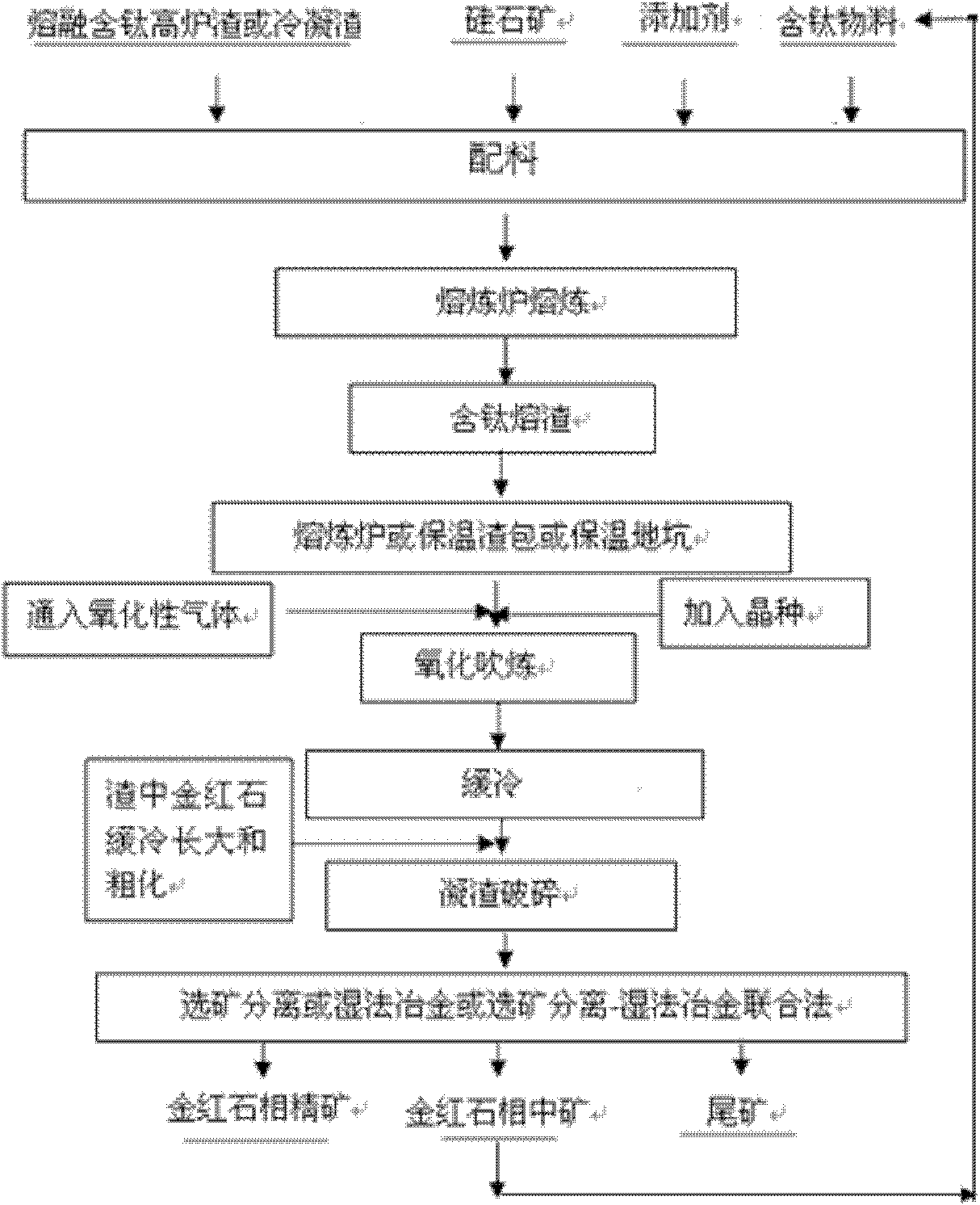

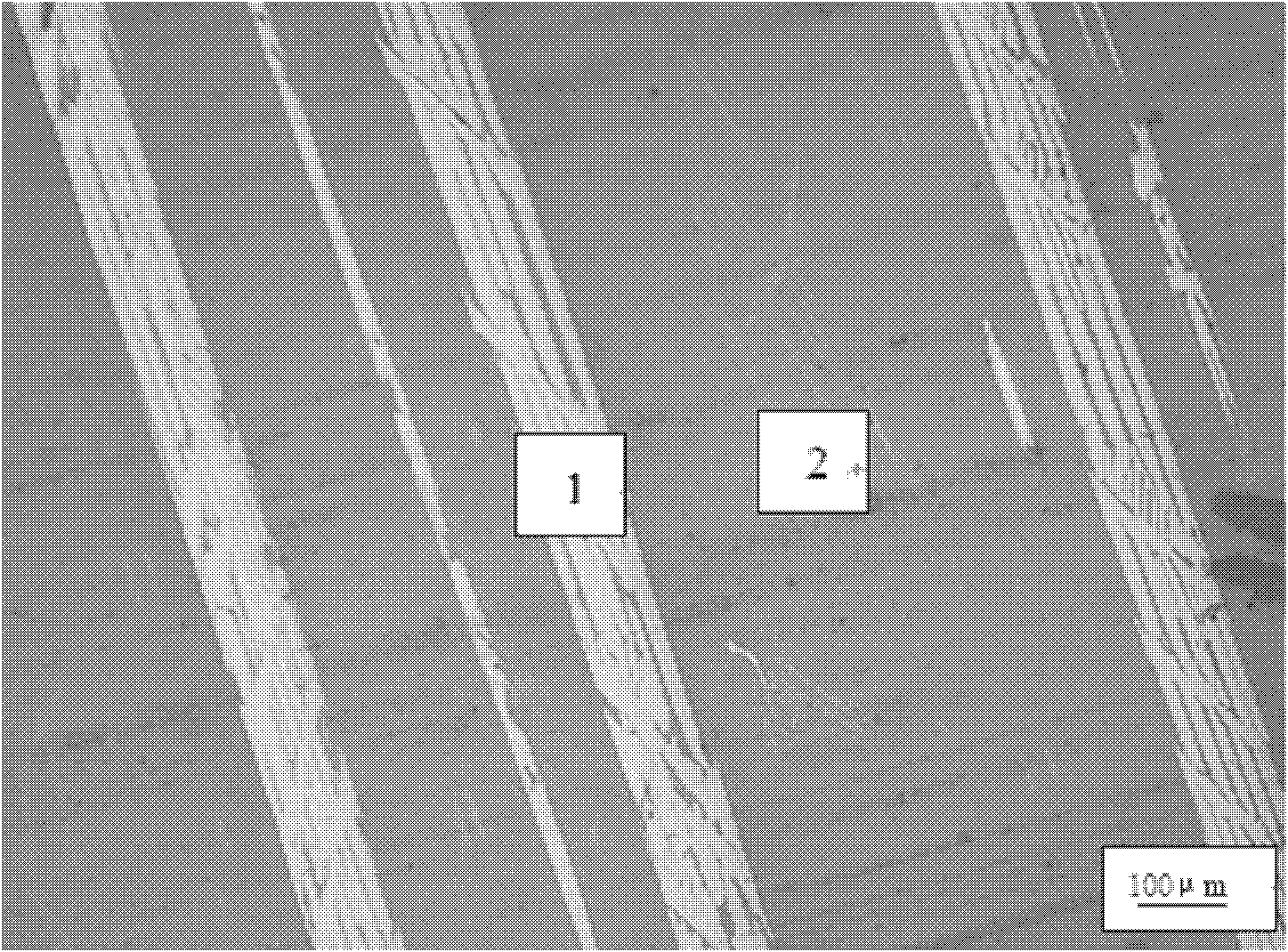

Method for producing artificial rutile from titanium-containing blast furnace slags

ActiveCN102154531ASimple compositionPromote coarseningRecycling and recovery technologiesProcess efficiency improvementTitaniumMolten slag

The invention provides a method for producing artificial rutile by taking the titanium-containing blast furnace slags as the raw material. The method has the advantages of short reaction time, high titanium recovery, low production cost, big treatment capacity and high product additional value and is environment-friendly. The method comprises the following steps: burdening: adding smelted or condensed titanium-containing blast furnace slags, a titanium-containing material, silica ores and an additive into a smelting furnace; smelting: smelting by the smelting furnace to keep the mixture underthe fusing state; oxidation: spraying and blowing an oxidizing gas into slags in the smelting furnace, or pouring the slags into a heat insulation slag tank or a heat insulation pit, spraying and blowing an oxidizing gas into slags in the heat insulation slag tank or the heat insulation pit to convert the titanium-containing substances in the slags into the rutile phase; cooling: keeping the temperature for the oxidized slags in the heat insulation slag tank or the heat insulation pit, and controlling the cooling rate to cool the slags to room temperature to cause the rutile phase to grow; and separation: and finally, breaking and levigating the oxidation modification condensed slags to separate the rutile phase to obtain the artificial rutile with high TiO2 grade.

Owner:喀左县钒钛资源综合开发利用工程技术研究中心 +1

Molten blast furnace slag sensible heat recovery method and device

InactiveCN101660014ASave energyRecycling and recovery technologiesProcess efficiency improvementRecovery methodThermal energy

The invention relates to the field of energy recovery utilization and in particular to a molten blast furnace slag sensible heat recovery method and a device; the method is characterized in that: themolten blast furnace slag carries out a first heat recovery in a granulator, and then a second heat recovery is carried out by a vibrated bed, and then a third heat recovery is carried out in a fluidized bed, and the reclaimed heat energy is reutilized or converted in a hot air or power generating way; the realization steps are that: 1) the molten blast furnace slag is arranged in the granulator for granulation; 2) the blast furnace slag granules carry out heat exchange in the vibrated bed; 3) the blast furnace slag granules carry out heat exchange in the fluidized bed; 4) after heat exchangeis carried out, the heat is used for power generation from air or is directly utilized in a hot wind way. The method has the beneficial effects that: the sensible heat of the molten blast furnace slagis utilized respectively in a way of waste heat stream power generation and in a way of blast furnace hot wind, compared with the existing water quenching method, 1.0-1.2t of fresh water can be savedwhen processing 1t of molten slag, and sulfides H2S and SO2 are not produced, and energy equivalent to 47kg of standard coal is saved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

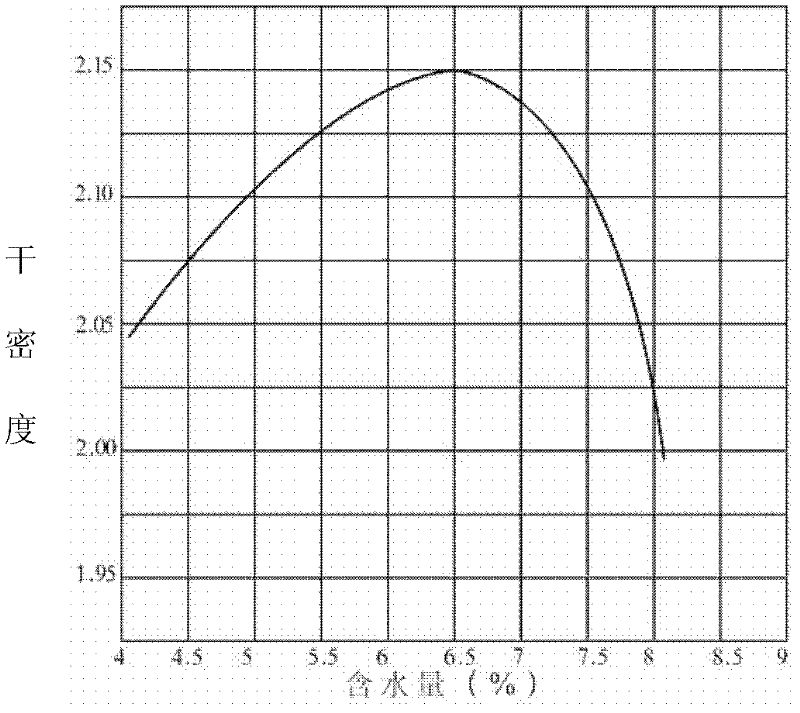

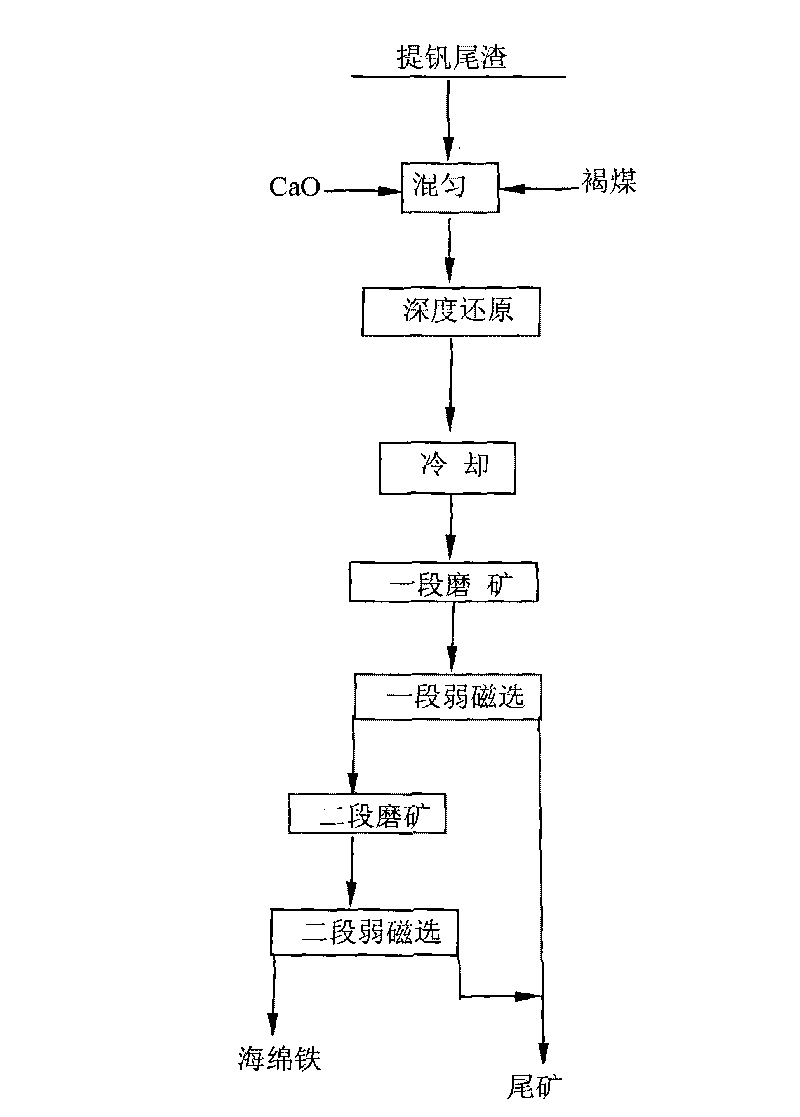

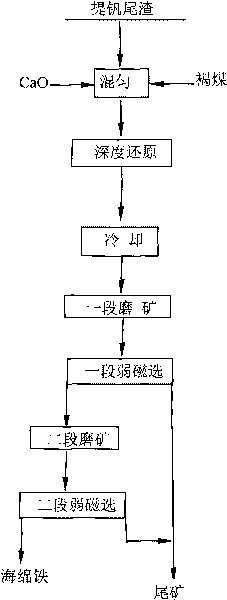

Technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings

The invention relates to a technique method for directly producing sponge iron by carrying out deep reduction on extracted vanadium tailings, belonging to the field of iron making. The method adopts brown coal as the reducing agent, and simultaneously CaO is added as slag former and used for increasing alkalinity to synergize with Na2O and K2O in the tailings to react with SiO2 and Al2O3 to generate zeolite-like stable mineral so as to boost extraction and separation of sponge iron in products of deep reduction. The products of deep reduction are subject to two-section ore grinding-two-section low intensity magnetic separation technique to obtain sponge iron with iron grade larger than 90% and TiO2 smaller than 0.20%. The invention is simple in technique and easy to control, and has large reserves of raw materials and low price; the product can be used as raw material for steel making; other impurities meet steel making requirements, the technique flow of processing iron ore into rolled steel is shortened, the environment pollution caused by sintering, pelletizing and blast furnace iron making of iron ore concentrate obtained by other methods can be avoided, and the invention has obvious environment benefit and energy conservation and consumption reduction effects.

Owner:UNIV OF SCI & TECH BEIJING

Fire-proof pouring material of iron tap channel of blast-furnace and production thereof

A fire-proof pouring material for blast-furnace iron tap channel and its production are disclosed. The pouring material consists of industrial schmigel, SiC fines, high-temperature asphalt superfine powder, alumina or calcium aluminate cement, a-Al2O3 superfine powder, SiO2 superfine micro-powder and metal silicon. The process is carried out by taking sodium tripolyphosphate or calgon or aluminum powder as additives, adding into aluminous fly ash, agitating, mixing, obtaining the pouring material, adding into 3-7% water, agitating, mixing, adding into mould, vibrating for vibrating bar or plate, naturally hardening and drying, demoulding, drying at 80-700 Deg C., heat treating and removing moisture. It costs low and has good availability.

Owner:无锡市南方耐材有限公司

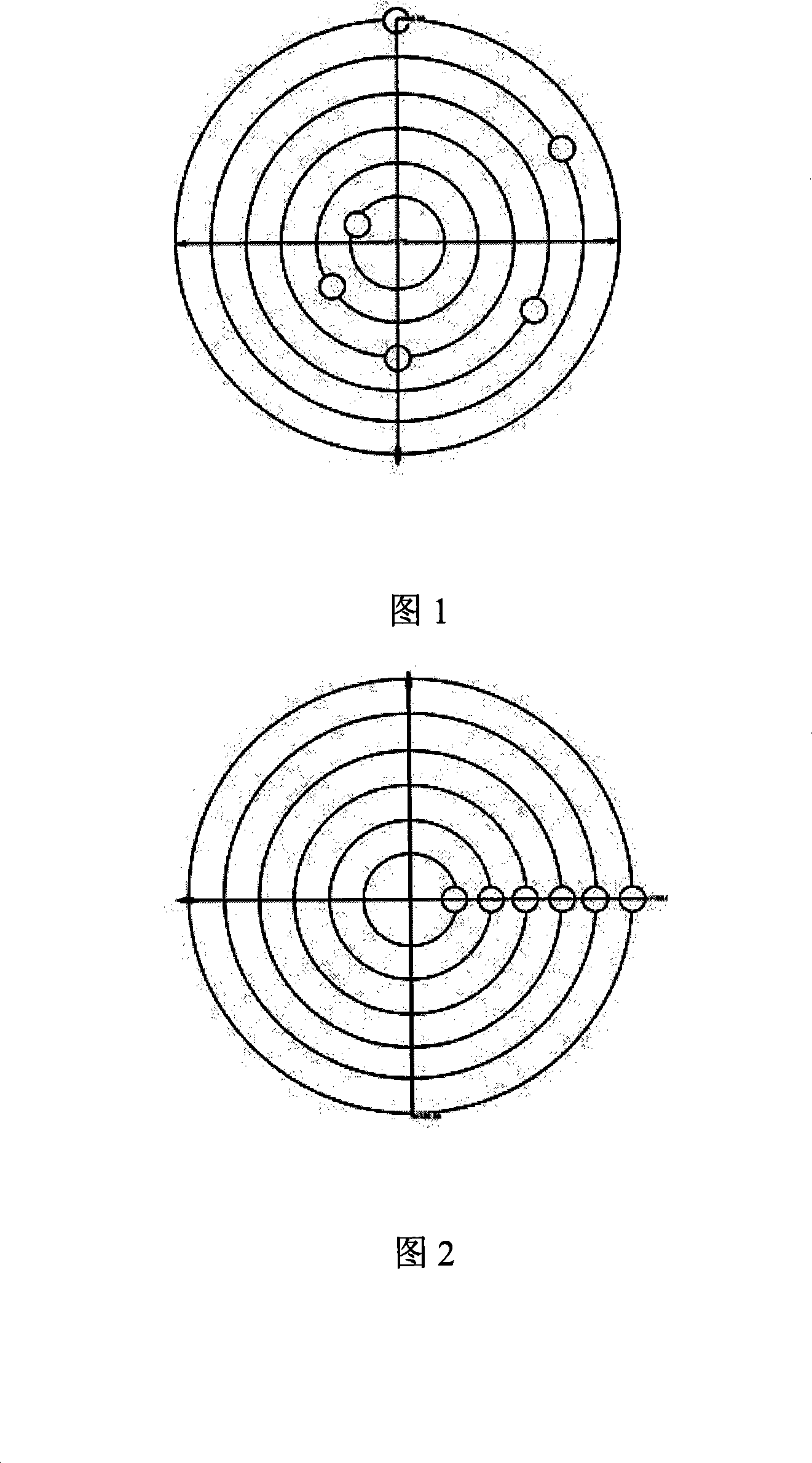

Dynamic stereo monitoring system and detection method for charge surface shape in blast furnace

The dynamic stereo monitoring system and detection method for charge surface shape in blast furnace belongs to the field of electronic measurement technology and computerized 3D technology. The dynamic stereo monitoring system includes radar, sleeves, a valve, a blast furnace, a radar data acquiring unit with a 24 channel signal access terminal board and a data acquisition board, and an imaging system comprising an industrial control computer and complementary monitoring software. The detection process includes the following steps: the real-time communication between the radar and radar data acquiring unit, converting inclined measured data into vertical curve data, and creating the 3D charge surface shape data. The present invention can realize the on-line real-time monitoring of charge surface shape in blast furnace under harsh operation condition.

Owner:北京普瑞玛仪表有限公司

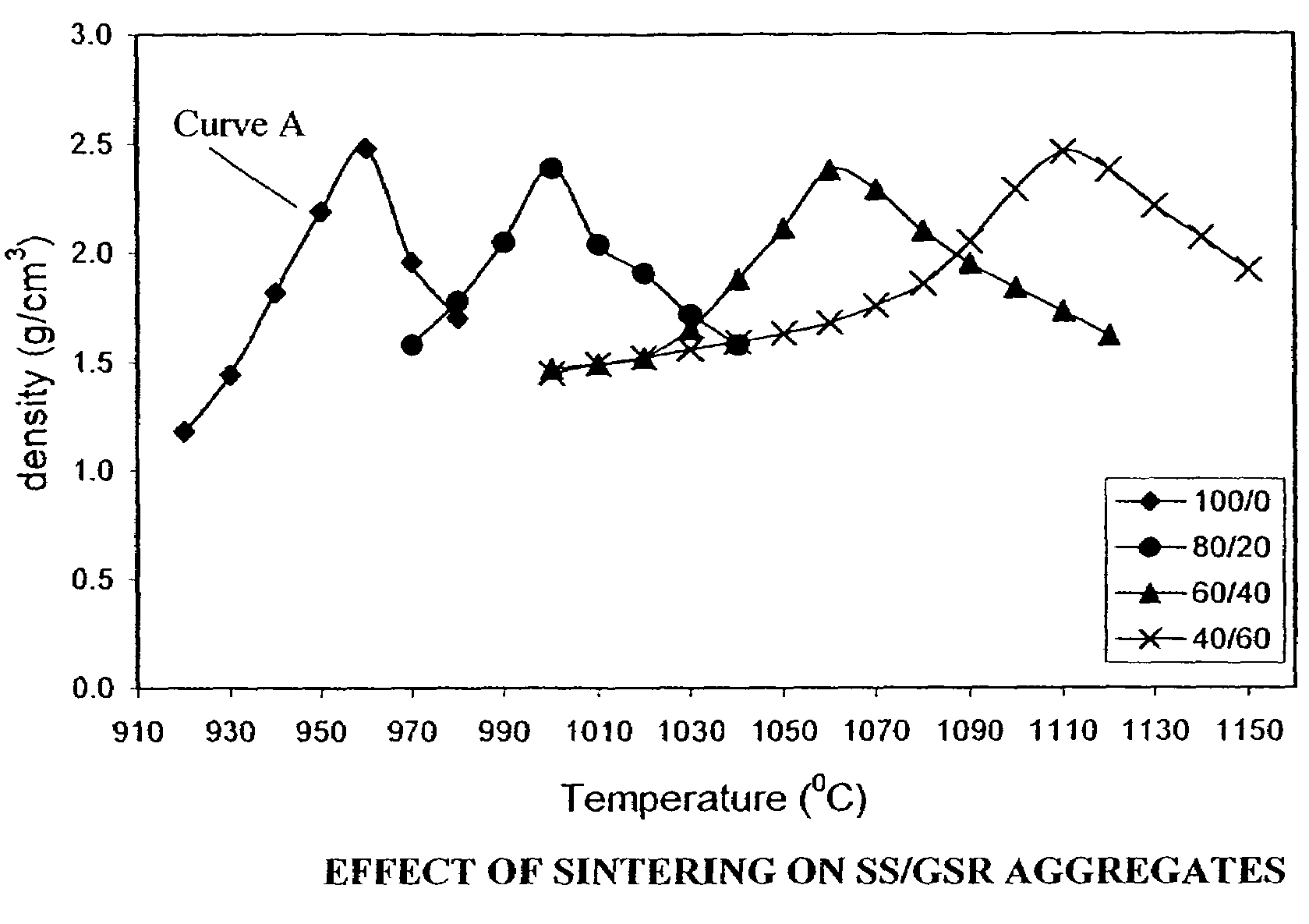

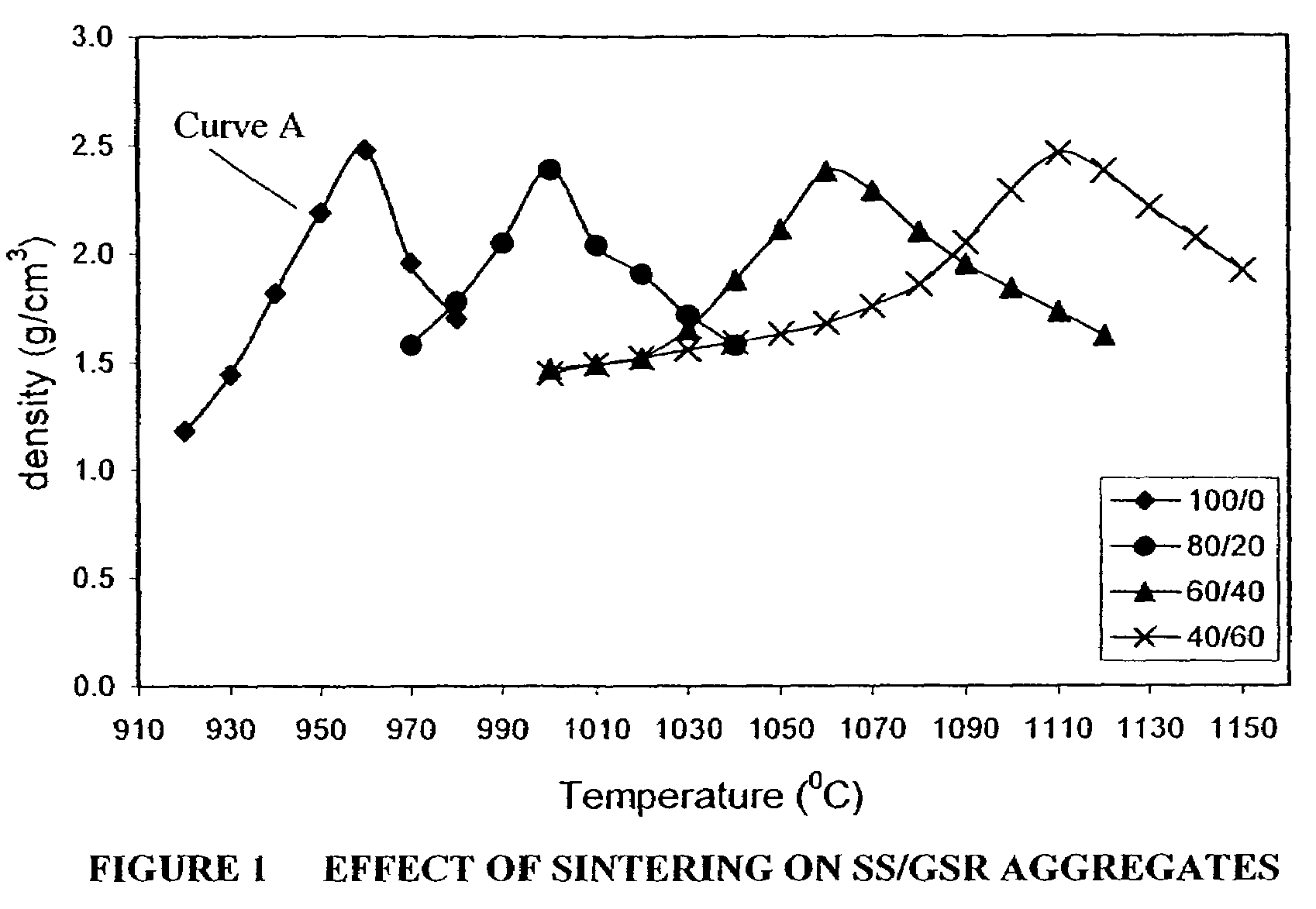

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com