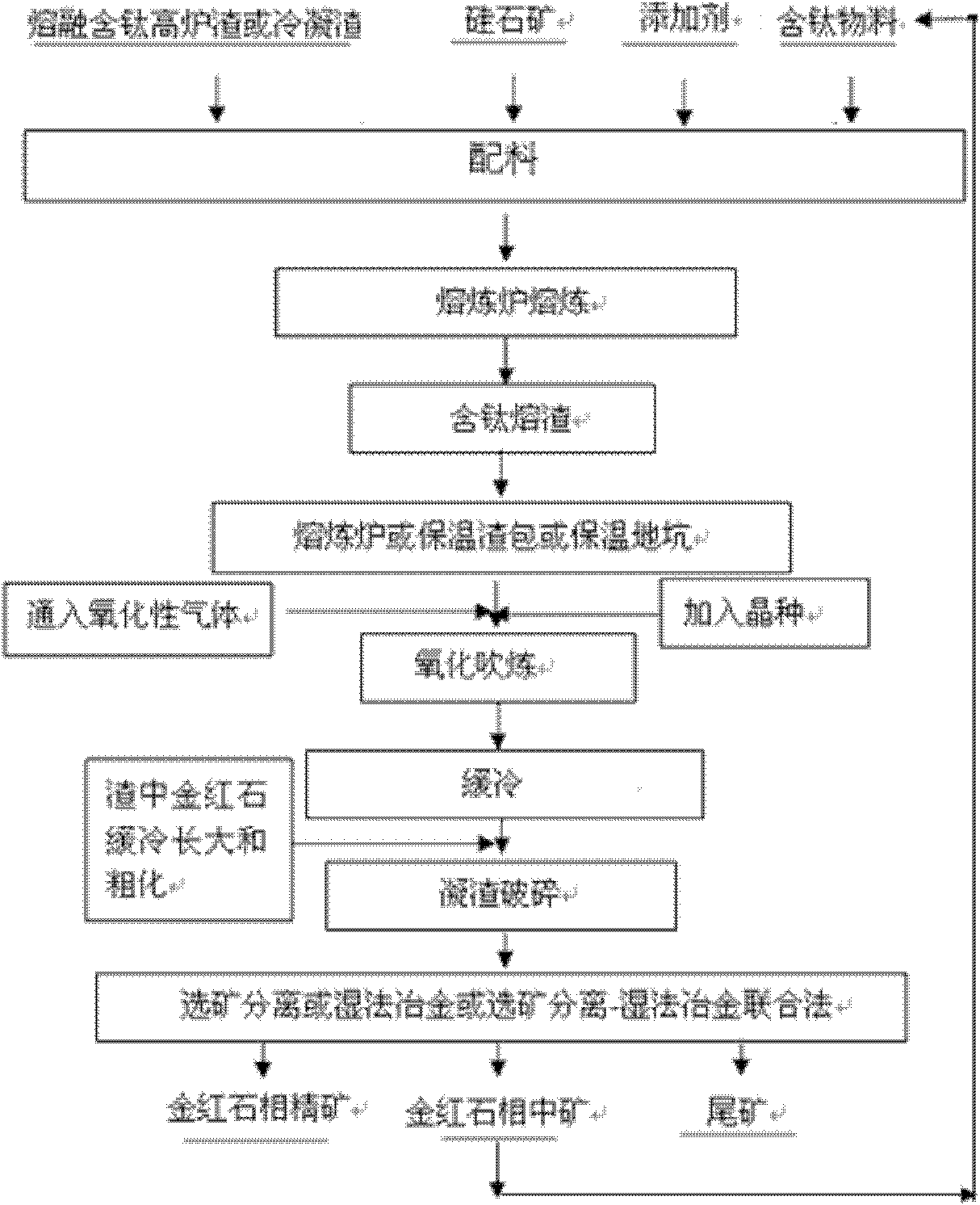

Method for producing artificial rutile from titanium-containing blast furnace slags

A technology of artificial rutile and blast furnace slag, which is applied in the direction of recycling technology and improvement of process efficiency, can solve the problems of difficult temperature control, small processing capacity, environmental pollution, etc., and achieve the promotion of coarsening and growth, efficient separation, and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

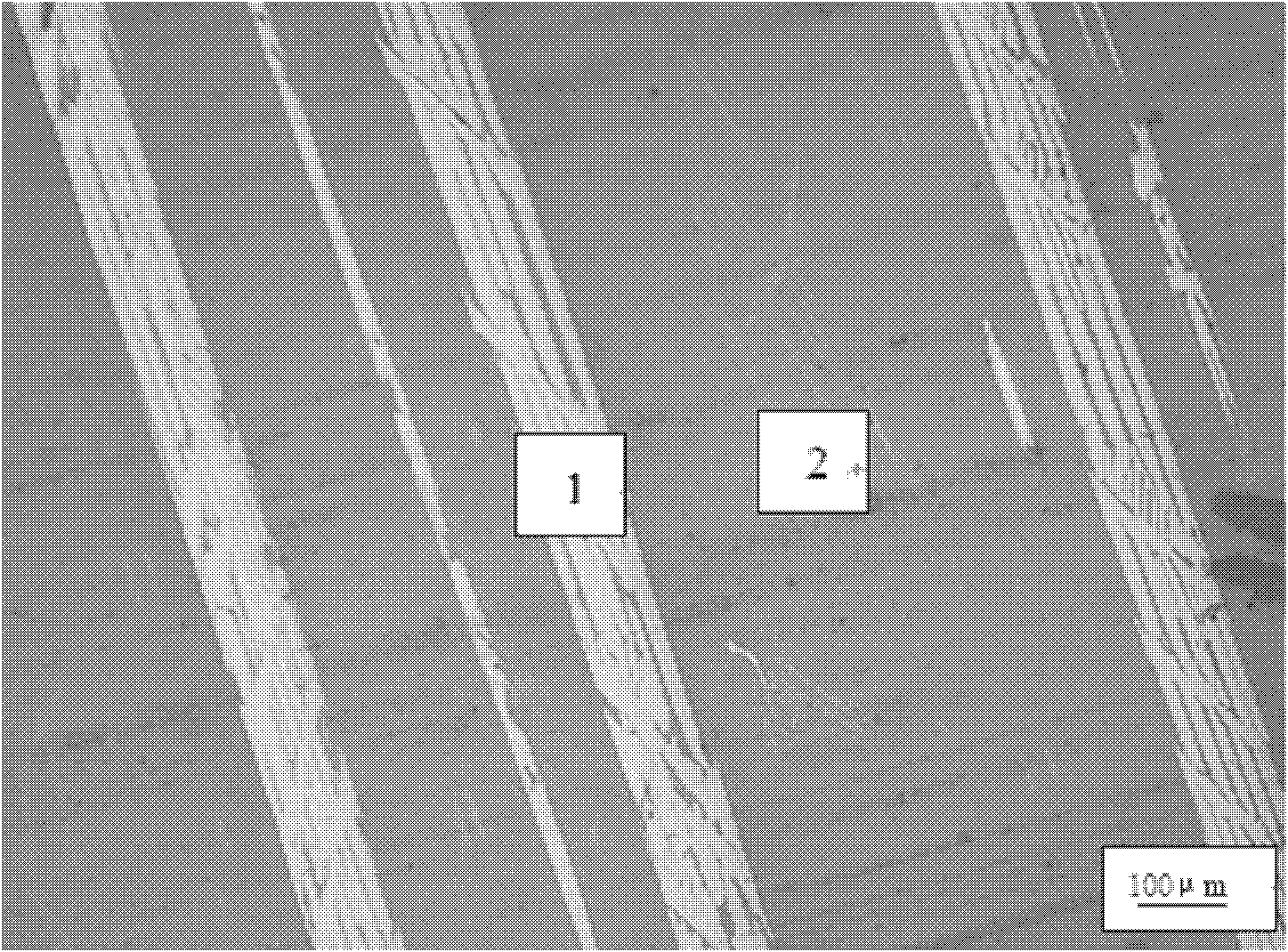

Embodiment 1

[0053] Ingredients: Titanium-containing blast furnace slag, 100g, its composition is 22.30wt% TiO 2 , 19.89wt% CaO, 8.92wt% MgO, 12.98wt% Al 2 o 3 , 4.23wt% FeO and 18.74wt% SiO 2 . High titanium slag, 40g, its composition is 76.81wt% TiO 2 , 4.25wt% CaO, 8.65wt% MgO, 3.20wt% Al 2 o 3 , 3.38wt% FeO. Silica ore, 40 g, its composition, 95wt% SiO 2 . CaF 2 , 5g. Add the above raw materials into the melting furnace; molten oxidation : The smelting furnace is heated to melt the slag, and the temperature continues to rise. When the temperature reaches 1550 ° C, keep the temperature constant for 10 minutes, and feed oxygen in the molten state. , the addition amount is 0.2wt%, and the oxidation time is 5 minutes; cool down: Cool down within the temperature range of 1550°C~1000°C, with a cooling rate of 10°C / min; Separation: The cooled oxidized slag is crushed and ground, with a particle size of 38-74 μm. Leach with 20 vol% hydrochloric acid, the leaching temperature...

Embodiment 2

[0055] Ingredients: Titanium-containing blast furnace slag, 100g, its composition is 22.30wt% TiO 2 , 19.89wt% CaO, 8.92wt% MgO, 12.98wt% Al 2 o 3 , 4.23wt% FeO and 18.74wt% SiO 2 . High titanium slag, 41g, its composition is 76.81wt% TiO 2 , 4.25% wtCaO, 8.65wt% MgO, 3.20wt% Al 2 o 3 , 3.38wt% FeO. Silica ore, 45 g, its composition, 95wt% SiO 2 . BaO, 4g. Add the above raw materials into the melting furnace; molten oxidation : The smelting furnace is heated to melt the slag, and the temperature continues to rise. When the temperature reaches 1550°C, the temperature is kept constant for 20 minutes, and oxygen is introduced in the molten state. The gas flow rate is 3 L / (min kg), and the seed crystal P is added at the same time 2 o 5 , the addition amount is 2wt%, and the oxidation time is 5 min; cool down: Cooling in the temperature range of 1550 ℃ ~ 1000 ℃, the cooling rate is 0.1 ℃ / min; Separation: The cooled oxidized slag is crushed and ground, with a parti...

Embodiment 3

[0057] Ingredients: Titanium-containing blast furnace slag, 100g, its composition is 22.30wt% TiO 2 , 19.89wt% CaO, 8.92wt% MgO, 12.98wt% Al 2 o 3 , 4.23wt% FeO and 18.74wt% SiO 2 . High titanium slag, 35g, its composition is 76.81wt% TiO 2 , 4.25wt% CaO, 8.65wt% MgO, 3.20wt% Al 2 o 3 , 3.38wt% FeO. Silica ore, 45 g, its composition, 95wt% SiO 2 . TiO 2 , 3g. Add the above raw materials into the melting furnace; molten oxidation : The smelting furnace is heated to melt the slag, and the temperature continues to rise. When the temperature reaches 1540 ° C, keep the temperature constant for 30 minutes, feed oxygen in the molten state, and the gas flow rate is 5L / (min kg), and add the seed crystal MgO simultaneously. The addition amount is 2wt%, and the oxidation time is 5 minutes; cool down: Cooling in the temperature range of 1540°C~1000°C, the cooling rate is 5°C / min; Separation: The cooled oxidized slag is crushed and ground, with a particle size of 38-74 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com