Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2827results about "Recycling and recovery technologies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medication & health, environmental, and security monitoring, alert, intervention, information and network system with associated and supporting apparatuses

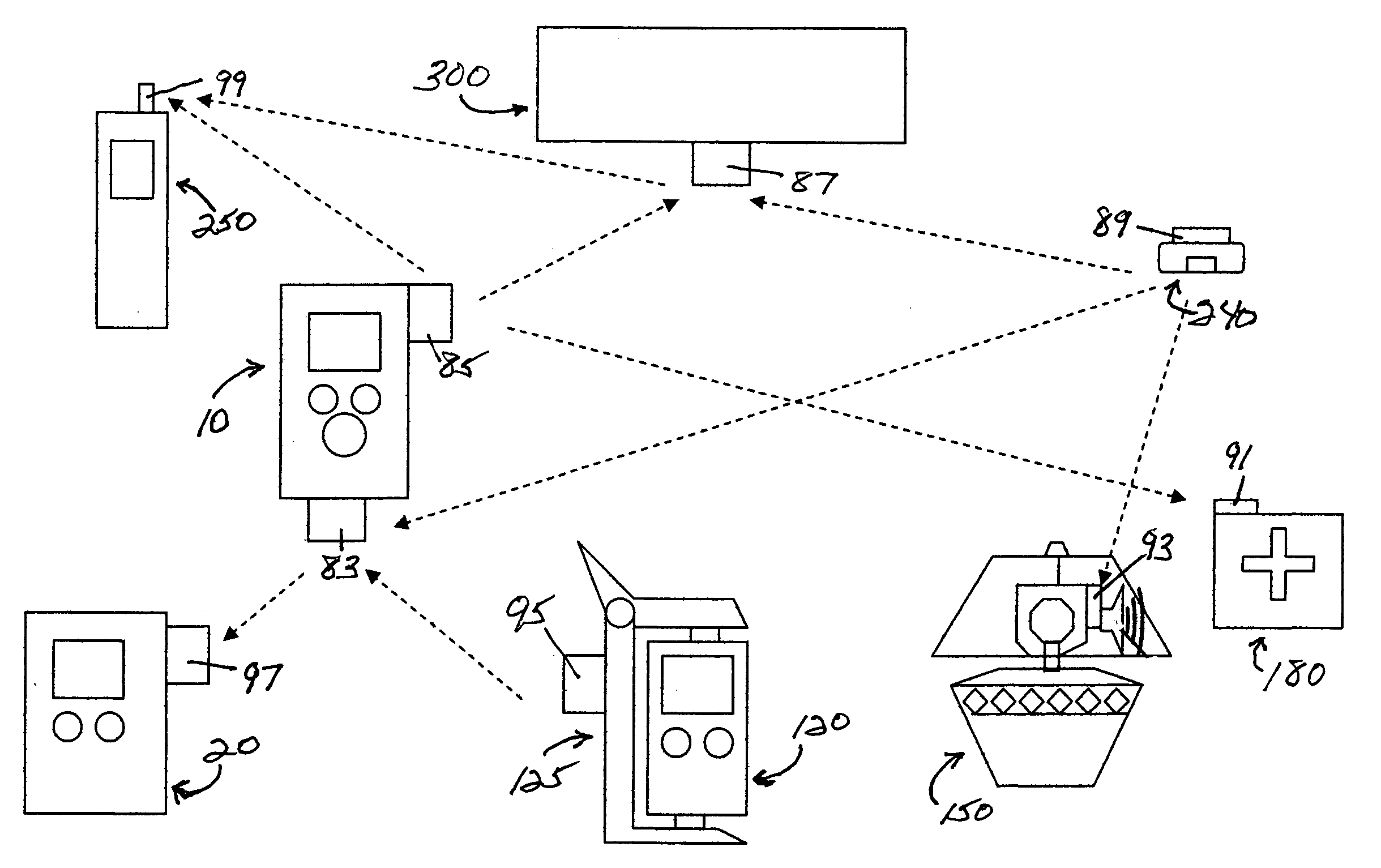

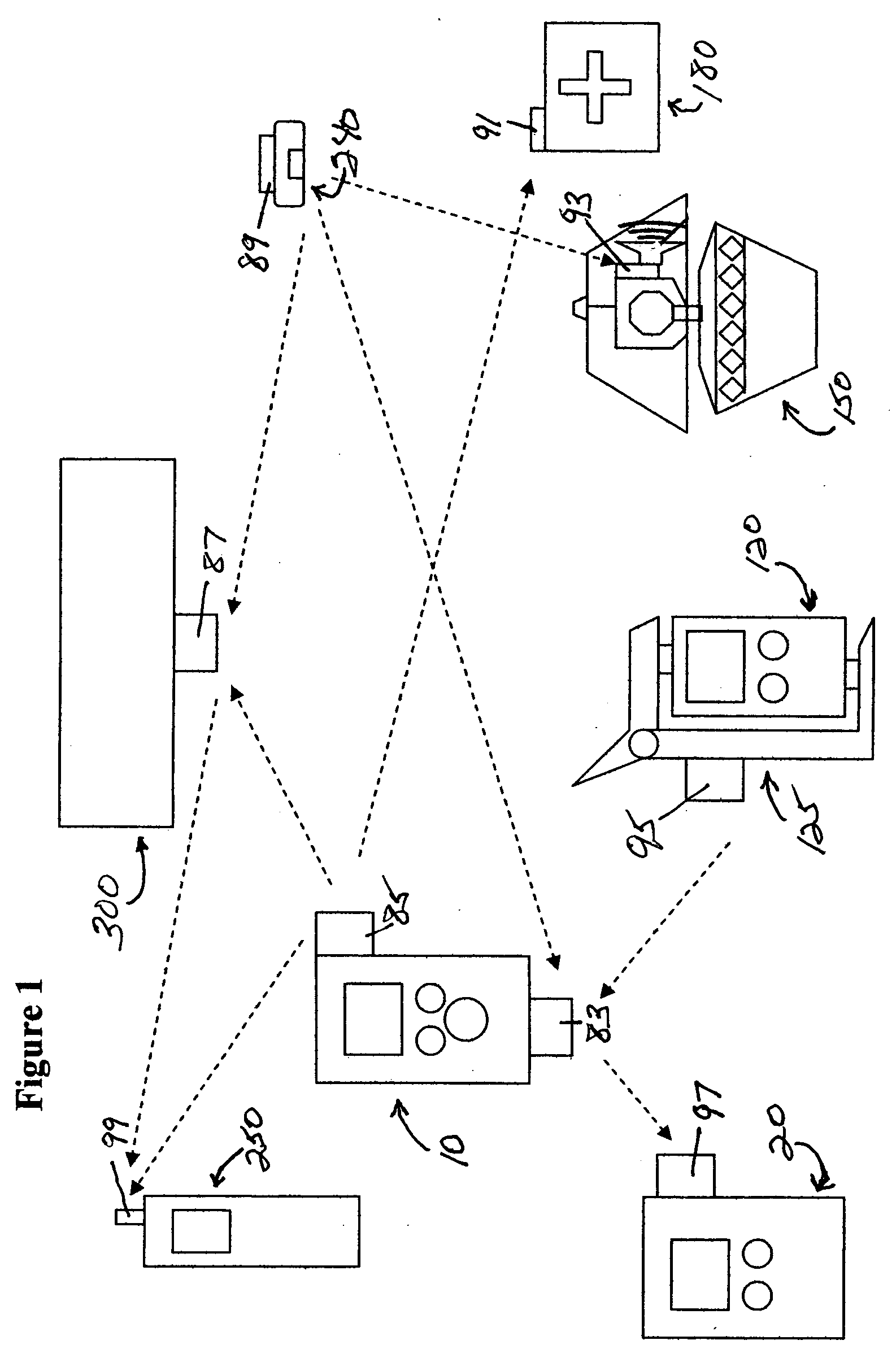

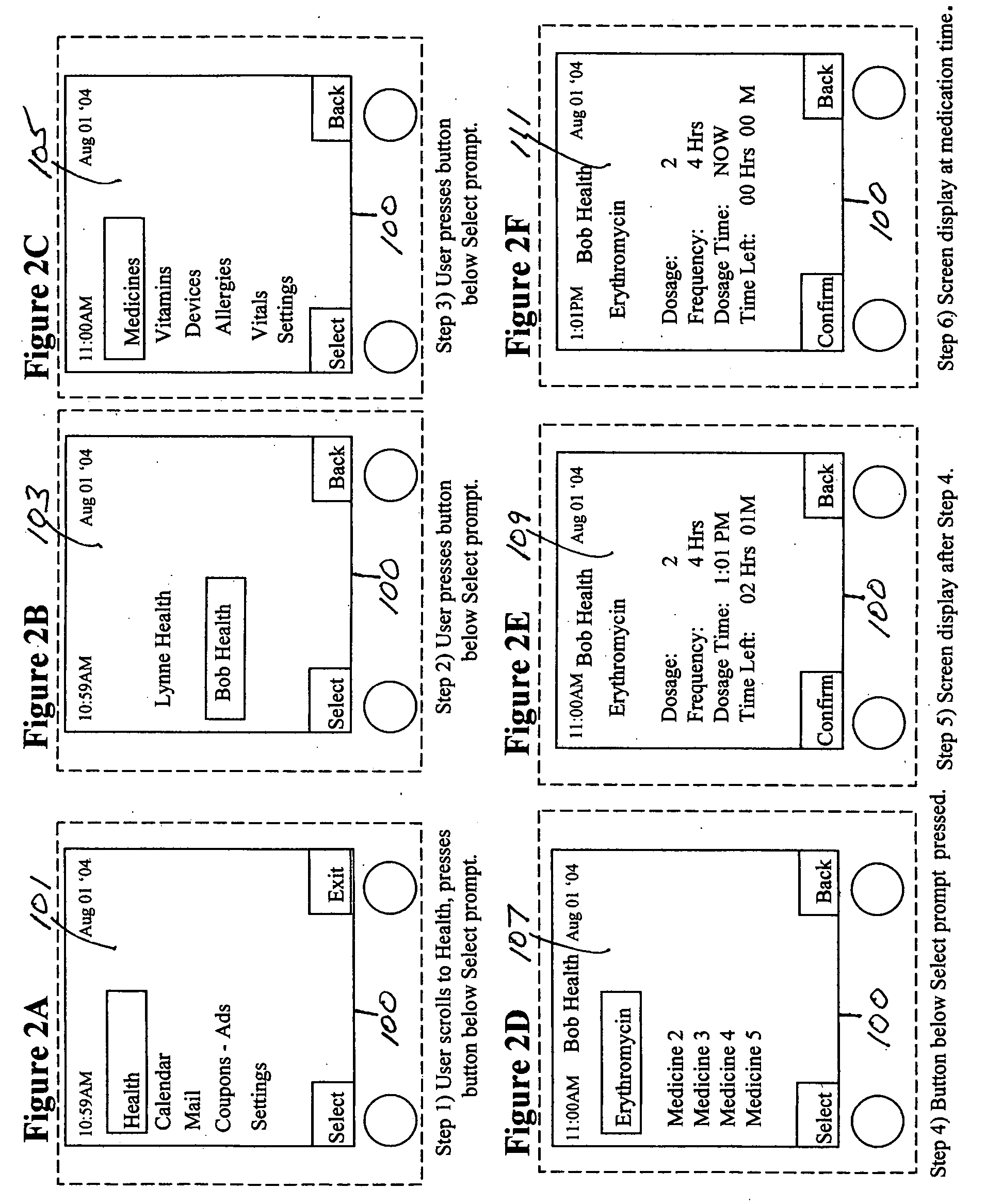

InactiveUS20060154642A1Facilitate user and/or occupant well beingExtended stayDispersed particle filtrationDrug and medicationsNetworked systemHealth administration

Systems and apparatuses include devices, biosensors, environmental sensors, security related sensors, networked products, communications processors and components, alert and information components, processors, and software to support: 1) facilitating medication regimen and patient / user health administration, dosage control, tracking, compliance, information inquiry and presentation, reminder and notification; 2) providing monitoring, information, ordering, and intervention; 3) presenting the option of leveraging the preventative care, alert and notification components with other components to facilitate user or occupant well being, along with living, work area and dwelling environmental or security safety; and 4) enhancing the dwelling, living or work area with products that may be networked to support the widespread acceptance of these systems and apparatuses. The systems include a) processing, centralizing and communicating device commands and / or programs, e.g. a multifunctional device controller; b) device administration; c) patient / user information; d) dwelling environmental safety; e) security breach information; f) centralized and remote apparatus and system activations through primary component or at least one backup.

Owner:INSIGNIO TECH

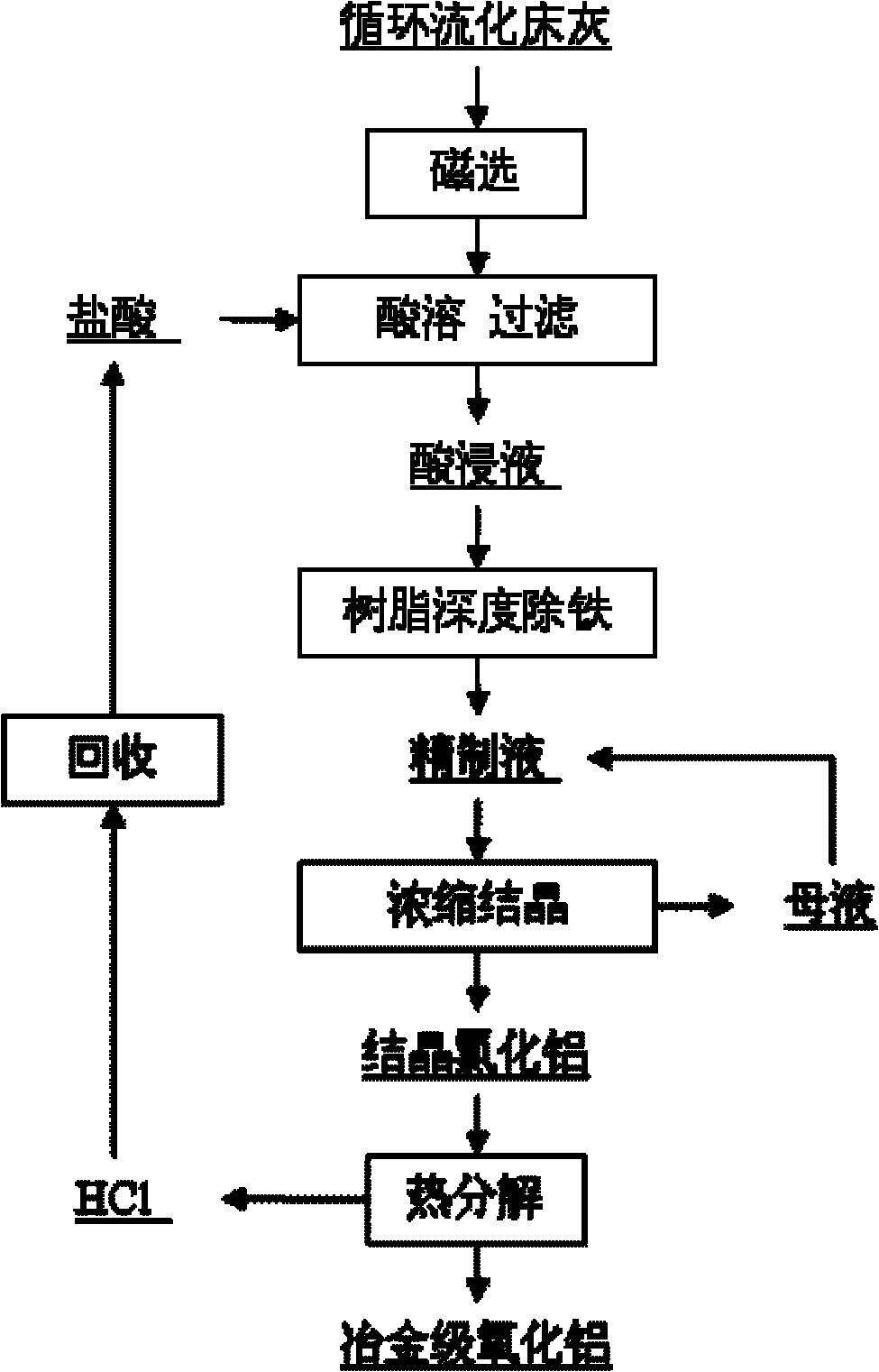

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

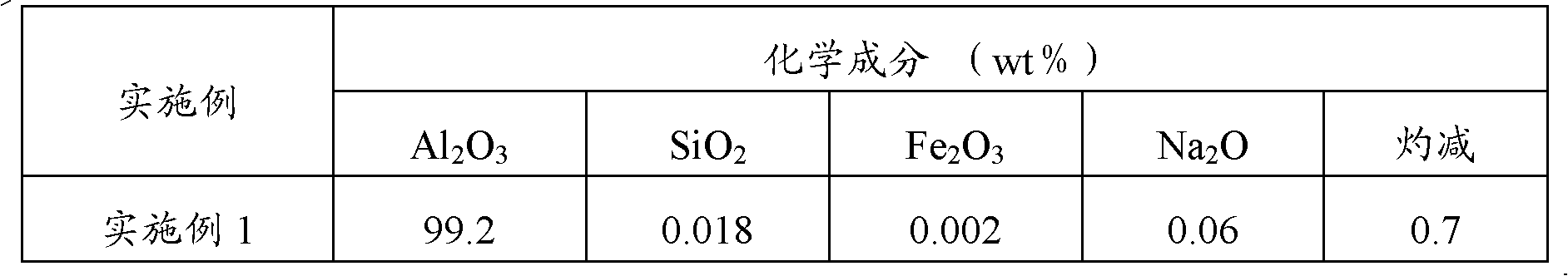

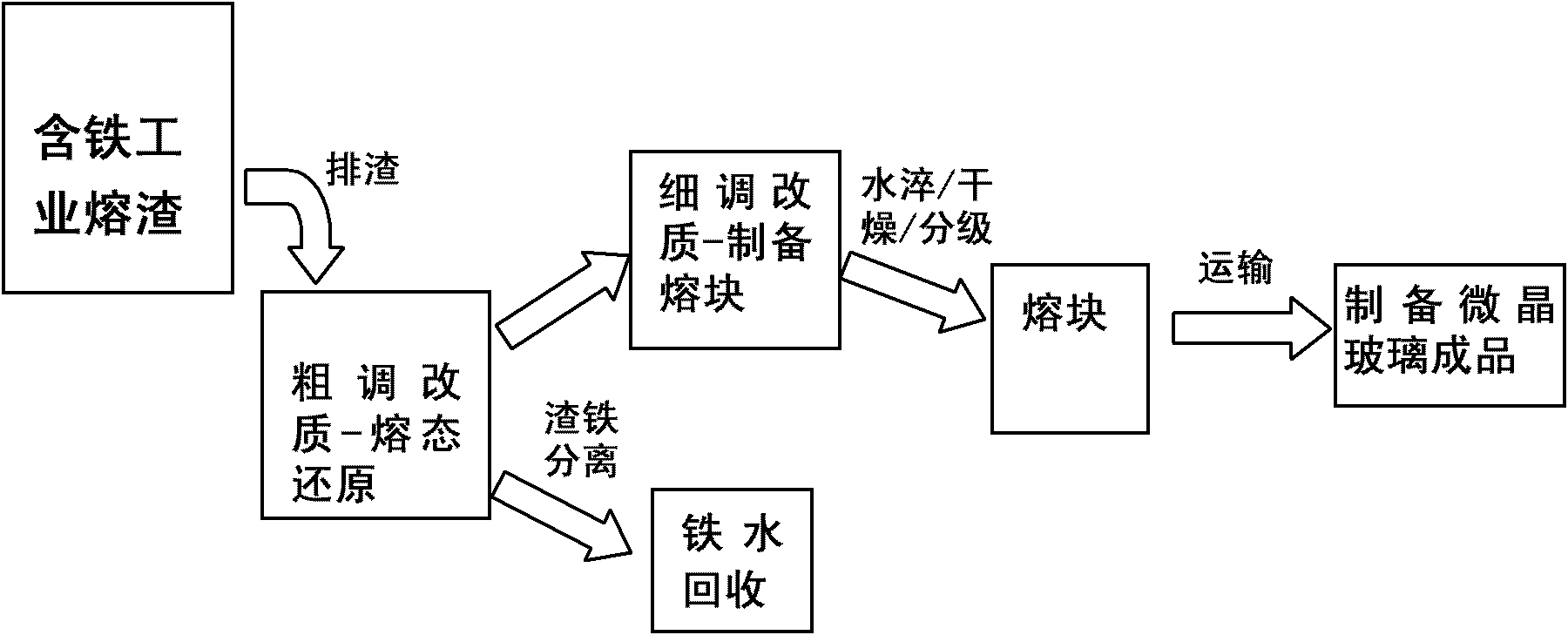

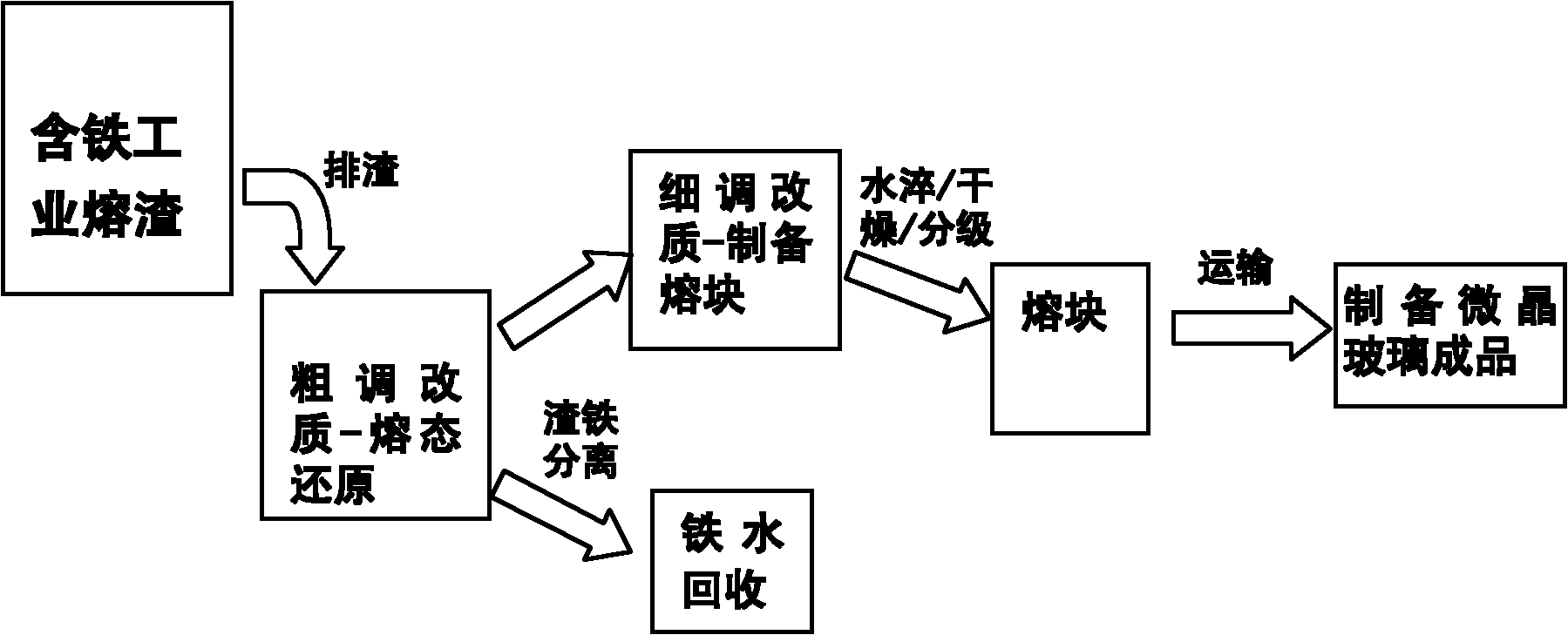

Method for recycling iron on line from iron-containing industrial slag and preparing glass ceramics frit

InactiveCN101914639AGuaranteed slag compositionRecycling and recovery technologiesProcess efficiency improvementMaterials preparationSlag

The invention relates to a method for recycling iron on line from iron-containing industrial slag and preparing a glass ceramics frit, belonging to the technical field of resource comprehensive utilization and material preparation and mainly comprising a two-step method process of iron-containing industrial slag online rough adjustment and modification for reducing iron and fine adjustment and modification for preparing the frit. The method comprises the steps of: discharging high-temperature iron-containing slag into a high-temperature furnace device, and simultaneously adding a reducing agent and a modifying agent to ensure that slag components are adjusted to reach the optimal component point in which iron oxide is reduced; after fully reacted, separating reduced molten iron from the slag, and recycling to obtain high-temperature molten iron; further adding a modifying agent and an adjusting agent into the slag remained after the separation to ensure that the slag components are adjusted to achieve the quality requirement of slag glass ceramics on the frit; and water-hardening, drying and grading the qualified slag to prepare the glass ceramics frit. The invention realizes multiple purposes that the heat of the slag is directly utilized and metal iron is recycled to prepare a high addition value product as well as solid wastes are massively utilized, and the like.

Owner:UNIV OF SCI & TECH BEIJING

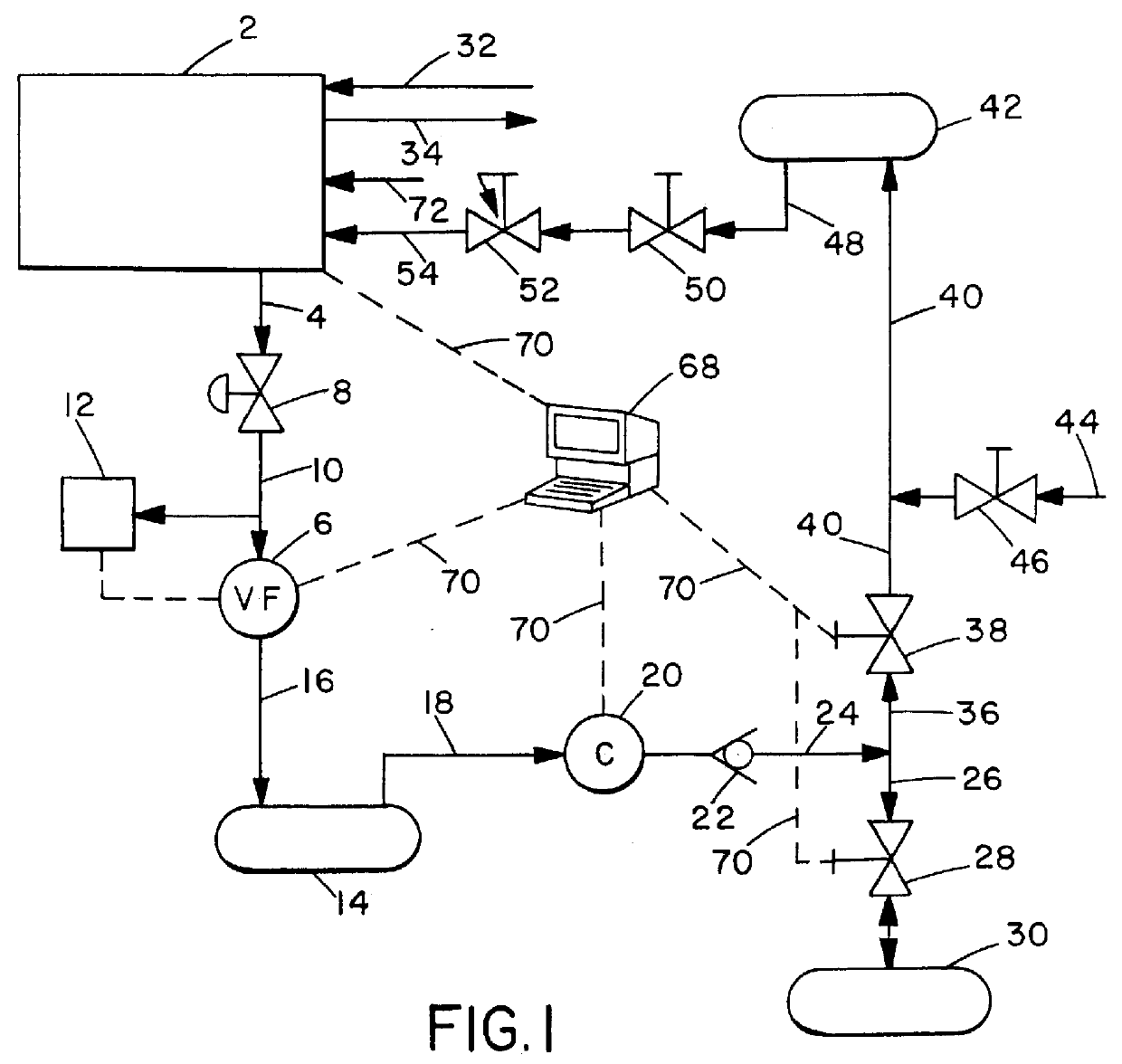

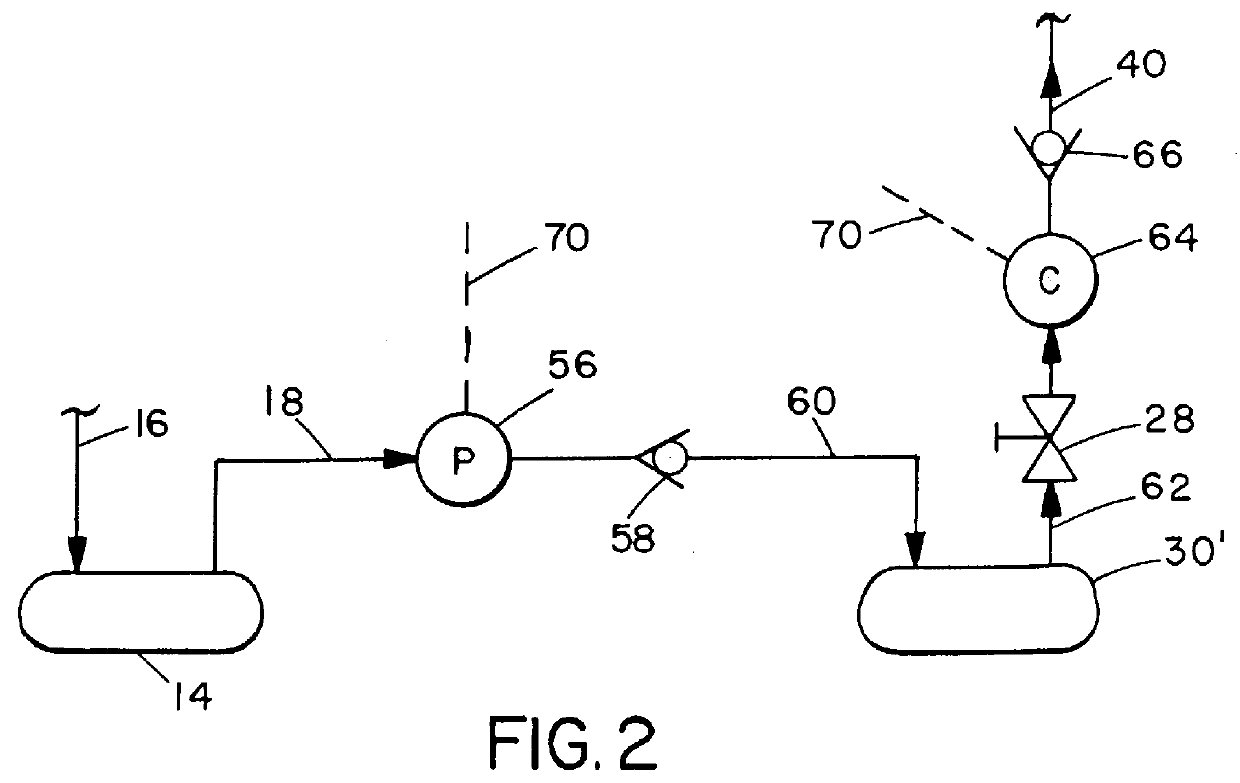

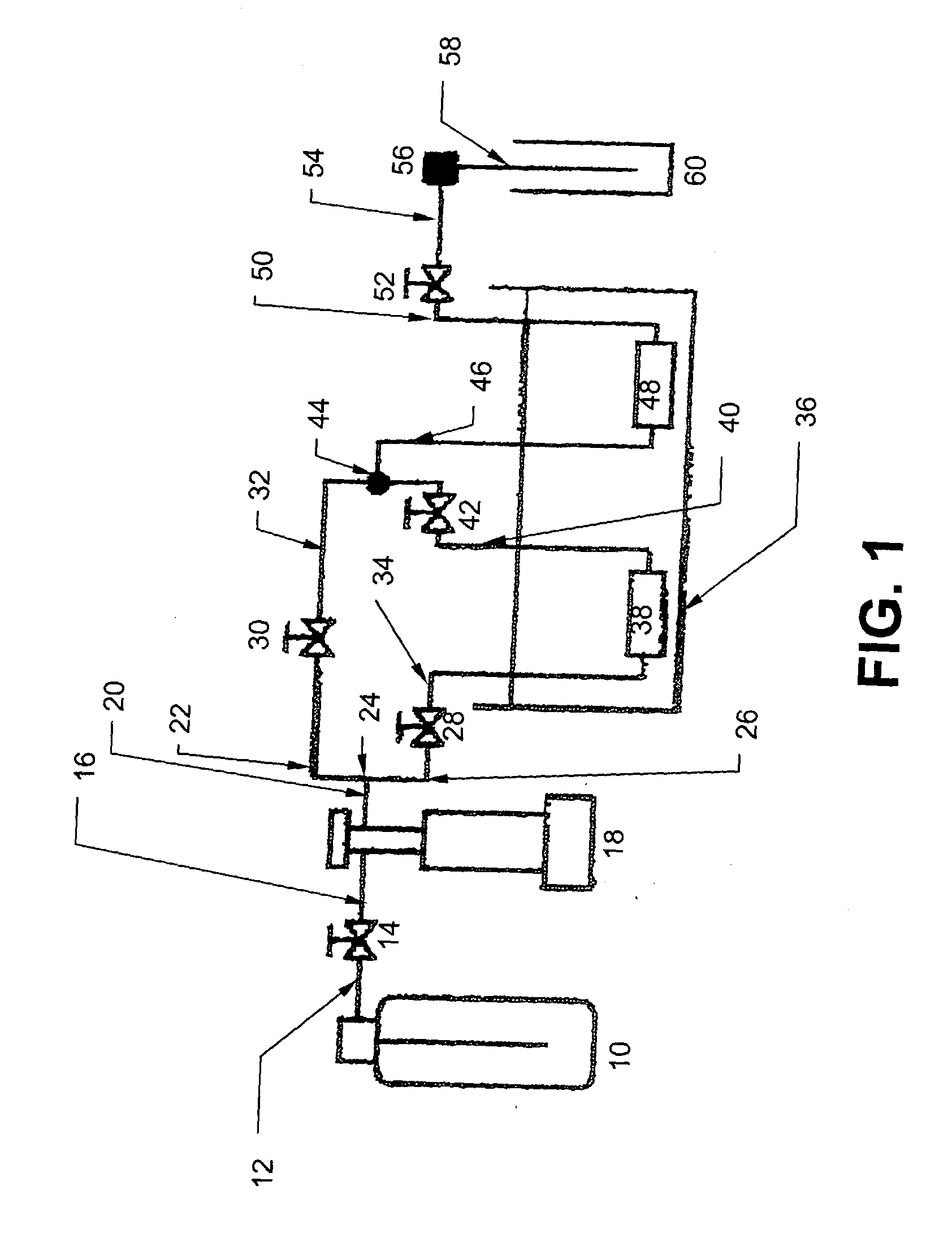

Method for recovery and reuse of gas

A gas recovery and reuse / recycle method is disclosed which can readily and economically recover valuable and / or environmentally hazardous gases from a manufacturing or chemical process and then return the gas to the process for reuse, and repeat this many times without significant contamination or degradation of the gas or the produced products. All gas transport, compression and storage equipment is designed and maintained so that it is non-contaminating to the process gas. Commonly the process gas will be a Group VIII gas, preferably He, Ne, Kr or Xe, or a gas which comprises a hazard to the ambient environment or beings therein, such as a carbon oxide gas, a halocarbon gas, an acid-precursor gas, a biologically hazardous gas, or a radioactive gas.

Owner:ENTEGRIS INC

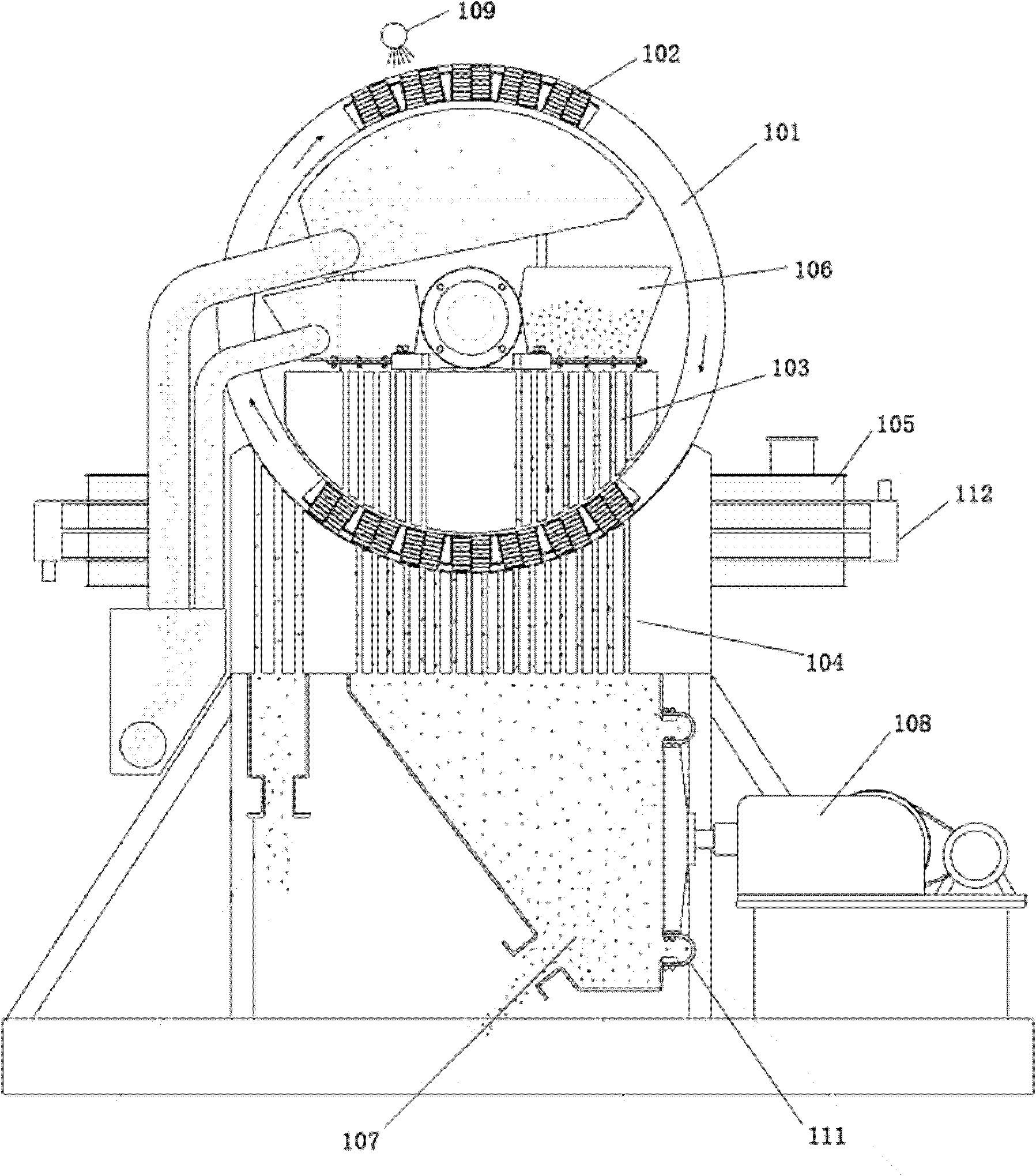

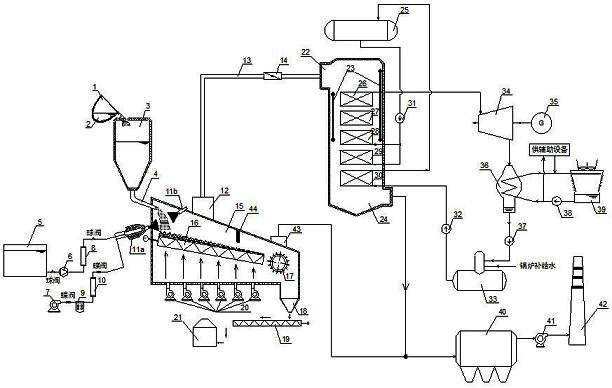

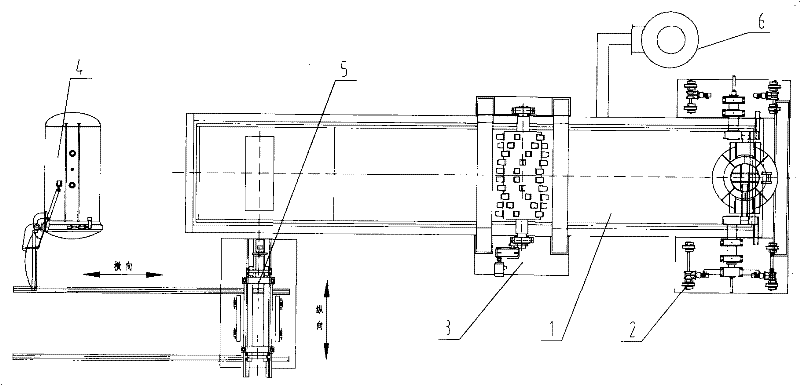

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

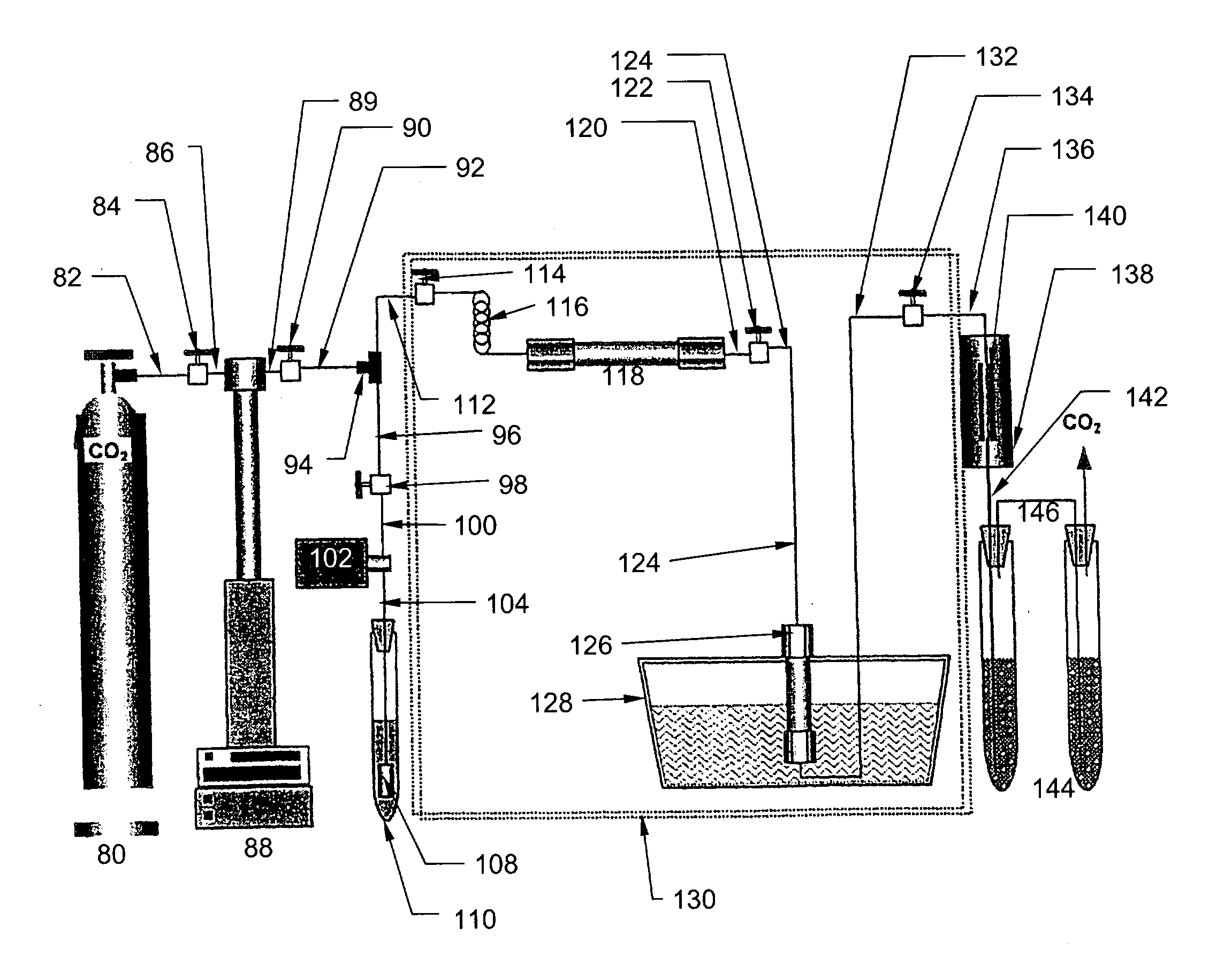

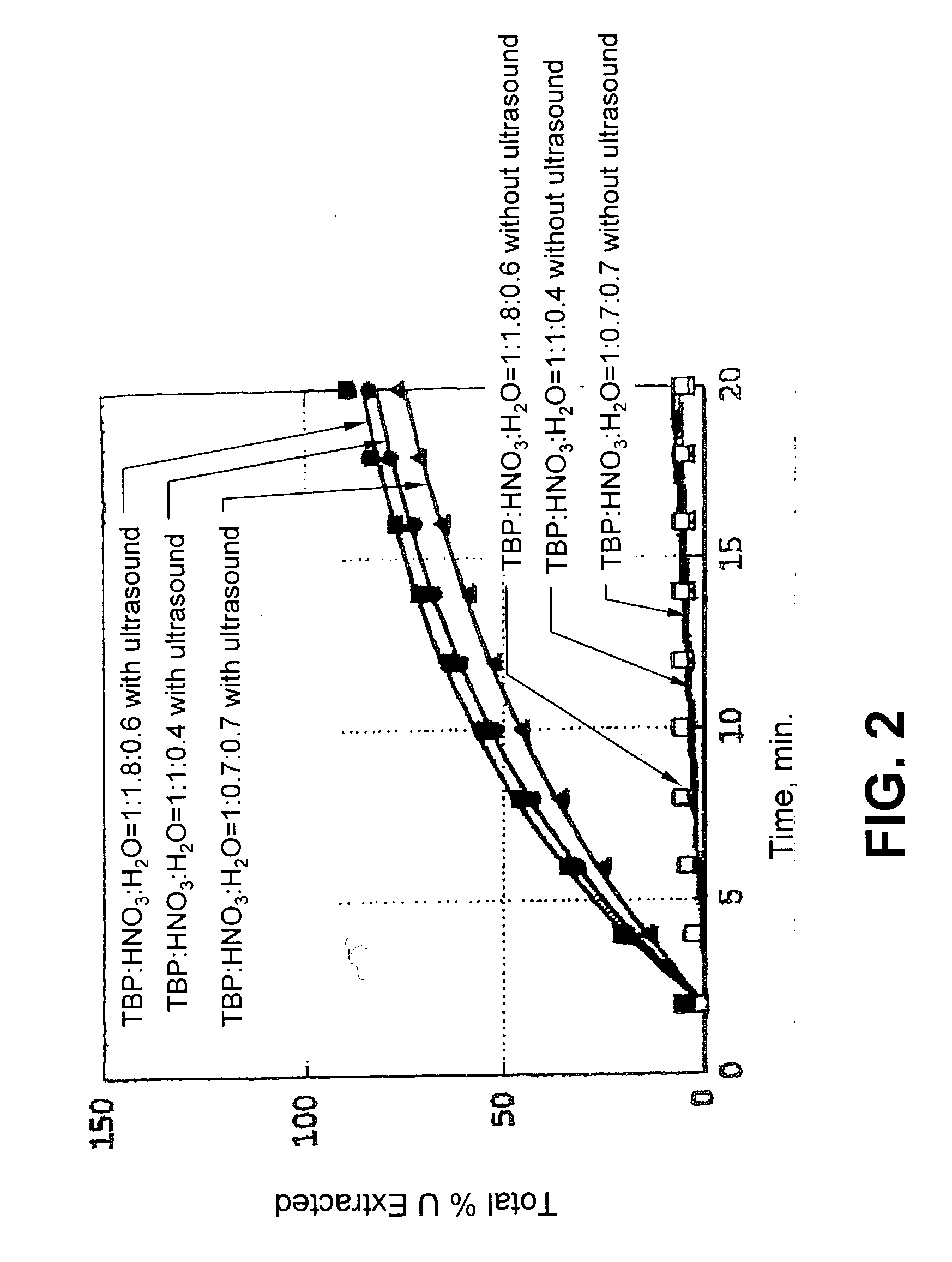

Ultrasound enhanced process for extracting metal species in supercritical fluids

InactiveUS20030183043A1Enhances rate and efficiencyReduce probabilitySolid sorbent liquid separationGold compoundsUranium oxidePresent method

Improved methods for the extraction or dissolution of metals, metalloids or their oxides, especially lanthanides, actinides, uranium or their oxides, into supercritical solvents containing an extractant are disclosed. The disclosed embodiments specifically include enhancing the extraction or dissolution efficiency with ultrasound. The present methods allow the direct, efficient dissolution of UO2 or other uranium oxides without generating any waste stream or by-products.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST +1

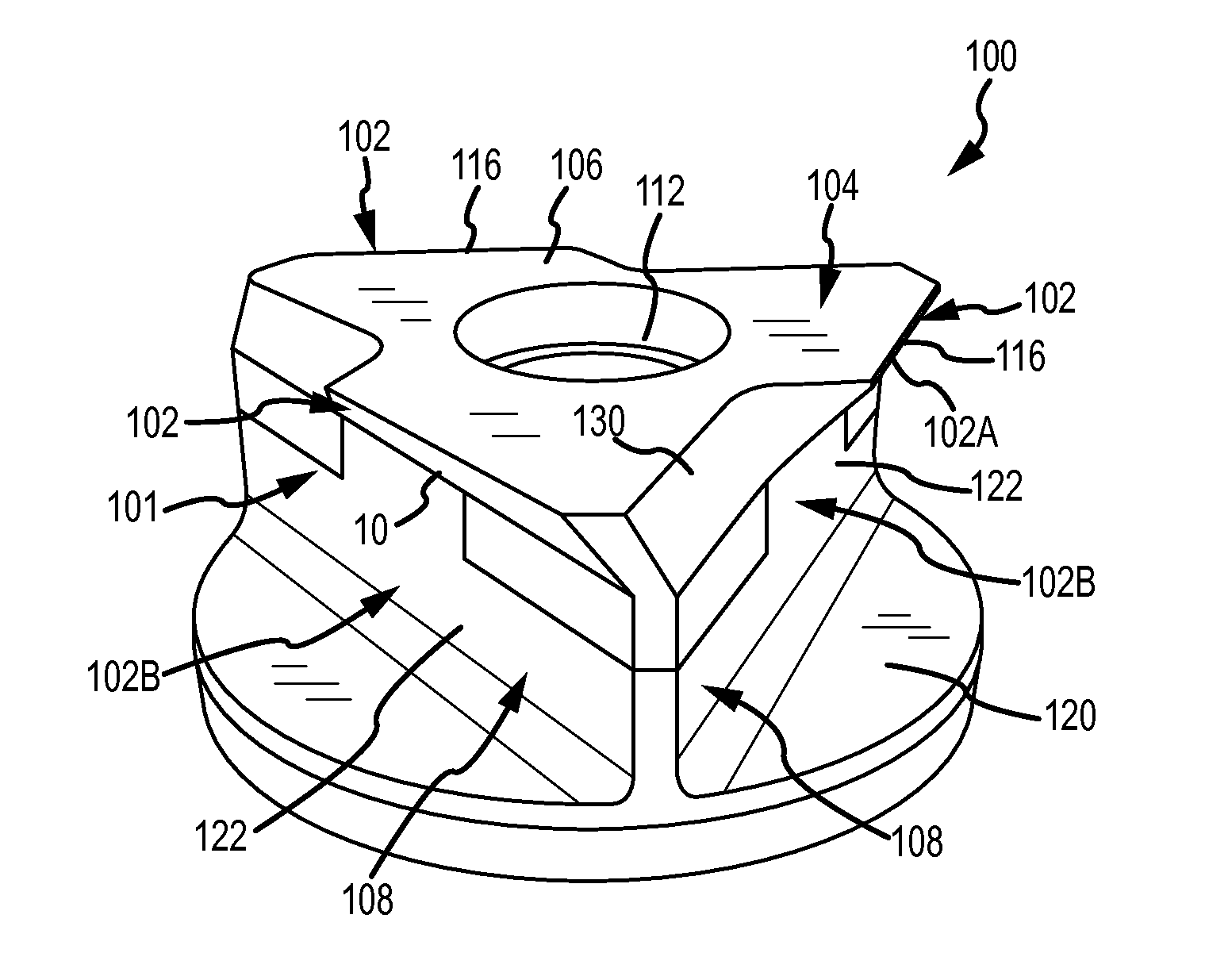

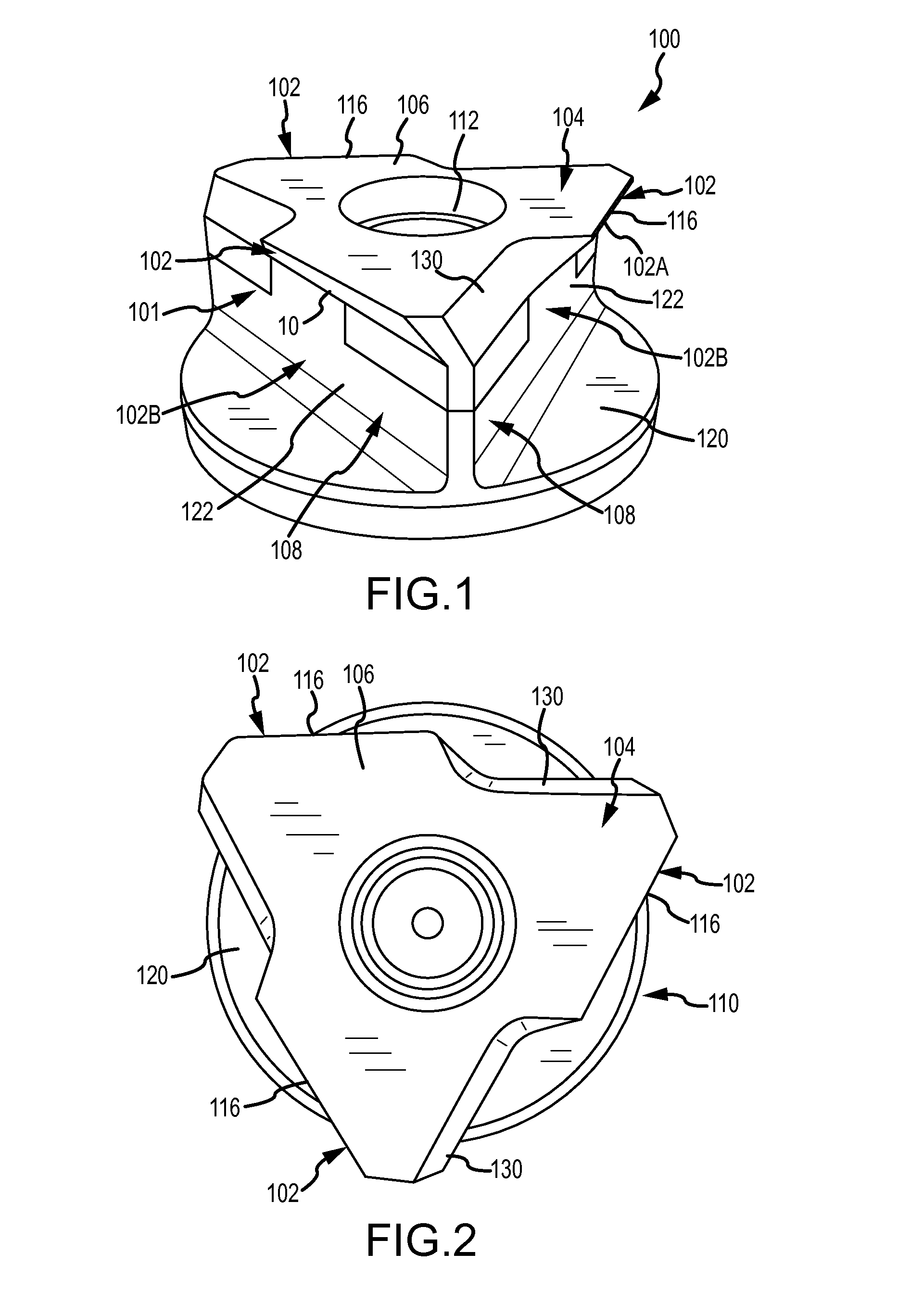

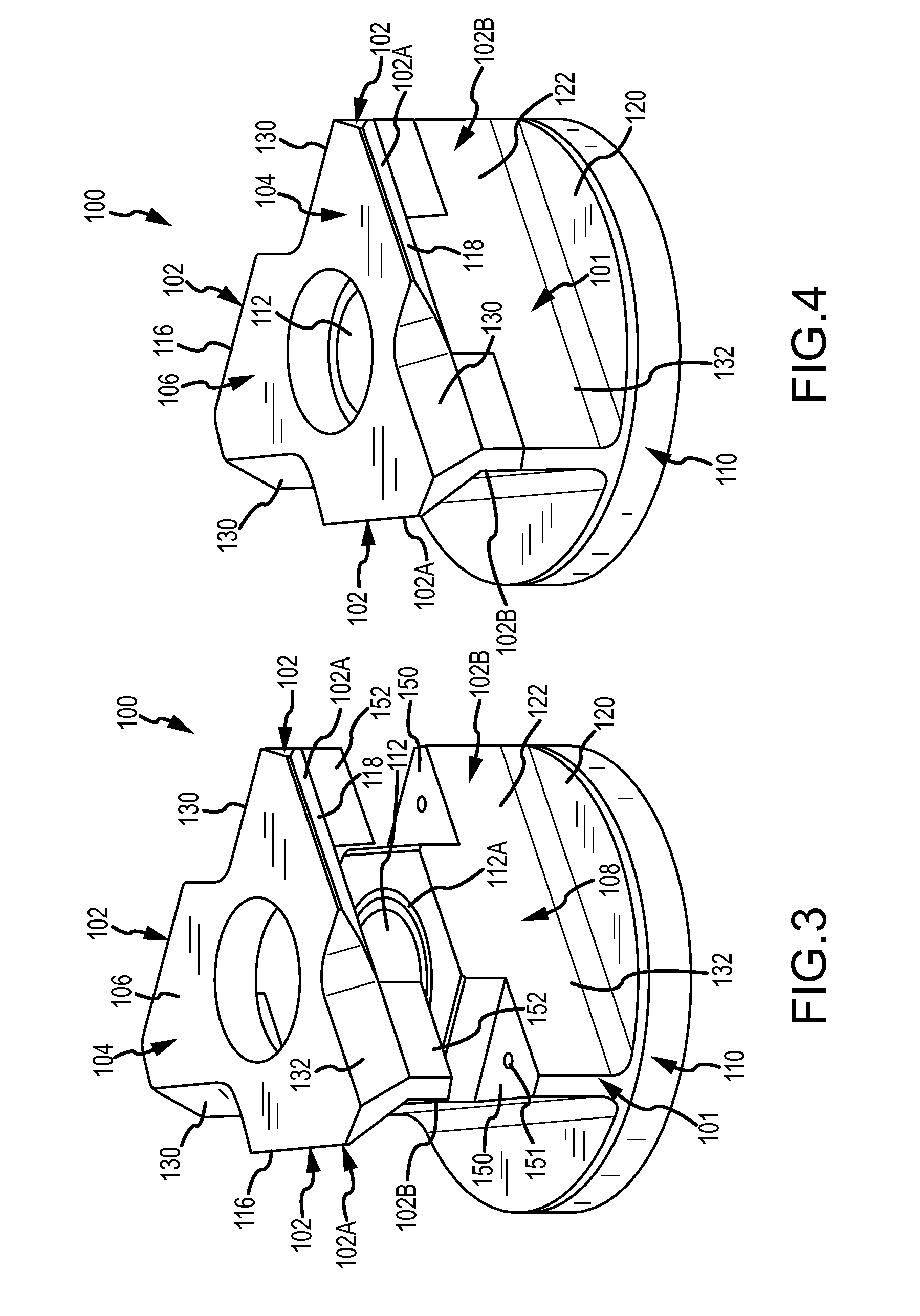

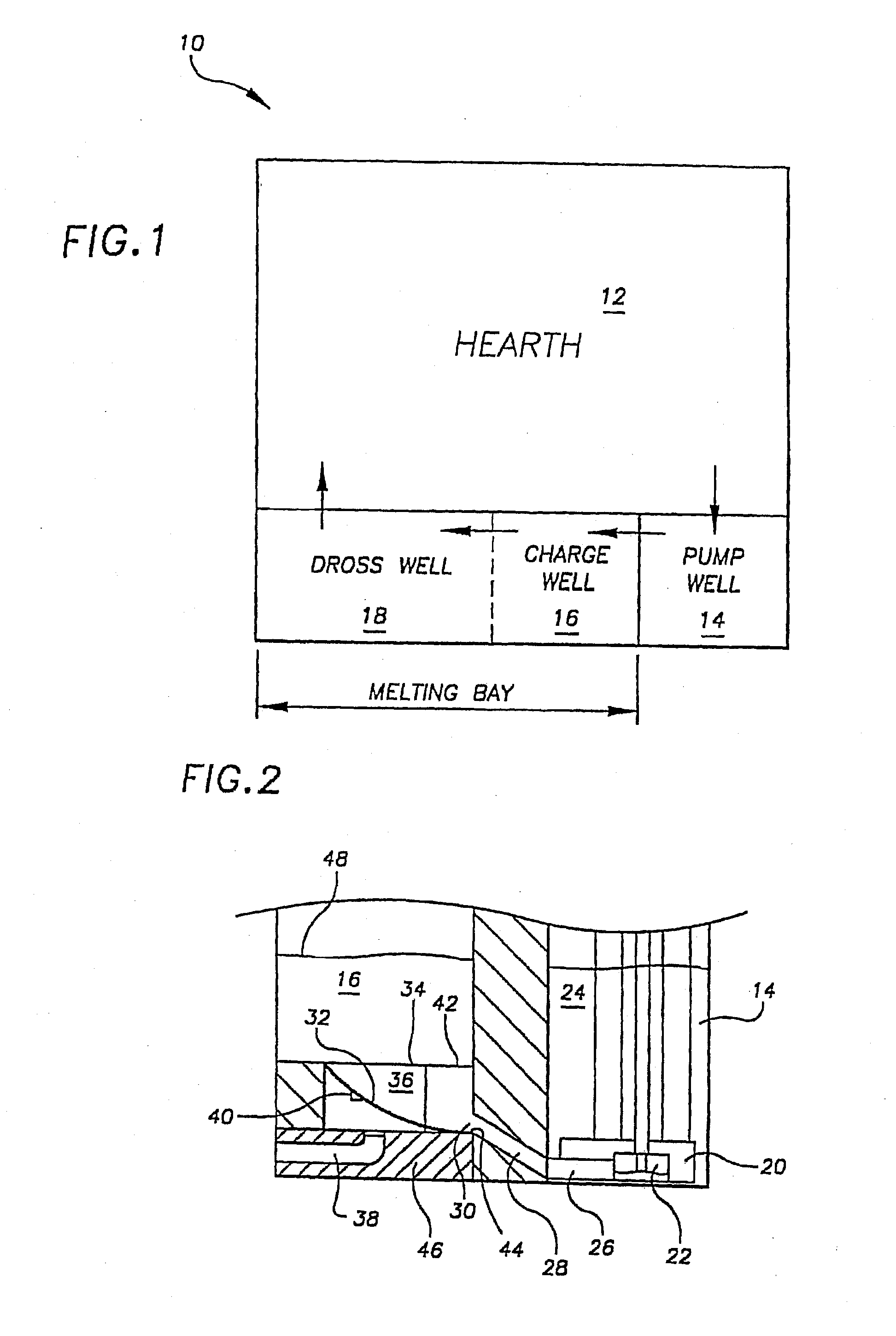

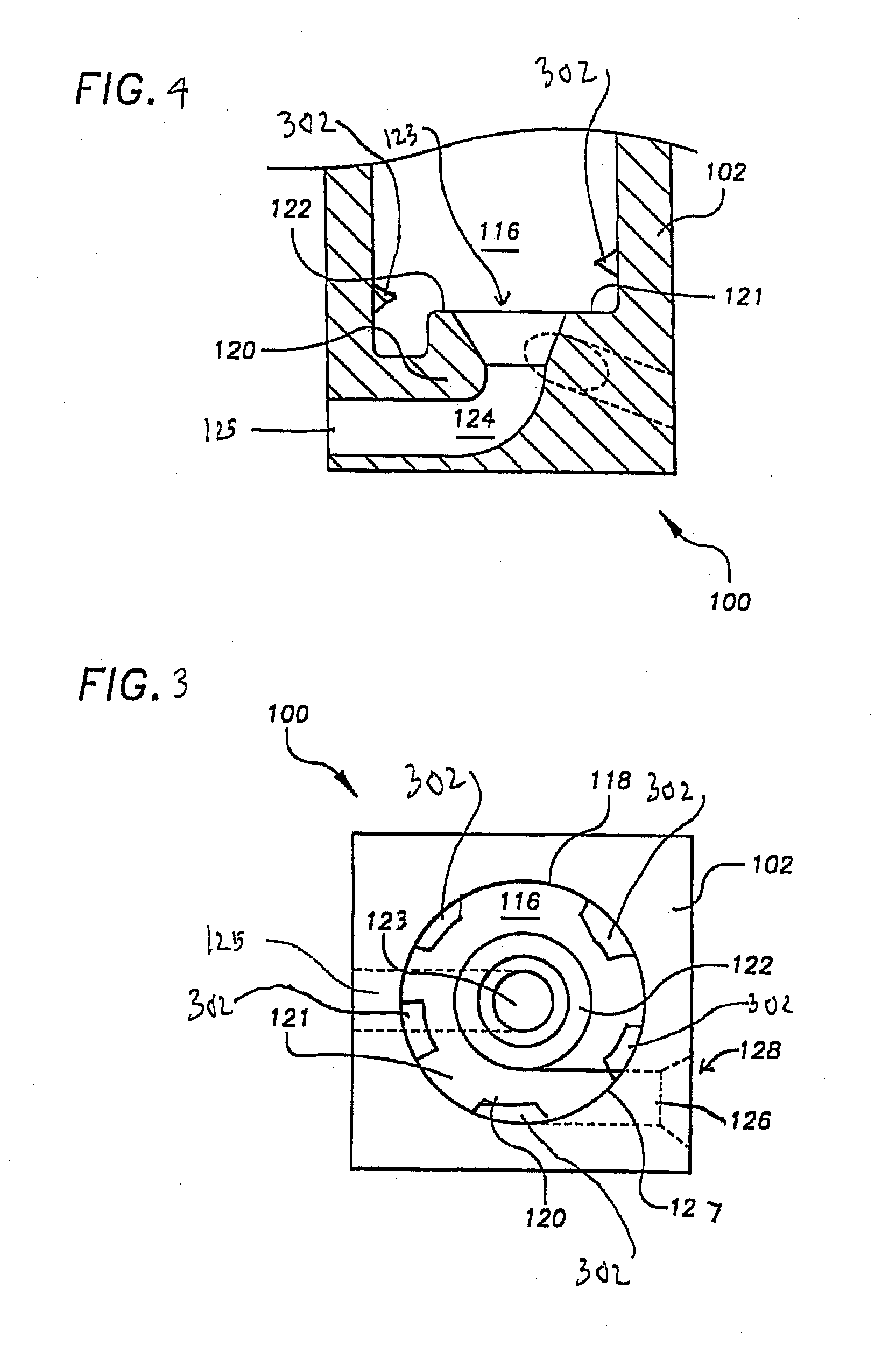

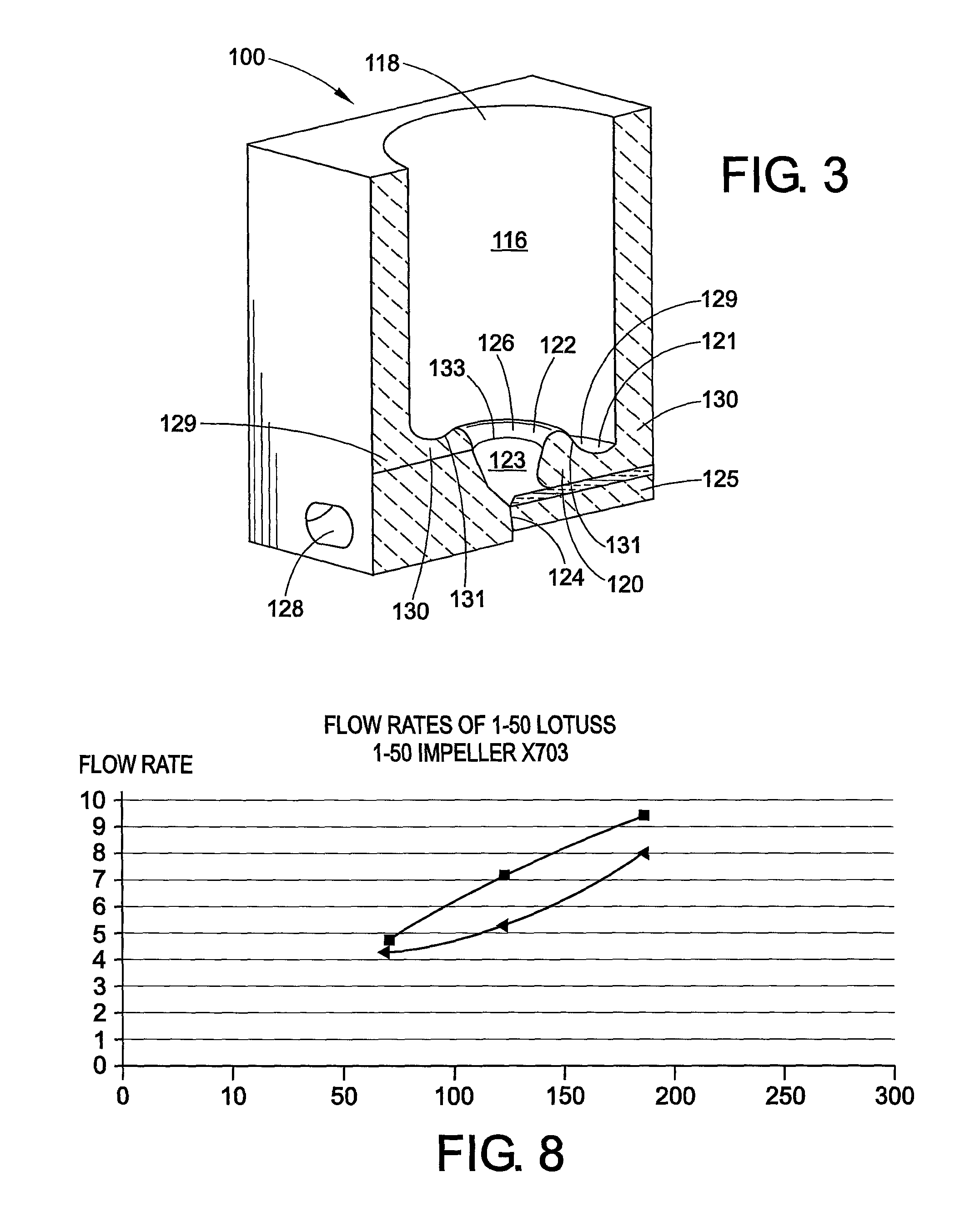

Molten metal rotor with hardened top

Embodiments of the invention are directed to a rotor for a molten metal pump and a molten metal pump including the rotor. The rotor has a main body and a top comprised of a material that is at least twice as hard as the main body. The top, among other things, may form a first portion of each rotor blade wherein the first portion directs molten metal into a pump chamber or other structure in which the rotor is mounted.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

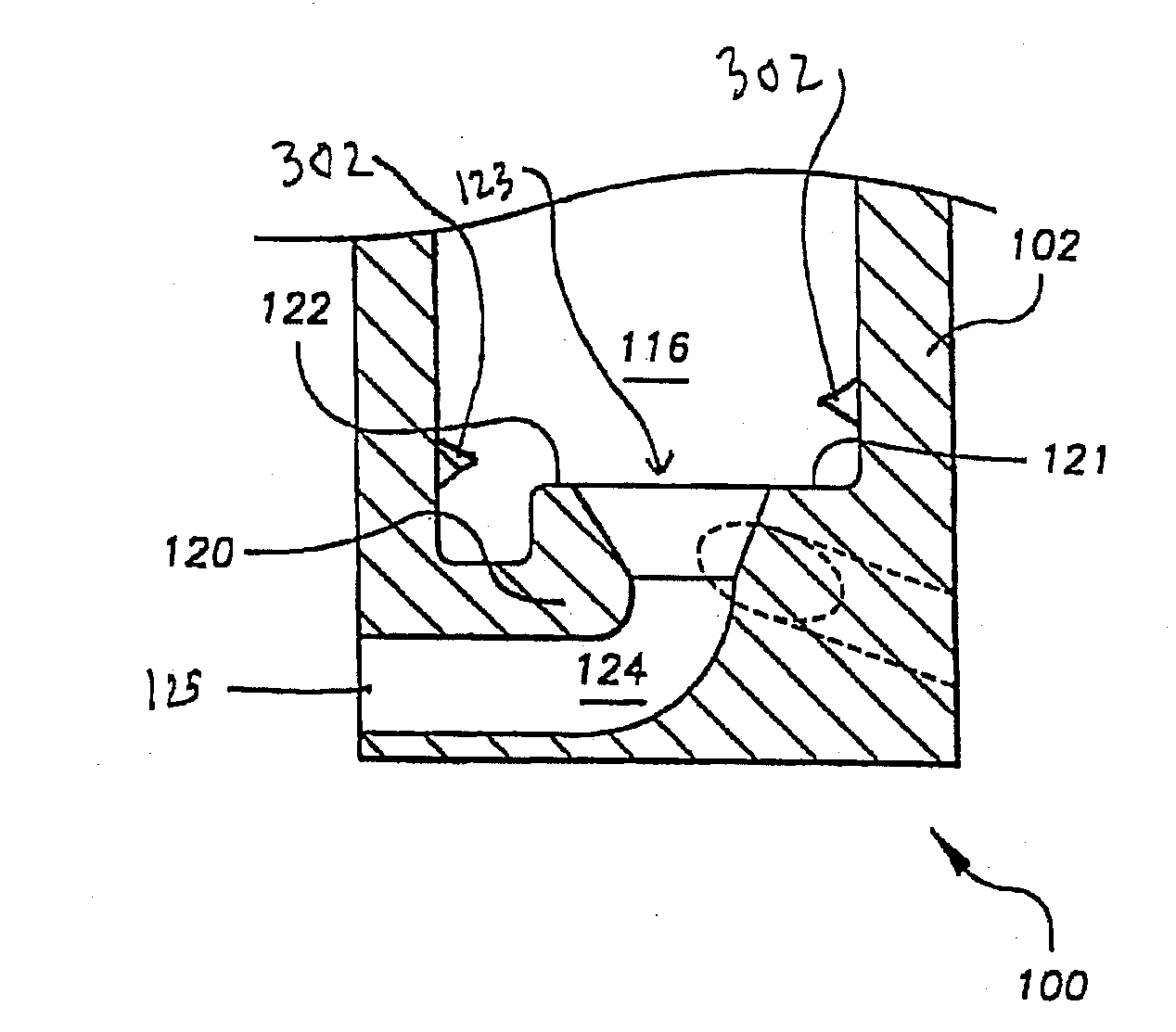

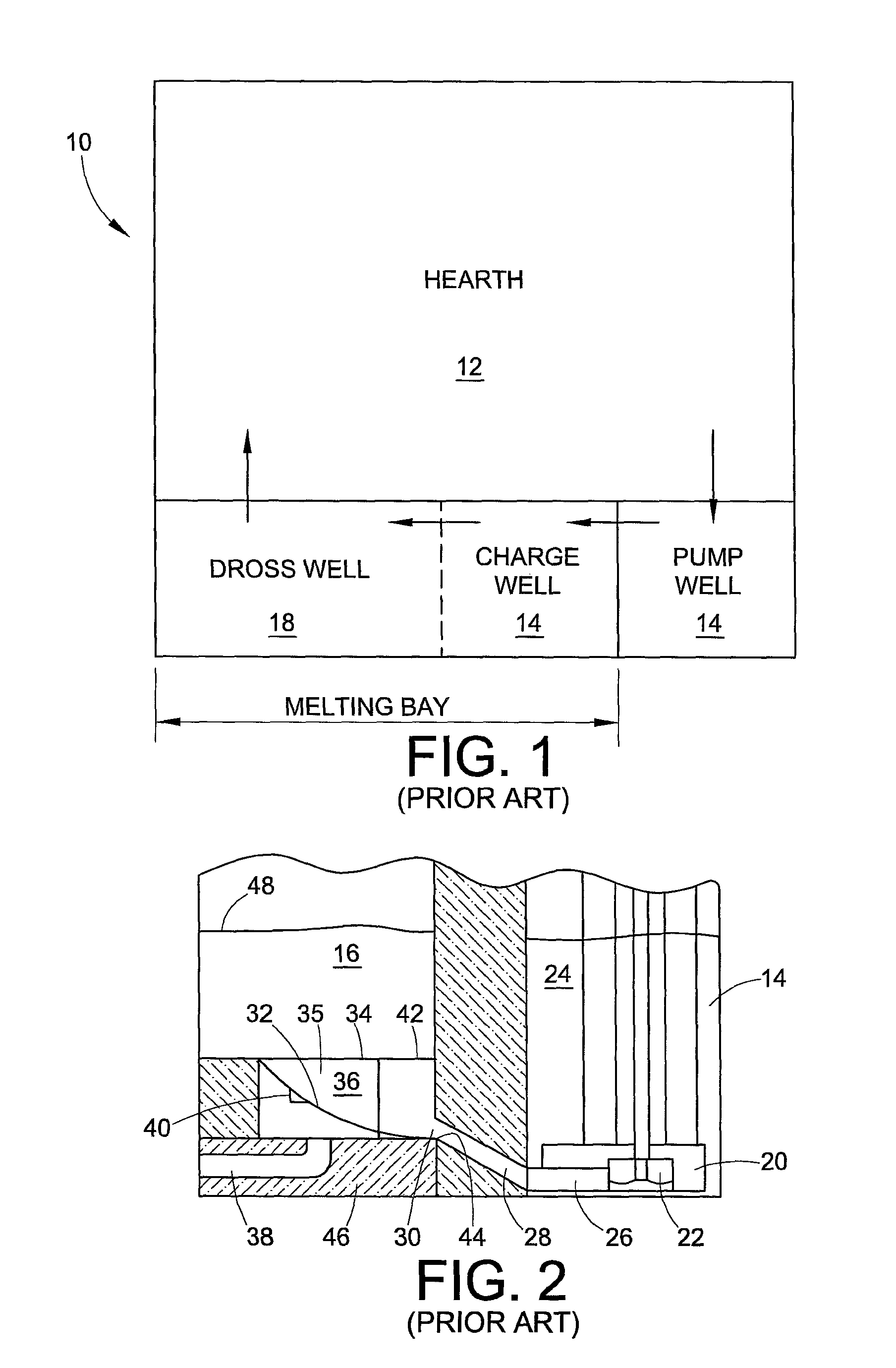

Molten metal scrap submergence apparatus

A metal scrap submergence device comprising an open top chamber including walls of a heat resistant material, an inlet positioned in a side wall of the chamber, an outlet positioned in the base of said chamber, and a ramp adjacent said side wall of the chamber. The side wall further includes a feature affecting molten metal flow. The feature can include, for example, a baffle, a vane, a passage, a diverging or converging shape and combinations thereof. Similarly, the molten metal flow can be affected by slanting the ramp inwardly or outwardly.

Owner:PYROTECK INC

Wear resistant low friction coating composition, coated components, and method for coating thereof

A composition for coating sliding or rolling or fretting or impacting members is formed by preparing a composite powder of TiB2 and BN, with a TiB2 to BN ratio ranging from 1:7 to 20:1, and a metallic matrix selected from the group consisting of nickel, chromium, iron, cobalt, aluminum, tungsten, carbon and alloys thereof.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

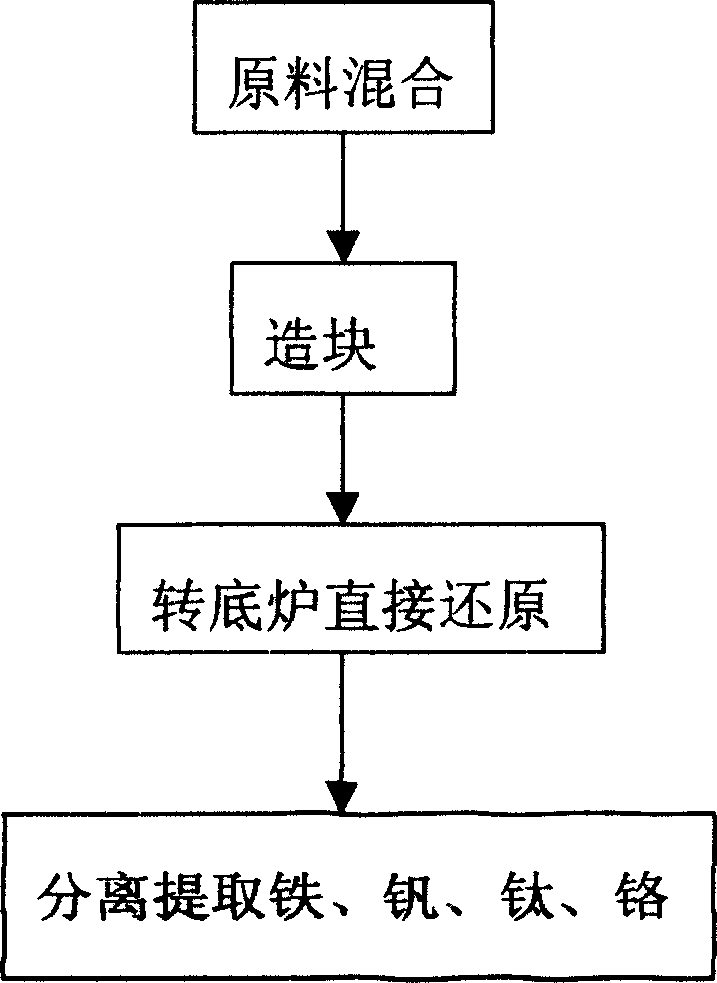

Method for separating and extracting metal element from varadium-titanium magnetite

InactiveCN1641045AFast reduction reactionShort recovery timeRecycling and recovery technologiesProcess efficiency improvementSlagAdhesive

The technological process of separating and extracting metal elements from V-Ti iron ore includes the steps of: agglomerating ore powder of mixing V-Ti iron ore powder, reductant, additives and adhesive, pressing the mixture into 10-25 mm diameter agglomerates and drying at 80-90 deg.c; reducing inside one bottom rotating furnace to obtain metal products; smelting the metal products in an electric furnace to obtain molten iron and V-Ti slag component, and smelting the V-Ti slag component to obtain V-Cr oxide and Ti slag as the material for producing titanium while. The present invention has high reduction temperature, fast reduction speed, short reduction time, high production efficiency, high metal and V-Ti recovering rate and less environmental pollution.

Owner:SICHUAN LOMON MINING & METALLURGY

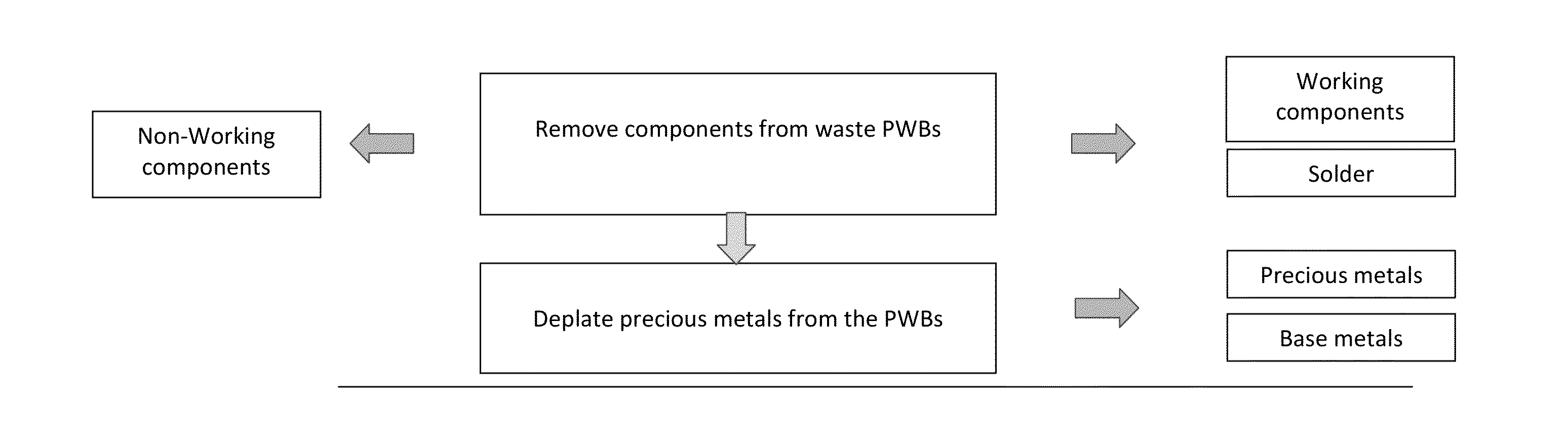

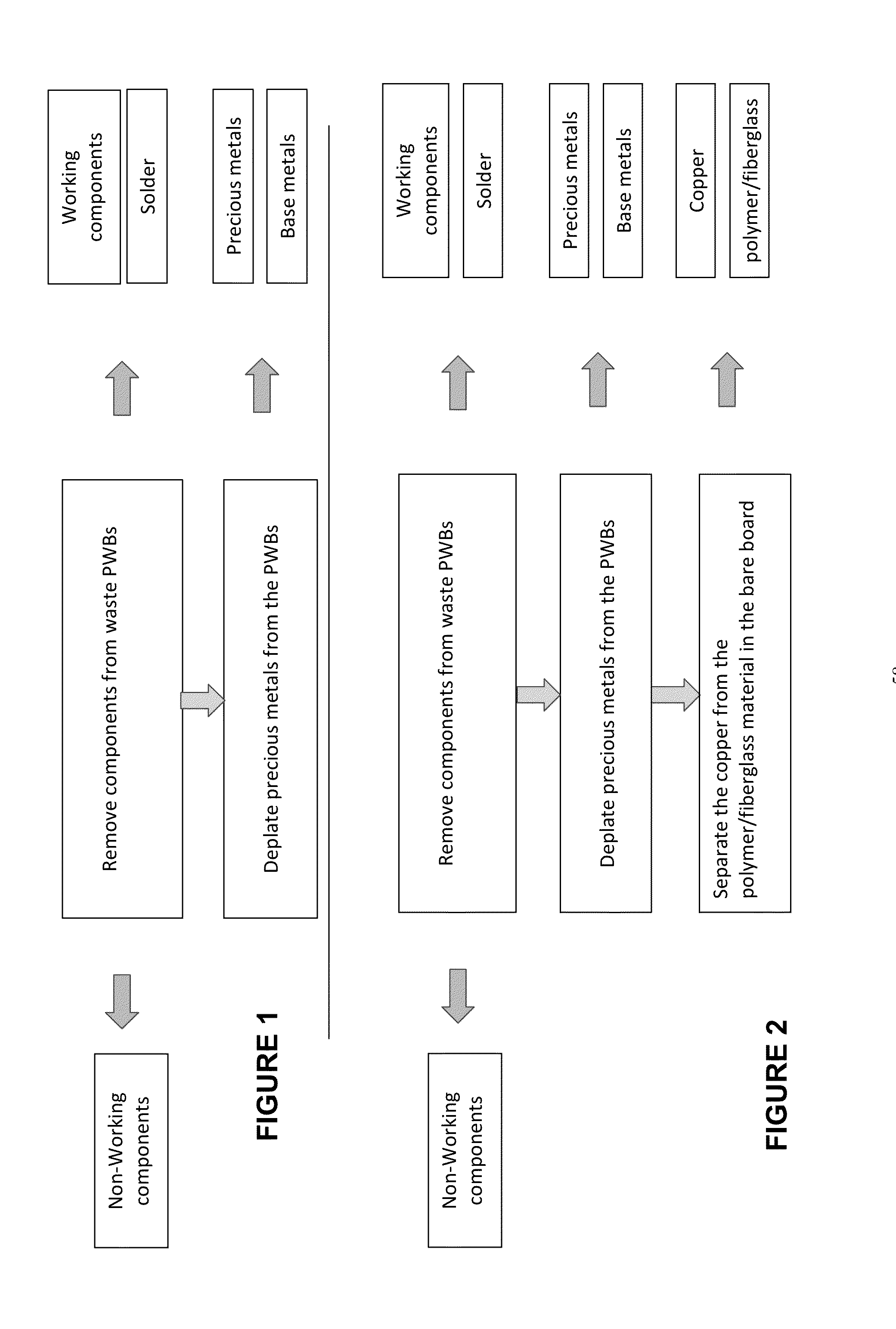

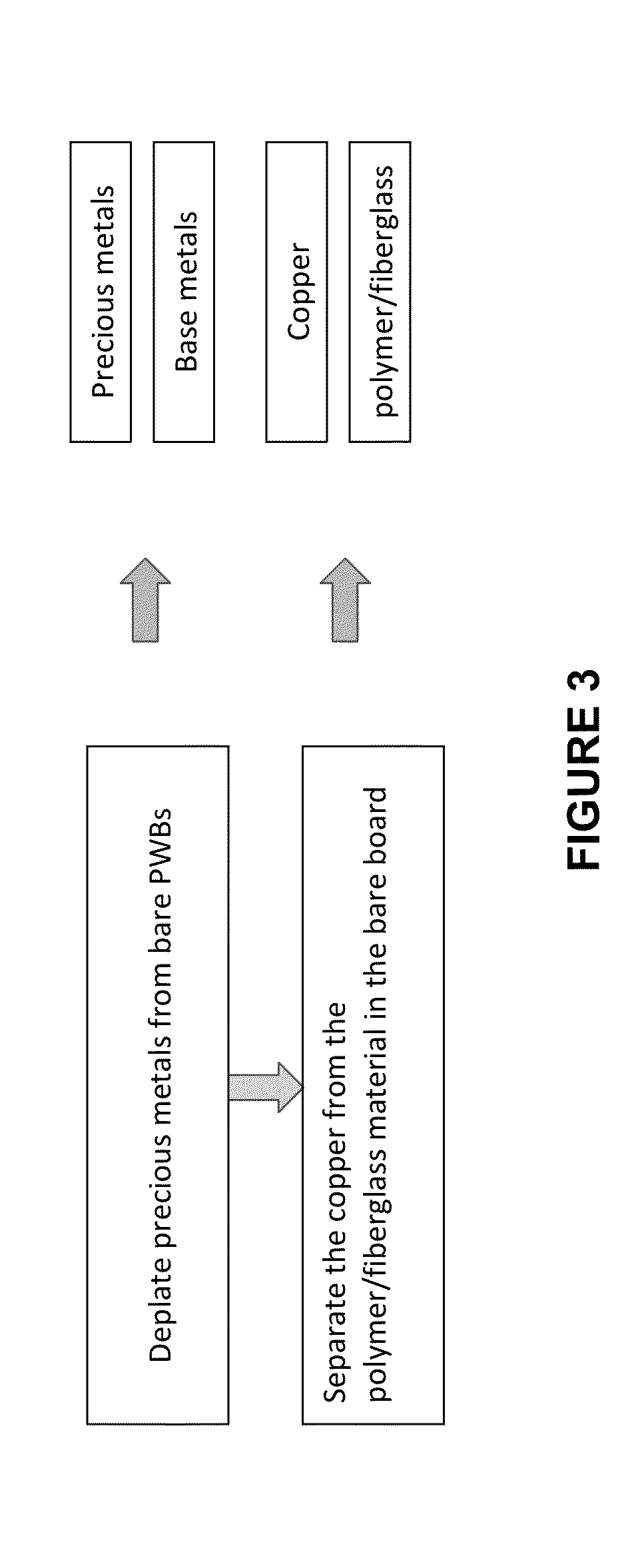

Method for recycling of obsolete printed circuit boards

ActiveUS20130276284A1Final product manufactureRecycling and recovery technologiesElectronic componentMaterials science

Owner:ENTEGRIS INC

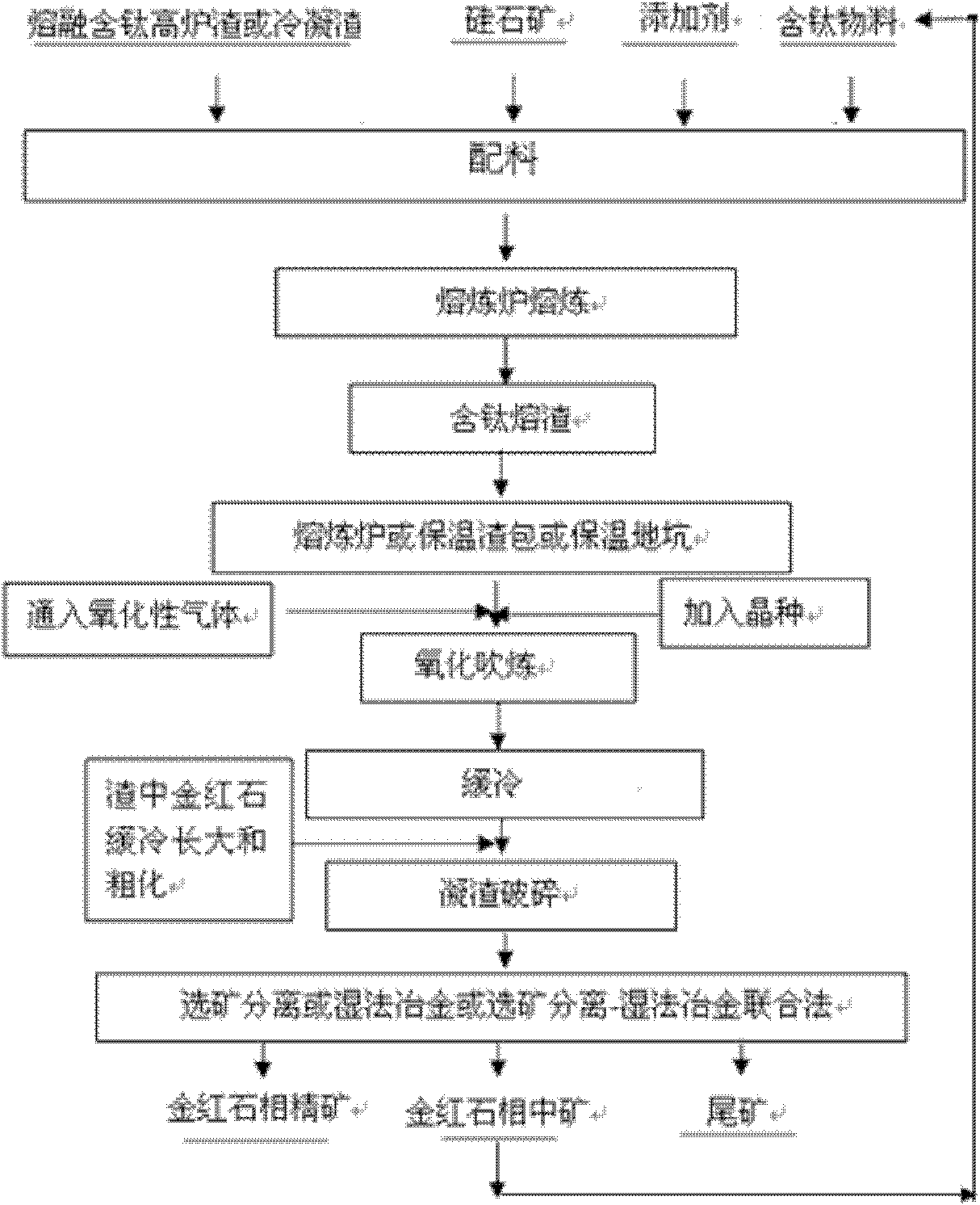

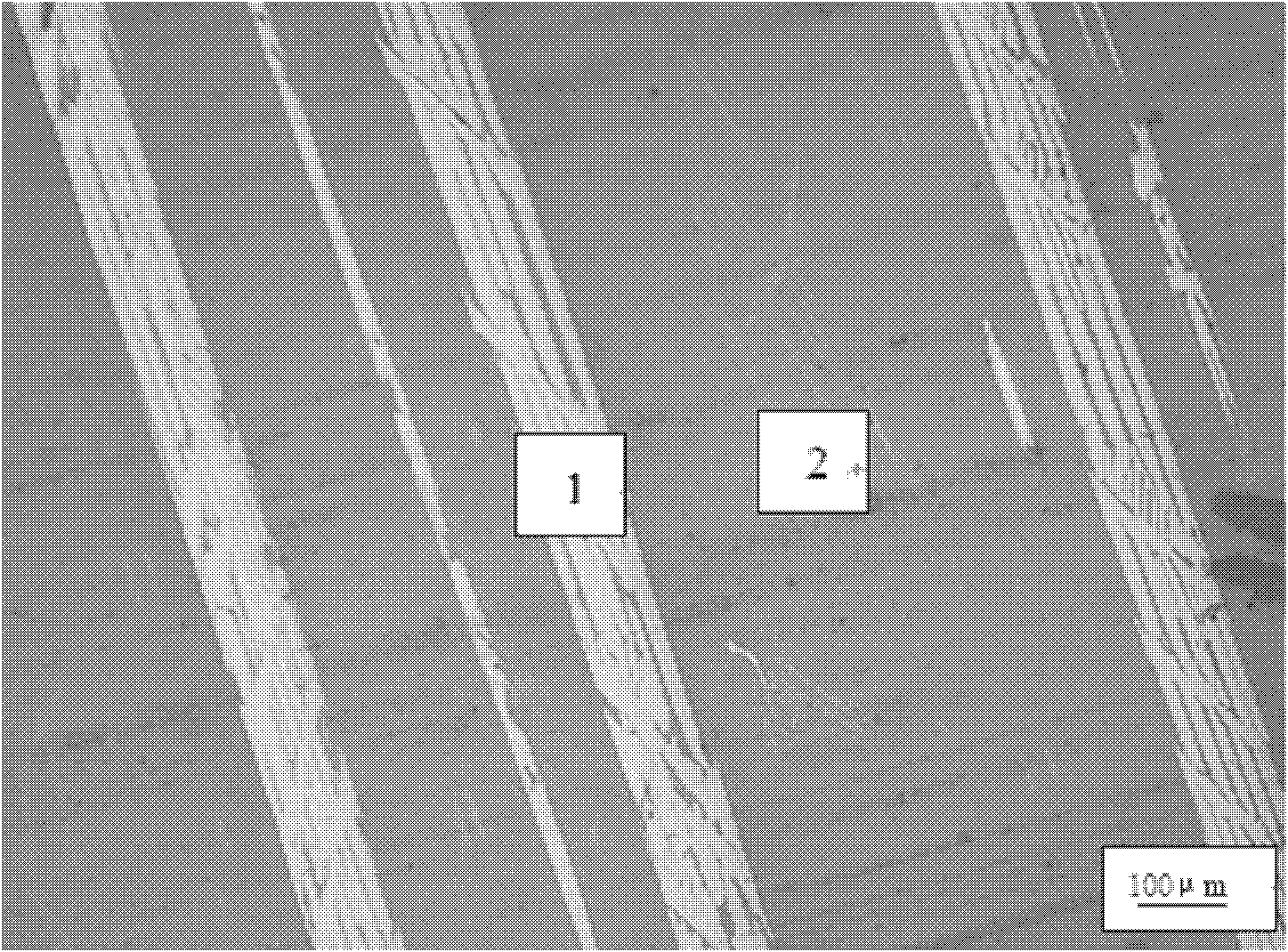

Method for producing artificial rutile from titanium-containing blast furnace slags

ActiveCN102154531ASimple compositionPromote coarseningRecycling and recovery technologiesProcess efficiency improvementTitaniumMolten slag

The invention provides a method for producing artificial rutile by taking the titanium-containing blast furnace slags as the raw material. The method has the advantages of short reaction time, high titanium recovery, low production cost, big treatment capacity and high product additional value and is environment-friendly. The method comprises the following steps: burdening: adding smelted or condensed titanium-containing blast furnace slags, a titanium-containing material, silica ores and an additive into a smelting furnace; smelting: smelting by the smelting furnace to keep the mixture underthe fusing state; oxidation: spraying and blowing an oxidizing gas into slags in the smelting furnace, or pouring the slags into a heat insulation slag tank or a heat insulation pit, spraying and blowing an oxidizing gas into slags in the heat insulation slag tank or the heat insulation pit to convert the titanium-containing substances in the slags into the rutile phase; cooling: keeping the temperature for the oxidized slags in the heat insulation slag tank or the heat insulation pit, and controlling the cooling rate to cool the slags to room temperature to cause the rutile phase to grow; and separation: and finally, breaking and levigating the oxidation modification condensed slags to separate the rutile phase to obtain the artificial rutile with high TiO2 grade.

Owner:喀左县钒钛资源综合开发利用工程技术研究中心 +1

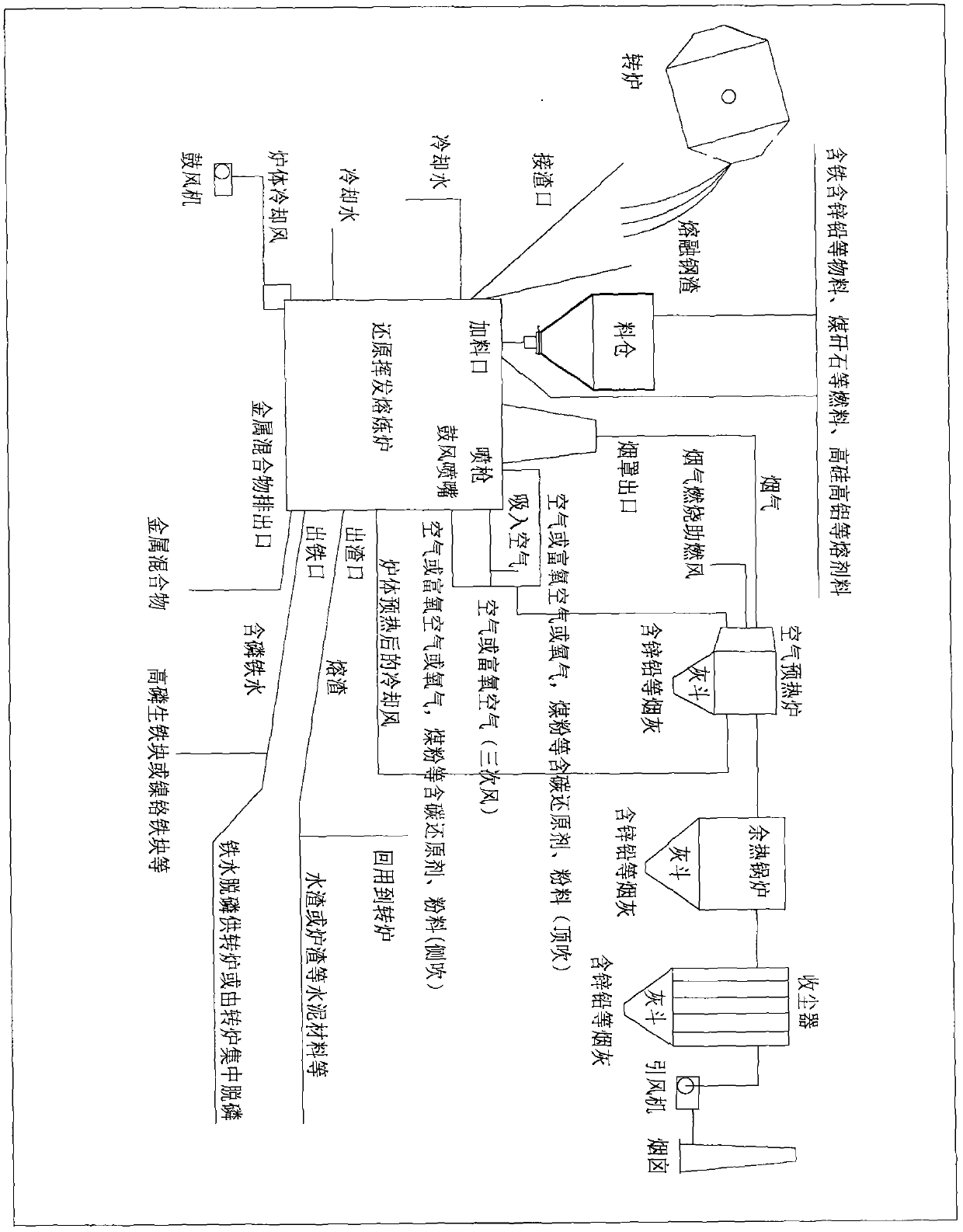

Molten blast furnace slag sensible heat recovery method and device

InactiveCN101660014ASave energyRecycling and recovery technologiesProcess efficiency improvementRecovery methodThermal energy

The invention relates to the field of energy recovery utilization and in particular to a molten blast furnace slag sensible heat recovery method and a device; the method is characterized in that: themolten blast furnace slag carries out a first heat recovery in a granulator, and then a second heat recovery is carried out by a vibrated bed, and then a third heat recovery is carried out in a fluidized bed, and the reclaimed heat energy is reutilized or converted in a hot air or power generating way; the realization steps are that: 1) the molten blast furnace slag is arranged in the granulator for granulation; 2) the blast furnace slag granules carry out heat exchange in the vibrated bed; 3) the blast furnace slag granules carry out heat exchange in the fluidized bed; 4) after heat exchangeis carried out, the heat is used for power generation from air or is directly utilized in a hot wind way. The method has the beneficial effects that: the sensible heat of the molten blast furnace slagis utilized respectively in a way of waste heat stream power generation and in a way of blast furnace hot wind, compared with the existing water quenching method, 1.0-1.2t of fresh water can be savedwhen processing 1t of molten slag, and sulfides H2S and SO2 are not produced, and energy equivalent to 47kg of standard coal is saved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

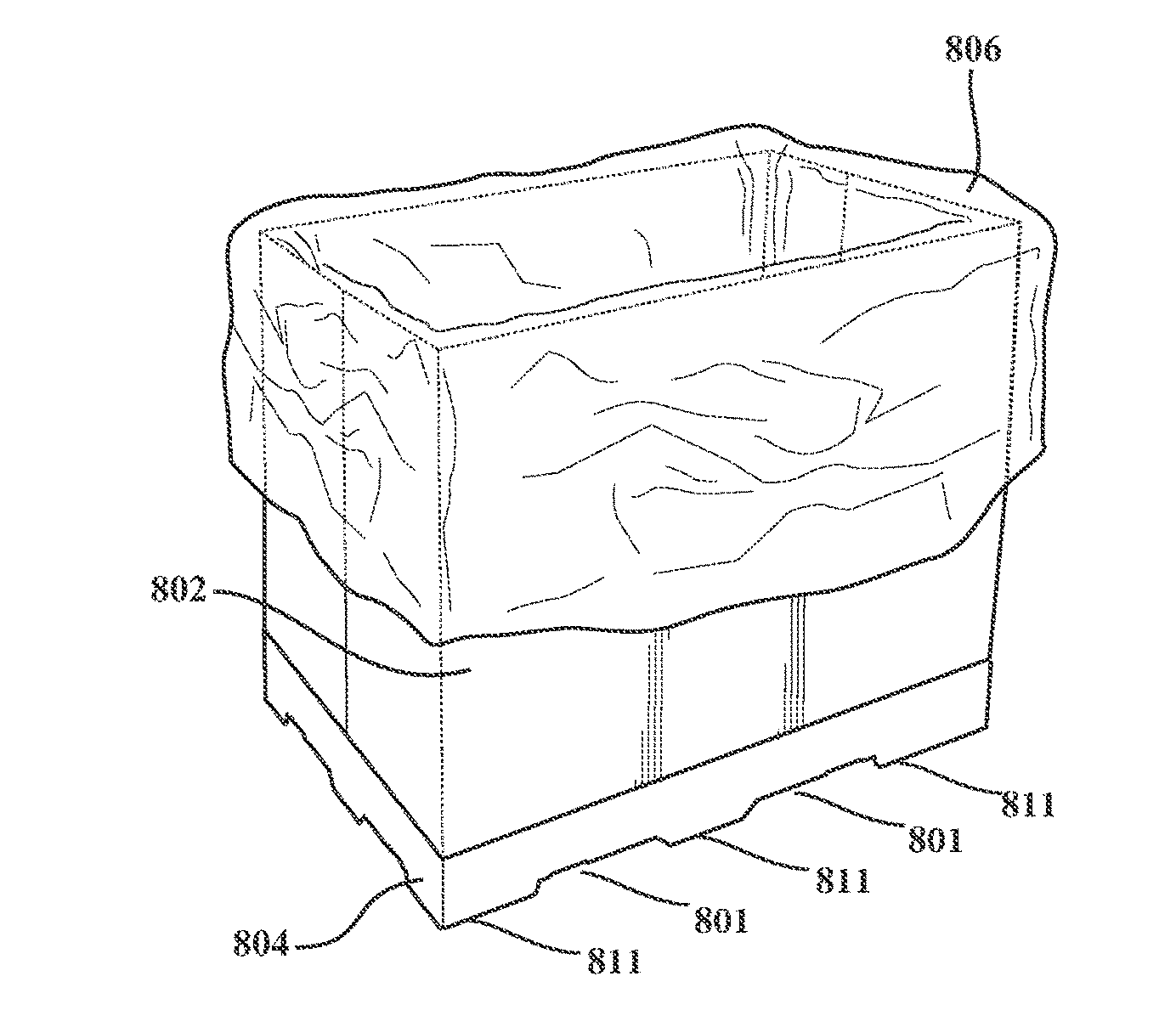

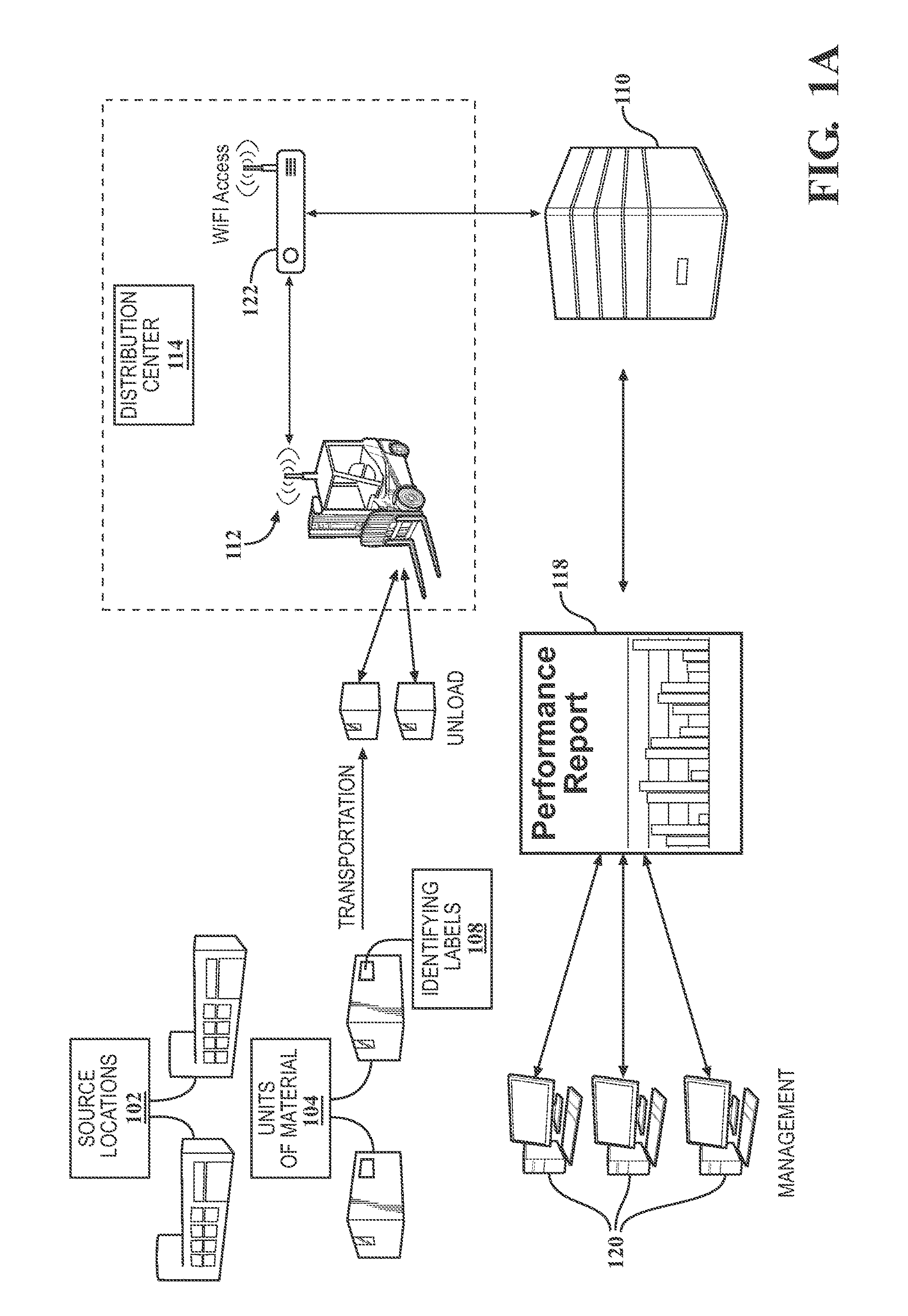

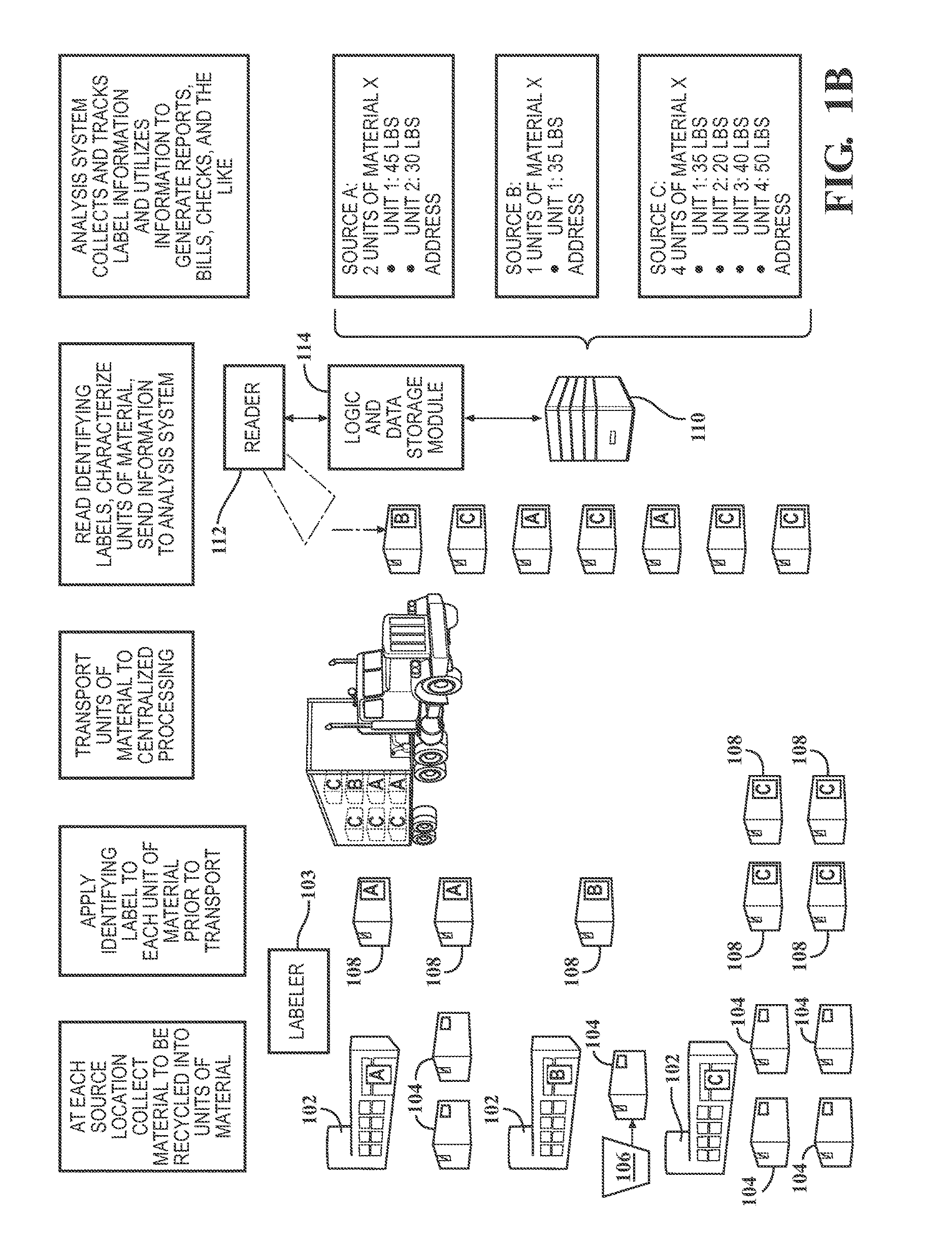

Bin for transporting waste or recyclable material

InactiveUS20170008671A1Facilitates determinationEasy to calculateImage analysisRefuse receptaclesWaste materialMaterial system

Systems, methods and devices are provided for transporting, tracking and managing waste or recyclable materials, which may include one or more devices for transporting waste or recyclable material. The device may comprise a base; and a collapsible sleeve movable between an open state and a collapsed state, wherein the collapsible sleeve in the open state interfaces in a nesting manner with the base to form a bin for receiving and transporting waste material.

Owner:DIVERT INC

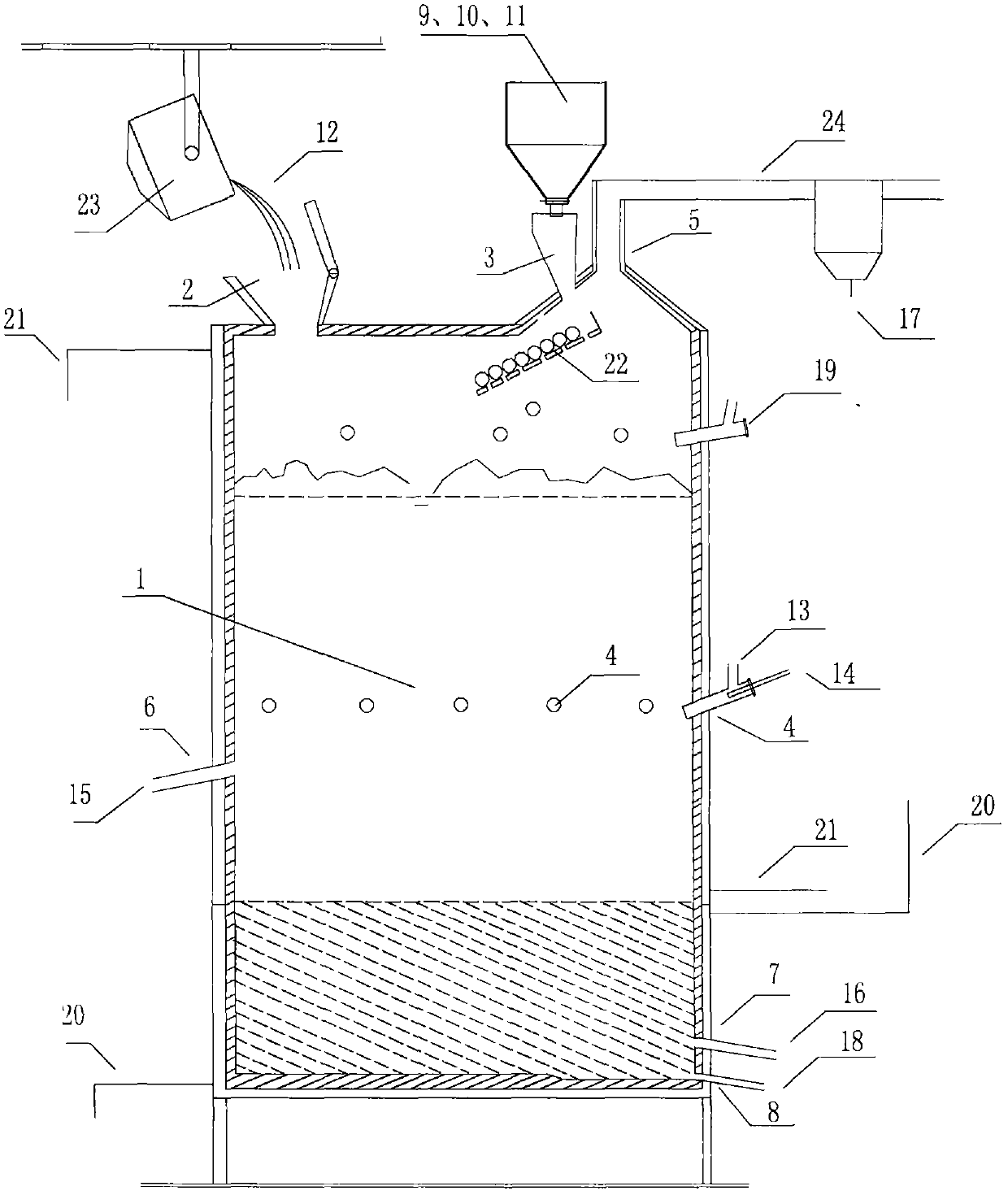

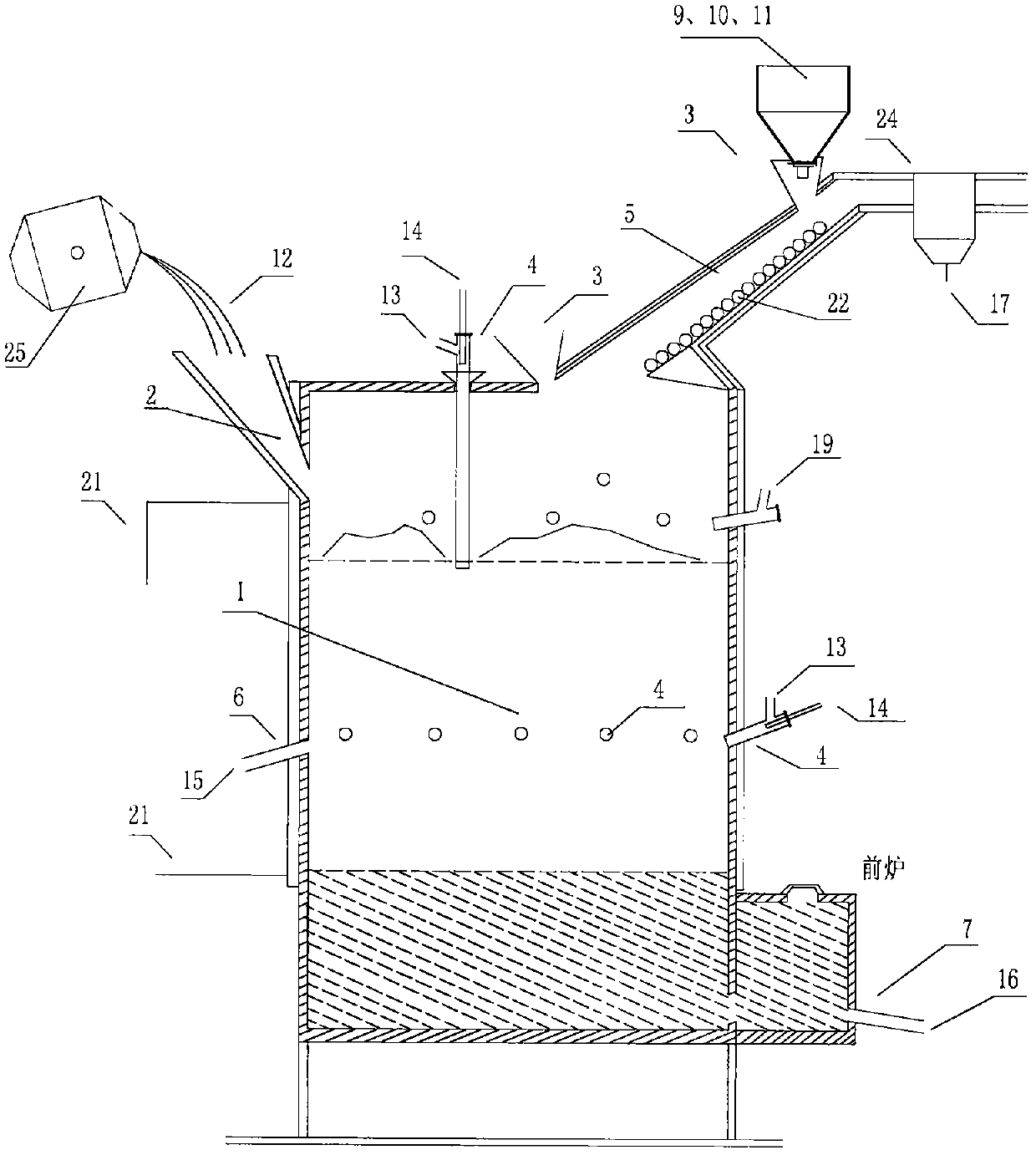

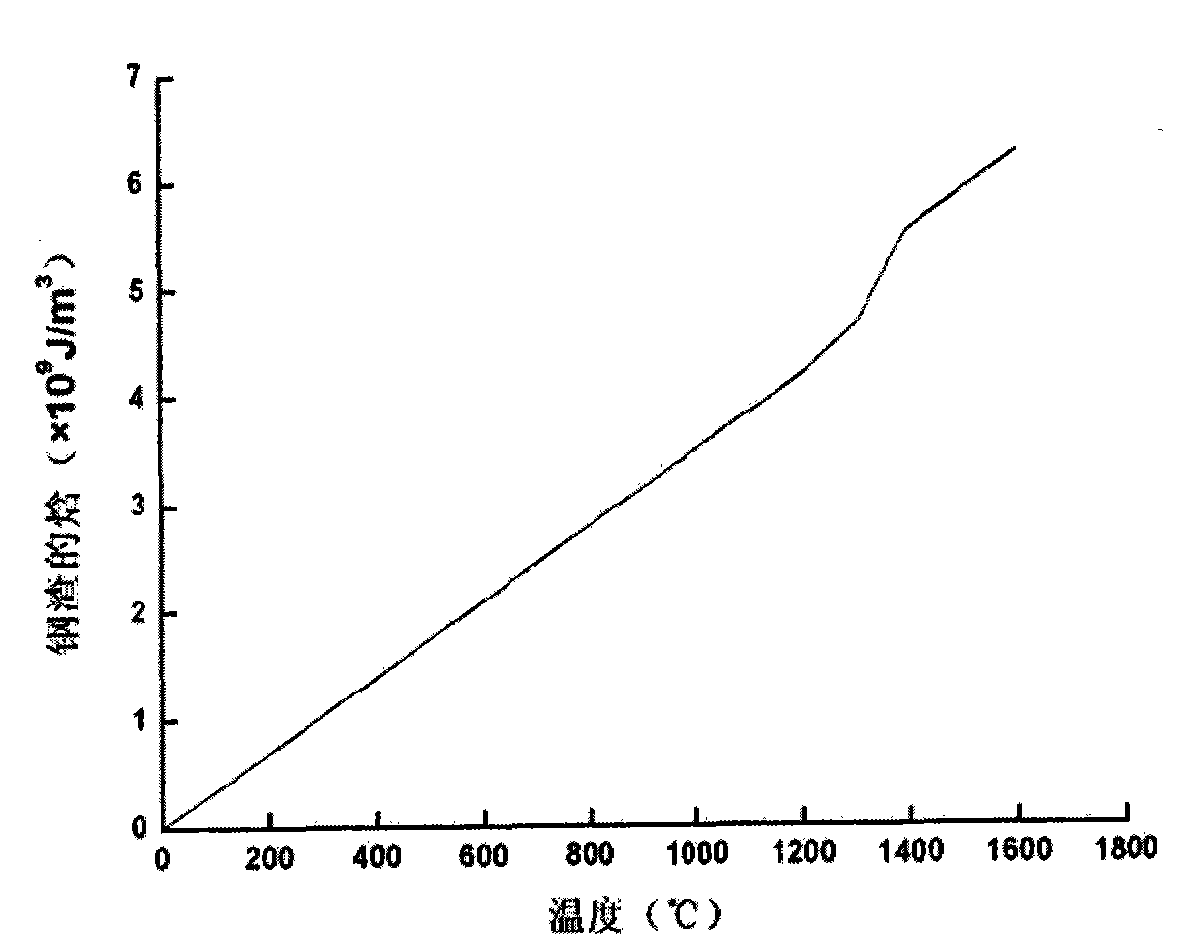

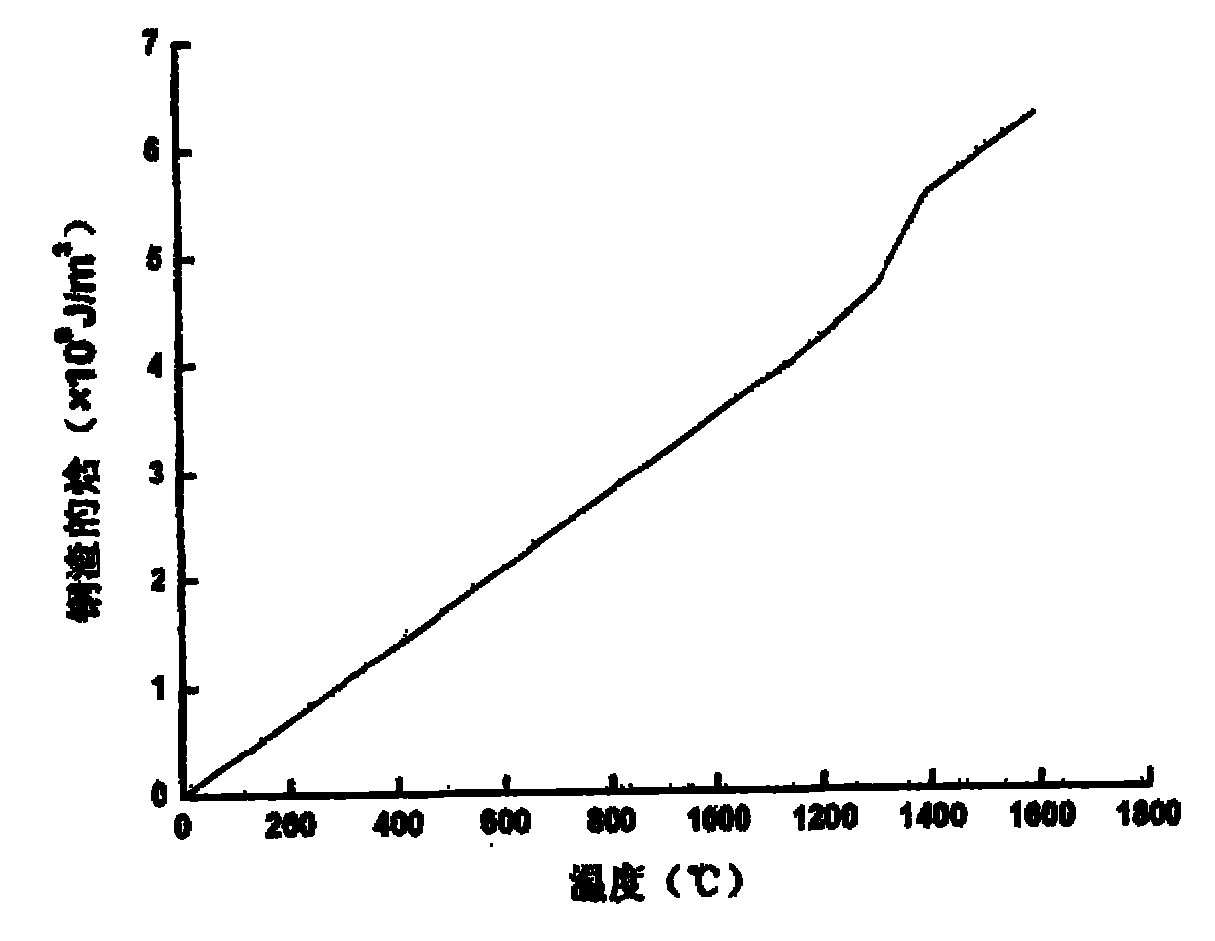

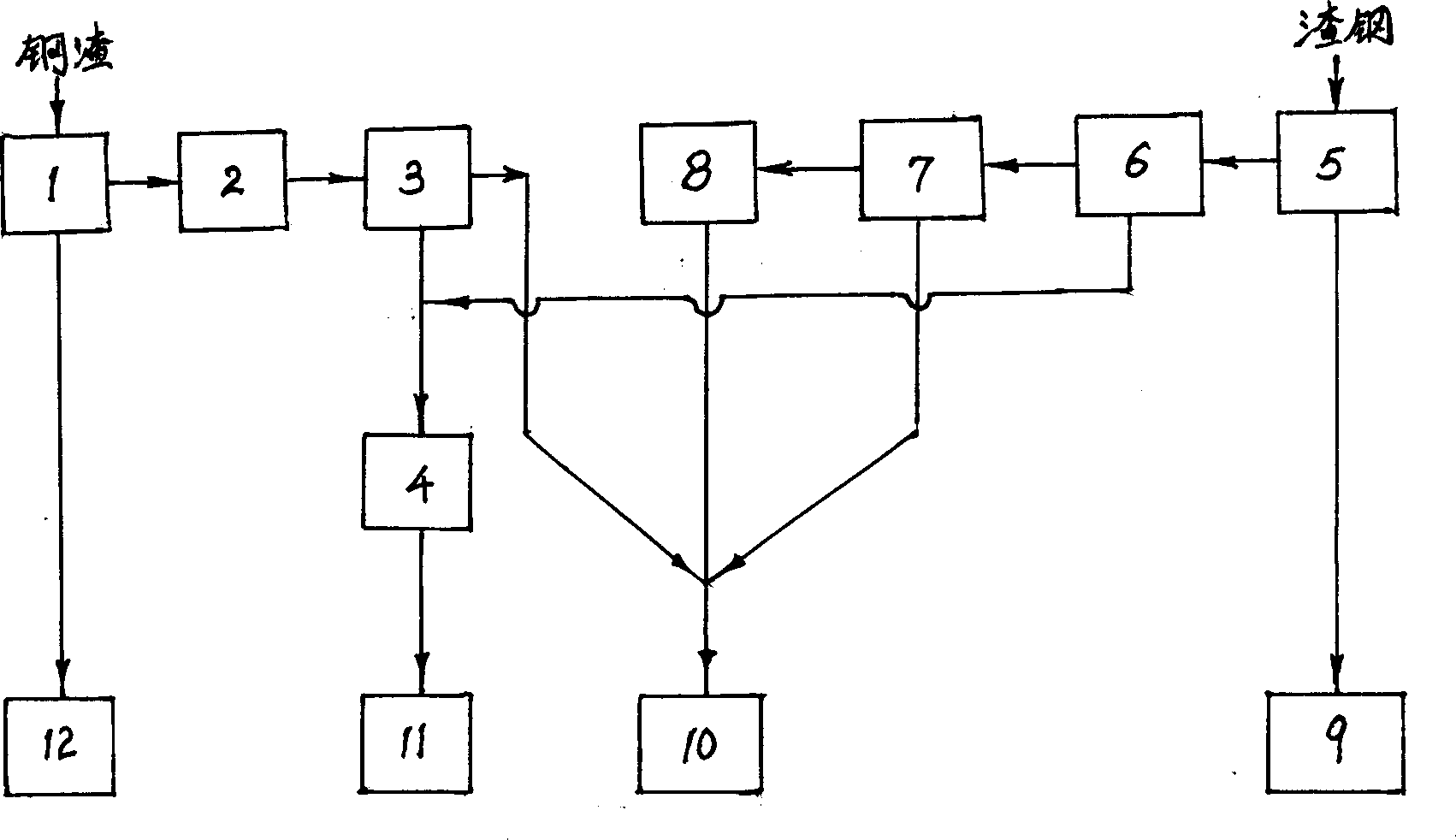

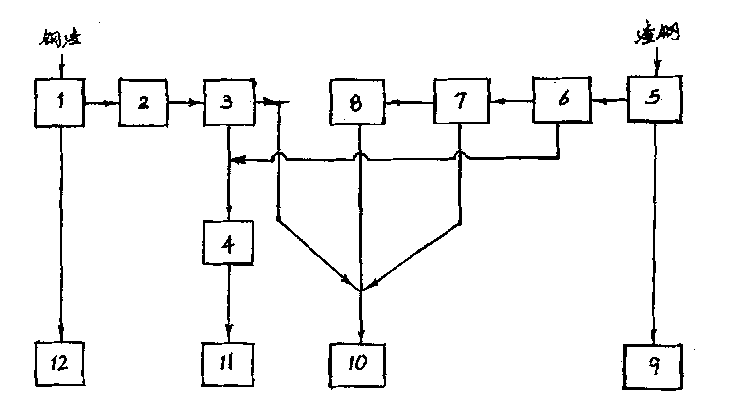

Cooperative processing and recycling method for material containing iron and/or zinc, lead, copper and tin, and the like and molten steel slag

PendingCN108676942AReduce outputEfficient recyclingRecycling and recovery technologiesProcess efficiency improvementMolten slagMaterials science

The invention discloses a process method for cooperatively and continuously processing waste containing iron and / or zinc, lead, copper and tin, and the like and molten steel slag on line, separating and recycling metal such as iron, zinc, lead, copper and tin as well as molten slag. The cooperative processing and recycling method is characterized in that pellets prepared from waste containing iron, zinc, lead, copper, tin and the like, particles, a blocky material containing iron, zinc, lead, copper, tin and the like and high-temperature molten steel slag are added into a reducing, volatilizing and smelting furnace, molten iron, which is obtained by air-blowing, adding of fuels such as coal gangues and flux such as high silicon and high aluminum, high-temperature reducing and volatilizingtreatment, is discharged from an iron outlet of the reducing, volatilizing and smelting furnace; volatilized substances such as zinc and lead and smoke gas are sucked into a dust collector for being collected and utilized; enriched metal such as gold, silver, copper, tin and lead is discharged from a discharge hole in the bottommost part of the reducing, volatilizing and smelting furnace for beingrecycled; and molten slag is discharged through a slag outlet, water slag and the like or the molten slag is returned into a converter for being recycled. Waste containing iron, zinc, lead, copper, tin and the like, molten steel slag and coal gangue waste slag and the like are cooperatively and continuously treated to separate and recycle useful metal, so that remarkable energy-saving environment-friendly social benefits and economic benefits are achieved.

Owner:湖南建鑫冶金科技有限公司

Energy-saving slag thermal insulator

InactiveCN101892332AImprove insulation effectLow raw material costRecycling and recovery technologiesChemical reactionSlag

The invention relates to an energy-saving slag thermal insulator, and belongs to the technical field of energy conservation, emission reduction and comprehensive utilization in the metallurgy industry. The thermal insulator comprises the following main chemical components in percentage by weight: 25 to 70 percent of SiO2, 1 to 25 percent of Al2O3, 1 to 40 percent of CaO, 0 to 20 percent of MgO, 0 to 10 percent of F<->, 0 to 10 percent of R2O (R is a monovalent metal ion), 0 to 10 percent of Fe2O3, 5 to 60 percent of fixed carbon with bulk density of 0.25 to 0.75g / cm<3>. The thermal insulator has high thermal insulation performance and can reduce the thermal loss of high-temperature slag; the thermal insulator contains a certain amount of fixed carbon, so heat generated in the chemical reaction of the fixed carbon can be used for further making up the thermal loss of the slag; meanwhile, the thermal insulator belongs to a silicon-aluminum material, and part or all of the thermal insulator can be dissolved in the slag finally so as to improve the chemical composition of the slag and reduce the melting point of the slag. The thermal insulator has the advantages of simple production process, low cost, and suitability for various processes for utilizing the sensible heat of the slag, increasing the fluidity of the slag or improving the performance of the slag.

Owner:UNIV OF SCI & TECH BEIJING

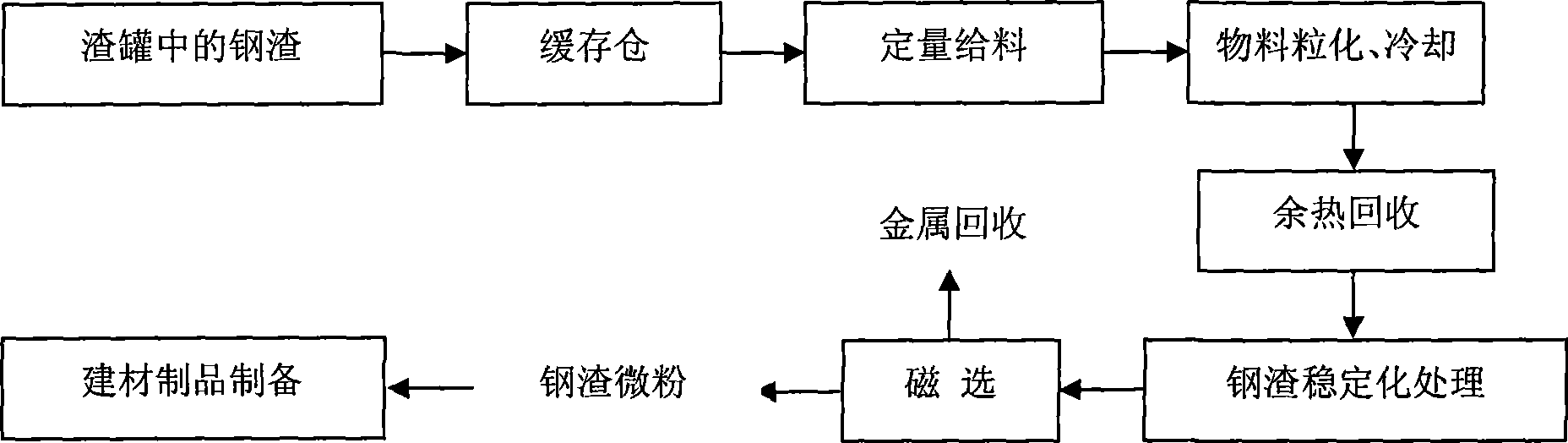

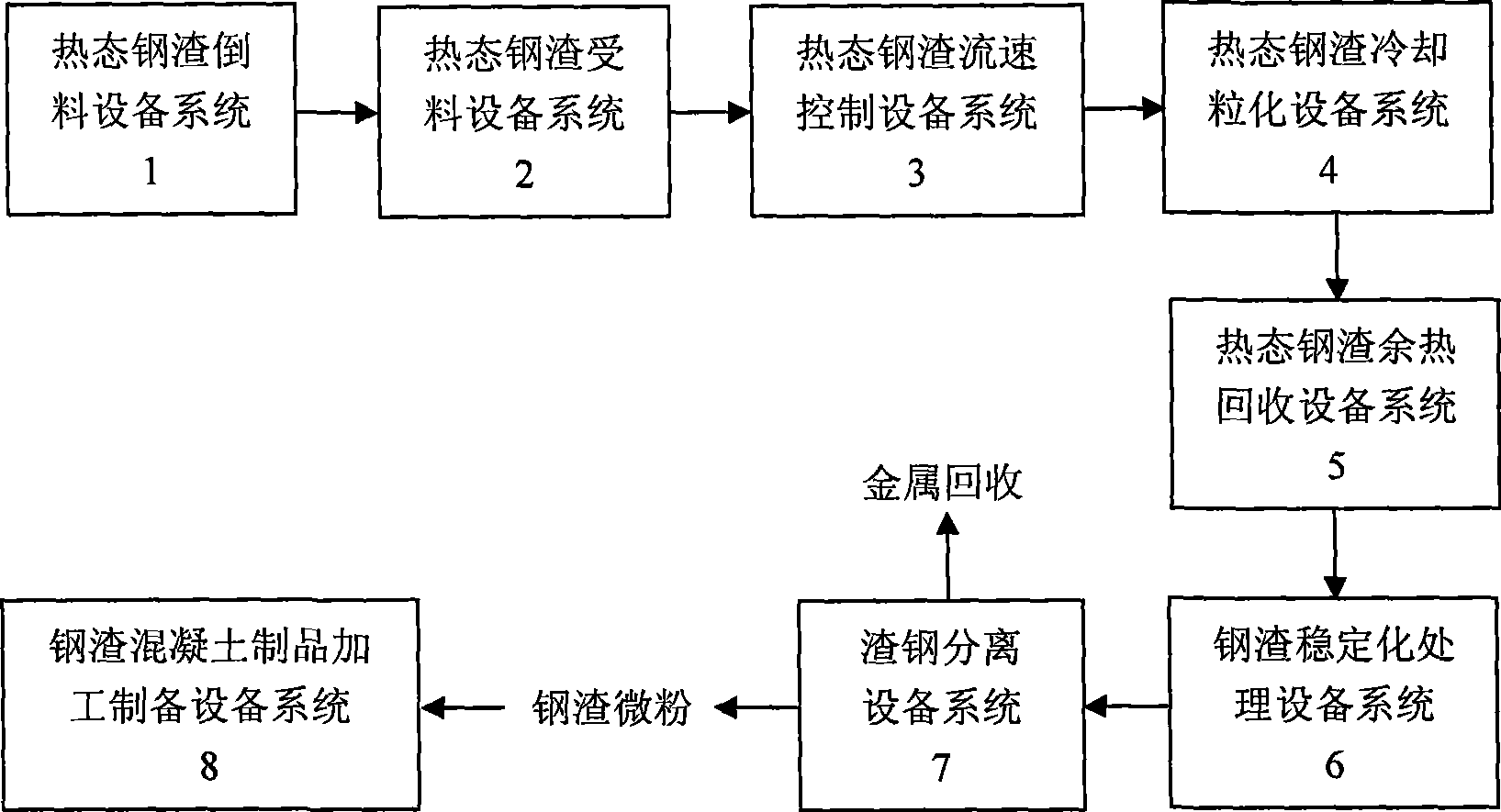

Method for recovery of waste heat of steel slag and comprehensively processing and utilizing steel slag

InactiveCN101413037AAvoid water explosionImprove energy efficiencyIncreasing energy efficiencyRecycling and recovery technologiesThermal stateSlag

The invention provides a mehtod for recovering waste heat of steel slag and comprehensively processing and using the steel slag, and belongs to the technical field of steel slag treatment. The method comprises the following steps: a thermal state steel slag material discharging system discharges steel slag into a thermal state steel slag material receiving system for primary crushing; the crushed steel slag is subjected to secondary crushing by a thermal state steel slag velocity control system and quantificationally fed into a thermal state steel slag cooling granulating system for re-crushing and cooling, high-temperaure hot air generatd in the cooling process is collected by a thermal state steel slag waste heat recovery system and enters a heat exchange system to form vapor for power generation or heat supply; the cooled steel slag enters a steel slag stabilizing treatment system, and the steel slag after the stabilizing treatment is treated by a steel slag separation system to obtain steel slag tailing micropowder and metal slag steel respectively; and, the steel slag micropowder is mixed with other materials and used to prepare concrete products by a steel slag concrete product processing preparation system. The method has the advantages of adaptability to various types of steel slag to be processed, good operational environment and no secondary pollution.

Owner:SHOUGANG CORPORATION

Waste-heat pressure closed-loop thermal treatment method for molten steel slag

ActiveCN102230036AHigh cold crushing efficiencyImprove performanceRecycling and recovery technologiesSlagClosed loop

The invention discloses a waste-heat pressure closed-loop thermal treatment method for molten steel slag and is characterized in that the method comprises the following steps of: (1) molten steel slag turning: turning the molten steel slag to a pre-treatment chamber through a slag tank over-turning vehicle; (2) rolling and crushing: spraying water onto the surface of the molten steel slag through automatic water sprayers in the pre-treatment chamber to cool the slag, and rolling and crushing the cooled slag through a rolling and crushing machine; (3) slag pushing: allowing the rolling and crushing vehicle to push the block-shaped high-temperature steel slag which is cooled in the pre-treatment chamber into a slag tank through a discharge port; (4) transport: transporting the slag tank which holds the block-shaped high-temperature steel slag to a waste-heat pressure closed-loop thermal treatment tank through a transport trolley; and (5) slaking: spraying water onto the surface of the block-shaped high-temperature steel slag to generate vapor, and converting f-CaO and f-MgO under the alternating vapor pressure to allow self-slaking and powdering of the steel slag. The method eliminates the limitations of temperature and fluidity of the steel slag, achieves the continuous, mechanical and automatic process of steel slag treatment, and has the advantages of energy conservation, land conservation, high efficiency and high safety.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Ni-Cr-Fe alloy and its production process

InactiveCN1847440ASave resourcesOptimize the smelting processBlast furnace detailsRecycling and recovery technologiesGranularityManganese

The present invention is Ni-Cr-Fe alloy and its production process. The Ni-Cr-Fe alloy contains Ni 1.5-6.0 wt%, Cr 3.0-21.0 wt%, Si 0.6-2.0 wt% and Mn 0.3-0.8 wt%, except Fe, and can meet the requirement for use as material smelting stainless steel. The production process includes the following steps: producing Ni-Cr agglomerate with industrial Ni-Cr waste, Ni-Cr ore powder of granularity smaller than 10 mm, flux, coke and water and through pelletizing, sintering and sieving; and smelting with the Ni-Cr agglomerate, Ni-Cr ore of granularity greater than 10 mm, flux and coke in a blast furnace. The present invention has sang in resource and environment friendship.

Owner:DONGDA CASTING WUJIANG

Treatment method for vitrifying arsenic-alkali residue

InactiveCN102965517ARecycling and recovery technologiesProcess efficiency improvementMolten stateIngot casting

The invention discloses a treatment method for vitrifying arsenic-alkali residue, aiming at solving the problem of pollution or potential menace of the existing arsenic-alkali residue treatment process on environment. The treatment method for vitrifying the arsenic-alkali residue comprises the following steps of: selectively reducing sodium antimonate in the arsenic-alkali residue to metallic antimony by a carbon reducing agent in a molten state and keeping arsenic in the residue in the form of sodium arsenate; and then adding a glass molten solvent in the arsenic-containing residue to form a low-temperature glass phase, discharging the glass phase, and then carrying out water-quenching on the glass phase into broken glass pieces or directly casting the glass phase into a glass ingot in an ingot casting mould, thus facilitating piling up or returning to a pit and land-filling. According to the invention, the recovery rate of antimony in the arsenic-alkali residue is greater than 95%, and the content of arsenic in the metallic antimony is less than 3%; and the arsenic-containing glass pieces belong to general solid wastes and can be directly piled up in the open air or land-filled.

Owner:CENT SOUTH UNIV

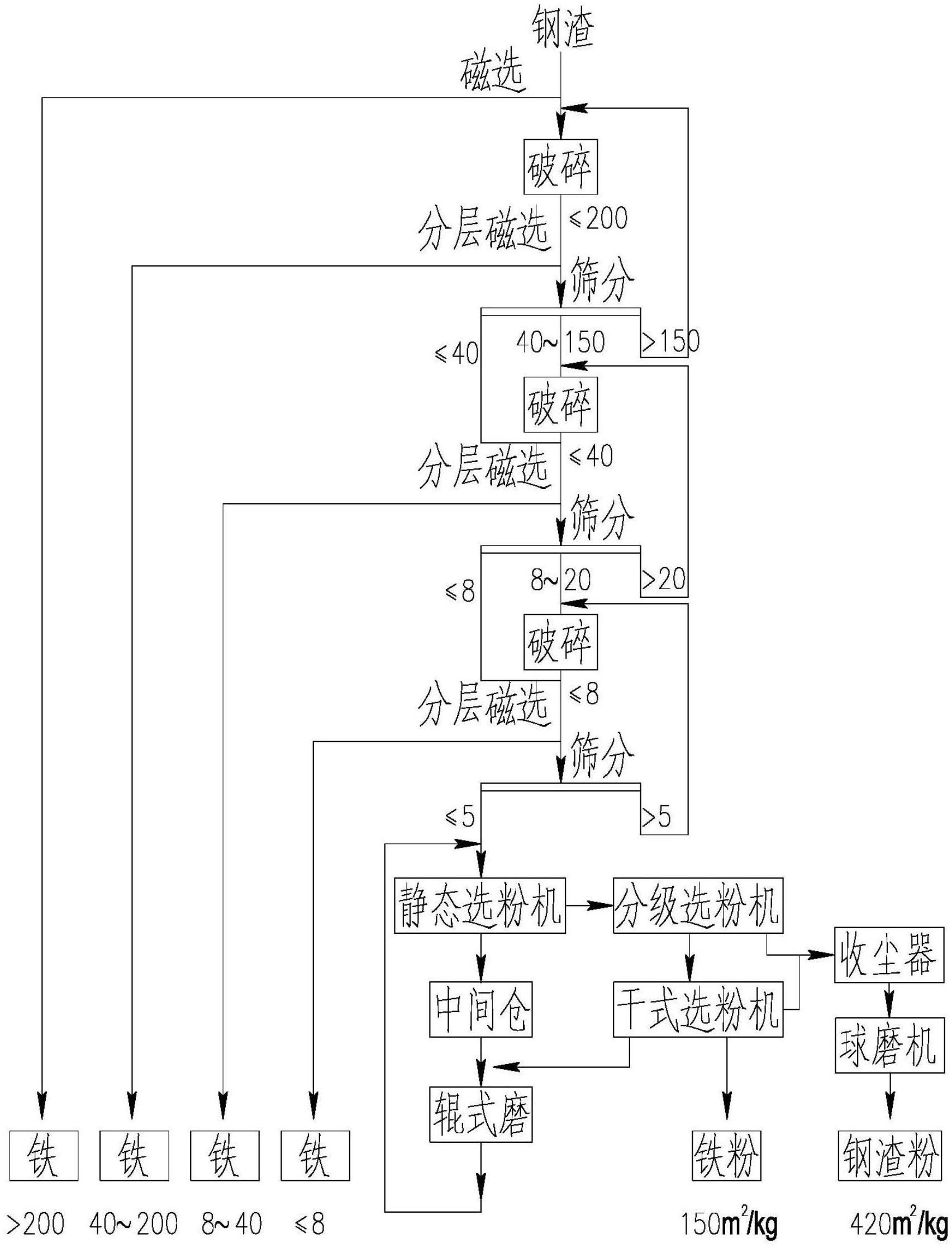

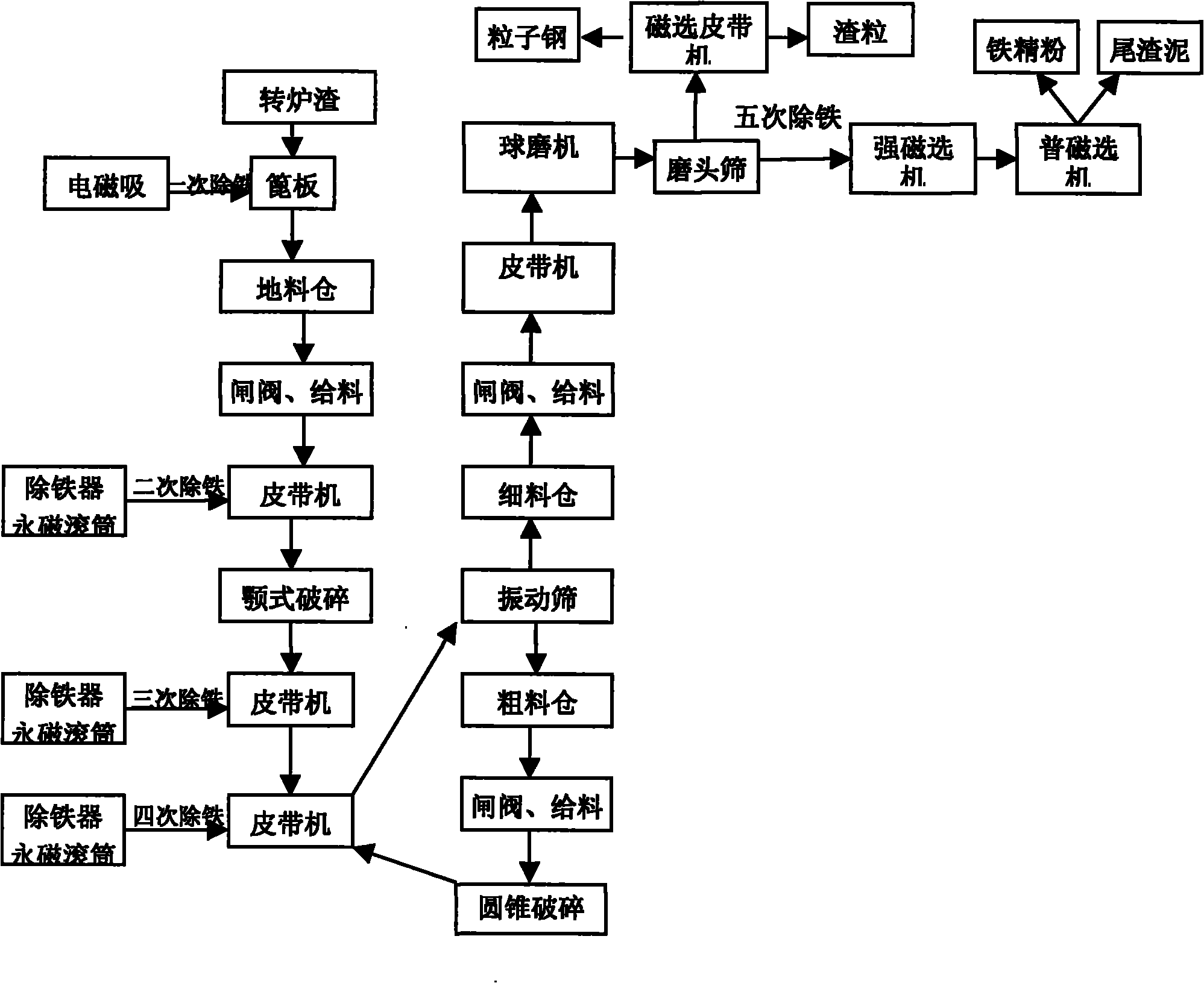

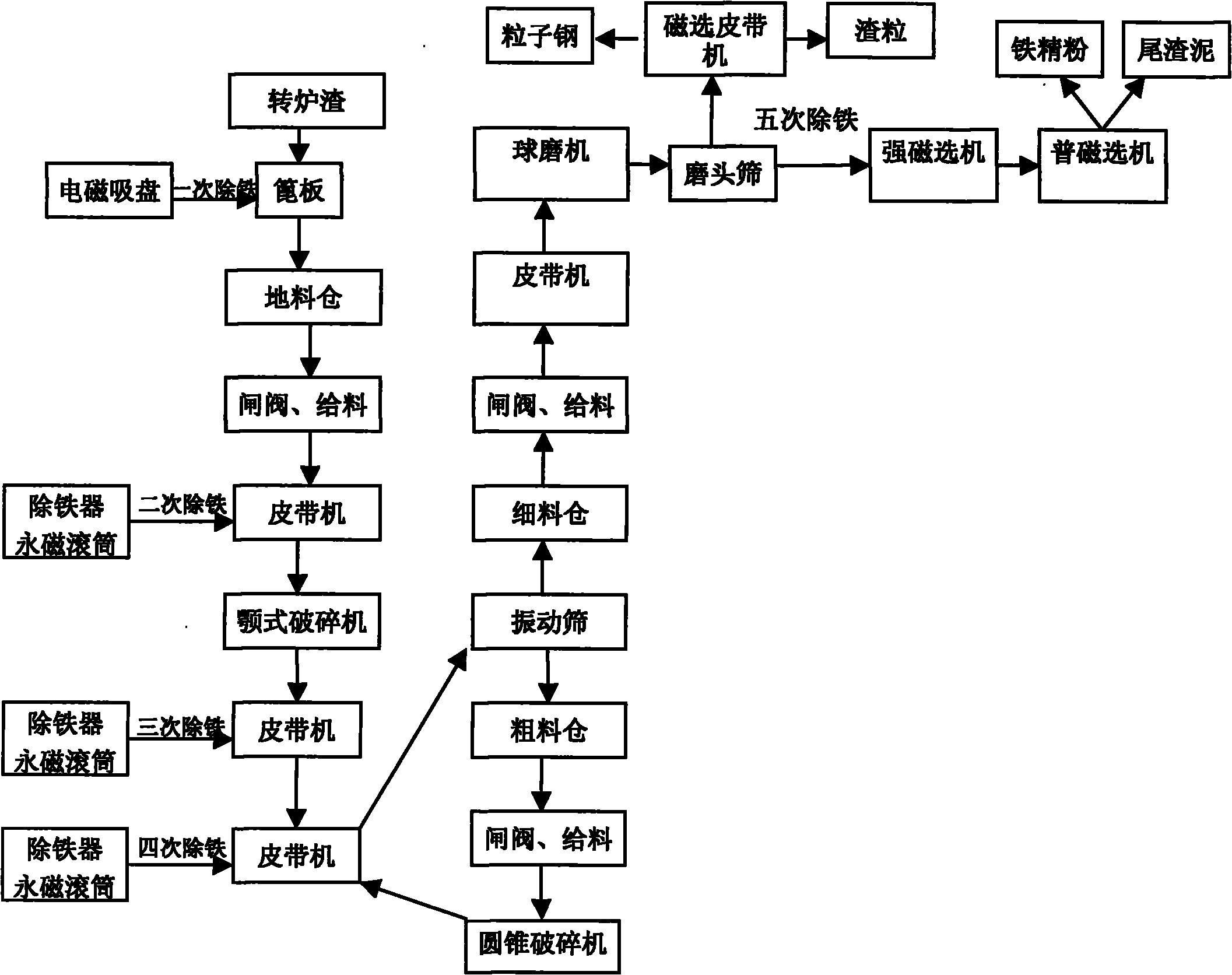

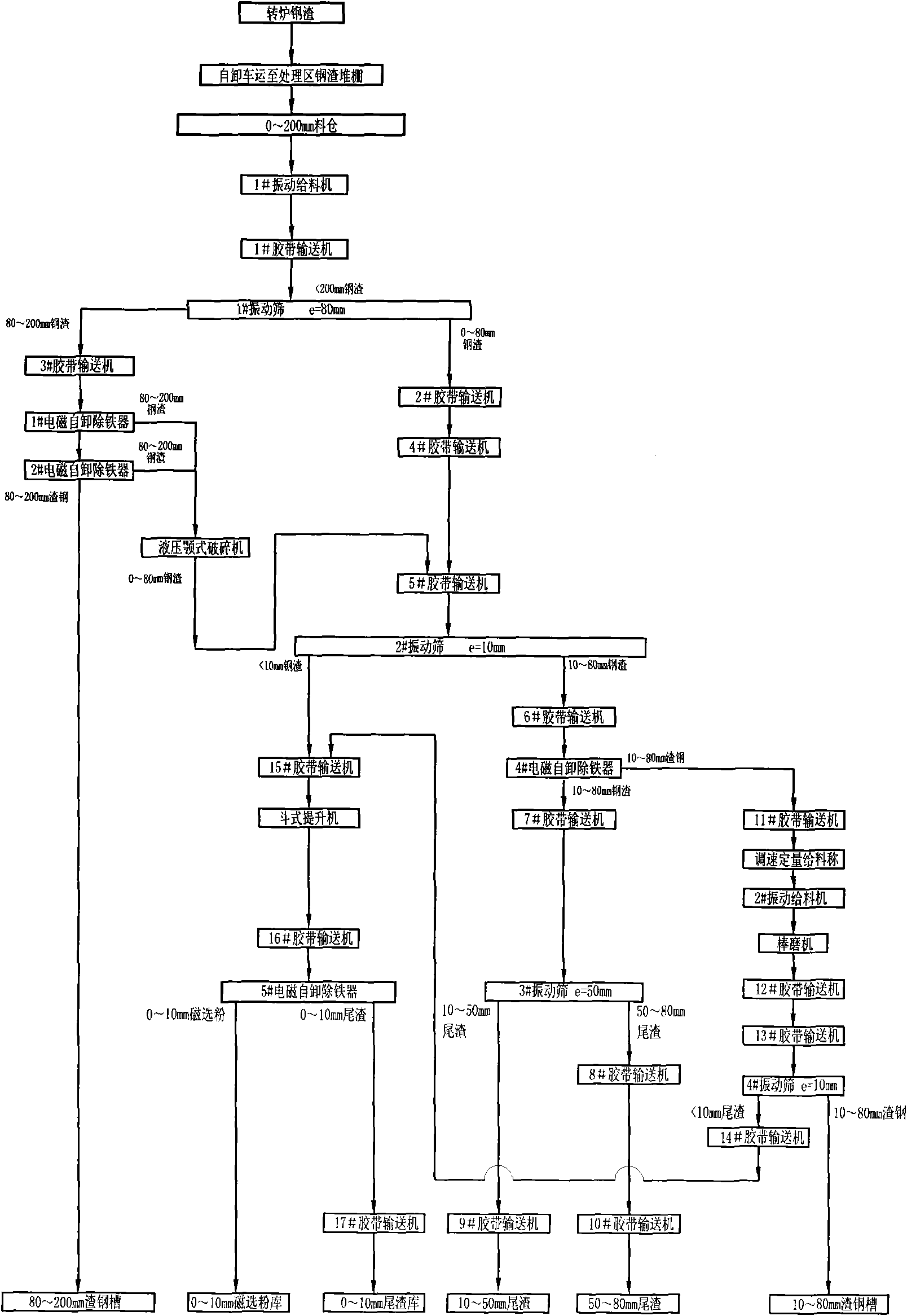

Method for efficiently recovering and reselecting steel slag

ActiveCN102688880AEffectively electedIncrease cycle loadSolid waste disposalRecycling and recovery technologiesEcological environmentSlag

The invention discloses a method for efficiently recovering and reselecting steel slag, comprising the following steps of: A, smashing and magnetically selecting: selecting iron in steel slag in a stock dump by a lifting electromagnet, directly charging the steel slag into a smasher to be smashed, and magnetically selecting the smashed steel slag by a rubber belt conveyor and a permanent magnetic iron remover in a layering way; B, smashing and magnetically selecting again: magnetically selecting the treated steel slag by the rubber belt conveyor of a head wheel belt permanent magnetic tumbling cylinder and the permanent magnetic iron remover in a layering way; C, extruding and smashing the steel slag into fine powder by a roller type grinding circulating system; D, selecting the iron powder with refine grain diameter by a dry type powder selector; and E, grinding the fine powder steel slag which is separated by the roller type grinding circulating system and a steel slag selecting and recovering system by a ball grinder system. The method is simple and easy, and convenient to operate, so that when the iron is selected, the steel slag low-heat concrete which accords with the national standard requirement can be produced by the steel slag. The production cost and the energy consumption can be reduced, the land occupancy can be reduced, the ecological environment can be protected, and the good economic benefit, social benefit and environmental benefit can be obtained.

Owner:武汉市天沭科技发展有限公司

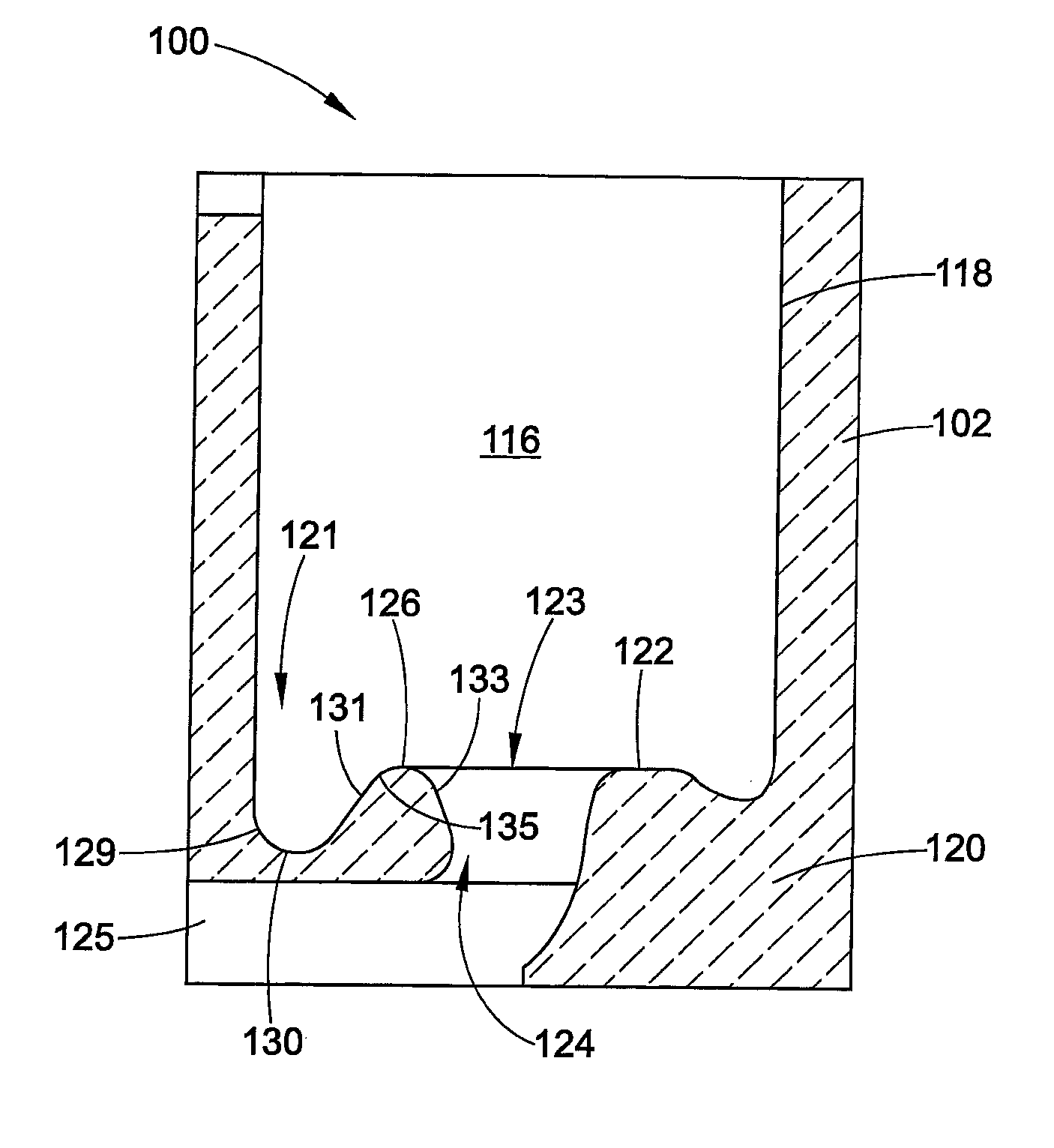

Impact resistant scrap submergence device

A metal scrap submergence device having an open top chamber including side and base walls of a heat resistant material. An inlet is included in a side or base wall of the chamber for receiving molten metal. An outlet is included in the base of the chamber. A ramp extends from the side wall of the chamber to an inner column defining the outlet. The ramp includes a first edge adjacent the side wall and second interior edge adjacent the inner column. The working surface of the ramp between the first and second edges is concave. The inner column includes an end wall disposed opposite the chamber base, the end wall includes rounded inner and outer edges.

Owner:PYROTECK INC

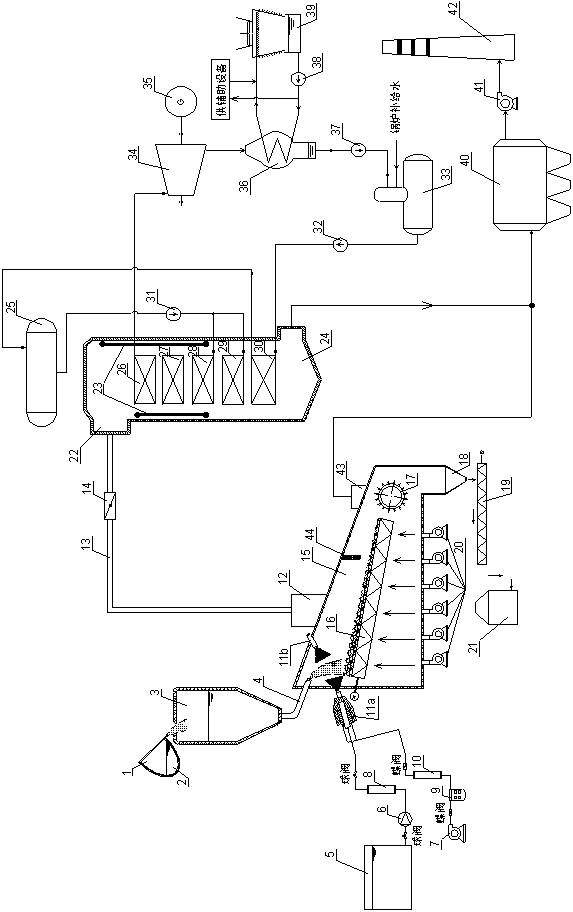

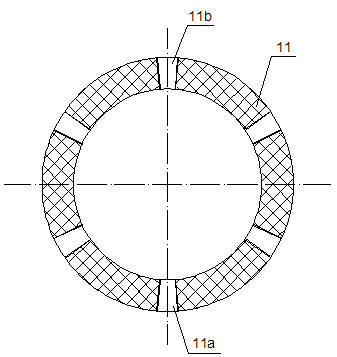

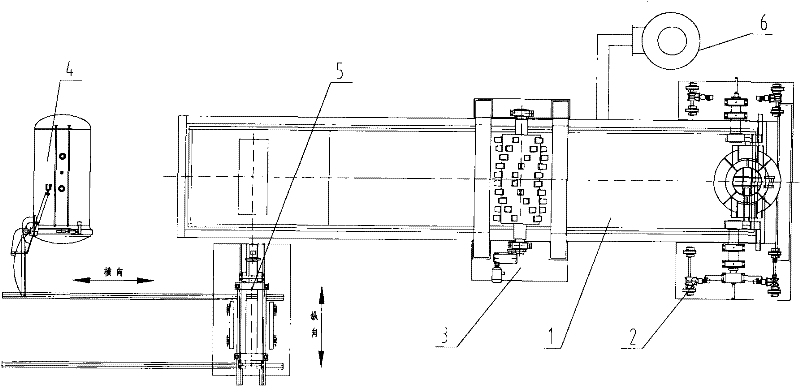

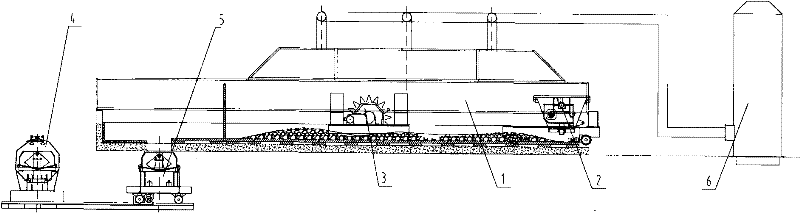

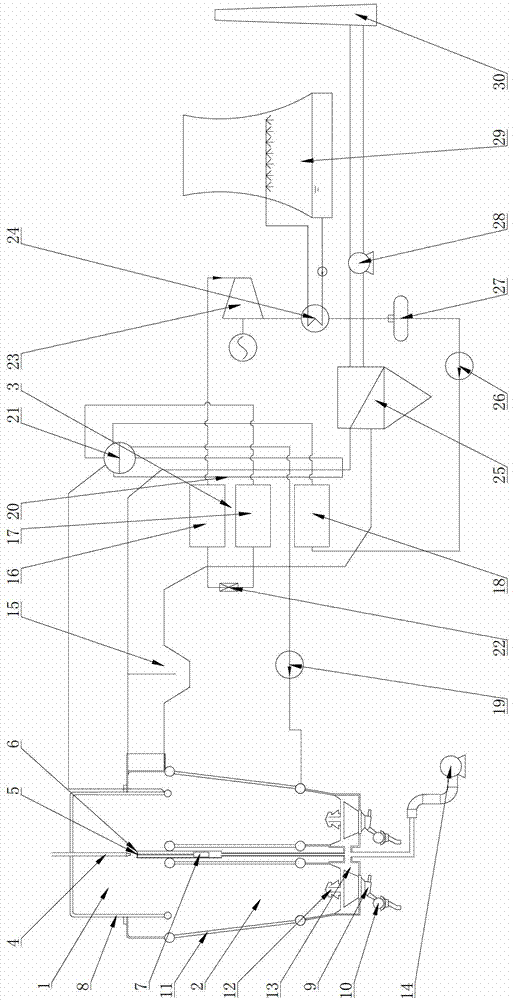

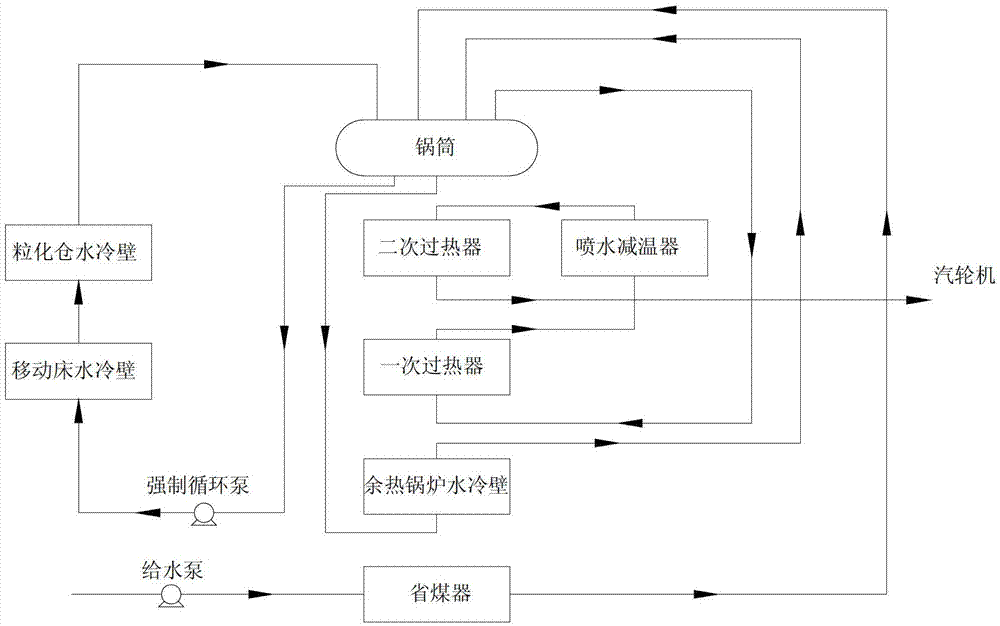

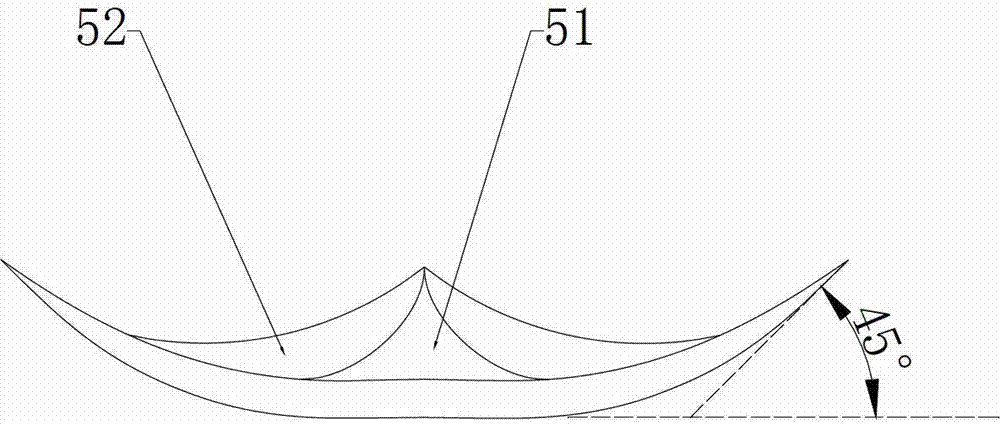

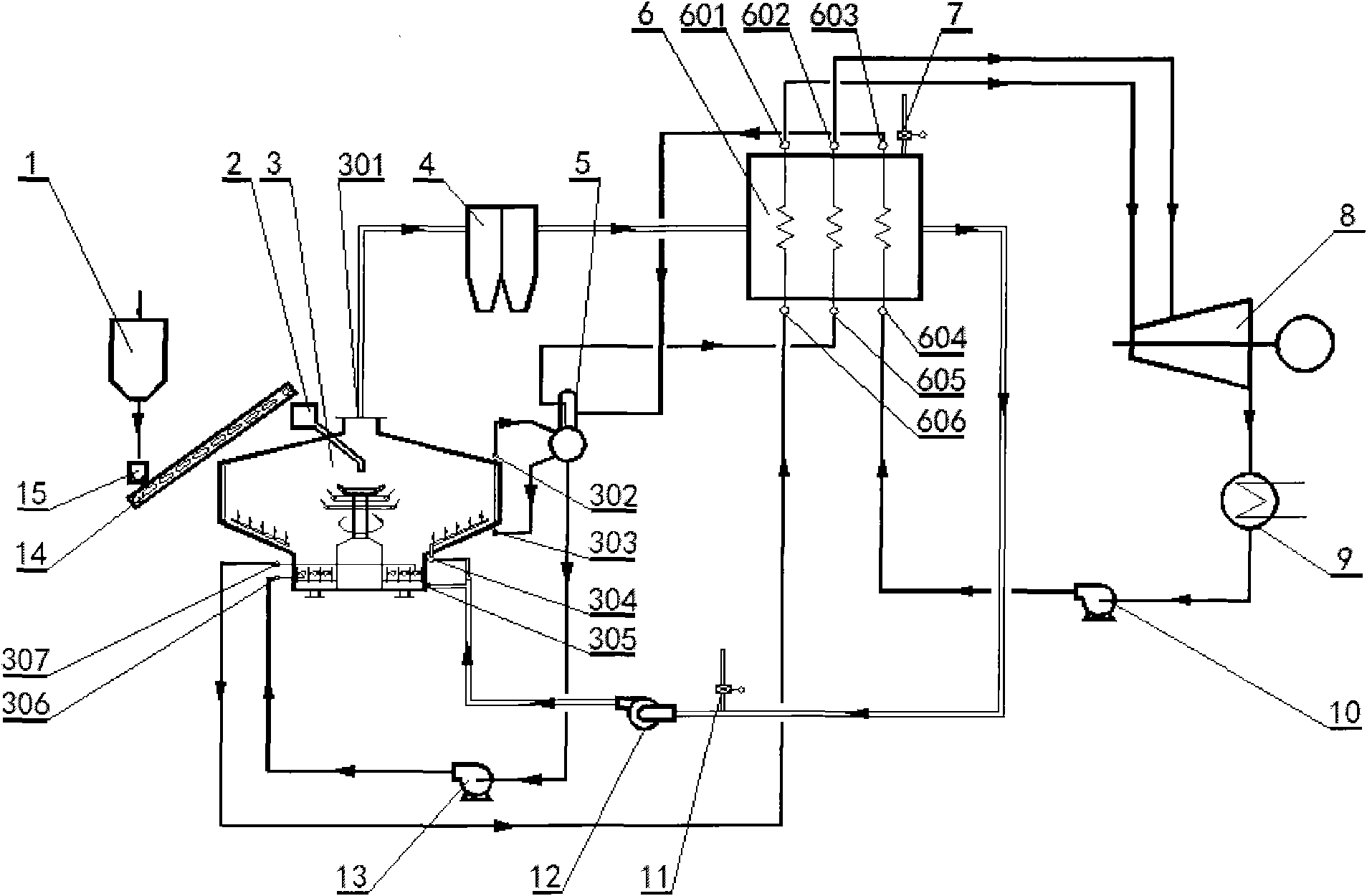

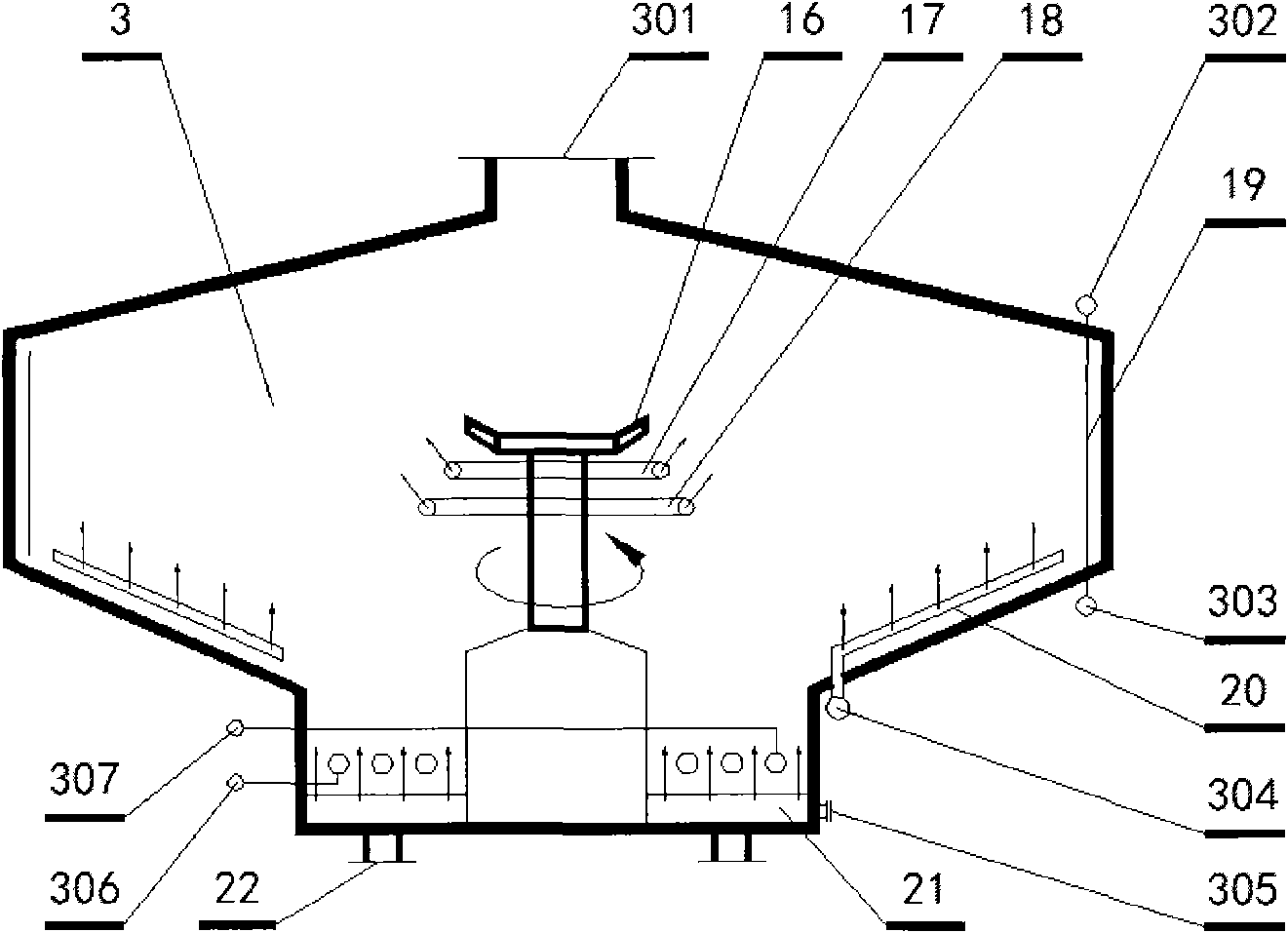

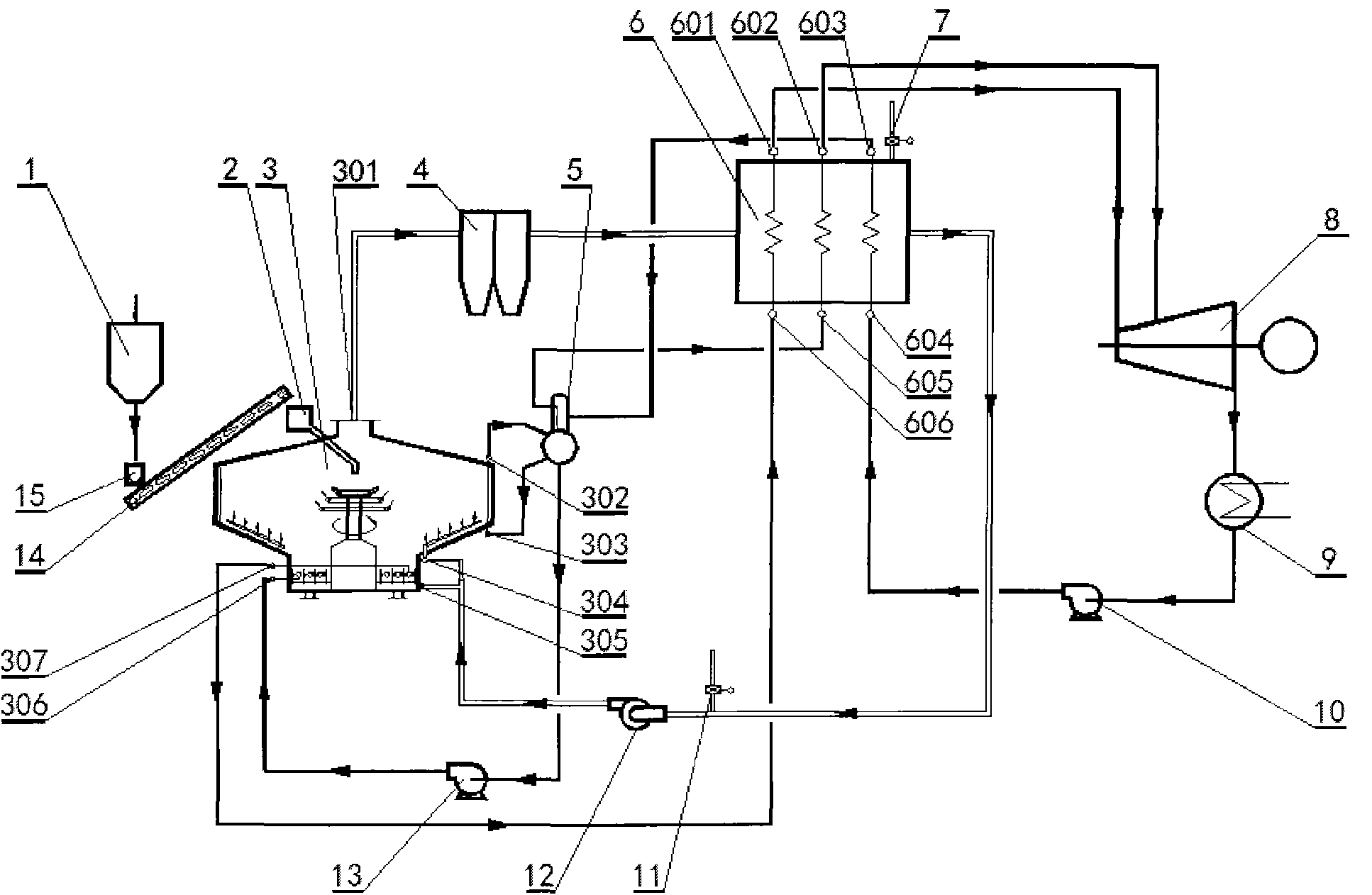

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

Process for treating steel slag

InactiveCN1390795AIncrease added valueSolve the pollution of the environmentRecycling and recovery technologiesProcess efficiency improvementIron powderSlag

A process for reclaiming the steel slags includes such steps as preparing steel slags and residual steel as raw material, sieving, ball grinding, magnetic separating, and wind classifying to obtain 4 products: high-quality waste steel used for smelting steel, refined iron powder used for smelting iron, micro slag powder used as high-activity additive of concrete, and steel slag aggregate used for slag-asphalt-concrte pavement of highway.

Owner:北京科美隆科技发展有限公司

Method for recycling iron from steel slag

InactiveCN101864501AEasy to separateAvoid artificial unluckyRecycling and recovery technologiesProcess efficiency improvementSlagGranularity

The invention belongs to the field of recycling of steel slag, in particular to a method for recycling iron from steel slag. The method comprises the following steps of: (1) pouring steel slag into a grate plate with the length and the width of 180 mm respectively, leading the steel slag with granularity smaller than 180 mm to enter an underground material bin and carrying out first iron recycling on the steel slag with granularity larger than 180 mm by an electromagnetic sucking disk; (2) magnetically separating and crushing the steel slag with granularity smaller than 180 mm, wherein the crushed granularity is smaller than 60 mm; (3) magnetically separating the crushed steel slag; (4) screening by a vibrating screen, leading steel slag with granularity larger than 25 mm to enter a cone crusher for carrying out second crushing with the crushed granularity smaller than 25 mm, and magnetically separating; (5) grinding steel slag with granularity smaller than 25 mm, screening by a cylinder screen with granularity of 2 mm and remelting particle steel with granularity larger than 2 mm for utilizing; and after magnetically separating steel slag with granularity smaller than 2 mm by a wet magnetic separator, separating iron fine powder and tailings. The invention can recycle iron in the steel slag and reduce the iron content of the steel slag below 0.5 percent.

Owner:XINXING HEBEI ENG & RES INC

Slag metallurgy smelting reduction production method

InactiveCN106755654AEfficient use ofRealize smelting reduction ironmakingRecycling and recovery technologiesProcess efficiency improvementSmeltingMolten state

The invention discloses a slag metallurgy smelting reduction production method and belongs to the field of non-blast-furnace ironmaking and comprehensive utilization of resources. The molten state is kept by adding a reducing agent and iron-containing materials in reaction slag, and smelting reduction ironmaking is performed; the requirements of temperature, alkalinity and sufficient mixing are met in the reacting process, the slag obtained through a reaction is treated; the reduced slag can serve as a cement adding agent and a cement adjusting agent or directly serves as cement clinker; other components can also be added to produce cement clinker high in additional value, and efficient and comprehensive utilization of resources is achieved; and the method is a new smelting reduction ironmaking method. The method is short in reaction time, high in metal recycling rate, low in production cost, high in raw material adaptability, large in treatment amount, environment-friendly and high in economic benefit, is a new smelting reduction ironmaking process, and can effectively solve the metallurgy resource recycling problem.

Owner:NORTHEASTERN UNIV

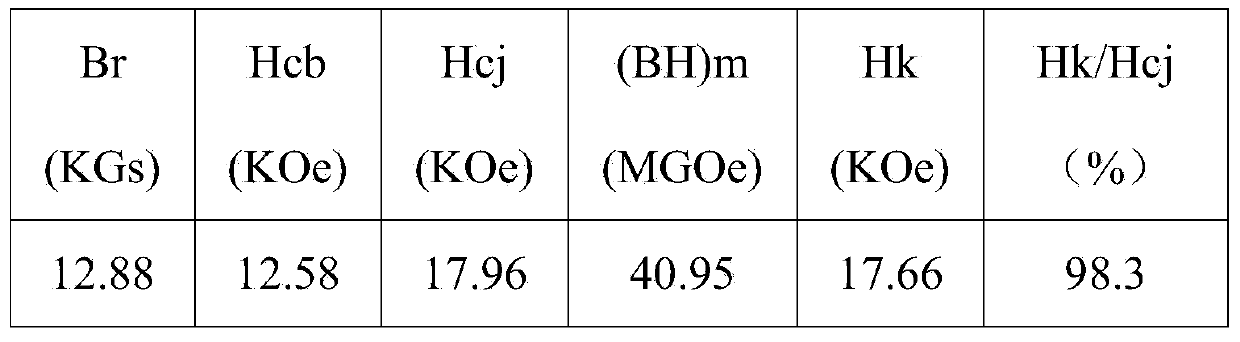

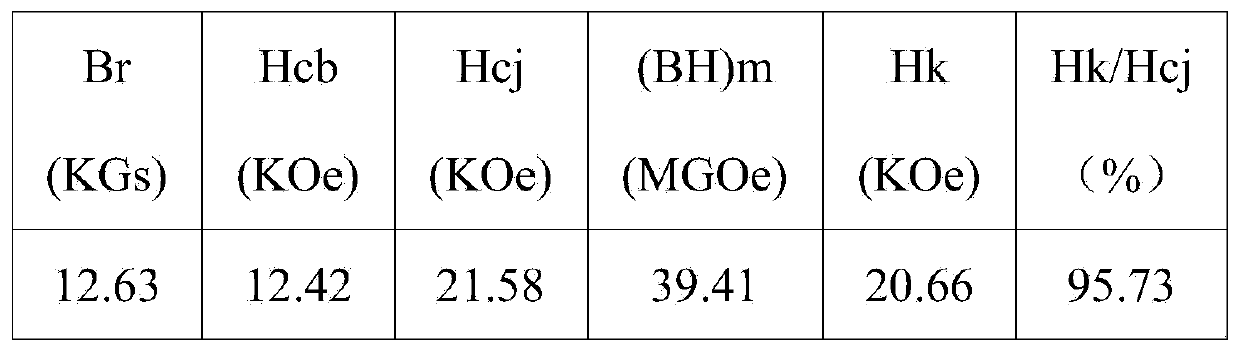

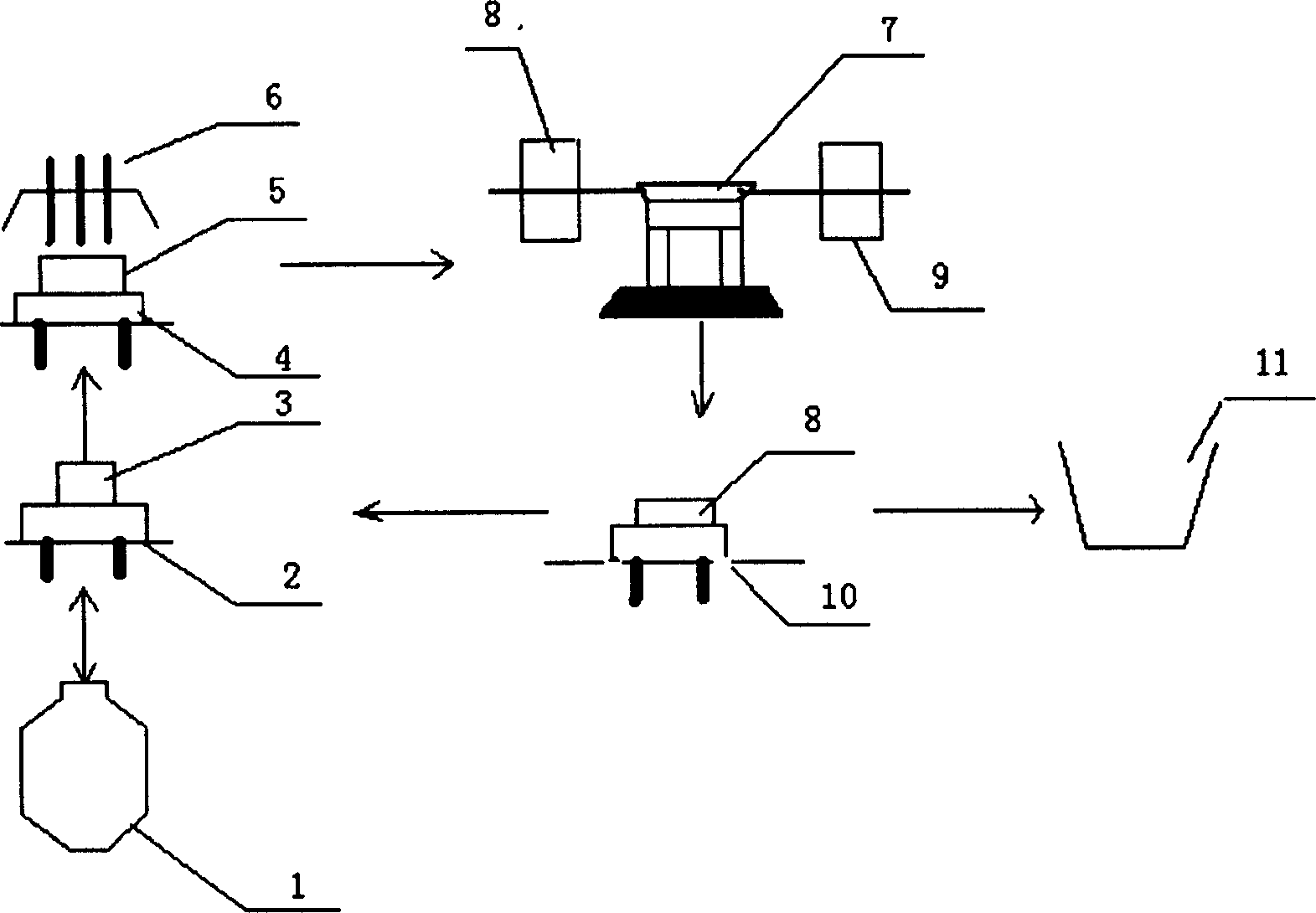

Method for recycling sintered neodymium-iron-boron waste materials

ActiveCN104190943ANo pollution in the processSave resourcesRecycling and recovery technologiesHazardous substanceAlloy

The invention discloses a method for recycling sintered neodymium-iron-boron waste materials. The method is characterized by including the following steps that the neodymium-iron-boron waste materials are classified and collected according to performance trade marks; the classified and collected waste materials and abrasive materials are mixed and then placed in a vibration polisher machine, and a cleaning agent is added for vibration finishing cleaning; the waste materials obtained after vibration finishing cleaning are ultrasonically cleaned and dried for standby; according to the standard identical to the performance trade marks of the waste materials obtained through the steps, alloy cast slices are prepared through batching, smelting and casting; the cleaned waste materials and the prepared alloy cast slices with the same trade marks are mixed, and hydrogen decrepitation processing is conducted on the mixture; the materials obtained after hydrogen decrepitation processing are ground into powder, pressed, formed, and sintered into a neodymium-iron-boron magnet. According to the method, no harmful matter is generated in the production process, the production process is environmentally friendly and free of pollution, resources can be effectively saved, the recovery rate is high, cost is reduced, and procedures are simple, easy and convenient to implement and feasible.

Owner:SINO MAGNETICS TECH

Method for reclaiming and cyclic utilizing residue molten steel slag in steel making

InactiveCN1804047AWell mixedReduce oxidationBlast furnace componentsBlast furnace detailsSulfurSludge

The method to pour residual hot steel sludge for recovery in steel production comprises: a. after casting, pouring the residual steel sludge into empty ladle; b. conveying the sludge to converter and tapping; c. refining; d. casting; repeating. This invention makes full use of the sulfur capacity and strong reducibility to absorb inclusion and improve liquid steel cleanness rapidly, overcomes the consumption for low-melting, and reduces pollution and cost.

Owner:HEBEI IRON AND STEEL

Metallurgical molten slag dry granulating and heat recovering system

ActiveCN101993964AAvoid wastingReduce consumptionRecycling and recovery technologiesThermal energyVitrification

The invention relates to a metallurgical molten slag dry granulating and heat recovering system and belongs to mechanical equipment. The metallurgical molten slag dry granulating and heat recovering system consists of a feeding system, a dry granulating device and a heat recovering system. Liquid molten slag is subjected to dry granulation in a way of centrifugal rotation and air flow pulse; and the molten slag is cooled and solidified after exchanging heat with a water cooled wall and fluidization gas. In the whole granulating process, water is not consumed or only a small amount of water is consumed, and a large quantity of waste water and harmful gases such as H2S and SOx and the like are not generated; sensible heat in the molten slag is fully recycled while the granulated slag with high vitrification rate is formed; waste of high-grade heat is effectively avoided; and energy consumption of metallurgical enterprises is saved. The granulated slag is subsequently used without being additionally dried; and the energy consumption in a subsequent using process is saved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Optimized process for processing steel slag by magnetic separation

The invention relates to an optimized process for processing steel slag by magnetic separation, which is characterized by comprising the following steps: (1) screening steel slag by using a No.1 vibrating screen, separating out the steel slag and slag steel by using a No.1 magnetic separator to separate the oversize material, feeding the slag steel to a slag steel tank, and feeding the steel slagto a jaw crusher; (2) feeding the screen underflow of the No.1 vibrating screen and the discharge of the jaw crusher to a No.2 vibrating screen together, separating the oversize material by using a No.2 magnetic separator, feeding the separated slag steel to a rod mill, and stripping steel slag on the slag steel by the vibration effect of the rod mill; (3) feeding the steel slag separated out by the No.2 magnetic separator to a No.3 vibrating screen, feeding the oversize material to a large-size tailing storeroom, and feeding the screen underflow to a medium-size tailing storeroom; and (4) feeding the discharge of the rod mill to a No.4 vibrating screen, feeding the oversize material the iron content of which is no less than 90% to the slag steel tank, feeding the screen underflow to a No.3 magnetic separator, feeding the separated steel slag magnetic separation powder to a magnetic separation powder storeroom, and feeding the steel slag to a small-size tailing storeroom. By using theinvention, high-quality slag steel the iron content of which is more than 90% can be obtained, thereby fully recovering the iron in the steel slag.

Owner:鞍钢绿色资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com