Method for recycling iron from steel slag

A technology for recycling iron and steel slag, applied in recycling technology, chemical instruments and methods, wet separation, etc., can solve the difficulty of increasing the crushing and grinding of steel slag, affecting the quality of steel slag powder products, and low recovery rate of steel materials, etc. problems, to achieve good slag and steel separation effect, avoid manual reverse transportation, and achieve the effect of high grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

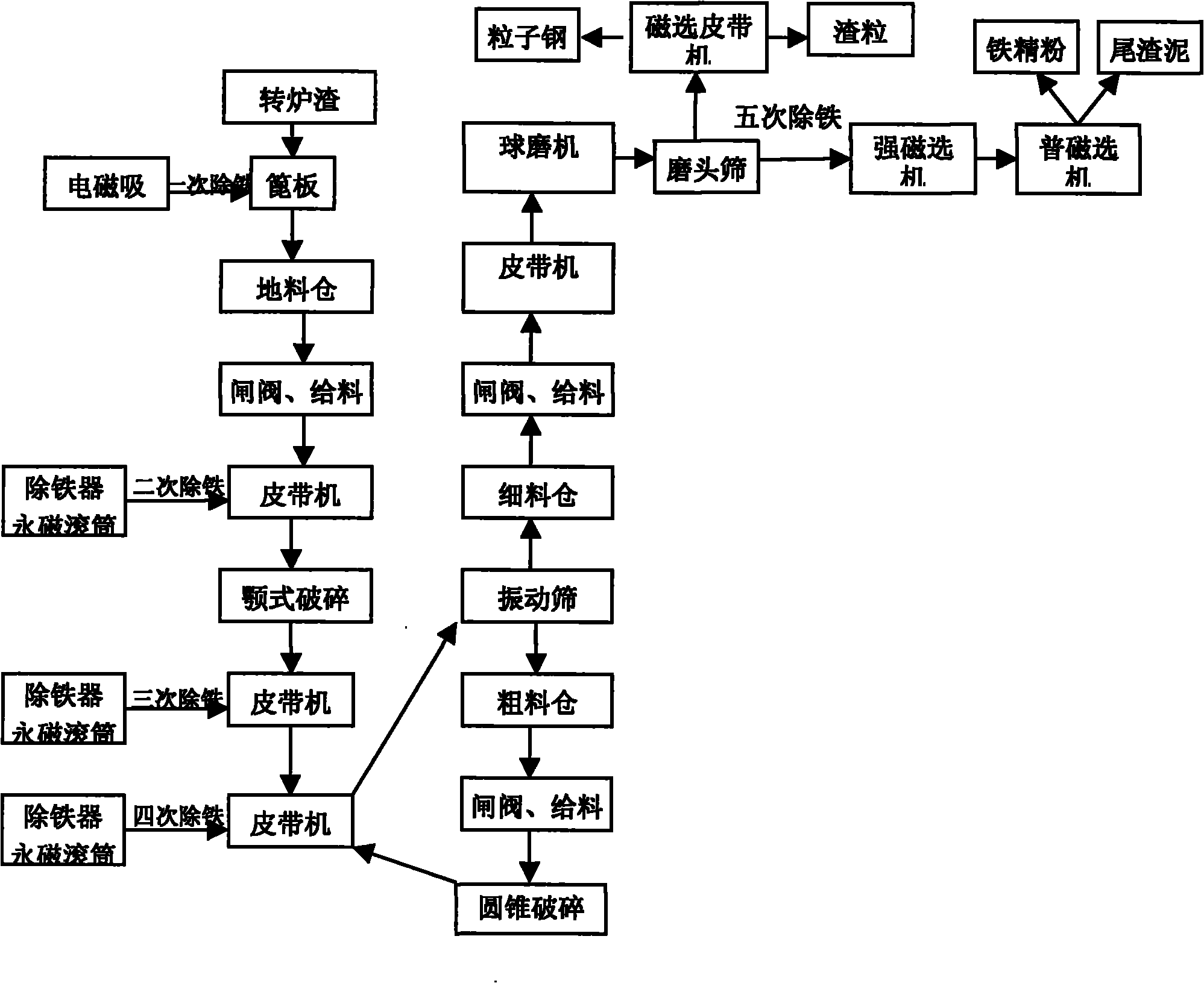

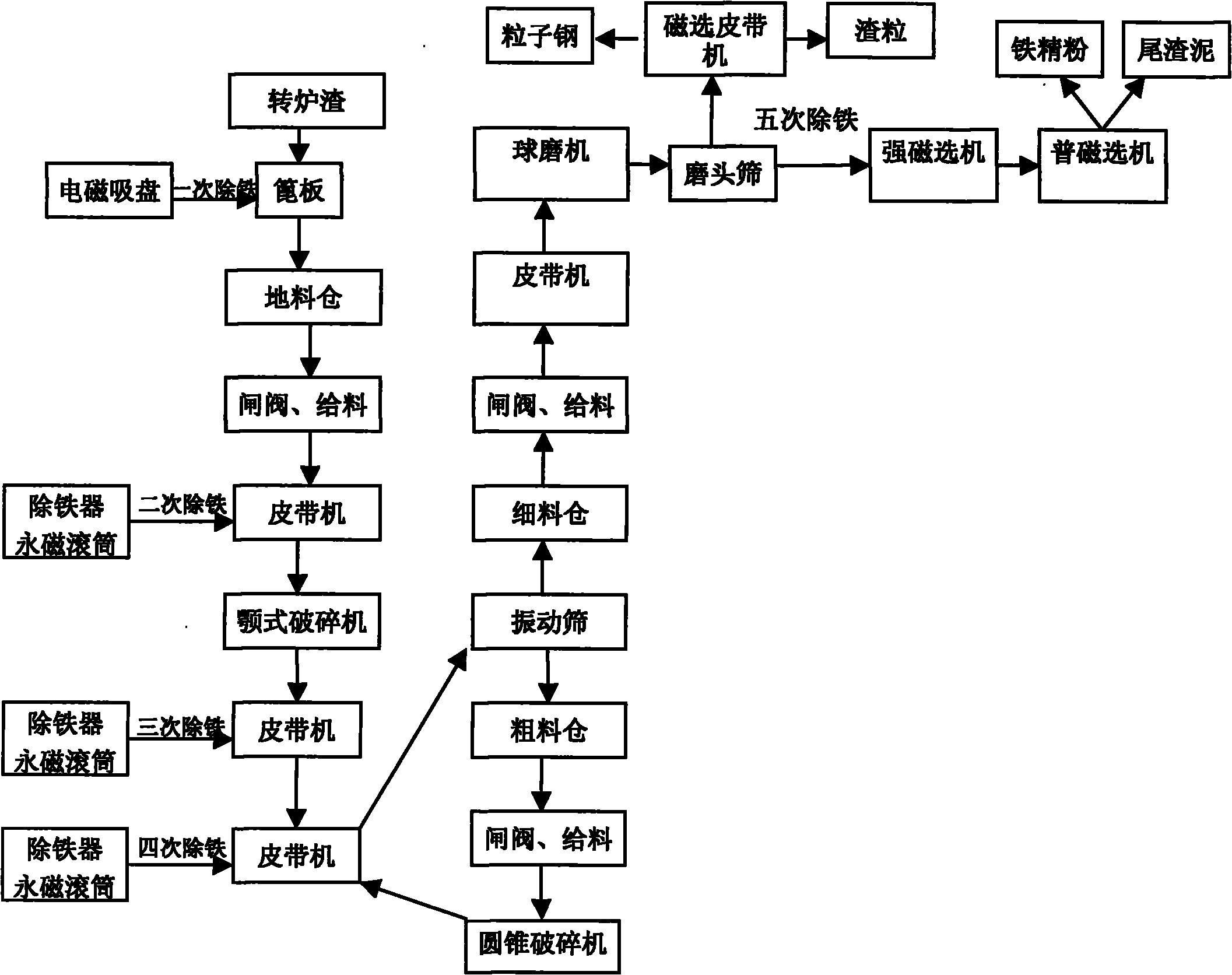

[0008] The present invention comprises the following steps: (1), the steel slag after cooling out of the furnace is poured into a grate plate of 180mm×180mm, the steel slag of 180mm uses an electromagnetic sucker to recover iron for the first time; (2), The steel slag of 25mm enters the cone crusher for the second crushing. After crushing, the particle size is 2mm are returned to the furnace for utilization, steel slag < 2mm is magnetically separated by a wet magnetic separator, and iron powder and tailings are separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com